Patents

Literature

24555results about "Organic fertilisers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

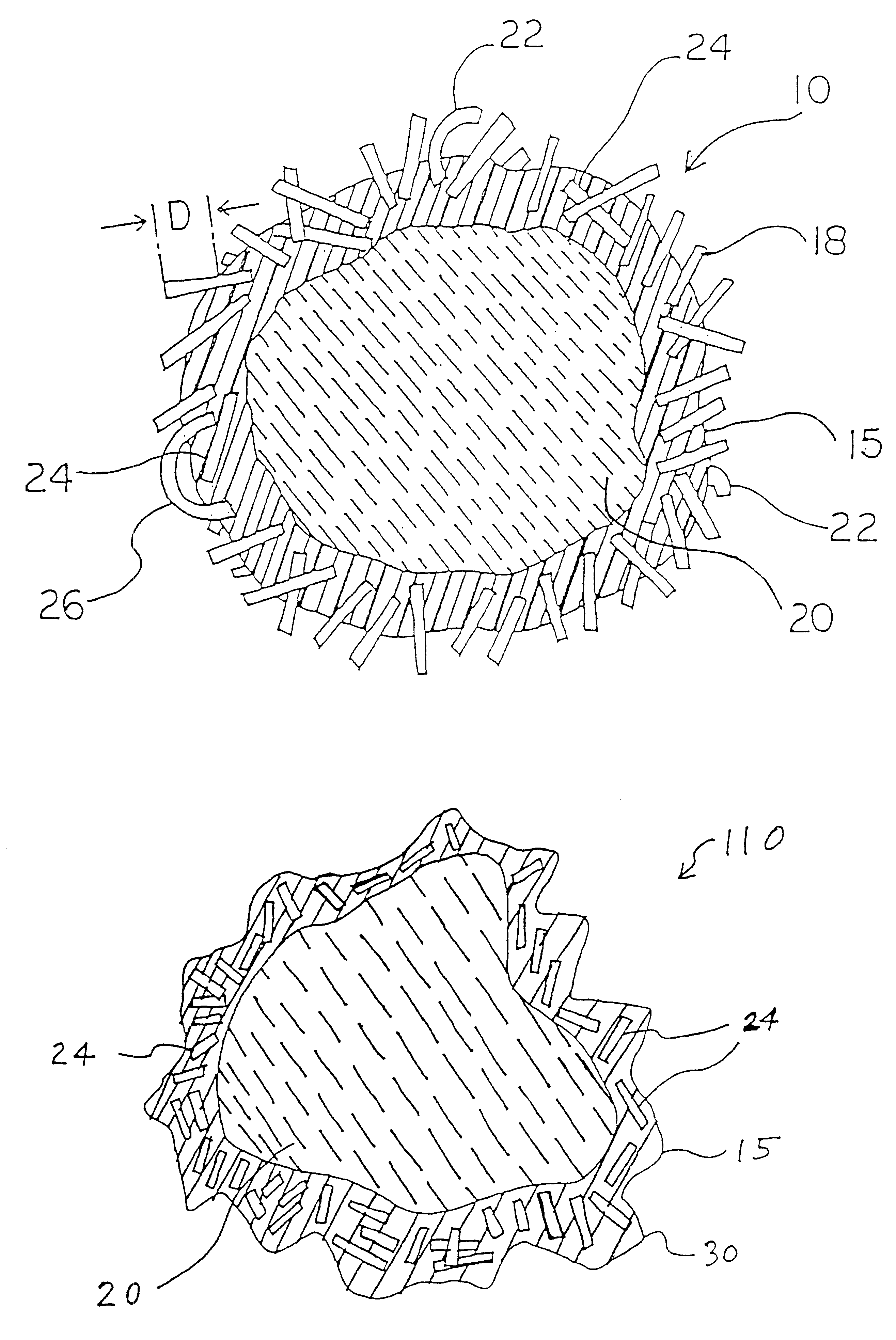

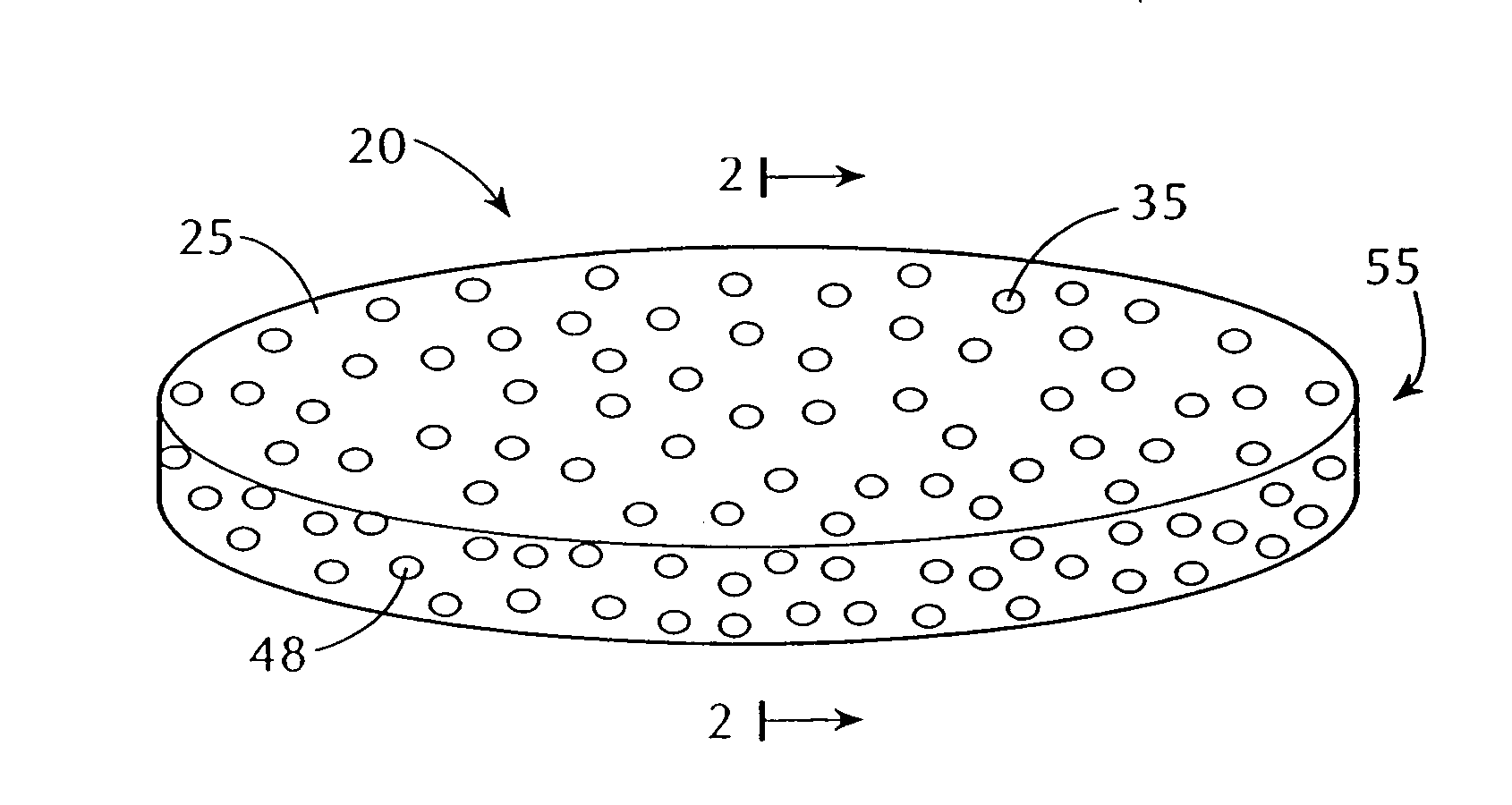

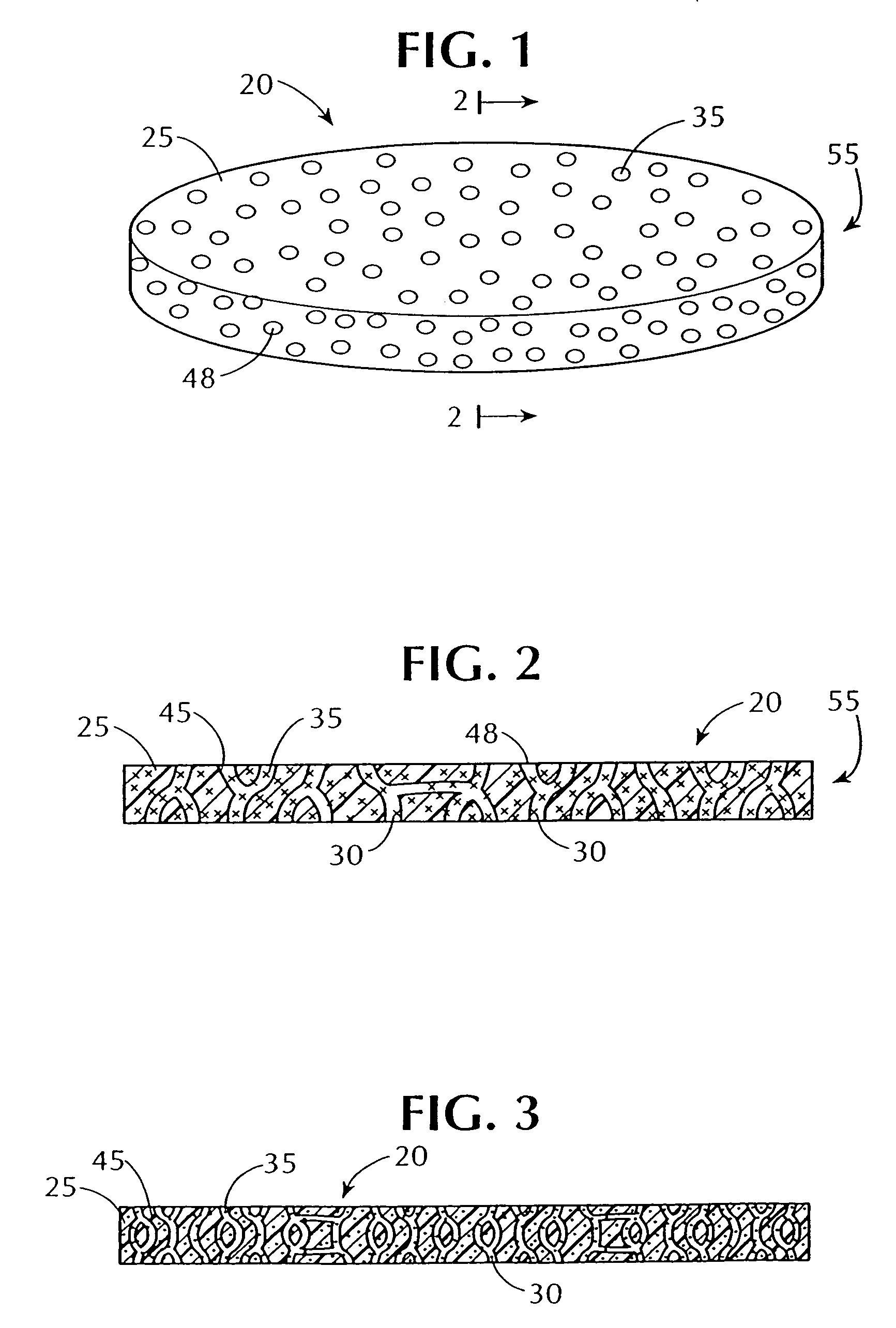

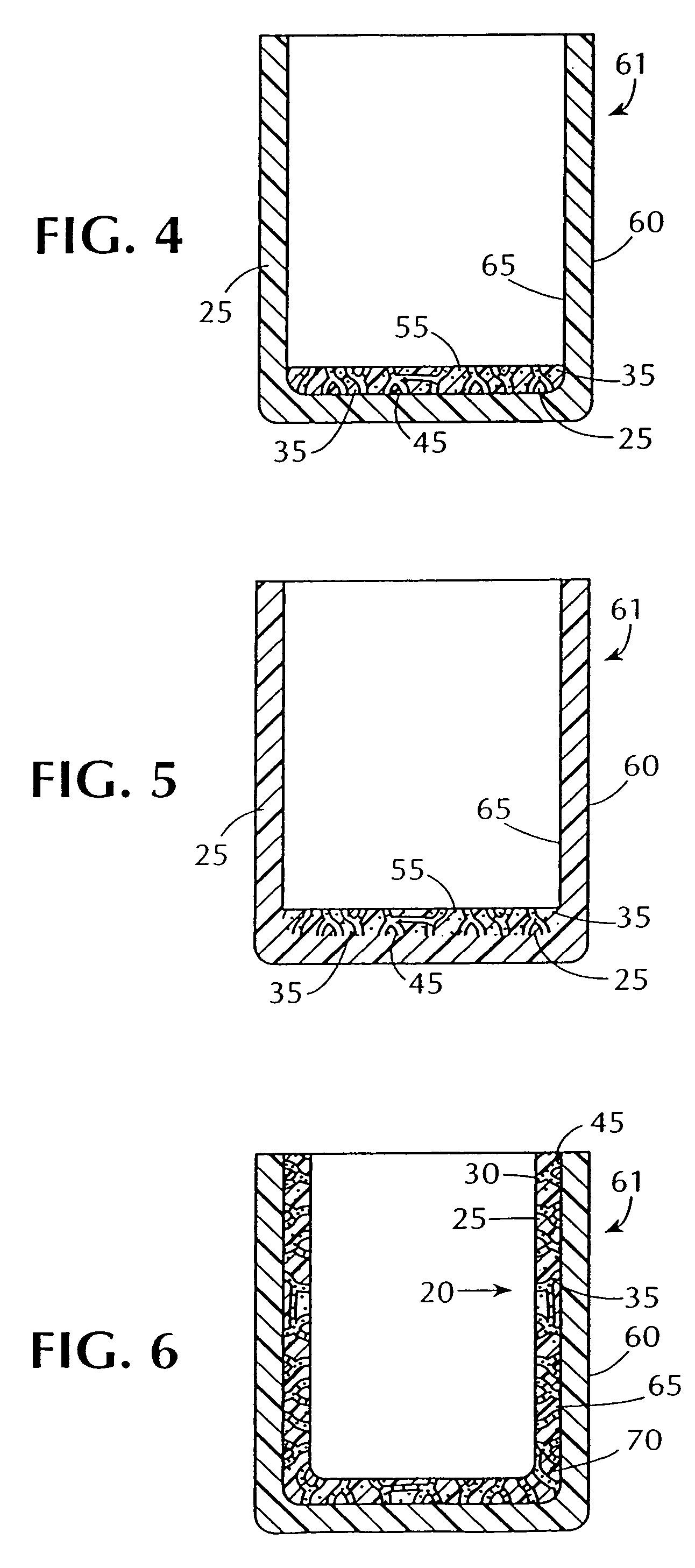

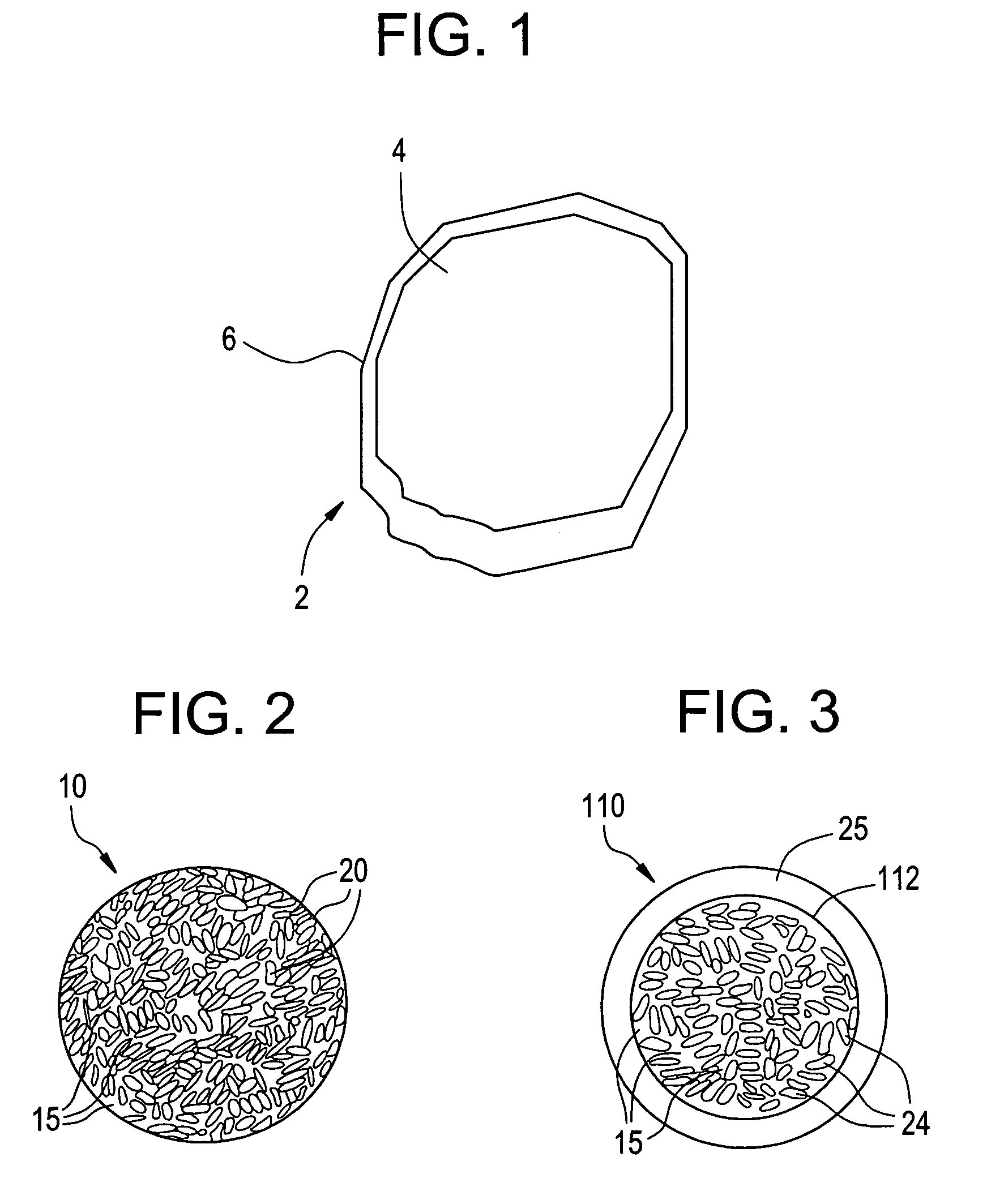

Composite proppant, composite filtration media and methods for making and using same

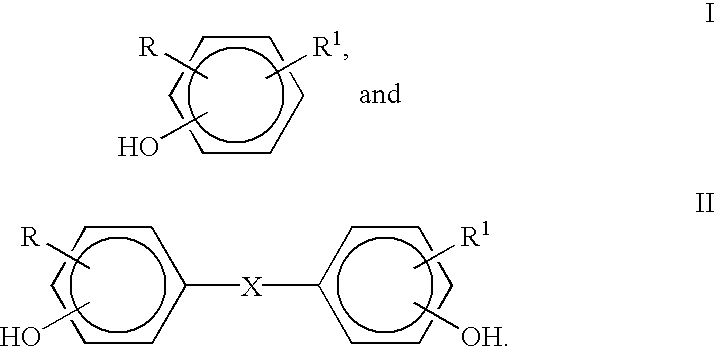

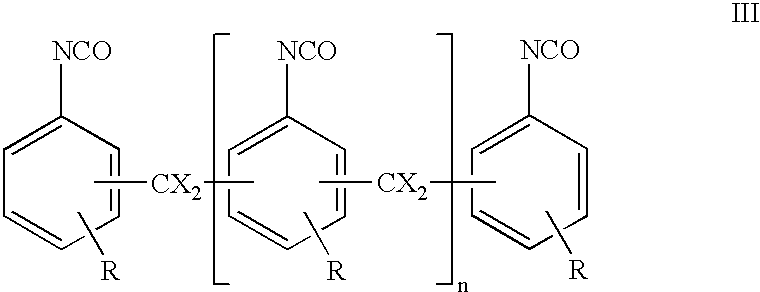

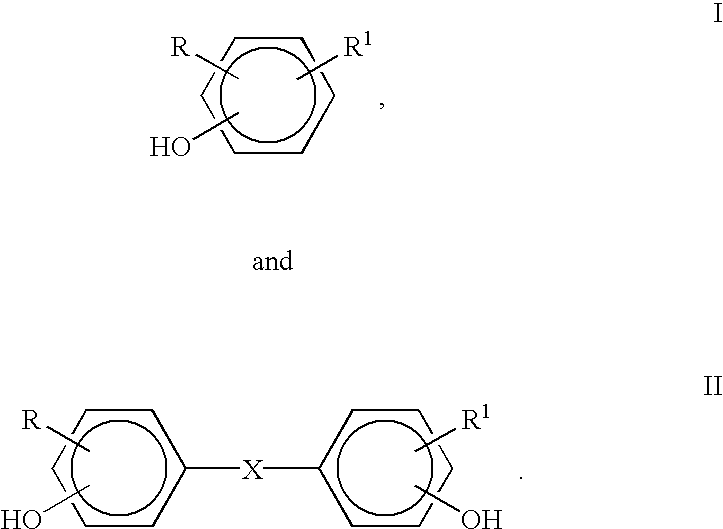

InactiveUS6632527B1Avoid condensationReduce molecular weightPretreated surfacesGlass/slag layered productsFiberFiltration

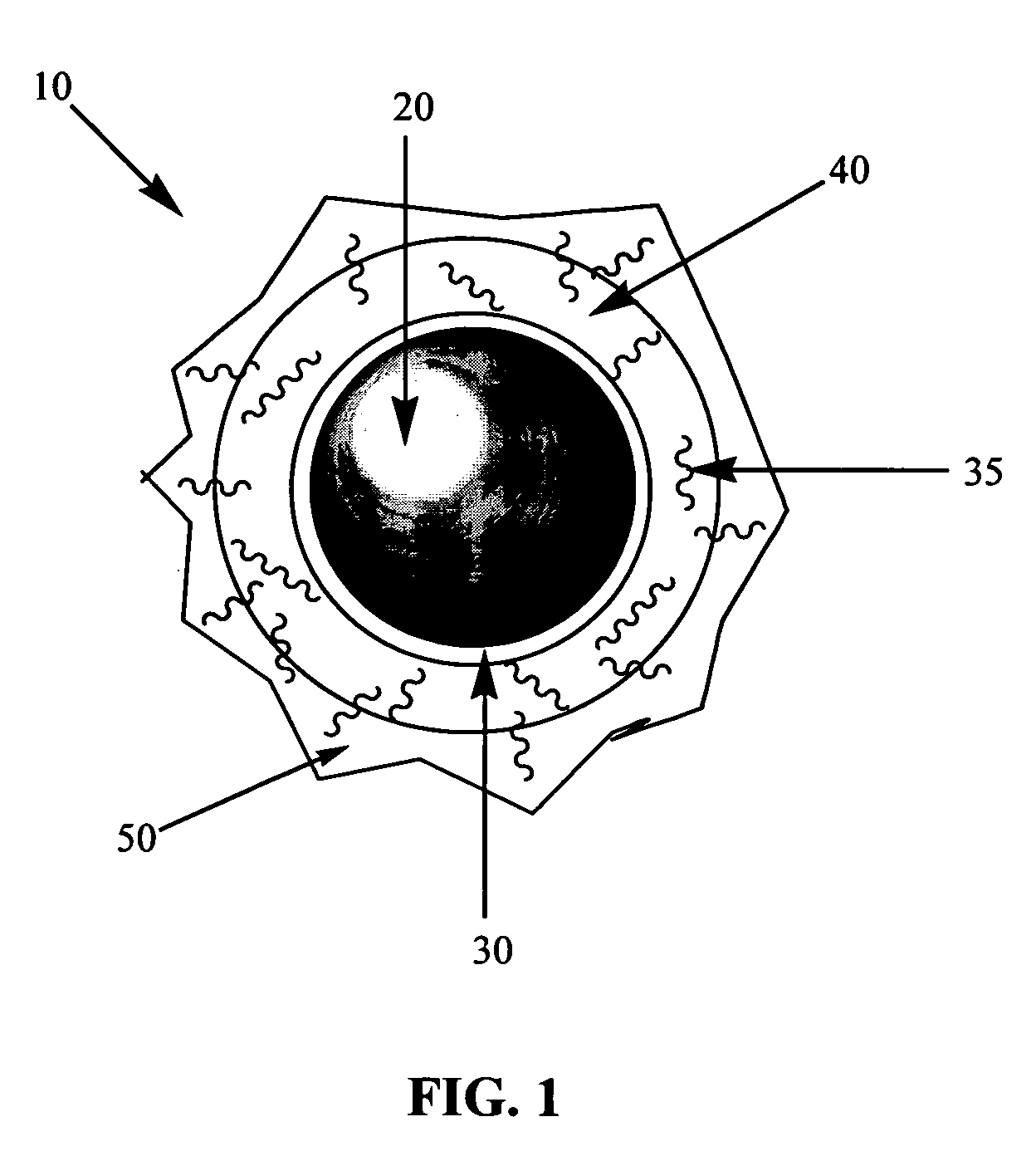

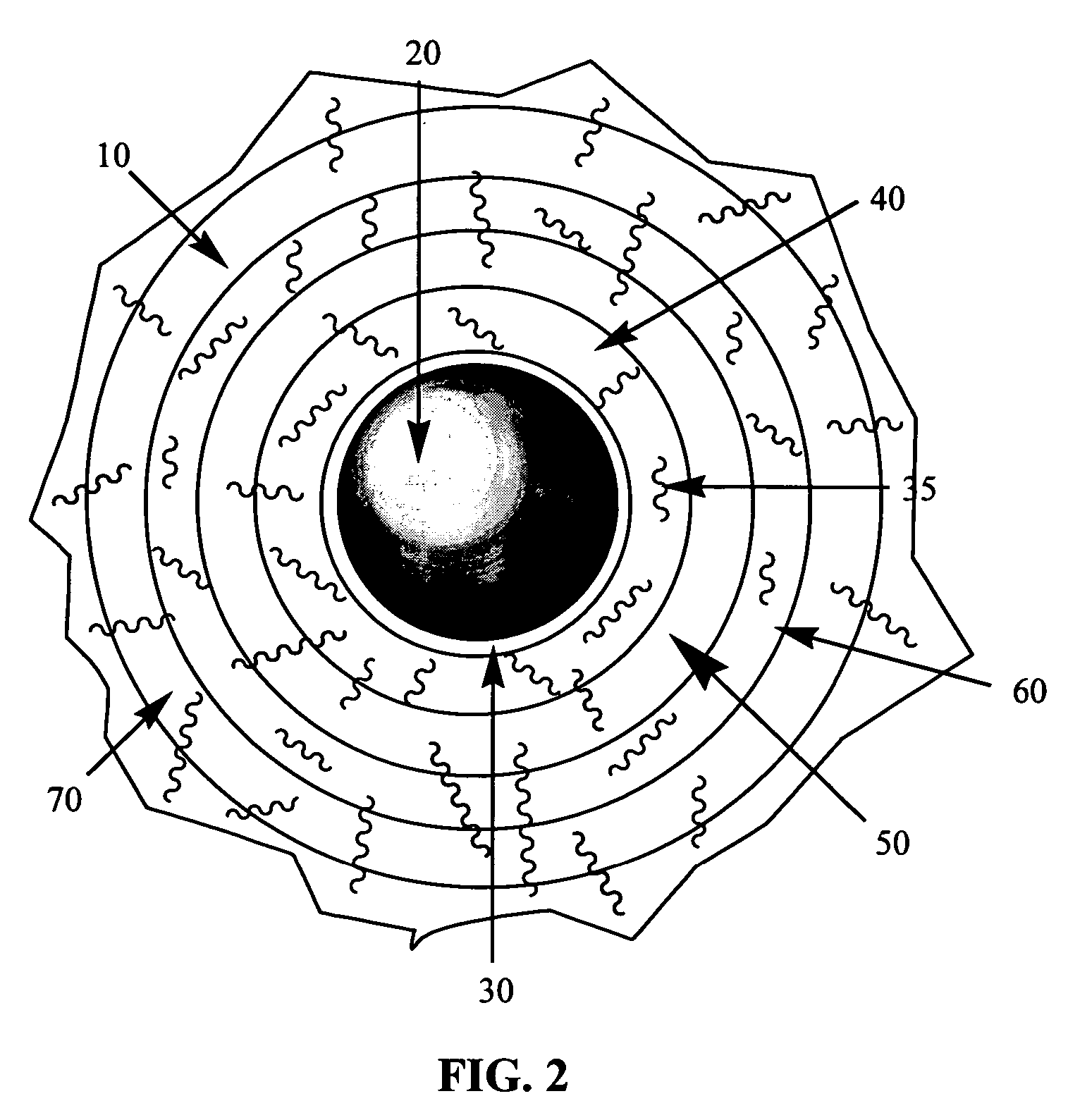

Composite particles made of a binder and filler material are provided for use in subterranean formations. The filler is finely divided mineral and optional fiber. The particles are proppants useful to prop open subterranean formation fractures. The particles are also useful for water filtration and artificial turf for sports fields. Methods of making the composite particles are also disclosed.< / PTEXT>

Owner:HEXION INC

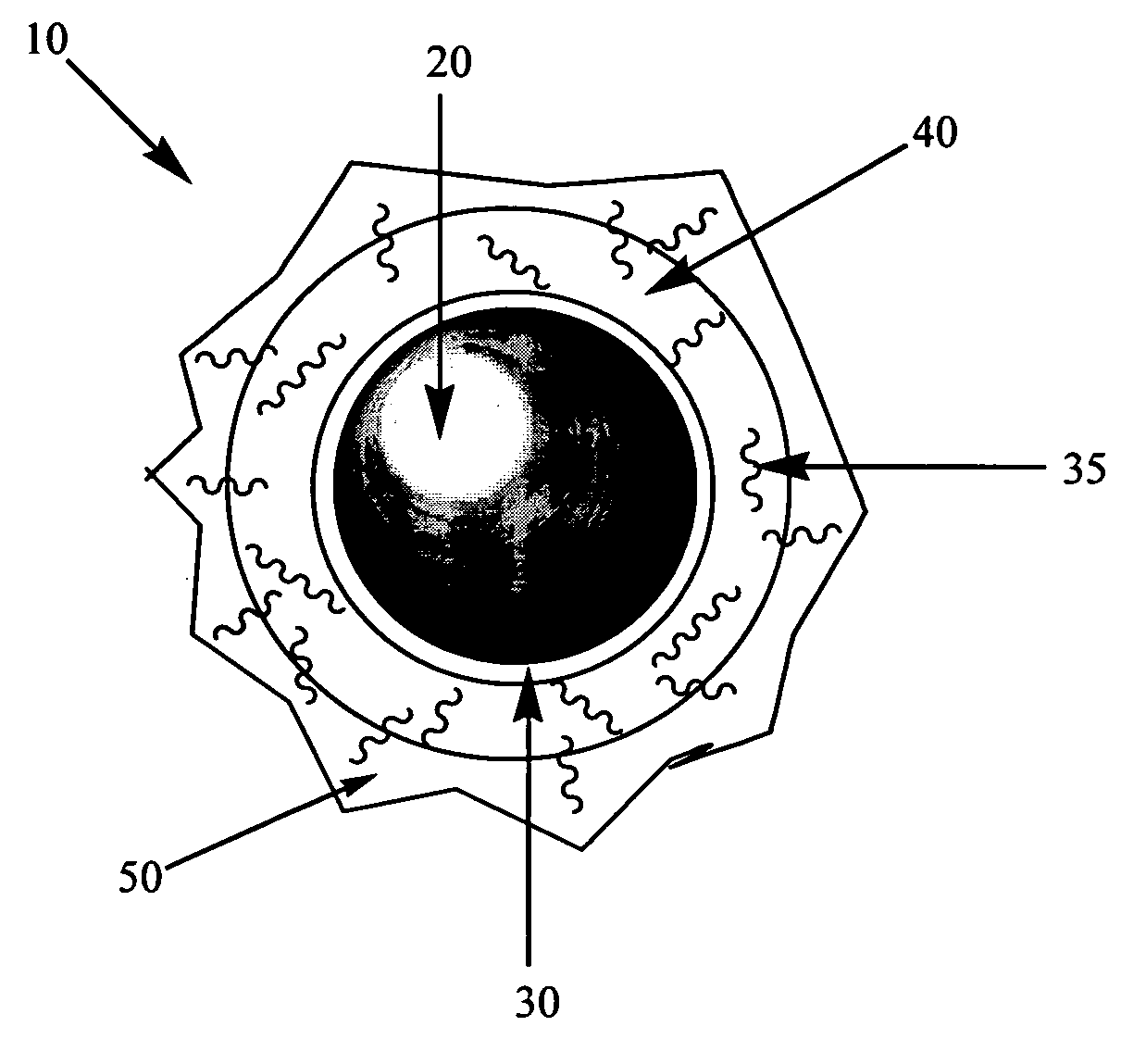

Proppants with fiber reinforced resin coatings

InactiveUS6528157B1High compressive strengthWithstanding stressCeramic layered productsDrilling compositionParticulatesResin coating

Coated particles made of particulate substrates having a coating of resin and fibrous material are provided for use in subterranean formations. The coated substrate particles are proppants useful to prop open subterranean formation fractures. The coated substrate particles are also useful for sand control, that is, acting as a filter or screen to prevent backwards flow of sand, other proppants or subterranean formation particles. Methods of making the coated particles are also disclosed.

Owner:HEXION INC

Desiccant entrained polymer

The present invention includes a composition having a co-continuous interconnecting channel morphology. These co-continuous interconnecting channels are predominately occupied with a polymer and particles that control the percolation through the composition. The particles are composed of a material such as an absorbing agent, releasing agent and / or activation agent. The polymer composition may be used to form a desired shaped article such as plug type inserts and liners for closed containers, or it may be formed into a film, sheet, bead or pellet.

Owner:CSP TECH NORTH AMERICA

Soluble fibers for use in resin coated proppant

Coated particle substrates having a coating of resin and / or water soluble polymers and soluble, fibrous material are provided for use in subterranean formations. The coated particle substrate particles are typically proppants used to prop open subterranean hydrocarbon formations during recovery processes, such as after a hydraulic fracture, and provide both improved settling characteristics and improved hydrocarbon flow characteristics due to the conductive channels formed by the soluble fibers downhole. Methods of making the coated particles are also described.

Owner:FAIRMOUNT SANTROL

Methods and compositions for production of lipo-chito oligosaccharides by rhizobacteria

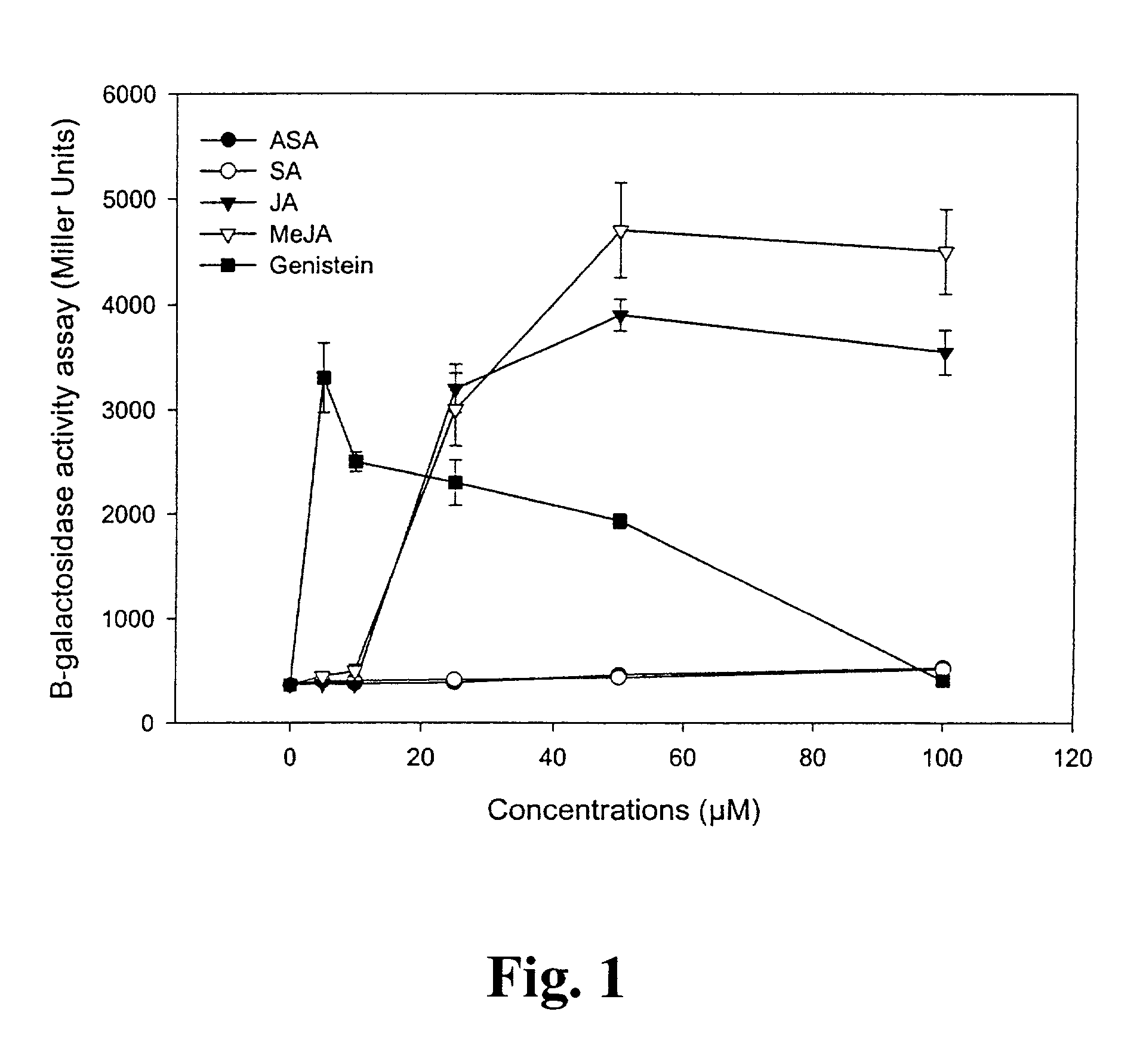

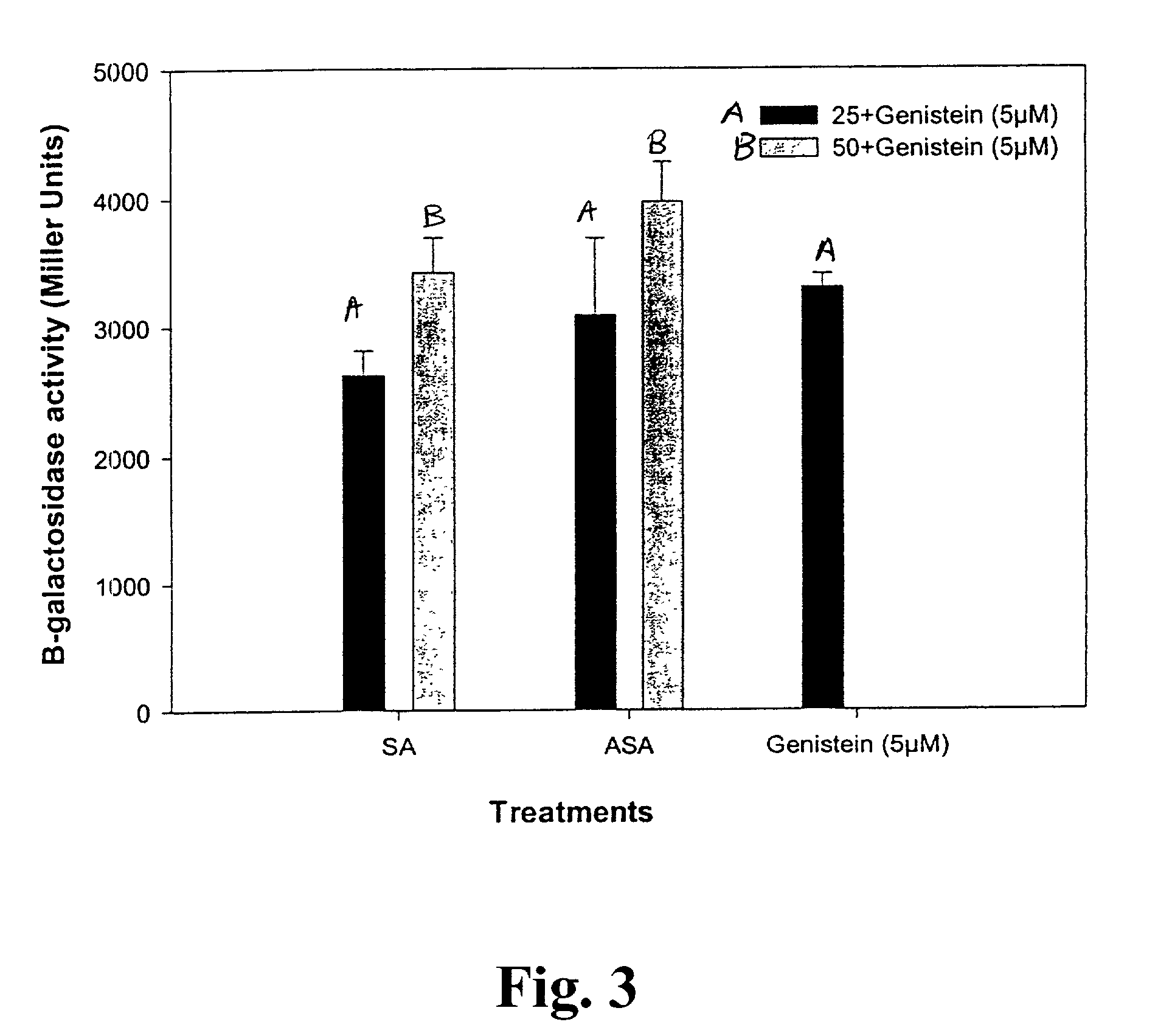

Lipo-chito oligosaccharides (LCOs) are produced by culturing rhizobacteria cells in or on a culture medium comprising at least one of: jasmonic acid or a derivative thereof; linoleic acid or a derivative thereof; or linolenic acid or a derivative thereof. Preferably, the rhizobacteria cells are Bradyrhizobium japonicum cells having the identifying characteristics of B. japonicum strain USDA 3. Preferably, the derivative of jasmonic acid is an ester thereof, preferably methyl jasmonate. Also provided are methods for improving LCO production at low temperatures, particularly temperatures below 25° C.

Owner:MCGILL UNIV

Data mining techniques for improving search engine relevance

InactiveUS20060224579A1Facilitate efficient searching and retrieval and analysisSimple processWeb data indexingSolid waste disposalLearning dataInformation retrieval

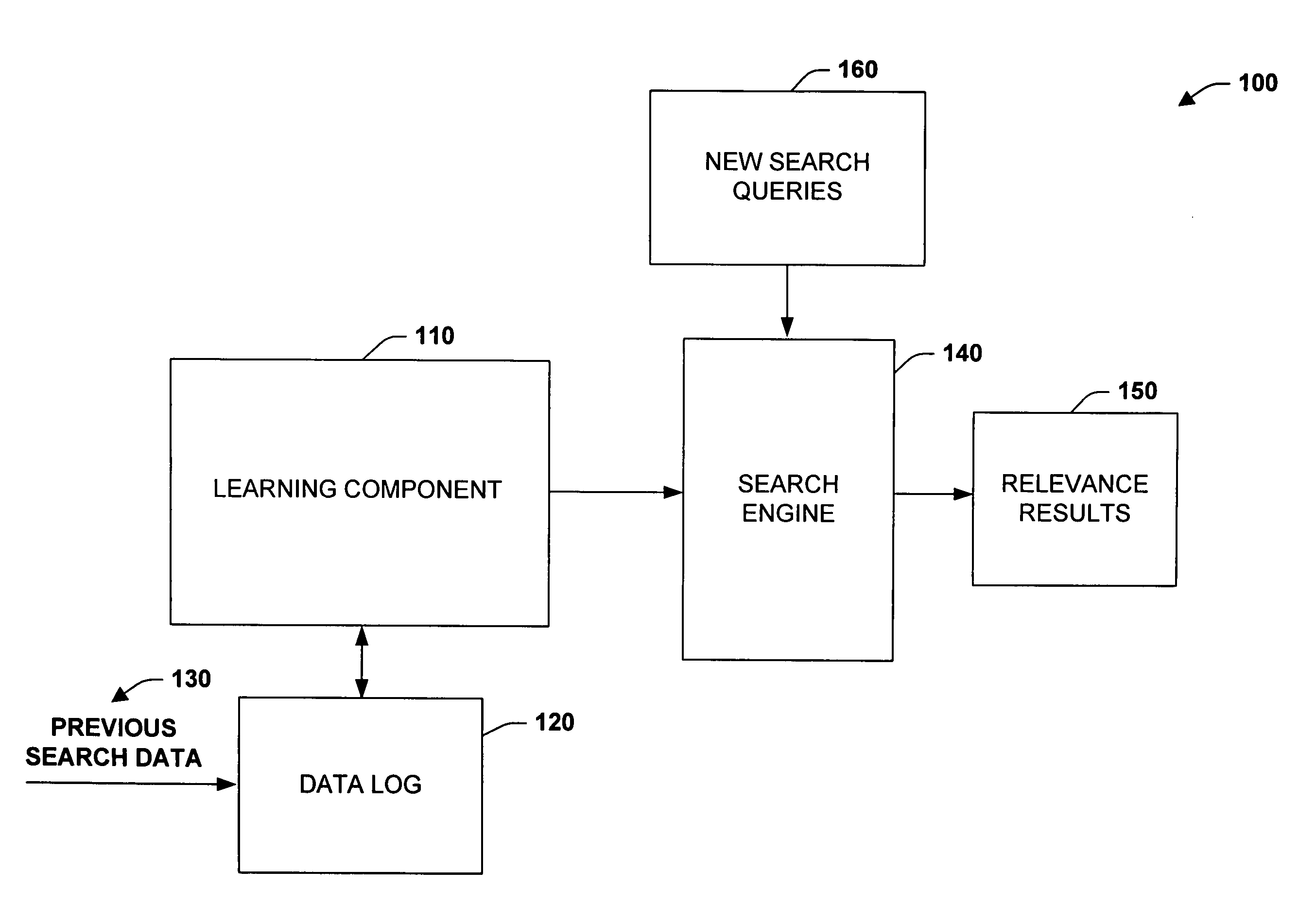

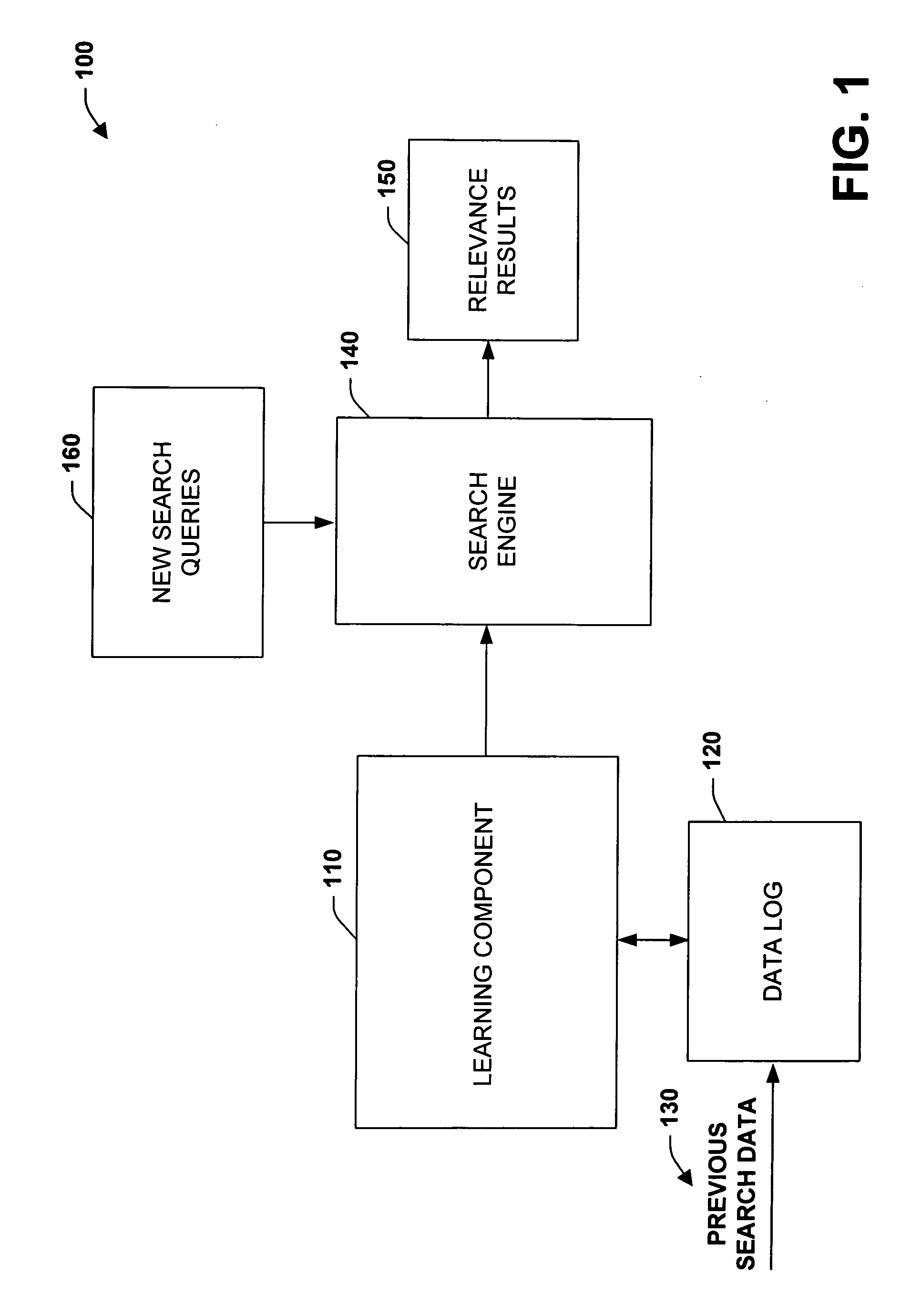

The subject invention relates to systems and methods that automatically learn data relevance from past search activities and apply such learning to facilitate future search activities. In one aspect, an automated information retrieval system is provided. The system includes a learning component that analyzes stored information retrieval data to determine relevance patterns from past user information search activities. A search component employs the learning component to determine a subset of current search results based at least in part on the relevance patterns, wherein numerous variables can be processed in accordance with the learning component to efficiently generate focused, prioritized, and relevant search results.

Owner:MICROSOFT TECH LICENSING LLC

Materials and process for enhancing selective separations

Use of a Maillard reaction product as an adjuvant in a variety of applications including solid-liquid separations, corrosion inhibition, emulsification, dust suppression, slow release fertilization, viscosity modification and others and especially as a depressant or collector in separation processes, including the selective separation of solids and / or ionic species from aqueous media, such as in the process of froth flotation.

Owner:GEORGIA PACIFIC CHEM LLC

Settable fluids and methods for use in subterranean formations

The present invention relates to subterranean operations, and more particularly, to settable fluids comprising vitrified shale and hydrated lime and methods of using such settable fluids in subterranean applications. In an exemplary embodiment, the settable fluids of the present invention may be used as a displacement fluid. In another exemplary embodiment, the settable fluids of the present invention may be used as a drilling fluid.

Owner:HALLIBURTON ENERGY SERVICES INC

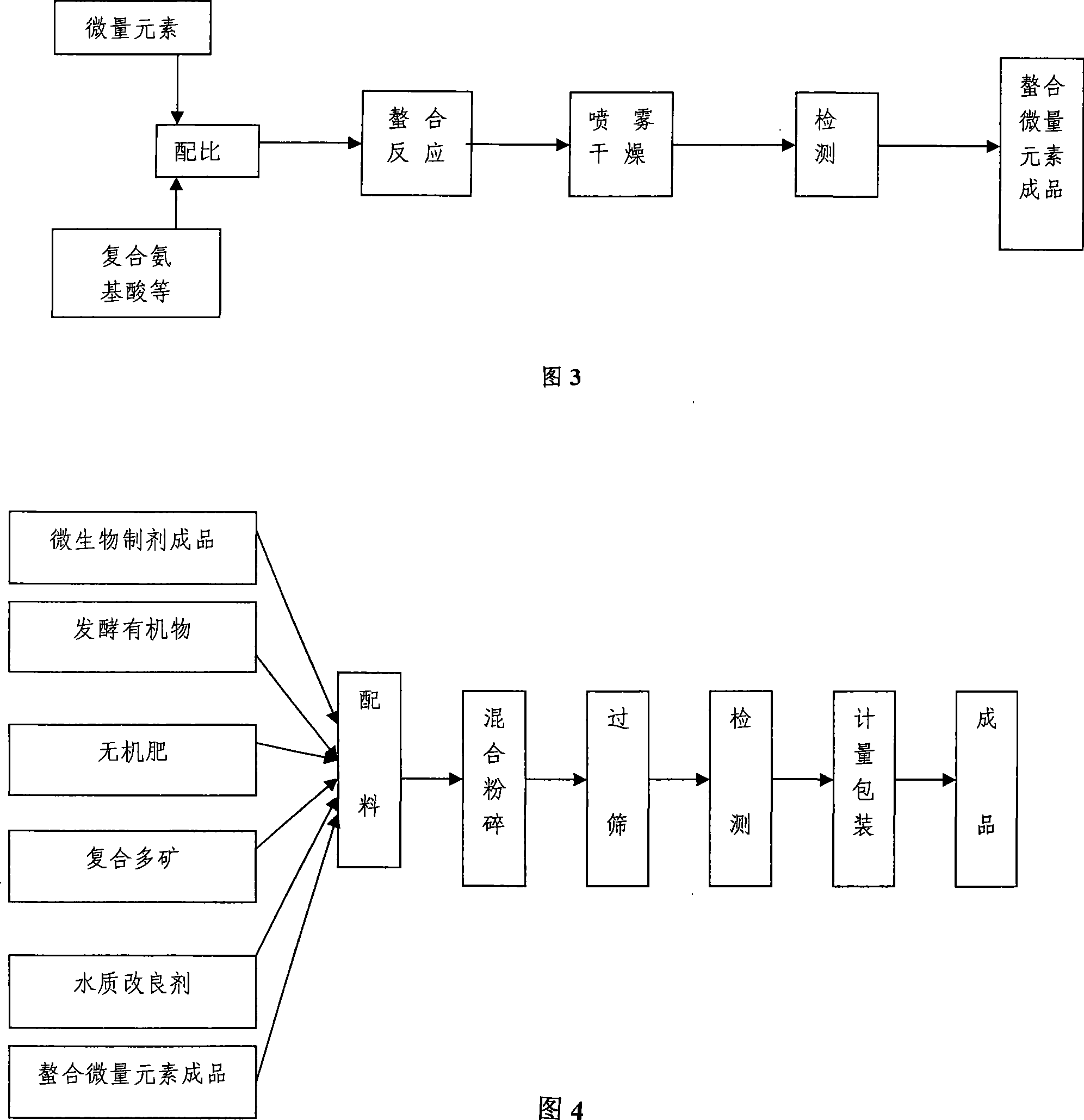

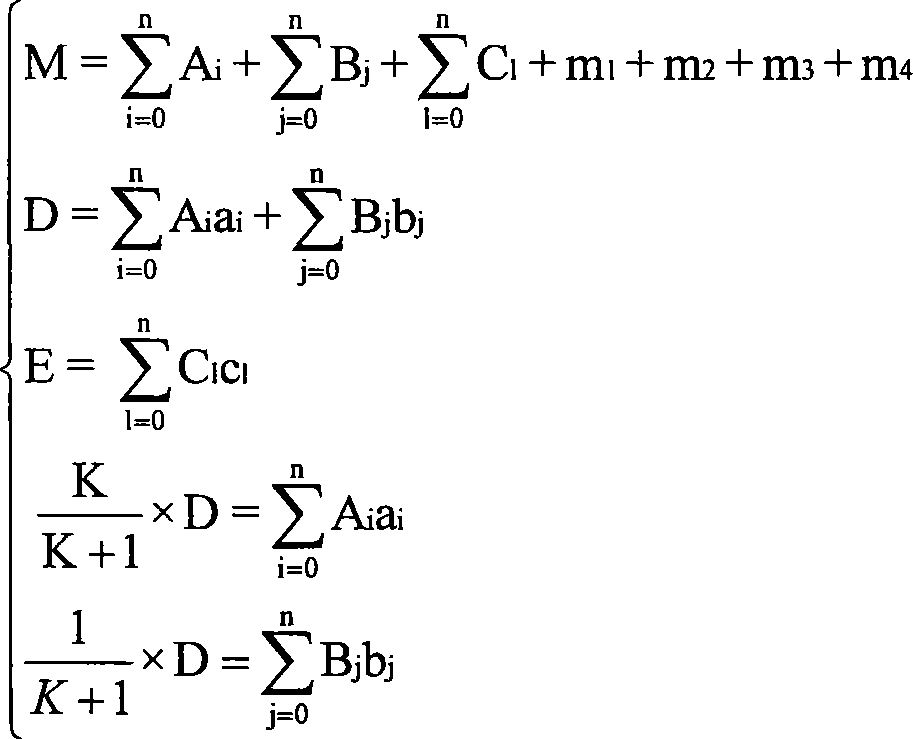

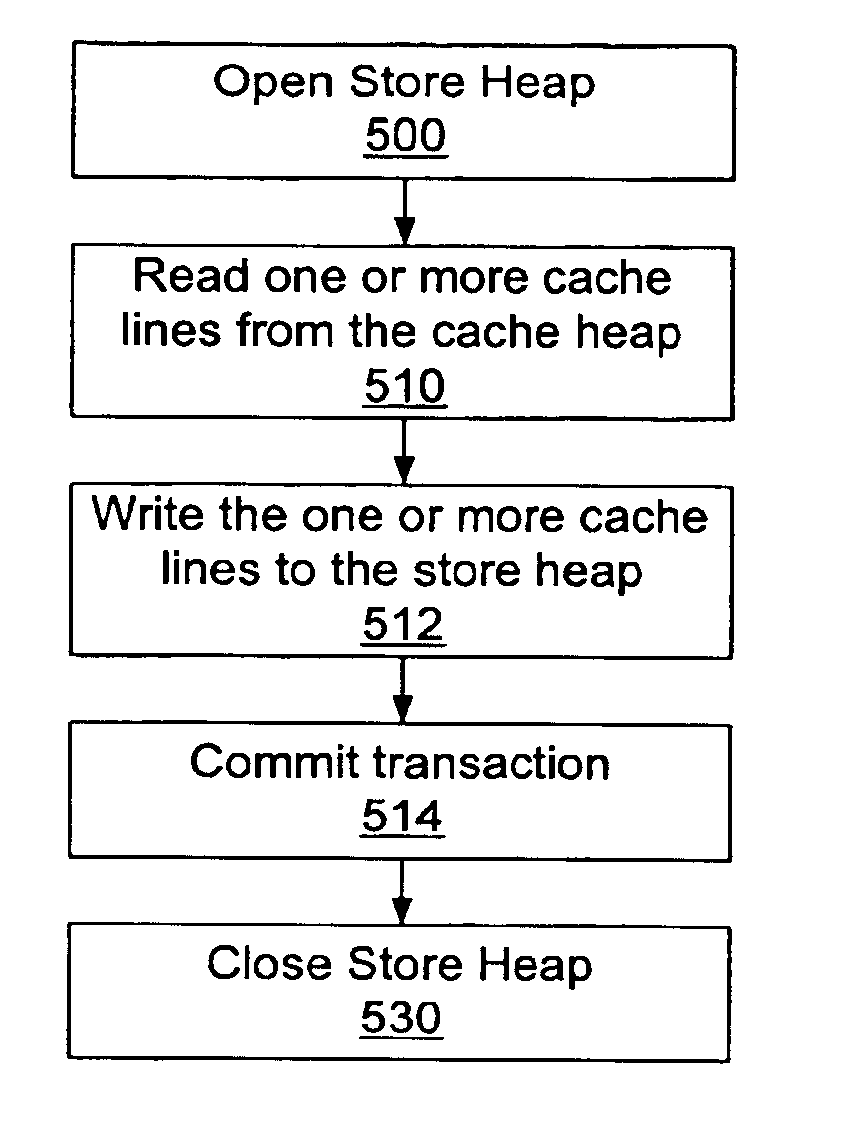

Special biological fish-fertilizer for aquaculture and preparation method thereof

ActiveCN101225007AMatching scienceIncrease profitClimate change adaptationPisciculture and aquariaDiseaseWater quality

The invention discloses a special biological fish fertilizer and a preparation method for the fertilizer used in aquiculture; wherein, the biological fish fertilizer mainly comprises raw materials as follows: microbiological preparation, inorganic fertilizers, fermentation organics, micro-mineral amino acid chelate, mineral composites, and water quality improver. The preparation method for the special biological fish fertilizer in aquiculture comprises steps as follows: microbiological preparation is produced; fermentation organics is then produced, and the micro-mineral amino acid chelate is produced, eventually the finished products are made. The special biological fish fertilizer has the advantages of limiting the growth and reproduction of the harmful algae, promoting the large-scale growth and reproduction of the suitable food for fish, effectively improving the water quality and purifying the water environment, strengthening the fish immunity, reducing the diseases, reducing cost due to the small use level, convenient use, mild odor, no pollution to the water, and environment protection. By combining the modern bioengineering technique, low-temperature drying technique, spray-drying technique, and super-fine crushing techniques, the preparation method has the advantages of stable quality for the fish fertilizers and lower overall cost.

Owner:WUHAN KEYANG BIOTECH

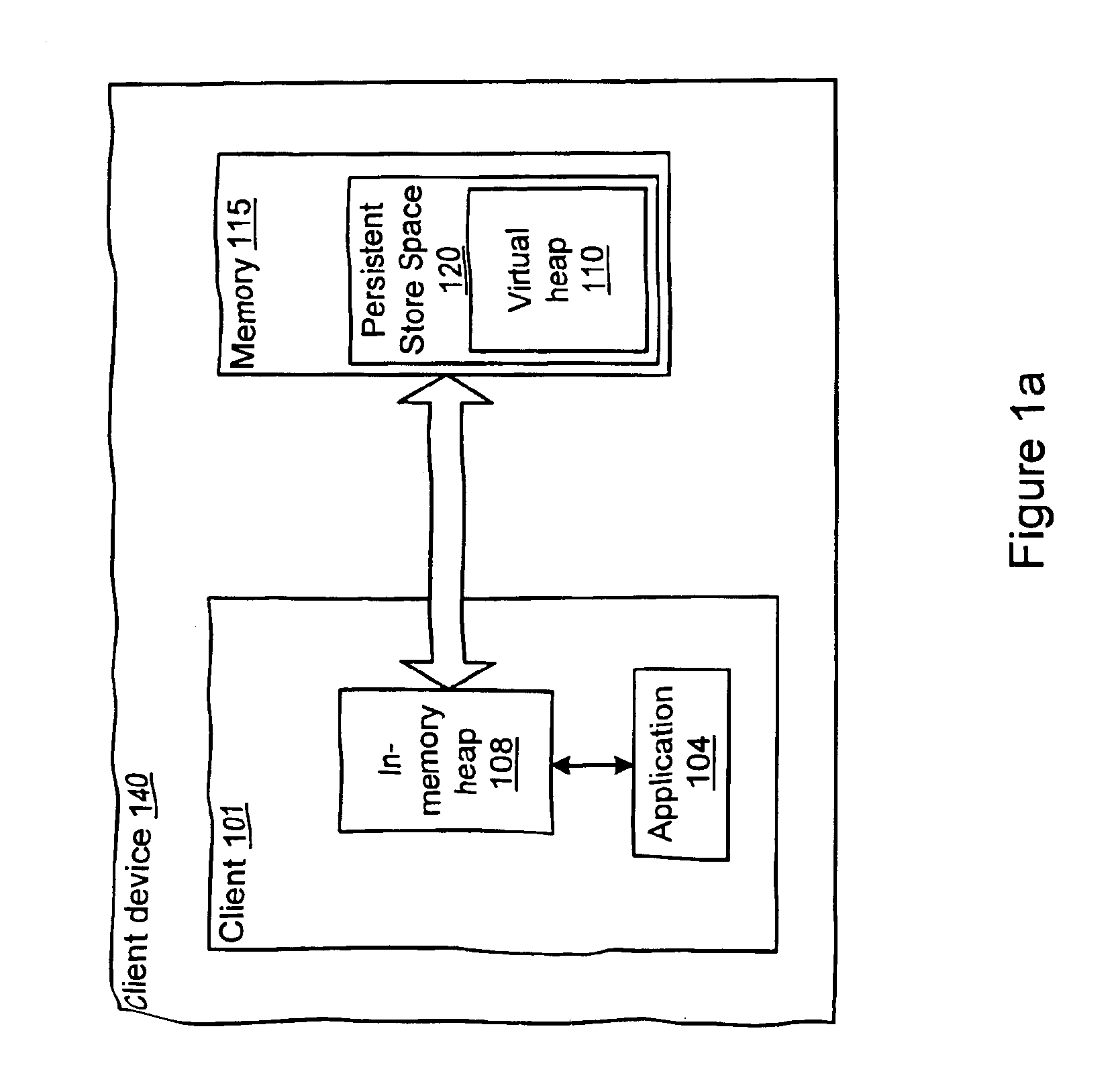

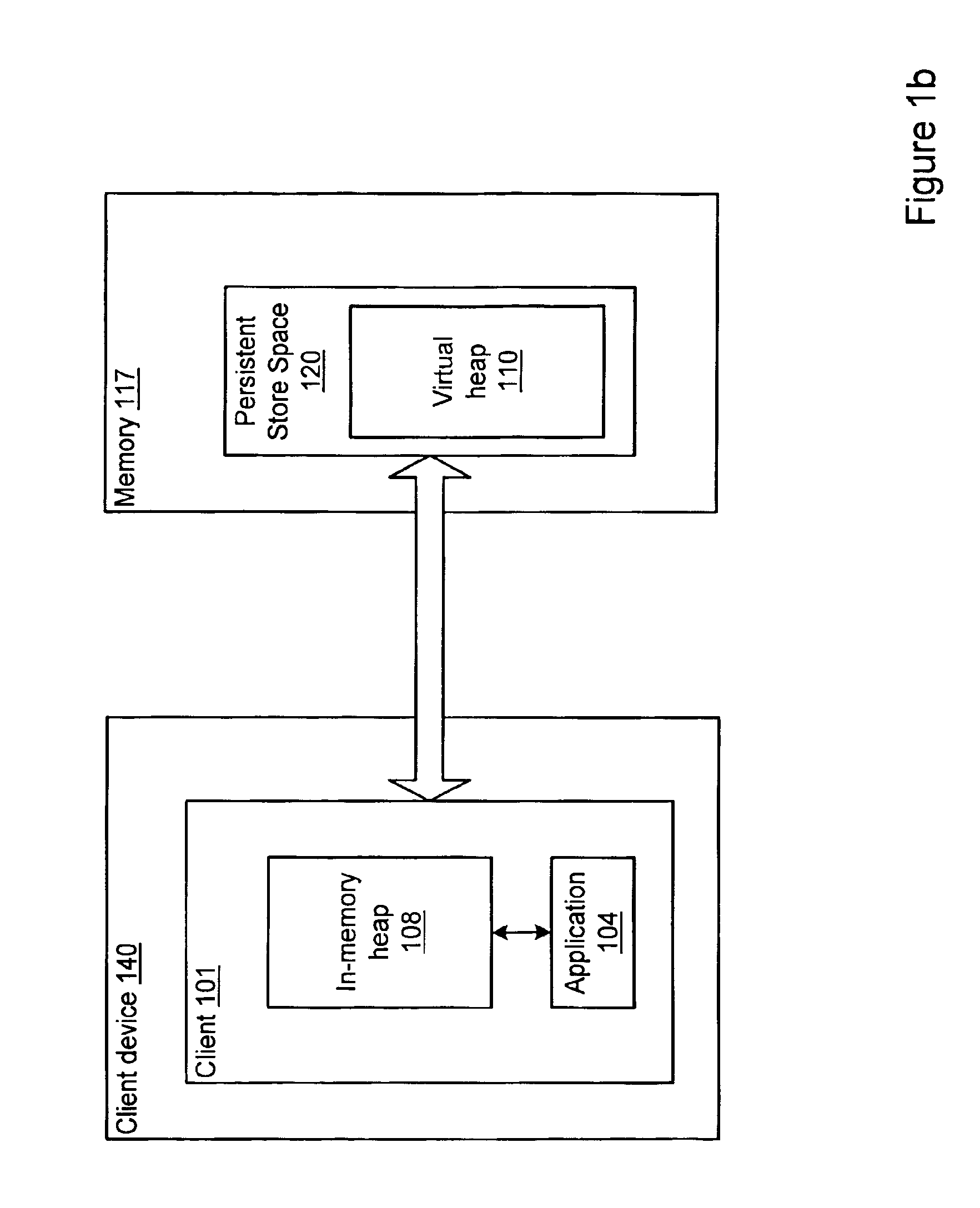

Database store for a virtual heap

InactiveUS6957237B1Meet constraintsEnsure consistencyData processing applicationsMemory adressing/allocation/relocationApplication programming interfaceApplication software

A database store method and system for a virtual persistent heap may include an Application Programming Interface (API) that provides a mechanism to cache portions of the virtual heap into an in-memory heap for use by an application. The virtual heap may be stored in a persistent store that may include one or more virtual persistent heaps, with one virtual persistent heap for each application running in the virtual machine. Each virtual persistent heap may be subdivided into cache lines. The store API may provide atomicity on the store transaction to substantially guarantee the consistency of the information stored in the database. The database store API provides several calls to manage the virtual persistent heap in the store. The calls may include, but are not limited to: opening the store, closing the store, atomic read transaction, atomic write transaction, and atomic delete transaction.

Owner:ORACLE INT CORP

Ion mineralization stabilizer for treating soil with heavy metal pollution and application method thereof

InactiveCN102766465AWide range of raw materialsEasy to obtainContaminated soil reclamationOrganic fertilisersSulfurPhosphor

The invention discloses ion mineralization stabilizer for treating soil with heavy metal pollution and an application method thereof. The ion mineralization stabilizer comprises, by weight percent, 5-30% of sulfur-based compound, 10-50% of phosphor-based compound, 10-50% of calcium-based compound, and 10-30% of silicon-based compound. The materials are respectively ground into powders with particle size not less than 200 meshes, and the powders are proportionally mixed well. The application method of the ion mineralization stabilizer for treating soil with heavy metal pollution includes: detecting arsenic content and leaching toxicity of the soil to be treated, placing the ion mineralization stabilizers in different proportions on the surface of the soil to be treated according to pollution level, well mixing to form mixed soil by ploughing and stirring, adding water to keep the water content of the mixed soil no less than 25%, covering the mixed soil with moisturizing material, curing for at least 5 days to keep heavy metals in the mixed soil to form stable minerals.

Owner:YONKER ENVIRONMENTAL PROTECTION

Humic acid composite material and preparation method thereof

InactiveCN101041600APromote absorptionGood water solubilityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphorNitrogen

The invention discloses a particle-typed composite fertilizer of humic acid and manufacturing method, which consists of dressing and karyosome, wherein the dressing contains nitrogen, phosphor and potassium. The manufacturing method comprises the following steps: graining humic acid; cladding; graining; solidifying fused fertilizer on the particle of humic acid; making the composite fertilizer dissolved into water without falling; fitting for large scale of agricultural product.

Owner:阴高鹏

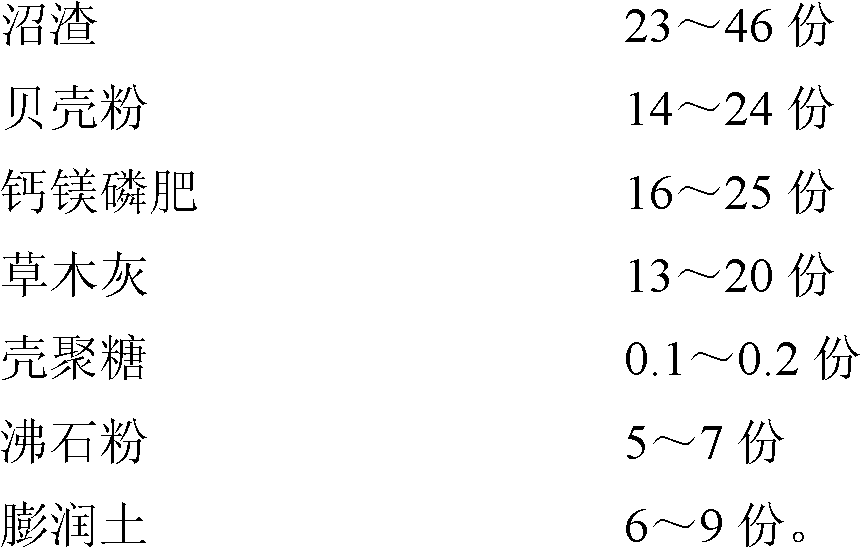

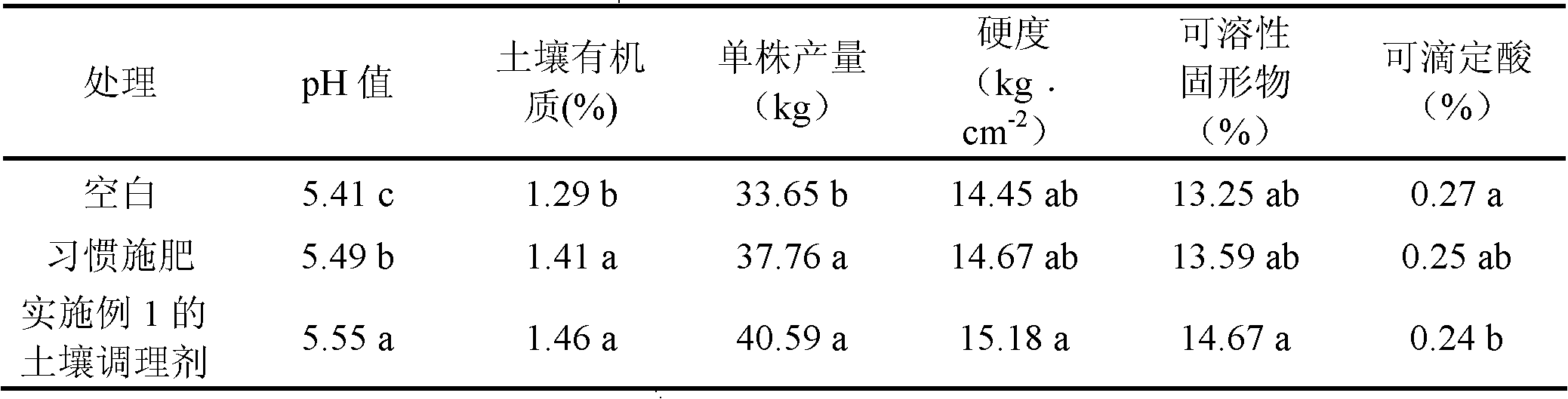

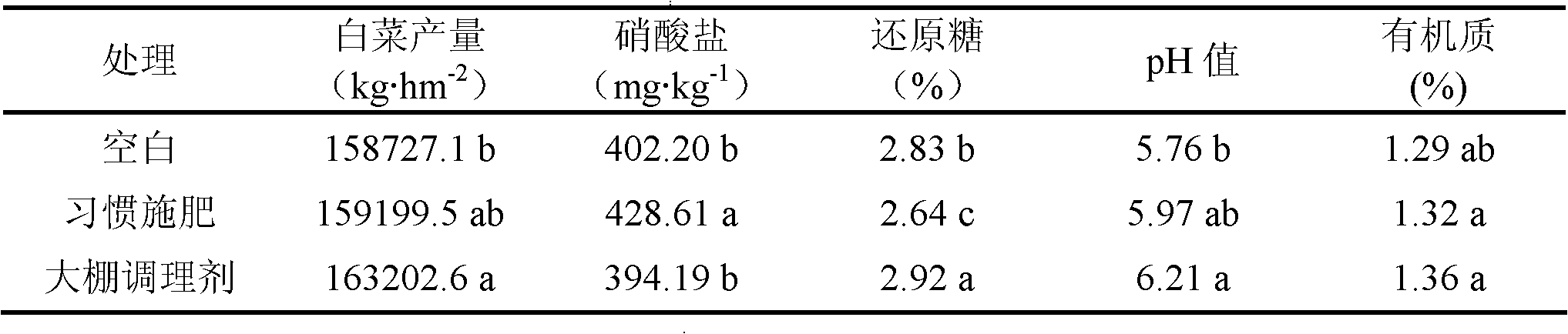

Organic environmentally-friendly soil conditioner for improving acidified or acid soil

ActiveCN102321484ARaw material safetyEfficient use ofOrganic fertilisersSoil conditioning compositionsSodium BentoniteHeavy metal poisons

The invention relates to an organic environmentally-friendly soil conditioner for improving acidified or acid soil and a preparation method thereof. The soil conditioner is prepared from the following raw materials in parts by weight: 23-46 parts of biogas residue, 14-24 parts of shell powder, 16-25 parts of calcium magnesium phosphate fertilizer, 13-20 parts of plant ash, 0.1-0.2 part of chitosan, 5-7 parts of zeolite powder and 6-9 parts of bentonite. The soil conditioner is prepared through pretreatment of the biogas residue, pretreatment of the shell powder and the like; through the produced soil conditioner, the pH value of soil can be increased; nutritive elements such as calcium, magnesium, phosphorus, potassium and the like in the soil are increased; the organic matter content in the soil is increased; the water retention and fertilizer retention capacity of the soil is improved; the physicochemical property of the soil is improved; the antiretroviral (diseases, pests, drought and the like) capacity of crops is improved; heavy metal poison is reduced; and the soil conditioner is convenient to apply, is not influenced by wind power and is suitable for mechanical working.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

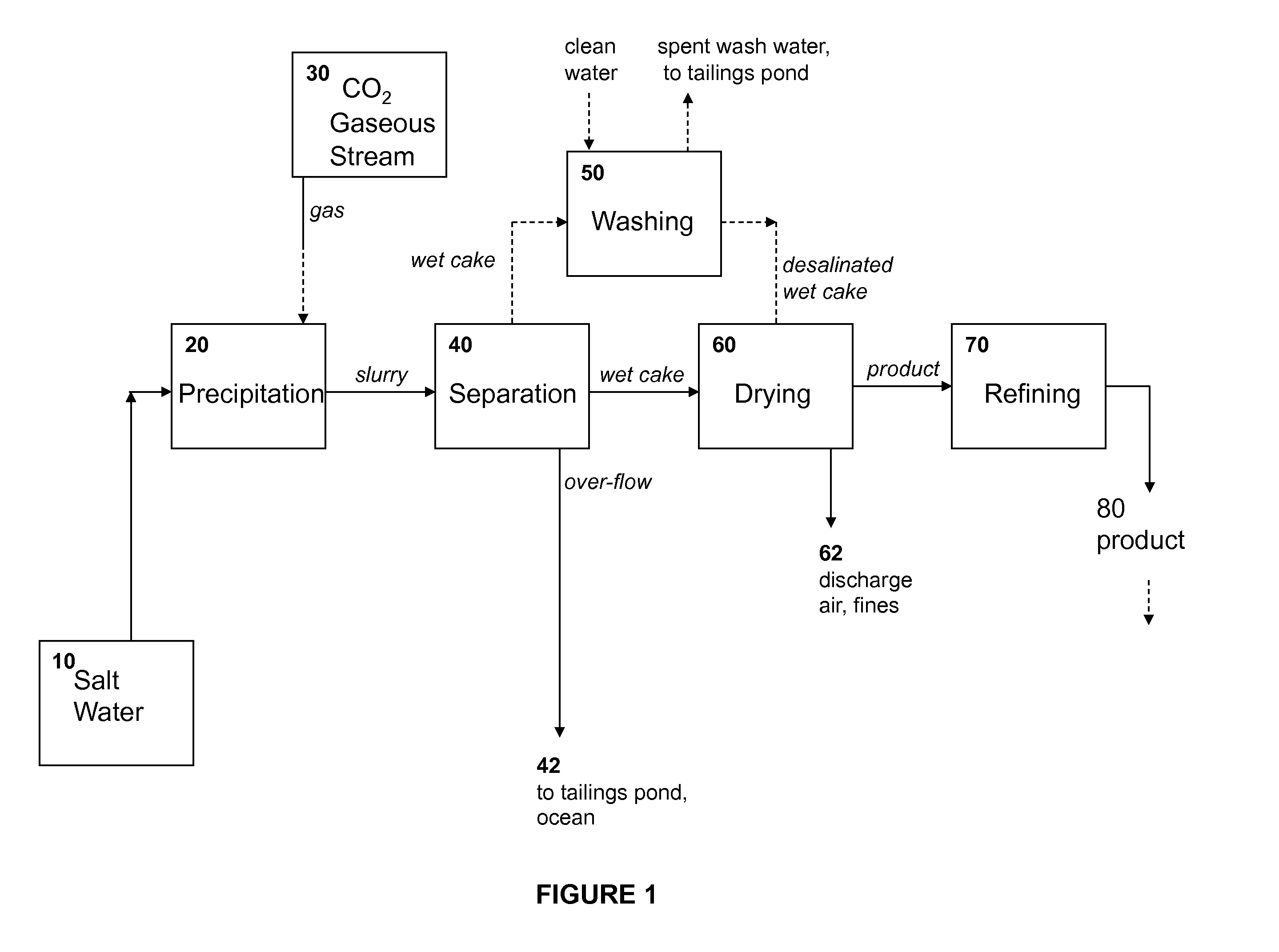

Co2 sequestering soil stabilization composition

InactiveUS20100196104A1Reduce carbon footprintComposition is stableOther chemical processesOrganic fertilisersSoil stabilizationCarbonate

CO2 sequestering soil stabilization compositions are provided. The soil stabilization compositions of the invention include a CO2 sequestering component, e.g., a CO2 sequestering carbonate composition. Additional aspects of the invention include methods of making and using the CO2 sequestering soil stabilization composition. The invention also comprises the method of stabilizing soil and producing a soil stabilized structure utilizing such compositions.

Owner:CALERA CORP

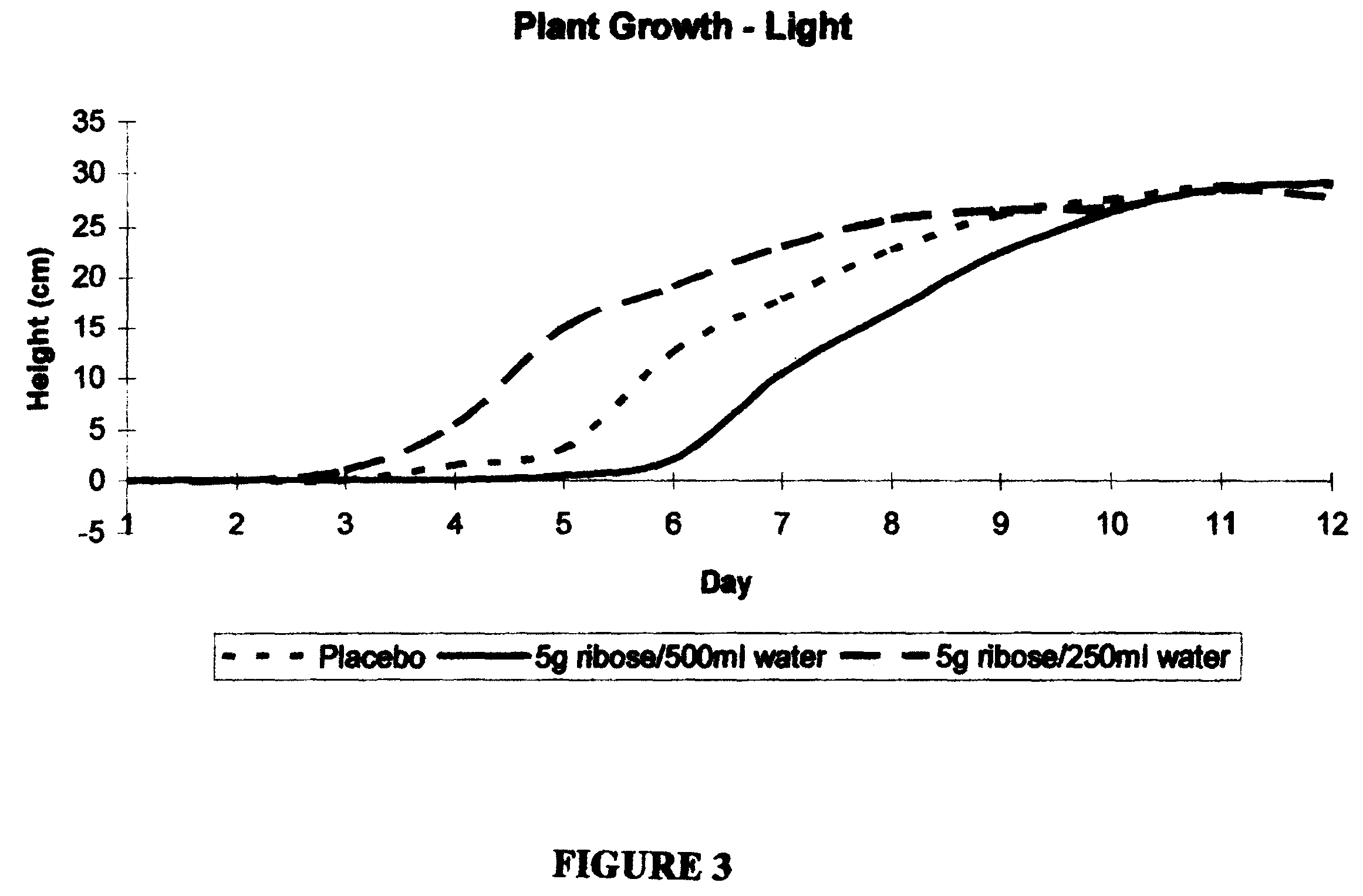

Use of ribose to enhance plant growth

Owner:BIOENERGY INC

Improved soil matrix and remediation method for green mine

InactiveCN109534737AFull of nutritionSuitable for growthGrowth substratesCulture mediaWater storageFriction angle

The invention provides an improved soil matrix and a remediation method for a green mine. According to the improved soil matrix and the remediation method for the green mine, a certain gradient of a mountain is formed by trimming a cliff of the mine, a hard material is laid in a certain mode, then a plastic-coated metal net covers the hard material, and finally, the novel improved soil matrix covers the plastic-coated metal net with a certain thickness so as to realize the effective remediation of the mine. The improved soil matrix and the remediation method for the green mine have the beneficial effects that the improved soil matrix can stably float on the surface of the mine with the gradient of less than 80 degrees, the adhesive force is greater than 20 Kpa, the inner friction angle isgreater than 18 degrees, the anti-corrosion index is greater than 99.1%, the anti-scouring index is greater than 2.0 L.min / g, the structure is high, and scouring of heavy rainfall or heavier can be effectively resisted after three days of spraying; the improved soil matrix is rich in nutrition, loose and breathable, and is suitable for growth of plants; and lots of organic matter such as agricultural and forestry leftovers are adopted, so that the water storage performance is high, and the construction cost and the maintenance cost are greatly saved.

Owner:杰瑞(莱州)矿山治理有限公司

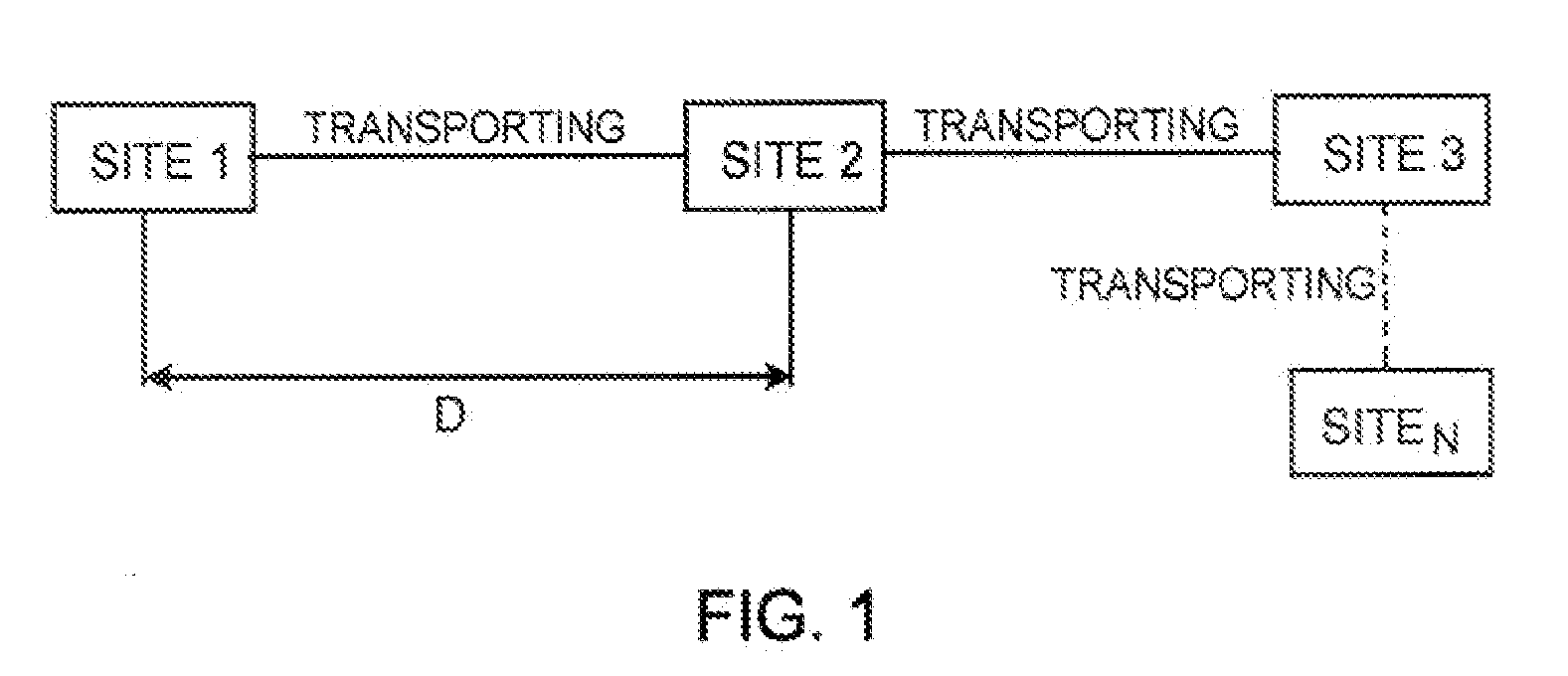

Conversion systems for biomass

ActiveUS20100064746A1Efficient and economical and convenient to moveEasy to transportBio-organic fraction processingBiofuelsBiomass transportationPetroleum

The efficient production of ethanol from low-cost biomass (e.g., corn, sugar beets, sugar cane, switchgrass and / or paper) has become increasingly important in making ethanol competitive with gasoline and decreasing the United States' dependence on foreign oil. For example, to reduce the cost of transporting biomass to ethanol production facilities, mobile systems for producing ethanol from biomass are provided. Also provided are small-scale ethanol production facilities. For example, instead of transporting biomass to the production facility, the facility is transported to the biomass or is located nearby the source of the biomass. The ethanol production facilities or components thereof may be transported via land, water, or air. Production of other products, such as hydrocarbons, natural gas, hydrogen gas, plastics, polymers, and proteins, can also be made by the methods and facilities. Any product described herein can be made in finished form or un-finished form and moved, e.g., to a fixed facility, e.g., fixed production facility.

Owner:XYLECO INC

Biological fertilizer based on yeasts

The present invention provides biological fertilizer compositions that comprise yeast cells that have an enhanced ability to fix atmospheric nitrogen, decompose phosphorus minerals and compounds, decompose potassium minerals and compounds, decompose complex carbon compounds, over produce growth factors, and over produce ATP. The biological fertilizer composition of the invention can replace mineral fertilizers in supplying nitrogen, phosphorus, and potassium to crop plants. Methods of manufacturing the biological fertilizer compositions and methods of uses are also encompassed.

Owner:ULTRA BIOTECH

Slow release nitrogen seed coat

Owner:KOCH AGRONOMIC SERVICES LLC

Competitive and Effective Bacterial Strains

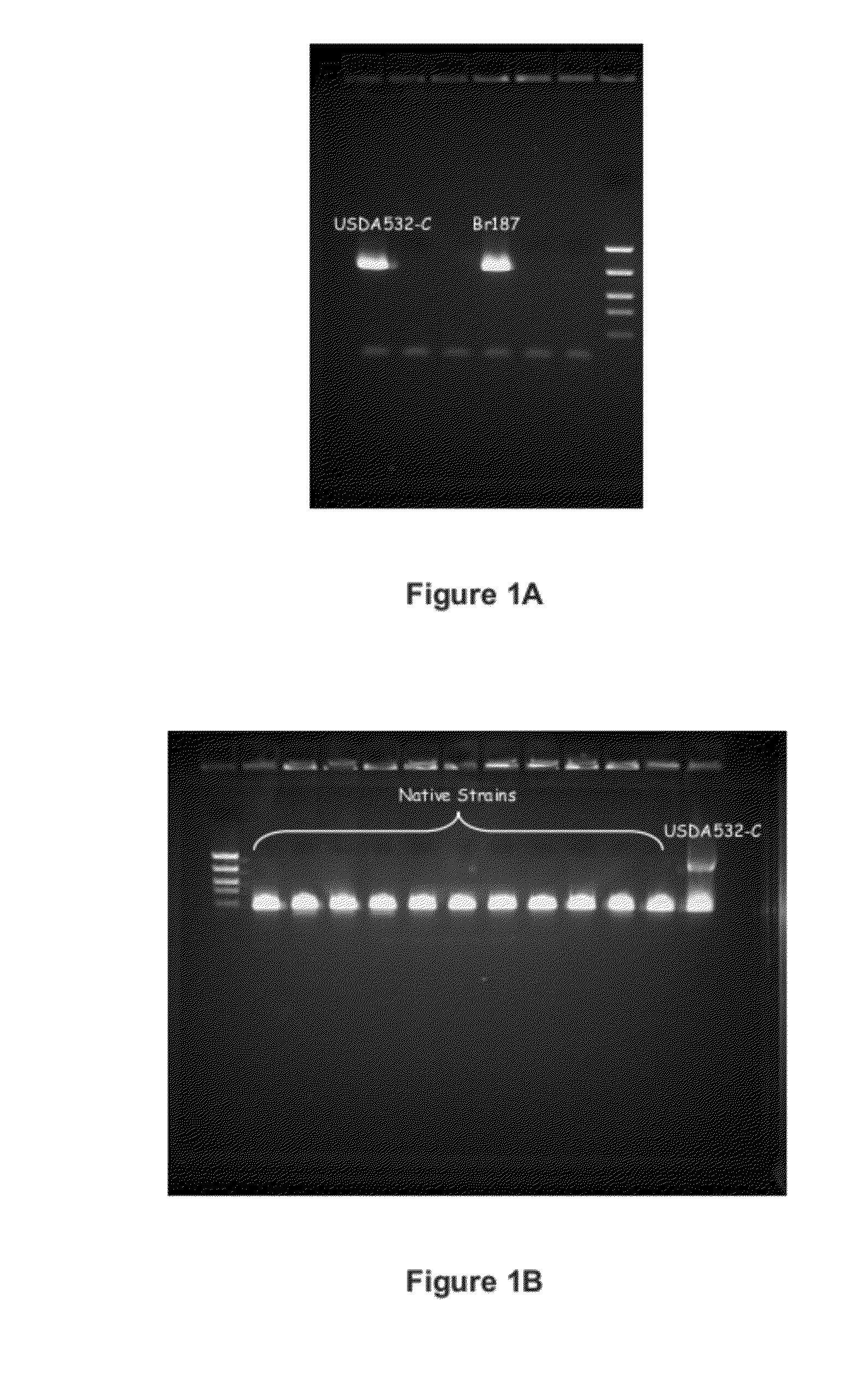

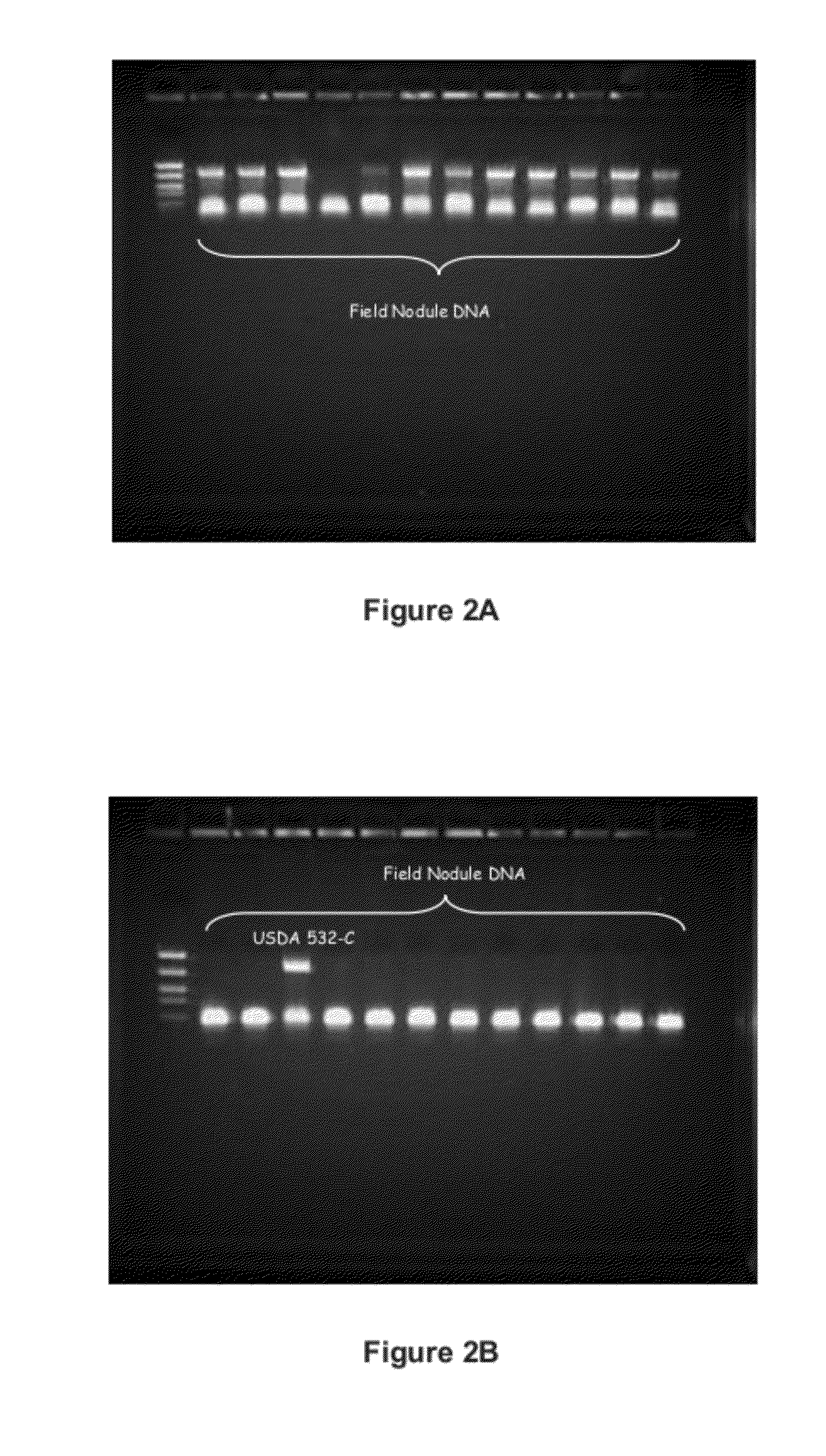

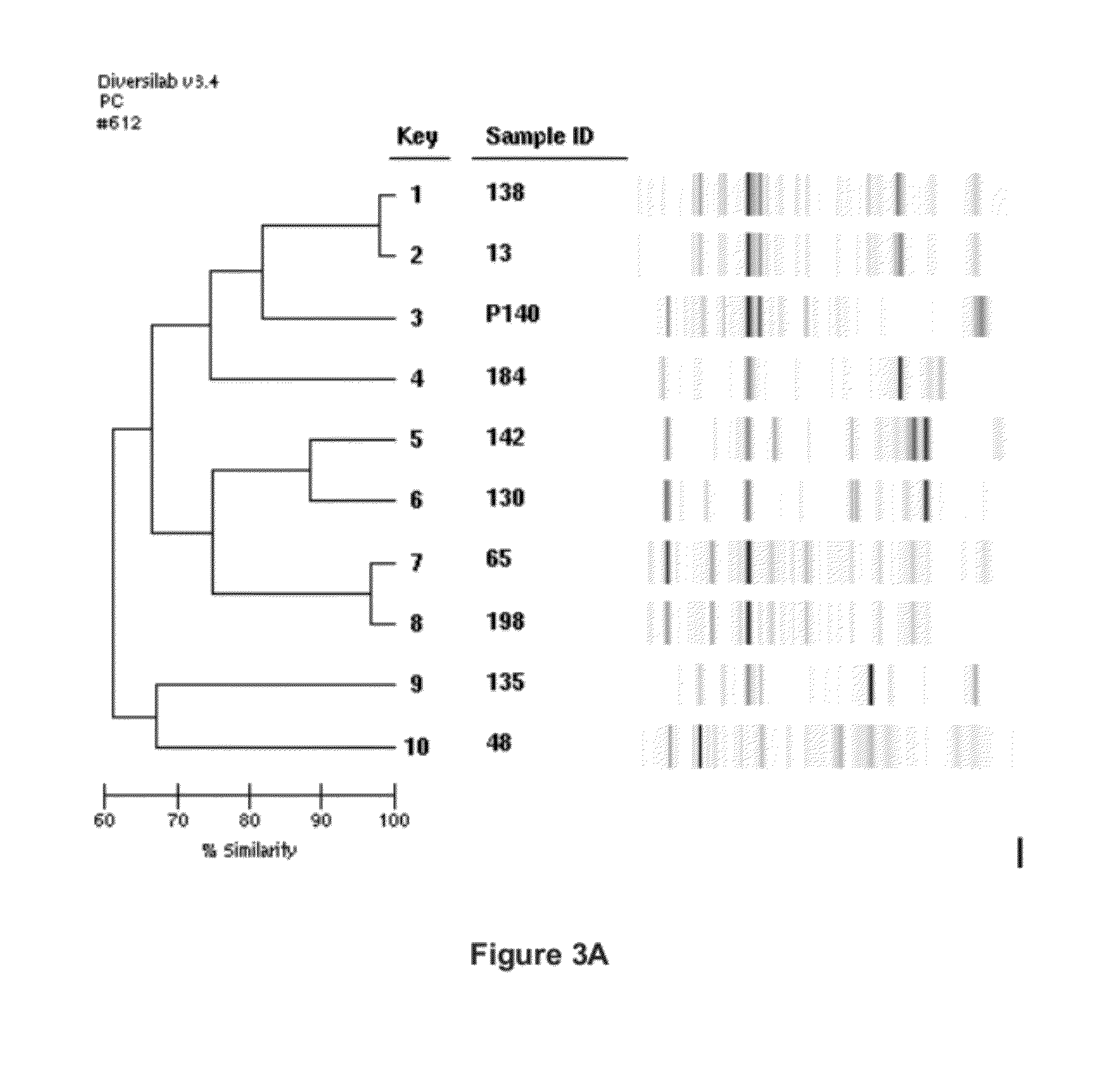

ActiveUS20120252672A1Improve availabilityImprove plant health of plantBiocidePlant growth regulatorsBacteroidesGrowth plant

According to the present invention new isolates of bacterial strains have been shown to possess unique properties. These bacterial strains are plant growth-promoting rhizobacterium (PGPR), posses an enhanced competitive advantage at colonizing leguminous plants, and enhance the overall performance of leguminous plant growth. Further still, the present invention discloses a novel method for screening and selecting bacterial strains having the aforementioned beneficial characteristics.

Owner:NOVOZYMES BIOLOGICALS

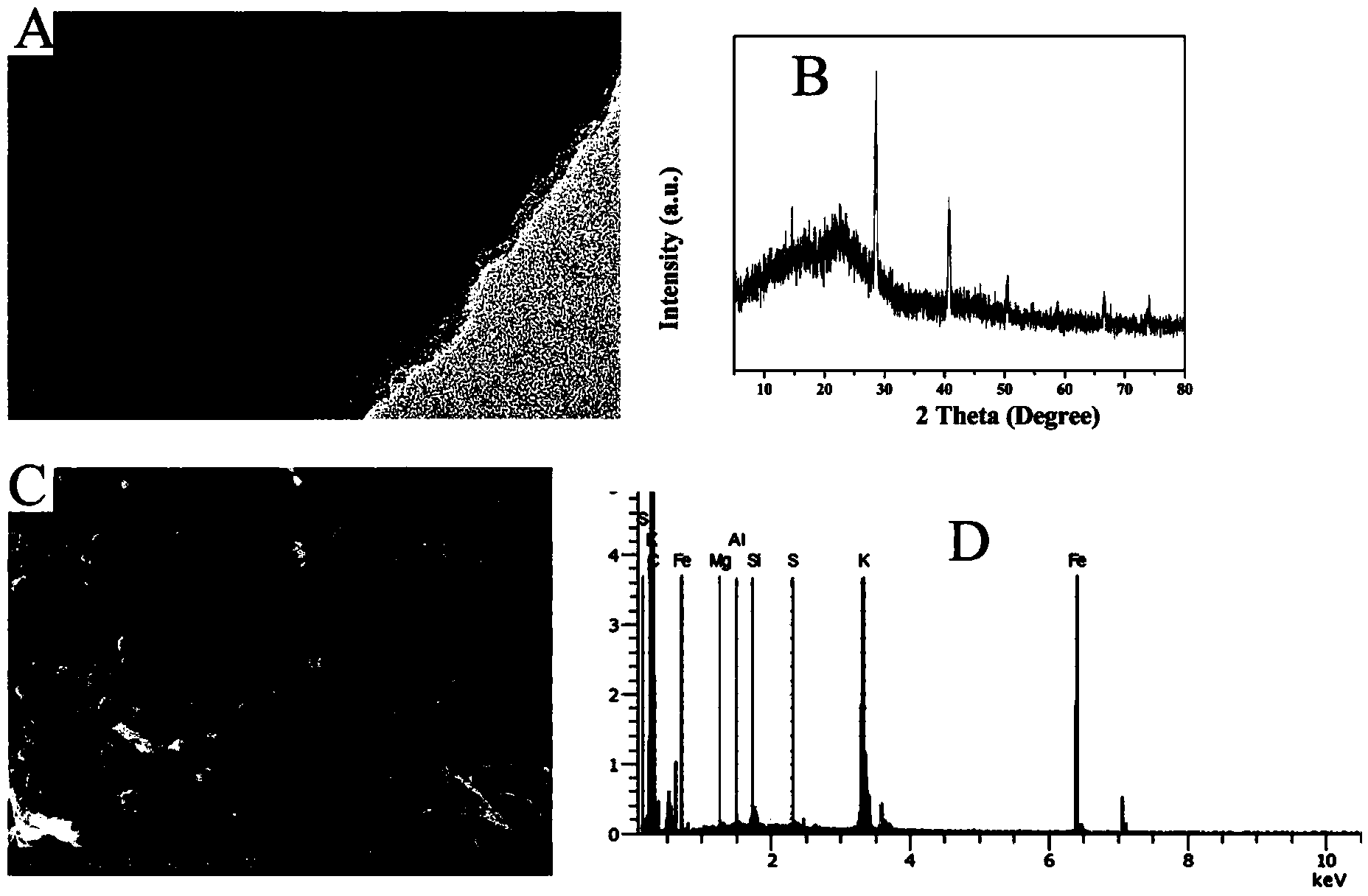

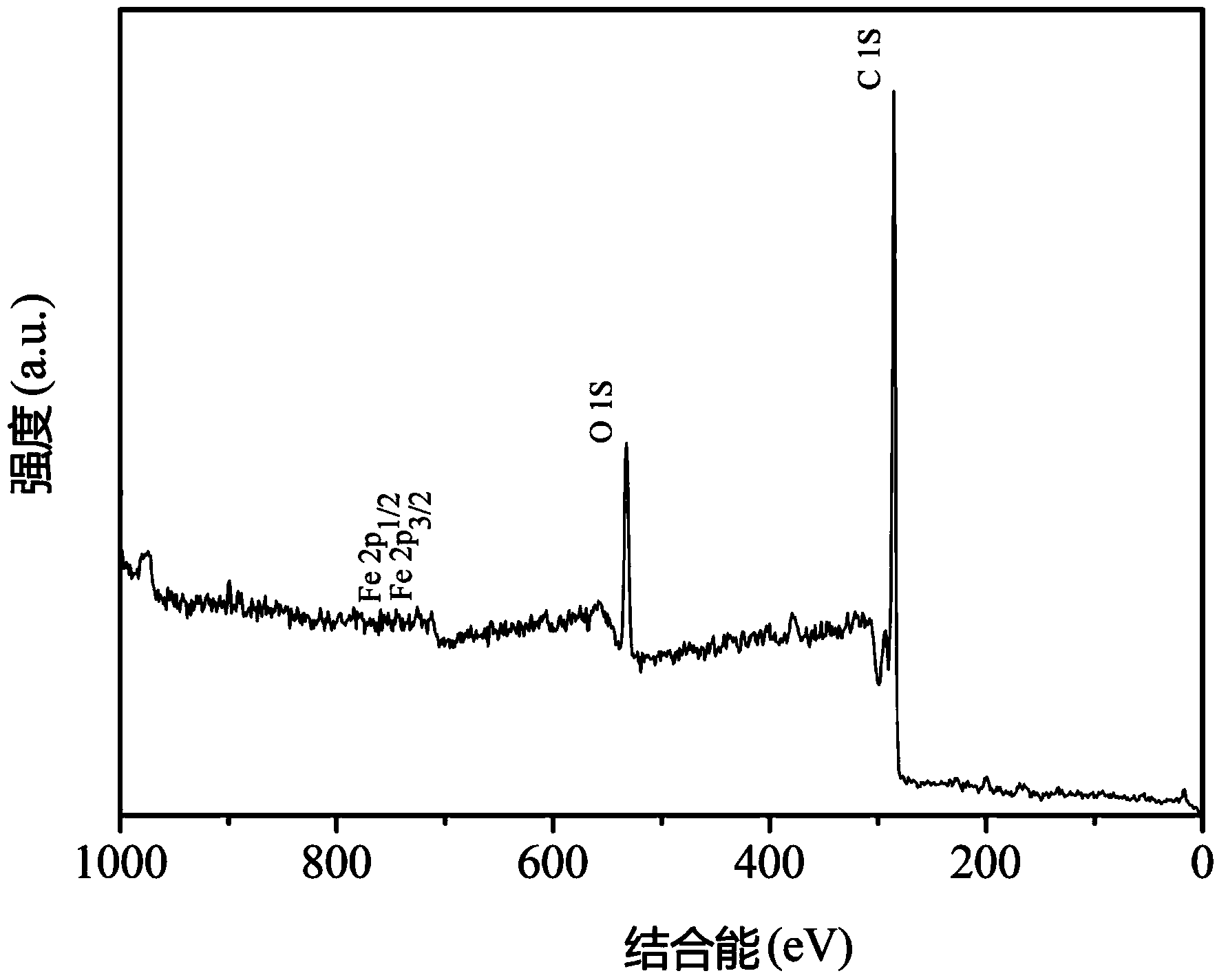

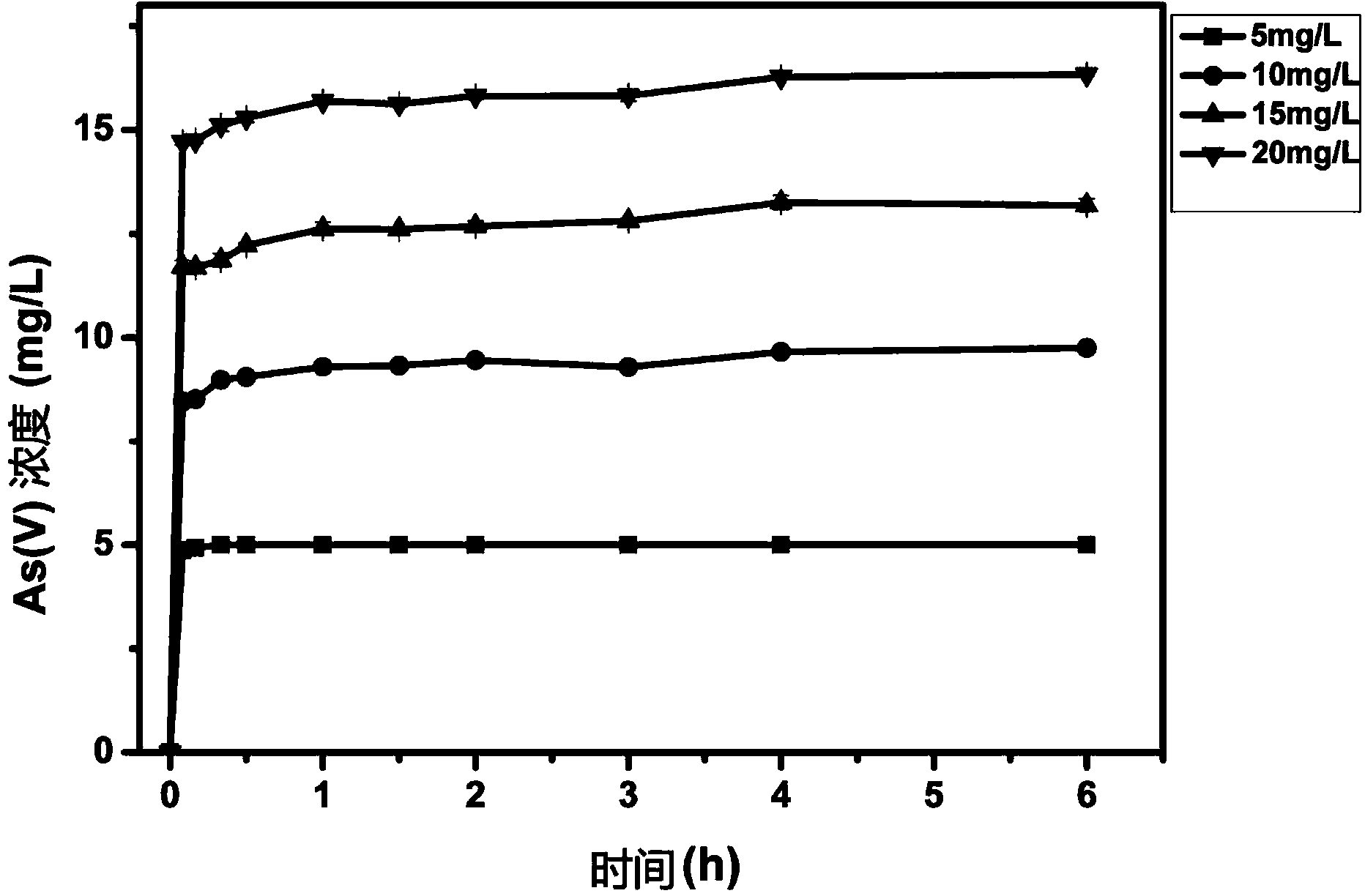

Iron-based bio-char material, preparation process thereof, and application thereof in soil pollution treatment

ActiveCN104388094AImprove performanceReduced bioavailabilityTransportation and packagingContaminated soil reclamationCarbonizationSoil heavy metals

The invention relates to the technical field of soil heavy metal remediation, and specifically discloses a method for preparing an iron-based bio-char material, a prepared iron-based bio-char material, and a method for applying the iron-based bio-char material in treating soil heavy metal pollution. According to the material, biomass is adopted as a raw material; a high-temperature carbonization method is adopted; during the bio-char preparation process, an iron-containing compound is added, such that iron is doped according to a certain ratio, and the iron-based bio-char material with special structure and function is formed. The material has the advantages of simple preparation process, low production cost, and short production period. The obtained iron-based bio-char material has a unique effect in repairing arsenic-cadmium composite polluted soil. With the material, bio-availability of arsenic and cadmium in soil can be effectively reduced, arsenic and cadmium contents in agricultural products planted in the arsenic-cadmium composite polluted soil can be greatly reduced, and no toxic or side effect is caused on crops. The material is safe to apply, and can be used in a large scale in treatment of arsenic-cadmium composite polluted soil.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

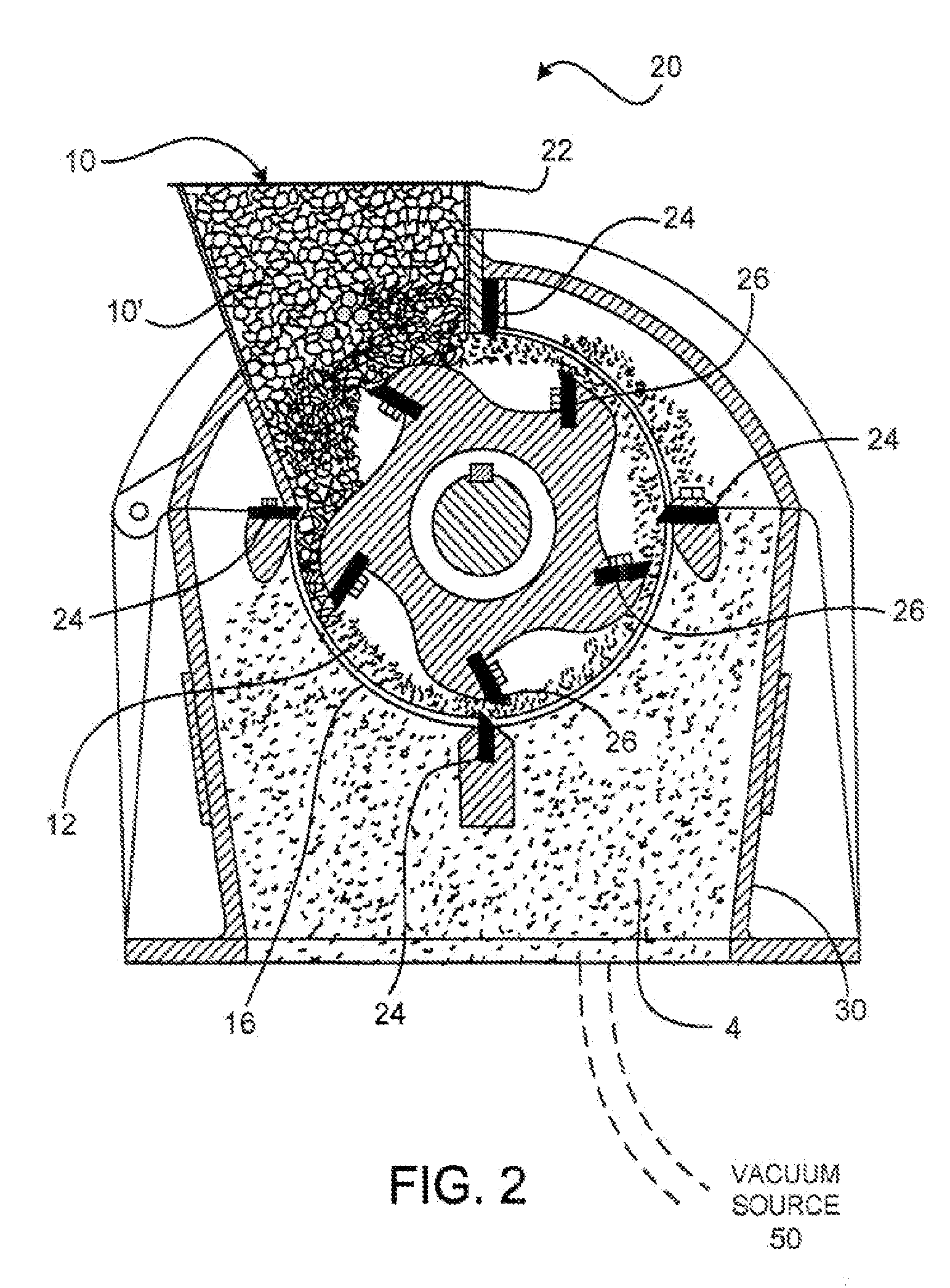

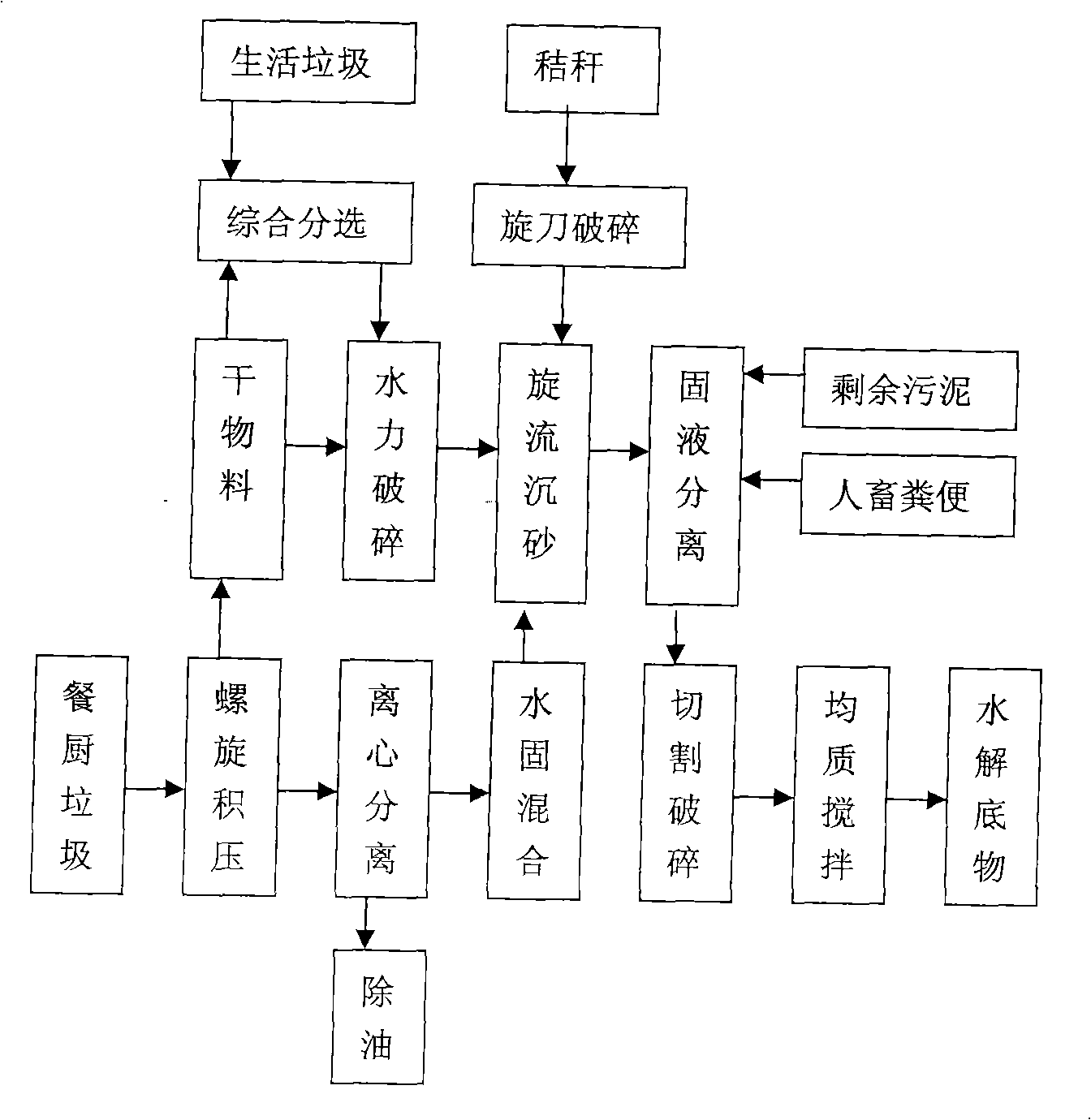

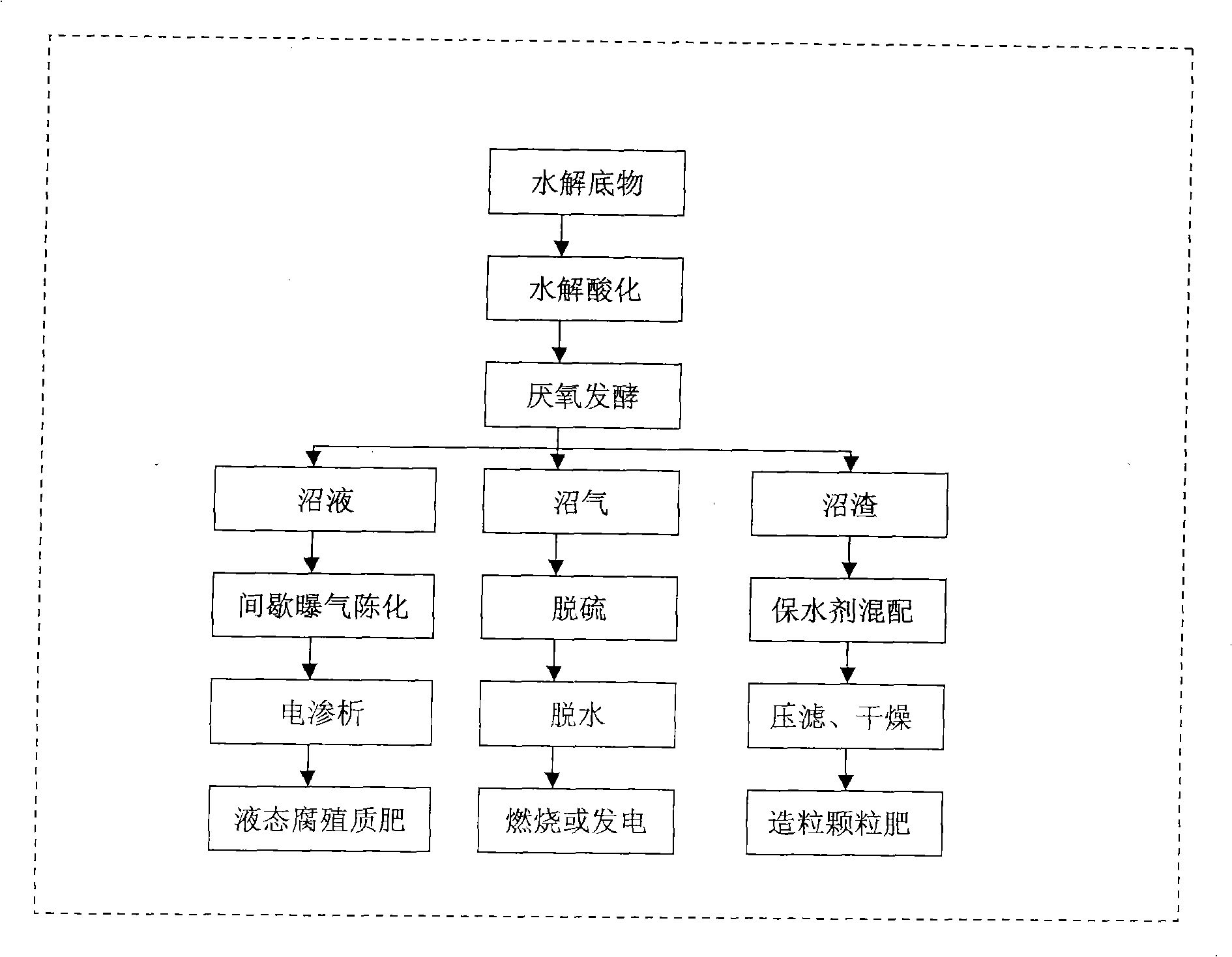

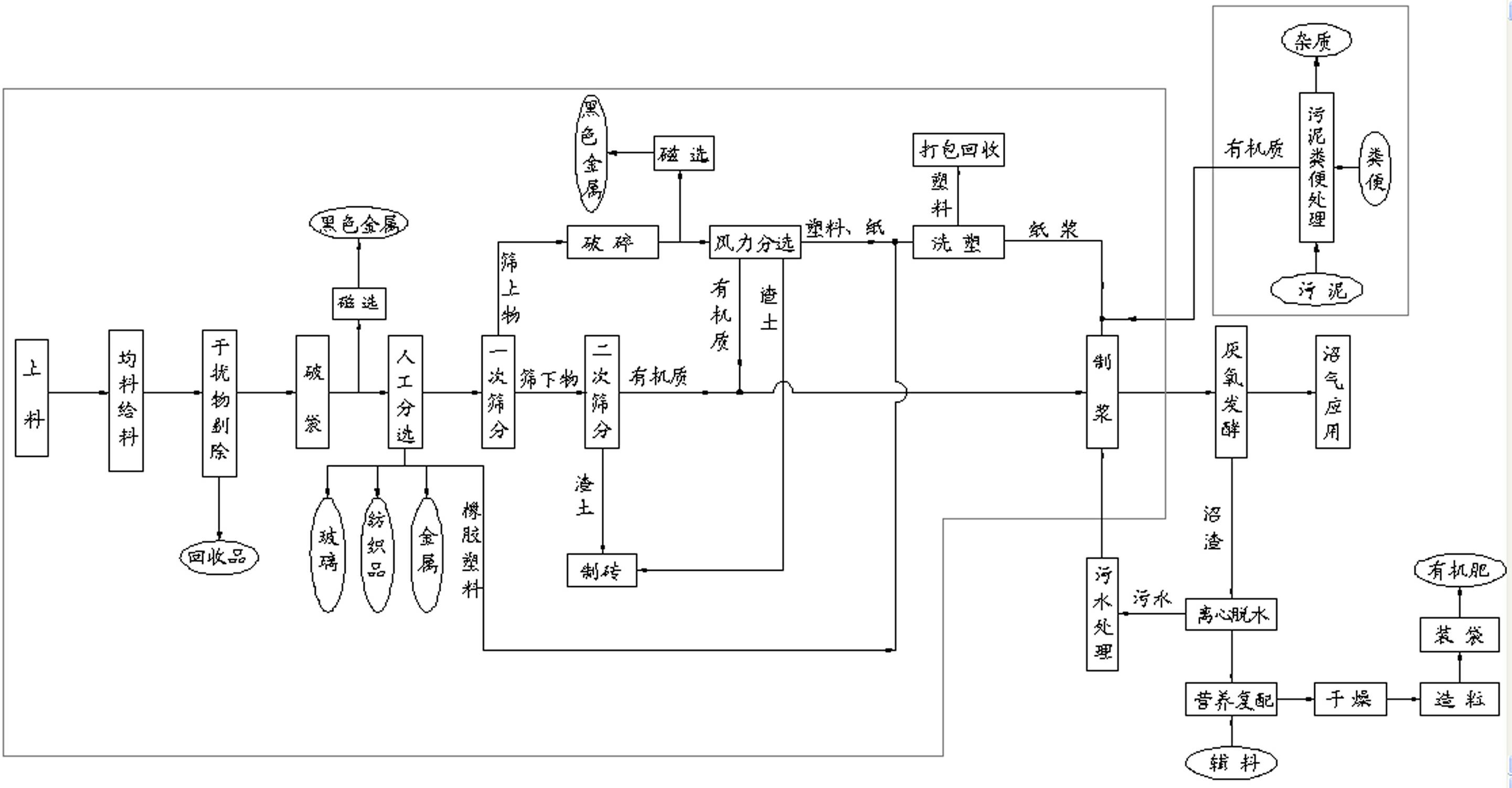

Combined anaerobic fermentation process for organic solid wastes

InactiveCN101337838AReduce consumptionImprove mass transfer efficiencyBio-organic fraction processingClimate change adaptationSludgeAnimal feces

The invention discloses a combined anaerobic fermentation method of organic solid wastes. The organic solid wastes used for the combined anaerobic fermentation include domestic wastes, excess sludge, feces, kitchen waste, straws, etc. The method comprises the following steps: carrying out different pre-processing processes to obtain organic materials with a granularity less than 5 mm; passing through a cutting pump, adjusting the C / N ratio, adjusting the water content, etc. to obtain a homogeneous fermentation substrate with a solid holdup of 2 to 10%; hydrolyzing and acidifying the fermentation substrate in the presence of a hydrolase; fermenting for a period of 15 to 25 days under the condition of stirring at a middle temperature of 32-38 DEG C to obtain biogas, which can be used for energy supply or output of a system; aging and desalting the biogas liquid to obtain a liquid humic acid fertilizer; and processing the biogas residues to a granular humic acid fertilizer. The fermentation substrate has proper C / N ratio to obviate feedback suppression of the substrate during the fermentation of a single material and simultaneously can enhance the hydrolysis effects of celluloses, lignin, hemicelluloses, etc. The method has the advantages of easy flow pattern control, low energy consumption, and no generation of sewages, and can obtain the high-quality biogas fluid and the high-quality granular humic acid fertilizer.

Owner:鄂尔多斯市城市矿产研究开发有限责任公司

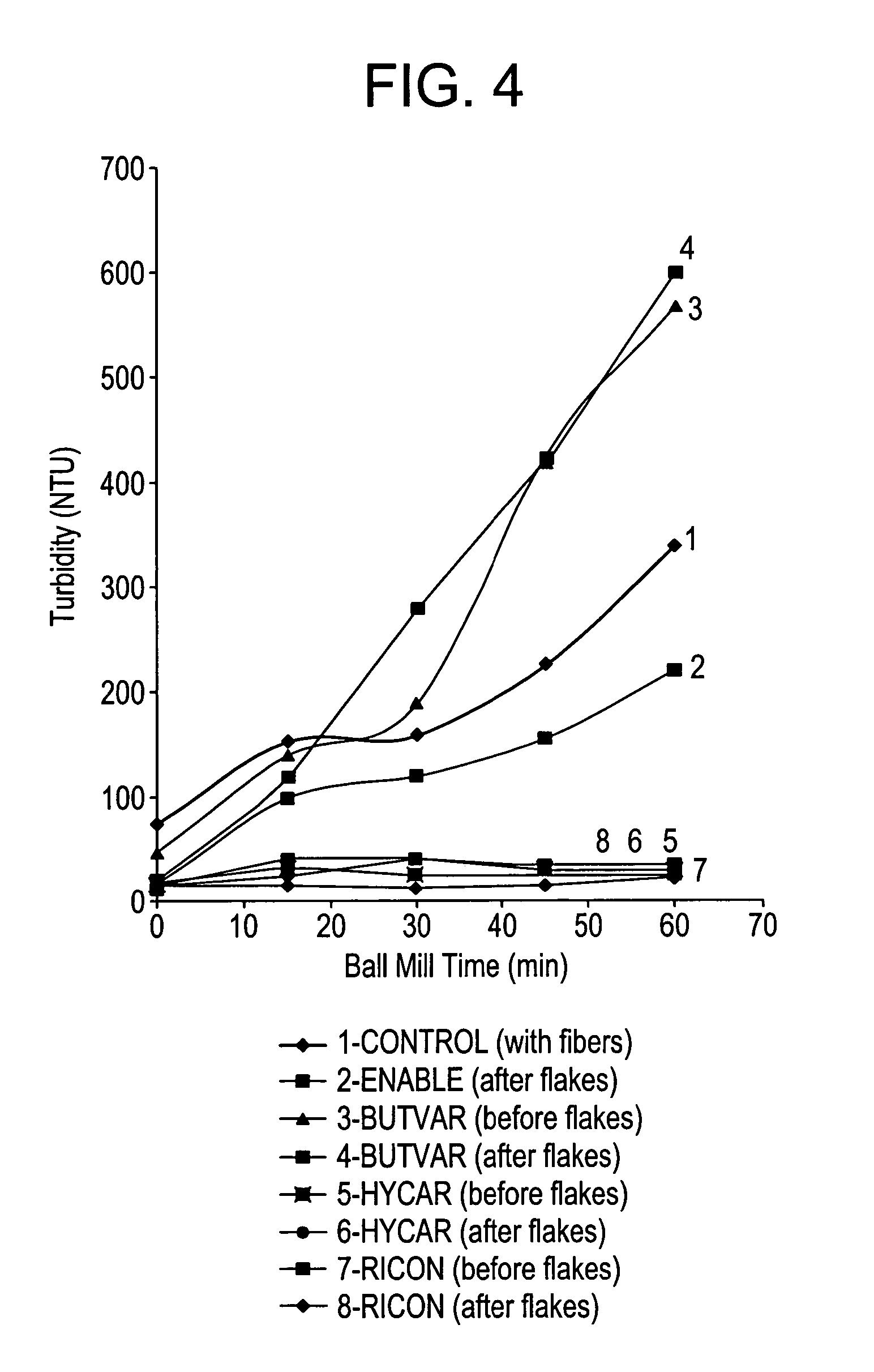

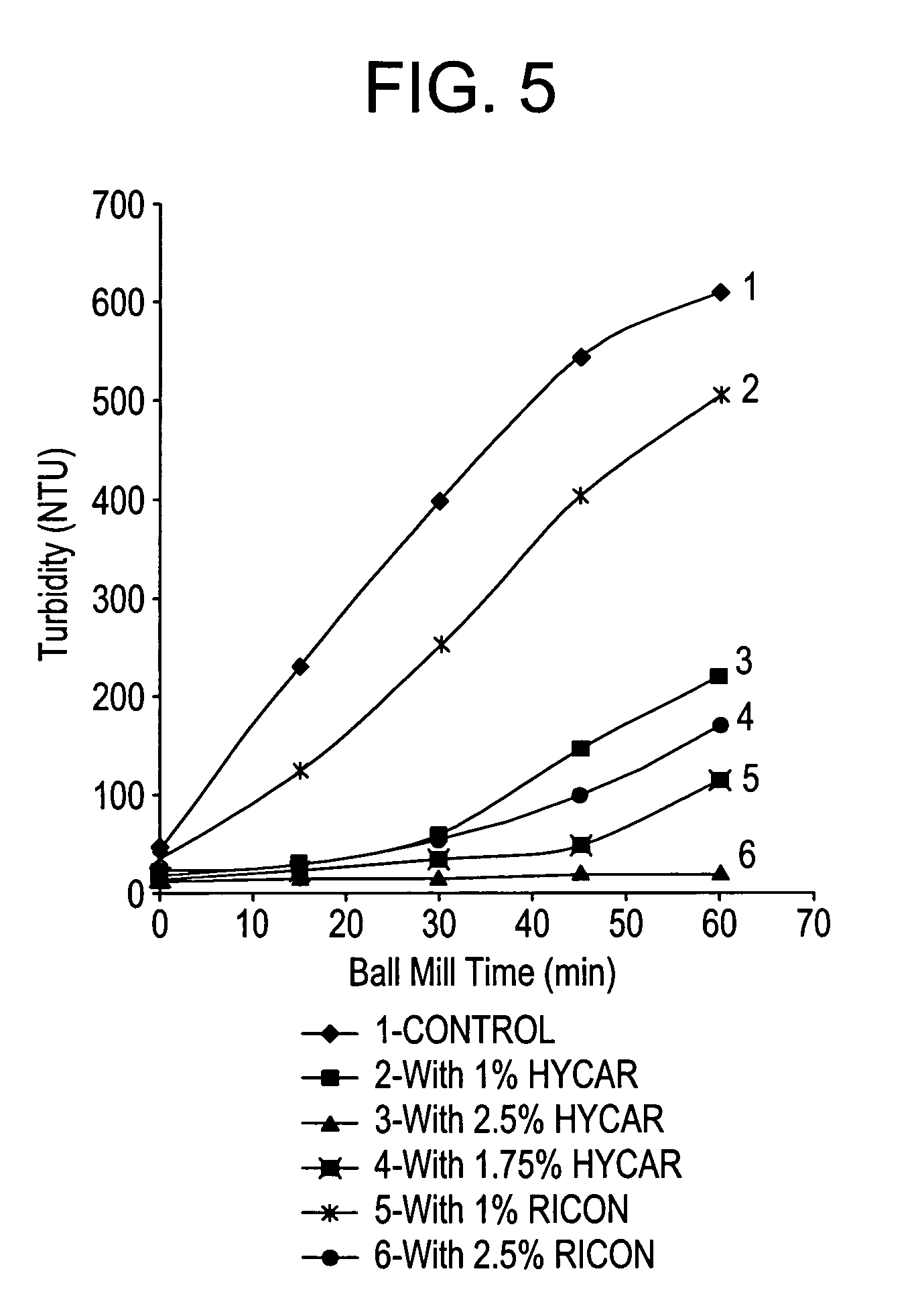

Particulate material containing thermoplastics and methods for making and using the same

ActiveUS7270879B2Trend downImprove abilitiesPretreated surfacesGlass/slag layered productsParticulatesThermoplastic

Disclosed herein is a particle comprising a particulate substrate; and a thermoplastic elastomer present on or in the substrate as an amount sufficient to improve the dust suppression of the particle above that which would occur if the thermoplastic elastomer was absent. Disclosed herein is a particle comprising a particulate substrate; and a thermoplastic elastomer, wherein the particle has a compressive strength retention of greater than about 50% as measured by a UCS test and a turbidity of about 10 to 200 NTU after a one hour ball mill test.

Owner:HEXION INC

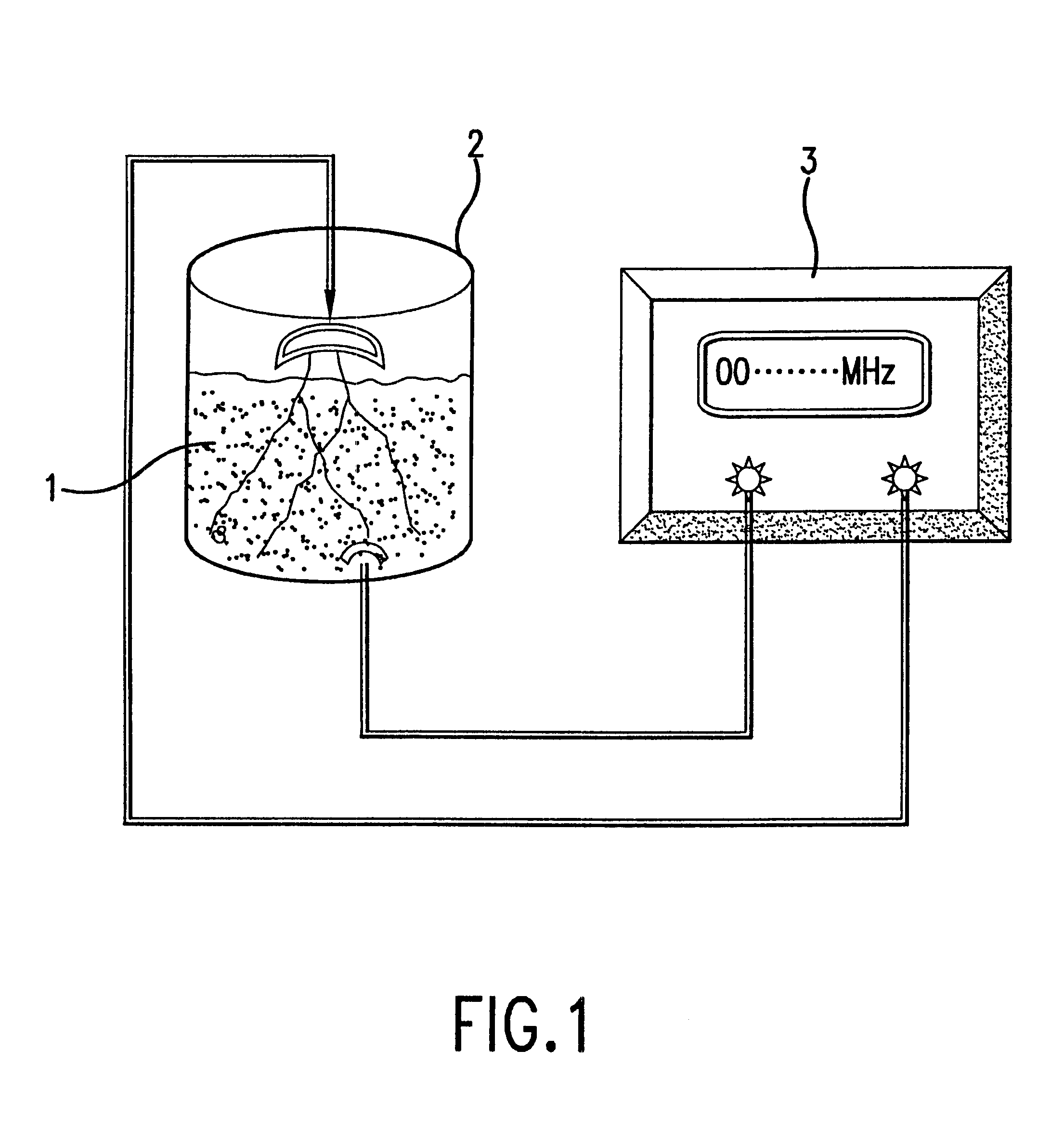

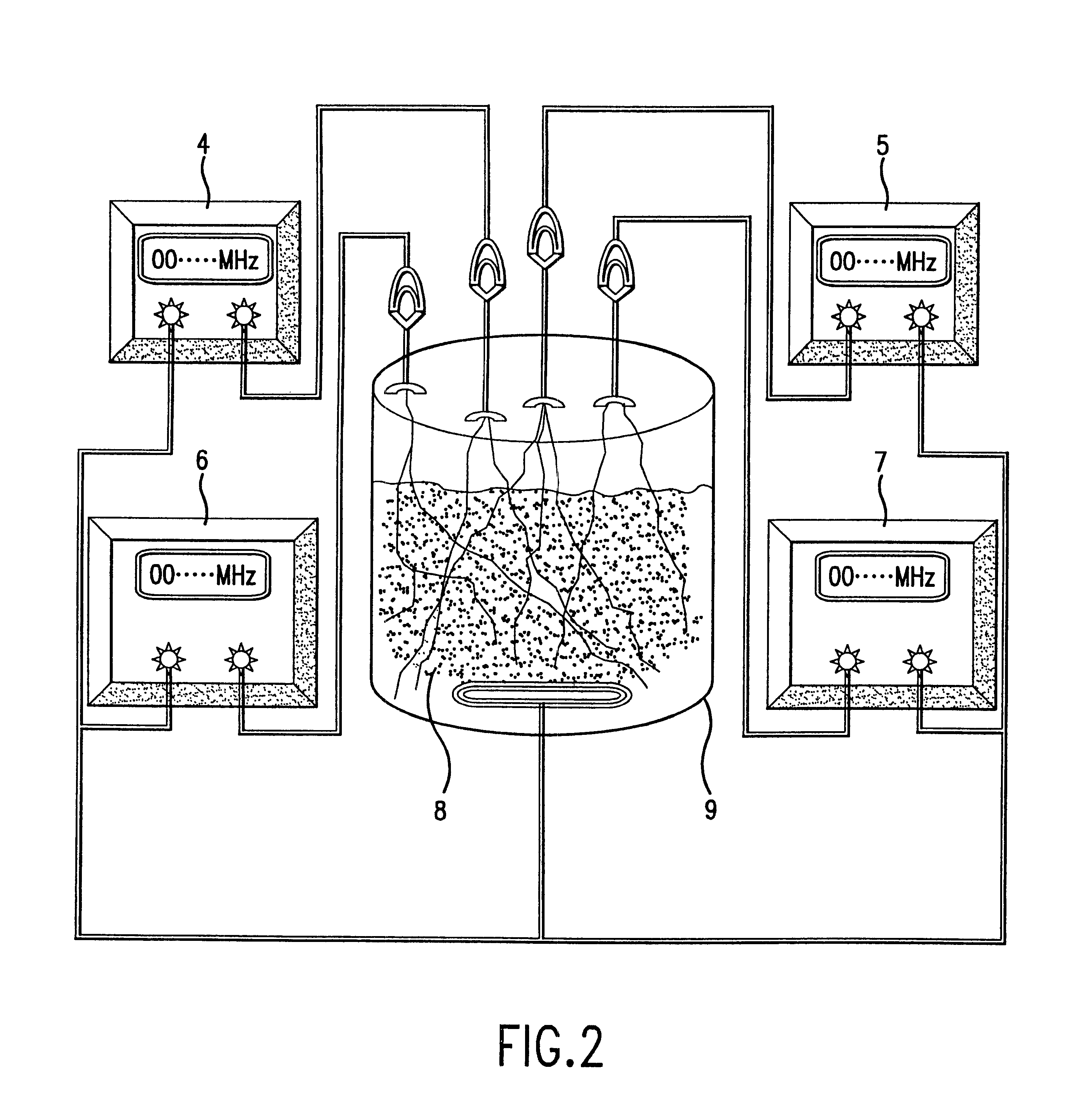

Method for preparing foliage fertilizer containing nucleic acid degradation product

InactiveCN101186534AFast absorptionPromote growthOrganic fertilisersNucleic acid metabolic processPurine

The invention relates to a preparation method of a foliar fertilizer which comprises nucleic acid degradation products. The invention is characterized in that: malt sprout is employed to obtain nuclease liquid with a low temperature water extraction method, nucleic acid solution and enzyme solution are blended according to a proportion by weight of 1 : 2 to 3 portions of nucleic acid and malt sprout, and the solution is hydrolyzed at a temperature of 65 DEG C and a condition of pH 5.6 for 3 to 4 hours, then a nucleic acid degradation product foliar fertilizer is obtained after enzyme dispelling, filtering, enzyme and milling. The preparation method of the invention is characterized by simple technique, easily available raw material, pollution free exhaust and low production cost; the prepared nucleic acid degradation products of the foliar fertilizer are nucleosides, nucleotides, pyrimidine, purine and other micromolecule, thus being beneficial to the metabolism process of nucleic acid, and the invention also contains a great amount of nutrient components such as glucide, protein and minerals, etc., which are needed by the growth of crops, thus promoting the growth of crops, strengthening resistance and obviously improving yield and quality; the yield of wheat is improved by 7 to 10 percent, protein content is improved by 1 percent and wheat gluten content is improved by 3 percent; solution is prepared by the foliar fertilizer of the invention according to requirements of the growth of crops to spray; absorption speed of foliage is fast, and brings no pollution to soil; the foliar fertilizer is a non polluted green fertilizer.

Owner:MICROBIOLOGY INST OF SHAANXI

Water absorbing hydrogels and methods of making and use thereof

The invention is directed to a crumbly, water-absorbing, soil-like hydrogel. The hydrogel comprises finely comminuted mineral substances, such as igneous rock; water-soluble alkali-silicate; solid and liquid nutrient additives; and ballast, bound in a cross-linked polymer. The hydrogel is structured like a sponge and absorbs water and liquids when in contact with water or aqueous liquids. The mineral substances present in the hydrogel may be present in an amount of at least 30% by weight of the dried hydrogel. Also, the invention encompasses methods of producing acidic and neutral to weakly alkaline hydrogels.

Owner:GEOHUMUS

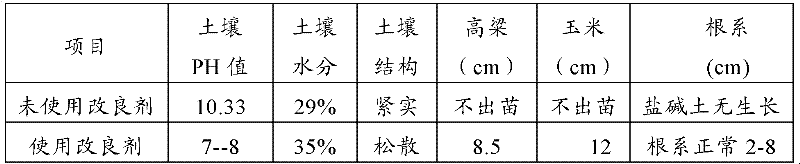

Saline-alkali soil improver

InactiveCN102517030ALower pHRaise the pHOther chemical processesOrganic fertilisersCis-Butenedioic AcidFatty alcohol

The invention relates to an improver for saline-alkali soil. The improver comprises a powder agent and a water agent, wherein the powder agent comprises the following components: organic matters, plant mycelium protein powder, active calcium, calcium superphosphate, aluminum sulfate, fatty alcohol polyoxyethylene ether ammonium sulfate, amino acid powder, bacillus subtilis and photosynthetic bacteria, and the water agent comprises the following components: citric acid, fulvic acid, humic acid, malic acid, maleic acid, fumaric acid, L-tartaric acid, pyrophosphoric acid, humic acid, lactic acid, oxalic acid, salicylic acid, sodium ion adsorbent, Tween-80 and water. The improver disclosed by the invention can improve the soil from multiple angles, namely soil structure, microorganism species, a chemical method and the like, obviously promote the release of iron and phosphorus in the soil, improve the soil structure, effectively reduce the content of sodium ions in the soil, reduce the pH value of the soil and restore land to a normal planting state after being used continuously for two years.

Owner:孙东军 +1

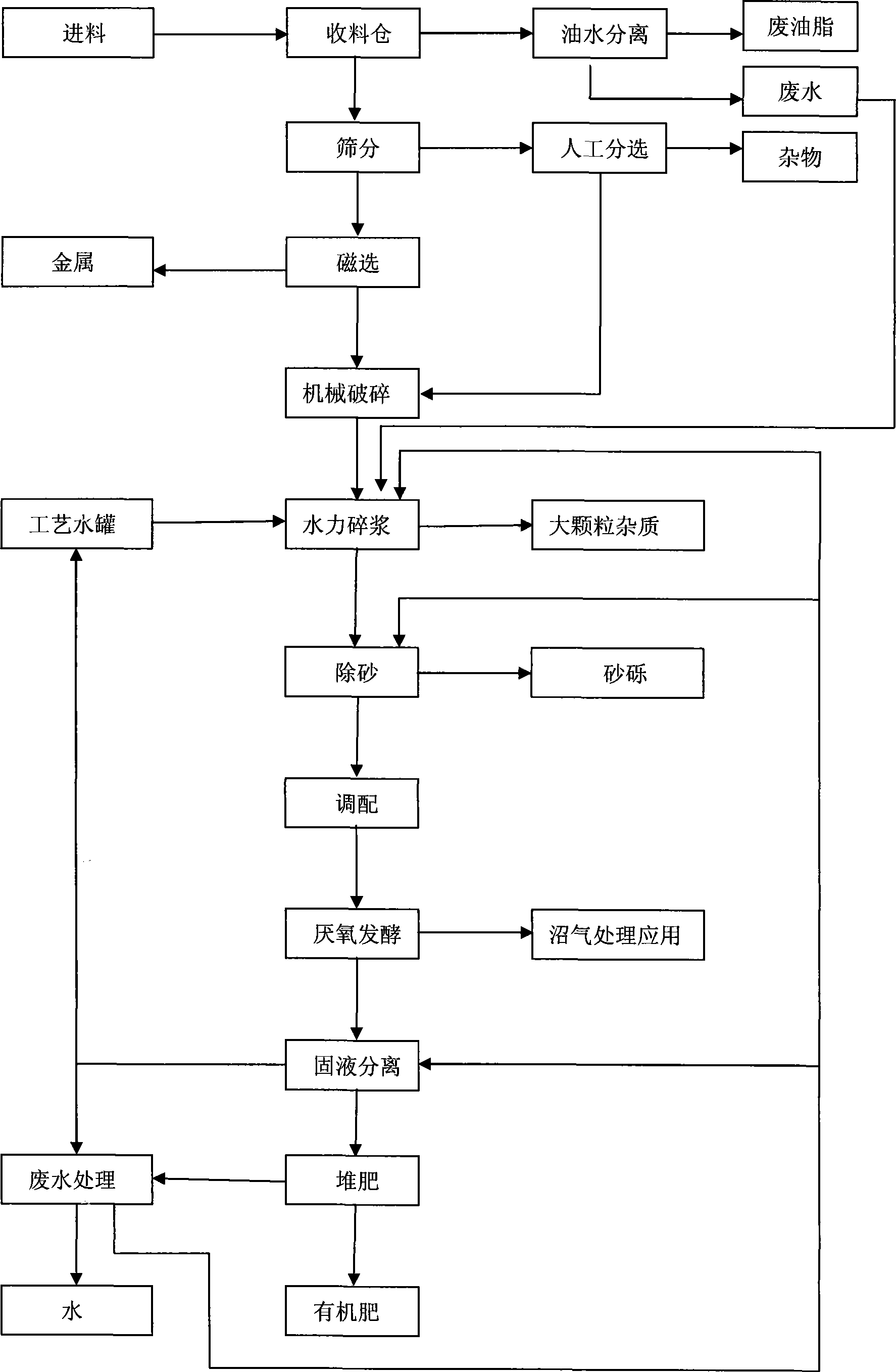

Anaerobic digestion handling method for restaurant garbage

ActiveCN101224999AHarmlessRealize resource processingBio-organic fraction processingClimate change adaptationSlurryOxygen

The invention provides a method for resourceful treatment of restaurant garbage, which is characterized in that the restaurant garbage is completely degraded after treatment with the working procedures of oil separating, preliminary selecting, mechanical crushing, hydraulic pulping, slurry blending, anaerobic fermentation and oxygen-control composting, finally the marsh gas is decomposed via anaerobic digestion and is utilized as energy after desulfurization treatment; the high-quality organic manure is produced from the biogas residues via oxygen-control composting; the separated oil can be recycled as the regenerated industrial raw oil; the wastewater generated in the treatment process can be recycled, and finally the redundant wastewater reaching the standard is discharged after biochemical treatment; and the odor generated by the garbage in the treatment process is directly discharged after reaching the standard via biofiltration treatment, thus the restaurant garbage can be transformed into the clean regenerated energy of electric power and the pollution-free organic manure to completely realize resourceful treatment of restaurant garbage. The resourceful treatment of restaurant garbage has the advantages of innocuity, no peculiar smell, no secondary pollution during the treatment process and realization of harmless and resourceful treatment of restaurant garbage.

Owner:宝林

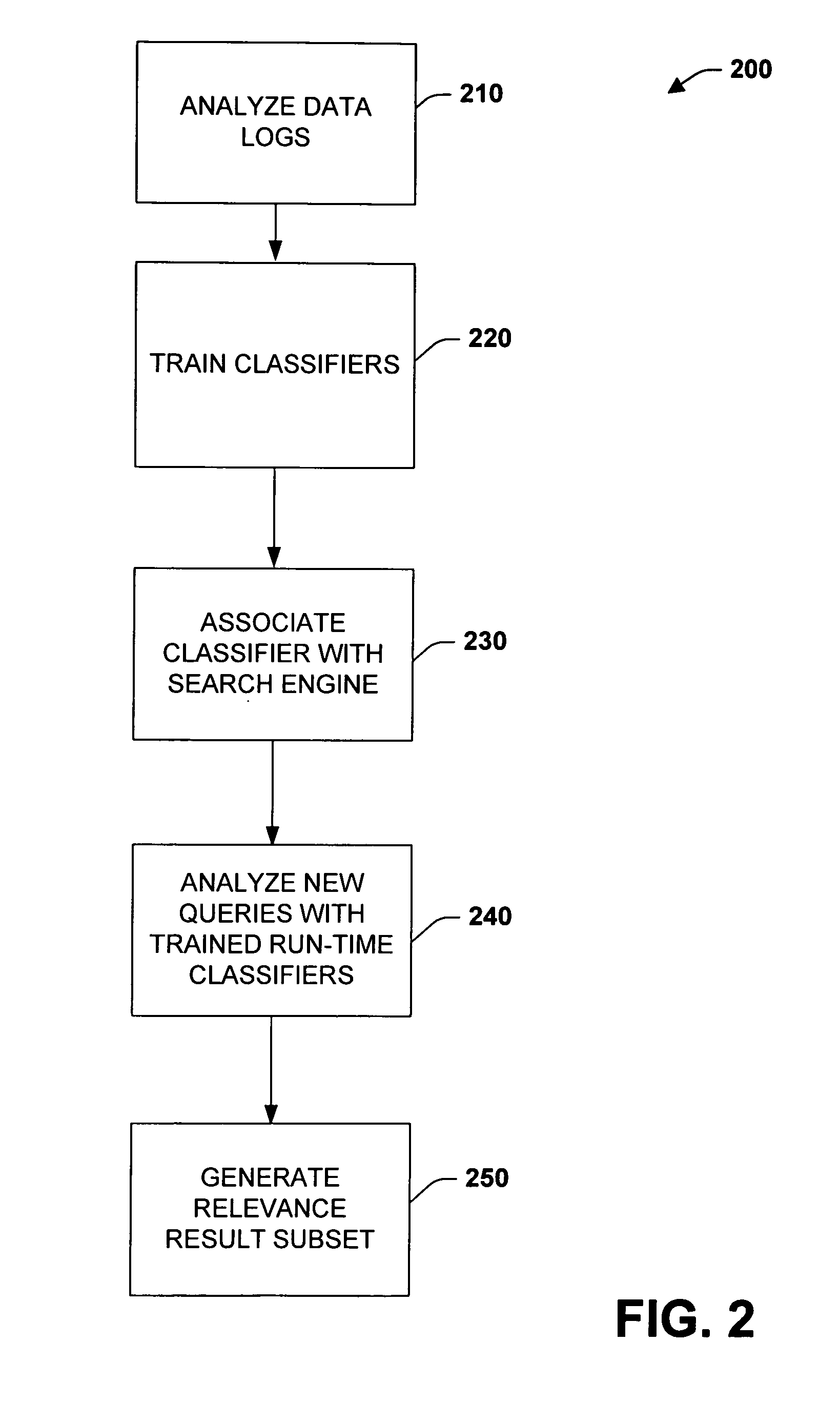

Microbial decomposing agent and production method thereof

ActiveCN102531766AReduce volatilityAccelerated ripeningOrganic fertilisersFertilizer mixturesMicroorganismLitter

The invention relates to a microbial decomposing agent and a production method thereof. The microbial decomposing agent consists of the following components in percentage by weight: 8 to 30 percent of compound microbial inoculant, 40 to 70 percent of organic material and 15 to 35 percent of mineral, wherein microbes in the compound microbial inoculant consist of bacteria, fungi and actinomycetes. The microbial decomposing agent can quickly decompose organic waste.

Owner:北京世纪阿姆斯生物技术有限公司

Use of fungal organism pythium oligandrum

InactiveUS20130035230A1Promote germinationDevelopmentBiocideFruit and vegetables preservationMicroorganismOrganism

The invention concerns the application of the fungal organism Pythium oligandrum as a strong mycoparasite in connection with the applicable inorganic or organic carrier of the efficient agens as a preparation for additional fertilization and for protection of plants against the originators of microbial diseases and as a preparation for the elimination of post-harvest losses and losses during storage of commodities coming from plant or animal production, including the preparation for the liquidation of wood-destroying fungi. The application of the preparation for the protection of plants against the originators of microbial diseases can also be performed in the form of aerial spraying.

Owner:BIOPREPARATY SPOL

Comprehensive treating system for domestic wastes

InactiveCN102527701AIncrease productionImprove qualityBio-organic fraction processingWaste processingSludgeOrganic manure

The invention discloses a comprehensive treating system for domestic wastes. Reutilizing comprehensive treatment for mixed wastes is realized by the system according to a comprehensive sorting technology and a combined anaerobic fermentation technology, wherein the advanced sorting techniques, such as, crushing, magnetic separating, sieving, air classifying, and the like, are adopted in the comprehensive sorting technology; reutilized products, such as metal, plastics, organic matters, and the like, are screened out; the screened organic matters are prepared into slurry together with sludge and excrements and are then subjected to the combined anaerobic fermentation; the reutilized products, such as methane, organic fertilizer, and the like, can be produced under the action of anaerobic fermentation; and after the methane is purified, the methane is used for generating power, domestic fuel or vehicle-mounted fuel. According to the technology, the intensified treatment for organic wastes, such as domestic wastes, sludge, excrements, kitchen wastes, and the like, can be realized. The comprehensive treating system is high in mechanical and automated degree. Compared with the prior art, the comprehensive treating system has the advantages of simplification, effectiveness, less labor power, and the like.

Owner:BEIJING HAOHAI TIANJI TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com