Patents

Literature

1048 results about "Cis-Butenedioic Acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Saline-alkali soil improver

InactiveCN102517030ALower pHRaise the pHOther chemical processesOrganic fertilisersCis-Butenedioic AcidFatty alcohol

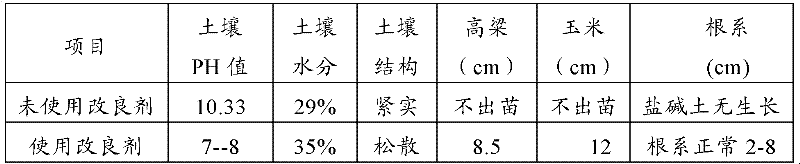

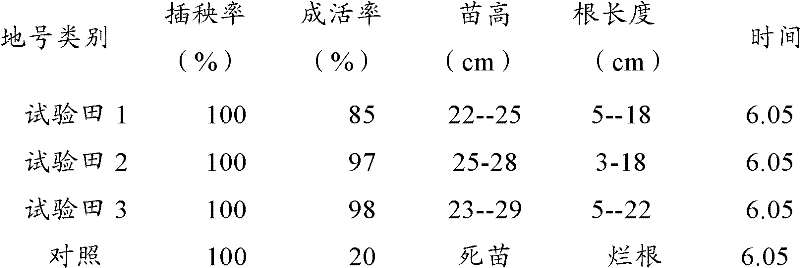

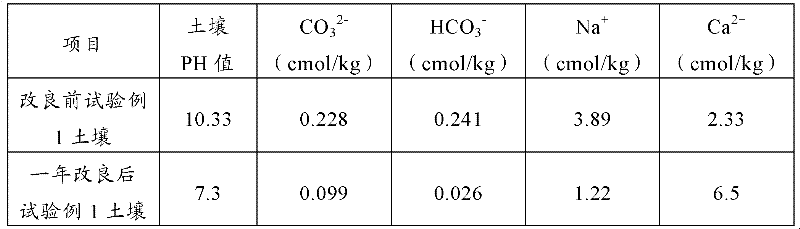

The invention relates to an improver for saline-alkali soil. The improver comprises a powder agent and a water agent, wherein the powder agent comprises the following components: organic matters, plant mycelium protein powder, active calcium, calcium superphosphate, aluminum sulfate, fatty alcohol polyoxyethylene ether ammonium sulfate, amino acid powder, bacillus subtilis and photosynthetic bacteria, and the water agent comprises the following components: citric acid, fulvic acid, humic acid, malic acid, maleic acid, fumaric acid, L-tartaric acid, pyrophosphoric acid, humic acid, lactic acid, oxalic acid, salicylic acid, sodium ion adsorbent, Tween-80 and water. The improver disclosed by the invention can improve the soil from multiple angles, namely soil structure, microorganism species, a chemical method and the like, obviously promote the release of iron and phosphorus in the soil, improve the soil structure, effectively reduce the content of sodium ions in the soil, reduce the pH value of the soil and restore land to a normal planting state after being used continuously for two years.

Owner:孙东军 +1

Electrolyte additive, high-voltage electrolyte and lithium ion battery containing electrolyte additive

InactiveCN103094616AInhibit surface activityAvoid contactSecondary cellsAluminium-ion batteryOrganic solvent

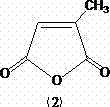

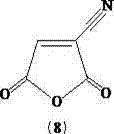

The invention discloses an electrolyte additive, a high-voltage electrolyte and a lithium ion battery containing the electrolyte additive. The high-voltage electrolyte is prepared by adding the electrolyte additive into the conventional electrolyte; the conventional electrolyte comprises a non-aqueous organic solvent and lithium salt, wherein the content of the non-aqueous organic solvent is 80-85 percent of the total mass; the mass of the electrolyte additive is 0.01-10 percent of the total mass; and the electrolyte additive is maleic anhydride C4H2O3 or one of derivatives thereof and has the structure formula as shown in the abstract. According to the high-voltage electrolyte, a stable interfacial film can be formed on the surfaces of a positive electrode and a negative electrode, the reaction activity on the electrode surface is inhibited, oxidative decomposition of the electrolyte is reduced, and gas swelling is effectively inhibited, so that the safety performance and the cycle performance of the lithium ion battery under normal pressure and high voltage are improved and the service life of the lithium ion battery under normal pressure and high voltage is prolonged. The electrolyte is simple in preparation process and is suitable for industrial production.

Owner:JIANGXI YOULI NEW MATERIALS

Method for producing 1,4-butanediol and coproducing tetrahydrofuran, and gamma-butyrolactone

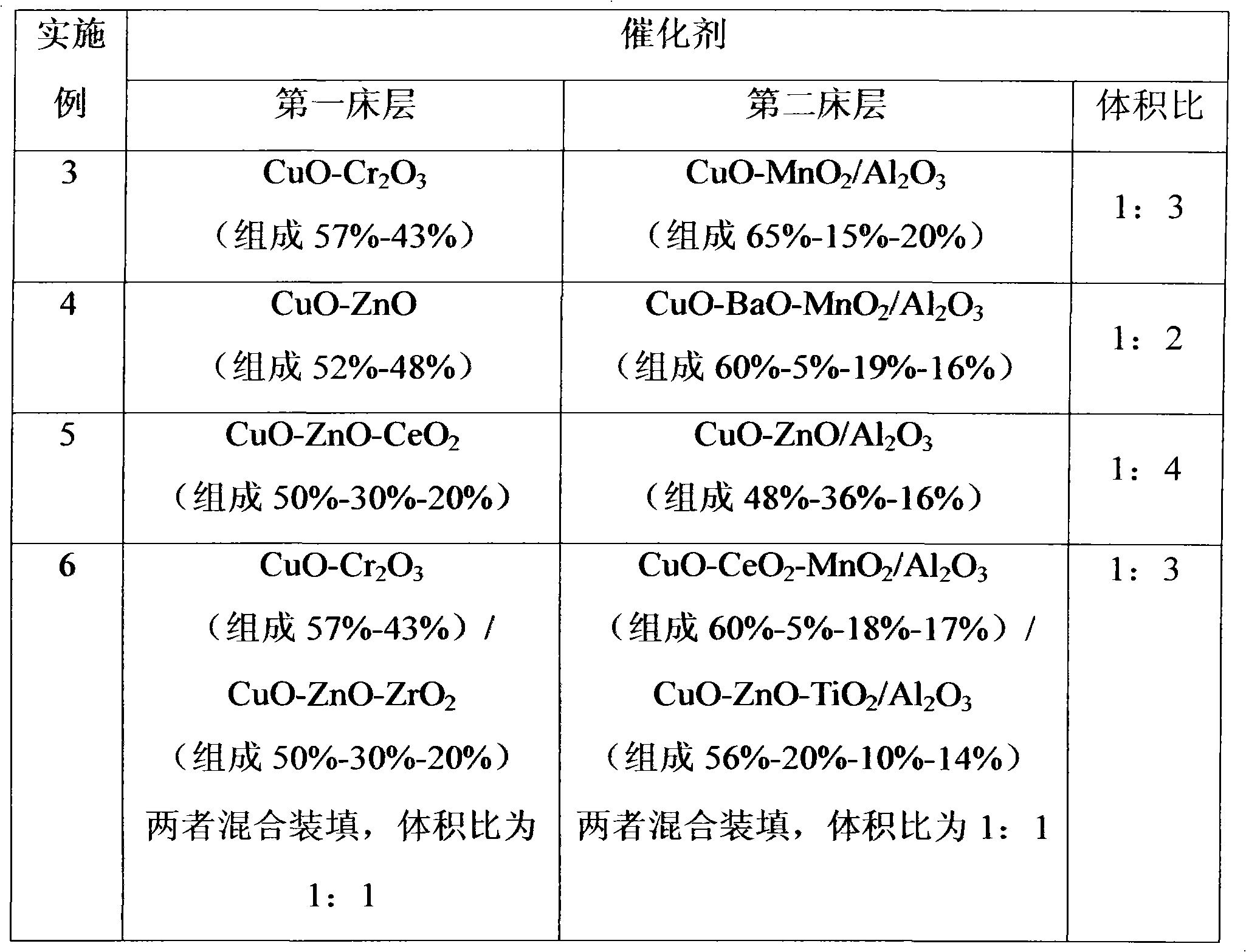

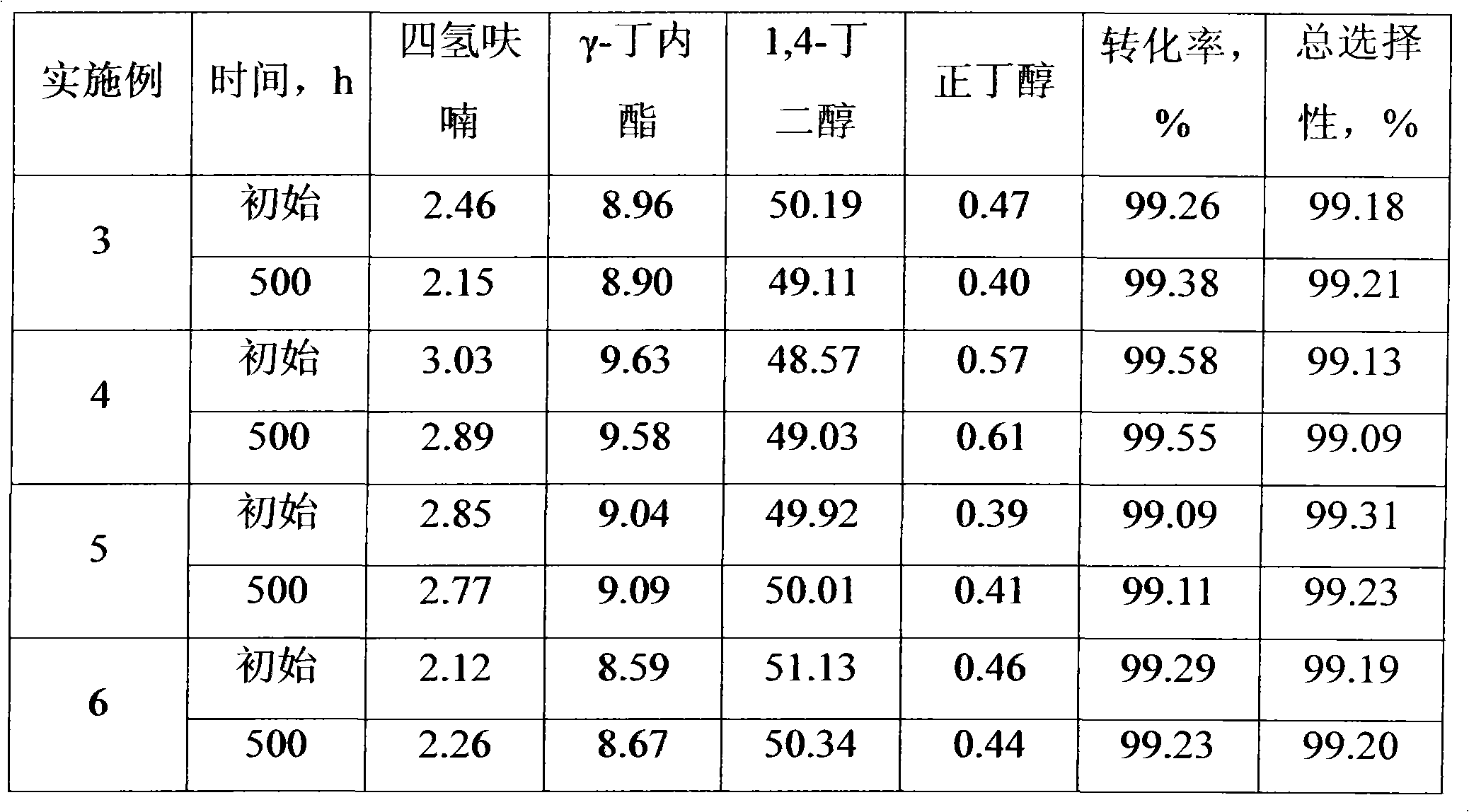

The invention relates to a method for producing 1, 4-butanediol and co-producing tetrahydrofuran and gamma-butyrolactone. The method comprises the following steps that: maleic dialkyl ester and / or succinic acid dialkyl ester are / is used as raw material; under hydrogen existence and reaction conditions, reaction material passes through a first catalyst bed layer of CuO-AO-BO, wherein AO is Cr2O3 and / or ZnO, and BO is one or a plurality of Ba, Mg, Ti, Ce, Si, Zr and Mn oxides; then the reaction material passes through a second catalyst bed layer of CuO-MO-Al2O3, wherein MO is one or a plurality of Mn, Zn, Ba, Mg, Ti, Ce, Si and Zr oxides. Compared with the prior art, the method has the advantages that: the raw material conversion rate is more than 99 percent; the total selectivity of 1, 4-butanediol, tetrahydrofuran and gamma-butyrolactone is more than 99 percent; the catalyst stability is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for purifying silk fibroin

ActiveCN103613652AAvoid corrosionLow costPeptide preparation methodsAnimals/human peptidesMicrospherePorous membrane

The invention discloses a method for purifying silk fibroin. According to the method, glycerin monostearate sulphate sodium salt, fatty alcohol-polyoxyethylene ether, and sodium diethylhexyl sulfosuccinate are taken as the penetrant. High molecular weight silk fibroin can be obtained through steps of steeping raw silks of silkworm or silkworm cocoon in the penetrant, degumming through weak base and enzyme so as to remove silk glue, then dissolving and dialyzing. The silk fibroin purified by the method does not contain silk glue, less molecular weight of silk fibroin is degraded, the chain H, chain L and P25 of the original silk fibroin can be reserved, the molecular weight of the original silk fibroin is reserved, and the materials such as silk fibroin membranes, fibroin gel, fibroin microsphere, and fibroin porous membranes prepared by the raw material silk fibroin are improved in properties.

Owner:河南丝绸之宝卫生用品有限公司

Far infrared negative ion functional non-woven fabric and preparation method thereof

InactiveCN103757820AHeat resistantCorrosion resistanceSynthetic resin layered productsNon-woven fabricsPolyethylene glycolCis-Butenedioic Acid

The invention discloses a far infrared negative ion functional non-woven fabric. The far infrared negative ion functional non-woven fabric consists of a top surface layer, a back face layer and a fiber cotton layer clamped between the top surface layer and the back face layer, wherein the top surface layer and the back face layer are made of a non-woven fabric material. The non-woven fabric is prepared from the following raw materials in parts by weight through a melt blowing method: 100 parts of isotactic polypropylene, 3-4 parts of tourmaline, 2-3 parts of aluminum oxide, 1-2 parts of zinc oxide, 12-15 parts of tributyl phosphate, 1-2 parts of titanium dioxide, 6-8 parts of dibutyl maleate, 2-3 parts of 3-aminopropyltrimethoxysilane, 2-3 parts of polyethylene glycol, 3-4 parts of urea, 2-3 parts of grassleaf sweelflag rhizome, 1-2 parts of lily, 2-3 parts of kudzuvine root and 4-5 parts of aid. The non-woven fabric has far infrared, negative ions, antibacterial and deodorization functions. Due to the adoption of the isotactic polypropylene, the non-woven fabric has the characteristics of heat resistance, corrosion resistance, nontoxicity and no odor, is high in tensile strength and bonding property, does not produce dust or scrap, and has the functions of perfuming and health care.

Owner:芜湖跃飞新型吸音材料股份有限公司

Polyamide resin composition with high metal texture and preparation method thereof

The invention relates to an aesthetic polyamide resin composition with high metal texture. The aesthetic polyamide resin composition is composed of the following components: 70-95 parts of polyamide (PA), 0-5 parts of auxiliary agent and 5.6-50 parts of special effect master-batch. The special effect master-batch is composed of the following components: 5-30 parts of polymethyl methacrylate grafted maleic anhydride / styrene (PMMA-g-MAH / St), 0.5-18 parts of special effect toner and 0.1-2 parts of additive. The additive is a dibutyltin maleate-methyl methacrylate-sodium methacrylate copolymer. The invention further provides a preparation method of the abovementioned composition. Compared with the prior art, a nylon material for a free-spraying aesthetic plastic is modified by using a brand-new technical scheme to obtain the aesthetic-texture polyamide composition with high metal texture, good mechanical property and surface property.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Method of preparing gamma-butyrolactone and/or 1,4-butanediol using chromium less catalyst

InactiveCN1493569AHigh activityEnsure safetyOrganic compound preparationHydroxy compound preparationCis-Butenedioic AcidButanediol

A process for preparing gamma-butyrolactone and / or 1,4-butanediol by use of Cr-free catalyst includes making the the dialkyl maleate and / or dialkyl succinate in contact with hydrocatalyst, reacting at 170-300 deg.c and 0.1-15 hr under 0.1-7 Mpa, and collecting products. Said hydrocatalyst is CuMnaAlbOc, where a=0.01-1.5, b=0.1-2 and c is number of necessary oxygen atoms. Its advantage is controllable ratio between both products.

Owner:CHINA PETROLEUM & CHEM CORP +1

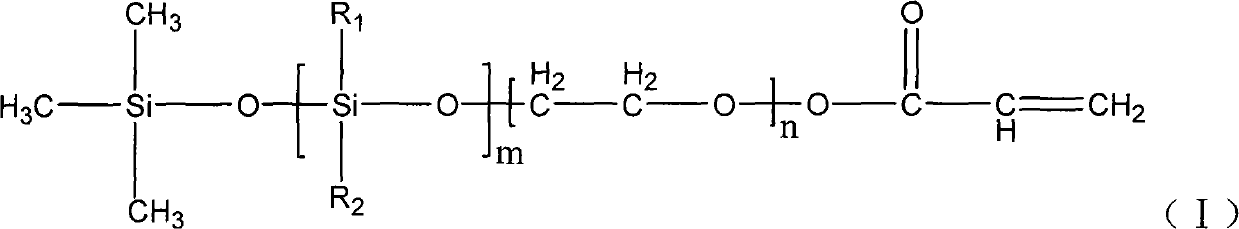

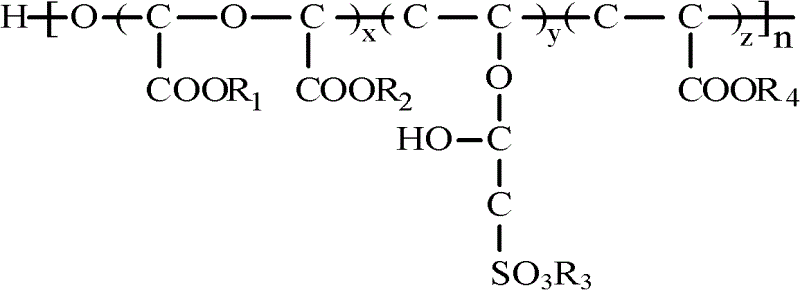

Poly-carboxylic acid water reducing agent and preparation method thereof

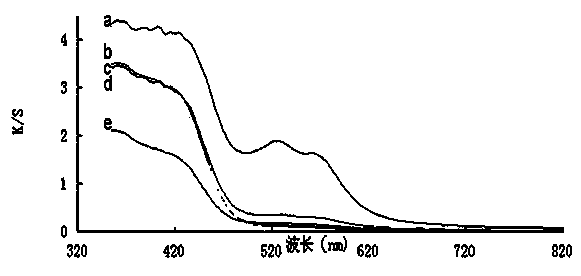

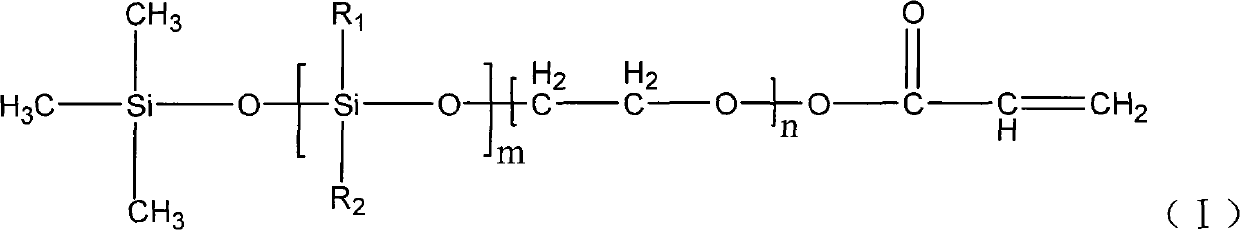

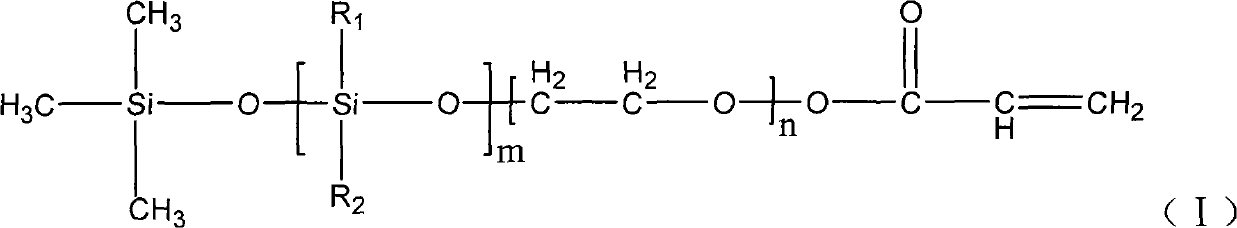

ActiveCN101792281AHigh bleed air performanceStrong molecular weight selectivityCis-Butenedioic AcidCarboxylic acid

The invention provides a concrete poly-carboxylic acid water reducing agent which is a polymer with the weight-average molecular weight of 10000-30000 formed by copolymerization of three monomers of A, B and C, wherein the molar ratio of the monomer A to the monomer B is 0.1-0.5:1,and the molar ratio of the monomer A to monomer C is 5-10:1; the monomer A is monohydroxy silicone oil polyoxyethylene ether acrylate, and the structure is shown in the formula (I) as follows, wherein R1 and R2 are methyl or amino; m is an integral number from 1 to 10; n is the integral number from 13 to 49; the monomer B is one of maleic anhydride, maleic acid, acrylic acid or methylacrylic acid; the monomer C is one of sodium vinyl sulfonate, sodium allyl sulfonate, sodium styrene sulfonate, 2-acrylamide-2-methylpropanesulfonic acid, methyl methacrylate, methyl acrylate or vinyl acetate. The water reducing agent has the advantages of stable performance, high water reducing rate, strong adaptability of cement, high air entraining performance and no environmental pollution. The invention further provides a preparation method of the water reducing agent, which has the advantages of simple process, strong operationability, low energy consumption and the like.

Owner:LIAONING OXIRANCHEM INC

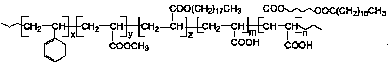

Reactive emulsifier phenylpropyl surface sizing agent and preparation method thereof

InactiveCN101831839AImprove water resistanceImprove bindingWater-repelling agents additionFiberPolyethylene glycol

The invention discloses a reactive emulsifier phenylpropyl surface sizing agent and a preparation method thereof. The reactive emulsifier phenylpropyl surface sizing agent has a molecular structure that the reactive emulsifier phenylpropyl surface sizing agent is prepared by using a method comprising the following steps of: preparing maleic acid polyethyleneglycol mono-stearate ester through the reaction of polyethyleneglycol, stearic acid and maleic anhydride, and preparing the reactive emulsifier phenylpropyl surface sizing agent through the copolymerization of the maleic acid polyethyleneglycol mono-stearate ester with styrene, octadecyl acrylate, acrylic acid and methyl acrylate by using ammonium sulfate as an evocating agent. The prepared reactive emulsifier phenylpropyl surface sizing agent can be well combined with paper fibers, the film forming property is good, and the water resistance and the ring crush compression resistance of semi-chemical corrugated paper can be improved.

Owner:SHAANXI UNIV OF SCI & TECH

High temperature-resisting cleaning CO2 foam fracturing liquid suitable for unconventional oil and gas reservoir development

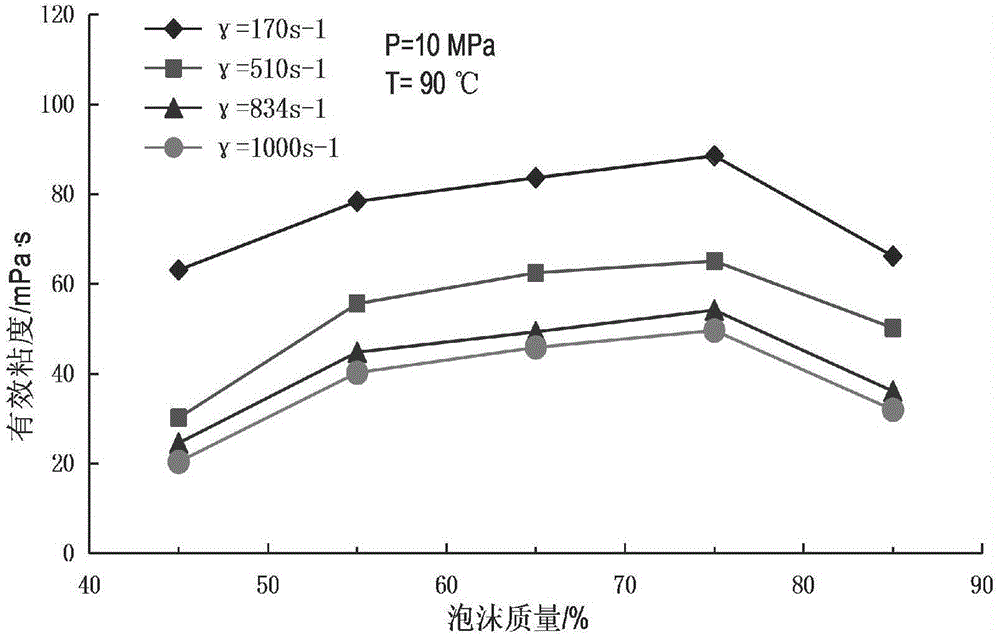

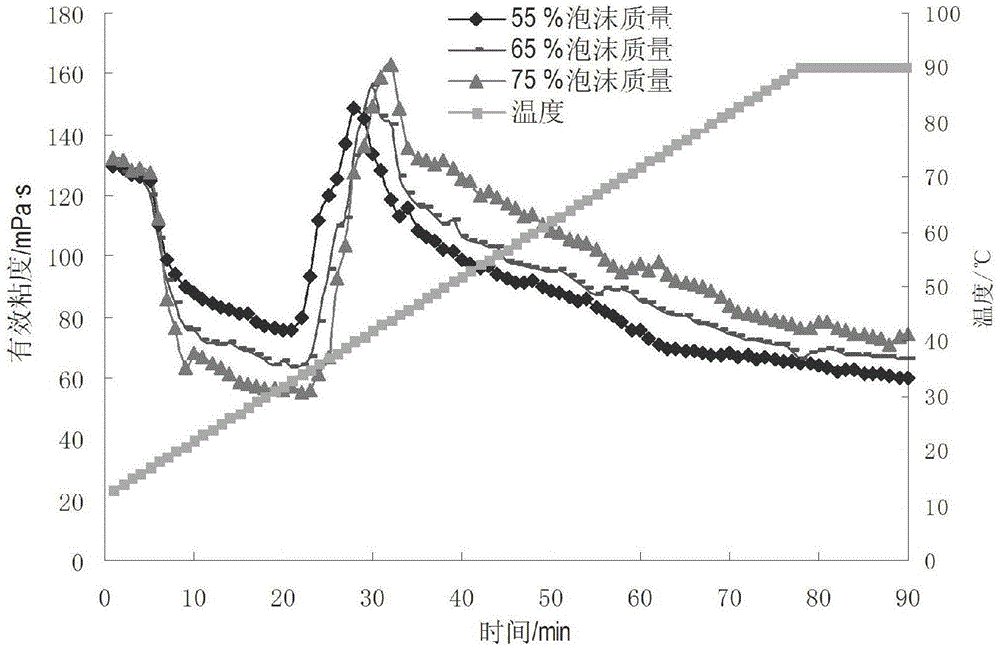

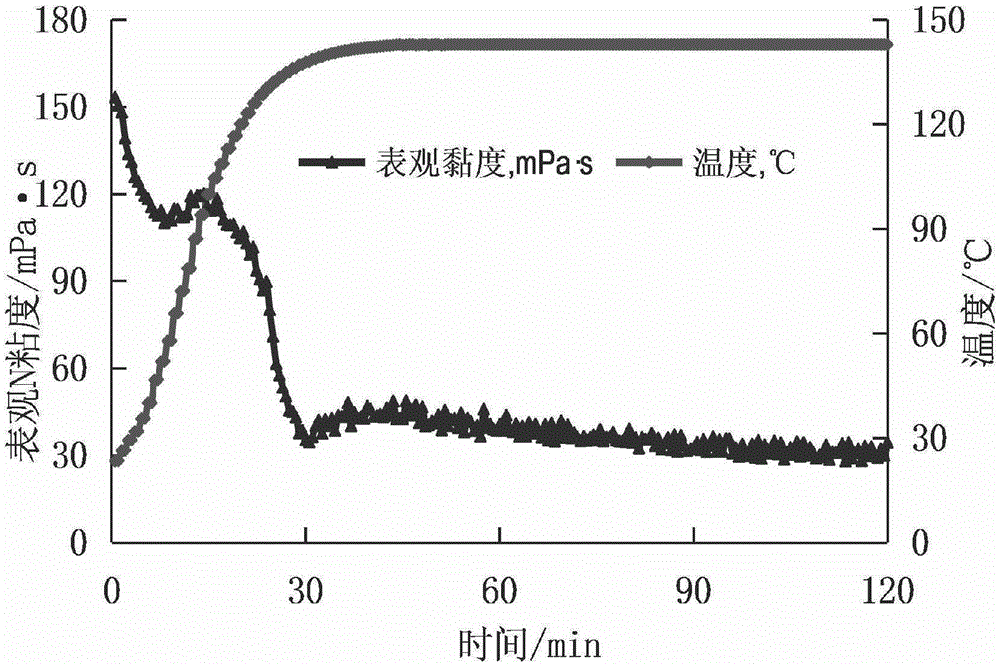

ActiveCN105567213ASolve the problem of water solubilityReduce or even eliminate residueDrilling compositionFunctional monomerGas phase

The invention discloses high temperature-resisting cleaning CO2 foam fracturing liquid suitable for unconventional oil and gas reservoir development. The high temperature-resisting cleaning CO2 foam fracturing liquid in gas phase is CO2; the high temperature-resisting cleaning CO2 foam fracturing liquid in liquid phase is high temperature-resisting cleaning fracturing liquid; the foam mass is 52 percent to 75 percent. The high temperature-resisting cleaning CO2 foam fracturing liquid is prepared from the following raw materials in percentage by weight: 0.3 to 0.65 percent of thickening agent, 0.2 to 0.5 percent of viscosity synergist, 0.2 to 0.3 percent of pH (Potential of Hydrogen) value modifier, 0 to 0.2 percent of high-temperature stabilizing agent, 0.01 to 0.1 percent of gel breaker and water, wherein the thickening agent is prepared from acrylamide, vinylpyrrolidone, maleic acid, anionic functional monomers, an initiating agent, inorganic salt and the like; the viscosity synergist is mainly prepared from an anionic surfactant; the pH value modifier is mainly prepared from an organic acid. According to the high temperature-resisting cleaning CO2 foam fracturing liquid disclosed by the invention, the temperature-resisting ability is up to 140 DEG C, the sand carrying performance is excellent, the frictional resistance is low, the foam stability is strong, the content of residual slag is extremely low, the stratum compatibility is good, back flowing is easy, the construction effect is quickly obtained, and important significances to effective development of an unconventional oil and gas reservoir and protection of a reservoir stratum are obtained.

Owner:CHENGDU BAICHUN PETROLEUM TECH

Pliable tough cold-resistant anti-aging modified acrylate rubber cable material

ActiveCN103589102AImprove performanceGood mechanical propertiesRubber insulatorsPlastic/resin/waxes insulatorsWear resistantPolyvinyl chloride

The invention relates to a cable material, and specifically relates to a pliable tough cold-resistant anti-aging modified acrylate rubber cable material. The cable material comprises the following raw materials in parts by weight: 25-30 parts of acrylate rubber, 15-20 parts of epichlorohydrin rubber, 12-15 parts of fluororubber, 23-26 parts of precipitation-process white carbon black, 18-20 parts of polystyrene, 15-18 parts of polyvinyl chloride, 12-15 parts of wollastonite powder, 2-3 parts of anti-aging agnet KY-405, 1-2 parts of anti-aging agent MB, 1-2 parts of anti-oxidant 1035, 3-4 parts of magnesium oxide, 4-5 parts of stearic acid, 1-2 parts of promoter PZ, 5-7 parts of acetyl triethyl citrate, 5-6 parts of dibutyl maleate, 30-34 parts of spraying carbon black, 4-5 parts of engine oil, 2-3 parts of sulphur, 2-3 parts of zinc oxide and 4-5 parts of an auxiliary agent. The cable material combines the advantages of acrylate rubber, epichlorohydrin rubber, fluororubber, polystyrene, polyvinyl chloride and the like, so that the properties of conventional acrylate rubber cable materials are improved; and the cable material provided by the invention has good mechanical properties, is pliable, tough, wear-resistant, low temperature resistant, anti-aging and long in service life, is capable of being adaptive to specific usage environment conditions, and has wide market application prospect.

Owner:东莞市胜牌电线电缆有限公司

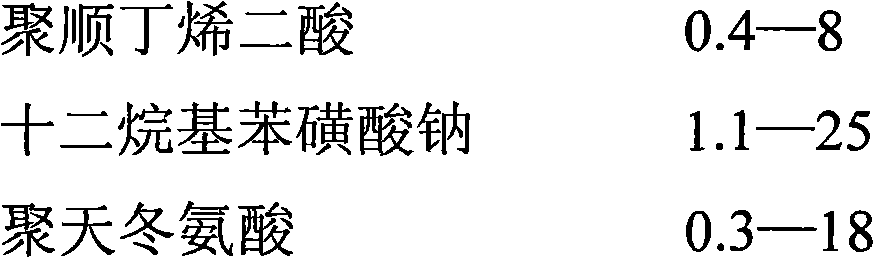

Saline-alkali soil modifier, and preparation method and application thereof

InactiveCN102766468ATroubleshoot the improvementAdaptive governanceOther chemical processesOrganic fertilisersAlkali soilCis-Butenedioic Acid

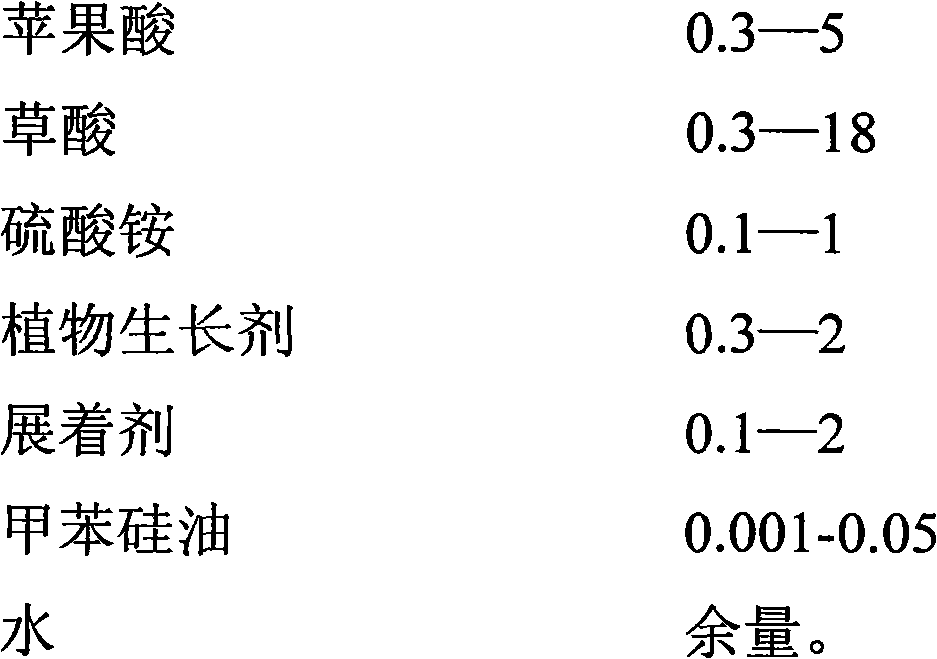

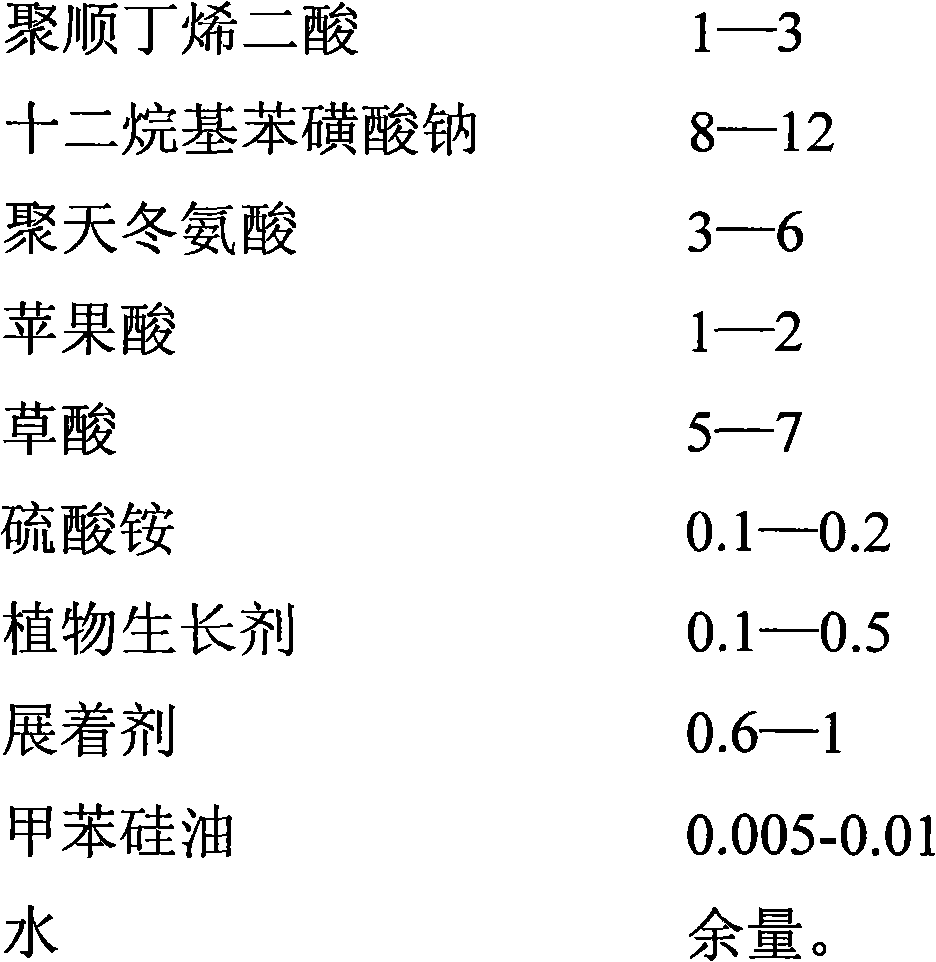

The invention discloses a saline-alkali soil modifier, a preparation method and application thereof, and relates to a saline-alkali soil modifier, and a preparation method and application technology thereof. The saline-alkali soil modifier is prepared by dissolving the following raw materials, by weight: 0.4-8 parts of poly maleic acid, 1.1-25 parts of sodium dodecyl benzene sulfonate, 0.3-18 parts of polyaspartic acid, 0.3-5 parts of malic acid, 0.3-18 parts of oxalic acid, 0.1-1 part of ammonium sulfate, 0.3-2 parts of a plant growth agent, 0.1-2 parts of a spreader, 0.001-0.05 part of toluene silicone oil and the balance of water. The application method is as below: diluting the modifier, adding to a trickle irrigation, and dripping the modifier on the soil. The invention solves the problems of the existing technology for saline-alkali soil improvement, such as high engineering cost, unobvious improvement effect, incapability to durable application, and difficulty in large area promotion.

Owner:乌鲁木齐金昌隆农业科技有限公司

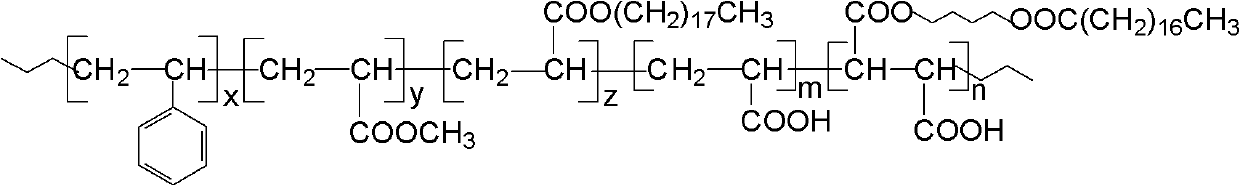

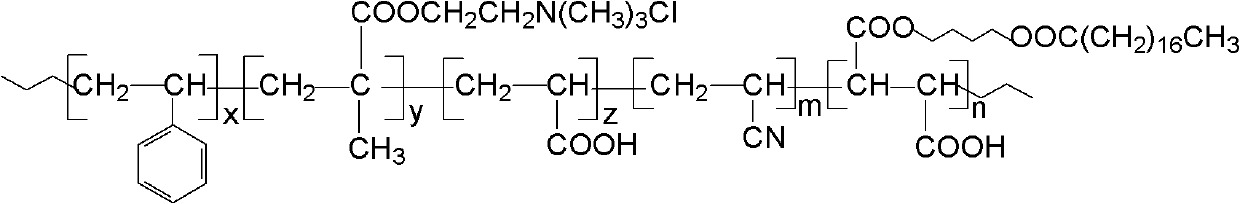

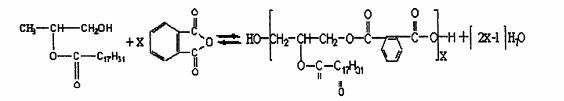

Reactive emulsifier amphiprotic styrene surface sizing agent and preparation method thereof

InactiveCN101871183AImprove clarityImprove fullnessWater-repelling agents additionFiberPolymer science

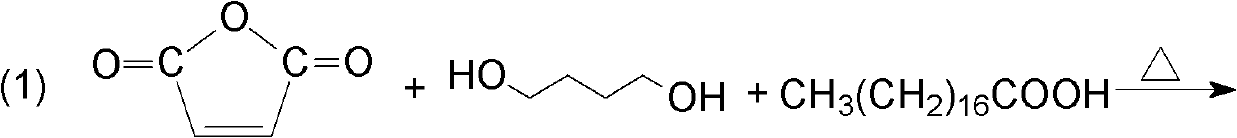

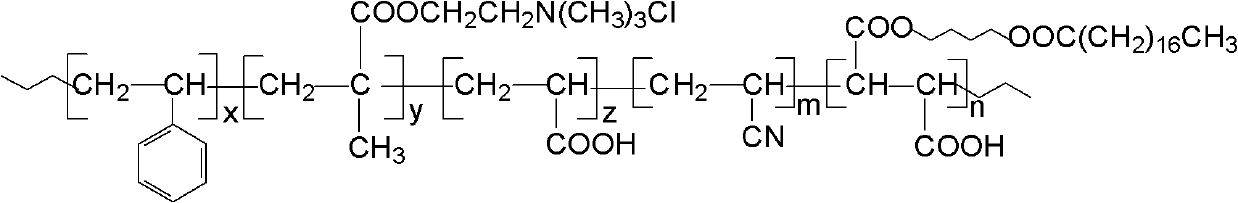

The invention discloses a reactive emulsifier amphiprotic styrene surface sizing agent and a preparation method thereof; the molecular structure of the reactive emulsifier amphiprotic styrene surface sizing agent is shown as the accompanying drawing. The preparation method of the reactive emulsifier amphiprotic styrene surface sizing agent comprises the following steps that: first, polyethylene glycol, stearic acid and maleic anhydride react to obtain maleic acid polyethylene glycol single-stearic acid ester; then ammonium persulfate serves as an initiator, and maleic acid polyethylene glycol single-stearic acid ester, styrene, acrylic acid, methacryloyloxyethyl trimethyl ammonium chloride and acrylonitrile are prepared into the reactive emulsifier amphiprotic styrene surface sizing agent through copolymerization reaction; and the obtained reactive emulsifier amphiprotic styrene surface sizing agent is characterized by excellent integration with fibers, reduced hair and powder drop, higher seizing degree, high surface strength, good ink absorbability, capability of adapting to high-speed printing and the like.

Owner:SHAANXI UNIV OF SCI & TECH

Imitation marble unsaturated polyester resin and preparation method thereof

The invention relates to imitation marble unsaturated polyester resin, which is liquid under normal temperature and comprises the following raw materials by weight percent: 10-14% of normal dihydric alcohol, 11-16% of special dihydric alcohol, 18-23% of isophthalic acid, 12-17% of phthalic anhydride, 10-14% of maleic anhydride and 24-31% of diluent. The preparation method comprises the following steps: under the protection of nitrogen, gradually polycondensing dihydric alcohol and isophthalic acid at the temperature of 190-210 DEG C for 10-14h until the acid value reaches 35-55 mgKOH / g, lowering the temperature to 160 DEG C and then adding phthalic anhydride and maleic anhydride to gradually polycondense for 6-8h, when reaction is completed till the acid value reaches 60+ / -5 mgKOH / g, reducing pressure and vacuumizing for 2-4h, then cooling down to 190 DEG C, adding polymerization inhibitor, lowering the temperature to 100-120 DEG C and then adding diluent, evenly stirring to obtain the unsaturated polyester resin.

Owner:浙江天和树脂有限公司 +2

Capacitor thin film containing modified sepiolite powder and preparation method thereof

InactiveCN103102581AImprove barrier propertiesImprove air tightnessFixed capacitor dielectricLow-density polyethylenePolymer science

The invention discloses a capacitor thin film containing modified sepiolite powder and a preparation method thereof. The capacitor thin film containing modified sepiolite powder comprises the following raw materials in parts by weight: 40-45 of metallocene polypropylene resin, 35-40 of LDPE (Linear low density polyethylene), 10-15 of homo-polypropylene, 3-5 of epoxy linseed oil, 2-3 of polyvinyl alcohol, 1-2 of aluminum hydroxide, 1-2 of polyisobutylene, 8-12 of diatomite, 1-2 of ferrocene, 2.2-2.5 of poly-4-methyl-1-amylene, 7.5-9.5 of modified sepiolite powder, 3.5-5 of zeolite, 1.2-1.5 of antioxidant DSTP, 0.9-1.1 of acetylcitric acid tris(2-ethylhexyl) ester, 0.8-1.2 of di-n-butyl maleate, 3-5 of calcium stearate, 2.5-3 of N-(beta-aminoethyl)-gamma-aminopropyl trimethoxysilane (triethoxysilane), and 0.5-0.7 of modified trees ash. The preparation method disclosed by the invention is simple; and simultaneously, the diatomite, the modified nano-titanium dioxide and the modified trees ash are added to the raw materials so that the barrier property and air tightness of the thin film are improved, and the thin film has good resistance to pressure and impact resistance and simultaneously has the characteristics of high heat-seal strength and good heat sealing property.

Owner:TONGLING YIHENGDA ELECTRONICS

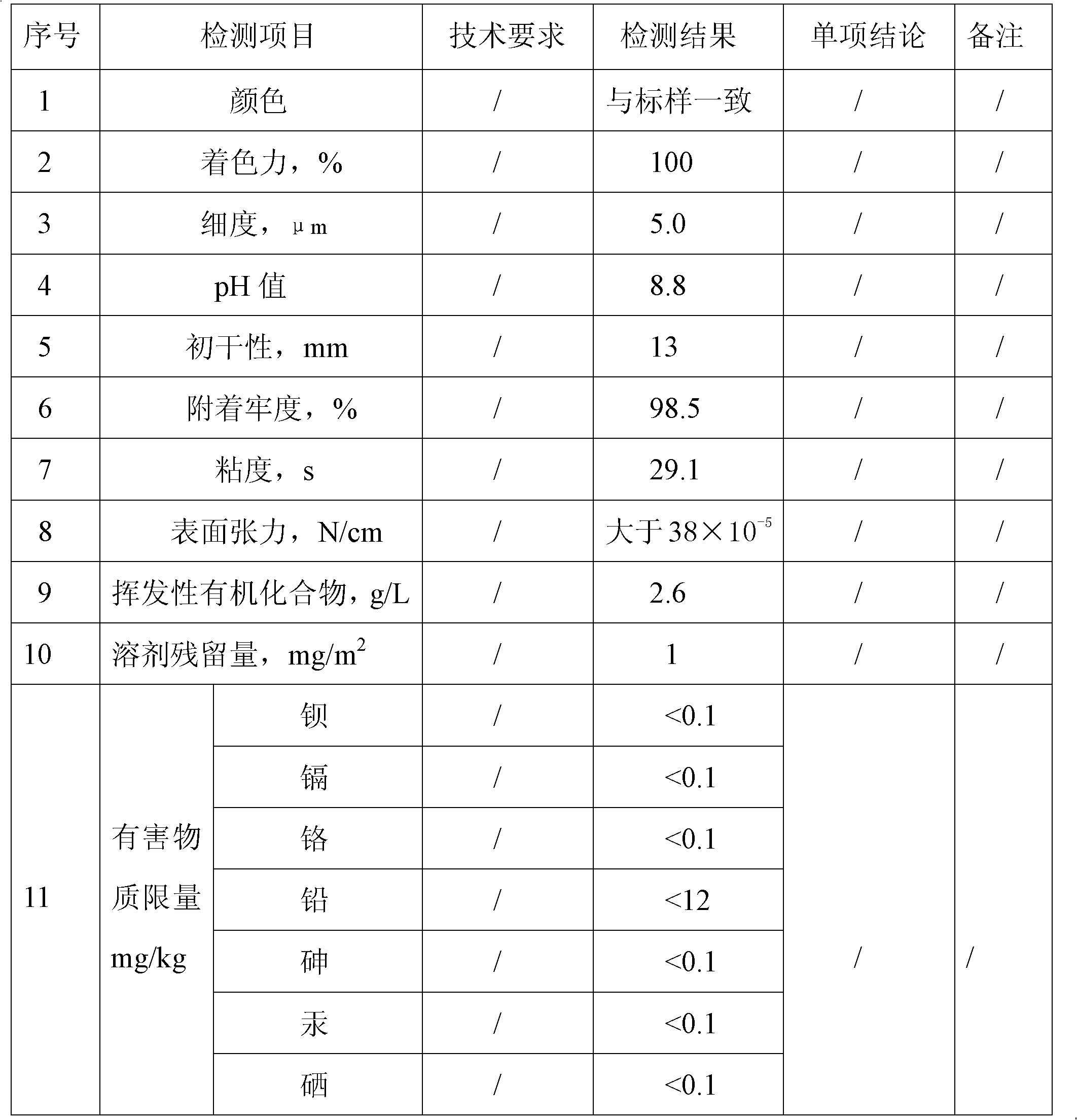

Plastic gravure waterborne ink

ActiveCN102516845ANo pollutionComply with food hygiene and safety requirementsInksActive agentPolyamide

The invention discloses plastic gravure waterborne ink, which belongs to the technical field of waterborne ink, and is characterized in that: water-soluble synthetic resin is prepared from the following components in percentage by weight: 25-35 parts of polyamide, 7-15 parts of an acrylic monomer, 5-15 parts of soybean oil, 1-6 parts of pentaerythritol, 8-15 pats of maleic anhydride, 0.0-1 part of magnesia, 30-40 parts of rosin and 1-3 parts of a crosslinking agent; water-soluble oleoresin is prepared form the following components in parts by weight: 45-50 parts of water-soluble synthetic resin, 15-20 parts of ethanol, 30-40 parts of water and 3-6 parts of ammonia water; and a plastic gravure waterborne ink product is prepared from the following components in parts by weight: 50-60 parts of water-soluble oleoresin, 10-30 parts of a pigment, 10-20 parts of water and 1-8 parts of an aid consisting of an active agent, a deforming agent, a stabilizing agent, a dispersing agent, a flatting agent and a slipping agent. The plastic gravure waterborne ink is environmentally-friendly, safe, nontoxic, harmless, noncombustible and non-explosive, does not pollute the atmospheric environment, is accordant with the food sanitation safety, and has high adhesive firmness, i.e., high adhesion.

Owner:浙江伟航新材料科技有限公司

Preparation method of package-purposed plastic-based film containing modified calcined fluorite powder

ActiveCN103044756AImprove barrier propertiesImprove air tightnessFlexible coversWrappersLow-density polyethylenePolyvinyl chloride

The invention discloses a preparation method of a package-purposed plastic-based film containing modified calcined fluorite powder. The package-purposed plastic-based film is prepared from the following raw materials in parts by weight:10-15 parts of SG-1 type polyvinyl chloride, 3-5 parts of epoxidized linseed oil, 2-3 parts of oxidized polyethlene wax powder, 1-2 parts of distearoyl isopropoxy aluminate, 8-12 parts of kieselguhr, 35-40 parts of mLLDPE (metallocene Linear Low-Density Polyethylene), 38-42 parts of ethylene / alpha olefin copolymer, 8-12 parts of LDPE, 1-2 parts of polyisobutene, 1.2-2.5 parts of poly-4-methyl-1-amylene, 0.8-1.6 parts of nano potassium feldspar powder, 4-6 parts of modified calcined fluorite powder, 1-2 parts of crosslinking agent TAIC (triallyl isocyanurate), 1.5-3 parts of dibutyl maleate, 0.5-1 part of dioctyl maleate, 0.8-1.6 parts of calcium stearate and 1-2 parts of modified sepiolite powder. The package-purposed plastic-based film has good barrier property, gas tightness, pressure resistance and impact resistance and has the characteristics of high heat seal strength and good heat seal property.

Owner:平湖市泓博科技有限公司

Diatomite modified polyvinyl chloride synthetic leather and manufacturing method thereof

InactiveCN102995445AGood flexibilityHas a natural and comfortable feelSynthetic resin layered productsLaminationPolyesterPolyvinyl chloride

The invention discloses diatomite modified polyvinyl chloride synthetic leather. The diatomite modified polyvinyl chloride synthetic leather comprises a surface layer, a foaming layer, a bonding layer and a brushing fabric and is characterized in that the surface layer is manufactured by blending the following raw materials in parts by weight into slurry: 40-50 parts of SG-1 type PVC (Polyvinyl Chloride) resin, 70-80 parts of SG-6 type PVC resin, 15-20 parts of sebacic acid propylene glycol polyester, 10-15 parts of acetyl triethyl citrate, 20-25 parts of di-n-butyl maleate, 5-6 parts of PVC color paste, 1-2 parts of imarcaptoacetate dioctyltin, 1-2 parts of dibasic lead phosphate, 1-2 parts of zinc stearate, 5-10 parts of nanometer calcium carbonate and 15-20 parts of modified attapulgite. Through an improvement of a formula and a technology, the flexibility of the synthetic leather is increased, and the diatomite modified polyvinyl chloride synthetic leather has the natural comfortable hand feel similar to that of natural leather and is not easily damaged or torn.

Owner:HEFEI ANSHAN COATING FABRICS

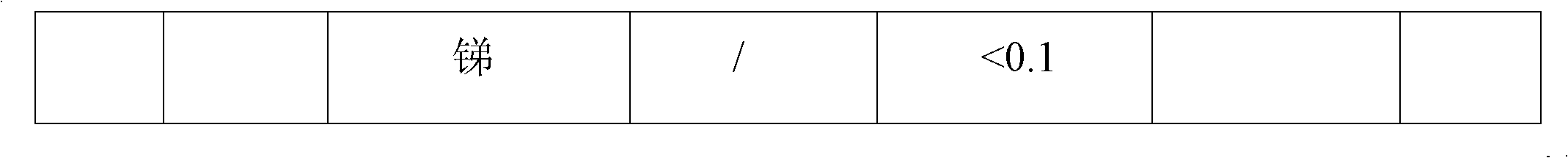

Method for preparing dimethyl succinate

ActiveCN101824627AThorough responseLow production costElectrolysis componentsOrganic compound preparationEvaporationCis-Butenedioic Acid

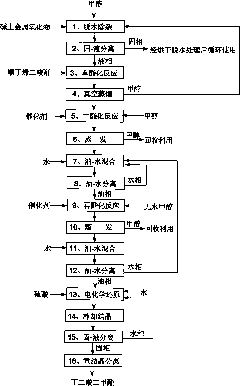

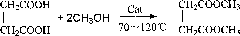

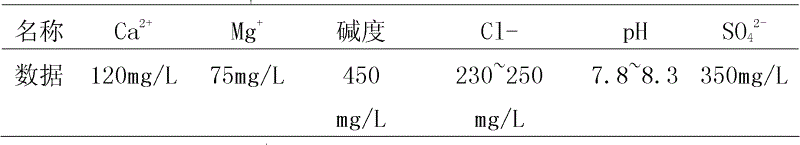

The invention relates to a method for preparing dimethyl succinate, which comprises the following steps that: (1) dehydration and decontamination: methanol and alkali-earth metal oxide are mixed, dehydrated and decontaminated; (2) separation of solid and liquid; (3) monoesterification reaction: maleic anhydride is added in the liquid-phase material which is obtained in the previous step; (4) vacuum distillation; (5) 2-esterification reaction; (6) evaporation; (7) mixing of oil and water; (8) separation of oil and water; (9) re-eesterification; (10) evaporation; (11) mixing of oil and water; (12)separation of oil and water; (13) electrochemical reduction: hydrogen is introduced to reduce dimethyl maleate to dimethyl succinate; (14) cooling and crystallization; (15) separation of solid and liquid: solid material enters the next step; (6) re-crystallization and separation: the product dimethyl succinate is obtained. The method is simple, and has reasonable process, low preparation cost, high product purity and good quality.

Owner:RUNTAI CHEM CO LTD

High-temperature resistance organic silicon impregnating varnish and preparation method thereof

ActiveCN103382366AHigh room temperature tensile shear strengthImprove heat resistanceEpoxy resin coatingsPolyester coatingsEpoxySilanes

A high-temperature resistance organic silicon impregnating varnish and a preparation method thereof are disclosed. The varnish is characterized by being composed of following components in parts by weight: 32 to 35 parts of organic silicon resin, 2 to 3 parts of vinyl triamine, 6 to 8 parts of alkyd resin, 10 to 12 parts of ethyl acetate, 14 to 16 parts of E-12 epoxy resin, 4 to 6 parts of maleic anhydride, 6 to 7 parts of glycol, 2 to 3 parts of dibutyltin dilaurate, 1 to 2 parts of cyanuric acid zinc, 4 to 5 parts of polyisobutylene, 2 to 3 parts of rosin acid polyoxyethylene ester, 3 to 4 parts of vinyl tri(beta- methoxyl ethoxyl) silane, 35 to 38 parts of xylene and 4 to 5 parts of film forming agent. The impregnating varnish has the advantages of good varnish membrane toughness, high impact resistance strength, varnish membrane compactness, yellowing resistance, high-temperature resistance, high dampness resistance, corrosion resistance, good electric insulation property and high mechanic strength, the heat conductivity of the varnish is improved, so the varnish can work at the temperature of 200 DEG C for a long period, and at the temperature of 220 DEG C for a short period, and the design requirements are fulfilled.

Owner:马鞍山采石矶涂料有限公司

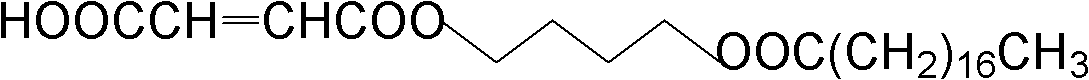

Biodegradable corrosion and scale inhibitor epoxy succinic acid copolymer and its preparation method

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Viscosity reducting, de-waxing, deoiling auxiliary agent in use for extracting petroleum, and preparation method

InactiveCN101092558ATo achieve the purpose of reducing viscositySolve process problemsDrilling compositionSludgeCis-Butenedioic Acid

This invention discloses additive used in petroleum exploitation. The additive is a milky or yellow viscose liquid, and the pH value is 7-8. The additive comprises: dispersant (dodecyl benzene) 18.0-38.0%, emulsifier (nonyl phenol polyoxyethylene ether) 8.0-18.0%, water 35.0-65.0%, penetrant (diethylhexyl sulfosuccinate) 5.0-11.0%, and catalyst (cobalt acetate) 1.0-3.0%. When the additive is combined with crude oil, colloid asphalt and wax in crude oil can be rapidly dispersed, and the sludge can be precipitated and separated, thus the viscosity can be reduced, wax and sludge can be removed, and the fluidity of crude oil can be improved. The viscosity reduction rate is 96.0-99.8%, the wax removal rate is 90-95%, and the sludge removal rate is 60-70%. The additive can avoid steam hot-exploitation of highly viscose crude oil.

Owner:大连四方电泵有限公司

Special reactive typehigh-activityleveling agent for epoxy powder coatings as well as preparation method and application of leveling agent

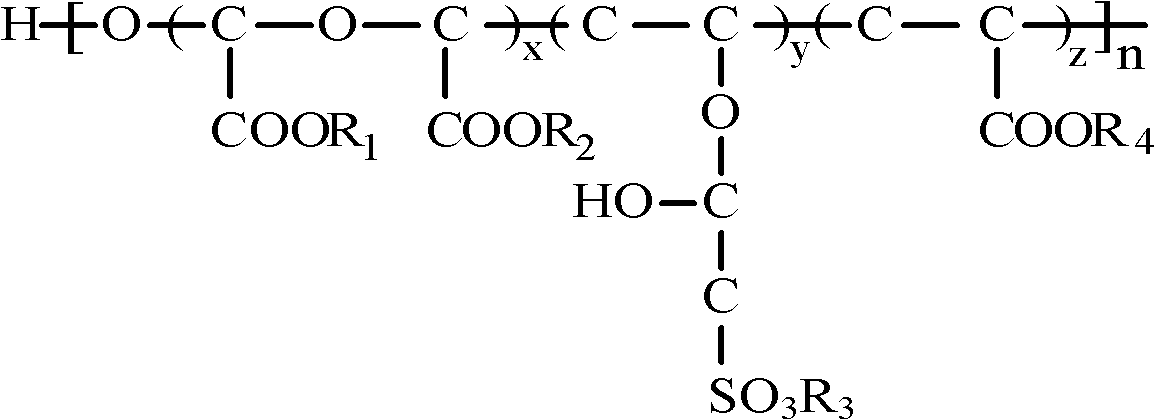

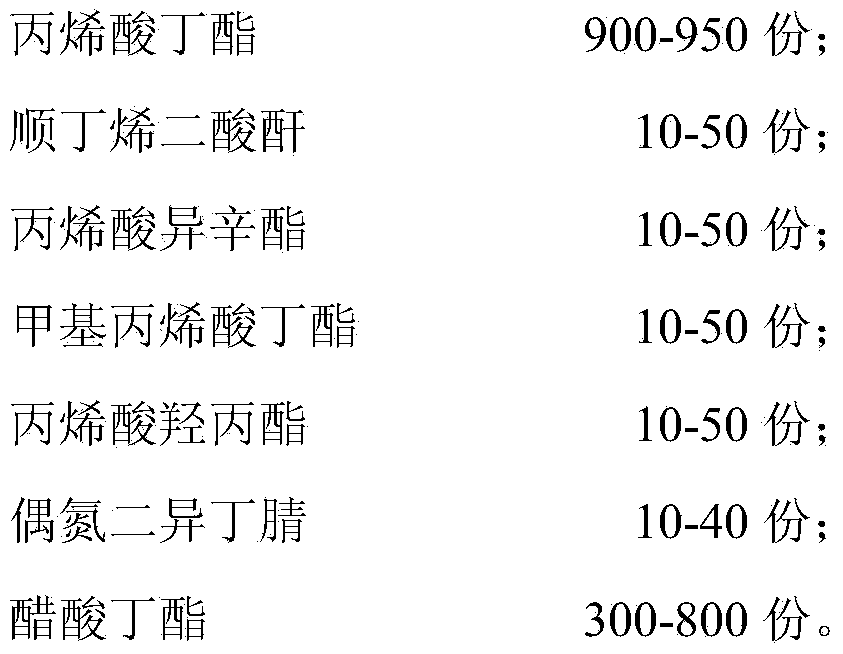

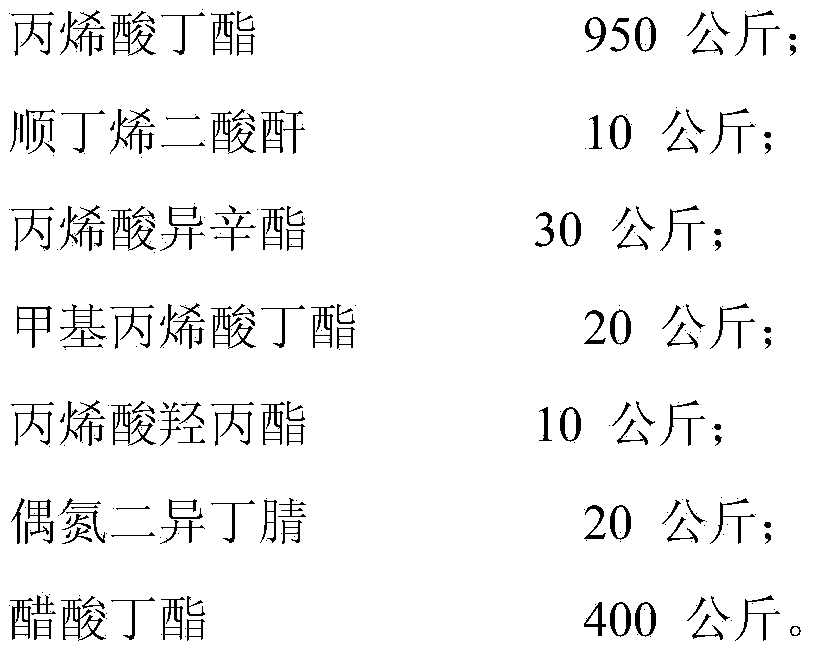

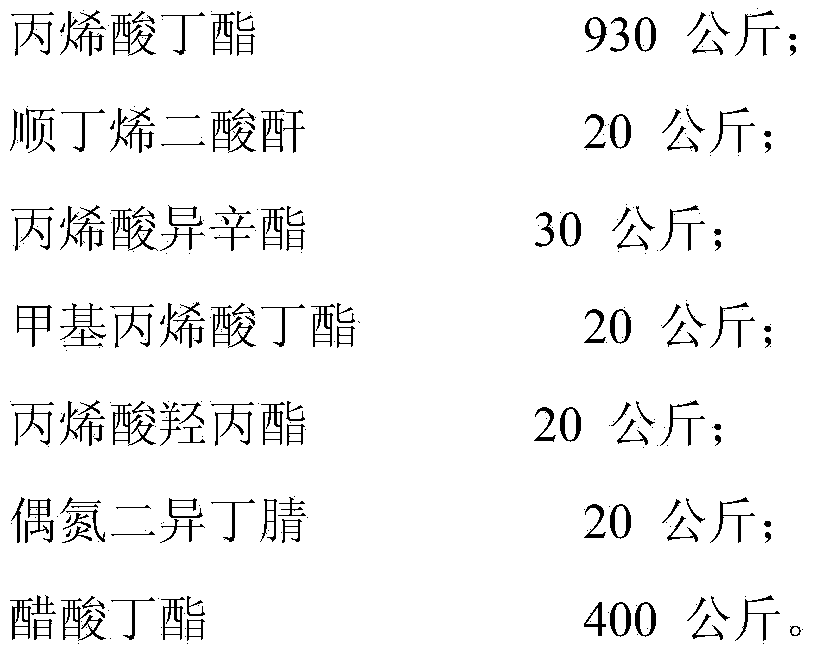

InactiveCN103965676AGood compatibilityImprove wettabilityPowdery paintsEpoxy resin coatingsEpoxyIsooctyl acrylate

The invention relates to a special reactive typehigh-activityleveling agent for epoxy powder coatings as well as a preparation method and an application of the leveling agent. Theleveling agent comprises the raw materials in parts by weight as follows: 900-950 parts of butyl acrylate, 300-800 parts of butyl acetate, 10-50 parts of maleic anhydride, 10-50 parts of hydroxypropyl acrylate, 10-50 parts of 2-ethylhexyl acrylate, 10-50 parts of butyl methacrylate and 10-40 parts of azobisisobutyronitrile. The leveling agent is mainly prepared into a solid leveling agent in the later period to be applied to the powder coatings, and polar groups such as hydroxyl groups, anhydride and the like are introduced, so that thecompatibility with epoxy resin in the powder coatings and the wettability of the coatings and substrates are promoted, and the coatings have excellent leveling and brightening effects; in addition, active groups, namely, carboxyl groups, participate in a curing reaction, so that the compactness of the coatings is improved, thesolvent resistance of films is improved, and theleveling agent is suitable for the various epoxy powder coatings.

Owner:TIANJIN XIANGSHENG NEW MATERIALS CO LTD

High-temperature alkali-resisting penetrant and preparation method thereof

The invention relates to a high-temperature alkali-resisting penetrant and a preparation method thereof and belongs to the technical field of the printing and dyeing auxiliaries. The high-temperature alkali-resisting penetrant is a complex of methanol polyoxyethylene ether phosphate and di-2-ethxlexyl maleate sulfonate in the mass ratio of (5-10) to 1. The high-temperature alkali-resisting penetrant can directly take part in a boiling-off step to shorten the process route and reduce the cost; the high-temperature alkali-resisting penetrant has the excellent high-temperature alkali-resisting penetrability, and is capable of reducing the weft-direction shrinkage rate of fabrics and even in mercerization.

Owner:ZHEJIANG HUANGMA TECH

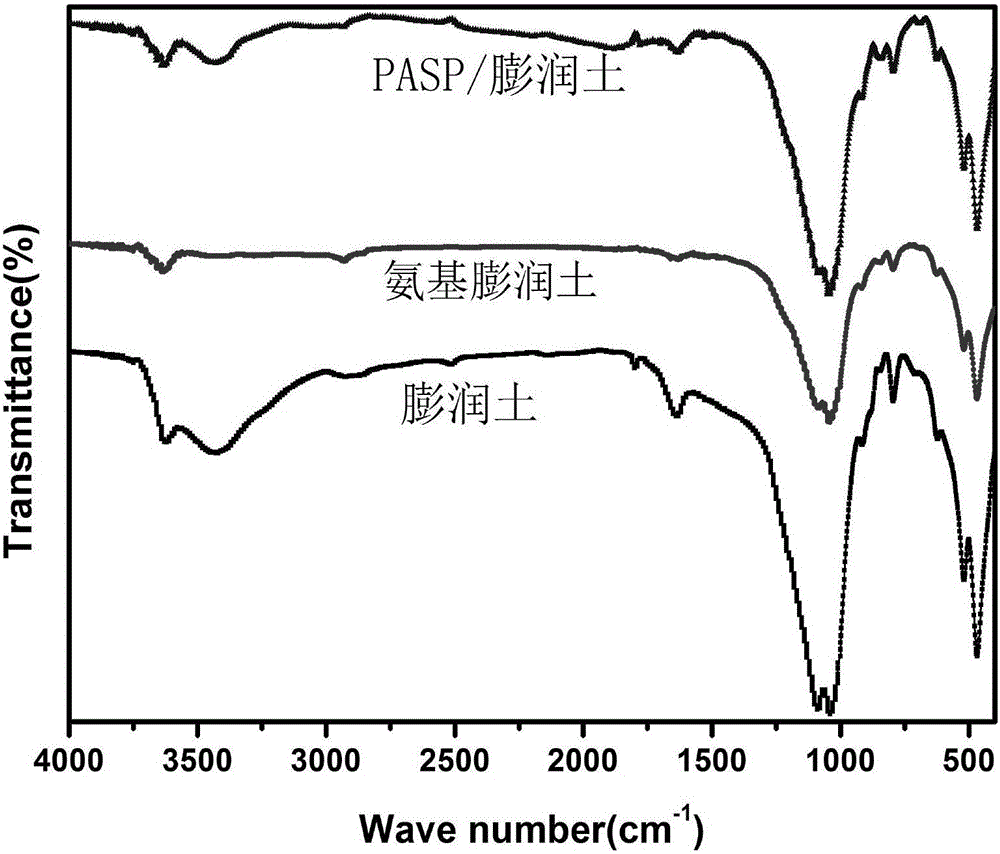

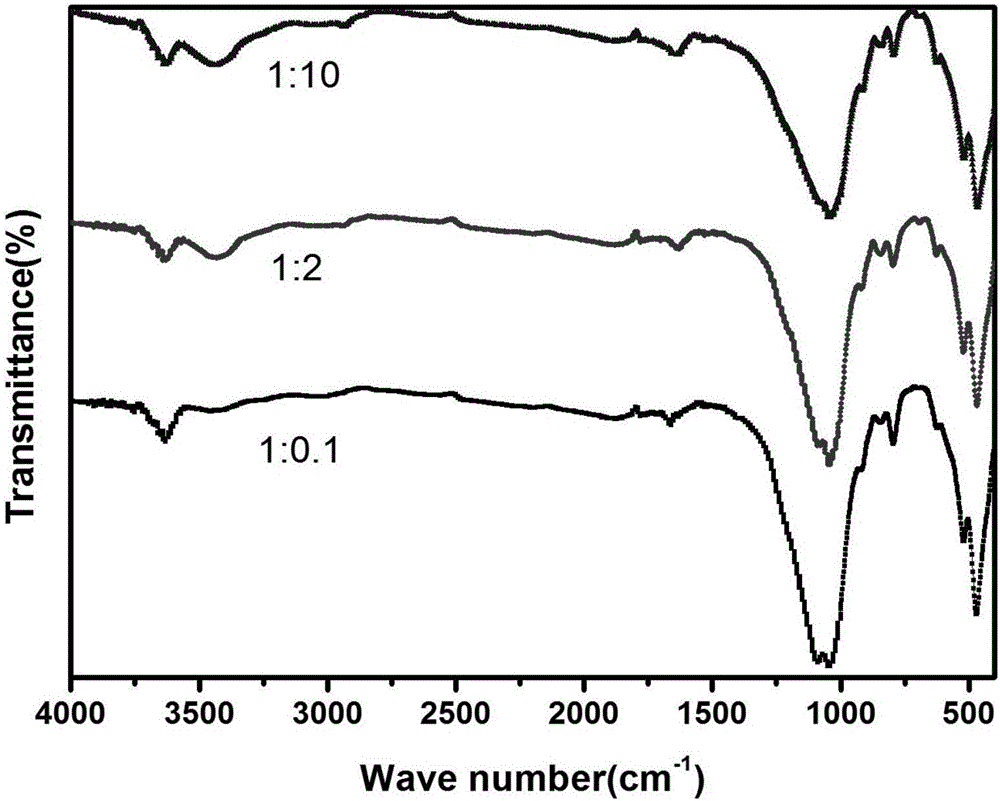

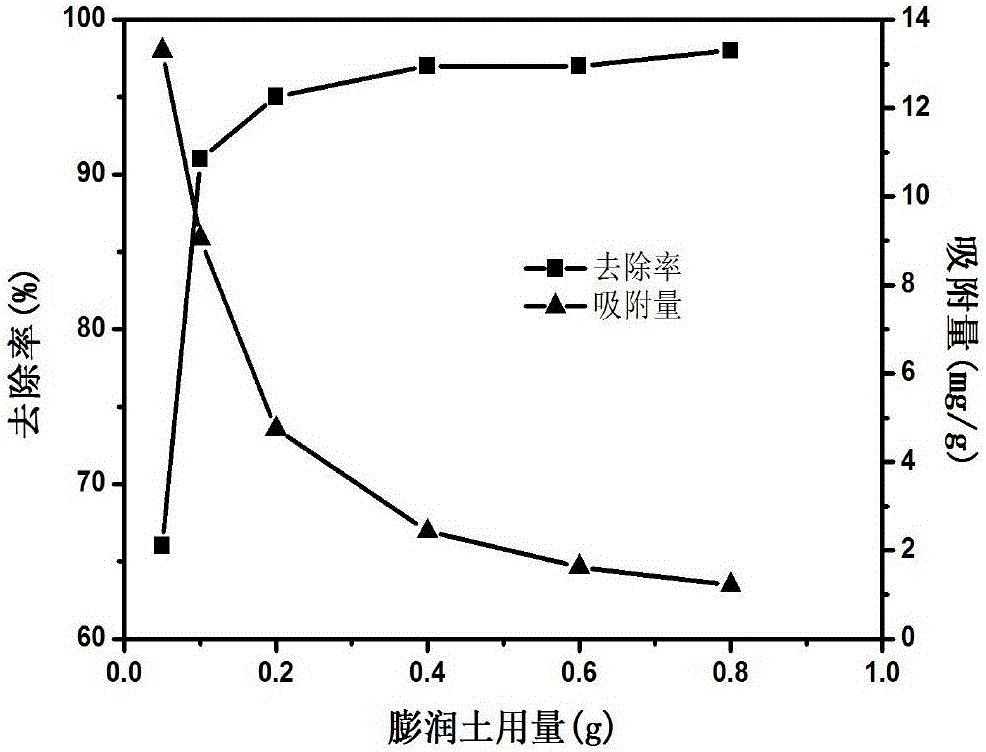

Polyaspartic acid and bentonite composite material for removing heavy metal ions and preparation method thereof

ActiveCN106622166AImprove the ability to chelate heavy metal ionsEfficient removalOther chemical processesWater contaminantsSodium BentoniteSilanes

The invention relates to the field of water treatment preparations and discloses a polyaspartic acid and bentonite composite material for removing heavy metal ions and a preparation method thereof. The polyaspartic acid and bentonite composite material is prepared from polysuccinimide, bentonite and a silane crosslinking agent used as raw materials, wherein the mass ratio of the bentonite to the polysuccinimide is 1 to 0.1-10, the mass of the silane crosslinking agent is 1-10% of the mass of the polysuccinimide, and the polysuccinimide is prepared from cis-butenedioic acid and liquid ammonia according to the mass ratio of 1 to 0.9-1.7. Firstly, the liquid ammonia is used as an ammonia source in the polysuccinimide preparation process, the nitrogen source in the polysuccinimide preparation process is enriched, and the nitrogen utilization efficiency is also improved; secondly, the bentonite is used as the raw material, the cost is low, the performance is excellent, the polyaspartic acid is an environmentally friendly material and can be degraded into amino acid micro-molecules by microbes and fungi, and finally water and carbon dioxide innocuous to the environment are generated.

Owner:NINGBO ZHETIE JIANGNING CHEM +1

Preparation method of starch water-retaining agent with high gel strength

InactiveCN103333291AFast water absorptionStrong water absorption rateCis-Butenedioic AcidWheat starch

The invention discloses a preparation method of a starch water-retaining agent with high gel strength. The preparation method is characterized by comprising the following steps of gelatinizing wheat starch, preparing a sodium acrylate solution under an ice bath condition, adding maleic acid, N,N-methylene bisacrylamide, ammonium persulfate and a sodium acrylate solution into the gelatinized wheat starch to obtain a mixed solution, stirring the mixed solution for graft copolymerization to form a copolymerization product, pouring the copolymerization product into a tetrafluoroethylene board for drying treatment, and obtaining the starch water-retaining agent with the high gel strength, wherein maleic acid can be changed to kaoline or kieselguhr. According to the method, maleic acid, kaoline or kieselguhr serves as a raw material to prepare the starch water-retaining agent, so that the prepared starch water-retaining agent is high in gel strength, biodegradability, water absorption velocity and salt tolerance, and the preparation method is simple and non-pollution and can be used for industrial production.

Owner:HEFEI UNIV OF TECH

Quick-drying alkyd resin for double-component polyurethane primer

ActiveCN102311542ALow in Vegetable Oleic AcidShort oilPolyurea/polyurethane coatingsBenzoic acidVegetable oil

The invention discloses a quick-drying alkyd resin for a double-component polyurethane primer for a wooden ware compatible with a polyurethane curing agent. The quick-drying alkyd resin comprises the following raw materials in parts by weight: 8-10 parts of monoacid, 9-11 parts of semidry vegetable oil acid, 0.5-1 part of maleic anhydride, 22-28 parts of phthalic anhydride, 4-6 parts of benzoic acid, 11-15 parts of pentaerythritol, 2-5 parts of trimethylolpropane, 6-9 parts of diglycol, 20-25 parts of dimethyl benzene and 5-8 parts of toluene. The quick-drying alkyd resin for the double-component polyurethane primer for the wooden ware has the characteristics of high drying speed, superior transparency, excellent rubbing property, high cost performance and the like, and also has high intermiscibility with the dimethyl benzene.

Owner:SKSHU PAINT

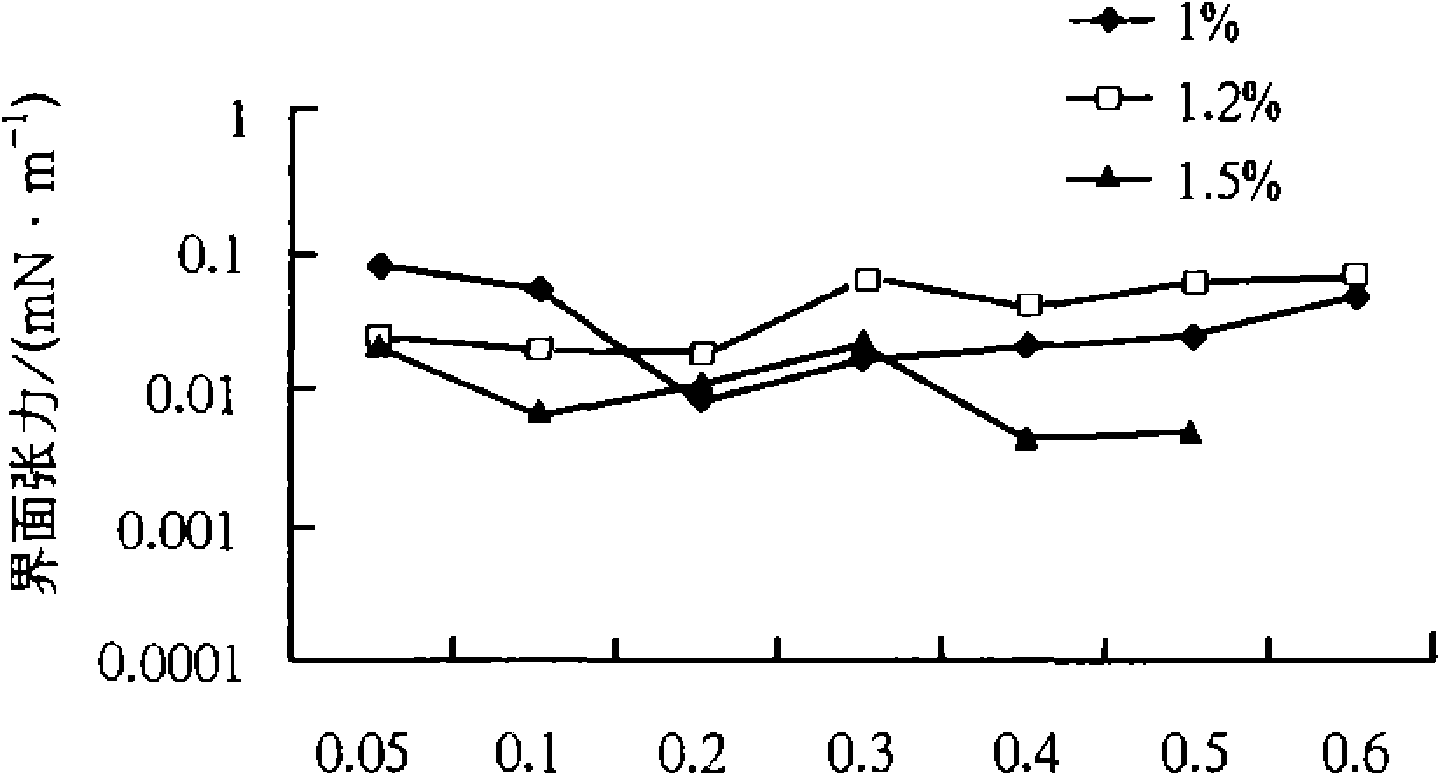

Complex biological oil displacement agent and application thereof

InactiveCN102492409AImprove oil displacement efficiencySimple preparation processFluid removalDrilling compositionPotassiumOil field

The invention discloses a complex biological oil displacement agent, which comprises a biosurfactant and a chemical surfactant which are prepared in a weight ratio of (1:1)-(8:1), wherein the biosurfactant is a rhamnolipid fermentation stock solution, and the chemical surfactant is fatty acid amide sulpho monoester potassium maleate. In the complex biological oil displacement agent, the using amount of the chemical surfactant is low (namely 0.0125 weight percent), and a complex system can reach ultra-low interfacial tension of less than 10<-2>mN / m order of magnitude, so the complex biological oil displacement agent has the advantages of high oil displacement efficiency, simple preparation process, low cost and the like, and is suitable for the popularization and application of the further improvement on a recovery ratio in high-water-content oil fields.

Owner:DAQING OILFIELD CO LTD

Process for improving friability and cold-flow of carbon dioxide epoxy propylane copolymer

Owner:迁安市宏奥低碳科技有限公司

Silicon wafer cleaning agent and use method thereof

InactiveCN101880609AEasy to operateWill not bring inSemiconductor/solid-state device manufacturingOrganic non-surface-active detergent compositionsOrganic baseStandard electrode potential

The invention discloses a silicon wafer cleaning agent and a use method thereof. The silicon wafer cleaning agent consists of oxidant, organic base, penetrant and water, and the volume ratio of the components is as follows: oxidant : organic base : penetrant : water equal to 0.02-0.1:1-4:0.5-1:30-50; the standard electrode potential of the oxidant is not less than 1.7V, and the oxidant is ozone or hydrogen peroxide; the organic base is selected from one or more of the following components: triethanolamine, sodium alkoxide, sodium alkyl, lithium alkyl, lithium amide and quaternary ammonium base; and the penetrant is fatty alcohol-polyoxyethylene ether or sodium diethylhexyl sulfosuccinate. The cleaning agent can be simply operated, silicon wafer cleaning does not become complex, the cost is low, no pollution is generated, and the cleaning agent cannot bring impurities to stain silicon wafers, and is environment-friendly.

Owner:GD SOLAR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com