Method for producing 1,4-butanediol and coproducing tetrahydrofuran, and gamma-butyrolactone

A technology of tetrahydrofuran and butanediol, which is applied in the direction of organic chemistry, can solve the problems of increased pressure drop in the reactor bed, poor catalyst stability, and reduced conversion rate of raw materials, etc., and achieves increased bed pressure drop and catalyst stability. Good, optimize the effect of grading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Using dimethyl maleate as raw material, the gas phase hydrogenation reaction is carried out in a fixed bed reactor. The catalyst is CuO-Cr with different loading ratios 2 o 3 (with comparative example 2) catalyst and CuO-MnO 2 / Al 2 o 3 (Same as Comparative Example 1) Graded packing, the process conditions are: temperature 190°C, pressure 6.0MPa, hydrogen ester molar ratio 200:1, volume space velocity of dimethyl maleate is 0.25h -1 , the reaction results are shown in Table 3.

[0030] Table 3 Catalyst graded loading test results

[0031] Filling ratio

Embodiment 2

[0033] Using dimethyl maleate as raw material, the gas phase hydrogenation reaction is carried out in a fixed bed reactor. The catalyst is CuO-Cr with a loading ratio of 1:3 2 o 3 (with comparative example 2) catalyst and CuO-MnO 2 / Al 2 o 3 (with comparative example 1), process condition is: temperature 190 ℃, pressure 6.0MPa, hydrogen ester mol ratio 200: 1, the volume space velocity of dimethyl maleate is 0.25h -1 , and the reaction results are shown in Table 4.

[0034] Table 4 Catalyst gradation loading stability test results

[0035]

time, h

THF

murmur

γ-Butine

ester

1,4-butane

Conversion rates,

%

total choice

sex,%

initial

2.46

8.96

50.19

0.47

99.26

99.18

100

2.92

8.78

51.19

0.52

99.28

99.05

200

2.13

8.69

49.41

0.51

99.41

99....

Embodiment 3~6

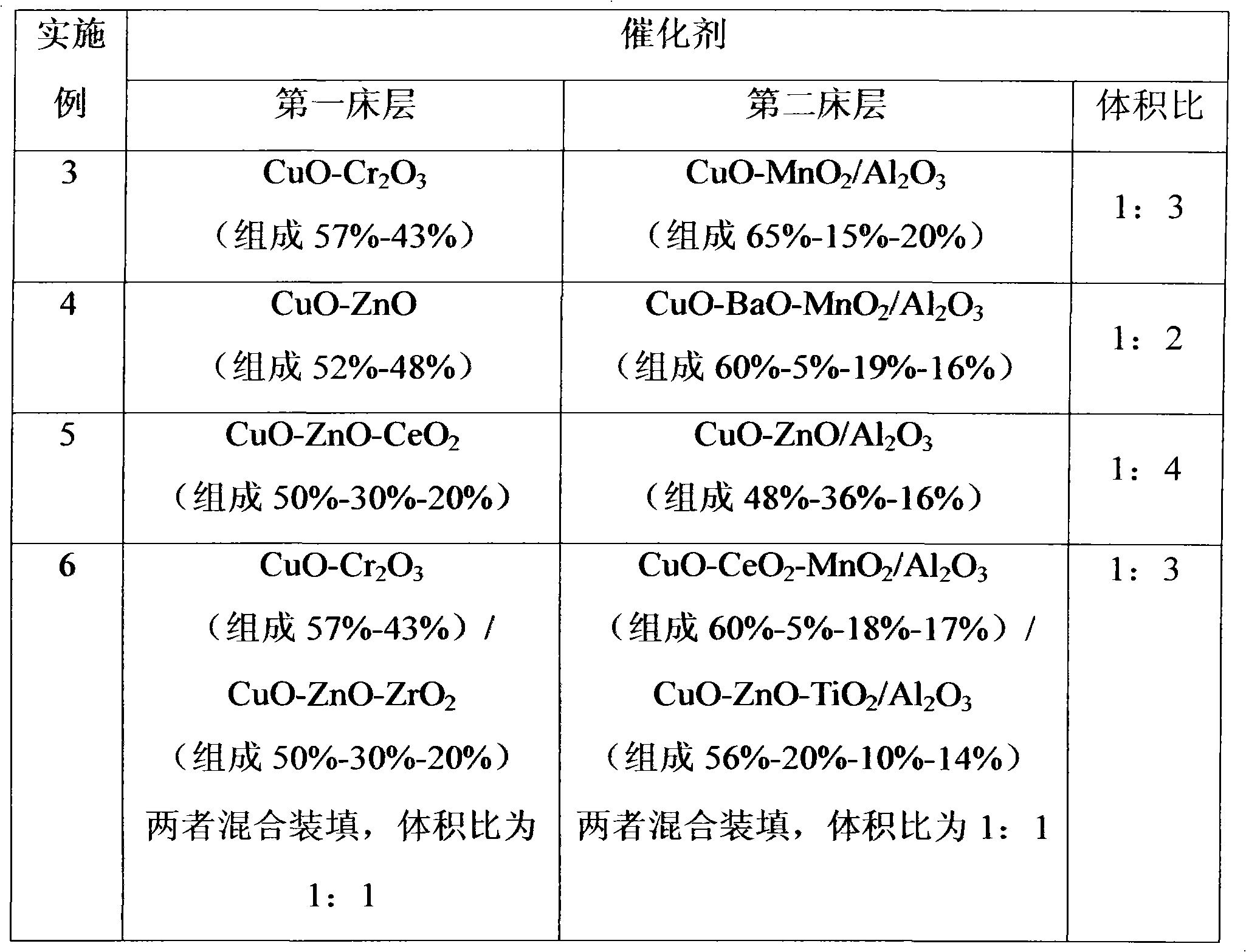

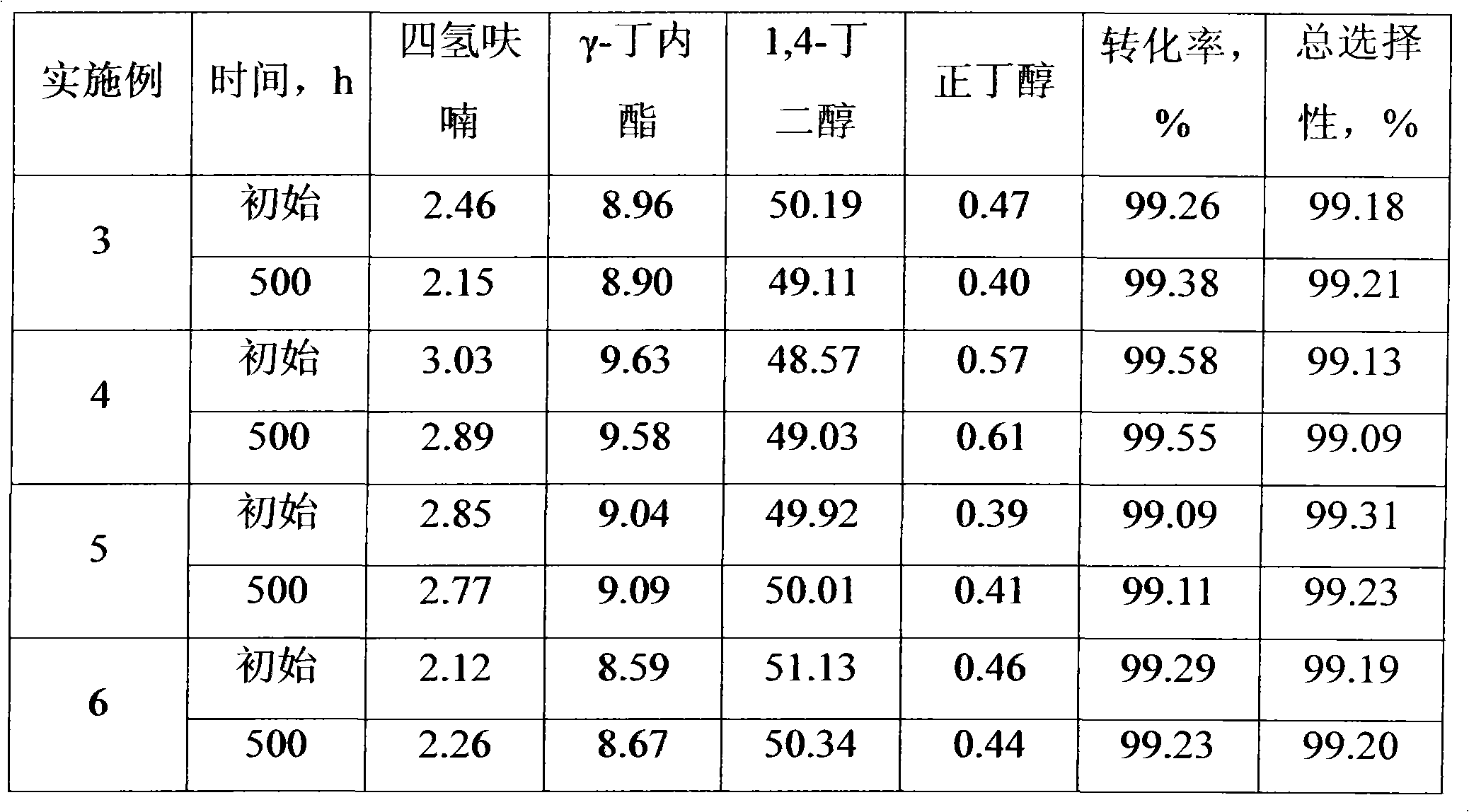

[0039] According to the method of the present invention, different catalysts are used, and suitable process conditions are used, and dimethyl maleate is used as a raw material for hydrogenation reaction. The specific conditions and reaction results are shown in Table 4, Table 5 and Table 6. If different types of catalysts are used in each catalyst bed, the catalysts are mixed and loaded in the same volume ratio. Wherein Example 6 uses a mixture of dibutyl maleate and dibutyl succinate in a volume ratio of 1:1 as a raw material.

[0040] Table 4 Embodiment 3~6 Catalyst

[0041]

[0042] Table 5 Embodiment 3~6 operating conditions

[0043] Example

temperature, ℃

pressure, MPa

Airspeed, h -1

hydrogen / ester ratio

3

190

6.0

0.25

200∶1

4

200

5.0

0.30

300∶1

5

195

6.0

0.40

200∶1

6

190

6.0

0.25

200∶1

[0044] Table 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com