Patents

Literature

76results about How to "Prevent pressure drop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

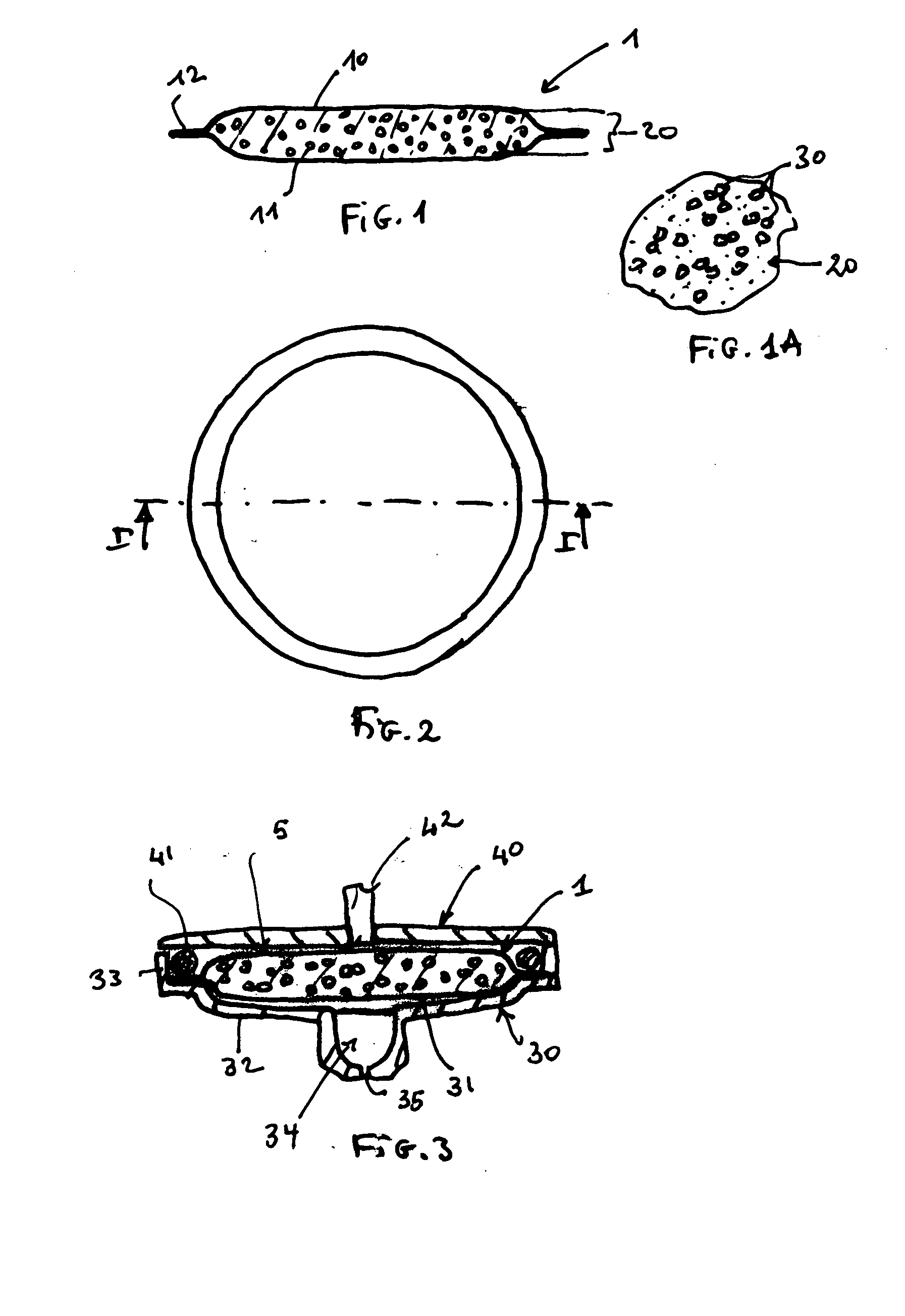

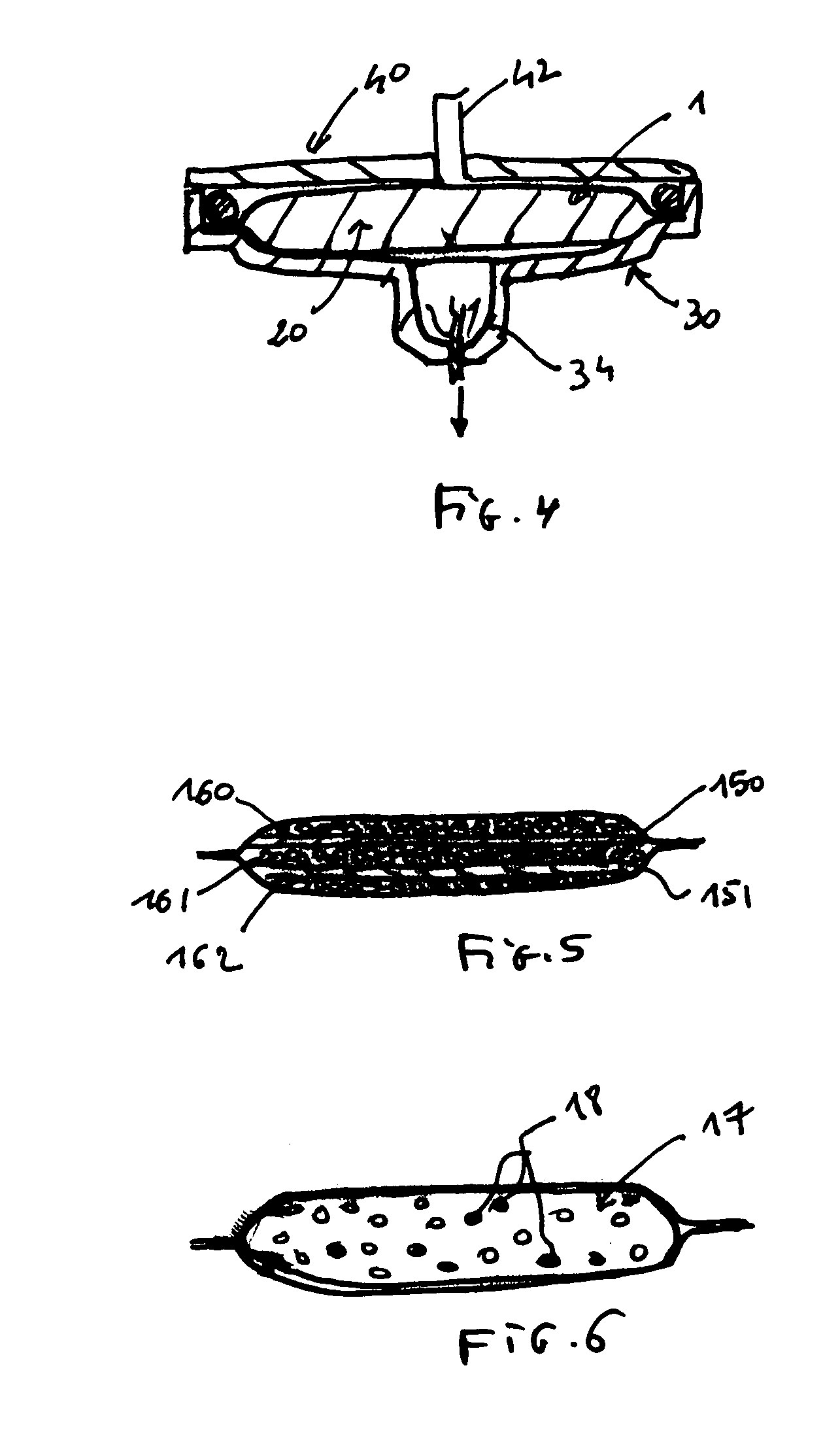

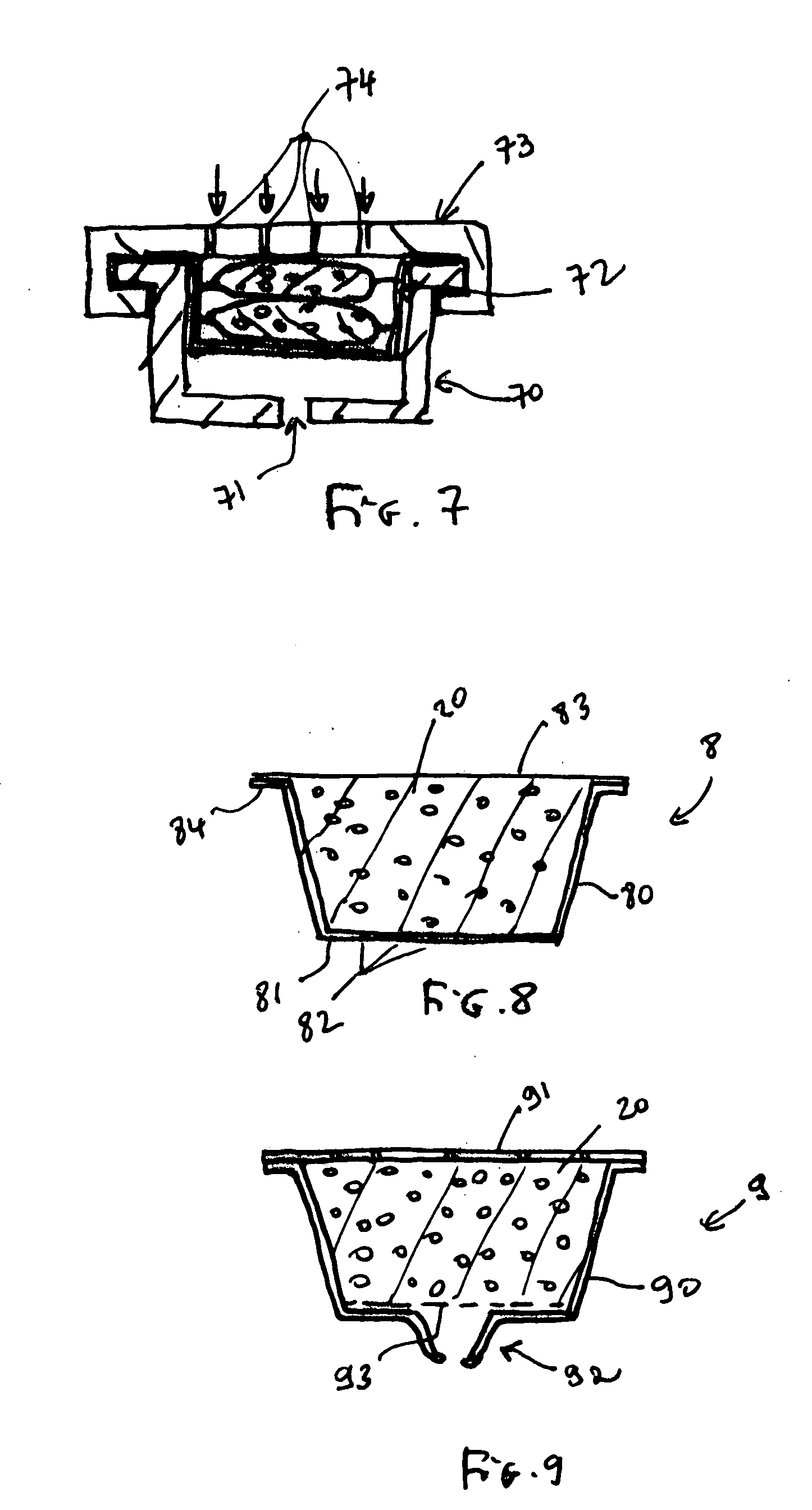

Beverage portioned package for preparing a foamy beverage from soluble powder

InactiveUS20050158426A1Sufficient pressureSufficient amountPackaging foodstuffsWater insolubleWadding

A beverage portioned package for preparing a beverage in an extraction device of which the package is held or clamped between a water supplying part and a receiver of the device. The package has a first surface for the water to be forced to flow there through under pressure when the package is held or clamped in the device; a second surface for the flow of beverage to be forced to flow there through so to be collected in the receiver, wherein the package contains a portion of water-soluble beverage material and a portion of a filler. The filler comprising water insoluble material adapted to maintain the extraction pressure above the pressure created by the sole resistance of the first and second surfaces when the package is emptied of said soluble material.

Owner:NESTEC SA

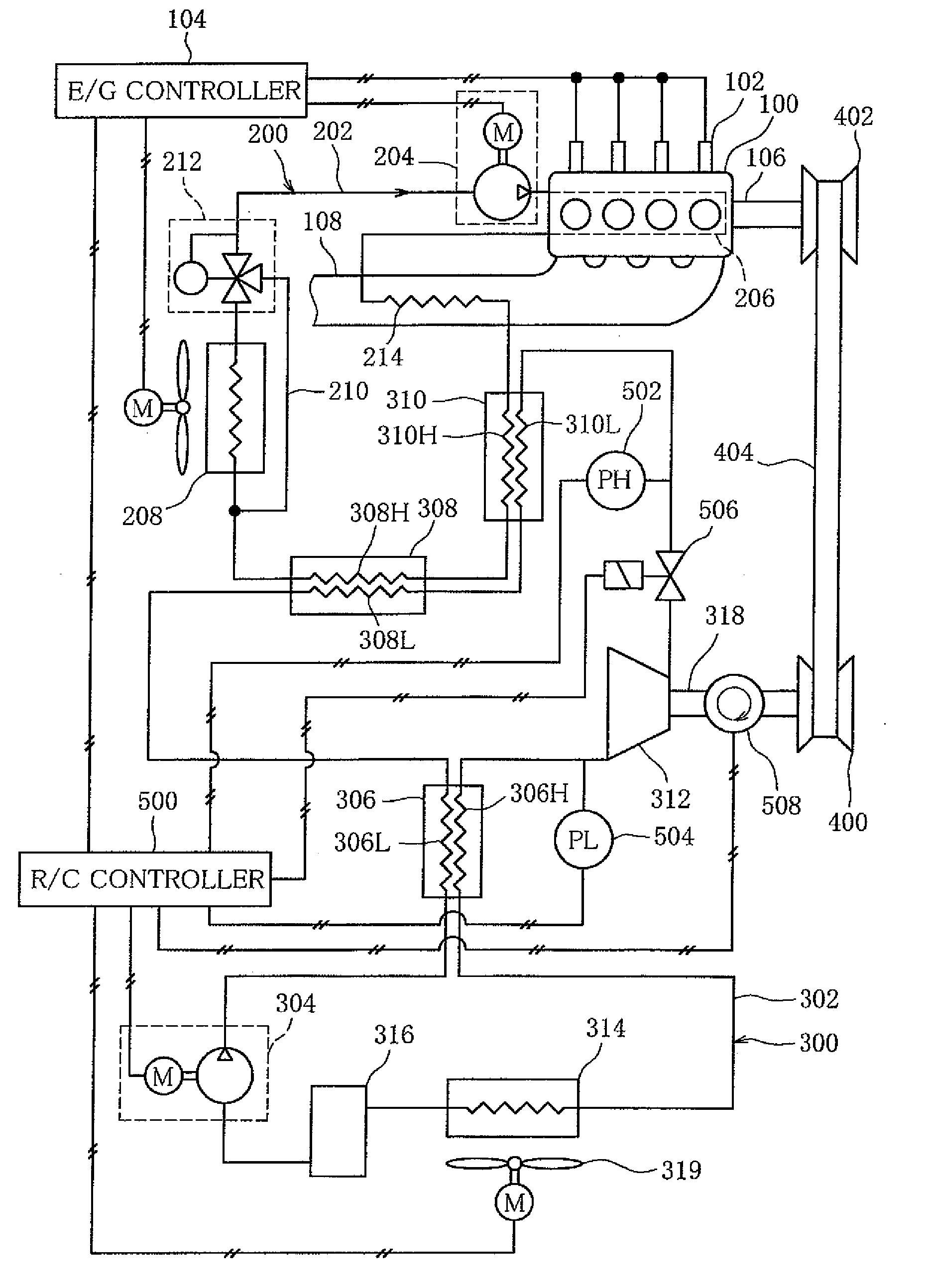

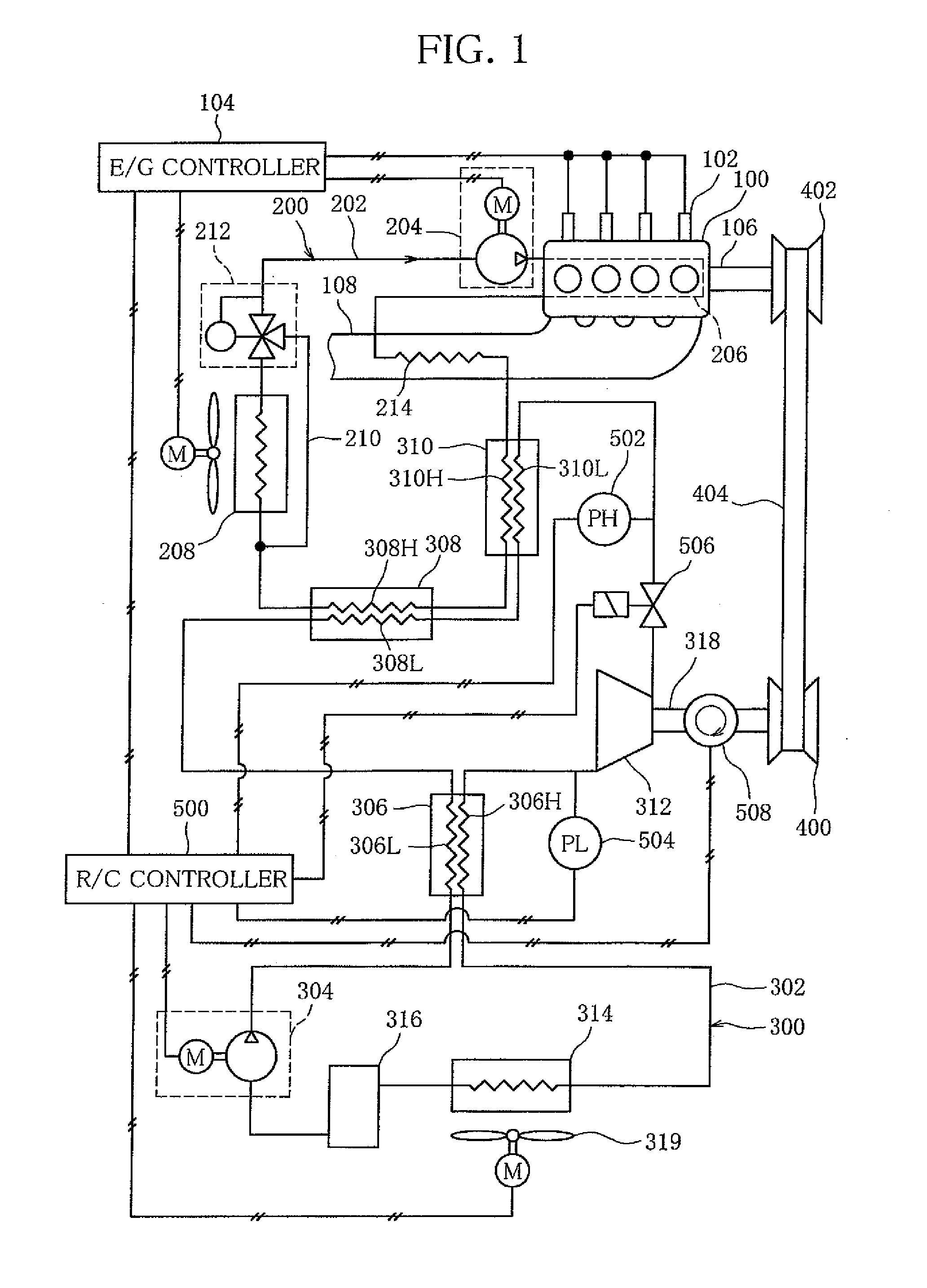

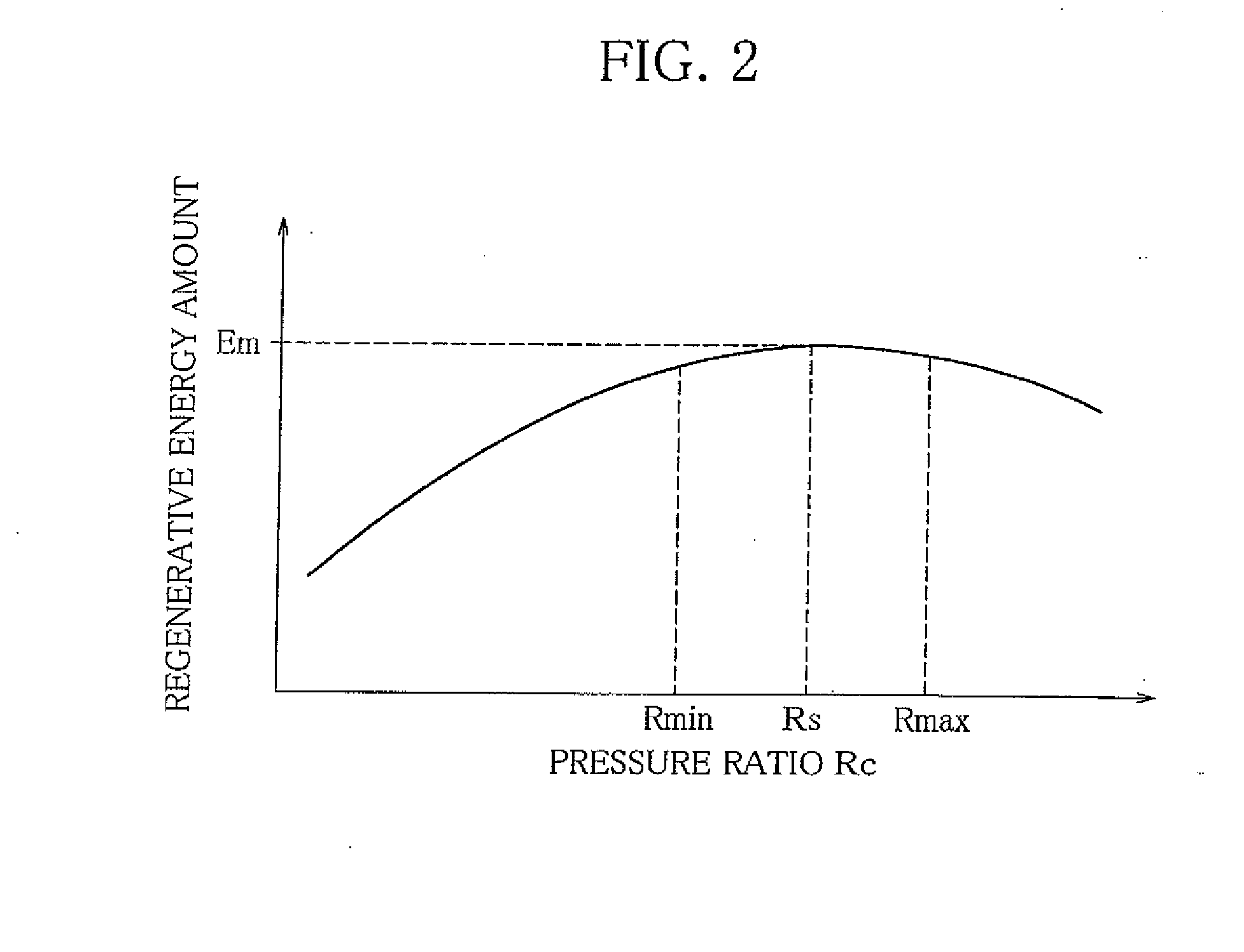

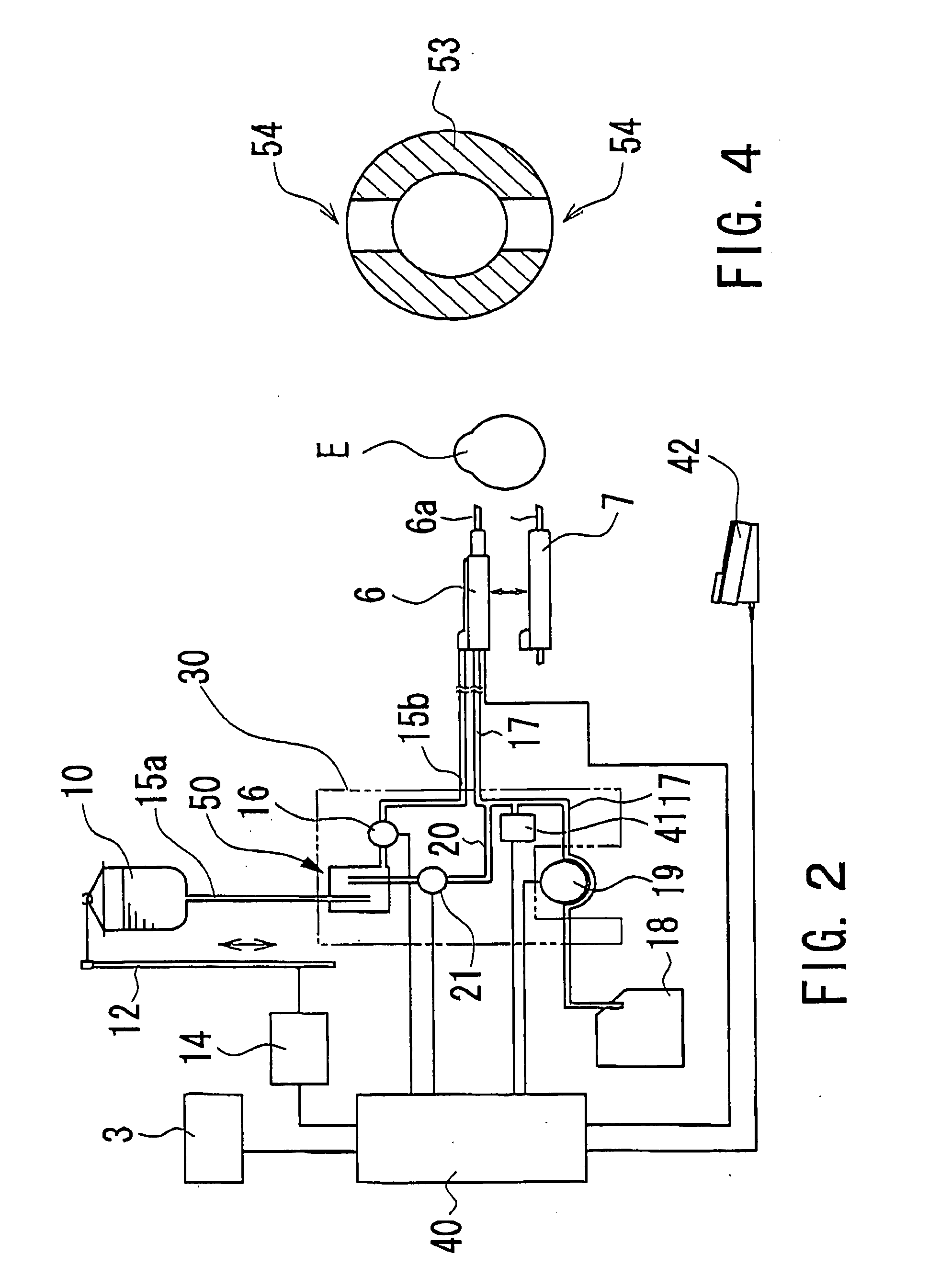

Waste Heat Recovery System of Internal Combustion Engine

InactiveUS20110192163A1Prevent pressure dropReduction in regenerative energy amountInternal combustion piston enginesExhaust apparatusWaste heat recovery unitExternal combustion engine

A waste heat recovery system of an internal combustion engine, in which the amount of regenerative energy transmitted to the internal combustion engine is increased with a simple mechanism. A controller of the waste heat recovery system of an internal combustion engine has at least determination means that makes a determination as to whether it is necessary to increase the pressure of heat-transfer media in a heat exchanger, on the basis of the pressure detected by the high-pressure sensor. When the determination means determines that it is necessary to increase the pressure in the heat exchanger, the controller causes a flow-rate regulating valve (506) to start regulating the flow rate of the heat-transfer media while leaving the pump working. The controller causes the flow-rate regulating valve to continue the regulation at least until the determination means determines that it is not necessary to increase the pressure in the heat exchanger, and then terminates the regulation.

Owner:SANDEN CORP

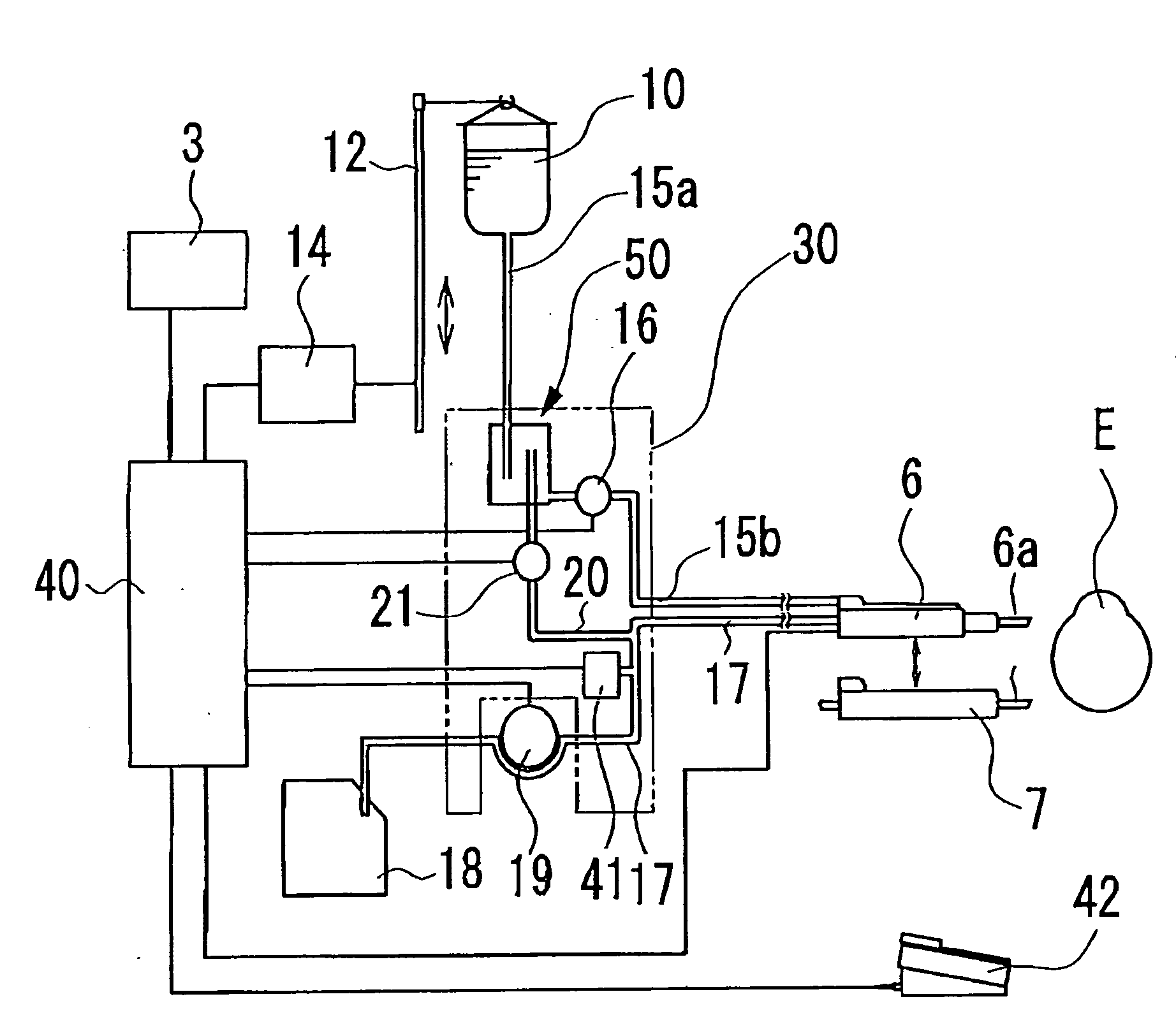

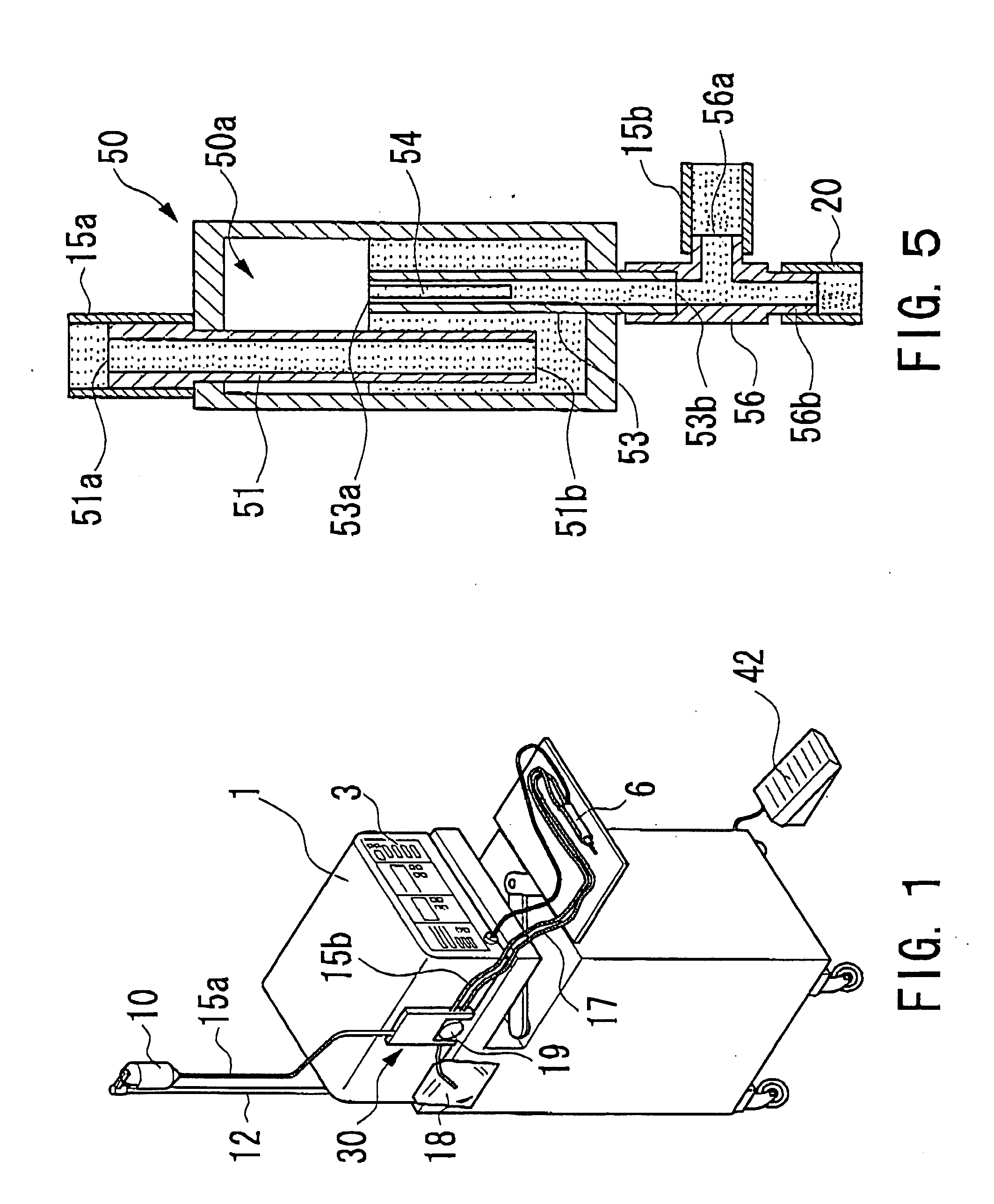

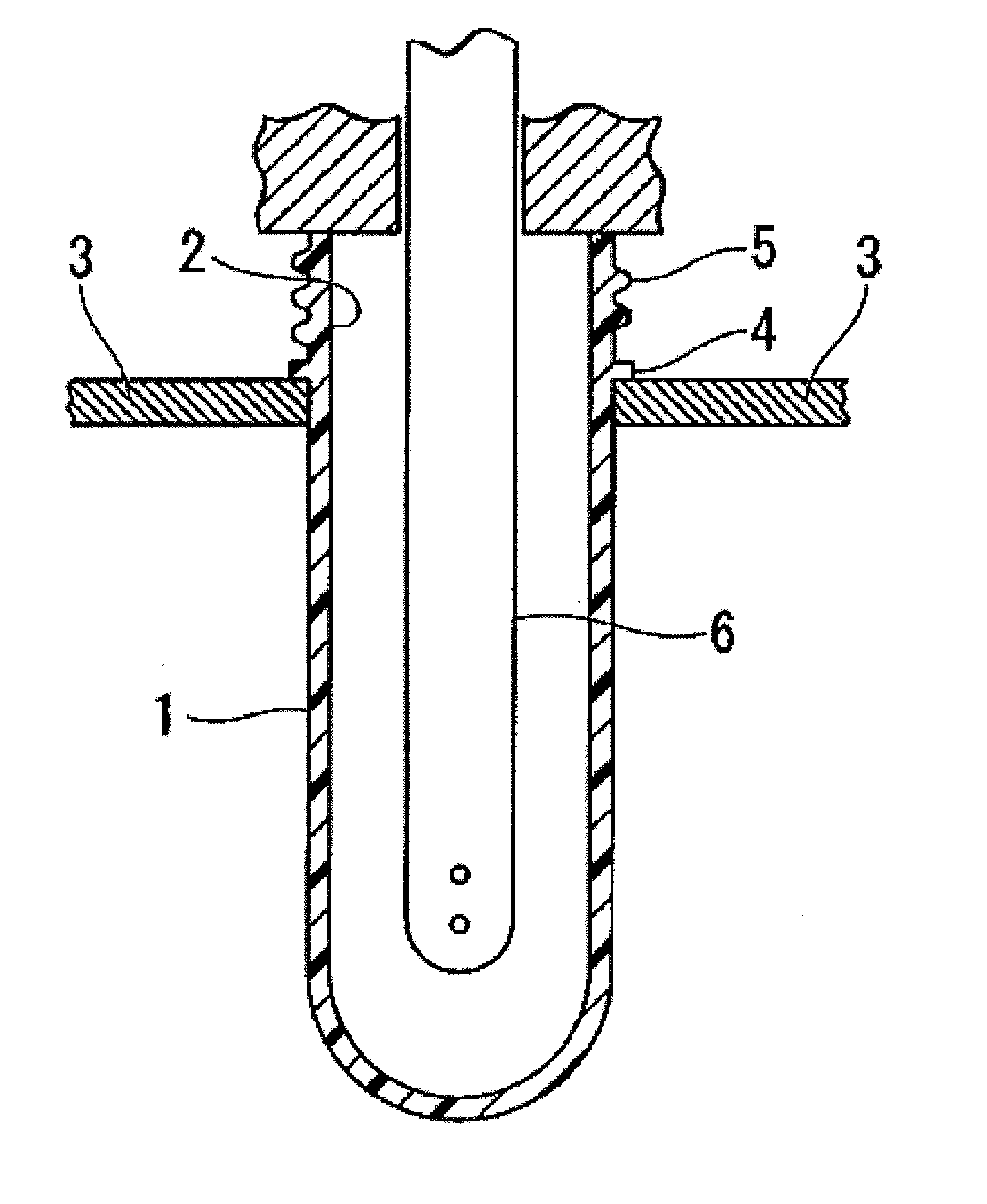

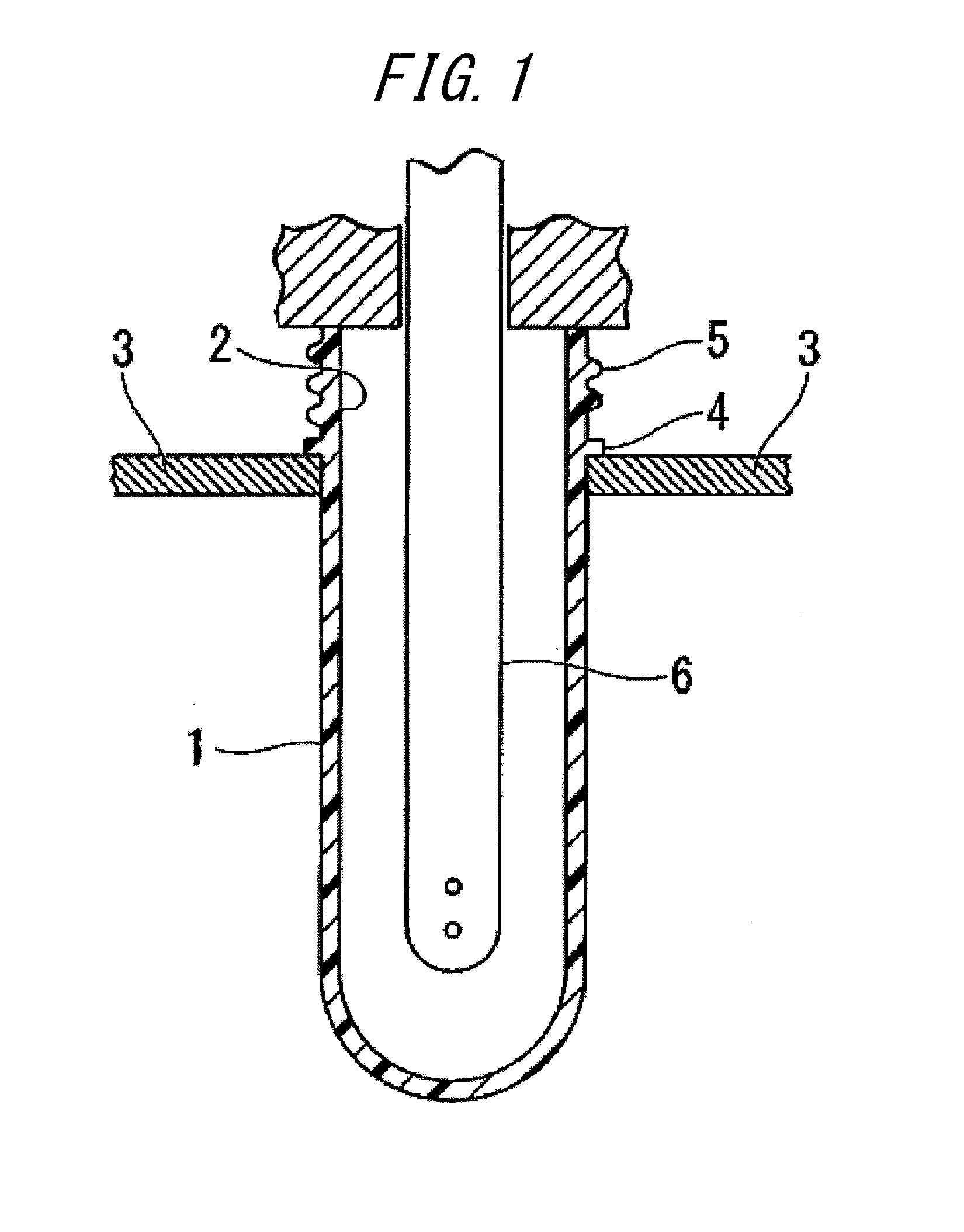

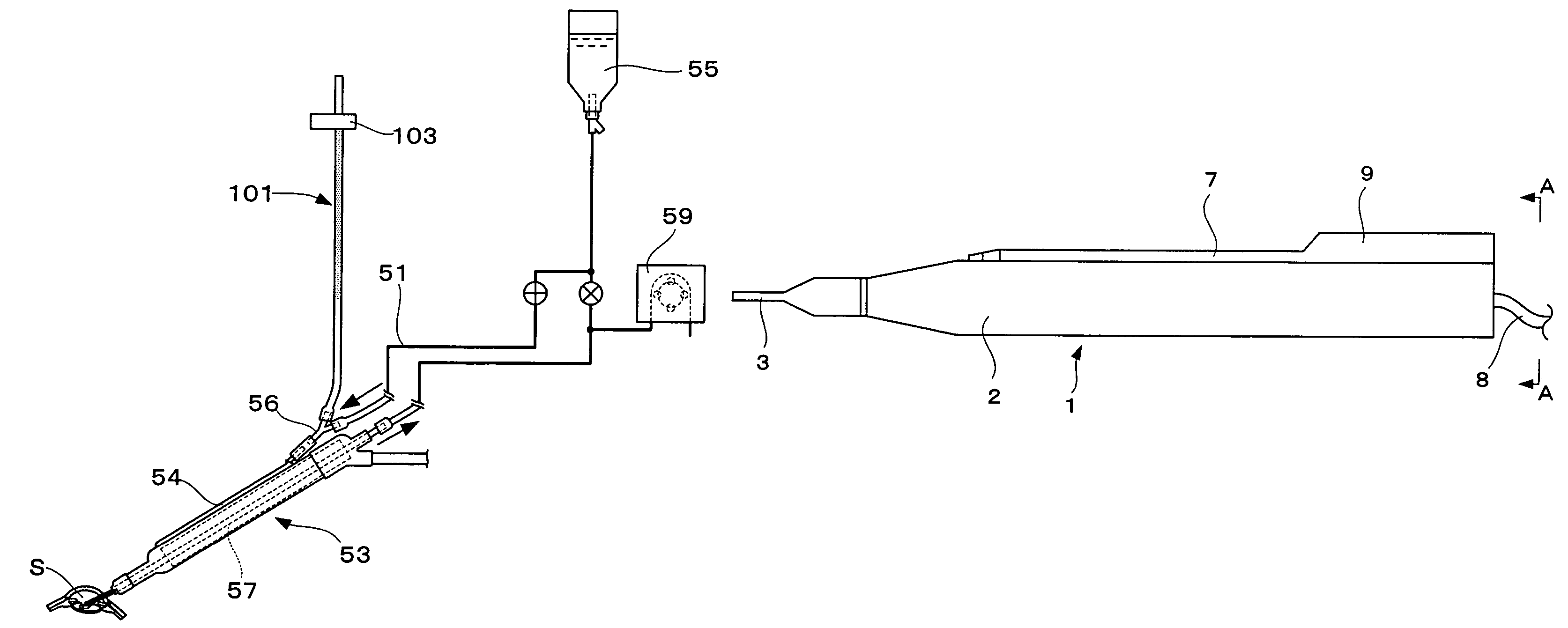

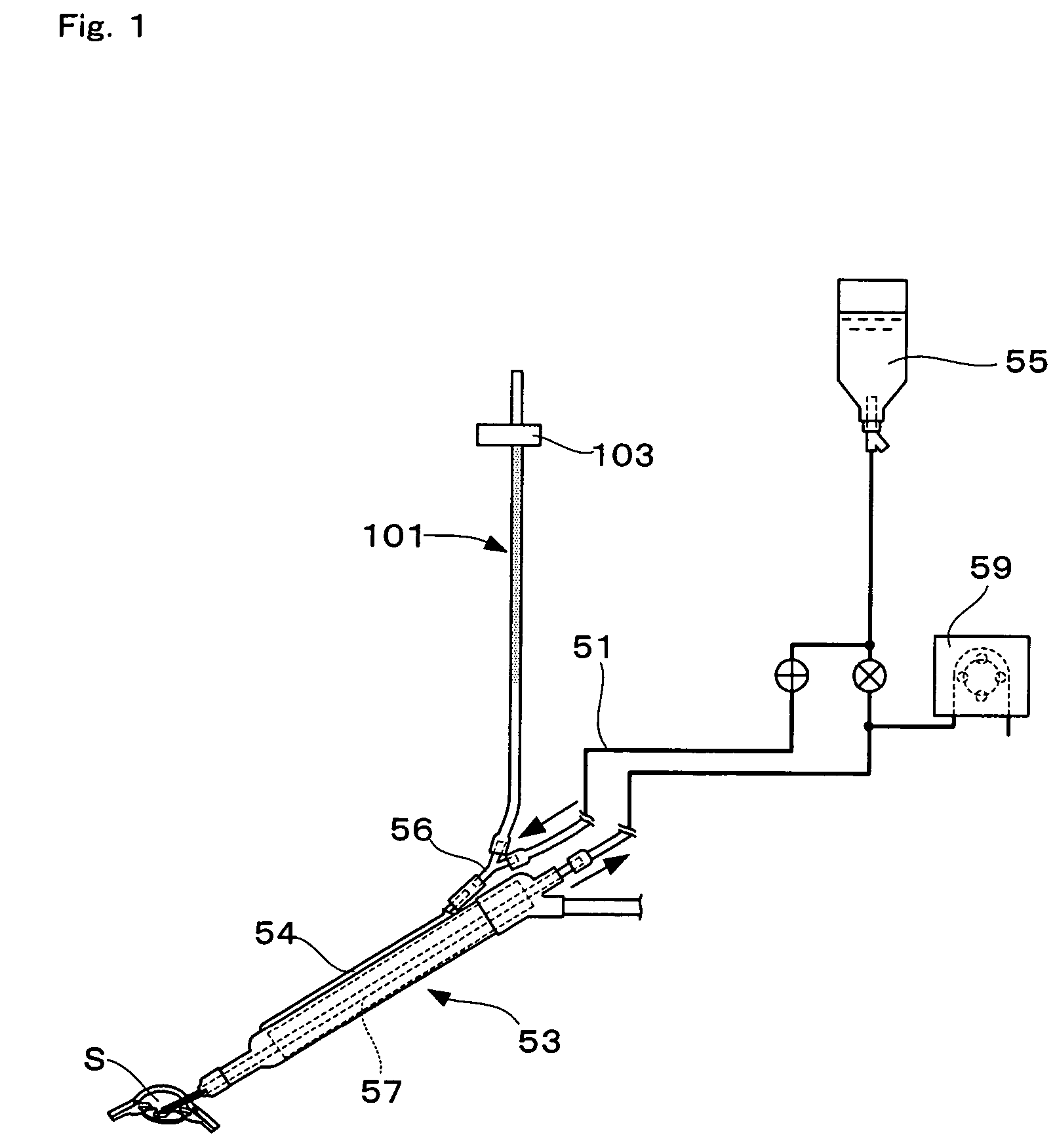

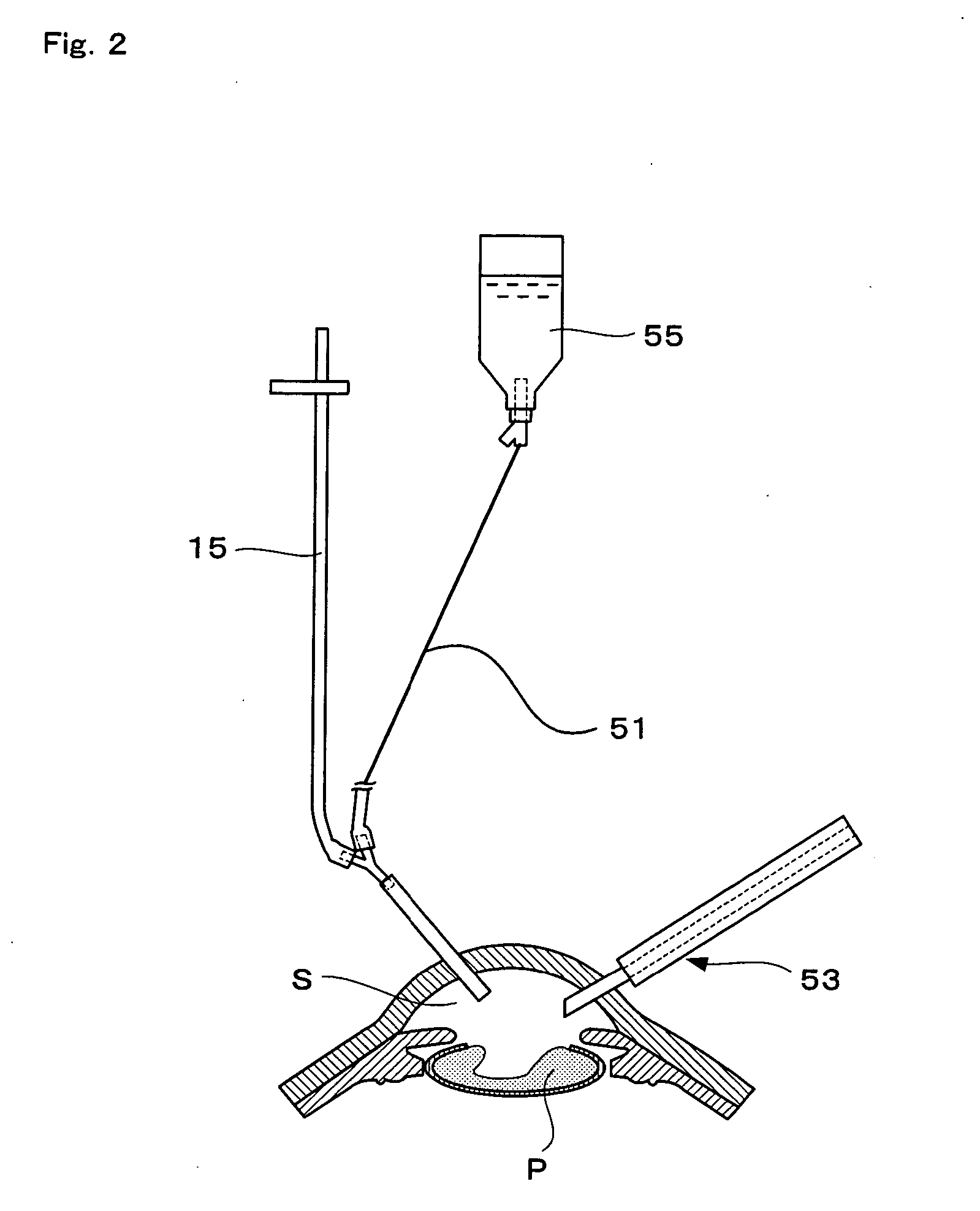

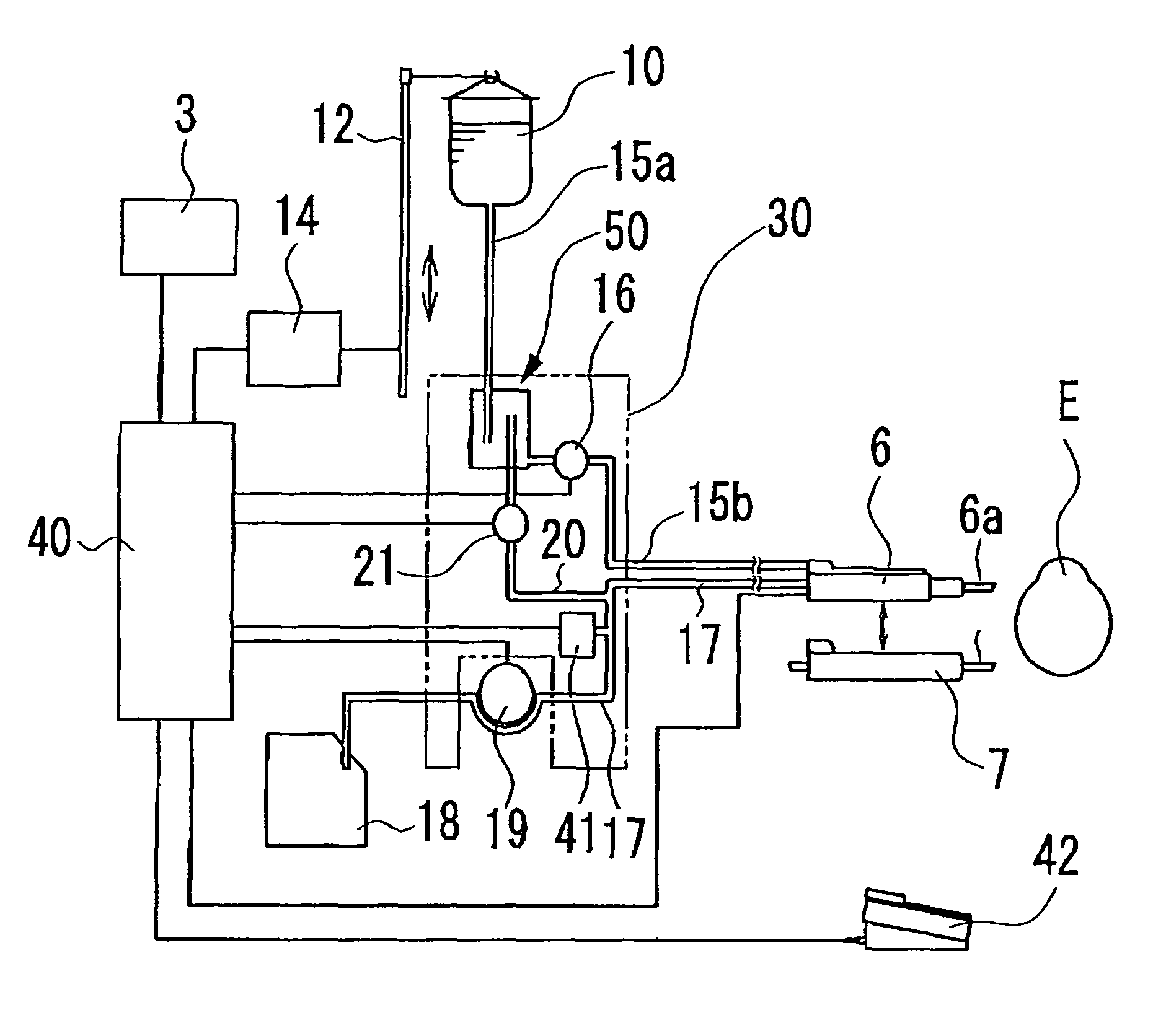

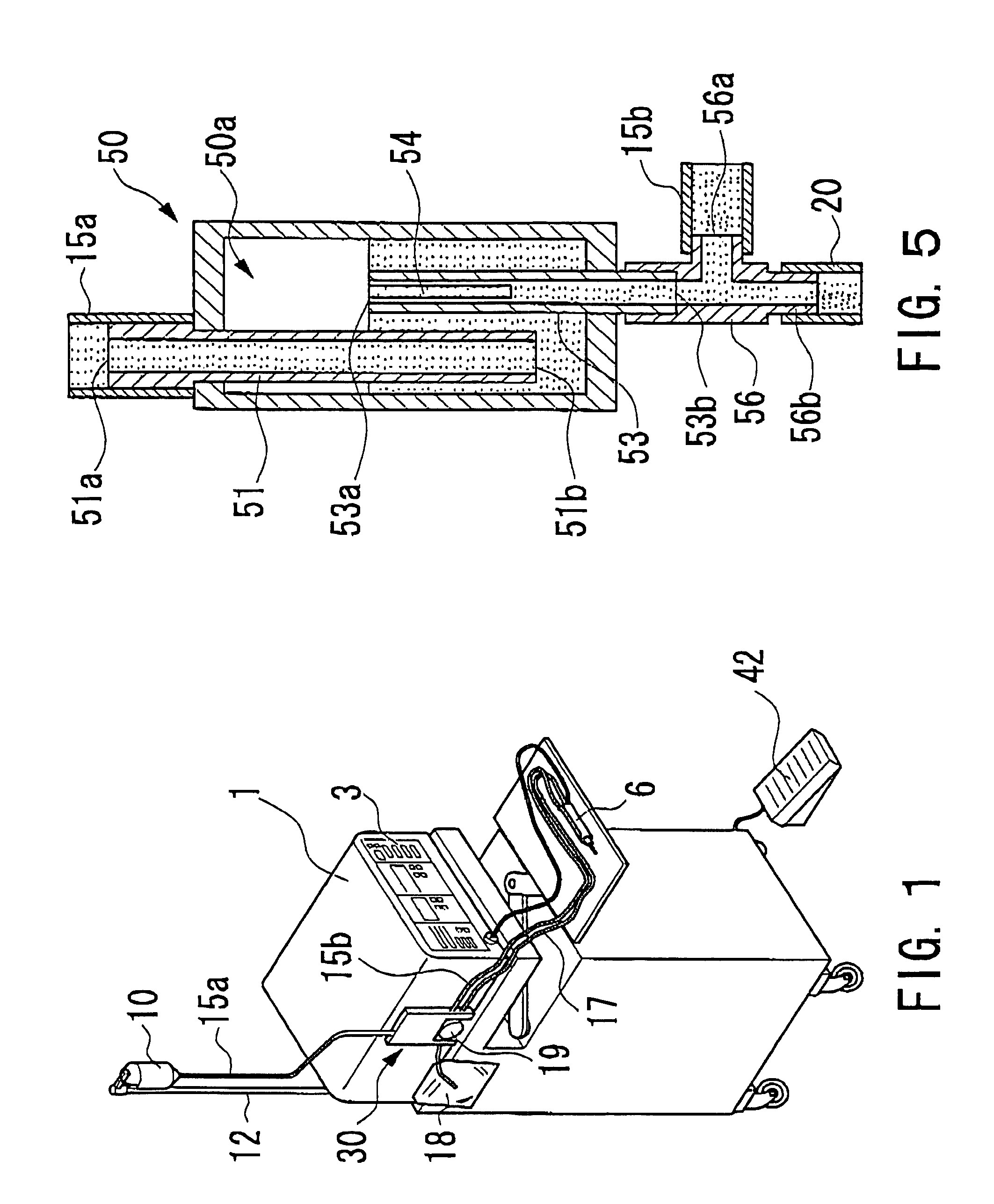

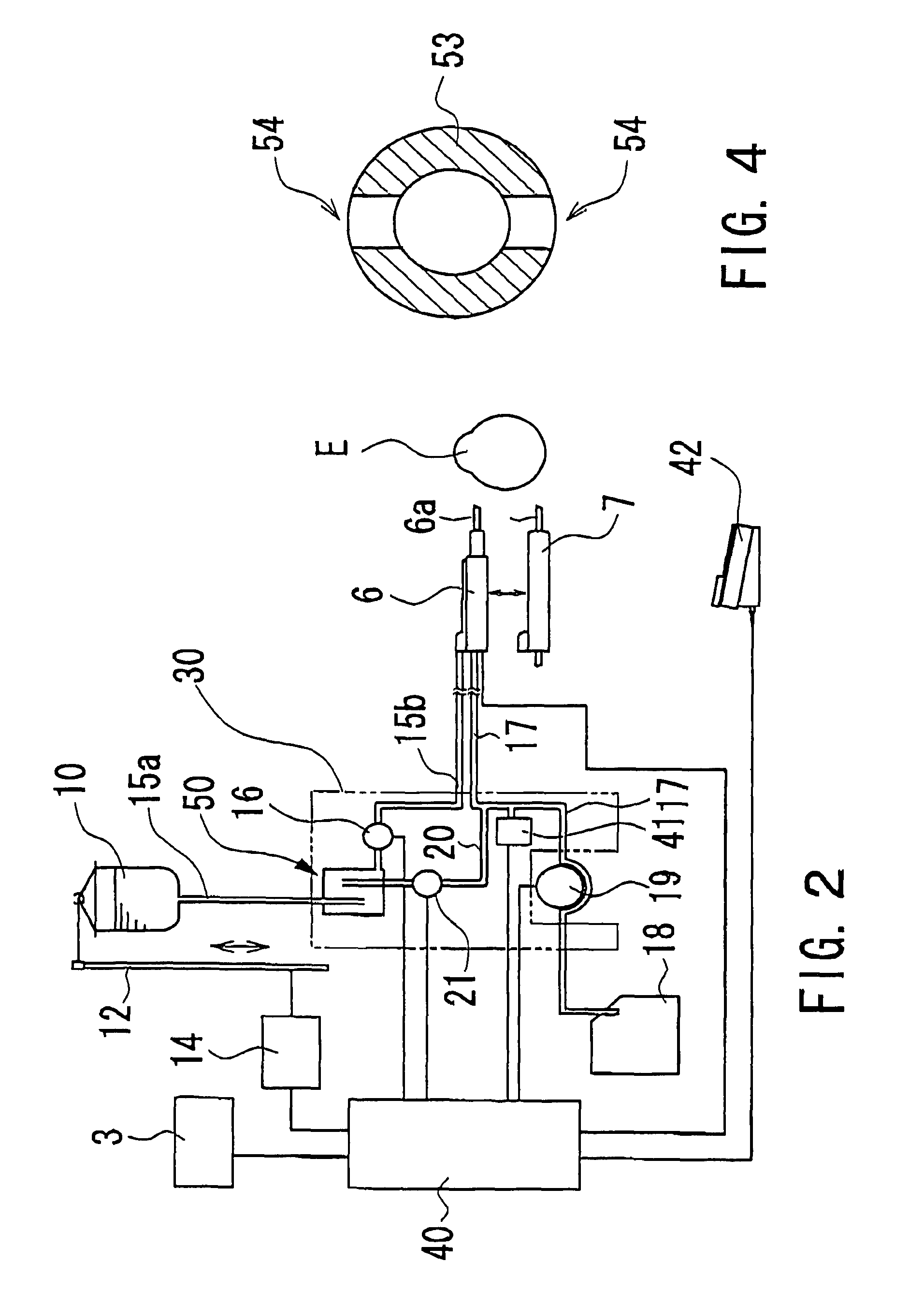

Irrigation/aspiration apparatus

InactiveUS20080033349A1Prevent pressure dropSimple constitutionMedical devicesIntravenous devicesEngineeringAir chamber

To provide an irrigation / aspiration apparatus by which a trouble for an operator is reduced and handling is facilitated and which is capable of preventing a sharp decrease of pressure of an anterior chamber with a simple constitution.The apparatus has a chamber storing an irrigation liquid, a vent tube for making the liquid flow into an aspiration tube, a leading vent leading the liquid into the chamber from an irrigation tubes an outflow pipe extended in an up-and-down direction, an opening formed on a wall of the outflow pipe, of which a width is narrow and set such that an opening is closed by the liquid under surface tension when a liquid level of the liquid inside the chamber rises, an outflow vent to which the irrigation tube or a vent tube is connected, and an air chamber which is a space provided above an inflow hole of the outflow pipe.

Owner:NIDEK CO LTD

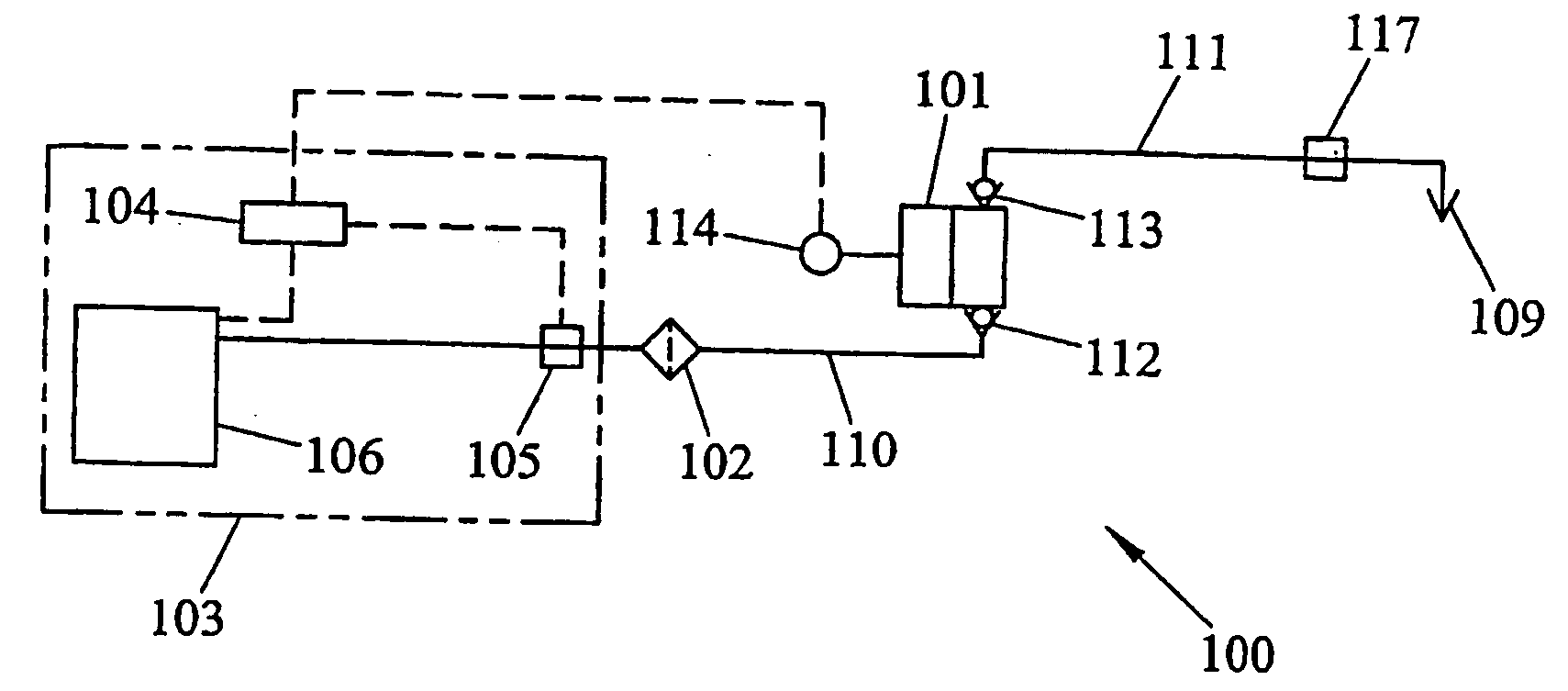

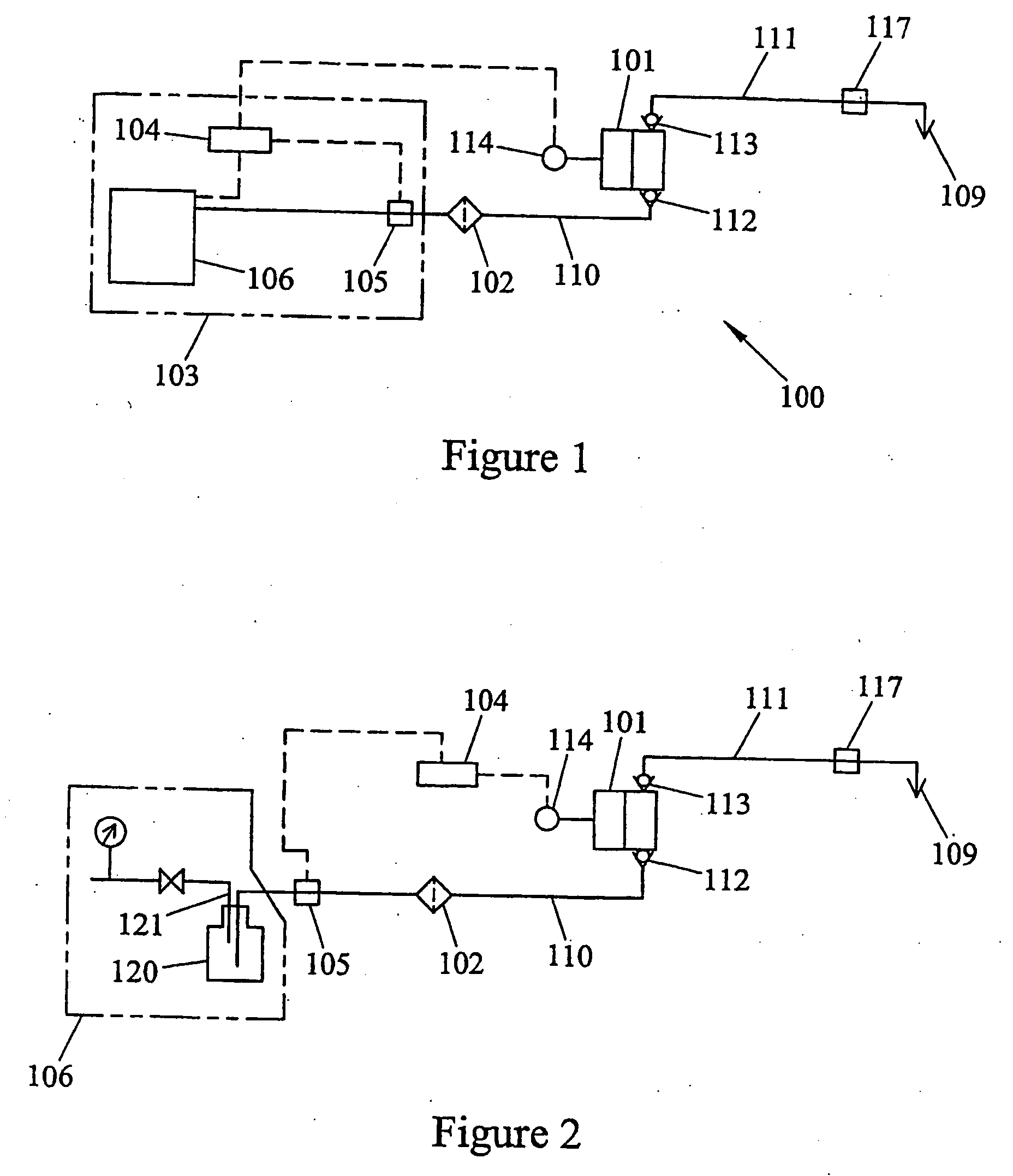

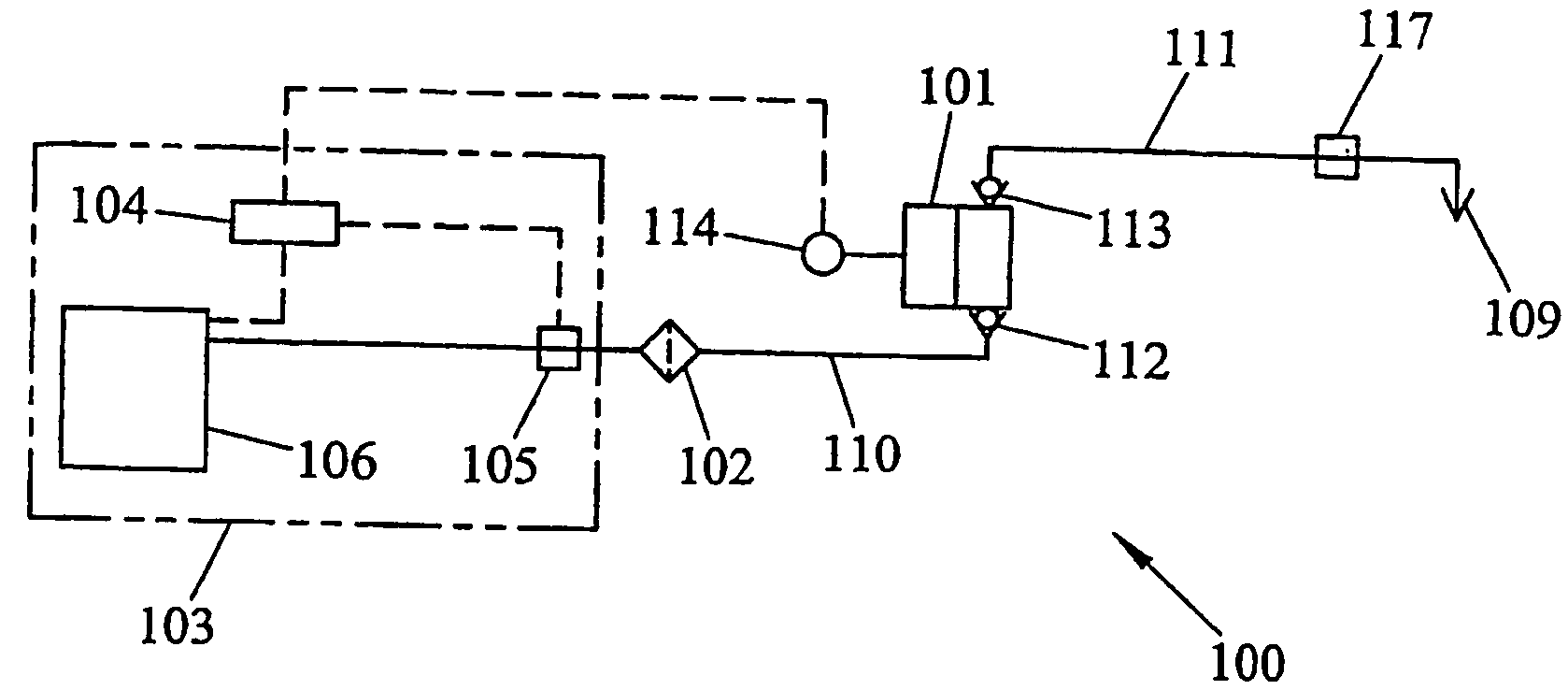

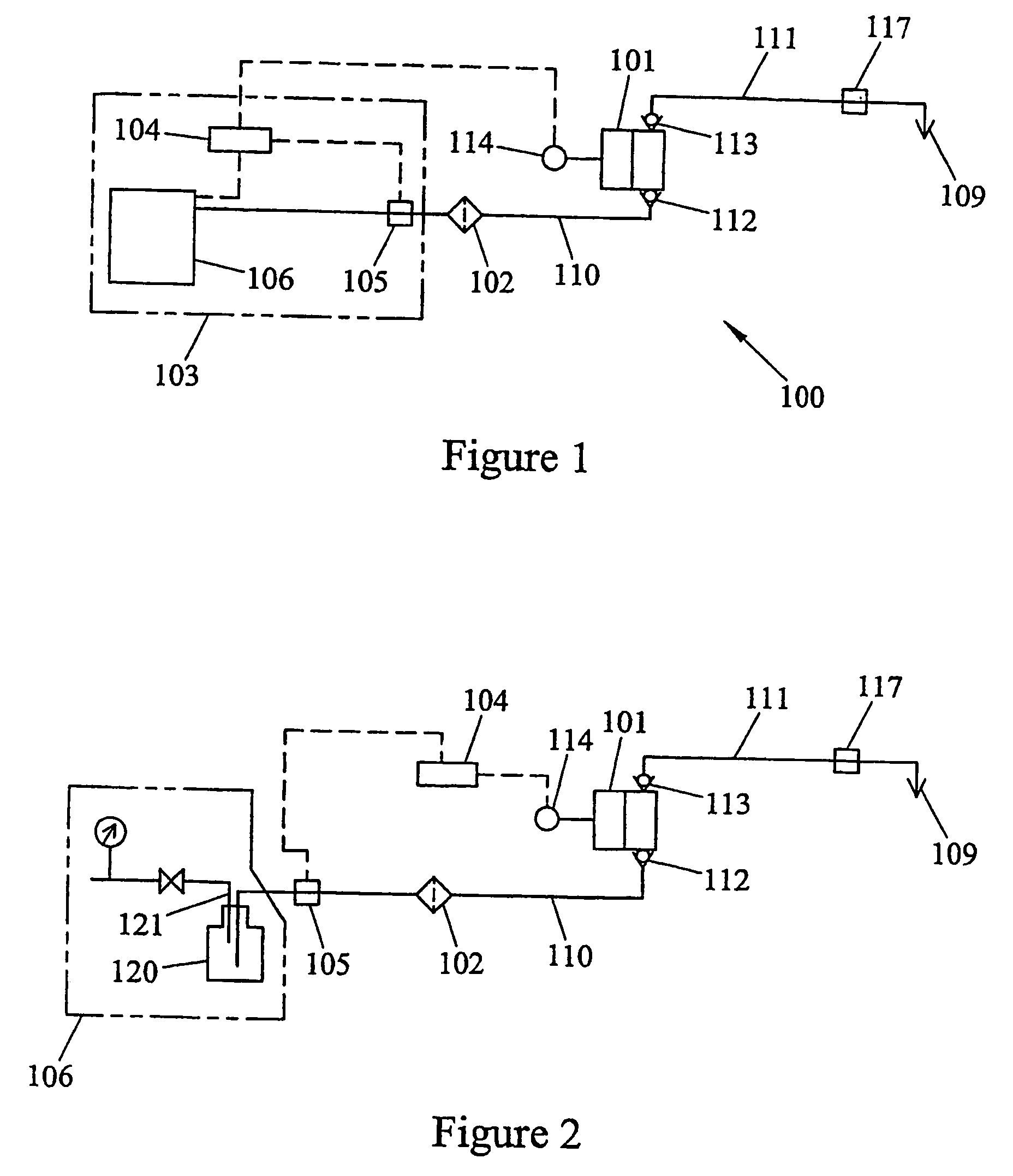

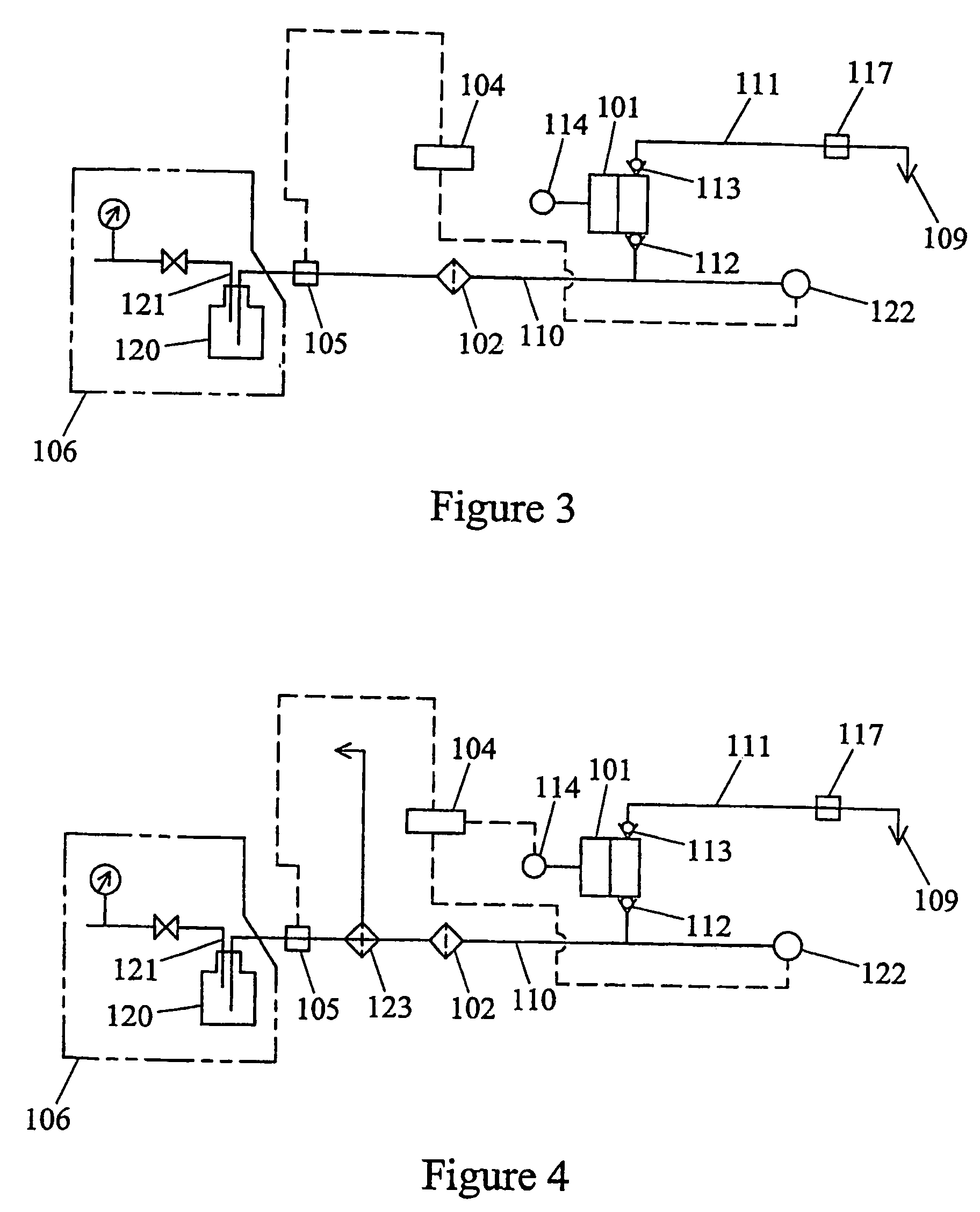

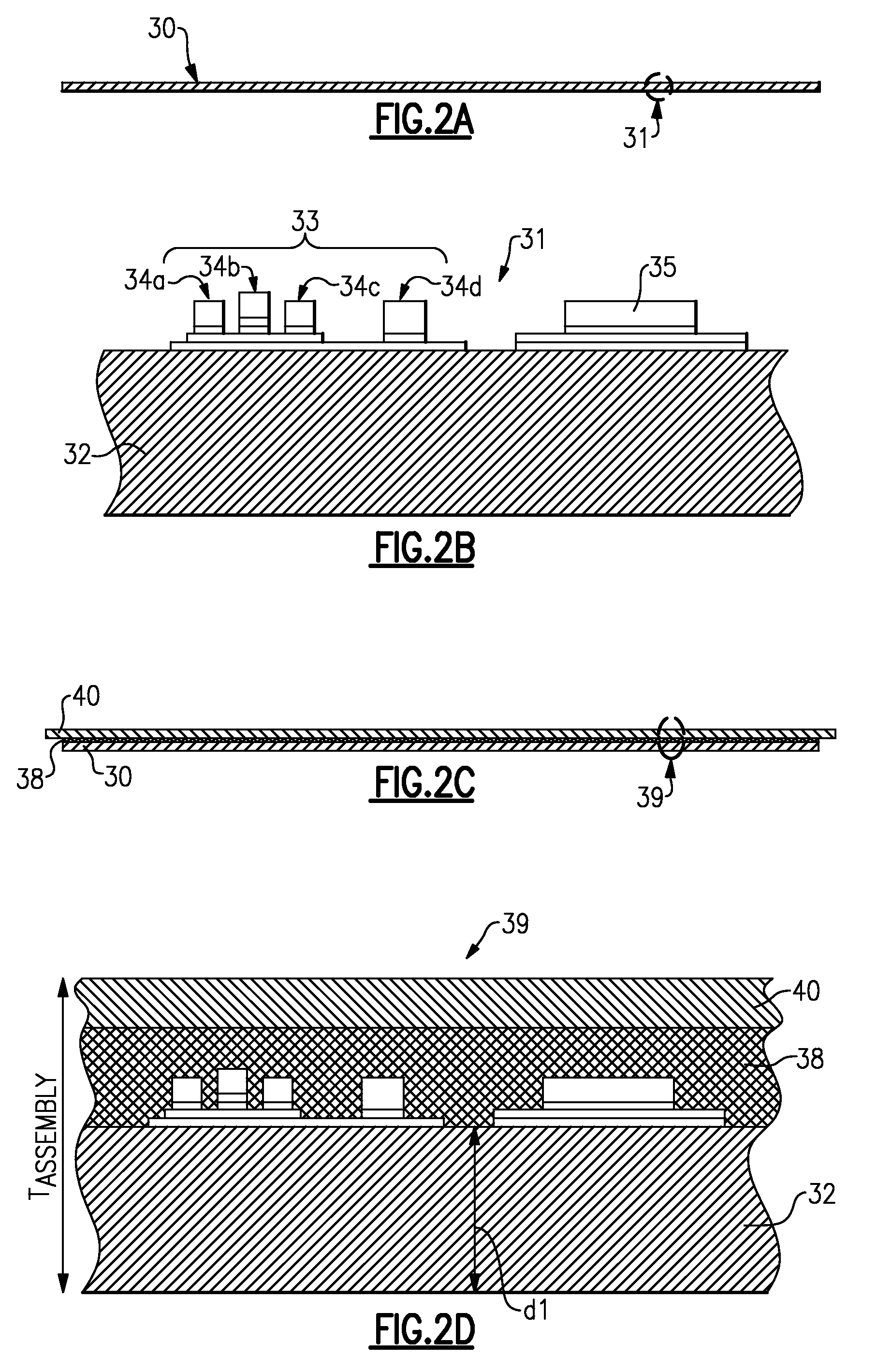

Liquids dispensing systems and methods

ActiveUS20050173458A1Minimize and prevent formation of bubbleImprove integrity and reliabilityPositive displacement pump componentsLiquid flow controllersBiomedical engineeringContamination

A liquid dispensing system (100) supplies a dispense liquid using a pump (101), wherein the system minimizes contamination of, and bubble formation in, the dispense liquid. The pressure at the suction side of the pump may be limited to a predetermined value.

Owner:PALL CORP

Method for manufacturing a container containing a content fluid, a method for placing an inside of a container under a positive pressure, a filled container, a blow molding method, and a blow molding device

ActiveUS20150076105A1Without compromising productivityInhibitory contentLarge containersSolid materialBlow moldingInternal pressure

Owner:DISCMA

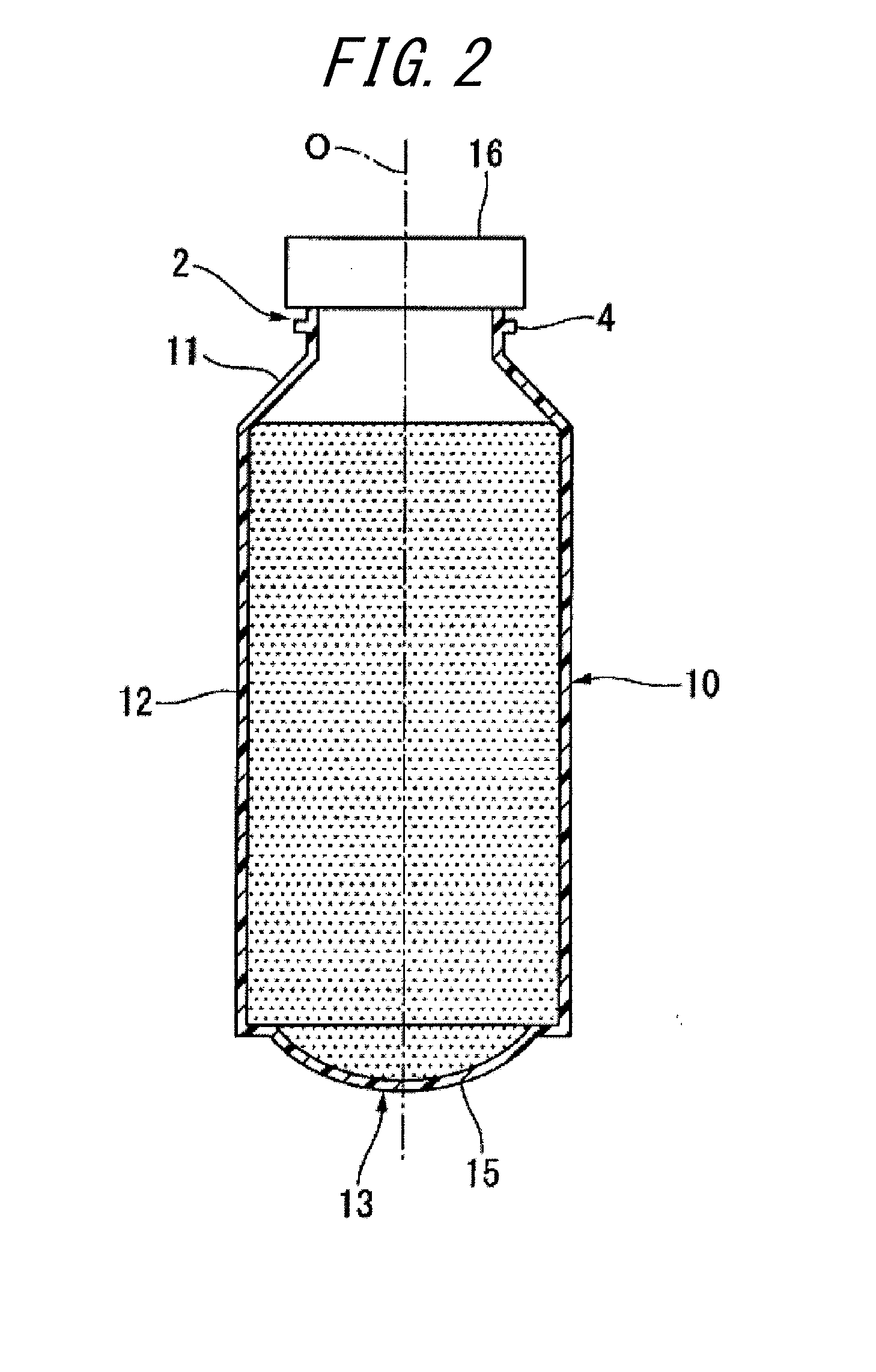

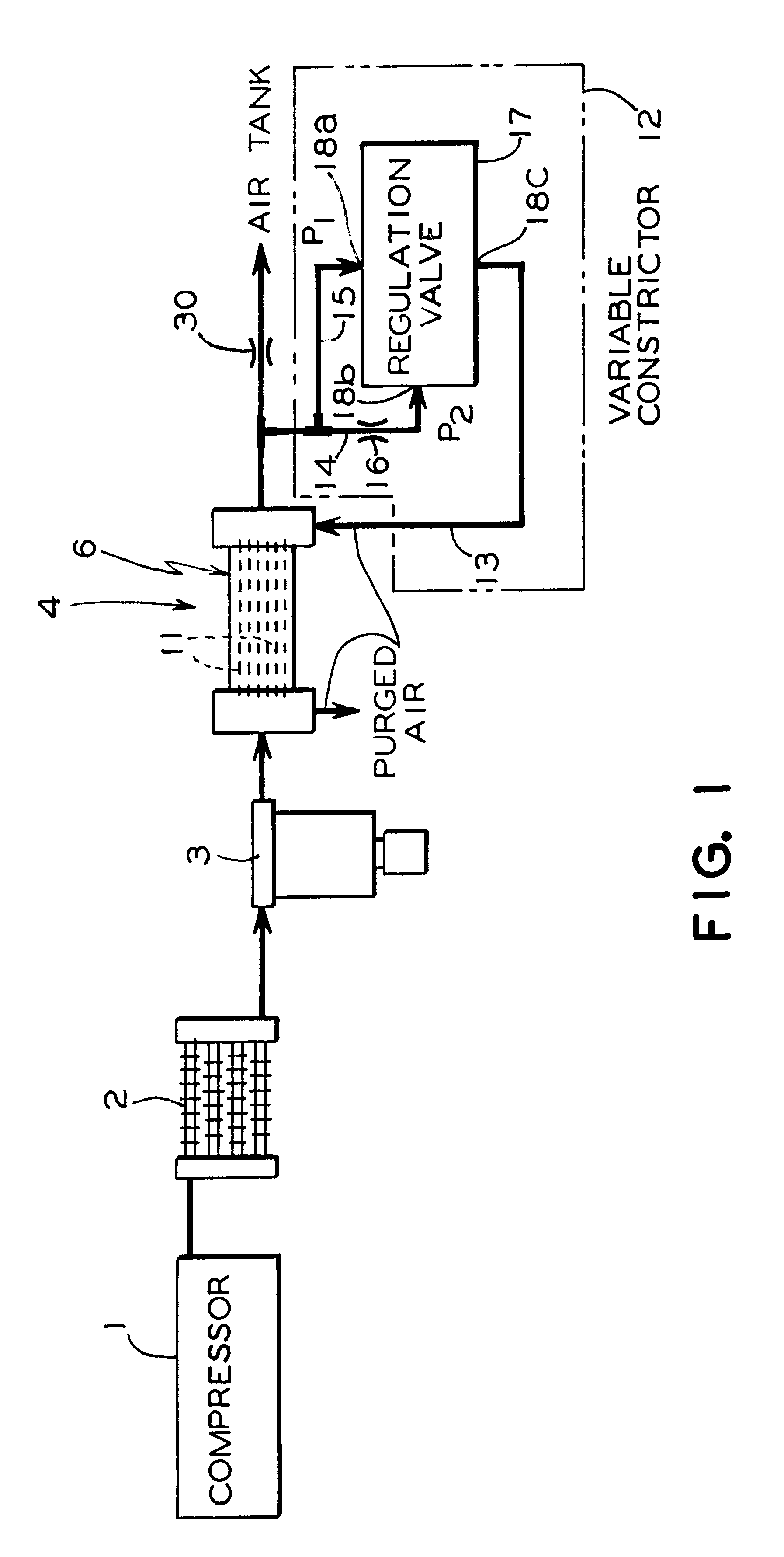

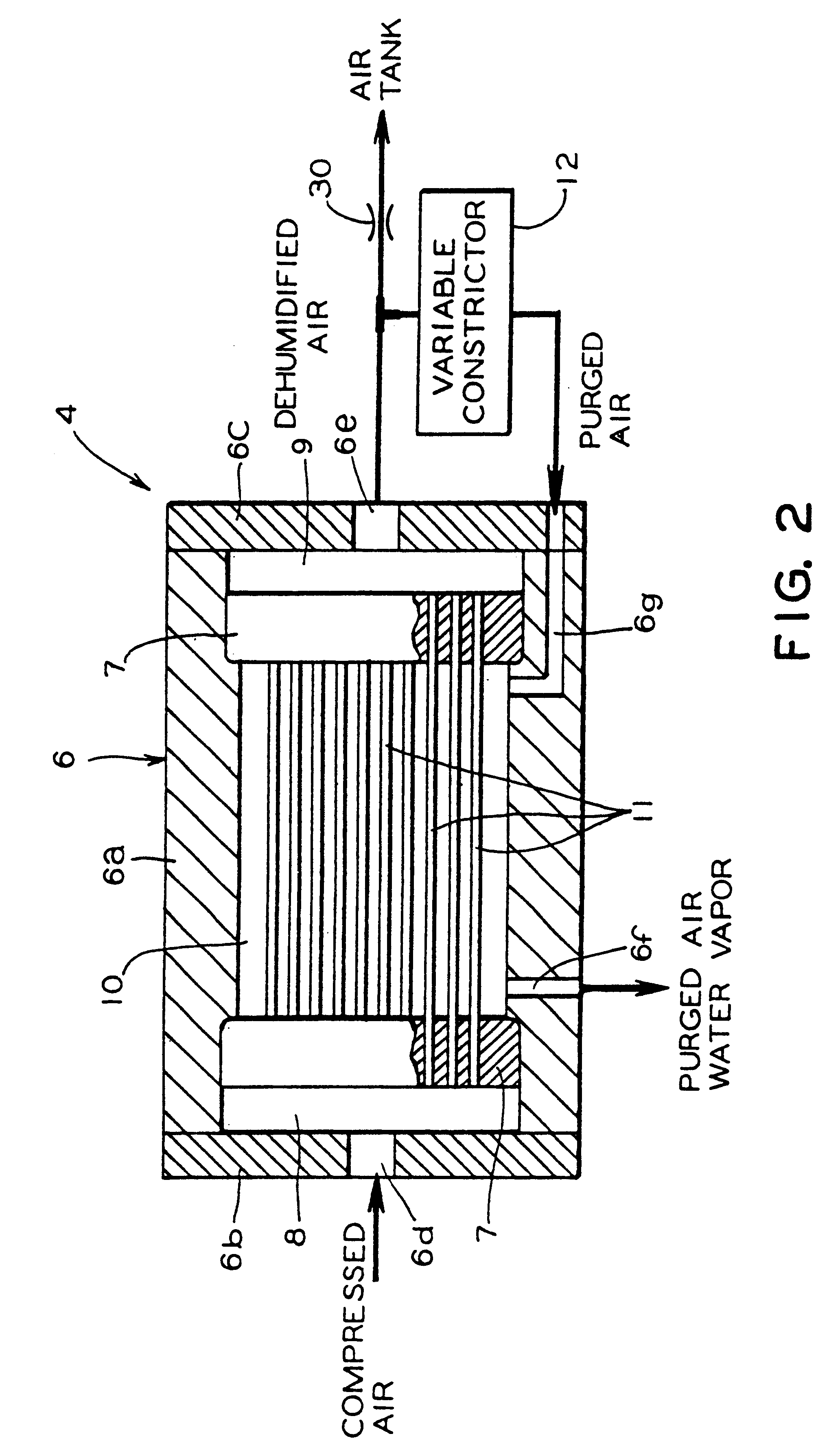

Hollow fiber membrane dehumidification device

InactiveUS6540817B1Reduce pressurePrevent pressure dropSemi-permeable membranesMembranesHollow fibre membraneMembrane configuration

A hollow fiber membrane dehumidification device that possess hollow fiber membranes that cause the compressed air supplied from one end to the interior to flow through and at the same time discharge moisture in the compressed air to the outside, and by so doing exhausts the compressed air to the other end as dehumidified air. There is a reflux route that causes a portion of the dehumidified air exhausted from the hollow fiber membranes to flow back to the outside of the hollow fiber membranes as purged air and a variable restrictor that is provided on the reflux route that increases or decreases the opening-closing volume in accordance with the increase or the decrease of the pressure of the compressed air that flows through the interior of the hollow membranes.

Owner:NABCO LTD

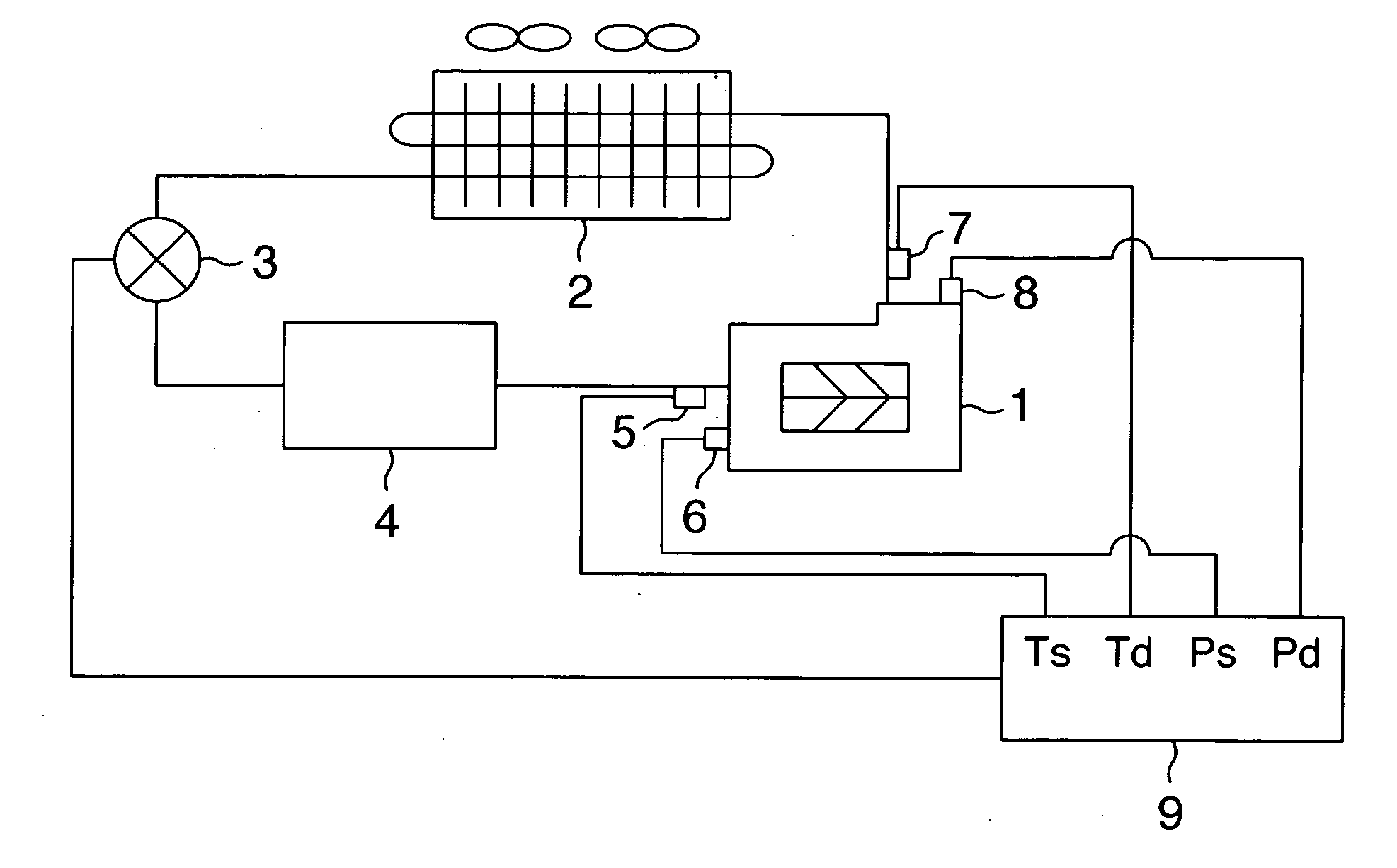

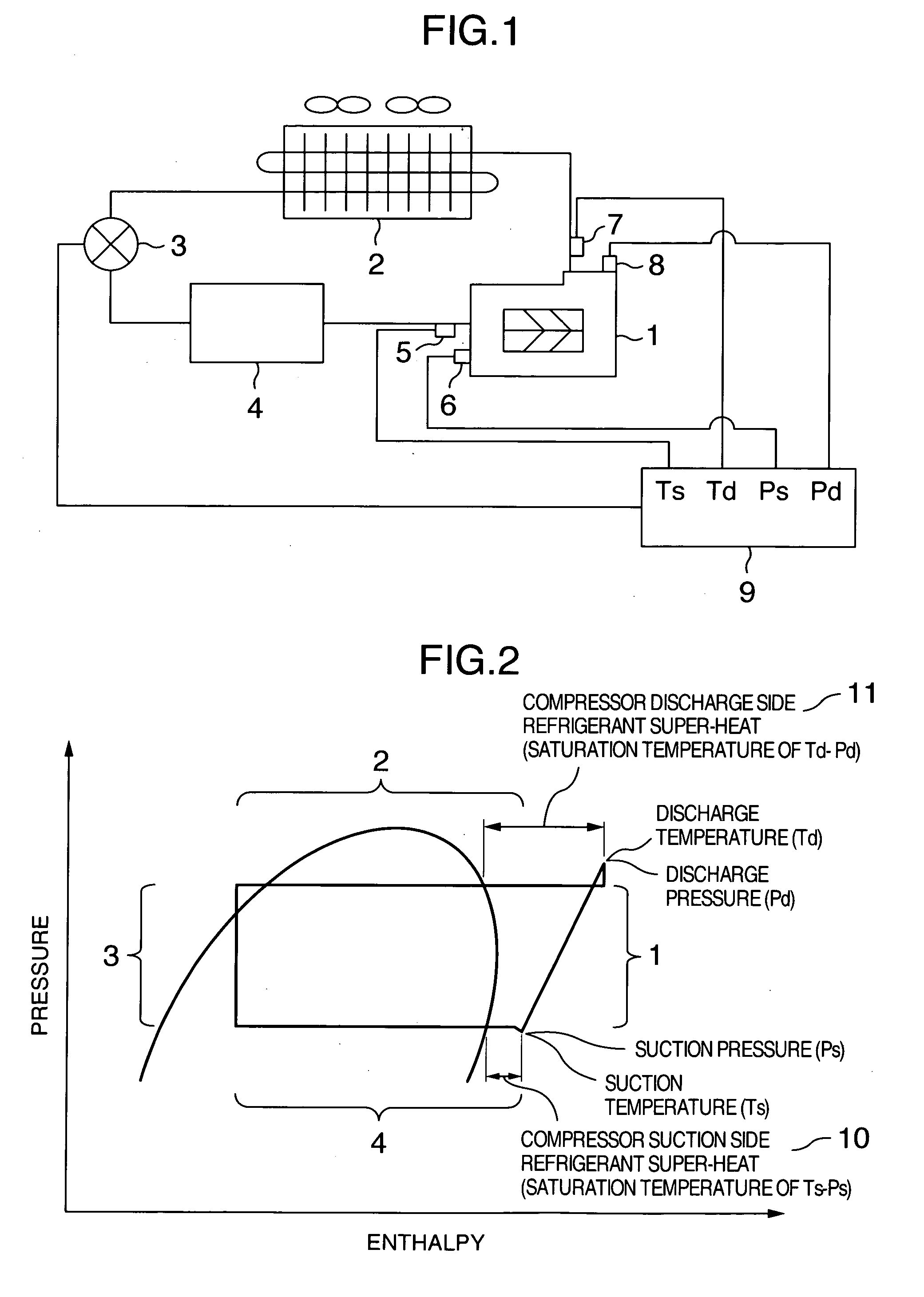

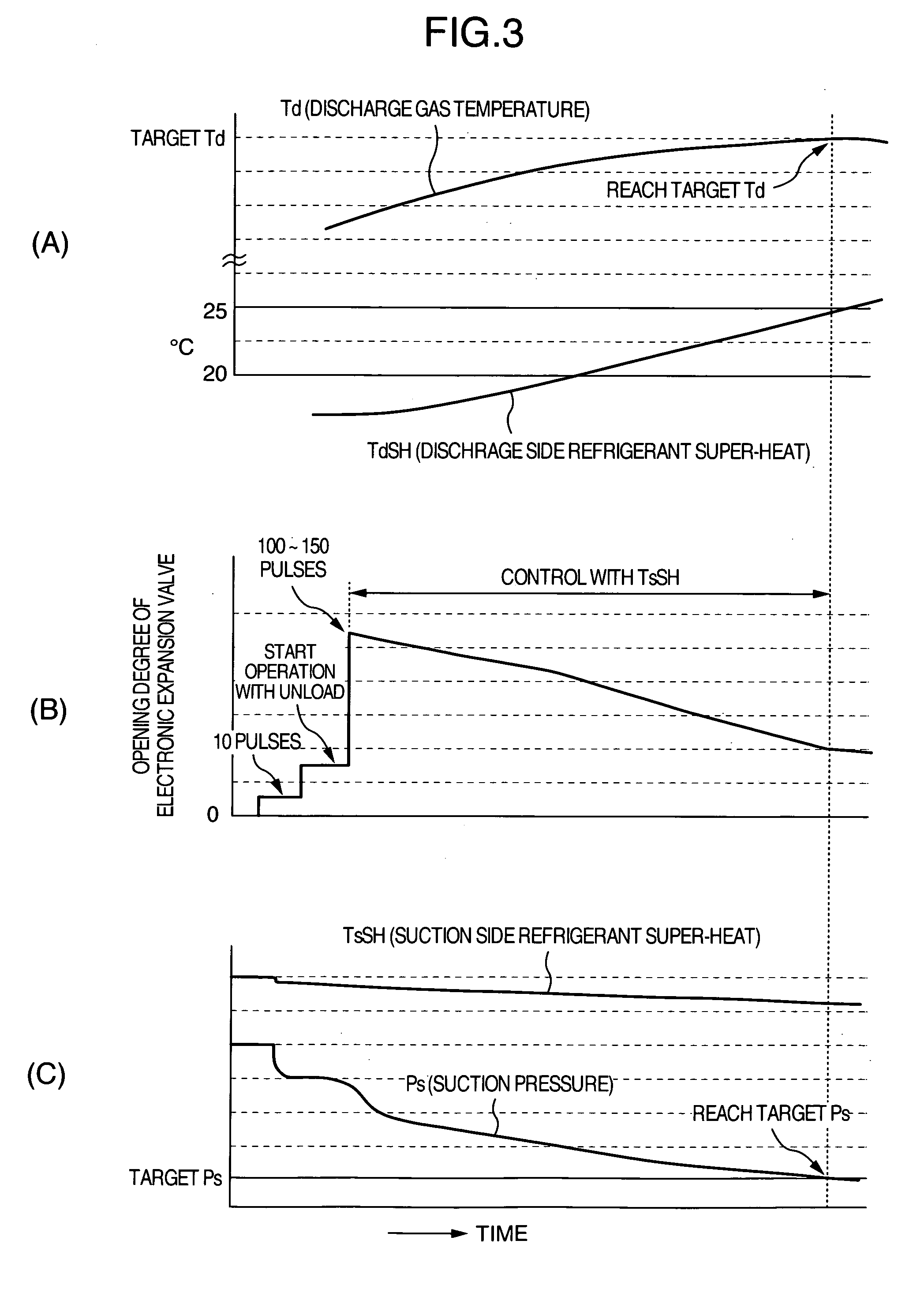

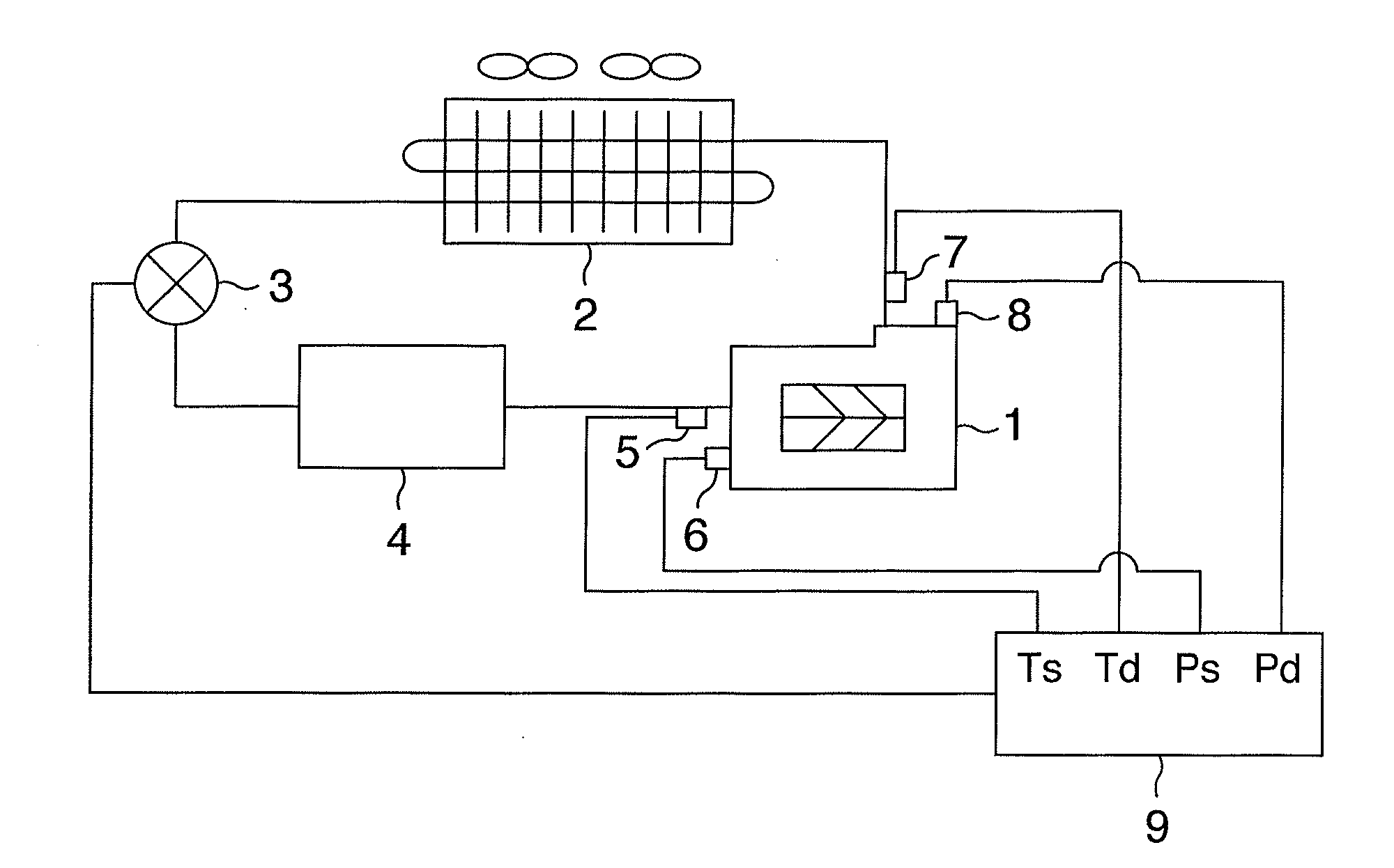

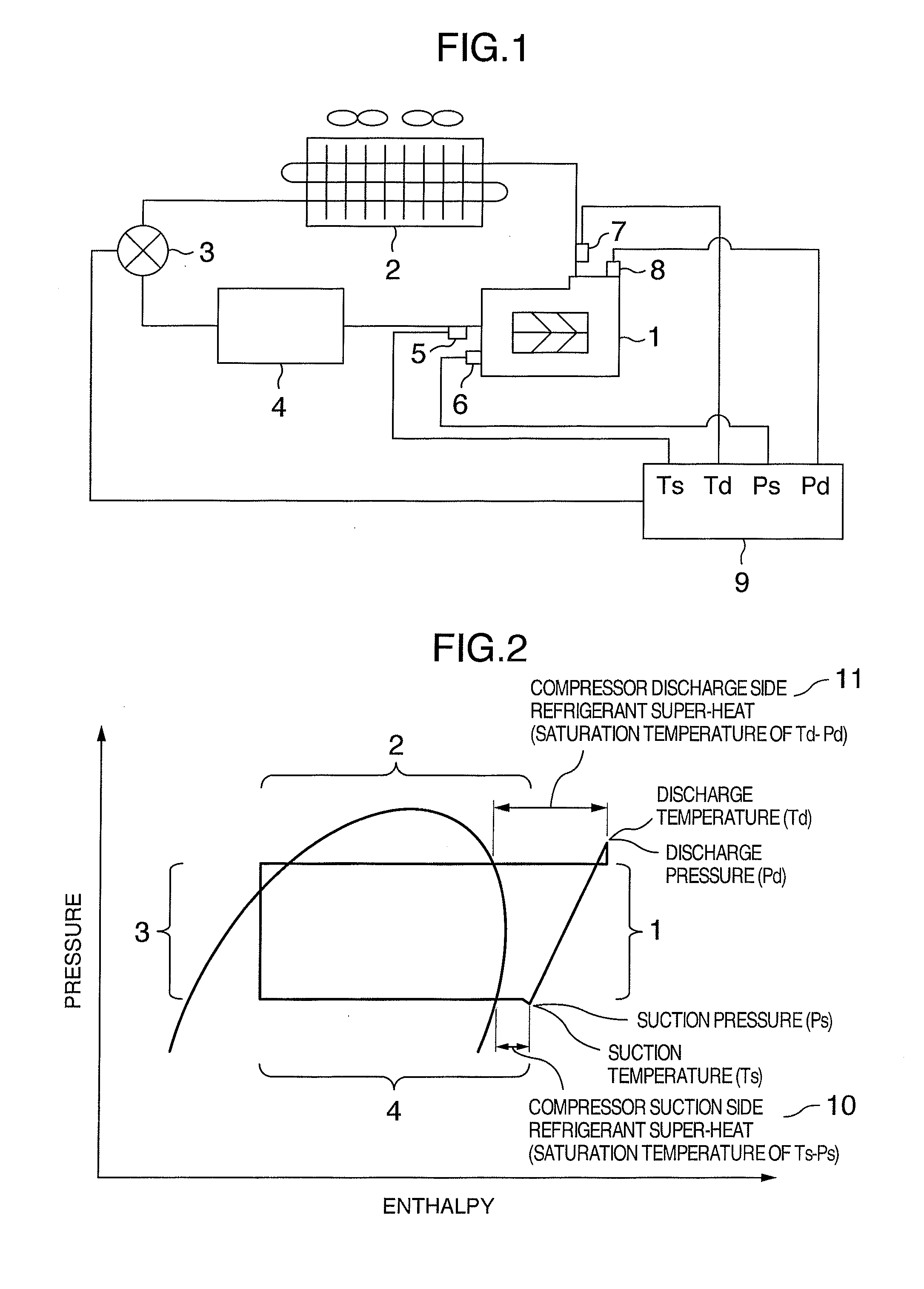

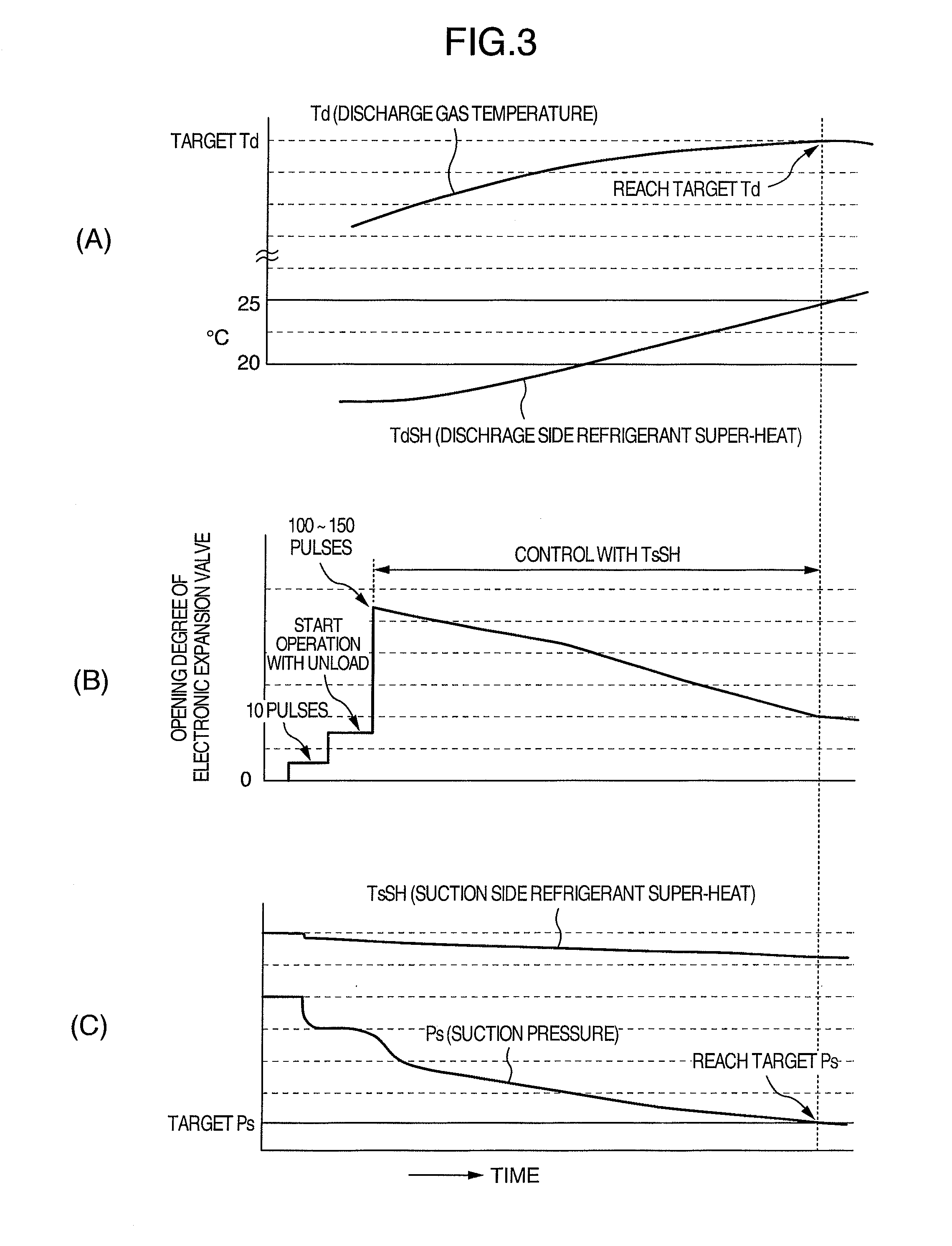

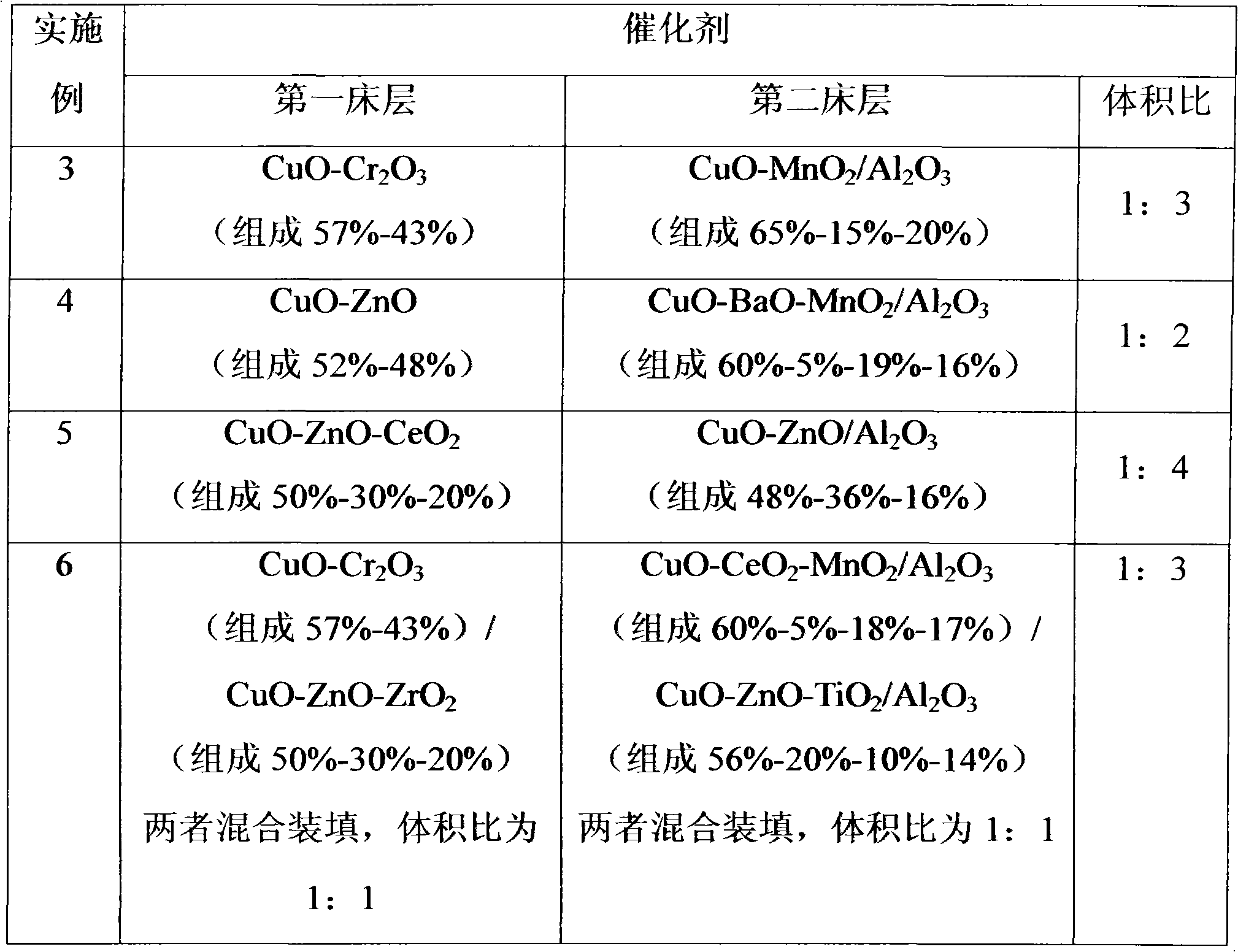

Heat source apparatus and method of starting the apparatus

InactiveUS20070062207A1Guaranteed uptimeRapid decrease in suction pressureMechanical apparatusEfficient regulation technologiesEngineeringChiller

After a chiller unit is started, an opening command of 10 pulses is output to an electronic expansion valve, and after a predetermined period of time (at the time of starting with unload) elapses, an opening command of 100 to 150 pulses is output to open the electronic expansion valve up to a predetermined opening degree. Thereafter, a discharge side refrigerant super-heat TdSH is monitored and a closing command of 1 pulse / sec is output to the electronic expansion valve to drive the same in a closing direction in a short time until TdSH becomes 20 K. After TdSH has reached 20 K, a closing command of 1 pulse / 3 sec is output to the electronic expansion valve, until TdSH becomes 25 K, to drive the electronic expansion valve 3 at a smaller speed in the closing direction than that speed in the closing direction until TdSH becomes 20 K. After TdSH reaches 25 K, it is judged that an operation has shifted to a stable operation, and the opening degree of the electronic expansion valve is controlled while a suction side refrigerant super-heat TsSH is monitored.

Owner:HITACHI APPLIANCES INC

Liquids dispensing systems and methods

ActiveUS7654414B2Minimize and prevent formation of bubbleHigh purityPositive displacement pump componentsLiquid flow controllersBiomedical engineeringContamination

A liquid dispensing system (100) supplies a dispense liquid using a pump (101), wherein the system minimizes contamination of, and bubble formation in, the dispense liquid. The pressure at the suction side of the pump may be limited to a predetermined value.

Owner:PALL CORP

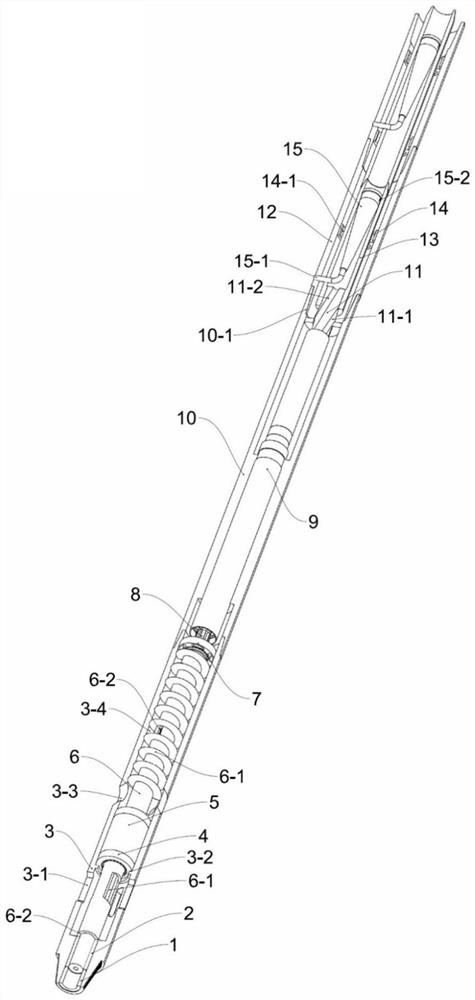

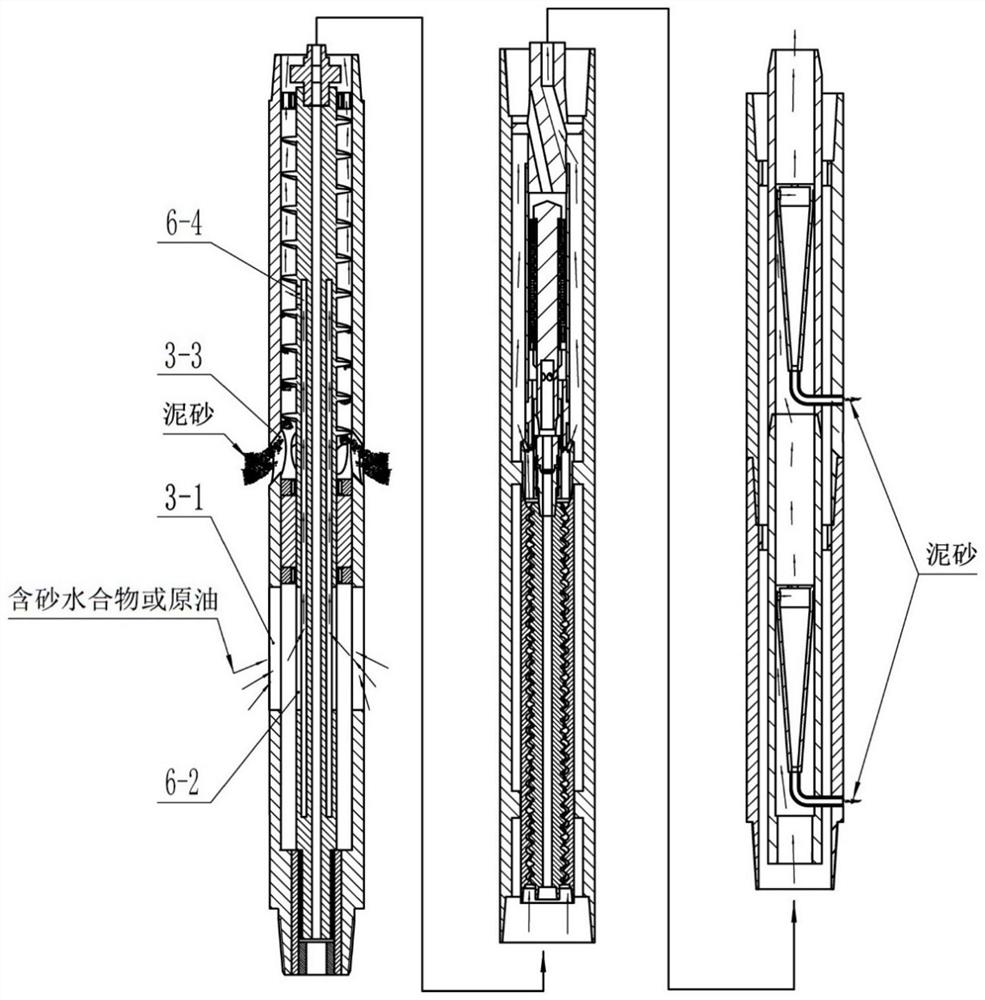

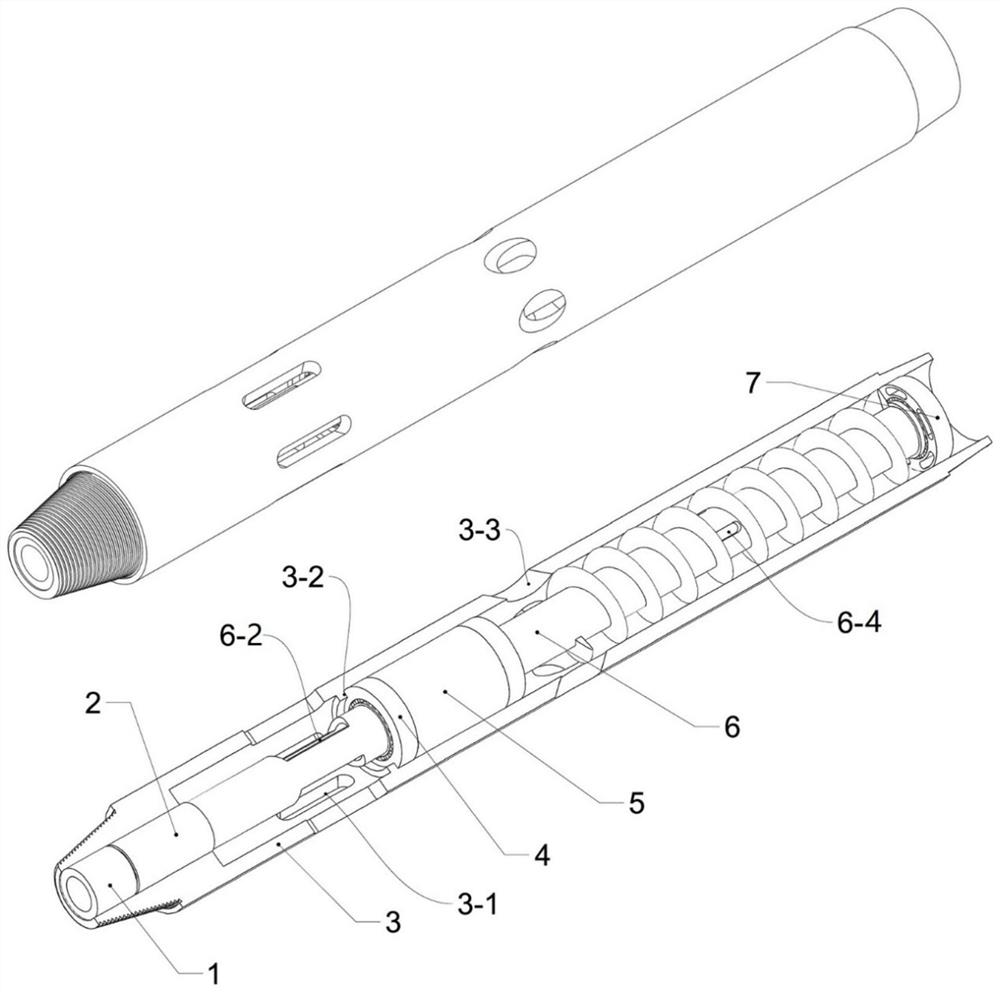

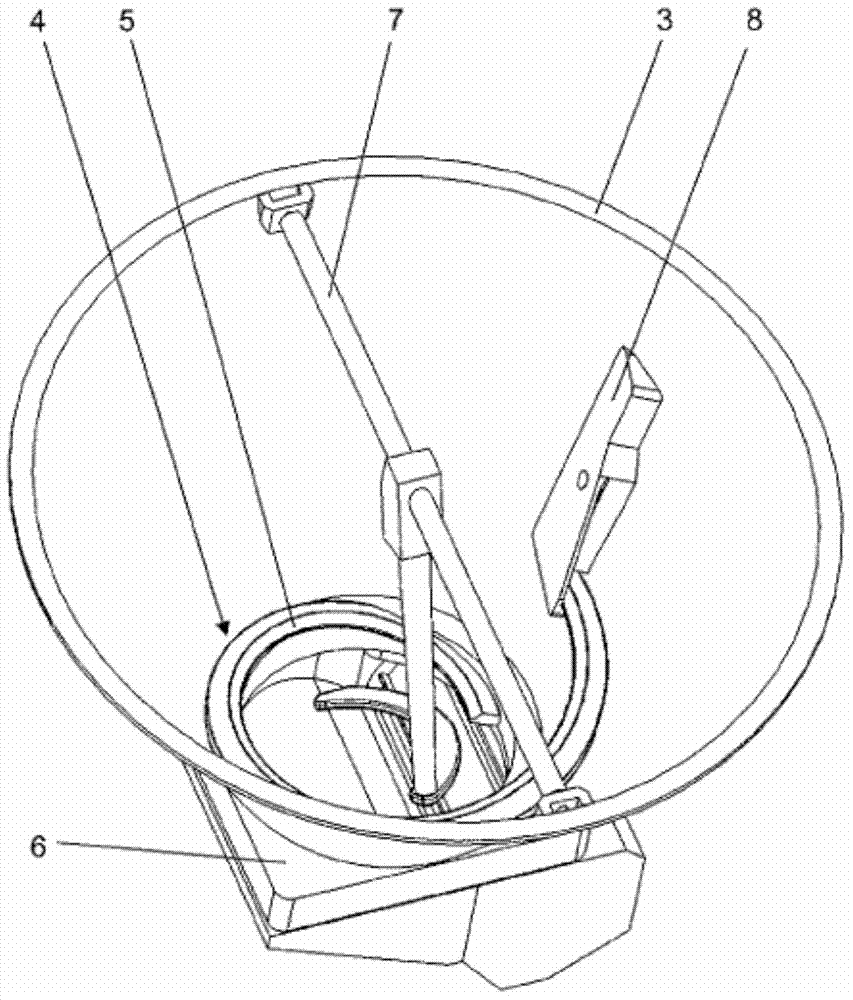

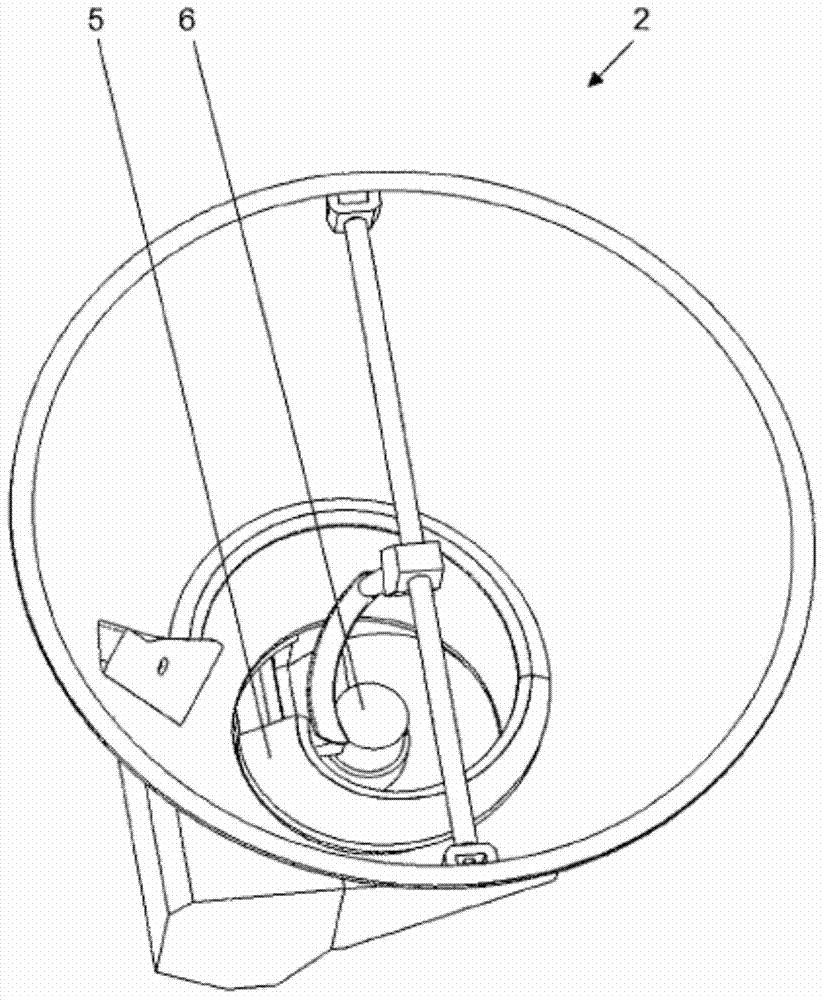

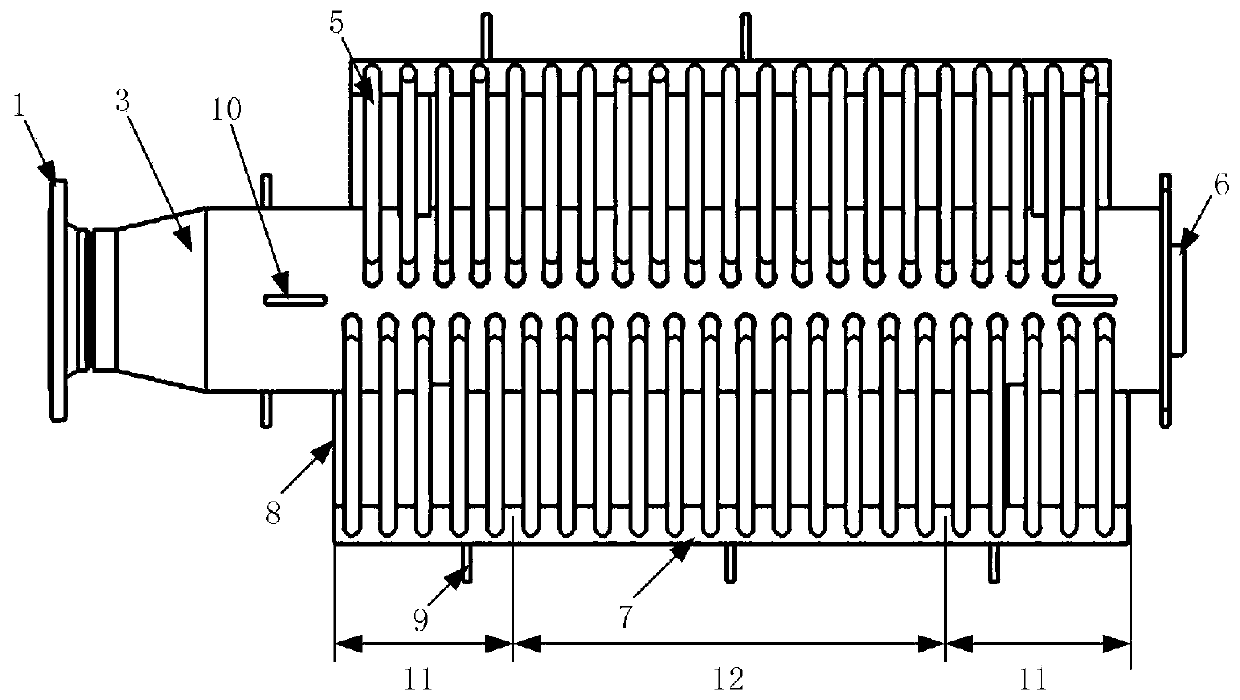

Underground hydraulically-driven spiral-rotational flow coupling tubular separator

The invention discloses an underground hydraulically-driven spiral-rotational flow coupling tubular separator. The underground hydraulically-driven spiral-rotational flow coupling tubular separator comprises a spiral crushing and separating device, a hydraulic motor screw pump device and a multi-stage rotational flow fine separating device; the upper end and the lower end are connected with a drill rod, the upper end of the spiral crushing and separating device is connected with the hydraulic motor screw pump device, and the upper end of the hydraulic motor screw pump device is connected withthe multi-stage rotational flow fine separating device; the drilling fluid flowing in the innermost casing drives a hydraulic motor to rotate, drives a hydraulic motor screw pump to work, and furtherdrives a separation screw to rotate. The underground hydraulically-driven spiral-rotational flow coupling tubular separator has the characteristics of spiral and rotational flow separation coupling principle and self-powered underground separation, secondary crushing and cementation breaking of hydrate solid-phase particles can be realized, underground in-situ real-time multiple separation and backfilling of high-sand-content mixed fluid in conventional petroleum or hydrate recovery can also be realized, and the problems that when underground mixed fluid is recovered, sand content is high, friction resistance is large, lifting is difficult, and serious erosion and blocking are caused to a shaft, equipment and the like are well solved.

Owner:SOUTHWEST PETROLEUM UNIV +1

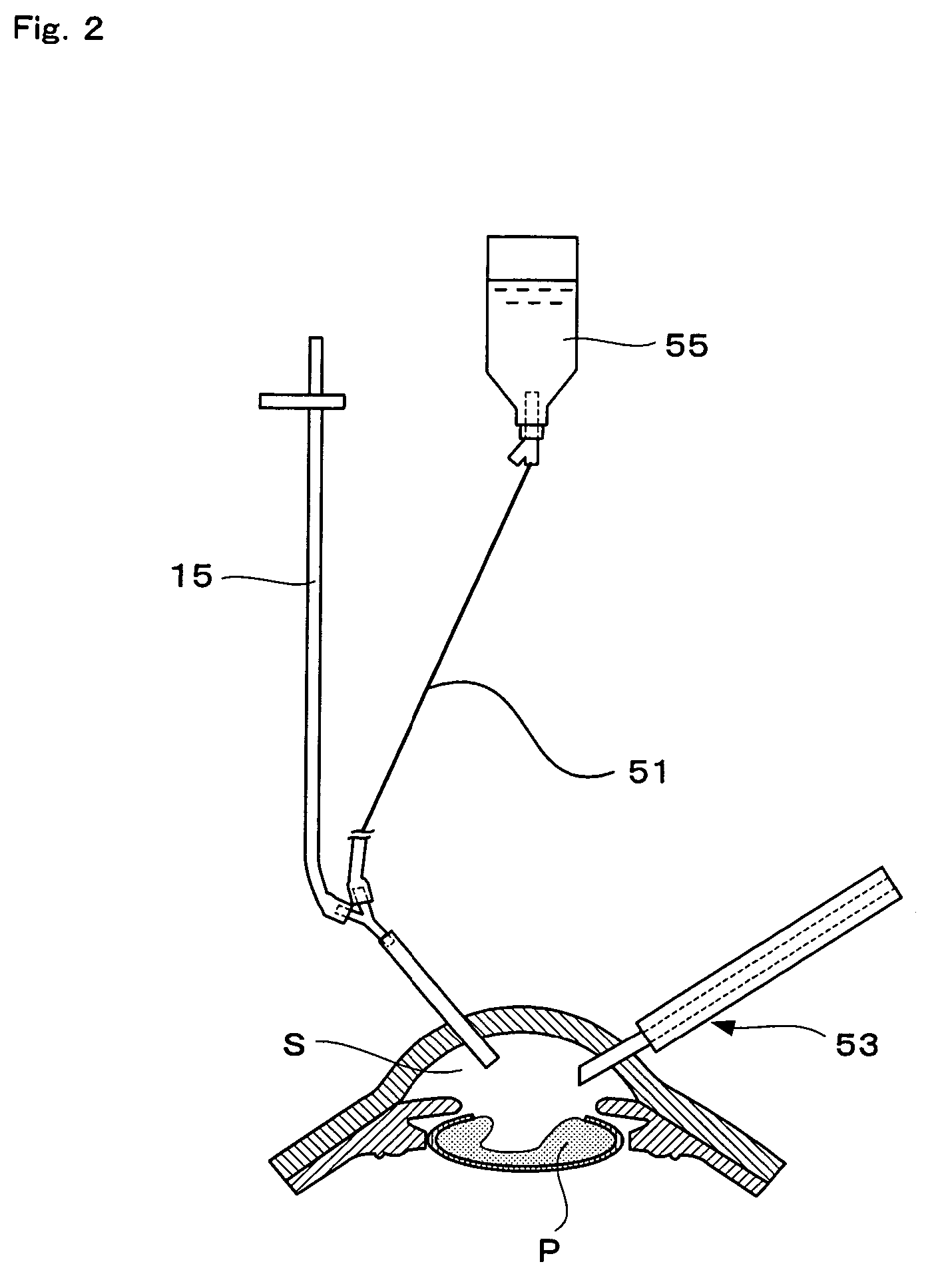

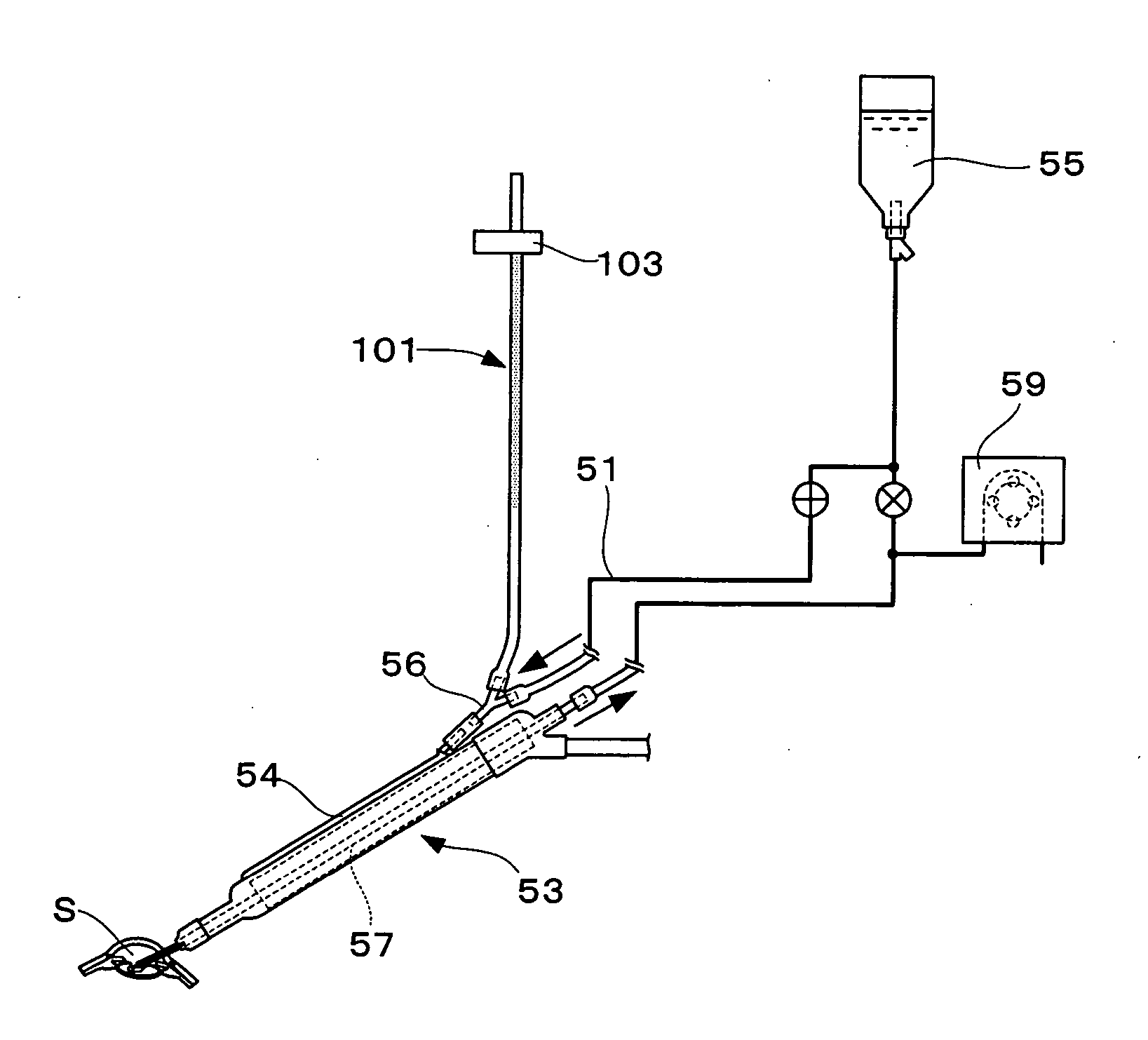

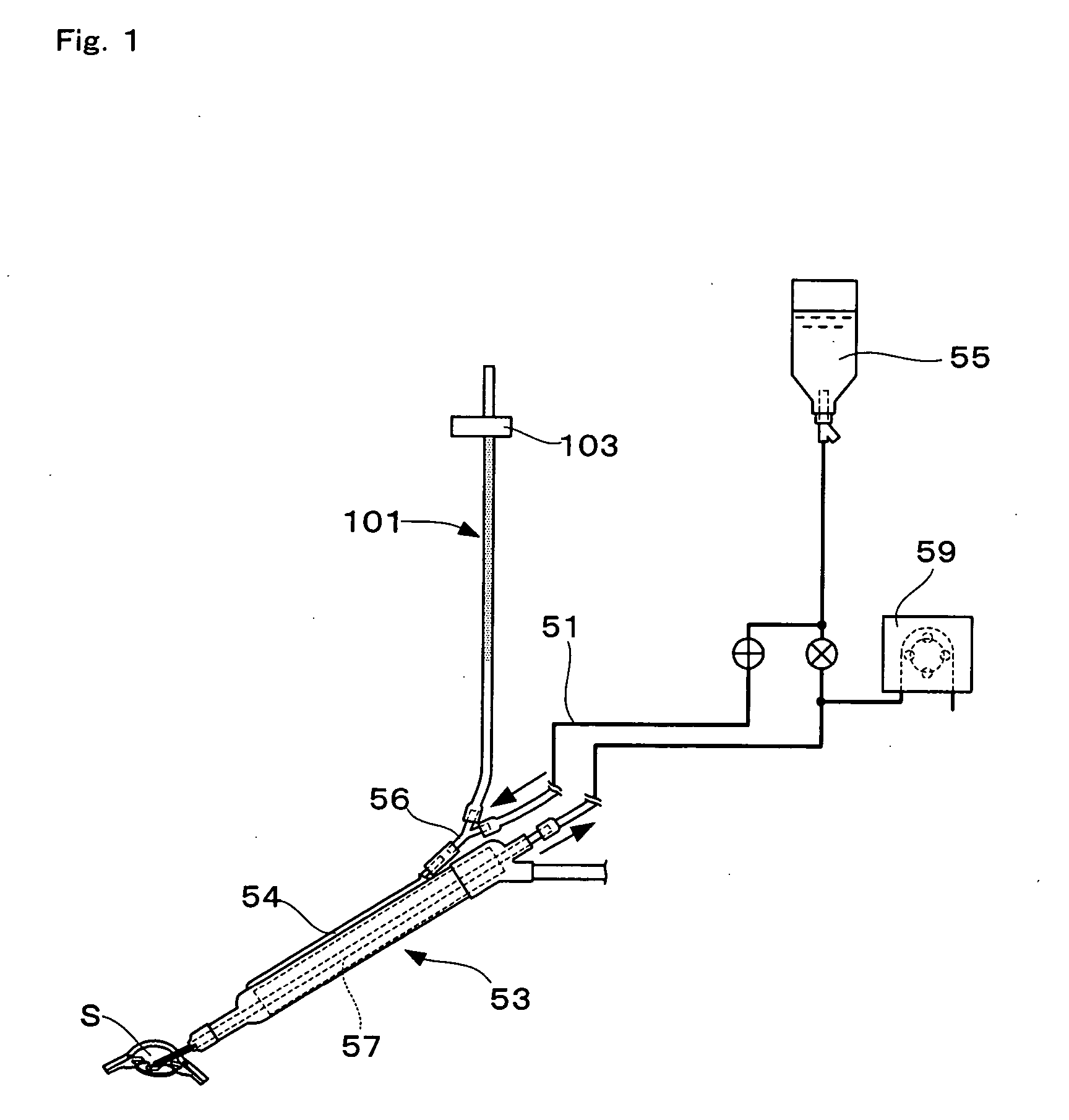

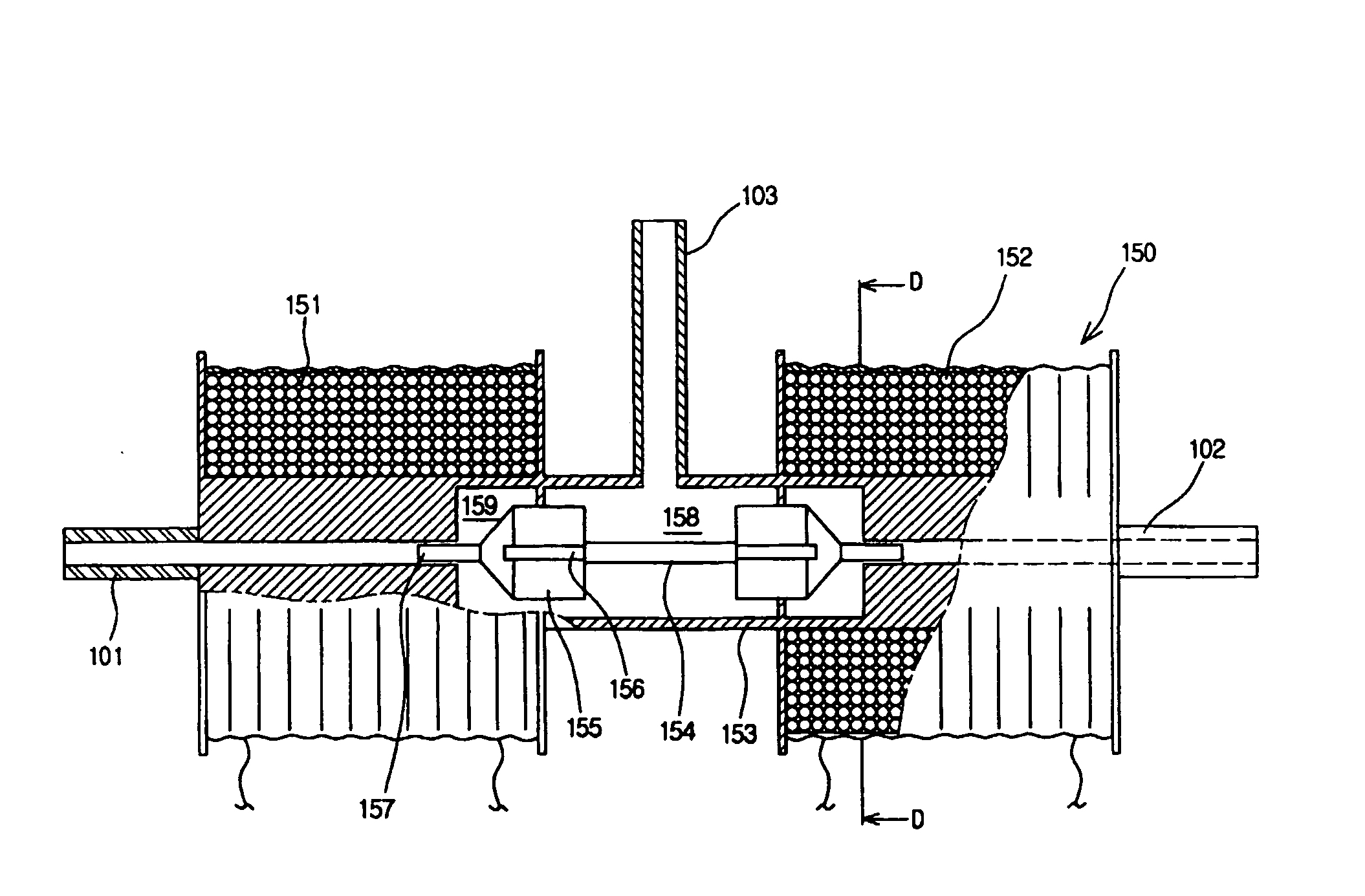

Decompression-compensating instrument for ocular surgery, instrument for ocular surgery provided with the same and method of ocular surgery

InactiveUS7303566B2Reduce pressurePrevent rapid decrease in inflow rateEye surgerySurgeryInternal pressureMedicine

The present invention relates to a decompression-compensating instrument for use in intraocular surgery, wherein a perfusate is supplied to an affected part of an eye via a supply channel at a predetermined pressure, and the perfusate is aspirated via an aspiration channel together with the affected tissues that are to be removed, the decompression-compensating instrument supplying the perfusate into the affected part when the internal pressure of the affected part is excessively lowered, and being constructed so as to be connectable to a point midway along the supply channel and comprising a storage-member that forms a chamber that is closable except for an opening from which the perfusate to be supplied to the supply channel flows, the capacity of the storage member being 7 cm3 to 22 cm3.

Owner:MAKOTO KISHIMOTO +2

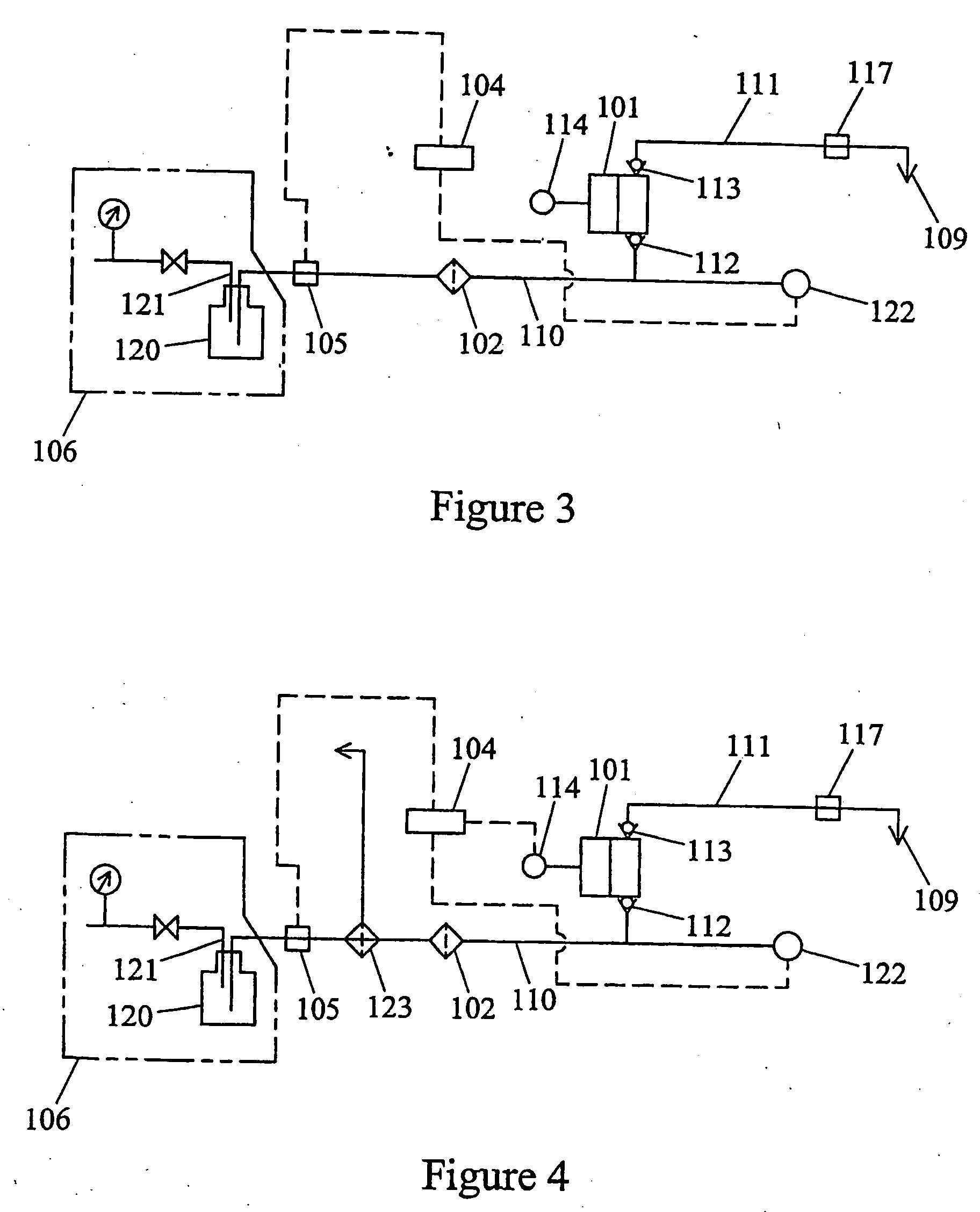

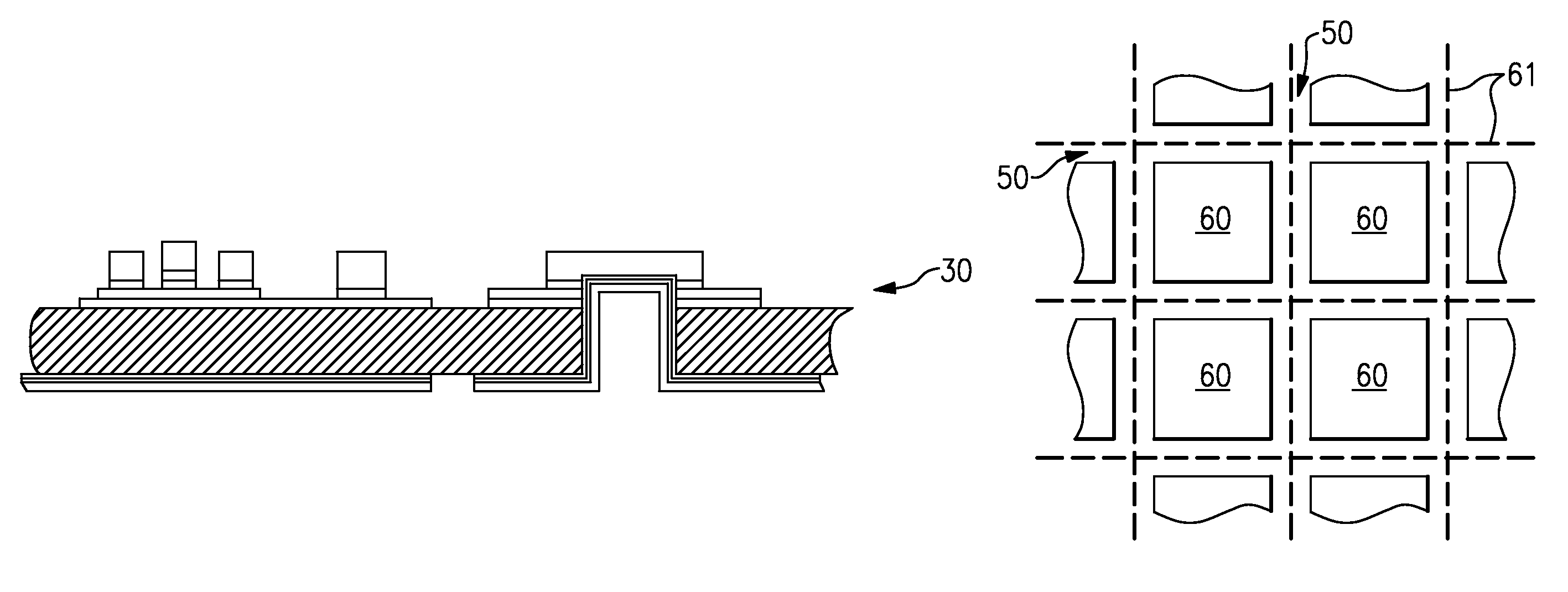

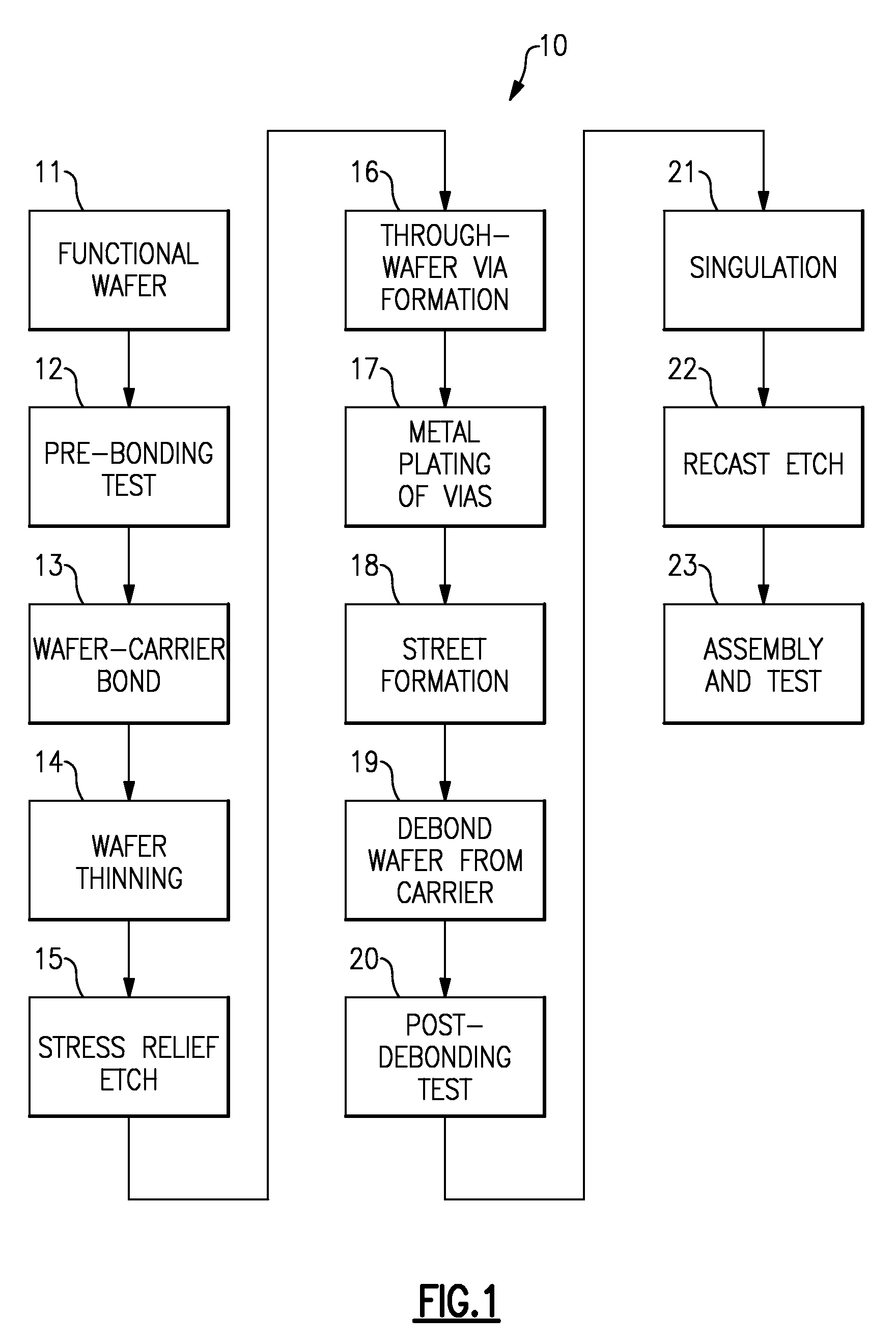

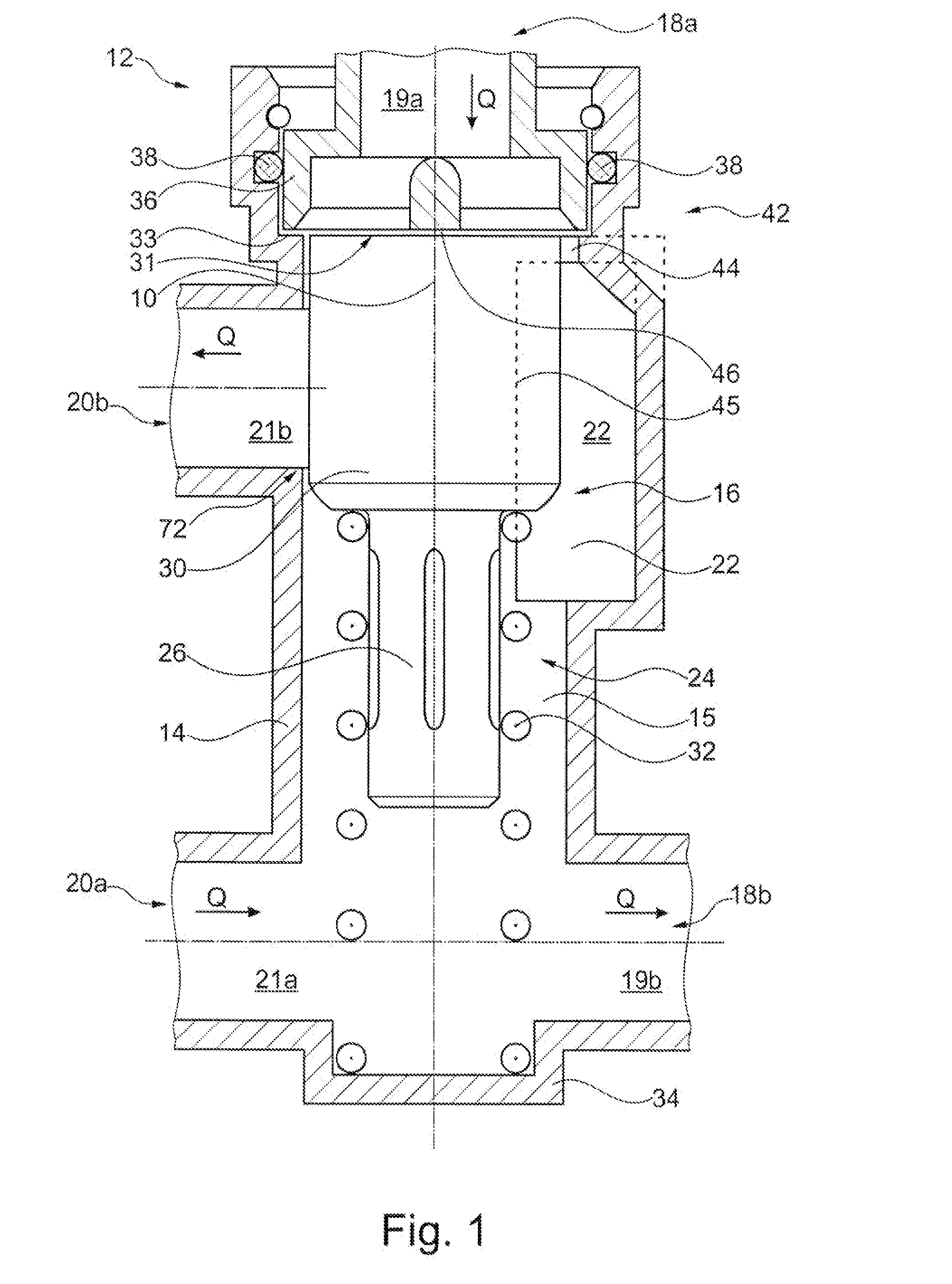

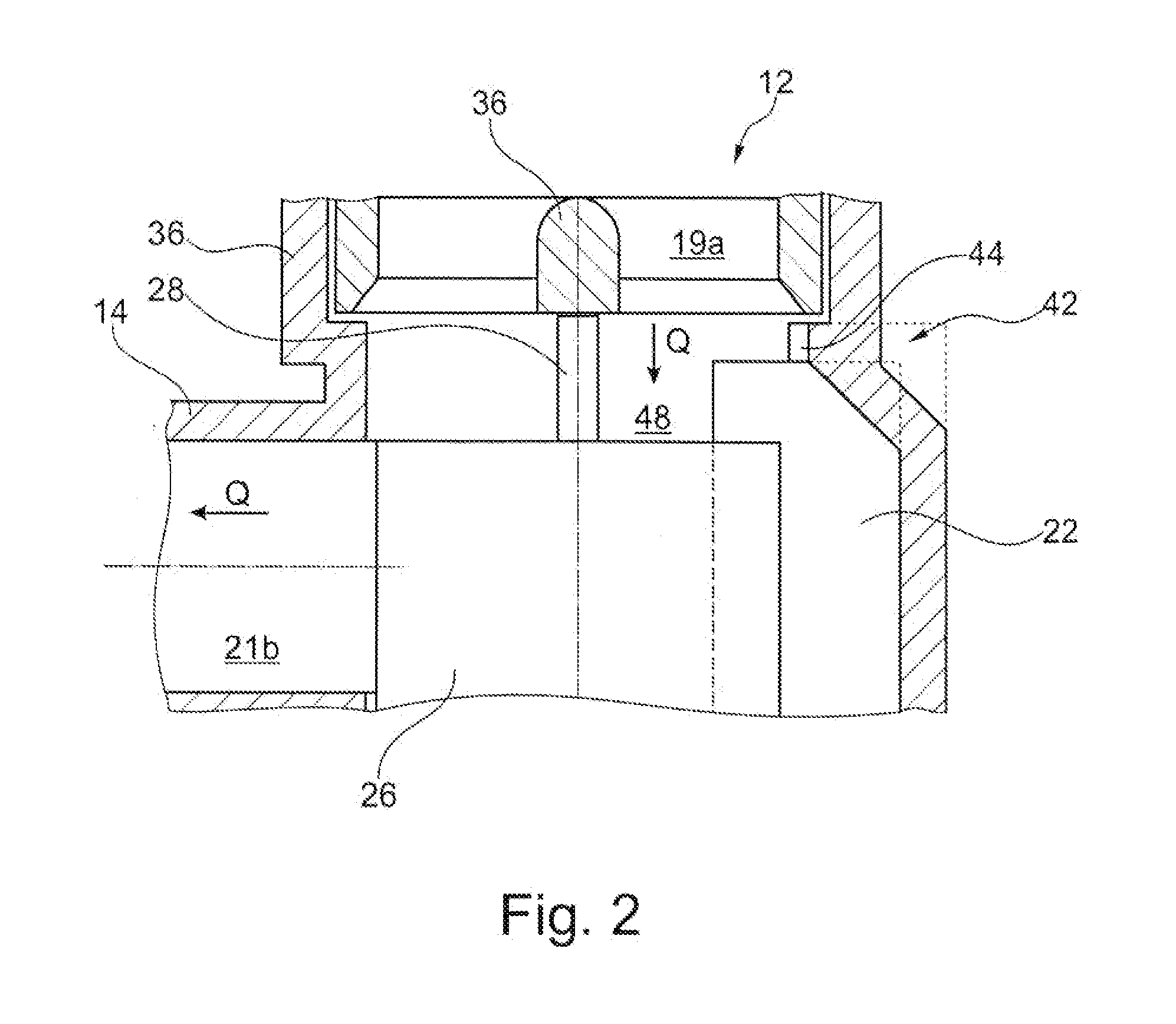

Apparatus and method for uniform metal plating

Apparatus and methods for uniform metal plating onto a semiconductor wafer, such as GaAs wafer, are disclosed. One such apparatus can include an anode and a showerhead body. The anode can include an anode post and a showerhead anode plate. The showerhead anode plate can include holes sized to dispense a particular plating solution, such as plating solution that includes gold, onto a wafer. The showerhead body can be coupled to the anode post and the showerhead anode plate. The showerhead body can be configured to create a seal sufficient to substantially prevent a reduction of pressure in the plating solution flowing from the anode post to holes of the showerhead anode plate.

Owner:SKYWORKS SOLUTIONS INC

Decompression-compensating instrument for ocular surgery, instrument for ocular surgery provided with same and method of ocular surgery

ActiveUS20060058811A1Reduce pressurePrevent rapid decrease in inflow rateEye surgeryMedical devicesInternal pressureIntraocular surgery

The present invention relates to a decompression-compensating instrument for use in intraocular surgery, wherein a perfusate is supplied to an affected part of an eye via a supply channel at a predetermined pressure, and the perfusate is aspirated via an aspiration channel together with the affected tissues that are to be removed, the decompression-compensating instrument supplying the perfusate into the affected part when the internal pressure of the affected part is excessively lowered, and being constructed so as to be connectable to a point midway along the supply channel and comprising a storage-member that forms a chamber that is closable except for an opening from which the perfusate to be supplied to the supply channel flows, the capacity of the storage member being 7 cm3 to 22 cm3.

Owner:MAKOTO KISHIMOTO +2

Irrigation/aspiration apparatus

InactiveUS7867191B2Prevent pressure dropTrouble for an operator is reducedMedical devicesIntravenous devicesEngineeringIrrigation

To provide an irrigation / aspiration apparatus by which a trouble for an operator is reduced and handling is facilitated and which is capable of preventing a sharp decrease of pressure of an anterior chamber with a simple constitution.The apparatus has a chamber storing an irrigation liquid, a vent tube for making the liquid flow into an aspiration tube, a leading vent leading the liquid into the chamber from an irrigation tube, an outflow pipe extended in an up-and-down direction, an opening formed on a wall of the outflow pipe, of which a width is narrow and set such that an opening is closed by the liquid under surface tension when a liquid level of the liquid inside the chamber rises, an outflow vent to which the irrigation tube or a vent tube is connected, and an air chamber which is a space provided above an inflow hole of the outflow pipe.

Owner:NIDEK CO LTD

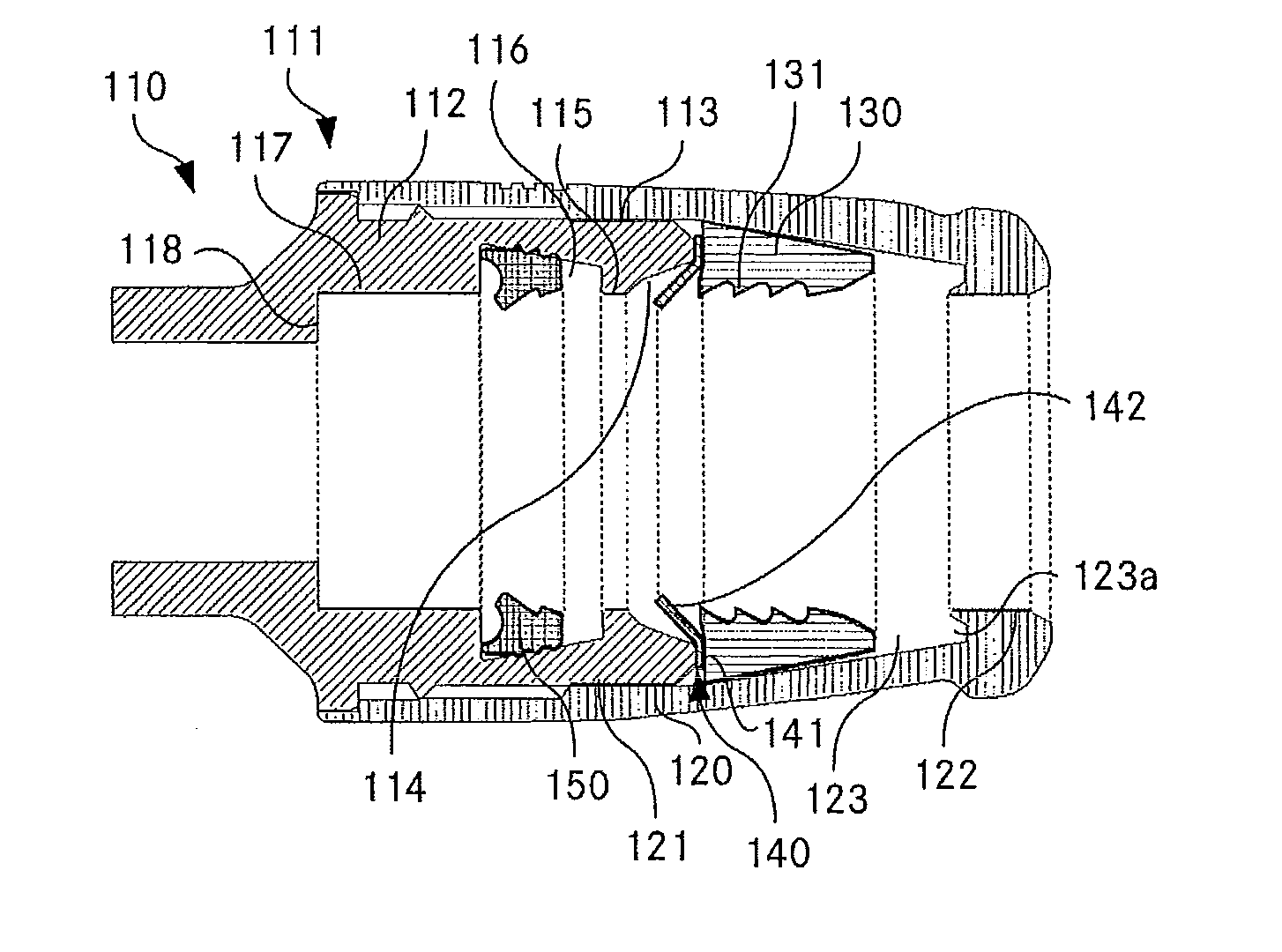

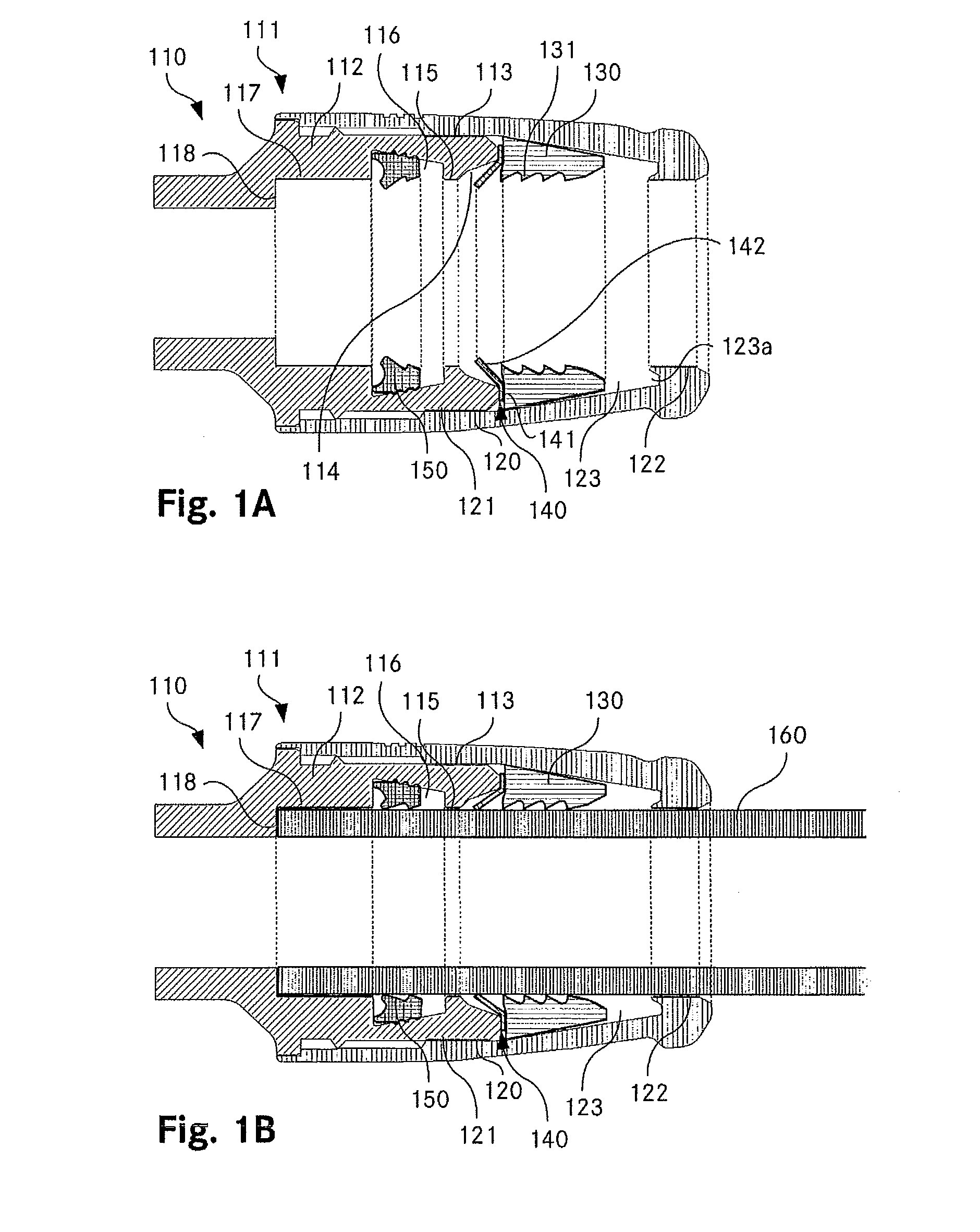

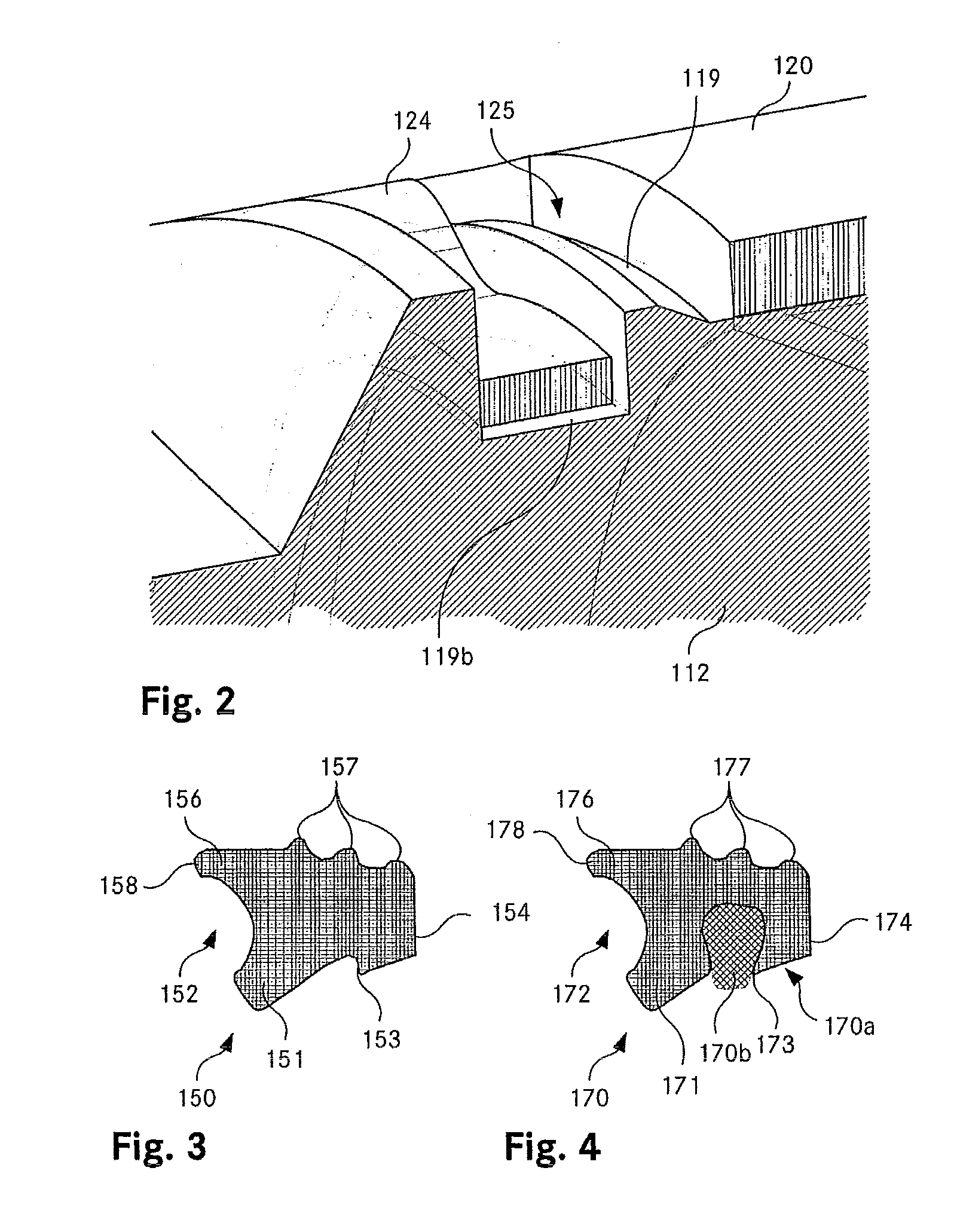

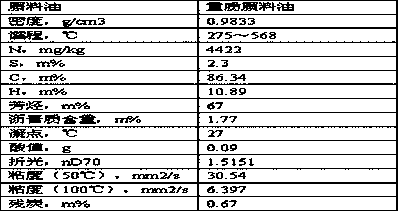

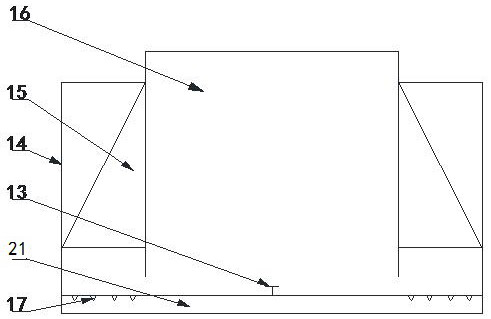

Connection piece

InactiveUS20110156383A1Avoids drop in pressurePrevent pressure dropPipe elementsCouplingsCross-linked polyethyleneEngineering

A connection piece (111) for a plug-in connection of a fluid-carrying system of lines for distributing drinking water within stories is formed without a supporting nipple. The connection piece (111) has in the region of an inner lateral surface of the first tubular part a first peripheral guiding surface (122) and a second peripheral guiding surface (117), arranged behind the first guiding surface (122) with respect to an insertion opening of the connection piece (111), for the second tubular part (160). A first axial extent of the first guiding surface (122) and a second axial extent of the second guiding surface (117) respectively make up each at least one sixth of an inside diameter of the first tubular part (112, 120). The connection piece (111) may form part of a fitting or a faucet and is suitable in particular for use with solid plastic pipes, for example of crosslinked polyethylene.

Owner:R NUSSBAUM & CO

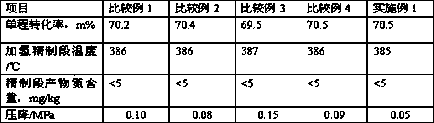

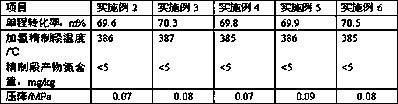

Hydrocracking method

ActiveCN108070404AAvoid cloggingExtended head skimming timeTreatment with hydrotreatment processesEngineeringMaterial flow

The invention discloses a hydrocracking method. The method comprises the following contents: heavy distillate oil raw material and hydrogen orderly enter a hydrorefining reactor, a hydrocracking reactor and a separation system after being mixed; a cylinder with a bottom is arranged at an upper part of the hydrorefining reactor, the height of the cylinder is 4%-20% of the height of the hydrorefining reactor, and the outer diameter of the cylinder is 85%-95% of the inner diameter of the hydrorefining reactor; holes through which the material flow can pass are formed on the bottom and the side wall of the cylinder, and the sizes of the holes are 1-40 mesh; the cylinder is filled with hydrorefining catalyst, the infrared acid amount and the active metal content of the filled catalyst are in anenhanced situation along the material flow direction, the catalyst pore volume, the particle size and the specific surface area are in a reduced situation, and the bottom of the cylinder is filled with the conventional hydrorefining catalyst. Compared with the existing hydrocracking technology, the hydrocracking process disclosed by the invention is more flexible in flow, can process more inferior raw material, and greatly improves the processing capacity of the device.

Owner:CHINA PETROLEUM & CHEM CORP +1

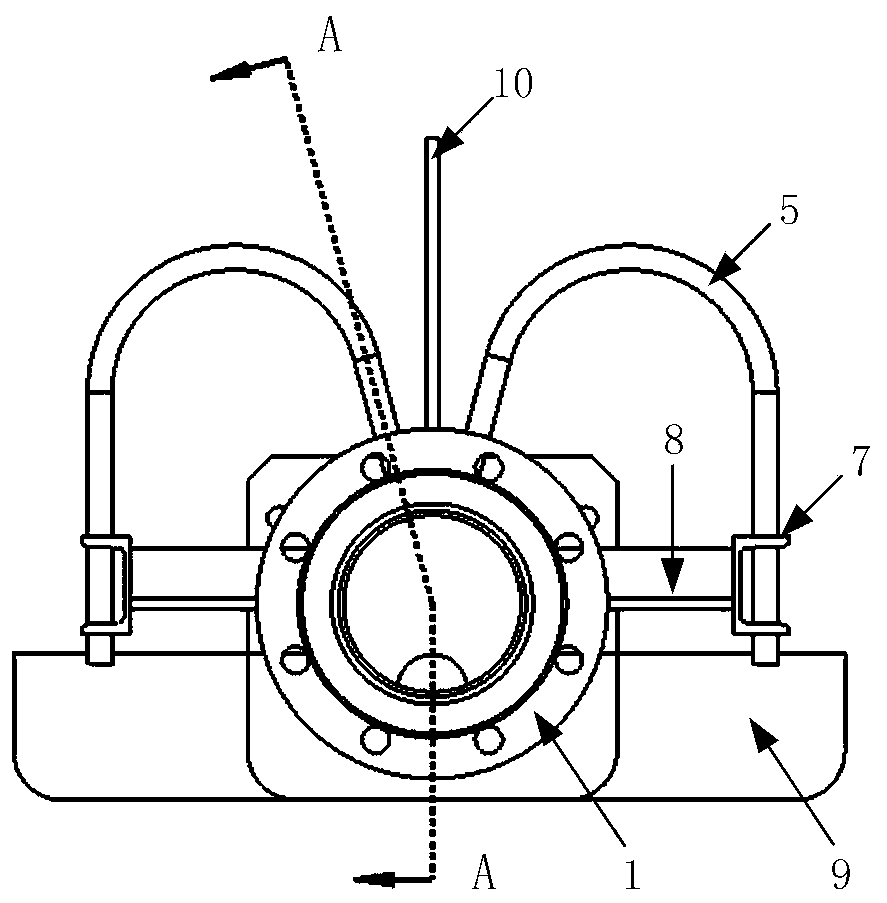

Mass supply system

ActiveCN104244722ASmall inertiaEasy to replaceMeat processingRotary piston pumpsEngineeringMechanical engineering

Owner:GEA FOOD SOLUTIONS BAKEL

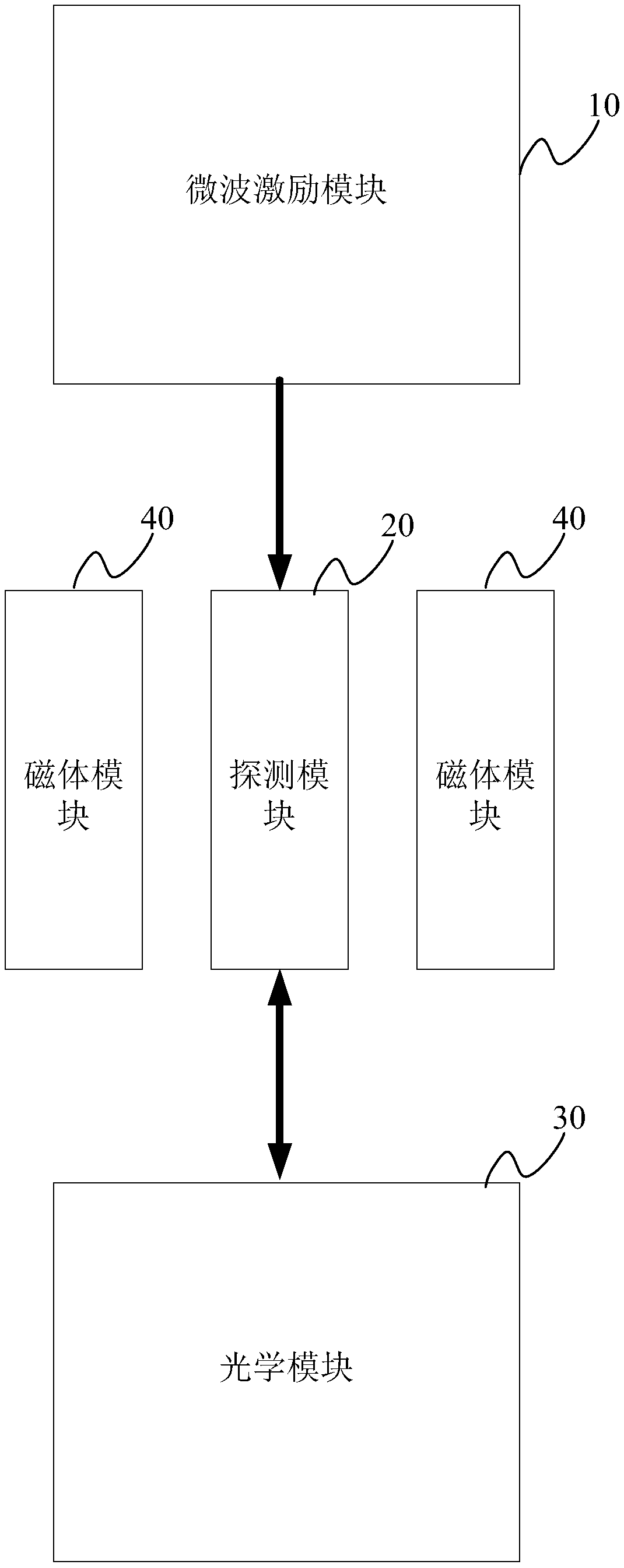

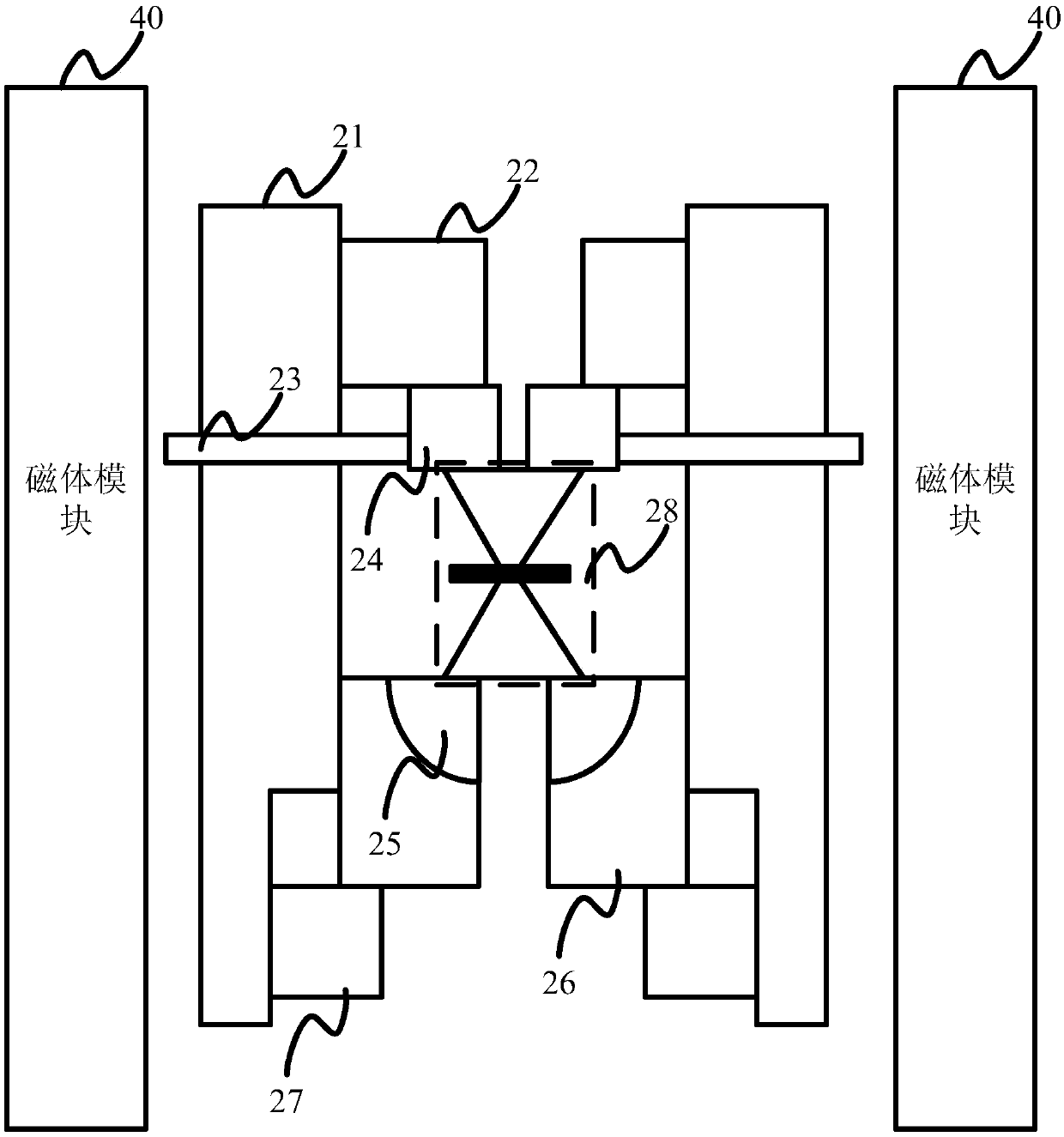

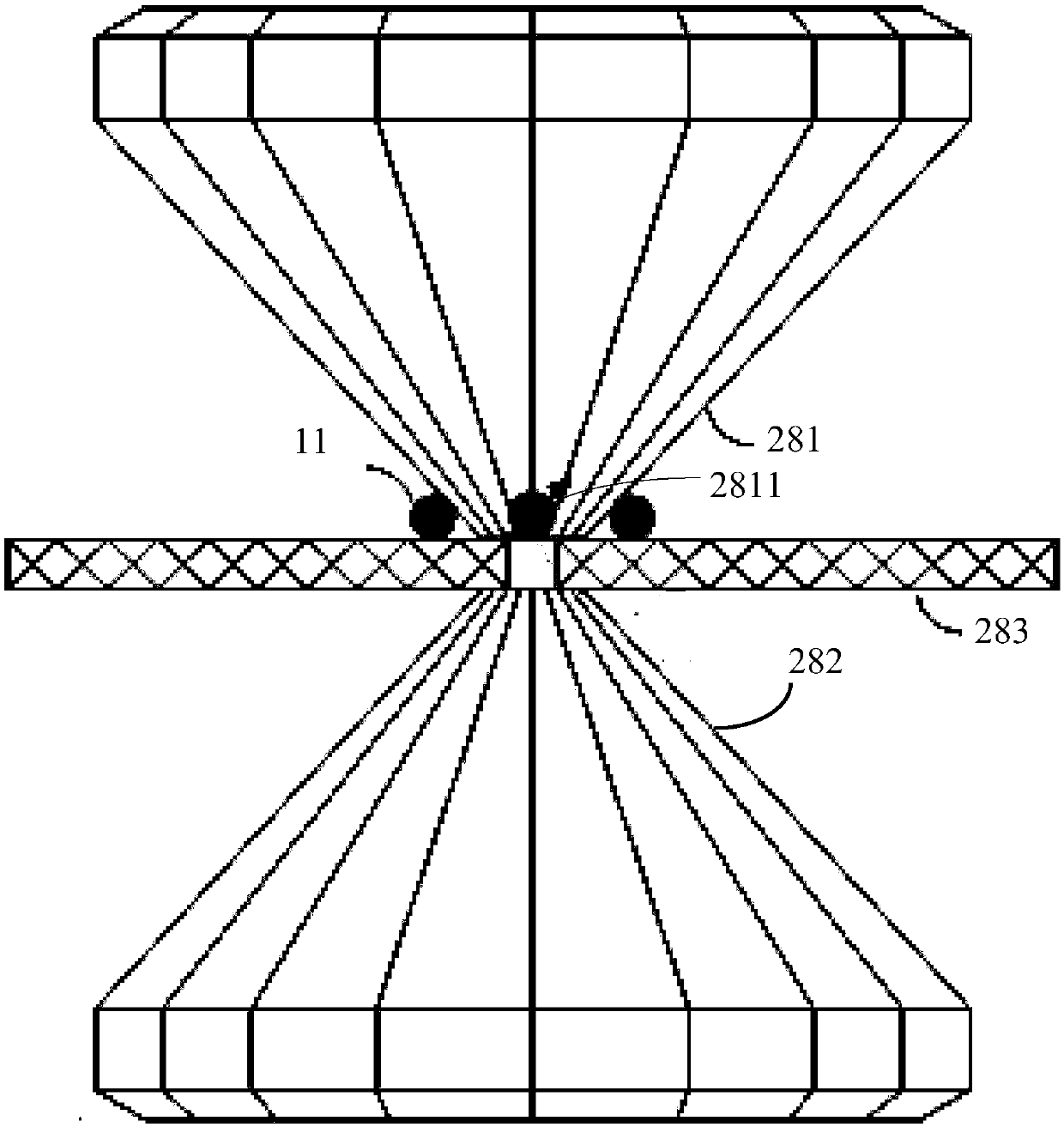

High-pressure magnetic resonance detection device

InactiveCN109632861AAvoid pressure dropsIncrease pressureAnalysis using nuclear magnetic resonanceColour centreDiamond color

The invention discloses a high-pressure magnetic resonance detection device. The high-pressure magnetic resonance detection device uses a diamond color center structure to serve as a probe structure of a detection module, and the diamond color center is prepared on an anvil surface of the diamond structure of a high pressure device, so that there is no need to occupy the space of a sample cavity,the occurrence of a circumstance that the pressure intensity capable of being provided by the high-pressure magnetic resonance detection device is reduced due to the occupation of the sample cavity space by an induction coil or the diamond color center structure is avoided, and thus the pressure intensity capable of being provided by the high-pressure magnetic resonance detection device is improved to a certain extent.

Owner:UNIV OF SCI & TECH OF CHINA

Heat source apparatus and method of starting the apparatus

ActiveUS20100089084A1Rapid decrease in suction pressureGuaranteed uptimeMechanical apparatusCompression machines with non-reversible cycleEngineeringElectronic expansion valve

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

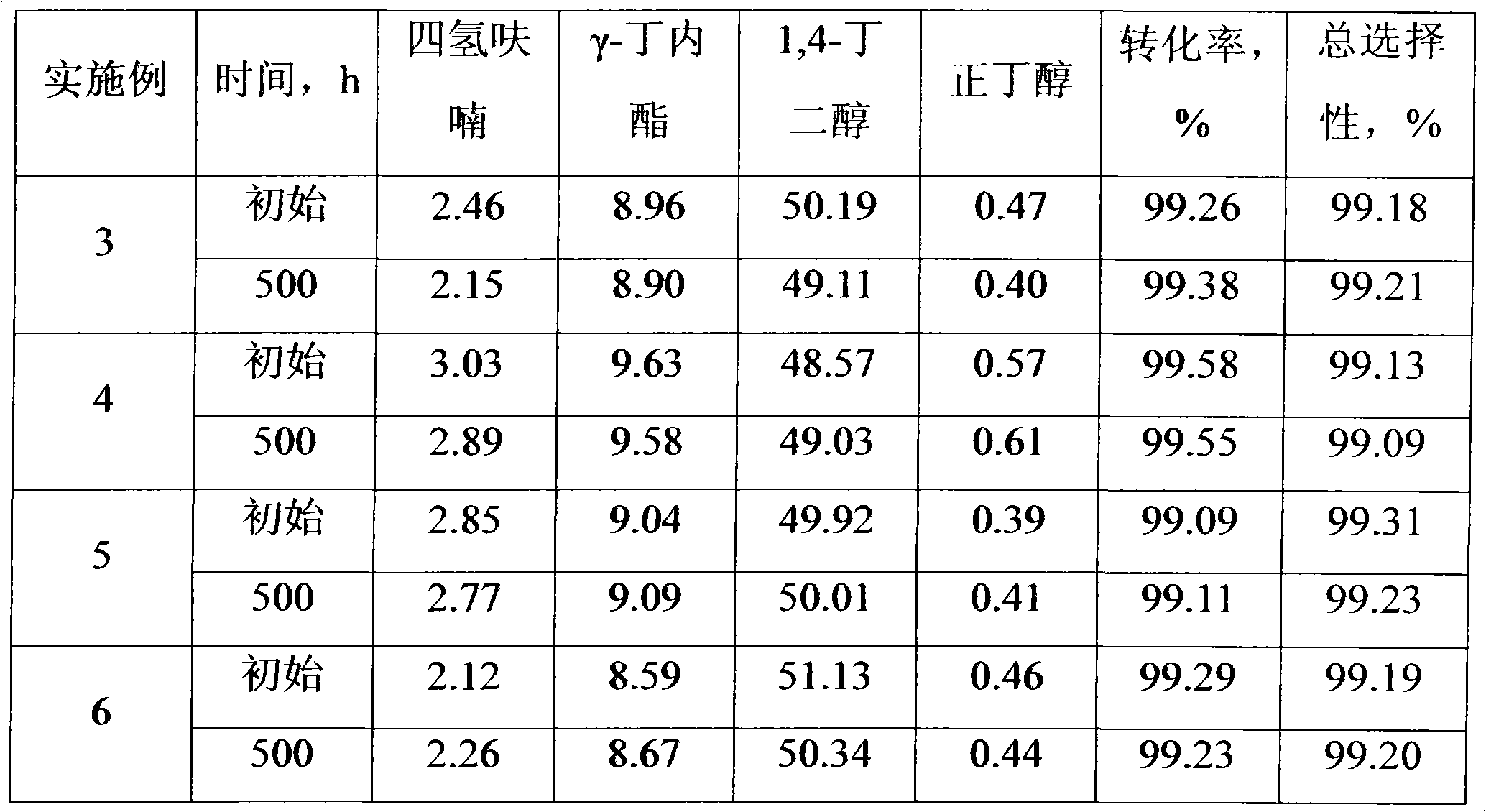

Method for producing 1,4-butanediol and coproducing tetrahydrofuran, and gamma-butyrolactone

Owner:CHINA PETROLEUM & CHEM CORP +1

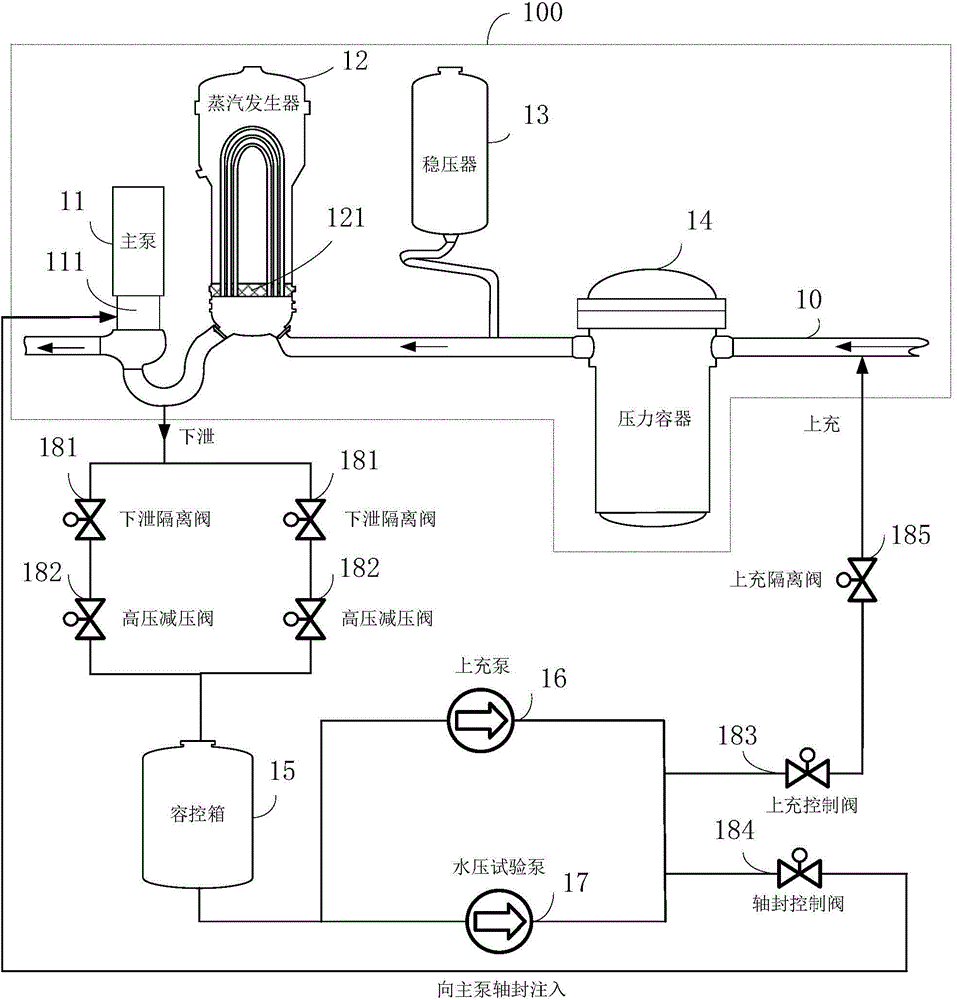

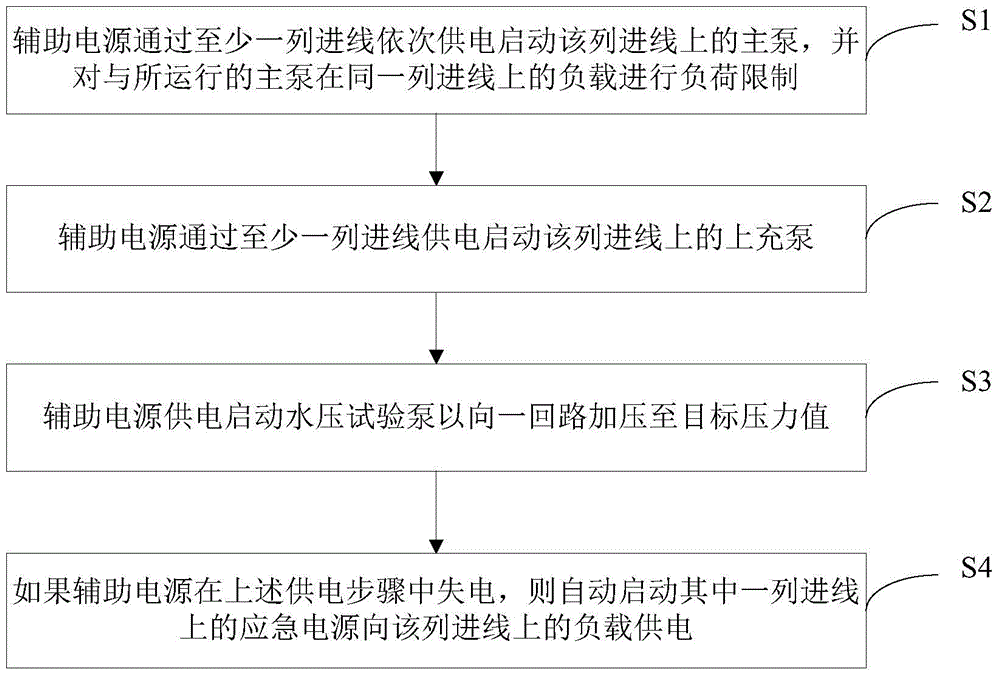

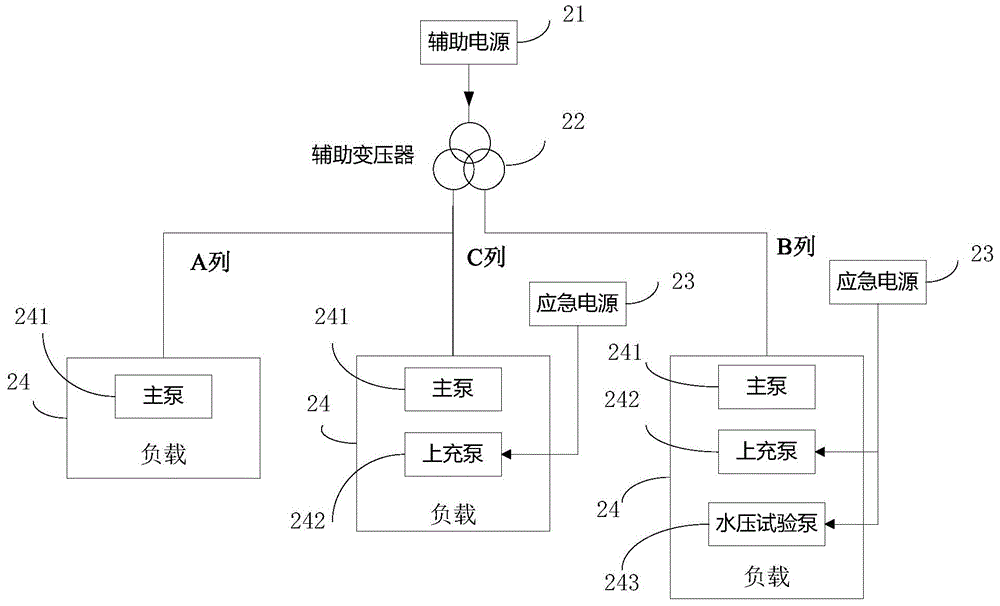

A power supply method and system for a nuclear power plant primary circuit hydraulic pressure test

ActiveCN106160202APrevent pressure dropImprove securityNuclear energy generationNuclear monitoringNuclear plantEmergency power system

The invention discloses a power supply method and system for a nuclear power plant primary circuit hydraulic pressure test. The power supply method comprises the following steps: S1. an auxiliary power source supplies electric power through at least one row of incoming lines sequentially to start a main pump on the row of incoming lines, and carries out load restriction on the equipment on the same row of incoming line as the main pump; S2. the auxiliary power source is used to start up a charging pump on row of incoming lines through power supplied via the at least one row of incoming lines; S3, the auxiliary power supply supplies power to start a hydraulic pressure test pump to pressurize a primary circuit to a reach a target pressure value; and S4, if the auxiliary power supply is de-energized in the power supply step described above, an emergency power supply on one row of incoming lines is automatically activated to supply power to the load on the row of incoming lines. According to the power supply scheme of the application, no primary power supply is needed, and the safety and reliability degrees are high.

Owner:中广核工程有限公司 +1

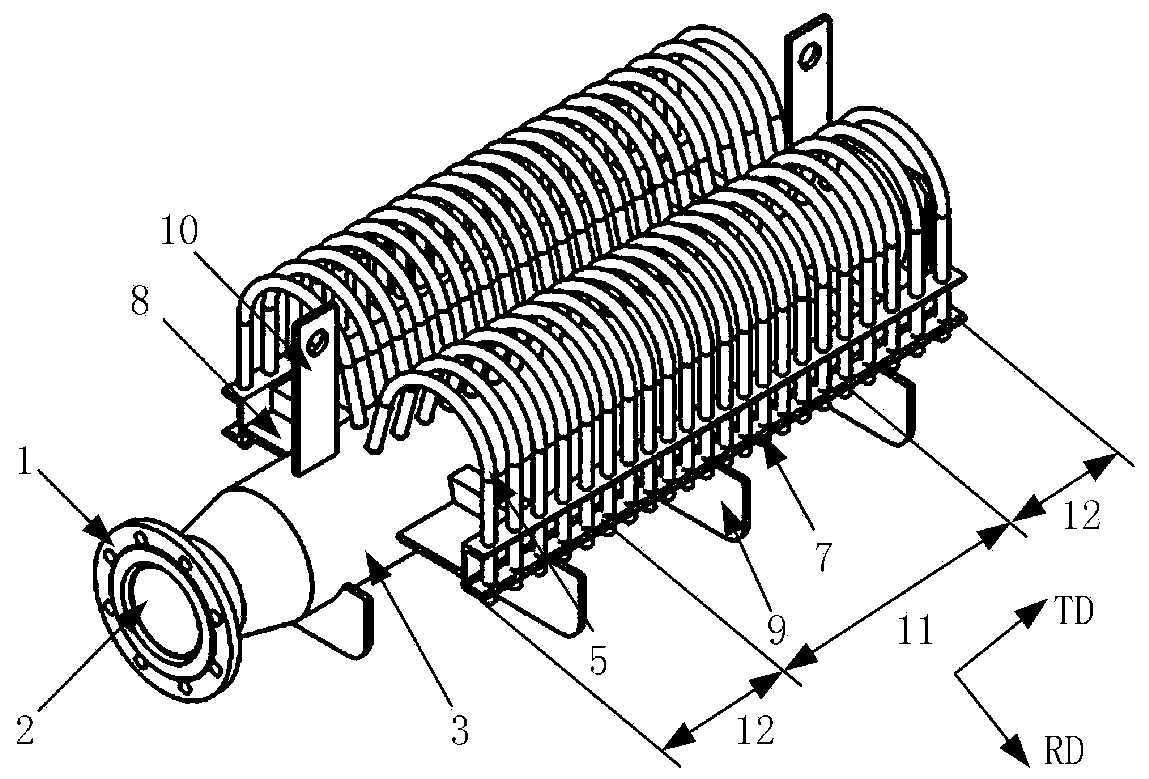

Upper cooling header with variable flow across width

ActiveCN109092911BUniform speedUniform pressureWork treatment devicesMetal rolling arrangementsStructure propertyWater flow

The invention discloses an upper cooling manifold with the variable flow in the width direction. The upper cooling manifold comprises a flange, a rectifier tube, a main manifold body, a plurality of throttling rings, a plurality of goosenecks, a sewage draining opening, a positioning frame, horizontal supporting rib plates, vertical supporting rib plates and hanging lugs, wherein the multiple throttling rings and the multiple goosenecks are evenly distributed in the transverse width direction of strip steel. The multiple throttling rings and the multiple goosenecks which are distributed alongthe two sides of the axis of the main manifold body are distributed in an evenly crossed mode in the transverse width direction of the strip steel. The transverse width direction of the strip steel isdivided into a middle section and two side edge parts. The throttling rings located at the middle section are the same as the goosenecks located at the middle section in size, the goosenecks locatedat the two side edge parts are the same in size, the inner diameters or the thickness of the throttling rings are distributed according to a functional form, thus precise adjusting of the cooling water flow and the cooling speed is achieved, finally, the comprehensive cooling speed in the transverse width direction of the strip steel is balanced and consistent, the uniform structure property is ensured, the defects of edge waves and buckling are avoided, the goosenecks are the same in size and belong to the standard specification, the processing and manufacturing costs are low, and the upper cooling manifold is suitable for mass production.

Owner:YANSHAN UNIV +1

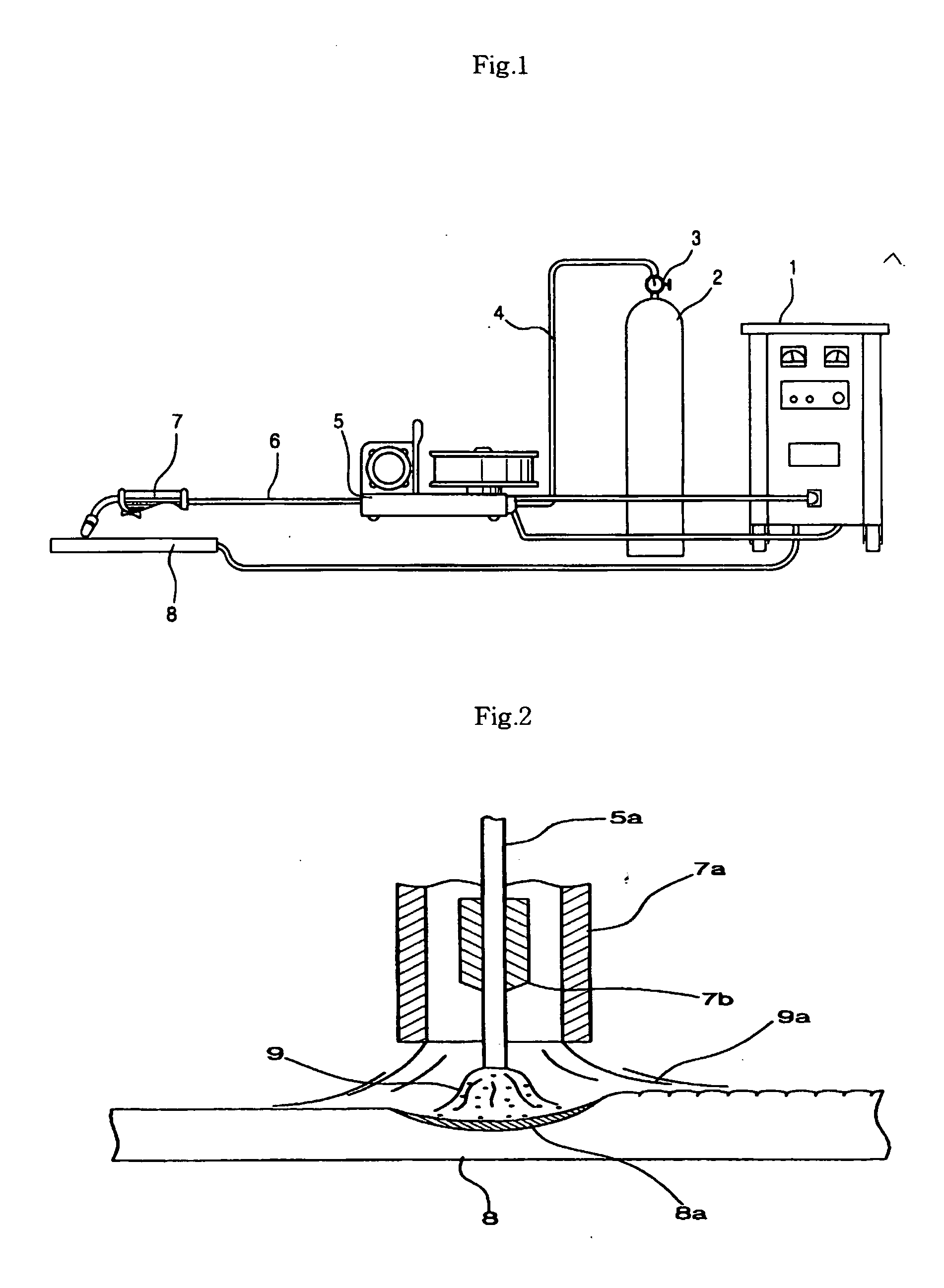

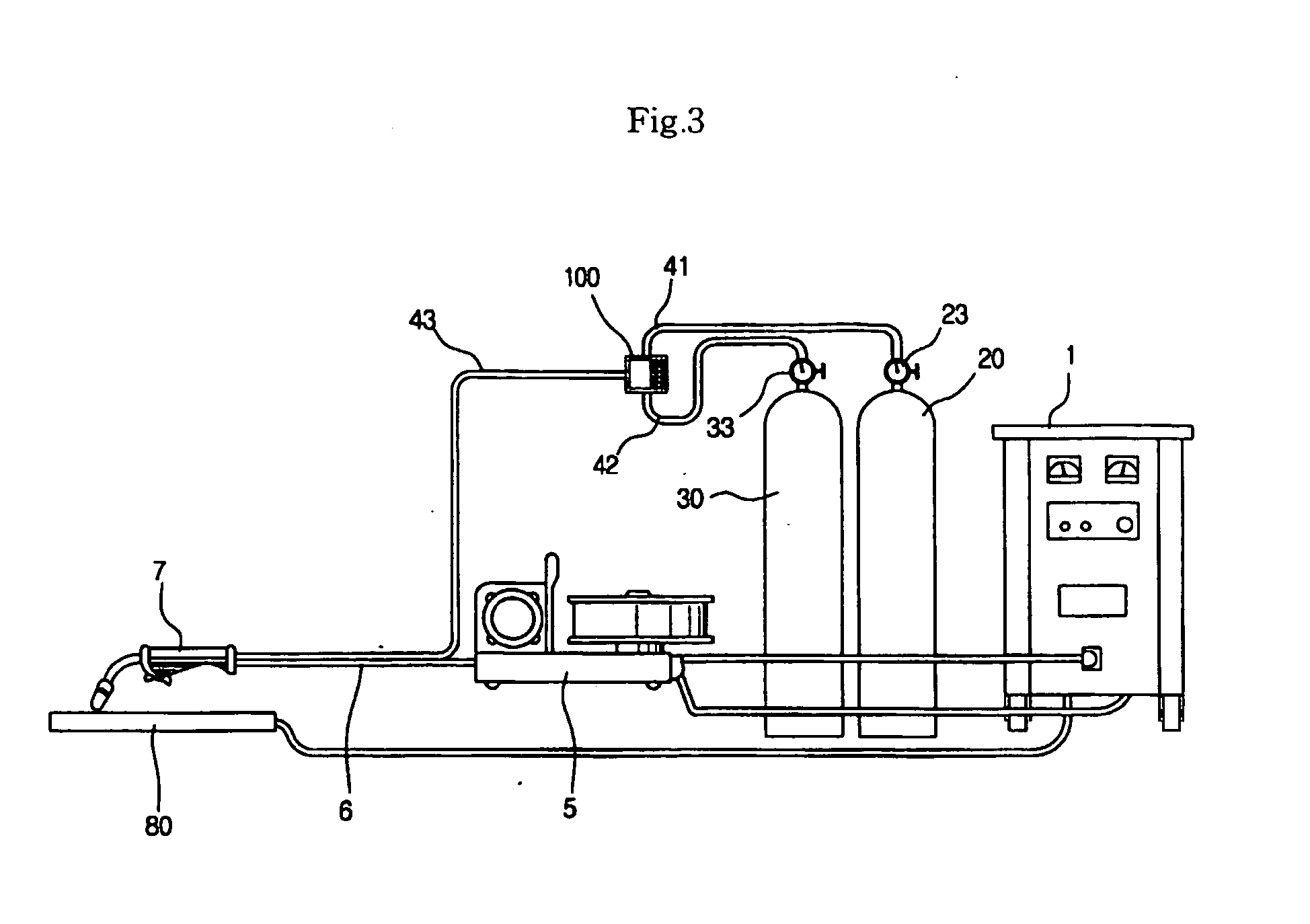

Impulse valve structure of apparatus for suppling inert gas alternately

InactiveUS20050039804A1Uniform surfacePrevent pressure dropOperating means/releasing devices for valvesArc welding apparatusEngineeringReciprocating motion

Owner:KR PRECISION CO LTD

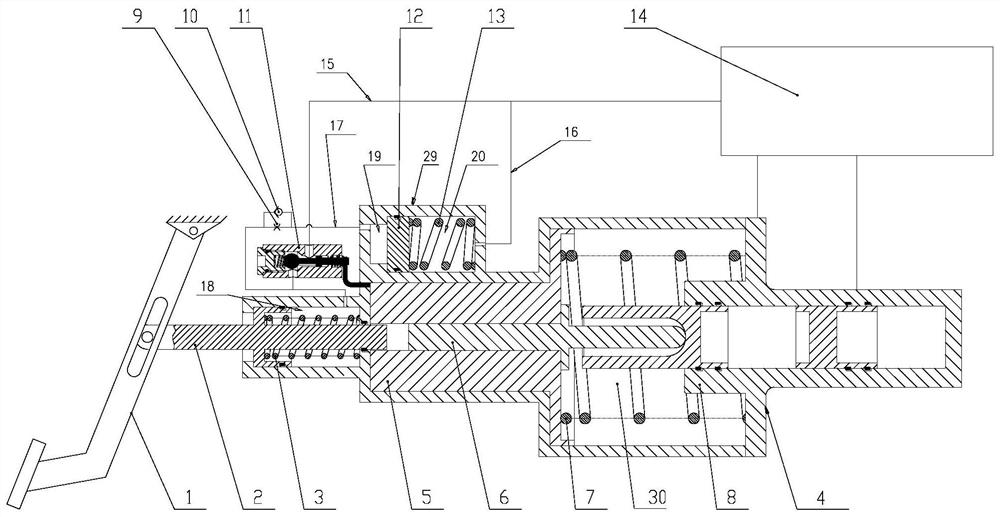

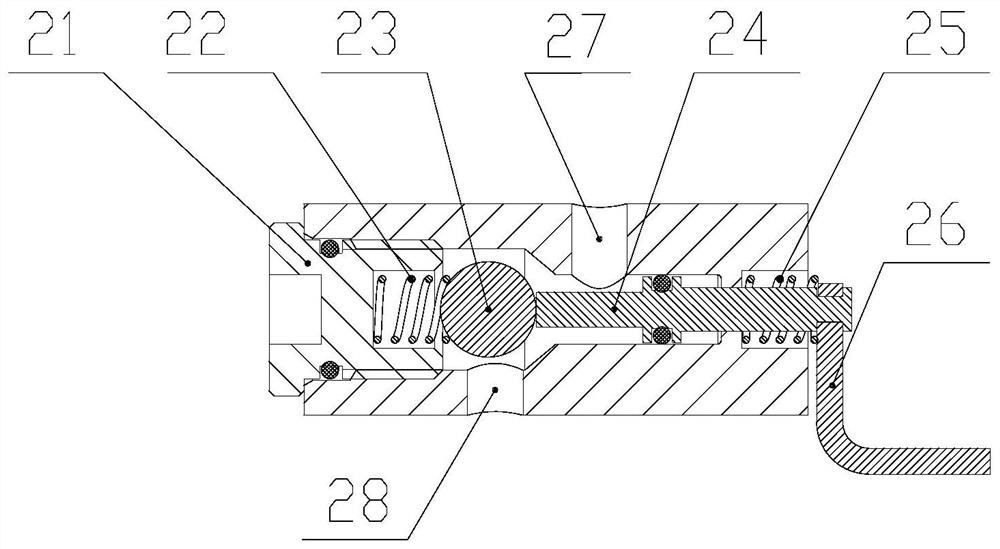

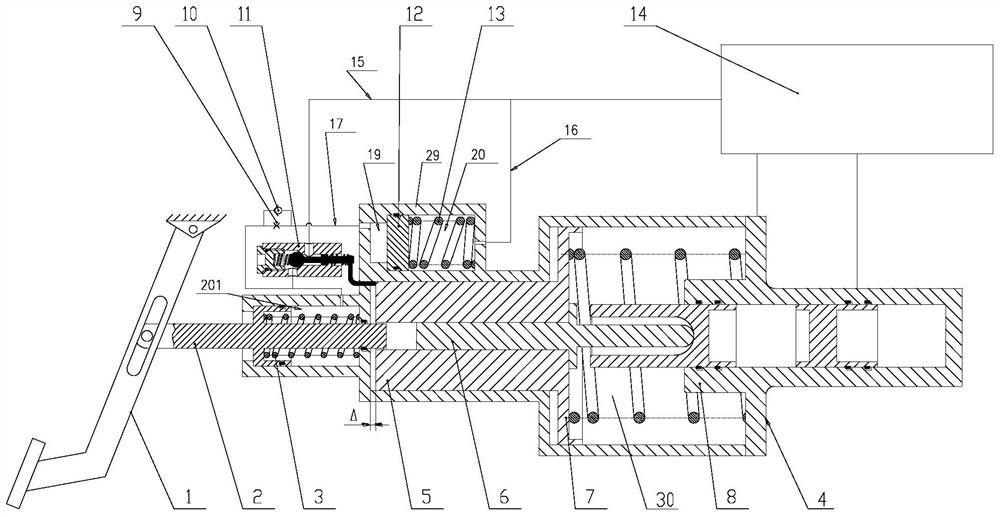

Electro-hydraulic servo braking system with pedal simulator

PendingCN112937532APrevent pressure dropImprove securityBraking action transmissionFoot actuated initiationsDriver/operatorSimulation

The invention discloses an electro-hydraulic servo braking system with a pedal simulator. The electro-hydraulic servo braking system comprises a shell, a brake pedal, a pushing mechanism driven by the brake pedal, a braking mechanism driven by the pushing mechanism to achieve braking, a braking pipeline hydraulic valve actively controlled by the pushing mechanism and a pedal simulator used for simulating the feeling of the brake pedal. The flow direction of brake fluid in the brake pipeline between a push rod piston cavity and a fluid storage tank is adjusted through the hydraulic valve, due to the incompressibility and liquidity of the brake fluid, the brake fluid flows in the push rod piston cavity, a first piston cavity, a second piston cavity and the fluid storage tank through the brake pipeline in the process that a driver steps on or loosens the brake pedal, pedal damping and hysteresis of the brake pedal are simulated, the hydraulic valve is a mechanical valve body, auxiliary electric control equipment does not need to be arranged, when a system fails, the hydraulic valve effectively avoids the situation that the pressure of the brake fluid flowing into a piston cavity of the simulator is reduced, and the incompressibility and the fluidity of the brake fluid are improved.

Owner:南京经纬达汽车科技有限公司

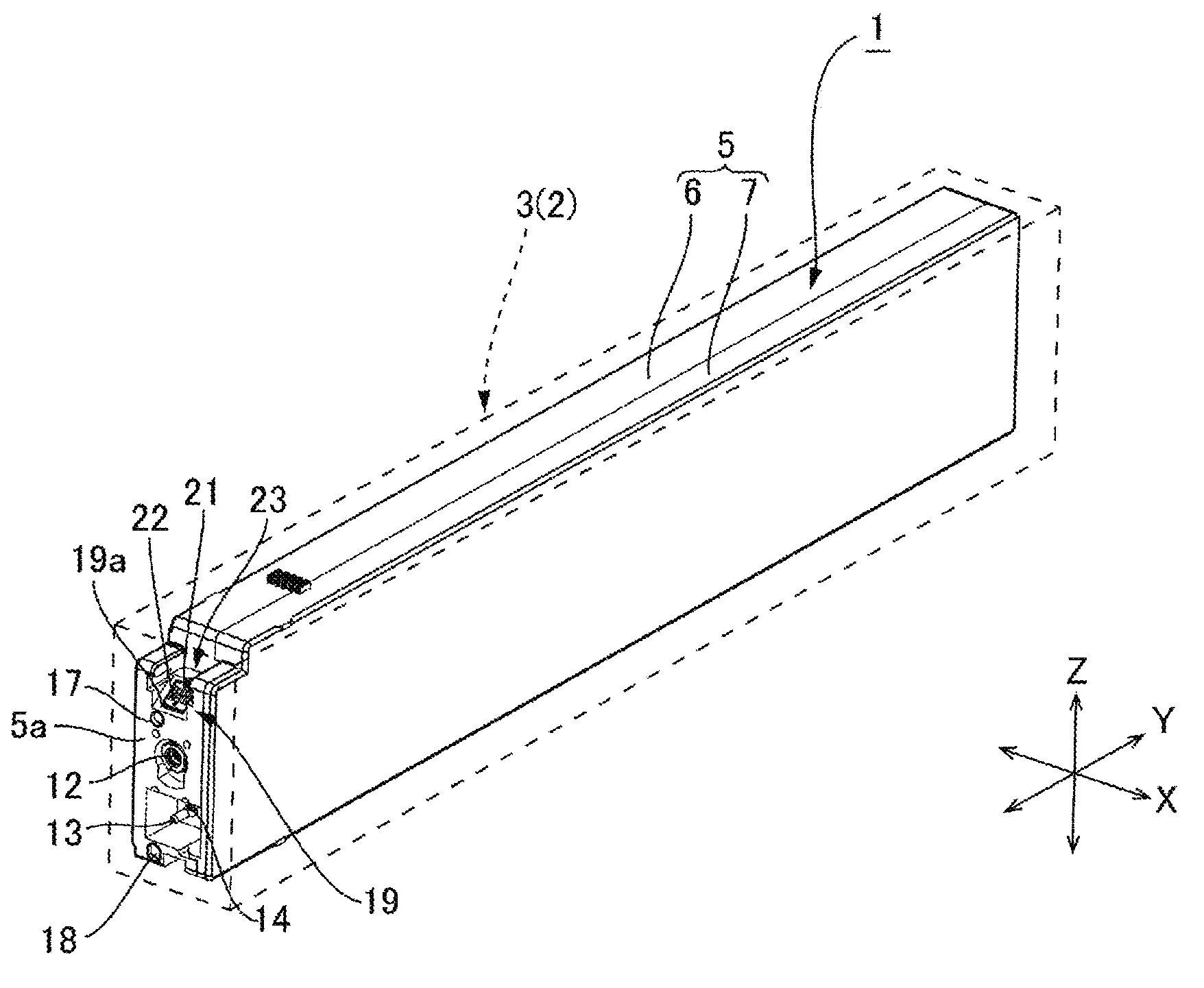

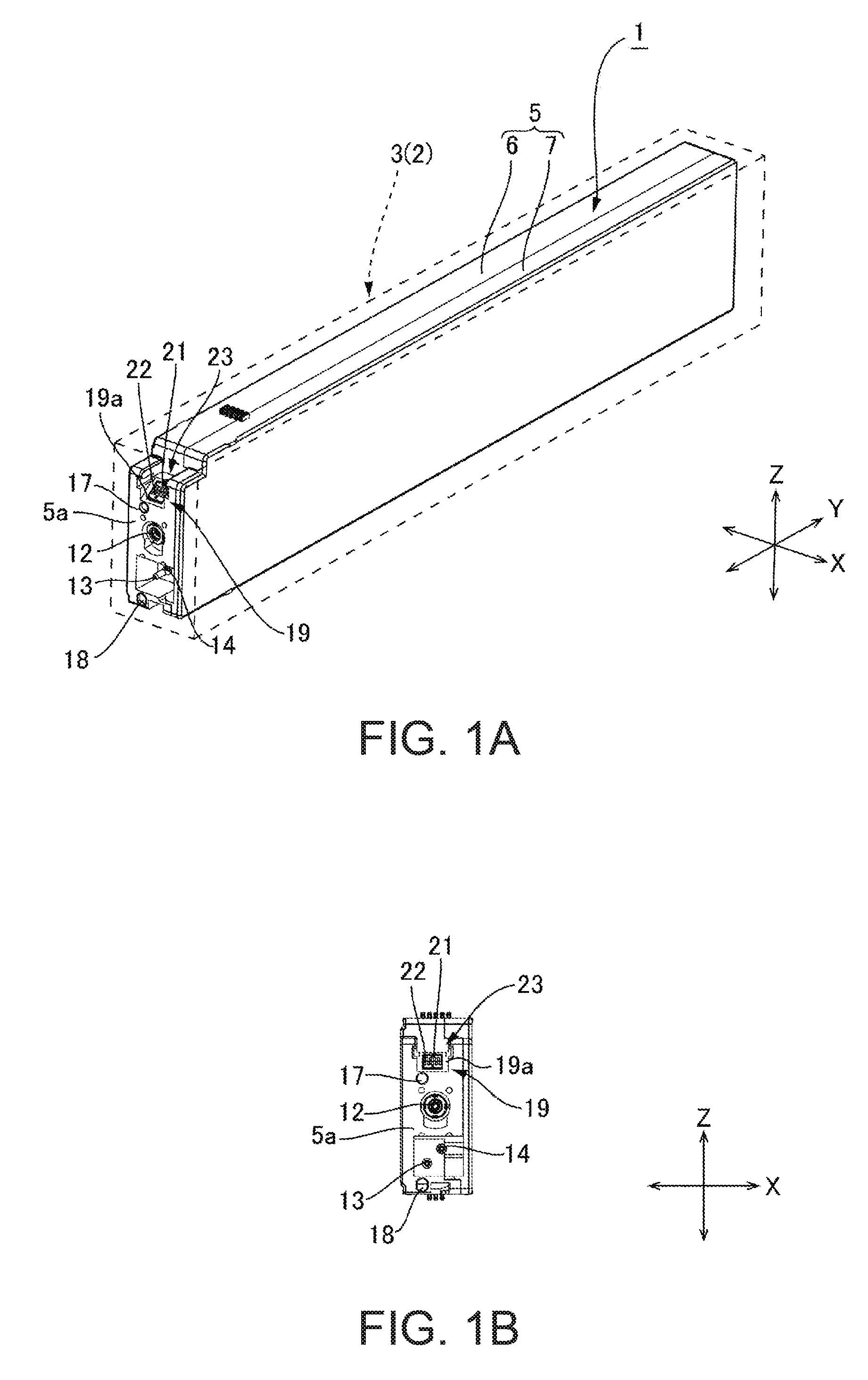

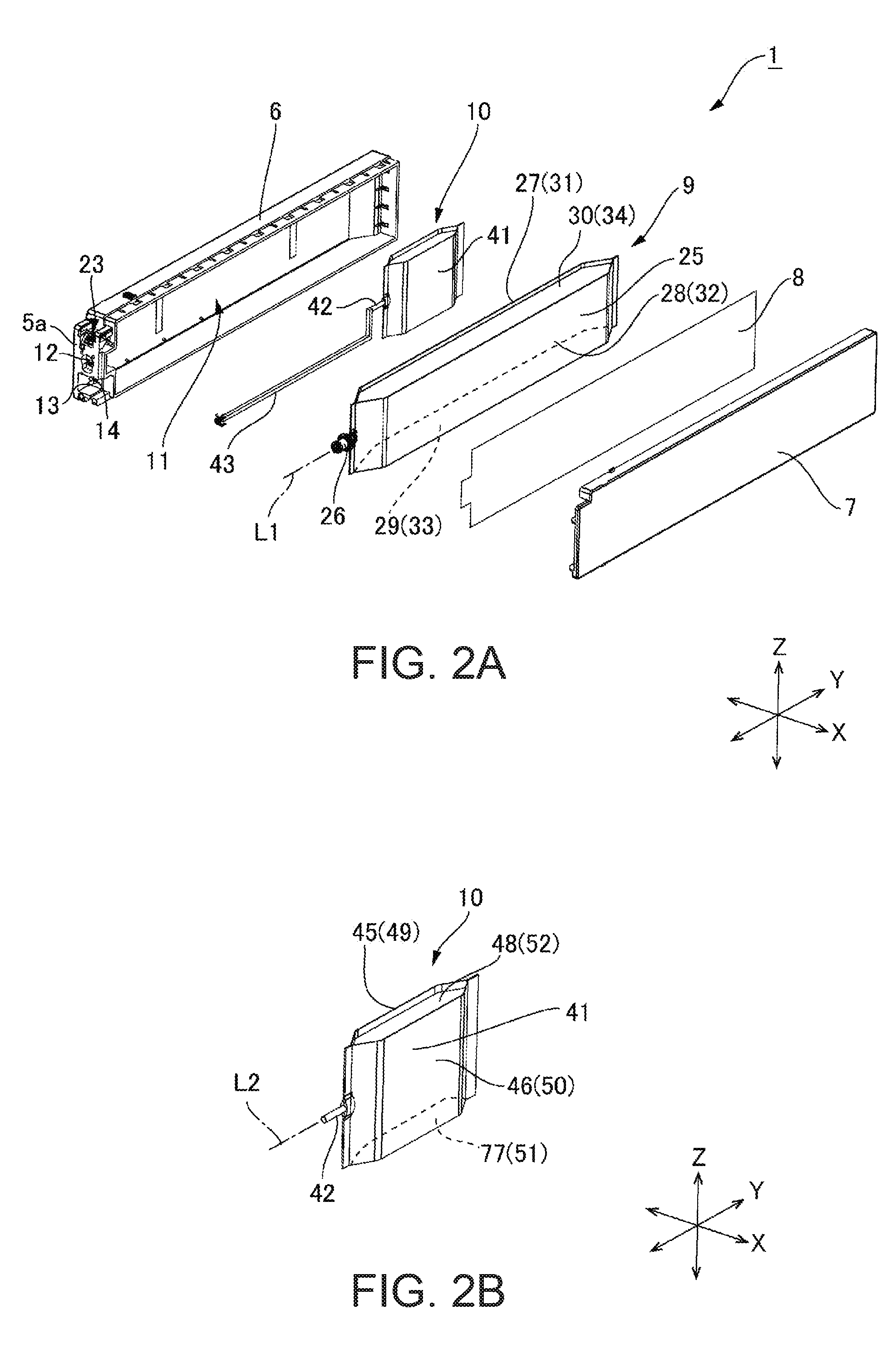

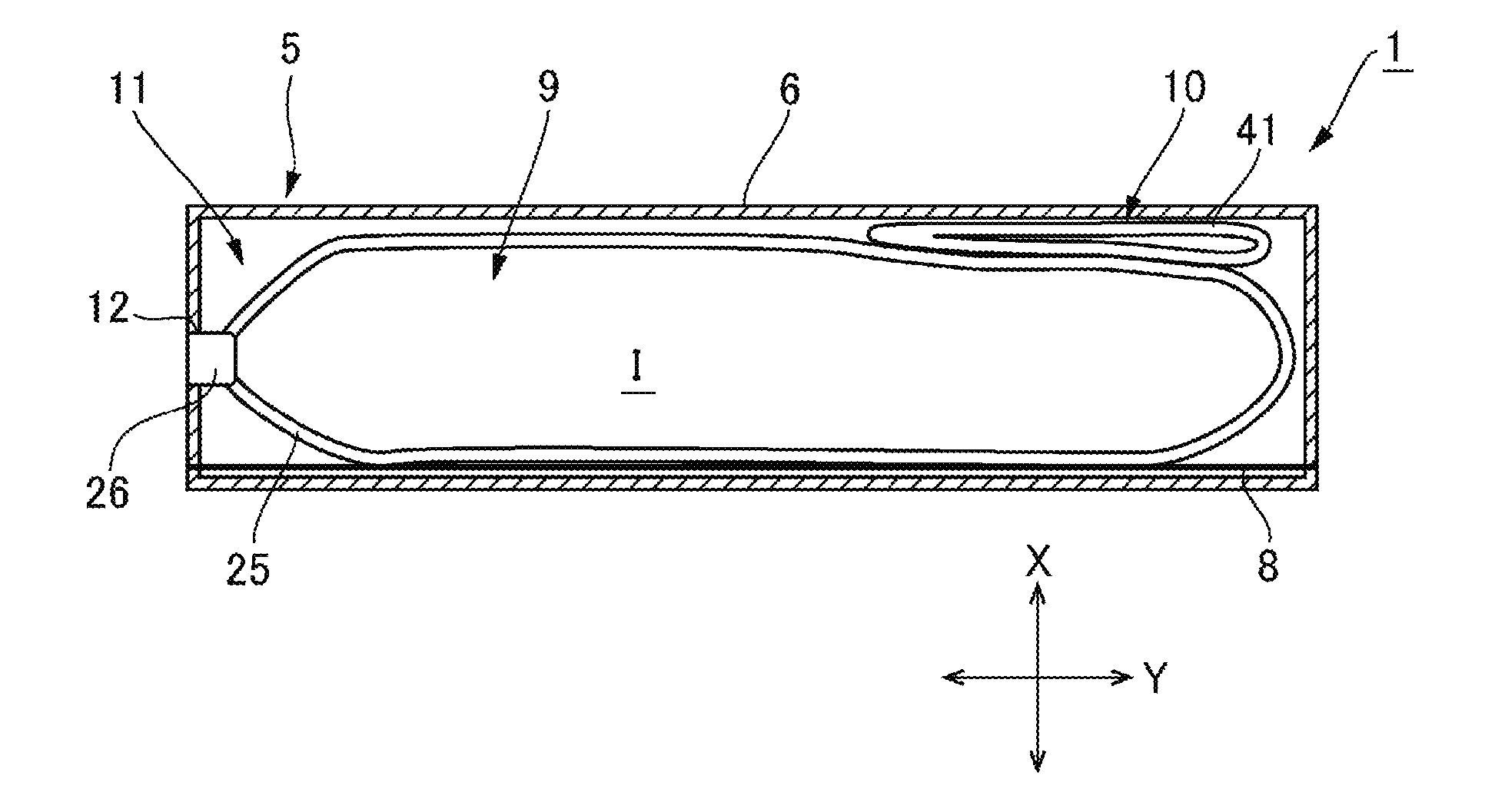

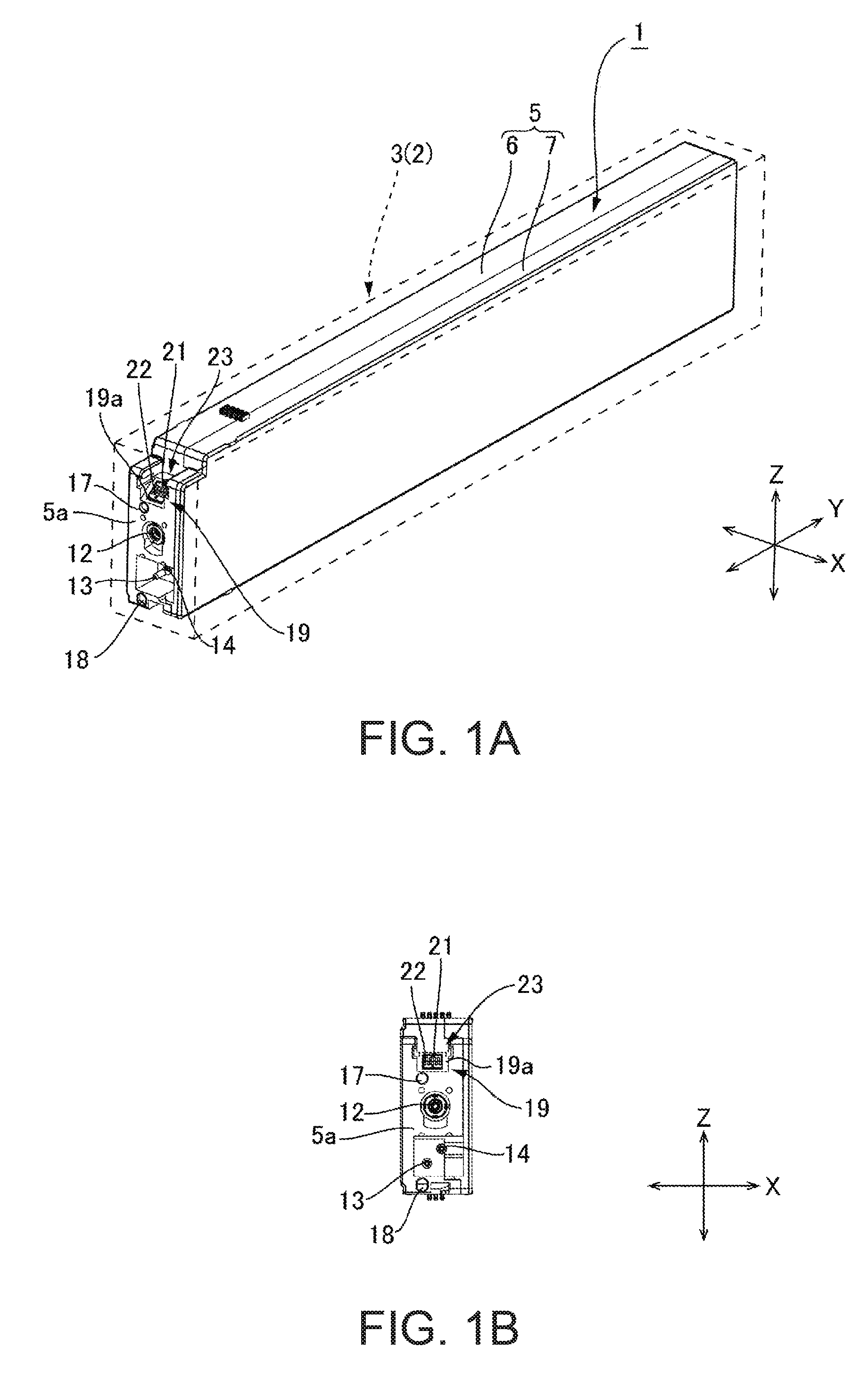

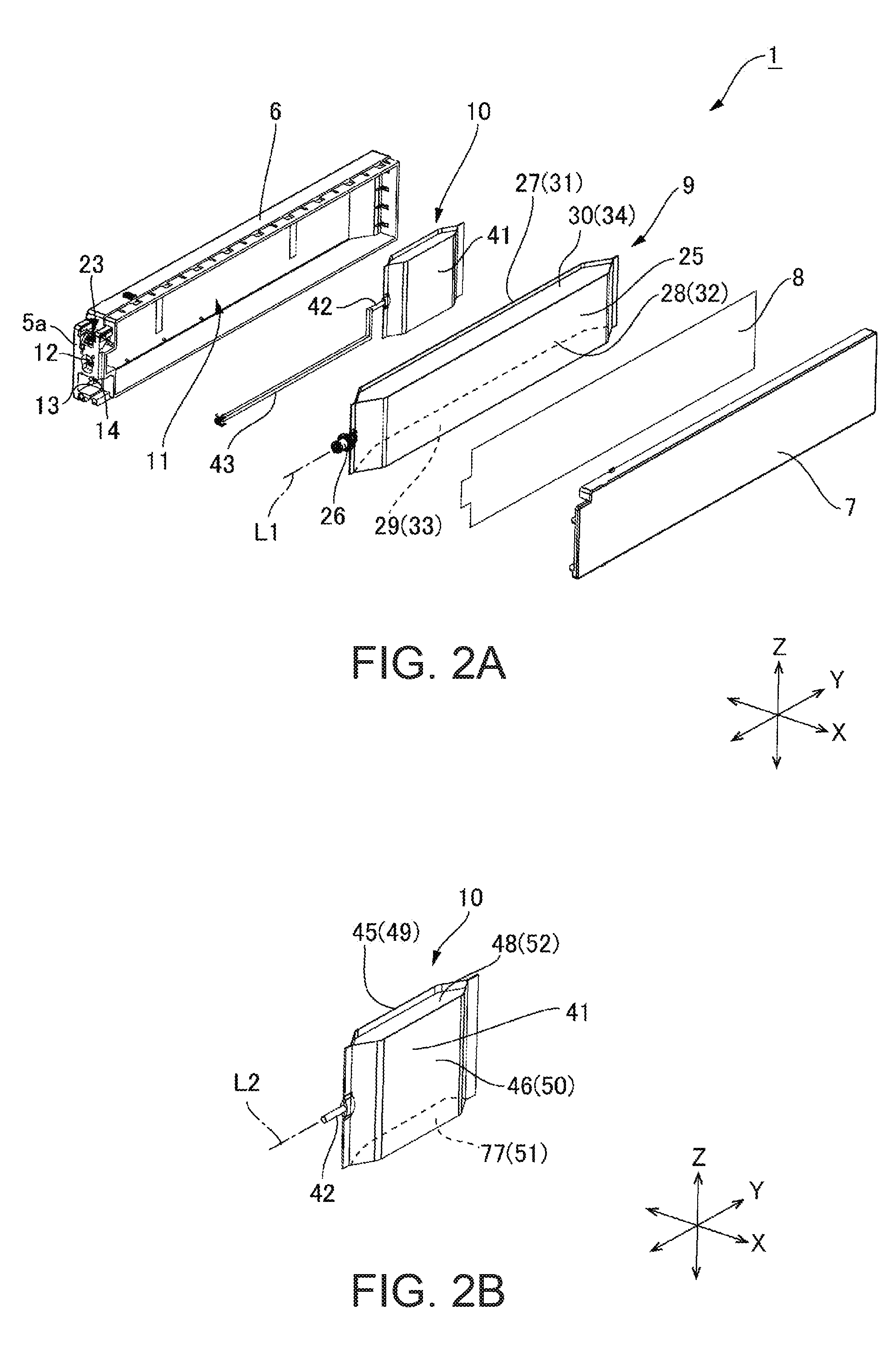

Cartridge and liquid supplying method

A cartridge 1 is provided with an ink pack 9, an air bag 10 capable of abutting the ink pack 9, and a pressurizing chamber 11 that stores the ink pack 9 and the air bag 10. In the case where the amount of ink in the ink pack 9 decreases, pressurized air is introduced into the air bag 10, the ink pack 9 is pressed against the air bag 10, and thereby the internal pressure of the ink pack 9 is increased. After that, pressurized air is introduced into the pressurizing chamber 11 so as to increase the internal pressure of the pressurizing chamber 11 and pressurize the ink pack 9 from outside. Accordingly, the ink in the ink pack 9 is supplied from an ink supply port 12 to the inkjet printer 2.

Owner:SEIKO EPSON CORP

Cartridge and liquid supplying method

A cartridge 1 is provided with an ink pack 9, an air bag 10 capable of abutting the ink pack 9, and a pressurizing chamber 11 that stores the ink pack 9 and the air bag 10. In the case where the amount of ink in the ink pack 9 decreases, pressurized air is introduced into the air bag 10, the ink pack 9 is pressed against the air bag 10, and thereby the internal pressure of the ink pack 9 is increased. After that, pressurized air is introduced into the pressurizing chamber 11 so as to increase the internal pressure of the pressurizing chamber 11 and pressurize the ink pack 9 from outside. Accordingly, the ink in the ink pack 9 is supplied from an ink supply port 12 to the inkjet printer 2.

Owner:SEIKO EPSON CORP

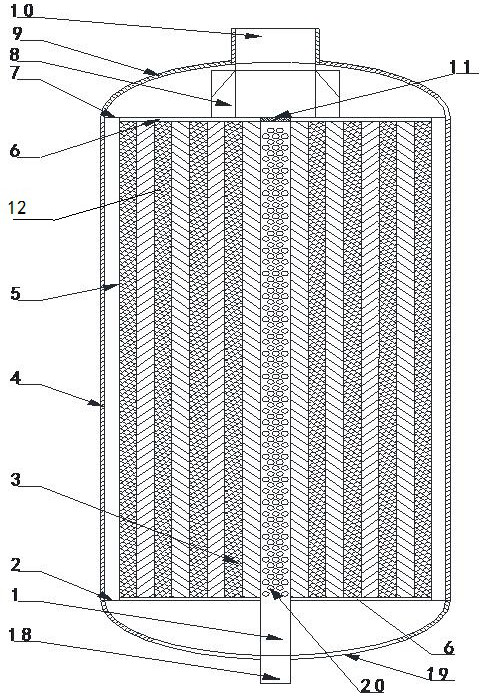

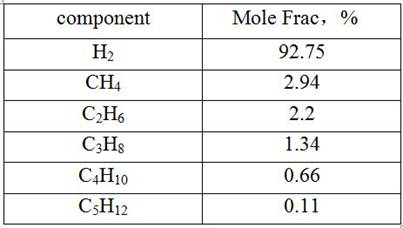

Radial adsorption tower and adsorption process

ActiveCN112742171AImprove performanceImprove adsorption capacityDispersed particle separationProduct gasTower

The invention discloses a radial adsorption tower. The adsorption tower comprises a tower body, an internal central pipe, a metal wire mesh rolling column and a cross section panel, the central pipe extends into the tower body from a quadrant point of an upper seal head or a lower seal head of the tower body and is fixed on a cross section panel of a tangent line of the lower part or the upper part in the tower body, and a check valve is arranged on the inner side of a tail end pipe of the extending end of the central pipe; a plurality of ventilation channels are formed in the central pipe, and the central pipe is wrapped with a metal wire mesh which is integrally fixed with a pipe body of the central pipe; and the metal wire mesh rolling column is a cylinder formed by rolling a metal wire mesh with the surface coated with an adsorbent coating. The pressure of the adsorption tower is reduced, the volume utilization rate of the tower is improved, and the influence of feeding fluctuation on an adsorbent bed layer and the quality and flow of product gas is reduced. The problems that in the prior art, the gas velocity change affects the performance of the adsorbent, and gas phase entrainment and adsorbent desorption are not thorough are solved, and the better adsorption effect is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

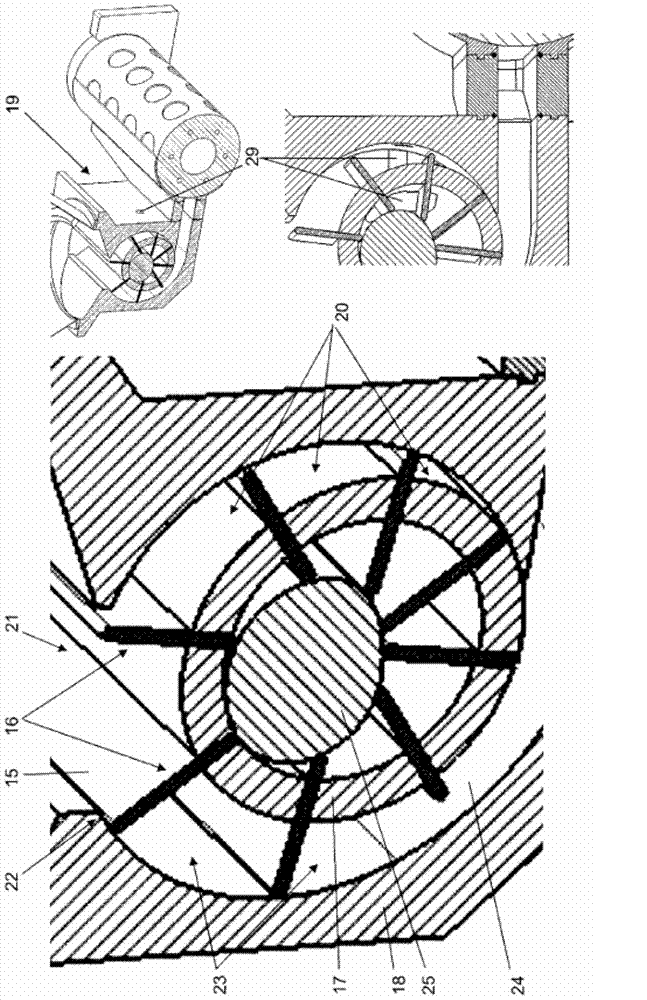

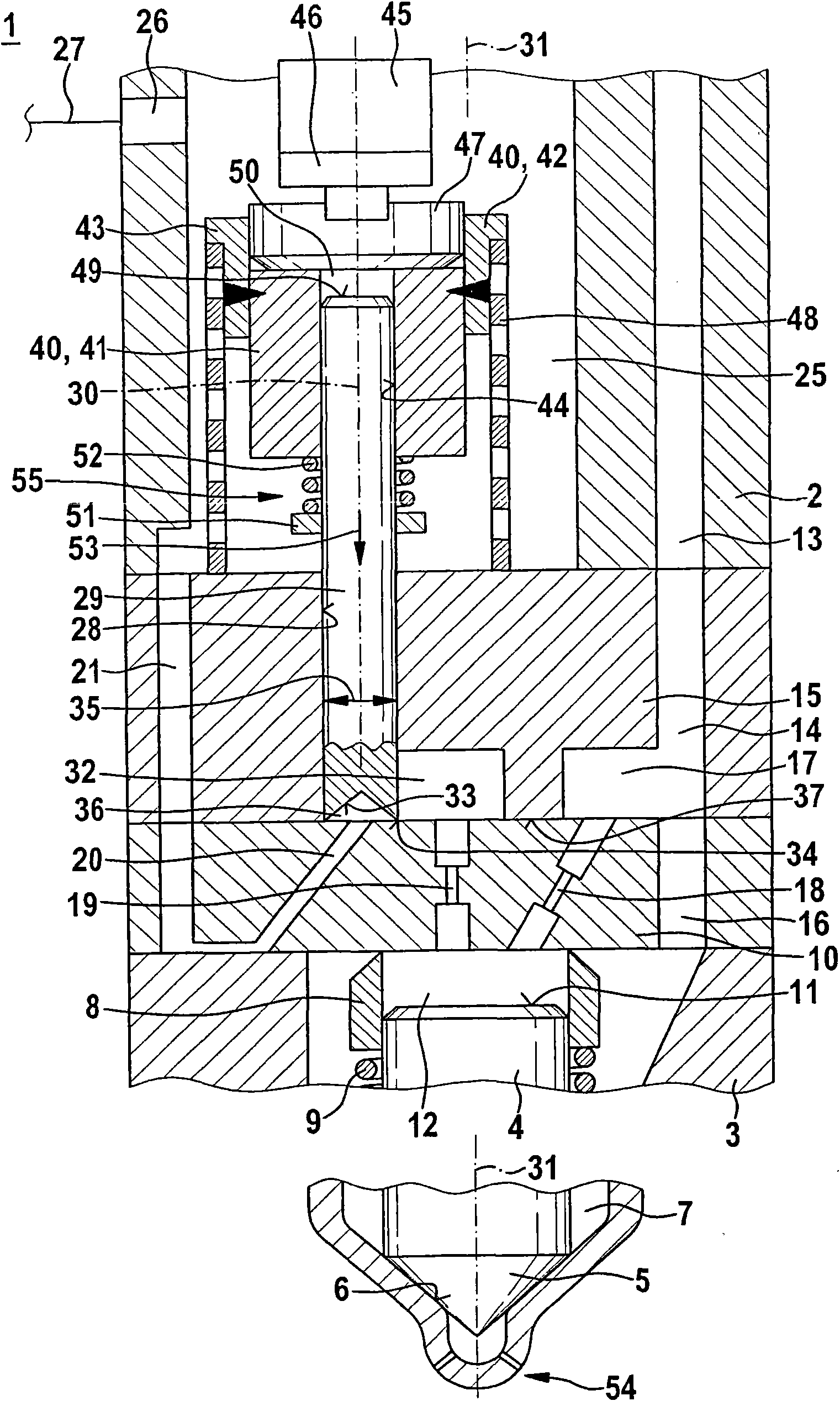

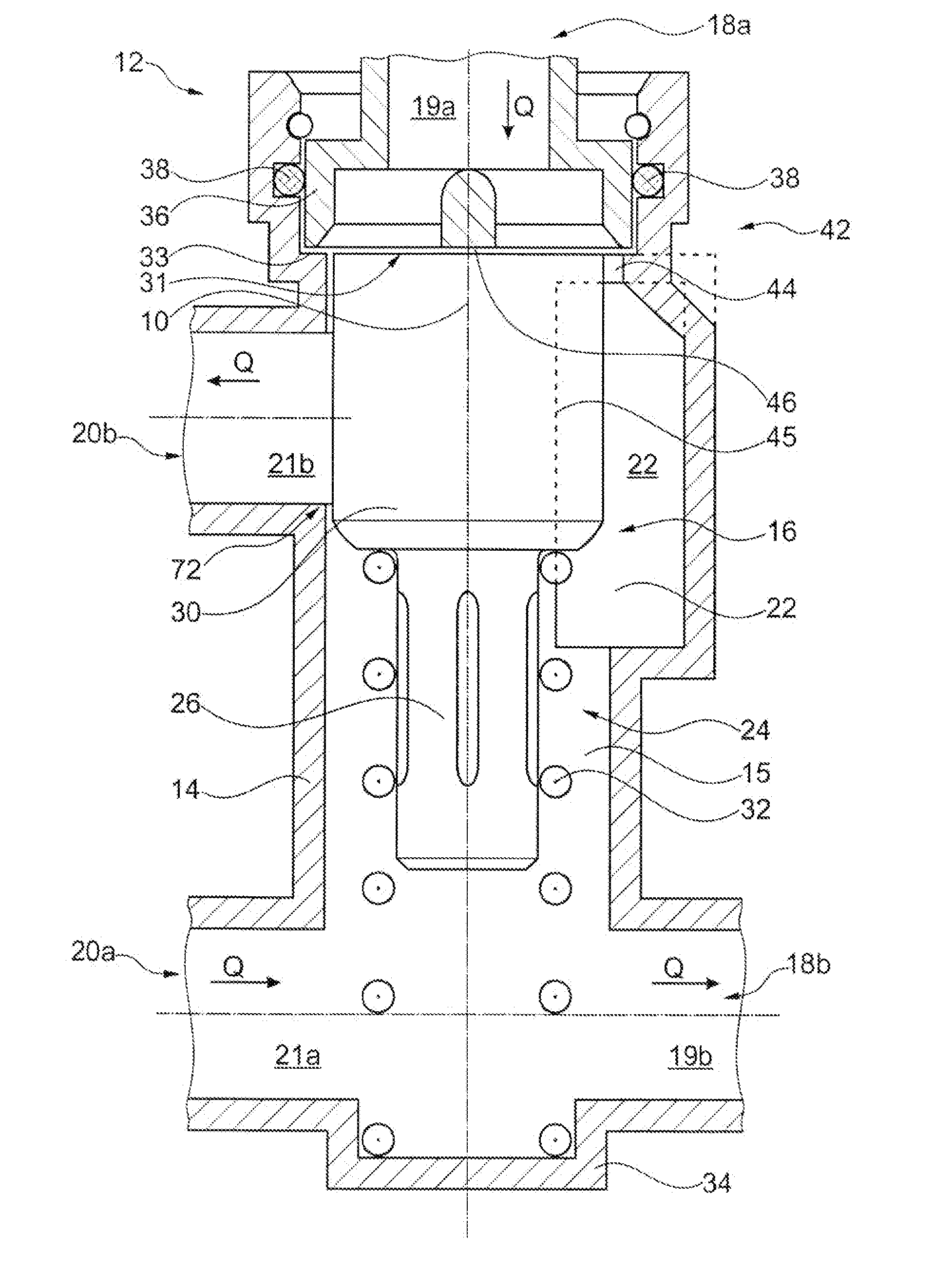

Fuel injector valve

InactiveCN101676549AShorten the lengthSimple structureFuel injection apparatusMachines/enginesEngineeringInternal combustion engine

A fuel injection valve (1), in particular an injector of a fuel injection device for compressing-air and self-ignition type internal combustion engine, is provided with a control valve (55) operated by an actuator (45). The control valve includes a valve rod (29), a valve plate (15) and a throttle plate (10). The valve plate (15) includes a through hole (28), the valve rod (29) is guided in the through hole (28), and the valve plate is provided with a dead slot (32) connected with the through hole (28) at a side facing the throttle plate (10). The throttle plate (10) is provided with an outputthrottle valve (19) communicated with the dead slot (32) of the valve plate (15) and a passage (20) connected with a low pressure return part (26), and the passage may be closed by the valve rod (29). When the control valve is operated, the valve rod releases the connection of the output throttle vlave (19) of the throttle plate (10) and the passage (20) of the throttle plate (10) by the dead slot (32) of the valve plate (15). Thereby, it is possible to implement pressure balance of the control valve (55). Furthermore, the valve plate (15) may have high component strength.

Owner:ROBERT BOSCH GMBH

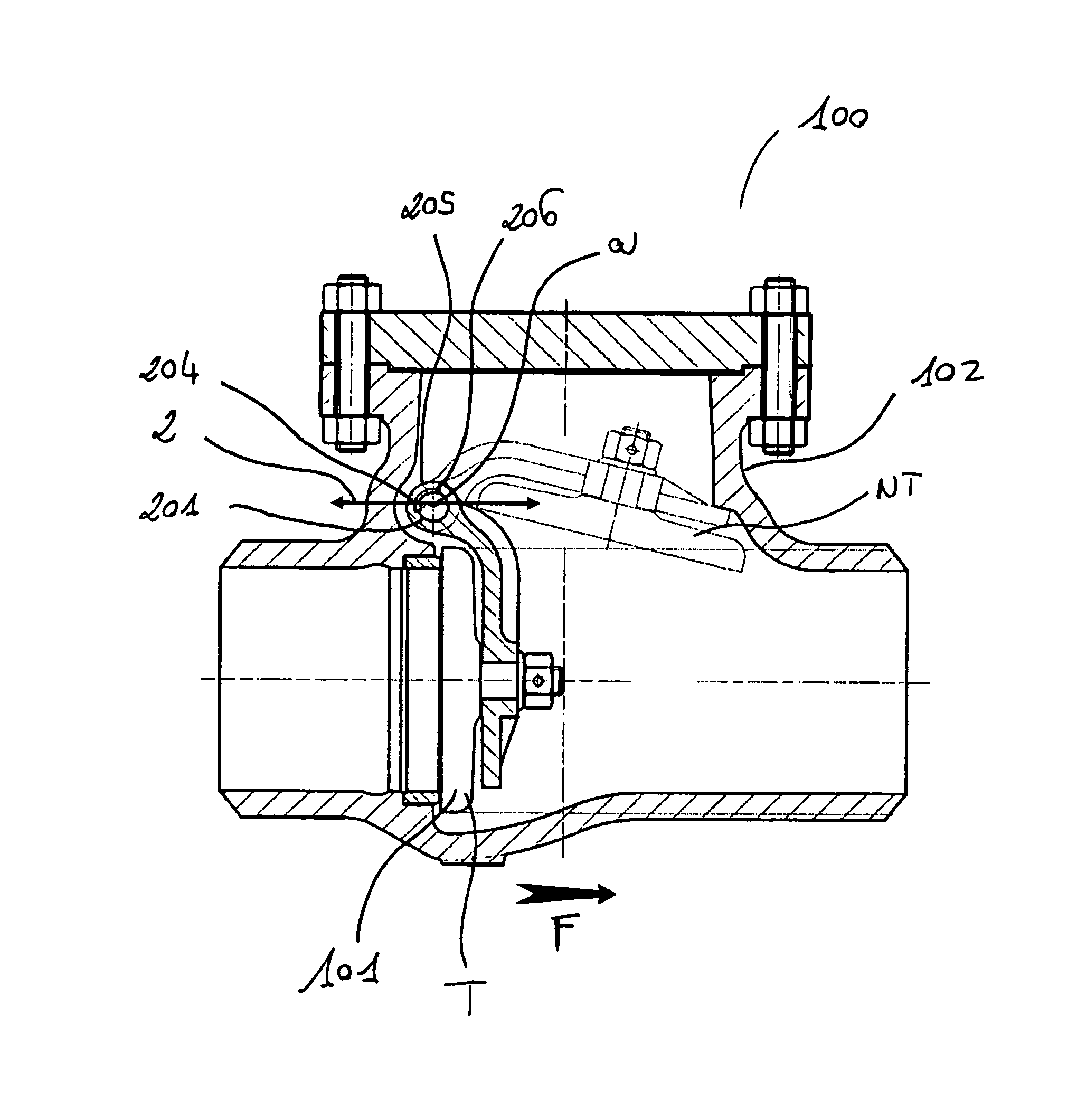

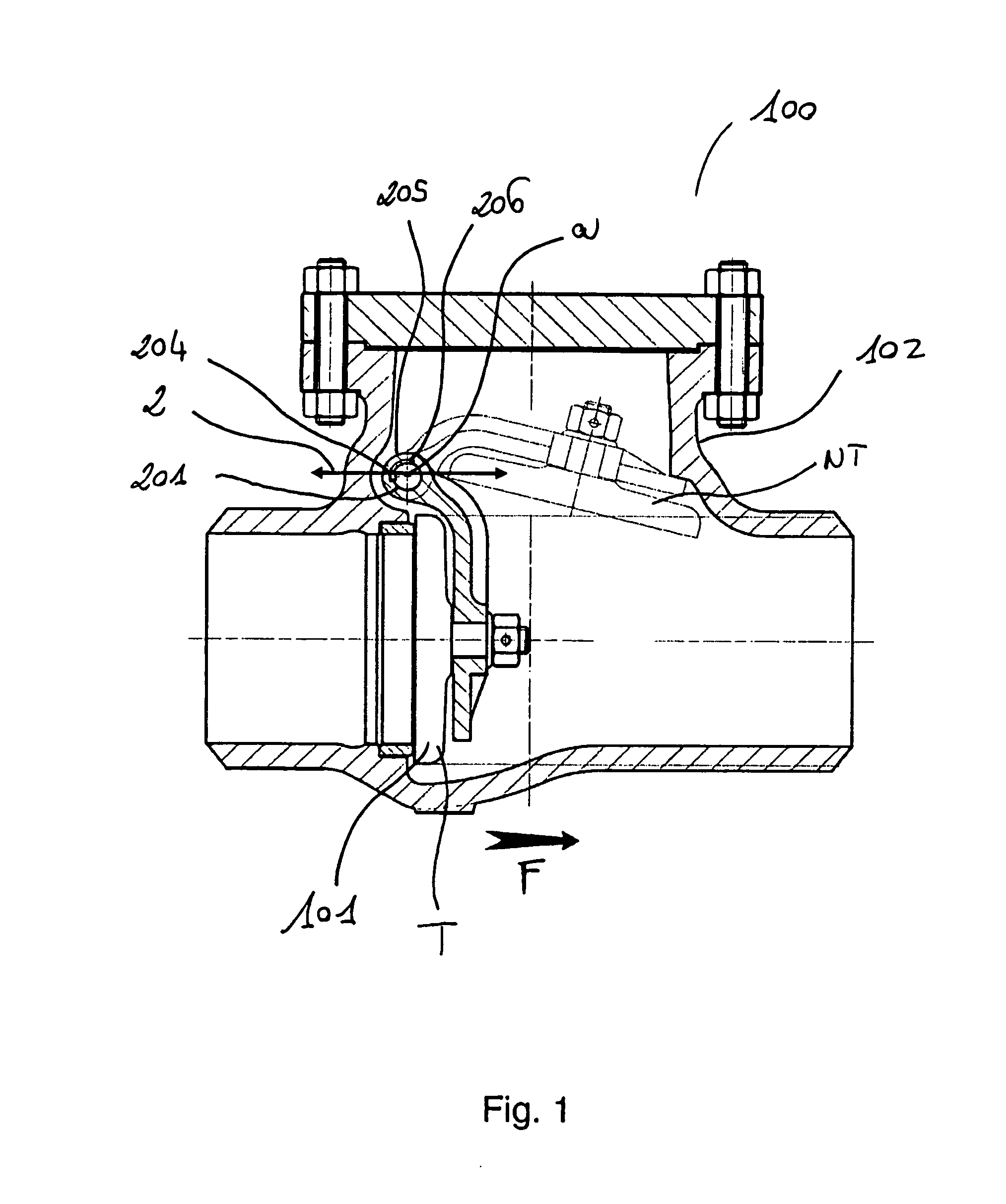

Check Valves, Systems and Methods of Operation of Same

InactiveUS20140216556A1Prevent pressure dropOperating means/releasing devices for valvesCheck valvesEngineeringCheck valve

A system and a method for actuating a sealing element (101) of a check valve (100) are shown wherein the sealing element (101) is forced to a non-sealing position corresponding to an opening degree of the valve (100) equal to or higher than a first predefined opening degree when the increase of the opening degree with respect to the sealing position (T) is equal to or higher than a predefined threshold. In this way, the problem of vibration or “chattering” of the sealing element of the valve is efficiently prevented.

Owner:PENTAIR VALVES & CONTROLS ITAL SRL

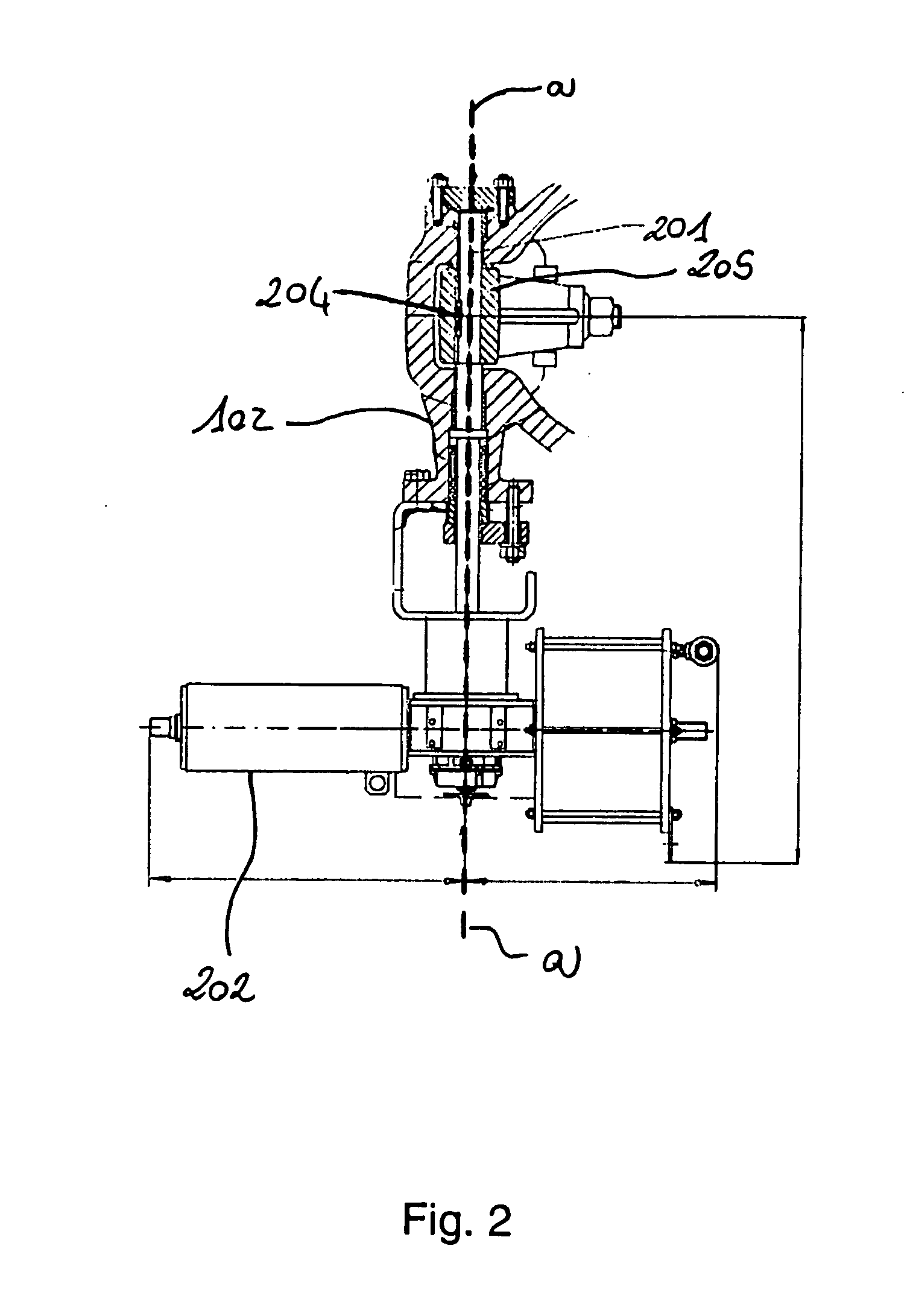

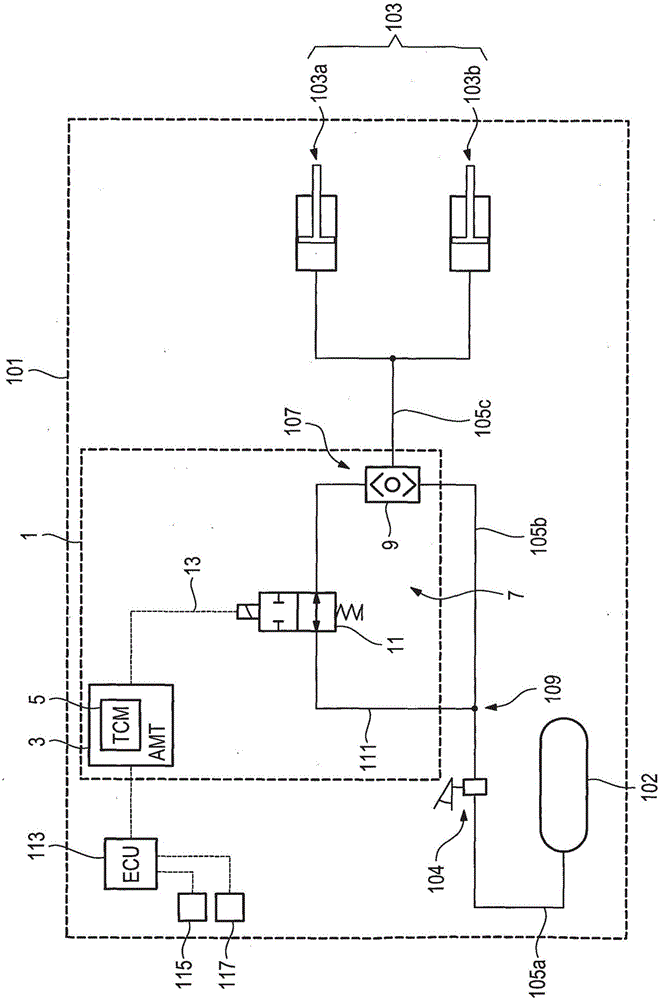

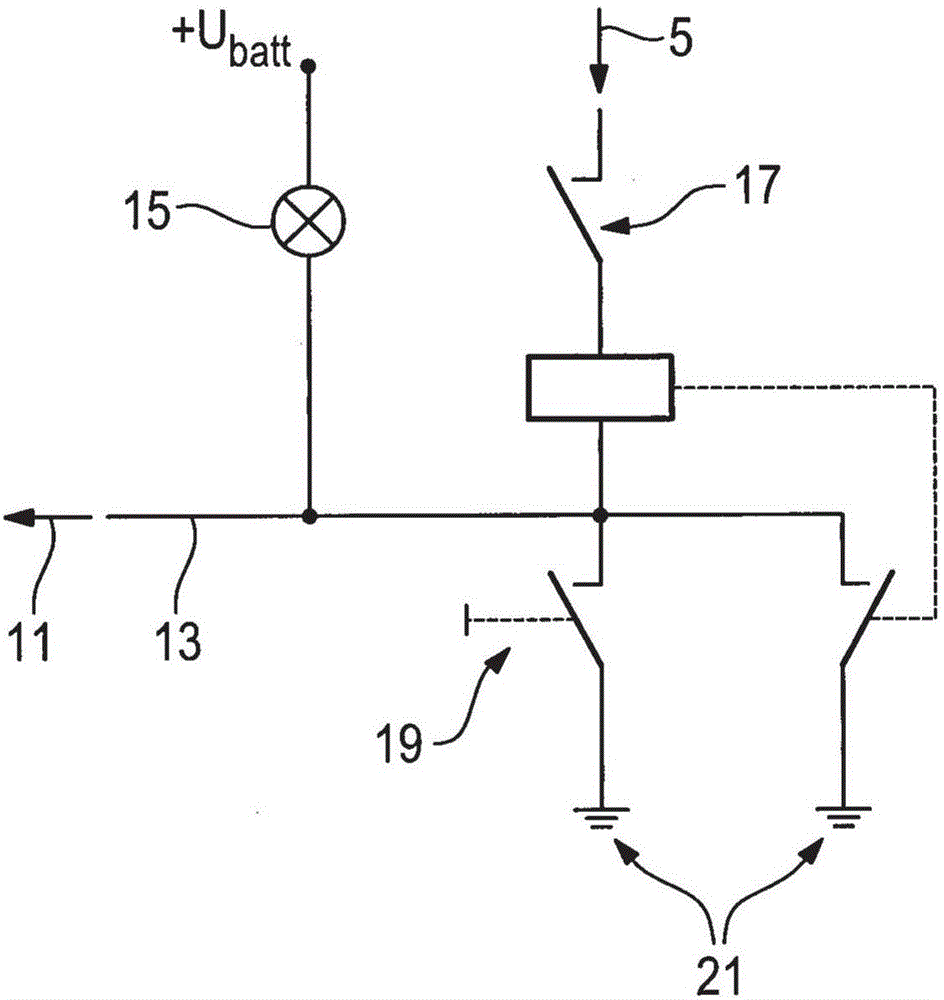

Hill start assist system and motor vehicle having same

ActiveCN106794826APrevent pressure dropBrake system interactionsBraking action transmissionElectronic controllerBraking system

The invention relates to a hill start assist system (1) for a motor vehicle (101), comprising an automated transmission (3), which has an electronic controller (5), and a valve assembly (7) for connecting between a compressed-air source (102) and a number of brake systems (103) of the motor vehicle (101) in order to conduct compressed air from the compressed-air source (102) to the brake systems (103) by means of actuation of a brake pedal unit (104). According to the invention, the valve assembly (7) is connected to the electronic controller (5) in a signal-conducting manner, and the electronic controller (5) is designed to activate and deactivate the valve assembly (7) in such a way that, in the deactivated state, the brake pressure triggered by means of actuation of the brake pedal unit (104) is conducted to the brake systems in an uninfluenced manner and, in the activated state, a triggered brake pressure is conducted to the number of brake systems (103) and is confined there.

Owner:ZF CV SYST EURO BV

Thermostatic valve

ActiveUS20150108229A1Great travelGreat cooling capacityTemperature control without auxillary powerCoolant flow controlPhysicsHeat exchanger

A thermostatic valve to connect a heat source, in particular a gear drive with a heat exchanger, particularly a motor vehicle, having a thermostatic valve housing with a first inlet connection for a first inlet port and a second inlet connection for a second inlet port as well as a first outlet connection for a first outlet port and a second outlet connection for a second outlet port, with a moveable working element in an intake opening of the thermostatic valve housing to open and close the inlet and outlet ports and a separate restriction element is provided in the thermostatic valve housing between the first inlet connection and the first outlet connection.

Owner:MAHLE INT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com