Fuel injector valve

A technology of fuel injection valve and fuel injection device, which is applied in the direction of fuel injection device, charging system, engine components, etc., can solve the problems of large total length and limited use range, and achieve simple manufacturing costs and omit etching geometry. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

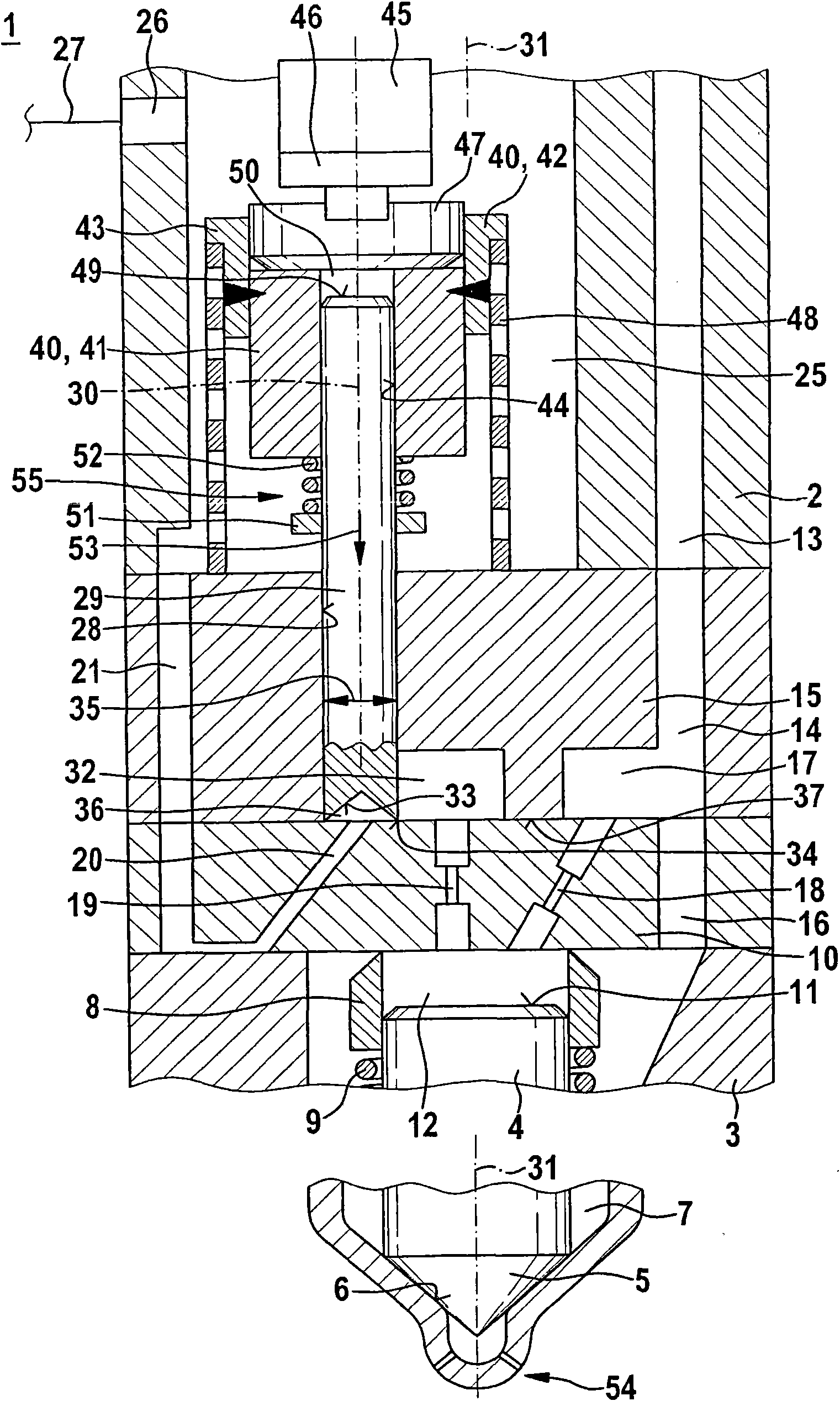

[0012] figure 1 An exemplary embodiment of a fuel injector 1 according to the invention is shown in a schematic, schematic axial section. The fuel injection valve 1 can be used in particular as an injector of a fuel injection system for an air-compressed self-ignition internal combustion engine. A preferred application of the fuel injection valve 1 is in a fuel injection system with a common rail which supplies a plurality of fuel injection valves 1 with diesel fuel under high pressure. However, the fuel injector 1 according to the invention is also suitable for other applications.

[0013] The fuel injector 1 has a holding body 2 and a nozzle body 3 . The nozzle body 3 is connected to the holding body 2 in a suitable manner. A nozzle needle 4 is arranged in the nozzle body 3 . The nozzle needle 4 has a valve closing body 5 . The nozzle body 3 has a valve seat surface 6 adapted to the valve closing body 5 . The valve closing body 5 cooperates in a sealing manner with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com