Patents

Literature

45results about How to "High component strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

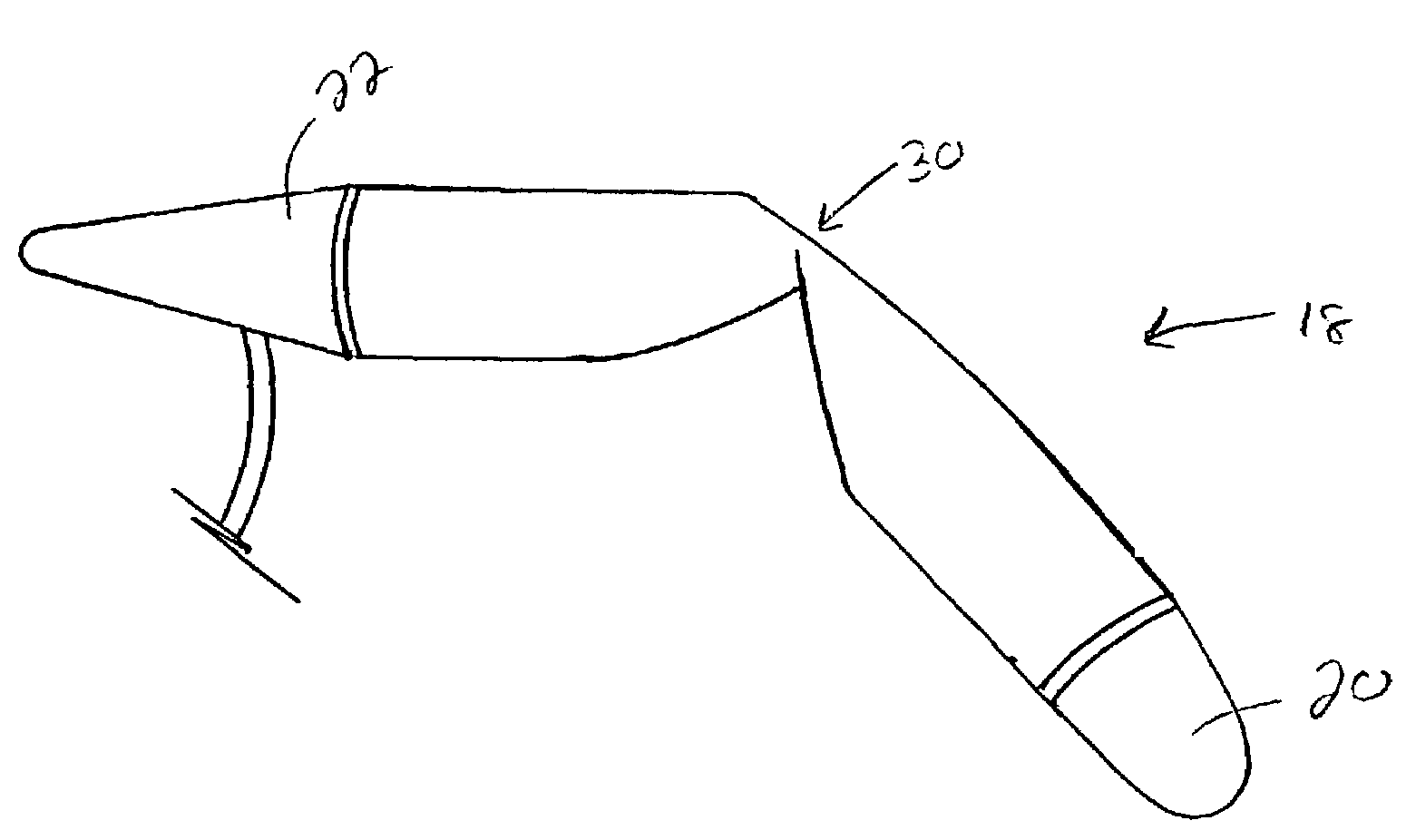

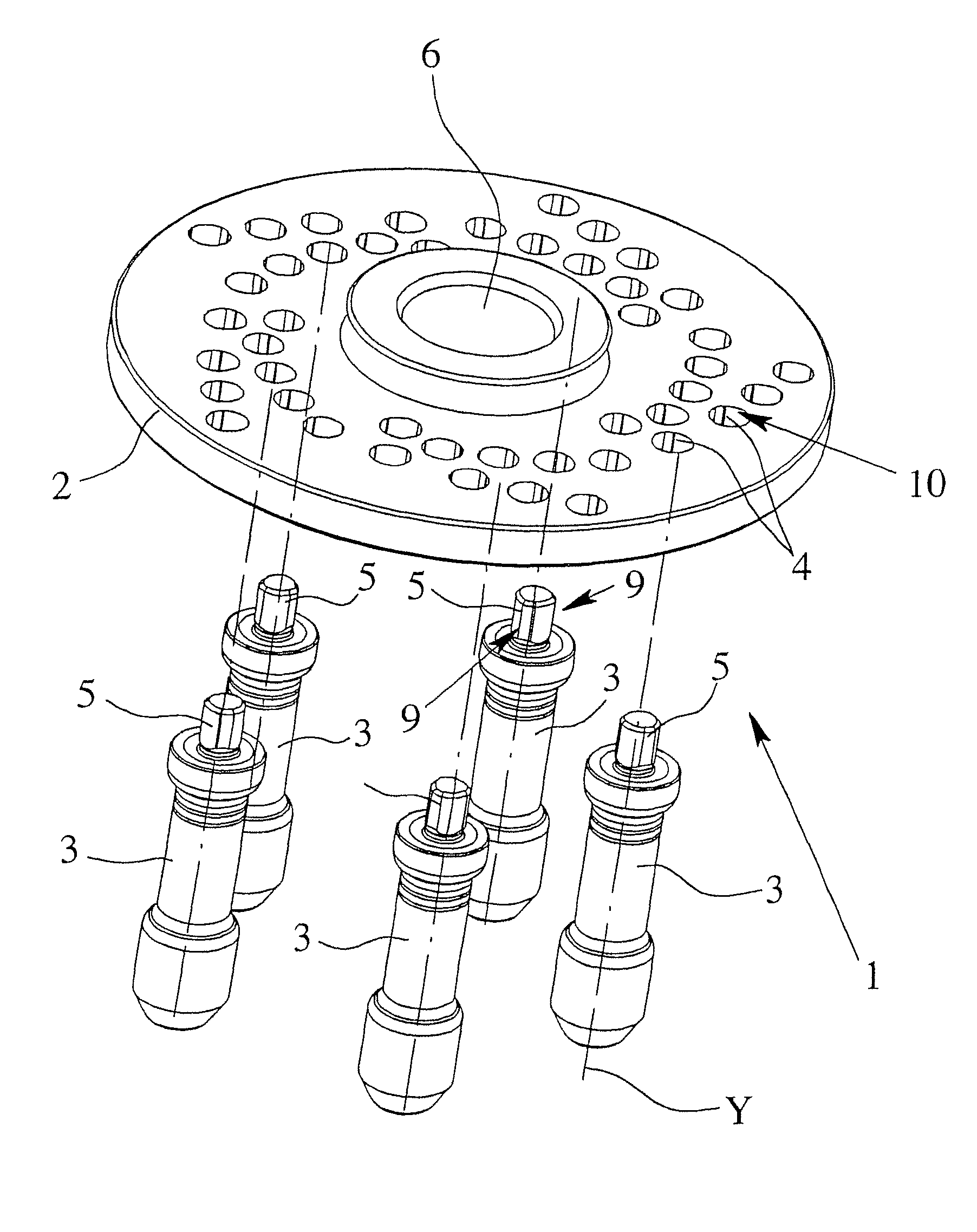

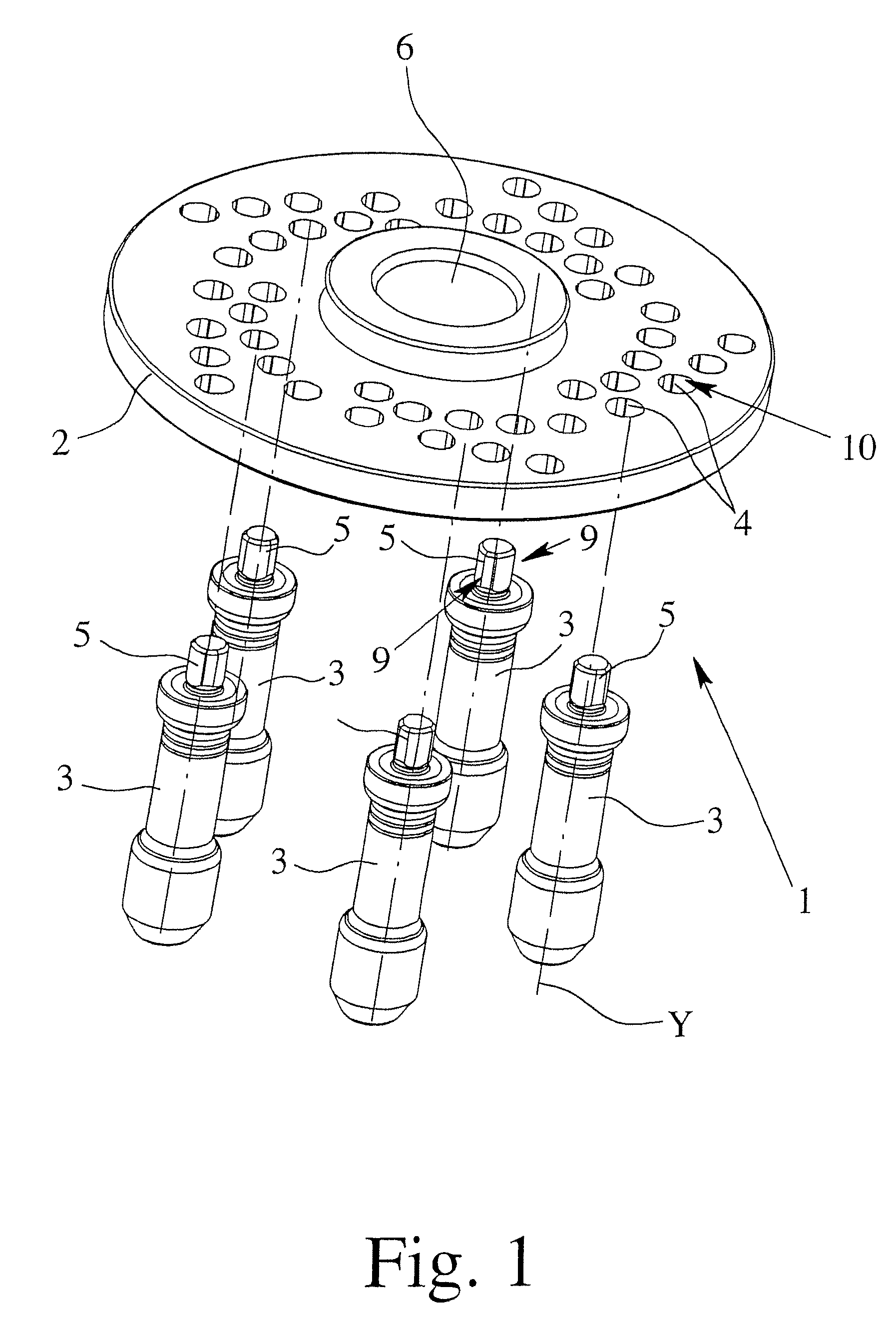

Shaft and post tensioning device

ActiveUS8444911B2High component strengthAvoid breakingPortable framesSpecific fluid pumpsEngineeringOuter core

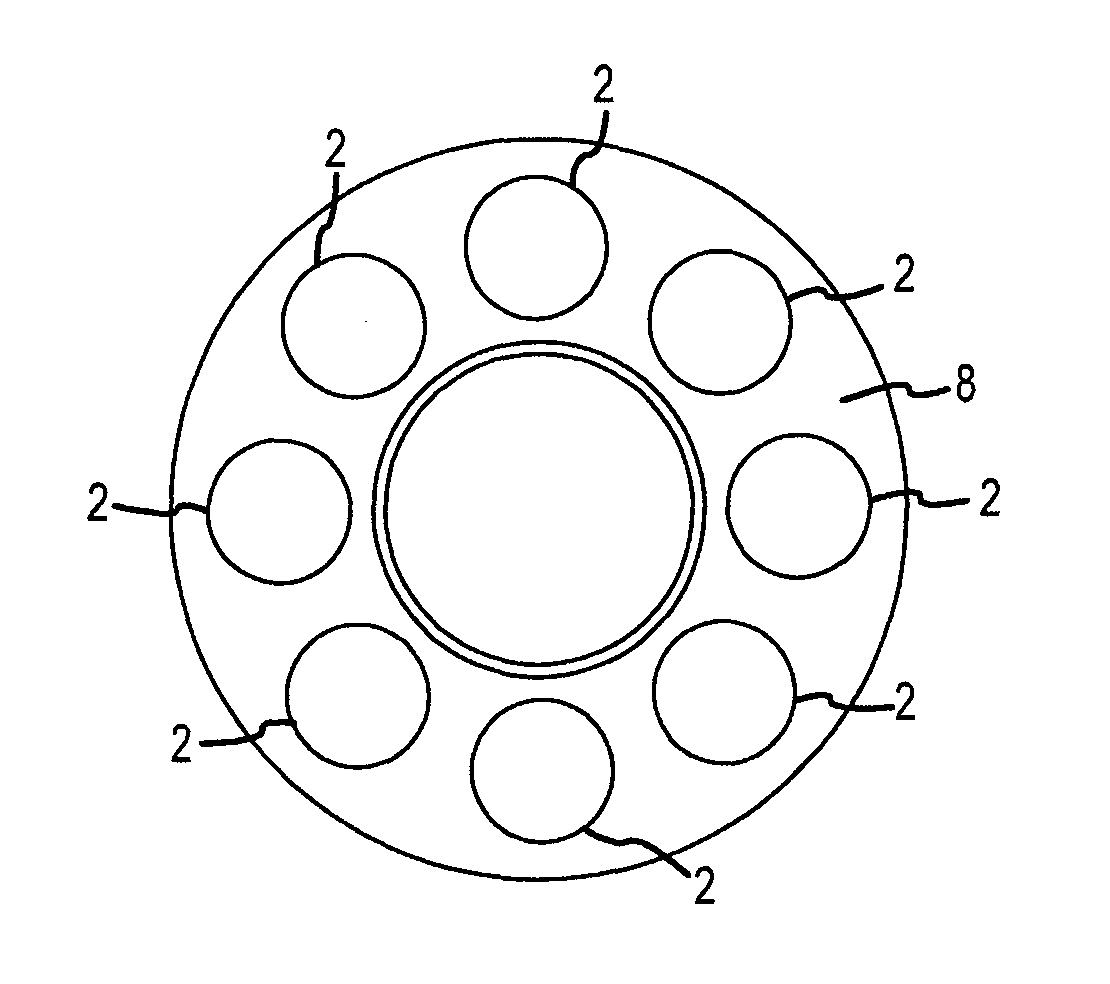

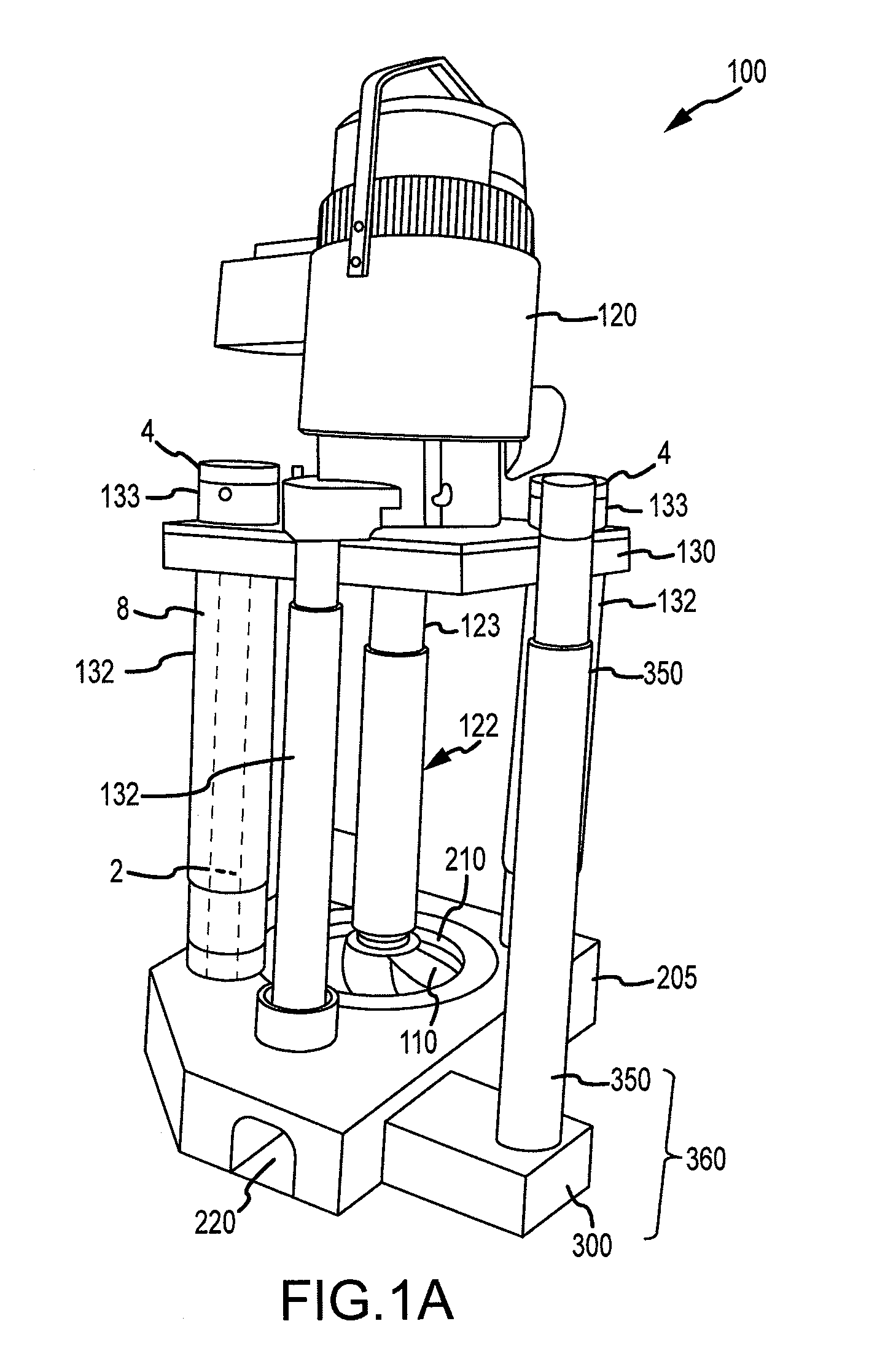

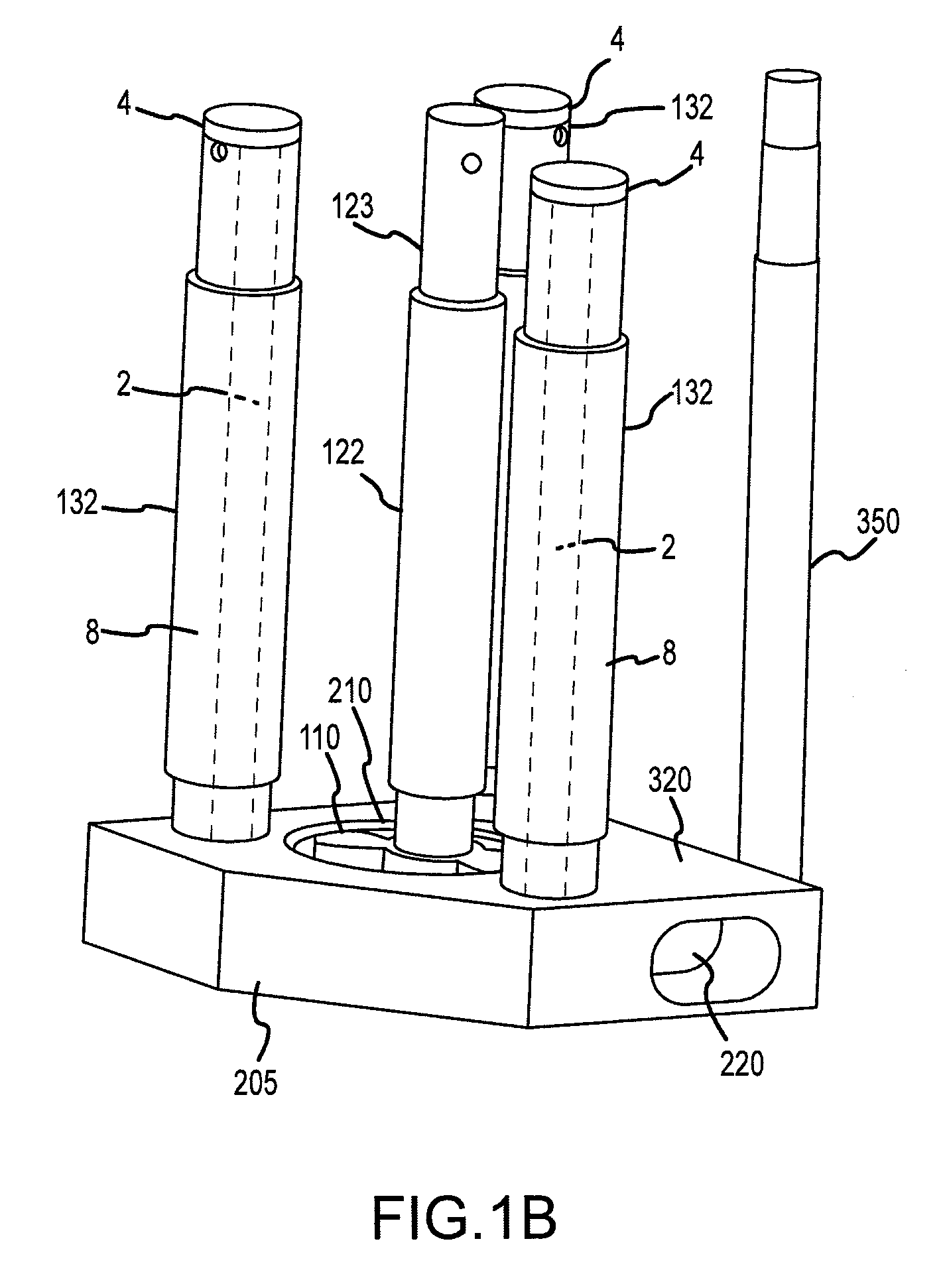

A system for applying tension to a component for use in molten metal processing. Preferably, the component includes an outer core and at least one tension rod positioned partially within the outer core. The component is preferably elongated, such as a support post or an impeller shaft. The tension rod applies compression to the outer cover, which makes the outer cover more resistant to breakage if it strikes, or is stricken by, an object.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

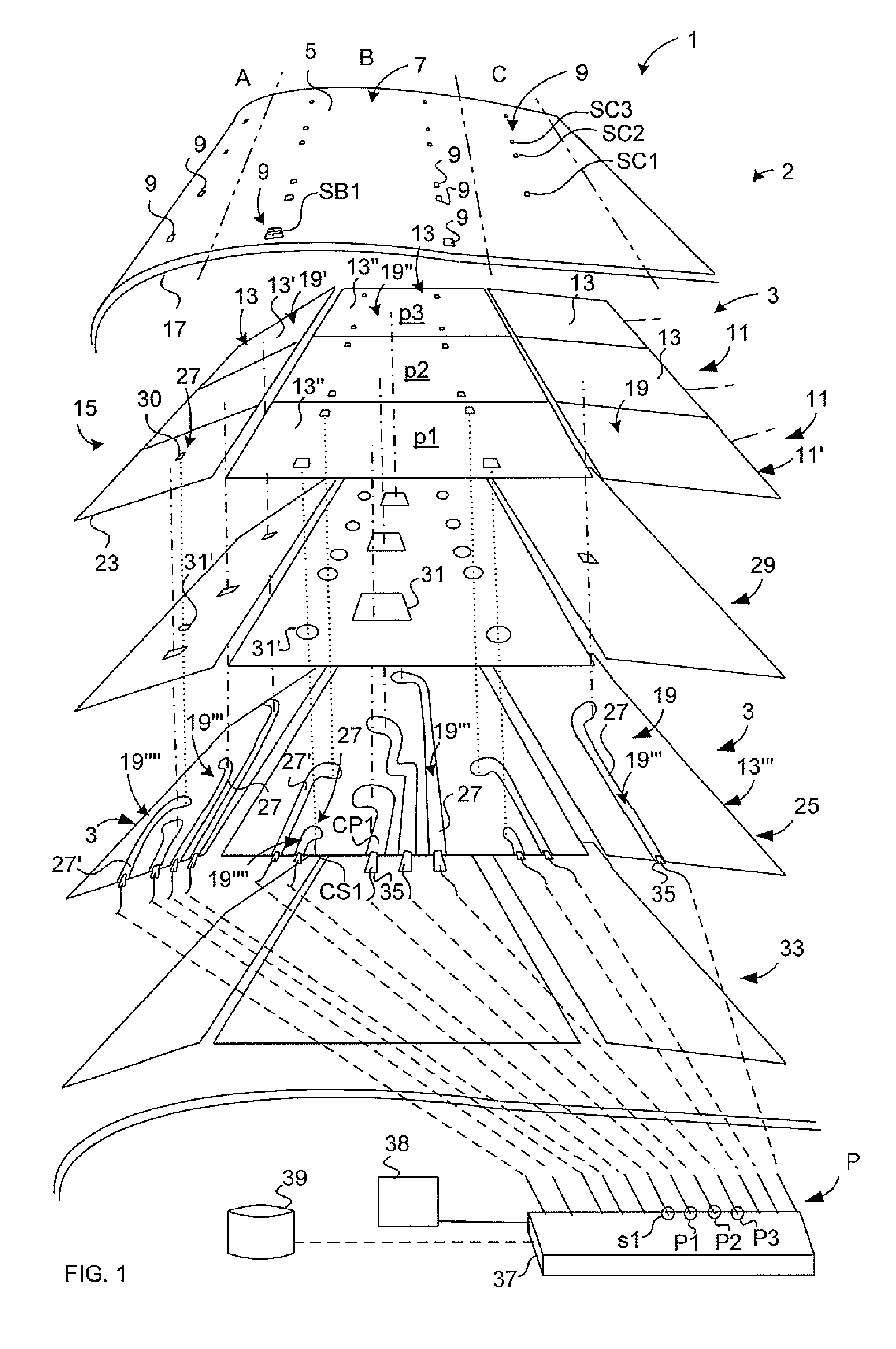

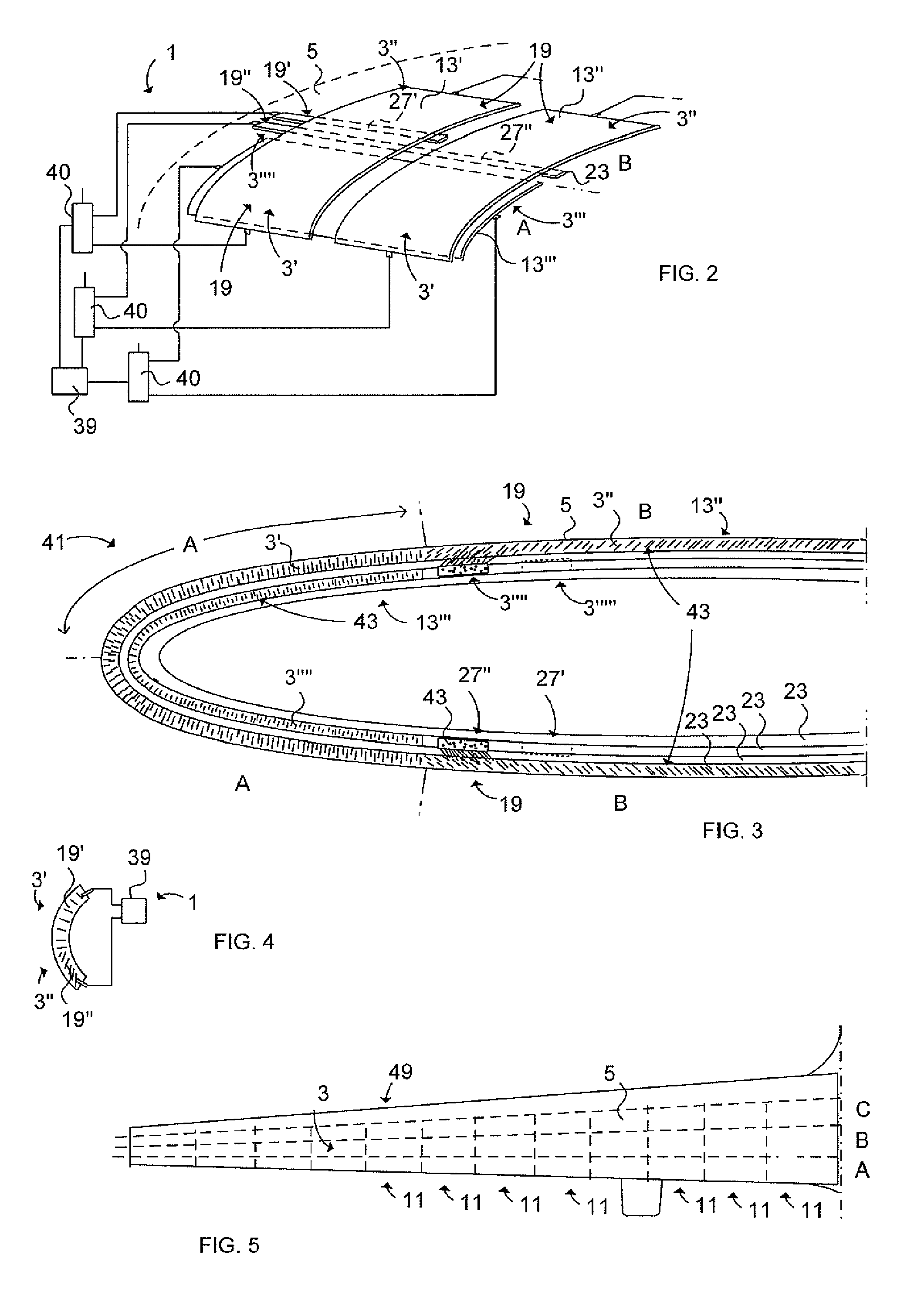

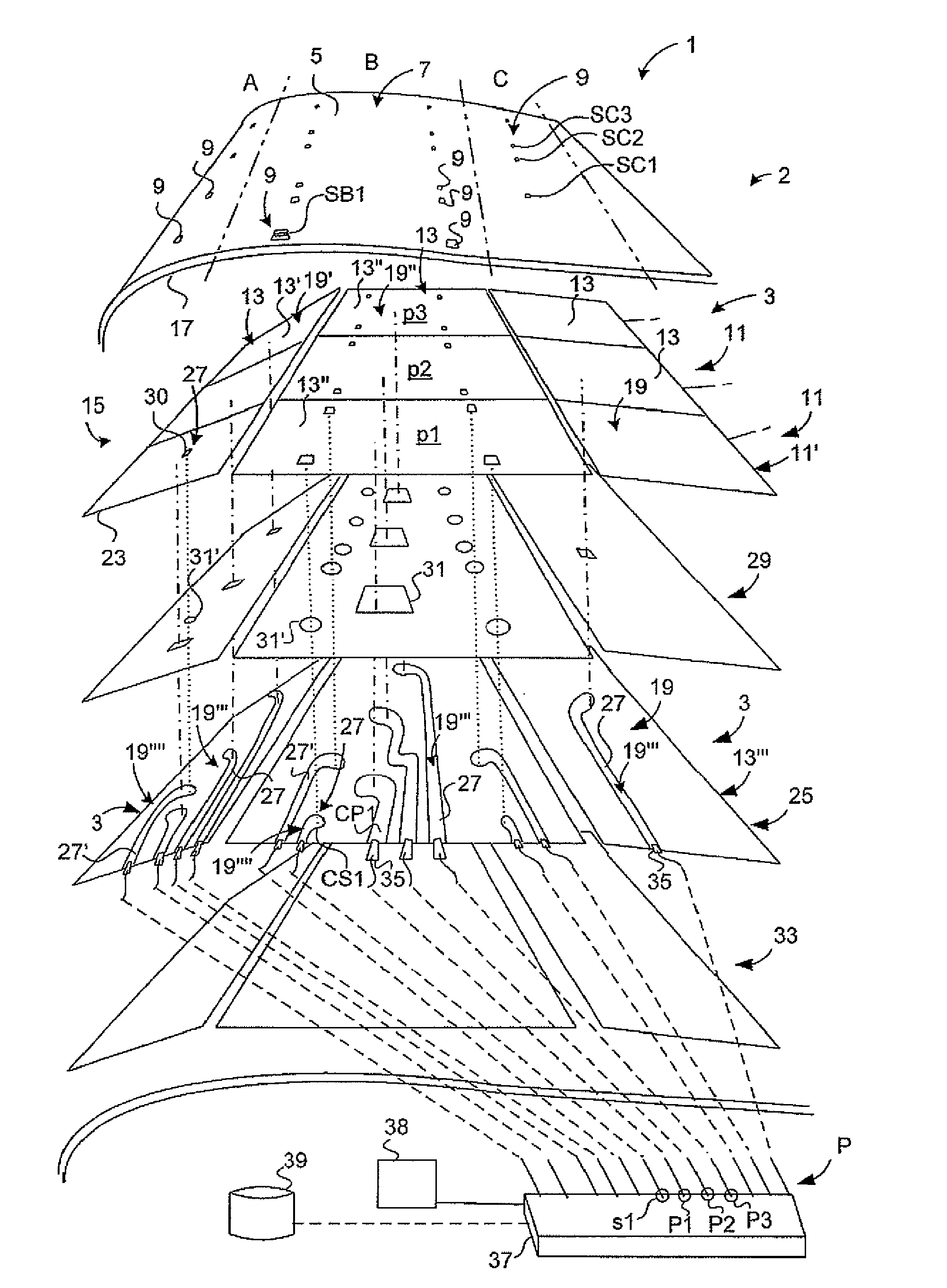

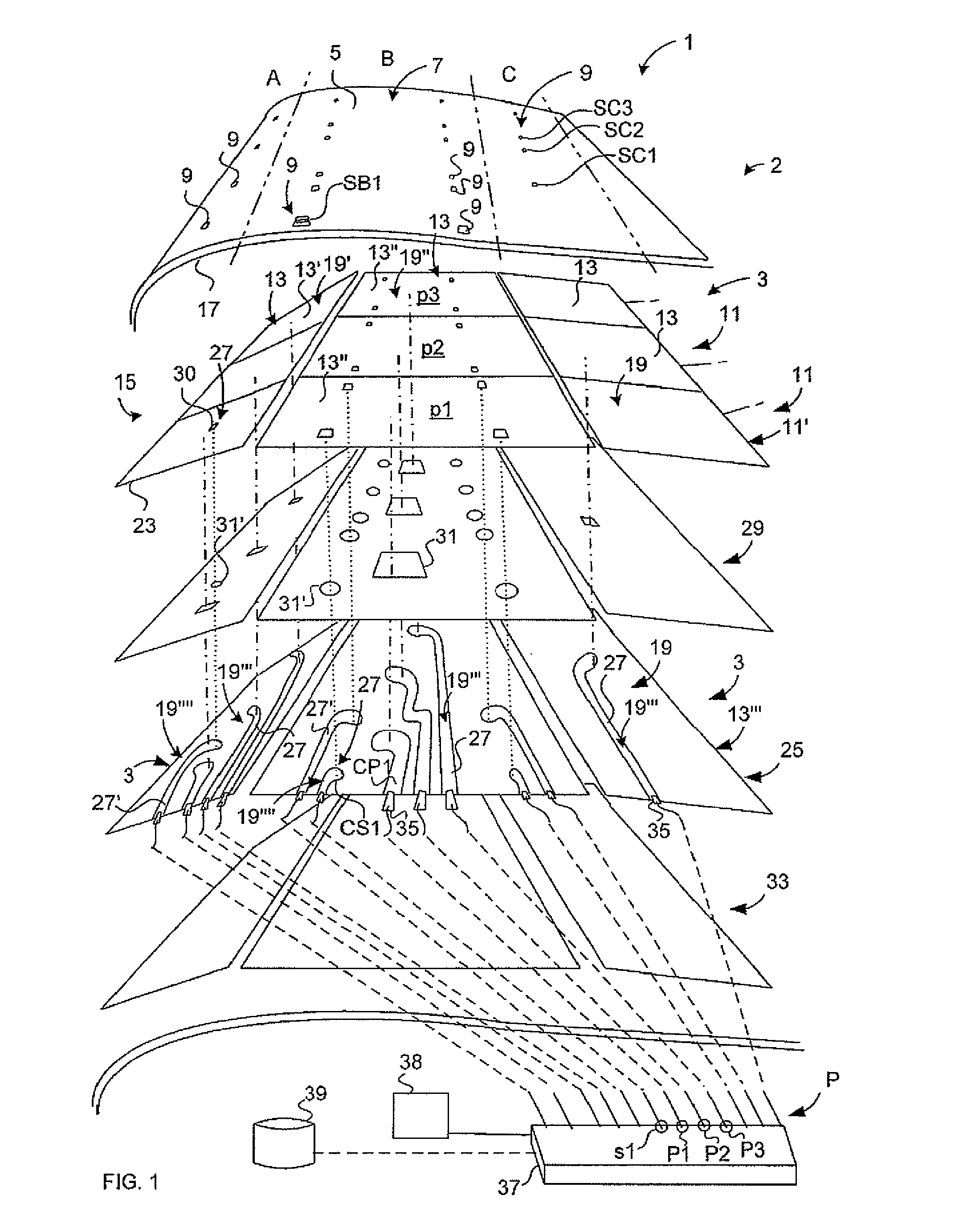

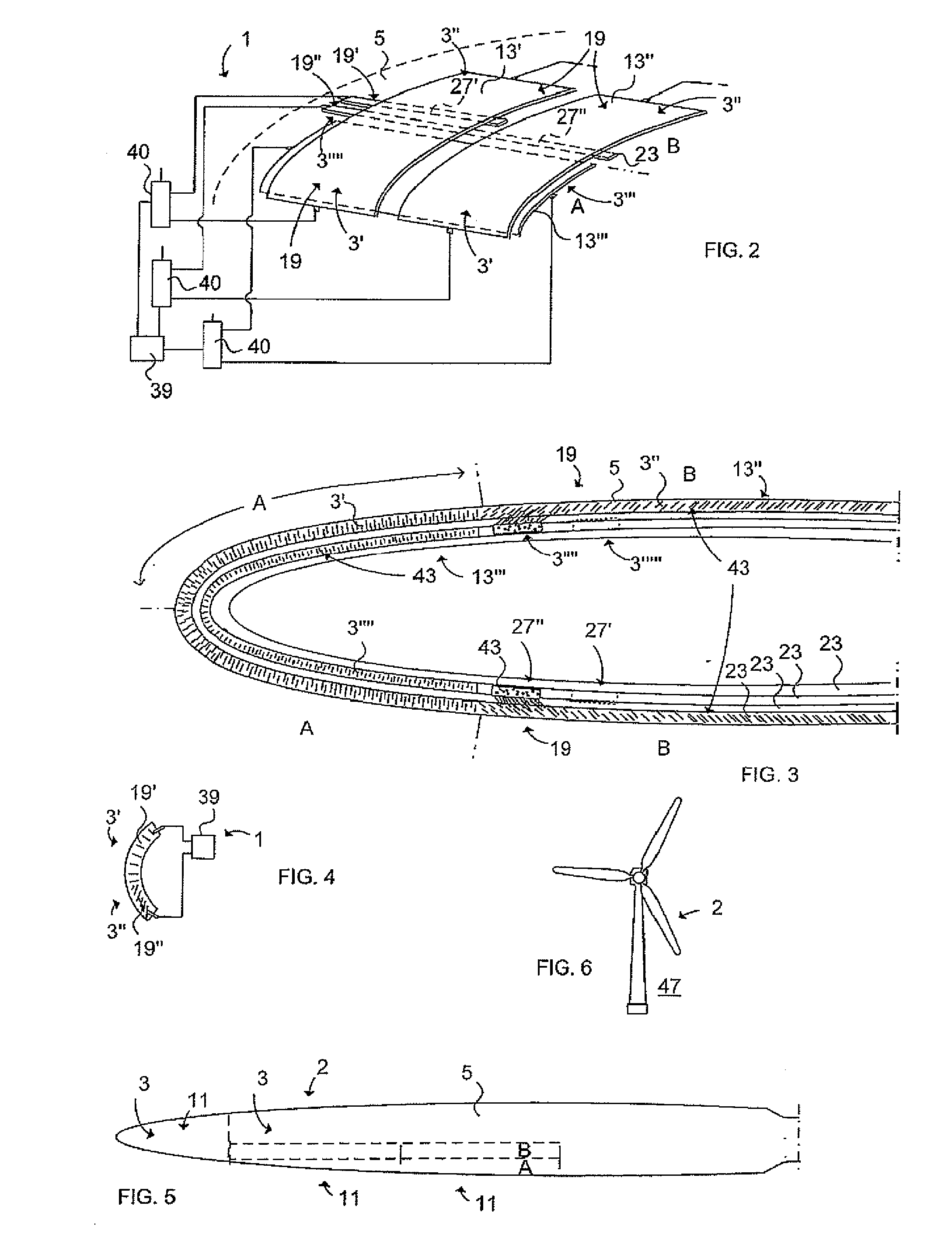

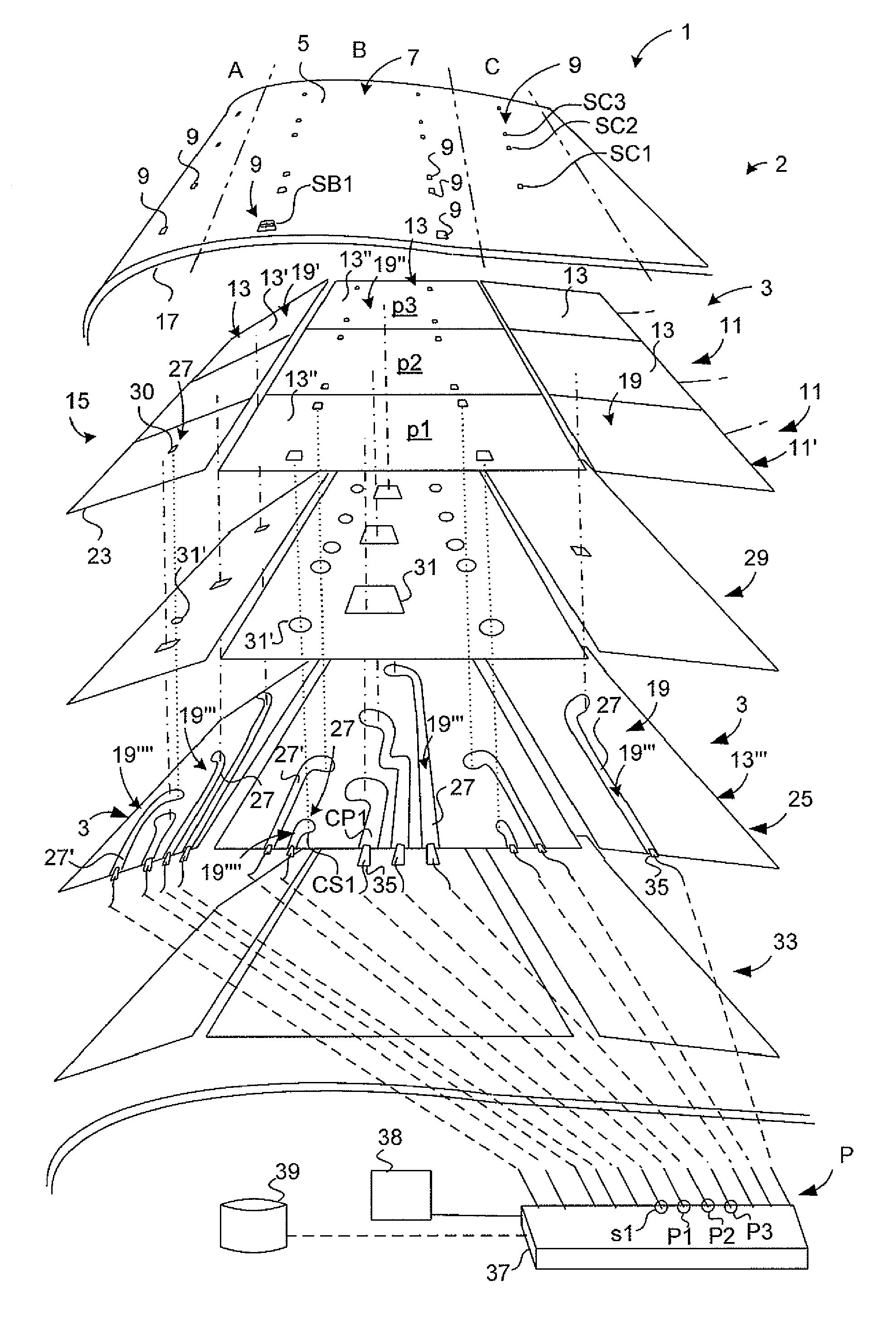

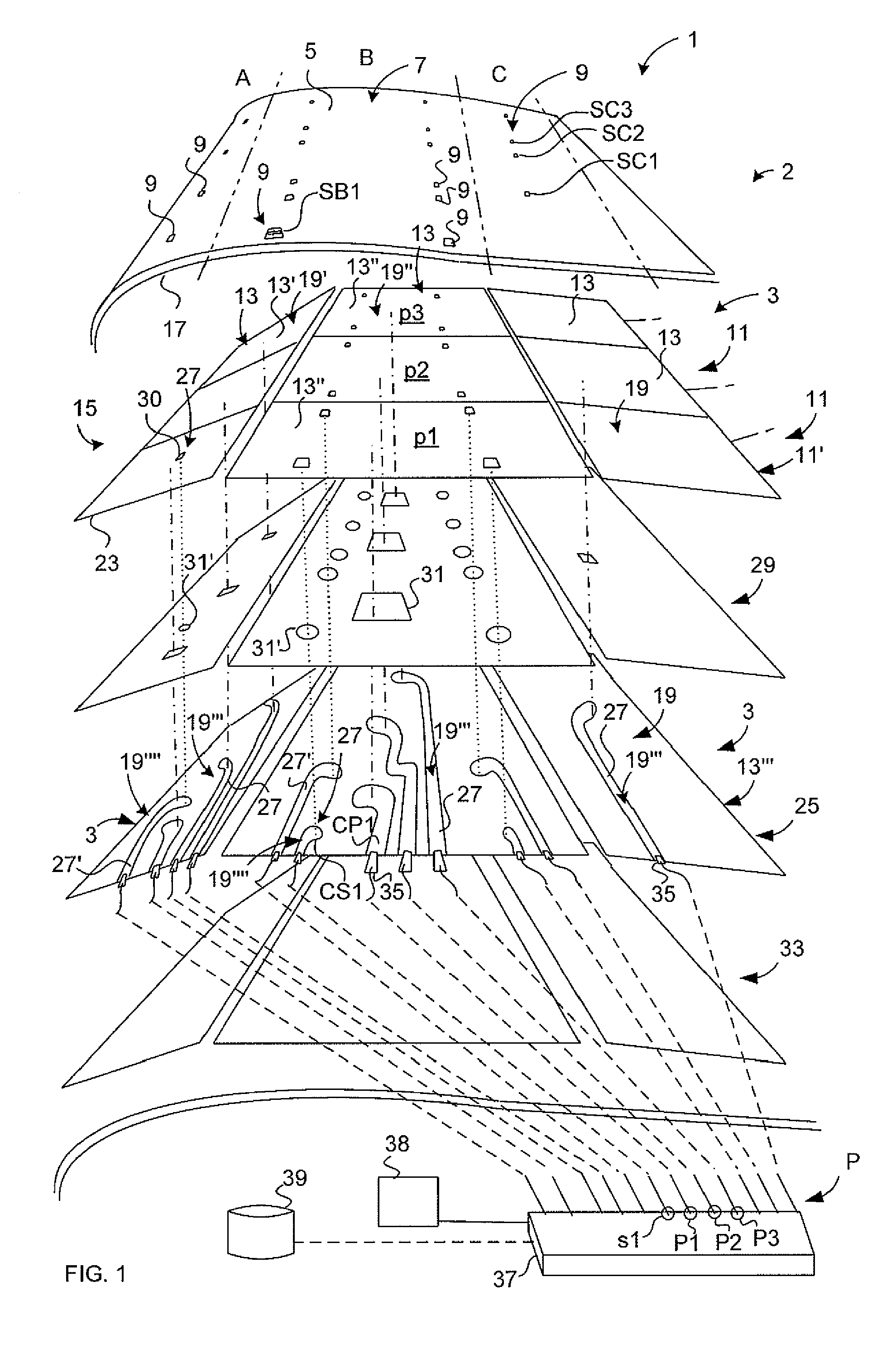

Multifunctional de-icing/Anti-icing system

ActiveUS20130043342A1Cost-effective and flexibleIncrease temperatureAircraft lighting protectorsDe-icing equipmentsNano structuringElectrical conductor

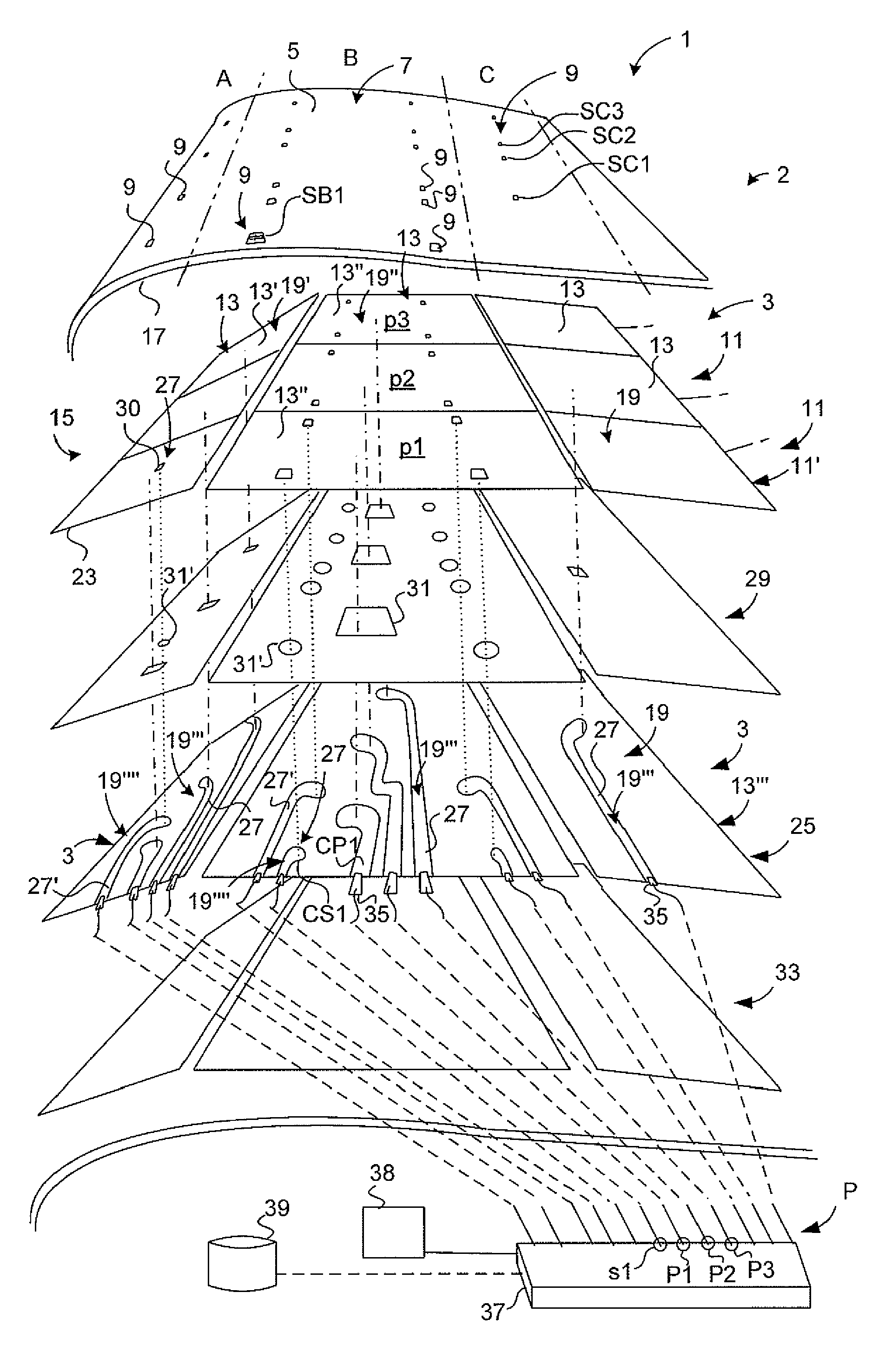

A de-icing / anti-icing system including at least two conductive structures embedded in an article that includes an outer surface designed as an aerodynamic surface. At least one of the conductive structures is arranged adjacent the outer surface. A control unit adapted to control the energy supply to the conductive structures for generating heat to the outer surface. A first of the conductive structures includes a first conductive nano structure and a second of the conductive structures includes a second conductive nano structure. A conductive property of the first of the conductive structures differs from a conductive property of the second of the conductive structures. The first conductive nano structure serves as a heating conductor and the second conductive nano structure serves as a heating element. The first and second conductive nano structures are embedded in a common plane of a resin layer forming the outer surface.

Owner:SAAB AB

Multifunctional de-icing/Anti-icing system of a wind turbine

InactiveUS20130028738A1Reduce weightIncrease temperaturePropellersPump componentsNano structuringTurbine blade

A de-icing / anti-icing system including at least two conductive structures embedded in a wind turbine blade. An outer surface is designed as an aerodynamic surface. At least one of the conductive structures is arranged adjacent the outer surface. A control unit adapted to control the energy supply to the conductive structures for generating heat to the outer surface. One conductive structure includes a first conductive nano structure. A conductive property of the conductive structure differs from a conductive property of the other conductive structure including a second conductive nano structure, for achieving different degrees of heat depending on the needed mode of the system.

Owner:SAAB AB

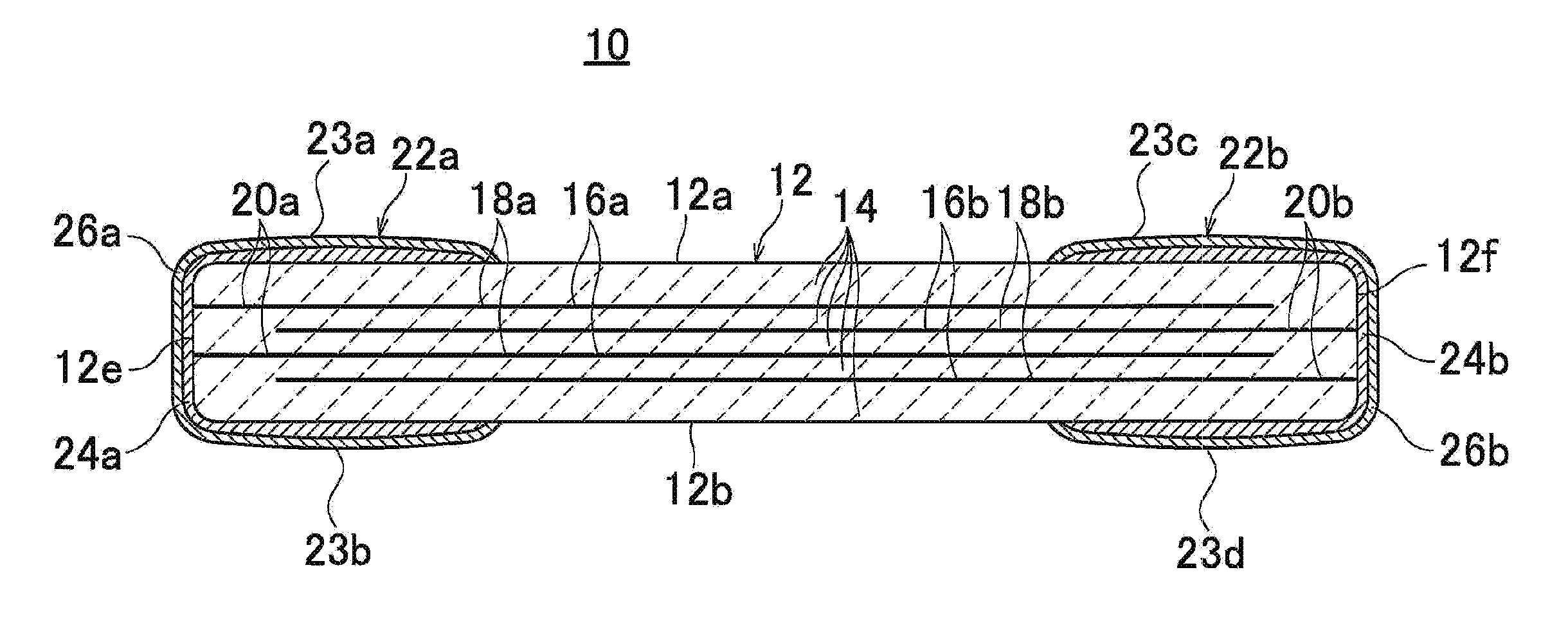

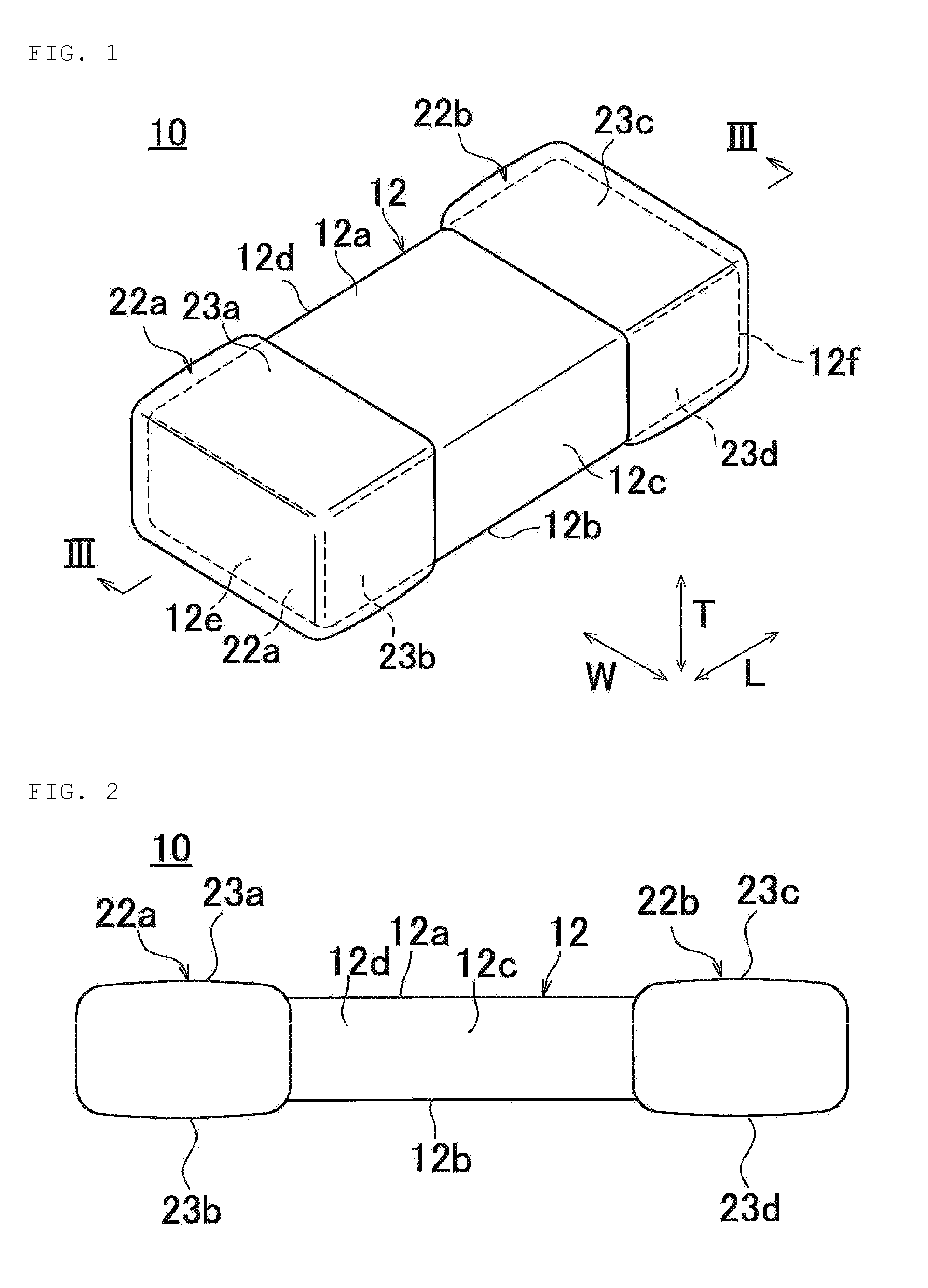

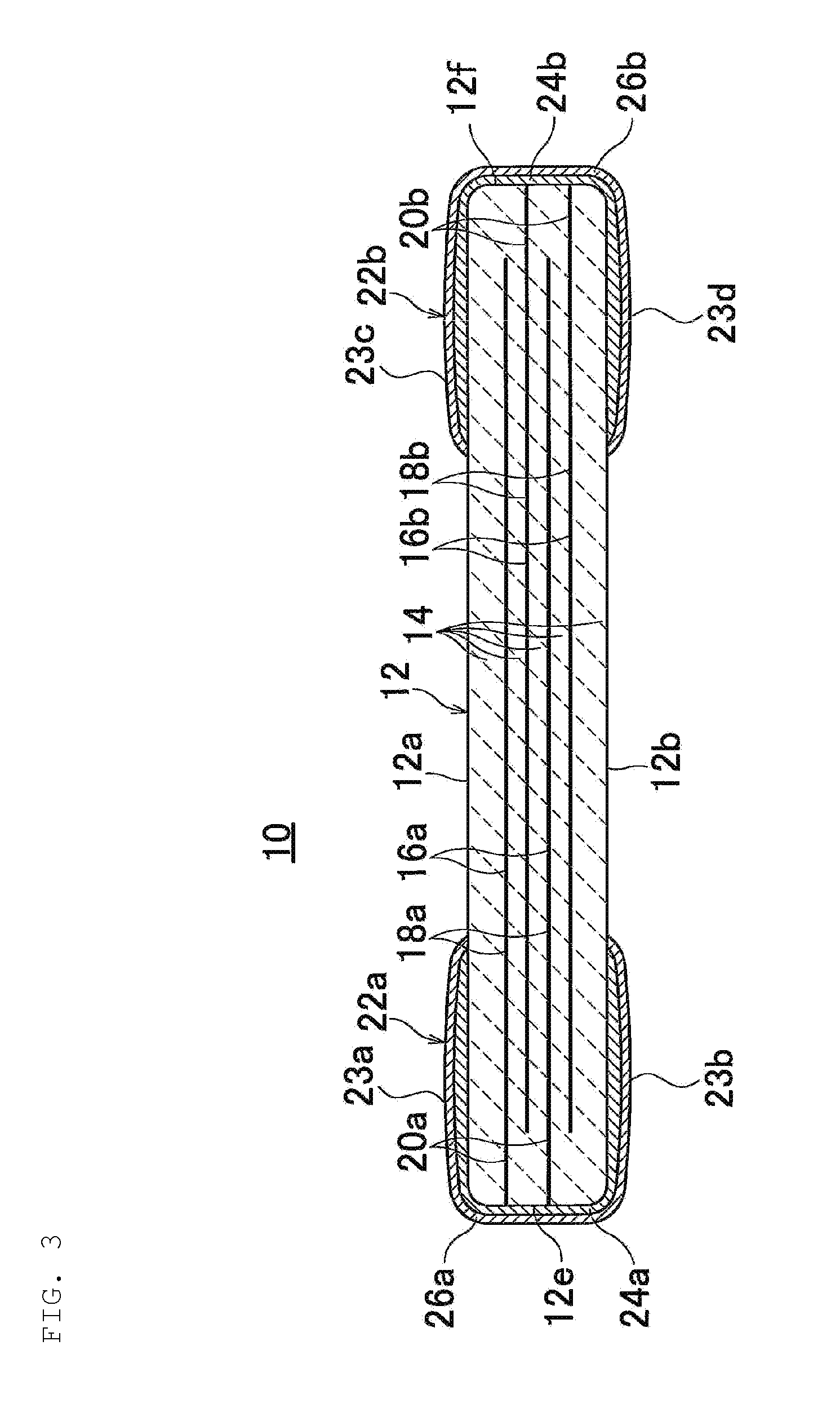

Multilayer ceramic capacitor

ActiveUS20160095223A1Improve thermal conductivityIncrease contentFixed capacitor electrodesPrinted electric component incorporationCeramic capacitorComposite material

A multilayer ceramic capacitor includes an external electrode on an end surface of a ceramic body to be connected to internal electrodes including a base layer including a sintered metal containing Cu and glass and a Cu plated layer on the base layer. The external electrode includes a principal surface portion disposed on a principal surface of the ceramic body. The Cu metal of the Cu plated layer is present in the base layer to a position of about ⅓ or more of the thickness of the base layer from a surface layer of the external electrode. The metal thickness of the external electrode is about 8.7 μm or more and about 13.9 μm or less.

Owner:MURATA MFG CO LTD

Multifunctional de-icing/anti-icing system

ActiveUS8931740B2Increase temperatureHigh component strengthDe-icing equipmentsSandwich constructionsIce protection systemElectrical conductor

A de-icing / anti-icing system including at least two conductive structures embedded in an article that includes an outer surface designed as an aerodynamic surface. At least one of the conductive structures is arranged adjacent the outer surface. A control unit adapted to control the energy supply to the conductive structures for generating heat to the outer surface. A first of the conductive structures includes a first conductive nano structure and a second of the conductive structures includes a second conductive nano structure. A conductive property of the first of the conductive structures differs from a conductive property of the second of the conductive structures. The first conductive nano structure serves as a heating conductor and the second conductive nano structure serves as a heating element. The first and second conductive nano structures are embedded in a common plane of a resin layer forming the outer surface.

Owner:SAAB AB

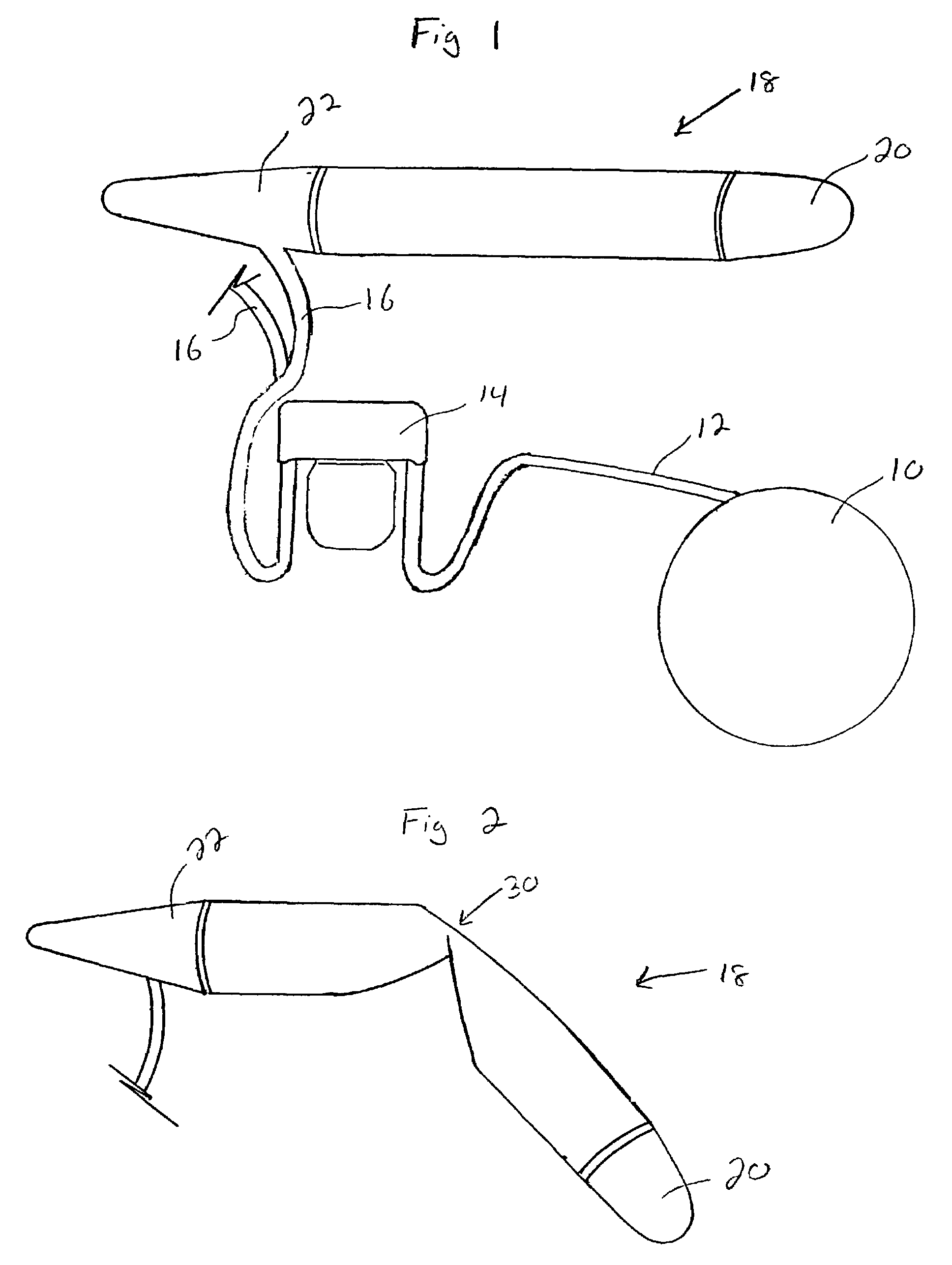

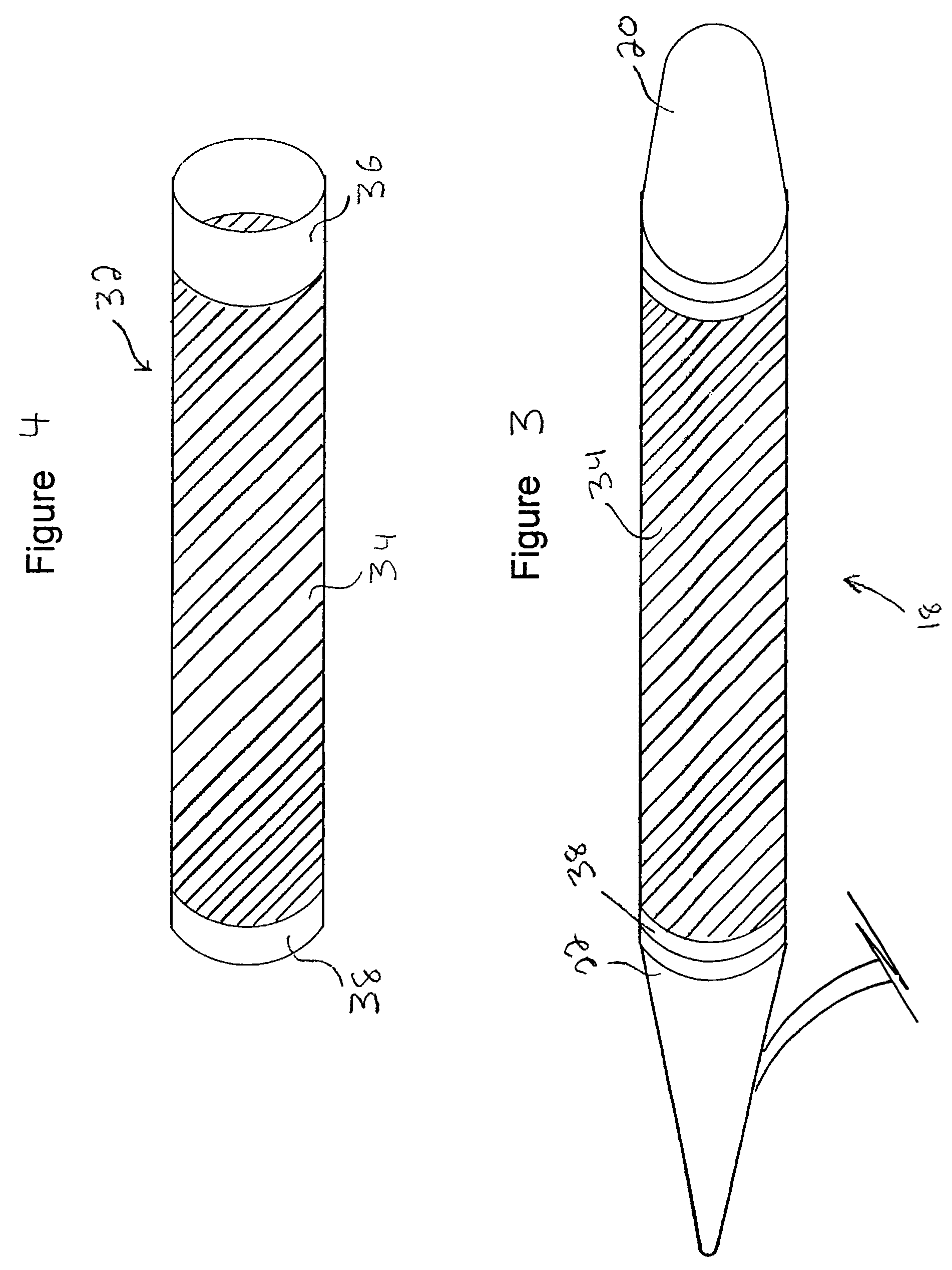

Parylene-coated components for inflatable penile prosthesis

InactiveUS7066877B2Minimize exposureReduce effectNon-surgical orthopedic devicesPenis implantsEngineeringDouble walled

A penile prosthesis beneficially includes components coated with parylene in order to increase product life and reduce wear. In particular, components of the inflatable cylinder benefits from having been coated with parylene. The parylene-coated cylinder components are resistant to wear generated by pinching of the cylinder when the cylinder is in a flaccid state. The parylene-coated cylinder may be formed by masking a tube of silicone (or other appropriate material) and vapor coating the silicone tube with parylene. Further, where a double walled cylinder is used, each of two tubes making up the double wall cylinder can have their surfaces coated with parylene, thus increasing cylinder life and avoiding wear.

Owner:BOSTON SCI SCIMED INC

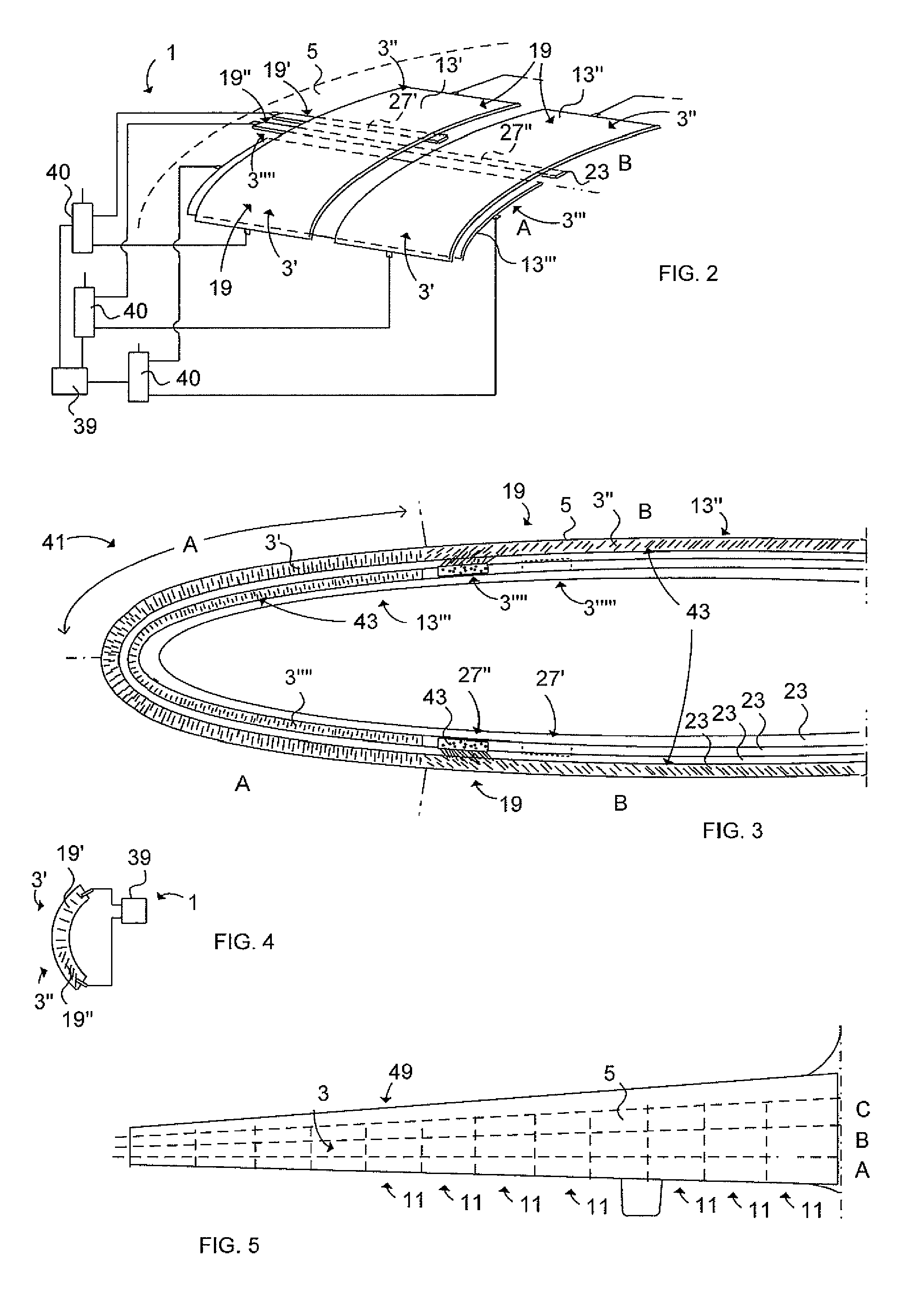

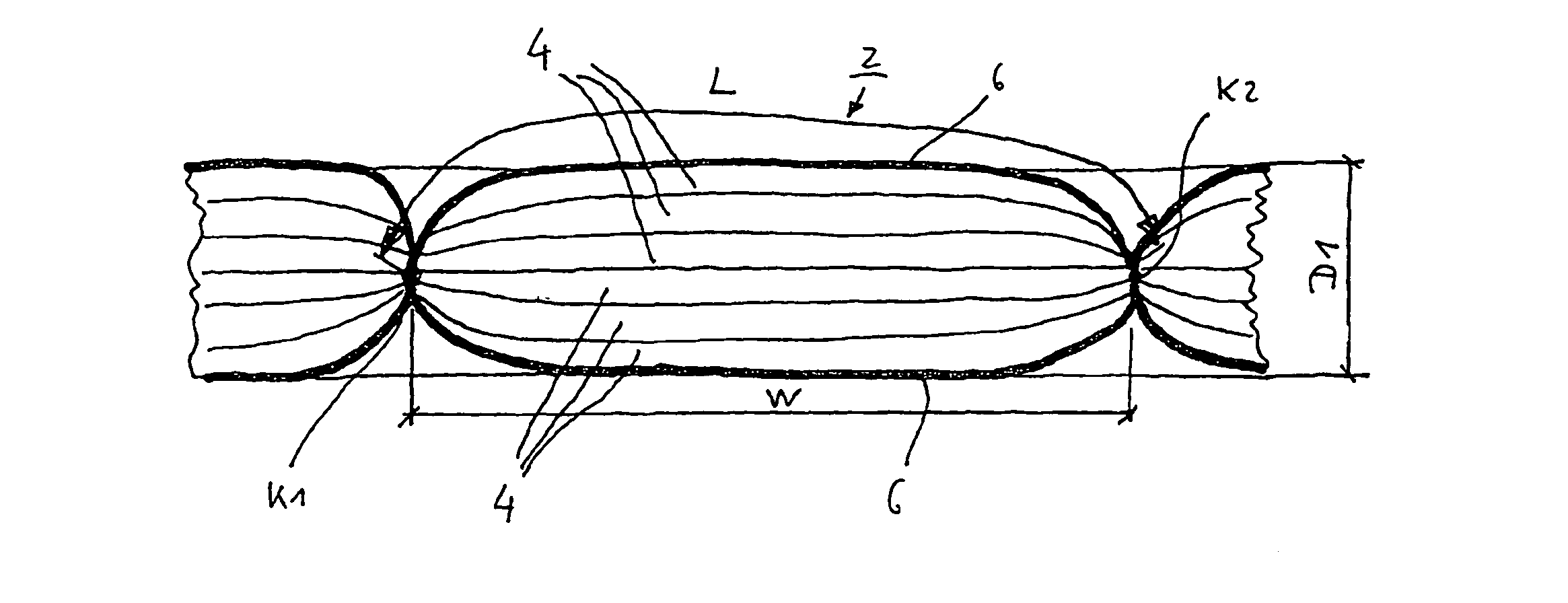

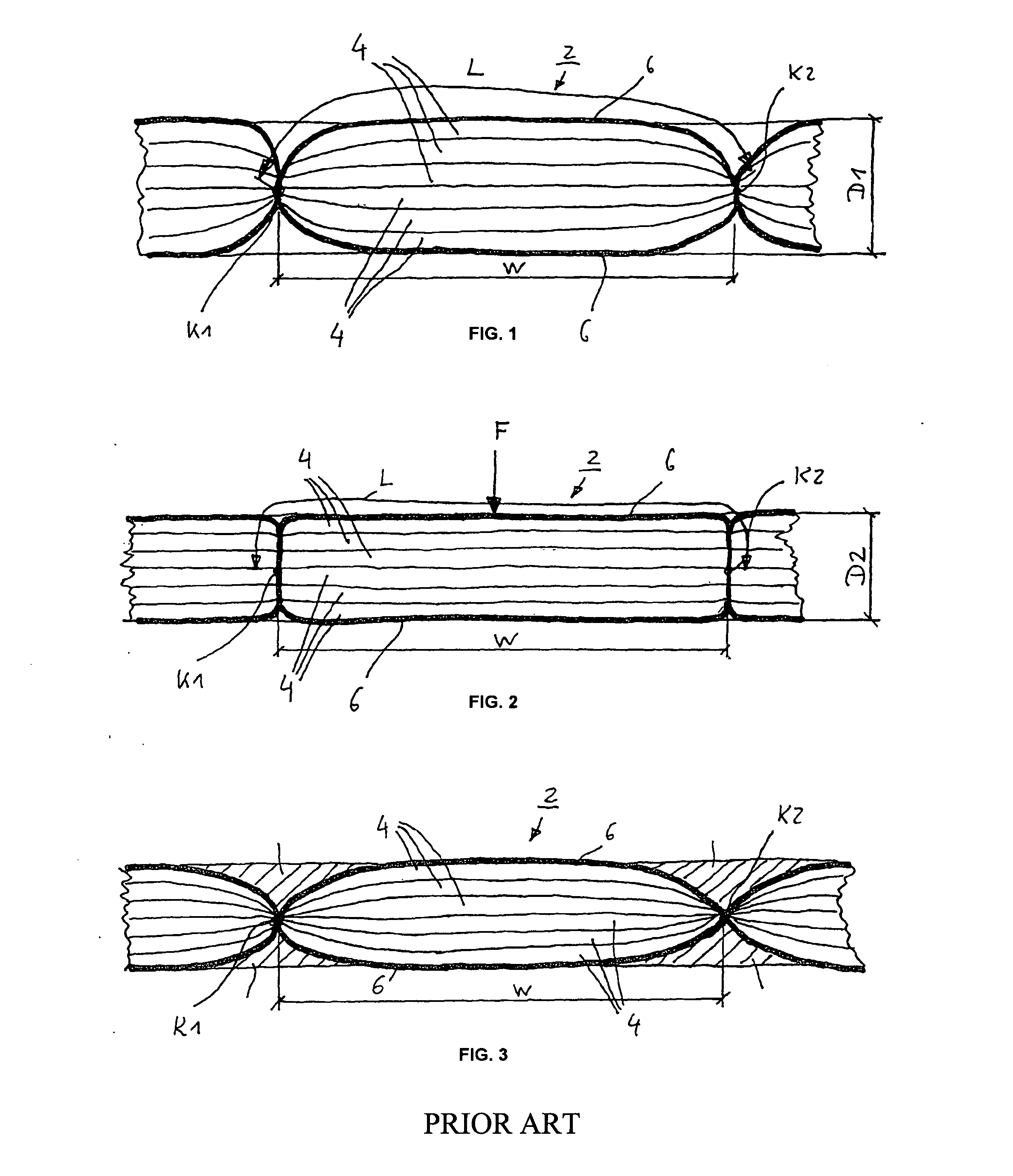

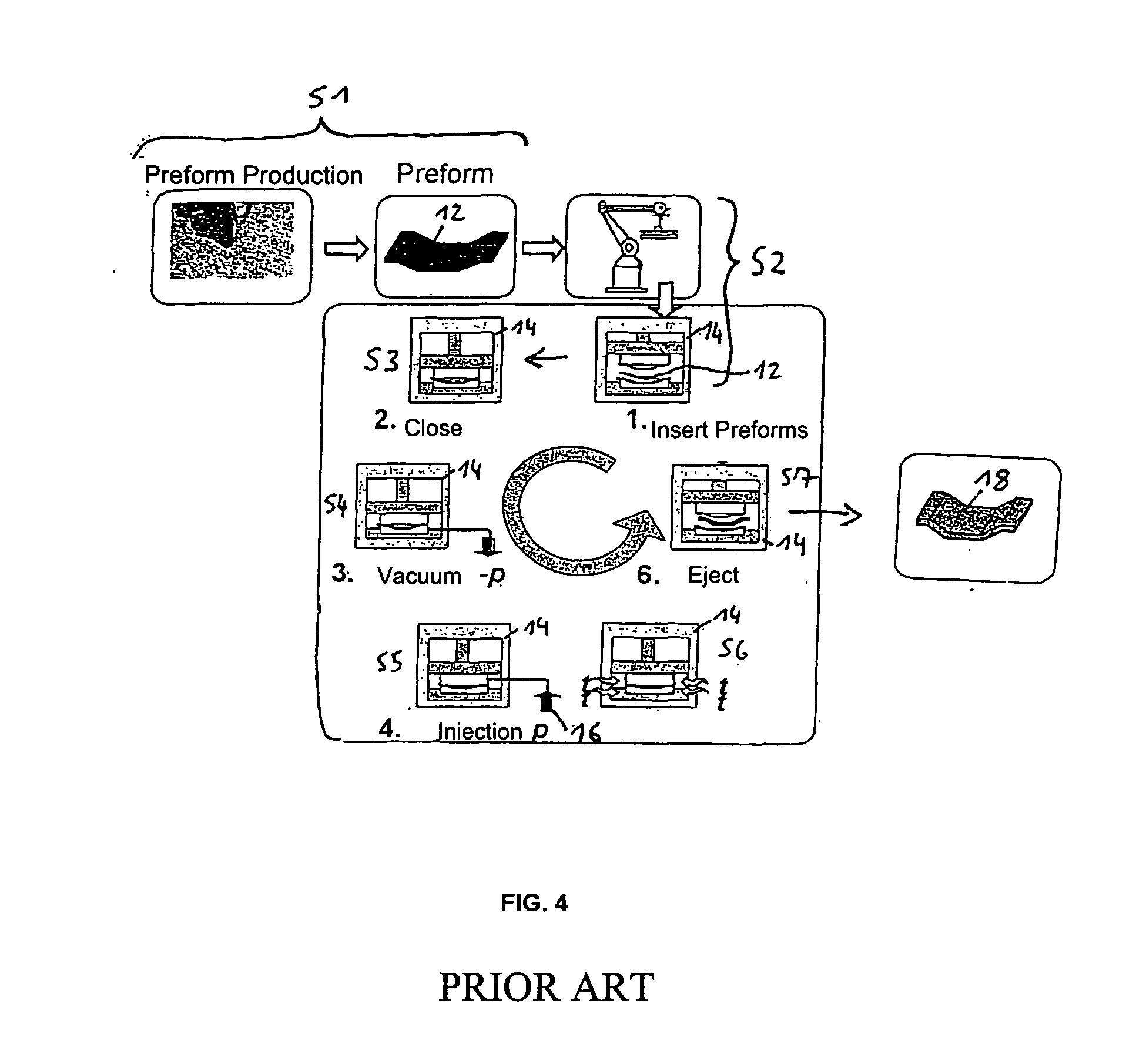

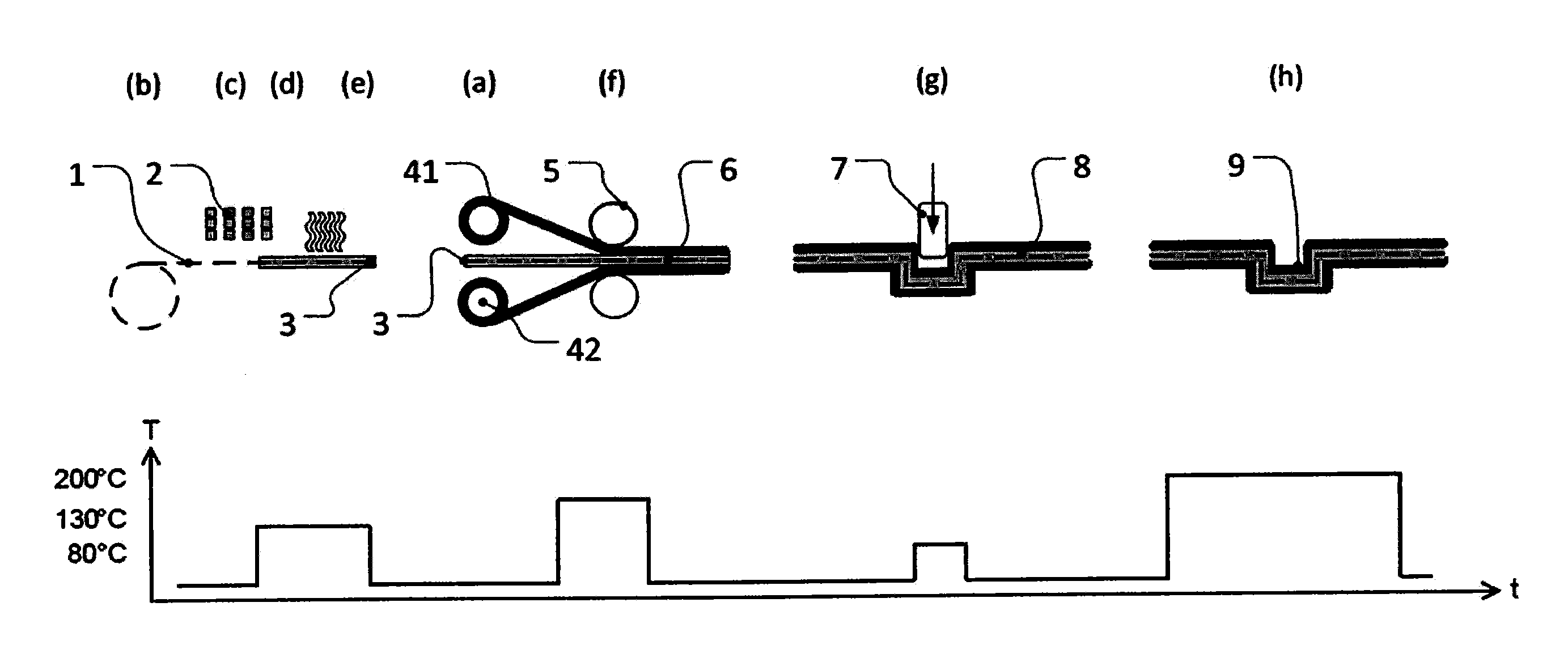

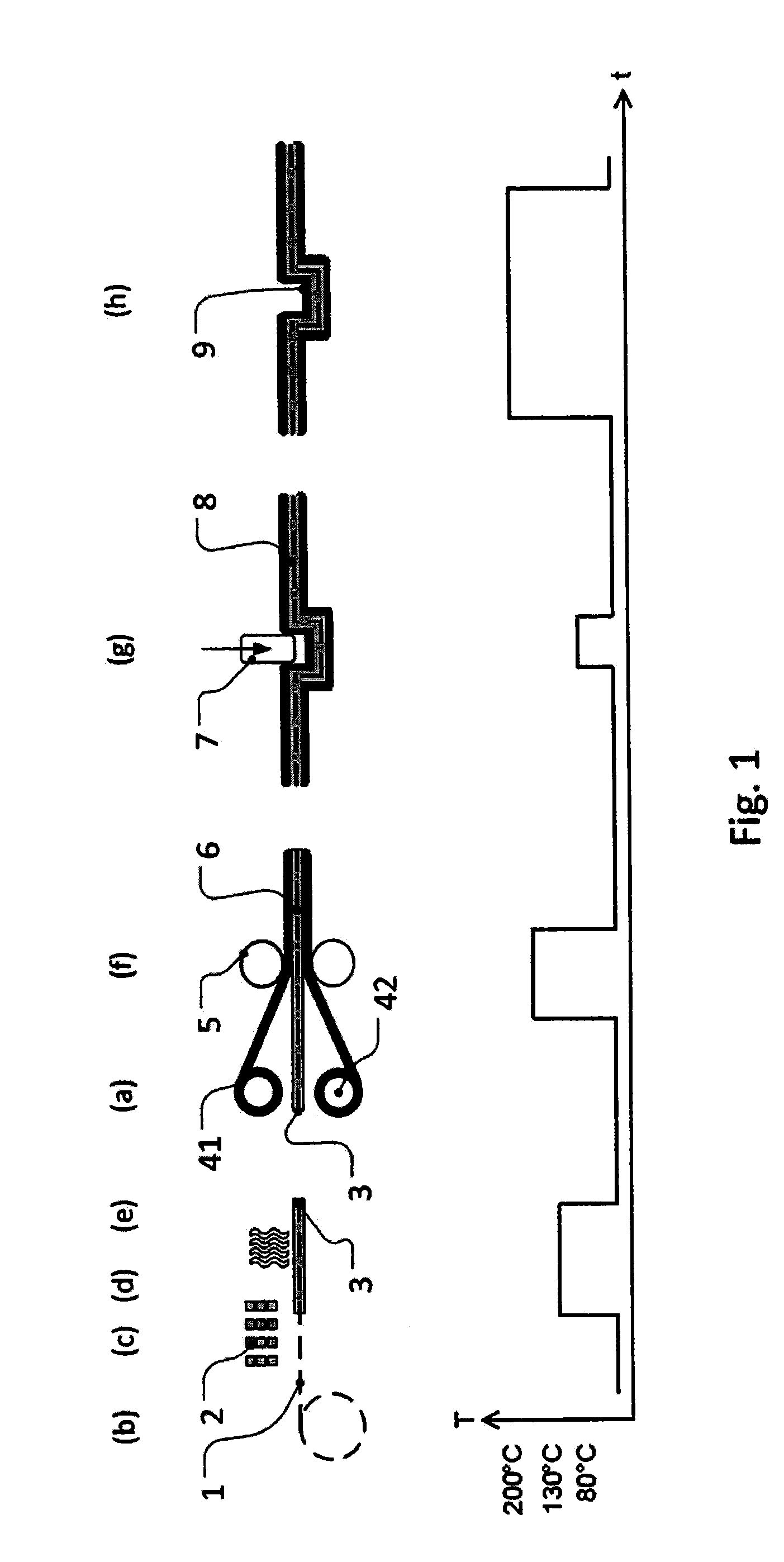

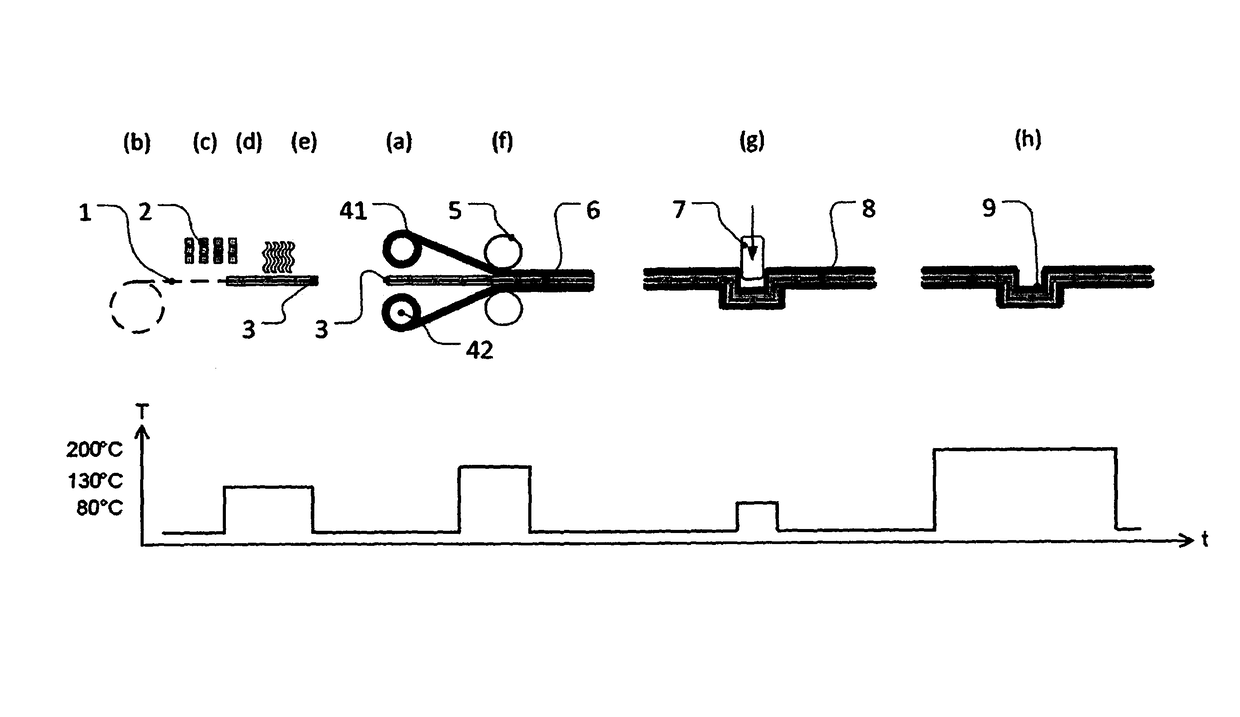

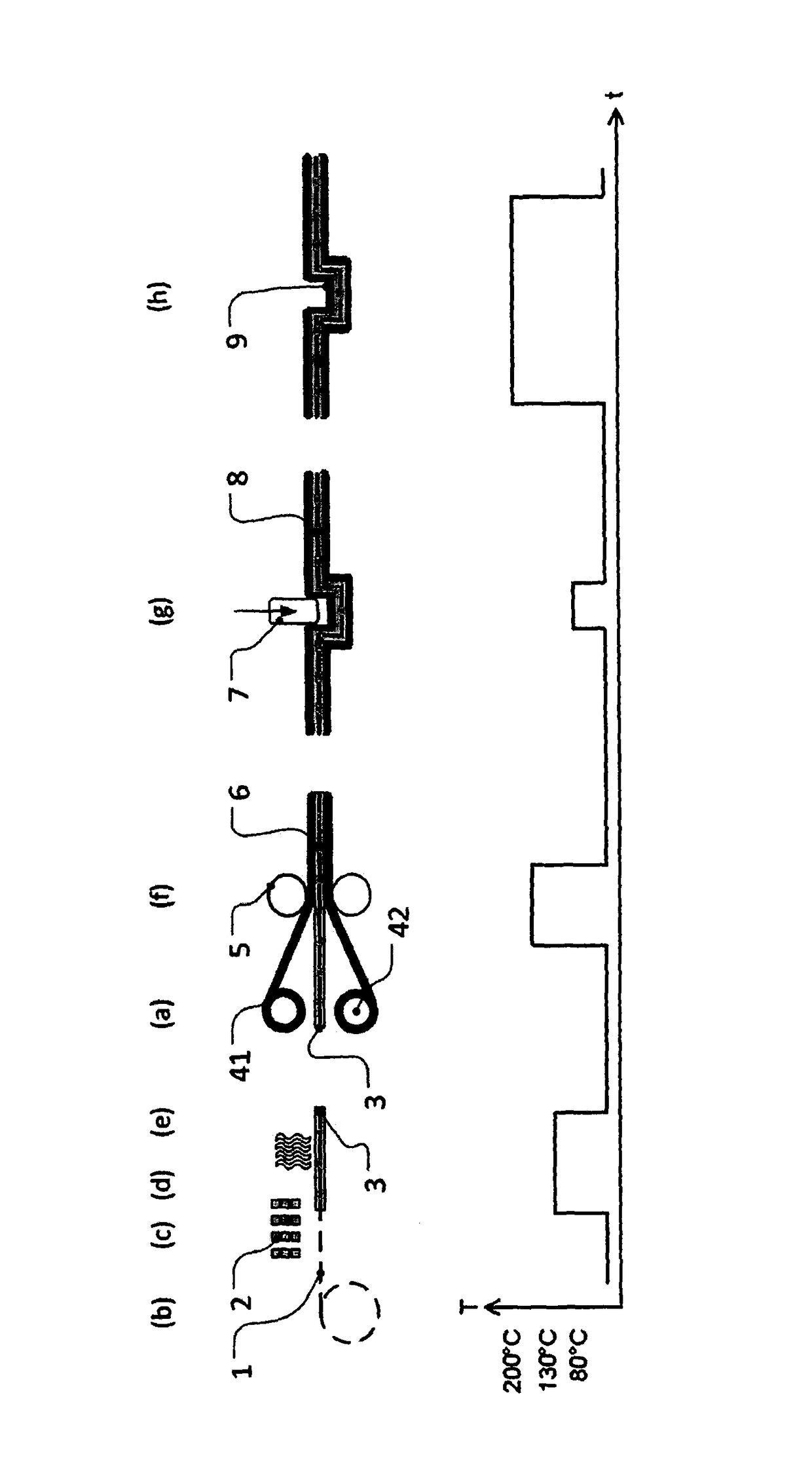

Method for the production of a fibre composite material component and intermediate product for such a method

InactiveUS20070020431A1Easy to relaxLarge capacityLaminationEfficient propulsion technologiesFibrous compositesMaterials science

A method for producing a component made of fiber composite material includes sewing a plurality of reinforcing-fiber layers together using a thread to create a seam and to form at least one reinforcing-fiber preform, wherein the seam has a predetermined thread tension and the sewing pre-compacts the reinforcing-fiber preform to a pre-compacting size. The at least one reinforcing-fiber preform is placed into an injection mold. A final compacting of the reinforcing-fiber preform to a final compacting size is performed by closing the injection mold, wherein the final compacting includes relaxing the thread tension of the seam. A resin is injected into the injection mold and the resin is cured. In addition, an intermediate product includes at least one reinforcing-fiber perform.

Owner:AIRBUS HELICOPTERS DEUT GMBH

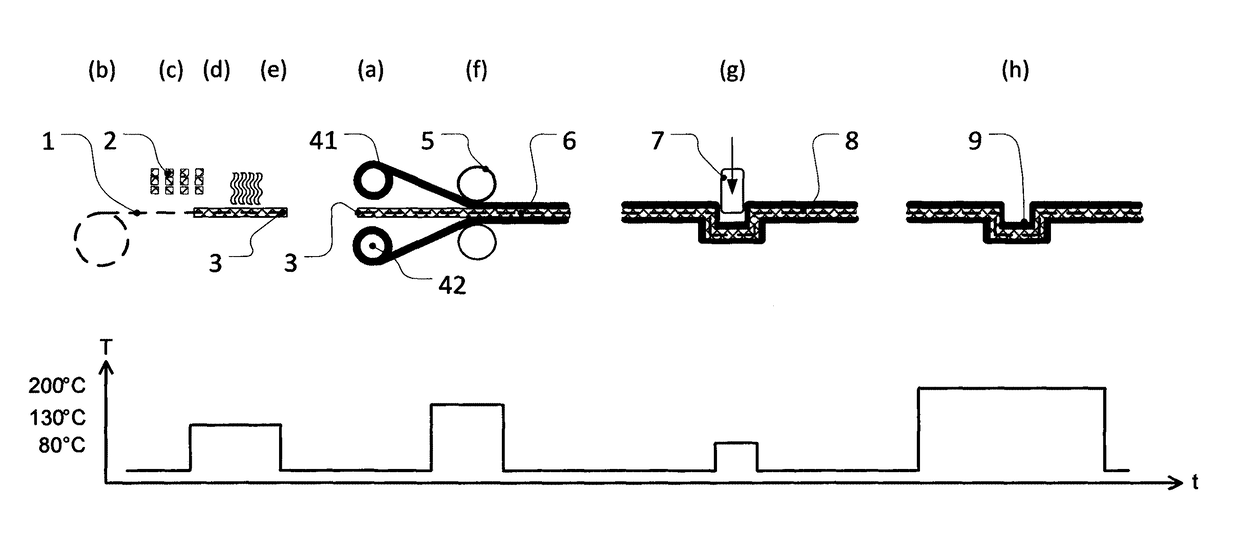

Production of fibre composite component part based on steel and polyurethane

InactiveUS20150321392A1High component strengthLamination ancillary operationsLayered product treatmentPolymer chemistryFibrous composites

A method of producing a fibre composite component part, contains the following steps: a) providing two or more steel sheets; b) providing at least one textile fabric; c) providing an anhydrous mixture having one or more than one hardener containing a uretdione having an NCO functionality of not less than two, one or more than one binder having hydroxyl groups to an OH functionality of three to six, and one or more than one cobinder having oxirane groups; d) coating the textile fabric with the mixture; e) applying energy to the mixture-coated fabric for the purpose of performing a first crosslinking reaction to react hardener, binder and cobinder to form a thermoplastic polymer adhering to the textile fabric; f) hot pressing the steel sheets and the textile fabric together with the thermoplastic polymer adhering thereto into a sandwich such that the thermoplastic polymer joins the steel sheets together while enclosing the textile fabric; g) forming the sandwich into a shaped article; h) heat treating the shaped article to obtain the fibre composite component part, wherein the thermoplastic polymer undergoes a second crosslinking reaction to convert into a thermoset polymer.

Owner:EVONIK DEGUSSA GMBH

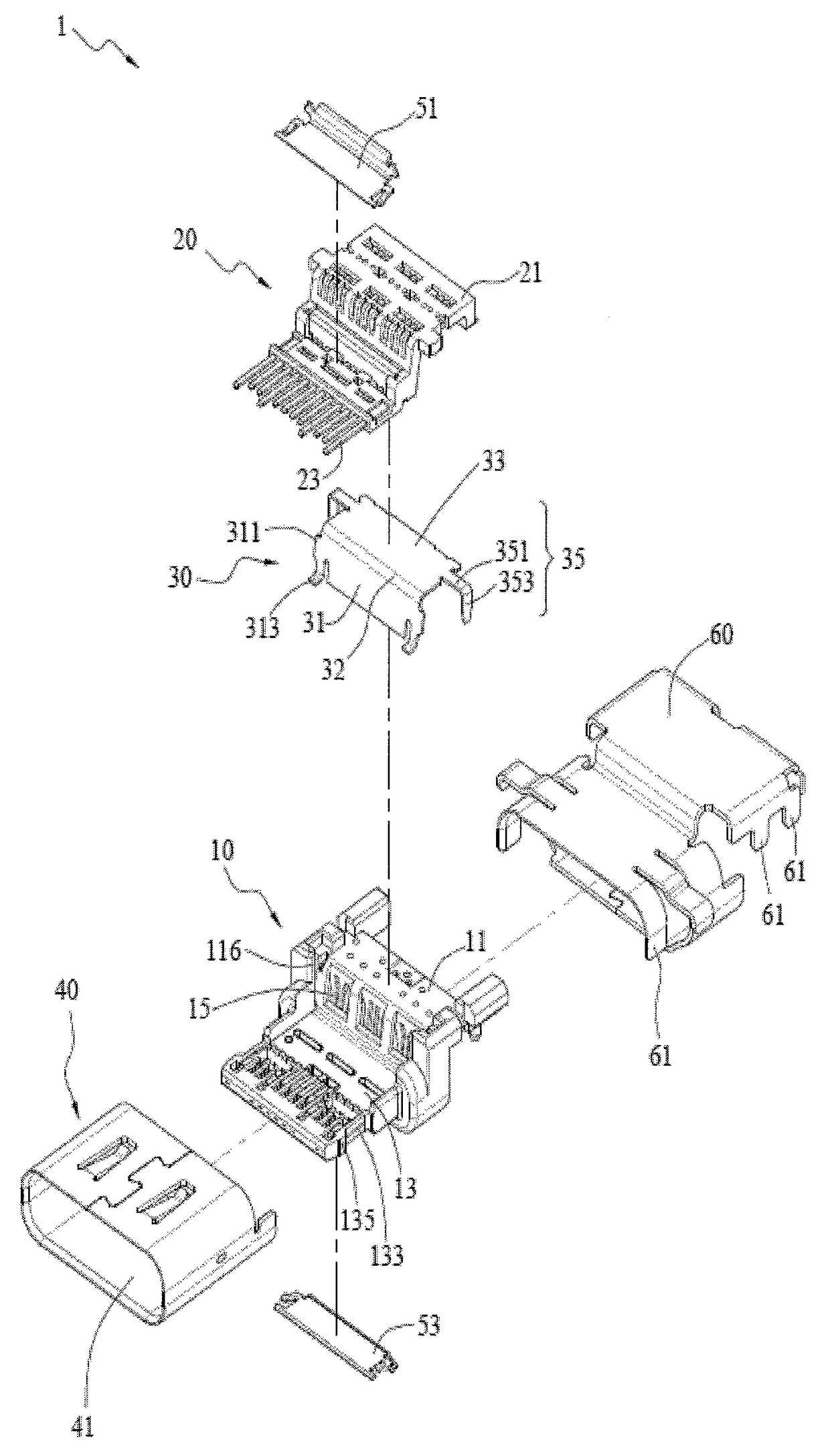

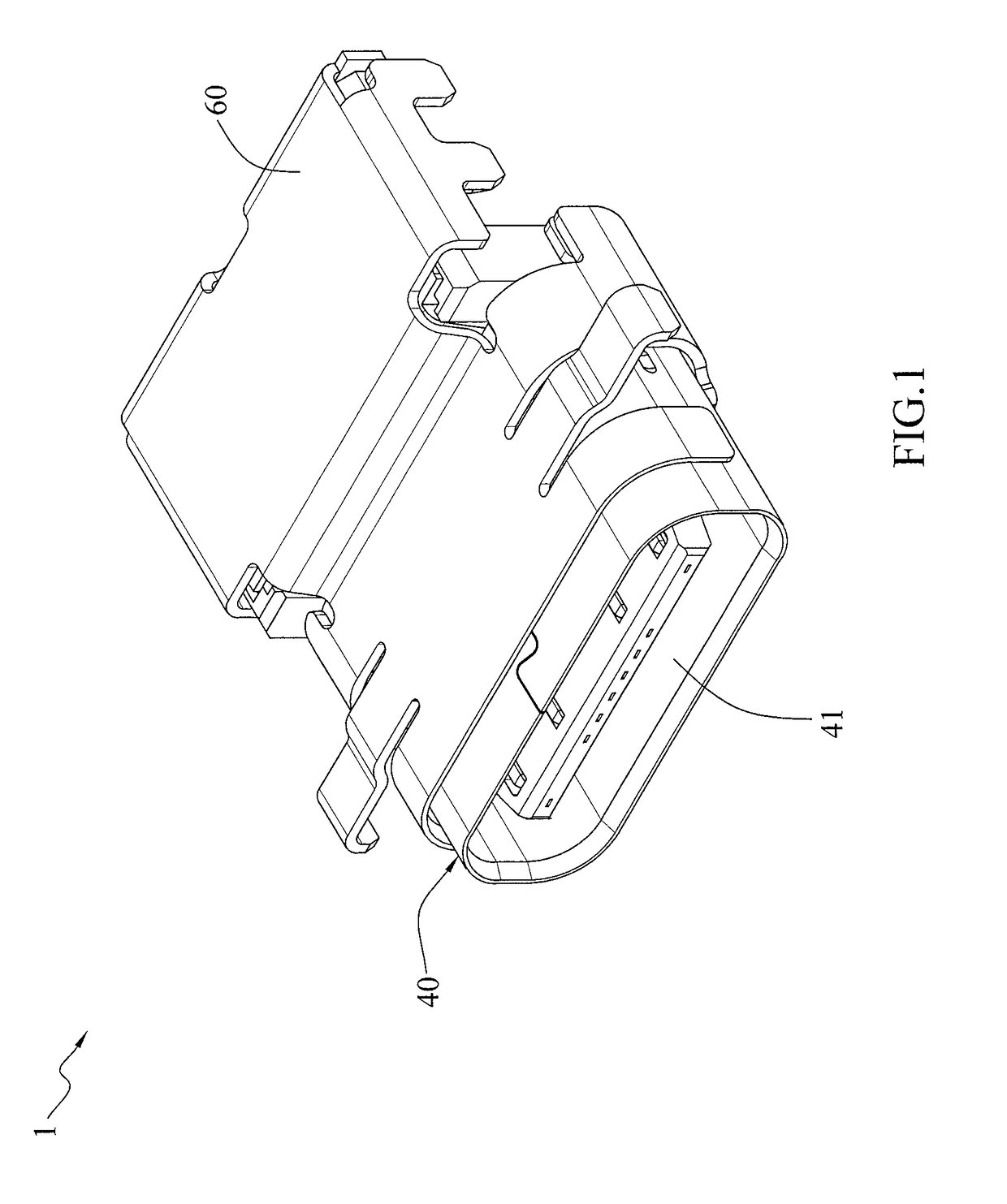

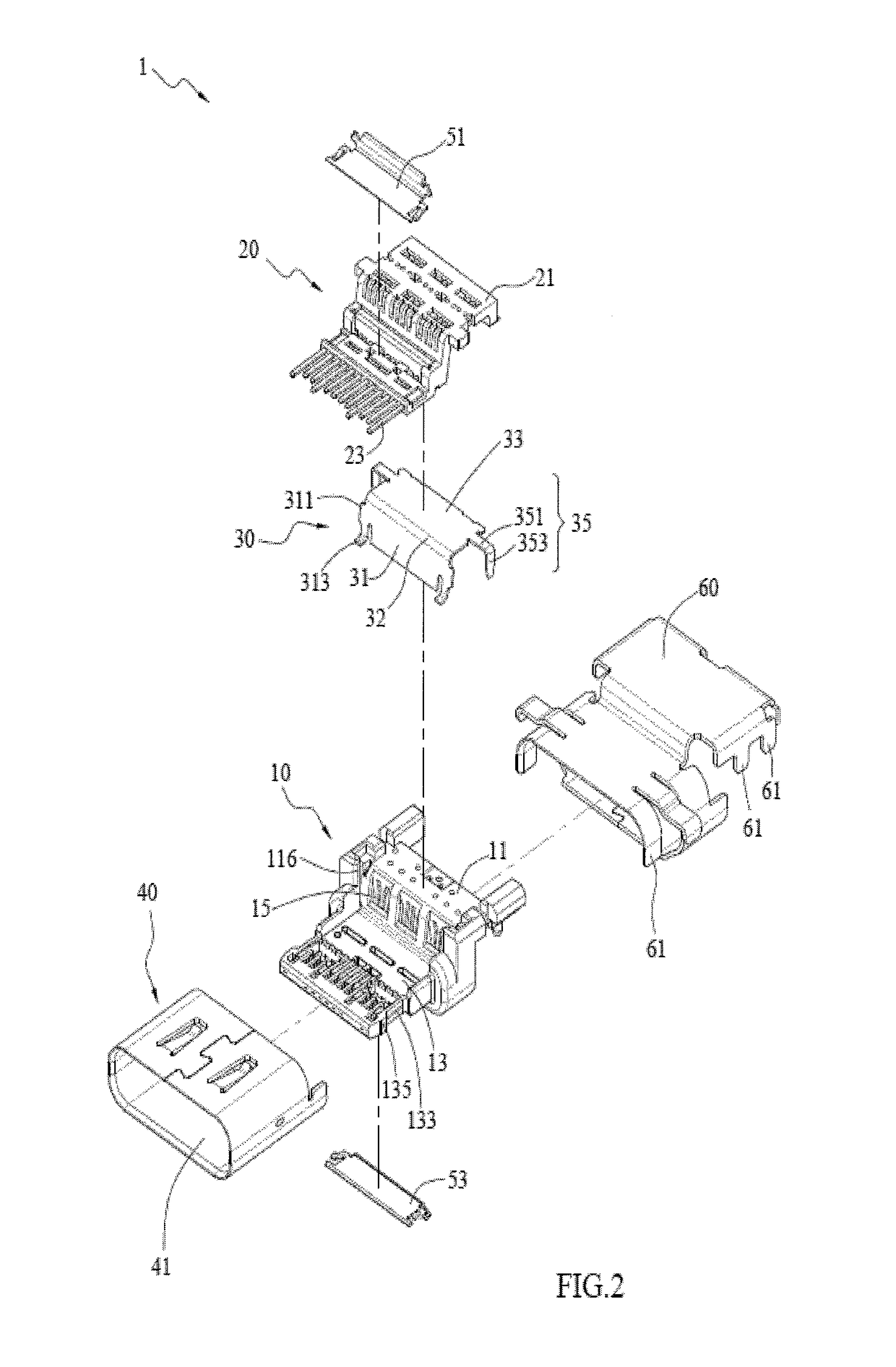

Electrical receptacle connector

ActiveUS9748701B2Improve shielding effectReduce electromagnetic interferenceTwo-part coupling devicesCoupling protective earth/shielding arrangementsEngineeringGround plate

Owner:ADVANCED CONNECTEK INC

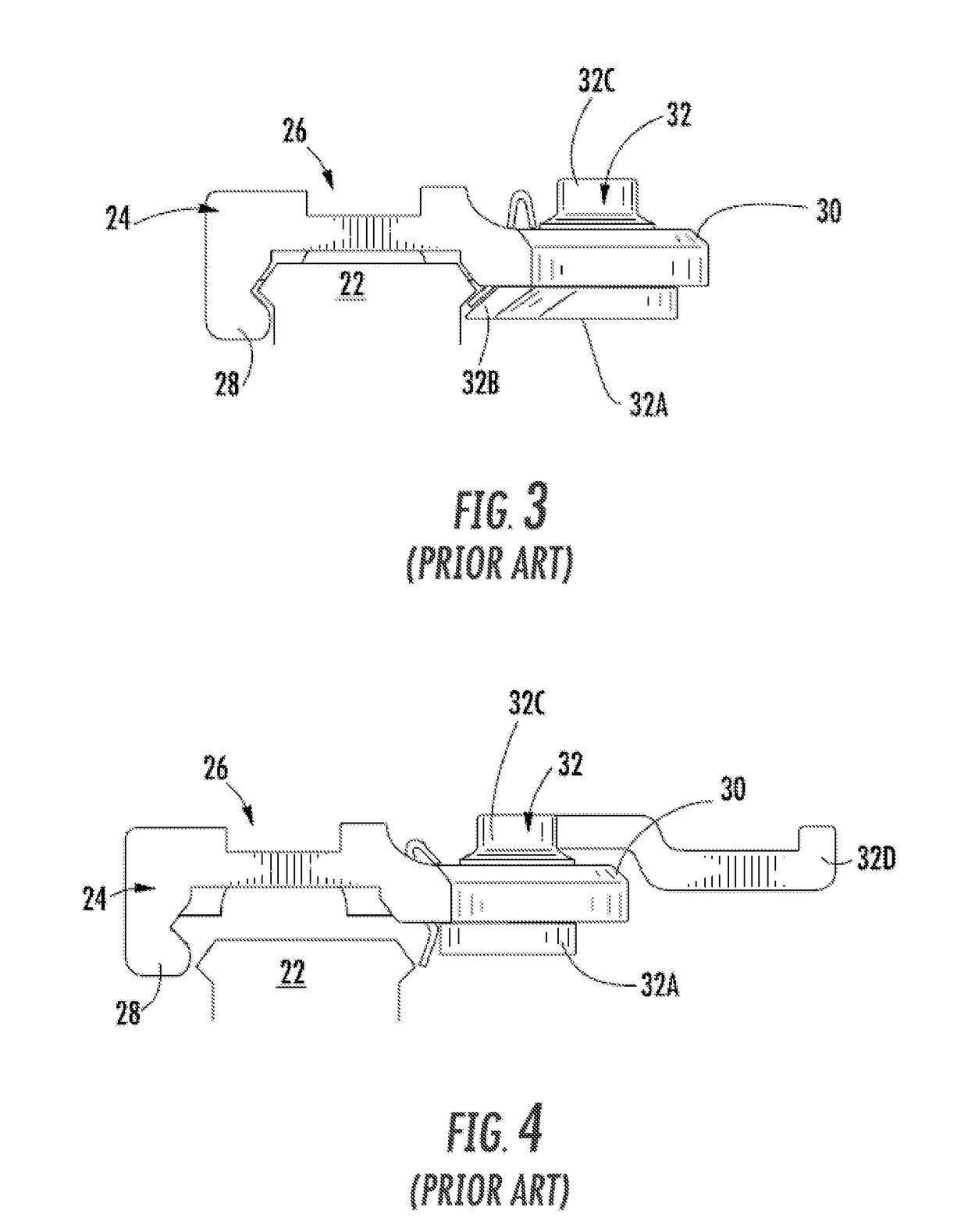

Mounting assembly with metal injection molded lever and selective threaded governor post

An improved mounting assembly is provided that is configured to be releasably attached to a dovetail rail profile, wherein the clamping tension of the clamping actuator is adjustable. The assembly includes a molded foot portion and a turned steel threaded governor post which provides superior strength and durability to a critical stress point in the assembly. The threaded, removable governor post configuration also provides the ability to change the post material to increase overall component strength and to increase thread strength. The arrangement further simplifies field maintenance and repair in the event of damage and reduces repair costs by not having to replace the entire lever assembly.

Owner:SWAN RICHARD E

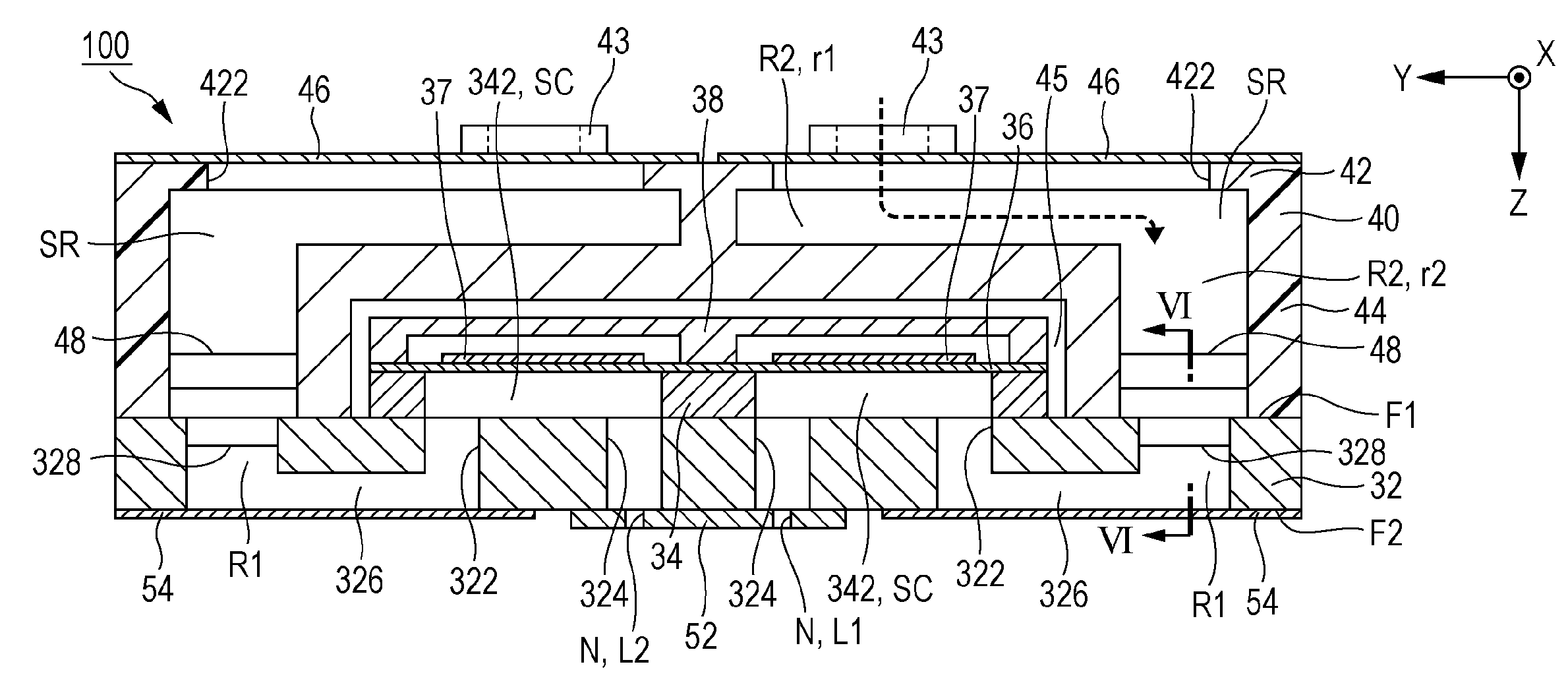

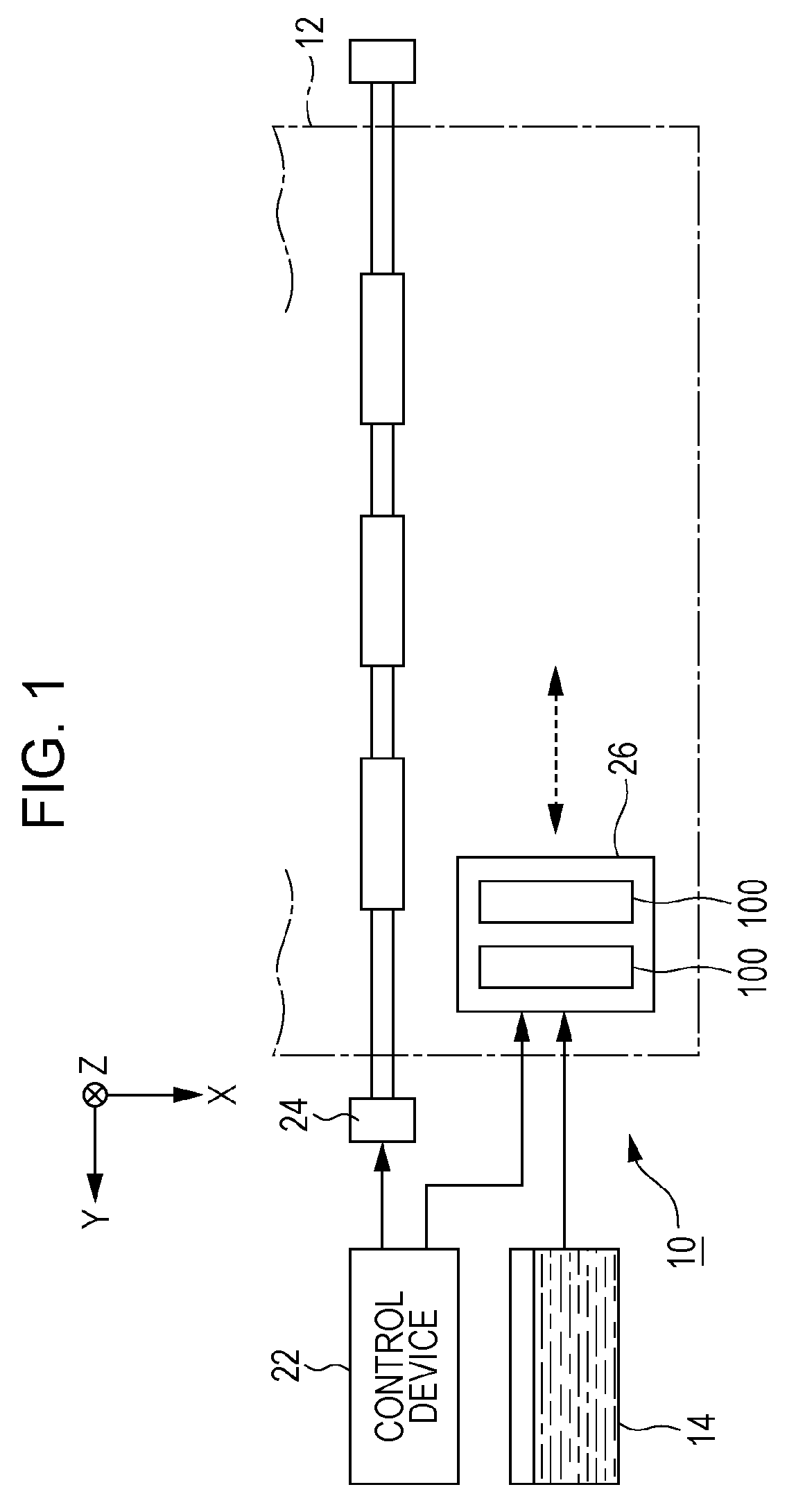

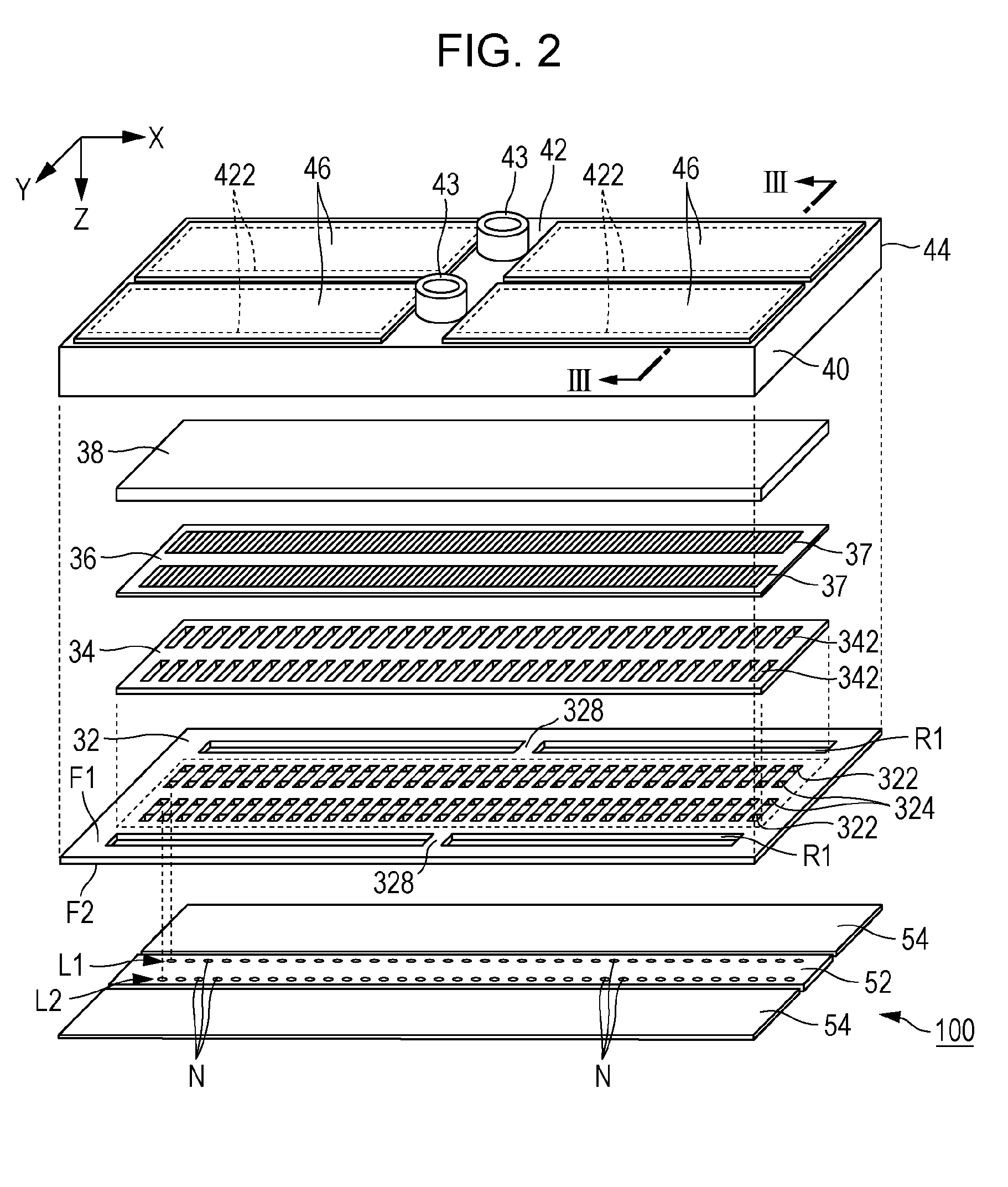

Liquid ejecting head and liquid ejecting apparatus

ActiveUS20160279938A1High component strengthHigh mechanical strengthInking apparatusEngineeringNozzle

A liquid ejecting head includes a pressure chamber substrate in which a pressure chamber space is formed, a flow path substrate having a first surface on which the pressure chamber substrate is installed and a second surface that is on the opposite side to the first surface, and in which a first space, a supply hole that enables communication between the first space and the pressure chamber space, and a communication hole that communicates with the pressure chamber space are formed, a nozzle plate that is installed on the second surface and in which a nozzle that communicates with the communication hole is formed, a second space that is installed on the first surface and that communicates with the first space of the flow path substrate, a housing unit in which an opening portion that communicates with the second space is formed, a compliance unit that is flexible and installed on the second surface and that seals the communication hole and the first space, and a beam-like portion that extends between inner wall surfaces of the second space in the housing unit.

Owner:SEIKO EPSON CORP

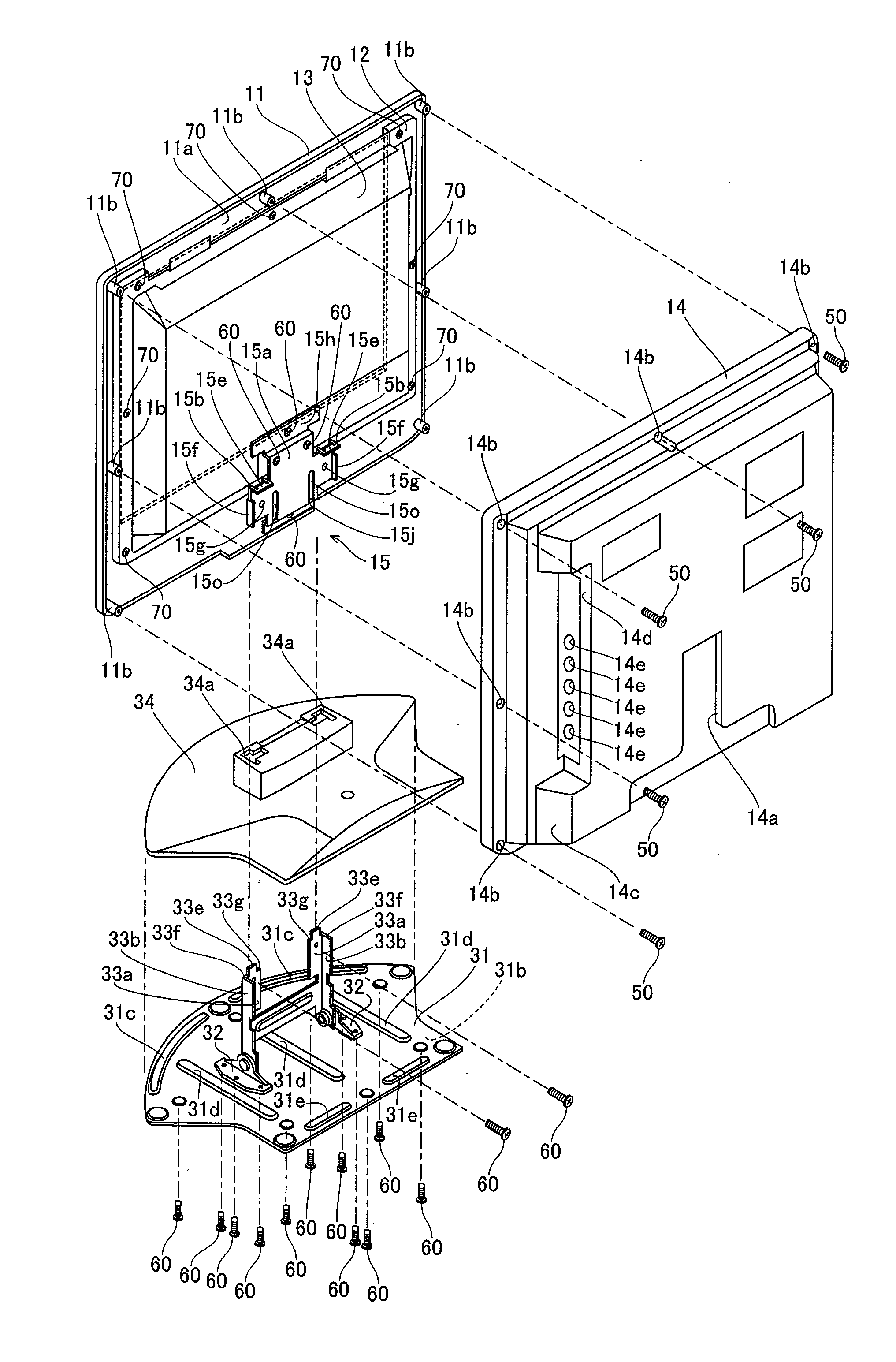

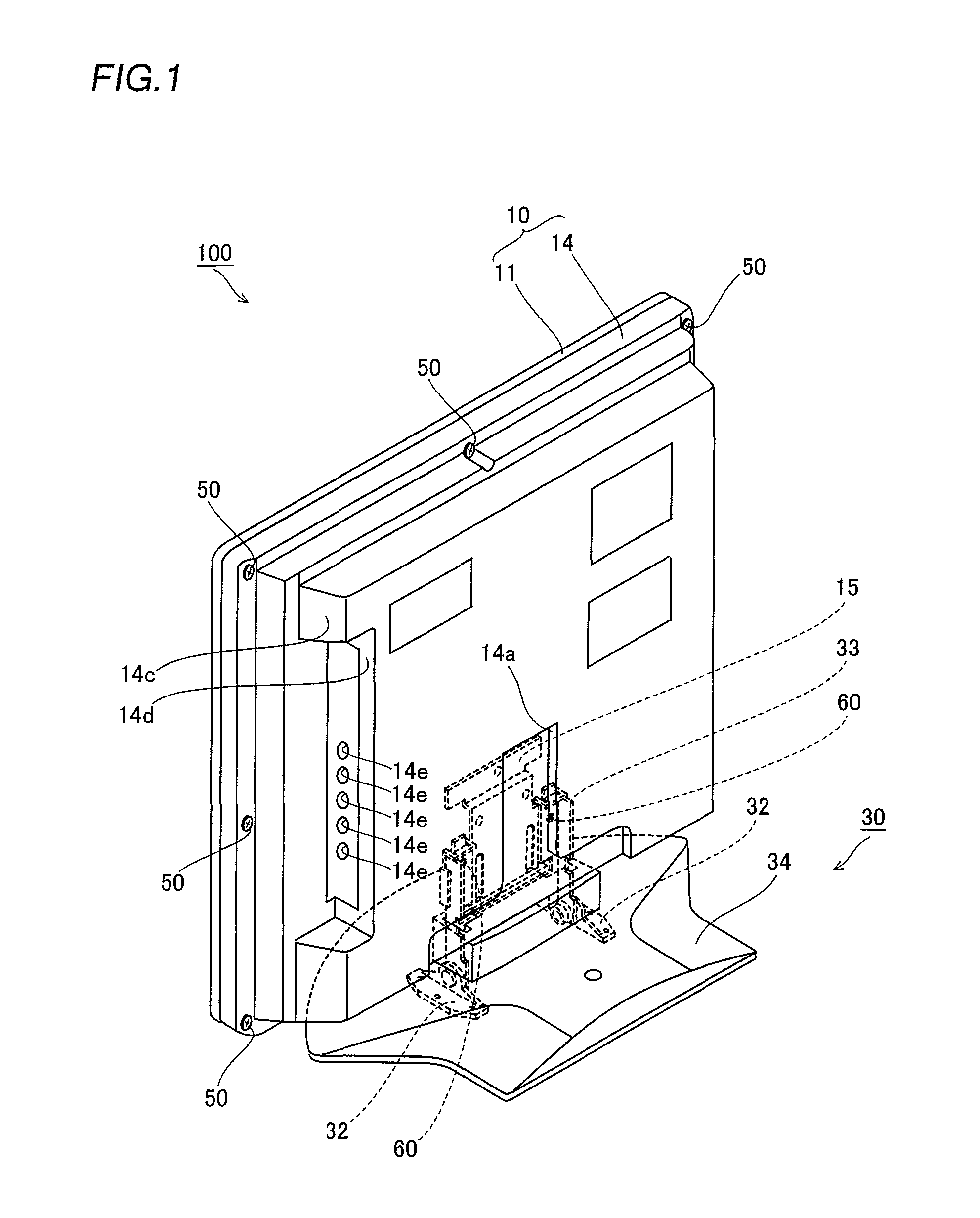

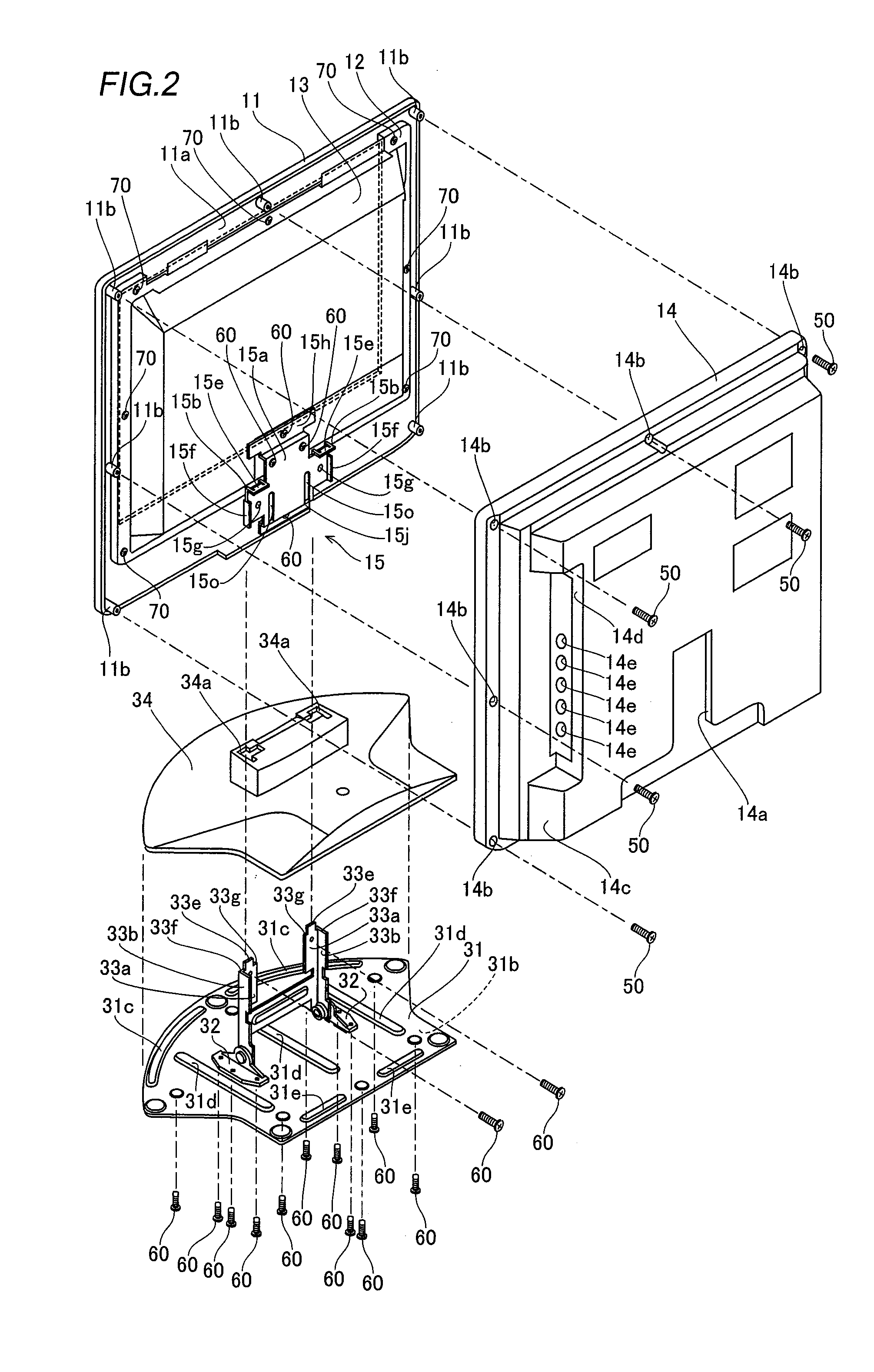

Display

InactiveUS7631843B2Place stableAdditional componentDigital data processing detailsStands/trestlesDisplay deviceEngineering

Owner:FUNAI ELECTRIC CO LTD

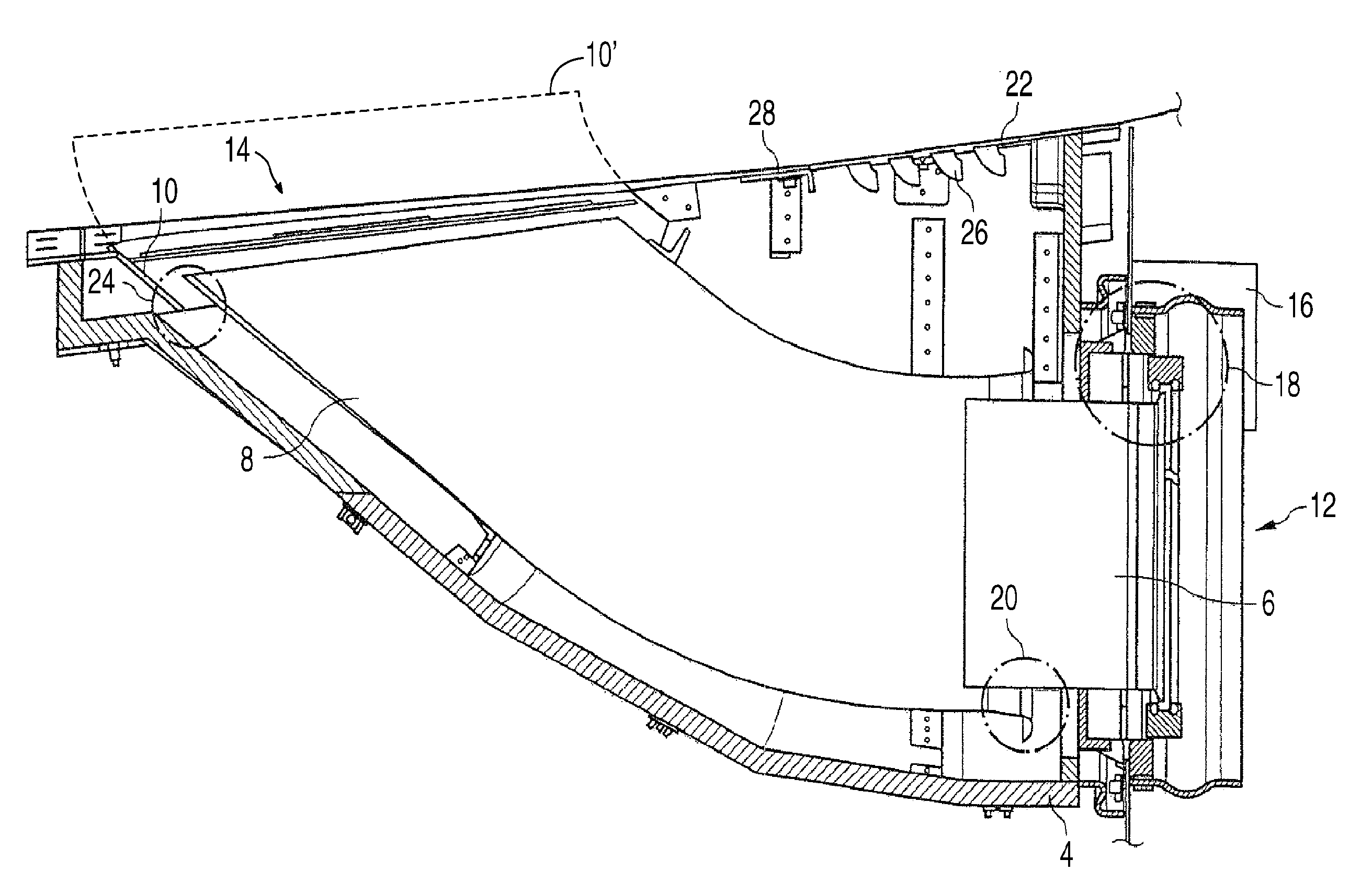

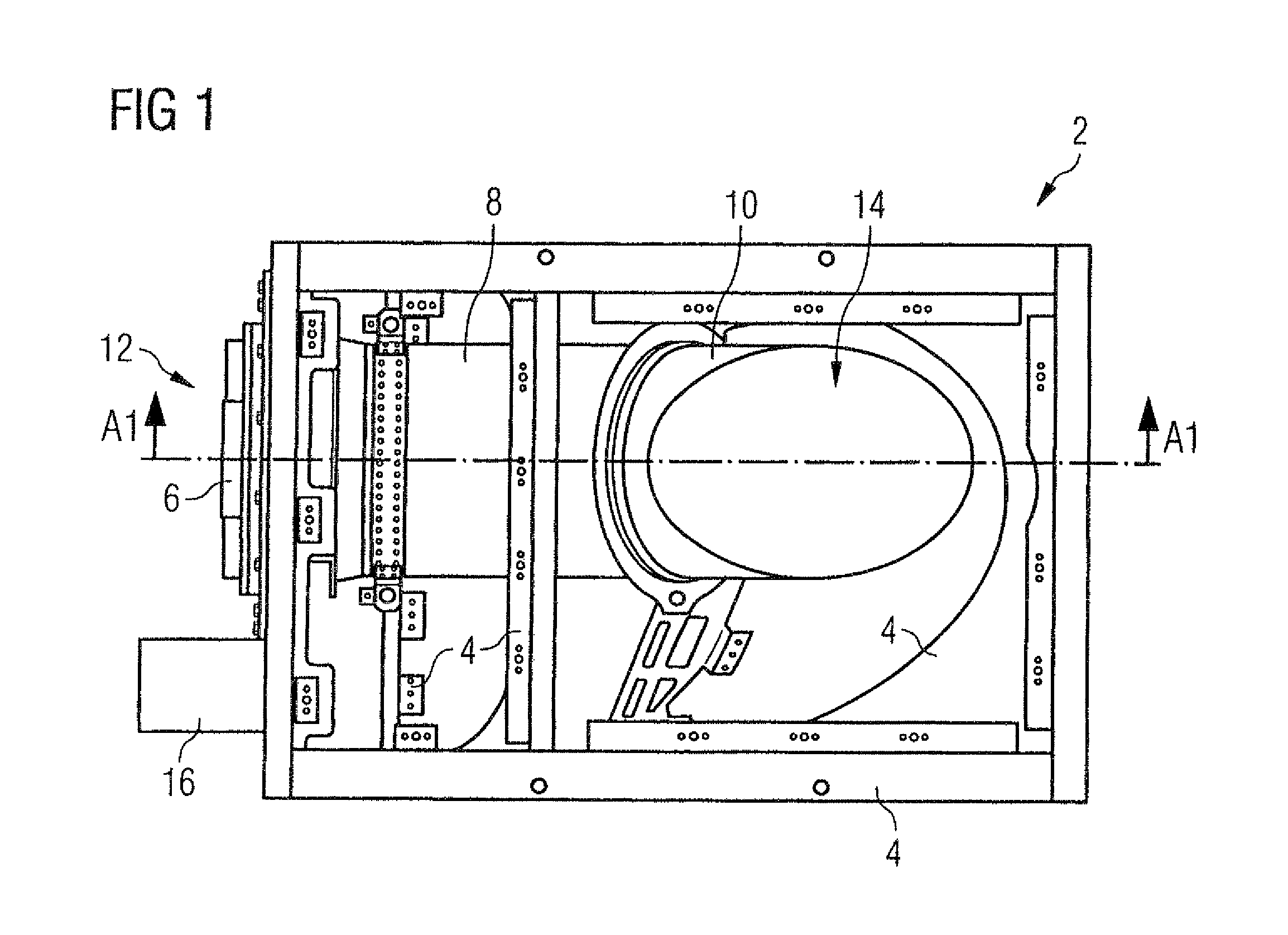

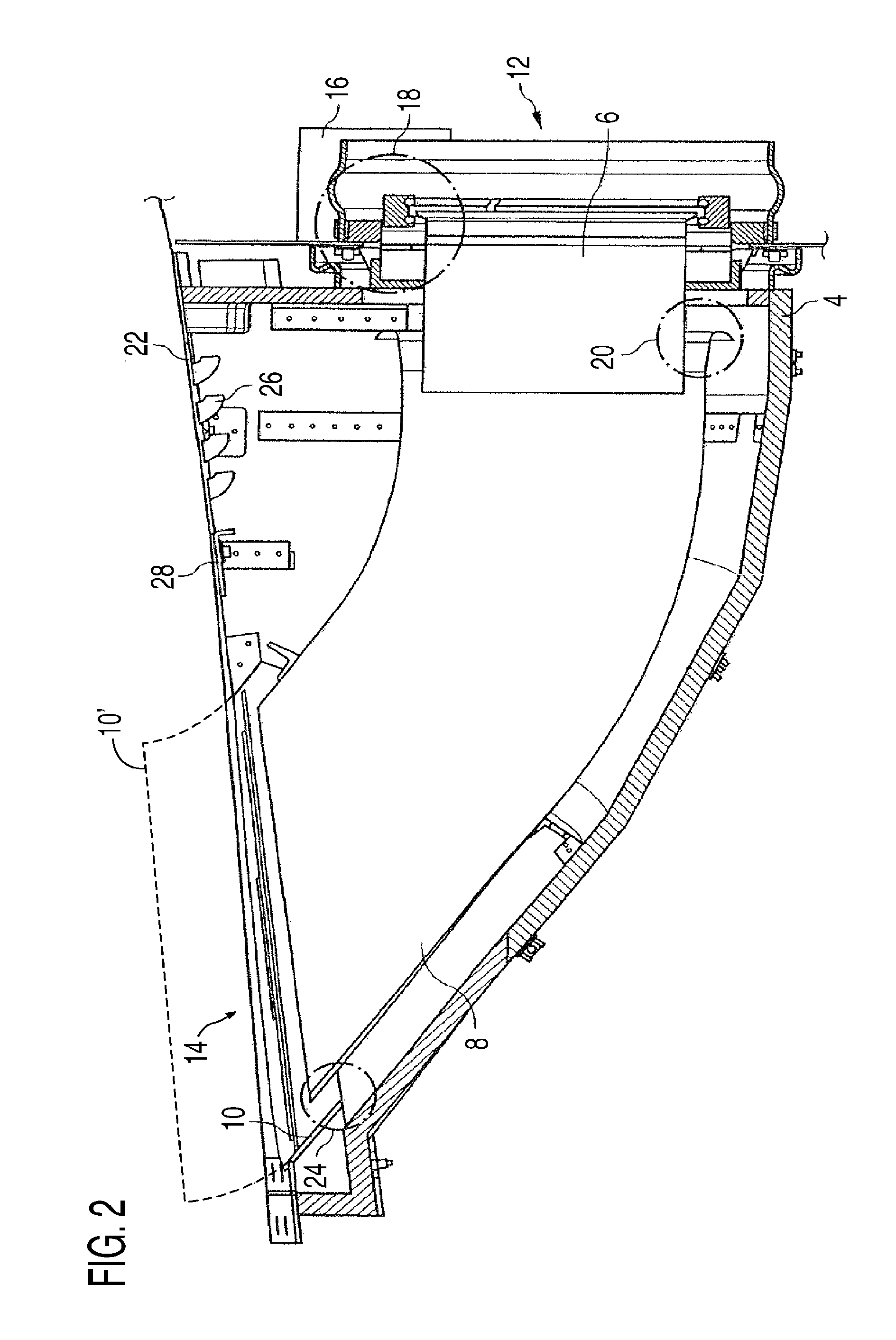

Device for cooling hot gas to be discharged from an aircraft

InactiveUS8371522B2Reduce flow soundReduce noisePower plant exhaust arrangementsPower installationsGas passingProduct gas

A device for cooling hot gas to be discharged from an aircraft includes a duct for leading the hot gas from a hot gas source which is connectable to the device to an outlet point, and a frame which surrounds the duct and serves for mounting the duct. The duct is formed from one or more pipe sections and has one or more cooling air inlet points which is connectable to one or more cooling air sources in order to mix the hot gas with cooling air. An outlet pipe section of the duct extends outwards beyond the aircraft outer skin to lead hot gas through and out of a flow boundary layer on the outer skin.

Owner:AIRBUS OPERATIONS GMBH

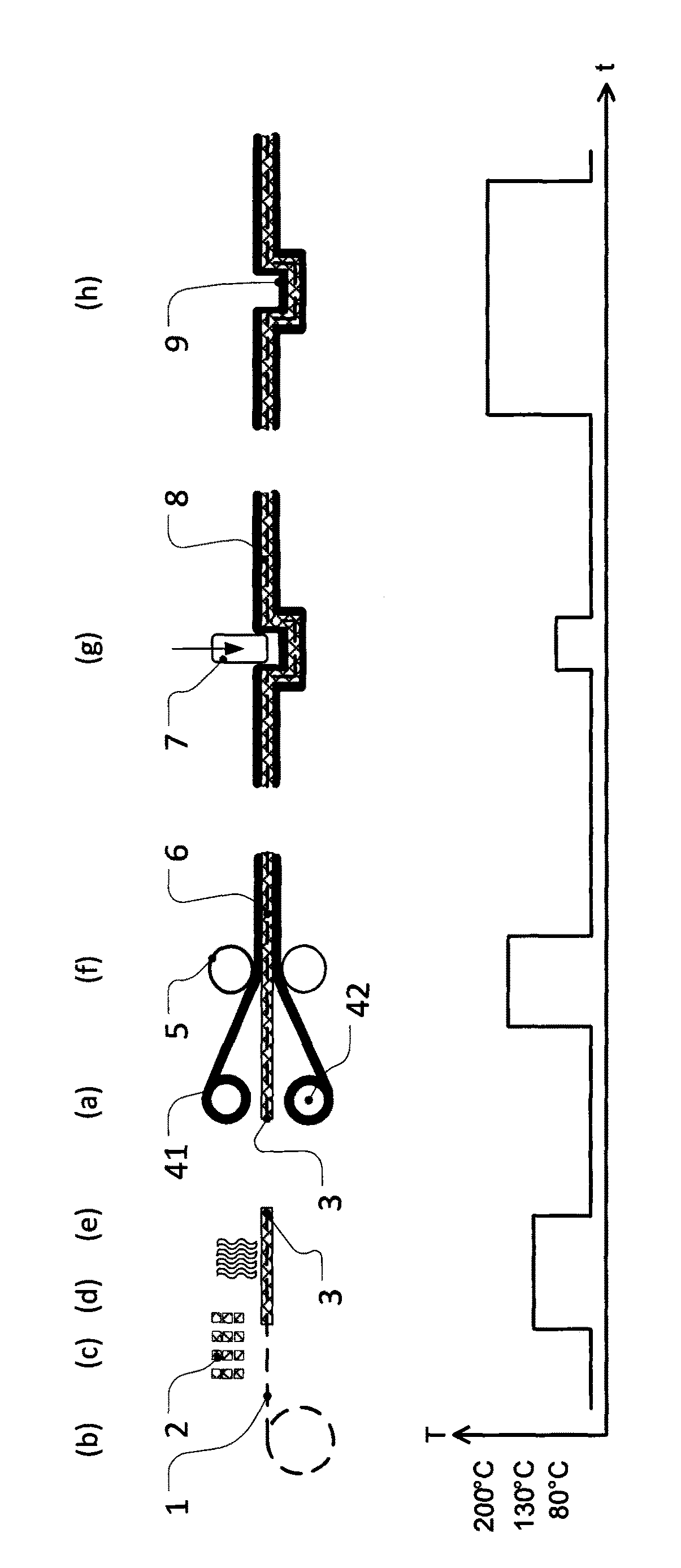

Production of fibre composite component part based on aluminium and polyurethane

InactiveUS9902096B2High component strengthLamination ancillary operationsPolyureas/polyurethane adhesivesPolymer scienceHeat treated

A method of producing a fiber composite component part has the following steps: a) providing two or more metal sheets each comprising an aluminum material; b) providing at least one textile fabric; c) providing an anhydrous mixture having one or more than one hardener having a uretdione having an NCO functionality of not less than two, one or more than one binder having hydroxyl groups to an OH functionality of three to six, and one or more than one cobinder having oxirane groups; d) coating the textile fabric with the anhydrous mixture, to obtain a mixture-coated fabric; e) applying energy to the mixture-coated fabric for the purpose of performing a first crosslinking reaction to react hardener, binder and cobinder to form a thermoplastic polymer adhering to the textile fabric; f) hot pressing the metal sheets and the textile fabric together with the thermoplastic polymer adhering thereto into a sandwich such that the thermoplastic polymer joins the metal sheets together while enclosing the textile fabric; g) forming the sandwich into a shaped article; and h) heat treating the shaped article to obtain the fiber composite component part, wherein the thermoplastic polymer undergoes a second crosslinking reaction to convert into a thermoset polymer.

Owner:EVONIK DEGUSSA GMBH

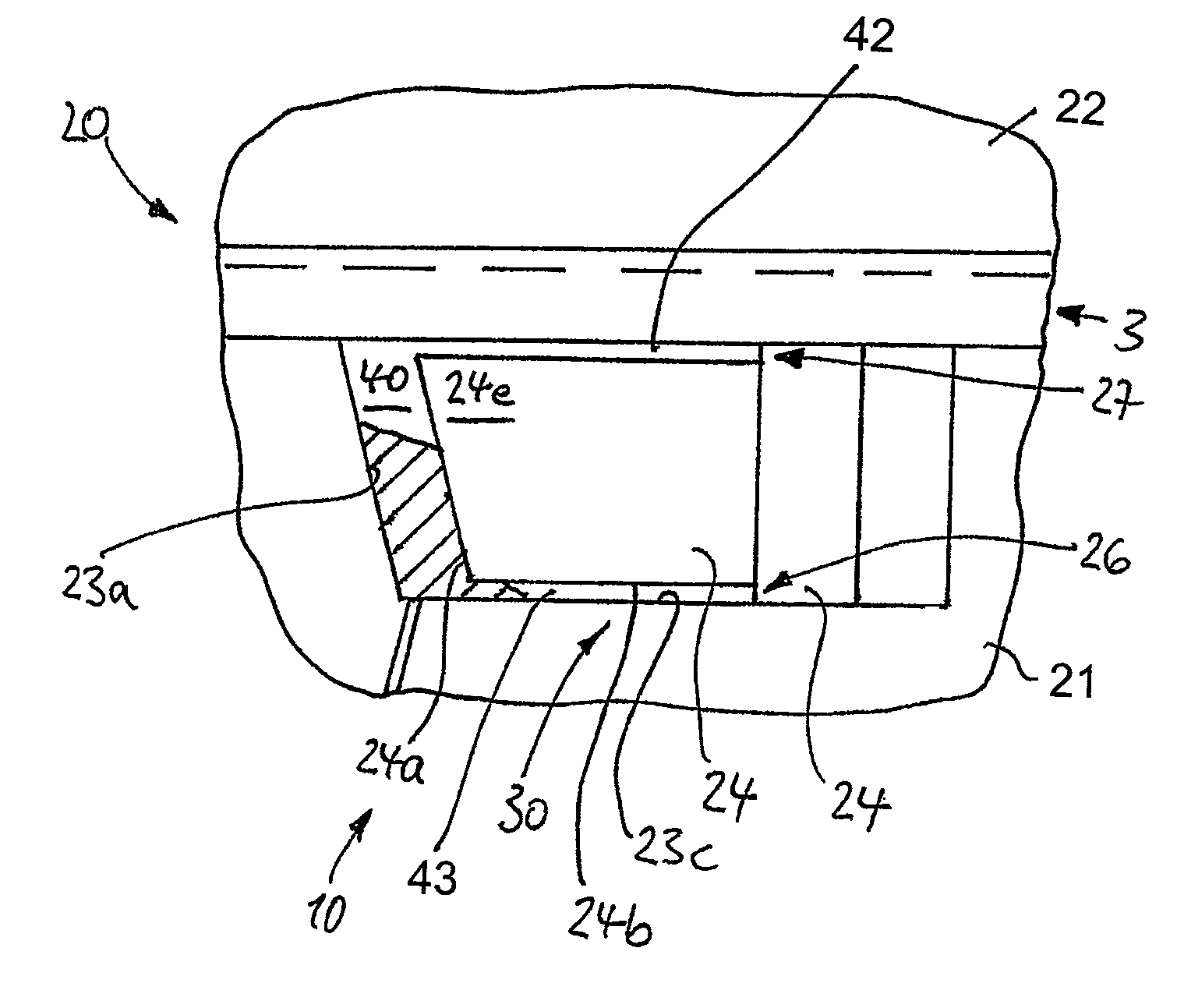

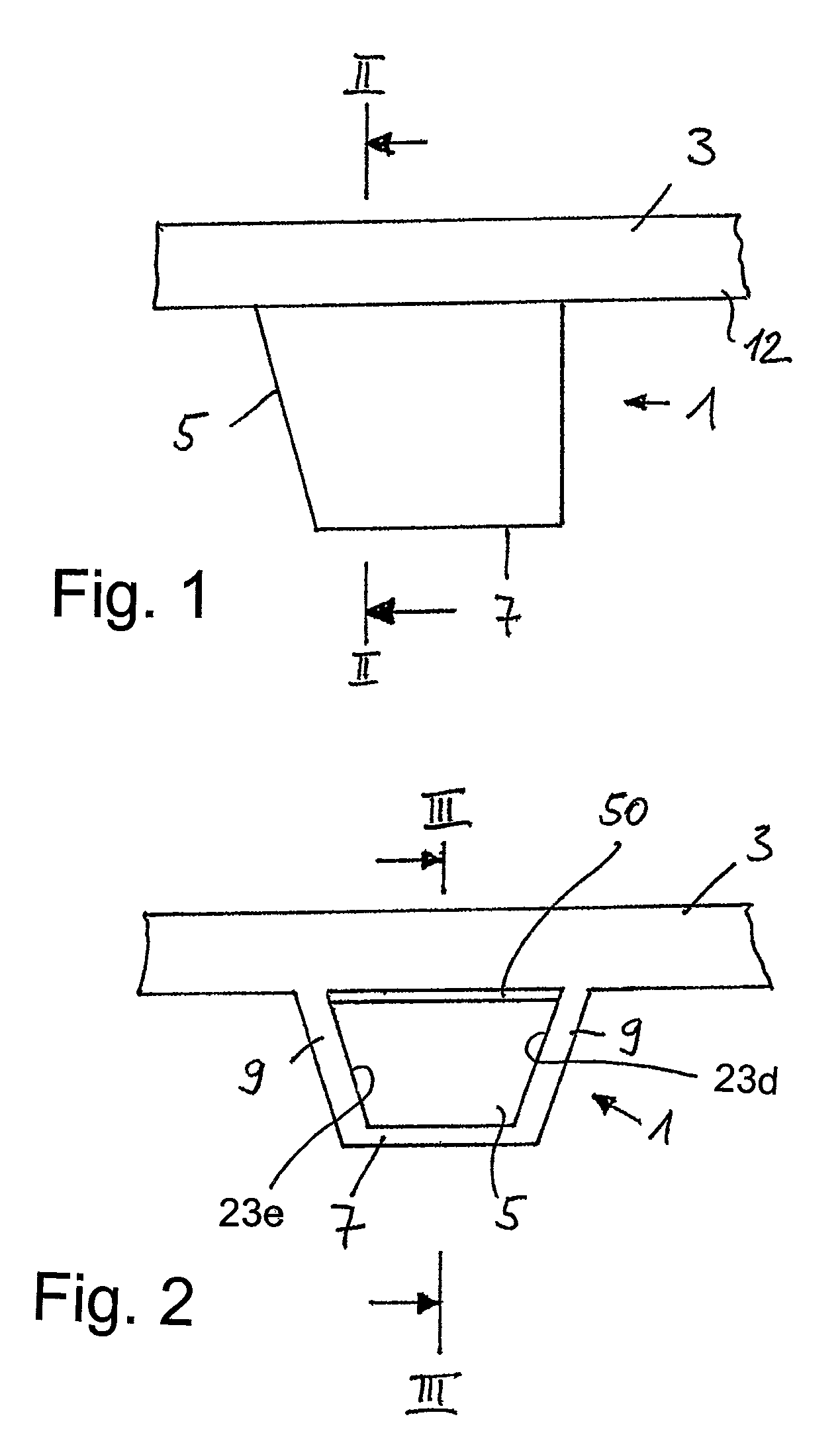

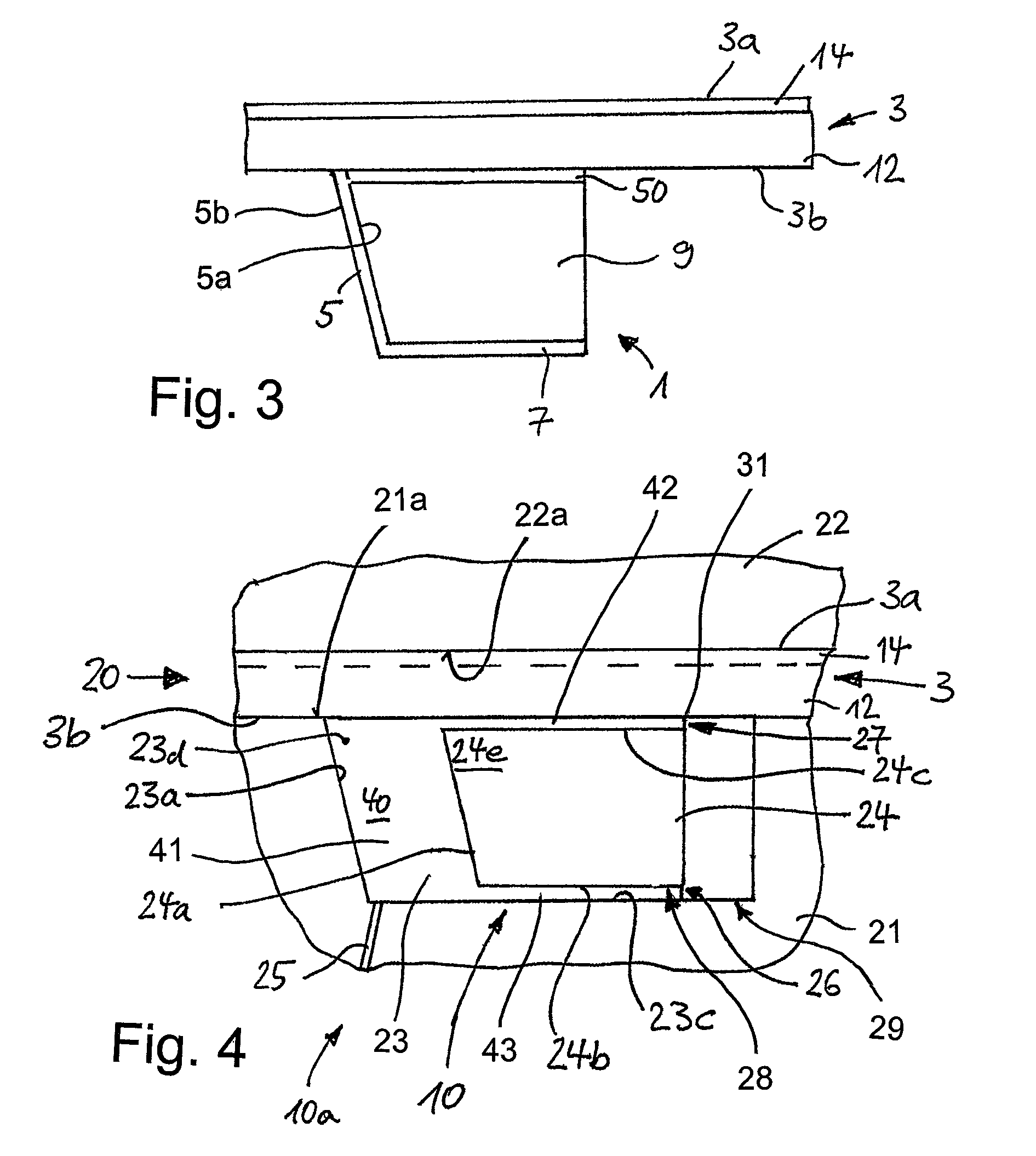

Method and tool for producing a plastic component with a decorative layer, a backing layer and an additional molded part attached thereto

InactiveUS7943074B2Complex shapeStable attachmentConfectioneryWood working apparatusFiberCompression molding

A method for producing a component (3) comprising a backing layer, a decorative layer and an additional molded part (1) attached to the component. The method includes the following steps: A plasticized mat comprising fiber fractions, which is a starting material for the backing layer (12), is introduced together with a blank, which is a starting material for the decorative layer (14), into a compression molding tool (20) composed of a first tool half (21) including a low pressure injection unit (10) for producing the additional molded part and a second tool half (22). The tool halves (21, 22) are pressed together to join the starting materials; a predetermined quantity of plastic in a fluid state is simultaneously or subsequently introduced into the cavity (23) of the compression molding tool through a supply conduit (25), and a slider (24) is thereafter extended to an end position inside the cavity (23). After cooling of the plastic, the slider is retracted to its starting position, and the tool halves are separated. The invention also includes an apparatus for carrying out the method.

Owner:FAURECIA INNENRAUM SYST

Production of fibre composite component part based on steel and polyurethane

InactiveUS9902095B2High component strengthLamination ancillary operationsLayered product treatmentEthylene oxideThermosetting polymer

A method of producing a fiber composite component part, contains the following steps: a) providing two or more steel sheets; b) providing at least one textile fabric; c) providing an anhydrous mixture having one or more than one hardener containing a uretdione having an NCO functionality of not less than two, one or more than one binder having hydroxyl groups to an OH functionality of three to six, and one or more than one cobinder having oxirane groups; d) coating the textile fabric with the mixture; e) applying energy to the mixture-coated fabric for the purpose of performing a first crosslinking reaction to react hardener, binder and cobinder to form a thermoplastic polymer adhering to the textile fabric; f) hot pressing the steel sheets and the textile fabric together with the thermoplastic polymer adhering thereto into a sandwich such that the thermoplastic polymer joins the steel sheets together while enclosing the textile fabric; g) forming the sandwich into a shaped article; h) heat treating the shaped article to obtain the fiber composite component part, wherein the thermoplastic polymer undergoes a second crosslinking reaction to convert into a thermoset polymer.

Owner:EVONIK DEGUSSA GMBH

Variable speed control method for cooling table output roller beds

InactiveCN107600960AUniform drag forceTroubleshootingAC motor controlControl devices for conveyorsFrequency conversionWorking environment

The invention discloses a variable speed control method for cooling table output roller beds. The cooling table output roller beds are sequentially grouped when conveying towards cold shears, and a control circuit of each group of roller beds is provided with a controller used for controlling the operation speed of a roller bed motor. The principle is simple, the transform difficulty is low, the cost is low, the labor intensity is small, the control way for the cooling table output roller beds is changed through frequency conversion, grouping and PLC analog quantity control technology, the control performance for the cooling table output roller beds is improved, the noise in the working environment is lowered, energy conservation and environmental protection are achieved, the improved cooling table output roller beds are stable and reliable in operation, and production efficiency is high.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

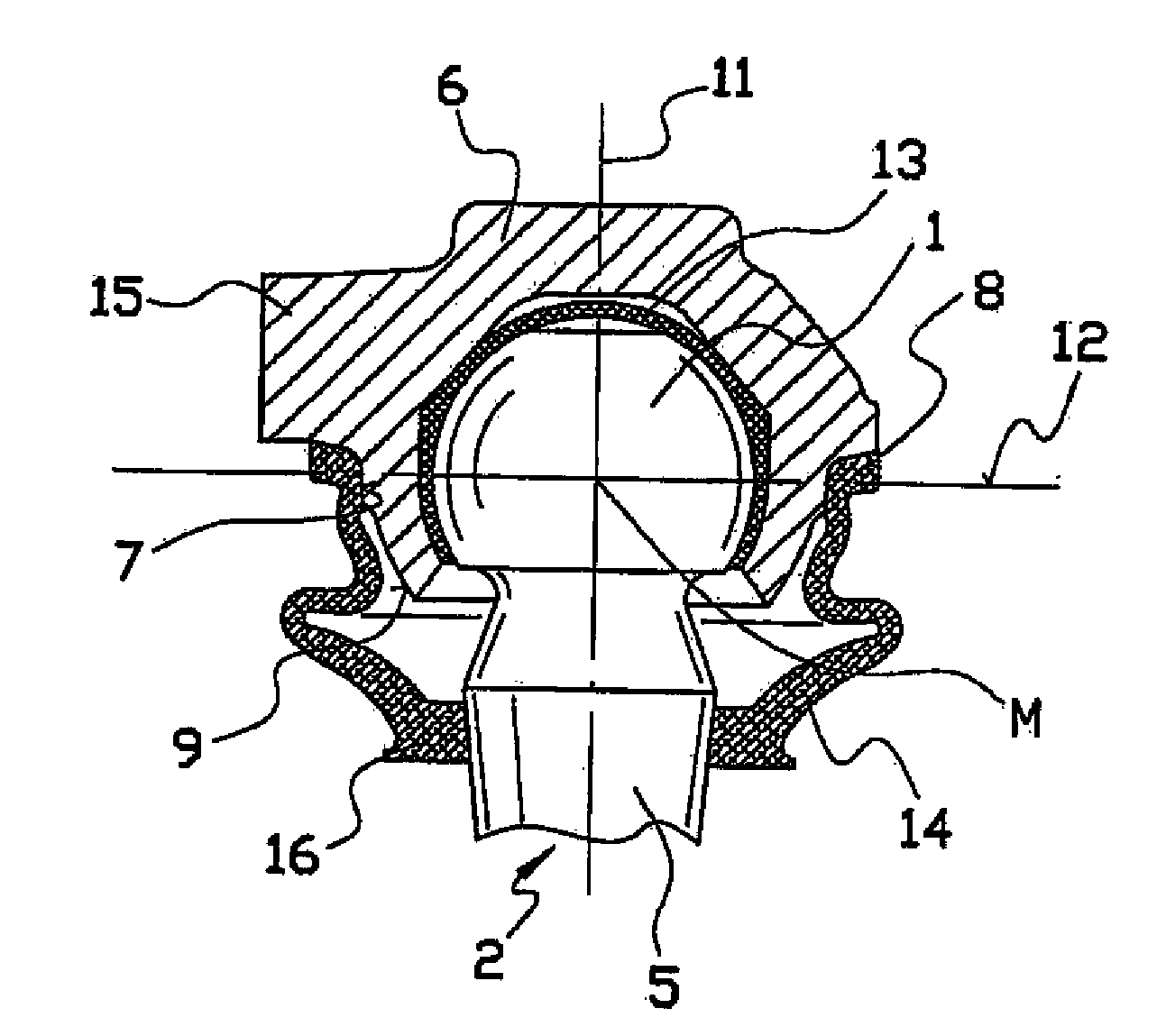

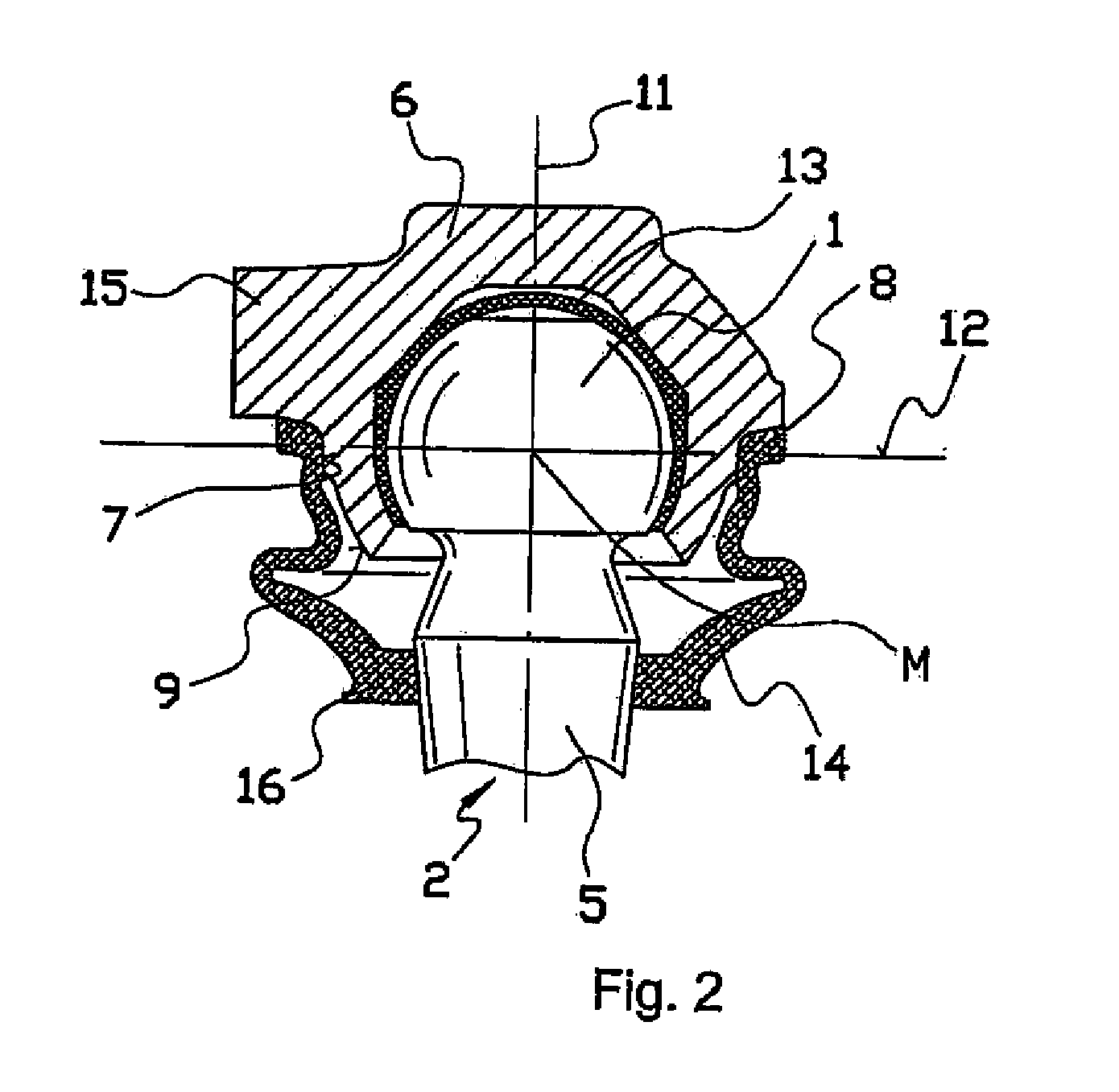

Housing for a ball joint

InactiveUS20120020723A1AdvantageousSimple manufacturing processCouplings for rigid shaftsPivotal connectionsInterior spaceEngineering

A housing component for a ball joint has an interior space (3) adapted for mounting the joint ball (1) of a ball journal, an opening (4) for guiding the journal section (5) of the ball journal (2) adjoining the joint ball (1), a contact region (7) formed on an outer lateral surface of the housing (6) for fastening a sealing bellows edge (8) and forming a seal, and a deformed section (9) which rotationally and pivotally fixes the joint ball (1) of the ball journal (2) in the interior space (3) of the housing (6). The deformed section (9) has a smaller material cross-section in comparison to the contact region (7) for the sealing bellows edge (8).

Owner:ZF FRIEDRICHSHAFEN AG

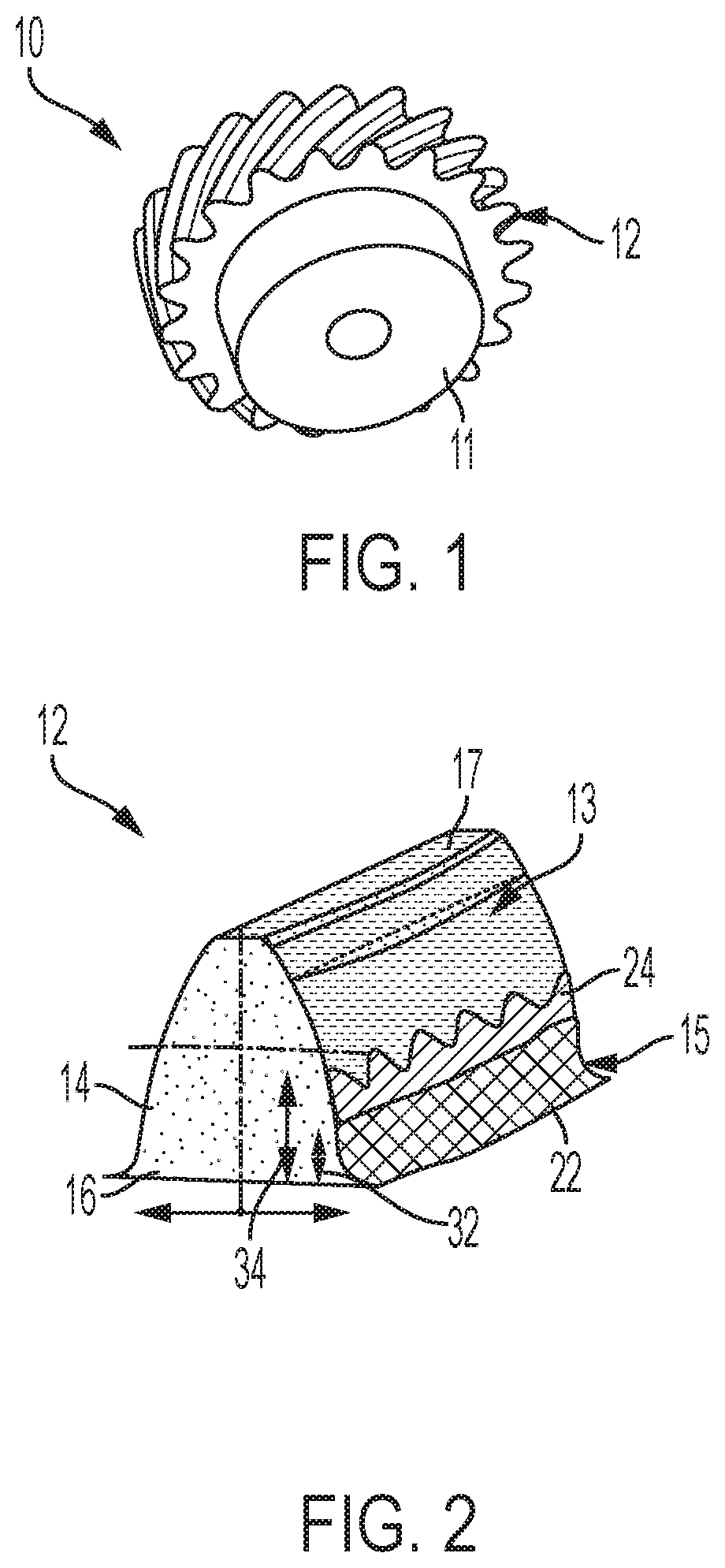

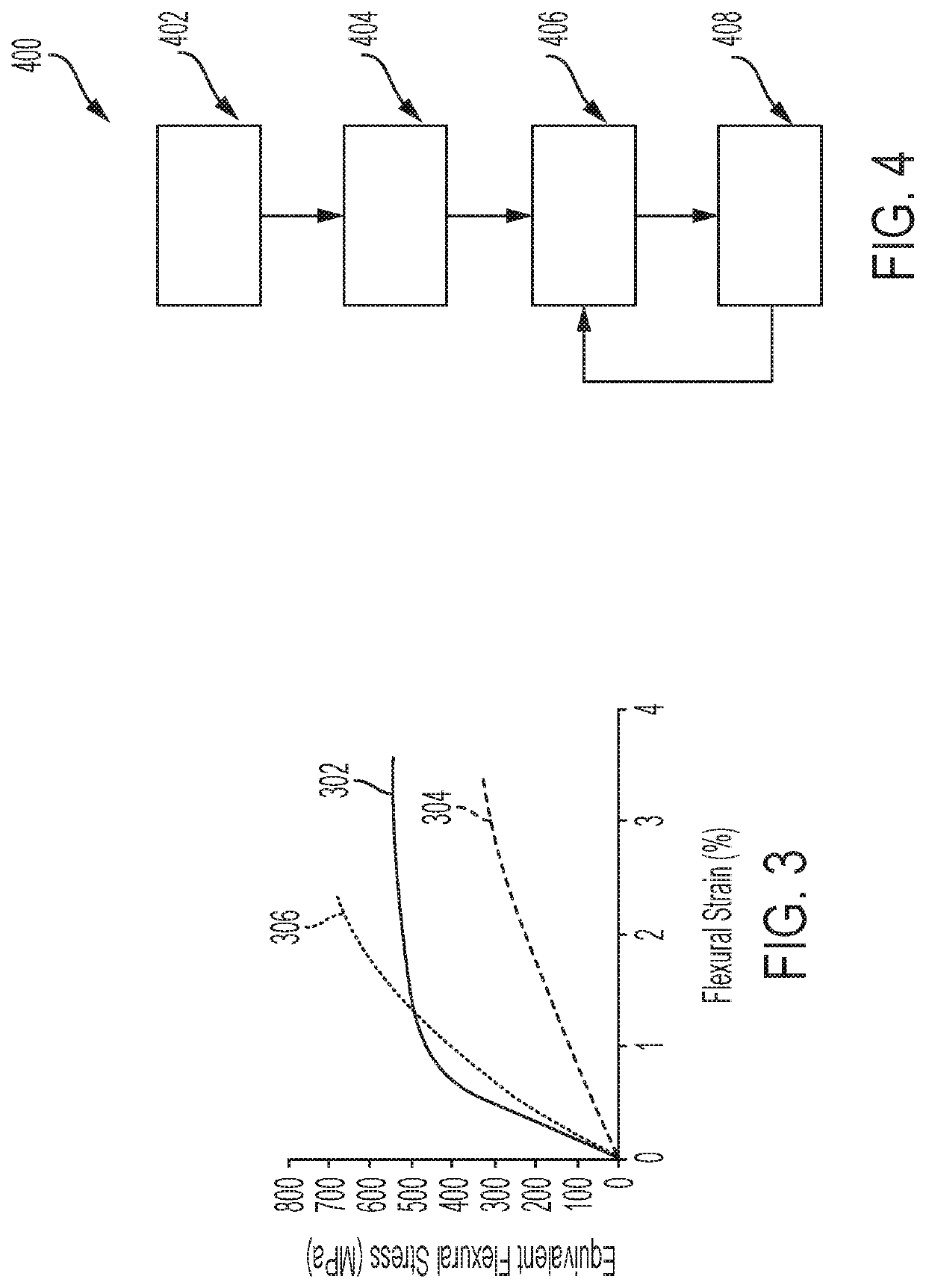

Methods and systems for producing high strength and adjustable stiffness components

ActiveUS20200393031A1Improve fatigue strengthAdjustable stiffnessAdditive manufacturing apparatusPortable liftingAdjustable stiffnessRooted tooth

A method for producing and reinforcing a composite gear includes providing a base material comprising a polymer and forming a composite gear from the base material, the composite gear having a gear body and at least one gear tooth extending from the gear body, the at least one gear tooth having a tooth face, a tooth flank, a tooth fillet, a tooth root, and a tooth tip. The method includes depositing a first metallic material to a first area of the at least one gear tooth of the composite gear, the first area including the tooth root of the at least one gear tooth and depositing a second metallic material to a second area of the at least one gear tooth of the composite gear. The first metallic material is applied in a first thickness and the second metallic material is applied in a second thickness.

Owner:GM GLOBAL TECH OPERATIONS LLC

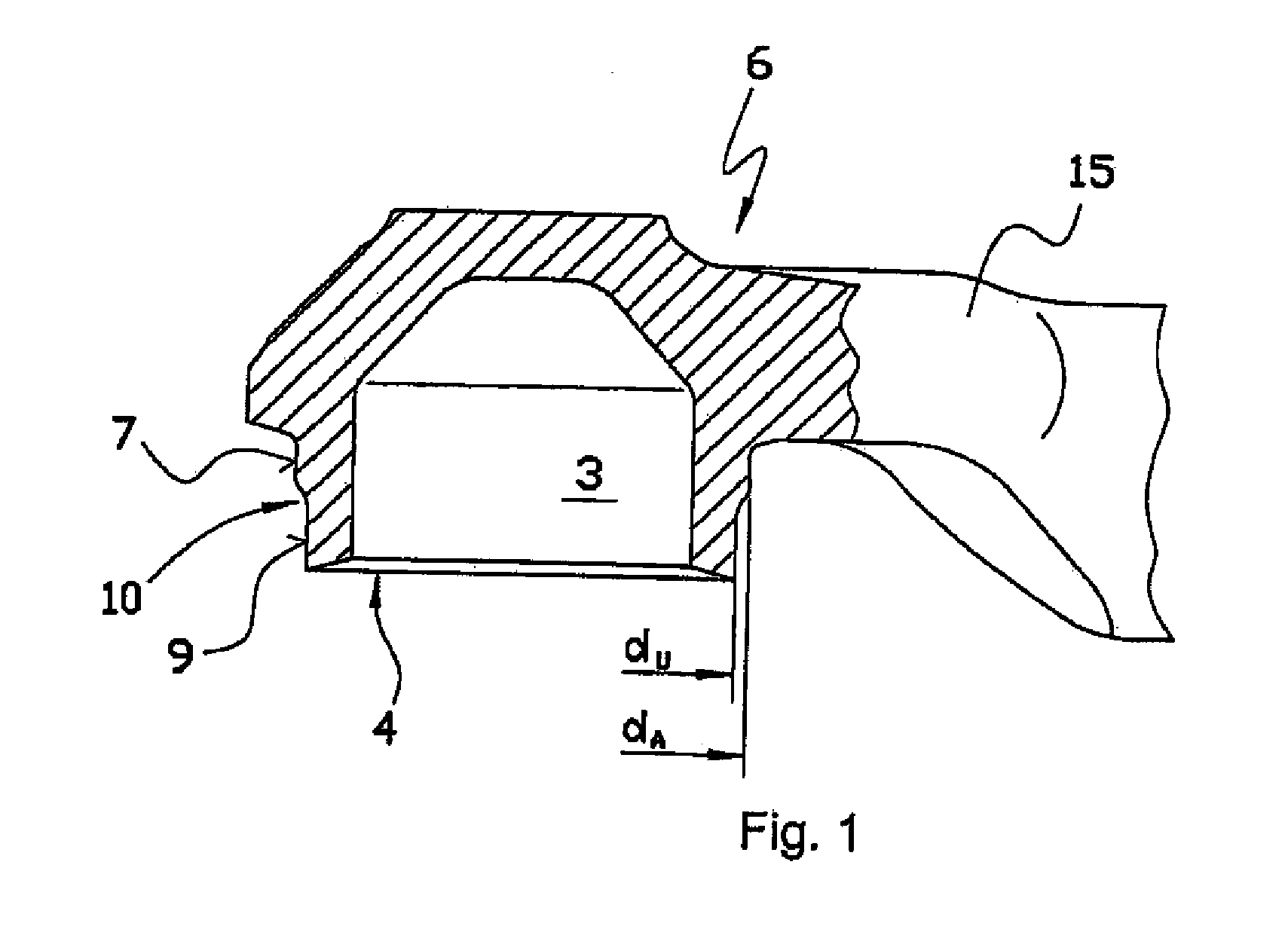

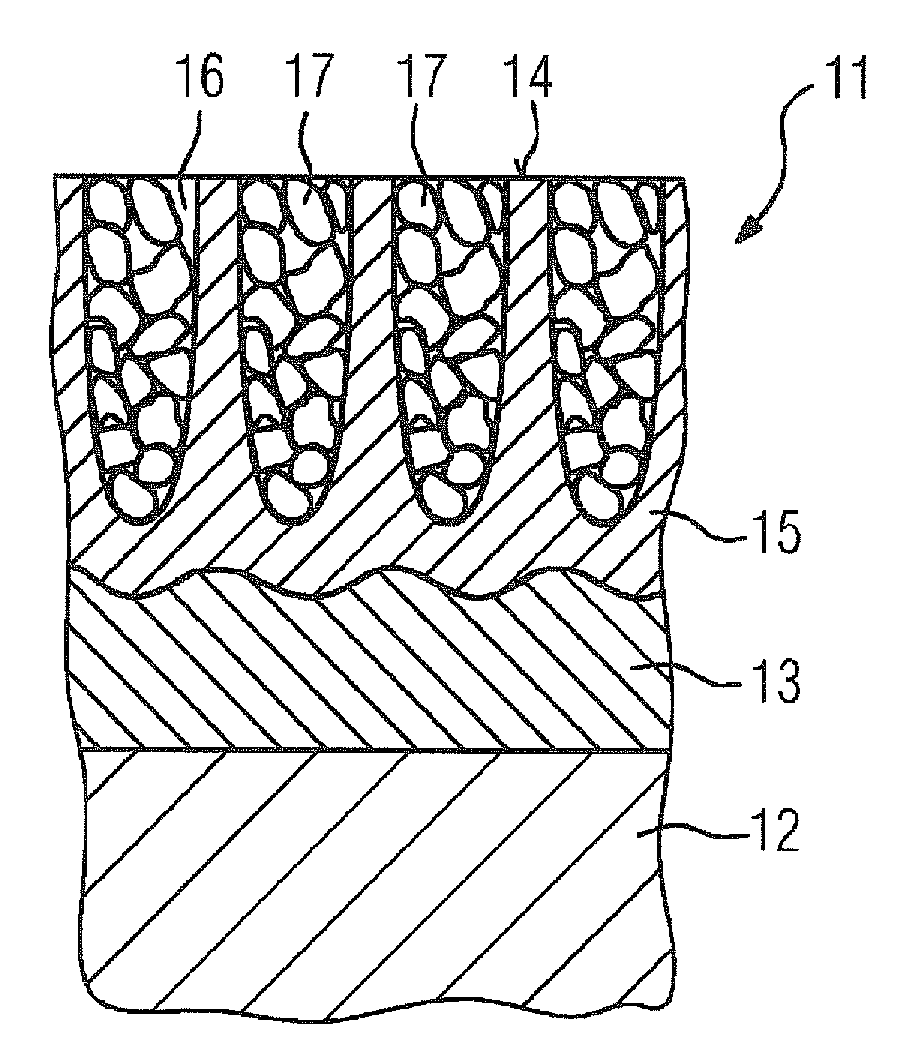

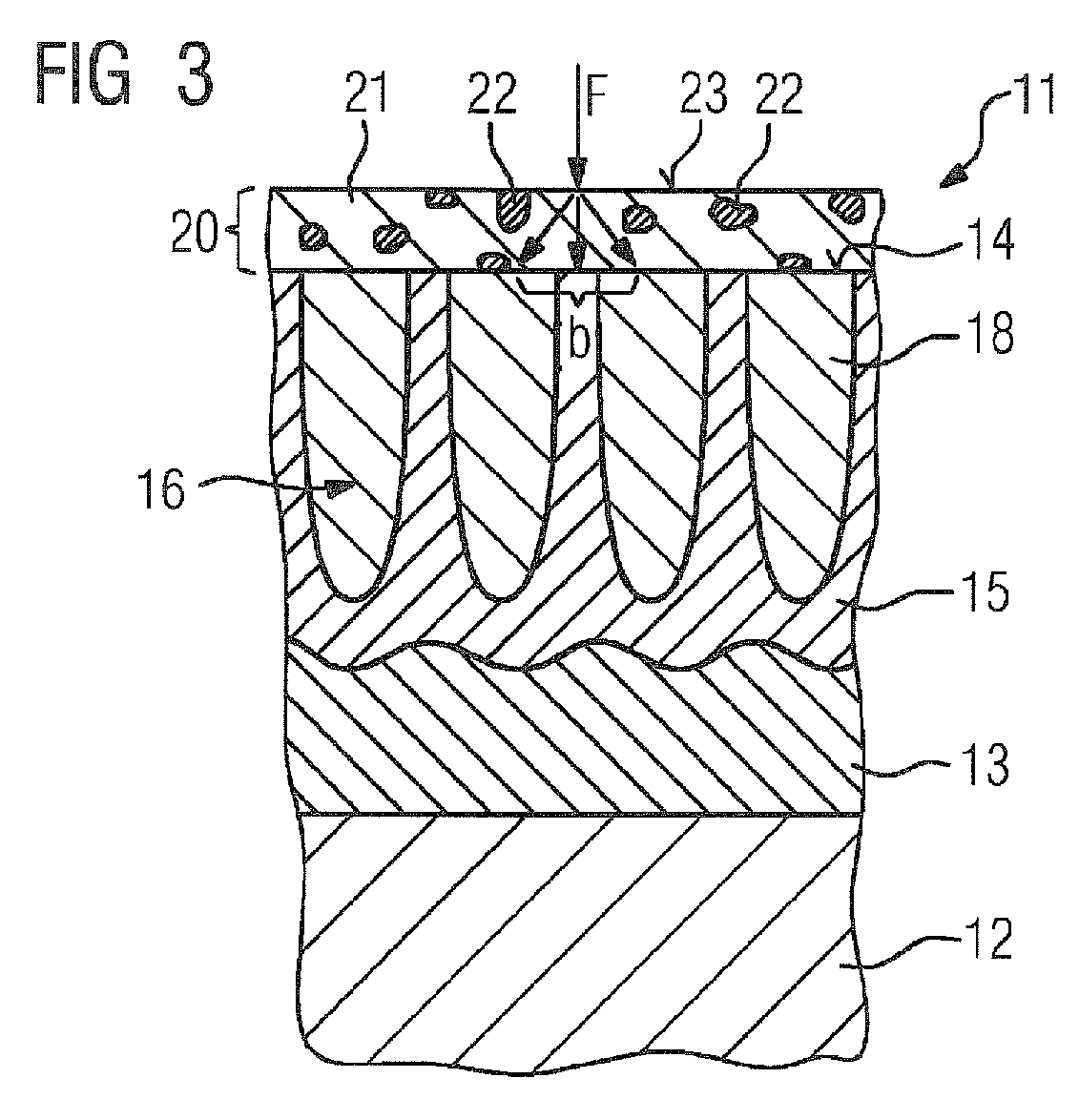

Component for the sliding support of another component, and process for producing it

The invention relates to a component that is suitable for use as a sliding bearing. The invention further relates to a method for the production of said component. The design of the component according to the invention provides a layer of a light metal material (13), which is provided with an oxide layer (15) containing pores (16) in the direction of the sliding surface (23) of the component. A hard material (18) is placed in the pores, which greatly increases the firmness of said layer region, thus creating the mechanical firmness for use as a sliding bearing. In order to counteract the tendency of said firm layer region to experience brittle failure, the oxide layer (15) is coated with a solid lubricant layer (20). Said solid lubricant layer comprises a metallic, ductile matrix (21), which distributes a force (F) acting at certain points over a larger surface region (b). In order to improve the sliding characteristics, particles of a solid lubricant (22) are simultaneously embedded in the solid lubricant layer (20).

Owner:SIEMENS AG

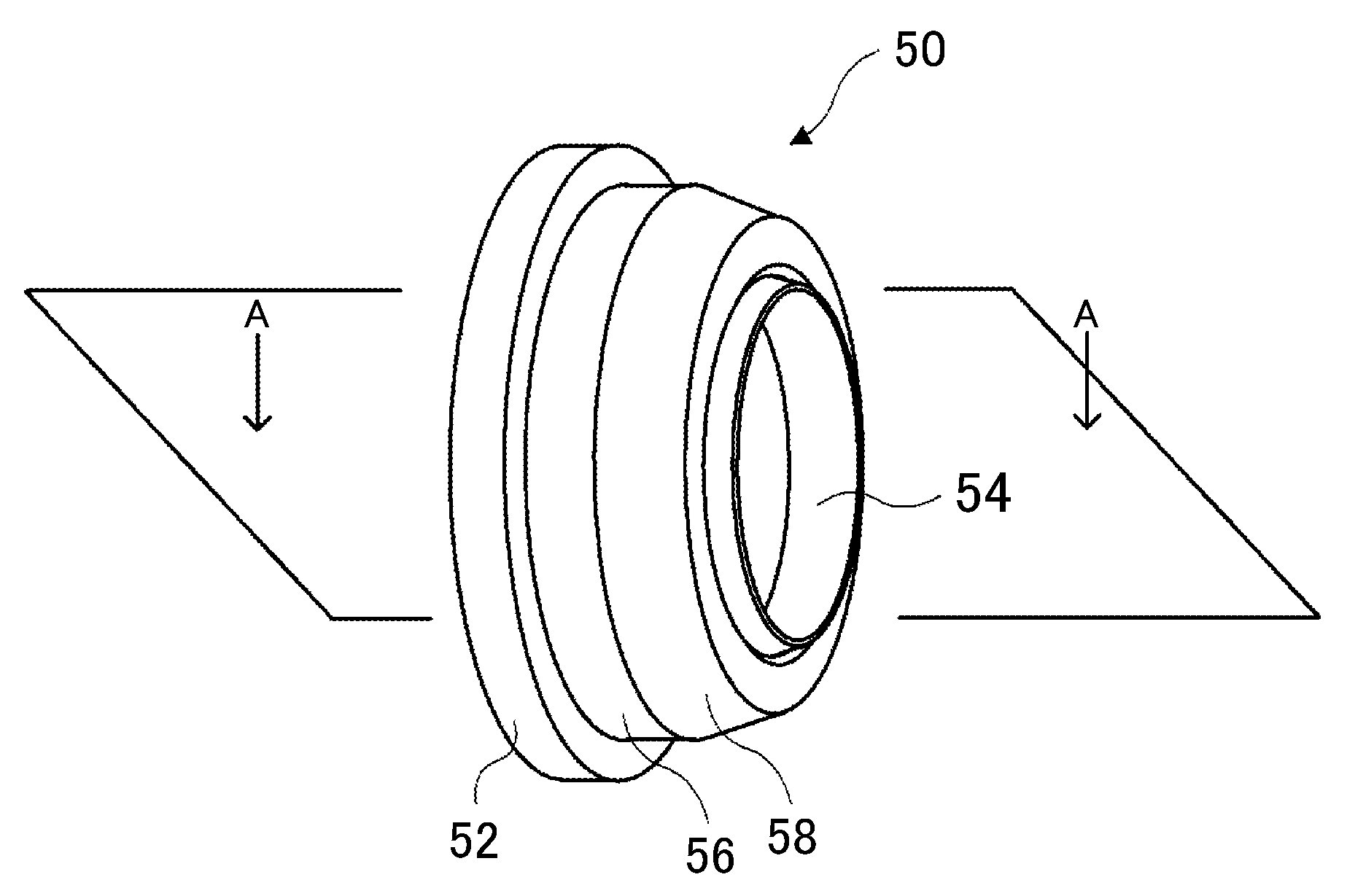

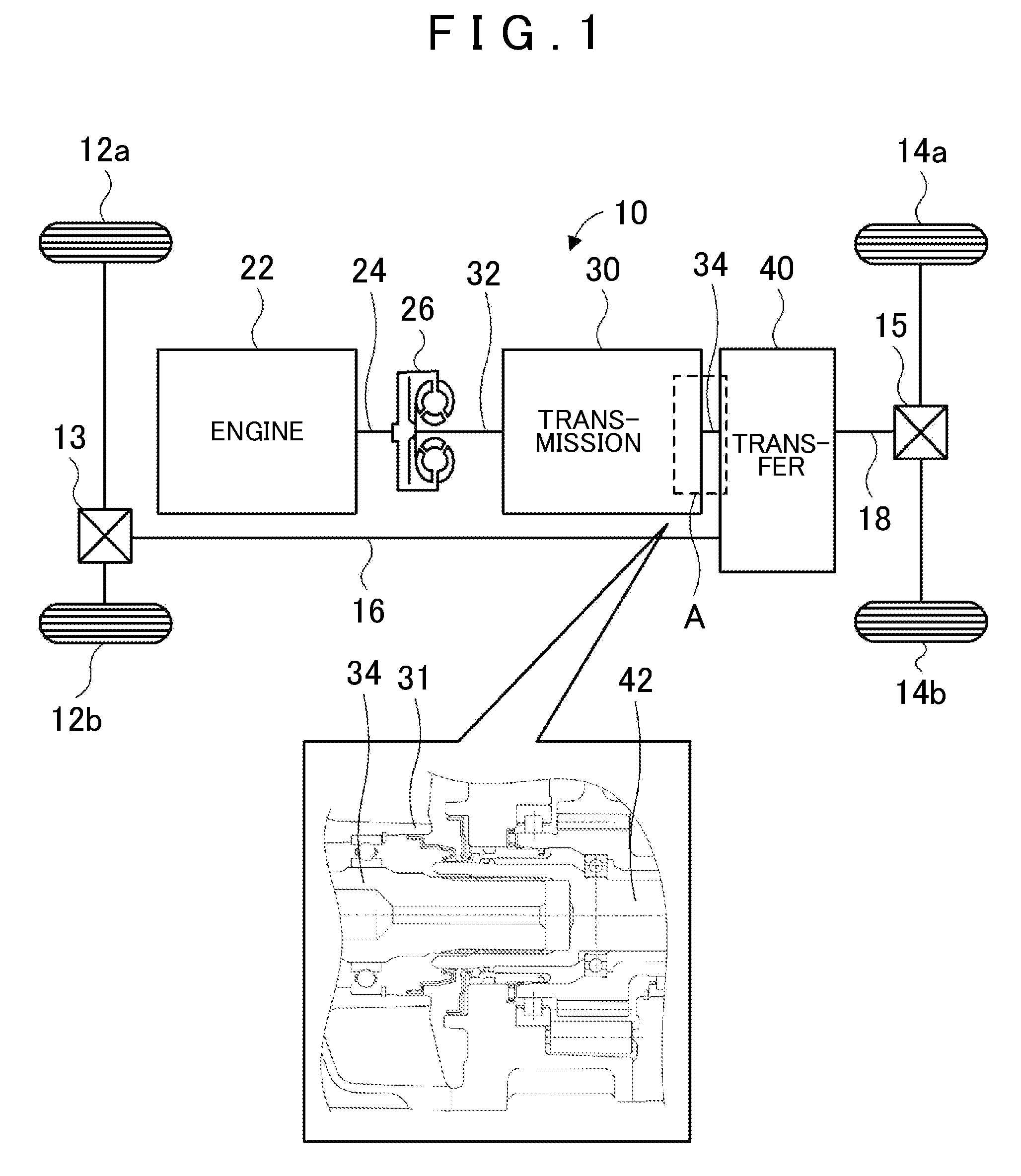

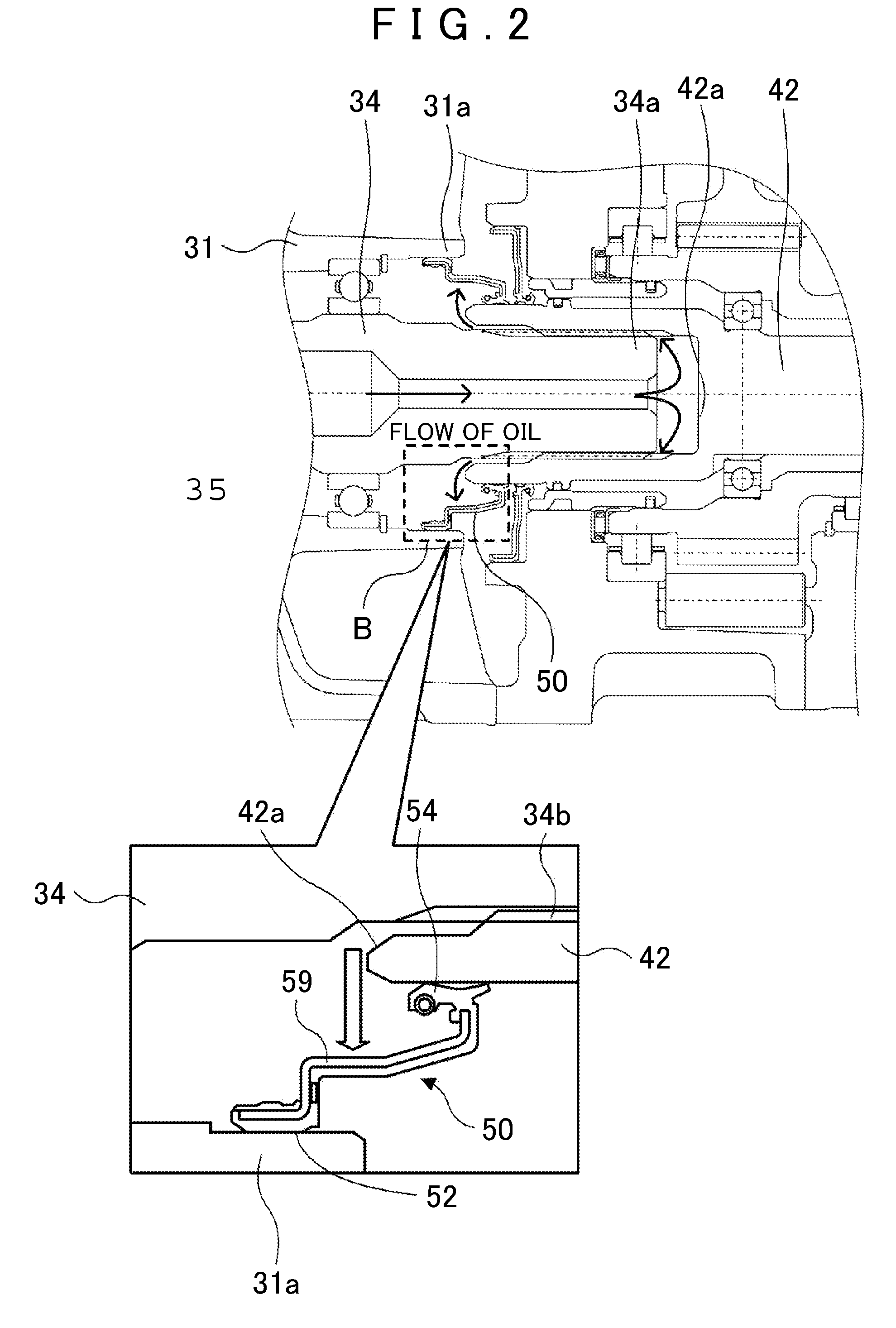

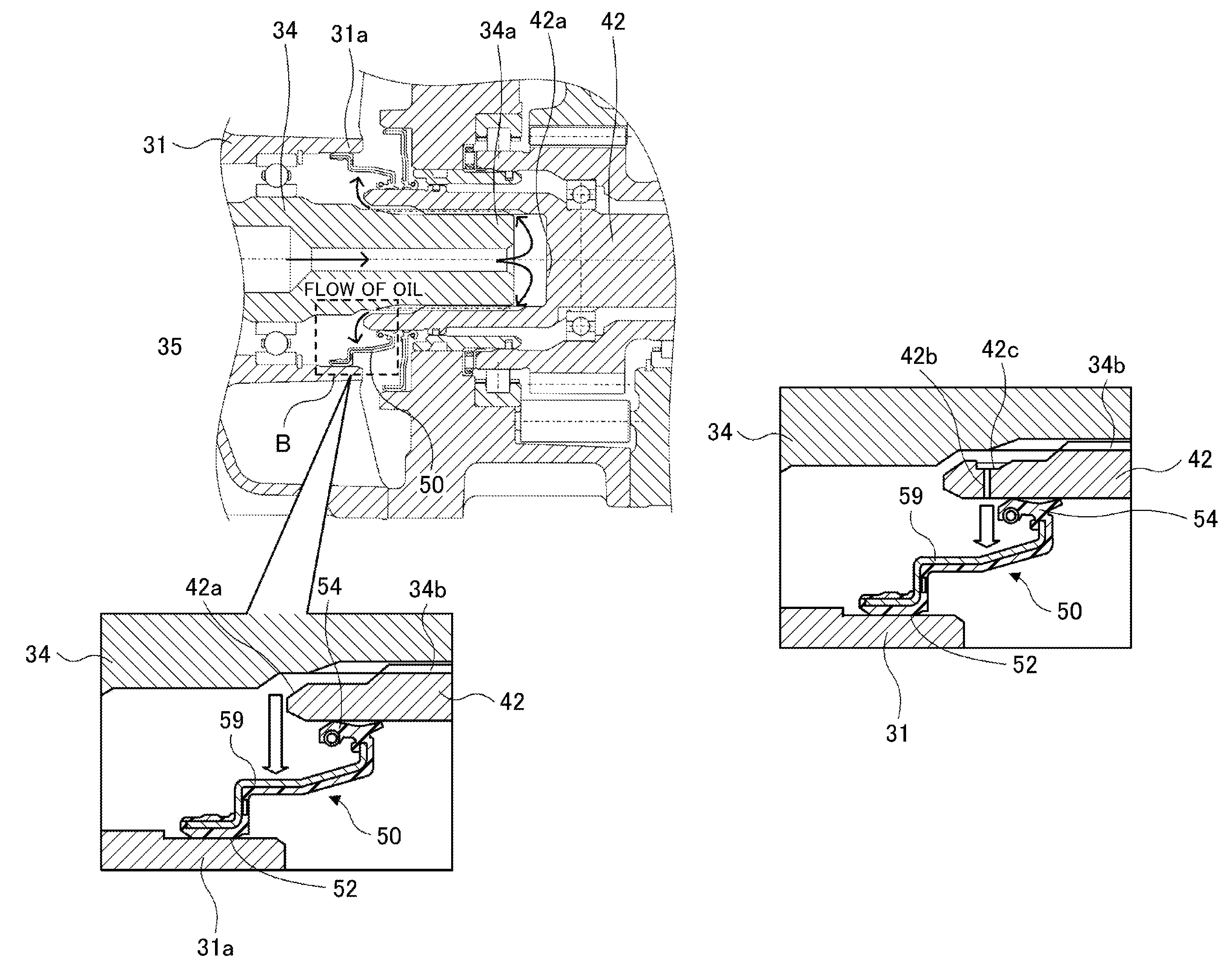

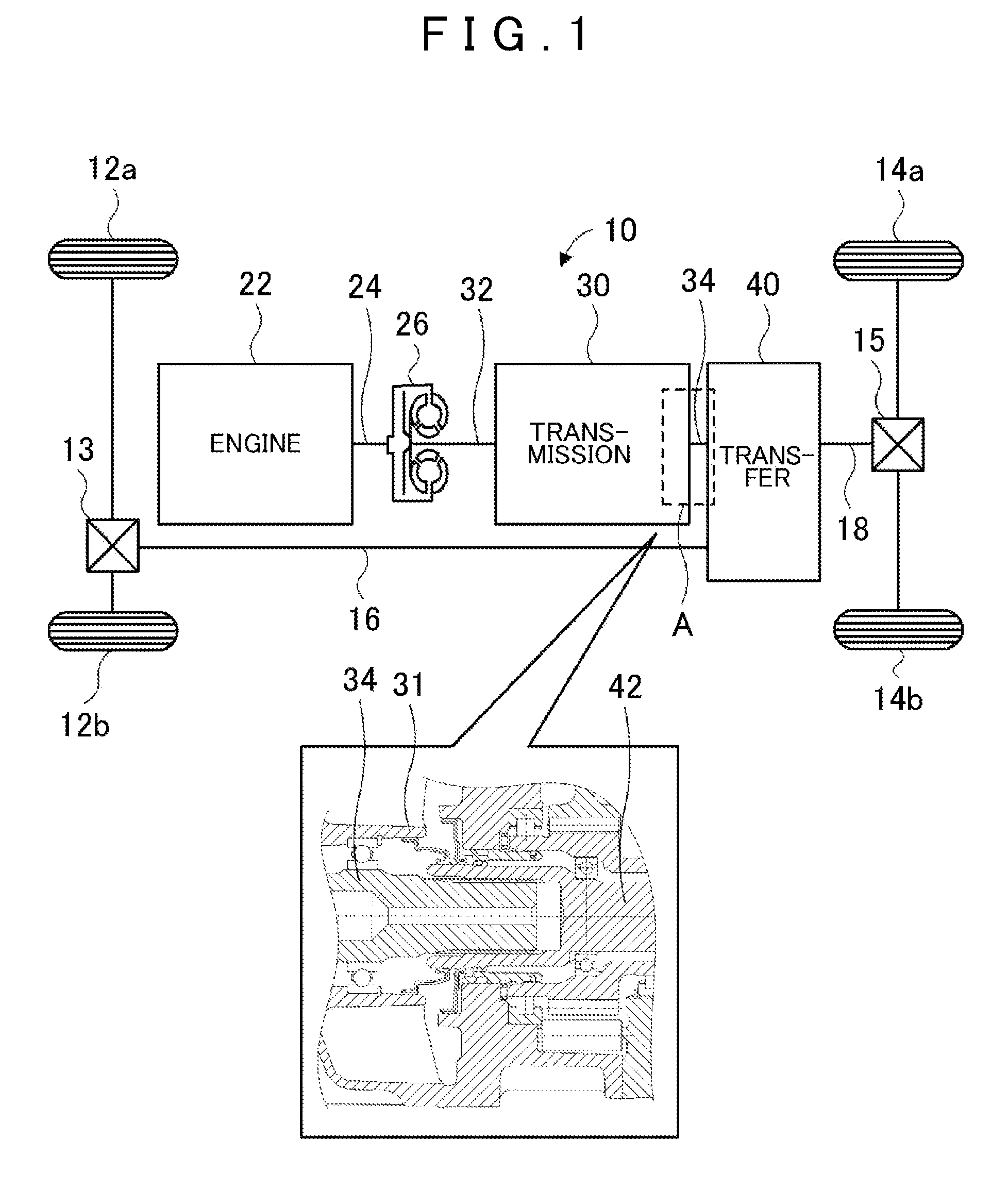

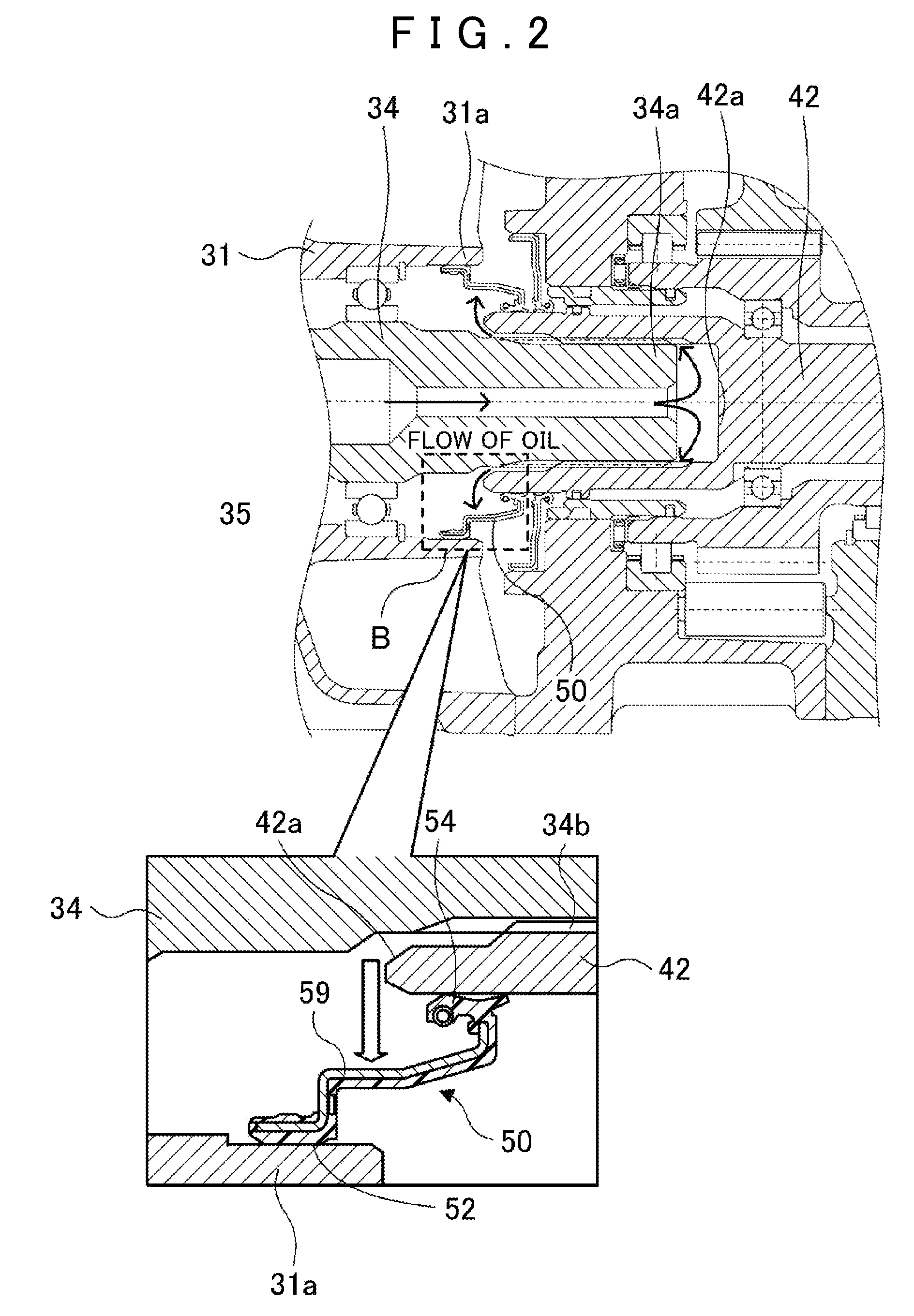

Oil seal and power transmission apparatus

InactiveUS20090243227A1Improve sealingImprove cooling effectEngine sealsShaftsMetallic materialsMotive power

An oil seal for sealing a hollow rotary shaft in a power transmission apparatus, wherein the rotary shaft is formed with an internal flow passage through which oil flows and constituted such that the oil flies out as the rotary shaft rotates, including: a fixed portion that is fixedly attached to a case of the power transmission apparatus; a seal portion that seals the rotary shaft at a position that is axially offset position from the fixed portion and allows the rotary shaft to rotate; and a radiator portion that is formed from a metallic material between the fixed portion and the seal portion, receives the oil that flies out as the rotary shaft rotates, and dissipates heat generated by the seal portion by exchanging heat with the oil.

Owner:AISIN AW CO LTD +1

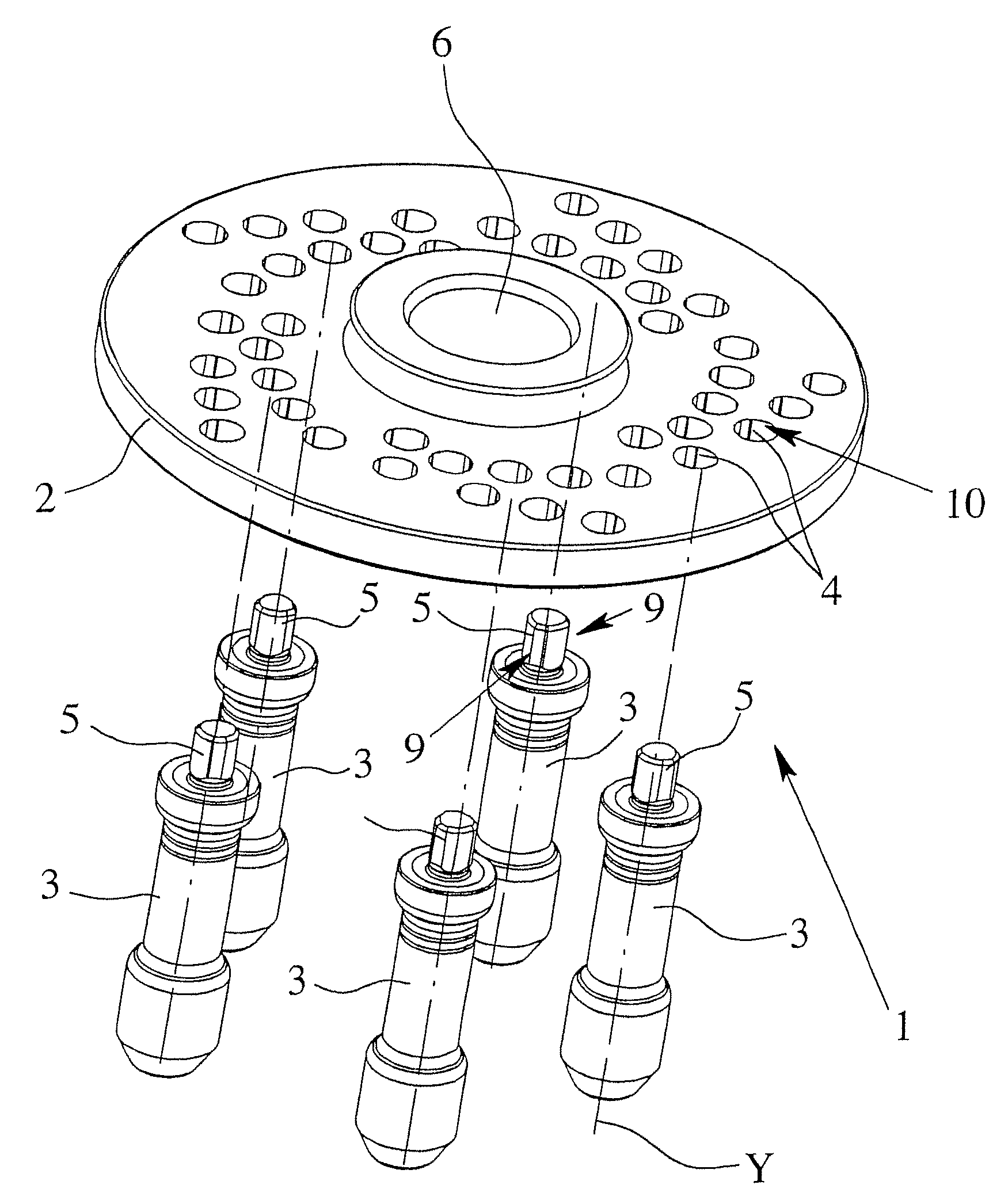

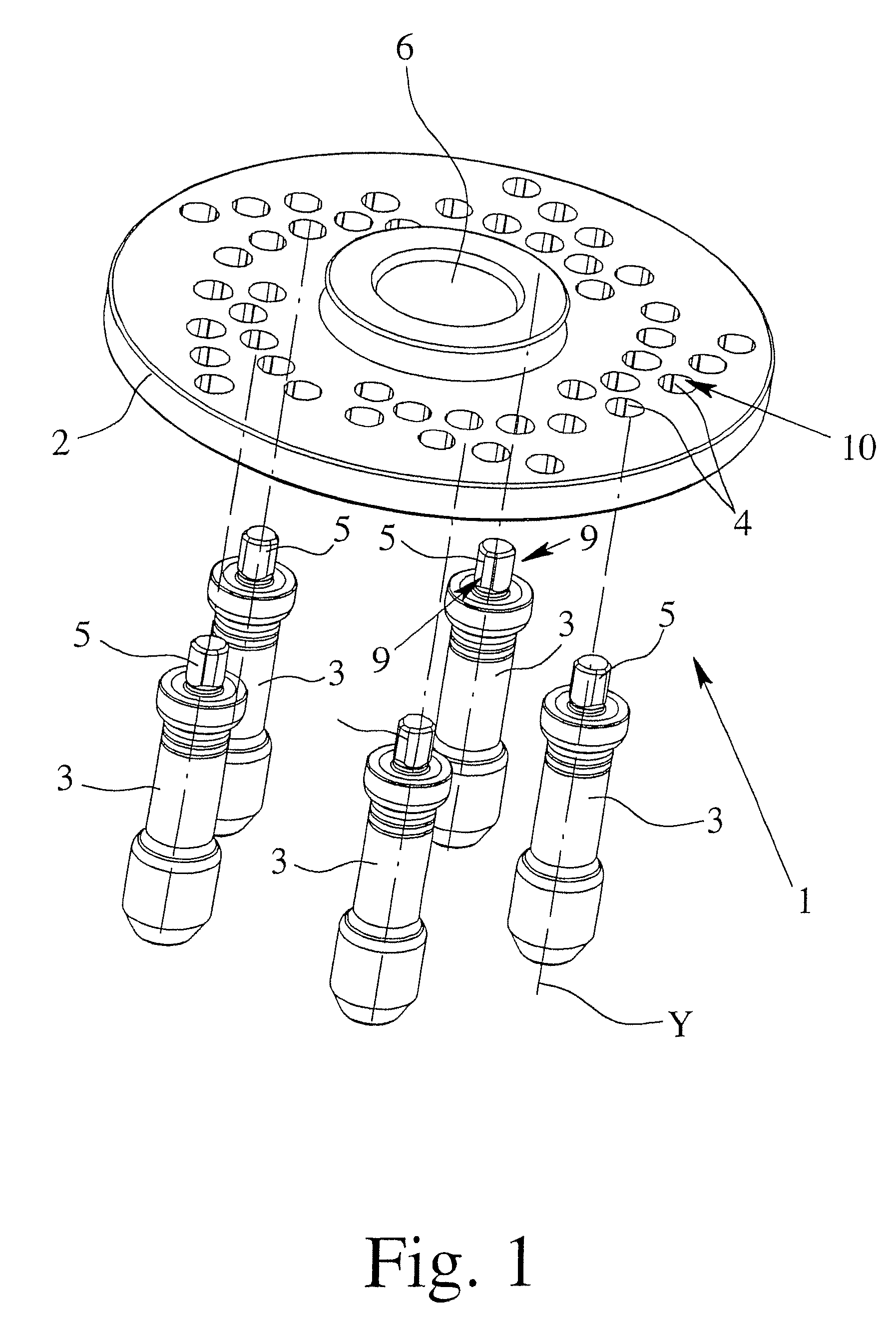

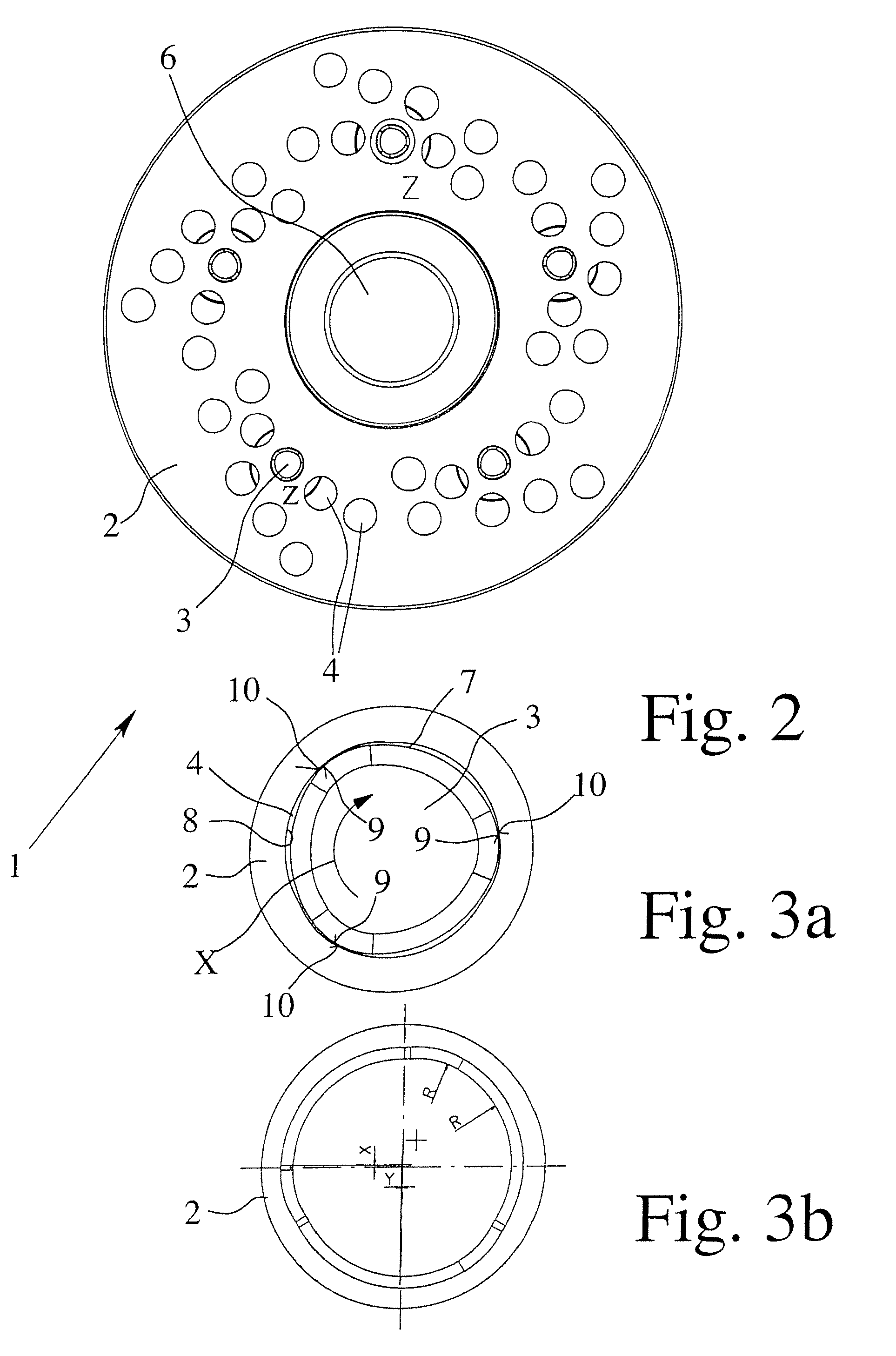

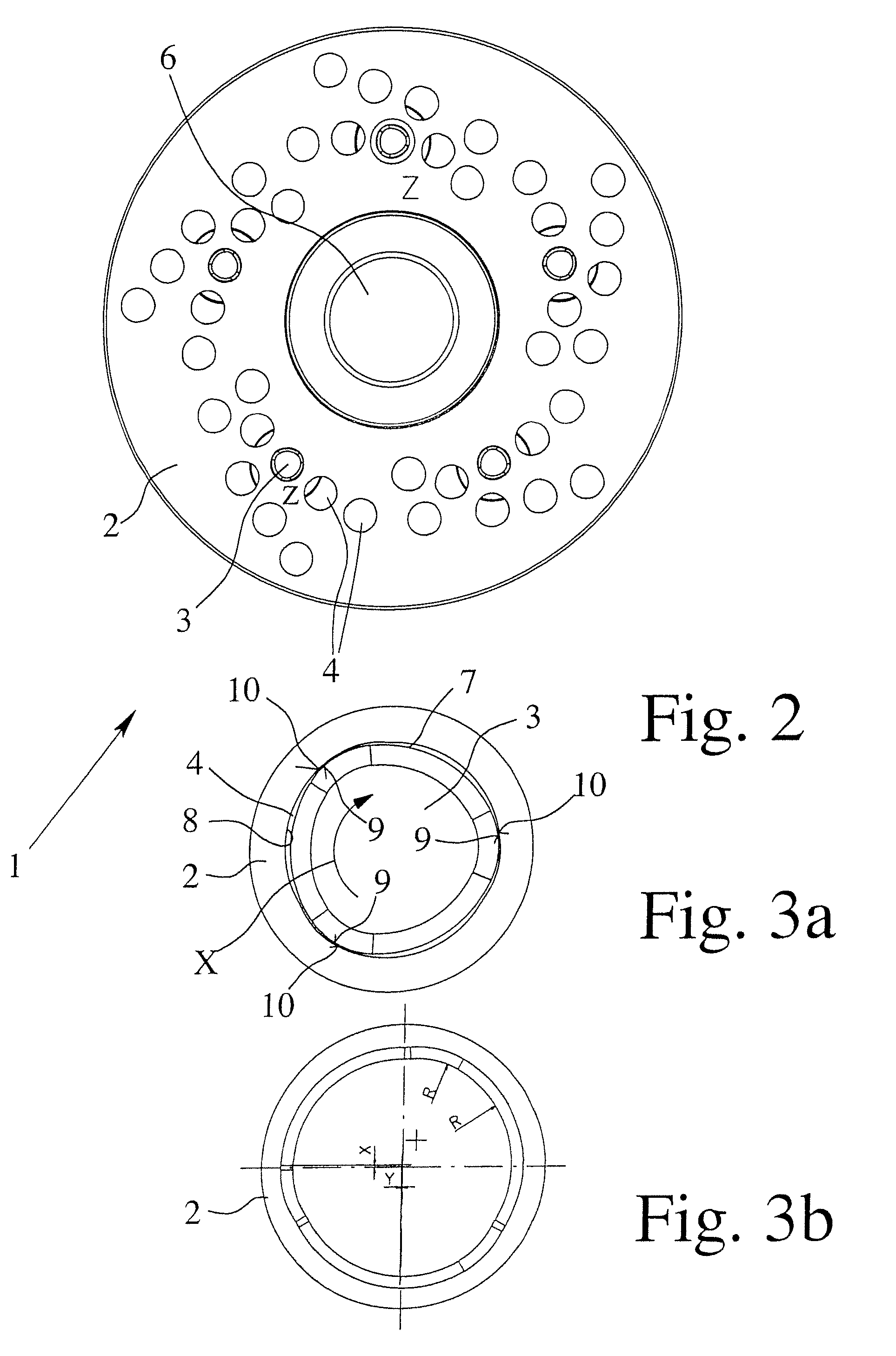

Clamping device

InactiveUS20100101736A1High component strengthWeakening componentAngles/taper measurementsMechanical counters/curvatures measurementsBalancing machineFlange

A clamping device for mounting a vehicle wheel on a balancing machine. The clamping device has a clamping flange and a plurality of centering bolts. The clamping flange is provided with plural sets of recesses for the centering bolts. An insertable section of each centering bolt is removably insertable into a recess. A profiled contour in the insertable section of the centering bolt and an inner contour of a sidewall of the clamping flange delimiting the recess are not circular and have complementary shapes such that the centering bolt is accommodated in the recess such that some sections of the centering bolt can be rotated about the longitudinal axis thereof. When the centering bolt is rotated, at least one subarea of a circumferential surface in the insertable section of the centering bolt frictionally engages with at least one adjacent subarea of the sidewall of the clamping flange delimiting the recess.

Owner:HAWEKA

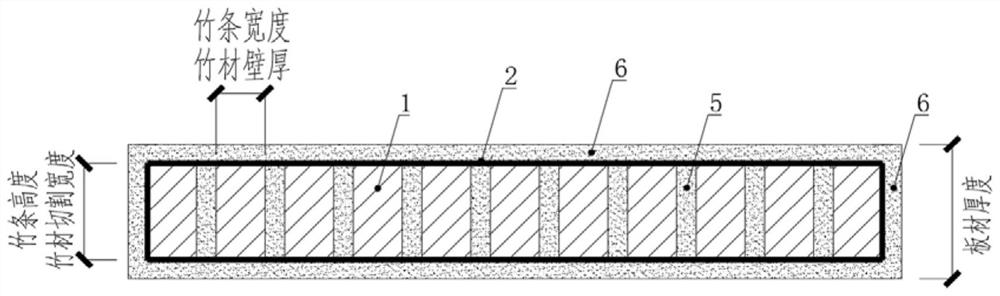

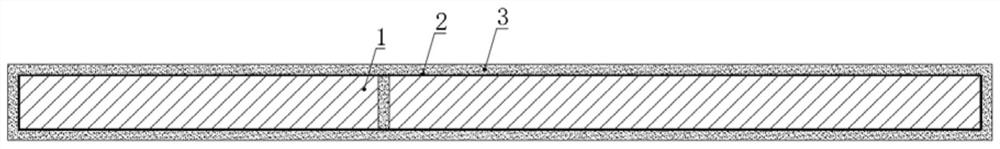

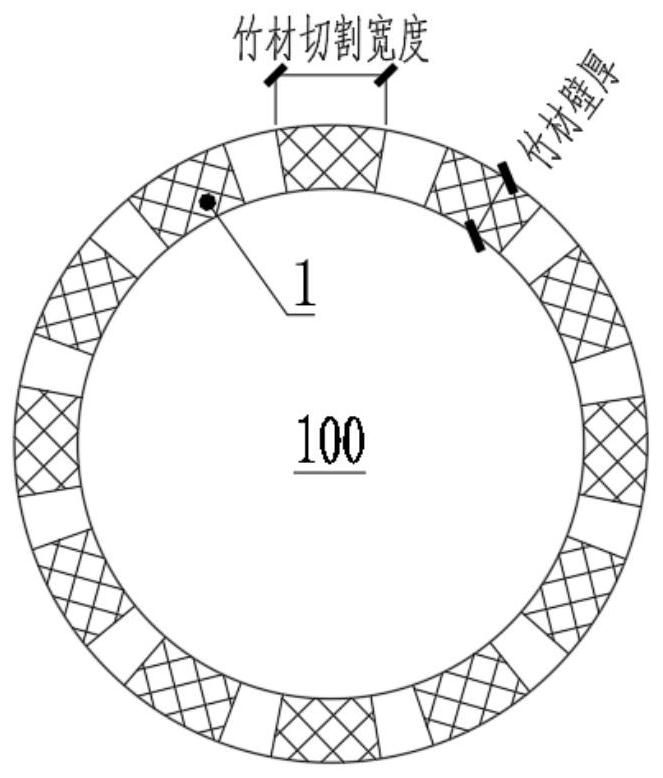

Permanent bamboo-based composite bearing plate and processing technology

The invention relates to a permanent bamboo-based composite bearing plate. The permanent bamboo-based composite bearing plate comprises assembly bamboo canes, fiber gridding cloth and a cementing material, wherein the assembly bamboo canes are formed by longitudinally cutting bamboos, the bamboo canes are vertically placed during assembly, and first gaps are formed between the adjacent bamboo canes at intervals; the fiber gridding cloth is attached to the upper surfaces and the lower surfaces of the assembly bamboo canes and completely wraps the side surfaces and the end surfaces of the assembly bamboo canes from the peripheries; the cementing material is poured into the first gaps, as well as the upper surface and the lower surface of the outer side and the peripheral side surface of thefiber gridding cloth, the cementing material in the first gaps forms thin-wall connecting supporting ribs, and the cementing material on the upper surface and the lower surface of the outer side and the peripheral side surface of the fiber gridding cloth forms a bearing protection bonding layer. The permanent bamboo-based composite bearing plate not only can give consideration to bearing strength,but also can realize the advantages of energy conservation, environmental protection, safety, low consumption, high temperature resistance, low temperature resistance, wear resistance, corrosion resistance, seepage resistance and high fire resistance.

Owner:西藏涛扬集团有限公司

Clamping device

InactiveUS7941933B2High component strengthWeakening componentAngles/taper measurementsMechanical counters/curvatures measurementsBalancing machineEngineering

A clamping device for mounting a vehicle wheel on a balancing machine. The clamping device has a clamping flange and a plurality of centering bolts. The clamping flange is provided with plural sets of recesses for the centering bolts. An insertable section of each centering bolt is removably insertable into a recess. A profiled contour in the insertable section of the centering bolt and an inner contour of a sidewall of the clamping flange delimiting the recess are not circular and have complementary shapes such that the centering bolt is accommodated in the recess such that some sections of the centering bolt can be rotated about the longitudinal axis thereof. When the centering bolt is rotated, at least one subarea of a circumferential surface in the insertable section of the centering bolt frictionally engages with at least one adjacent subarea of the sidewall of the clamping flange delimiting the recess.

Owner:HAWEKA

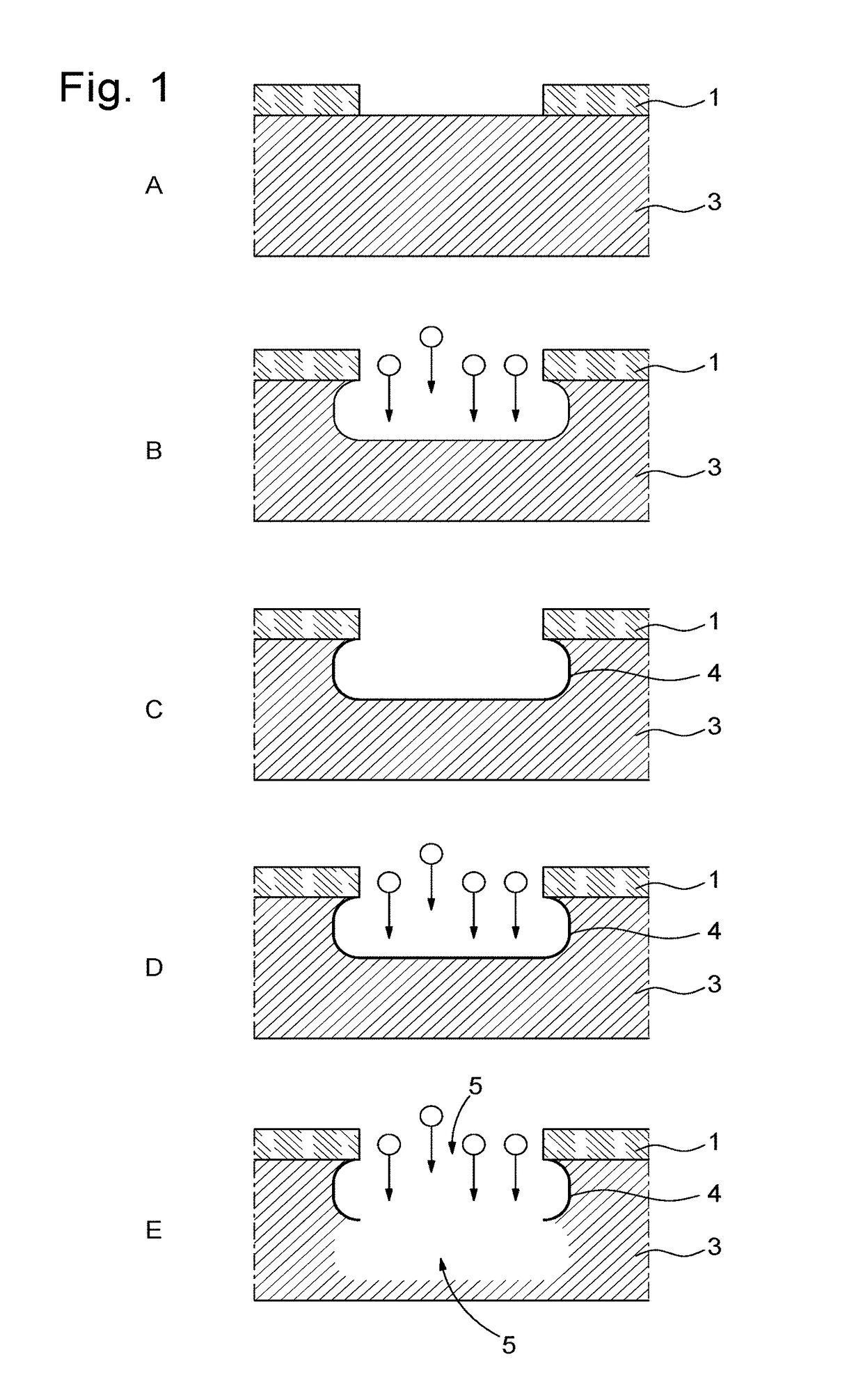

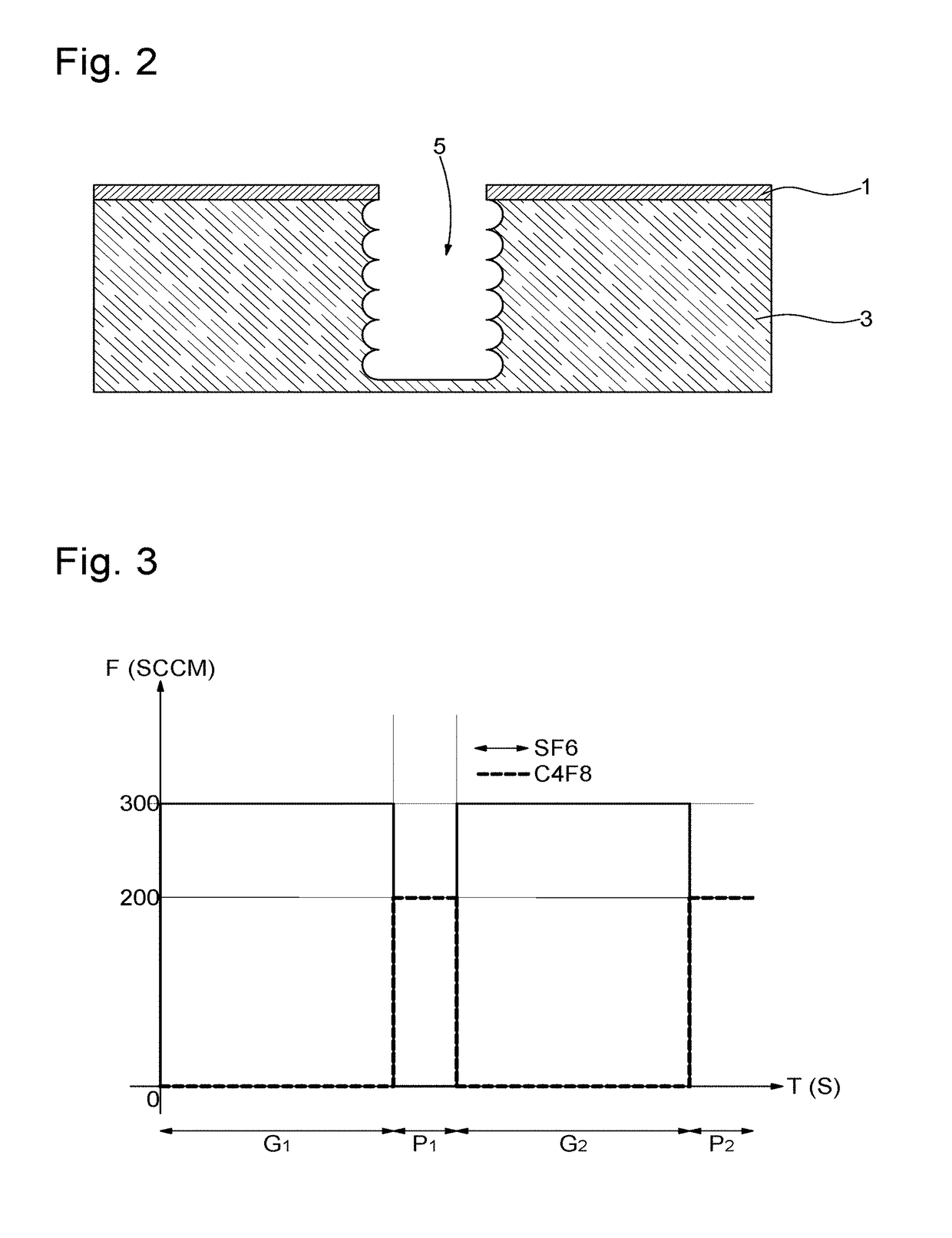

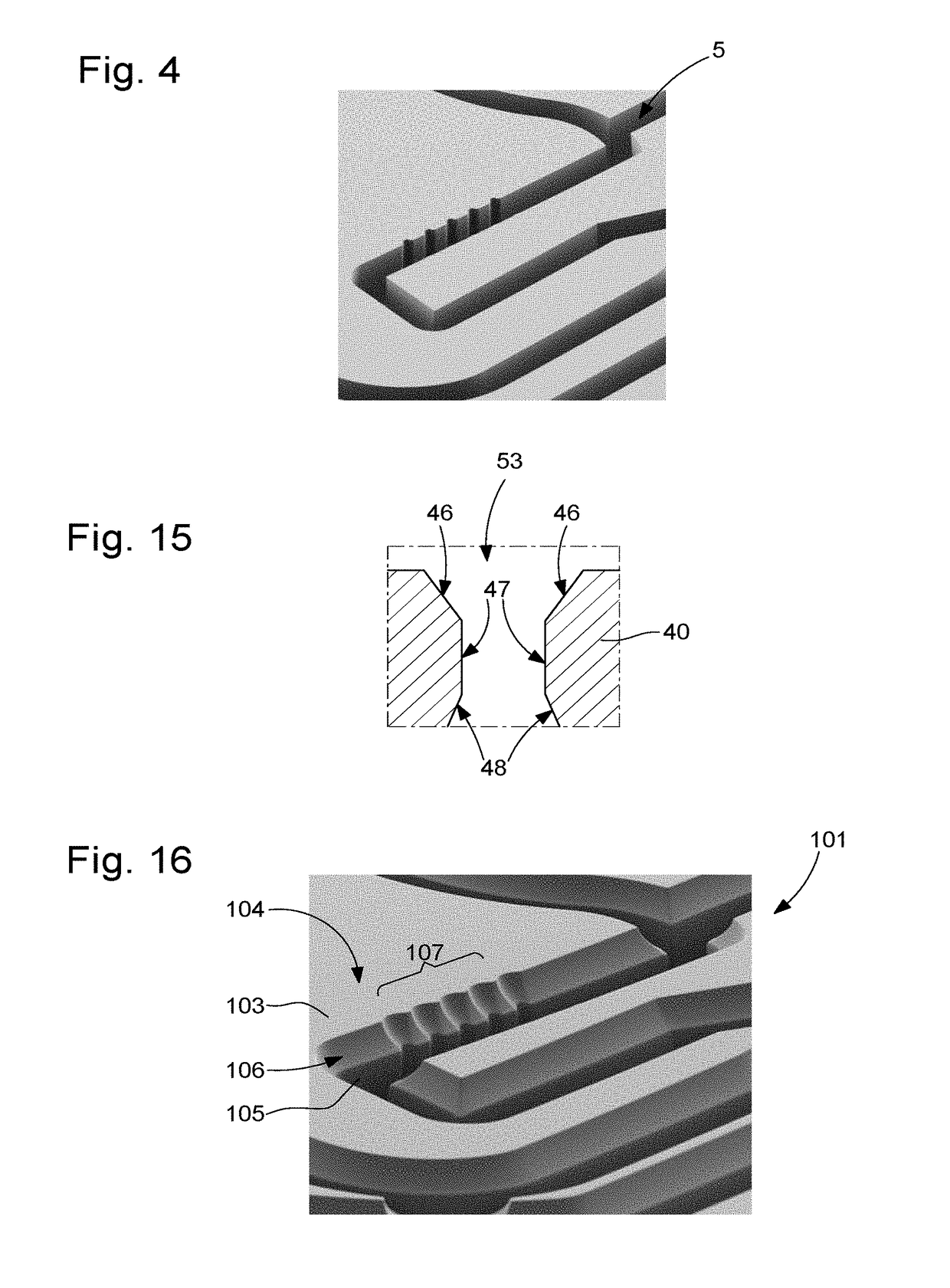

Silicon-based component with at least one chamfer and its fabrication method

ActiveUS10197973B2Improve aestheticsHigh component strengthVisual indicationFrequency stabilisation mechanismUltimate tensile strengthMaterials science

The invention relates to a silicon-based component with at least one chamfer formed from a method combining at least one oblique side wall etching step with a “Bosch” etching of vertical side walls, thereby enabling aesthetic improvement and improvement in the mechanical strength of components formed by micromachining a silicon-based wafer.

Owner:NIVAROX FAR

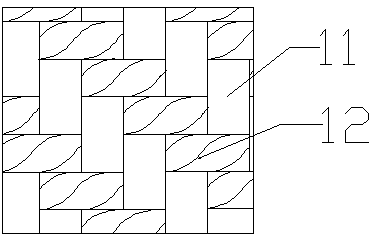

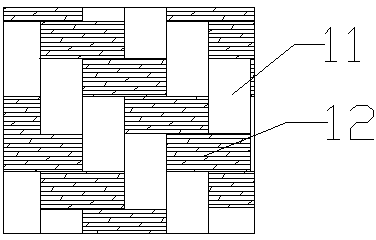

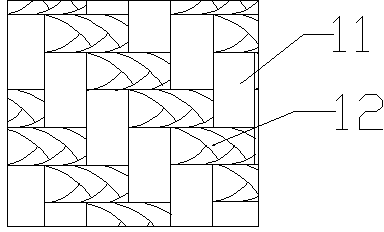

Printed composite mat

The invention discloses a printed composite mat, wherein the surface of the mat is printed, the color fastness is good, the cool degree is adjustable, the air permeability is good, the comfort is good, and the mat is safe and wholesome, can be used for a long time and convenient to fold and store. The mat comprises the mat surface and a liner layer, wherein the mat surface is formed by weaving warps and wefts, the warps and the wefts are in a flat belt shape, the component of the warps is regenerated fiber, the component of the wefts is any of or a combination of two or three of polyester fiber, jute fiber and bamboo fiber, and the mat surface is printed. The mat is suitable for being used by people at various ages in four seasons, and can meet double requirements of people for use quality and appearance of a summer sleeping mat.

Owner:台州市丝丝美席业股份有限公司

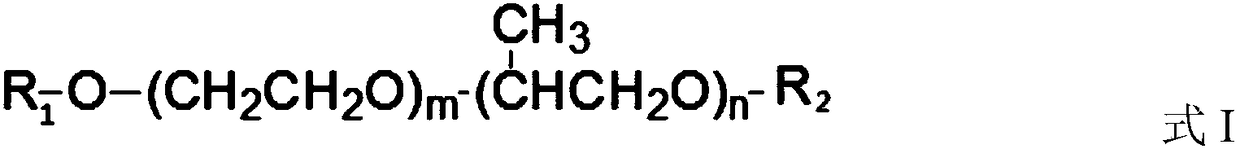

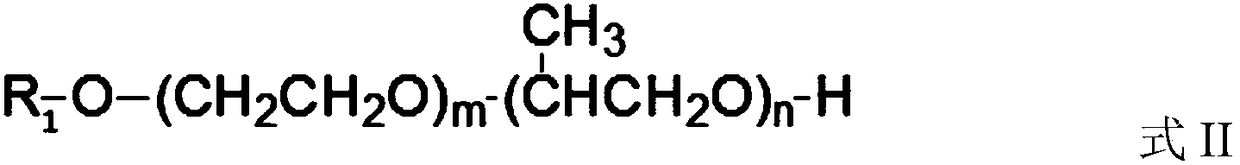

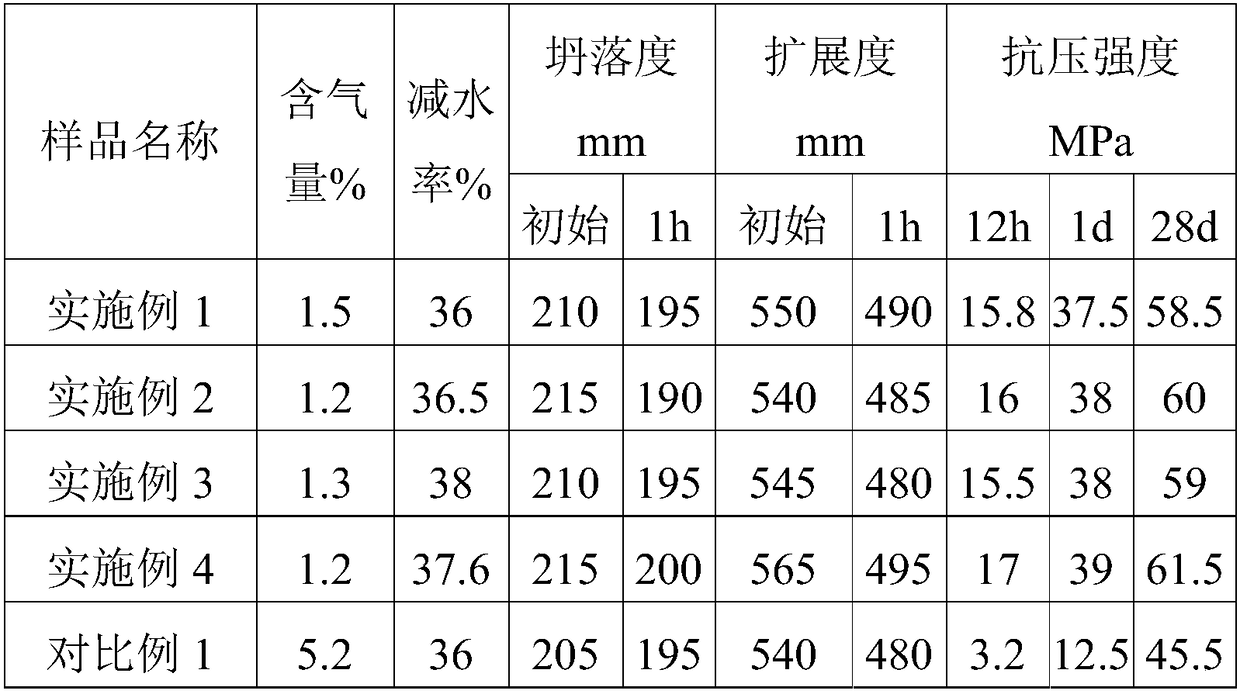

Polycarboxylate-type water reducing agent as well as preparation method and application thereof

The invention discloses a polycarboxylate-type water reducing agent as well as a preparation method and an application thereof. The polycarboxylate-type water reducing agent is prepared from the following raw materials in parts by mass: 100 parts of monomer A, 10-20 parts of liquid-state unsaturated carboxylic acid, 3-8 parts of unsaturated amide, 0.6-2 parts of initiator, 0.15-0.5 part of reducing agent, 0.6-2 parts of chain transfer agent, 8-20 parts of neutralizing agent and 80-150 parts of water. In the water reducing agent disclosed by the invention, through synergistic effect of the components, the surface tension can be adjusted to realize relatively low air entraining performance, bubbles mixed in the gel material are remarkably reduced, the product surface is denser and more beautiful, and the component strength is enhanced; the cement hydration process can be promoted to improve the early strength; and moreover, the dispersing power is enhanced, the water consumption for thegel material is reduced, the particles are dispersed, and the hydration degree is better.

Owner:SHANGHAI DONGDA CHEM

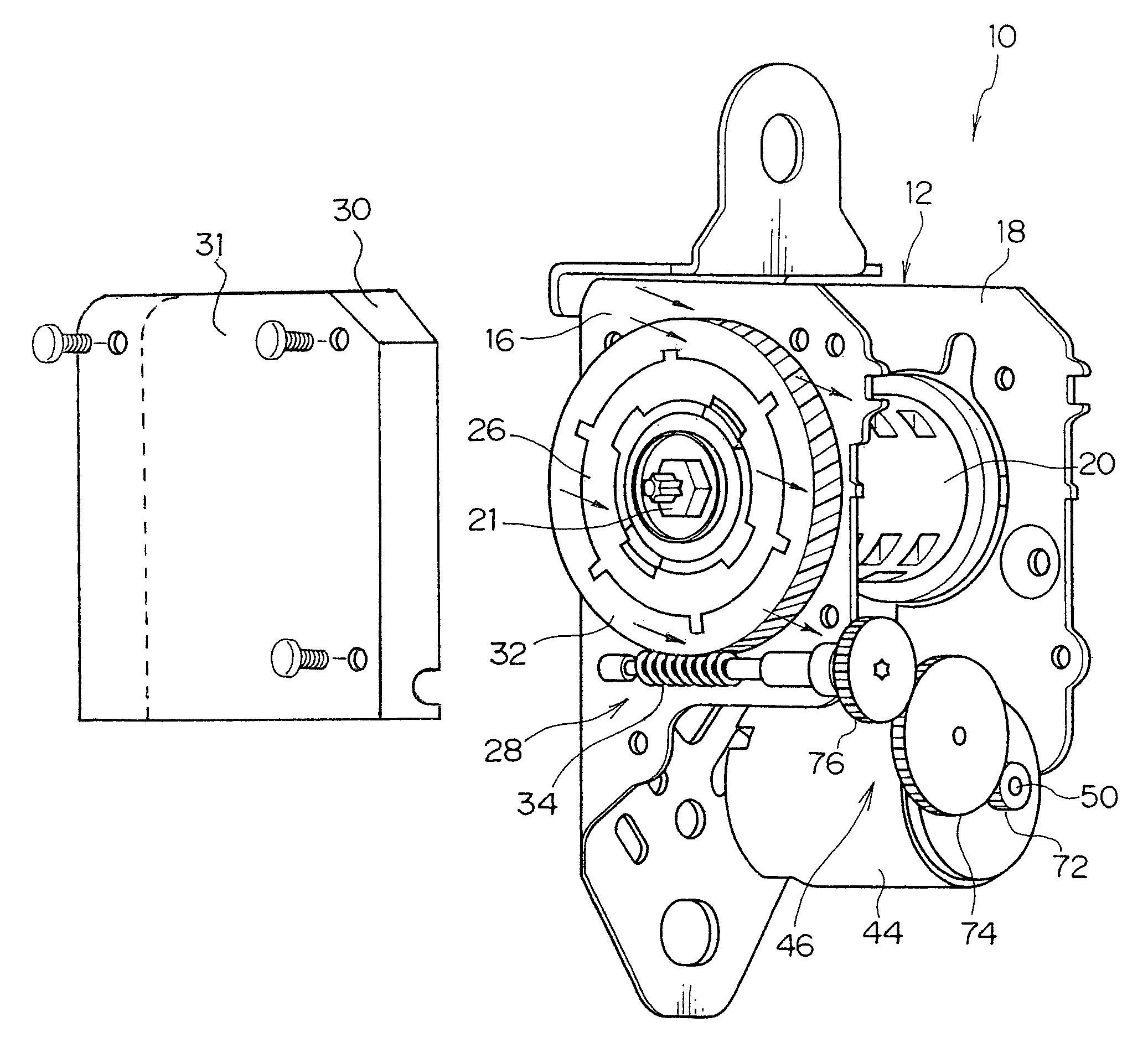

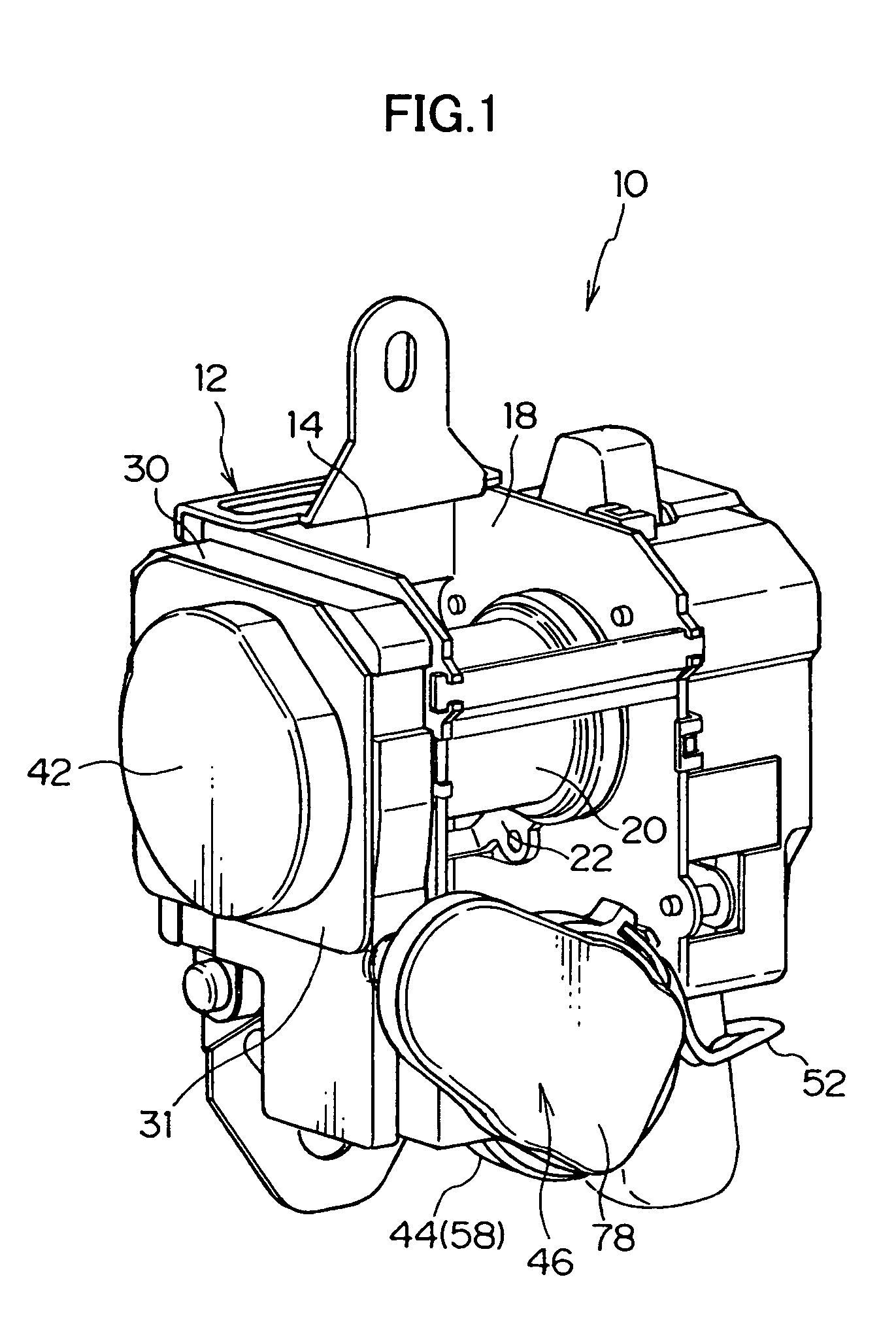

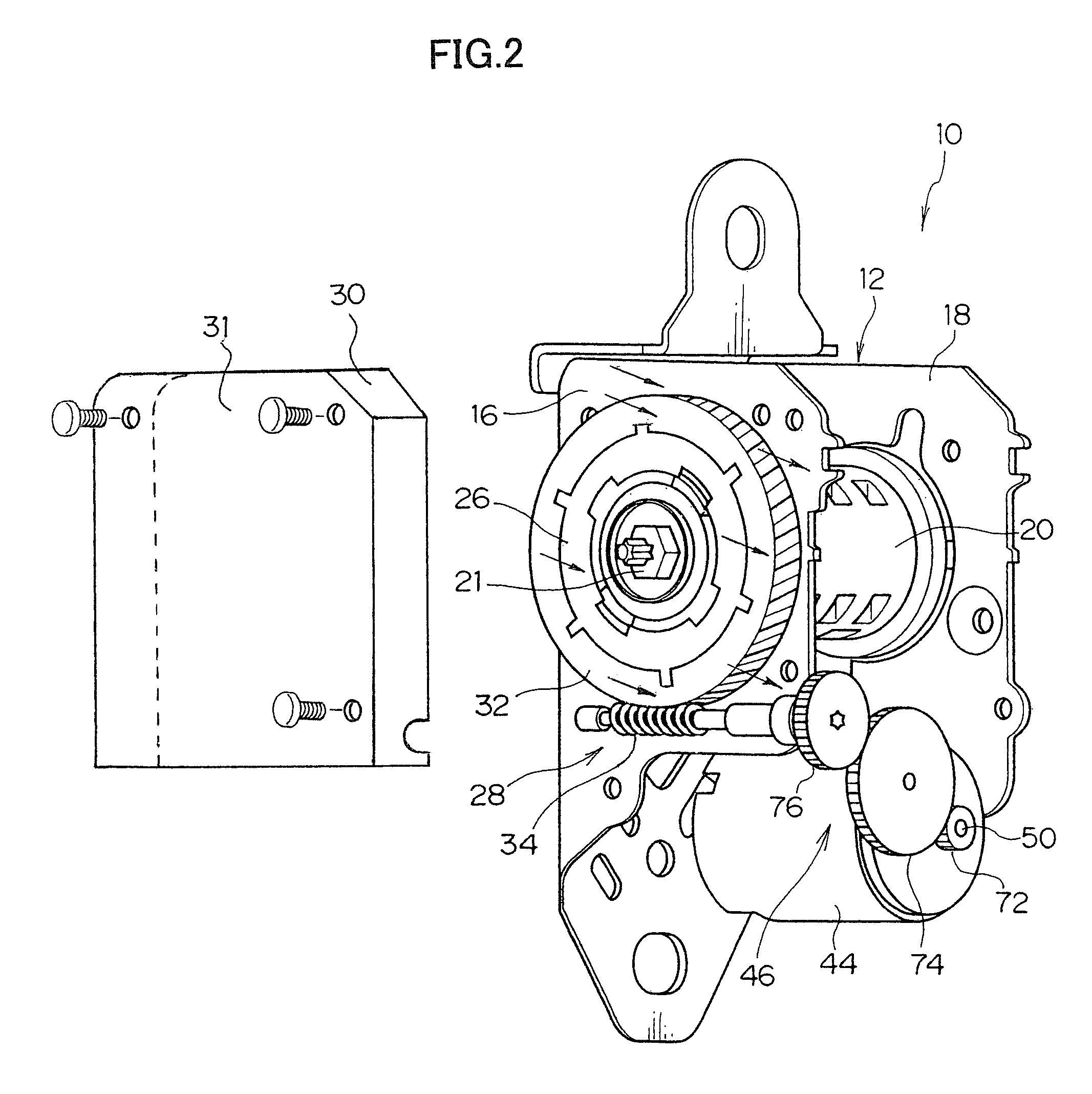

Webbing take-up device

ActiveUS8028949B2Good effectHigh component strengthBelt retractorsBelt control systemsGear wheelEngineering

Owner:KK TOKAI RIKA DENKI SEISAKUSHO

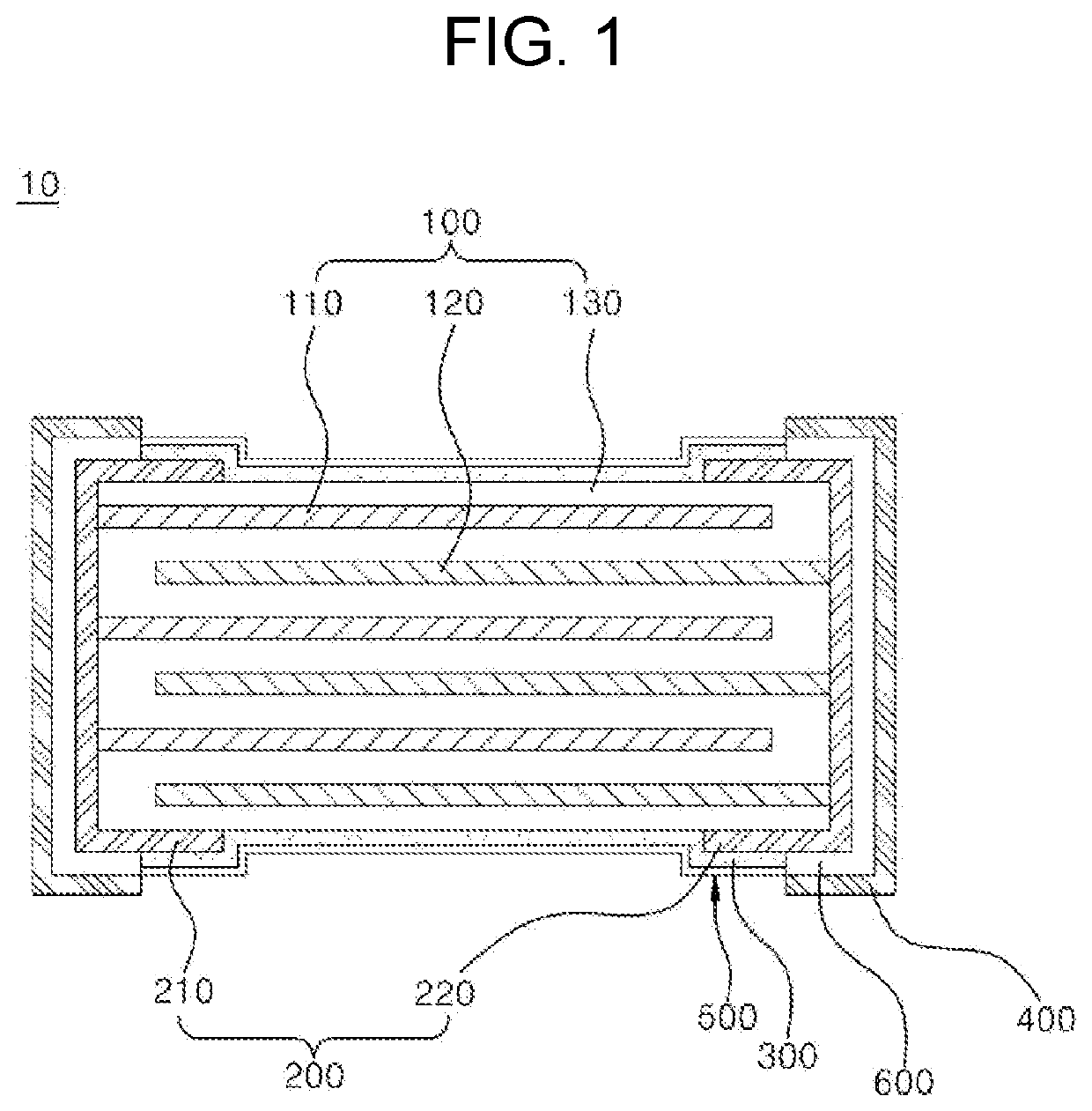

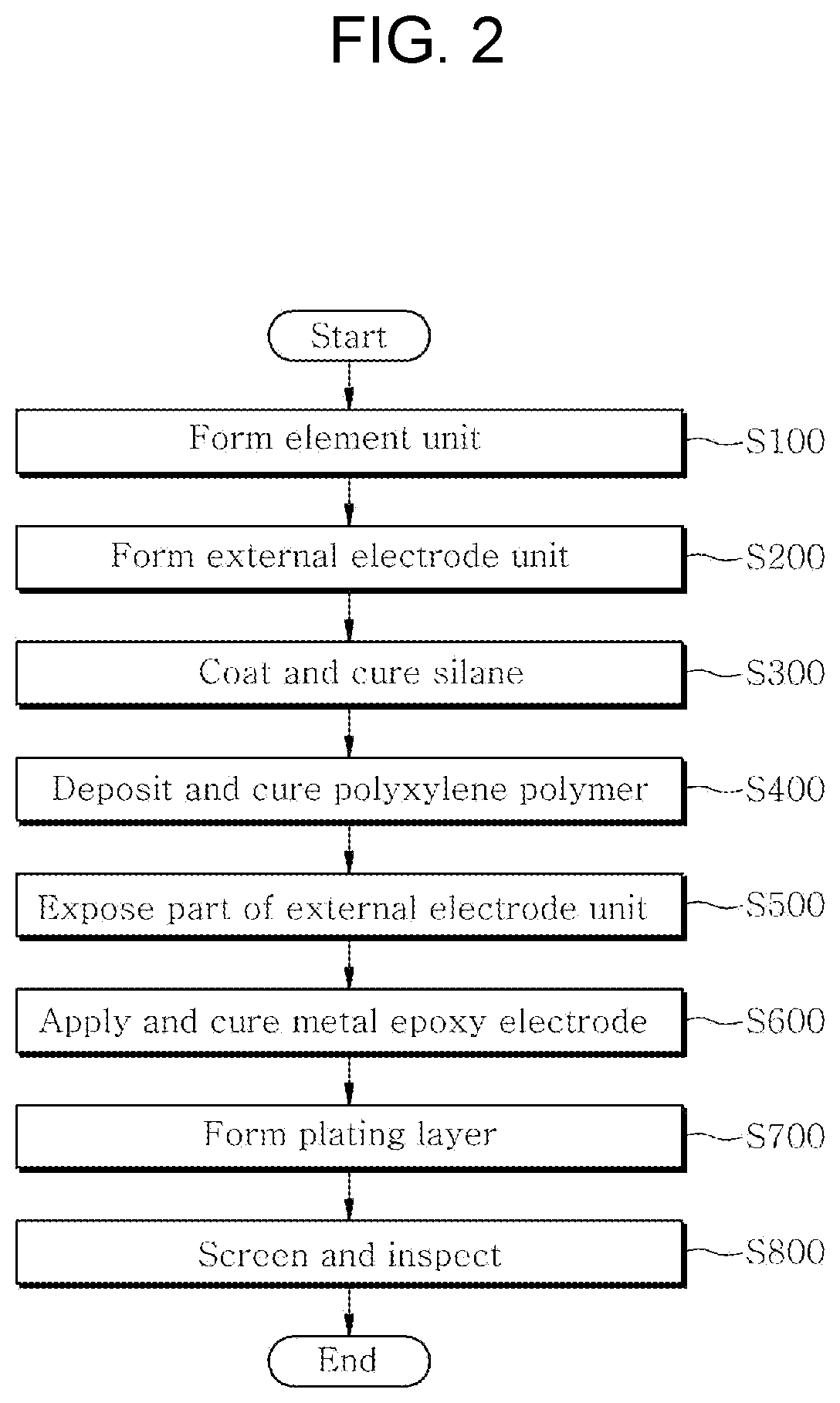

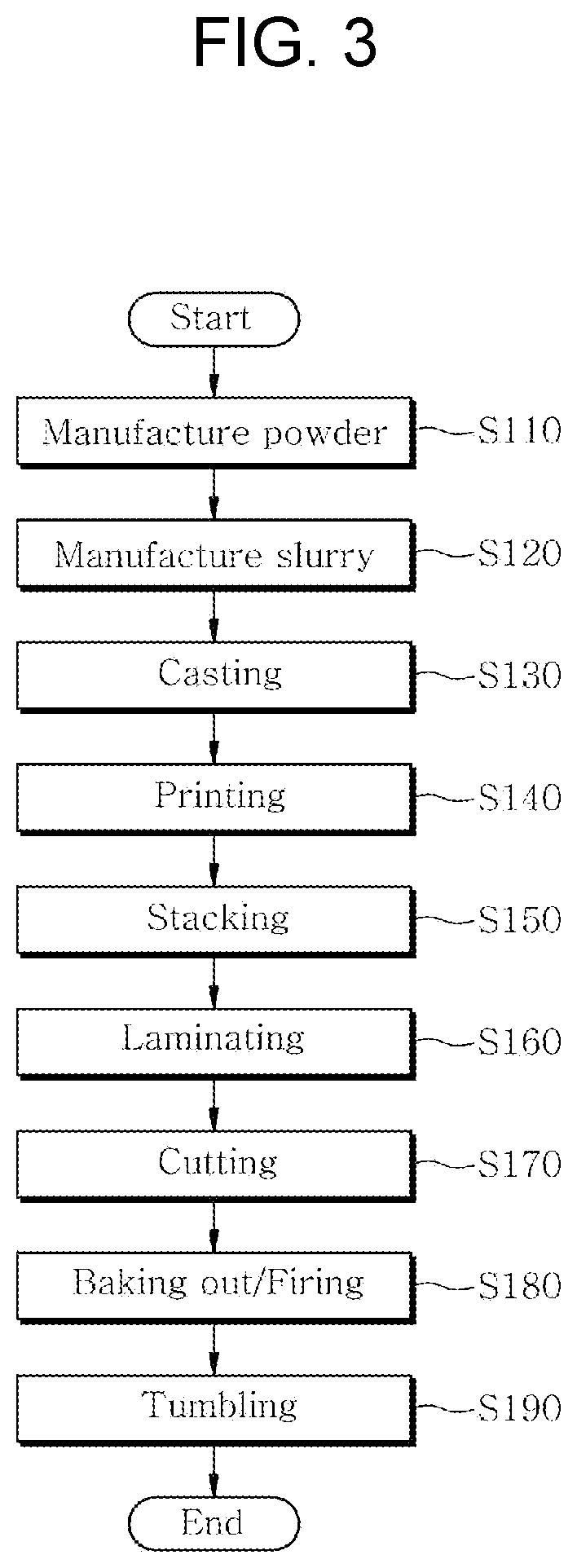

Multilayer ceramic electronic component and manufacturing method thereof

ActiveUS20210319953A1Extend the lifespanImprove reliabilityFixed capacitor electrodesFixed capacitor dielectricElectronic componentComposite material

Owner:SAMHWA CAPACITOR

Oil seal and power transmission apparatus

InactiveUS8262093B2Improve sealingImprove cooling effectEngine sealsShaftsMetallic materialsEngineering

An oil seal for sealing a hollow rotary shaft in a power transmission apparatus, wherein the rotary shaft is formed with an internal flow passage through which oil flows and constituted such that the oil flies out as the rotary shaft rotates, including: a fixed portion that is fixedly attached to a case of the power transmission apparatus; a seal portion that seals the rotary shaft at a position that is axially offset position from the fixed portion and allows the rotary shaft to rotate; and a radiator portion that is formed from a metallic material between the fixed portion and the seal portion, receives the oil that flies out as the rotary shaft rotates, and dissipates heat generated by the seal portion by exchanging heat with the oil.

Owner:AISIN AW CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com