Patents

Literature

30results about How to "Cost-effective and flexible" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

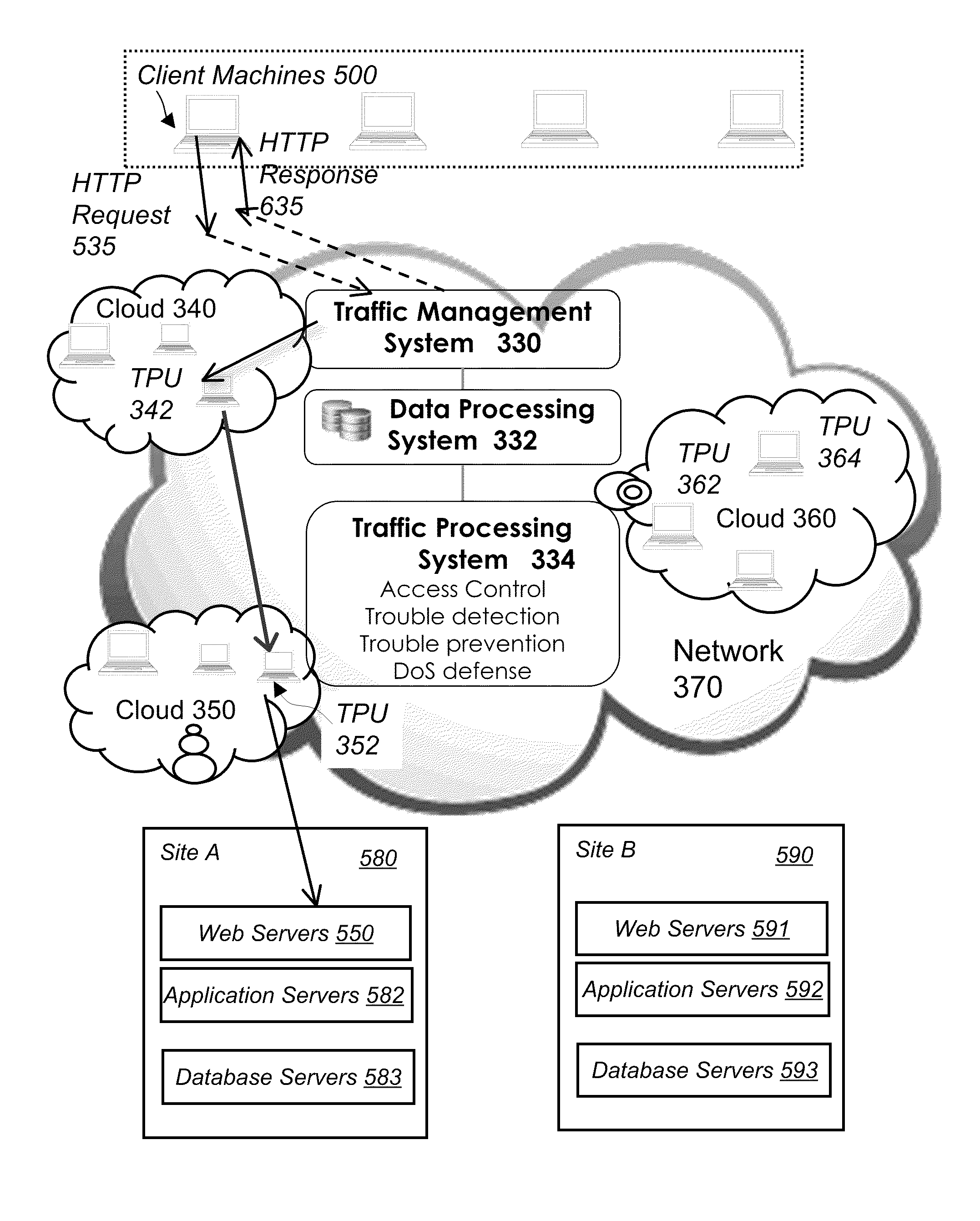

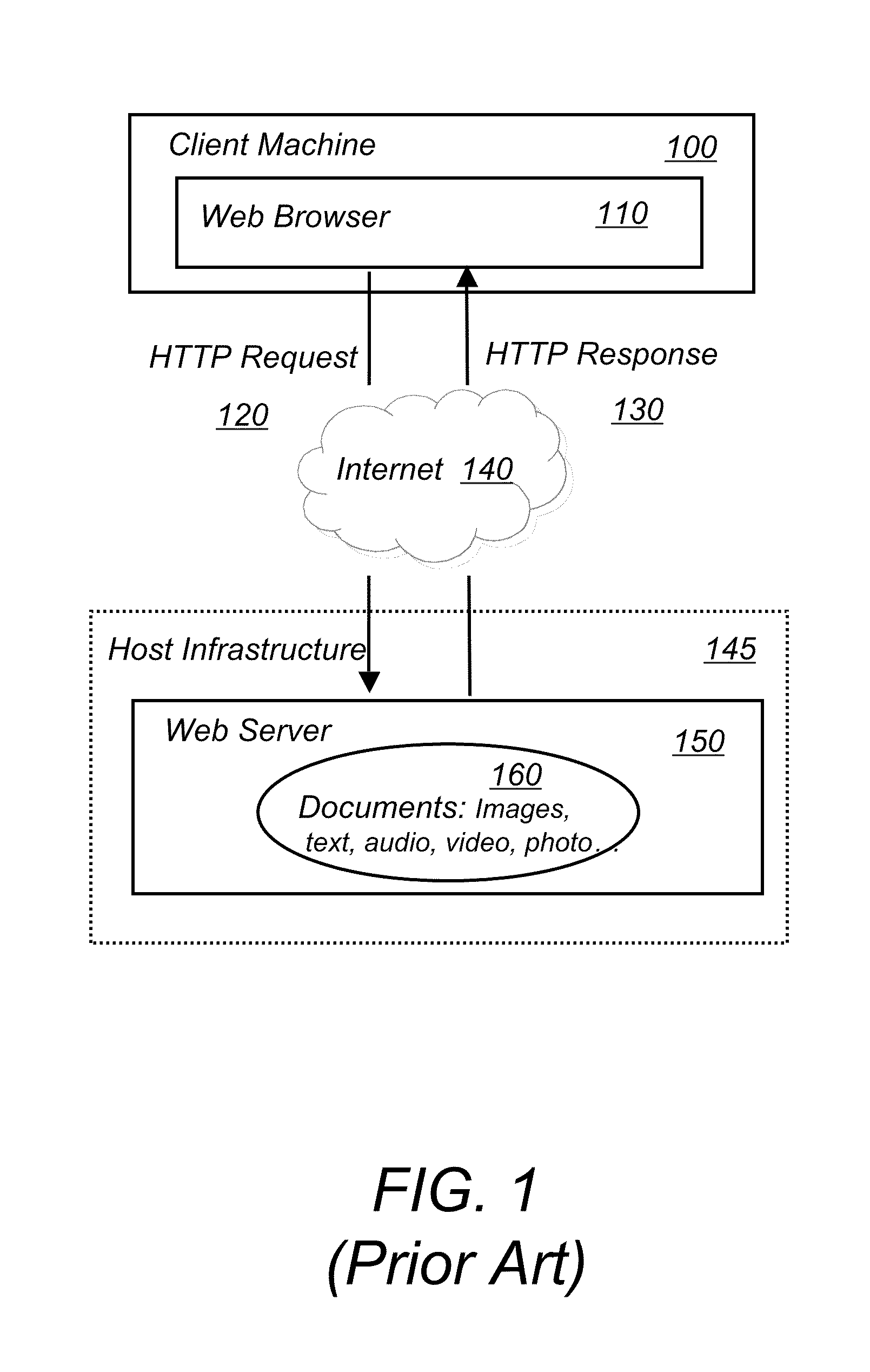

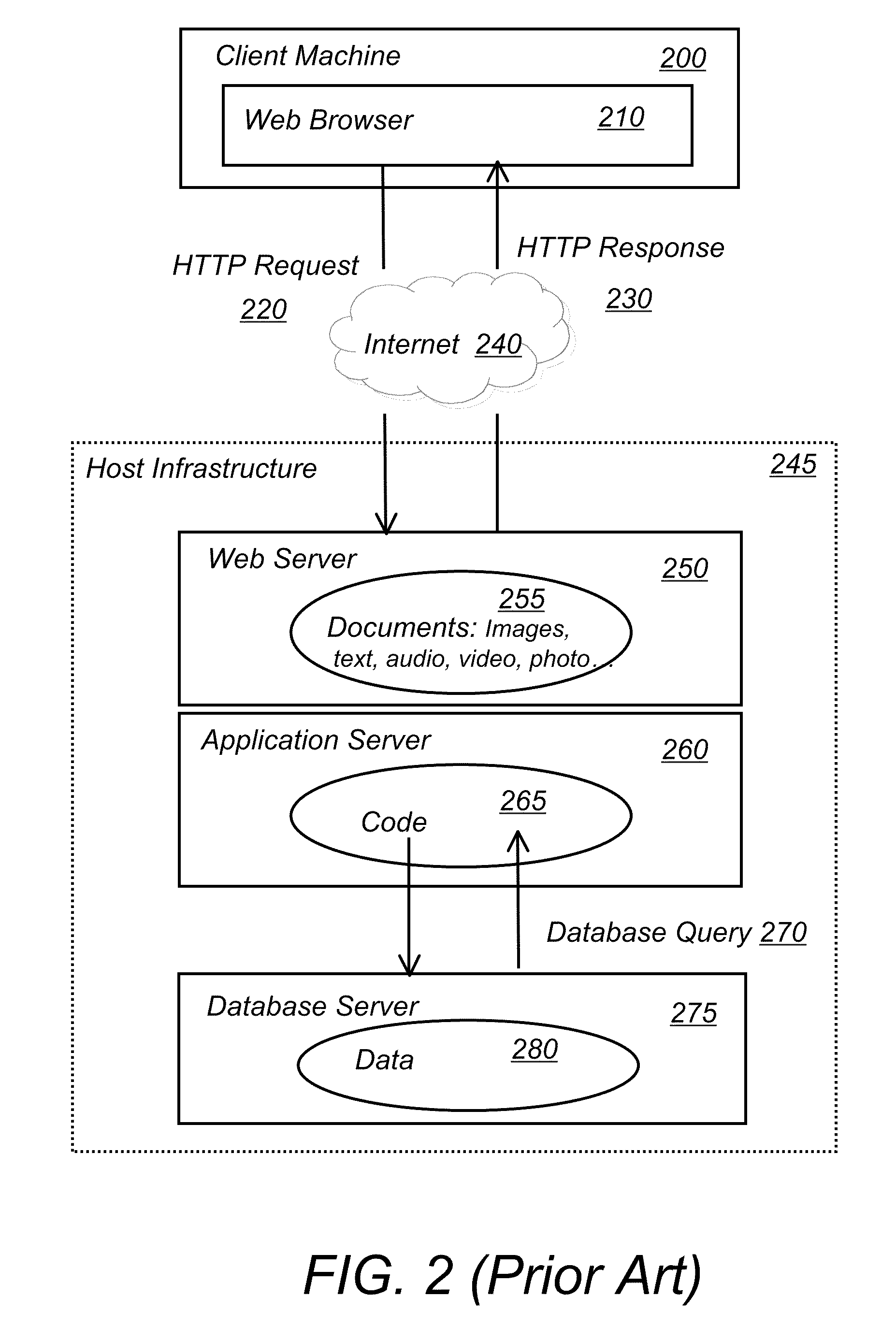

System and method for network traffic management and load balancing

InactiveUS20100223364A1Improve application performanceImprove availabilityMultiple digital computer combinationsLocation information based serviceTraffic capacityFailover

A method for providing load balancing and failover among a set of computing nodes running a network accessible computer service includes providing a computer service that is hosted at one or more servers comprised in a set of computing nodes and is accessible to clients via a first network. Providing a second network including a plurality of traffic processing nodes and load balancing means. The load balancing means is configured to provide load balancing among the set of computing nodes running the computer service. Providing means for redirecting network traffic comprising client requests to access the computer service from the first network to the second network. Providing means for selecting a traffic processing node of the second network for receiving the redirected network traffic comprising the client requests to access the computer service and redirecting the network traffic to the traffic processing node via the means for redirecting network traffic. For every client request for access to the computer service, determining an optimal computing node among the set of computing nodes running the computer service by the traffic processing node via the load balancing means, and then routing the client request to the optimal computing node by the traffic processing node via the second network.

Owner:YOTTAA

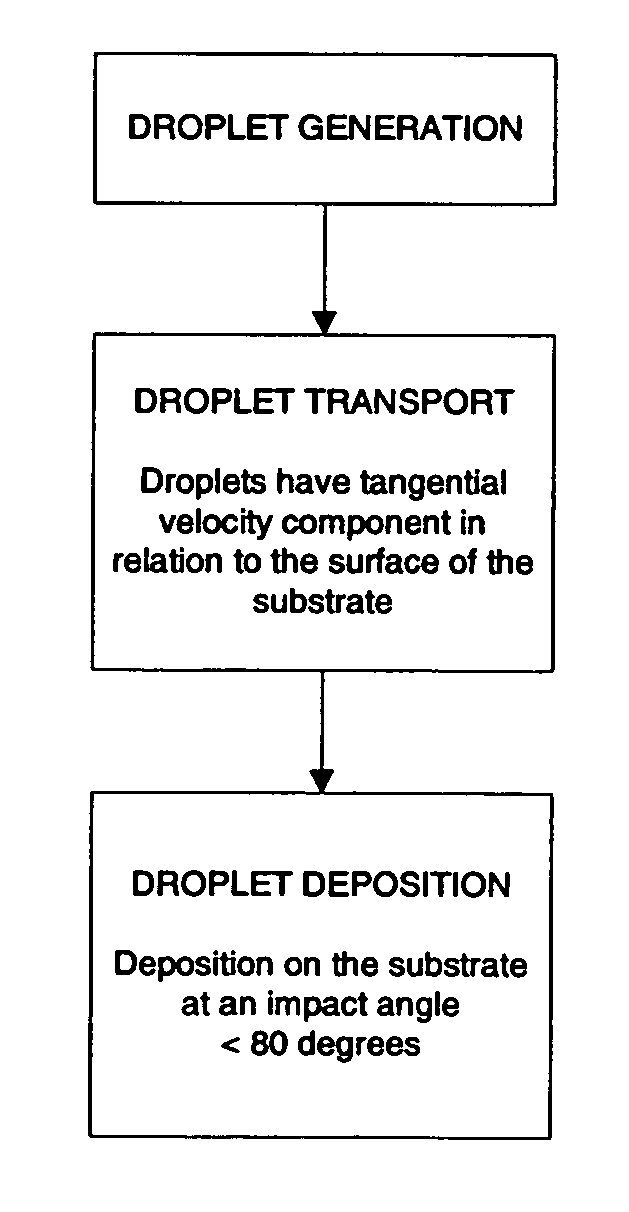

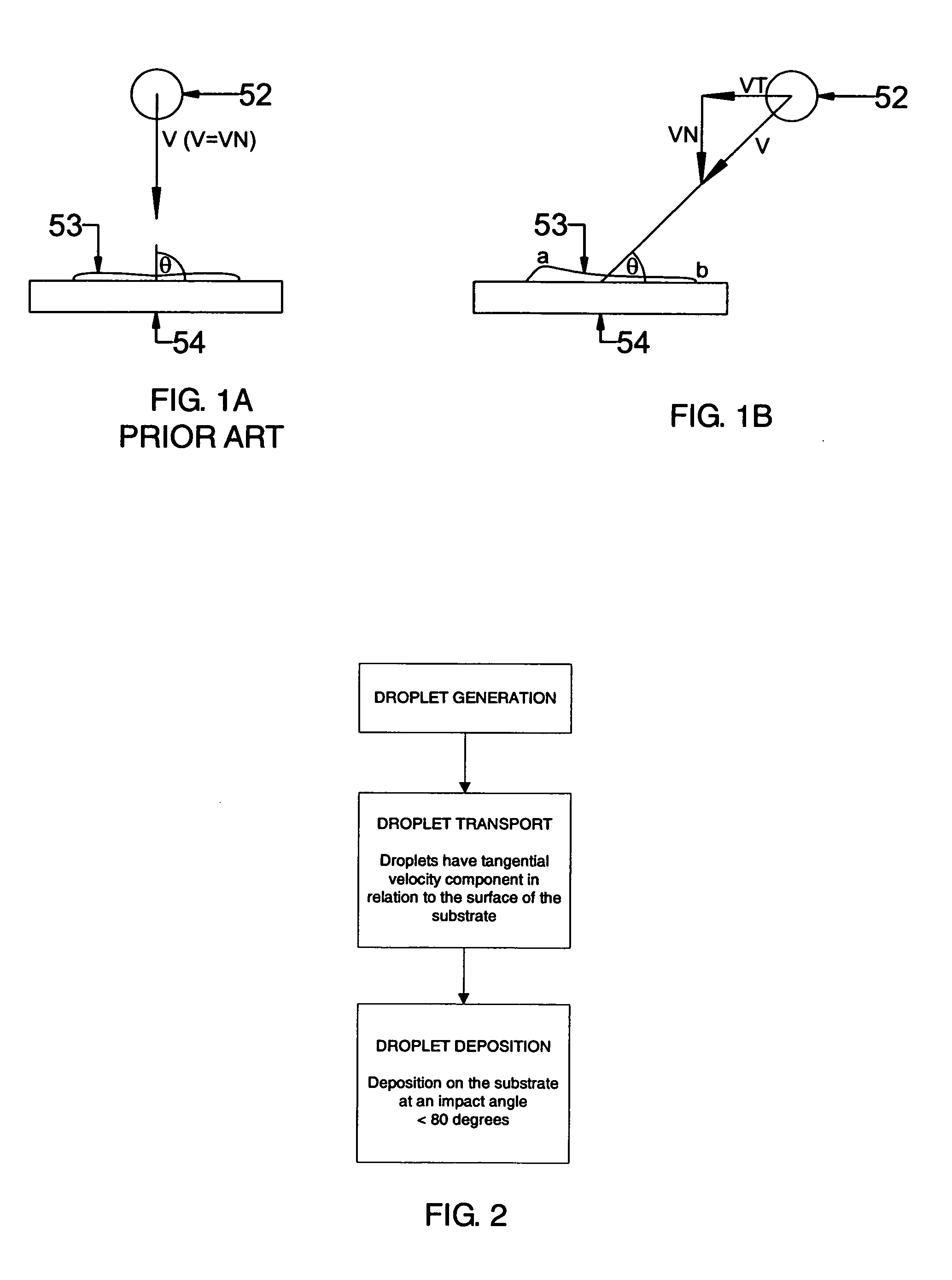

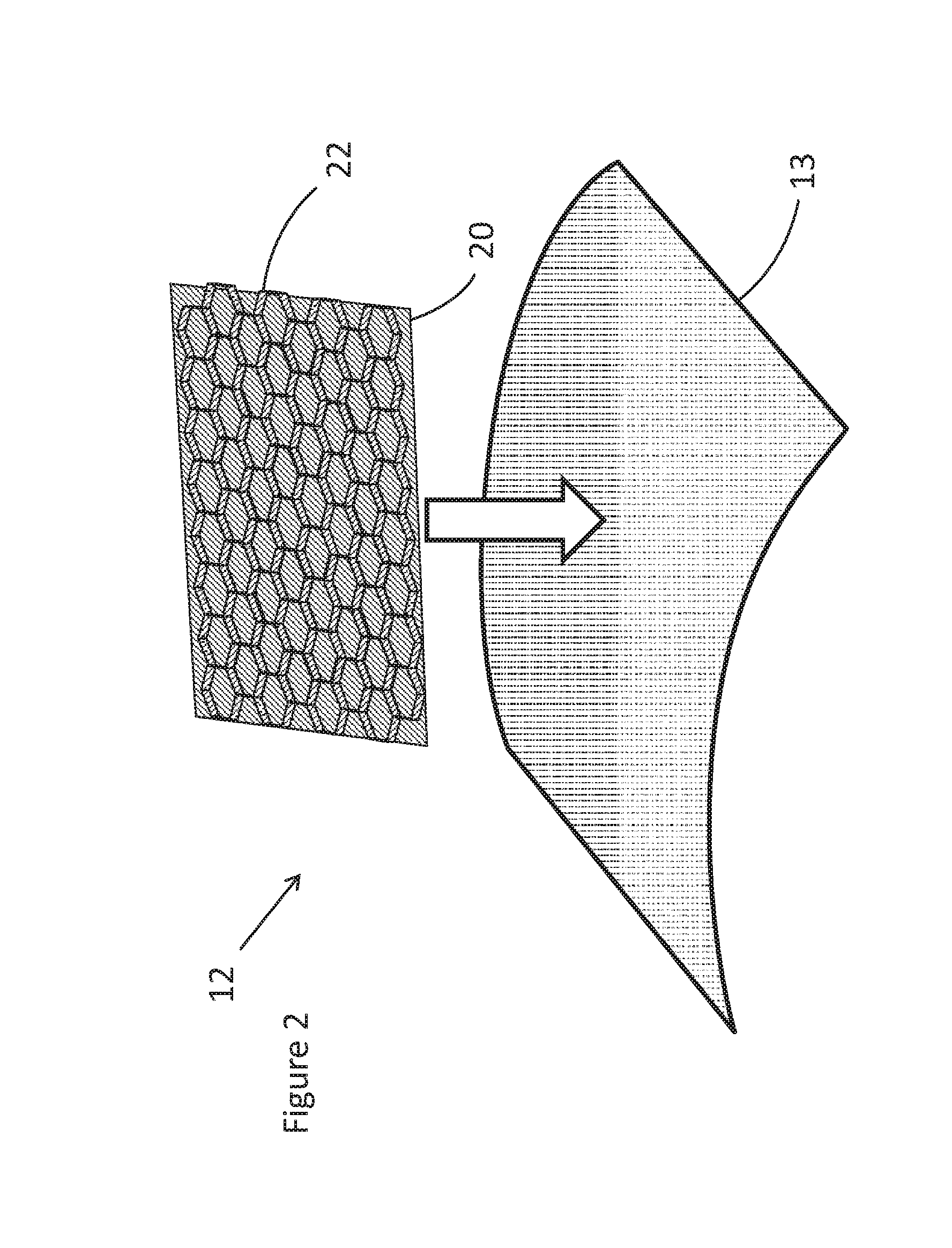

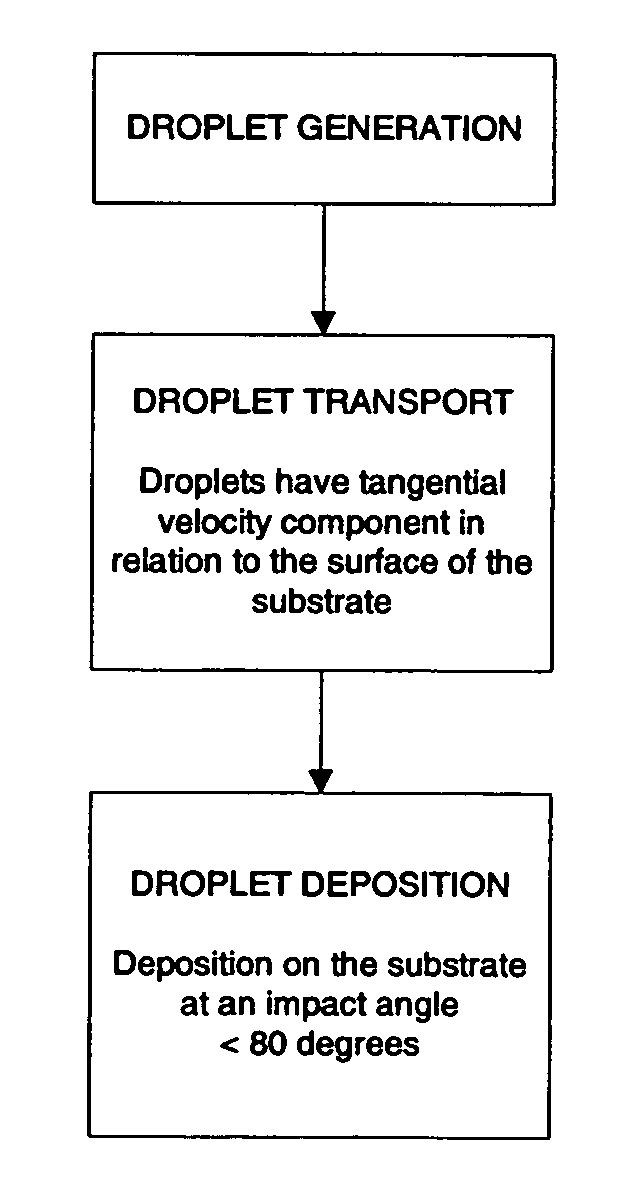

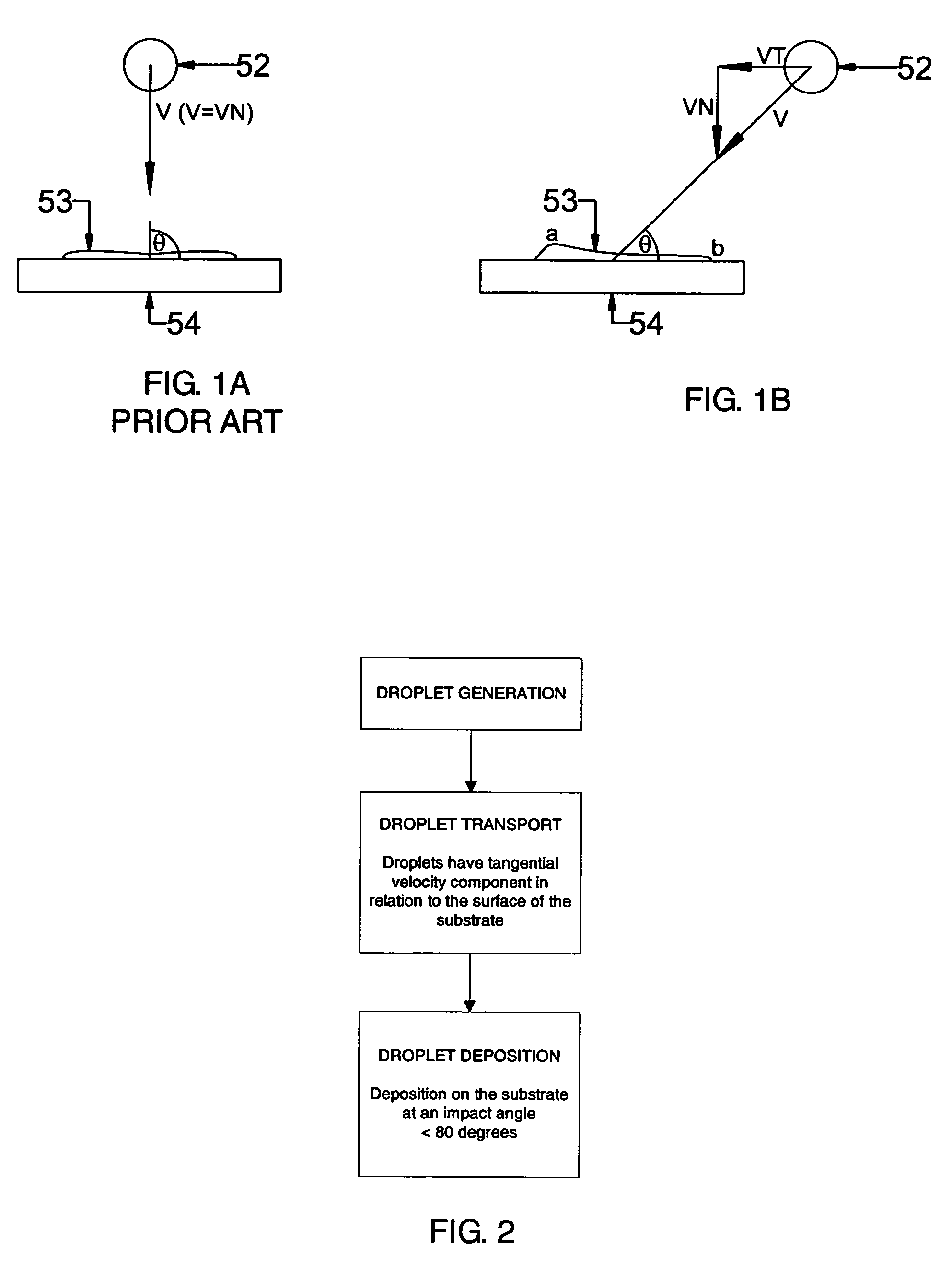

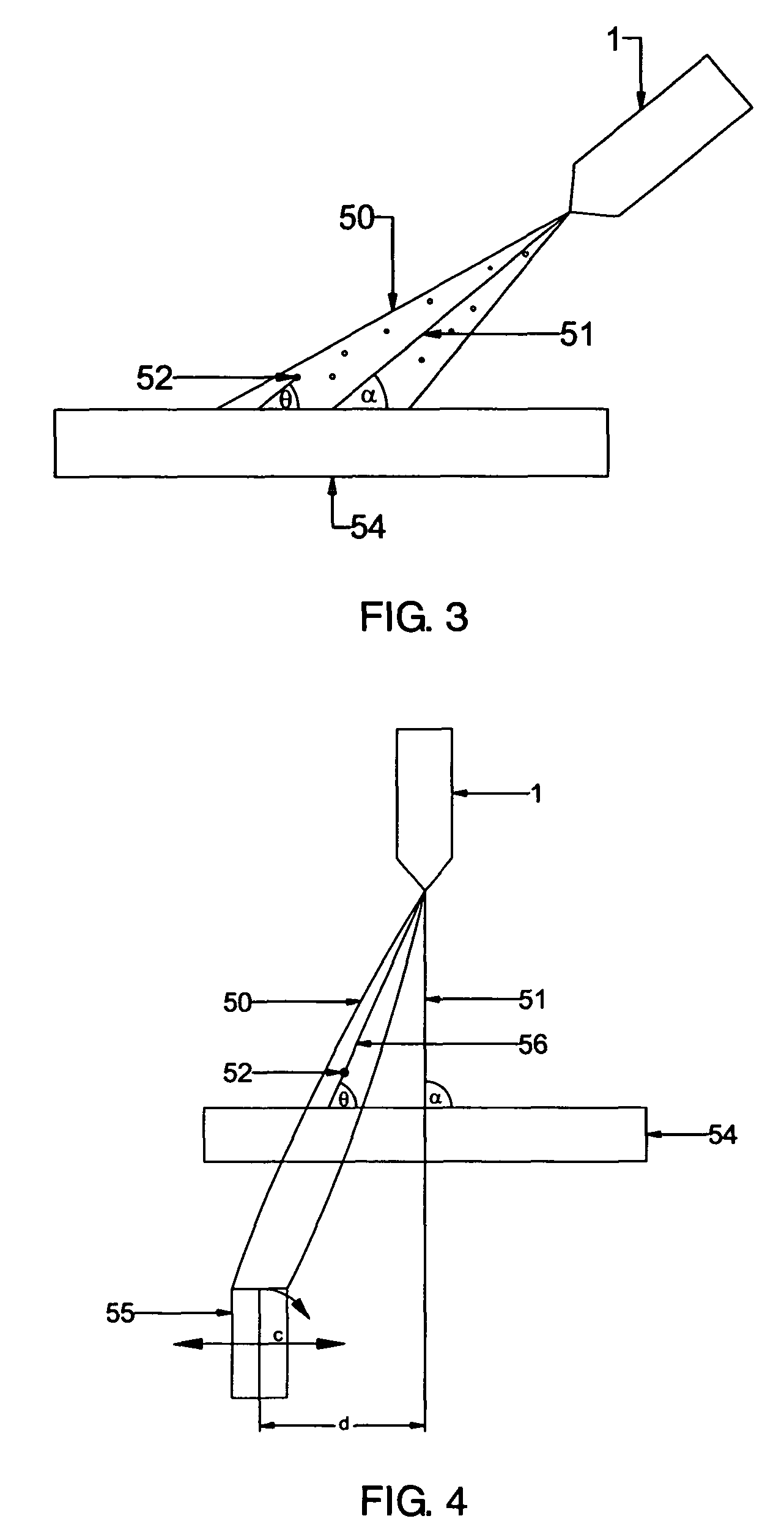

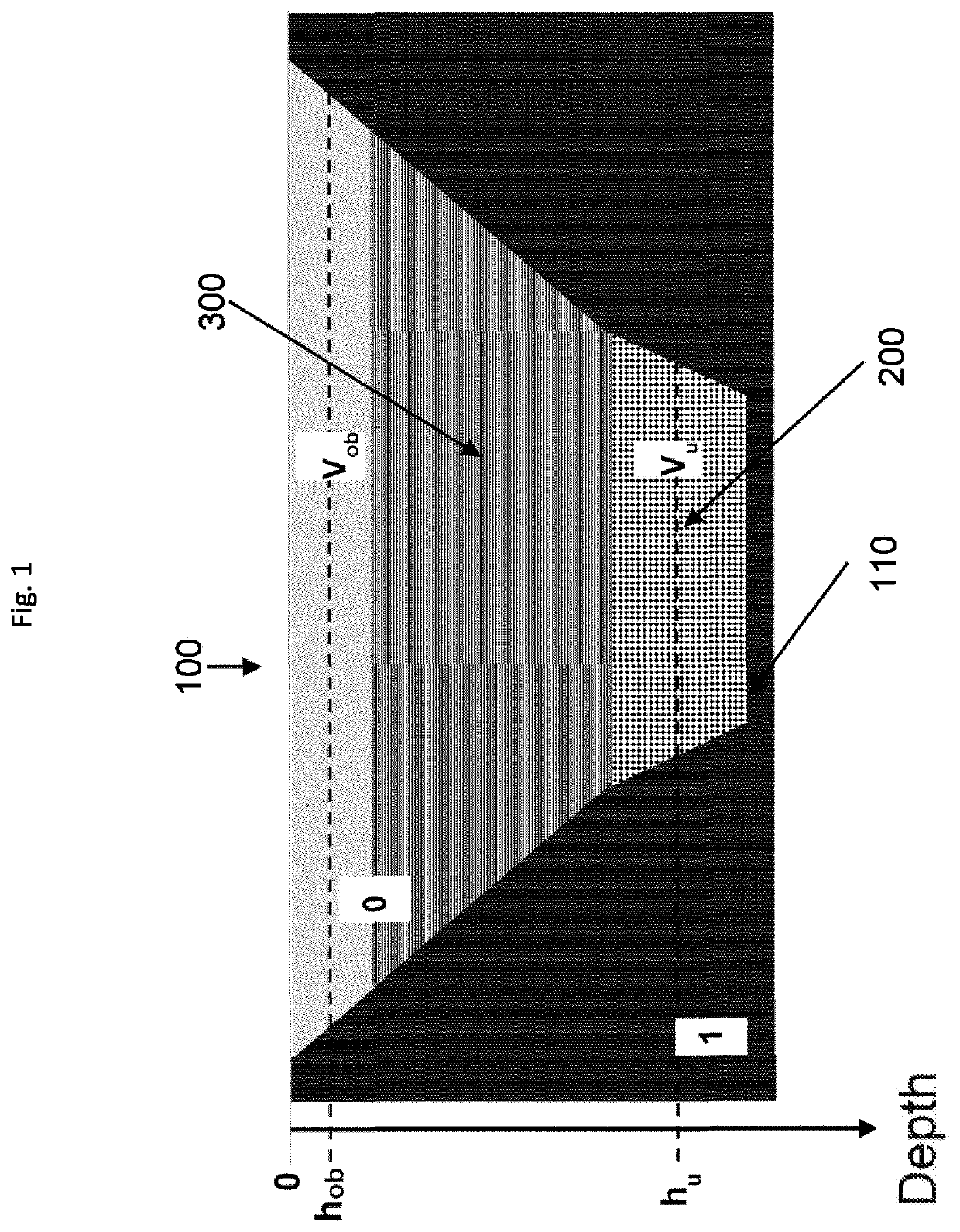

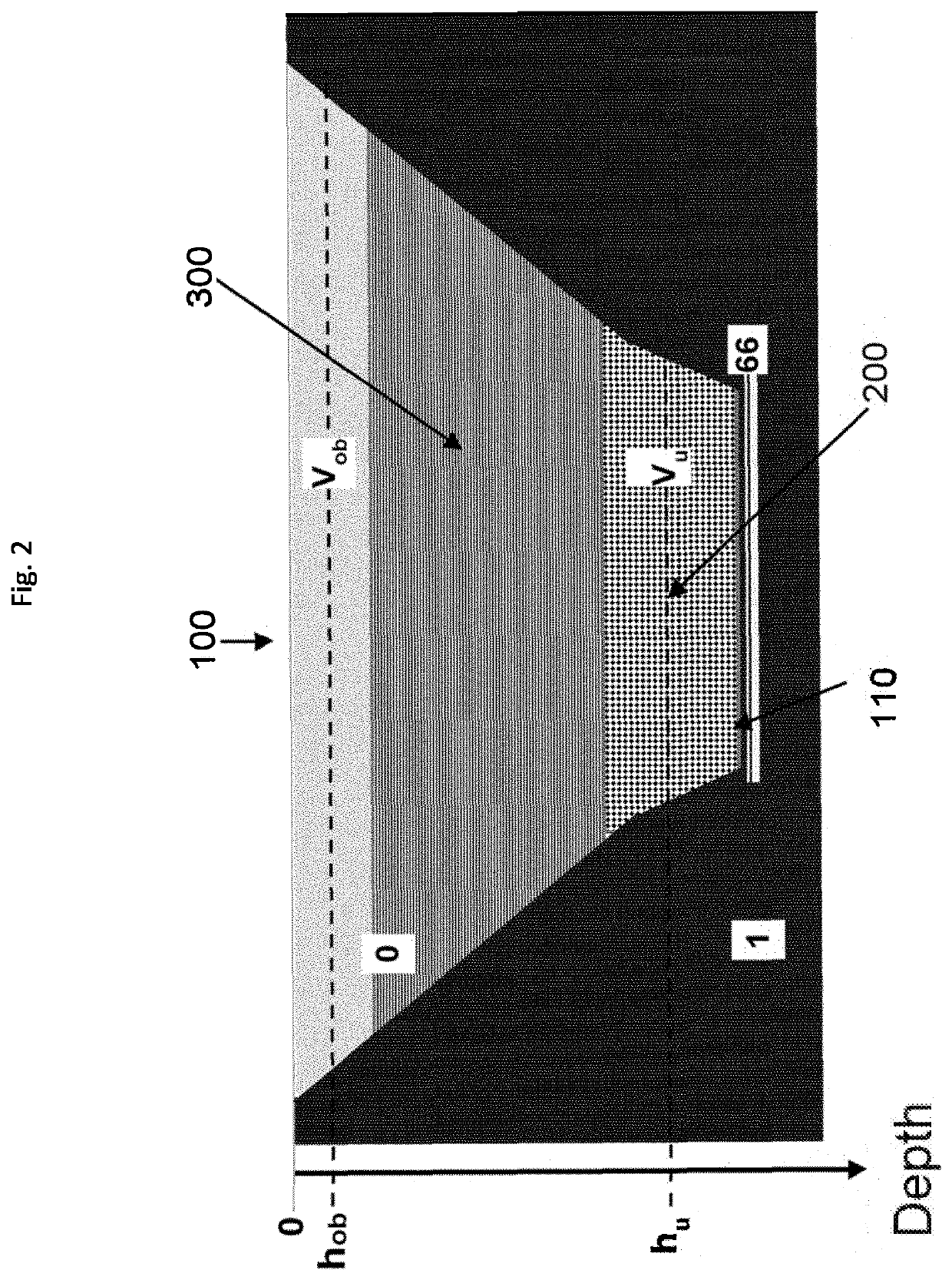

Process for coating a substrate

ActiveUS20080286440A1Inexpensive and flexibleCost-effective and flexibleSurgeryPharmaceutical containersMaterials scienceCoating

A method to coat a substrate for the formation of coatings having a desired surface morphology is provided, wherein the roughness and the total surface area of the coating can be varied during the coating process. The method of the present invention comprises the steps of generating droplets from a coating composition, transporting the droplets to the substrate and depositing a majority of the droplets on the substrate.

Owner:IOOS LLC

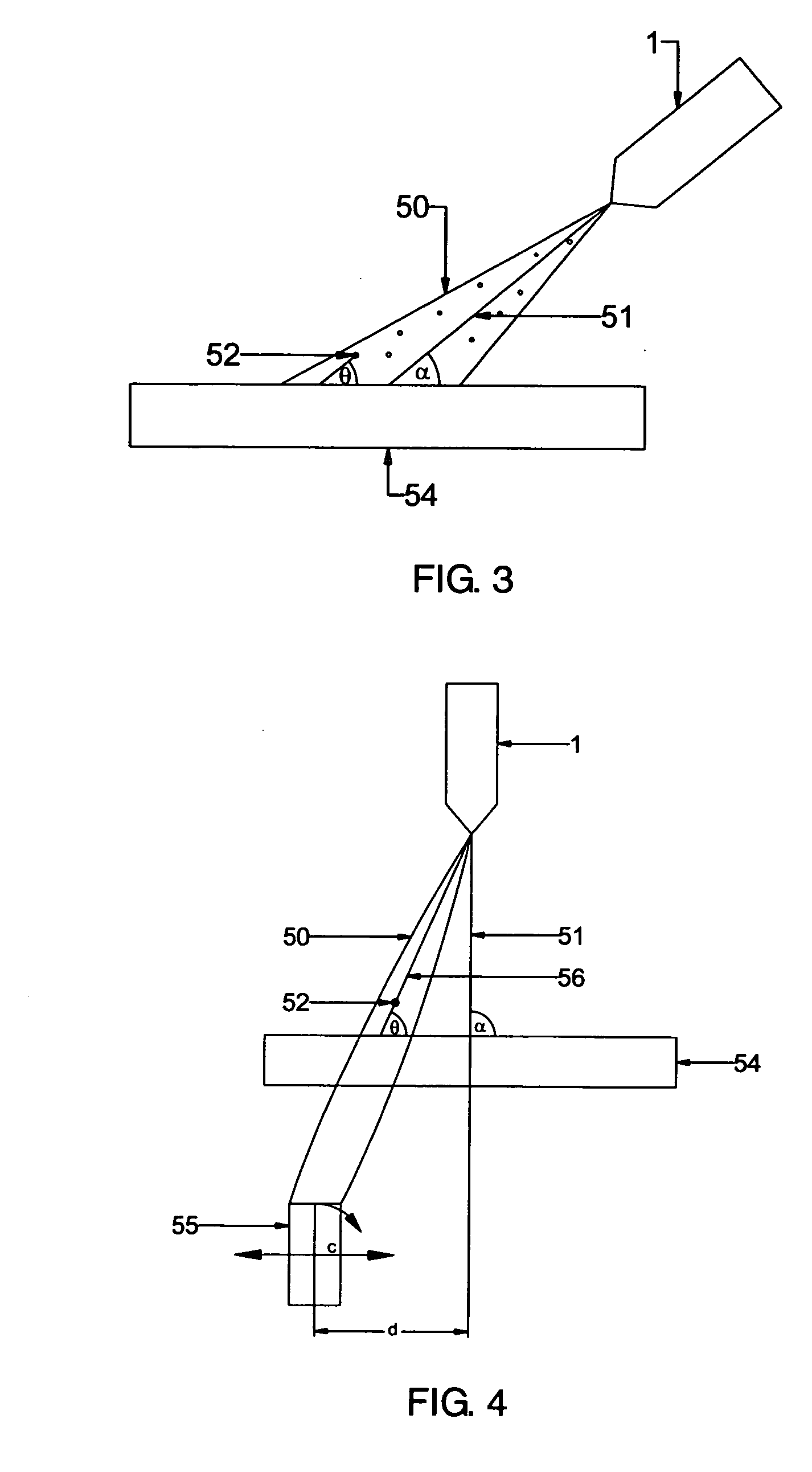

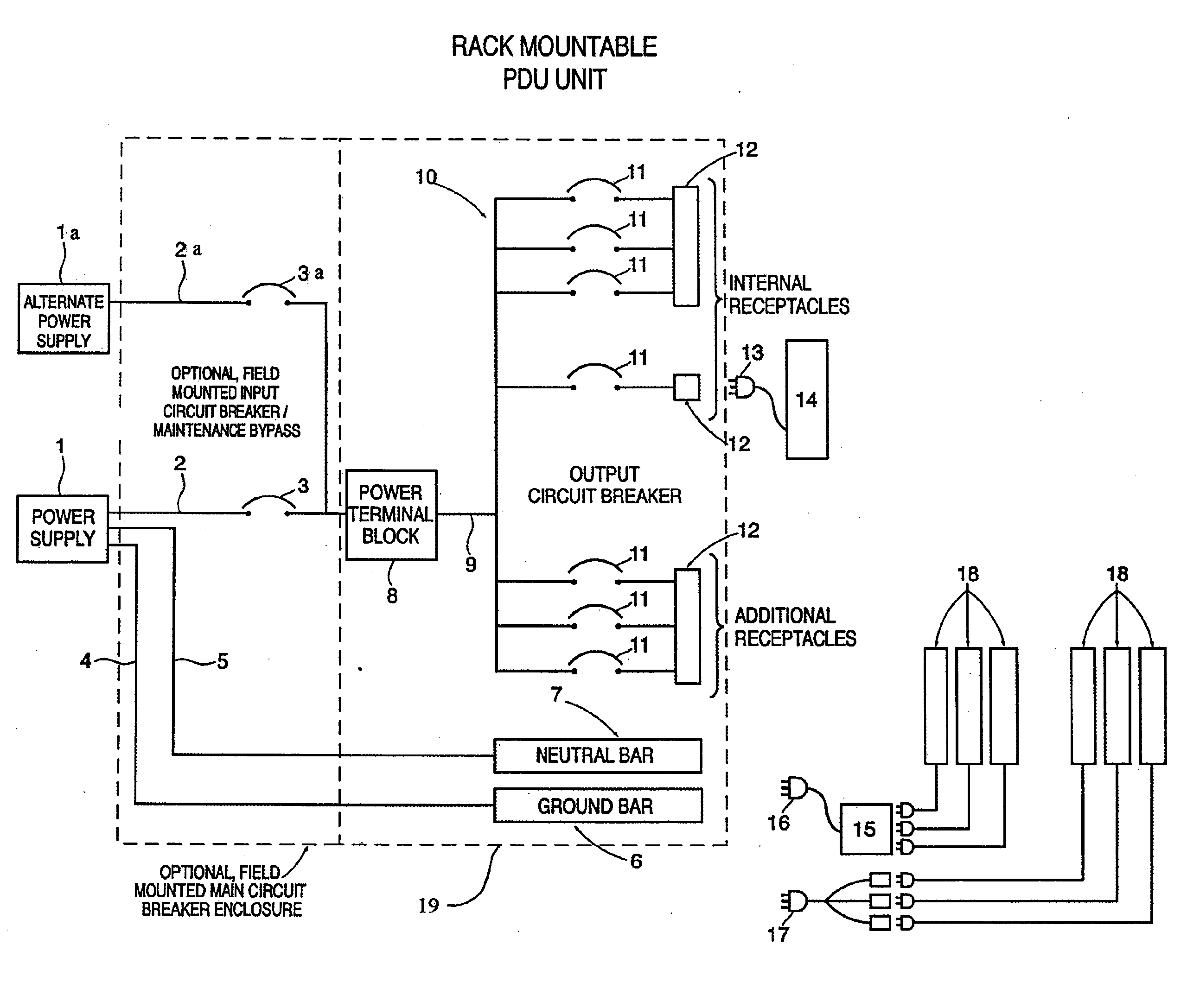

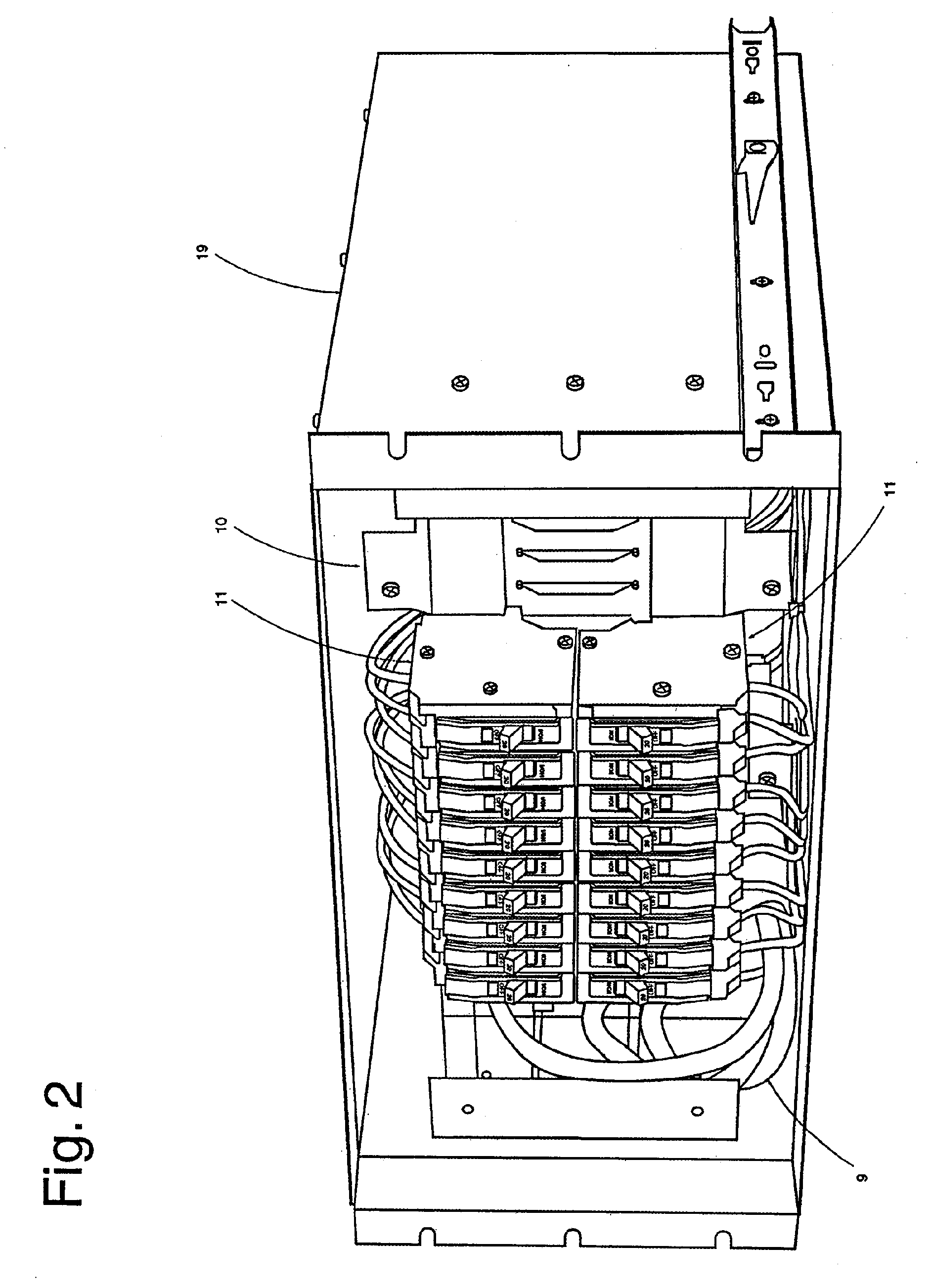

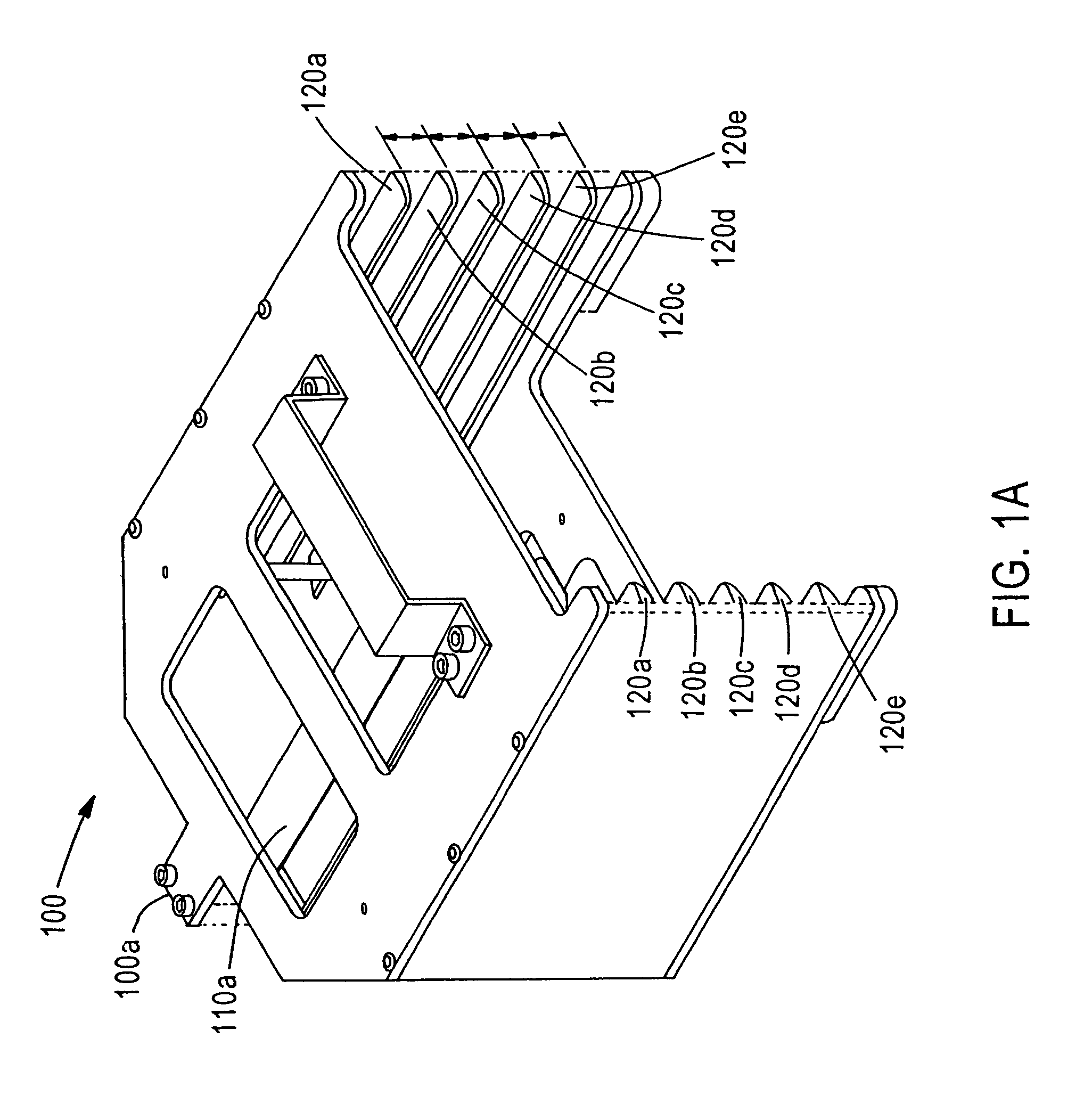

Power distribution device

InactiveUS20060146581A1Cost effective and flexibleCost effective, flexible and versatileServersSubstation/switching arrangement detailsSingle phaseAmpacity

A rack power distribution system includes a unique configuration of electrical power wiring, branch circuit panels, branch circuit breakers, and three-phase power distribution devices packaged in the compound housing that mounts within standard EIA racks. The input side receives three-phase power, includes an input breaker and an optional maintenance bypass switch. The output side of the device utilizes multiple three-phase power output assemblies which can be connected to different breakout units designed to support several alternatives such as single phase power strips. As one option, the output may consist of a breakout cable consisting of a wiring harness with a three-phase plug at one end and one to three single phase receptacles of matching or lesser ampacity on the other end. The invention includes a housing which is provided with easily removed front and top panels and side-mounted rails / slides for a “draw out” type mounting in the rack.

Owner:RACK DISTRIBUTION PRODS

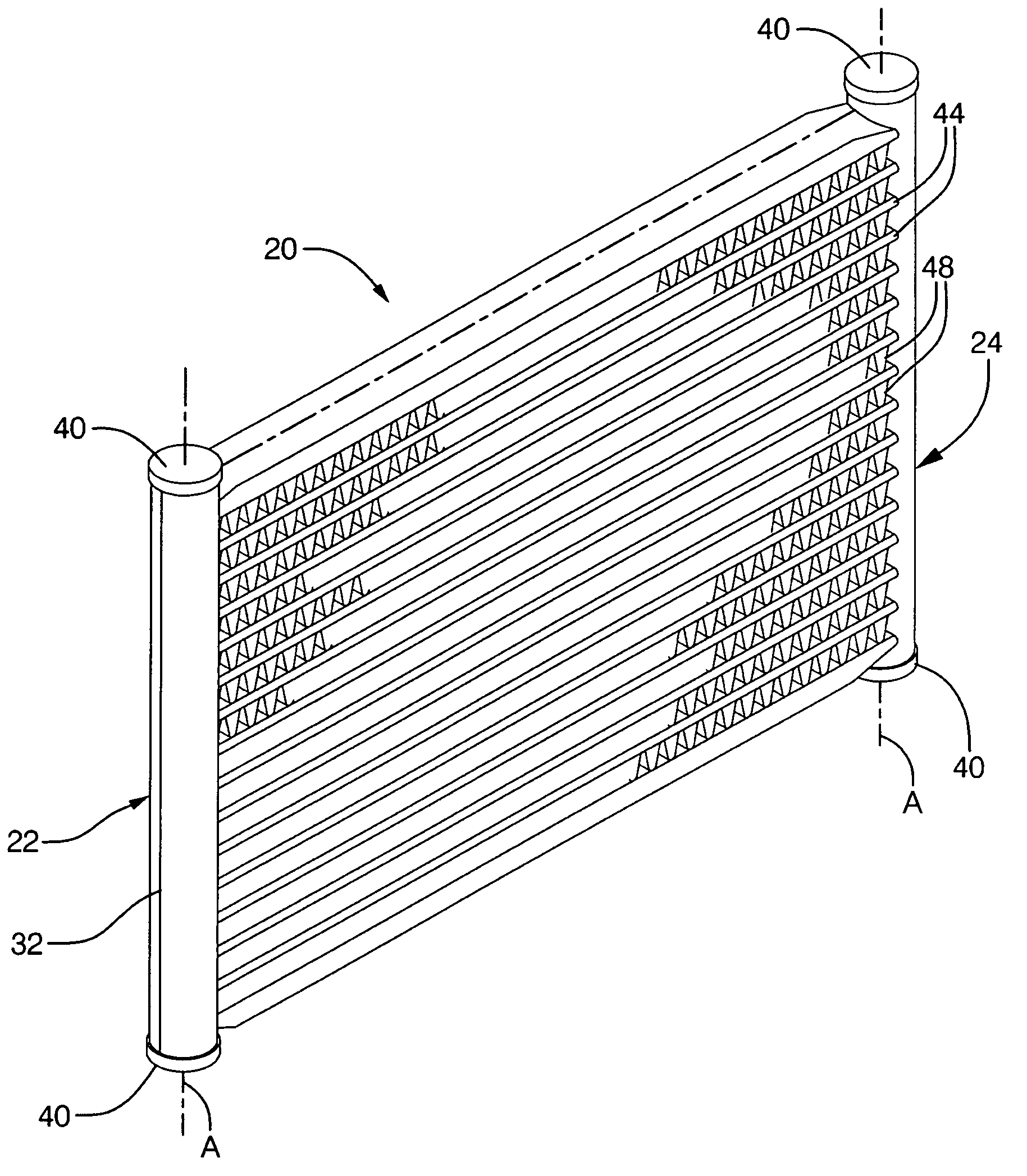

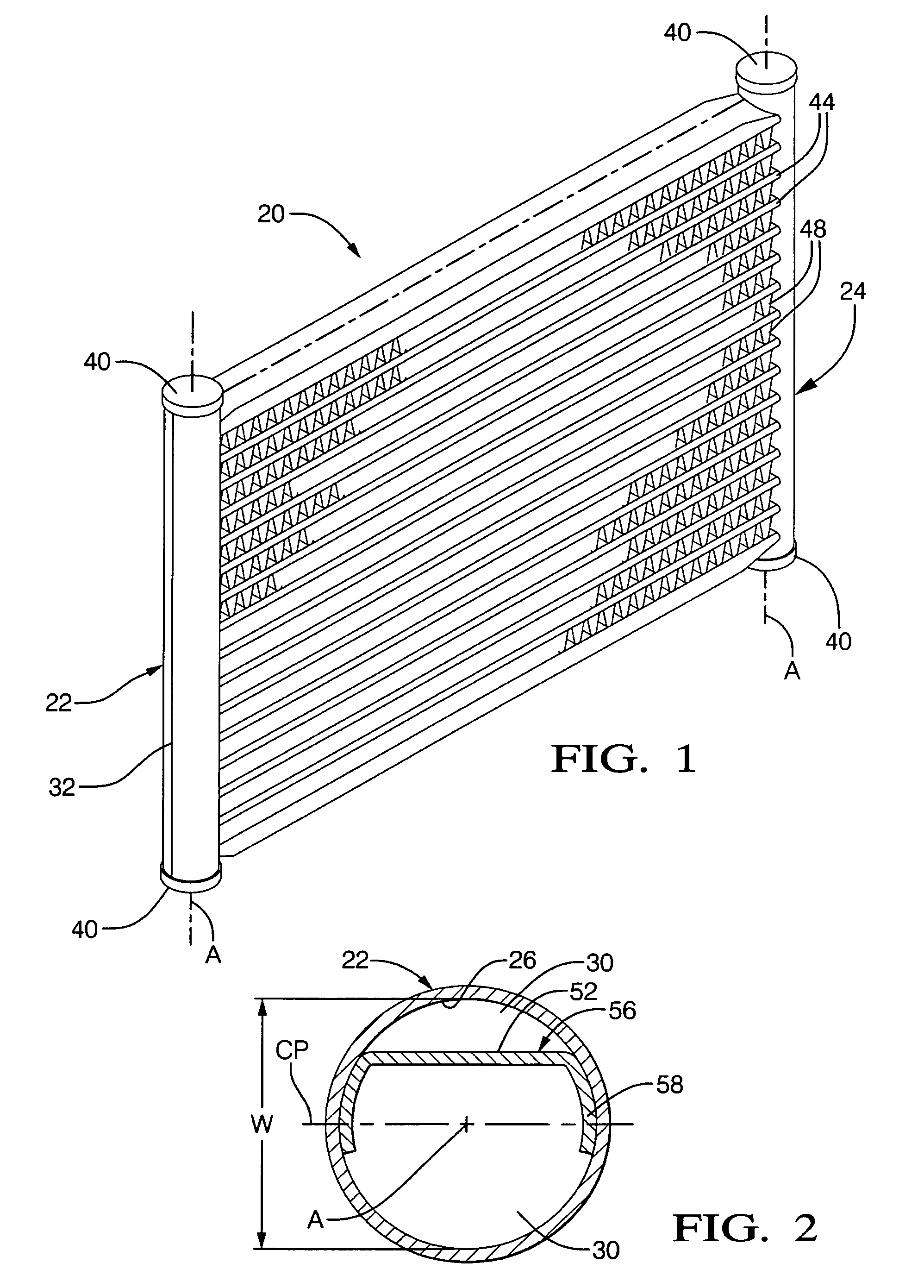

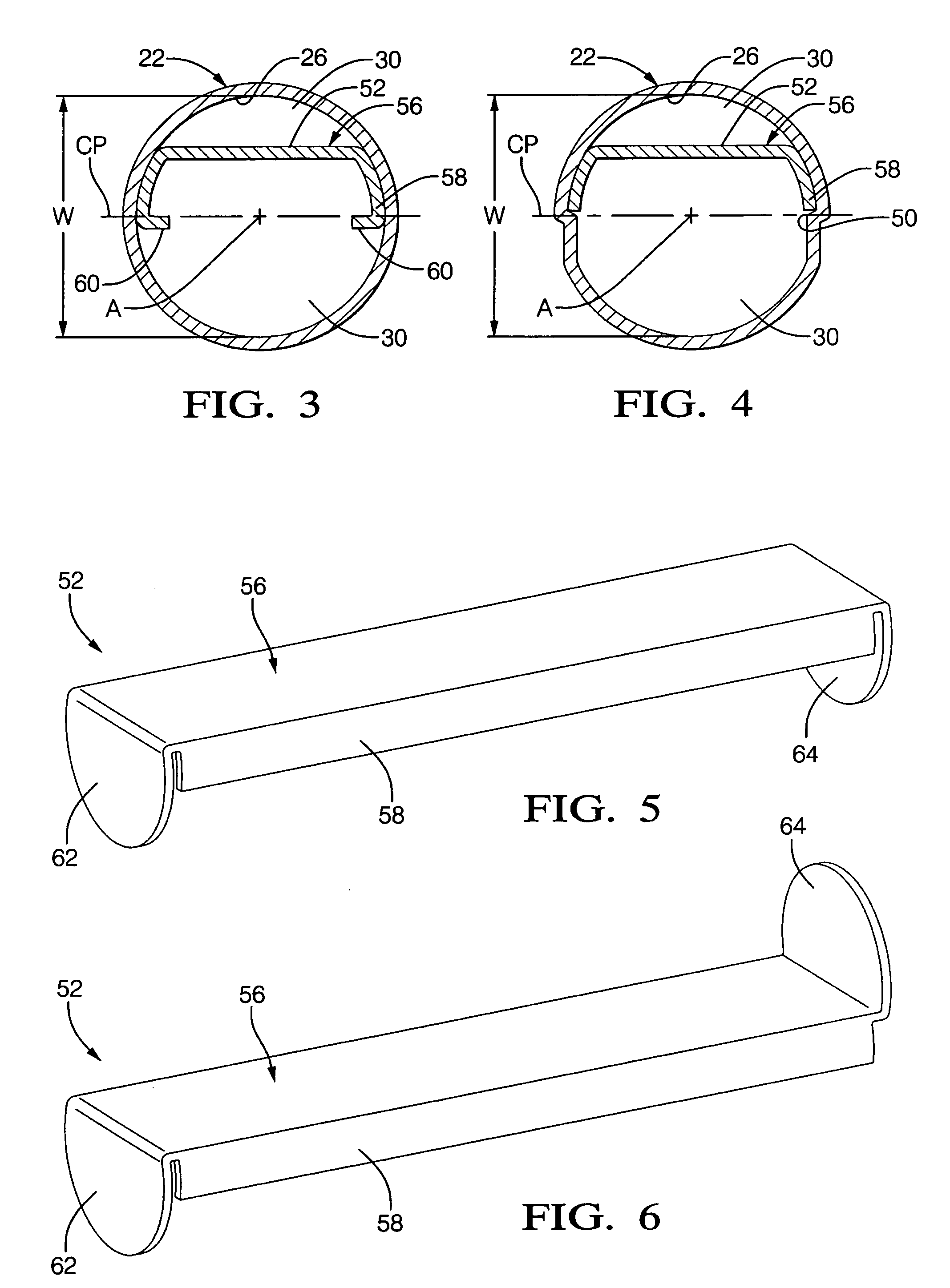

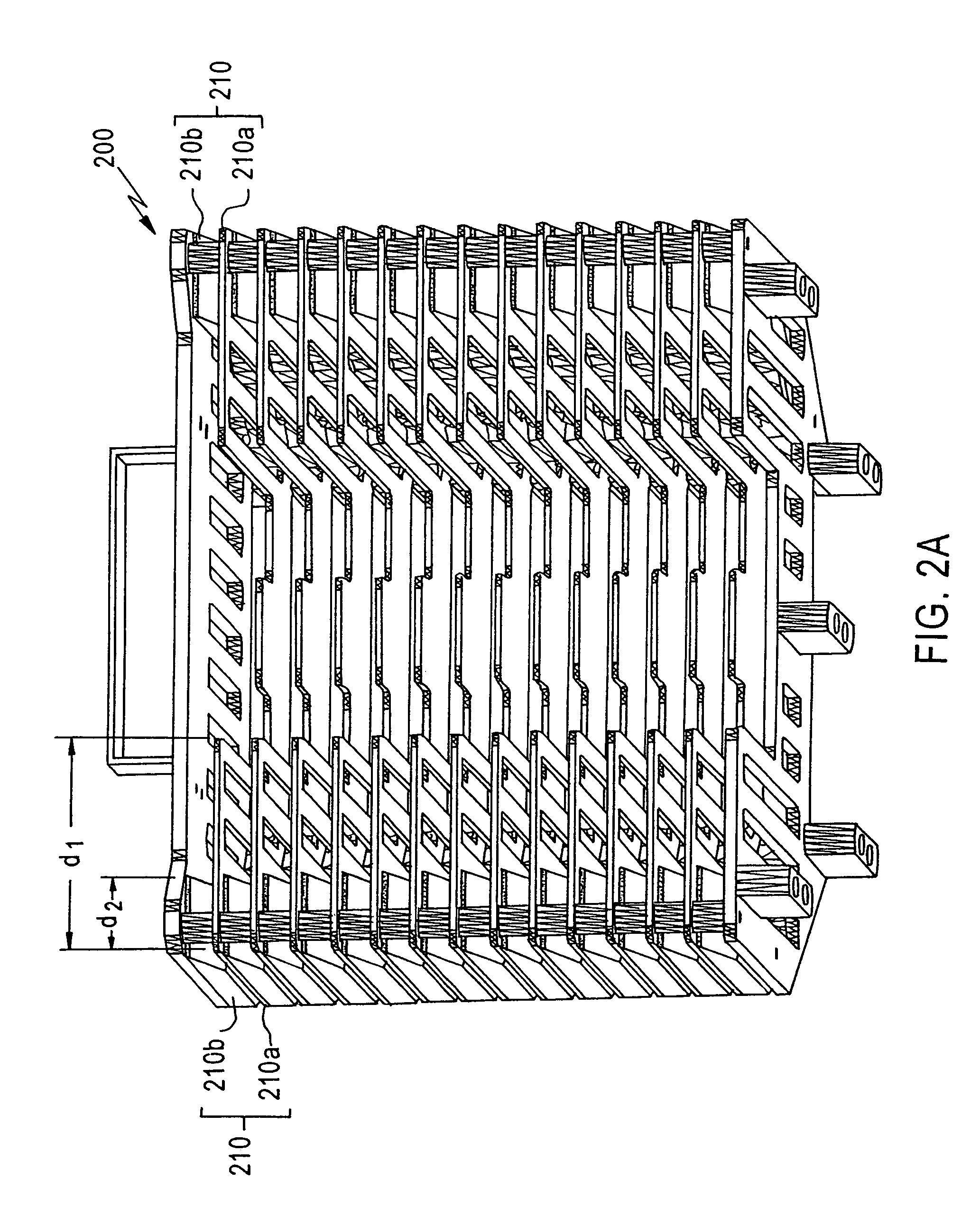

Heat exchanger assembly

ActiveUS20080023186A1Manufacturing cost be reduceCost effective and flexibleStationary conduit assembliesHeat exchanger casingsEngineeringHeat exchanger

A heat exchanger assembly includes a first and second manifold. Each of the manifolds includes a tubular wall and a pair of manifold ends spaced from each other defining a flow path. A plurality of flow tubes extend between the manifolds and are in fluid communication with the flow paths. An insert is slidably disposed in the flow path of the first manifold. The insert divides the flow path into a plurality of chambers. The chambers and the flow tubes cooperate to establish a plurality of flow passes. The flow passes are for directing a heat exchange fluid through the heat exchanger assembly. The chambers are useful for orienting and connecting plumbing connections at various locations along the manifolds.

Owner:MAHLE INT GMBH

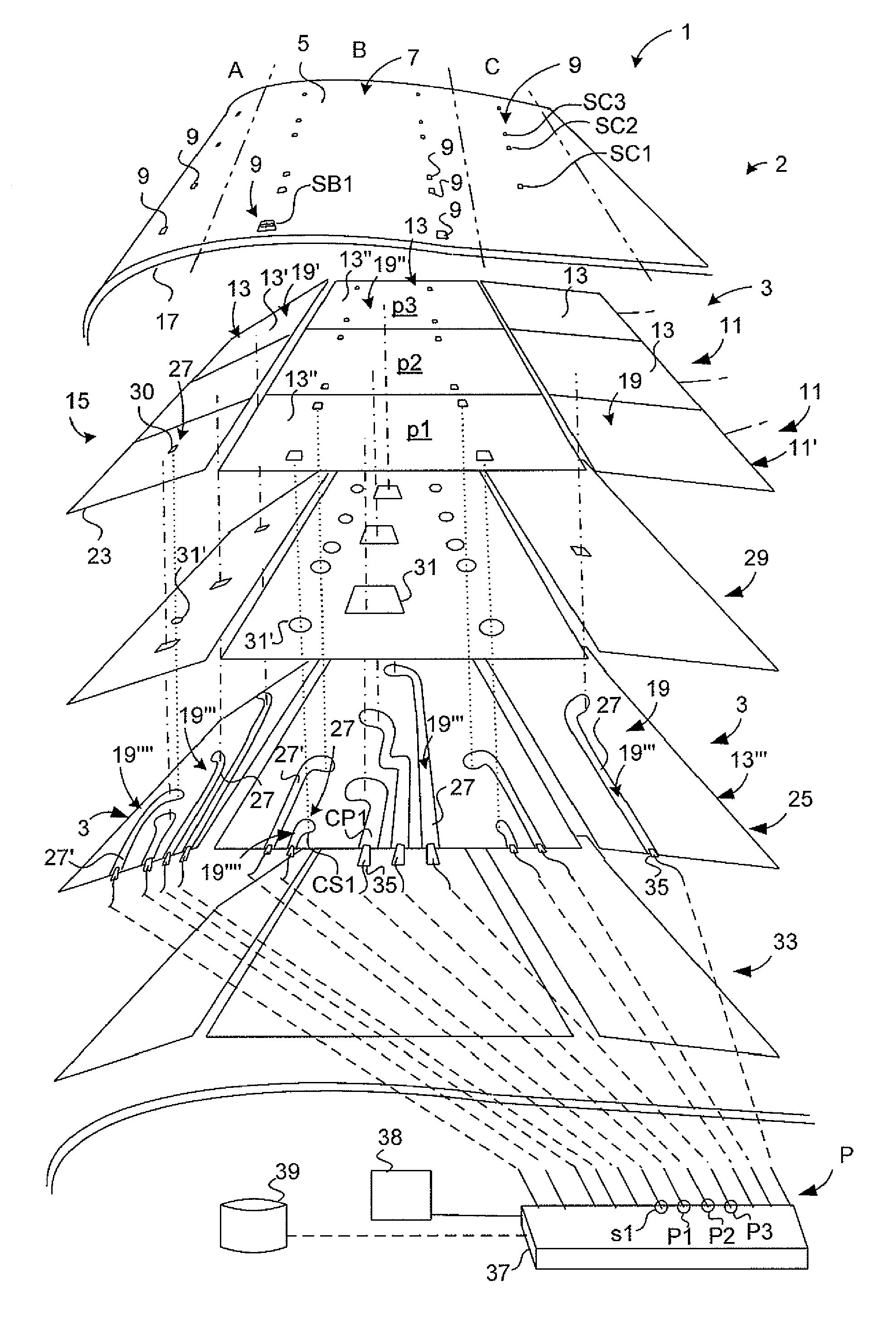

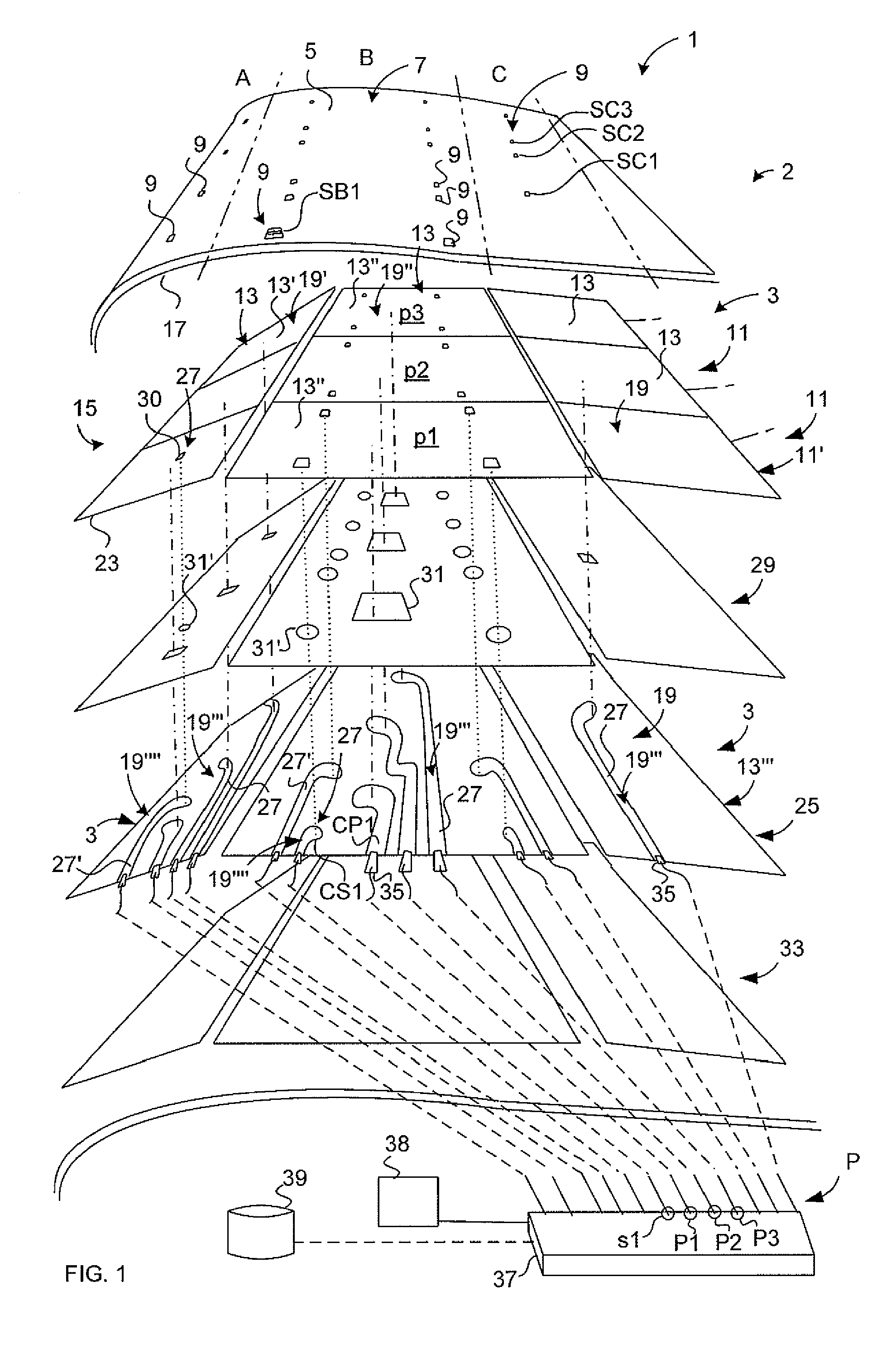

Multifunctional de-icing/anti-icing system

ActiveUS8931740B2Increase temperatureHigh component strengthDe-icing equipmentsSandwich constructionsIce protection systemElectrical conductor

A de-icing / anti-icing system including at least two conductive structures embedded in an article that includes an outer surface designed as an aerodynamic surface. At least one of the conductive structures is arranged adjacent the outer surface. A control unit adapted to control the energy supply to the conductive structures for generating heat to the outer surface. A first of the conductive structures includes a first conductive nano structure and a second of the conductive structures includes a second conductive nano structure. A conductive property of the first of the conductive structures differs from a conductive property of the second of the conductive structures. The first conductive nano structure serves as a heating conductor and the second conductive nano structure serves as a heating element. The first and second conductive nano structures are embedded in a common plane of a resin layer forming the outer surface.

Owner:SAAB AB

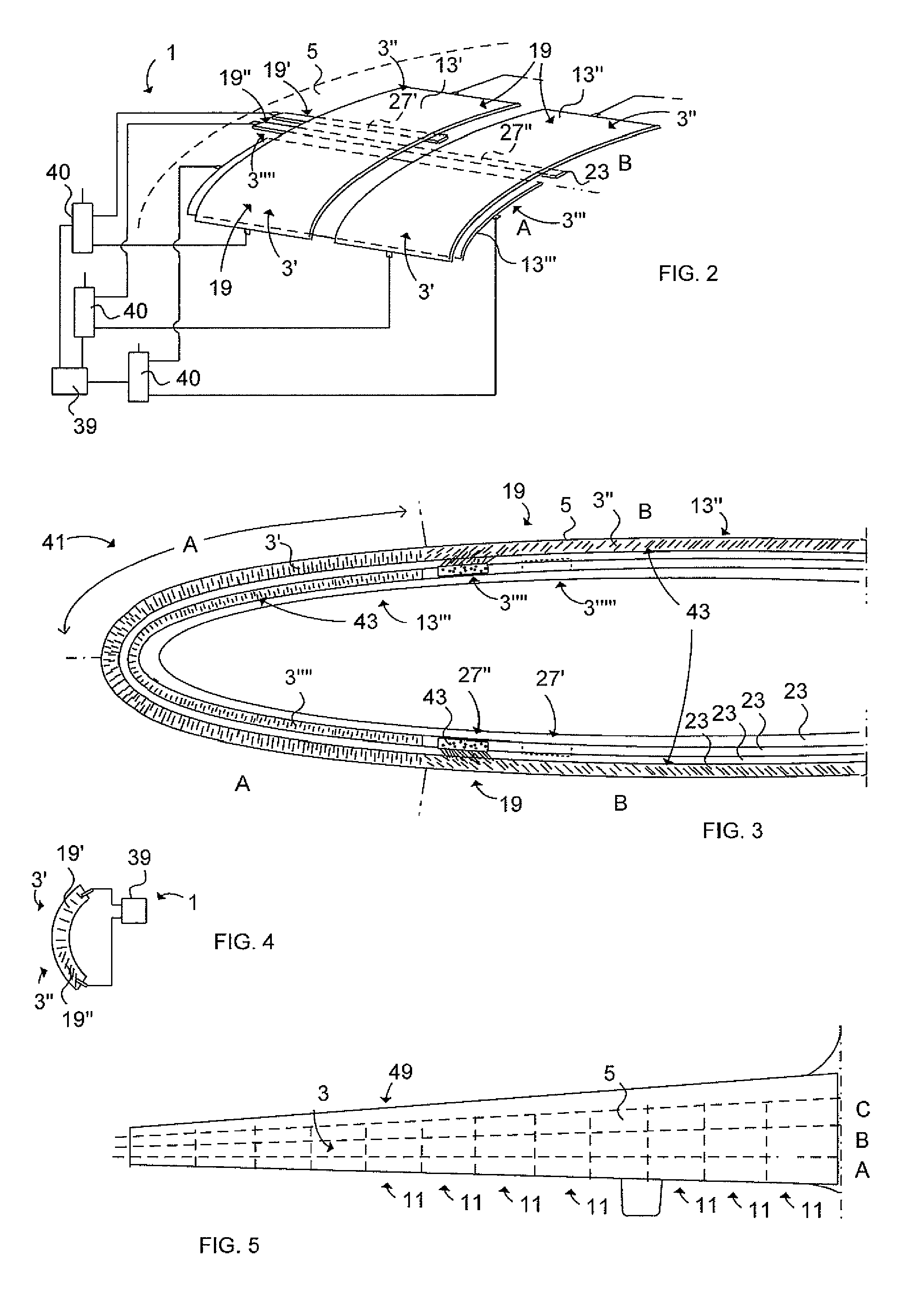

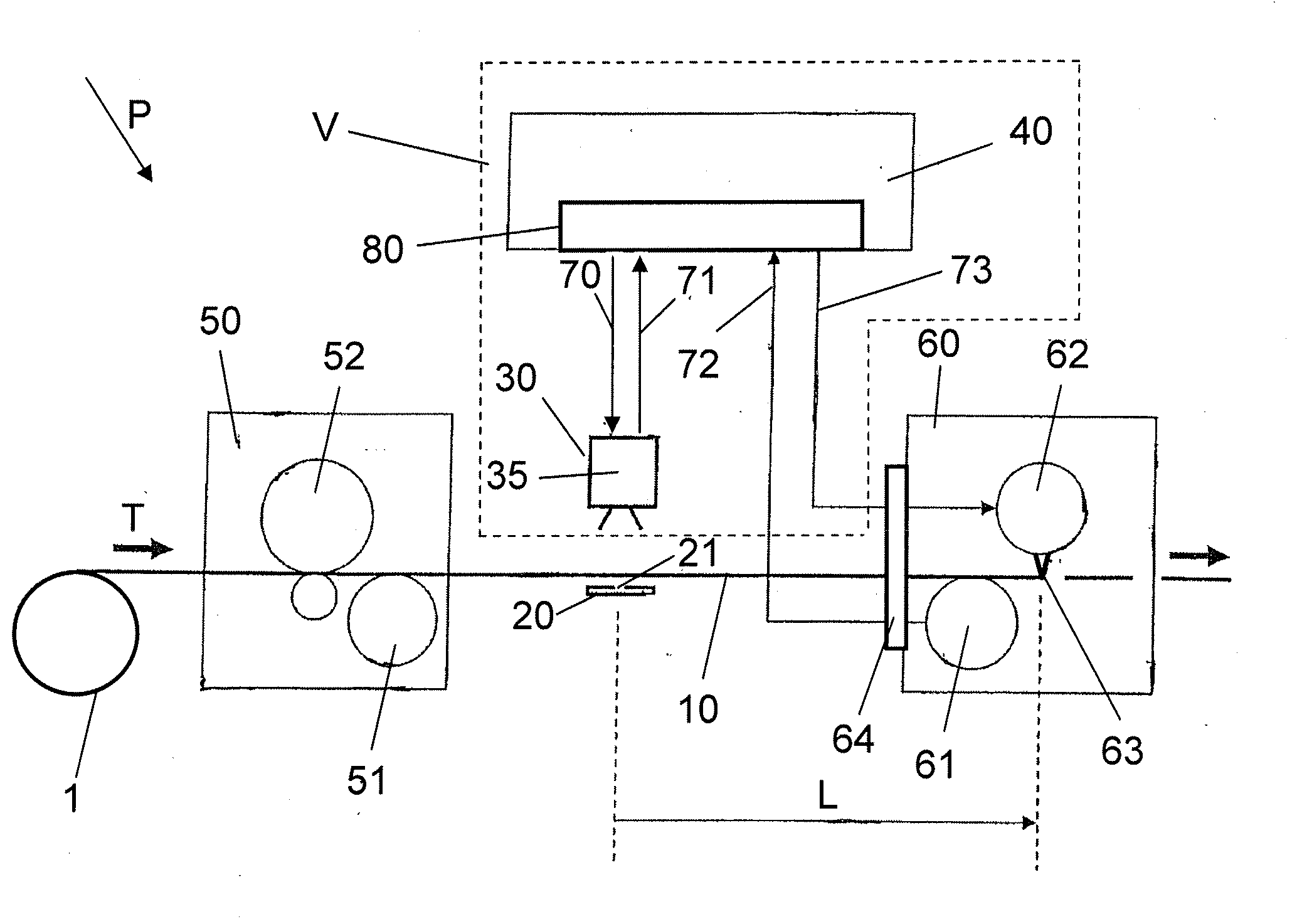

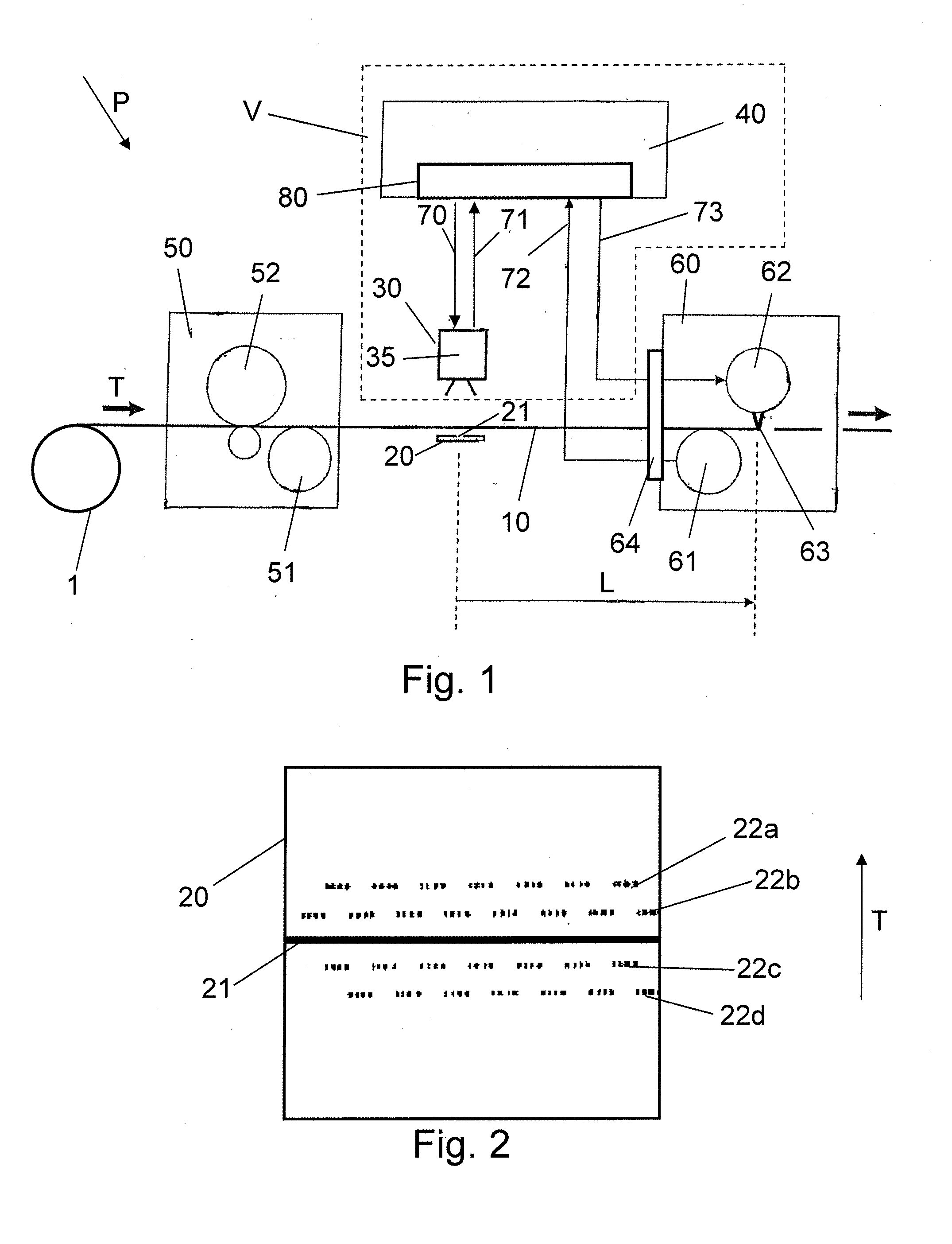

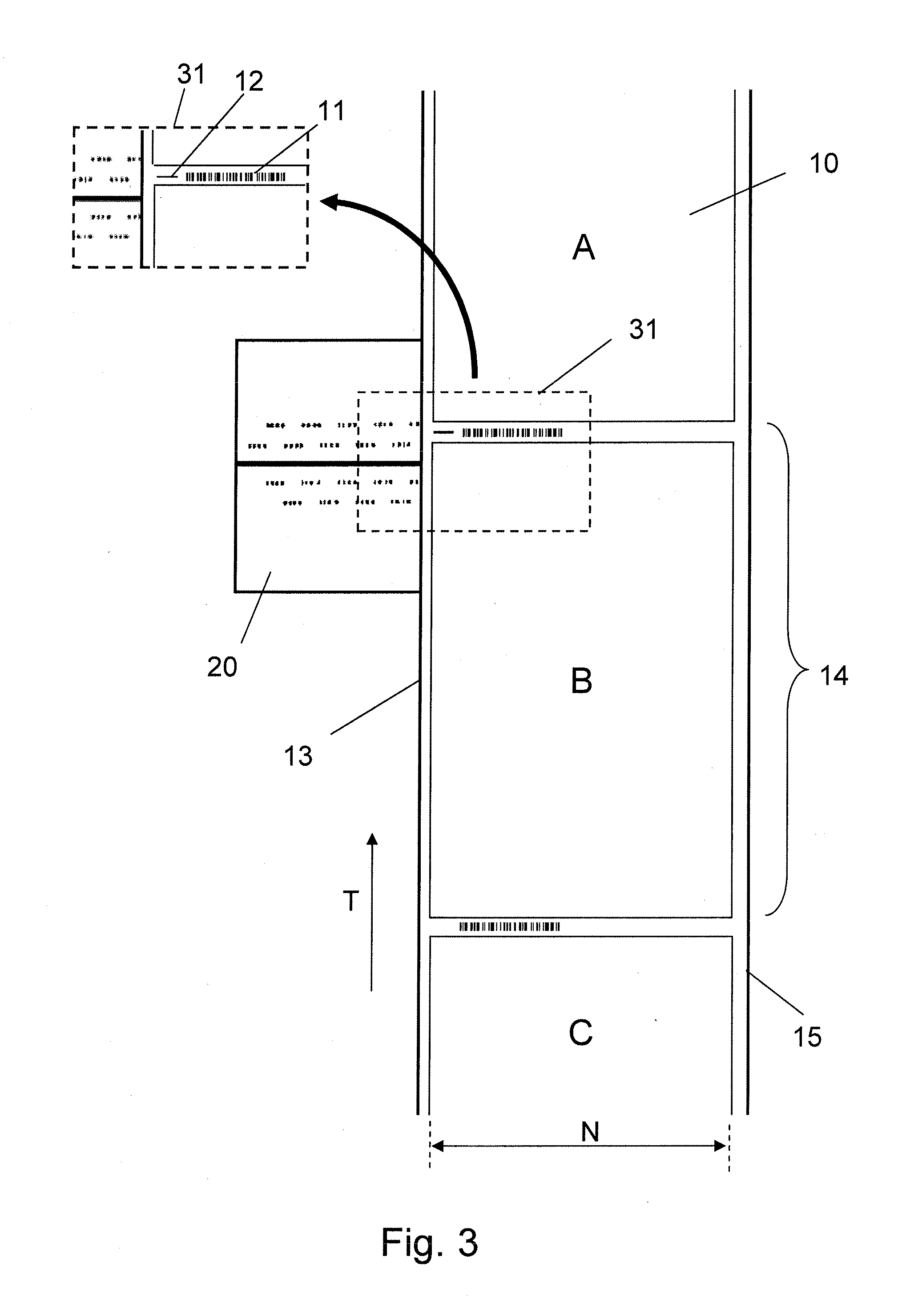

Device and method for processing printing substrate web into printed products

InactiveUS20120194791A1Cost-effective and flexibleLow production costRotary pressesPhotographic printingComputer graphics (images)Image display

A method for processing a web to form printed products includes affixing a print mark assigned to a printed sheet of the web to a useful strip of the web. The print mark includes a coded print mark. An image is recorded that shows a region of the web in which the affixed print mark is located. The print mark in recorded image is searched for and identified. A position of the print mark in the recorded image is determined, and based on the determined position, the position of the print mark on the web is inferred. A correction value is determined for synchronizing a subsequent further processing of the web in dependence on the position of the print mark on the web.

Owner:MULLER MARTINI HLDG

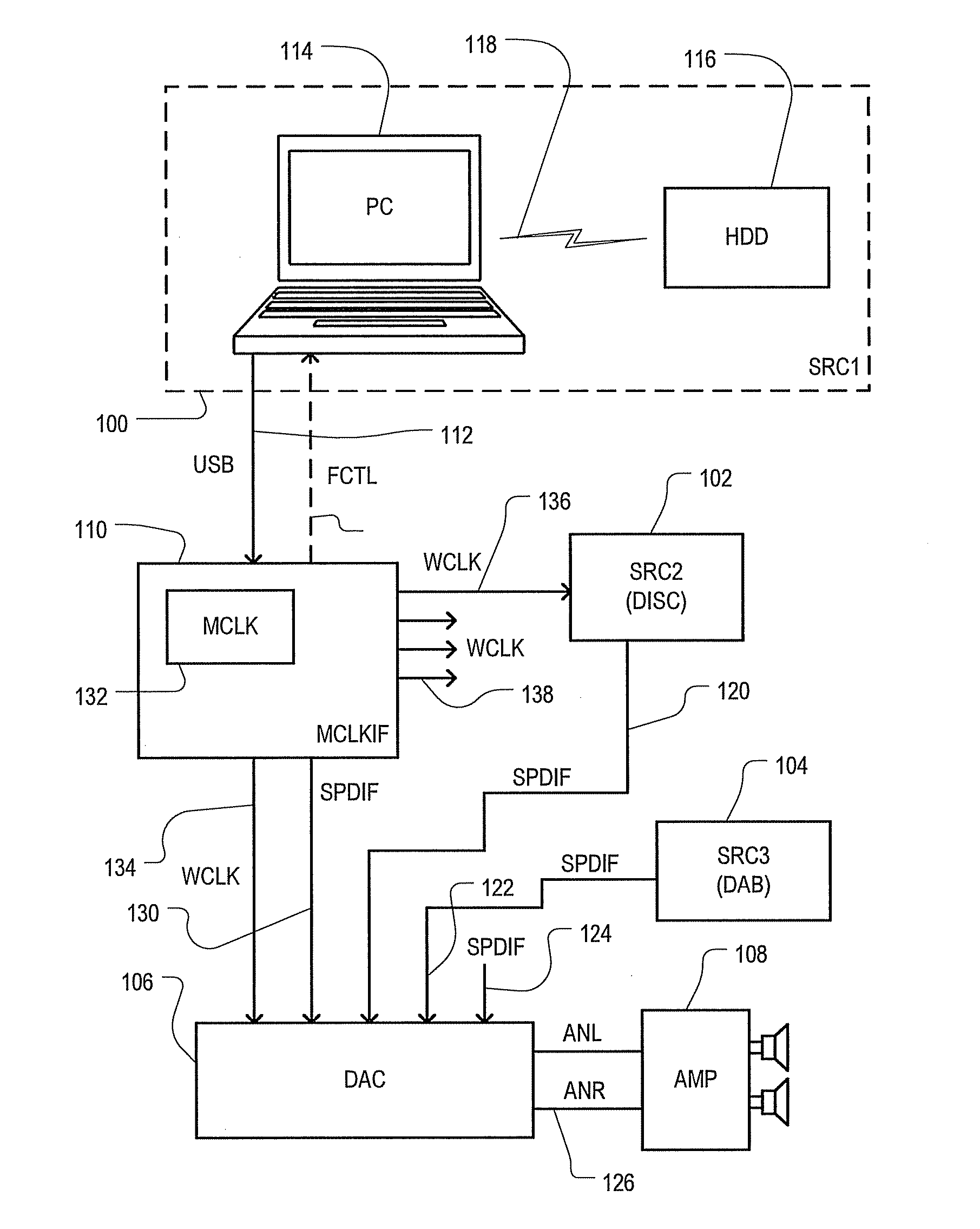

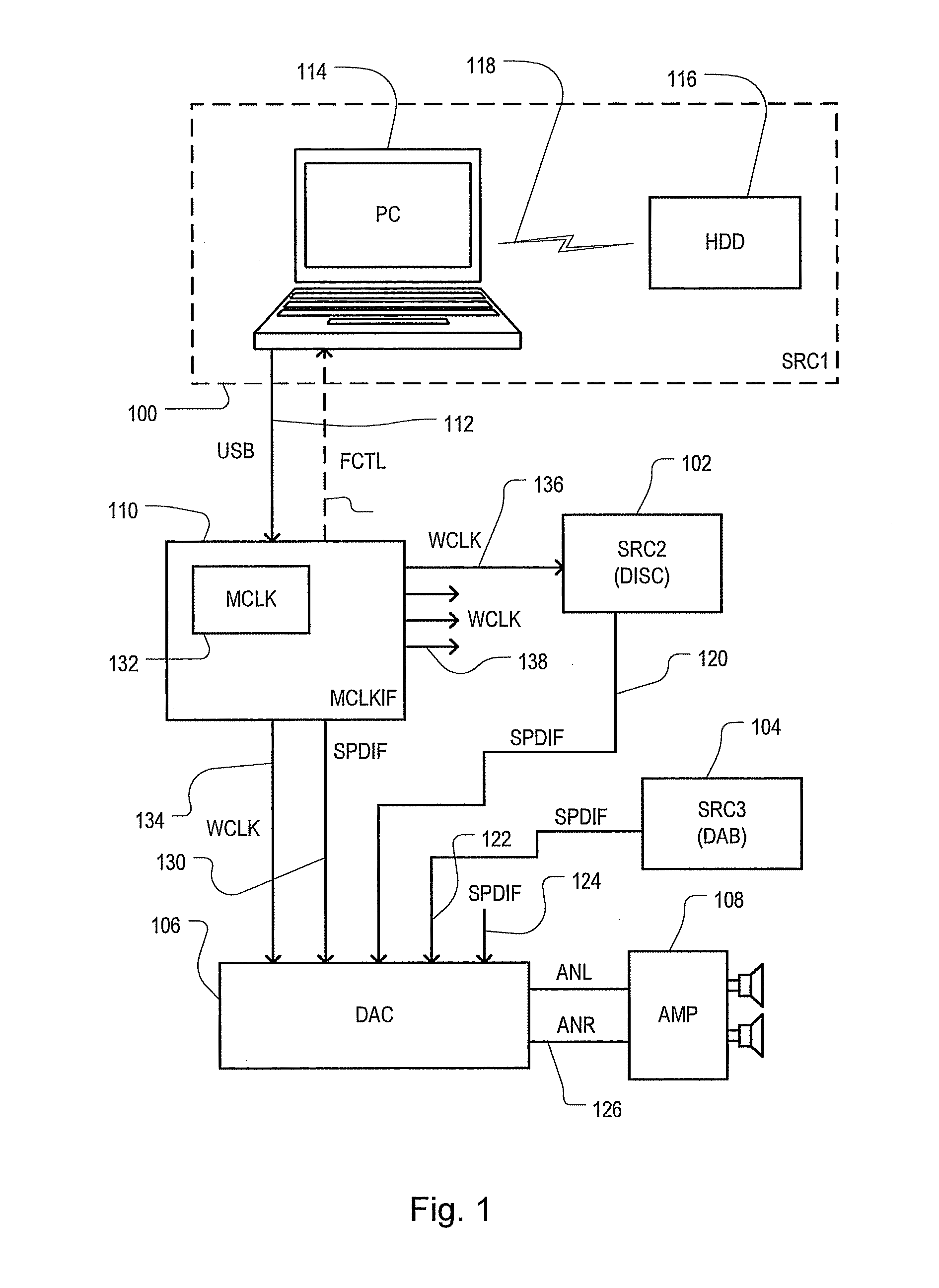

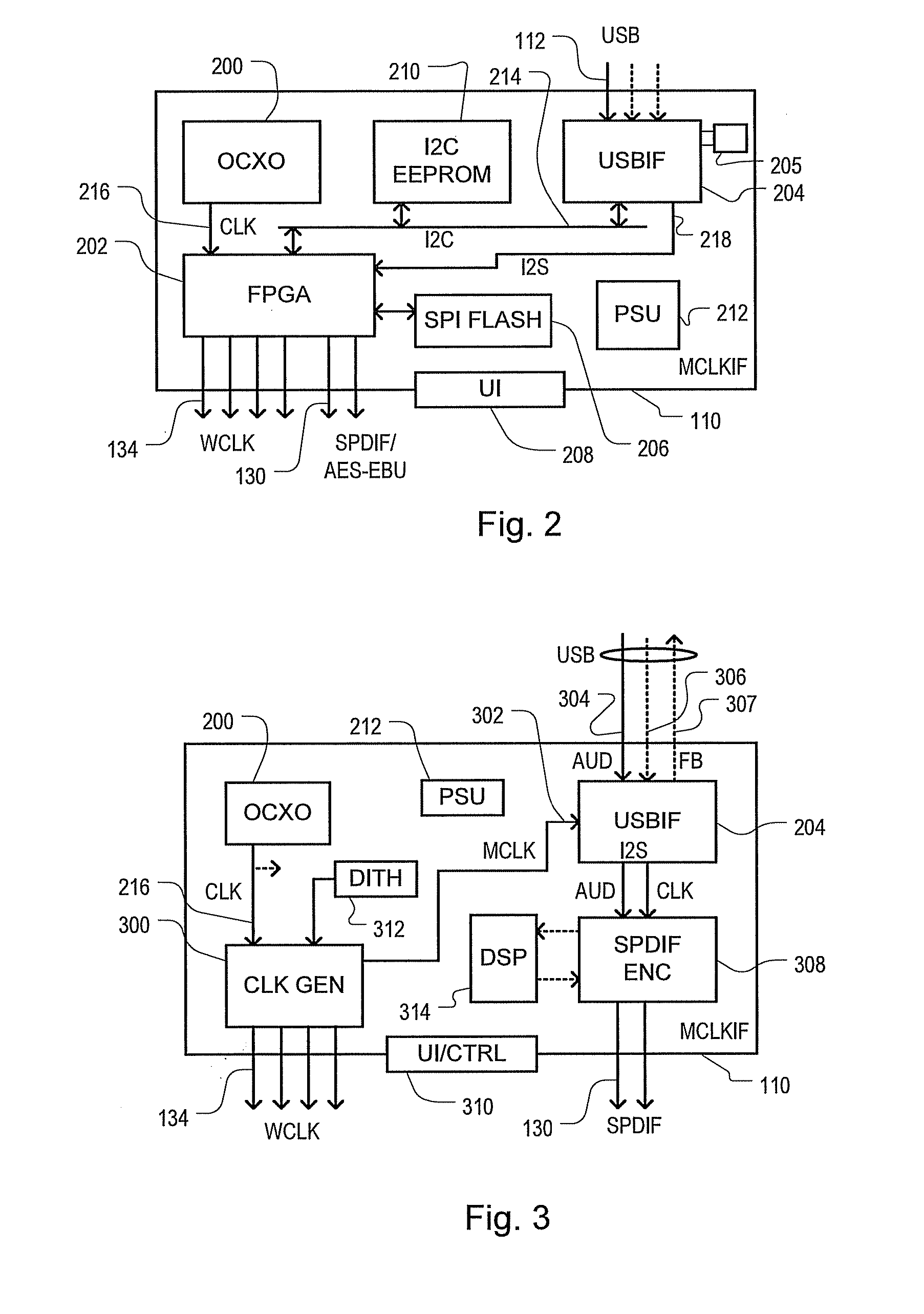

Computer audio interface units and systems

InactiveUS20100077247A1Without qualityCost-effective and flexibleGenerating/distributing signalsTransmission path multiple useSerial computerWord clock

A computer audio interface unit (110) comprises a serial computer interface (e.g. USB) (204) providing a connector (112) for connection to an external, computer-based source (100) of digital audio data samples. A digital audio output connector (130) provides a digital audio output signal to external audio reproduction apparatus (106, 108). A word clock output connector (134) provides a word clock signal to external audio reproduction apparatus, in parallel with said digital audio output signal. An encoder (202 / 308) receives digital audio data via said USB interface and outputs said digital audio output signal. Clocking circuitry (202 / 300, 312) is responsive to a timing reference signal (200) independent of said external source (100), and generates said word clock signal for output to the external reproduction apparatus. Said clocking circuitry further generates a clock signal (302) for the USB interface (204) so as to synchronise the drawing of said audio data samples via said USB interface with the generated external word clock signal and the digital audio output signal. Interface and encoder functions may be housed separately from a master clock function.

Owner:DATA CONVERSION SYST

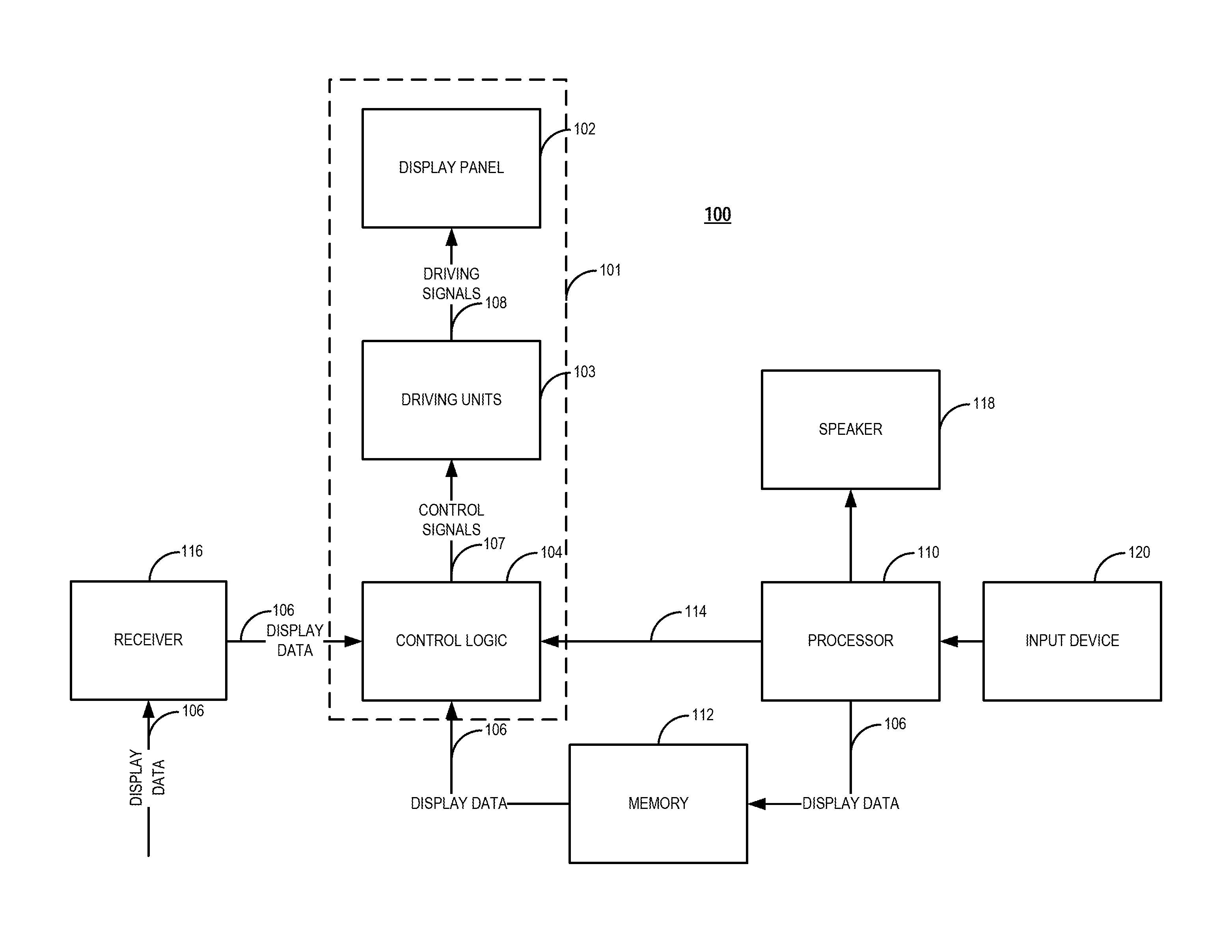

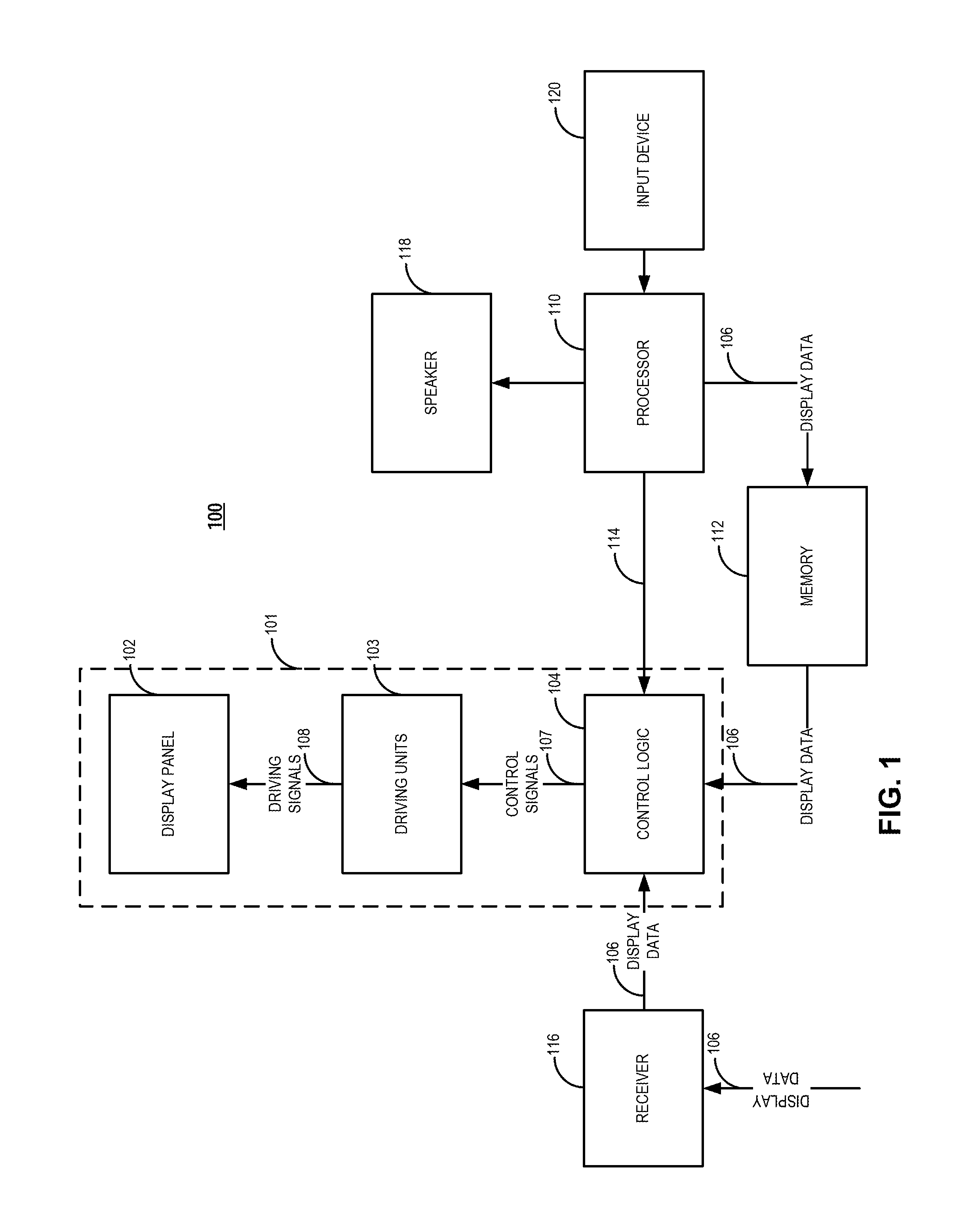

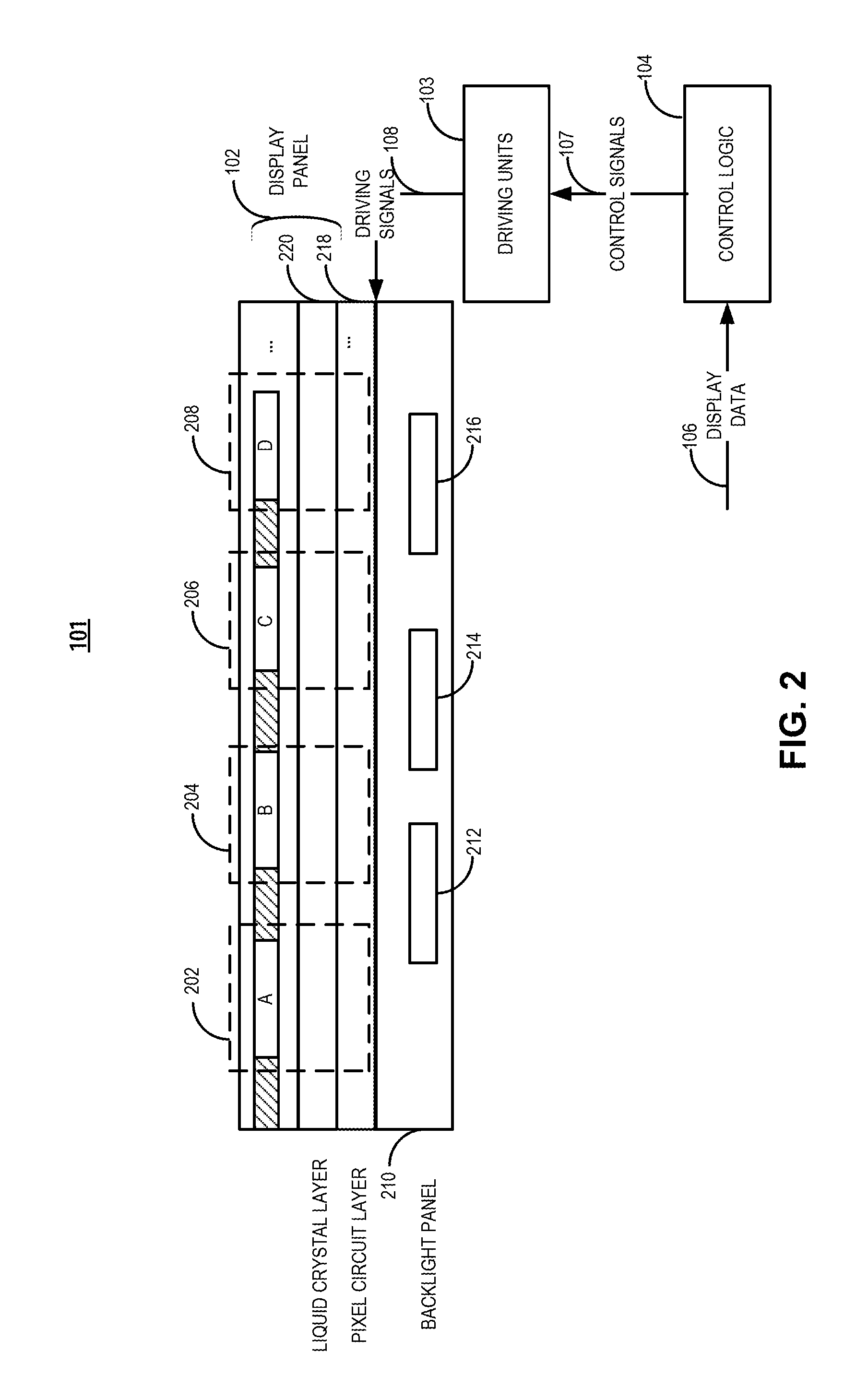

Field sequential color display

InactiveUS20150070256A1Increasing LC setting speedSuppress colorStatic indicating devicesComputer visionControl logic

An apparatus includes control logic and a scan driving unit. The control logic is configured to control driving of a display panel having an array of pixels divided into groups of pixels. Each group of pixies includes rows of pixels. The control logic is configured to control sequentially applying of multiple backlights having different colors to the array of pixels in multiple time periods. The scan driving unit is operatively coupled to the control logic and is configured to, in each time period, scan the rows of pixels of each group of pixels according to a row scanning sequence. For each group of pixels, in a first time period, the scan driving unit sequentially scans the rows of pixels according to a first row scanning sequence; in a second time period, the scan driving unit sequentially scans the rows of pixels according to a second row scanning sequence.

Owner:SHENZHEN YUNYINGGU TECH CO LTD

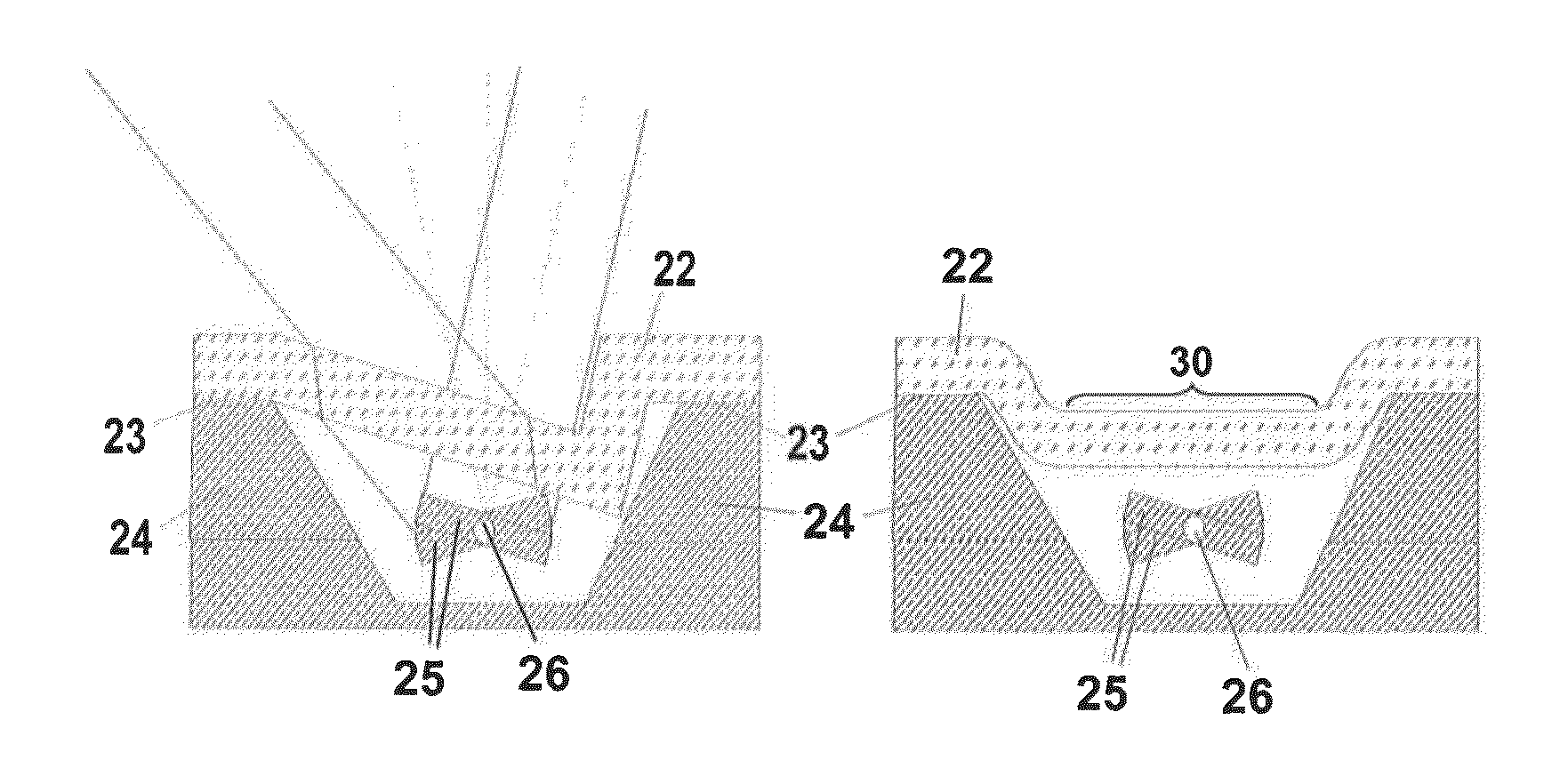

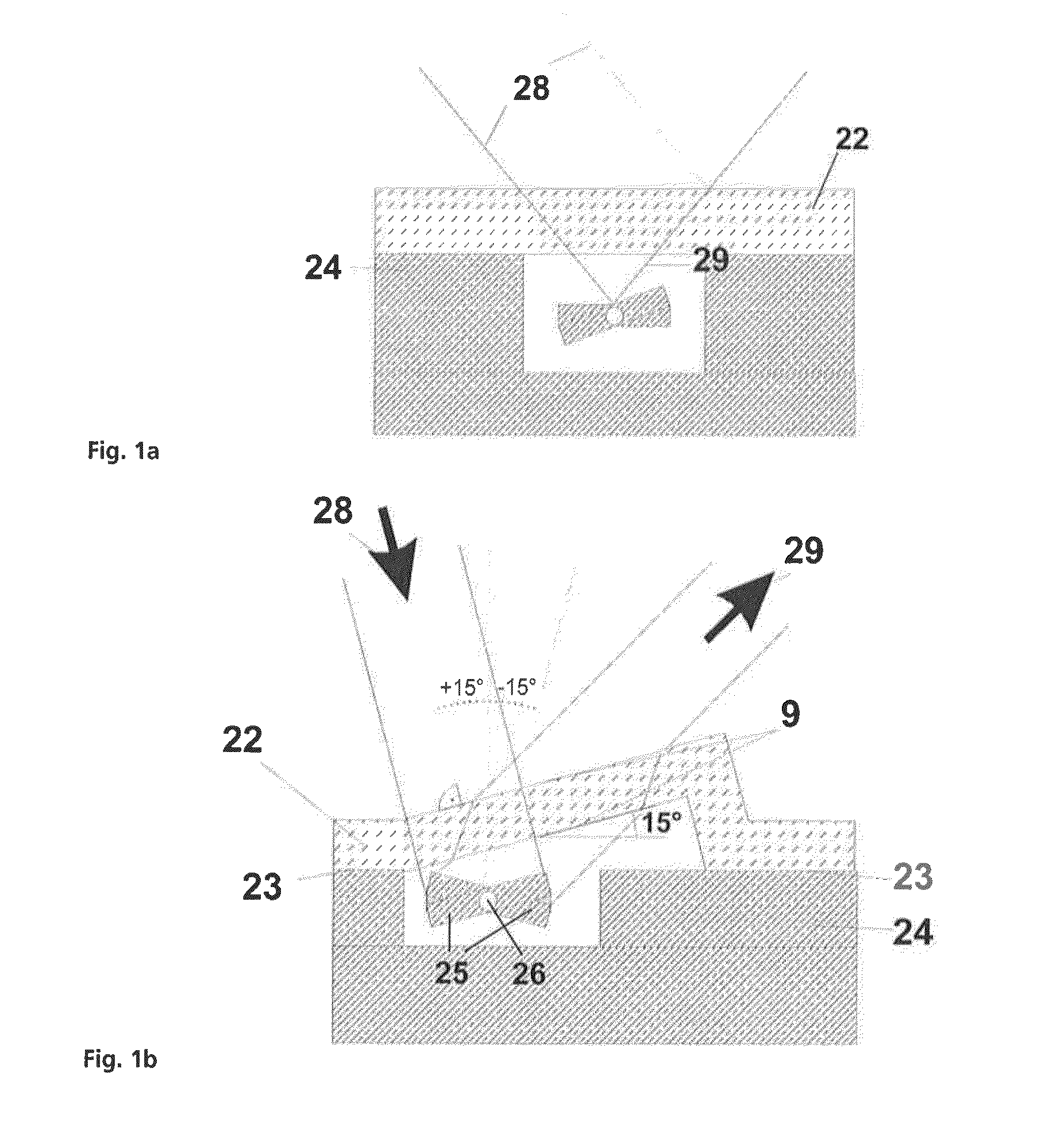

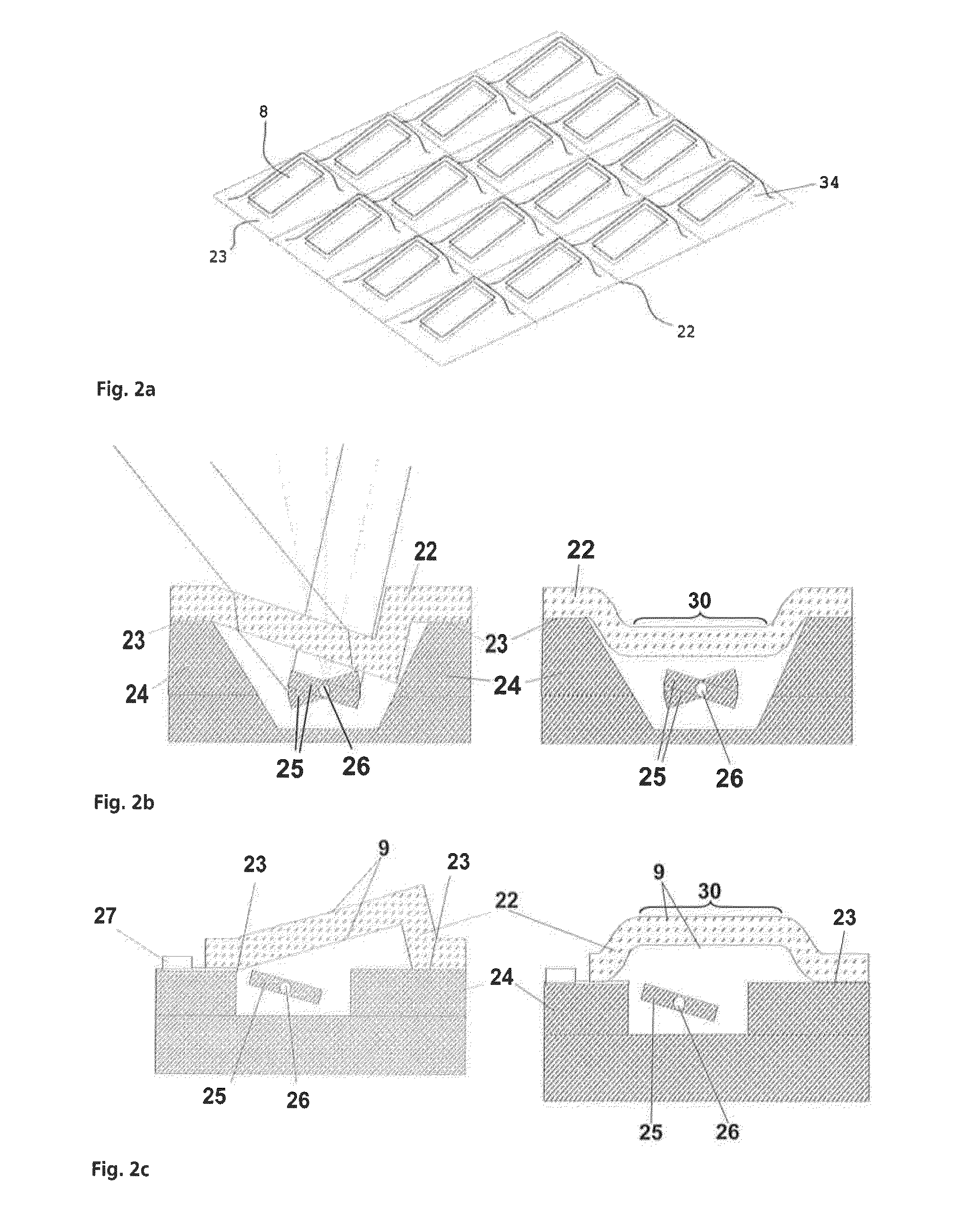

Method for producing structured optical components

ActiveUS20150040368A1Cost-effective and flexibleImprove surface qualityDecorative surface effectsOptical articlesAlternative methodsEngineering

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

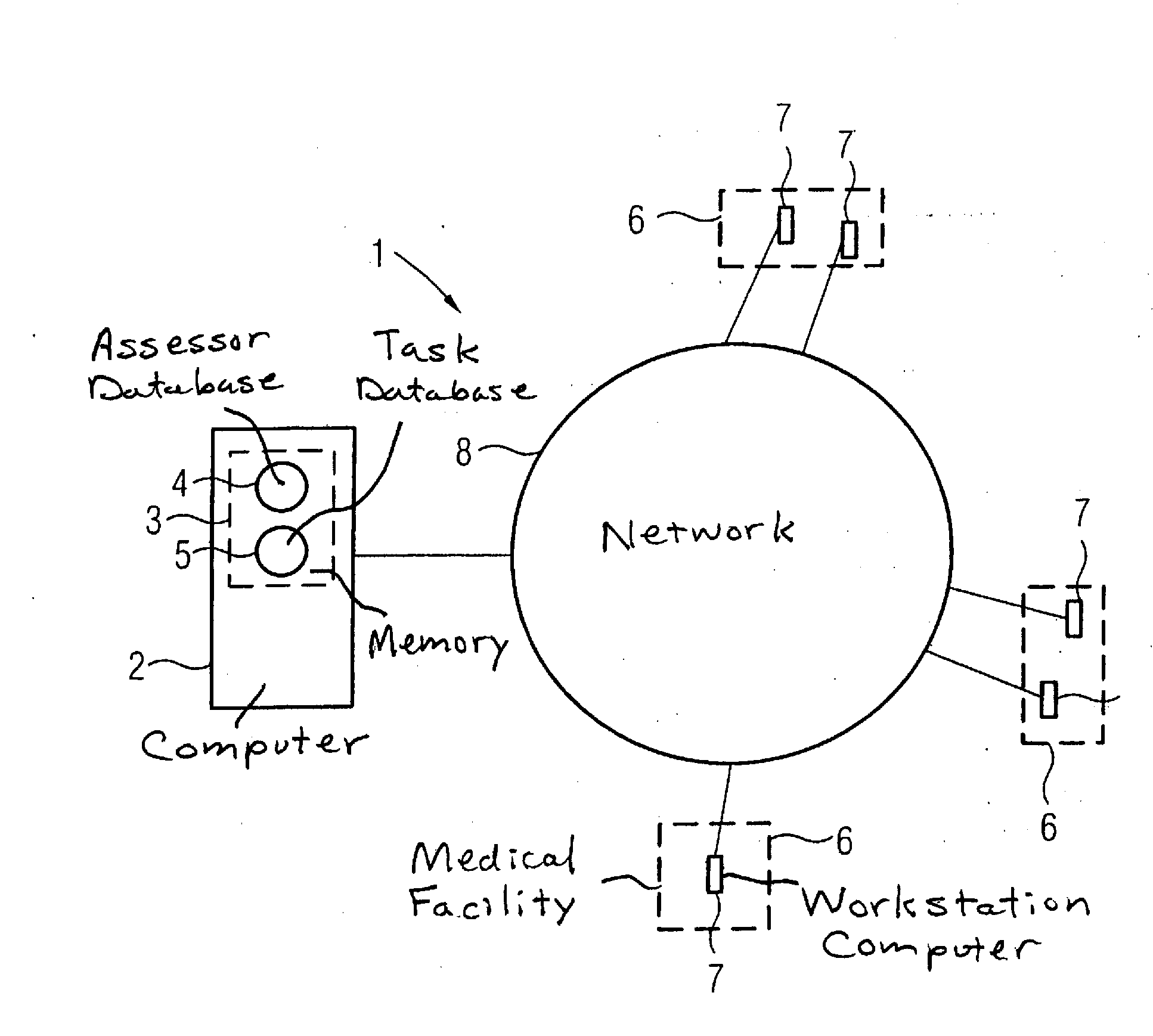

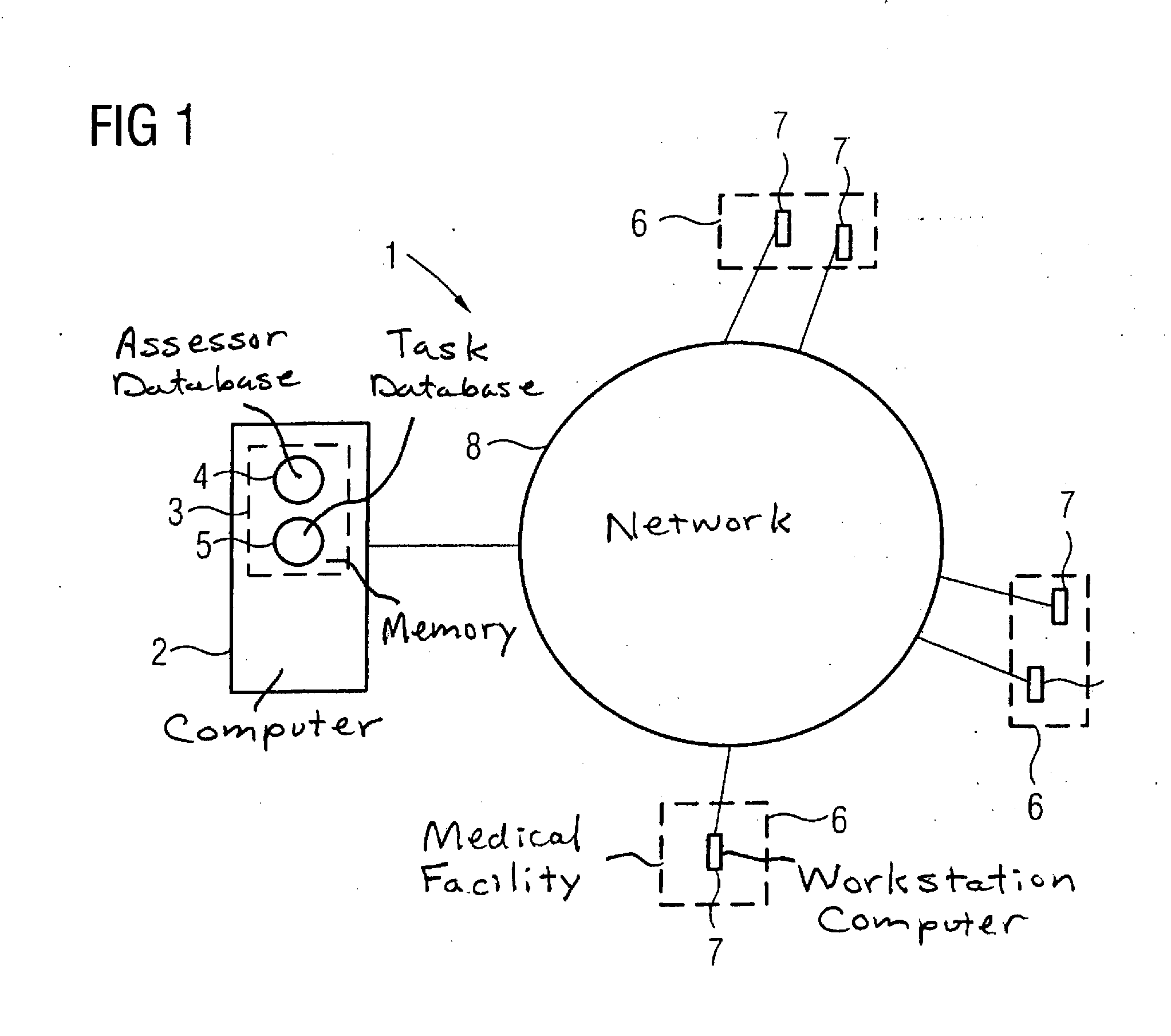

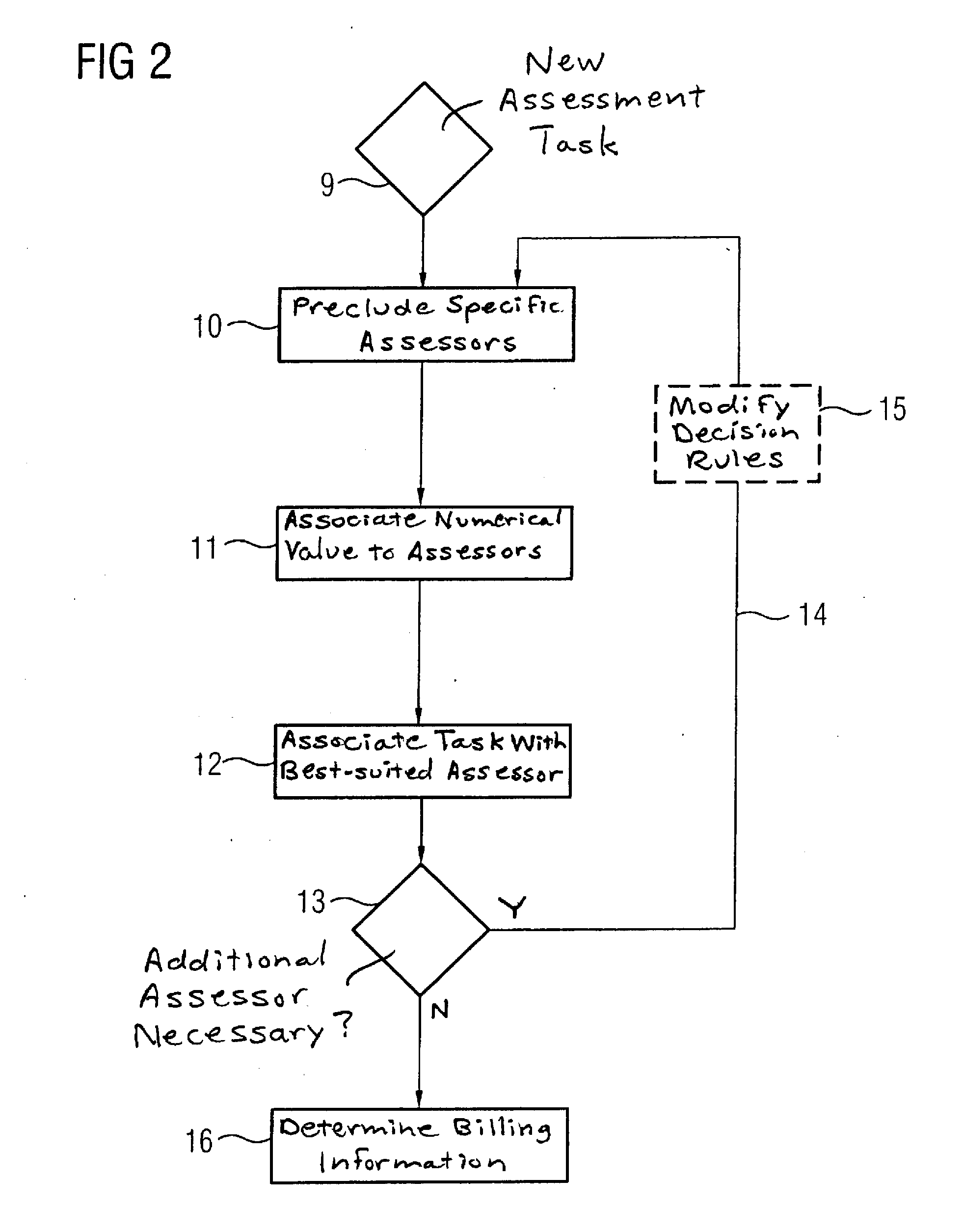

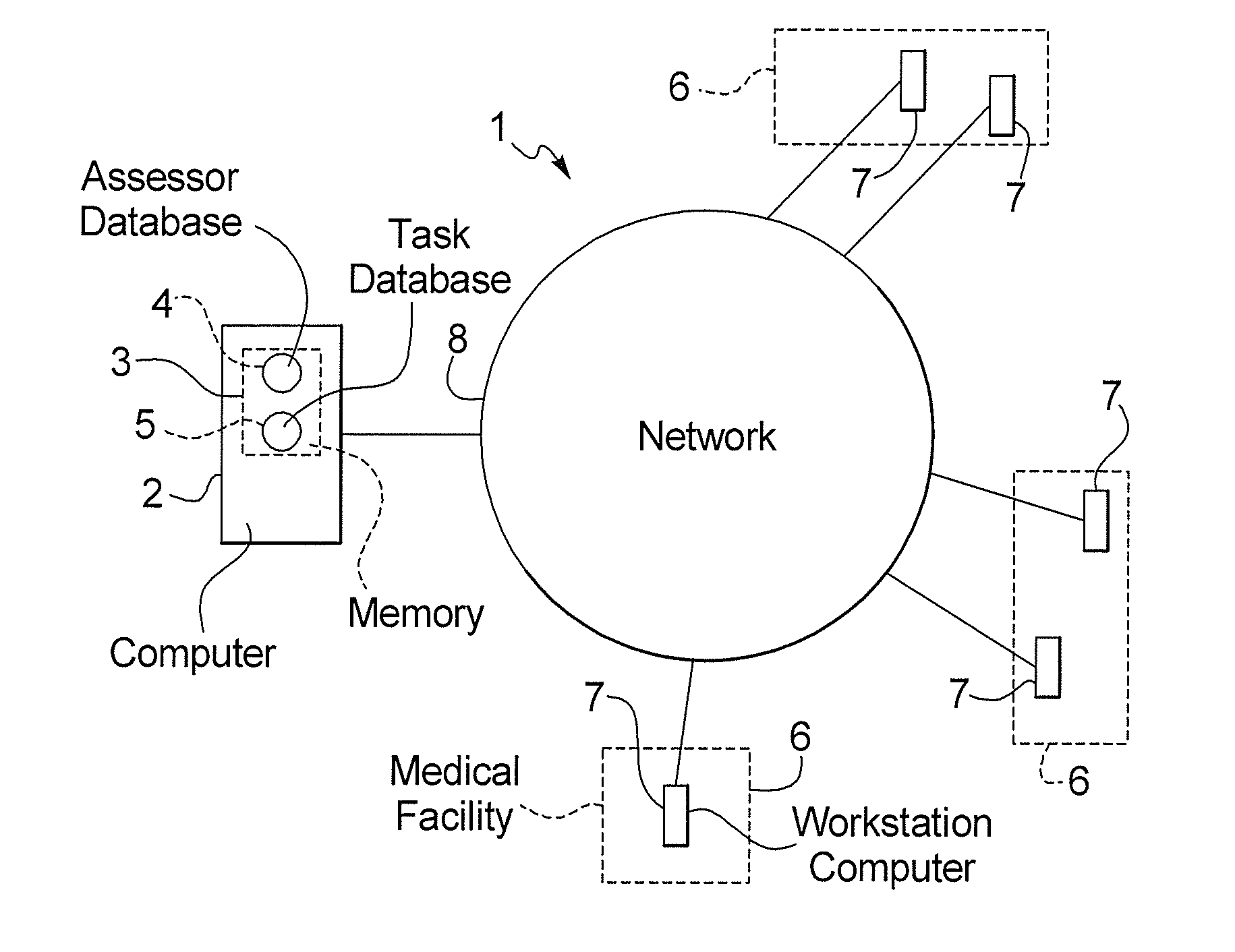

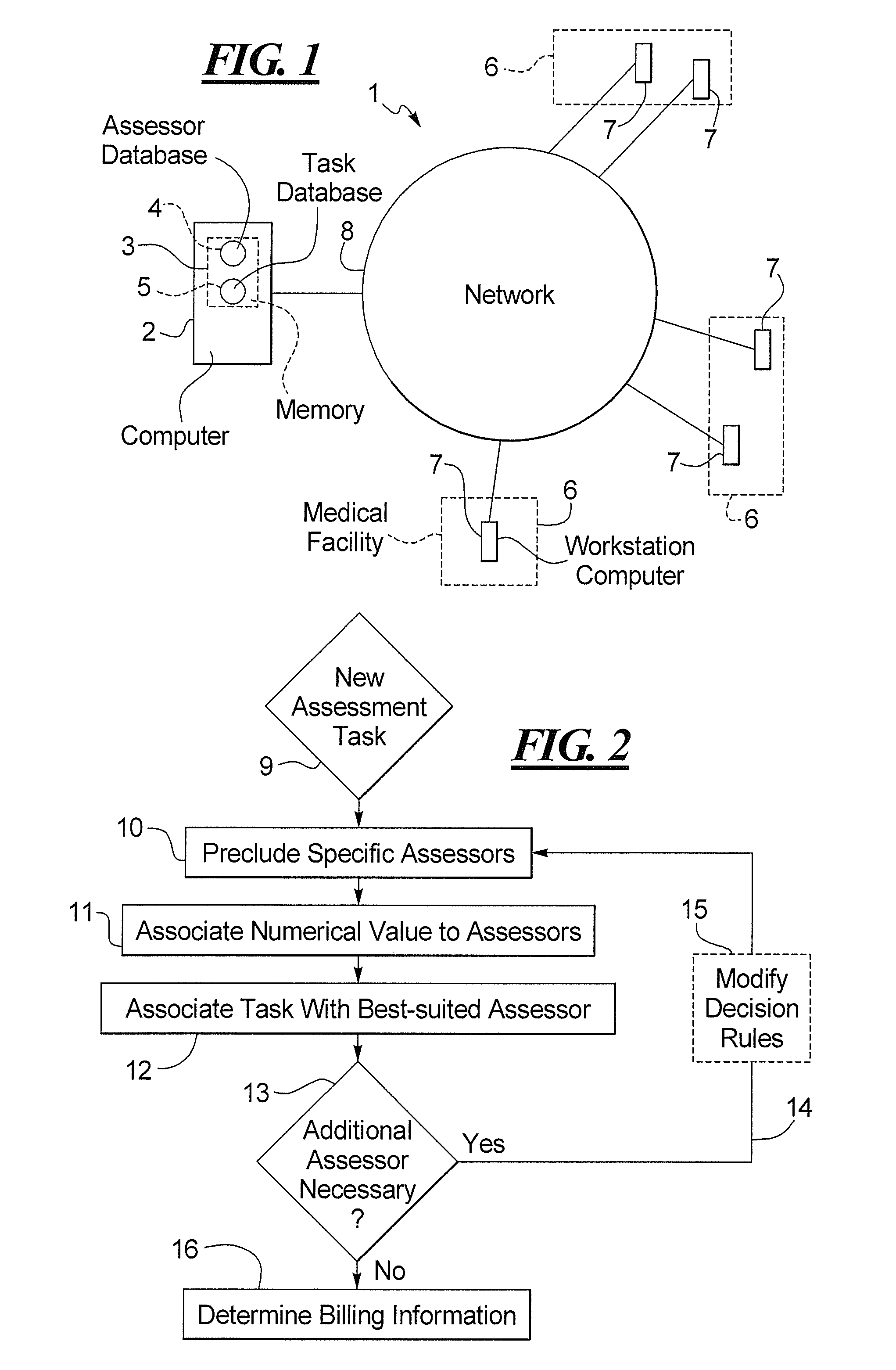

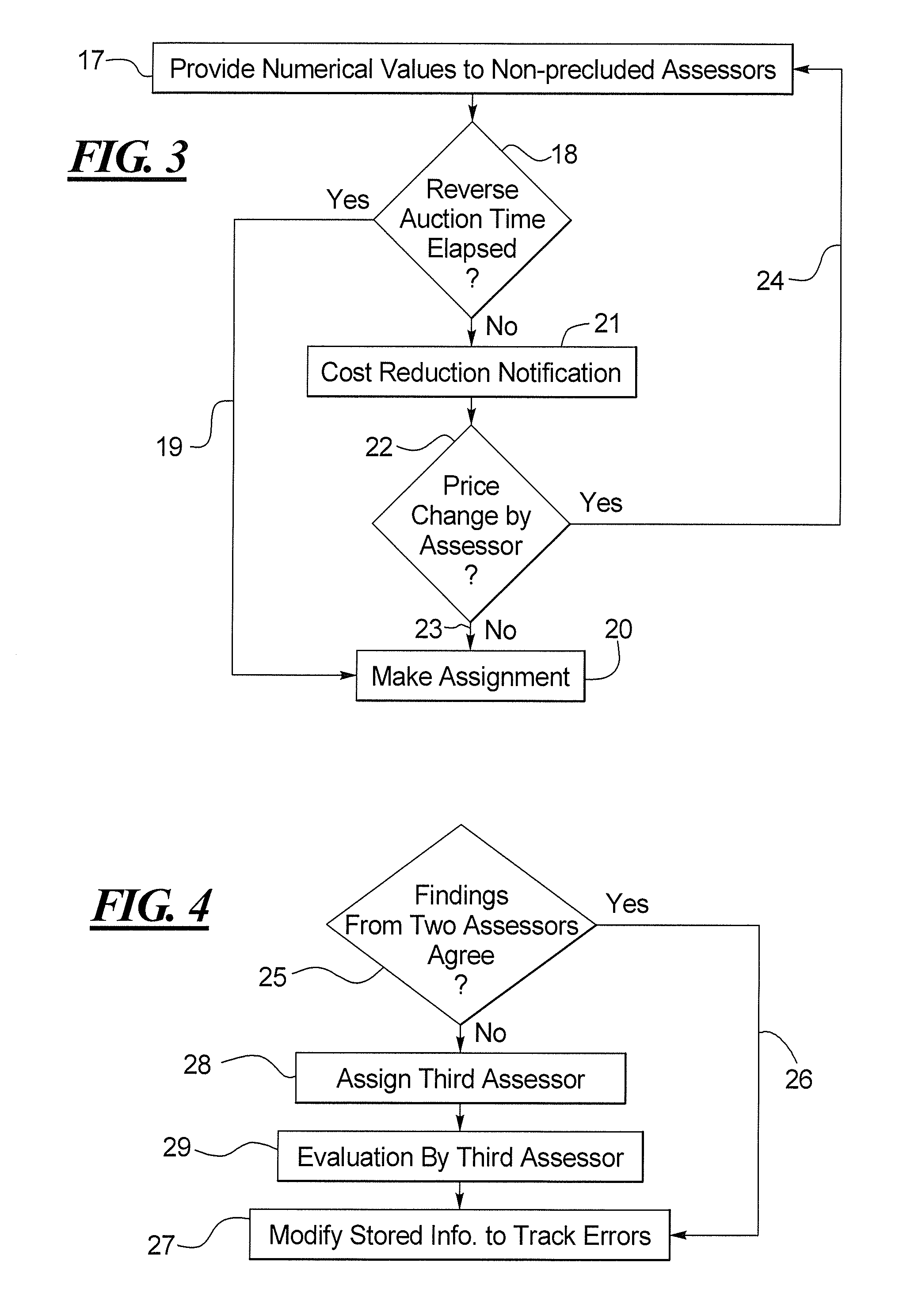

Method and system for automatically associating an assessor with a medical assessment task

InactiveUS20090307010A1Cost-effective and flexibleImprove overall utilizationFinanceMedical automated diagnosisData setMedical treatment

In a method and system for automated association of an assessor with an assessment task (in particular an evaluation of an image data set) an assessor database is used that contains assessors as well as selection information associated with assessors and task information associated with assessment tasks. A medical assessment is automatically associated with an assessor using at least one decision rule, starting from the task information and with consideration of the relevant selection information.

Owner:SIEMENS HEALTHCARE GMBH

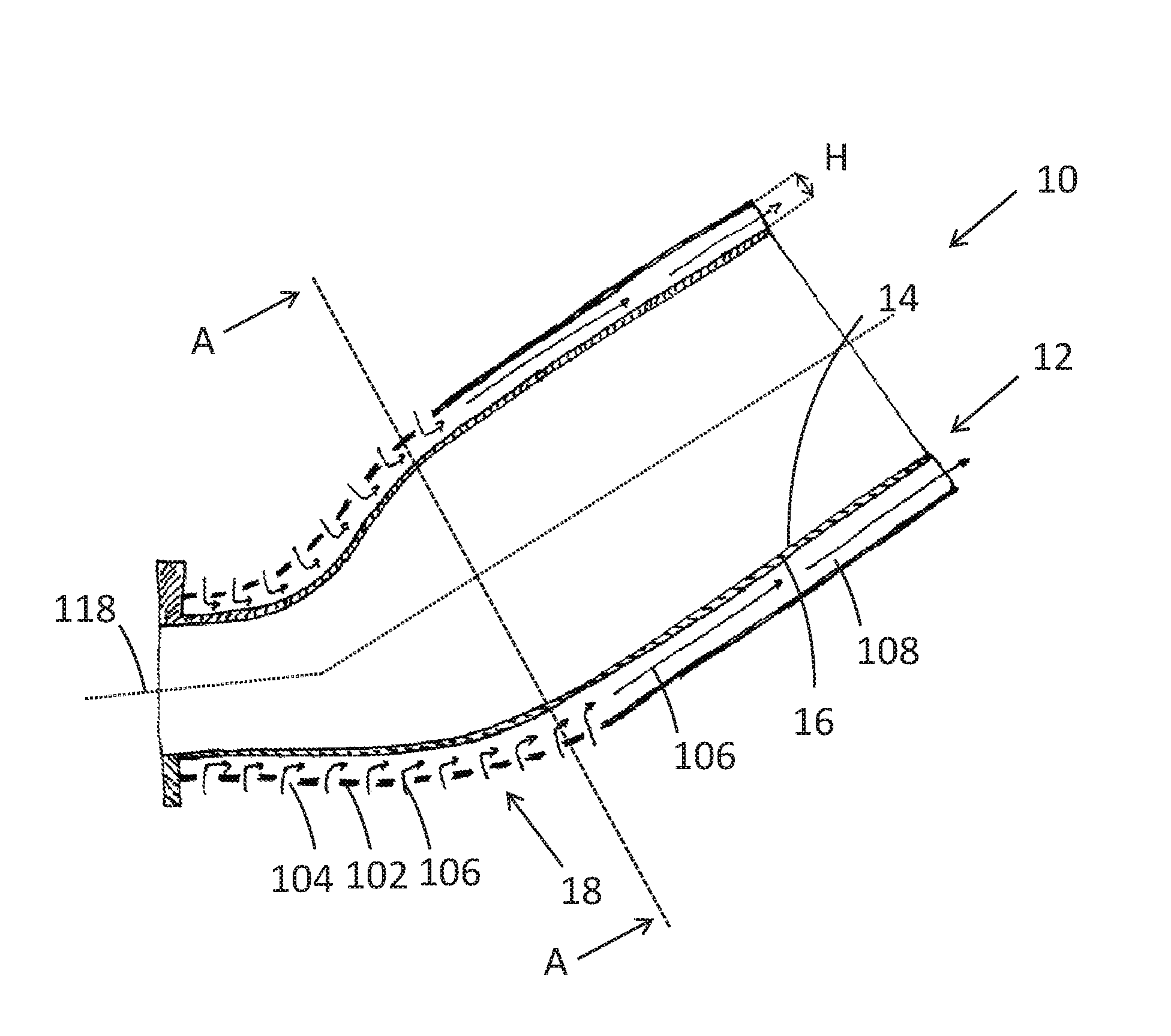

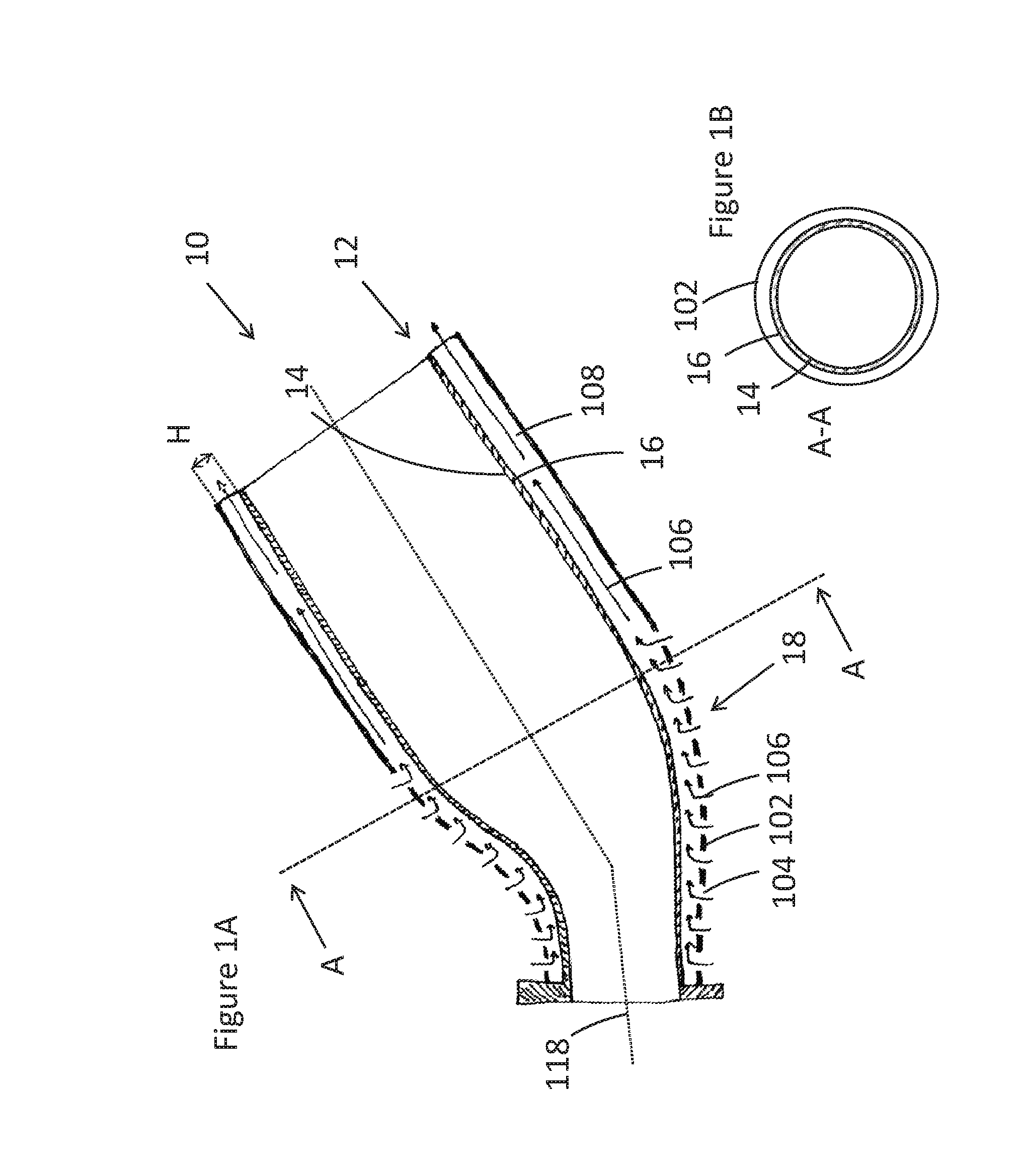

Method and apparatus for cooling a hot gas wall

ActiveUS20160209034A1Cost-effective and flexibleImproved convection coolingContinuous combustion chamberEngine manufactureElectrical resistance and conductanceEngineering

A method of manufacturing a hot gas wall for a gas turbine is described. The method is carried out on a hot gas wall having a wall part with a front side and a back side, the wall part being for exposure to a hot fluid on the front side, and the hot gas wall also having a turbulator structure. In an exemplary embodiment, a turbulator structure is attached to the wall by placing a braze foil on the back side of the wall part, placing a turbulator structure on the braze foil, and brazing to attach the turbulator structure to the wall part. In another embodiment, the turbulator structure is attached by passing a current through the turbulator structure part and the wall part to resistance weld the turbulator structure part to the wall part.

Owner:ANSALDO ENERGIA SWITZERLAND AG

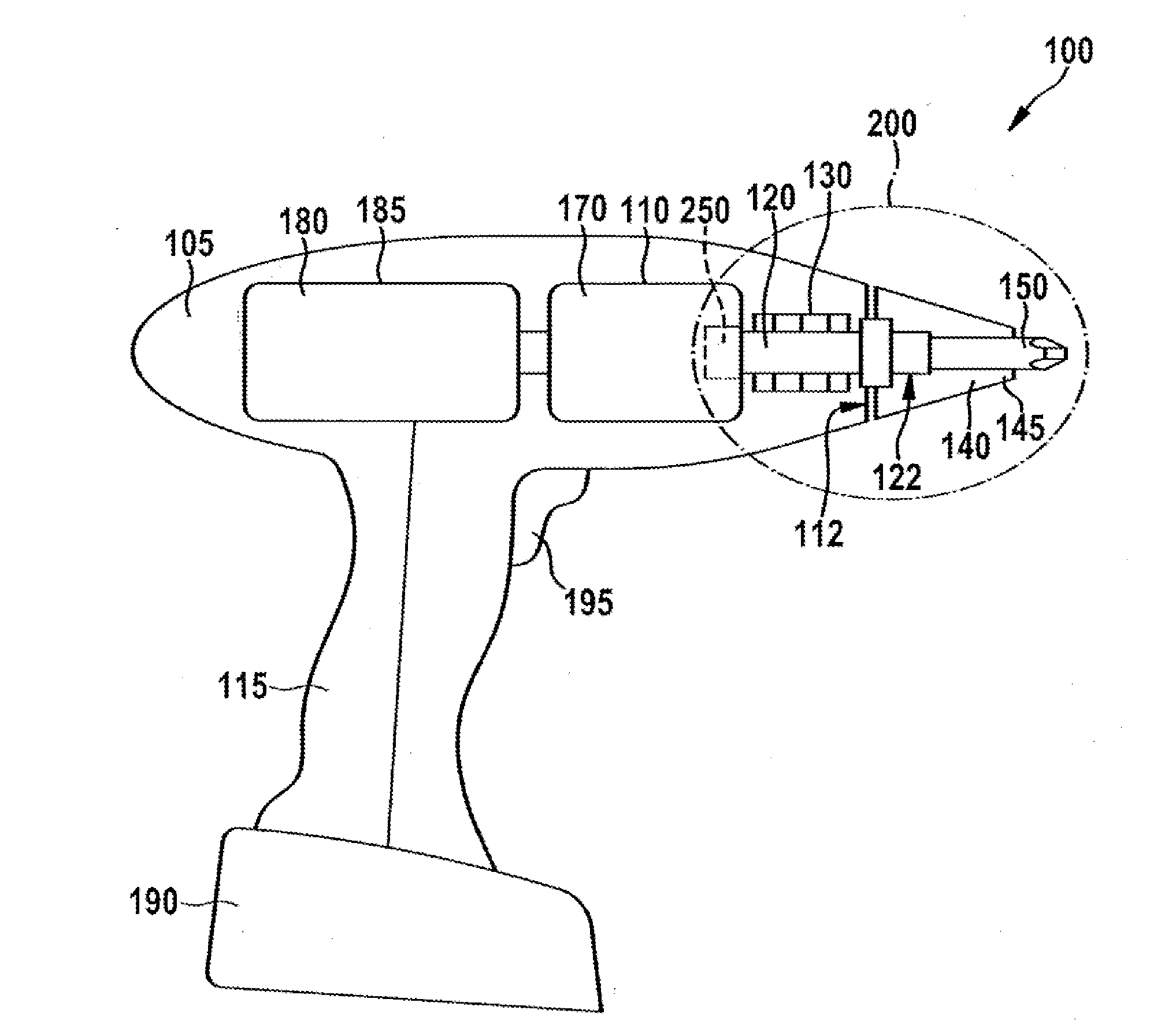

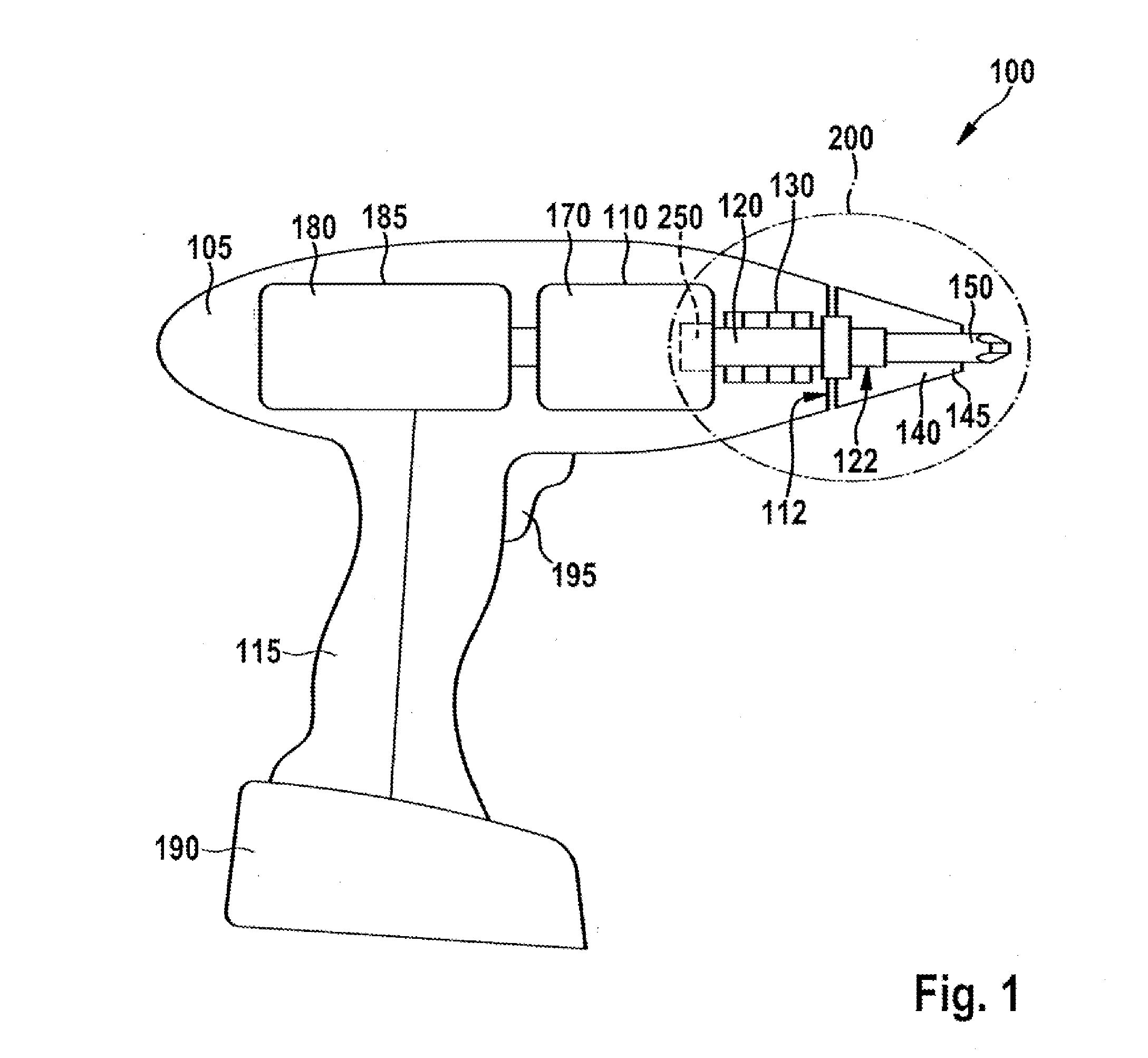

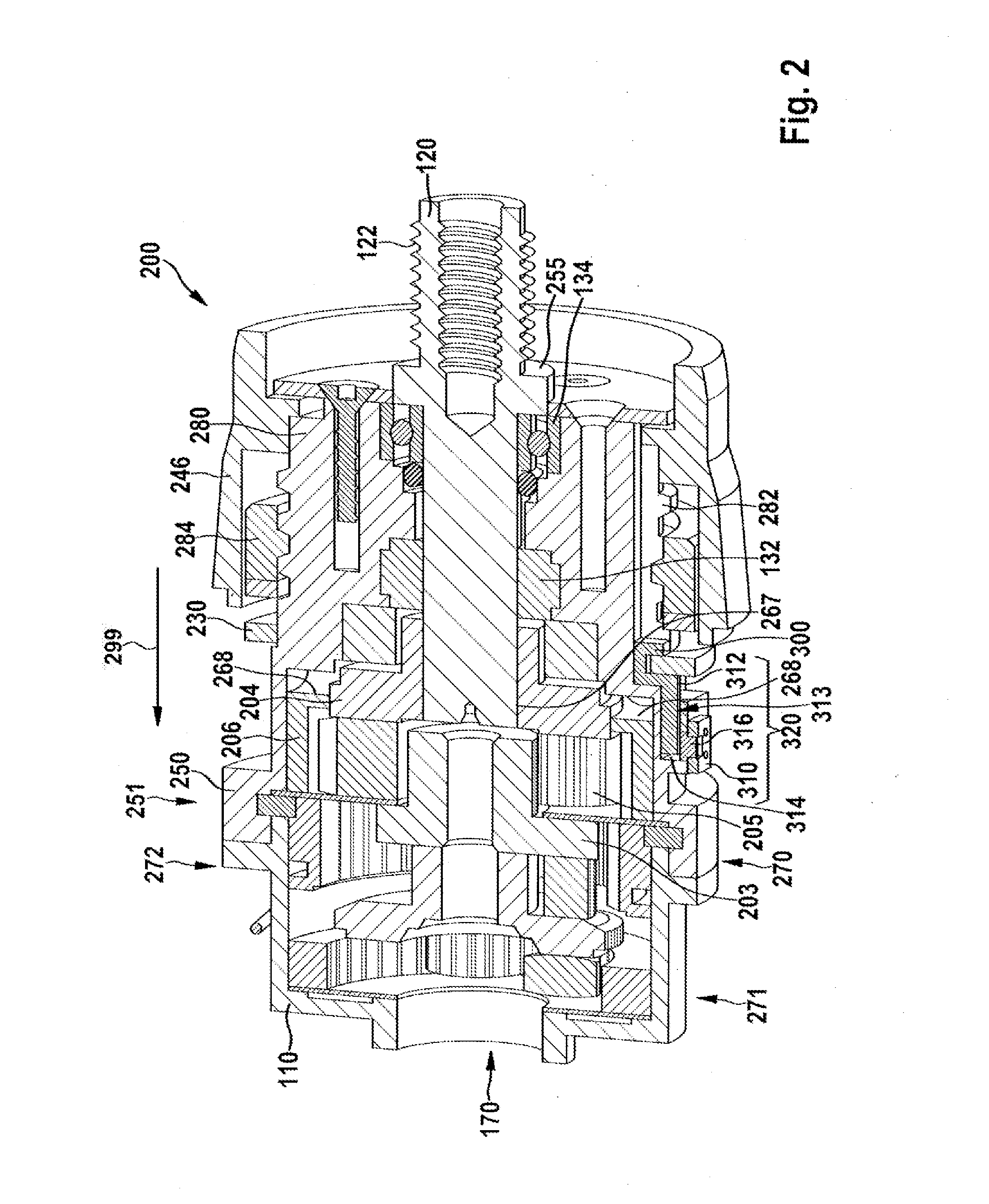

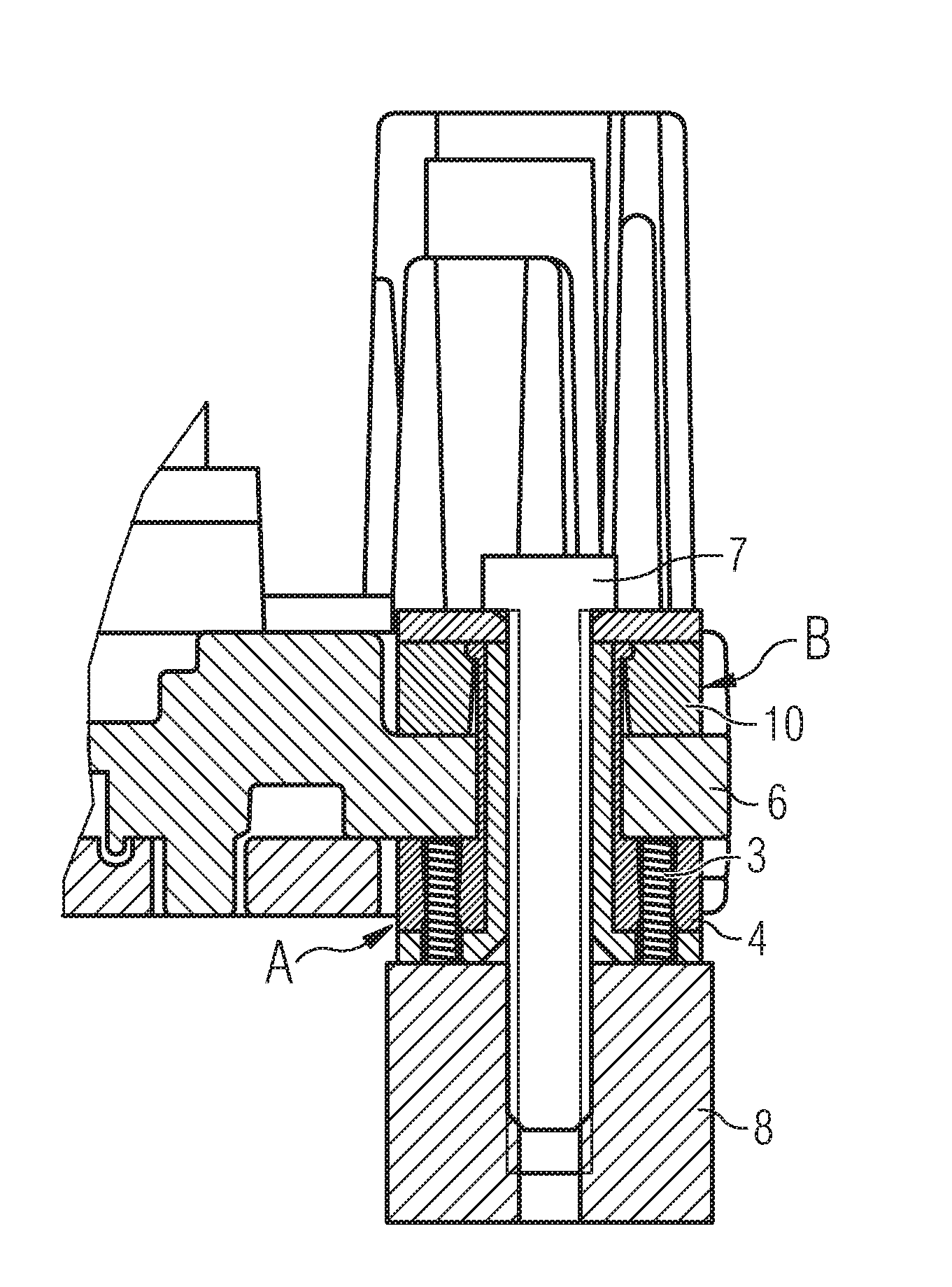

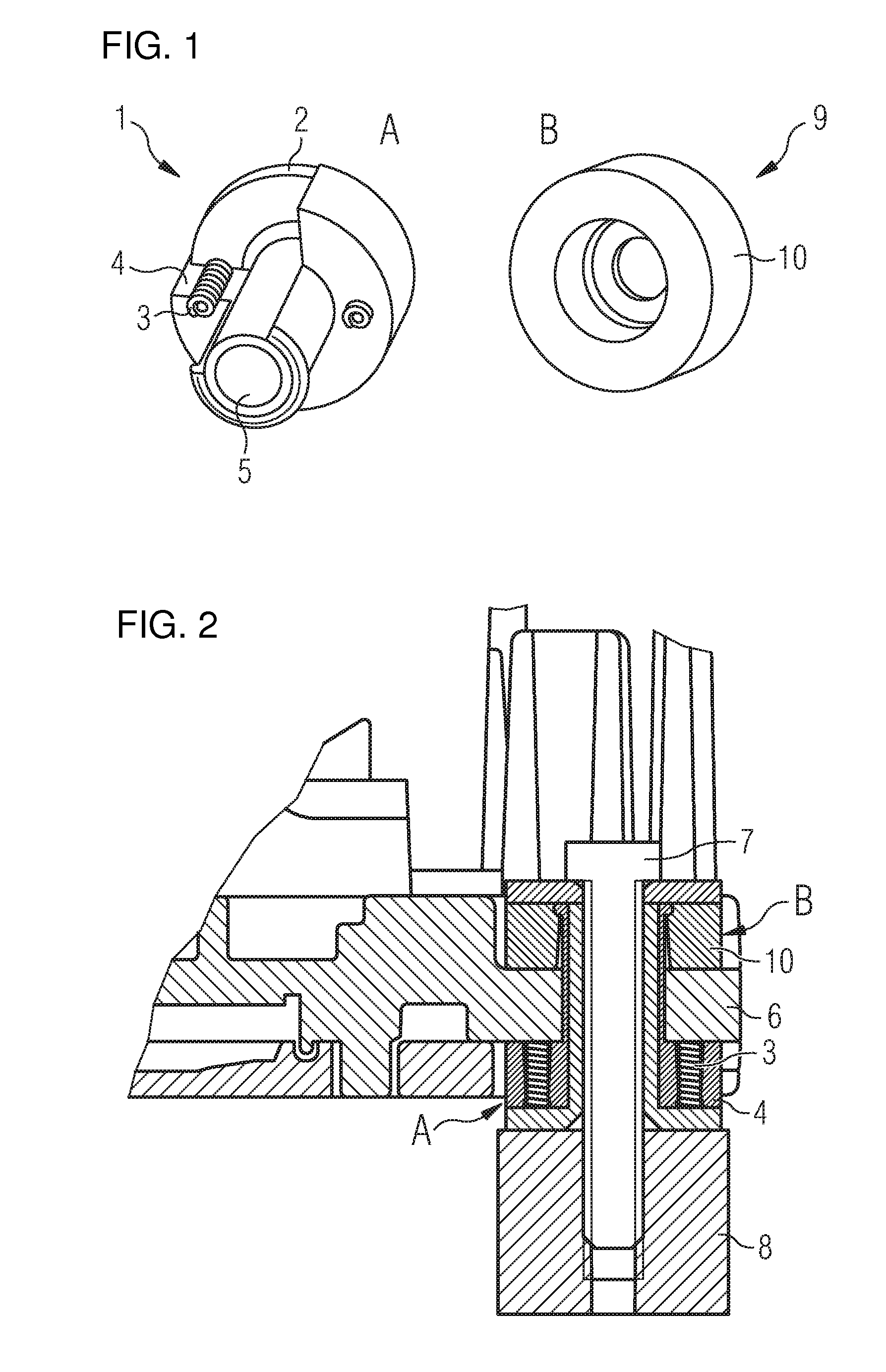

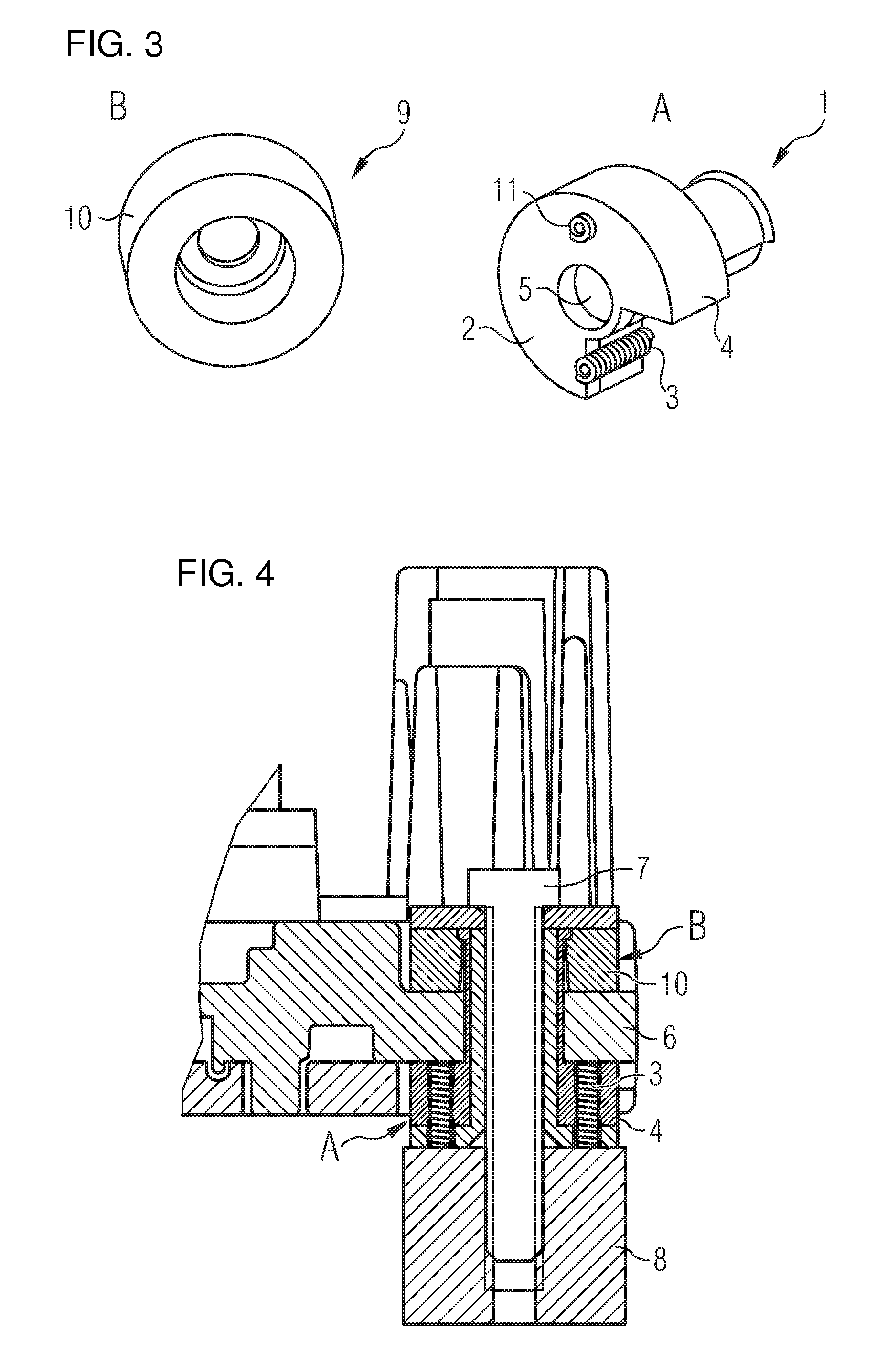

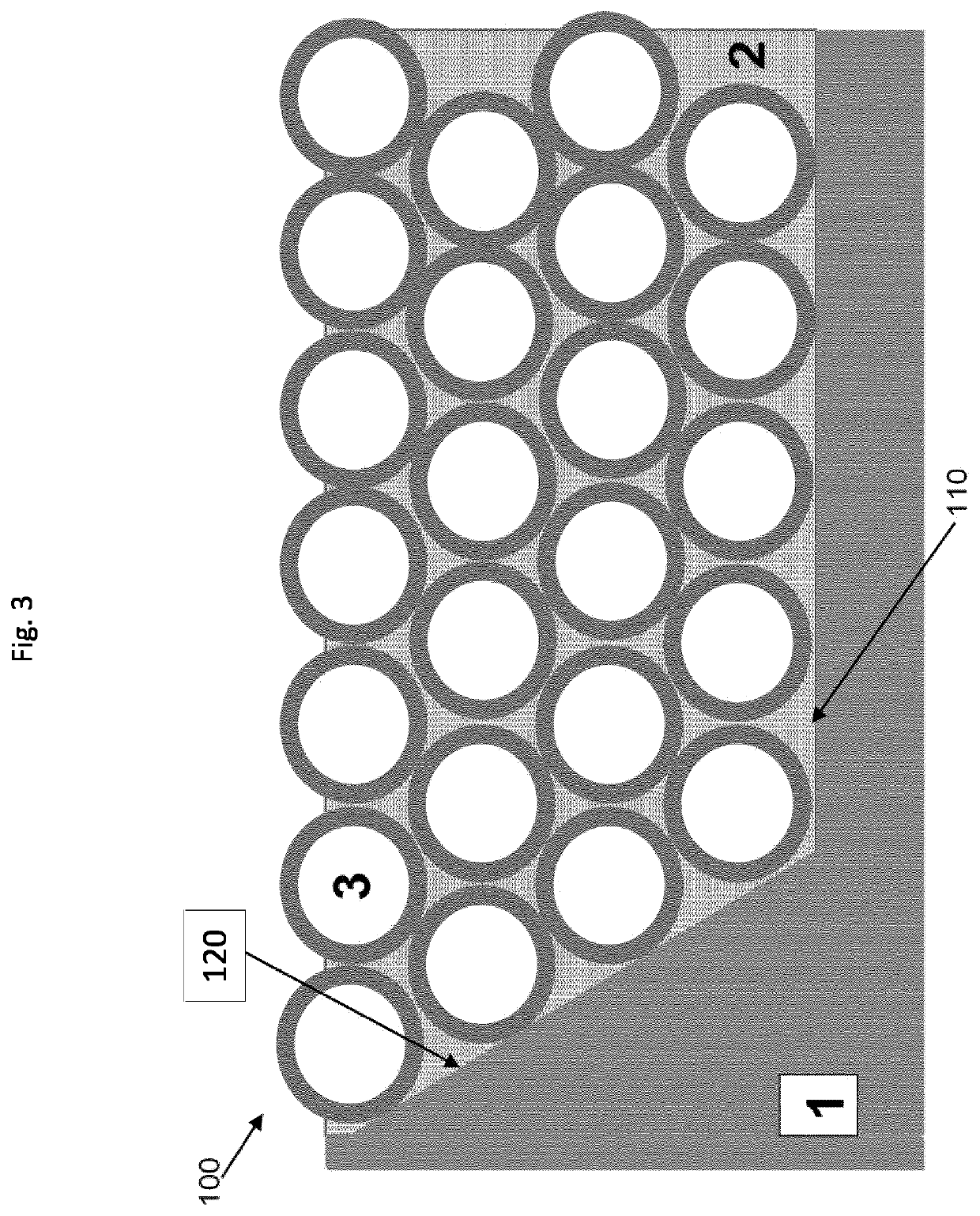

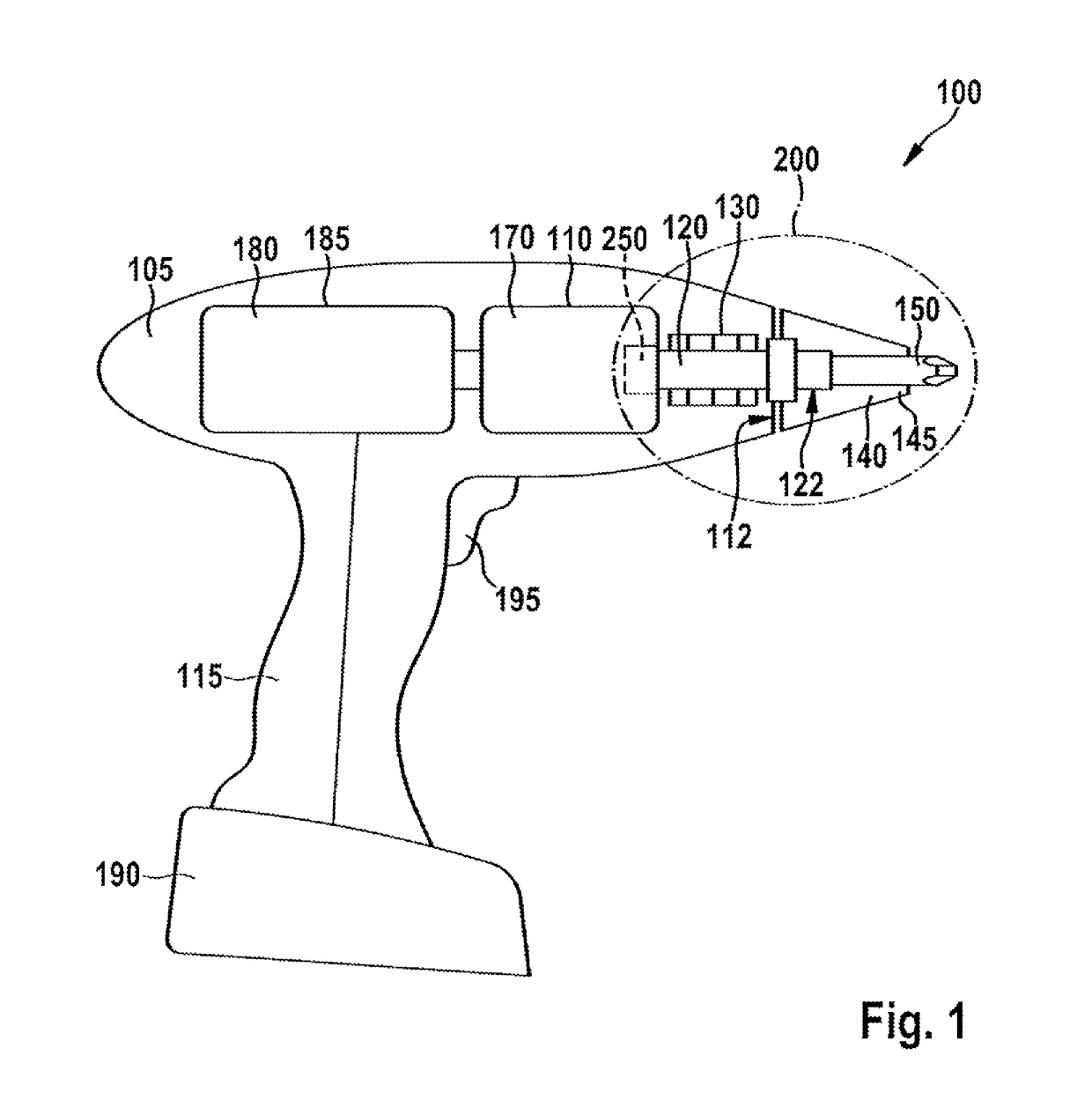

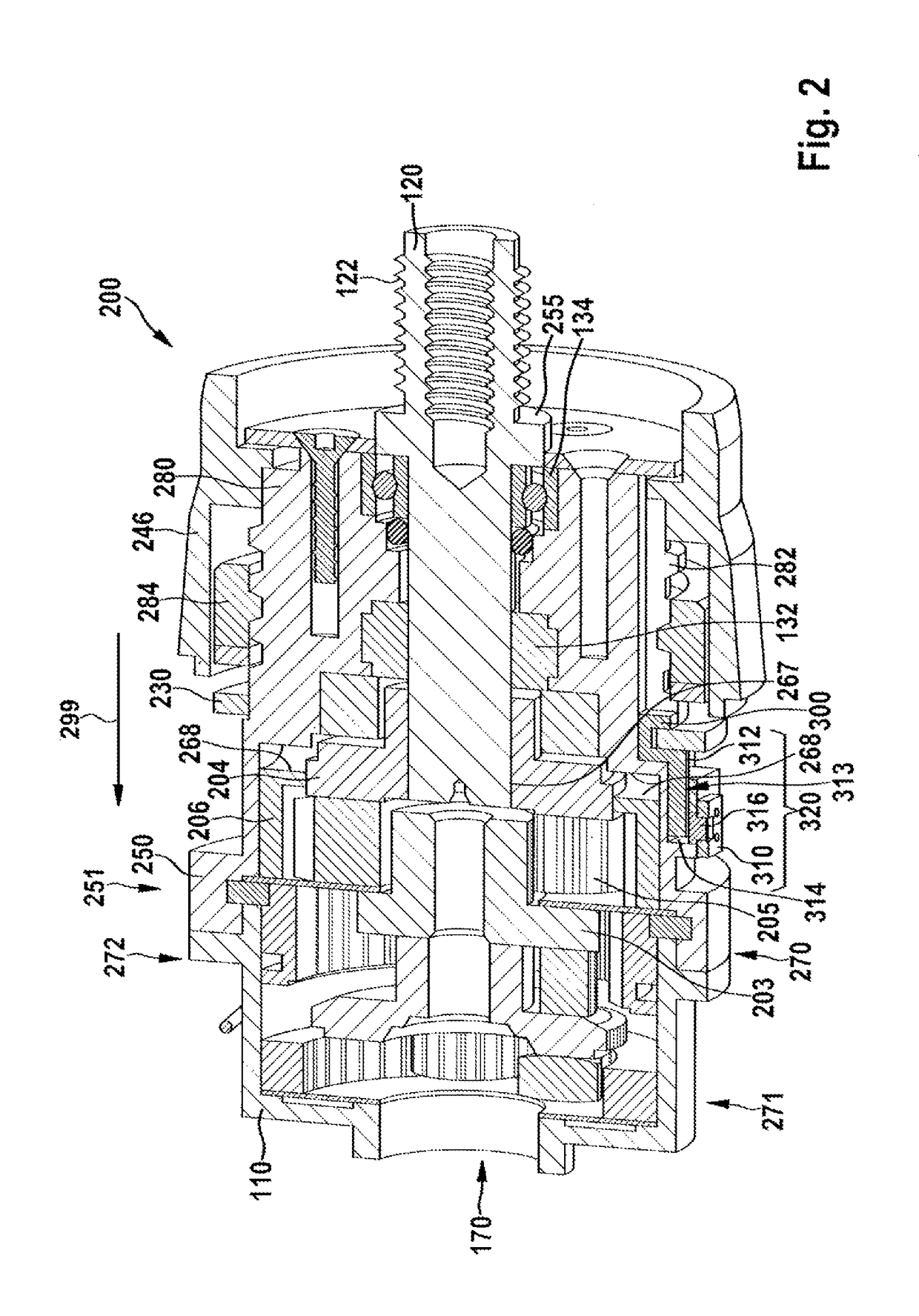

Hand-held power tool

A hand-held power tool is provided which includes a clutch housing of a torque clutch, and a planetary gear, situated in a gear housing, for transmitting a torque which is generated by a drive motor to a drive shaft. The clutch housing cooperates with the planetary gear via a pressure plate. The pressure plate is displaced in the axial direction in order to disengage the torque clutch. The axial relative motion of the pressure plate causes an axial relative motion between a switching element and an associated optical sensor, via which the drive motor may be switched off.

Owner:ROBERT BOSCH GMBH

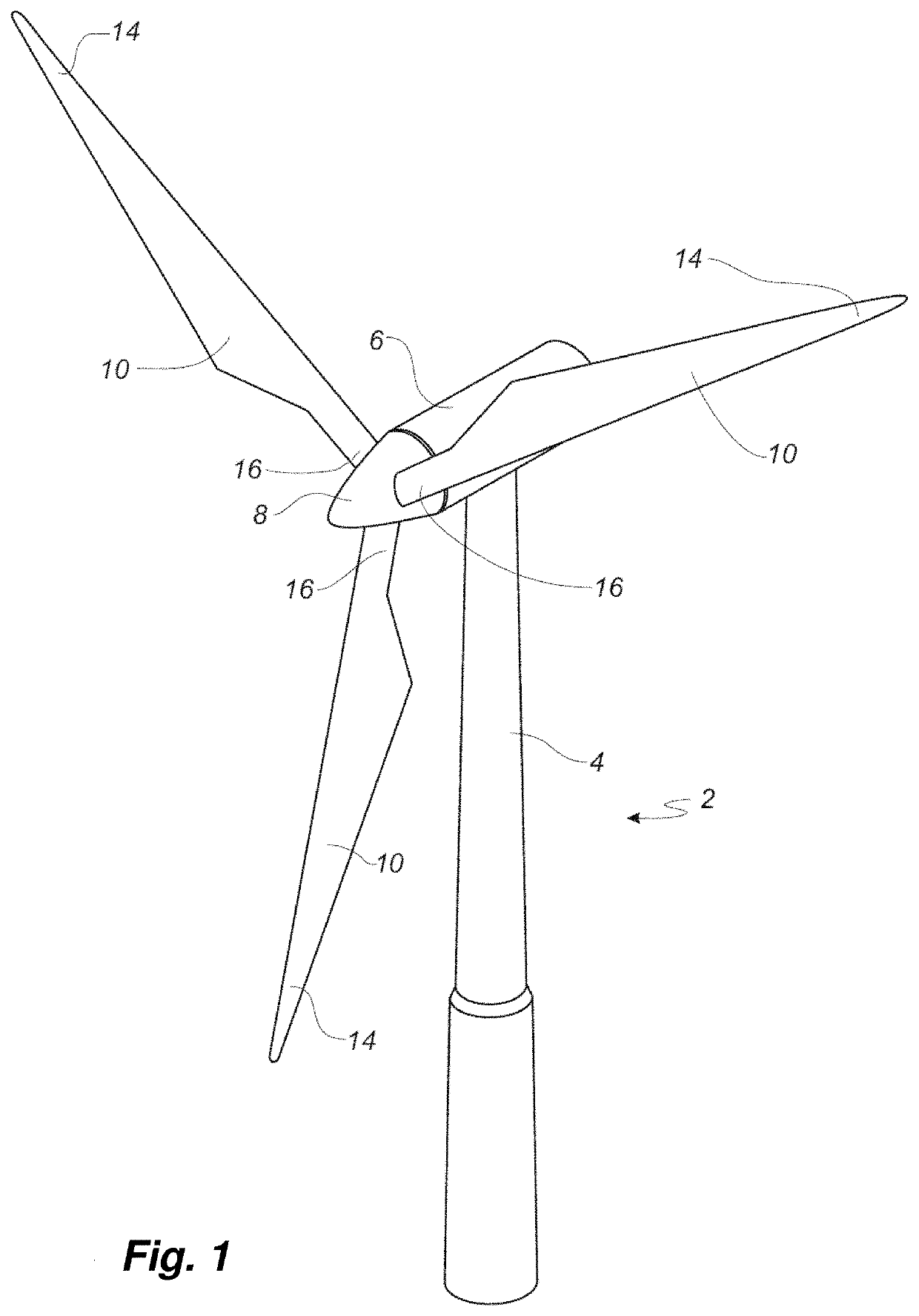

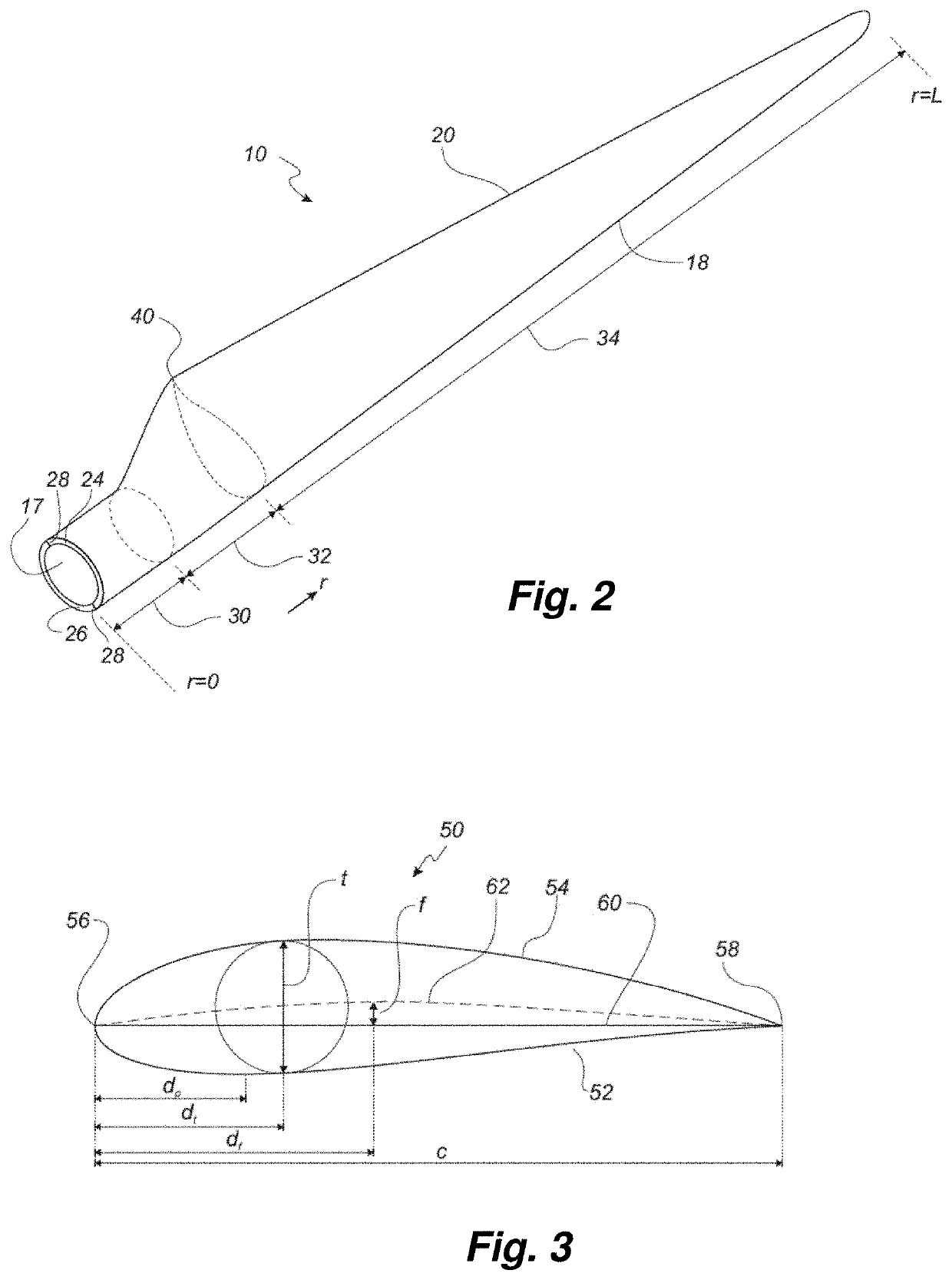

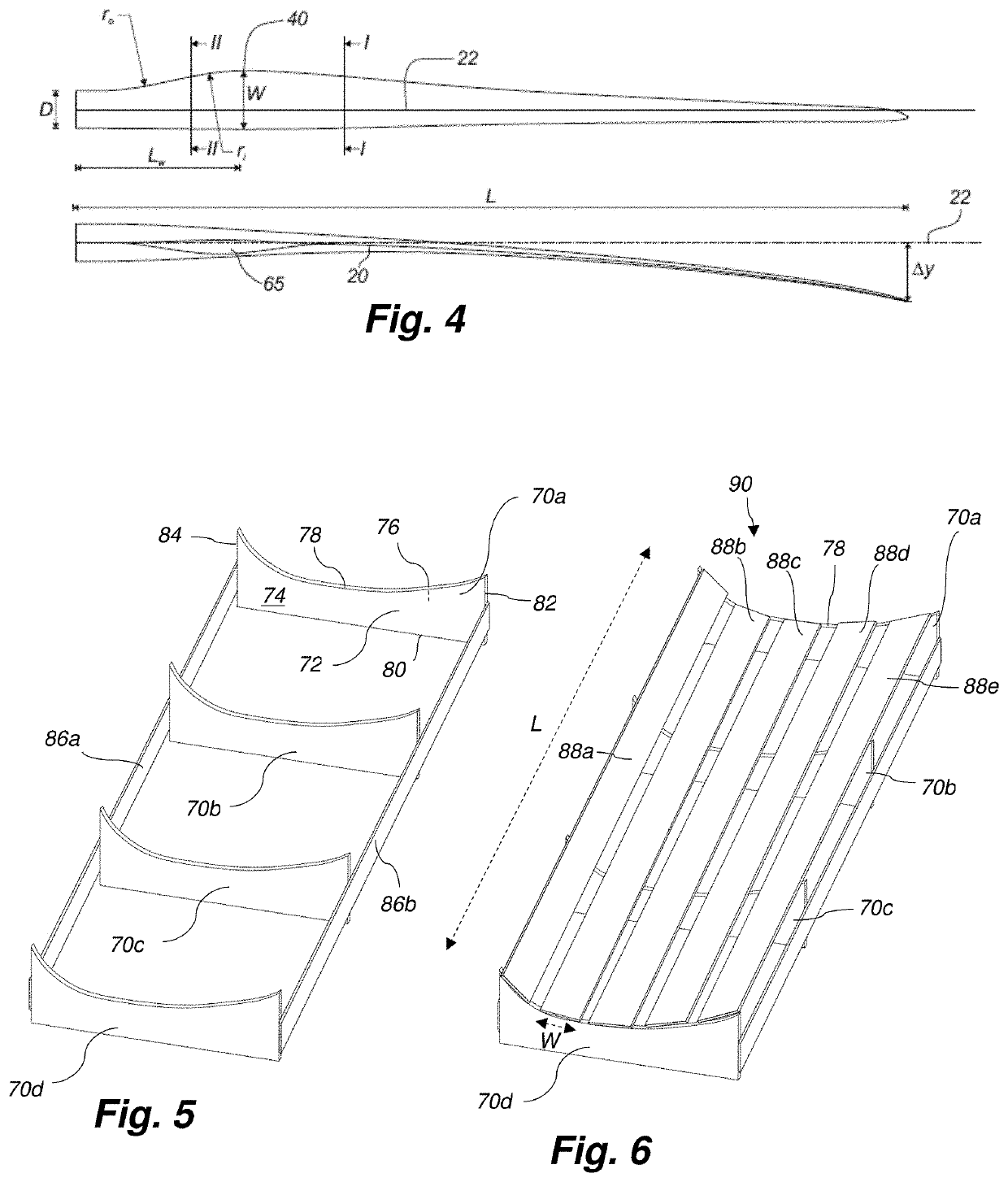

Method and mould for manufacturing preforms for a wind turbine rotor blade

PendingUS20210060878A1Improved and safe layup processFlexible and cost-efficient manufacturing processFinal product manufactureWind energy generationTurbine bladeMechanical engineering

The present invention relates to a method of manufacturing a preform for a wind turbine blade and to a preform mould. The method involves providing a plurality of support elements (70), each support element (70) comprising a planar member (72), arranging a plurality of strips (88) on the top surface (78) of the planar member (72) of each support element (70), wherein the strips (88) are arranged in juxtaposition. Subsequently, a fibre material and a binding agent may be laid on at least part of the strips (88) for forming the preform.

Owner:LM WIND POWER INT TECH II APS

Method and system for automatically associating an assessor with a medical assessment task

InactiveUS8321238B2Cost-effective and flexibleImprove overall utilizationFinanceMedical automated diagnosisData setComputer science

In a method and system for automated association of an assessor with an assessment task (in particular an evaluation of an image data set) an assessor database is used that contains assessors as well as selection information associated with assessors and task information associated with assessment tasks. A medical assessment is automatically associated with an assessor using at least one decision rule, starting from the task information and with consideration of the relevant selection information.

Owner:SIEMENS HEALTHCARE GMBH

Process for coating a substrate

ActiveUS7892593B2Cost-effective and flexibleIncrease the areaSurgeryPharmaceutical containersMaterials scienceCoating

A method to coat a substrate for the formation of coatings having a desired surface morphology is provided, wherein the roughness and the total surface area of the coating can be varied during the coating process. The method of the present invention comprises the steps of generating droplets from a coating composition, transporting the droplets to the substrate and depositing a majority of the droplets on the substrate.

Owner:IOOS LLC

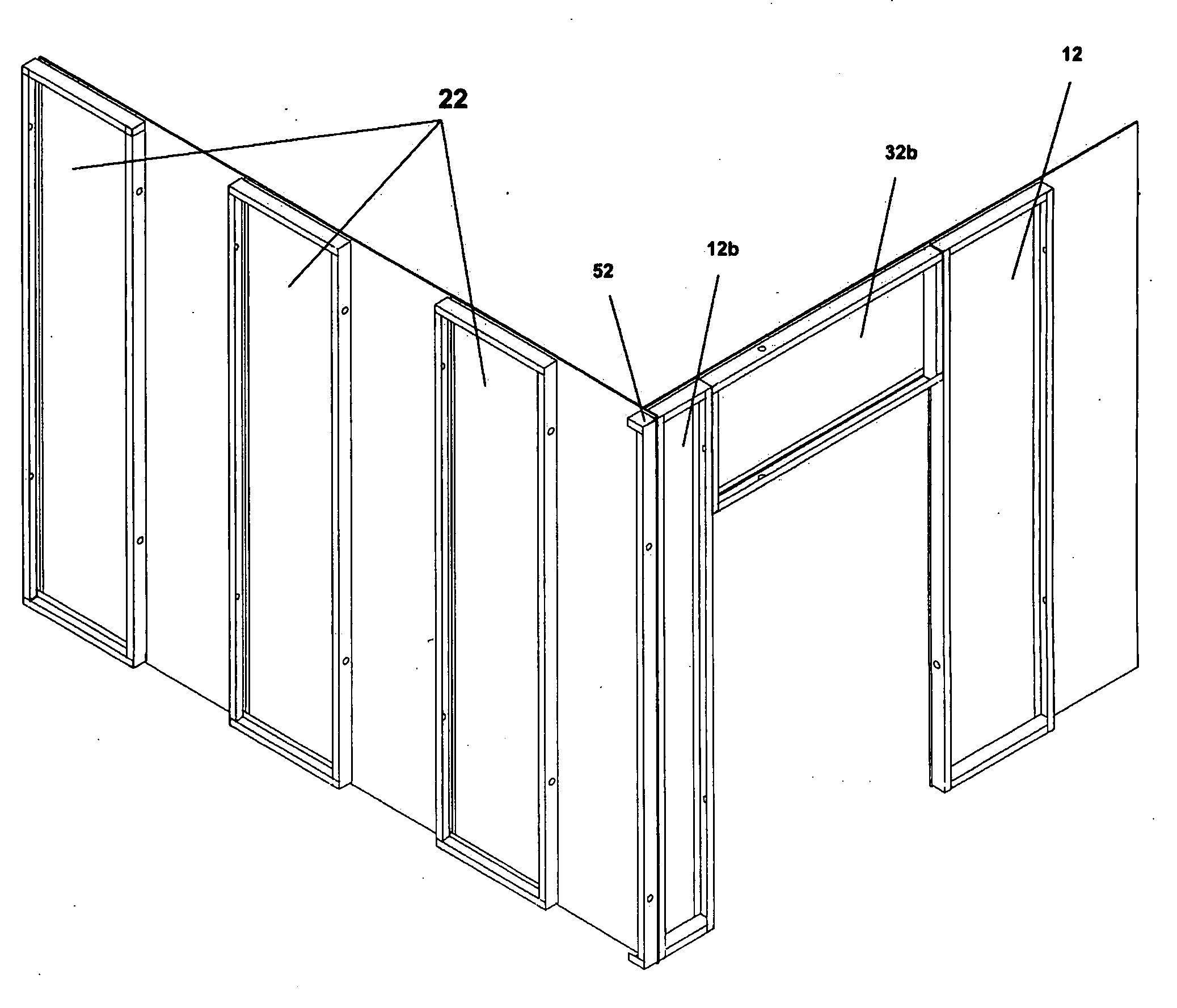

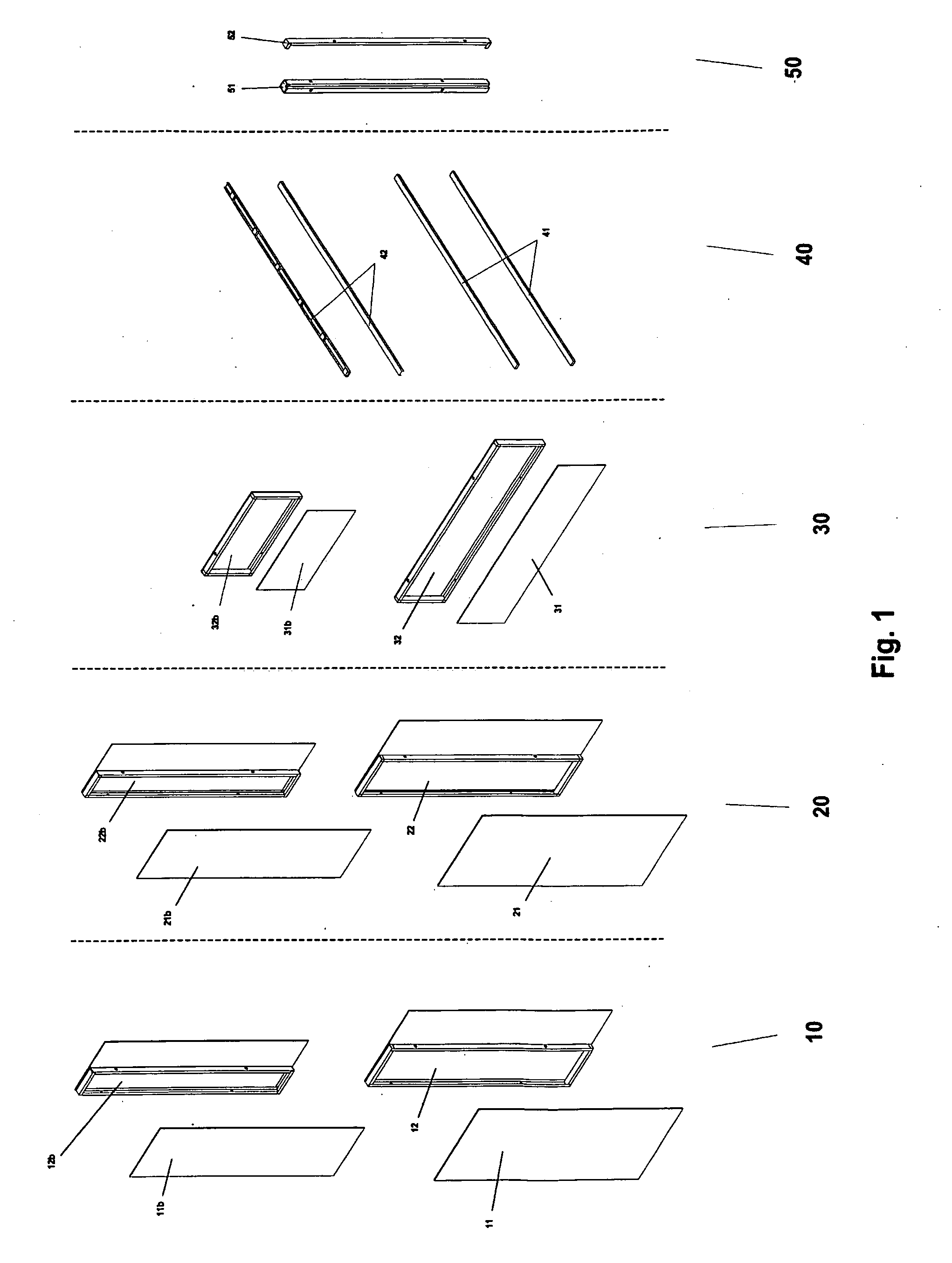

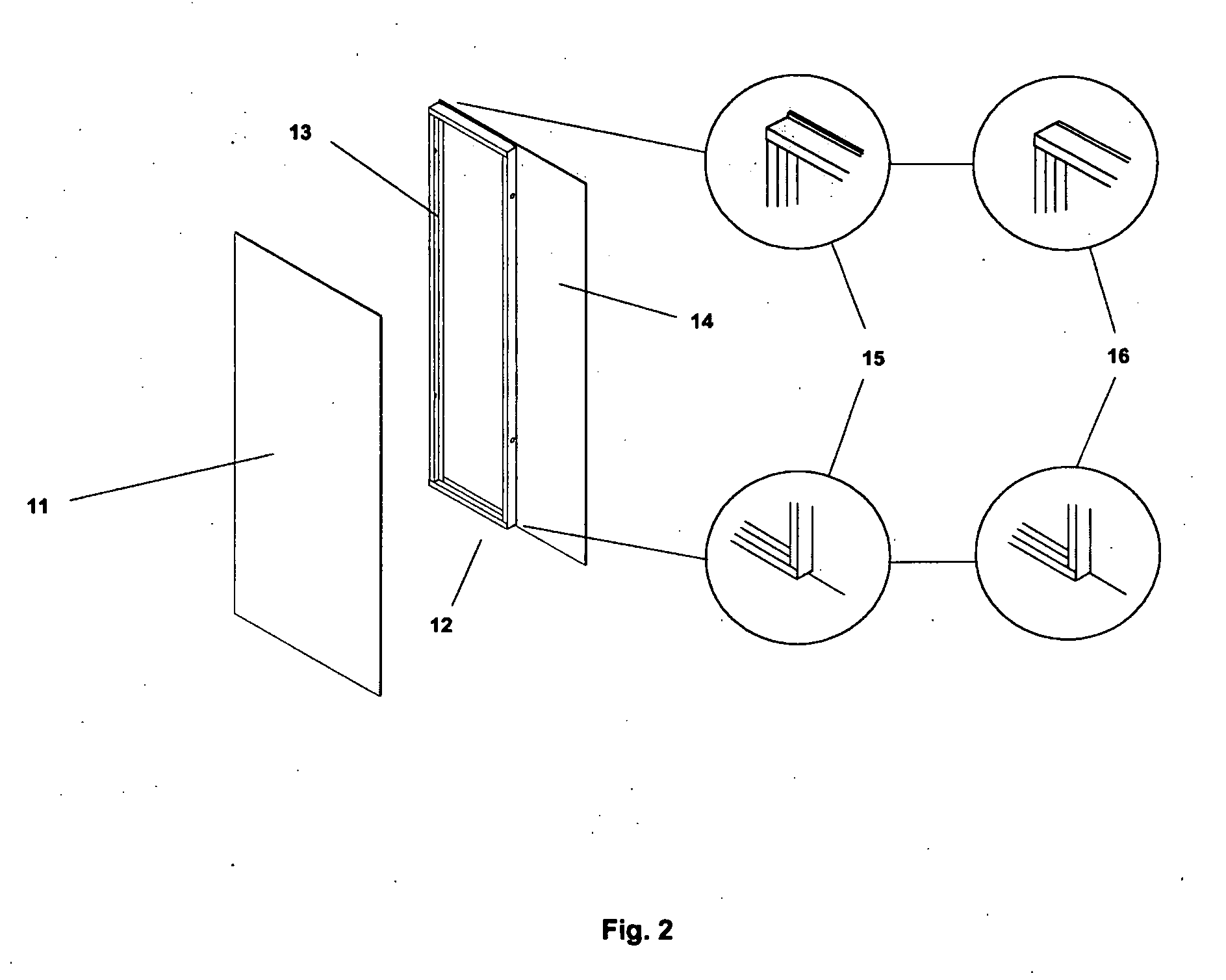

Component wall system

This invention is of a component wall system that is cost effective and flexible enough to be adapted for both interior partitions and exterior walls. The basic component system is comprised of a number of component types: two main wall panel component types, opening header panel type, and other supplementary types that allow the other components to be assembled into closets, interior wall sections with or without door openings, and all exterior wall sections including openings.

Owner:BUI THUAN

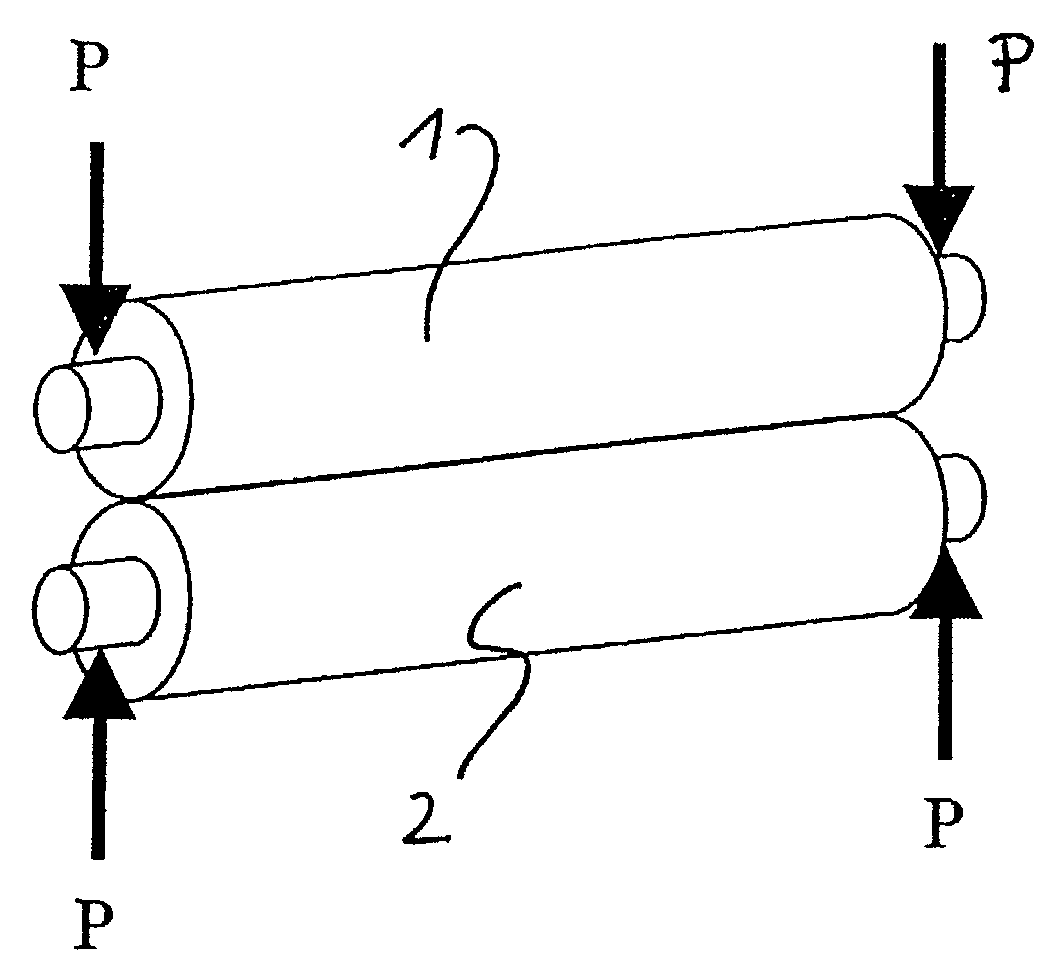

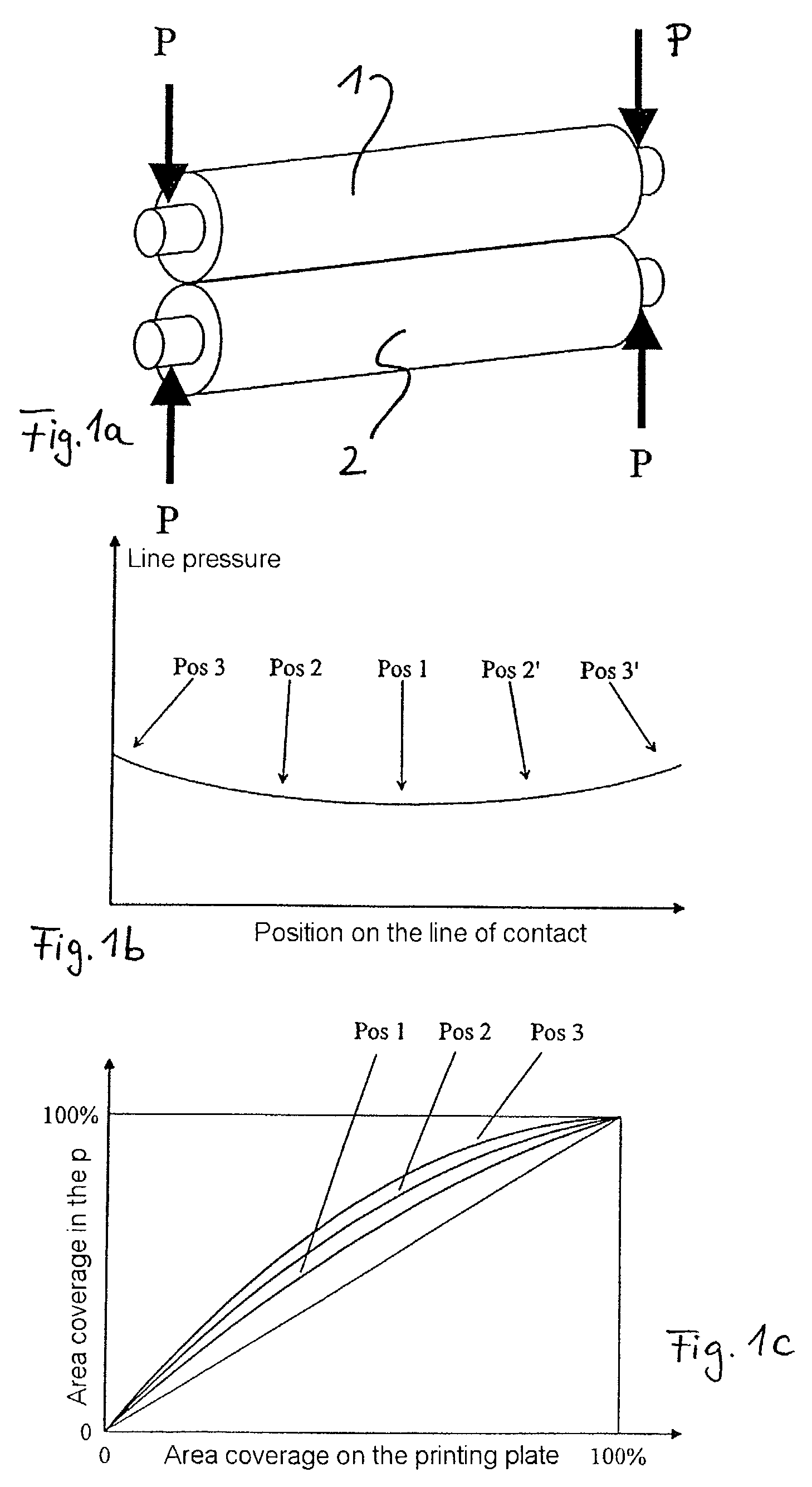

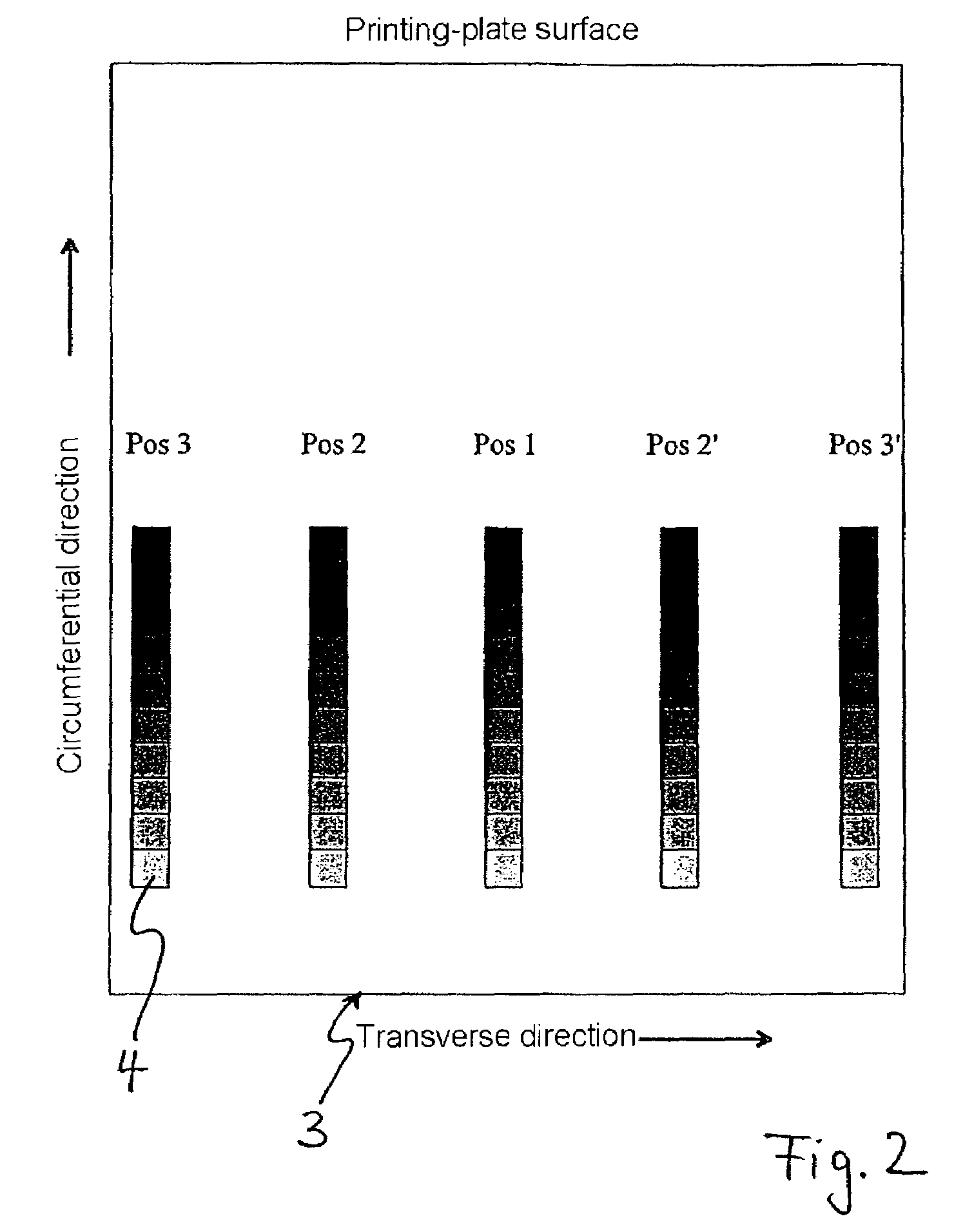

Method of producing a printing plate on a cylindrical printing-plate carrier in a rotary printing press

InactiveUS7224490B2Cost-effective and flexibleQuality assuranceCylinder pressesTransfer printingRaster image processorAxial length

A method of producing a printing plate on a cylindrical printing-plate carrier includes subdividing the printing-plate carrier by computation in terms of its width and axial length into at least two circumferential subareas. Then an actual transfer characteristic curve for each subarea is determined and compared by computation with a predetermined desired printing characteristic curve for each subarea to find a deviation. The method further includes calculating a correction to compensate for each deviation; receiving a digital image data in a first data format using a raster image processor; converting the digital image data into machine-specific image data including the position and the tonal value in the form of a bitmap; applying the correction for a predetermined desired printing characteristic curve for the edition print to the machine-specific image data using the raster image processor; and supplying the corrected machine-specific image data to an imagesetting unit.

Owner:MANROLANAD AG

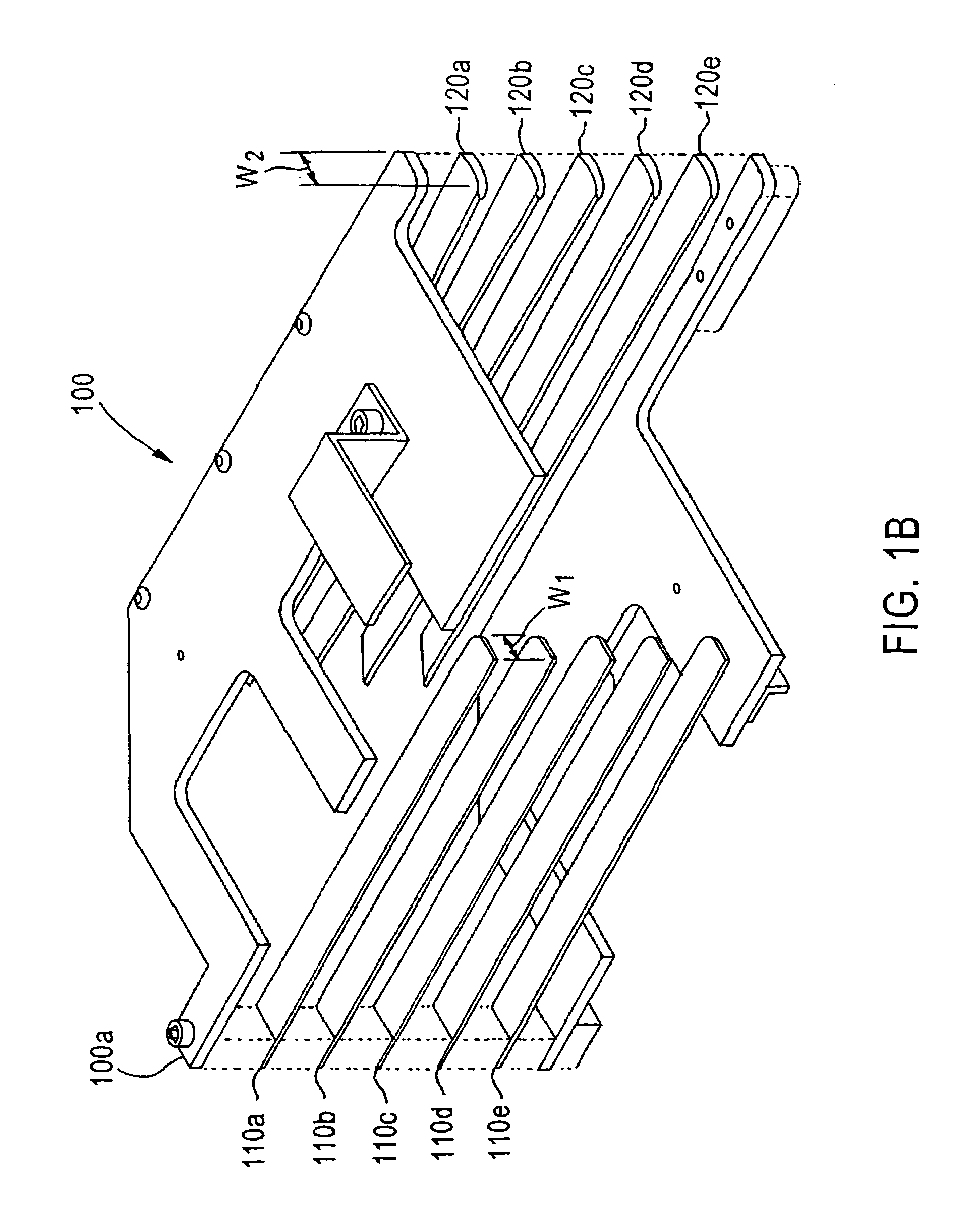

Method and apparatus for handling thin semiconductor wafers

InactiveUS7157376B1Safe handlingWafer thickness reductionSemiconductor/solid-state device manufacturingWaferingEngineering

Cassettes for holding thin semiconductor wafers for safe handling are provided, along with an improved methodology for reducing the thickness of semiconductor wafers. Embodiments include a cassette for holding thin semiconductor wafers, having a plurality of sets of center and edge supports, the sets being spaced from each other a distance greater than a sag amount of the wafers. The thin wafers are supported in a predetermined reference plane, so that tools such as robots or automatic handlers can be programmed to pick them up without damaging them. In another embodiment, a double into single pitch wafer cassette is provided having a wafer entrance section with spacing twice as large between sets of edge supports as a conventional cassette, to accommodate the sag / warp of the thin wafers, and a “flattening section” which guides and flattens the wafers between opposing edge supports as they are pushed into the cassette, such that the wafers are held substantially planar. Because the wafers are held substantially planar, they can be safely removed from the cassette by automatic tools. A methodology is also provided for reducing the thickness of a semiconductor wafer, comprising grinding the back side of the wafer to reduce its initial thickness to an intermediate thickness, and plasma etching the back side of the wafer to reduce the intermediate thickness to a final thickness. The two-step grinding / etching process is faster and less expensive than conventional multi-step grinding / polishing processes, because it requires less steps, each step is accomplished relatively quickly, and it employs standard grinding and etching equipment, rather than expensive dedicated equipment.

Owner:ADVANCED MICRO DEVICES INC

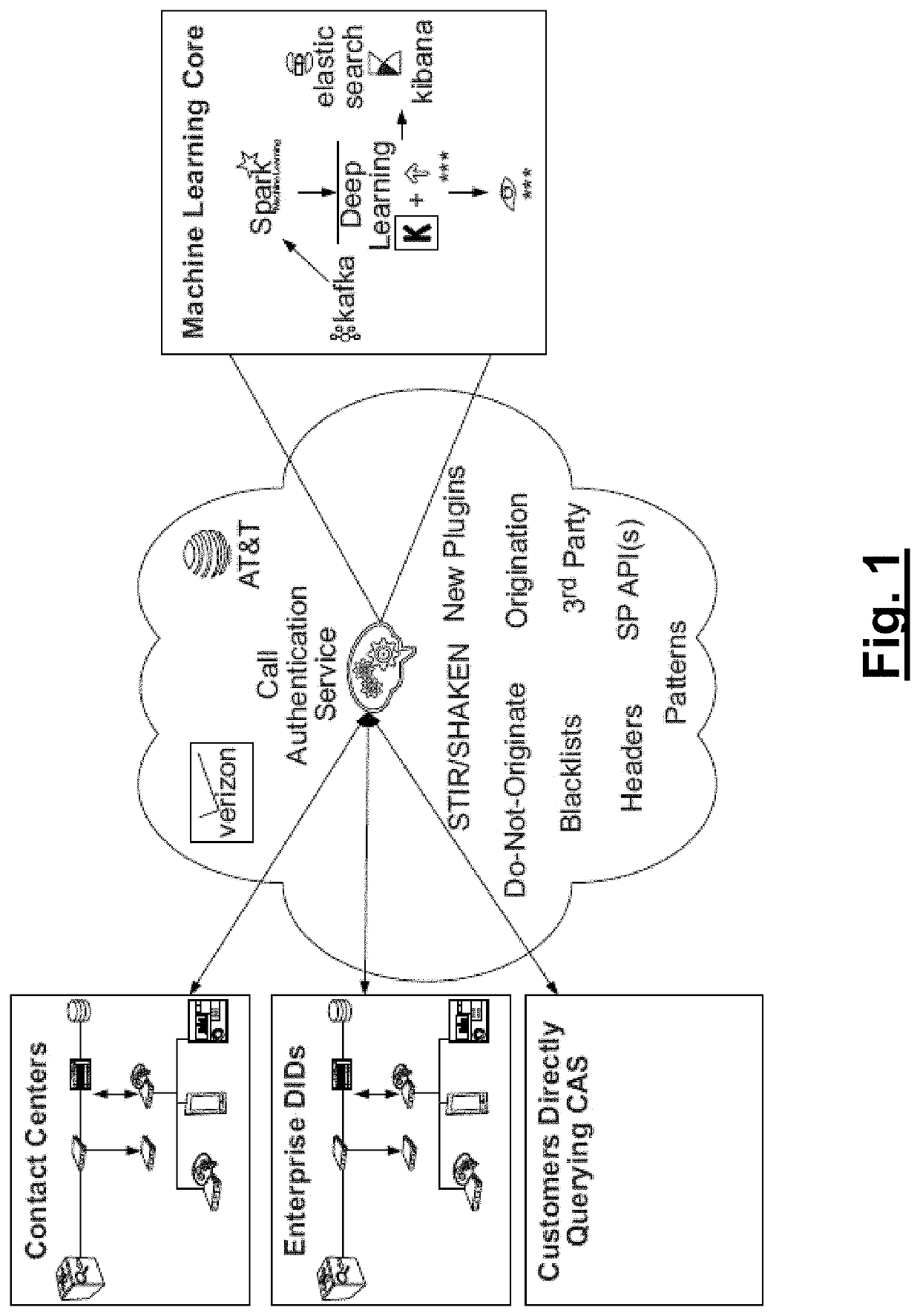

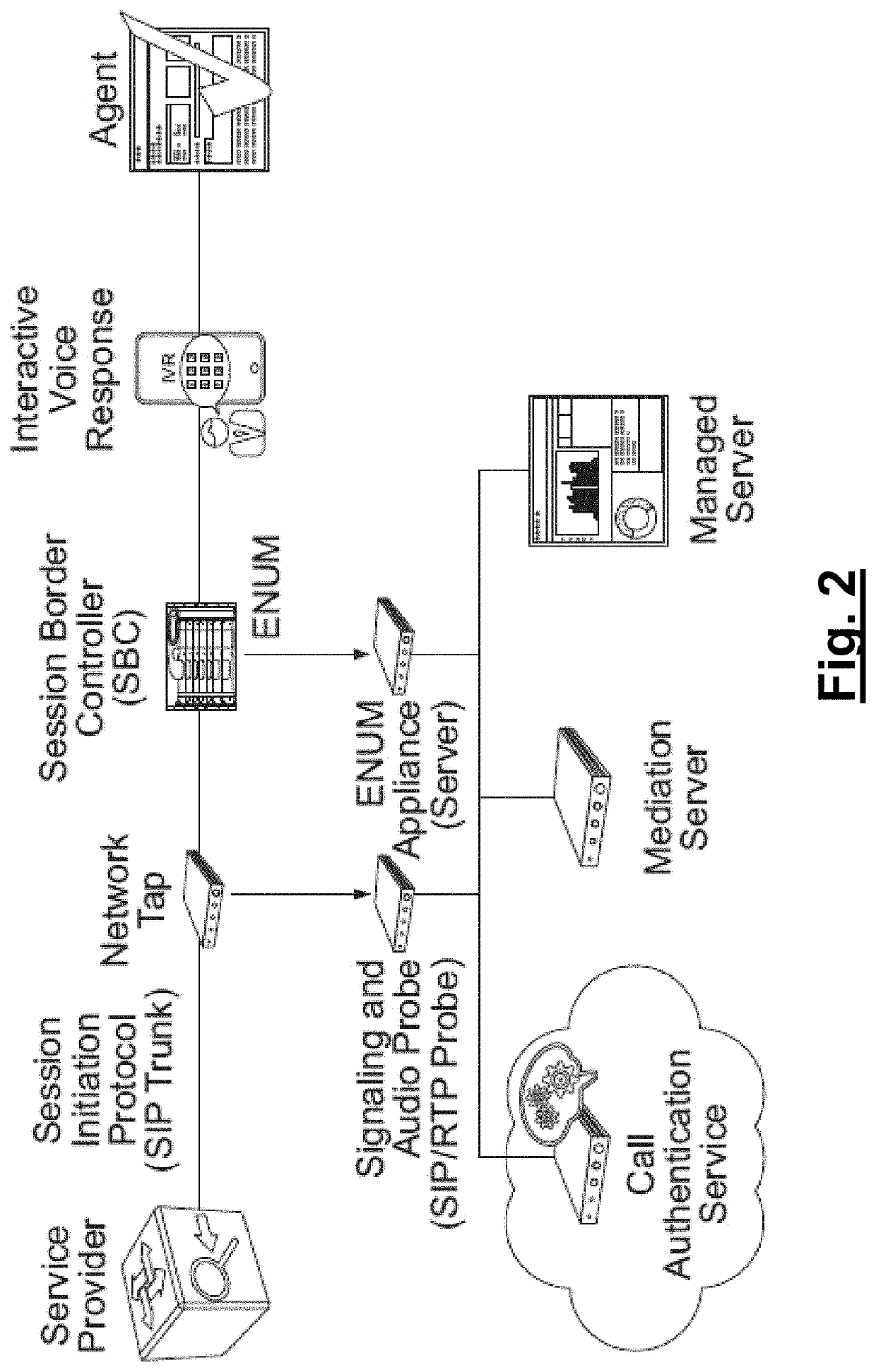

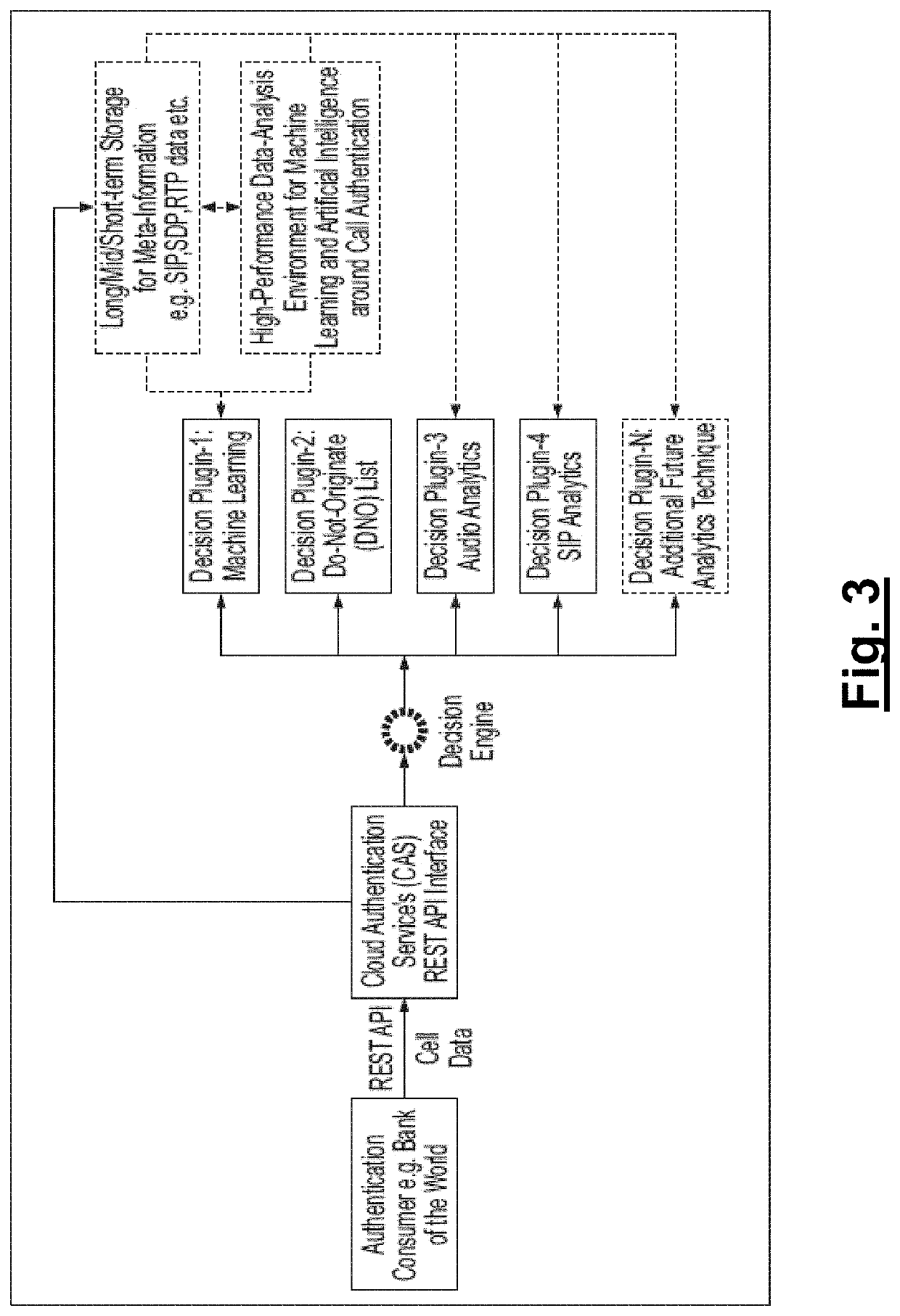

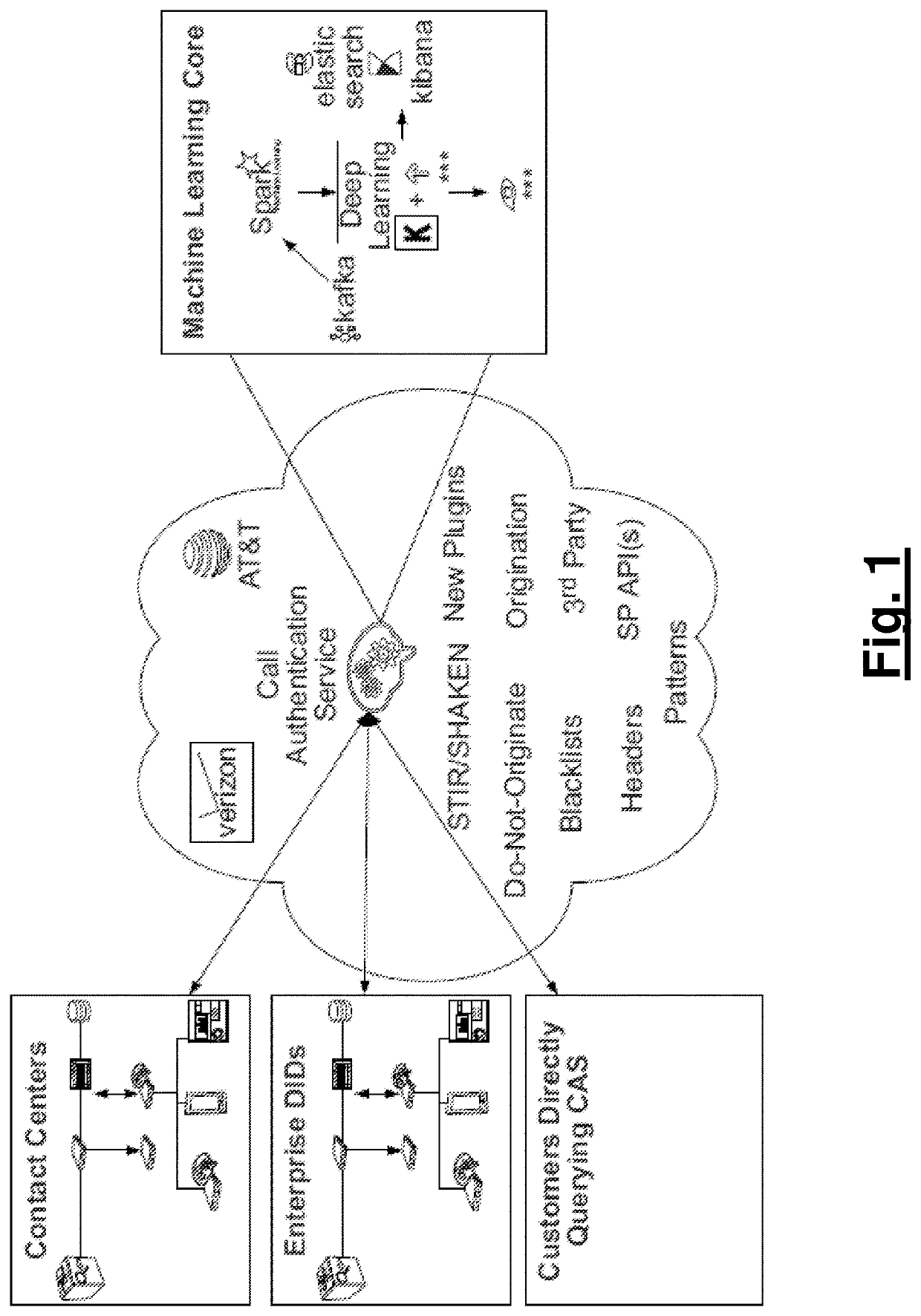

Call authentication service systems and methods

ActiveUS11349987B2Cost-effective and flexibleEasy to integrateDigital data authenticationAutomatic exchangesBusiness enterpriseEngineering

Owner:SECURELOGIX CORP

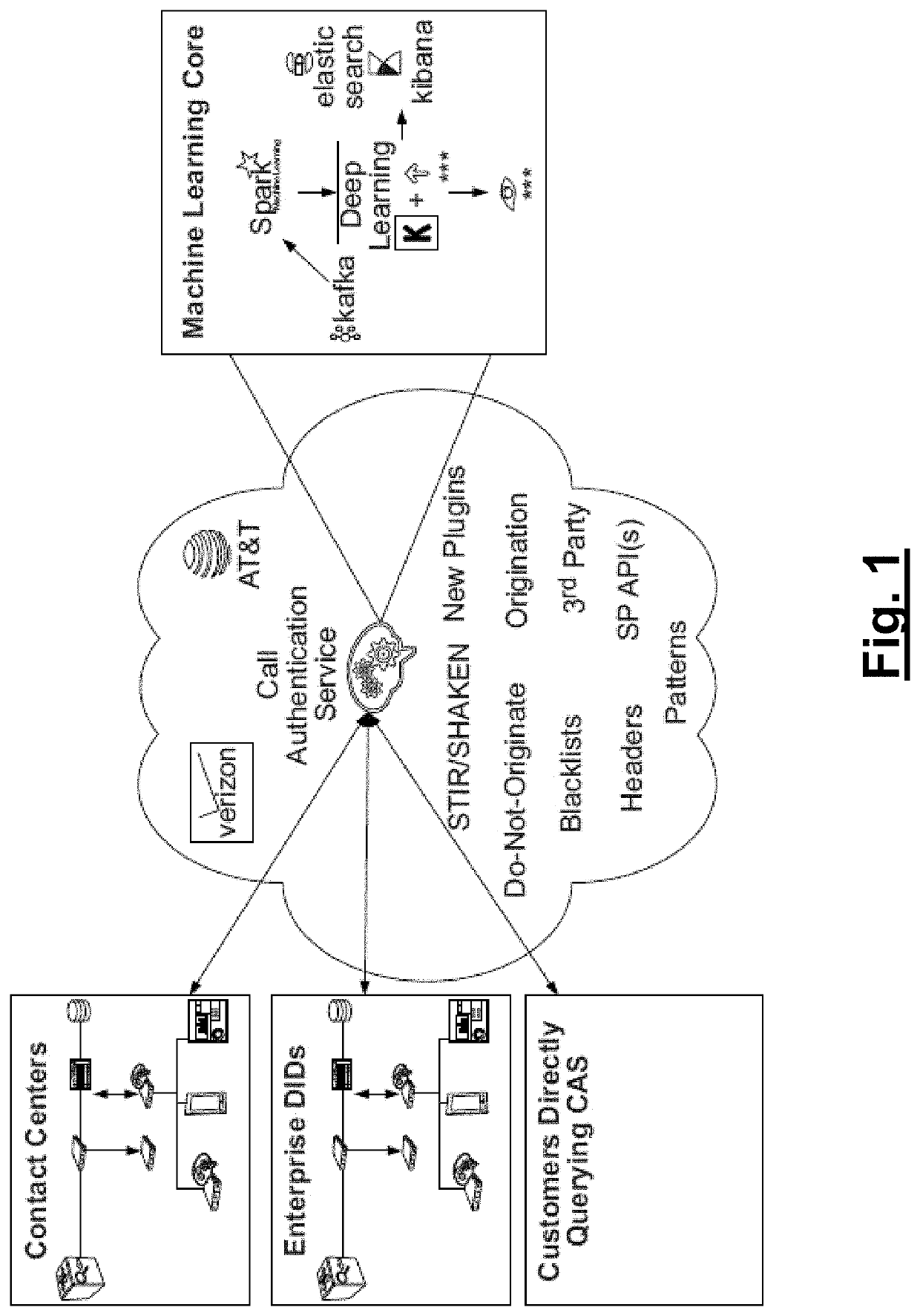

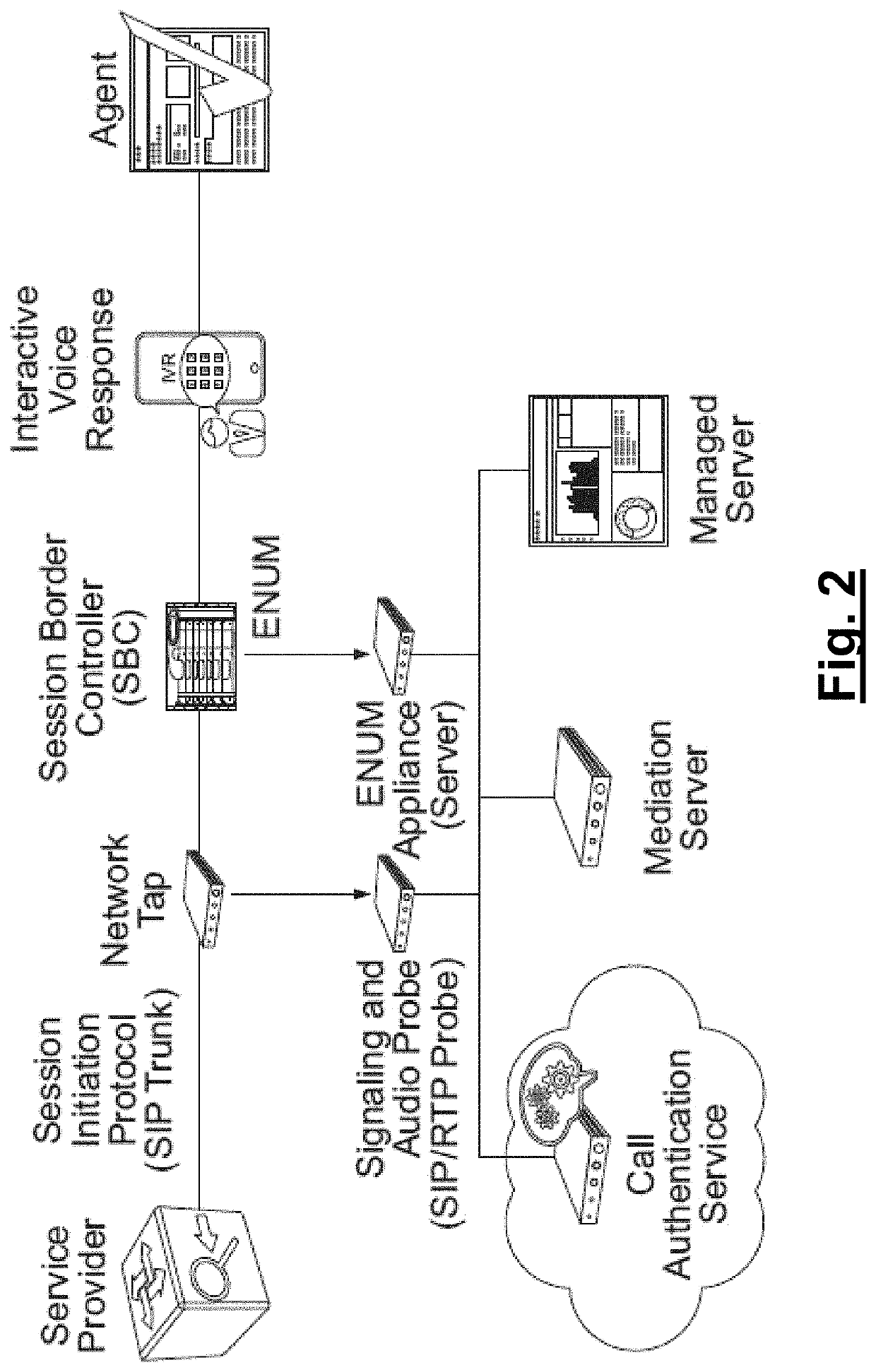

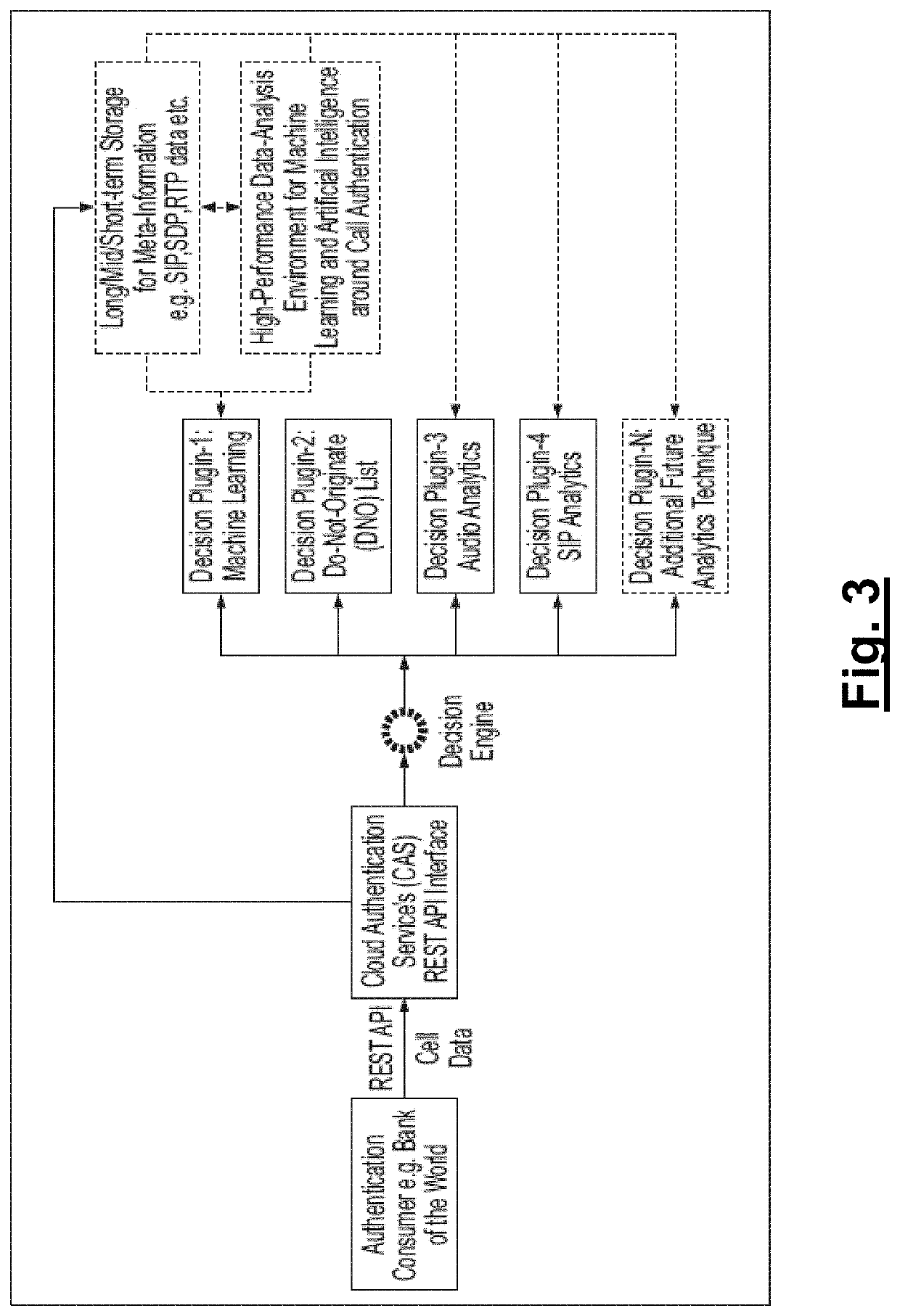

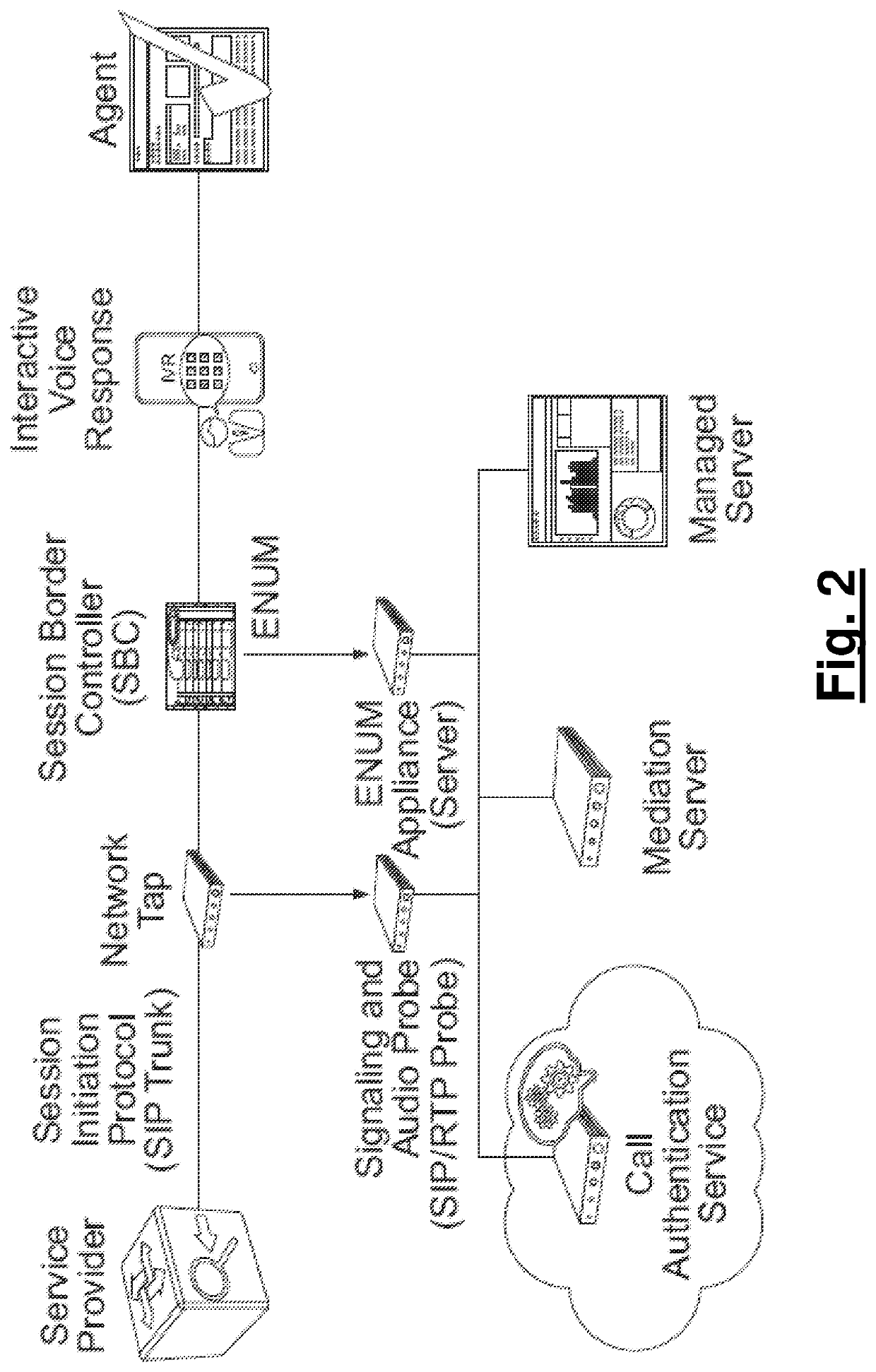

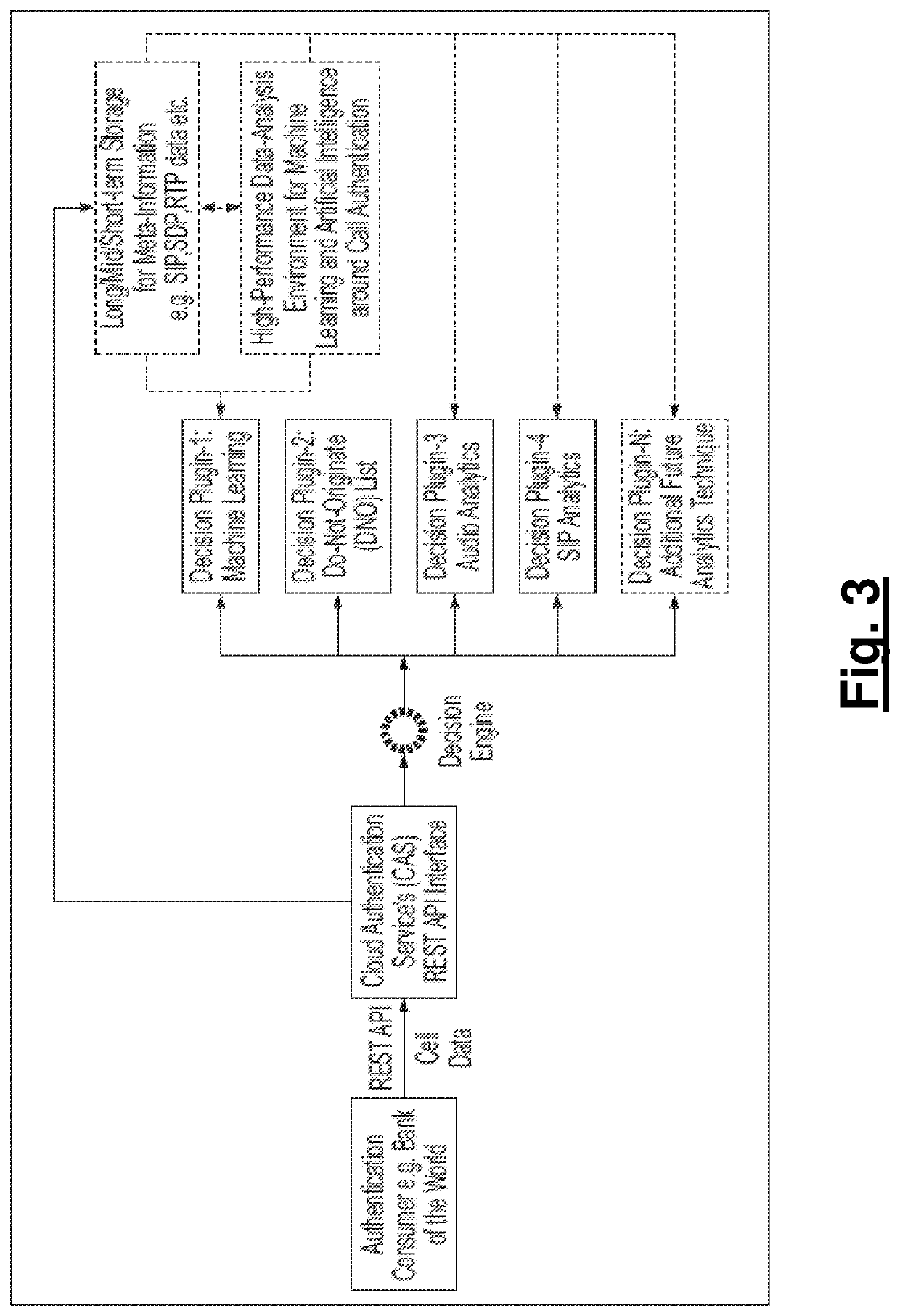

Call Authentication Service Systems and Methods

ActiveUS20210195022A1Cost-effective and flexibleEasy to integrateDigital data authenticationAutomatic exchangesService systemSystem usage

A system for authenticating the calling device used to place a call to an enterprise call center. The system uses a premise component, a cloud-based Call Authentication Service (CAS), and orchestration between these two components. The premise component includes a number of sub-components including servers and probes. The CAS includes a Decision Engine that utilizes a number and variety of authentication plugins. The disclosed system may be used independently or as part of a multi-factor authentication strategy with other techniques such as reduced Knowledge-Based Authentication or voice biometrics.

Owner:SECURELOGIX CORP

Ground connection comprising a vibrational damper for electronic devices

InactiveUS7934940B2Easy to assembleEasy to useVehicle connectorsRotary current collectorSnubberElectronic component

A ground connection system for electronic components that are exposed to vibrations, wherein the system is mounted on a ground carrier, has a metal bushing and an elastic damping element. One or more electrically conductive spiral springs are fitted inside the metal bushing together with the elastic damping element. The springs form an electrically conductive connection between the electronic component and the ground carrier.

Owner:VITESCO TECH GERMANY GMBH

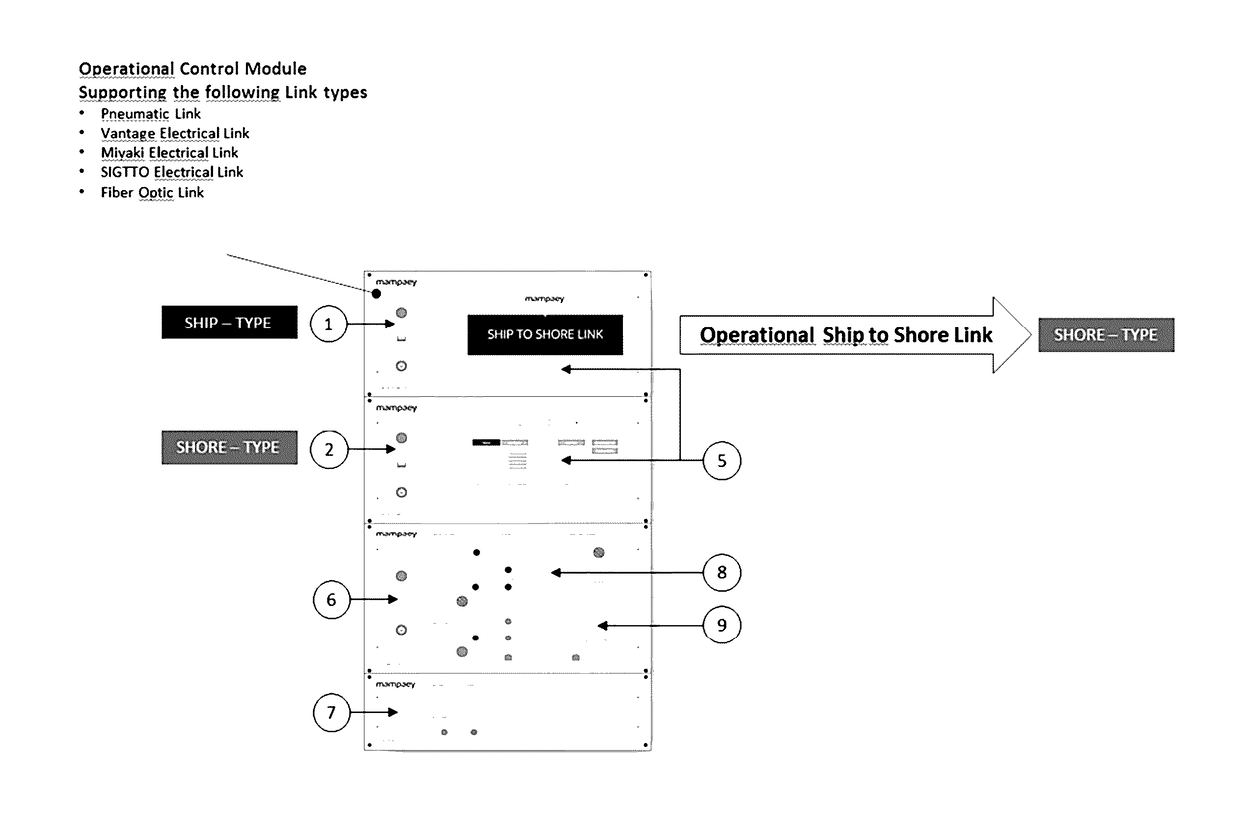

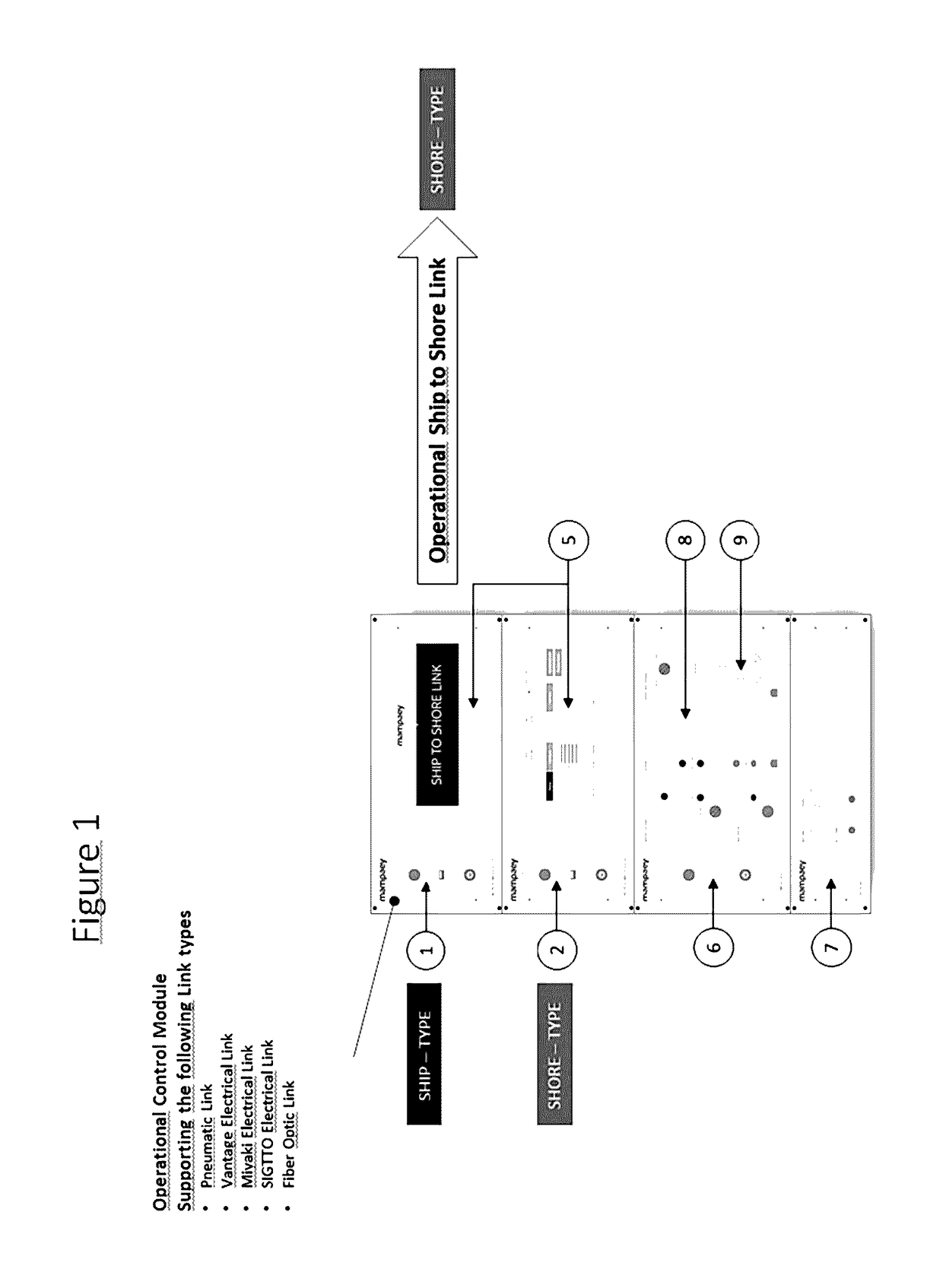

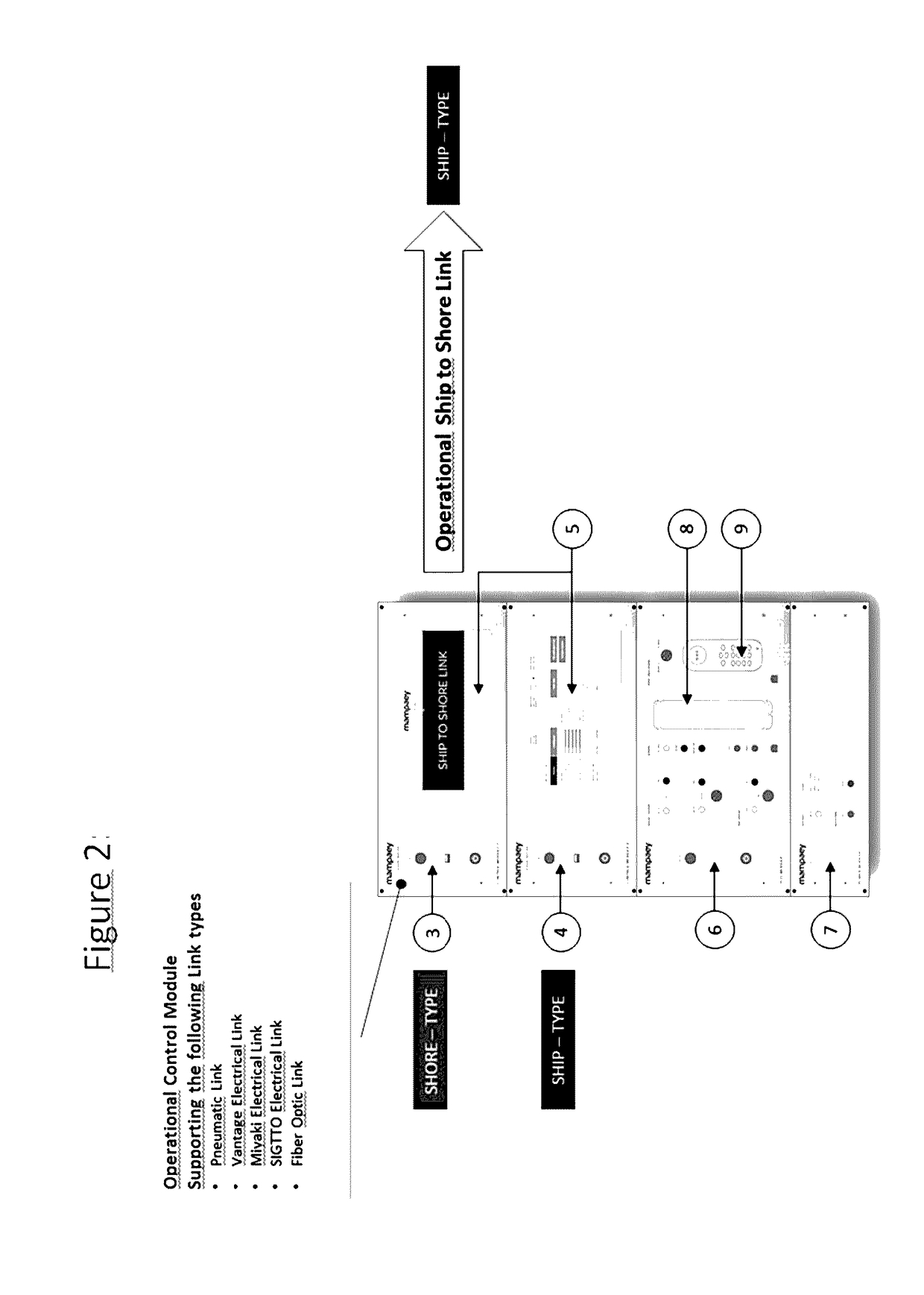

Safety link for ship to shore-, shore to ship- and/or ship to ship-communications

InactiveUS20170077992A1Simple processCost-effective and flexible shipCommunication between movable stationsElectric signal transmission systemsMarine engineeringTransfer switch

Control module(s) and safety link(s) for ship communications arranging for emergency shutdown ESD communication between an unloading storage facility for hazardous goods on either ship or shore and a loading storage facility for hazardous goods on either ship or shore, with at least one umbilical line, connectors for coupling the control module(s) with the lines, the lines using bidirectional communication between a ship type control module and a shore type control module, and a transfer switch to switch the communication mode of the concerning control module between ship type and shore type.

Owner:EURON INTELLIGENCE

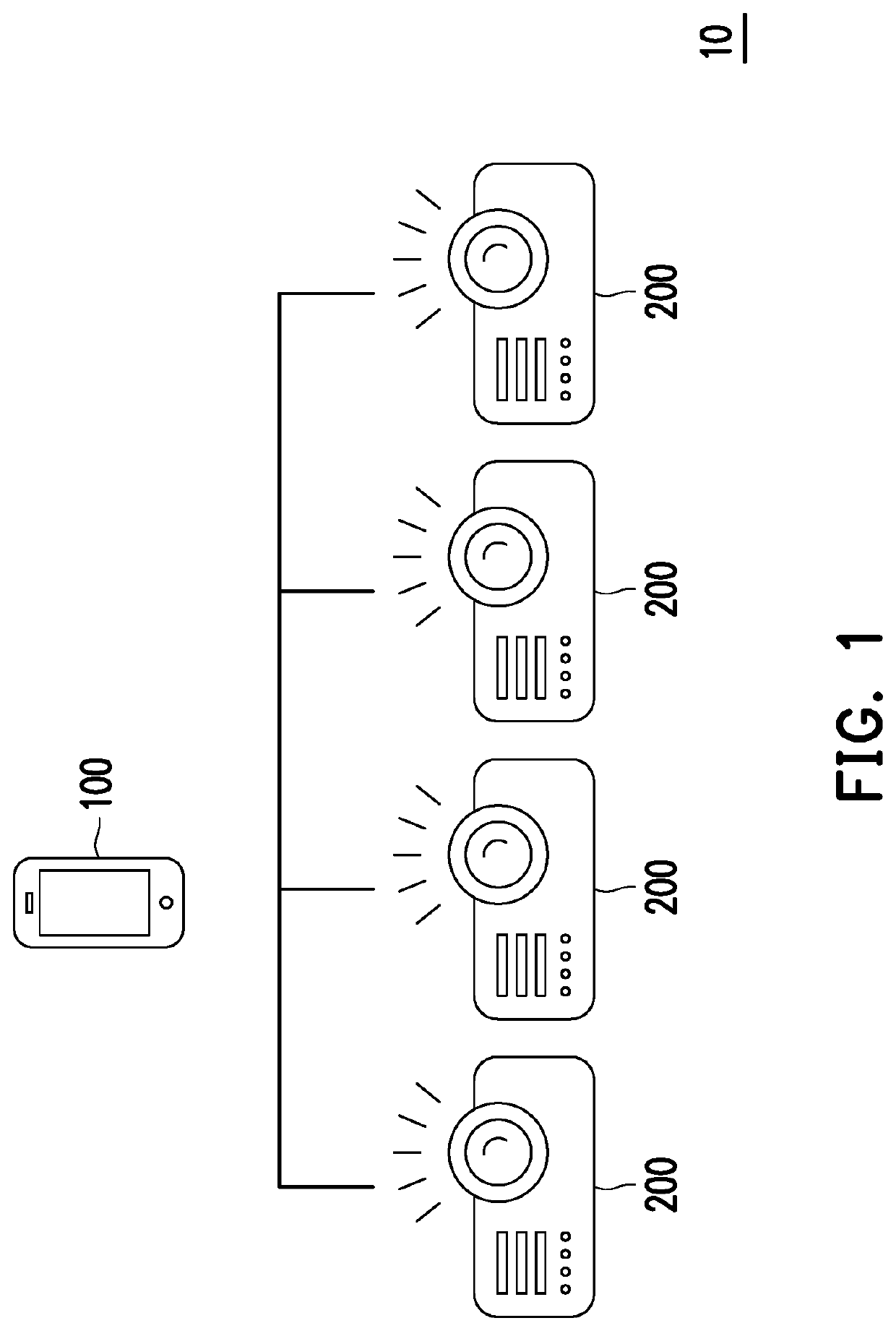

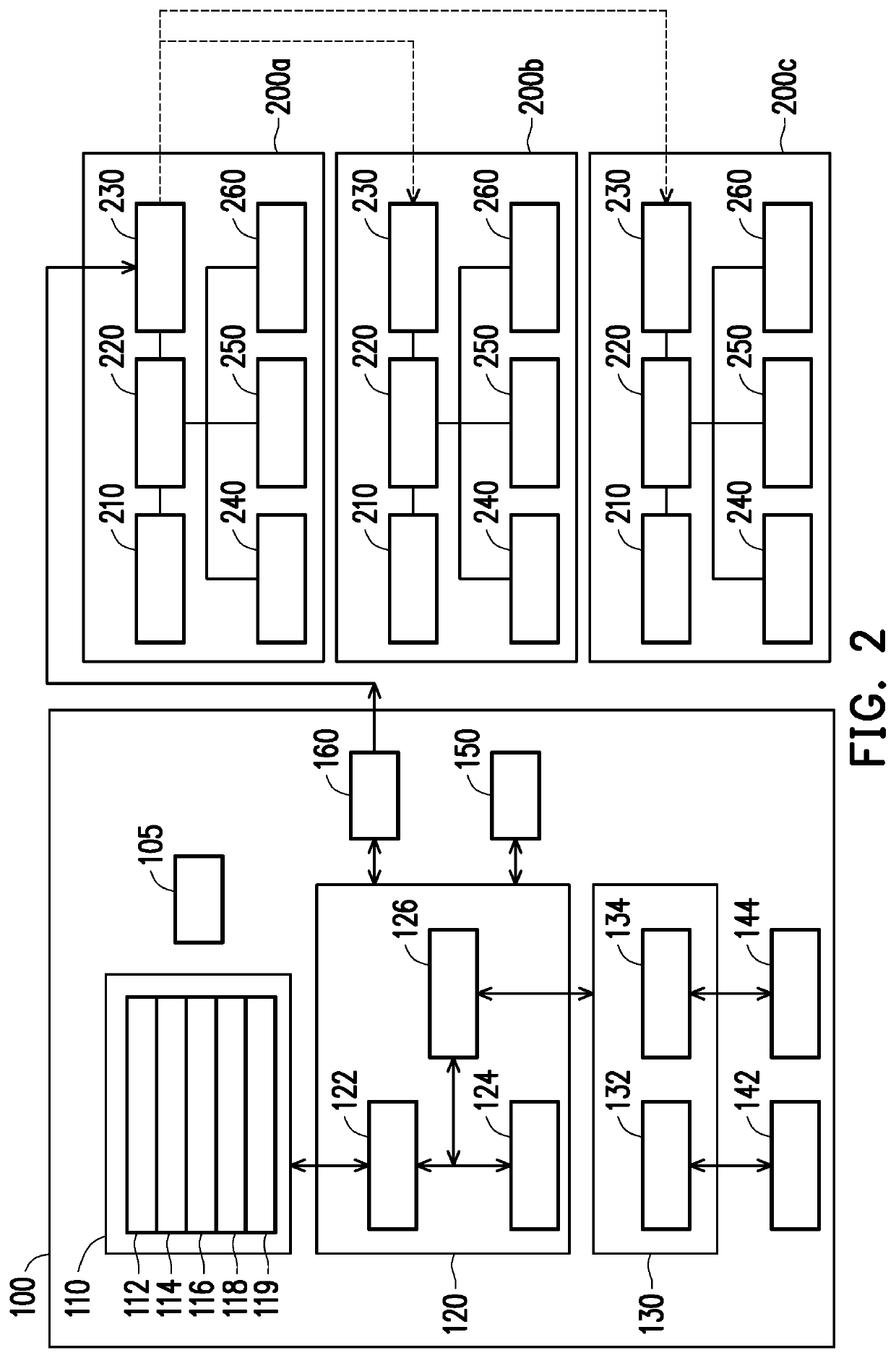

Projection system and projection setting method thereof

PendingUS20200166829A1Cost effective and flexibleCost-effectiveProjectorsColor television detailsCommunications-electronicsProjection system

A projection system having projection devices and an electronic device is provided. The projection devices respectively project an image, and each projection device is connected to and communicates with each other. The electronic device is connected to and communicates with the projection devices. A projection setting method of the projection system is also provided, and the projection setting method includes inspecting projection devices by an electronic device and identifying a main projection device from the projection devices. The electronic device is connected to an application program interface of the main projection device and transmits at least one setting command to the main projection device. The main projection device controls at least one corresponding projection device according to the setting command, so that the corresponding projection device is operated according to the setting command.

Owner:CORETRONIC

Call Authentication Service Systems and Methods

ActiveUS20220272193A1Cost-effective and flexibleEasy to integrateDigital data authenticationAutomatic exchangesInternet privacyBusiness enterprise

A system for authenticating the calling device used to place a call to an enterprise call center. The system uses a premise component, a cloud-based Call Authentication Service (CAS), and orchestration between these two components. The premise component includes a number of sub-components including servers and probes. The CAS includes a Decision Engine that utilizes a number and variety of authentication plugins. The disclosed system may be used independently or as part of a multi-factor authentication strategy with other techniques such as reduced Knowledge-Based Authentication or voice biometrics.

Owner:SECURELOGIX CORP

Method for Constructing a Pumped Storage Power Plant in a Ground Depression, in Particular in an Open-Cast Mine

PendingUS20220364539A1Firmly connectedCost-effective and flexibleEngine fuctionsHydro energy generationStored energyPower station

The energy transition involves the electrical power supply being almost completely covered by renewable energy sources such as solar plants or wind turbines. However, due to their naturally fluctuating output, these energy sources require the use of large energy storage systems, the realization of which still represents a major problem today. The present invention provides a solution which aims to secure the entire short-term storage capacity needed for the energy transition in Germany (and even Europe). For this purpose, in particular, the invention proposes the construction of a large-scale pumped-storage power plant in the Hambach open-pit mine, as a result of which the can mine be put to subsequent use in a sustainable way. The invention also relates to the construction and partial commissioning of the plant in parallel with the use that is being phased out, in particular that of lignite mining (by 2038). This is to avoid the loss of a significant number of existing jobs. After construction, it is not uncommon for lifetimes of over 100 or even over 1,000 years to be possible, which means that a particular level of sustainability can be ensured.

Owner:SCHMIDT BOCKING HORST +1

Hand-held power tool

A hand-held power tool is provided which includes a clutch housing of a torque clutch, and a planetary gear, situated in a gear housing, for transmitting a torque which is generated by a drive motor to a drive shaft. The clutch housing cooperates with the planetary gear via a pressure plate. The pressure plate is displaced in the axial direction in order to disengage the torque clutch. The axial relative motion of the pressure plate causes an axial relative motion between a switching element and an associated optical sensor, via which the drive motor may be switched off.

Owner:ROBERT BOSCH GMBH

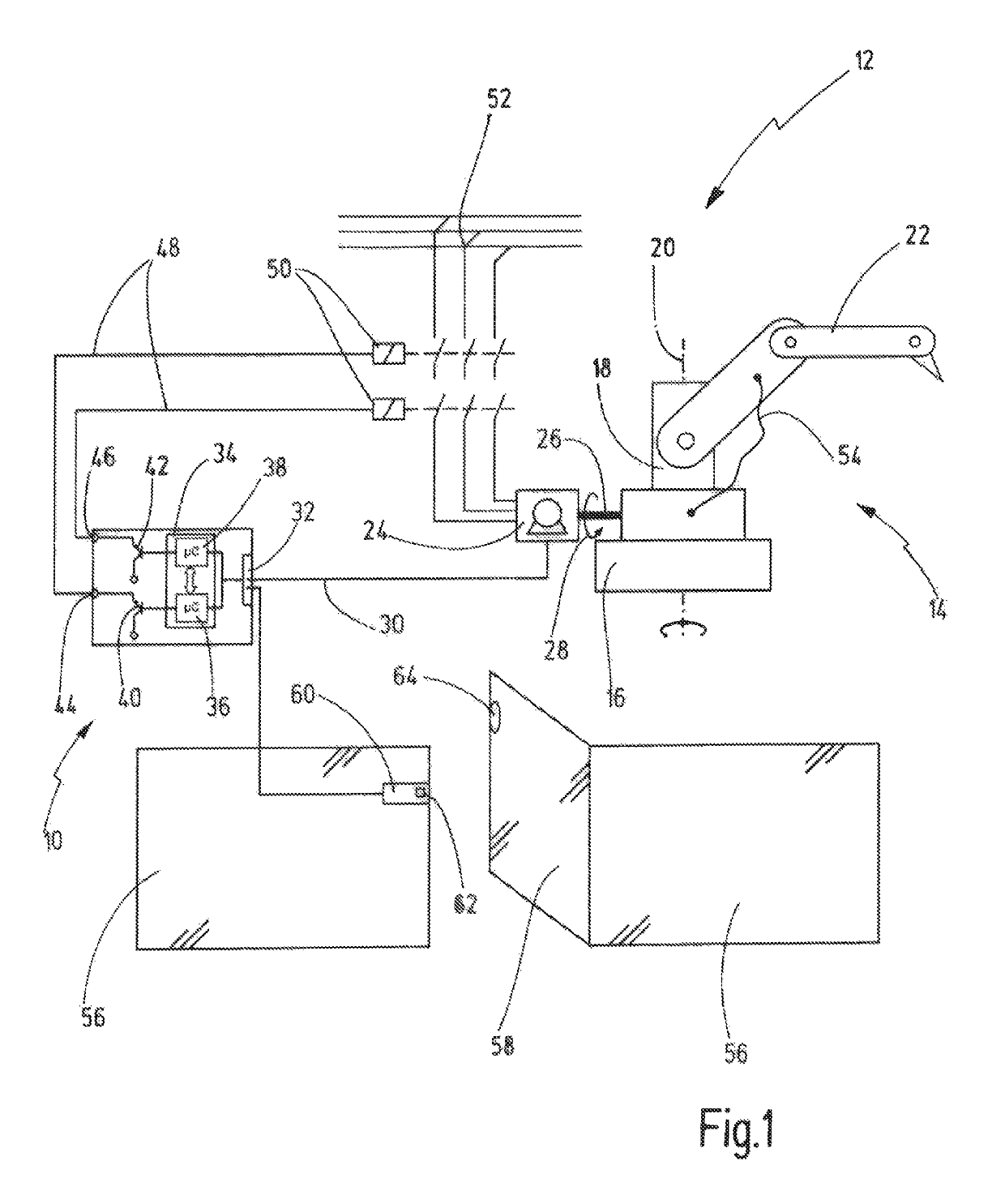

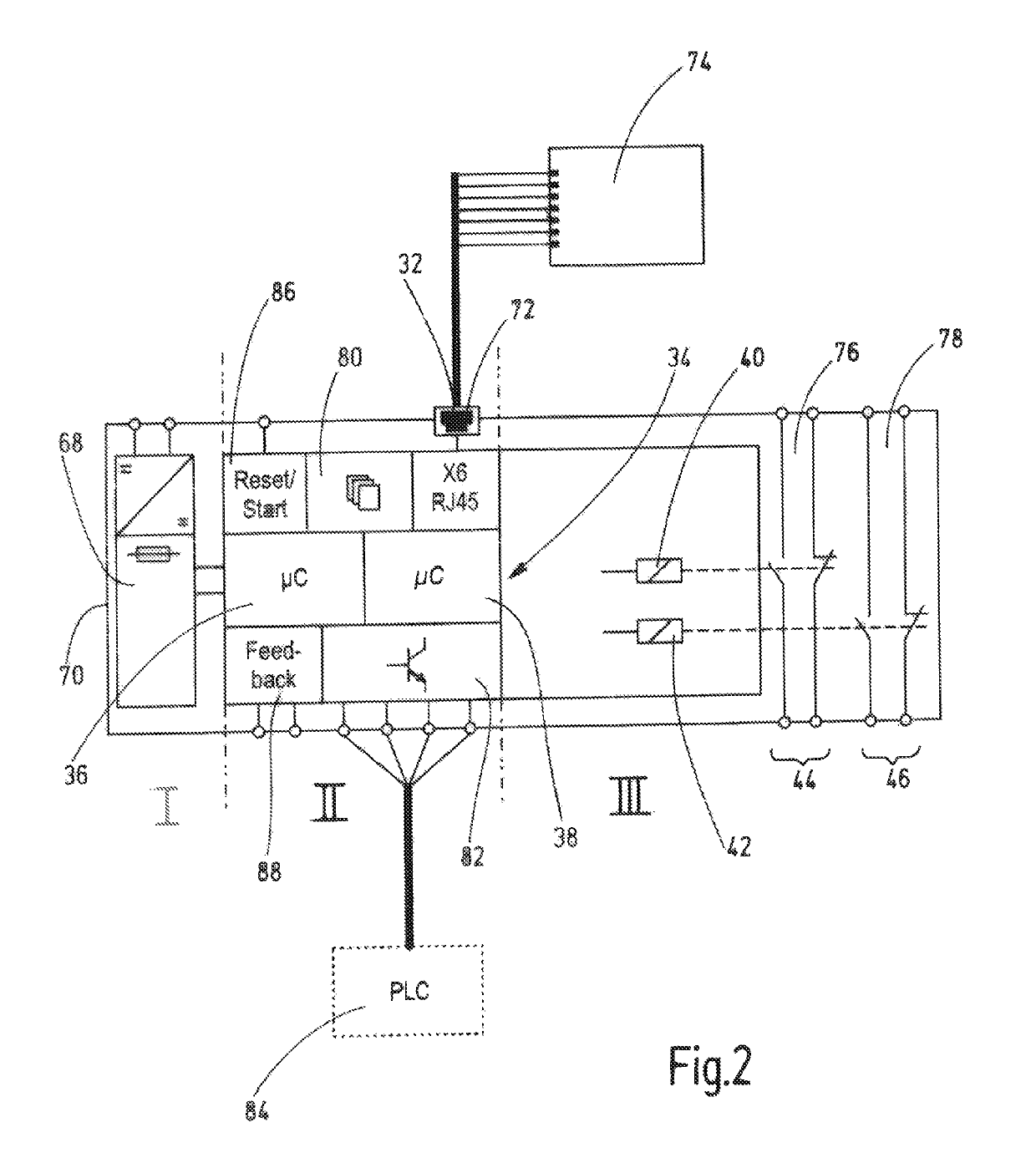

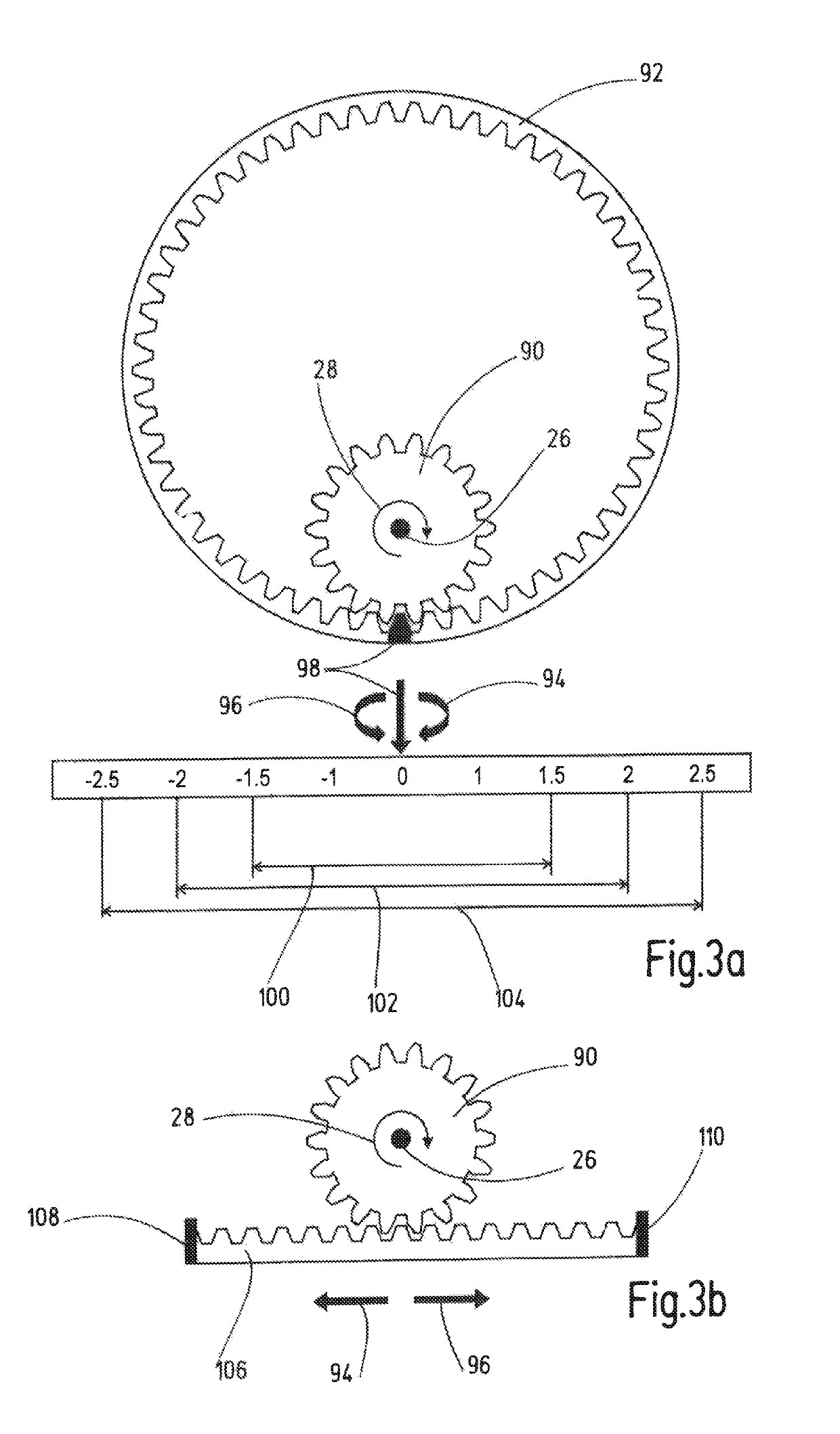

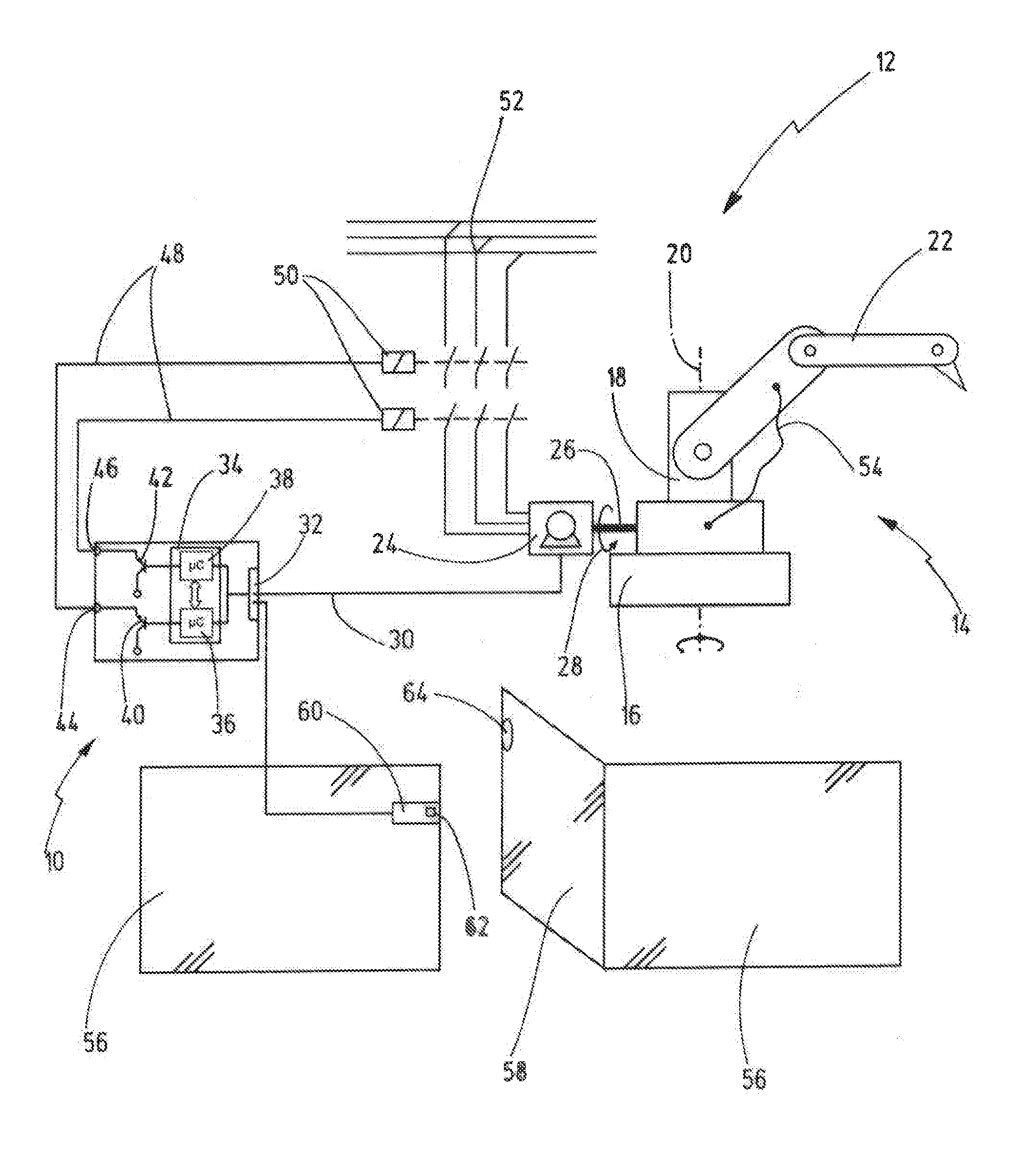

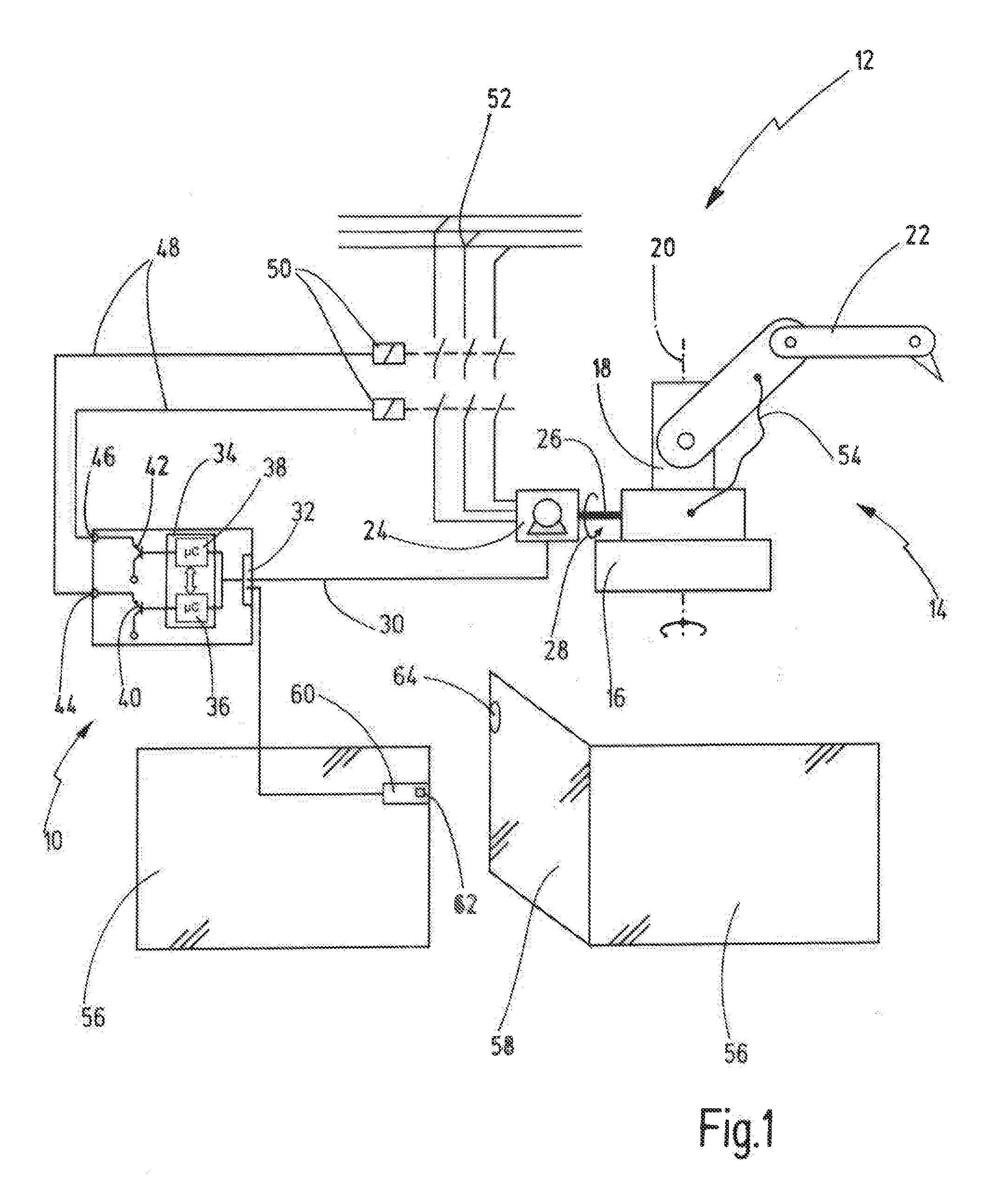

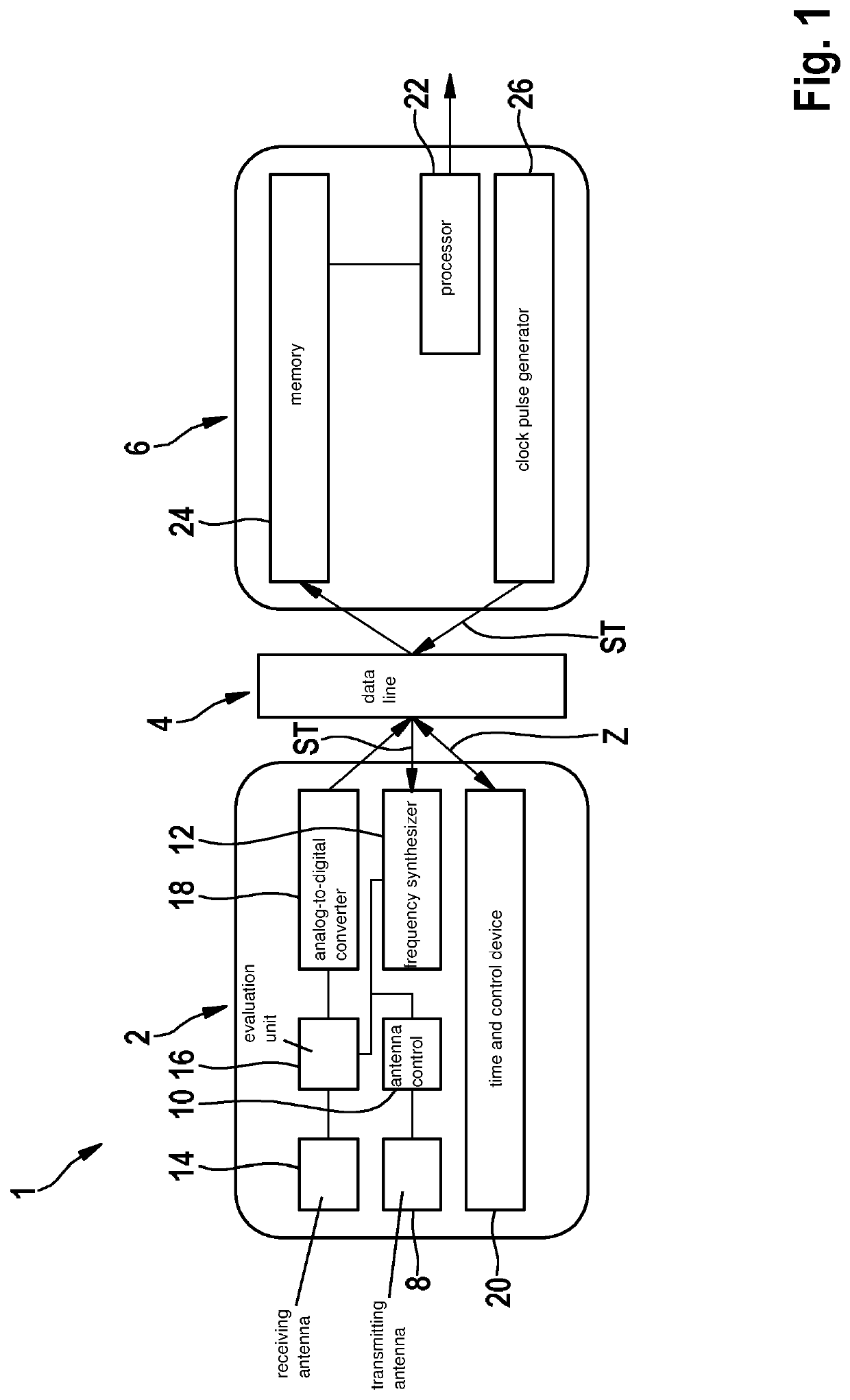

Device and method for failsafe monitoring of a moving machine part

A device for failsafe monitoring a number of passes of a moving machine part through a defined movement region comprising an input for receiving an encoder signal, which represents a motion value of the moving machine part. The device further comprises a failsafe evaluation unit for providing a failsafe shutdown signal as a function of the number of passes of the moving machine part through the defined movement region. The failsafe evaluation unit is configured to determine the number of passes of the moving machine part through the defined movement region from the motion value.

Owner:PILZ (COMPANY)

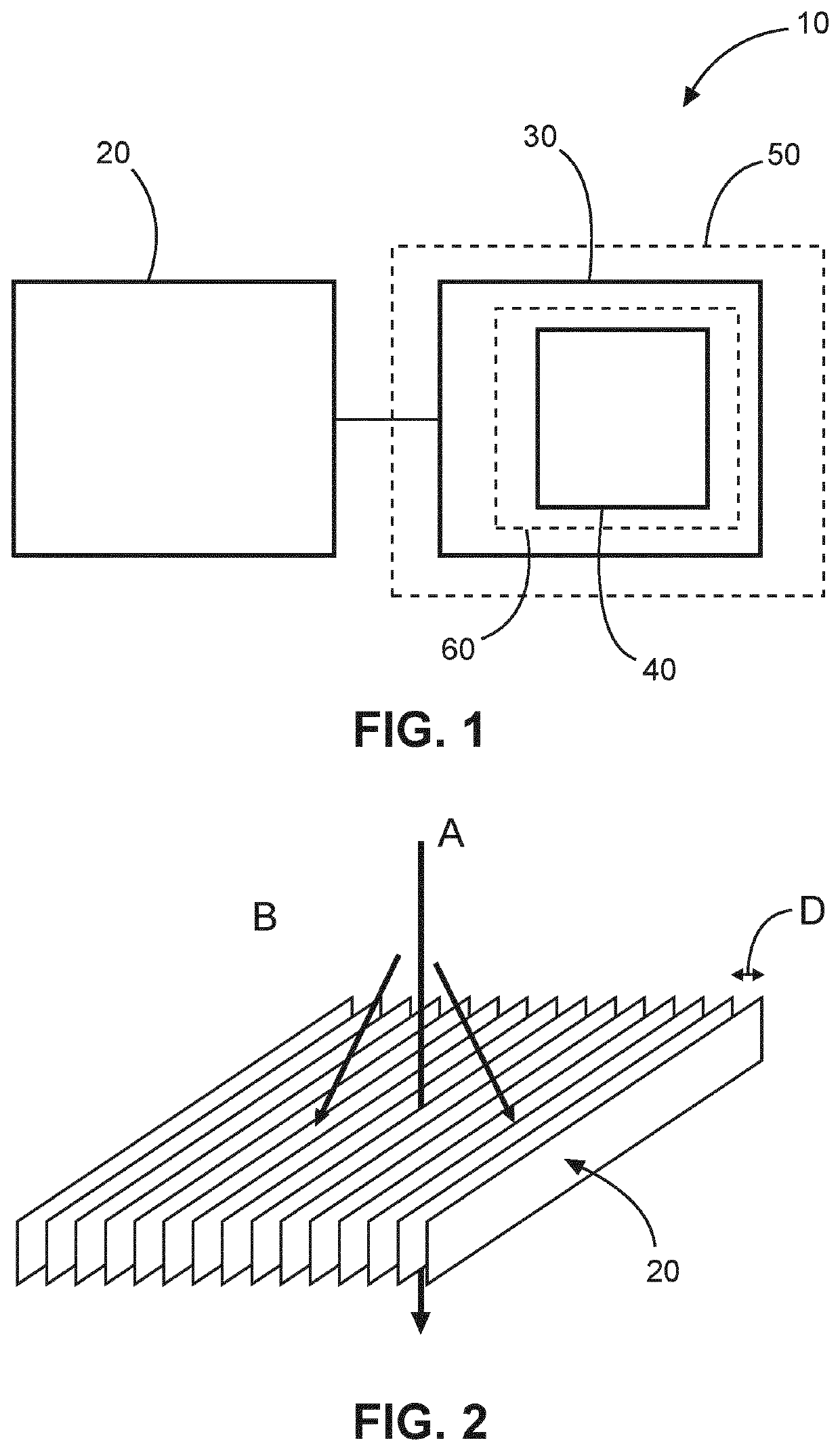

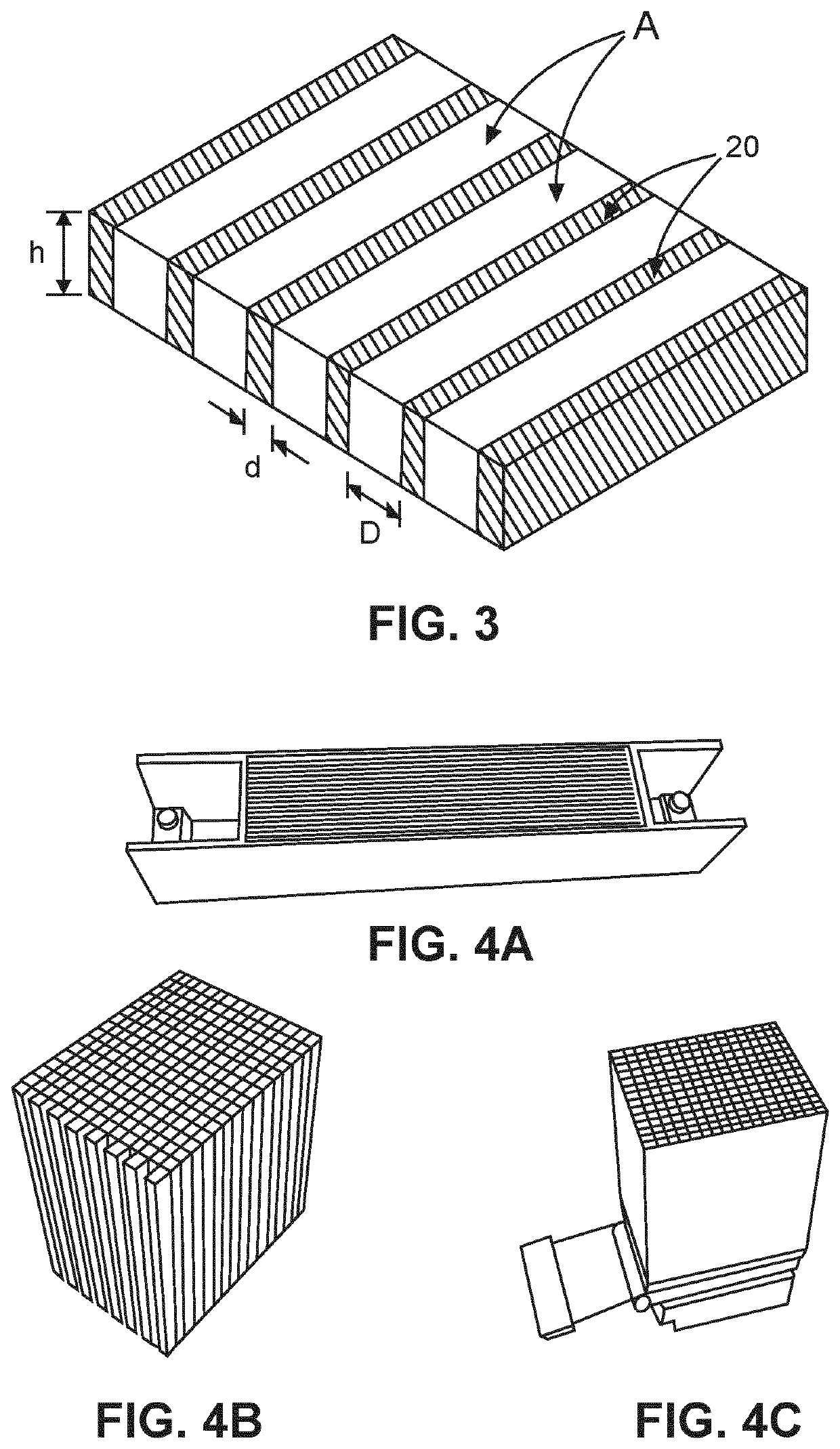

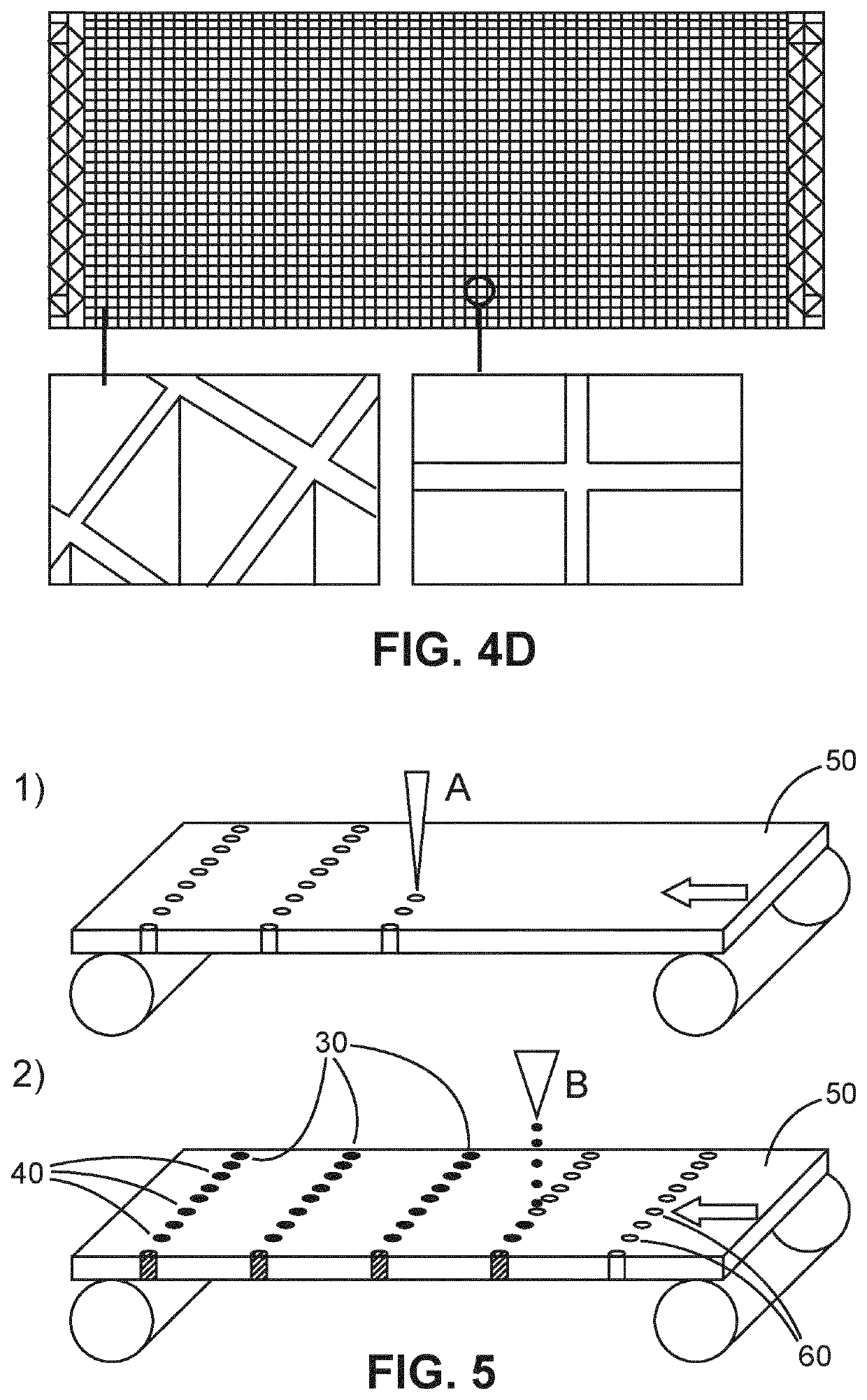

X-ray anti scatter grid

PendingUS20220338824A1Cost-effective and flexibleHandling using diaphragms/collimetersRadiation diagnosticsMechanical engineeringRay

The present invention relates to an X-ray anti-scatter grid (10). The anti-scatter grid comprises a plurality of primary septa walls (20), and a plurality of secondary septa walls (30). The plurality of primary septa walls comprise an X-ray absorbing material. The plurality of primary septa walls are substantially parallel to one another. The plurality of secondary septa walls are located between adjacent pairs of walls of the plurality of primary septa walls such that each secondary septa wall is located between an adjacent pair of walls of the plurality of primary septa walls. Each secondary septa wall of the plurality of secondary septa walls is formed from a plurality of columnar structures (40) extending between the plurality of primary septa walls. The plurality of columnar structures comprise an X-ray absorbing material.

Owner:KONINKLJIJKE PHILIPS NV

Device and method for failsafe monitoring of a moving machine part

ActiveUS20170045878A1Cost-effective and flexibleAvoid disadvantagesProgramme controlSafety arrangmentsMachine partsComputer science

A device for failsafe monitoring a number of passes of a moving machine part through a defined movement region comprising an input for receiving an encoder signal, which represents a motion value of the moving machine part. The device further comprises a failsafe evaluation unit for providing a failsafe shutdown signal as a function of the number of passes of the moving machine part through the defined movement region. The failsafe evaluation unit is configured to determine the number of passes of the moving machine part through the defined movement region from the motion value.

Owner:PILZ (COMPANY)

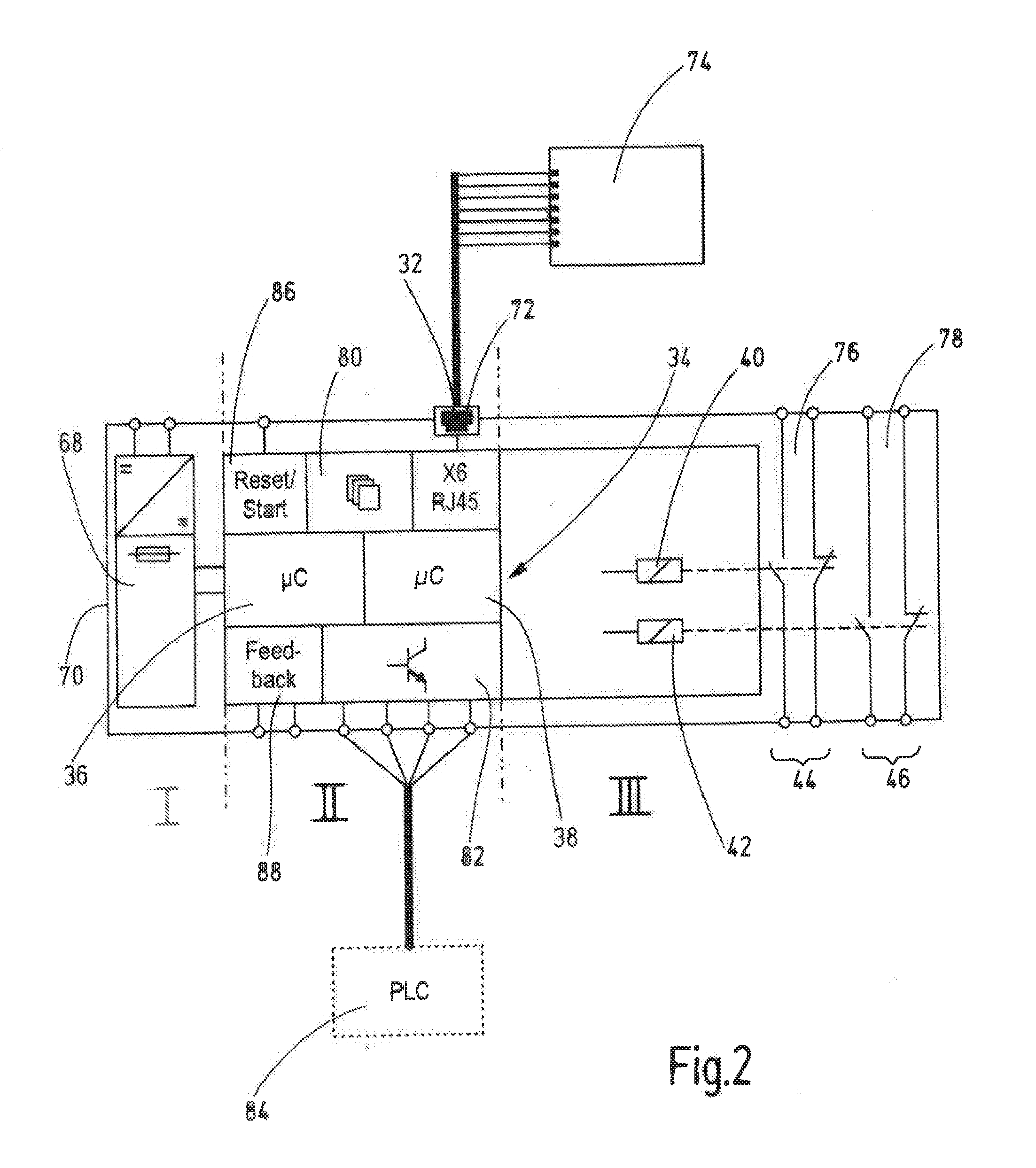

Radar system having a clock pulse generator integrated into a central control unit

PendingUS20200278436A1Scalable in its capacityCost-effective and flexibleRadio wave reradiation/reflectionRadar systemsElectrical and Electronics engineering

A radar system for a vehicle. The radar system has at least one central control unit for transmitting data and for processing received data, at least one radar sensor head, which is set apart from the central control unit and has at least one transmitting antenna for generating and at least one receiving antenna for receiving radar waves, and having at least one data line between the at least one central control unit and the at least one radar sensor head, with the at least one central control unit having a clock pulse generator for generating a reference frequency and the reference frequency being transmittable via the at least one data line to the at least one radar sensor head.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com