Component wall system

a wall system and component technology, applied in the direction of building components, building roofs, walls, etc., can solve the problems of high material waste, inconsistent labor costs in almost every stage of construction, and high labor costs, and achieve the effect of cost-effective and flexibl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

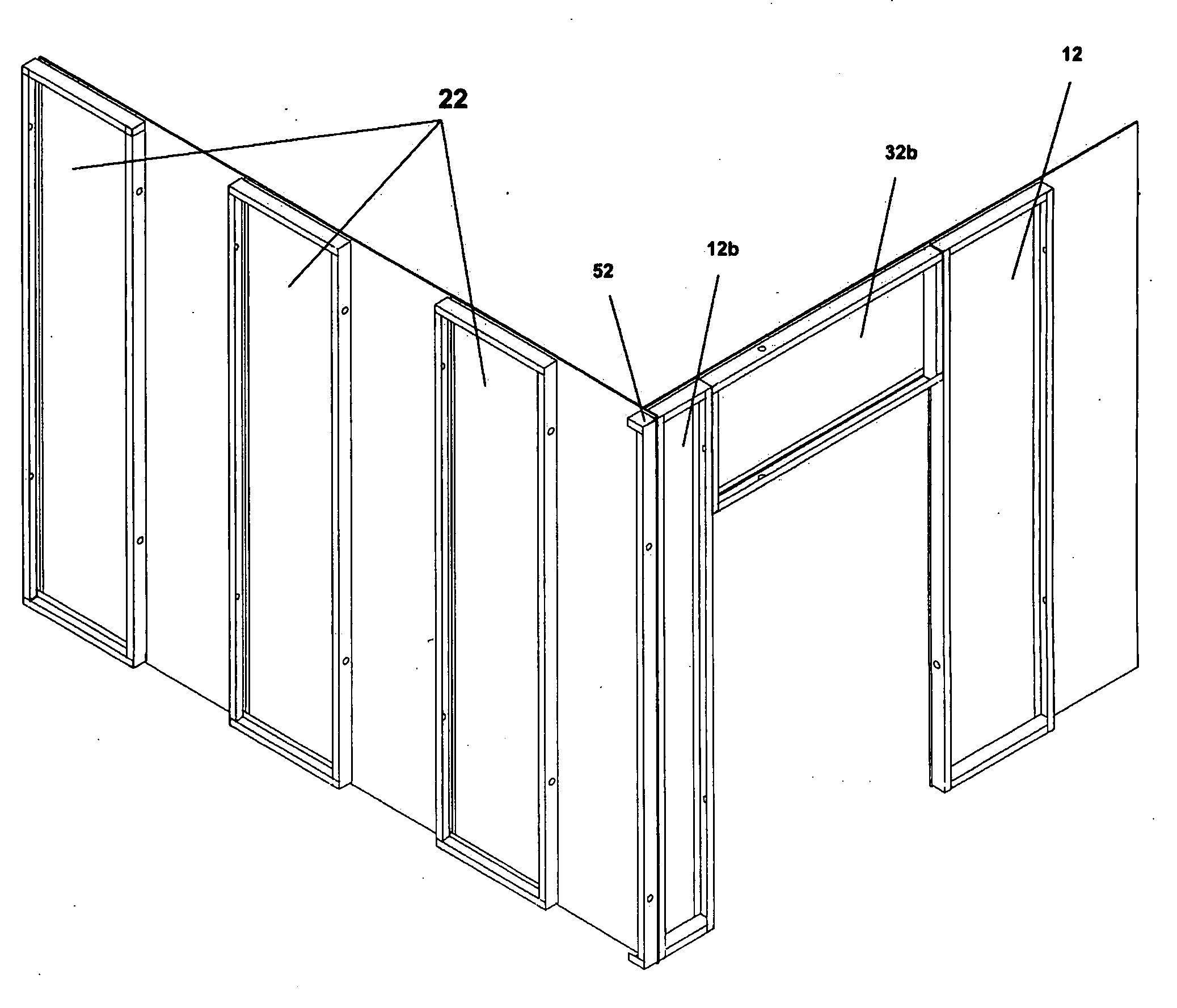

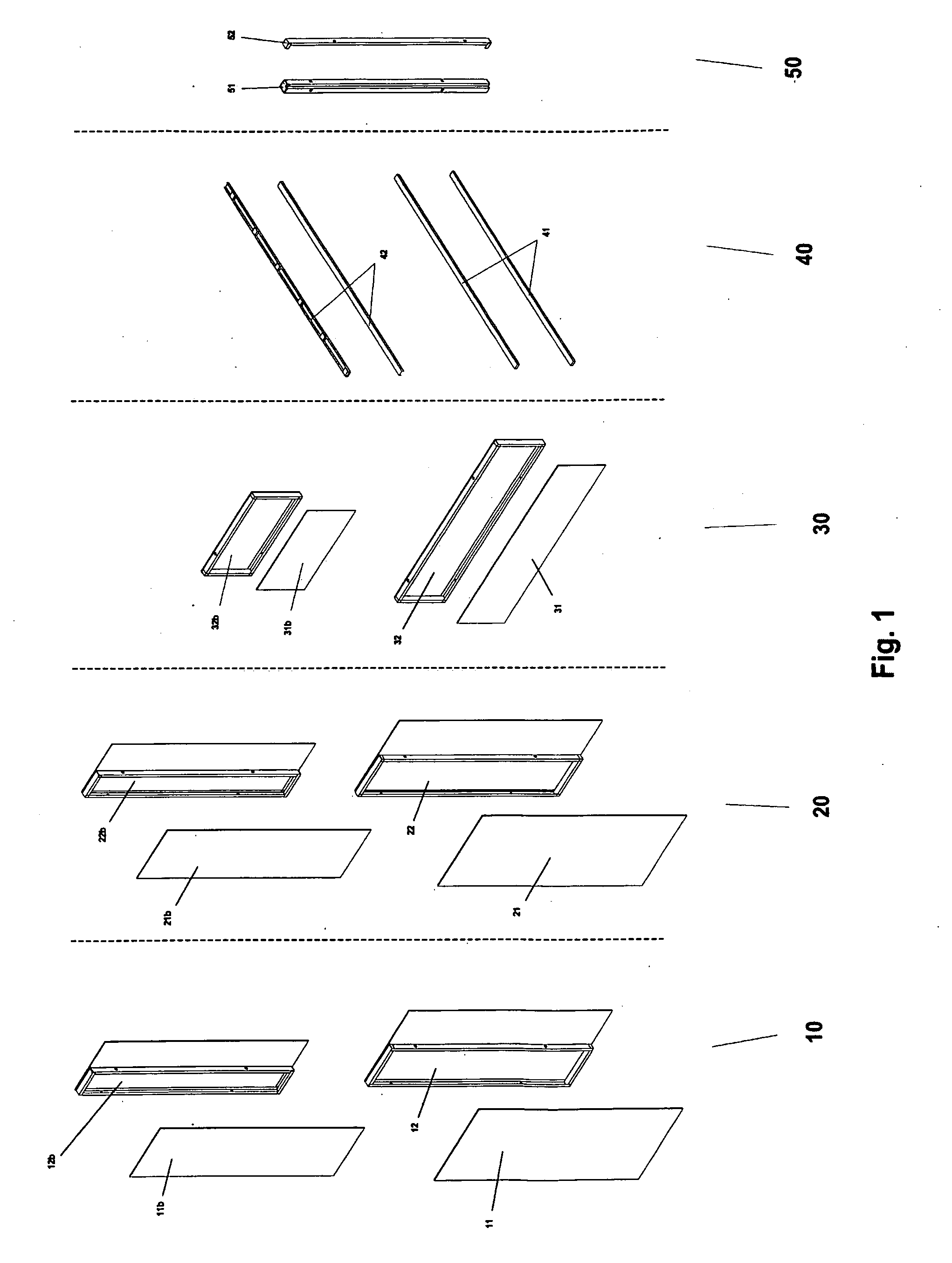

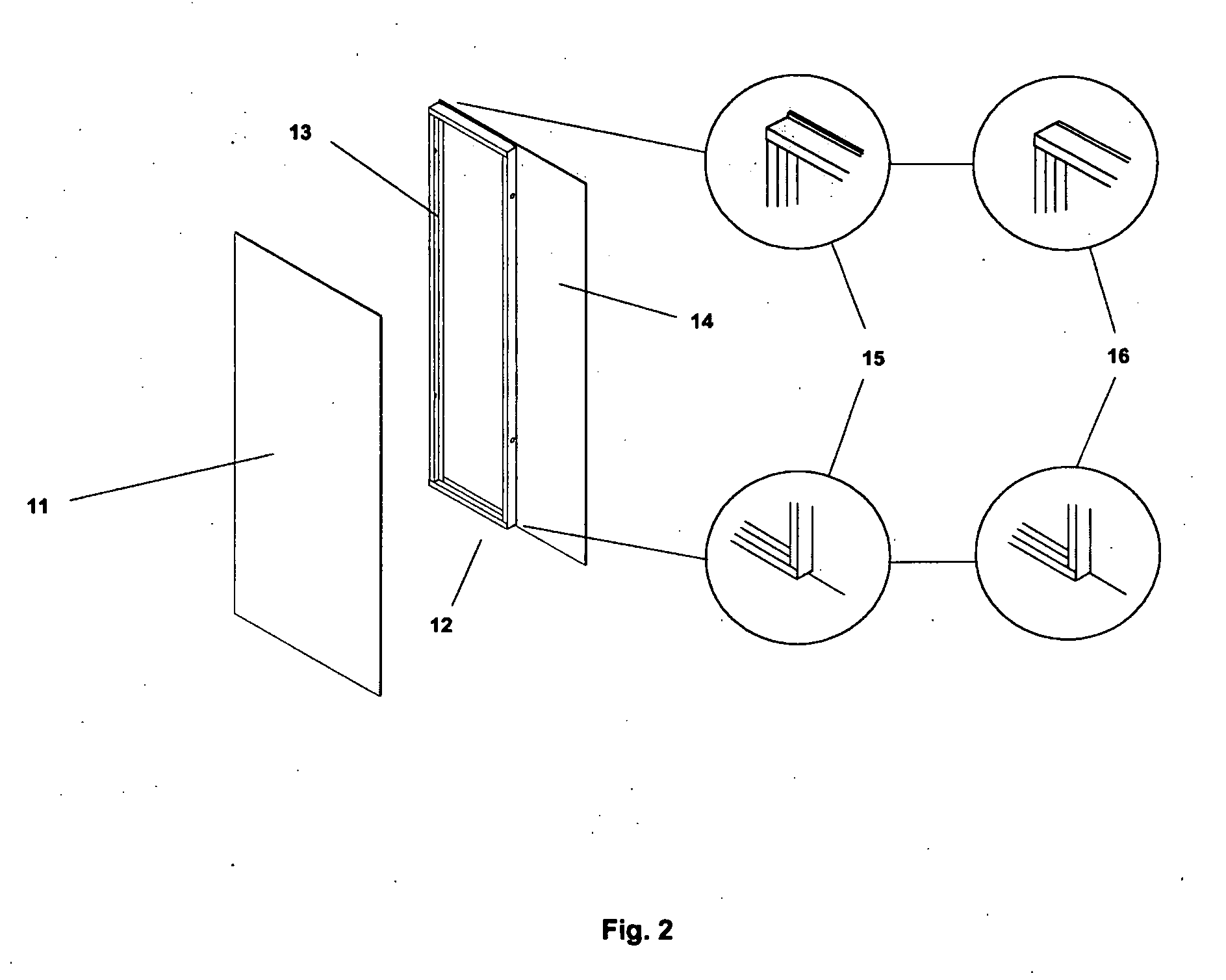

[0019]The component wall system has two major wall panel component types (10 and 20), opening header type (30), track type (40), and corner piece type (50) as illustrated in FIG. 1. The panel component types (10, 20, and 30) can have various width and size of the design and each panel component of a type is made of two pieces: the main panel with steel frame support and a plain board that closes the panel. As illustrated in FIG. 1, the first major wall panel component type (10) like the other two panel component types (20 and 30) can have two available component sets (11 and 12, 11b and 12b) of the same type. The width of the component set (11b and 12b) is half of the wider component set (11 and 12). Having various sizes of the component sets within the three panel component types (10, 20, and 30) is designed to accommodate various size openings and length of partitions. FIG. 2 illustrates the basic design of first major wall component type (10). The component type is comprised of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com