Patents

Literature

6467results about "Building roofs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

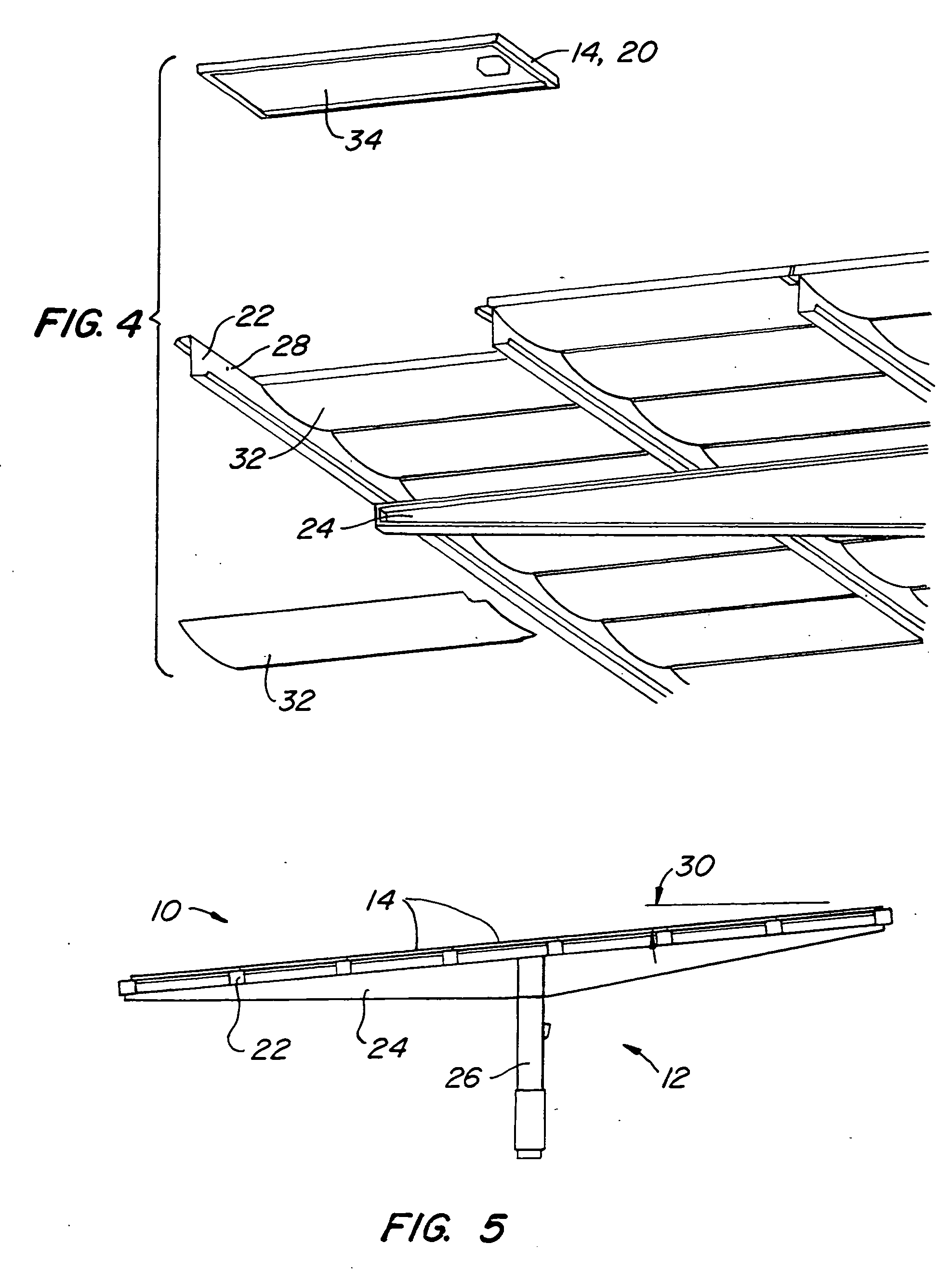

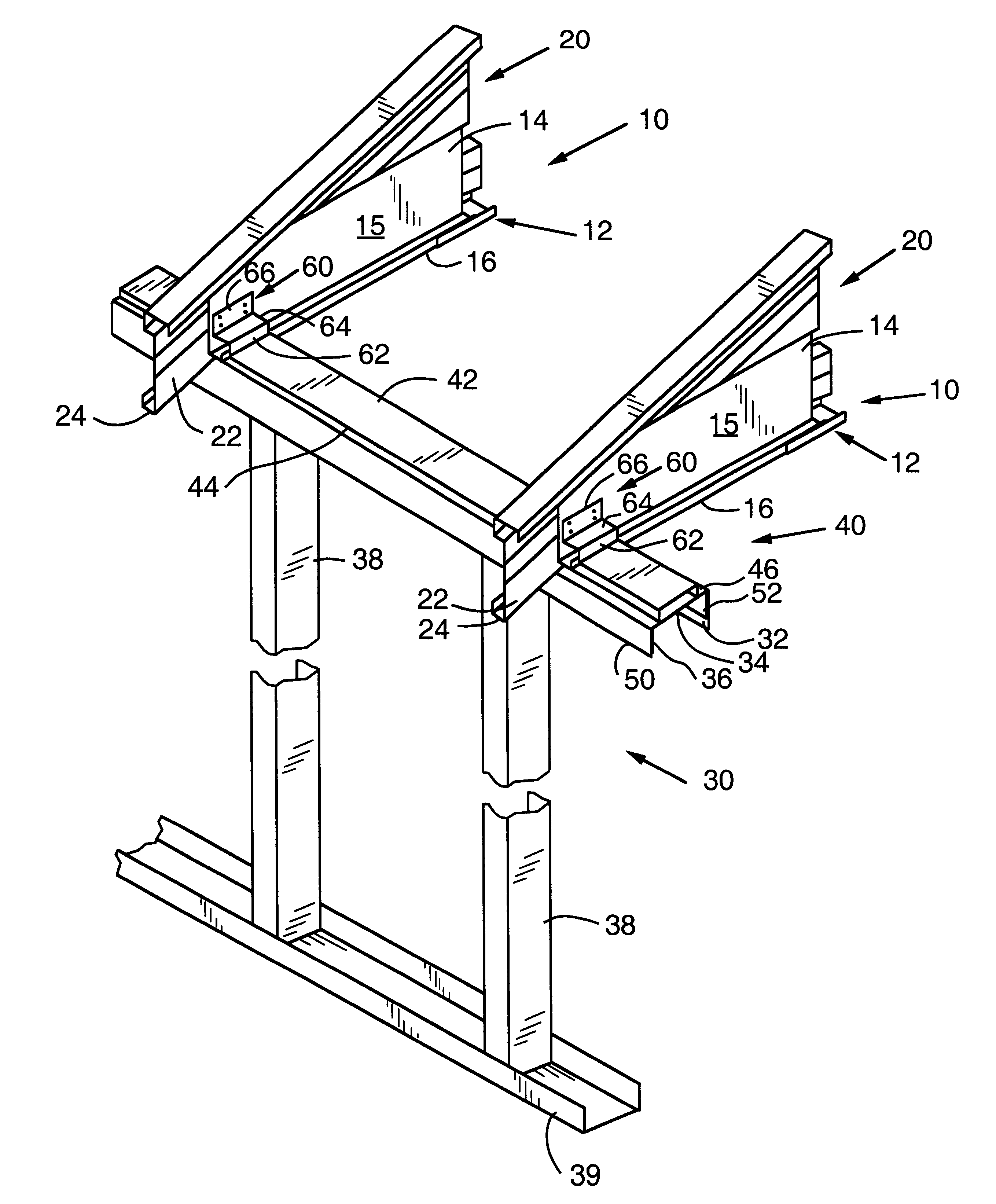

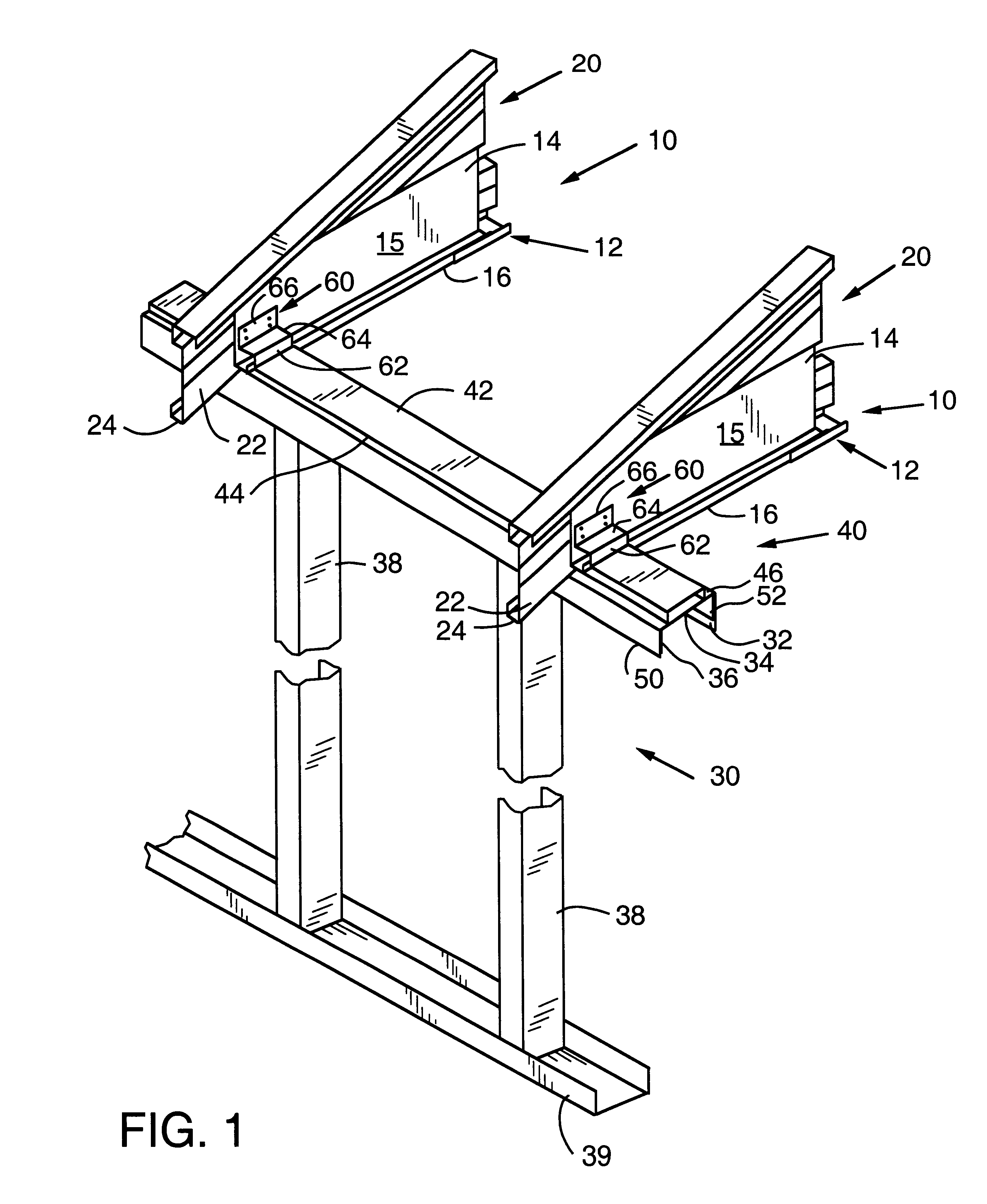

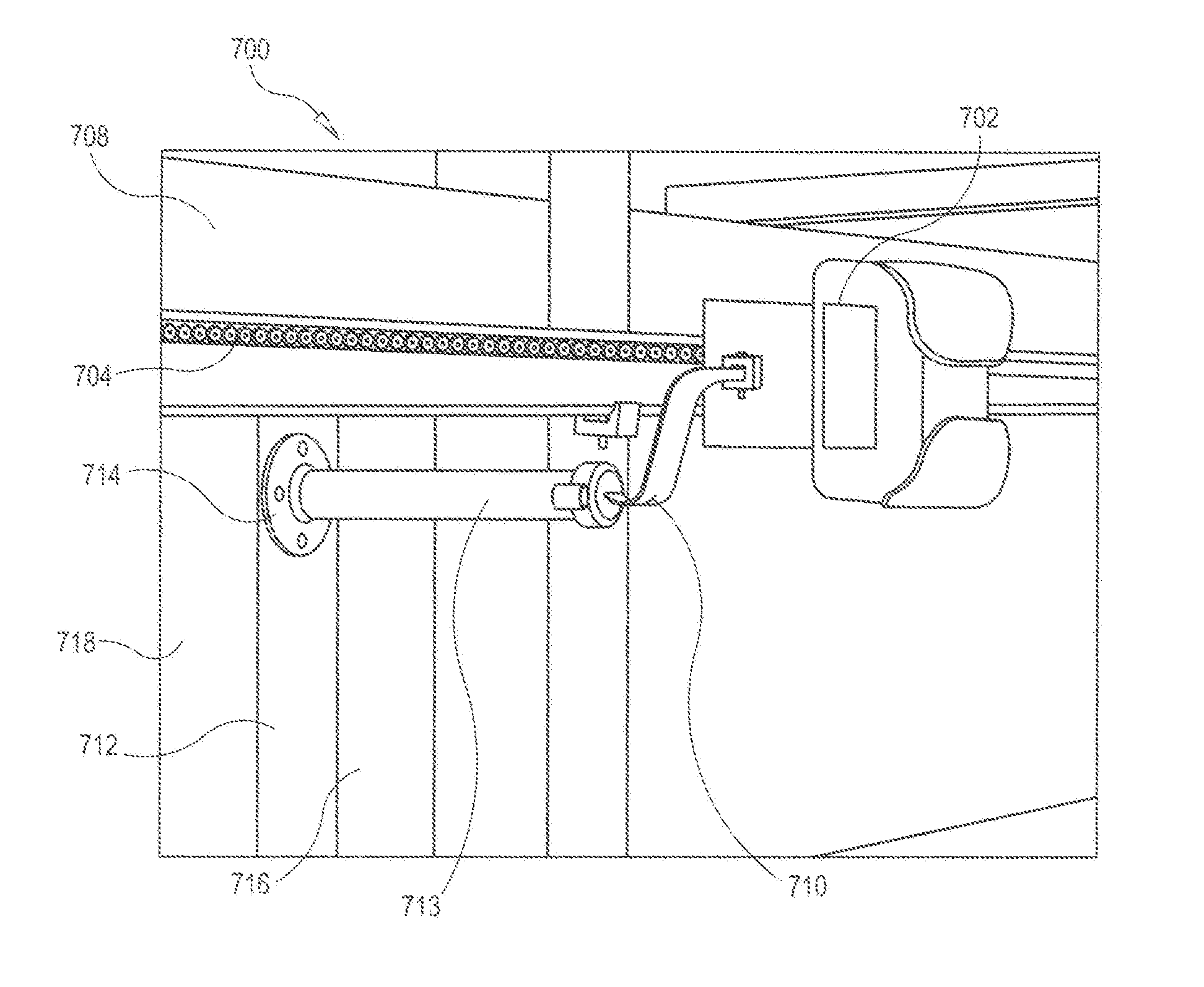

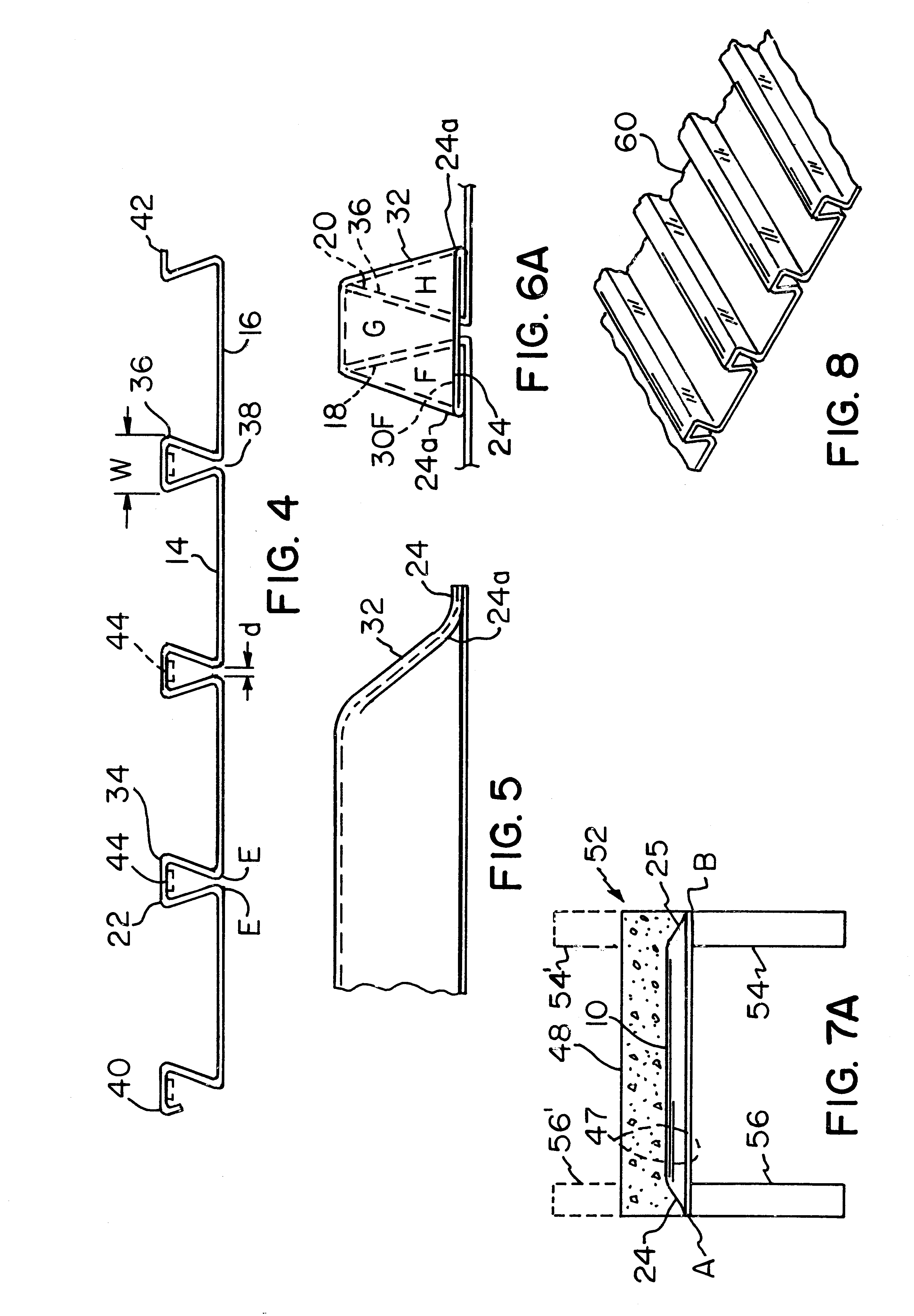

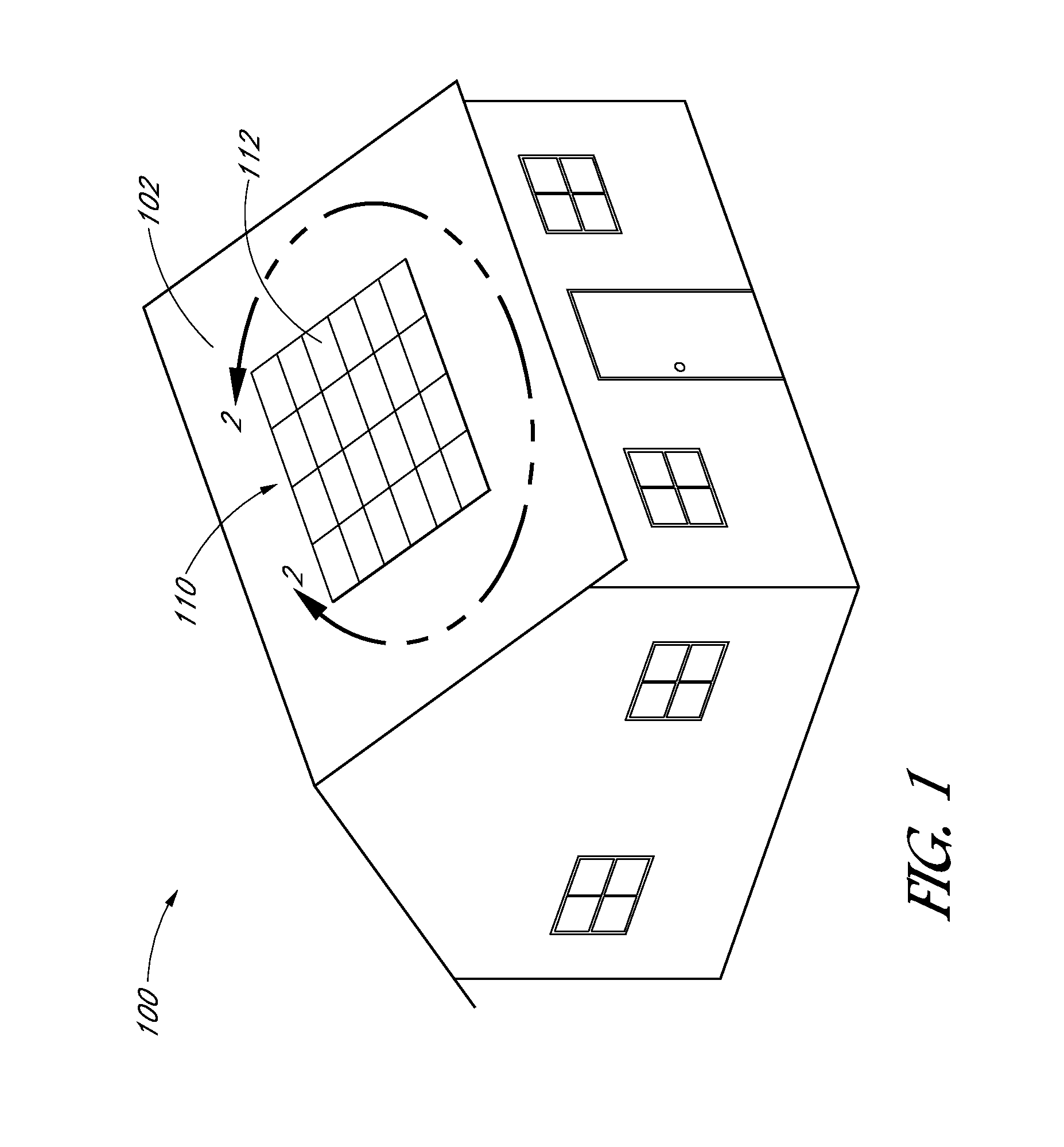

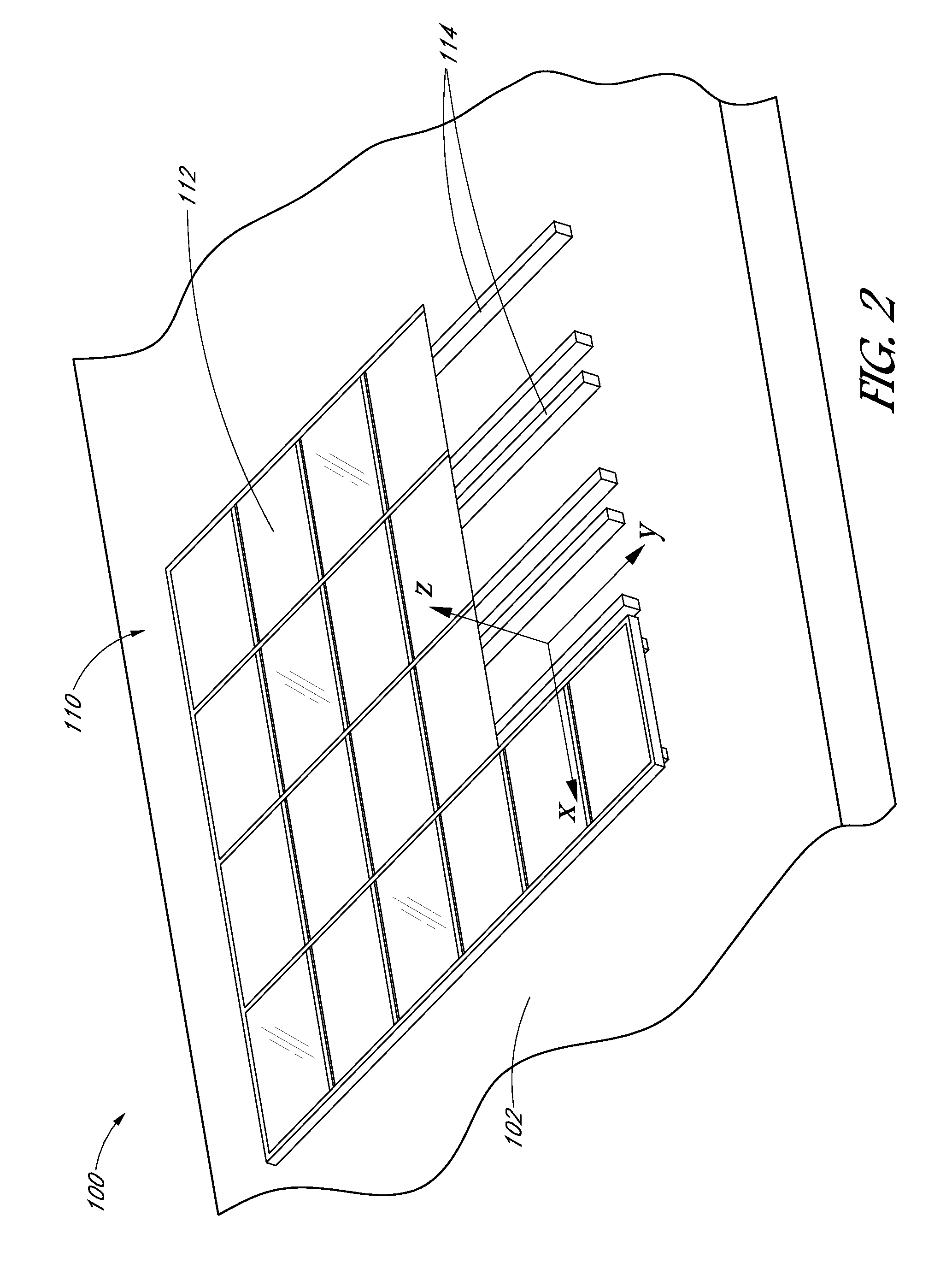

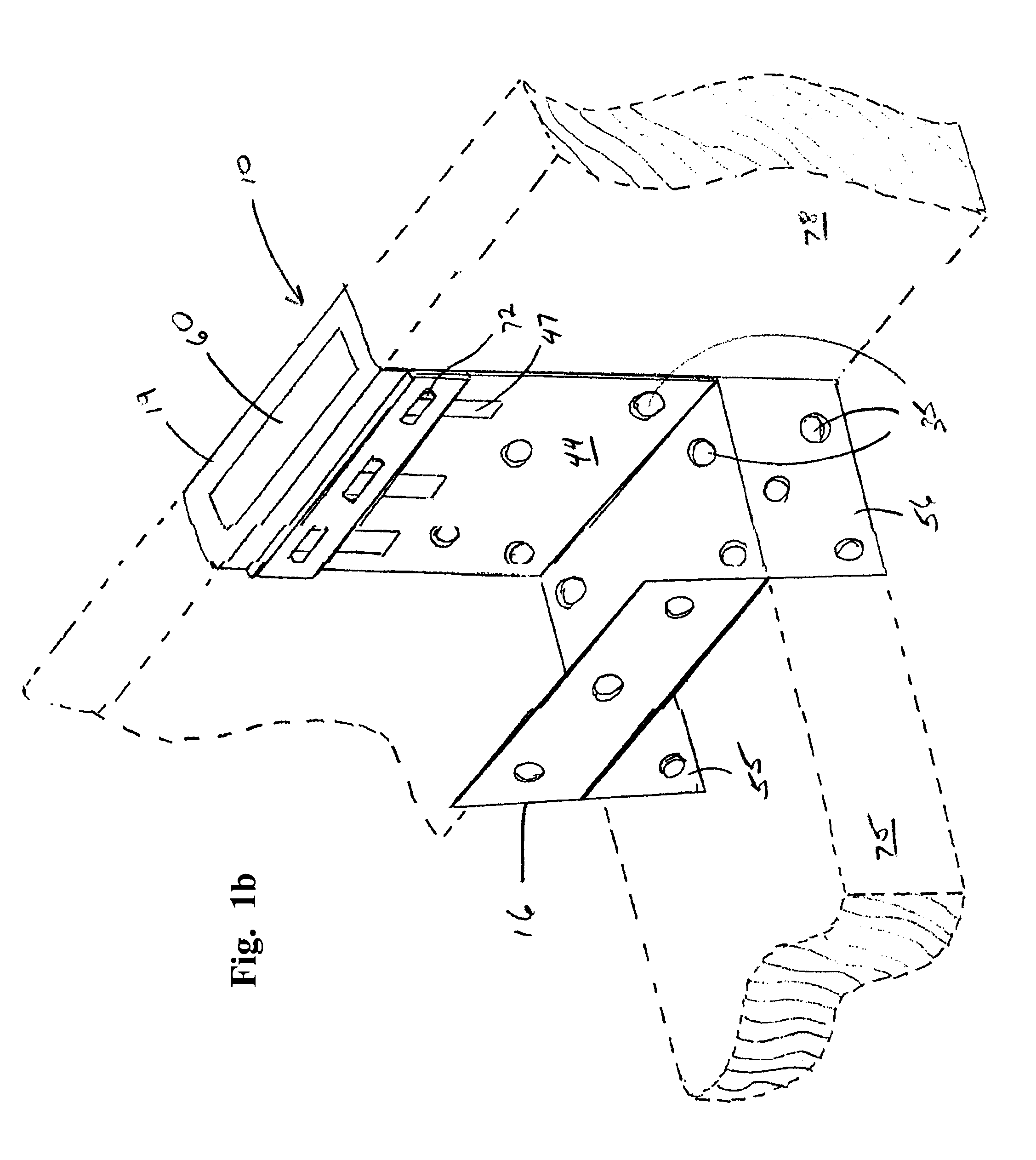

Photovoltaic mounting system with locking connectors, adjustable rail height and hinge lock

InactiveUS20090282755A1Cost-effectiveTurn easilyPhotovoltaic supportsSolar heating energyElectricityPhotovoltaic mounting system

A cam-actuated connection device joins rail mounting members of a photovoltaic panel array. The connection device slides within channels of mounting members until the members are in a properly positioned grid. When in position, the connection device is rotated to lock the mounting members in a rigid grid network. The connecting device can be subsequently loosened, repositioned and locked into position. The rail-mounting members create a grid for installation of multiple PV panels. The mounting rail allows the unit to remain relatively compact in nature but still covers a wide range of PV panel thicknesses. The rail system has a hinged connection with the mounting rail that allows an installer to assemble the module in a near perpendicular fashion to the mounting rail, make the required electrical connections and then lower the PV module into its working position. The unit is then locked into its working position.

Owner:POWERMOUNT SYST +1

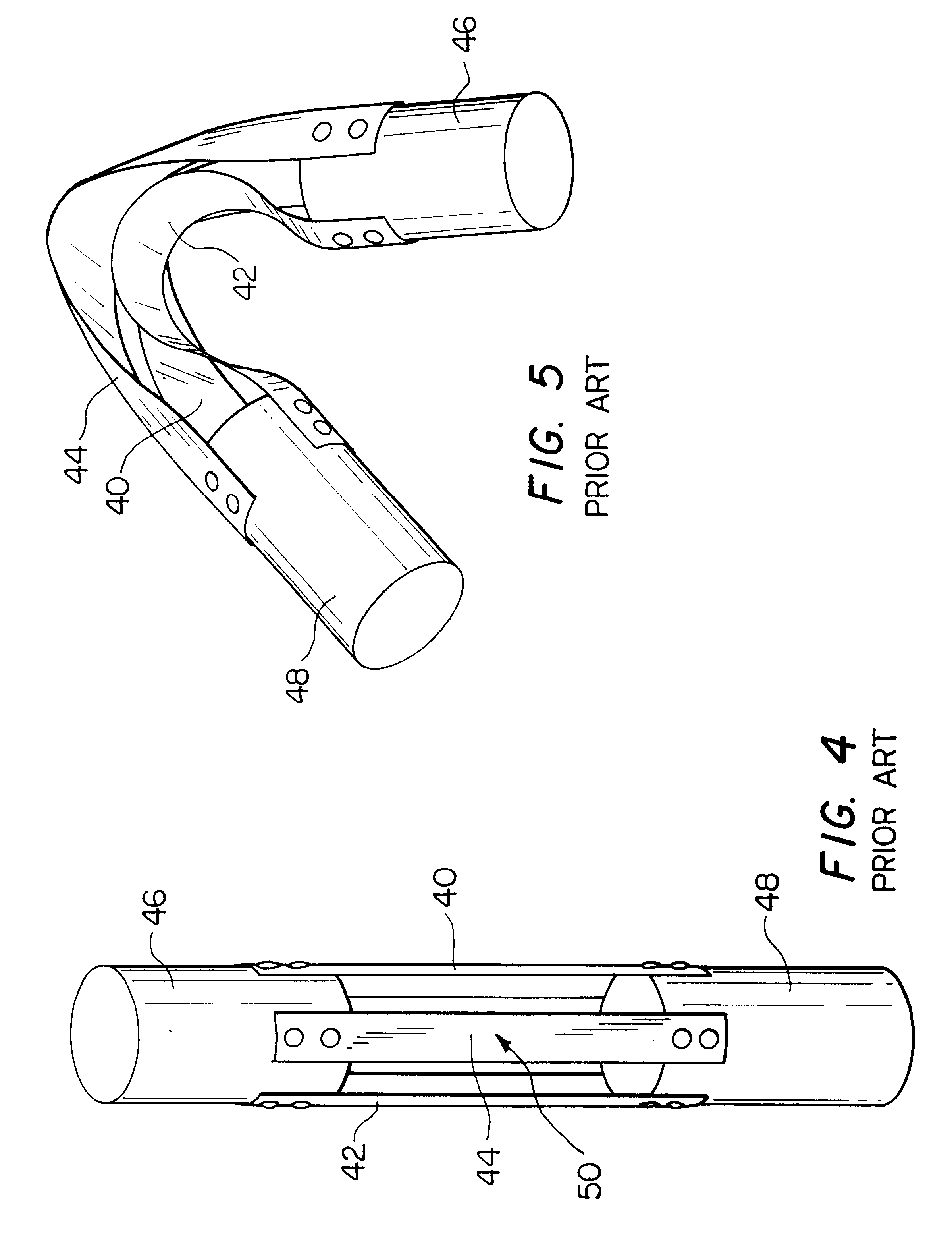

Moisture management system

InactiveUS6470638B1Improve adhesionImprove moisture managementBuilding roofsRoof covering using slabs/sheetsAdhesiveEngineering

An improved moisture management system for installation over doors and windows in buildings that included exterior, stucco-covered, curtain walls comprising an integrally formed, three sided, elongated track including a base, an upright front wall that includes at its base weep holes for the removal of entrained moisture as well as a longitudinal forward extending finish stop above the weep holes, and an upright rear wall at opposing elongated edges of the base, and, extending angularly downward from the outside of the base, and integrally formed therewith, a drip plate that permits ready drainage of water exiting the moisture management system through the weep holes in the upright front wall. Preferably, elongated striations in the front faces of both the front and rear upright walls as well as holes in the upright front wall above the finish stop provide improved adherence of sealants and adhesives used in the installation process.

Owner:PLASTIC COMPONENTS

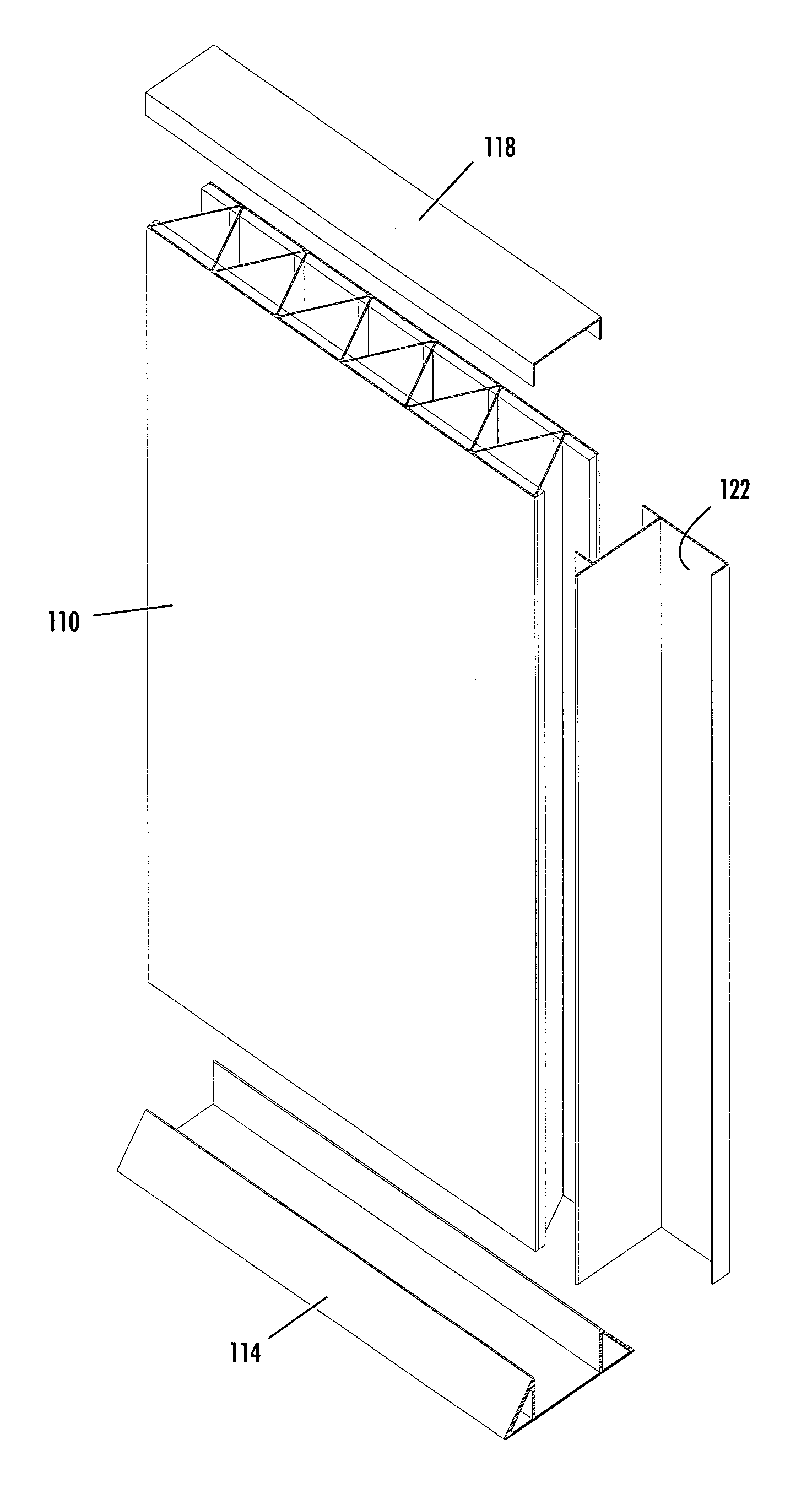

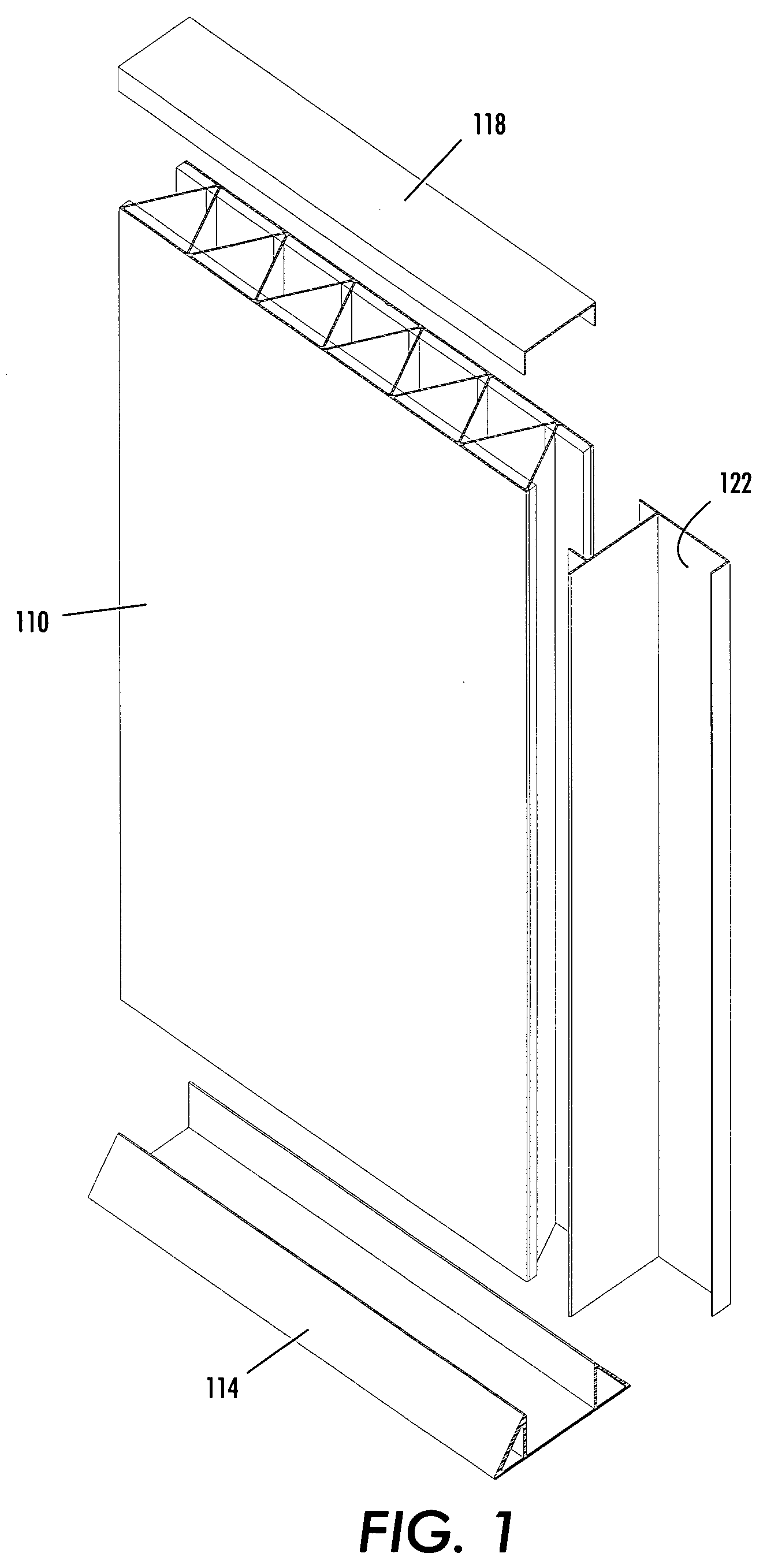

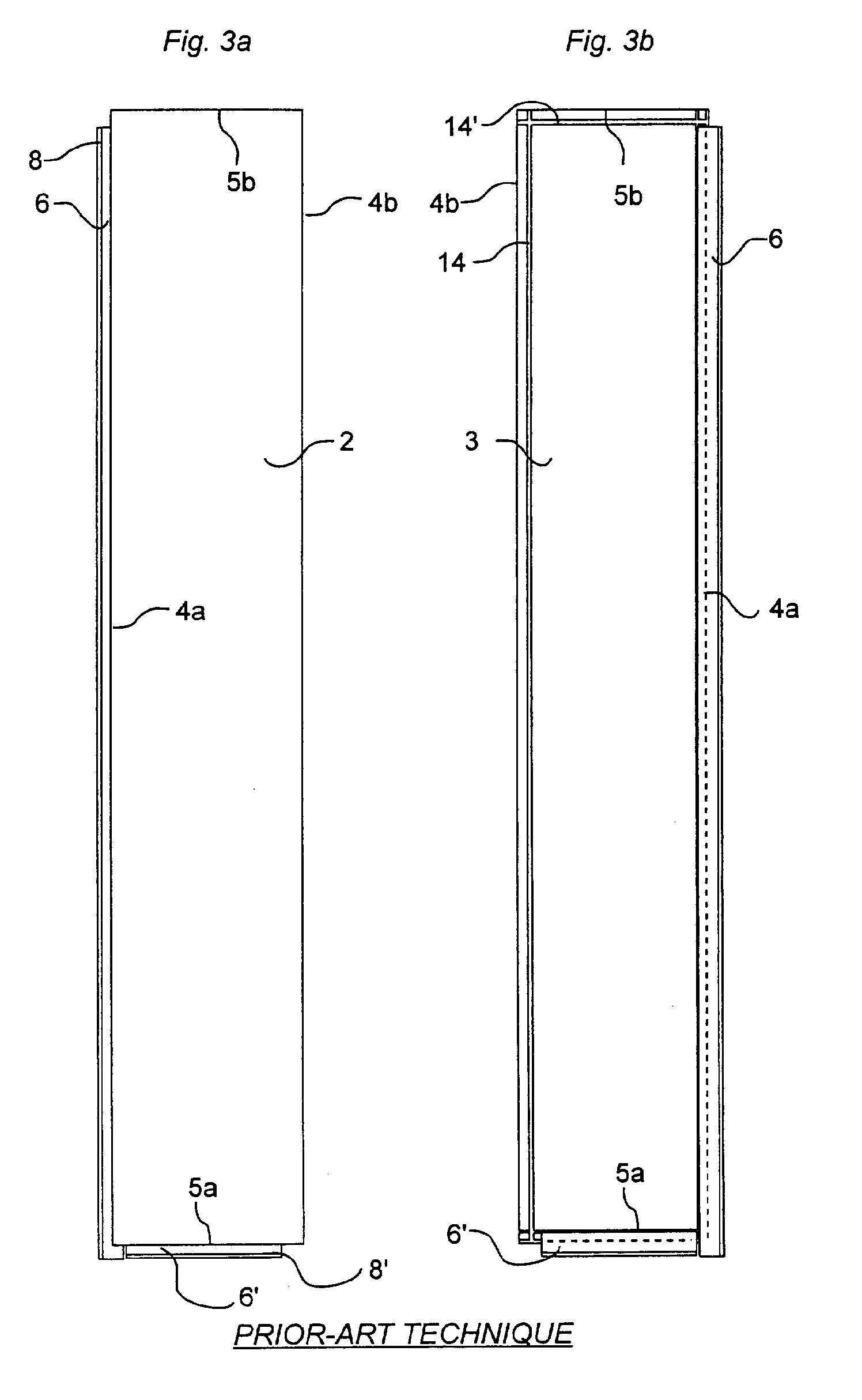

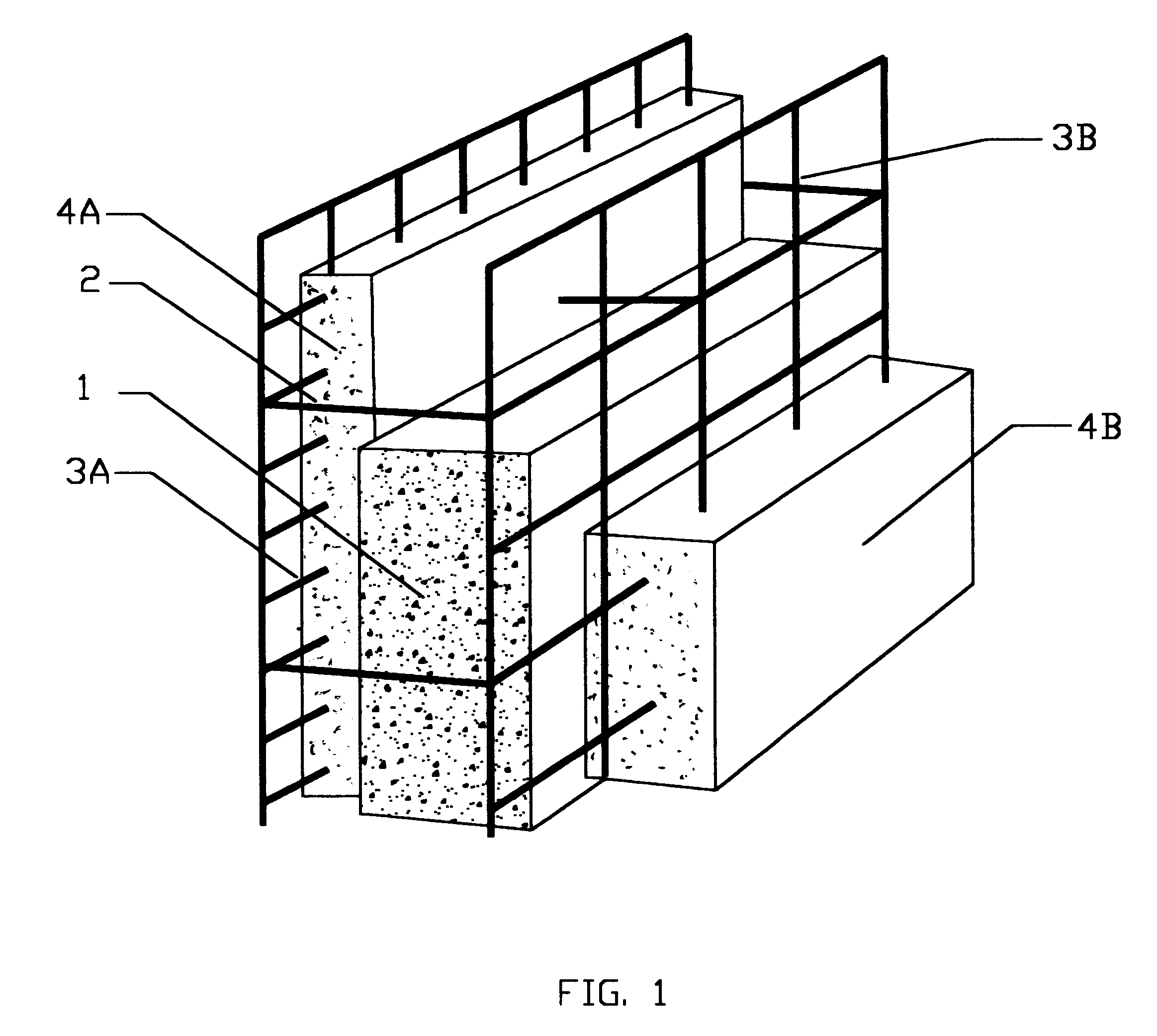

Modular structure for building panels and methods of making and using same

The present invention is a polymeric panel system and method for production and use thereof, enabling the rapid construction of a building foundation wall or other structure and in particular a below-grade foundation. The polymeric foundation system includes polymeric wall panels and other components suitable for withstanding lateral and end compression loads. The walls include two parallel faces separated by a series of webs or ribs, where the webs and faces of the wall panels may be formed of a similar polymer material such as polyvinylchloride (PVC). The wall panels and / or other components may be extruded so as to enable the rapid production of sections of wall panels, where the panels may be cut to length and then affixed to adjacent panels to form a foundation wall. The method of affixing adjacent panels may include welding, gluing or other techniques and may be performed on the job site or in a pre-fabrication facility. Furthermore, the wall panels may be co-extruded with an insulating material inserted in the voids between the parallel faces so as to provide improved thermal performance of the foundation as well.

Owner:DOUGLAS ROBERT B

Containerized habitable structures

An engineered purpose-built portable habitable structure formed of a transformable rectangular enclosure that includes a base shell having hingedly attached exterior and interior walls that fold out to form a habitable structure. The walls of the structure are pre-wired and pre-plumbed and are adapted to connect to appropriate supply sources exterior to the structure.

Owner:CIOTTI THEODORE T

Insulative concrete building panel with carbon fiber and steel reinforcement

InactiveUS6898908B2High strengthImprove insulation performanceBuilding roofsConstruction materialFiberCarbon fibers

An insulative, lightweight concrete building panel is provided with one or more fiber or steel reinforcements which are manufactured in a controlled environment and can be easily transported and erected at a building site.

Owner:OLDCASTLE PRECAST

Non-combustible reinforced cementitious lighweight panels and metal frame system for a fire wall and other fire resistive assemblies

ActiveUS20060168906A1Reduce buildReduce capacityBuilding roofsSolid waste managementMicrosphereMetal framework

A fire resistive assembly including metal framing members, for example, C-joists, U-joists, open web joists, HAMBRO or other metal frame systems that support a reinforced, lightweight, dimensionally stable SCP panel. The assembly is non-combustible, water durable, mold and rot resistant, termite resistant and is capable of resisting shear loads equal to or exceeding shear loads provided by plywood or oriented strand board panels. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

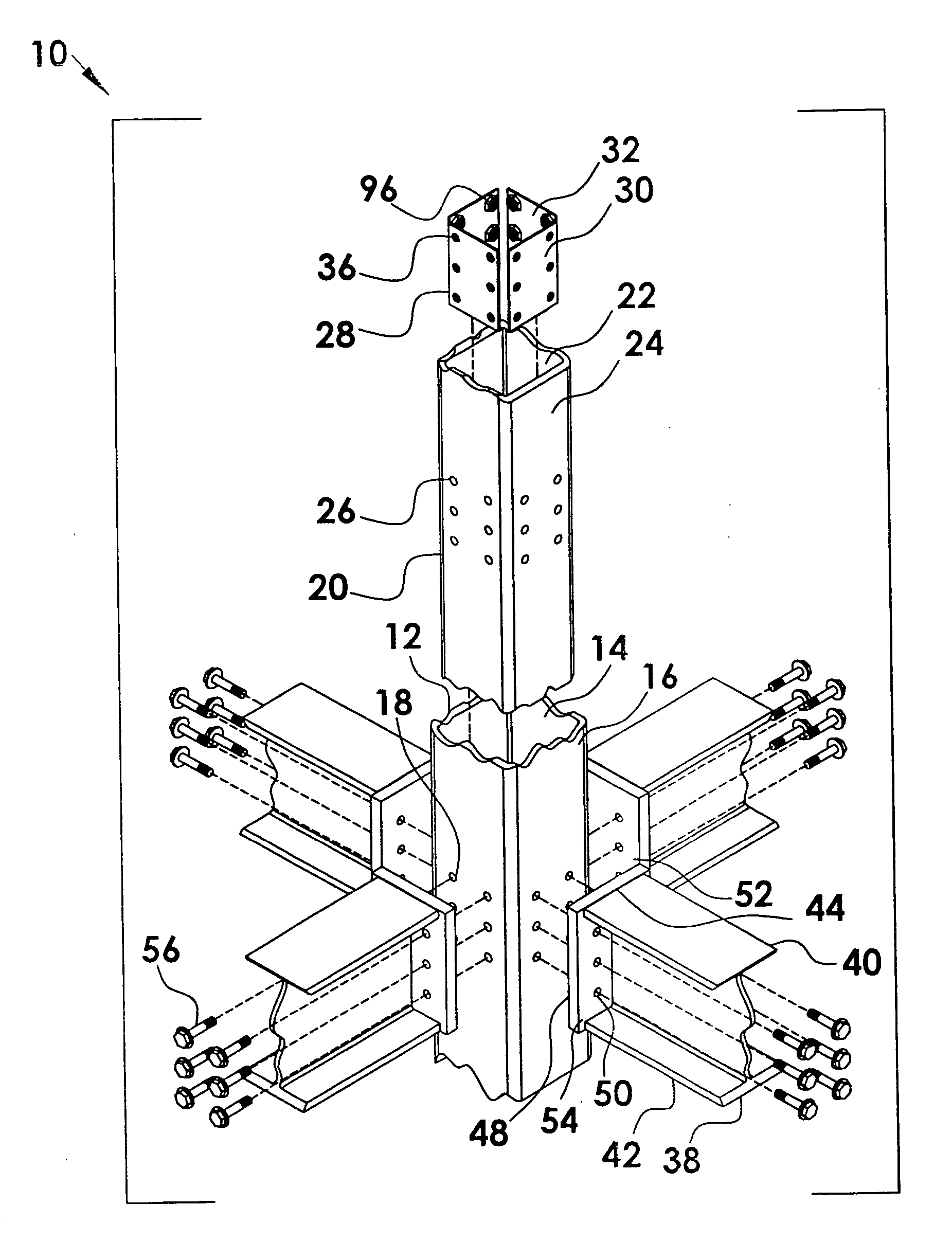

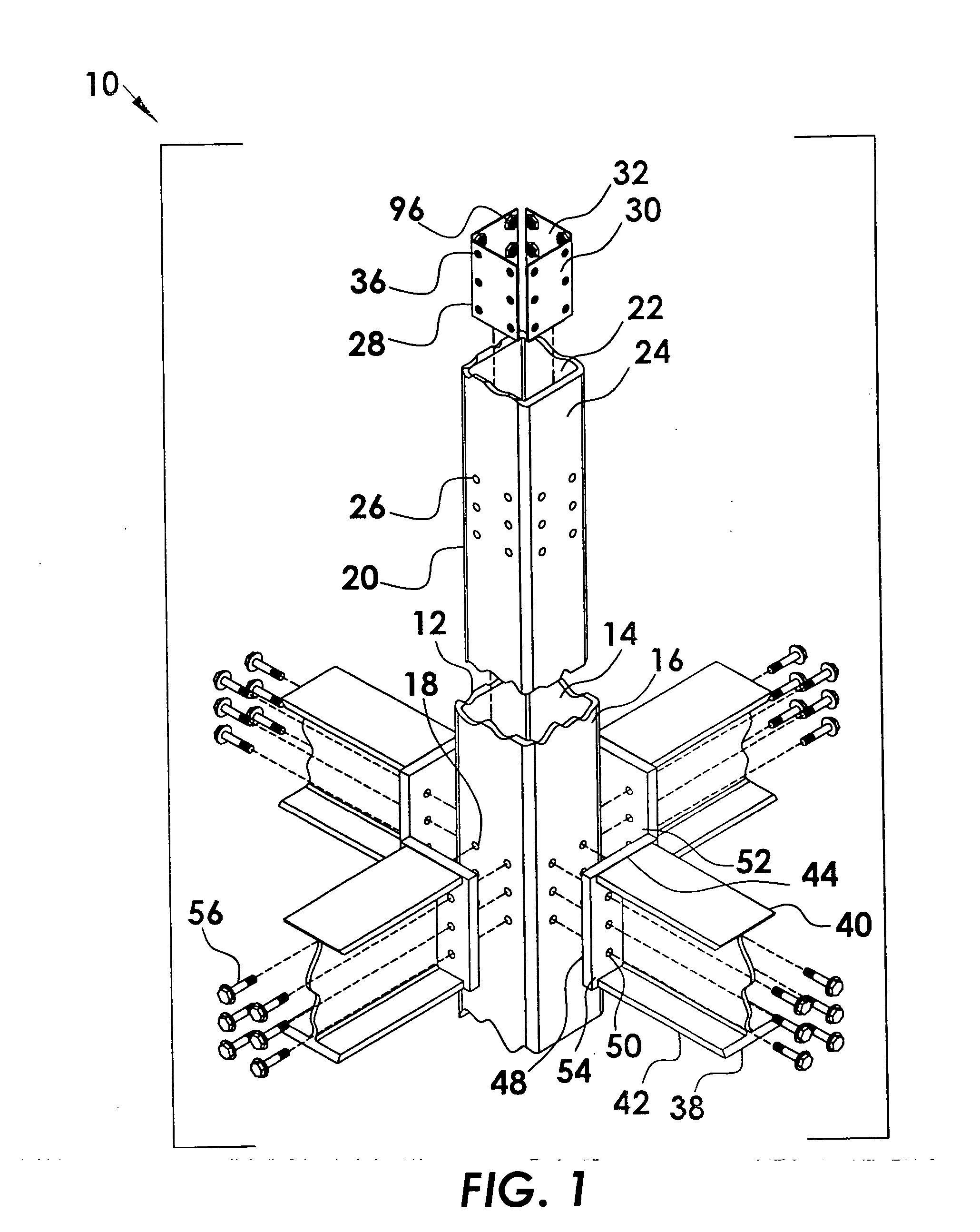

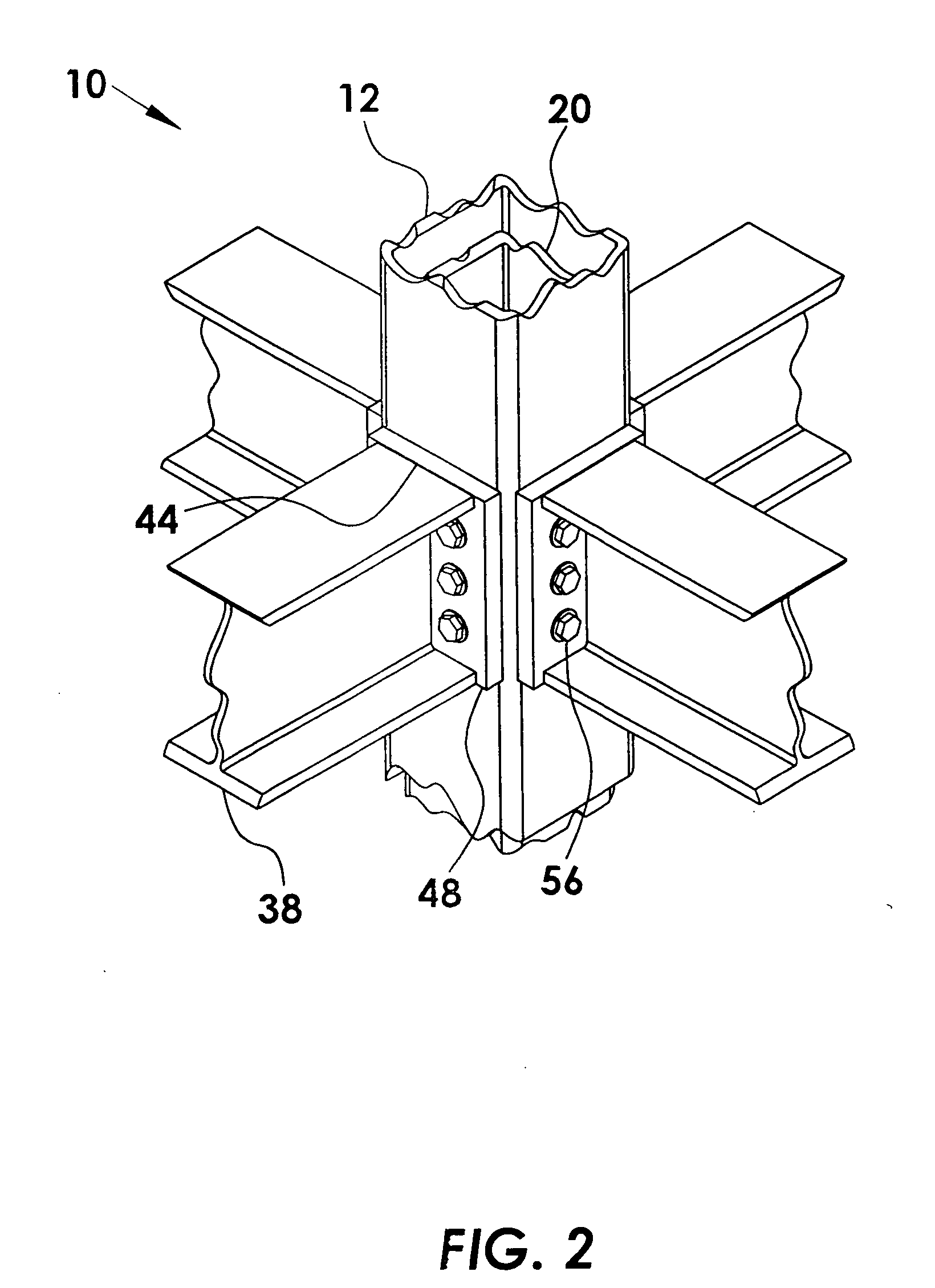

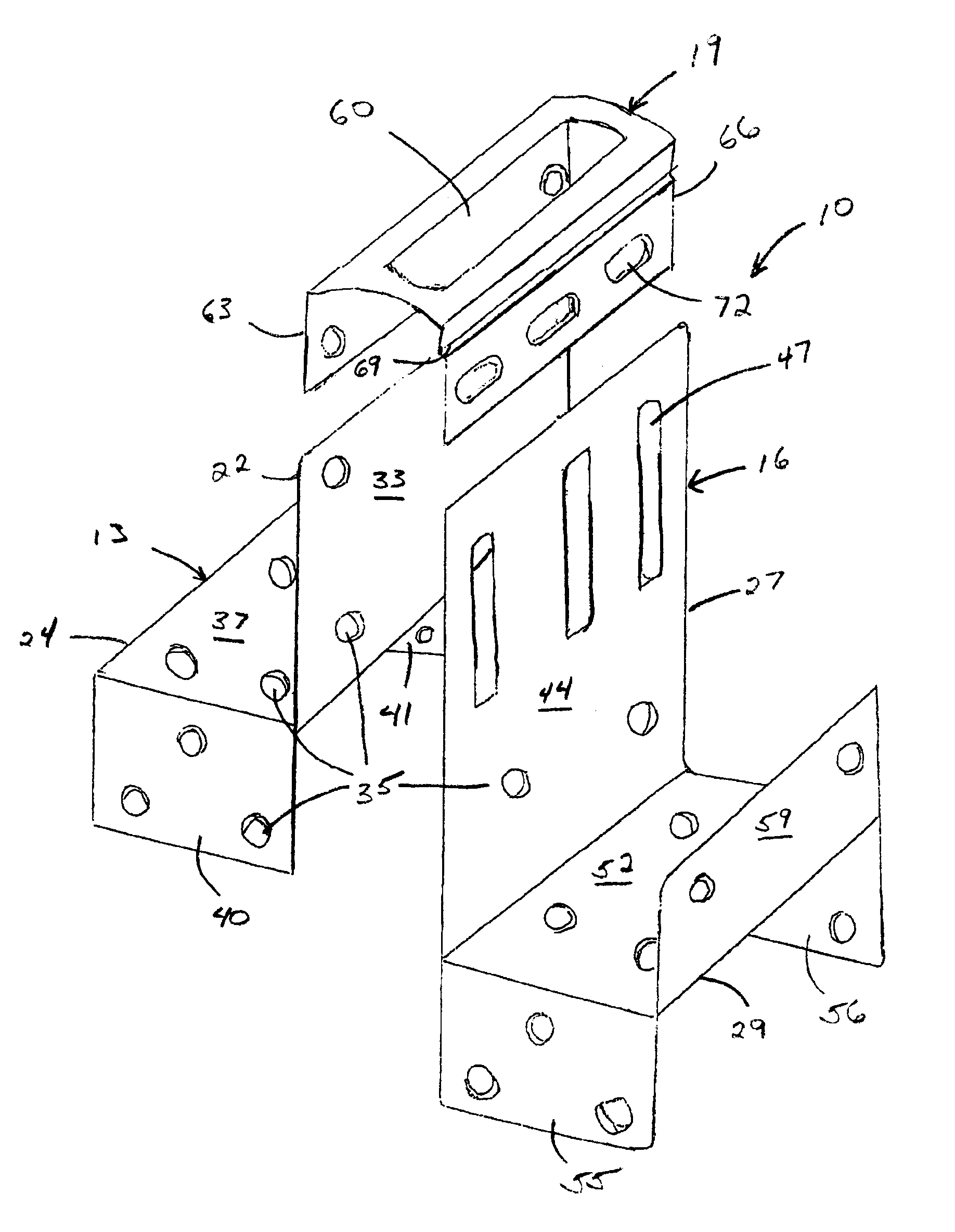

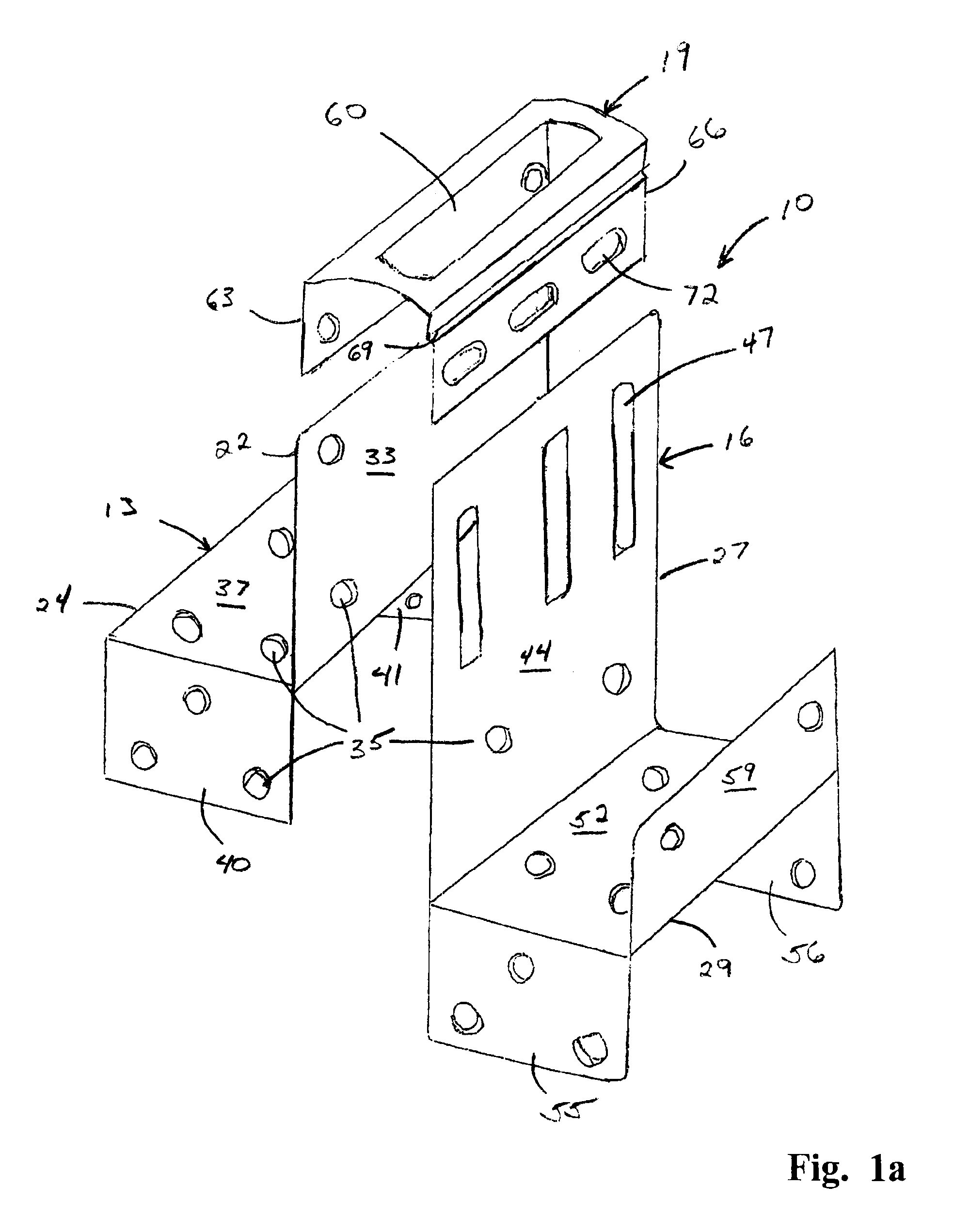

Moment-resistant building column insert system and method

InactiveUS20070209314A1Improves building column strength strengthImprove connection strengthBuilding roofsFloorsArchitectural engineeringVertical load

The invention is a novel moment-resistant building column insert system for distributing lateral and vertical loads between the column-beam and column-foundation connections. Loads are distributed between the column and beam using a column insert, nut plates and beam end plates incorporated to beam-ends. The column insert is hollow and similar cross-section shape to the building column for inserting there to. The column, column insert, nut plates and endplates have patterns of mounting holes for receiving mounting bolts tightened to nuts held by nut plates. Loads are distributed between the column and foundation using a base plate, column insert, and insert plates integrated with anchor bolts, nuts and washers in a concrete foundation. The base plate having mounting holes is incorporated to the building column bottom end to receive the plurality of anchor bolts there through for fixedly tightening as an exposed end of the column insert fits in the column.

Owner:VAUGHN WILLAIM B

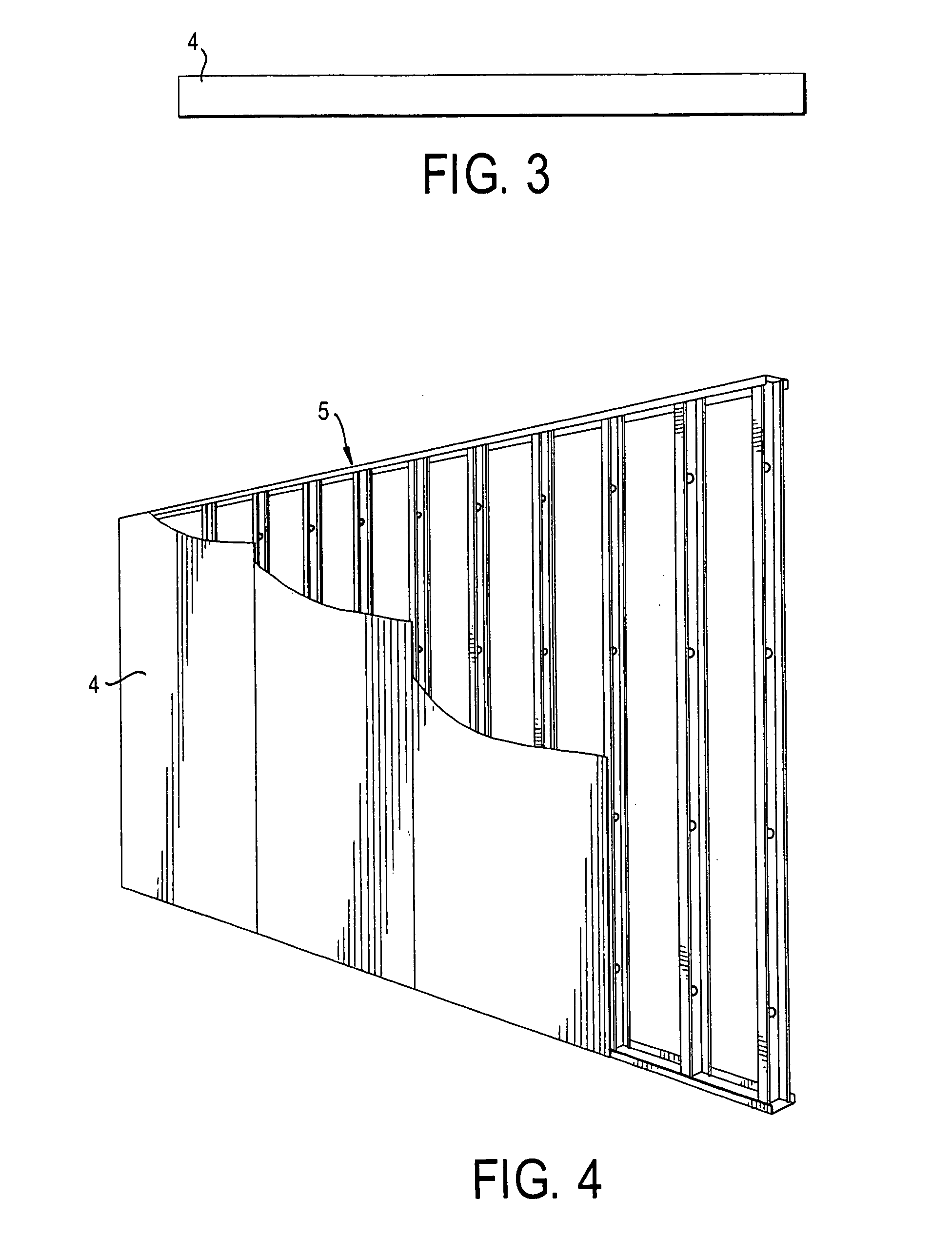

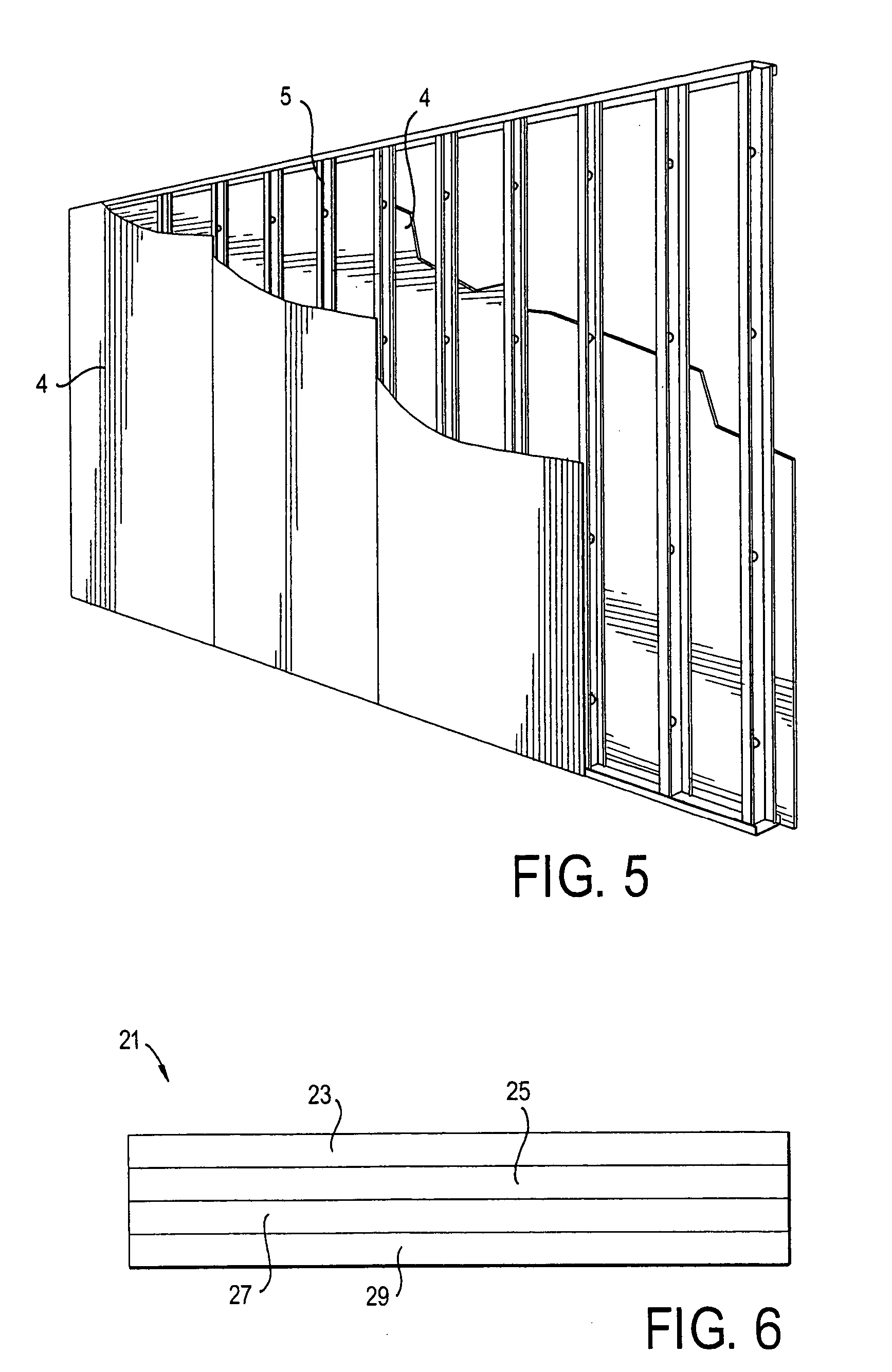

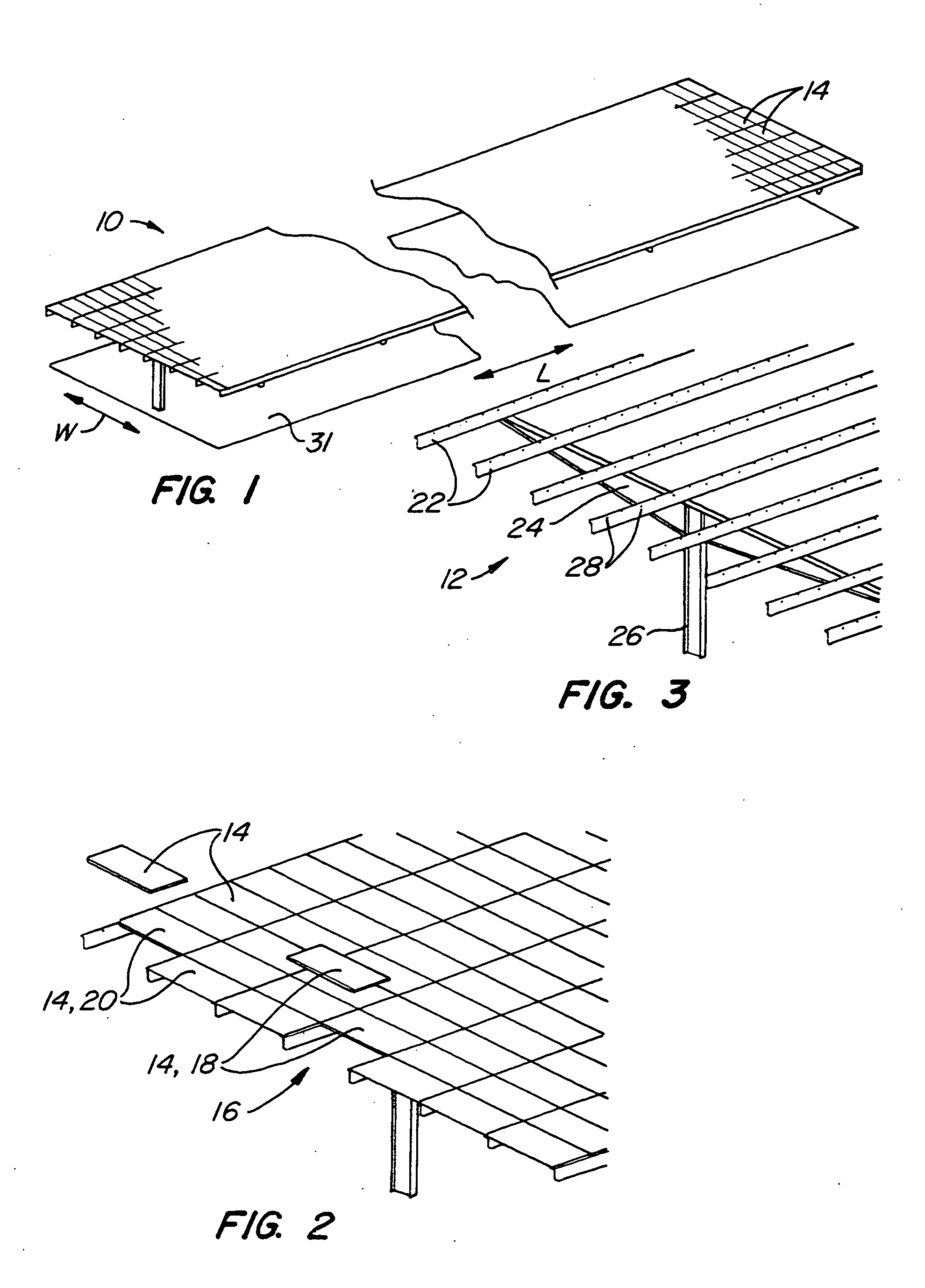

Laminated composite building component

InactiveUS6205728B1Maximized encapsulationHigh strengthBuilding roofsConstruction materialAdhesiveEngineering

A laminated composite building component, capable of sustained axial stress as a primary support structure and enclosure of a building structure, comprising a lamination of rigid and resilient material, said rigid material formed of sheets with continuous corrugations parallel to the supporting axis and which have opposite faces being bonded to and encapsulated by said resilient material, said resilient material being a cellular foam matrix, an adhesive or fusion that bonds the rigid and resilient material together in either a static or continuous laminating process, said resilient material forming two outer surfaces spaced from the rigid material, said rigid material having opposite lateral edges being exposed from said resilient material, said lateral edges of the rigid material having return flanges for interlocking said laminated composite building component with adjacent building component, and said building components capable of being supplied and distributed in generic lengths and custom field-cut like lumber.

Owner:RYN SUTELAN

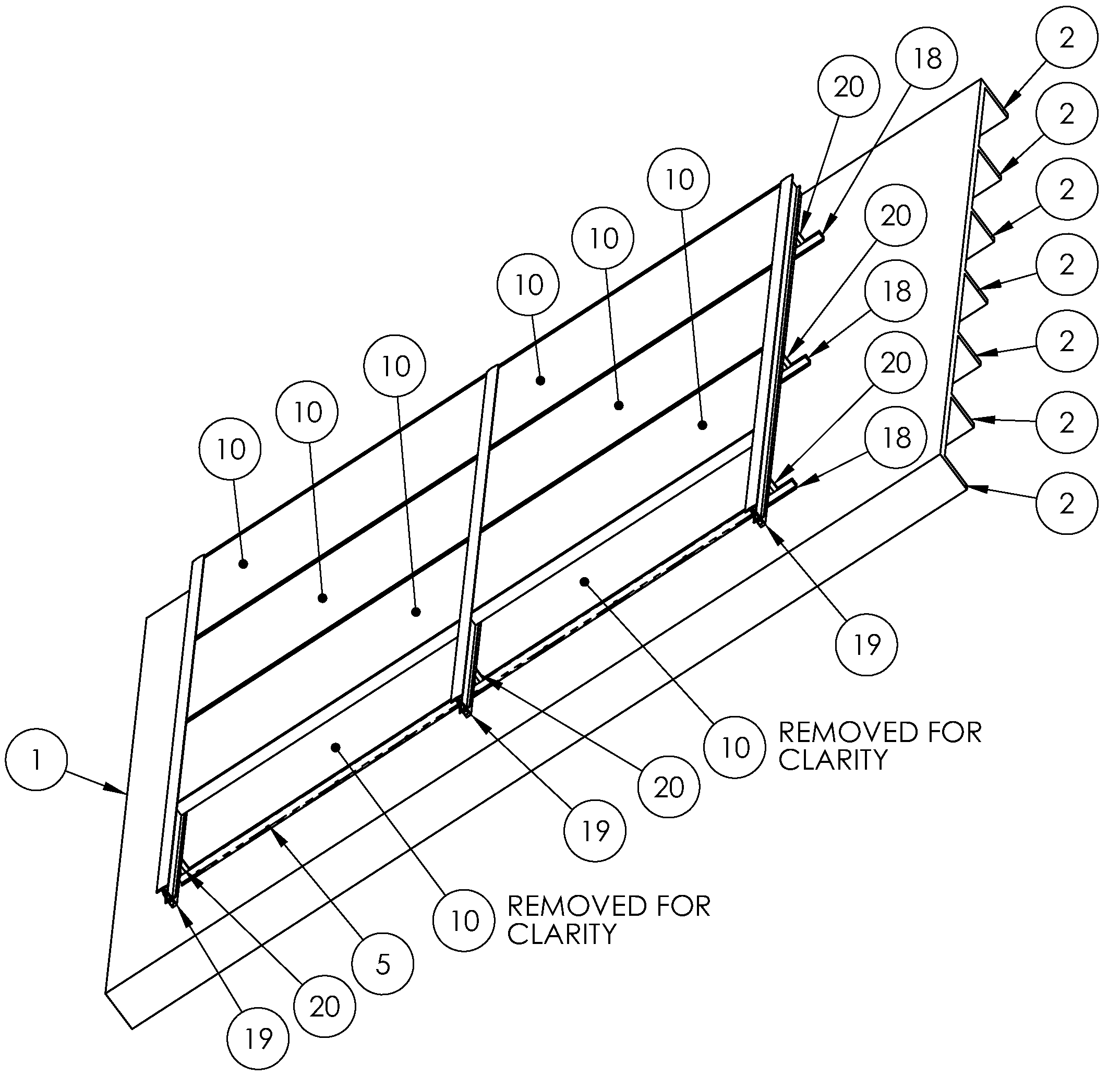

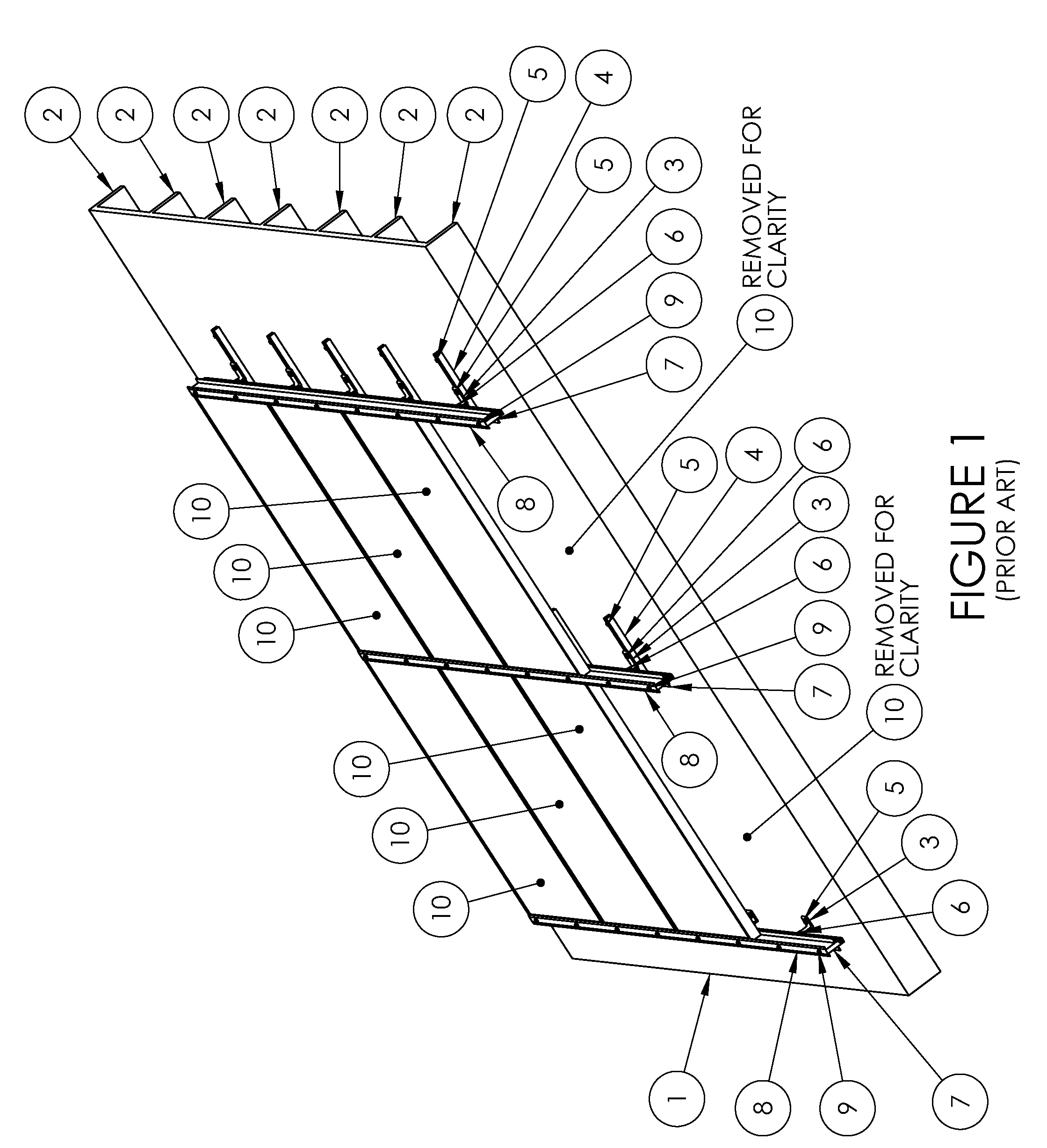

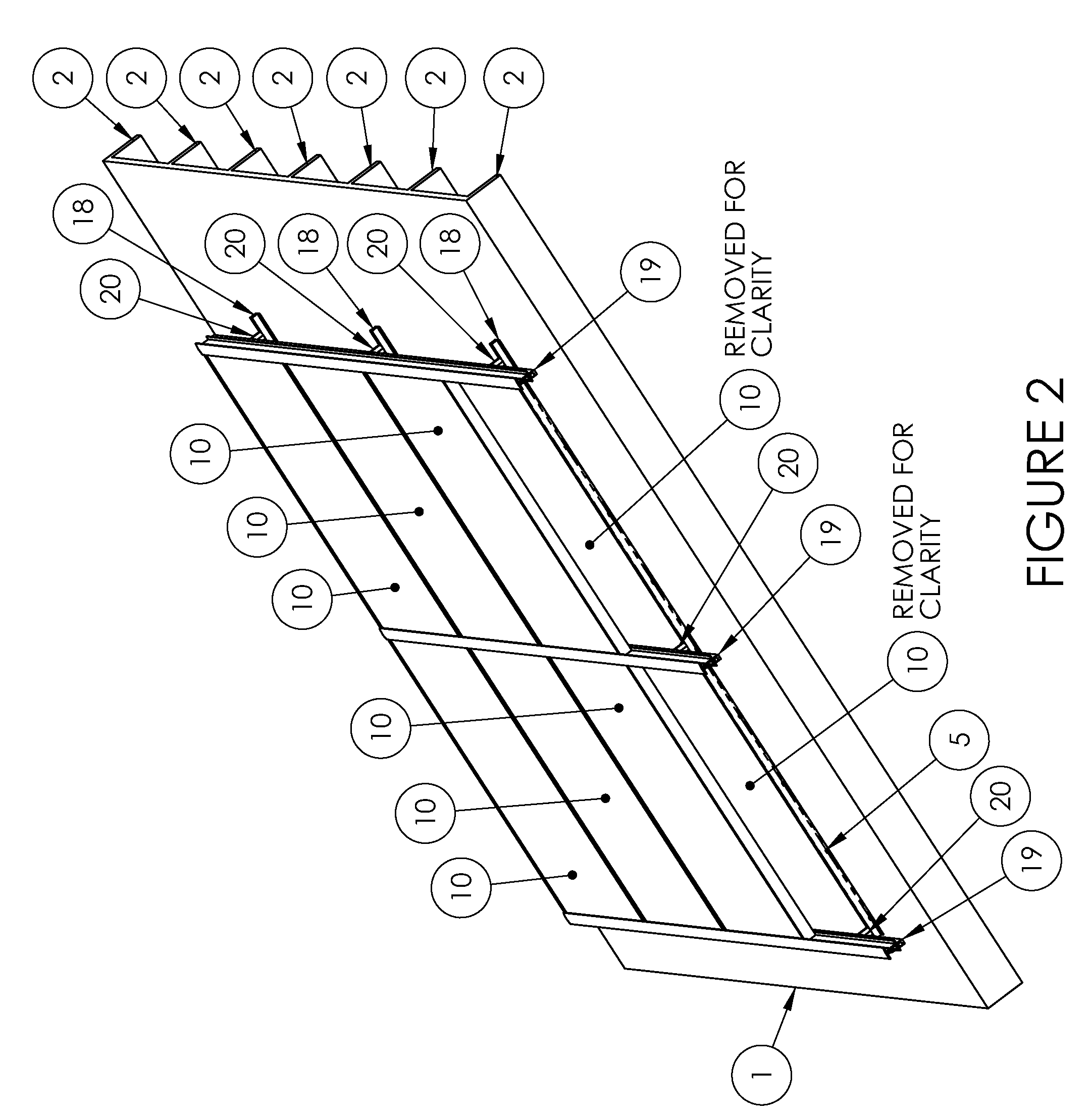

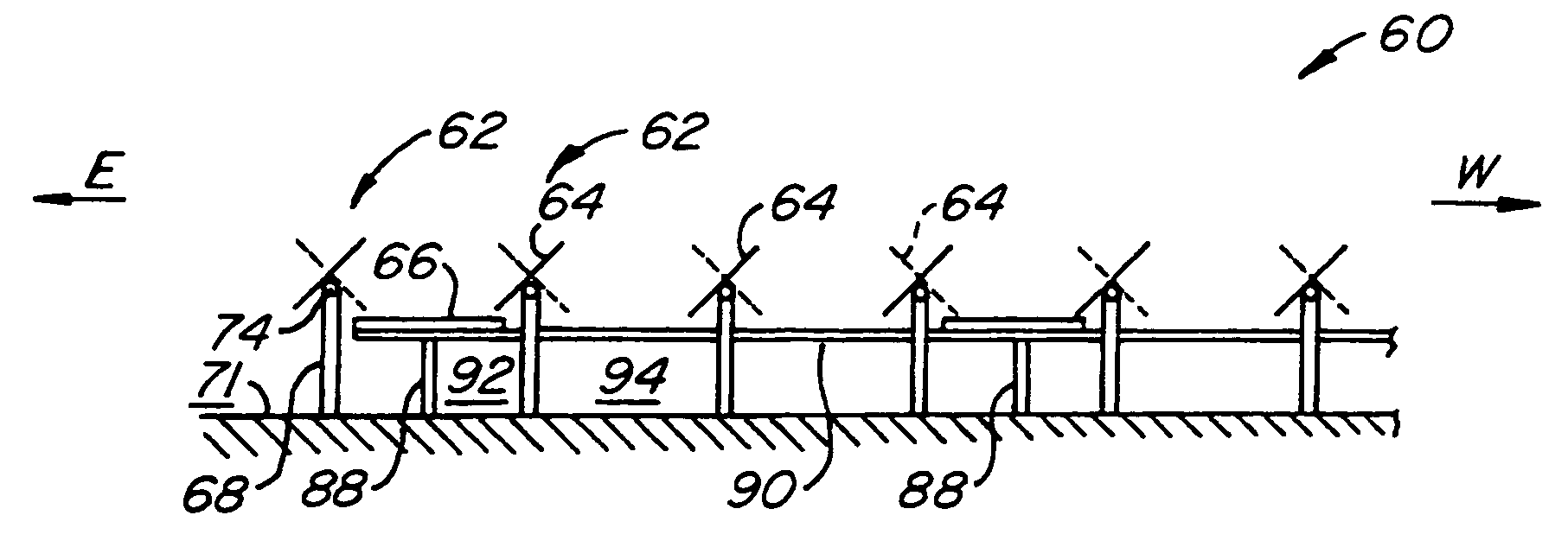

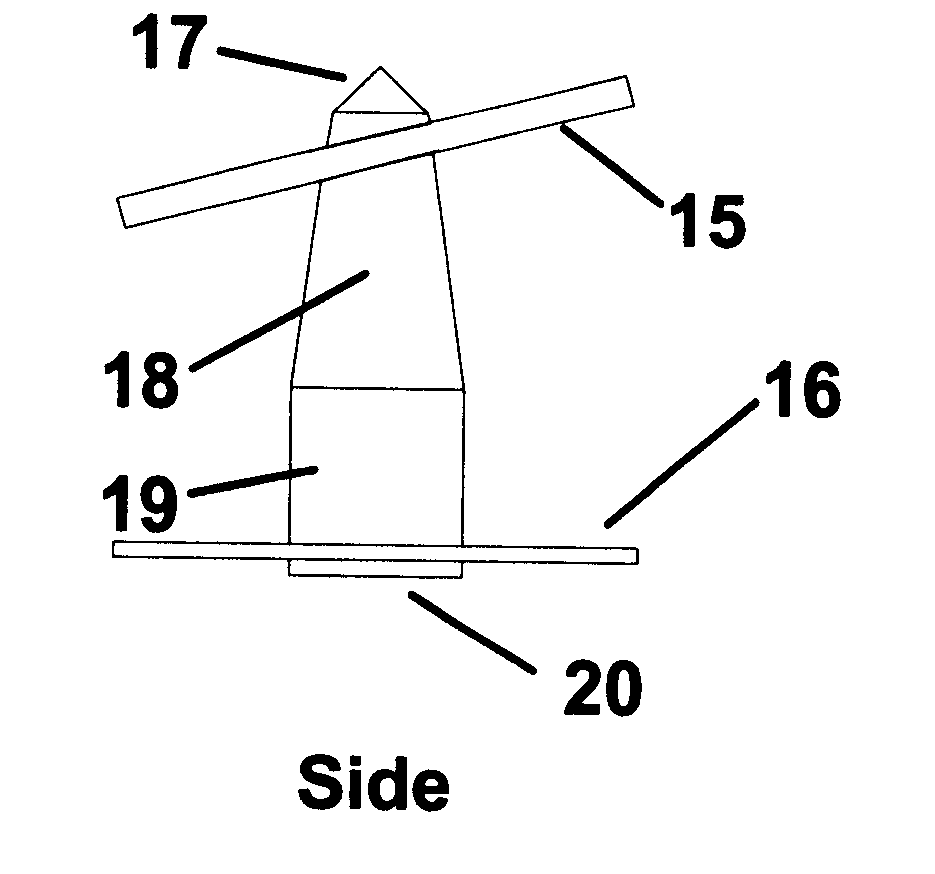

Modular shade system with solar tracking panels

A modular shade system with solar tracking panels includes a series of generally North-South oriented, spaced apart torque tubes, each torque tube having an axis, a series of panels mounted to at least some of the torque tubes to create spaced-apart rows of panels along the torque tubes, at least some of the panels being solar collector panels. The system also includes a shade structure, positioned at a selected location between selected ones of the torque tubes and above the support surface so to provide an enhanced shaded region thereunder, and a support structure. The support structure includes a first mounting assembly mounting each torque tube above the support surface for rotation about the axis of each torque tube and a second mounting assembly supporting the shade structure at the selected location. The system further comprises a tilting assembly selectively rotating each torque tube about its axis.

Owner:TOTALENERGIES ONETECH

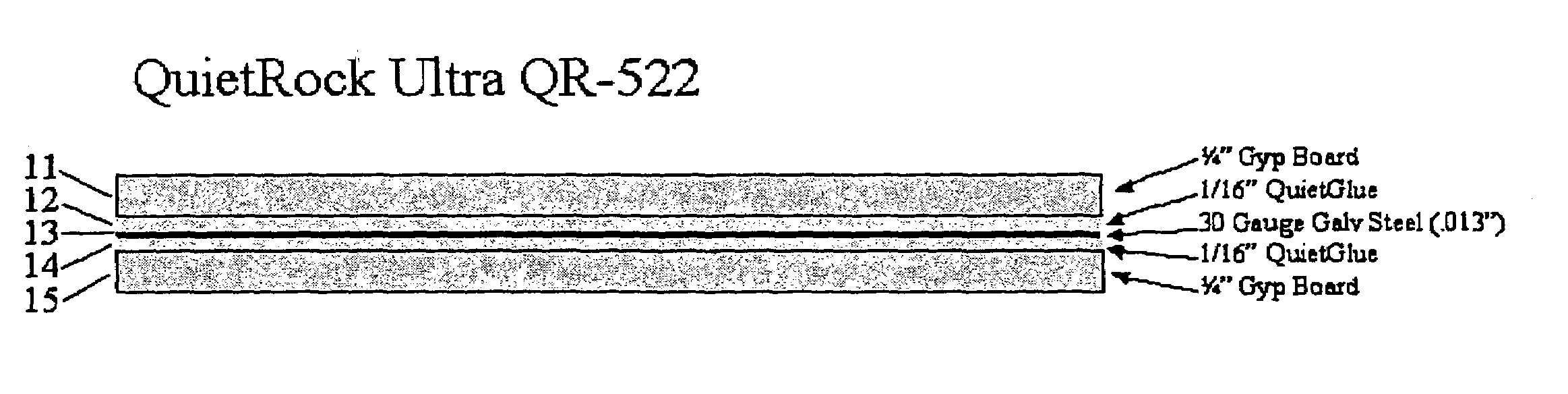

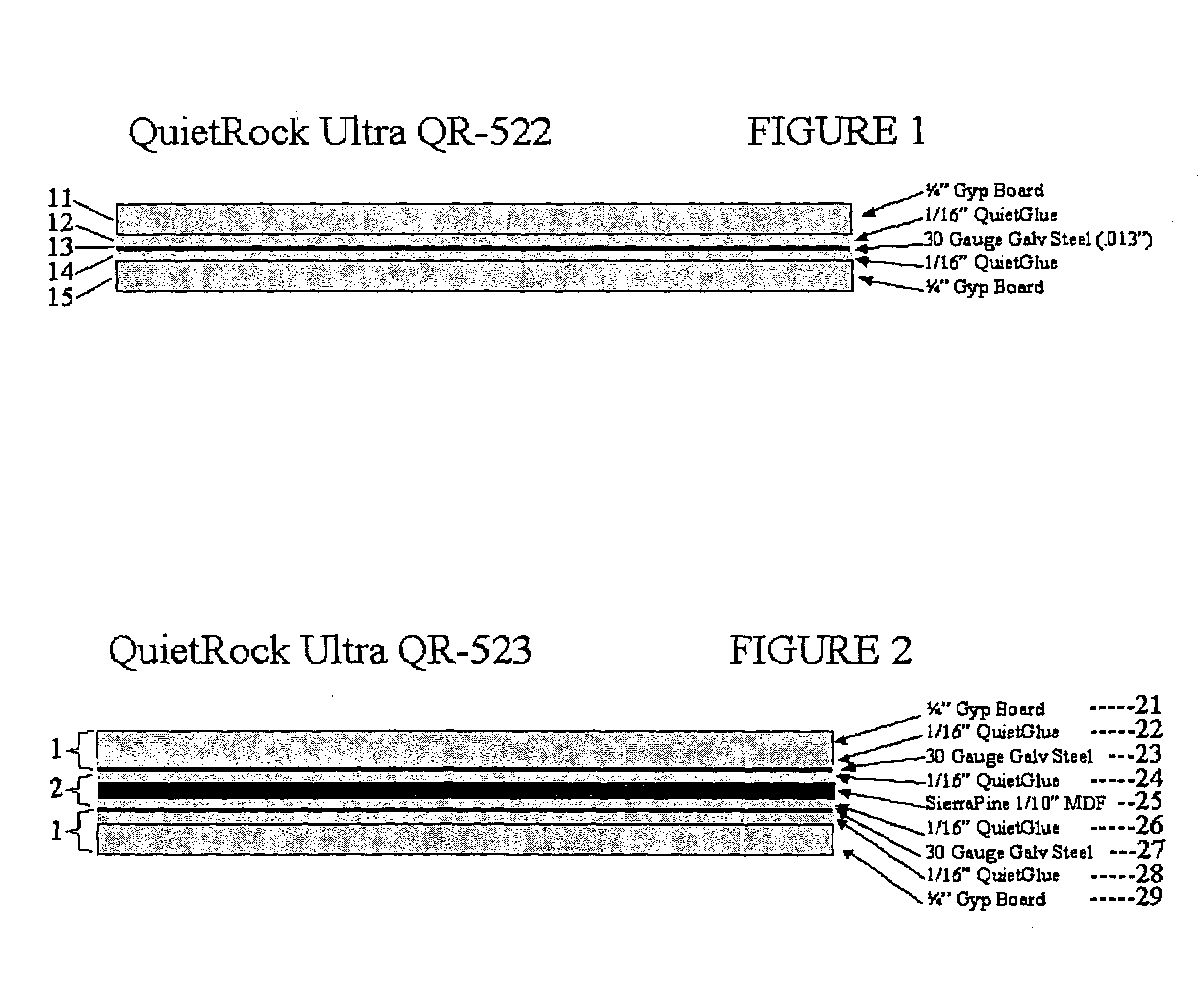

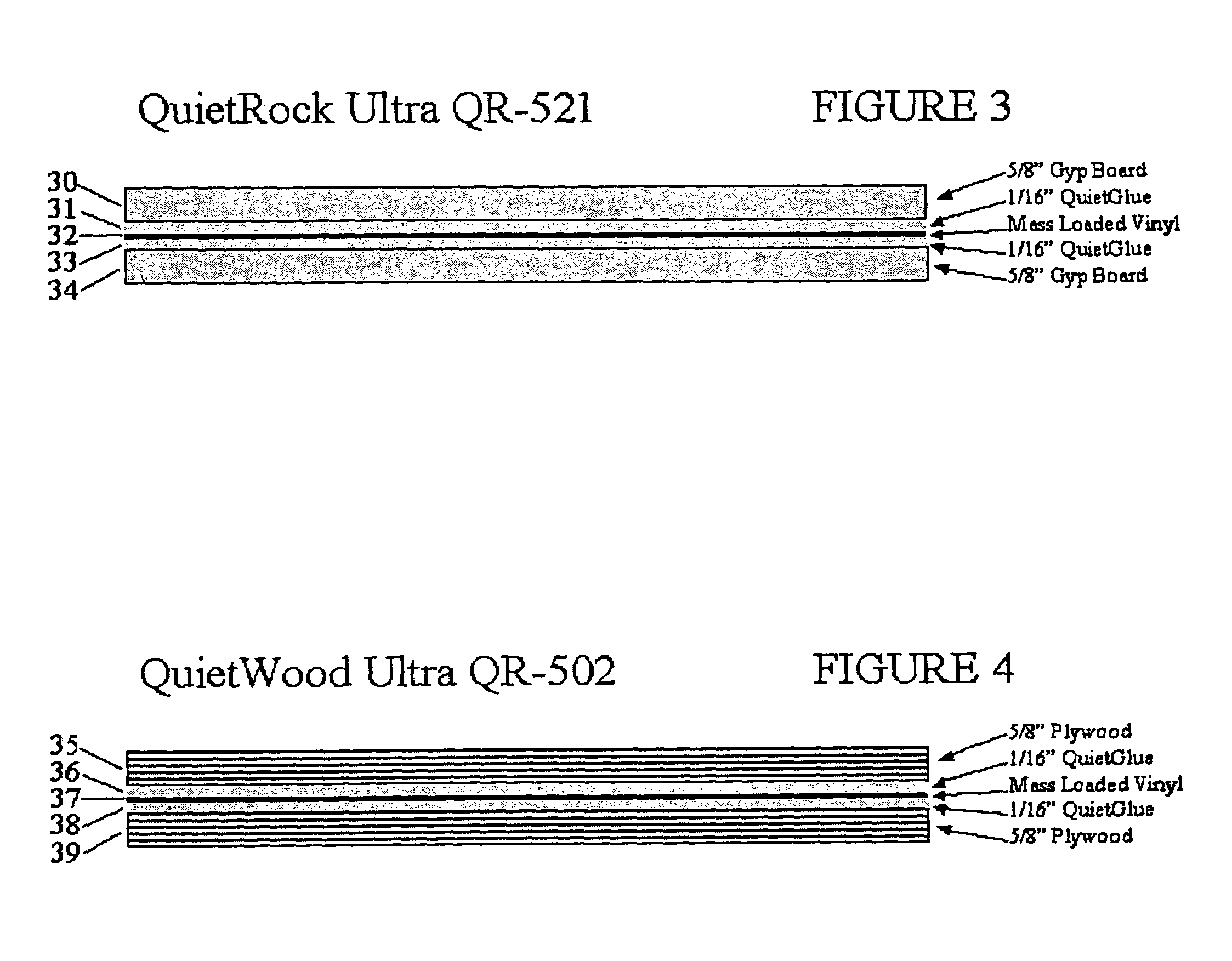

Acoustical sound proofing material and methods for manufacturing same

ActiveUS7181891B2Improve abilitiesReduce sound transmissionBuilding roofsCeilingsUltrasound attenuationCellulose

An improved acoustical damping wall (ceiling or floor) or door material comprises a laminar structure having as an integral part thereof one or more layers of viscoelastic material which also functions as a glue and one or more constraining layers, such as metal, cellulose, wood, or petroleum-based products such as plastic, vinyl, plastic or rubber. In one embodiment, standard wallboard, typically gypsum, comprises the external surfaces of the laminar structure; and one or more constraining layers are fabricated between the gypsum exterior. The resulting structure improves the attenuation of sound transmitted through the structure.

Owner:PACIFIC COAST BUILDING PRODS

Top plate

InactiveUS6430881B1Easy to manufactureEasy to installBuilding roofsStrutsMechanical engineeringEngineering

Owner:MITEK HLDG INC

Foldable member

InactiveUS6374565B1Weight increaseDimensional instabilityBuilding roofsCosmonautic vehiclesMechanical engineeringEngineering

Owner:FOSTER-MILLER

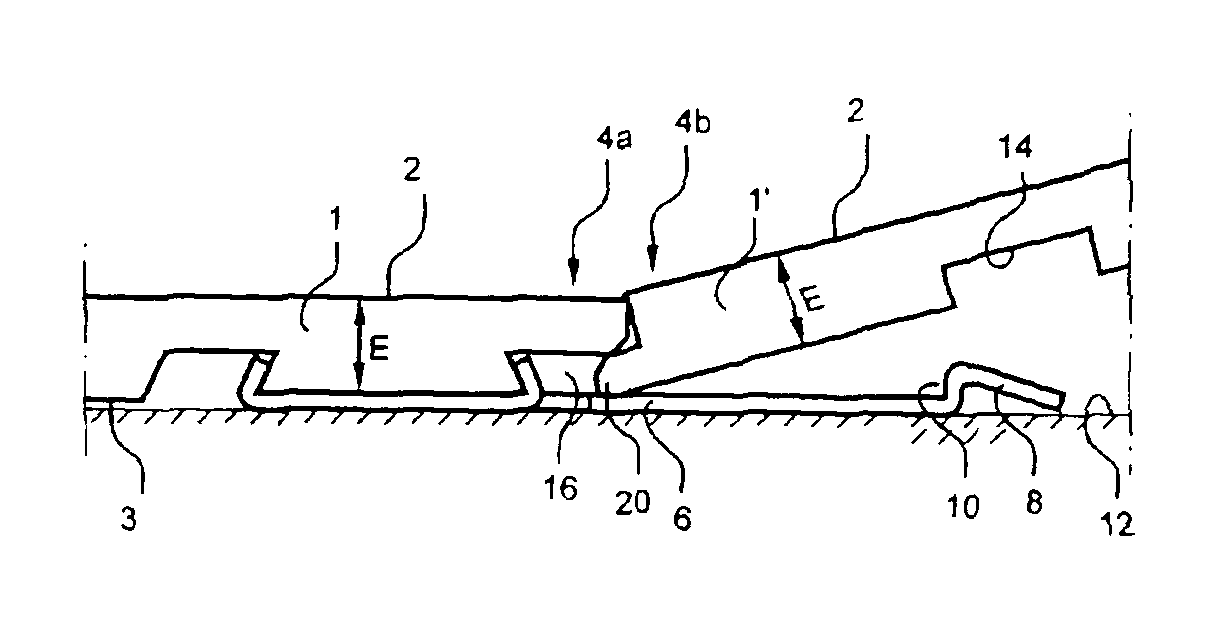

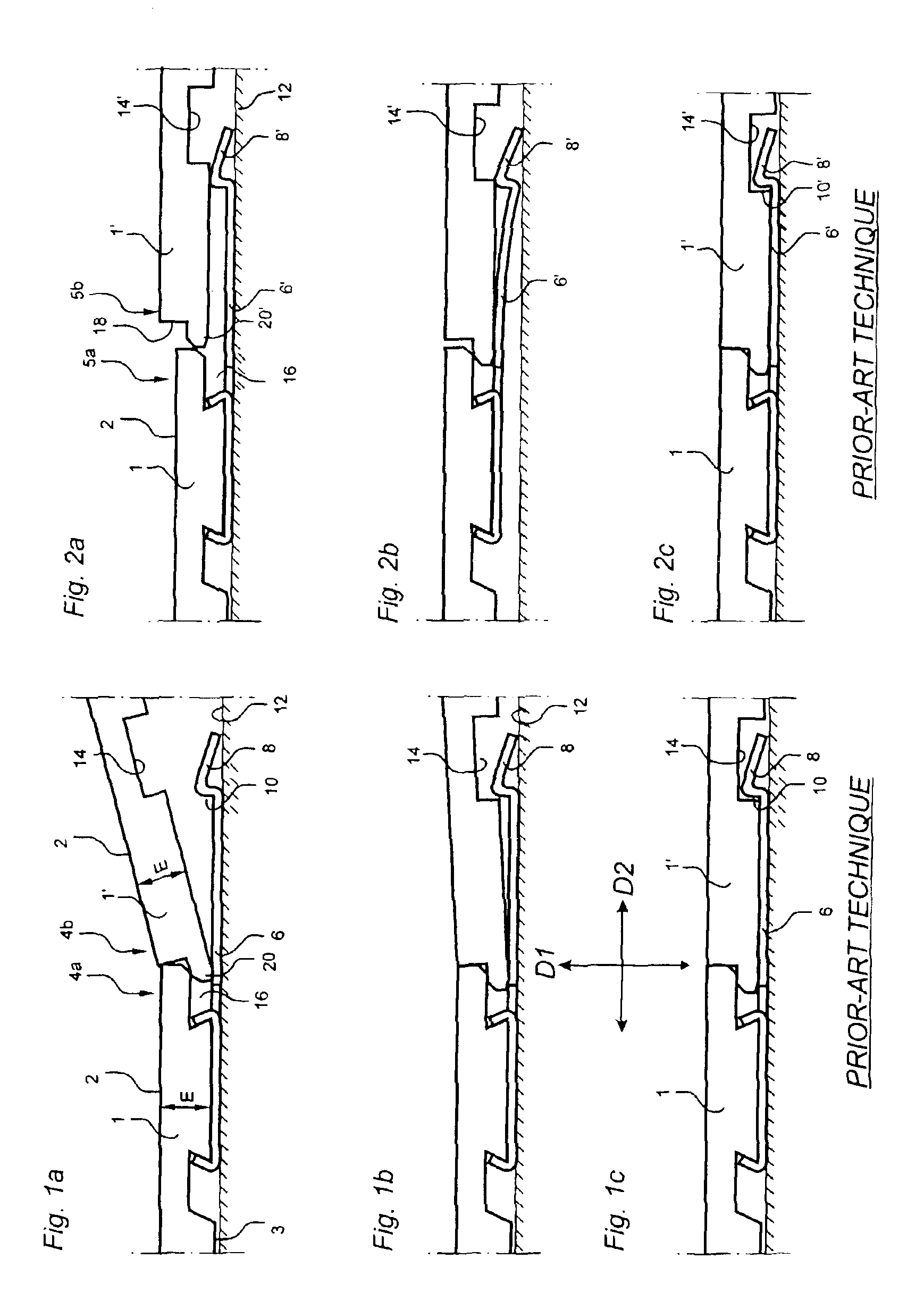

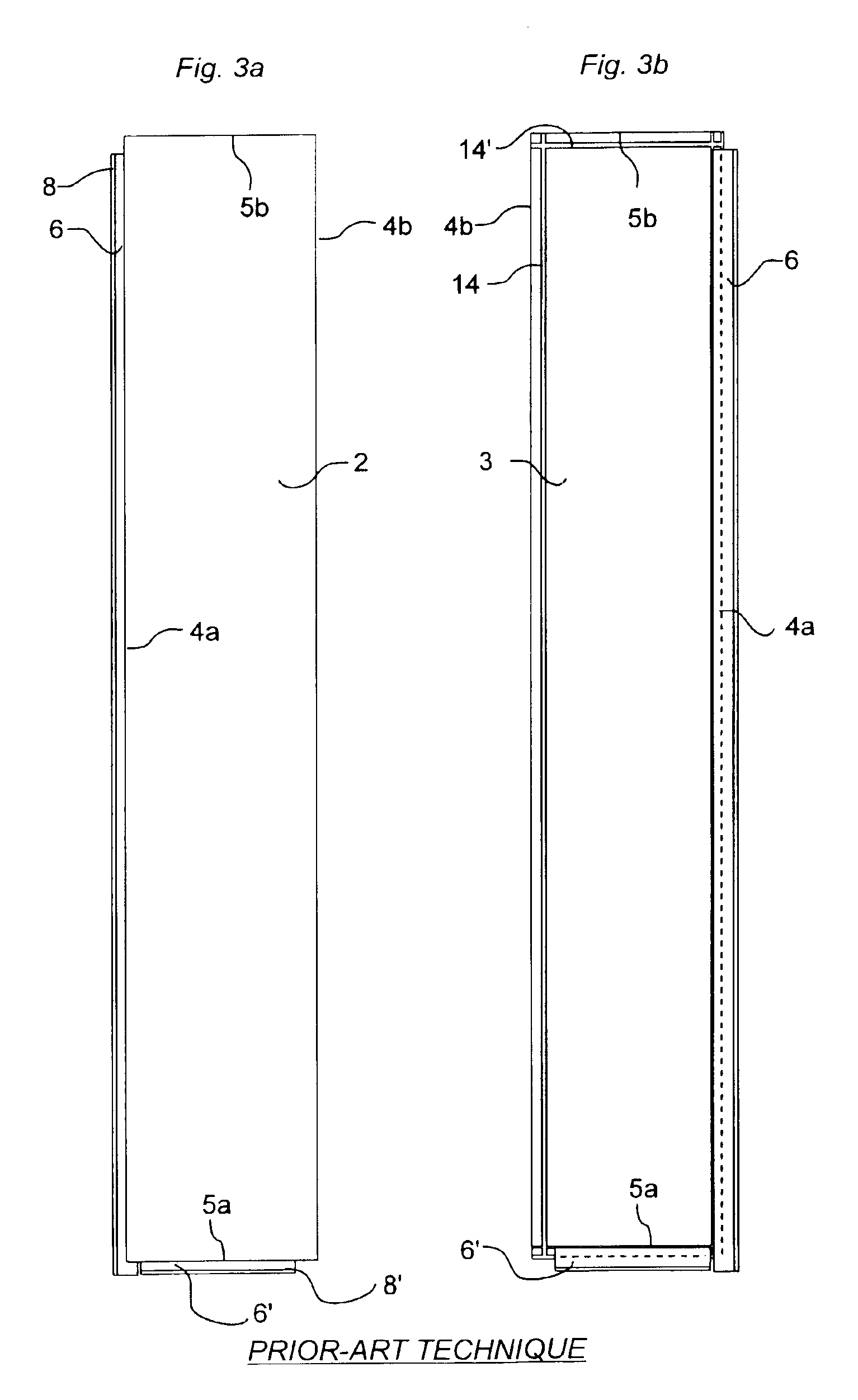

Locking system and flooring board

A floorboard system includes a plurality of floorboards, wherein each of the floorboards is a rectangular floorboard provided with long edges and short edges and having a floorboard body provided with an integrated long edge locking system and an integrated short edge locking system for mechanical joining, both vertically and horizontally, the floorboards, along the long edges thereof and along the short edges thereof. The long edge locking system differs from the short edge locking system in respect of at least one of material composition and material properties. And, at least one of the long edge locking system and the short edge locking system includes a separate element which is integrally connected with the floorboard body at the factory and is made of a material other than that included in the floorboard body.

Owner:VALINGE ALUMINUM AB

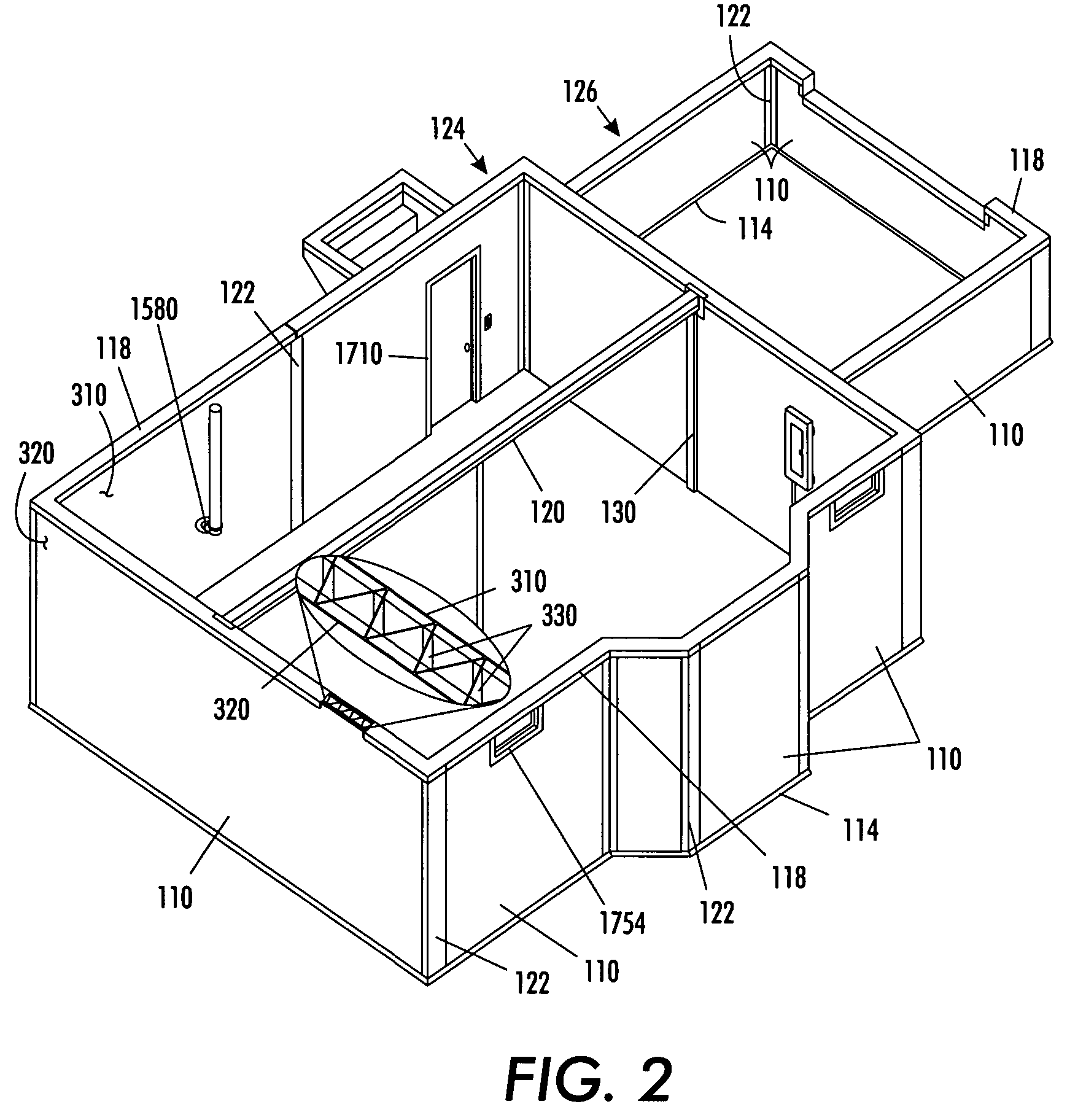

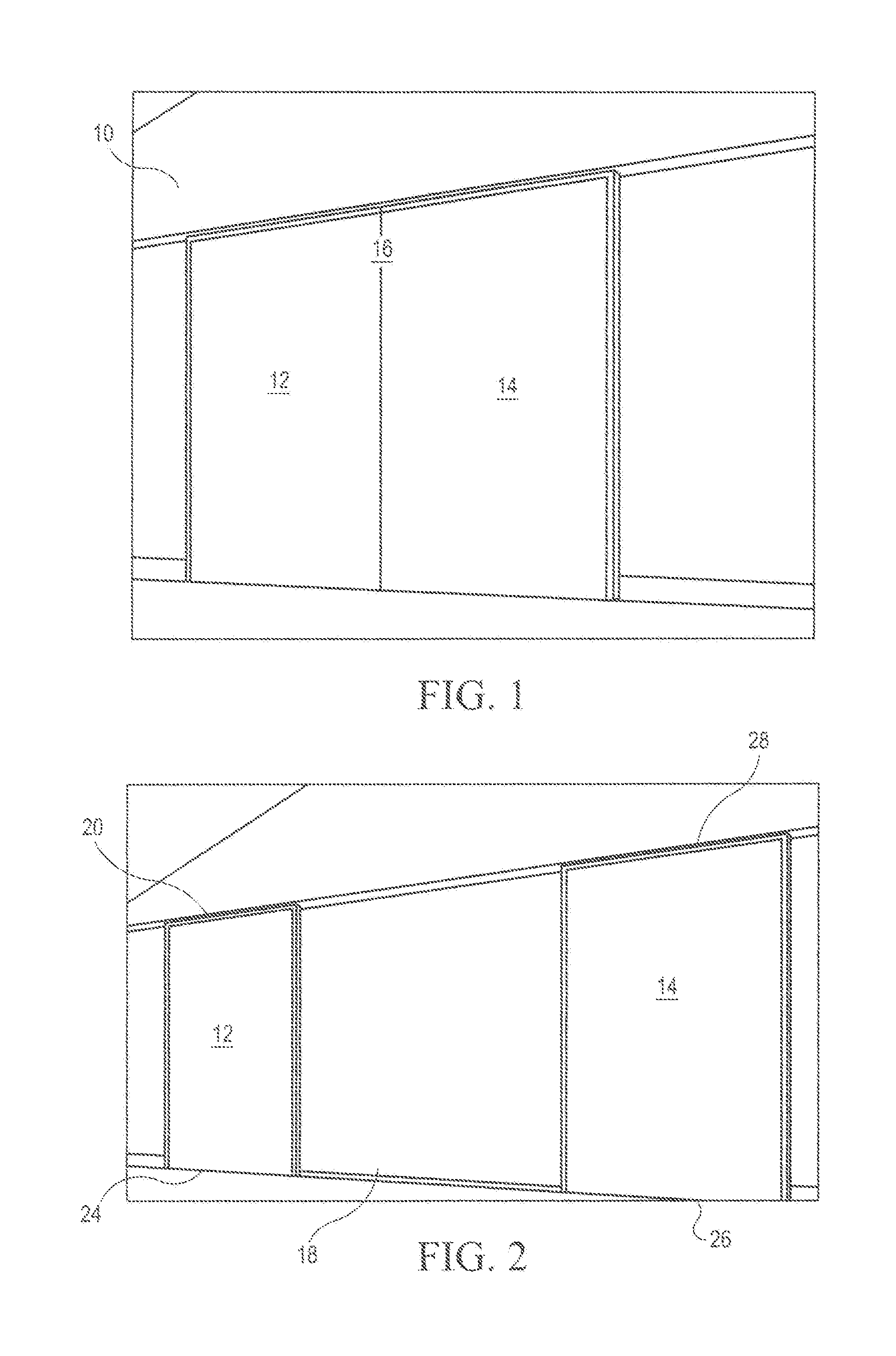

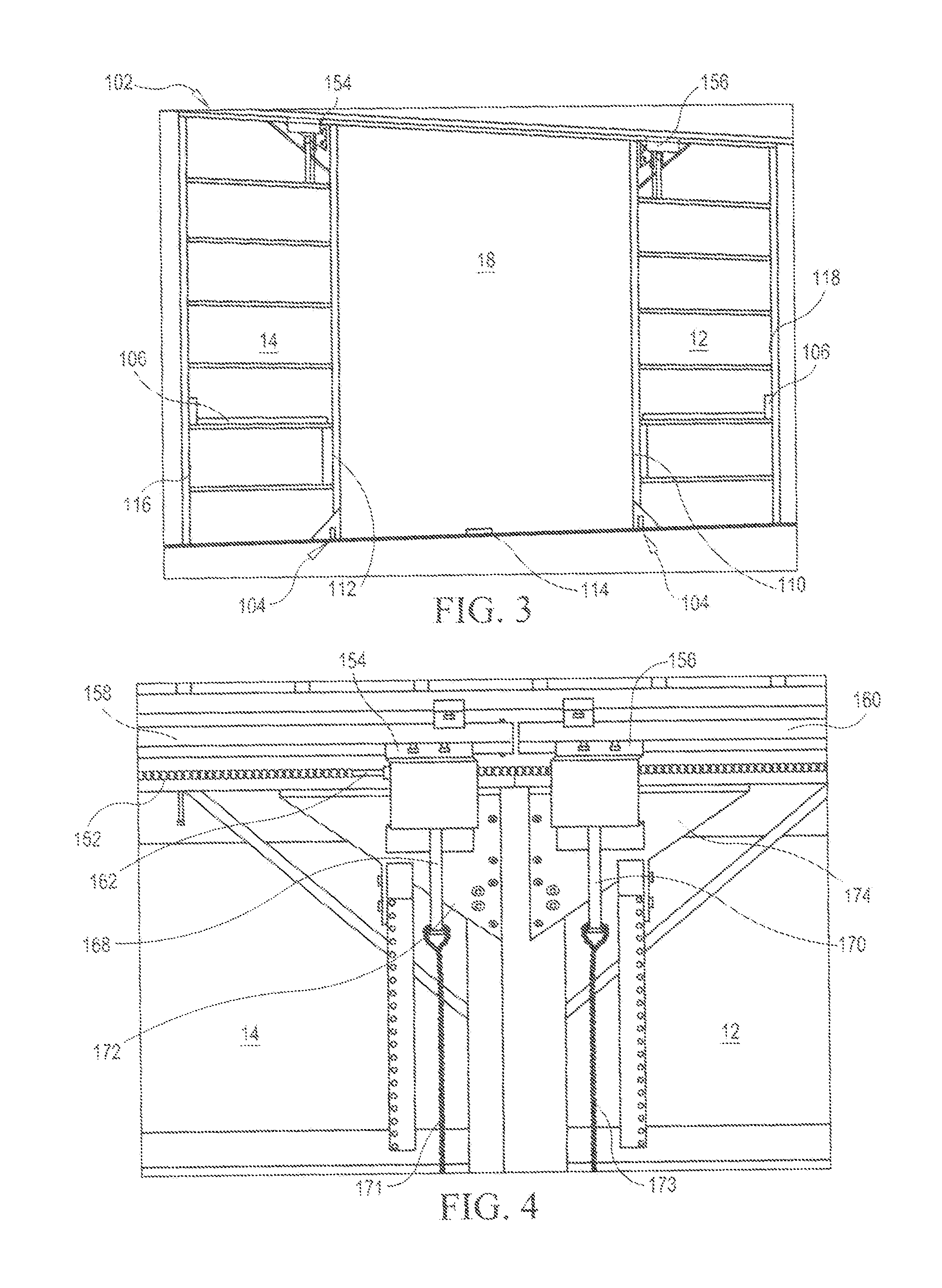

Automatic sliding door systems, apparatus and methods

The present invention relates to sliding door systems, apparatus and methods of using and making the same. Specifically, the present invention relates to systems for opening horizontally sliding doors on a structure, such as, for example, a barn, warehouse, hangar, or other building or structure. Moreover, the present invention relates to apparatuses for providing the automatic opening of sliding doors. In addition, methods of making and using the same are provided.

Owner:PROPEL DOORS

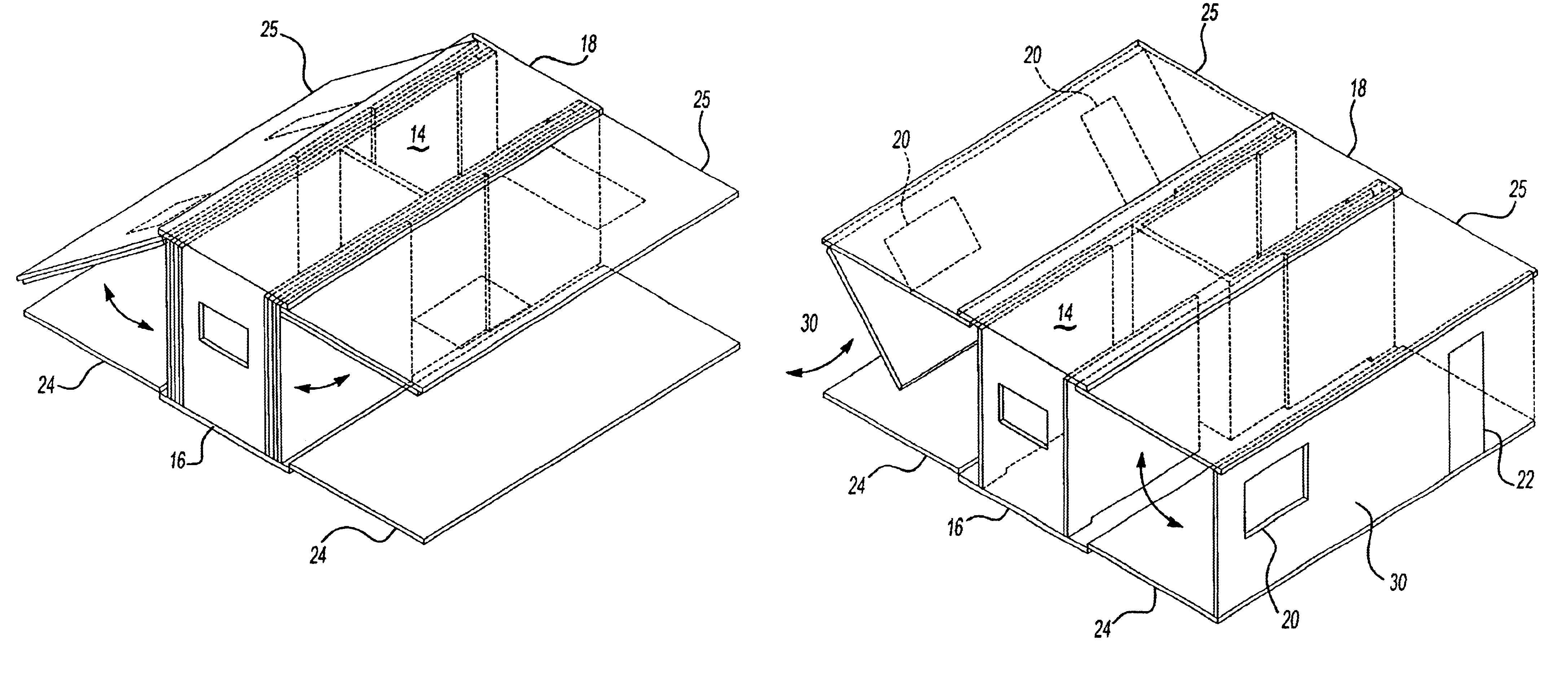

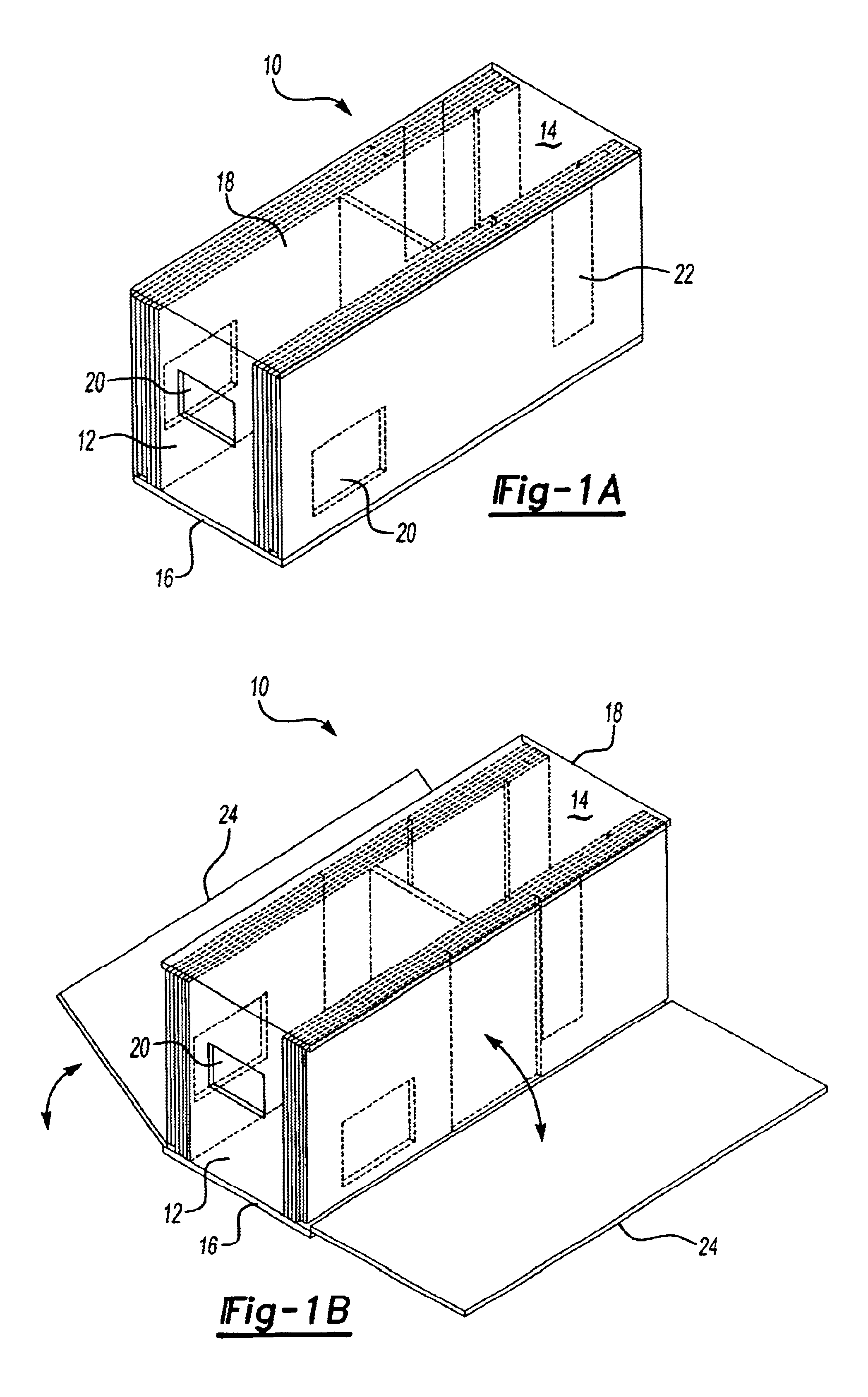

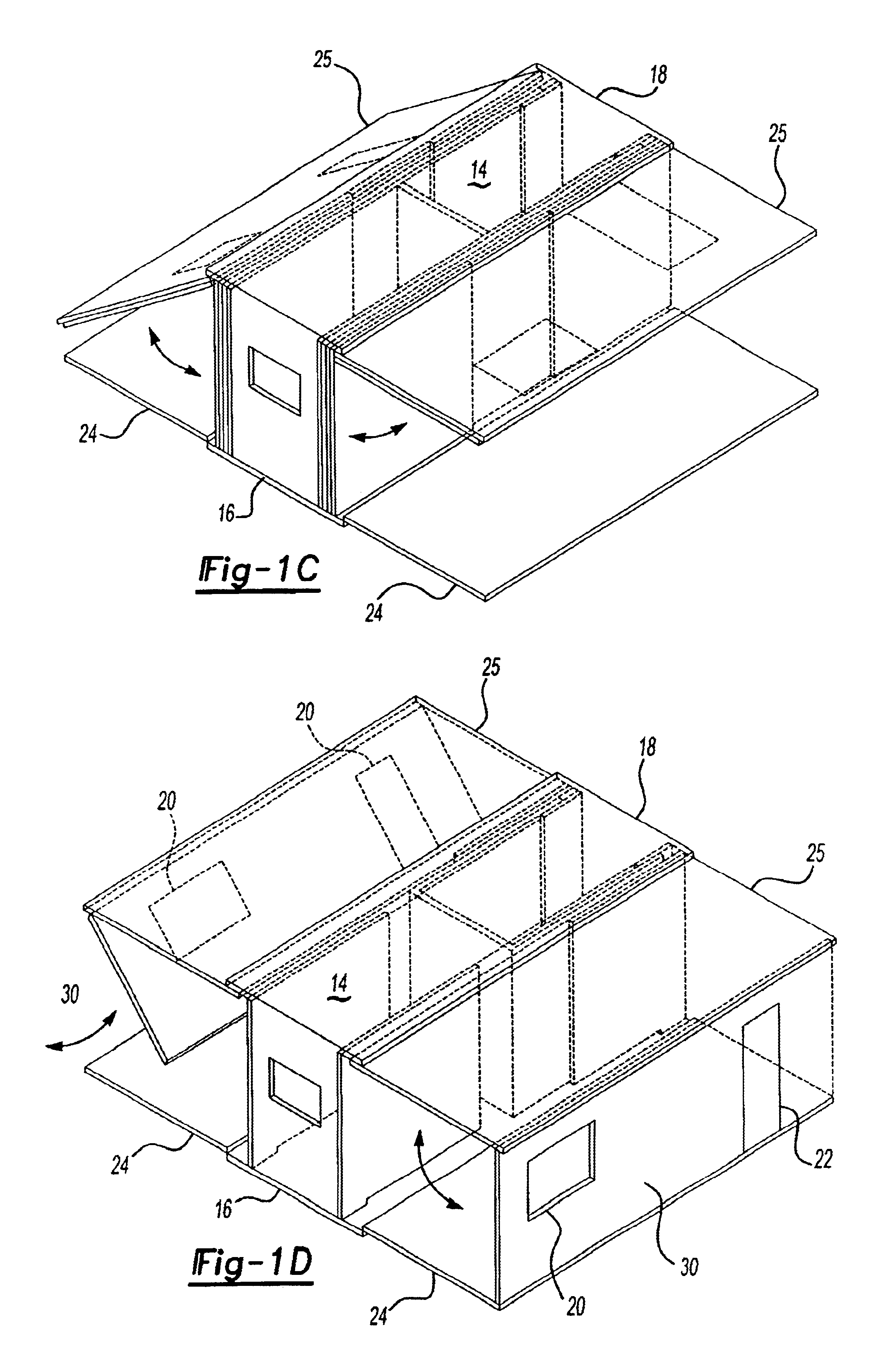

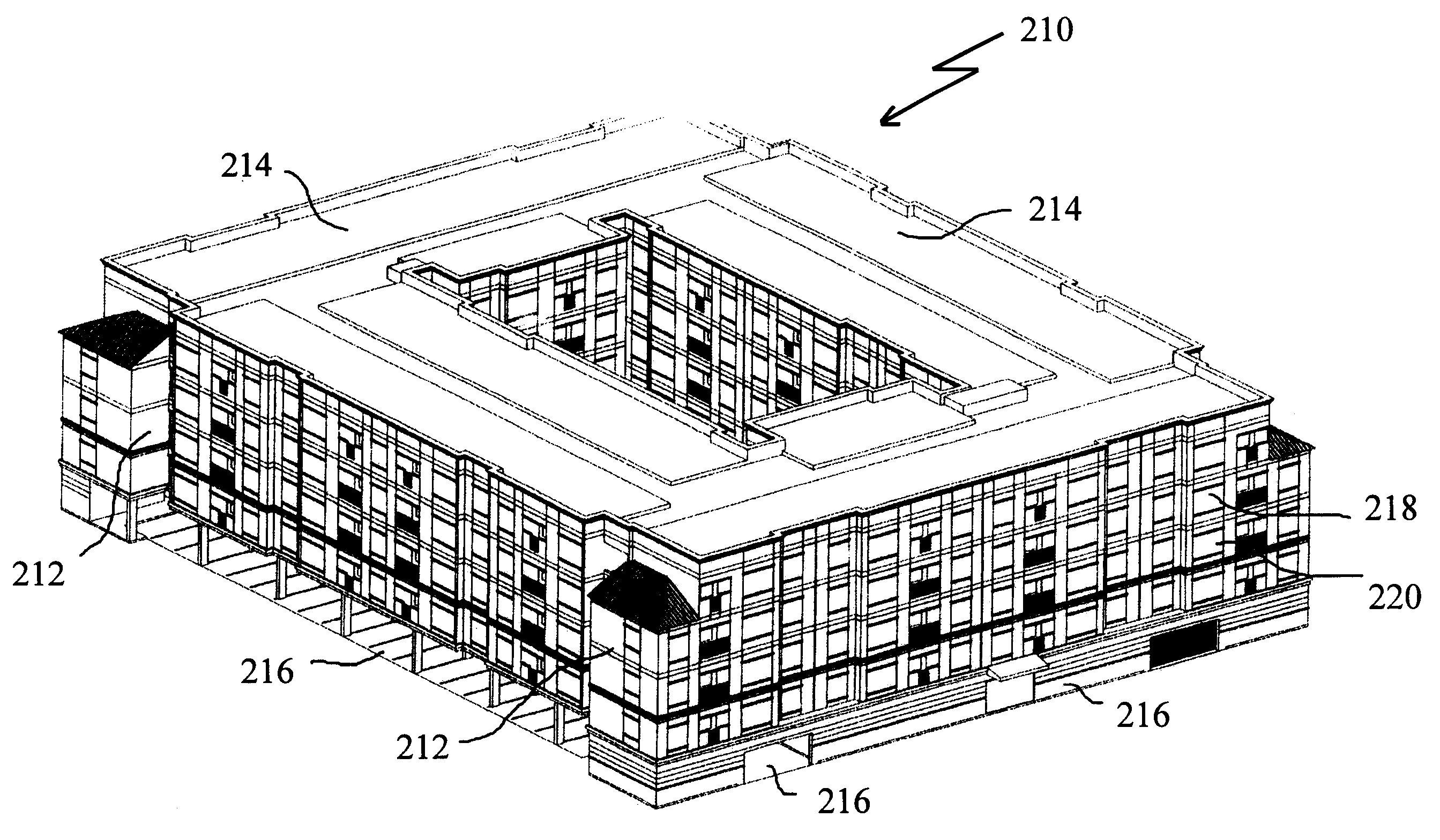

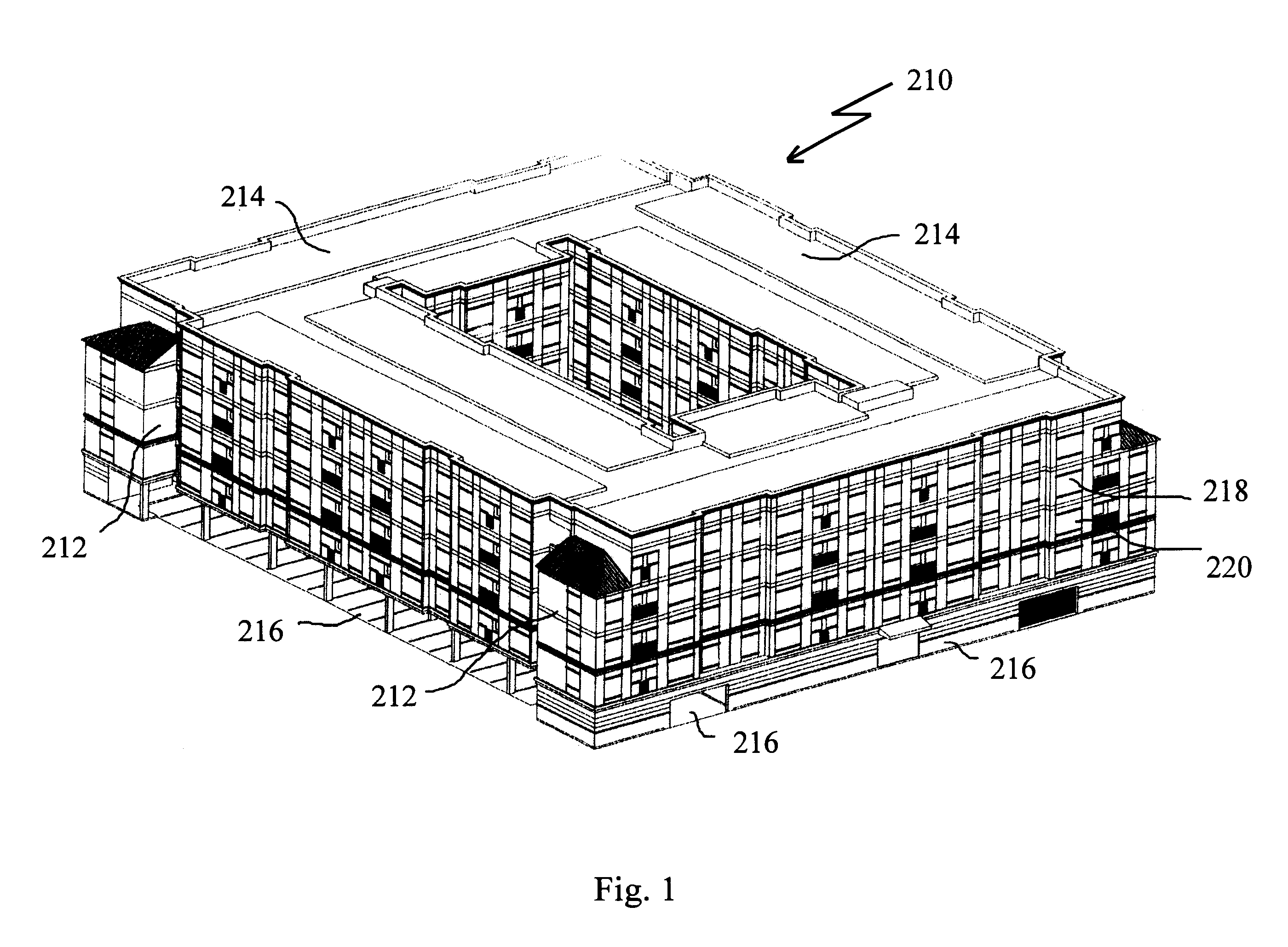

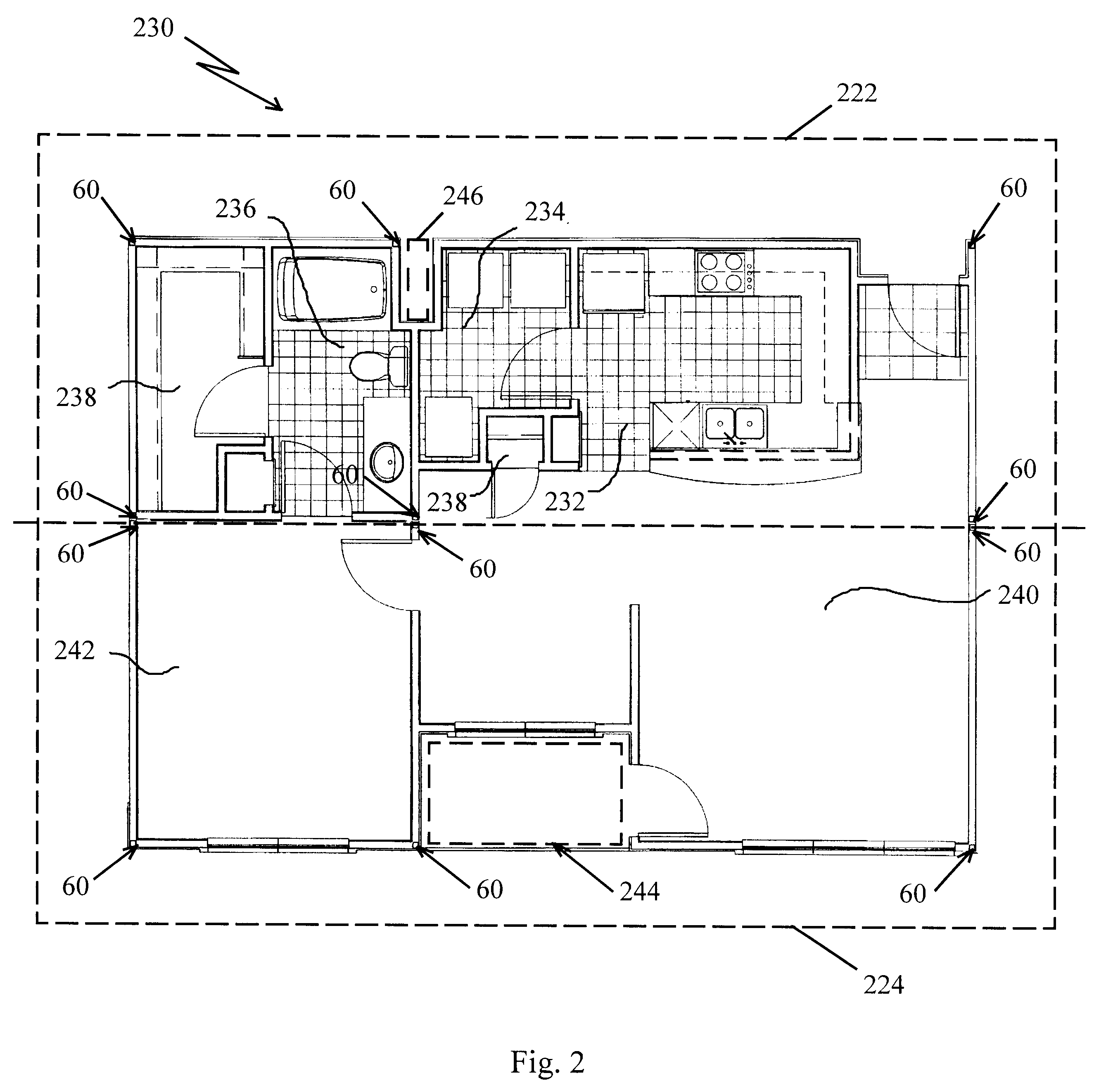

Construction system for manufactured housing units

Owner:LORWOOD PROPERTIES

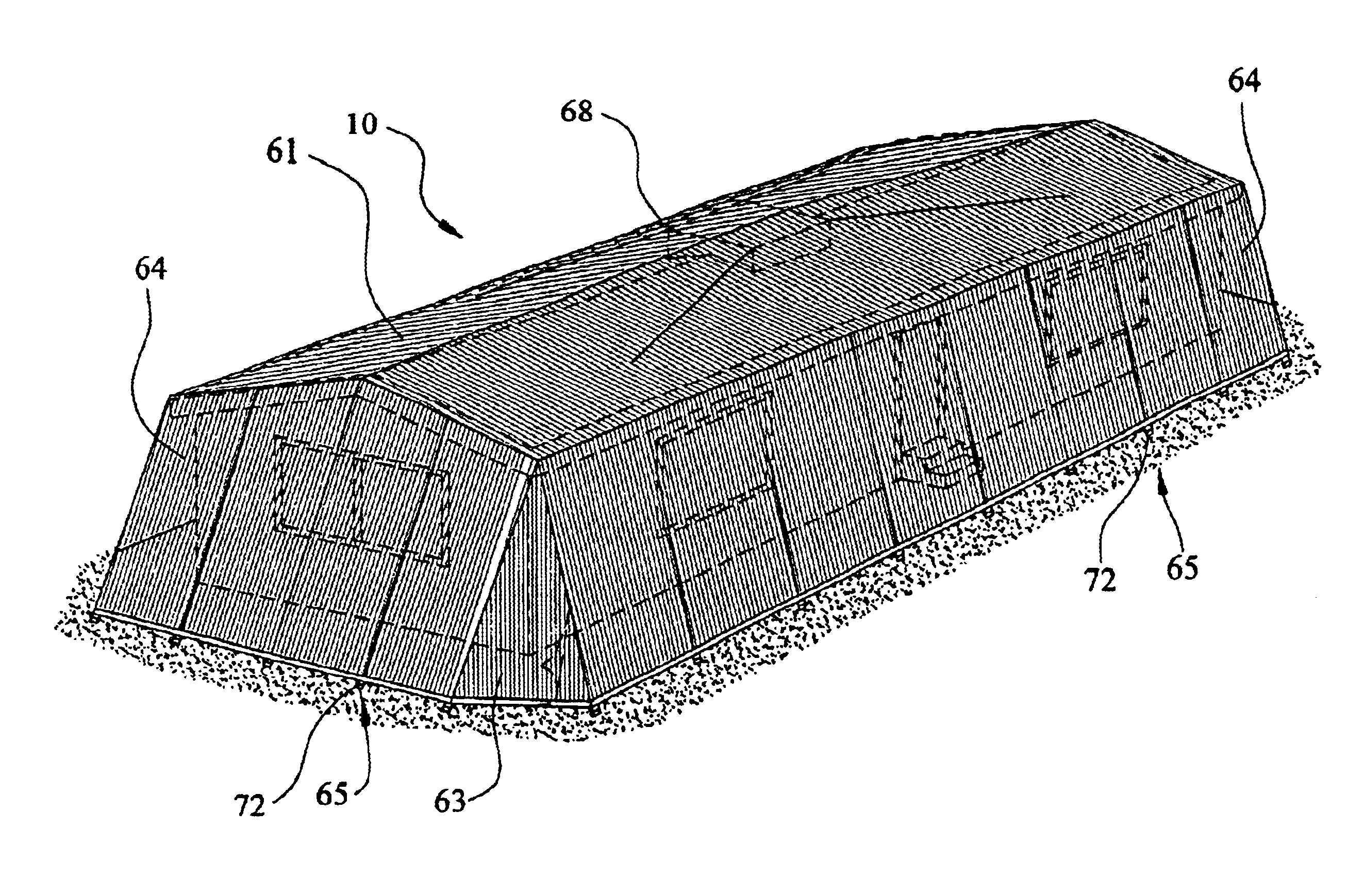

Flexible wind abatement system

A device for protection of property against high winds comprising a flexible material of predetermined strength and stretch characteristics, and in the form of a panel or several panels, utilized to protect the side of a structure including its windows and doors from the strong winds and debris impacts occurring during a hurricane. The device is anchored in a manner to space it out from the area being protected according to formula provided, and can safely dissipate substantial impacting energy. The preferred embodiment attaches to an overhanging eave and the ground below protecting in addition to the windows and doors, plantings, outdoor furniture, decorative shutters, downspouts, and such as are enclosed behind the barrier. Several methods of storage and deployment of said curtain are described including rolling, sliding, and converting to awning. The barrier has the added feature of acting as a tie down in certain applications.

Owner:ARMOR SCREEN

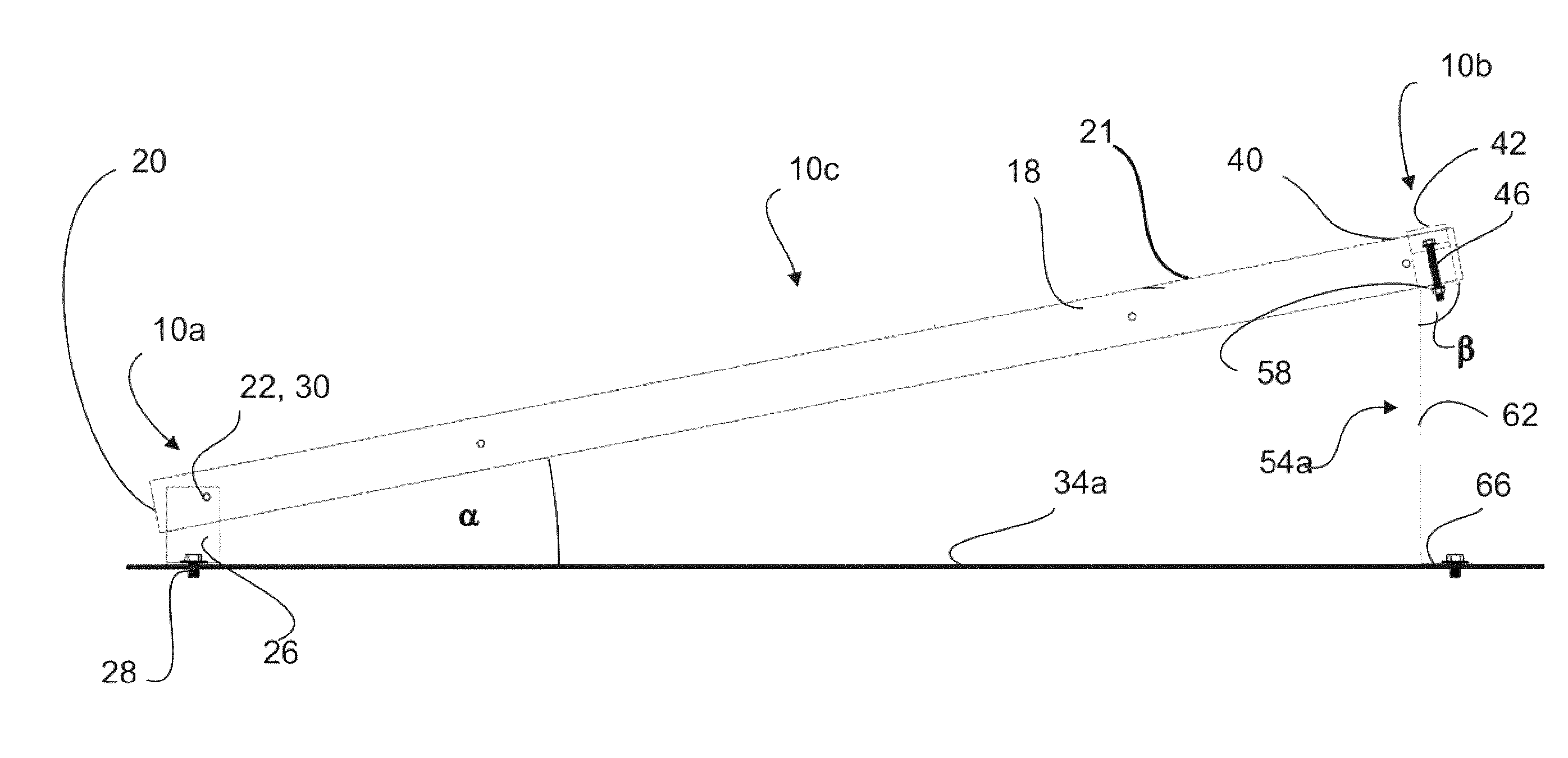

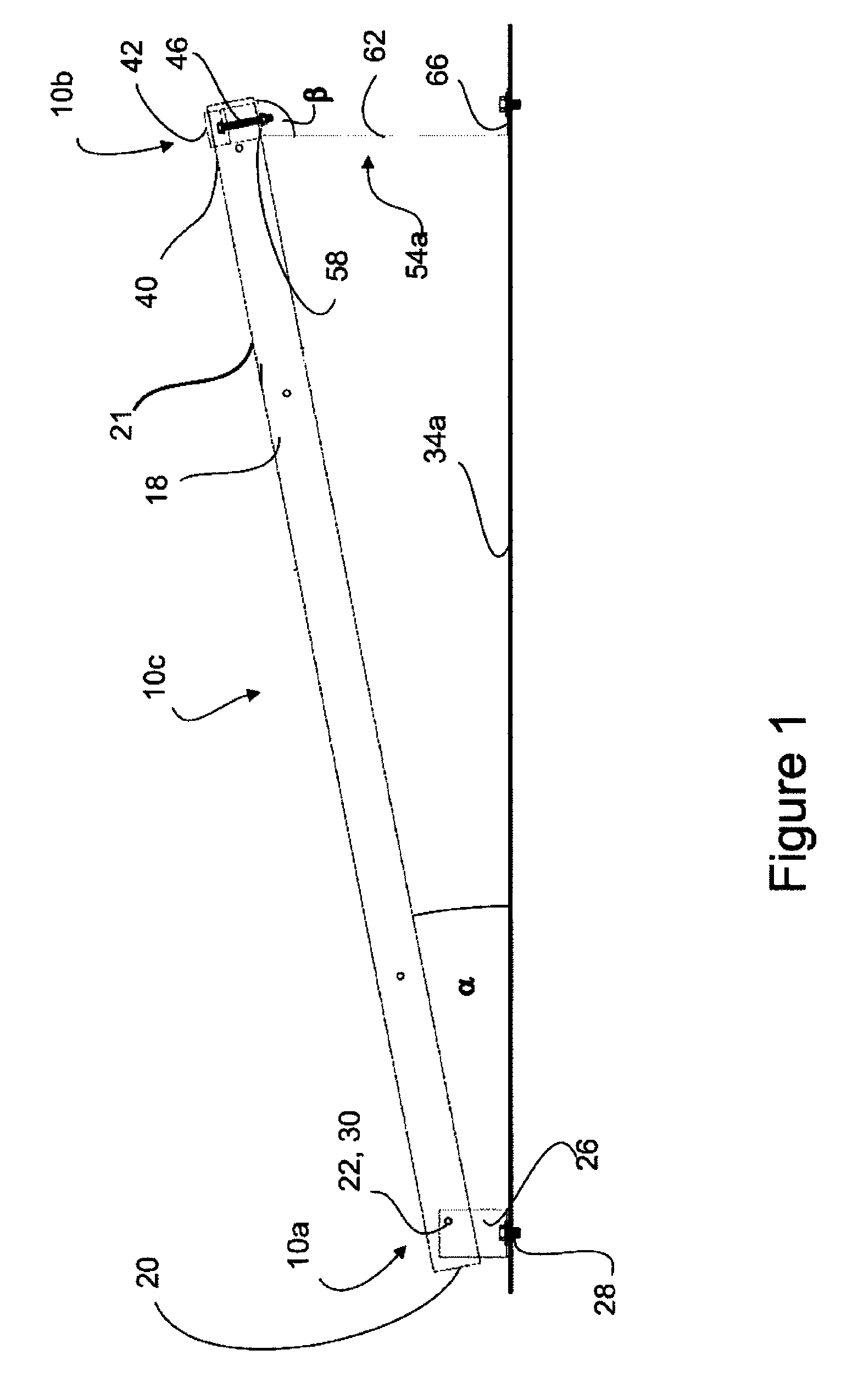

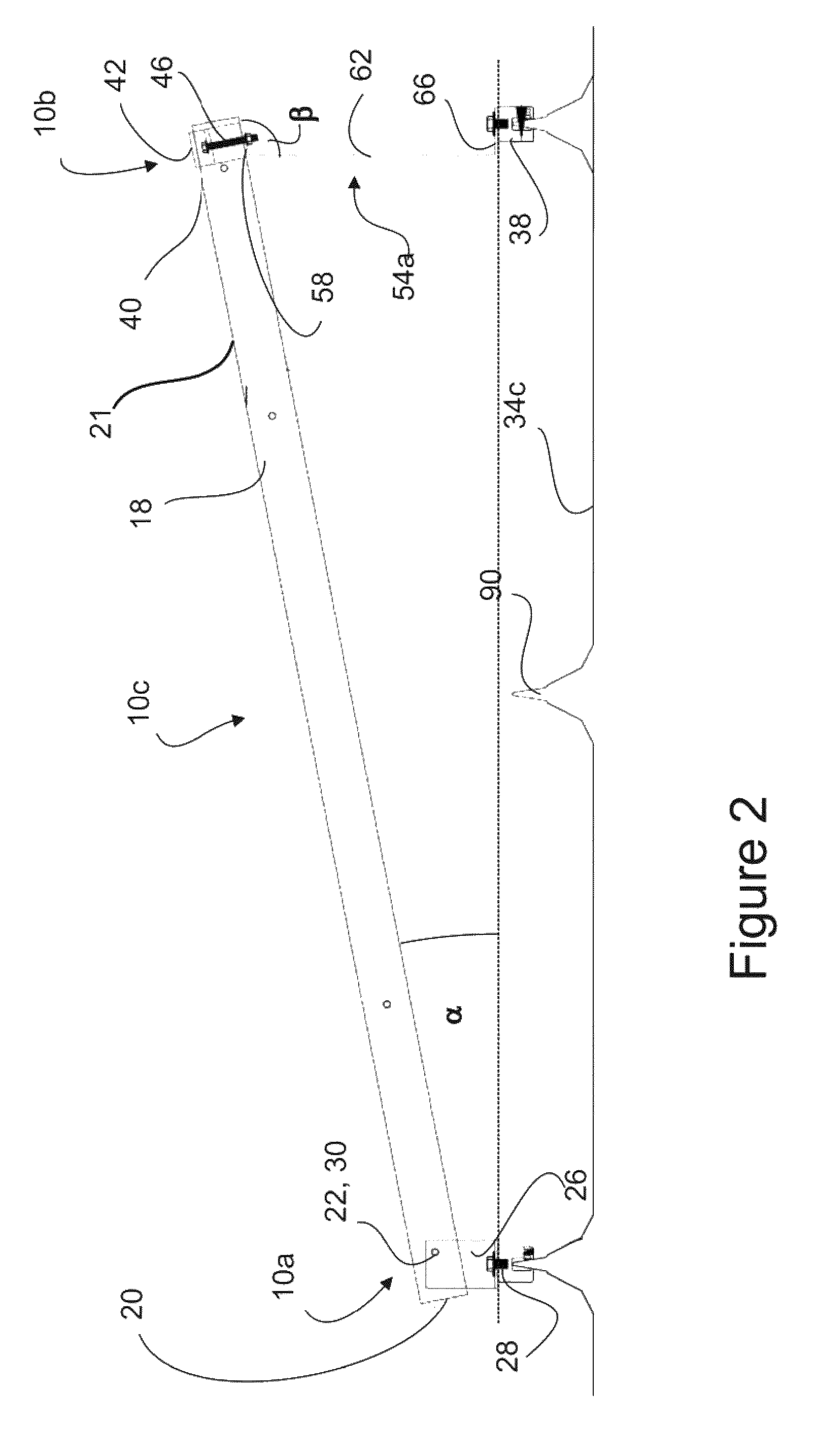

Solar panel mounting systems

ActiveUS7814899B1Minimize the numberEasy to installPhotovoltaic supportsSolar heating energySolar energy harvestingSurface plate

Owner:SOLARSTRAP TECH LLC

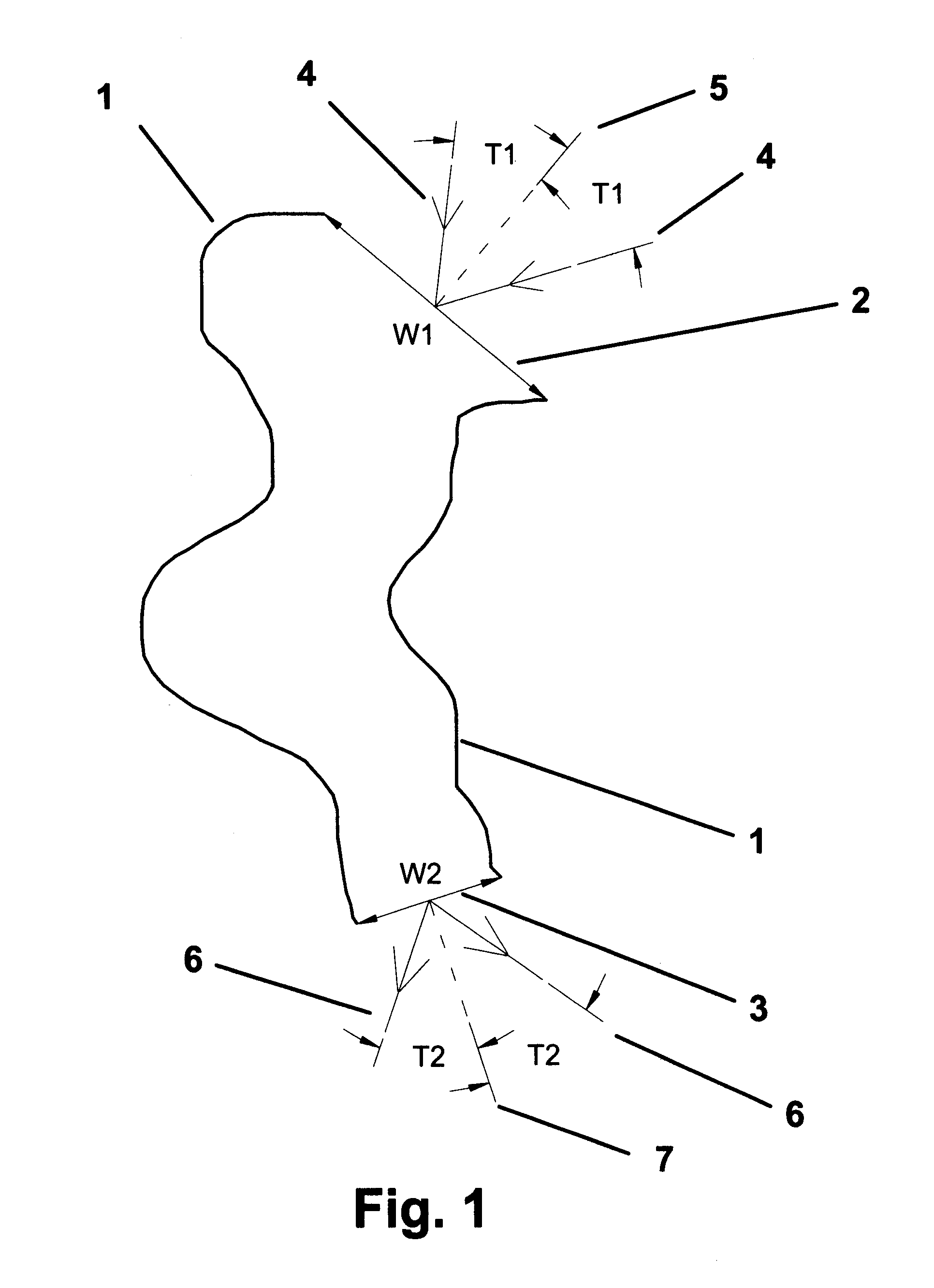

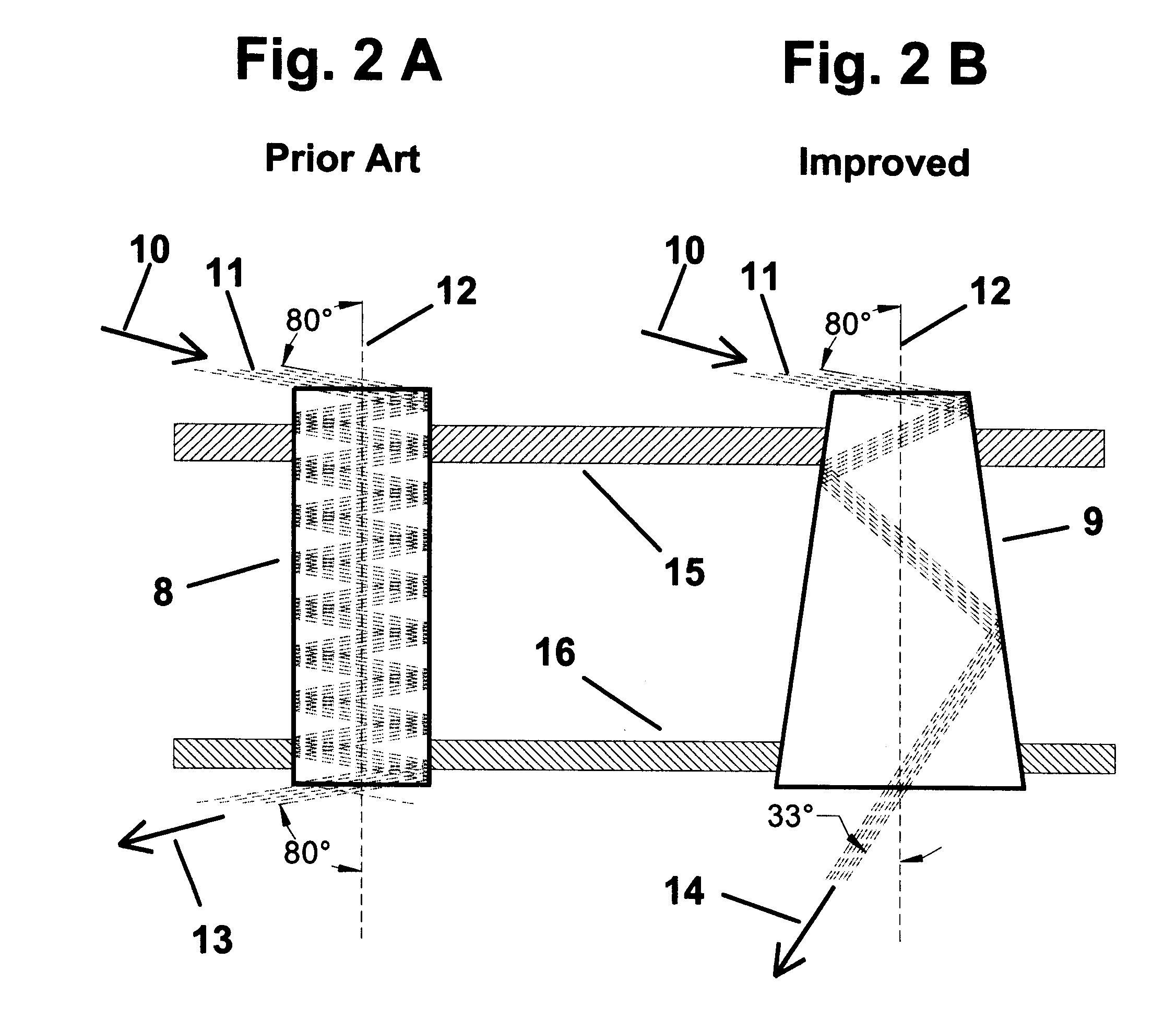

Passive collimating tubular skylight

InactiveUS6363667B2Convenient lightingImproved passive tubular skylightsBuilding roofsCeilingsEngineeringSpecular reflection

A passive collimating tubular skylight consisting of a radiant energy-collecting aperture, a radiant energy-delivering aperture, and a radiant energy passageway between these two apertures, the passageway having a specularly reflective interior surface and a configuration to improve the collimation of the radiant energy passing therethrough. The skylight can be configured with the radiant energy-collecting aperture located above the roof of a building, oriented to collect sunlight; and equipped with a sealed weatherproof glazing, with the radiant energy-delivering aperture, or luminaire, located at ceiling level within the building, and equipped with a diffusing glazing; and with the reflective tubular light passageway constructed with a larger cross sectional area near the radiant energy-delivering aperture than near the radiant energy-collecting aperture. In complete accord with the second law of thermodynamics, and as proven by experimental results, the new passive collimating tubular skylight provides significant advantages over the prior art, including better solar energy collection, higher throughput optical efficiency, improved radiant energy collimation, enhanced interior illumination levels, and more precise positional control of the interior illumination.

Owner:ENTECH INC

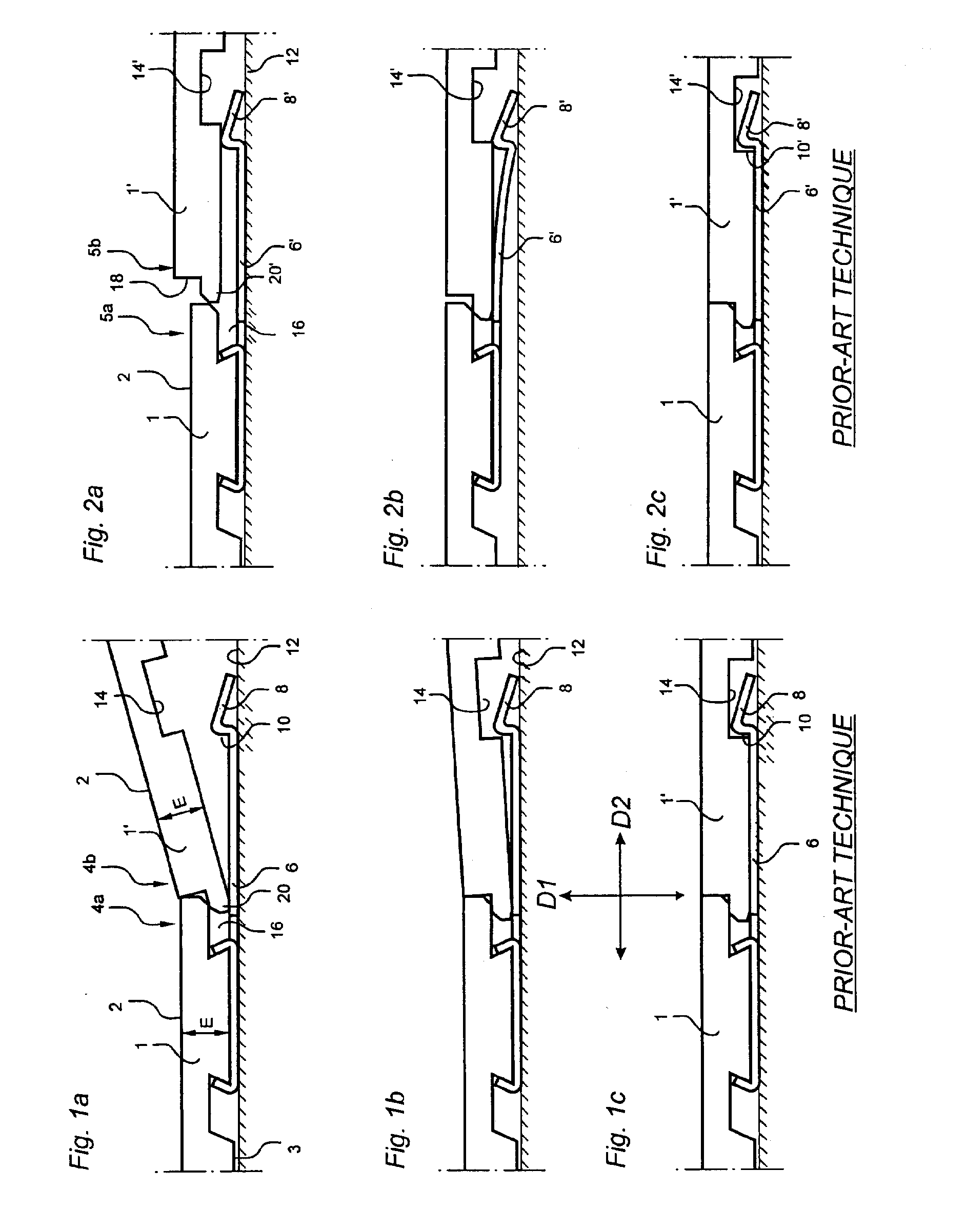

Locking System And Flooring Board

InactiveUS20050102937A1Good orientationReduce frictionBuilding roofsStrutsEngineeringMechanical engineering

A locking system for mechanical joining of floorboards has a locking groove which is formed in the underside of and extends in parallel with the first joint edge at a distance from the joint plane, and a portion projecting from the lower part of the second joint edge and below the first joint edge and integrated with a body of the board. The projecting portion supporting at a distance from the joint plane a locking element cooperating with the locking groove and thus positioned entirely outside the joint plane seen from the side of the second joint edge, the projecting portion having a different composition of materials compared with the body of the board. The projecting portion presents at least two horizontally juxtaposed parts, which differ from each other at least in respect of the parameters material composition and material properties.

Owner:VÄLINGE INNOVATION AB

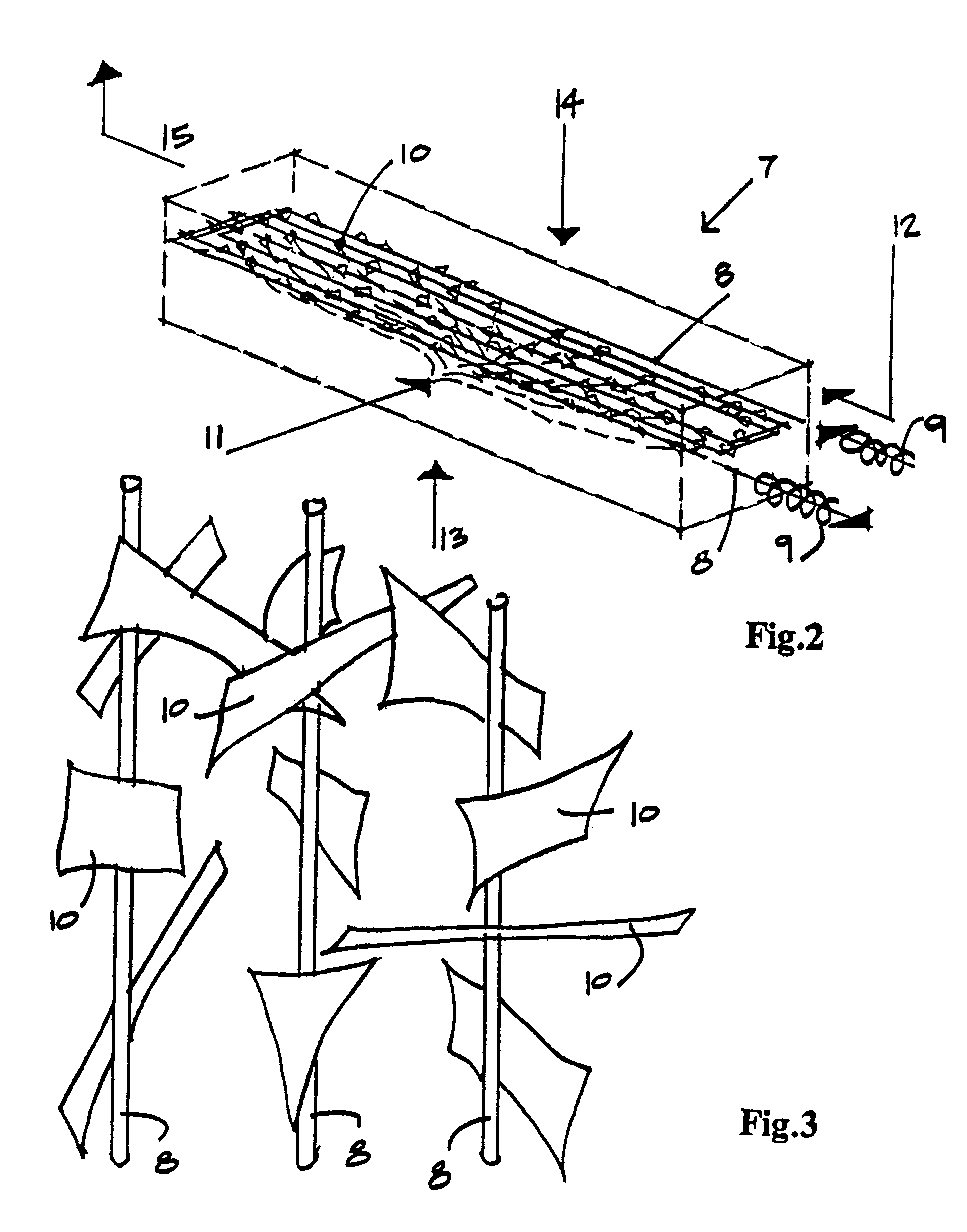

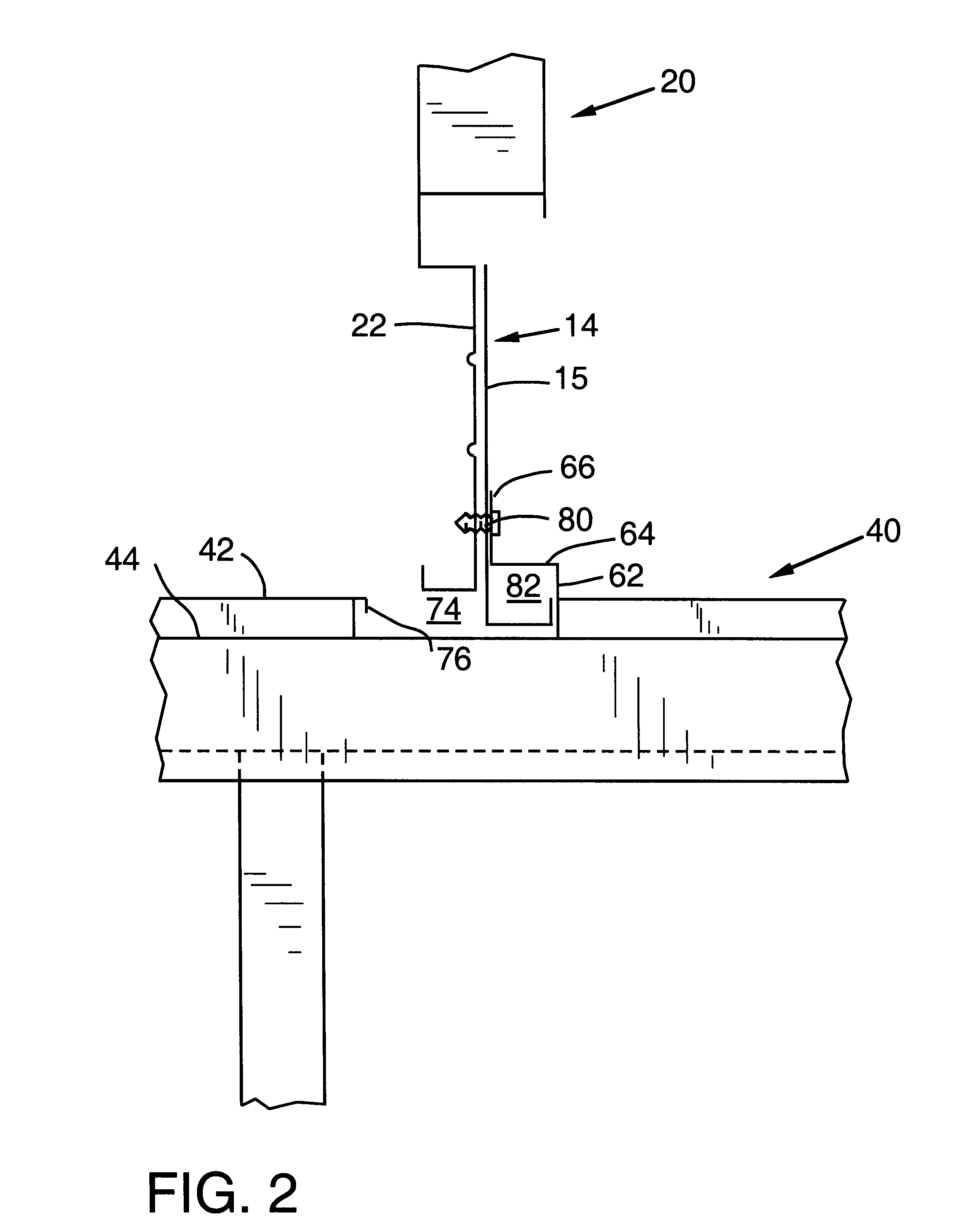

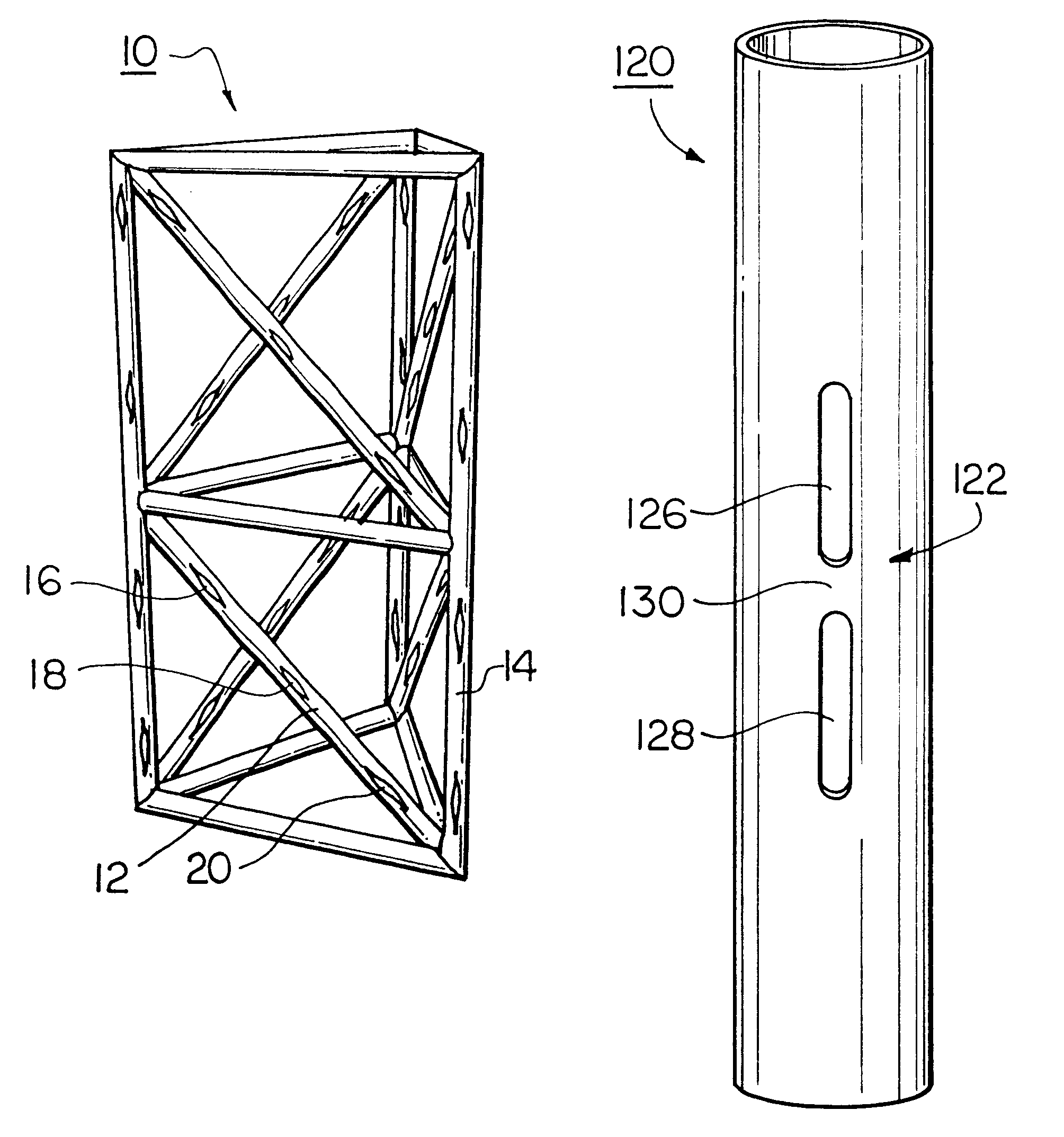

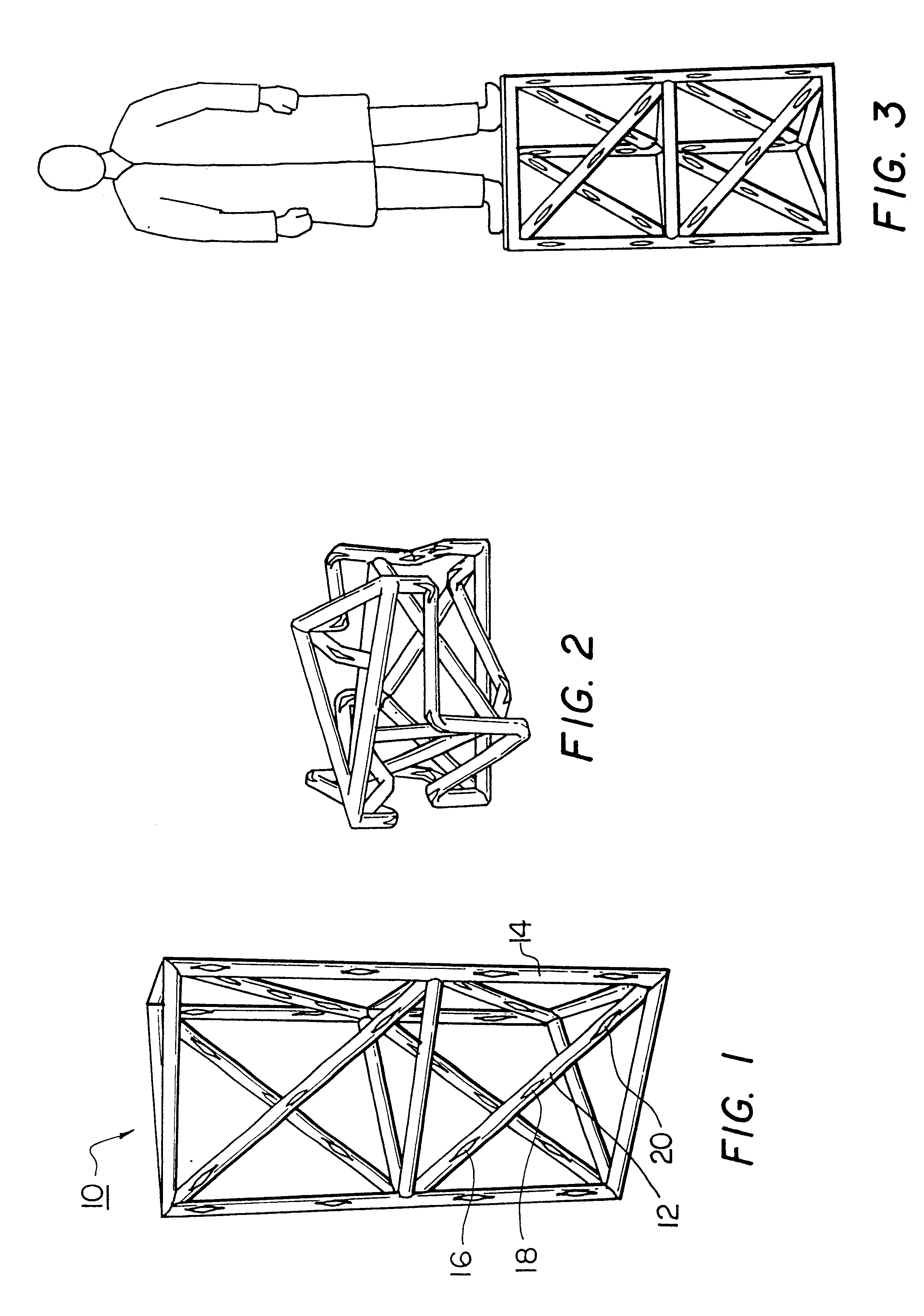

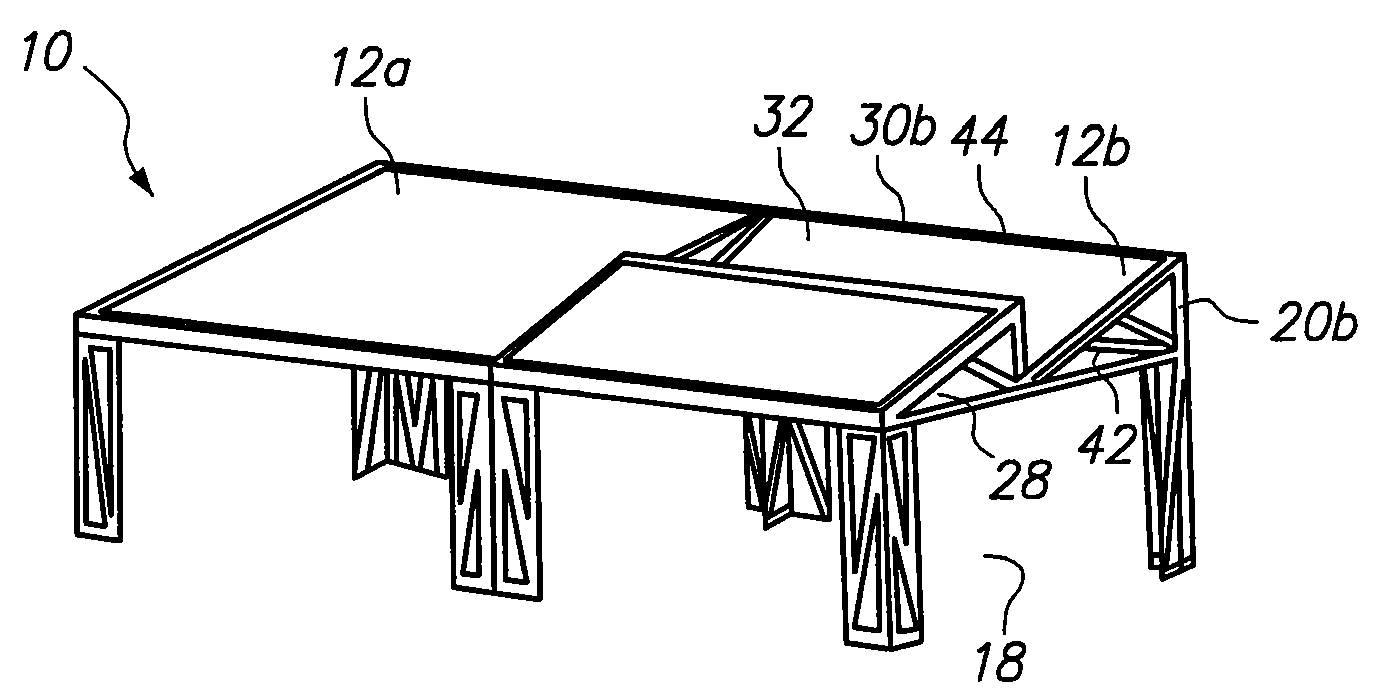

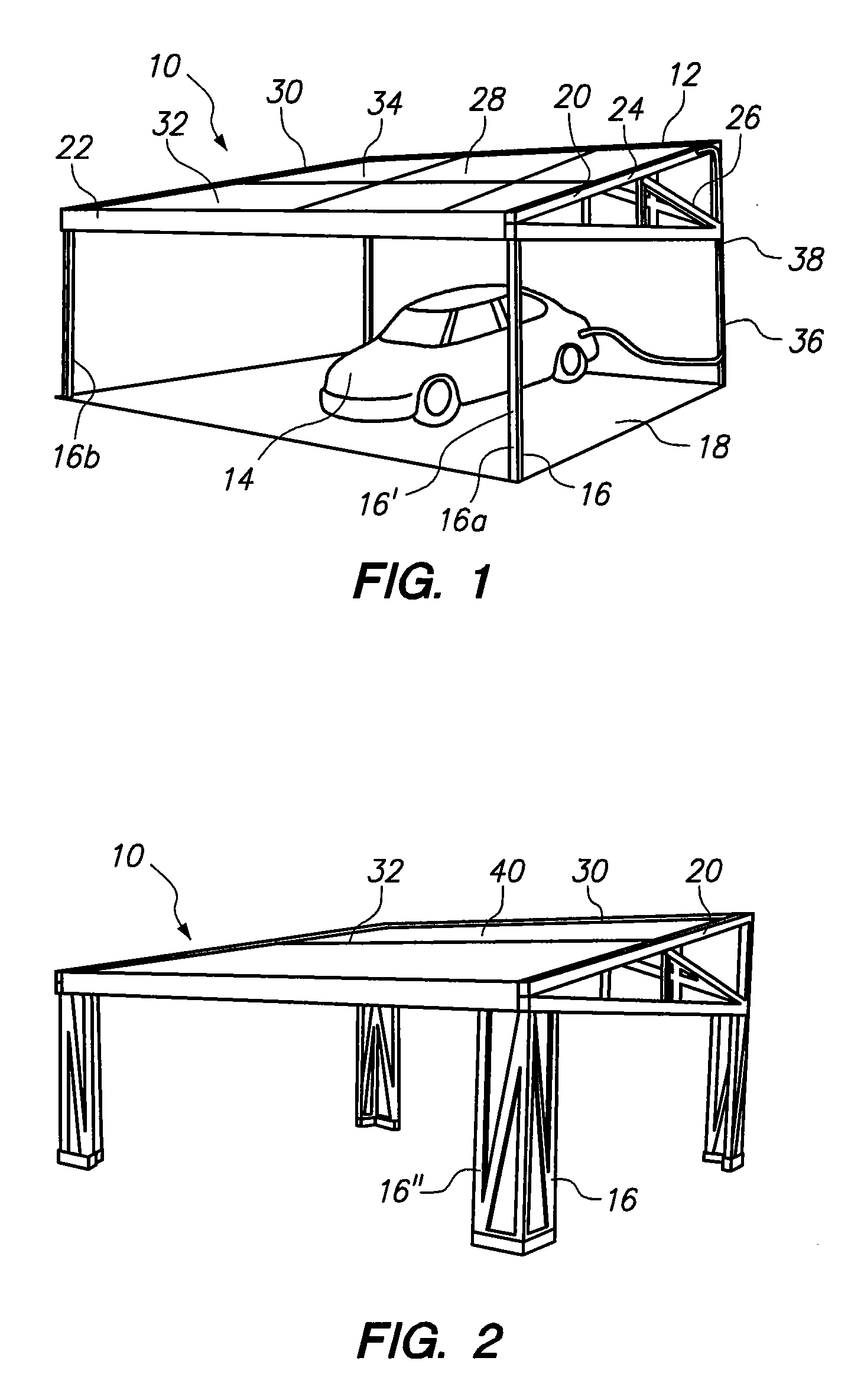

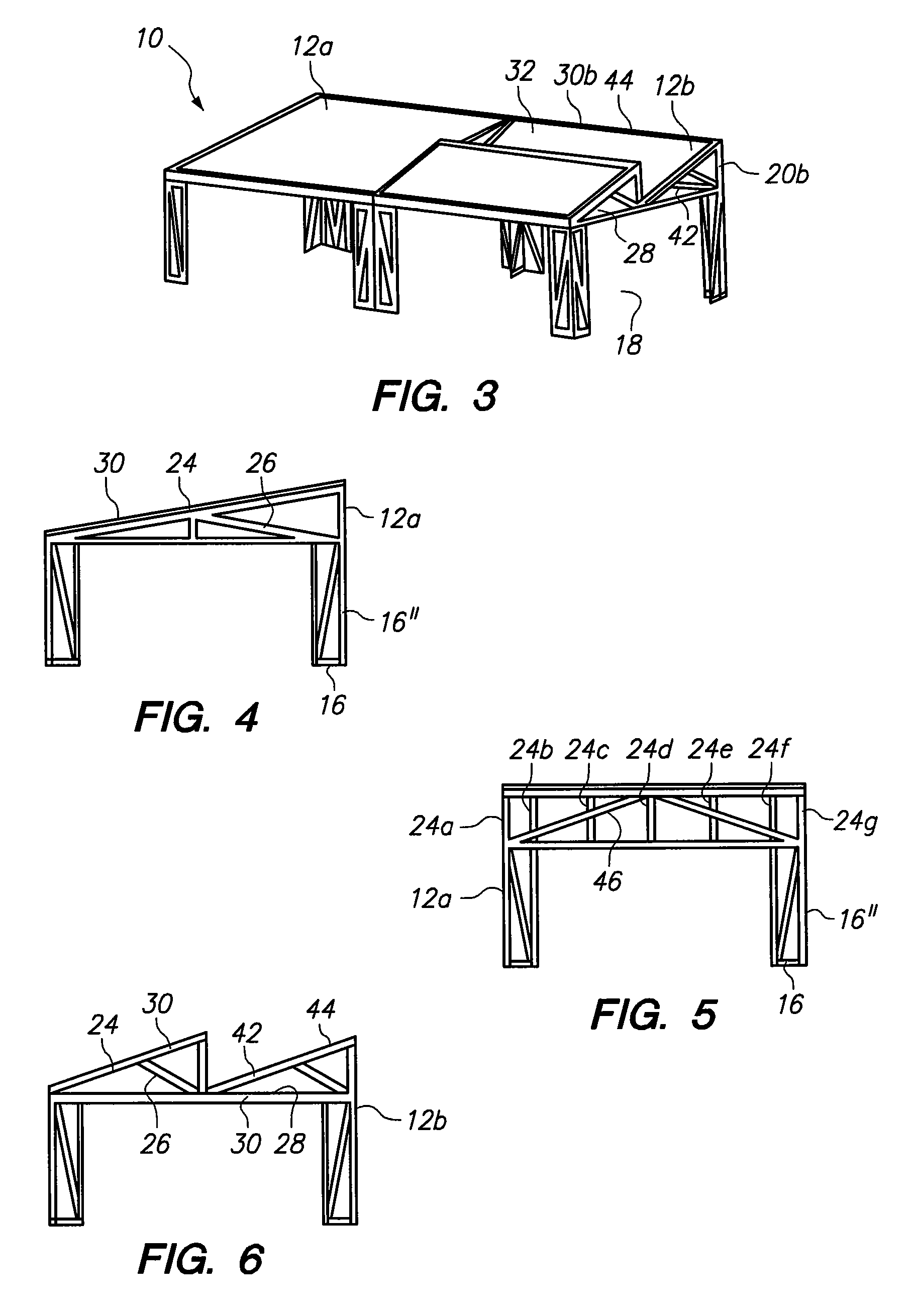

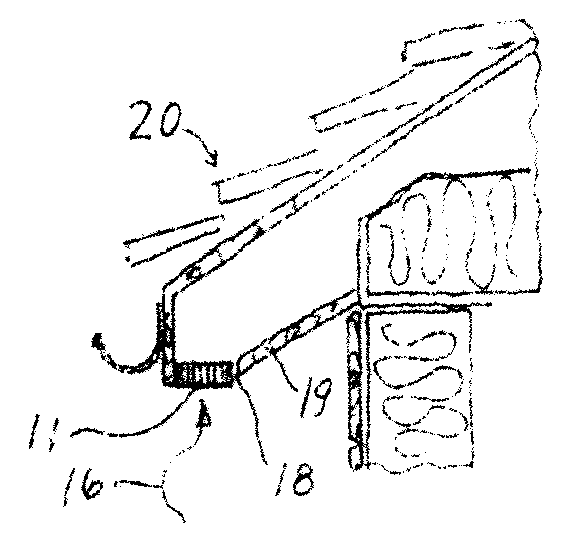

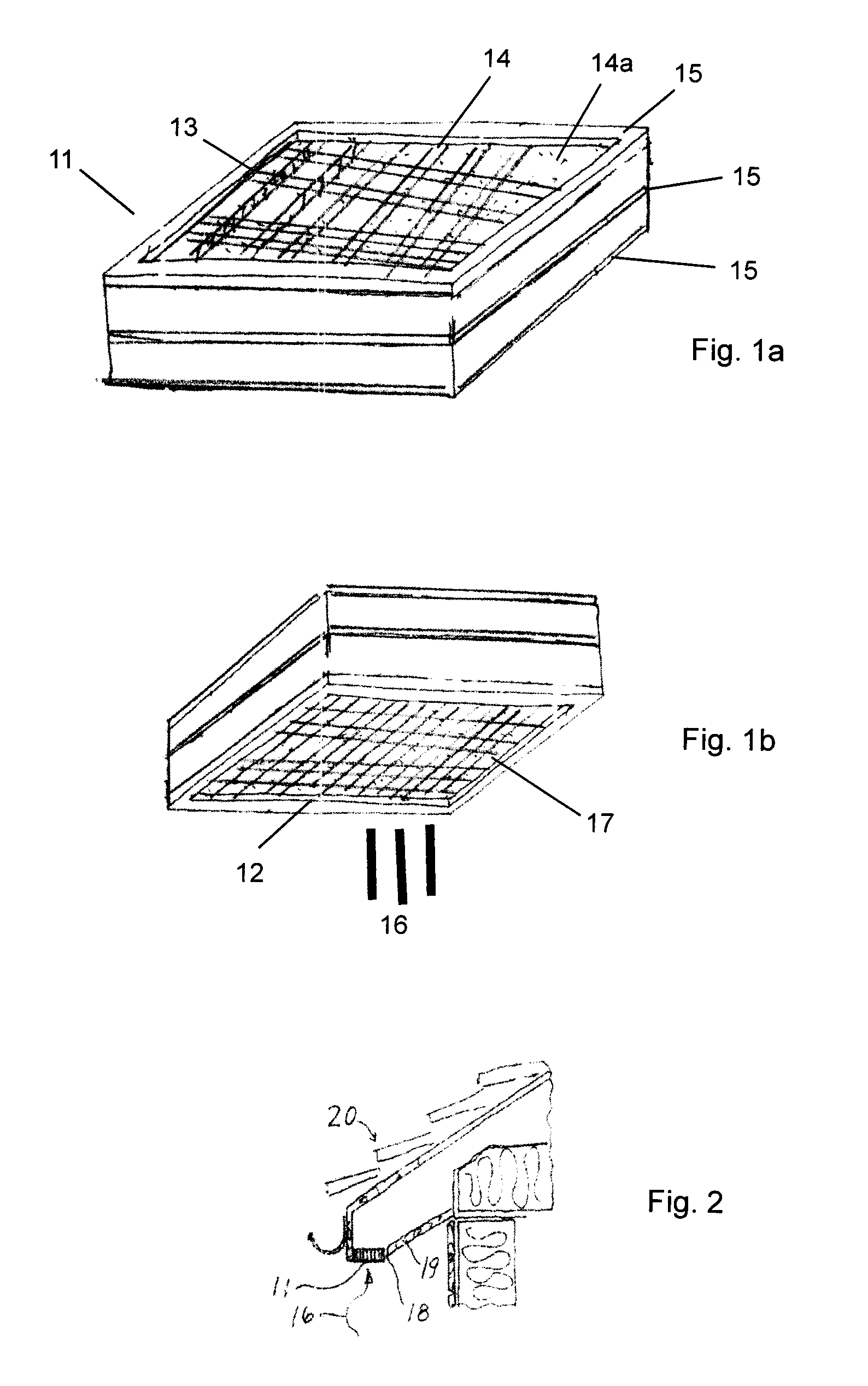

Support system for a photovoltaic system

InactiveUS20090050194A1Convenient amountPhotovoltaic supportsBuilding roofsSupporting systemElectricity

A method and modular assembly provide shade and generate electricity using photovoltaic cells. In the method, a kit includes a plurality of columns, a truss assembly, a rack, and a plurality of photovoltaic cells for converting solar energy into electricity. First, four columns are erected at a distance from one another to define an area. Then, the truss assembly is suspended between the columns. Thereafter, the rack is mounted to the truss assembly to form an open roof. To enclose the roof, the photovoltaic cells are arranged on the rack to block sunlight to shade the area, while converting the sunlight to electricity.

Owner:ENVISION SOLAR INT

Tornado and hurricane roof tie

InactiveUS6837019B2Easily damagedBetter resist any upward liftBuilding roofsRoof covering using slabs/sheetsRafterFastener

Owner:COLLIE ANTHONY D

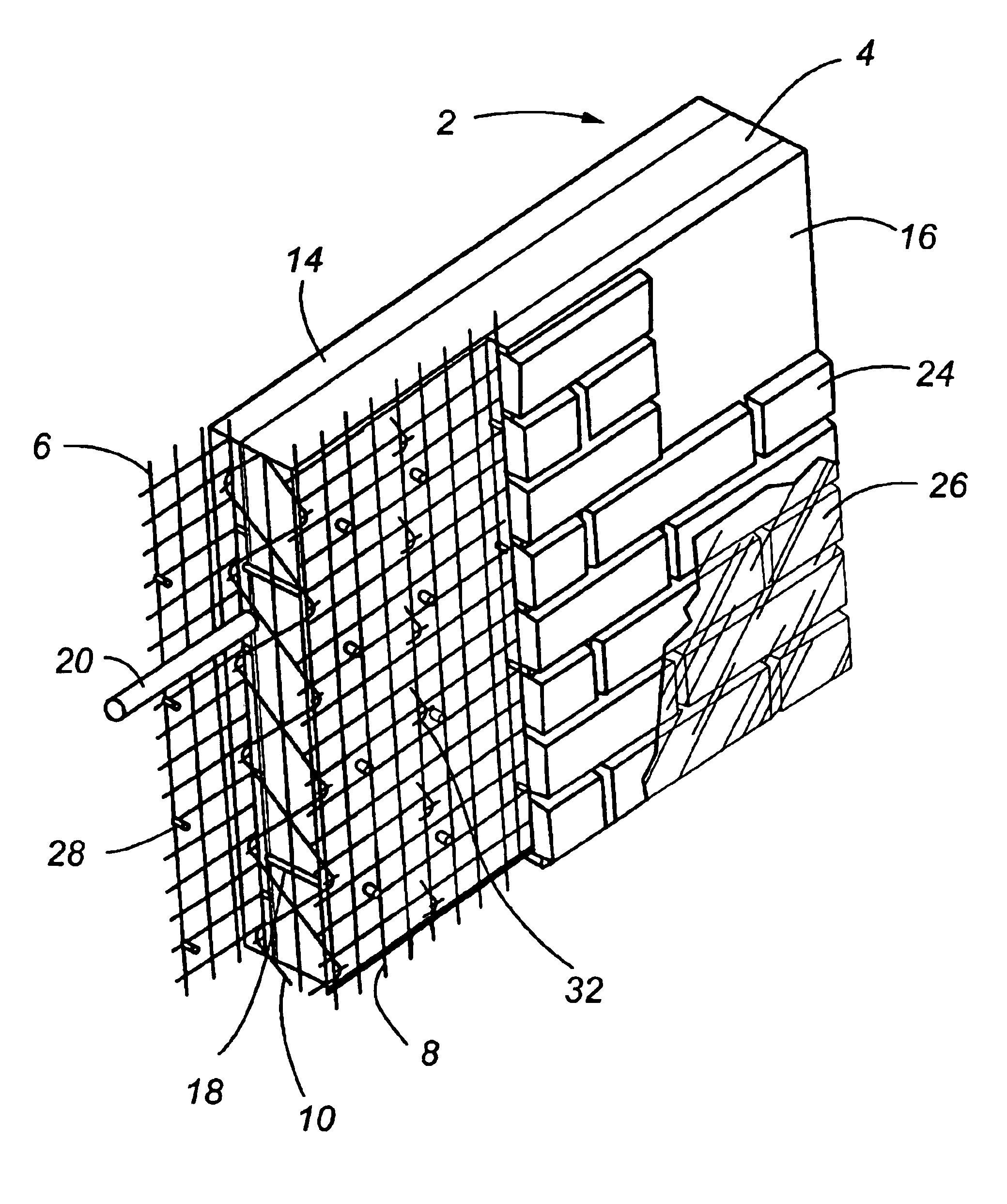

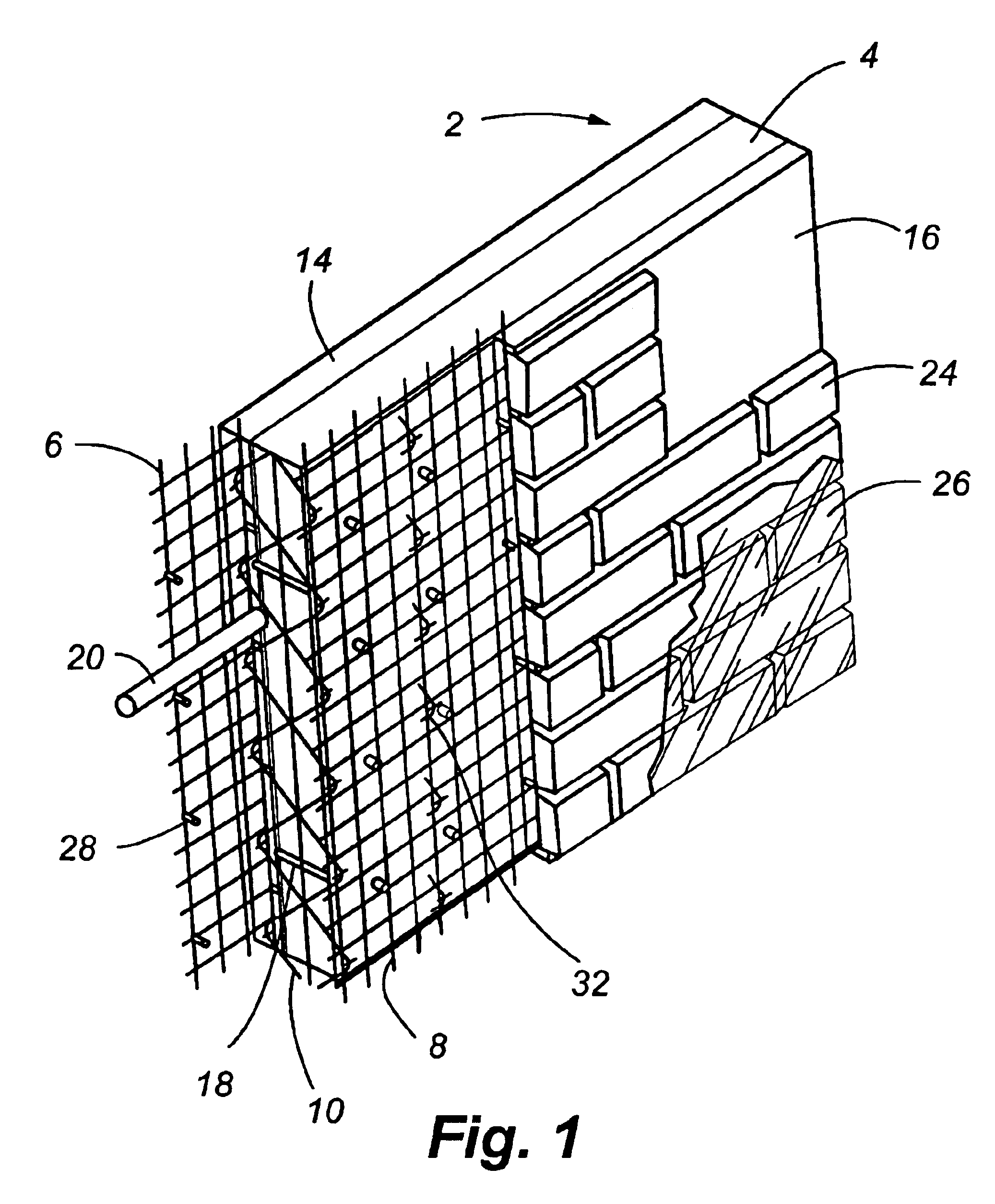

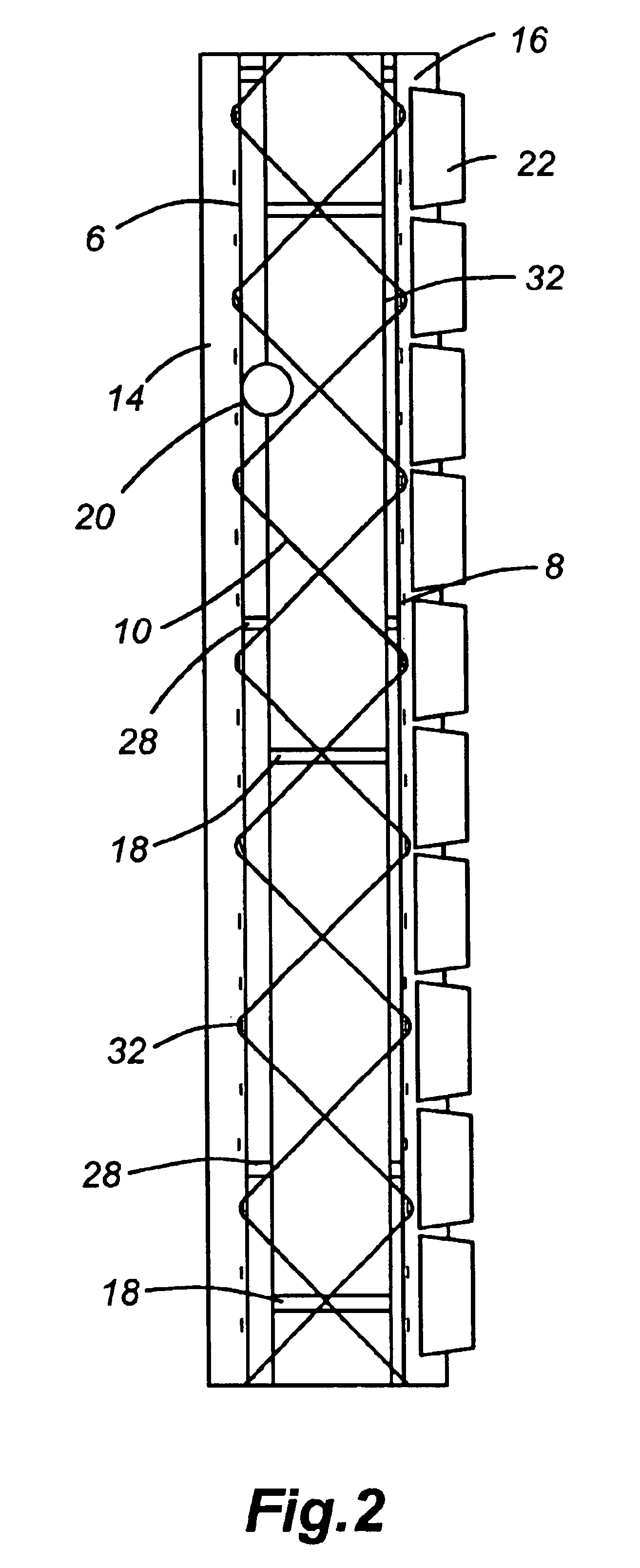

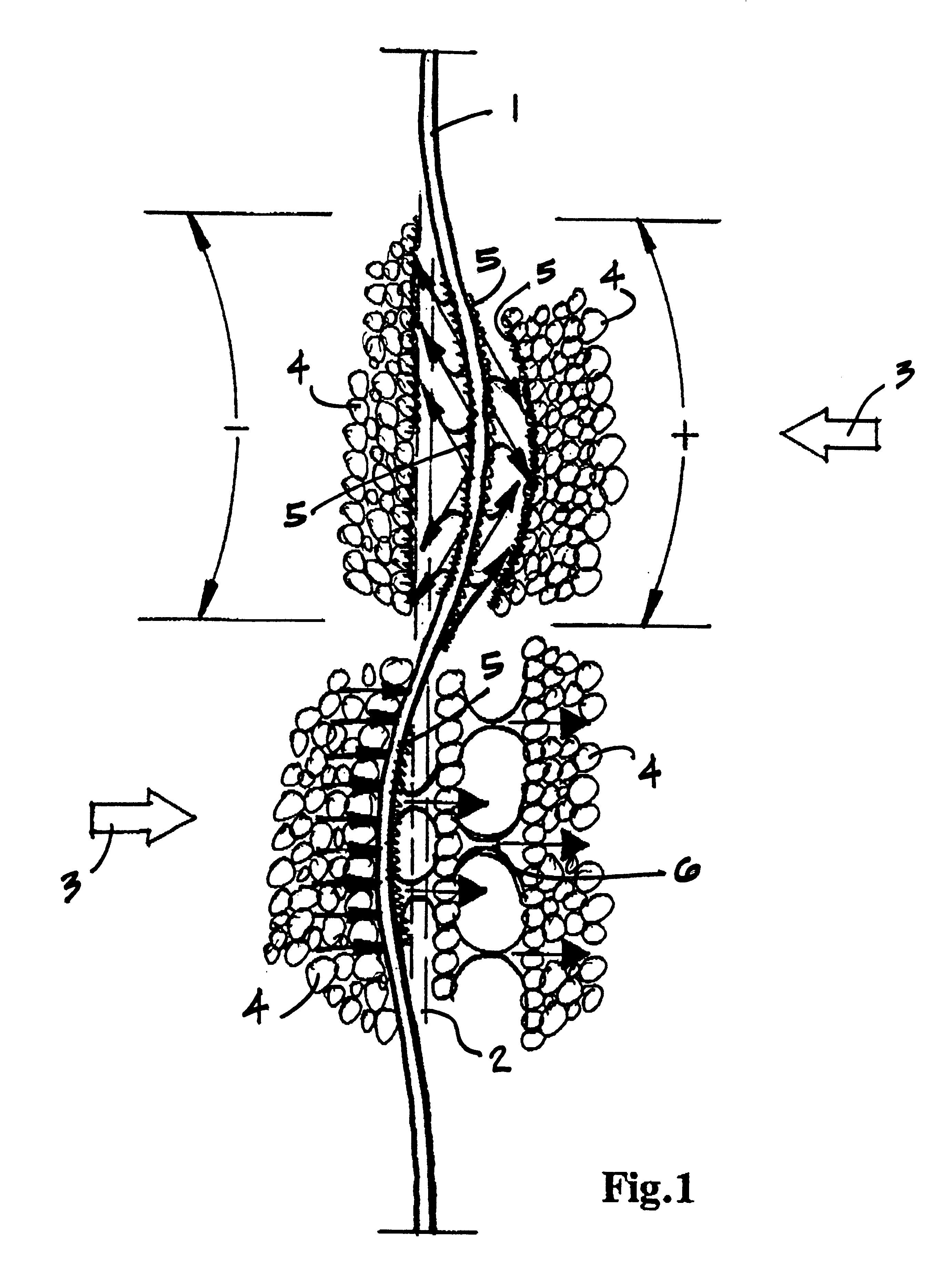

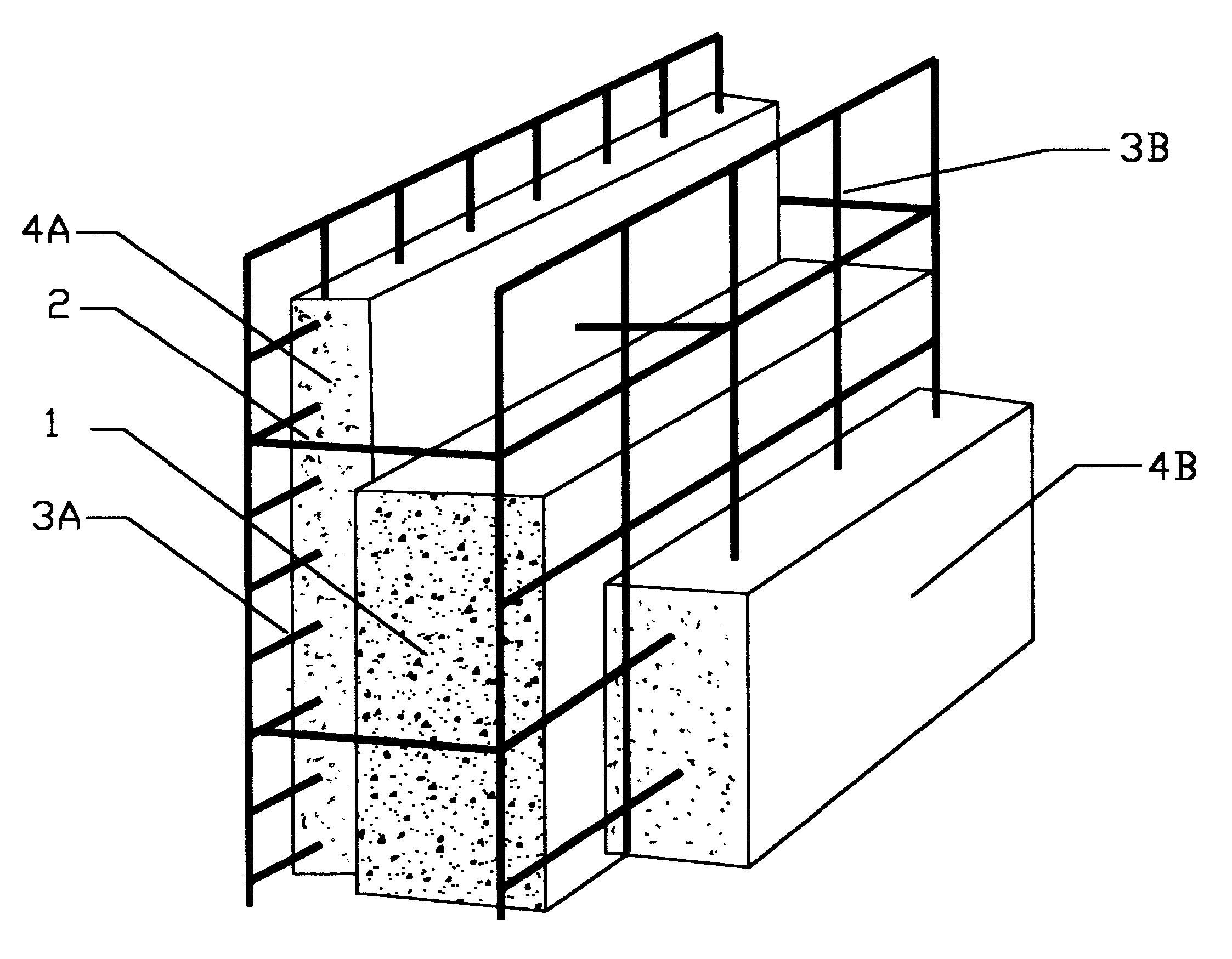

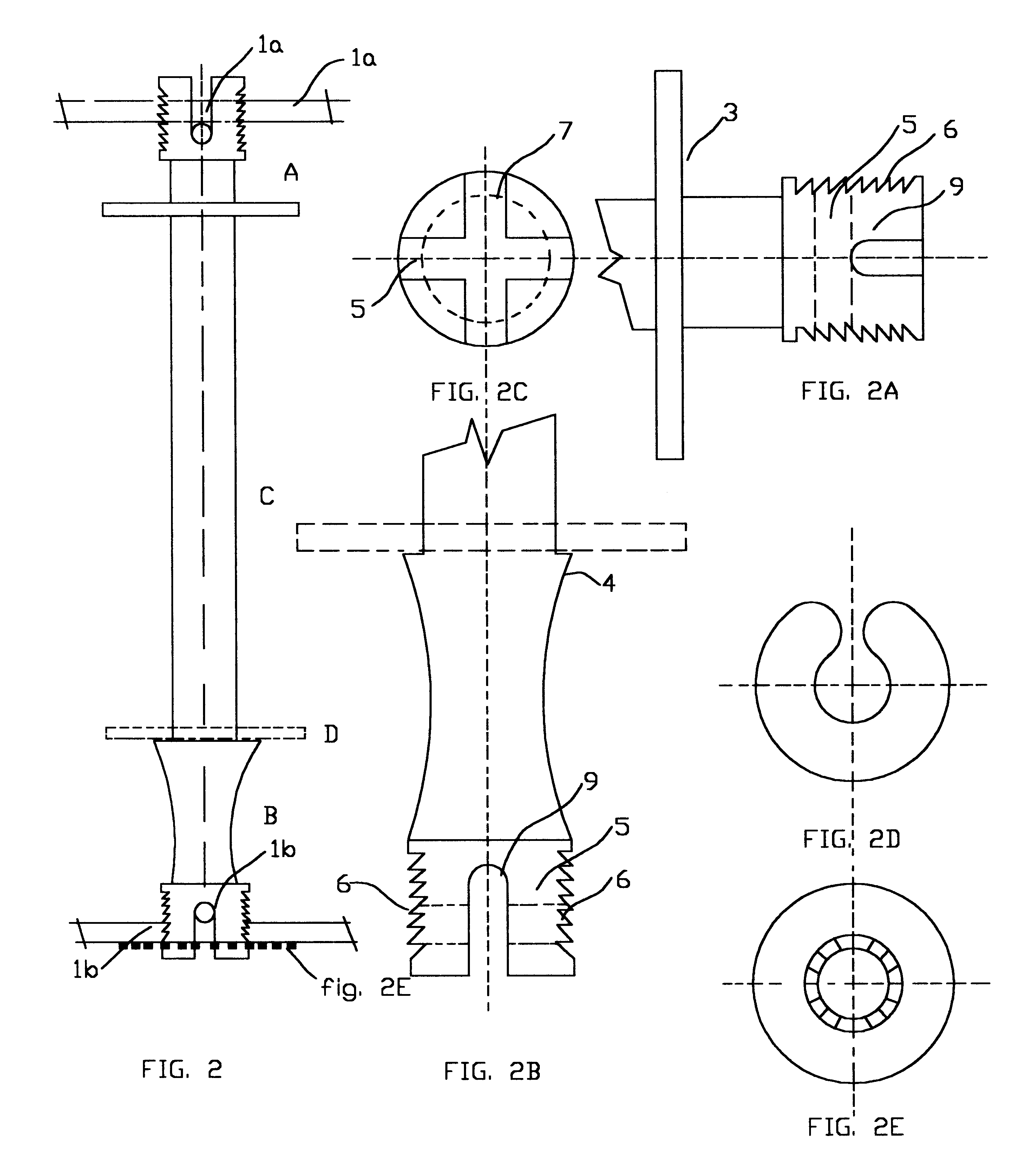

Method for concrete building system using composite panels with highly insulative plastic connector

InactiveUS6202375B1Easy to assembleEasy to transportBuilding roofsConstruction materialFiberShotcrete

The present invention comprises a concrete building system with a method for fabricating composite panels using an improved design plastic connector and assembling them at the construction site to a structure which will be shotcreted on both sides to a concrete building which is highly insulated, is fire and termite proof, hurricane, earthquake and flood resistant and fulfills the requirement for flexible design. The Composite Panels are composed of two concrete layers, enclosing an insulative foam core. The skins are reinforced with wire mesh as structurally required and are connected through the foam core by structural highly insulative plastic connectors using the snap connection on both ends of the connectors so they form a tri-dimentional system and hold the wire mesh in place for the onsite shotcrete application, which includes an application of fiber for shrinkage and cracking. This replaces the welded wire fabric use for secondly reinforcing and let the wire mesh reinforcing only related to the structural strength of the composite panel. The plastic connector guarantees that no thermal bridging occurs like in other systems also the inside layer of the shotcrete panel.

Owner:FCN FOUND FOR THE CONSERVATION OF NATURE

Vented eaves closure

InactiveUS6941706B2Increase air circulationMinimize heat transferRoof covering using slabs/sheetsBuilding roofsWind drivenRoof tile

A method is provided for installing a ventilated eaves closure and tile support apparatus along the eaves of a roof. A vented eaves closure apparatus is disposed along the eaves to support the first course of roof tiles at a desired pitch. The apparatus provides support, ventilation, and drainage, while also providing a barrier to wind-driven precipitation, bird nesting, and animal invasion. The apparatus includes an array of openings configured to allow drainage and facilitate the flow of air beneath the tiles and throughout the air space between the roof deck and the tiles. The method and apparatus can be adapted to fit a variety of roof types and roof tiles having different sizes, shapes, and profiles.

Owner:BORAL LIFETILE +1

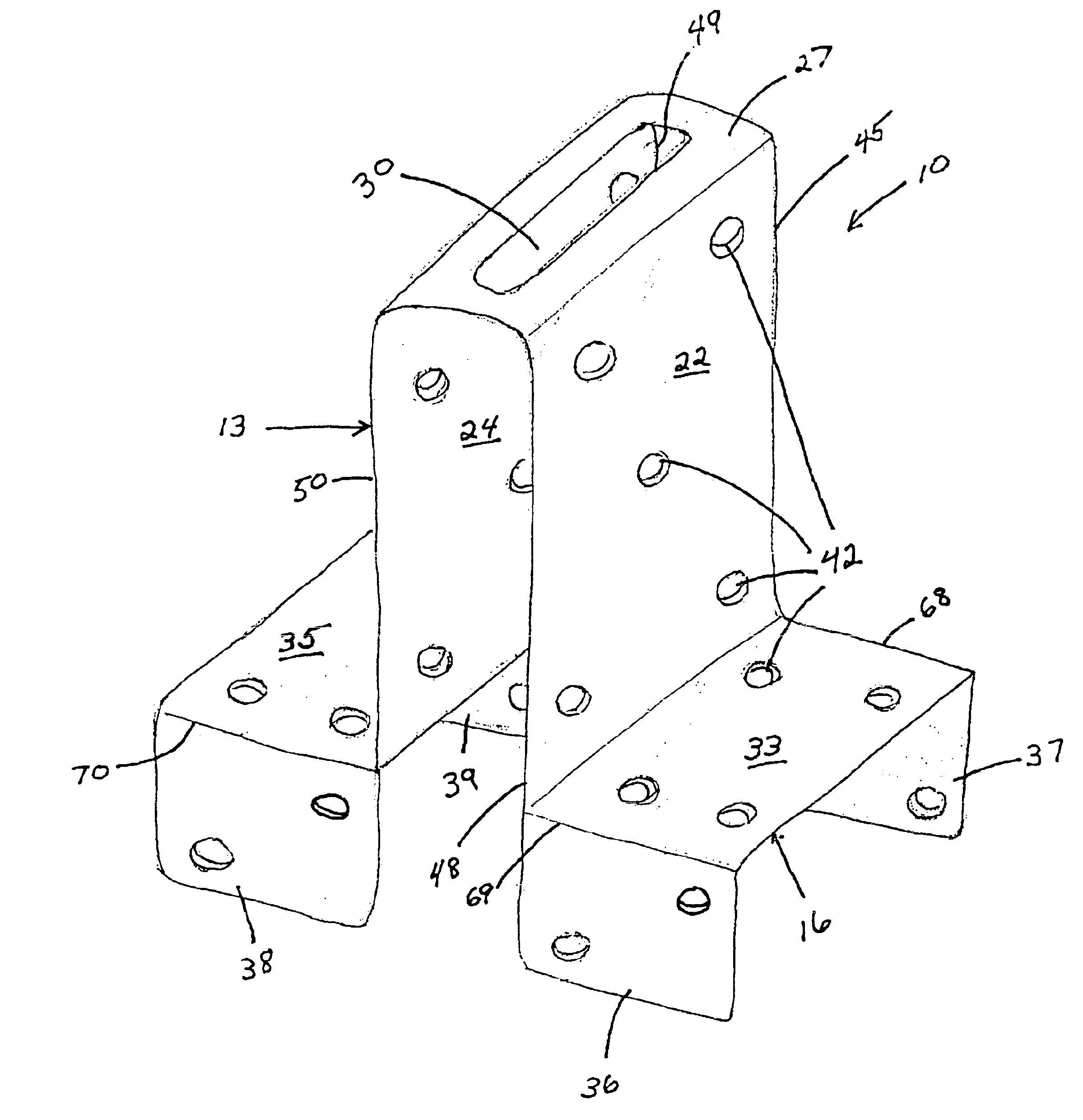

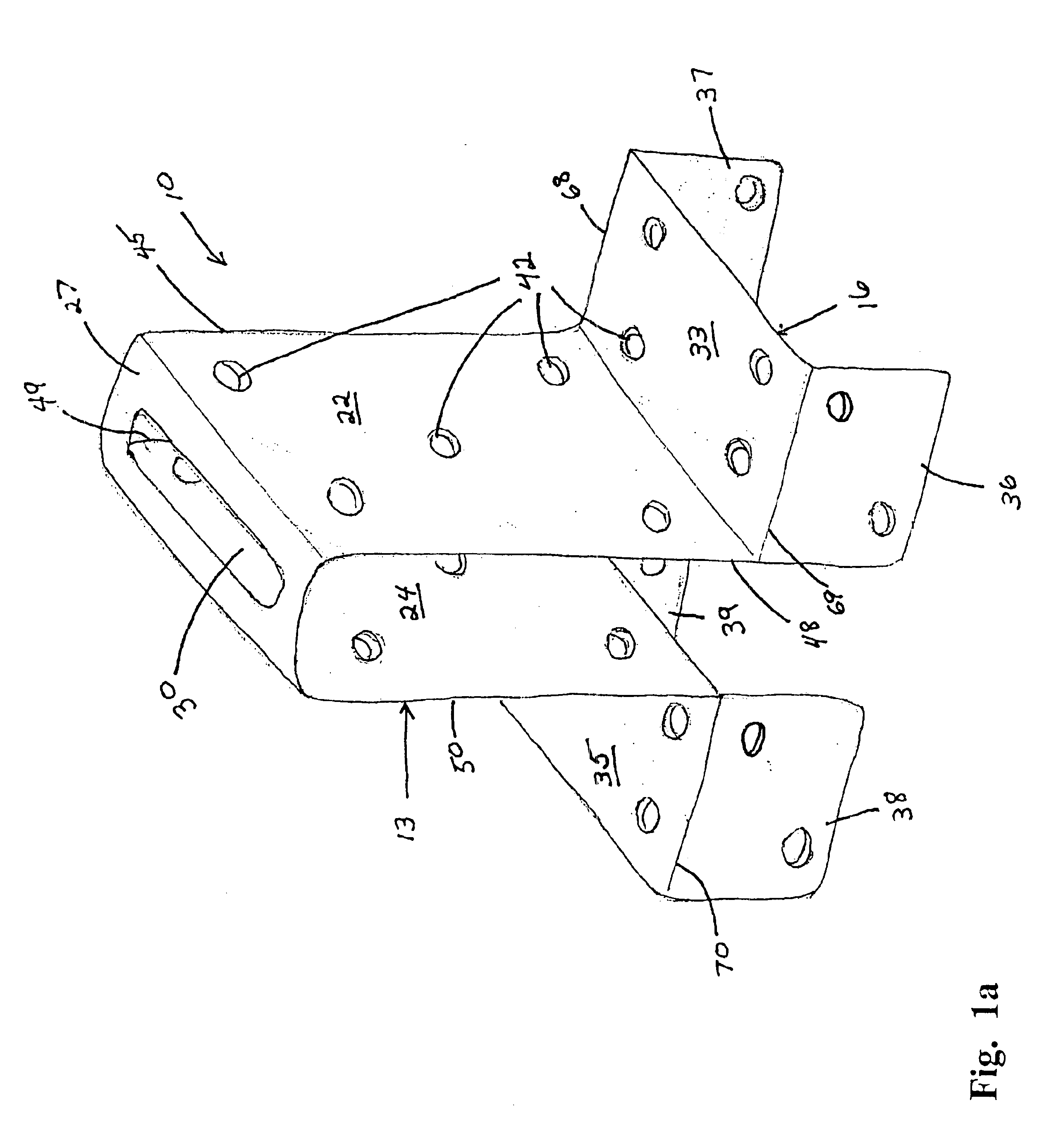

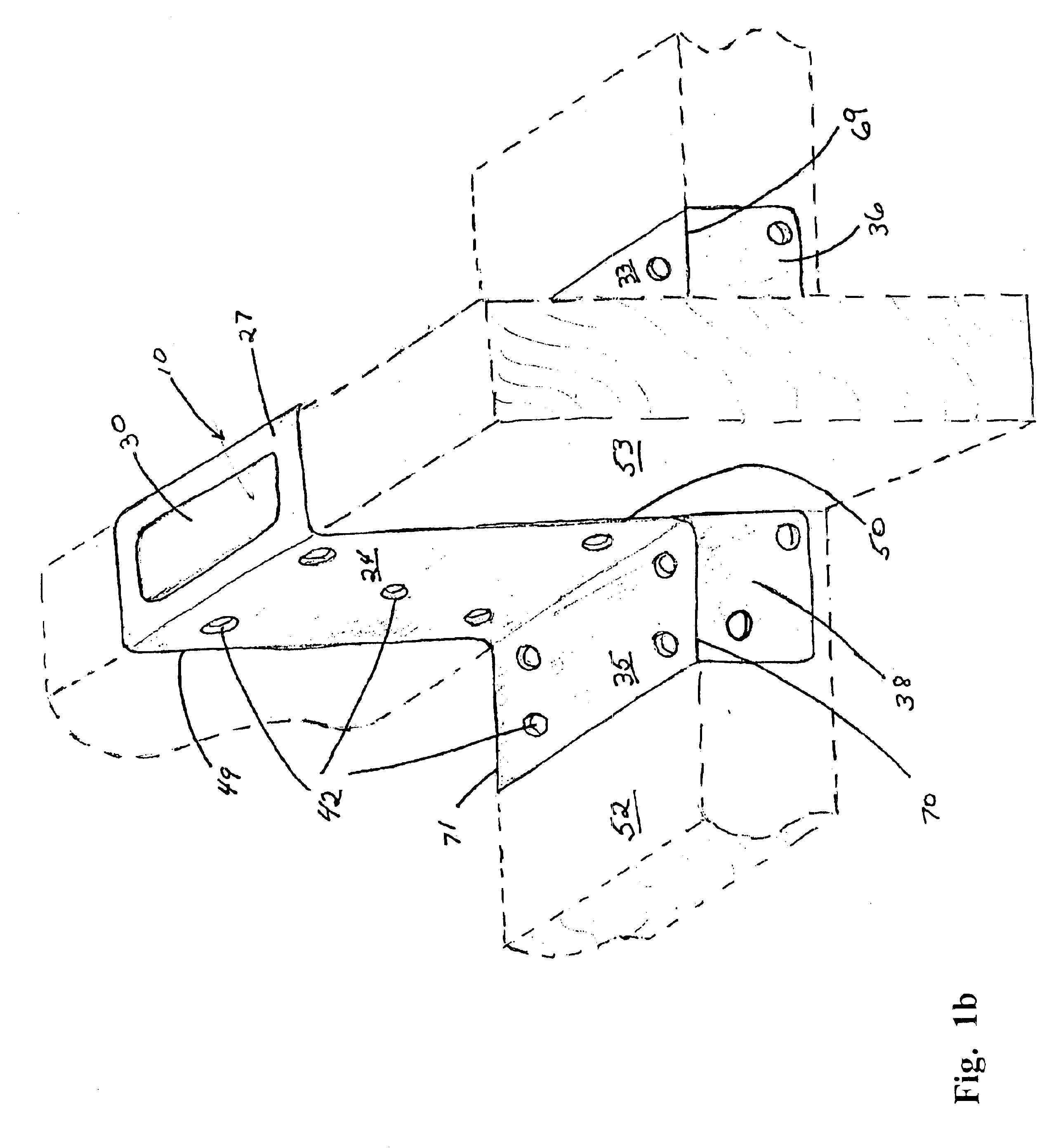

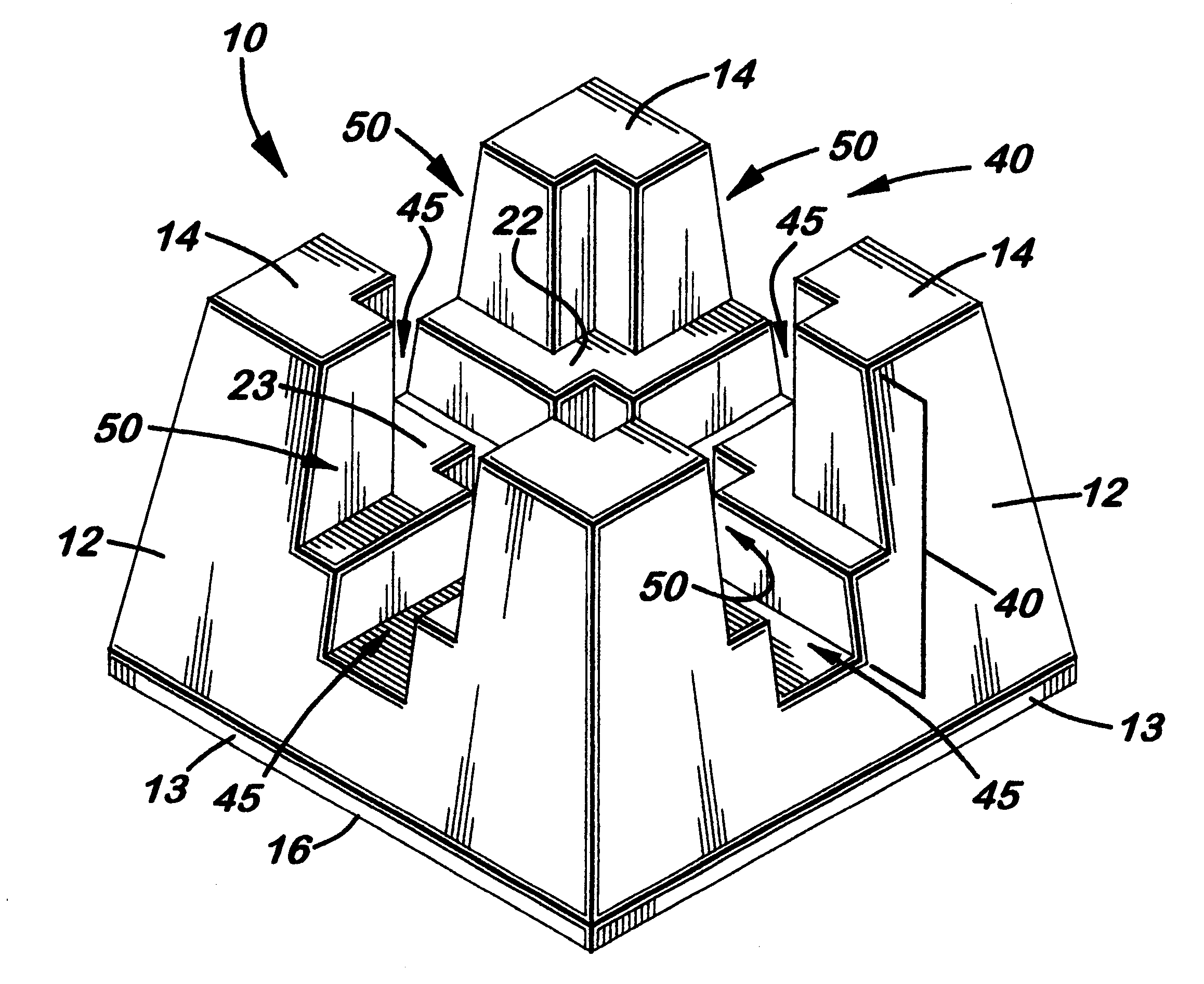

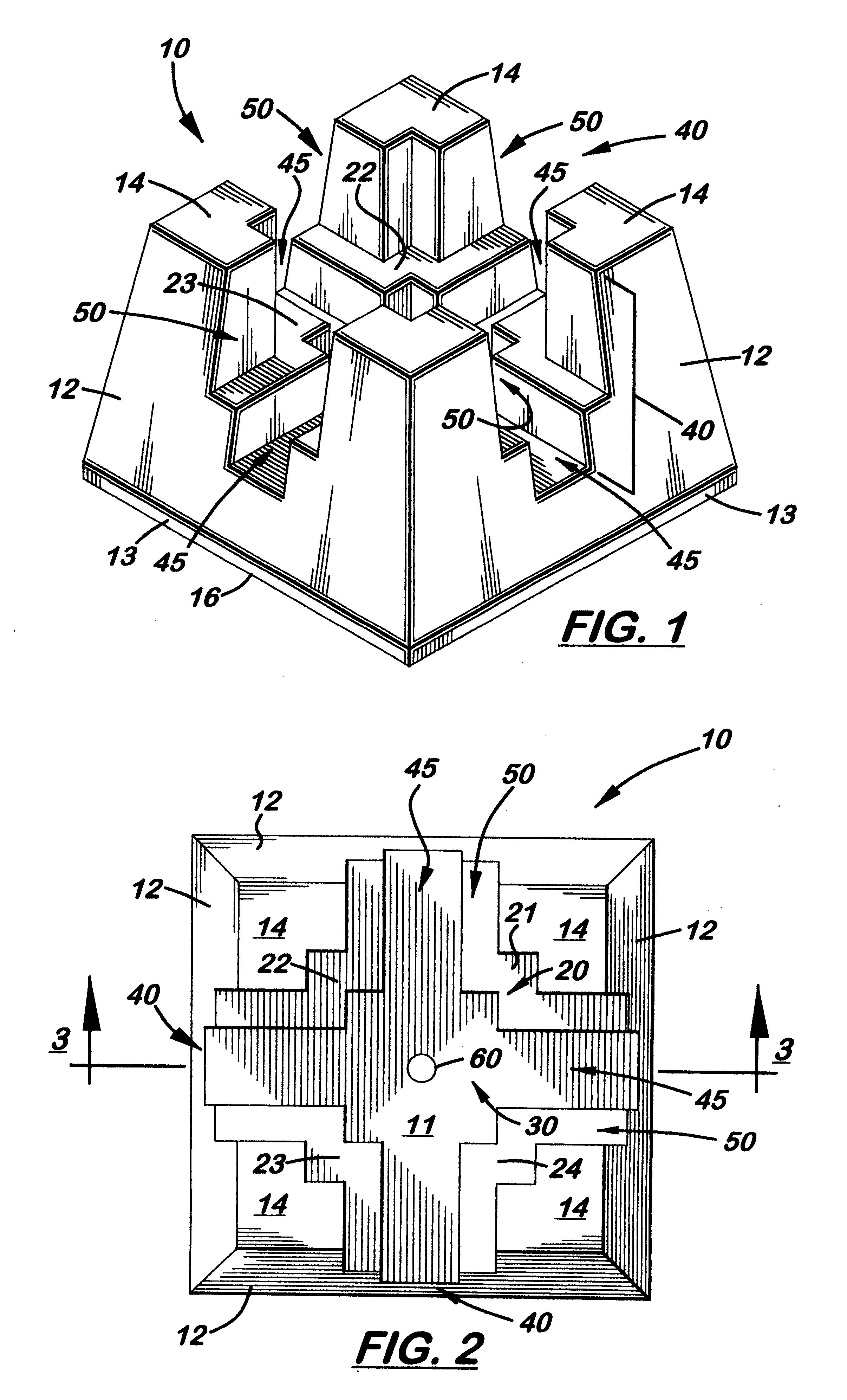

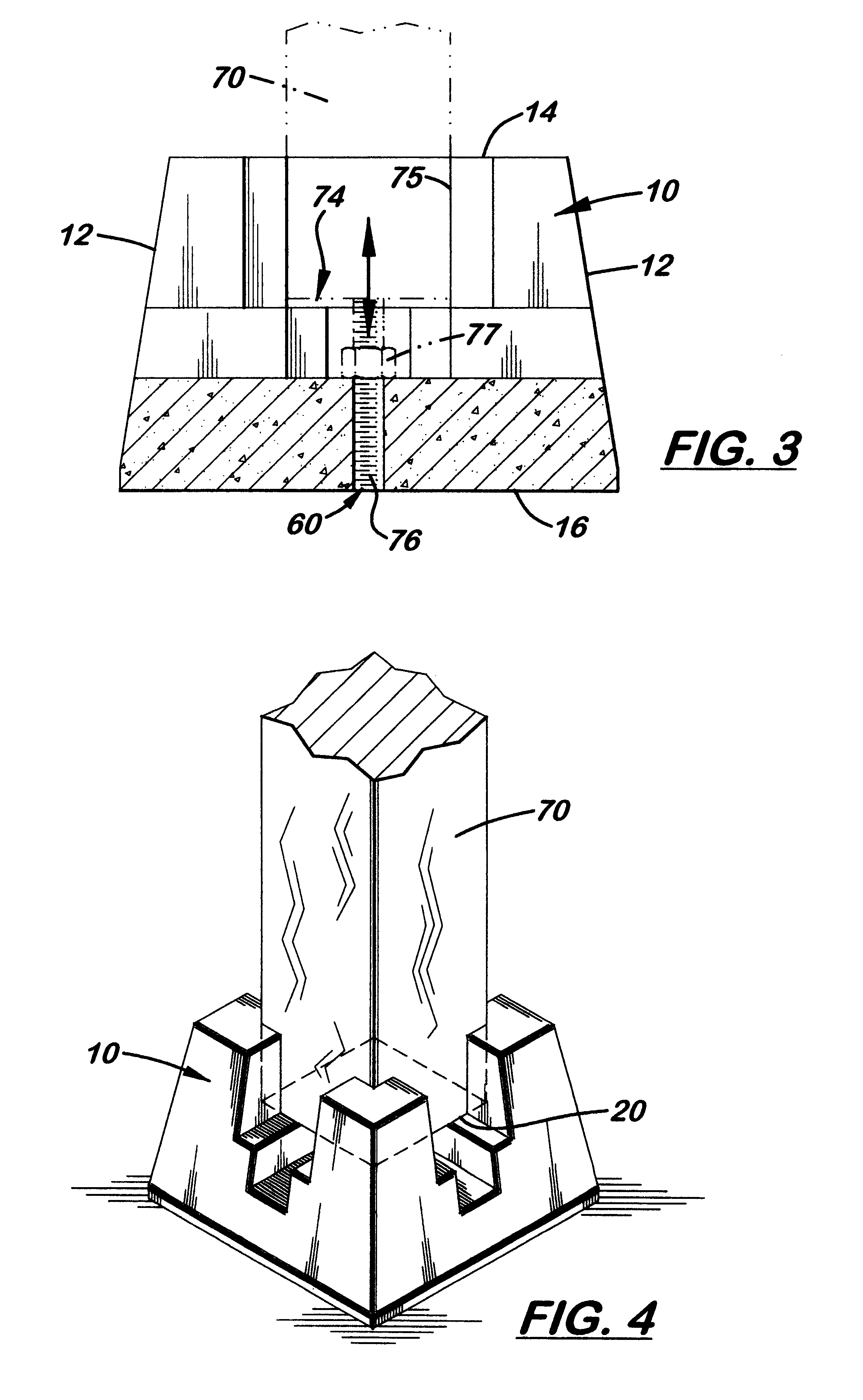

Universal pier block

A universal block made of concrete designed to be used with different size posts and beams. The pier block is a conical, six-sided structure and includes two concentrically aligned, post-receiving voids designed to receive the ends of a (4x4) or (6x6) inch post. The (6x6) inch void is positioned above the (4x4) inch void. Formed horizontally on the top surface of the pier block are two transversely aligned beam-receiving slots. Each beam-receiving slot includes a narrow and a wide slot longitudinally aligned. The wide slot is positioned above the narrow slot. A vertically aligned drain hole is formed through the pier block from the bottom surface of the (4x4) inch void to the bottom of the pier block, which allows water to drain from the post-receiving voids.

Owner:TRIPLETT DAVID

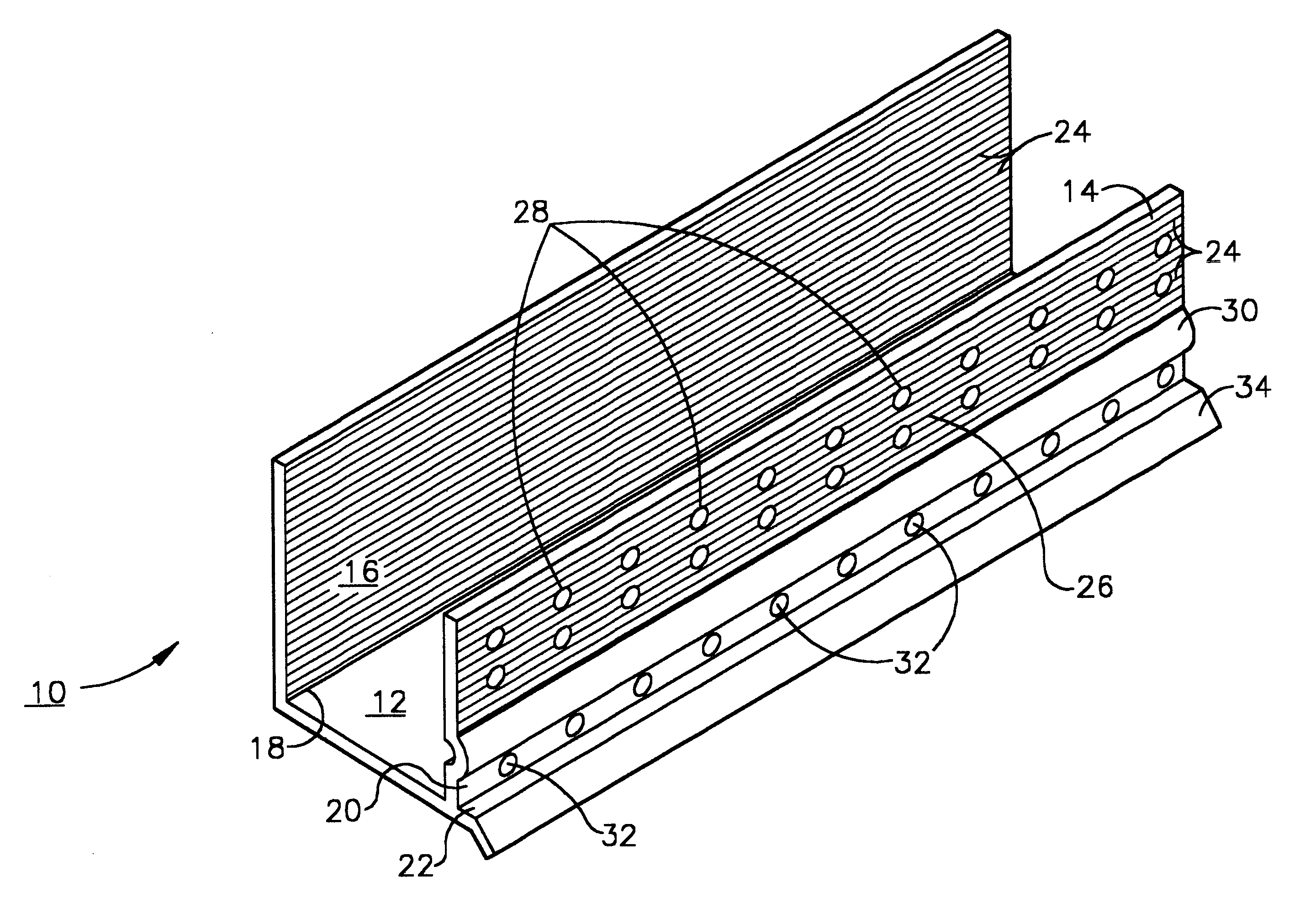

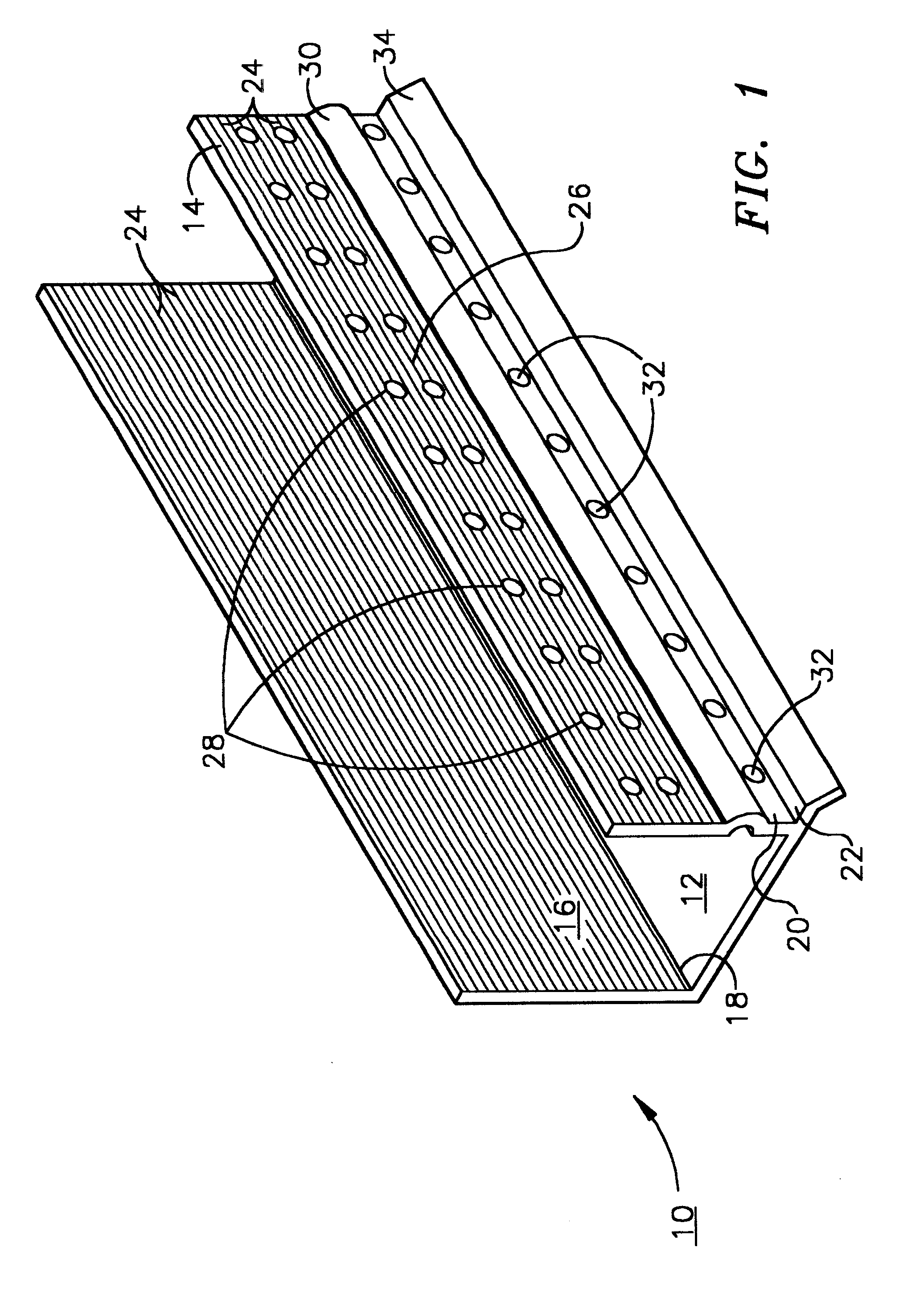

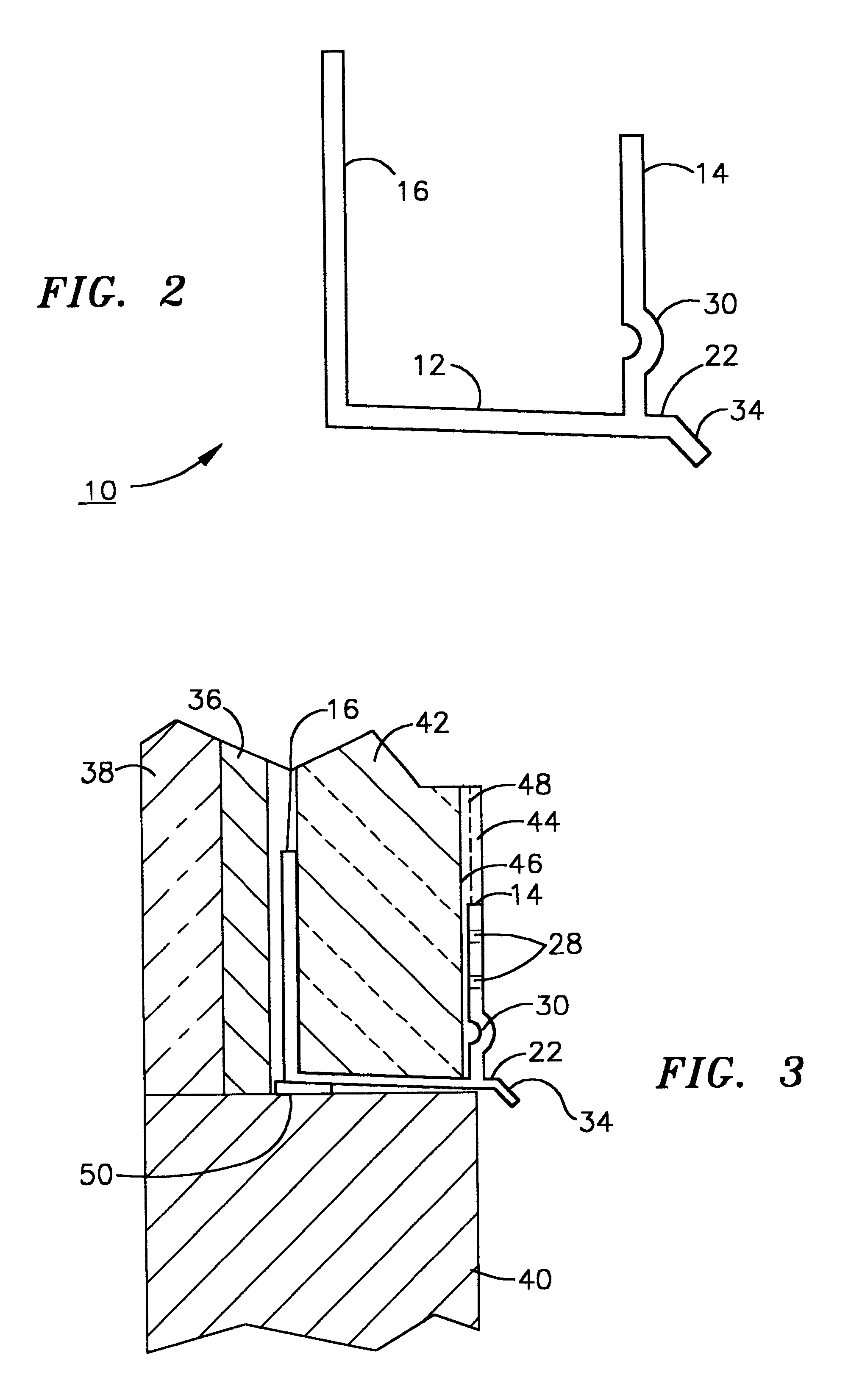

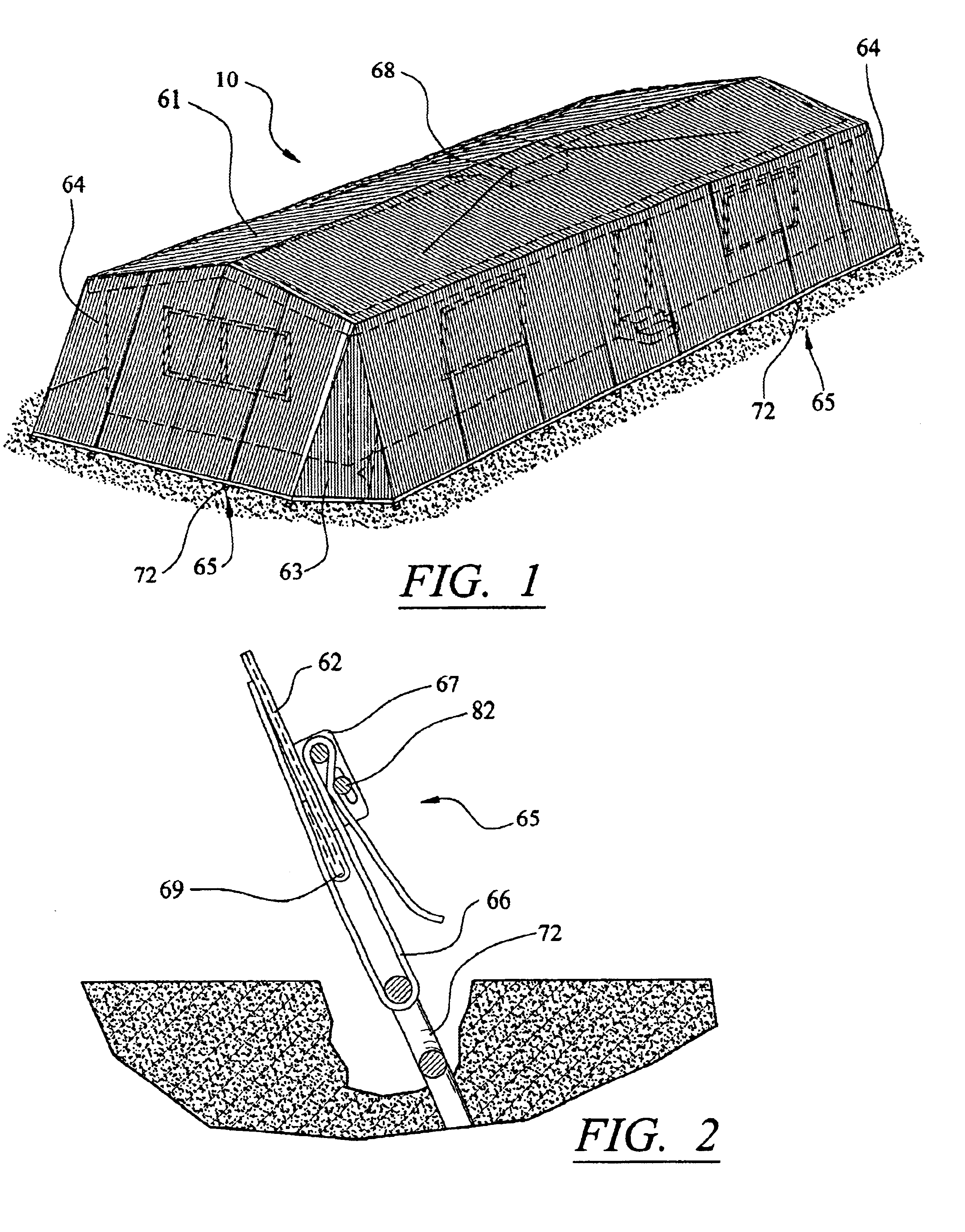

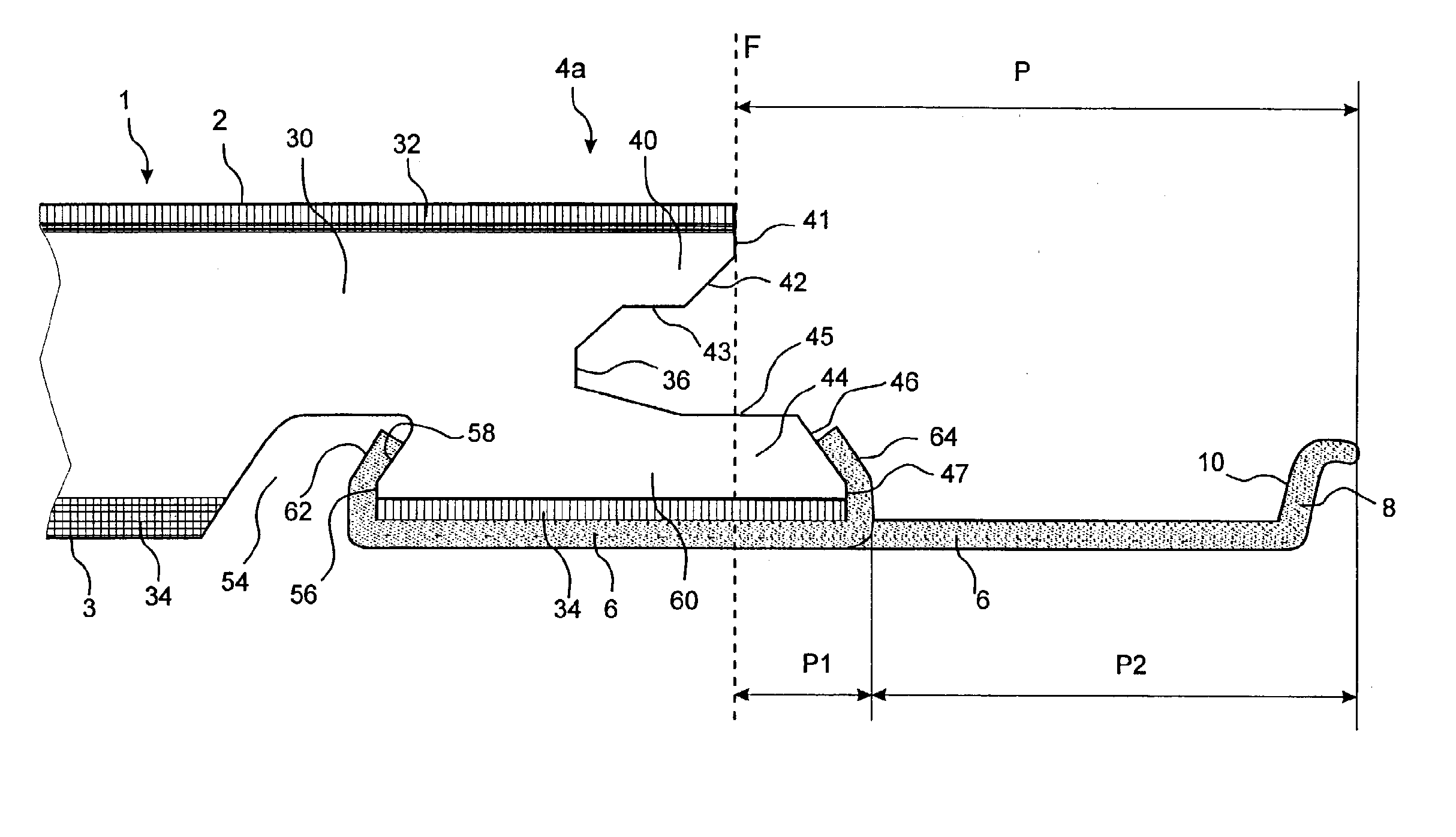

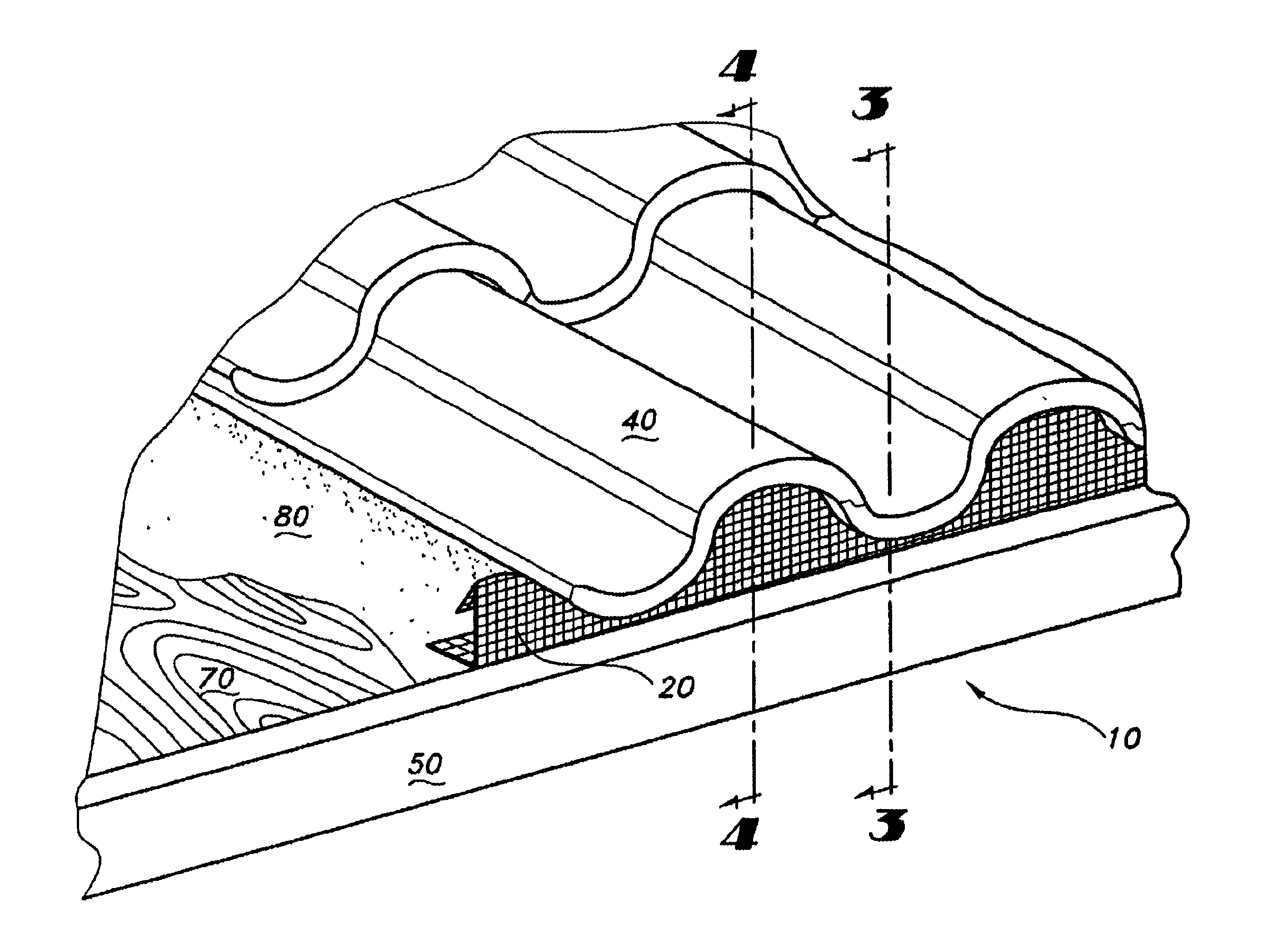

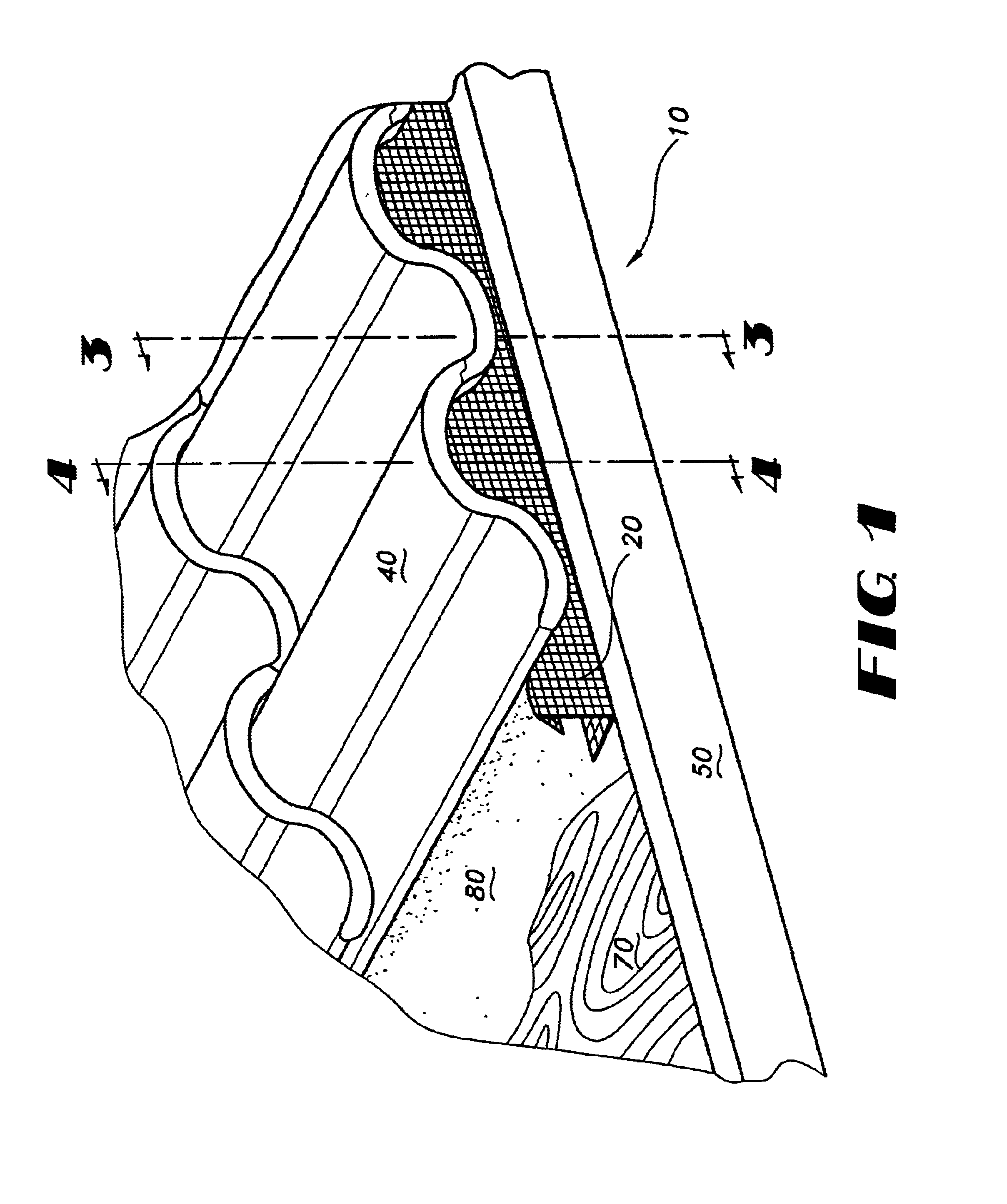

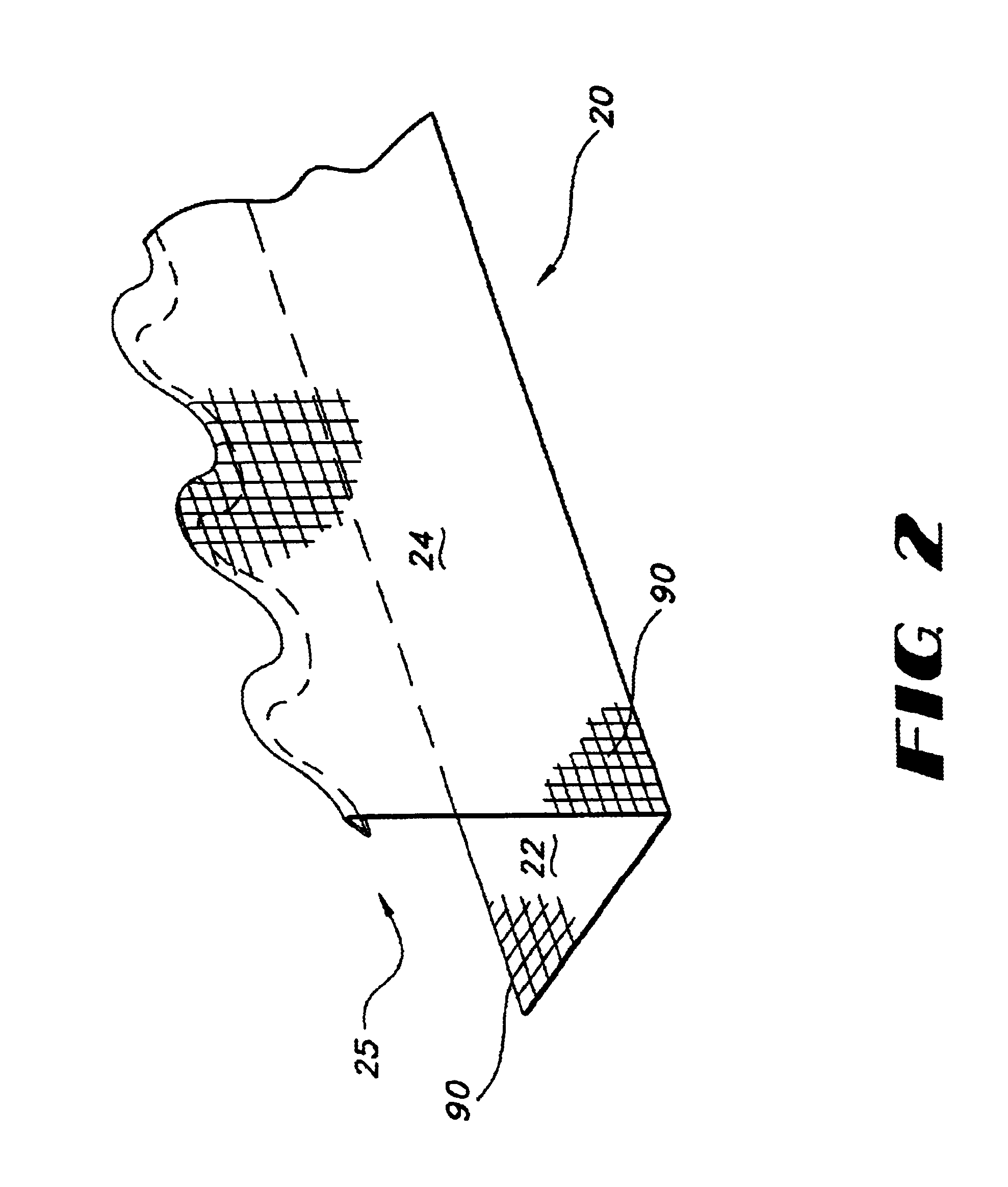

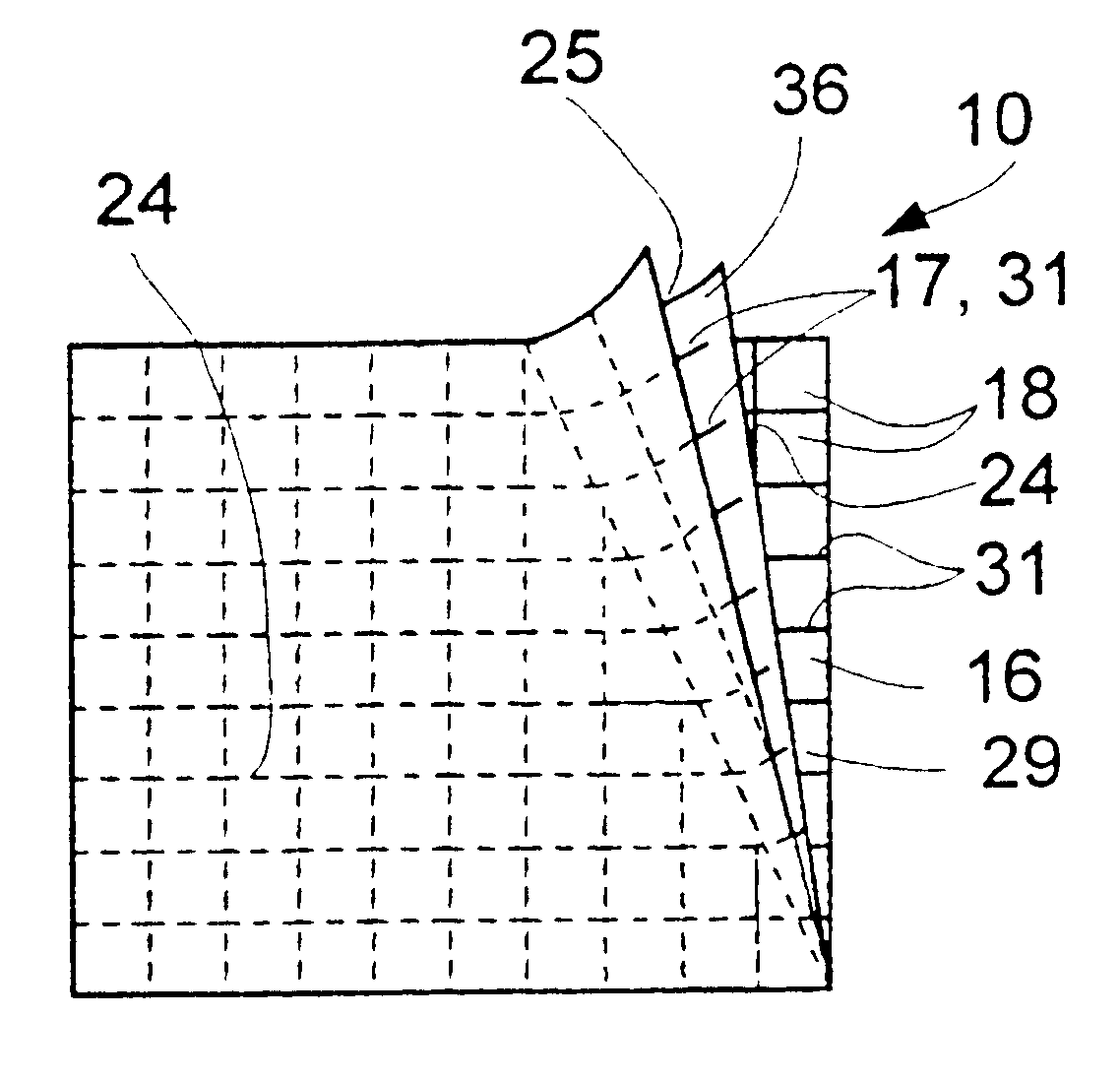

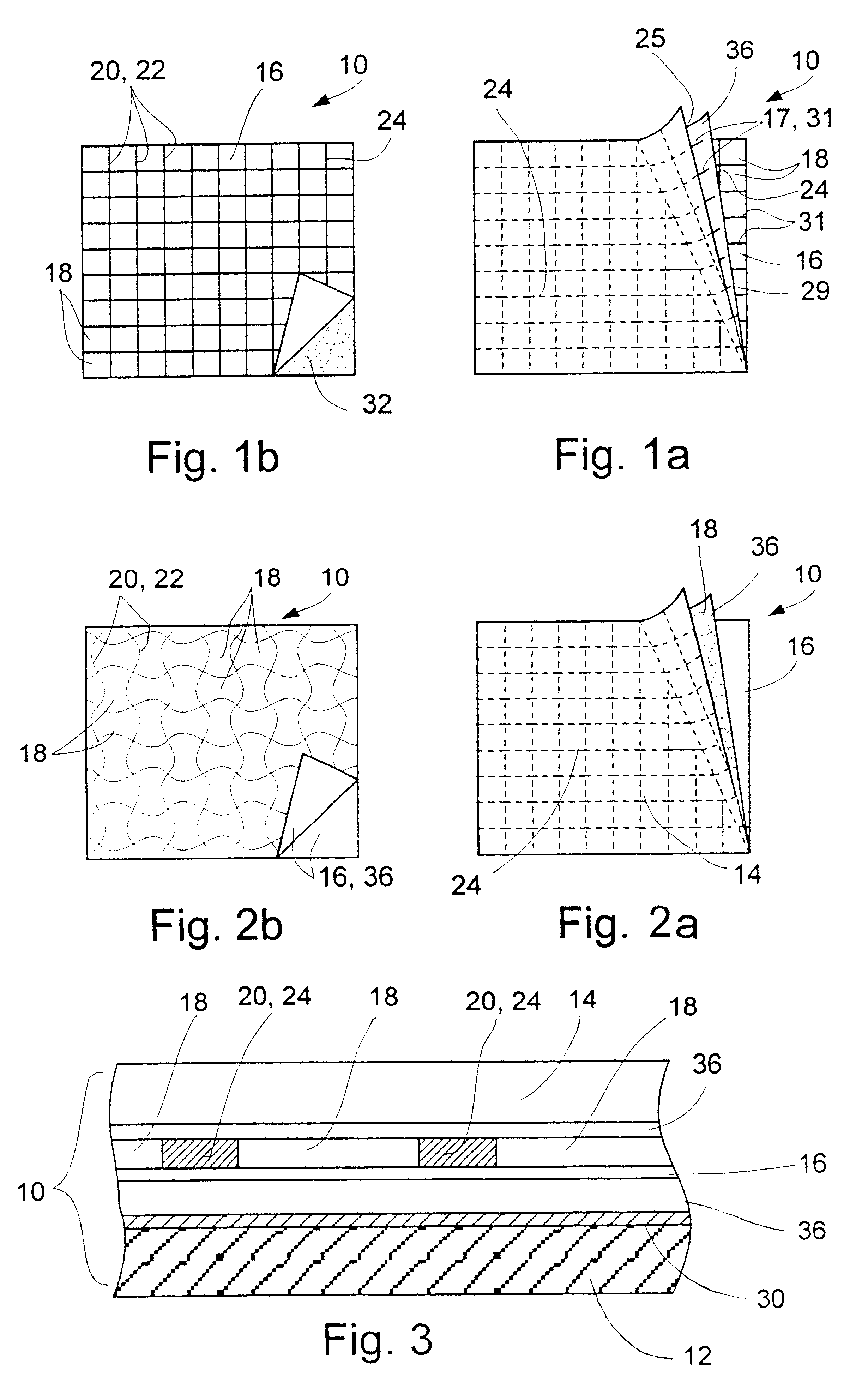

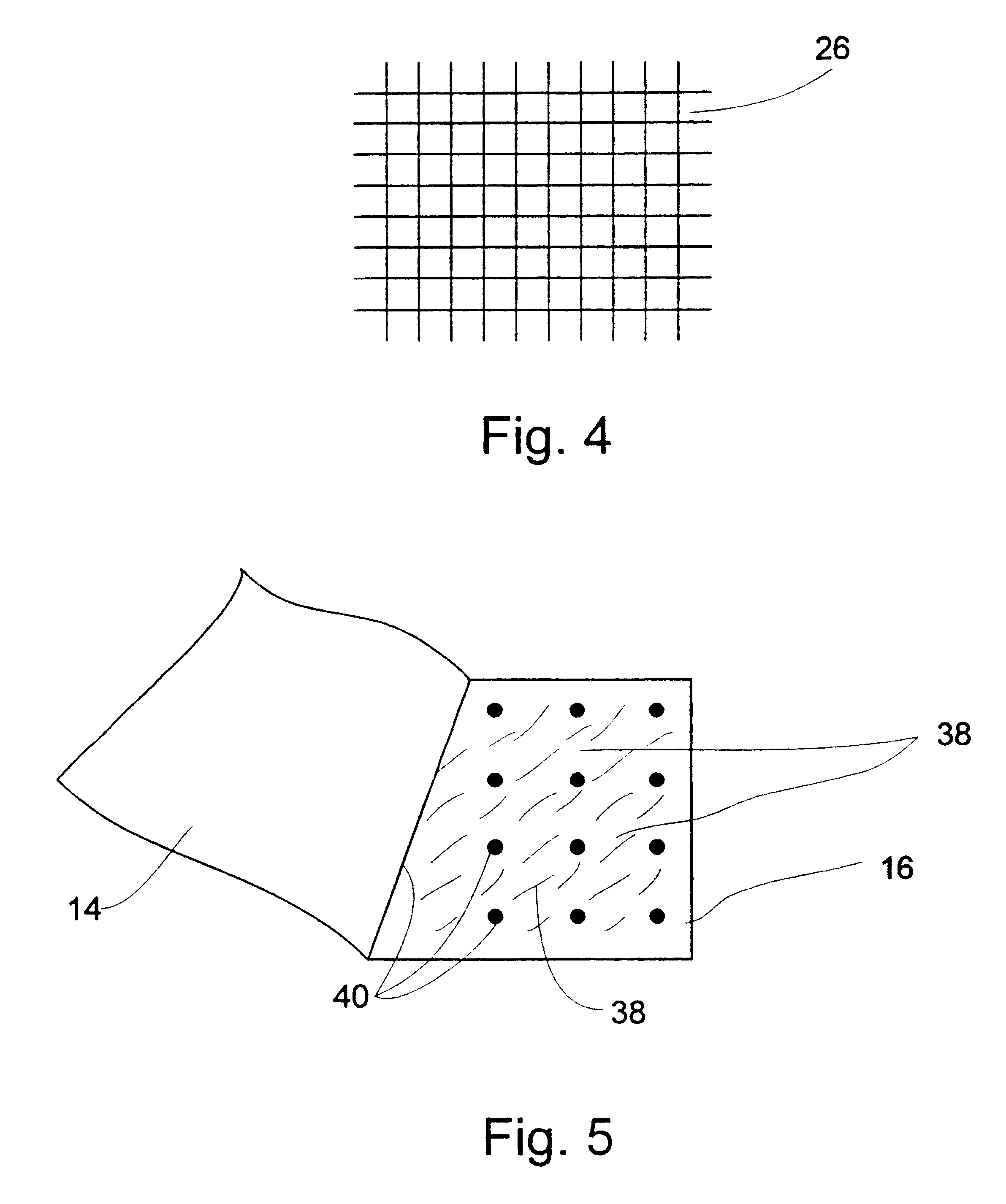

Sealing sheet assembly for construction surfaces and methods of making and applying same

InactiveUS6586080B1Low costReduce thicknessBuilding roofsRoof covering using flexible materialsRelative displacementClassical mechanics

A sealing sheet (10) assembly bondable to a construction surface comprising (a) an upper layer (14) of a first substance, the upper layer being selected fluid impermeable; and (b) a lower flexible layer (16) of a second substance, the lower flexible layer being bondable to the construction surface. The upper layer and the lower flexible layer are at least partially attached to one another, wherein a combination of the upper layer, the lower layer and the attachment or the partial attachment of the layers to one another are selected such that tensile forces resulting from constructional movements acting upon the sealing sheet result in a local detachment or relative displacement of the upper layer and the lower flexible layer, thereby the ability of the lower flexible layer of transmitting the forces onto the upper layer is remarkably reduced, resulting in improved service of the sealing cover as a whole. The attachment is selected such that a spread of a leakage between the layers via a tear formed in the upper layer is locally restricted.

Owner:HEIFETZ RAPHAEL

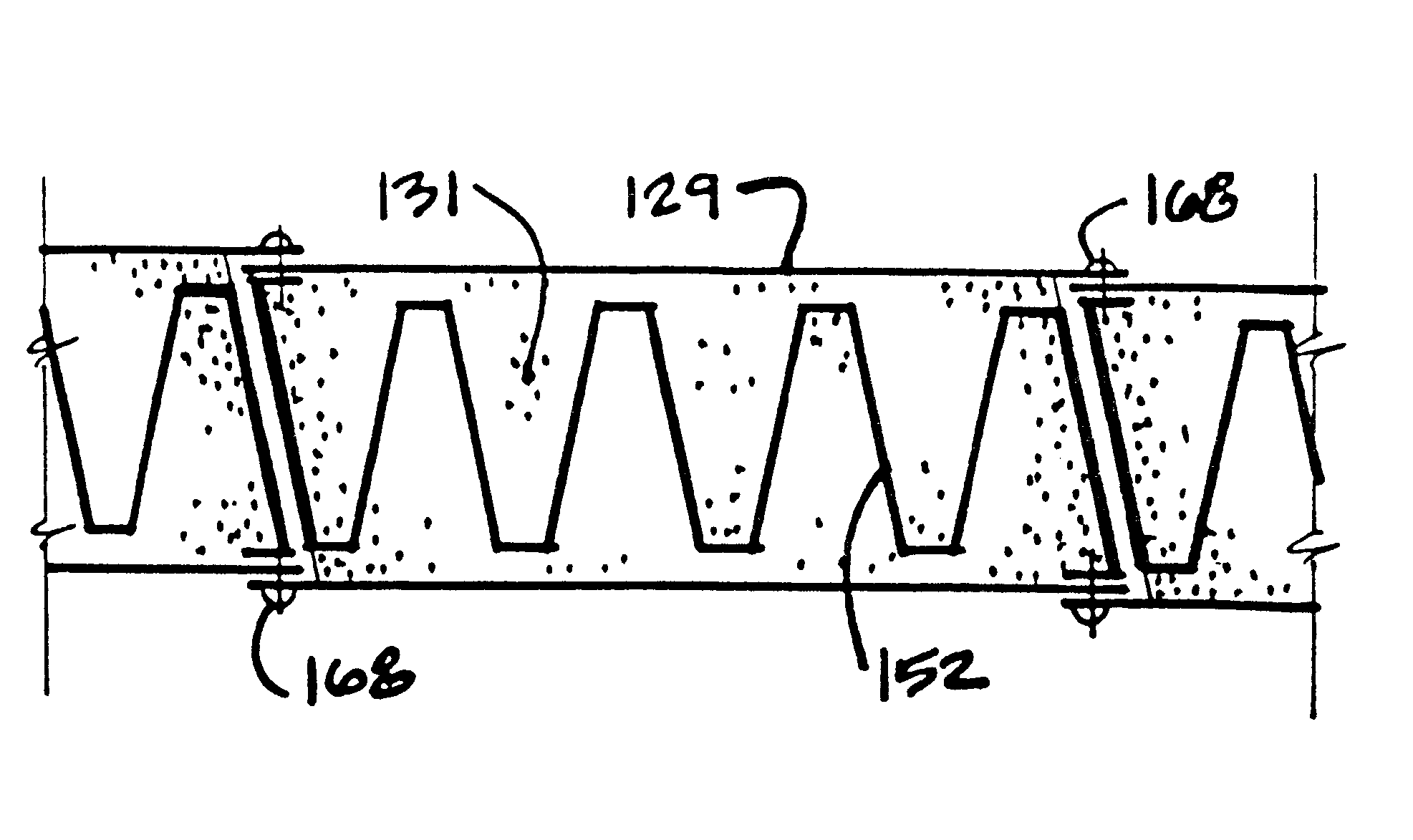

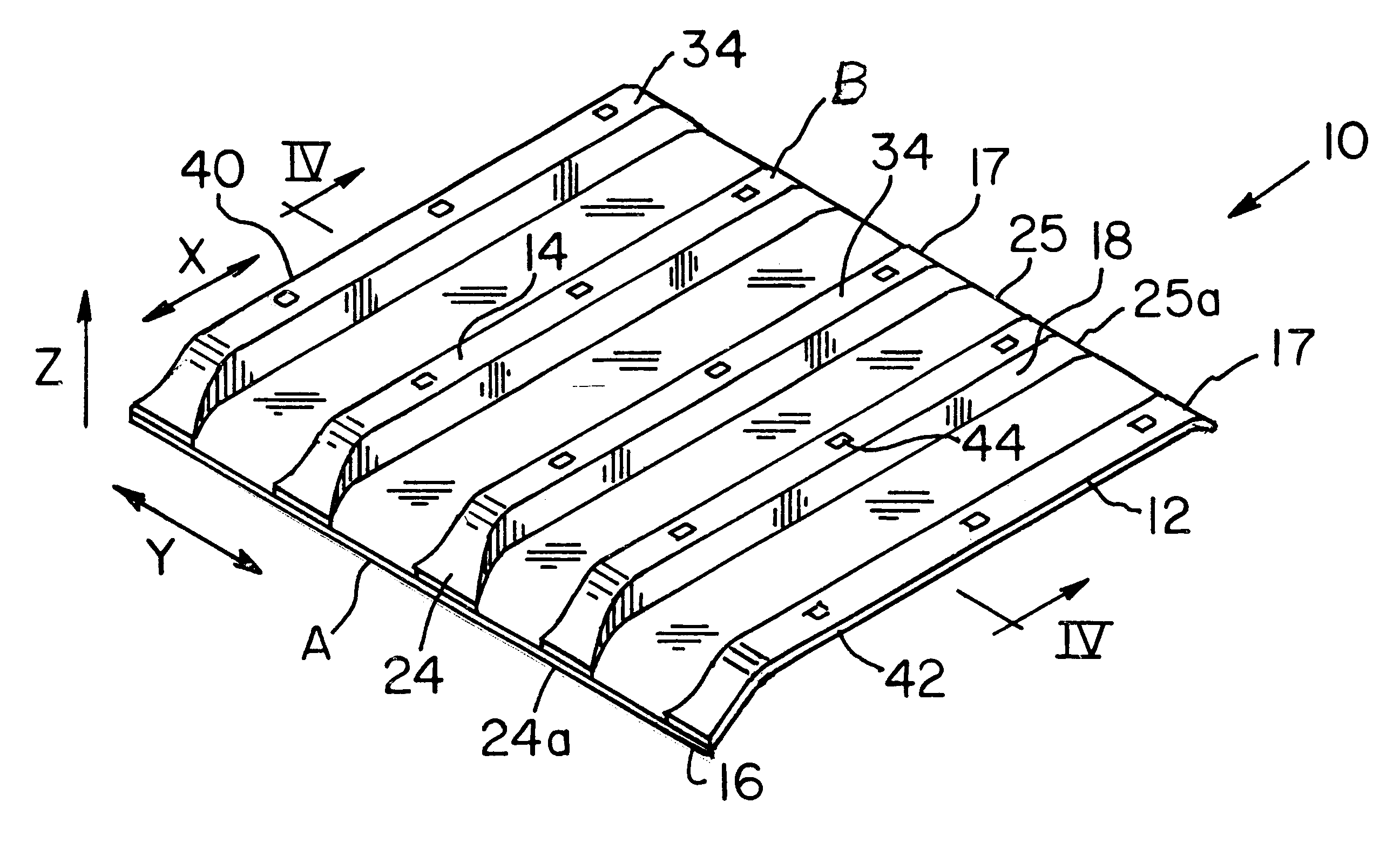

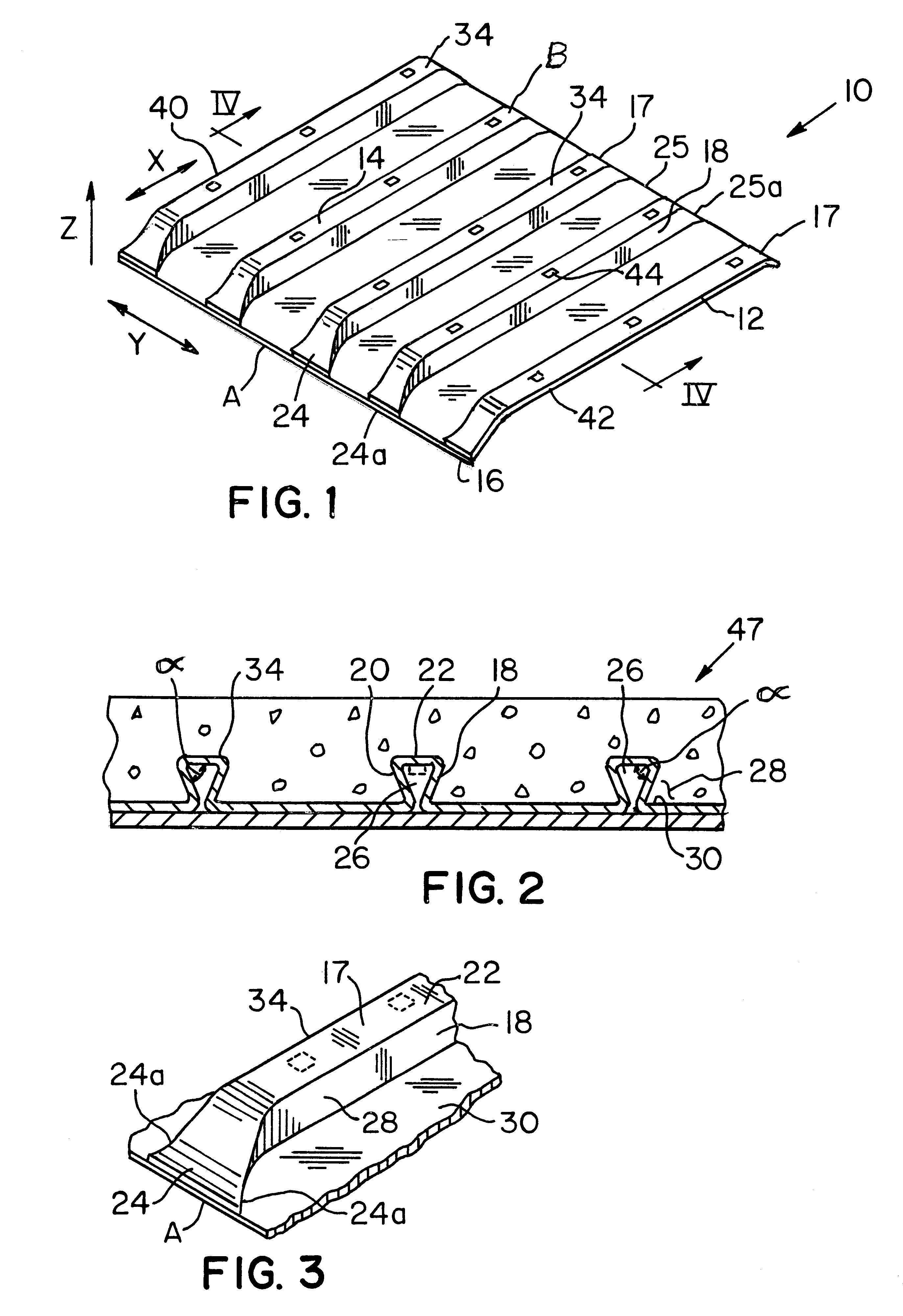

Composite deck

InactiveUS6357191B1Improve the quality of sound insulationImproved rodent and insect controlBuilding roofsCeilingsComposite slabMechanical engineering

A ribbed metal plate for a composite slab that includes a substantially planar plate having an upper surface and a lower surface and a plurality of laterally-spaced, longitudinally-extending ribs that have a keystone profile and wherein the sidewalls are angled toward each other. Ends of the ribs are integrally formed. The rib plate is secured to bearing walls in a structure and concrete is poured on the ribs to form a composite deck. The ends of the ribs extend in the lateral direction to form a composite structure retarding movement of cured concrete in a longitudinal direction. The ribbed plate can also be used in composite beams.

Owner:EPIC METALS

Fireblocking device

ActiveUS7540118B2Low costInexpensive materialsBuilding roofsRoof covering using slabs/sheetsEngineeringProcess plant

Fireblocking device for preventing transfer of fire through ventilating apertures or similar passages, in openings for thermal fire ventilation, in ventilation ducts, in process plants or in vented facade exteriors, in vented fire blankets, vented fire protective curtains or vented protective screens against explosions. The device includes a combination of a heat absorbing and heat storing body, and an element which includes and / or adsorbs and intumescent material.

Owner:SCUTI

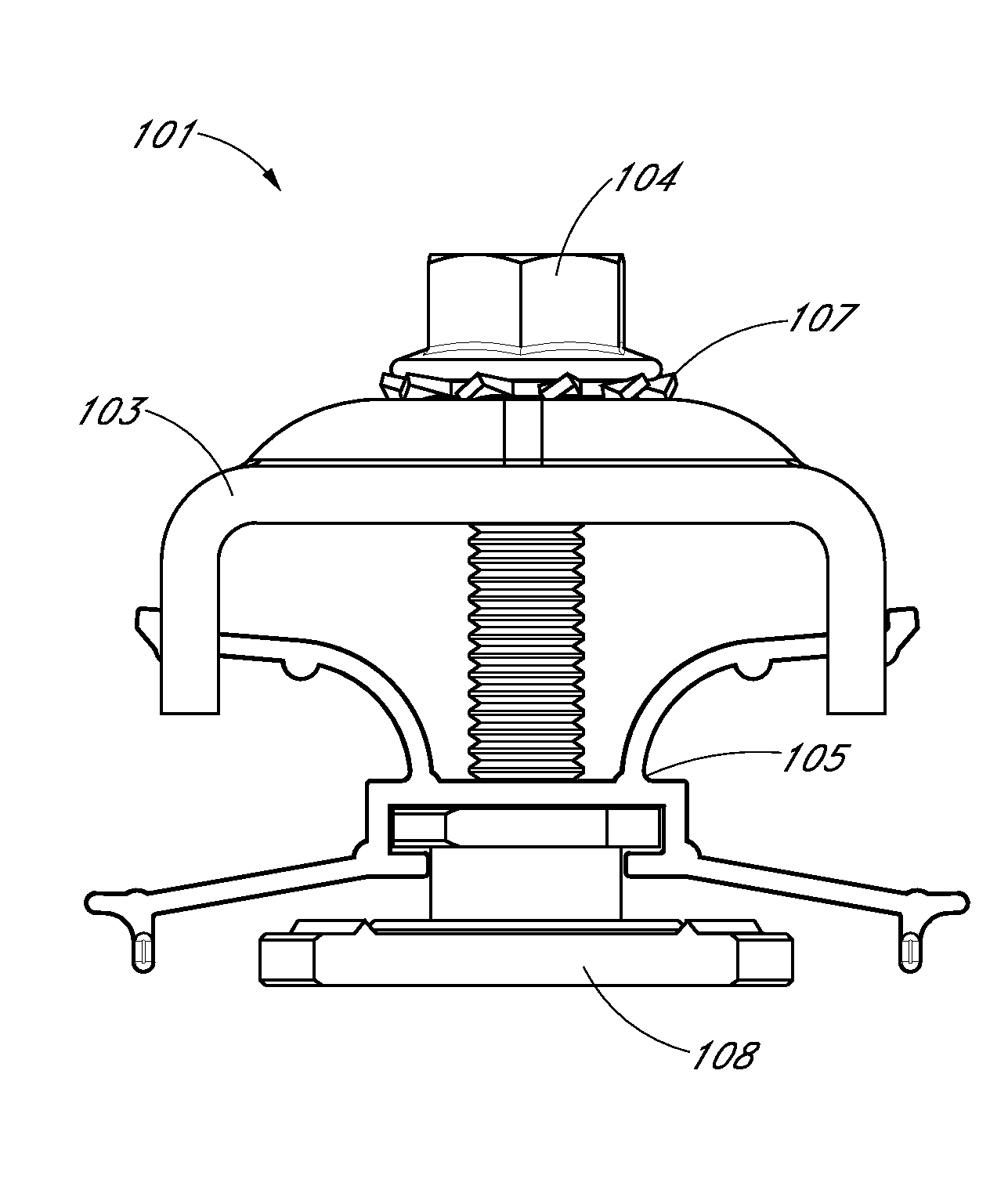

End clamps for solar systems

ActiveUS20150249423A1Prevent rotationSufficient clearancePhotovoltaic supportsBuilding roofsEngineeringSolar power

A solar power system can include an array of solar modules. The system can include a rail and a solar module positioned at an outer end of the array. The solar module can have a frame around a periphery of the solar module. The frame can include a flange along an edge of the solar module that is disposed at the outer end of the array. The flange can project inwardly from the frame underneath the solar module. A clamp assembly can be disposed underneath the solar module and can mechanically secure the solar module to the rail. The clamp assembly can include a clamp body and a base. The clamp body and the base can cooperate to clamp the flange between the clamp body and the rail.

Owner:SUNPOWER CORPORATION

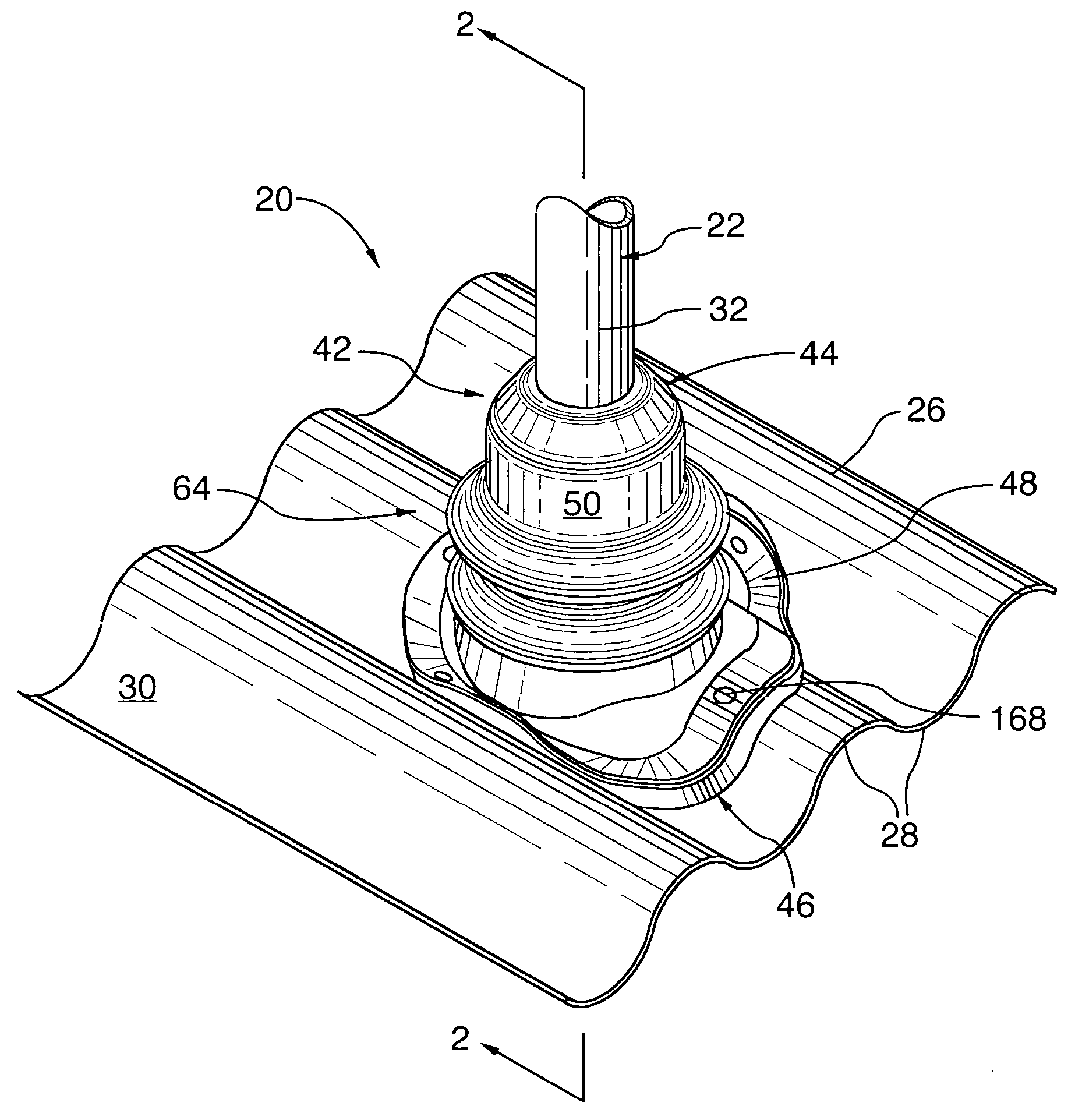

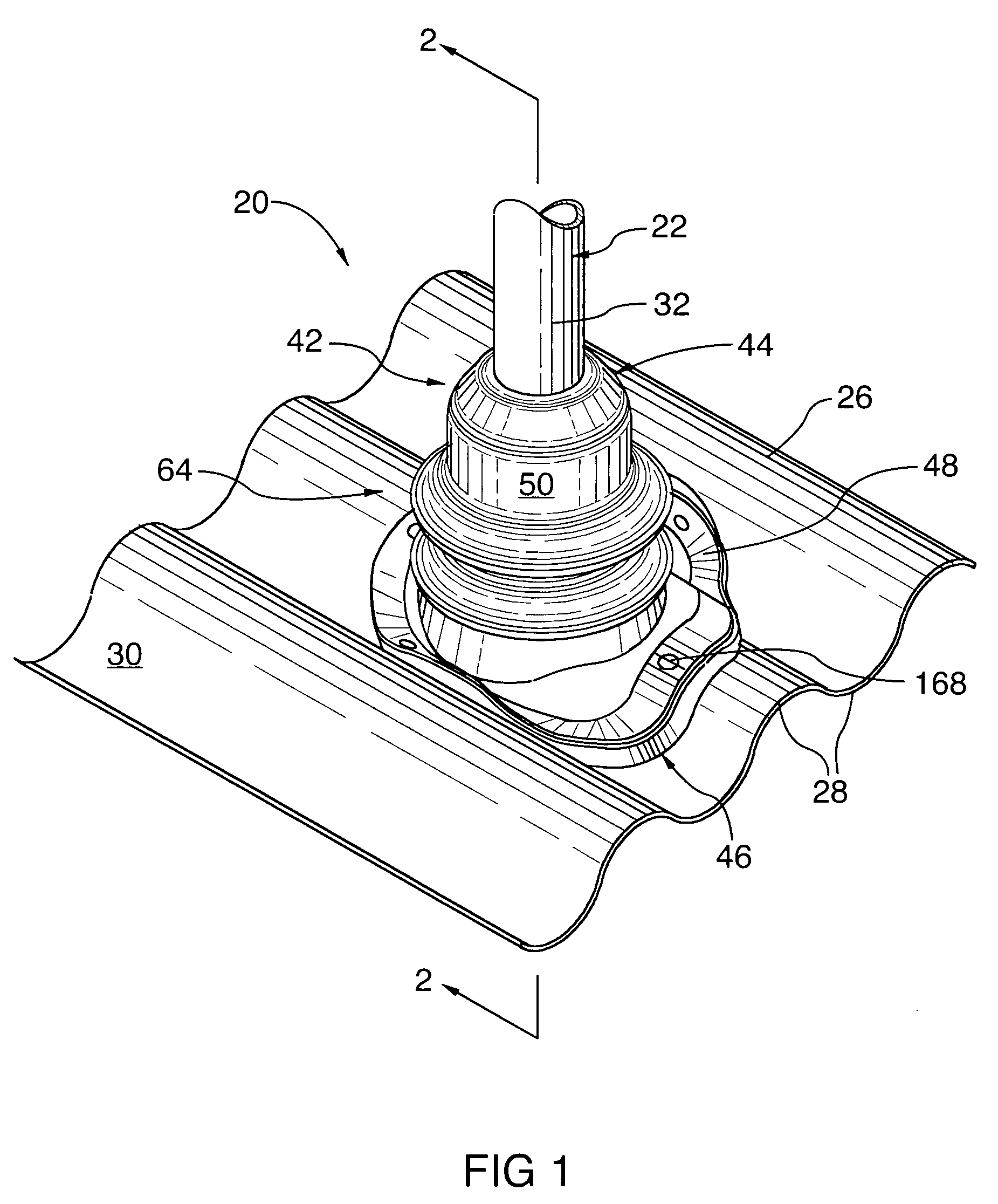

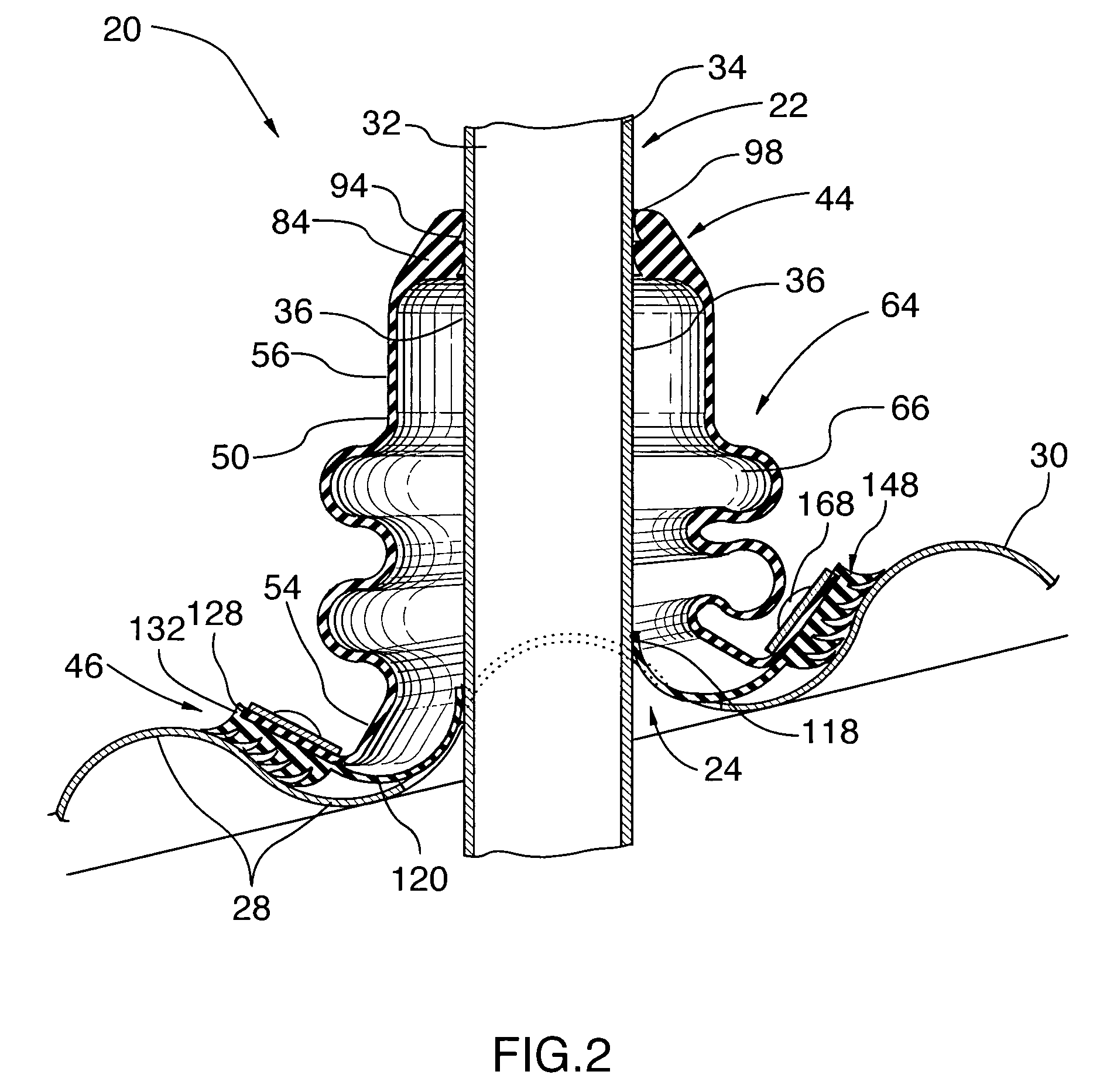

Roof flashing assembly

The present invention relates to a roof flashing assembly for use on a sloped roof surface having an elongate projection extending substantially upwardly therefrom in skewed relation thereto. The roof flashing assembly has a resilient, flexible, sleeve sized to fit over, and surround, the projection. The sleeve has a base portion, a neck portion and a passageway defined therebetween for receiving the projection therethrough. A bellows tube is formed on the neck portion to permit the sleeve to flex adaptively to accommodate for the skewed orientation of the projection relative to the sloped roof surface. The roof flashing assembly also includes a grommet which is positionable in surrounding relation with the projection. The grommet has three beveled lip members, which frictionally sealingly engage the exterior surface of the projection when urged in abutting relation therewith. An annular gasket positionable below the base portion of the sleeve, is also provided. The gasket frictionally sealingly engages the external surface of the projection. When urged in abutting relation with the sloped roof surface, flexible ring seal members formed on the underside of the gasket create a watertight seal with the roof surface. During installation, anchoring means are used to secure the sleeve and the gasket to the sloped roof surface.

Owner:THALER KEN

Tornado and hurricane roof tie

InactiveUS6931813B2Easily damagedResist upward liftBuilding roofsBuilding reinforcementsUltimate tensile strengthRafter

A building roof tie for attaching roof trusses and rafters to wood top plates in building structures, such roof tie having a sheet metal body with risers and a bridge for overlapping a rafter and flaps for wrapping on the sides of the top plate. A generally triangular shaped reinforcing wing provides strength and stability, and can also provide additional hold-down strength, allowing the roof tie to be manufactured from different weights of steel. Turnbuckles attached to the bridge provide additional hold-down strength against increased uplift forces. The roof ties are pitched to conform to a variety of framing applications. A plurality of apertures is formed in the roof tie to provide openings for fasteners for connecting the tie to the wood top plate and rafter.

Owner:COLLIE ANTHONY D

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com