Patents

Literature

33 results about "Second law of thermodynamics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

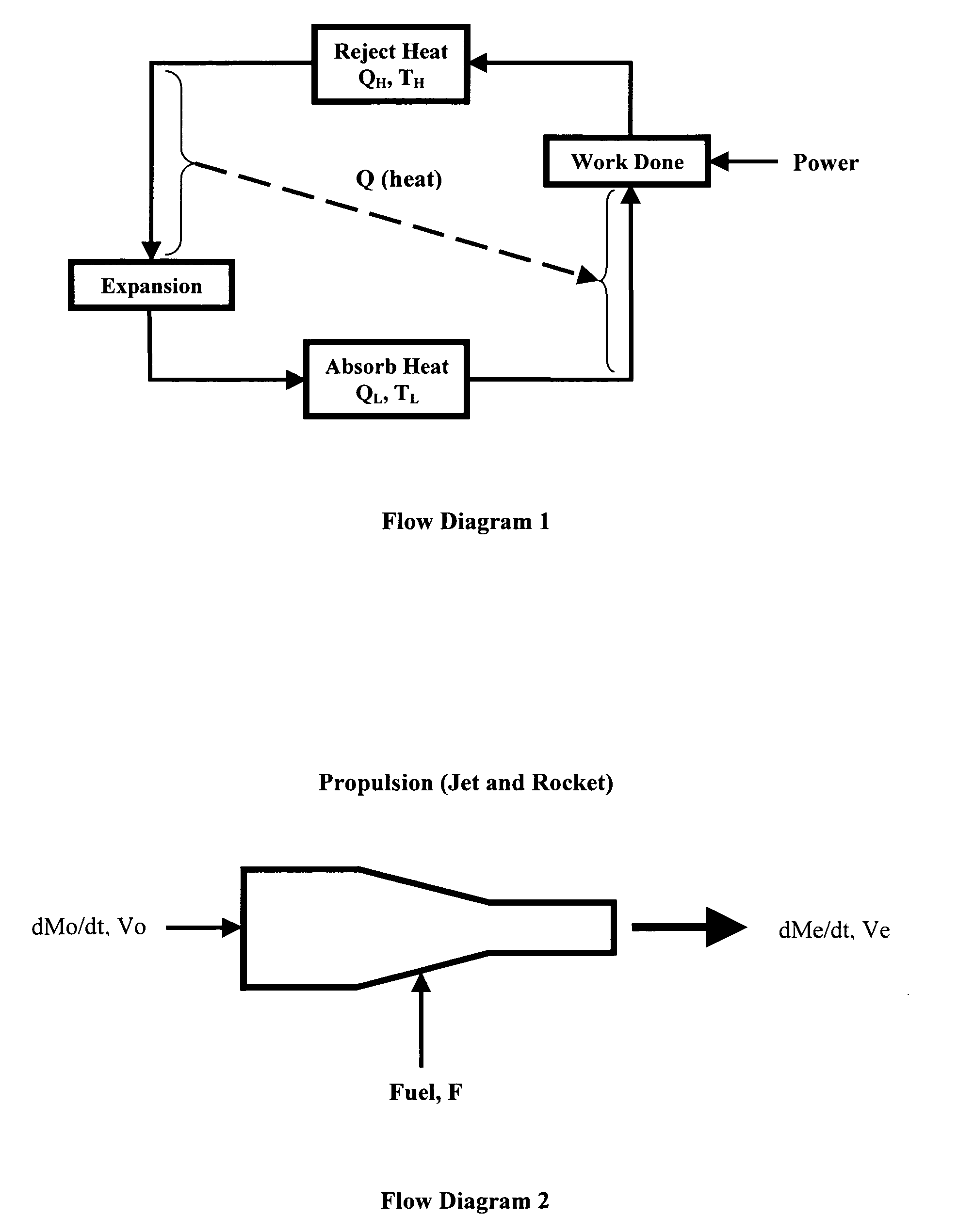

The second law of thermodynamics states that the total entropy of an isolated system can never decrease over time. The total entropy of a system and its surroundings can remain constant in ideal cases where the system is in thermodynamic equilibrium, or is undergoing a (fictive) reversible process. In all processes that occur, including spontaneous processes, the total entropy of the system and its surroundings increases and the process is irreversible in the thermodynamic sense. The increase in entropy accounts for the irreversibility of natural processes, and the asymmetry between future and past.

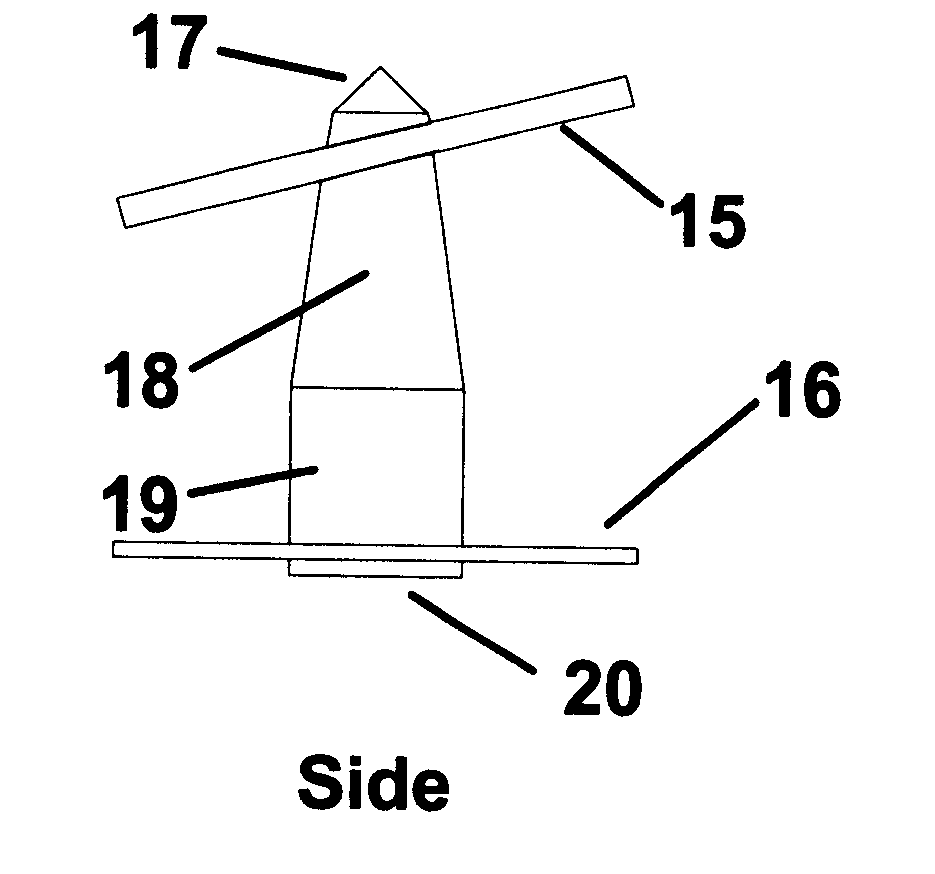

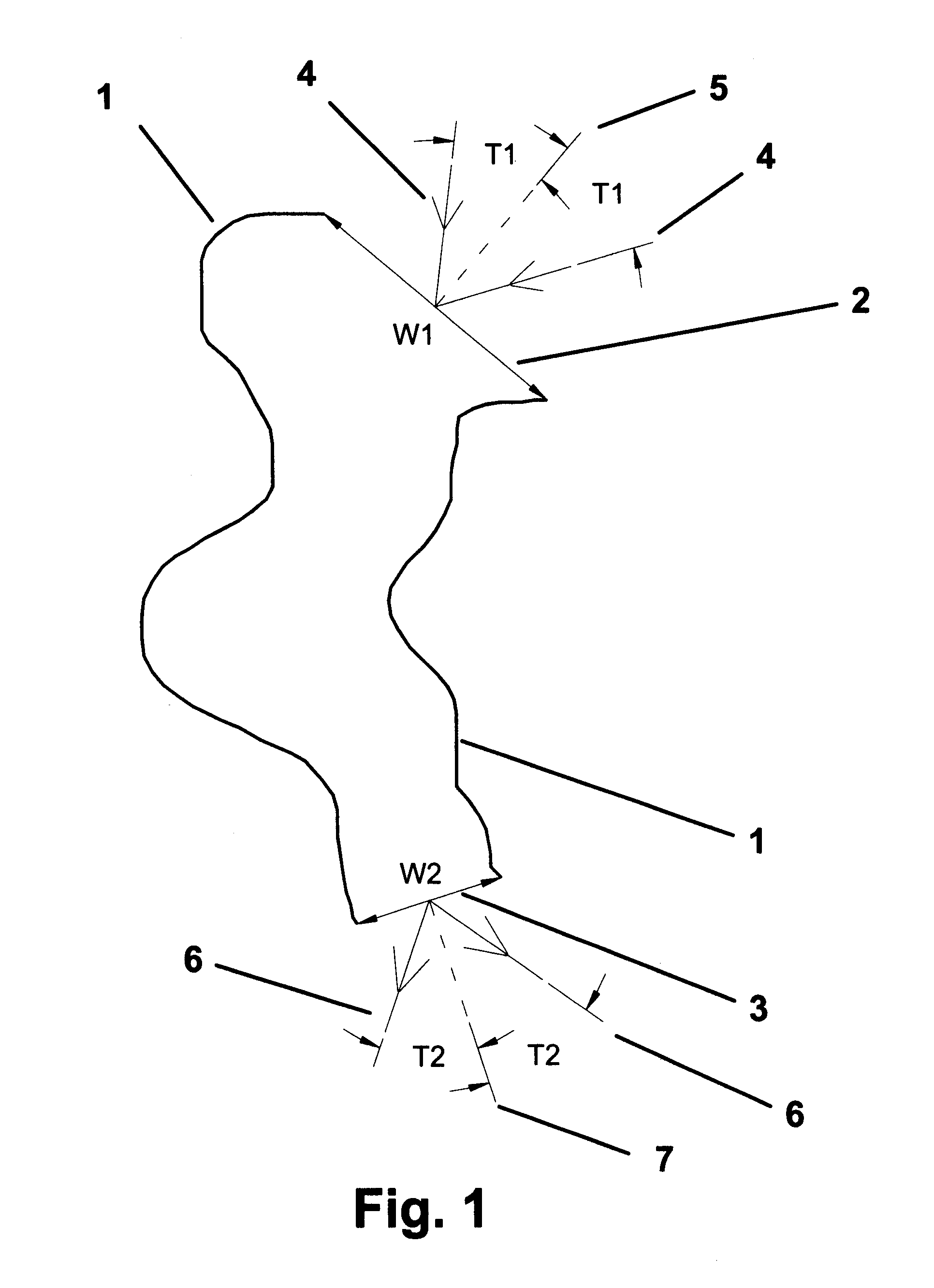

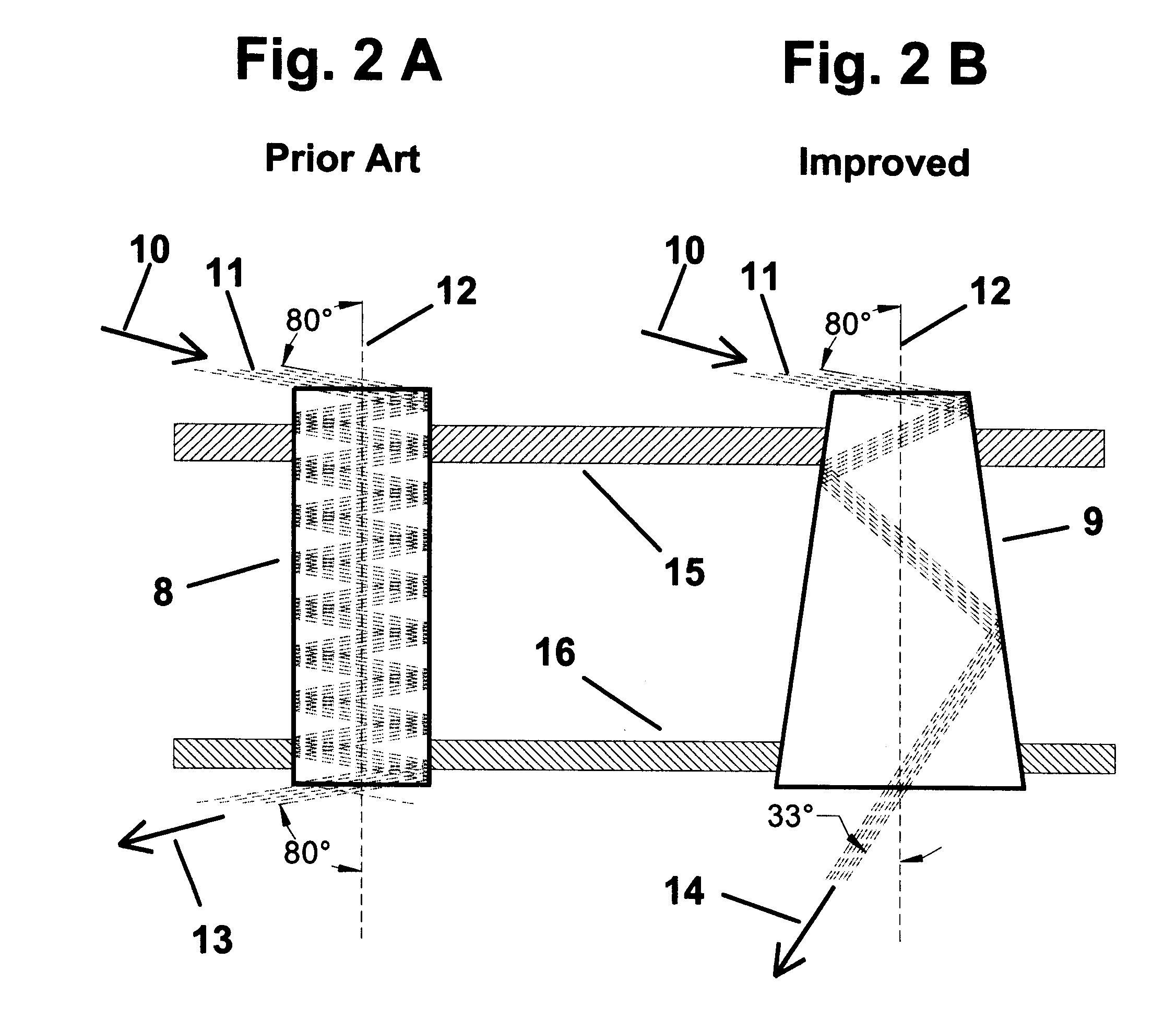

Passive collimating tubular skylight

InactiveUS6363667B2Convenient lightingImproved passive tubular skylightsBuilding roofsCeilingsEngineeringSpecular reflection

A passive collimating tubular skylight consisting of a radiant energy-collecting aperture, a radiant energy-delivering aperture, and a radiant energy passageway between these two apertures, the passageway having a specularly reflective interior surface and a configuration to improve the collimation of the radiant energy passing therethrough. The skylight can be configured with the radiant energy-collecting aperture located above the roof of a building, oriented to collect sunlight; and equipped with a sealed weatherproof glazing, with the radiant energy-delivering aperture, or luminaire, located at ceiling level within the building, and equipped with a diffusing glazing; and with the reflective tubular light passageway constructed with a larger cross sectional area near the radiant energy-delivering aperture than near the radiant energy-collecting aperture. In complete accord with the second law of thermodynamics, and as proven by experimental results, the new passive collimating tubular skylight provides significant advantages over the prior art, including better solar energy collection, higher throughput optical efficiency, improved radiant energy collimation, enhanced interior illumination levels, and more precise positional control of the interior illumination.

Owner:ENTECH INC

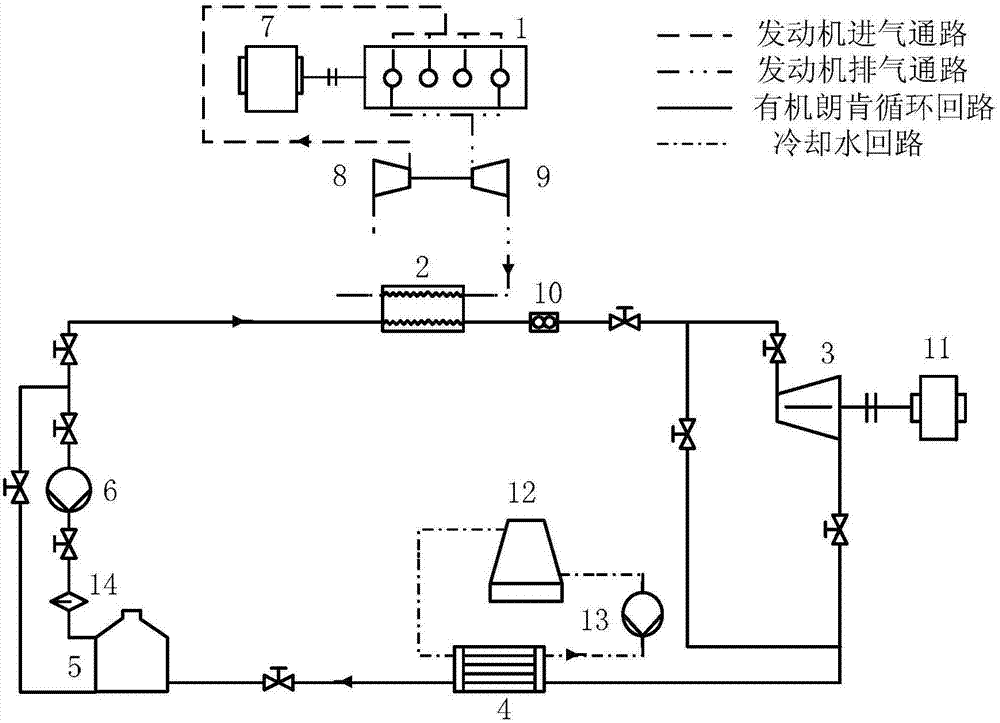

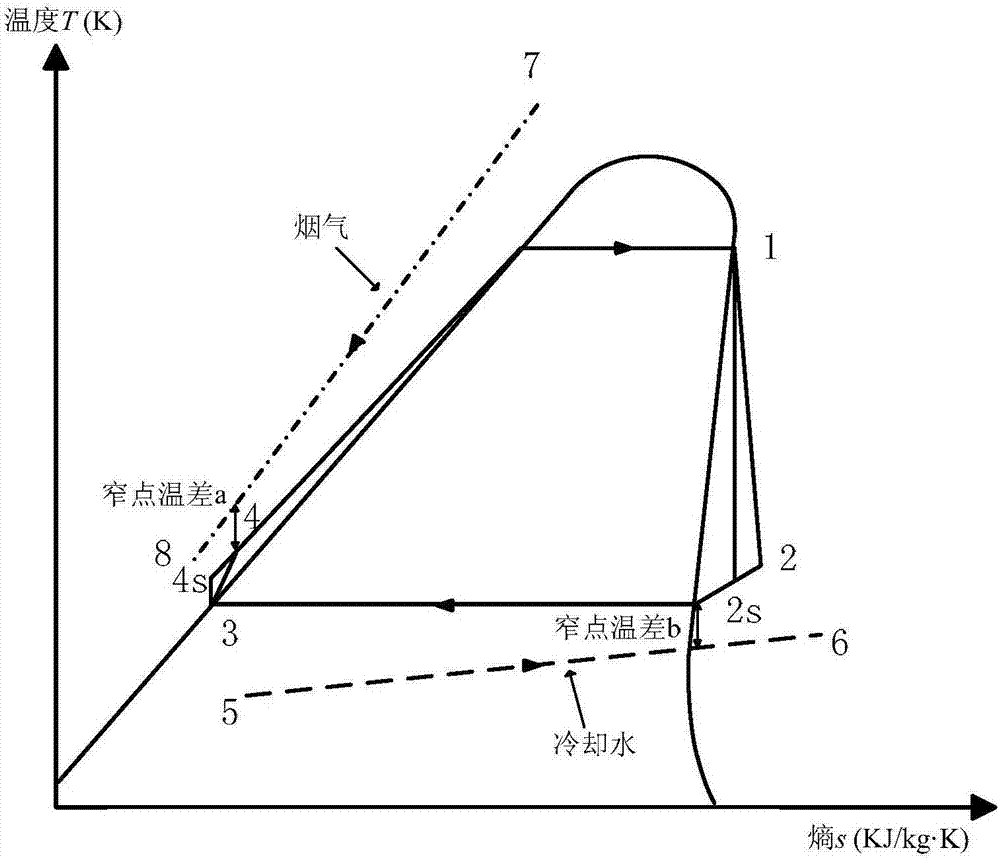

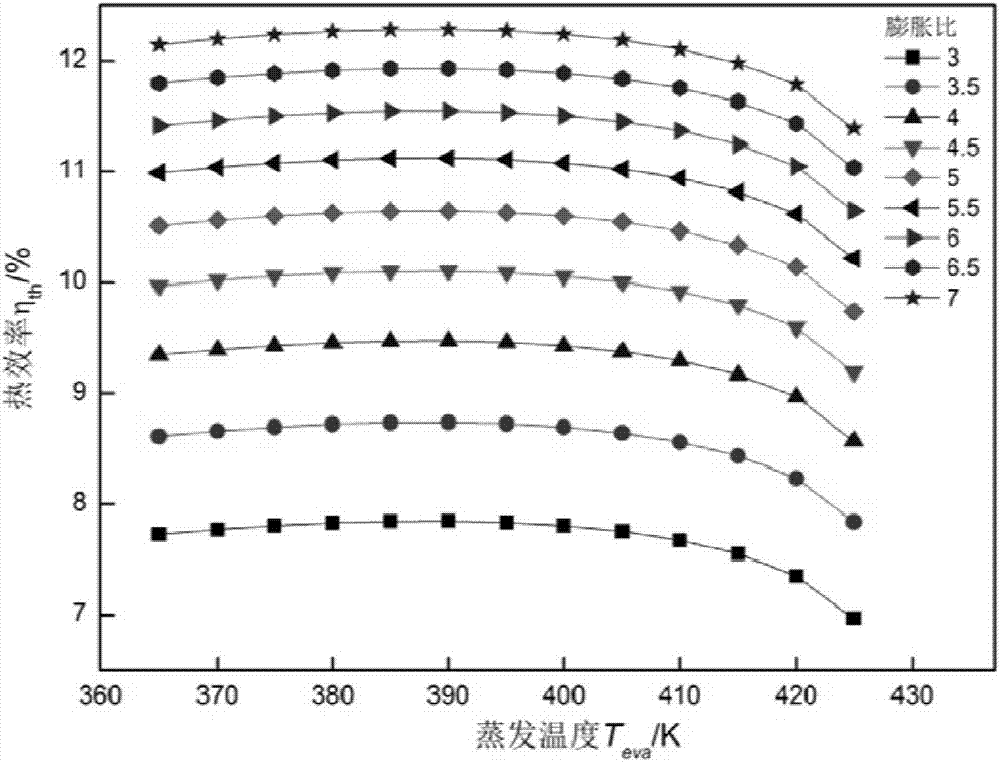

Optimization method for determining flue gas excess heat organic Rankine cycle system parameter

InactiveCN107016187AIncrease profitEmission reductionGeneral water supply conservationForecastingOrganic Rankine cycleSecond law of thermodynamics

The invention provides an optimization method for determining a flue gas excess heat organic Rankine cycle system parameter. The optimization method comprises the steps of taking into account of a cooling water cycle to establish a thermodynamic model; through a first law of thermodynamics and a second law of thermodynamics, obtaining system net output power, water pump waste power, heat efficiency, (the formula is shown in the description) efficiency and irreversible loss, and according to the influence of an evaporation temperature and an expansion ratio on system thermodynamic performance, determining an optimal evaporation temperature; under the optimal evaporation temperature, calculating heat exchange areas of an evaporator and a condenser, wherein it is defined that an economical objective function is the ratio of the system net output power to the area of the evaporator to the area of the condenser, and the comprehensively evaluation function is the weighted sum the economical objective function (the formula is shown in the description) and the efficiency; with the comprehensive evaluation function being an optimization target, determining an optimal condensation temperature; according to the optimal evaporation temperature and the optimal condensation temperature, determining system parameters of work medium mass, cooling water mass, evaporation pressure, condensation pressure, an expansion ratio, the net output power, the heat efficiency and the irreversible loss. According to the optimization method for determining the flue gas excess heat organic Rankine cycle system parameter, the optimal evaporation temperature and the condensation temperature can be determined, and thus the optimal system parameter is determined.

Owner:TIANJIN UNIV

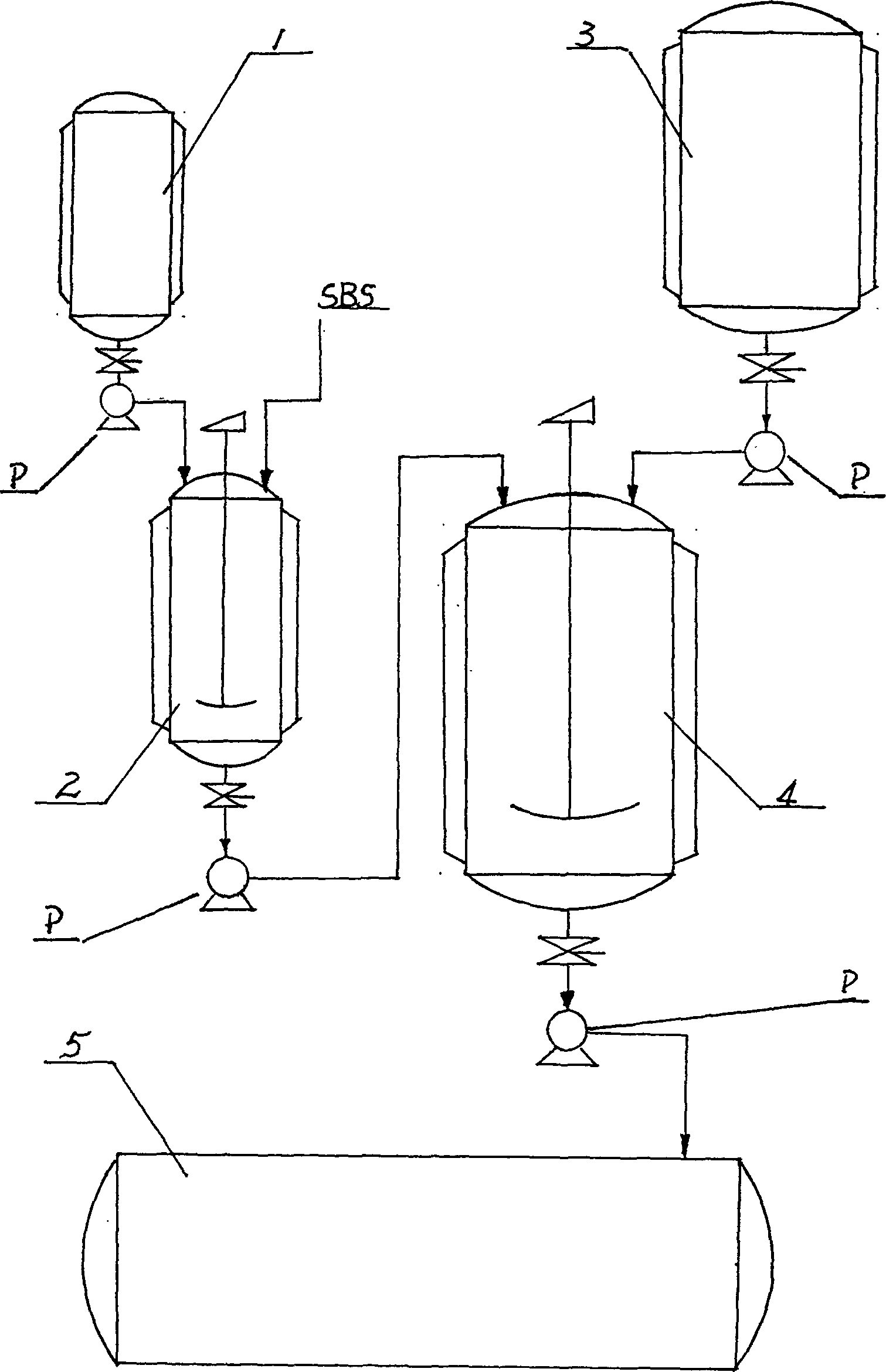

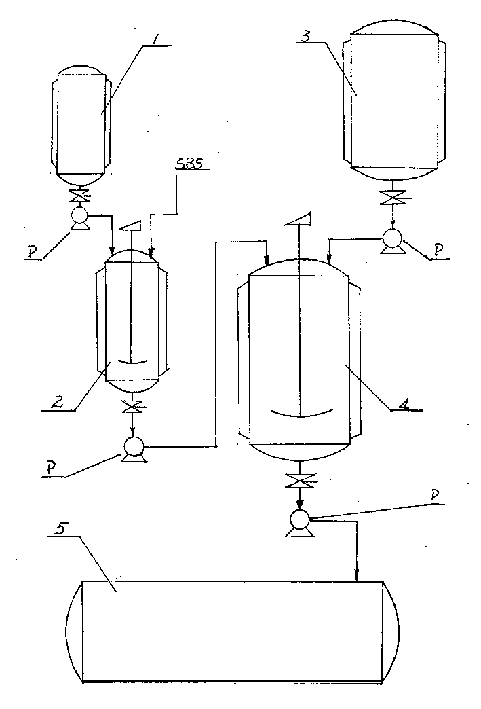

Modified asphalt and its preparation method

InactiveCN1414038AReduce consumptionReasonable workmanshipBuilding insulationsThermoplastic elastomerSolvent

A modified asphalt is prepared through preparing the homogeneous body from cosolvent, refined furfural oil, and thermoplastic elastomer SBS, through hot mixing and stirring, and mixing it with the heated asphalt. Its advantages are no coagulation and educing, and low cost.

Owner:大连市政设施管修处

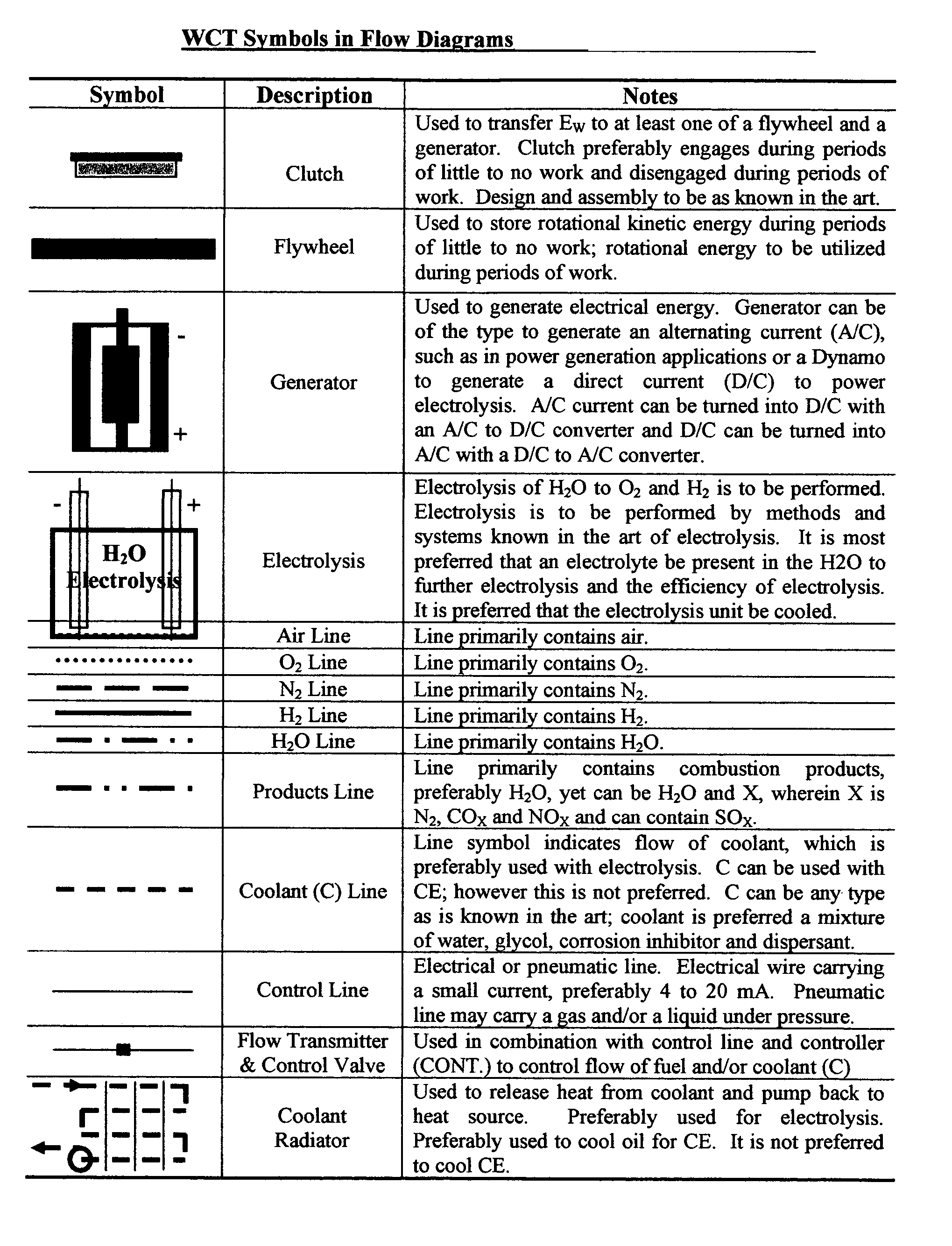

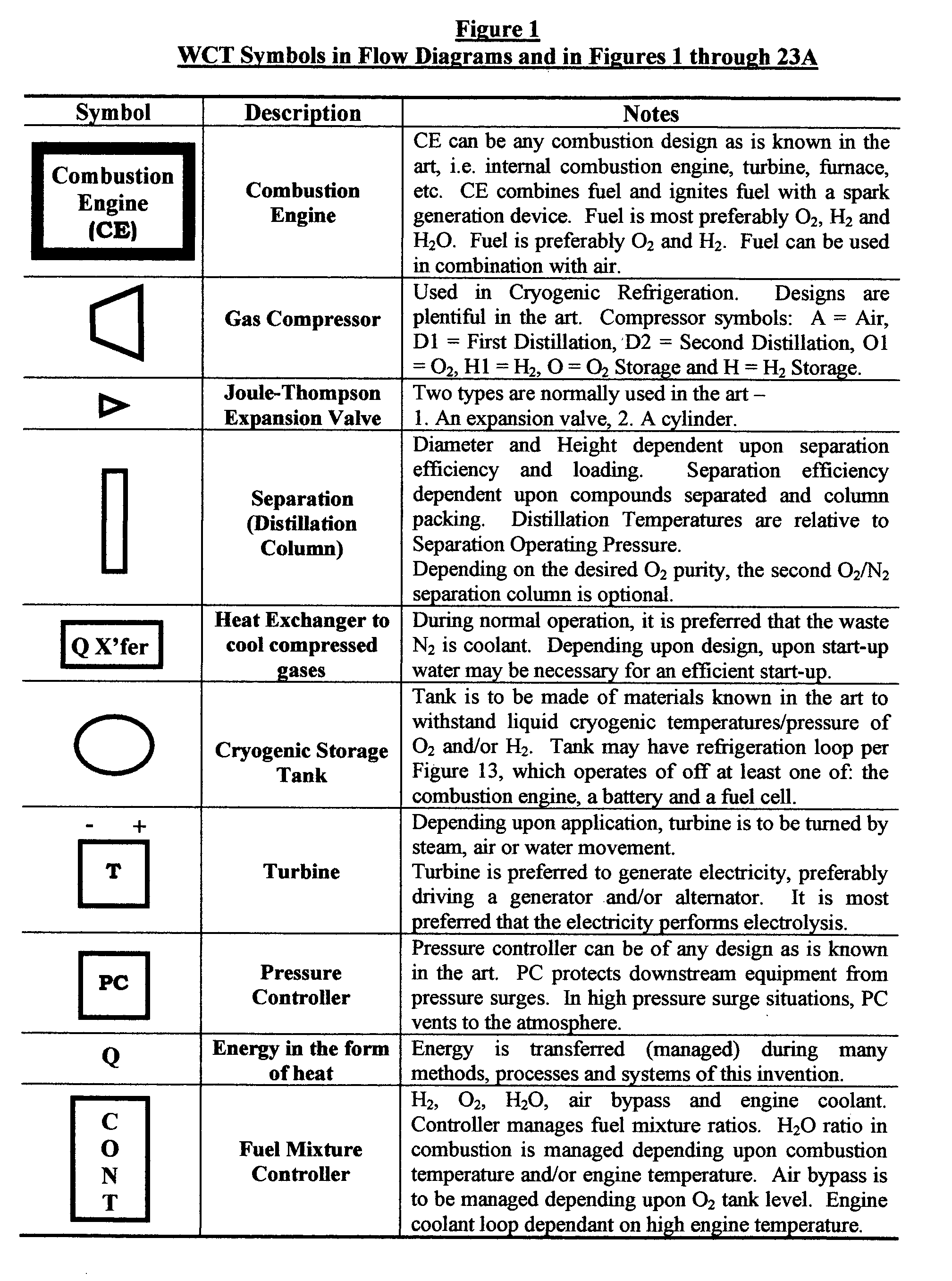

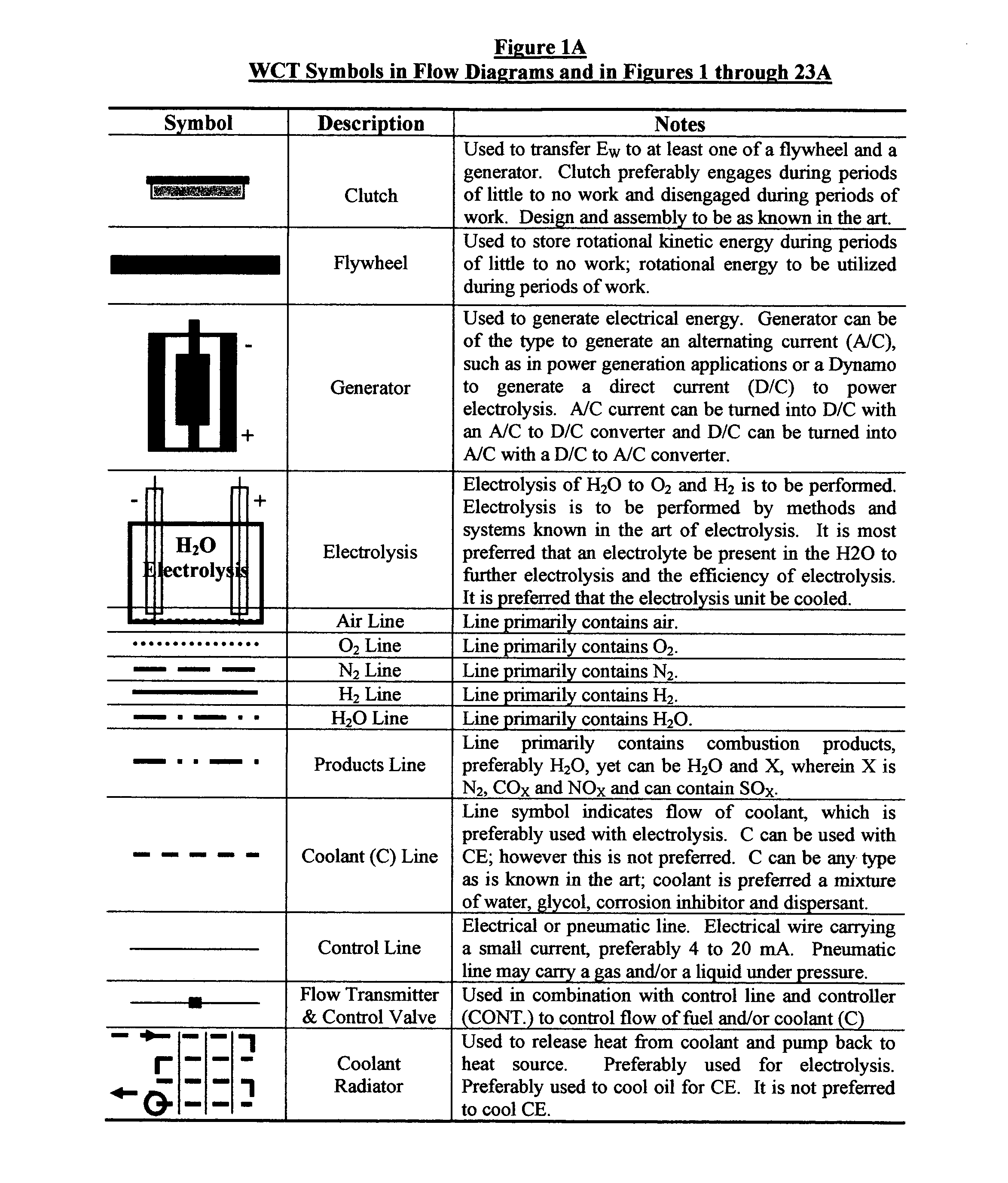

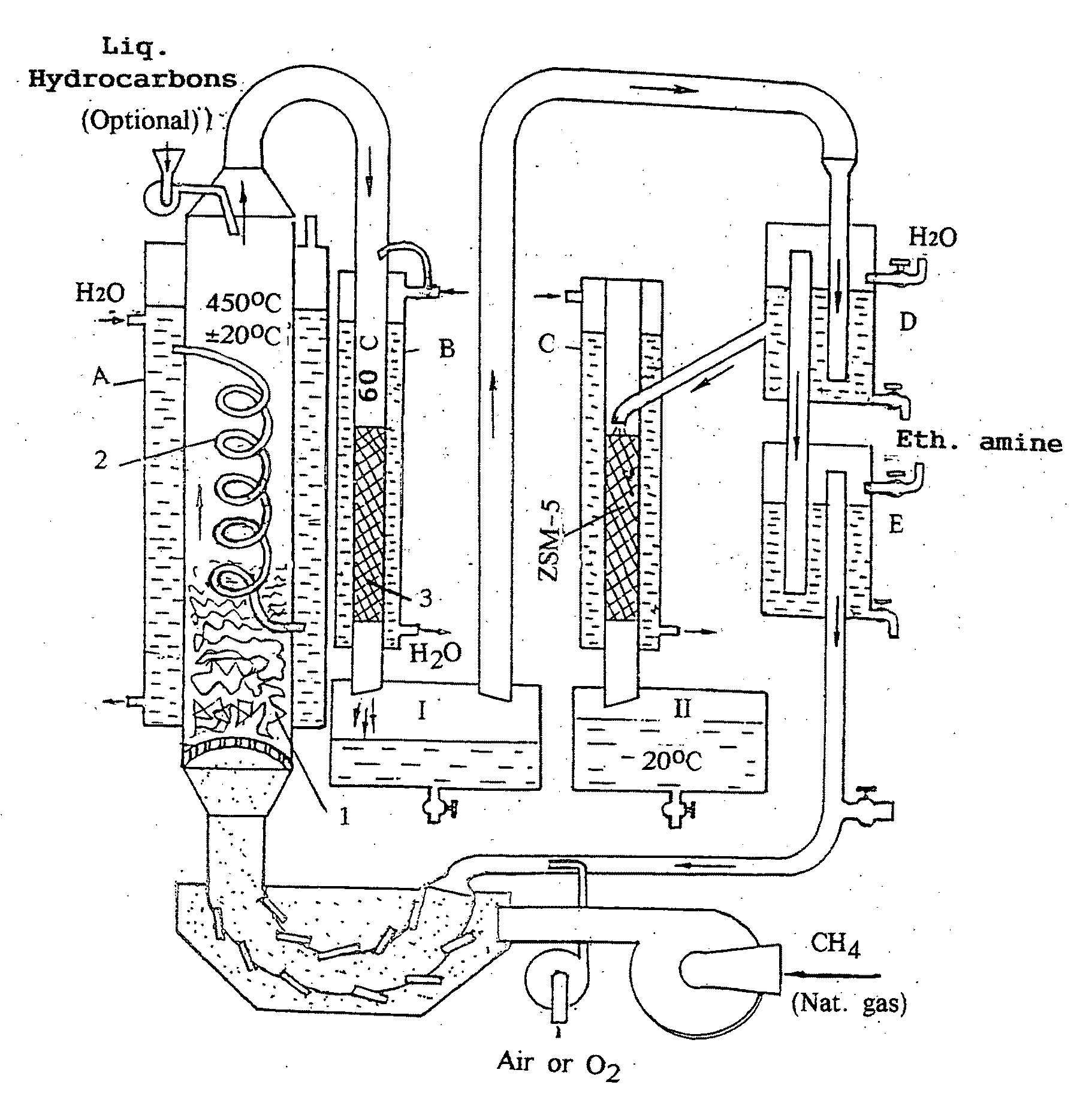

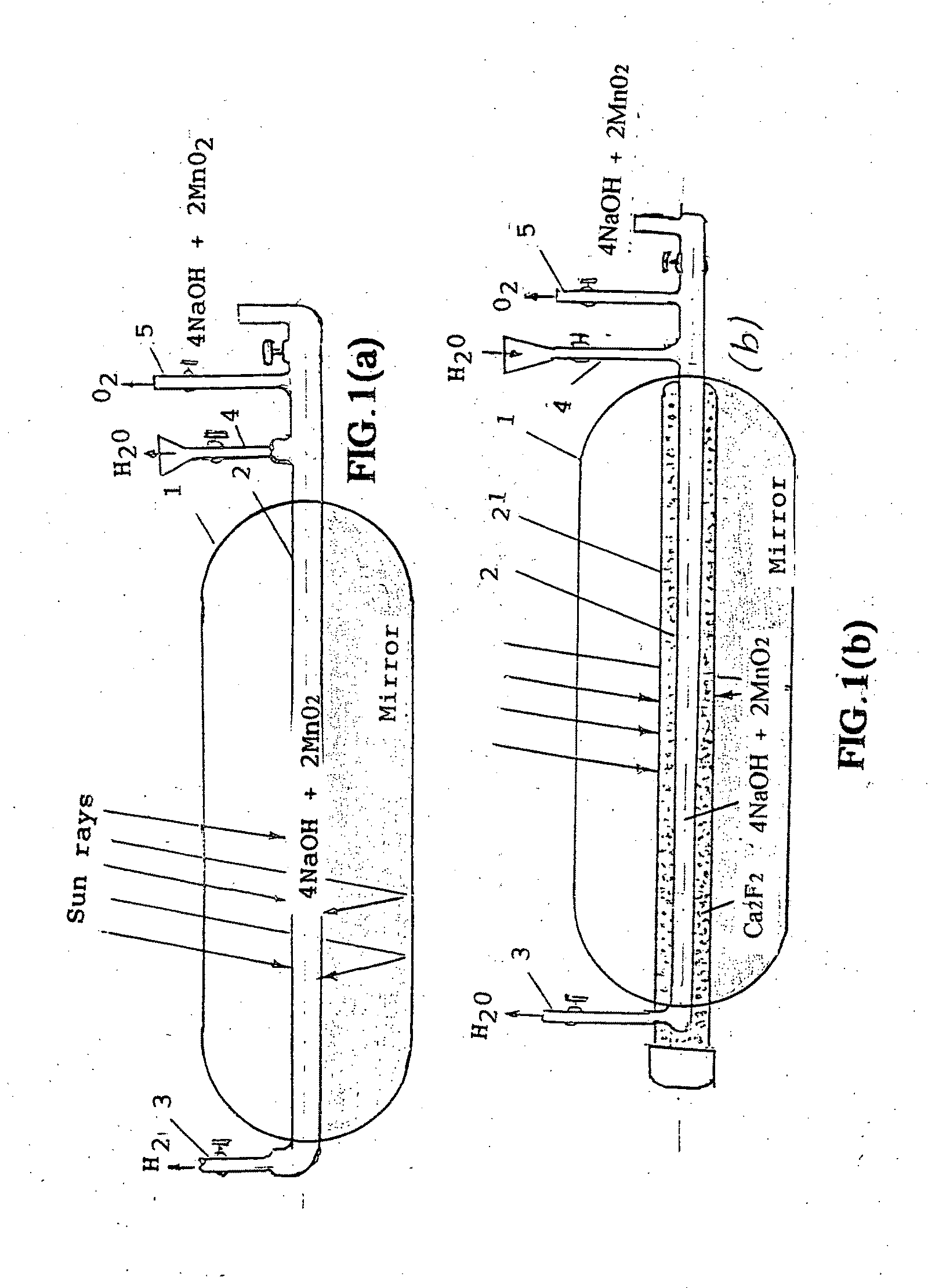

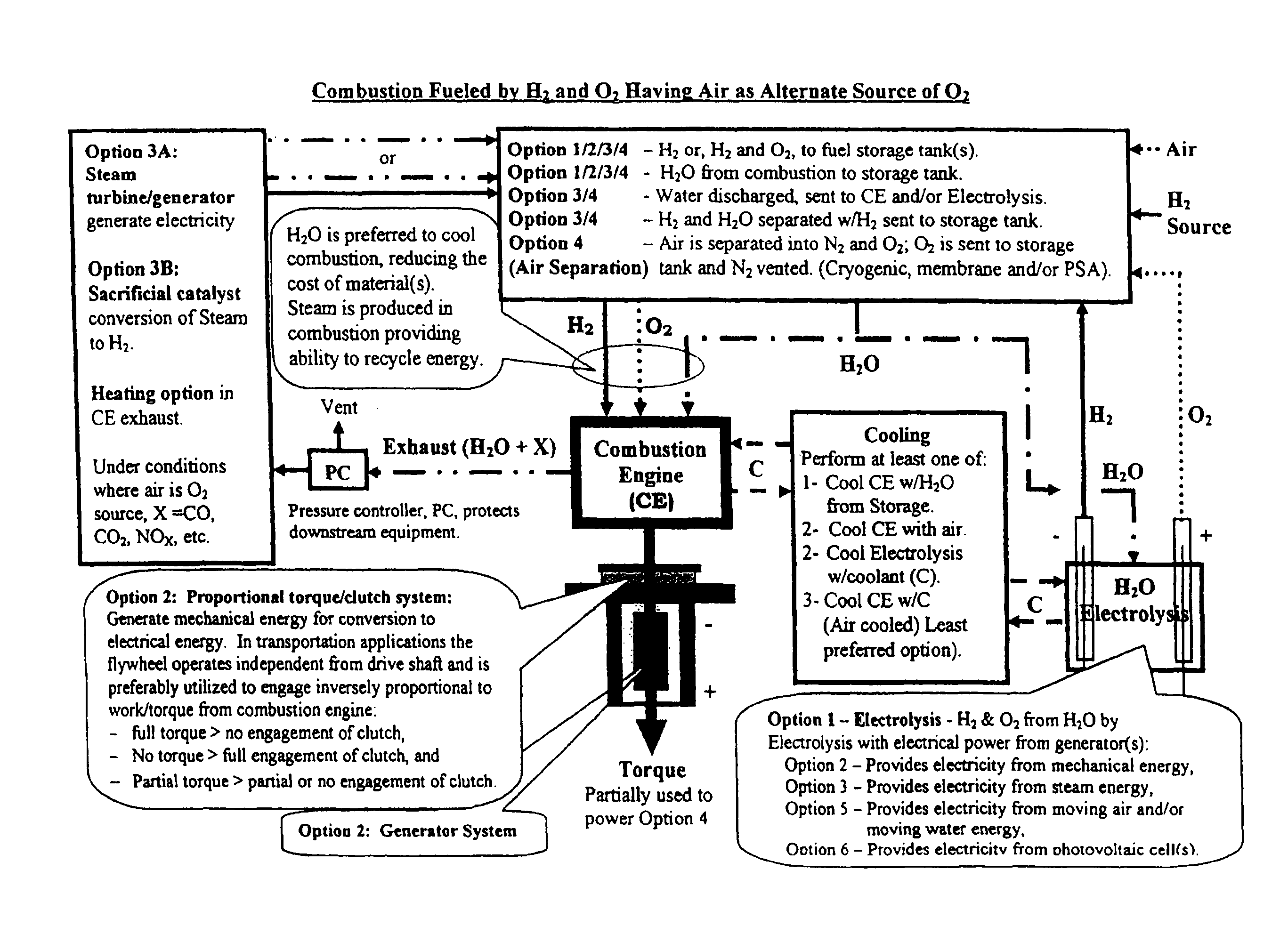

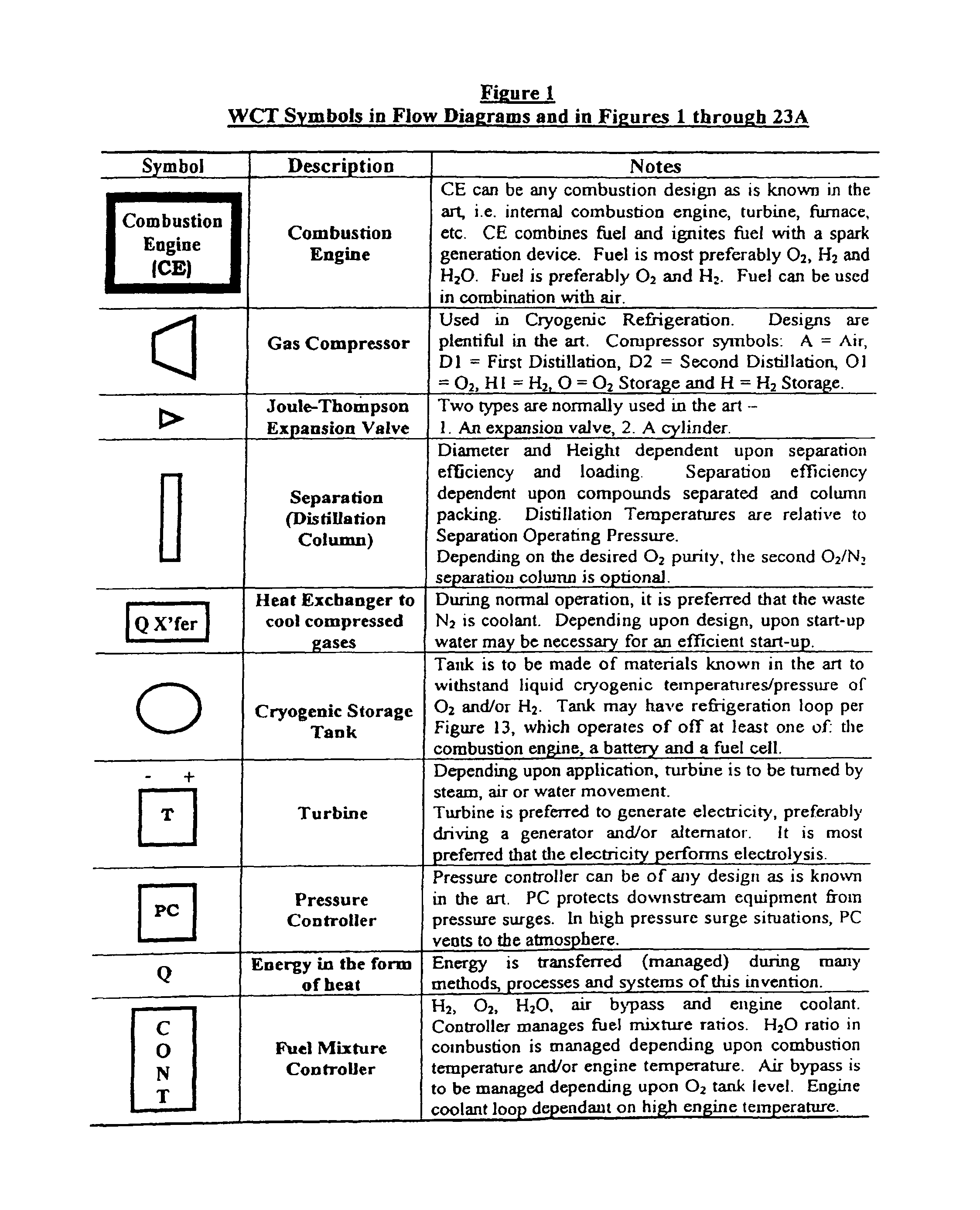

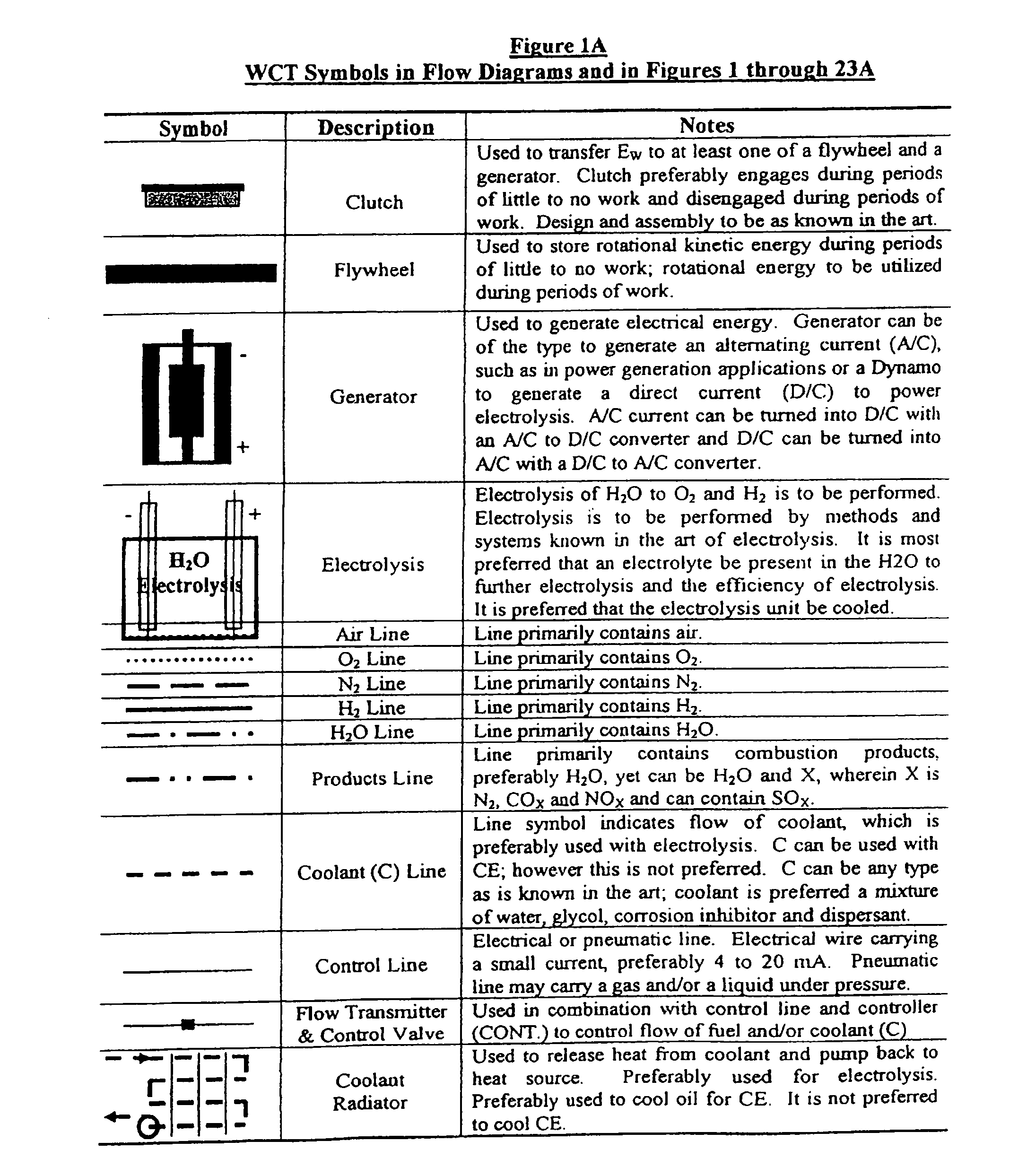

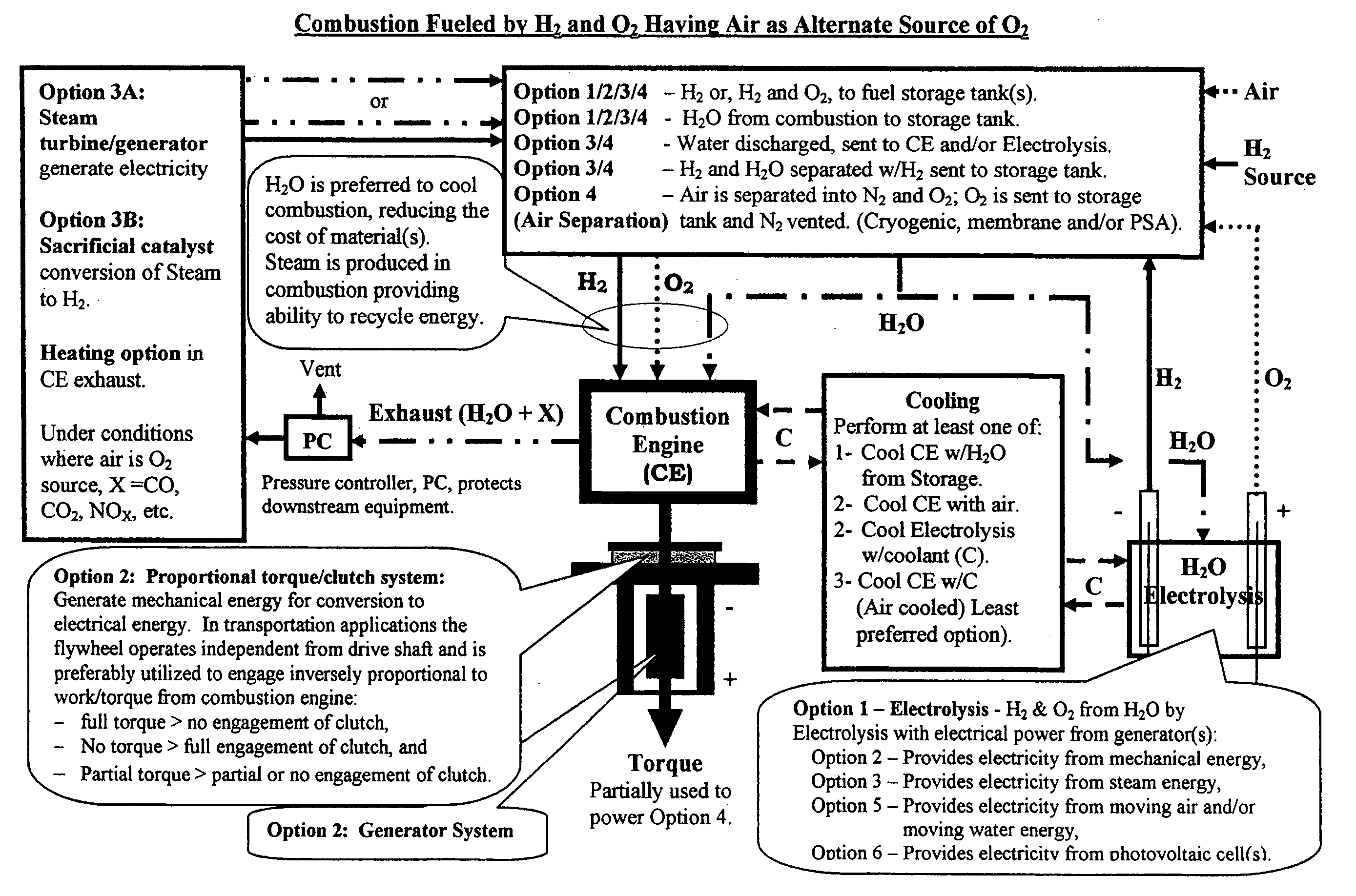

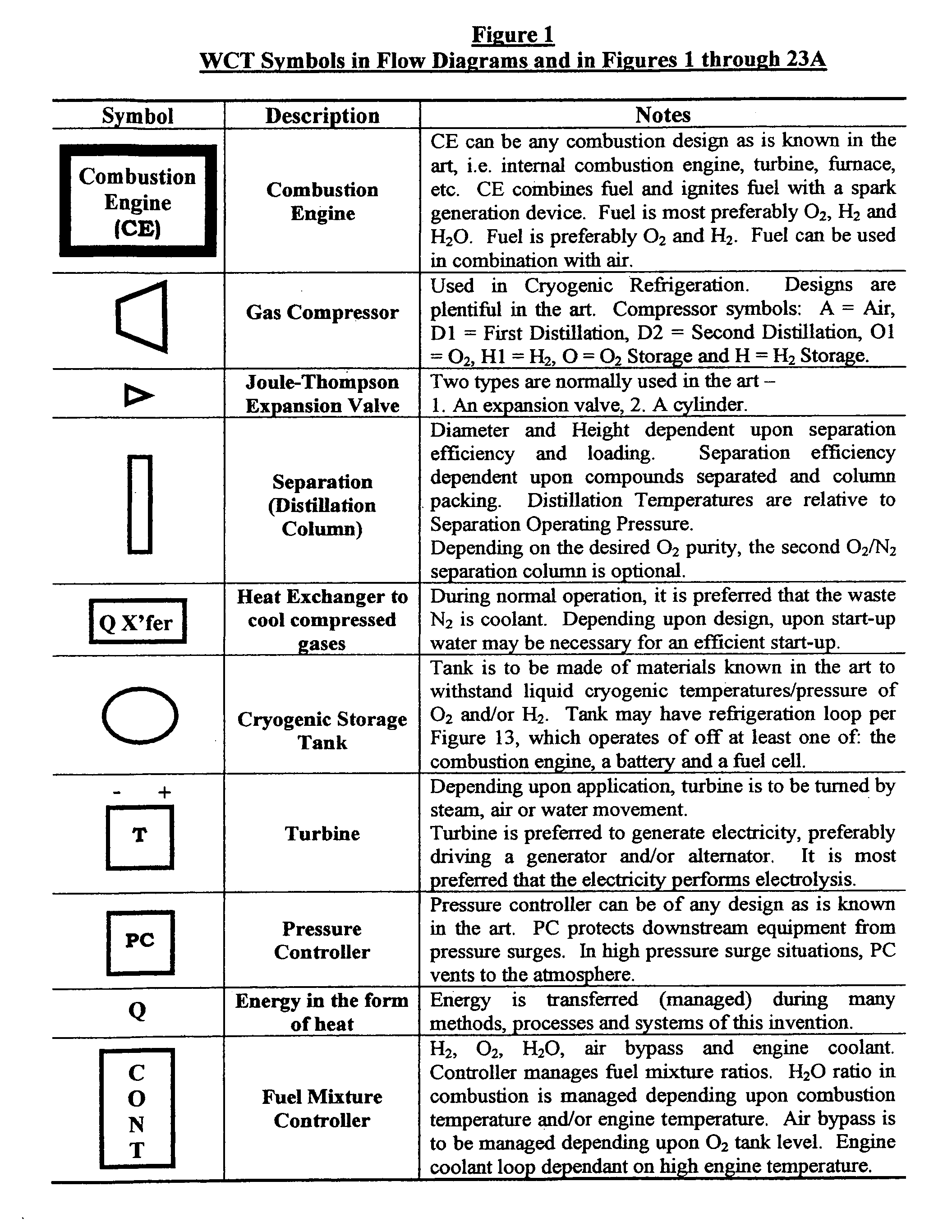

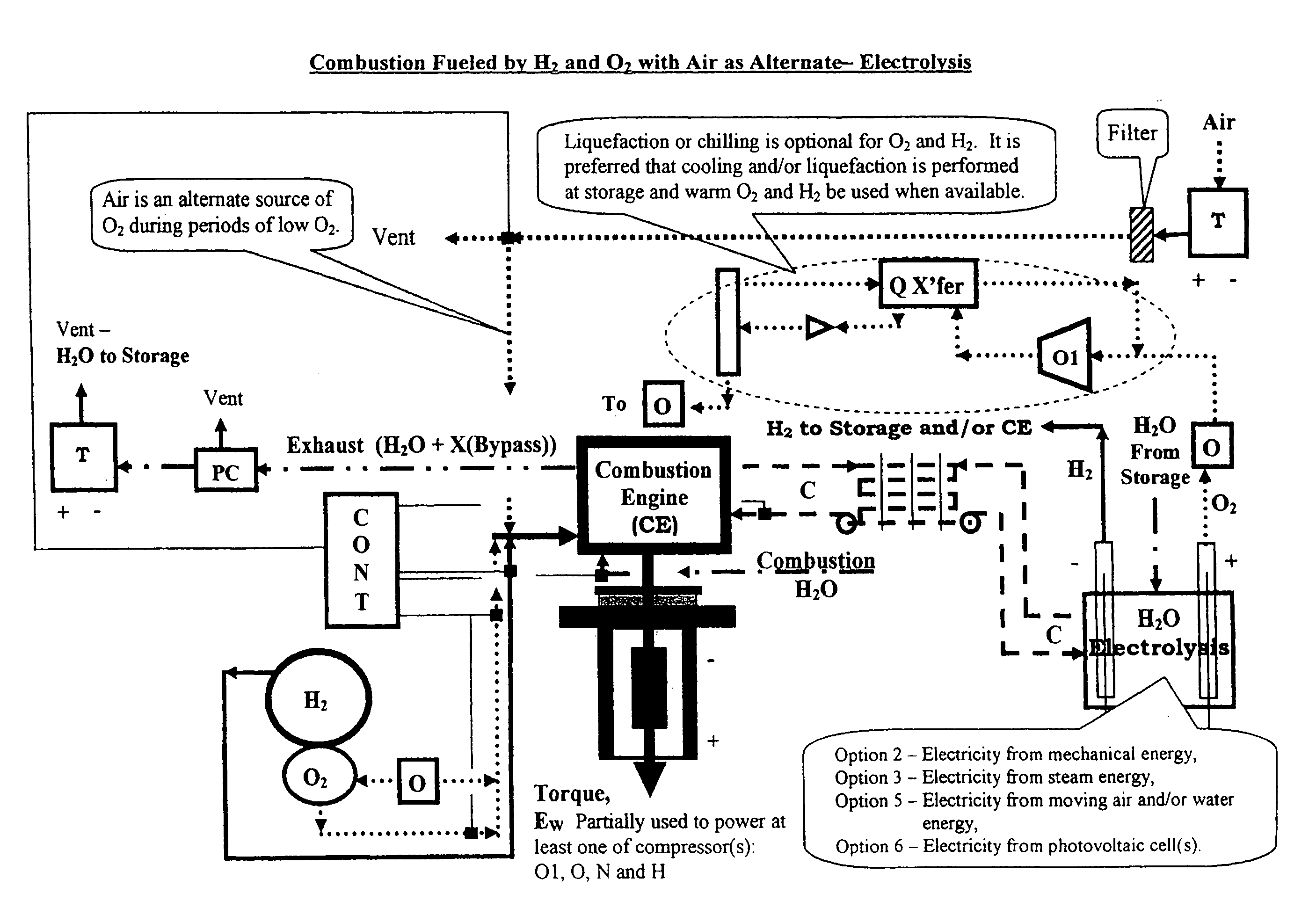

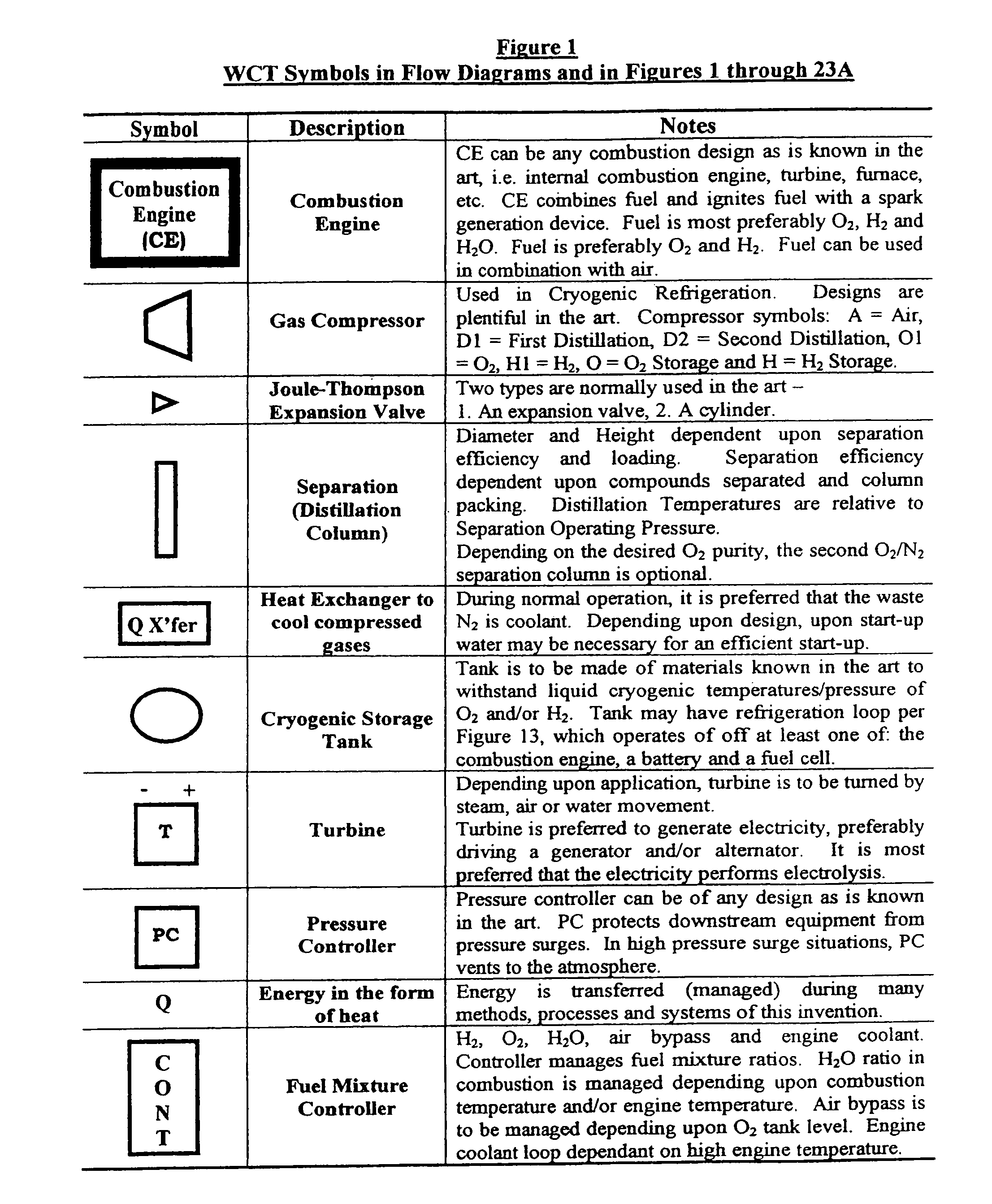

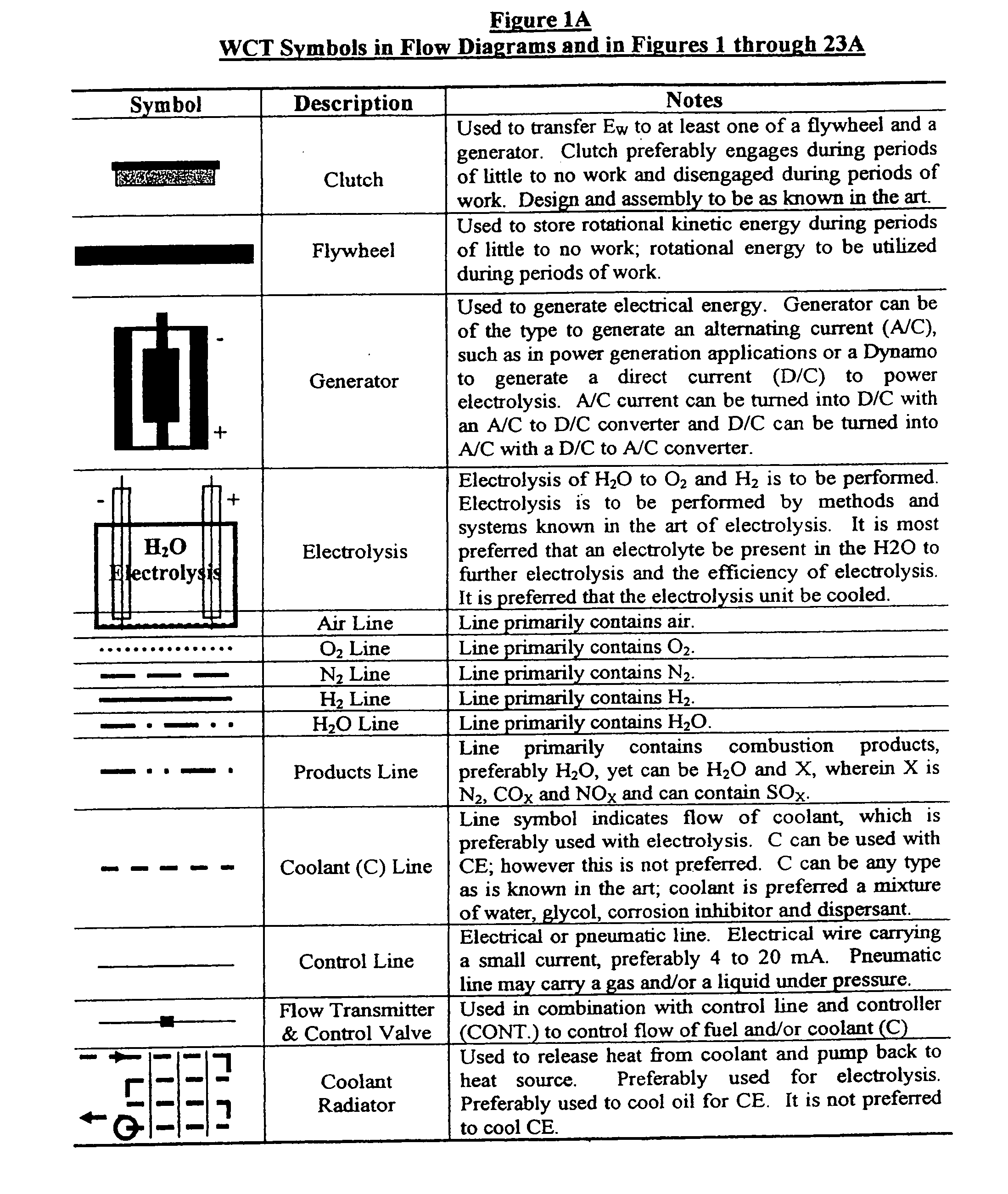

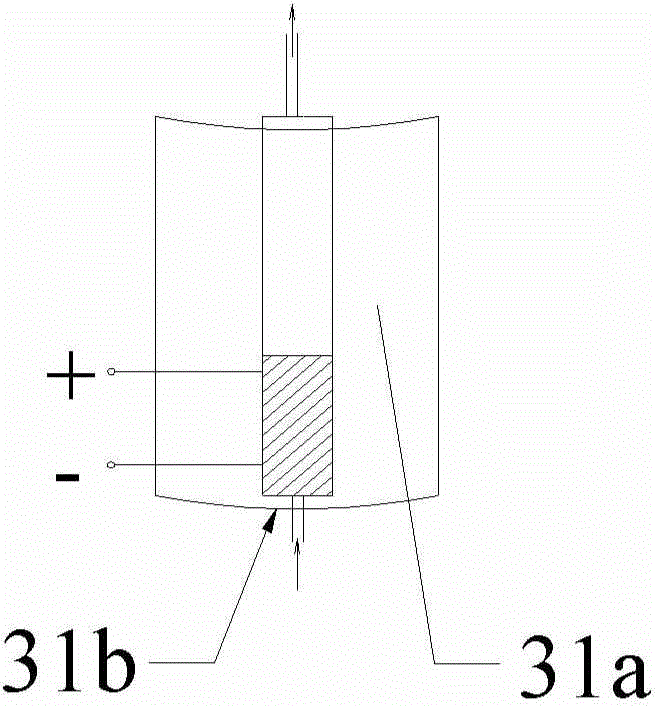

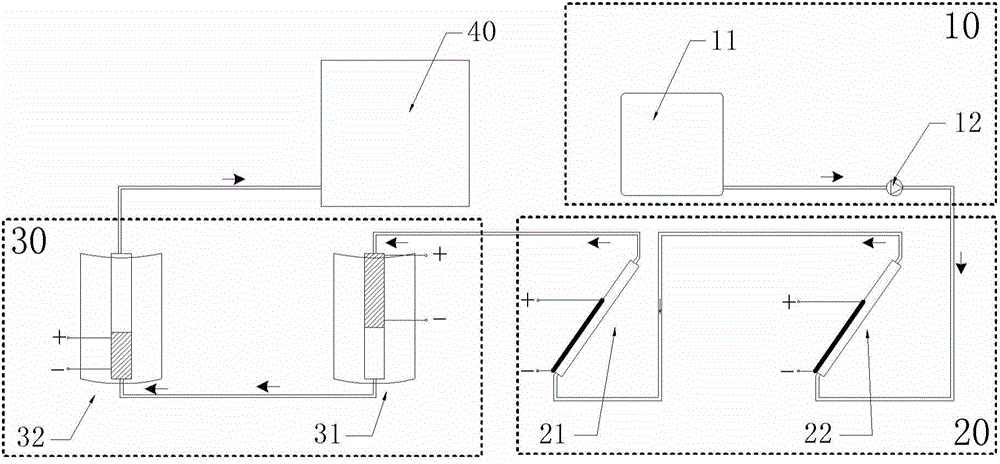

Water combustion technology - methods, processes, systems and apparatus for the combustion of hydrogen and oxygen

InactiveUS20050198958A1Easy to handleImprove featuresAuxillary drivesSolidificationCombustion chamberHydrocotyle bowlesioides

This invention presents improved combustion methods, systems, engines and apparatus utilizing H2, O2 and H2O as fuel, thereby providing environmentally friendly combustion products, as well as improved fuel and energy management methods, systems, engines and apparatus. The Water Combustion Technology; WCT, is based upon water (H2O) chemistry, more specifically H2O combustion chemistry and thermodynamics. WCT does not use any hydrocarbon fuel source, rather the WCT uses H2 preferably with O2 and secondarily with air. The WCT significantly improves the thermodynamics of combustion, thereby significantly improving the efficiency of combustion, utilizing the first and second laws of thermodynamics. The WCT preferably controls combustion temperature with H2O and secondarily with air in the combustion chamber. The WCT preferably recycles exhaust gas energy as fuel converted from water. The WCT minimizes external cooling loops and minimizes exhaust and / or exhaust energy, thereby maximizing available work and internal energy while minimizing enthalpy and entropy losses.

Owner:CLEARVALUE TECH

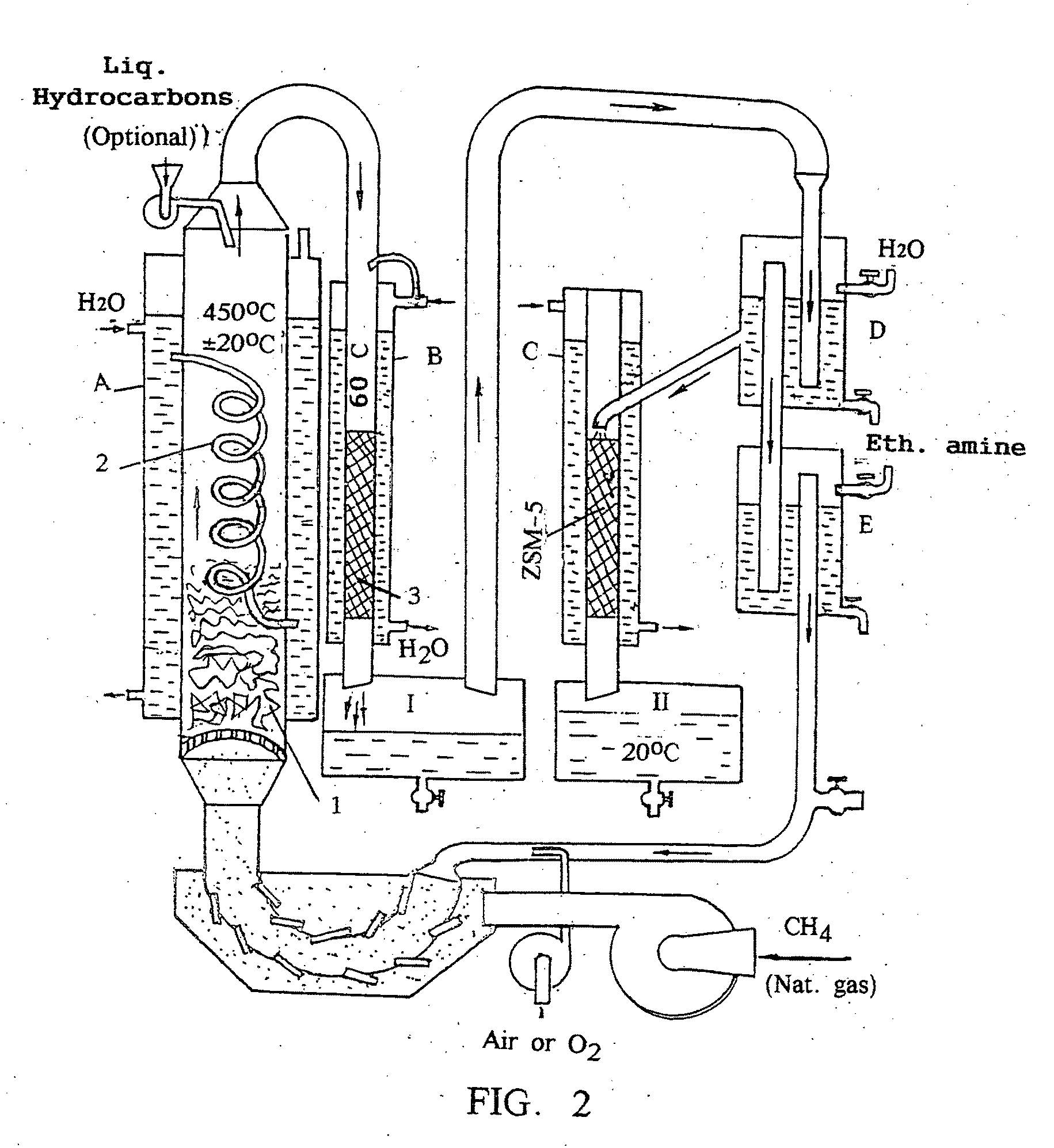

Process of processes for radical solution of the air pollution and the global warming, based on the discovery of the bezentropic thermomechanics and eco fuels through bezentropic electricity

This high tech invention stems from the recent discovery of a new natural thermal law and its numerous applications, named for short ‘universal law of bezentropy’. Its full name is; ‘Law of the bezentropic spontaneous natural and artificial rectification of the disorderly vibrating gas and steam molecules into colinear ordered molecular jets, creating a valuable new science termed ‘bezentropic thermomechanics’ permitting (practically) full conversion of the heat into work, which is otherwise prohibited by the law of ‘entropy”, a.k.a, the second law of thermodynamics. The precursors of this important discovery are found in the startling paradoxes nos: 1, 2, and 3, included within this disclosure, and discovered as well by this inventor. They help in better understanding the law of bezentropy.

Owner:VAN MICHAELS CHRISTOPHER

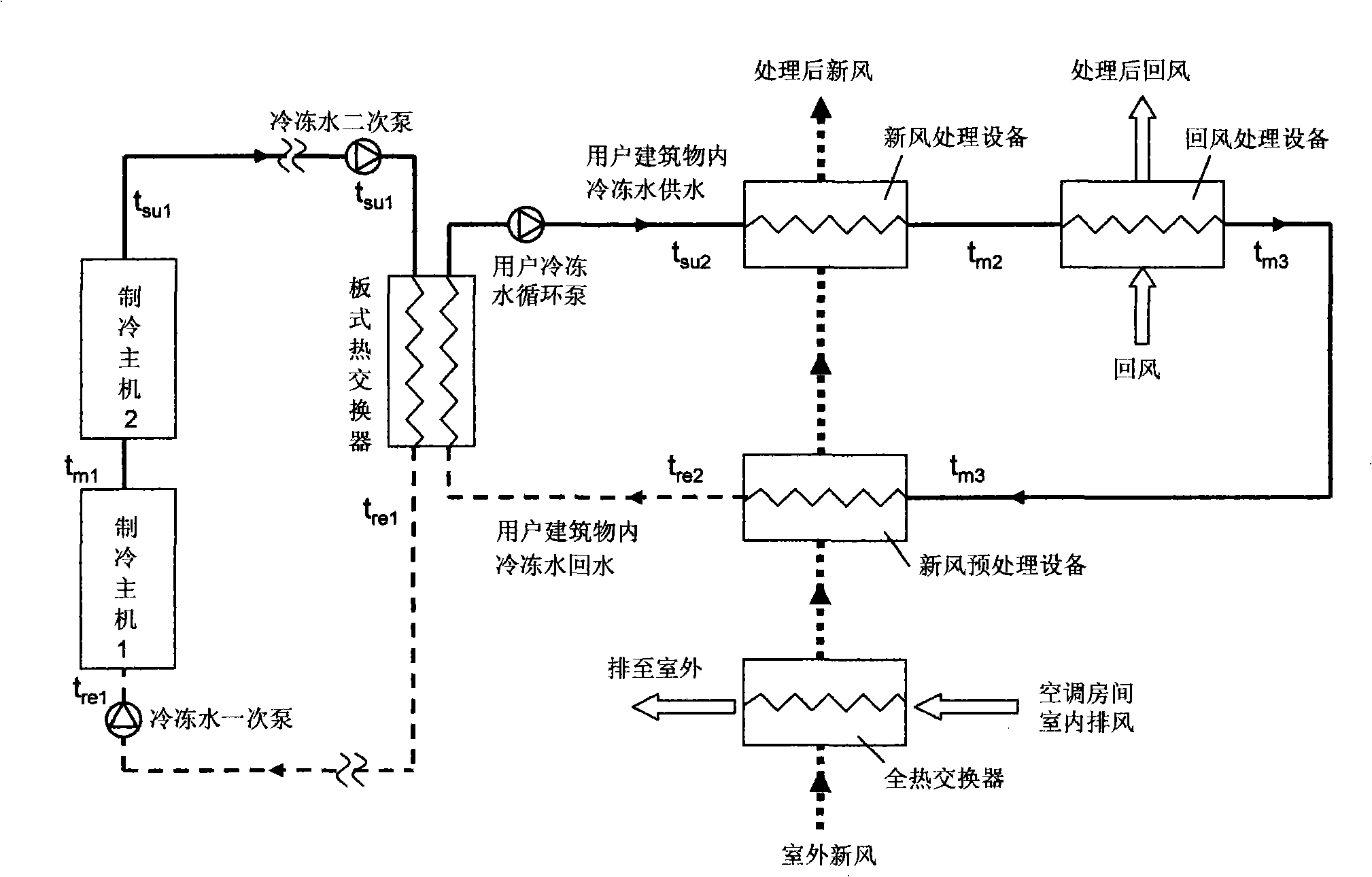

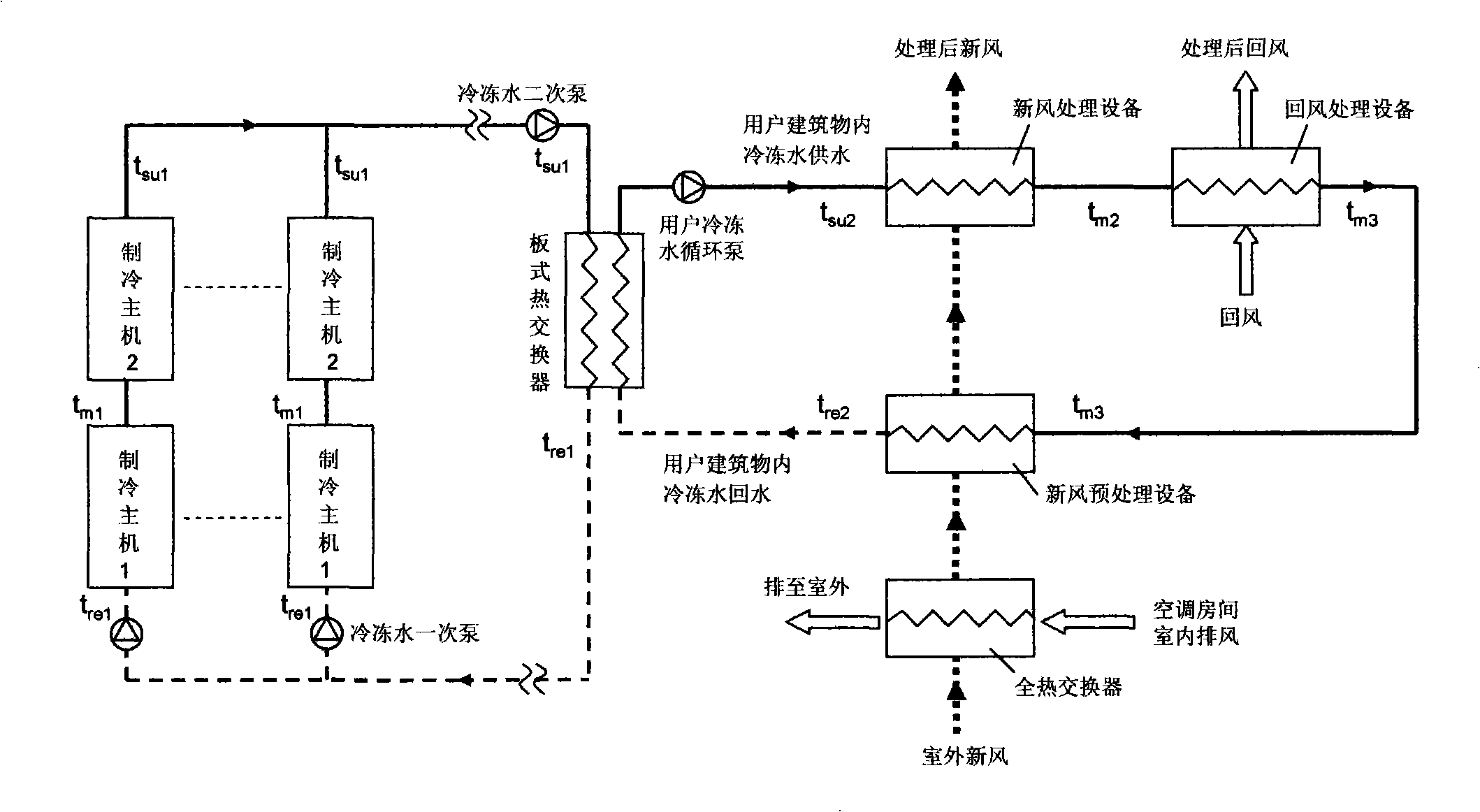

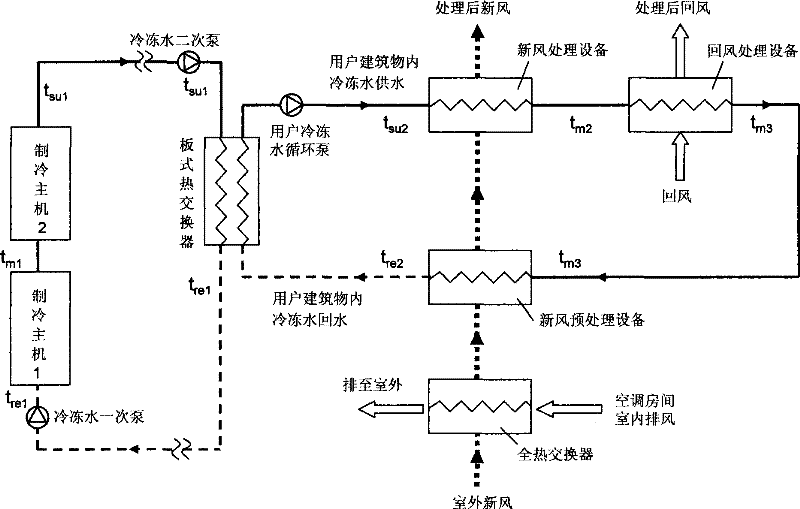

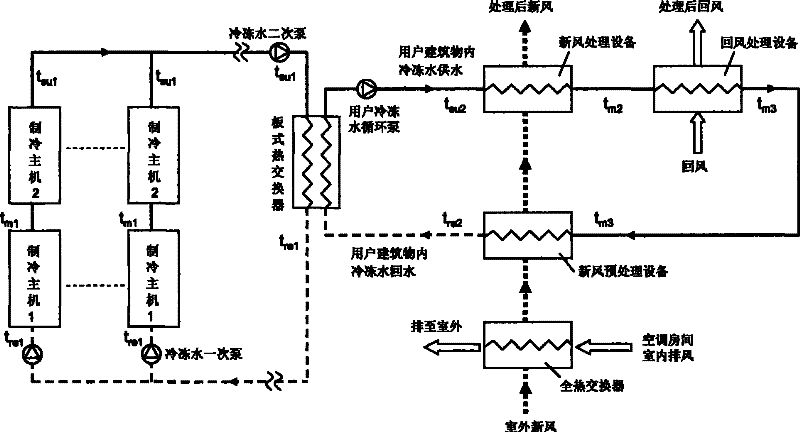

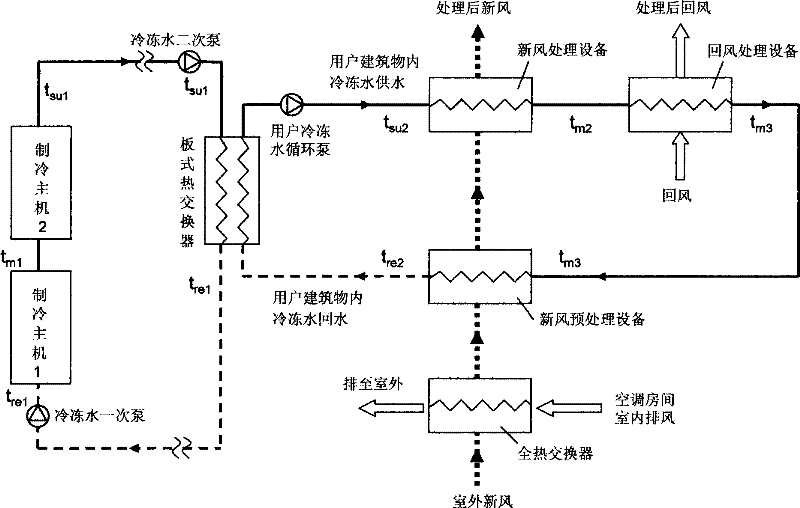

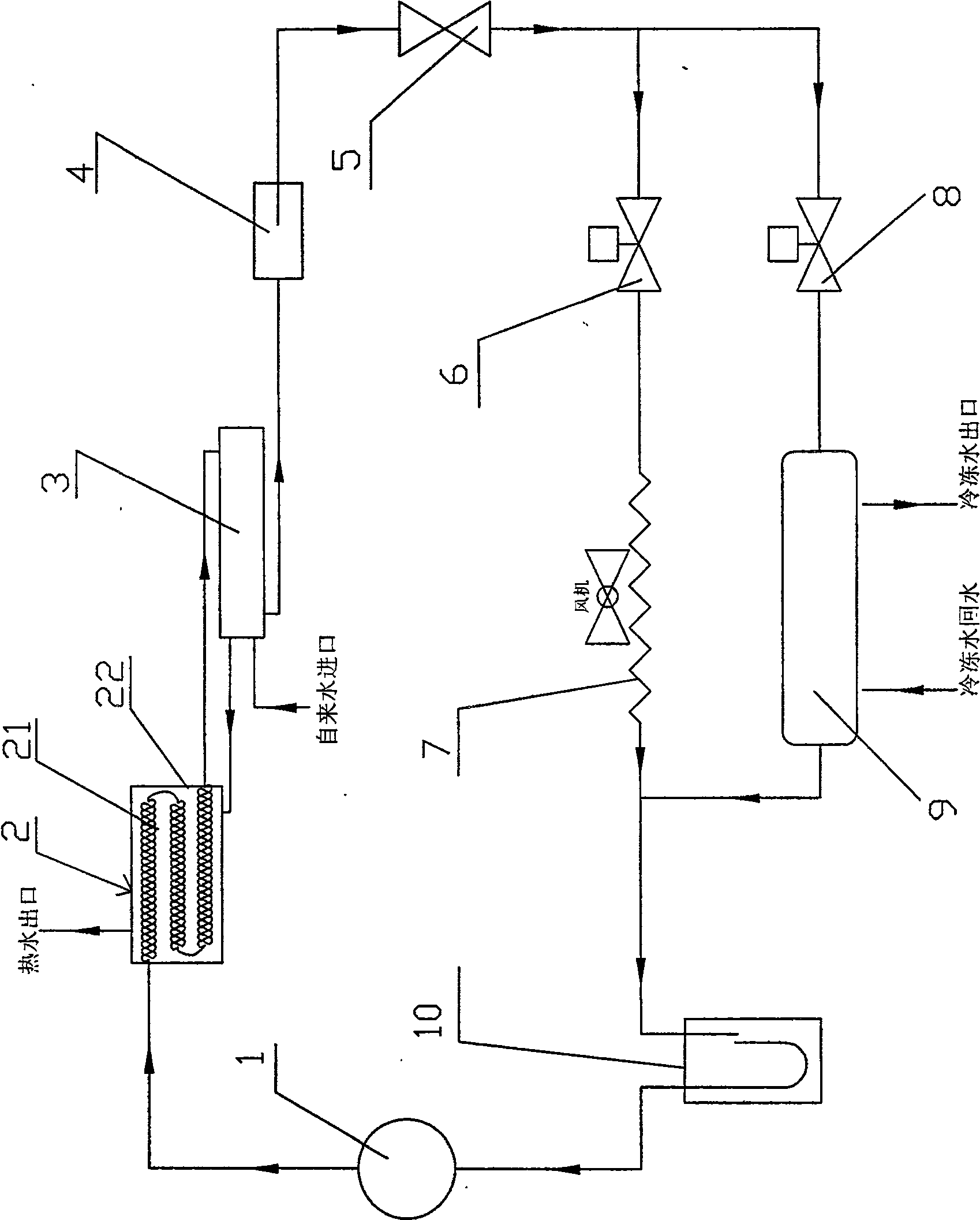

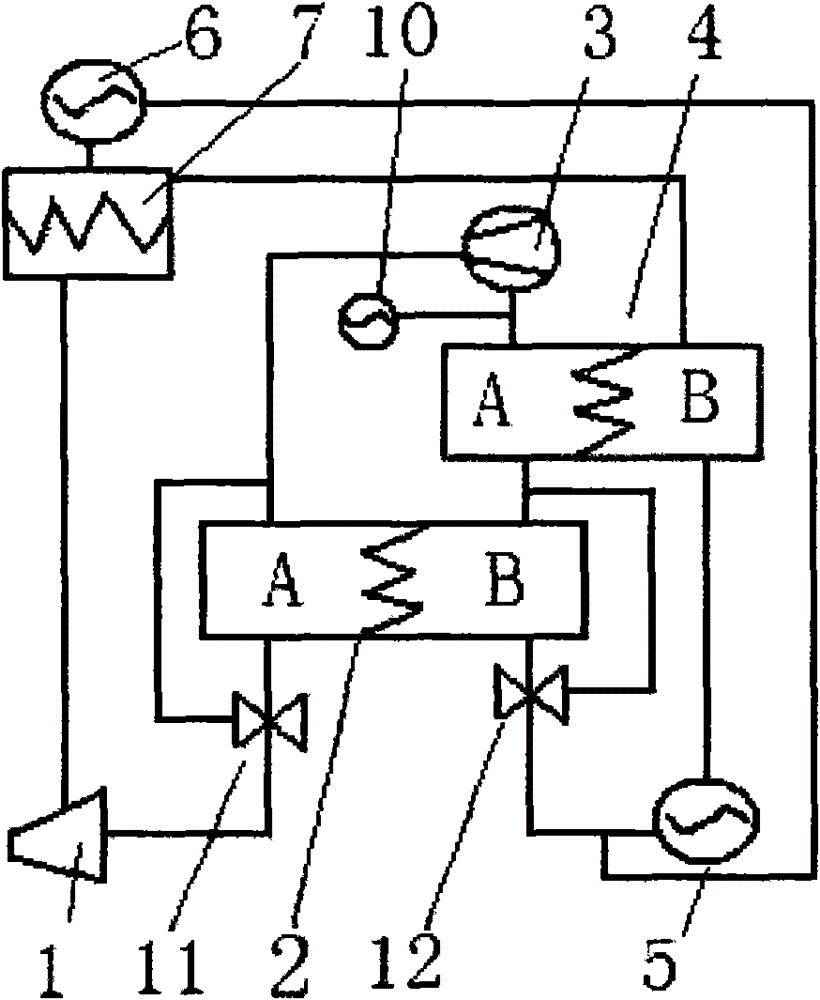

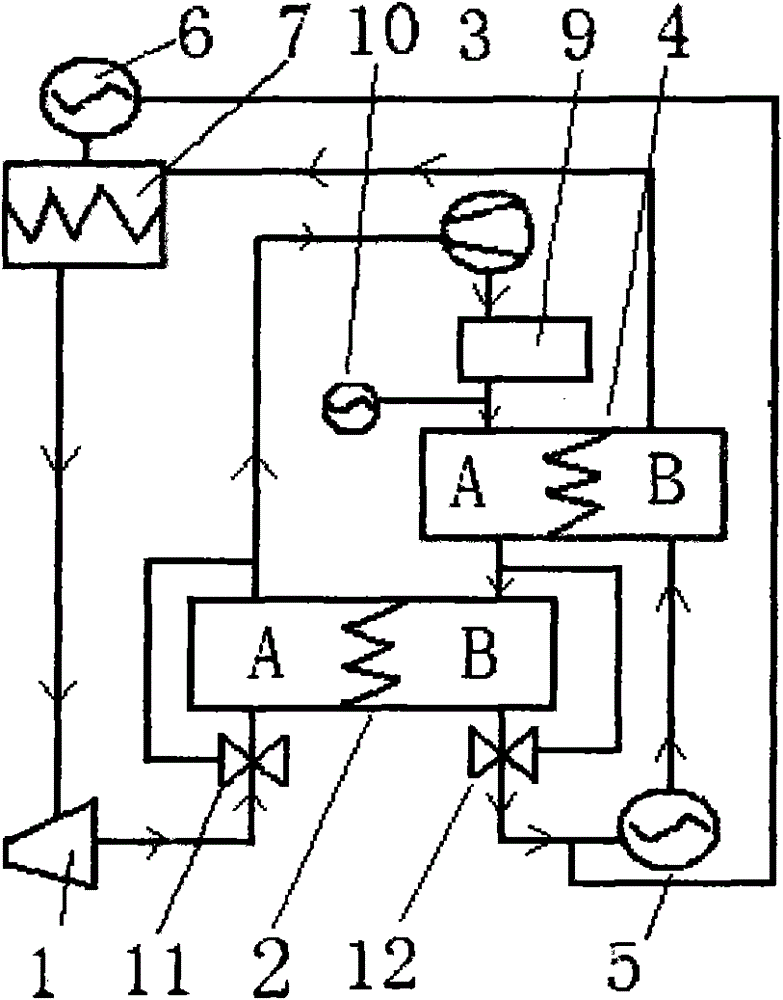

High-efficiency energy-saving air conditioning system used for area cold supplying and its implementing method

InactiveCN101344291AReduce energy consumptionReduce initial investmentLighting and heating apparatusAir conditioning systemsPlate heat exchangerEconomic benefits

The invention provides a high-efficient and energy-saving air-conditioning system used for district cooling, which comprises a refrigeration host, a chilled water primary pump, a chilled water secondary pump, a plate heat exchanger, a new air processing device, a return air processing device, a new air pre-processing device, a user chilled water circulating pump and a total heat exchanger. The invention further provides a realization method of the air-conditioning system. The high-efficient and energy-saving air-conditioning system and the realization method of the invention are based on the second law of thermodynamics and the economic optimized scientific energy utilization principle, and realizes the purposes of increasing the temperature difference between the supply water and the return water of a chilled water secondary pipeline and reducing the flow rate thereof by the method of connecting two levels of refrigeration with the refrigeration host in series and the innovative cold energy gradual utilization of a tail-end device. Therefore, the energy consumption of the chilled water secondary pump and the initial investment of the secondary pipeline network are reduced, the economic benefits and the energy utilization ratio are improved, and the advantages of the district cooling system are further played.

Owner:SOUTH CHINA UNIV OF TECH

Water combustion technology--methods, processes, systems and apparatus for the combustion of hydrogen and oxygen

InactiveUS8161748B2Improve economyImprove efficiencySolidificationLiquefactionCombustion chamberEngineering

Owner:CLEARVALUE TECH

Water combustion technology- methods, processes, systems and apparatus for the combustion of hydrogen and oxygen

InactiveUS20090193781A1Improve efficiencyLow conversion costSolidificationLiquefactionCombustion chamberLaws of thermodynamics

This invention presents improved combustion methods, systems, engines and apparatus utilizing H2, O2 and H2O as fuel, thereby providing environmentally friendly combustion products, as well as improved fuel and energy management methods, systems, engines and apparatus. The Water Combustion Technology; WCT, is based upon water (H2O) chemistry, more specifically H2O combustion chemistry and thermodynamics. WCT does not use any hydrocarbon fuel source, rather the WCT uses H2 preferably with O2 and secondarily with air. The WCT significantly improves the thermodynamics of combustion, thereby significantly improving the efficacy of combustion, utilizing the first and second laws of thermodynamics. The WCT preferably controls combustion temperature with H2O and secondarily with air in the combustion chamber. The WCT preferably recycles exhaust gases as fuel converted from water. The WCT minimizes external cooling loops and minimizes exhaust and / or exhaust energy, thereby maximizing available work and internal energy while minimizing enthalpy and entropy losses.

Owner:HAASE RICHARD ALAN

Water combustion technology - methods, processes, systems and apparatus for the combustion of Hydrogen and Oxygen

InactiveUS20090194996A1Improve efficiencyLow conversion costSolidificationLiquefactionCombustion chamberLaws of thermodynamics

This invention presents improved combustion methods, systems, engines and apparatus utilizing H2, O2 and H2O as fuel, thereby providing environmentally friendly combustion products, as well as improved fuel and energy management methods, systems, engines and apparatus. The Water Combustion Technology; WCT, is based upon water (H2O) chemistry, more specifically H2O combustion chemistry and thermodynamics. WCT does not use any hydrocarbon fuel source, rather the WCT uses H2 preferably with O2 and secondarily with air. The WCT significantly improves the thermodynamics of combustion, thereby significantly improving the efficacy of combustion, utilizing the first and second laws of thermodynamics. The WCT preferably controls combustion temperature with H2O and secondarily with air in the combustion chamber. The WCT preferably recycles exhaust gases as fuel converted from water. The WCT minimizes external cooling loops and minimizes exhaust and / or exhaust energy, thereby maximizing available work and internal energy while minimizing enthalpy and entropy losses.

Owner:CLEARVALUE TECH

Photovoltaic and photo-thermal chemical combination solar energy comprehensive utilization device and system

ActiveCN104676911AAvoid direct conversionIncrease incomeSolar heating energyHydrogenThermal physicsPower capability

The invention provides a photovoltaic and photo-thermal chemical combination solar energy comprehensive utilization device and system. According to the principle of gradient utilization of cycling energy, sunlight energy is firstly utilized through a photovoltaic system, and the residual heat of the photovoltaic system is converted into high-grade (fuel) chemical energy through absorbing by a chemical reaction. Compared with the way of directly utilizing the residual heat of a solar photovoltaic battery in a physical way, the method for coupling thermal physics and thermal chemistry has the advantages that the power capability of solar energy is fully explored, the second law of thermodynamics efficiency of solar energy utilization can be greatly increased, and the electric energy output of the system can be more stabilized.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Thermoelectric heat energy recovery module

InactiveUS20180058295A1Minimize exhaust system back pressureMinimizes back pressureHybrid vehiclesInternal combustion piston enginesThermal energyExternal combustion engine

This embodiment is a Stirling-Electric Hybrid automotive exhaust module generator device for converting waste heat energy into electrical energy by employing the Seebeck Effect. The disclosure herein describes how the invention converts heat energy, from hot exhaust gases, from the operation of an automotive external combustion engine (e. g. Stirling Cycle engine), into electrical energy which is fed back into the electrical system of the Stirling-Electric Hybrid Automobile (U.S. Pat. No. 7,726,130 B2) minimizing losses due to the second law of thermodynamics. The improvements on the art in this disclosure focuses on employing a plurality of thermopiles and materials with improved coefficients of thermal conductivity and increasing residence time of the hot exhaust gases by inducing turbulent flow through the module generator device in conjunction with external cooling plate(s), heat sink(s); in the form of a plurality of pin(s), on the interior and exterior surface(s) of the module generator device.

Owner:QUANTUM INDUSTRIAL DEVELOPMENT CORP

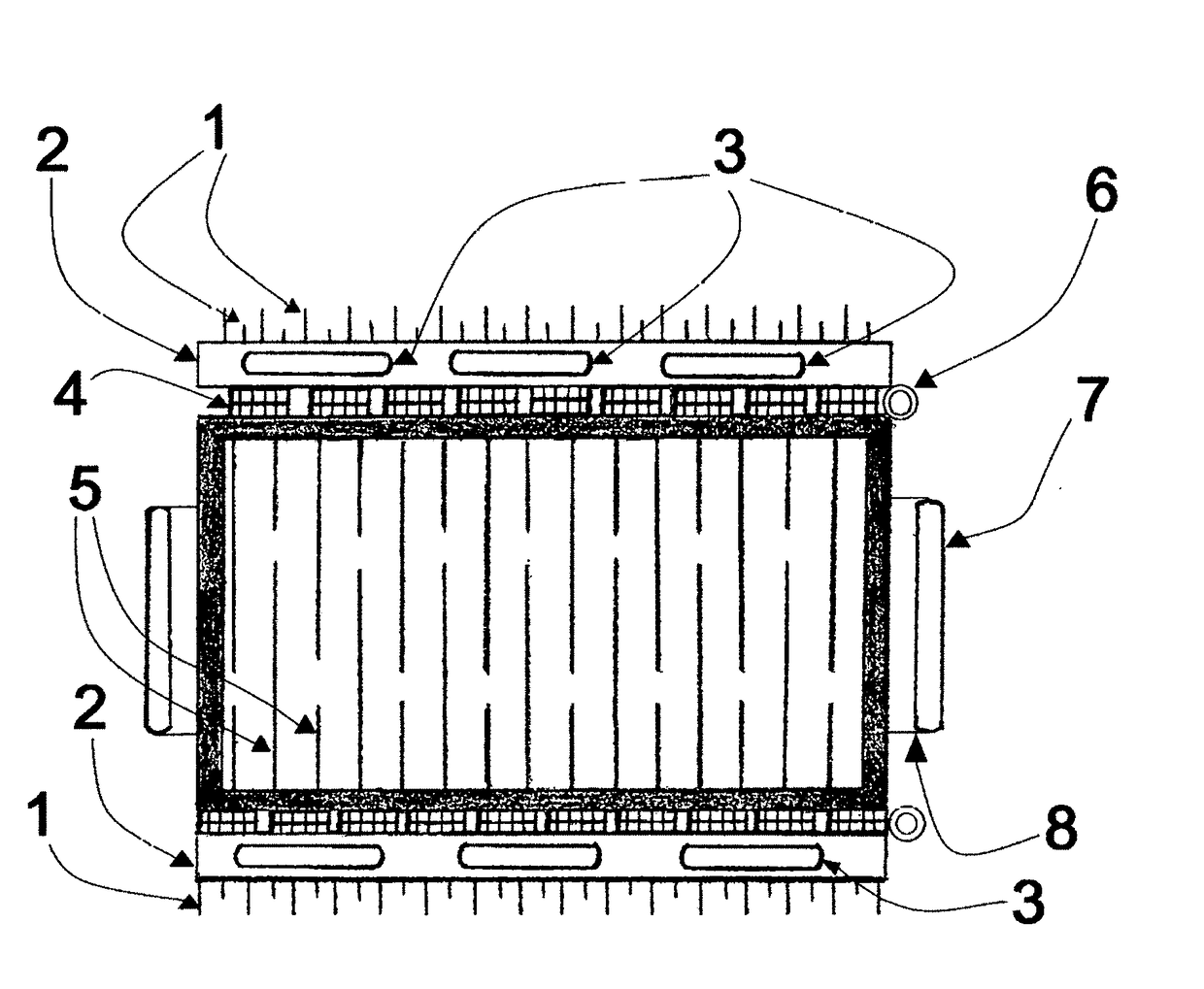

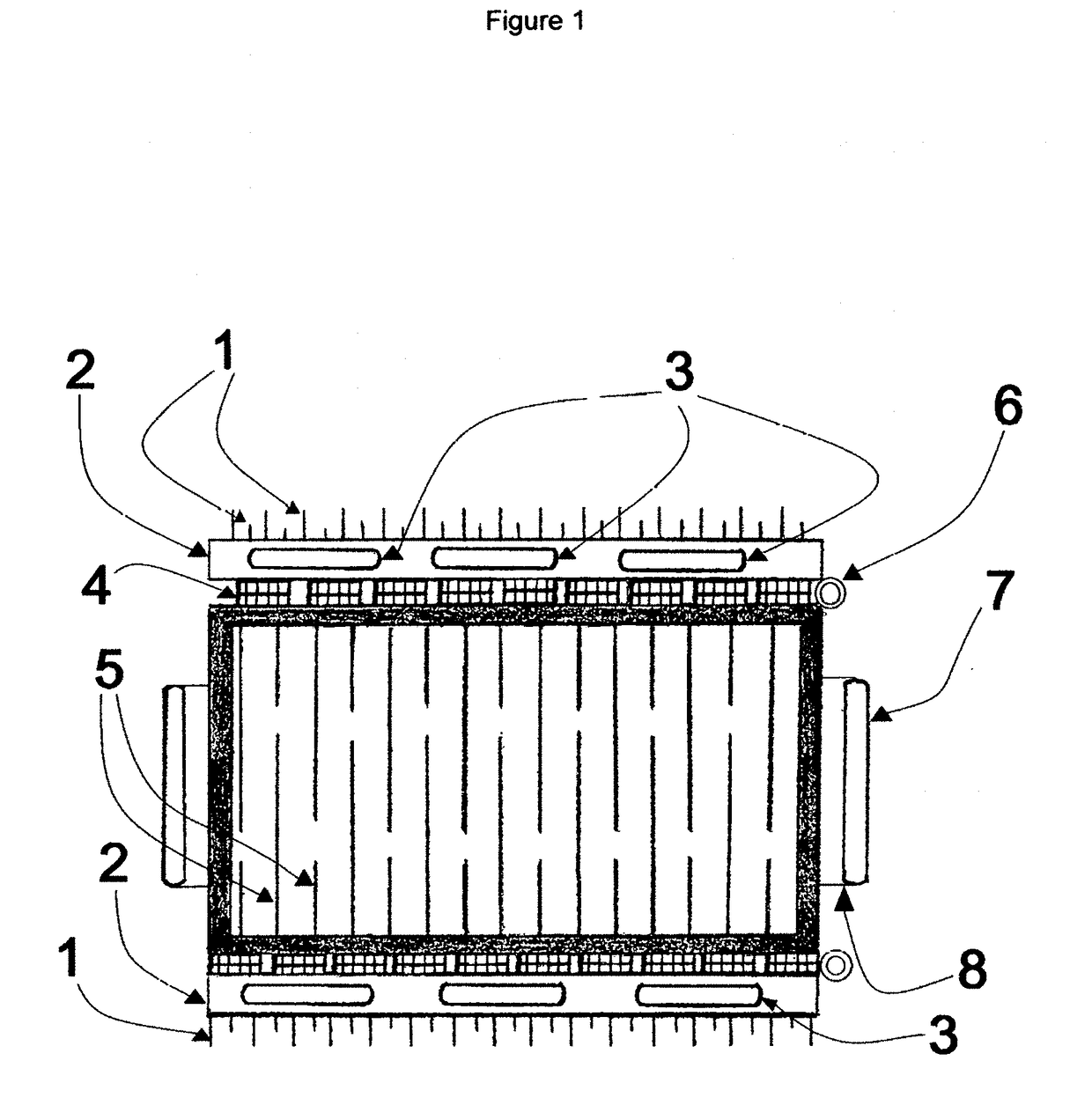

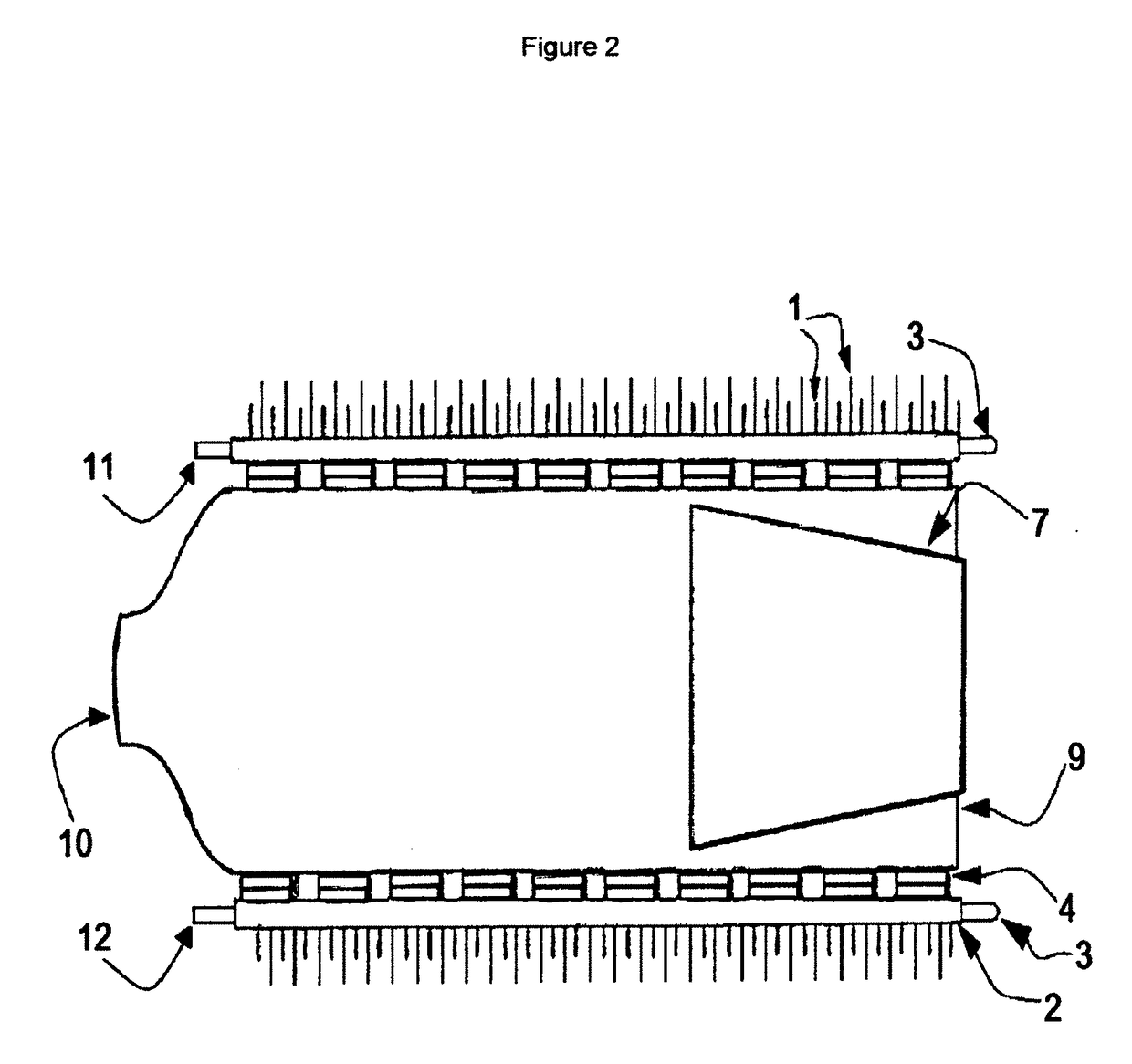

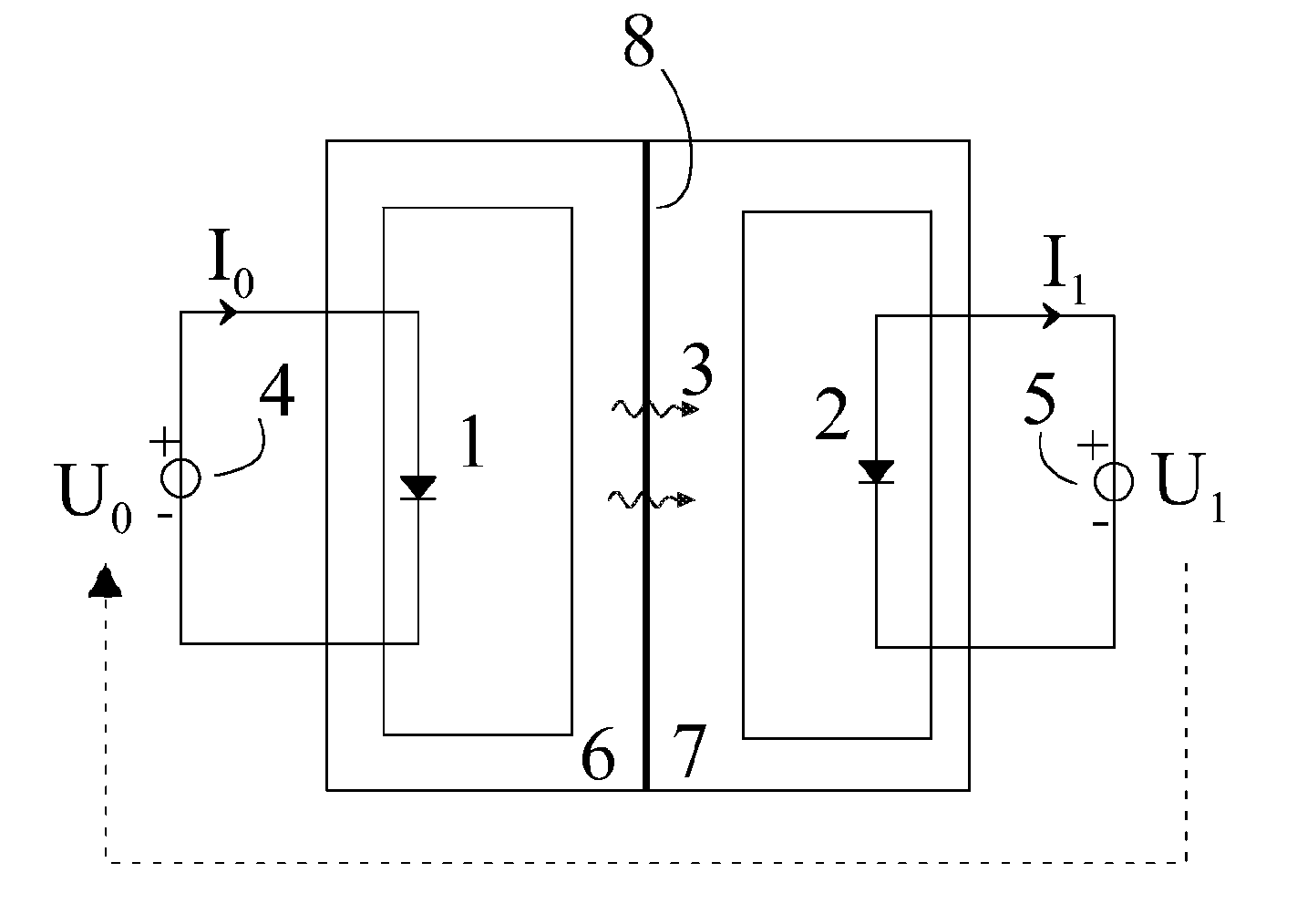

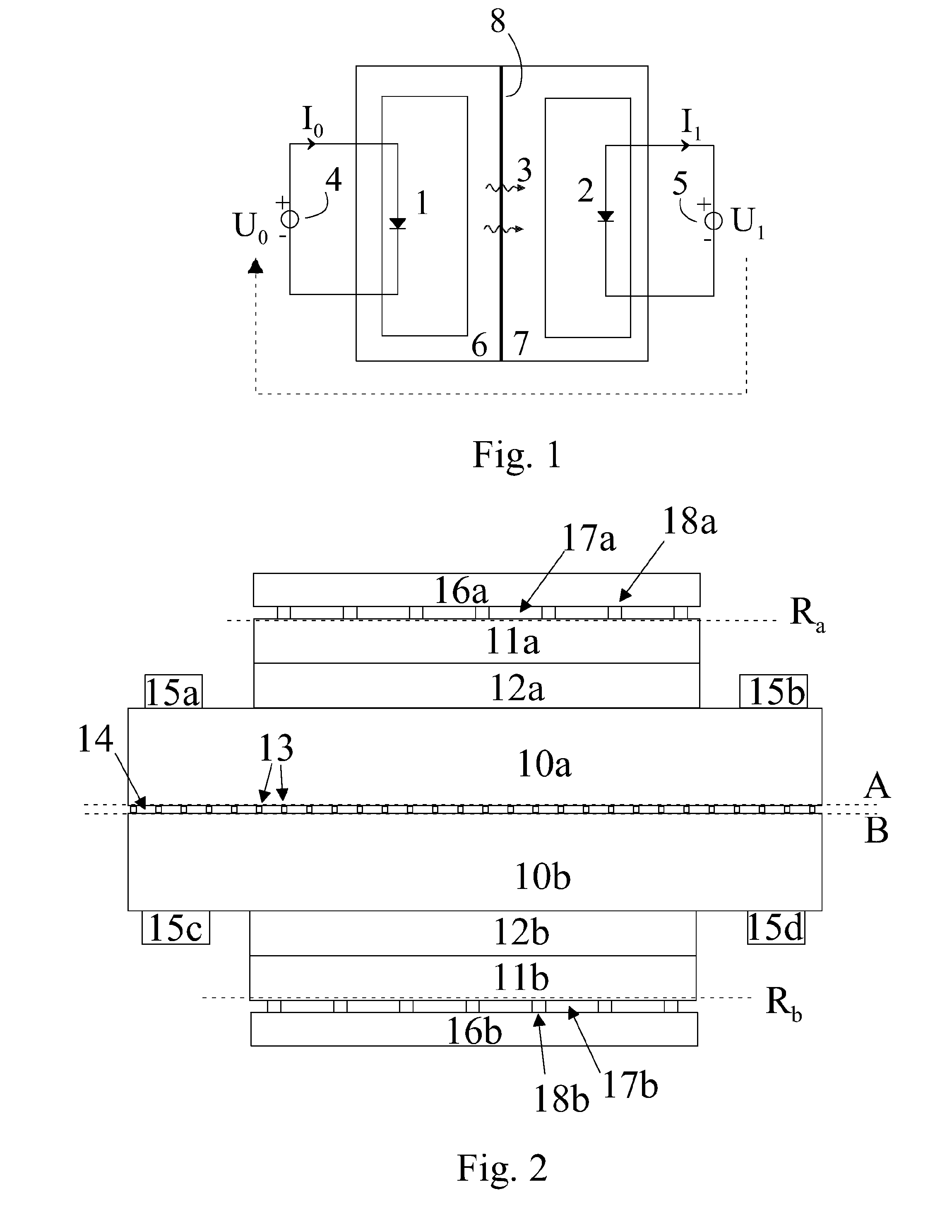

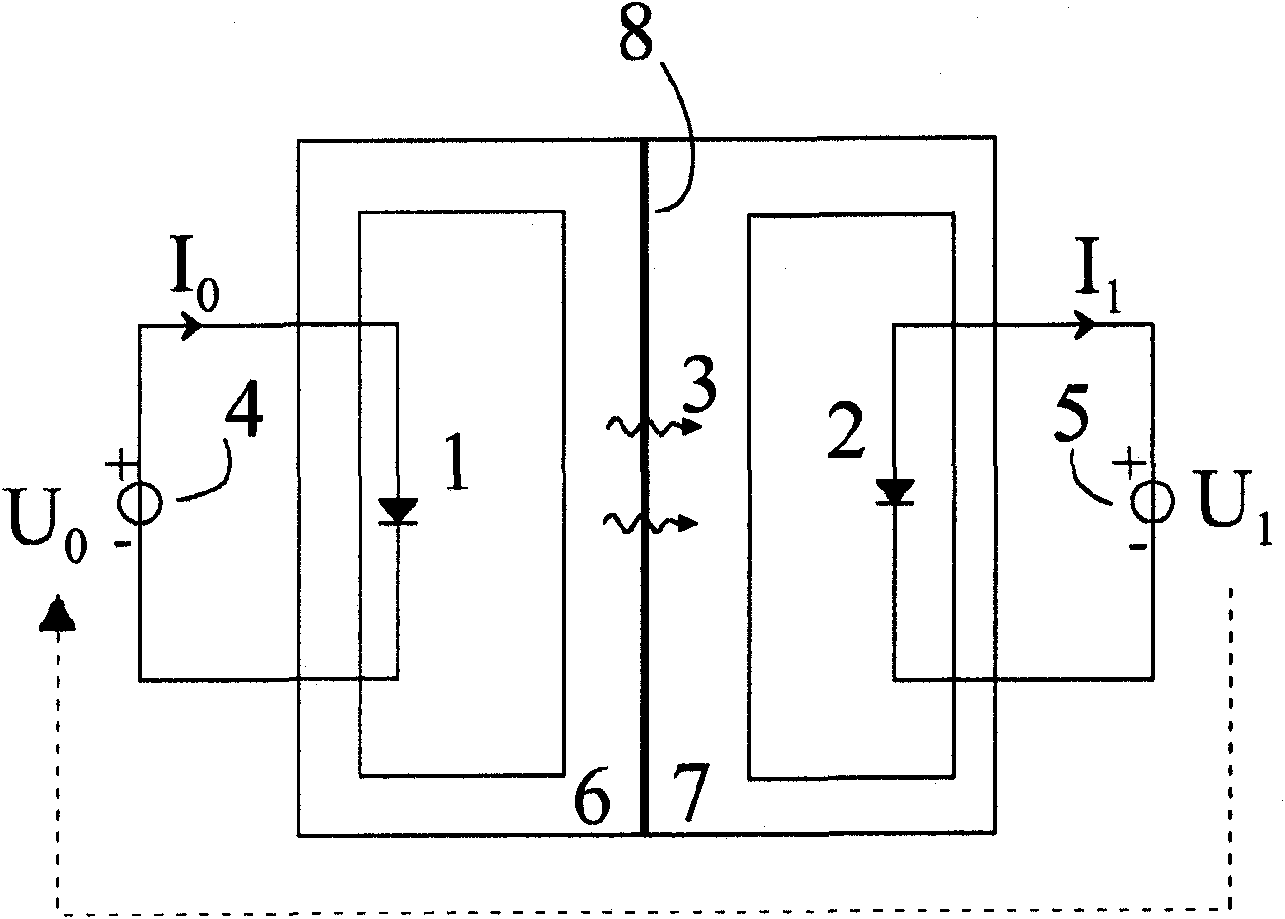

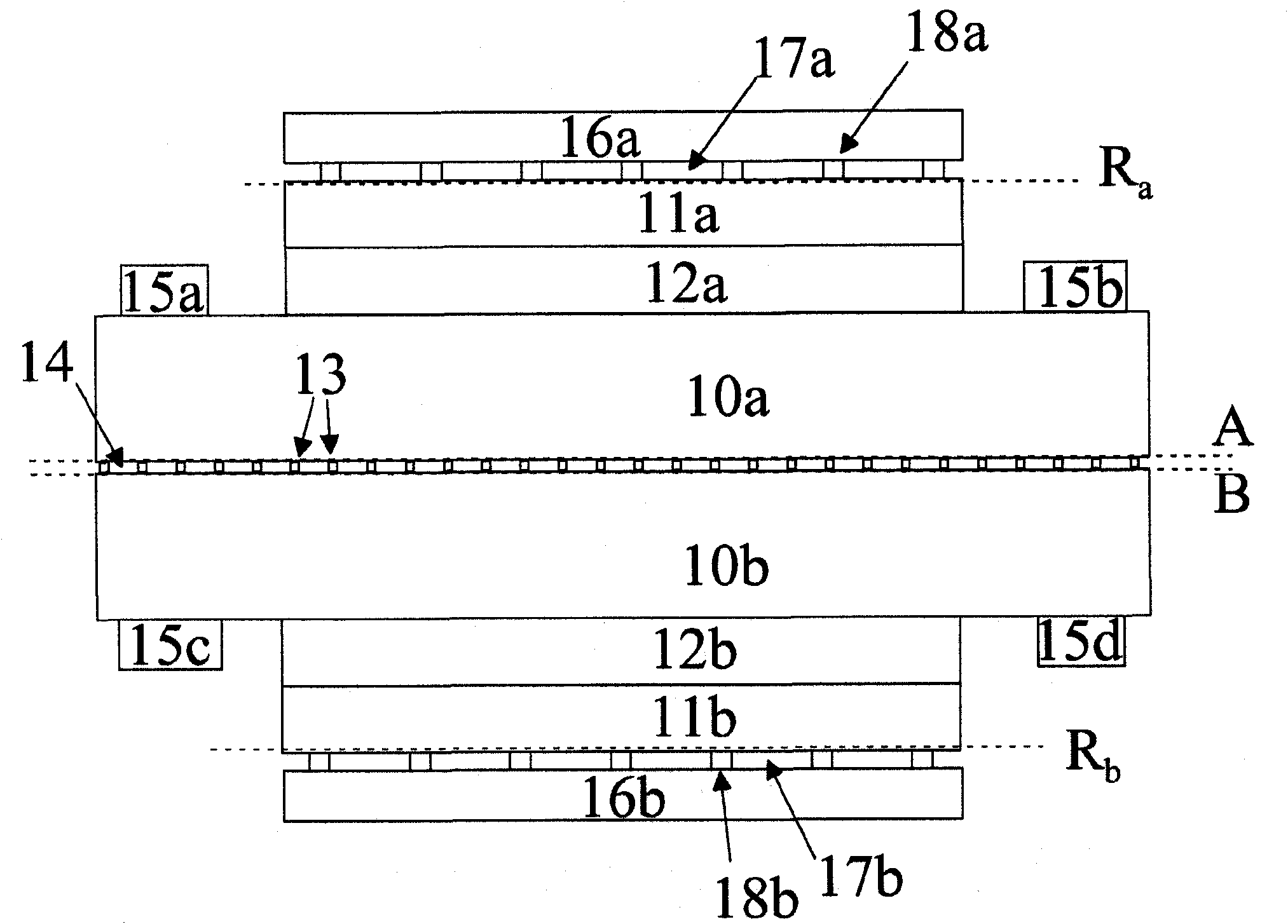

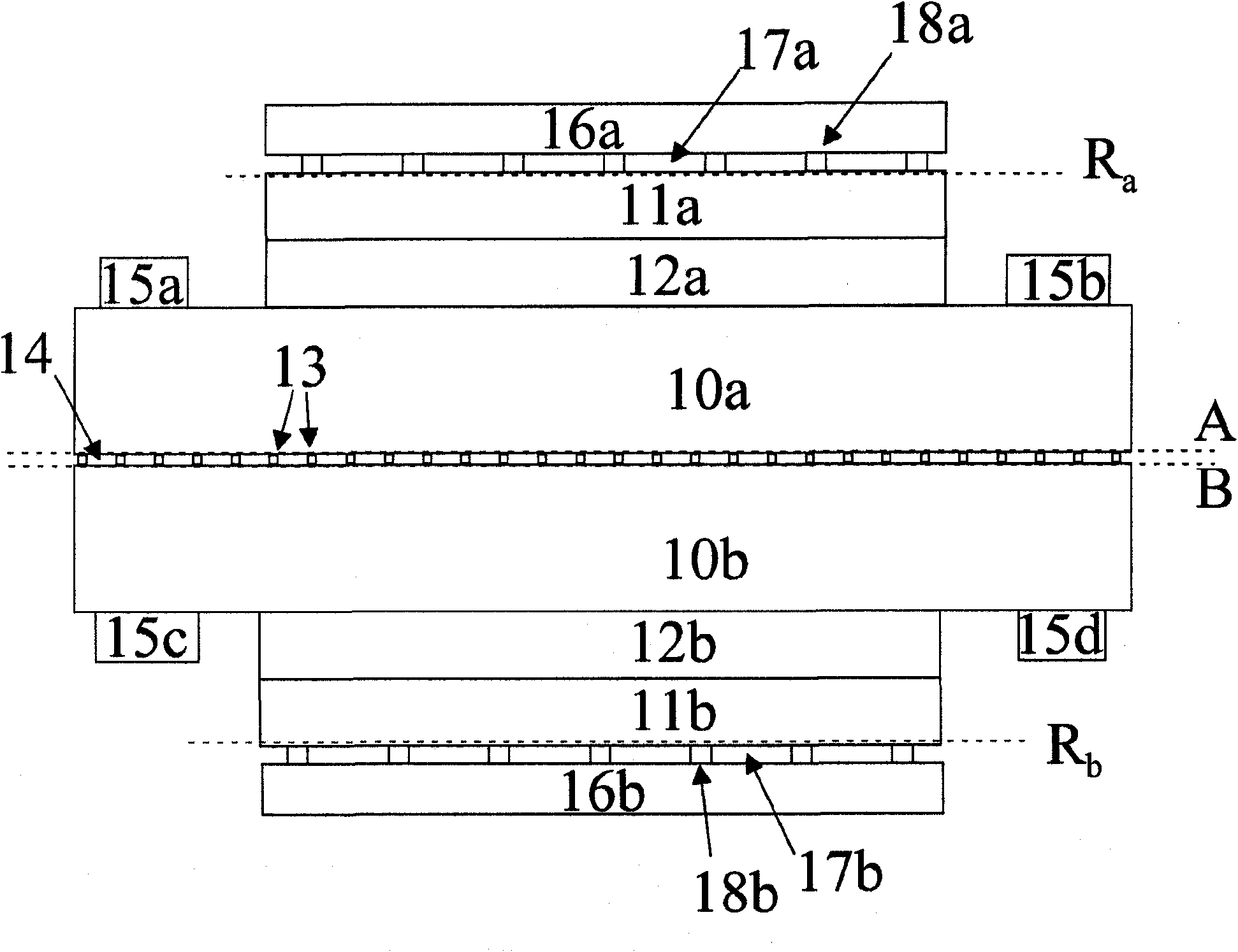

Method and device for transferring heat

InactiveUS20110107770A1Small sizeLarge coefficient of performanceBeam/ray focussing/reflecting arrangementsTemperatue controlForms of energyMechanical energy

A method and device for transferring heat in a heat pump, where heat energy is transferred with the aid of light or other electromagnetic radiation from an element (1) emitting radiation to an element (2) absorbing radiation in a direction opposite to the direction defined by the second law of thermodynamics and in which a part of the energy of the absorbed radiation is converted back to an exploitable form of energy, like electrical or mechanical energy.

Owner:OKSANEN JANI +1

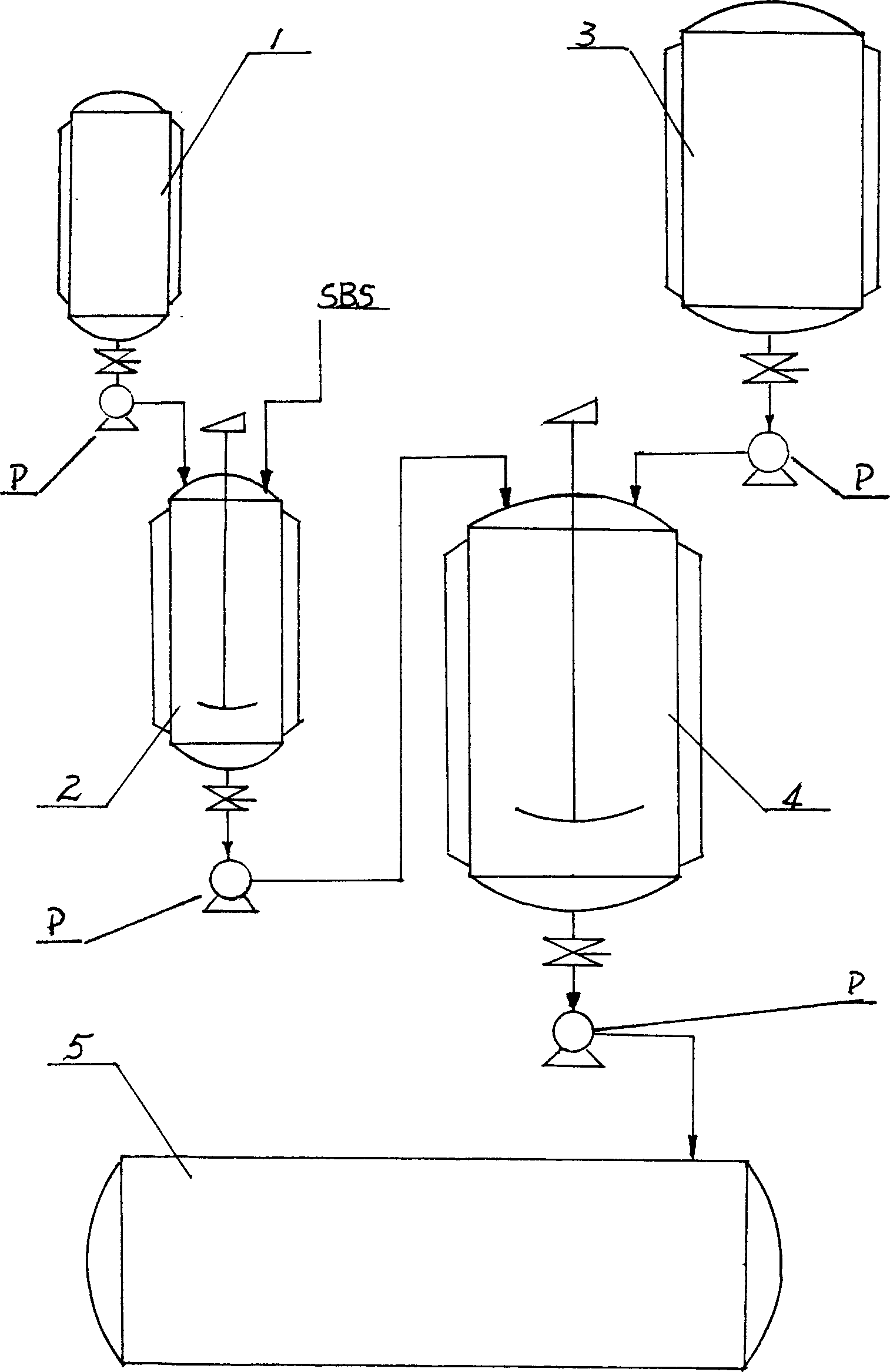

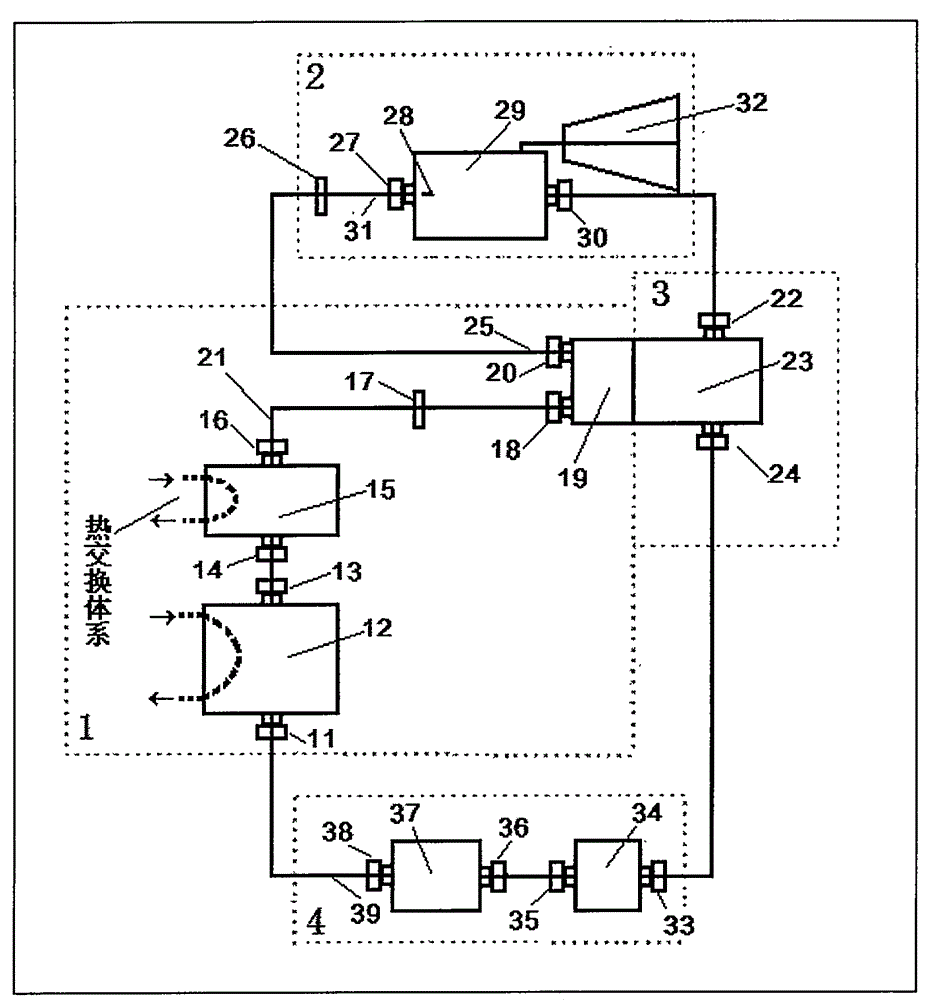

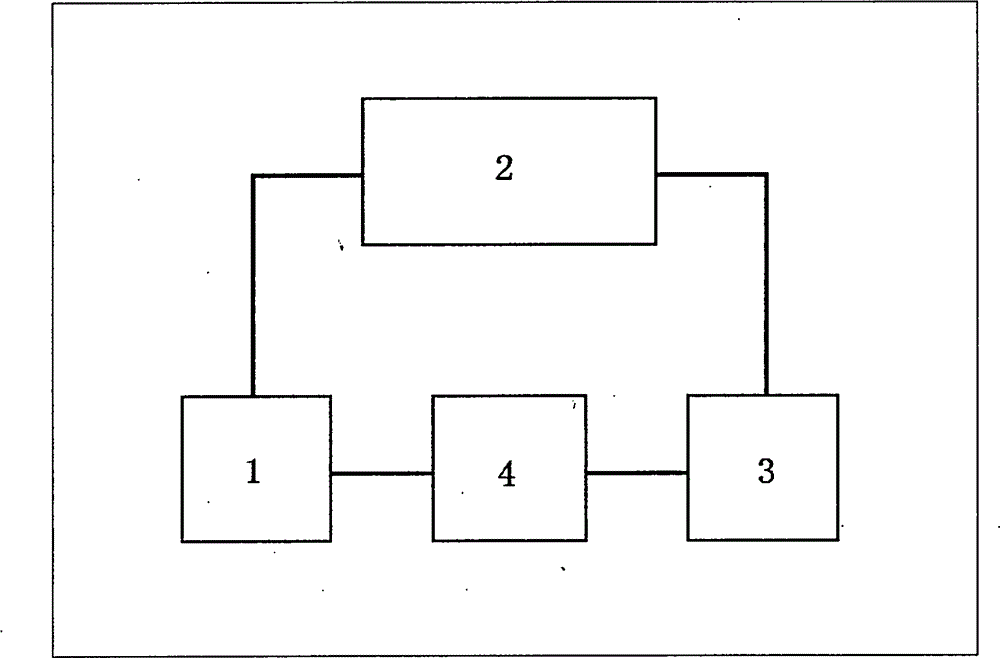

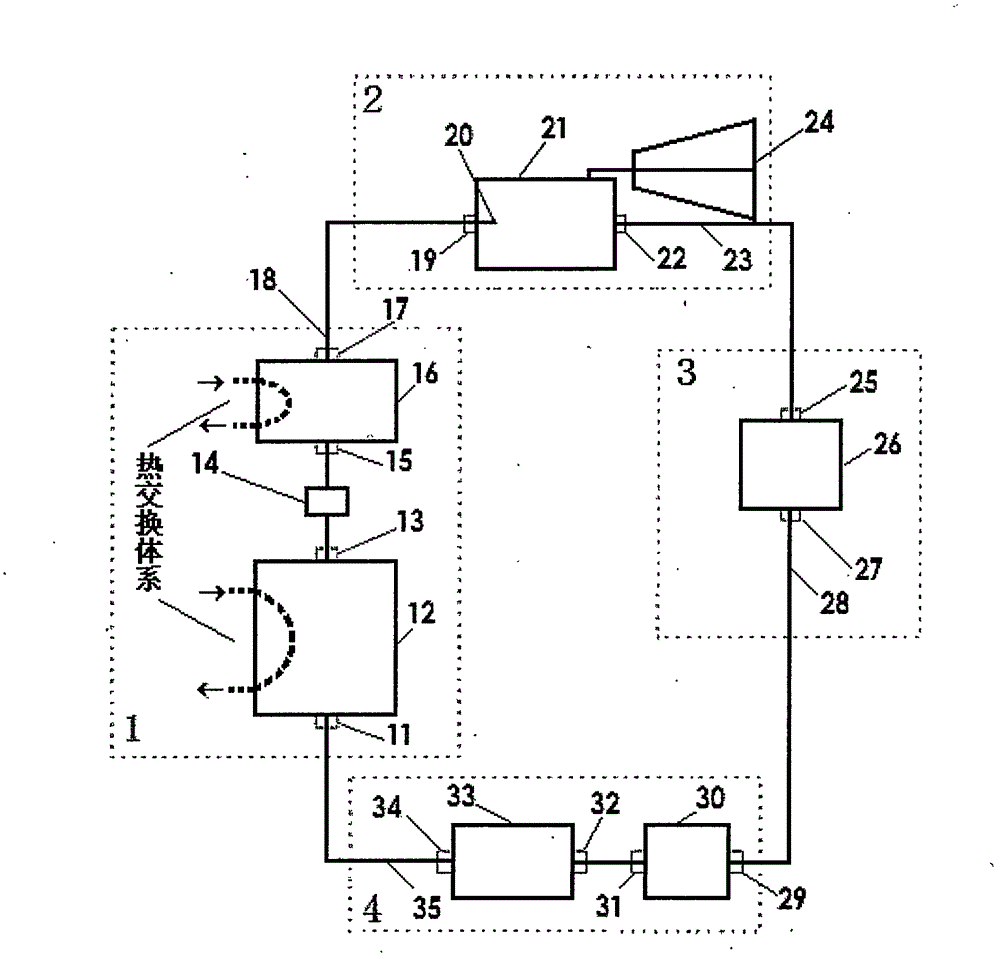

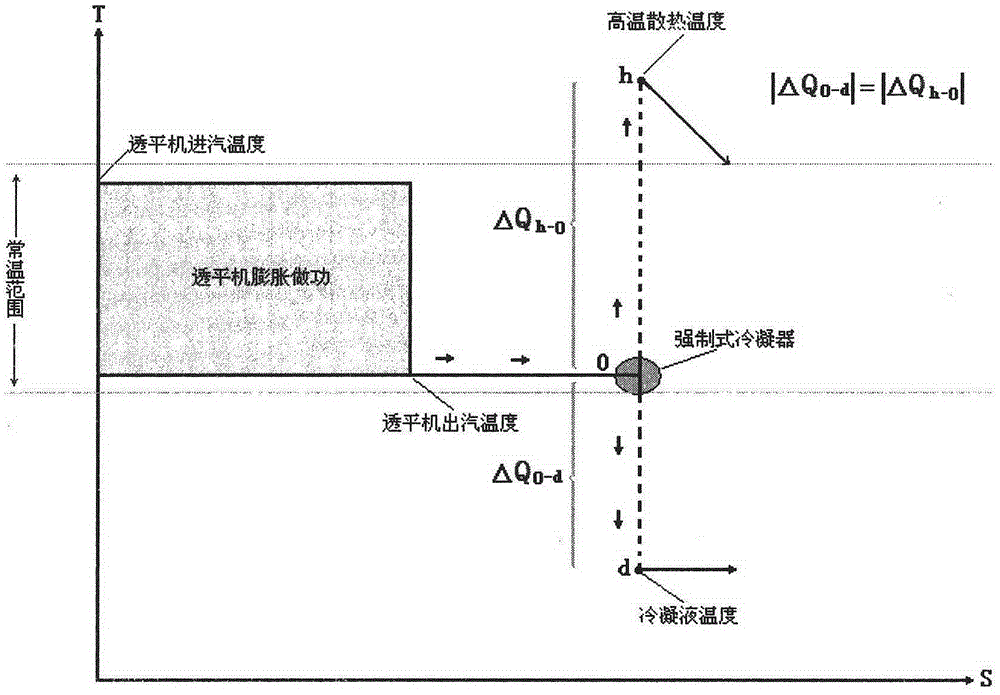

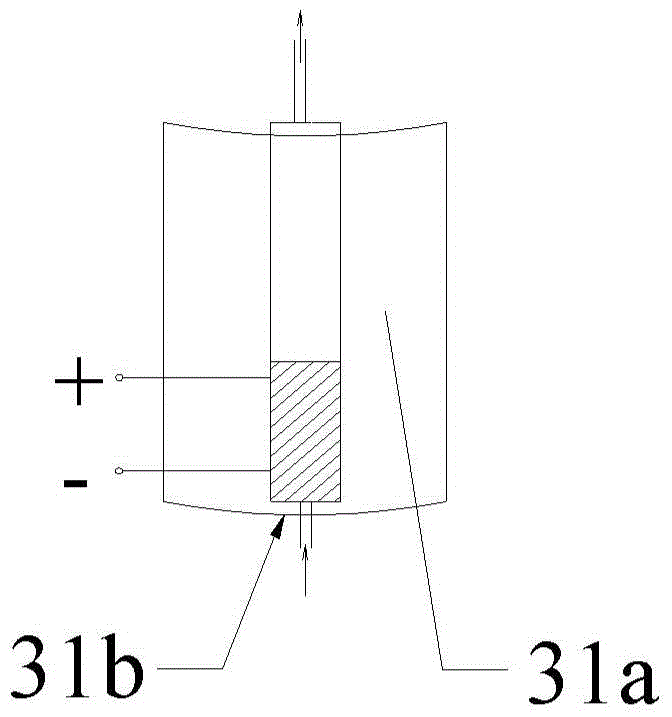

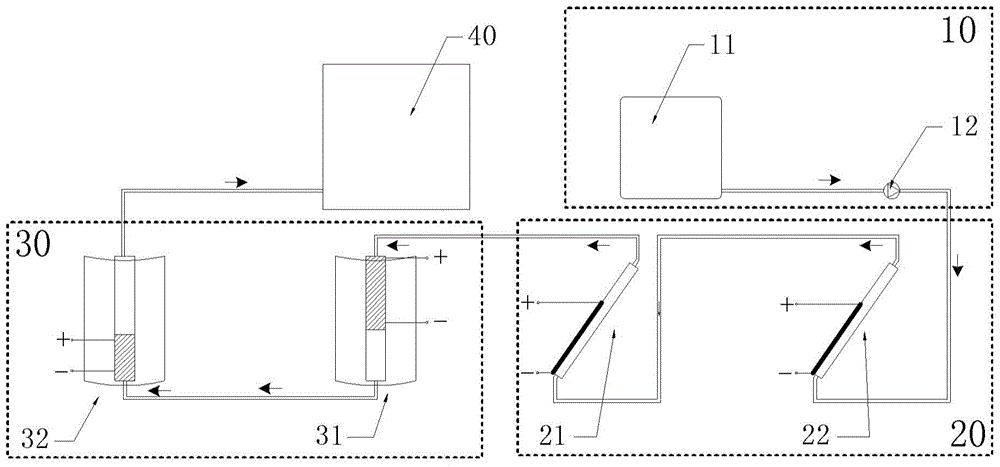

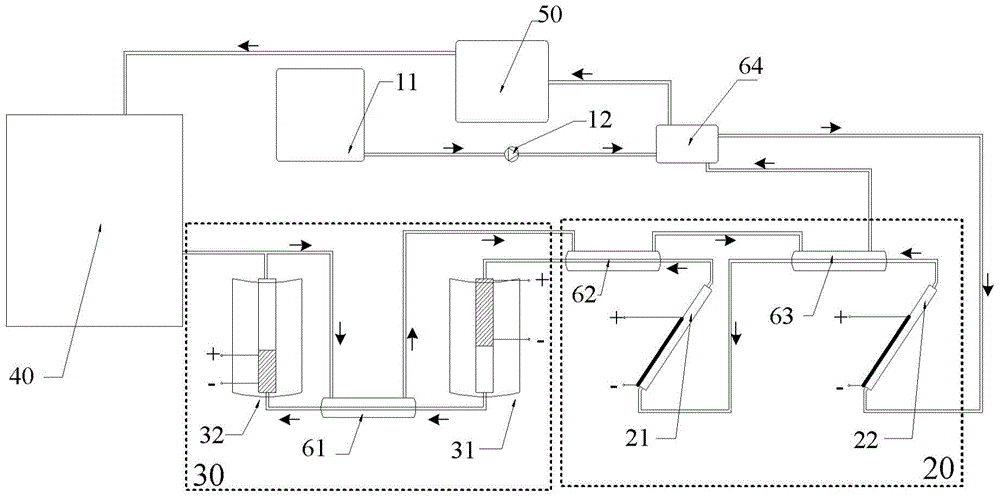

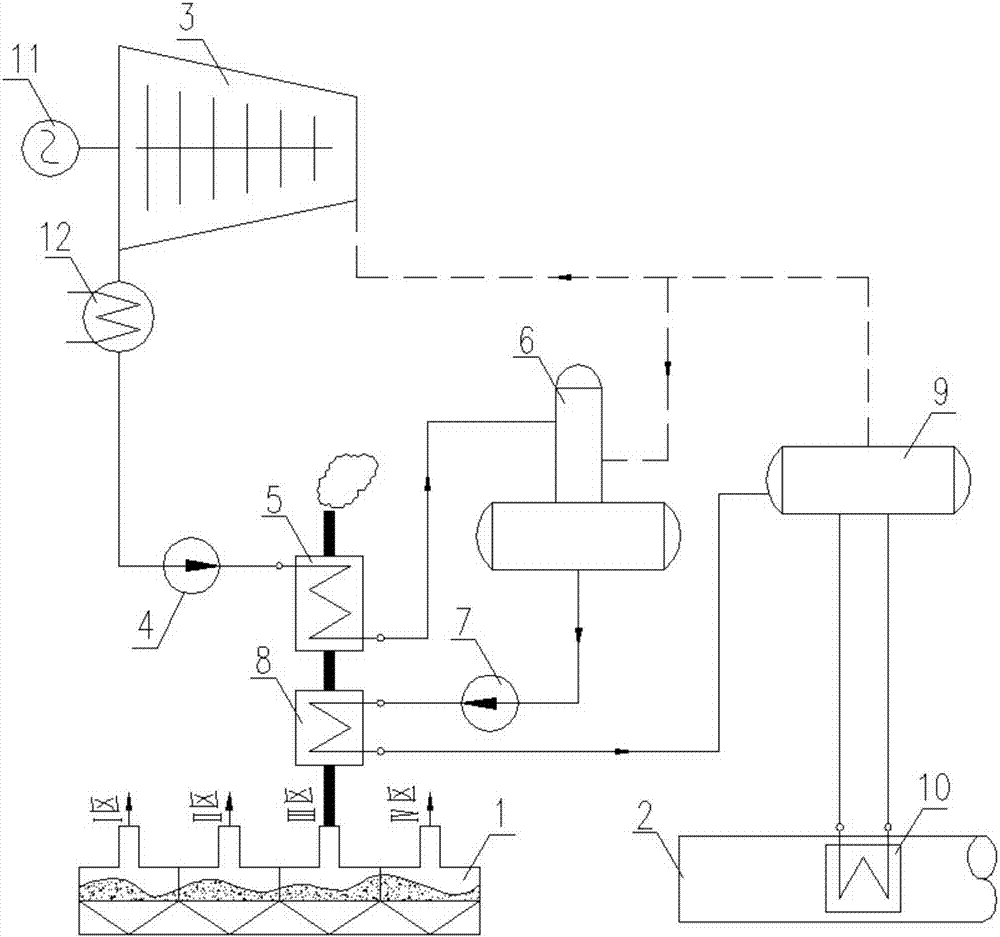

Novel energy conversion system

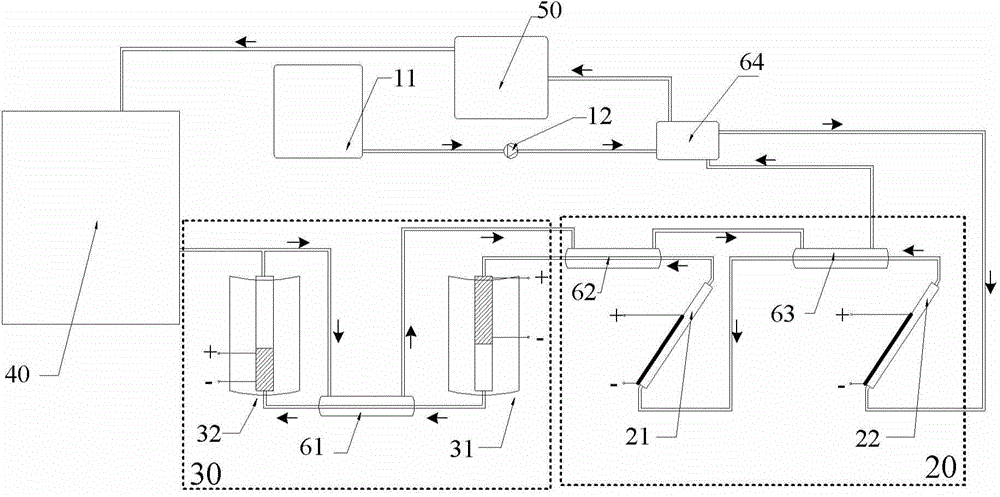

ActiveCN105317485APowerful abilityImprove heat utilizationSteam engine plantsThermal energyLiquid storage tank

The invention discloses a novel energy conversion system. The novel energy conversion system comprises a heat gathering mechanism, a heat conversion mechanism, a cooling and liquefying mechanism and a working medium circulation mechanism. Any two of the heat gathering mechanism, the heat conversion mechanism, the cooling and liquefying mechanism and the working medium circulation mechanism are connected. The whole system conforms to the Rankine cycle operation principle and the second law of thermodynamics. The heat gathering mechanism gathers and transfers heat in the natural environment heat source and the artificial environment heat source to a system working medium with the utilization of a gas-fluid phase combination heat exchange component technology, so that the working medium is warmed and vaporized. According to the cooling and liquefying mechanism, a forcing-type condenser technology is adopted to achieve efficient heat dissipation and liquidation of working medium tail gas. According to the working medium circulation mechanism, a liquid pump and a liquid storage tank are utilized to provide the working medium with the possibility of circulation movement which are conducted in cycles. According to the energy conversion mechanism, with the adoption of a nozzle and an airflow adjusting valve, the airflow thermal energy of the working medium entering into the energy conversion mechanism is converted into mechanical energy, and then the mechanical energy is converted into electric energy. According to the novel energy conversion system, an improved and innovative ultralow-temperature power generation system is provided; the novel energy conversion system can utilize and is not limited to all kinds of low-grade heat energy, and the low-grade heat energy is converted into mechanical power to do work; the novel energy conversion system becomes a novel power generation system by connecting to an electric generator.

Owner:忻元敏

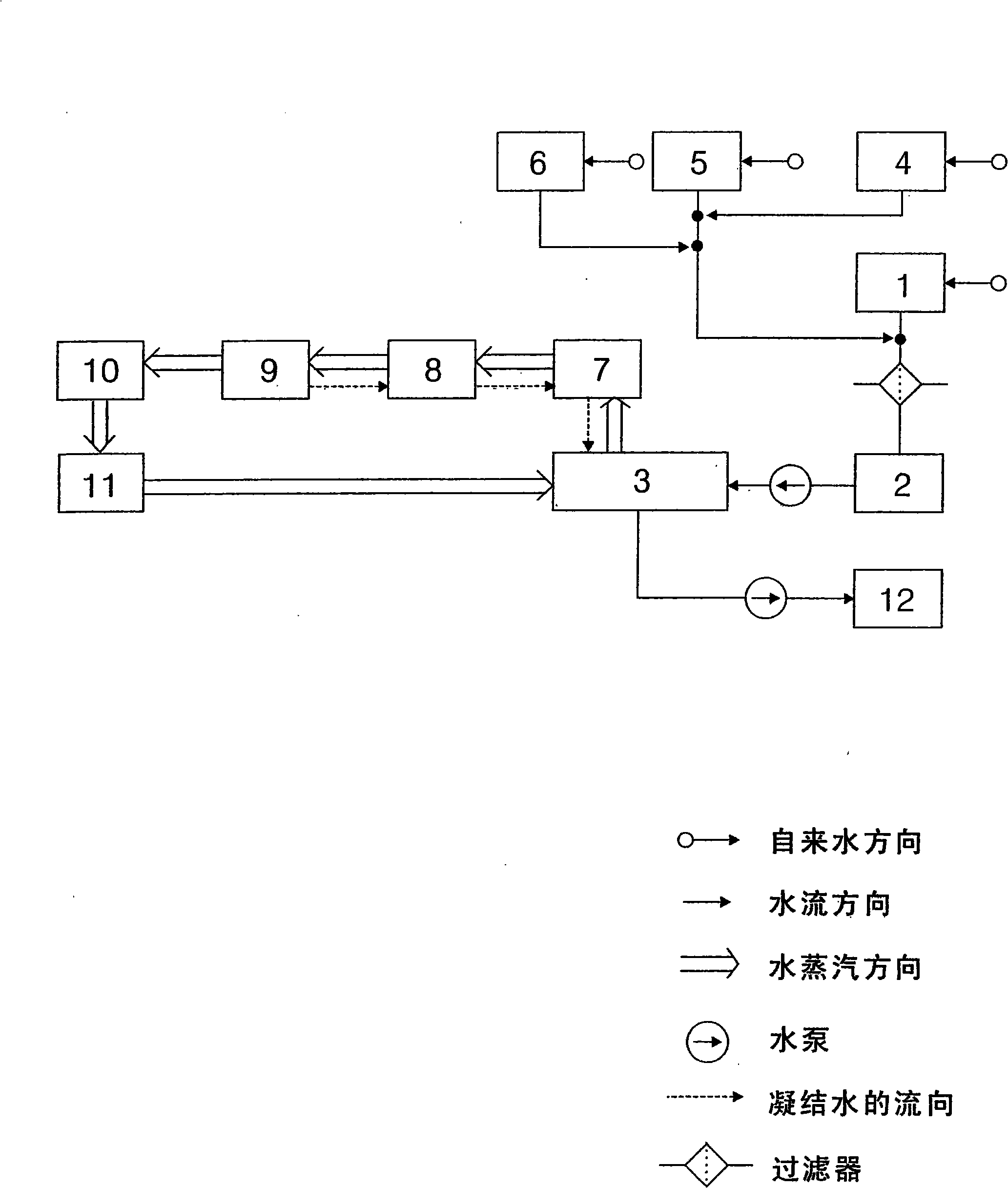

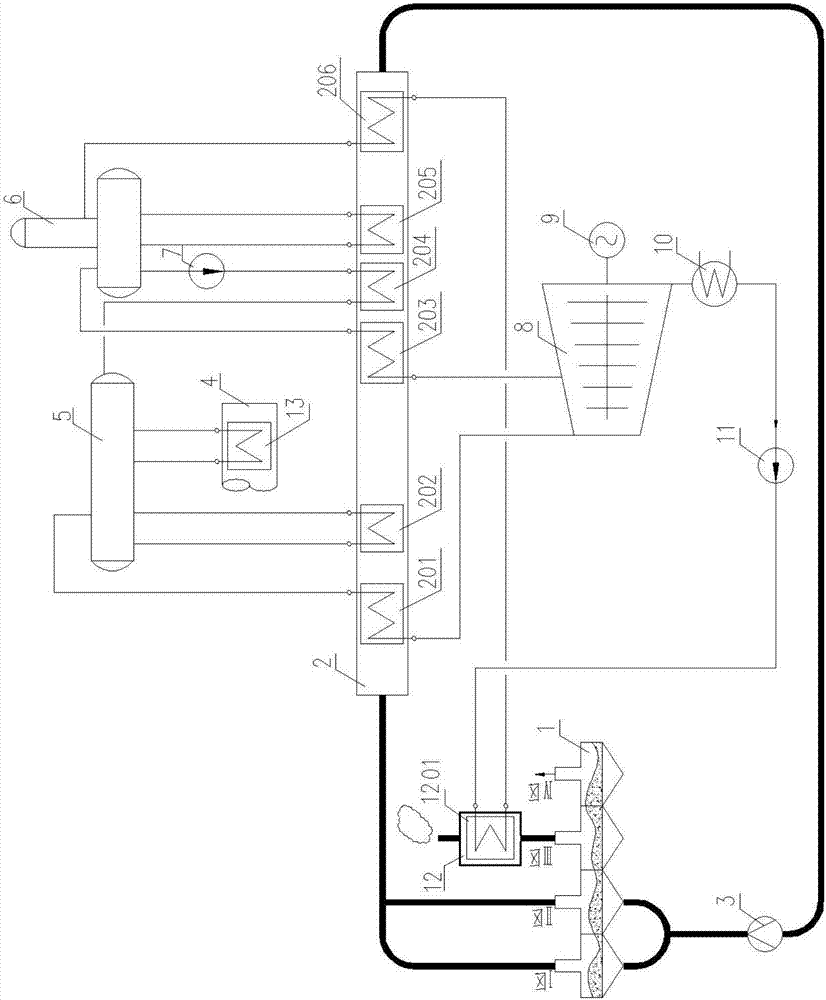

Solar energy and residual heat combining generate electricity technological flow with lower generating cost than fire power generate electricity

InactiveCN101275471ALow costReduce power generation costsEnergy industrySteam engine plantsElectricityWater vapor

The invention discloses a technological process for generating electricity by solar energy and hot water generated by cooling devices, which has a cost less than that of thermal power generation. The invention is based on the law of conservation and transformation of energy, and the supplement to the second law of thermodynamics by the inventor: by the thermodynamic property of working materials, a low temperature heat source can be uses as a high temperature heat source by a heat pump. High-temperature high-pressure water vapor is generated by hot water produced by a solar water heater, a user cooling device and an air conditioner, and used for driving a steam turbine to generate electricity. According to the invention, solar energy which is omnipresent, inexhaustible and cleanest on the earth and waster heat are used, the cost is far less than that of thermal power generation. Therefore, the invention has epochal great significance.

Owner:冼泰来

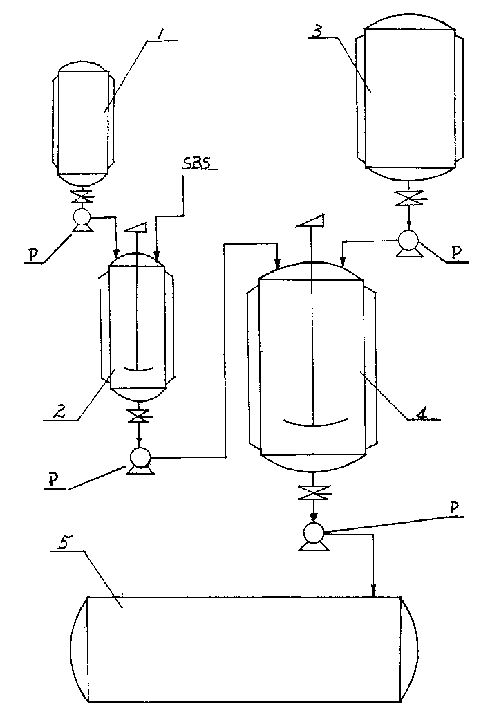

Novel energy conversion system

InactiveCN104454049AReduce construction costsLow running costSteam engine plantsMechanical energyLiquid storage tank

The invention discloses a novel energy conversion system. The novel energy conversion system includes a heat aggregation mechanism, an energy conversion mechanism, a cooling and liquefying mechanism, and a working medium circulation mechanism which are connected in a pairwise manner. The whole system accords with the operating principle of the Rankine heat engine cycle system and the second law of thermodynamics. In the heat aggregation mechanism, a gas-liquid phase combined heat exchange component is used for technological aggregation and transfer of heat from a natural environmental heat source or an artificial environmental heat source to a working medium; in the cooling and liquefying mechanism, a forced type condenser technology is used to achieve effective heat dissipation and liquefaction of a working medium tail gas; in the working medium circulation mechanism, a working medium pump and a liquid storage tank are used to achieve the possibility of circulatory movements of the working medium in a closed system; in the energy conversion mechanism, an energy conversion assembly is used to convert the heat energy of working medium gas flows entering the mechanism into mechanical energy, or further convert the mechanical energy into electric energy. The energy conversion system provided by the invention is an improved and innovative energy conversion system, which can utilize energies, including but not limited to various low-grade heat energies, and convert the low-grade heat energies into mechanical power for work. The novel energy conversion system is a novel power generation system when connected with a power generator.

Owner:忻元敏

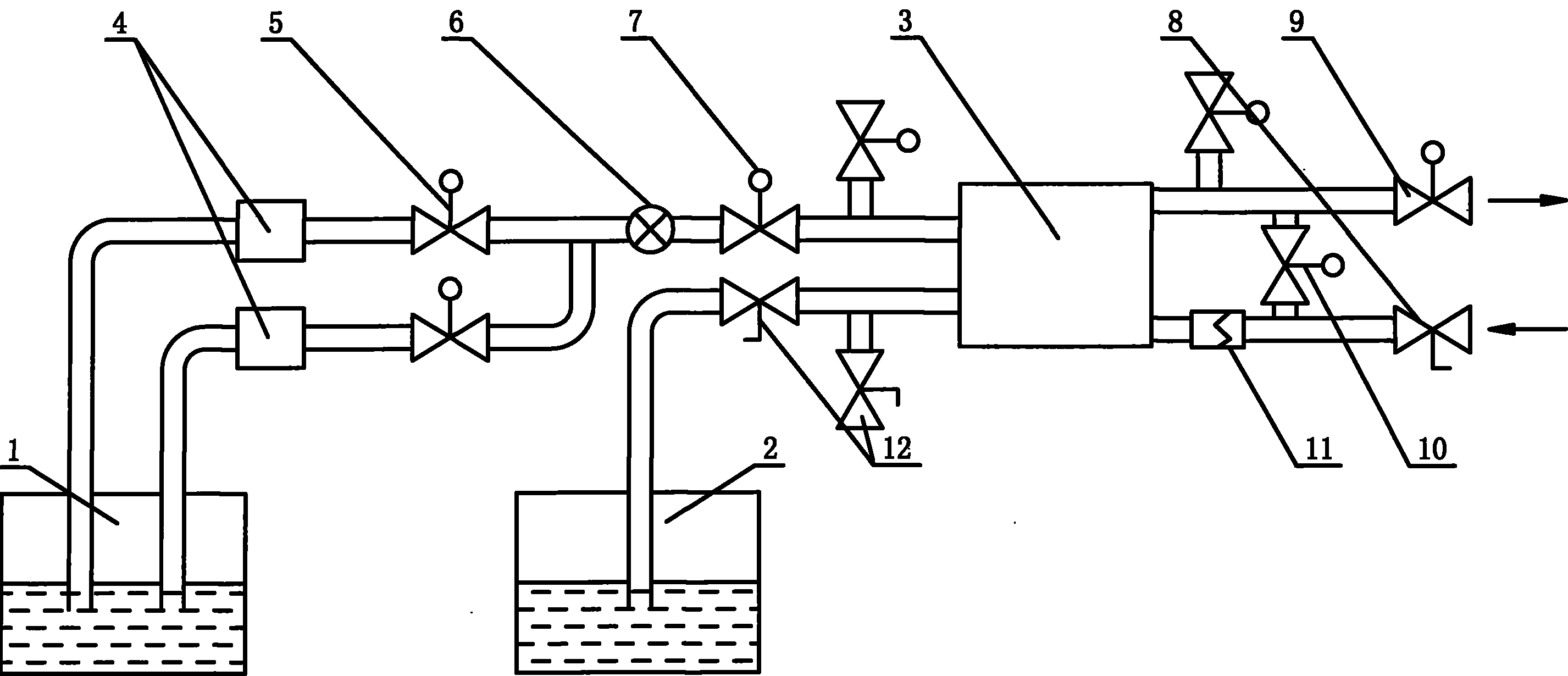

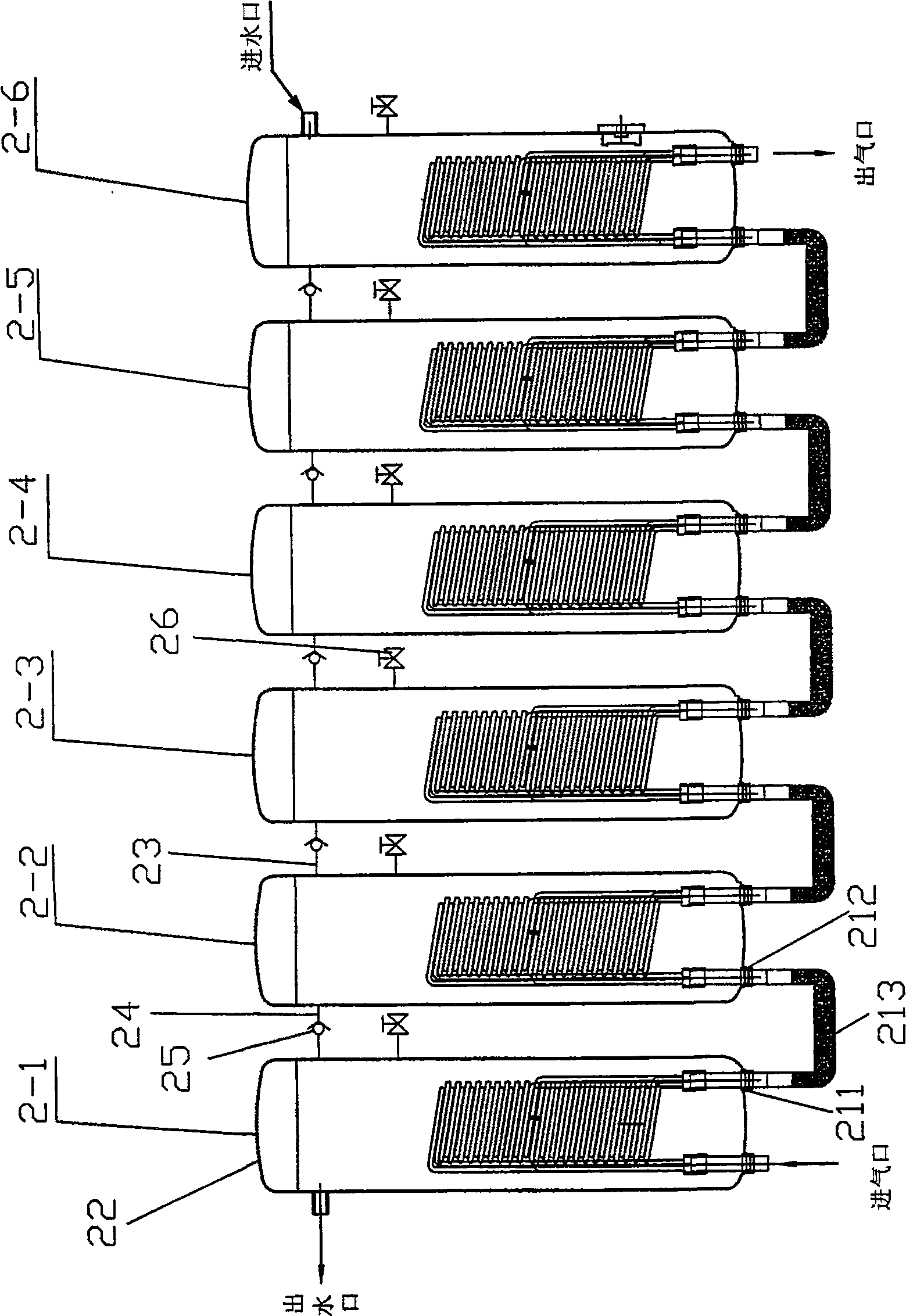

Dual-cartridge filter type wastewater thermal energy recovery system

InactiveCN101915473ALower discharge temperatureLow costOther heat production devicesMultistage water/sewage treatmentFiltrationWastewater

The invention relates to a dual-cartridge filter type wastewater thermal energy recovery system comprising dual filter cartridges, a centrifugal pump and a heat exchanger. The water inlet pipes of the dual filter cartridges are inserted into a cesspool through coarse filtration, and the dual filter cartridges are in the manner of parallel connection; and the heat exchanger is provided with a pipeline respectively connected with a clear water inlet and a sewage outlet and further provided with a pipeline connected to a constant pressure hot water pool, and a hand valve is arranged on the pipeline. In the invention, by utilizing the first law of thermodynamics and the second law of thermodynamics, the energy conversion is carried out on the filtered high temperature wastewater and the equivalent cold clear water through the heat exchanger so as to achieve the purposes of raising the temperature of the clear water, saving steams, synchronously reducing the discharge temperature of the wastewater and decreasing subsequent wastewater costs.

Owner:WUXI QIAOXING MACHINERY

Environmental-friendly and energy-saving multifunctional ceramic tube water air conditioning system and operation method thereof

InactiveCN105783164AImprove water retentionGuaranteed to workLighting and heating apparatusSpace heating and ventilation detailsWater sourceEnergy exchange

Owner:NORTHWEST A & F UNIV

Method and device for transferring heat

InactiveCN102216701AImprove the coefficient of performanceSmall sizePV power plantsTemperatue controlForms of energyMechanical energy

A method and device for transferring heat in a heat pump, where heat energy is transferred with the aid of light or other electromagnetic radiation from an element emitting radiation to an element absorbing radiation in a direction opposite to the direction defined by the second law of thermodynamics and in which a part of the energy of the absorbed radiation is converted back to an exploitable form of energy, like electrical or mechanical energy.

Owner:雅尼·奥克萨南 +1

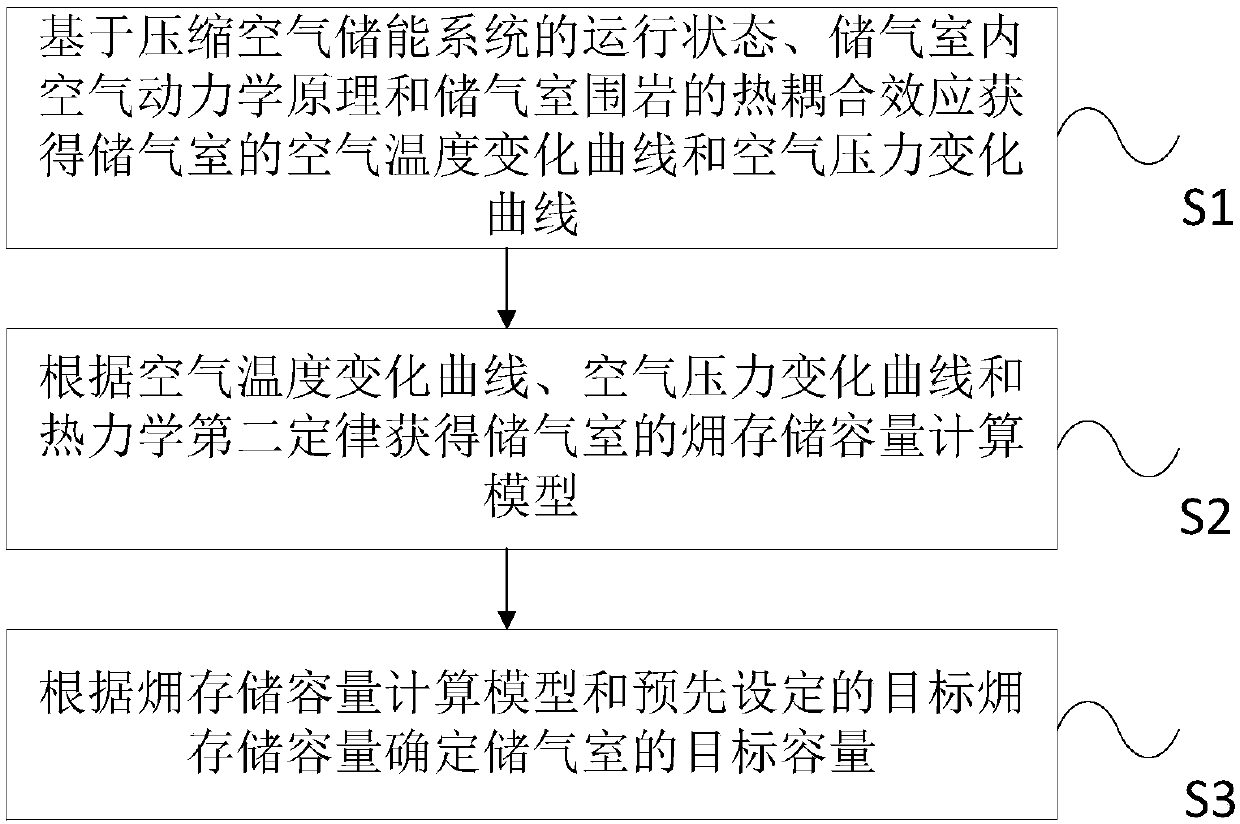

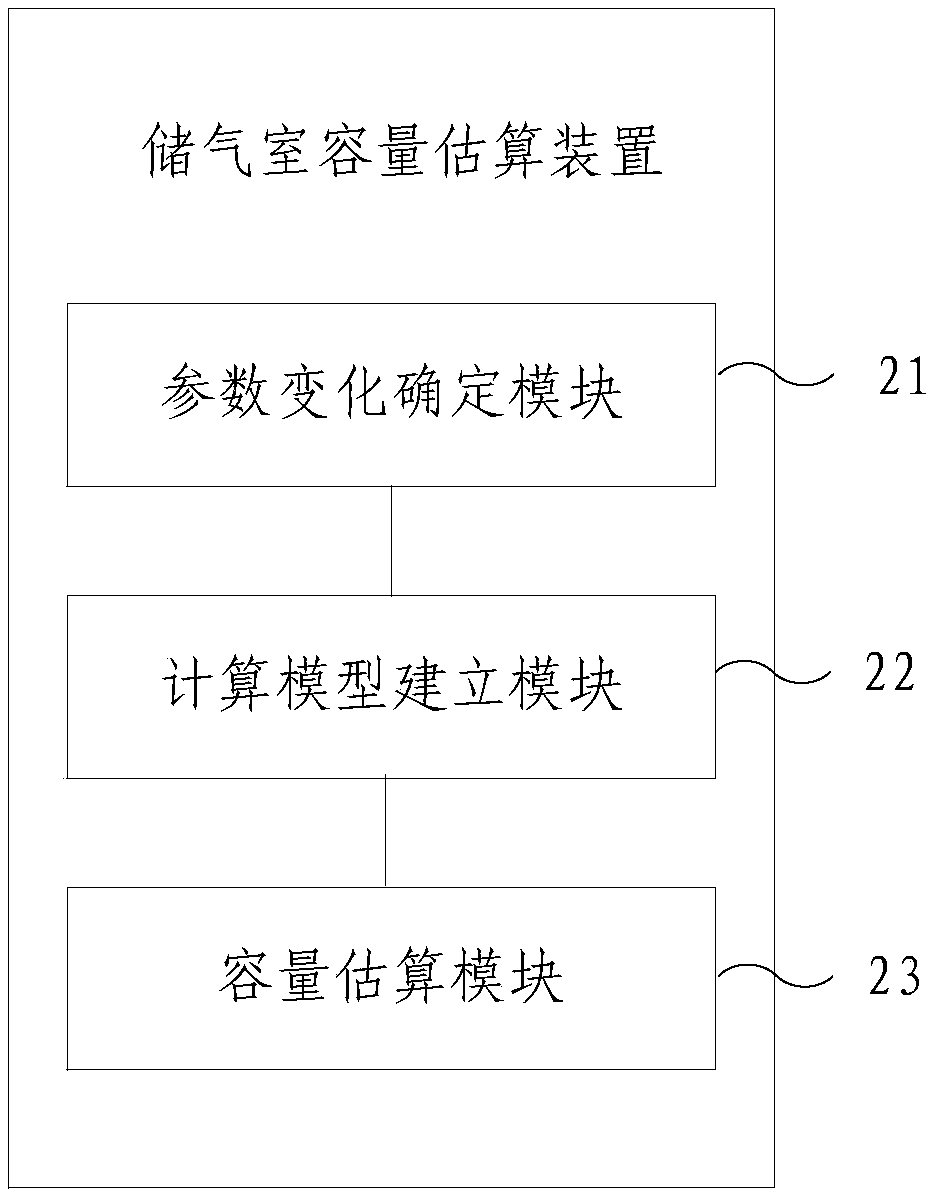

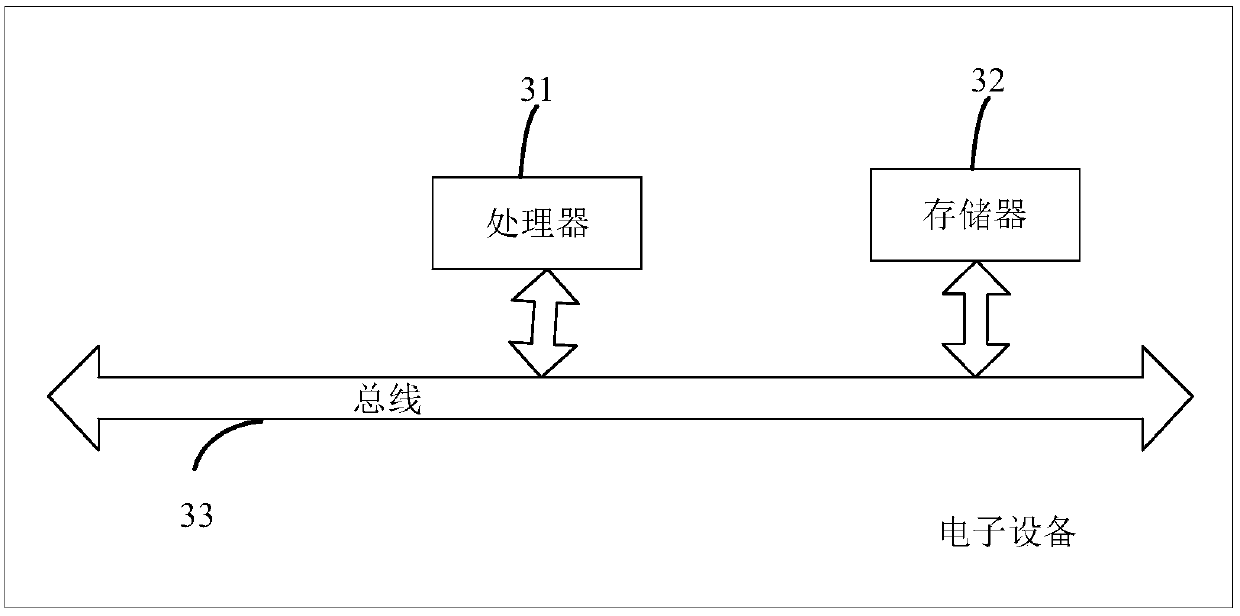

Method and device for estimating capacity of air storage chamber of compressed air energy storage system

ActiveCN109543214AAccurate assessmentBalance accuracyDesign optimisation/simulationSpecial data processing applicationsPressure curveThermal energy storage

The embodiment of the invention provides a method and a device for estimating the capacity of an air storage chamber of a compressed air energy storage system. Based on the operation state of the compressed air energy storage system, the aerodynamic principle of the air storage chamber and the thermal coupling effect of the surrounding rock of the air storage chamber, the air temperature change curve and the air pressure change curve of the air storage chamber are obtained. According to the air temperature curve, the air pressure curve and the second law of thermodynamics, the storage capacitycalculation model of the gas storage chamber is obtained. In accordance with storage capacity calculation model and a preset target ( storage capacity, the target capacity of the gas storage chamberis determined. Considering the aerodynamic principle of the gas storage chamber and the thermal coupling of the surrounding rock, Combined with the running state of compressed air energy storage system, the calculation of the storage capacity of the gas storage chamber is accurately modeled in order to achieve accurate evaluation of the capacity of the gas storage tank. The method can effectivelybalance the rapidity and accuracy of capacity estimation, can be used for early planning and design of compressed air energy storage system.

Owner:TSINGHUA UNIV +4

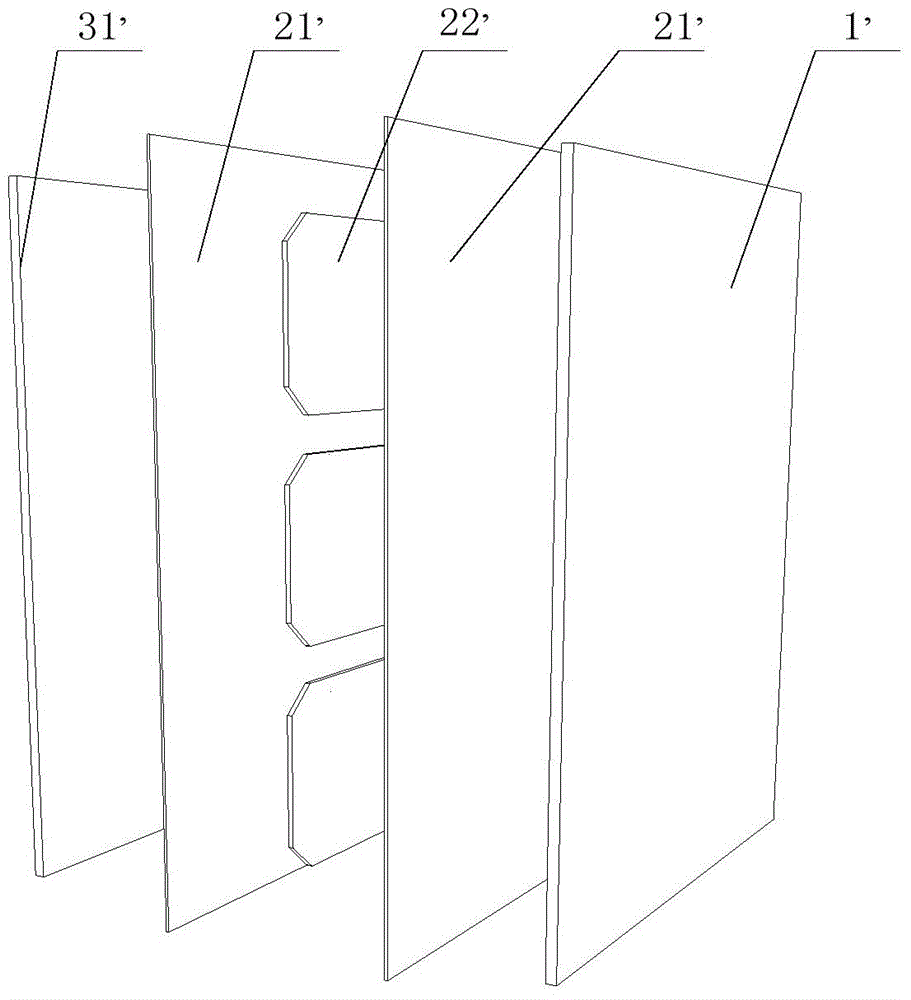

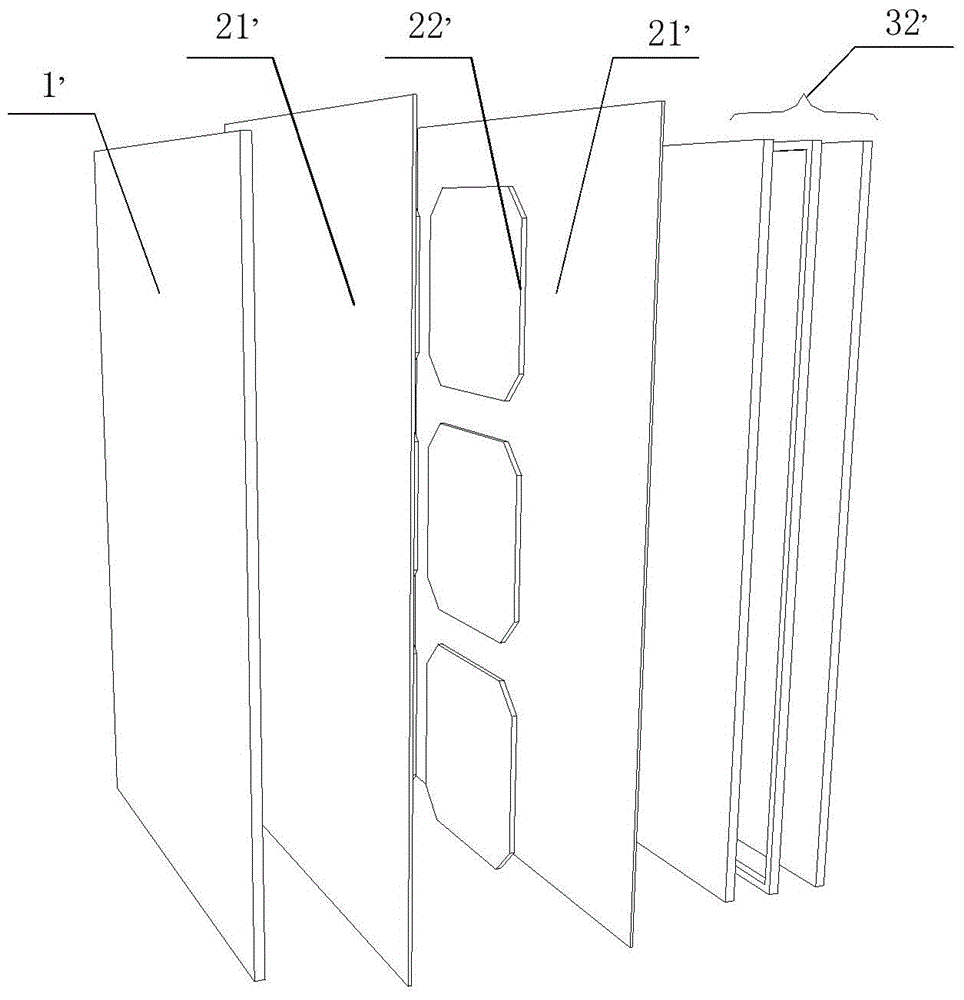

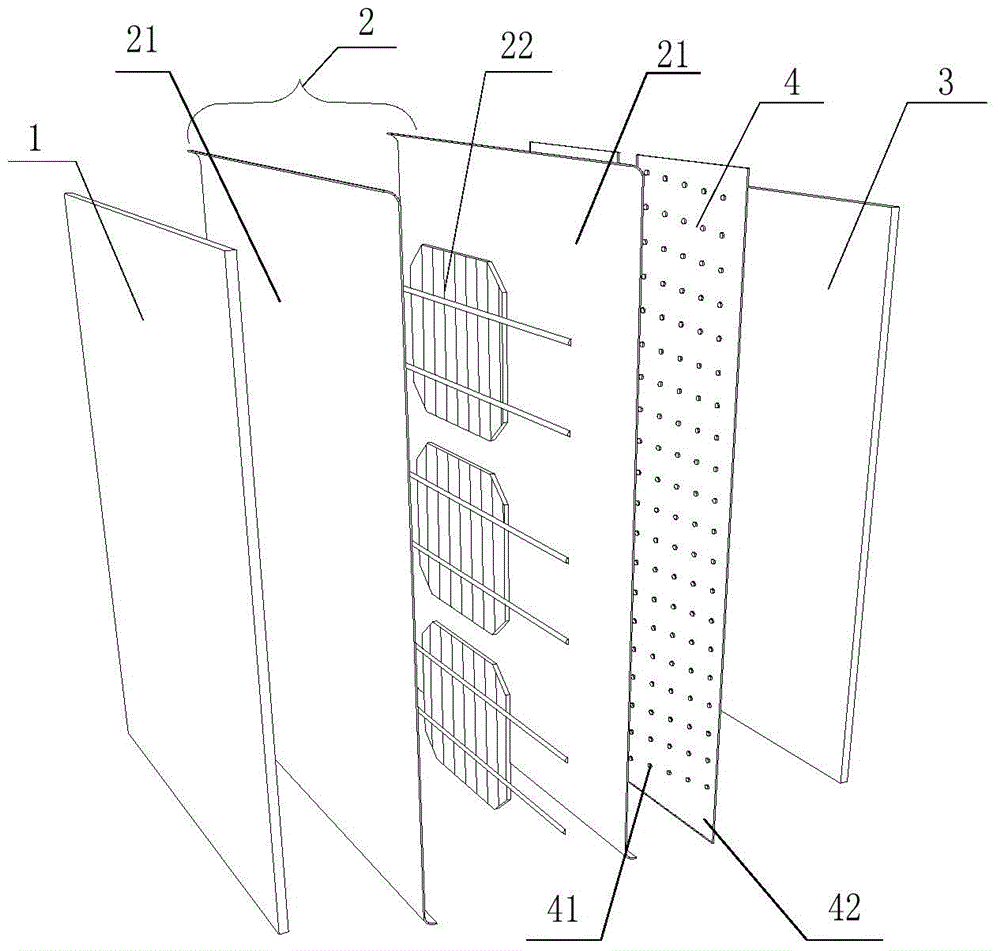

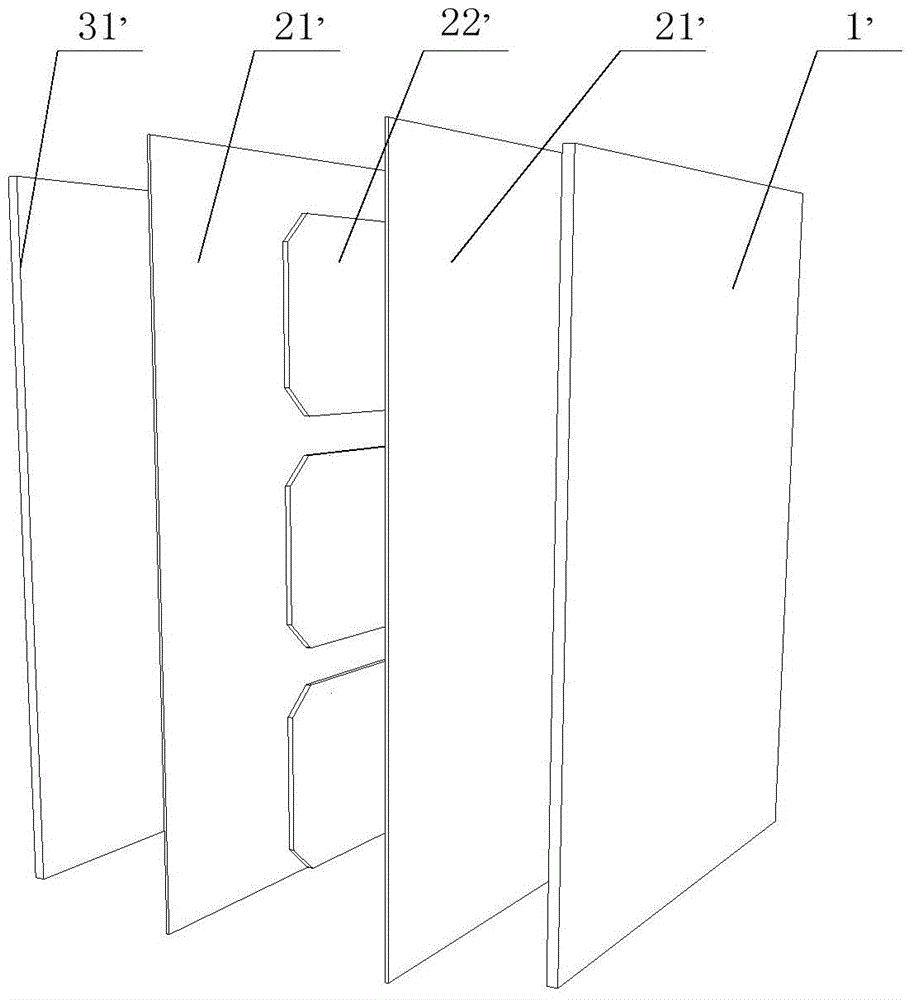

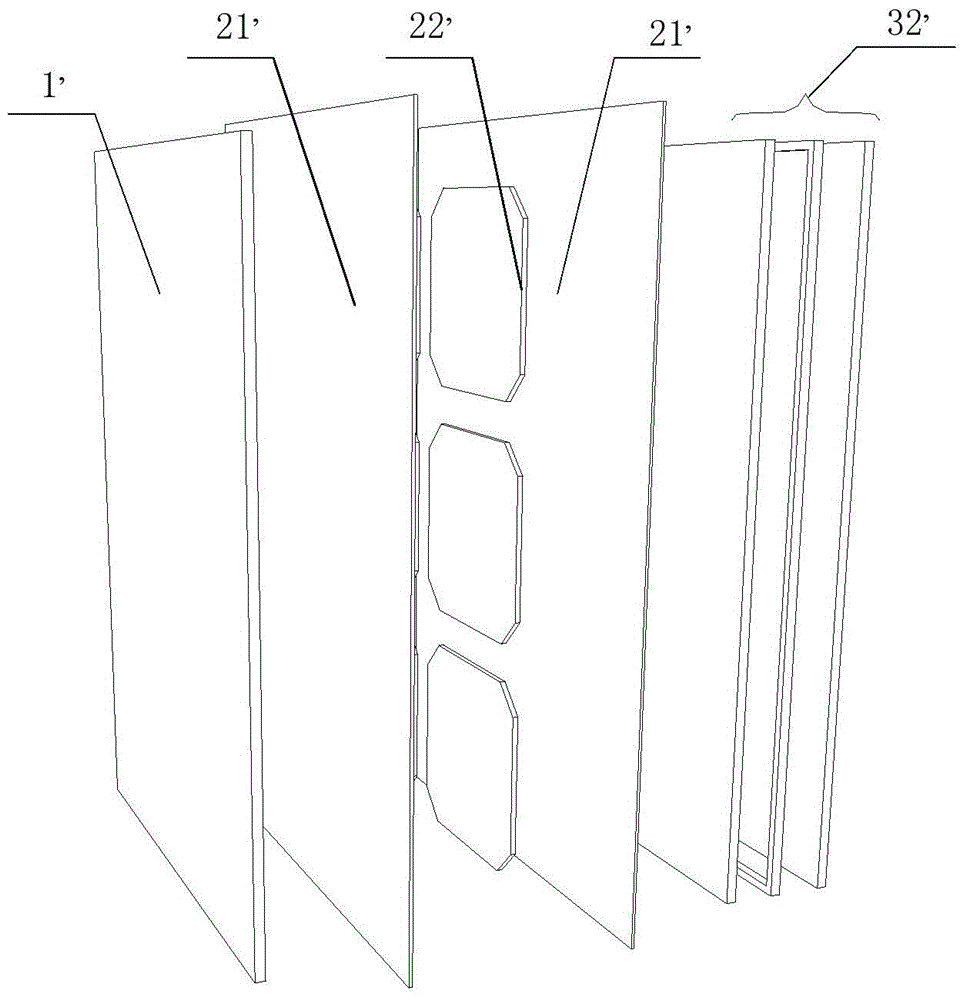

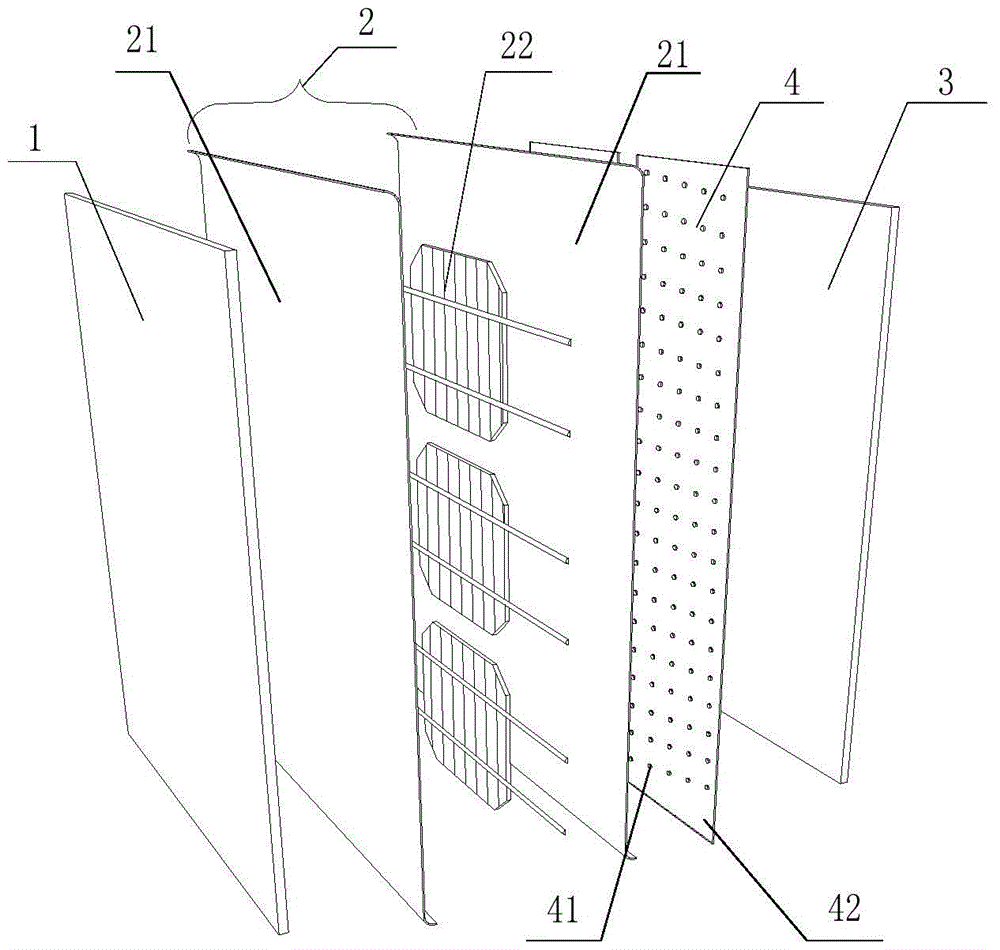

Photovoltaic glass component and photovoltaic curtain wall provide with same

ActiveCN104485381AImprove work efficiencyImprove cooling effectWallsPhotovoltaic energy generationInterliningEngineering

The invention provides a photovoltaic glass component and a photovoltaic curtain wall provide with the same, wherein the photovoltaic glass component comprises surface glass, an interlining, lining glass and a cooling plate, wherein the surface glass, the interlining and the lining glass are sequentially arranged; the cooling plate is arranged between the interlining and the lining glass. According to the second law of thermodynamics, heat can be automatically transmitted from a relatively hot object to a relatively cold object and cannot be automatically transmitted from the relatively cold object to the relatively hot object, for the photovoltaic glass component disclosed by the invention, the heat is transmitted from the interlining which is at a relatively high temperature to the cooling plate which is at a relatively low temperature, so that the heat generated in the interlining can be enabled to be continuously emitted outwards, and finally the cooling effect of the interlining can be improved.

Owner:深圳市光锦绿色科技有限公司

Friction and wear management using solvent partitioning of hydrophilic-surface-interactive chemicals contained in boundary layer-targeted emulsions

ActiveUS9023773B1Promote resultsSpeed up the flowOrganic chemistryOther chemical processesWater basedEmulsion

Lubrication additives of the current invention require formation of emulsions in base lubricants, created with an aqueous salt solution plus a single-phase compound such that partitioning within the resulting emulsion provides thermodynamically targeted compounds for boundary layer organization thus establishing anti-friction and / or anti-wear. The single-phase compound is termed “boundary layer organizer”, abbreviated BLO. These emulsion-contained compounds energetically favor association with tribologic surfaces in accord with the Second Law of Thermodynamics, and will organize boundary layers on those surfaces in ways specific to the chemistry of the salt and BLO additives. In this way friction modifications may be provided by BLOs targeted to boundary layers via emulsions within lubricating fluids, wherein those lubricating fluids may be water-based or oil-based.

Owner:DFHS LLC

High-efficiency energy-saving air conditioning system used for area cold supplying and its implementing method

InactiveCN101344291BAchieve step-by-step utilizationIncrease return water temperatureLighting and heating apparatusAir conditioning systemsPlate heat exchangerEngineering

The present invention provides a high-efficient and energy-saving air-conditioning system used for district cooling, which comprises a refrigeration host, a chilled water primary pump, a chilled water secondary pump, a plate heat exchanger, a new air processing device, a return air processing device, a new air pre-processing device, a user chilled water circulating pump and a total heat exchanger. The present invention further provides a realization method of the air-conditioning system. The high-efficient and energy-saving air-conditioning system and the realization method of the invention are based on the second law of thermodynamics and the optimized scientific energy utilization principle of exergy economics, and realizes the purposes of increasing the temperature difference between the supply water and the return water of a chilled water secondary pipeline and reducing the flow rate thereof by the method of connecting two levels of refrigeration with the refrigeration host in series and the innovative cold energy gradual utilization of a tail-end device.

Owner:SOUTH CHINA UNIV OF TECH

Modified asphalt and its preparation method

InactiveCN1222577CReduce consumptionReasonable workmanshipBuilding insulationsThermoplastic elastomerSolvent

Owner:大连市政设施管修处

Photovoltaic glass component and photovoltaic curtain wall provided with the photovoltaic glass component

ActiveCN104485381BImprove work efficiencyImprove cooling effectWallsPhotovoltaic energy generationInterliningCooling effect

The invention provides a photovoltaic glass component and a photovoltaic curtain wall provide with the same, wherein the photovoltaic glass component comprises surface glass, an interlining, lining glass and a cooling plate, wherein the surface glass, the interlining and the lining glass are sequentially arranged; the cooling plate is arranged between the interlining and the lining glass. According to the second law of thermodynamics, heat can be automatically transmitted from a relatively hot object to a relatively cold object and cannot be automatically transmitted from the relatively cold object to the relatively hot object, for the photovoltaic glass component disclosed by the invention, the heat is transmitted from the interlining which is at a relatively high temperature to the cooling plate which is at a relatively low temperature, so that the heat generated in the interlining can be enabled to be continuously emitted outwards, and finally the cooling effect of the interlining can be improved.

Owner:深圳市光锦绿色科技有限公司

Solar energy comprehensive utilization device and system combining photovoltaic and photothermal chemistry

ActiveCN104676911BAvoid direct conversionIncrease incomeSolar heating energyHydrogenThermal physicsChemical reaction

The invention provides a photovoltaic and photo-thermal chemical combination solar energy comprehensive utilization device and system. According to the principle of gradient utilization of cycling energy, sunlight energy is firstly utilized through a photovoltaic system, and the residual heat of the photovoltaic system is converted into high-grade (fuel) chemical energy through absorbing by a chemical reaction. Compared with the way of directly utilizing the residual heat of a solar photovoltaic battery in a physical way, the method for coupling thermal physics and thermal chemistry has the advantages that the power capability of solar energy is fully explored, the second law of thermodynamics efficiency of solar energy utilization can be greatly increased, and the electric energy output of the system can be more stabilized.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

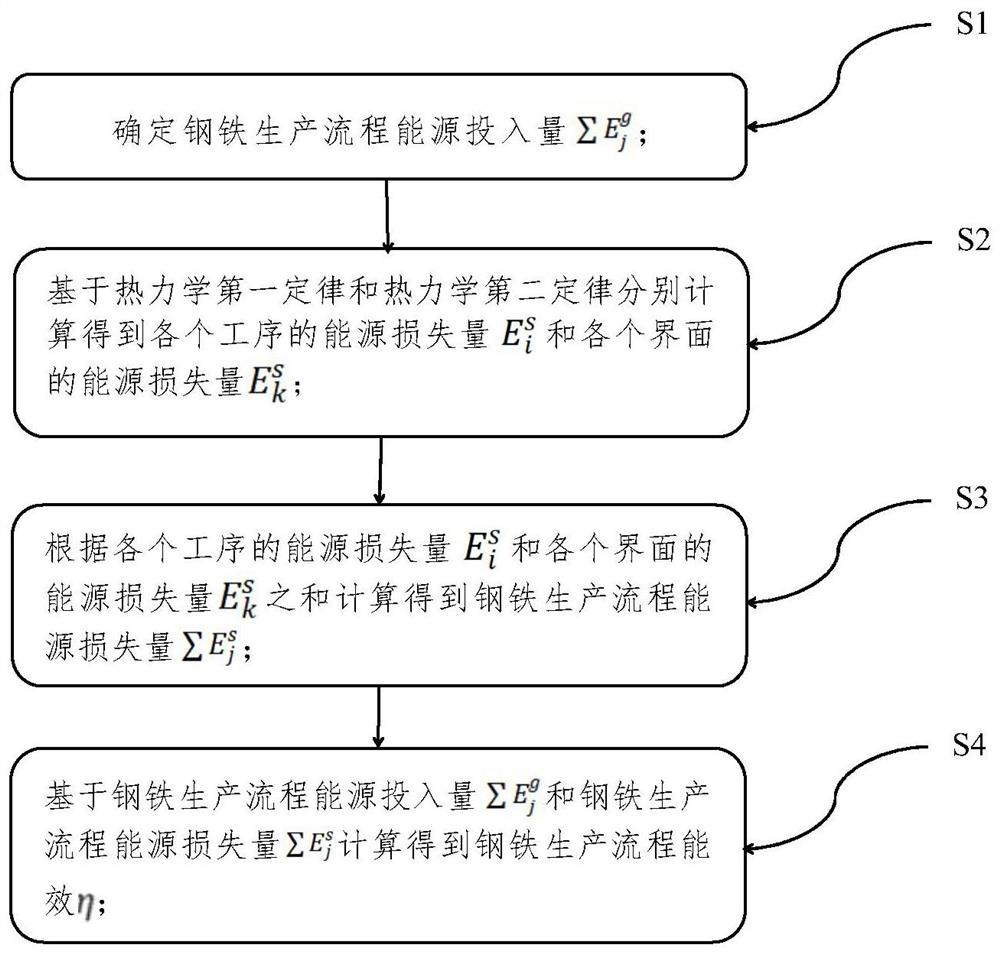

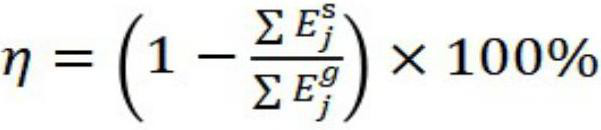

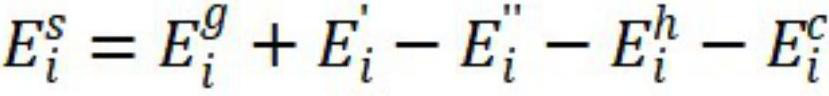

Steel flow energy efficiency calculation method

PendingCN113705014AImprove energy efficiencyHave objectivityDesign optimisation/simulationSpecial data processing applicationsProcess engineeringSecond law of thermodynamics

The invention relates to a steel flow energy efficiency calculation method. The method comprises the following steps: determining energy input of a steel production process; respectively calculating energy loss of each process and energy loss of each interface based on the first law of thermodynamics and the second law of thermodynamics; calculating energy loss of the steel production process based on the sum of the energy loss of each process and the energy loss of each interface; and calculating the energy efficiency eta of the steel production process based on the energy input of the steel production process and the energy loss amount of the steel production process. The steel flow energy efficiency calculation method provided by the invention makes up a blank in energy efficiency evaluation of current steel flow energy systems.

Owner:NORTHEASTERN UNIV

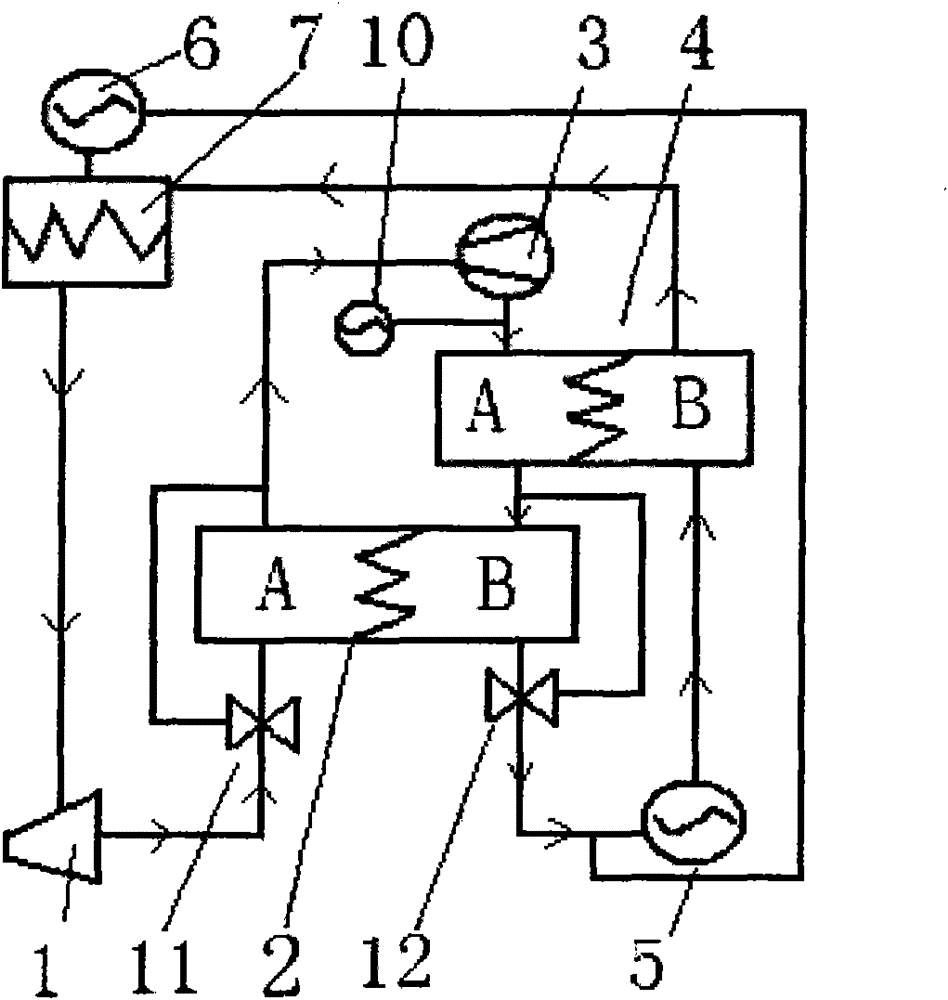

Heat, cold bi-directional coexistence system

InactiveCN100526758CSave on purchasesSave on infrastructure investmentCompression machines with non-reversible cycleCompression machines with several condensersAtmospheric emissionsThermal energy

The invention relates to a device capable of both heating and cooling, especially a heat and cold two-way symbiosis system that only consumes refrigeration energy in one direction and obtains two-way energy output, and can also cool when hot water and steam of different temperatures are produced. According to the second law of thermodynamics, through the work of the compressor, the heat is transferred from the air (cooling and cooling the surrounding air) to the hot water. The heat exchanger solves the problem of today's heat supply without a special boiler; the waste heat generated during cooling is fully recycled through the heat exchanger, and no longer emits waste heat to the atmosphere. It does not affect cooling and cooling at the same time, and obtains hot water The investment of installing a water heater and the cost of special heating of hot water are saved, and the invention is applicable to all occasions that require refrigeration and obtain cheap heat energy.

Owner:DONGGUAN HOTWHEELS ENERGY TECH

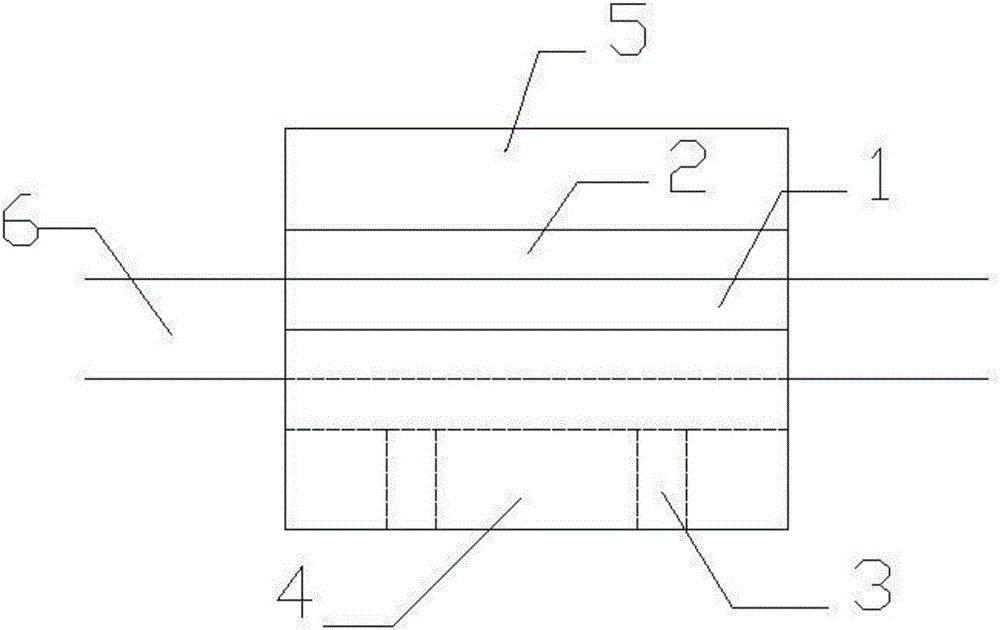

Comprehensive utilization system for ring cooling machine waste gas and sintering large flue exhaust gas waste heat

PendingCN107036062AImprove power generation efficiencyReduce in quantityLiquid degasificationIncreasing energy efficiencySuperheaterHigh pressure

The invention discloses a comprehensive utilization system for ring cooling machine waste gas and sintering large flue exhaust gas waste heat. The system comprises a ring cooling machine front area waste heat recycling device, a low pressure steam drum and a high pressure steam drum. The ring cooling machine front area waste recycling device comprises a heat exchange device. The heat exchange device comprises a box body, and a high pressure superheater, a high pressure evaporator, a low pressure superheater, a high pressure coal economizer, a low pressure evaporator and a low pressure coal economizer which are sequentially arranged in the box body in the exhaust gas flowing direction. High-temperature exhaust gas waste heat in a sintering large flue and sintering ore cooled waste gas waste heat of a ring cooling machine are recycled, low-temperature waste gas waste heat of the III area of the ring cooling machine is utilized, the system is reasonably arranged in the heated face of the sintering large flue and the ring cooling machine waste heat recycling device according to the second law of thermodynamics, flue gas waste heat in the flue is recycled stepwise, two kinds of high-grade steam are produced, the power generation efficiency is improved, one steam drum is adopted for recycling waste heat in the sintering large flue and the ring cooling machine, the equipment number is reduced, and the investment cost is reduced.

Owner:HUATIAN NANJING ENG & TECH CORP MCC

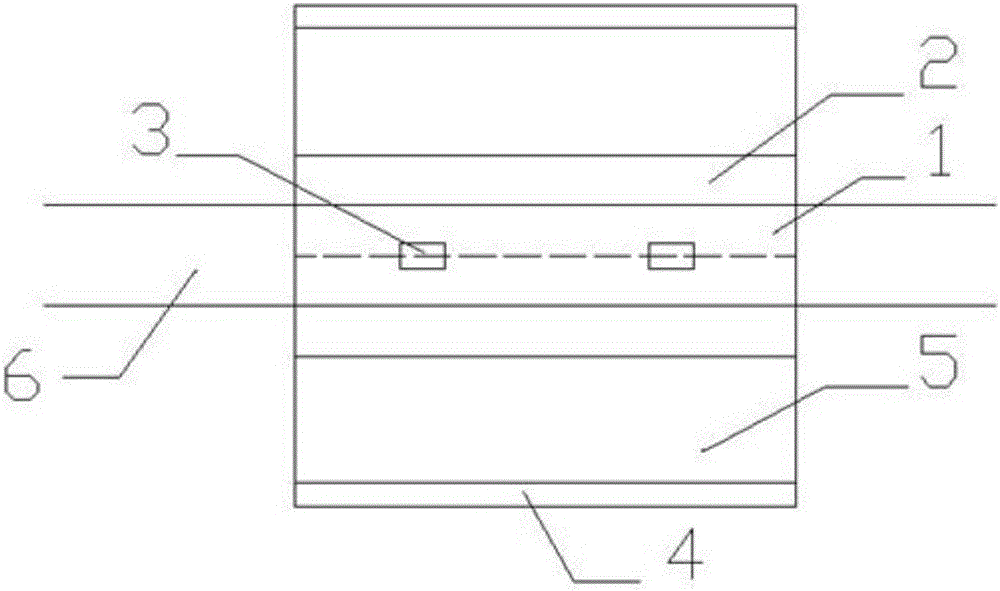

Comprehensive utilization system of waste heat of ring cooling machine low-temperature exhaust gas and sintering large flue smoke

PendingCN107060929ALow running costIncrease waste heat recoveryIncreasing energy efficiencySteam engine plantsSteam powerEngineering

The invention discloses a comprehensive utilization system of waste heat of ring cooling machine low-temperature exhaust gas and sintering large flue smoke. The comprehensive utilization system of the waste heat of the ring cooling machine low-temperature exhaust gas and the sintering large flue smoke comprises a steam pocket, a ring cooling machine low-temperature area waste heat recycling device, a sintering large flue waste heat recycling device and a steam power generation device. A water outlet of the ring cooling machine low-temperature area waste heat recycling device communicates with a water inlet of the steam pocket. A water outlet of the steam pocket communicates with a water inlet of the sintering large flue waste heat recycling device. A steam water outlet of the sintering large flue waste heat recycling device communicates with a steam water inlet of the steam pocket. A steam outlet of the steam pocket communicates with a steam inlet of the steam power generation device. A water outlet of the steam power generation device communicates with a water inlet of the ring cooling machine low-temperature area waste heat recycling device. The comprehensive utilization system of the waste heat of the ring cooling machine low-temperature exhaust gas and the sintering large flue smoke recycles the waste heat of sintering high-temperature smoke of a sintering machine and waste heat of low-temperature exhaust gas at the temperature of 100-150 DEG C of a III area of a ring cooling machine, a heating surface is reasonably arranged according to the second law of thermodynamics, stairstep recycling of the waste heat of the smoke is achieved, and the recycling amount of the waste heat is improved to the greatest extent.

Owner:HUATIAN NANJING ENG & TECH CORP MCC

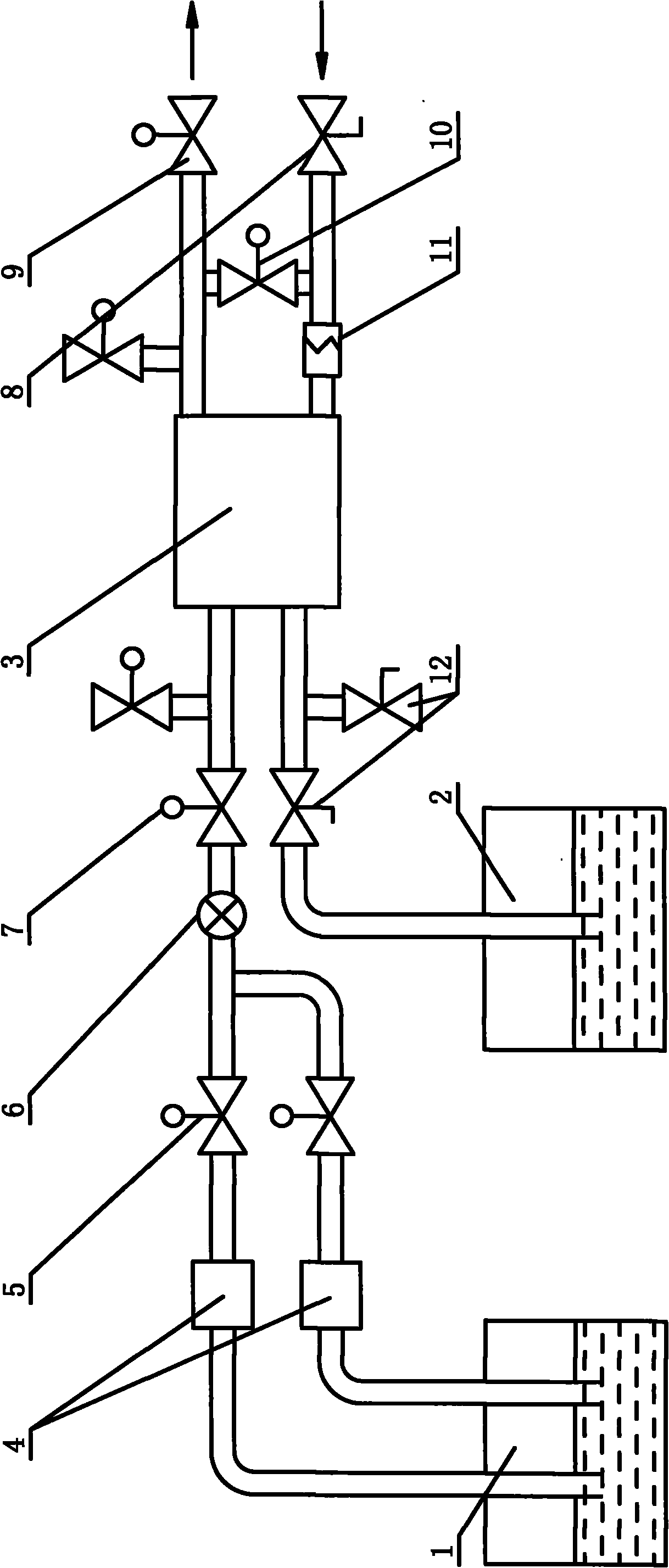

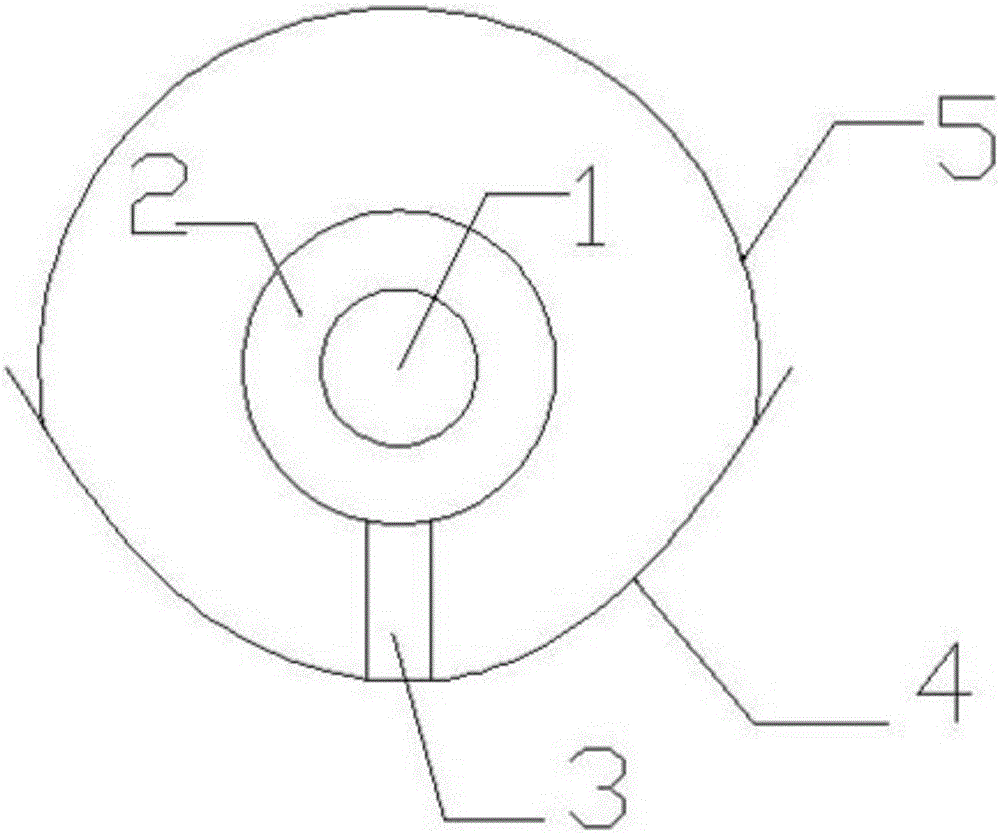

Method and device for generating kinetic energy and refrigerating

ActiveCN102720553AGet rid of dependenceEnd harmCompression machines with non-reversible cycleSteam engine plantsEngineeringSecond law of thermodynamics

The invention relates to a technology and a device that employ a heat source at a normal temperature to generate kinetic energy and refrigerate. The technical content of the work circulation comprises the steps of allowing refrigerant that has absorbed heat and heated up in an evaporator (7) to work in an expander (1), allowing a compressor (3) to carry out compression heating on the vaporous working refrigerant that has worked in the expander (1) and enters the compressor through an A cavity of a heat exchanger (2), allowing the heat exchanger (2) to enable the vaporous working refrigerant that has undergone compression heating in the B cavity to release heat to the vaporous refrigerant that flows from the expander (1) after working and is in the A cavity to produce liquid refrigerant, and allowing the liquid refrigerant that is from the B cavity of the heat exchanger (2) and is in the B cavity of a main heat exchanger to absorb the compression heat of the vaporous refrigerant that has undergone compression heating, is from the compressor (3) and is in the A cavity of the main heat exchanger and then to enter the evaporator (7). The above work circulation simply converts parts of the heat energy to kinetic energy, which does not violate the first law and the second law of thermodynamics and is feasible.

Owner:王法文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com