Dual-cartridge filter type wastewater thermal energy recovery system

A heat energy recovery and filter technology, applied in heating devices, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of heat energy waste, energy waste, affecting aerobic biochemical treatment, etc. effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

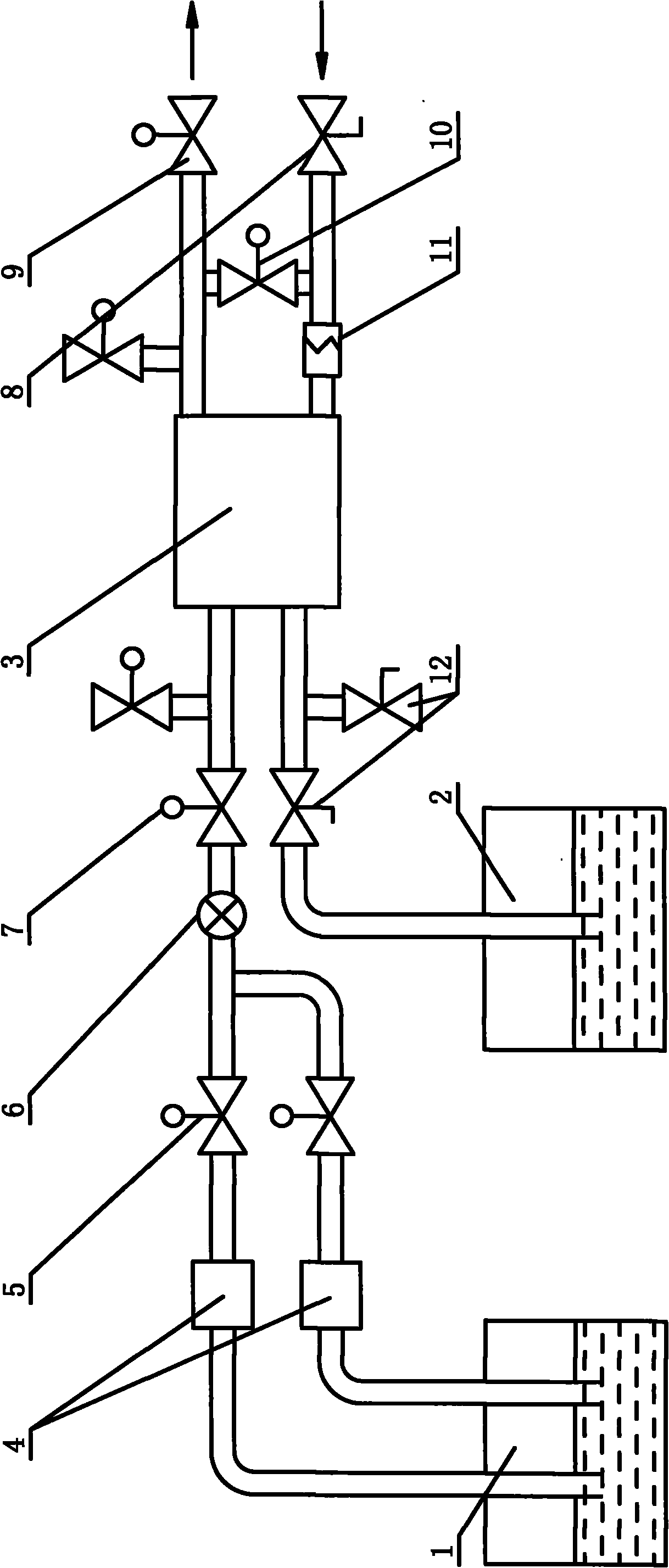

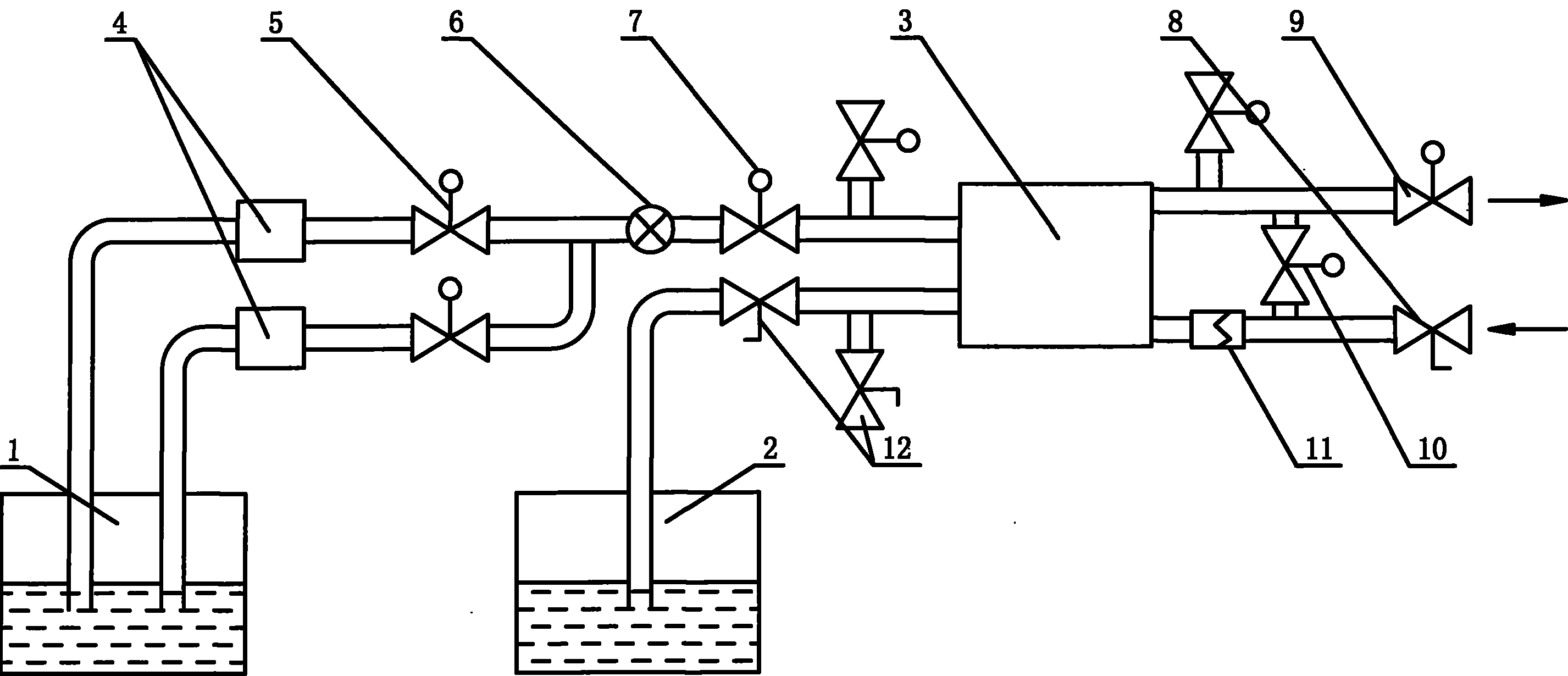

[0009] Such as figure 1 As shown, the double-tube filter waste water heat energy recovery system includes a double filter cartridge 4, a centrifugal pump 6 and a heat exchanger 3, and the water inlet pipe of the double filter cartridge 4 is inserted into the coarsely filtered sewage pool 1, and the double filter cartridge 4 In a parallel connection, the double filter cartridges 4 further filter the high-temperature sewage, and the pipelines connected to the outlets of the double filter cartridges 4 are connected to the heat exchanger 3, and a pneumatic valve 5 is set on the pipelines at the outlets of each filter cartridge 4, and the two pipes A centrifugal pump 6 and a pneumatic valve 7 are arranged on the pipeline after the roads are brought together; the heat exchanger 3 is provided with pipelines respectively connected to the clean water inlet and the sewage outlet, and the two pipelines are respectively provided with pneumatic valves 9 and 8, and the clean water A flowmet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com