Patents

Literature

2853results about "Combustion technology mitigation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

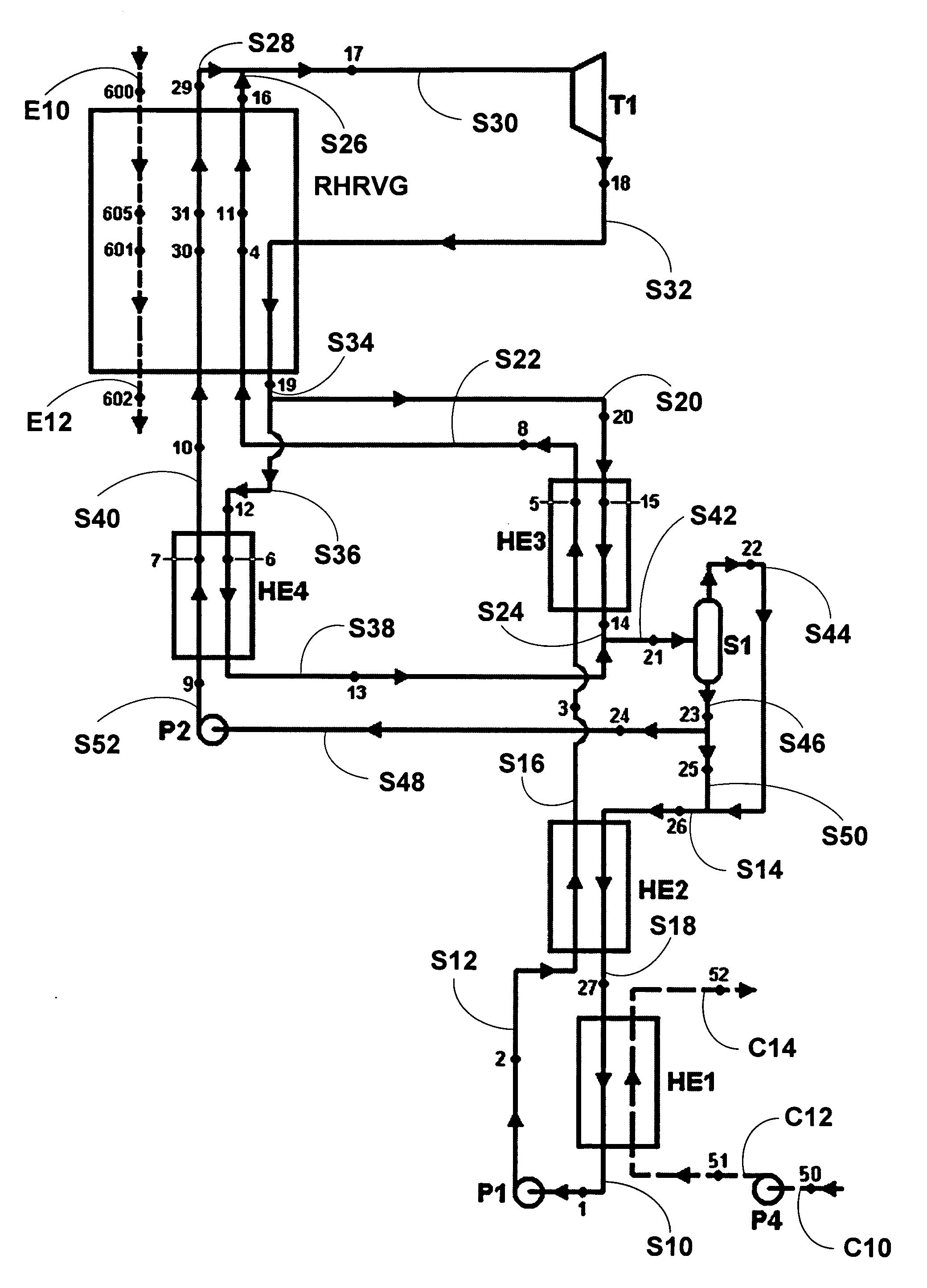

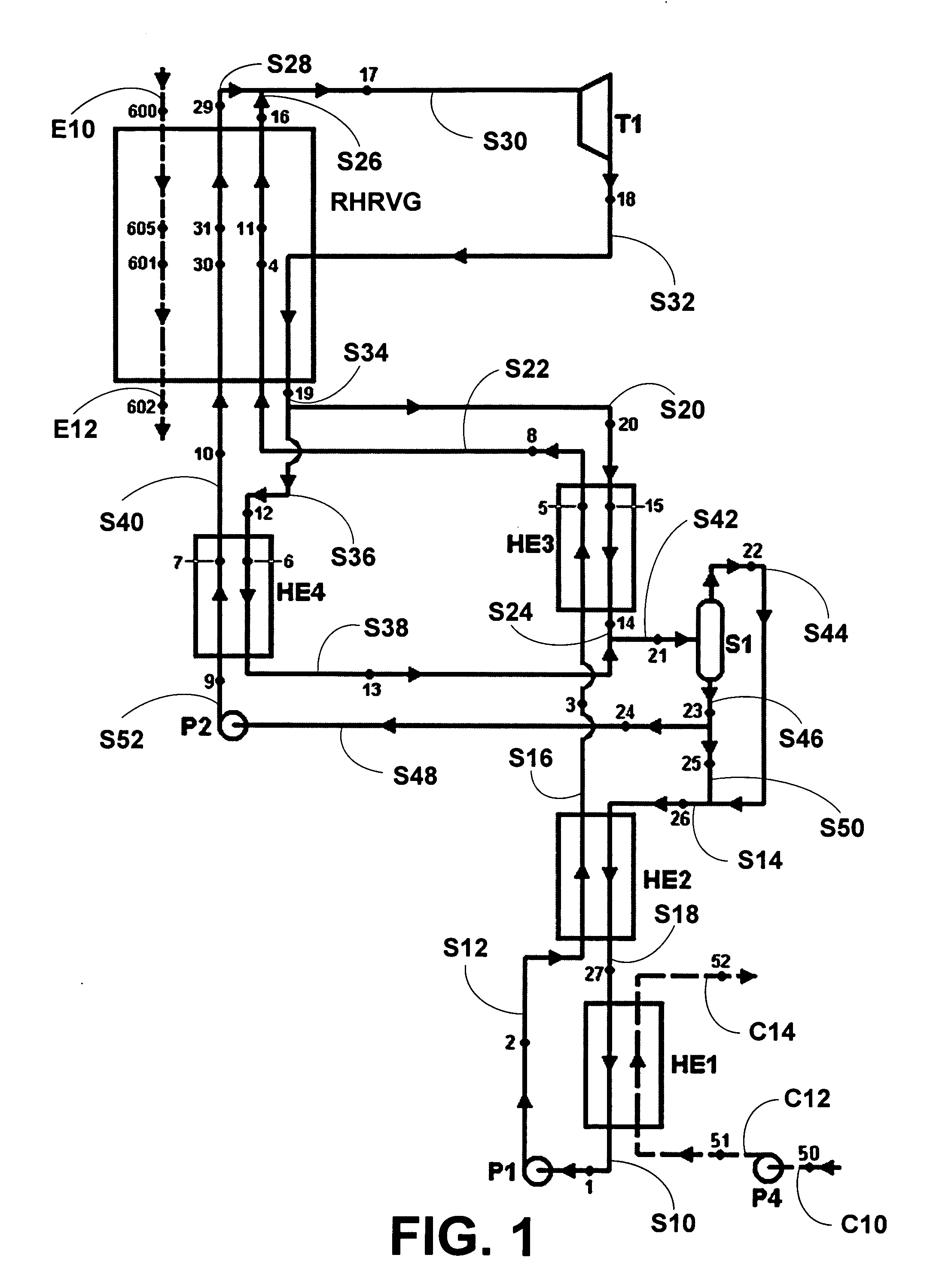

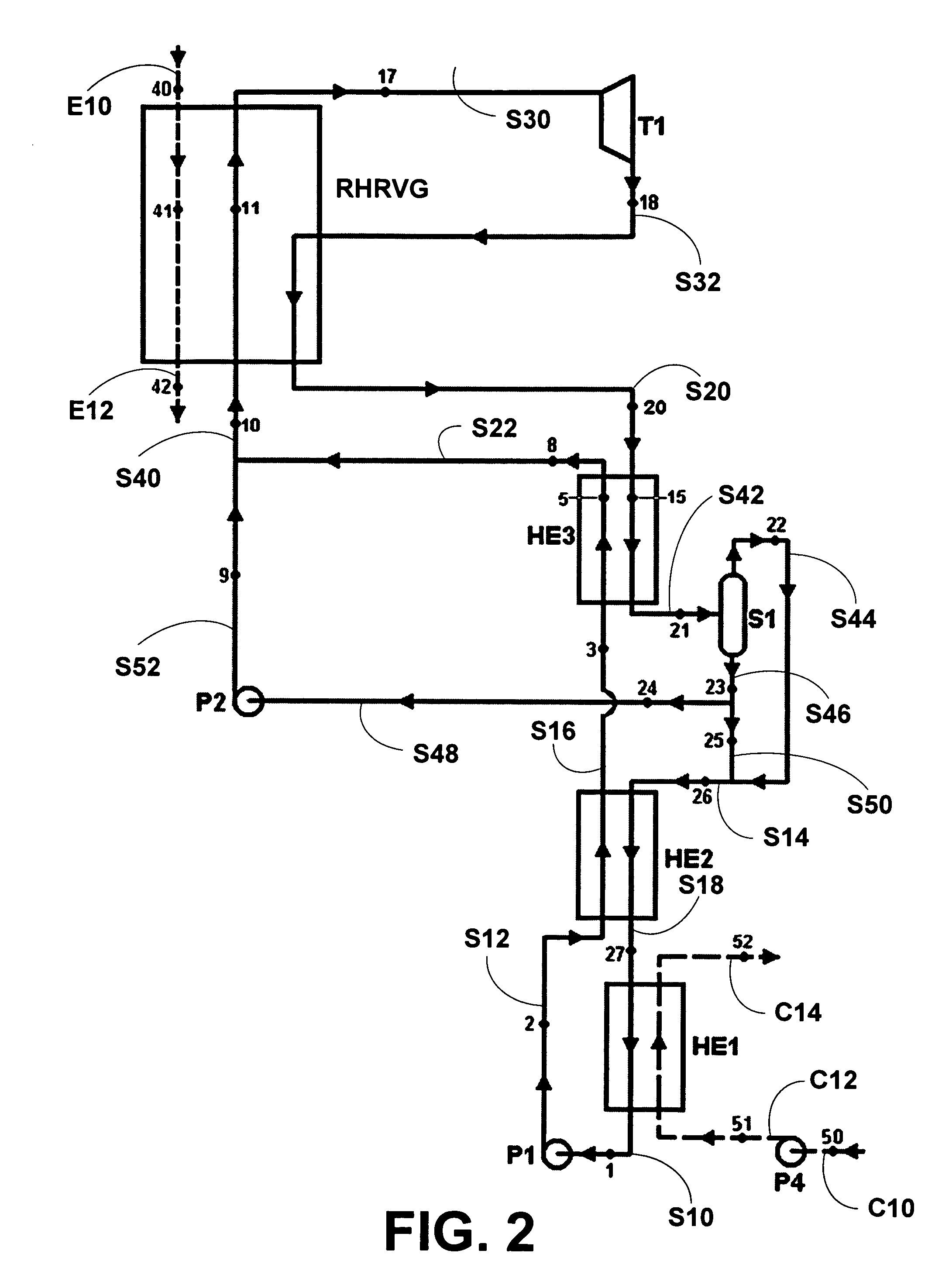

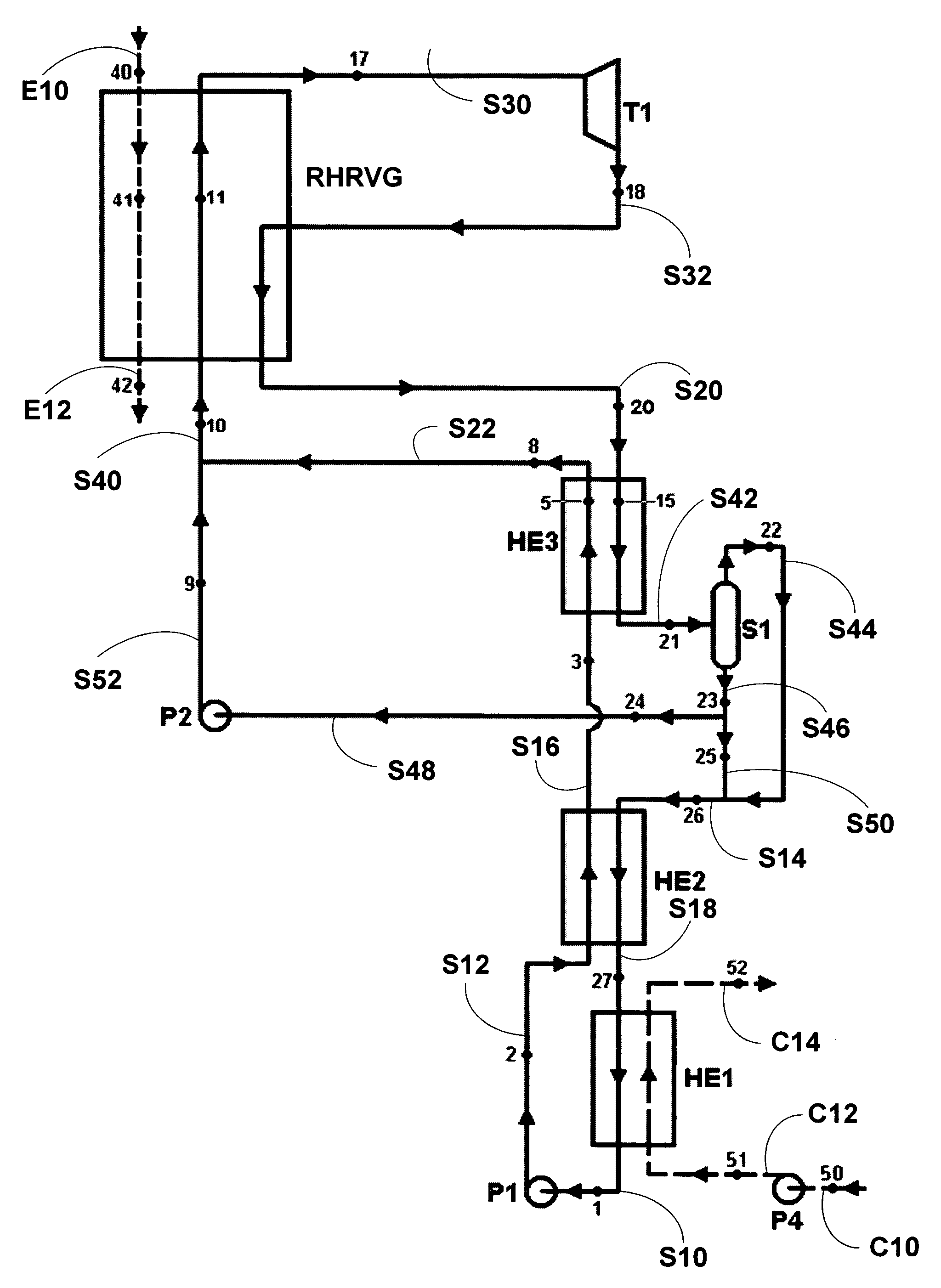

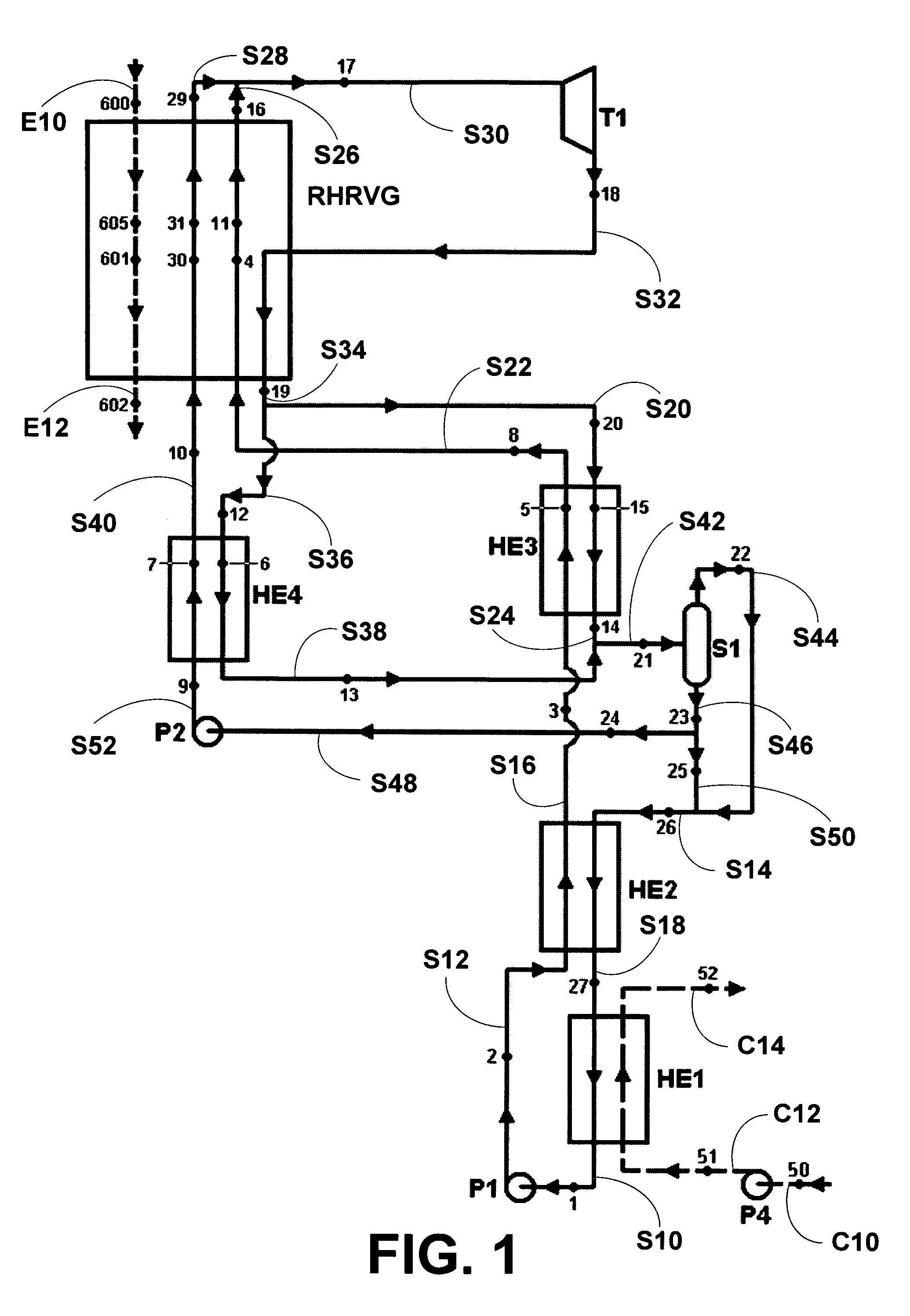

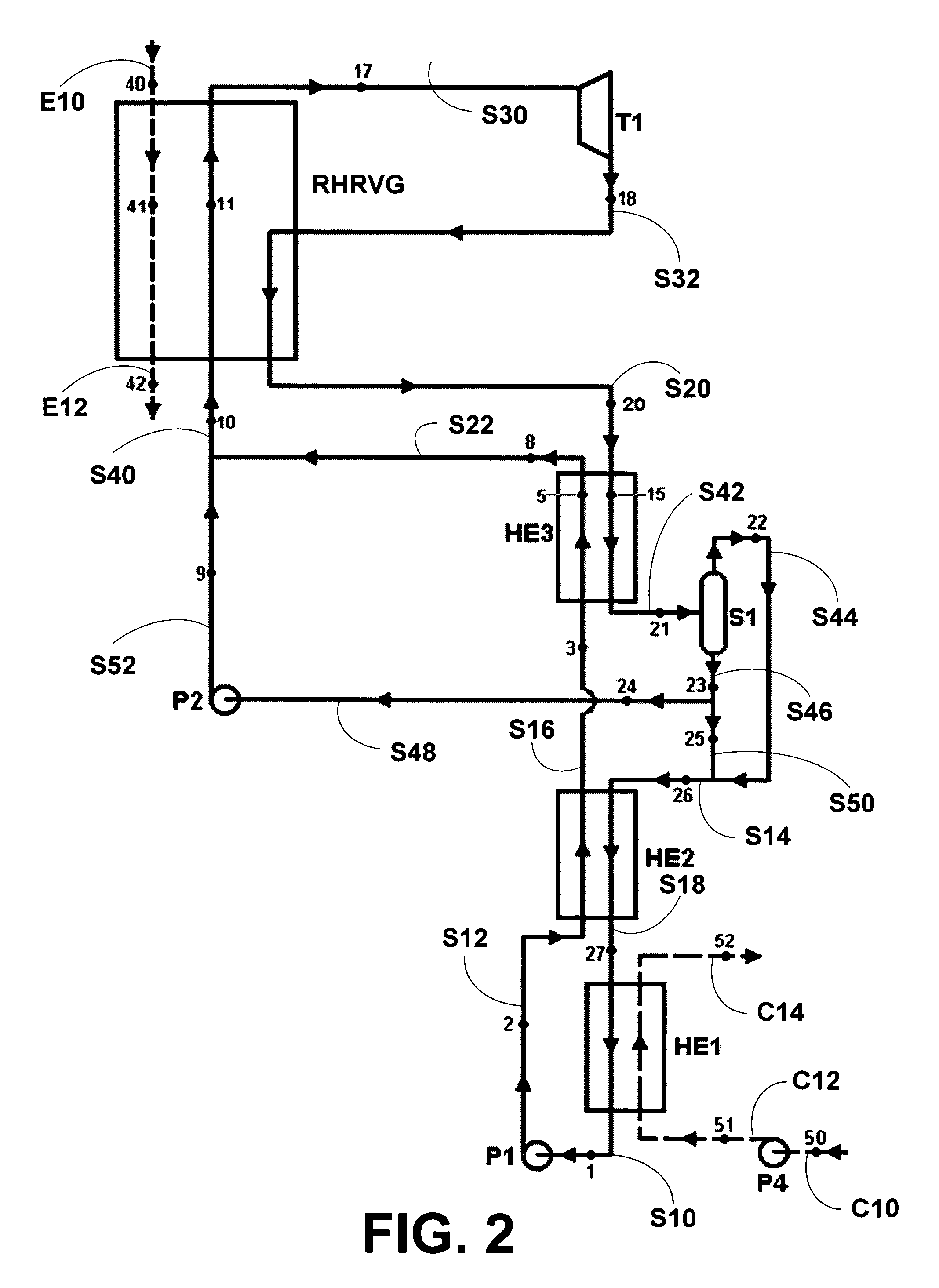

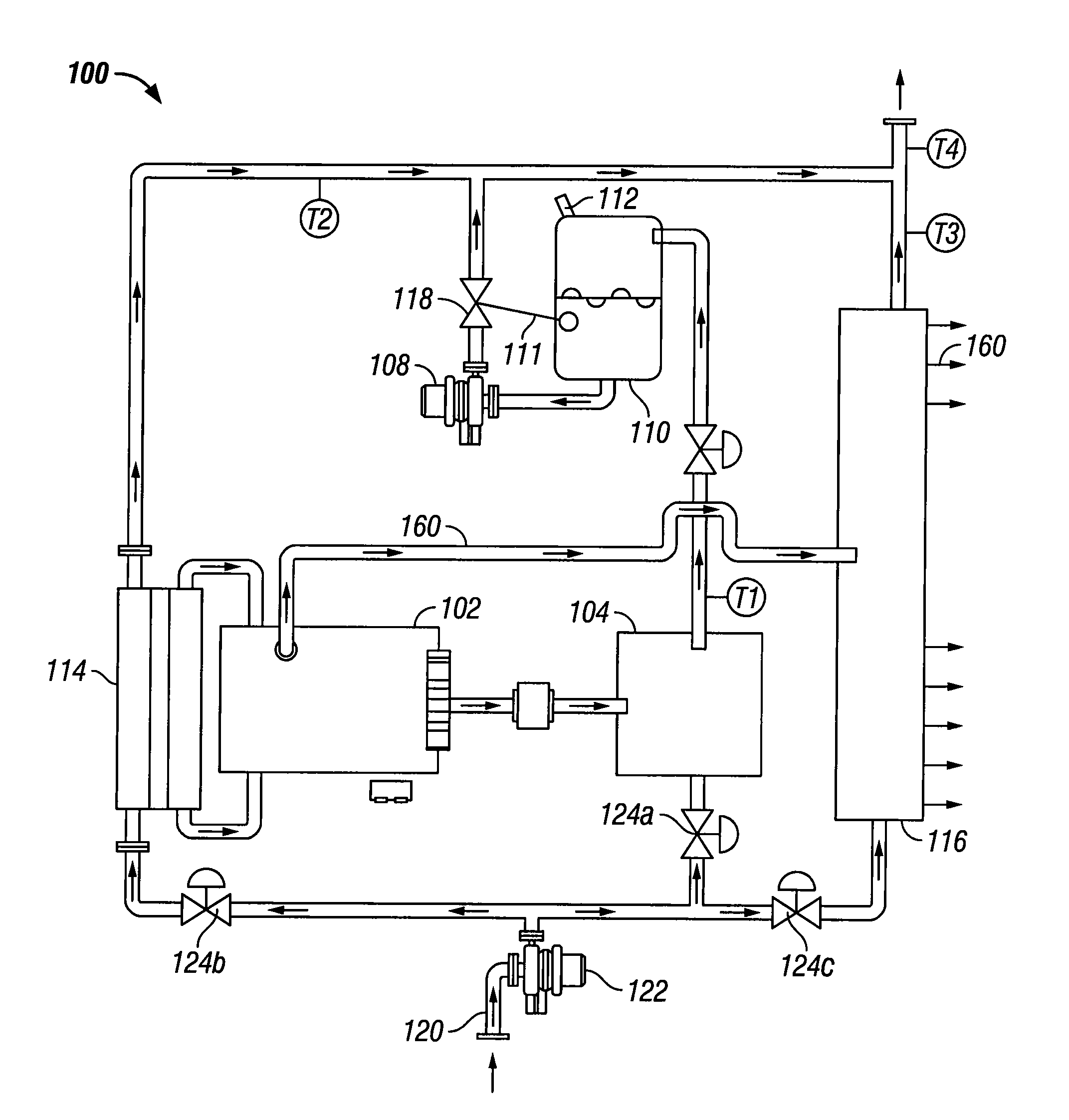

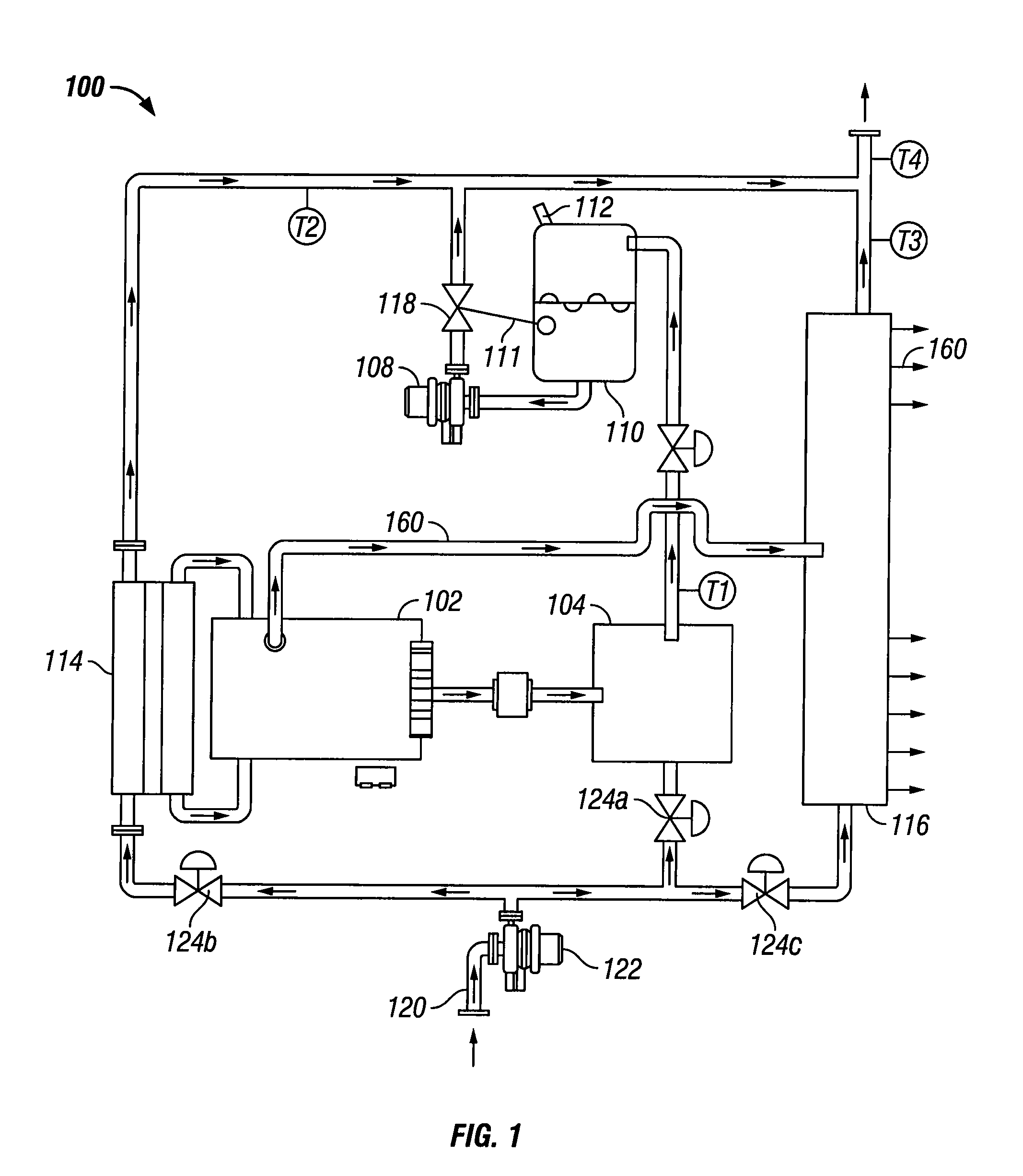

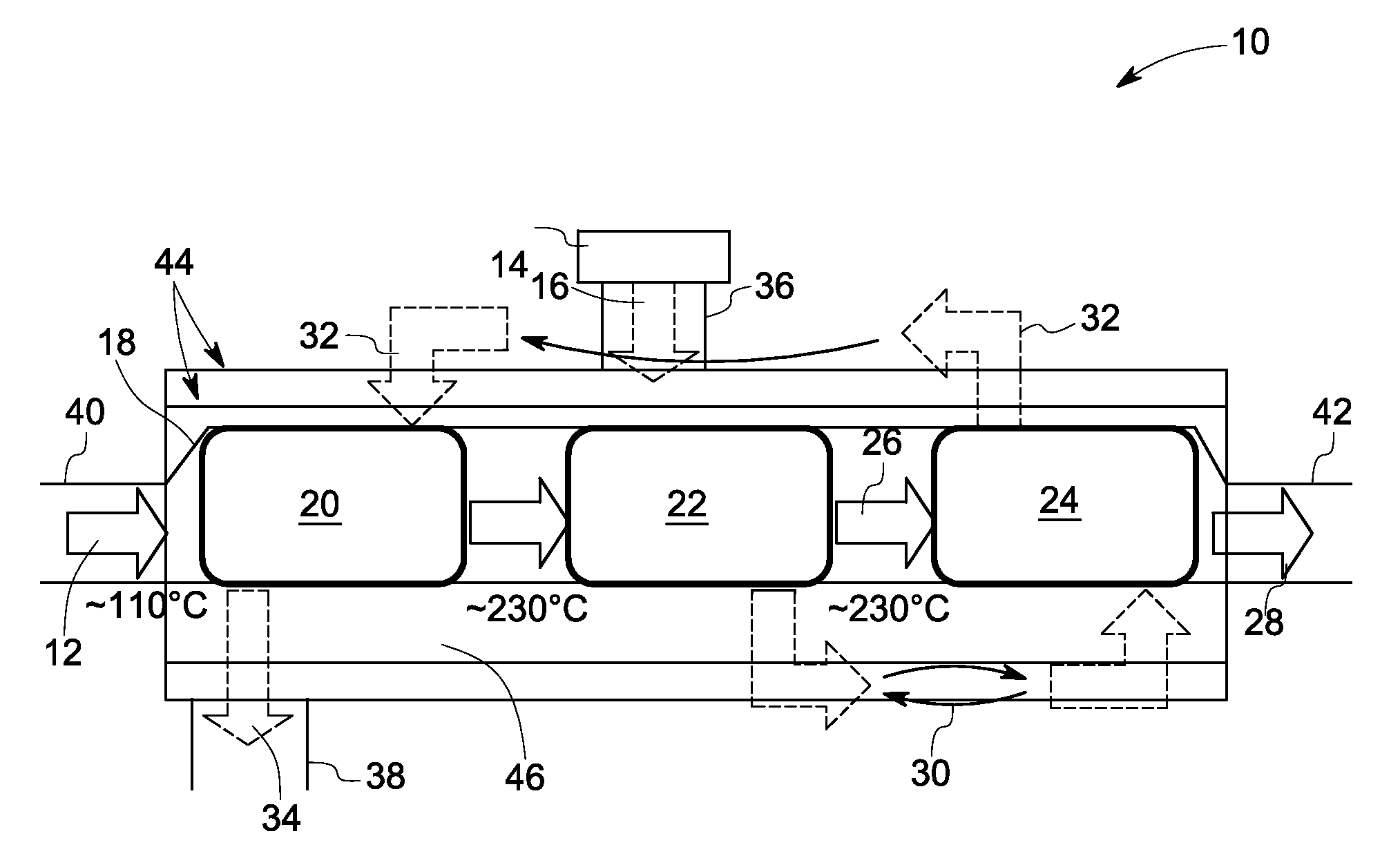

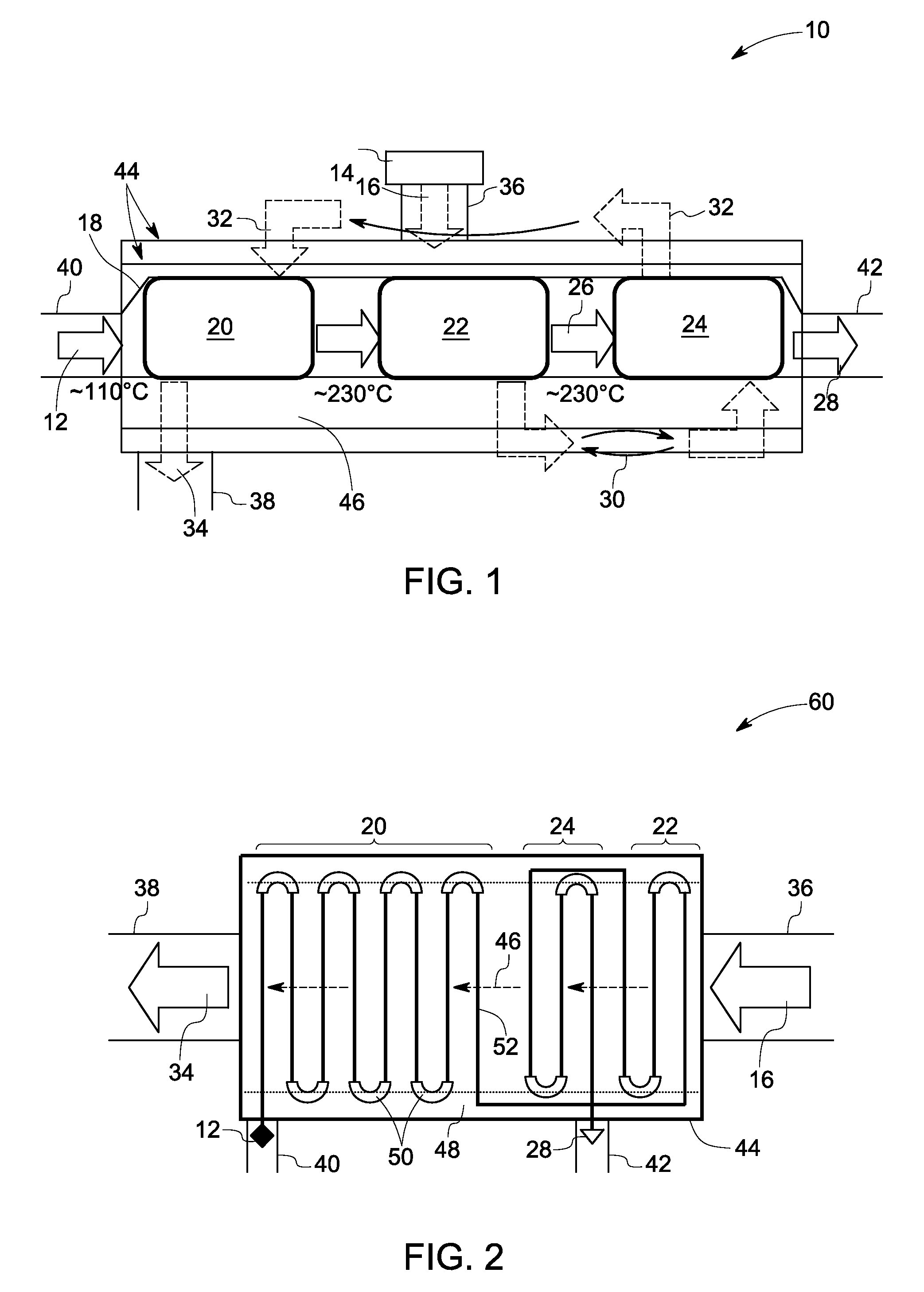

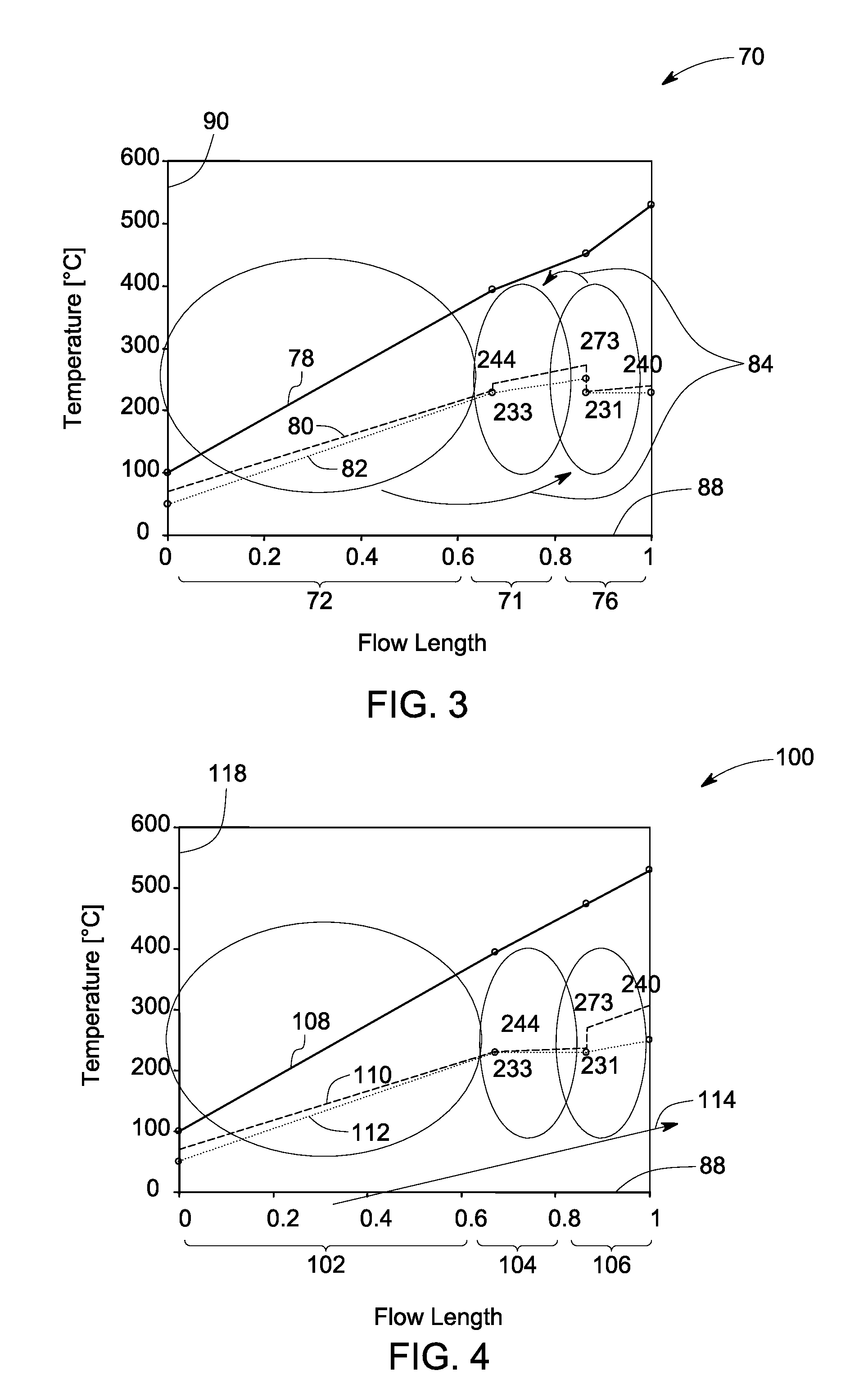

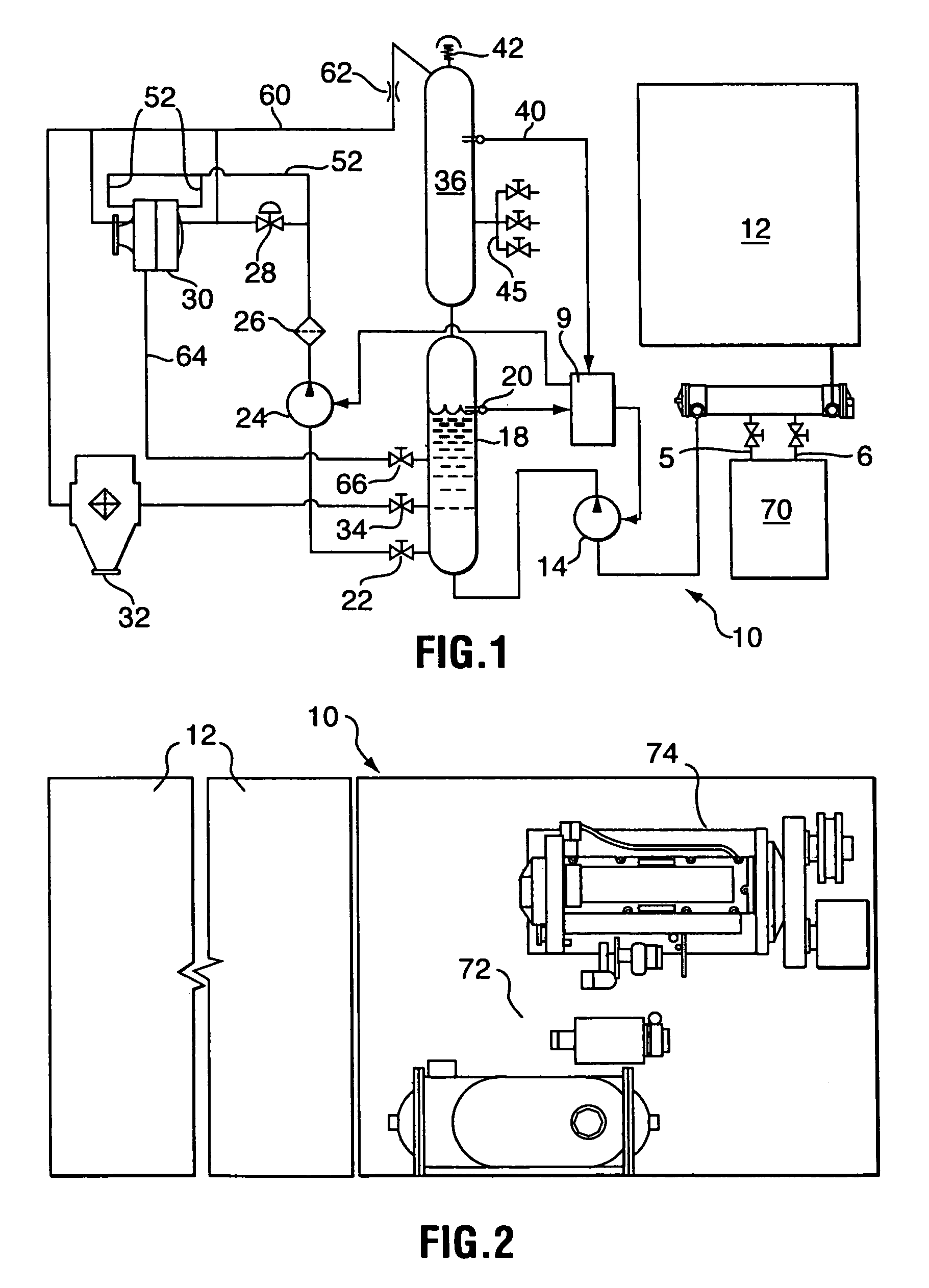

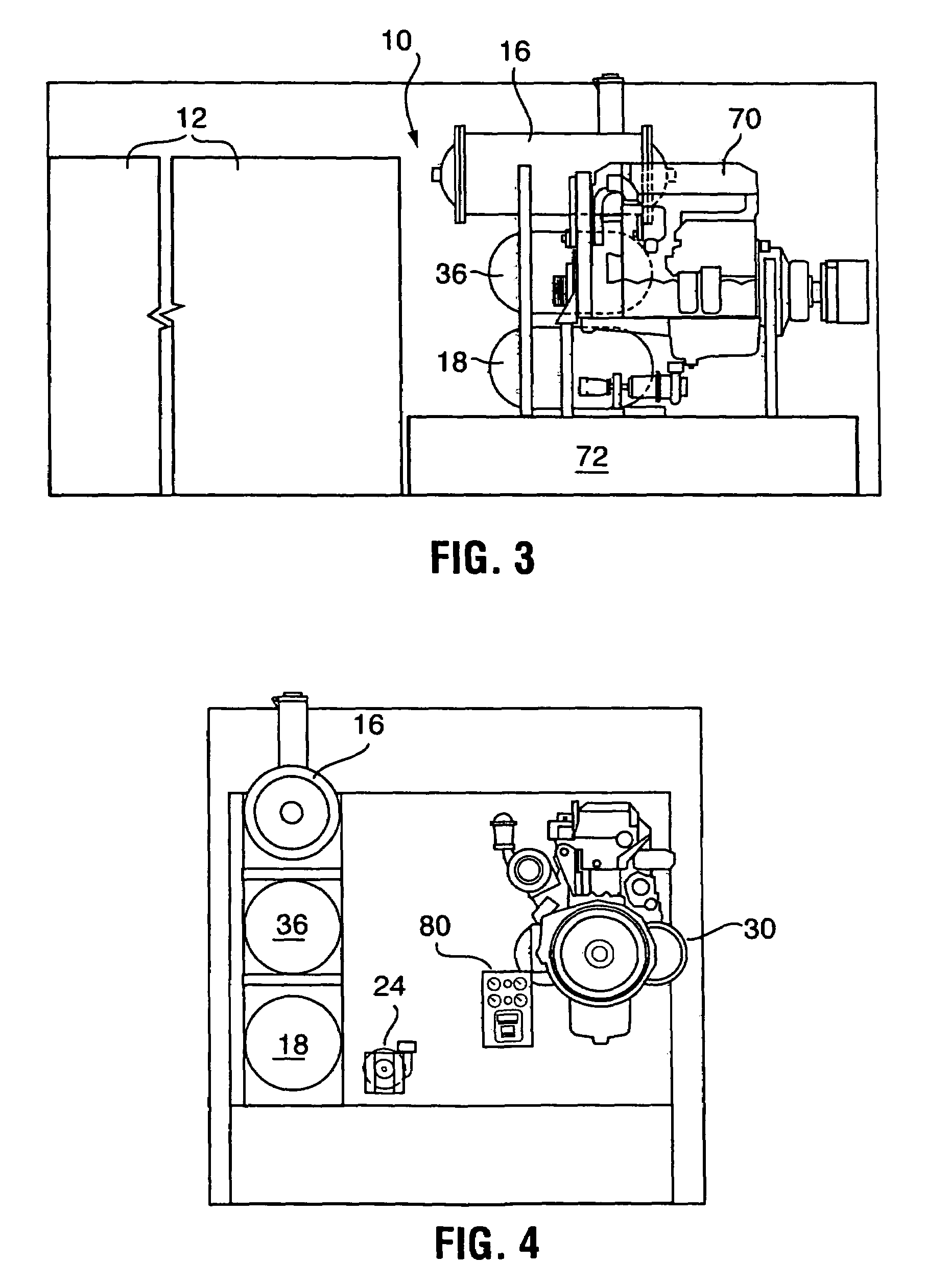

Power system and apparatus utilizing intermediate temperature waste heat

ActiveUS20080053095A1Simple bottoming cycleSteam generation heating methodsCombustion technology mitigationThermal energyForms of energy

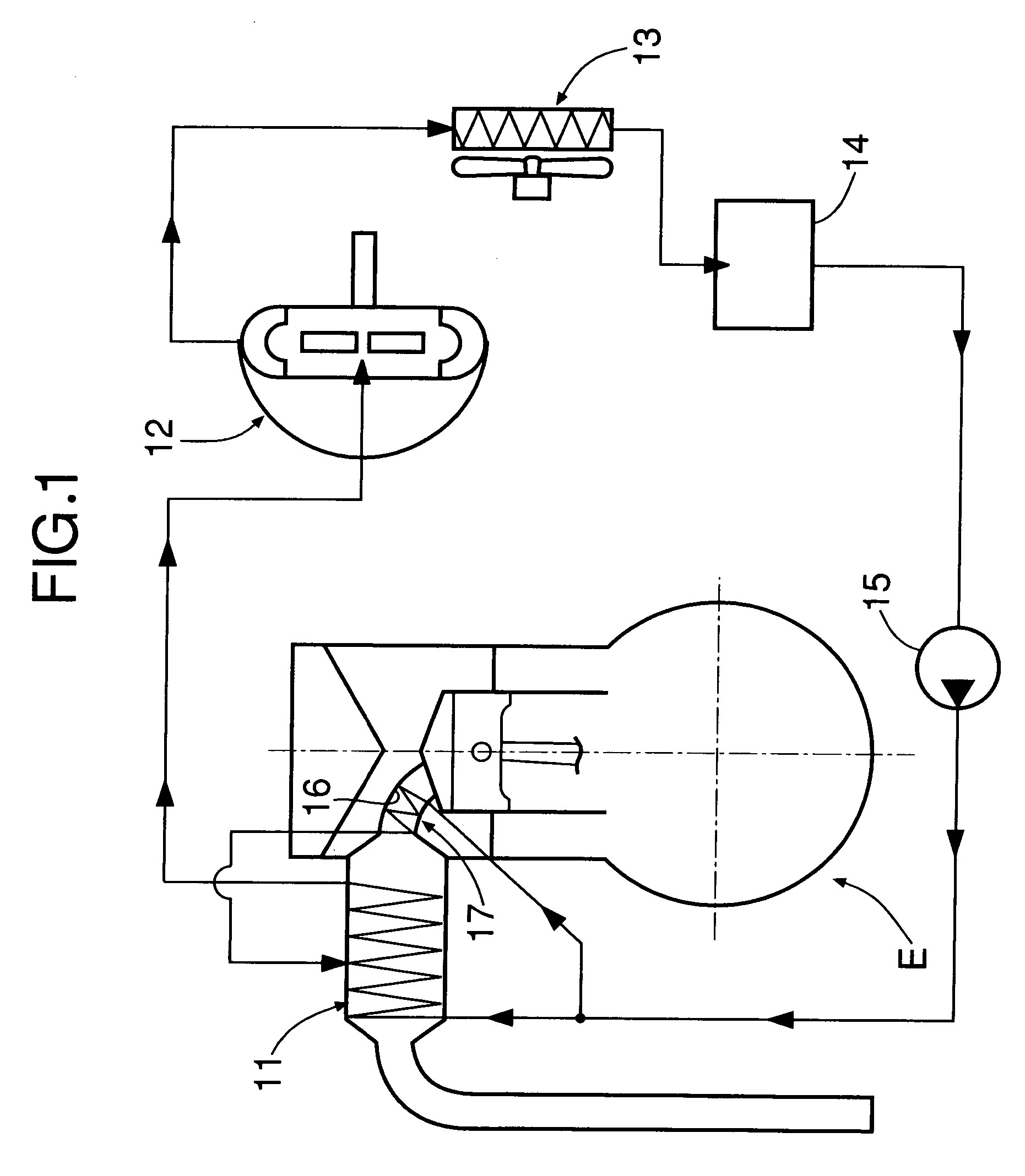

system and method is disclosed to increase the efficient of internal combustion engines using to generate electric power, where the system and method converts a portion of thermal energy produced in the combustion process to a usable form of energy.

Owner:KALINA POWER LTD

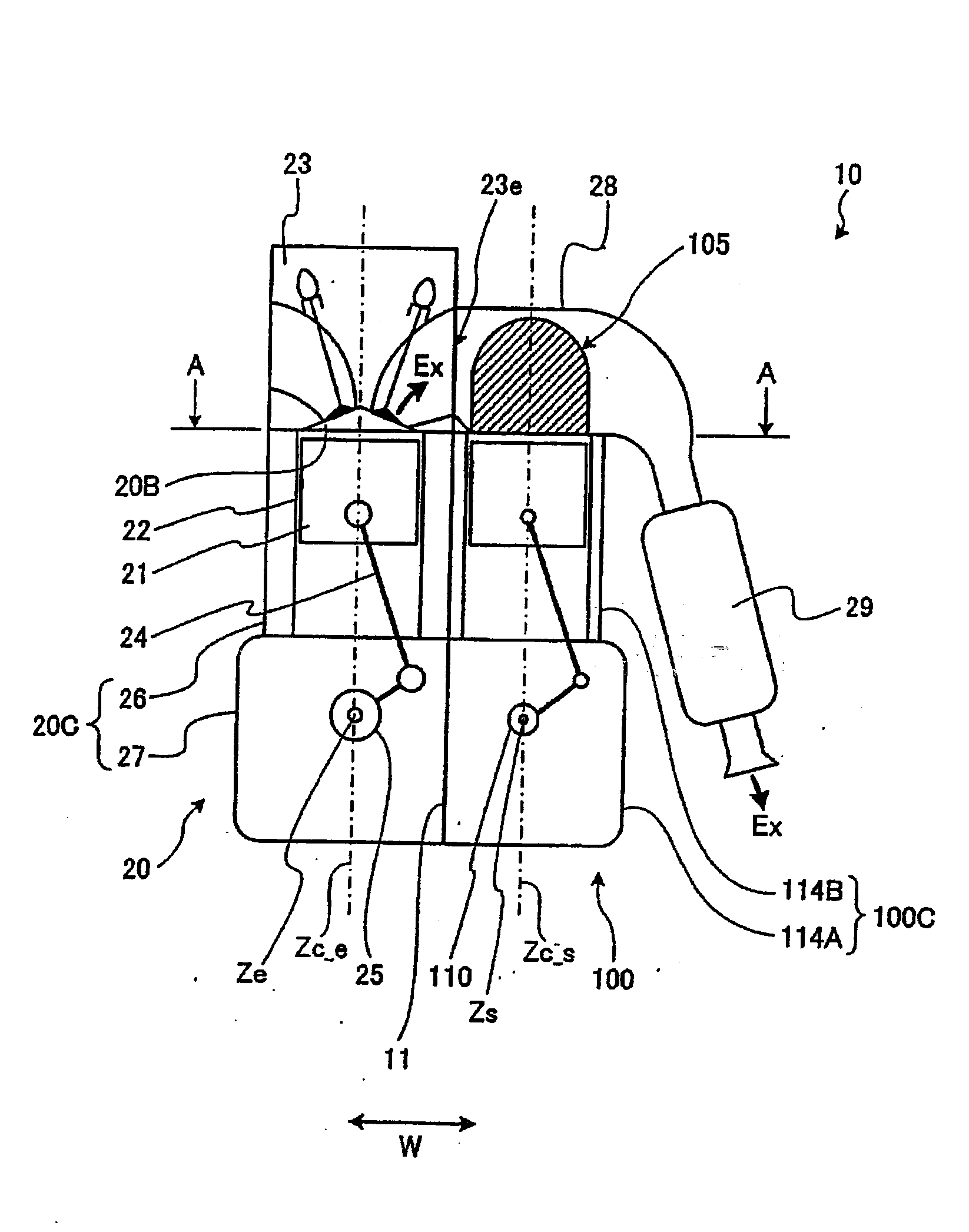

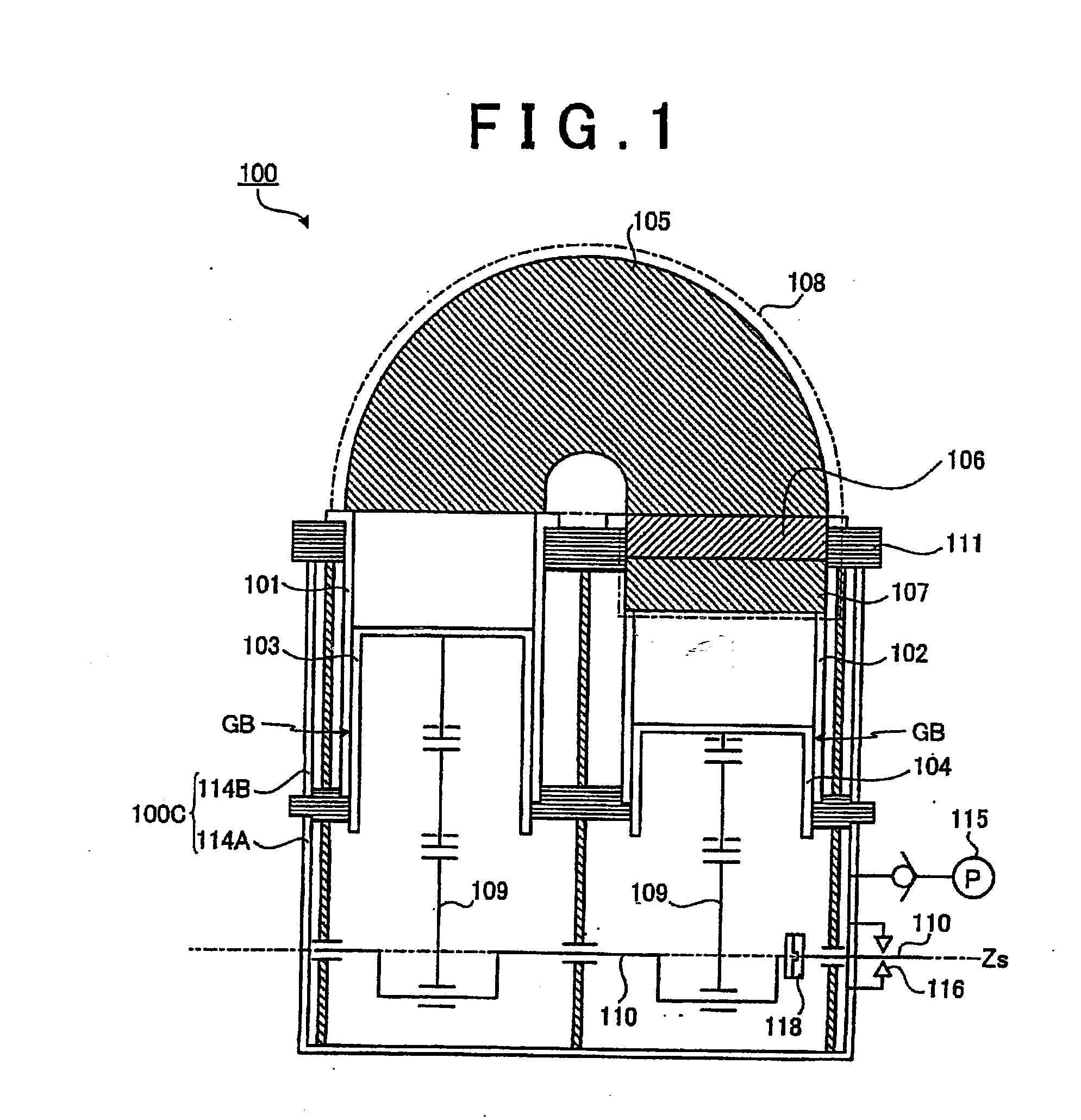

Internal combustion engine

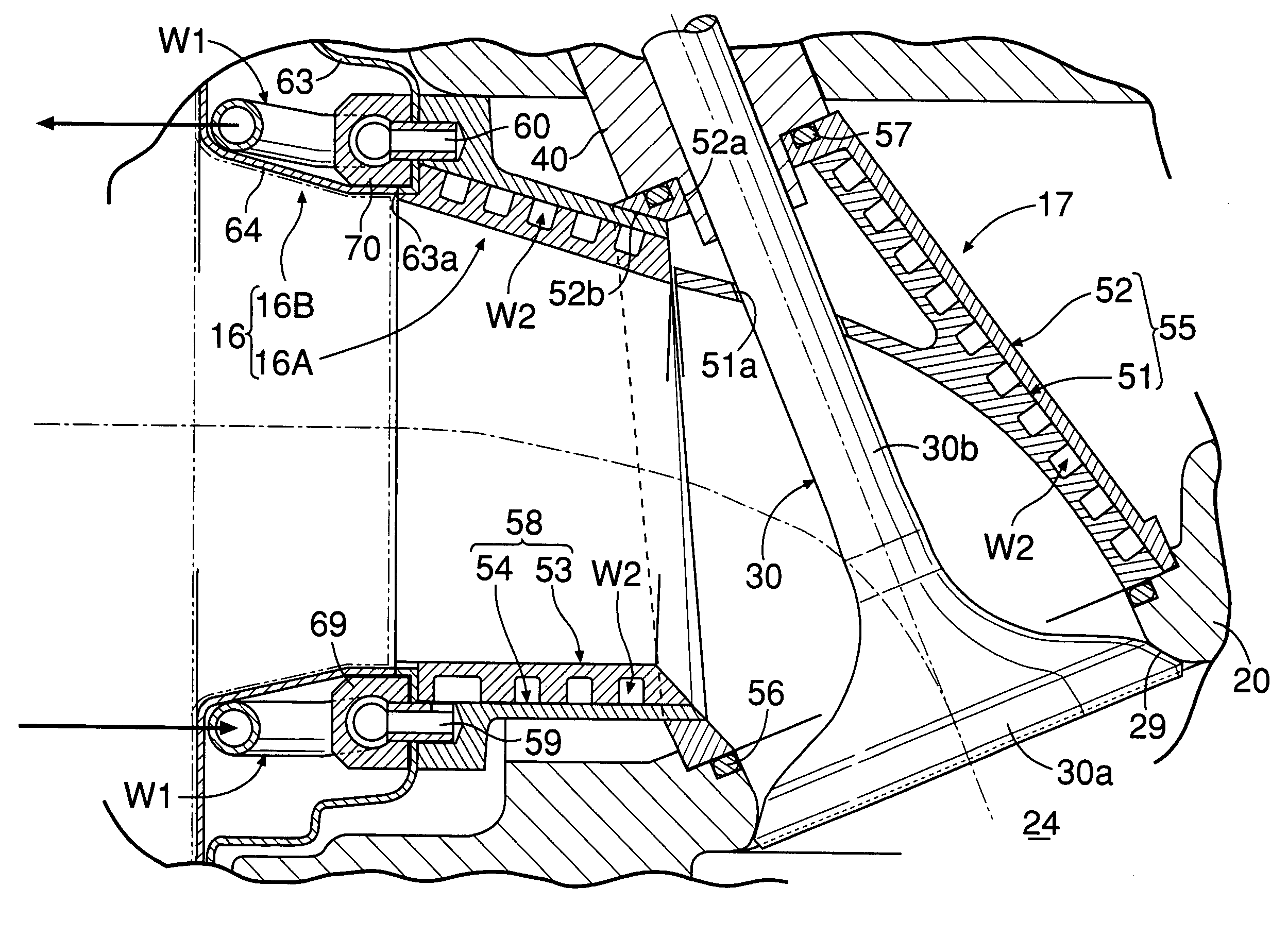

InactiveUS7069884B2Improve cooling effectWaste heat recoveryLiquid coolingInternal combustion piston enginesCombustion chamberCylinder head

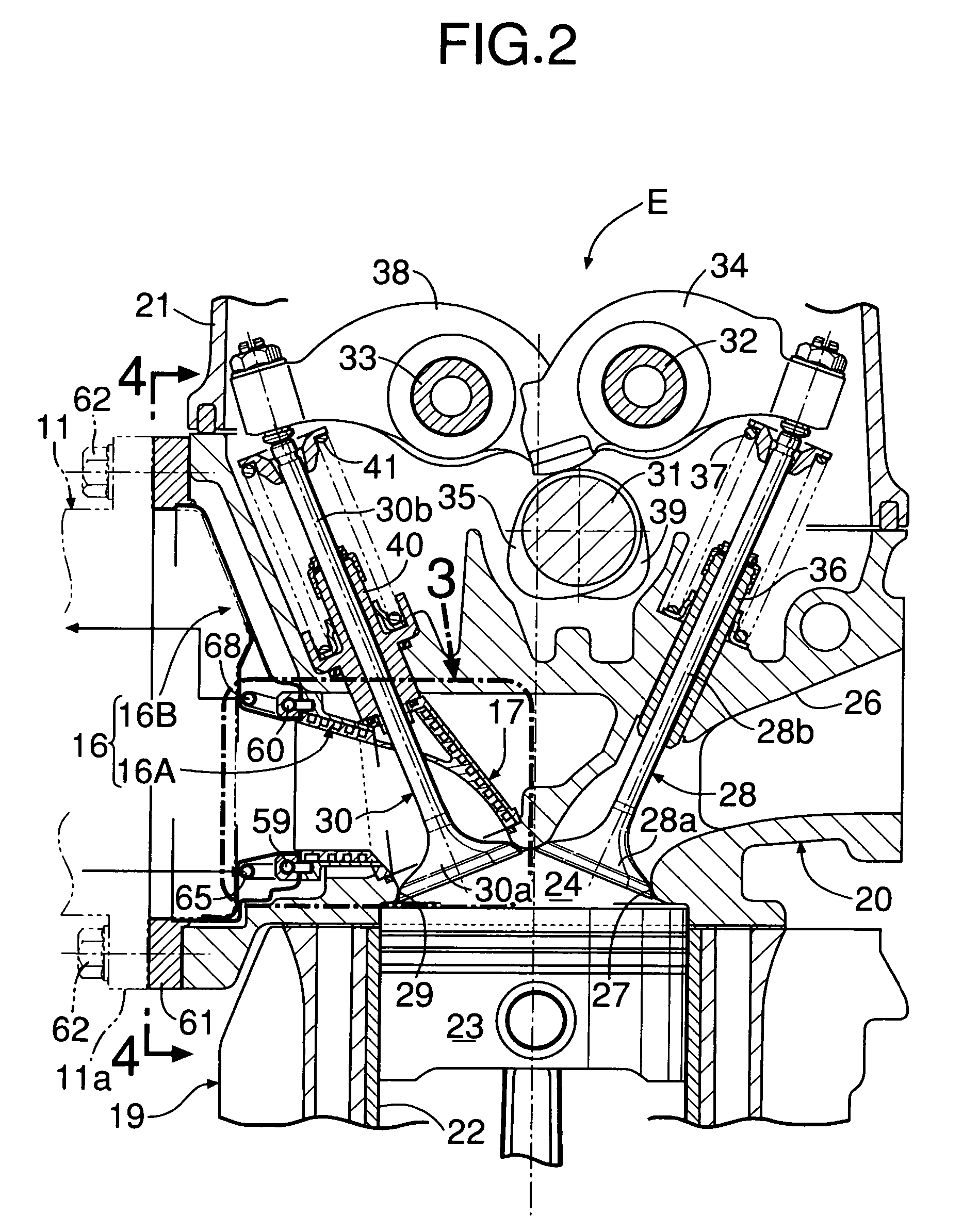

An internal combustion engine is provided in which an exhaust port communicating with a combustion chamber formed in a cylinder head is formed from independent exhaust ports, which are positioned on the upstream side, and a grouped exhaust port, in which the plurality of independent exhaust ports are combined. Water supplied from a supply pump passes through a water passage of the grouped exhaust port and a water passage of the independent exhaust ports while cooling the exhaust port, and a valve seat and valve guide on the periphery of the exhaust port, which have high temperatures, thus heating the water itself and thereby recovering waste heat of the internal combustion engine. The heated water carries out heat exchange with exhaust gas in an evaporator provided in an exhaust passage and turns into high temperature, high pressure steam, which drives an expander of a Rankine cycle system. It is thereby possible to maximize the recovery of heat transferred from the exhaust port to the cylinder head of the internal combustion engine.

Owner:HONDA MOTOR CO LTD

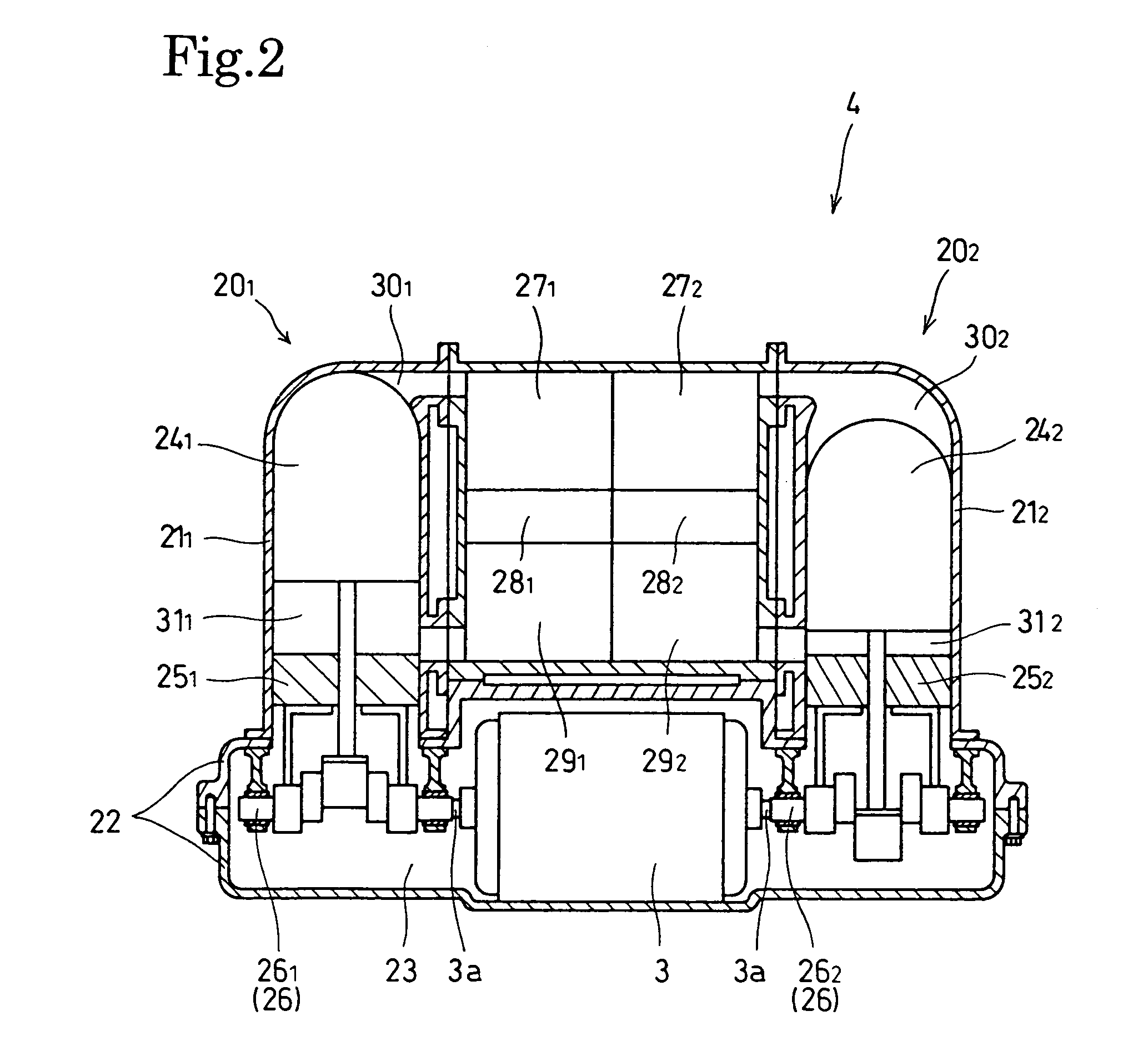

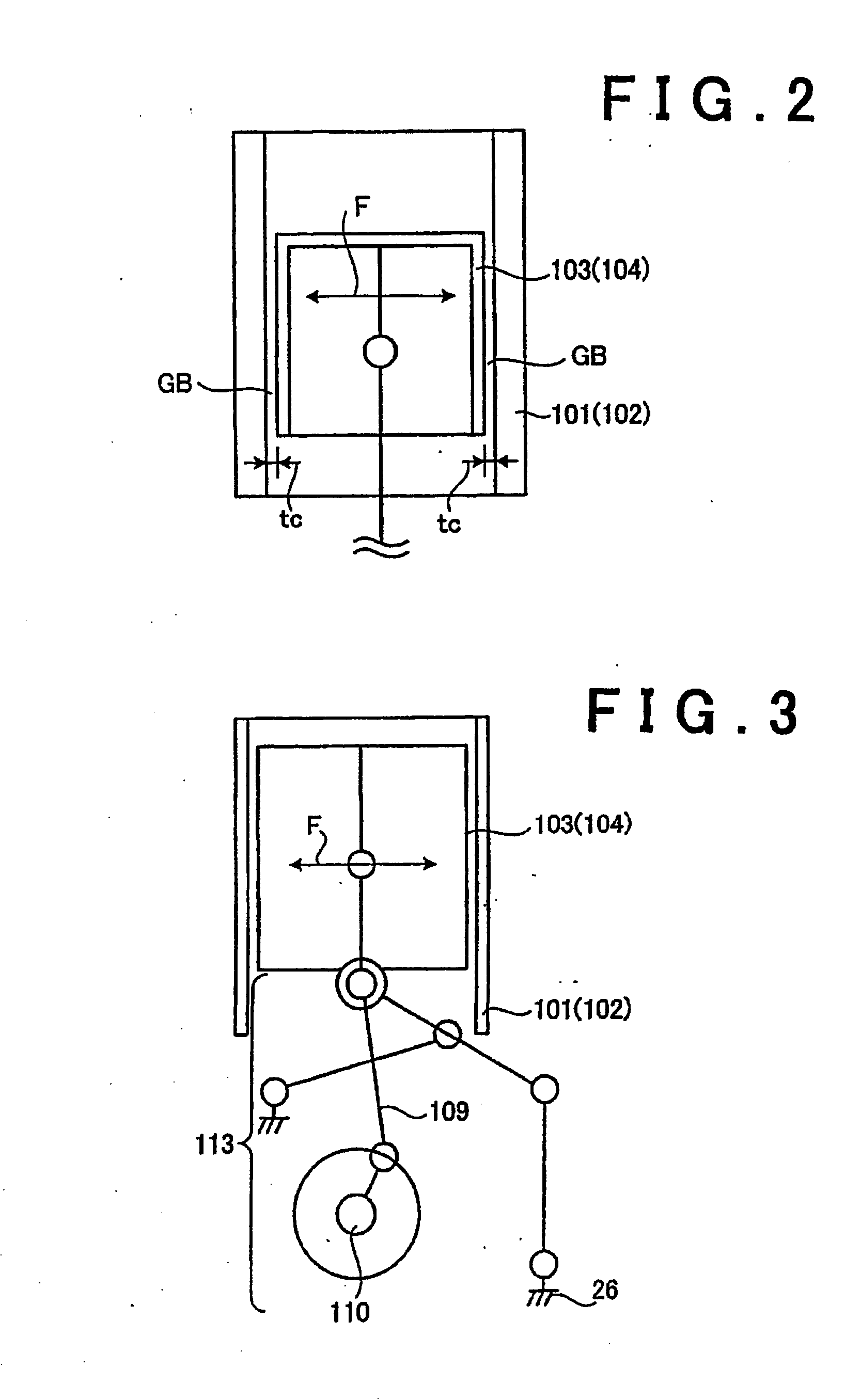

Power device equipped with combustion engine and stirling engine

InactiveUS7181912B2Reduce fuel consumptionRecover energyReciprocating combination enginesInternal combustion piston enginesCombustionEngineering

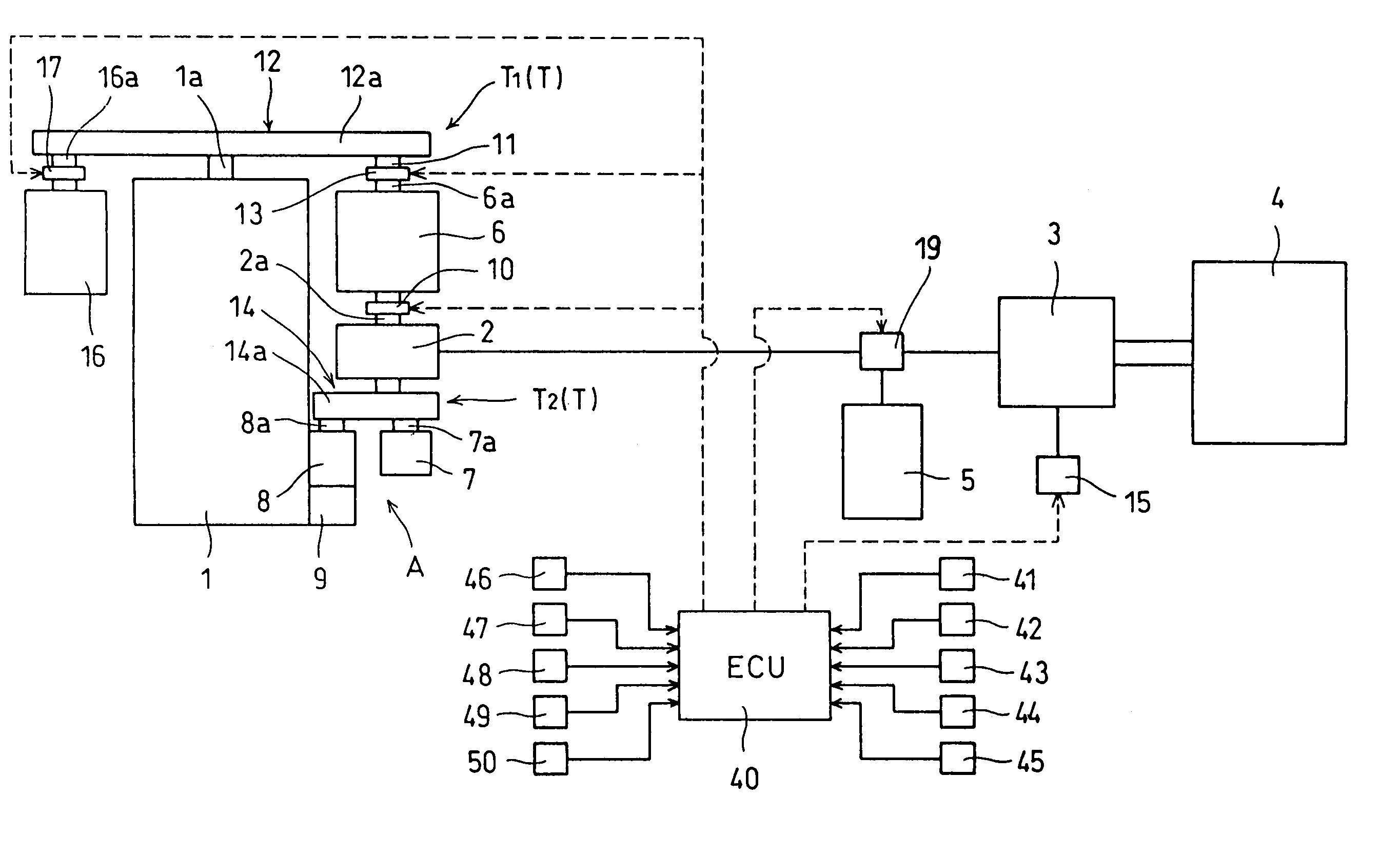

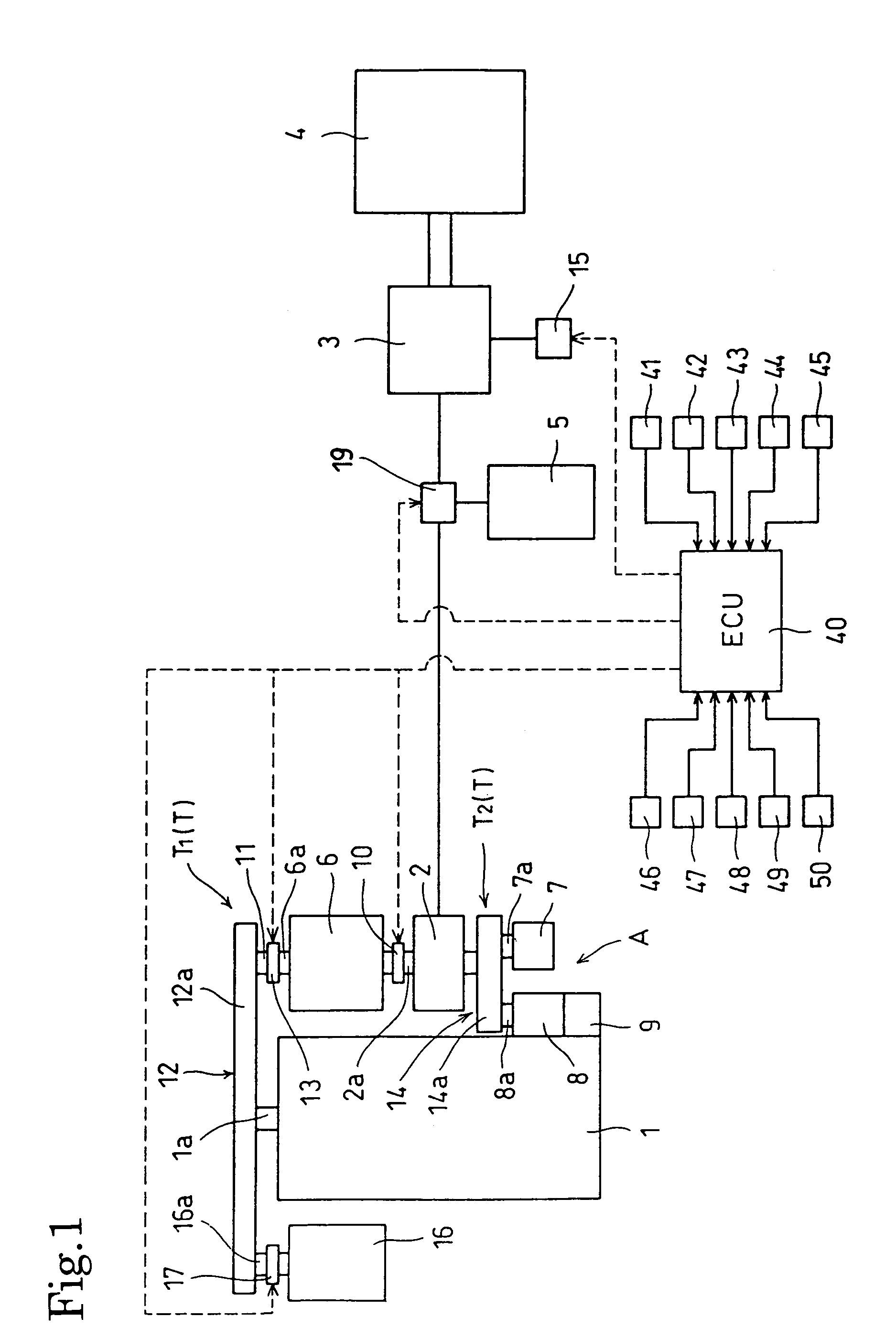

A power unit for a vehicle, such as an automobile, includes an internal combustion engine 1 as a prime mover for the vehicle, a generator 3, and a Stirling engine 4 for driving the generator 3. The Stirling engine 4 uses the exhaust gas discharged by the internal combustion engine 1 as a high-temperature heat source. Power generated by the generator 3 is supplied to an electric motor 2 for driving auxiliary machines 7, 8 and 9, and to a battery 5 for supplying power to the electric motor 2. The engine speed of the Stirling engine 4 is controlled through the control of the load on the generator 3 by a field regulator 15. An optimum engine speed of the Stirling engine 4 is determined such that the brake horsepower of the Stirling engine 4 increases to a maximum or substantially maximum brake horsepower. The fuel consumption of the internal combustion engine 1 as the prime mover that produces waste heat as a high-temperature heat source for the Stirling engine 4 is reduced, and the auxiliary machines are driven so as to fully exercise their functions even in a state where the brake horsepower of the Stirling engine 4 is low.

Owner:HONDA MOTOR CO LTD

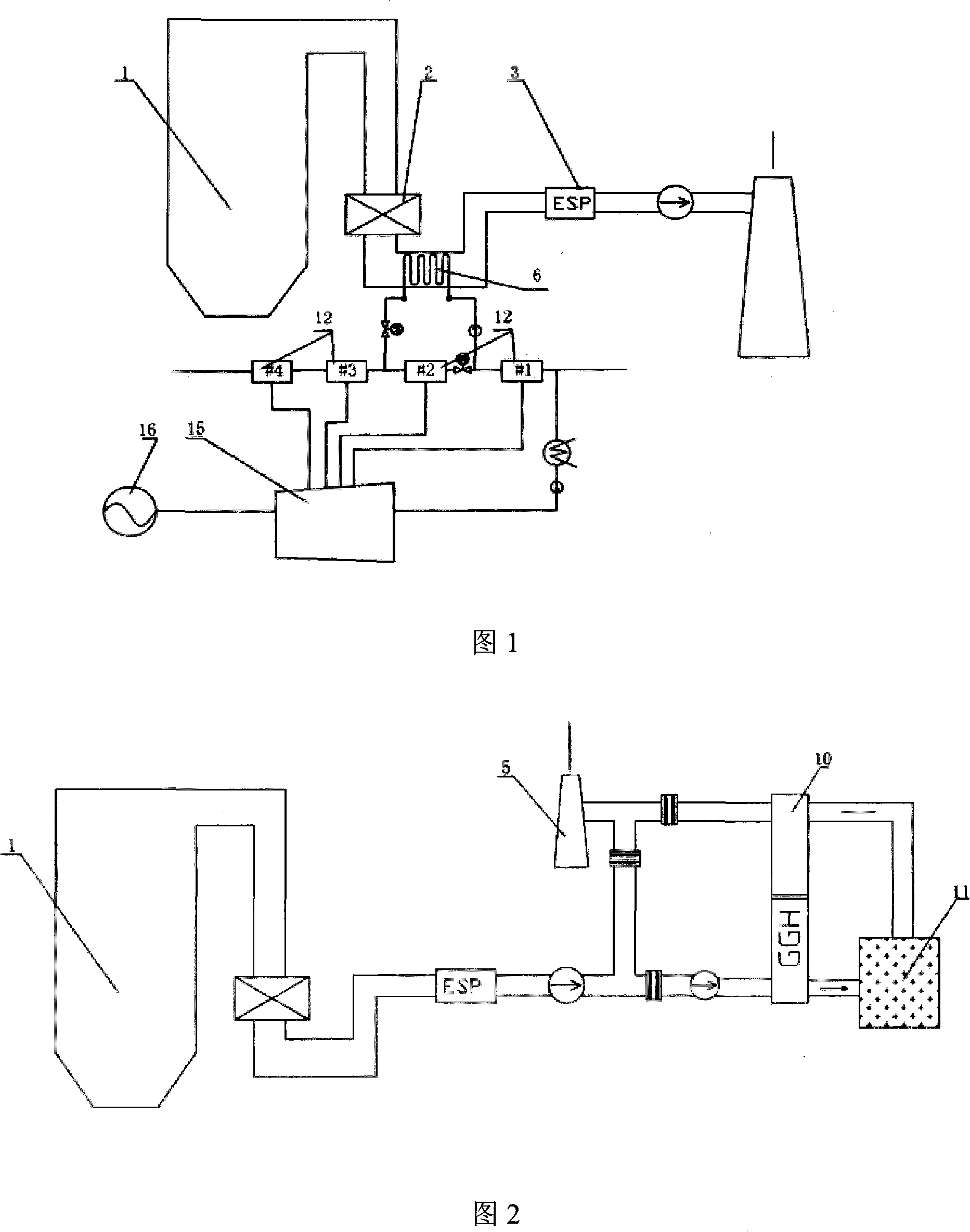

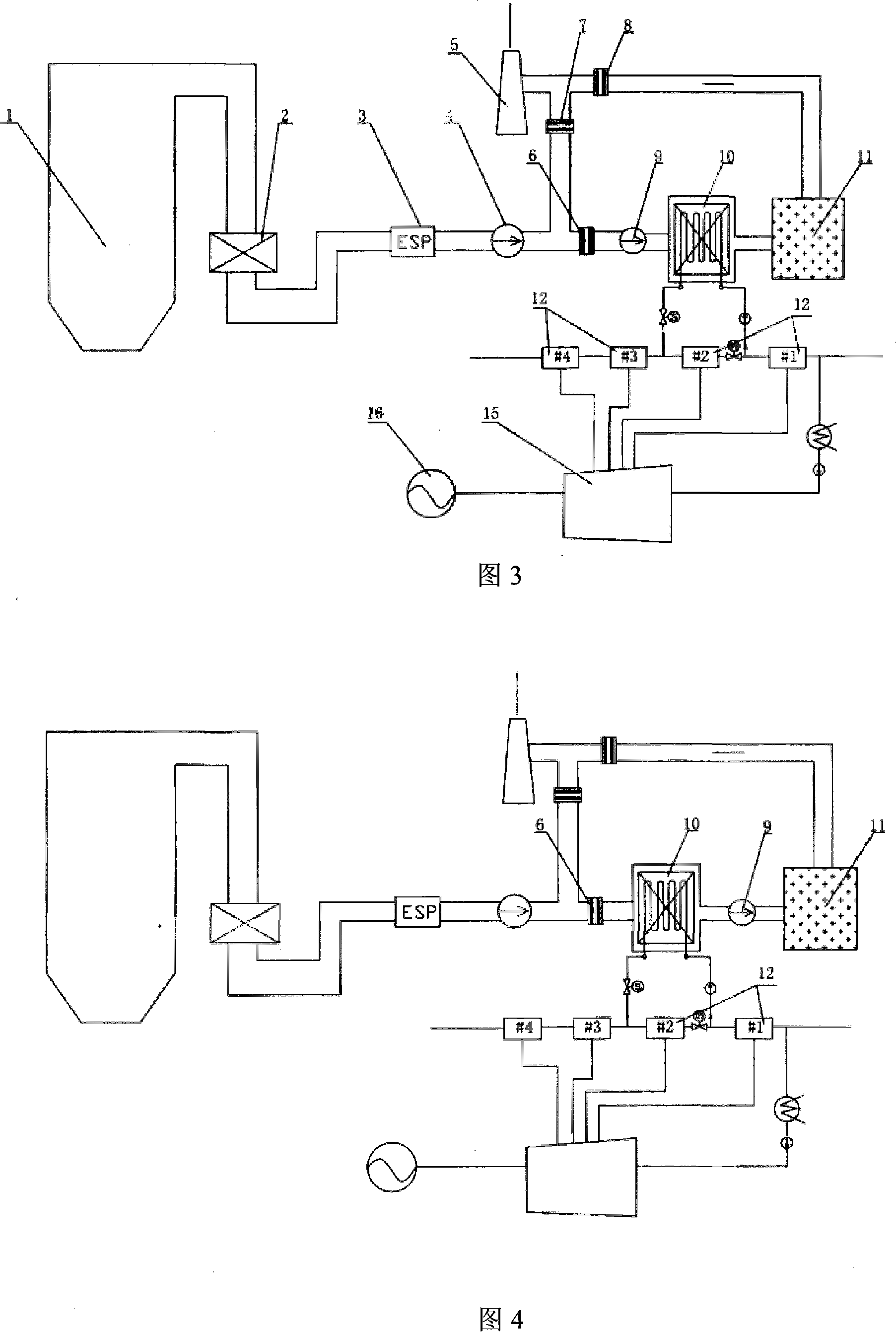

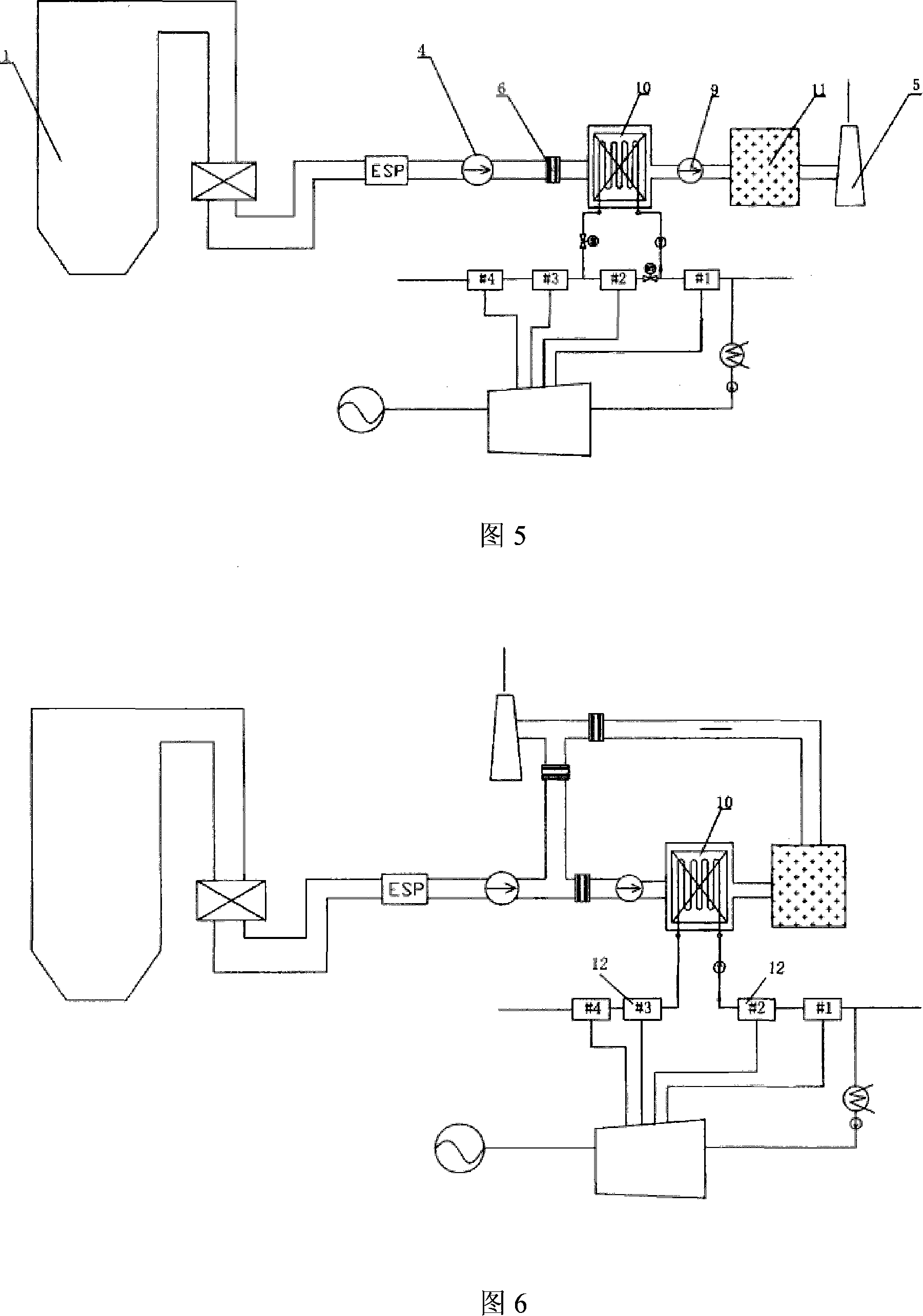

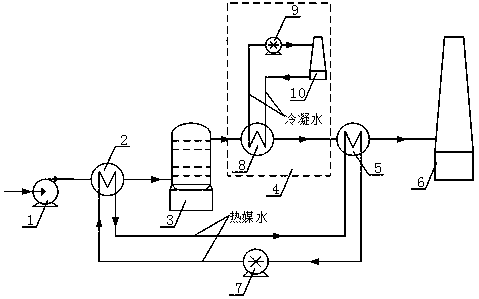

Desulfurize flue gas waste heat recovery system used in fire coal electric generating set

InactiveCN101140072AImprove utilizationOvercoming wear and tearLighting and heating apparatusCombustion technology mitigationThermal energyInlet channel

The invention discloses a desulfurization flue gas waste heat recovery system for a coal-fired generator set, which comprises at least a gas-water heat exchanger for exchanging heat energy between gas state and liquid state, a flue gas inlet channel and a flue gas outlet channel respectively independently communicated with the gas-water heat exchanger, and a condensation water inlet pipeline and a condensation water outlet pipeline; a flue gas inlet of the gas-water heat exchanger is communicated with a rear flue gas channel of a boiler flue gas dust remover in the coal-fired generator set; a flue gas outlet of the gas-water heat exchanger is communicated with the flue gas inlet of a desulfurization absorption tower in a desulfurization system; a condensation water inlet and a condensation water outlet of the gas-water heat exchanger can be in sereies or parallel with at least a first-stage low-pressure heater of a regenerative system. The desulfurization flue gas waste heat recovery system provided in the invention has the advantages of the high waste heat utilization ratio, saving energy and water, the obvious discharge reducing benefit and the high comprehensive utilization degree of abandoned resources.

Owner:SHANGHAI WAIGAOQIAO NO 3 POWER GENERATION

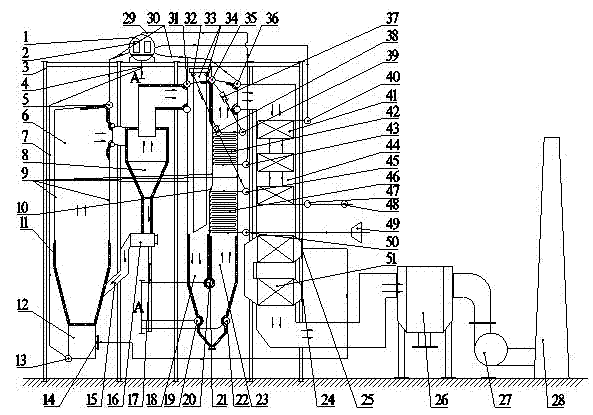

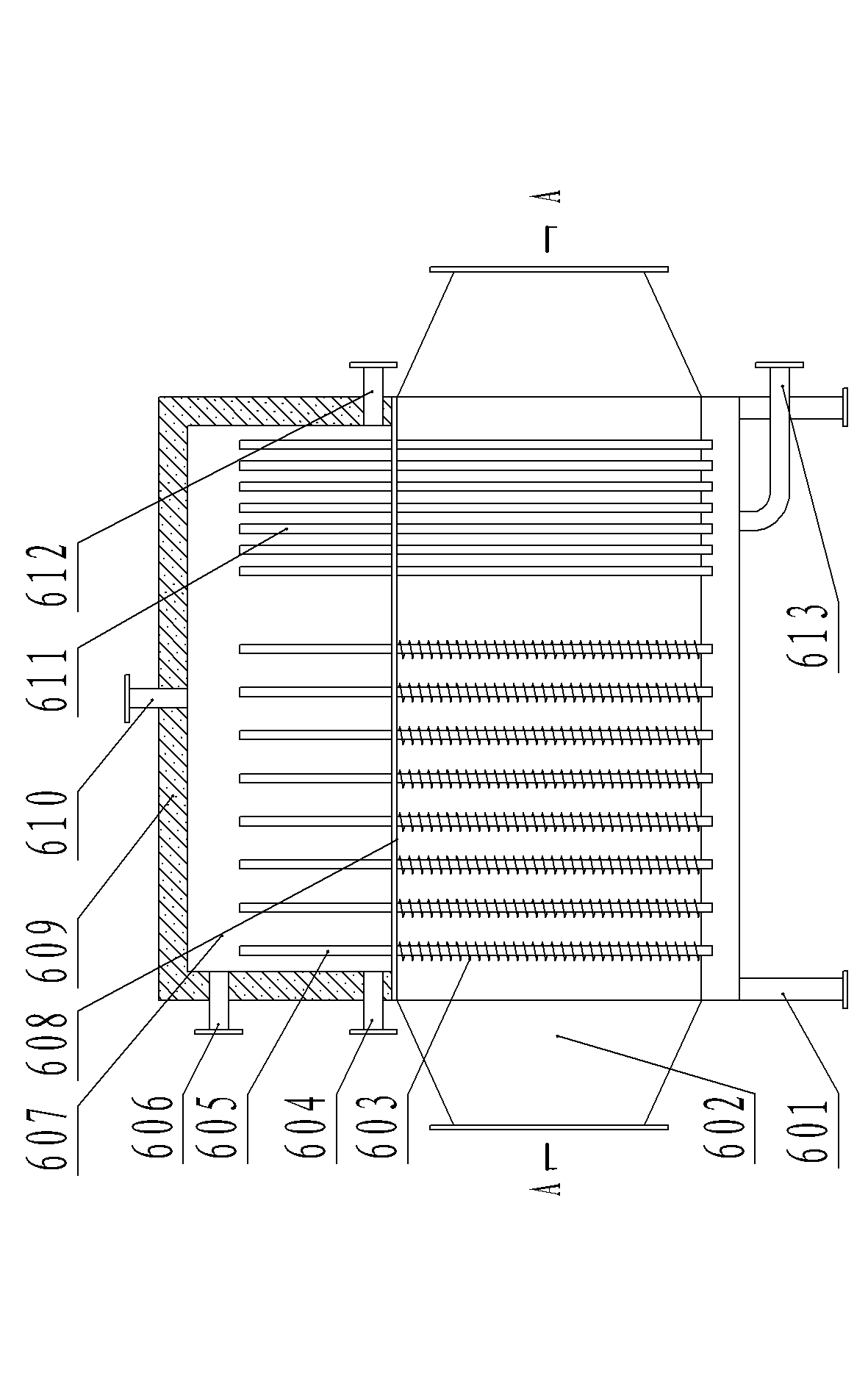

A membrane-type water-cooled wall four-flue biomass circulating fluidized bed boiler

InactiveCN102297423AIncrease profitGuaranteed uptimeFluidized bed combustionCombustion technology mitigationSuperheaterHeat energy

A membrane water-cooled wall four-flue biomass circulating fluidized bed boiler, including a drum, a furnace, a cyclone separator, a return device, a second flue, a third flue, a fourth flue, an economizer, and a dust collector appliance, induced draft fan, chimney. The furnace, the second flue and the third flue are surrounded by membrane water-cooled walls; in the lower part of the furnace and the inner surface of the flue gas outlet, the cyclone separator and the inner surface of the flue gas outlet, the second flue and the third flue Refractory castables are laid around the connecting parts of the flue; a medium-temperature screen superheater is arranged at the upper end of the second flue; high-temperature and low-temperature convection superheaters are spaced in the third flue; the middle wall adopts a tapered wall structure; low-temperature convection superheater The first water spray desuperheater and the second water spray desuperheater are respectively arranged between the high temperature convection superheater and the medium temperature screen convection superheater. The invention improves the combustion heat energy utilization rate of the biomass fluidized bed boiler, reduces the wear and alkali metal corrosion of the inner wall of the flue by high-speed and high-temperature flue gas, and enhances the wear resistance of the wall surface.

Owner:JIANGSU SIFANG BOILER +1

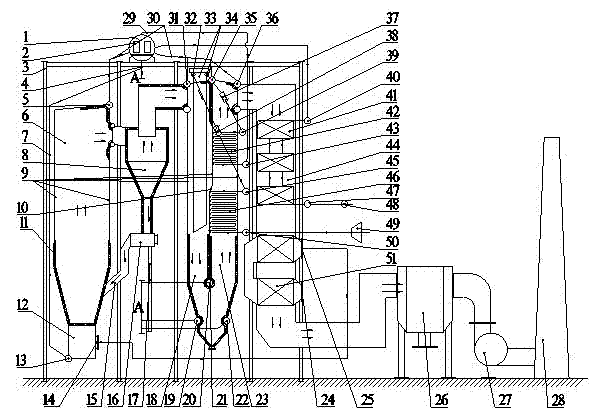

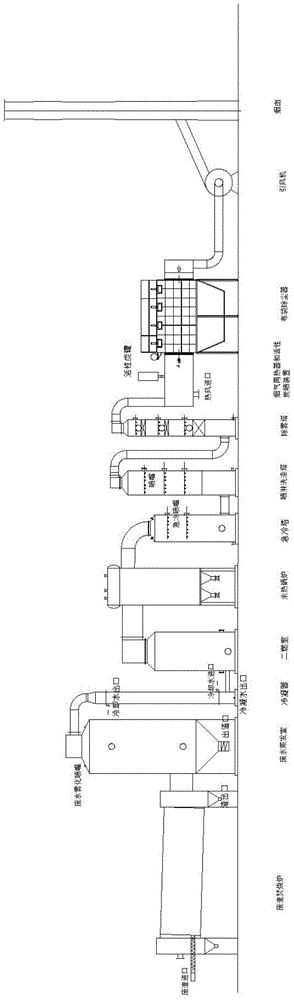

Method for treating high-concentration salty waste water and waste residue at low cost, and device thereof

ActiveCN105090997ATo achieve the purpose of initial dehydrationSave energyEmission preventionCombustion technology mitigationHigh concentrationWater vapor

The invention provides a method for treating high-concentration salty waste water and waste residue at low cost. The method is characterized by comprising a step 1 of mixing high-temperature smoke generated by burning of the waste residue with atomized waste water, and separating out water vapor smoke; a step 2 of separating out smoke through condensing of the water vapor smoke; a step 3 of subjecting the smoke to secondary burning, waste heat recovery, rapidly quenching treatment and purification treatment, and discharging the treated smoke. The method and the device thereof can simultaneously treat the waste residue and the waste water, and the treatment cost is low.

Owner:季栋梁

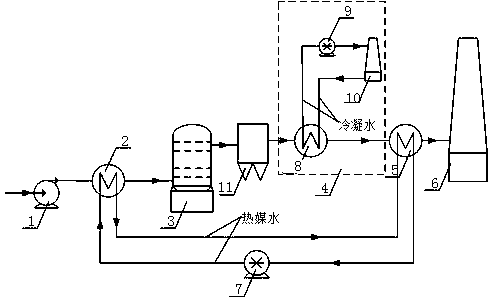

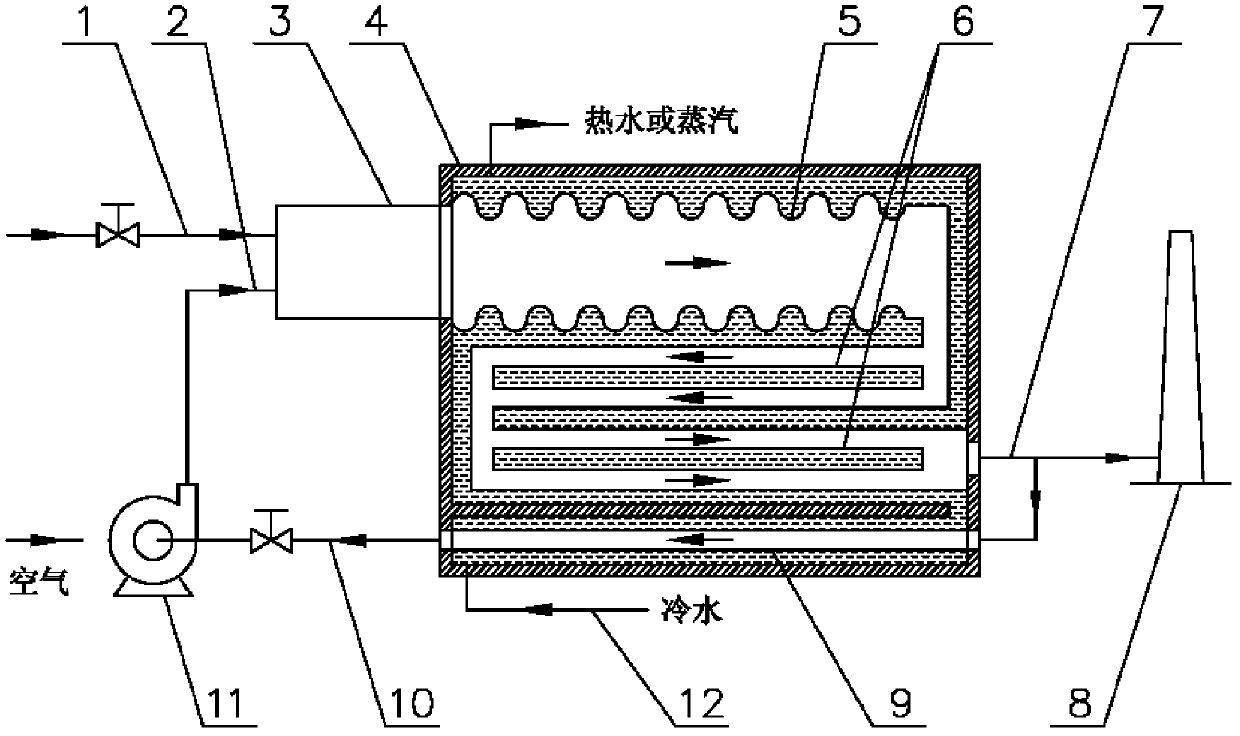

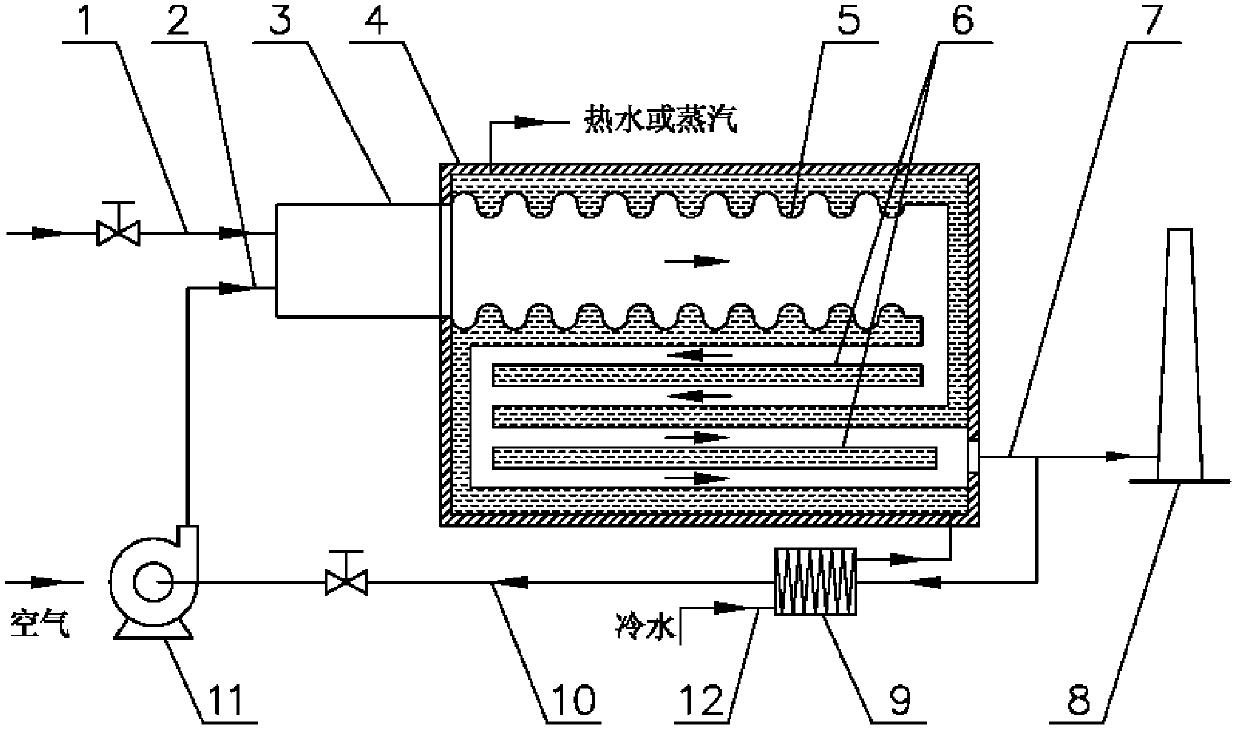

Device for efficiently getting water, eliminating white smoke and cooperatively removing contaminants and working method for device

PendingCN107676805AReduce corrosionEliminate white phenomenonEmission preventionCombustion technology mitigationCooling towerSmoke plume

The invention relates to a device for efficiently getting water, eliminating white smoke and cooperatively removing contaminants and a working method for the device. The device comprises a draught fan, a deep waste heat recycling system, a desulfurization system, an efficient condensing and water-getting system, a smoker re-heating and white smoke eliminating system, a chimney and a heat medium water circulating pump, wherein the efficient condensing and water-taking system comprises a condensing and water-getting heat exchange system, a condensing water circulating pump and a mechanical ventilating cooling tower; the condensing and water-getting heat exchange system is arranged at an outlet flue of the desulfurization system; the condensing and water-taking heat exchange system is connected with the condensing water circulating pump; the condensing water circulating pump is connected with the mechanical ventilating cooling tower; the condensing and water-taking heat exchange system isconnected with the mechanical ventilating cooling tower; the deep waste heat recycling system is connected with the heat medium water circulating pump; the heat medium water circulating pump is connected with the smoker re-heating and white smoke eliminating system; and the deep waste heat recycling system is connected with the smoker re-heating and white smoke eliminating system. The device is used for recycling a great deal of water in smoke, greatly saves water consumption amount of the desulfurization system, eliminates visual pollution of white smoke plume, and effectively reduces anti-corrosion grade of the chimney.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

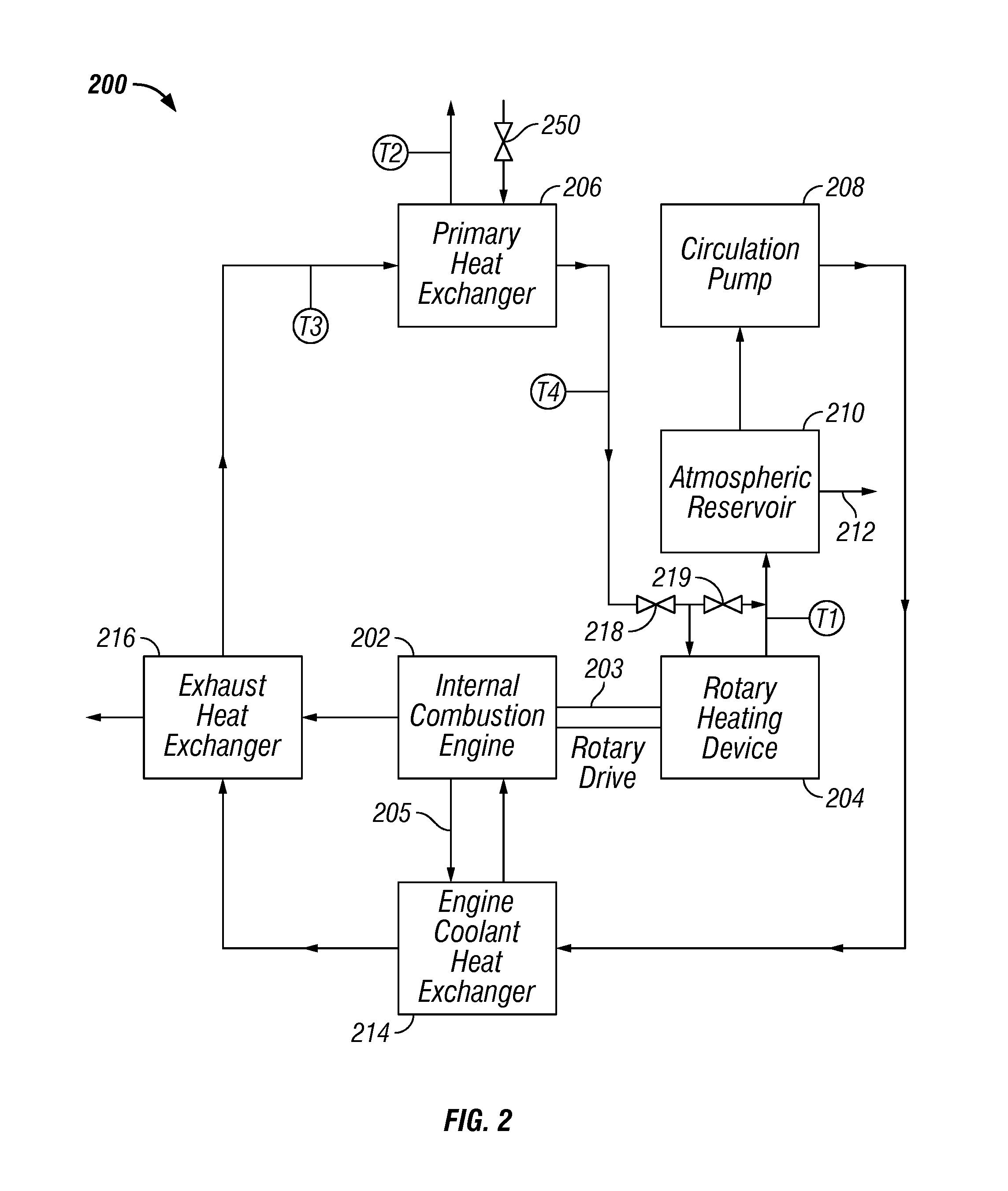

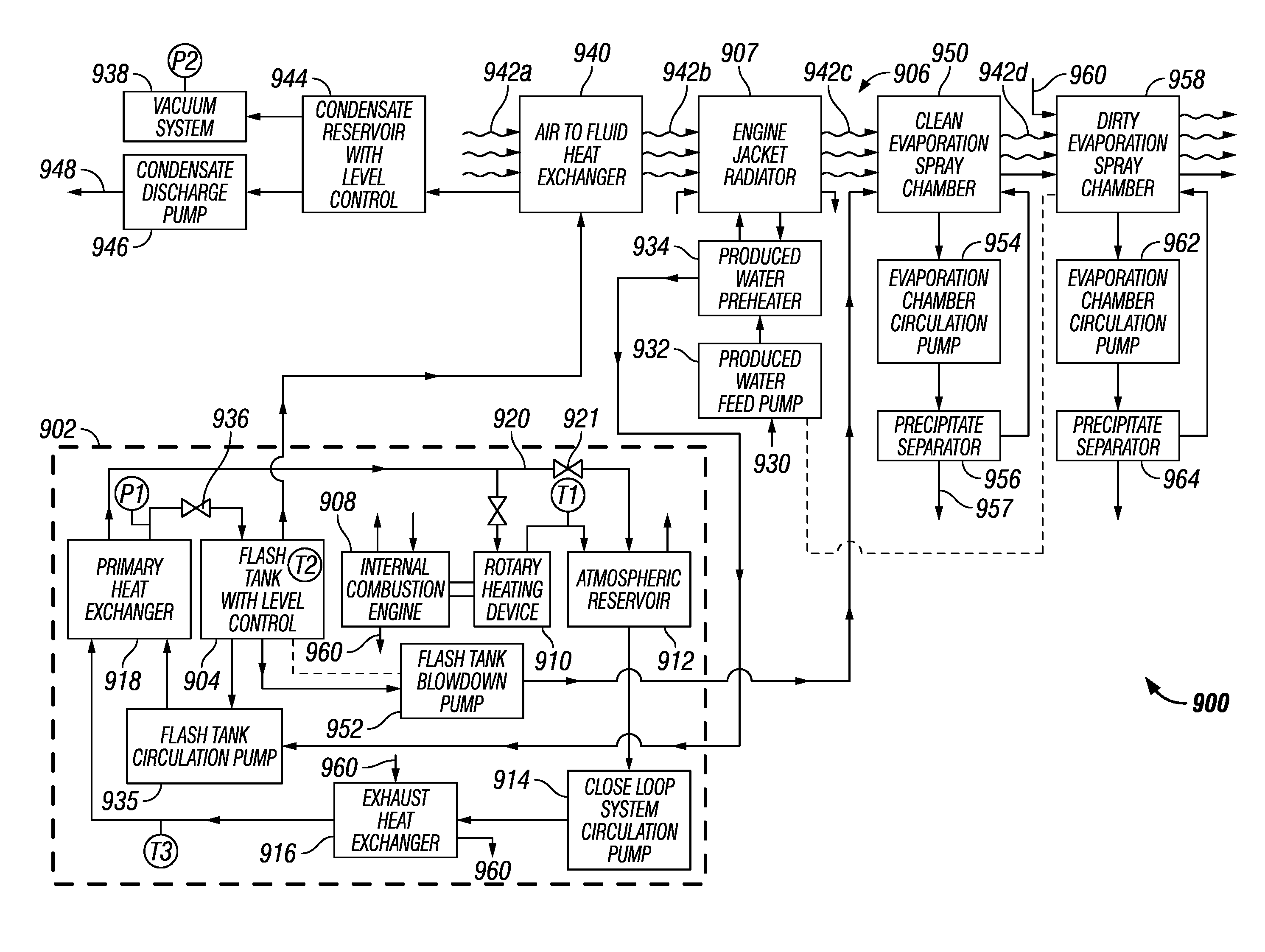

Power system and apparatus utilizing intermediate temperature waste heat

ActiveUS7841179B2Steam generation heating methodsCombustion technology mitigationThermal energyForms of energy

System and method is disclosed to increase the efficient of internal combustion engines using to generate electric power, where the system and method converts a portion of thermal energy produced in the combustion process to a usable form of energy.

Owner:KALINA POWER LTD

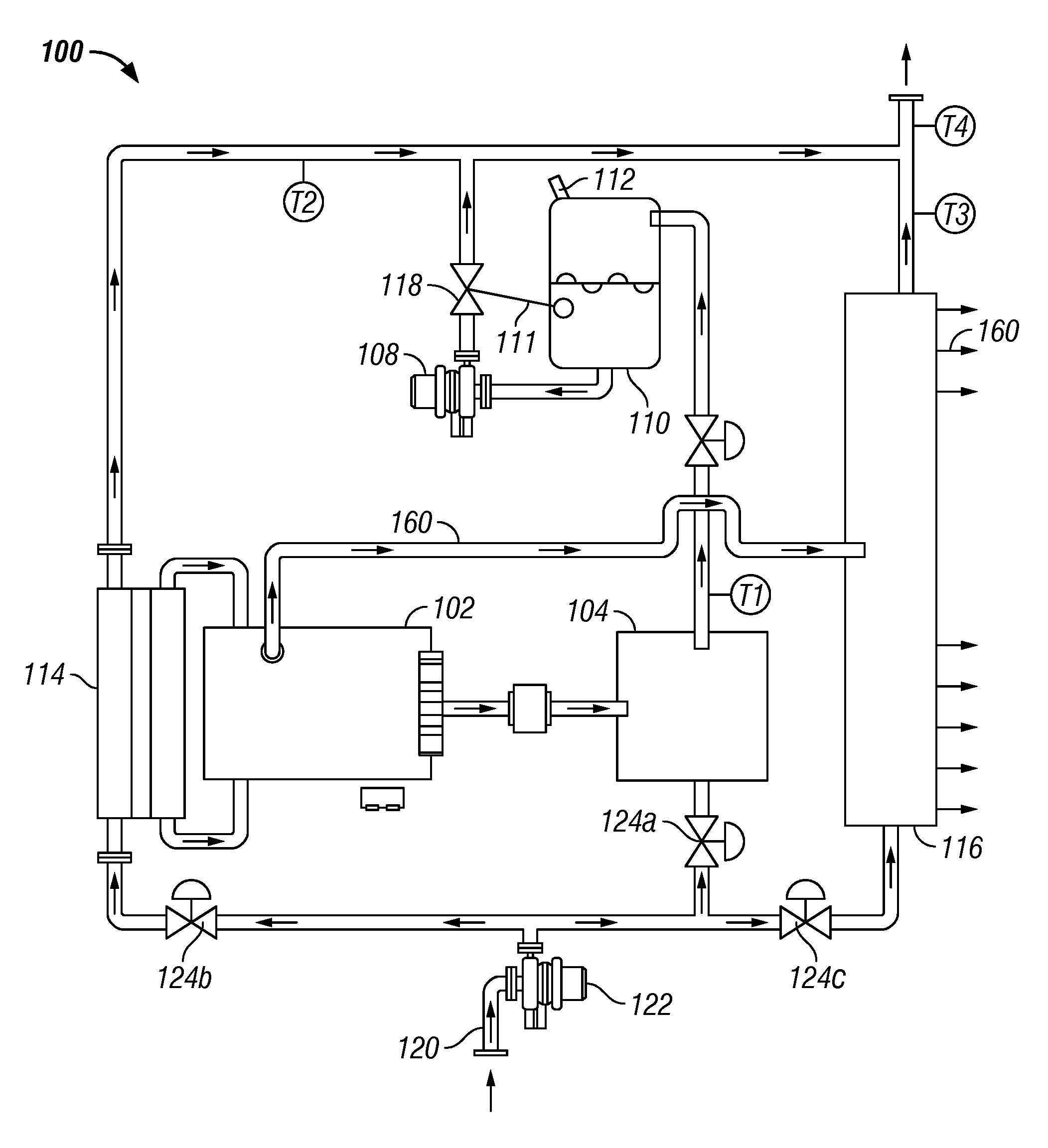

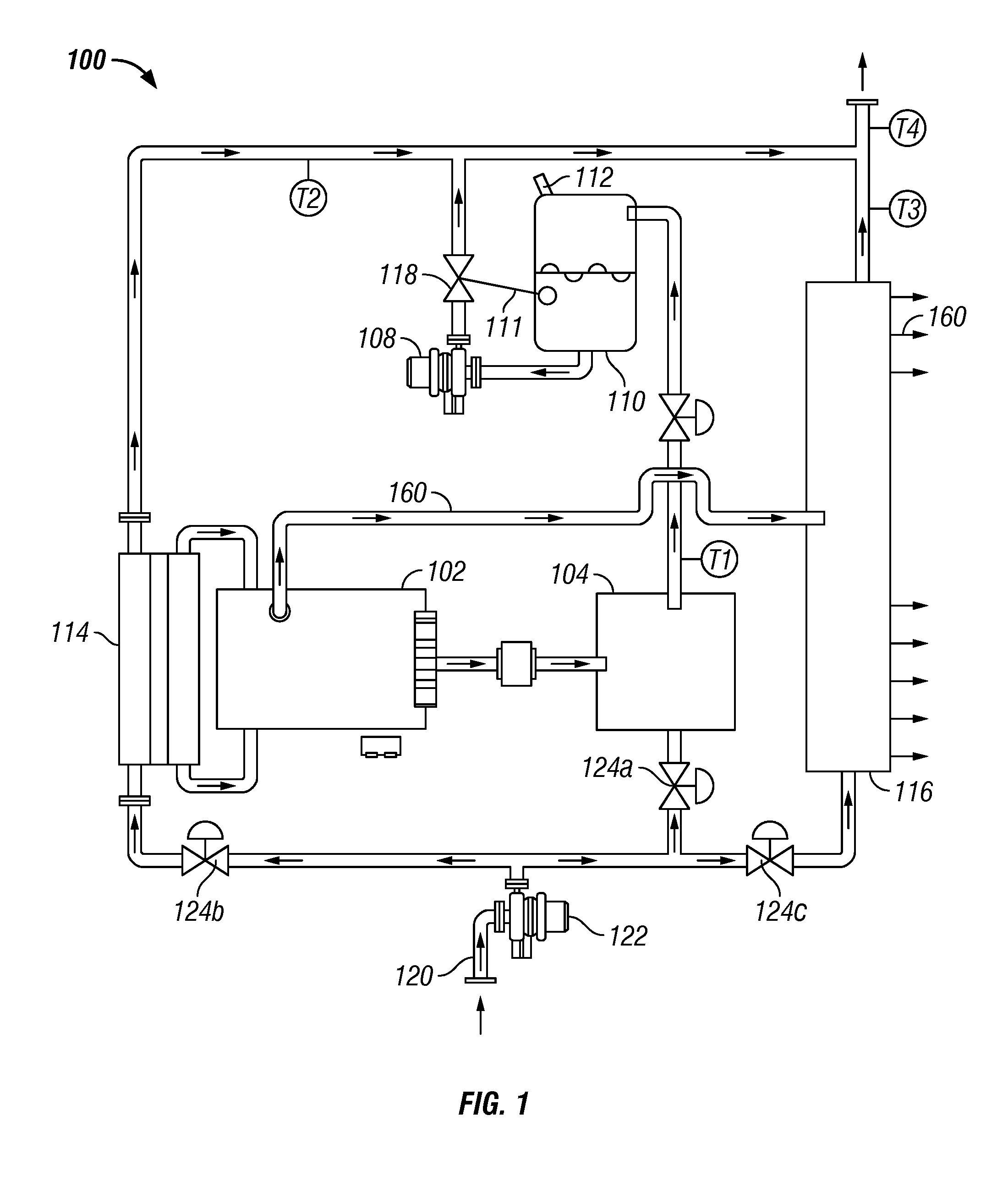

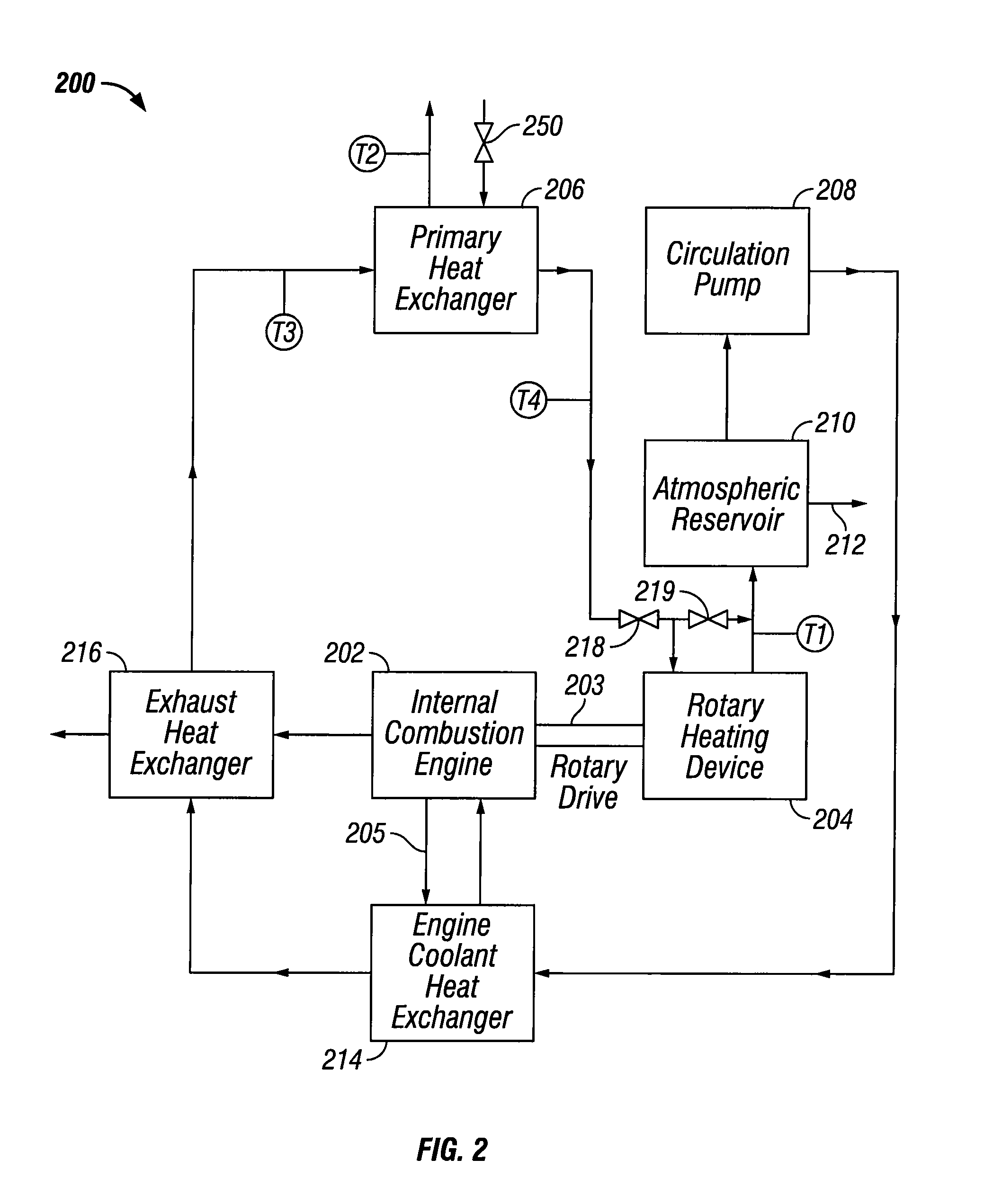

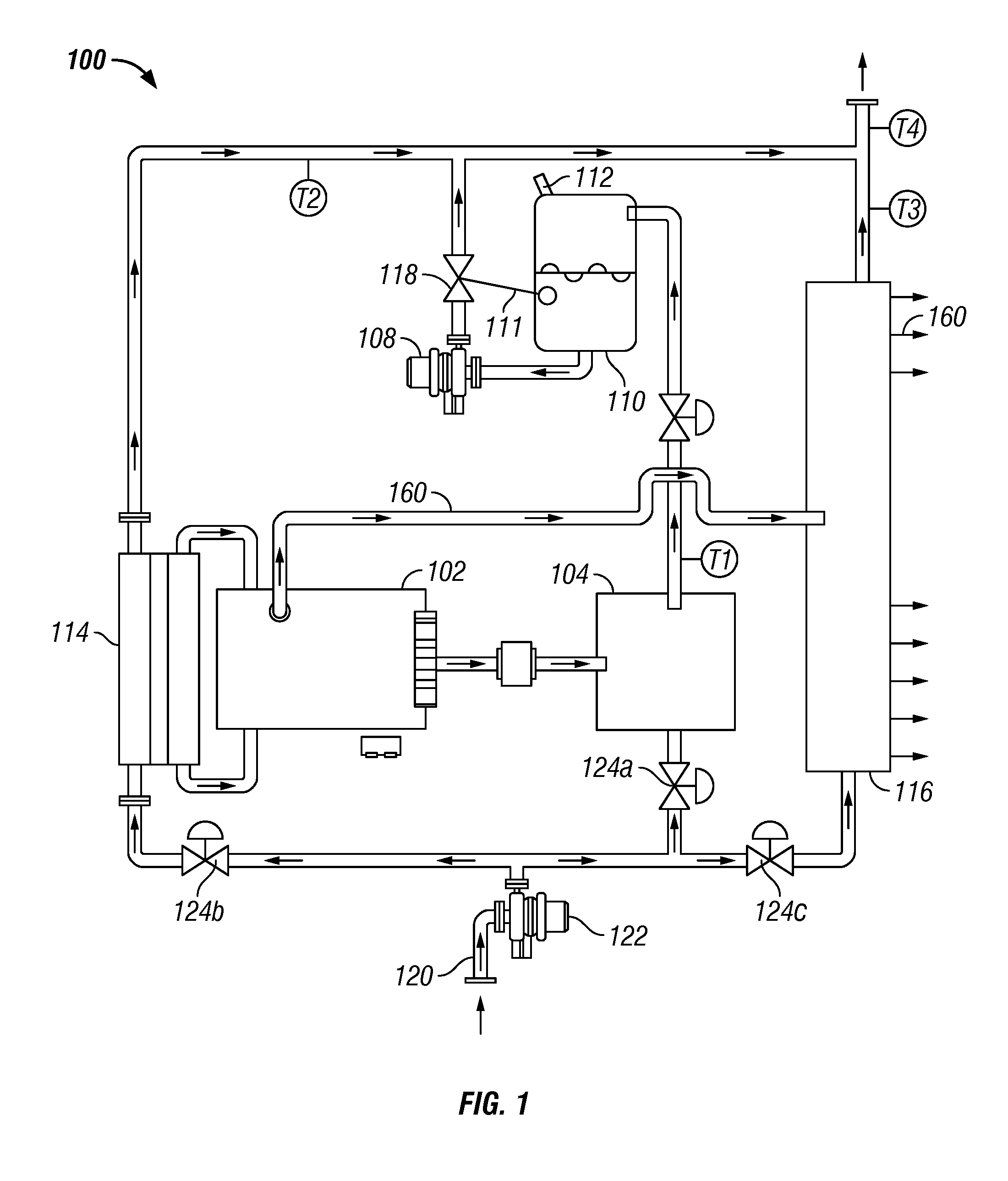

Methods and apparatuses for heating, concentrating and evaporating fluid

InactiveUS20100154395A1Steam generation using mechanical energyAir-treating devicesWater brakeClosed loop

Systems and methods are provided for heating a fluid comprising an opened-loop heating circuit or a closed-loop heating circuit both comprising a rotary heating device, such as a water brake, and a closed-loop direct-fired boiler heating circuit; and systems and methods for evaporating a fluid and systems and methods for concentrating a fluid based on these heating circuits.

Owner:PHOENIX CALIENTE INC

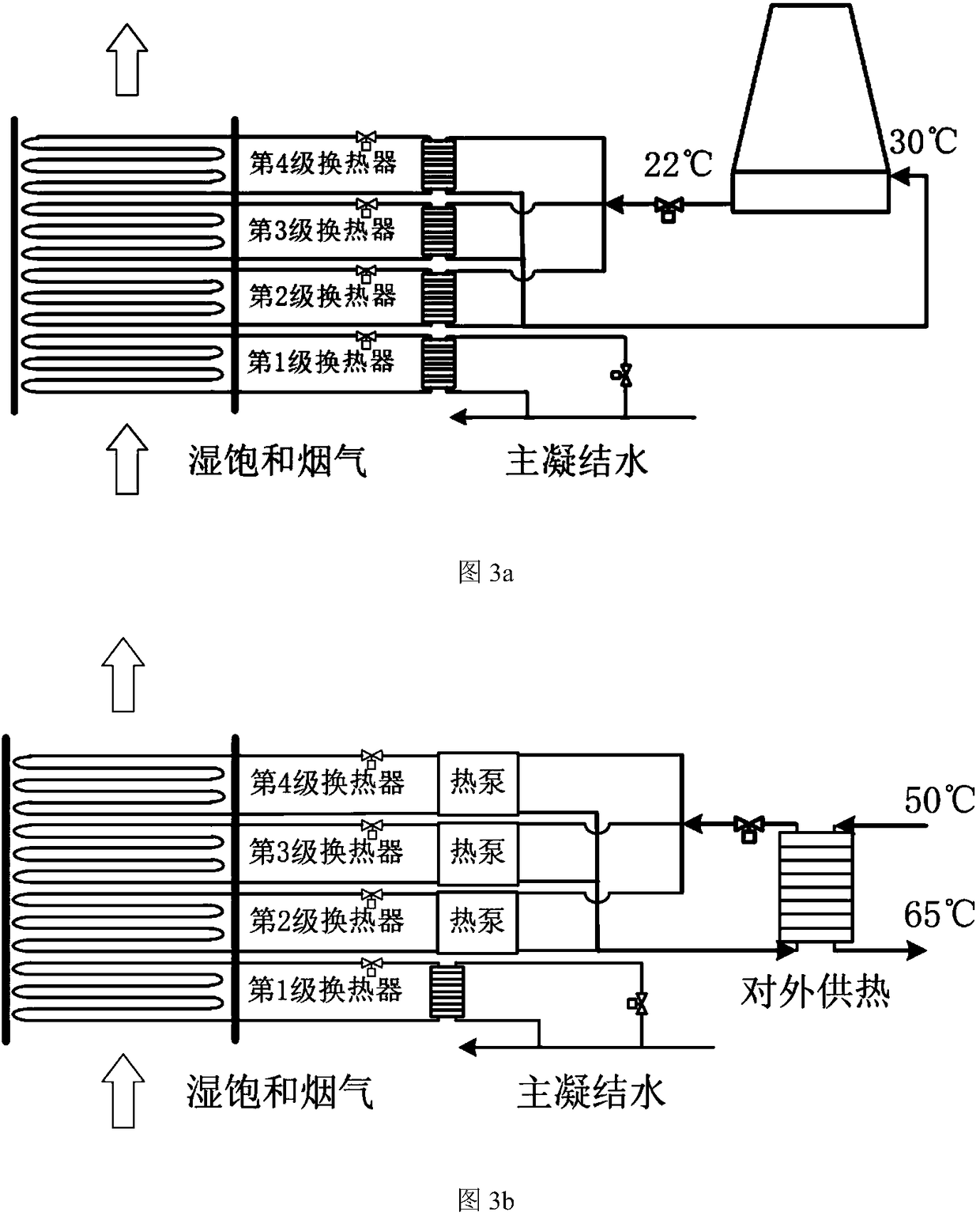

Smoke cooling, condensing, dehumidifying, pollution removing, reheating and white eliminating system and method

PendingCN109045953ALow costImprove thermal conductivityDispersed particle separationCombustion technology mitigationEngineeringTitanium alloy

The invention discloses a smoke cooling, condensing, dehumidifying, pollution removing, reheating and white eliminating system and method. The system comprises a smoke deep cooler, a smoke condensingand heat exchanging device, a smoke reheater, a cold source and the like; the smoke deep cooling process is carried out to supply a heat source for reheating smoke, so as to heat main condensing waterand decrease the smoke temperature at an outlet of a desulfurizing tower; the main condensing water can be heated in the smoke condensing process, the heat source is supplied to a heat pump, the water resource is recovered, and the water content of smoke is decreased; the relative humidity of exhausted smoke is reduced in the smoke reheating process, so that white smoke can be visibly removed. The invention further discloses a cooling, condensing, dehumidifying, pollution removing, reheating and white eliminating method. According to the system and the method, the structure of a condensing and heat exchanging device is innovated; 316L is adopted to replace fluoroplastic, titanium alloy and the like; a mechanical ventilating brine tower and an intelligent adjusting and controlling system are launched, so that the construction cost and the energy consumption of the device and a system can be decreased; the afterheat in the smoke can be recovered by steps while the white smoke is visiblyremoved; 50% or more than 50% of PM2.5, SO3 and 15% or more than 15% of NOx can be removed; and the environment protection benefit and the economic benefit are ensured.

Owner:XI AN JIAOTONG UNIV

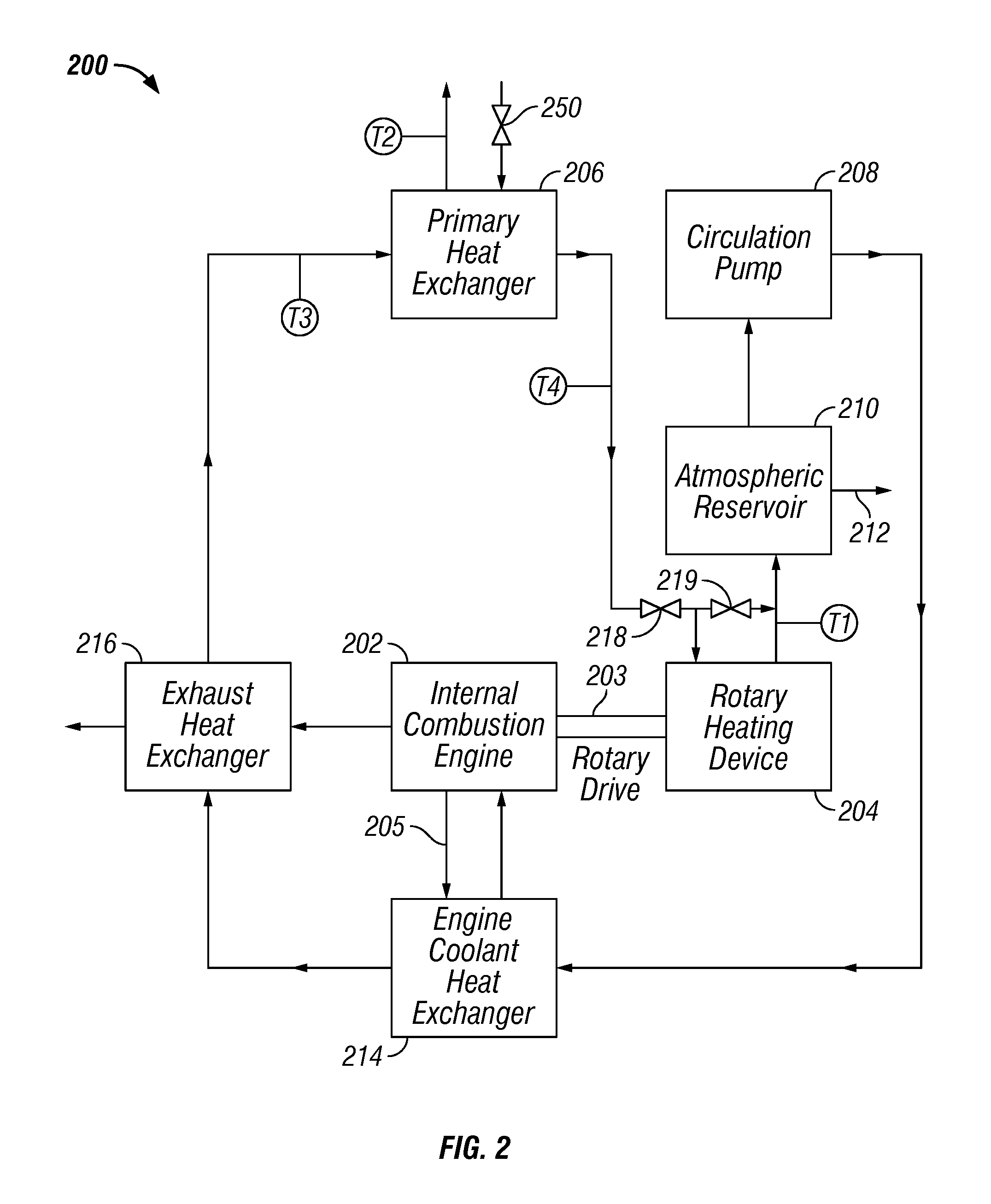

Methods and apparatuses for heating and manipulating fluid

InactiveUS20120048717A1Steam generation using mechanical energyInternal combustion piston enginesBoiling pointWater brake

Systems and methods are provided for separating a fluid into some or all of boiling point components comprising an opened-loop heating circuit or a closed-loop heating circuit both comprising a rotary heating device, such as a water brake, or a closed-loop direct-fired boiler heating circuit, or an electric heater circuit; and systems and methods for separating a fluid.

Owner:PHOENIX CALIENTE

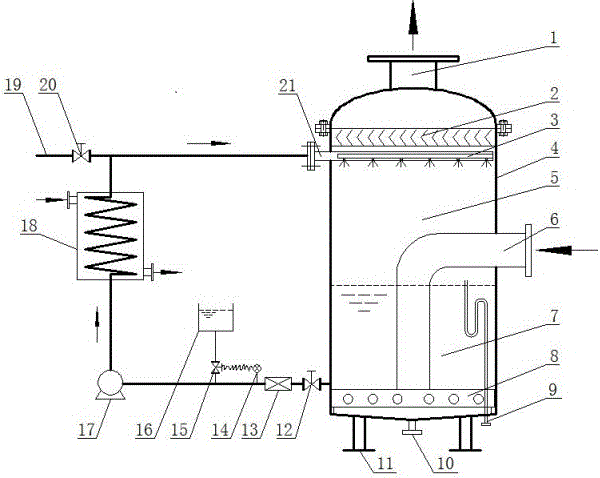

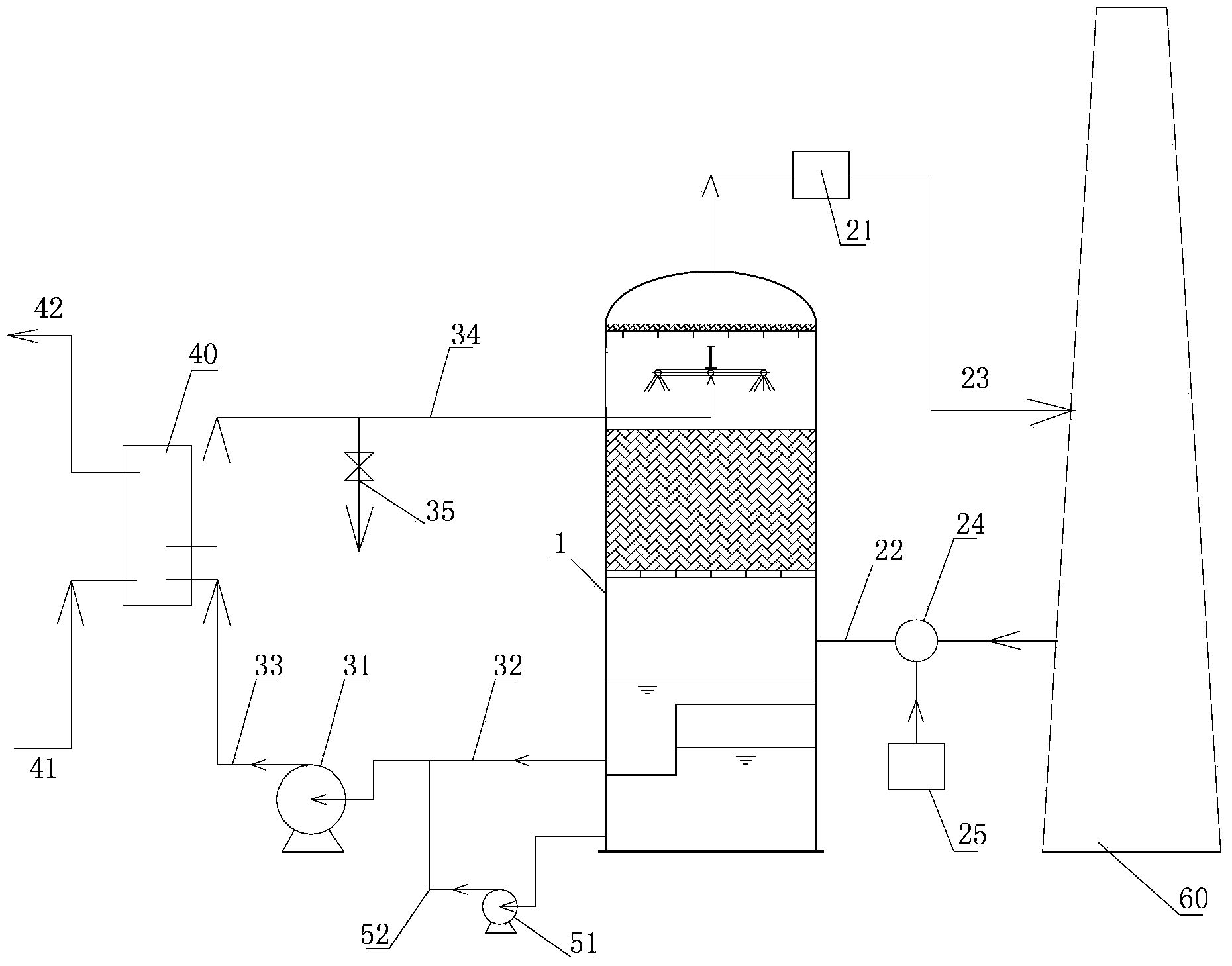

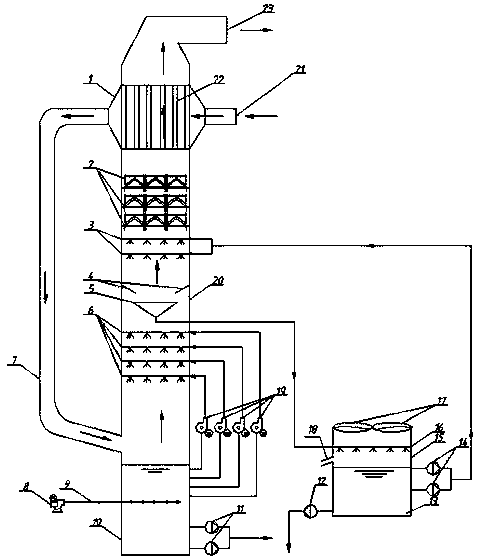

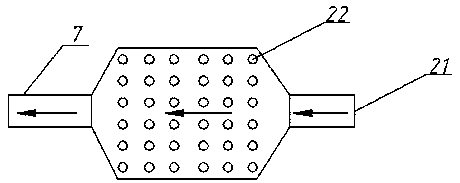

Heat supplying device for smoke purification and waste heat recovery

InactiveCN104791823AEvenly distributedReduce resistanceCombustion technology mitigationWater heatersThermal engineeringWaste heat recovery unit

The invention discloses a heat supplying device for smoke purification and waste heat recovery. The heat supplying device comprises a direct contact type waste heat recovery device and a circulating water system and is characterized in that the direct contact type waste heat recovery device comprises a bubbler, a smoke inlet pipe, an overflow pipe, a cylinder, a bubbling section, a spraying section, a sprayer, a water inlet pipe, a demister and a smoke exhaust pipe. The high temperature smoke enters cooling water in the bubble form through the bubbler and carries out direct contact type heat and mass transfer in the bubbling section; smoke discharged from the cooling water enters the spraying section and is in direct contact with the cooling water sprayed out of the sprayer again to transfer heat and mass; the cooling water absorbing heat enters the circulating water system, and a heat medium is heated through a heat exchanger in the circulating water system so as to supply heat outwards; the purified and cooled smoke is exhausted from a chimney at the upper portion of the cylinder. Two-section type direct contact of the smoke and the cooling water is adopted in the heat supplying device to transfer heat and mass, so that the smoke is fully cooled and completely purified, and the heat supplying device is suitable for smoke purification and waste heat recovery of all gas thermal engineering equipment.

Owner:ZHENGZHOU UNIV

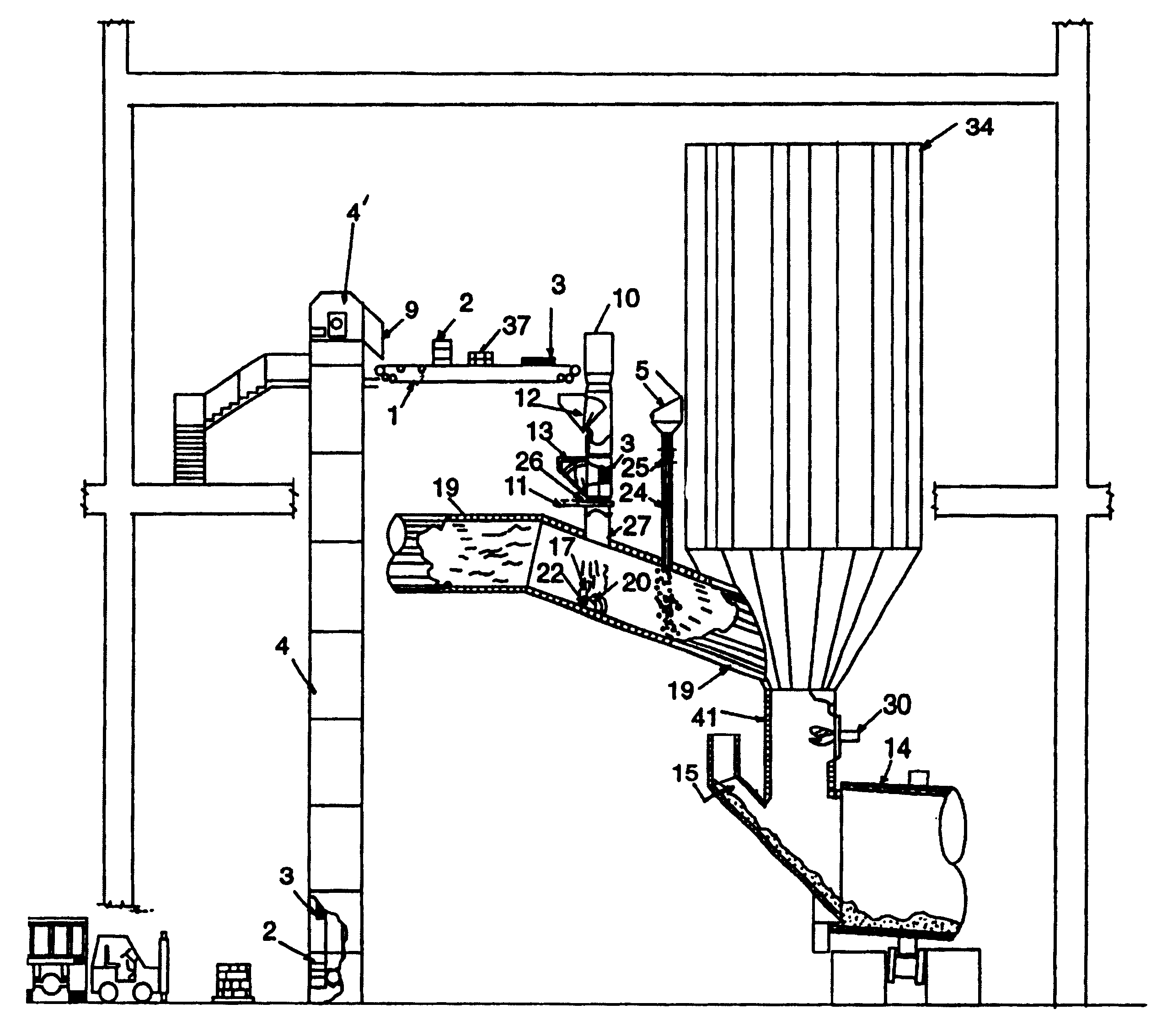

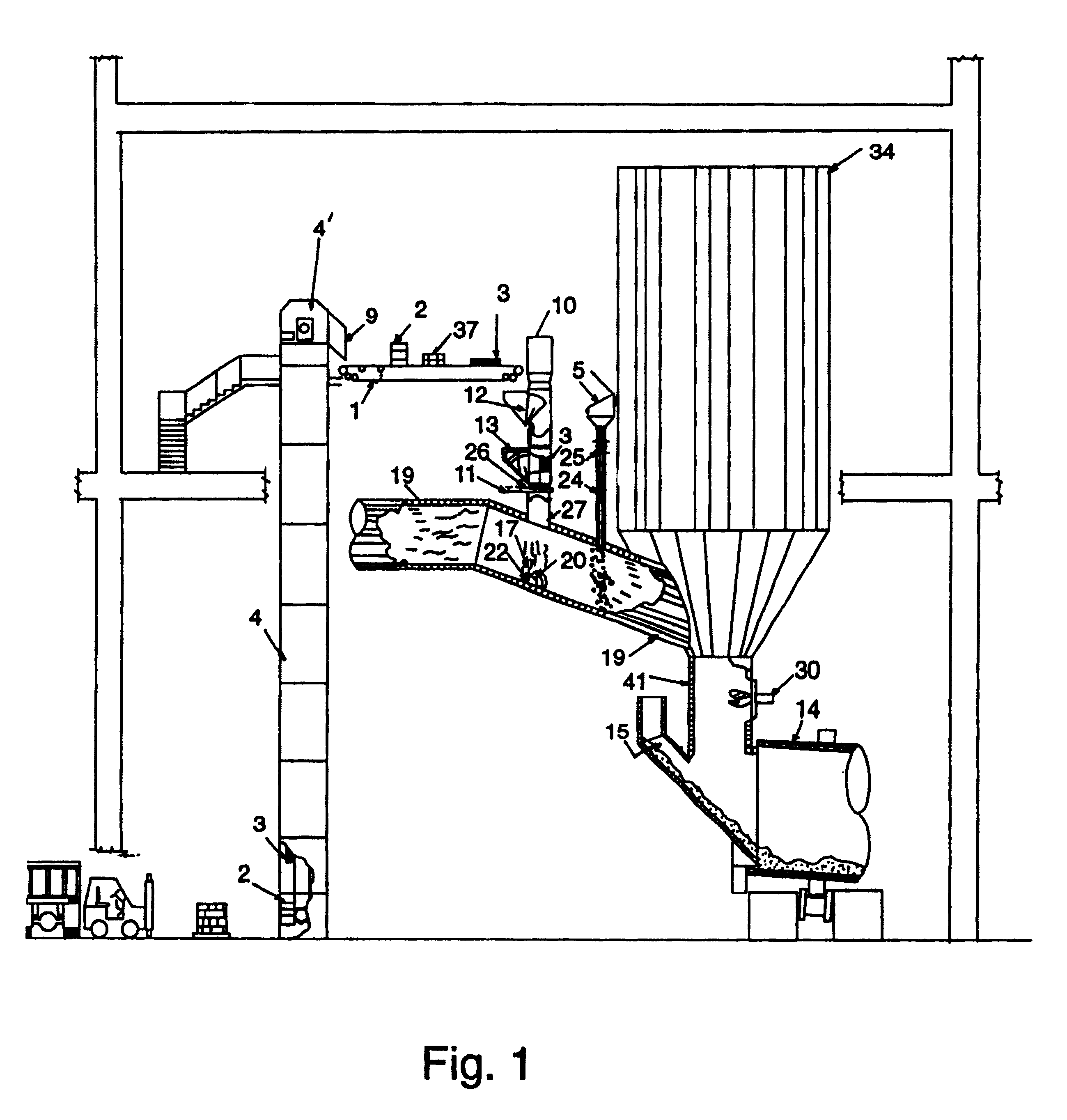

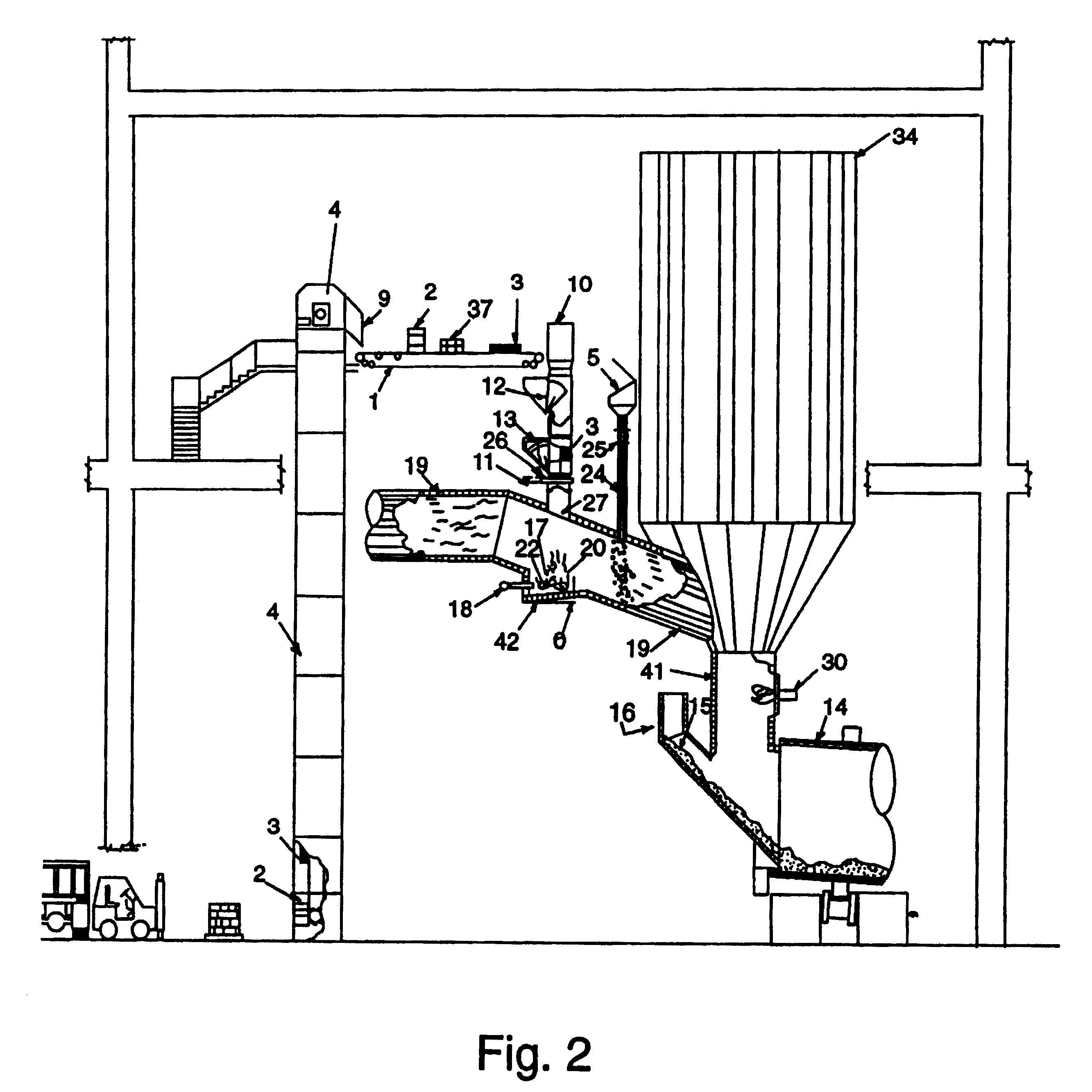

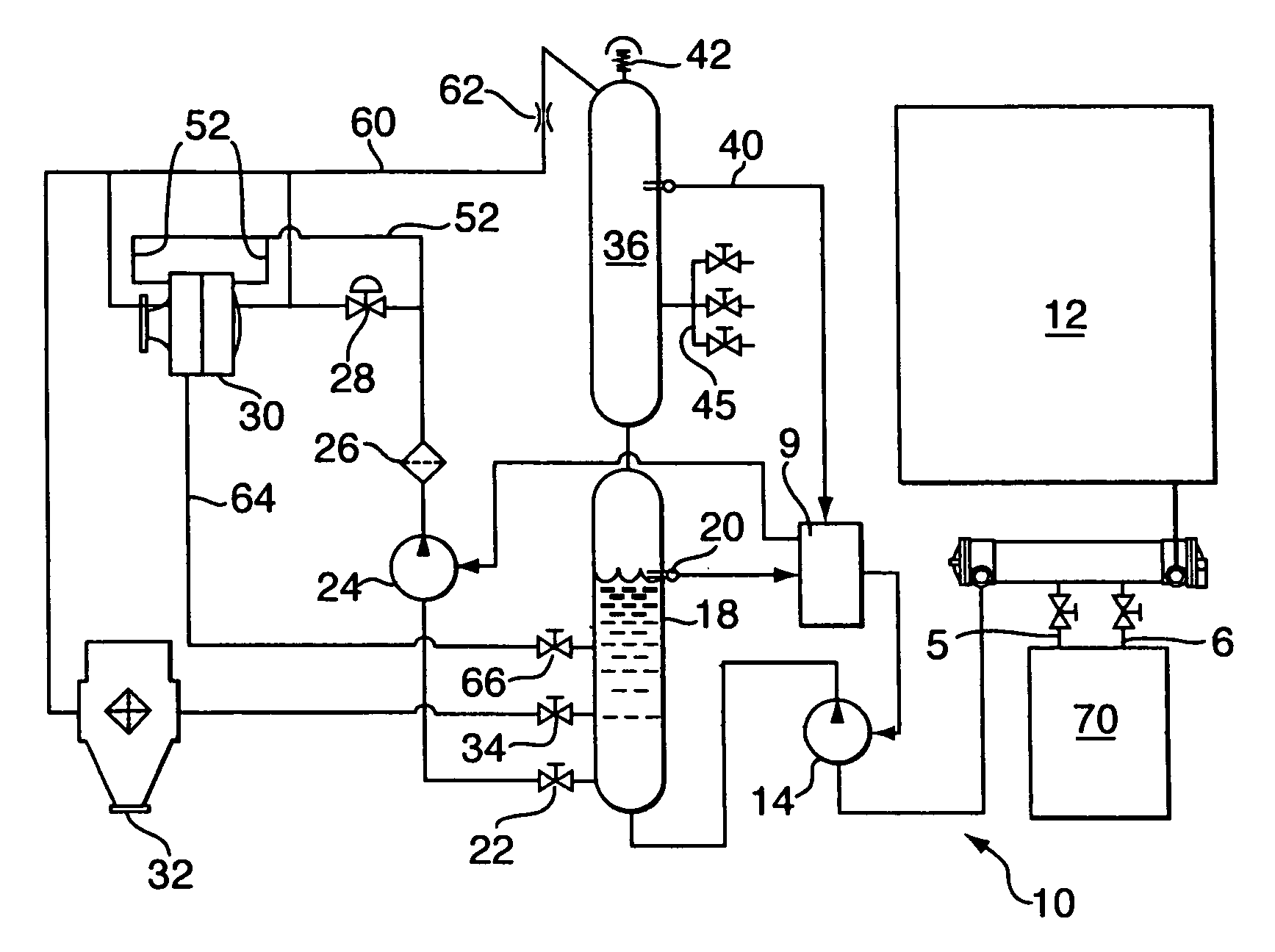

Method and apparatus for recovering energy from wastes by combustion in industrial furnaces

InactiveUS6470812B1Efficient energy recoveryEffective recoveryBranding equipmentMechanical apparatusWastewaterAtmospheric pollution

Method and apparatus to recover energy from waste by means of combustion of such waste in industrial furnaces, particularly of the rotary type, that has an external calciner, feeding such waste into the tertiary air duct of the calciner and burning the waste inside the duct itself, to efficiently make use of the energy produced by such combustion, as a contribution of the total cost of fuel necessary to operate the industrial furnace. The method and apparatus permit the elimination of hazardous wastes that are efficiently disassociated when burned sufficiently to produce effluents that are typically non-toxic, producing greatly reduced or even no atmospheric pollution nor environmental damage.

Owner:CEMEX DE C V

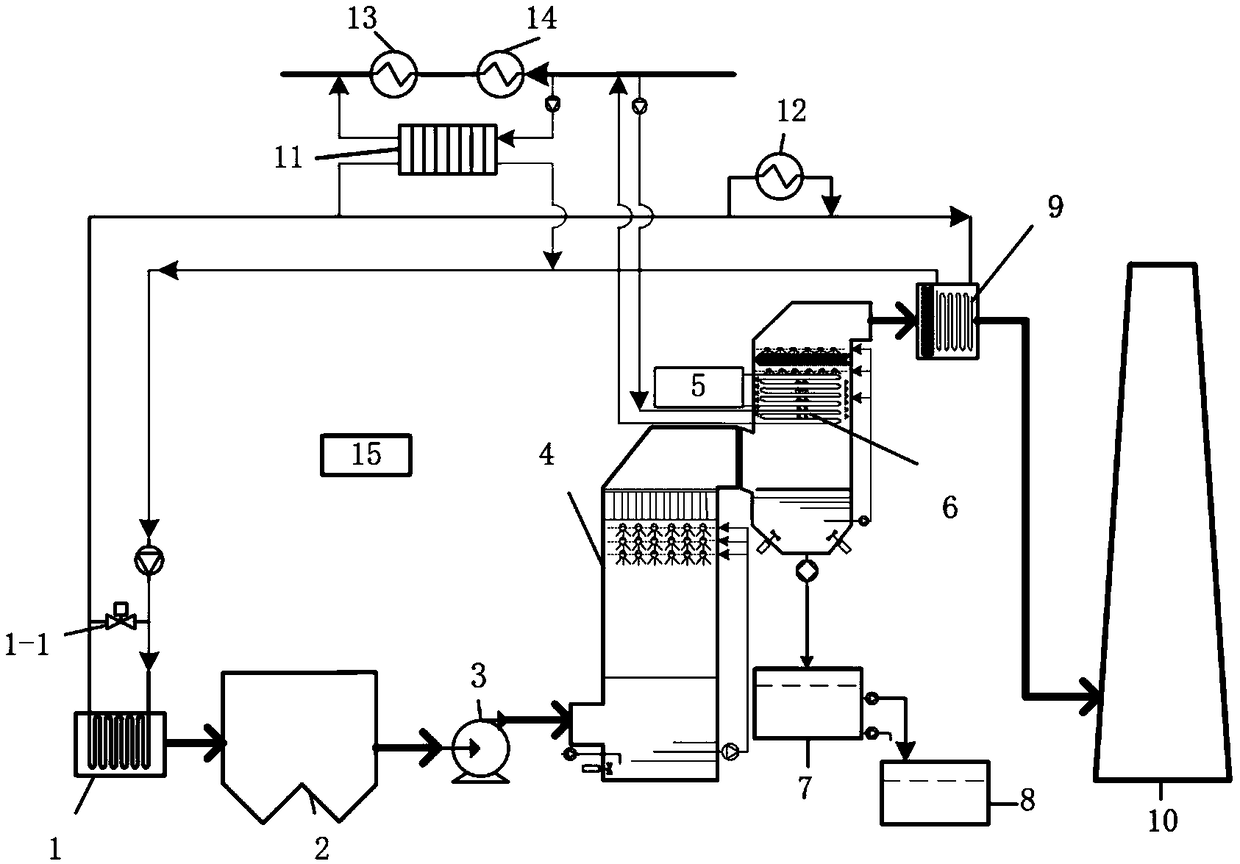

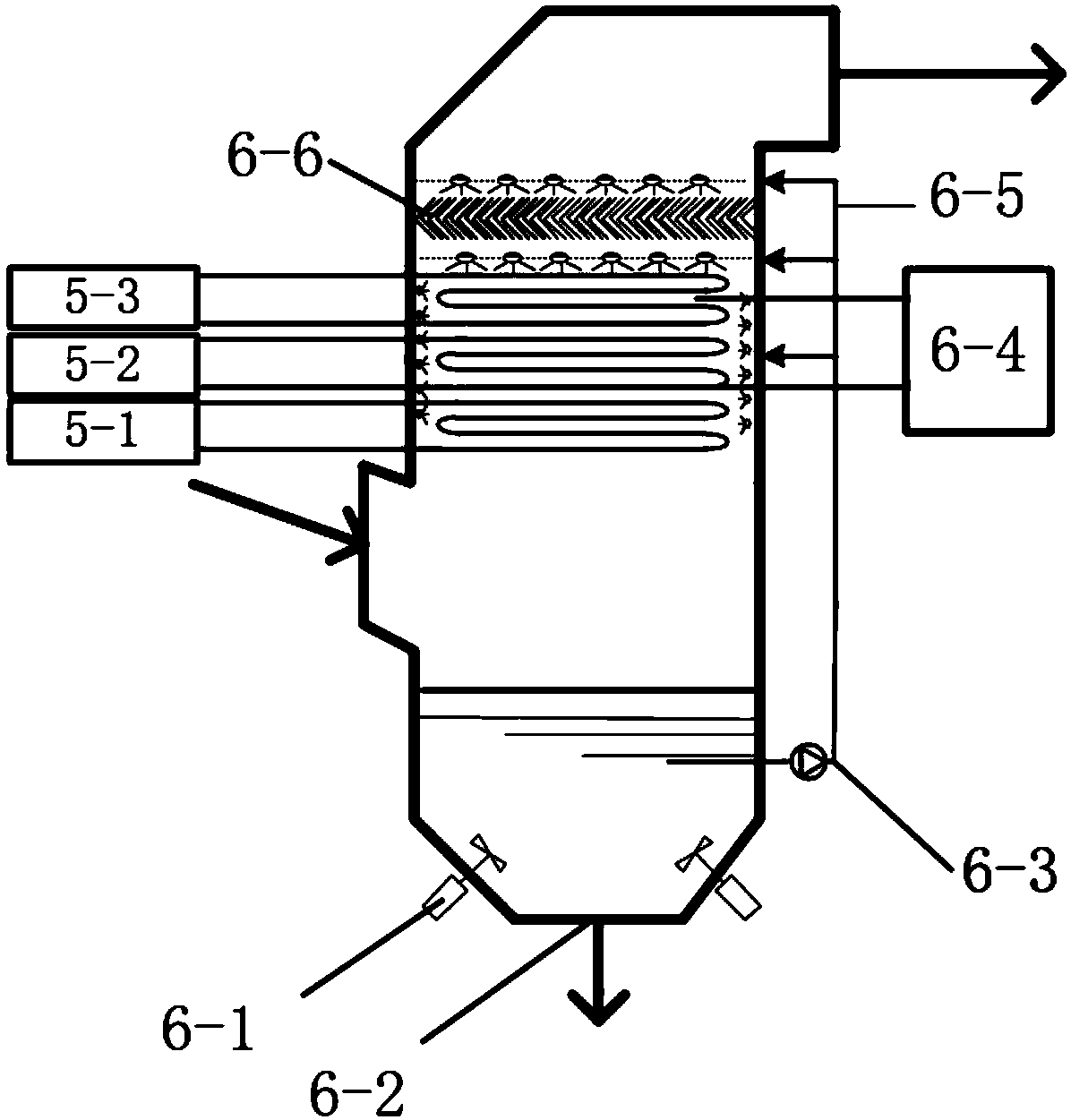

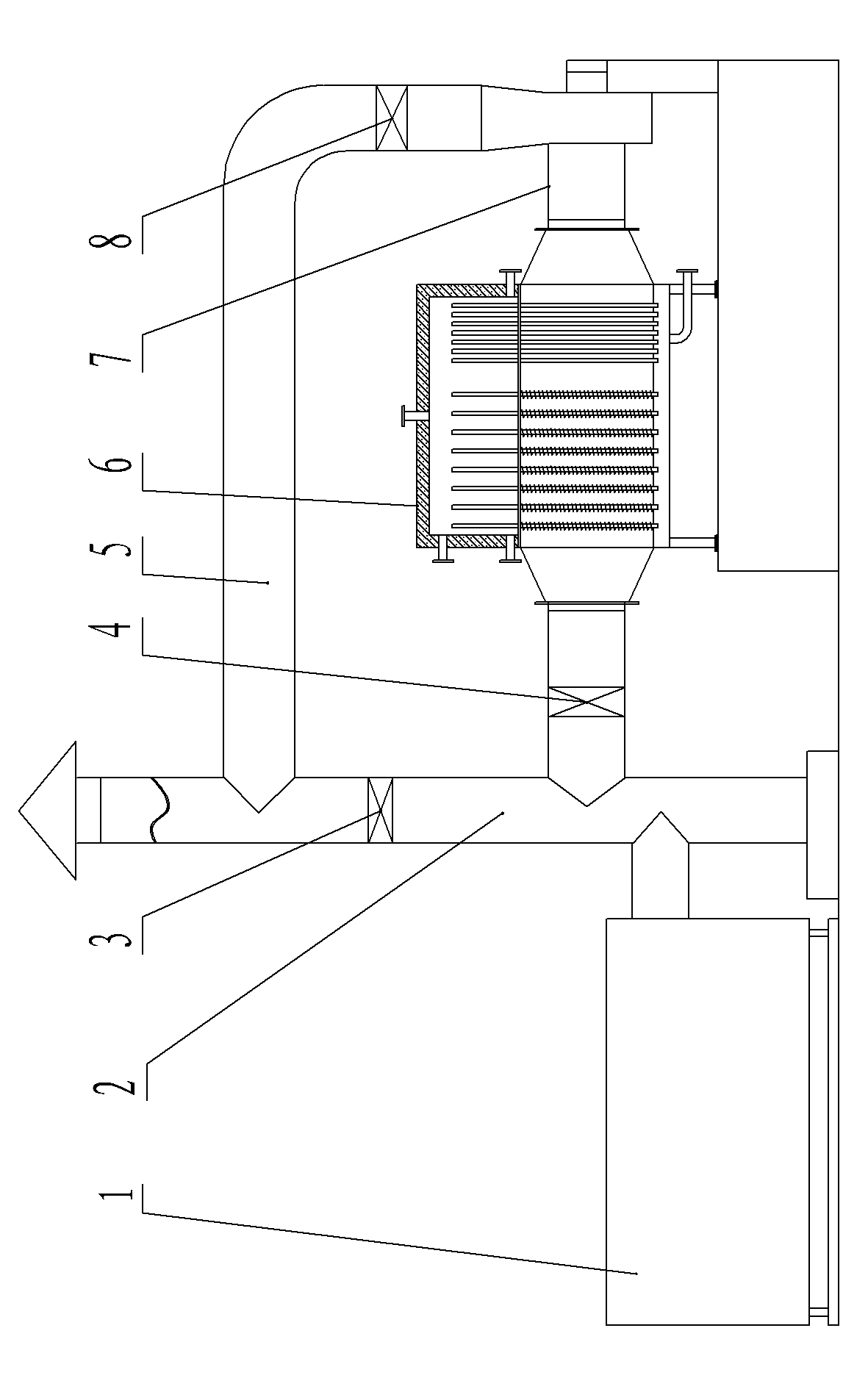

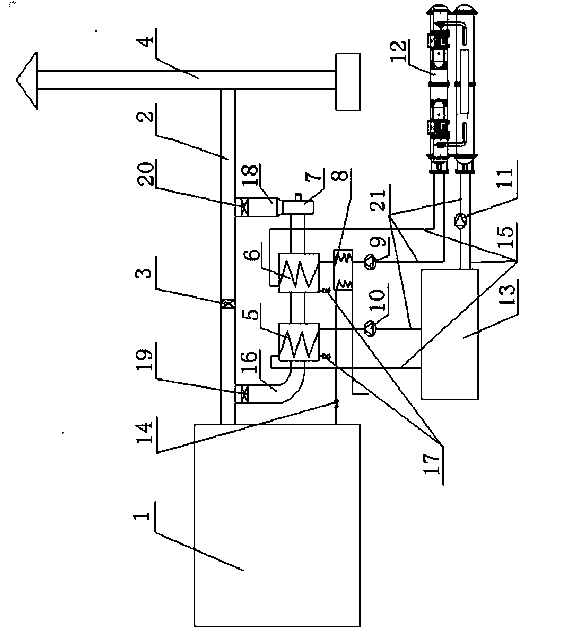

Waste heat recovering system of boiler

InactiveCN102183007ACombustion conditions unchangedWill not affect normal production and operationCombustion technology mitigationFeed-water heatersWaste heat recovery unitEngineering

The invention discloses a waste heat recovering system of a boiler, which comprises the boiler (1), a chimney (2), a main flue and a smoke waste heat recovering device (6) of the boiler, wherein the main flue is from a smoke outlet of the boiler (1) to a smoke outlet of the chimney (2), a cooling water tank is arranged in the smoke waste heat recovering device (6) of the boiler, a bypass flue is connected to the main flue, a draught fan (7) and the smoke waste heat recovering device (6) of the boiler are connected in series to the bypass flue, and a switching valve (3) used for selecting one of the main flue and the bypass flue for the smoke of the boiler is arranged on the main flue. Compared with the traditional waste heat recovering system of the boiler, the waste heat recovering system disclosed by the invention can be used for solving the problems of low waste heat recovery rate, inconvenience for maintenance, and need of stopping the boiler for maintenance when the smoke waste heat recovering device of the boiler is in failure.

Owner:GUANGXI ZHIYUAN ENERGY SAVING & ENVIRONMENTAL PROTECTION EQUIP

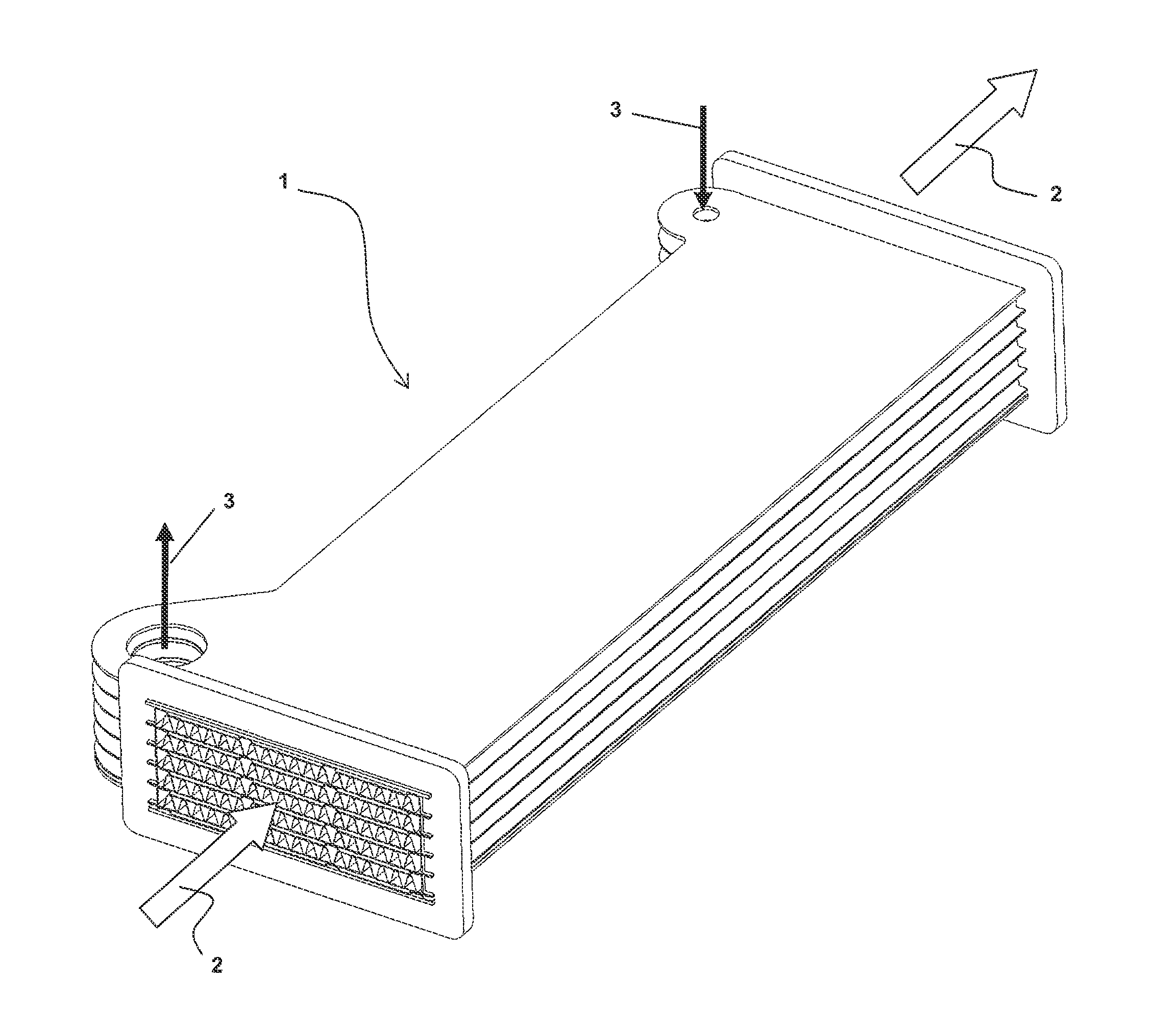

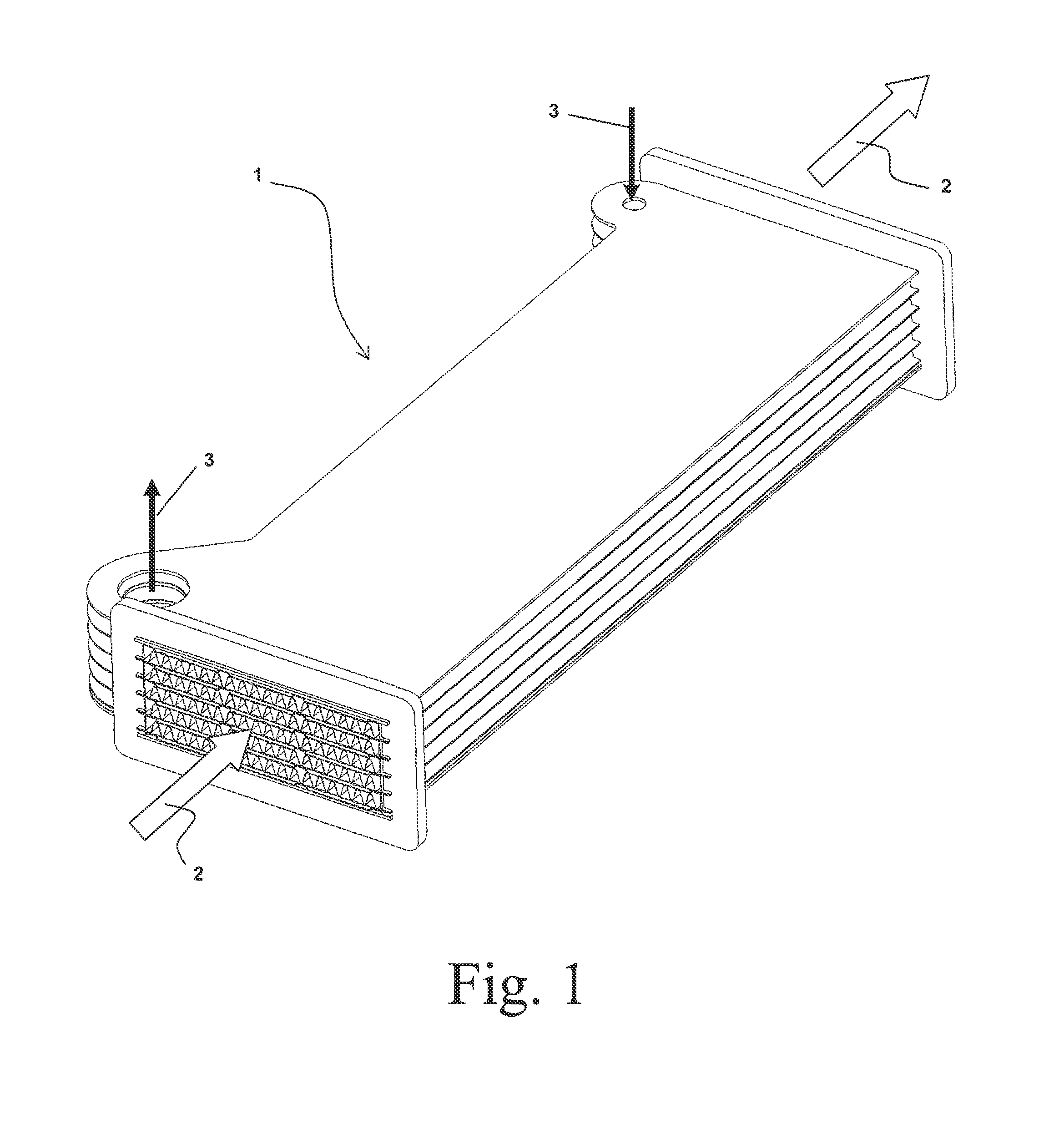

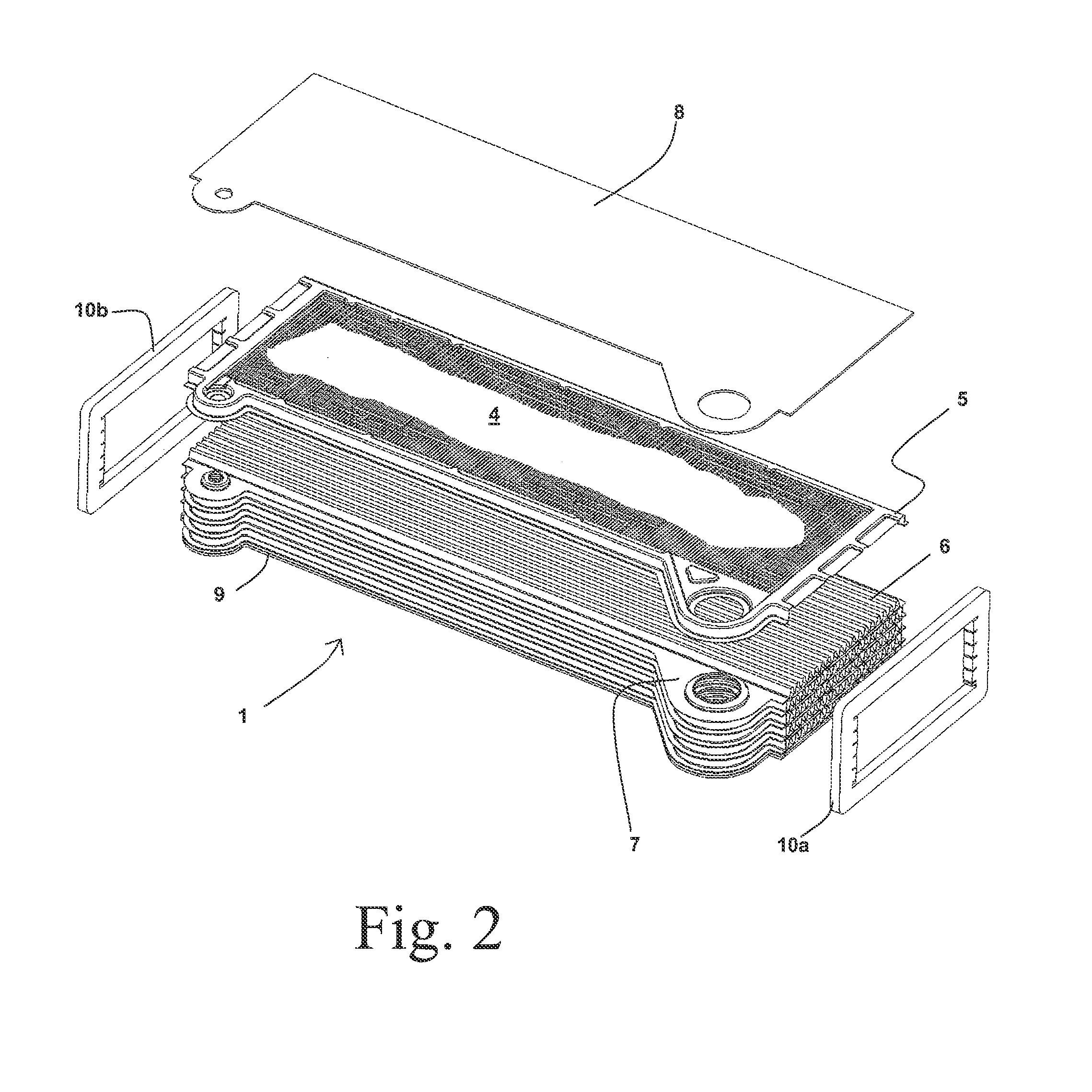

Heat exchanger and method of operating the same

InactiveUS20140060789A1Increase heatIncrease resistanceSteam generation heating methodsRecuperative heat exchangersEngineeringMicro heat exchanger

An evaporative heat exchanger includes first and second stacked plates forming a first fluid flow path between a first end and a second end. The first stacked plate defines a plane. Third and fourth stacked plates define a second fluid flow path. A fluid flow plate is positioned between the first and second stacked plates, and has a plurality of flow channels extending substantially parallel to the plane between the first end and the second end. At least one of the first and second stacked plates defines slots that form a portion of the first fluid flow path so that fluid flowing along the first fluid flow path flows along the flow channels in the first direction, then flows along at least one of the slots, then flows into adjacent flow channels and then along the adjacent flow channels in a second direction parallel to the first direction.

Owner:MODINE MFG CO

Direct evaporator apparatus and energy recovery system

InactiveUS20110061388A1Steam generation heating methodsInternal combustion piston enginesWorking fluidOrganic Rankine cycle

In one aspect of the present invention provides a direct evaporator apparatus for use in an organic Rankine cycle energy recovery system, comprising: (a) a housing comprising a heat source gas inlet, and a heat source gas outlet, said housing defining a heat source gas flow path from said inlet to said outlet; and (b) a heat exchange tube disposed entirely within said heat source flow path, said heat exchange tube being configured to accommodate an organic Rankine cycle working fluid, said heat exchange tube comprising a working fluid inlet and a working fluid outlet, said heat exchange tube defining three zones, a first zone adjacent to said heat source gas outlet, a second zone adjacent to said heat source gas inlet, and a third zone disposed between said first zone and said second zone, said working fluid inlet being in direct fluid communication with said first zone, and said working fluid outlet being in direct fluid communication with said third zone; wherein said first zone is not in direct fluid communication with said third zone. An organic Rankine cycle energy recovery system and a method of energy recovery are also provided.

Owner:GENERAL ELECTRIC CO

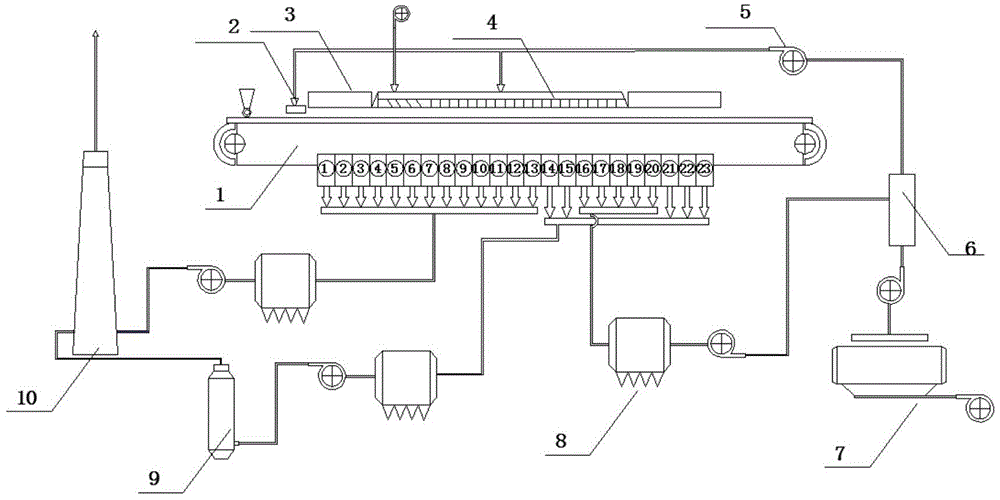

Energy-saving environment-friendly sintering waste gas waste-heat utilization and pollutant purification process and system

InactiveCN104132550AReduce purification costsEmission reductionCombustion technology mitigationWaste heat treatmentSulfurDecomposition

The invention relates to an energy-saving environment-friendly sintering waste gas waste-heat utilization and pollutant purification process and system. The energy-saving environment-friendly waste gas waste-heat utilization and pollutant purification process includes that sintering waste gas is divided into a low-temperature low-sulfur sintering waste gas, a middle-temperature high-sulfur sintering waste gas and a high-temperature middle-sulfur sintering waste gas according to waste gas temperature and pollutant discharge characteristics; content of sintering waste gas SO2 of the low-temperature low-sulfur is below the national discharge standard, and the SO2 can be directly discharged after dust removal; after the sintering waste gas in a middle-temperature high-sulfur section is subjected to dust removal and desulfurization processing, the SO2 meets the national discharge standard and can be discharged; the sintering waste gas in a high-temperature middle-sulfur section mixed with ring-cold waste gas is led into a sintering machine, and hot-wind igniting and hot-wind sintering are performed. The invention further provides a system for implementing the energy-saving environment-friendly sintering waste gas waste-heat utilization and pollutant purification process. Waste heat of the sintering waste gas can be recycled in classification and gradiently utilized, so that energy can be saved; the low-sulfur waste gas can be discharged directly, so that desulfurization cost of the waste gas is lowered; part of the high-sulfur waste gas participate in circulation, so that total discharge amount of pollutants is decreased, splitting decomposition of dioxin happens due to high temperature, and the purification function of the sintering waste gas is achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Fuel oil/gas boiler for reducing emission of nitric oxides and method

ActiveCN102635852AReduce the temperatureWide stable rangeBurnersCombustion technology mitigationLow nitrogenFuel oil

The invention relates to a fuel oil / gas boiler for reducing emission of nitric oxides and a method, belonging to the technical fields of energy saving and emission reduction and boilers. The fuel oil / gas boiler for reducing emission of nitric oxides comprises a fuel pipeline, a combustion-supporting air pipeline, a low-nitrogen combustor, a boiler body, a smoke discharging pipeline, a chimney, a smoke circulating pipeline, a combustion-supporting fan and a water inlet pipe. Compared with the common boiler, the fuel oil / gas boiler has the advantages of reducing radiation heat exchange area by 30-50%, and increasing heat convection area by 15-25%; and 15-25% of boiler low-temperature smoke enters the combustion-supporting fan after passing through a smoke circulating cooler and the smoke circulating pipeline, and is mixed with fresh air to be used as combustion-supporting air to enter the low-nitrogen combustor. According to the invention, on the premise of no reduction of the heat efficiency of the fuel oil / gas boiler and no increase of operation cost, the emission of the nitric oxides of the fuel oil / gas boiler can be reduced by 20-50%.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

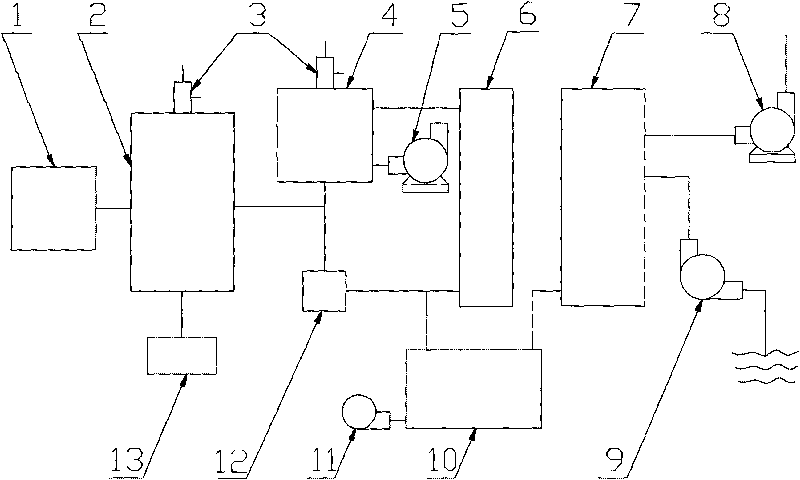

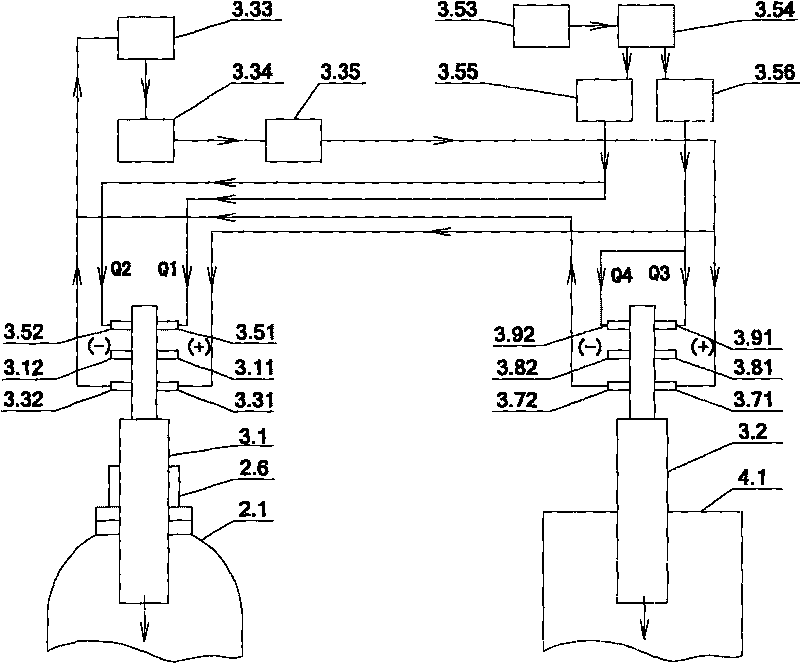

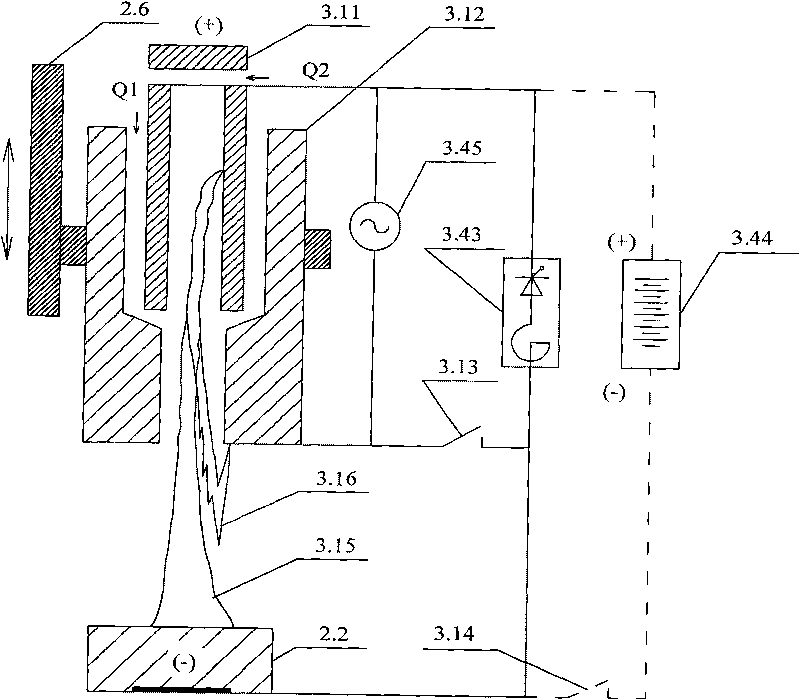

Thermal plasma device for incinerating marine garbage

ActiveCN101737785AGood heat transfer performanceImprove incineration efficiencyCombustion technology mitigationIncinerator apparatusLoss rateMelting tank

The invention relates to a thermal plasma device for incinerating marine garbage, which comprises a feed system, an incinerator, a plasma system, a secondary combustion chamber, a blast blower, a heat exchanger, a desulfurization and dust removal tower, a draught fan, a first water pump, a quench cooler, a second water pump, a tapping device and an automatic control system. The invention adopts a transferred-arc and non-transferred arc dual-purpose direct-current plasma generator as an incineration heat source, which not only can make full use of a shipborne dynamic power supply (or an accumulator battery) but also can use a non-transferred arc in the initial stage of incineration and adopt the working mode of a transferred arc after a molten pool is molten. Compared with a single non-transferred arc operation mode, the heat transmission property is better, the incineration efficiency is higher, and more energy is saved; in the invention, the secondary combustion chamber adopts plasma heating in a similar way, and the condition that new pollution is generated in the treatment process of secondary combustion is avoided; and by high temperature generated by the plasma generator adopted by the invention, the temperature of the molten pool exceeds 1500 DEG C and is sufficient to enable inorganic substances, slag and heavy metal to be fused together, the inorganic substances, the slag and the heavy metal are solidified in a neutral vitreous body and are not easy to precipitate, the treatment of the garbage is finished by one step, and the thermal ignition loss rate is less than 3%.

Owner:AEROSPACE ENVIRONMENTAL ENG

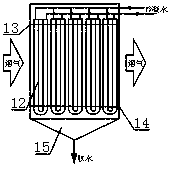

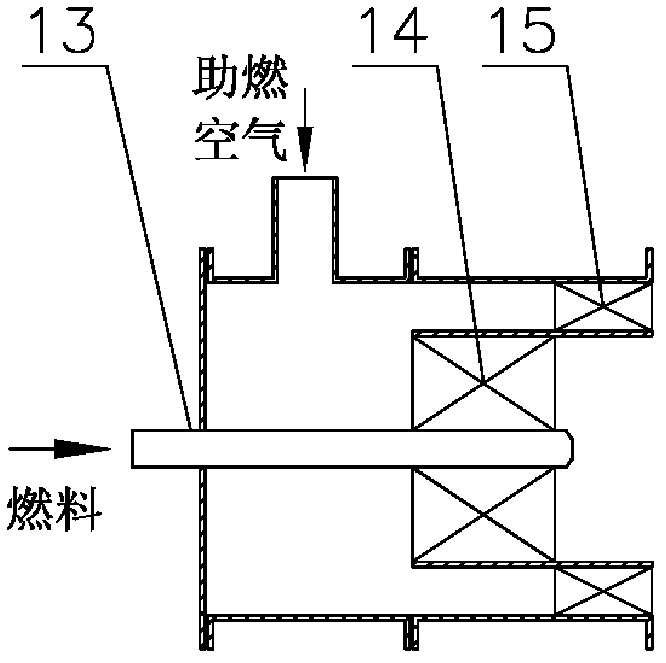

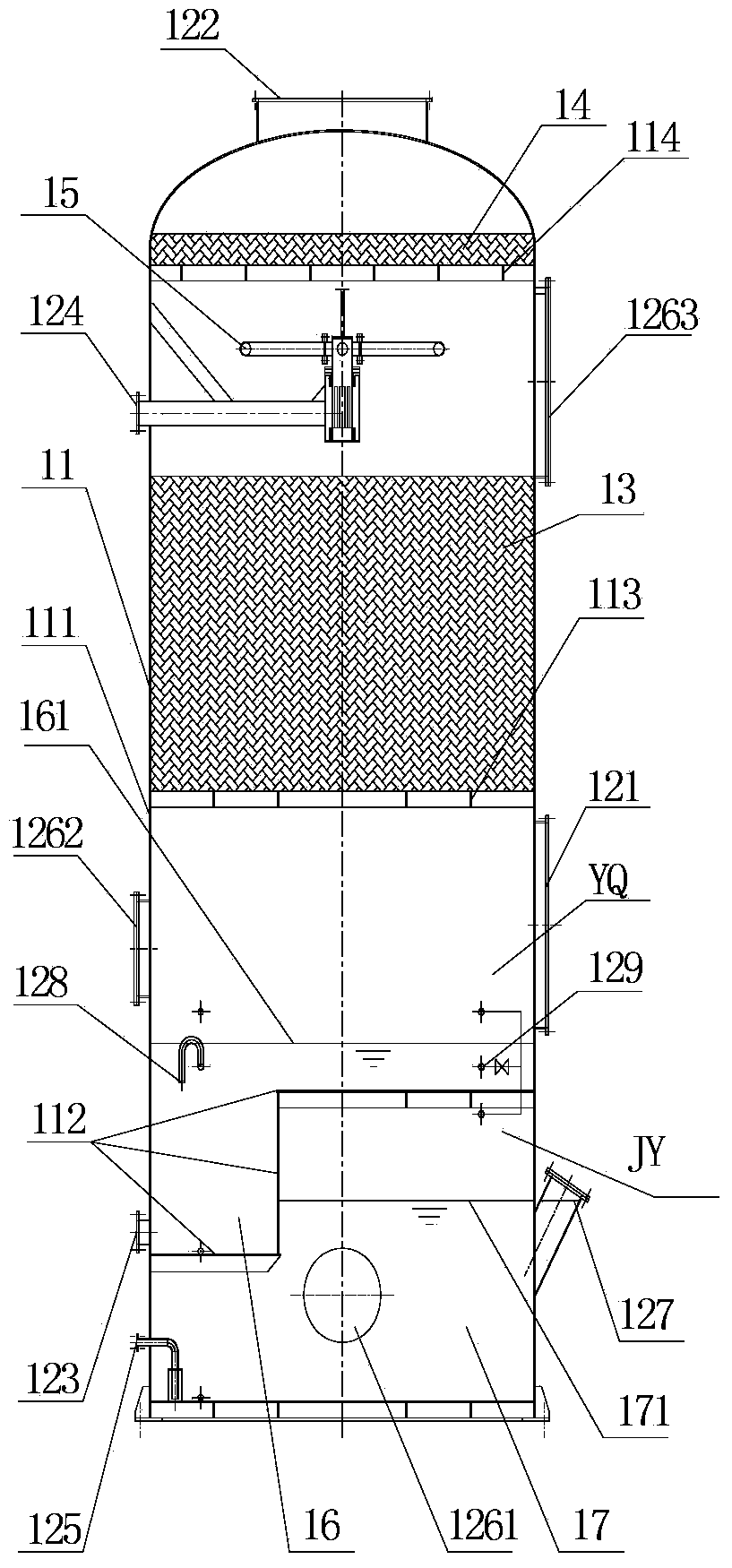

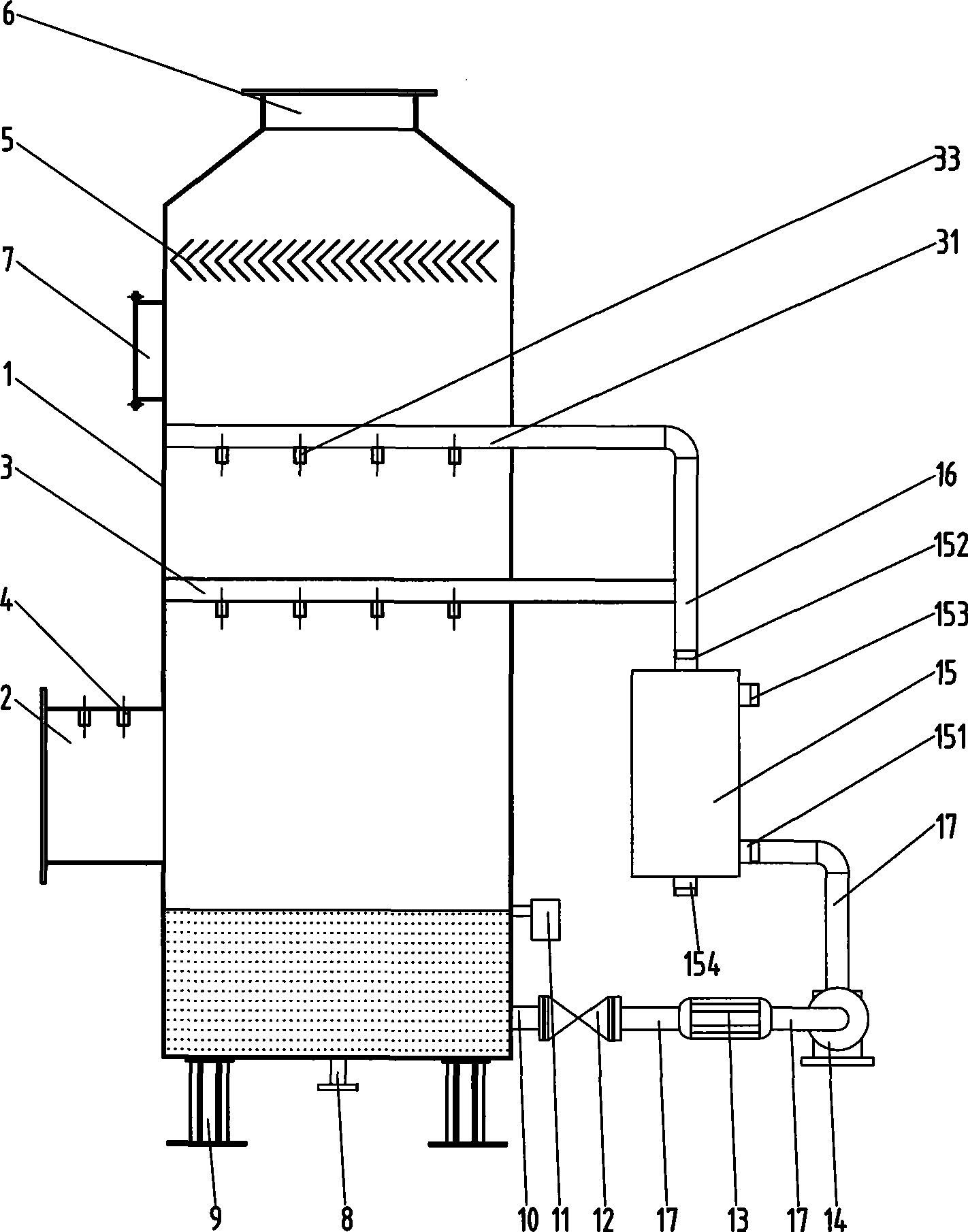

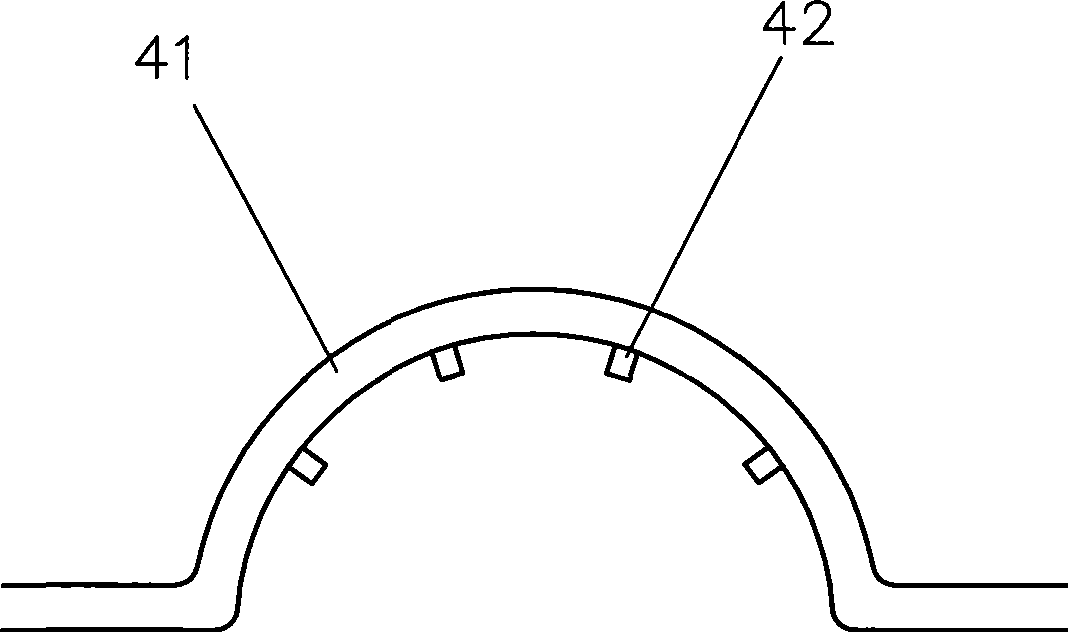

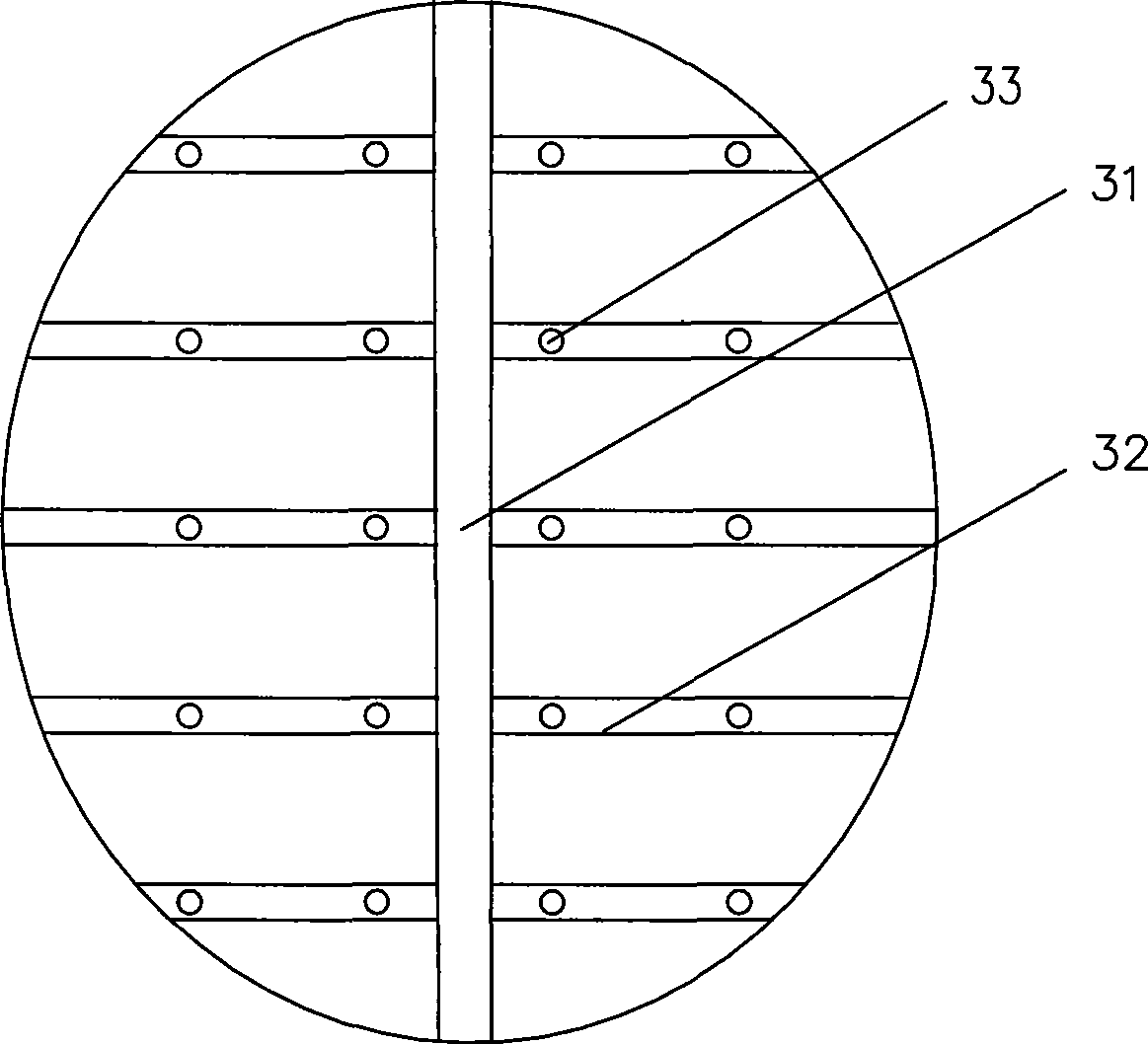

Integrated spray flue gas waste heat recovery and denitration device

InactiveCN104162357ALow flow resistanceFacilitate contact areaLighting and heating apparatusDispersed particle separationContact timeFlue gas

The invention provides an integrated spray flue gas waste heat recovery and denitration device. The device comprises a spray filler and alkali storage tower (1), a flue gas conveying and oxidization loop system, a spray conveying loop system, a heat energy utilization system and an alkalifying neutralization system, wherein the spray filler and alkali storage tower (1) comprises a spray filler and alkali storage tower main body structure part (11), a spray filler and alkali storage tower connector, filler (13), a dehydrator (14) and a spray component (15). According to the device, spray water is in contact with flue gas for heat exchange through the filler with a large specific surface area, the stable contact heat exchange area of gas and liquid phases is remarkably increased, the contact time of gas and liquid phases is remarkably prolonged and the uniformity of gas and liquid phases is remarkably improved, and the performance and the stability of gas liquid heat exchange are remarkably improved, so that the flue gas waste heat recovery efficiency and the denitration / desulfurization effect are remarkably improved.

Owner:BEIJING YUANSHEN ENERGY SAVING TECH

Flue gas waste heat recovery method and system for oil and gas boiler

InactiveCN101398181AReduce the burden onTo achieve the purpose of pre-coolingLighting and heating apparatusCombustion technology mitigationRecovery methodFlue gas

The invention discloses a recycling method and a system for the afterheat of the smoke gas of oil and natural gas boilers. The method comprises the steps as follows: the smoke gas with high temperature is pre-sprayed and cooled in the inlet pipe seat of the smoke gas with high temperature through a nozzle before entering the main cylinder of an afterheat recycling device; the smoke gas with high temperature after being pre-sprayed and cooled is led to enter into the main cylinder along the tangent direction of the main cylinder, rotate and float upwards in the main cylinder; the smoke gas with high temperature which rises in a rotating way is mainly sprayed and cooled in the middle upper part of the main cylinder through the nozzle; the smoke gas with high temperature flows out of the main cylinder from the upper part of the main cylinder after conversely contacting and changing heat with spraying water fog. In the invention, pre-spraying and cooling are adopted to lead the smoke gas with high temperature to be directly contacted and mixed and change heat with the spraying and cooling water fog when the smoke gas with high temperature passes through a smoke gas inlet; on one hand, the burden of a mist trap can be reduced; on the other hand, the burden of heat and mass exchange of the main cylinder can be reduced, thus leading the volume of the main cylinder to be smaller and the structure of the main cylinder to be more compact.

Owner:GUANGZHOU DESHANG ENERGY TECH

Methods and apparatuses for heating, concentrating and evaporating fluid

InactiveUS8371251B2Steam generation using mechanical energyAir-treating devicesWater brakeClosed loop

Systems and methods are provided for heating a fluid comprising an opened-loop heating circuit or a closed-loop heating circuit both comprising a rotary heating device, such as a water brake, and a closed-loop direct-fired boiler heating circuit; and systems and methods for evaporating a fluid and systems and methods for concentrating a fluid based on these heating circuits.

Owner:PHOENIX CALIENTE INC

Flameless boiler

InactiveUS7637232B2Heat recoverySaving weightSteam generation using mechanical energyAir-treating devicesEngineeringGenerators (Apparatus)

A flameless boiler comprising generator means for generating heat in fluid circulated therethrough by shearing of the fluid; a prime mover drivingly connected to the generator means for shearing of the fluid; a supply reservoir for the fluid; a first pump for circulating the fluid from the supply reservoir to the generator means; and a pressure vessel in fluid communication with the generator means for receiving heated fluid therefrom, the pressure vessel having an outlet for drawing steam therefrom.

Owner:LEADER ENERGY SERVICES

Exhaust heat recovery apparatus

InactiveUS20090013686A1Reduce outputIncrease flexibilityInternal combustion piston enginesExhaust apparatusThermal energyExternal combustion engine

An exhaust heat recovery apparatus includes a reciprocating internal combustion engine in which a piston reciprocates in a cylinder to generate motive power; and a Stirling engine that recovers the thermal energy of the exhaust gas discharged from the internal combustion engine and converts the thermal energy into kinetic energy. The Stirling engine is united with the internal combustion engine. A heater that the Stirling engine includes is disposed in an exhaust manifold of the internal combustion engine. With this configuration, it is possible to restrict reduction in the power output from the exhaust heat recovery means.

Owner:TOYOTA JIDOSHA KK

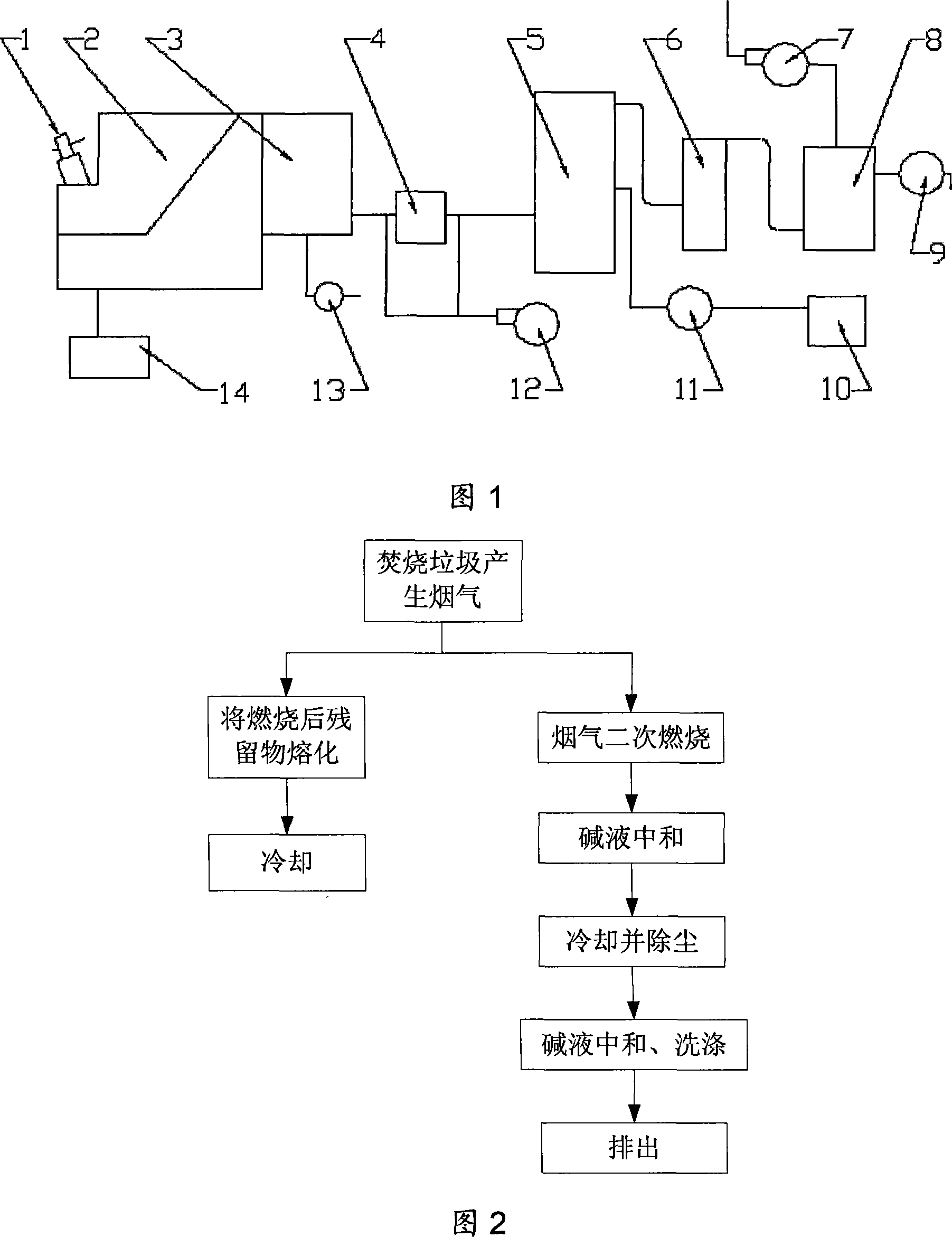

Plasma medical refuse burning methods

ActiveCN101178181ALower manufacturing requirementsProduction controlDispersed particle separationCombustion technology mitigationCombustion chamberMedical waste

The invention relates to a plasma medical waste incineration method, comprising the steps that:(1) the inside temperature of an incinerator is heated to more than 1100 DEG C through plasmas, and the medical wastes are incinerated inside the incinerator; the oxygen content inside the incinerator is controlled to be less than 0.09 percent; and the burned residue is continuously heated till melted inside a melt chamber in the incinerator, and the molten slag flows into a slag separator and are cooled while the smokes generated by burning enter a secondary burning chamber;(2) the generated smokes are burned secondarily at 1150 to 1250 DEG C, and the external oxygen supplied for the secondary burning chamber is controlled so that the oxygen content inside the secondary burning chamber is controlled to be more than 10 percent;(3) the smokes produced by the secondary burning is reacted with the sprayed alkali liquor at an outlet of the secondary burning chamber, so that the part of CL, I and S elements inside the smokes can be fixed in a slat mode;(4) the processed smokes are cooled, so that the temperature of the smokes can be decreased to 155 to 180 DEG C; and the cooled smokes are dedusted to obtain waste gases; (5) the waste gases are sprayed with the alkali liquor and then are discharged after being neutralized and fully washed.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

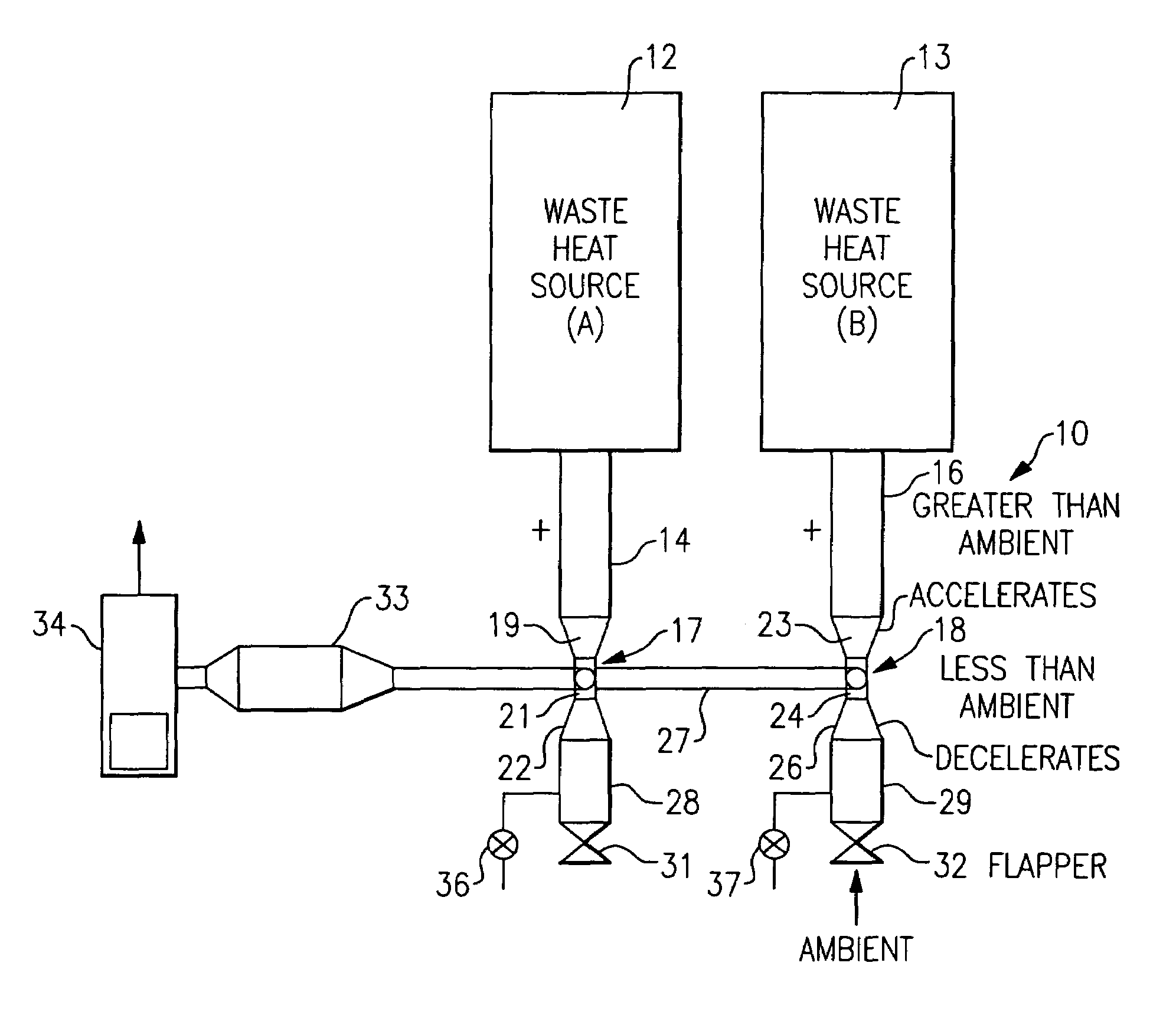

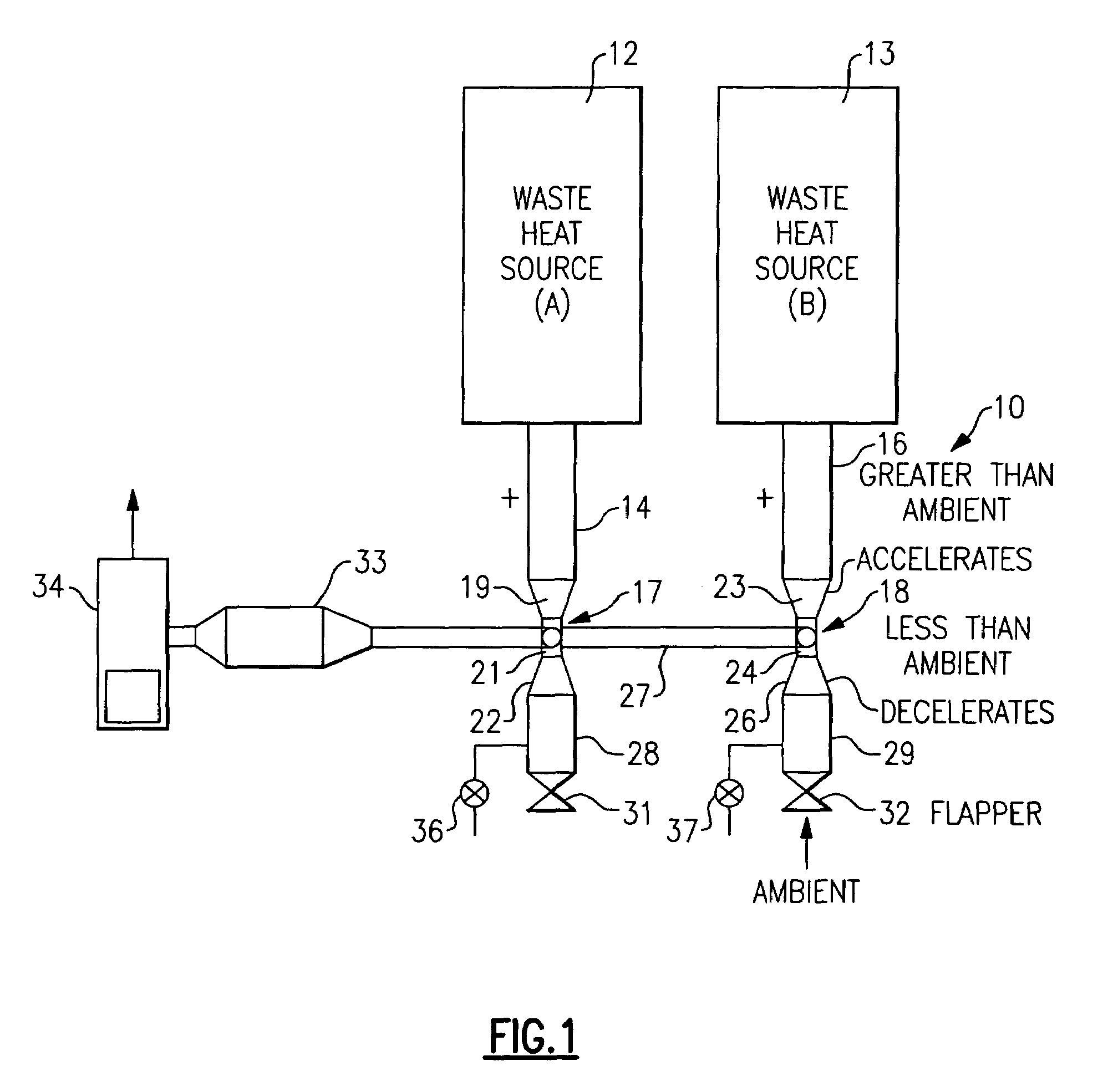

Apparatus for extracting exhaust heat from waste heat sources while preventing backflow and corrosion

InactiveUS7043912B1Reducing temperature and concentration and dewpointLiquid degasificationInternal combustion piston enginesLow speedExhaust fumes

In a waste heat recovery system wherein a heat exchanger derives heat from an engine exhaust, a venturi is fluidly connected to an engine exhaust port so as to thereby increase the flow rate and reduce the pressure in a manifold which is fluidly connected between the venturis and the heat exchanger. A fan is provided downstream of the heat exchanger to draw hot gases from the manifold, through the heat exchanger and discharge it to ambient. But when the fan is not operating during periods in which the engine is operating, the lower pressure manifold will draw ambient air in through the fan and through the heat exchanger, with the ambient air then being entrained in the exhaust gases being discharged from an exhaust channel downstream of the venturi. In one embodiment, a plurality of heat sources are provided with each having its own venturi connected to the common low pressure manifold. One or more of the plurality of waste heat source may be nonoperative or operating at a lower speed, but because of the low pressure manifold, the hot gases from the operative / higher speed waste heat source will not flow to the nonoperative or slower running waste heat source. Check valves are provided to allow the discharge of hot gases to ambient from the exhaust channels but not allow the flow of ambient air into the exhaust channels. A bypass valve is provided to selectively allow for the flow of ambient air into the exhaust channel and into the manifold for purposes of dilution during periods in which the fan is in operation.

Owner:UNITED TECH CORP

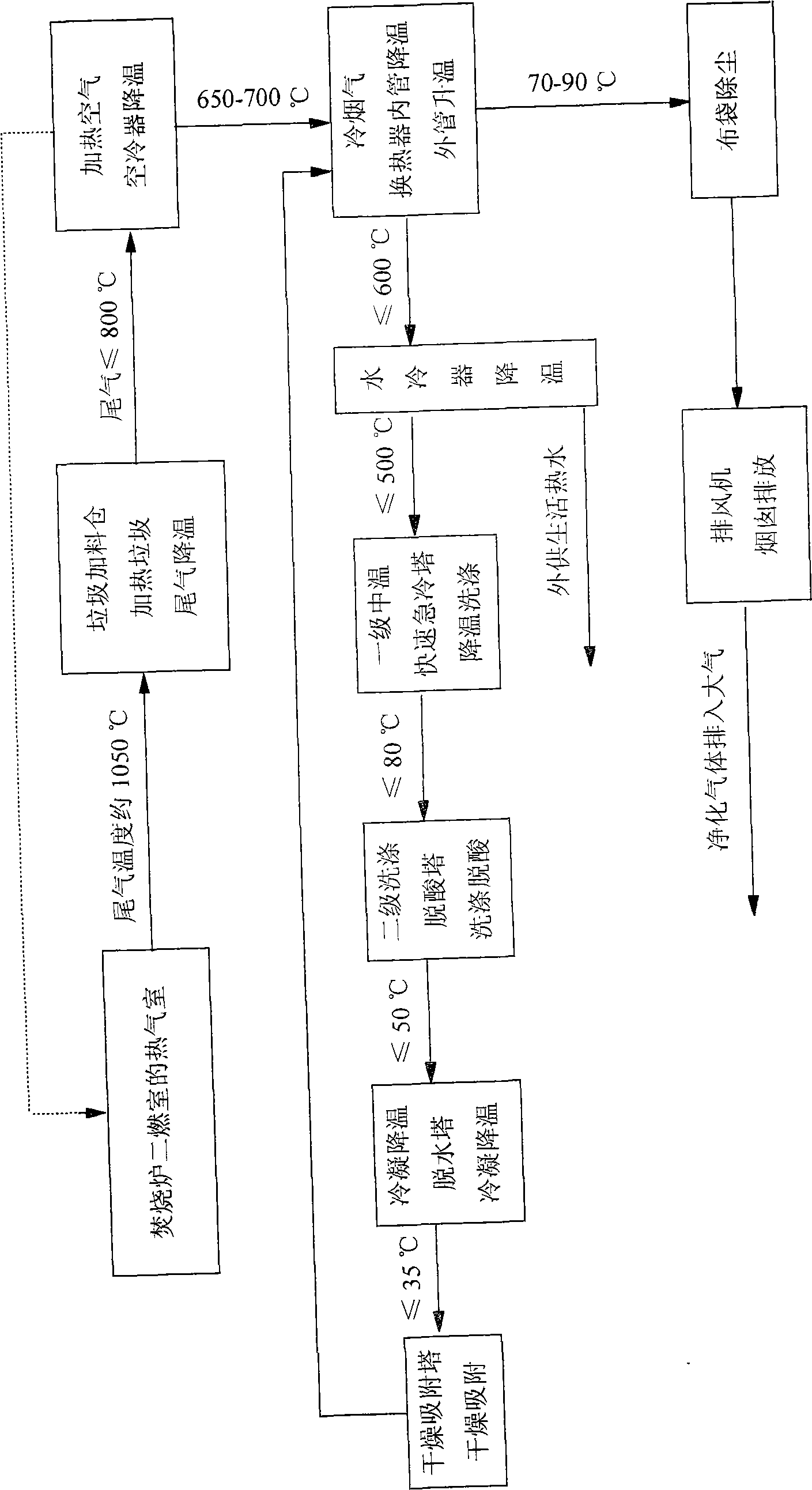

Process technique for incineration tail gas of medical waste, hazardous waste and consumer waste

InactiveCN101498455AControl secondary synthesisEfficient dryingLighting and heating apparatusCombustion technology mitigationCombustion chamberHeat exchanger

The invention relates to the technical field of environment protection, in particular to a process for treating the incineration tail gas of medical waste, dangerous waste and domestic garbage. The process flow comprises the following steps: (1) firstly cooling tail gas discharged from ht-air chambers of two combustion chambers of an incinerator to 650-700 DEG C by an air cooler; (2) cooling the tail gas to not higher than 600 DEG C by a cold-smoke-gas heat-exchanger; (3) cooling the tail gas to not higher than 500 DEG C by a water cooler; (4) sharply cooling the tail gas to not higher than 200 DEG C in one minute by a primary middle-temperature fast quench tower and continuously washing and cooling the cooling the tail gas to not higher than 80 DEG C through a duplex base of the fast quench tower; (5) cooling the tail gas to not higher than 50 DEG C through neutralization and absorption in a secondary washing and deacidifying tower; (6) cooling the tail gas to not higher than 35 DEG C through condensation and dehydration; (7) drying and absorbing the cooling the tail gas at low temperature; (8) backing to the cold-smoke-gas heat-exchanger in the step (2) to heat the tail gas to 70-90 DEG C; (8) and finally dedusting by a cloth bag; and (10) exhausting the purified tail gas by an exhaust system. The invention solves the problems of incomplete purifying treatment, failures of high-temperature neutralization reaction and high-temperature absorption, low efficiency and poor effect in the prior tail gas treatment process and is especially suitable for treating harmful incineration tail gas of medical waste, dangerous waste and domestic garbage.

Owner:HUANGSHI XIANGHE ENVIRONMENTAL PROTECTION EQUIP

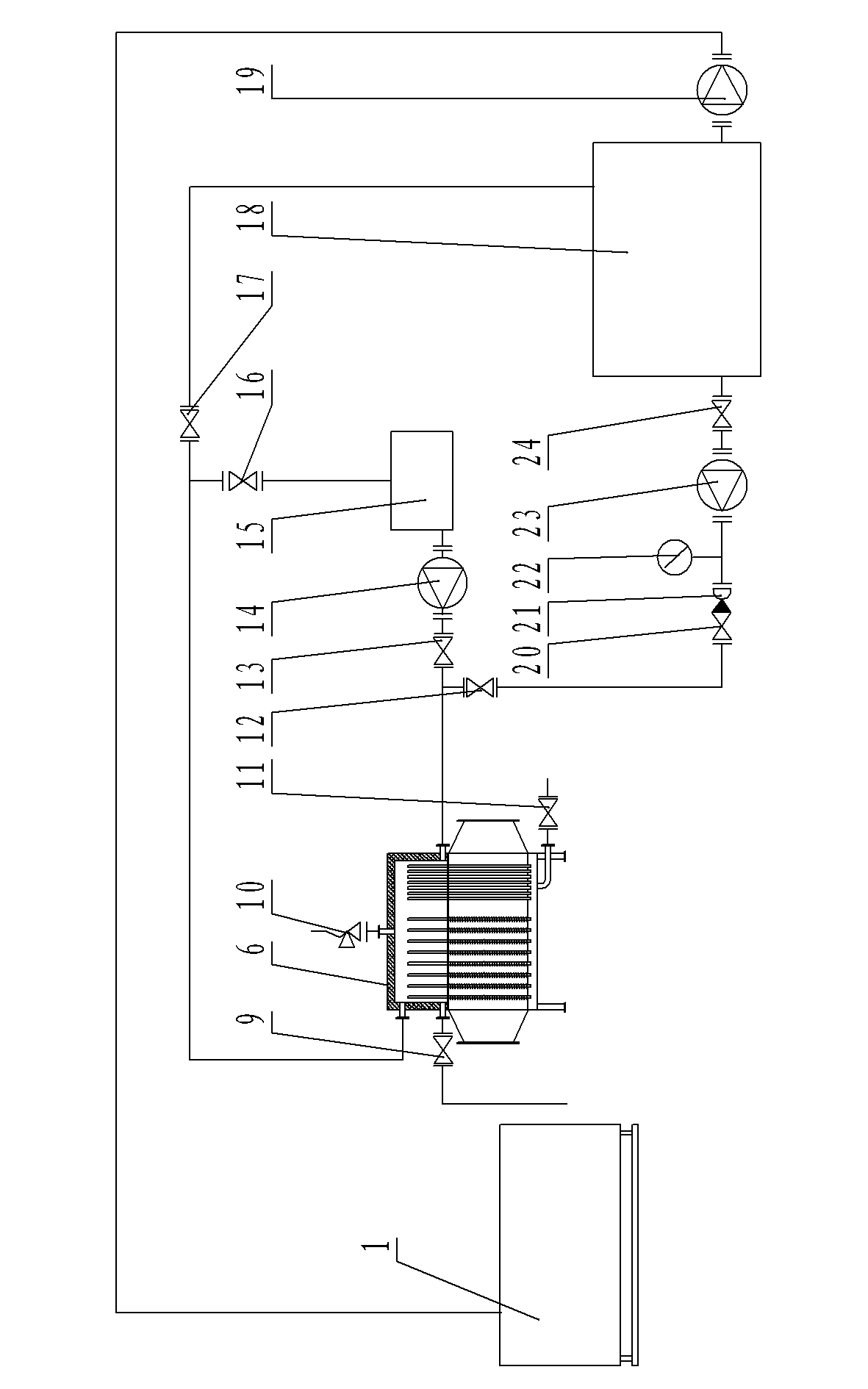

Boiler flue gas pollution discharge and waste heat recovery heat pump heating system and application method thereof

ActiveCN103225834AImprove waste heat recovery rateReduce the temperatureHeat recovery systemsLighting and heating apparatusAtmospheric airHazardous substance

The invention discloses a boiler flue gas pollution discharge and waste heat recovery heat pump heating system and an application method thereof. The boiler flue gas pollution discharge and waste heat recovery heat pump heating system is characterized in that a boiler is a gas-fired boiler, and the boiler flue gas pollution discharge and waste heat recovery heat pump heating system comprises a main flue, a chimney, a flue gas waste heat recovery device, a hot water box and a high-temperature heat pump unit, wherein one end of the main flue is connected with the gas-fired boiler, the other end of the main flue is connected with the chimney, the main flue is also provided with a bypass flue, the main flue is communicated with the flue gas waste heat recovery device through the bypass flue, and the main flue and the bypass flue are both provided with changing-over valves. The boiler flue gas pollution discharge and waste heat recovery heat pump heating system disclosed by the invention has the advantages that the structure is simple and reasonable, the flue gas waste heat recovery ratio is high, and the overhaul and maintenance are convenient through changing over the valves; due to the condensation action, the hazardous substance discharged to the atmosphere is also greatly reduced, the waste heat is recycled, the flue gas temperature is reduced, and a greenhouse effect is reduced, meanwhile, the hazardous gas discharged by the gas-fired boiler to the atmosphere is reduced, and the environment is protected.

Owner:QINGDAO HONGYU ENVIRONMENTAL PROTECTION AIR CONDITIONING EQUIP

Desulfuration dust-collection white-elimination deep purification device

PendingCN108465368ASolve the problem of high water consumptionLow running costGas treatmentLighting and heating apparatusFlue gasSlurry

The invention belongs to the technical field of atmosphere pollution treatment environment protection, in particular relates to a desulfuration dust-collection white-elimination deep purification device, and aims to solve the problems that large floor spaces are required and the operation cost is high since a common process in the market is a condensation-reheating process, that is, a flue gas cooler, an air cooler and a flue gas heater are arranged outside a tower. According to the technical scheme of the invention, the device comprises an absorption tower body, wherein a flue gas inlet and aflue gas outlet are formed in the upper end of the absorption tower body; the flue gas inlet is positioned lower than the flue gas outlet; the absorption tower body is provided with a demister, a condensed water spraying layer, a liquid collection layer, a slurry spraying layer and a slurry pool from top to bottom in sequence; the liquid collection layer comprises a liquid collection plate and aliquid collection disc which is arranged below the liquid collection plate; a flue gas inlet pipeline is further arranged on one side outside the absorption tower body; one end of a flue gas inlet pipeline is parallel to the flue gas inlet; the other end of the flue gas inlet pipeline extends between the slurry spraying layer and the slurry pool; a heat exchanger is arranged at the communicating part of the flue gas inlet and the flue gas inlet pipeline.

Owner:XIAN XIKUANG ENVIRONMENTAL PROTECTION

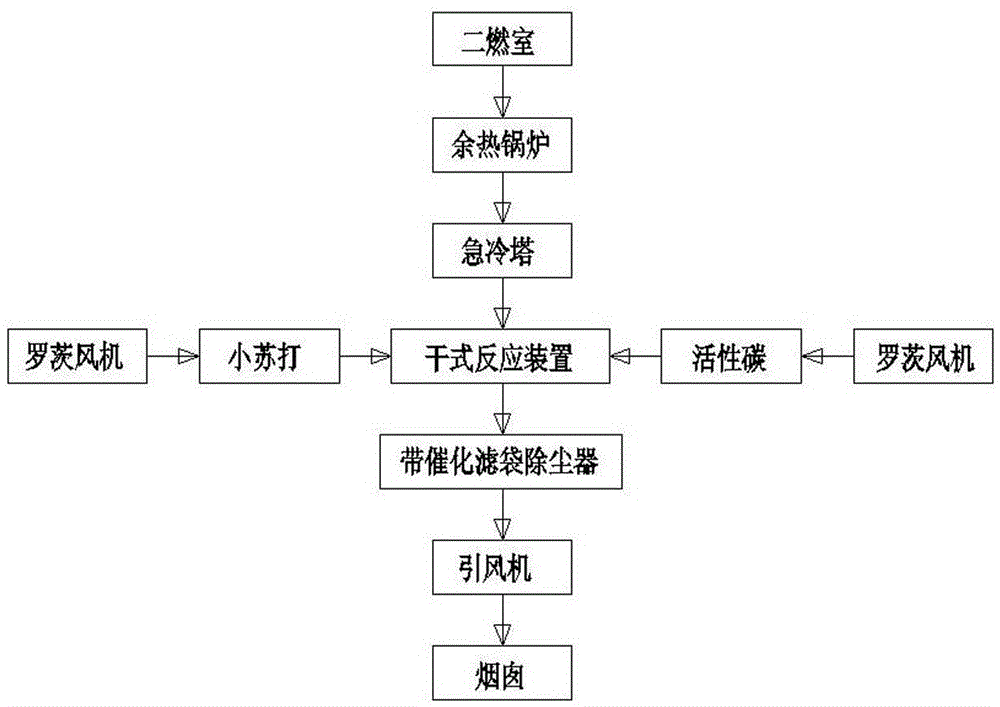

Ultra-clean treatment method for incinerated tail gas

InactiveCN105627335ALow powerSmall running resistanceDispersed particle separationCombustion technology mitigationCombustion chamberAtmospheric air

The invention discloses an ultra-clean treatment method for incinerated tail gas. The ultra-clean treatment method is characterized by sequentially comprising the steps that the tail gas continues to be combusted through a secondary combustion chamber; heat recovery is conducted on the tail gas through a waste heat boiler; the tail gas is cooled through a quench tower; baking soda powder and active carbon powder are sprayed into the tail gas exhausted out of the quench tower, and the tail gas, the baking soda powder and the active carbon powder are mixed and fed into a dust remover provided with a catalytic filtering bag to remove heavy metal and dioxin in the tail gas; and the qualified tail gas with the acid gas being removed is exhausted into the atmosphere through an induced draft fan and a chimney. The ultra-clean processing method is simple in technique. By treating and incinerating the tail gas through the method, spraying, washing and smoke reheating are not needed, the effect for removing the dioxin in the tail gas is good, fire disasters can be avoided, and the operation cost is reduced; and in addition, secondary pollution such as sewage is avoided. The ultra-clean processing method is suitable for treating the tail gas exhausted from household refuse and hazardous waste combustion furnaces.

Owner:JIANGSU QUANNENG ELECTROMECHANICAL EQUIP ENG LTD BY SHARE LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com