Smoke cooling, condensing, dehumidifying, pollution removing, reheating and white eliminating system and method

A flue gas condensation and flue gas cooling technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of high construction and operation costs of whitening systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

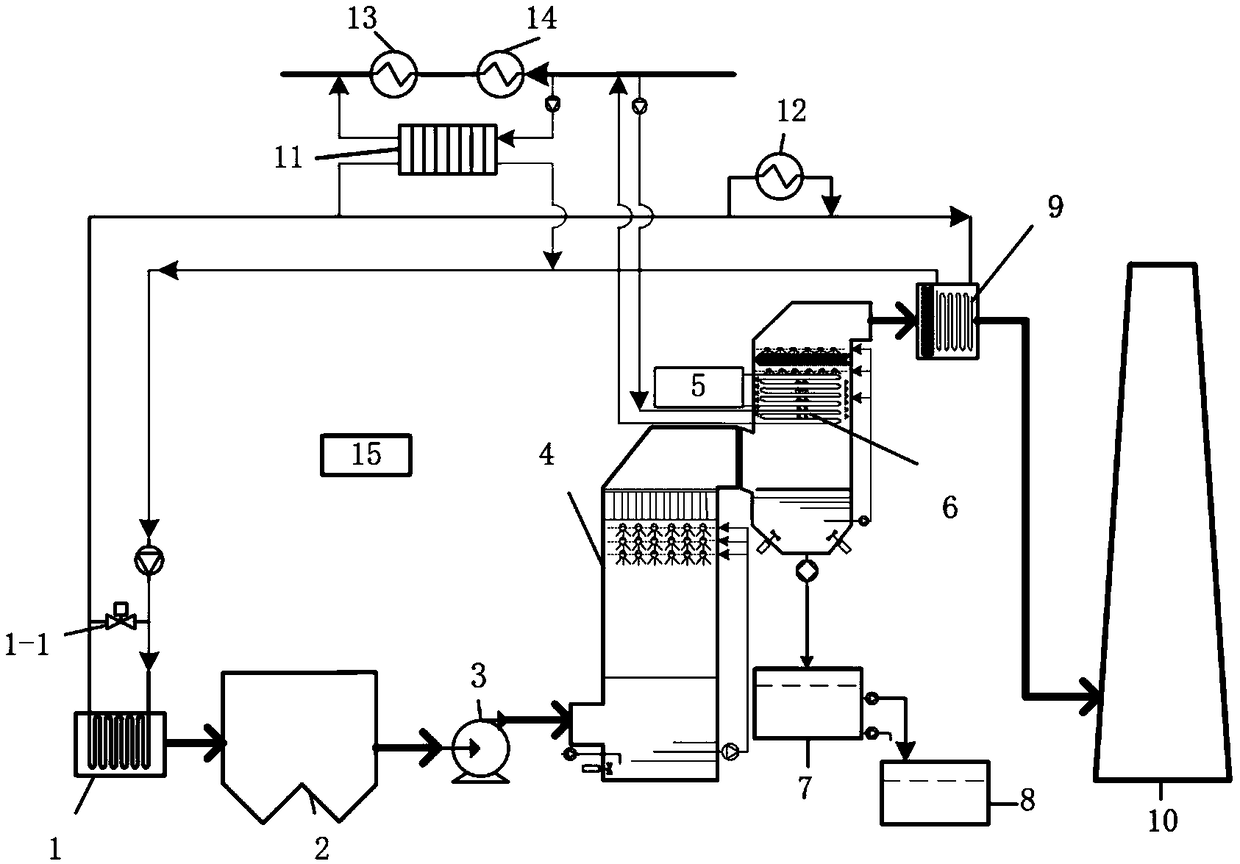

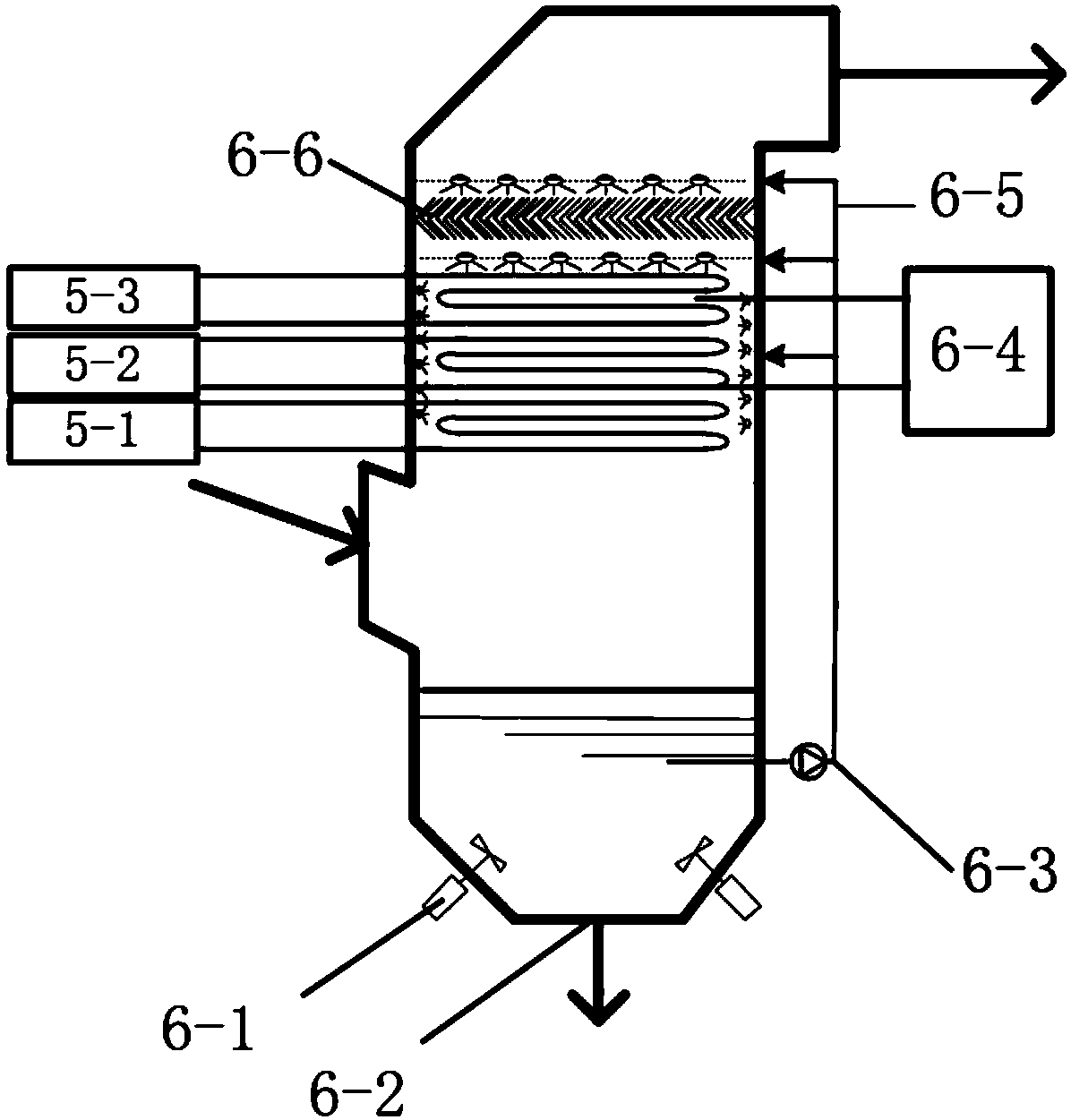

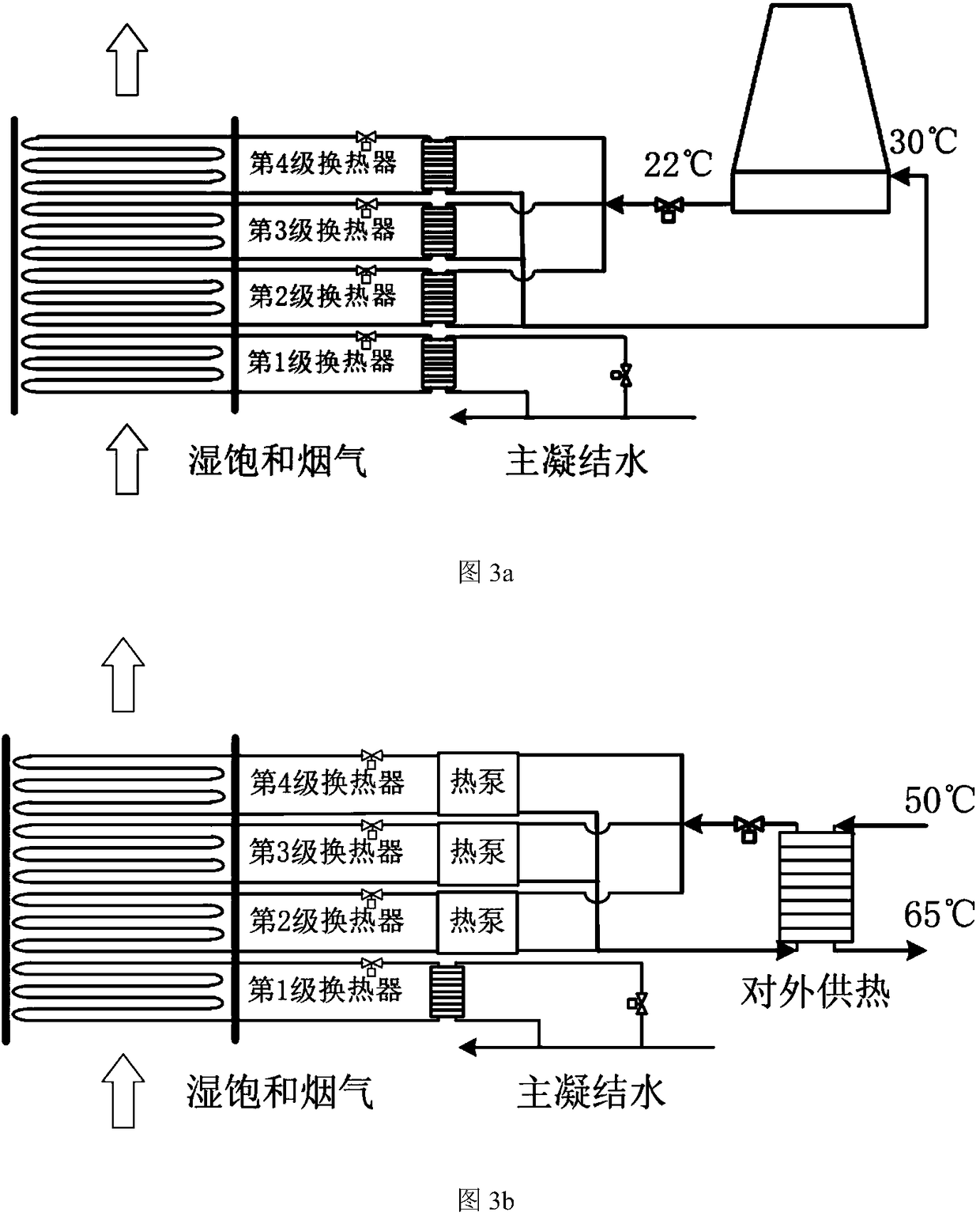

[0040] Such as figure 1 As shown, a flue gas cooling, condensation, dehumidification, decontamination, decontamination, reheating and whitening system of the present invention includes a flue gas deep cooler 1, an electrostatic precipitator 2, an induced draft fan 3, a desulfurization tower 4, a cold source 5, and flue gas condensation heat exchange 6, sedimentation tank 7, desulfurization process water tank 8, flue gas reheater 9, chimney 10, condensate heater 11, auxiliary heat heater 12, No. ;The exhaust gas from the boiler body first enters the flue gas deep cooler 1, recovers the waste heat of the flue gas at 150°C to 90°C in the flue gas, and uses it to heat the main condensate 5-1 and reheat the flue gas; the flue gas then enters the electrostatic precipitator in turn 2, induced draft fan 3, desulfurization tower 4; the wet saturated flue gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com