Patents

Literature

363 results about "Flue-gas condensation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flue gas condensation is a process, where flue gas is cooled below its water dew point and the heat released by the resulting condensation of water is recovered as low temperature heat. Cooling of the flue gas can be performed either directly with a heat exchanger or indirectly via a condensing scrubber.

Energy supply system mainly through gas and steam combined cycle cogeneration

ActiveCN101858231AIncrease heat to power ratioAvoid transmission and distribution lossesHeat recovery systemsSteam useWater sourceCogeneration

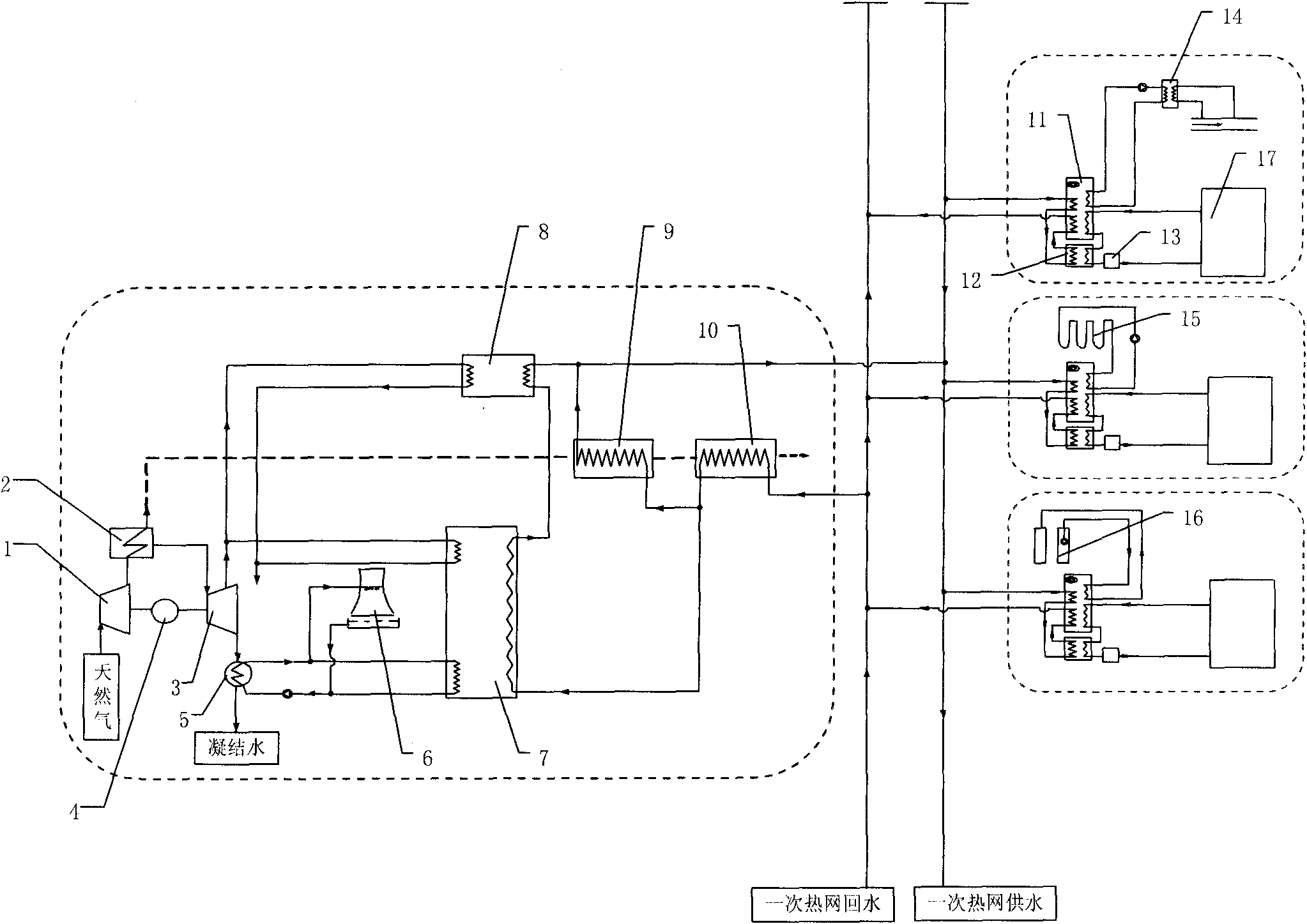

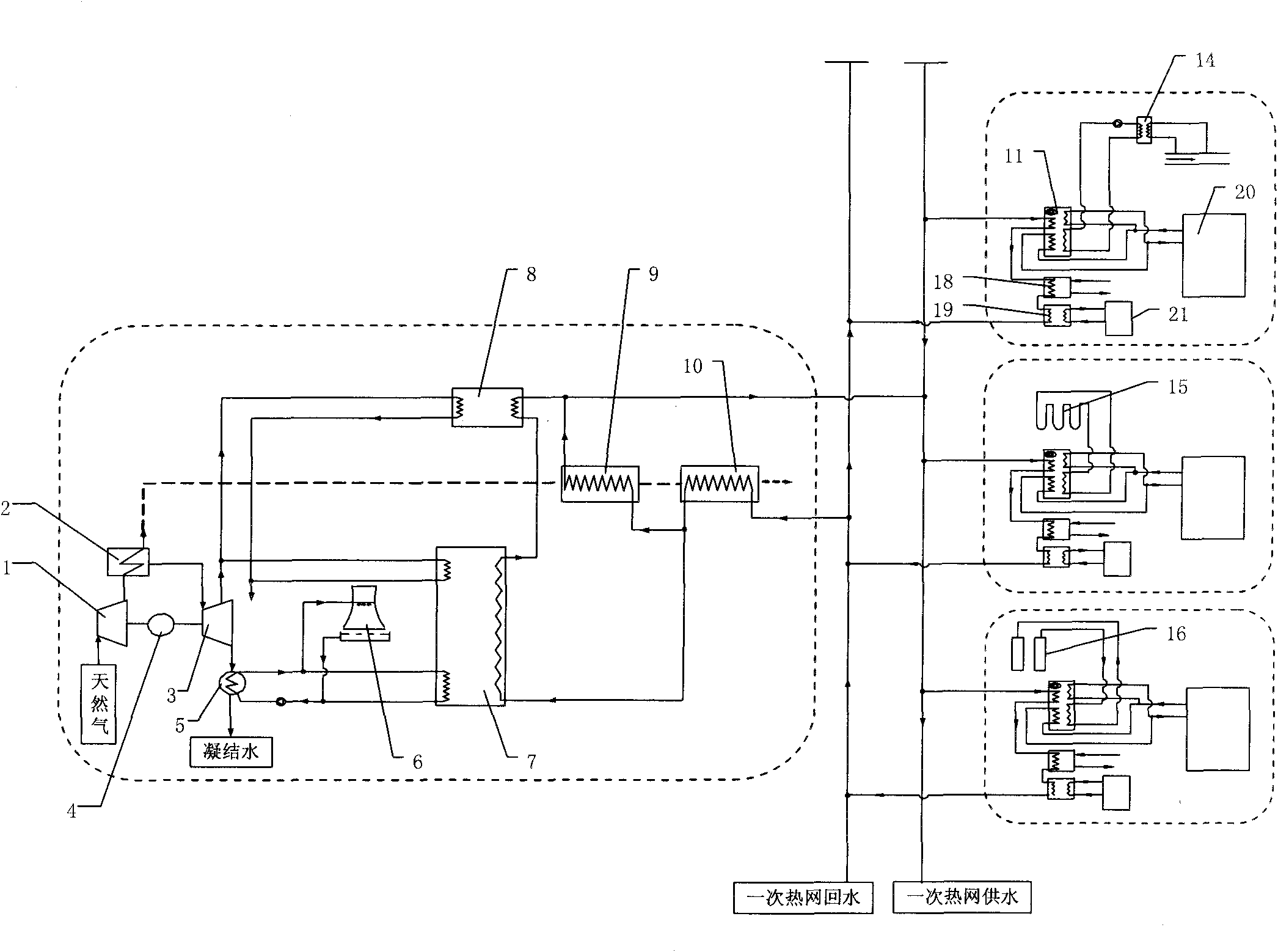

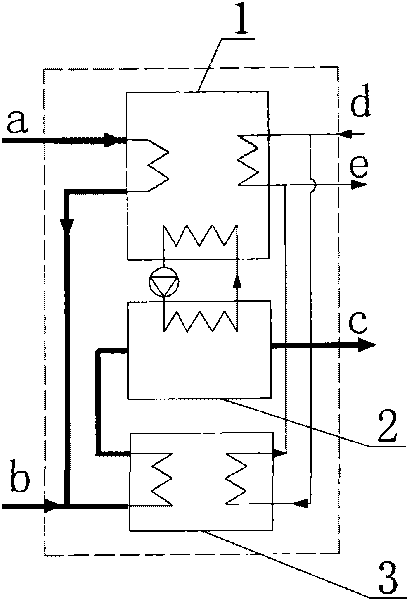

The invention relates to an energy supply system mainly through gas and steam combined cycle cogeneration, and belongs to the technical field of energy sources. The system adopts a mode of combined heating of a smoke condensing heat exchanger, a condenser, a steam absorption heat pump, a high-temperature smoke heat exchanger and a steam-water heat exchanger on a heat source side; return water of a heat supply network directly recovers low-temperature smoke condensed waste heat, high-temperature smoke waste heat or condensed steam waste heat; and simultaneously, the steam absorption heat pump driven by extracted steam is used for recovering condensed steam discharged heat or partial smoke waste heat. During heat supply in winter, a client uses a supplementary-fired hot water absorption heat pump and a water-water heat exchanger to heat secondary water in the heat supply network for heat supply and extract low-grade heat for heat supply from a superficial layer soil source, an underground water source or a geothermal water source; and in summer, the client uses the hot water absorption heat pump to refrigerate hot water in the heat supply network and a liquid desiccant air conditioner to remove humidify and preheat domestic hot water. Compared with the conventional system, the system of the invention has good economy and application prospect; and the energy utilization rate of the system is greatly improved.

Owner:TSINGHUA UNIV +1

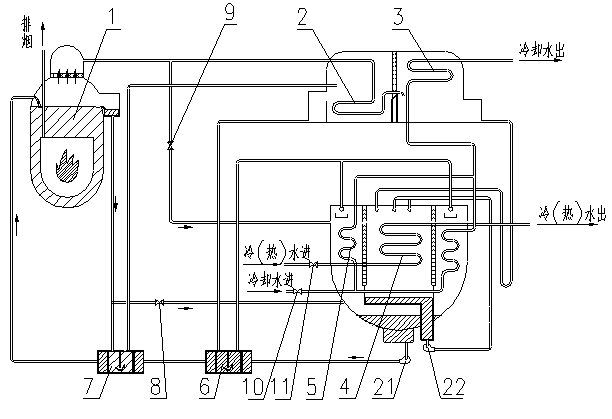

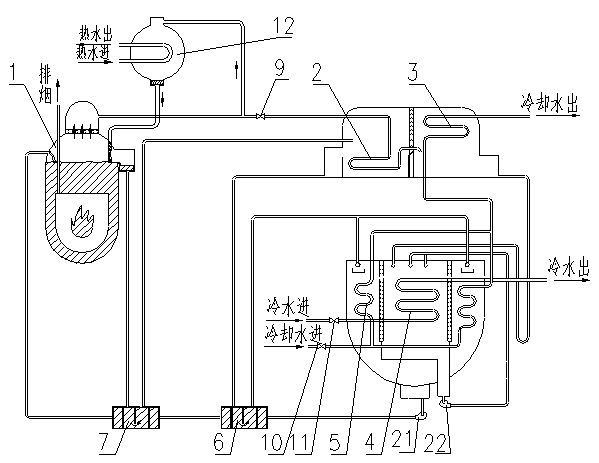

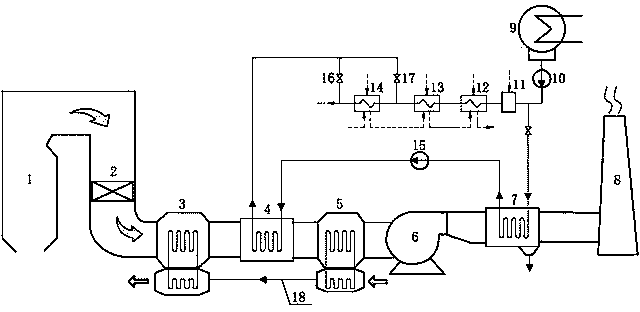

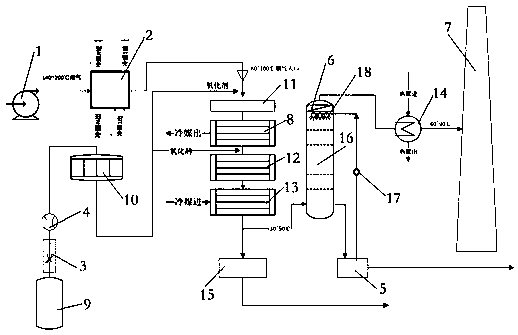

Heatpump type gas-fired boiler waste heat recovery unit

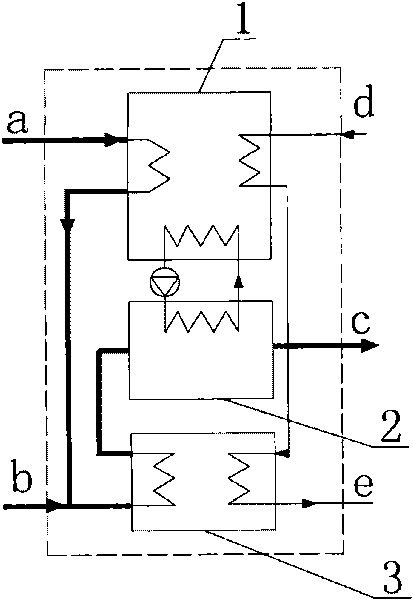

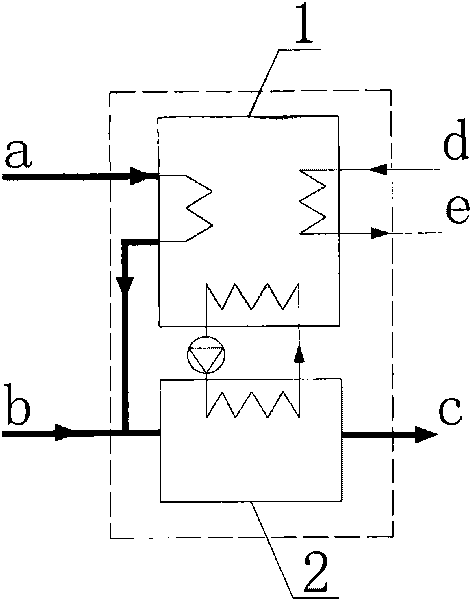

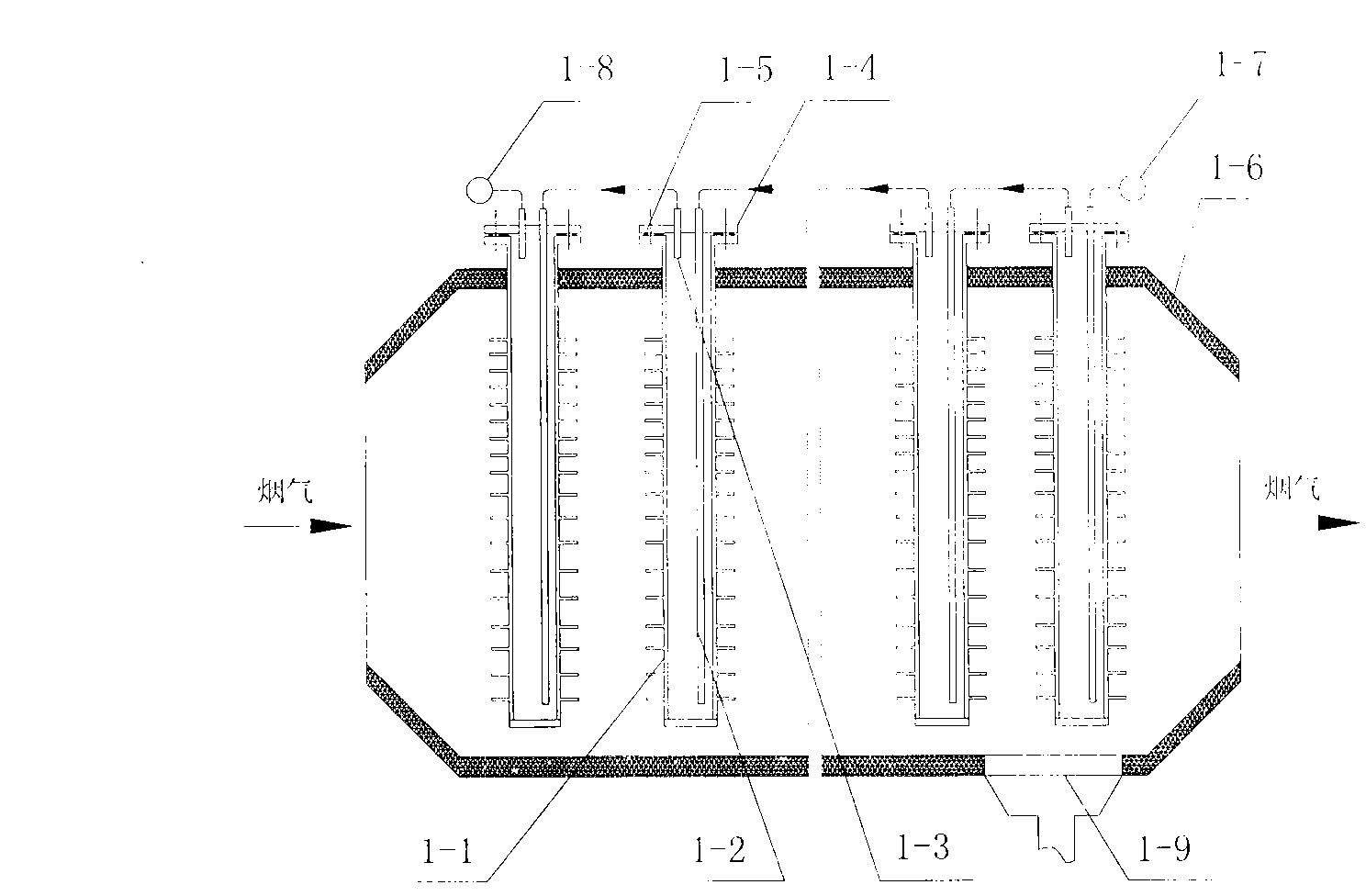

ActiveCN101726110ARealize cascade utilizationEmission reductionHeat recovery systemsClimate change adaptationEngineeringAbsorption heat pump

The invention belongs to the field of energy technology application, particularly relates to a heatpump type gas-fired boiler waste heat recovery unit. The unit comprises an absorption heat pump, a flue gas-water heat exchanger, a flue gas condensation heat exchanger, various connecting pipelines and accessories. The connecting pipelines comprise a first side pipeline, a middle water circulating pipeline and a second side pipeline. First side natural gas as a driving heat source enters a generator of the absorption heat pump and then enters the flue gas-water heat exchanger and the flue gas condensation heat exchanger with smoke exhausted by the gas fired boiler, the natural gas firstly passes through a water side circulating pipeline of the flue gas-water heat exchanger to heat second side return hot water and then exchanges heat with the generator side of the absorption heat pump to be as a low level heat source through the middle water circulating pipeline of the flue gas condensation pipeline, and the heat is transferred to a second side heating network by the absorption heat pump. The unit realizes cascade utilization for flue gas heat, greatly reduces the temperature of exhausted smoke, improves the energy utilization efficiency and is mainly used for gas-fired boiler waste heat recovery in a heating system.

Owner:TSINGHUA UNIV +1

Economizer capable of recycling waste heat of flue in depth and concealing, desulfurizing and aspirating flue of coal-fired boiler

InactiveCN102980171AGuaranteed uptimeImprove reliabilityUsing liquid separation agentTubular elementsEconomizerErosion

The invention relates to an economizer capable of recycling waste heat of flue in depth and concealing, desulfurizing and aspirating the flue of a coal-fired boiler. The economizer capable of recycling the waste heat of the flue in depth and concealing, desulfurizing and aspirating the flue of the coal-fired boiler mainly comprises heat exchanging pipes, a casing body, a concealed liquid collection opening, a water inlet linkage tank and a water outlet linkage tank. The heat exchanging pipes are made of graphite. The economizer can run far below a acid dew point temperature so as to reduce the temperature of exhausted flue to 60 DEG C or so and recycle sensible heat of the flue and vaporized latent heat of partial steam. Thus, the flue is severely congealed and forms dew and thick congealed liquid membranes are generated on the surfaces of heat exchanging pipes to absorb, suck and remove SO2 and SO3 which occupy 30%-35% of the flue and subtle particles which can not be removed by a regular dust remover and have the function of self-cleaning. The economizer capable of recycling the waste heat of the flue in depth and concealing, desulfurizing and aspirating the flue of the coal-fired boiler is simple in structure, high in heat exchanging efficiency, good in low-temperature resistance and anti-erosion performance, and obvious in reduction of energy consumption and running cost of the boiler and can be widely applied in a coal-fired industrial boiler, a coal-fired utility boiler and even in all coal-fired boilers. Efficiency of the boilers can be improved by 5% to 10 %.

Owner:陈兴元 +2

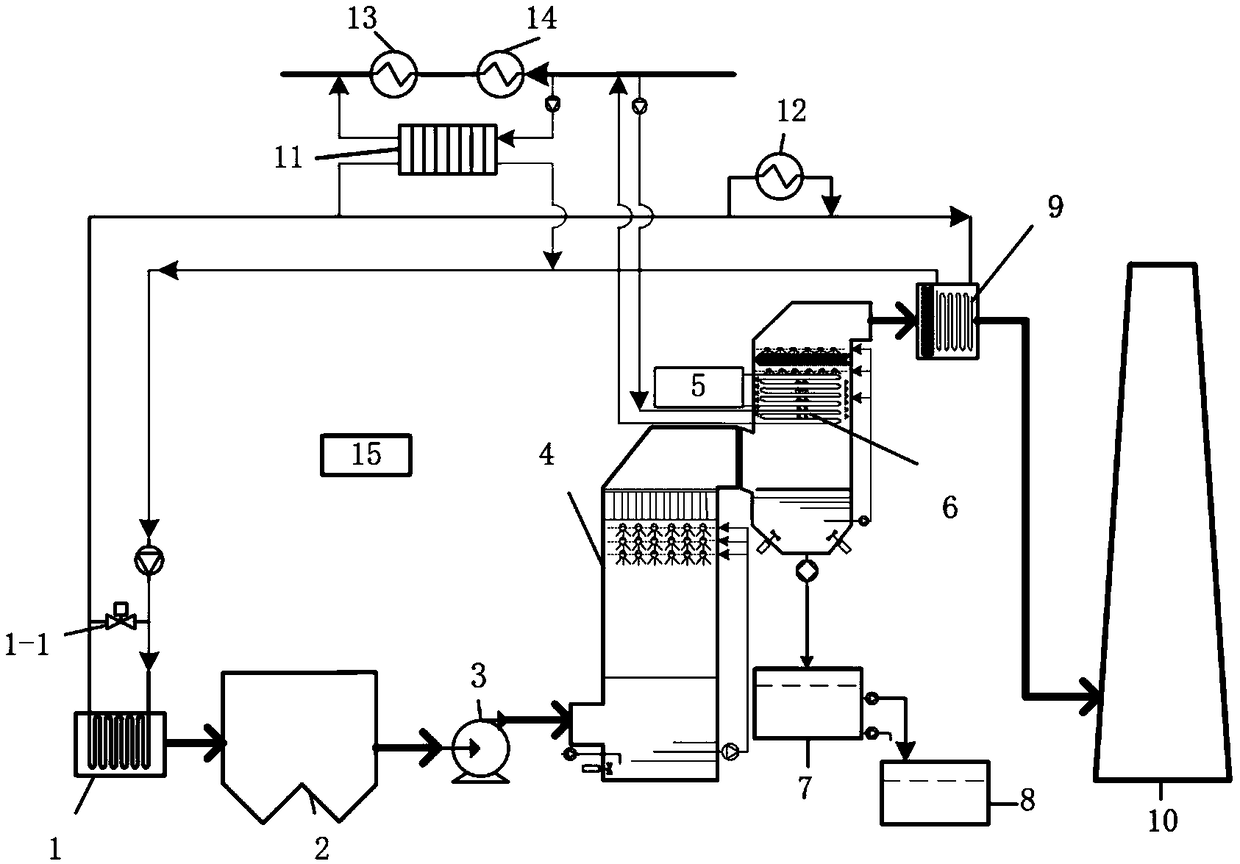

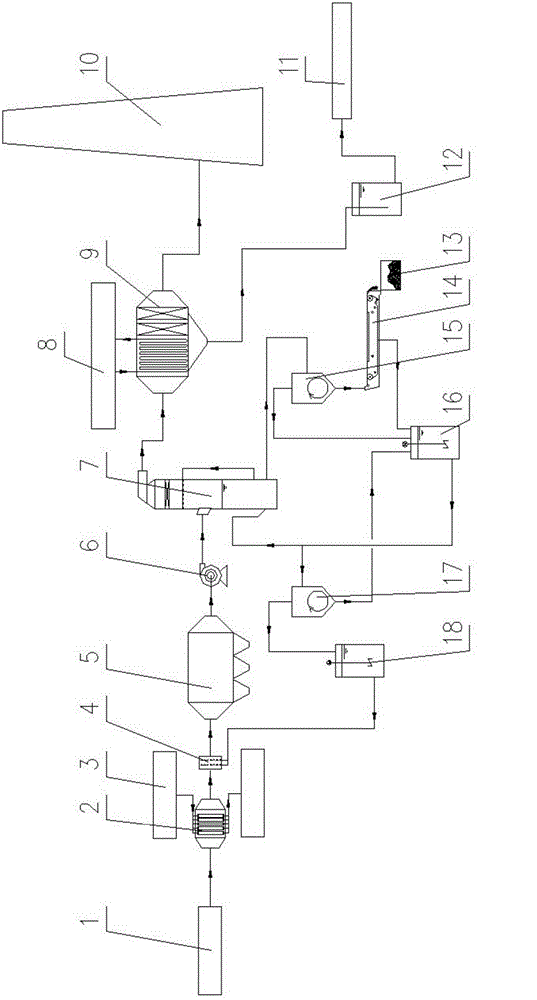

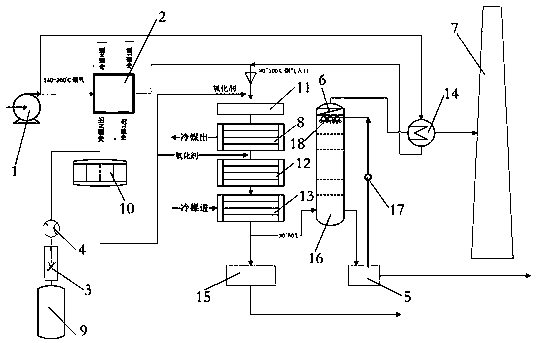

Smoke cooling, condensing, dehumidifying, pollution removing, reheating and white eliminating system and method

PendingCN109045953ALow costImprove thermal conductivityDispersed particle separationCombustion technology mitigationEngineeringTitanium alloy

The invention discloses a smoke cooling, condensing, dehumidifying, pollution removing, reheating and white eliminating system and method. The system comprises a smoke deep cooler, a smoke condensingand heat exchanging device, a smoke reheater, a cold source and the like; the smoke deep cooling process is carried out to supply a heat source for reheating smoke, so as to heat main condensing waterand decrease the smoke temperature at an outlet of a desulfurizing tower; the main condensing water can be heated in the smoke condensing process, the heat source is supplied to a heat pump, the water resource is recovered, and the water content of smoke is decreased; the relative humidity of exhausted smoke is reduced in the smoke reheating process, so that white smoke can be visibly removed. The invention further discloses a cooling, condensing, dehumidifying, pollution removing, reheating and white eliminating method. According to the system and the method, the structure of a condensing and heat exchanging device is innovated; 316L is adopted to replace fluoroplastic, titanium alloy and the like; a mechanical ventilating brine tower and an intelligent adjusting and controlling system are launched, so that the construction cost and the energy consumption of the device and a system can be decreased; the afterheat in the smoke can be recovered by steps while the white smoke is visiblyremoved; 50% or more than 50% of PM2.5, SO3 and 15% or more than 15% of NOx can be removed; and the environment protection benefit and the economic benefit are ensured.

Owner:XI AN JIAOTONG UNIV

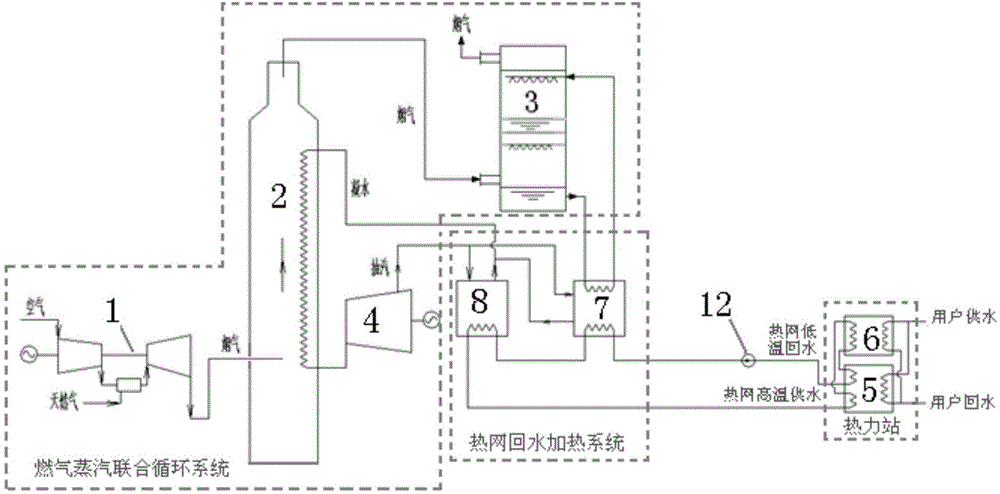

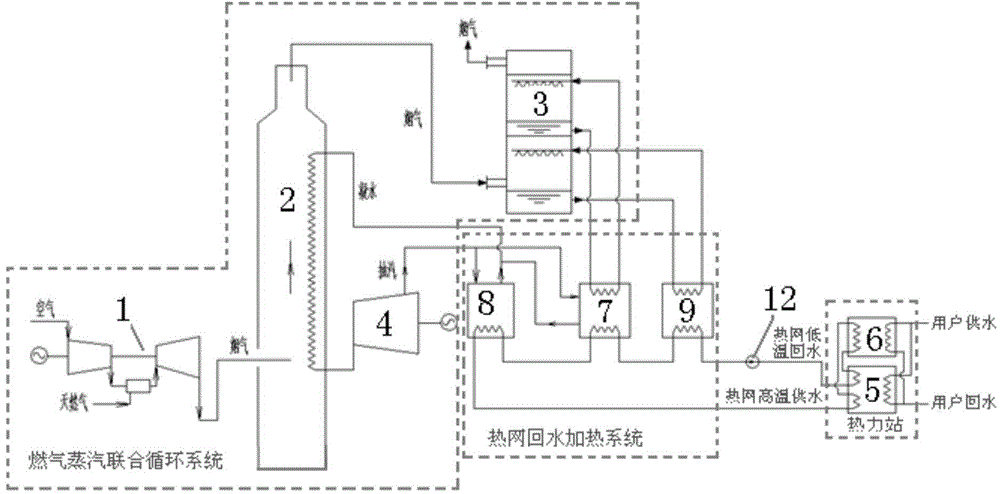

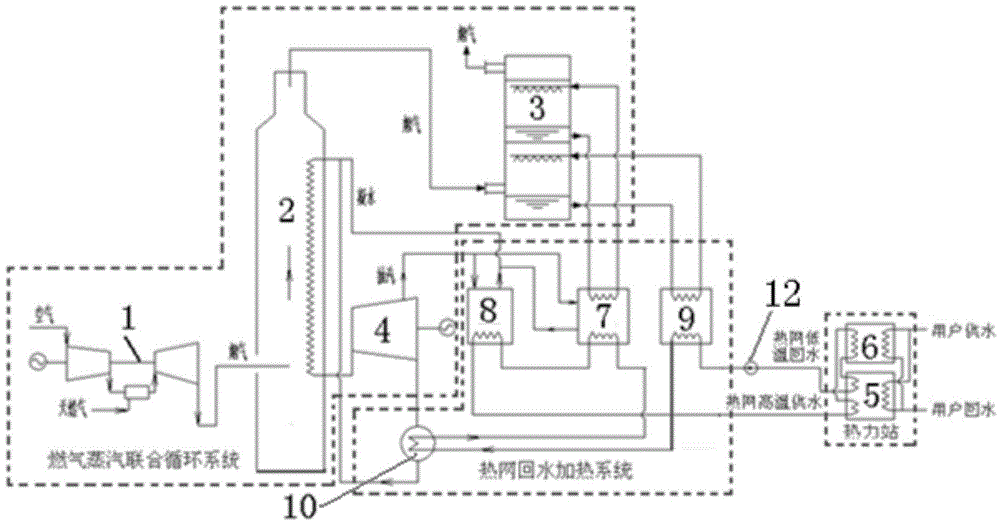

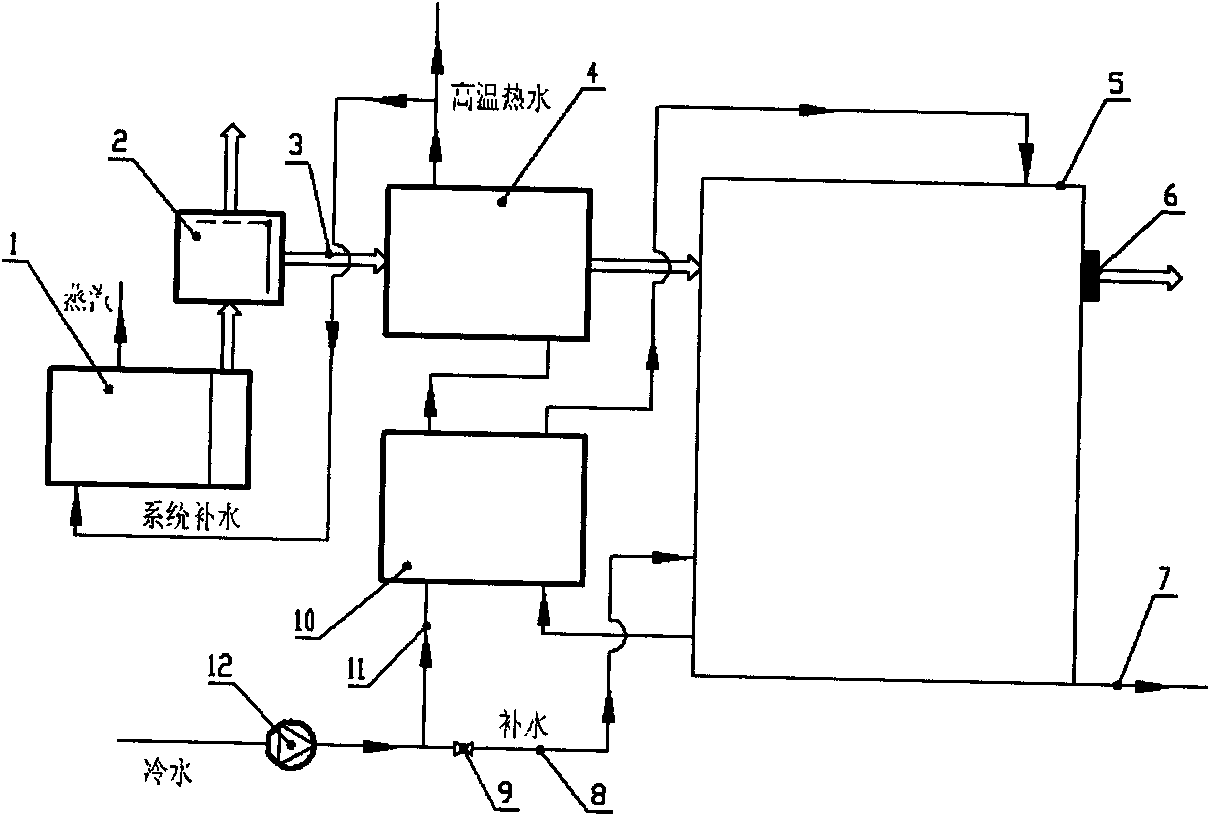

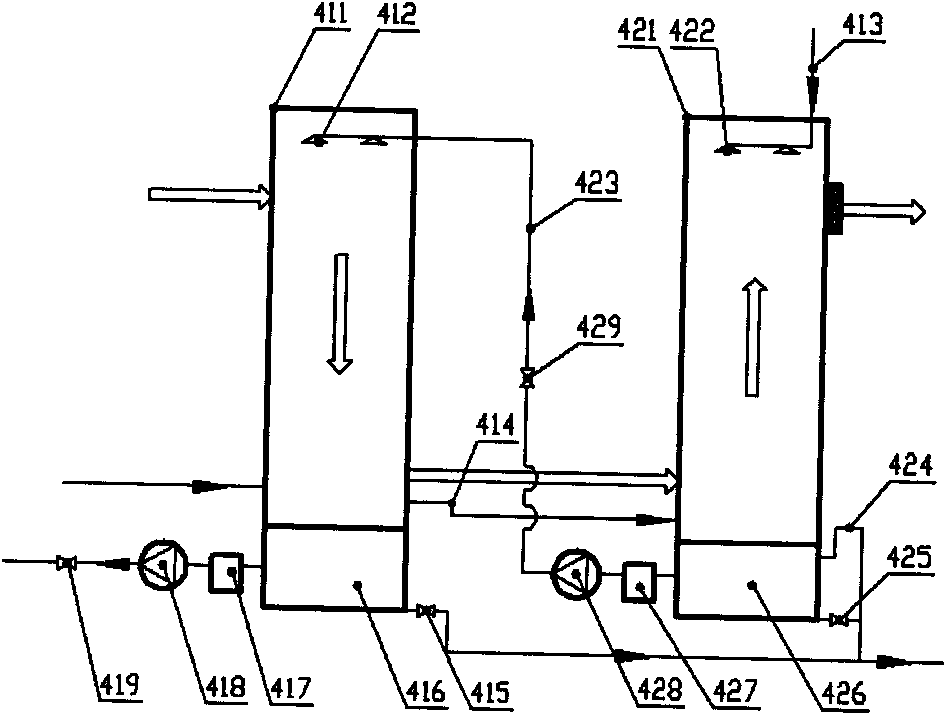

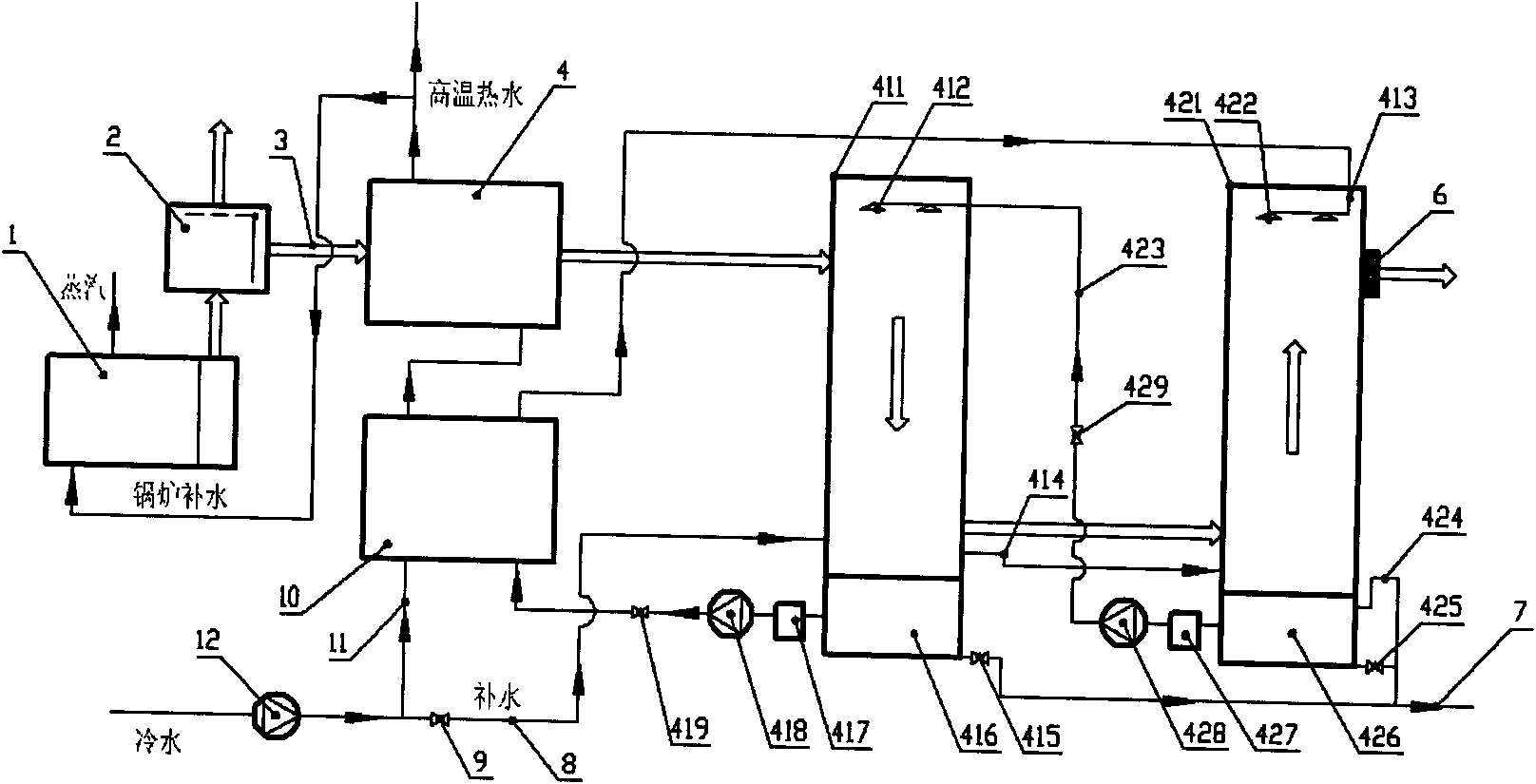

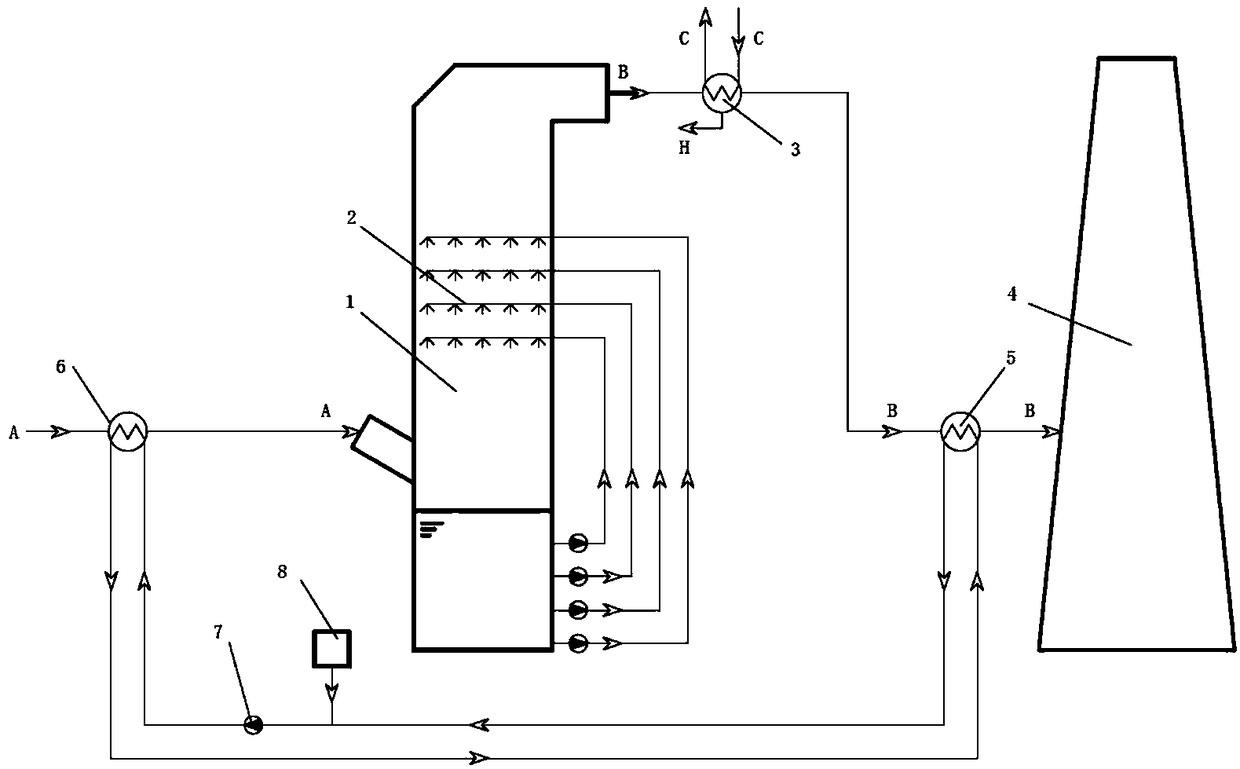

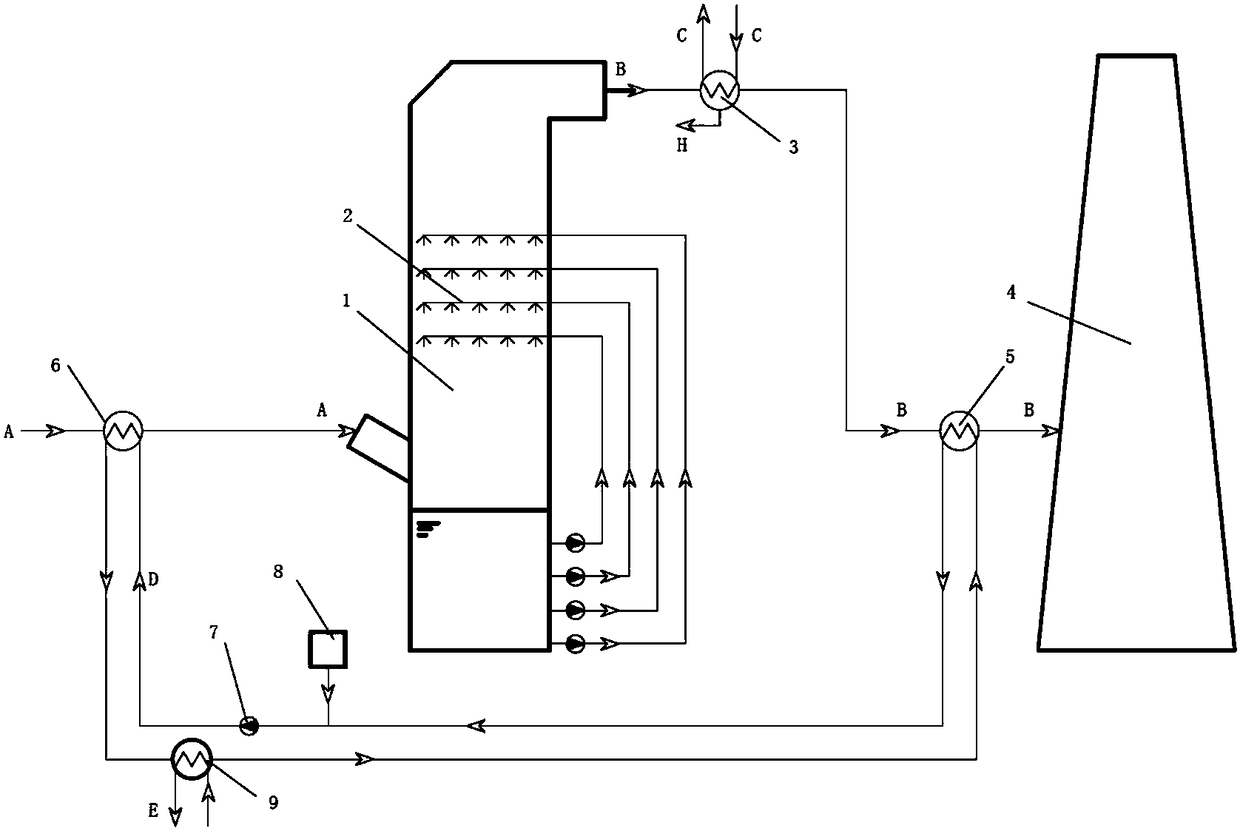

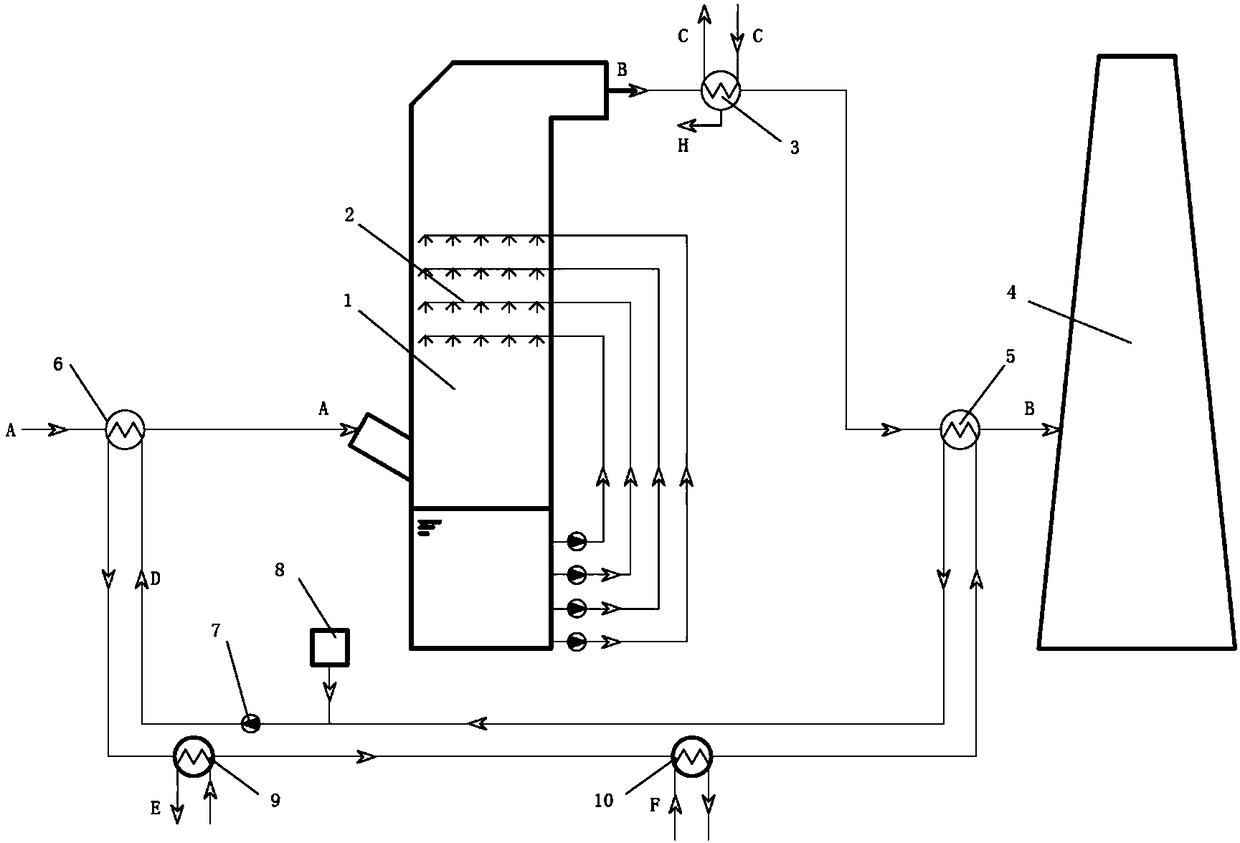

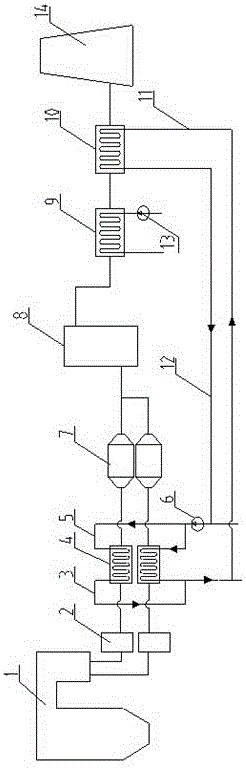

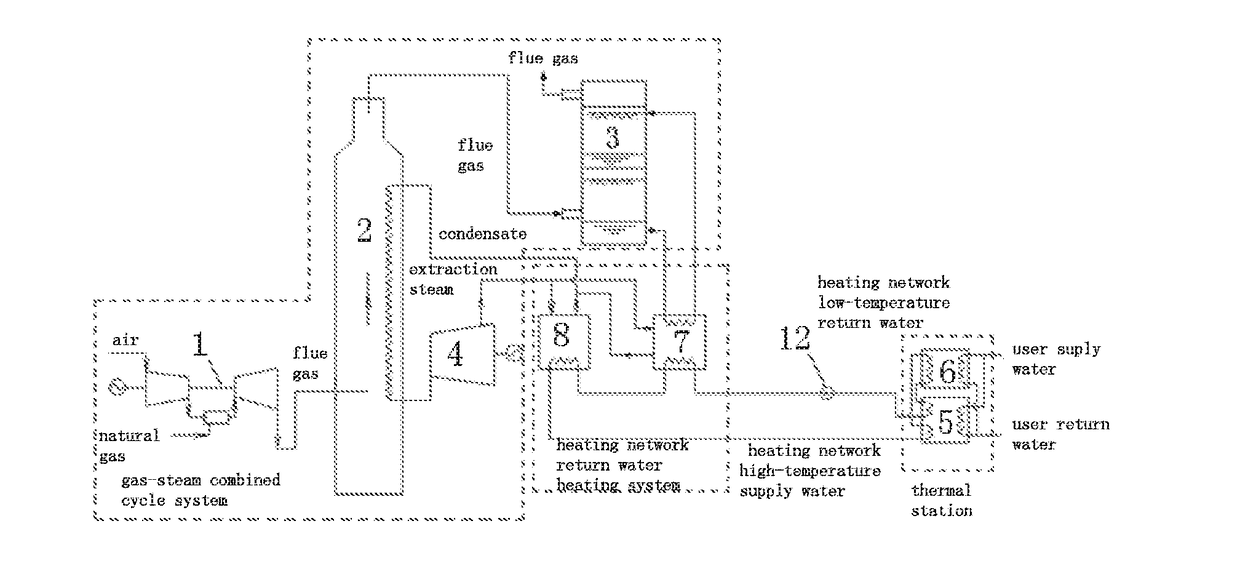

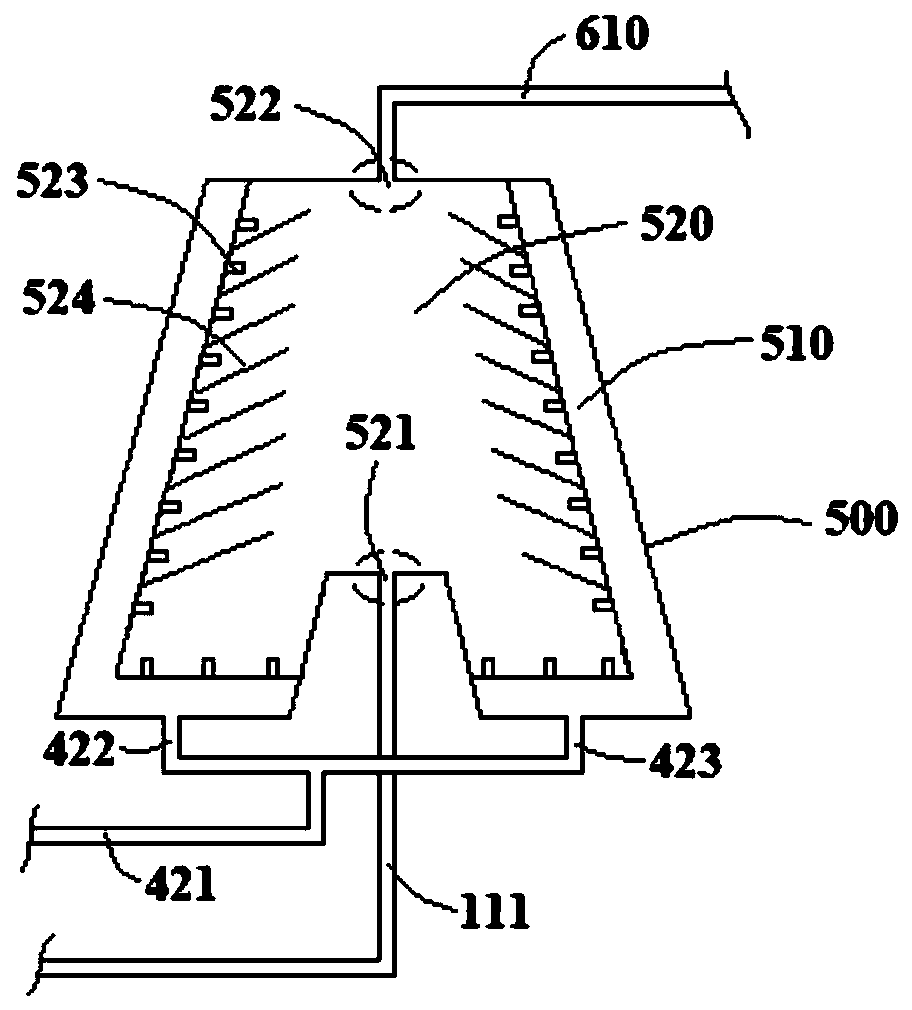

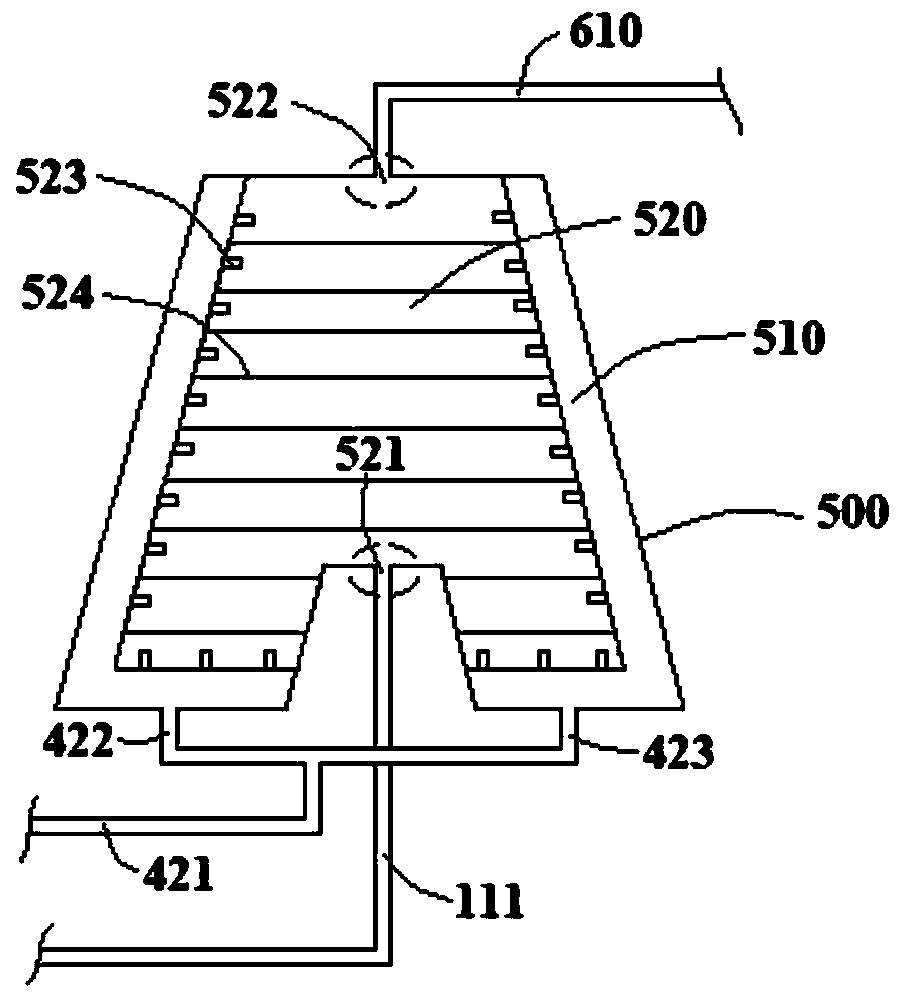

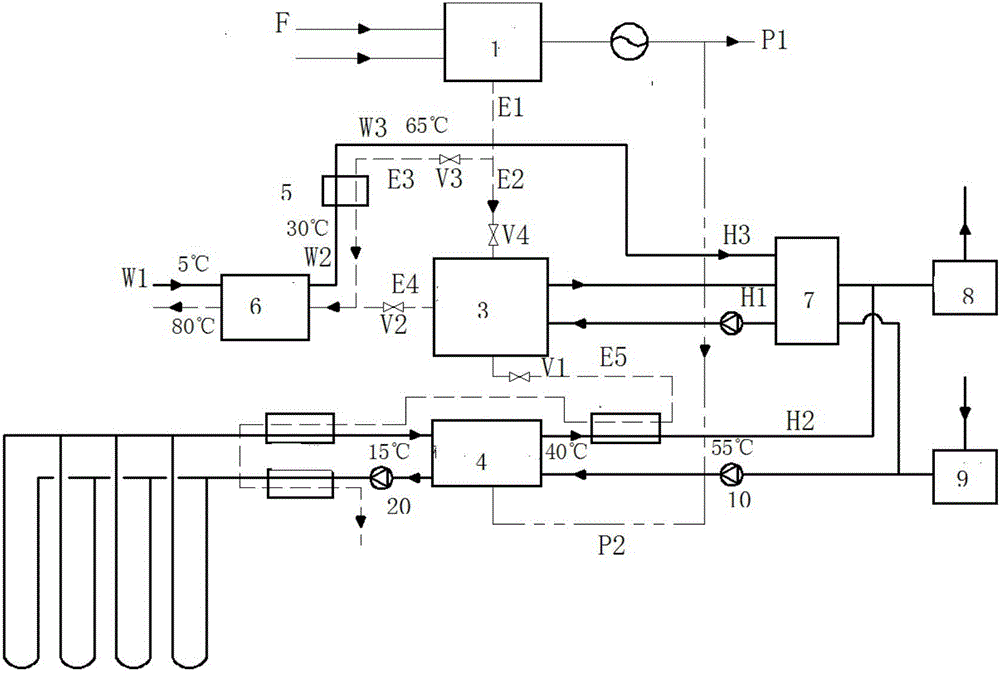

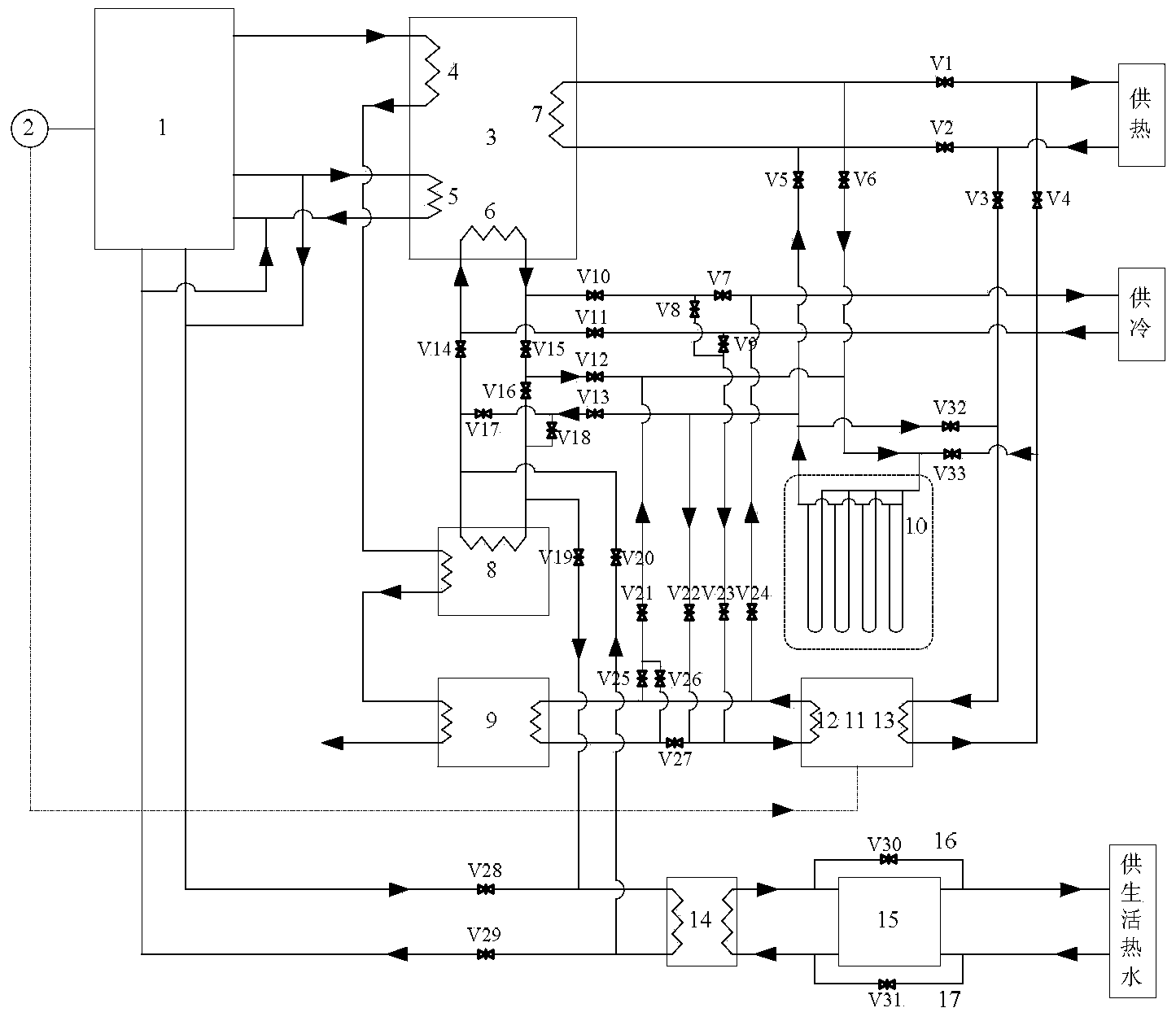

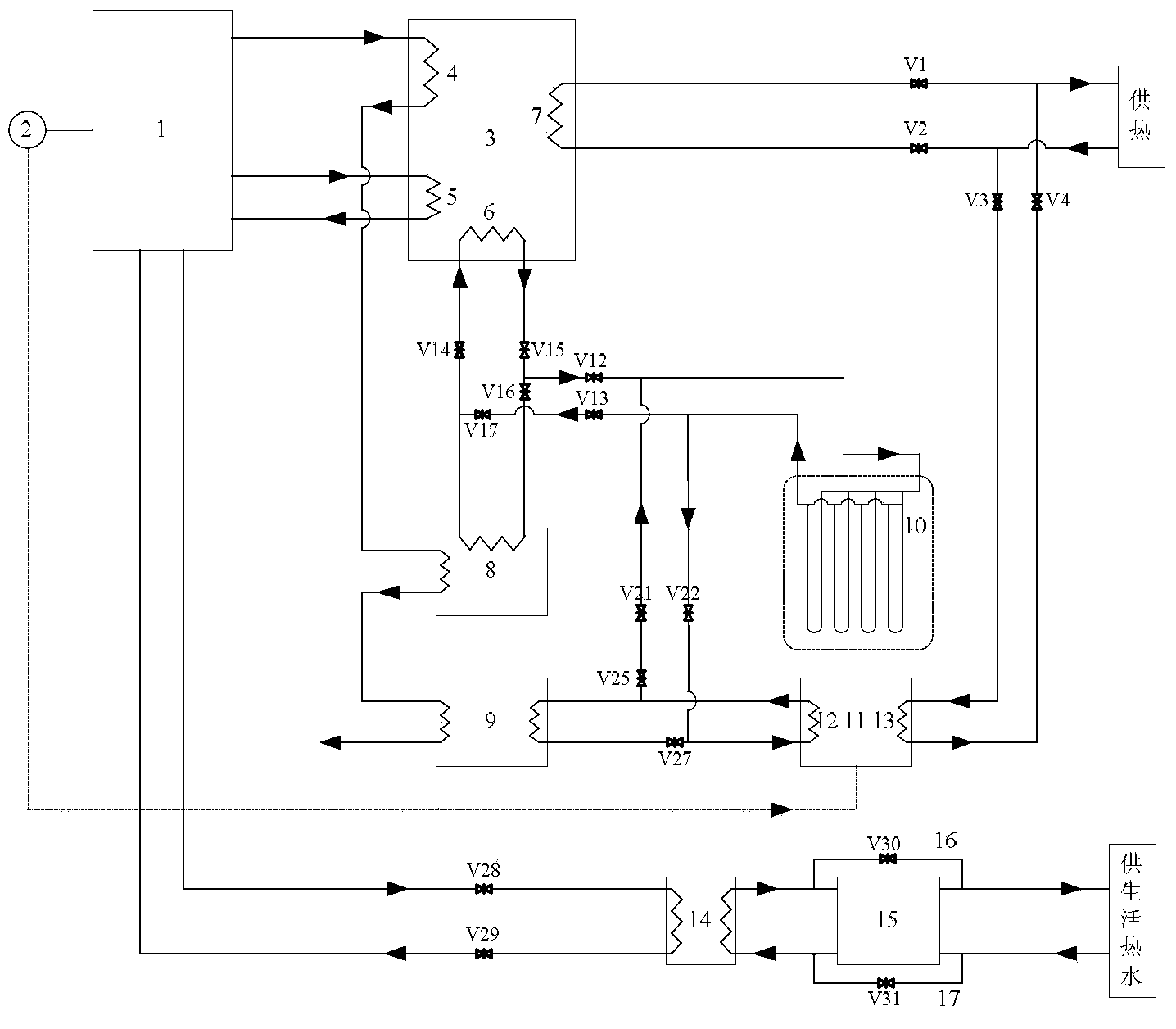

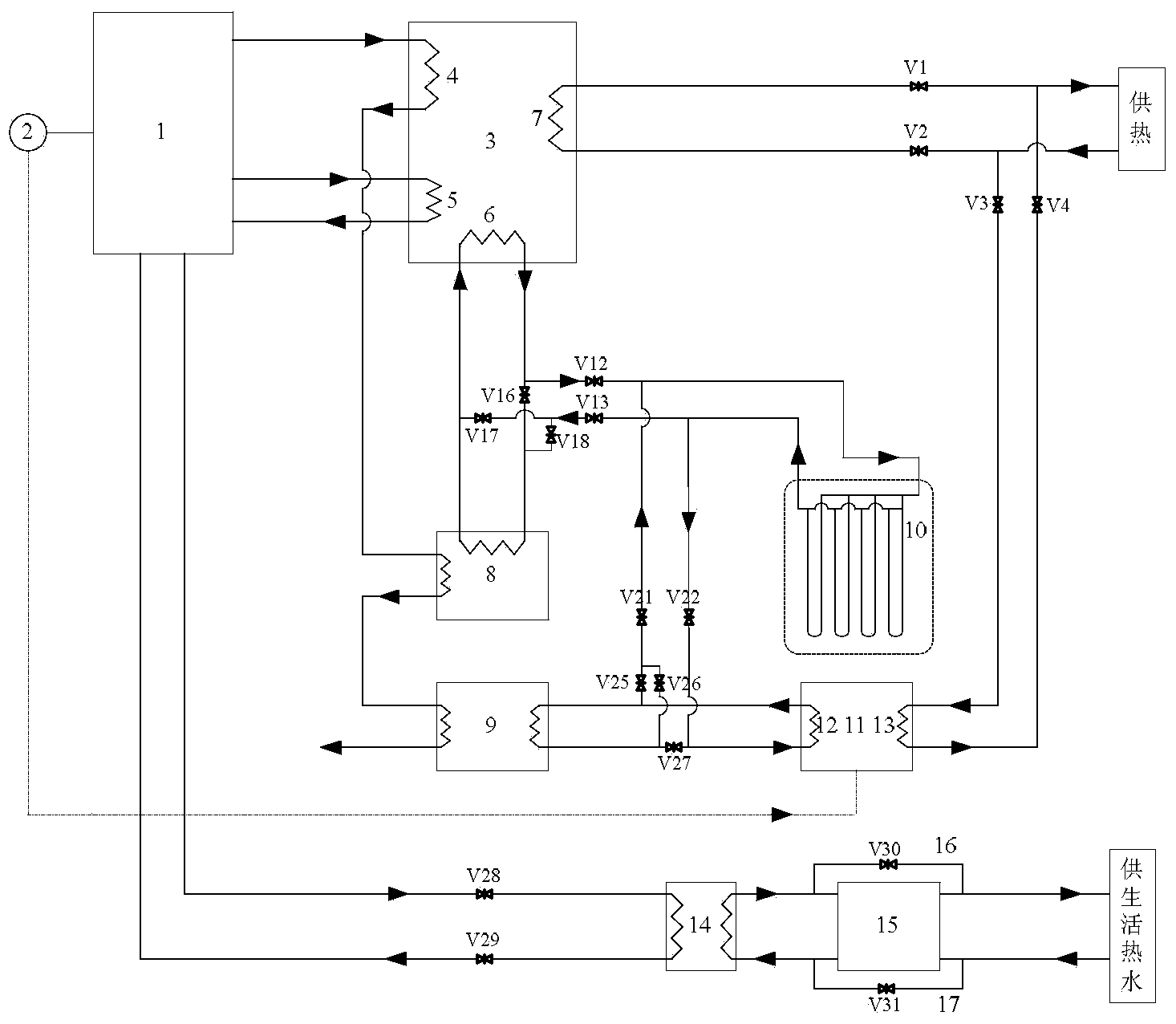

Gas steam combined cycle central heating device and heating method

InactiveCN104534539AReduce pollutionReduce wasteInternal combustion piston enginesRecuperative heat exchangersFlue gasRecuperator

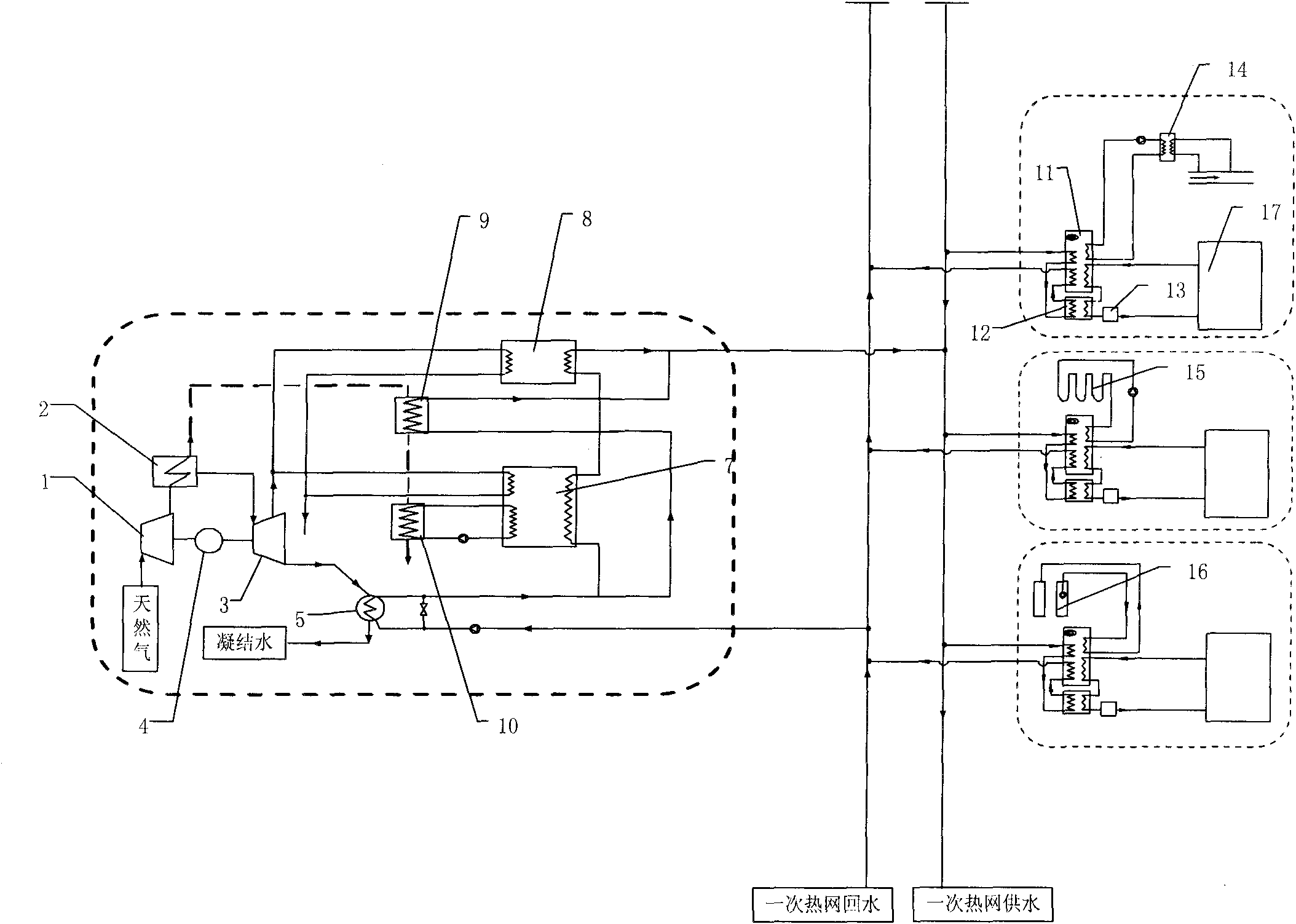

The invention relates to a gas steam combined cycle central heating device and heating method. The device comprises a gas steam combined cycle system, a heat supply network backwater heating system and a thermal station, and the gas steam combined cycle system is connected with the thermal station through the heat supply network backwater heating system; the gas steam combined cycle system comprises a gas turbine, a waste heat boiler, a direct contact flue gas condensing heat exchanger and a steam turbine; the gas turbine is connected with the waste heat boiler, and the waste heat boiler is connected with the direct contact flue gas condensing heat exchanger and the steam turbine; the thermal station comprises a hot water absorption heat pump and a water-water heat exchanger; the heat supply network backwater heating system comprises a steam absorption heat pump used for recovering flue gas waste heat and a steam-water heat exchanger; the steam absorption heat pump used for recovering the flue gas waste heat is connected with the steam-water heat exchanger, the direct contact flue gas condensing heat exchanger, the waste heat boiler, the steam turbine and the thermal station, and the steam-water heat exchanger is connected with the waste heat boiler, the steam turbine and the thermal station. The gas steam combined cycle central heating device and heating method can be widely applied to the industry of recycling waste heat of power plants.

Owner:TSINGHUA UNIV

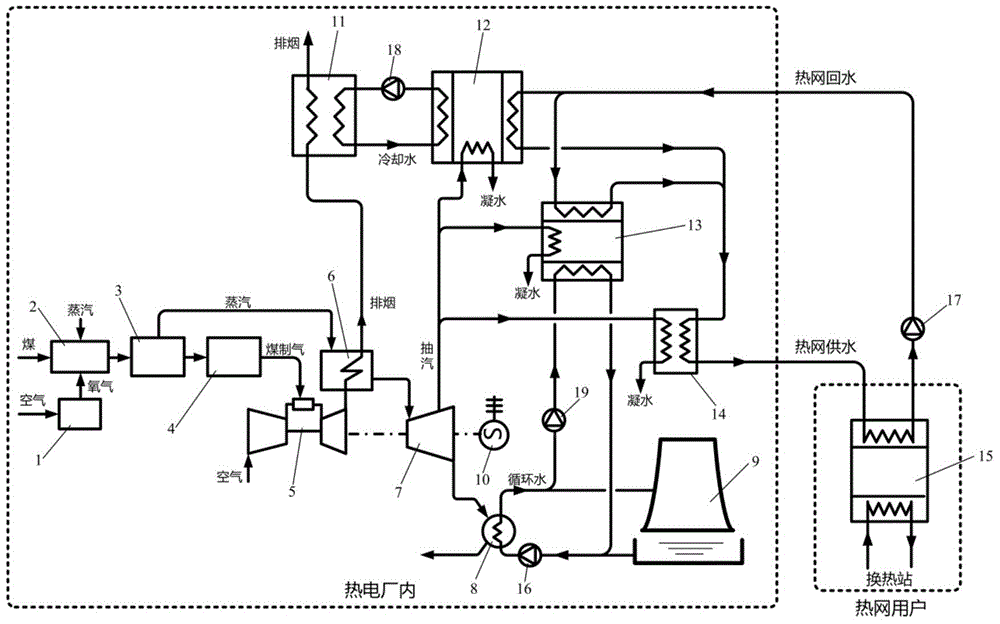

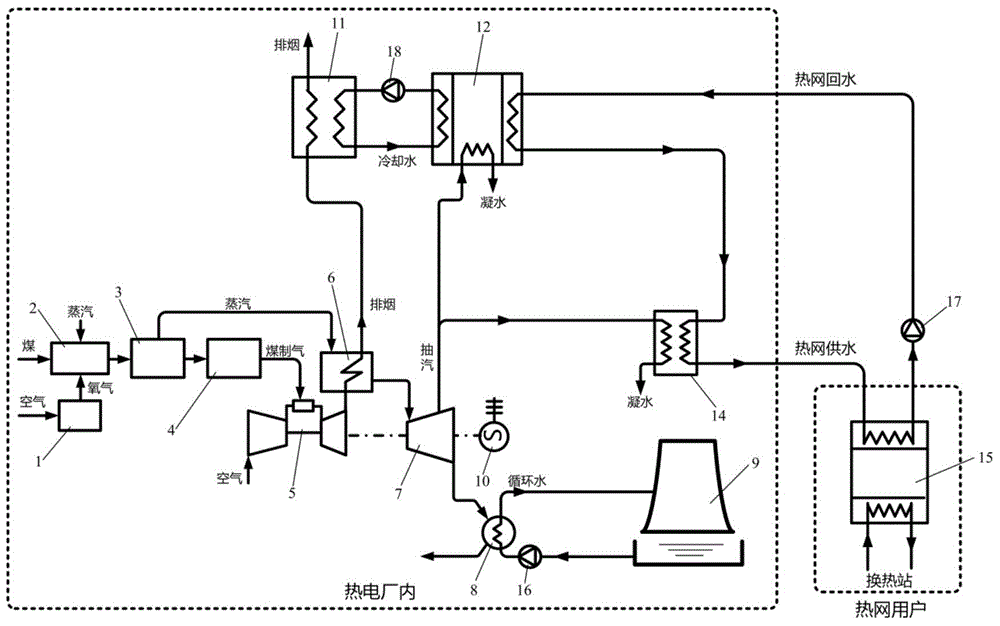

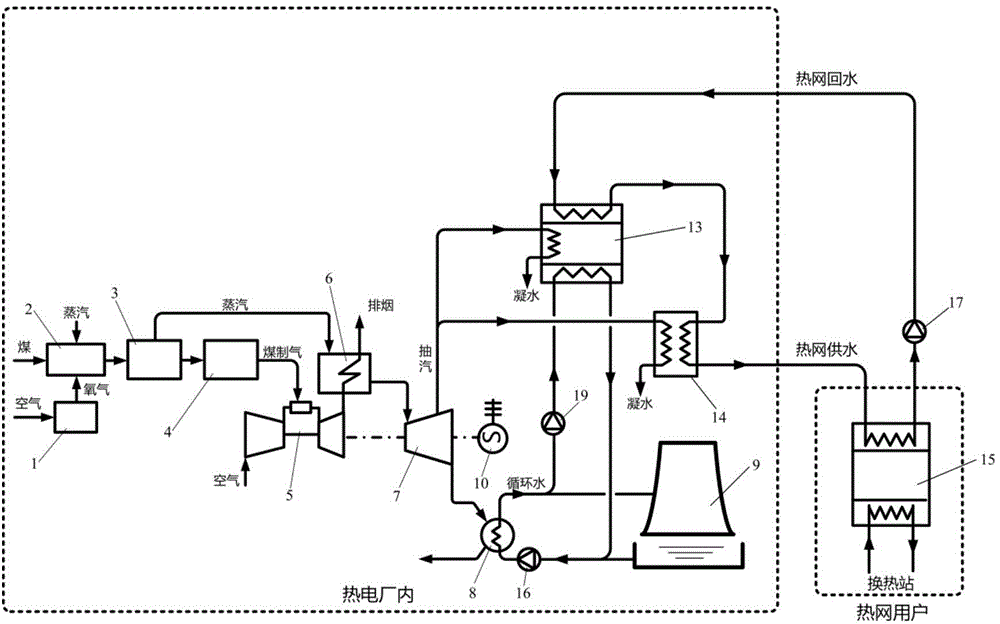

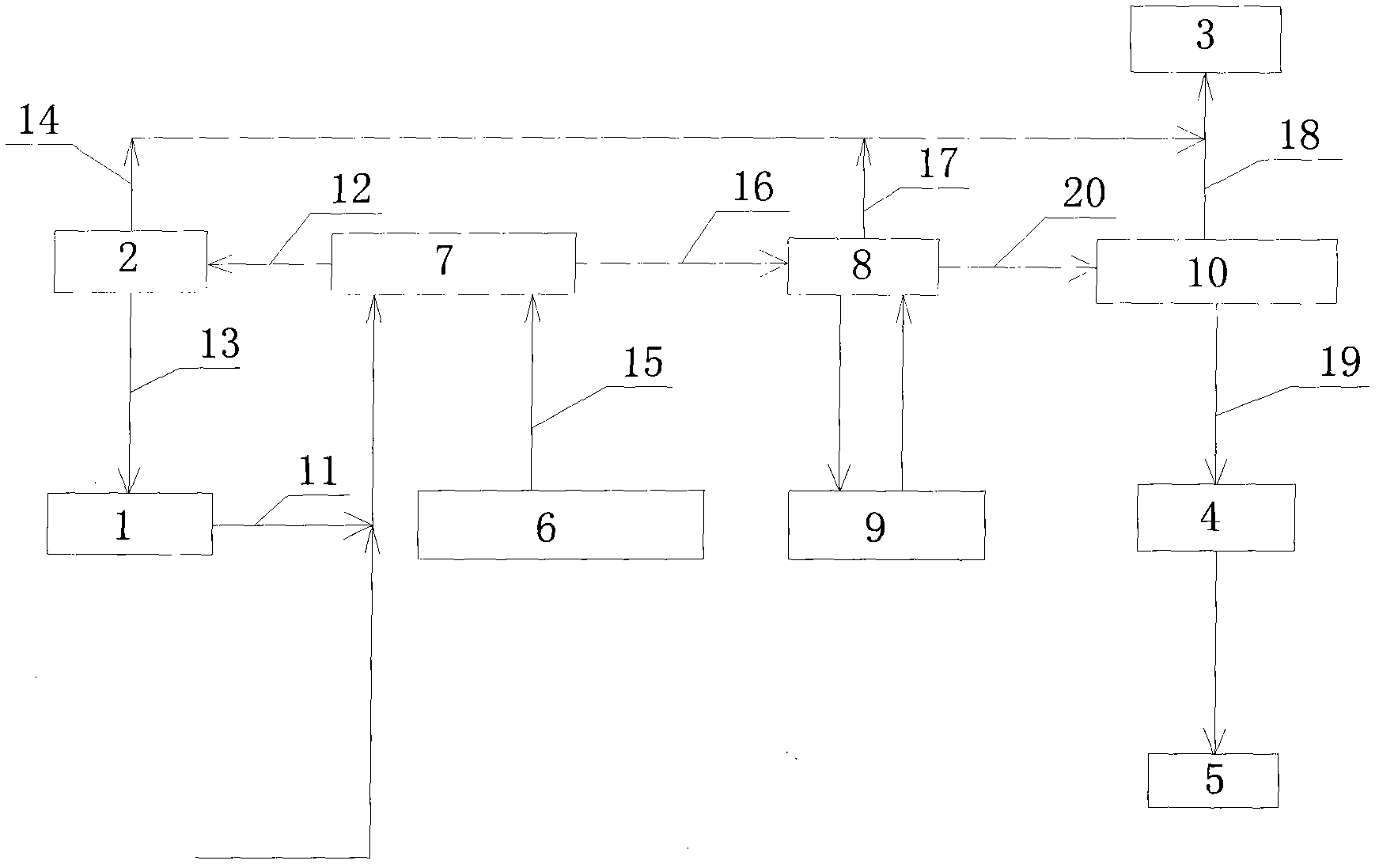

Waste heat recovery IGCC (integrated gasification combined cycle) combined heat and power generation central heating system and method

ActiveCN104533551AImprove economyGuaranteed annual power generation hoursLighting and heating apparatusSteam useCooling towerMature technology

The invention discloses a waste heat recovery IGCC (integrated gasification combined cycle) combined heat and power generation central heating system and method. The system comprises an air separation unit, a gasification furnace, a gas cooler, a purification plant, a gas turbine, a waste heat boiler, an absorption heat pump and a heat exchanger, which are connected successively. An exhaust smoke outlet of the waste heat boiler is emptied or is connected with a smoke inlet of a smoke condensation heat exchanger; a steam outlet of the waste heat boiler is connected with an inlet of a steam turbine; an exhaust steam outlet of the steam turbine is connected with a steam inlet of a condenser; a circulating water outlet of the condenser is connected with a cooling tower; a low-pressure extracted steam outlet of the steam turbine is divided into three paths, two paths or one path of temperature drop, and heat supply network return water is conveyed to a heat supply network for use after being heated. The invention also provides a central heating method. Clean and efficient IGCC is combined with extracted steam heat supply of the steam turbine, the extracted steam of the steam turbine is used for driving the absorption heat pump, the exhaust steam waste heat of the steam turbine and the smoke waste heat are recycled, and the extracted steam heat of the steam turbine and the recycled waste heat are utilized for central heating. The recovery waste heat IGCC combined heat and power generation central heating system and method have the characteristics of cleanliness, high efficiency, mature technology, high recycled waste heat amount, and capability of recycling smoke condensate water.

Owner:HUANENG CLEAN ENERGY RES INST +1

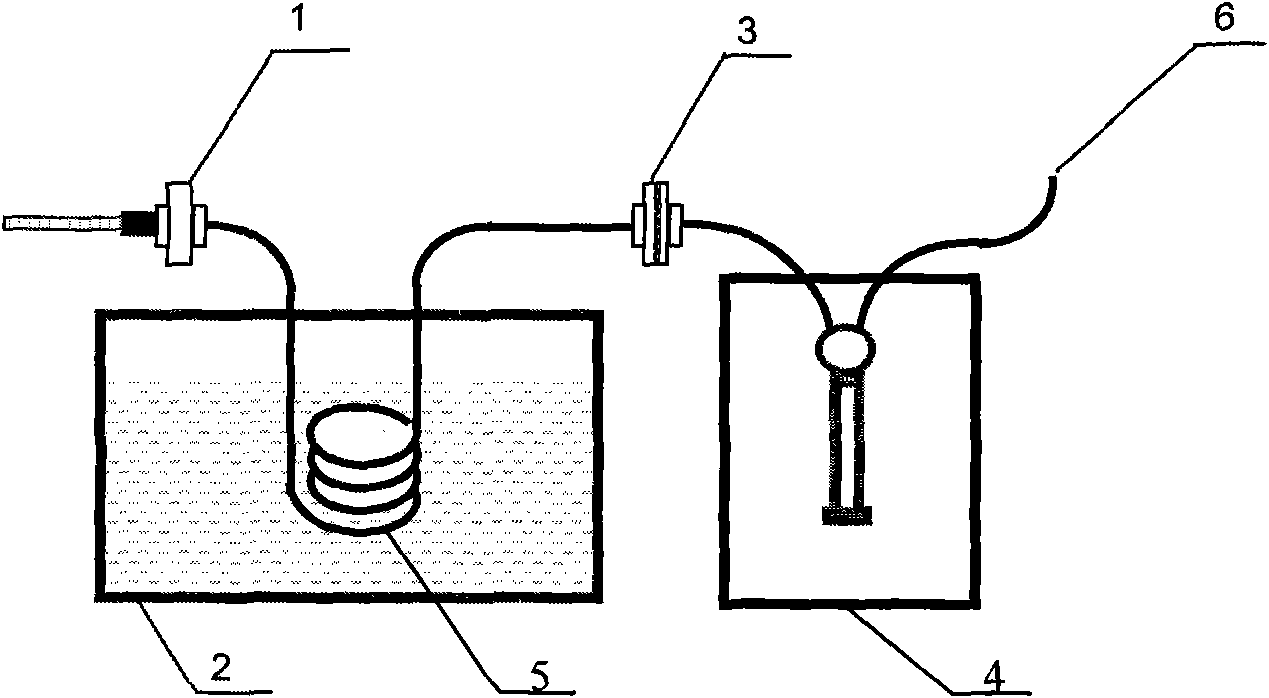

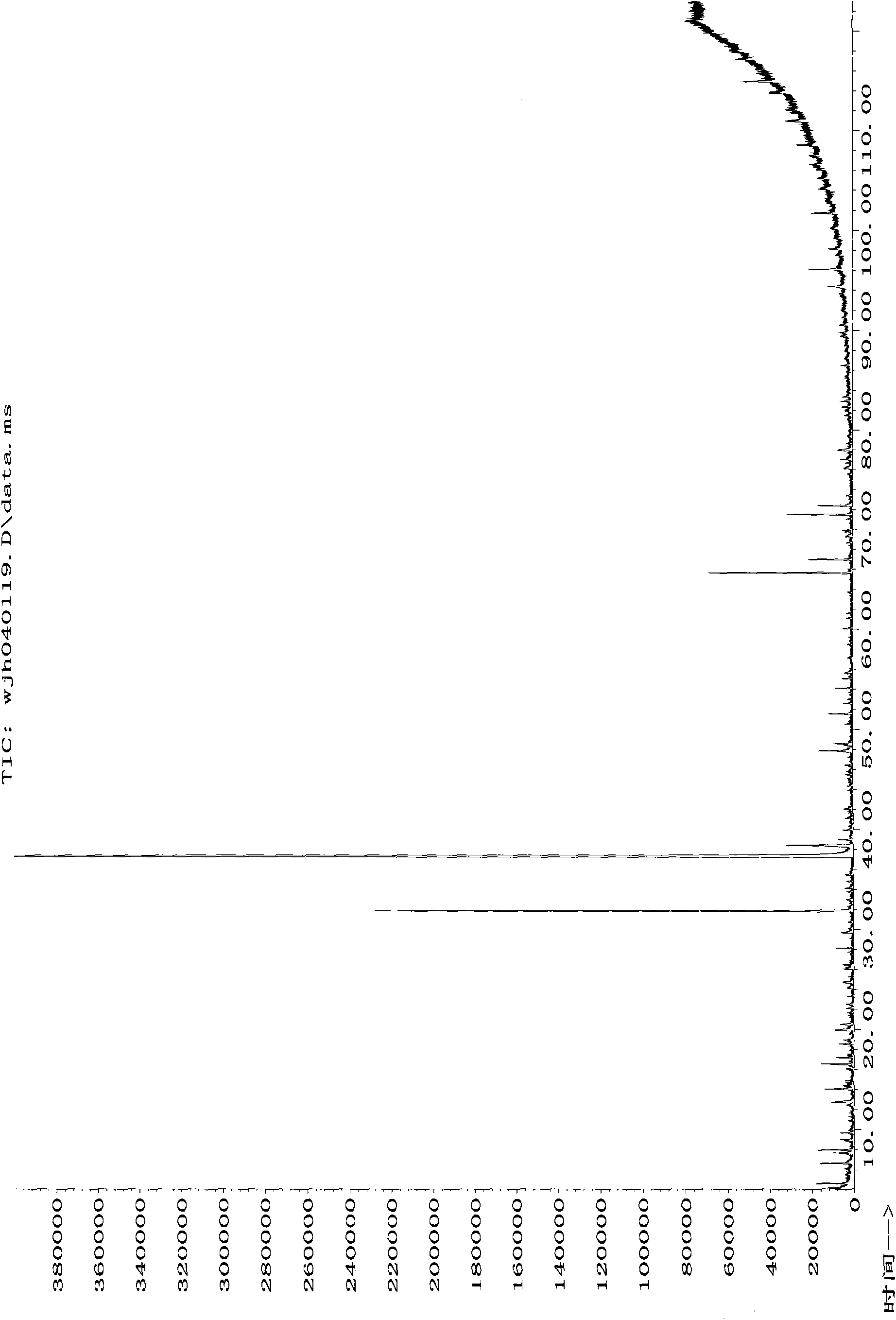

Smoking machine-mainstream flue gas cold trap integrated device and using method thereof

ActiveCN101566535AConditions are easy to controlFully condensedSolidificationLiquefactionEngineeringIntegrated devices

The invention discloses a smoking machine-mainstream flue gas cold trap integrated device and a using method thereof. The integrated device comprises a smoke holder, a cold trap device, a cambridge filter and a single-passage smoking machine that are sequentially connected by pipelines; the cold trap device comprises a mainstream flue gas trap pipe and is internally provided with a refrigerant; the mainstream flue gas trap pipe is dipped in the refrigerant; and the mainstream flue gas trap pipe is a quartz pipe of a spiral shape. After the sucking of a cigarette is completed, an organic solvent is added in the mainstream flue gas trap pipe and the mainstream flue gas trap pipe is vibrated sufficiently; the mainstream flue gas condensate is extracted repeatedly; subsequently, the extract is combined; and then the mainstream flue gas sample is analyzed. The method has higher and safer trap efficiency on the aroma-active components in the mainstream flue gas, effectively avoids the generation of various side effects during the flue gas sample treatment process, simplifies the treatment process, shortens time and has higher repeatability. The method has important application prospect in the fields of analyzing cigarette quality and researching flue gas fingerprints.

Owner:CHINA TOBACCO HUNAN INDAL CORP

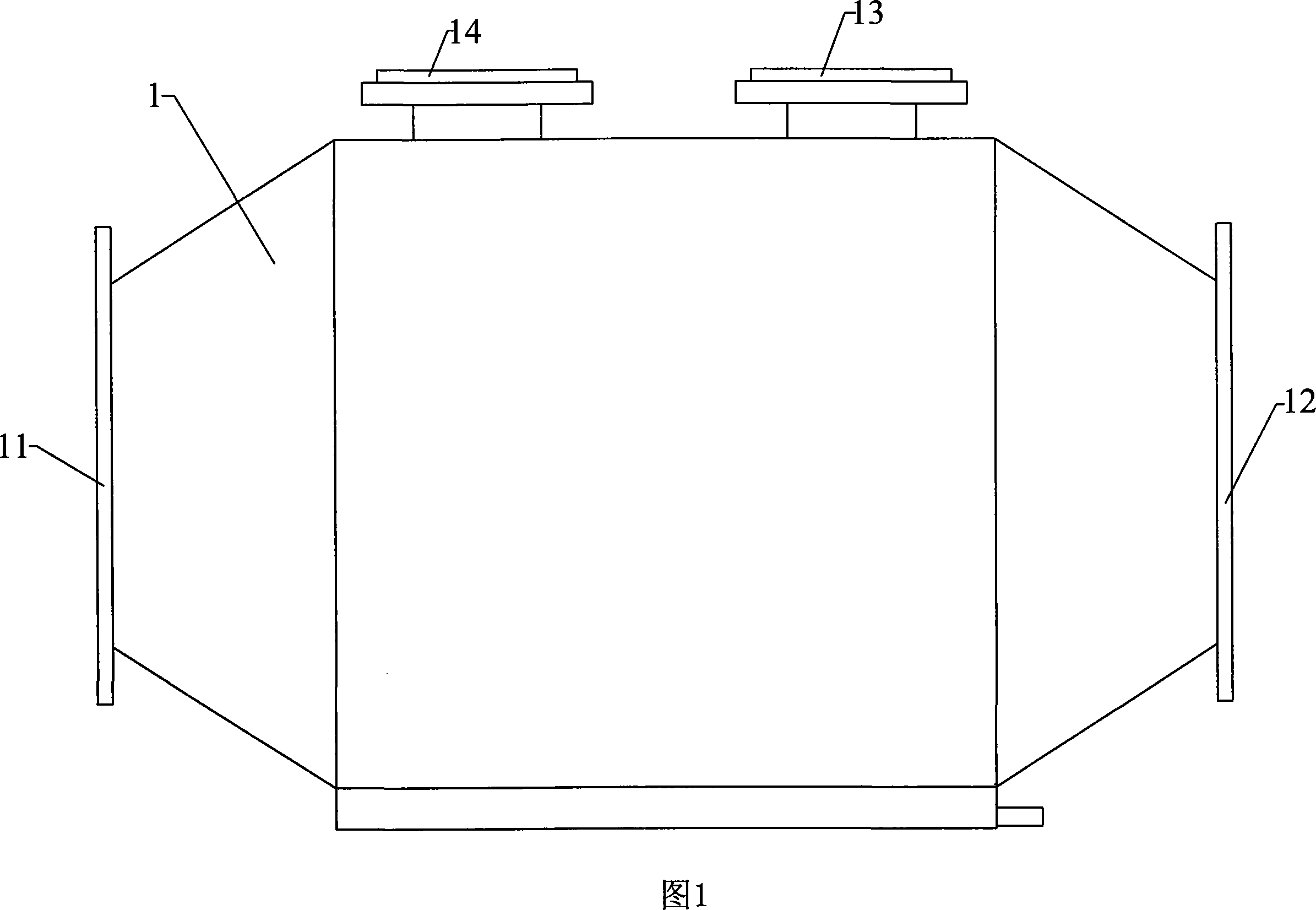

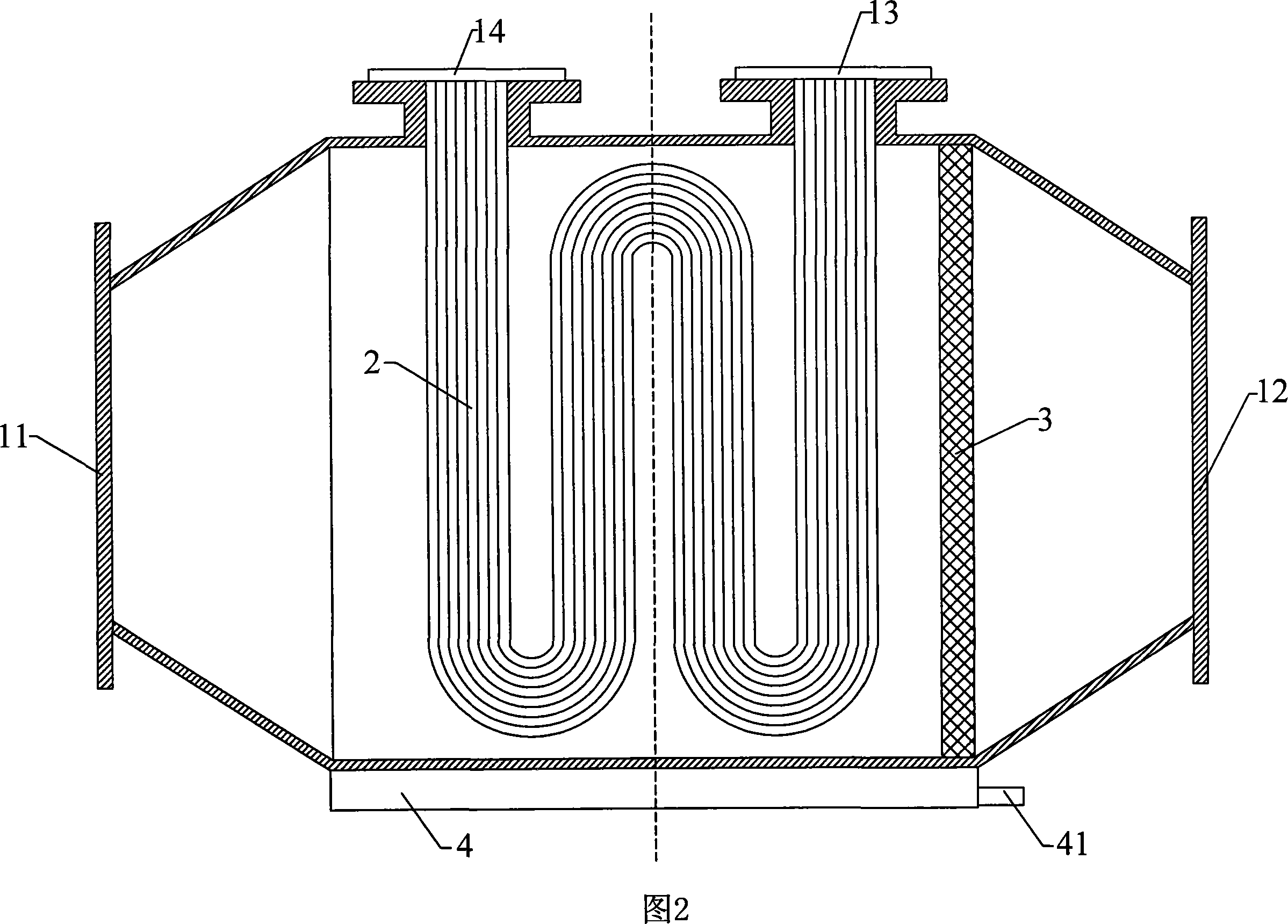

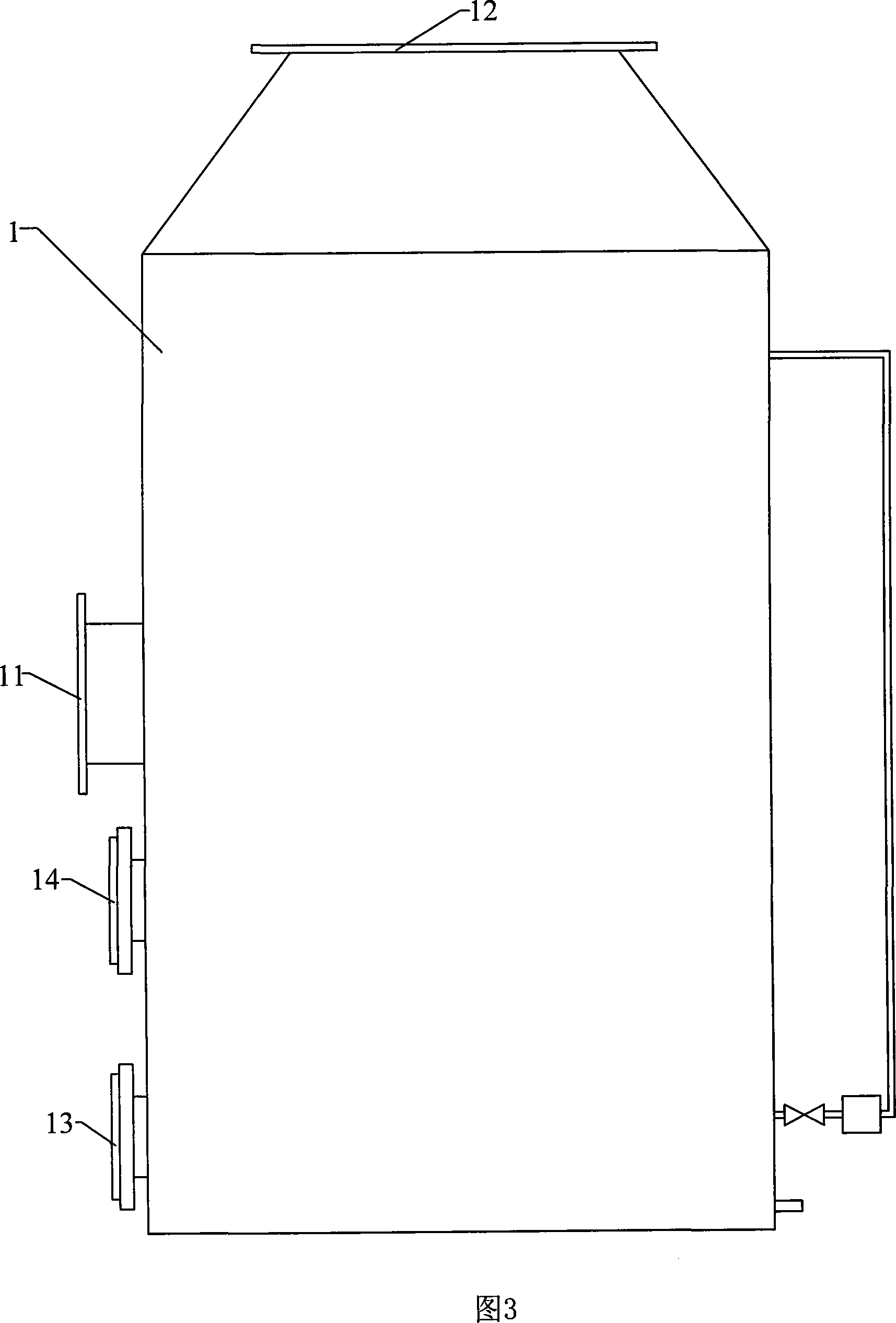

Flue gas condenser

ActiveCN101221021AIncrease the heating areaAvoid erosionStationary tubular conduit assembliesTrickle coolersFlue gasEngineering

The invention discloses a flue gas condenser, comprising an outer casing, a heat exchanging component, a flue gas inlet, a flue gas outlet, a cooling water inlet and a cooling water outlet. The heat exchanging component is a capillary, two ends of which are respectively connected with the cooling water inlet and outlet. Compared with the prior art, the invention enlarges a heated area of the heat exchanging component so as to further recycle heat and to more effectively enhance the heating efficiency of the equipment. Simultaneously, the PTFE and anti-corrosion materials are adopted to effectively prevent the corrosion of acid condensed water so as to avoid early damage due to corrosion to the condenser and to prolong the service life of the equipment.

Owner:FOSHAN SHENGKAI HEAT ENERGY EQUIP CO LTD

Stepped recycle method for residual heat of fuel gas

InactiveCN102650431AImprove efficiencyReduce consumptionEfficient regulation technologiesTrickle coolersWater useHeat energy

A stepped recycle method for residual heat of fuel gas adopts two heat transfer methods (an indirect gas-water heat exchange method and a direct gas-water heat exchange method) which are connected in series to recycle low-grade heat energy in flue gas of a fuel gas in a stepped manner, so as to continuously rise the temperature of heated water; and heated water, of which the temperature is increased twice continuously to 60 to 100 DEG C, serve as steam boiler replenishing water, waste heat boiler replenishing water, water used in other processes or domestic hot water. The system can be widely applied to fuel gas thermotechnical equipment, only consumes a little high-grade electric energy, can effectively recycle low-grade heat energy in the flue gas, has an efficiency improved by 8 to 13 percent, imroves fuel utilization efficiency, realizes energy conservation and emission reduction, and absorbs smoke, NOX and other pollutants of discharged flue gas with condensed water generated during the condensing process of the flue gas, so as to reduce the concentrations of smoke and NOX in the discharged flue gas and further reduce environmental pollution.

Owner:大连丰泽节能环保工程技术有限公司

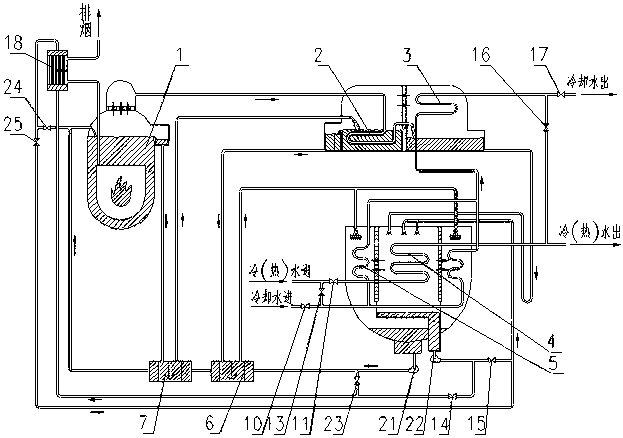

Direct-burning lithium bromide absorbing cold hot water unit capable of recycling smoke waste heat

ActiveCN102997483AReduce consumptionImprove cooling effectEnergy efficient heating/coolingClimate change adaptationLithium bromideInlet valve

The invention relates to a direct-burning lithium bromide absorbing cold hot water unit capable of recycling smoke waste heat. A smoke condensation heat exchanger (18) is arranged at a smoke discharging outlet pipe of a direct-burning high pressure generator, an outlet refrigerant water pipeline of a refrigerant pump (22) is divided into two branches, one branch is connected with an evaporator (4) through a refrigeration refrigerant water valve (15), and the other branch is connected with the smoke condensation heat exchanger (18) through a heating refrigerant water inlet valve (14) and then connected and joined with a pipeline at the rear side of the refrigeration refrigerant water valve (15) through a heating refrigerant water outlet valve (25) or connected with the evaporator (4) alone. A solution pump outlet dilute solution pipeline is divided into two branches, one branch of dilute solution is heated through a low-temperature solution heat exchanger and a high-temperature solution heat exchanger to be connected with the direct-burning high pressure generator, and the other branch of dilute solution is connected with a smoke condensation heat exchanger through a dilute solution inlet valve to be connected and joined with a pipeline at the rear side of the high-temperature solution heat exchanger through a dilute solution outlet valve or connected with the direct-burning high pressure generator alone. The direct-burning lithium bromide absorbing cold hot water unit can fully use the smoke heat and improves efficiency.

Owner:SHUANGLIANG ECO ENERGY SYST CO LTD

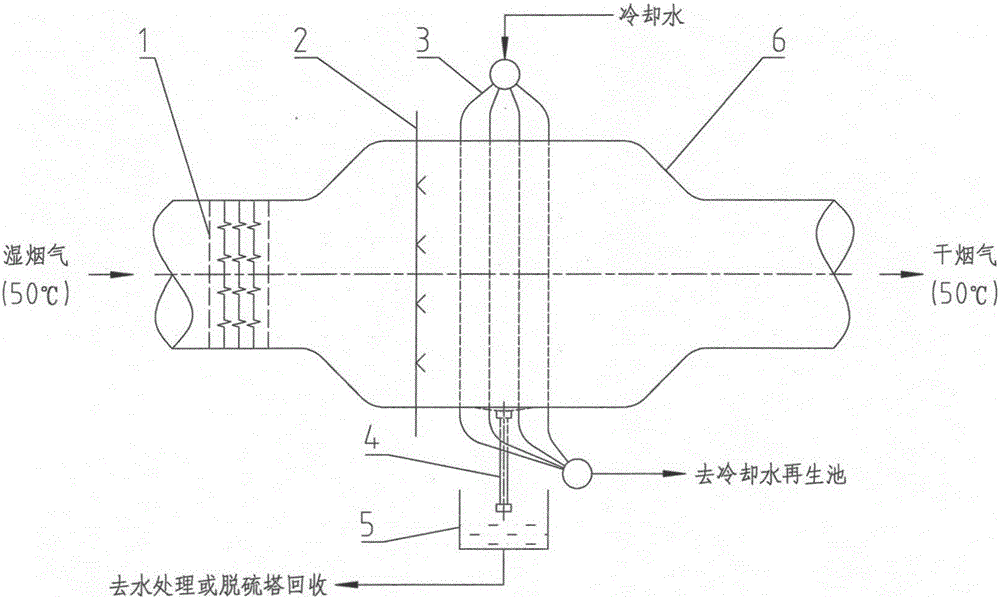

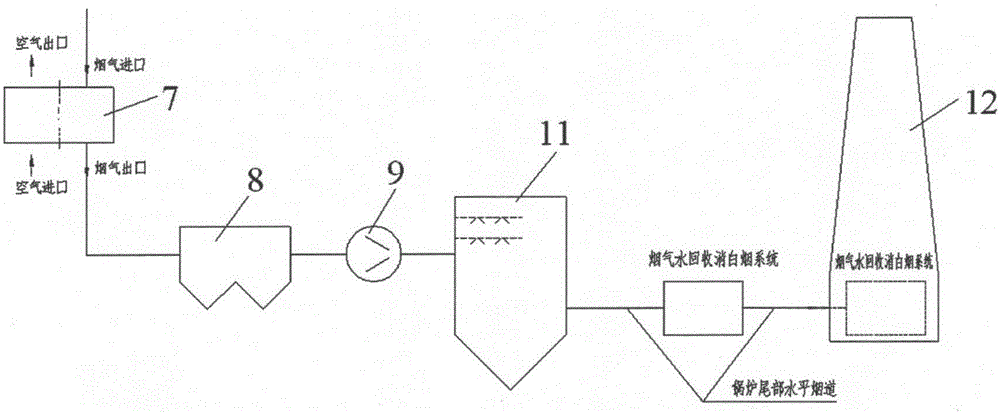

Exhaust gas water recycling and white smoke eliminating system through condensation method

InactiveCN105709573AReduce resistanceReduce energy consumptionGas treatmentLighting and heating apparatusEnvironmental engineeringEngineering

The invention discloses an exhaust gas water recycling and white smoke eliminating system through a condensation method. The system is characterized by comprising an exhaust gas condensation chamber; a condensation pipe bundle is arranged at an inlet of the exhaust gas condensation chamber, a water flushing device is arranged on one side of the condensation pipe bundle, and a condensation water draining device is arranged at the lower portion of the condensation pipe bundle. By adopting the exhaust gas water recycling and white smoke eliminating system, water recycling and utilization are performed before wet purified exhaust gas is exhausted from a wet-type desulfuration tower, the gypsum component is recycled along with water, the total amount of gypsum rain and aerosol drained to air can be effectively lowered fundamentally, the exhausted exhaust gas temperature is lowered slightly, exhaust gas is exhausted in a dried mode, the white smoke phenomenon at an outlet of a chimney can be greatly reduced, and the effect of eliminating white smoke and gypsum rain can be achieved when no exhaust gas heating device is adopted.

Owner:SHANGHAI BOILER WORKS

Zero-water-consumption zero-wastewater-draining desulfurization system and application

InactiveCN105180187AEasy to useEasy to operateDispersed particle separationFeed-water heatersAir preheaterElectricity

The invention relates to a zero-water-consumption zero-wastewater-draining desulfurization system. The system comprises a boiler air preheater, a low-temperature heat exchange device, a desulfurization wastewater atomization device, a dry type electric dust removal device, a boiler induced draft fan, a desulfurization absorption tower, a smoke condensation mist removing device and a chimney which are sequentially connected. The system further comprises a condensation water tank which is connected with the smoke condensation mist removing device. According to the desulfurization system, the low-temperature heat exchange device, the desulfurization wastewater atomization device, the smoke condensation mist removing device, a water resource recycling device and the like are additionally arranged on a traditional boiler tail smoke purification system, so that circular utilization of process water of the wet method desulfurization system is achieved, and zero consumption of the process water and zero emission of wastewater of the whole desulfurization system are achieved; in addition, the zero-water-consumption zero-wastewater-draining desulfurization system is convenient to operate, the running cost of equipment is reduced, failures are not prone to happening, and the system can be widely applied to desulfurization of wet method smoke.

Owner:AEROSPACE ENVIRONMENTAL ENG

Outside-tower condensed heat-medium smoke plume elimination system for flue gas

PendingCN108126482AReduce heat loadReduce overall form factorGas treatmentDispersed particle separationWater vaporAtmospheric air

The invention discloses an outside-tower condensed heat-medium smoke plume elimination system for flue gas, and relates to a smoke plume elimination system for desulfurized flue gas. The outside-towercondensed heat-medium smoke plume elimination system comprises a desulfurizing tower, a heat medium water closed cycle and a plate type flue gas condenser, wherein the heat medium water closed circleconsists of a temperature lowering section heat exchanger and a temperature raising section heat exchanger. Raw flue gas is cooled by heat medium water through the temperature lowering section heat exchanger and then enters the desulfurizing tower; desulfurized flue gas is cooled and dehumidified through the flue gas condenser, then enters the temperature raising section heat exchanger, and is discharged into the atmosphere through a chimney after being heated by the heat medium water; through the condensation, on purified flue gas, of the flue gas condenser, the reduction of the moisture content of the flue gas and the reduction of the smoke plume elimination heat load of the flue gas are realized; the purified flue gas is heated by utilizing the heat of the raw flue gas; the degree of superheat of the dehumidified flue gas is further improved; the elimination of a smoke plume and the abatement of the emissions of mill dust and water vapor are realized; as the flue gas condenser is arranged outside the system, condensed fluid separated out by the water vapor in the flue gas is discharged outside the system, and the influence cannot be generated to the water balance in the desulfurizing tower.

Owner:TIANJIN HUASAIER HEAT TRANSFER EQUIP

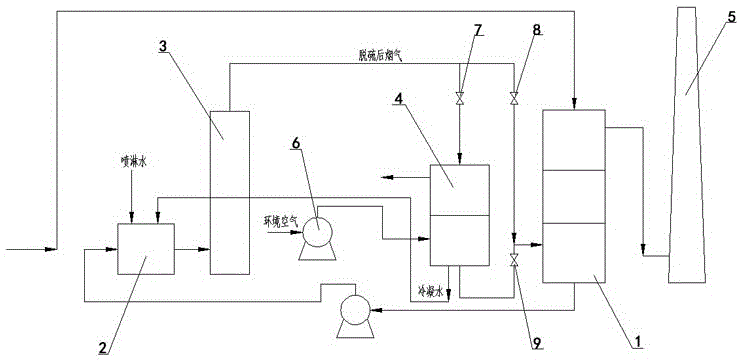

Device for smoke condensation haze-eliminating and white-removing after wet desulphurization and technical method

ActiveCN105688616AReduce energy consumptionRealize heat recovery and utilizationGas treatmentDispersed particle separationAtmospheric airEngineering

The invention relates to a device for smoke condensation haze-eliminating and white-removing after wet desulphurization and a technical method. The device comprises a smoke dehumidifier, a water spraying tower, a desulphurization tower and a smoke deep cooler. Preprocessed smoke exchanges heat with the discharged smoke to enter a chimney through the smoke dehumidifier; the smoke enters the water spraying tower through a draught fan; the smoke after being sprayed enters the desulphurization tower; the smoke after desulphurization treatment is differently treated according to different environmental temperatures; when the environmental temperature is low, the ambient air exchanges heat with the smoke after desulphurization in the smoke deep cooler under the effect of an air blower; and preheated air is supplied to a production system, so that the heat recycling is realized and the fuel energy consumption of the production system can be reduced. According to the smoke haze-eliminating and white-removing device and the technical method provided by the invention, the temperature of the smoke discharged to the atmosphere can be increased, the water content in the smoke and the contents of pollutants, such as NOx and SOx, can be reduced, the smoke diffusion speed is higher, and the generation of environmental haze can be extremely avoided.

Owner:LUOYANG RUICHANG PETROCHEM EQUIP

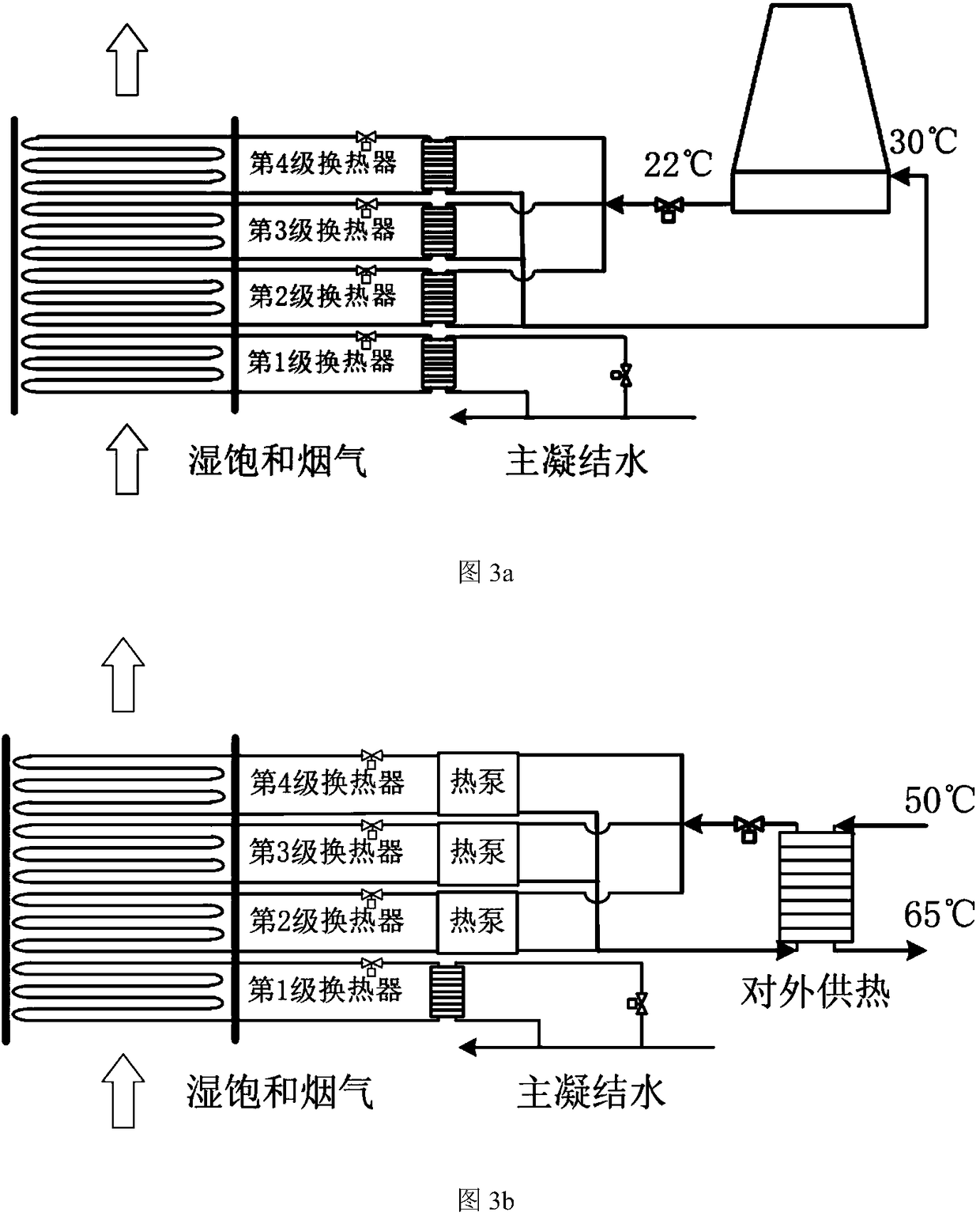

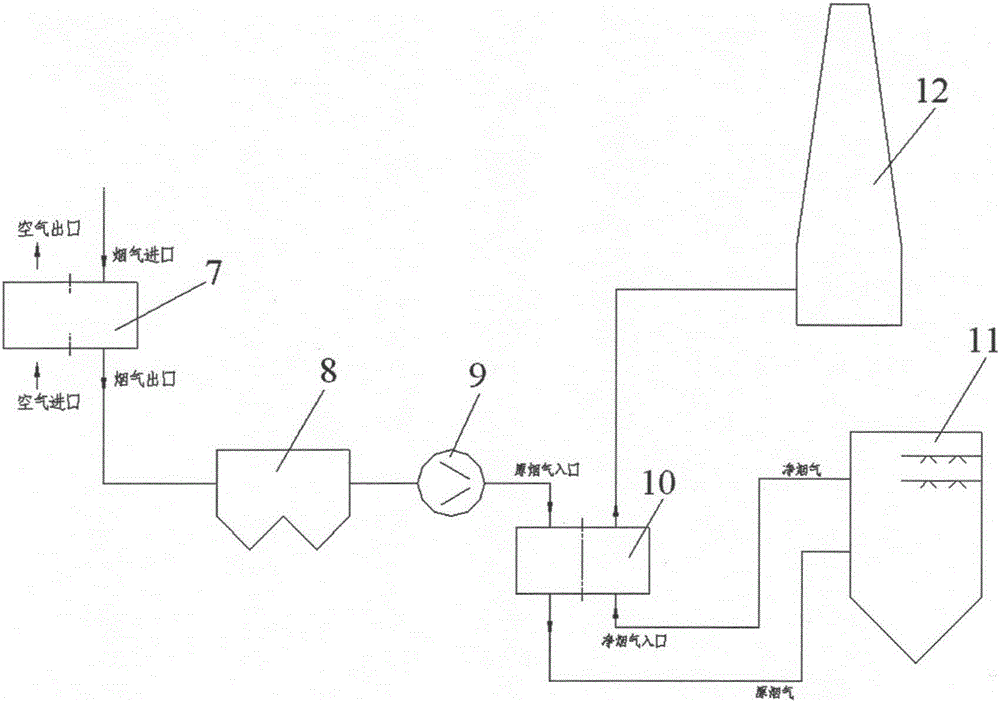

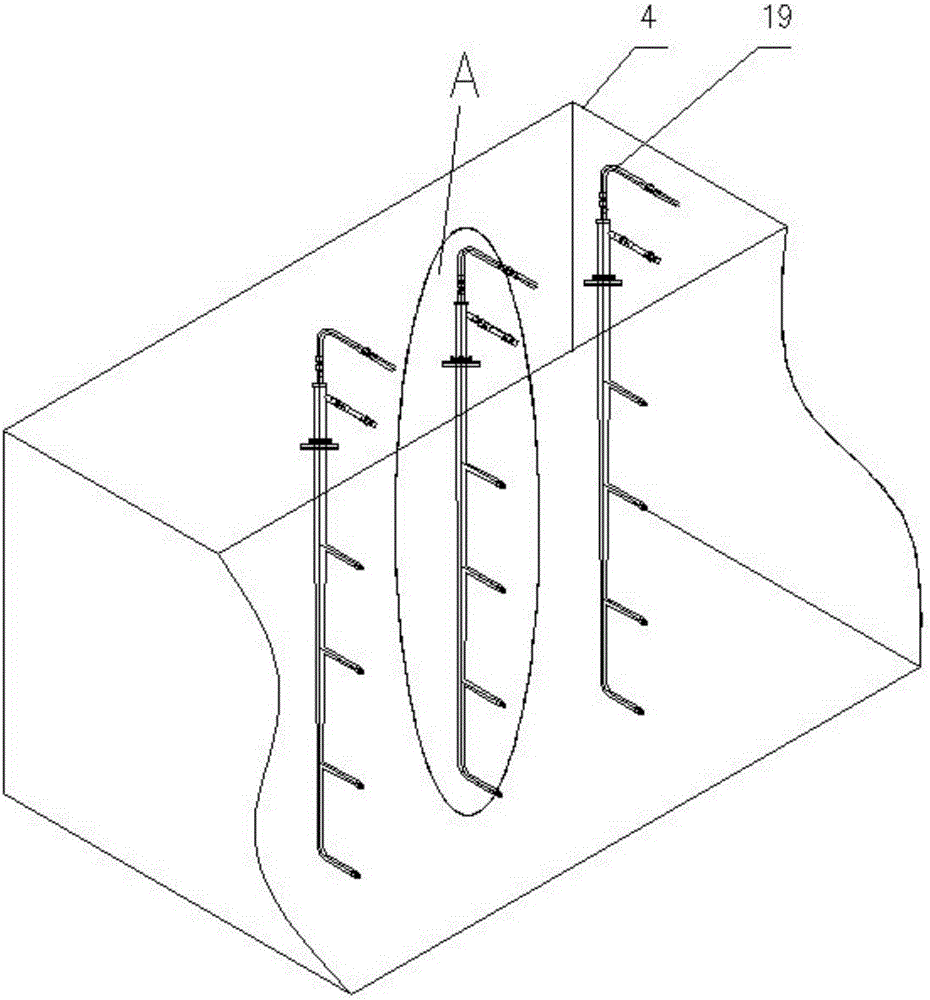

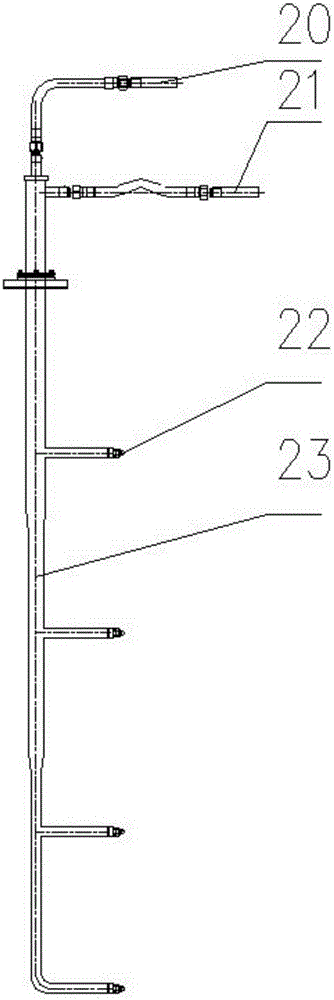

Power station boiler condensing flue gas dehumidification and purification energy-saving system

InactiveCN105937773AImprove efficiencySolve the problem of corrosionEmission preventionIndirect carbon-dioxide mitigationAir preheaterWater vapor

The invention relates to a boiler flue gas comprehensive utilization system, and particularly discloses a power station boiler condensing flue gas dehumidification and purification energy-saving system, which comprises a power station boiler, and is characterized in that the boiler is sequentially connected with air preheaters, electric precipitators, a desulfurizing tower and a chimney through flue pipes; flue gas coolers are arranged in the flue pipes between the air preheaters and the electric precipitators; a flue gas condenser and a flue gas reheater are sequentially arranged in an outlet flue pipe for connecting the desulfurizing tower and the chimney. According to the power station boiler condensing flue gas dehumidification and purification energy-saving system provided by the invention, the waste heat of flue gas can be recovered for heating condensed water, so that the coal consumption is reduced, the moisture content of the flue gas is reduced, pollutants in the flue gas are absorbed, condensed or cleared, water vapor in the flue gas is changed into an overheated state from a saturation state, the problem of the low-temperature corrosion of the chimney is solved, the aims of flue gas dehumidification and purification are achieved, and the whole operation profit of a power station is improved.

Owner:SHANDONG HONGAO POWER TECHNOLOGY CO LTD

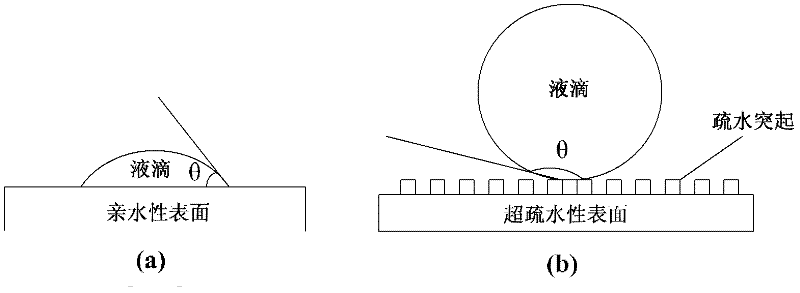

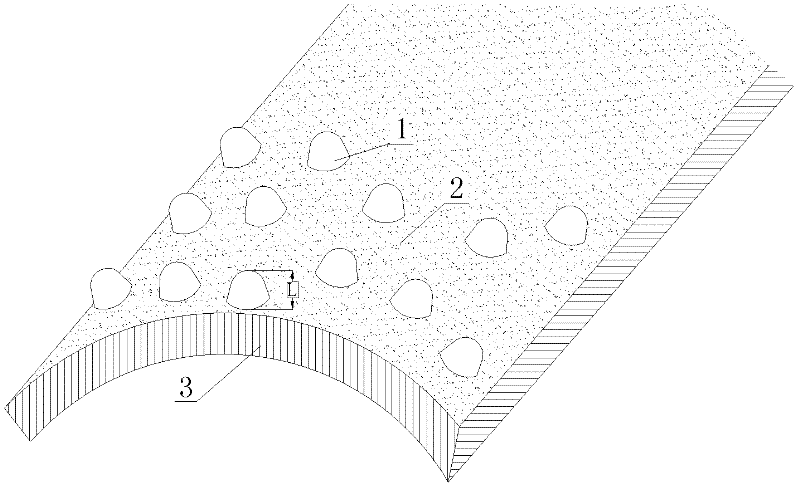

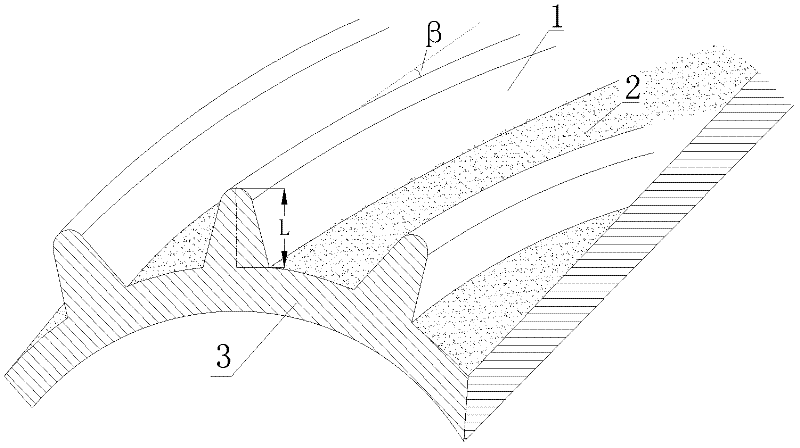

Flue gas condensation-type heat transfer pipe with bionic structure

InactiveCN102538542AGuaranteed safety and reliabilityReduce rolling resistanceHeat transfer modificationTubular elementsWater vaporPolymerization

The invention discloses a flue gas condensation-type heat transfer pipe with a bionic structure. The surface of the conventional flue gas condensation-type heat transfer pipe is prepared into a bionic structure surface which is characterized in that hydrophilic protrusions are distributed on an ultra hydrophobic base. When flue gas passes through the heat transfer pipe, water vapor in the flue gas is subjected to the condensation process comprising three links, namely absorption, polymerization growing and falling off, on the bionic structure surface. The flue gas condensation-type heat transfer pipe with the bionic structure can deeply intensify the condensation link of the water vapor in the flue gas, and bead-shaped condensate can be stably formed on the surface of the heat transfer pipe. According to the invention, waste heat and water resources in the industrial flue gas can be recycled efficiently, the energy resource utilization ratio is improved, and low-temperature corrosion can be prevented to a certain extent. The flue gas condensation-type heat transfer pipe with the bionic structure provided by the invention is quite suitable for the low-temperature-difference heat transfer in the industrial field.

Owner:XI AN JIAOTONG UNIV

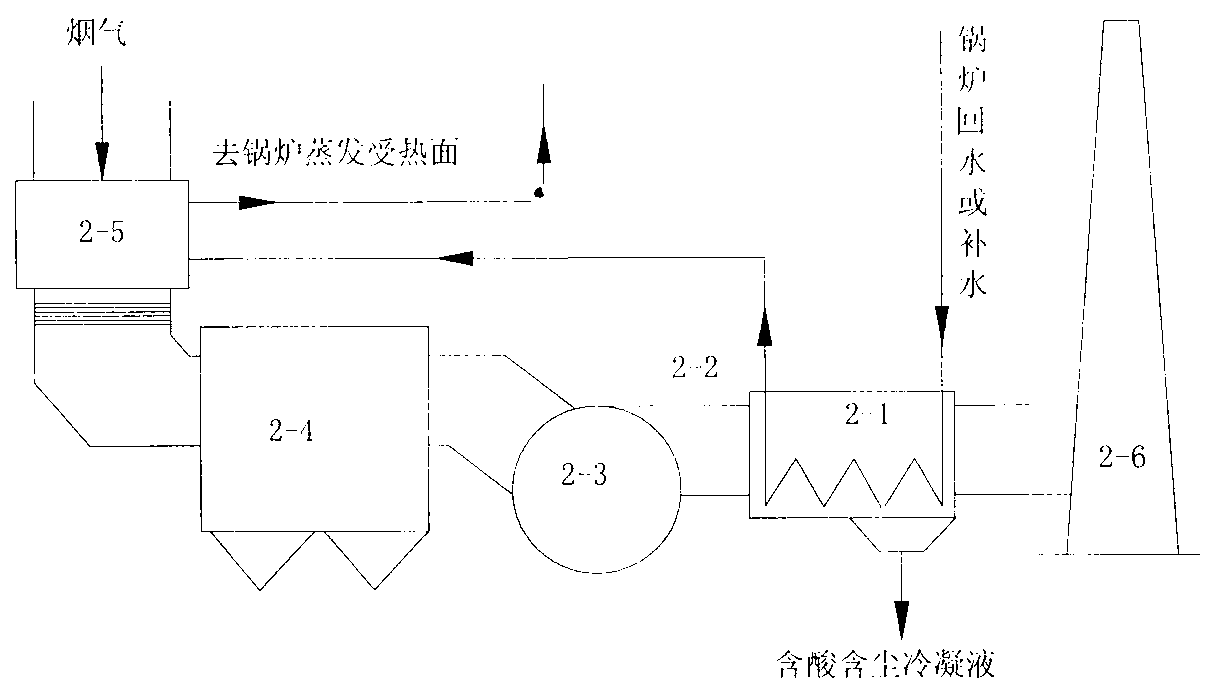

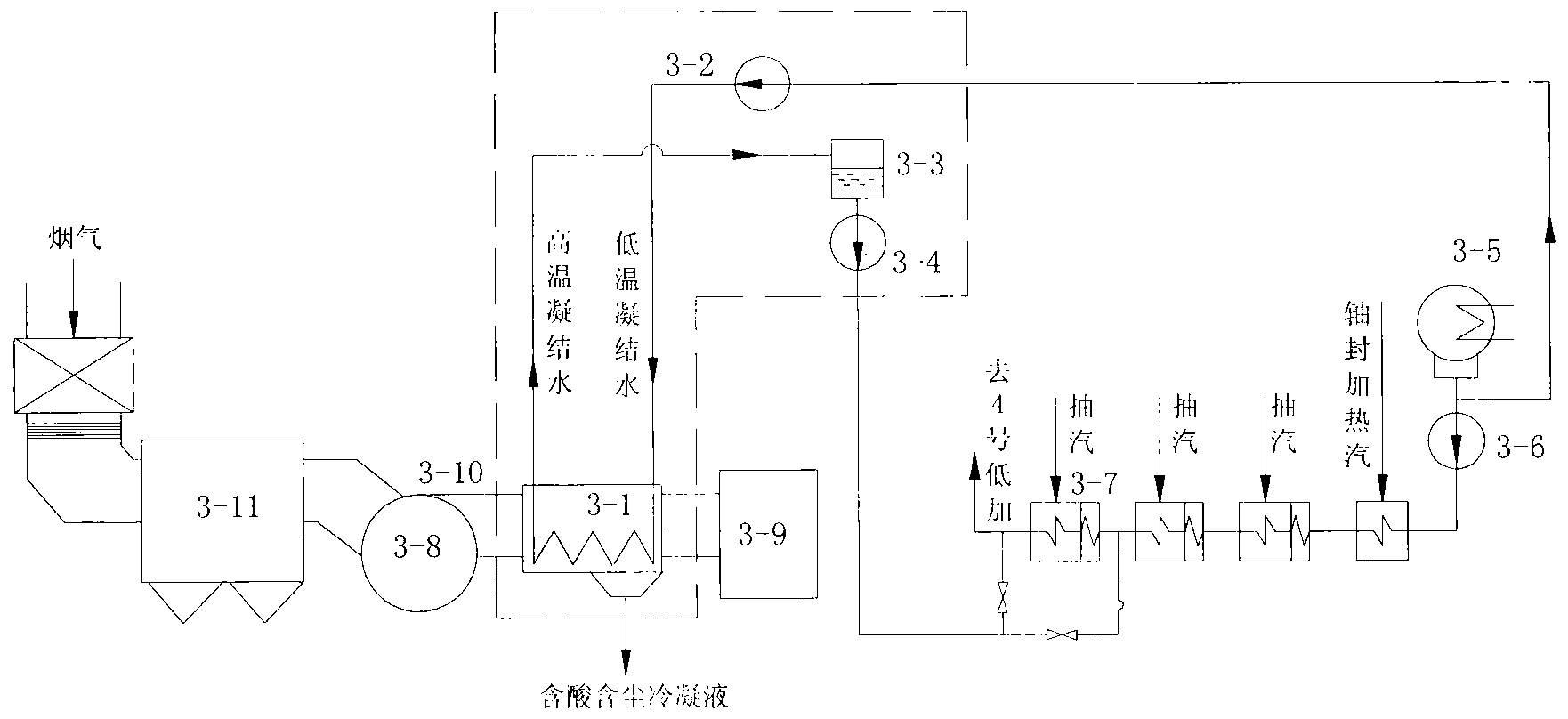

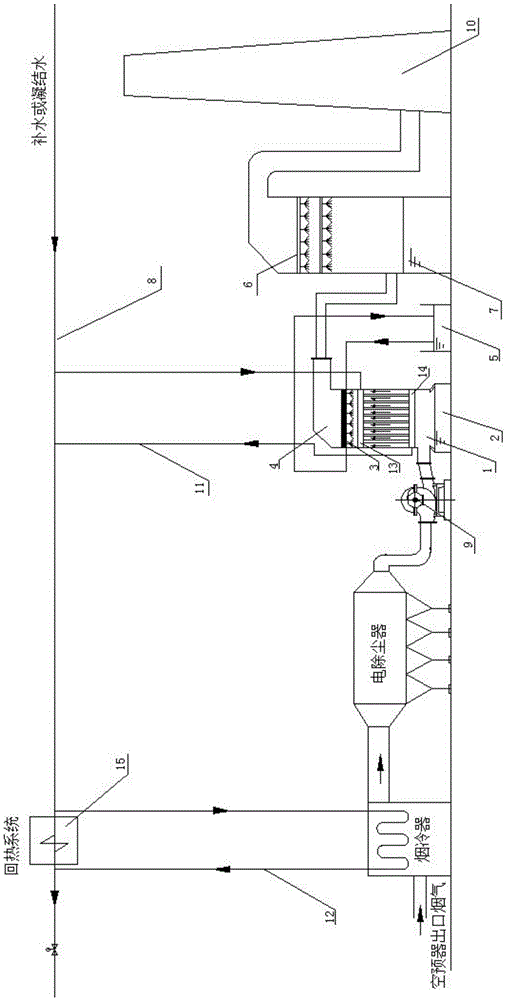

Blast furnace gas boiler flue gas waste heat deep recycling system

InactiveCN103939932ALower exhaust gas temperatureHigh thermal efficiencyFeed water supplyCombustion processAir preheaterFlue gas

The invention discloses a blast furnace gas boiler flue gas waste heat deep recycling system. The shortcoming that in the prior art, blast furnace gas boiler tail flue gas waste heat is not fully used is overcome. The blast furnace gas boiler flue gas waste heat deep recycling system comprises a boiler, an air preheater, a flue gas circulating unit and a condensation water circulating unit. The flue gas circulating unit comprises a second-level flue gas-coal gas heat exchanger, a second-level flue gas-condensation water heat exchanger, a first-level flue gas-coal gas heat exchanger, an induced draft fan and a first-level flue gas-condensation water heat exchanger which are connected in series in sequence on a flue gas pipeline. The condensation water circulating unit comprises a steam condenser, a steam condensing water pump, a shaft seal heater, a first-level low-pressure heater, a second-level low-pressure heater and a third-level low-pressure heater which are connected in series in sequence on a main condensation water pipeline. Boiler exhaust smoke temperature can be effectively lowered, boiler thermal efficiency is improved, and then the using rate of boiler flue gas waste heat is improved.

Owner:HUATIAN ENG & TECH CORP MCC

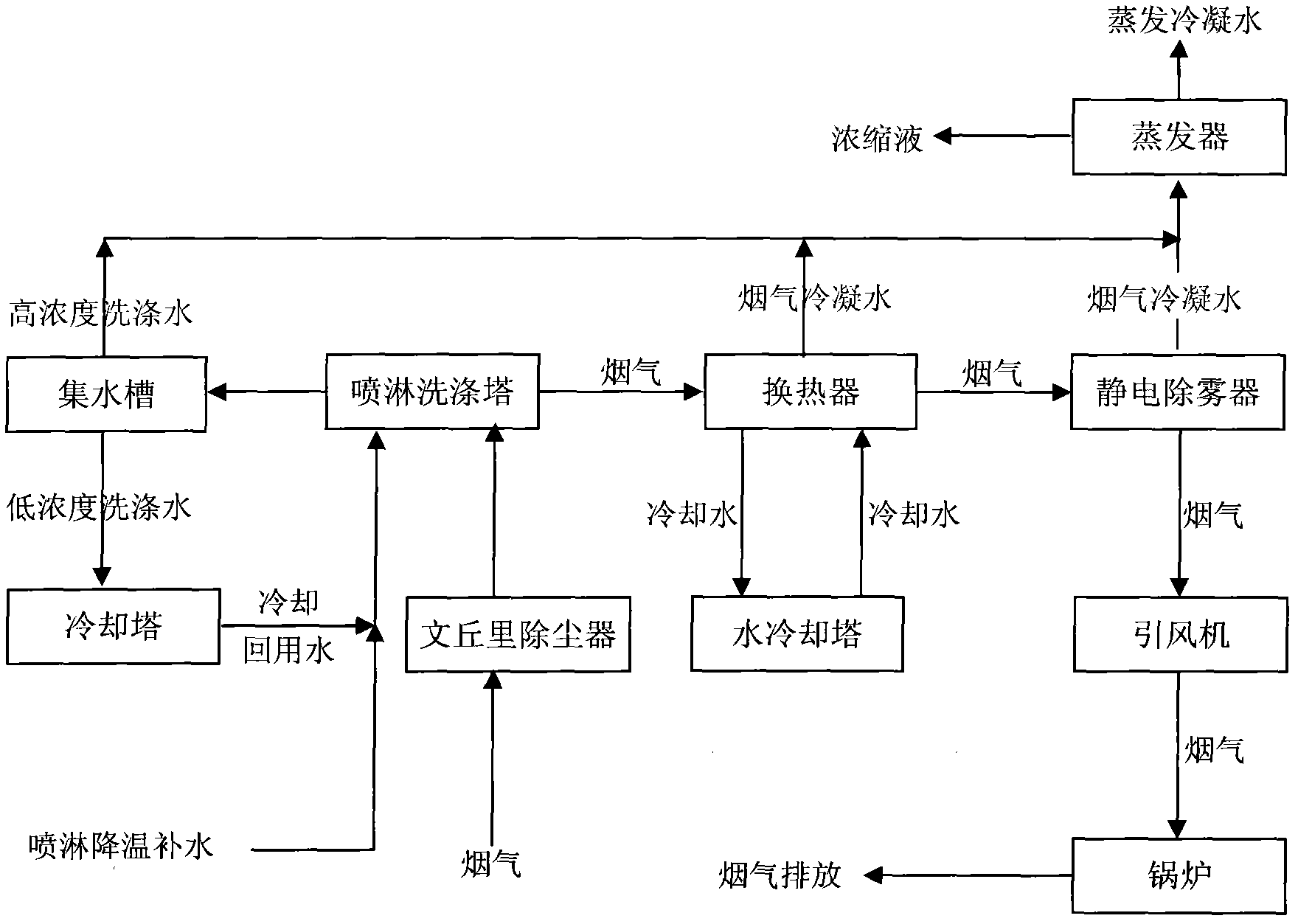

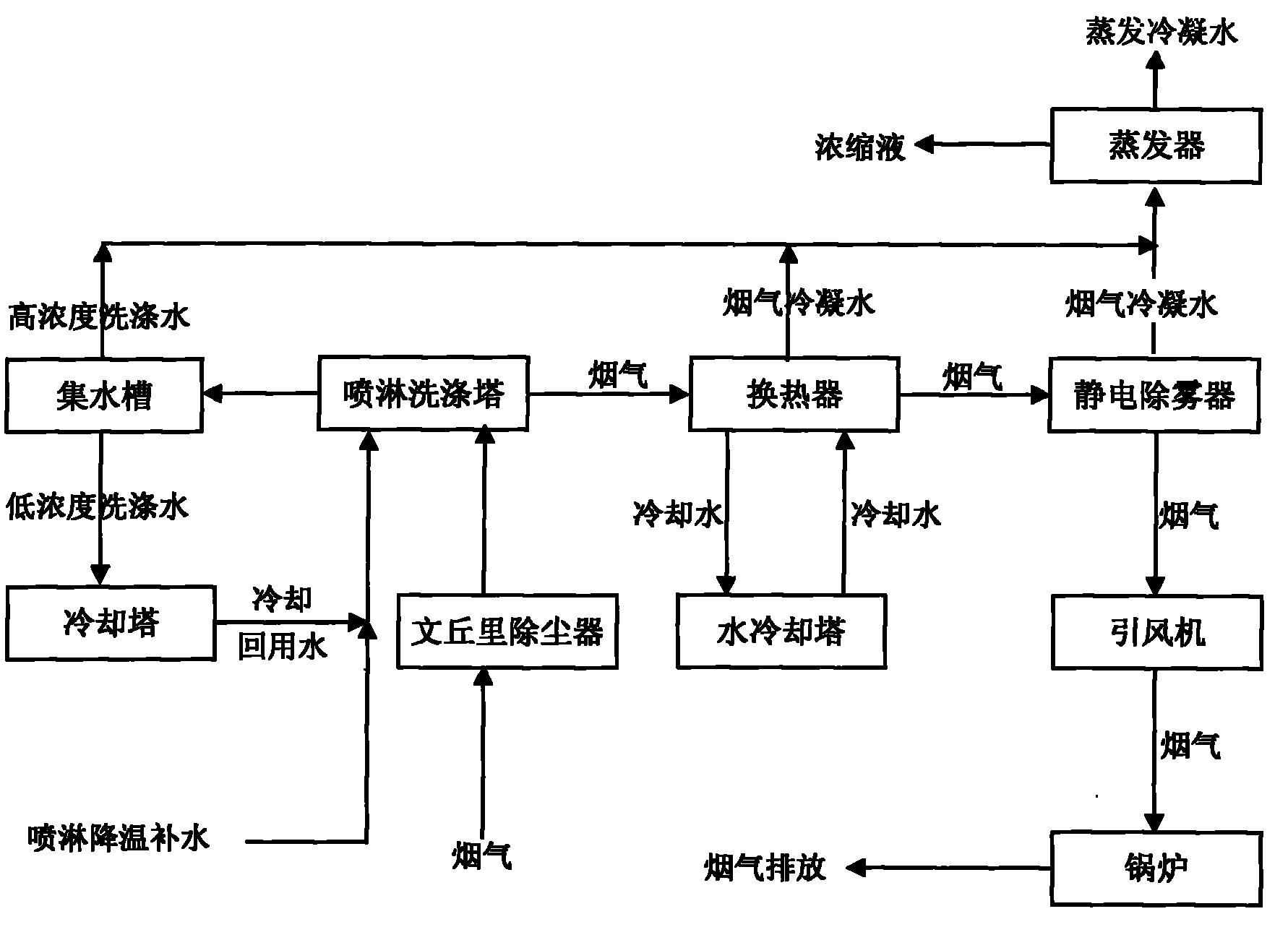

Spraying granulation flue gas treatment system and process

ActiveCN102210959ACause secondary pollutionReduce the temperatureCombination devicesElectrostatic separationEngineeringTreatment system

The invention discloses a spraying granulation flue gas treatment system and a spraying granulation flue gas treatment process. The process flow comprises the following steps that: flue gas passes through a venturi, a spraying spray scrubber, a heat exchanger, an electric demister and a draught fan, and is introduced into a boiler to serve as inlet air to support combustion, and is discharged through a chimney. Meanwhile, wastewater generated through condensation of the flue gas is evaporated and concentrated. The invention reduces pollutant emission and water consumption, increases the yield of a spraying granulation product, and has certain economic benefit, environmental benefit and social benefit.

Owner:内蒙古阜丰生物科技有限公司

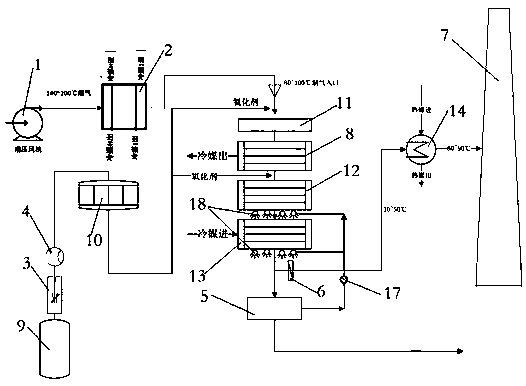

Low temperature flue gas waste heat utilization, desulphurization, denitration and white smoke elimination integrated system of industrial furnace

PendingCN109210955ADoes not affect normal production operationReduce consumptionEmission preventionIncreasing energy efficiencyPollutionIntegrated systems

The invention discloses a low temperature flue gas waste heat utilization, desulphurization, denitration and white smoke elimination integrated system of an industrial furnace. The system comprises asupercharging wind turbine, a multi-refrigerant heat exchange system, a flow control valve, a flow meter, a flue gas condensation and denitration reactor, an alkaline pool, a demisting filter and a chimney. The system has the following advantages that convenience is provided for operation of the industrial furnace, and online construction is realized; fuel consumption is reduced, and the thermal efficiency of the industrial furnace is improved; the service life of system equipment and parts is ensured; flue gas waste heat utilization, desulphurization, denitration and white smoke elimination are integrated; the denitration efficiency is >=80% and the desulphurization efficiency is >=90%; water consumption is reduced; the land occupation area is reduced, and the cost is reduced; droplet water in the discharged flue gas is reduced; the concentration of pollutants in the local region near the chimney is reduced; energy is saved, environment pollution is reduced, and visual pollution is eliminated; energy-saving, emission-reducing, water-saving and steam-saving are all realized; the operation cost is low; and the application range is wide.

Owner:上海孚旺炉业有限公司 +1

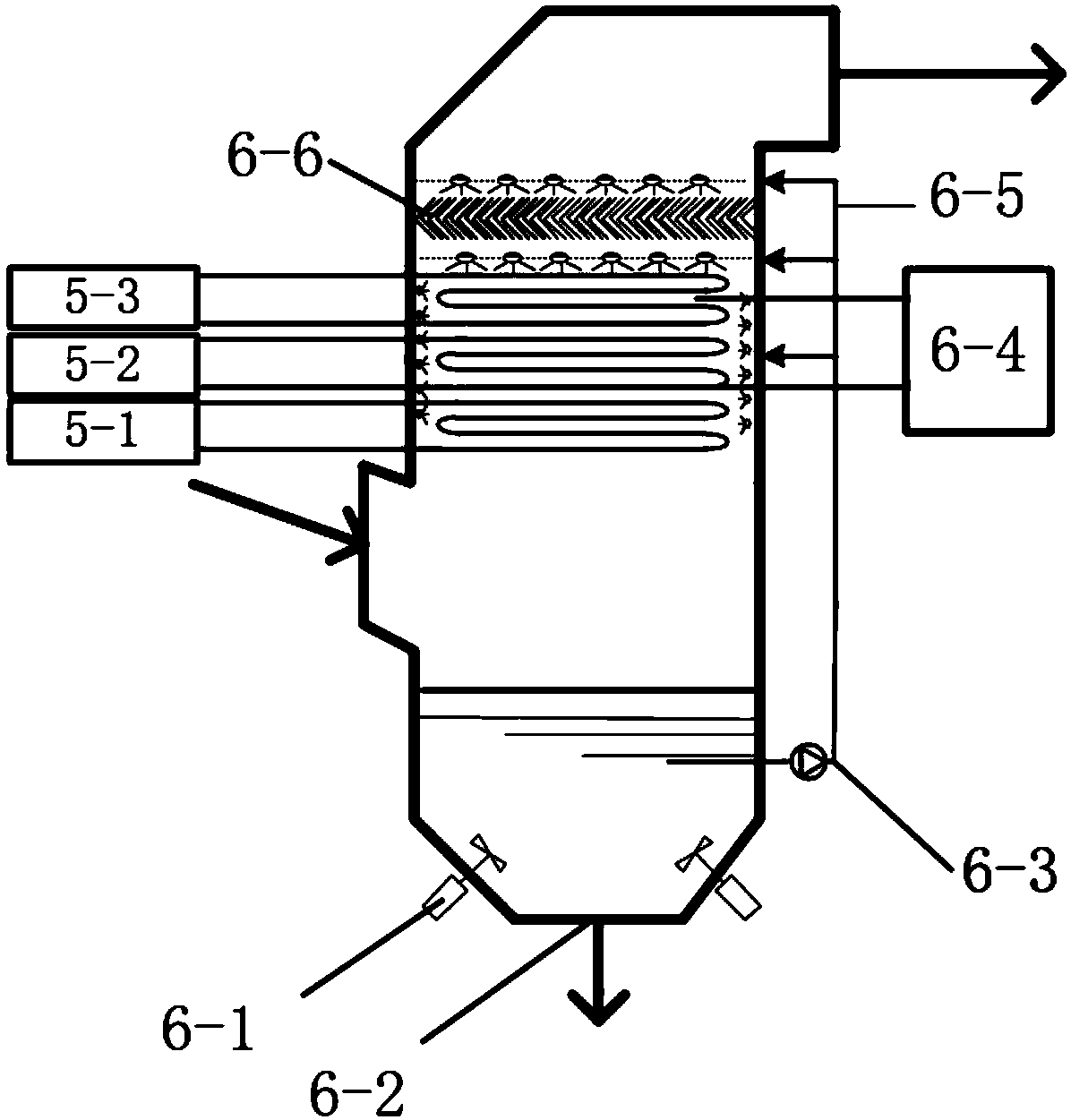

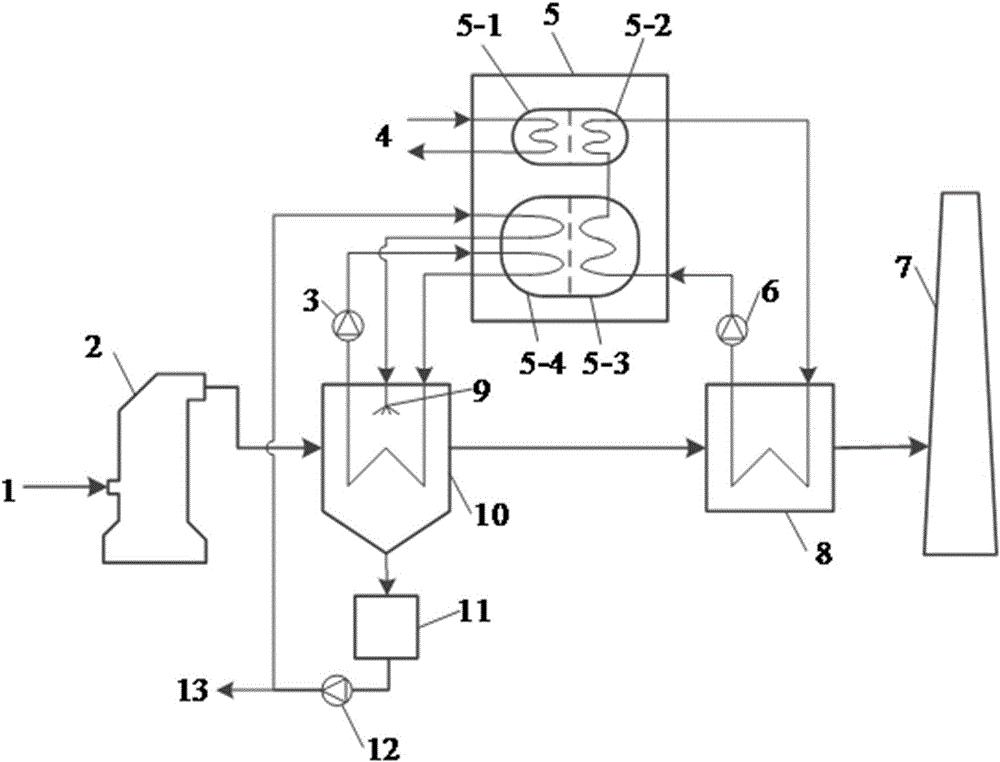

Energy-saving type thermal power plant flue gas moisture recovering system

InactiveCN106440465AImprove energy utilizationReduce energy consumptionEnergy efficient heating/coolingEmission preventionThermal energyAbsorption heat pump

The invention provides an energy-saving type thermal power plant flue gas moisture recovering system. The energy-saving type thermal power plant flue gas moisture recovering system comprises a wet-type desulfurizing tower, a flue gas condensation system, an absorption heat pump, a flue gas reheater and a chimney. The flue gas condensation system comprises an internal heat exchange tube bank, a spraying device, a condensation water tank and a circulating pump. The absorption heat pump comprises an absorber, a condenser, an evaporator and a generator. According to the energy-saving type thermal power plant flue gas moisture recovering system disclosed by the invention, moisture in flue gas can be recovered, and meanwhile the recovering system is matched with the absorption heat pump to recover low-grade waste heat in the flue gas, and obtained medium-grade heat energy can be used for a dry flue gas exhaust flue gas reheating system and other systems, so that energy consumption is reduced, water consumption cost is also reduced, pollutant handling capacity is improved, and the comprehensive energy utilization rate of a thermal power plant is increased.

Owner:ZHEJIANG ZHENENG ENERGY SAVING TECH

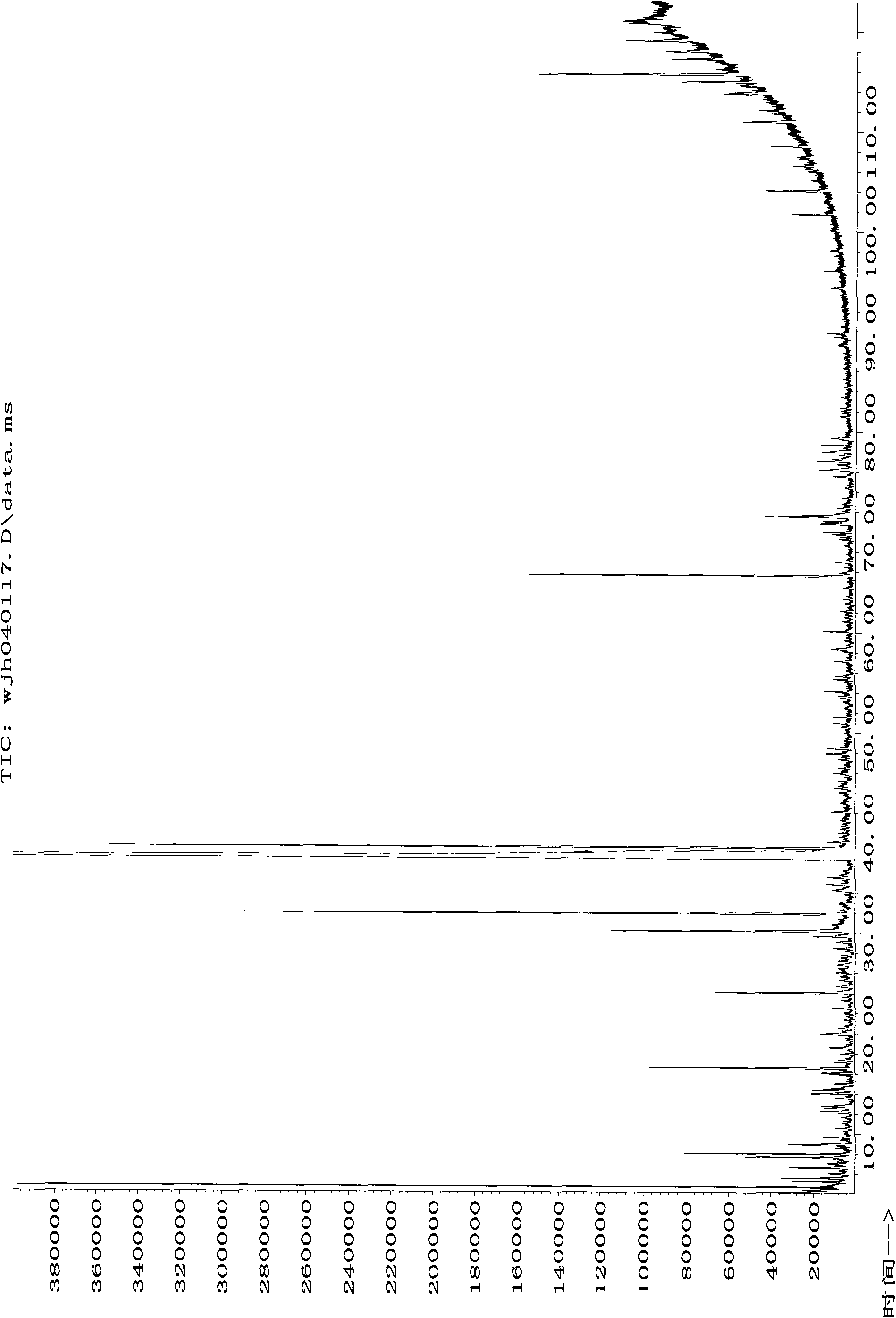

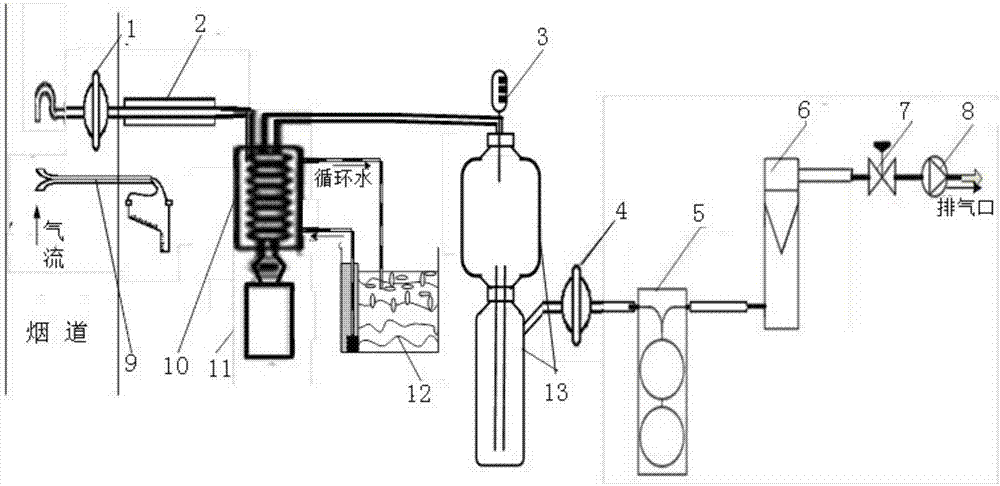

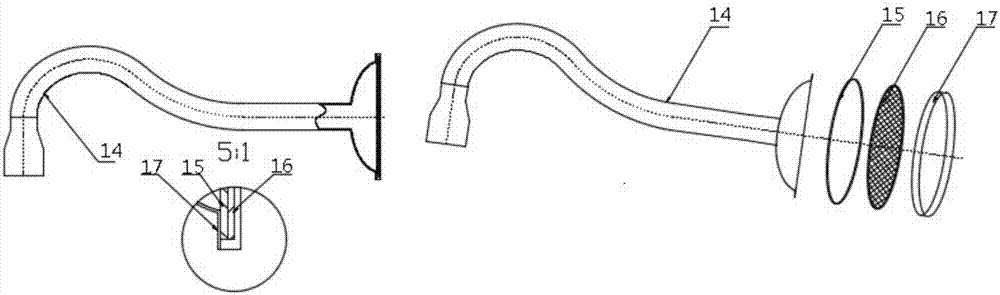

Sampling device and determination method of total particulate matters in exhaust gas

ActiveCN107421787AAccurate assessment of actual emission levelsAccurate Emission RateWeighing by removing componentWithdrawing sample devicesFlow transducerHigh humidity

The invention relates to a sampling device and a determination method of total particulate matters in exhaust gas. The sampling device comprises a combined heating and sampling gun, a glue gas condenser, a flue gas buffer, a CPM-F filter membrane clamp, a flue gas drier, a flow sensor, a flow automatic tracking and adjusting device and an exhaust device which are successively connected through a connecting pipeline. The sampling device and the determination method provided by the invention are suitable for determining total particulate matters in high humidity exhaust gas in a low concentration FPM emission level and can accurately evaluate the actual emission level of the particulate matters in the high humidity exhaust gas, in particular, the emission condition of fine particulate matters.

Owner:BEIJING MUNICIPAL ENVIRONMENTAL MONITORING CENT

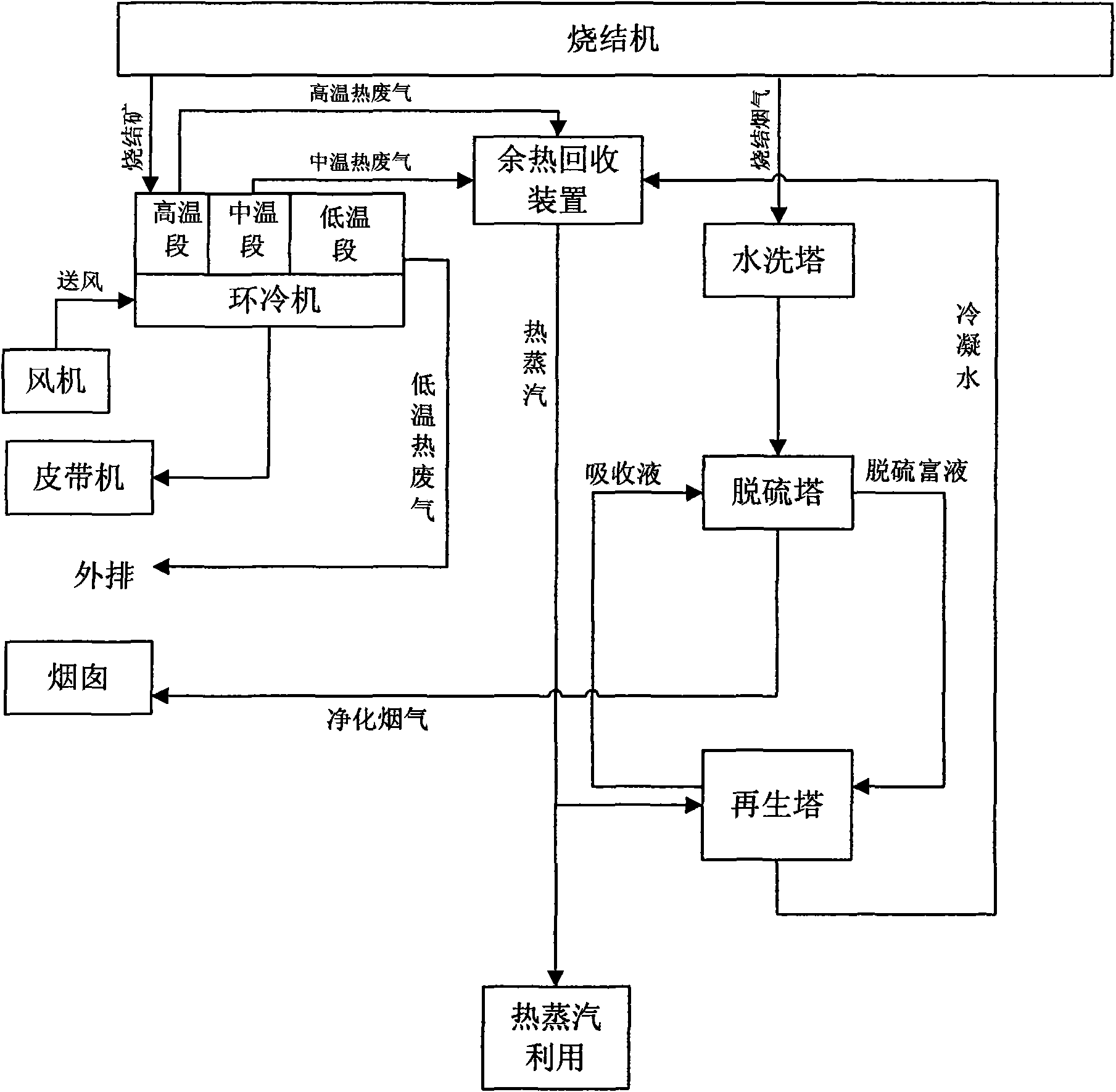

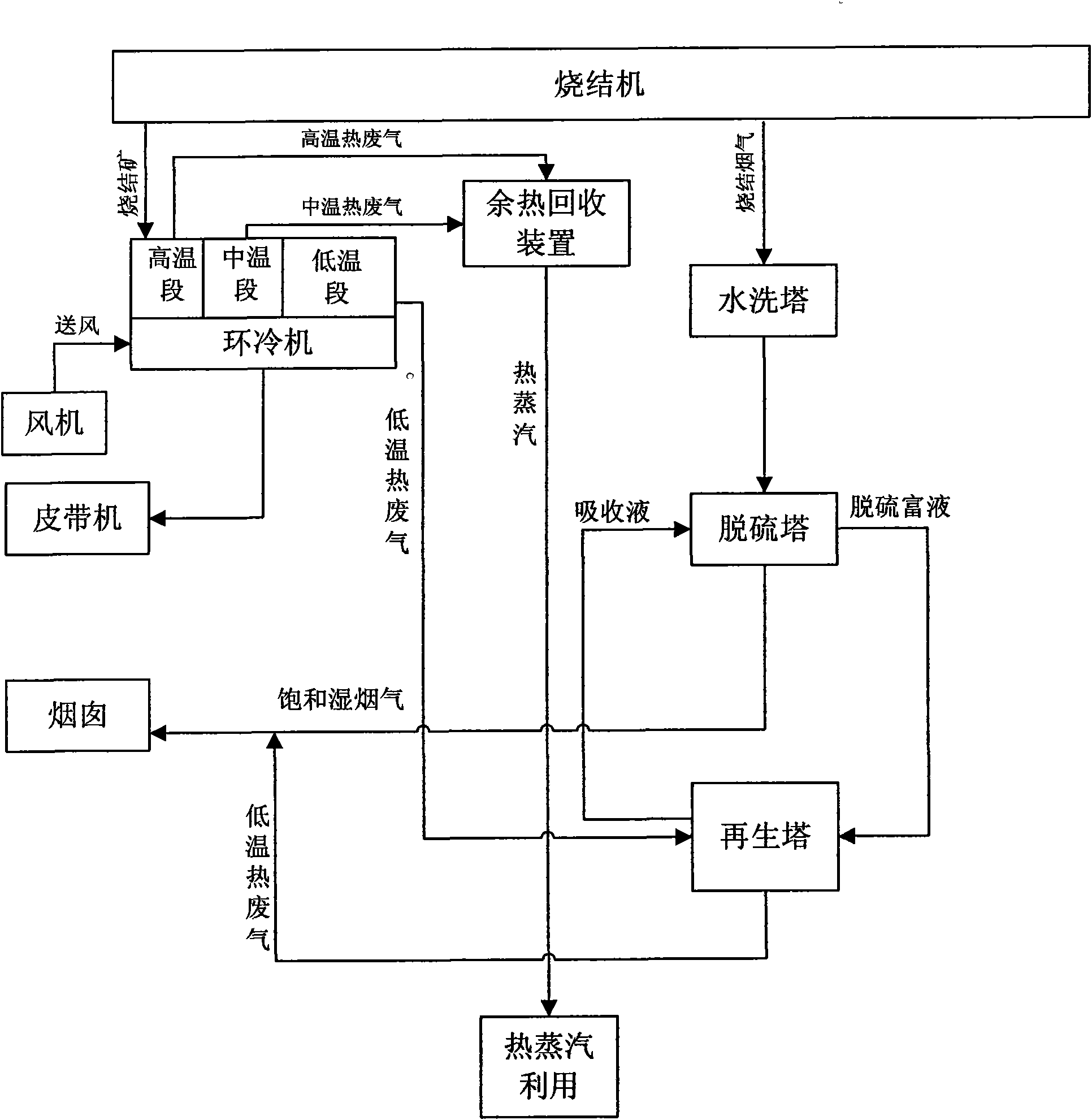

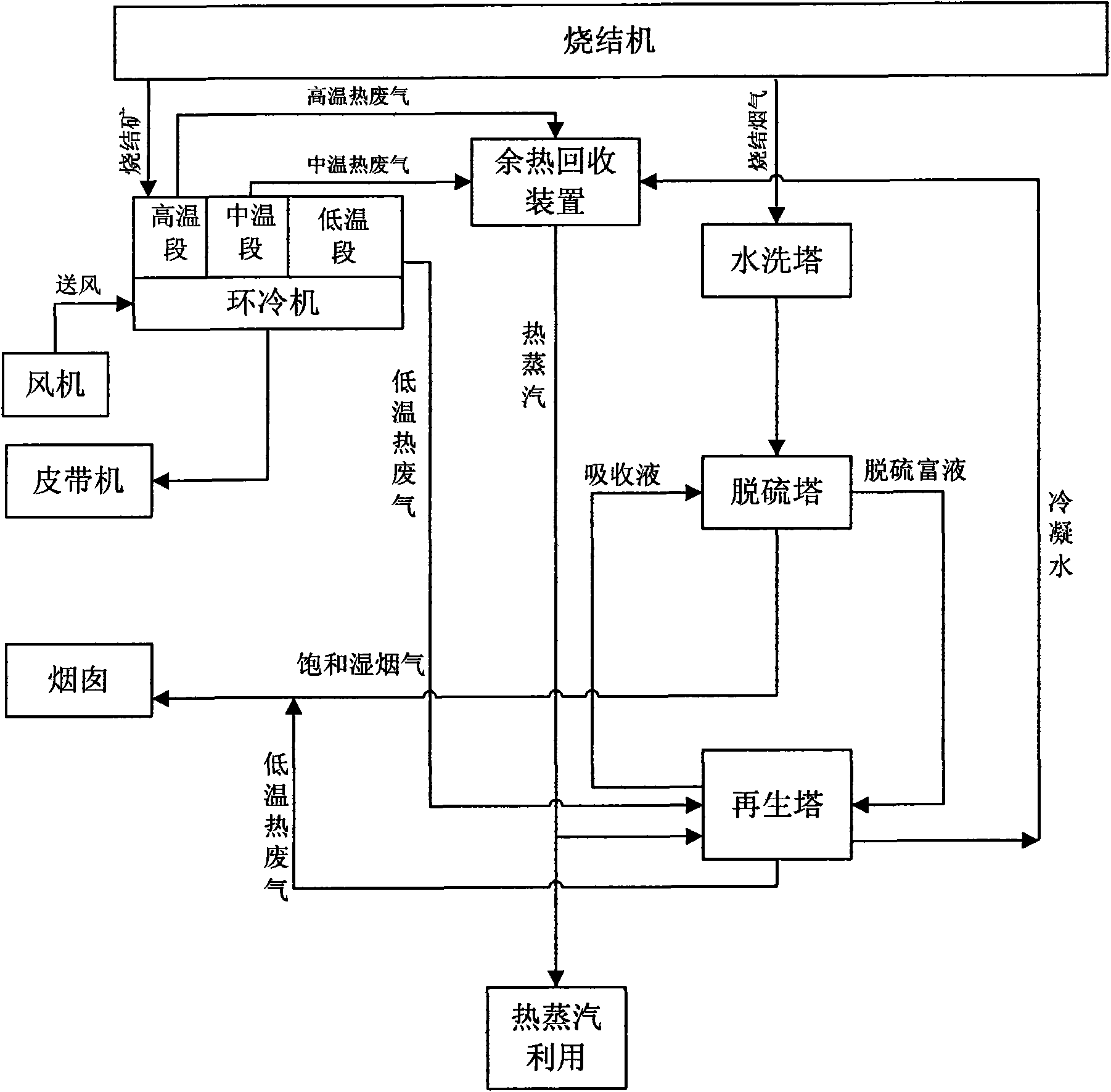

Flue gas desulfurization process for comprehensively utilizing hot waste gas of circulation cooler in sintering process

ActiveCN101569820AGuaranteed normal operationReduce consumptionDispersed particle separationFurnace typesFlue gasExhaust fumes

The invention discloses a flue gas desulfurization process for comprehensively utilizing hot waste gas of a circulation cooler in a sintering process, which comprises two main steps of washing and dedusting sintering flue gas produced by a sintering machine and performing cyclical absorption and desulphurization by absorption liquid. Sintering ore produced by the sintering machine is cooled by the recirculation cooler, a desulphurization rich solution produced in the step of the cyclical absorption and desulphurization of the absorption liquid is recycled through a regeneration tower, low-temperature hot waste gas produced in a low-temperature region of the recirculation cooler is conveyed to the regeneration tower, and the low-temperature hot waste gas is utilized to heat and decompose the desulphurization rich solution in the regeneration tower. The flue gas desulfurization process fully makes use of the hot waste gas resource of the circulation cooler, has the advantages of less energy consumption, low cost, simple operation and the like, and can effectively reduce the occurrence of phenomenon of flue gas condensation.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

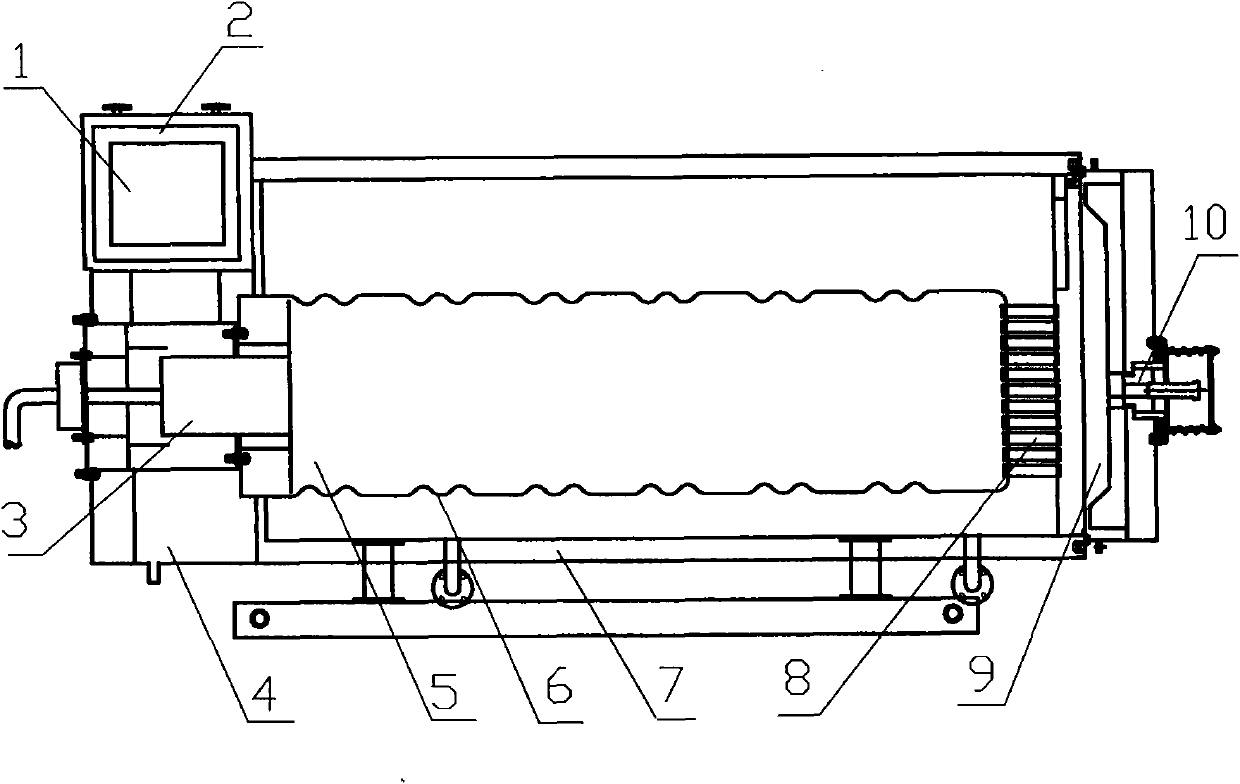

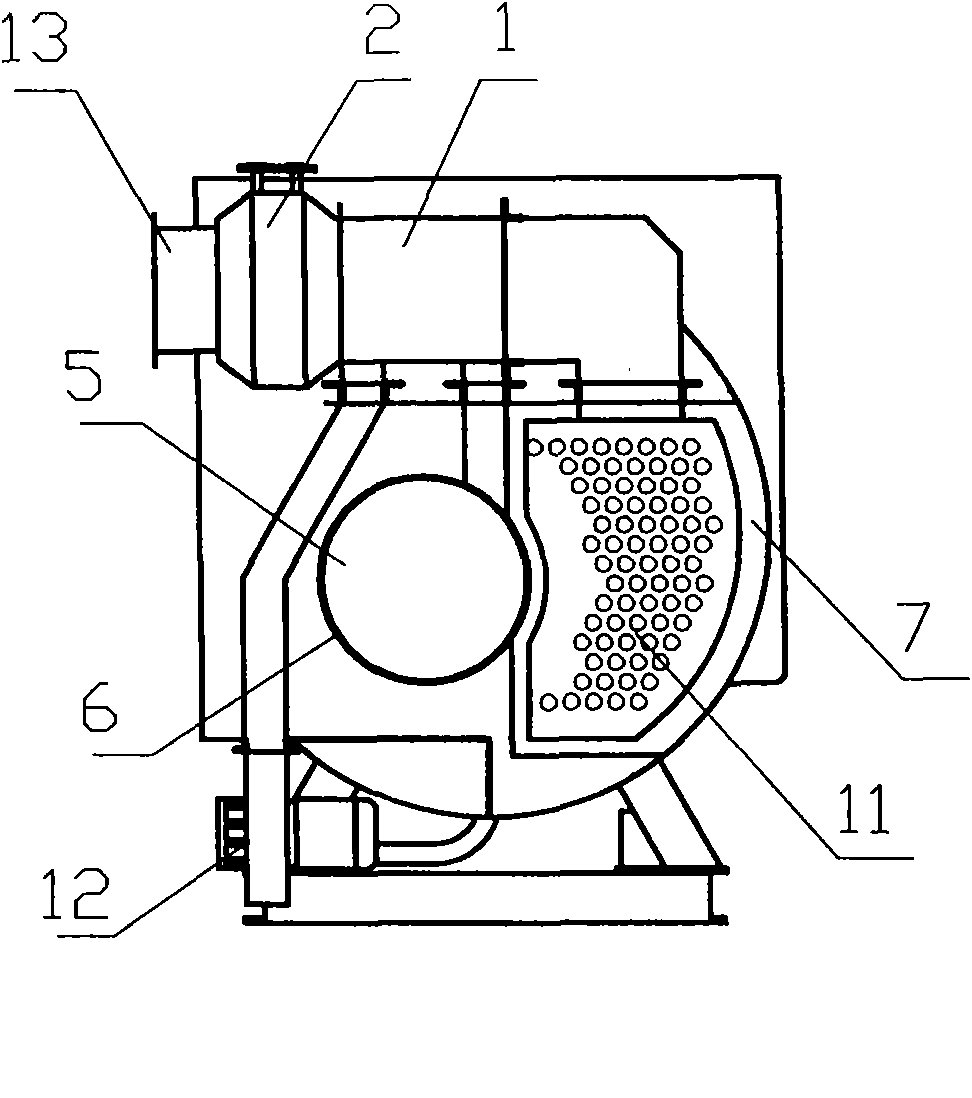

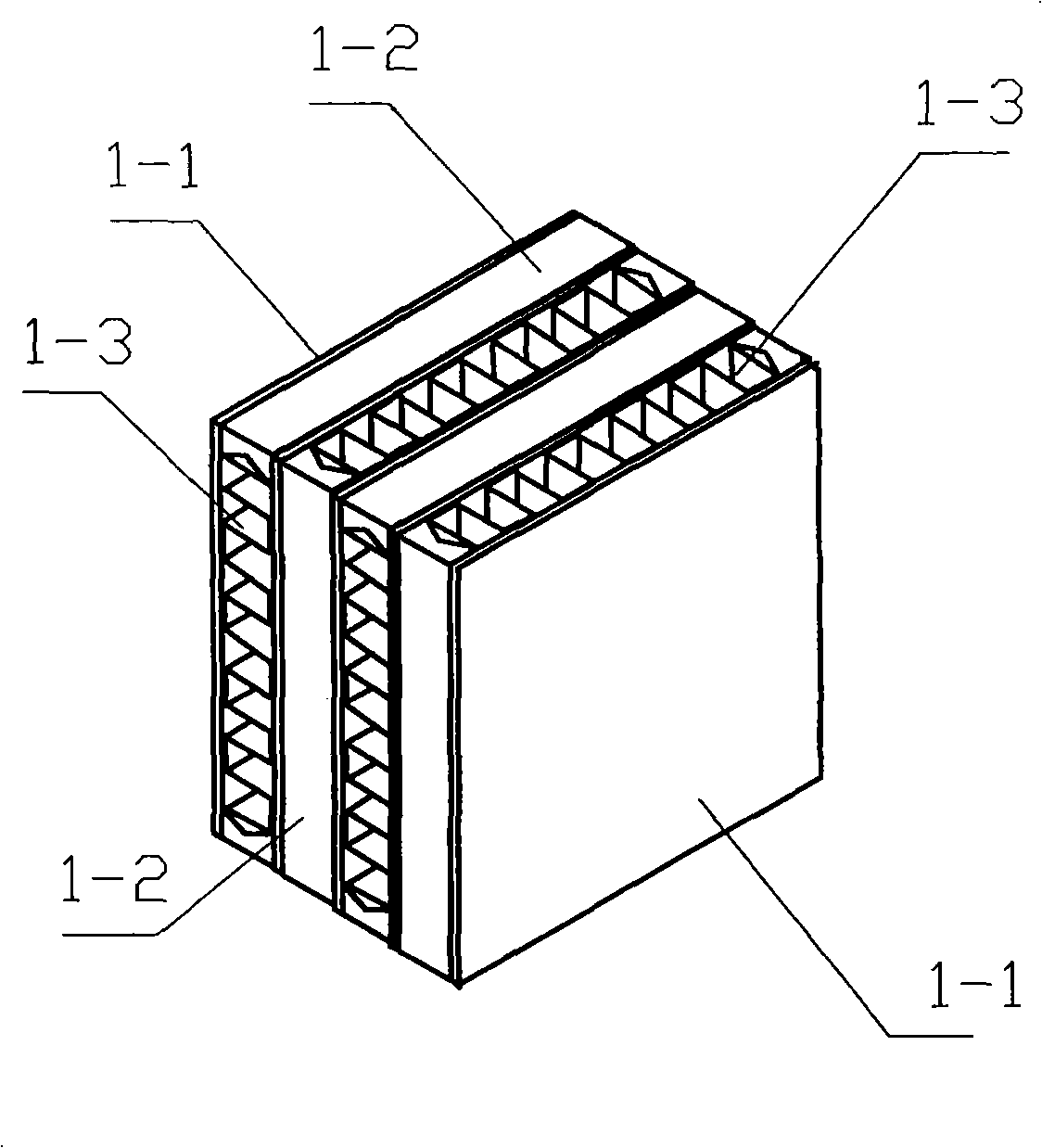

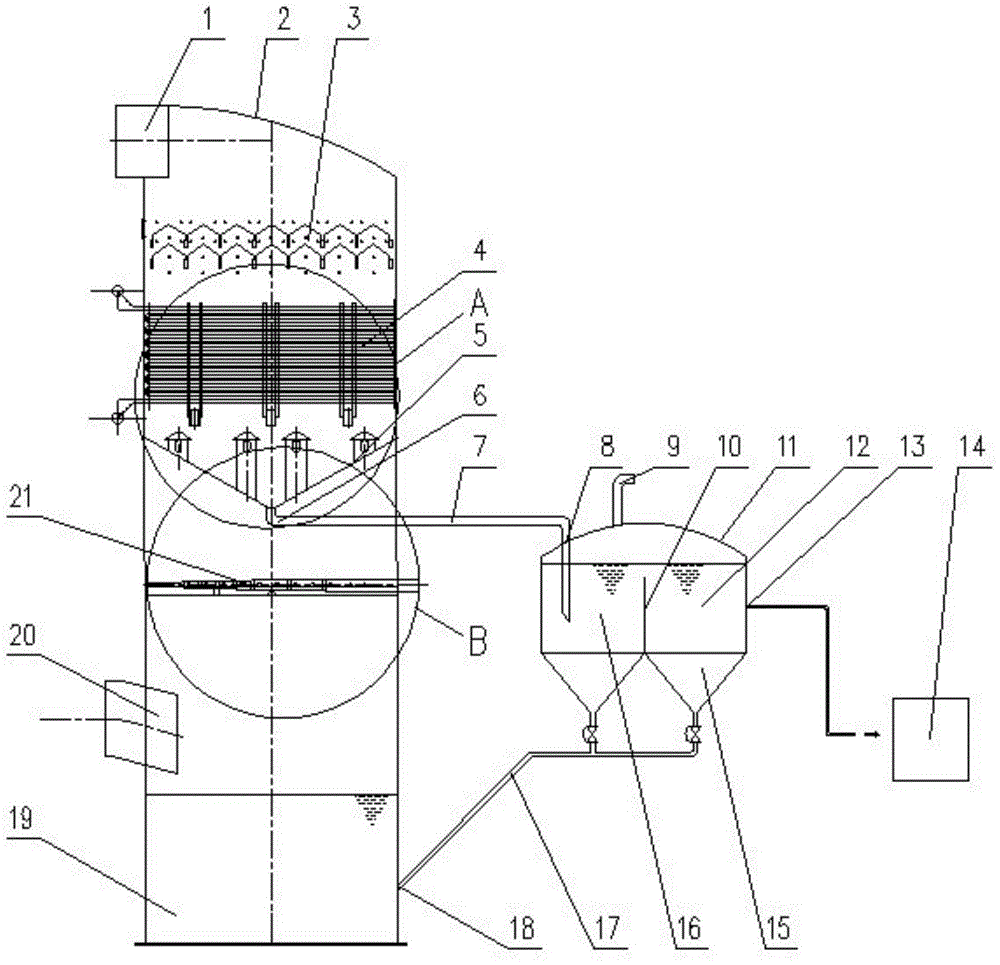

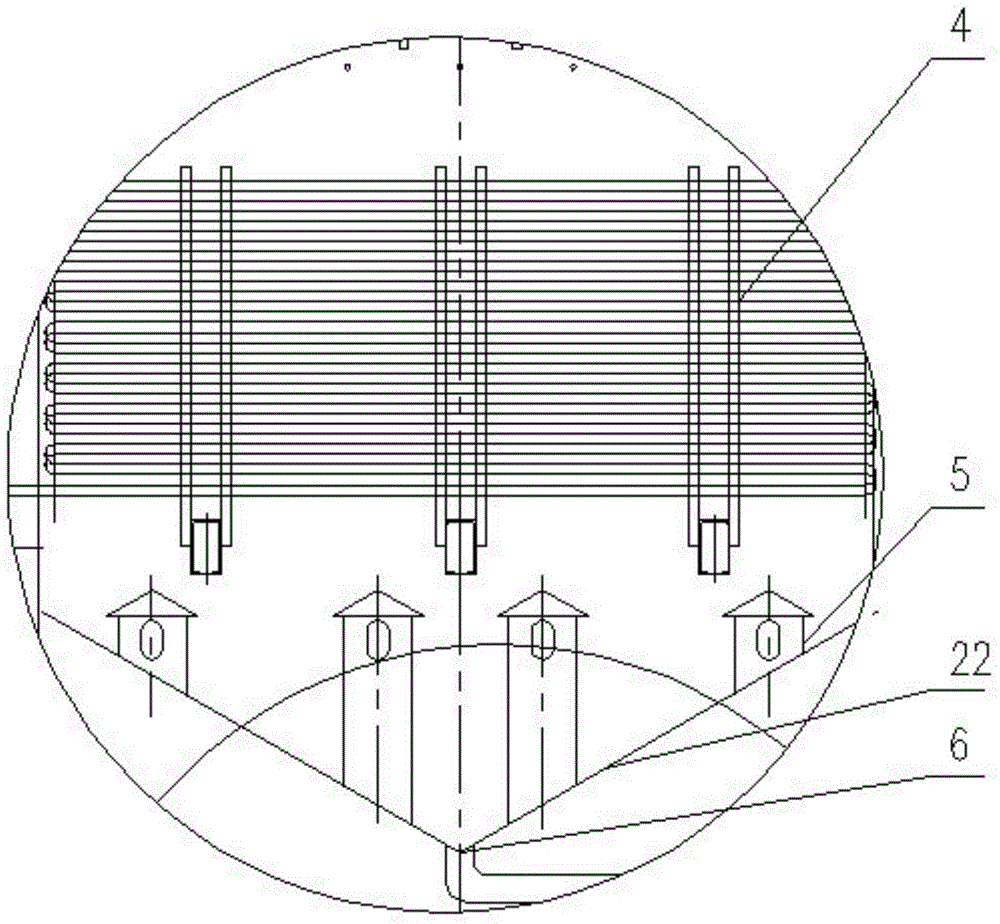

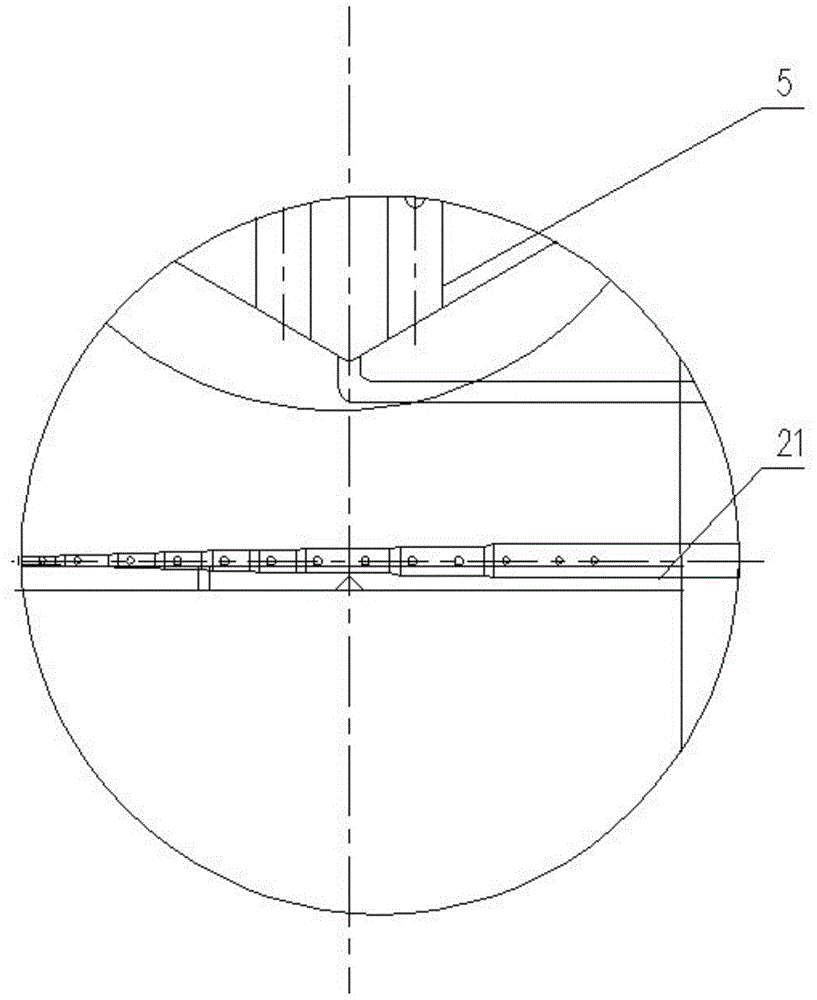

Integrated flue gas condensing waste heat recovery boiler

InactiveCN101793434AImprove recycling effectCompact structureCombustion processEnergy efficient heating/coolingAir preheaterSteam condensation

The invention relates to an integrated flue gas condensing waste heat recovery boiler, and belongs to the field of heating equipment, in particular to an oil-fired and gas-fired two-return-stroke shell type hot water or steam condensing boiler. The technical scheme of the invention is as follows: an air inlet of a plate-fin type air pre-heater is connected with a blower, and an air outlet is connected with the air inlet of a burner; a flame hole of the burner is connected with the left end of a hearth, and the shell of the hearth is of a corrugated flue; the right end of the corrugated flue is of a corrugated flue top, and the corrugated flue top is communicated with the front wall of a back smoke box by a convection tube bank; the back smoke box is communicated with a convection heating surface, and the convection heating surface is communicated with a front smoke box; the front smoke box is communicated with a flue gas inlet of the air pre-heater, and the flue gas outlet of the air pre-heater is communicated with a flue gas inlet of a condenser; and the flue gas outlet of the condenser is communicated with a smoke exhaust port, and the parts and the boil shell form an integrated structure. The invention has the advantages: the air pre-heater, the flue gas condenser and the boiler are integratively designed, so that the whole structure of the boiler is more compact, the corrosion-resistant ability is strong, the equipment is safer, the use is stable and reliable, and the service life is longer.

Owner:ANYANG FANGKUAI BOILER

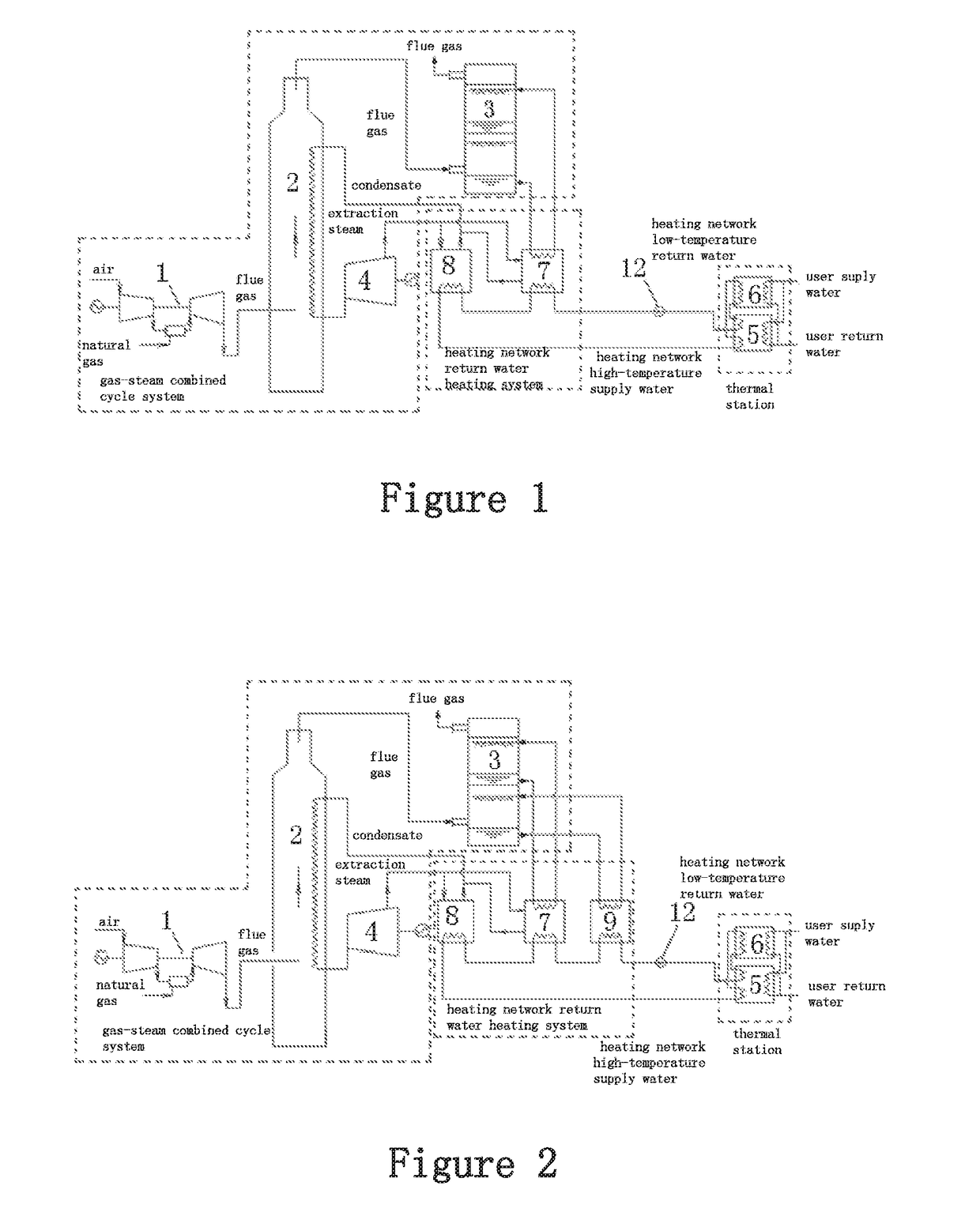

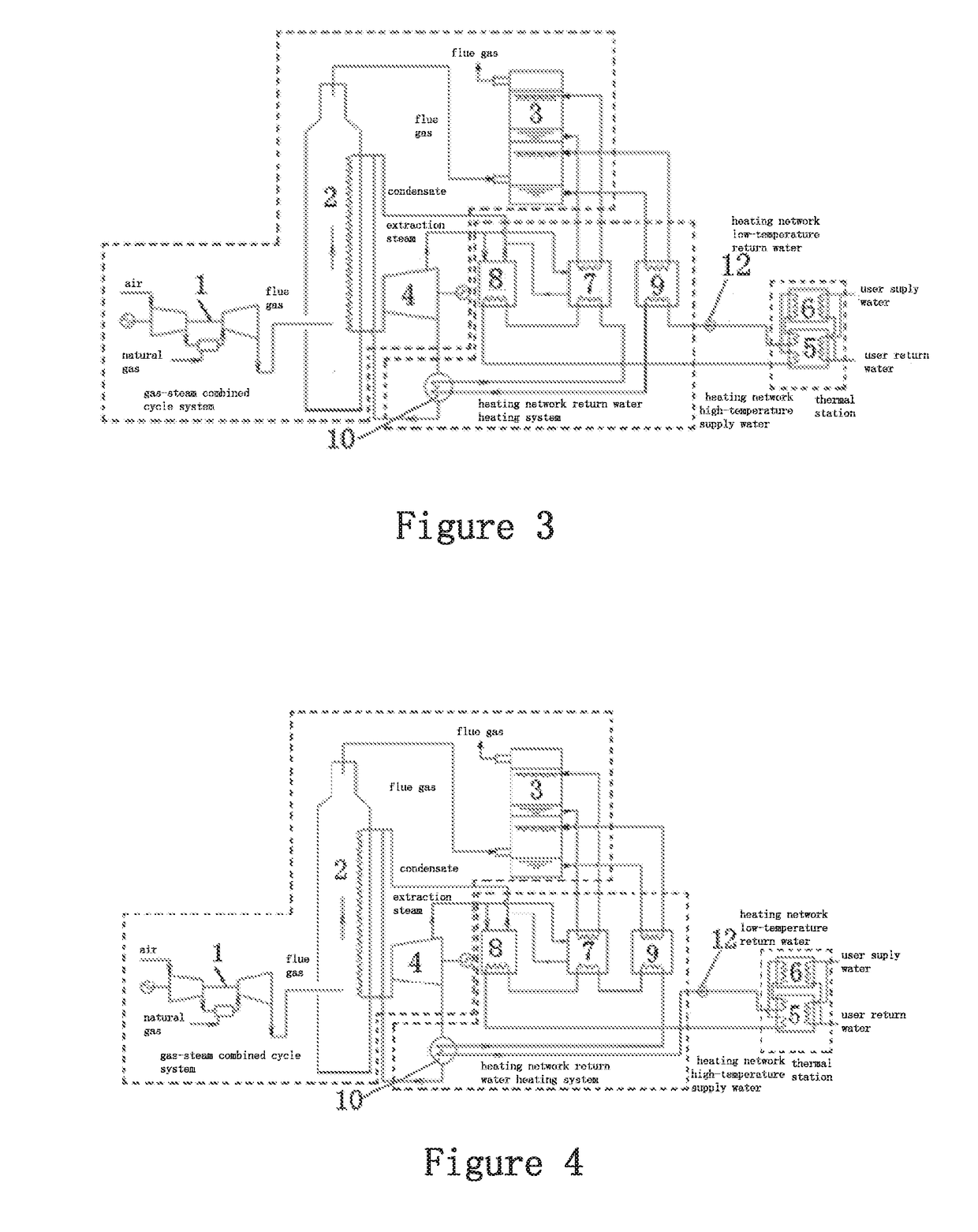

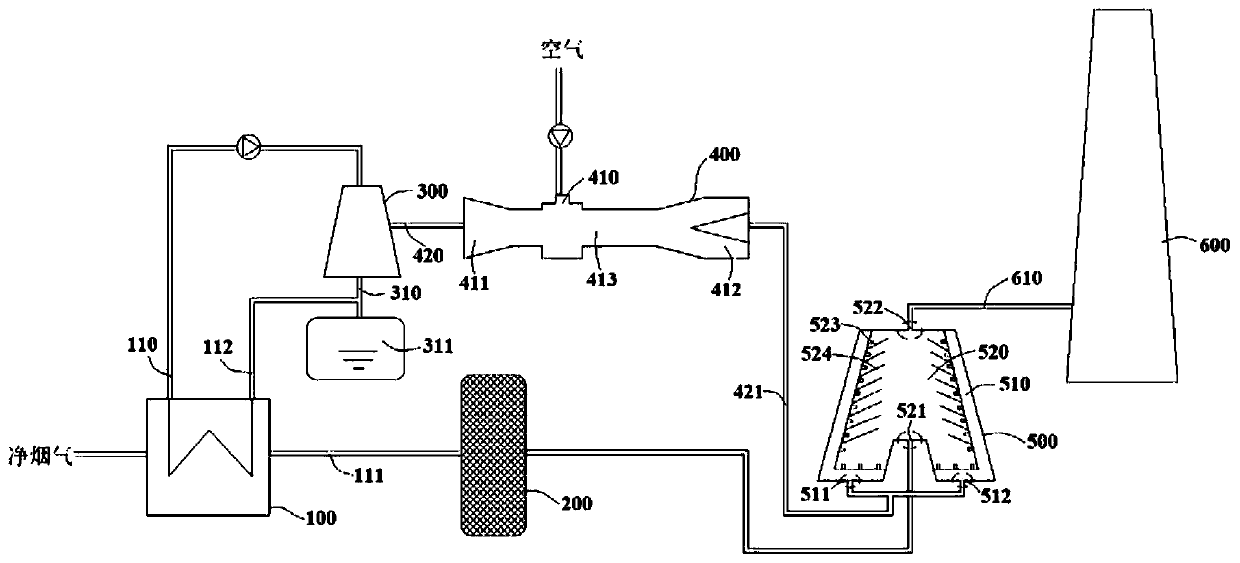

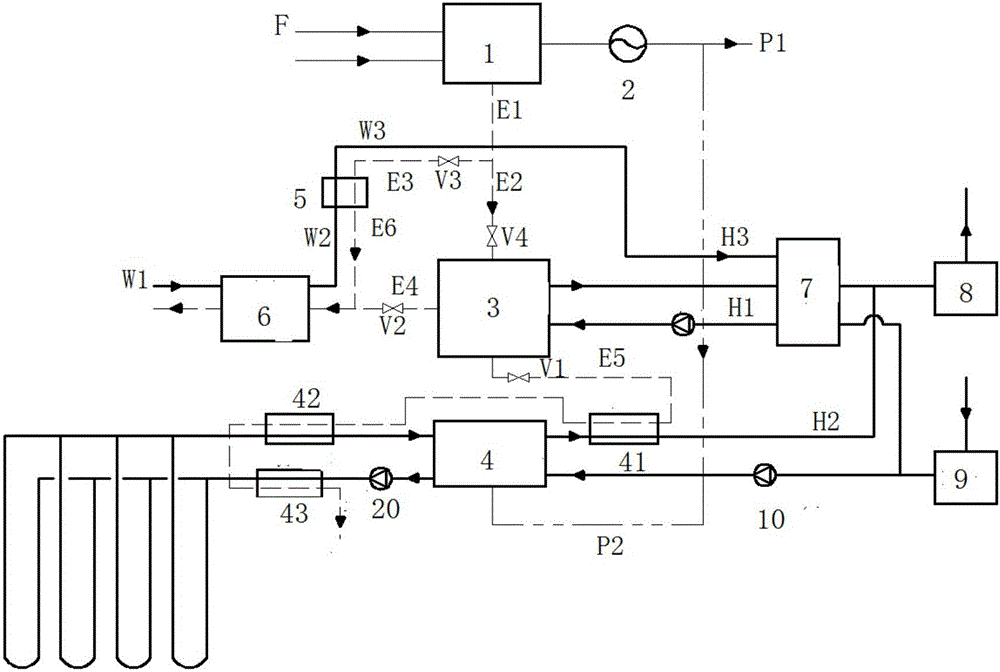

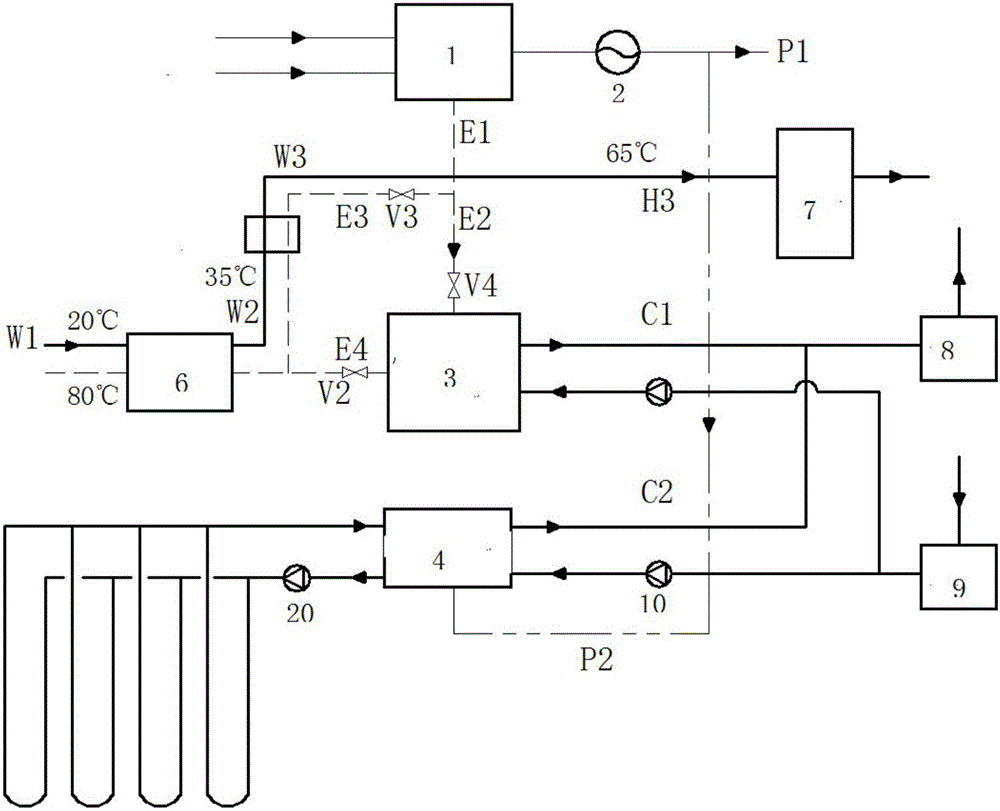

Gas-steam combined cycle centralized heat supply device and heat supply method

ActiveUS20180223699A1Improve utilization efficiencyReduce energy consumptionInternal combustion piston enginesRecuperative heat exchangersFlue gasAbsorption heat pump

The present invention relates to a gas-steam combined cycle centralized heat supply device and a heat supply method. The gas-steam combined cycle centralized heat supply device comprises a gas-steam combined cycle system connected with a thermal station through a heating network return water heating system; the gas-steam combined cycle system comprises a gas turbine connected with a direct contact type flue gas condensation heat exchanger and a steam turbine via a waste heat boiler; the thermal station comprises a hot water type absorption heat pump and a water-water heat exchanger; the heating network return water heating system comprises a steam type absorption heat pump for recovering flue gas waste heat and a steam-water heat exchanger. The present invention can be widely applied to the industry of power plant waste heat recovery.

Owner:TSINGHUA UNIV

Boiler flue gas white smoke removal system

PendingCN110882611AHeating evenlyEduce condensation efficiencyGas treatmentDispersed particle separationCold airCooling tower

Belonging to the technical field of environmental protection, the invention discloses a boiler flue gas white smoke removal system. According to the boiler flue gas white smoke removal system, a cooling tower and a vortex tube are arranged between a flue gas condenser and a flue gas heater, and the flue gas condenser and the vortex tube are separated by the cooling tower, thus preventing reductionof flue gas condensation efficiency and heat exchange efficiency caused by mixing of cold air flow and hot air flow. A flow splitting chamber on the outer layer of the flue gas heater is arranged along the circumferential direction of an mixing chamber on the inner layer, the mixing chamber is communicated with the flow splitting chamber through flow guide pipes arranged on the surface of the mixing chamber, under the flow splitting effect of the flow guide pipes, the hot air flow generates uniform and stable thermal shunts, thus achieving uniform heating of flue gas in the mixing chamber; and the thermal shunts cannot press flue gas into a flue gas inlet pipeline due to too large air pressure, thus effectively preventing backflow of flue gas and improving the white smoke removal effect.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Combined cooling heating and power supply composite energy supply system based on waste heat deep recycling

ActiveCN105841396AReduce the burden onIncrease the thermoelectric ratio adjustment rangeFluid heatersClimate change adaptationRecuperatorAbsorption heat pump

The invention belongs to the correlated technical field of energy utilization and discloses a combined cooling heating and power supply composite energy supply system based on waste heat deep recycling. The combined cooling heating and power supply composite energy supply system comprises a gas turbine, a generator set, a potassium bromide absorption heat pump unit, a magnetic suspension heat pump unit, a high-temperature flue gas heat exchanger, a flue gas condensing heat exchanger and the like. A flue gas outlet of the gas turbine is divided into two pipelines, the first pipeline is connected with the flue gas type potassium bromide absorption heat pump and drives the flue gas type potassium bromide absorption heat pump to achieve refrigerating and heating, and the second pipeline is connected with the high-temperature flue gas heat exchanger and used for heating tap water preheated through the flue gas condensing heat exchanger to a required temperature. An outlet of the high-temperature flue gas heat exchanger is connected with a flue gas inlet of the flue gas condensing heat exchanger. In addition, one part of electricity generated through the gas turbine is supplied to users, and the other part of the electricity generated through the gas turbine is used for driving the magnetic suspension heat pump unit to conduct refrigerating and heating. According to the combined cooling heating and power supply composite energy supply system based on waste heat deep recycling, flexible composite energy supplying can be carried out, and meanwhile waste heat deep recycling can be achieved; and the combined cooling heating and power supply composite energy supply system has the characteristics of being compact in structure, convenient to control, high in adaptability and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

High-efficiency water-saving wet desulphurization absorption tower and application thereof

ActiveCN105056718AReduce water consumptionReduce consumptionDispersed particle separationWater savingFlue gas

The invention relates to a high-efficiency water-saving wet desulphurization absorption tower, comprising an absorption tower body, a slurry storage section, an absorbent circulating spraying pipeline, an in-tower recycle-water collecting device, an in-tower flue gas condensation device, an out-of-tower recycle-water collecting and precipitating device, a demister, a flue gas inlet and a flue gas outlet, wherein the interior of the part of the absorption tower body located between the flue gas outlet and the flue gas inlet is successively provided with, from bottom to top, the absorbent circulating spraying pipeline, the in-tower recycle-water collecting device, the in-tower flue gas condensation device and the demister, and the out-of-tower recycle-water collecting and precipitating device is arranged out of the absorption tower body. The high-efficiency water-saving wet desulphurization absorption tower provided by the invention can highly efficiently recover condensed water in desulphurized flue gas and demister washing water, so energy is saved and water consumption of wet desulphurization system is reduced; thus, water consumption of desulphurization technology is greatly decreased and water saving effect is achieved.

Owner:AEROSPACE ENVIRONMENTAL ENG

Combined cooling, heating and power supply system based on gradient utilization and deep recovery of waste heat

InactiveCN103670791AReduce wasteNo wasteInternal combustion piston enginesEngine componentsFlue gasLithium bromide

The invention discloses a combined cooling, heating and power supply system based on gradient utilization and deep recovery of waste heat. The combined cooling, heating and power supply system comprises a gas engine, wherein a flue gas outlet of the gas engine is divided into a first flue gas pipeline and a second flue gas pipeline. The first flue gas pipeline is connected with a temperature difference power generation device. Flue gas in the first flue gas pipeline is used for driving the temperature difference power generation device to realize thermoelectric conversion. A flue gas outlet of the temperature difference power generation device is connected with a flue gas inlet of a flue gas condensation heat exchanger. The second flue gas pipeline is connected with a flue gas lithium bromide absorption heat pump. Flue gas in the second flue gas pipeline is used for driving the double-effect flue gas lithium bromide absorption heat pump to realize refrigeration or heating. The flue gas outlet connected with the double-effect flue gas lithium bromide absorption heat pump is connected with the flue gas inlet of the flue gas condensation heat exchanger. The flue gas condensation heat exchanger is connected with the external environment. By means of the combined cooling, heating and power supply system based on gradient utilization and deep recovery of the waste heat, the flue gas waste heat with a high temperature can be converted into electric energy, and therefore waste of the flue gas waste heat can be reduced when cold loads or hot loads are insufficient.

Owner:SHANGHAI JIAO TONG UNIV

Geothermal energy compound type gas-fired cooling, heating and power trigeneration system

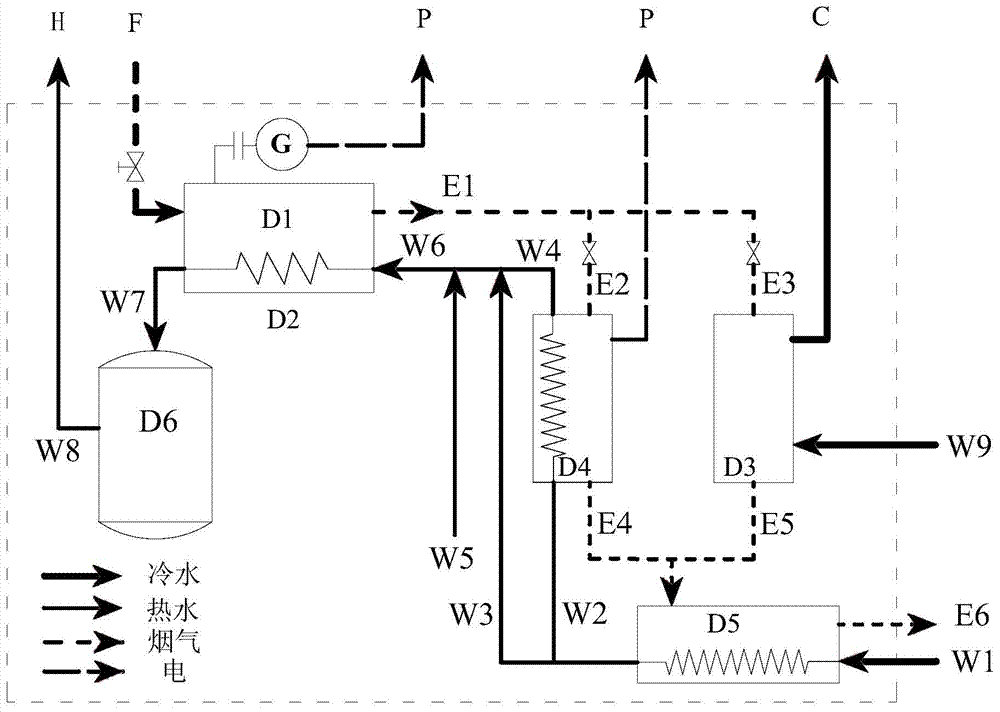

ActiveCN103759469AEmission reductionStrong complementarityOther heat production devicesGeothermal energy generationGas heaterPollutant emissions

The invention relates to a geothermal energy compound type gas-fired cooling, heating and power trigeneration system realizing thorough recovery of flue gas condensation heat. The system comprises a gas engine, a power generator, an absorption heat pump, an electric heat pump, a first spraying type gas-gas heater, a second spraying type gas-gas heater, a ground heat exchanger, a water-water heat exchanger, a heat storage water tank, connection pipes and valves. Heating and cooling can be realized by the system, the system is capable of thoroughly recovering flue gas condensation heat to greatly lower exhaust gas temperature and reduce pollutant emission and further capable of extracting superficial terrestrial heat to realize complementation of fossil energy and renewable energy sources, and improvement of energy utilization efficiency of the system is facilitated.

Owner:TSINGHUA UNIV +1

Pollutant pretreating tower condensing based on flue gas

ActiveCN105536484ASimple internal structureReduce power consumptionUsing liquid separation agentAir quality improvementChemical reactionWater vapor

The invention provides a pollutant pretreating tower condensing based on flue gas. The pollutant pretreating tower comprises a condensation pipe bundle, an alkaline water storage slot, a spraying device, an alkaline liquor circulating sedimentation tank, a condensation pipe bundle external circulating pipeline, upper and lower headers and the like. The flue gas passes through a flue gas cooler and an electrostatic precipitator in sequence and enters the pollutant pretreating tower; heat exchange between the flue gas and condensation water, boiler feed water or replenished water, in the condensation pipe bundle, at about 20 to 38 DEG C occurs, so that steam in the flue gas is cooled and condensed; acid gases such as SO2, CL2, F2 and NOx are reacted with water to generate acid solutions such as H2SO3, H2SO4, HCL and HF; the acid solutions are collected by the alkaline liquor circulating sedimentation tank; meanwhile ammonia gas escaped from the flue gas is also chemically reacted with the acid solutions, so that the escaped ammonia gas can be removed. By arranging the condensation type pollutant pretreating tower disclosed by the invention, pollutants can be removed partially; the structure of a desulfurizing tower is simplified; the pressure of the desulfurizing tower is relieved; the flow resistance of the flue gas is greatly reduced so as to reduce the power consumption of a fan and save energy resources; according to the pollutant pretreating tower disclosed by the invention, the flow path of the flue gas is basically not changed, the change range is small, and the cost is reasonable.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com