Sampling device and determination method of total particulate matters in exhaust gas

A sampling device and particulate matter technology, which is applied in the direction of sampling device, measuring device, particle suspension analysis, etc., can solve the problems of FPM test error, FPM test result error, error, etc., and achieve the goal of reducing debris loss, accurate evaluation, and ensuring condensation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048]In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

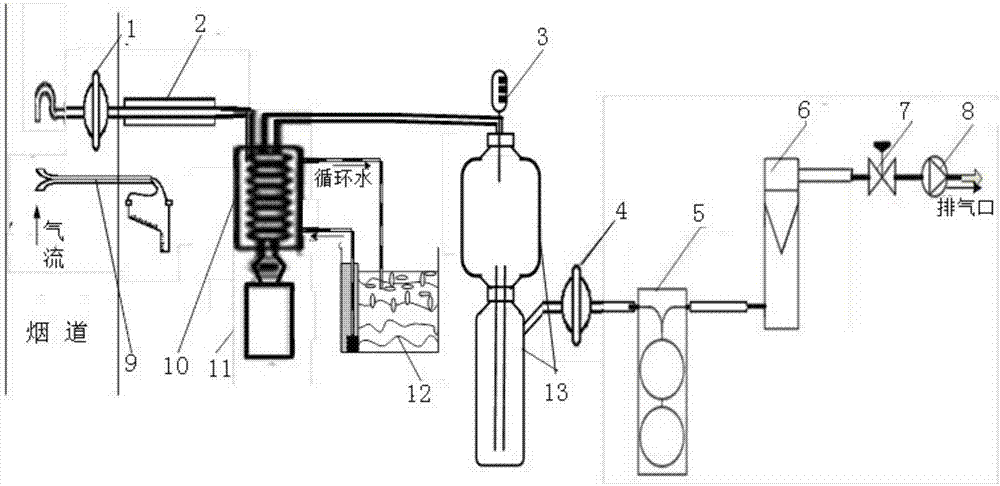

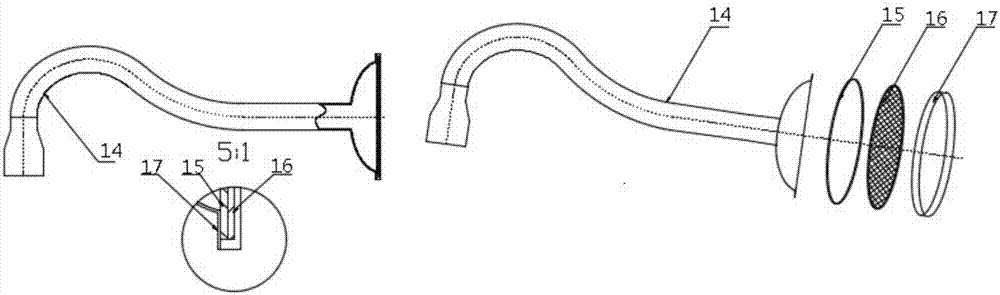

[0049] The sampling device of the present invention utilizes the principle of constant velocity sampling to collect a certain amount of dust-laden flue gas through the filter membrane in the flue to collect filterable particles under the action of the air pump, and the flue gas after passing through the filter membrane is heated to 120 After the sampling gun at ℃, it enters the flue gas condenser and is rapidly cooled to ≤30°C. The inorganic or organic vapor in the flue gas is directly condensed or reacted to form filterable condensable particulate matter, which is re-captured by the particulate matter trapping device, and finally the flue gas After the gas passes through the dryer, it is discharged by the suction pump. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com