Flow measurement and control with bubble detection

a flow measurement and control technology, applied in the direction of liquid/fluent solid measurement, process and machine control, instruments, etc., can solve the problems of spurious measurement, instability of the controlled flow, and the signal upon which the flow meter bases its flow measurement, so as to minimize the effect of the bubble effect and the stability of the liquid flow control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

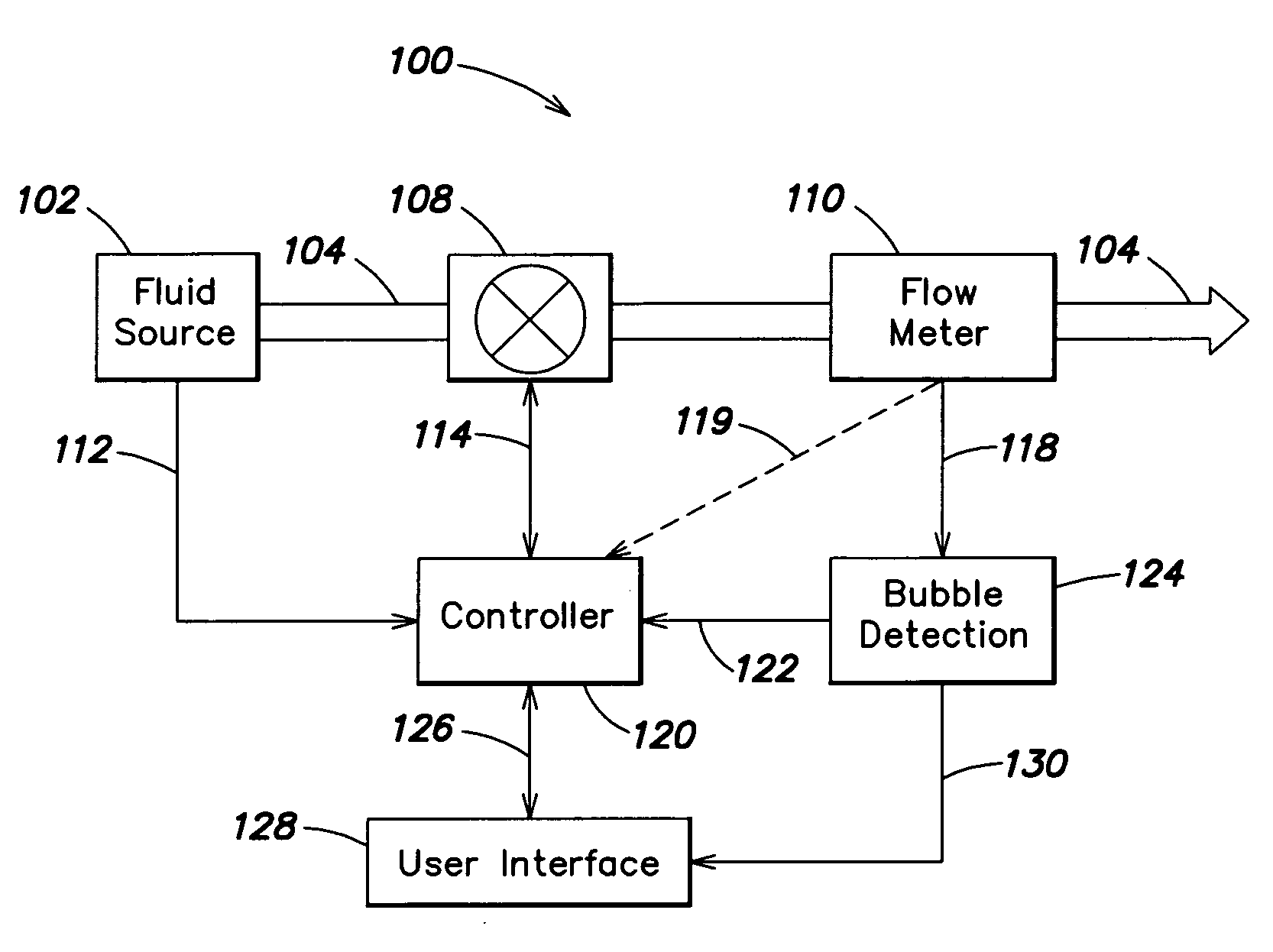

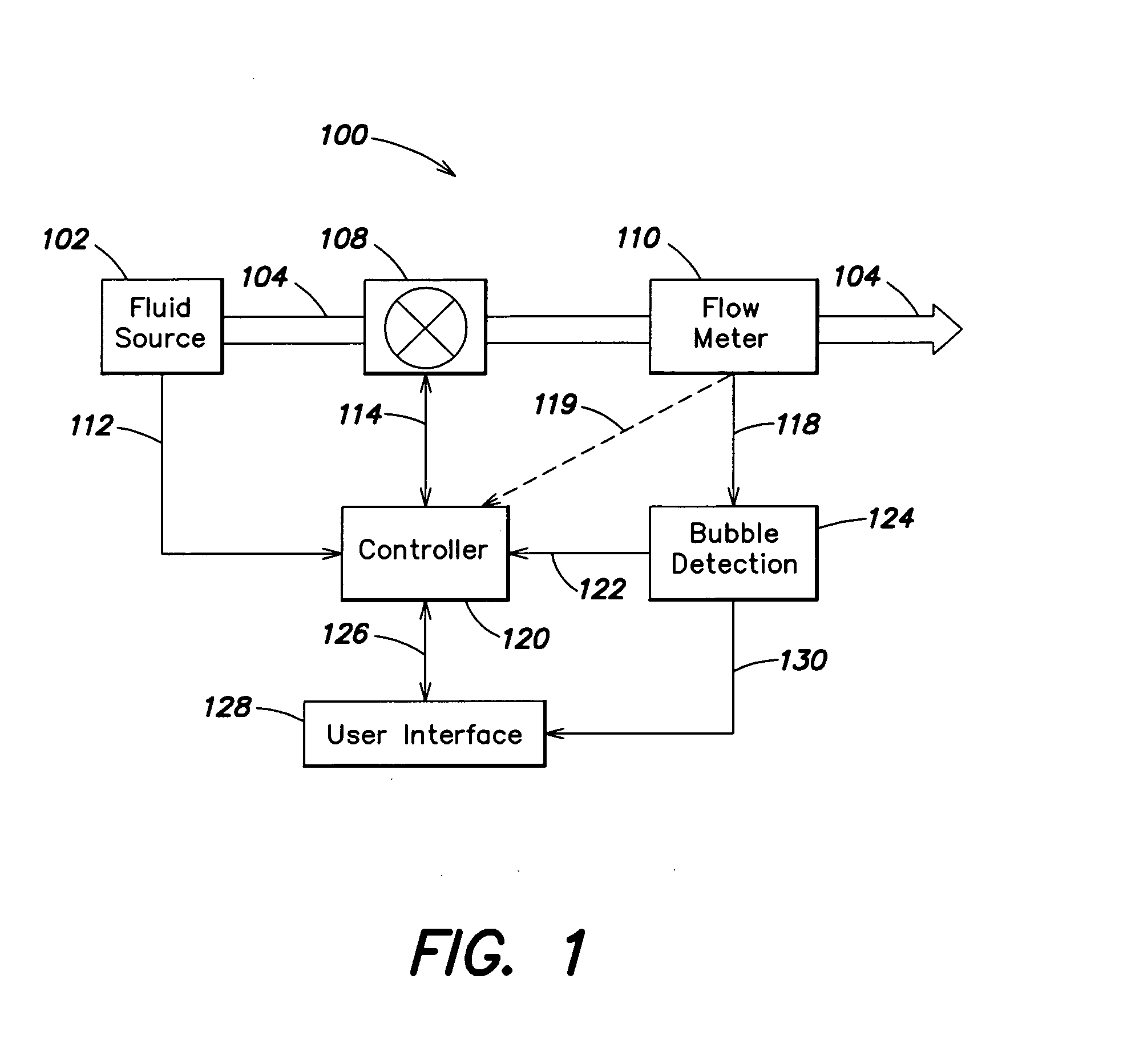

[0037] Referring to FIG. 1, there is illustrated a schematic block-diagram of one example of a liquid control system according to aspects of the present invention. The system 100 as illustrated includes a controllable valve 108 through which liquid flows, as indicated by line / arrow 104. It is to be appreciated that although the following discussion will refer primarily to element 108 being a controllable or variable valve, element 108 may also be another type of liquid actuator such as, for example, a pump. The valve 108 may be, for example, an electronically controlled variable valve that may be adjusted to vary the flow rate of the liquid through the system. The valve 108 is controlled by a controller 120 as indicated by line 114. The controller 120 may be, for example, a microprocessor-based controller. A liquid flow meter 110 may be positioned downstream of the valve 108, as shown. Alternatively, the liquid flow meter 110 may be disposed upstream of the valve 108. The flow of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com