Patents

Literature

1579 results about "Flow transducer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flow transducers are used to measure air and liquid flow velocity. Flow transducers use different measuring principles. By means of the flow velocity, analysis units of flow transducers can calculate the flow level or determine the amount of flow with a counter. Our flow transducers operate based on ultrasound.

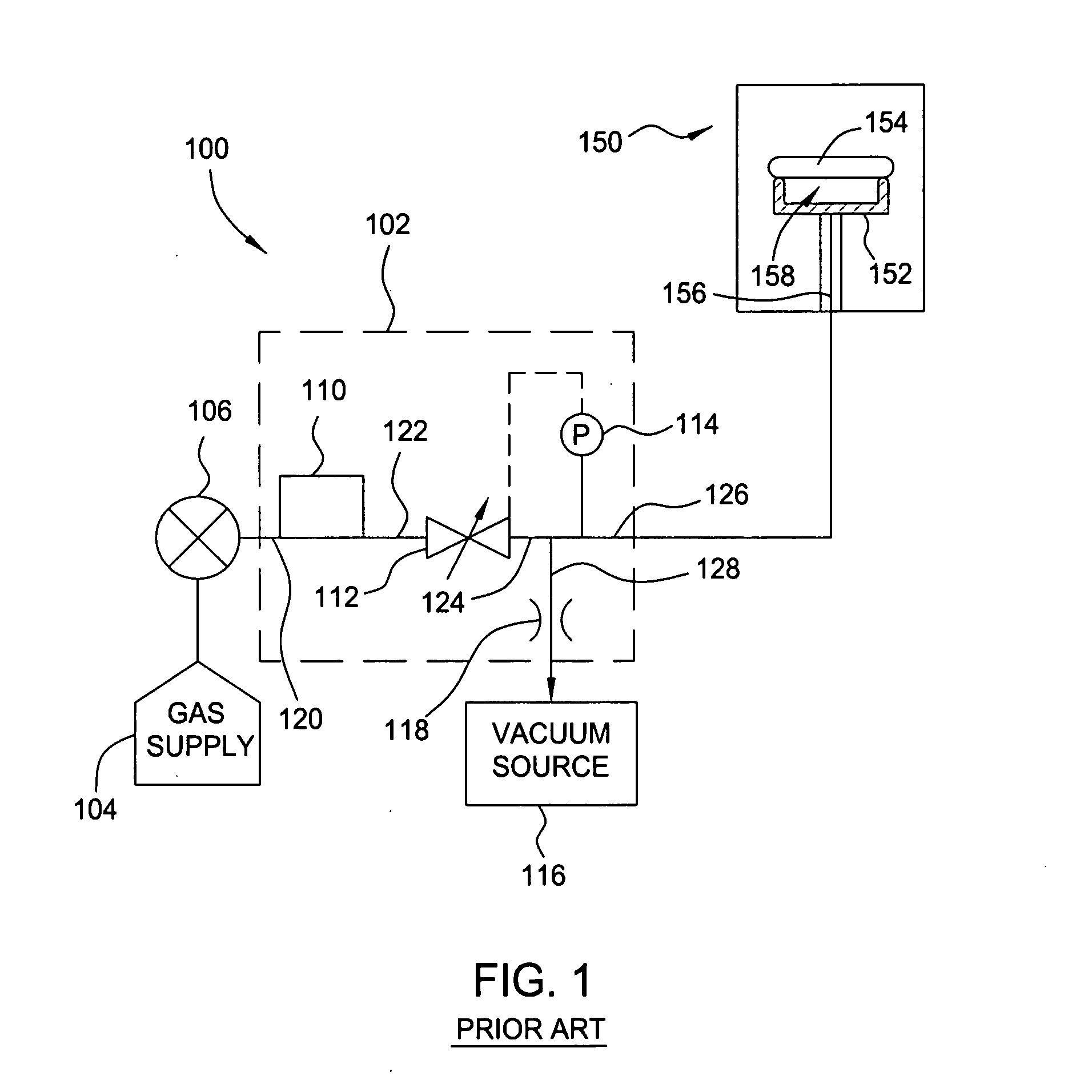

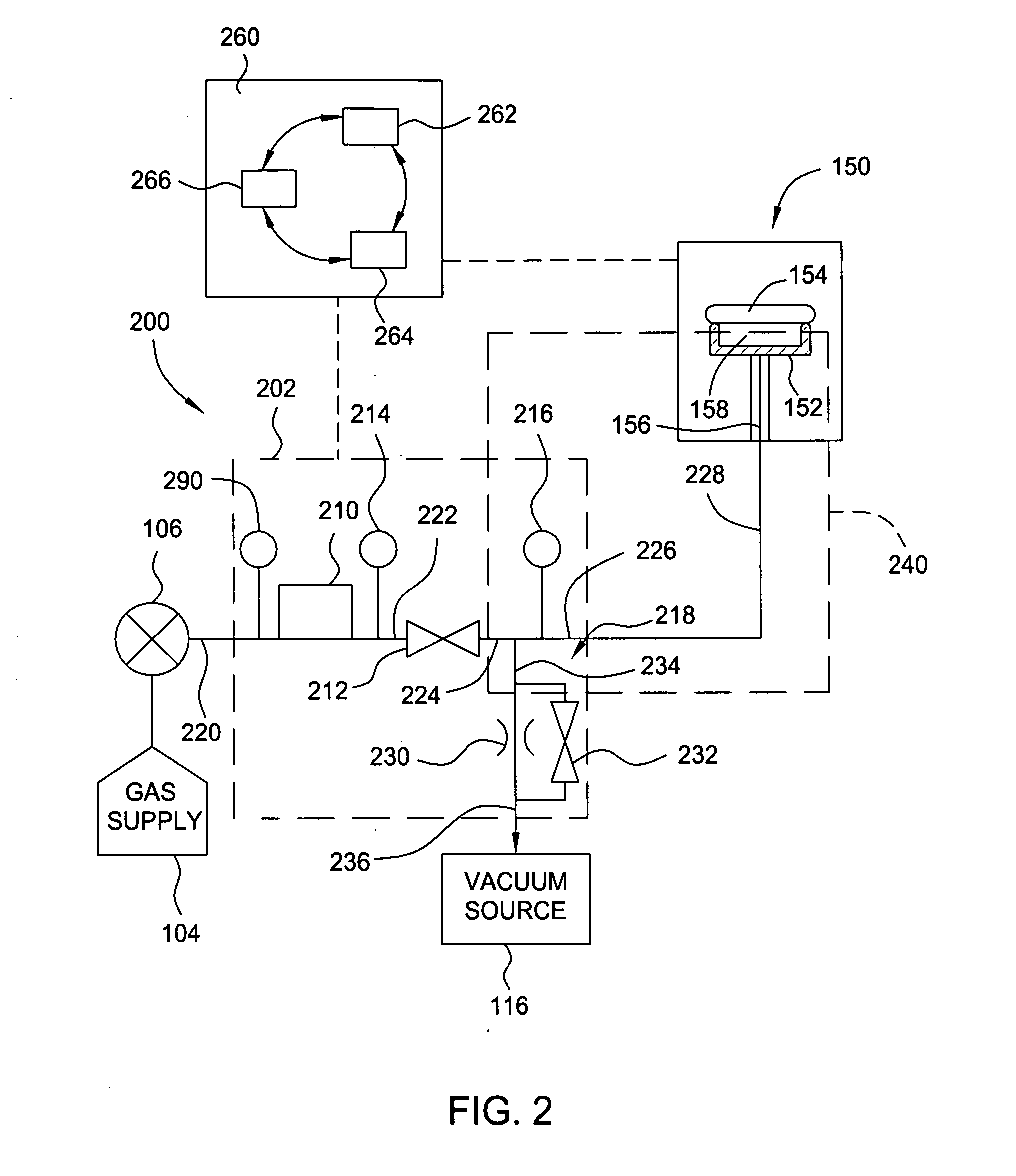

Method and apparatus for substrate temperature control

InactiveUS20050120805A1Electric discharge tubesAerodynamic testingTemperature controlFlow transducer

A method and apparatus for gas control is provided. The apparatus may be used for controlling gases delivered to a chamber, controlling the chamber pressure, controlling the delivery of backside gas between a substrate and substrate support and the like. In one embodiment, an apparatus for controlling gas control includes at least a first flow sensor having a control valve, a first pressure sensor and at least a second pressure sensor. An inlet of the first flow sensor is adapted for coupling to a gas supply. A control valve is coupled to an outlet of the flow sensor. The first pressure sensor is adapted to sense a metric indicative of the pressure upstream of the first flow sensor. The second pressure sensor is adapted to sense a metric indicative of the pressure downstream of the control valve.

Owner:APPLIED MATERIALS INC

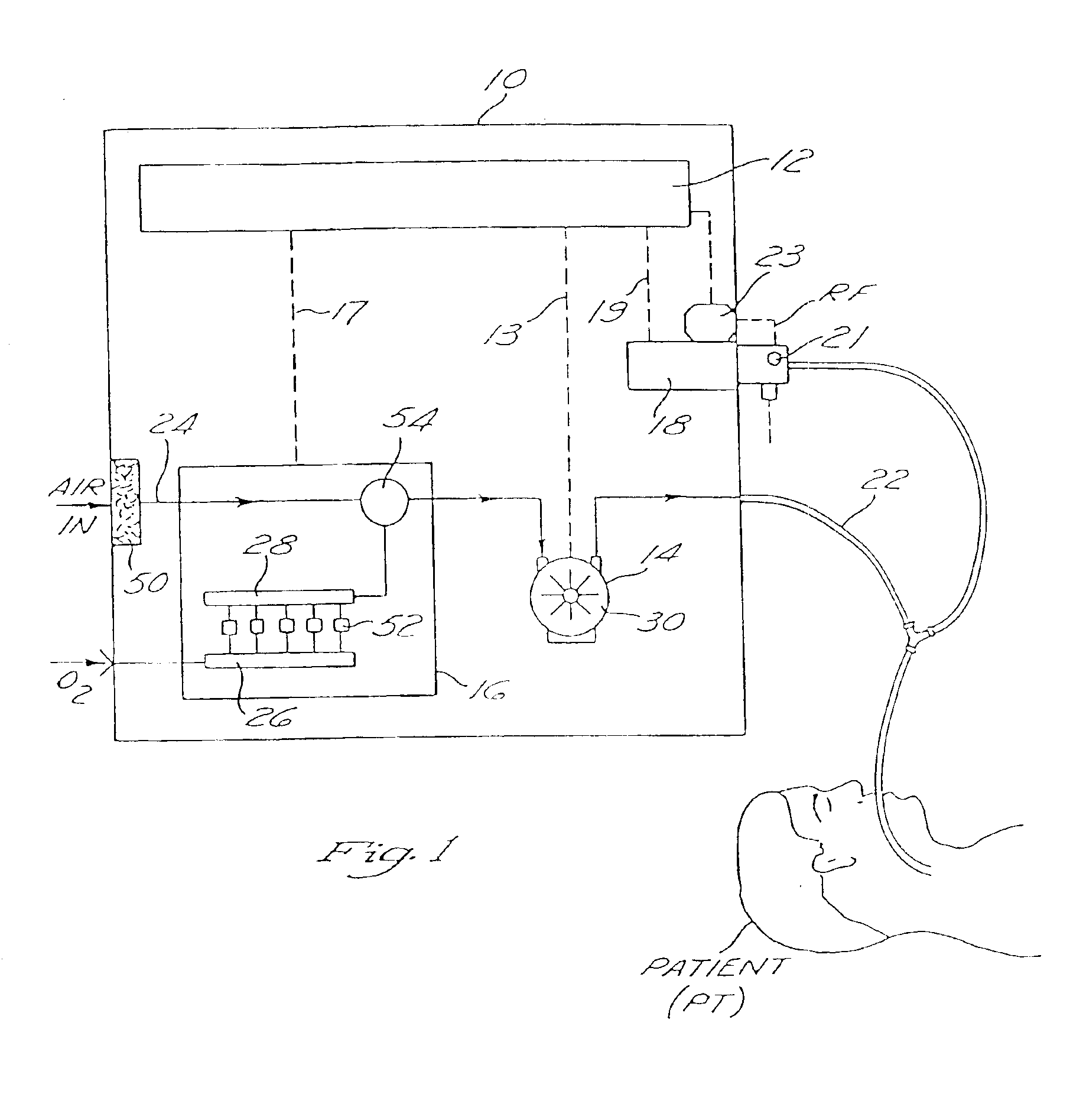

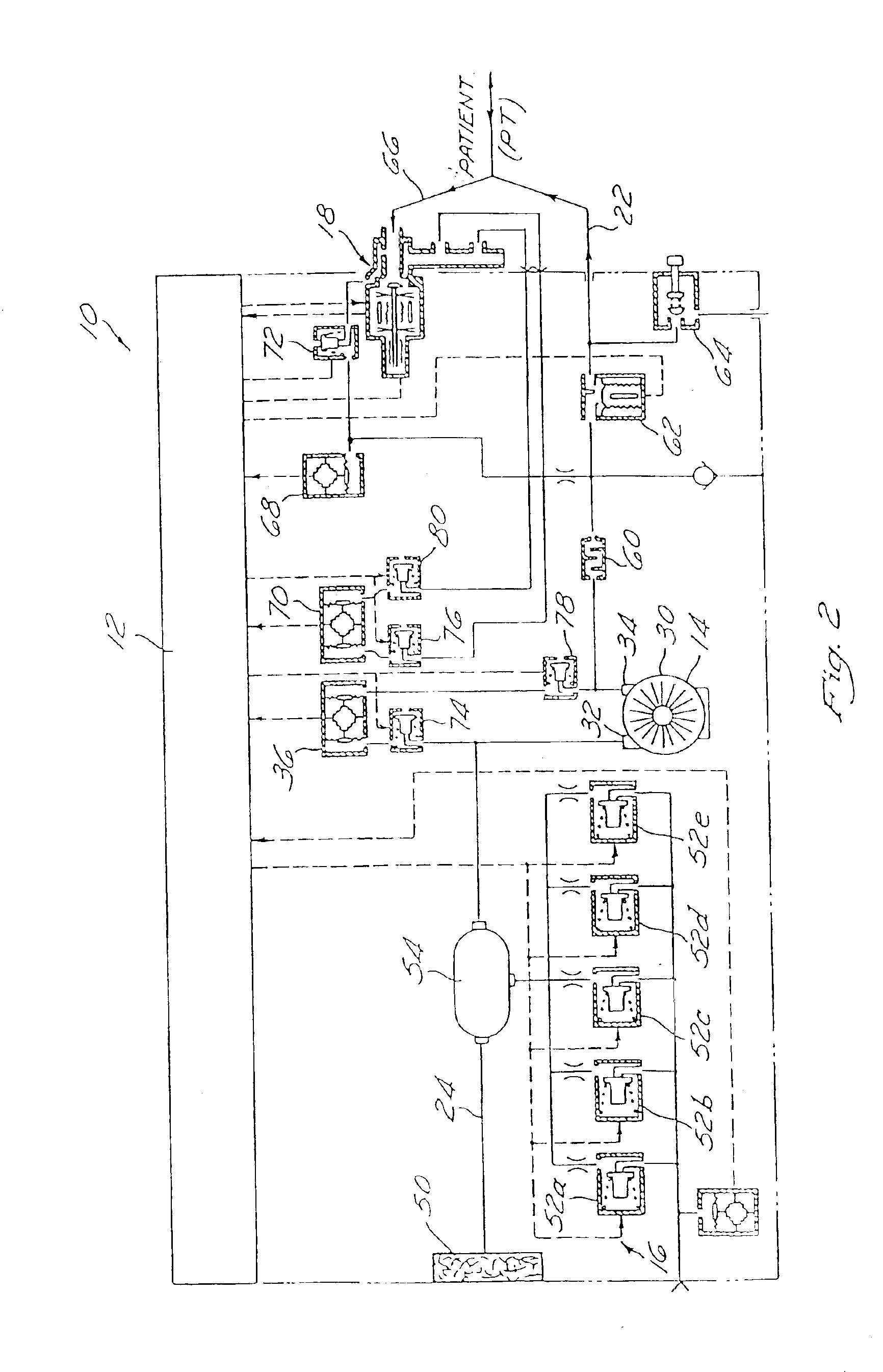

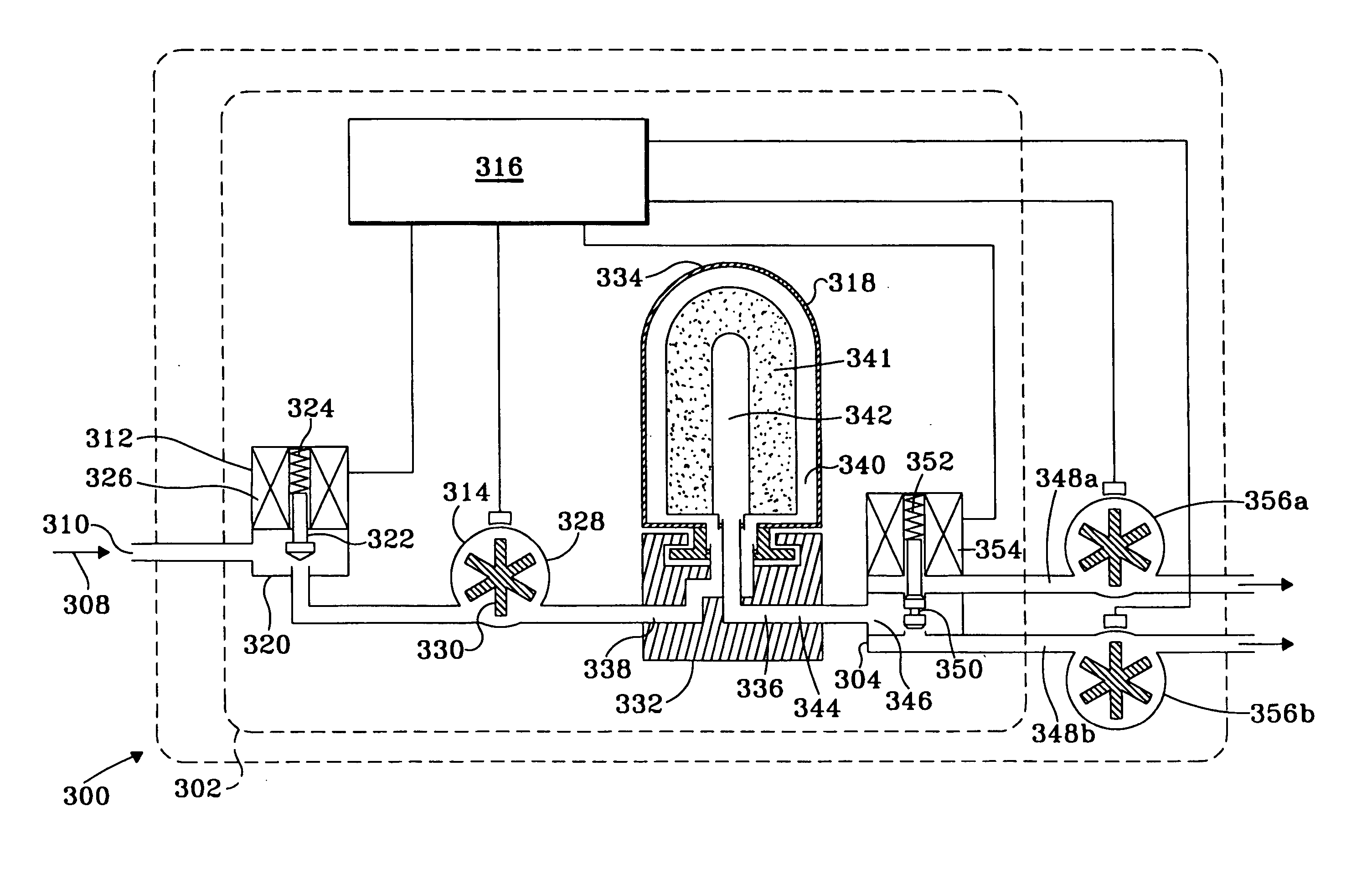

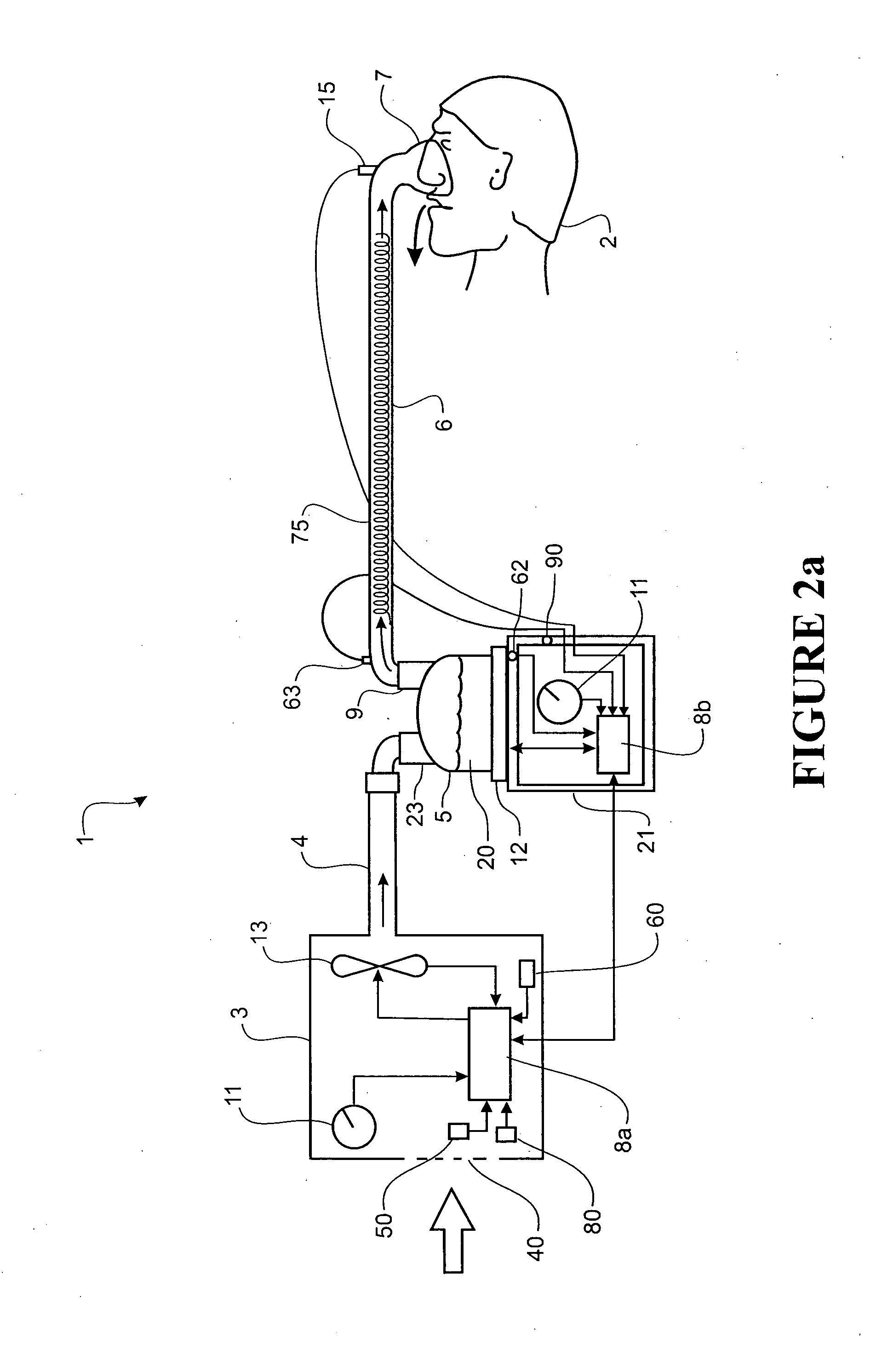

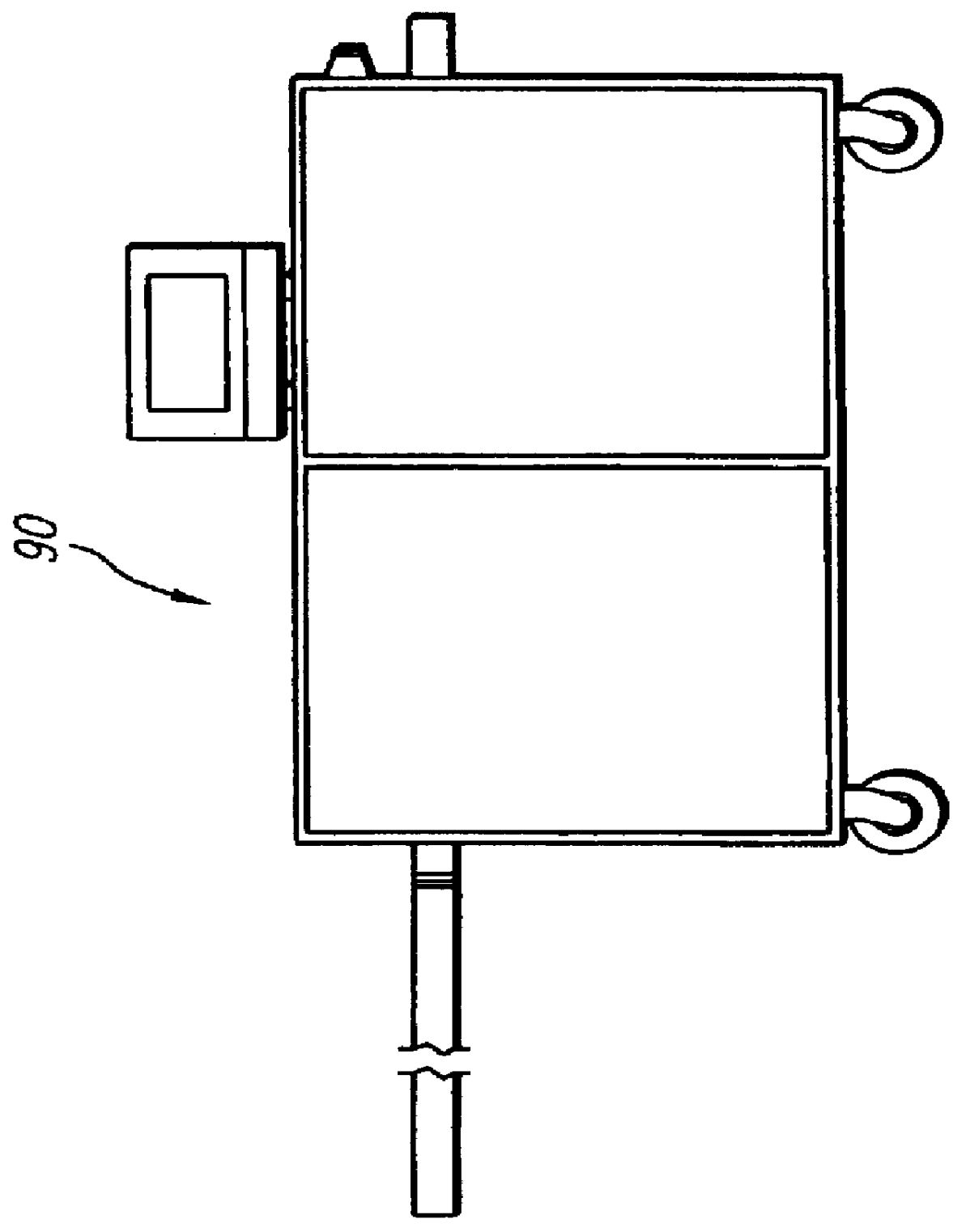

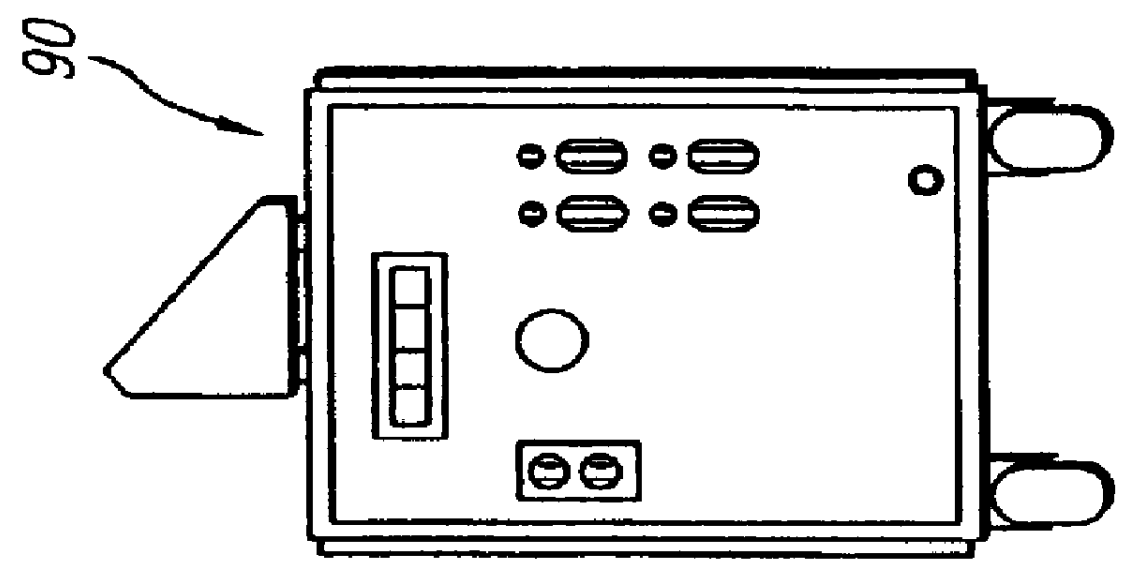

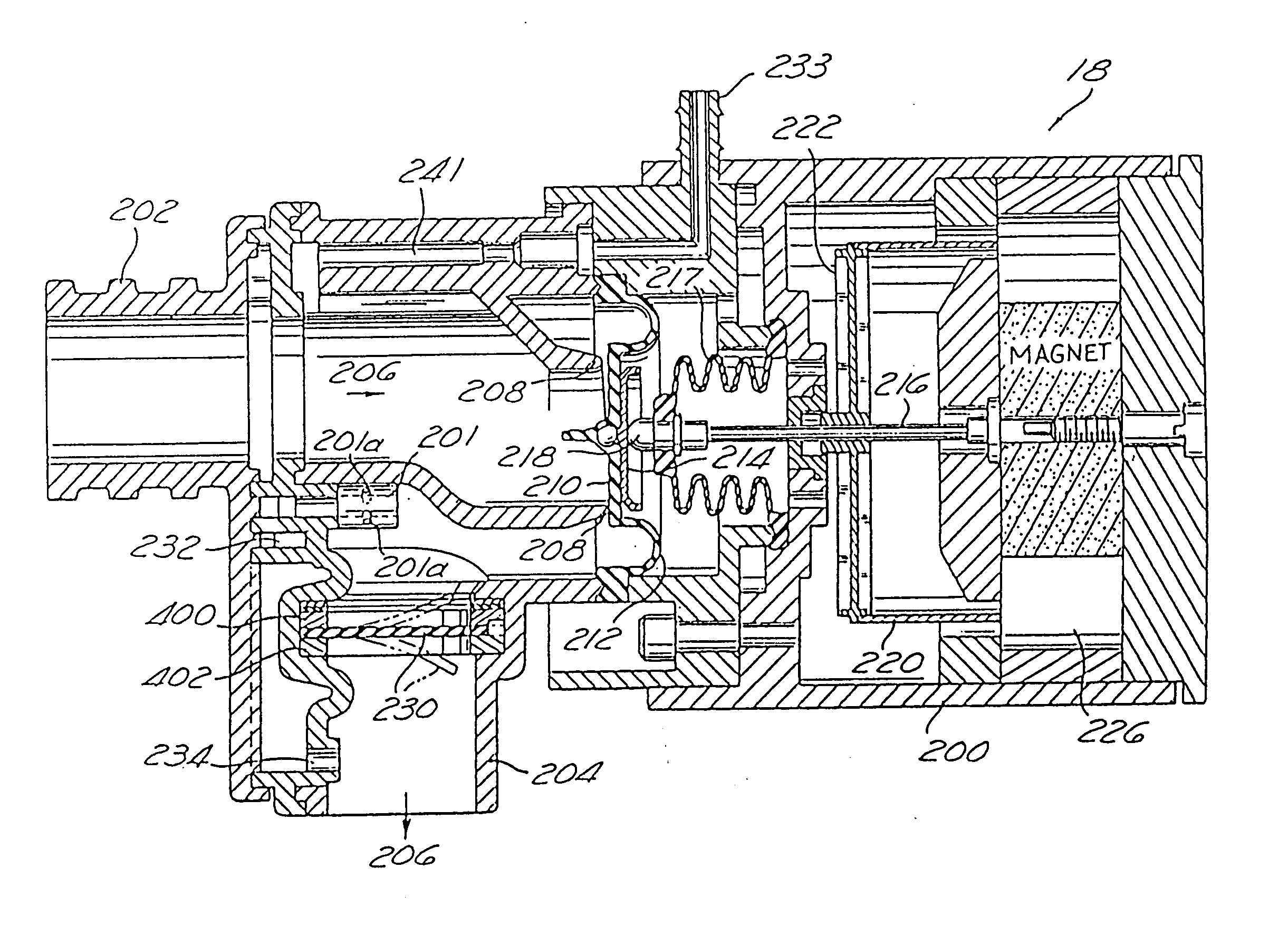

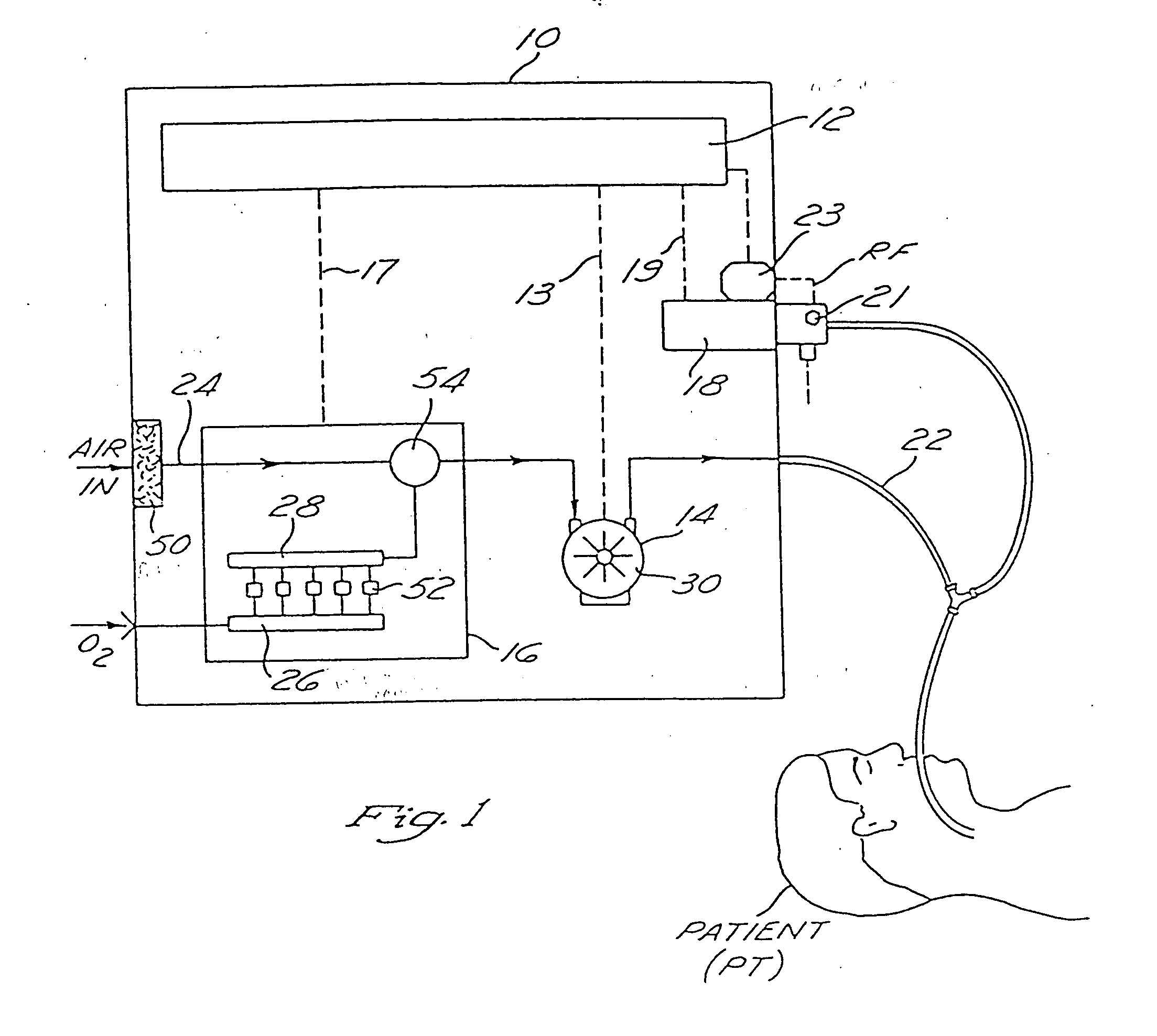

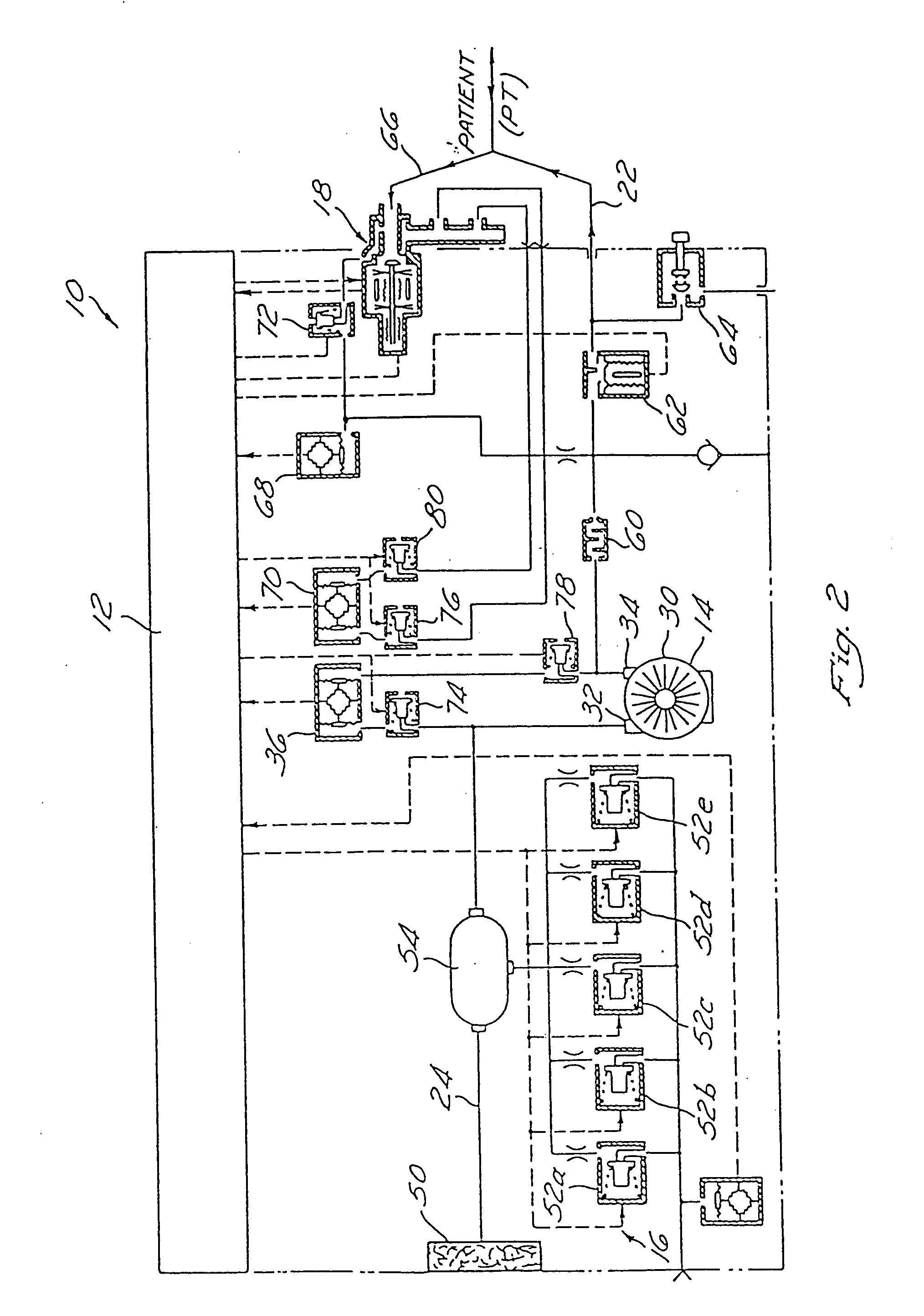

Portable drag compressor powered mechanical ventilator

InactiveUS6877511B2Accurate measurementMinimize fabrication inaccuracyRespiratorsOperating means/releasing devices for valvesSolenoid valveEngineering

A ventilator device and system comprising a rotating compressor, preferably a drag compressor, which, at the beginning of each inspiratory ventilation phase, is accelerated to a sufficient speed to deliver the desired inspiratory gas flow, and is subsequently stopped or decelerated to a basal flow level to permit the expiratory ventilation phase to occur. The ventilator device is small and light weight enough to be utilized in portable applications. The ventilator device is power efficient enough to operate for extended periods of time on internal or external batteries. Also provided is an oxygen blending apparatus which utilizes solenoid valves having specific orifice sizes for blending desired amounts of oxygen into the inspiratory gas flow. Also provided is an exhalation valve having an exhalation flow transducer which incorporates a radio frequency data base to provide an attendant controller with specific calibration information for the exhalation flow transducer.

Owner:BIRD PRODS

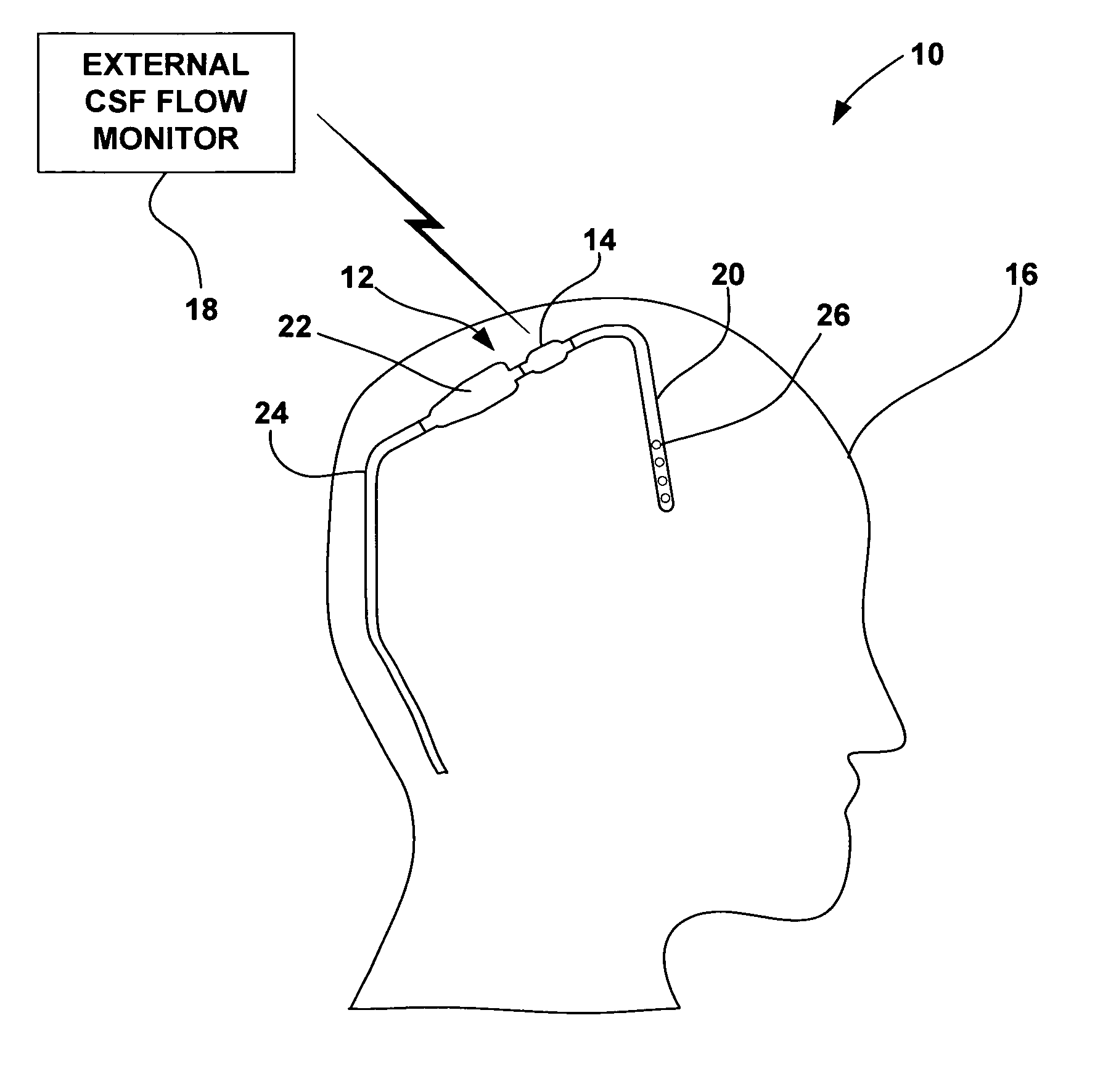

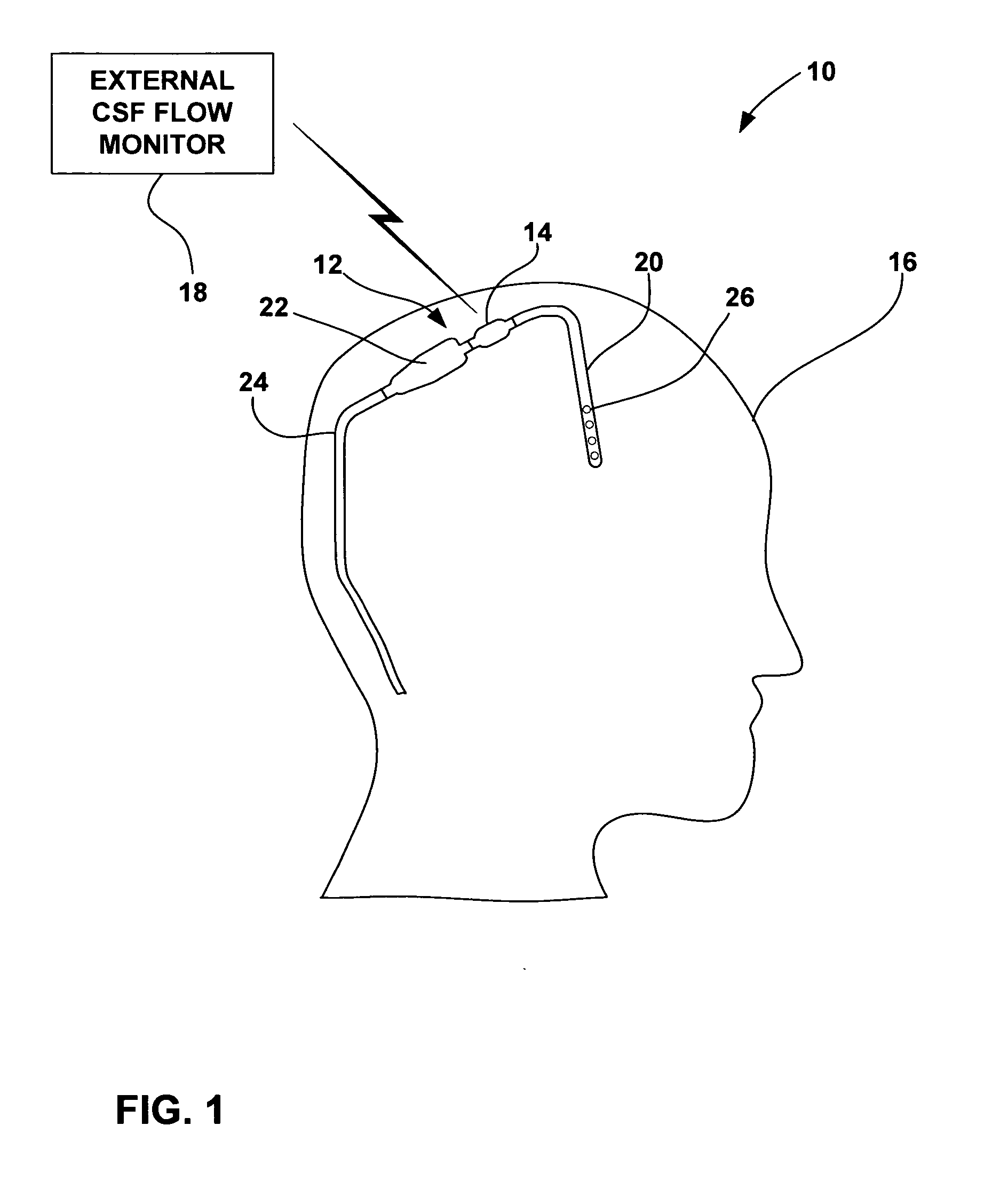

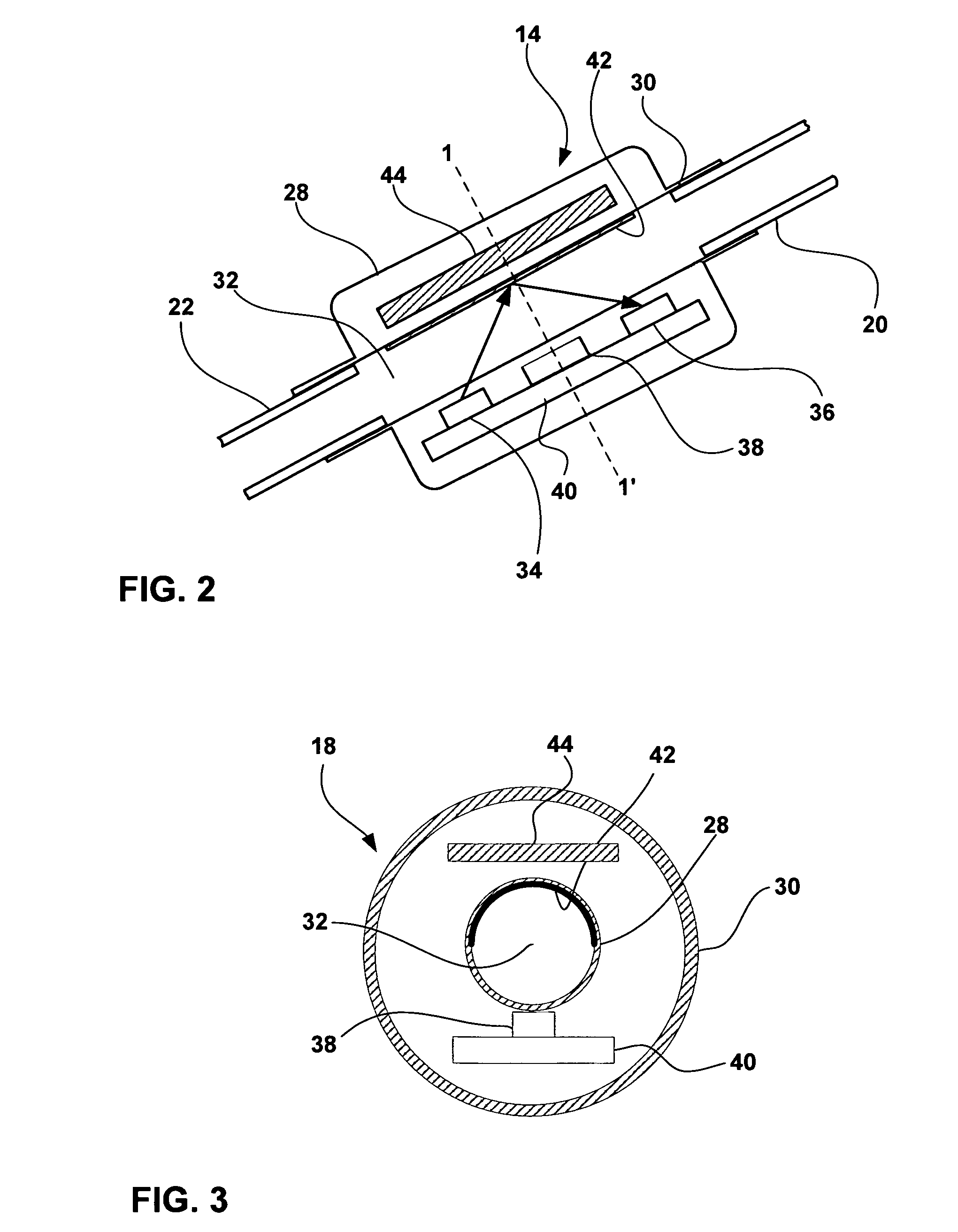

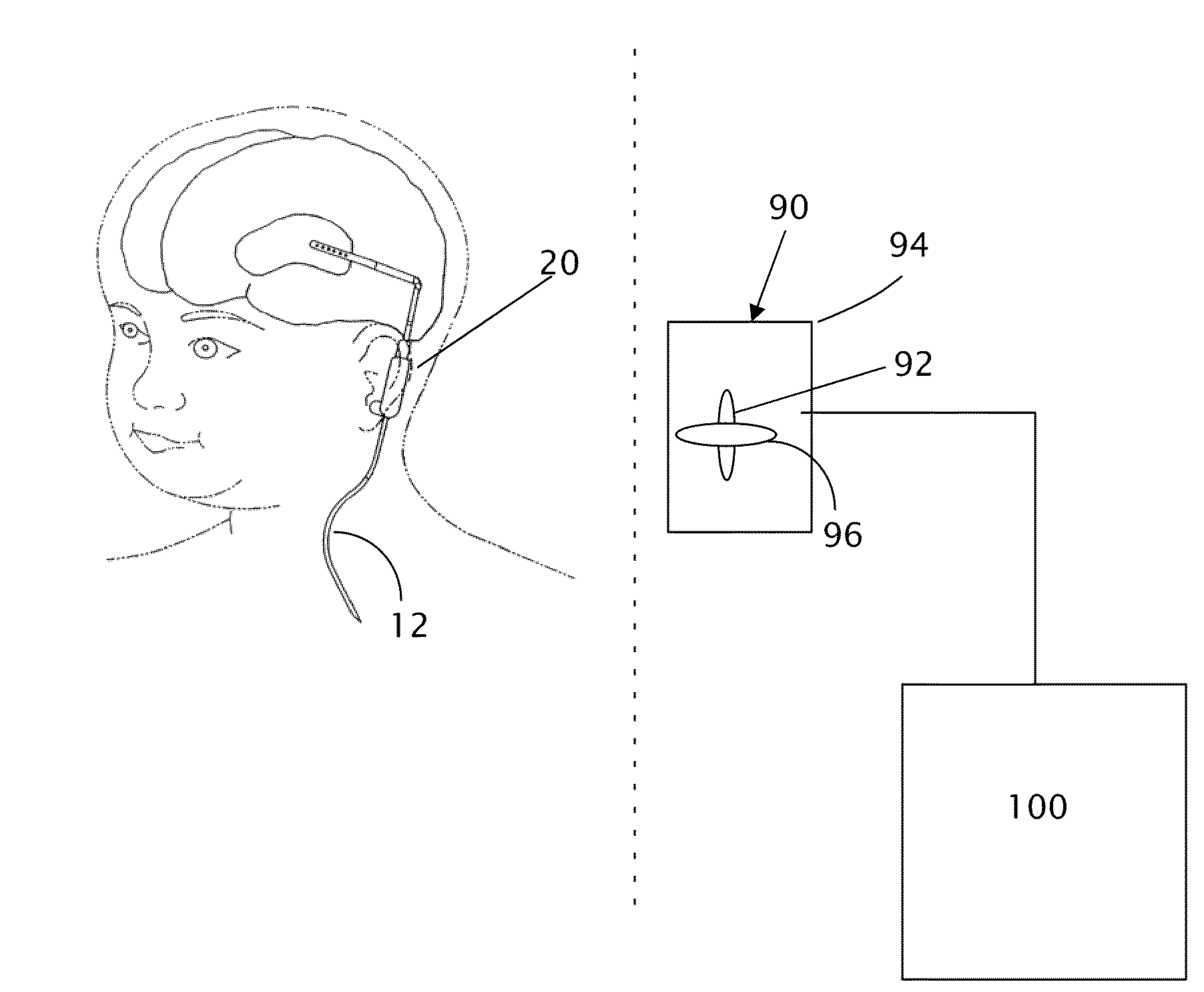

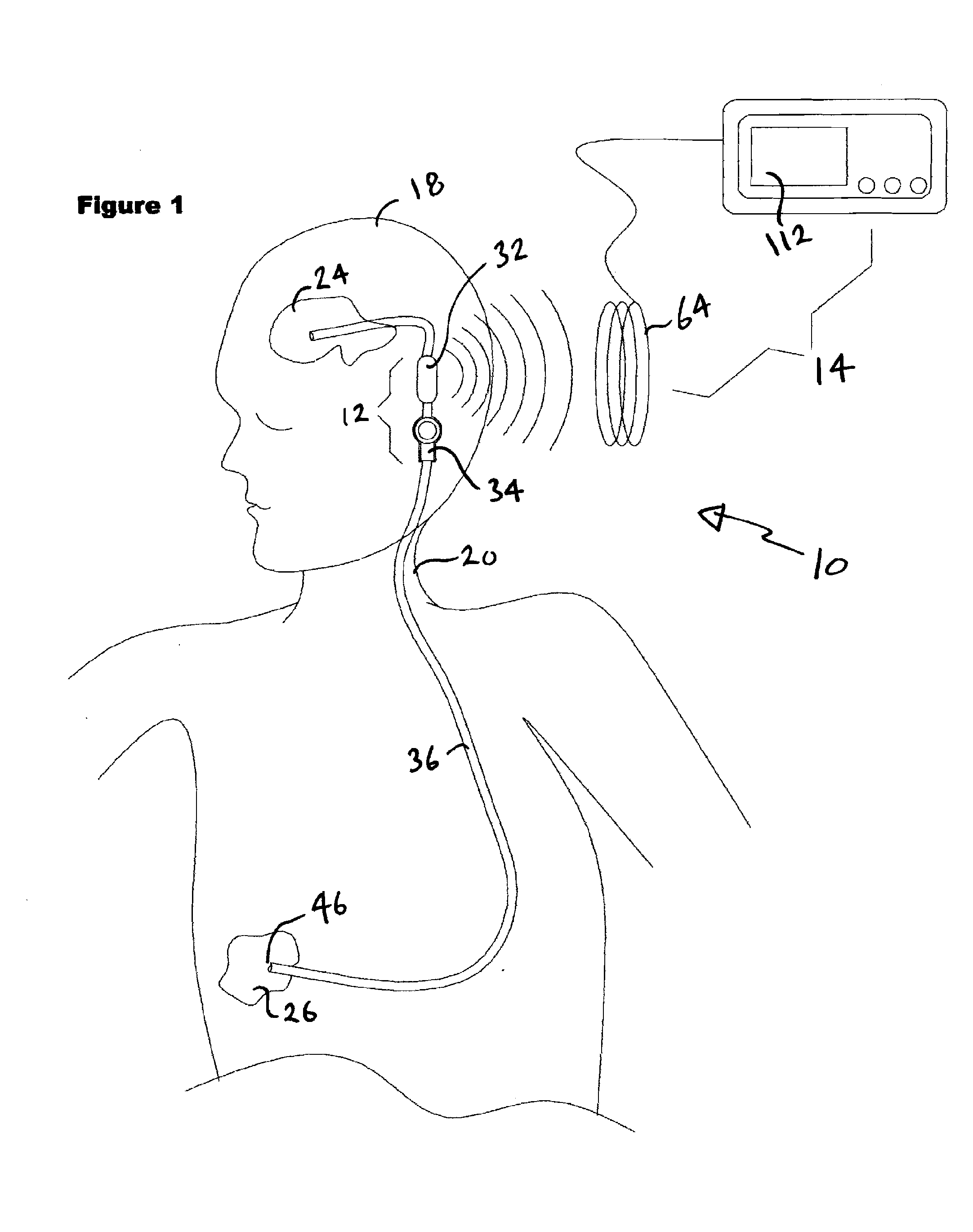

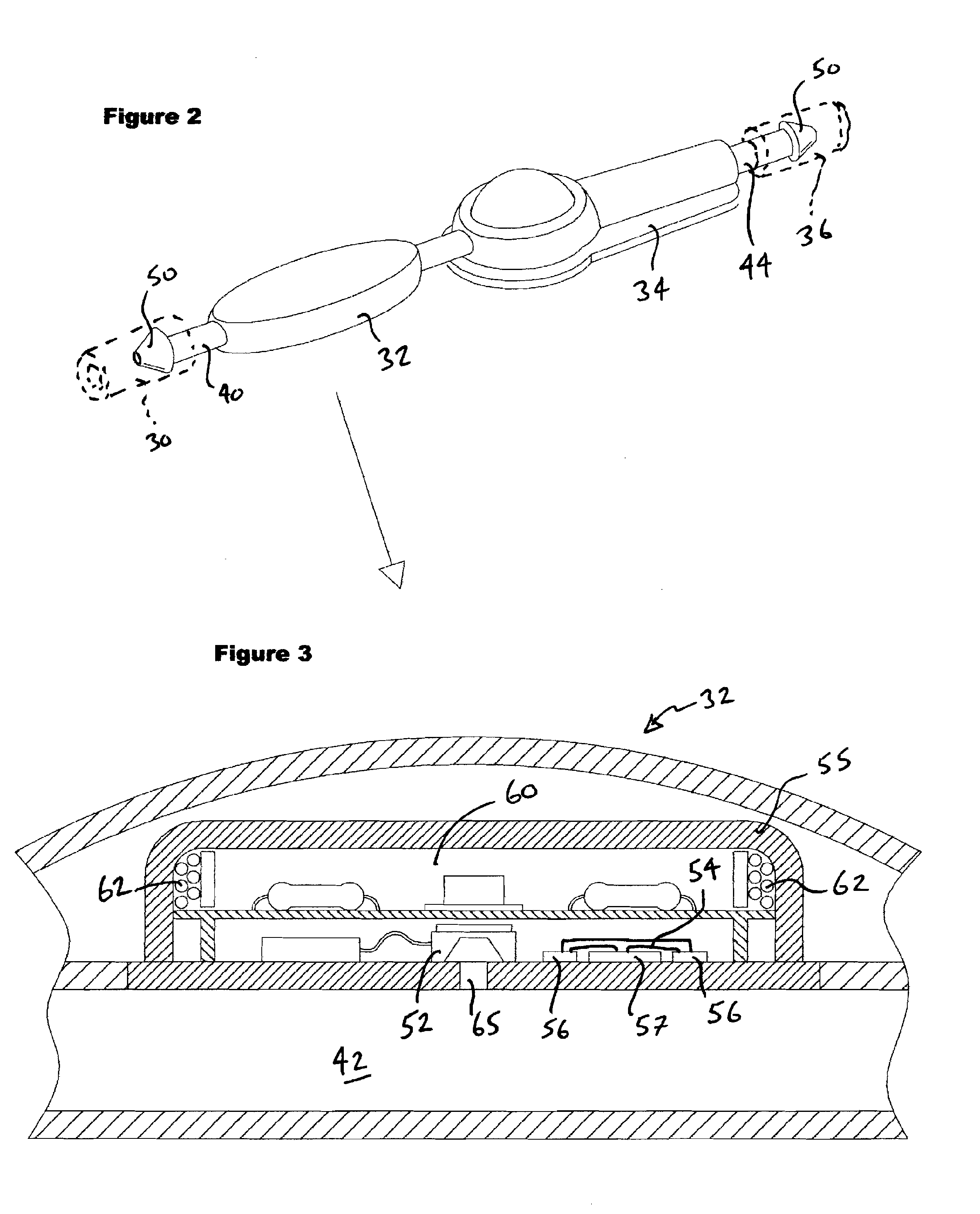

Cerebral spinal fluid flow sensing device

InactiveUS20060020239A1Evaluate performance of ventricular shuntEnsure correct executionWound drainsEndoradiosondesFlow transducerCsf shunt

The disclosure is directed to an implantable device for sensing CSF flow through an implantable ventricular shunt. The sensing device is implanted with the CSF shunt, and includes a flow sensor to sense flow rate or shunt blockage. The sensing device is either placed within or adjacent to the fluid path through the shunt. The sensing device transmits the sensed flow rate to an external monitoring device by wireless telemetry. The sensing device may be integrally formed as part of the shunt, or clamped onto a portion of the shunt, in which case the sensing device may be resusable. An external monitor receives the transmitted flow signal and presents information based on the flow signal. The sensing device may be inductively powered or include its own power supply.

Owner:MEDTRONIC INC

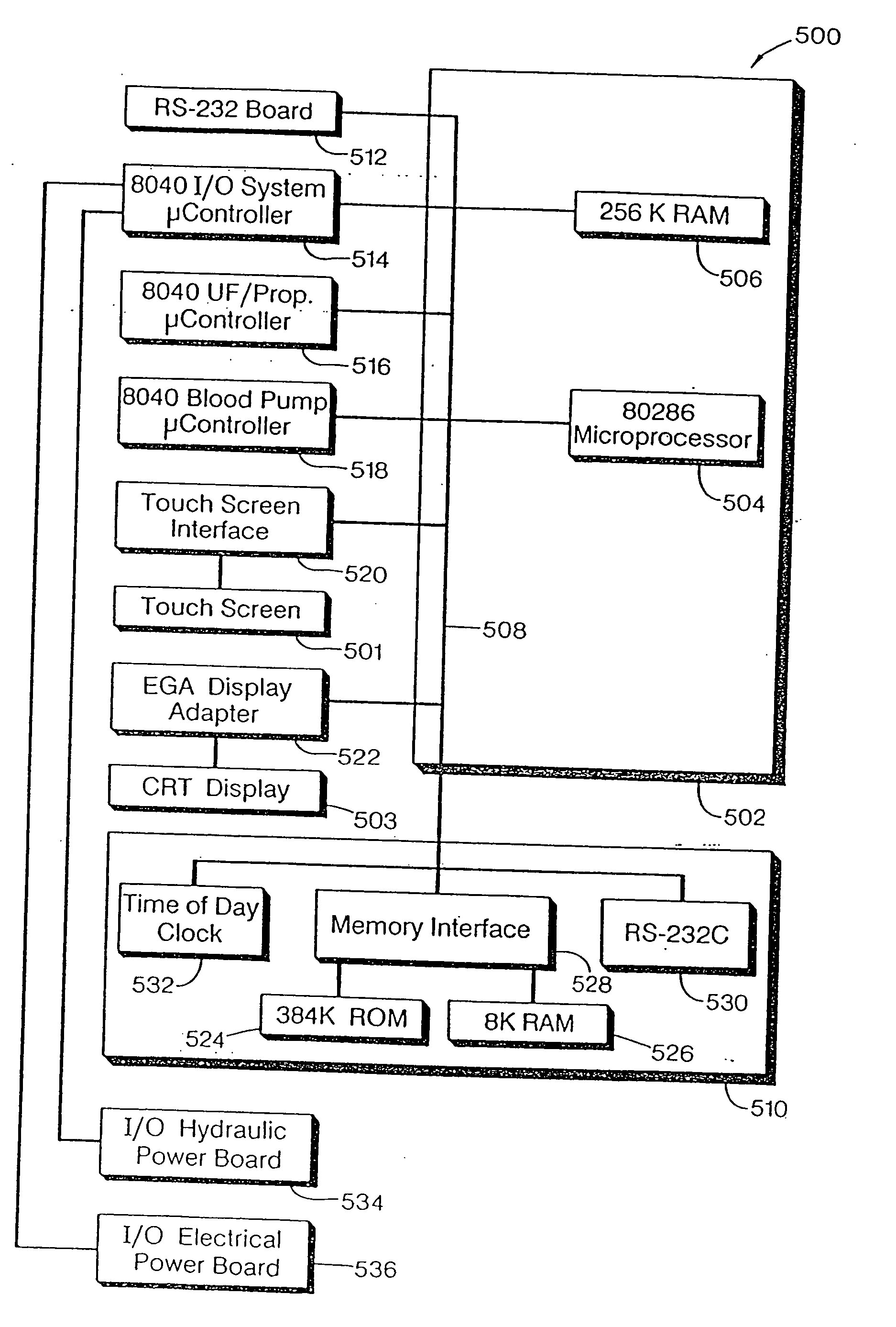

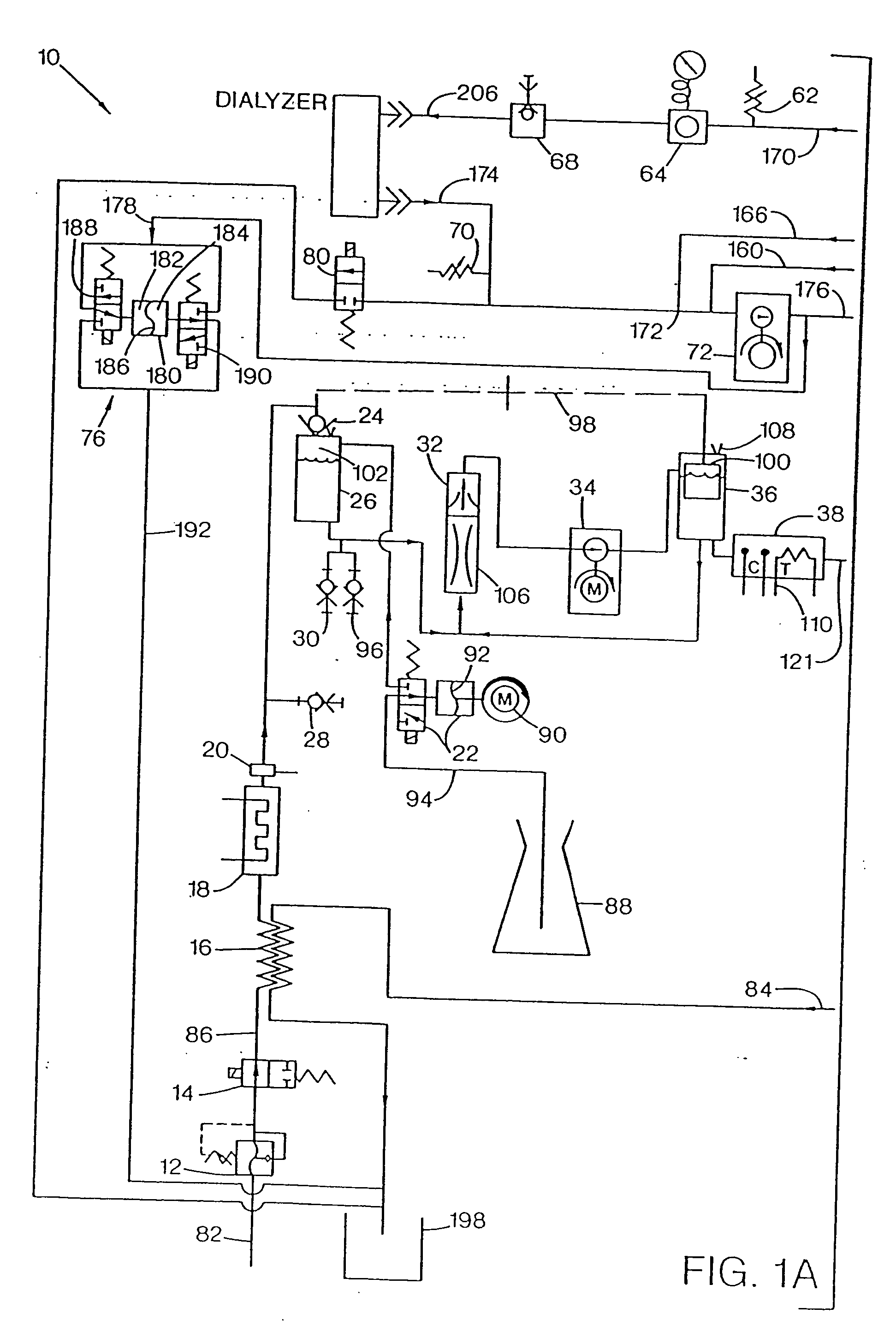

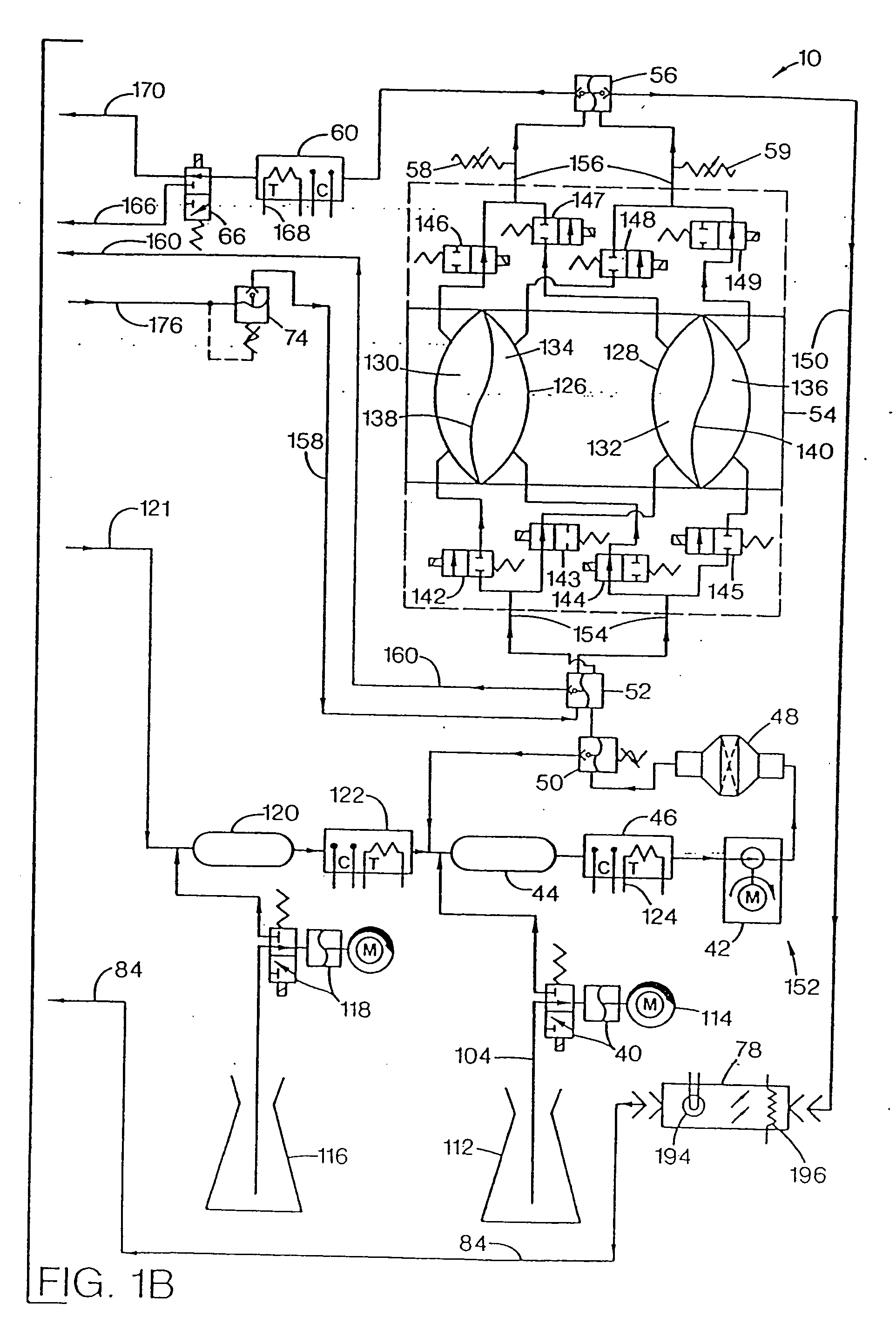

Method and apparatus for kidney dialysis

InactiveUS20050242034A1Mechanical/radiation/invasive therapiesOther blood circulation devicesUltrafiltrationDischarge measurements

Owner:BAXTER INT INC

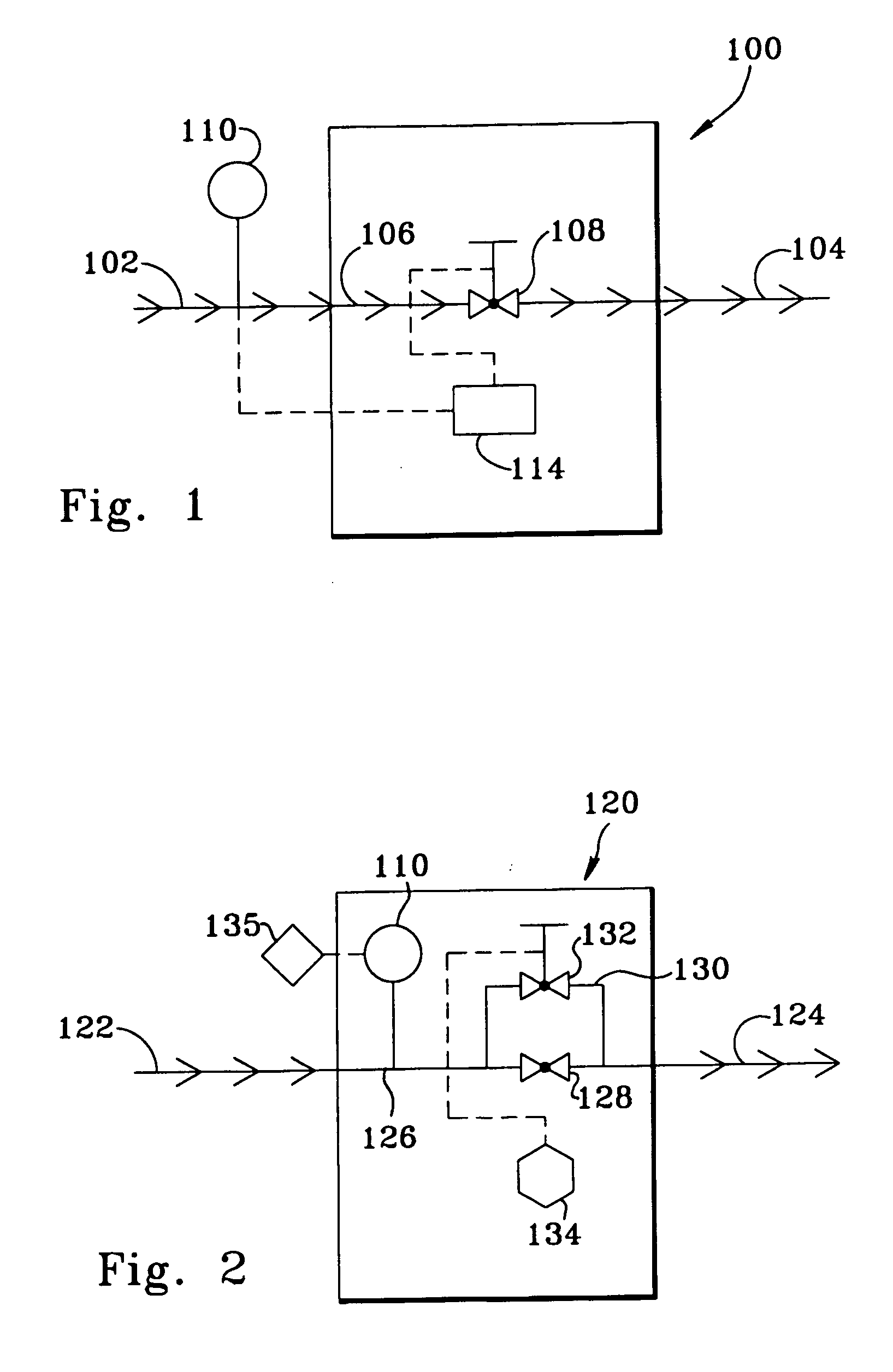

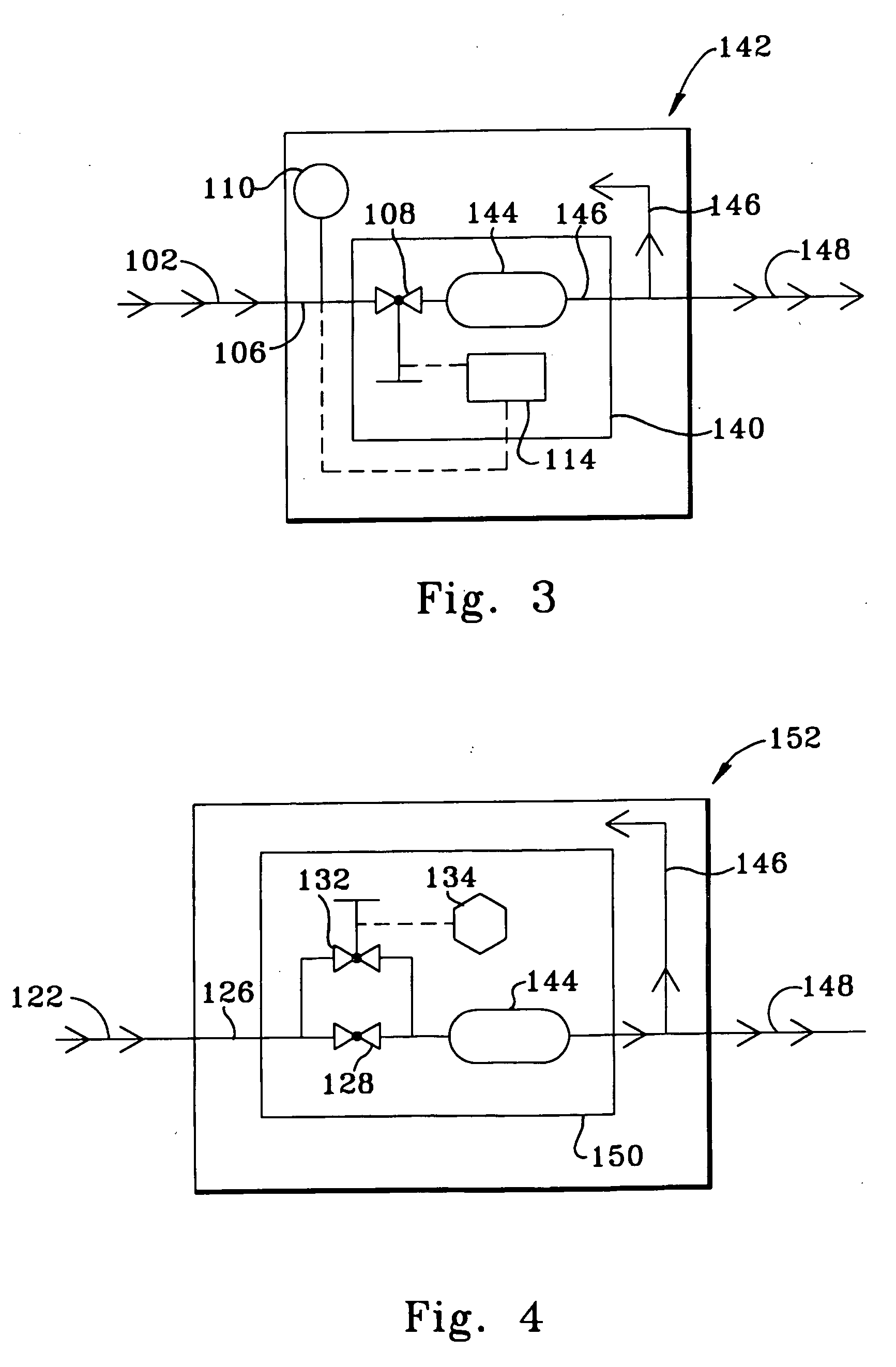

Systems and methods for detecting and eliminating leaks in water delivery systems for use with appliances

InactiveUS20060027267A1Prevent water flowQuick installationOperating means/releasing devices for valvesLighting and heating apparatusFlow transducerIsolation valve

Apparatus and methods for detecting and eliminating water flow leakage conditions within appliances having integral water filtration systems. Leak free water delivery systems for use with an appliance can include an isolation valve and flow sensor for providing a response mechanism for possible water leakages within the integral water filtrations system. The appliance makes use of a flow sensor to sense water flow rates within a preselected flow range. When water flow rates outside the preselected flow range are sensed, the isolation valve is closed to prevent non-transient water flow through the water system. The isolation valve can be remotely located on an inlet line or can be as a part of the integral water filtration system. The integral water filtration system can include a manual or automatic reset mechanism such that a user can restore water flow after a low flow or high flow situation has been rectified.

Owner:3M INNOVATIVE PROPERTIES CO

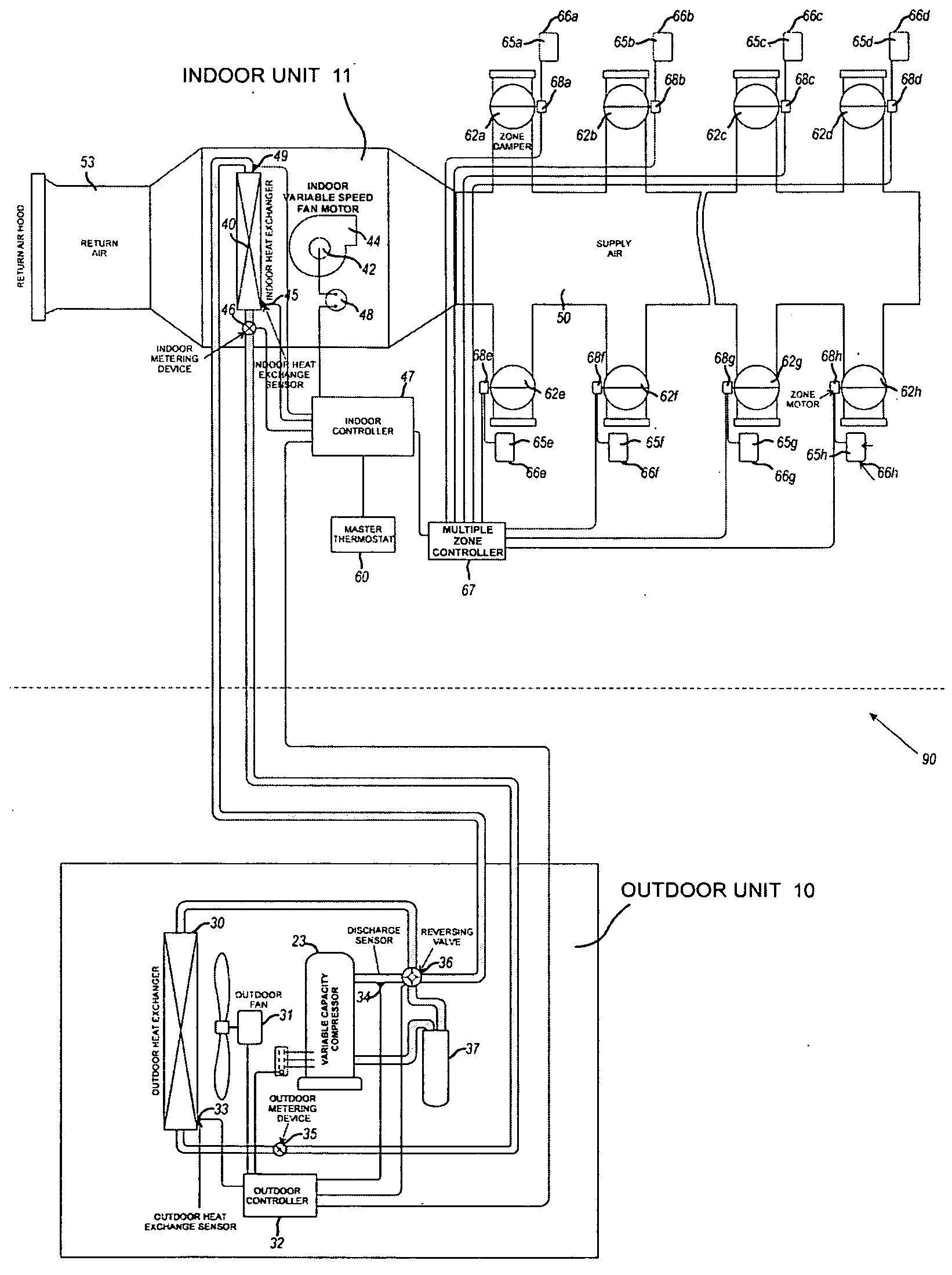

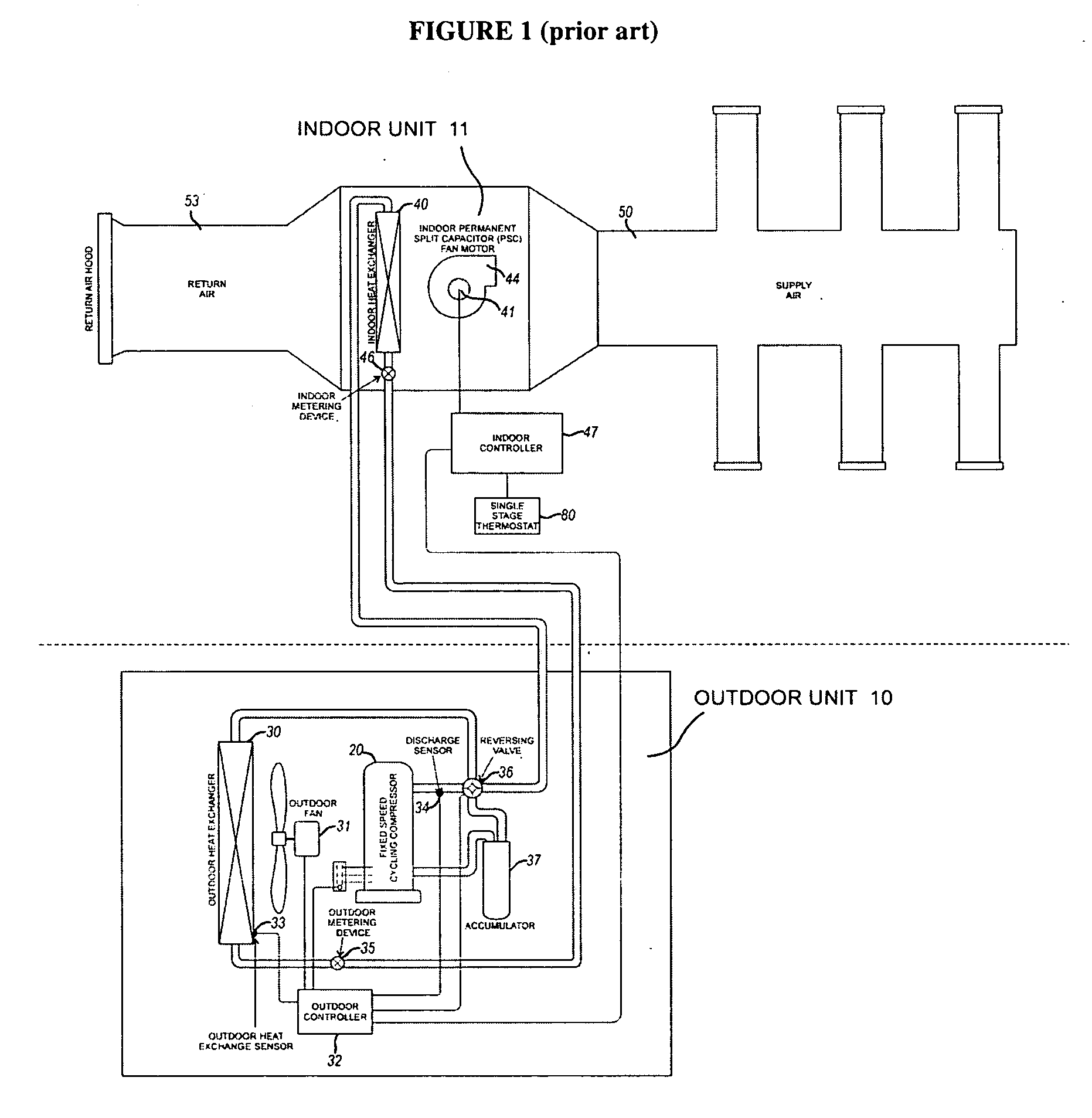

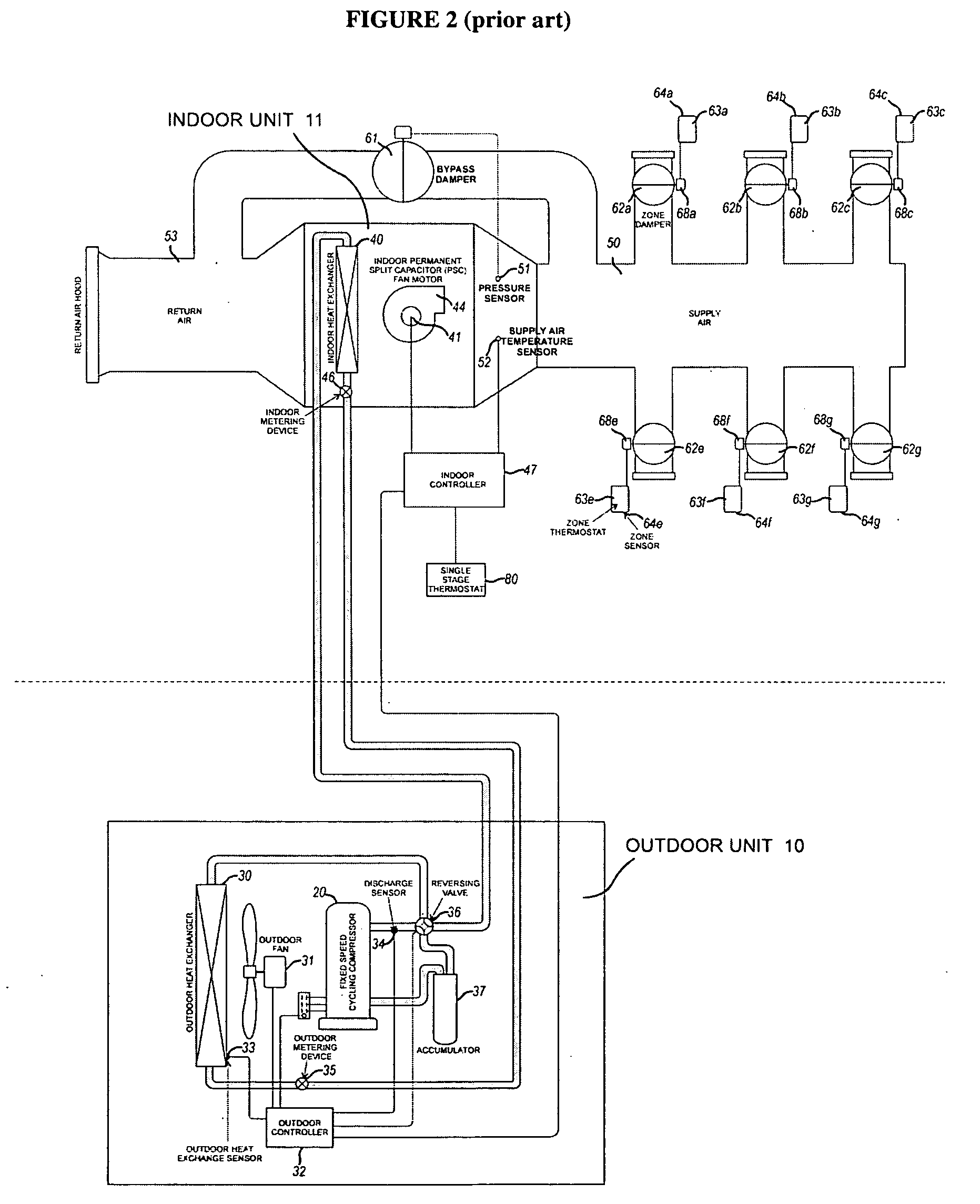

Air conditioning system and method of control

InactiveUS20100082162A1Eliminate needImprove comfortMechanical apparatusDomestic cooling apparatusFlow transducerAir volume

An air conditioning system and control method to allow individual zone thermostats to directly control a variable capacity compressor and adaptively adjust the indoor supply air volume to meet zoning demands, without using static pressure or flow sensors or entering a set of pre-defined air flow values for each zone into a controller. The method controls an air conditioning system that is able to receive signals or commands from individual zone thermostats and give priority to a highest demand zone / thermostat. For example, a priority thermostat can be used to directly control the variable capacity compressor via an indoor controller and outdoor controller.

Owner:ACTRON AIR

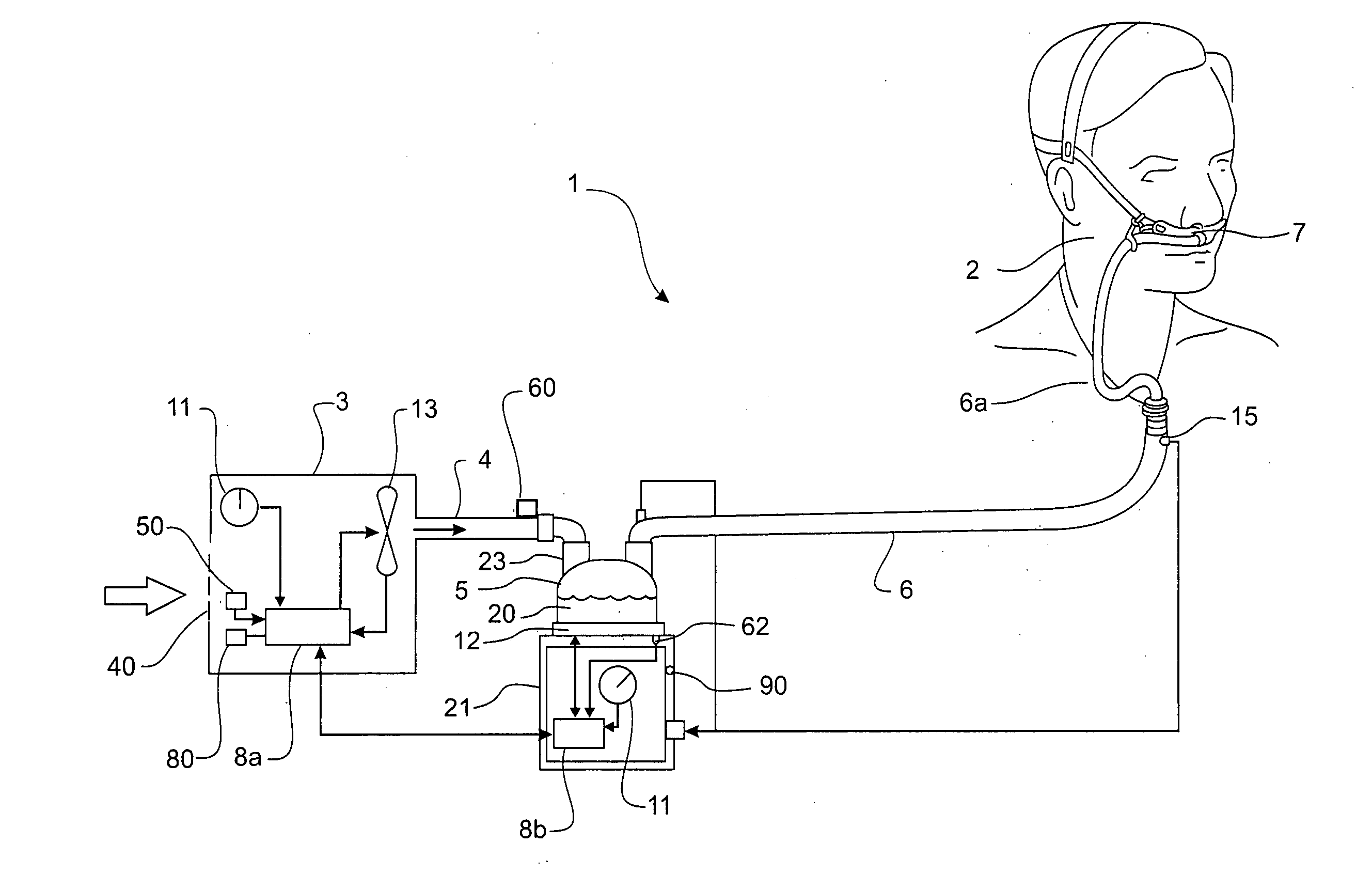

Control of humidifier chamber temperature for accurate humidity control

A breathing assistance system for delivering a stream of heated, humidified gases to a user, comprising a humidifier unit which holds and heats a volume of water, and which in use receives a flow of gases from a gases source via an inlet port, the flow of gases passing through the humidifier and exiting via an exit port, the system further having a temperature sensor which measures the temperature of the gases exiting the humidifier unit, an ambient temperature sensor which measures the temperature of gases before they enter the humidifier unit, and a flow sensor which measures the flow rate of the gases stream, the system also having a controller which receives data from the temperature and flow sensors, and which determines a control output in response, the control output adjusting the power to the humidifier unit to achieve a desired output at the humidifier unit exit port.

Owner:FISHER & PAYKEL HEALTHCARE LTD

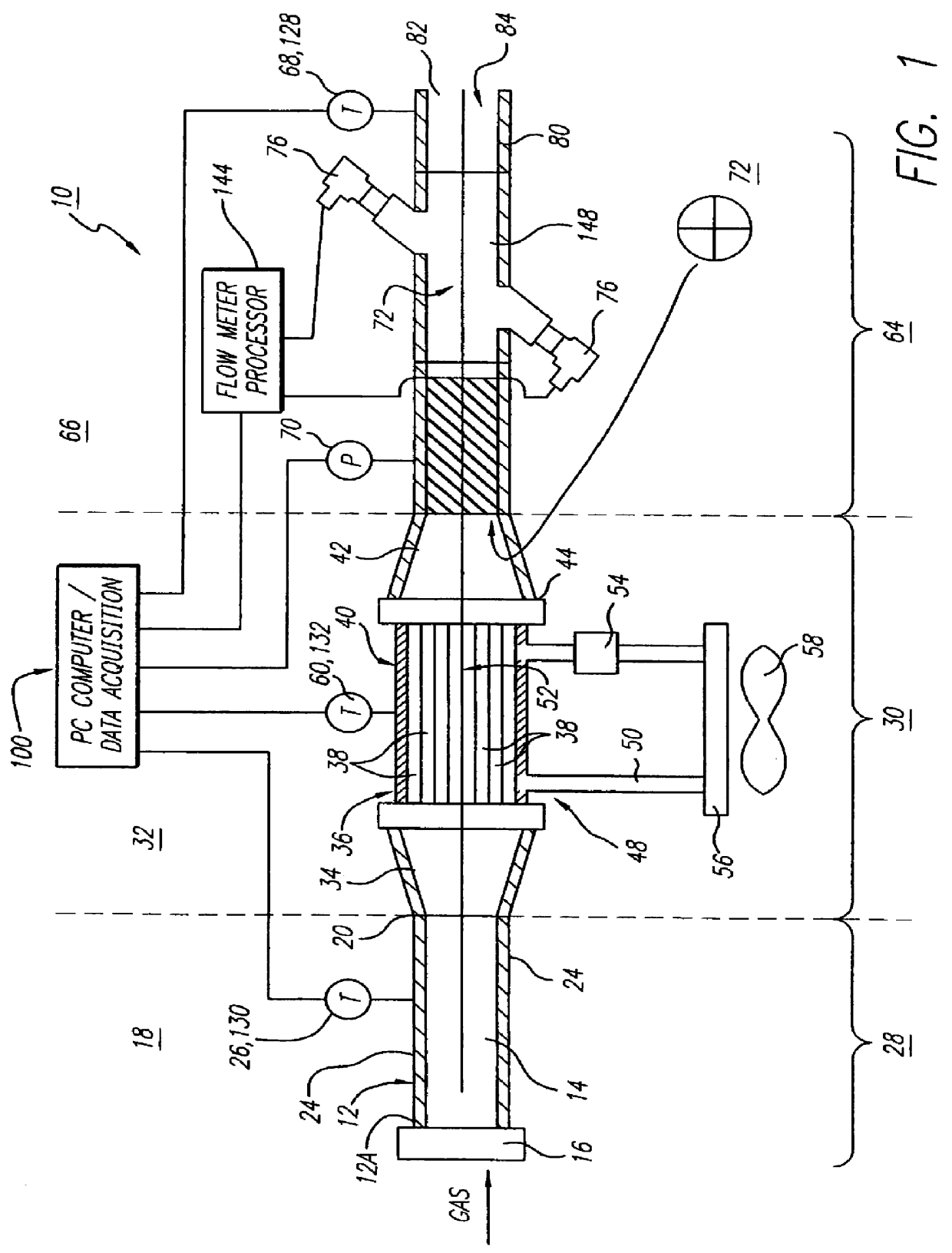

Gas flow rate measurement apparatus and method

InactiveUS6053054AHigh measurement sensitivityShort response timeVolume meteringIndirect mass flowmetersMeasurement deviceState variable

A gas flow rate measurement apparatus for obtaining a normalized flow rate of a gas having at least one liquid component. The gas travels from an upstream position and in a downstream direction. The gas flow rate measurement apparatus comprises a gas inlet conduit in the upstream position for receiving the gas; a gas flow conditioning section in fluid communication with the gas inlet conduit and in a first downstream position for conditioning the gas to vaporize substantially all of the at least one liquid component without adding any other gas; a flow rate measurement section in fluid communication with the gas flow conditioning section and in a second downstream position more distant from the upstream position than the first downstream position, the flow rate measurement section including at least one sensor for sensing at least one state variable for the gas and generating at least one gas state signal, and a flow rate sensor for measuring an actual flow rate of the gas and generating a flow rate signal, and a processing device operatively coupled to the flow rate measurement section for using the at least one gas state signal and the flow rate signal to obtain the normalized mass flow rate. A related method also is provided.

Owner:FLOW TECH

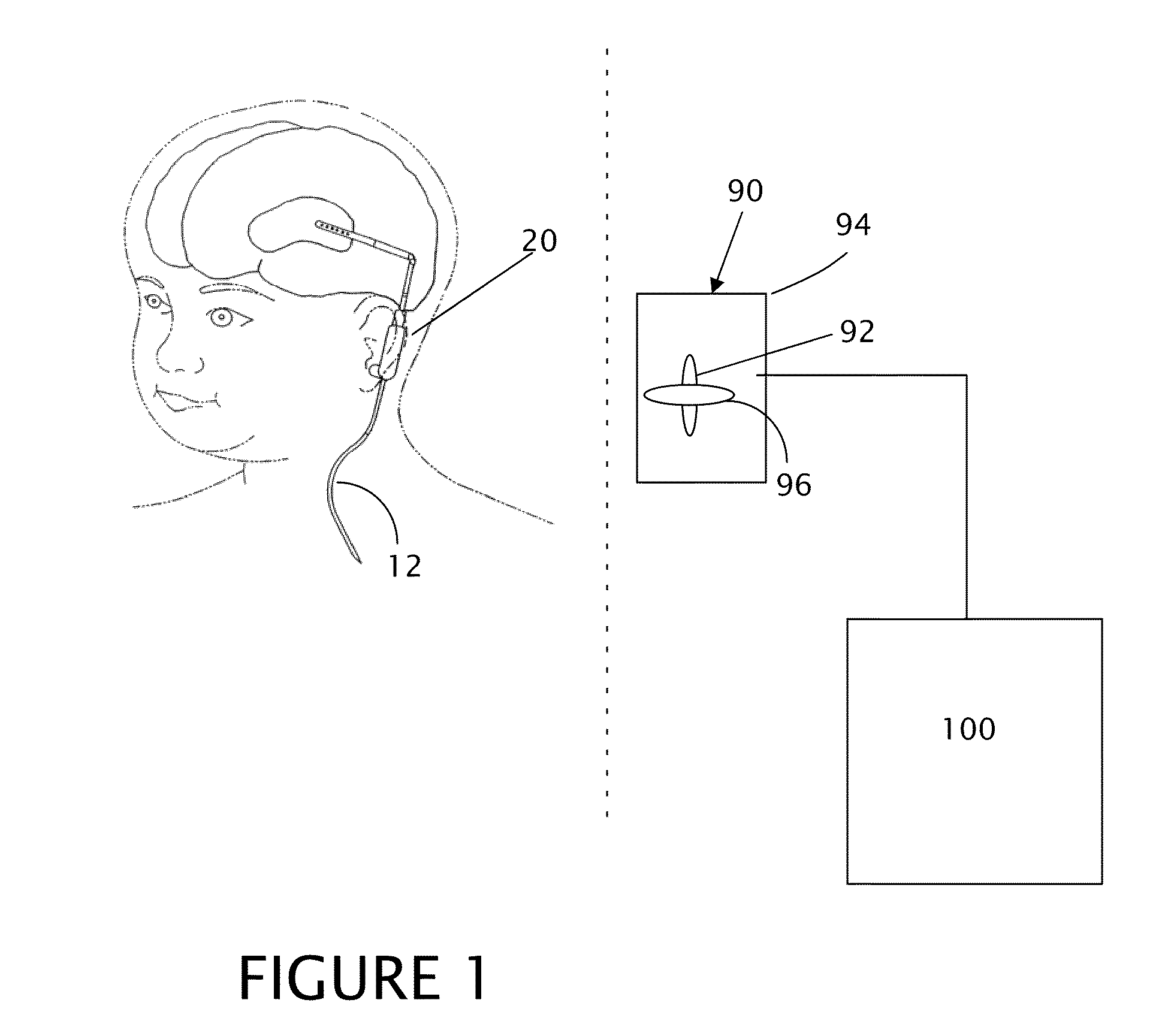

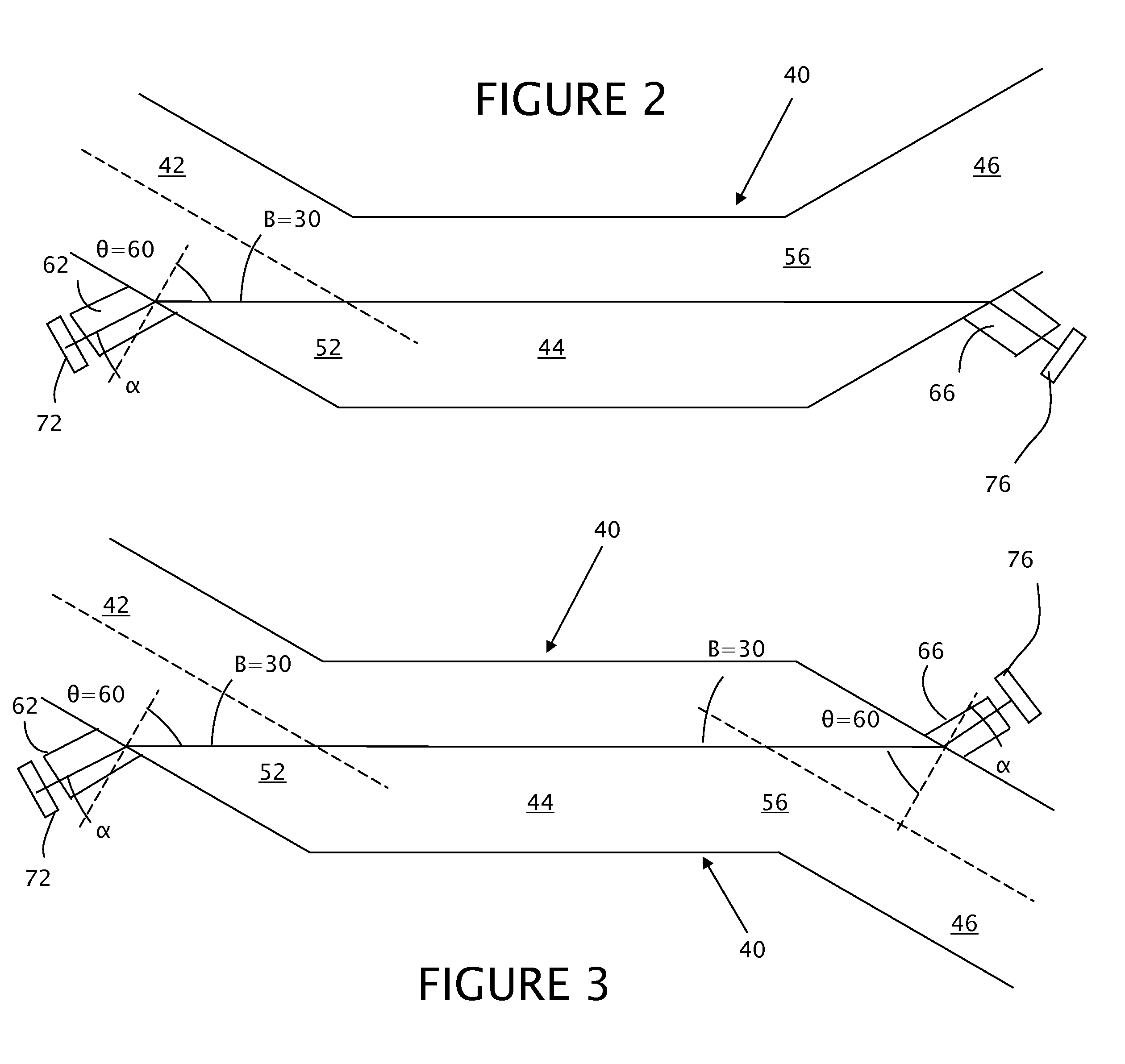

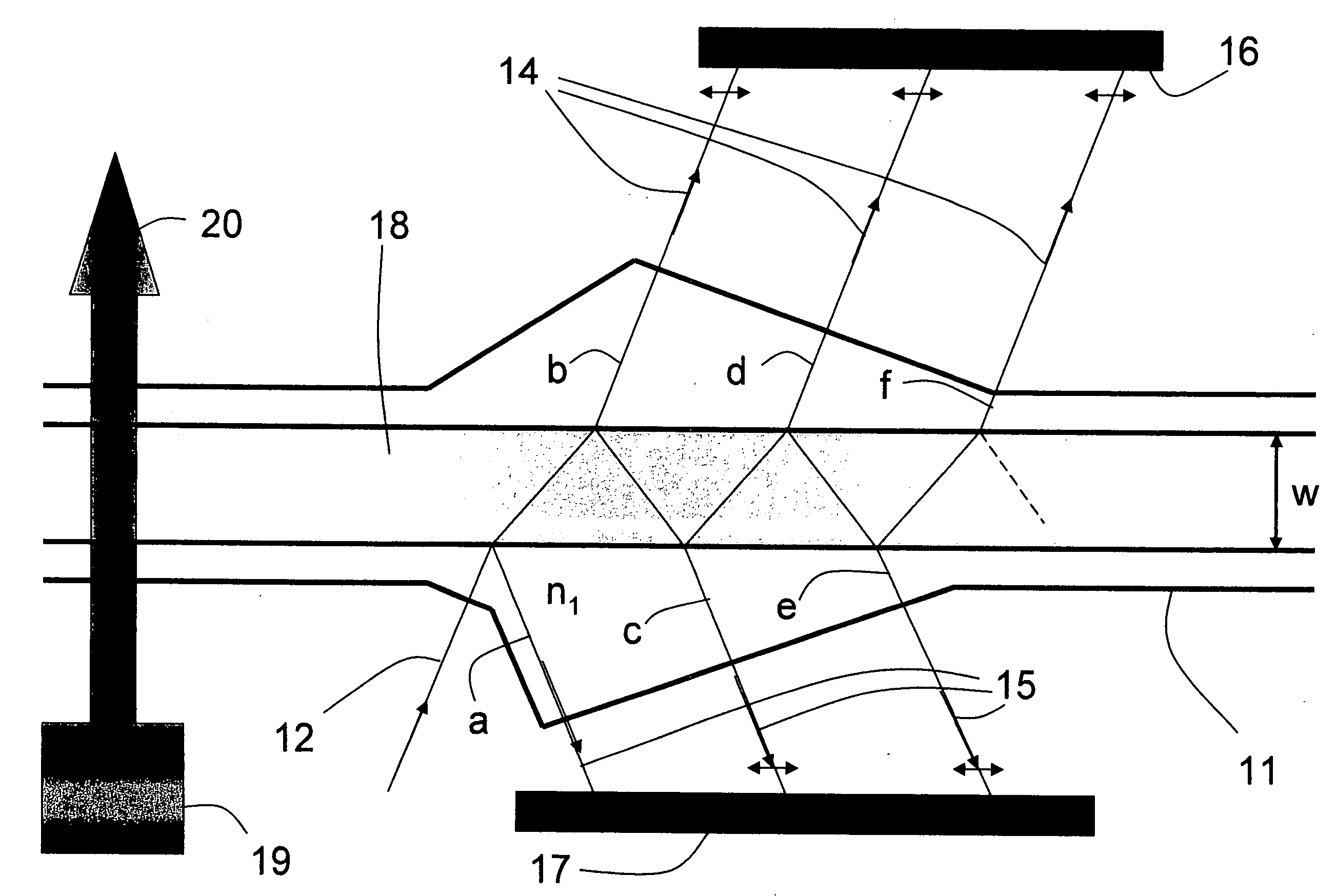

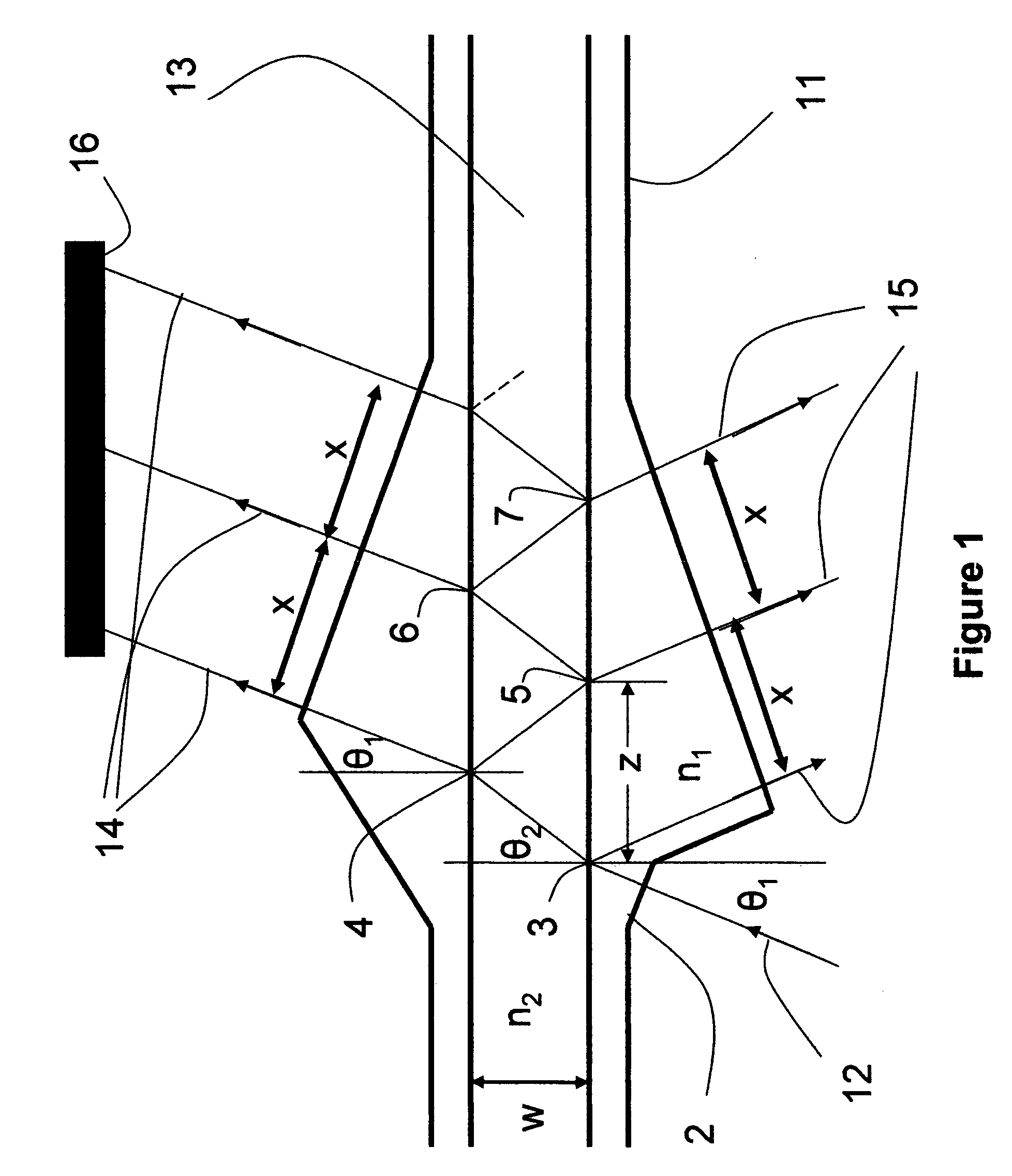

Transit time ultrasonic flow measurement

InactiveUS20090143673A1Ultrasonic/sonic/infrasonic diagnosticsEndoradiosondesTransmitted powerEngineering

A transcutaneous energy transfer system with subcutaneous non coupled coils is used to transmit power and signals to an implanted biological support device or sensor, such as a flow sensor for measuring relatively low flow rates, such as hydrocephalic shunt flow. The flow sensor is configured to convert a shear wave generated by a transducer to a longitudinal wave at the interface of a signal pathway and the flow, wherein the longitudinal wave travels parallel to the flow and exits a flow channel to convert to a shear wave which intersects a second transducer. The transcutaneous energy transfer employs a pair of inductive coupling coils, wherein the coils are disposed in zero coupling orientation which can include a perpendicular orientation of corresponding coil axes.

Owner:TRANSONIC SYST

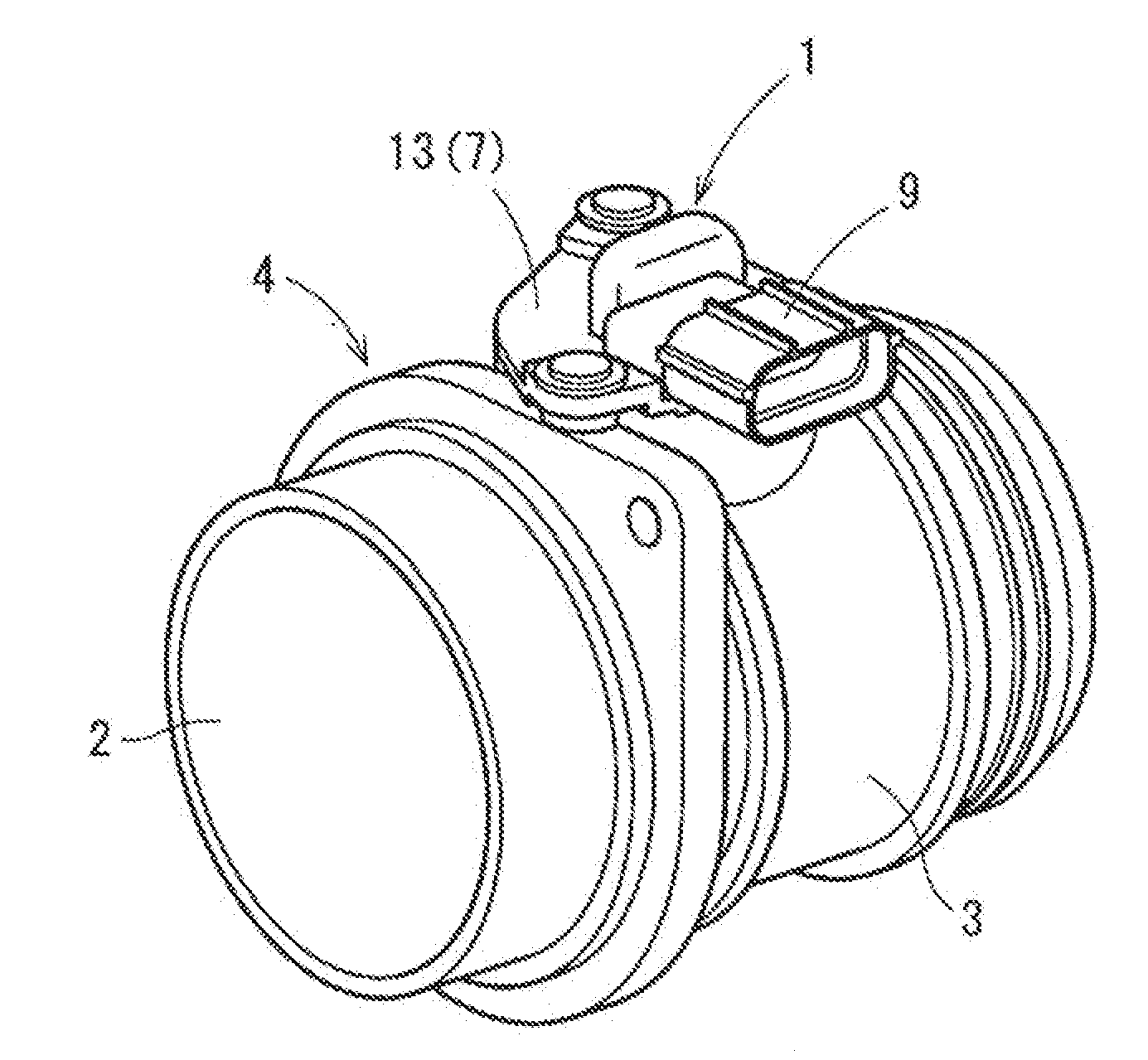

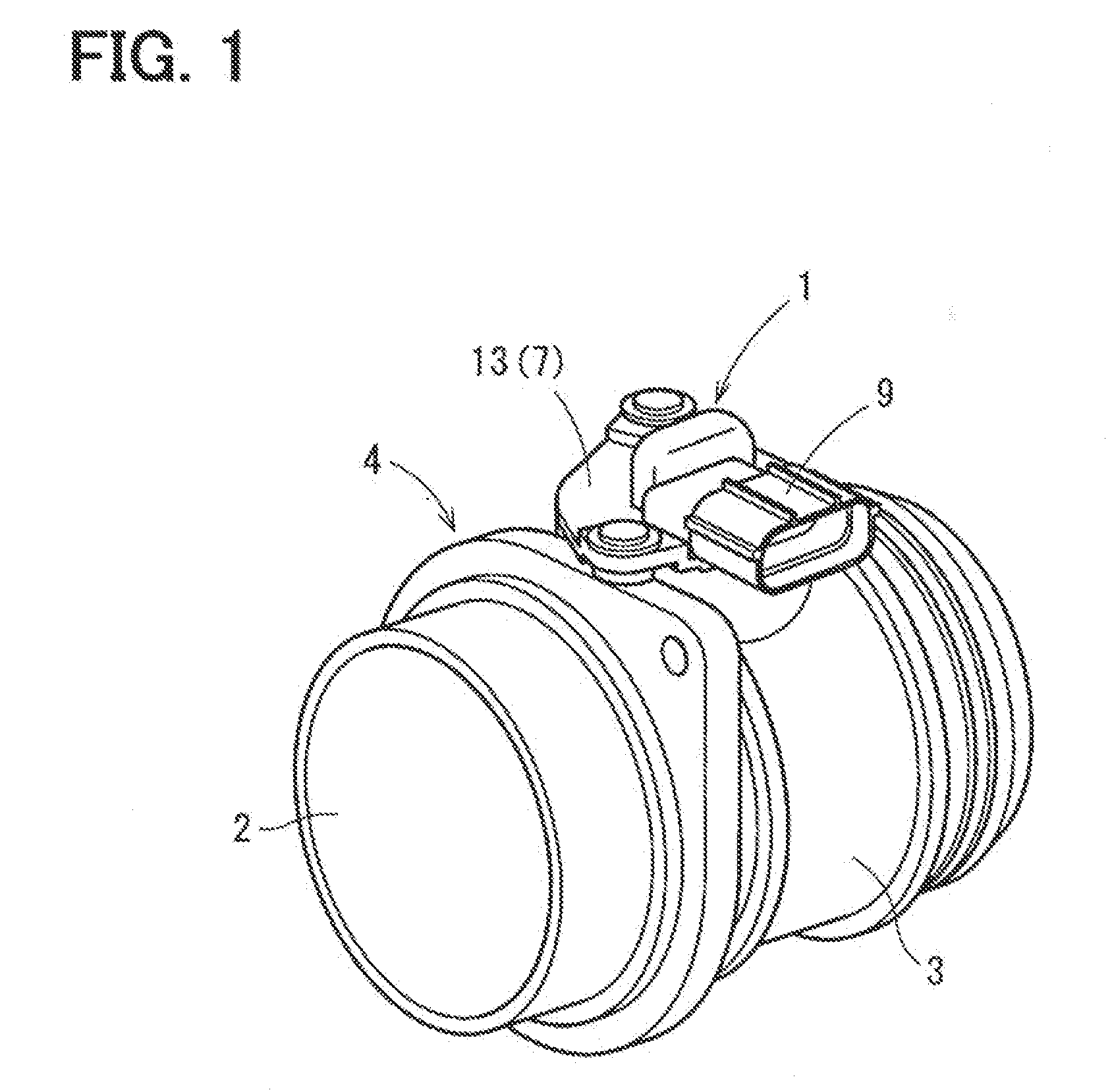

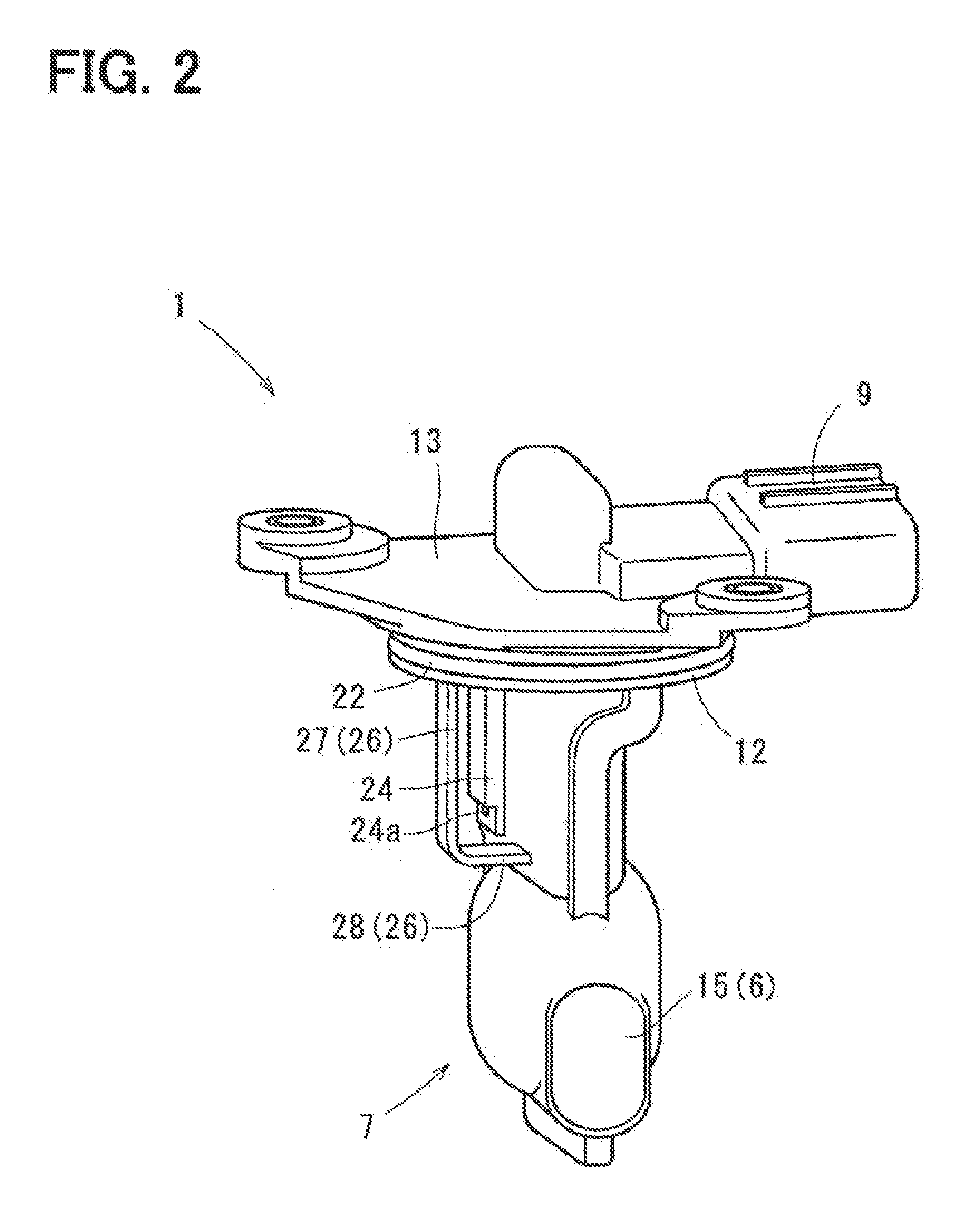

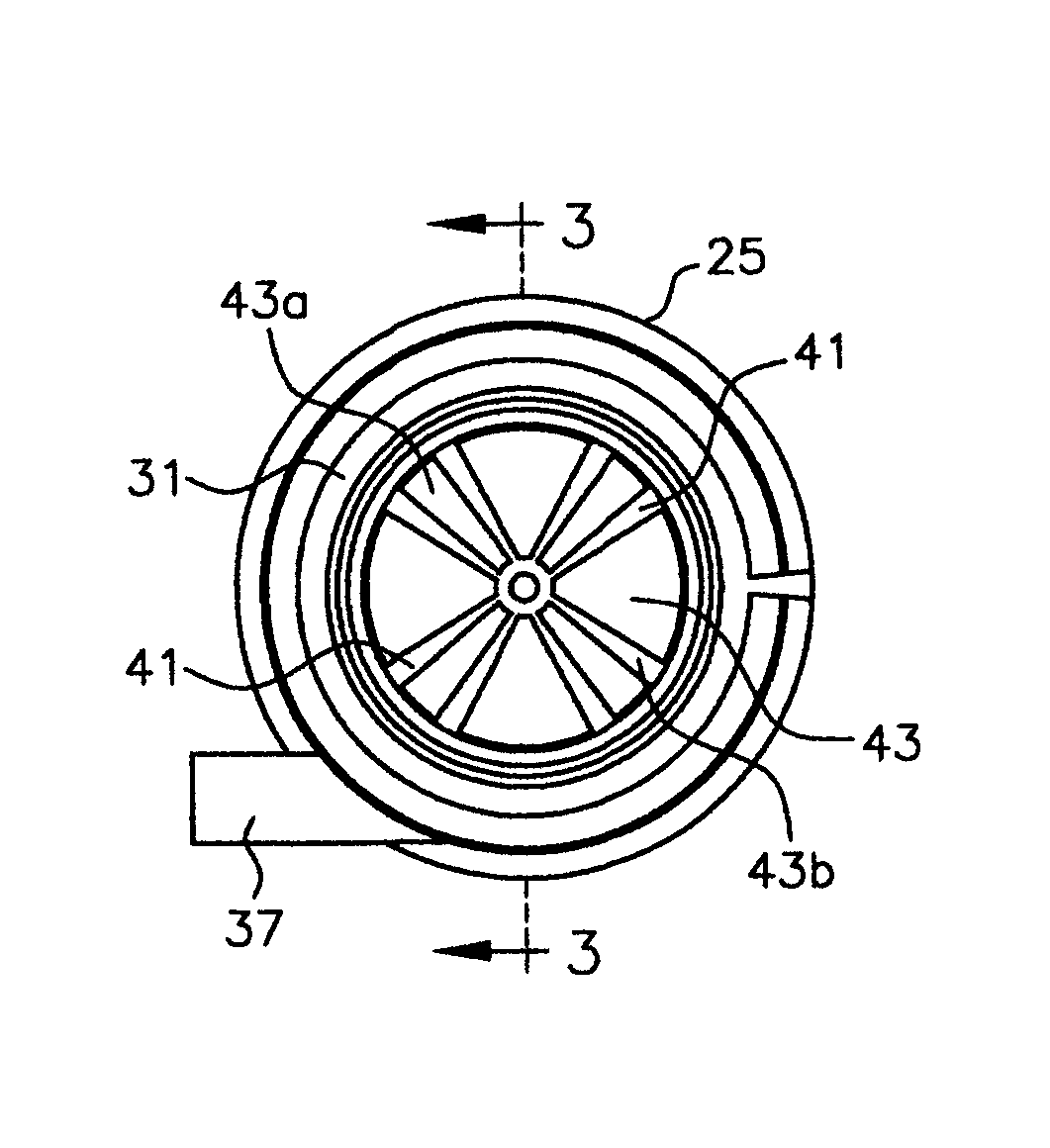

Air flow measuring device

ActiveUS20130036806A1Internal-combustion engine testingVolume/mass flow by thermal effectsFlow transducerMeasurement device

An air flow measuring device includes a housing, flow sensor, and a humidity sensor. The housing defines a bypass flow passage through which intake it passes. A part of intake air is taken into the bypass flow passage to pass through the bypass flow passage. The flow sensor includes a sensing part disposed in the bypass flow passage, and produces a signal which is in accordance with the flow rate of intake air as a result of heat transfer between intake air taken into the bypass flow passage and the sensing part. The humidity sensor includes a sensing part exposed to the intake passage, and projects from an outer wall of the housing into the intake passage. The humidity sensor produces a signal which is in accordance with humidity of intake ail flowing through the intake passage.

Owner:DENSO CORP

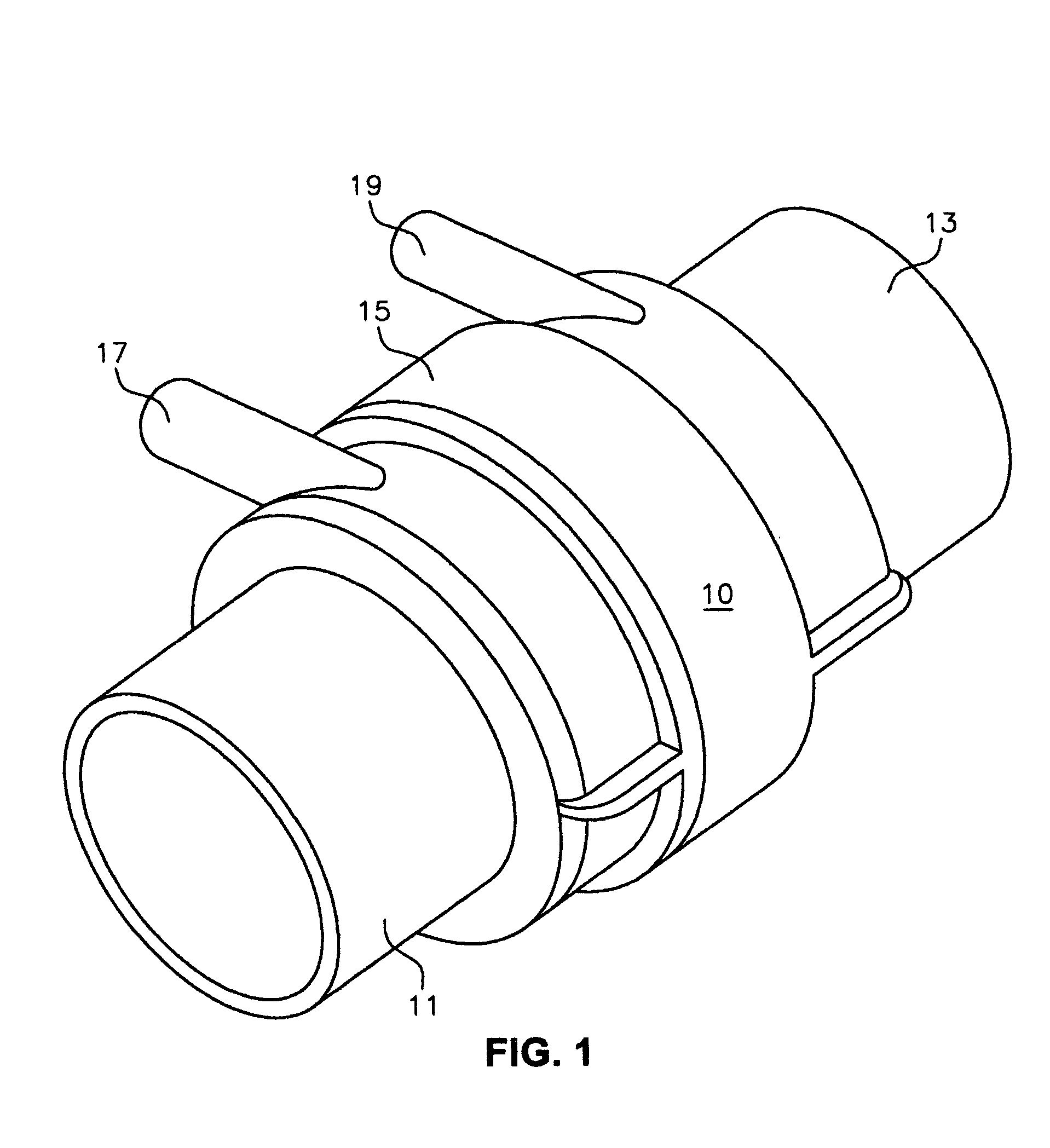

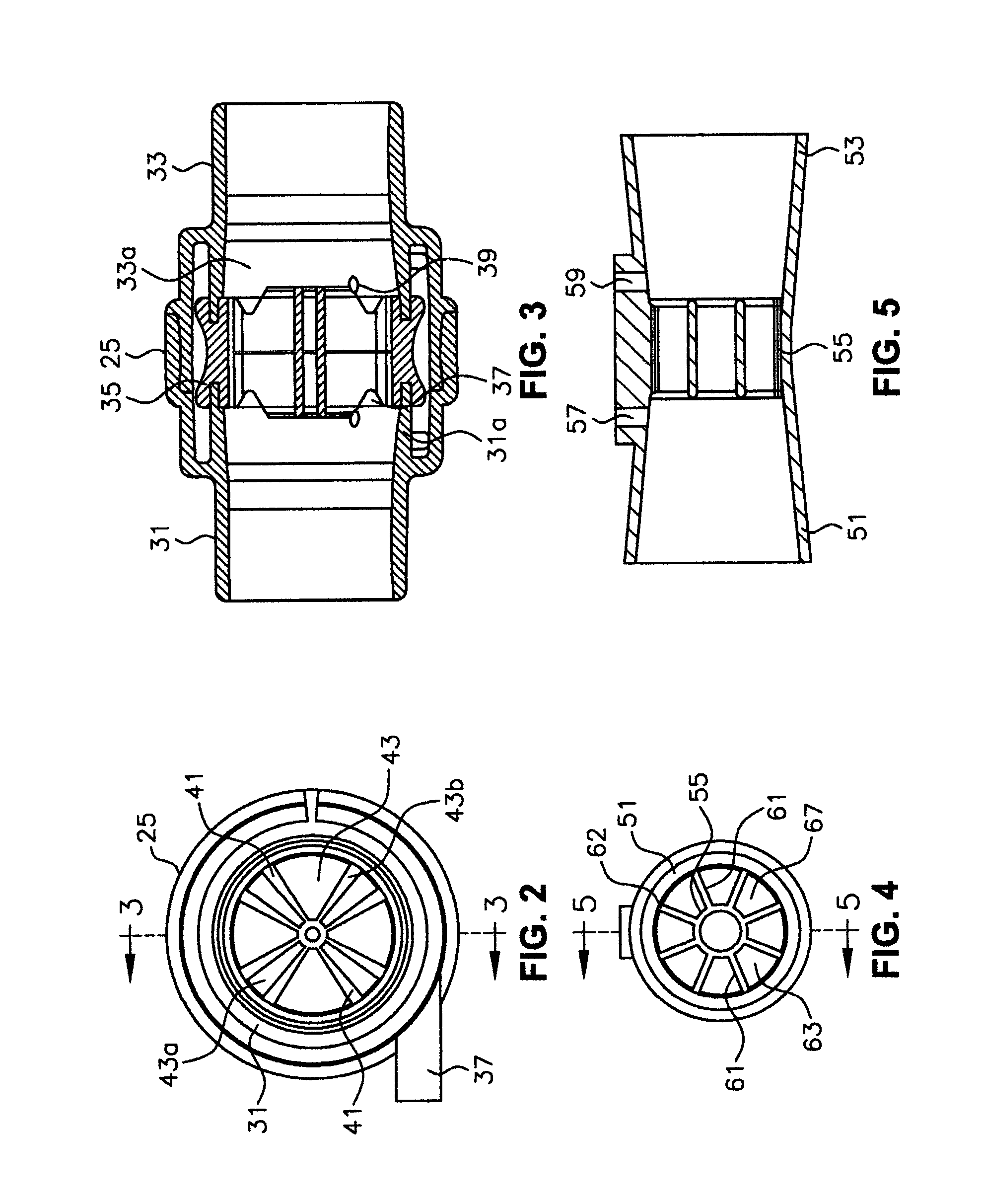

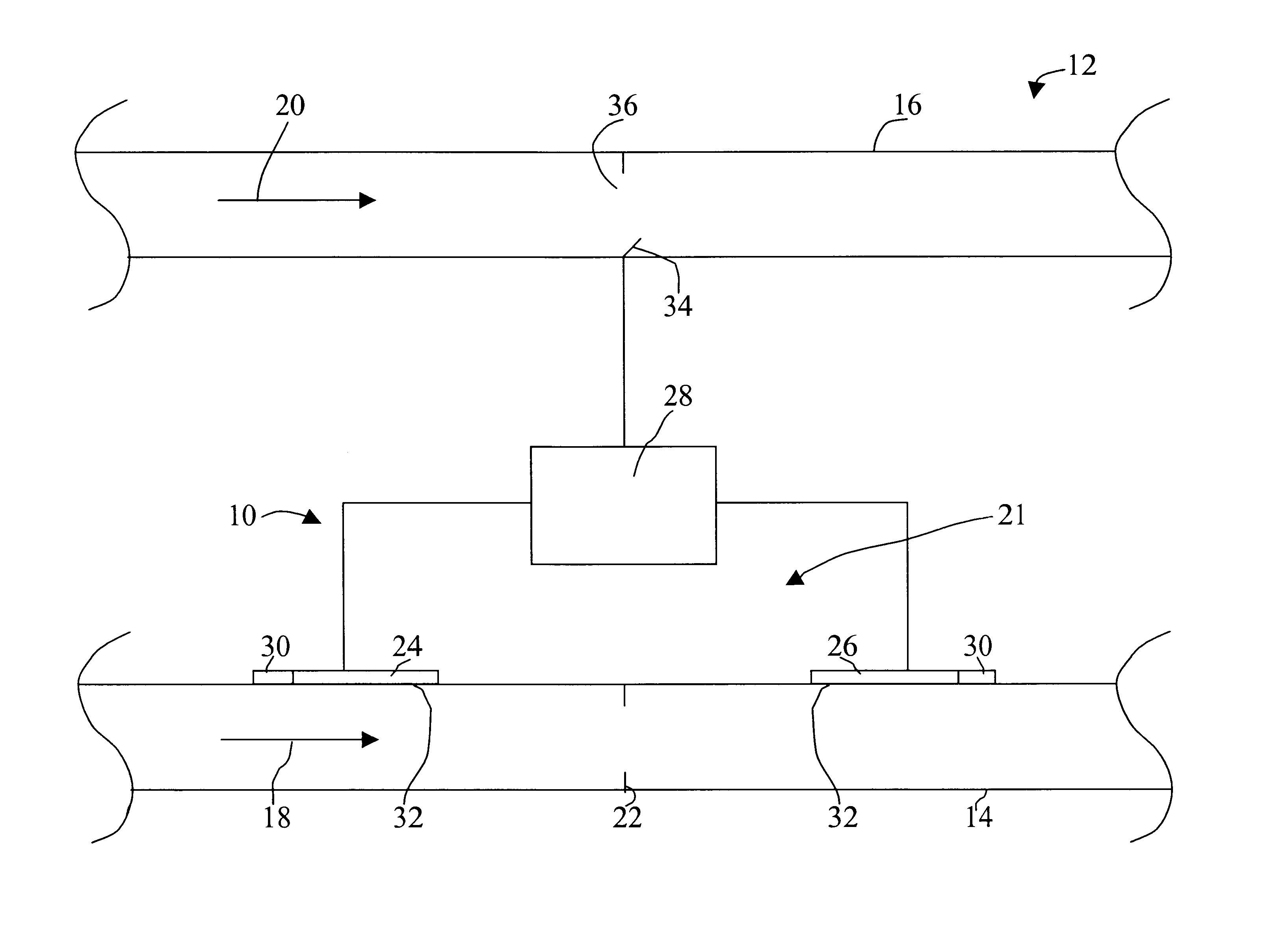

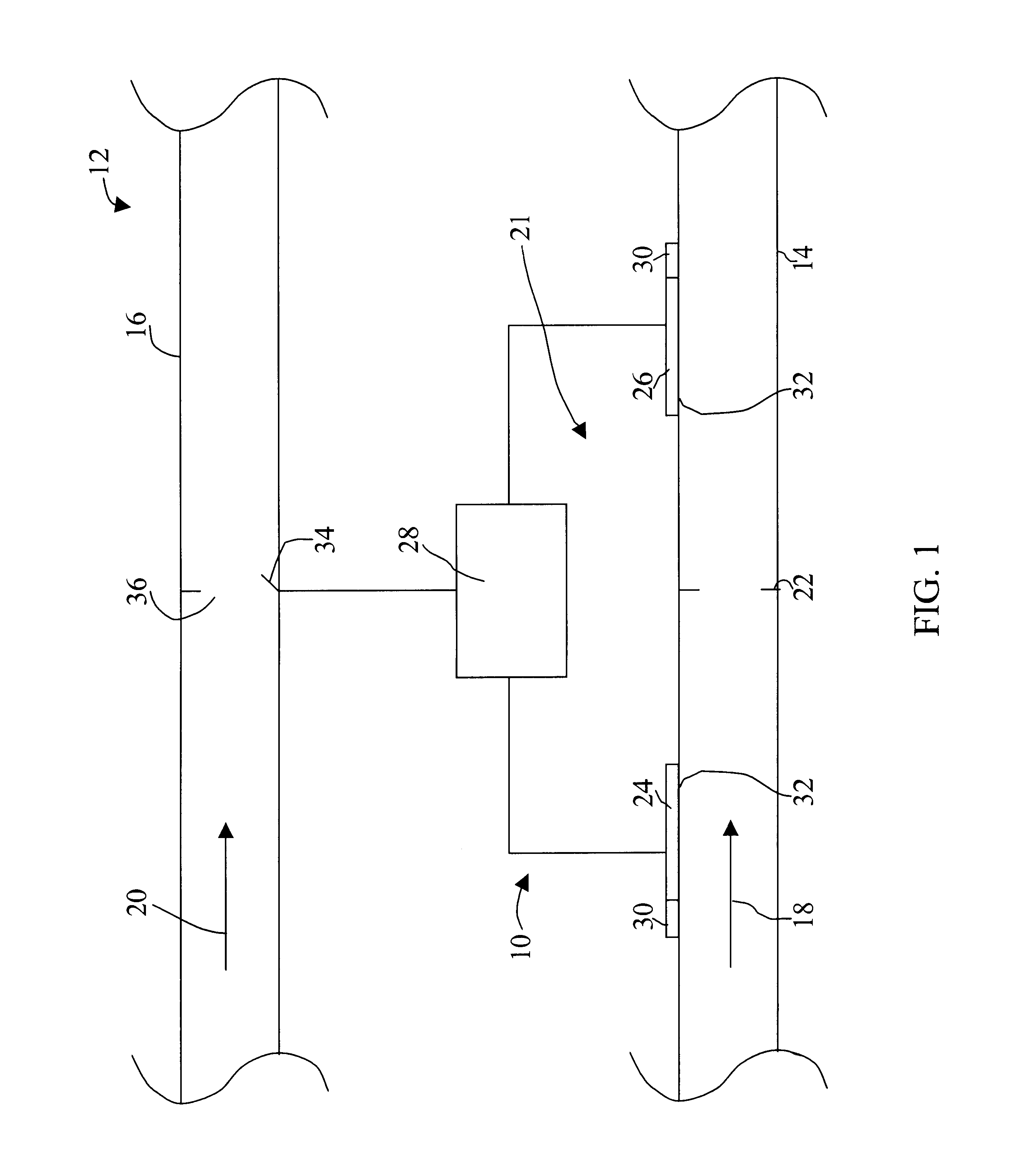

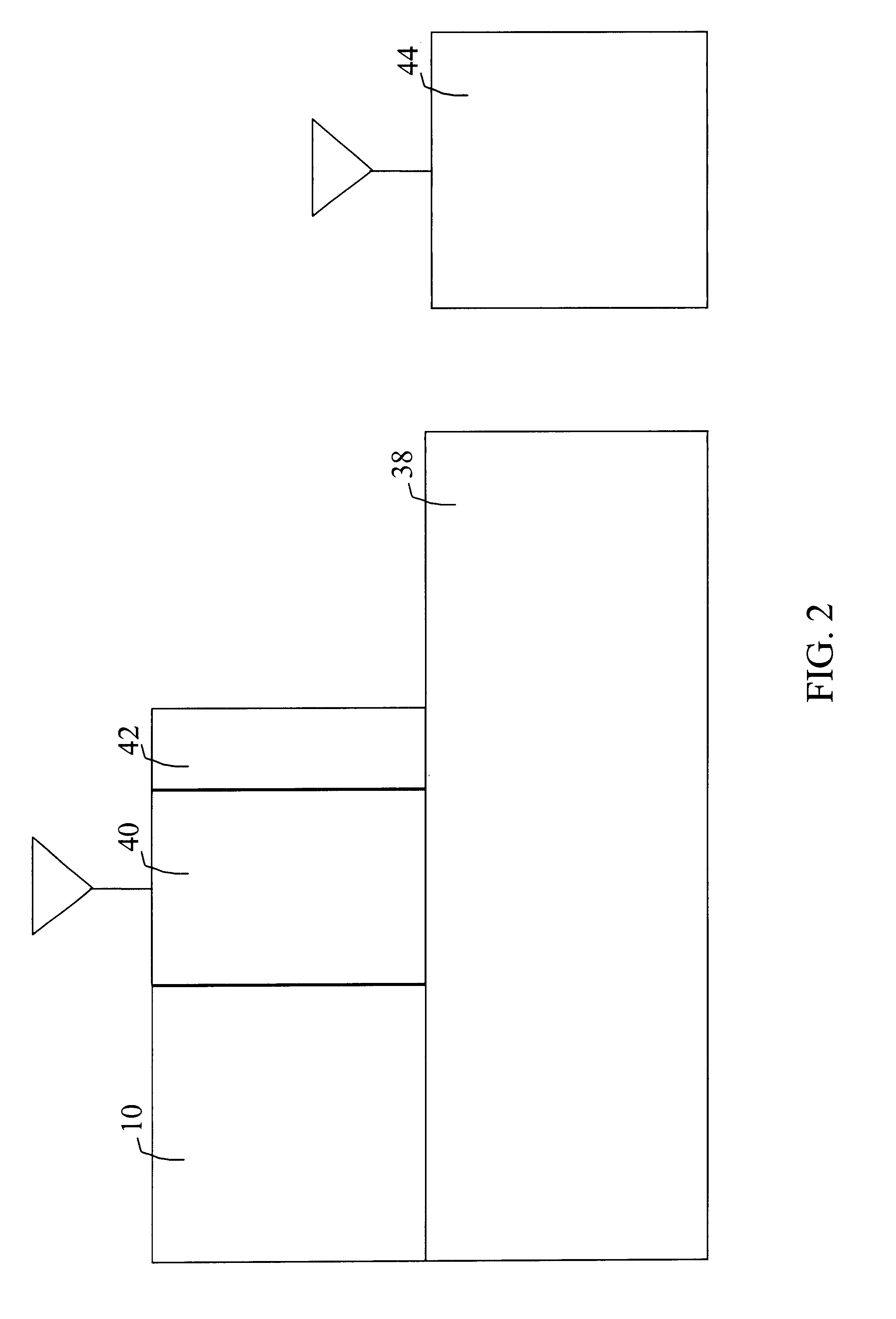

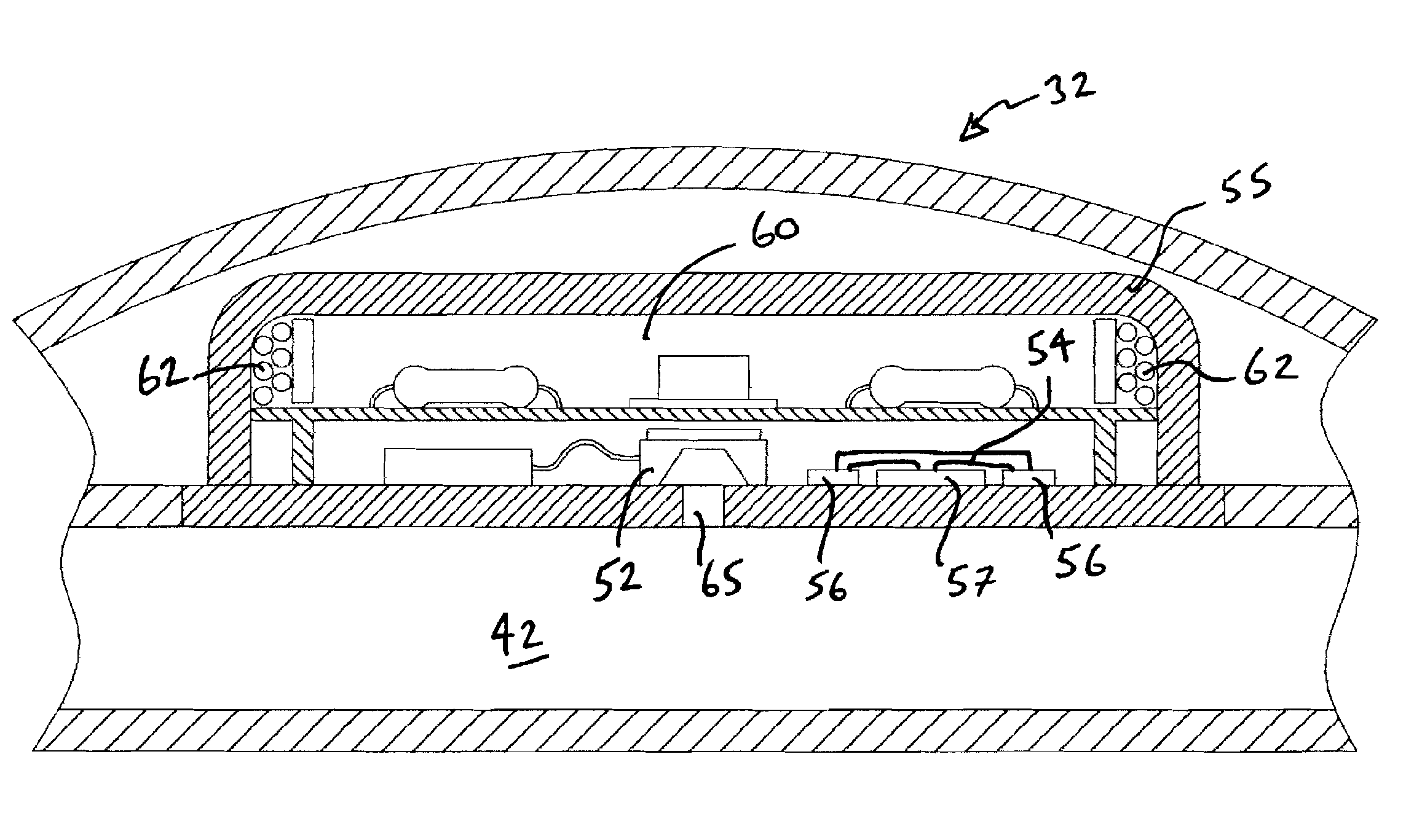

Flow sensor with integrated delta P flow restrictor

A high mass flow sensor device having a flow restrictor formed by a body having a generally cylindrical shape with an upstream end and a downstream end separated by a center portion having pressure taps proximate the junction of the ends with the center portion. Flow passes from upstream to downstream. The upstream end has a decreasing tapering inner surface for contact with the flow and the downstream end having an increasing tapering inner surface for contact with the flow. A center portion has radial and axial restrictor elements positioned forming axial openings in the path of flow through the center portion. The restrictor elements having tapered leading edges. One opening is formed by a central tube having a predetermined diameter and the remaining openings are radially extending members supporting the central tube, each of the radially extending members having substantially the same cross-sectional area as the central tube.

Owner:RESPIRONICS

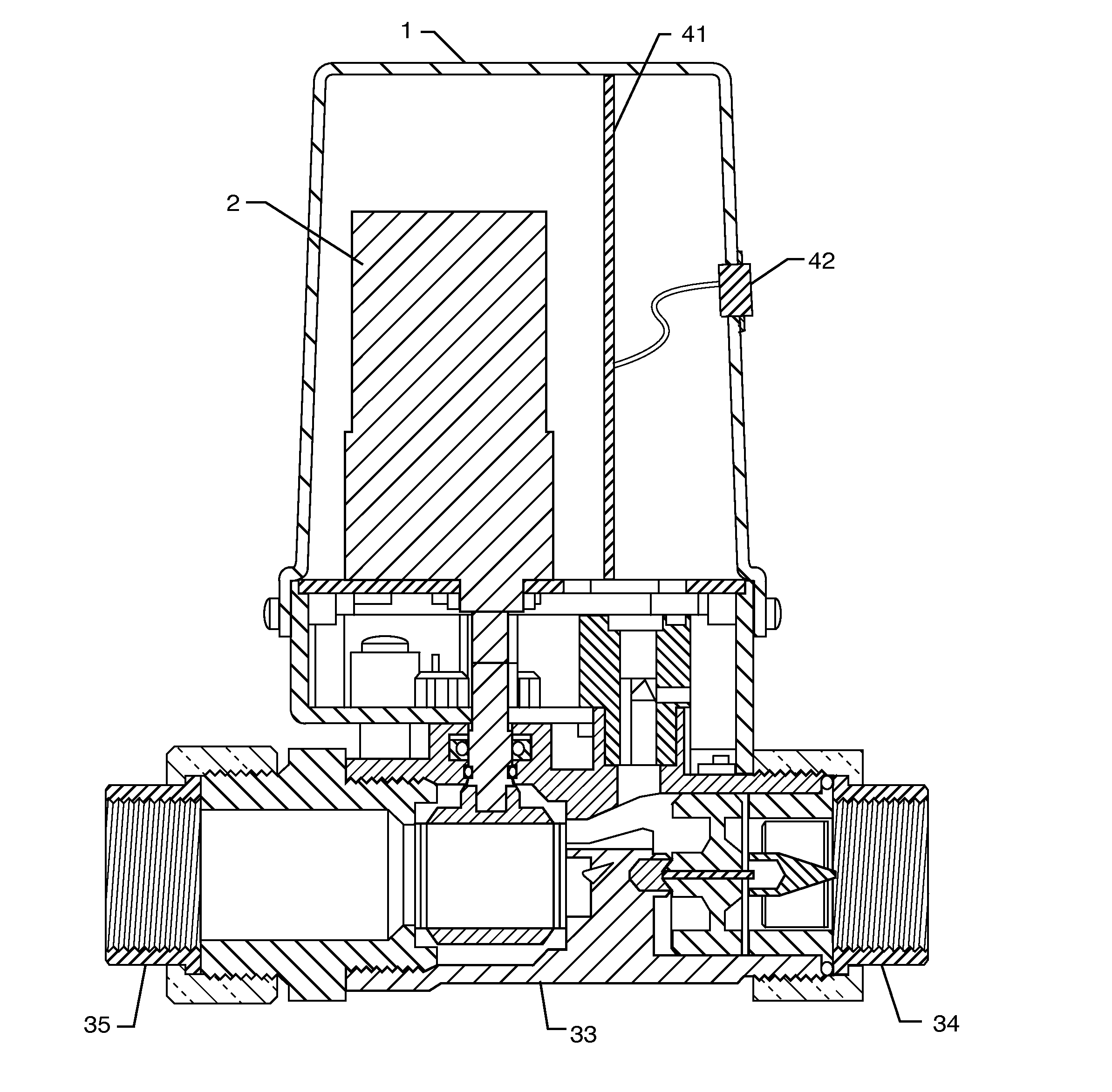

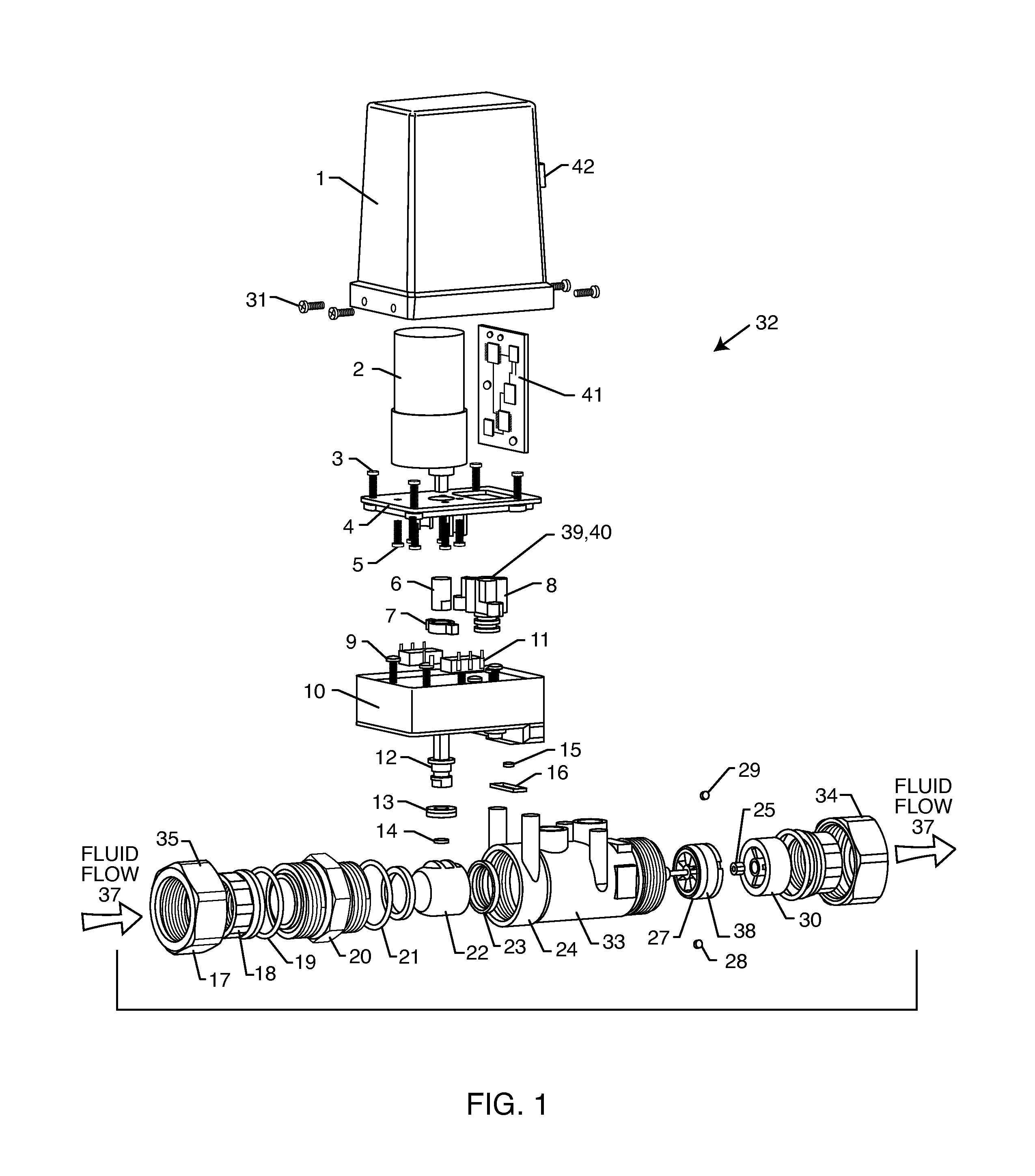

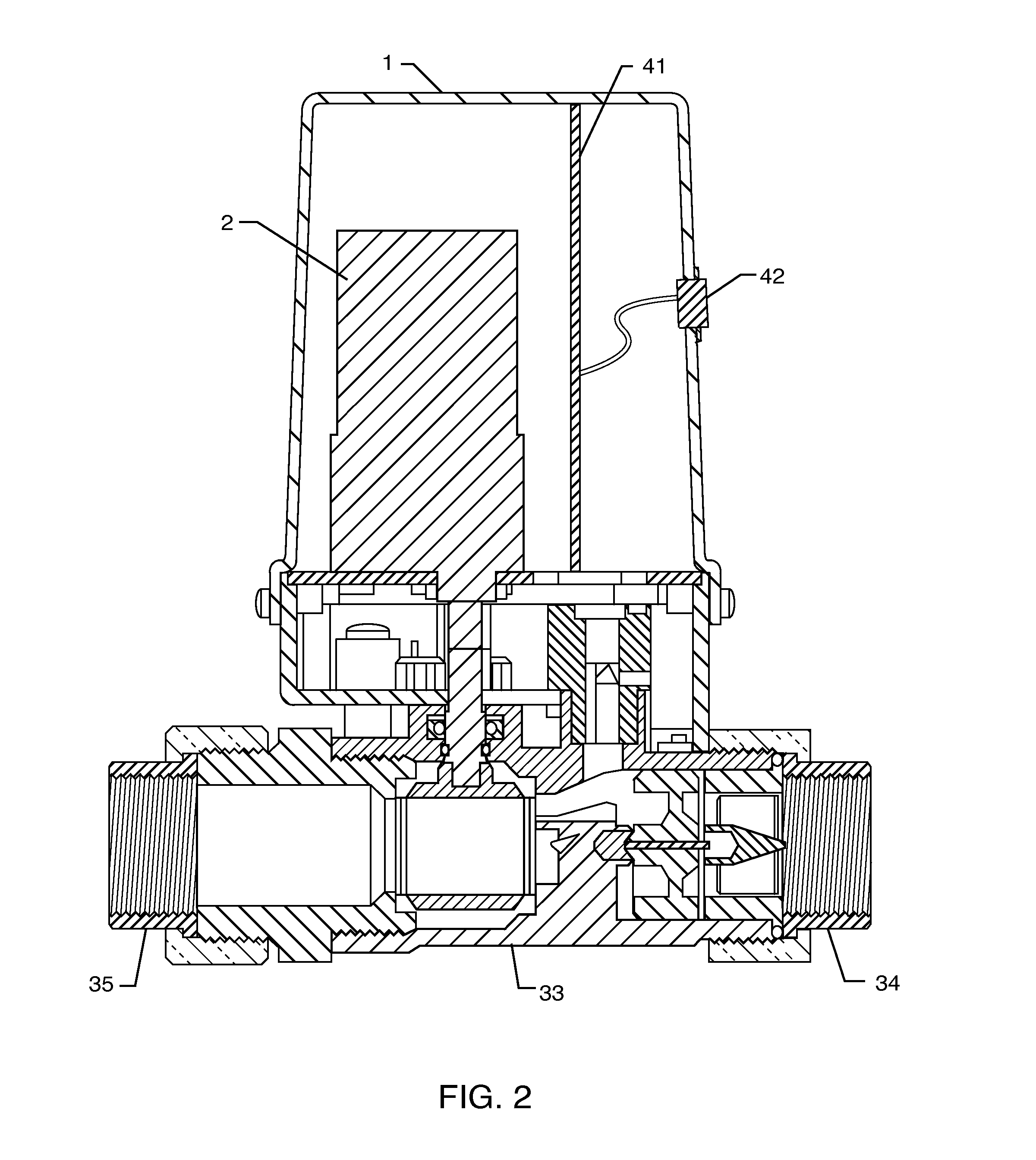

Fluid monitoring and control system

ActiveUS20140230925A1Use of fluid can be goodQuick fixOperating means/releasing devices for valvesFlow control using electric meansFlow transducerControl system

A fluid monitoring and control system includes a central hub having a central processor, a user interface and an input / output port. A plurality of control devices communicate with the central hub. Each control device includes a fluid pipe section including a fluid inlet and a fluid outlet. A fluid valve is coupled in series within the fluid pipe section and an electric motor is mechanically connected to the fluid valve. A temperature sensor, pressure sensor and flow rate sensor are coupled to the fluid pipe section monitoring a temperature, pressure and flow rate of the fluid flow within the fluid pipe section. A control device processor is controllably connected to the electric motor, temperature sensor, pressure sensor and flow sensor. A control device input / output port is coupled to the control device processor, the control device input / output port in communication with the input / output port of the central hub.

Owner:FORTUNE BRANDS WATER INNOVATIONS LLC

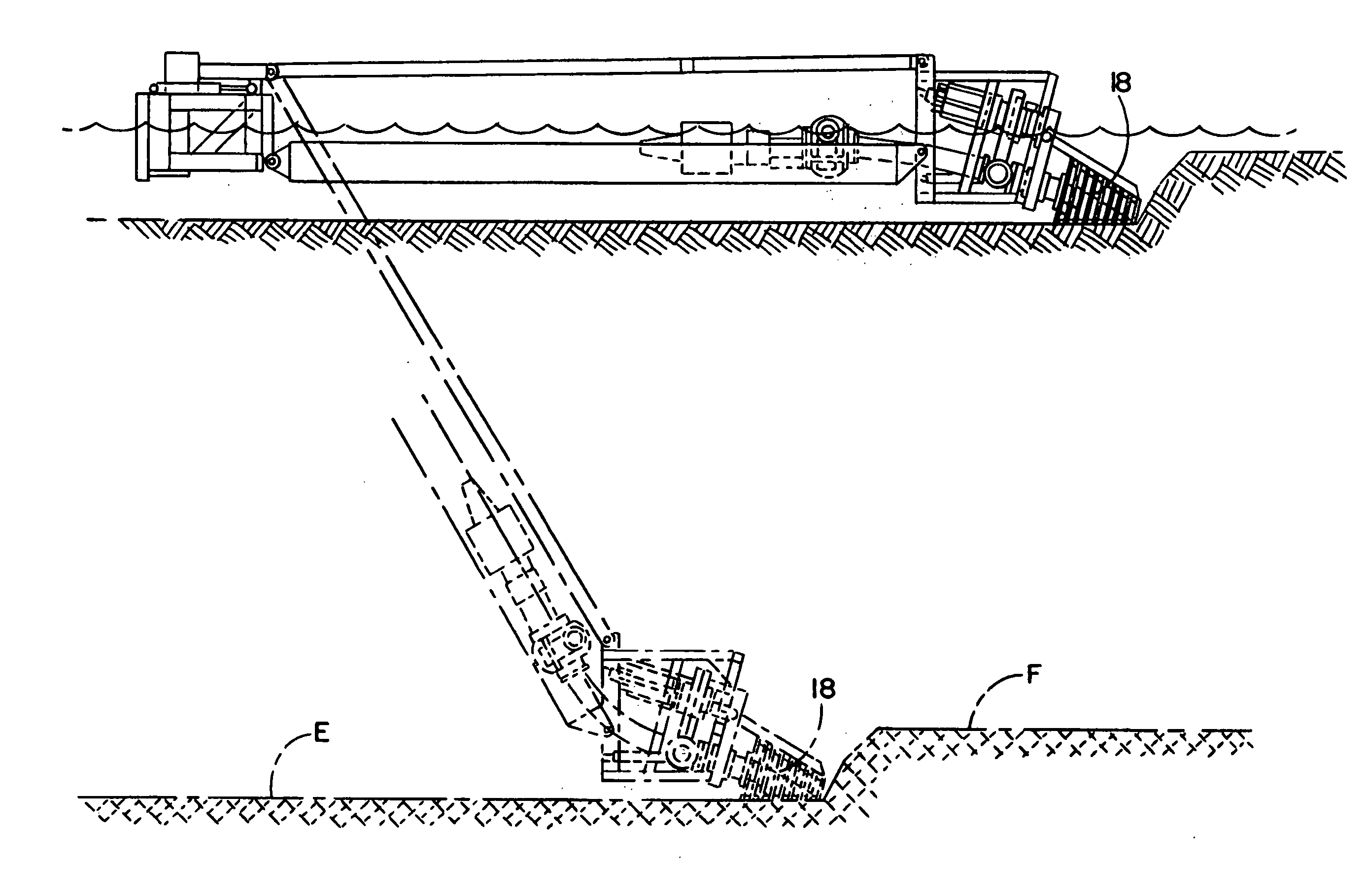

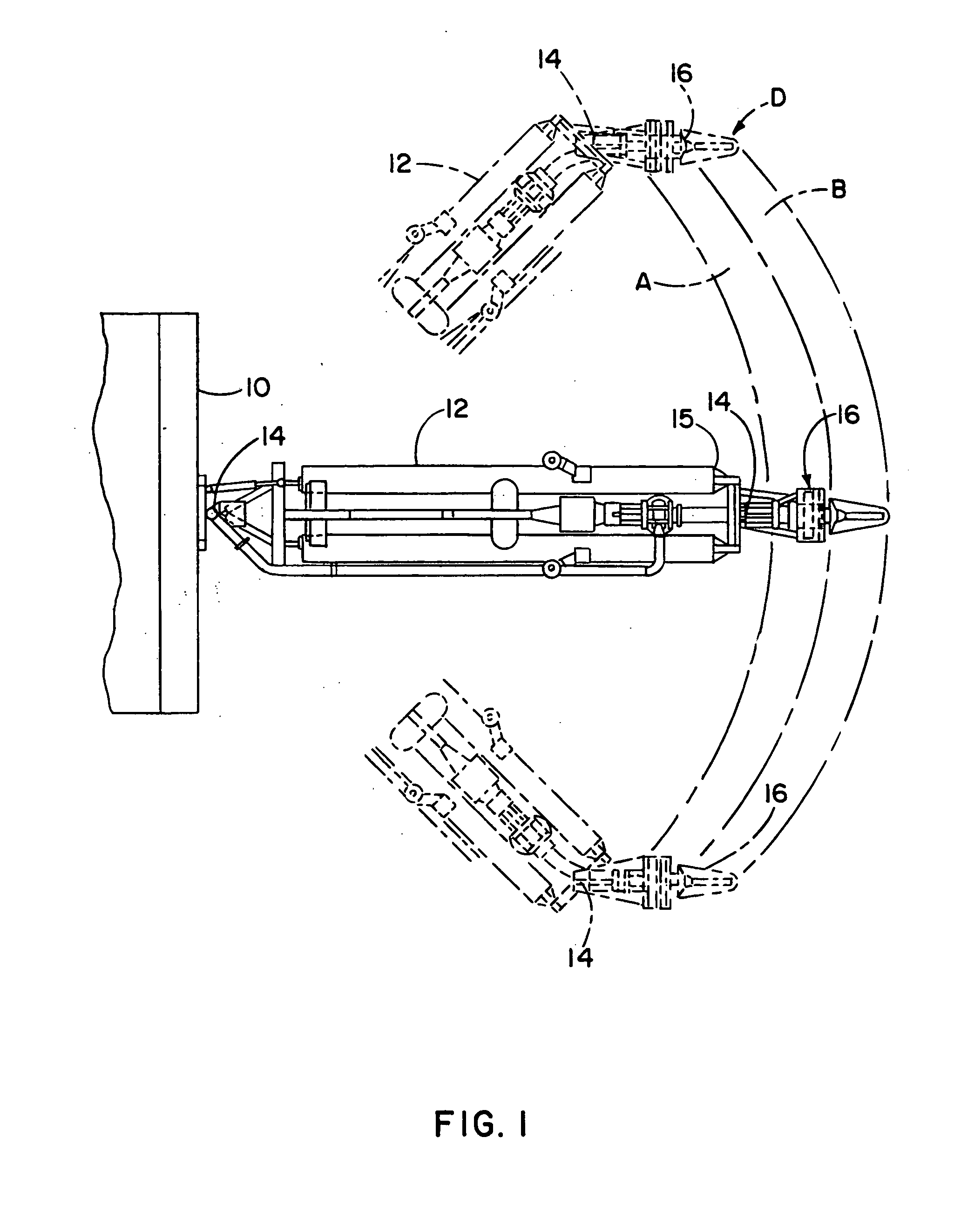

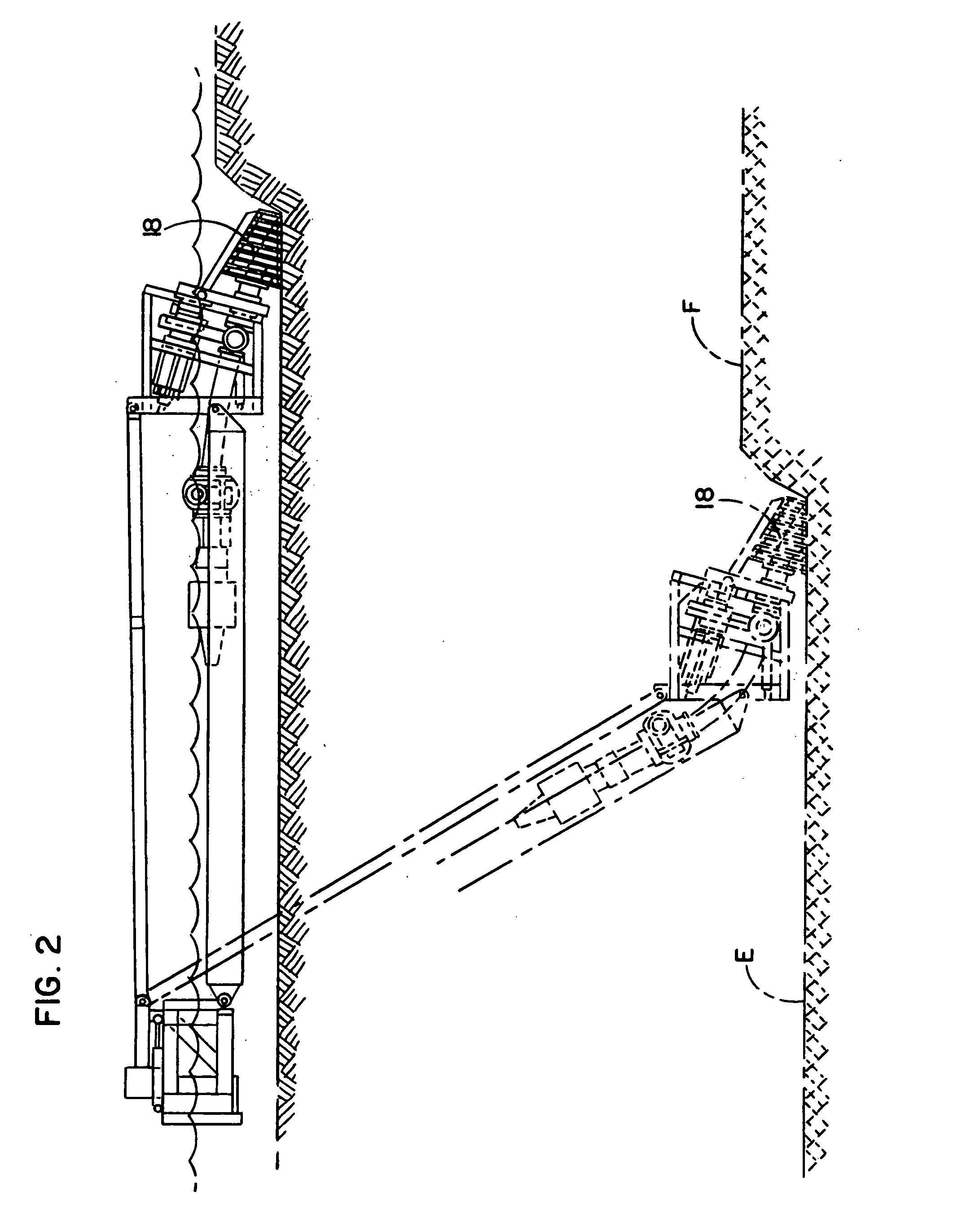

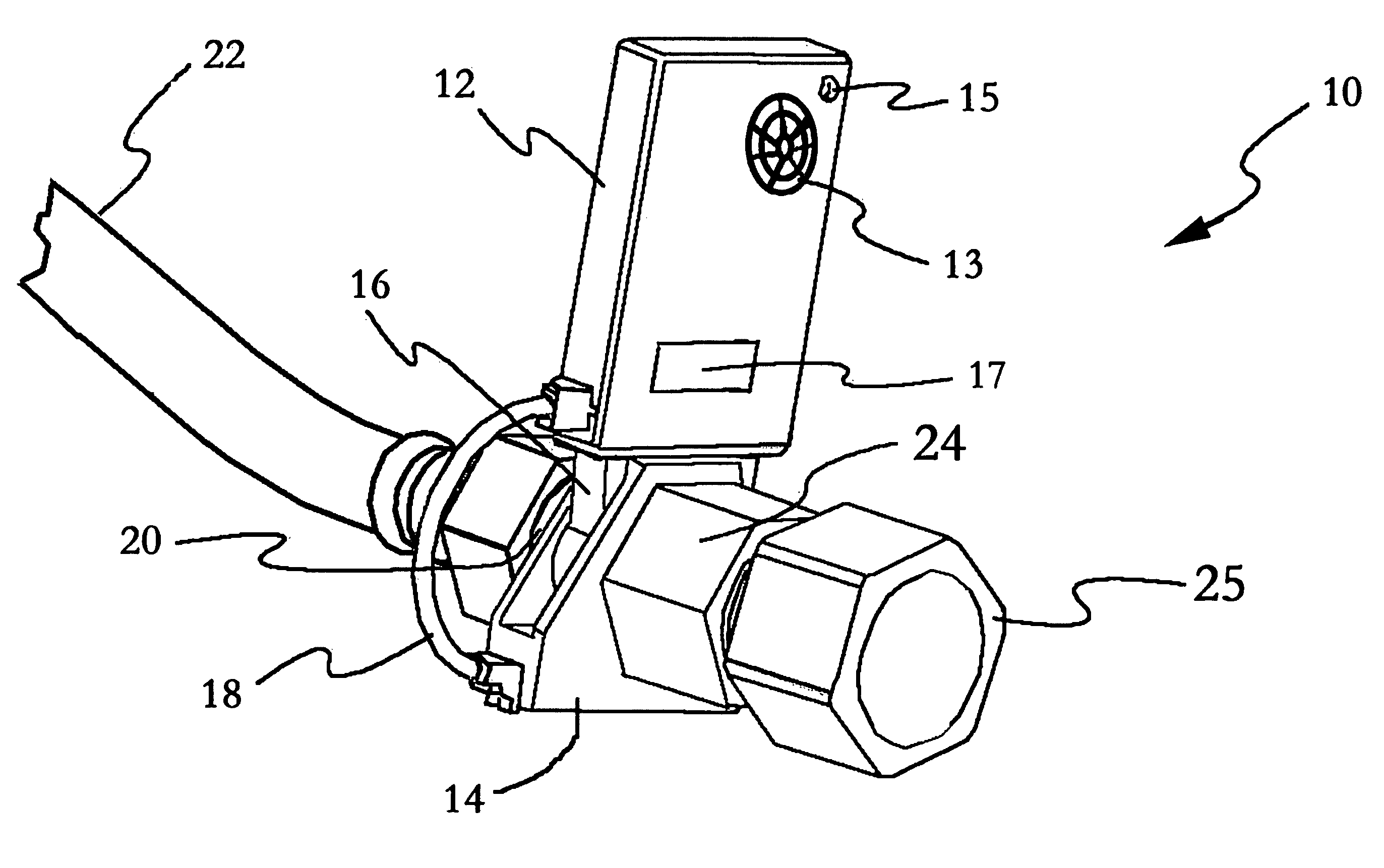

Method and apparatus for pumping with a dredge

InactiveUS20050268499A1Reduce turbidityGreat tractionSpecific fluid pumpsAgricultural machinesFlow transducerTurbidity

A system usable for dredging may include a suction bypass system for automatically maintaining a sufficiently high, liquid flow velocity. Preferably, a flow sensor monitors flow velocity and when the monitor flow decreases to an extent that plugging may occur, a liquid bypass valve is opened and an intake line valve is closed until the flow velocity increases whereupon the valves are returned to their original positions. An automatic level cut removes a relatively constant layer of material from a contoured bottom. The illustrated automatic level cut process comprises adjusting the force with which the suction head engages the bottom, moving the suction head in a direction opposite to the direction of the swing of the boom to keep the suction head pointing straight ahead, and maintaining the suction head to stay substantially level with the bottom even though the angle of the boom increases to the surface of the water body. A leveling device comprising a parallelogram linkage may be used to maintain the suction head substantially level with the bottom. A predetermined amount of load force may be applied by the head against the bottom. Herein, a winch and cable and the controller are operated to lift some of the head weight until the desired predetermined head force is applied to the bottom. A walking system moves the pipe intake for taking a sideways cut without the use of a spud pole, anchors and anchor lines. Large blade members or feet travels in an endless path with the feet entering the bottom while vertically disposed and remained disposed vertically while entering and leaving the bottom so as not to dig or stir the bottom that will cause large liquid turbidity. A low turbidity head cleaning system prevents the head from being plugged and debris or sticky material. Preferably, a rotatable cone-shaped head is provided with spaced rings and bars that define sized openings that limit the size of debris entering into the intake. A fixed comb removes material stuck on the rotating head. A shroud has an open bottom side thereby preventing bottom material from escaping and increasing with turbidity. A suction head articulation system keeps the head pointed in the forward direction of dredge advancement to create a smooth finish grade.

Owner:EDDY PUMP CORP

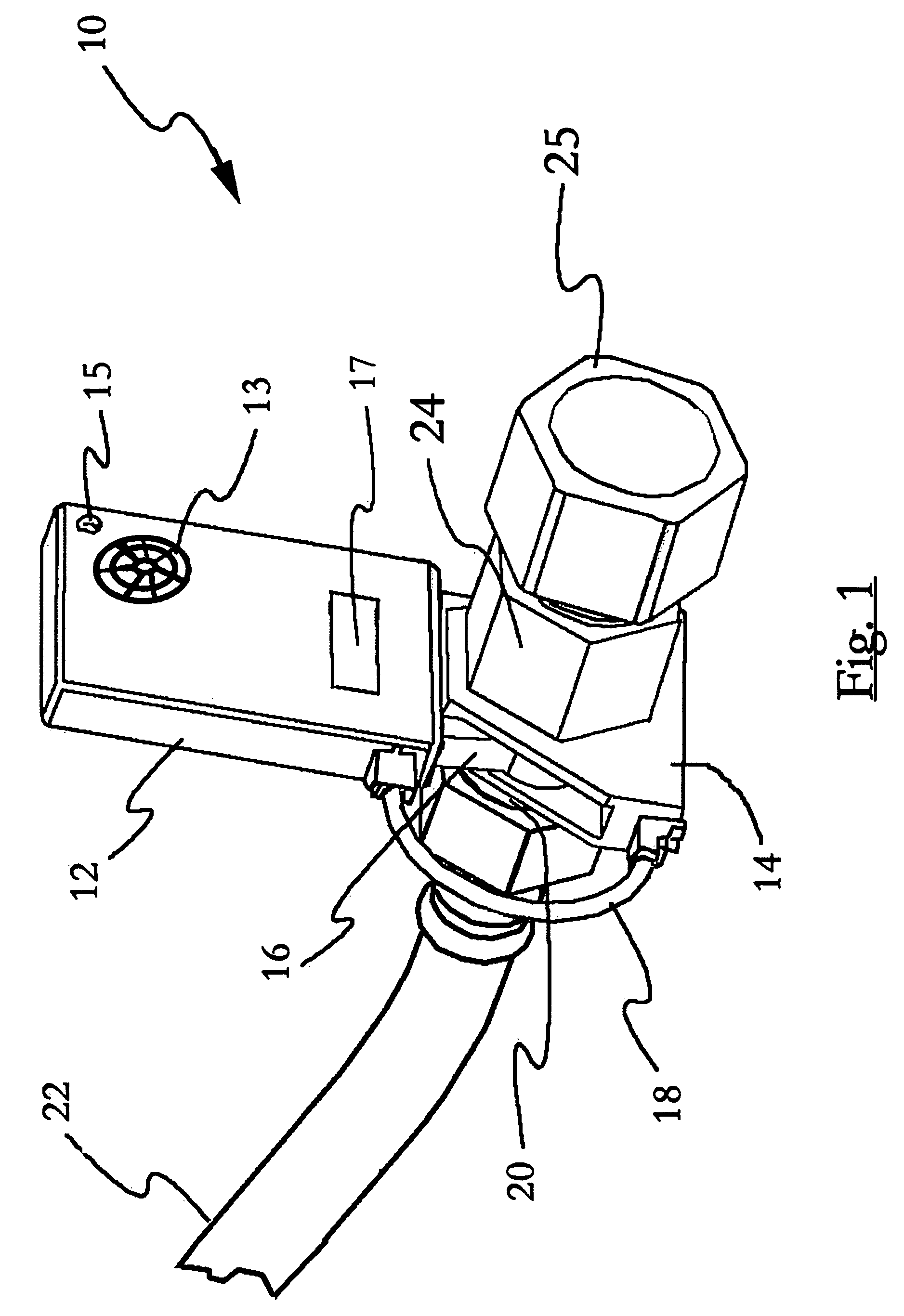

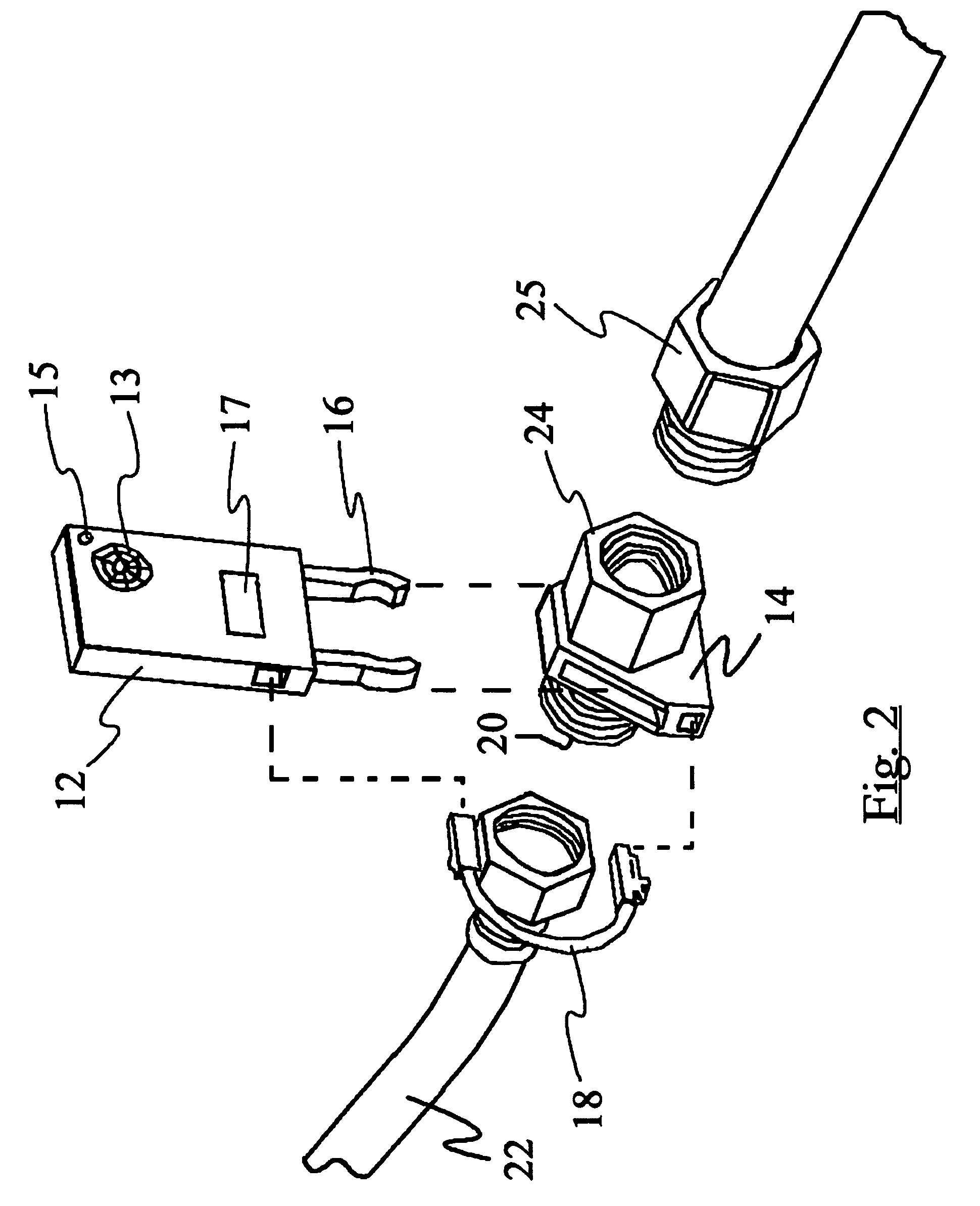

Flow detector with alarm features

InactiveUS7969318B2Strengthen incentivesMeasurement of fluid loss/gain rateFire alarm radiation actuationFlow transducerEmbedded system

Owner:WHITE MATT +1

Fluid flow sensor

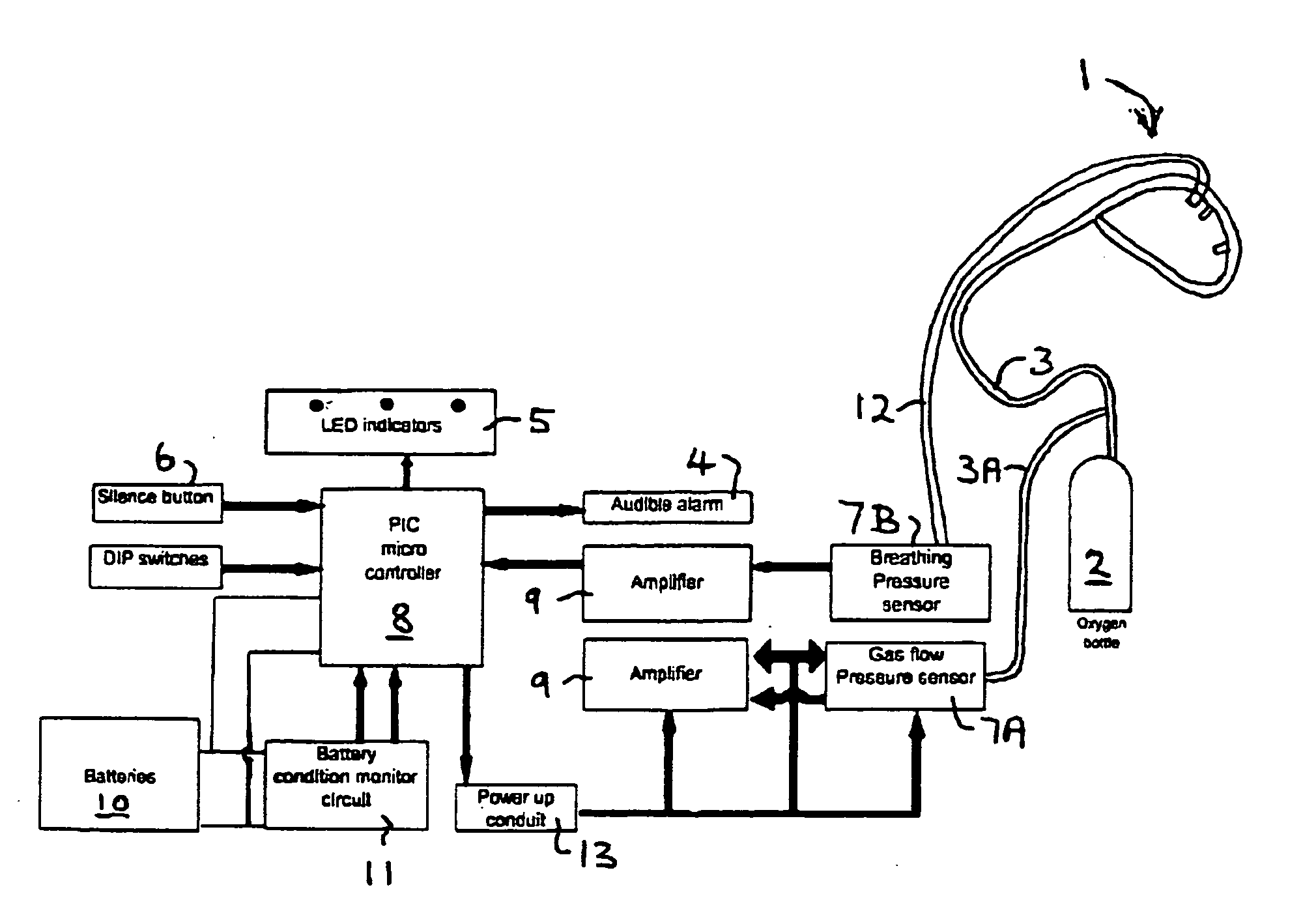

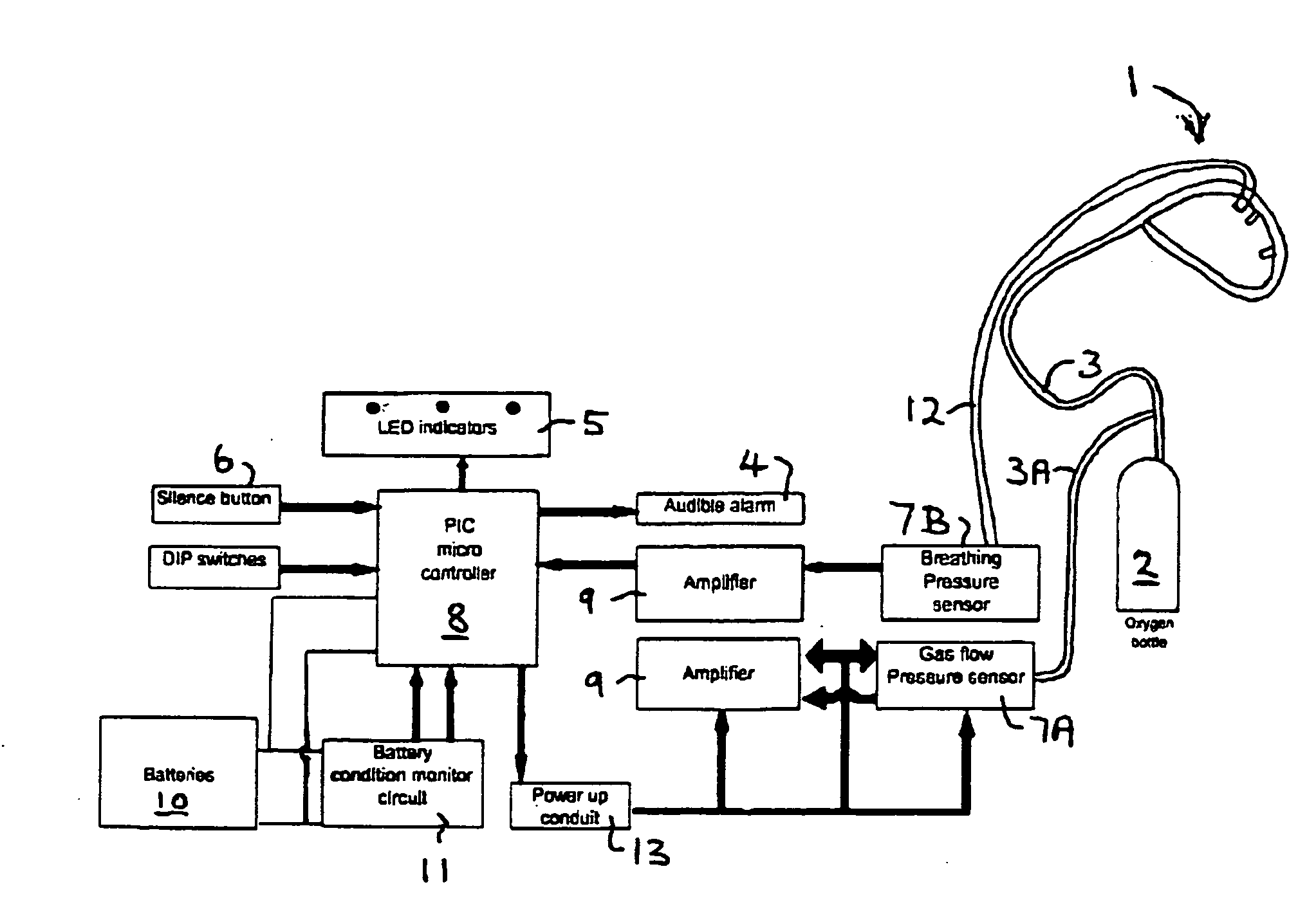

InactiveUS20060070458A1Failure be imminentRespiratory masksVolume/mass flow measurementFlow transducerEngineering

A fluid flow sensor for a device, such as breathing apparatus in the form of a cannula pipe or face mask, the sensor having means for monitoring and indicating the pressure or absence of a fluid flow in a conduit for supplying fluid from a fluid supply to the device. A means is provided responsive to back pressure in the conduit to actuate an indicator of the sensor to alert a use of the device of the presence and / or absence of the fluid flow.

Owner:OXYMON

Flow measuring device based on predetermine class of liquid

InactiveUS6609431B1Liquid dispensingVolume/mass flow by differential pressureVolumetric Mass DensityDischarge measurements

A flow meter and method for determining the corrected flow rate of a liquid falling into a predetermined class of liquids based on its viscosity and density is disclosed. The flow meter comprises a flow sensor for measuring an uncorrected flow rate of the liquid, a temperature sensor for measuring the temperature of the liquid, and a microprocessor for calculating the corrected flow rate based on the liquids predetermined class and the measured temperature. The flow sensor can include a restriction in the fluid flow path, first and second pressure sensors positioned one on each side of the restriction and a temperature sensor. The first and second pressure sensors measure the drop in fluid pressure created by the restriction and the temperature sensor measures the temperature of the liquid. By basing the corrected flow rate calculation on the predetermined class of the liquid, the calculation becomes a closed form solution that is deterministic providing for quick and accurate corrected flow rate calculation. A flow meter according to the present invention can be used in many applications such as, among others, liquid beverage dispensers and variable speed pumps.

Owner:SYS

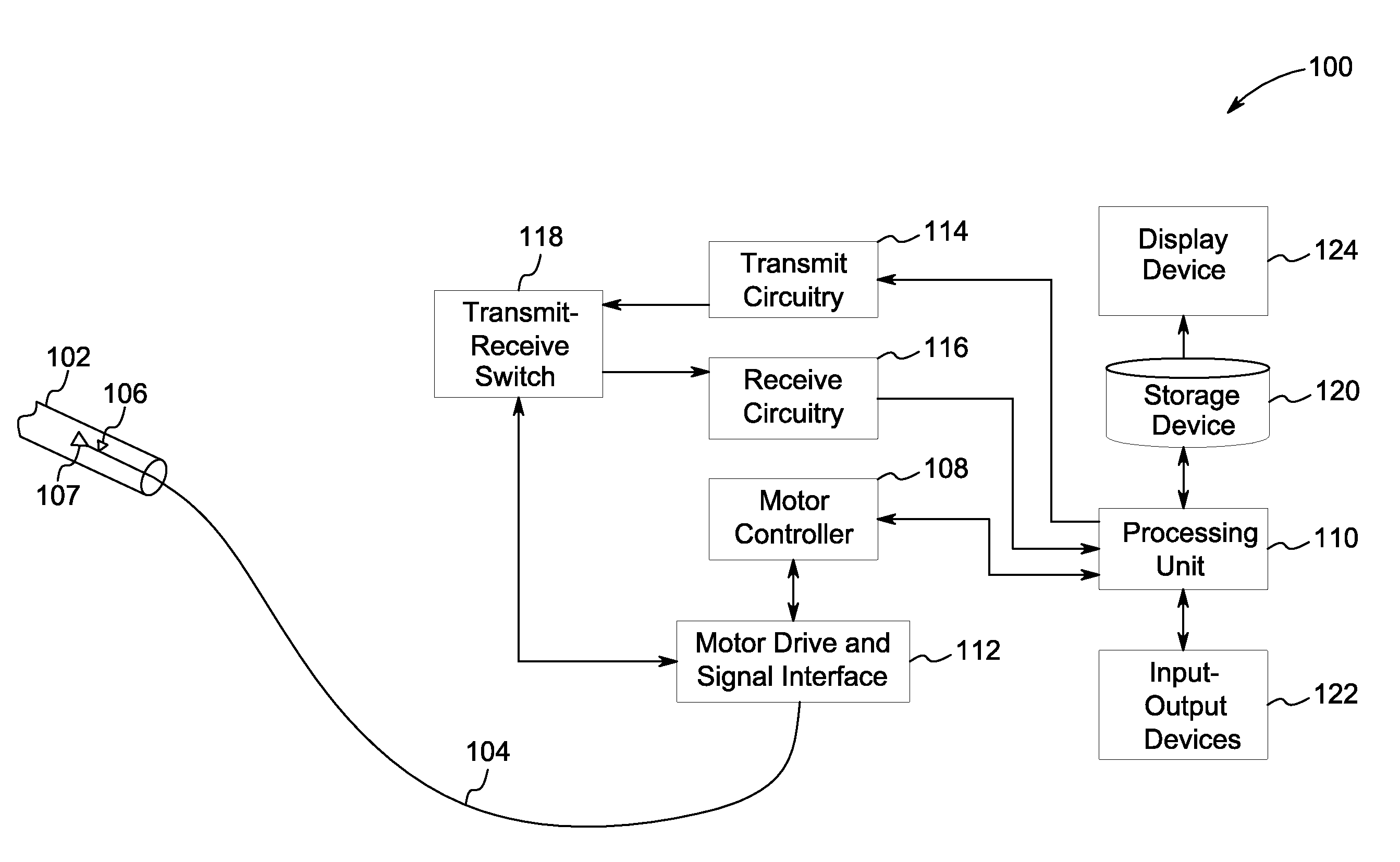

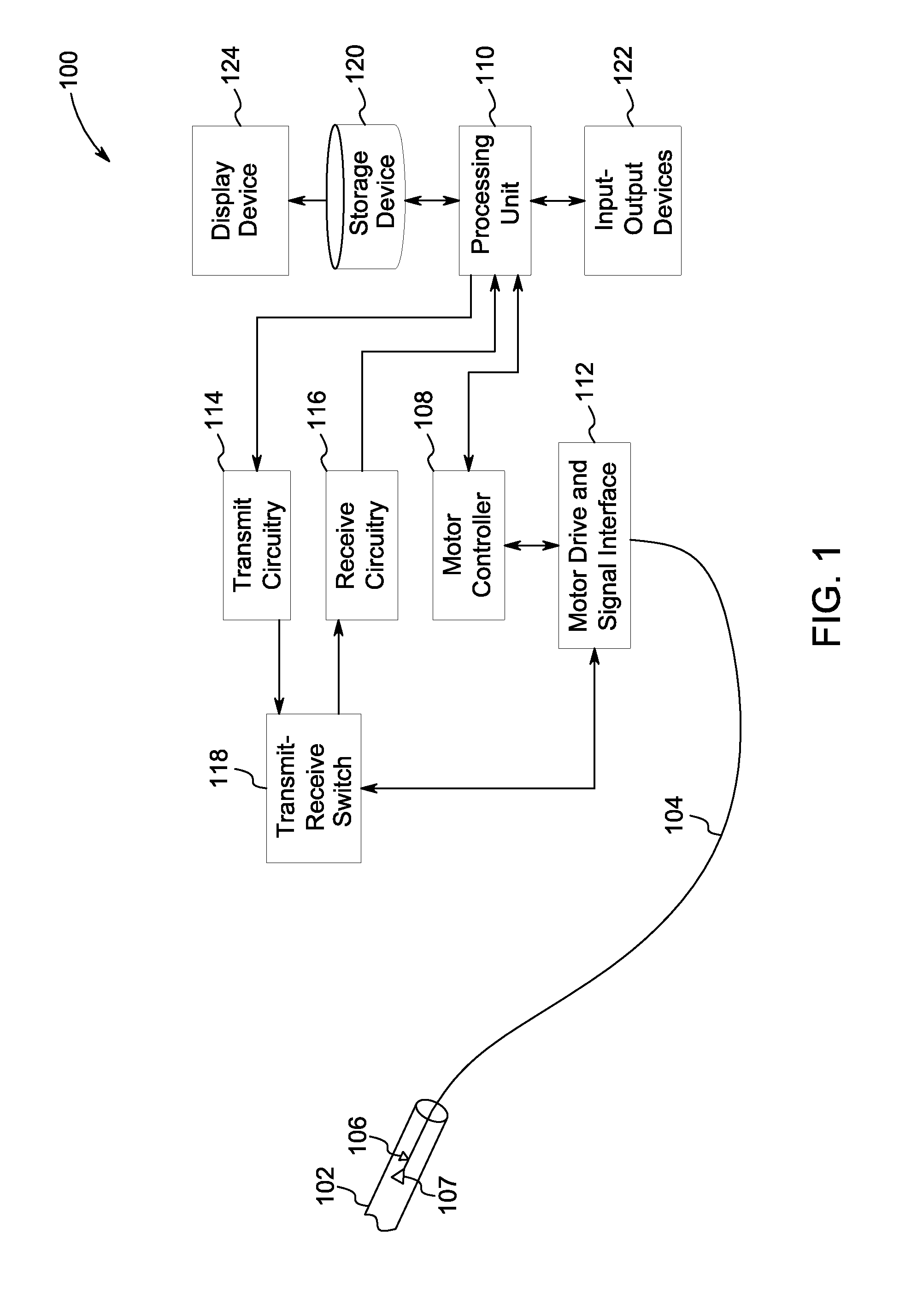

Methods and systems for simultaneous interventional imaging and functional measurements

InactiveUS20140236011A1Simple working processLesion can be correctedSurgeryCatheterFlow transducerInterventional imaging

Methods and systems for performing an interventional procedure are presented. A first set of pulses are delivered using at least one image sensor simultaneously with a second set of pulses delivered using at least one flow sensor disposed in an integrated interventional device towards a target region in a subject. Further, structural information corresponding to the target region at a designated time is determined using imaging signals received in response to the first sets of pulses. Additionally, volumetric information corresponding to the target region at the designated time is determined using signals received in response to the second sets of pulses. Moreover, the structural and volumetric information is processed using a determined model to compute one or more diagnostic parameters corresponding to the target region. A diagnostic assessment of the target region is then provided based on the computed diagnostic parameters.

Owner:GENERAL ELECTRIC CO

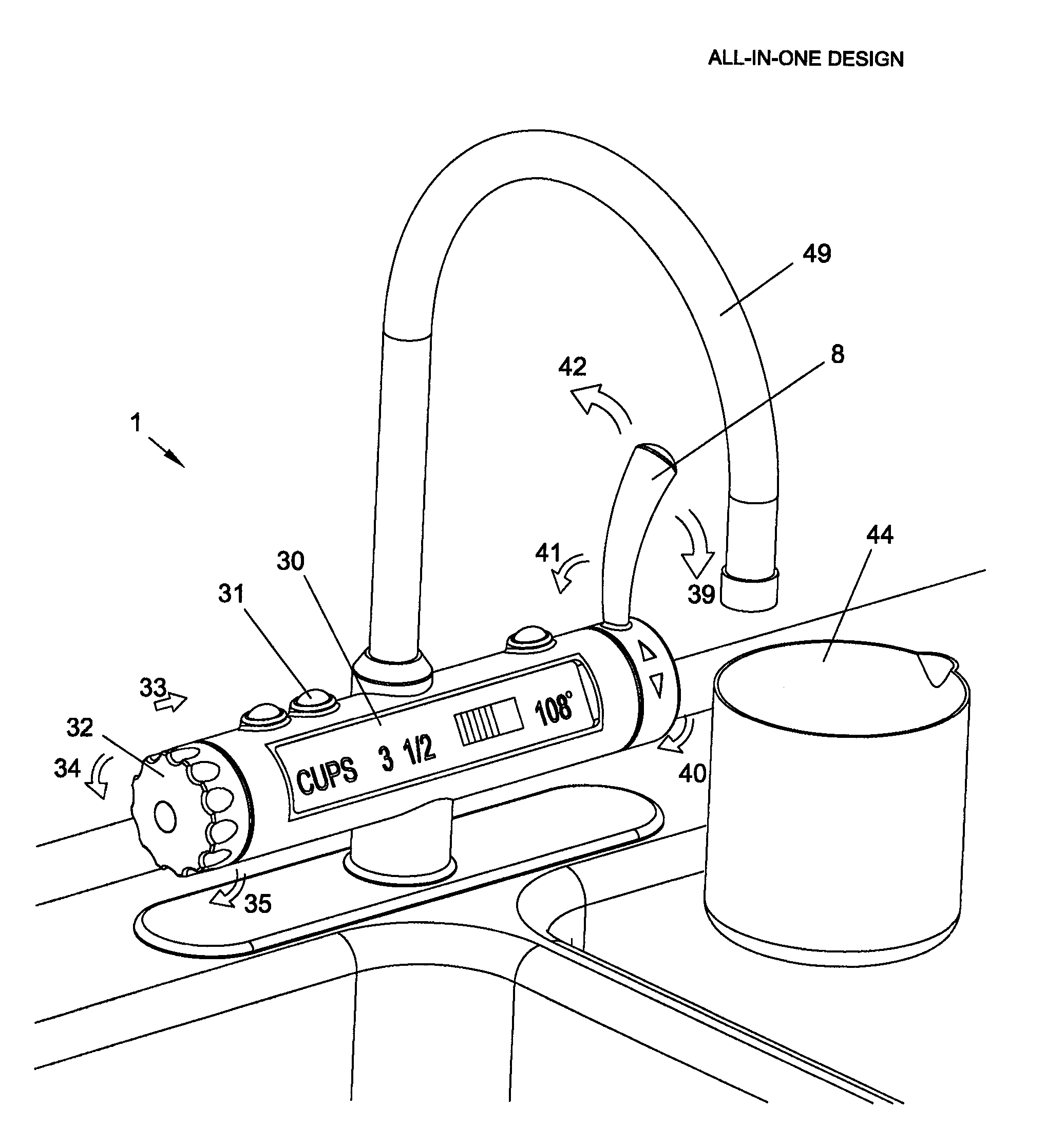

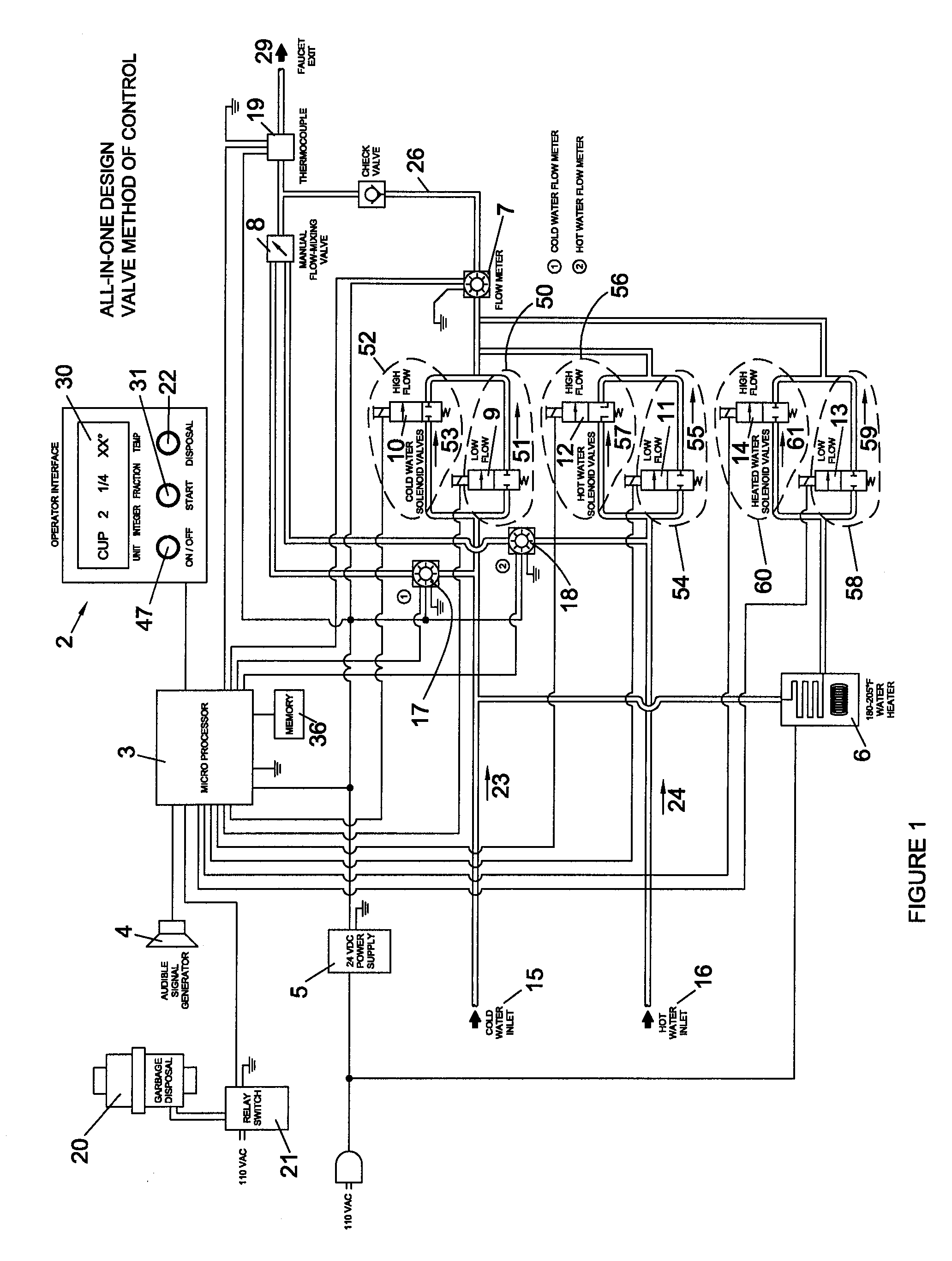

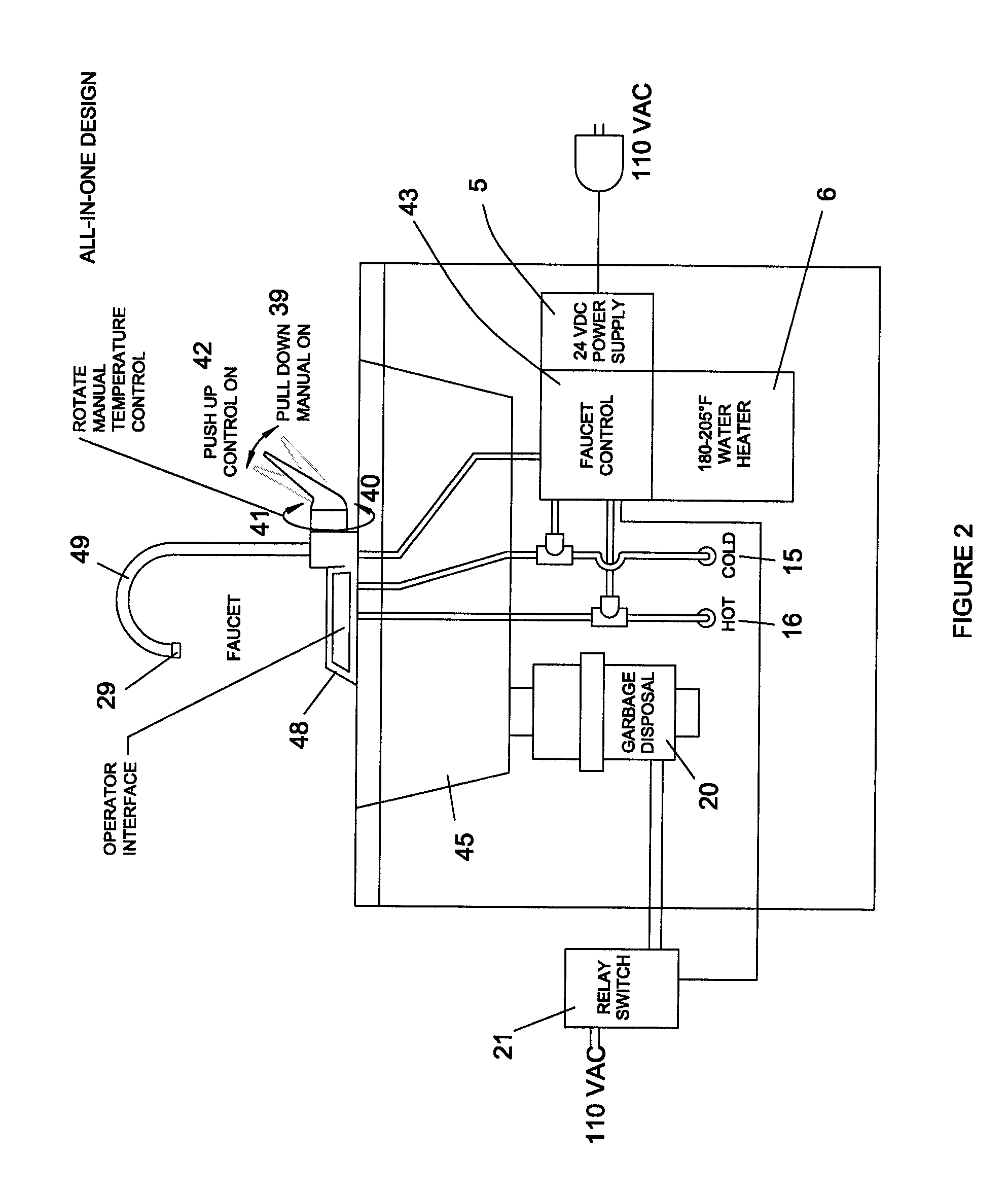

Electronic kitchen dispensing faucet

InactiveUS20070152074A1Avoid damageSufficient volumeTemperature control without auxillary powerDomestic plumbingFlow transducerEngineering

An electronic kitchen faucet dispensing apparatus capable of dispensing measured operator-selectable quantities of hot or cold liquid into a container with a flow rate suitable to prevent splashing and loss of the ensuing mixture while maintaining a rapid flow rate to quickly fill larger containers. The dispensing faucet can be used for measuring liquids required for preparing recipes, making instant beverages, or in the preparation of pre-packaged foods, and may be retrofitted to an existing faucet. The apparatus may utilize various controls to automatically control liquid flow, including 1) flow sensors and control valving; 2) positive-displacement pumps; and 3) flow-restrictors with shut-off valves. Also, it can be connected to a garbage disposal to prevent damage to the disposal.

Owner:EDGEWATER FAUCET

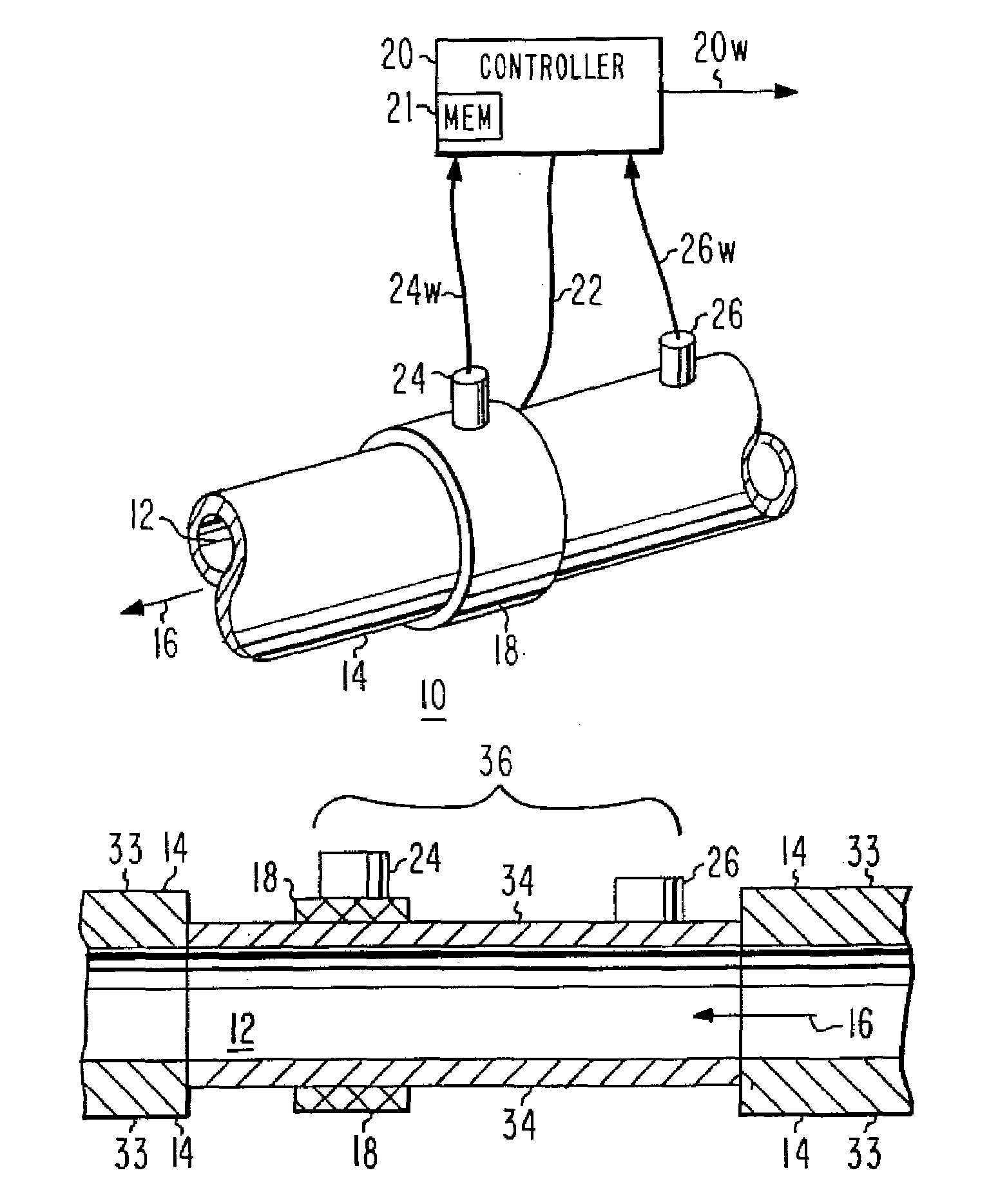

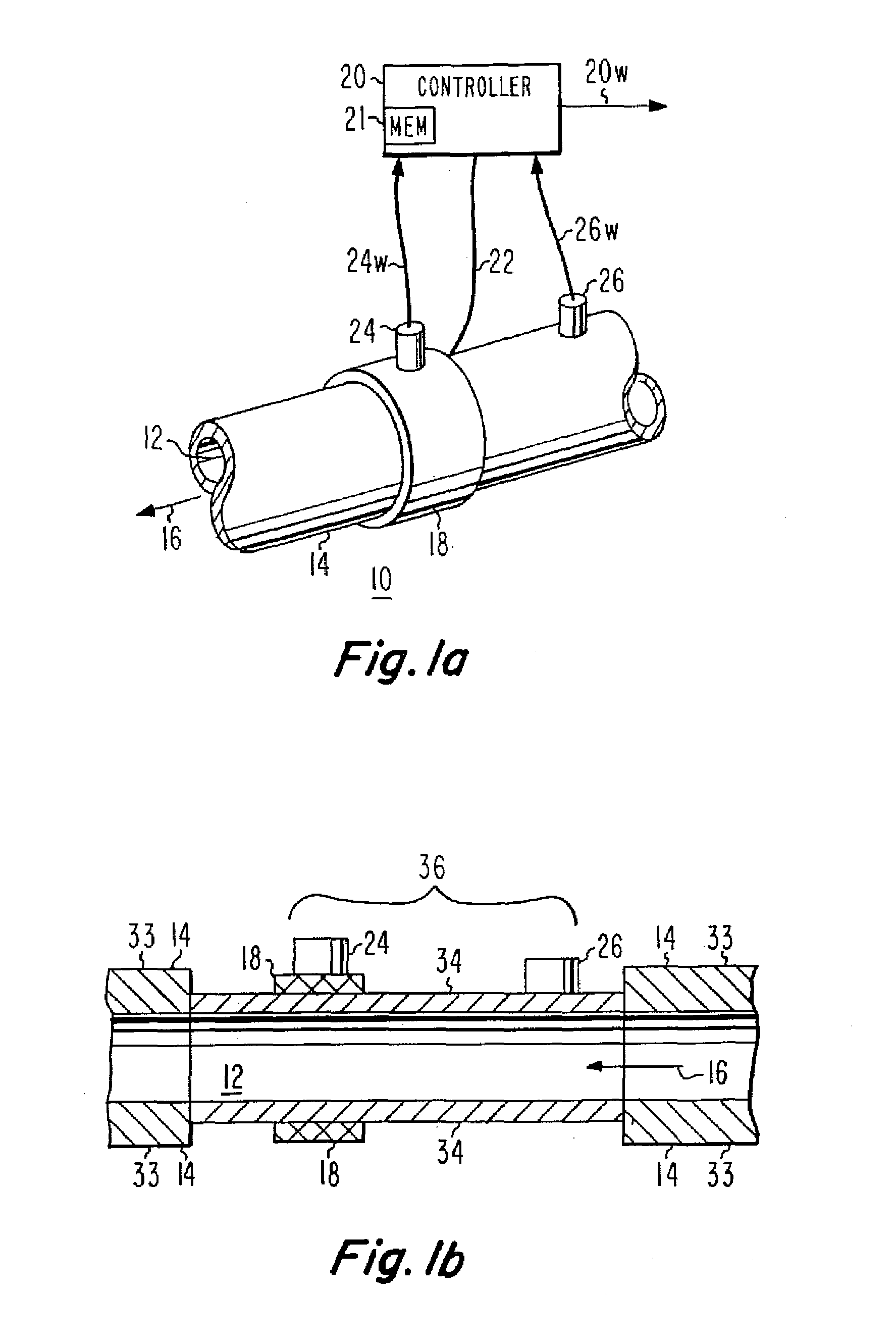

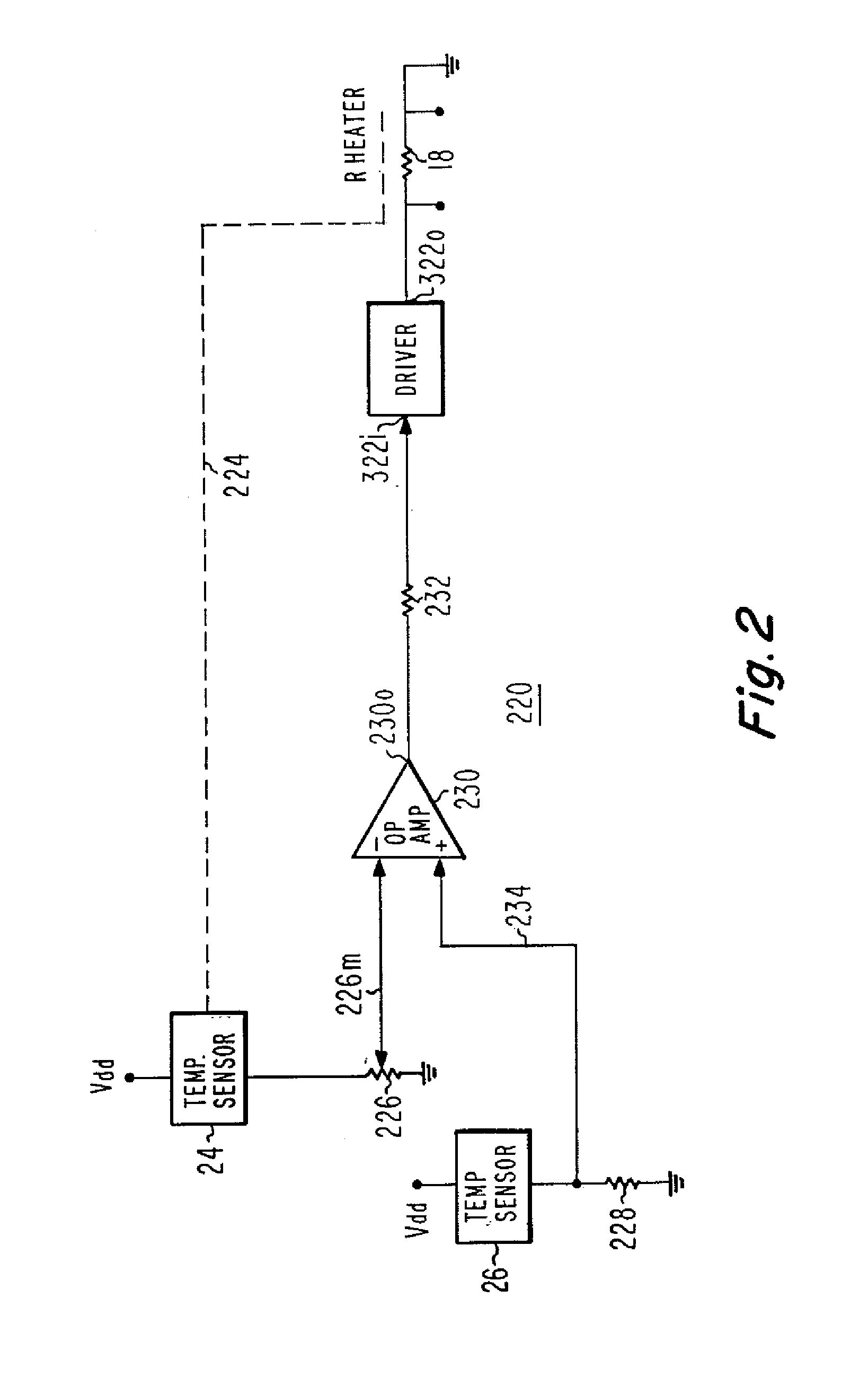

Constant-temperature-difference flow sensor, and integrated flow, temperature, and pressure sensor

InactiveUS7624632B1Verify integrityVolume/mass flow by thermal effectsFluid-tightness measurementFlow transducerElectric force

An integrated sensor for automated systems includes a flow sensor, a temperature sensor, a pressure sensor, and a network interface. In a particular embodiment of the invention, the flow sensor includes a temperature sensor (26) which determines the temperature of the fluid flowing in a flow path (12). A heater (18) is coupled to the flow path, and is energized by a controller (20) with sufficient electrical power to raise the temperature of the heater above the measured fluid temperature by a fixed temperature difference. In order to aid in determining the temperature difference, a sensor (24) may be associated with the heater (18). The amount of power required to maintain the temperature difference is a measure of the flow velocity. The volumetric flow rate is the product of the flow velocity multiplied by the area of the flow sensor. The mass flow rate is the product of the volumetric flow rate multiplied by the mass density of the fluid. In a particular embodiment, the pressure sensor is ratiometric.

Owner:GENERAL ELECTRIC CO +1

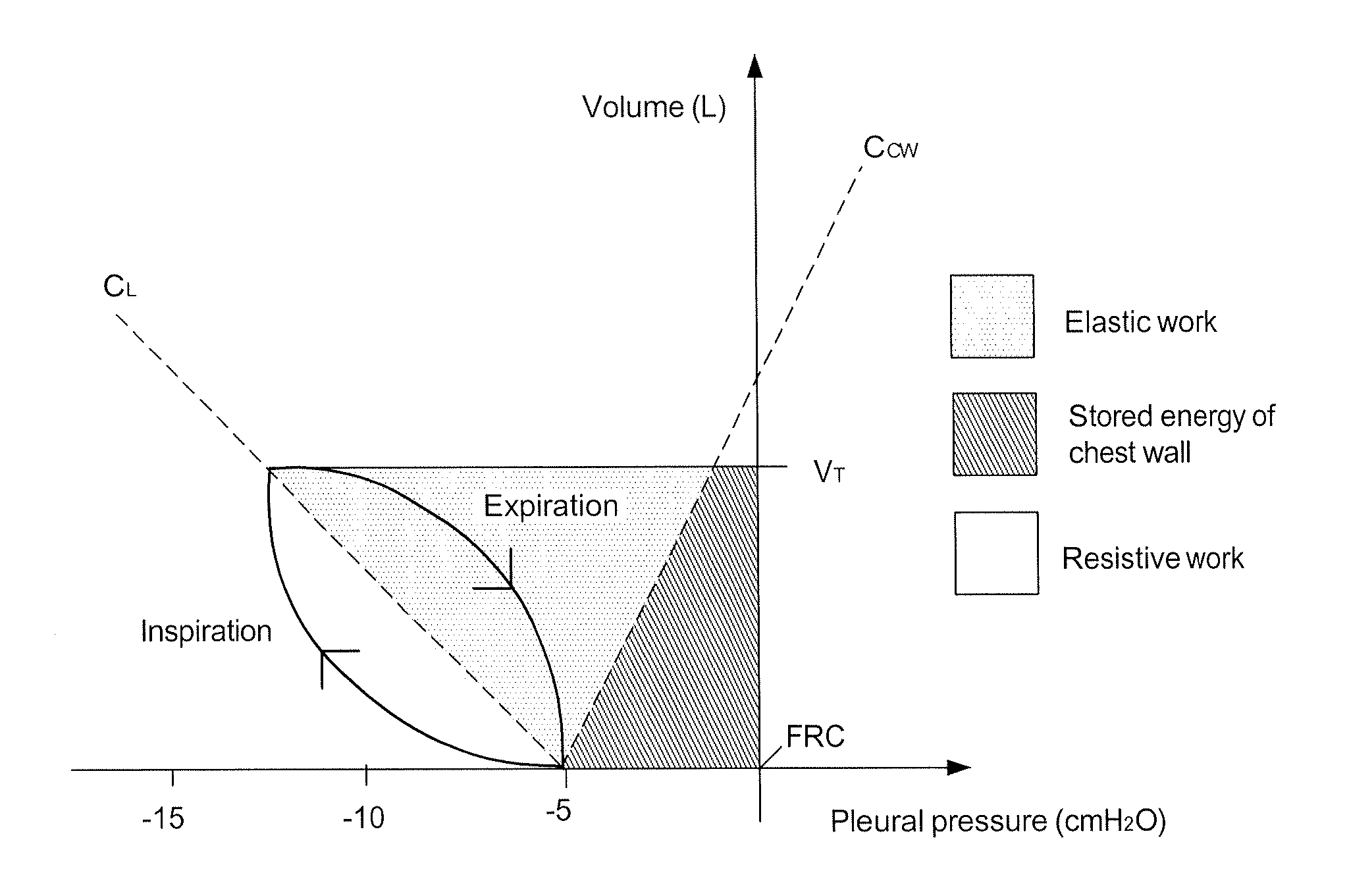

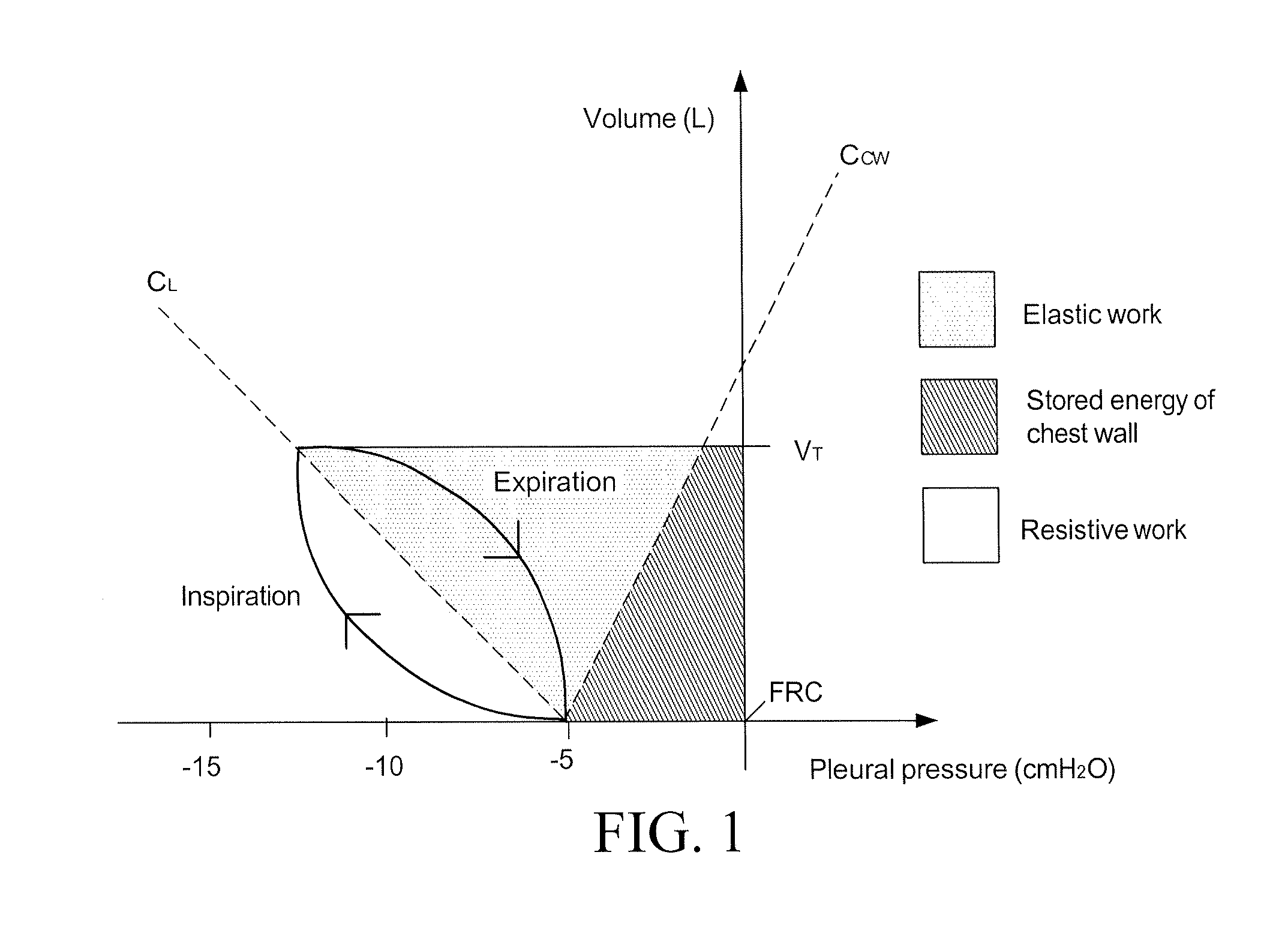

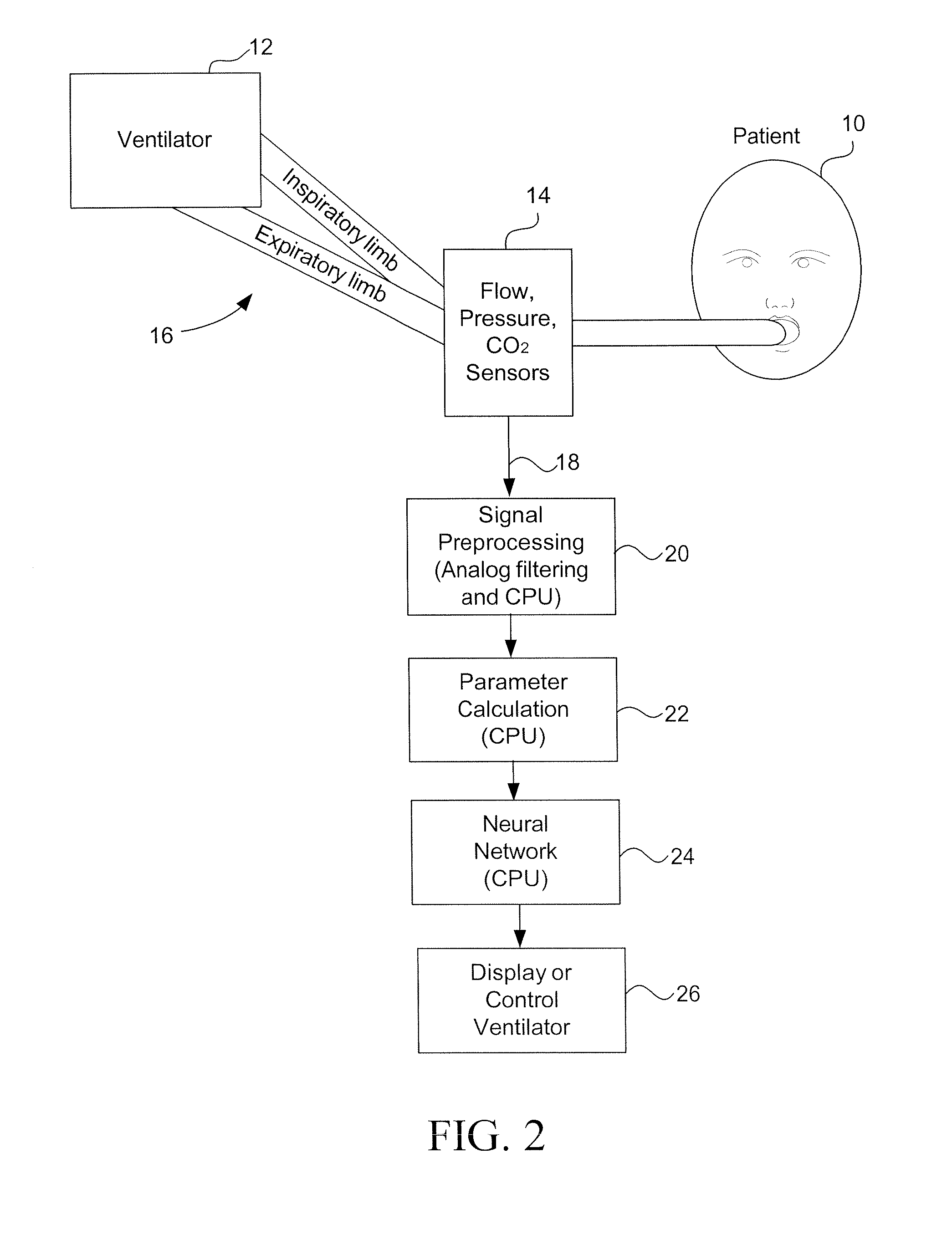

Method and Apparatus for Predicting Work of Breathing

ActiveUS20070232951A1Avoids respiratory muscle fatigue respiratory muscleAvoids respiratory muscle respiratory muscle deconditioningRespiratorsOperating means/releasing devices for valvesFlow transducerMathematical model

A method of creating a non-invasive predictor of both physiologic and imposed patient effort from airway pressure and flow sensors attached to the patient using an adaptive mathematical model. The patient effort is commonly measured via work of breathing, power of breathing, or pressure-time product of esophageal pressure and is important for properly adjusting ventilatory support for spontaneously breathing patients. The method of calculating this non-invasive predictor is based on linear or non-linear calculations using multiple parameters derived from the above-mentioned sensors.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

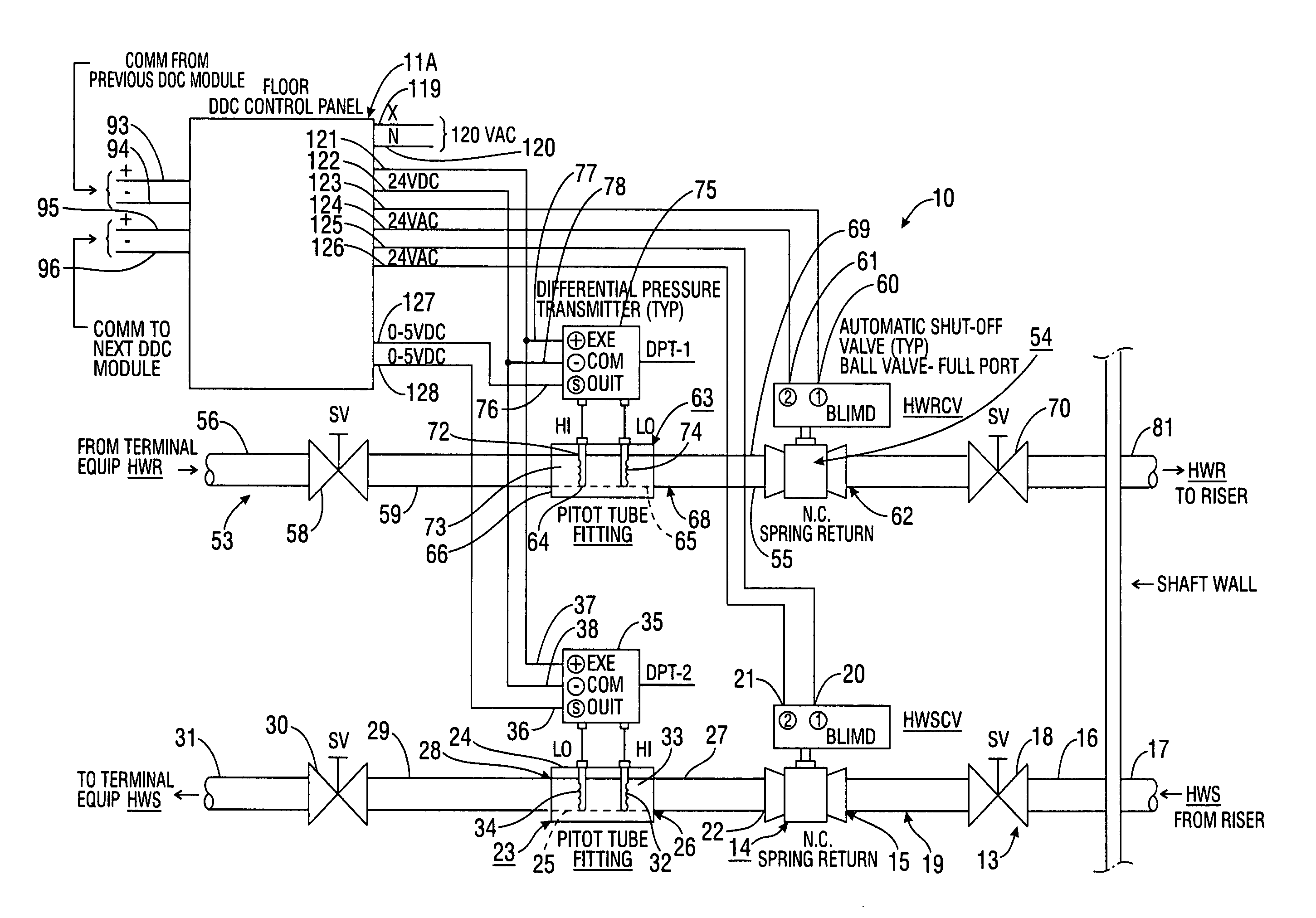

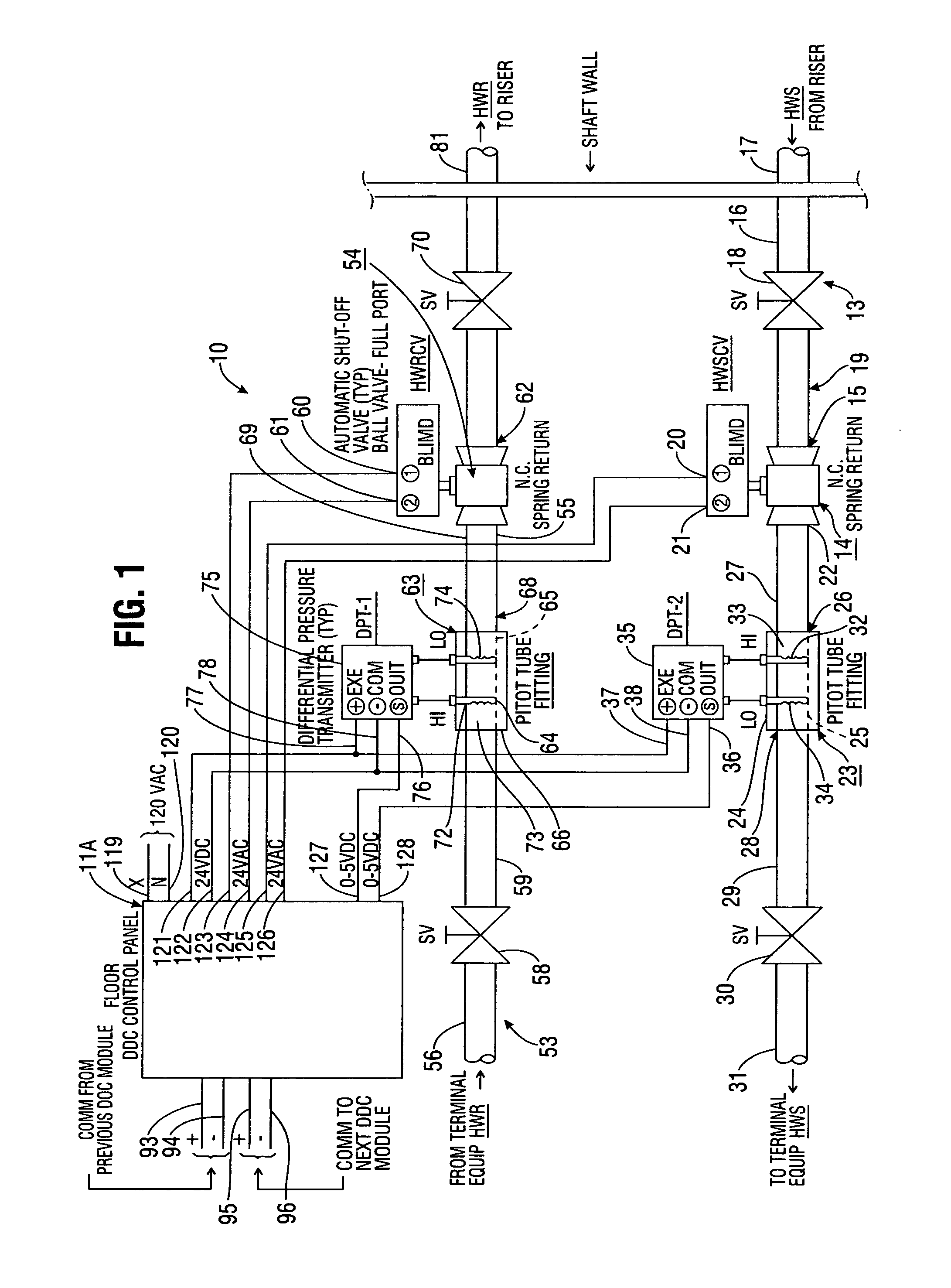

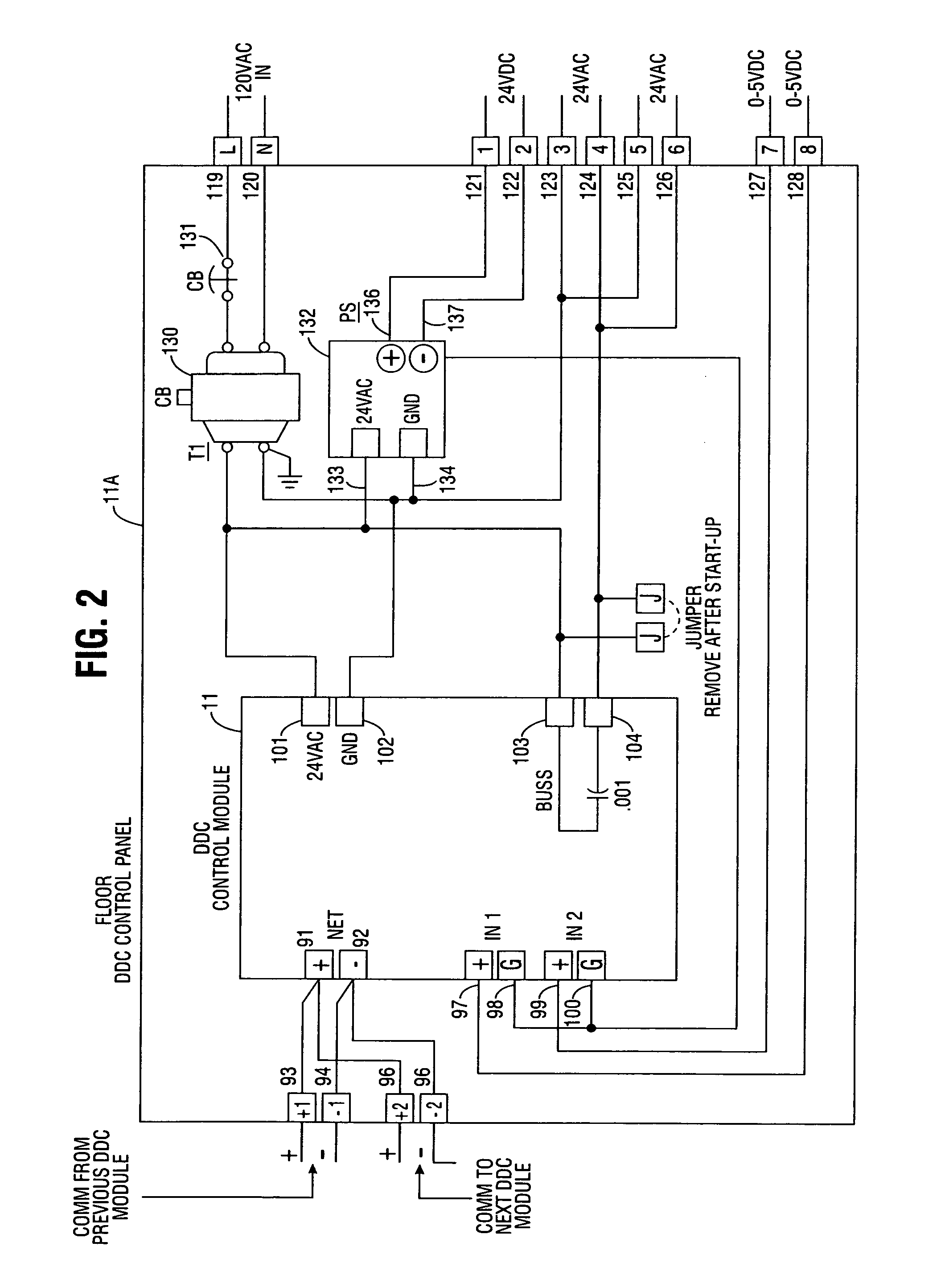

Water leak detection and shut-off method and apparatus using differential flow rate sensors

InactiveUS8749393B1Minimize damageMinimize injuriesDetection of fluid at leakage pointMeasurement of fluid loss/gain rateEngineeringWater leak

A method and apparatus for detecting leakage of flowing liquids from pipes includes an upstream flow-rate sensor positioned between a source of a flowing liquid which is conducted from a source to a destination terminal such as a VAV heat exchanger, and a downstream flow-rate sensor positioned between an outlet port of the destination terminal and a return line for the flowing liquid. The apparatus includes electronic control circuitry which is responsive to a differential flow-rate between upstream and downstream measured flow rates which exceeds a predetermined limit value in removing a valve-opening signal to the upstream shut-off valve, thus closing the valve to interrupt flow of liquid through the valve if the differential flow-rate signifies a leak. Optionally, the apparatus also includes a downstream shut-off valve positioned between the destination terminal and a return line, which is also closed in response to a differential flow-rate exceeding the limit value.

Owner:CONTROL AIR CONDITIONING

Flow metering system

InactiveUS20060260416A1Accurate measurementStrong enoughVolume/mass flow measurementFlow transducerStream flow

A non-contact fluid flow monitor that enables a two component system comprised of a removable conduit and reusable flow rate sensor is described. The monitor is capable of measuring fluid flow velocity and the dimensions of the removable conduit thereby calculating a true volumetric flow rate. The monitor is further capable of determining the refractive index of the fluid thereby verifying that the fluid flowing through the conduit has this expected property.

Owner:SAGE BURTON H +2

Redundant array control system for water rides

InactiveUS20050034768A1Closely spacedGuaranteed uptimeSki bindingsAquatic toysFlow transducerControl system

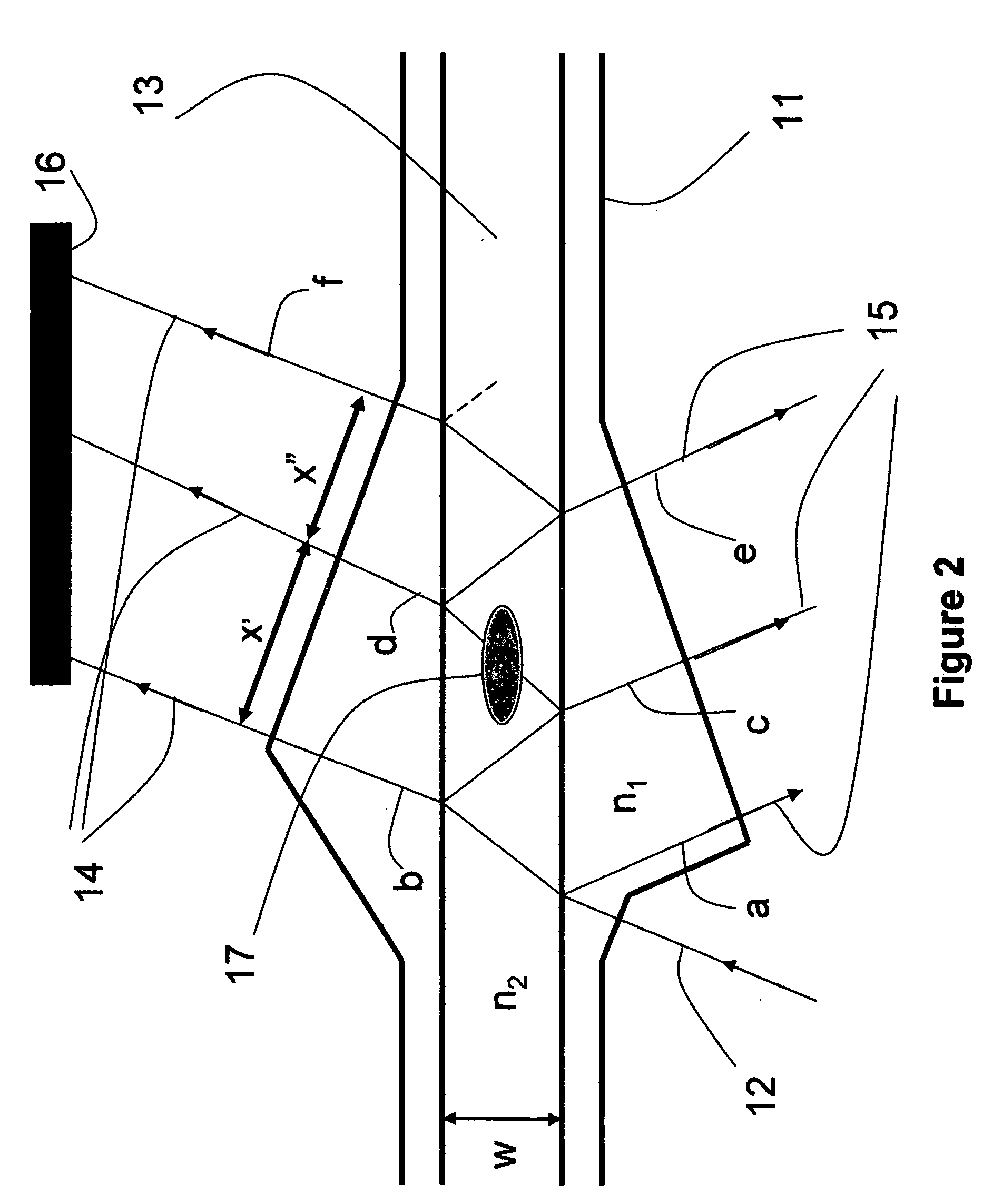

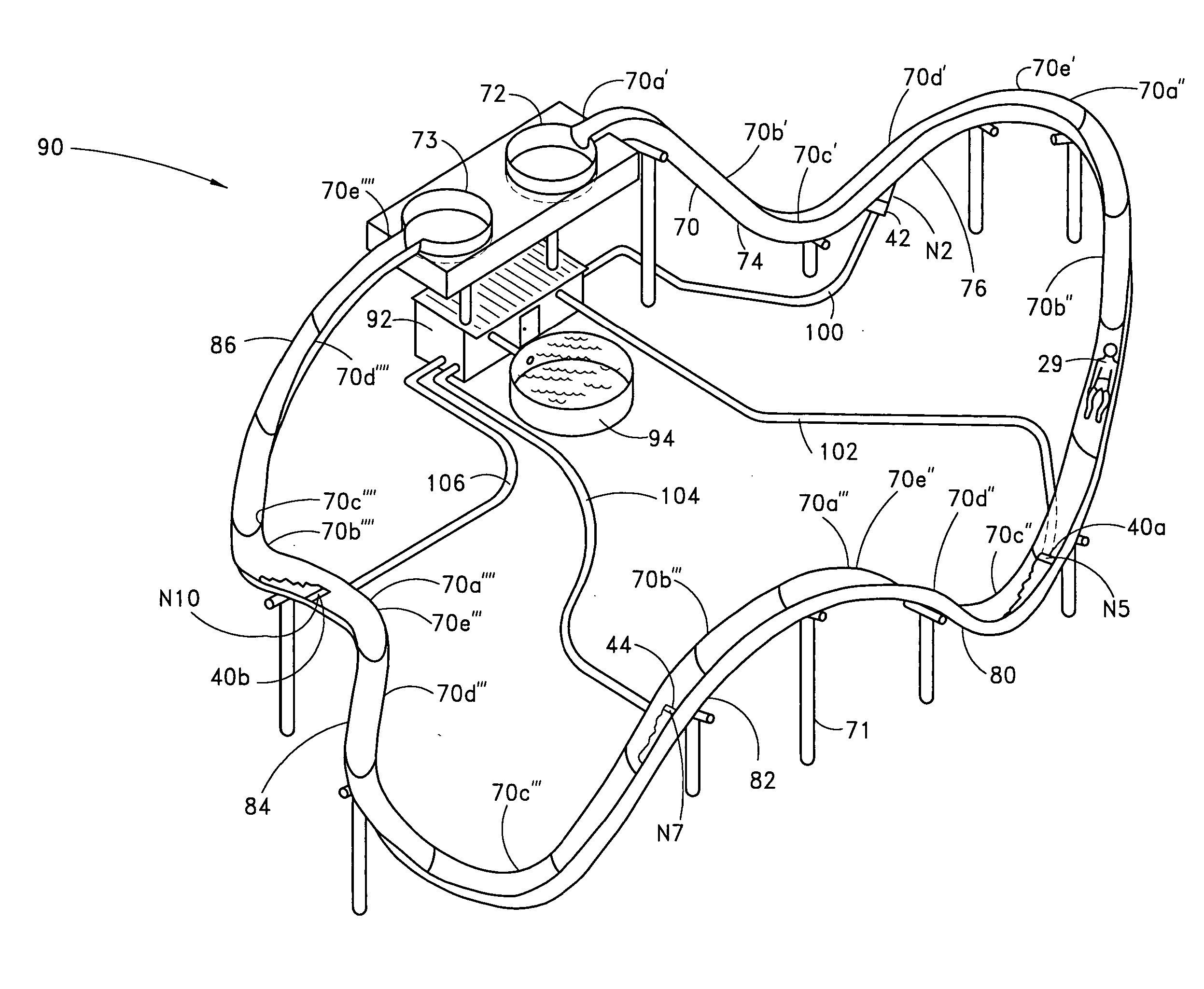

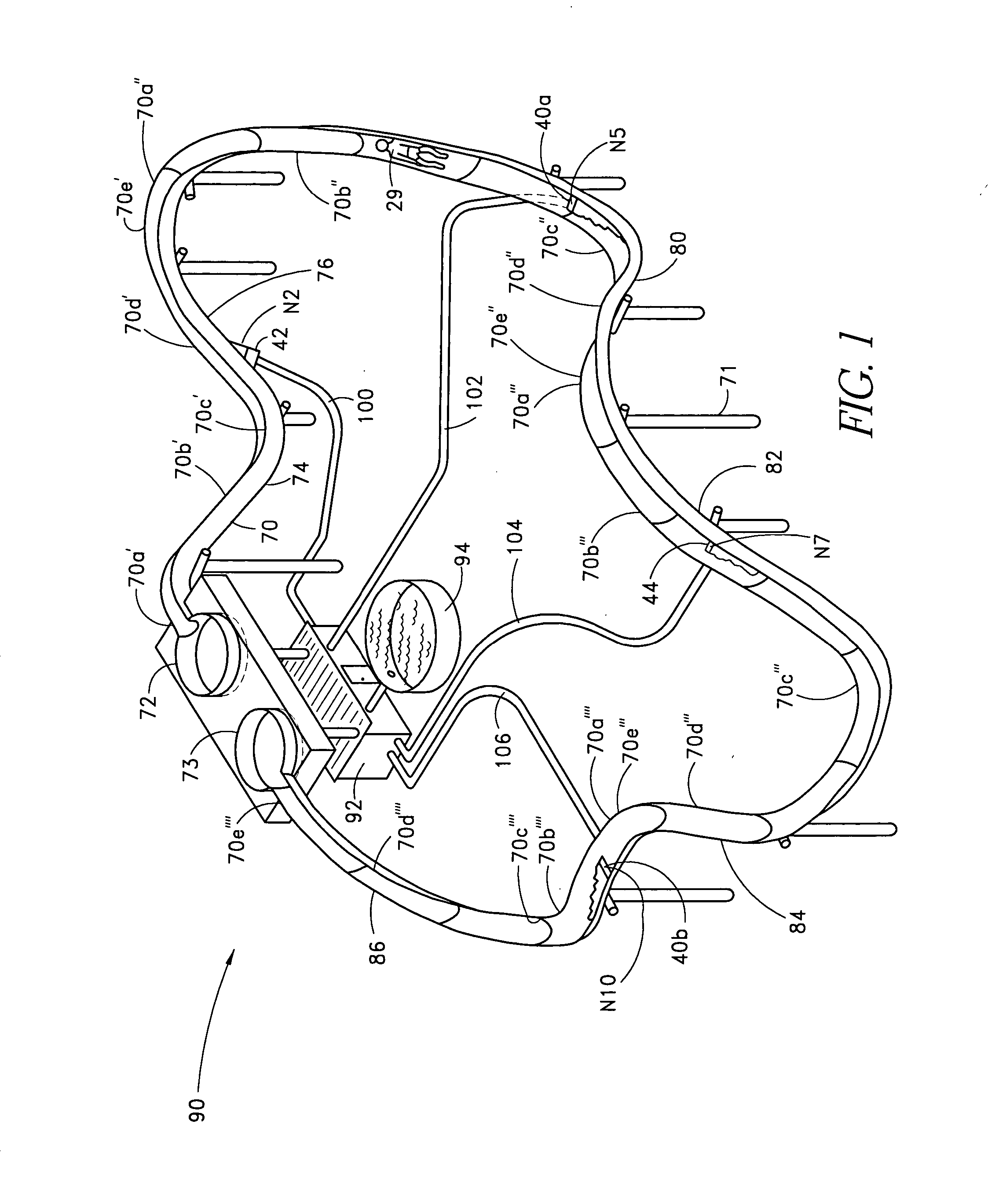

A redundant array pumping system and control system is provided for water rides for ensuring continuous and non-disruptive supply of water. The pumping system incorporates a redundant pump and filter array in conjunction with a nozzle system for injecting water onto a ride surface. The nozzle system may incorporate a plurality of redundant or quasi-redundant nozzles. The hydraulic system can include many levels of redundancy as applied to its various components, such as pumps, filters and nozzles. Additionally, the system can be equipped with a plurality of pressure and flow sensors for monitoring and controlling the performance of the pumps, filters and nozzles of the hydraulic system.

Owner:LIGHT WAVE

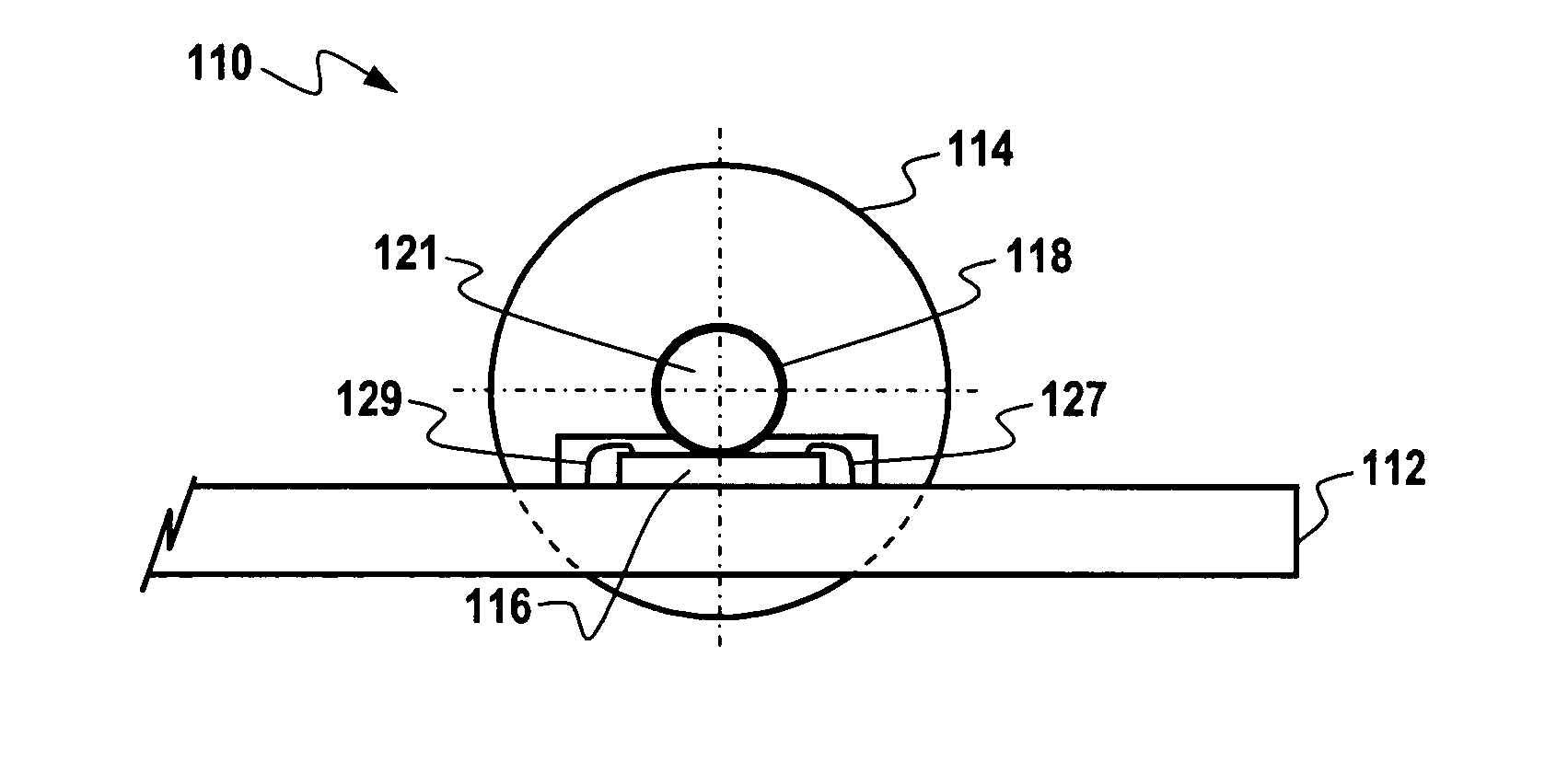

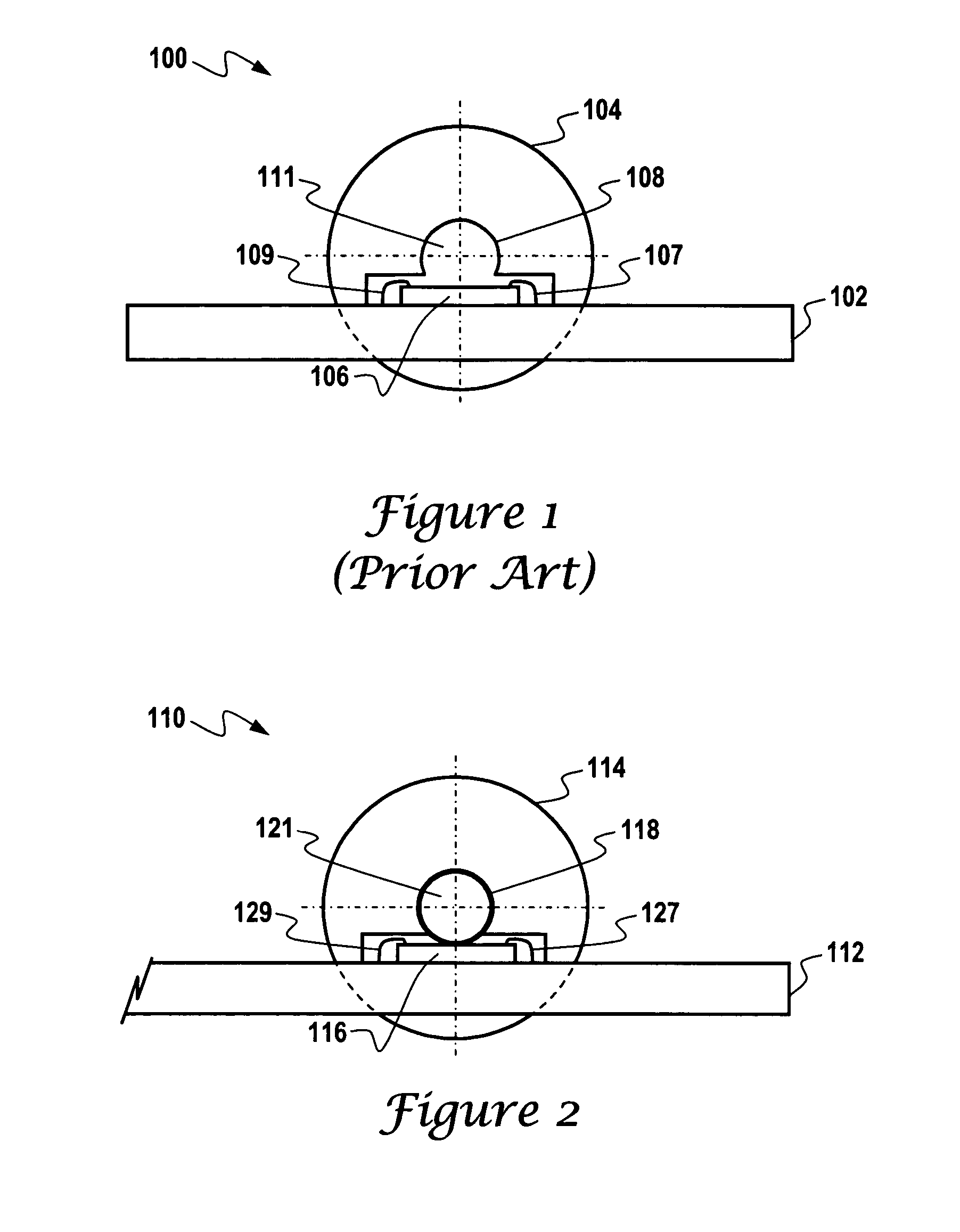

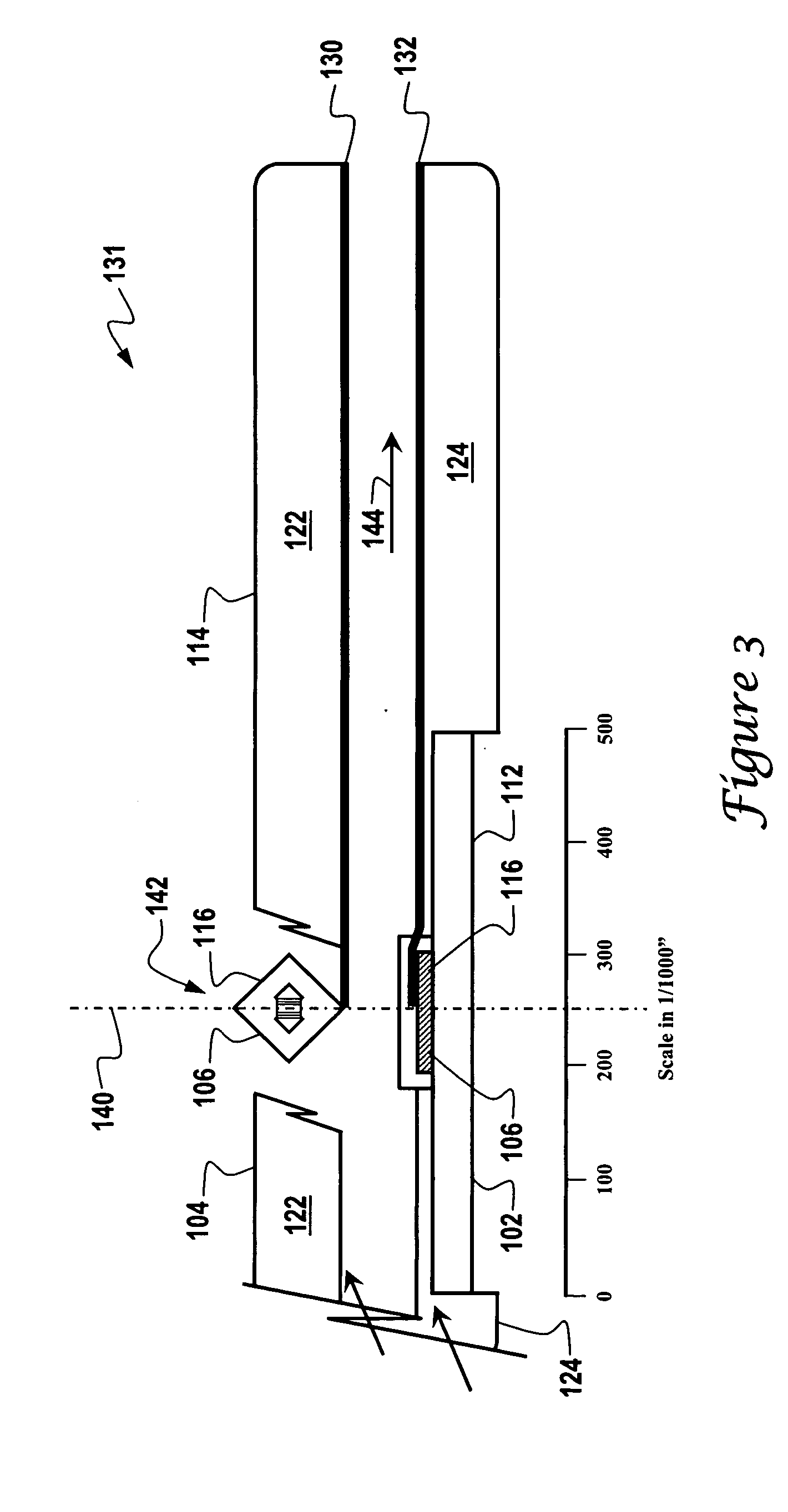

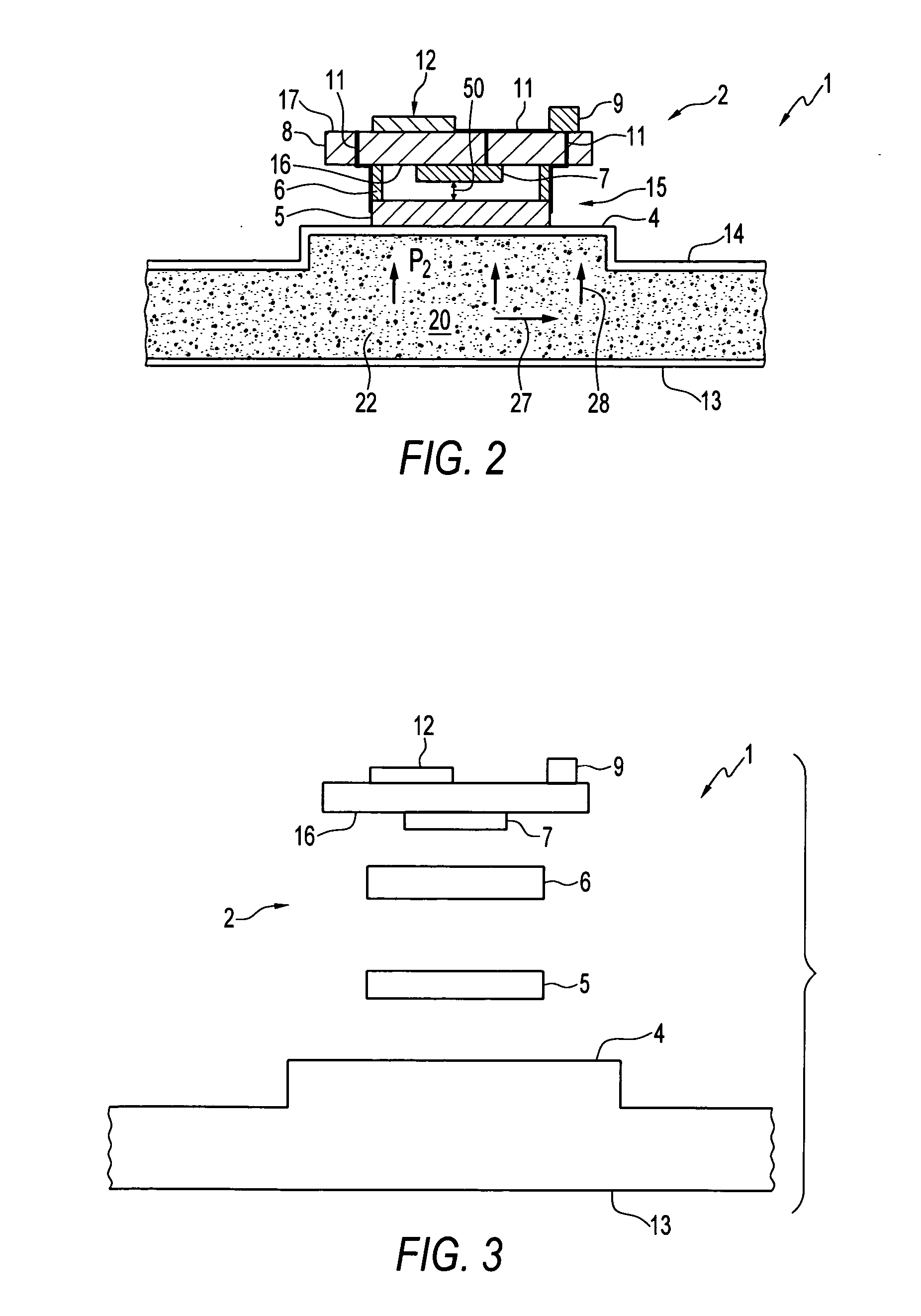

Flow sensor with self-aligned flow channel

InactiveUS20050022594A1Reduce flow noiseReduces potential corrosionMaterial thermal conductivityVolume/mass flow by thermal effectsFlow transducerEngineering

A flow sensor is provided having a substrate with a sensing element and flow channel aligned over the sensing element. The sensing element senses at least one property of a fluid. The flow channel is aligned by one or more guide elements formed in an alignment layer. The flow channel across the sensing area is accurately and precisely aligned due to the guide elements provided at the wafer-level, facilitating reliable, low-cost, and consistent results among multiple flow sensors. The flow sensor is adapted for use in harsh environments.

Owner:HONEYWELL INT INC

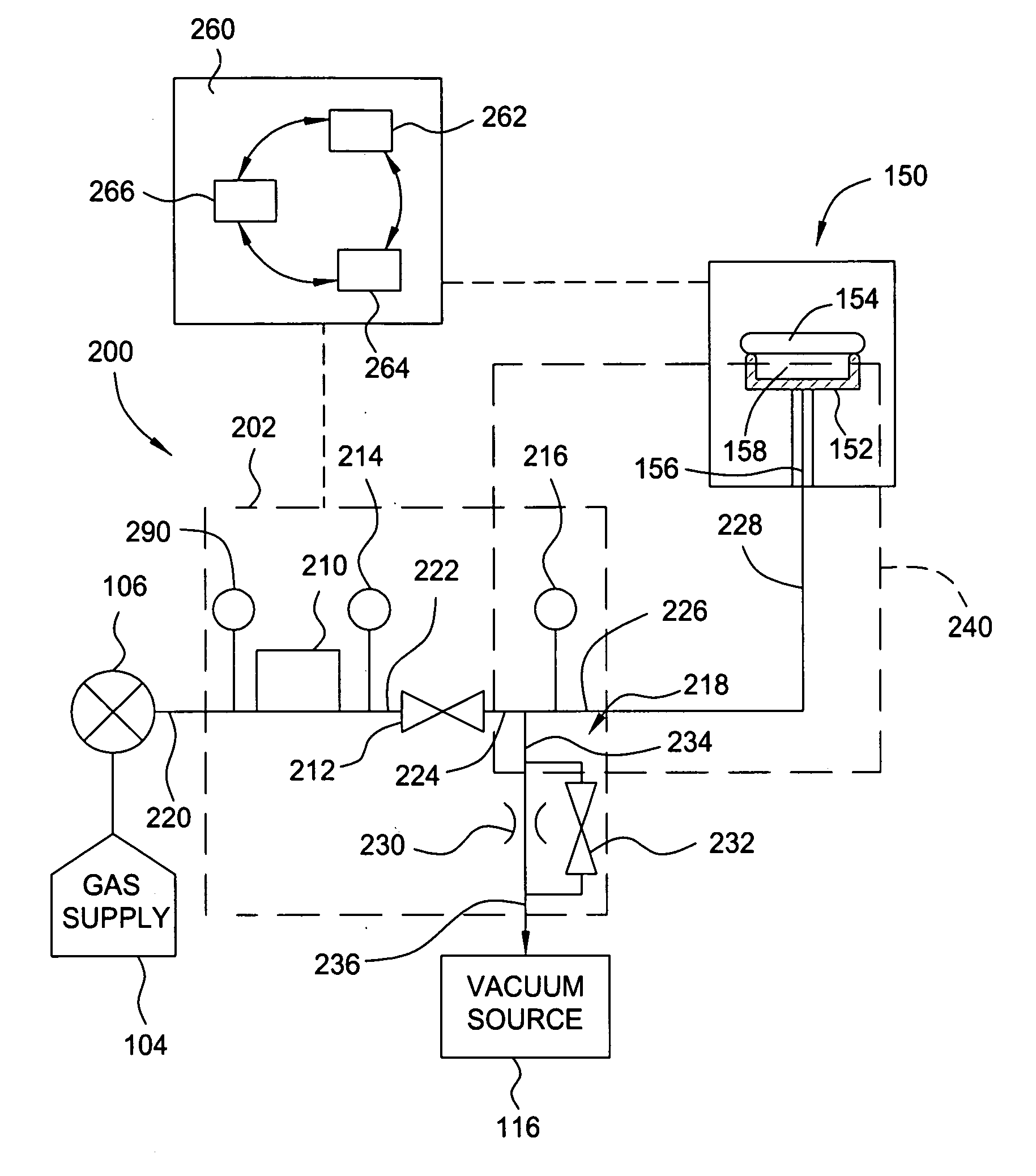

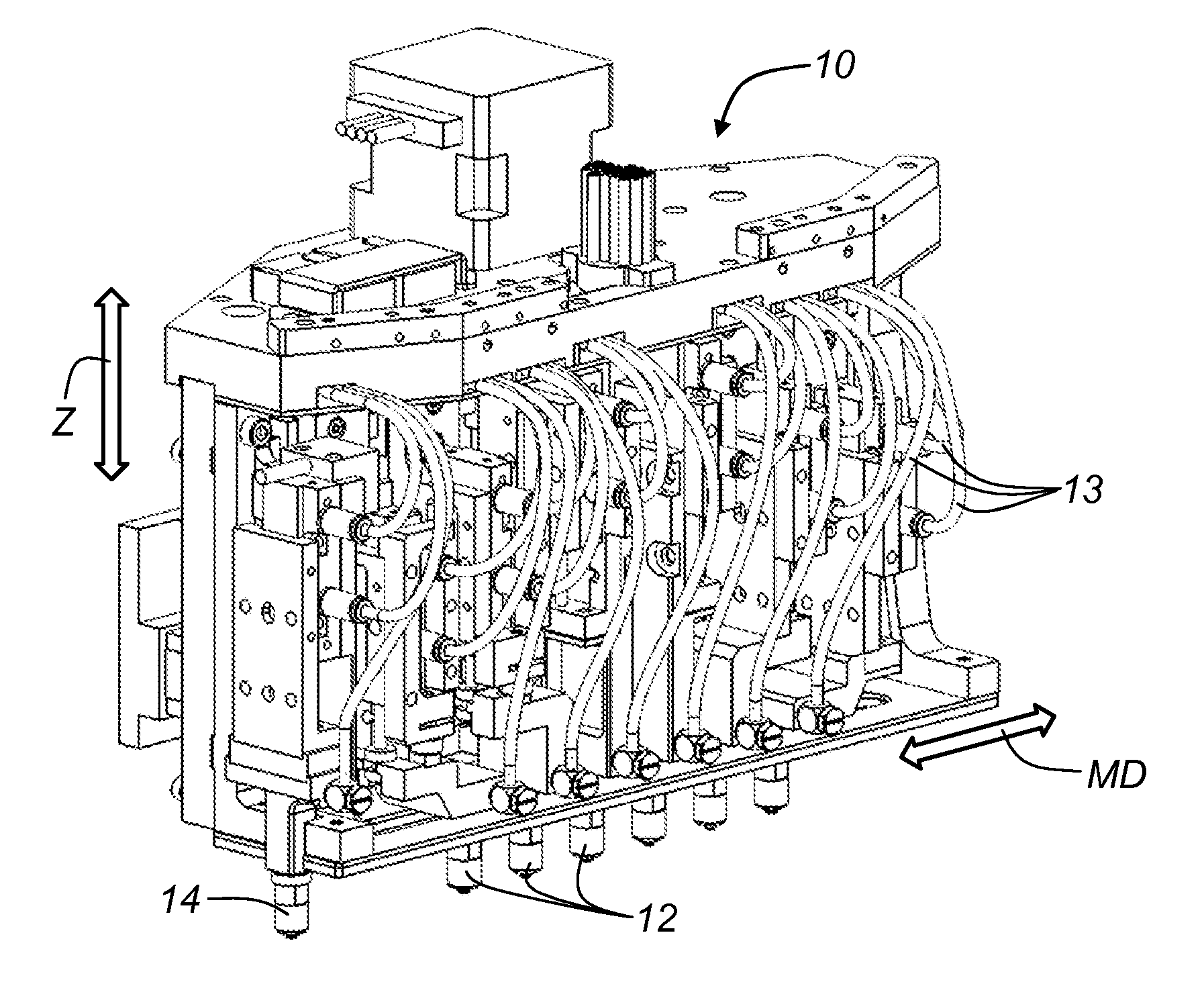

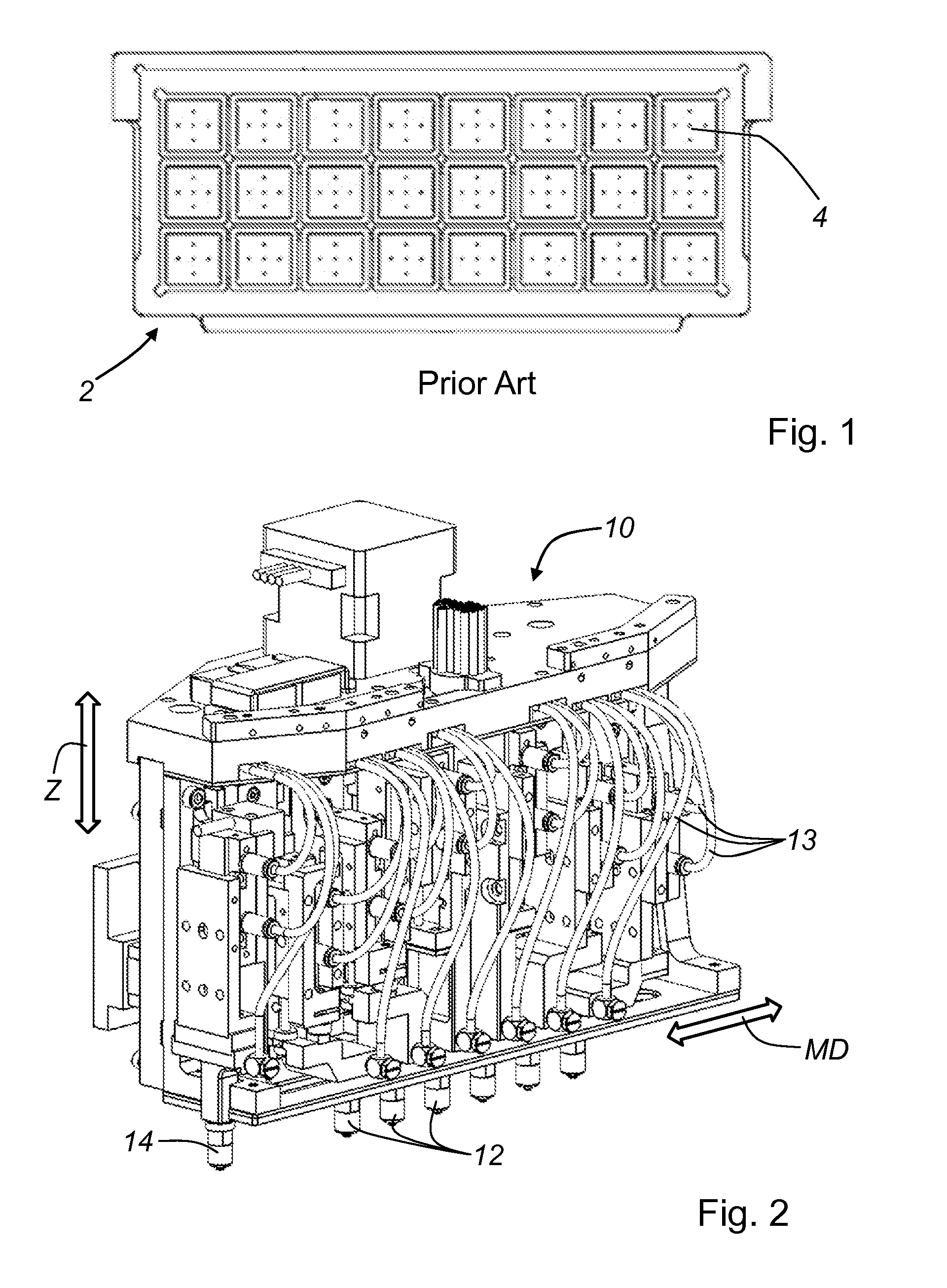

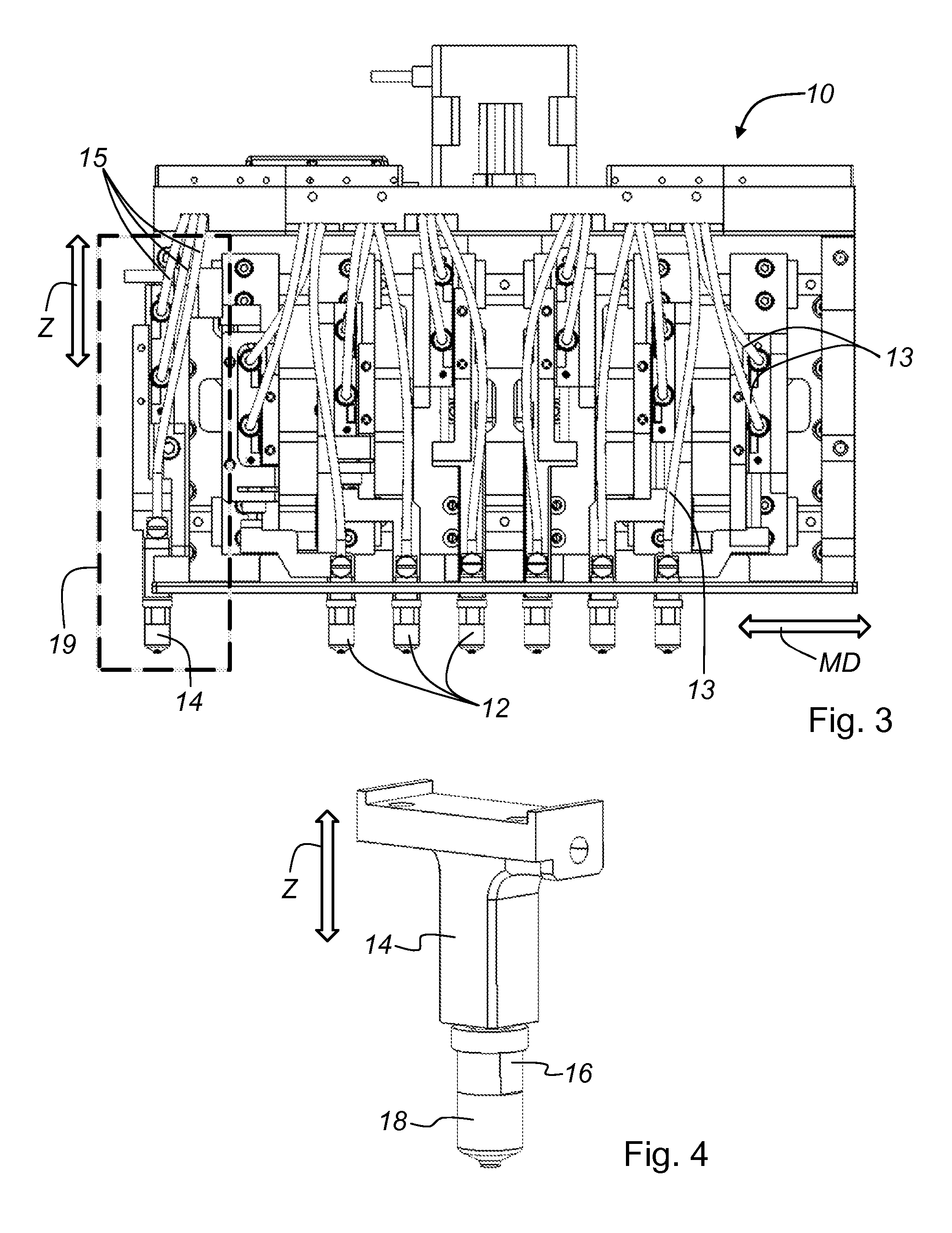

Pick and place device with automatic pick-up-height adjustment and a method and a computer program product to automatically adjust the pick-up-height of a pick and place device

ActiveUS20150298316A1Finish quicklyAvoid damageProgramme-controlled manipulatorDigital data processing detailsFlow transducerInlet valve

A pick and place device, a method and a computer program product for automatic pick- up-height adjustment. A first pneumatic system has a first and second controllable valves. The second controllable valve is connected with its input port to a vacuum source. An output port of the first controllable valve and an output port of the second controllable valve are connected to a common tube in fluid communication with at least one vacuum nozzle of the pick and place device. A second pneumatic system, with an inlet valve and an outlet valve are in fluid communication via a connecting tube. An open air exhaust and a flow controller are arranged in the connecting tube between the inlet valve and the outlet valve. A flow sensor detects the changes of the small air flow. The flow sensor is via a tube in fluid communication with the at least one vacuum nozzle.

Owner:KLA TENCOR TECH CORP

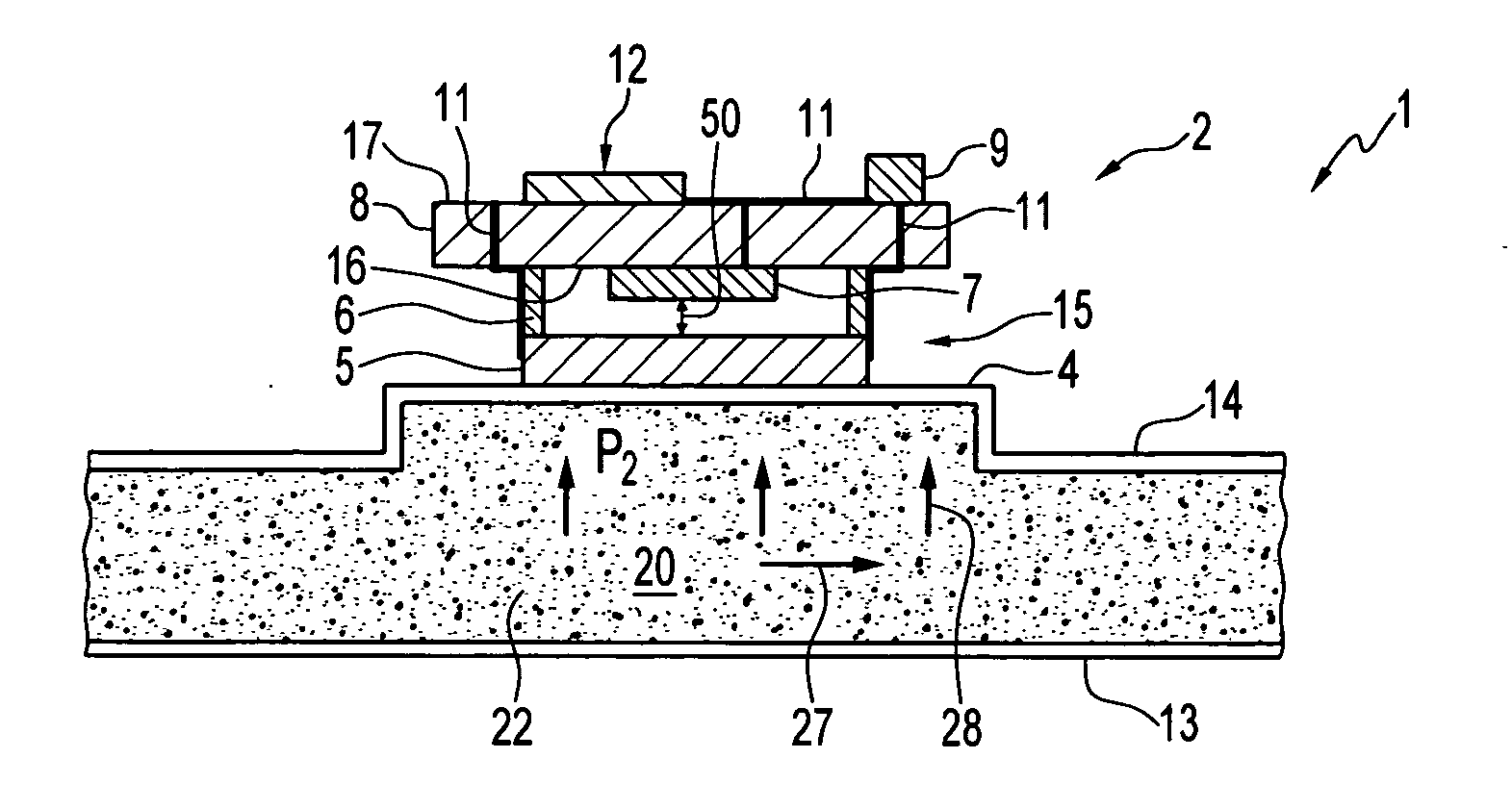

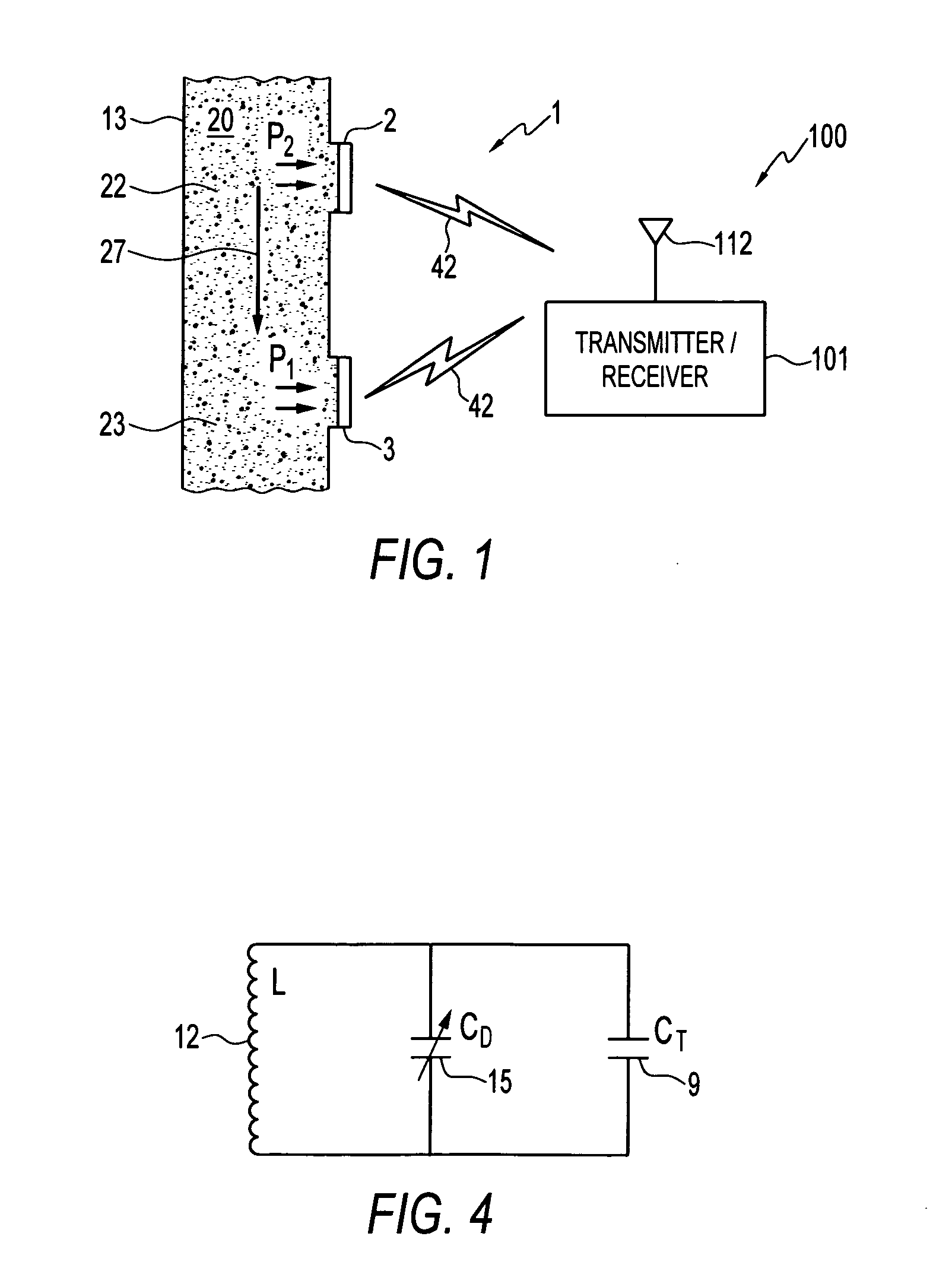

Pressure flow sensor systems and pressure flow sensors for use therein

ActiveUS20060144155A1Low costLow power flowFluid pressure measurement using inductance variationCatheterDifferential pressurePressure sense

A differential pressure flow sensor system comprises a disposable flow sensor which has upstream and downstream pressure sensing devices for detecting a differential pressure in a flow channel. Each sensing device comprises a diaphragm, a capacitor and an inductor electrically coupled to the capacitor so as to form an LC tank circuit. The capacitor and / or inductor can be mechanically coupled to the diaphragm such that a deflection of the diaphragm in response to fluid pressure applied thereto causes a change in the resonant frequency of the LC tank. The differential pressure and flow rate can be determined by detecting changes in the resonant frequency using interrogation electronics which can wirelessly interrogate the devices. A calibration capacitor and / or inductor can be formed on each sensing device and trimmed thereon for calibration purposes. Such pressure flow systems can be implemented in medical applications.

Owner:HONEYWELL INT INC

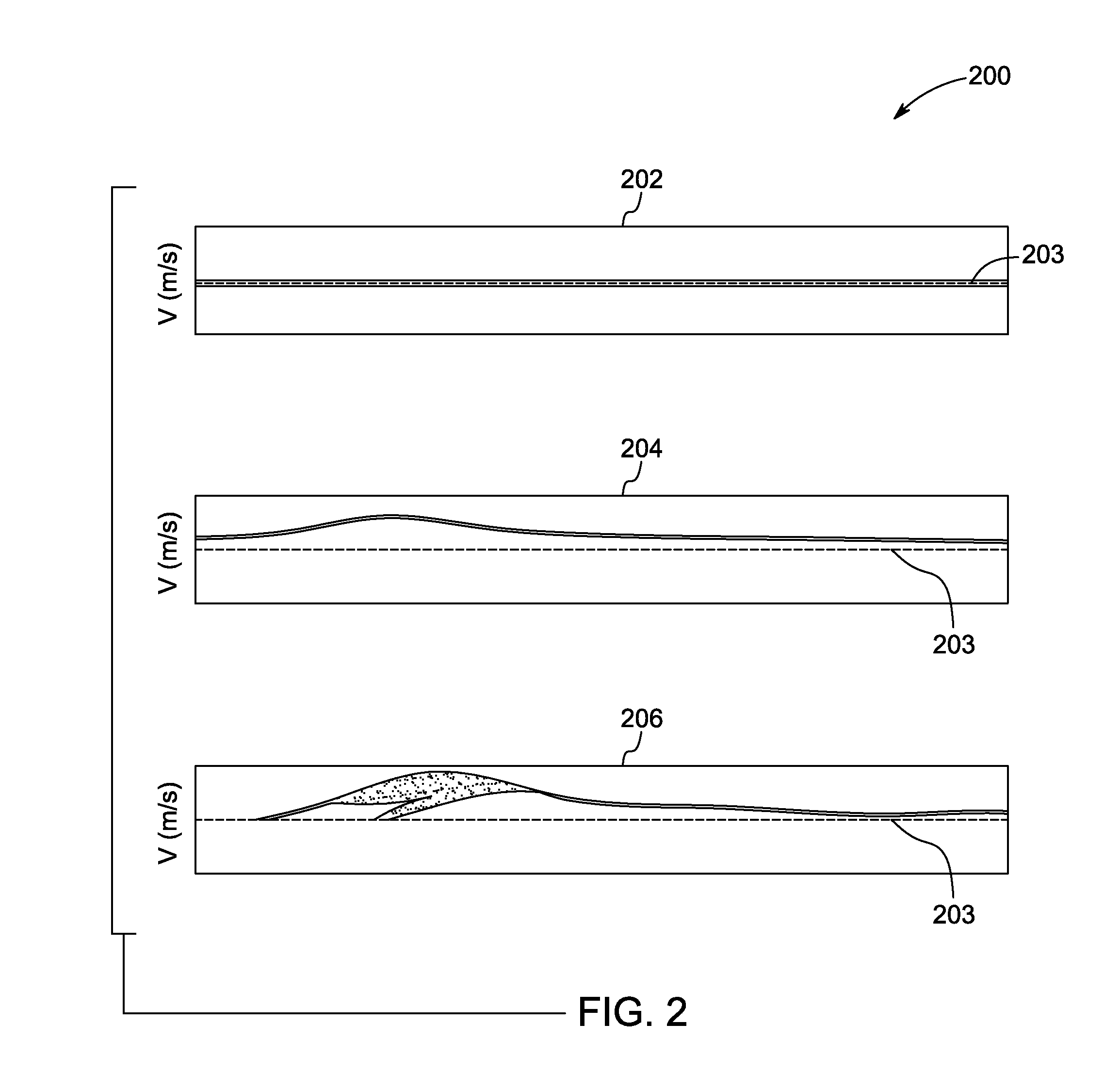

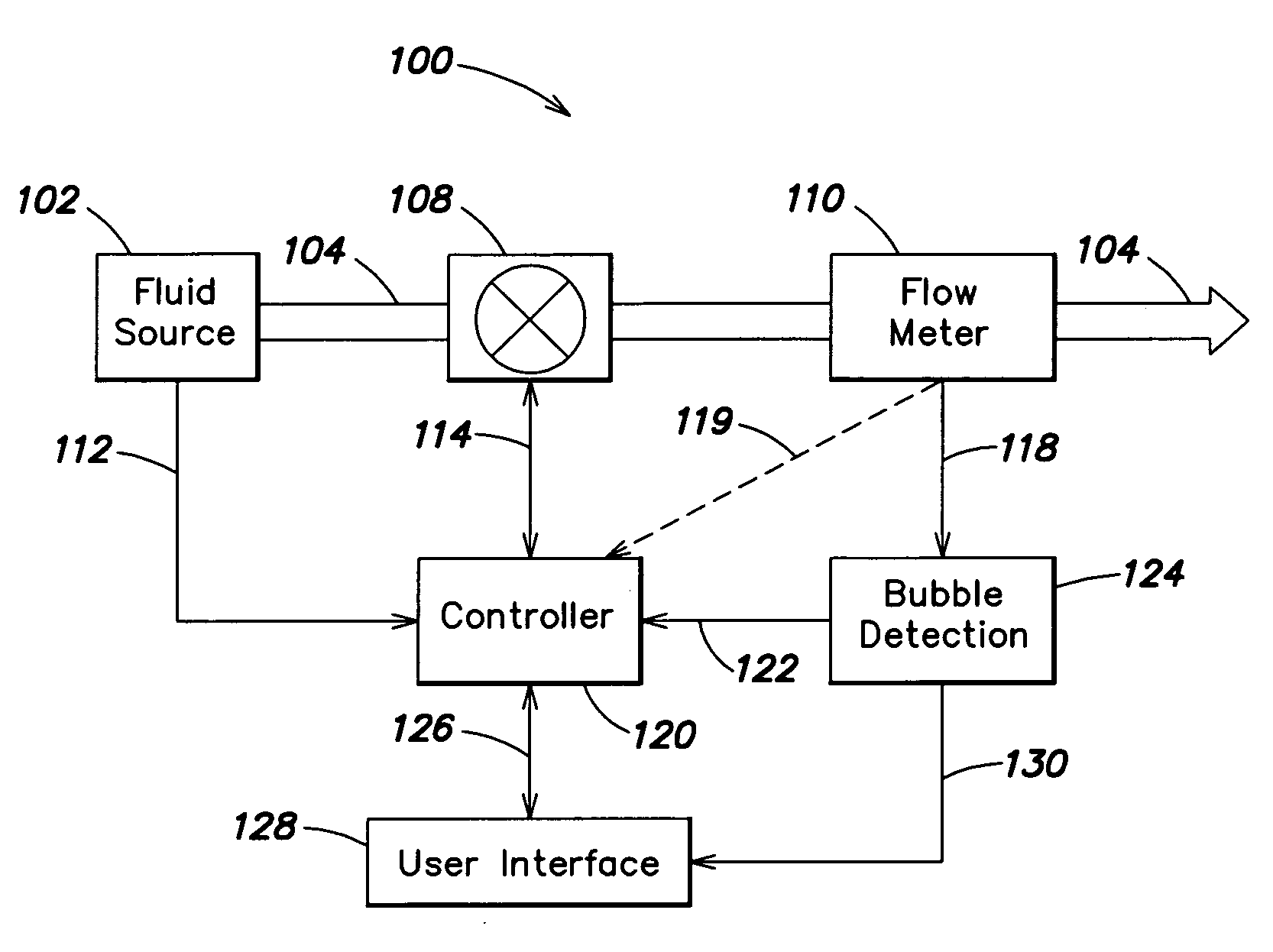

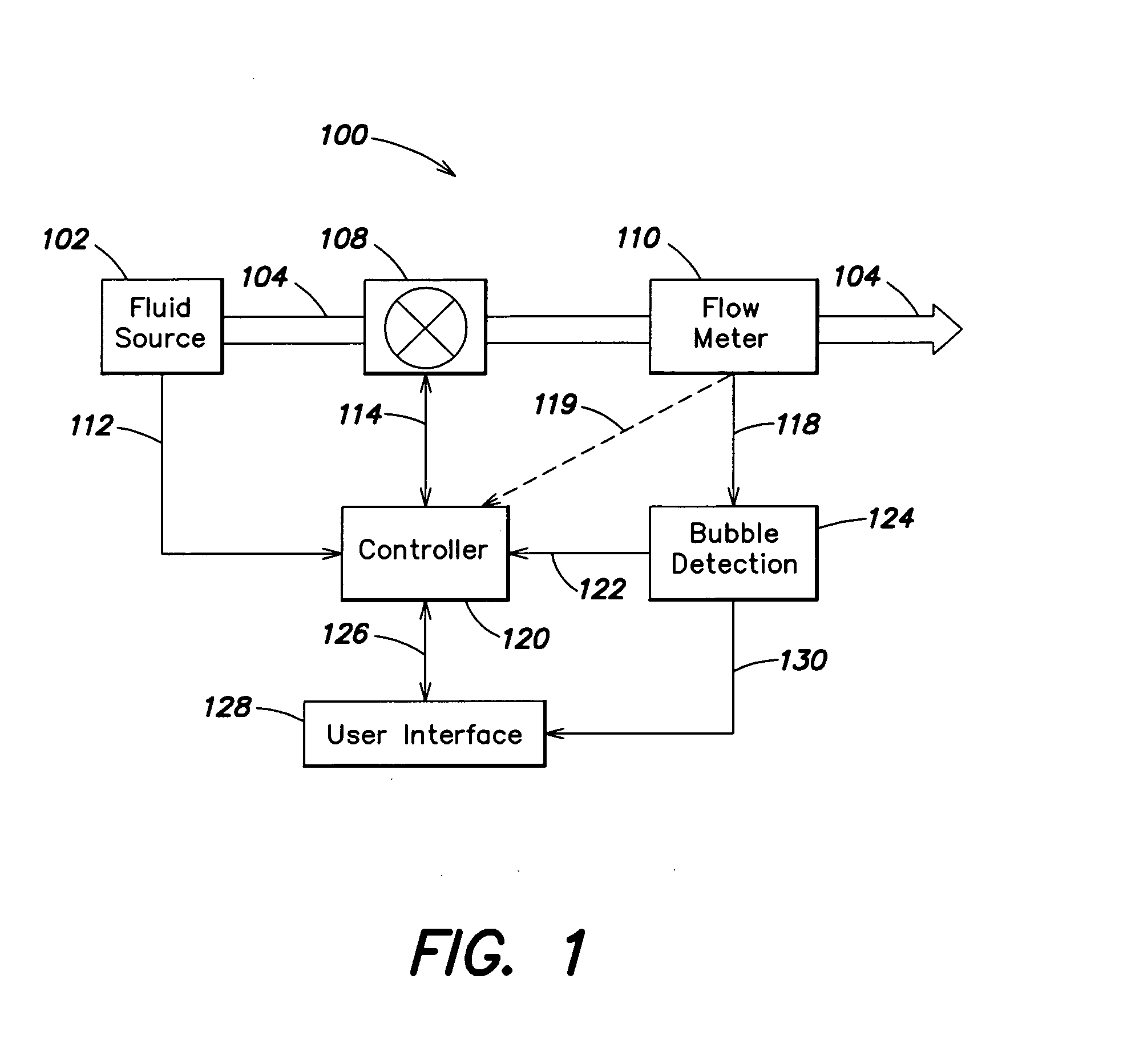

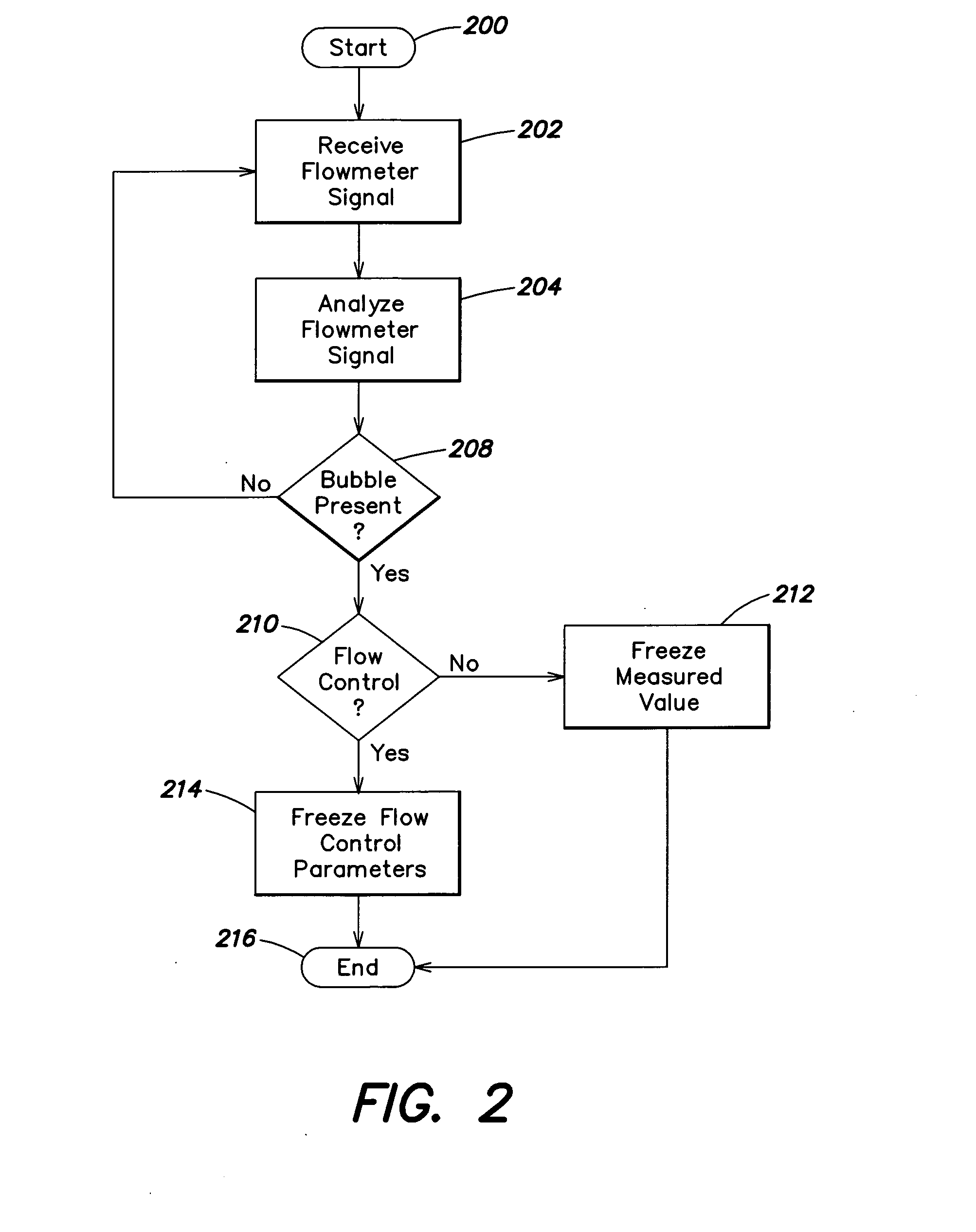

Flow measurement and control with bubble detection

InactiveUS20070191990A1Guaranteed uptimeMinimize impactVolume/mass flow measurementTesting/calibration for volume flowFlow transducerControl system

Systems and methods for liquid flow sensing and control for use with a variety of different types of liquid flow measurement and control systems. The liquid flow sensor system senses a flow signal indicative of the flow rate of the liquid flowing in a sensor conduit and analyzes the flow signal to determine, by detecting characteristic changes in the signal, whether a bubble is present in the sensor conduit. Where the system determines that a bubble is present, it may generate an alarm signal indicative of the presence of the bubble. A flow control system incorporating the flow sensor as a feedback source may respond to the detection of a bubble by temporarily freezing the flow control parameters until the bubble has exited the sensor conduit. The flow control system can implement procedures for clearing a bubble from the sensor conduit where the system detects that the bubble has become stuck.

Owner:CELERITY

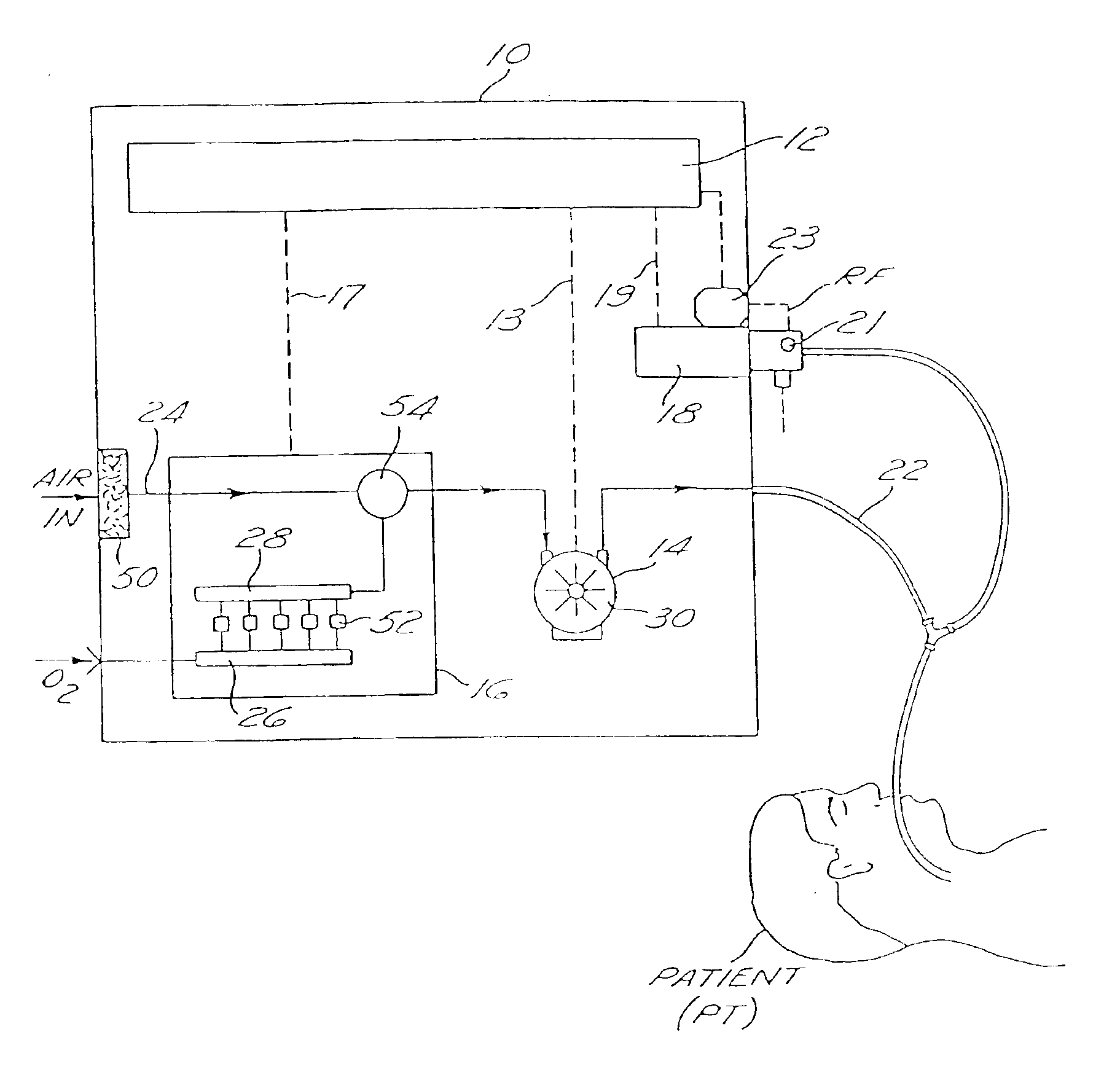

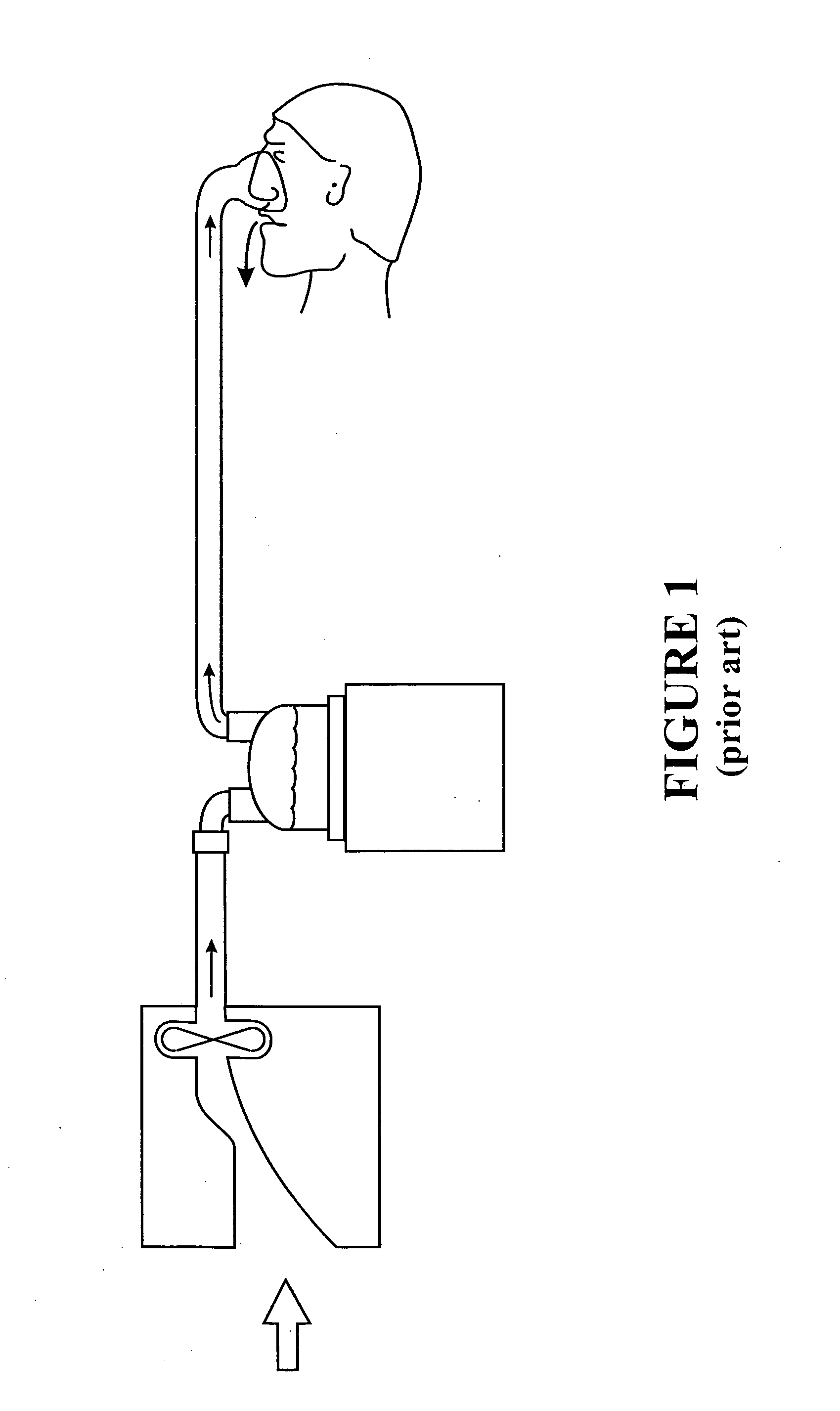

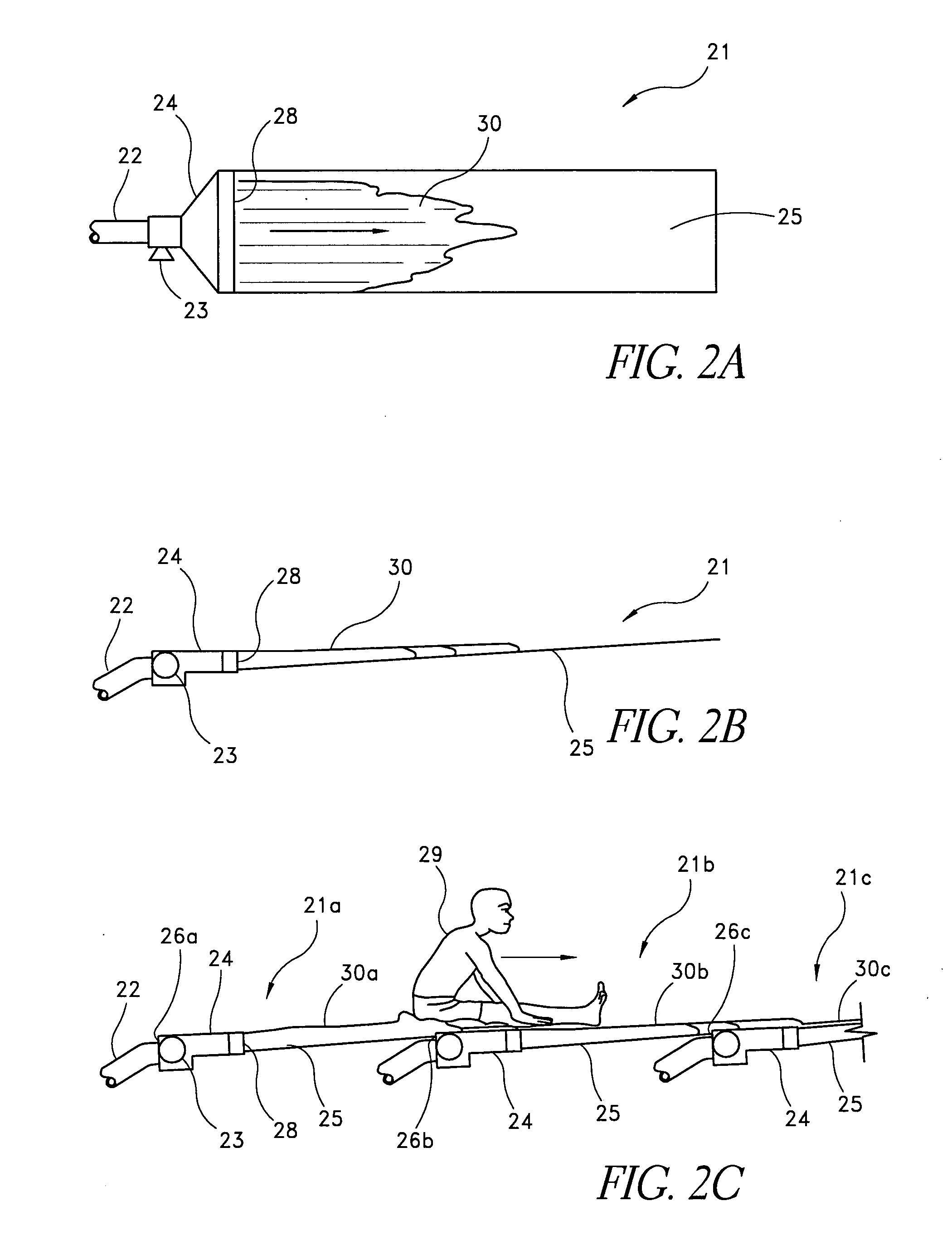

Portable drag compressor powered mechanical ventilator

InactiveUS20050150494A1Accurate measurementMinimize inaccuracyRespiratorsOperating means/releasing devices for valvesSolenoid valveEngineering

A ventilator device and system comprising a rotating compressor, preferably a drag compressor, which, at the beginning of each inspiratory ventilation phase, is accelerated to a sufficient speed to deliver the desired inspiratory gas flow, and is subsequently stopped or decelerated to a basal flow level to permit the expiratory ventilation phase to occur. The ventilator device is small and light weight enough to be utilized in portable applications. The ventilator device is power efficient enough to operate for extended periods of time on internal or external batteries. Also provided is an oxygen blending apparatus which utilizes solenoid valves having specific orifice sizes for blending desired amounts of oxygen into the inspiratory gas flow. Also provided is an exhalation valve having an exhalation flow transducer which incorporates a radio frequency data base to provide an attendant controller with specific calibration information for the exhalation flow transducer.

Owner:BIRD PRODS

Combined Pressure and Flow Sensor Integrated in a Shunt System

A shunt system for implantation into a patient for diverting excess fluid from the lateral ventricles of the patient's brain to a diversion site. The present shunt includes a pressure transducer for measuring ICP, a rate of flow transducer for measuring the flow rate of the CSF flowing within the shunt, and telemetry circuitry. A remote reader with an antenna is provided to selectively interrogate and provide inductive power to the implanted shunt. Upon interrogation, the pressure and rate of flow measurements are calibrated, multiplexed and transmitted on a carrier signal back to the remote reader / antenna. The reader / antenna extracts the pressure and flow rate data from the carrier wave and further separates the data by demultiplexing the signal. The reader further includes a barometer for providing local barometric pressure and uses this information together with the data from the implanted transducers to calculate and display real-time adjusted ICP, CSF flow-rate within the shunt and brain compliance.

Owner:MEDOS INT SARL

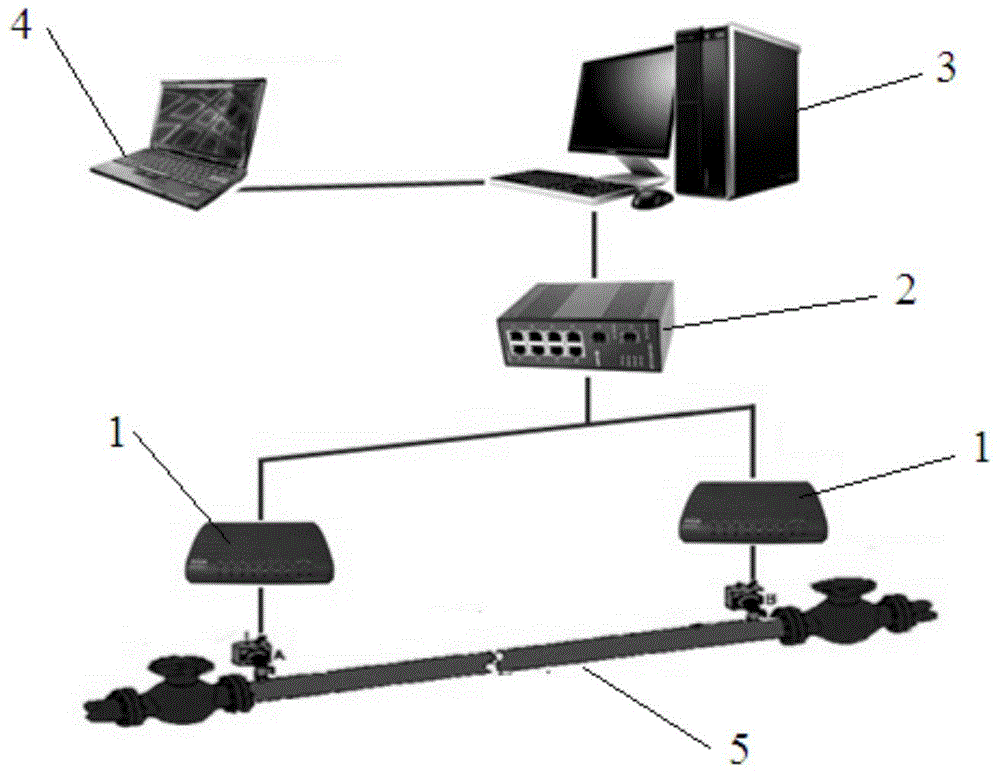

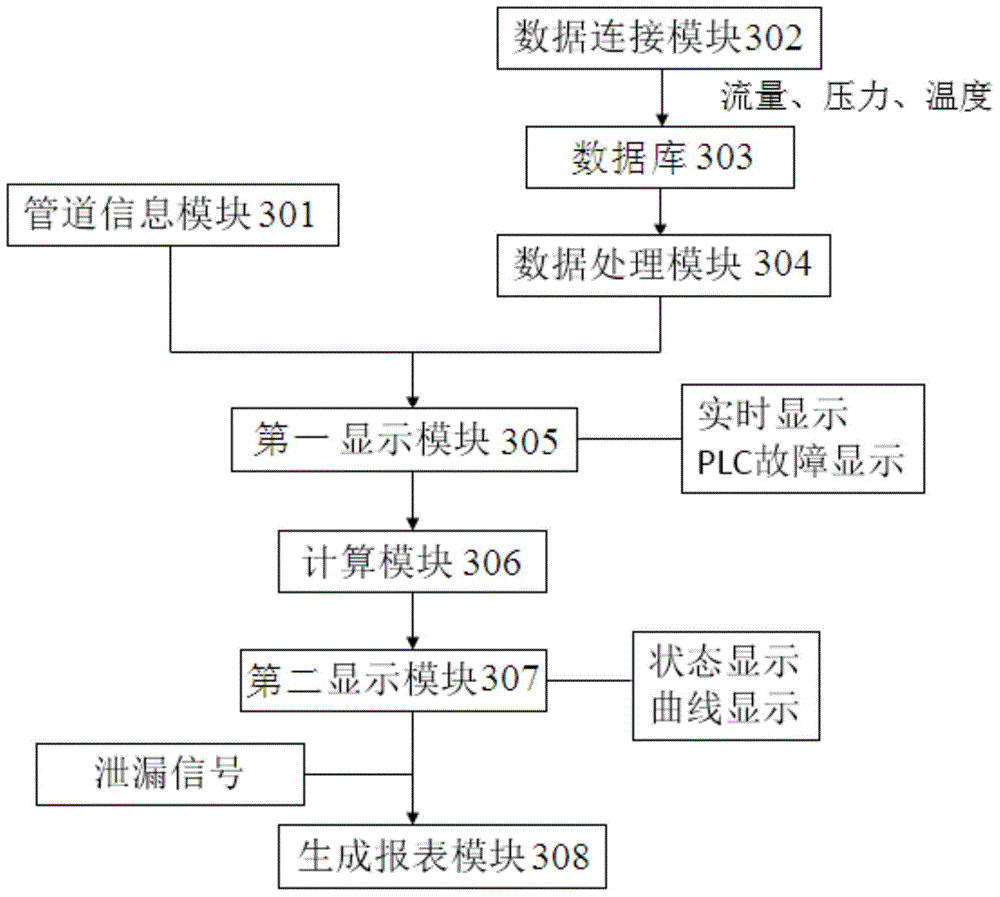

Subsea pipeline leakage monitoring system

The invention relates to a subsea pipeline leakage monitoring system. The subsea pipeline leakage monitoring system comprises controllers, flow sensors, pressure sensors, temperature sensors and a center host computer. The inlet end and the outlet end of a pipeline to be monitored are each provided with one flow sensor, one pressure sensor and one temperature sensor. The flow sensor, the pressure sensor and the temperature sensor at the inlet end collect the flow, pressure and temperature signals of the inlet end in real time and send the flow, pressure and temperature signals to the first controller. The flow sensor, the pressure sensor and the temperature sensor at the outlet end collect the flow, pressure and temperature signals of the outlet end in real time and send the flow, pressure and temperature signals to the second controller. The controllers send the signals to the center host computer through an Ethernet switch, the leakage monitoring system inside the center host computer displays the information in real time and judges where the pipeline to be monitored is leaked or not, a leakage alarm is given out when leakage happens, and the leakage amount and leakage position are worked out and displayed. The center host computer sends the received signals and the judgment result to remote monitoring devices.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com