Patents

Literature

191 results about "Shunt flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

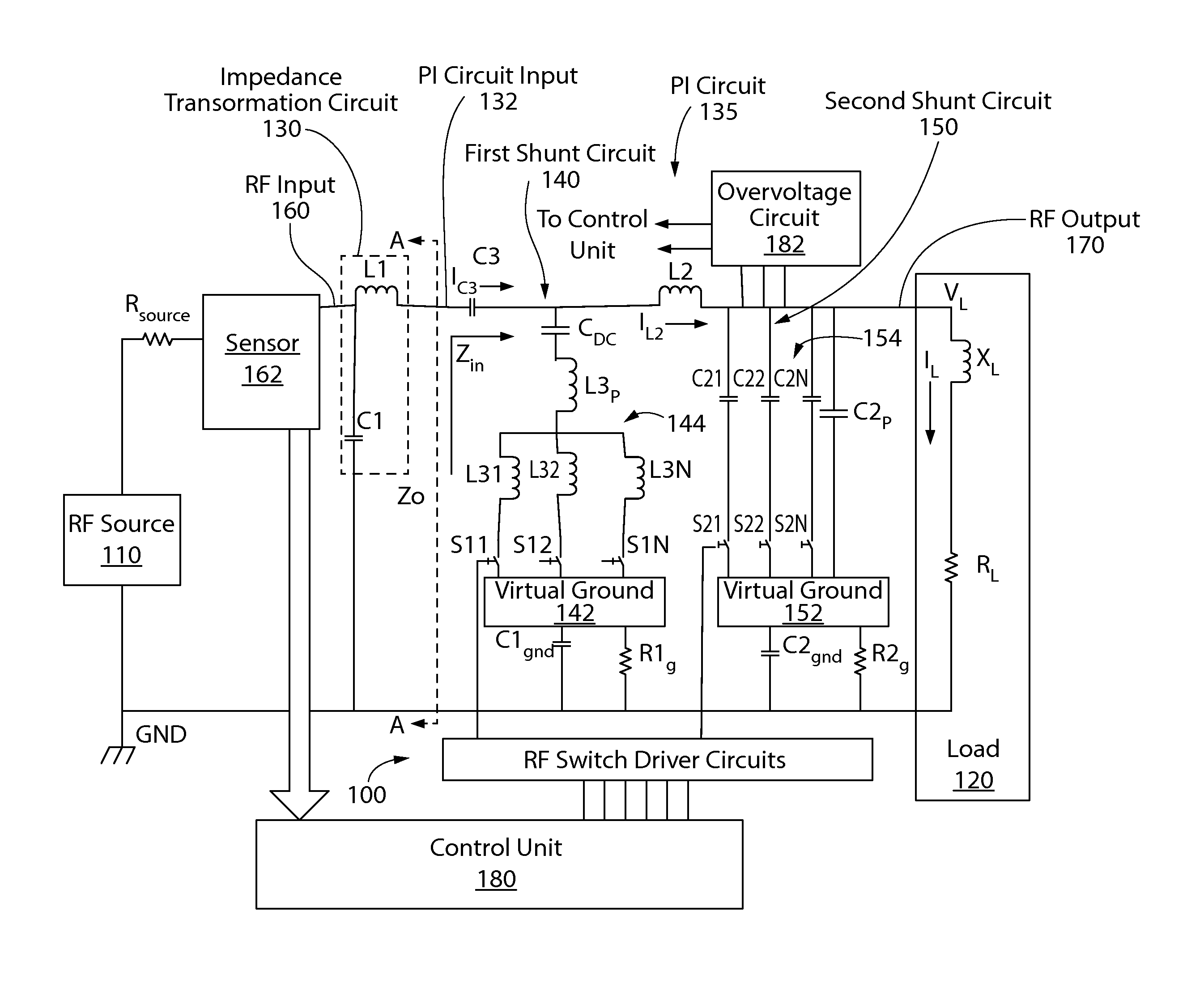

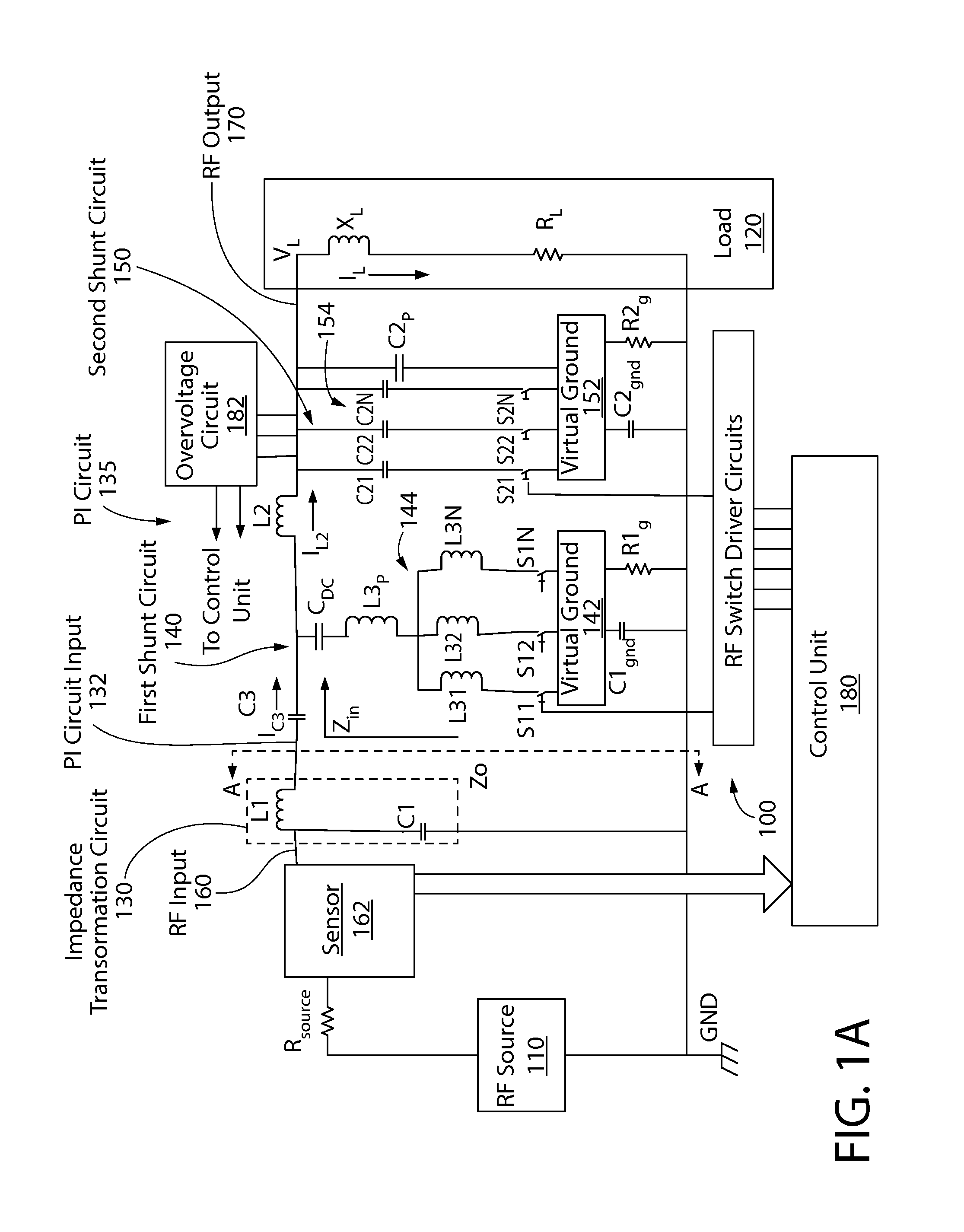

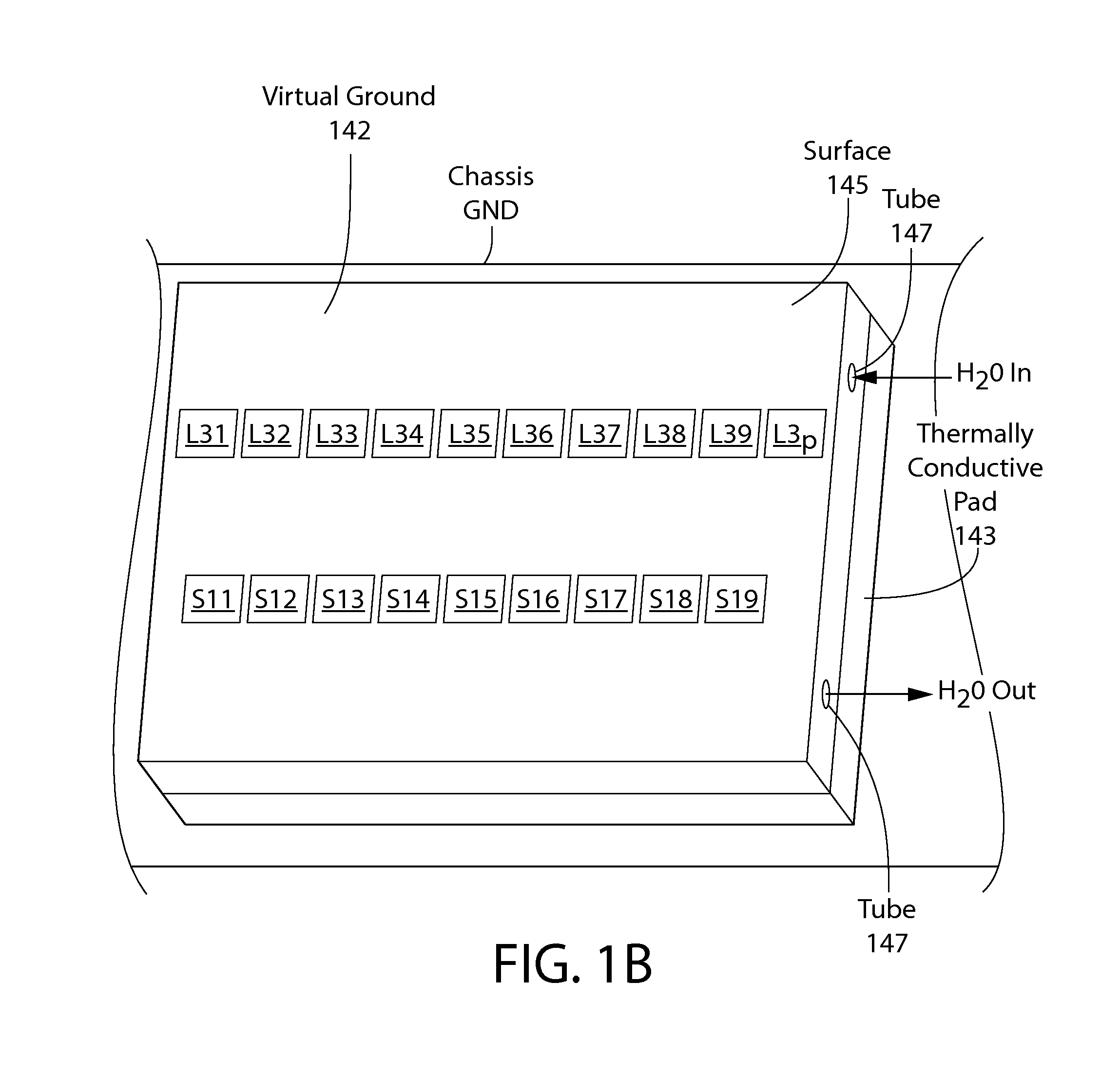

RF impedance matching network

An RF impedance matching network includes a transformation circuit configured to provide a transformed impedance; a first shunt circuit in parallel to the RF input, the first shunt circuit including a first shunt variable capacitance component comprising (a) a plurality of first shunt capacitors coupled in parallel, and (b) a plurality of first shunt switches coupled to the plurality of first shunt capacitors and configured to connect and disconnect each of the plurality of first shunt capacitors to a first virtual ground; and a second shunt variable capacitance component including (a) a plurality of second shunt capacitors coupled in parallel, and (b) a plurality of second shunt switches coupled to the plurality of second shunt capacitors and configured to connect and disconnect each of the plurality of second shunt capacitors to a second virtual ground.

Owner:ASM AMERICA INC

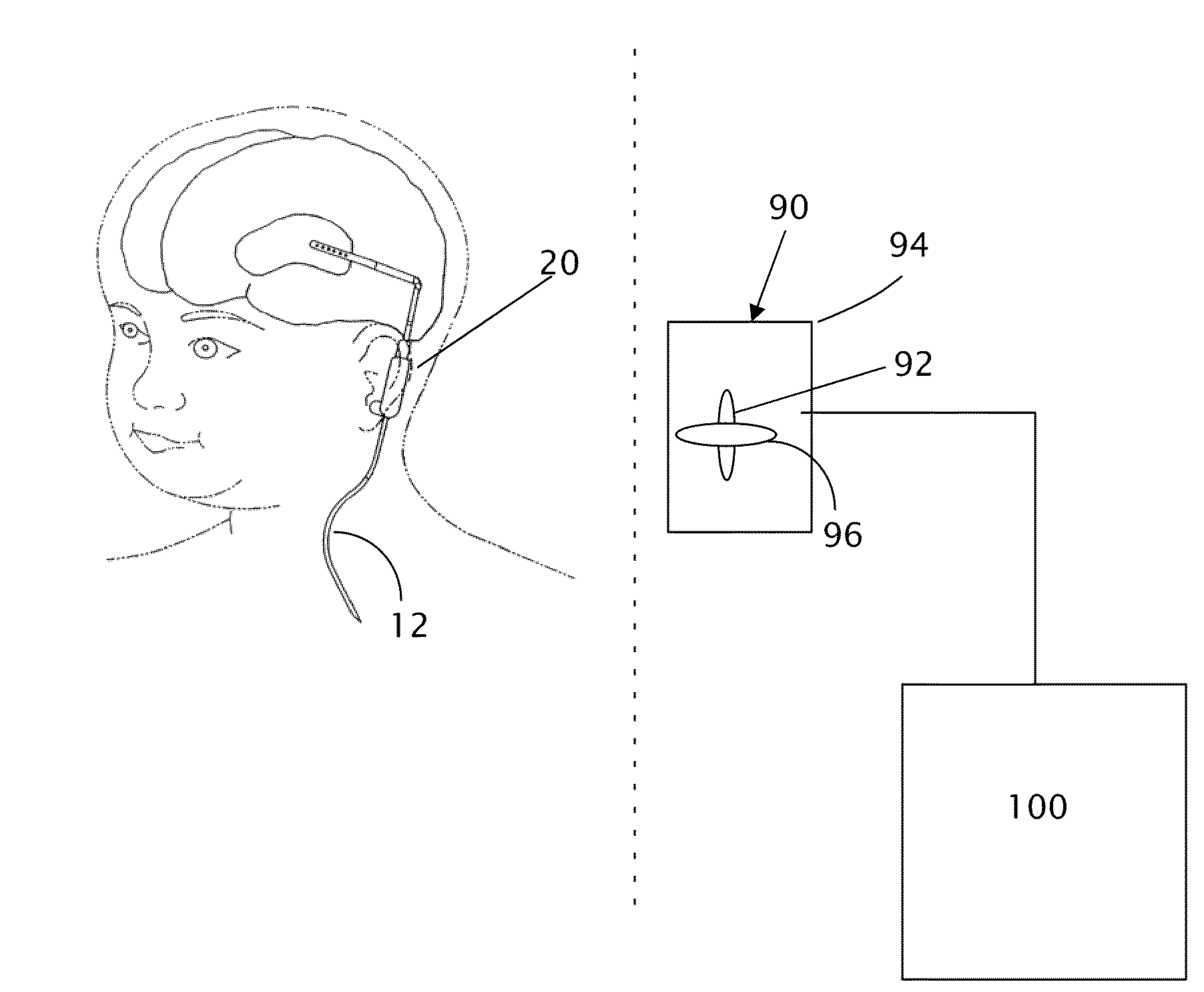

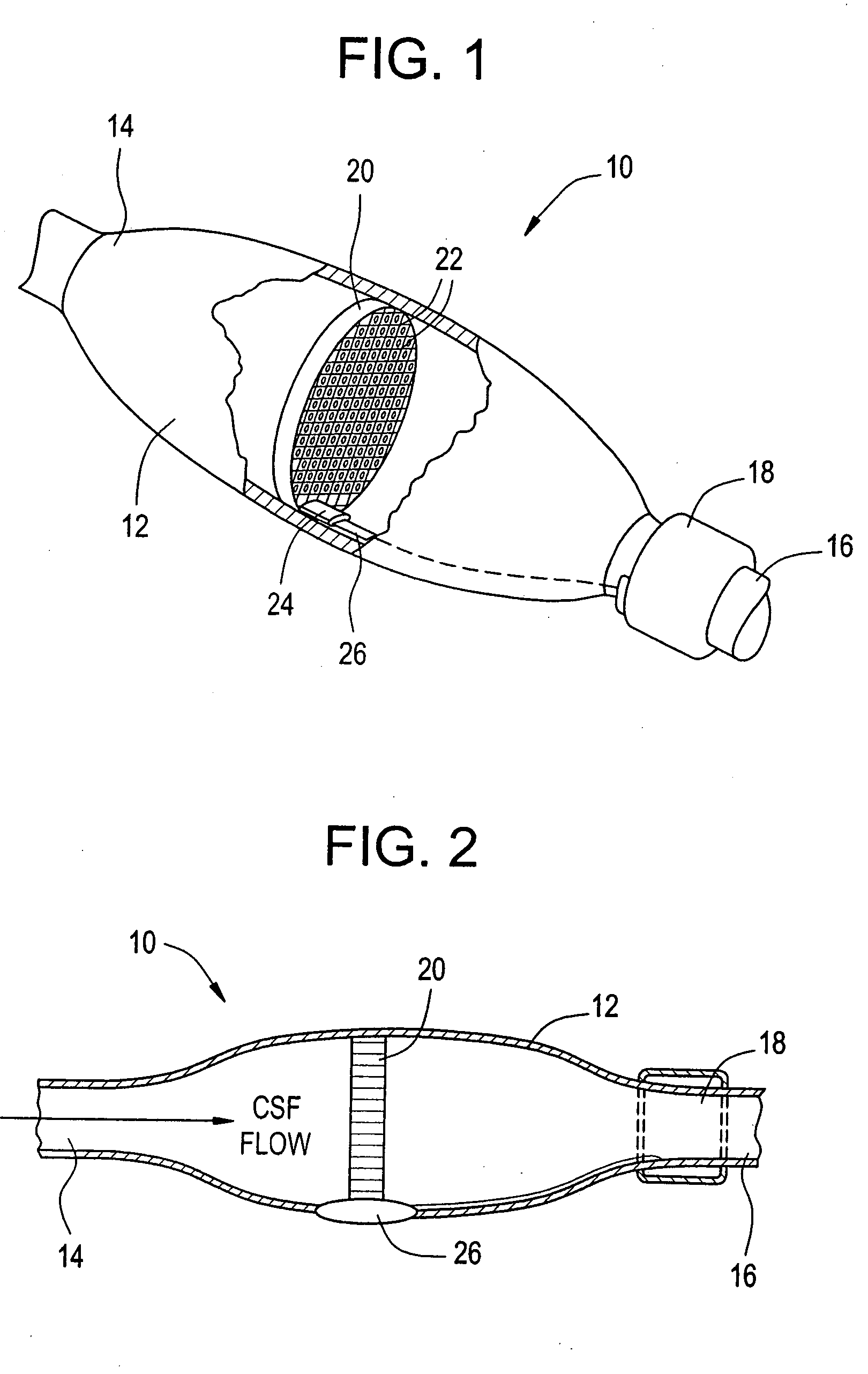

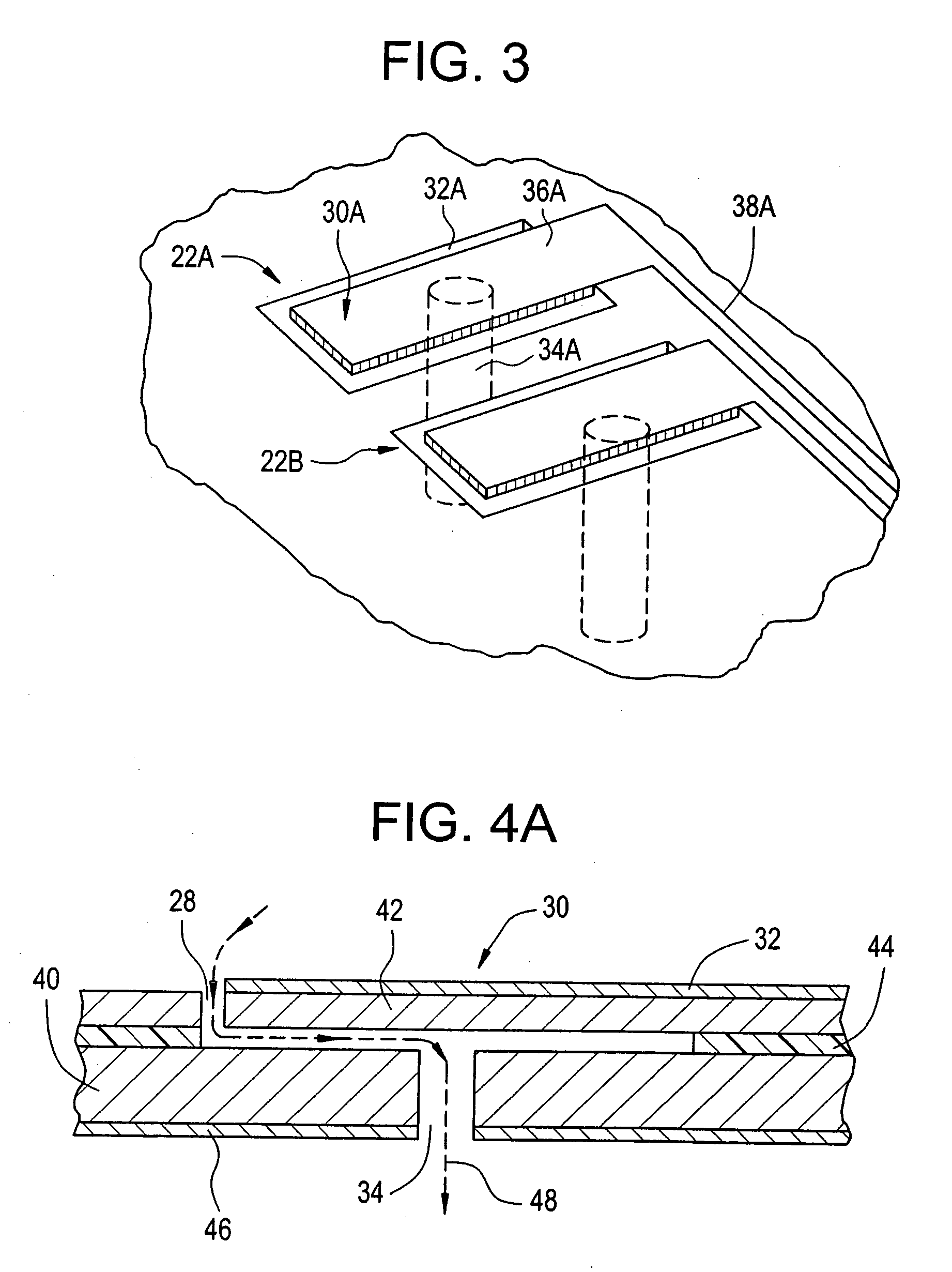

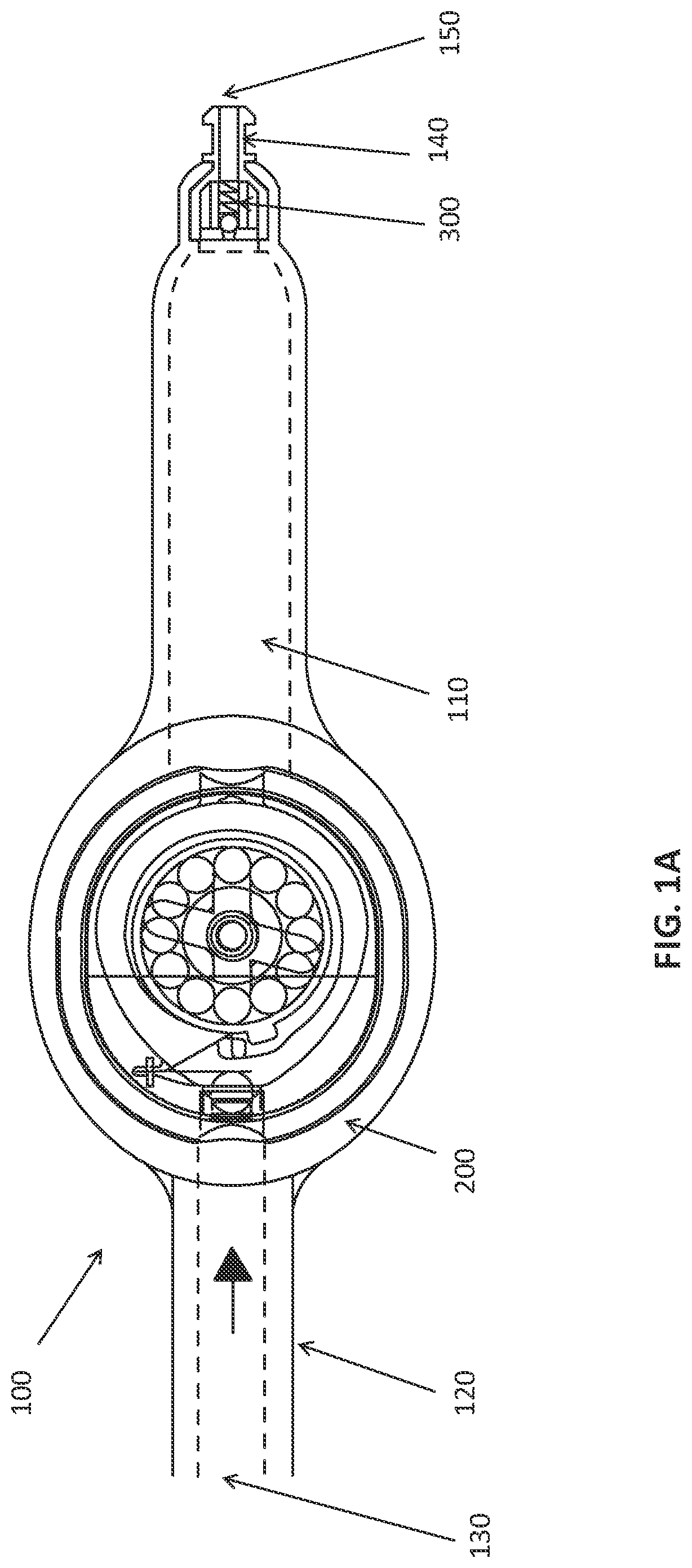

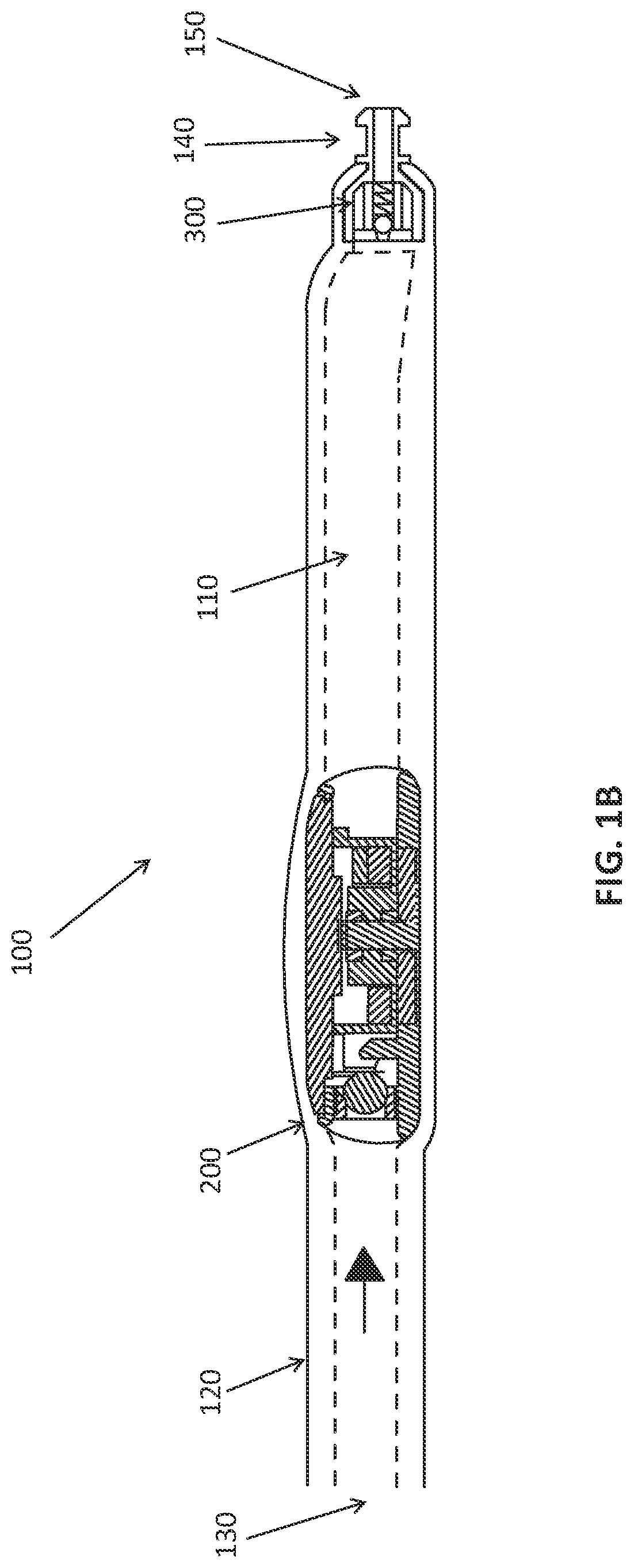

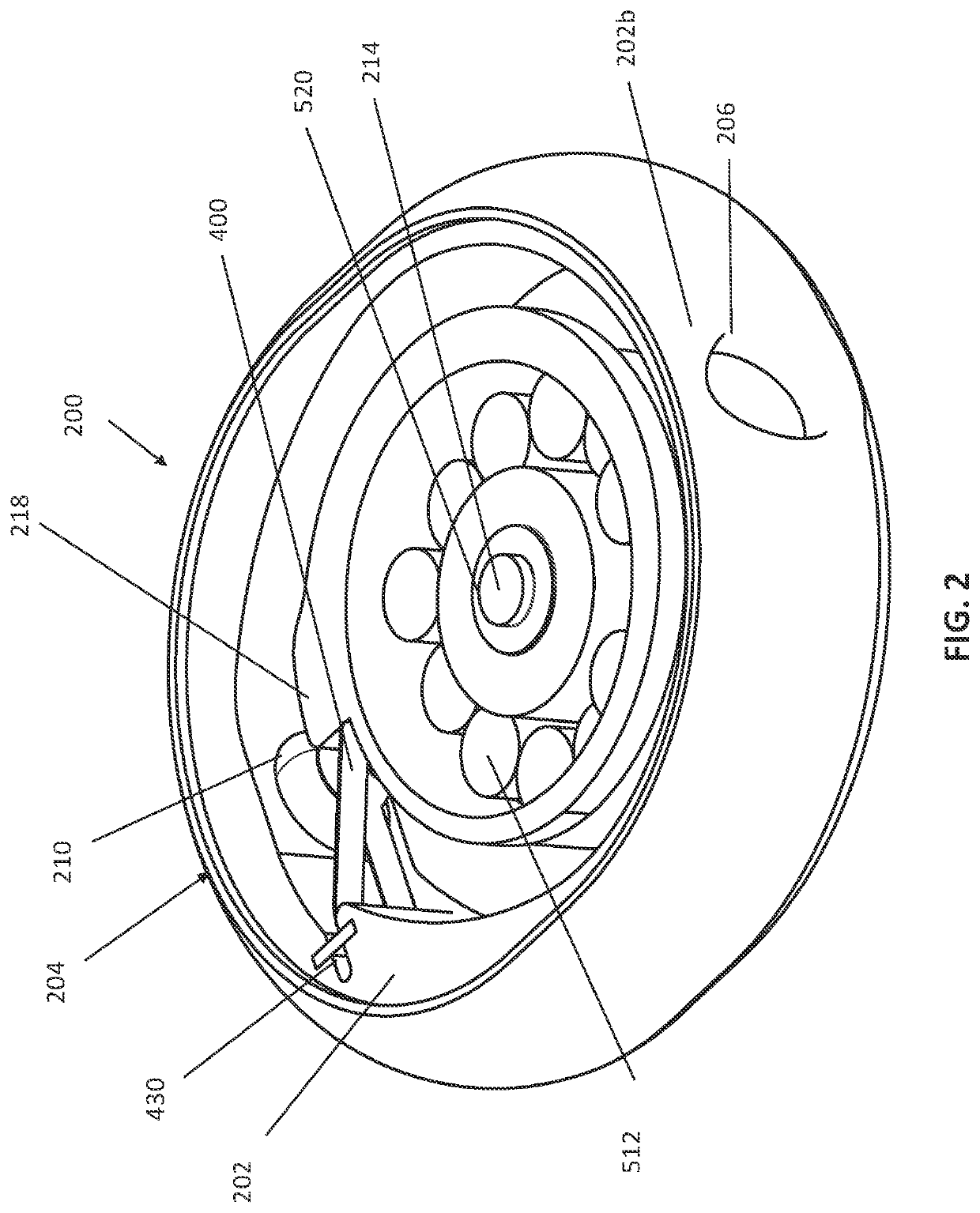

Transit time ultrasonic flow measurement

InactiveUS20090143673A1Ultrasonic/sonic/infrasonic diagnosticsEndoradiosondesTransmitted powerEngineering

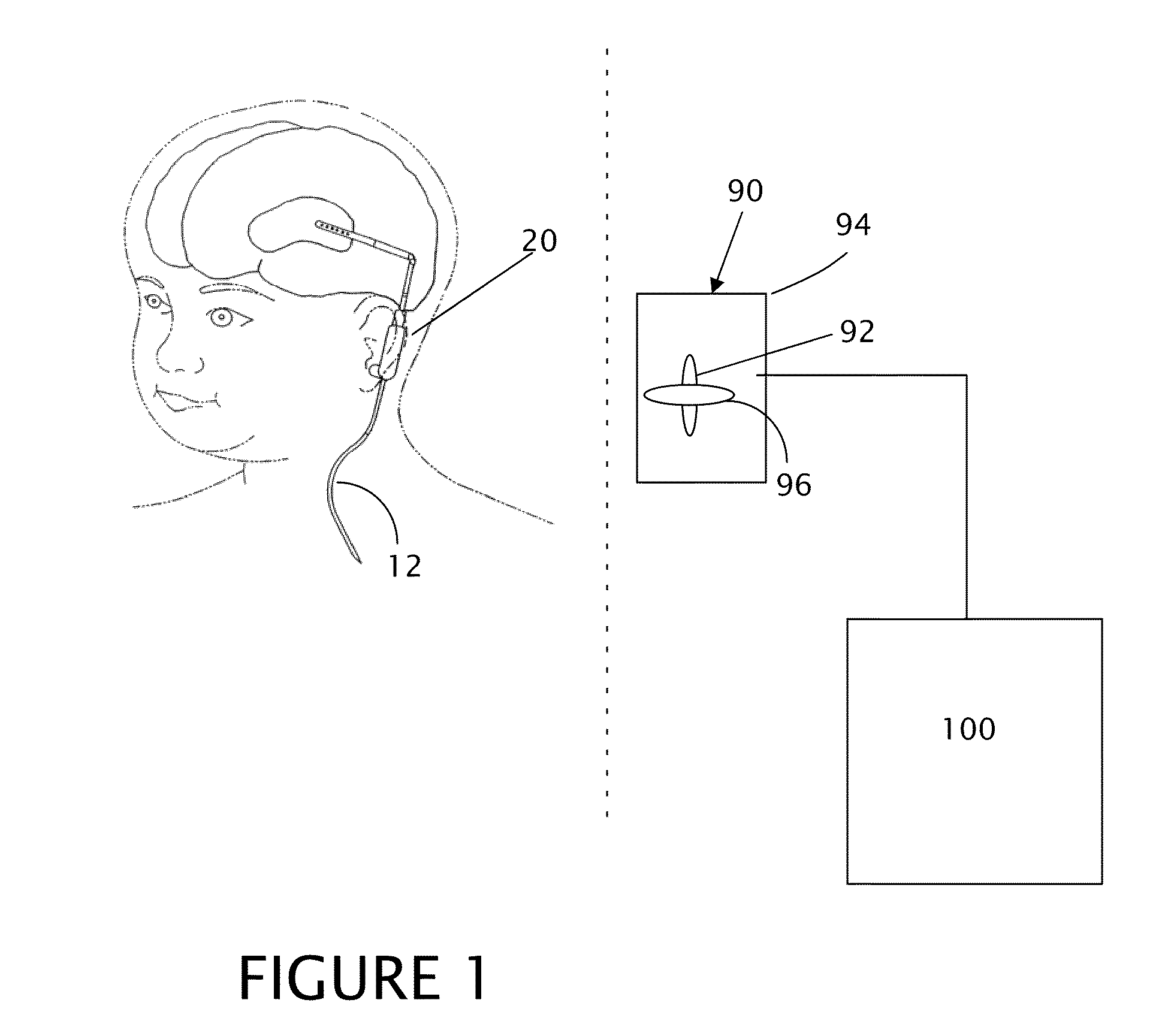

A transcutaneous energy transfer system with subcutaneous non coupled coils is used to transmit power and signals to an implanted biological support device or sensor, such as a flow sensor for measuring relatively low flow rates, such as hydrocephalic shunt flow. The flow sensor is configured to convert a shear wave generated by a transducer to a longitudinal wave at the interface of a signal pathway and the flow, wherein the longitudinal wave travels parallel to the flow and exits a flow channel to convert to a shear wave which intersects a second transducer. The transcutaneous energy transfer employs a pair of inductive coupling coils, wherein the coils are disposed in zero coupling orientation which can include a perpendicular orientation of corresponding coil axes.

Owner:TRANSONIC SYST

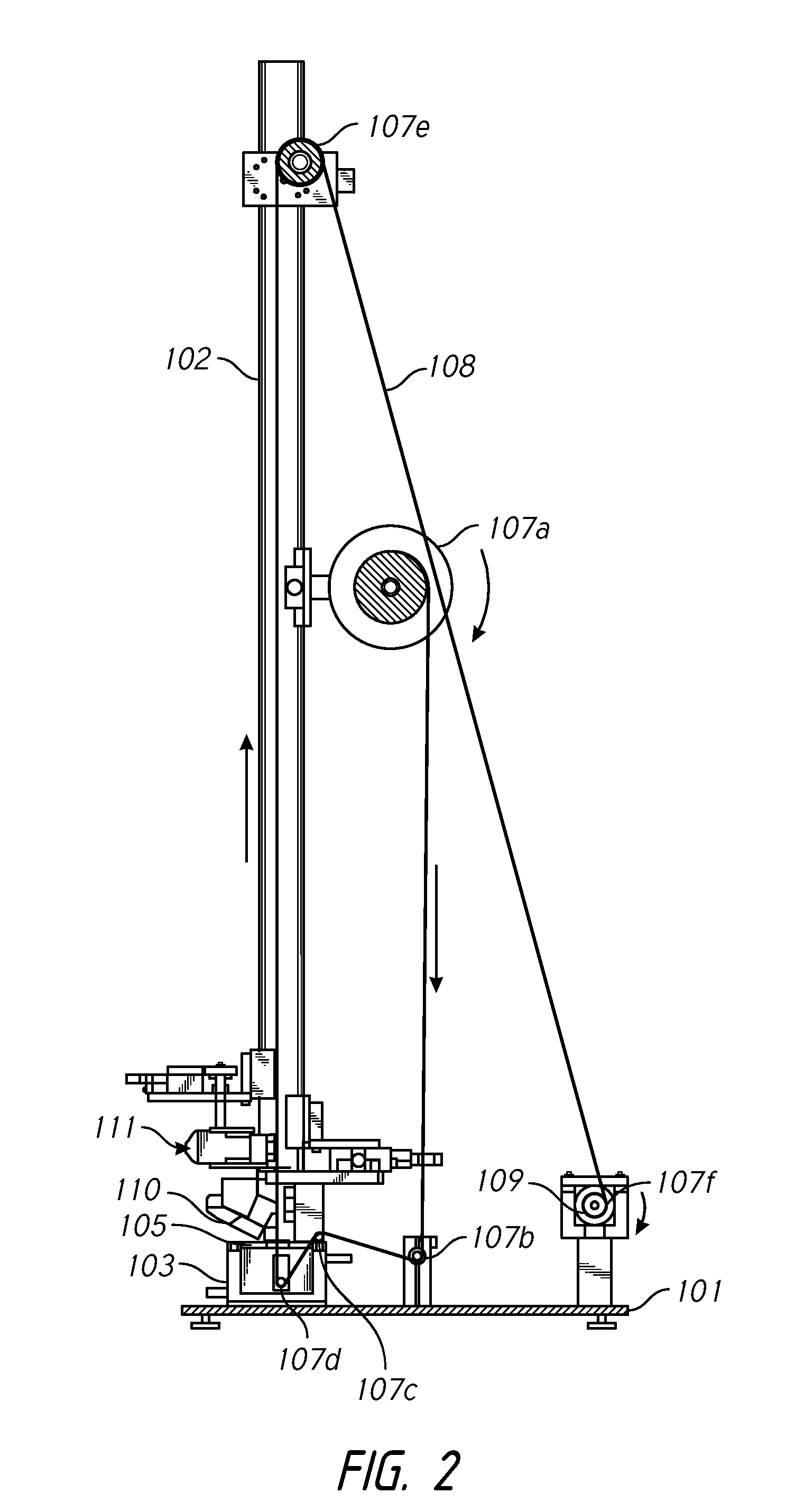

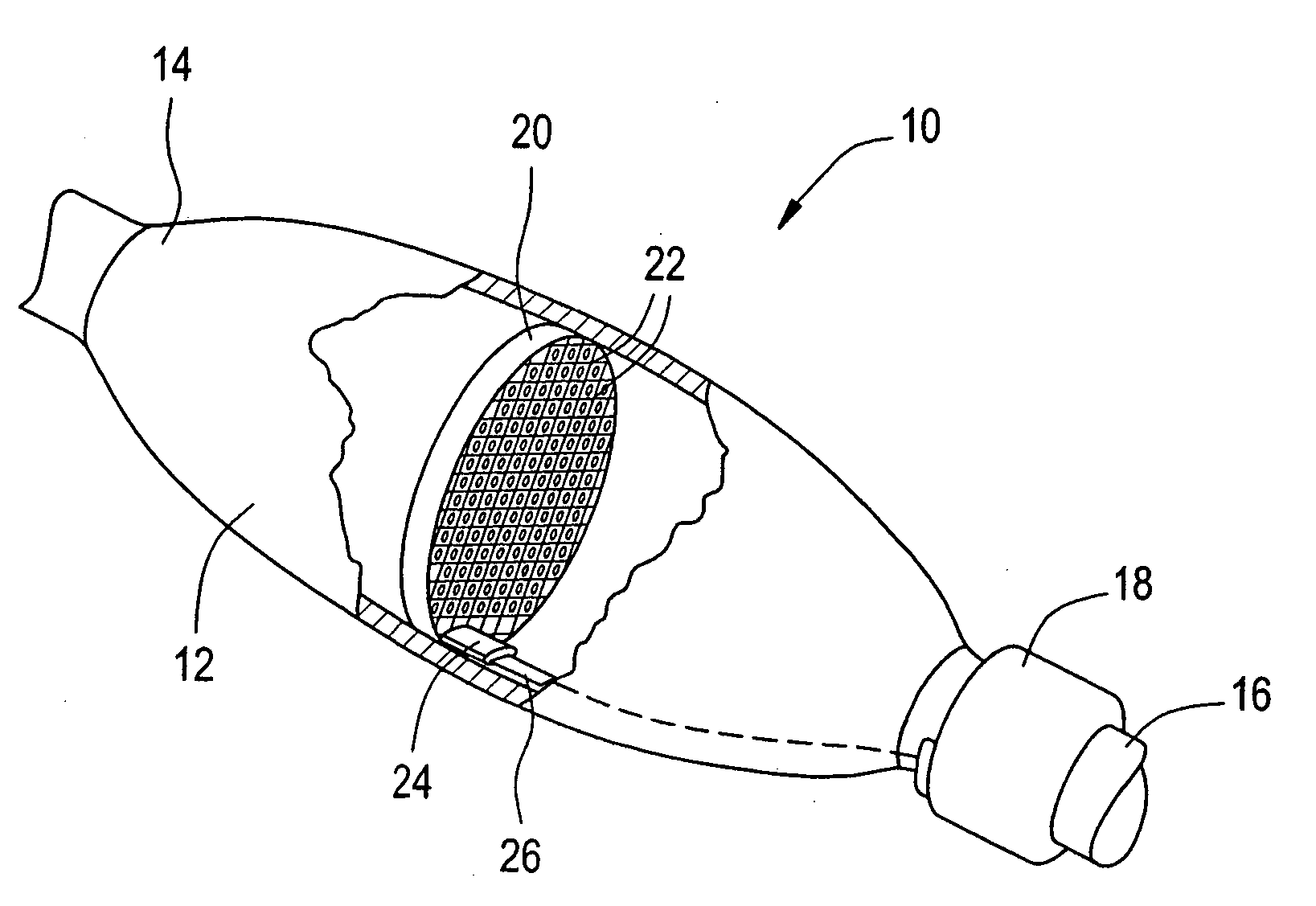

Intraocular shunt manufacture

ActiveUS20140287077A1Reduce skin effectUniform shapeLiquid surface applicatorsEye surgeryOphthalmologySurgery

An intraocular shunt can be manufactured using a system that includes a liquid bath and a wire, which is moved through the bath. When moved through the bath, the wire is coated with a material, such as gelatin. For example, the liquid bath can have a top layer, including water, and a bottom layer, including gelatin. The coated wire passes through an aperture formed in a plate component of the system. The gelatin can be dried on the wire in a humidity-controlled space, thereby forming the shunt.

Owner:AQUESYS INC

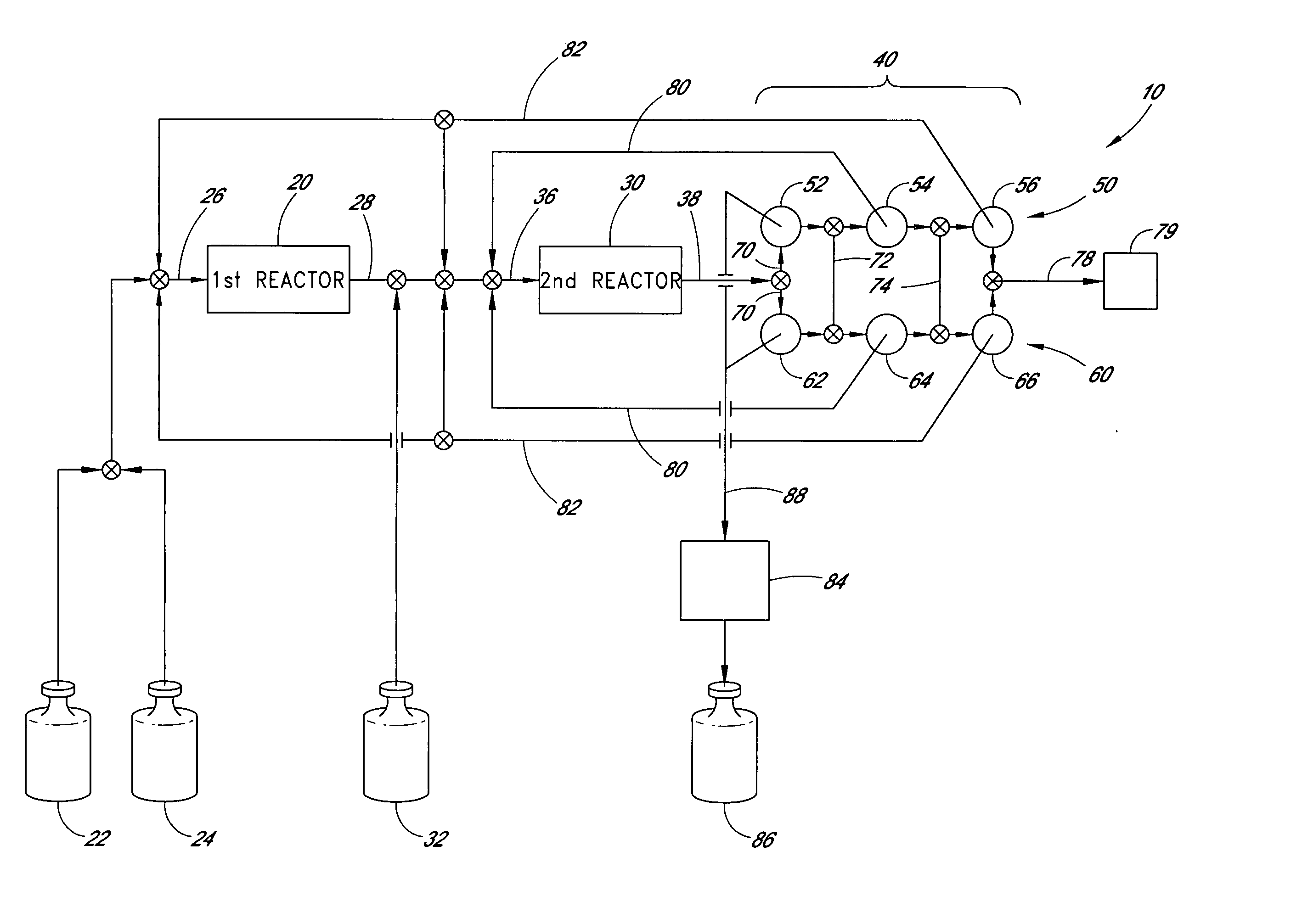

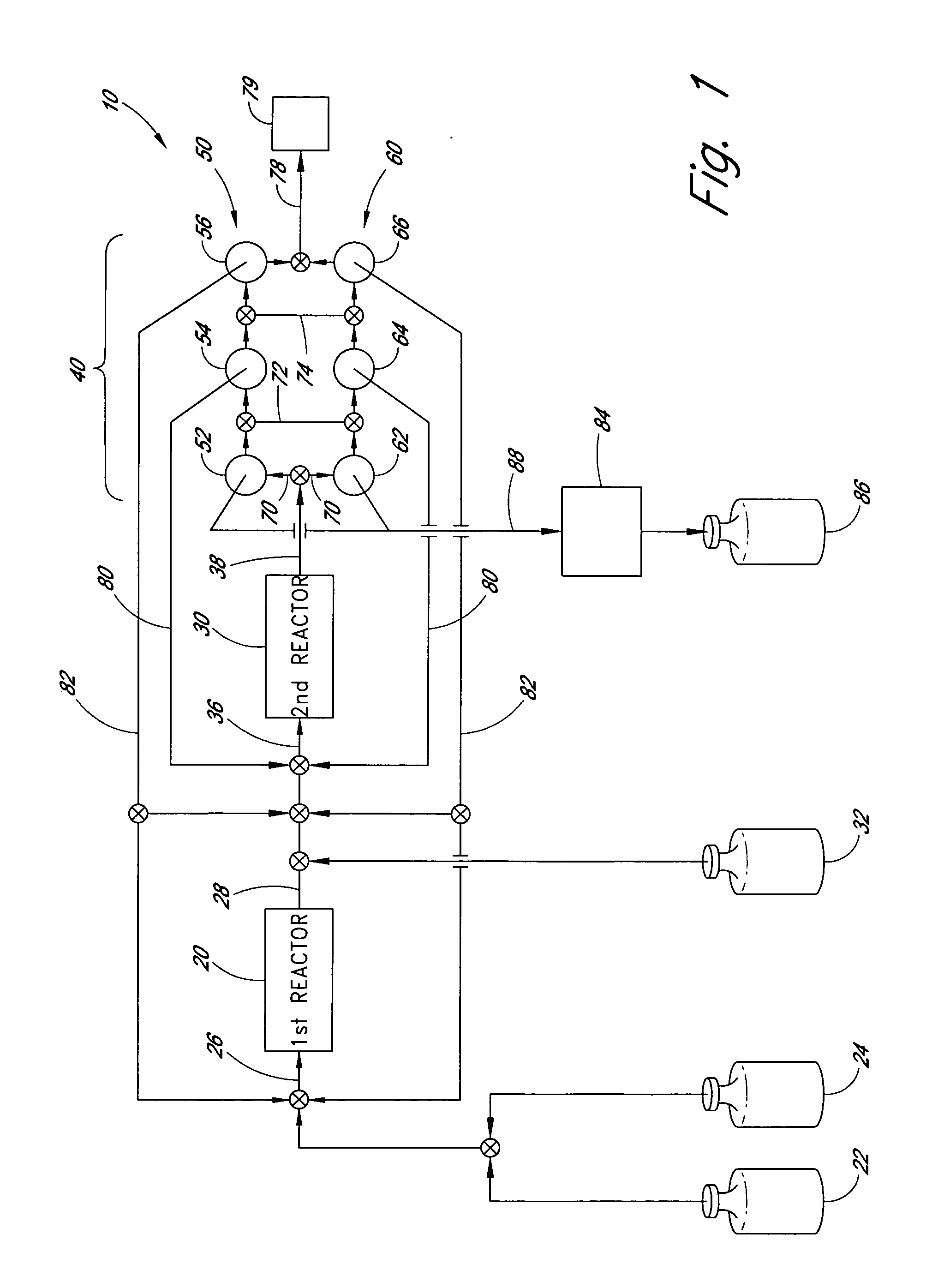

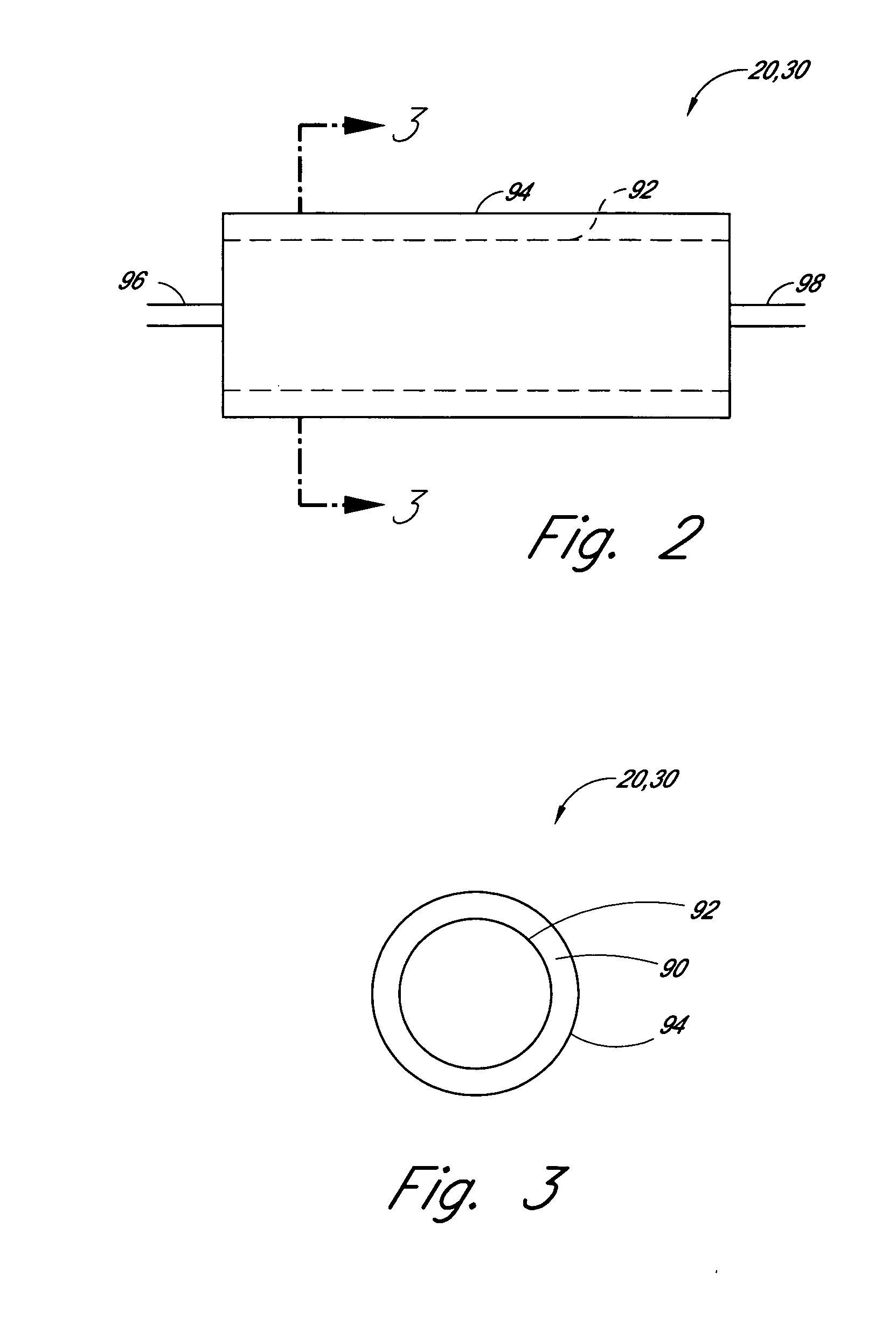

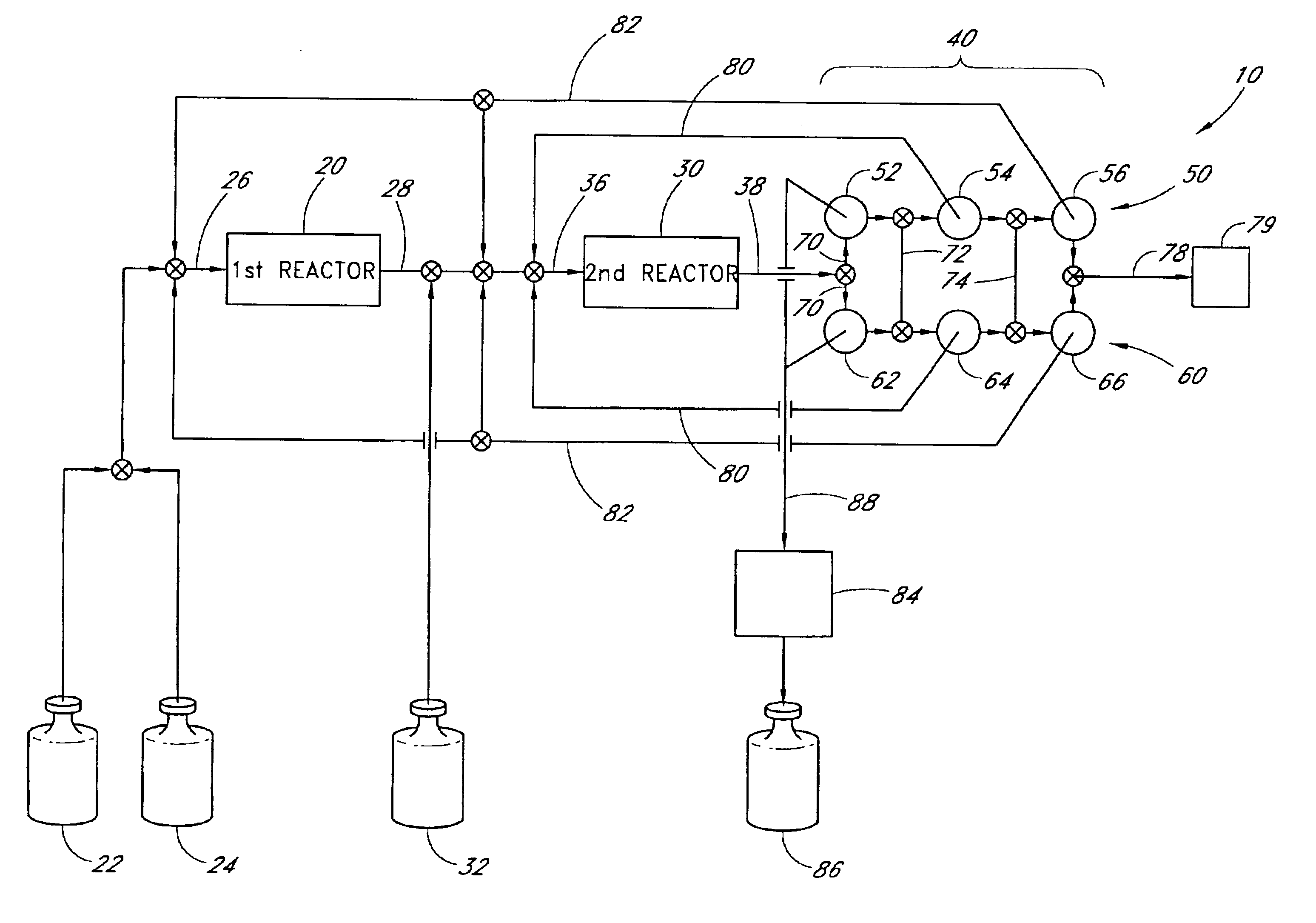

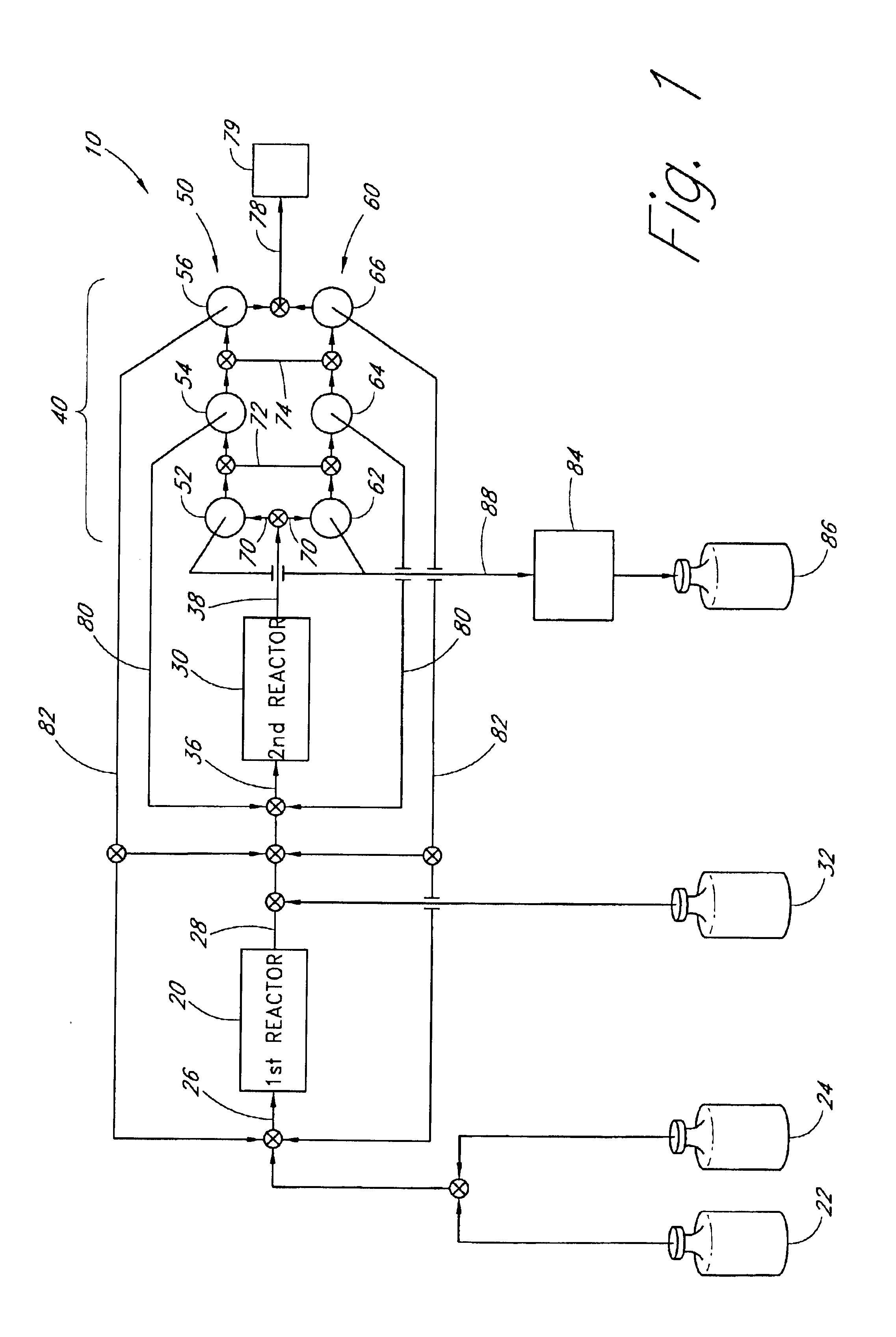

Method and apparatus for chemical synthesis

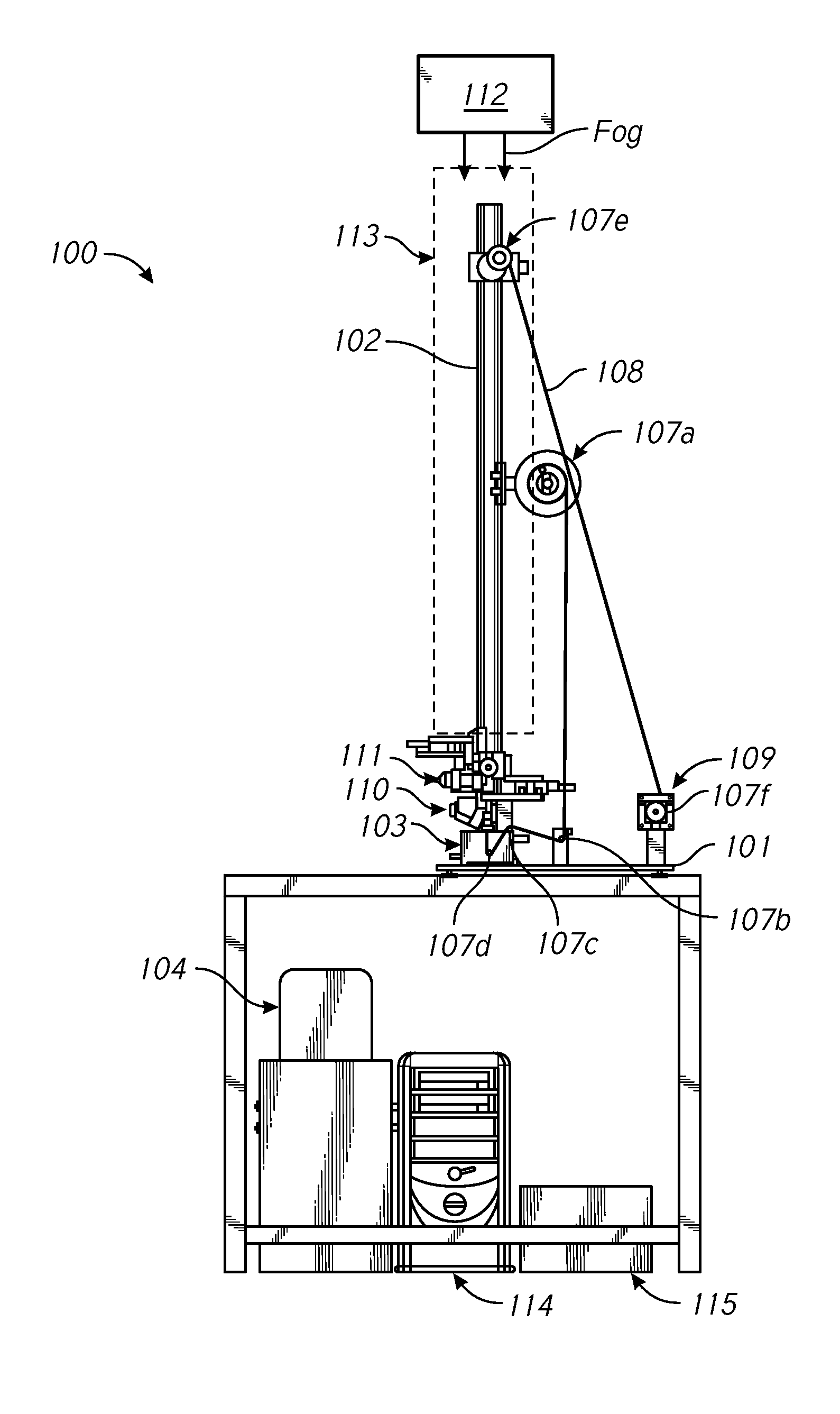

InactiveUS20050142046A1Silicon hydridesEnergy based chemical/physical/physico-chemical processesChemical synthesisCondensation trap

An apparatus is provided for synthesis and collection of higher order chemical compounds from lower order precursors. The apparatus includes a first silent electric discharge reactor configured to synthesize an intermediate product (e.g., disilane) from a precursor chemical (e.g., monosilane). A second silent electric discharge reactor is connected downstream of the first reactor. This second reactor is configured to convert the intermediate product into the higher order chemical compound (e.g., trisilane). Multiple condensation traps are also connected to receive effluent from the second reactor, which will generally include the compound of interest as well as unreacted precursor and intermediate product. In the illustrated embodiment, a parallel second condensation traps is also included to shunt flow and continue collection while the chemical of interest is removed for purification. Moreover, parallel second condensation traps for the intermediate product and unreacted (or recombined) precursor allow continued collection while the contents of the first traps are recycled in the reactor(s).

Owner:ASM AMERICA INC

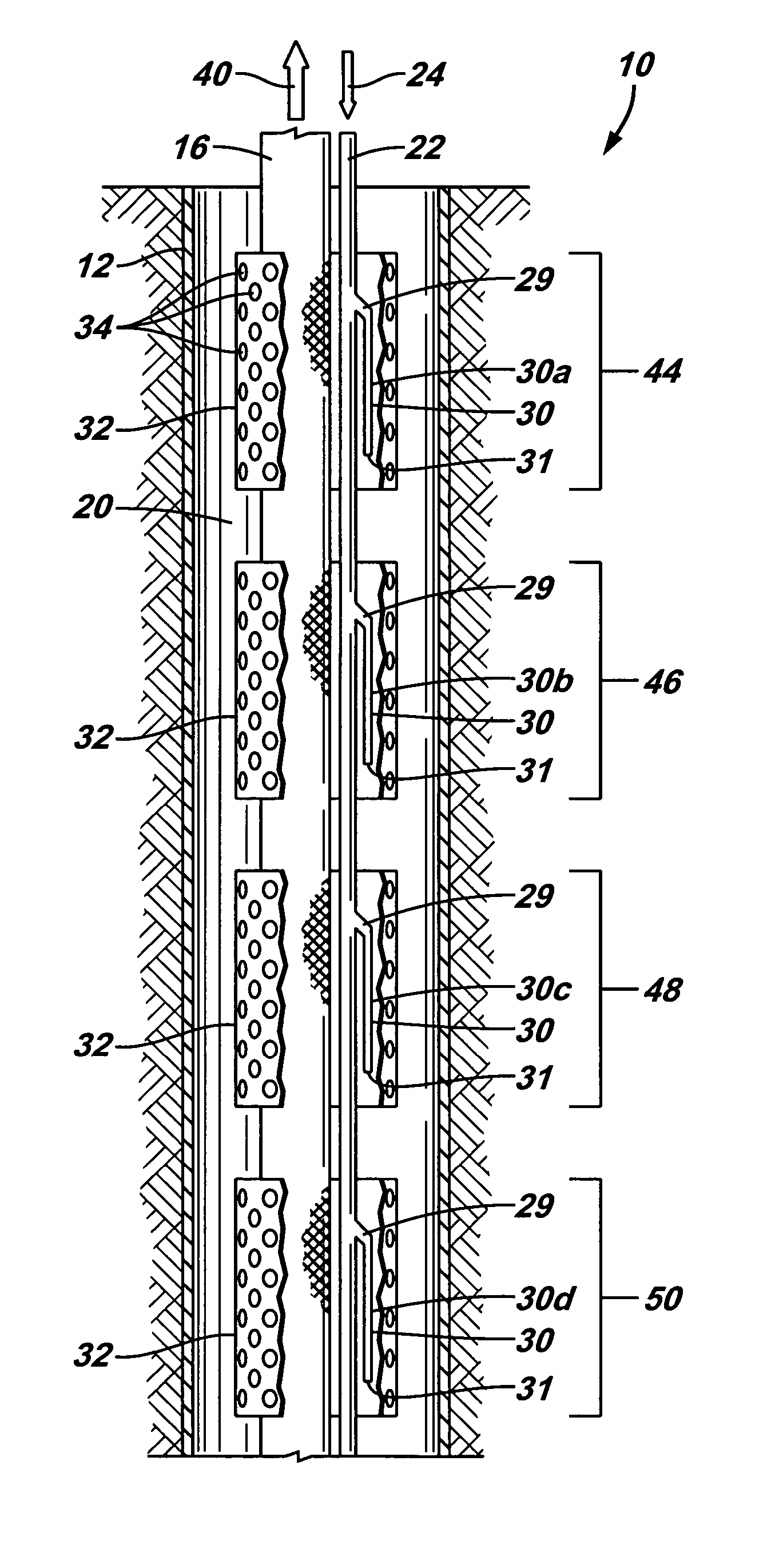

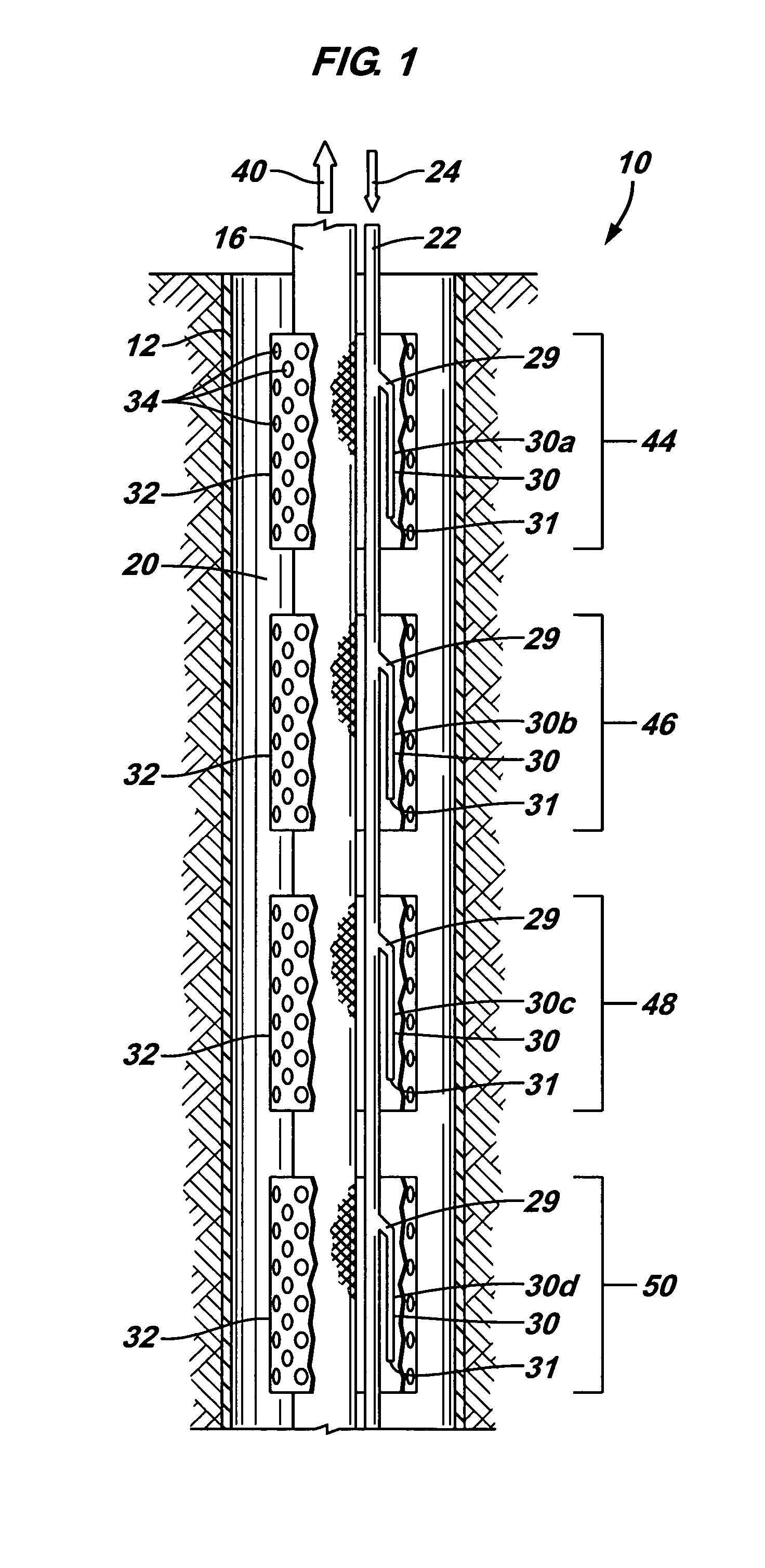

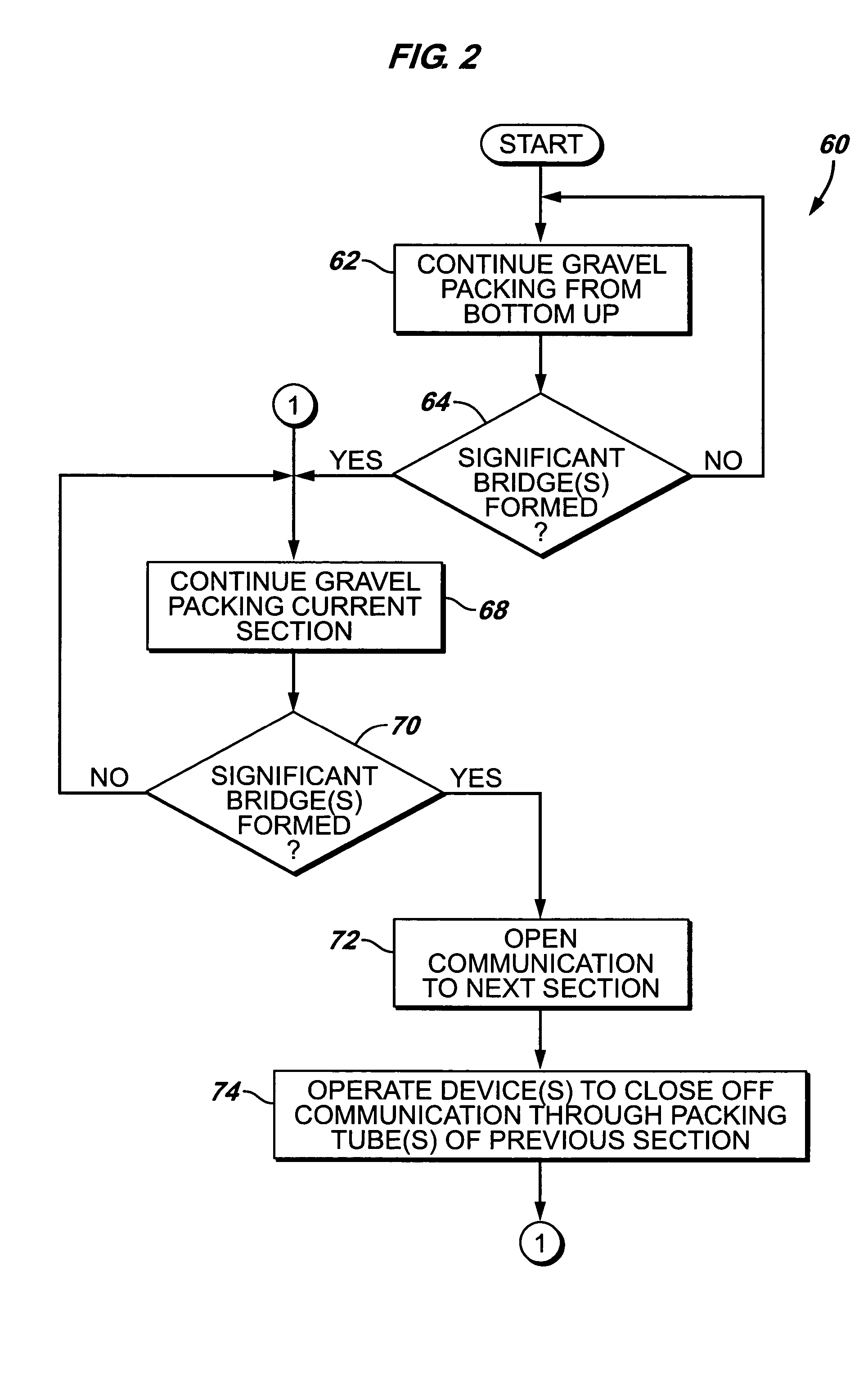

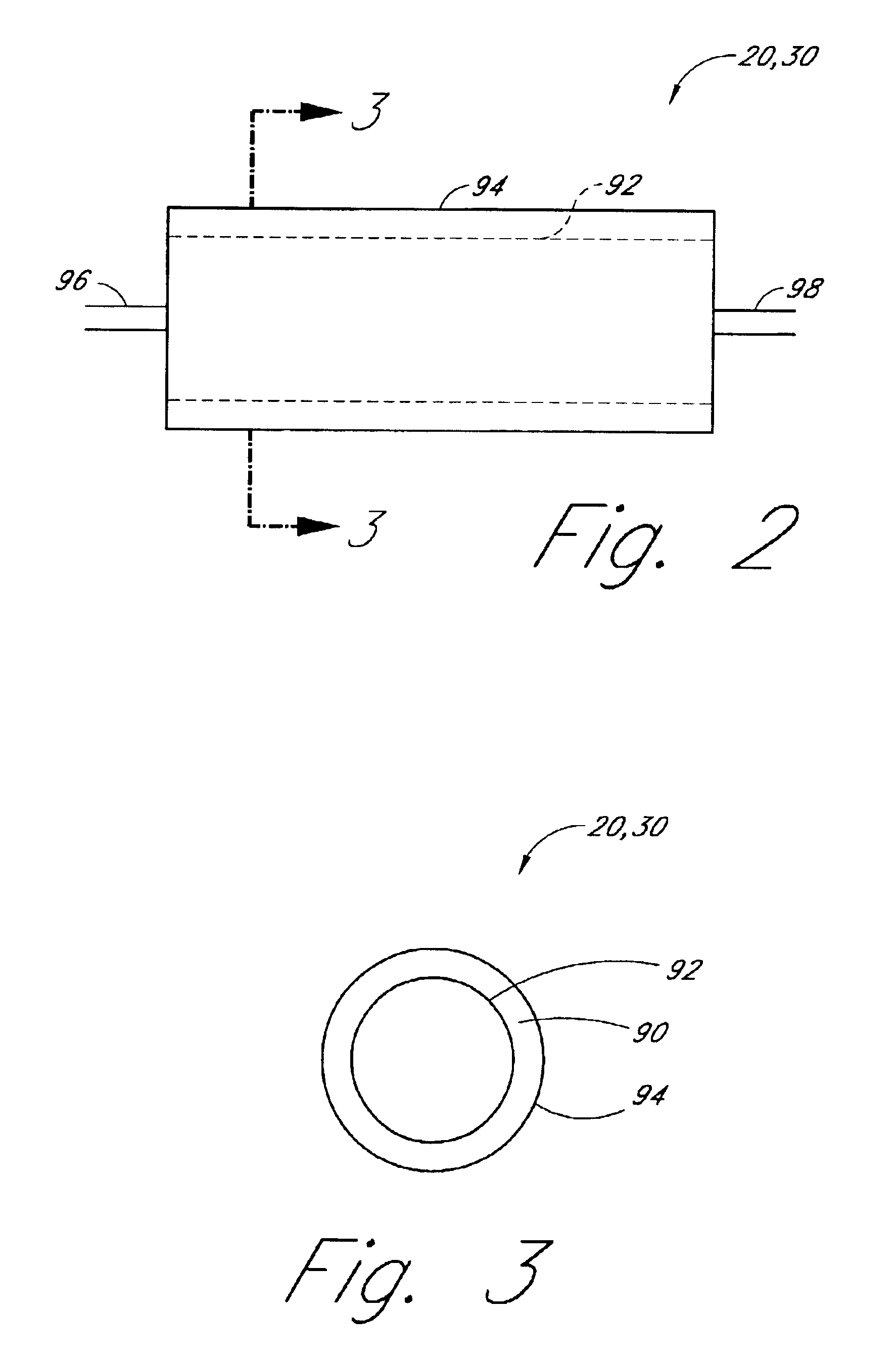

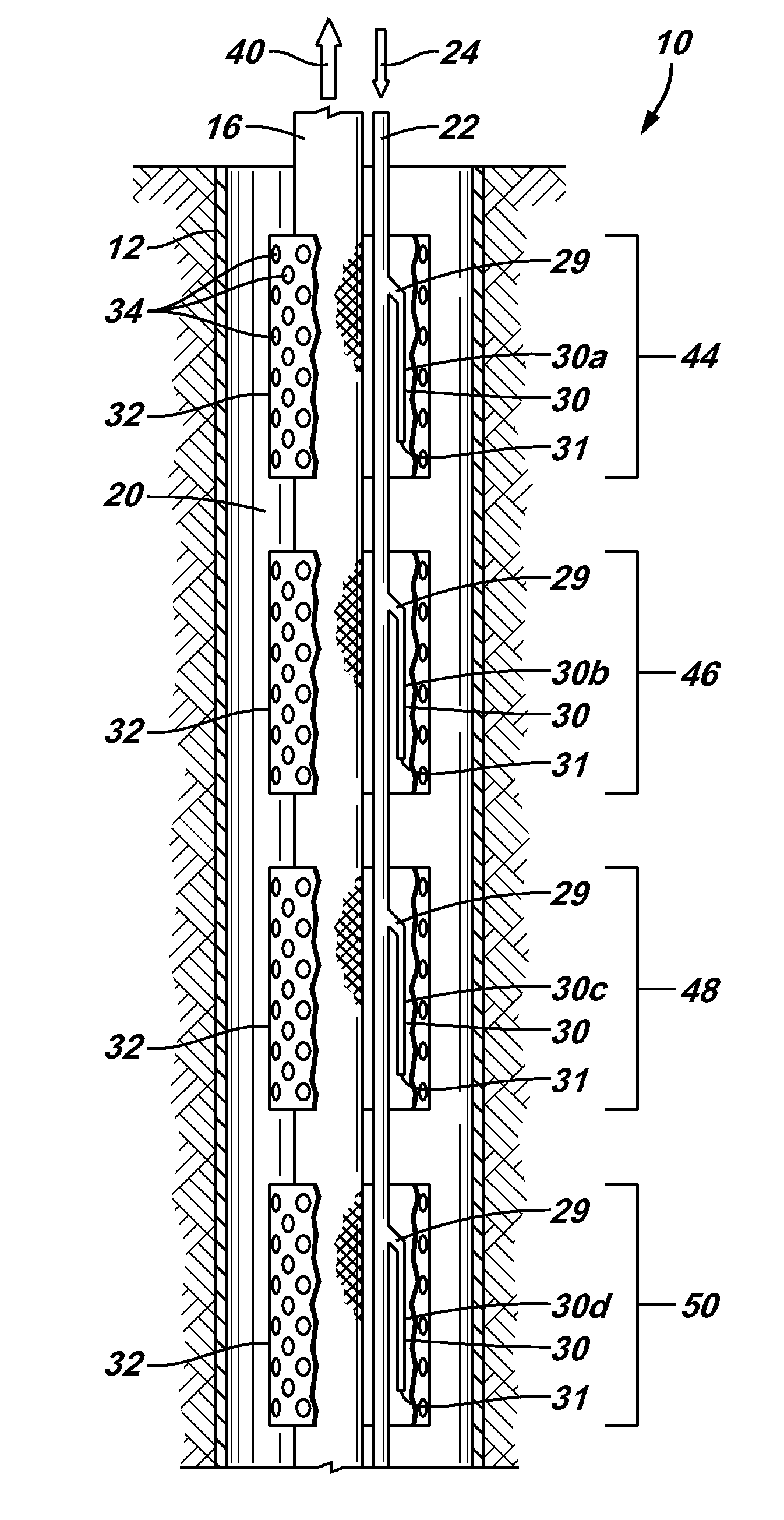

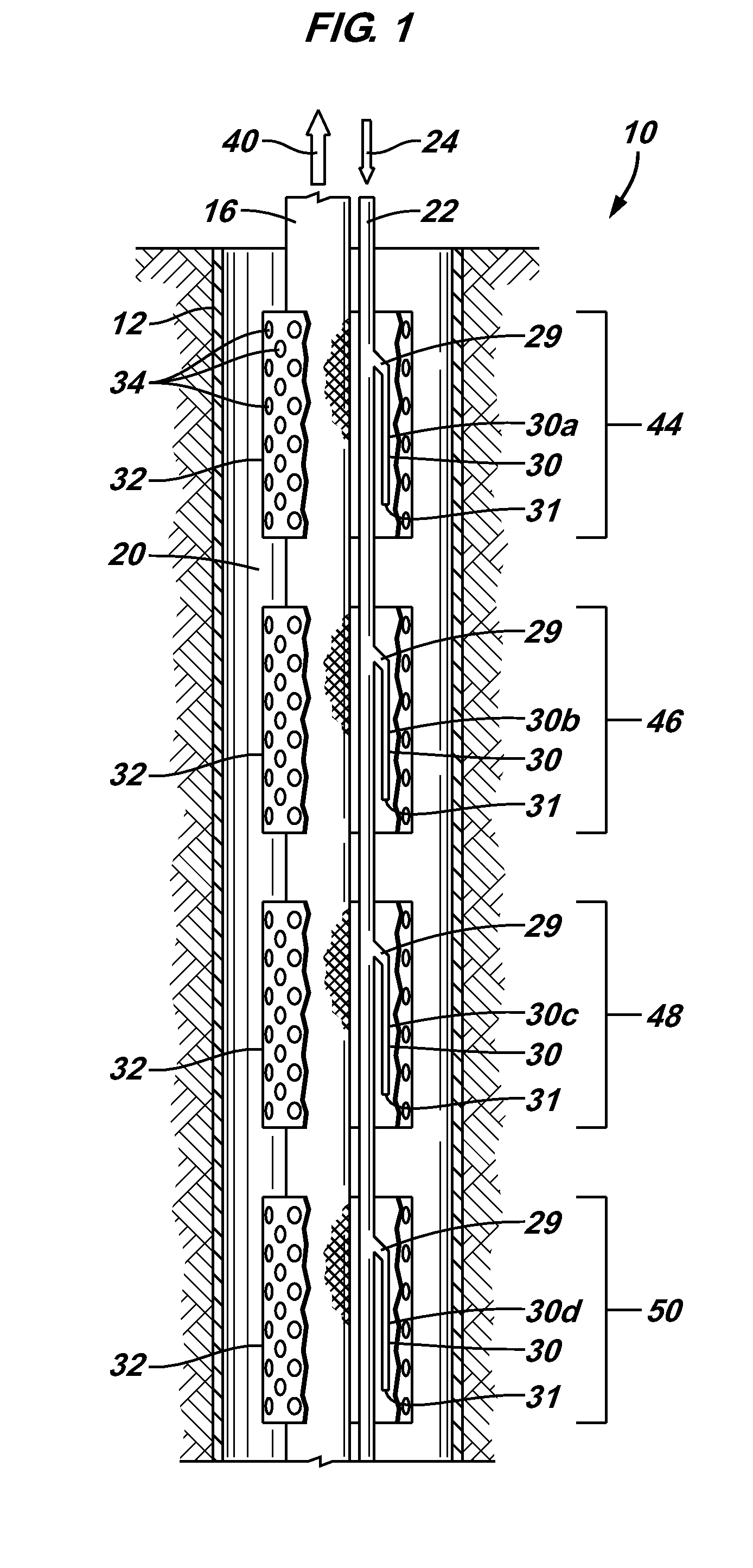

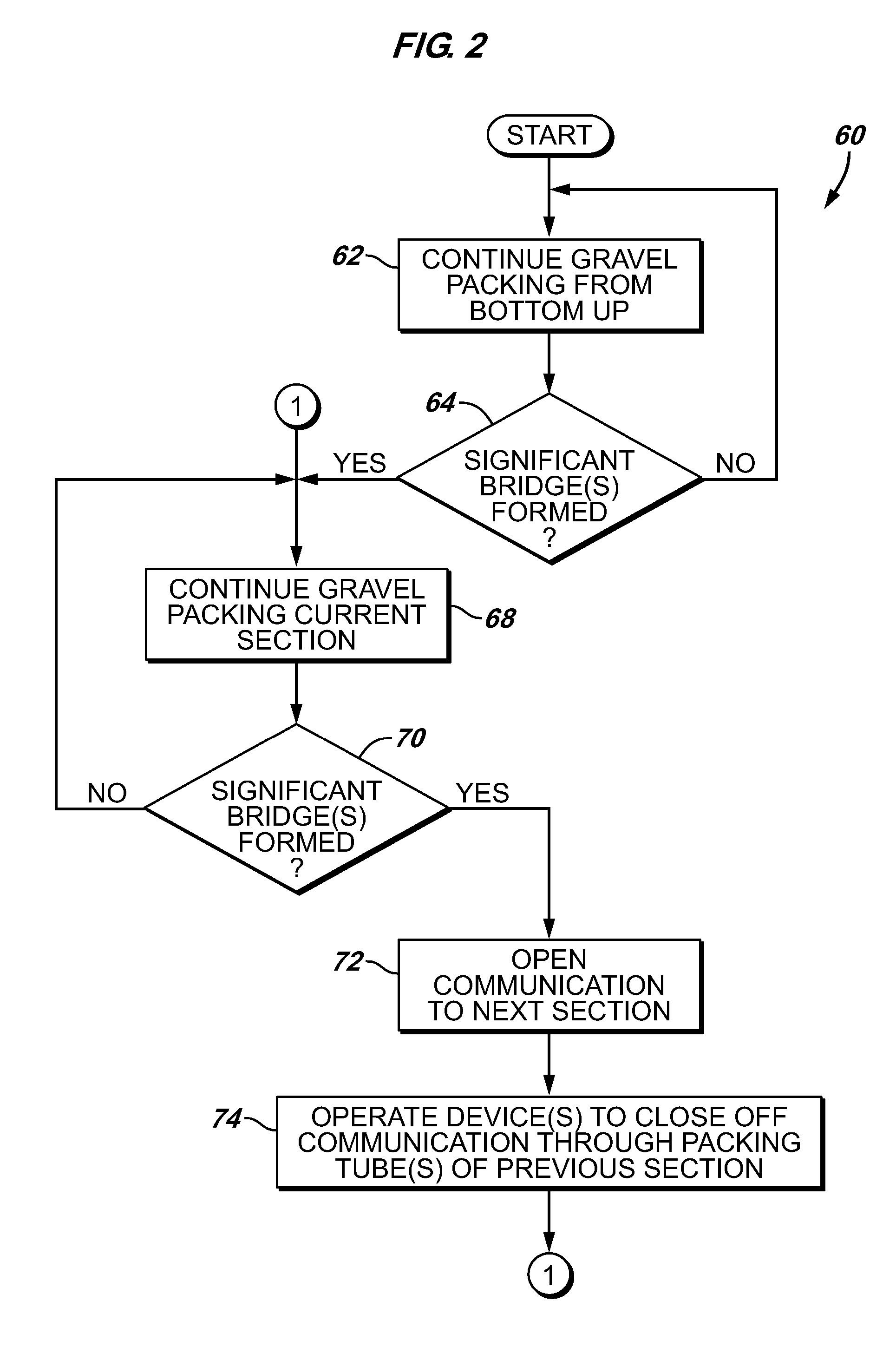

Gravel packing a well

A technique that is usable with a subterranean well includes communicating a slurry through a shunt flow path and operating a control device to isolate slurry from being communicated to an ancillary flow path. The system may include a shunt tube and a diverter. The shunt tube is adapted to communicate a slurry flow within the well to form a gravel pack. The diverter is located in a passageway of the shunt tube to divert at least part of the flow. A slurry may be communicated through the shunt flow path, and a control device may be operated to isolate the slurry from being communicated to the ancillary flow path.

Owner:SCHLUMBERGER TECH CORP

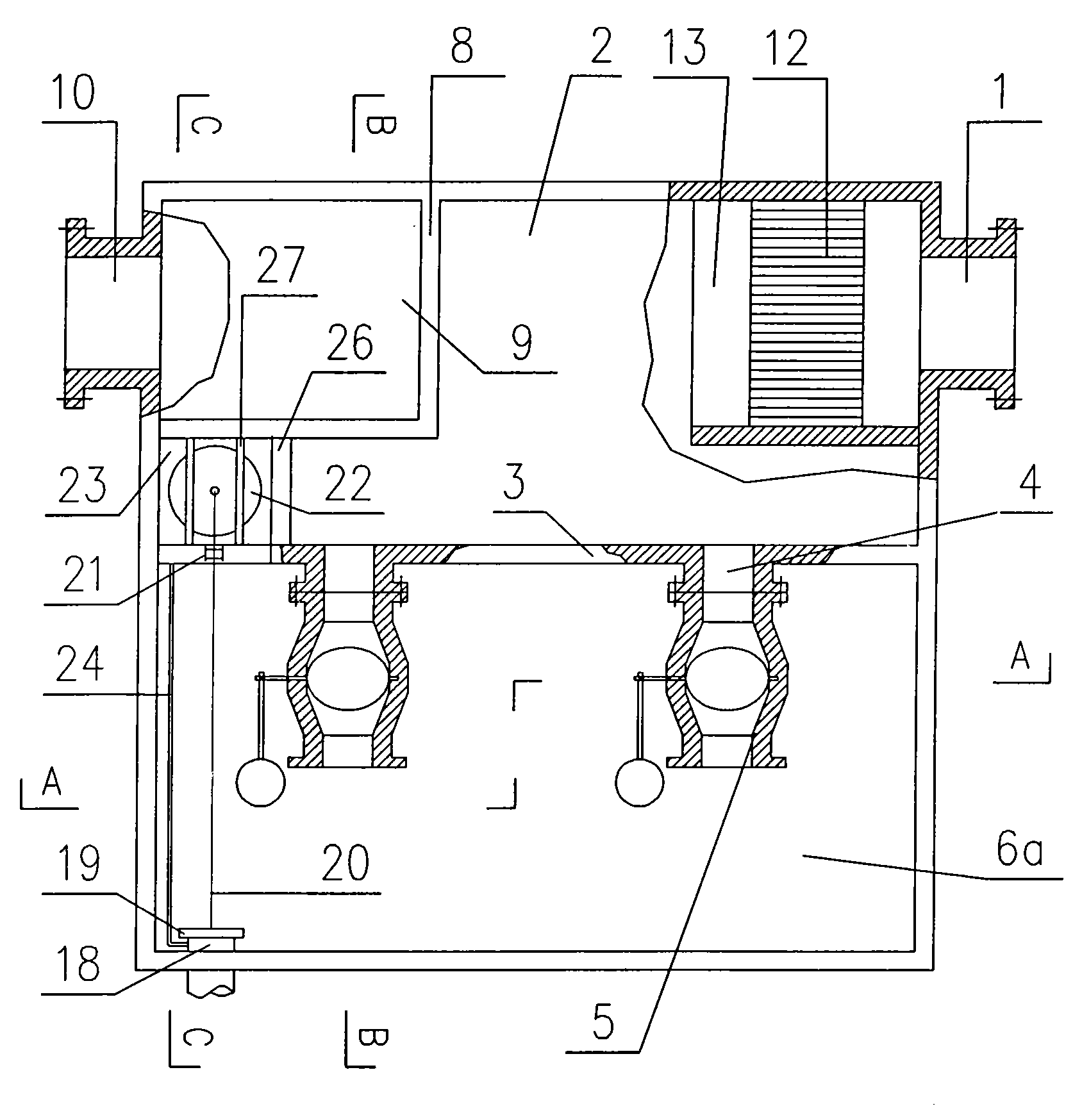

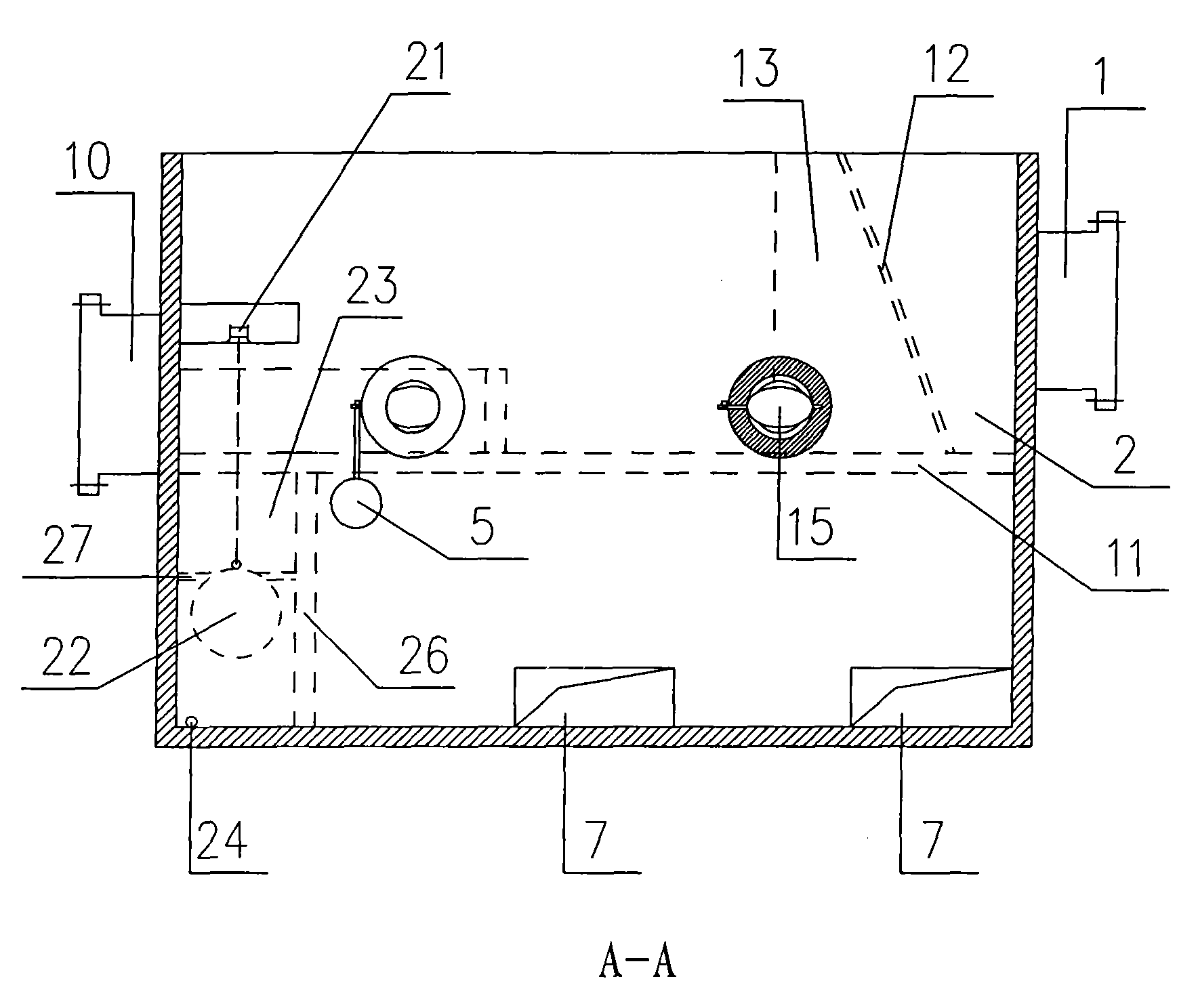

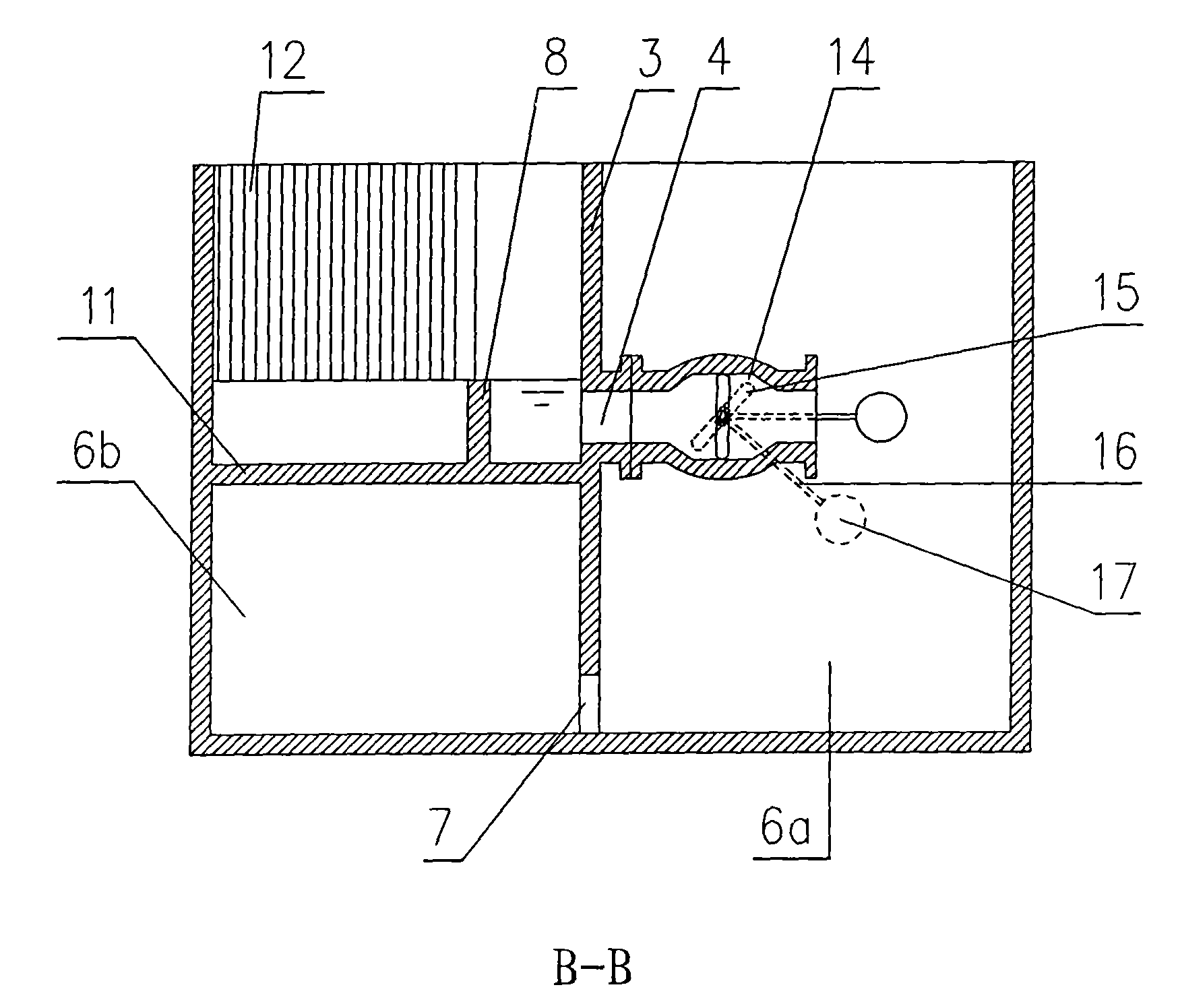

Initial stage rain water flow discharging device

InactiveCN101660319AAvoid separationEfficient separationSewerage structuresGeneral water supply conservationWater flowEnvironmental engineering

The invention discloses an initial stage rain water flow discharging device which is mainly composed of an impoundment chamber, a flow discharging partition, a flow discharging water communicating pipe, a water flow control mechanism, a flow discharging front chamber, a flow discharging rear chamber, a shunting downflow weir, a shunting flow conduction chamber, a delayed automatic draining mechanism and the like. Compared with the prior art, the device of the invention can effectively separate severely polluted initial stage rain water from later stage clean rain water, has the advantages of optimized structure, compact structure, high space utilization ration, space occupation saving, no energy consumption, no need of staff operation, high automation degree, convenient management and thelike.

Owner:CHONGQING UNIV

Method and apparatus for chemical synthesis

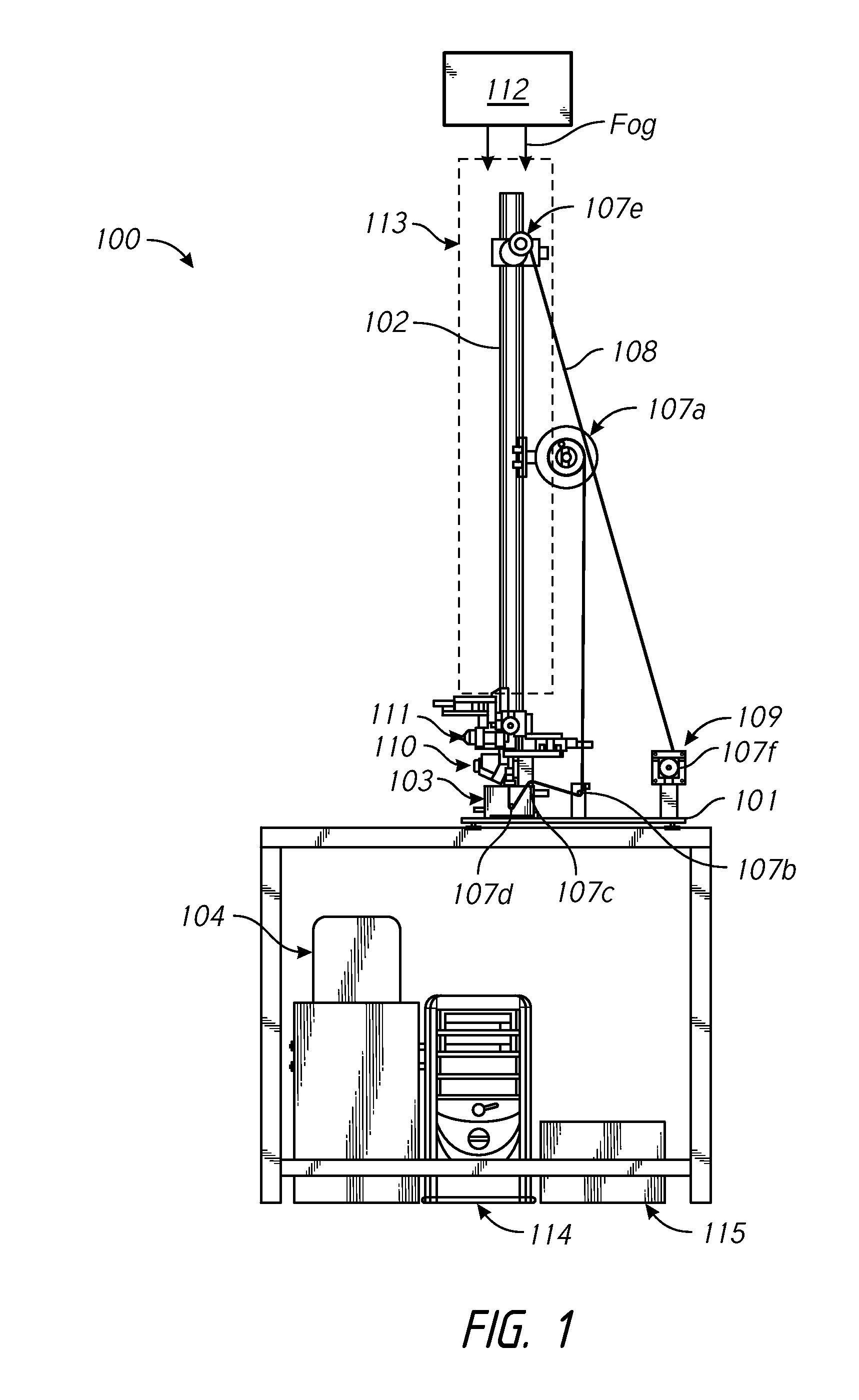

InactiveUS6858196B2Easy to operate continuouslyHighly orderedNitrogen compoundsMetal silicidesCondensation trapChemical synthesis

An apparatus is provided for synthesis and collection of higher order chemical compounds from lower order precursors. The apparatus includes a first silent electric discharge reactor configured to synthesize an intermediate product (e.g., disilane) from a precursor chemical (e.g., monosilane). A second silent electric discharge reactor is connected downstream of the first reactor. This second reactor is configured to convert the intermediate product into the higher order chemical compound (e.g., trisilane). Multiple condensation traps are also connected to receive effluent from the second reactor, which will generally include the compound of interest as well as unreacted precursor and intermediate product. In the illustrated embodiment, a parallel second condensation traps is also included to shunt flow and continue collection while the chemical of interest is removed for purification. Moreover, parallel second condensation traps for the intermediate product and unreacted (or recombined) precursor allow continued collection while the contents of the first traps are recycled in the reactor(s).

Owner:ASM IP HLDG BV

Gravel Packing A Well

Owner:SCHLUMBERGER TECH CORP

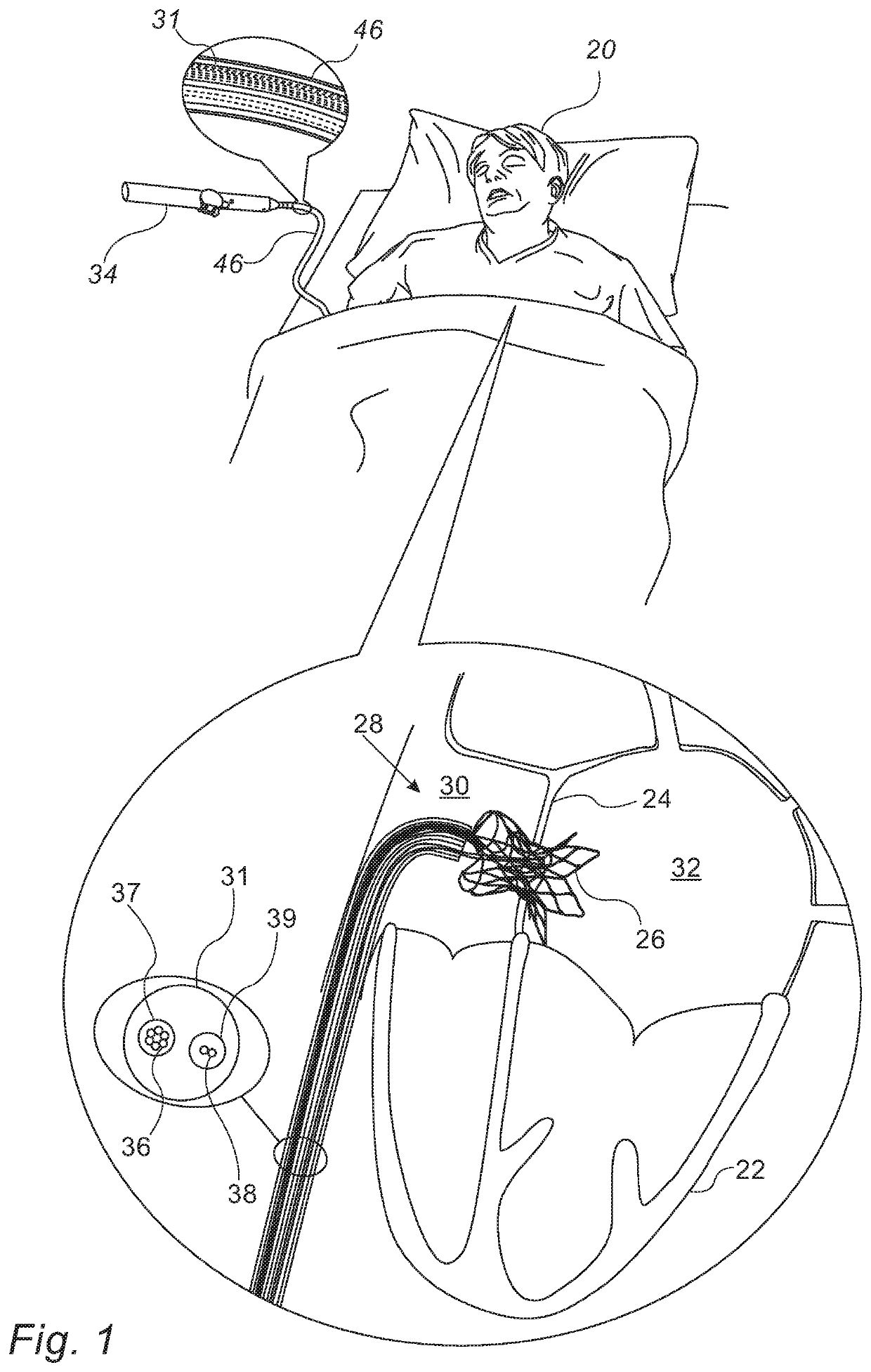

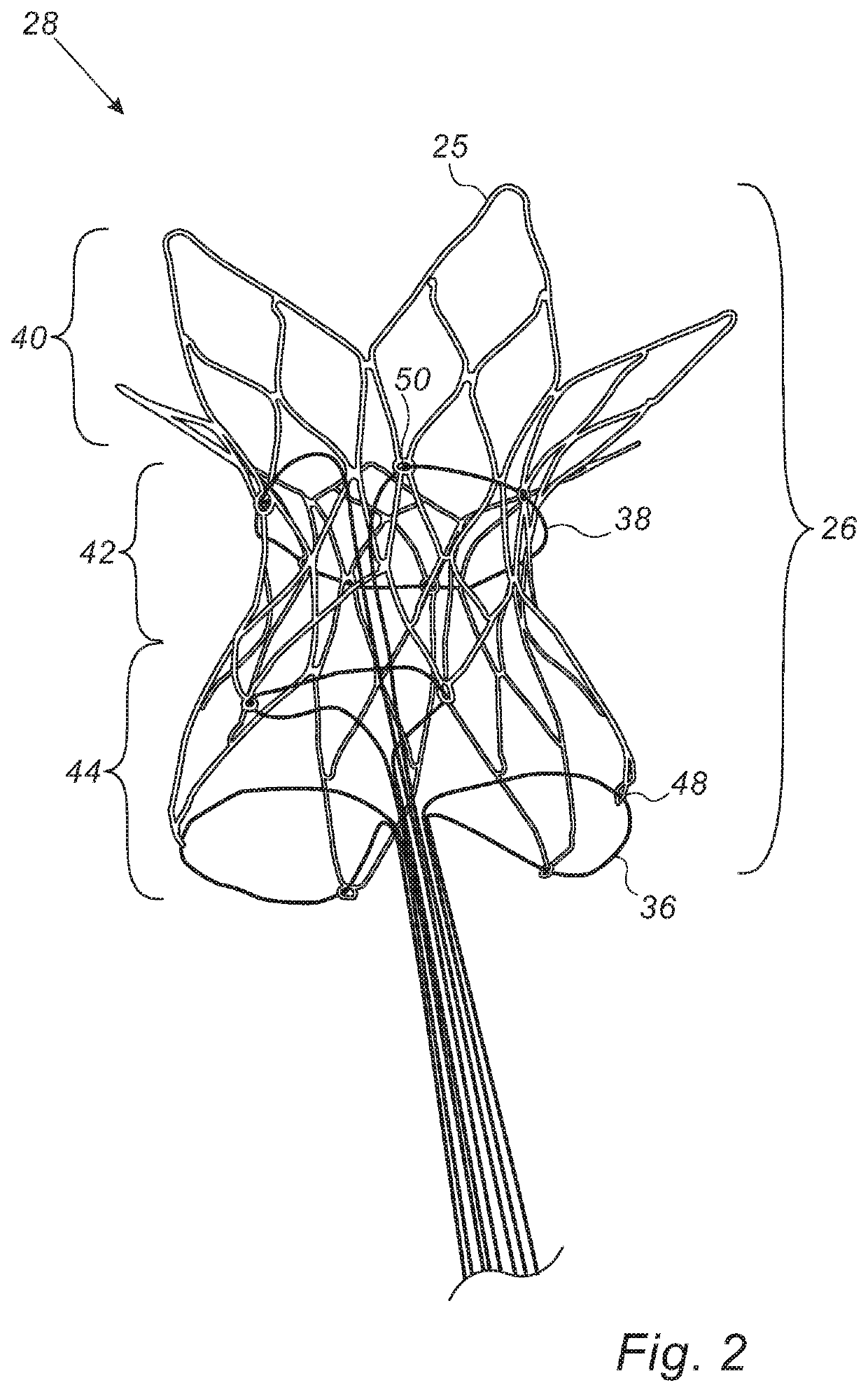

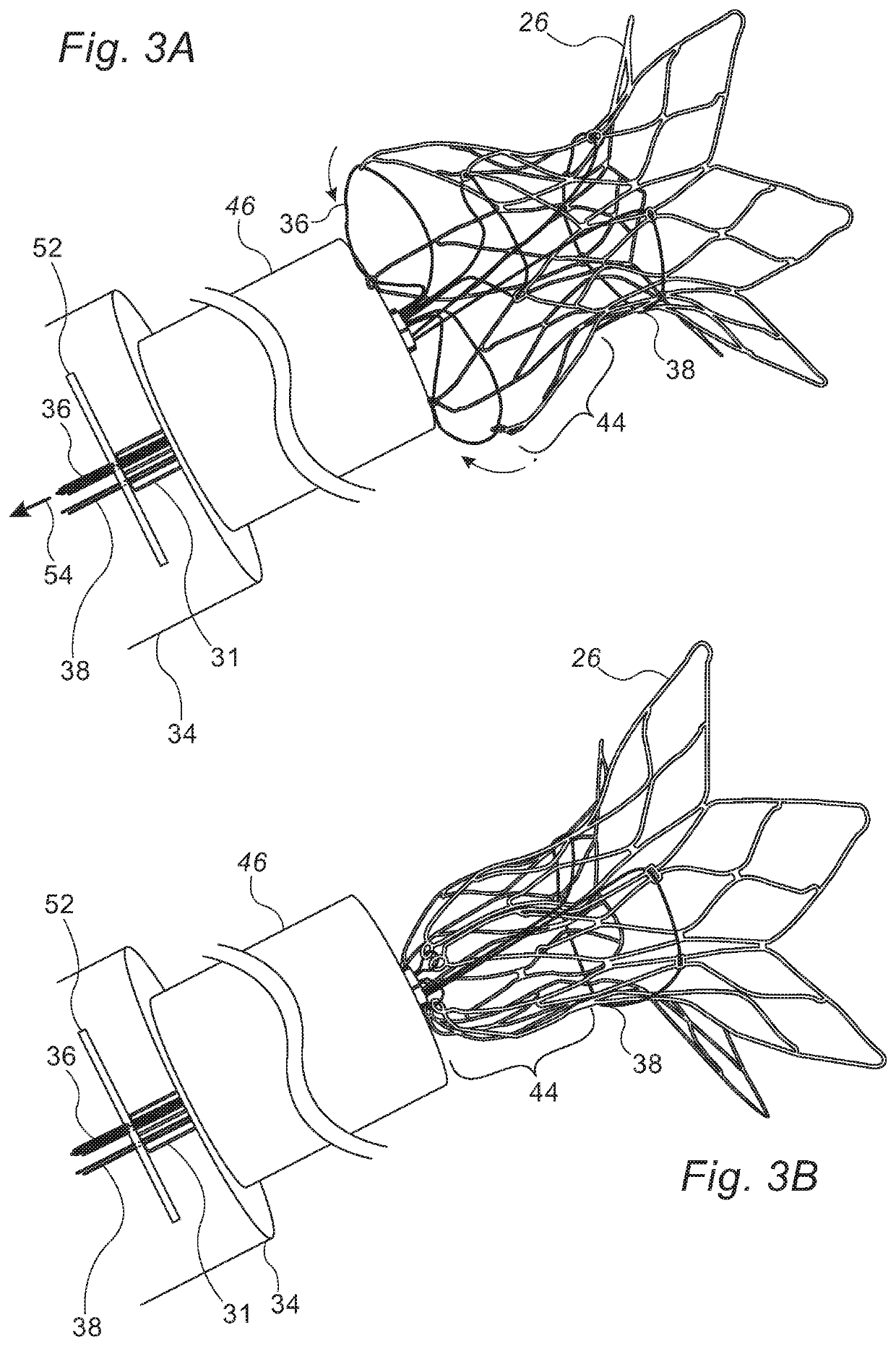

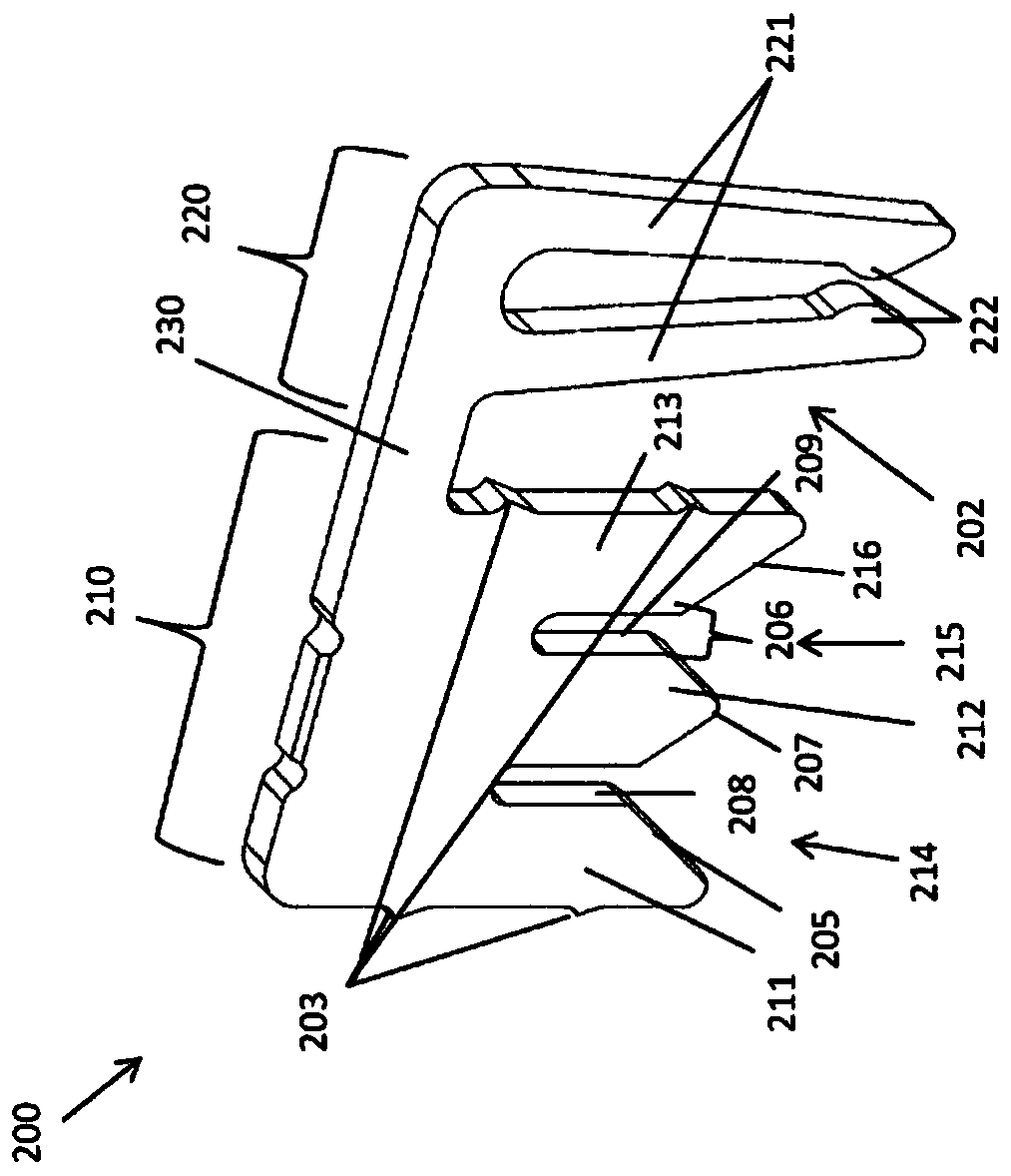

Temporary interatrial shunts

Described embodiments include apparatus (28) that includes a shunt (26). The shunt includes a flared distal portion (40), a flared proximal portion (44), and an intermediate portion (42), disposed between the distal portion and the proximal portion. The apparatus further includes a constricting flexible longitudinal element (38) passing circumferentially along the intermediate portion of the shunt, configured to constrict the intermediate portion of the shunt, and one or more proximal-portion-collapsing flexible longitudinal elements (36) configured to collapse the proximal portion of the shunt. Other embodiments are also described.

Owner:WAVE LTD V +1

Waveform sensing and regulating fluid flow valve

InactiveUS20060241545A1Rapid responseEasy to controlPiezoelectric/electrostriction/magnetostriction machinesServomotor componentsEngineeringVALVE PORT

Microfluidic shunt valves are disclosed having a deflectable element capable of being held in a closed position to occlude the passage of fluid between an inlet and outlet and, when not held in the closed position, the deflectable element is adapted to oscillate in response to fluid pressure pulses and thereby facilitate fluid passage through the valve. Controls for activating the deflectable element to permit fluid passage are also included.

Owner:CHILDRENS MEDICAL CENT CORP +1

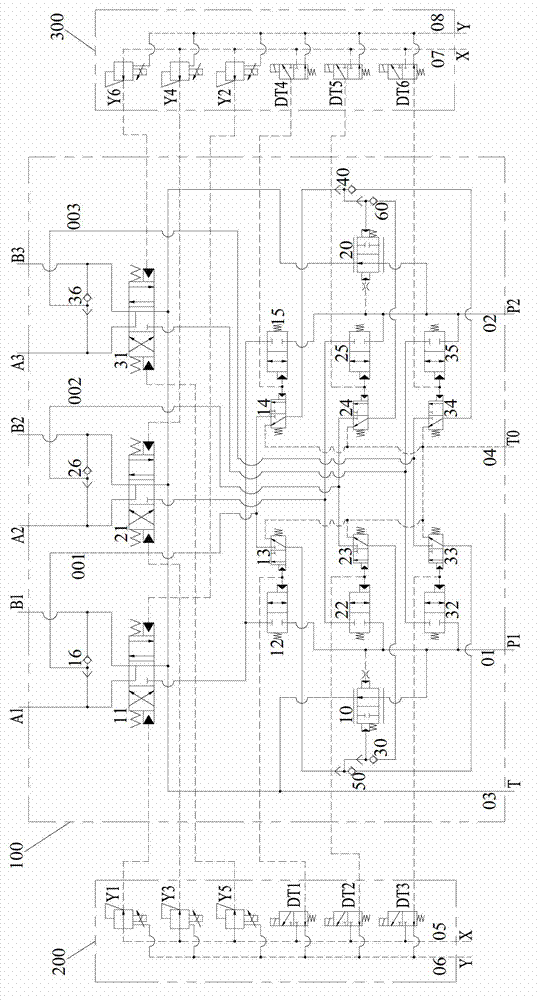

Multipath valve and engineering machinery

ActiveCN102889259AAvoid the effects of load changesReduce energy lossServomotor componentsDifferential pressureEngineering

The invention relates to the technical field of engineering machinery, and discloses a multipath valve and engineering machinery. The multipath valve comprises a main valve group, wherein the main valve group comprises a first main reversing valve, a second main reversing valve, a first differential pressure valve, a second differential pressure valve, a first switching valve, a second switching valve, a third switching valve, a first pressure selection valve, a second pressure selection valve, a third pressure selection valve, a first oil inlet path, a second oil inlet path, an oil returning path, a first feedback oil path and a second feedback oil path. By the multipath valve, shunting flow and convergence flow of double pumps can be controlled, so that composite action and single action of at least two working execution elements can be realized. Compared with the prior art, the multipath valve has the advantages that energy loss is reduced; furthermore, during shunting and convergence, before and after differential pressure of each main reversing valve is kept constant; and influence of load change on flow control of each main reversing valve is avoided.

Owner:SANY HEAVY IND CO LTD (CN)

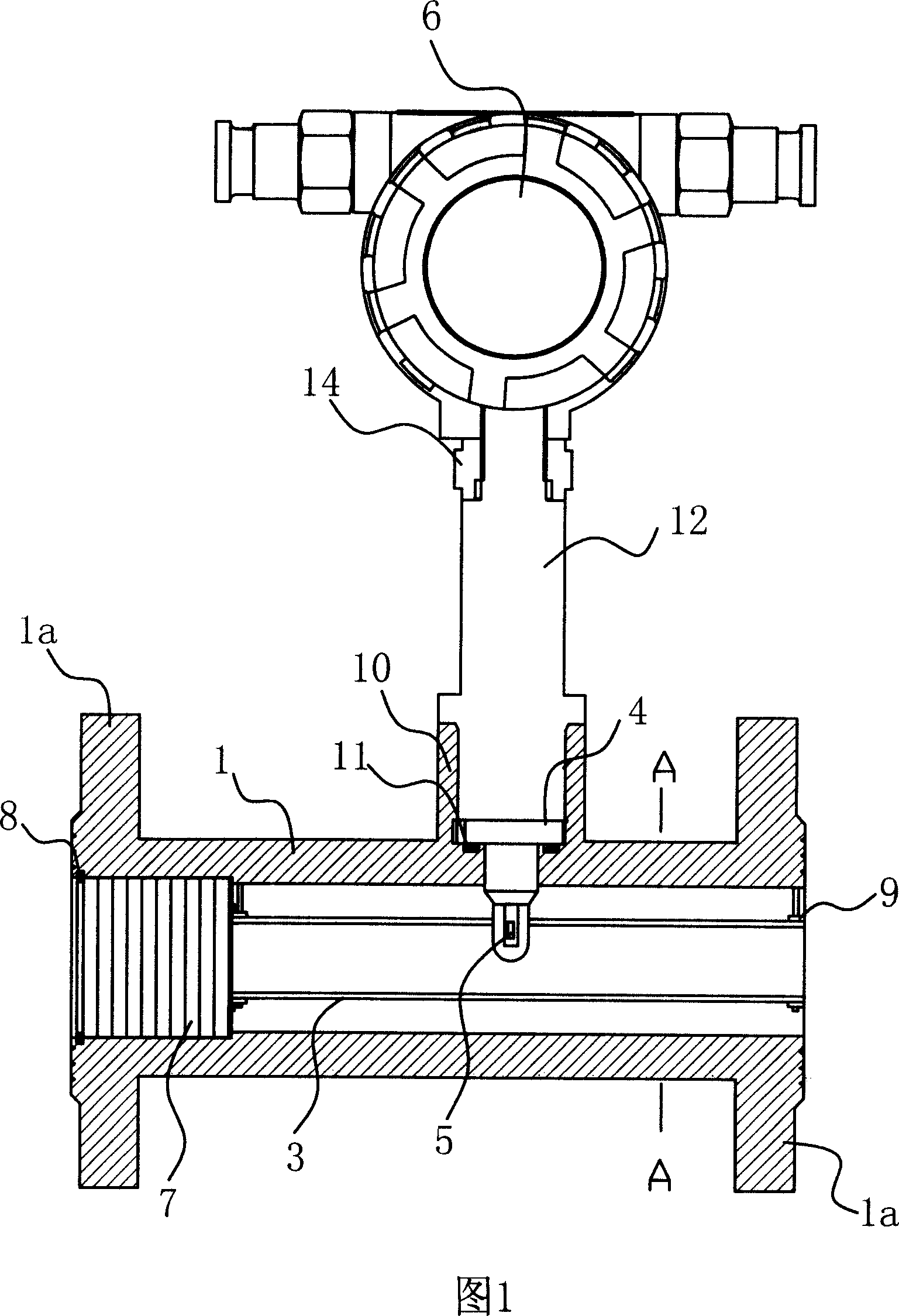

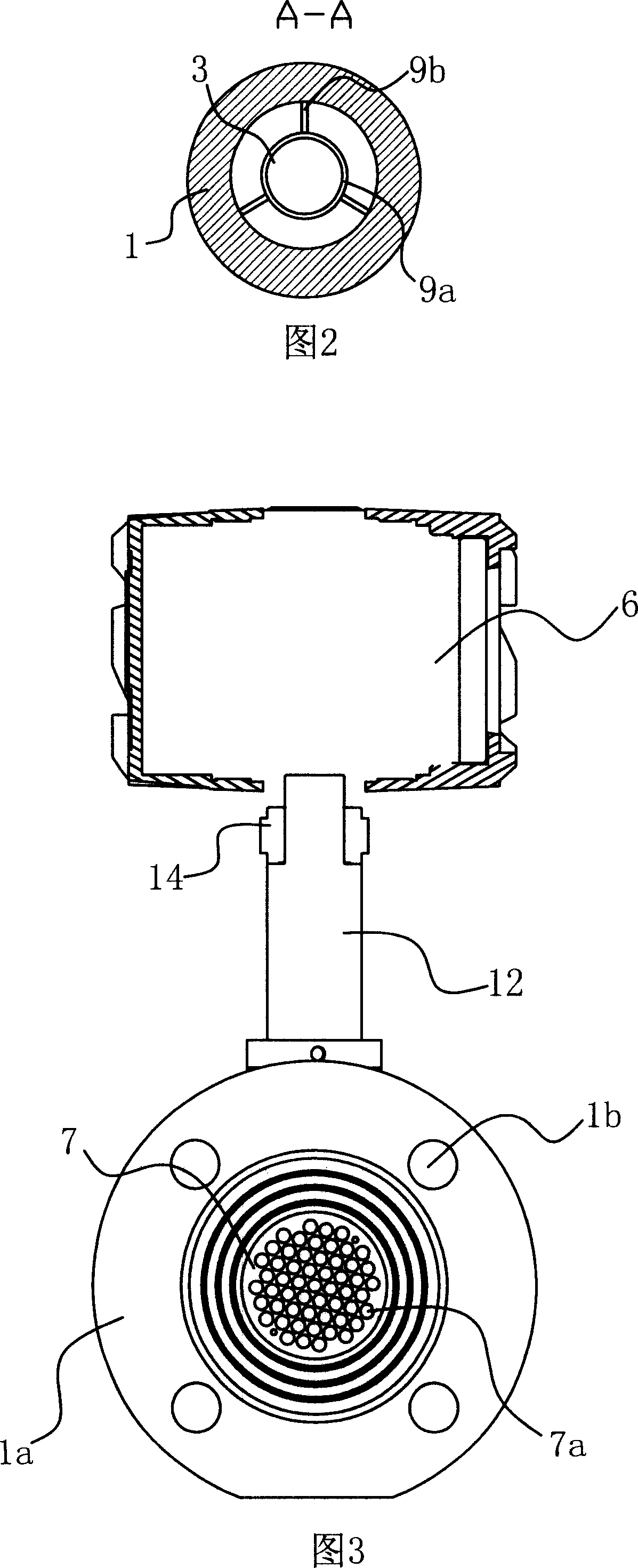

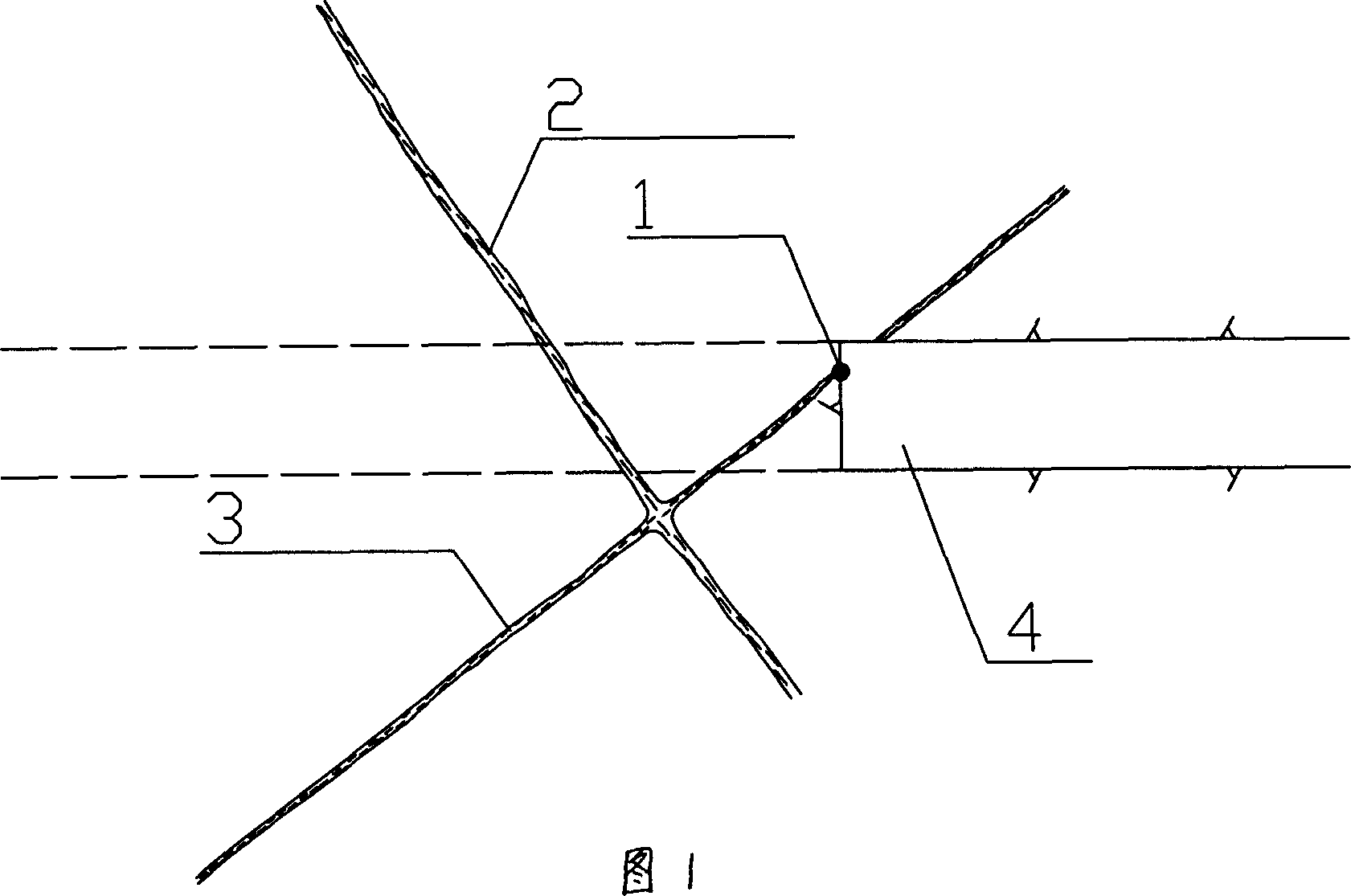

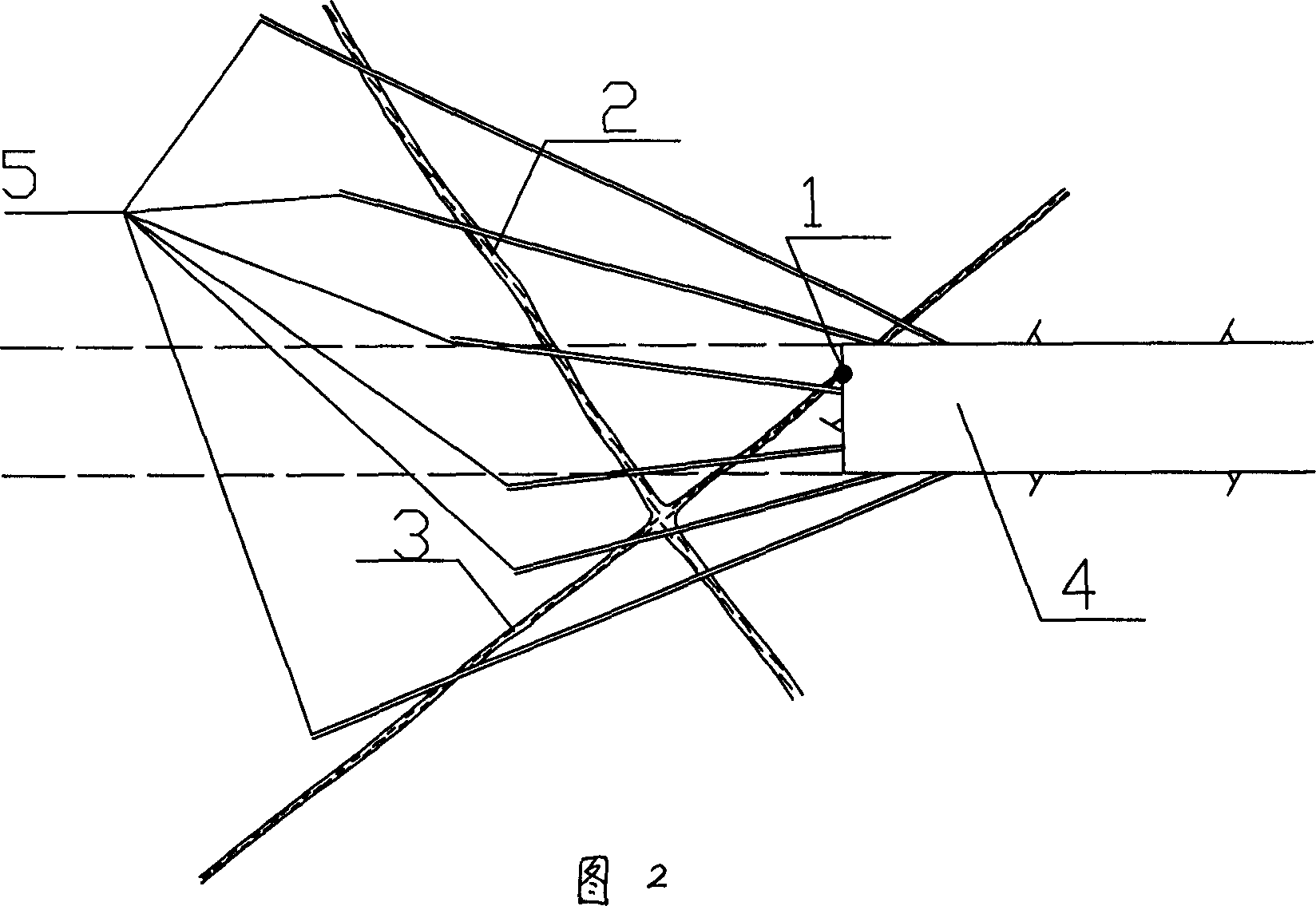

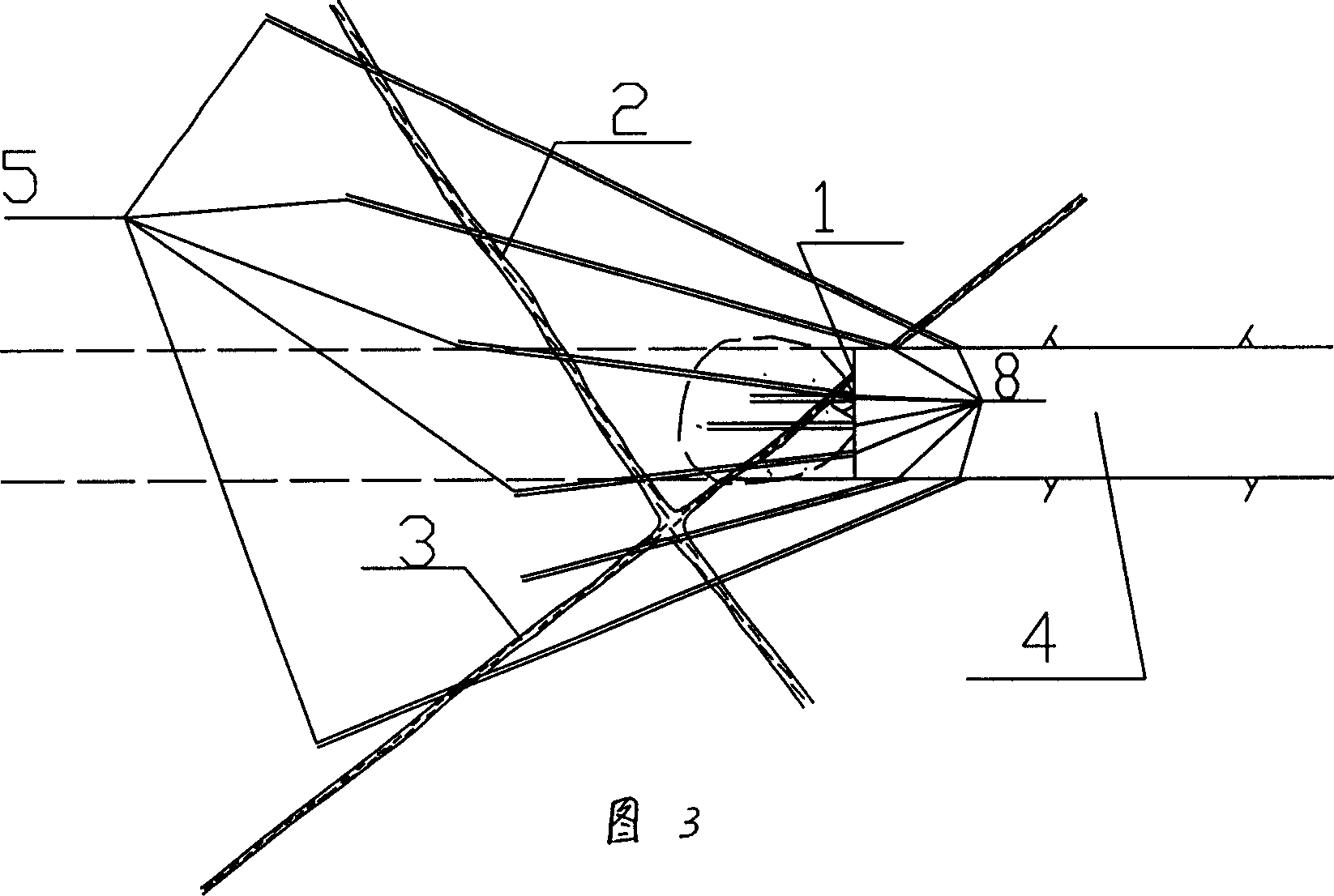

Small section branch-flow measuring method for large-diameter gas flow and apparatus thereof

InactiveCN1936506AIncrease flexibilityHigh precisionVolume/mass flow measurementVolume meteringShunt DeviceEngineering

This invention relates to a test method for small sections of large caliber gas flows and an informed structure of the device including the following measurement steps: a, shunting in proportion, b, testing the shunt flow, c, converting the flow, in which, a shunt pipe is set in the channel of a ventilation pipeline of small aperture and parallel to the pipeline, one end of a sensor frame passes through the wall of the shunt tube and a sensor is fixed at the end connected with a measurement meter and a shunt device shunting in proportion is set at an end of the shunt tube. Advantage: taking part of sections with stable fluid in a large aperture pipeline as the sample for test and the test is accurate.

Owner:MEMSIC SEMICON WUXI

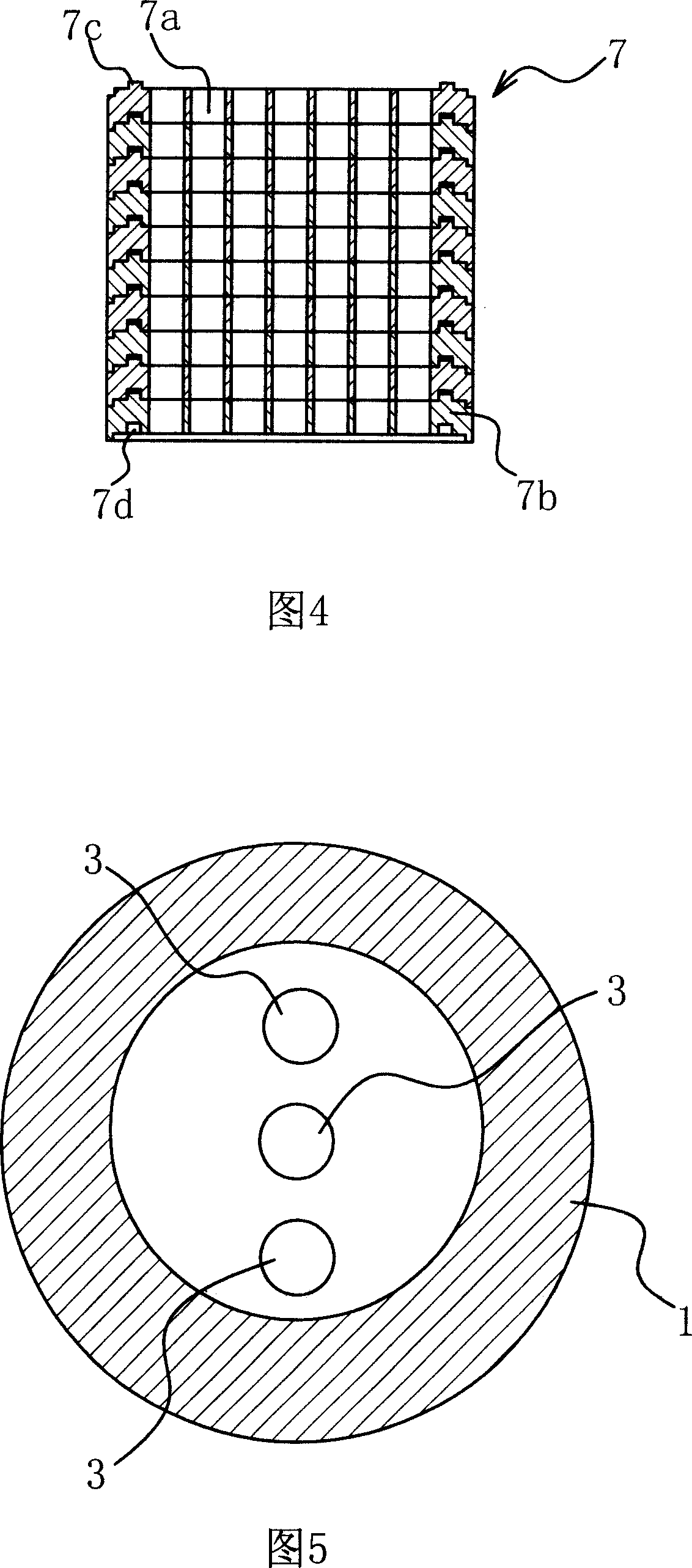

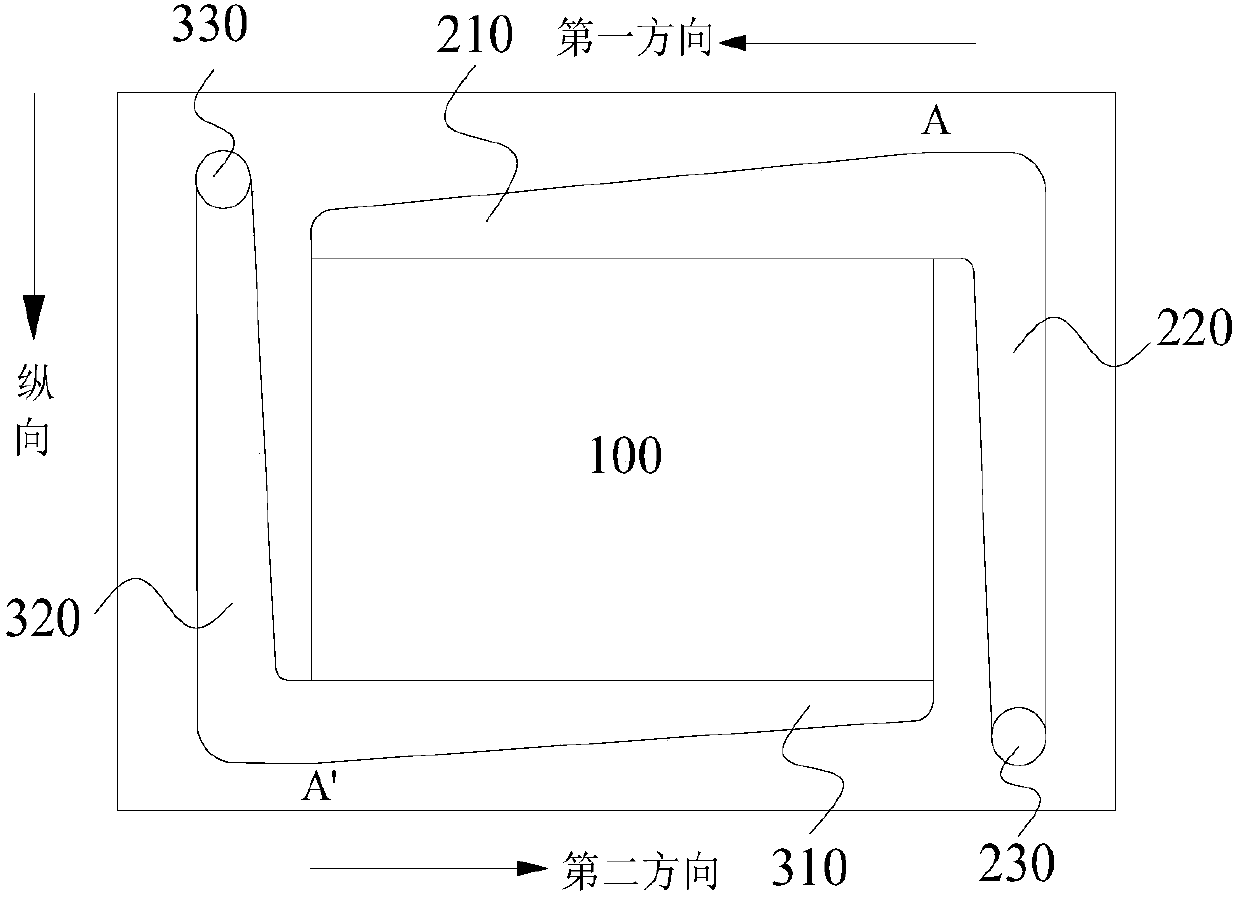

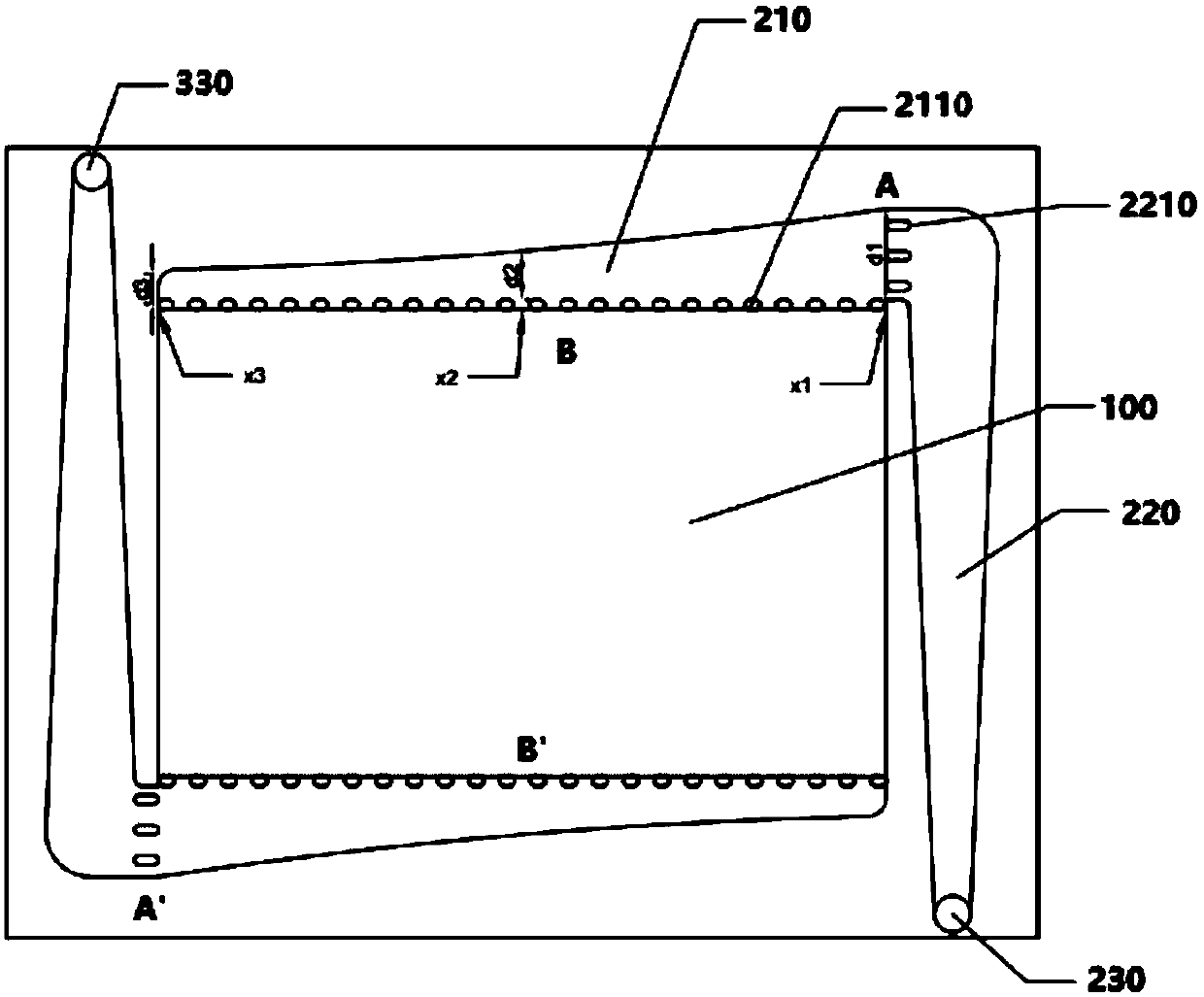

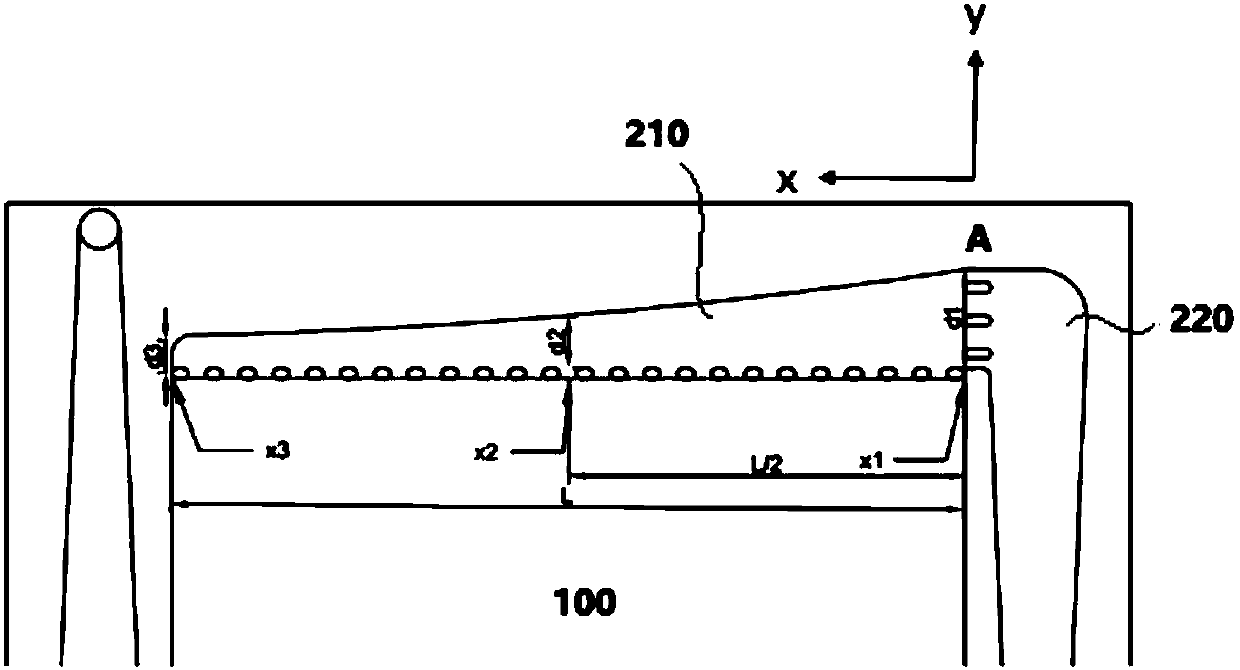

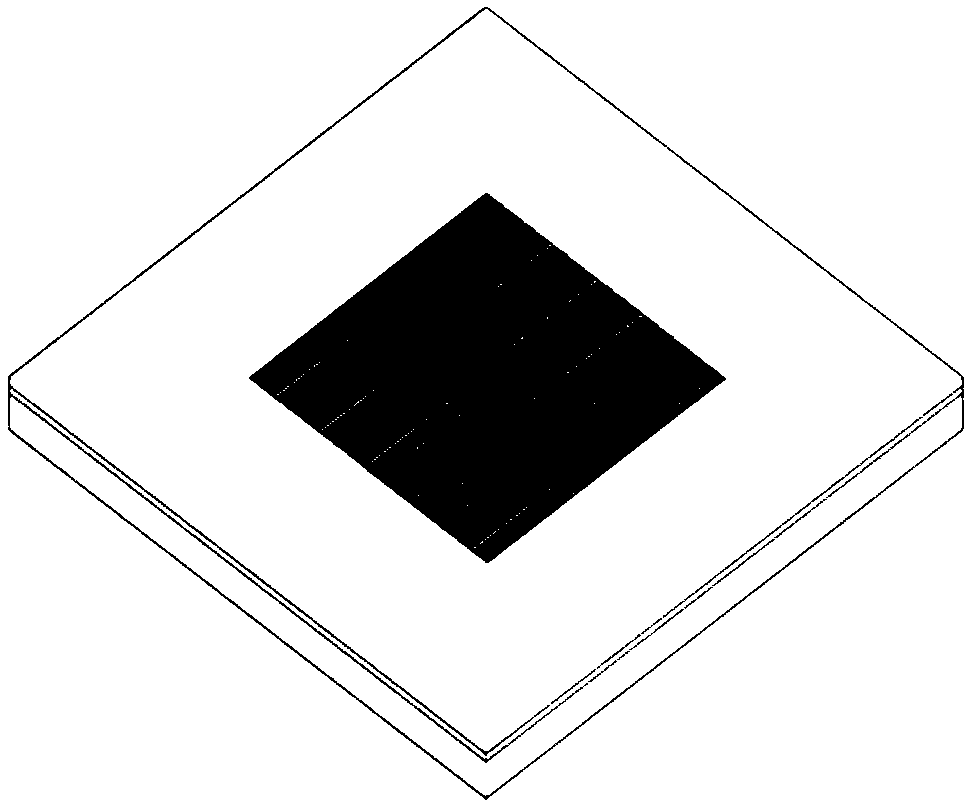

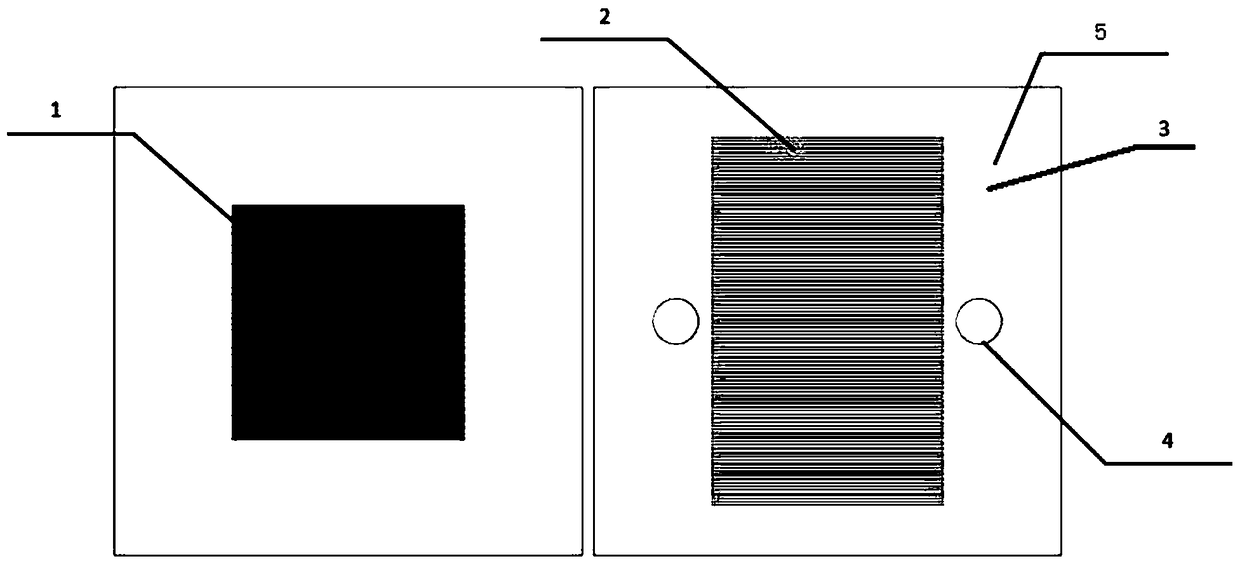

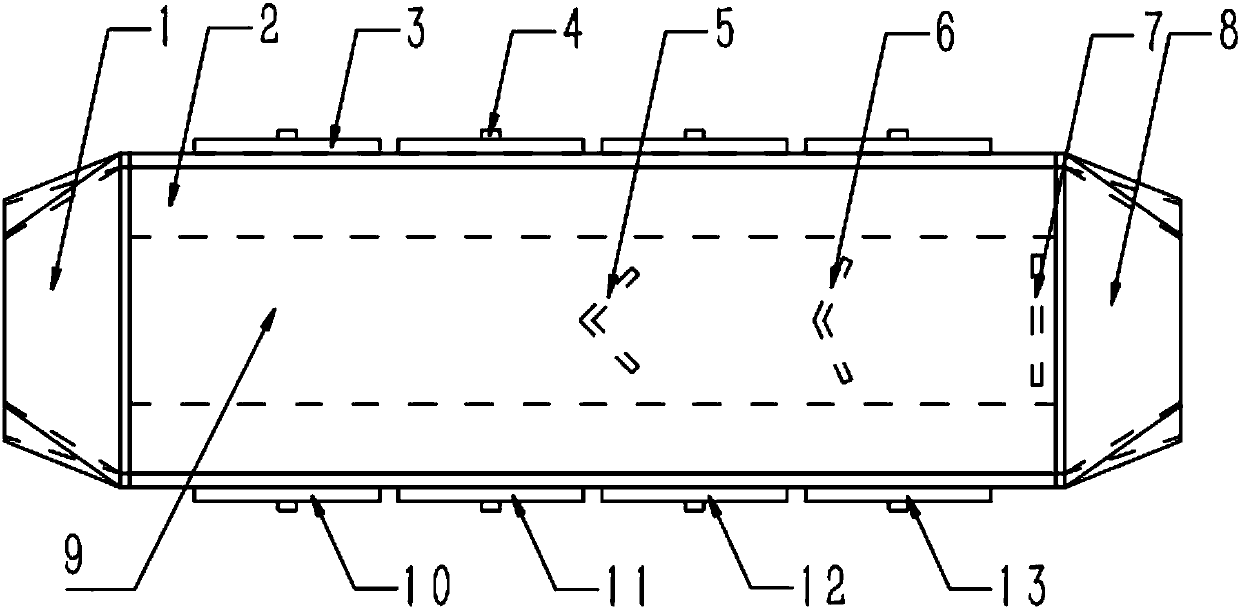

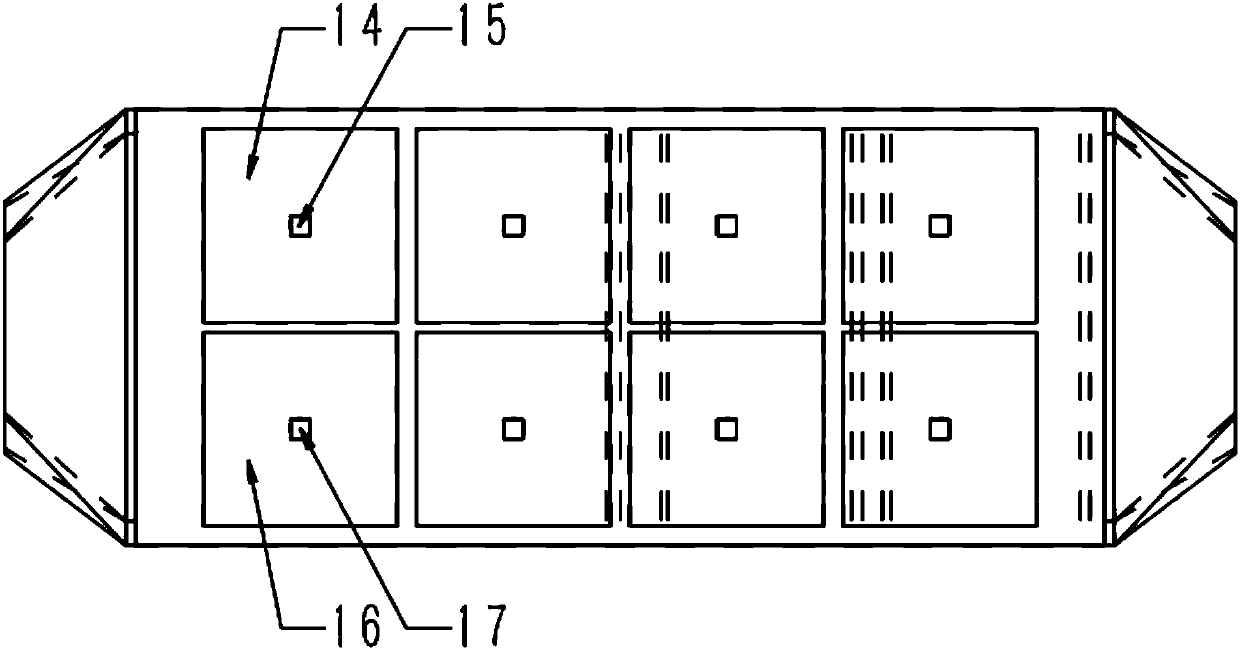

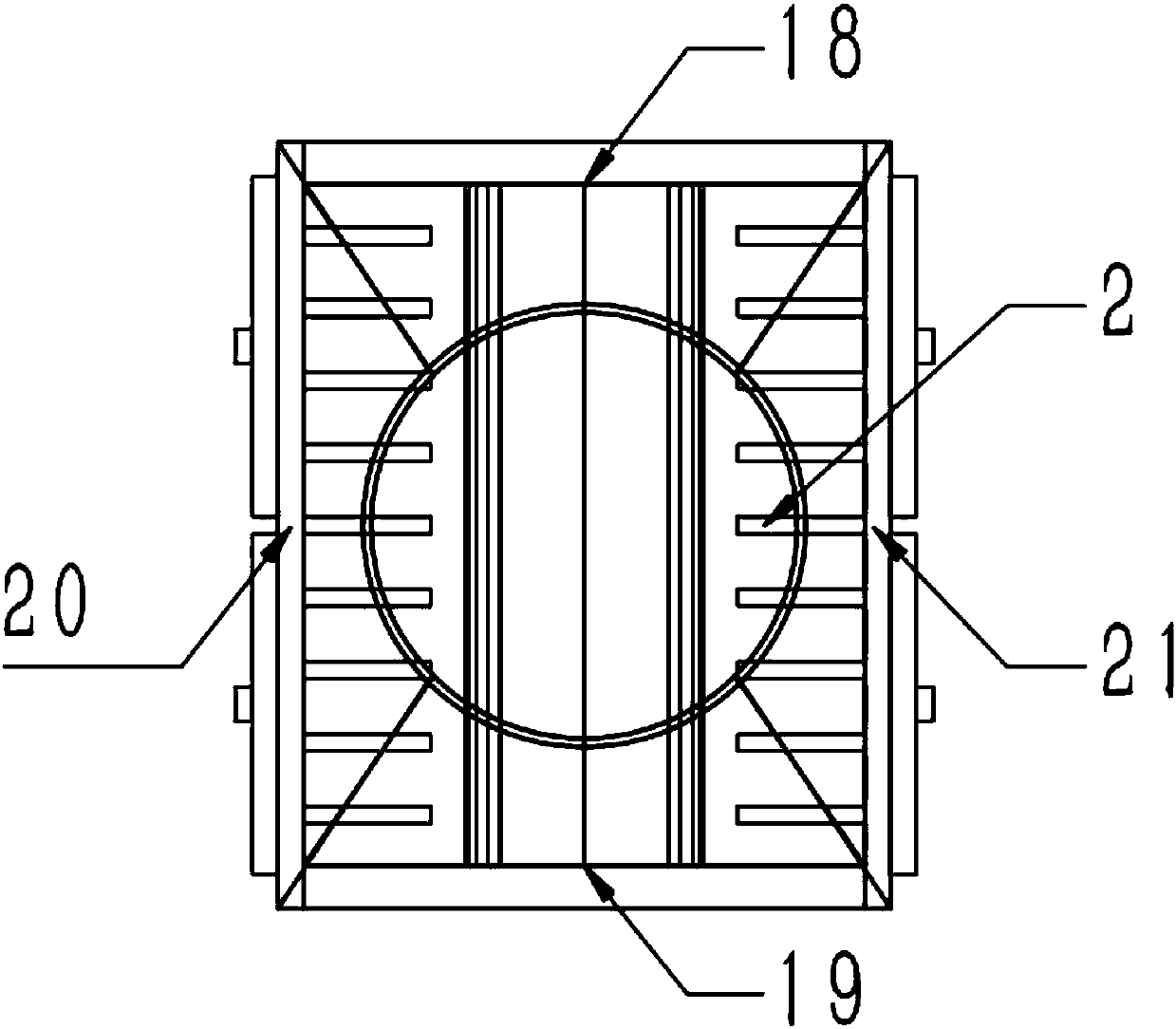

Liquid flow frame for liquid flow battery

The invention provides a liquid flow frame for a liquid flow battery. The liquid flow frame includes a first shunt flow channel, a first transition flow channel, a second shunt flow channel and a second transition flow channel; the first shunt flow channel is arranged at one end of a reaction zone and communicates with the reaction zone, and a longitudinal cross-sectional area of the first shunt flow channel decreases gradually in a first direction; one end of the first transition flow channel communicates with one end, having larger longitudinal cross-sectional area, of the first shunt flow channel, and the other end of the first transition flow channel is provided with a first liquid port; the second shunt flow channel is arranged at the other end of the reaction zone and communicates with the reaction zone, and the longitudinal cross-sectional area of the second shunt flow channel decreases gradually in a second direction; one end of the second transition flow channel communicates with one end, having larger longitudinal cross-sectional area, of the second shunt flow channel, and the other end of the second transition flow channel is provided with a second liquid port, wherein the first direction and the second direction are opposite. According to the liquid flow frame provided by the invention, and with the shunt flow channels having the flow channel width decreasing gradually, the flow quantity and speed of an electrolyte solution flowing into the reaction zone are more homogenized, and the service life of electric piles is prolonged.

Owner:TSINGHUA UNIV

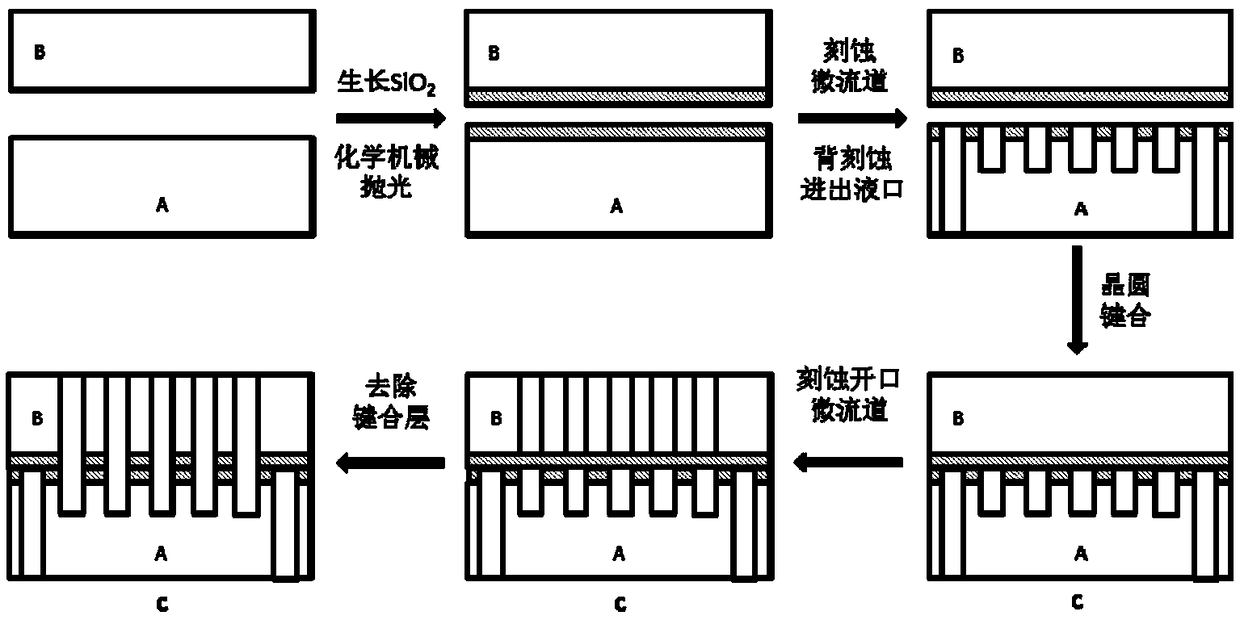

Micro-channel radiator structure and preparation method thereof

ActiveCN108666283AImprove cooling effectUniform heat dissipationSemiconductor/solid-state device detailsSolid-state devicesState of artHeat flow

The invention provides a micro-channel radiator structure and a preparation method thereof. The micro-channel radiator structure comprises embedded flowing channels and a liquid inlet / liquid outlet formed in an A silicon wafer, wherein the A silicon wafer and a B silicon wafer are bonded together; the micro-channel radiator structure also comprises opening flowing channels and shunting flowing channels; the opening flowing channels are formed in the B silicon wafer, and are connected with a part of the embedded flowing channels in the A silicon wafer in a one-to-one correspondence manner; theopening flowing channels run through the B silicon wafer; and the shunting flowing channels are formed in the radiator, and are connected with the embedded flowing channels and the liquid inlet / liquidoutlet. Compared with the prior art, heat dissipation is more uniform, the heat dissipation effect is higher, and the heat dissipation heat flux density is greater than 600W / cm<2>; and when the heatflux density is 600W / cm<2>, the temperature rise of a chip on the surface of the radiator is less than 40 DEG C.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

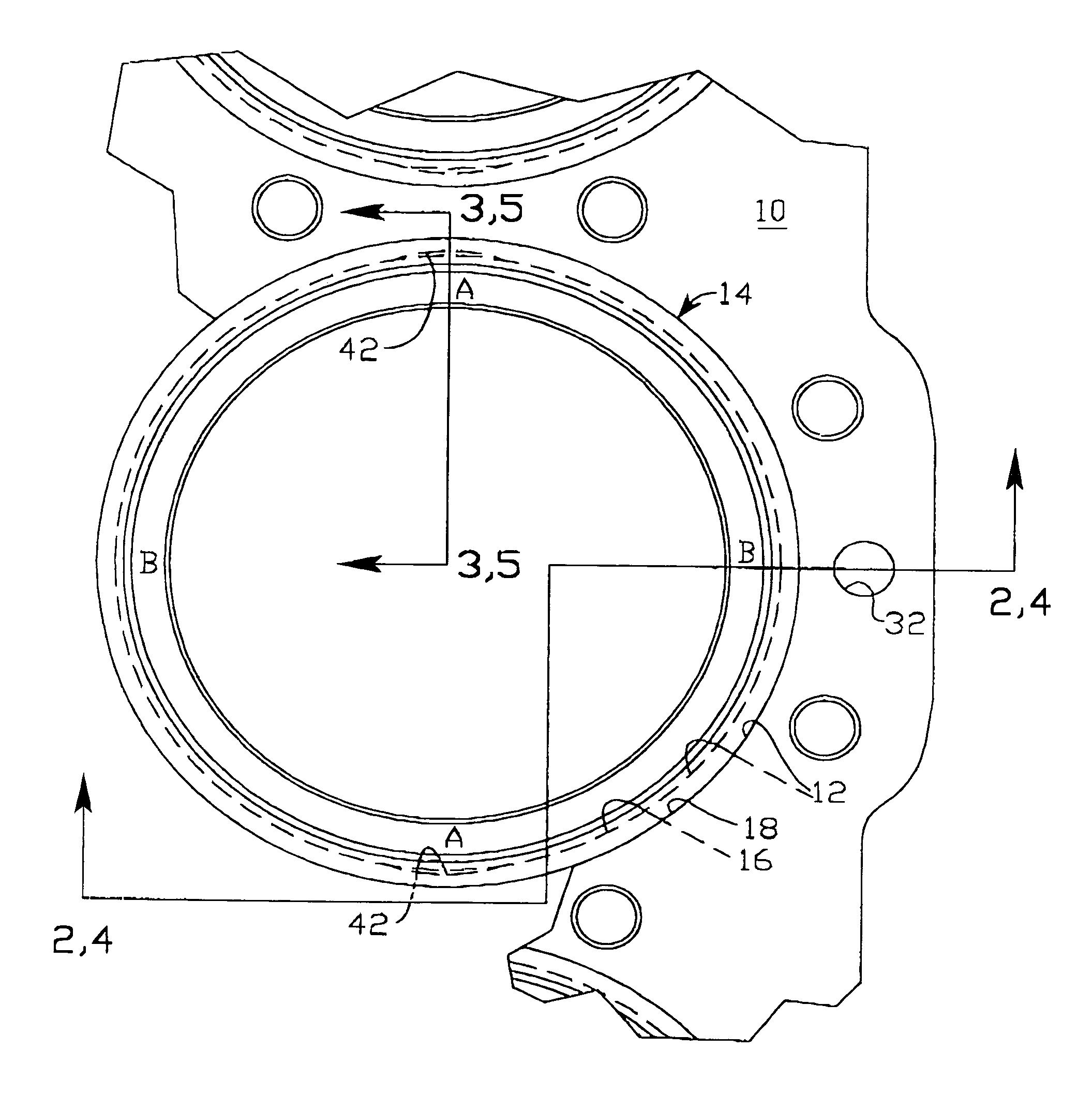

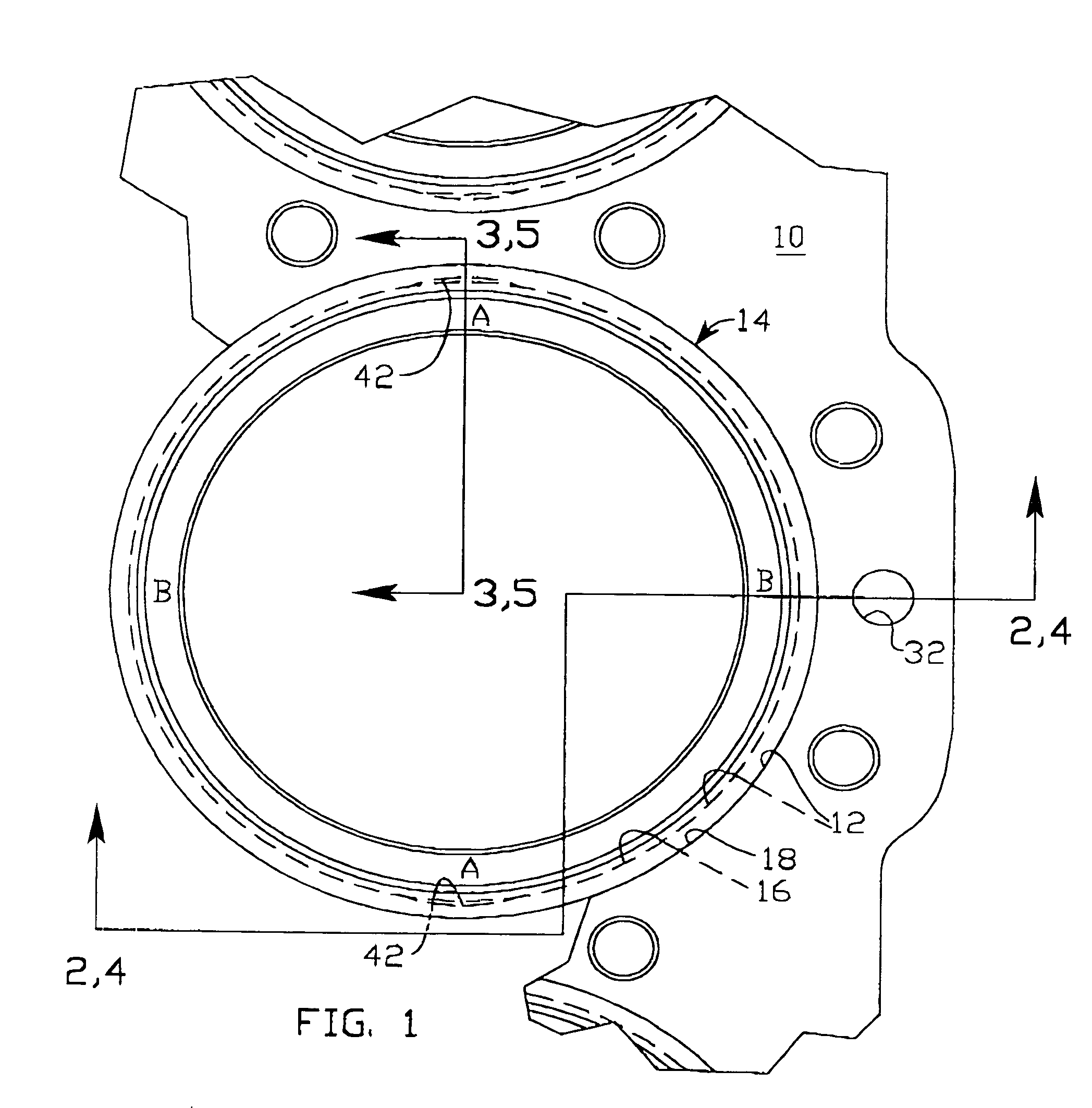

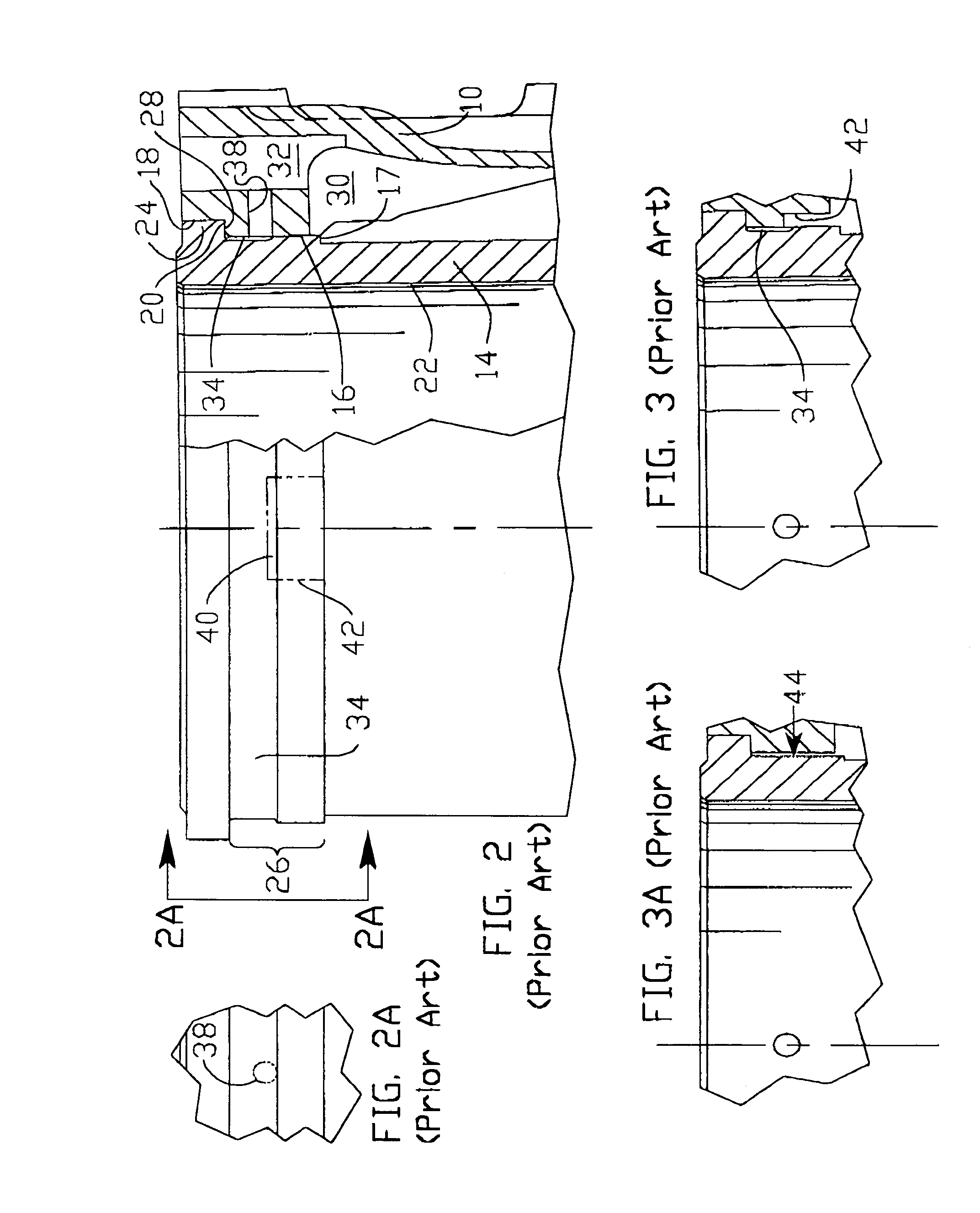

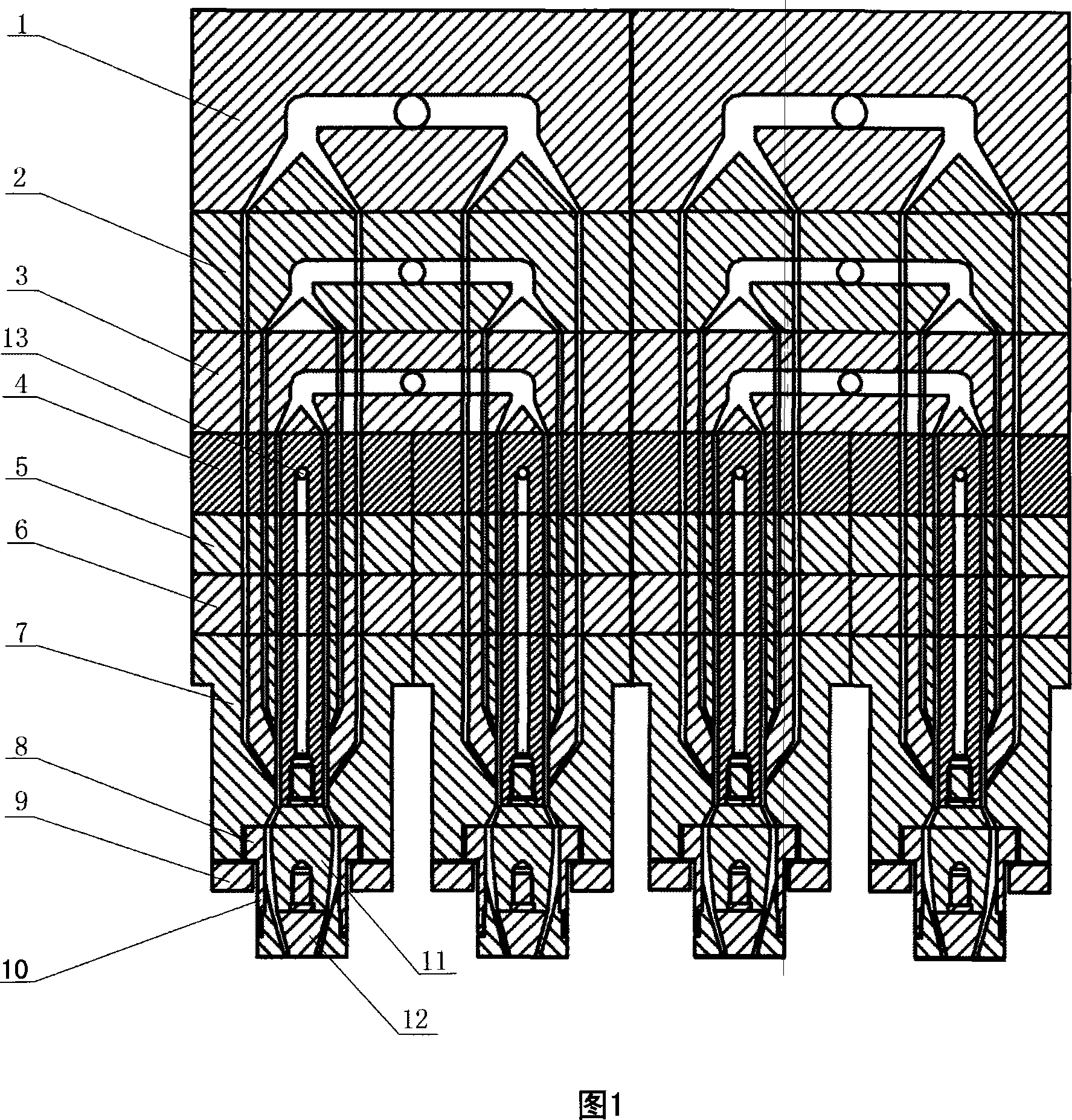

Cylinder liner providing coolant shunt flow

InactiveUS7131417B1Increase the heat exchange areaIncrease the areaCylinder headsCylindersCoolant flowEngineering

A coolant-shunt-providing cylinder liner of the flanged type is provided with a shunt circuit within the liner for coolant flow through the liner. The shunt circuit includes an array of three annular cooling channels separated from each other by two annular ribs. The width (axial extent) of each channel is substantially less than half the axial extent of the liner's cylinder block engaging portion that is associated with the upper end of the liner. The width (axial extent) of the array of three channels is substantially greater than half the axial extent of the cylinder block engaging portion. Cutouts in the ribs are provided for distributing incoming coolant to the three cooling channels from a main coolant chamber of a cylinder block in which the liner is receivable.

Owner:BUESCHER DEV

Externally programable magnetic valve assembly and controller

PendingUS20210069486A1Increase pressureReduce pressureOperating means/releasing devices for valvesWound drainsElectric machineWorking pressure

An externally programmable shunt valve assembly that includes a motor having a rotor that is operable in response to an externally applied magnetic field and configured to increase or decrease the working pressure of the shunt valve assembly. The motor may further include a position sensing mechanism that allows a position of the rotor, and associated pressure setting of the valve, to be determined using an external magnetic sensor. In certain examples the motor further includes a mechanical brake that is magnetically operable between a locked position and an unlocked position and which, in the locked position, prevents rotation of the rotor.

Owner:CEREDYN BIOTECHNOLOGY LLC

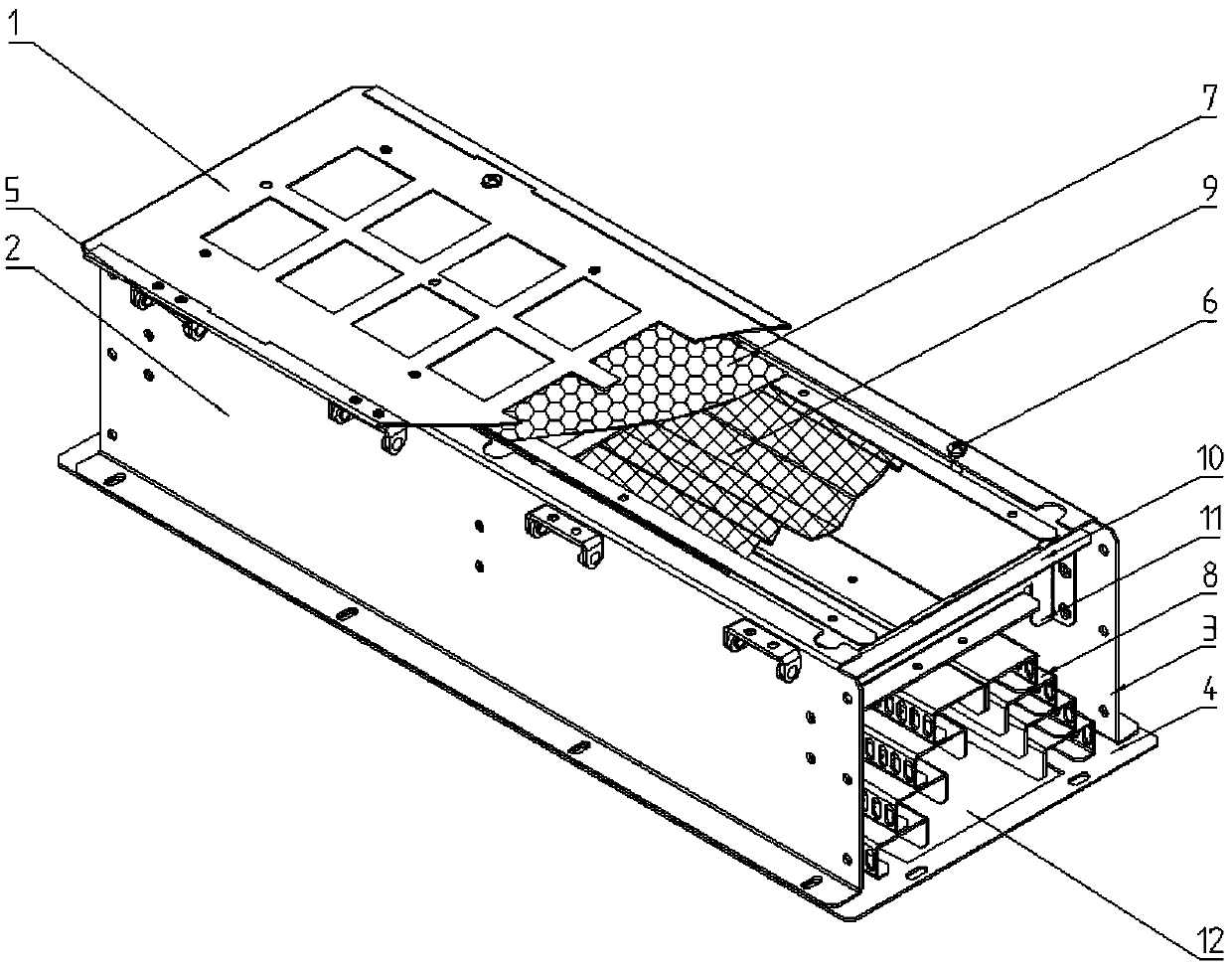

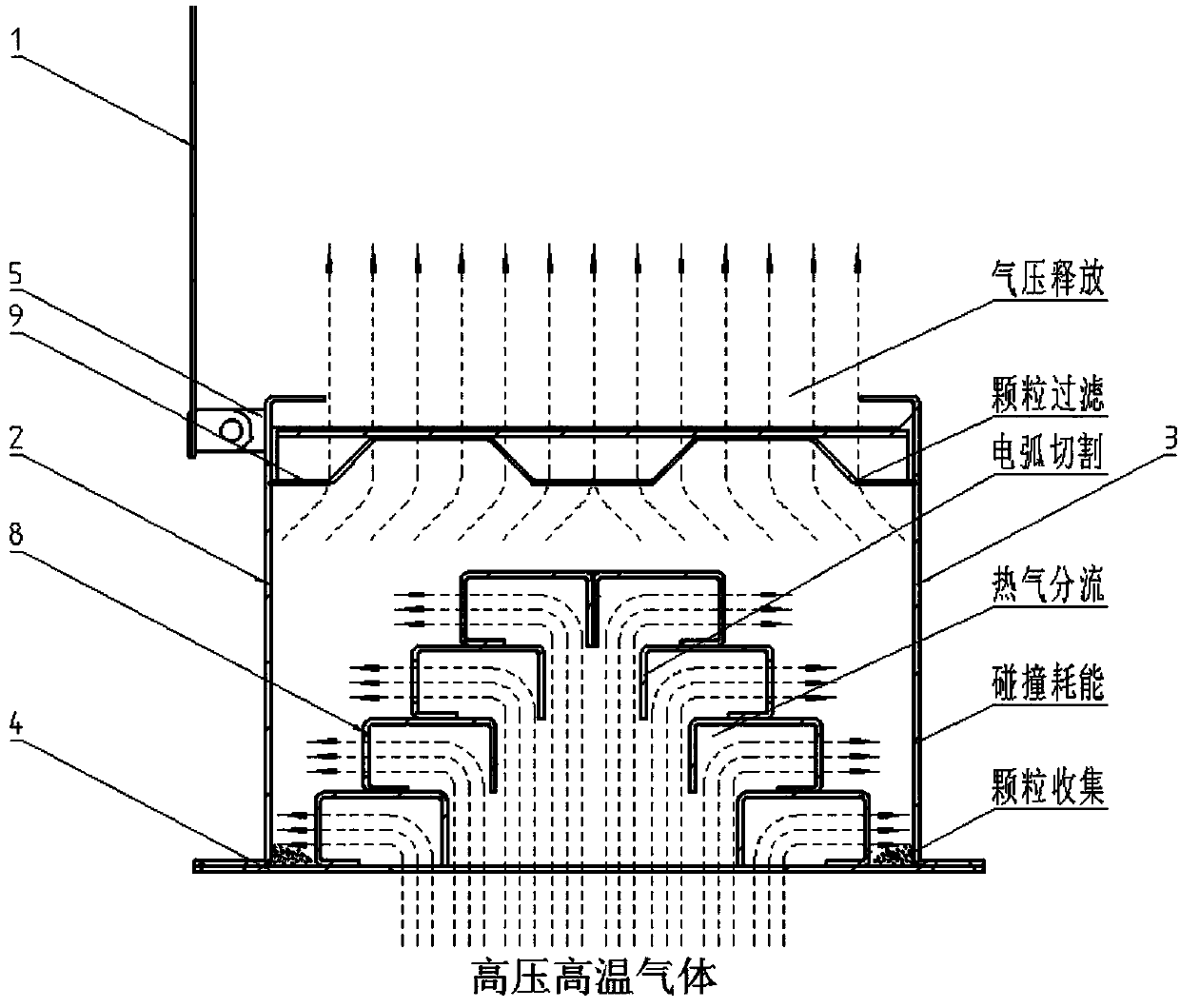

Shunting pressure relief device

PendingCN107910790APlay a diversion roleEffective filteringSwitchgear arrangementsSubstation/switching arrangement cooling/ventilationEngineeringTower

The invention provides a shunting pressure relief device comprising a housing. A tower-shaped pressure relief structure is arranged in the housing and comprises a shunting guide plate stacked in a tower shape. The shunting guide plate comprises a shunting surface and a ventilating surface. Ventilation holes are arranged on the ventilating surface. After the effect of the shunting pressure relief device, the energy of hot air is consumed and hot particles are filtered out, thereby greatly improving the safety of a switch cabinet and not influencing the external dimensions of the switch cabinet.

Owner:WECOME GRP

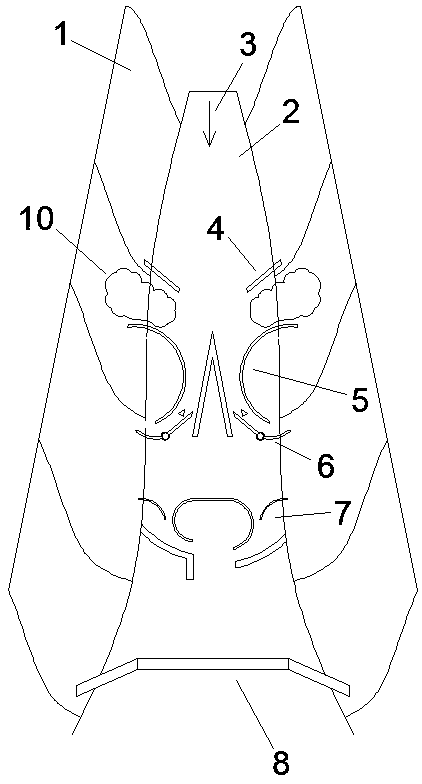

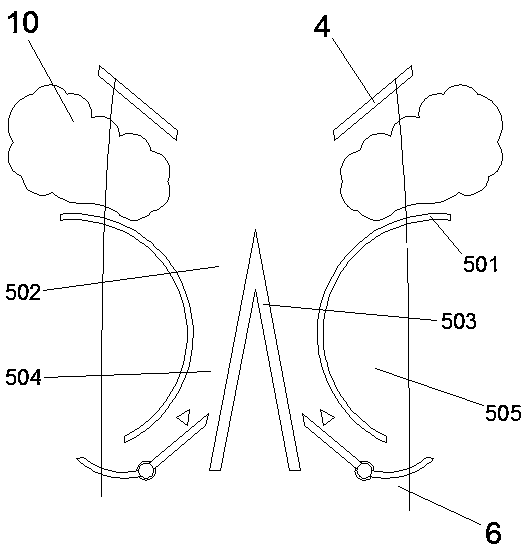

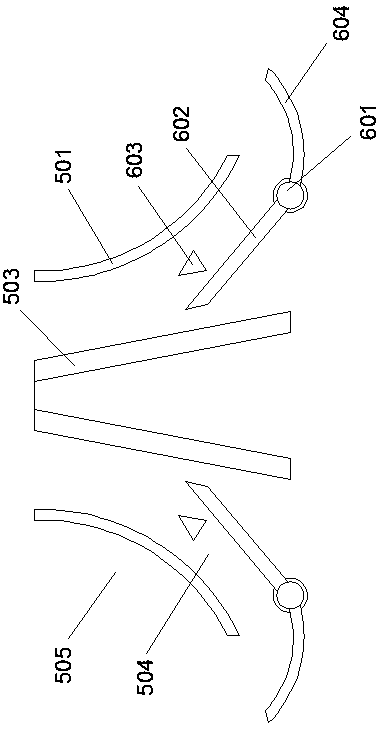

Movable shunting blocking system for debris flow prevention and control

PendingCN111335260AReduce impactAvoid damageBarrages/weirsDamsClassical mechanicsStructural engineering

Owner:段刚强

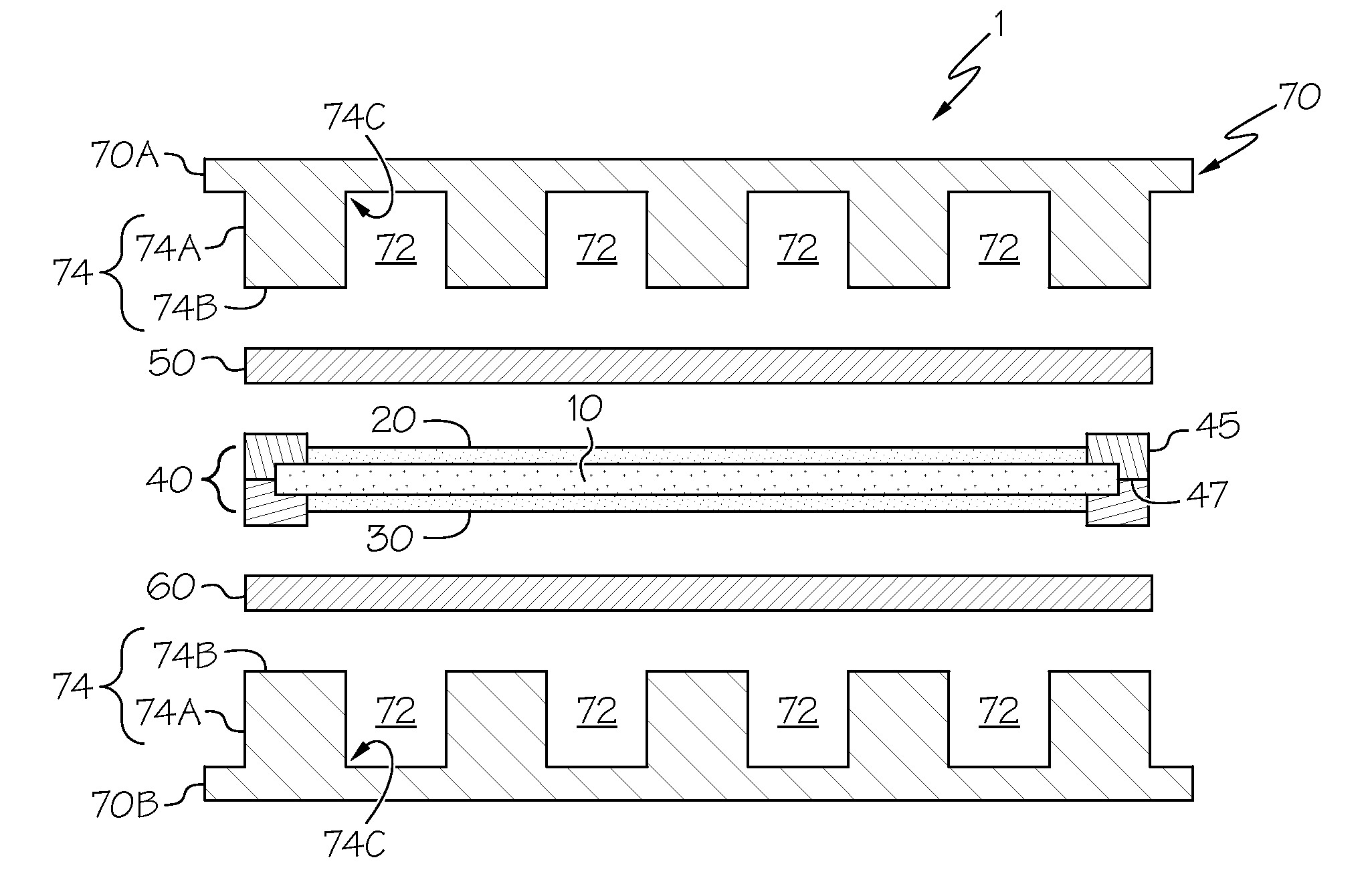

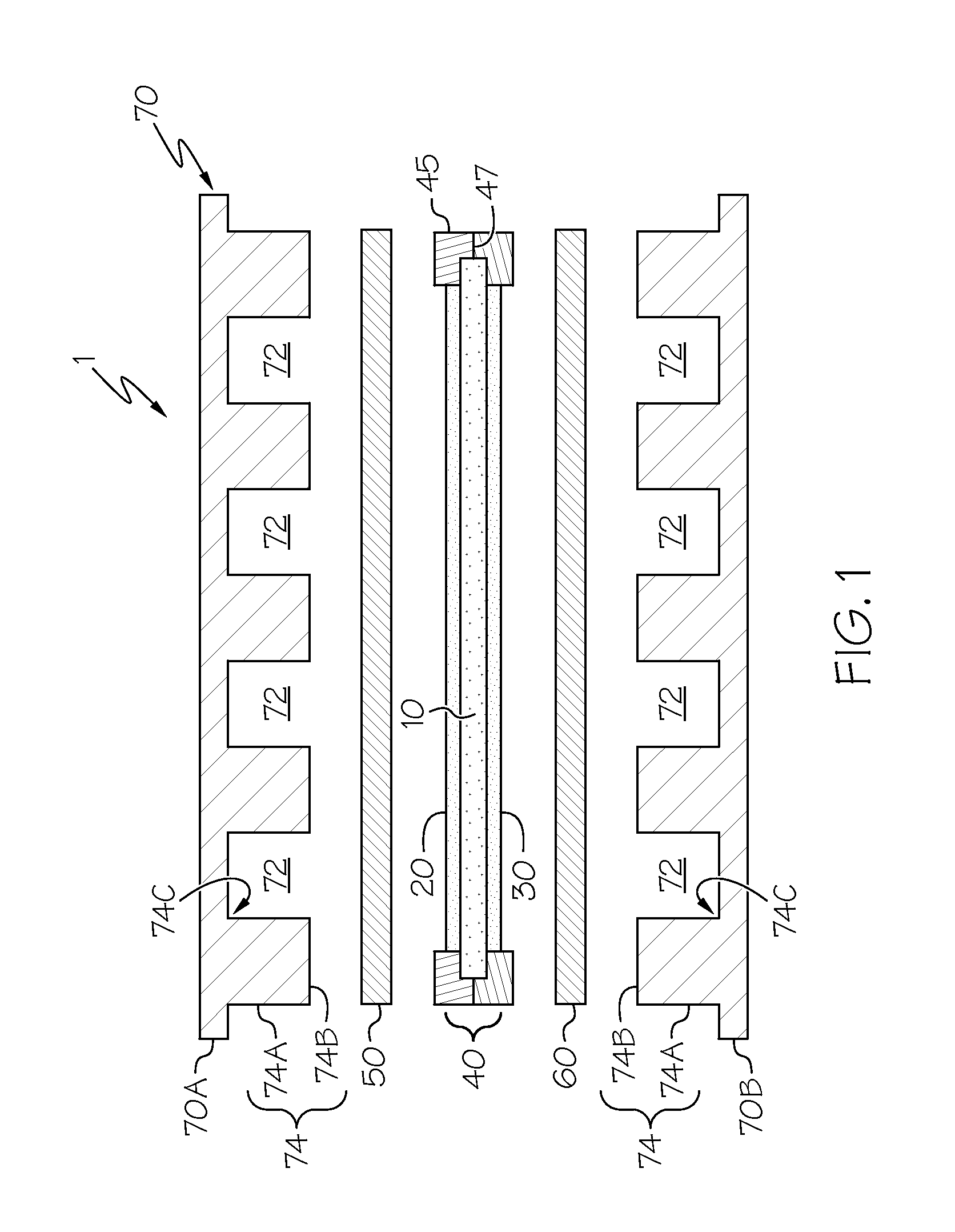

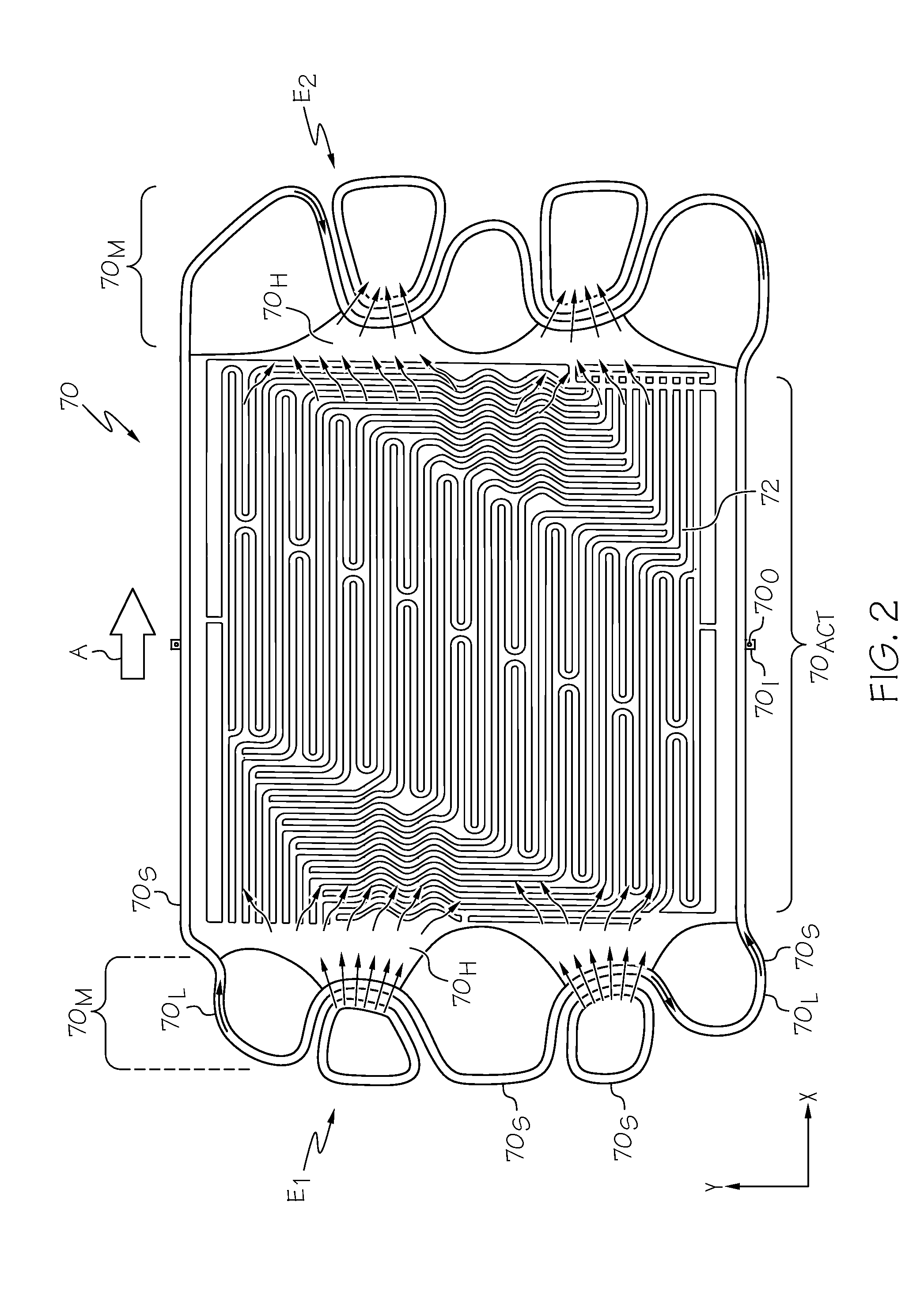

Injected metal bead channel seal achieved through stamped plate features on fuel cell bipolar plates

ActiveUS20160301088A1Improve sealingWithout complexityFuel cells groupingCell electrodesIn planeFuel cells

A fuel cell system with reduced leakage and a method of assembling a fuel cell system. Bipolar plates within the system include reactant channels and coolant channels that are fluidly coupled to inlet and outlet flowpaths, all of which are formed within a coolant-engaging or reactant-engaging surface of the plate. One or more seals are also formed on the fluid-engaging surface to help reduce leakage by maintaining fluid isolation of the reactants and coolant as they flow through their respective channels and flowpaths that are defined between adjacently-placed plates. The seal—with its combination of in-plane and out-of-plane dimensions—forms a substantially hollow volume, into which a plug is placed to reduce the tendency of the seal to form a shunted flow of the coolant or reactant around the intended active area of the plate. A fluid port intersection is integrally formed with the seal and is formed to be fluidly cooperative with the volume, and is capable of accepting the introduction of a fluent precursor of the plug material such that upon curing, the precursor material forms a substantially rigid insert that continuously fills both the volume and intersection, thereby increasing the resistance of the plug to movement and the seal to shunted flow. In one form, the geometry of the fluent material injection site is such that it promotes plug anchoring within its intended location, while also providing a manufacturing aid to visually inspect for plug installation, as well as to serve as a bipolar plate stacking alignment locator and verification.

Owner:GM GLOBAL TECH OPERATIONS LLC

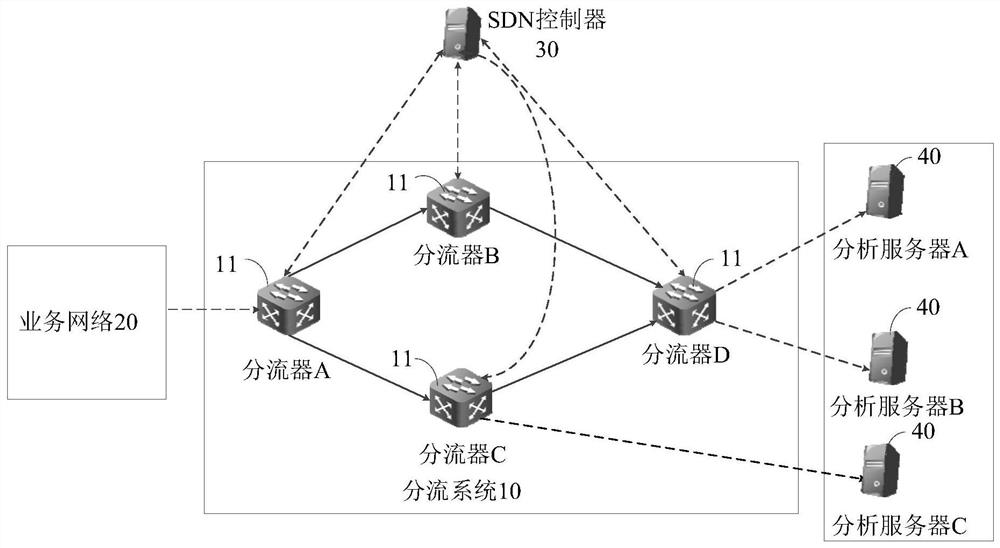

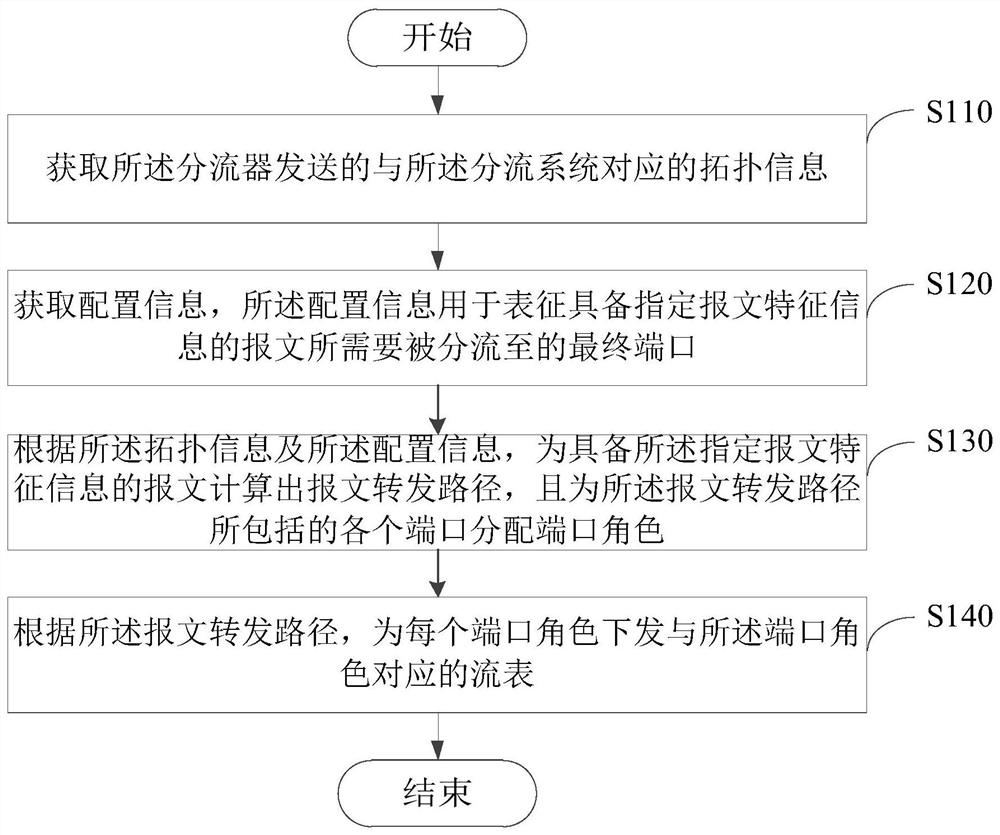

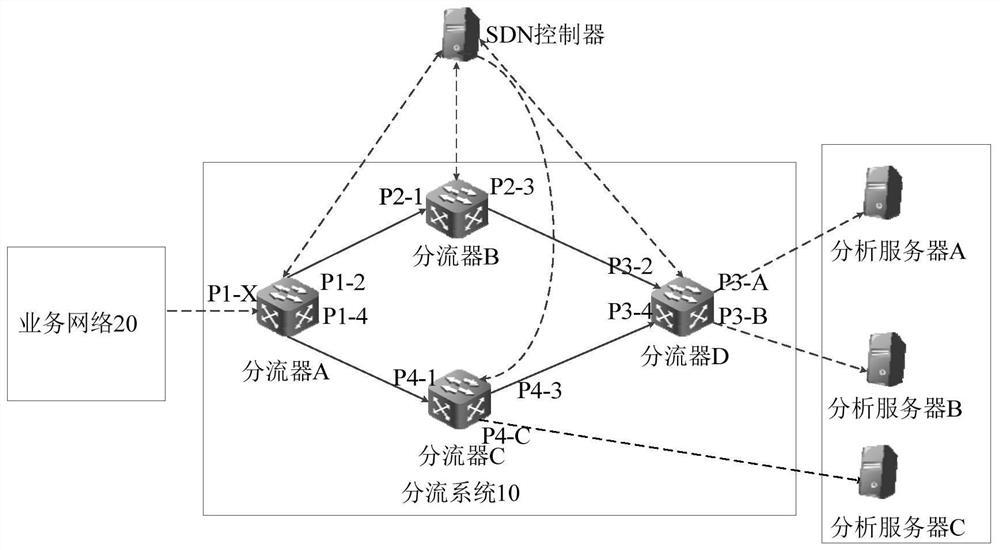

Shunting method, device and system, network equipment and computer readable storage medium

The invention relates to a shunting method, device and system, network equipment and a computer readable storage medium, and belongs to the field of communication. A shunt acquires a flow table issuedby an SDN controller for a port included in the shunt in advance, so that the shunt can shunt a message based on the flow table acquired in advance after acquiring the message according to the port,the situation that the shunt cannot find the corresponding flow table to process the message can be avoided, and the shunt can be prevented from sending the message to the SDN controller. The SDN controller does not need to participate in the shunting stage, so that the possibility that the SDN controller becomes the performance bottleneck of the shunting system can be reduced.

Owner:MAIPU COMM TECH CO LTD

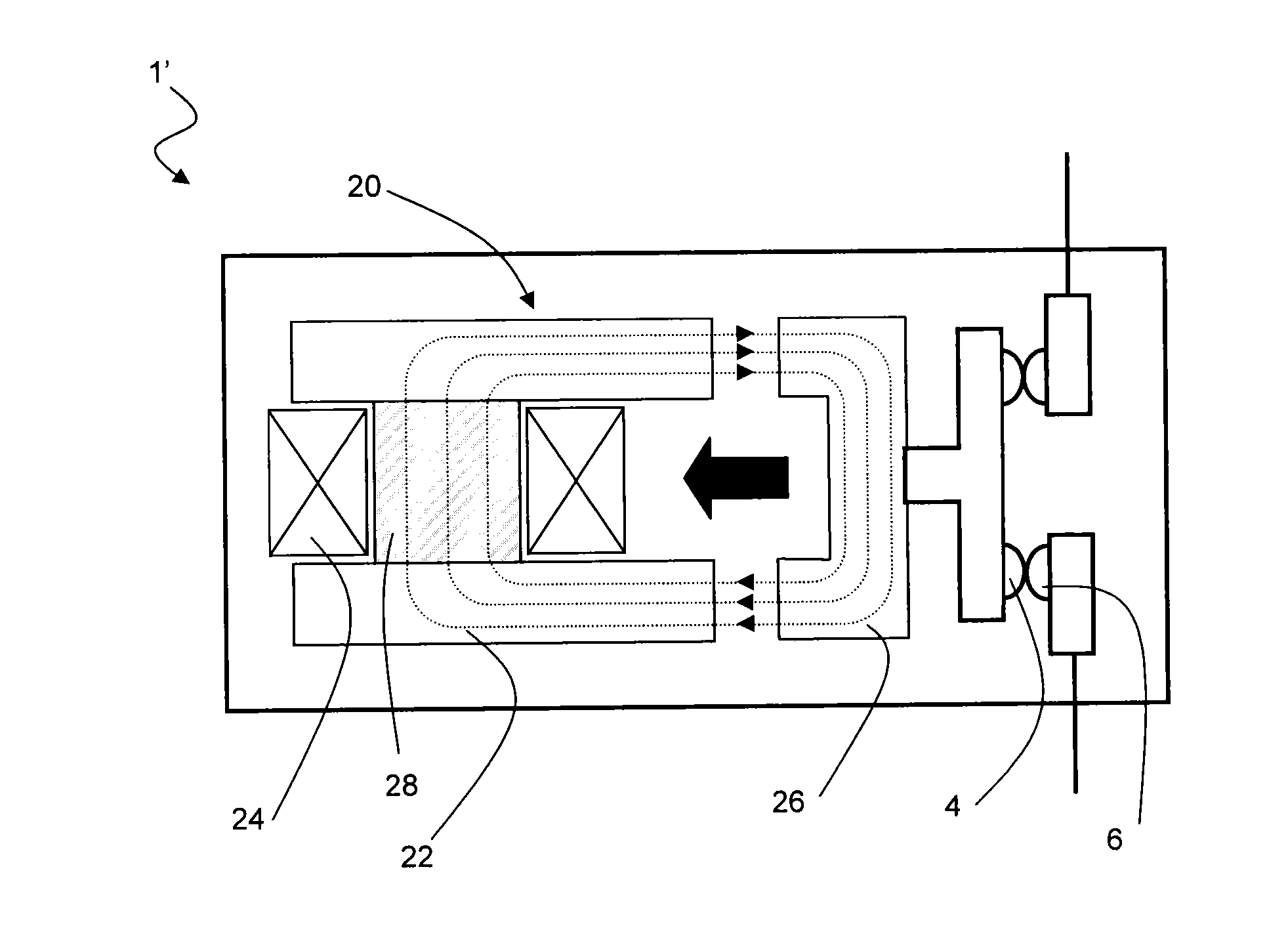

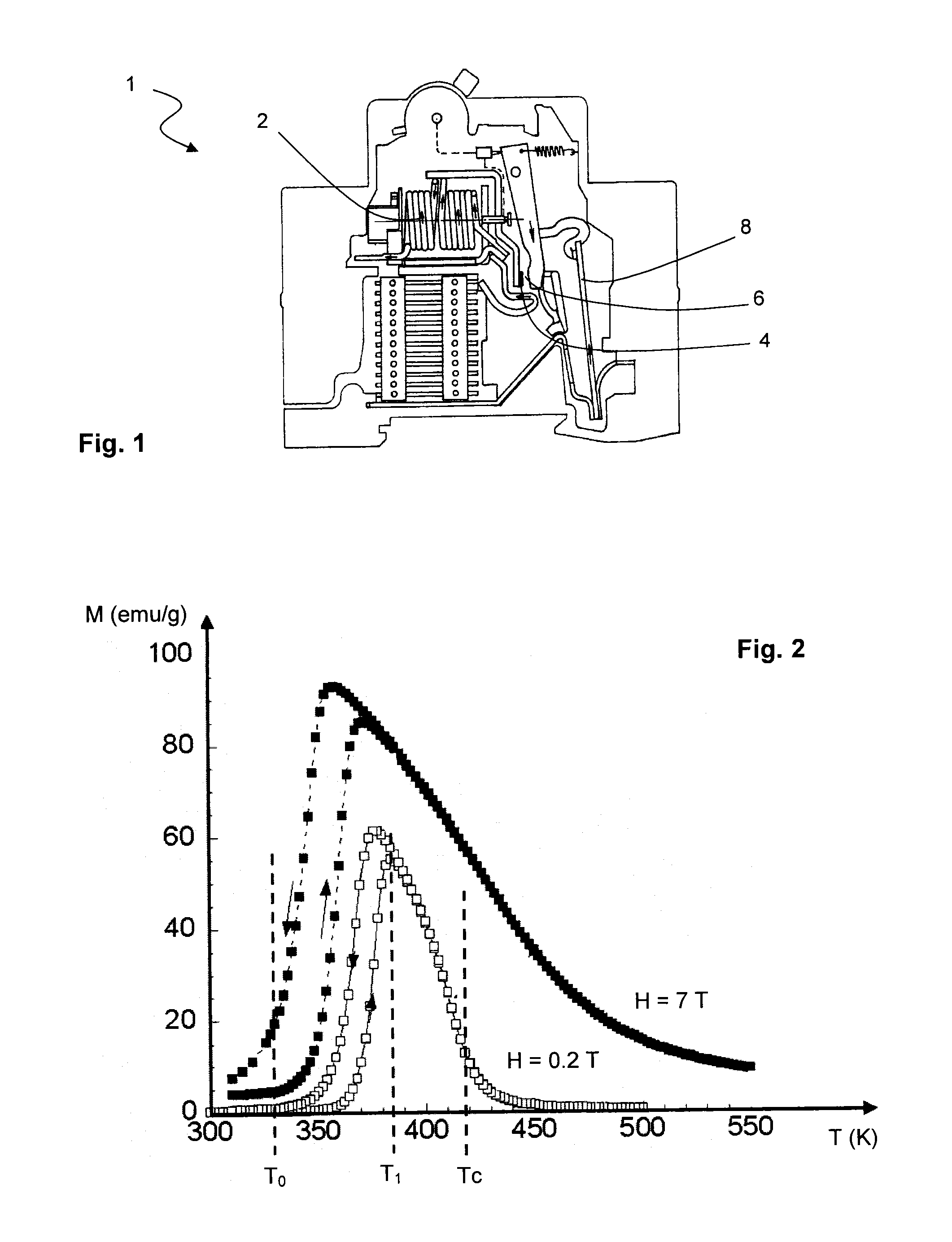

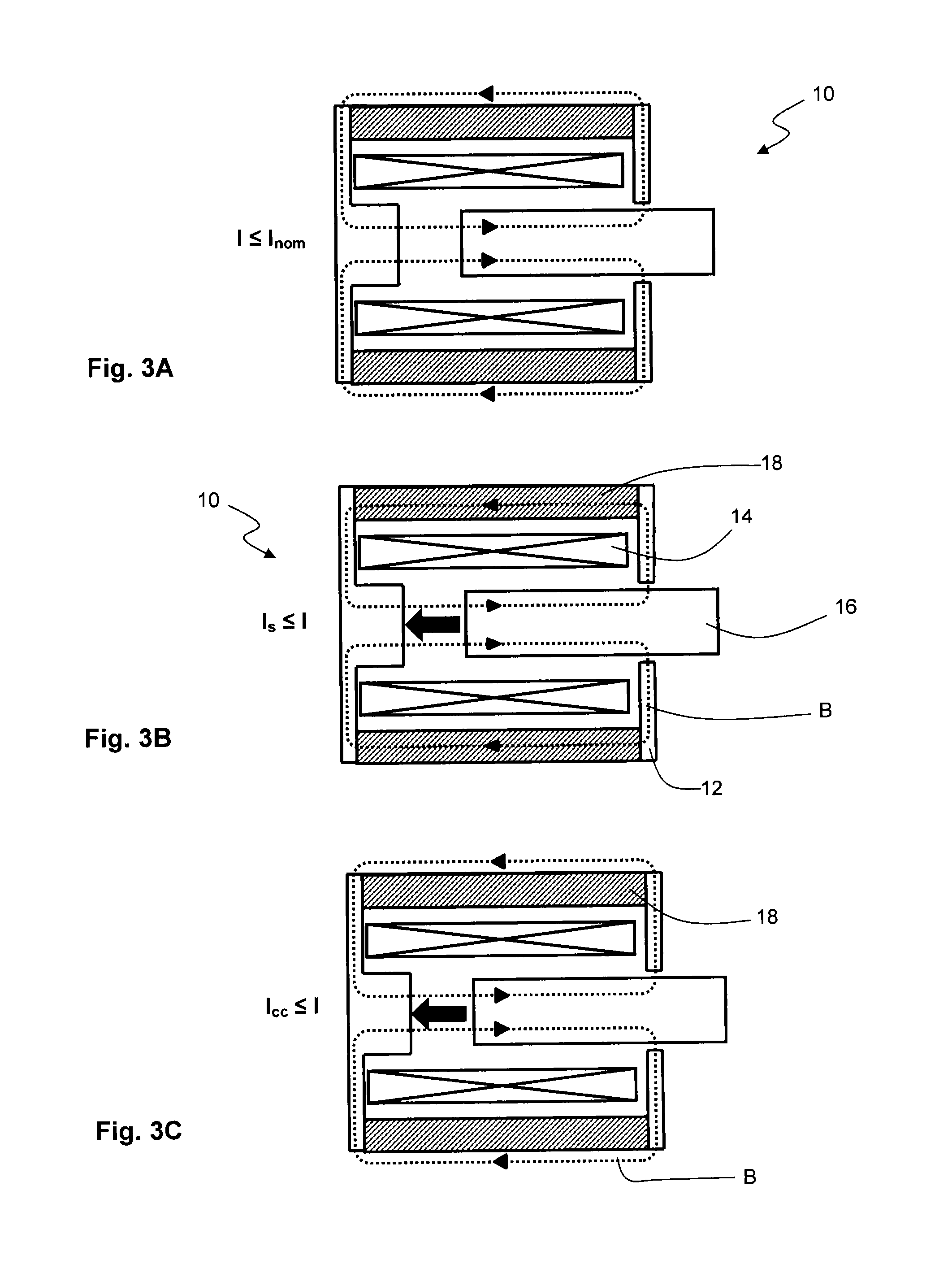

Actuator with thermomagnetic shunt, especially for triggering a circuit breaker

ActiveUS20150318135A1Overcomes drawbackSwitches with electrothermal openingMagnetsShunt DeviceElectric current flow

An electromagnetic actuator including a saturable magnetic shunt system. The shunt is associated with a coil of the actuator and allows channeling of a more or less large part of the flow according to current circulating in the product. In this way, when the actuator is used in a circuit breaker, the actuator allows the circuit breaker to be triggered from a short circuit as usual and also from overload caused by action of the shunt.

Owner:SCHNEIDER ELECTRIC IND SAS

Ultrahigh pressure bursting underground flowing water split-flow pressure reduced treatment

ActiveCN1614158AShorten the construction periodReduce engineering processing and construction difficultyFoundation engineeringPressure decreaseEngineering

A pressure-decreasing shunt method for treating the accident ultrahigh-pressure underground water spray-out includes such steps as drilling holes near the spraying point to decrease the flow and pressure of spray, installing the enclosing unit in each hole, blocking spray point when the flow and pressure are decreased to a certain value, enclosing the holes one by one, drilling the grouting holes near the spray point, and pouring grout in the holes.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

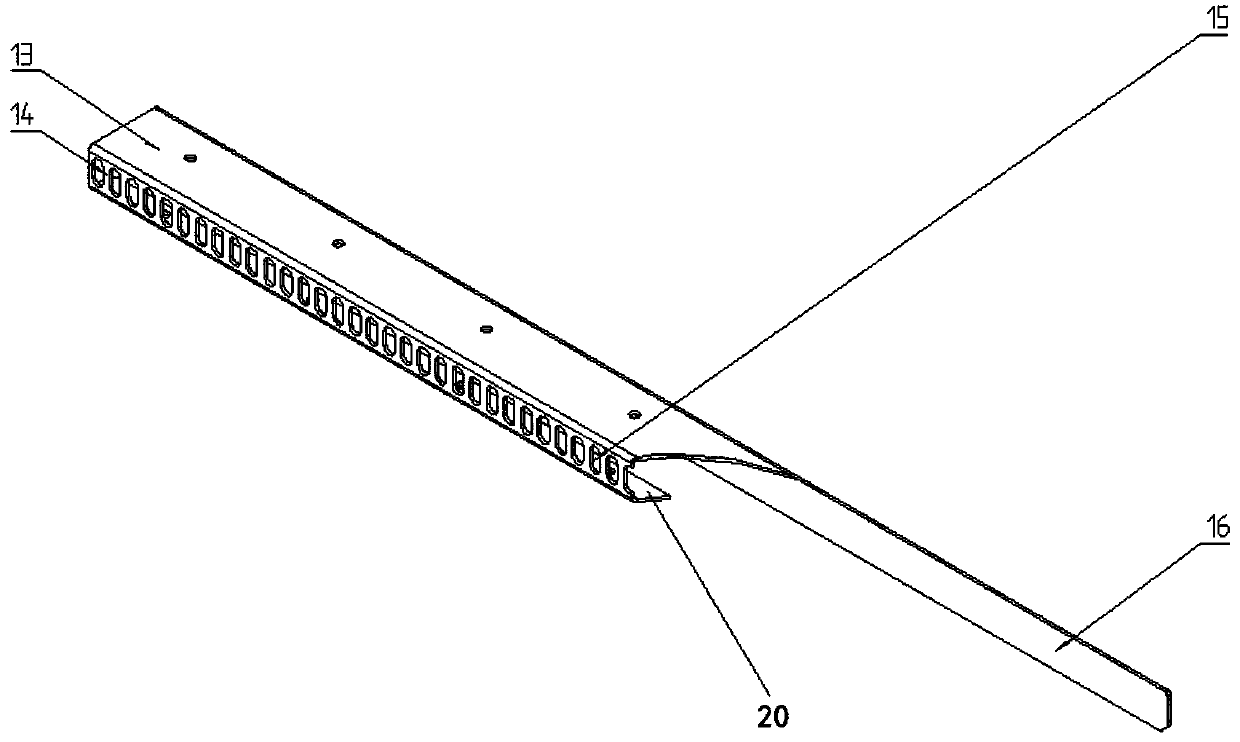

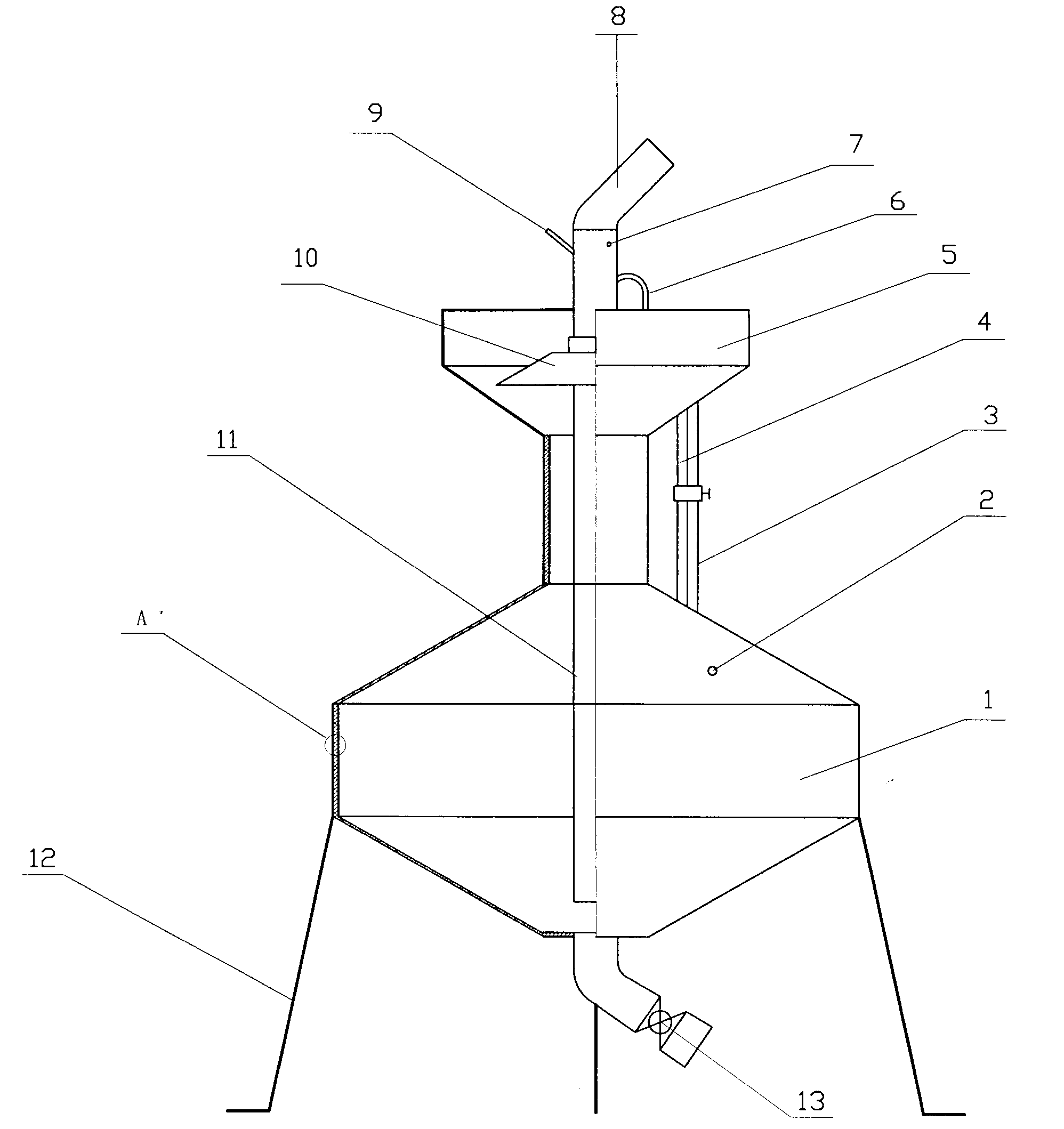

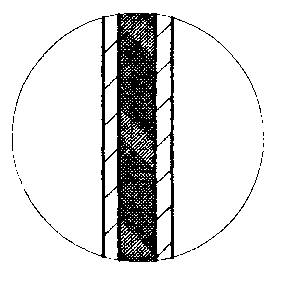

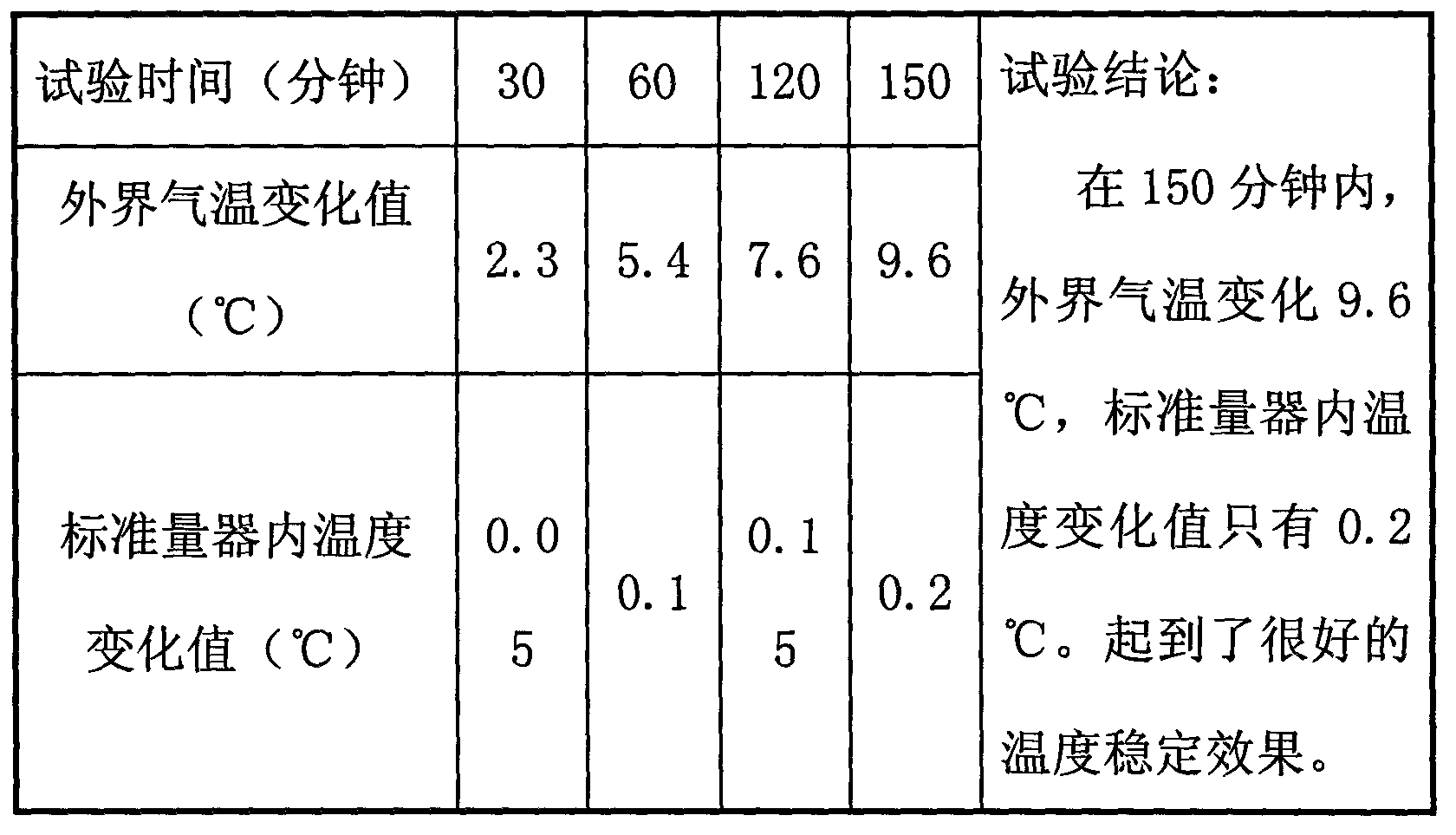

Novel standard metal measuring vessel with double-layer structure and internally-clamped heat insulation layer for testing oiling machine

ActiveCN102798442AUniform and stable flow rateReduce productionTesting/calibration apparatusMicrocomputerInsulation layer

The invention disclsoes a novel standard metal measuring vessel with a double-layer structure and an internally-clamped heat insulation layer for testing an oiling machine, belongs to the technical field of a standard measuring vessel and aims at solving the problems that the conventional standard metal measuring vessel for testing the oiling machine is unreasonable in structural design, adopts a single-layer metal measuring vessel main body and is relatively poor in comprehensive function. According to the novel standard metal measuring vessel, an adopted standard metal measuring vessel main body has a double-layer metal plate structure and is internally provided with the heat insulation layer in a clamping way, a liquid level pipe is provided and connected with two vernier calipers form an angle being 90 degrees, an oiling gun support is movable, a pressure relief shunting flow bent pipe is installed and connected on a drainage pipe connected with the movable oiling gun support, a vent hole is formed in the drainage pipe connected with the movable oiling gun support, a liquid outlet of the pressure relief shunting flow bent pipe is connected in an overflow cover in an inserting manner, a liquid splashing prevention conical cover disc is sheathed on a drainage pipe body positioned in an inner cavity of the overflow cover, and dual-channel microcomputer thermodetectors are installed and connected in a gun outlet temperature measuring hole sleeve and an oil temperature measuring hole sleeve of the metal measuring vessel main body. The novel standard metal measuring vessel has a simple and practical structure and is suitable for testing various types of oiling machines.

Owner:车建军

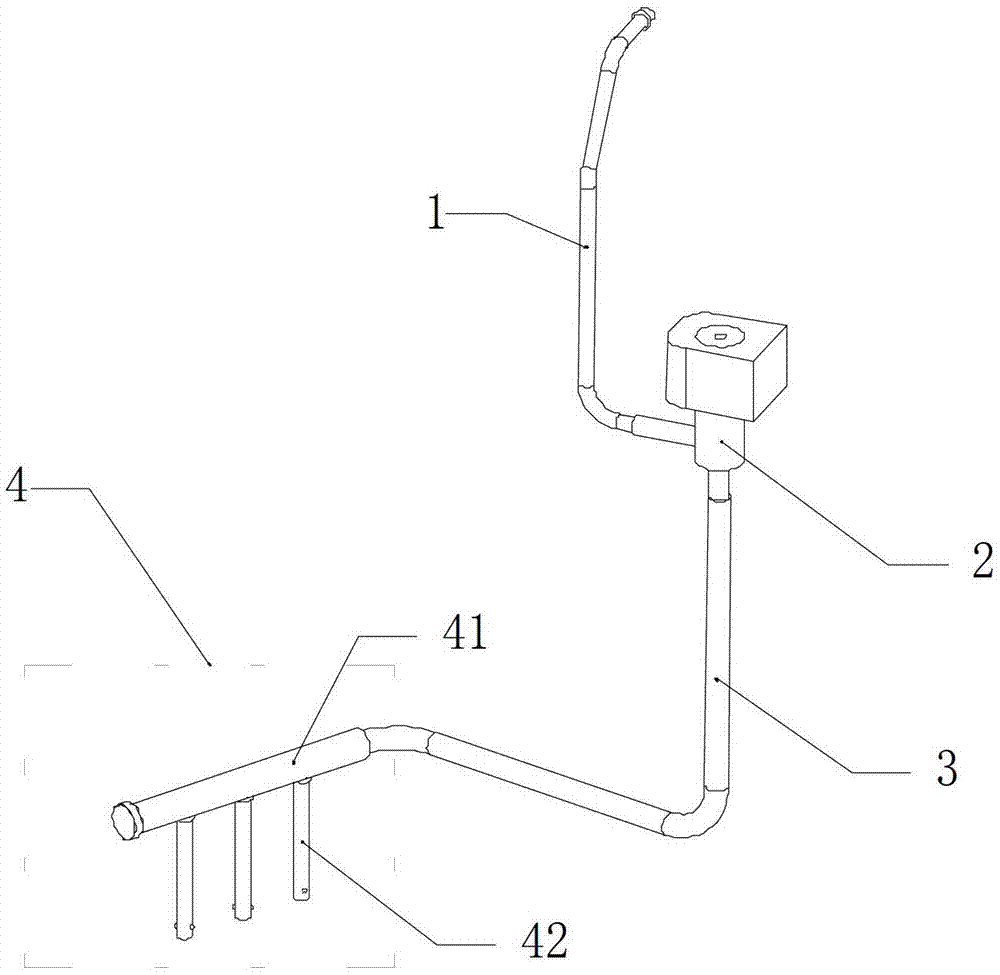

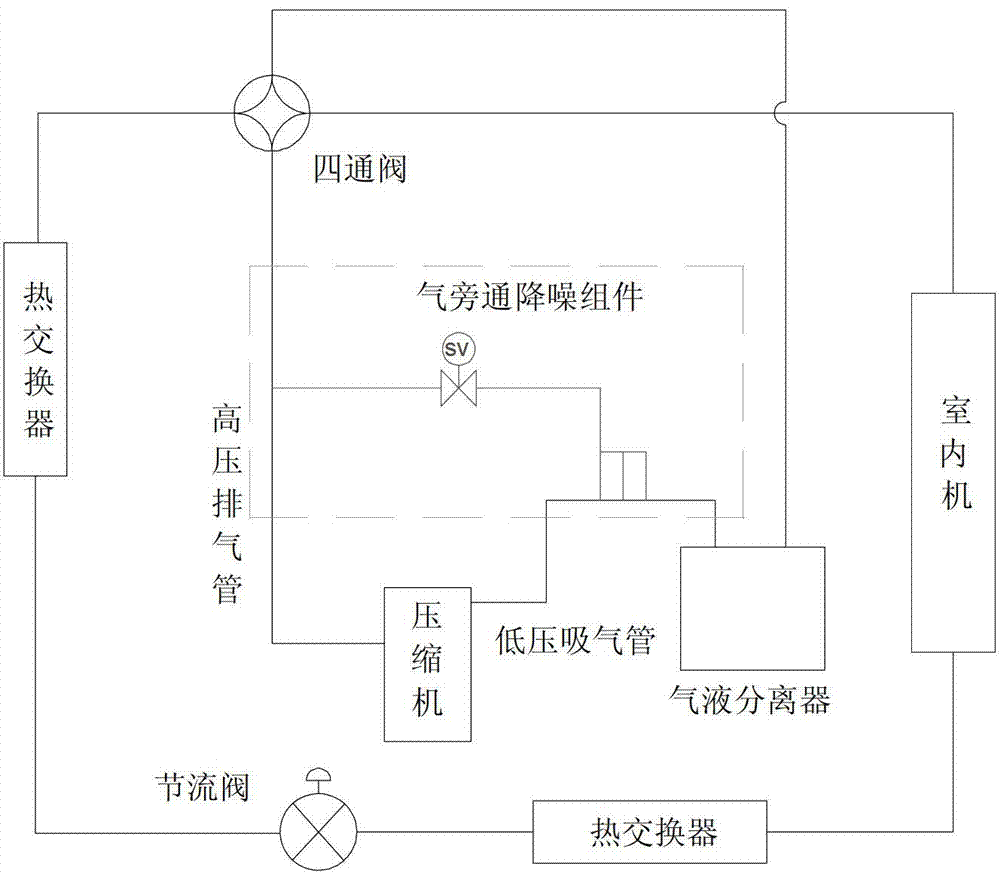

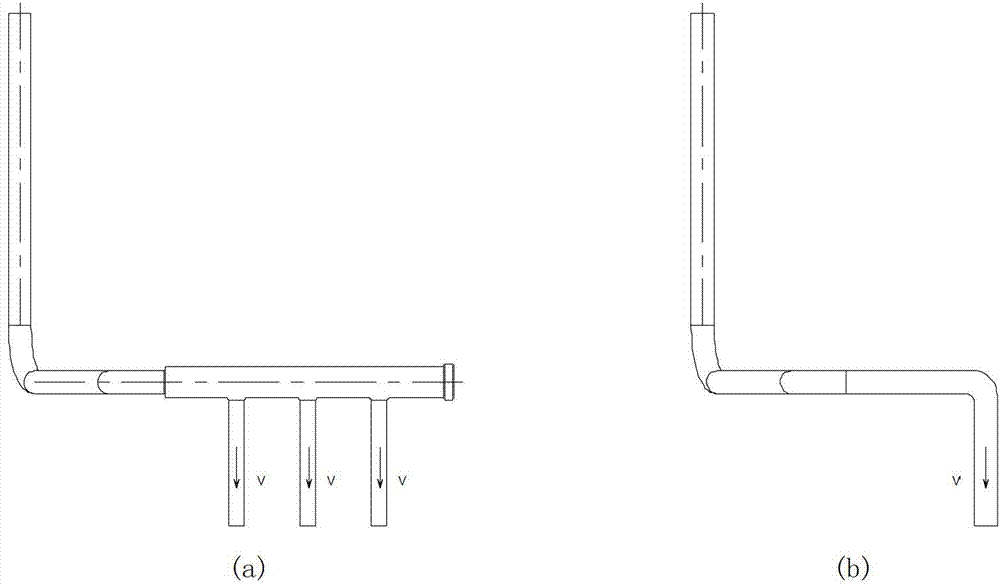

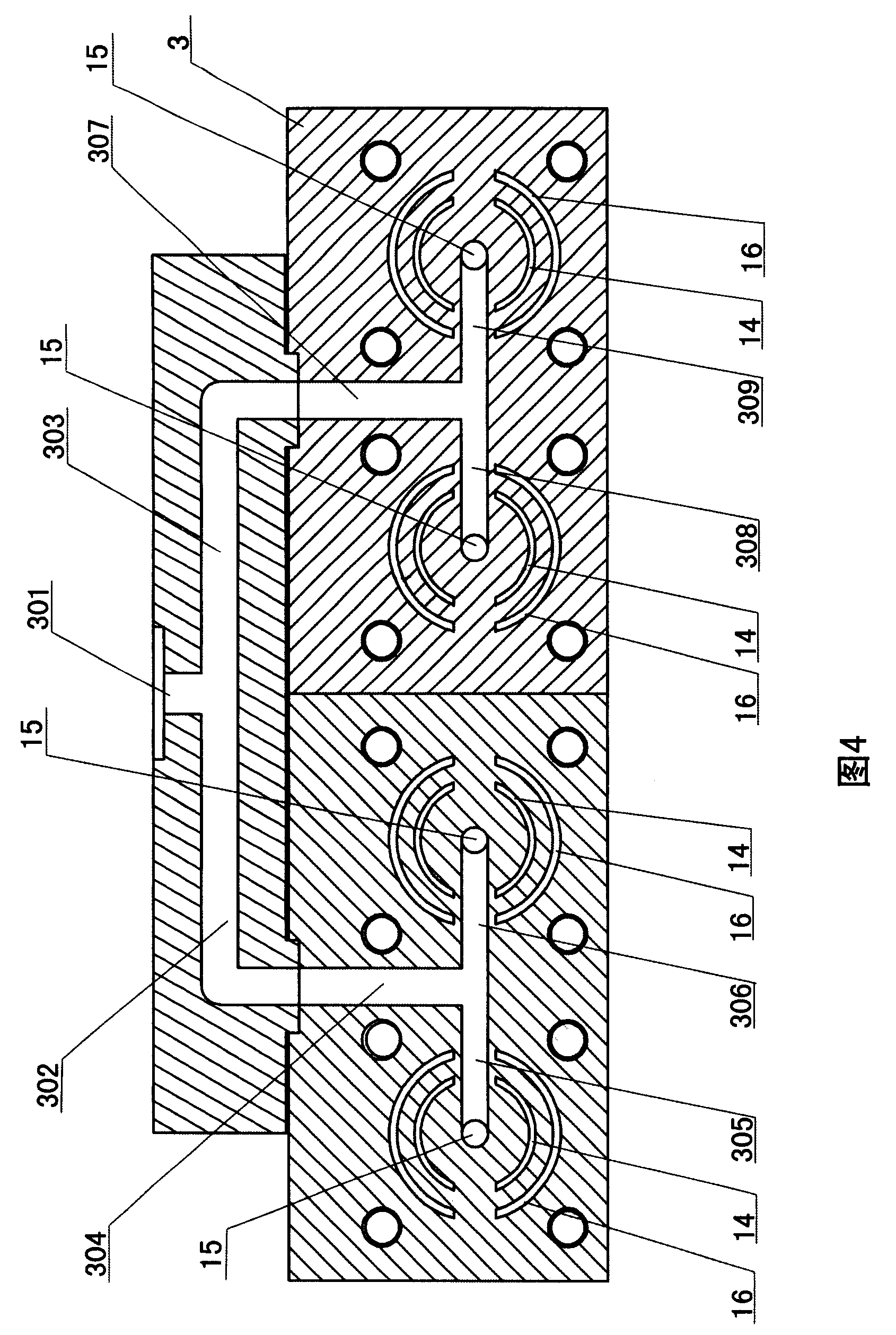

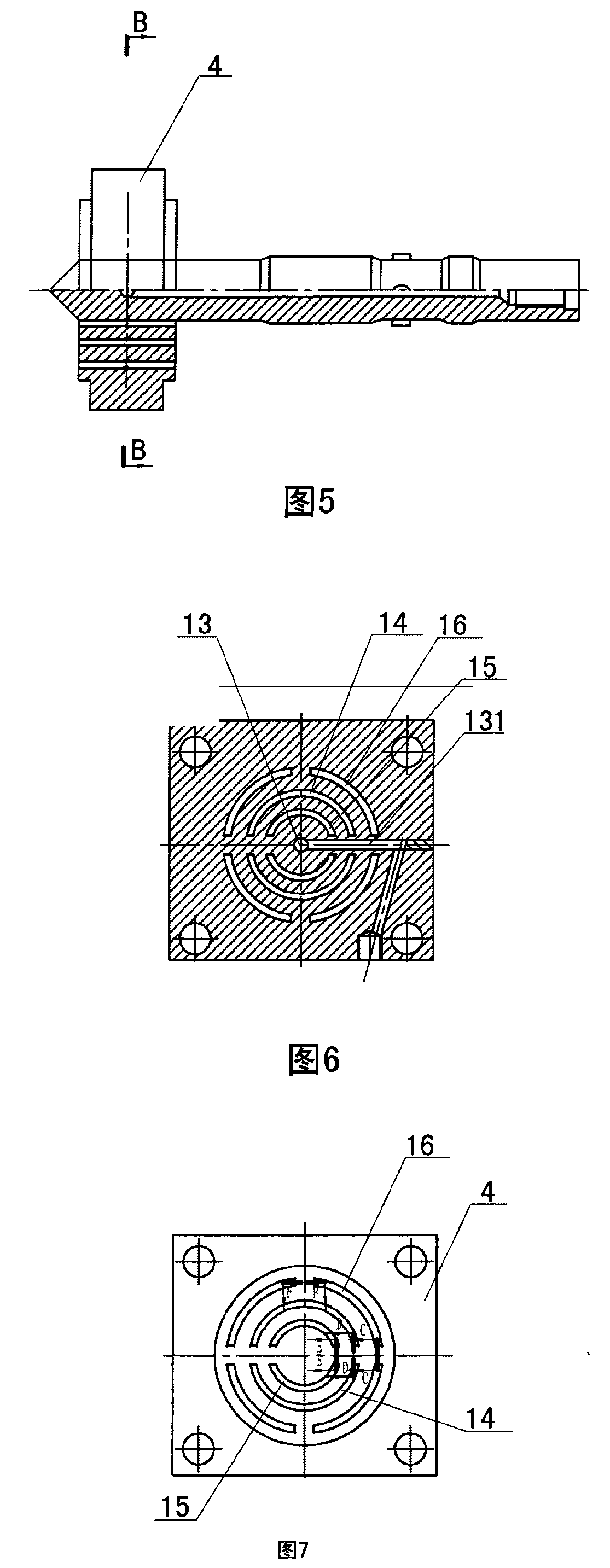

Air conditioner gas bypass noise reduction method and structure

ActiveCN103032945ASlow down flow impact speedReduce noiseNoise suppressionEngineeringNoise reduction

The invention discloses an air conditioner gas bypass noise reduction method and a structure, and relates to the field of air conditioner noise reduction, in particular to a noise reduction method and a noise reduction structure of an air conditioner gas bypass pipe. The air conditioner gas bypass noise reduction method comprises the following steps: A. arranging a gas bypass noise reduction structure between a high-pressure exhaust pipe and a low-pressure gas suction pipe of the air conditioner, wherein the gas bypass noise reduction structure is a shunt noise reduction component at one end of the low-pressure gas suction pipe; and B. calculating the amount of shunt flow by adopting high-pressure and low-pressure bypass coolants, and identifying the number of shunt pipes of the shunt noise reduction components, the size of the diameter of each pipe, and the gas flow velocity in each pipe. With the adoption of the air conditioner gas bypass noise reduction method and the structure, the flow impact speed of the coolants entering a gas suction side is slowed down through the condition that a bypass fluid is shunted in proportion, so that the gas bypass noise is reduced, the low-frequency vibration amplitude of a copper pipe is reduced, and the service life of the gas bypass pipe is prolonged.

Owner:SHENZHEN MCQUAY AIR CONDITIONING

Blow-moulding device for composite plastic bottle and method for manufacturing composite plastic bottle

The invention discloses a composite plastic bottle blowing molding device, which comprises a material shunting mechanism and at least two die heads. The material shunting mechanism is installed on the upper ends of both die heads; each die head comprises a die casing, a die core and a die ring which is sheathed at the outer side of the die core and is fixed at the lower end of the die casing, and an air inlet is arranged on the die core; the material shunting mechanism comprises at least two shunting blocks which are piled up in sequence, a shunting pipeline is arranged inside in each shunting block, the shunting pipelines comprise inlets which can be connected with a material supplying device and shunting outlets with the amount being identical with that of the die heads, and each shunting outlet is connected with the shunting flow channel inlet of a die head. A composite plastic bottle manufacturing method comprises the following steps: at least two materials are evenly and respectively fed to each die head; the materials are respectively conveyed downward to the outlet opening of the die head through the shunting flow channel to be converged, are extruded from the lower end of the die head; and therefore the high-barrier composite plastic bottle is produced. The composite plastic bottle blowing molding device has the advantages of high production efficiency, simple structure, lower cost, and good operation effect.

Owner:肖曼华

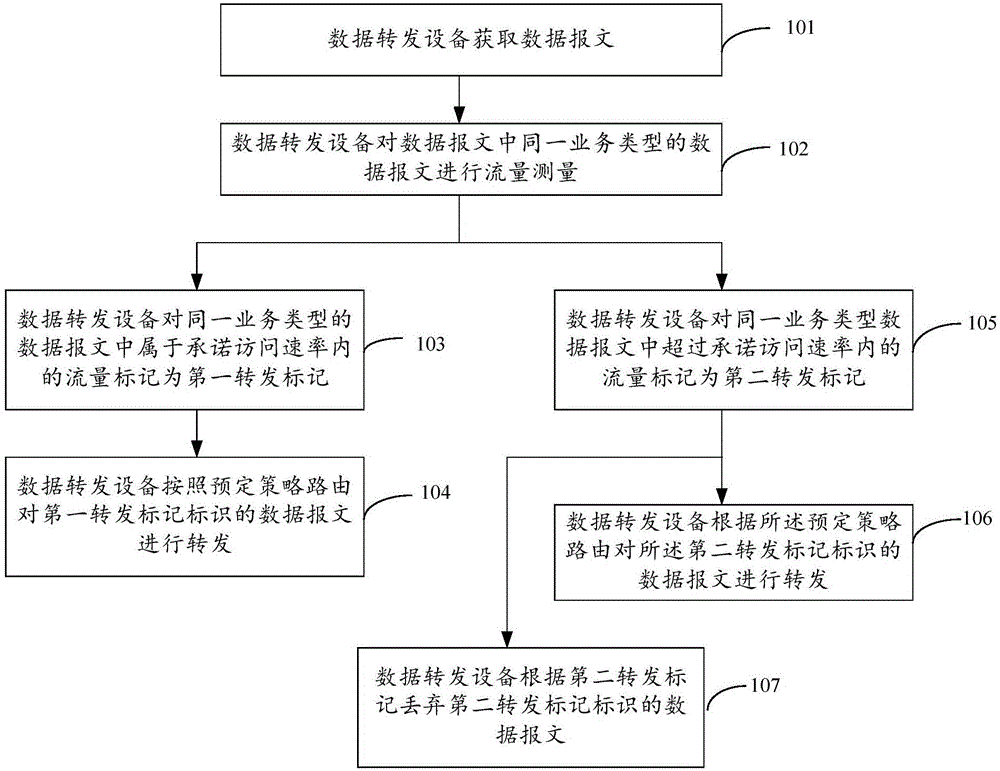

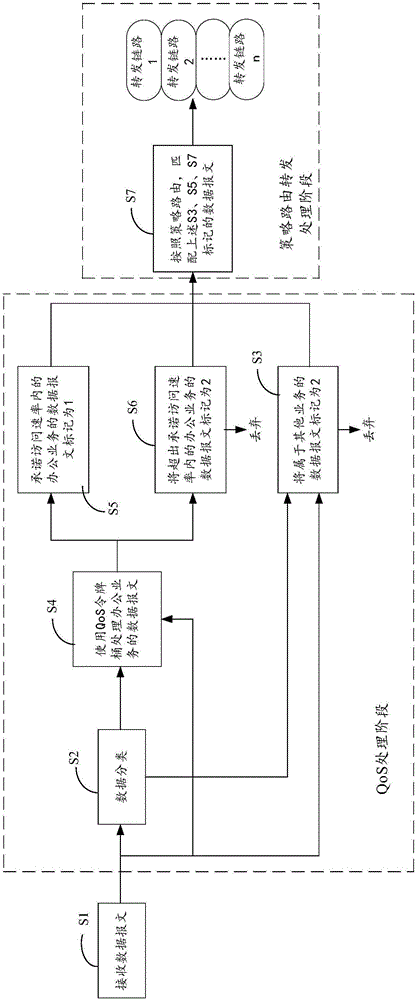

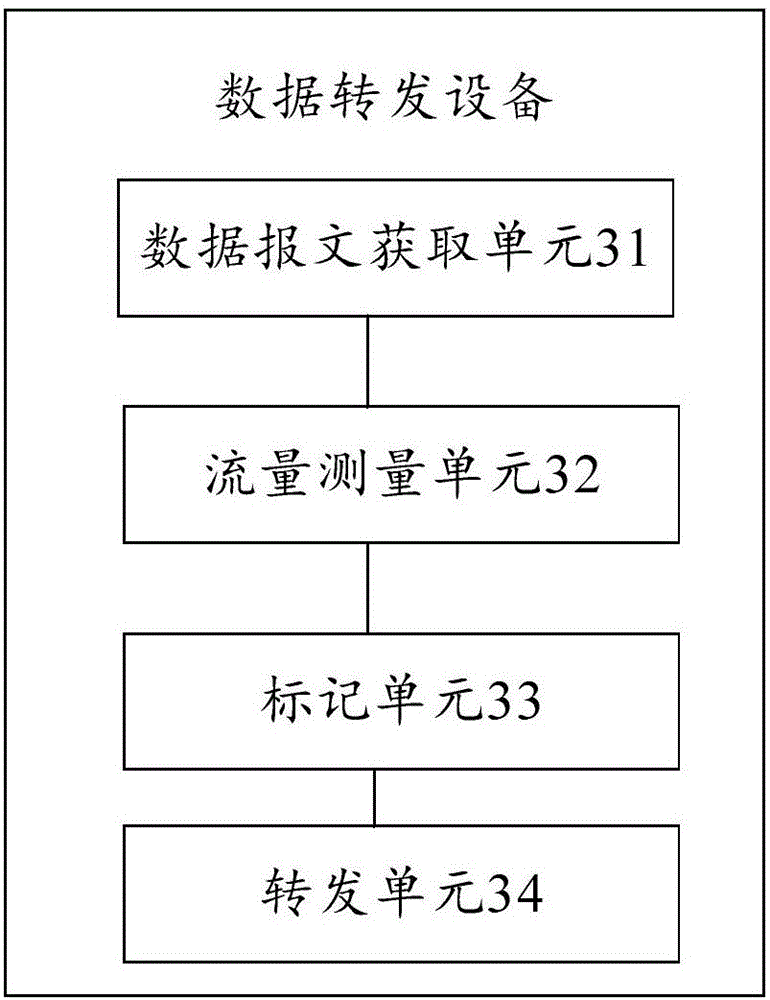

Data forwarding method and device

InactiveCN106357538ARequirements for realizing load forwardingIncrease flexibilityData switching networksTraffic capacityMulti link

The embodiment of the invention discloses a data forwarding method and device, and relates to the communication field. The demand of performing link load forwarding on the data message classification shunt flow can be realized, and the flexibility of the multi-link load forwarding is improved. The data forwarding method comprises the following steps: acquiring data messages; measuring the flow of the data messages with the same service type in the data messages; marking the flow belonging to the promised access rate in the data messages with the same service type as a first forwarding marker; and forwarding the data message with the first forwarding marker identifier according to the preset strategy routing. The method and device disclosed by the embodiment of the invention are used for data forwarding.

Owner:MAIPU COMM TECH CO LTD

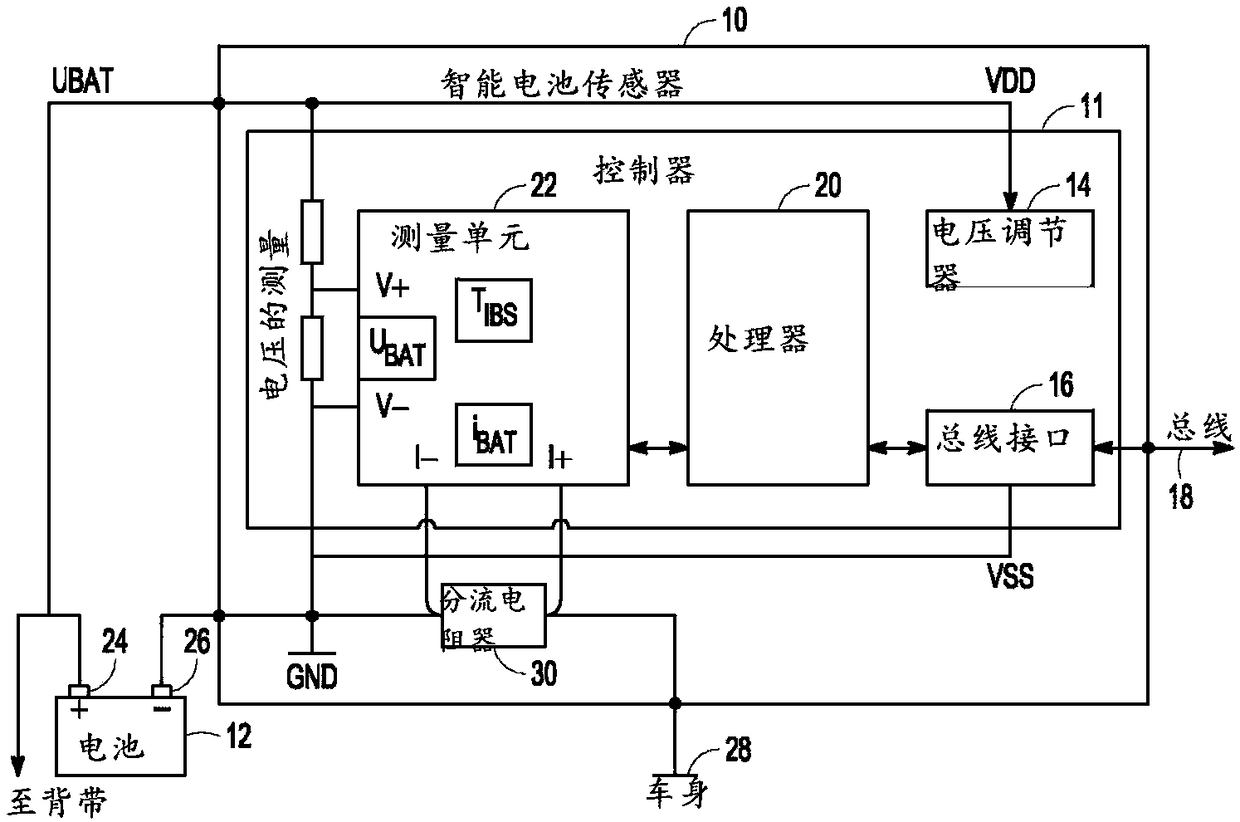

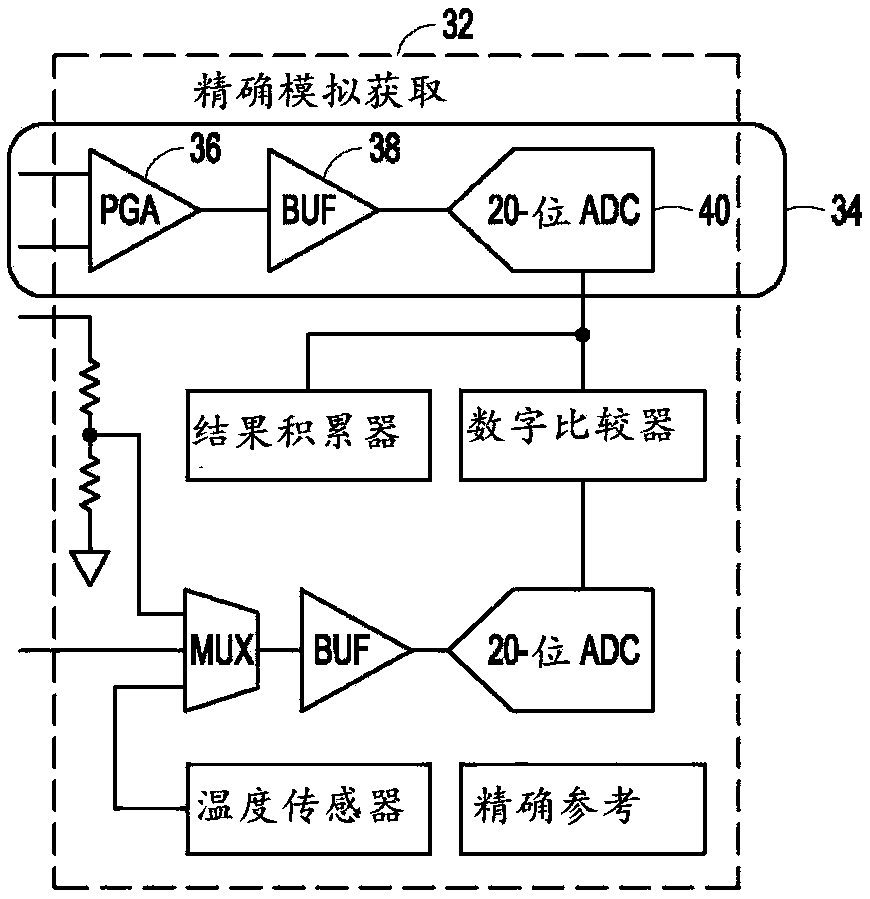

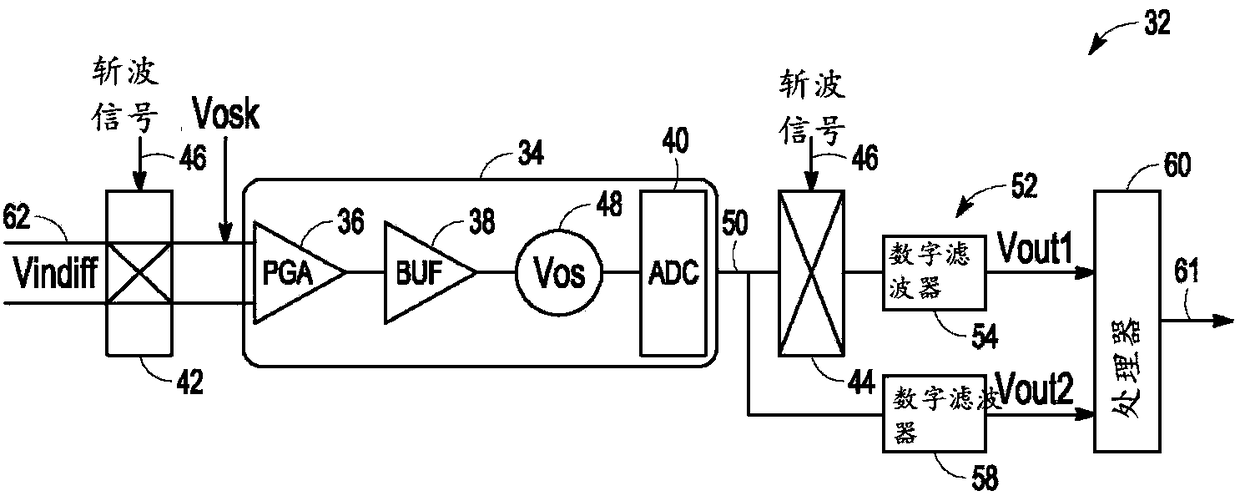

Current measurement techniques to compensate for shunt drift

ActiveCN108693399AResistance/reactance/impedenceSecondary cellsElectrical resistance and conductanceControl theory

The disclosure relates to current measurement techniques to compensate for shunt drift. Described are various current measurement techniques that can compensate for drift in shunt resistance. Determining a resistance of a shunt resistor, e.g., coupled to a battery terminal, can include introducing a known signal in sync with the chop phases of a dual system chop scheme, chopping the known signal out in the main signal path, and explicitly extracting the known signal in a parallel, additional signal deprocessing path.

Owner:ANALOG DEVICES INT UNLTD CO

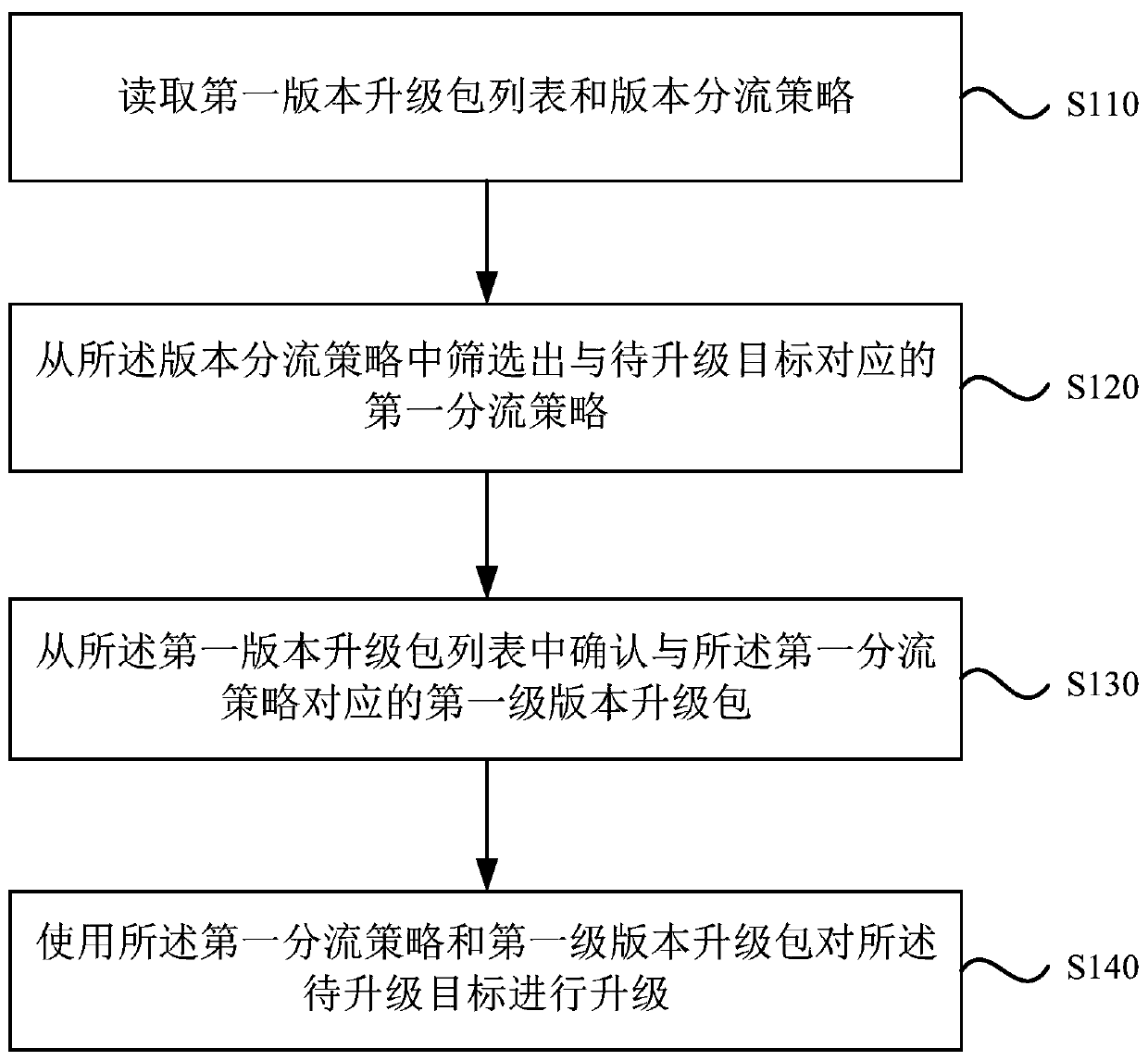

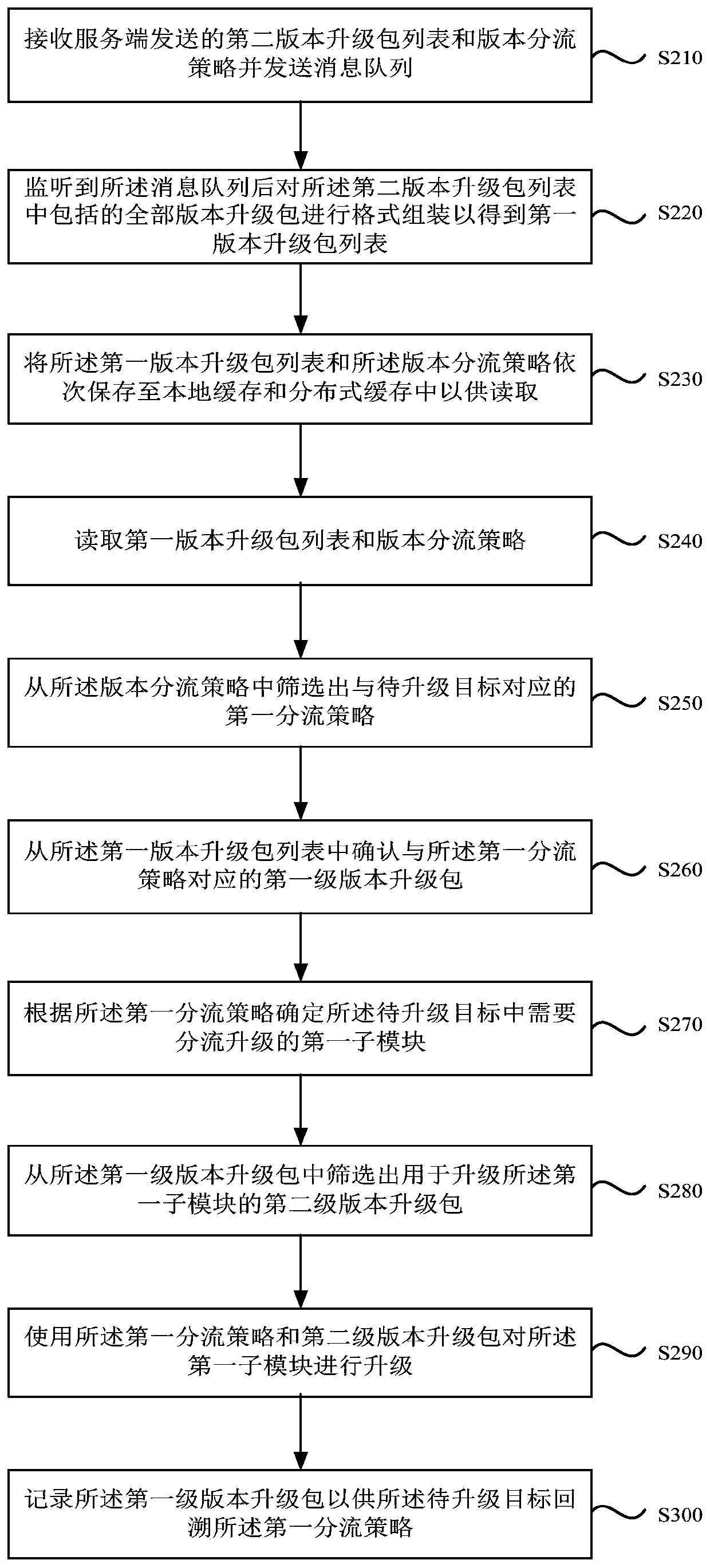

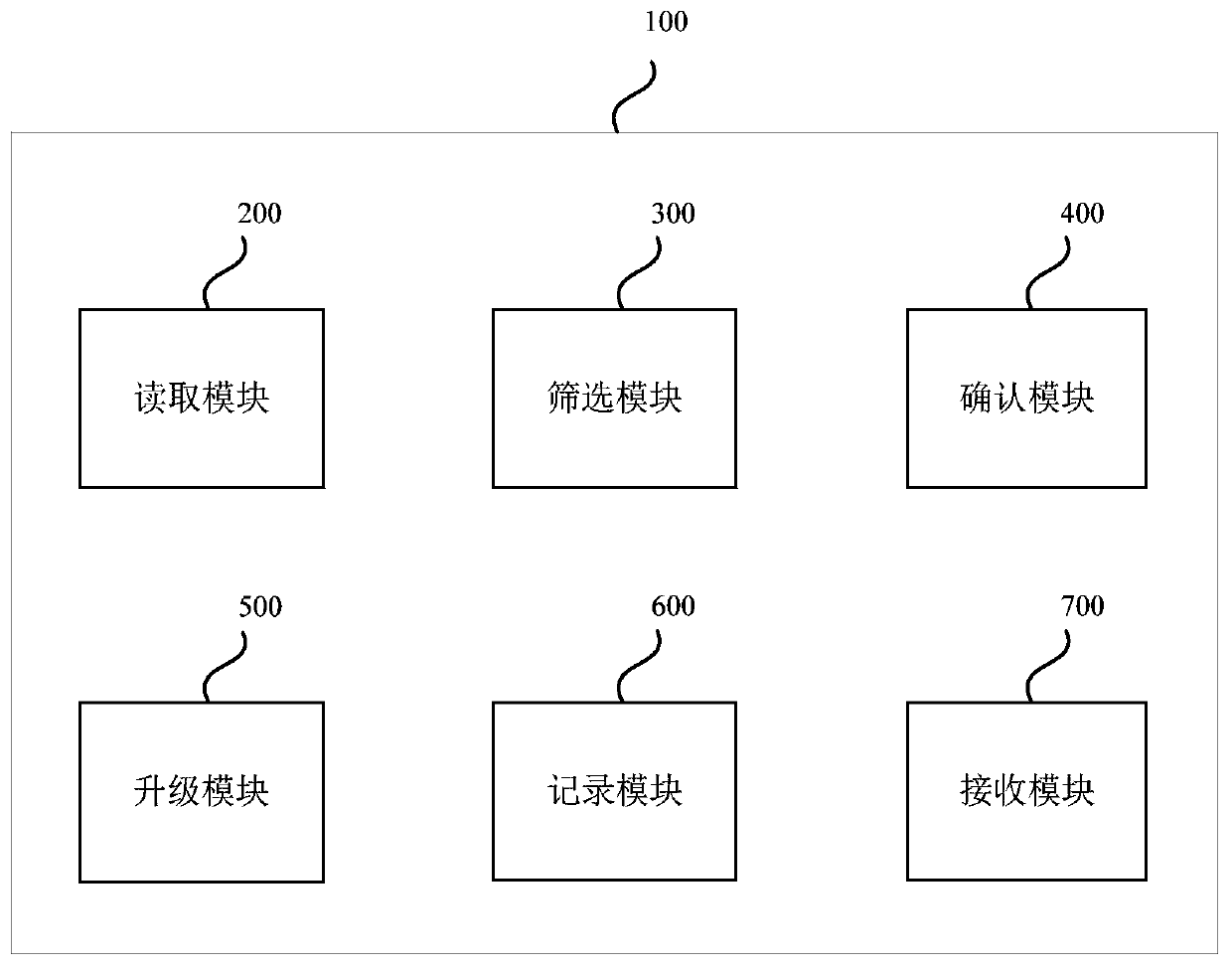

Version upgrading method and device based on shunting, equipment and storage medium

ActiveCN111258607AAchieve unificationAchieve precise resultsTransmissionEnergy efficient computingSoftware engineeringMechanical engineering

The embodiment of the invention discloses a version upgrading method and device based on shunting, equipment and a storage medium. The version upgrading method based on shunting comprises the following steps: reading a first version upgrading package list and a version shunting strategy; screening out a first shunting strategy corresponding to a to-be-upgraded target from the version shunting strategies; determining a first-level version upgrade package corresponding to the first shunting strategy from the first version upgrade package list; and upgrading the to-be-upgraded target by using thefirst shunting strategy and the first-level version upgrading package. According to the embodiment of the invention, the unification and accuracy of shunting during version updating are realized.

Owner:SHENZHEN LEXIN SOFTWARE TECH CO LTD

Flat plate type thermoelectric generator with shunting fins, and fin angle determination method thereof

ActiveCN108390591AImprove output performanceSmall temperature differenceInternal combustion piston enginesEngine componentsHeat conductingEngineering

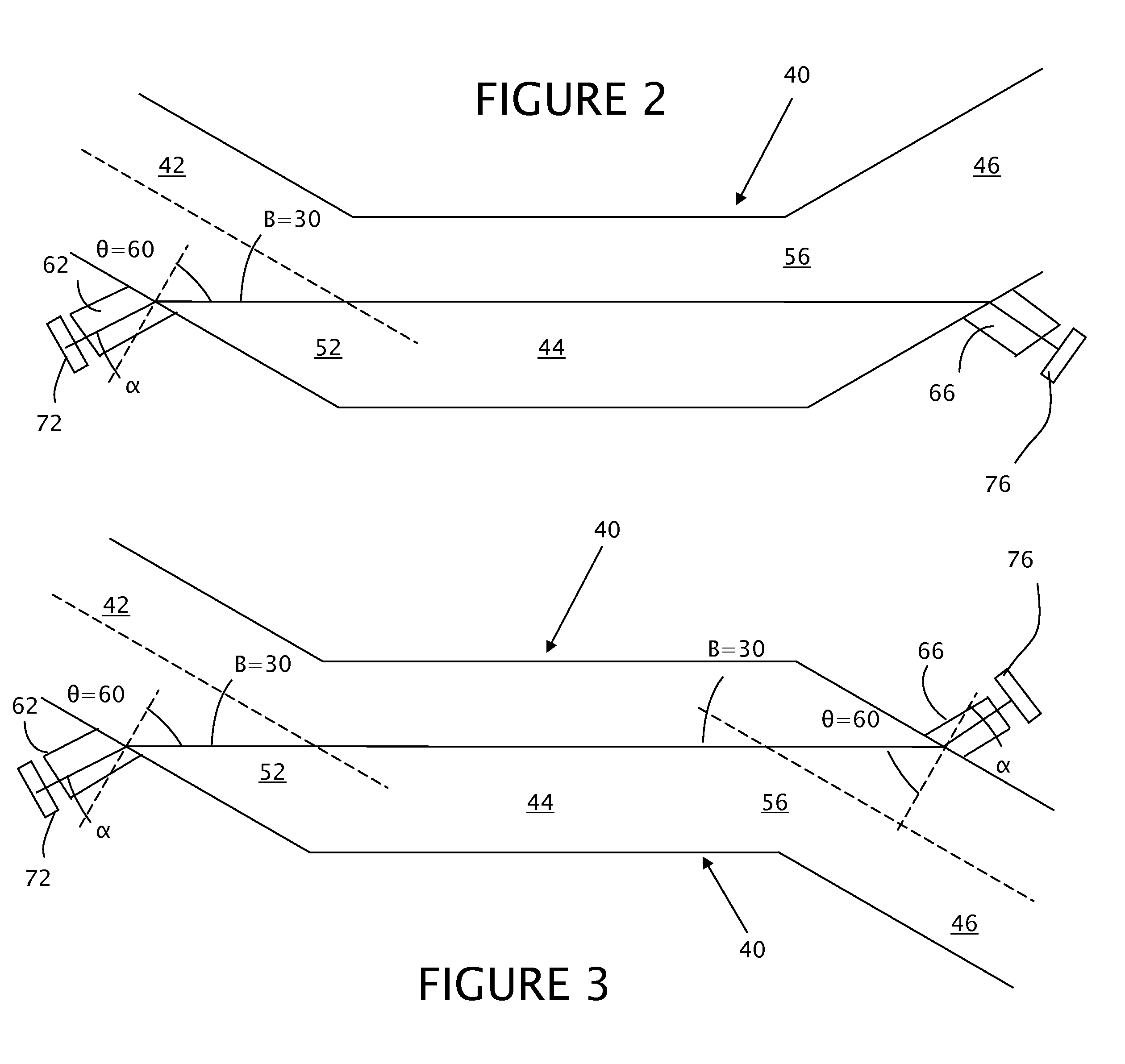

The invention discloses a flat plate type thermoelectric generator with shunting fins, and a fin angle determination method thereof. Three columns of shunting fins are arranged in an air flow direction, including a first shunting fin (mounted in the middle part of a heat collection box with a fixed angle of 45 degrees), a second shunting fin (mounted between the first and third shunting fins witha variable angle of <alpha>), and a third shunting fin (mounted on the tail part of the heat collection box with a fixed angle of 90 degrees). When tail gas flows from an inlet to the heat collectionbox, the tail gas flows to the two ends attached with heat conducting fins under the shunting effect of the shunting fins, so that the wall surface temperature of a hot end is increased; and meanwhile, the second shunting fin is designed with a reasonable angle of <alpha>, so that the overall temperature distribution on the wall surface can be more uniform, and the outputs of the modules are consistent. The flat plate type thermoelectric generator is capable of improving efficiency, simple in structure and wide in application prospect.

Owner:JIANGSU UNIV

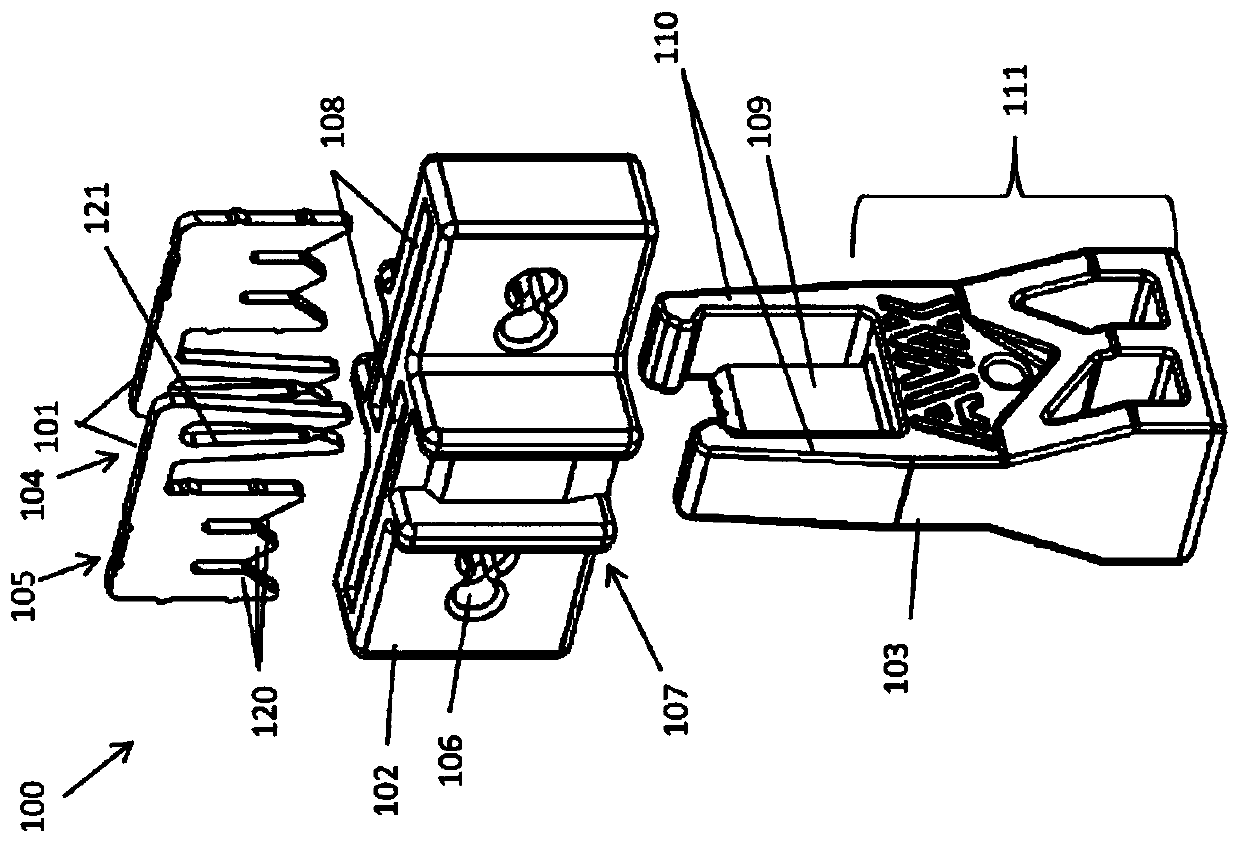

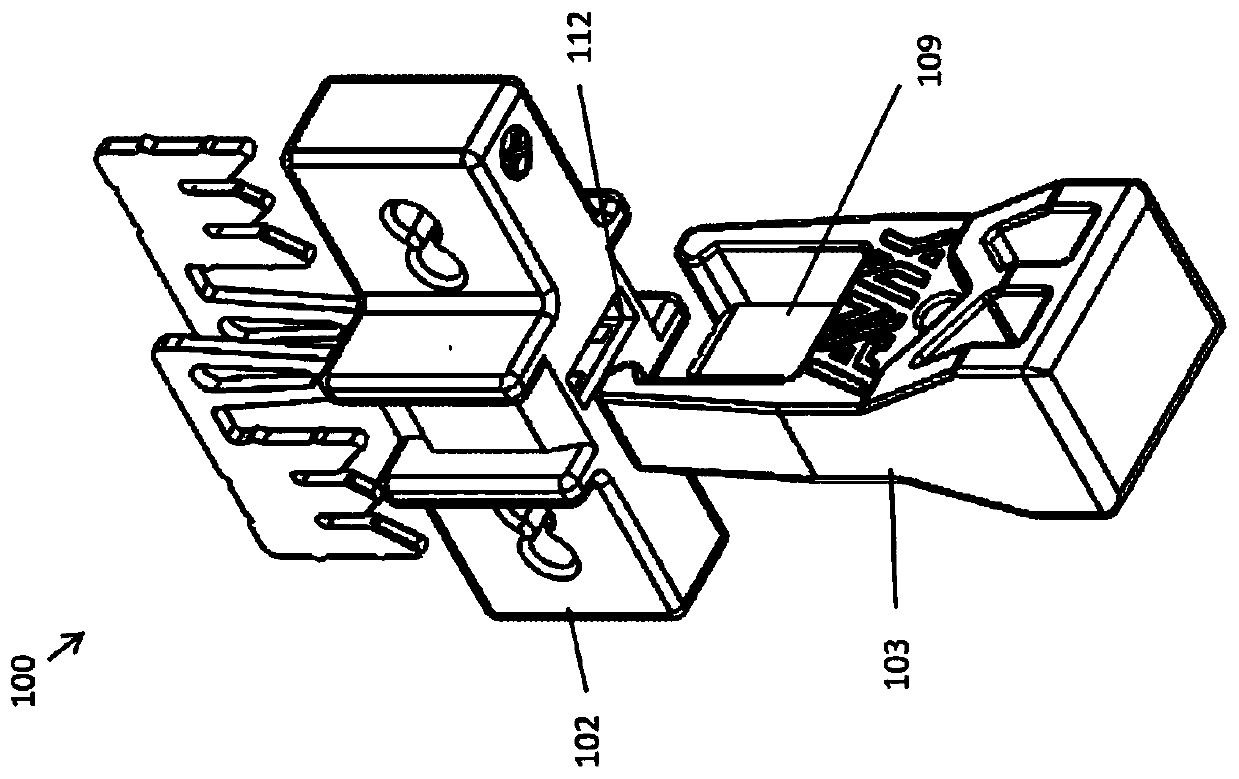

Wire-to-wire connector with shunt

ActiveCN110679042ARelieving strain on wire connectionCoupling contact membersShunt DeviceEngineering

This disclosure provides a method and apparatus for connecting and disconnecting a first wire to a second wire. More specifically, an apparatus that includes a first electrical contact, a second electrical contact, an insulated housing, and a male contact prong (i.e., a shunt) is disclosed. In an embodiment, the first and second electrical contacts conductively connect with a first and second wire, respectively, via an insulation displacement connector. Furthermore, the male contact prong conductively connects (i.e., shunts) the first and second electrical contacts together. A wire-to-wire contact with shunt allows for two wires to be quickly and efficiently connected and disconnected.

Owner:AVX CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com