Small section branch-flow measuring method for large-diameter gas flow and apparatus thereof

A technology for gas flow and measuring device, which is applied in the direction of measuring device, measuring flow/mass flow, liquid/fluid solid measurement, etc. Flexibility of use, ease of assembly and operation, great effect of flexibility of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

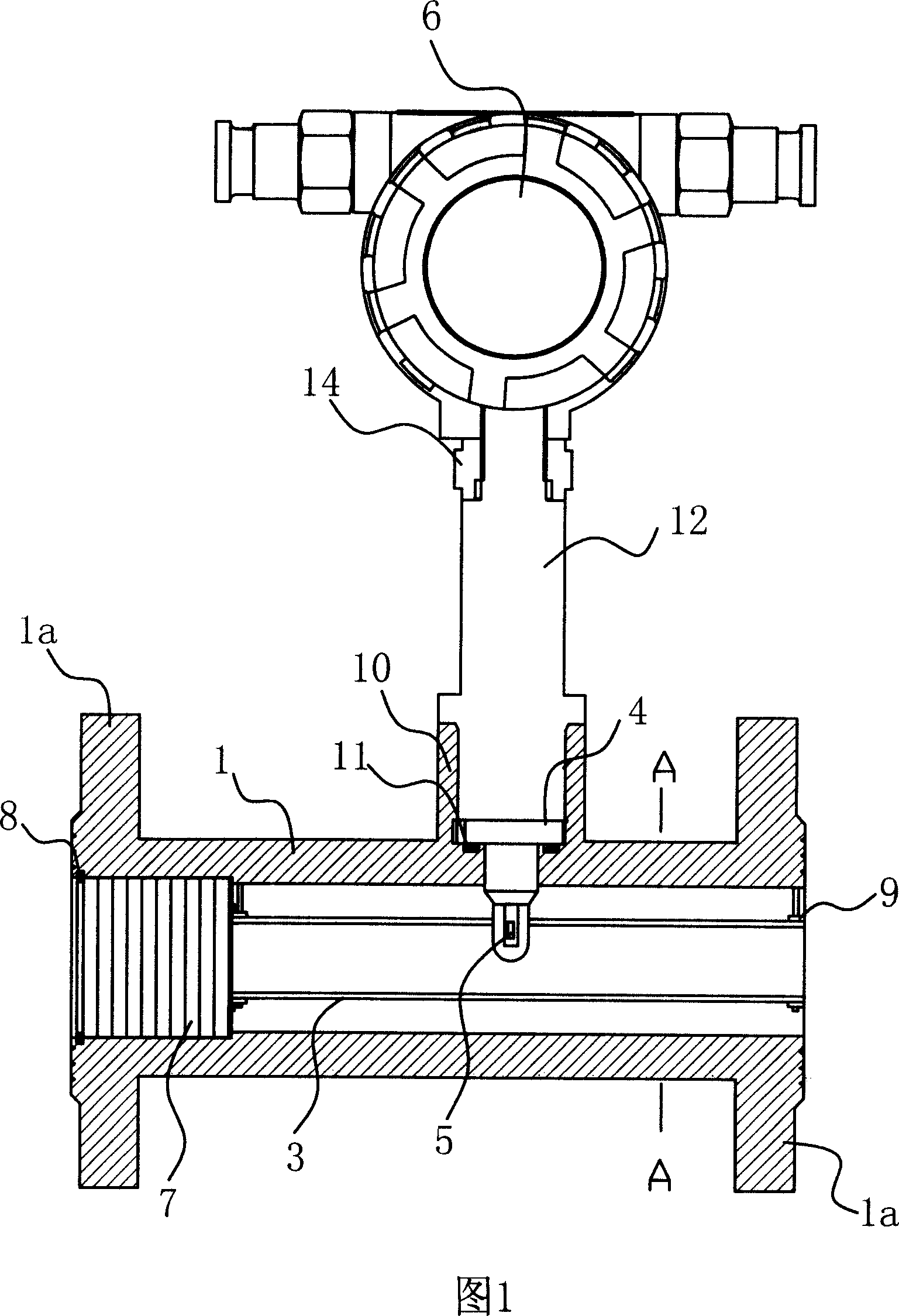

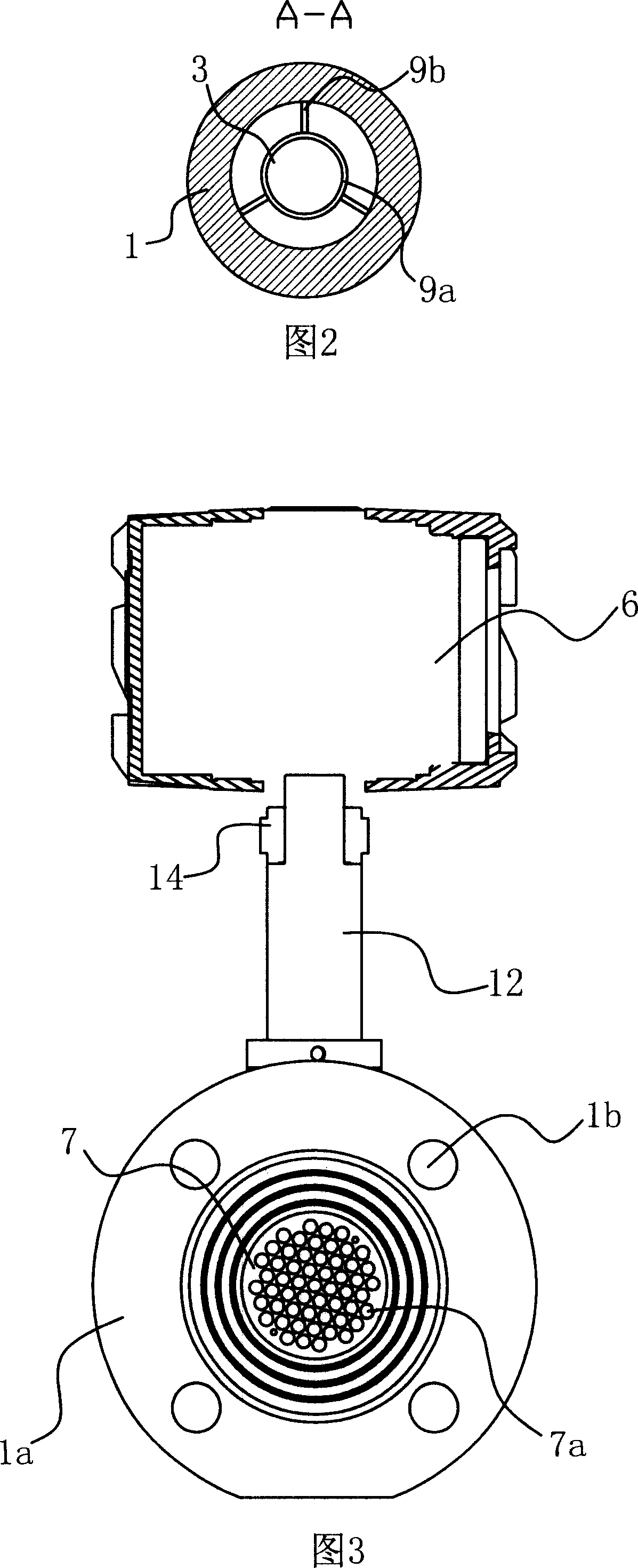

[0031] The small-section shunt measurement method for large-diameter gas flow includes the following measurement steps: a. Proportional shunt: at least one shunt pipe with a smaller diameter is set in the large-diameter pipeline, and the airflow to be measured in the large-diameter pipeline is divided by the shunt device. Divert the flow into the shunt according to the preset ratio; b. Flow measurement of the shunt: set a flow sensor in the shunt, and detect the gas flow in the shunt through the flow sensor; c. Flow conversion: measure the flow value in the shunt according to the set value. The given diversion ratio is converted into the total gas flow rate in the large-diameter pipeline.

[0032] In this embodiment, a shunt pipe is provided, and the shunt pipe is arranged on the central axis of the pipeline. The flow sensor used to measure the flow is a thermal mass flow sensor and rectifies the air flow before it is proportionally split.

[0033] The above method is realize...

Embodiment 2

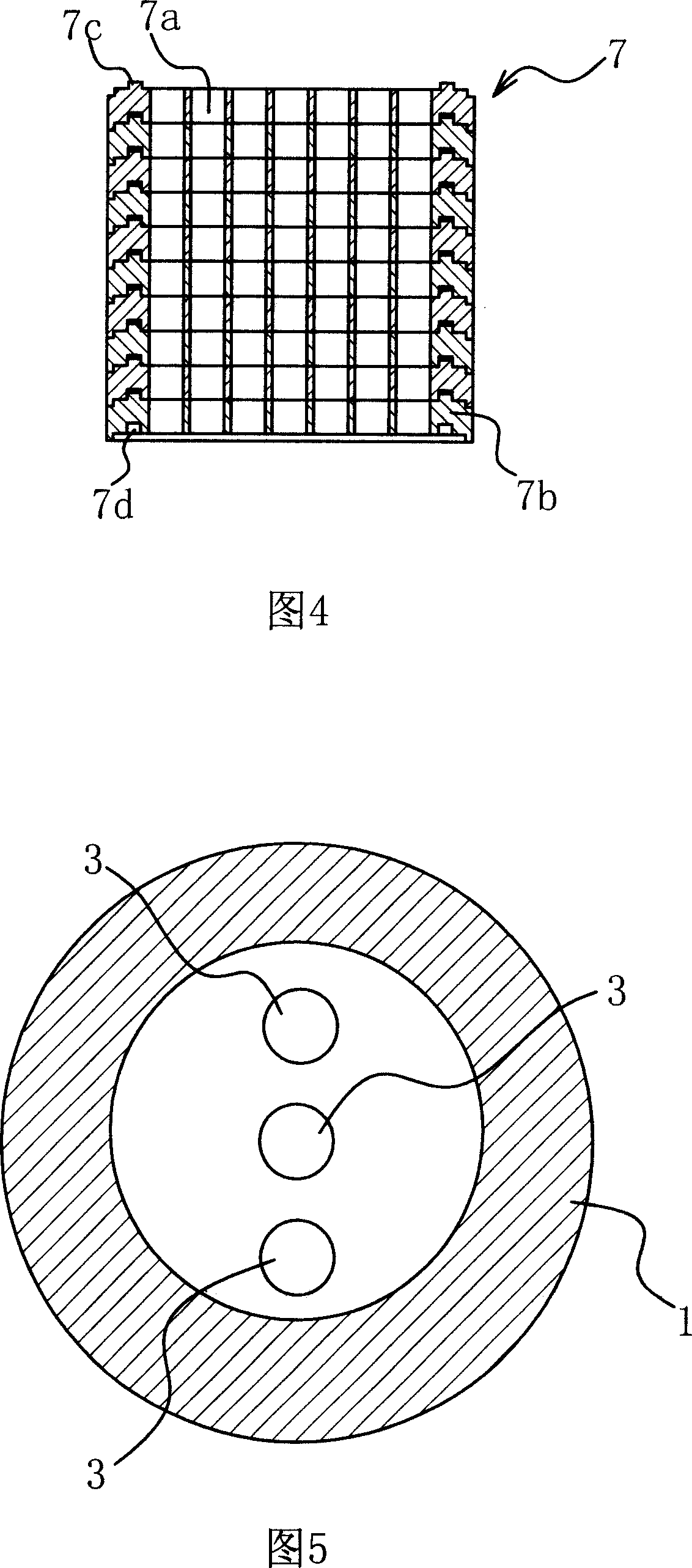

[0037] As shown in FIG. 5 , three shunt pipes 3 are provided in the ventilation pipe 1 . The shunt pipes 3 are evenly distributed in the ventilation pipe 1 , and one shunt pipe 3 is arranged on the central axis of the ventilation pipe 1 . Take the average value of the shunt flow rate measured in each shunt pipe 3, and use the average value to calculate the total gas flow rate in the large-diameter pipeline according to the shunt ratio. The rest are similar to those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0039] In this embodiment, the values of the divided flow measured in each of the divided pipes are accumulated, and the accumulated value is used to calculate the total gas flow rate in the large-diameter pipe according to the divided flow ratio. The rest are similar to those in Embodiment 2, and will not be repeated here.

[0040] In the present invention, the signal processing process and the proportional calculation process of the flow sensor are well known in the prior art, and can be easily implemented by those skilled in the art, which will not be described herein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com