Flat plate type thermoelectric generator with shunting fins, and fin angle determination method thereof

A technology for thermoelectric generators and determination methods, which is applied in the direction of generators/motors, electrical components, engine components, etc., and can solve problems such as uneven temperature distribution on the wall surface of the hot end of TEG, inconsistent output of a single thermoelectric power generation module, and influence on TEG output power, etc. , to achieve the effect of improving the output performance and reducing the overall temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

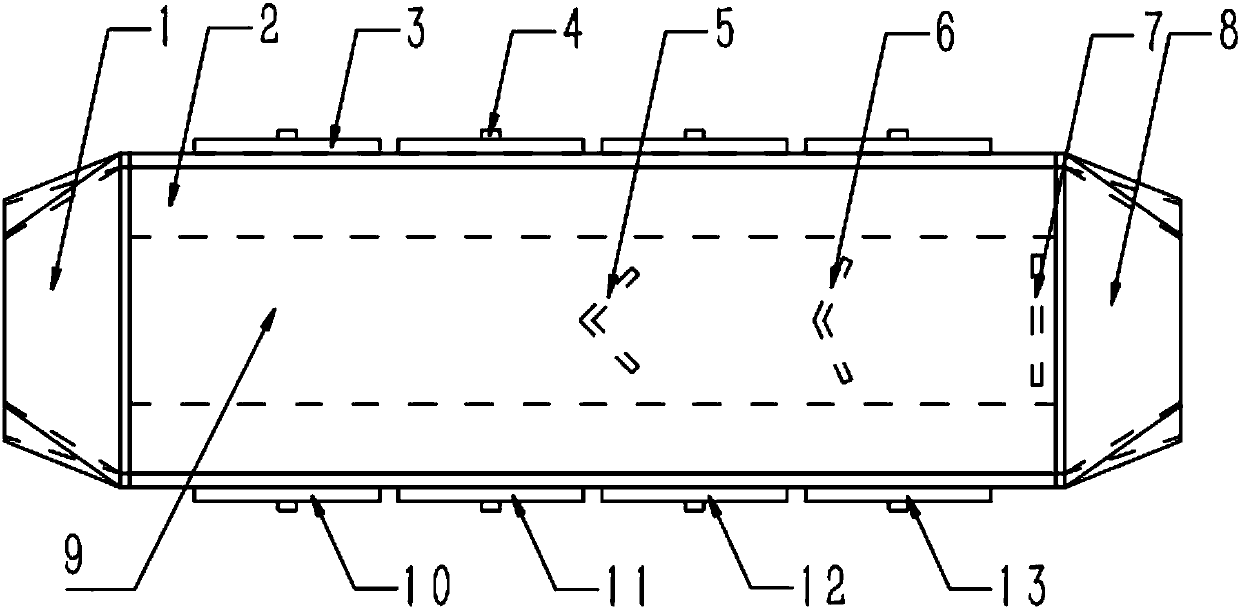

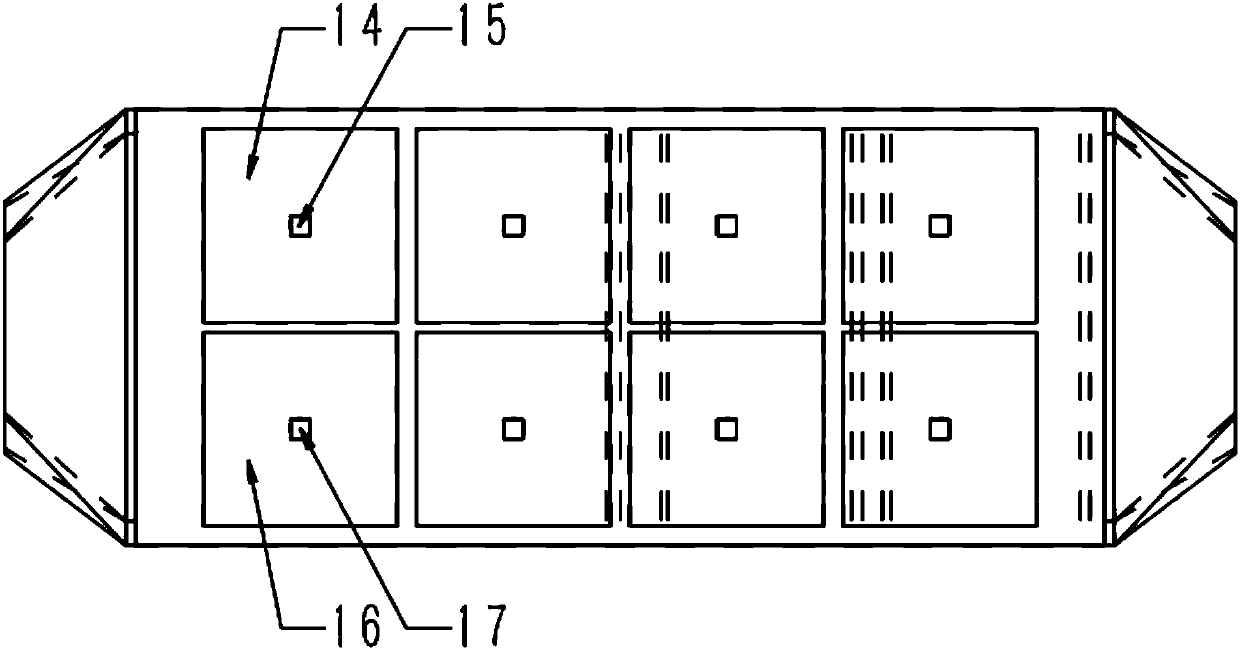

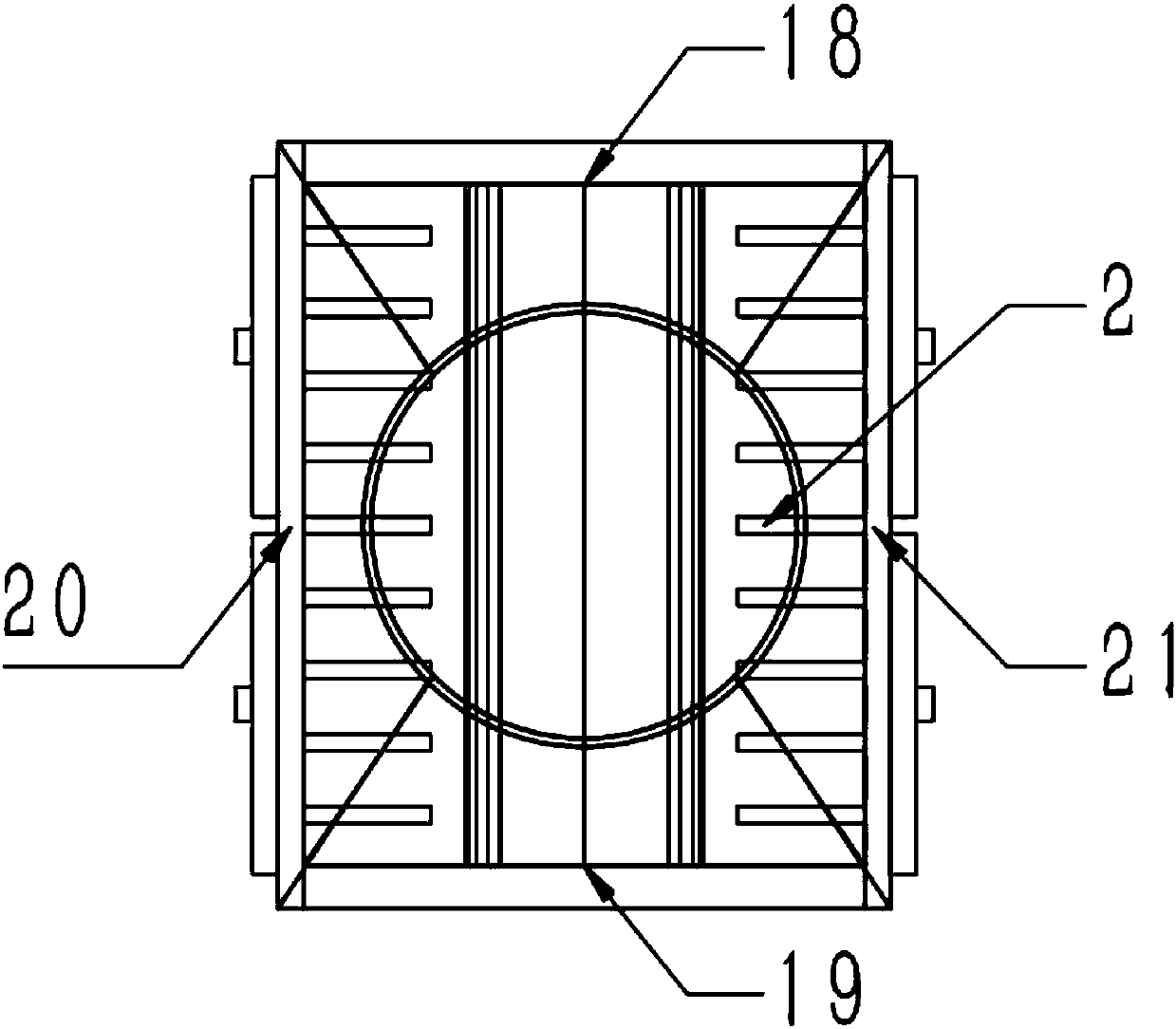

[0036] Such as Figure 1-3 As shown, a flat-plate thermoelectric generator with shunt fins includes a heat collection box 9, a heat conduction fin 2, a flow splitter, a thermoelectric power generation module 3, and a temperature sensor 4; the heat conduction fin 2 is attached to the set On the wall a20 on both sides of the heat box and the wall a'21 of the heat collection box; the splitter fins are connected to the upper wall b18 and the lower wall b'19 inside the heat collection box, including the first splitter fin 5, the second splitter fin Fins 6, third splitter fins 7; the thermoelectric power generation modules 3 are evenly distributed on both side walls outside the heat collecting box, including thermoelectric power generation module 1 zone 10, thermoelectric power generation module 2 zone 11, thermoelectric power generation module Zone 3 12 and zone 4 of thermoelectric power generation module 13, the inlet end cover 1 of the heat collector box is close to zone 1 of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com