Compound anode of solid-oxide fuel battery and method for producing the same

A solid oxide and composite anode technology, applied in the field of solid oxide fuel cells, can solve the problems of nickel-based catalyst sintering, weak interaction, low anode activity, etc., achieve low polarization resistance, high activity, improve anode performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Effects of Lanthanum-modified Solid Oxide Fuel Cell Composite Anodes on Battery Performance

[0028] Using the co-decomposition method of nitrate (decomposition at 800°C), the lanthanum-modified nickel oxide is obtained. Lanthanum-modified nickel oxide (wherein Ni:La=1:0.08, molar ratio) is selected as the anode catalytic material, in which 8YSZ (the molar content of yttrium oxide in YSZ is 8%) accounts for 40% (weight ratio), and is prepared by dry pressing A composite anode substrate with a thickness of 0.7 mm was sintered at 1200° C. for 5 hours to obtain a composite anode; a layer of slurry containing YSZ with a thickness of 10 μm was coated on it. The anode / electrolyte assembly was obtained by sintering at 1600 °C for 3 h; after the LSM electrocatalyst and YSZ were mixed (50:50 by weight), the composite cathode was prepared by screen printing and sintered at 1100 °C for 5 h.

[0029] The conventional Ni-YSZ anode battery was used as a comparison battery. When hyd...

Embodiment 2

[0031] Effects of composite anodes for solid oxide fuel cells prepared by directly mixing lanthanum oxide with nickel oxide and YSZ on battery performance

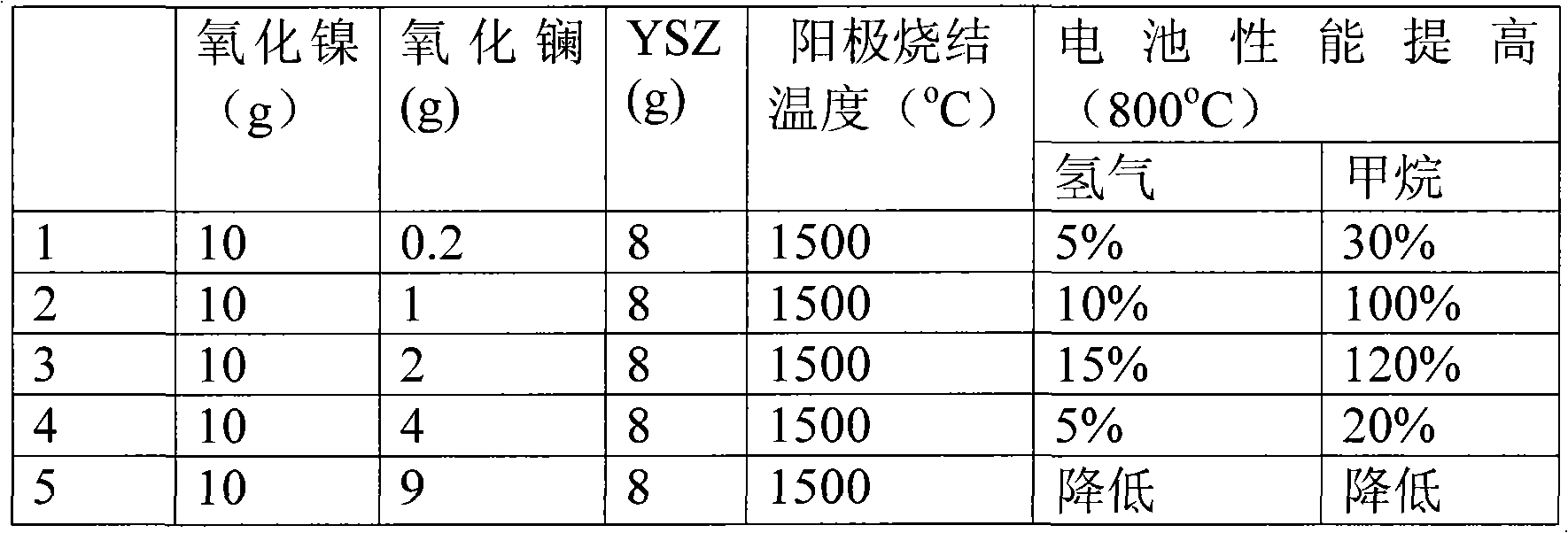

[0032] A composite anode was prepared by directly mixing lanthanum oxide, nickel oxide and 8YSZ (the molar content of yttrium oxide in YSZ was 8%), and a battery was prepared. The modification results of the battery are shown in Table 1.

[0033] Table 1

[0034]

[0035] It can be seen from Table 1 that the battery performance gradually increases with the increase of the lanthanum content, but the battery performance deteriorates when the lanthanum content is high.

Embodiment 3

[0037] Effects of Lanthanum Modified Composite Anodes on the Performance of Tubular Solid Oxide Fuel Cells

[0038]Using the co-decomposition method of nitrate (decomposition at 800°C), the lanthanum-modified nickel oxide is obtained. Select lanthanum-modified nickel oxide as the anode catalyst material (wherein Ni:La=1:0.1, molar ratio), mix it with 8YSZ (the molar content of yttrium oxide in YSZ is 8%) (50:50 by weight), and use inorganic A tubular anode support was prepared by membrane technology, and a layer of slurry containing YSZ with a thickness of 50 μm was coated on it. After drying, it was sintered at 1600°C for 2h to obtain an anode / electrolyte assembly. After LSM electrocatalyst and YSZ were mixed (weight ratio 50:50), the composite cathode was prepared and sintered at 1300°C for 3h. The traditional Ni-YSZ anode tubular battery was used as a comparison battery. When hydrogen is used as the fuel gas, the performance of the lanthanum-modified battery is compared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com