Patents

Literature

1571 results about "Yttrium(III) oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Yttrium oxide, also known as yttria, is Y₂O₃. It is an air-stable, white solid substance. Yttrium oxide is used as a common starting material for both materials science as well as inorganic compounds.

Yttria-based material coated chemical vapor deposition chamber heater

ActiveUS20140263272A1Improve wear resistanceImprove flexural strengthLiquid surface applicatorsMolten spray coatingYTTERBIUM OXIDEFlexural strength

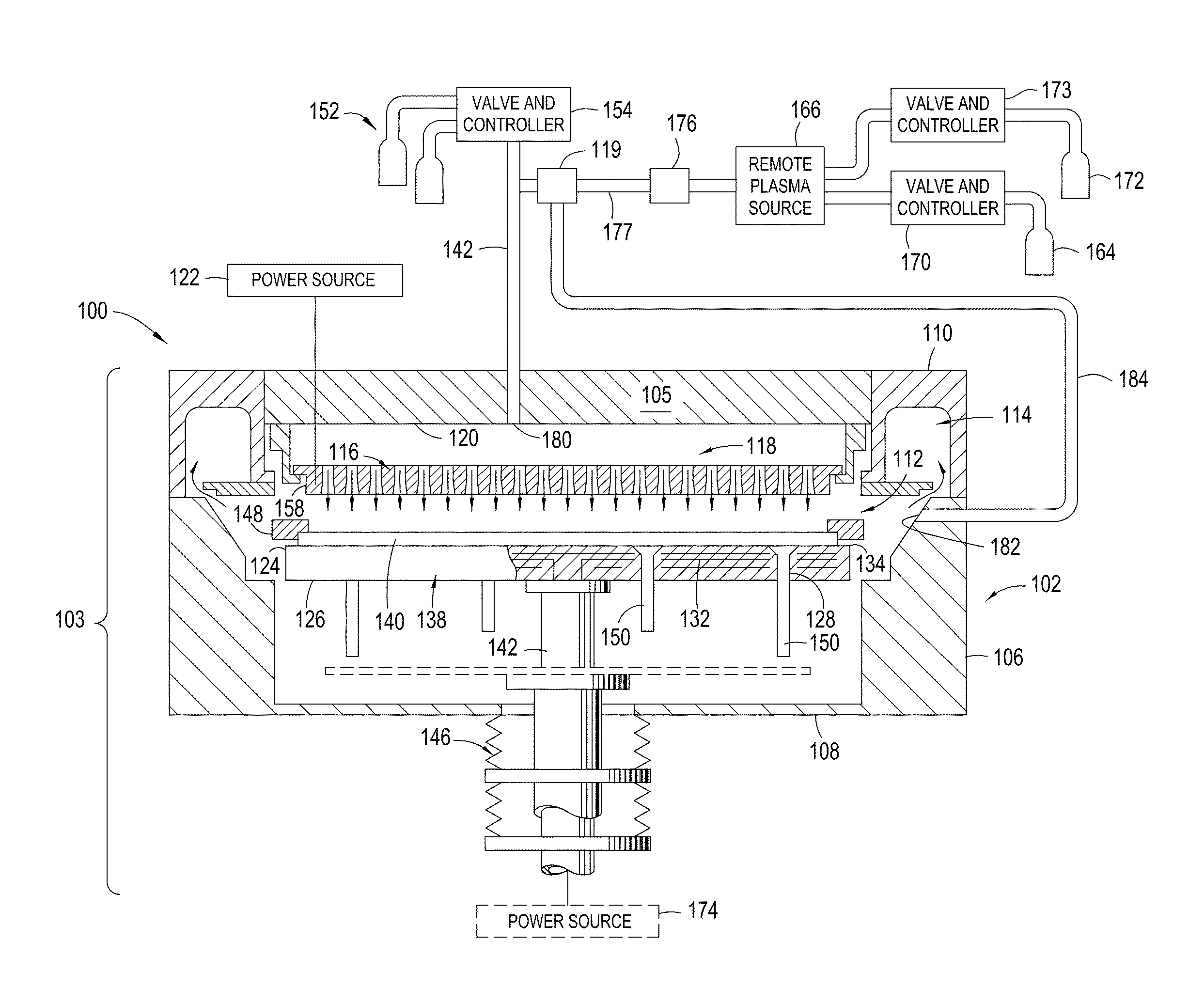

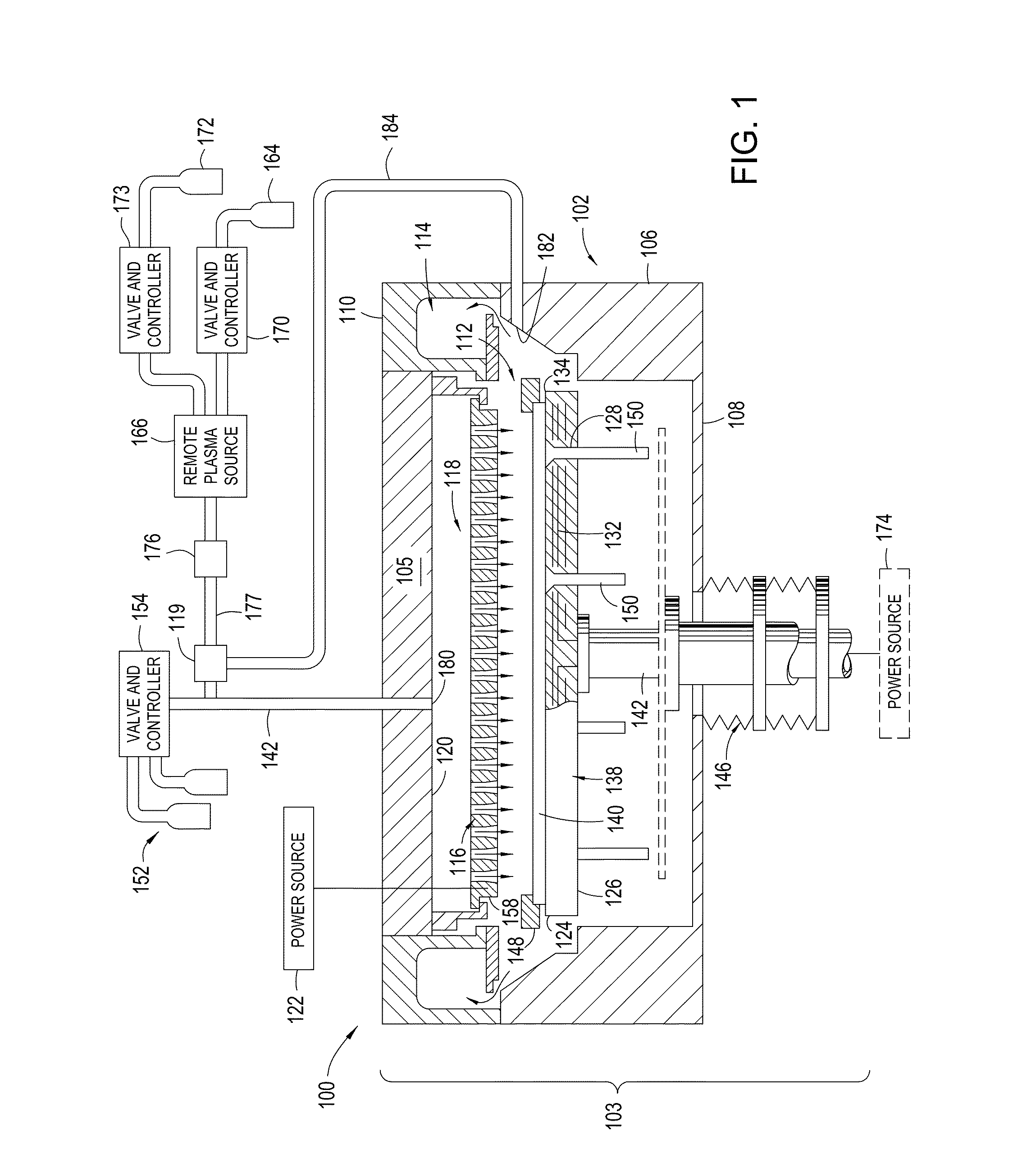

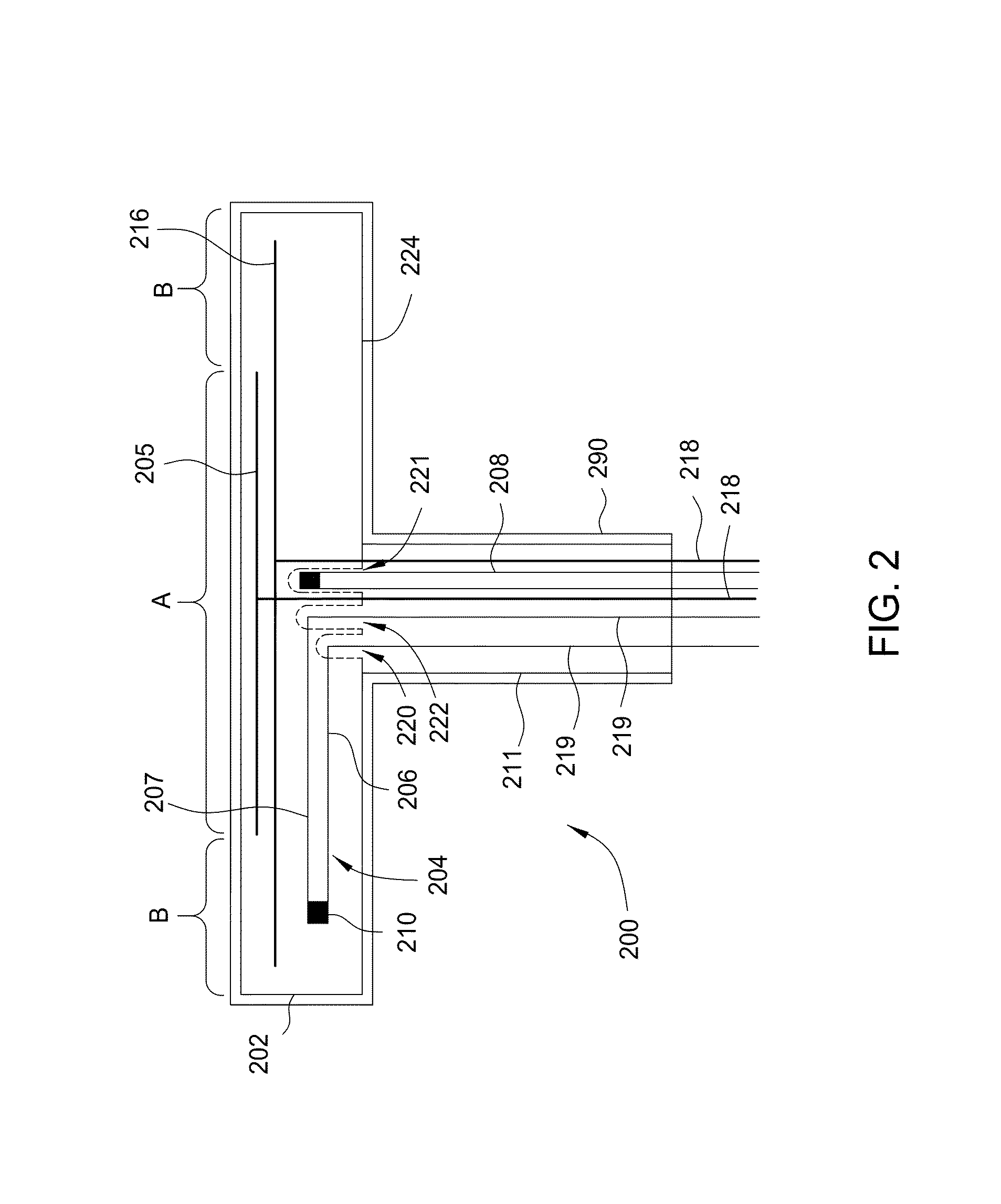

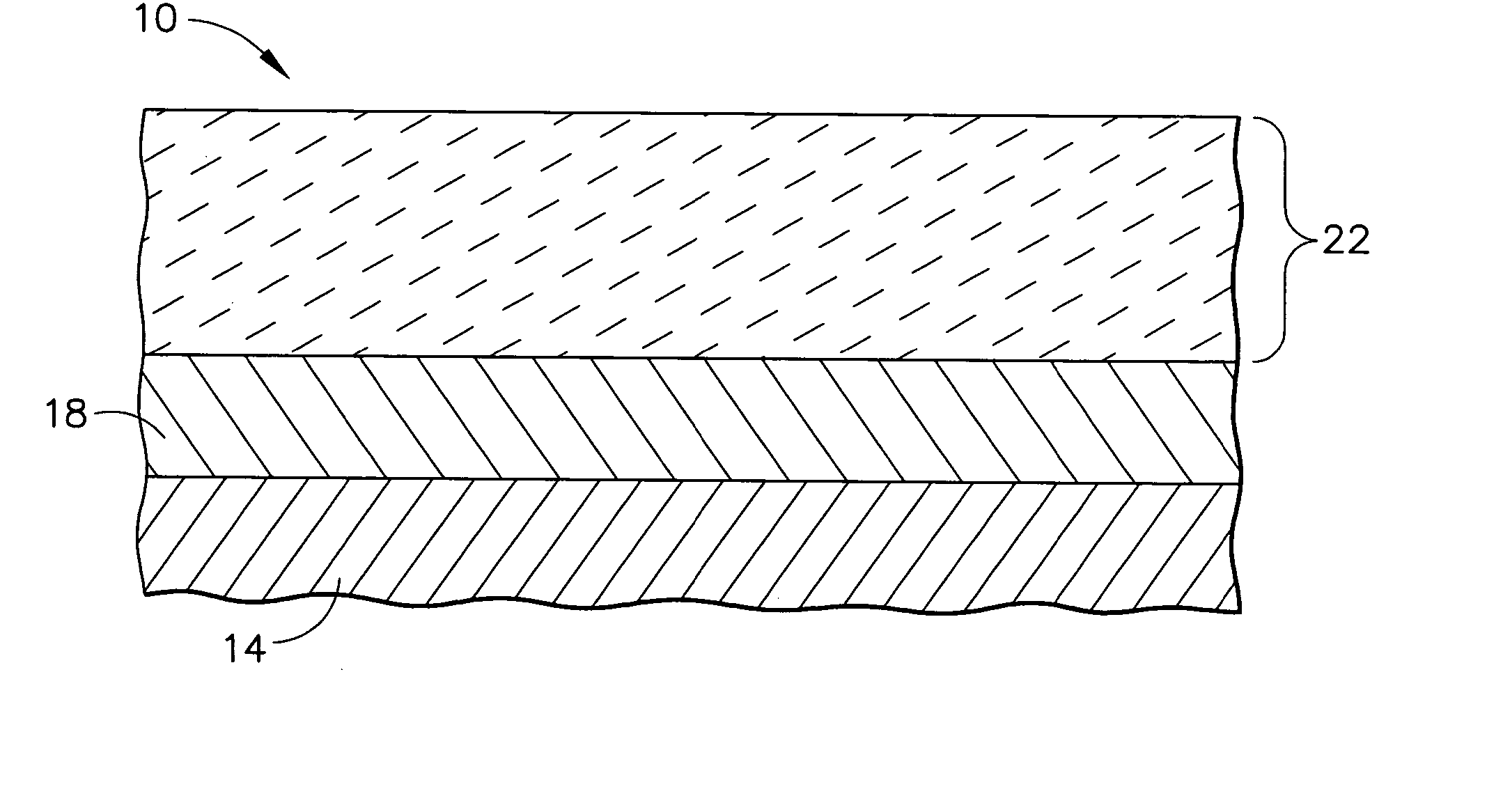

Embodiments of the present invention generally relate to heated substrate supports having a protective coating thereon. The protective coating is formed from yttrium oxide at a molar concentration ranging from about 50 mole percent to about 75 mole percent; zirconium oxide at a molar concentration ranging from about 10 mole percent to about 30 mole percent; and at least one other component, selected from the group consisting of aluminum oxide, hafnium oxide, scandium oxide, neodymium oxide, niobium oxide, samarium oxide, ytterbium oxide, erbium oxide, cerium oxide, and combinations thereof, at a molar concentration ranging from about 10 mole percent to about 30 mole percent. The alloying of yttrium oxide with a compatible oxide improves wear resistance, flexural strength, and fracture toughness of the protective coating, relative to pure yttrium oxide.

Owner:APPLIED MATERIALS INC

Clean, dense yttrium oxide coating protecting semiconductor processing apparatus

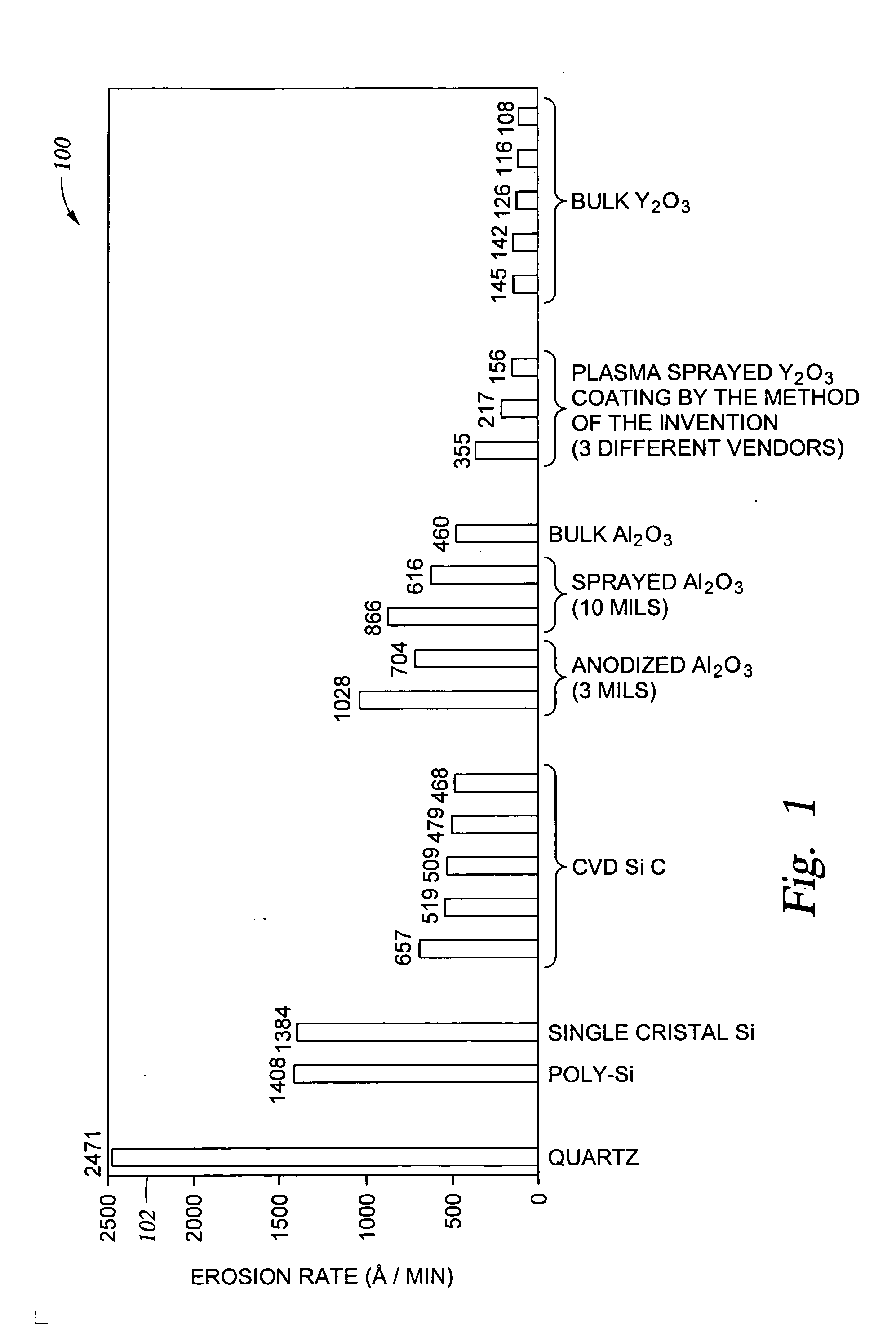

ActiveUS20050037193A1Extended service lifeExcellent plasma corrosion-resistanceLiquid surface applicatorsMolten spray coatingPlasma coatingChemical vapor deposition

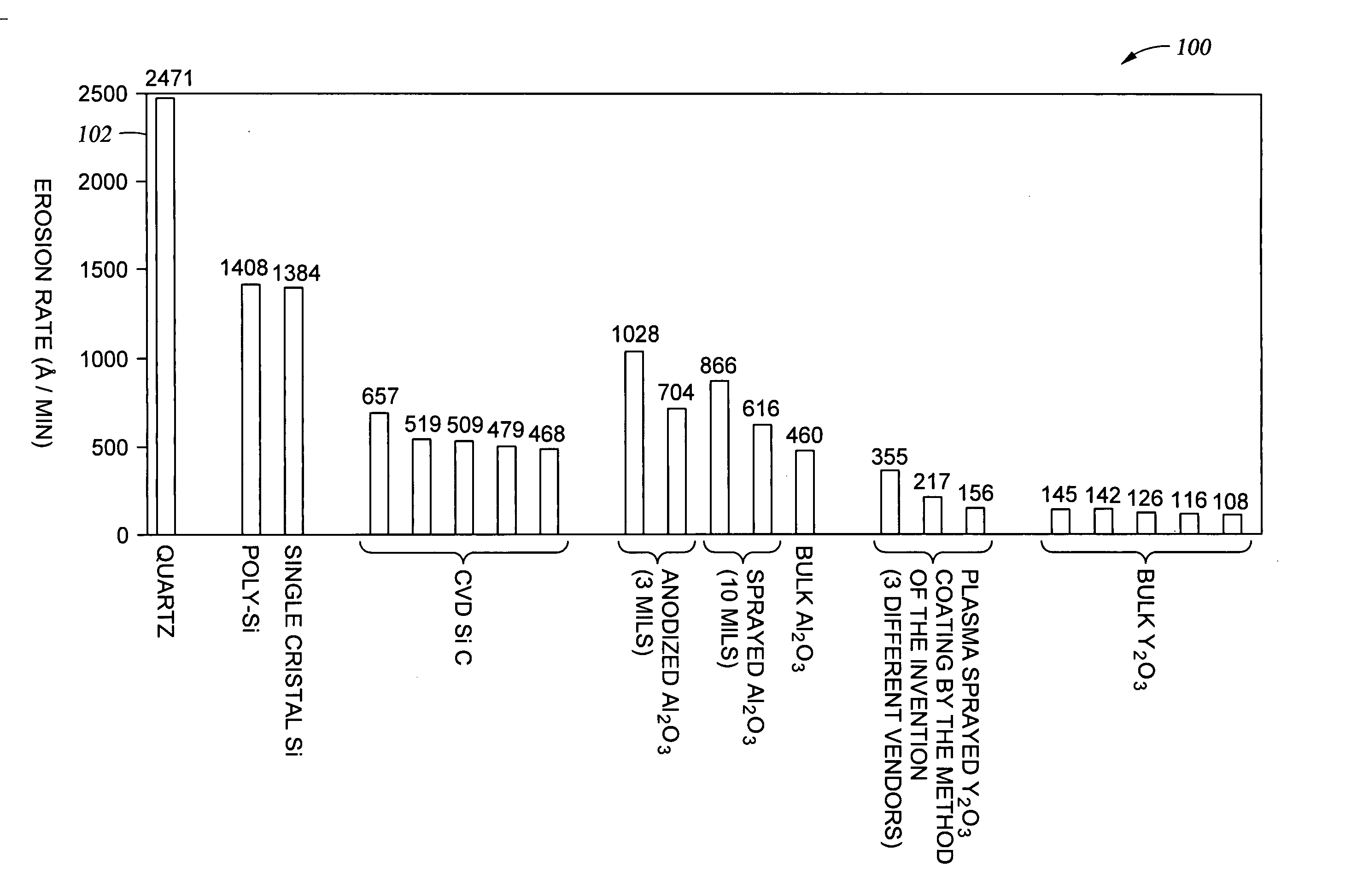

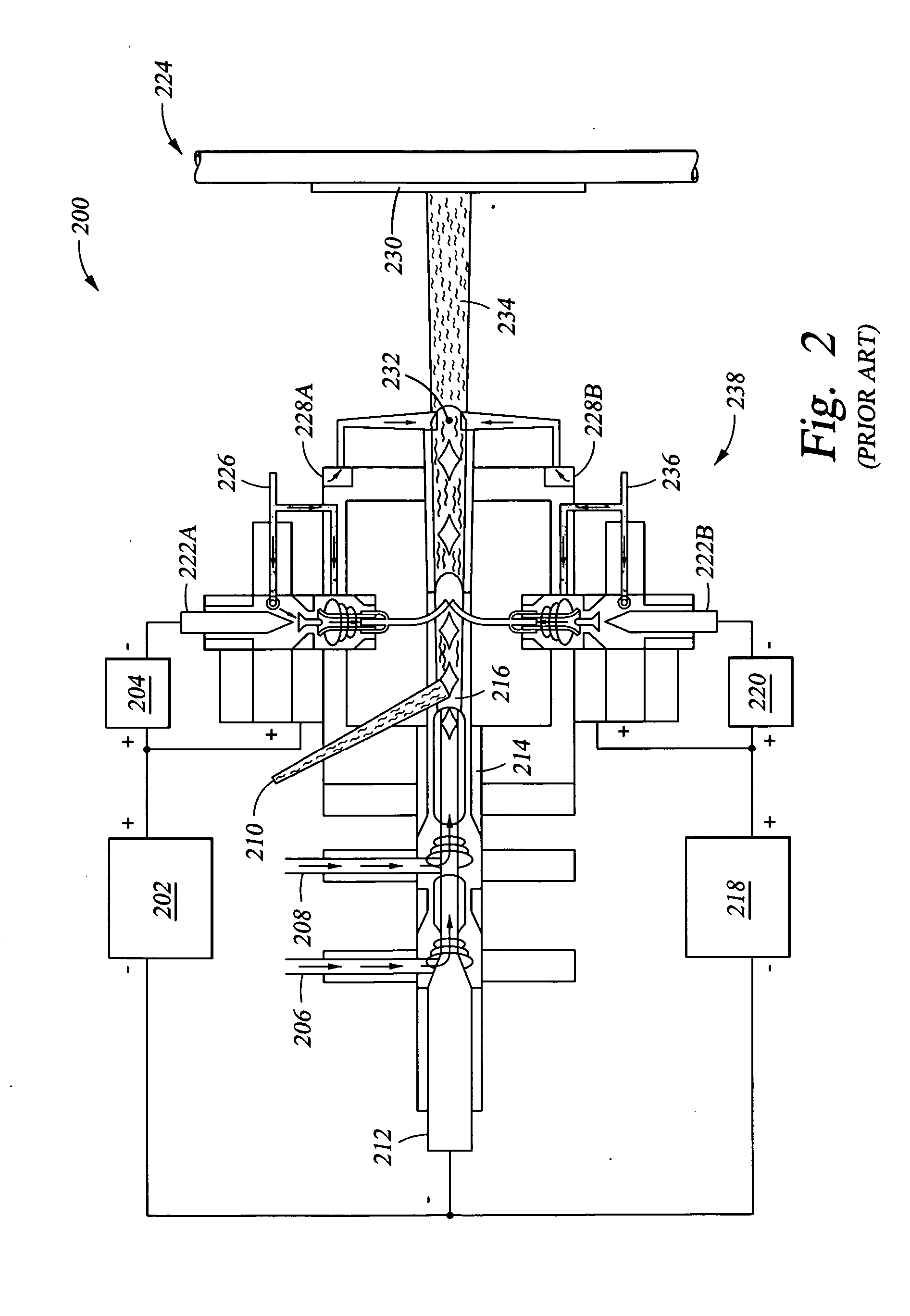

Disclosed herein is a method for applying plasma-resistant coatings for use in semiconductor processing apparatus. The coatings are applied over a substrate which typically comprises an aluminum alloy of the 2000 series or the 5000 through 7000 series. The coating typically comprises an oxide or a fluoride of Y, Sc, La, Ce, Eu, Dy, or the like, or yttrium-aluminum-garnet (YAG). The coating may further comprise about 20 volume % or less of Al2O3. The coatings are typically applied to a surface of an aluminum alloy substrate or an anodized aluminum alloy substrate using a technique selected from the group consisting of thermal / flame spraying, plasma spraying, sputtering, and chemical vapor deposition (CVD). To provide the desired corrosion resistance, it is necessary to place the coating in compression. This is accomplished by controlling deposition conditions during application of the coating.

Owner:APPLIED MATERIALS INC

Method of depositing rare earth oxide thin films

InactiveUS6858546B2Increase probabilityIncrease ratingsPolycrystalline material growthSemiconductor/solid-state device manufacturingDeposition temperatureGadolinium

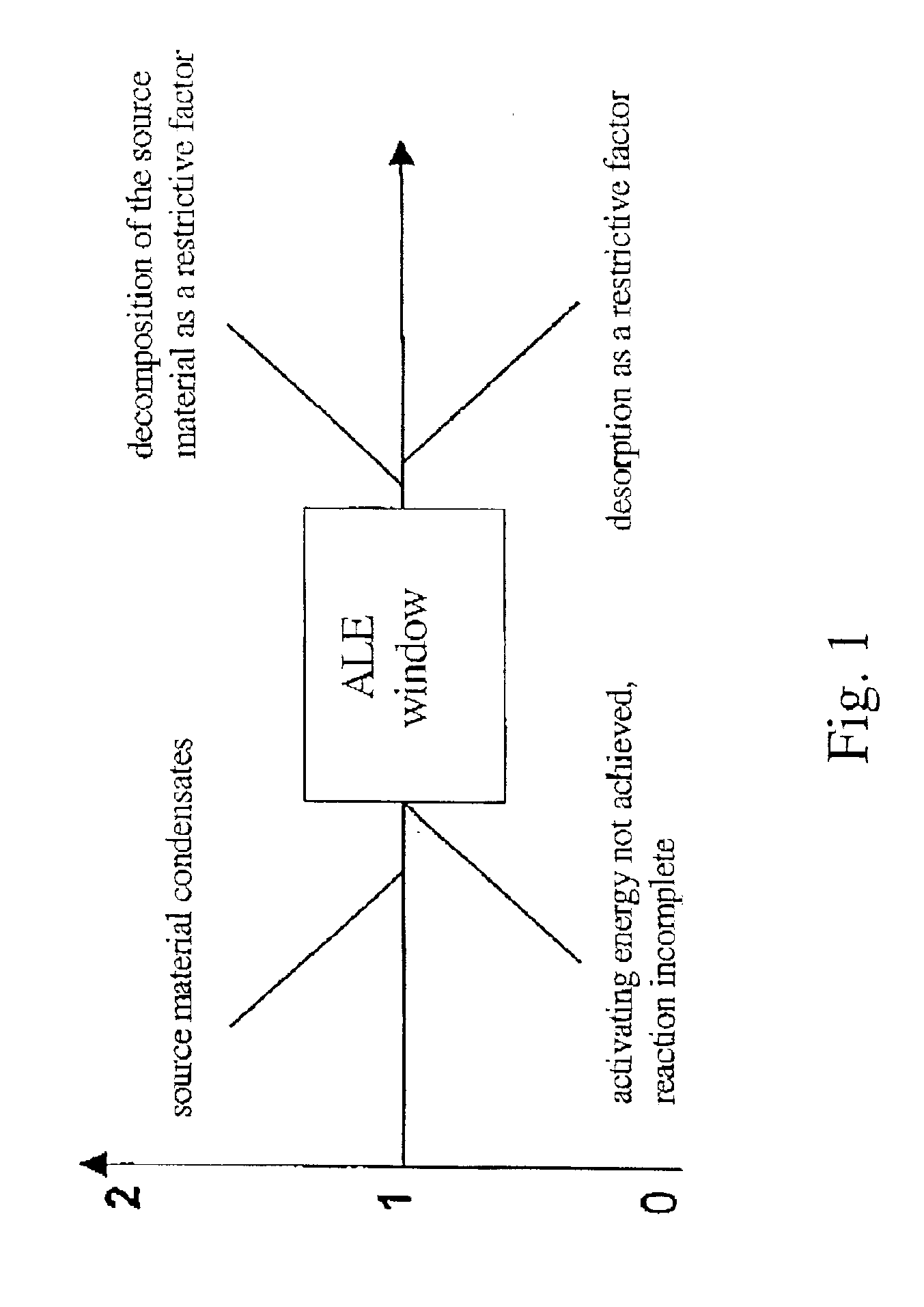

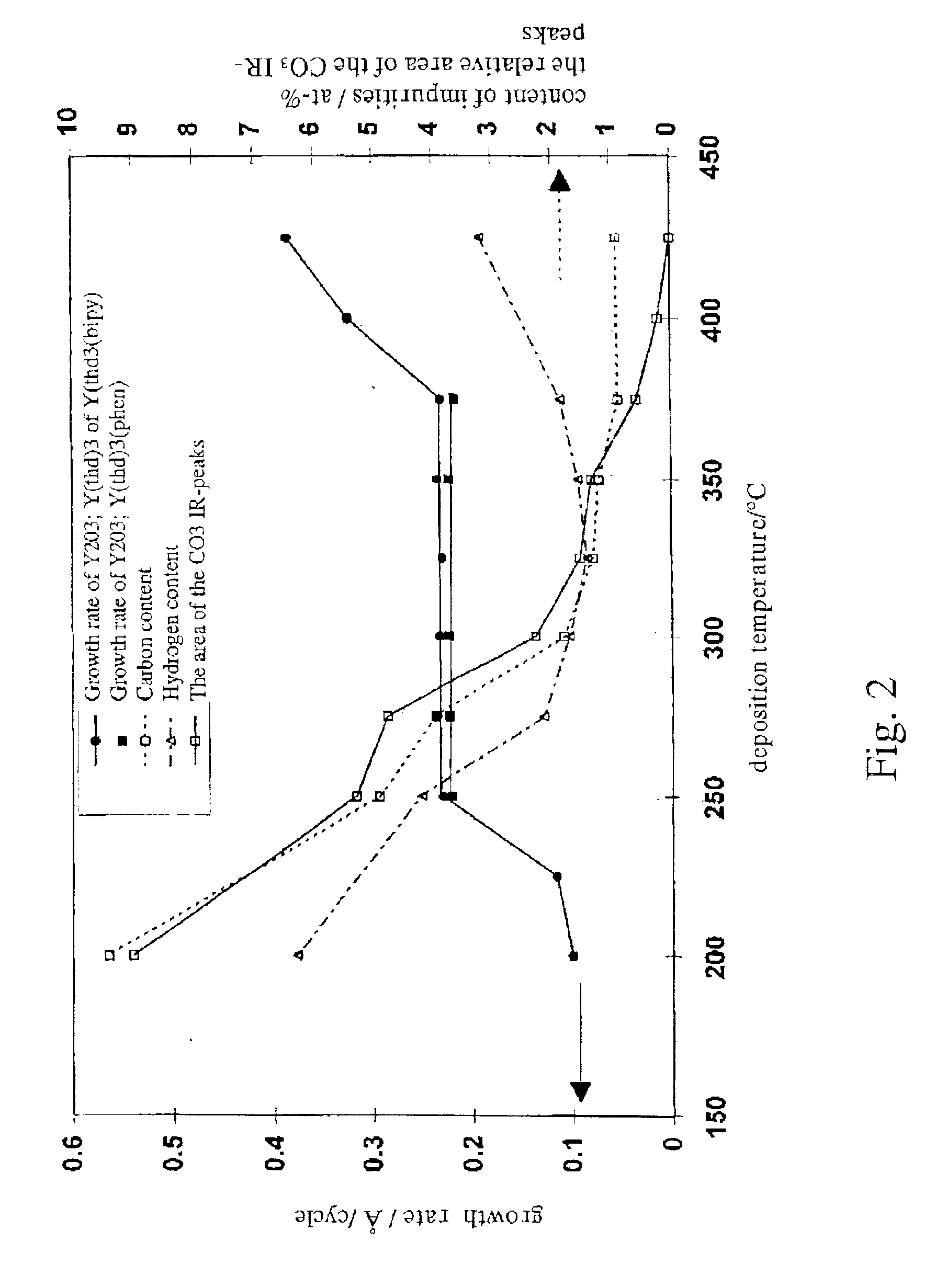

The present invention concerns a process for depositing rare earth oxide thin films, especially yttrium, lanthanum and gadolinium oxide thin films by an ALD process, according to which invention the source chemicals are cyclopentadienyl compounds of rare earth metals, especially those of yttrium, lanthanum and gadolinium. Suitable deposition temperatures for yttrium oxide are between 200 and 400° C. when the deposition pressure is between 1 and 50 mbar. Most suitable deposition temperatures for lanthanum oxide are between 160 and 165° C. when the deposition pressure is between 1 and 50 mbar.

Owner:ASM INTERNATIONAL

Semiconductor processing apparatus comprising a solid solution ceramic of yttrium oxide and zirconium oxide

ActiveUS20100160143A1Reduce erosion rateImprove mechanical propertiesElectric discharge tubesSemiconductor/solid-state device manufacturingHalogenSolid solution

Owner:APPLIED MATERIALS INC

Erosion-resistant components for plasma process chambers

An erosion-resistant article for use as a component in plasma process chamber. The erosion-resistant article comprises a support and an oxide coating comprising yttrium, which is disposed over the support. The support and the oxide coating preferably have material compositions that differ from one another in coefficient of thermal expansion by no more than 5x10<-6> / K. Preferred oxide coating compositions include yttria and yttrium aluminum garnet. Preferred supports include alumina supports and aluminum-silicon carbide supports.

Owner:APPLIED MATERIALS INC

Calcium oxide-based ceramic core for casting titanium alloy and manufacturing method thereof

The invention discloses a calcium oxide-based ceramic core for casting titanium alloy and a manufacturing method of the calcium oxide-based ceramic core. The calcium oxide-based ceramic core comprises the following components by weight percent: 1.0-15.0% of zirconium dioxide, 0.5-10.0% of yttrium oxide, 0.05-0.1% of thorium oxide and the balance of calcium oxide, and the sum of the contents of the above the component is 100%. According to the ceramic core, the bending strength is 15-30Mpa at room temperature, the bending strength is 5-10Mpa at high temperature, the high-temperature deflection is 0.2-0.5%, the firing shrinkage ratio is 1-1.5%, and the porosity is 40-50%. Compared with the existing commercial alumina-based ceramic core and silicon oxide-based ceramic core, the calcium oxide-based ceramic core of the invention greatly reduces the reactivity with molten titanium, and has the advantages of high temperature resistance, easiness in core leach, low in cost and the like.

Owner:BEIHANG UNIV

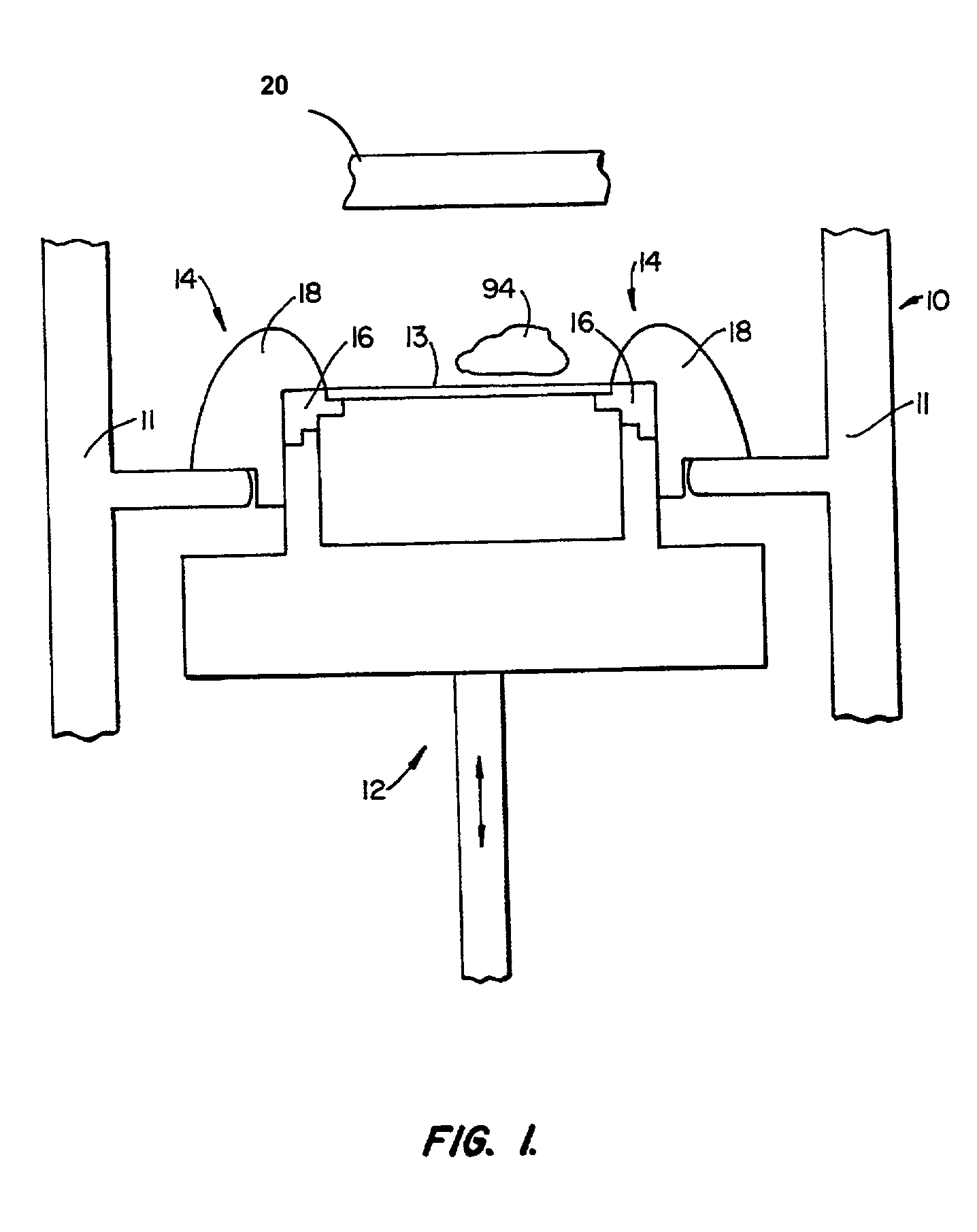

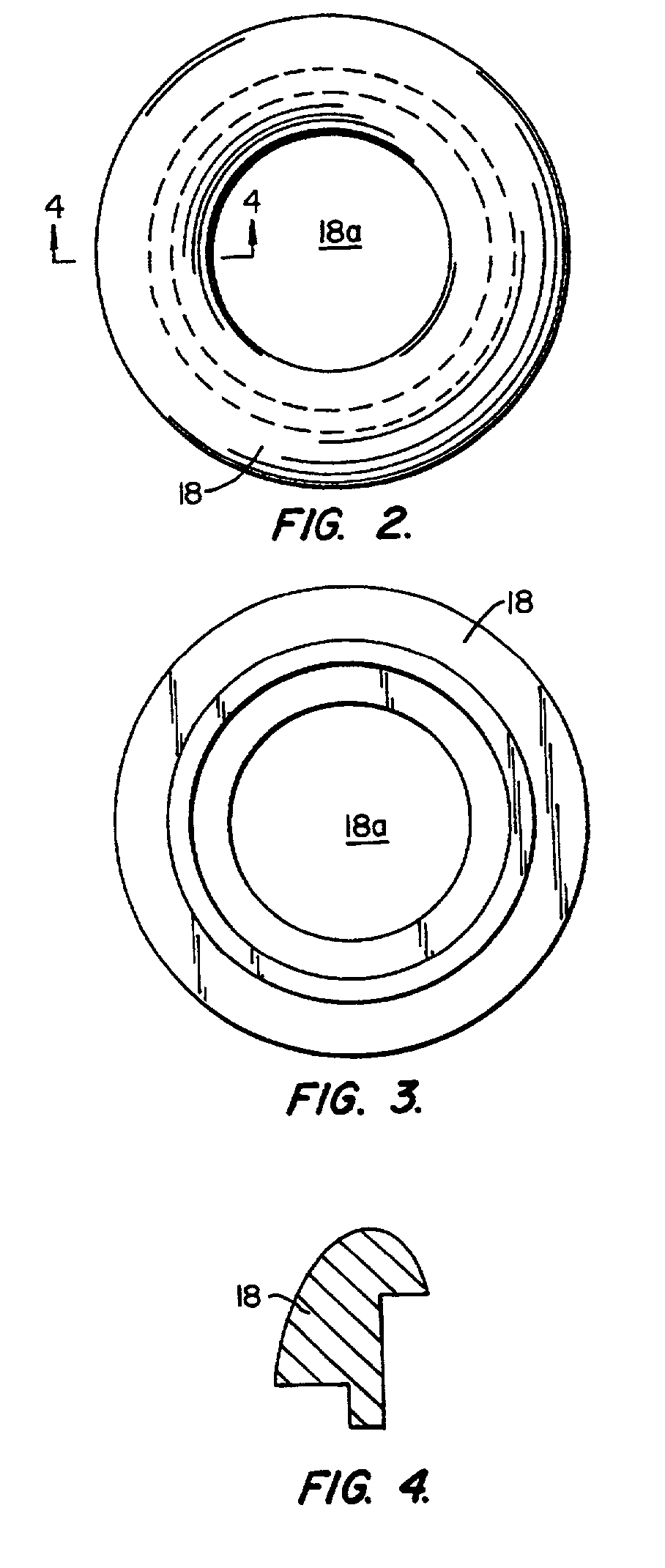

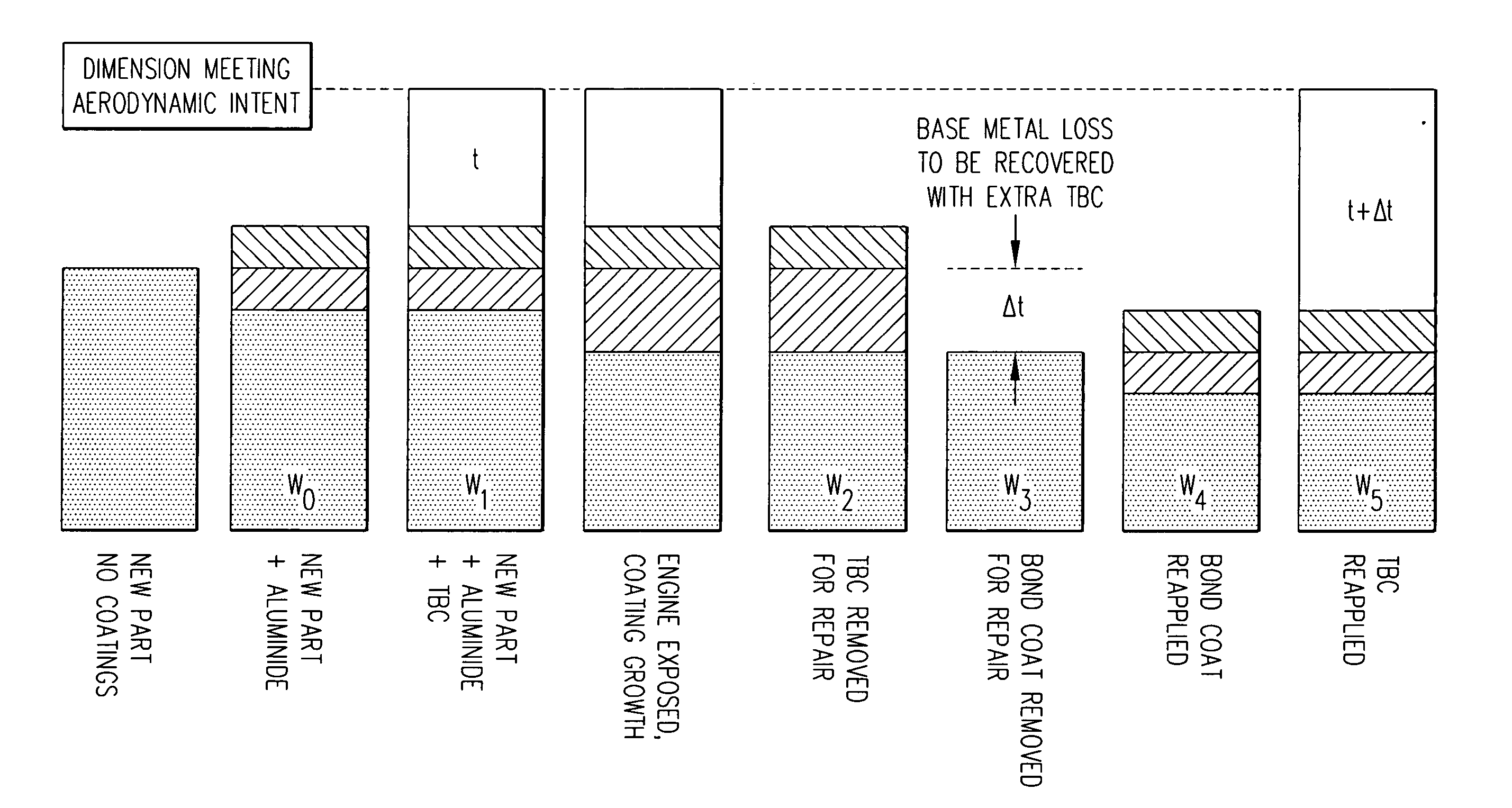

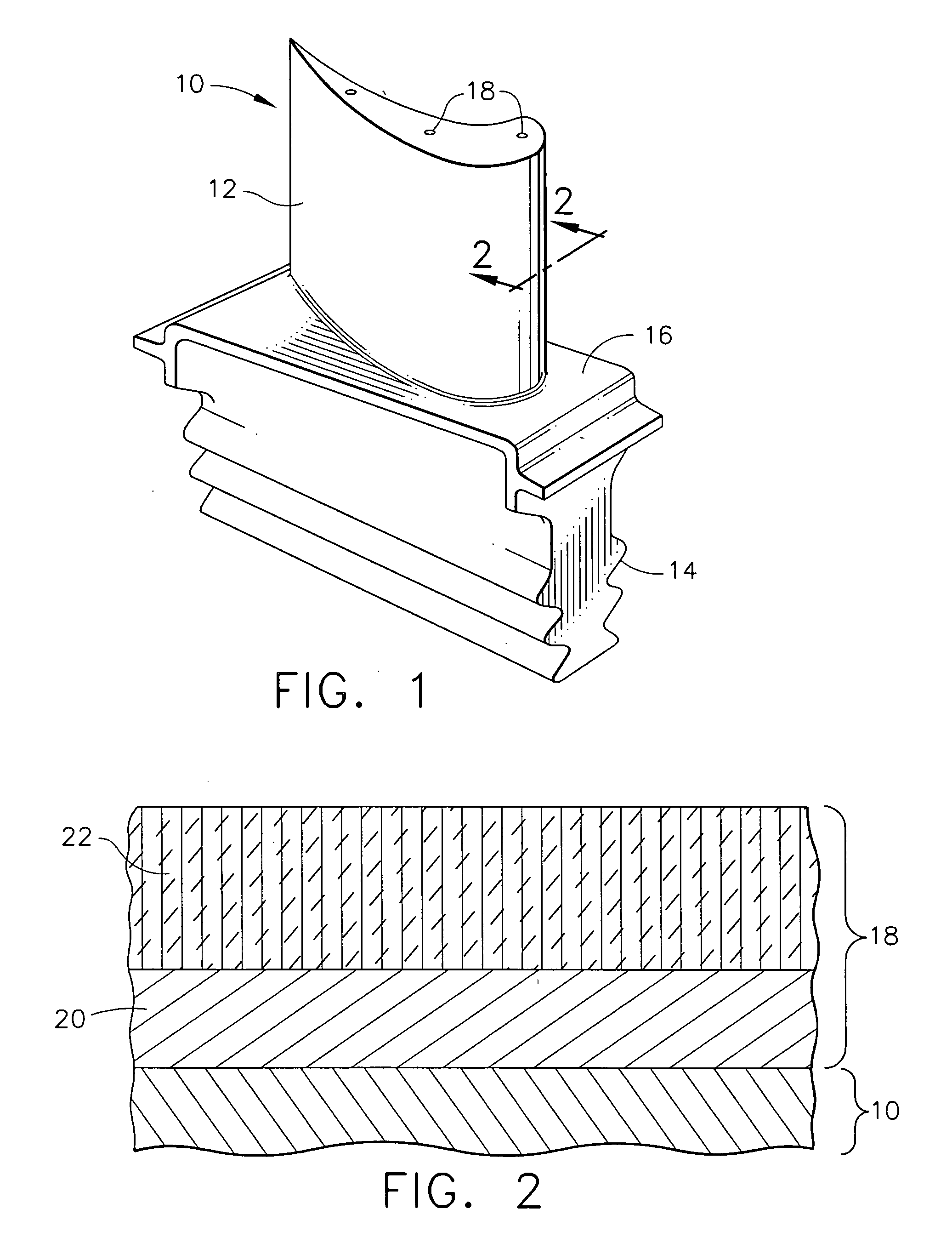

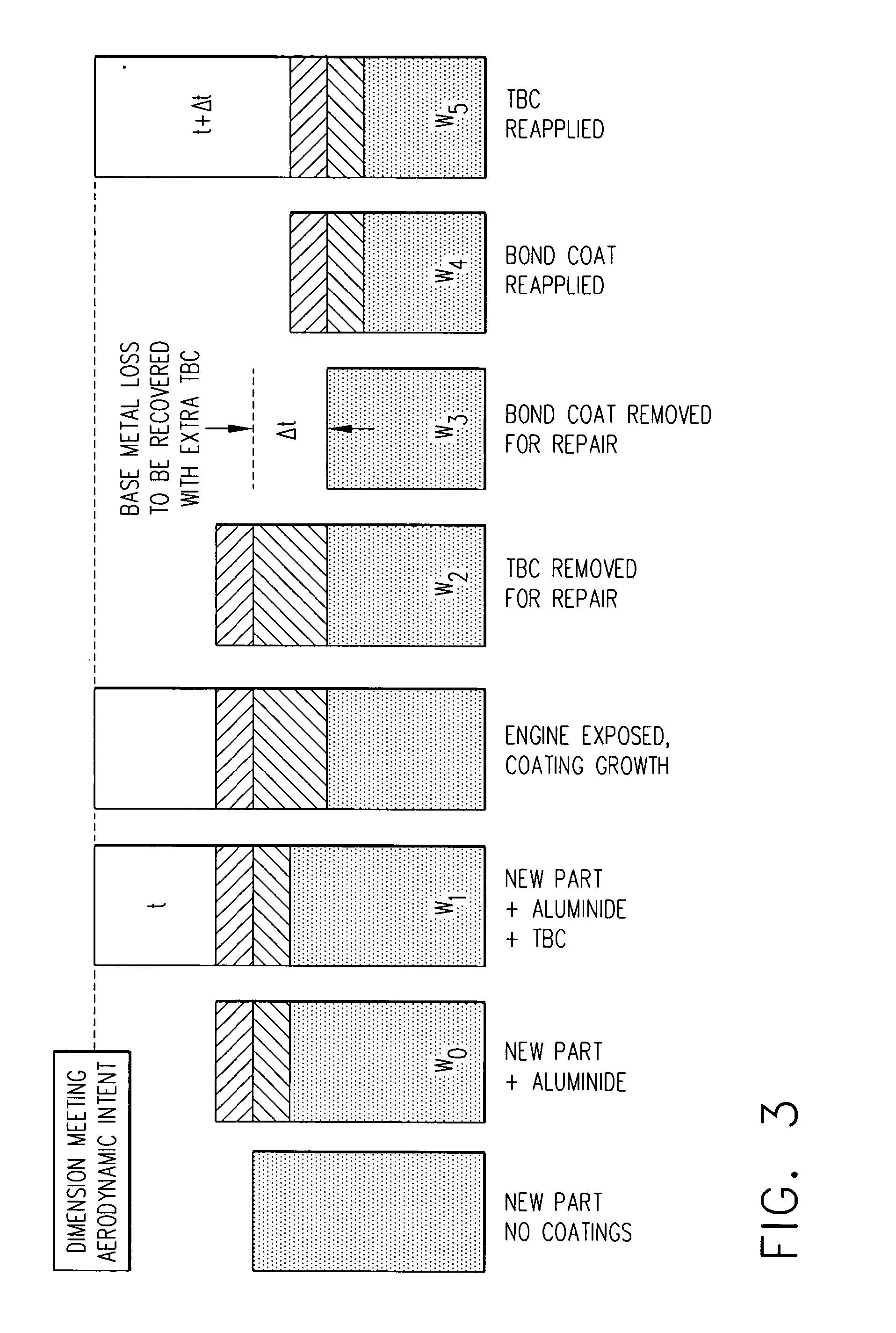

Method for repairing coated components

ActiveUS20050106316A1Increase ceramic spallation lifeReduce coatingMolten spray coatingLayered productsTurbine bladeAlloy

According to an embodiment of the invention, a method for repairing a coated high pressure turbine blade, which has been exposed to engine operation, to restore coated airfoil contour dimensions of the blade, is disclosed. The method comprises providing an engine run high pressure turbine blade including a base metal substrate made of a nickel-based alloy and having thereon a thermal barrier coating system. The thermal barrier coating system comprises a diffusion bond coat on the base metal substrate and a top ceramic thermal barrier coating comprising a yttria stabilized zirconia material. The top ceramic thermal barrier coating has a nominal thickness t. The method further comprises removing the thermal barrier coating system, wherein a portion of the base metal substrate also is removed, and determining the thickness of the base metal substrate removed. The portion of the base metal substrate removed has a thickness, Δt. The method also comprises reapplying the diffusion bond coat to the substrate, wherein the bond coat is reapplied to a thickness, which is about the same as applied prior to the engine operation; and reapplying the top ceramic thermal barrier coating to a nominal thickness of t+Δt, wherein Δt compensates for the portion of removed base metal substrate. Advantageously, the coated airfoil contour dimensions of the high pressure turbine blade are restored to about the coated dimensions preceding the engine run.

Owner:GENERAL ELECTRIC CO

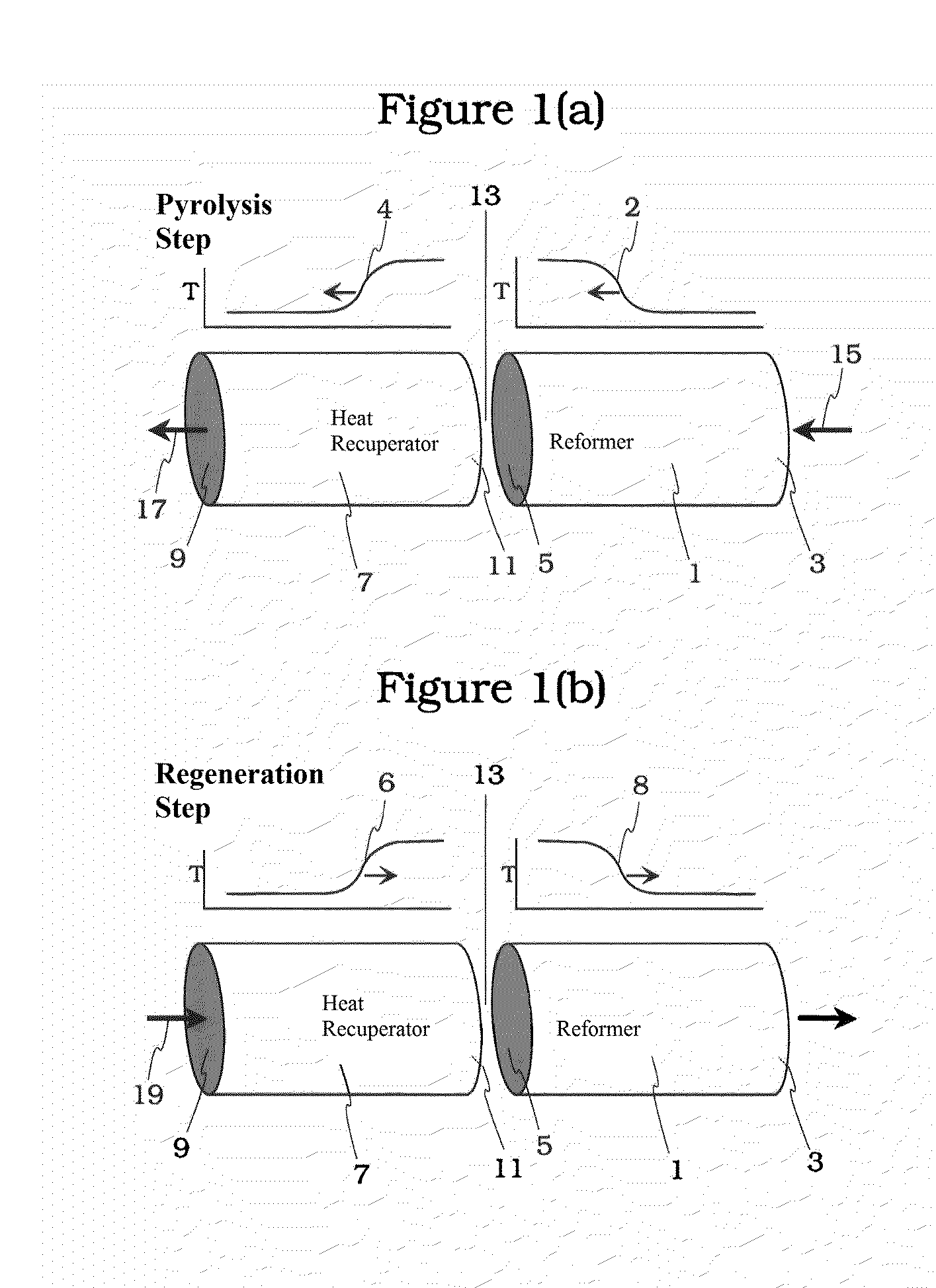

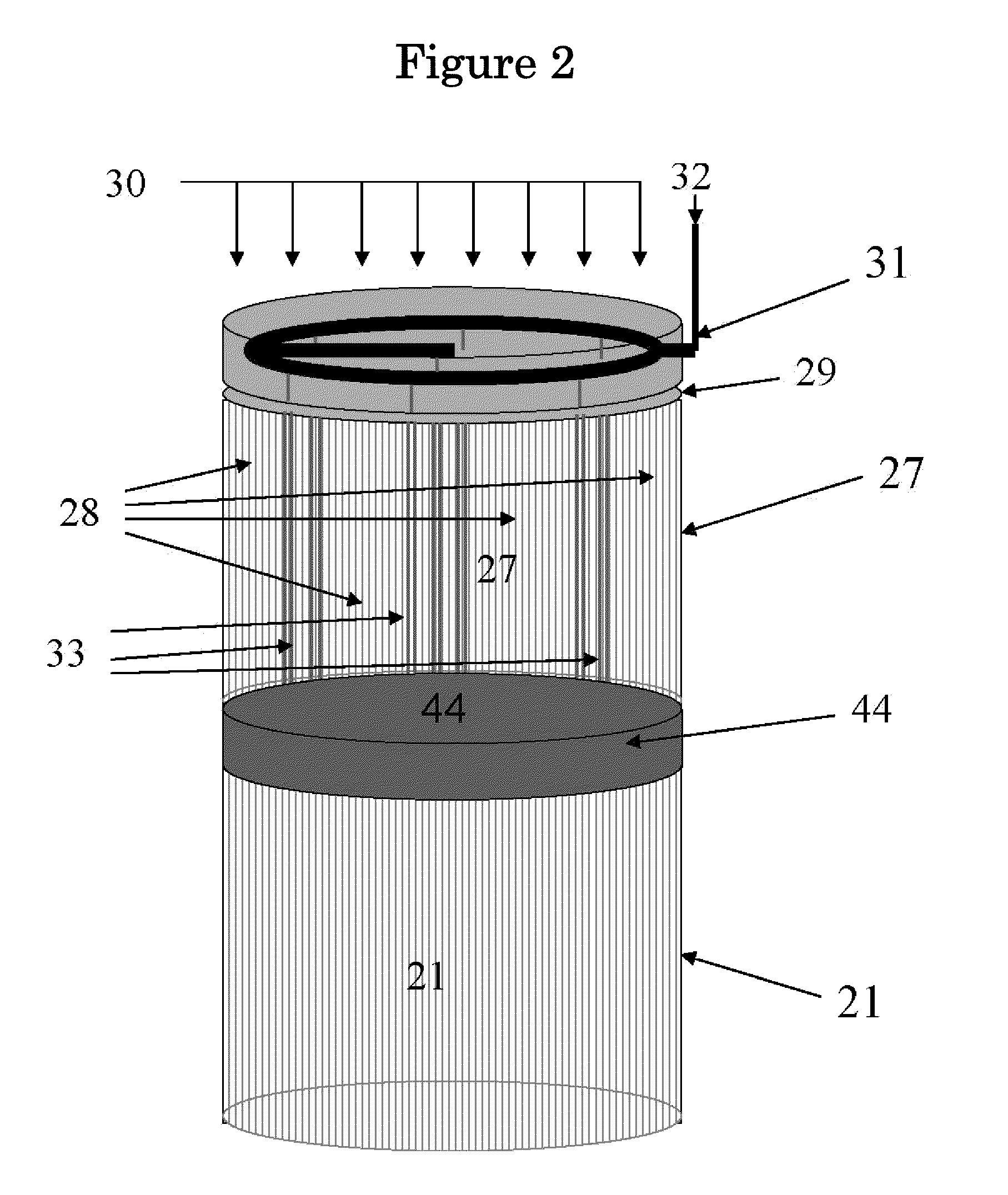

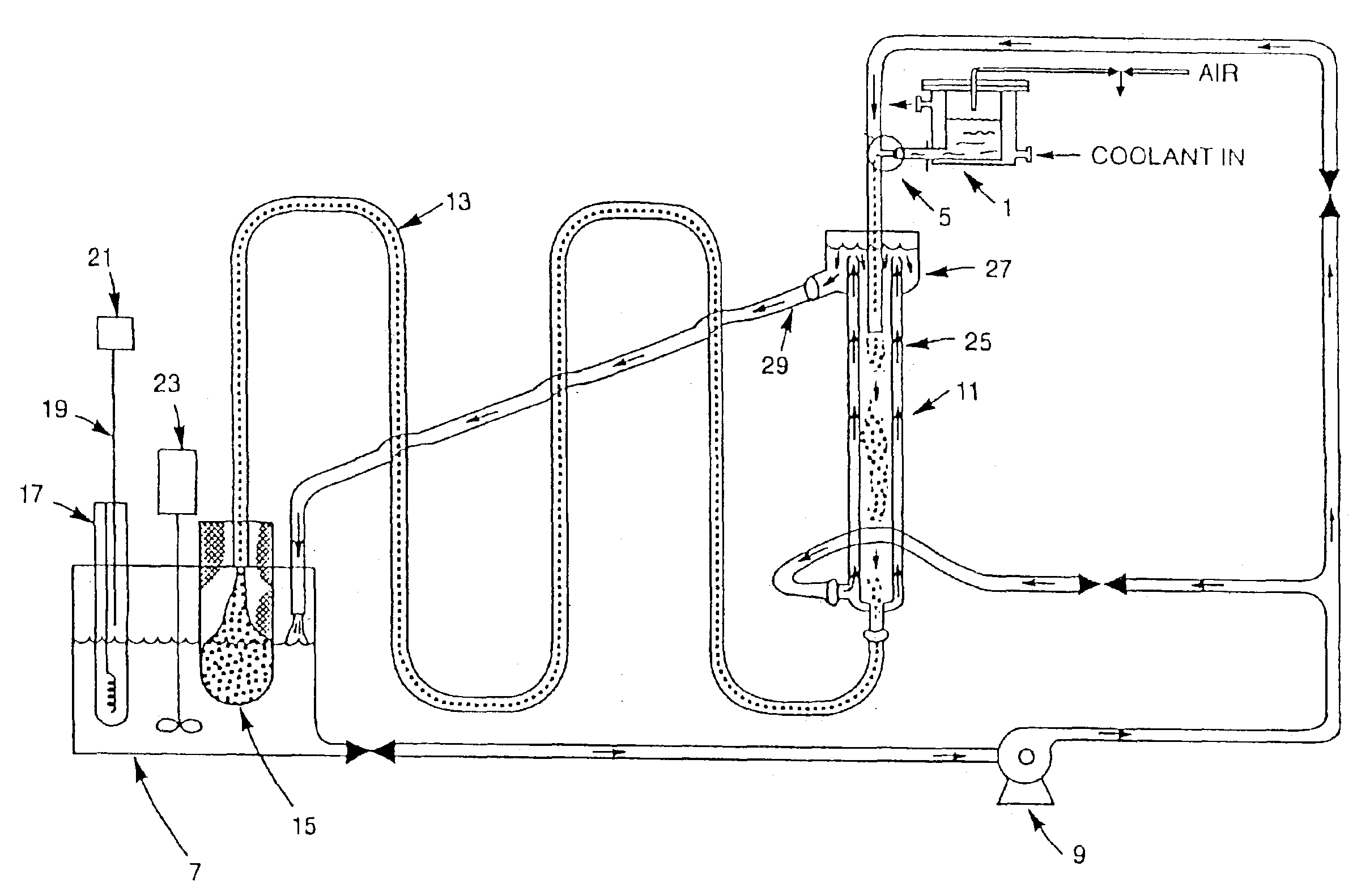

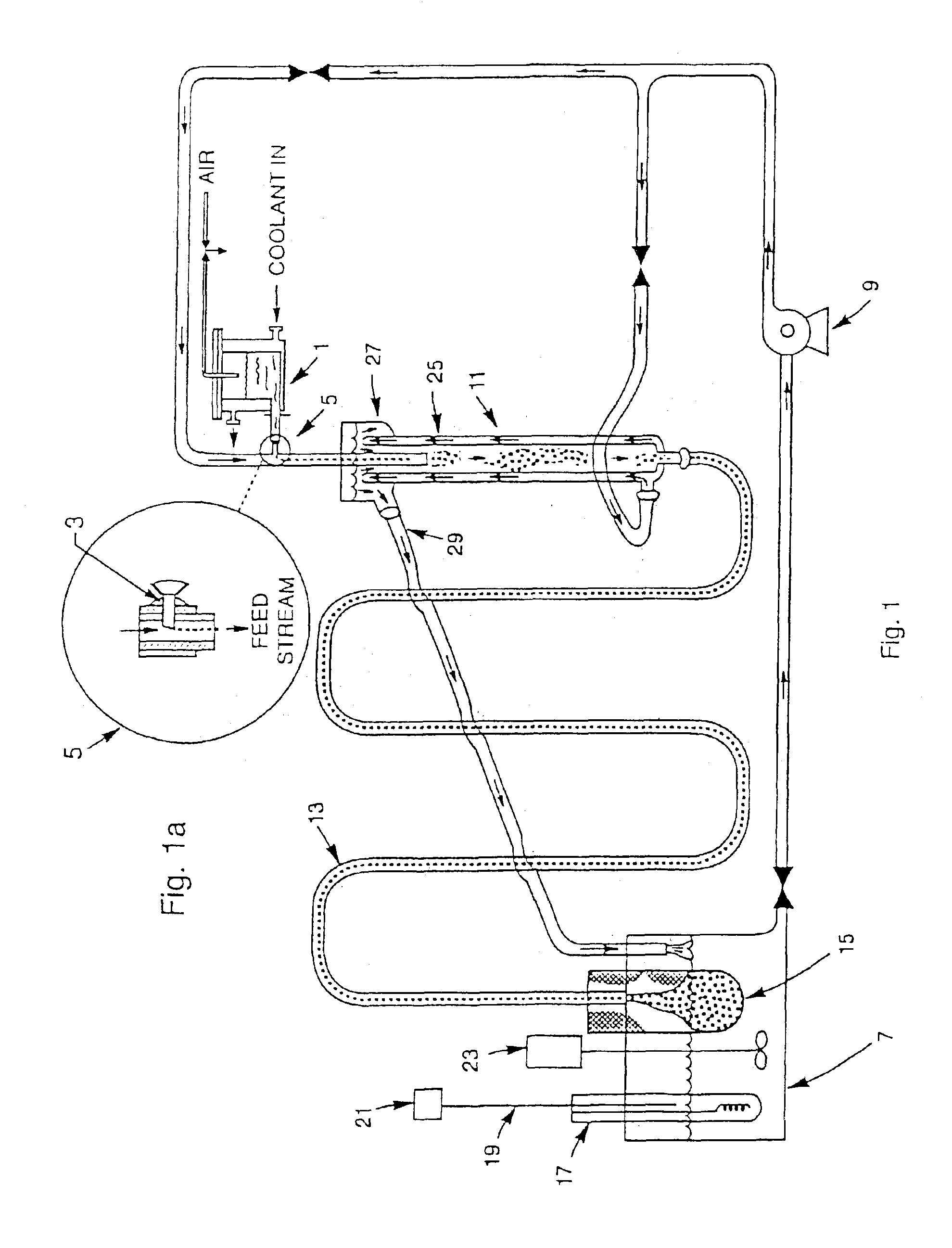

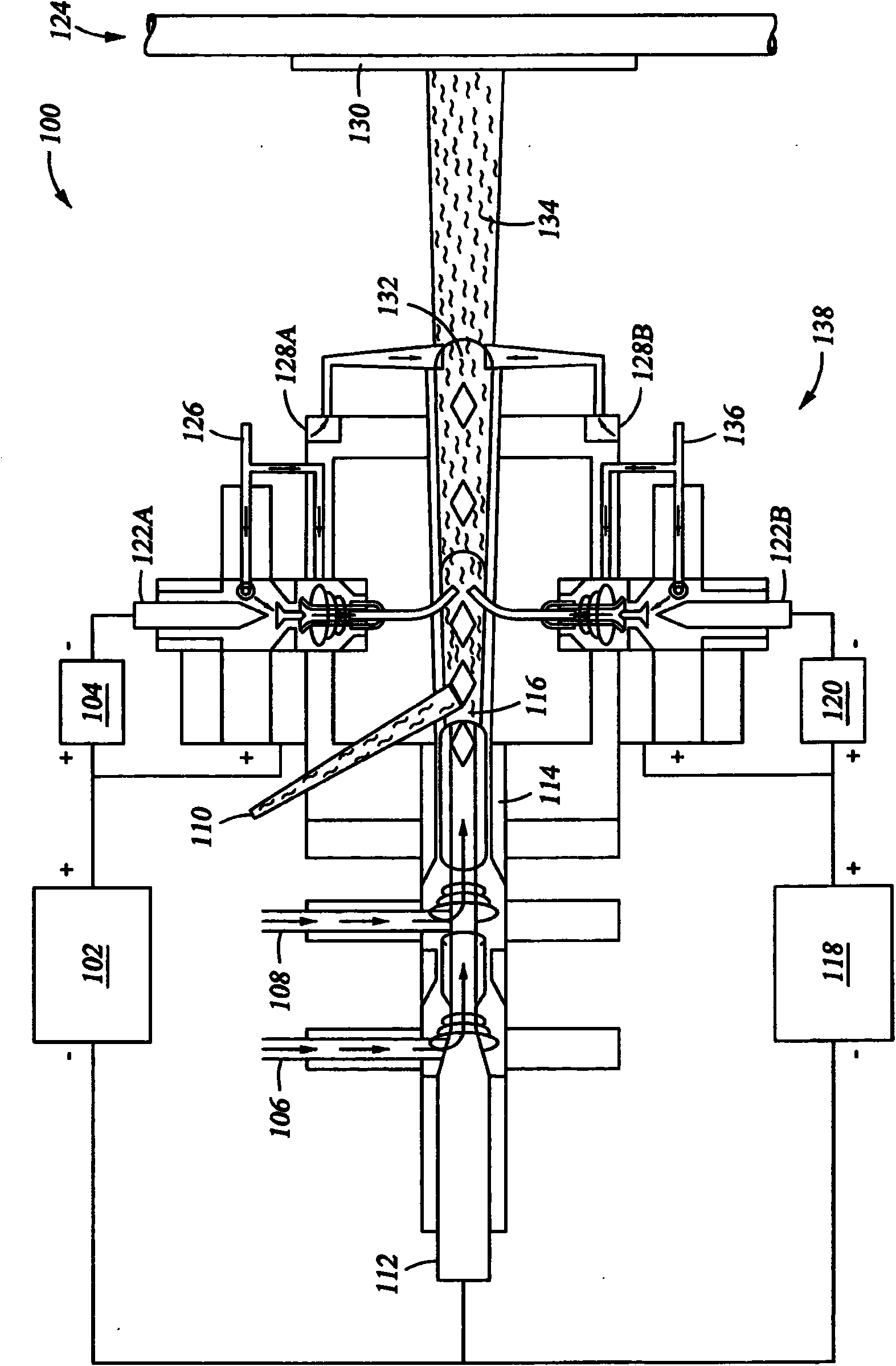

Pyrolysis Reactor Materials and Methods

ActiveUS20100290978A1Reduce corrosionChemical/physical/physico-chemical processesRare earth metal compoundsPorosityReactor system

In one aspect, the invention includes a refractory material for a pyrolysis reactor for pyrolyzing a hydrocarbon feedstock, the refractory material comprising an yttria stabilized zirconia, the refractory material comprising at least 21 wt. % yttria based upon the total weight of the refractory material. In another aspect, this invention includes a method for mitigating carbide corrosion while pyrolyzing a hydrocarbon feedstock at high temperature using a pyrolysis reactor system comprising the steps of: (a) providing a pyrolysis reactor system comprising stabilized zirconia in a heated region of the reactor, the stabilized zirconia including at least 21 wt. % yttria and having porosity of from 5 vol. % to 28 vol. %; (b) heating the heated region to a temperature of at least 1500° C.; and (c) pyrolyzing a hydrocarbon feedstock within the heated region.

Owner:EXXONMOBIL CHEM PAT INC

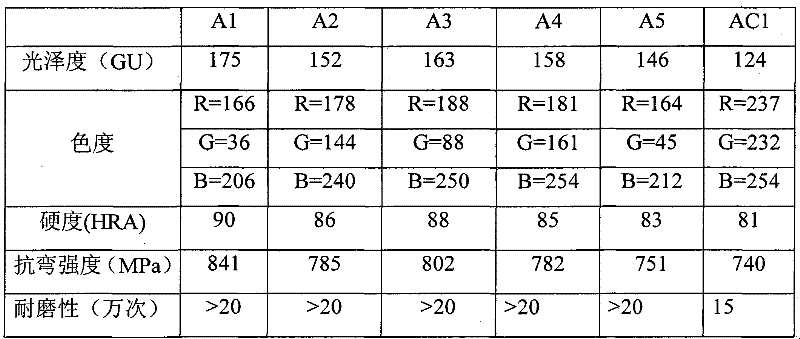

Modified zirconium oxide ceramic material and application thereof

InactiveCN104446457ARich Appearance StyleHigh dielectric constantBarium titanateUltimate tensile strength

The invention discloses a modified zirconium oxide ceramic material. The modified zirconium oxide ceramic material comprises the following components in percentage by molar concentration: 0-6mol% of yttrium oxide, 0-15mol% of cerium oxide, 0.02-1mol% of titanium oxide, 0-20mol% of aluminum oxide, 0-5mol% of barium titanate and the balance of zirconium oxide. The invention also discloses zirconium oxide ceramic and a dielectric cover plate prepared from the modified zirconium oxide ceramic material. The dielectric cover plate prepared from the modified zirconium oxide ceramic material has the advantages of high hardness, good toughness, high strength and high dielectric constant.

Owner:CHAOZHOU THREE CIRCLE GRP

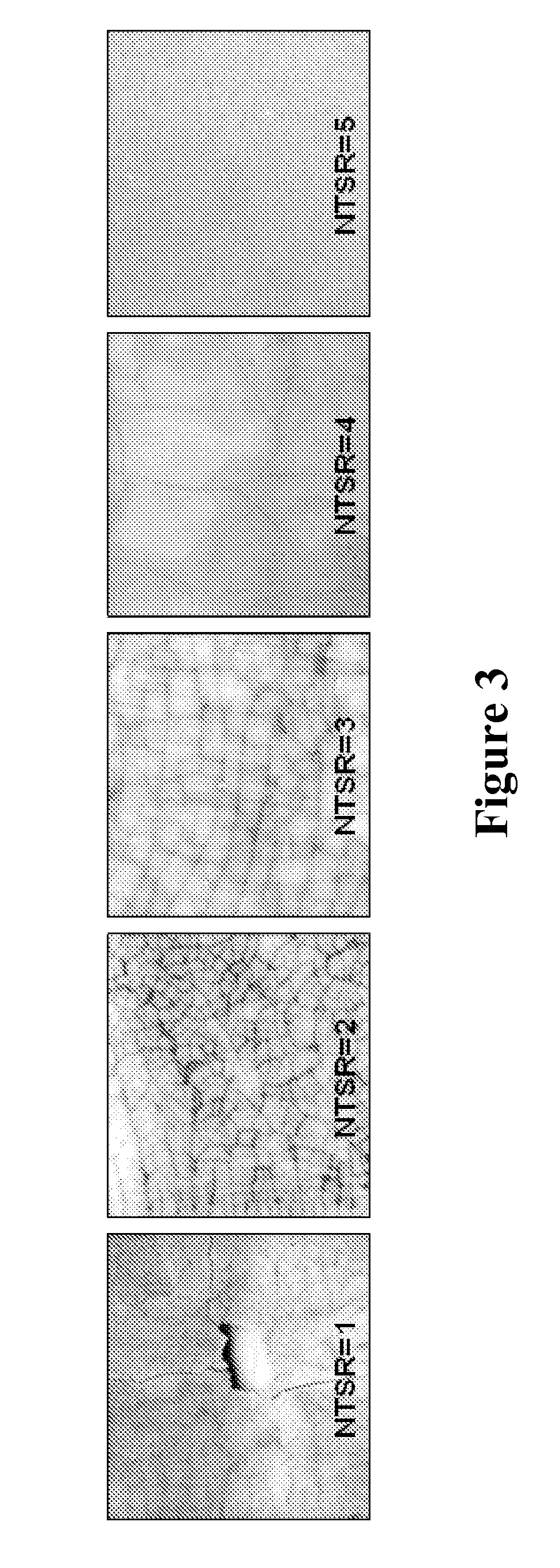

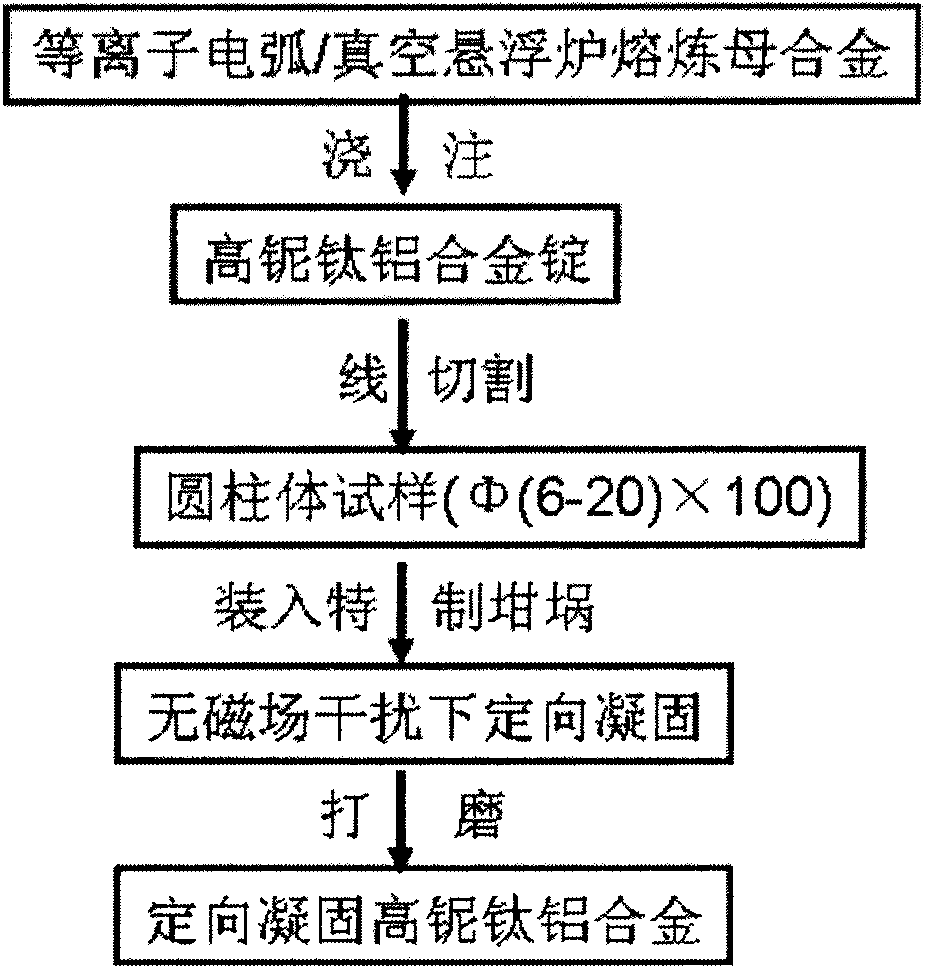

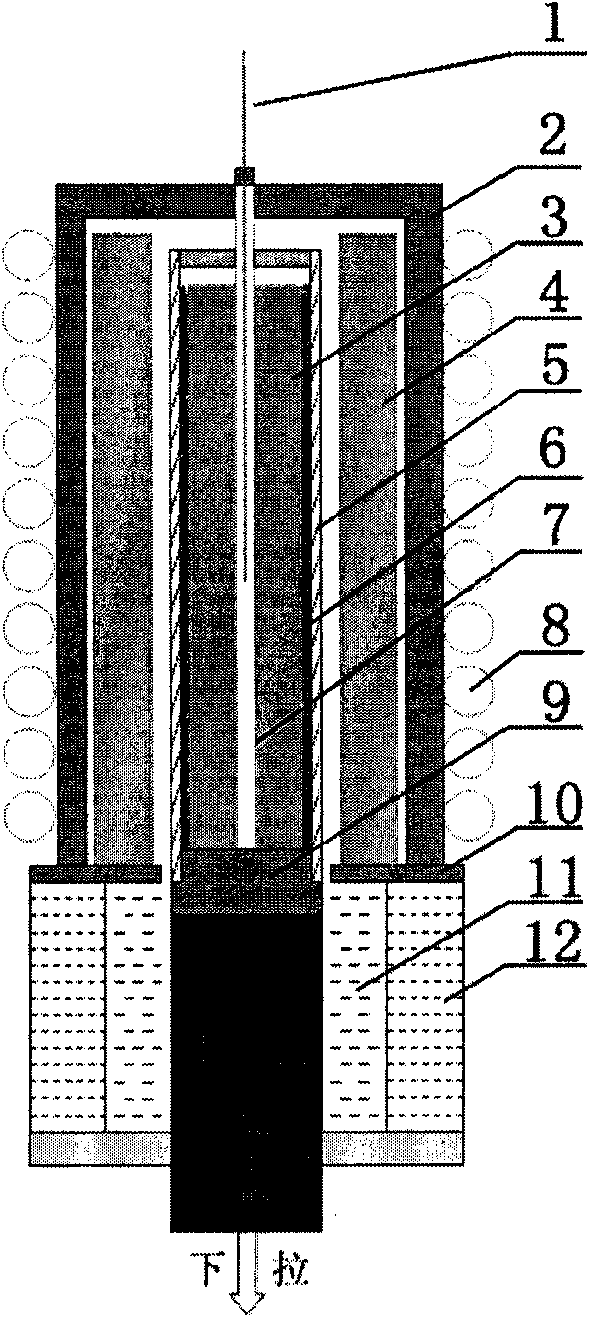

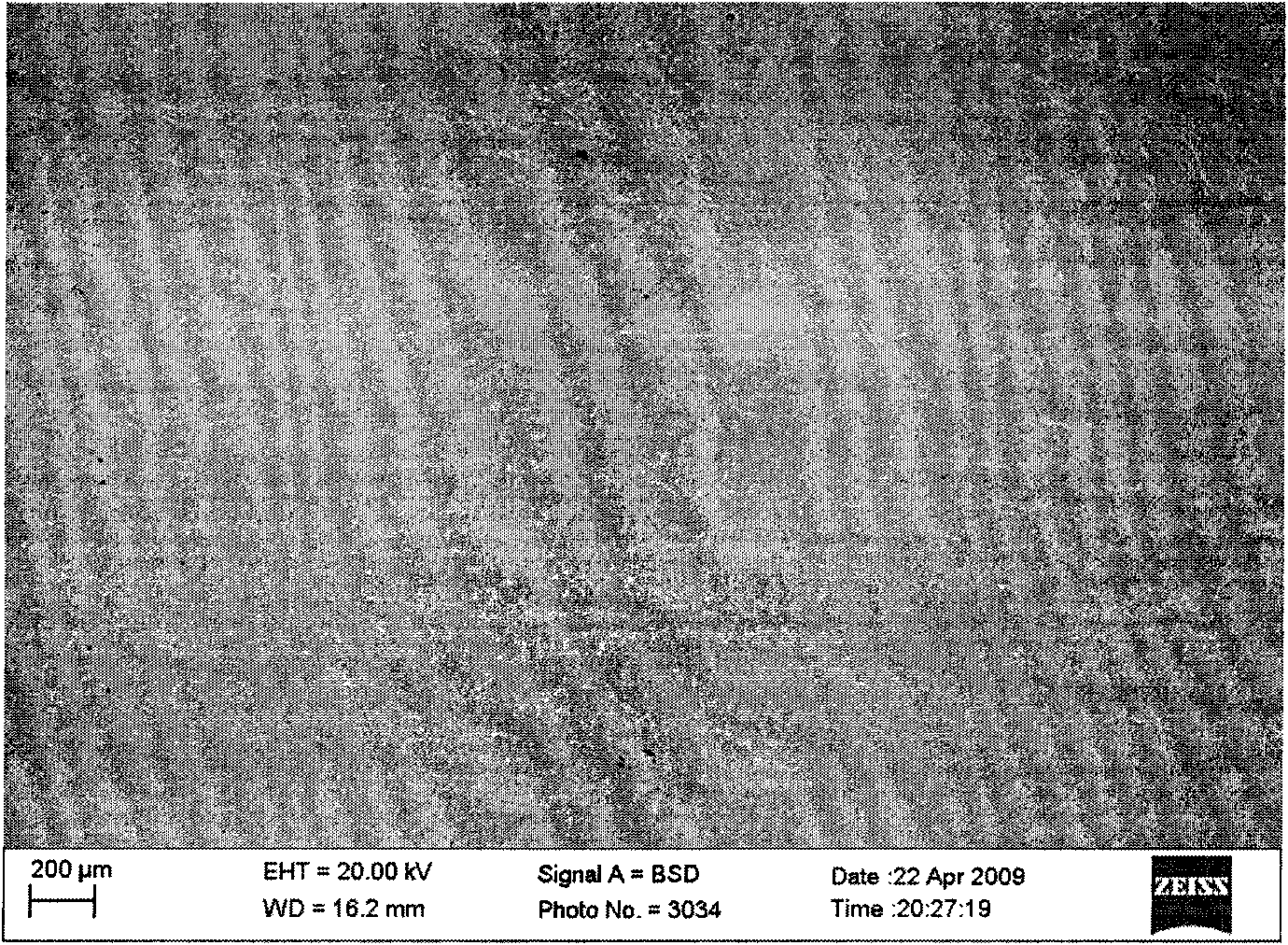

Preparation method of directional solidification high-niobium TiAl-base alloy

ActiveCN101875106AHigh melting pointImprove room temperature performanceMetallic materialsZone melting

The invention discloses a preparation method of a directional solidification high-niobium TiAl-base alloy, which belongs to the field of metal material preparation. The high-niobium TiAl-base alloy contains Ti, Al, Nb, W, Mn, C, B and Y, and the atomic percentage is: (43-49) Ti-(45-46) Al-(6-9) Nb-(0-0.5) (W and Mn)-(0-0.5) (C and B)-(0-0.5) Y, an as-cast master alloy rod which is smelted by plasma arc or vacuum suspension is taken as a raw material, a high-purity alumina ceramic tube with a coating layer of which the main component is yttrium oxide is used as a crucible, Ga-In-Sn alloy liquid is cooling liquid, and the directional solidification high-niobium TiAl-base alloy is successfully prepared by using an improved zone-melting and directional solidification system. The processing technology is simple and reliable, the directional solidification effect is obvious, and the method has universal applicability. The directional solidification high-niobium TiAl-base alloy which is prepared by the directional solidification method has comprehensive and good high temperature performance and room temperature ductility and has wide application prospect in terms of high temperature structural materials.

Owner:UNIV OF SCI & TECH BEIJING

Inorganic optical taggant and method of making

InactiveUS6899827B2Overcomes shortcomingDesired performanceCell electrodesMachines/enginesExplosive AgentsTitanium oxide

Owner:UT BATTELLE LLC

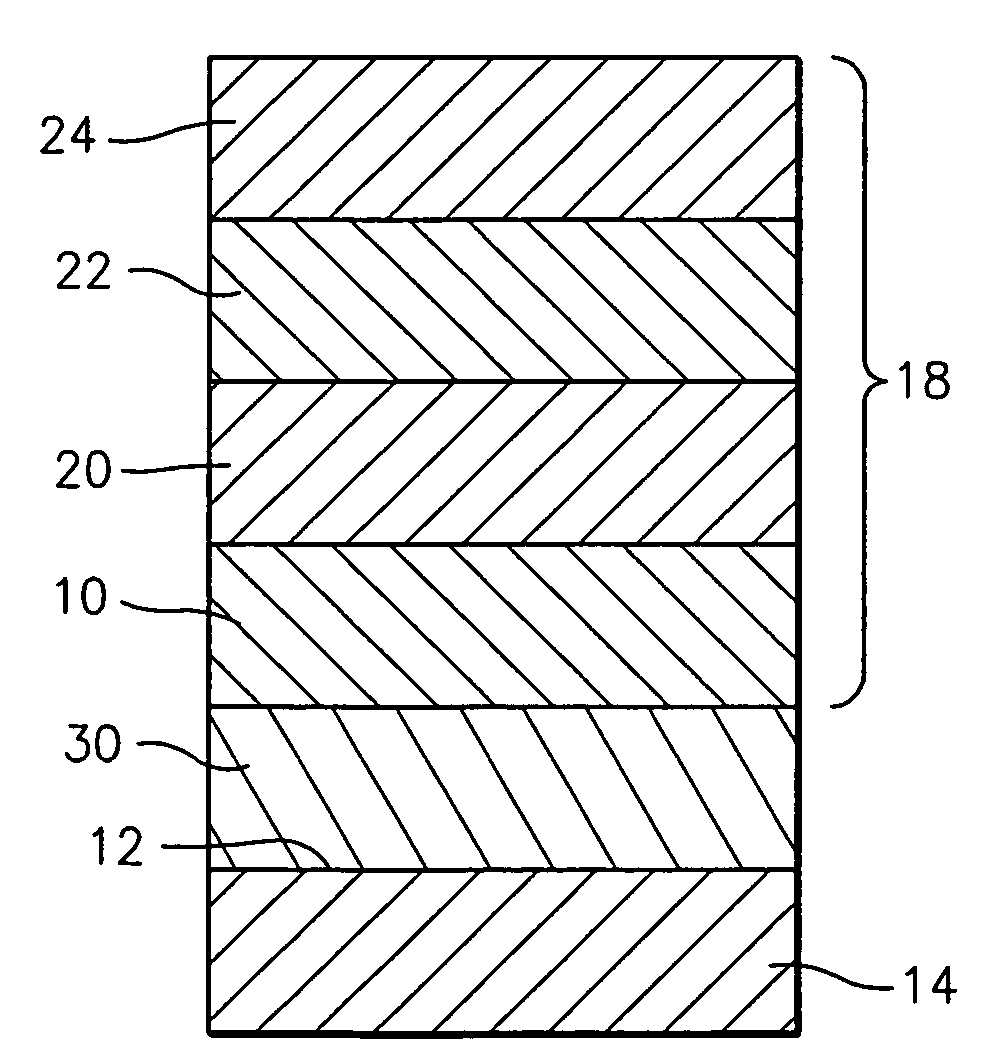

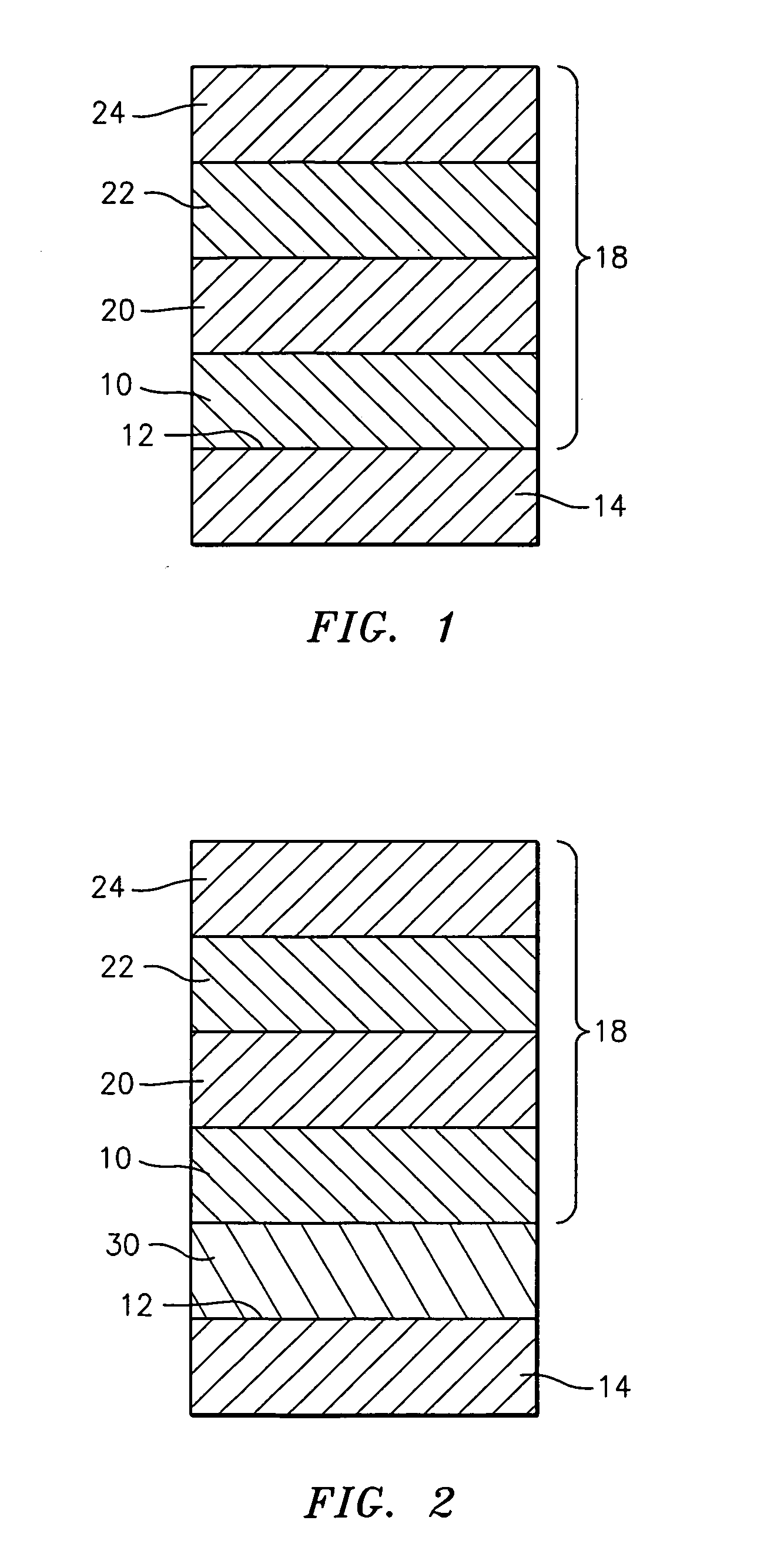

CMAS resistant thermal barrier coating

ActiveUS20070172703A1Reduce componentsReduces sand related distressMolten spray coatingBlade accessoriesIndiumCerium

A turbine engine component is provided which has a substrate and a thermal barrier coating applied over the substrate. The thermal barrier coating comprises alternating layers of yttria-stabilized zirconia and a molten silicate resistant material. The molten silicate resistant outer layer may be formed from at least one oxide of a material selected from the group consisting of lanthanum, cerium, praseodymium, neodymium, promethium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium, lutetium, scandium, indium, zirconium, hafnium, and titanium or may be formed from a gadolinia-stabilized zirconia. If desired, a metallic bond coat may be present between the substrate and the thermal barrier coating system. A method for forming the thermal barrier coating system of the present invention is described.

Owner:RTX CORP

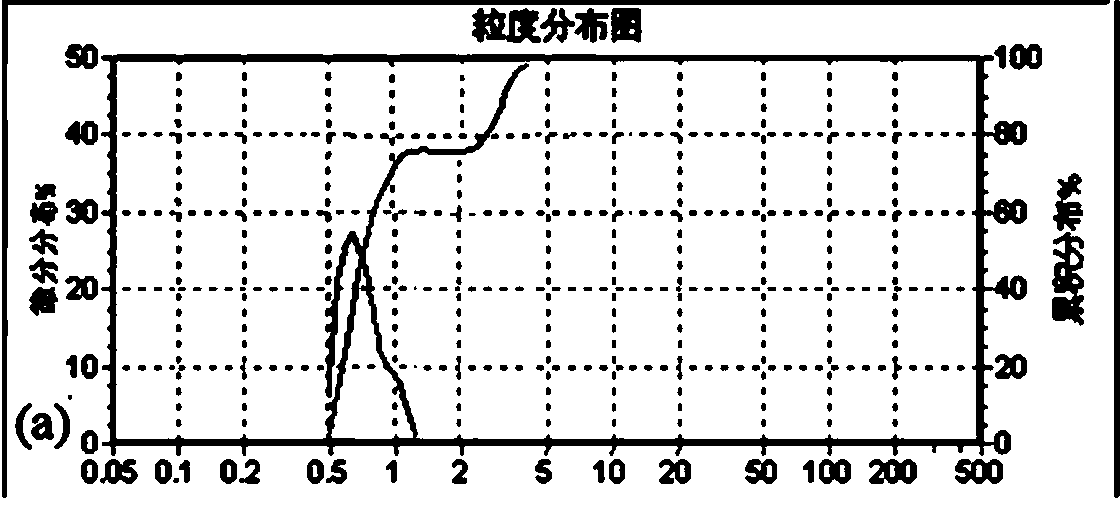

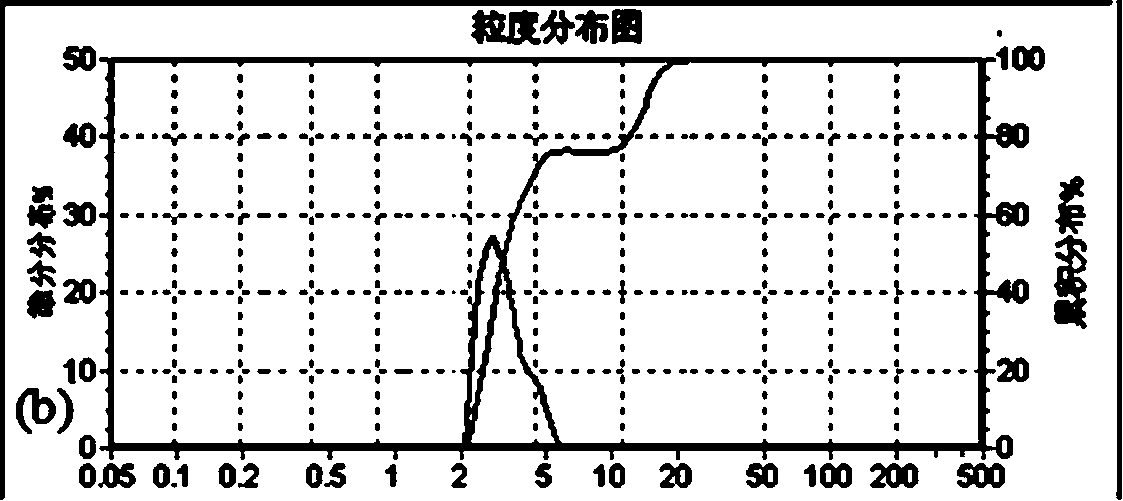

Yttria-stabilized zirconia powder and preparation method thereof

The invention relates to yttria-stabilized zirconia powder and a preparation method thereof. The yttria-stabilized zirconia powder has the composition characteristics that yttria is taken as a stabilizer of a zirconia material; the powder comprises a doping system formed by one or more following third components: alumina, ceria, lanthana, copper oxide, magnesium oxide and calcium oxide, wherein the weight of the yttria is 2-8mol%, and the total doping weight of the alumina, the ceria, the lanthana, the copper oxide, the magnesium oxide and the calcium oxide is 0-5wt%. According to the yttria-stabilized zirconia powder and the preparation method, the deficiencies of an existing liquid phase preparation process of nanometer zirconia powder are overcome, and the prepared nanometer ZrO2 composite powder has the performance of uniformity in dispersion of components, uniform grain size, super-fineness, high sintering activity, good liquidity and the like. Furthermore, the preparation method is simple in process and low in cost and is easy to industrialize.

Owner:YAAN YUANCHUANG CERAMIC

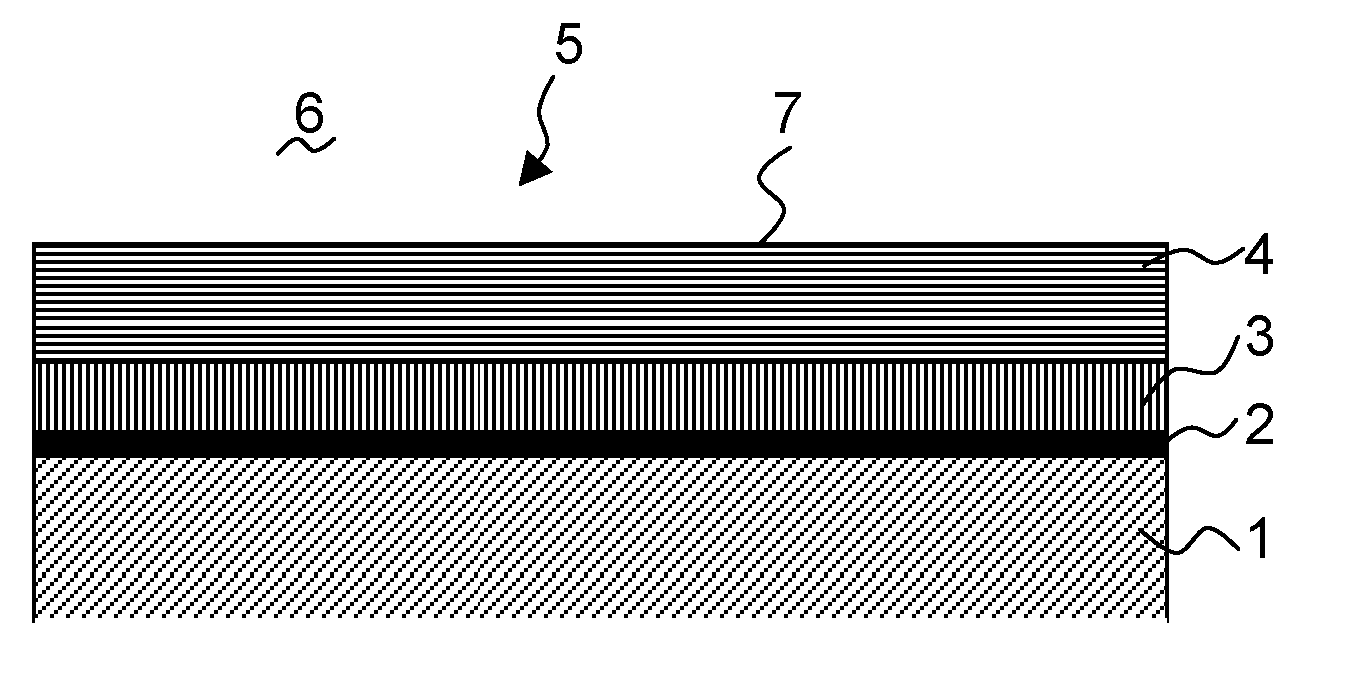

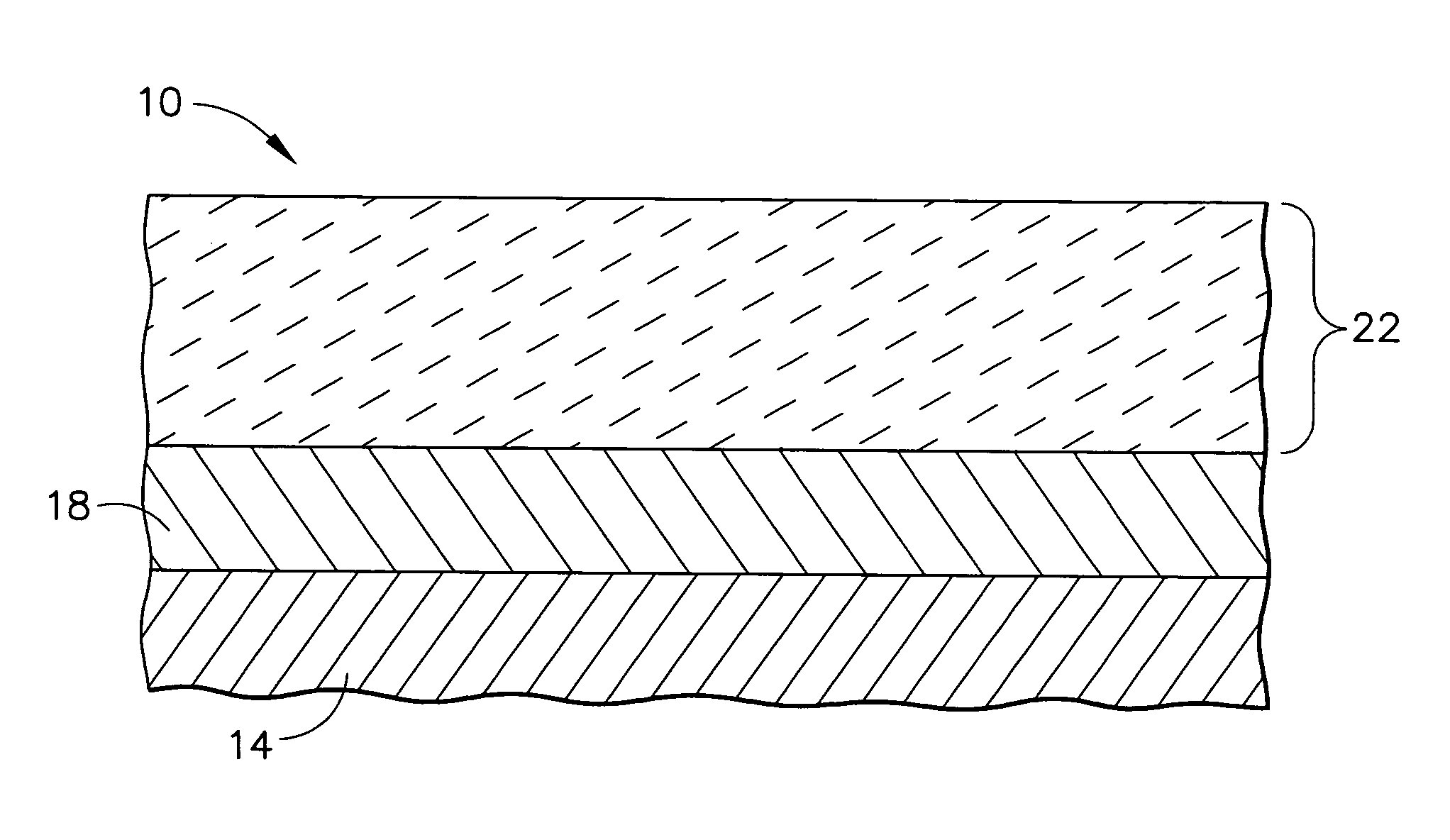

Thermal barrier coating system, components coated therewith and method for applying a thermal barrier coating system to components

A thermal barrier coating system on a base material includes a bond coat layer with a lower face in direct contact with the base material and an upper face, a first ceramic layer in direct contact with the upper face of the bond coating layer and a second ceramic layer disposed on an outermost surface of the coating system and configured to be exposed to hot gas. The first ceramic layer includes a layer, combination, mixture, alloy, blend or multilayer structure of at least one of yttria-stabilized zirconia with a yttria content in a range of 6-8 wt-%, YTaO4 doped zirconia, and titania doped zirconia. The second ceramic layer includes a layer, combination, mixture, alloy, blend or multilayer structure of at least one of YTaO4 doped zirconia, titania doped zirconia, scandia stabilized zirconia, ceria containing perovskite material, yttrium aluminium garnet material, Monazite material, and spinel material. A material of the second ceramic layer is different from a material of the first ceramic layer.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Hydrothermal synthesis method for IVB-group metal oxide

InactiveCN101613123AImprove performanceAvoid reunionTitanium oxides/hydroxidesZirconium oxidesDispersityHafnium

The invention provides a hydrothermal synthesis method for IVB-group metal oxide. The IVB-group metal oxide is the oxide of titanium, zirconium or hafnium. The method comprises: adding IVB-group metal salt solution to alkaline precipitant and obtaining hydroxide precipitate; washing and precipitating to remove other impurities; adding water to the hydroxide precipitate to prepare suspension liquid and then performing hydrothermal reaction to obtain metal-oxide suspension liquid; and performing post-treatment to the metal-oxide suspension liquid to obtain metal oxide powder. The hydrothermal synthesis method can form zirconia powder through reaction at low temperature, thereby overcoming the disadvantage of using a co-precipitation method to product zirconia, avoiding powder agglomeration caused by high-temperature calcinations, ensuring the extremely excellent performance of the obtained zirconia powder and having the advantages of uniform particle size, good dispersity, strong maneuverability and the like. According to the hydrothermal synthesis method, zirconia composite material can also be produced by further adding stabilizers, such as yttrium-oxide compound zirconia, magnesium-oxide compound zirconia, cerium-oxide compound zirconia, calcium-oxide compound zirconia and the like.

Owner:邢长生

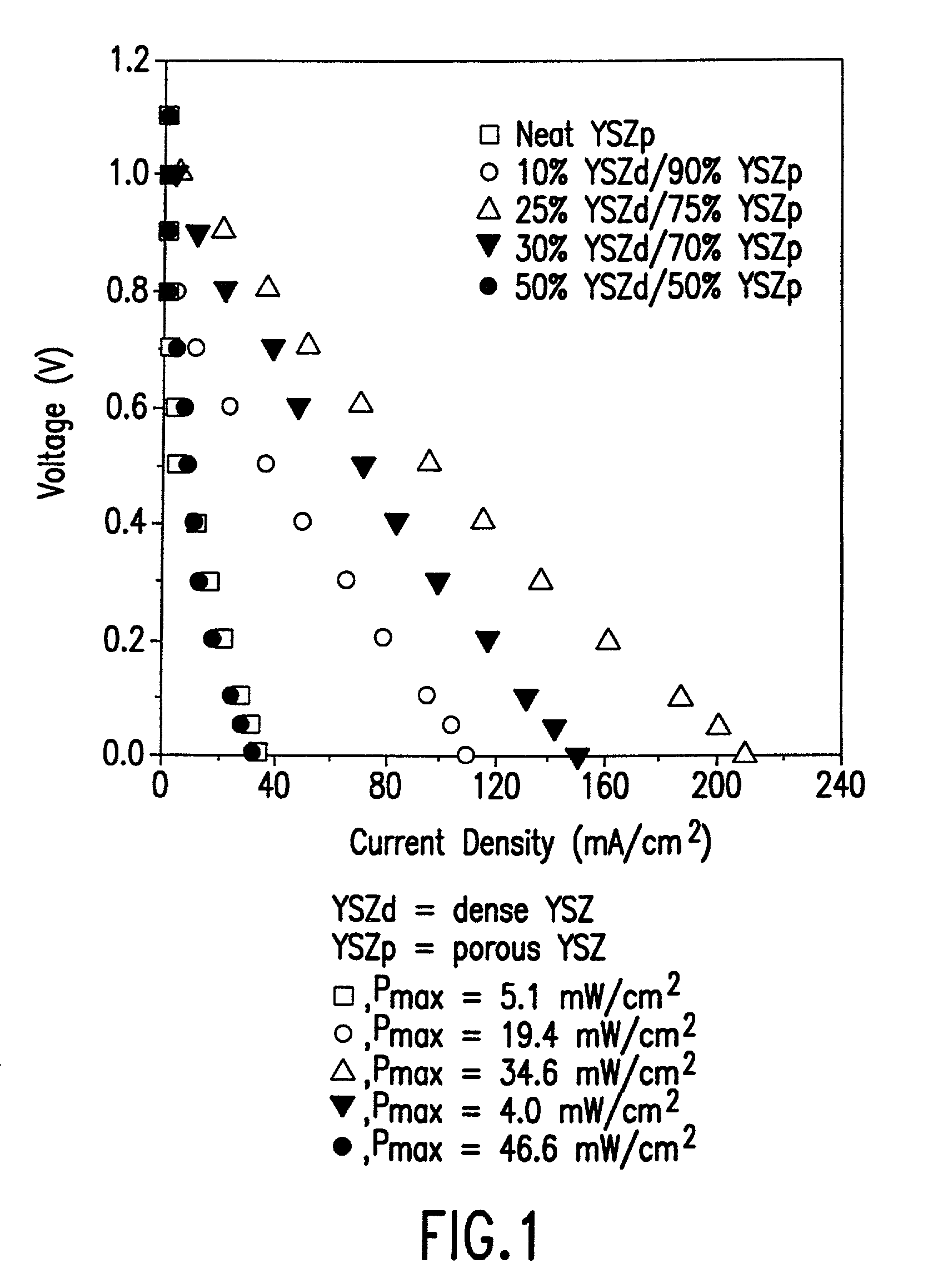

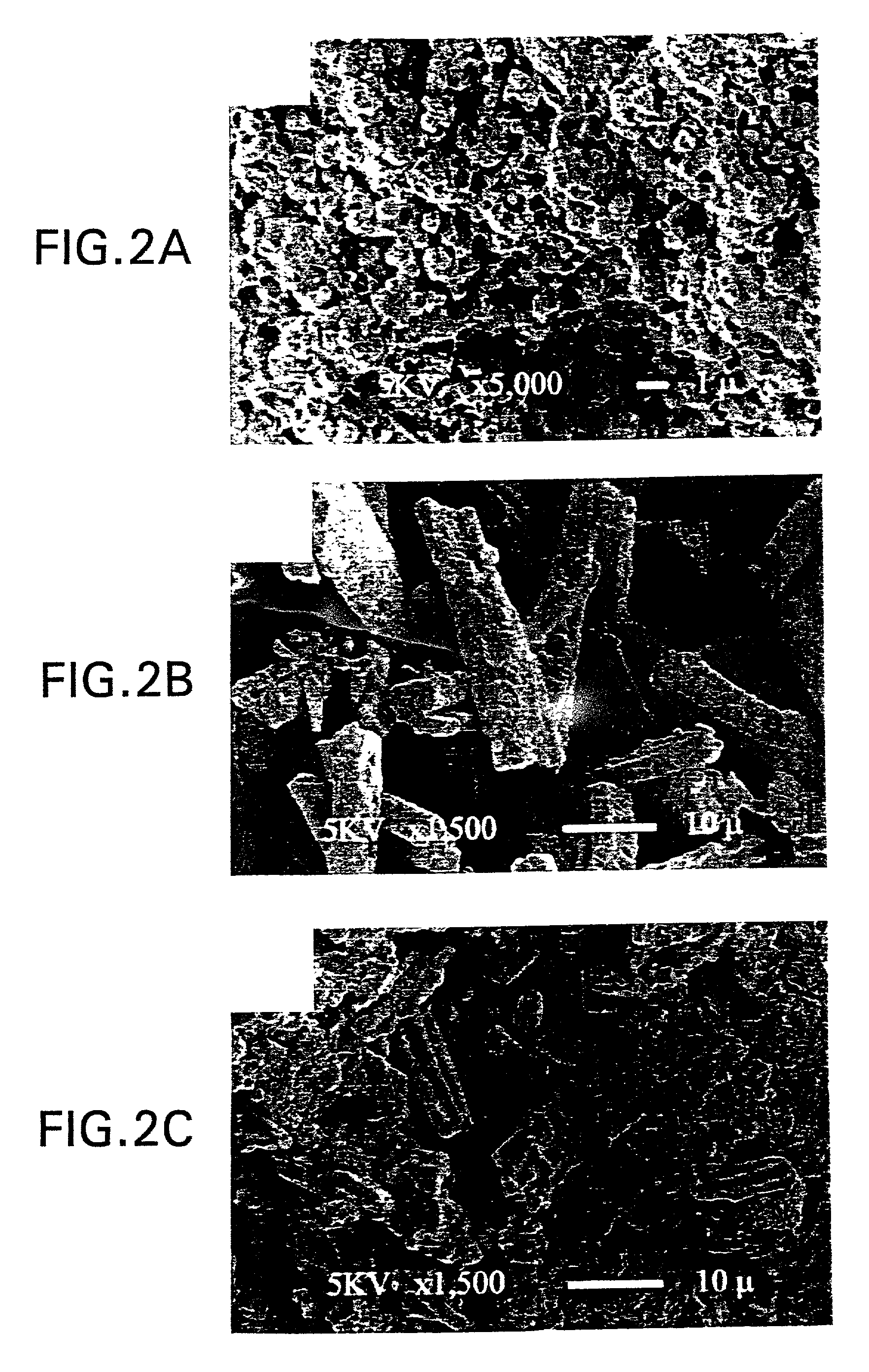

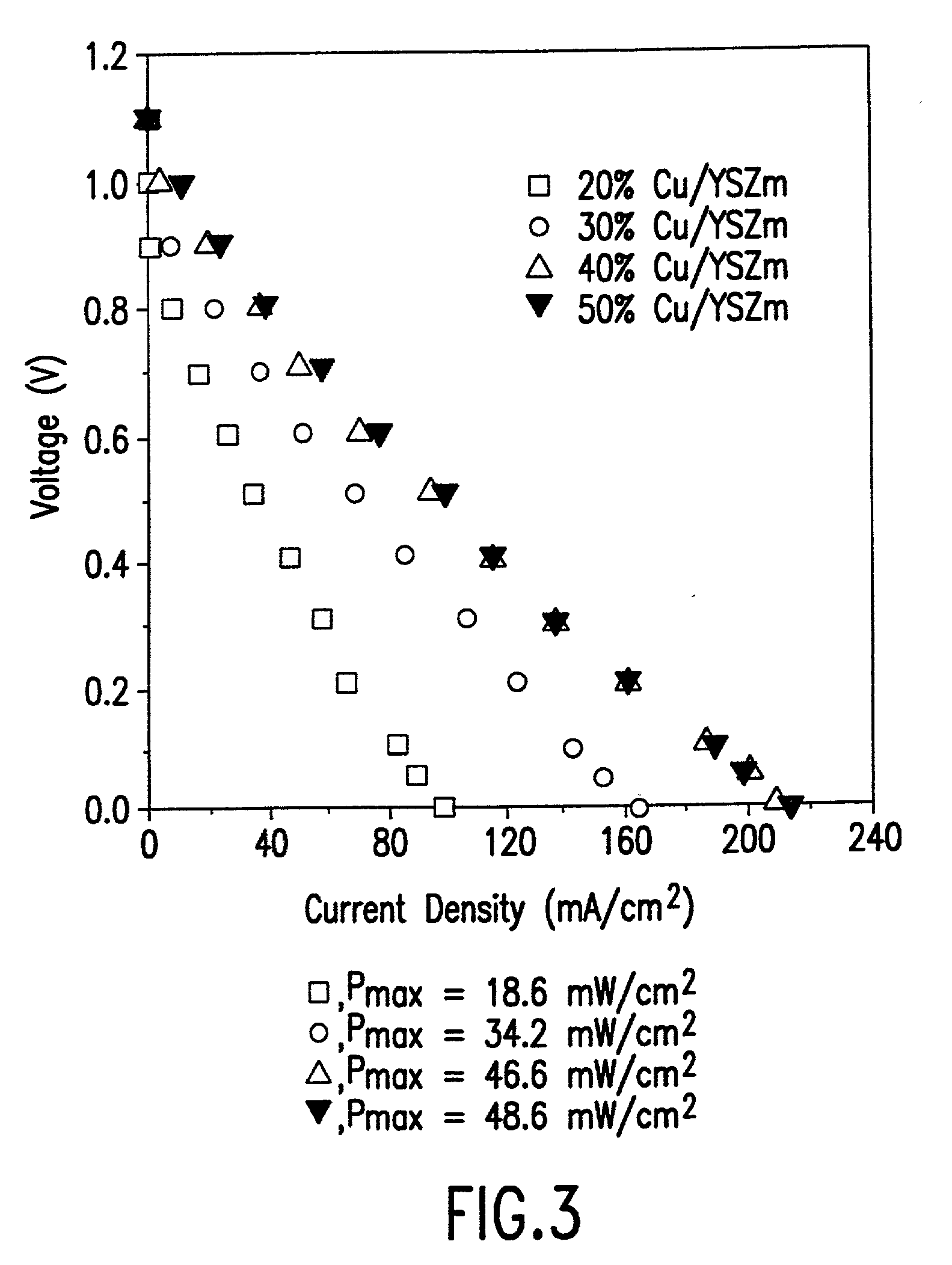

Method for solid oxide fuel cell anode preparation

InactiveUS20010029231A1Easy to operateLower performance requirementsFinal product manufacturePrimary cellsFiberPowder mixture

A method for preparation of an anode for a solid oxide fuel cell in which a plurality of zircon fibers are mixed with a yttria-stabilized zirconia (YSZ) powder, forming a fiber / powder mixture. The fiber / powder mixture is formed into a porous YSZ layer and calcined. The calcined porous YSZ layer is then impregnated with a metal-containing salt solution. Preferred metals are Cu and Ni.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

Method for preparing nano oxide dispersion reinforced superfine crystal tungsten-based composite material

The invention provides a method for preparing a nano oxide dispersion reinforced superfine crystal tungsten-based composite material. The method comprises the following steps of: taking 0.1 to 1 weight percent of micro tungsten powder, nano yttrium oxide powder or yttrium metal powder and 0 to 2 weight percent of titanium metal powder or molybdenum powder or tantalum powder, blending the materials, mechanically alloying the materials, sintering discharge plasma and the like to prepare the superfine crystal tungsten composite material. The method has the following advantage that: the nearly full-densification superfine crystal tungsten-based composite material can be obtained by the method for preparing the nano oxide dispersion reinforced superfine crystal tungsten-based composite material. Complex phase doping of yttrium oxide or yttrium metal and titanium metal, molybdenum or tantalum powder not only realizes sintering densification of tungsten at a lower temperature, but also inhibits grain growth of tungsten crystals during sintering. The tungsten crystal grain size of the yttrium oxide reinforced superfine crystal tungsten-based composite material prepared by adopting the method is less than or equal to 3 microns, and the composite material has good mechanical property and thermal shock resistance.

Owner:UNIV OF SCI & TECH BEIJING

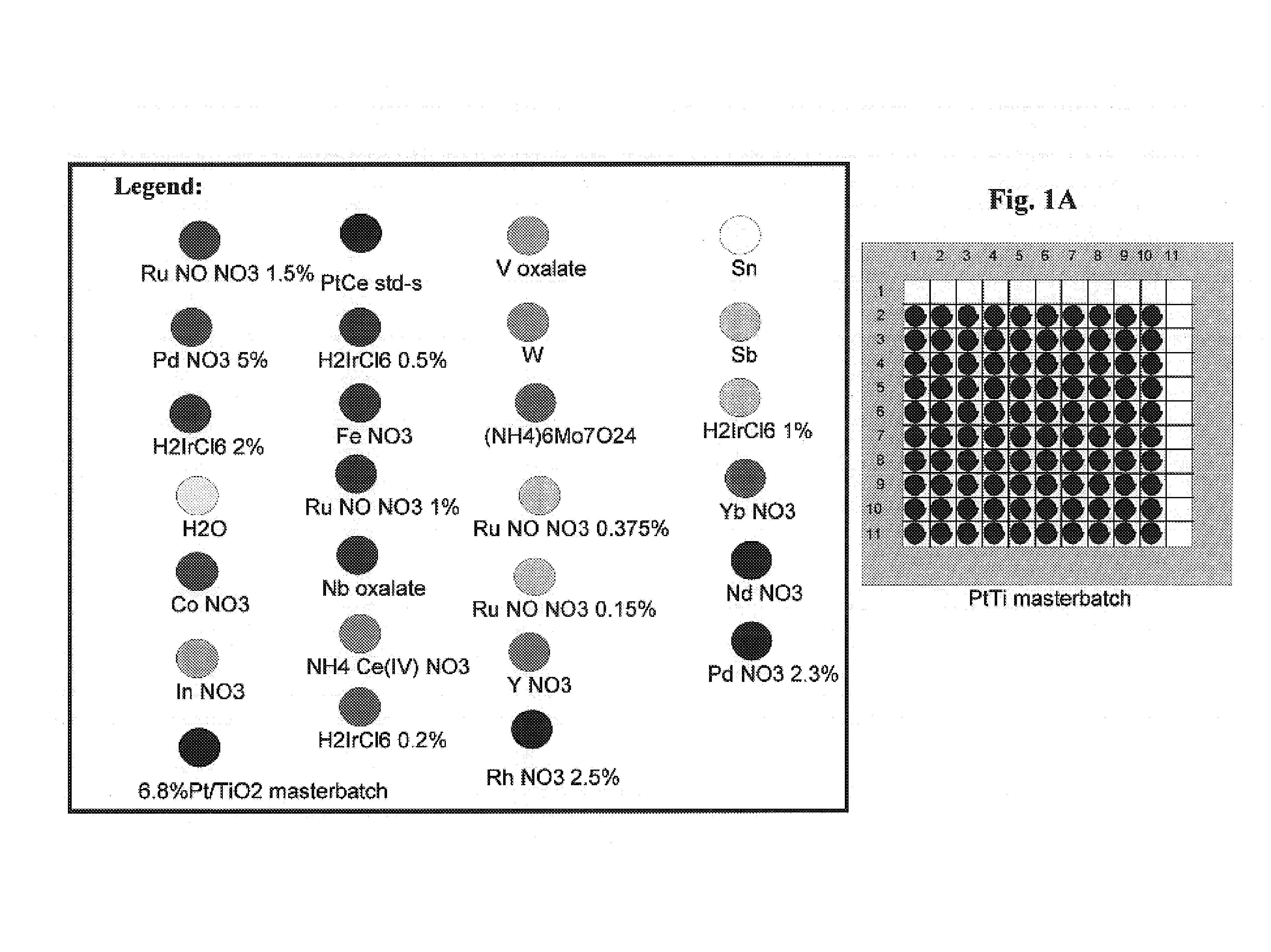

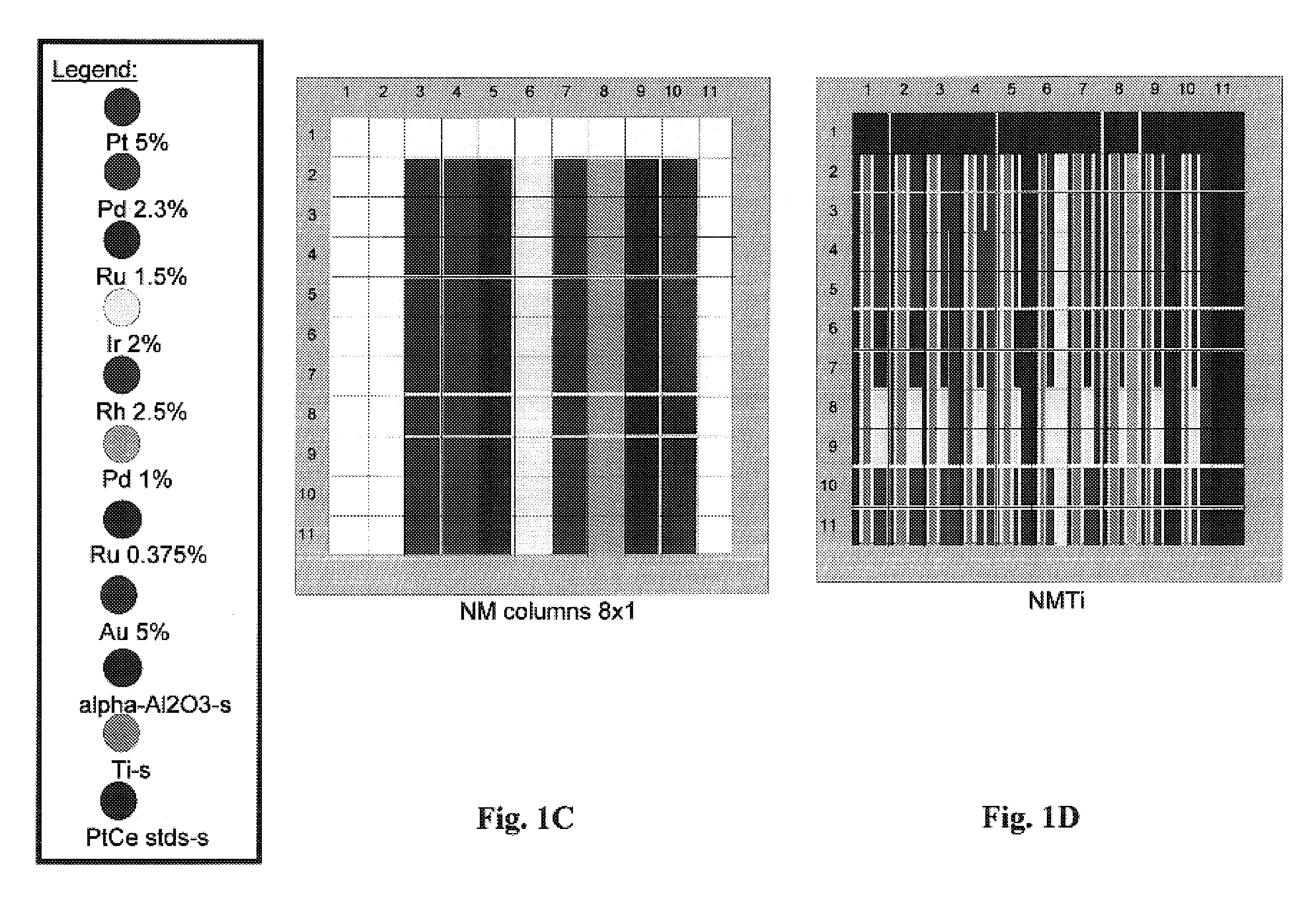

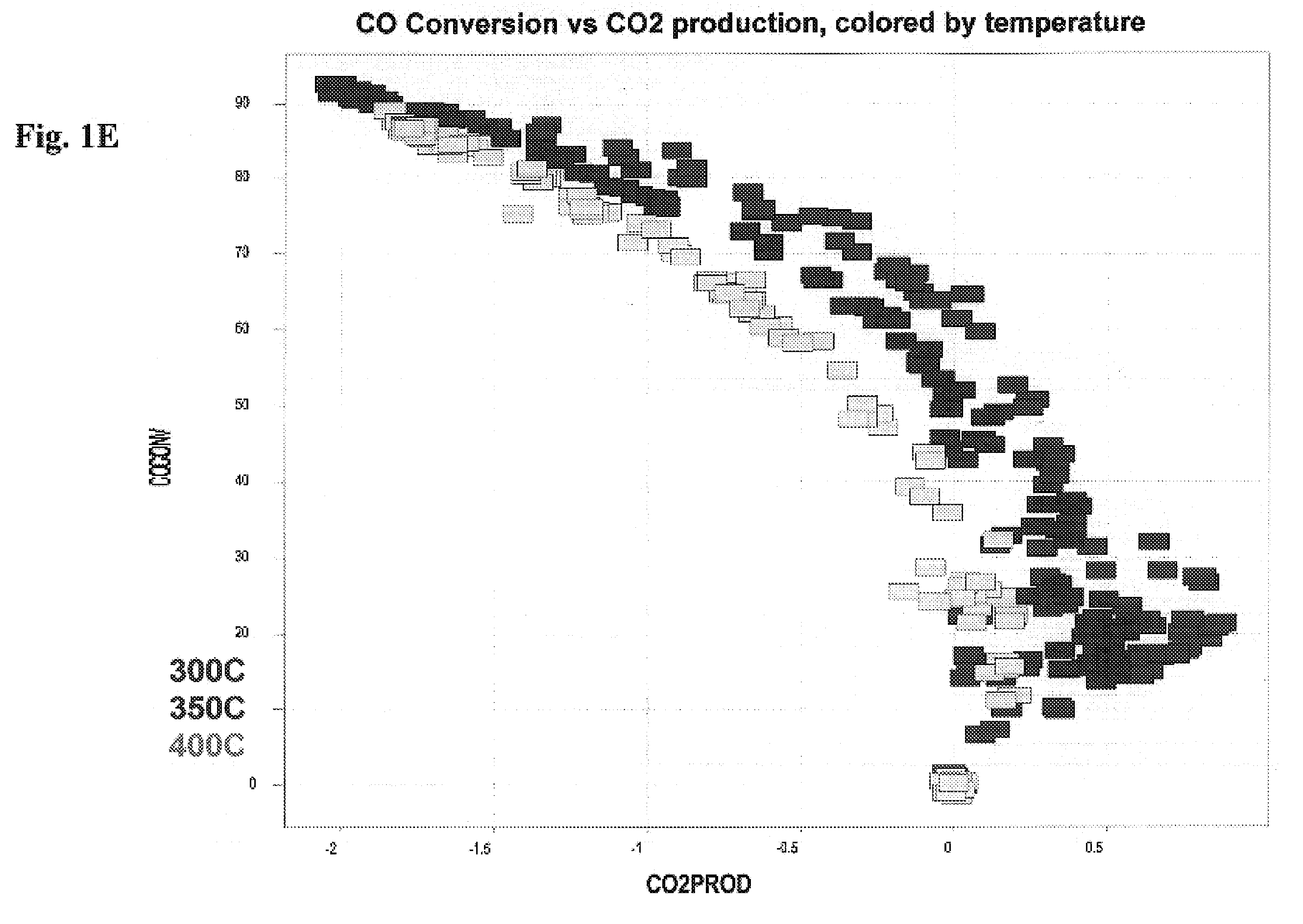

Platinum-ruthenium containing catalyst formulations for hydrogen generation

A method and catalysts for producing a hydrogen-rich syngas are disclosed. According to the method a CO-containing gas contacts a water gas shift (WGS) catalyst, optionally in the presence of water, preferably at a temperature of less than about 450° C. to produce a hydrogen-rich gas, such as a hydrogen-rich syngas. Also disclosed is a water gas shift catalyst formulated from:a) Pt, its oxides or mixtures thereof;b) Ru, its oxides or mixtures thereof; andc) at least one of Li, Na, K, Rb, Cs, Mg, Ca, Sr, Ba, Sc, Y, Ti, Zr, V, Mo, Mn, Fe, Co, Rh, Ir, Ge, Sn, Sb, La, Ce, Pr, Sm, and Eu. Another disclosed catalyst formulation comprises Pt, its oxides or mixtures thereof; Ru, its oxides or mixtures thereof; Co, its oxides or mixtures thereof; and at least one of Li, Na, K, Rb, Cs, Mg, Ca, Sr, Ba, Sc, Y, Ti, Zr, V, Mo, Mn, Fe, Rh, Ir, Ge, Sn, Sb, La, Ce, Pr, Sm, and Eu, their oxides and mixtures thereof. The WGS catalyst may be supported on a carrier, such as any one member or a combination of alumina, zirconia, titania, ceria, magnesia, lanthania, niobia, zeolite, perovskite, silica clay, yttria and iron oxide. Fuel processors containing such water gas shift catalysts are also disclosed.

Owner:FREESLATE +1

Thermostable white nano far-infrared ceramic powder and preparation method thereof

The invention discloses a thermostable white nano far-infrared ceramic powder and a preparation method thereof. The thermostable white nano far-infrared ceramic powder is prepared from the following components in percentage by weight: 20-30% of nano alumina, 3-8% of nano magnesia, 15-25% of nano monox, 10-20% of nano zirconia, 15-25% of nano zinc oxide, 7-10% of nano titanium oxide, 1-3% of nano rare earth oxide and 0.1-0.3% of nano precious metal oxide. In the invention, the nano rare earth oxide is one of yttrium oxide or lanthana or cerium oxide, and the nano precious metal oxide is one of platinum oxide or palladium oxide. The nano far-infrared ceramic powder can be subjected to subsequent processing at the high temperature of 1300-1450 DEG C, without reduction of radiance and radiation intensity, wherein the radiance can reach 0.90-0.94, and the nano far-infrared ceramic powder is white and can be widely applied to far-infrared household porcelain, wall and floor tiles, heating ceramic plates and high-temperature coating.

Owner:JINGDEZHEN BOZHI CERAMICS

Black zirconia ceramic and preparation method thereof

The invention discloses black zirconia ceramic material composition which comprises the following components in percentage by mass: 0-5% of ferric oxide, 0-5% of cobaltous oxide, 0-5% of chromic oxide, 0-5% of aluminum oxide, 0-5% of nickel oxide, 0-5% of manganese oxide, 0-5% of zinc oxide, 2-6% of yttrium oxide, 0-5% of titanium oxide, 0-5% of silicon dioxide, 0-5% of cerium oxide and the balance of zirconium oxide containing hafnium oxide. The black zirconia ceramic material composition disclosed by the invention is small in powder granularity and uniform in distribution, and black zirconia ceramic containing the black zirconia ceramic material composition is relatively good in covering power, high in blackness and relatively low in transmittance of light. Meanwhile the invention further discloses black zirconia ceramic prepared from the black zirconia ceramic material composition and a preparation method of the black zirconia ceramic.

Owner:CHAOZHOU THREE CIRCLE GRP

Catalyst formulations containing Group 11 metals for hydrogen generation

ActiveUS7179442B2Maintain good propertiesExhaust apparatusElement comparisonCerium(IV) oxideSilicon dioxide

A method and catalysts and fuel processing apparatus for producing a hydrogen-rich gas, such as a hydrogen-rich syngas are disclosed. According to the method a CO-containing gas, such as a syngas, contacts a water gas shift (“WGS”) catalyst, in the presence of water, preferably at a temperature of less than about 450° C. to produce a hydrogen-rich gas, such as a hydrogen-rich syngas. Also disclosed is a water gas shift catalyst formulated from:a) at least one of Rh, Ni, Pt, their oxides and mixtures thereof,b) at least one of Cu, Ag, Au, their oxides and mixtures thereof; andc) at least one of K, Cs, Sc, Y, Ti, Zr, V, Mo, Re, Fe, Ru, Co, Ir, Pd, Cd, In, Ge, Sn, Pb, Sb, Te, La, Ce, Pr, Nd, Sm, Eu, their oxides and mixtures thereof. Another disclosed catalyst formulation comprises Rh, its oxides or mixtures thereof, Pt, its oxides or mixtures thereof and Ag, its oxides or mixtures thereof. The WGS catalyst may be supported on a carrier, such as any one member or a combination of alumina, zirconia, titania, ceria, magnesia, lanthania, niobia, zeolite, pervoskite, silica clay, yttria and iron oxide. Fuel processors containing such water gas shift catalysts are also disclosed.

Owner:HONDA MOTOR CO LTD +1

A kind of zirconia ceramic and its preparation method

The invention, belonging to the technical field of zirconia ceramic, discloses a zirconia ceramic and a preparation method thereof. The ceramic comprises matrix, sintering aid, neodymium oxide and additive, wherein, the matrix is yttria stabilized zirconia, the additive is selected from one or more of zinc oxide, barium carbonate and calcium fluoride, and the diffraction peak of the XRD appears when the 2 theta is 34.8-36.2 degrees. The zirconia ceramic has stable and beautiful purple. The preparation method comprises the following steps: adding neodymium oxide particles in a diethanolamine solution for soaking, then carrying out solid-liquid separation; carrying out ball mill mixing of the matrix, processed neodymium oxide particles, sintering aid and additive, then carrying out die forming and high temperature sintering. The preparation method provided by the present invention is simple and easy, and is suitable for large-scale industrial production.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

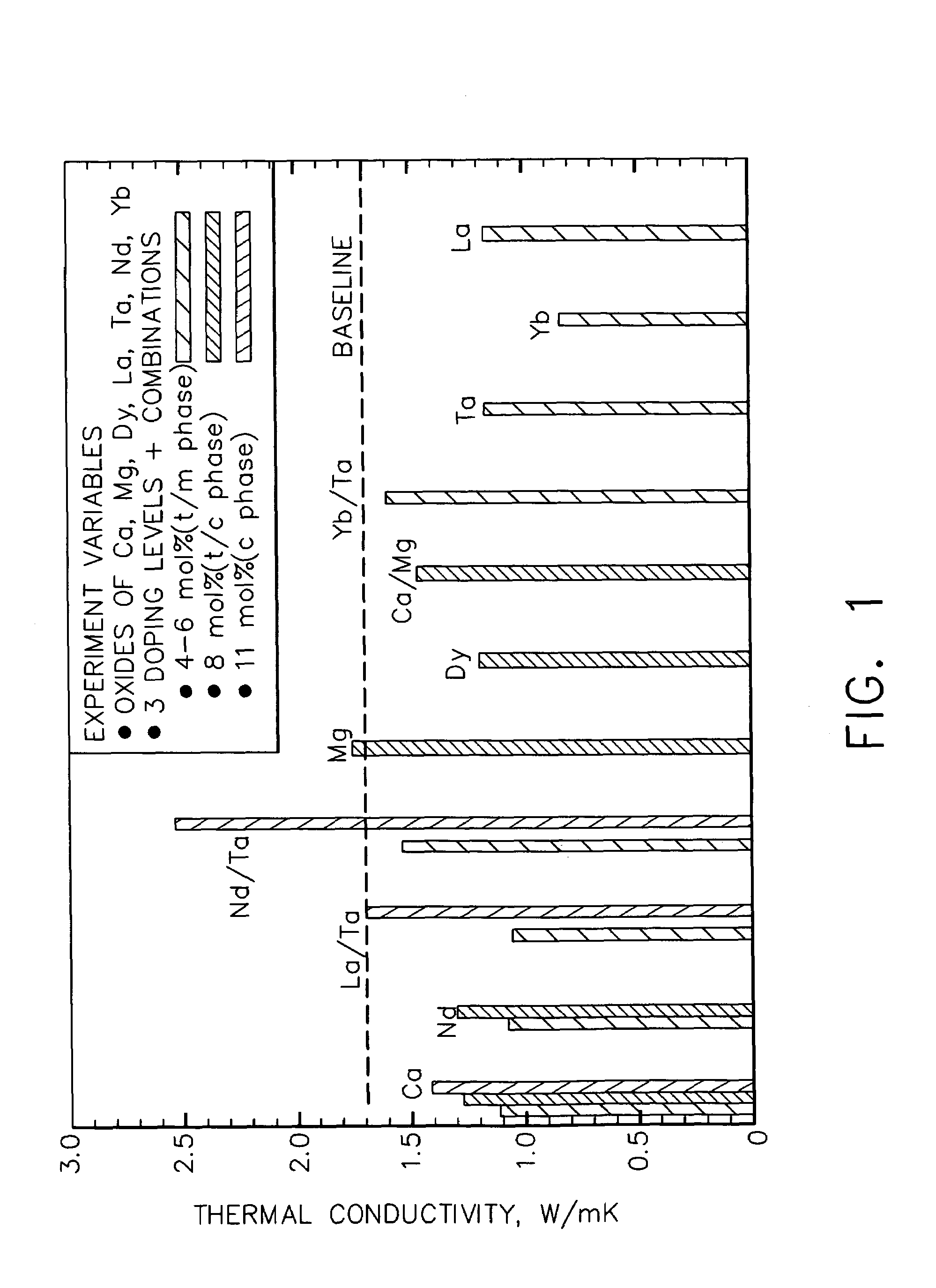

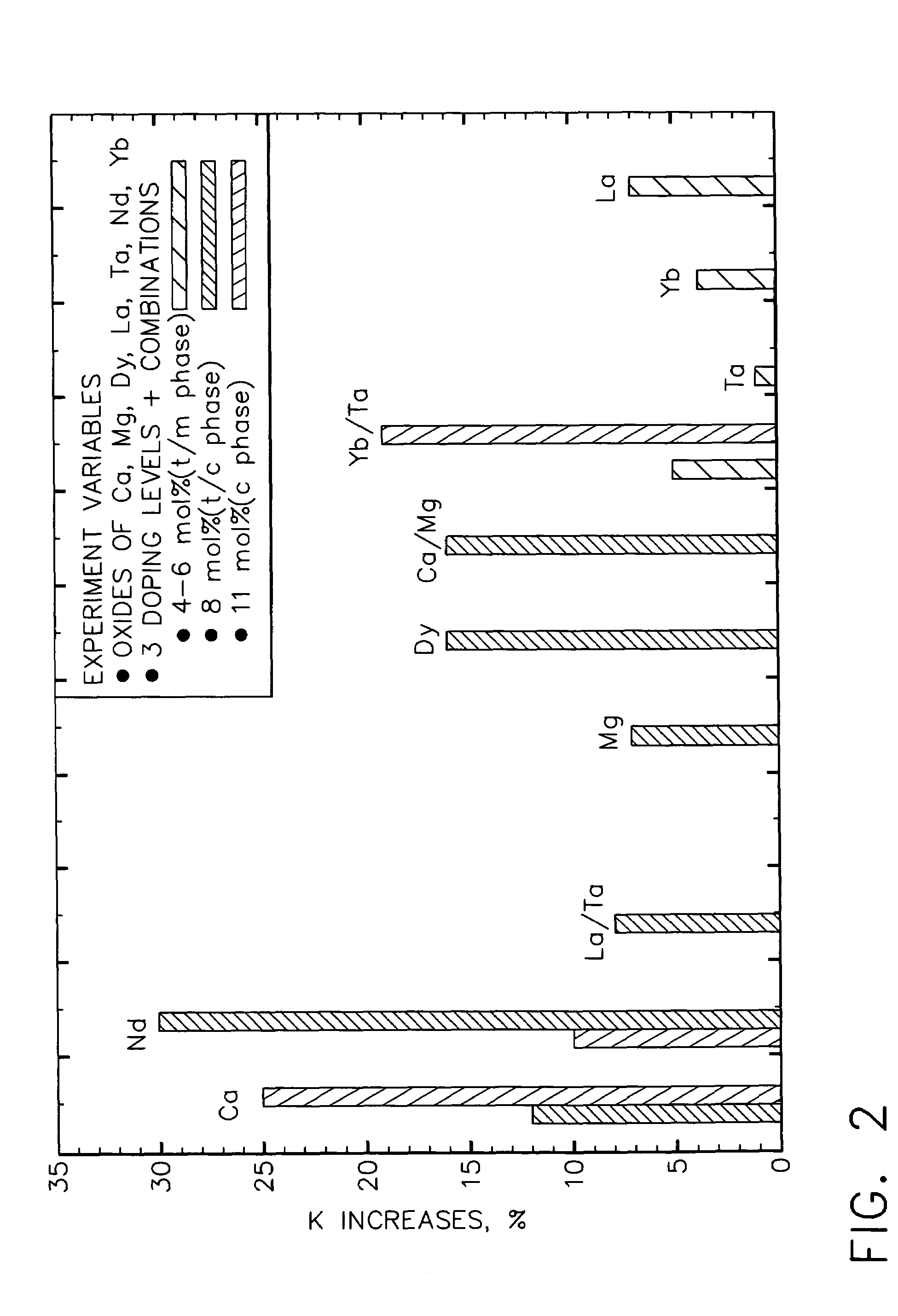

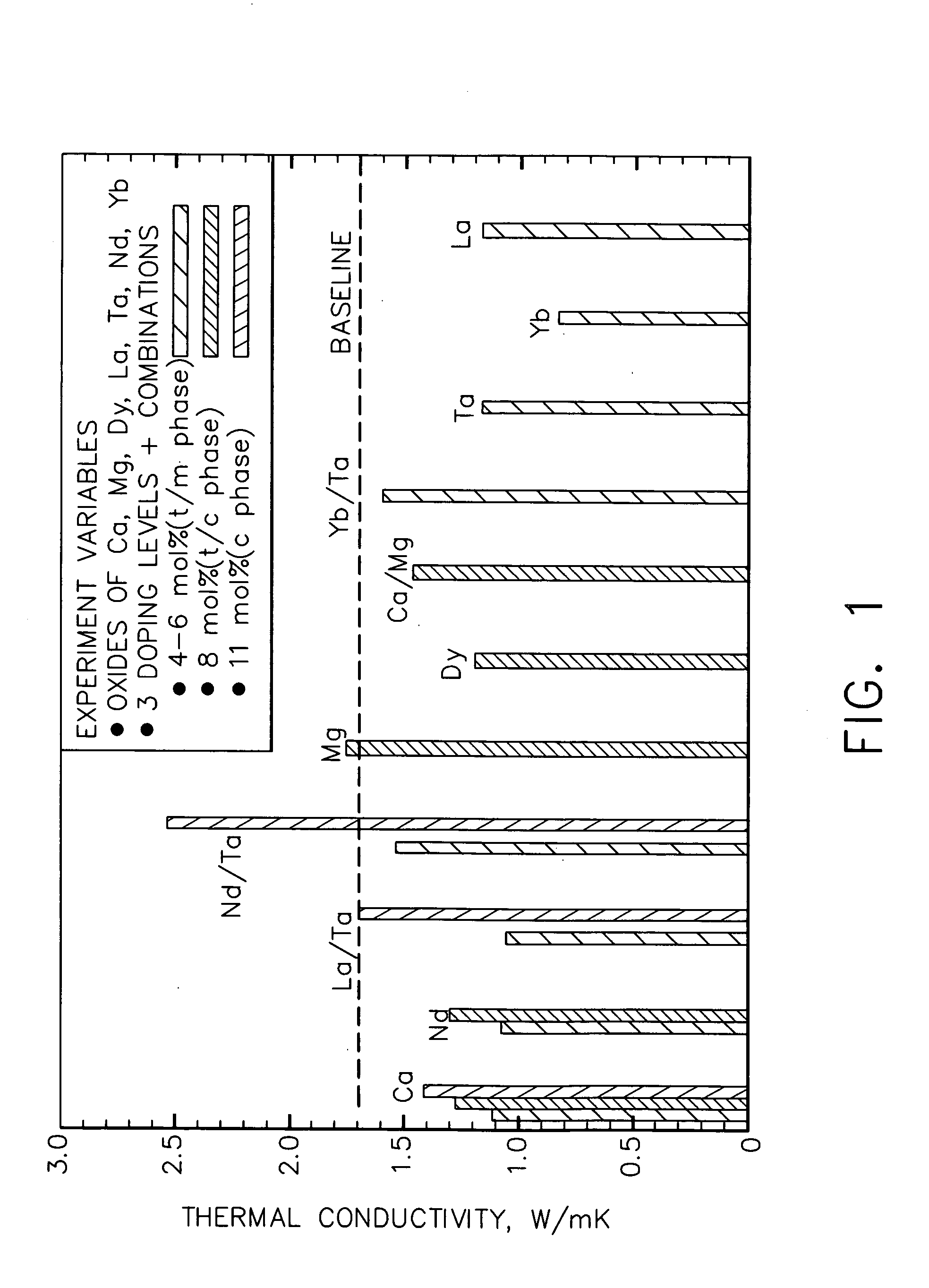

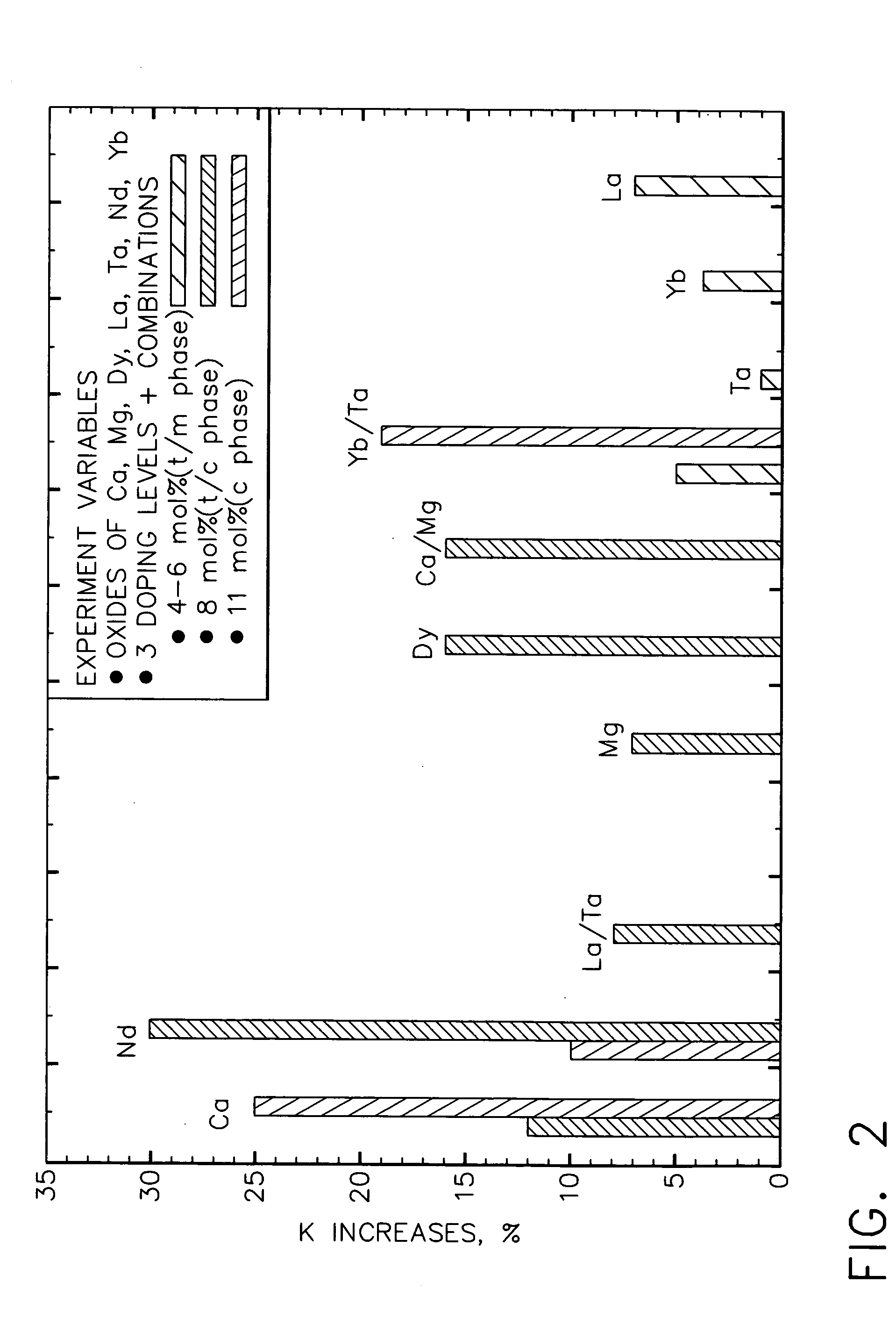

Ceramic compositions useful for thermal barrier coatings having reduced thermal conductivity

InactiveUS6960395B2Reduced and minimized tendency to sinterReduce conductivityMolten spray coatingVacuum evaporation coatingCeriumEngineering

Ceramic compositions comprising at least about 91 mole % zirconia and up to about 9 mole % of a stabilizer component comprising a first metal oxide having selected from the group consisting of yttria, calcia, ceria, scandia, magnesia, india and mixtures thereof. This stabilizer component further comprises a second metal oxide of a trivalent metal atom selected from the group consisting of lanthana, gadolinia, neodymia, samaria, dysprosium, and mixtures thereof and a third metal oxide of a trivalent metal atom selected from the group consisting of erbia, ytterbia and mixtures thereof. These ceramic compositions are useful in preparing thermal barrier coatings having reduced thermal conductivity for the metal substrate of articles that operate at, or are exposed to, high temperatures.

Owner:GENERAL ELECTRIC CO

Rare earth doped yttrium oxide fluorescent nano-fiber and preparation method thereof

InactiveCN101805942AEasy to operateLarge specific surface areaFilament/thread formingImage/pattern display tubesFiberFluorescence

The invention discloses a rare earth doped yttrium oxide fluorescent nano-fiber and a preparation method thereof. The nano-fiber comprises yttrium oxide and rare earth oxide, wherein the yttrium oxide accounts for 70-99.9 percent by weight, and the rare earth oxide accounts for 0.01-30 percent by weight. The diameter of the rare earth doped yttrium oxide fluorescent nano-fiber is 50-1000nm, and the nano-fiber is provided with small holes or small balls with diameters being 5-80nm. The preparation method comprises the following steps: preparing electrostatic spinning solution, making the electrostatic spinning solution into a composite nano-fiber precursor with spinning polymer resin, yttrium salt and rare earth salt through electrostatic spinning equipment under high-voltage electrostatic electricity, drying the composite nano-fiber precursor with the spinning polymer resin, the yttrium salt and the rare earth salt, and calcining to obtain the rare earth doped yttrium oxide fluorescent nano-fiber. The prepared rare earth doped yttrium oxide fluorescent nano-fiber has the advantages of large specific surface area, high fluorescence, easy recovery and recyclable property, and is applicable to biological sensors, field emission displays and other fields.

Owner:FUJIAN NORMAL UNIV

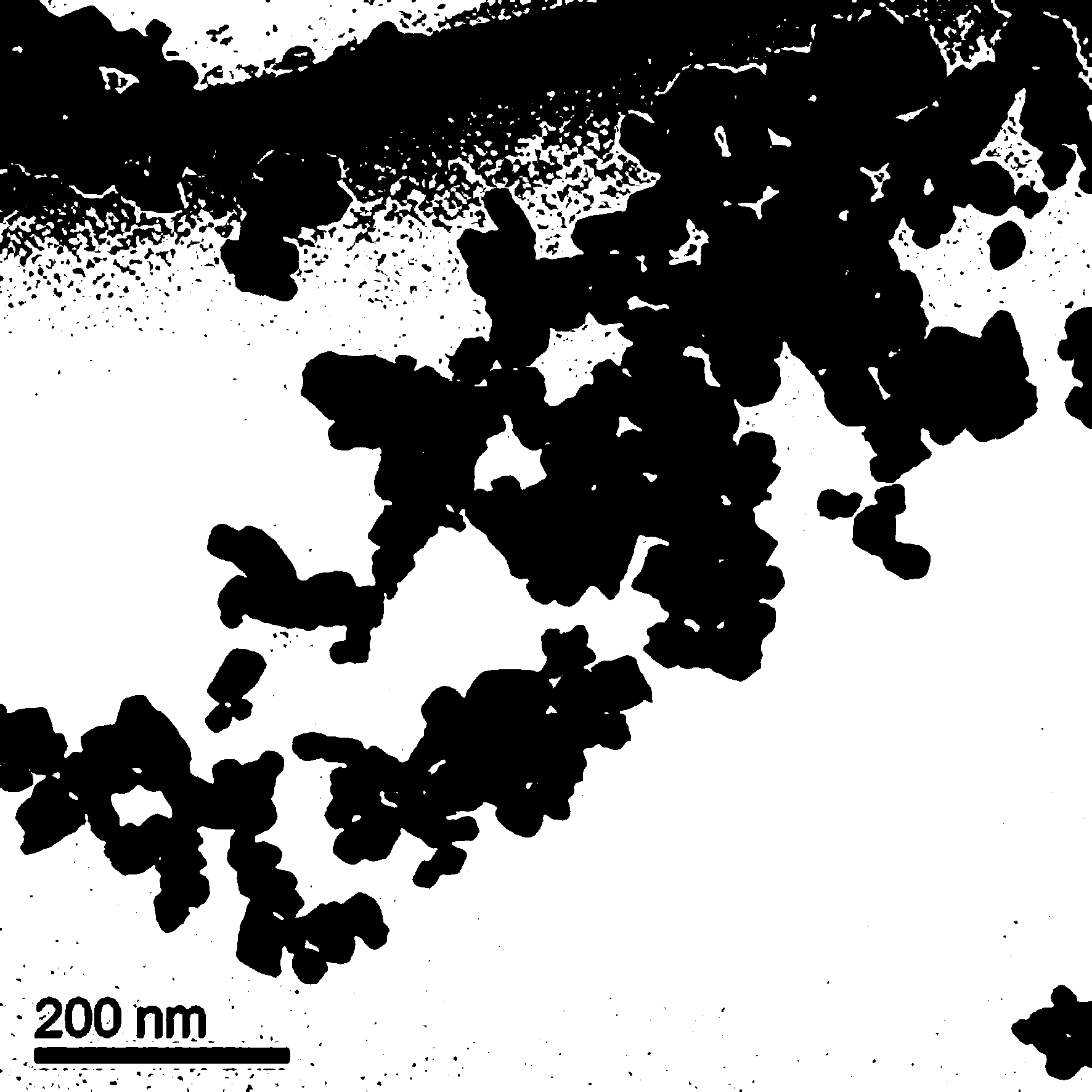

Ceramic coating comprising yttrium which is resistant to a reducing plasma

ActiveCN102084020AReduce formationReduce the probability of attackMolten spray coatingThin material handlingParticulatesPorosity

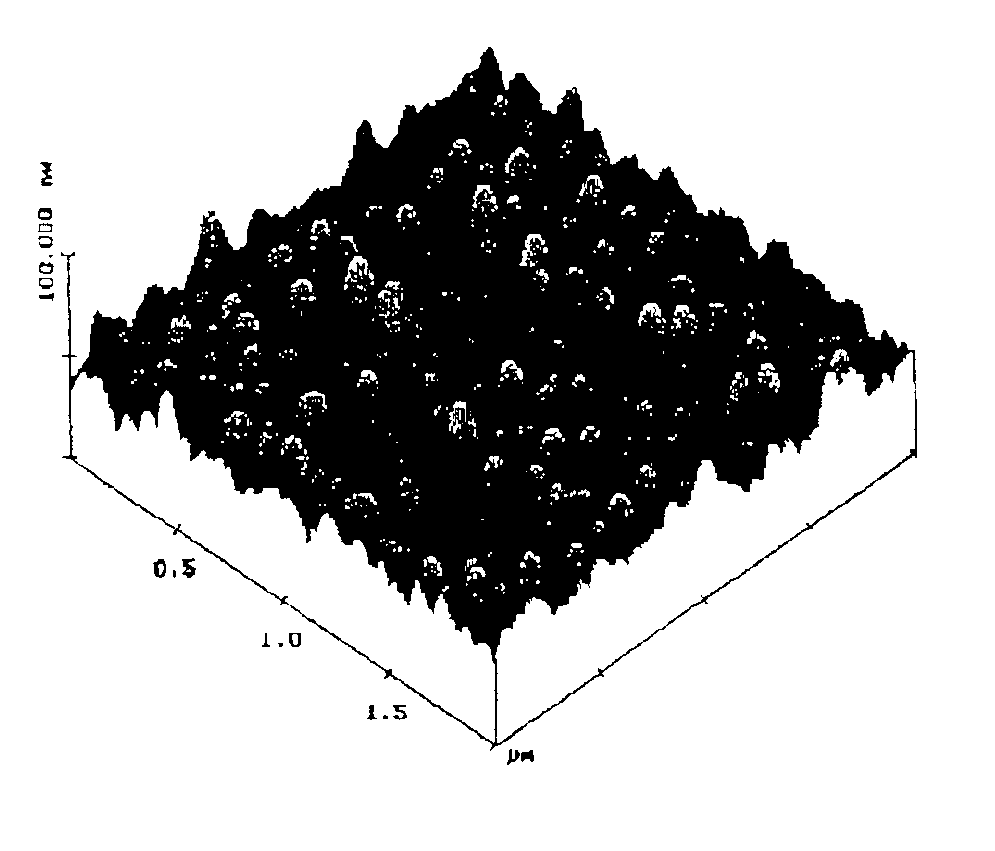

Particulate generation has been a problem in semiconductor device processing in highly corrosive plasma environments. The problem is exacerbated when the plasma is a reducing plasma. Empirically produced data has shown that the formation of a plasma spray coated yttrium-comprising ceramic such as yttrium oxide, Y2O3-ZrO2 solid solution, YAG, and YF3 provides a low porosity coating with smooth and compacted surfaces when such ceramics are spray coated from a powder feed having an average effective diameter ranging from about 22 [mu]m to about 0.1 [mu]m. These spray-coated materials reduce the generation of particulates in corrosive reducing plasma environments.

Owner:APPLIED MATERIALS INC

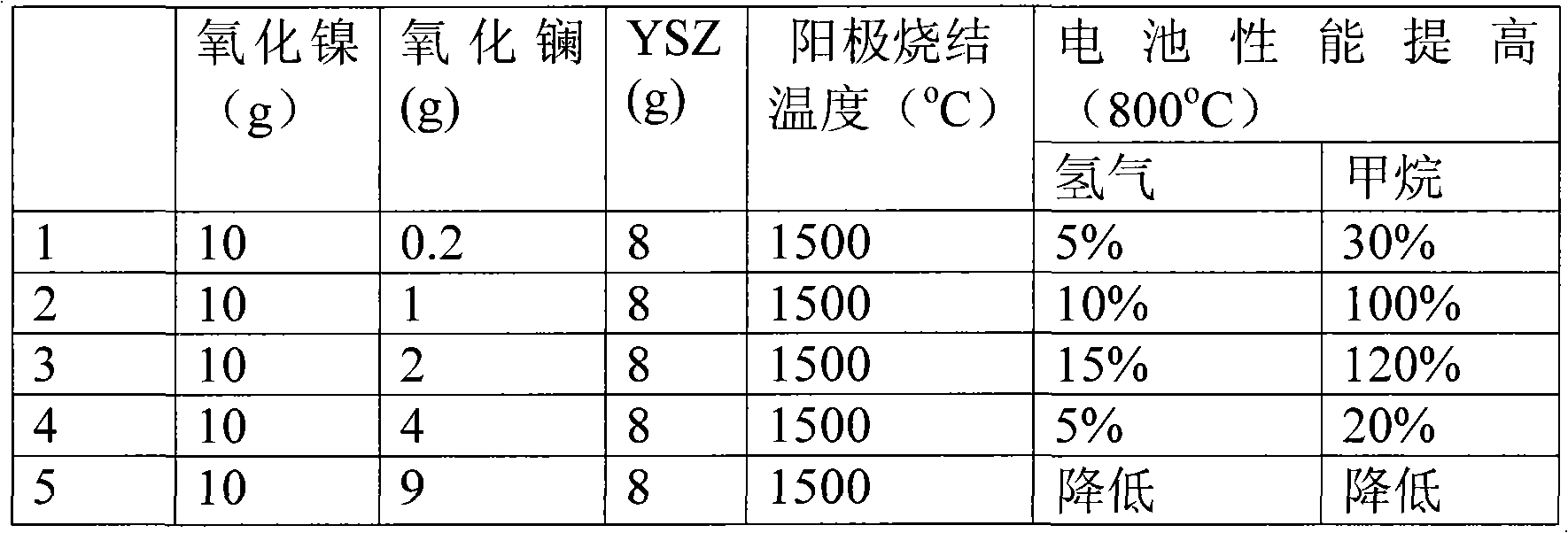

Compound anode of solid-oxide fuel battery and method for producing the same

InactiveCN101295792AGood electrode microstructureHigh activityCell electrodesSolid electrolyte fuel cellsFuel cellsRare earth

The invention relates to a solid oxide fuel cell, in particular to a composite anode of the solid oxide fuel cell and a preparation method thereof. According to weight percentage, the weight composition of the composite anode comprises 30 to 69.9 percent of NiO, 0.1 to 35 percent of rare earth materials and 30 to 69.9 percent of zirconia YSZ with stable yttrium oxide. The composite anode of the solid oxide fuel cell is compounded by adding the rare earth materials to the traditional anode of nickel oxide and zirconia with stable yttrium oxide, and the rare earth materials are added to the anode so as to improve the performance of the anode; the composite anode has the advantages of even distribution of electrode structure, tight interface contact between nickel and YSZ, low polarization impedance, high activity, etc., thus improving the output performance of the cell. The novel composite anode can be applied to flat type, tube type and flat tube type solid oxide fuel cells.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

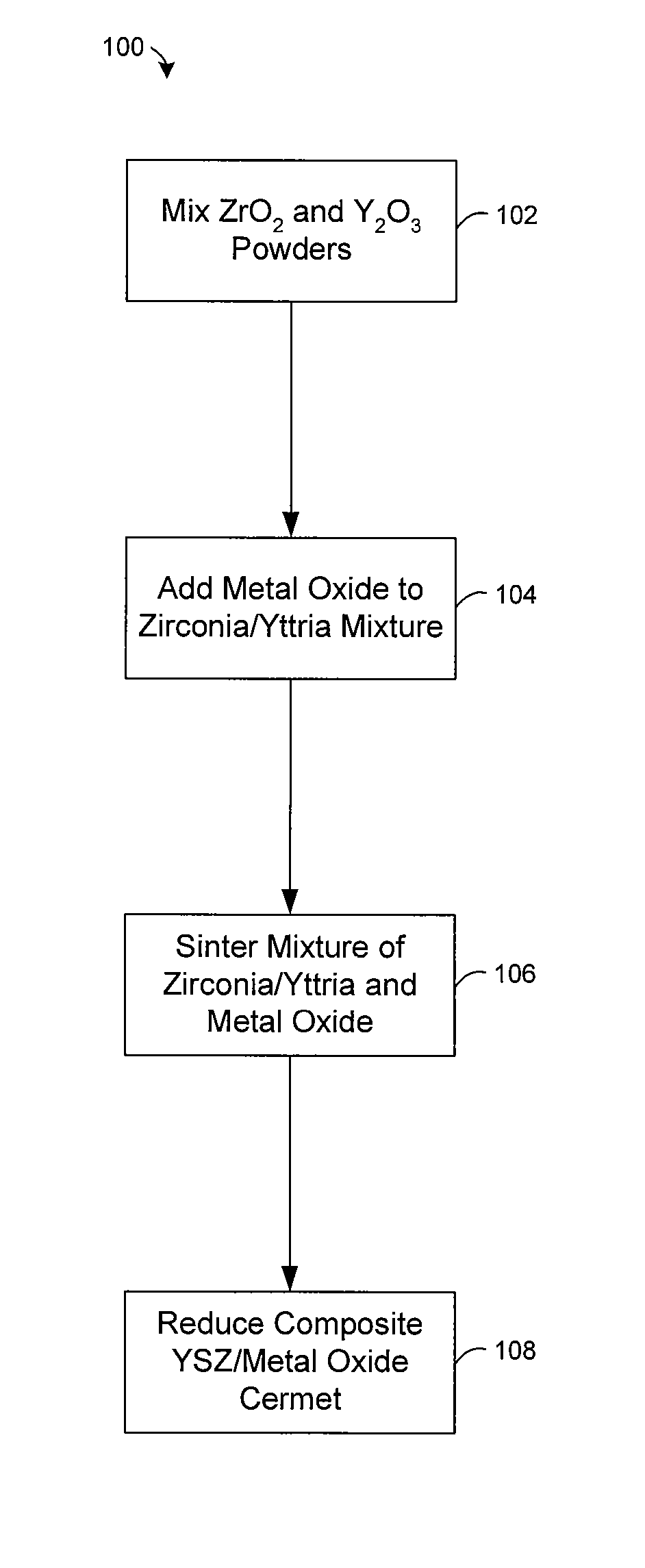

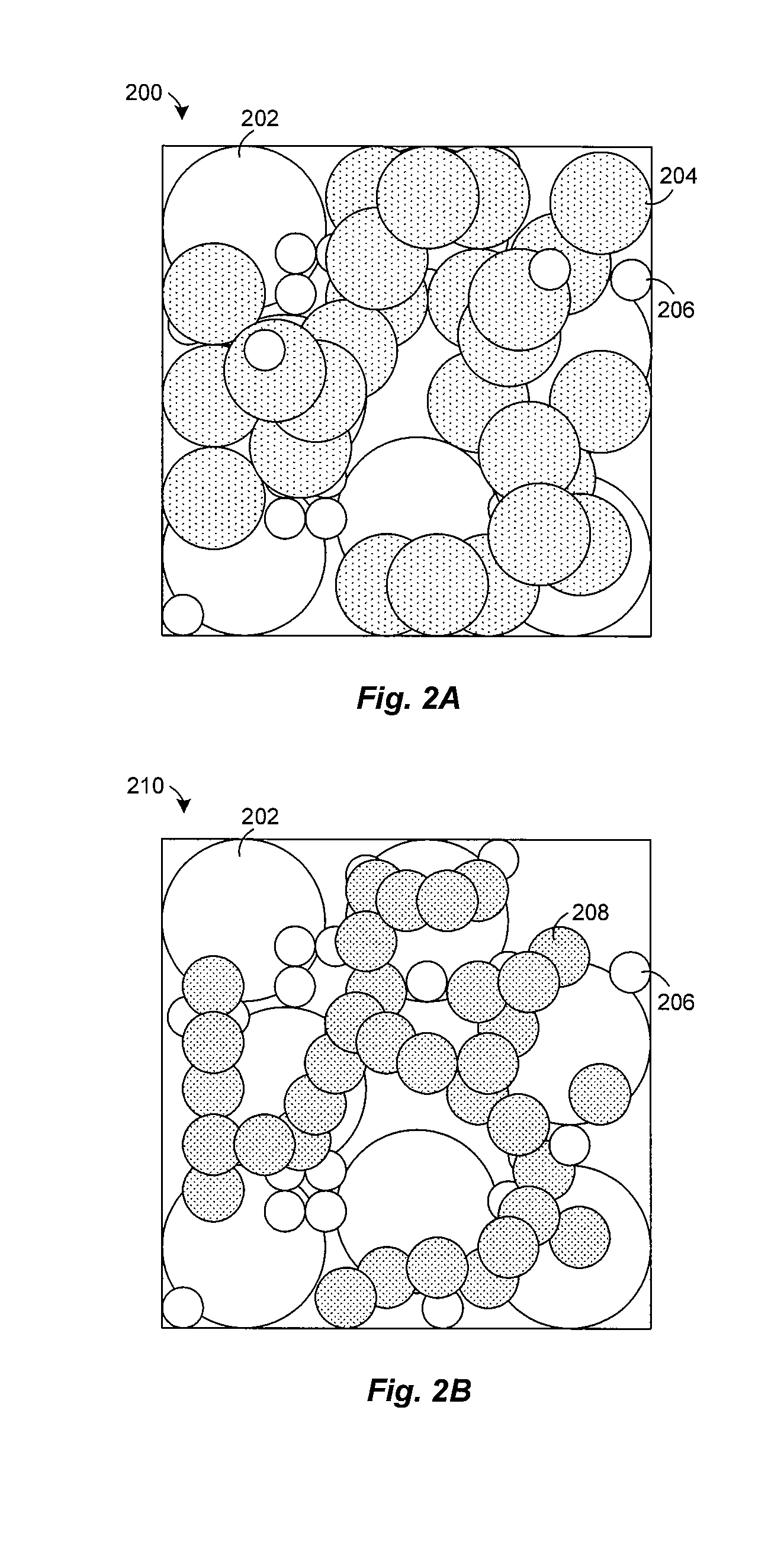

Preparation of yttria-stabilized zirconia reaction sintered products

A method of making a solid electrolyte-YSZ product, where the method includes the step of providing a powdered mixture of zirconia, yttria and about 2%, by wt., or less of a metal oxide, where yttria-stabilized zirconia is not added to the mixture. The method also includes sintering the powdered mixture at about 1500° C. or less, for about 5 hours or less, to form a reaction sintered YSZ. Also, a method of making a fuel cell electrolyte that includes the step of forming a green body that includes zirconia, yttria and about 2%, by wt., or less of a metal oxide, where yttria-stabilized zirconia is not added to the green body. The method also includes shaping the green body into a form of the electrolyte, and sintering the green body at about 1500° C. or less to form a reaction sintered yttria-stabilized zirconia and metal oxide electrolyte.

Owner:COORSTEK INC

Ceramic compositions useful for thermal barrier coatings having reduced thermal conductivity

InactiveUS20050142392A1Reduced and minimized tendency to sinterReduce conductivityMolten spray coatingVacuum evaporation coatingDysprosiumThermal barrier coating

Ceramic compositions comprising at least about 91 mole % zirconia and up to about 9 mole % of a stabilizer component comprising a first metal oxide having selected from the group consisting of yttria, calcia, ceria, scandia, magnesia, india and mixtures thereof. This stabilizer component further comprises a second metal oxide of a trivalent metal atom selected from the group consisting of lanthana, gadolinia, neodymia, samaria, dysprosium, and mixtures thereof and a third metal oxide of a trivalent metal atom selected from the group consisting of erbia, ytterbia and mixtures thereof. These ceramic compositions are useful in preparing thermal barrier coatings having reduced thermal conductivity for the metal substrate of articles that operate at, or are exposed to, high temperatures.

Owner:GENERAL ELECTRIC CO

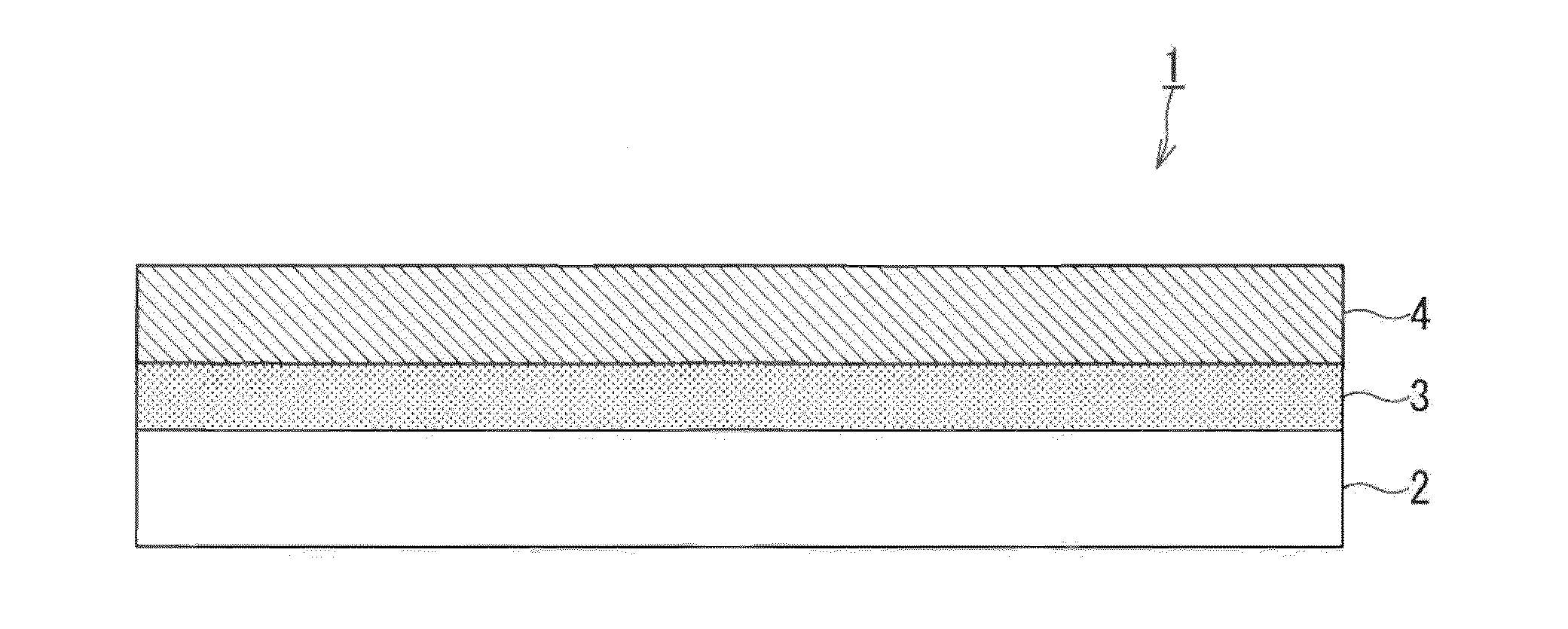

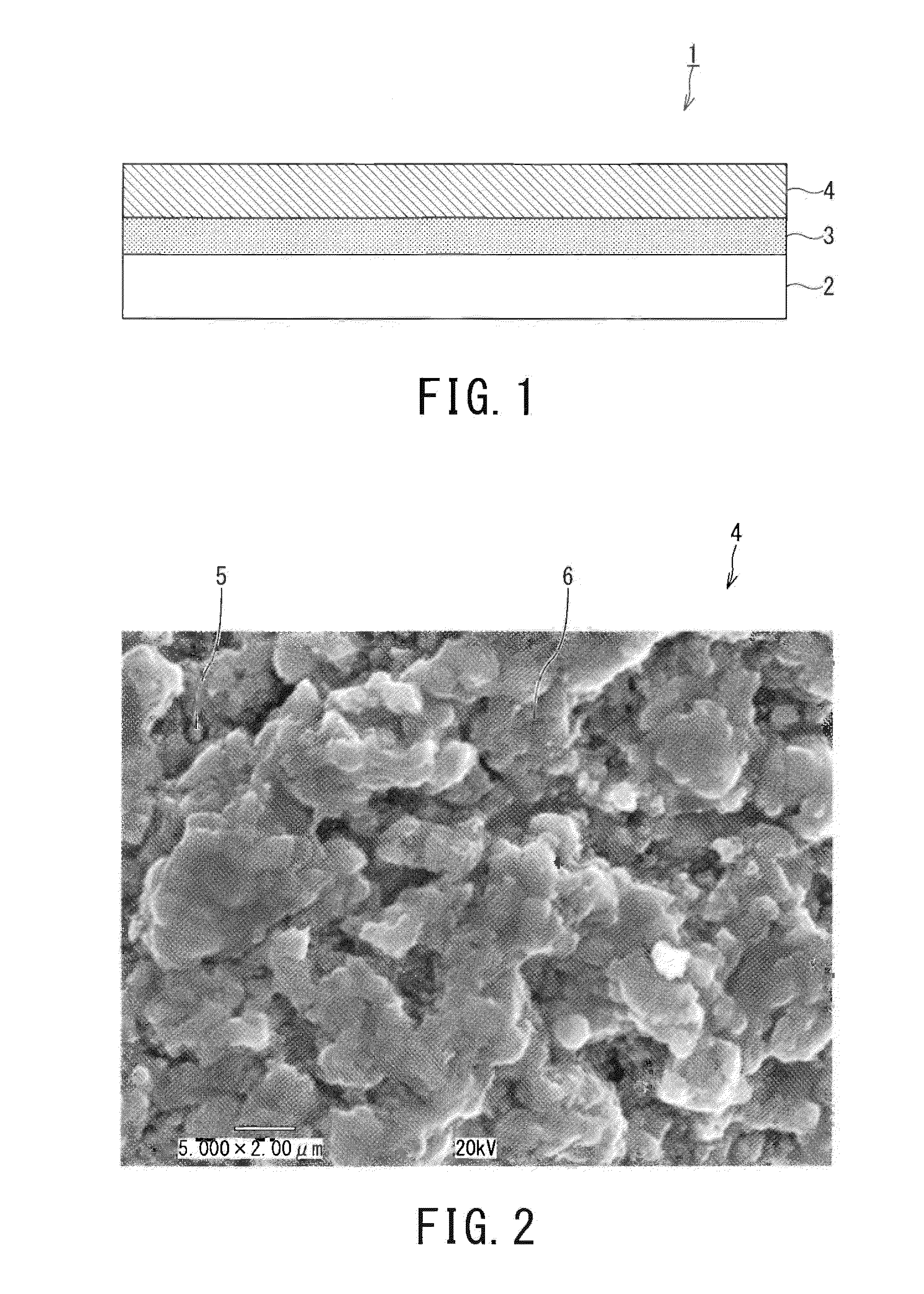

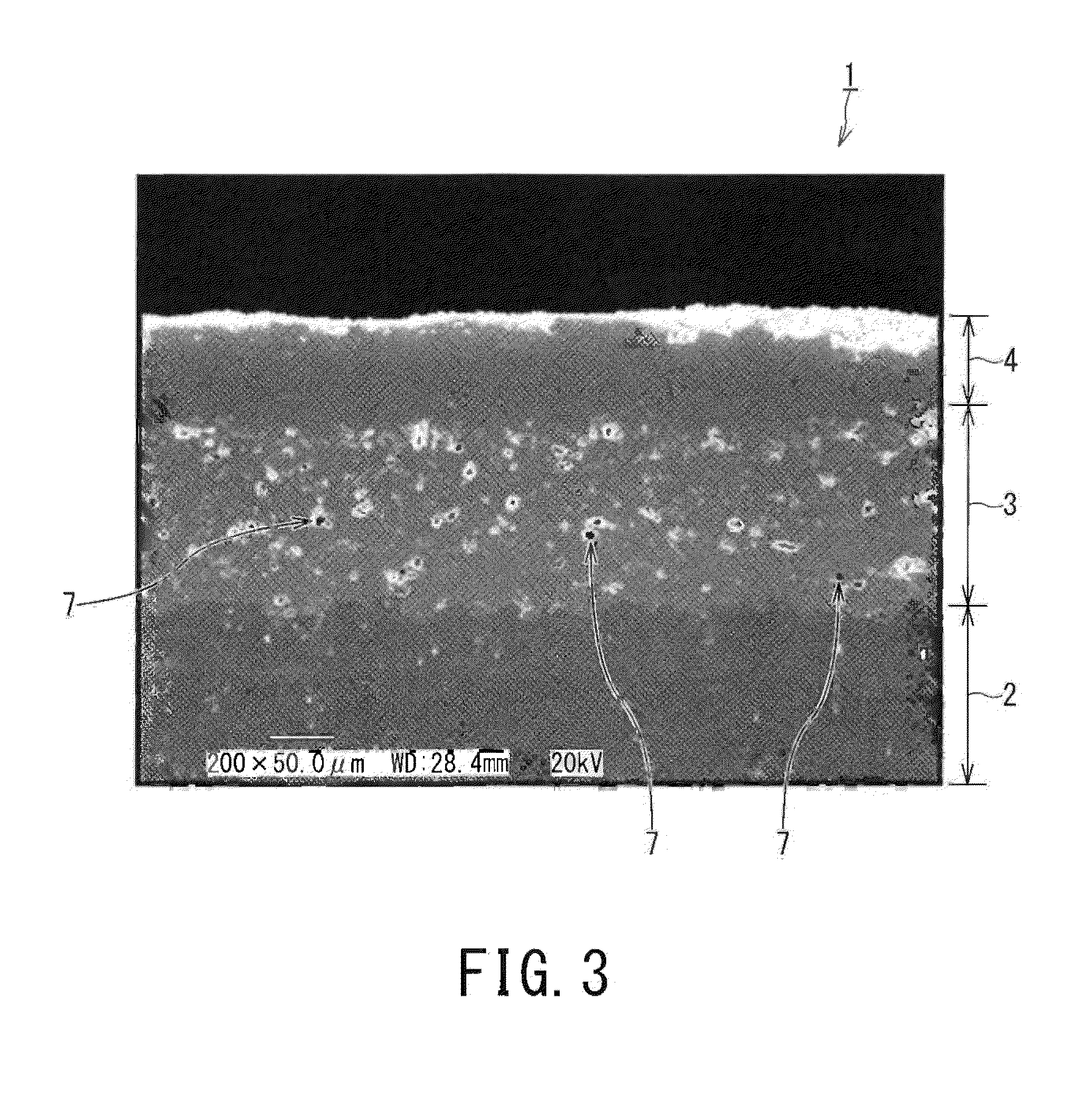

Component for plasma processing apparatus and method for manufacturing component for plasma processing apparatus

ActiveUS20150152540A1Improve plasma resistanceSuppress generation of particleLiquid surface applicatorsMolten spray coatingEngineeringGrain boundary

Owner:KK TOSHIBA +1

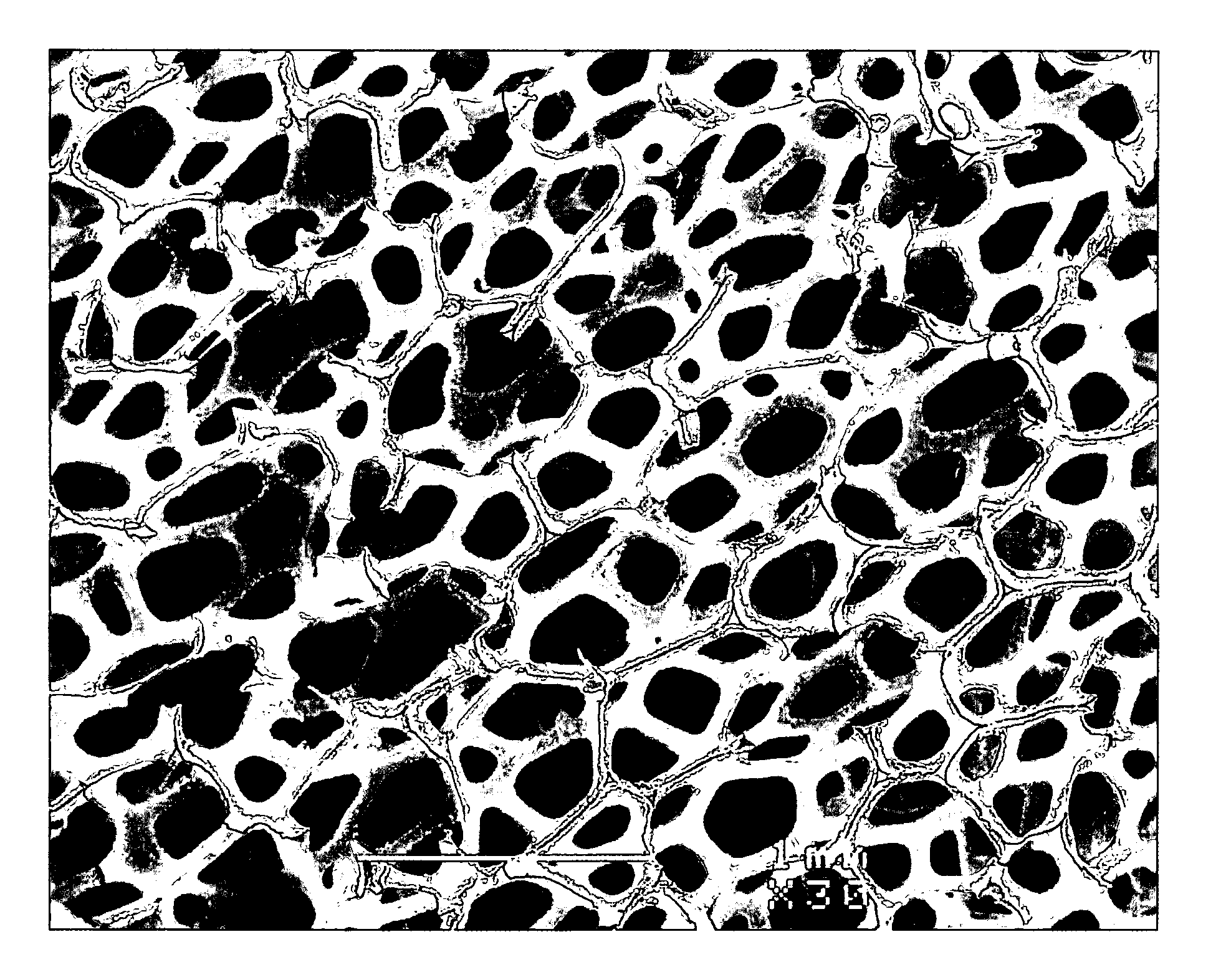

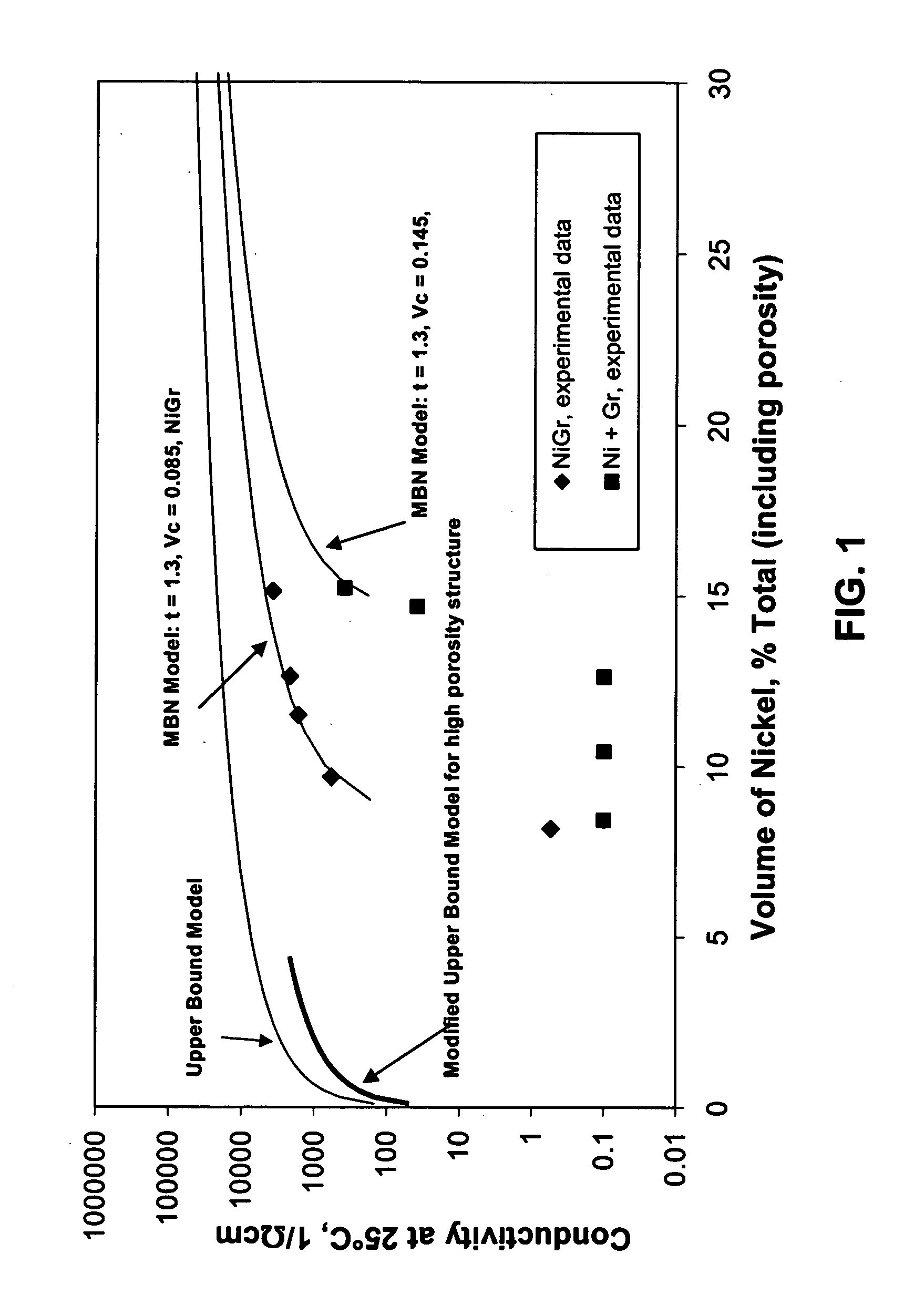

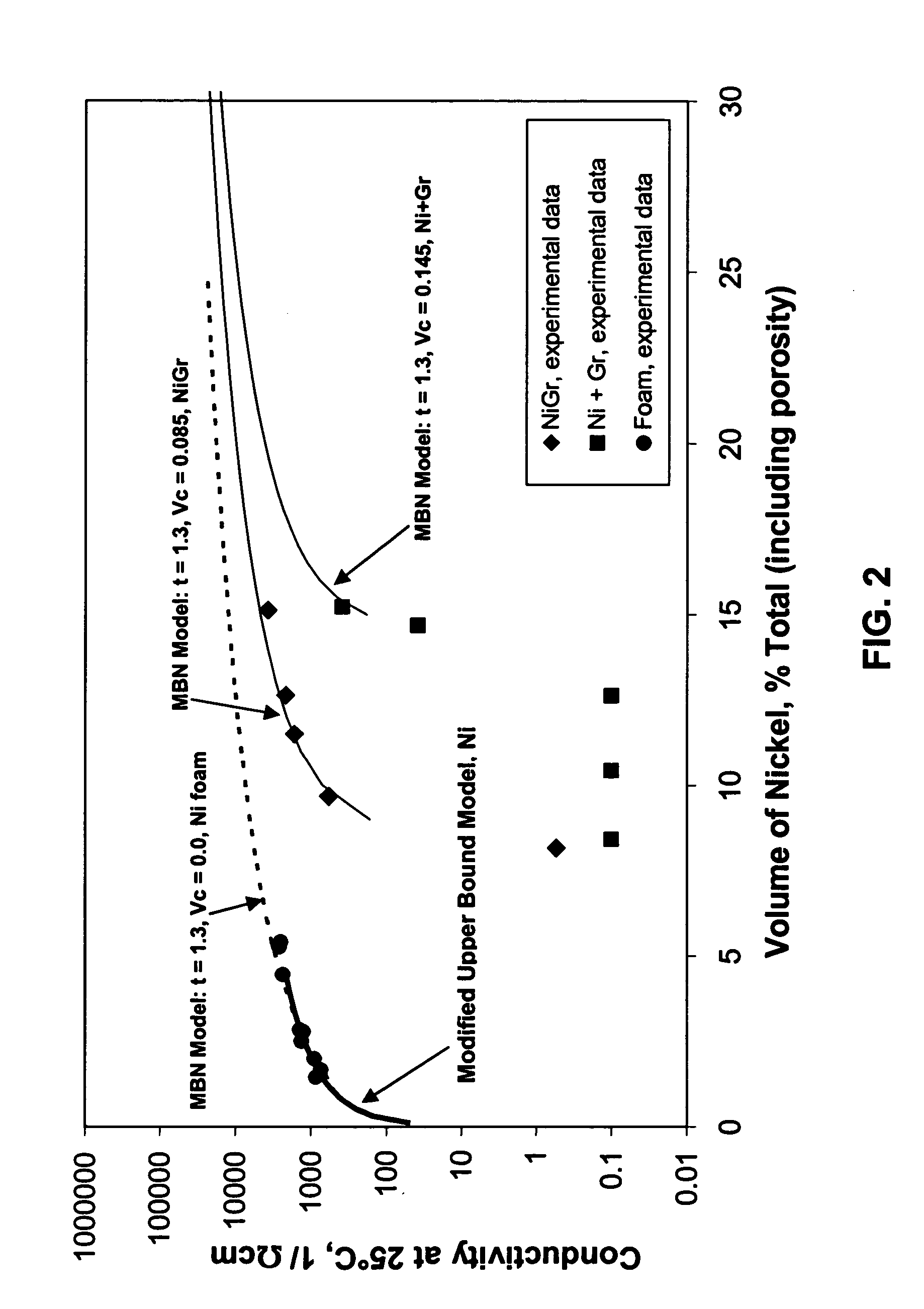

Nickel foam and felt-based anode for solid oxide fuel cells

InactiveUS20050221163A1Improve conductivityReduce in quantityPhotography auxillary processesVacuum evaporation coatingFuel cellsThermal expansion

A solid oxide fuel cell anode is comprised of a nickel foam or nickel felt substrate. Ceramic material such as yttria stabilized zirconia or the like is entrained within the pores of the substrate. The resulting anode achieves excellent conductivity, strength and low coefficient of thermal expansion characteristics while effectively reducing the overall quantity of nickel contained in the fuel cell. Equivalent or better fuel cell anode characteristics result in the present invention as compared to conventional anode designs while simultaneously employing significantly less nickel.

Owner:INCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com