Patents

Literature

926results about How to "Beautiful color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quick preparation method for pickled vegetable containing biodiasmin

InactiveCN103120294AImprove production efficiencyIncrease productivityFood preparationVegetable processingSalt content

The invention provides a quick preparation method for a pickled vegetable containing biodiasmin. The quick preparation method comprises the following steps of: preparing biodiasmin liquor, preparing pickled vegetable fermentation liquor, preparing a seasoning fermentation liquor, pre-treating and preparing a finished pickled vegetable containing biodiasmin. According to the quick preparation method disclosed by the invention, the pickled vegetable fermentation liquor is independently prepared according to the conventional pickled vegetable production way, and the pickled vegetable fermentation liquor is treated by seasoning to form seasoning fermentation liquor; osmotic dehydration and the brittleness-keeping treatment are carried out on the fresh vegetable to obtain a semi-finished product; and the semi-finished product is pickled by the seasoning fermentation liquor, and the seasoning fermentation liquor is quickened up to permeate into the vegetable through the vacuum treatment to obtain the delicious finished pickled vegetable. The pickled vegetable is prepared by the preparation method disclosed by the invention is low in salt content, short in production time, high in calcium content and biodiasmin content and beneficial to the body health of a user; and moreover, the automation degree of the pickled vegetable processing is improved.

Owner:HEFEI UNIV

Method for blending and setting wood

ActiveCN101596730AAlleviate the prominent contradiction between supply and demandExpand the scope of useWood compressionWood treatment detailsPulp and paper industryDistortion

The invention relates to the technique field of wood processing treatment, in particular to a method for blending and setting wood. The method for blending and setting wood comprises steps of sorting treatment, softening process, blending and deforming, setting, temperature reduction and humidifying, and cooling and health preserving. The method solves the problems existing in the existing traditional wood blending and distortion technique that wood utilization ratio is low, obtained products have poor size stability and high recovery rate of radius of curvature and is easy to crack, deform, decay and go moldy, etc.

Owner:ZHEJIANG SHIYOU TIMBER

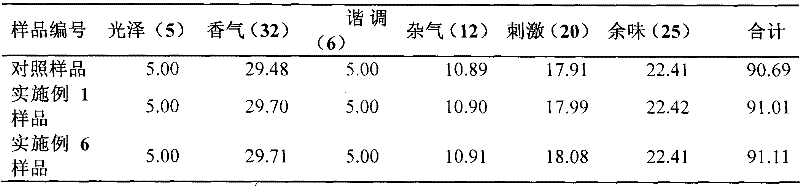

Coated and perfumed environment-friendly lining paper of cigarette packet

ActiveCN102127879AImprove aging environmentImprove cigarette smokingPaper coatingCoatingsAntioxidantEnvironmentally friendly

The invention discloses coated and perfumed environmentally-friendly lining paper of a cigarette packet. The surface of a paper base of the lining paper is coated with a coating solution taking a tobacco extract as a major solute component, wherein the coating solution comprises the following components in percentage by weight: 5-20 percent of tobacco extract, 0-20 percent of ethanol, 60-90 percent of water, 0.1-1.2 percent of thickening agent, 0.05-0.2 percent of pH regulator and 0.02-0.1 percent of antioxidant. In the invention, the tobacco extract is taken as a major raw material, so that cigarettes are damp-proof and perfumed, the microscopic ageing environment of the cigarettes is changed through volatilization of natural cigarette perfume, the inside of the cigarette packet is rich in perfume, perfume of the cigarettes is well balanced, the sniffing perfume of the cigarettes is increased and the smoking effect of the cigarettes is improved.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

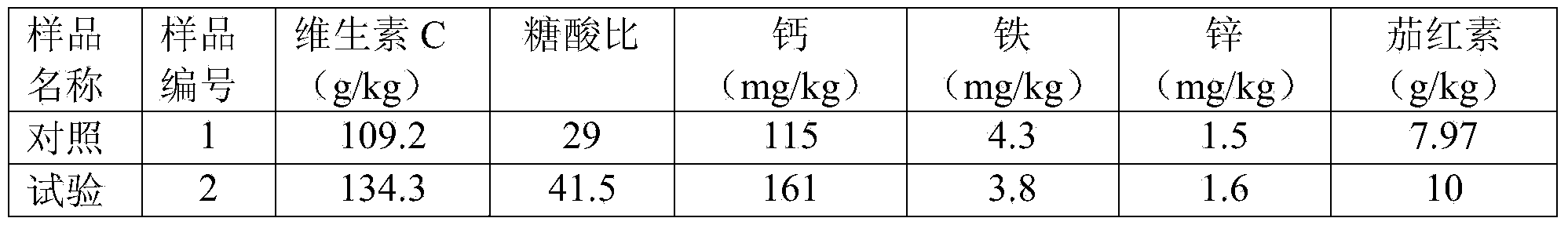

Tea glutinous rice cake product

InactiveCN101194690AImprove nutrition and health ingredientsFull of nutritionFood preparationAdditive ingredientPotassium

The invention provides a tea-rice cake product, which is substantially made from the following raw material components: main materials are deep color rice and white round shaped rice whose mass ratio is 2-25:75-98, incidental components comprise tea power or tea extract whose mass is 0.1-5 percent of the mass of the main materials, and the dark color rice is black glutinous rice or purple glutinous rice or black round shaped rice or purple round shaped rice. The invention provides a novel wet ground rice cake which take orders of local characteristics of ningbo, improves nourishing compositions and enriches the colors and patterns of the rice cake. The product is waxy but not is sticky, storage is long and is indehiscent, the odor is cleaning favor, the color is beautiful, the nutrition is rich, and the contents of specific dietary fiber and minerals such as k-rich, calcium and zinc and the like are best diet for patients with cardiovascular diseases. In generally, potassium content is increased by 2-3 times than traditional wet ground rice cake, the contents of calcium and zinc are respectively increased by 30 percent, total content of minerals are increased by 1.0-1.5 time than traditional wet ground rice cake, and total amino acid content is increased above 10 percent. The invention has no chemical preservative and chemical pigments, and the shelf life is capable of being reached more than 3 months below15 DEG C.

Owner:NINGBO ACAD OF AGRI SCI

Production method for mycelium pellets of edible and medicinal fungi and products of mycelium pellets of edible and medicinal fungi

InactiveCN102550285AFull of nutritionUnique flavorHorticultureFertilizer mixturesBiotechnologyMycelium

A production method for mycelium pellets of edible and medicinal fungi uses fruit and vegetable juice as main materials obtained by liquid fermentation, and fermentation medium with pH5-8 is made of the fruit and vegetable juice 50-300ml / L, granulated sugar 5-20g / L, KH2PO4 1-5g / L, MgSO4X7H2O 1-5g / L, ZnSO4X7H2O 0-0.5g / L and CaCO3 3-7g / L by adding water to meter the volume. The mycelium pellets of edible and medicinal fungi produced by the method and products of the mycelium pellets have the colors of natural fruit and vegetable juices and functional ingredients of edible and medicinal fungi, and the products are nutritious, unique in flavor, bright and attractive, and have the health functions of coloration, fragrance and taste, and have great market potential.

Owner:YUANTUO FUZHOU BIO TECH

Walnut kernel peeling method

The present invention relates to a method for removing walnut kernel seed cover under the condition of normal temperature after the walnut kernel is frozen at low-temperature. It is characterized by that for dried walnut kernel the walnut kernel is soaked in the water with 0-10deg.C, after the walnut kernel is reconstituted, the walnut kernel is frozen; for fresh walnut kernel whose water content is greater than or equal to 45% it has no need of reconstitution, can be directly frozen; its freeze temperature is -5 - -25deg.C; after a lyer of ice cover is formed on the walnut kernel surface, the walnut kernel can be taken out and can be placed at normal temperature or into water with 30-60deg.C to melt the ice cover, then a manual method or mechanical method can be adopted to strip seed cover of walnut kernel. Its technological process includes the following steps: reconstitution, freezing, melting, stripping seed cover so as to obtain finished product.

Owner:SHANDONG INST OF POMOLOGY

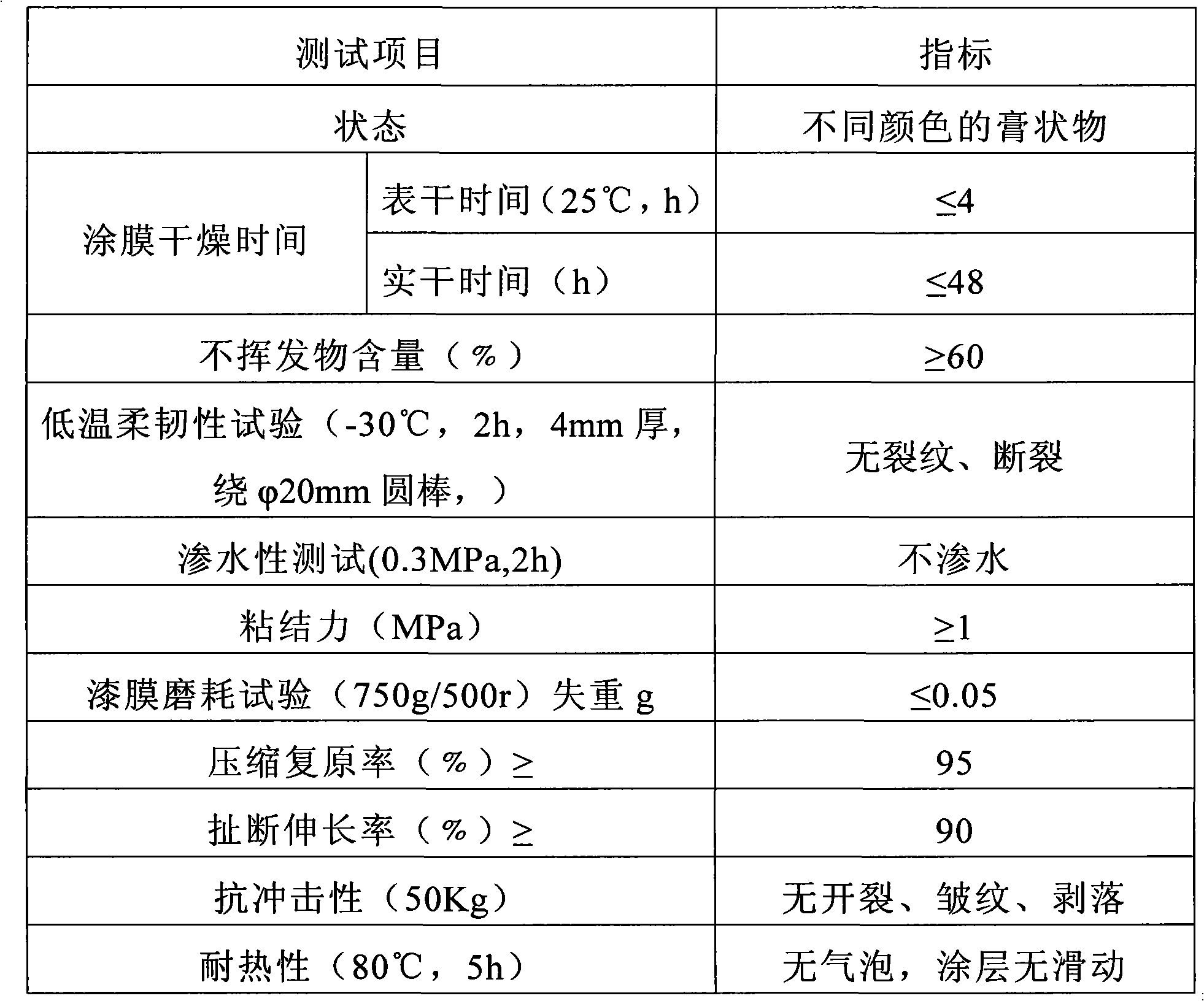

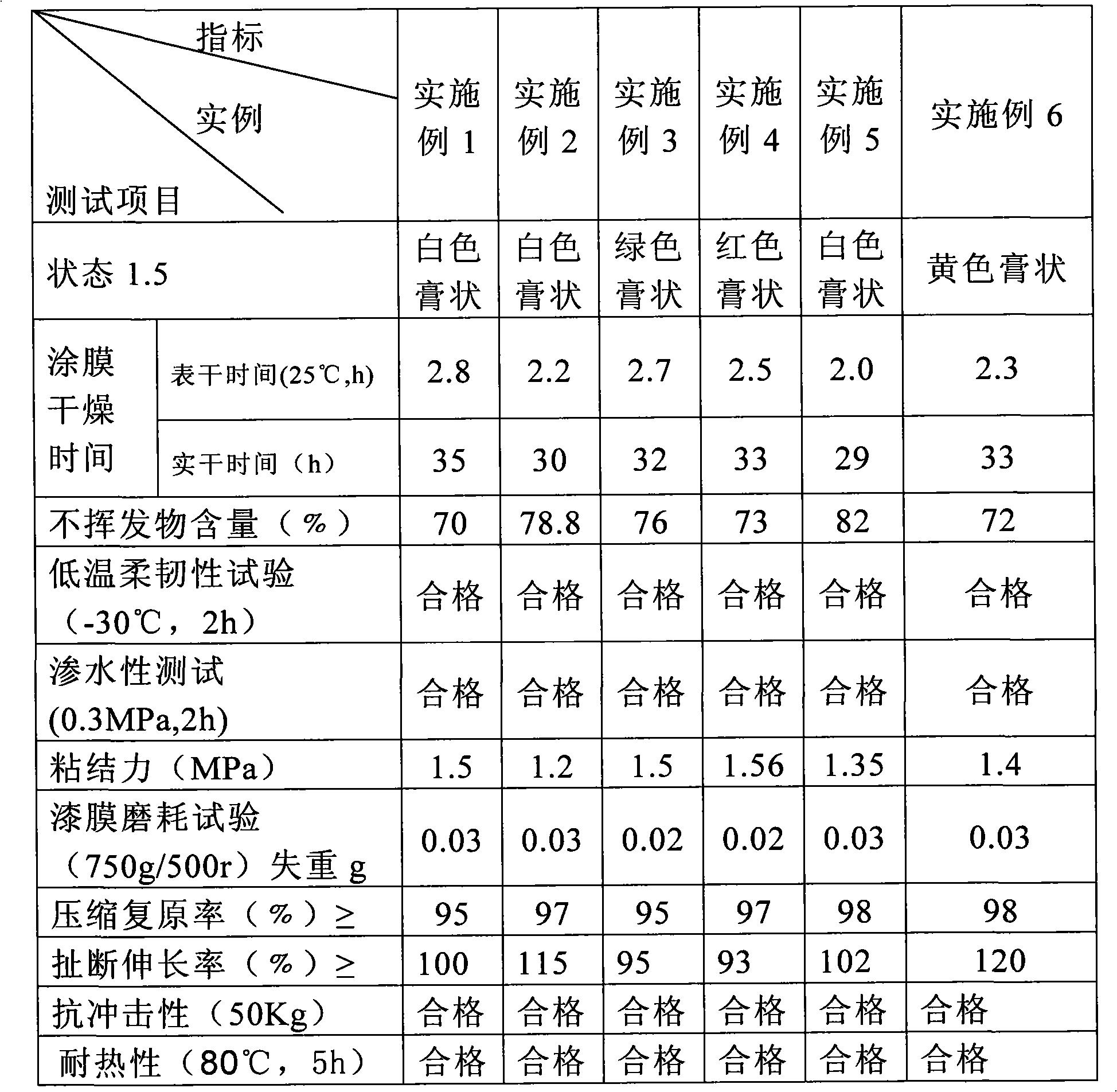

SBS aqueous thick environment protection waterproof paint with high elasticity and preparation method thereof

The invention relates to SBS aqueous thick environment protection waterproof paint with high elasticity and a preparation method thereof, belonging to the field of paint. The paint of the invention is obtained by stirring the following materials according to parts by weight: base stock: 20-40 parts of aqueous acrylic emulsion; elastomer: 10 to 50 parts of SBS aqueous rubber latex; 20-50 parts of inorganic filler; 1-10 parts of accessory ingredient; 5-15 parts of water. The invention has high elasticity and favourable waterproofness which the existing aqueous paint does not have, and the novel aqueous thick environment protection waterproof paint with high elasticity has the advantages of innocuity, no ignition, no burst, abrasion resistance and no pollution. The paint of the invention is a favourable product widely used in basketball courts, tennis courts, volleyball courts, badminton courts, table tennis courts, swimming pools, parking lots and the like, and also can be used in gymnasiums and physical recreational activity fields to be made into colourful and elastic terraces.

Owner:JILIN ZHENGJI TECH DEV

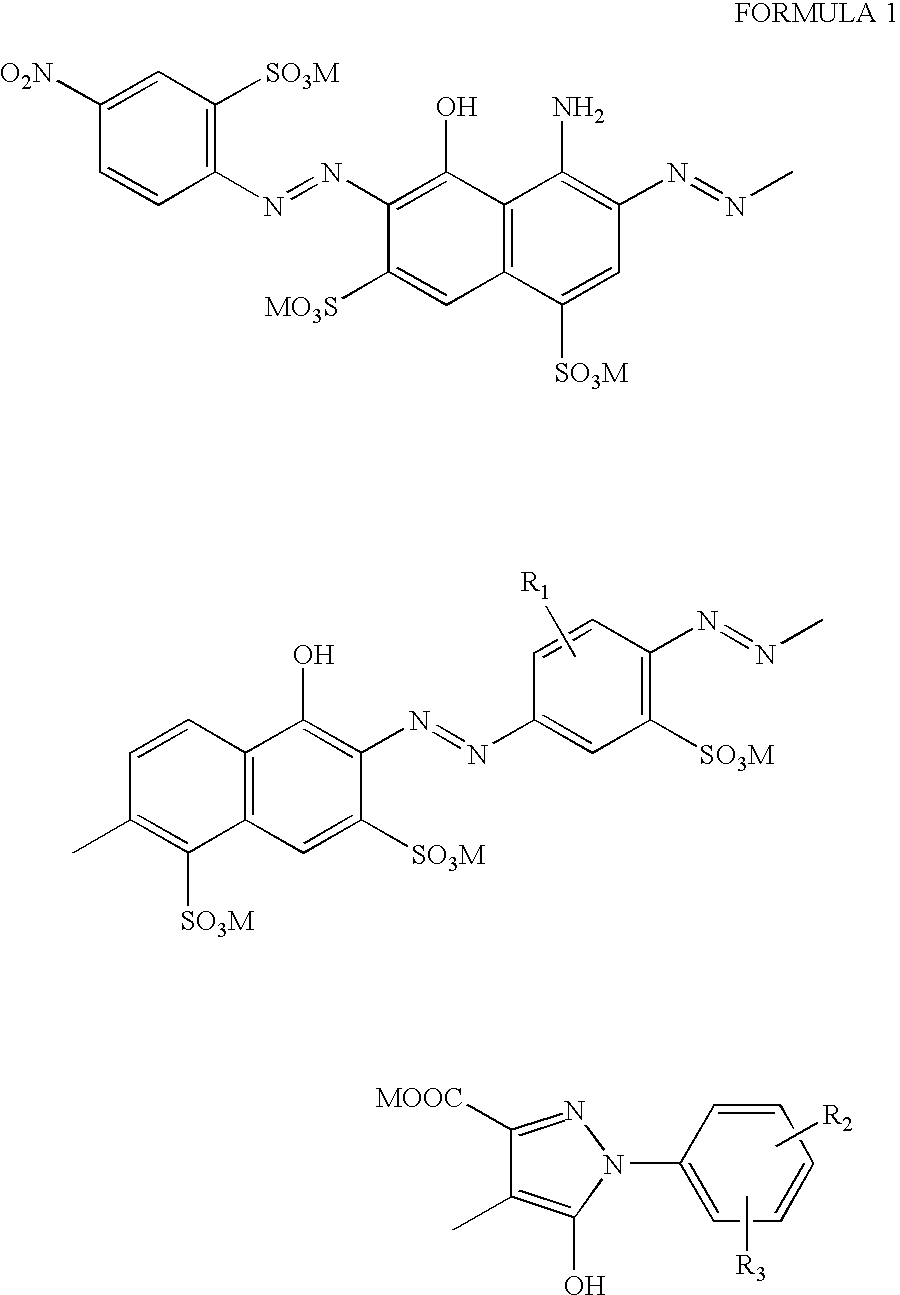

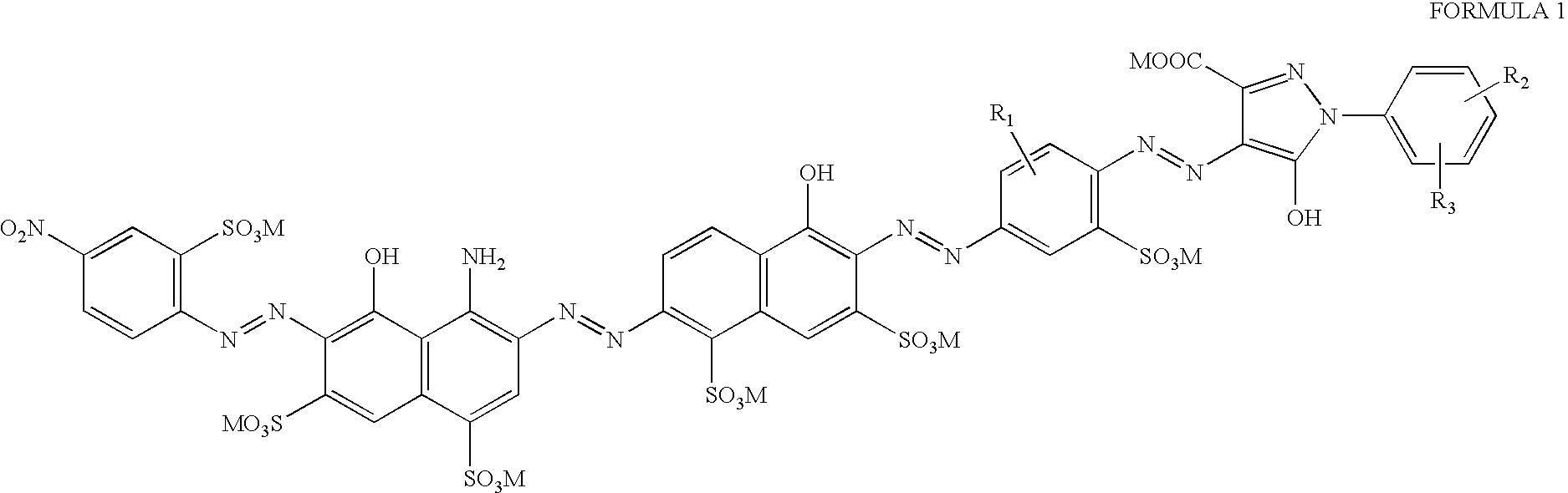

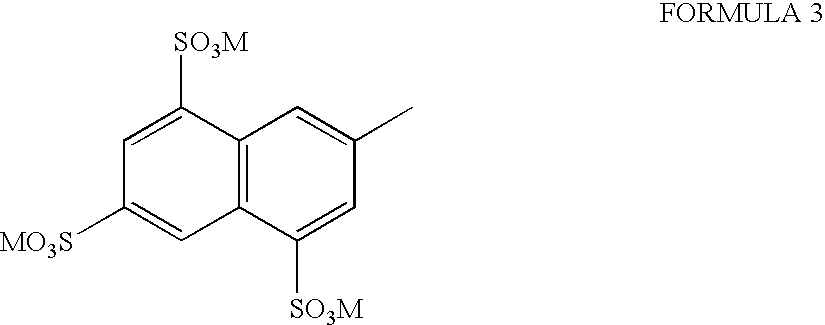

Black ink composition, ink set, ink cartridge, inkjet recording method and recorded product

InactiveUS7465346B2Guaranteed fastnessImprove printing qualityDisazo dyesMeasurement apparatus componentsPolymer scienceColoring agents

Owner:SEIKO EPSON CORP

Health preserving tea

InactiveCN102113584AImprove kidney deficiencyGrowth QiPre-extraction tea treatmentLithocarpusBlack tea

The invention relates to health preserving tea which is prepared from lohanguo siraitia fruit, boat-fruited sterculia seed, rose, red date, dwarf lilyturf root tuber, wolfberry fruit, aloe, licorice root, lotus plumule, eucommia bark, black tea, Americans ginseng, ganoderma lucidum spore powder, tuber fleeceflower root, poria cocos, Chinese yam rhizome, Cassia occidentalis, cassia seed, mulberry leaves, Lithocarpus polystachyus wild tea, raw hawthorn, Grifola frondosa and Antrodia camphorate. The health preserving tea has the effects of clearing and nourishing throat, invigorating qi, tonifying kidney, tranquilizing mind, improving sleeping, caring skin, removing toxic materials, losing weight, and the like, does not contain artificial sugar, and has sweet taste and esthetic color. The health preserving tea can effectively enhance immunity of human body, and has simple production process, convenience in consumption and moderate price, and is very suitable for modern sub-health people for conditioning and health preserving.

Owner:黄选明

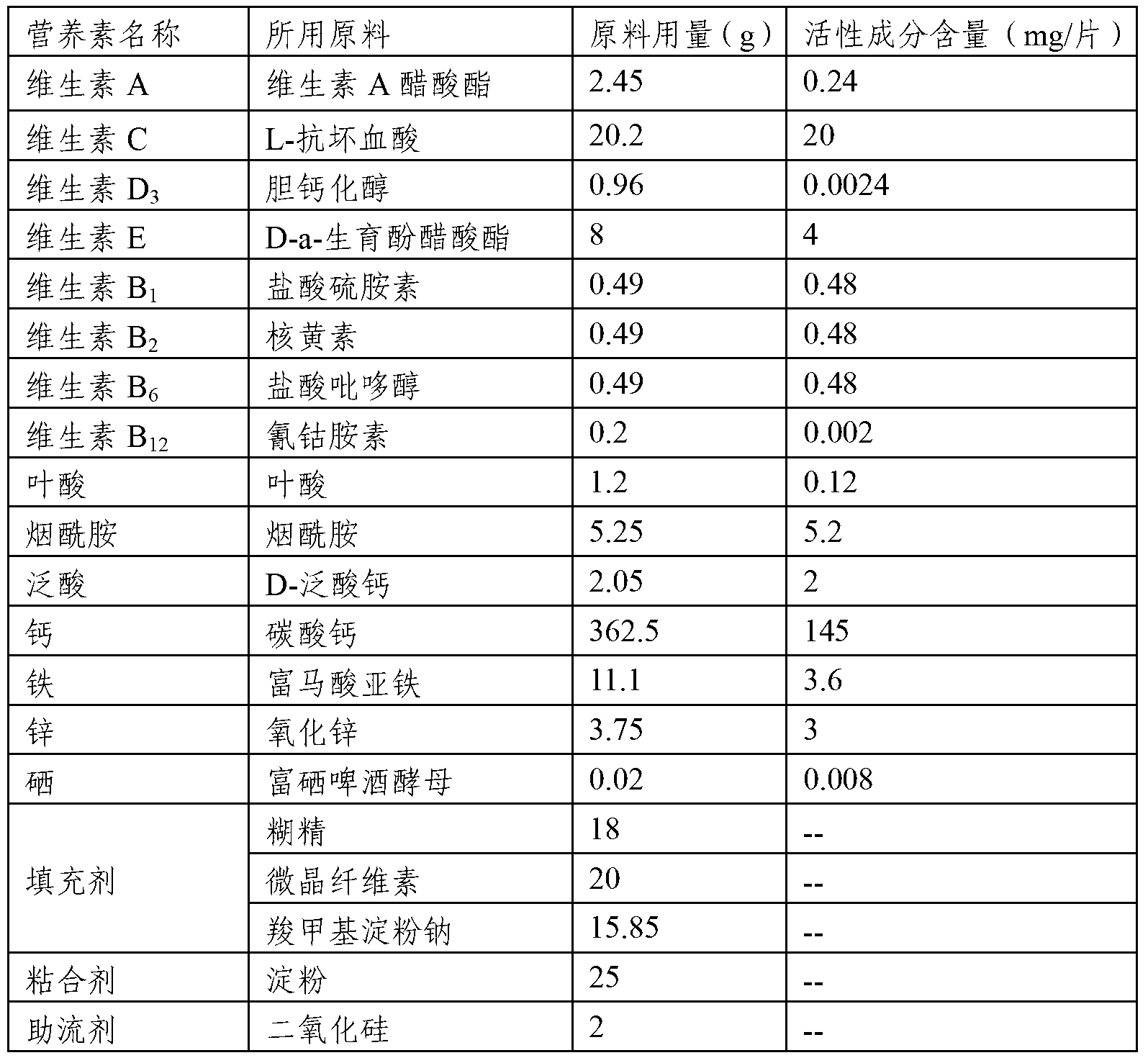

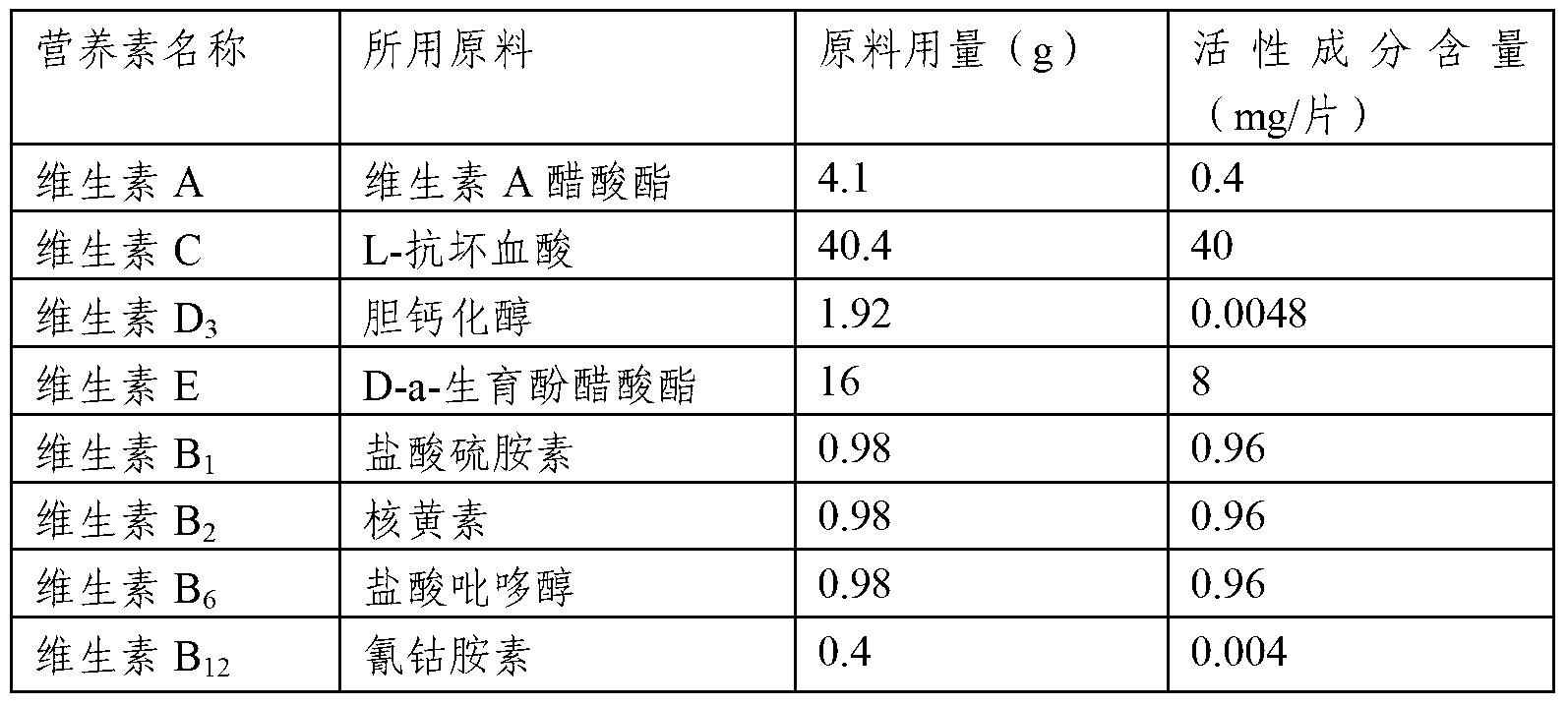

Composition comprising a plurality of vitamins and mineral substances

InactiveCN103284164AAvoid destructionIncrease mineralsFood preparationAdditive ingredientPantothenic acid

The invention relates to a composition comprising vitamins and mineral substances. The composition comprises the vitamins and the mineral substances, wherein the vitamins include vitamin A, vitamin C, vitamin D3, vitamin E, vitamin B1, vitamin B2, vitamin B6, vitamin B12, folic acid, nicotinic acid amide and pantothenic acid, and the mineral substances include calcium, iron, zinc, and selenium. According to the composition, the amounts of the vitamins and the mineral substances are reasonably proportioned strictly according to the needing amounts of a human body; the mineral substance iron is supplied by ferrous fumarate, so that the destroy on the active substances, such as vitamins, by the addition of the inorganic iron can be effectively prevented; the mineral substance selenium is provided by selenium enriched beer yeast, the toxic and side effects of chemical selenium (such as sodium selenite) on the human body and intestines and stomach stimulation are eliminated, and therefore the selenium can be absorbed and utilized by the human body more efficiently and safely.

Owner:HARBIN ZHENBAO PHARMA

Fishskin recuperating food and preparation thereof

InactiveCN101233936AFull of nutritionBeautiful colorFood preparationSodium bicarbonateAdditive ingredient

The invention relates to a fishskin nursing food which takes fishskin as raw material and is prepared through removing of fishy smell, blanching, seasoning or vegetable ingredients are added after seasoning. A preparation method of the fishskin nursing food comprises the following steps: (1) the fishskin is soaked in a mixing liquid with 1-2 percent of sodium bicarbonate, 0.5-1.8 percent of sodium chloride, 5-20 percent of ethanol and rest percent of water so as to remove the fishy smell for 15-25 minutes; (2) the fishskin after removing the fishy smell is taken out and soaked in water at 60-90 DEG C for blanching for 20-60 seconds; (3) after the fishy smell is removed and blanching is carried out for the fishskin, the fishskin is mixed with the seasoning and then put into a retort punch for vacuum package; (4) the packed fishskin is put into a high pressure sterilizing pot for sterilization for 10-30 minutes at 100-110 DEG C or for 5-20 minutes at 110-115 DEG C or combination of sterilization for 5-15 minutes at 100-110 DEG C and for 5-15 minutes at 110-115 DEG C. Then the fishskin is cooled by spraying with water below 30 DEG C and refrigerated at 0-4 DEG C or -18 DEG C.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

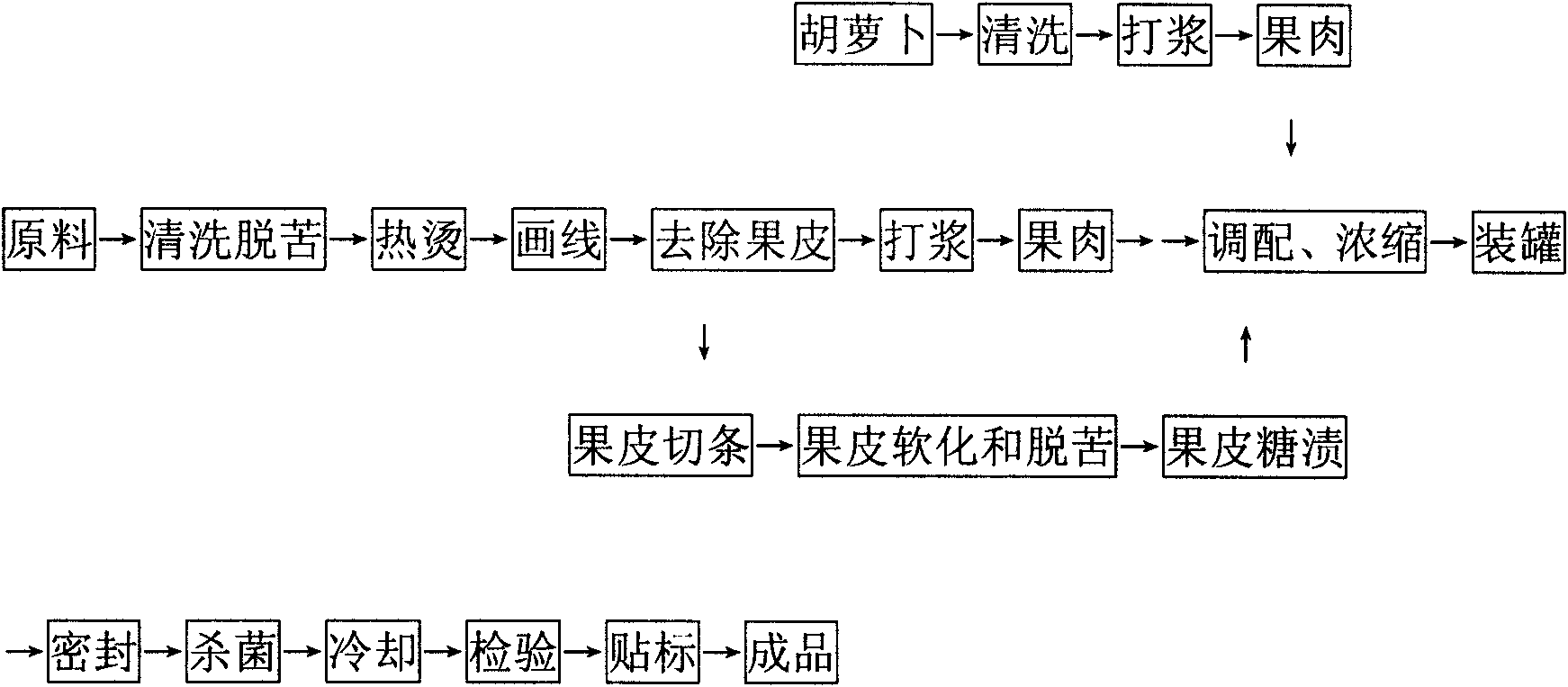

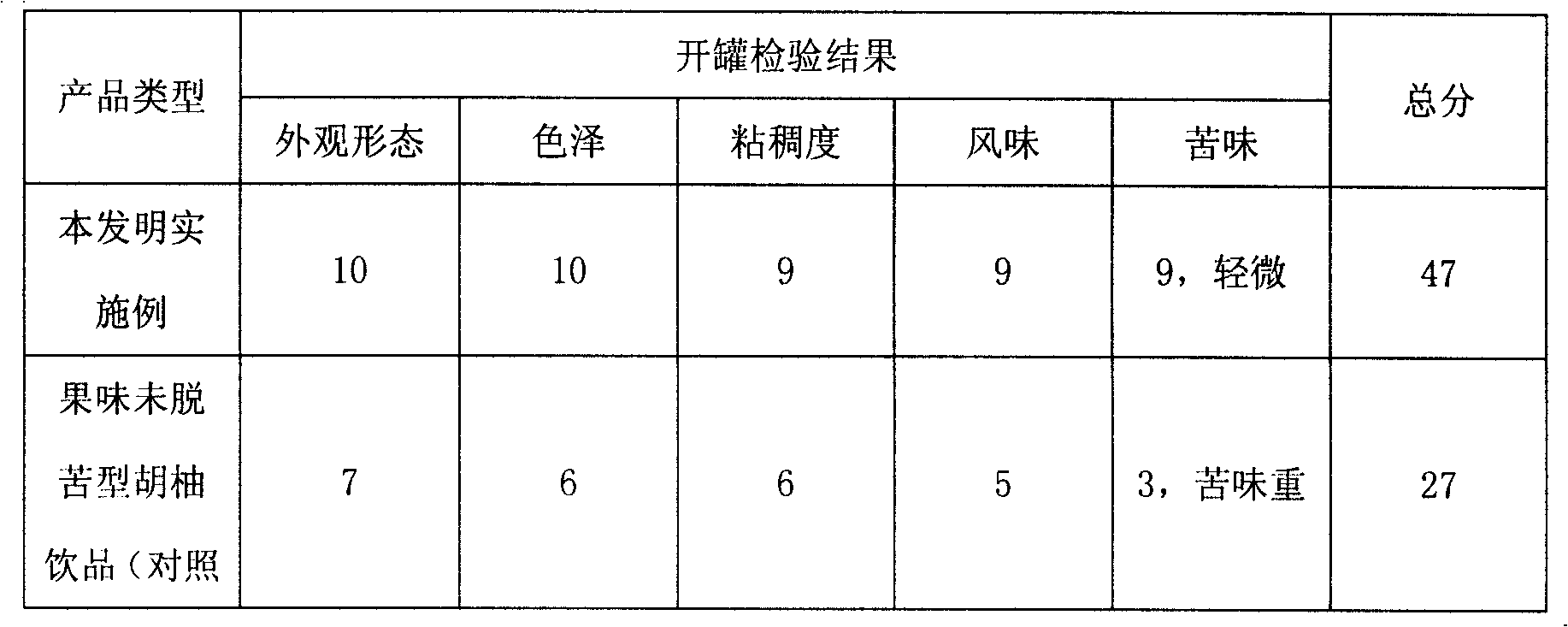

Method for manufacturing low bitter hu pomelo honey tea beverage

InactiveCN101589828ARetain nutrientsRetain activityTea substituesFood preparationCuticleProcess conditions

The invention relates to a method for manufacturing low bitter hu pomelo honey tea beverage, which comprises the following steps of: taking whole fruits of hu pomelos as a raw material, performing washing and debittering treatment on the outer skin of the hu pomelos first, then separating fruit peels and fruit pulps, further performing debittering treatment on the fruit peels after the shredding, mixing the fruit pulps after the mesocarp removal and pulping with the fruit peels according to the proportion, then adding a sweetening agent, a sour agent, carrot paste, a debittering agent, a stabilizing agent and the like into the mixture, and then producing qualified products through technological processes such as concentration, canning, sealing, sterilization, cooling and the like. The method does not adopt a method for removing bitter substances in the hu pomelos, but adopts reasonable process conditions and formula design, effectively reduces the concentration of the bitterness particularly through two debittering processes, ensures that the product has good mouthfeel, and better retains nutrient substances and bioactive substances in the hu pomelos.

Owner:HUBEI UNIV OF TECH

Antibacterial elastic polyurethane nanometer composite material and its preparation method

An antibacterial elastic nano-class polyurethane composition is prepared through mixing antibacterial agent, SiO2 or ZnO nanoparticles or laminated nano material, and polyether polyol, vacuumizing, dewatering, degassing, adding assistants to obtain nano material B, preparing polyurethane prepolymer as B, proportional mixing A with B, adding catalyst, stirring and solidifying. Its advantages are outstanding antibacterial performance and high mechanical performance.

Owner:苏州中科纳米高弹材料有限公司

Glaze composition for redware products

The invention provides a glaze composition for redware products and relates to the technical field of redware. The glaze composition is prepared from the following components in parts by weight: 1-3 parts of copper oxide, 5-9 parts of barium oxide, 4-6 parts of silicon carbide, 25-35 parts of quartz, 10-20 parts of borax, 0.1-0.5 part of graphene, 0.005-0.03 part of ferric oxide, 0.01-0.06 part of titanium carbide, 10-20 parts of dolomite, 5-15 parts of shell and 0.1-1 part of glass. According to the invention, lead material is removed and the quartz and glass are added, the quartz is used for increasing the surface strength of glazing color, the glass is used for increasing smoothness, and the hand feeling is good. The graphene and titanium carbide are added, so that the adsorption capacity among materials is great, and a layer of mesh structure can be formed on the surface of a green body and cannot fall off after firing.

Owner:卢群山

Preparation method of CAD/CAM personalized resin pre-formed crown and bridge

InactiveCN105616020ALess discomfortReduce the possibility of postoperative infectionDental implantsDesign softwareDentistry

The invention discloses a preparation method of a CAD / CAM personalized resin pre-formed crown and bridge. According to the method, data are acquired through oral clinical examination and oral CBCT, an implant scheme is designed by six-dimensional tooth implantation design software with repair as guide, implantation data are acquired, and a corresponding repair working model is obtained; a corresponding implantation replacement body is inserted into the repair working model, the position, the direction and the depth of the obtained replacement body and data of remaining teeth within a mouth are scanned with a scanner, a pre-formed crown and bridge module is designed with EXOCAD software according to the pre-designed upper repair body requirement by the combination of patient gingiva thickness, and a gap is reserved for placing a temporary drill base and a screw hole; finally, the CAD / CAM personalized resin pre-formed crown and bridge is obtained through cutting processing and finishing and polishing of a resin disc. According to the method, the immediate repair body can be put on at the same day after operation, modeling is not required in the patient mouth after the operation, the possibility of postoperative infection is reduced compared with the traditional technology, the time is saved, and the discomfort of the patient is effectively reduced.

Owner:杭州口腔医院集团有限公司

Wormwood rice cake

InactiveCN102038127AWith phlegm and coughIt has the effect of promoting qi and relieving painClimate change adaptationFood preparationAdhesiveAllergy

The invention relates to a wormwood rice cake. The main materials of the wormwood rice cake comprise sticky rice and glutinous rice with the mass ratio of 3-4:7-6. The additional materials of the wormwood rice cake comprise wormwood extractive and sweet osmanthus flower extractive, wherein the mass ratio of the wormwood extractive to the main materials is 1:1, and the sweet osmanthus flower extractive accounts for 5-10 by mass of the main materials. The wormwood rice cake can improve nutrition health-care components, can enrich the designs, the colors and the types of the rice cake, is glutinous and non-adhesive, can not be cracked after the wormwood rice cake is stored for a long time, is faint scent in smell, is beautiful in color and luster, and is abundant in nutrition. The wormwood not only contains the main component-volatile oil, but also contains tannin, flavones, alcohol, polysaccharide, trace elements, other organic components and the like; and the pharmacological research discovers that the wormwood has the functions of being antibacterial and antiviral, relieving asthma, relieving cough, eliminating phlegm, stopping bleeding, resisting coagulation, calming and resisting allergy.

Owner:郭旭东

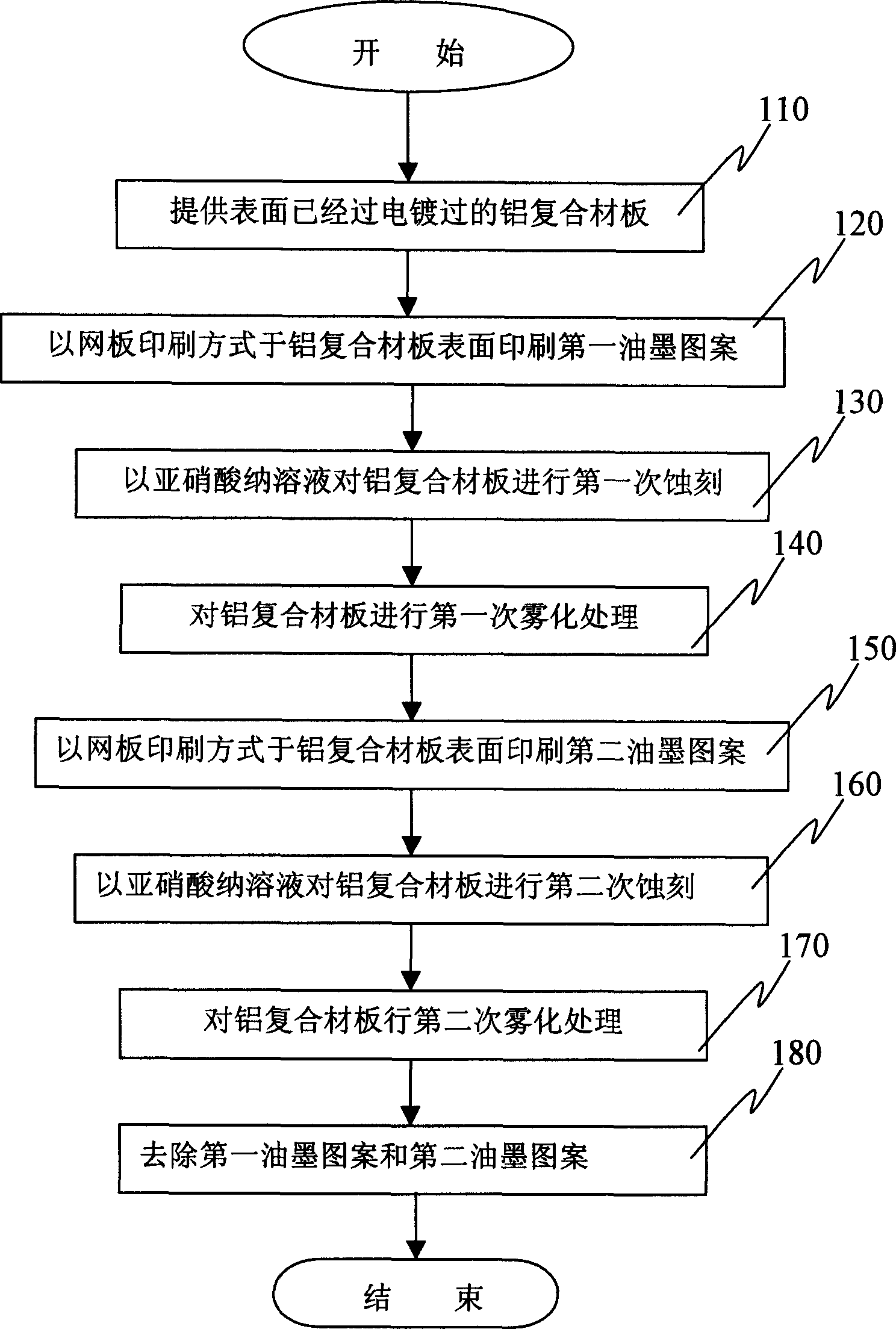

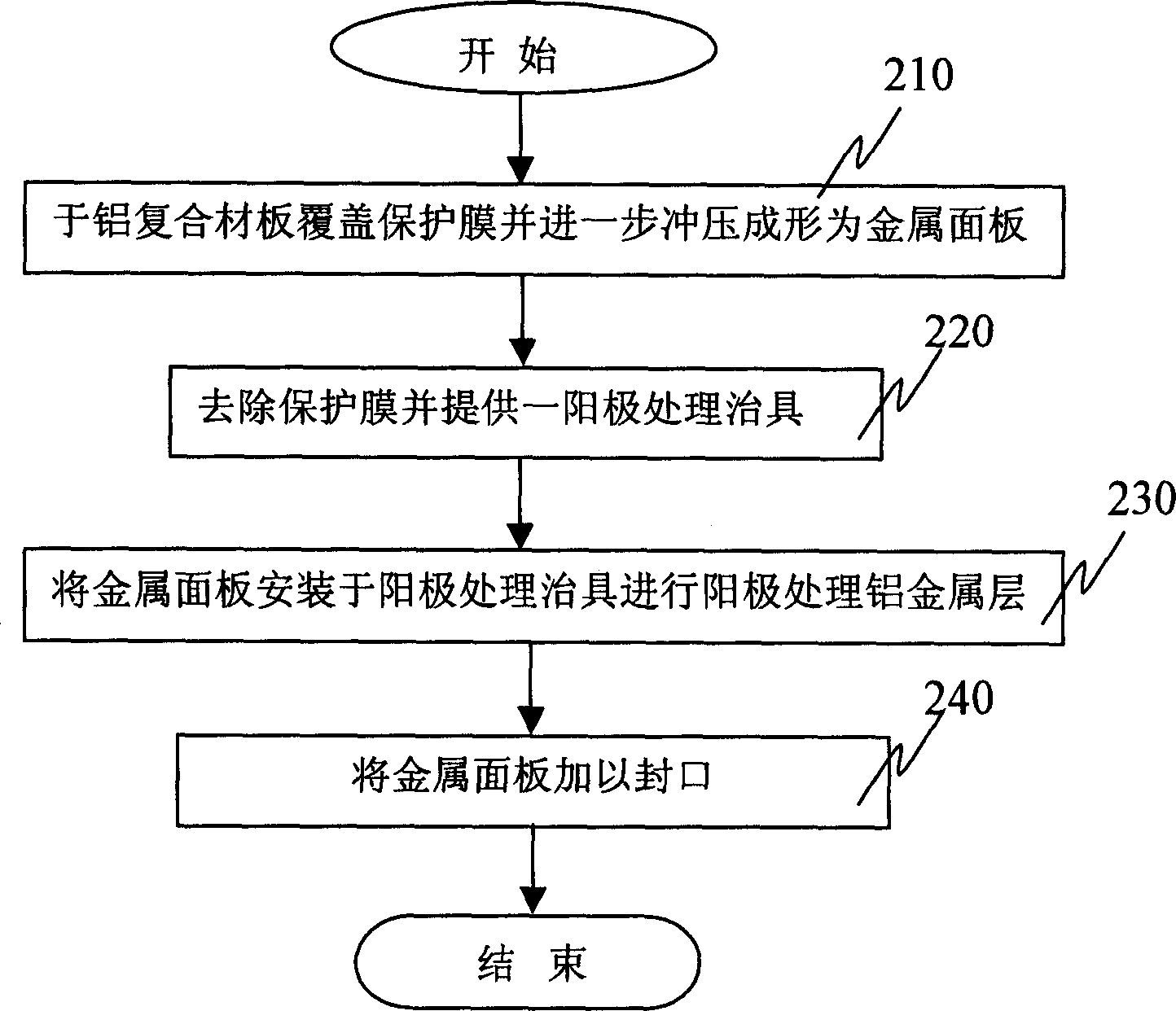

Method for forming multilayered patterns on aluminium composite board surface

InactiveCN1634713AImprove corrosion resistanceBeautiful colorDecorative surface effectsAluminum compositesEtching

This invention discloses a method to form multilevel pattern on the aluminum compound board surface, which comprises the following steps: providing one aluminum compound material metal board materials and forming first ink pattern on the metal surface; making first etching on the metal board to form first pattern on the shielding area of the first ink pattern; forming second ink pattern on the metal surface; making second etching on the metal board to form second pattern on the shielding area of the second ink pattern; removing the first and second ink patterns; processing the metal board by positive electrode and sealing its opening.

Owner:GIGA BYTE TECH CO LTD

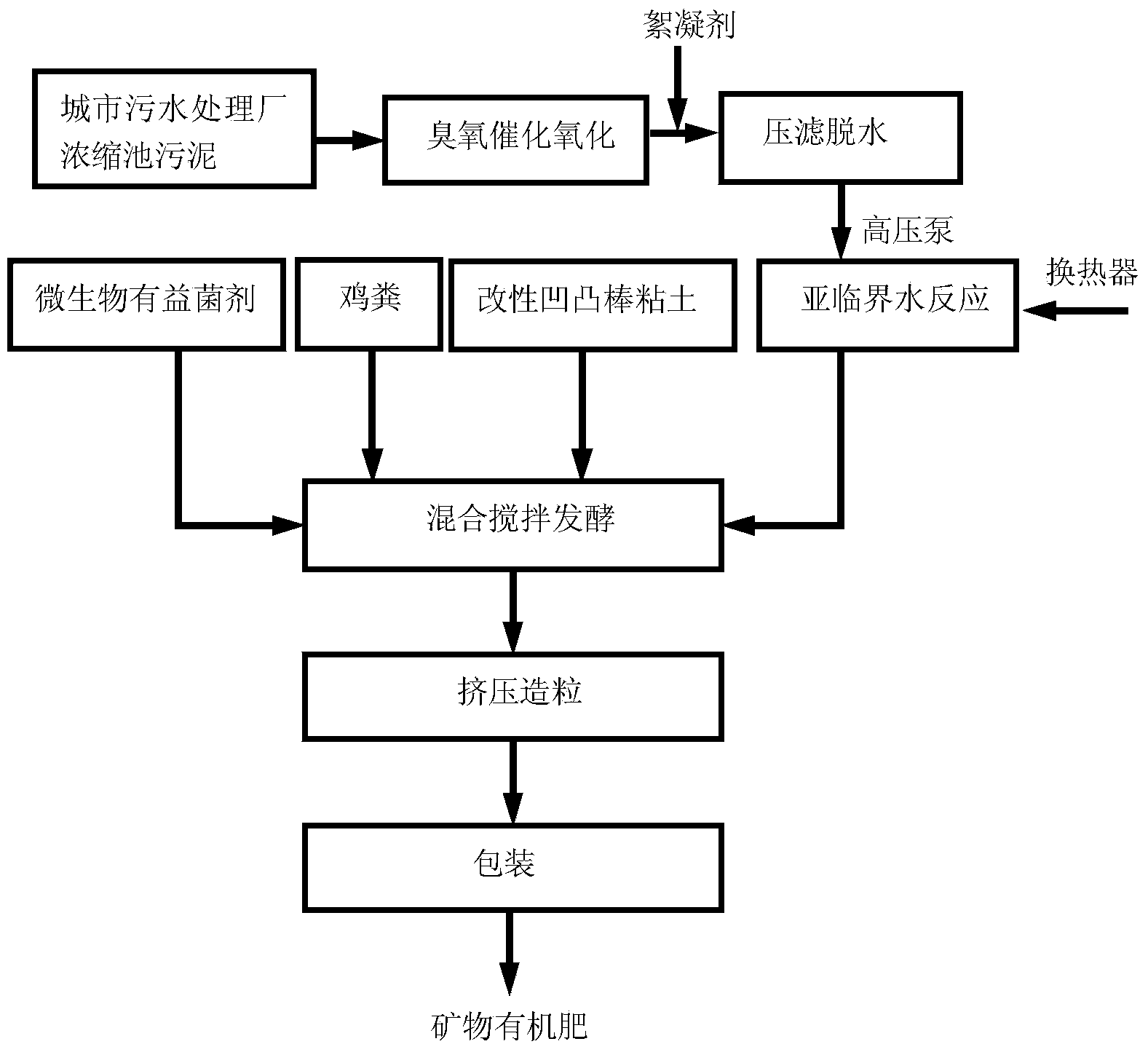

Method for preparing mineral organic fertilizer by using surplus sludge in municipal sewage plants

InactiveCN103755400AImprove oxidation activityIncreased redox potentialBio-organic fraction processingFertiliser formsMicroorganismControlled release

The invention discloses a method for preparing mineral organic fertilizer by using surplus sludge in municipal sewage plants. The method mainly comprises the following three steps: firstly reducing sludge in a sludge thickening tank, dehydrating the reduced sludge by adopting a catalytic ozonation method, carrying out subcritical water reaction on the dehydrated sludge, and discharging solids subjected to harmless treatment; finally mixing modified attapulgite clay with the sludge subjected to harmless treatment, chicken manure and microorganism beneficial microbial agents, and fermenting the mixture to obtain the mineral ecological organic fertilizer. The method is green and environment-friendly and realizes the harmless and resourceful treatment of the sludge; the obtained mineral organic fertilizer is capable of obviously improving the structure of soil, enabling the volume-weight of soil to be reduced, the holes of soil to be increased and the ventilation and water permeability of the soil to become good and adjusting the uniform growth of crops and has a good controlled release effect, thus the quality of the crops is improved.

Owner:安徽乐农环保科技有限公司

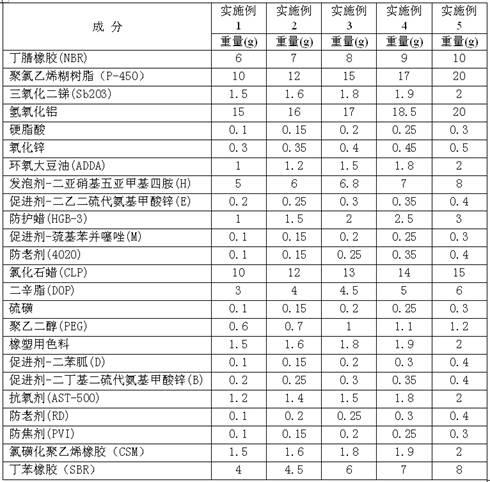

Color rubber and plastic heat-insulating material and preparation method thereof

The invention relates to a color rubber and plastic heat-insulating material and a preparation method thereof. The rubber and plastic heat-insulating material is prepared from polrvinyl chloride paste resin, dinitrosopentamethylene tetraamine, an antiager, styrene rubber, protective wax, an antioxidant, chlorosulfonated polyethylene rubber, diphenyl guanidine, mercaptobenzothiazole, zinc dibutyl dithiocarbamate, zinc diethydithiocarbamate and the like. The performance and the color difference of the product are stabilized by adding a coloring material to perform banburying on the finished rubber again and combining a new vulcanizing foaming technology and a super-long water-cooling system; the prepared color rubber and plastic heat-insulating material does not have fibers and dust, prevents dew formation, has a smooth surface and high cleanliness, has the same bright color as equipment, is environmentally-friendly and non-toxic, reduces secondary construction, saves cost, greatly improves the using performance of the product, prolongs the service life and takes full advantage of the product performance.

Owner:WINCELL INSULATION CO LTD

Purple sand glass ceramic bowl and preparation process thereof

The invention discloses a purple sand glass ceramic bowl, belonging to the technical field of tableware. The purple sand glass ceramic bowl is composed of the following components in parts by weight: 40-70 parts of silicon dioxide, 10-20 parts of Suzhou soil, 3-8 parts of titanium dioxide, 10-15 parts of purple sand, 0.5-1 part of vermiculite powder, 2-4 parts of shell powder, 0.2-2 parts of copper oxide, 2-4 parts of lignin, 0.5-1 part of carbon nanotube, 2-5 parts of graphene nanoplatelets, 1-3 parts of sulfate, 0.1-0.8 part of tin oxide, 3-5 parts of dolomite, 3-7 parts of nano silicon carbide, 0.5-2 parts of stainless steel fiber and 0.1-0.5 part of silver fiber. By virtue of special preparation on raw materials, the prepared bowl is smooth in surface and good in strength, cannot be broken when falling off and does not scald the hand, and compared with a conventional process, a process for preparing the purple sand glass ceramic bowl disclosed by the invention is short in time, low in energy consumption, good in product quality and free of toxic or harmful substance residue.

Owner:ANHUI PROVINCIAL HANSHAN MINSHENG PORCELAIN

Method for making seasoned fried fish skin food

The invention relates to a method for making a seasoned fried fish skin food, which comprises the following steps: removing fish scales, mucus, blood stains and other impurities on the surface of fish skin, cleaning, draining, soaking in tea water for removing fishy smell, shaping, starching, seasoning, frying, packaging and obtaining a finished product; and starchy seasoning liquid adopted for starching and seasoning comprises the following components by weight percent: 8-12% of sugar, 2-3% of aromatic vinegar, 2-4% of salt, 0.5-1% of ginger juice, 1.8-4% of sesame oil, 2-3% of monosodium glutamate, 1-3% of pepper powder, 3-5% of chili oil, 1.5-3% of yellow rice wine, 20-30% of mixed flour (flour: starch powder is equal to 2:1), 3-5% of yeast powder and the balance of water. The made seasoned fried fish skin food has the advantages of abundant nutrition, beautiful color and luster, crisp, delicious and special taste, and convenient eating, and the preparation method has the advantages of reasonable process, simple operation and stable product quality, thereby having good commercial value.

Owner:TAIXIANG GRP TECH DEV

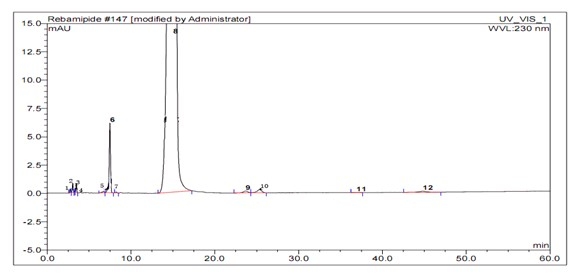

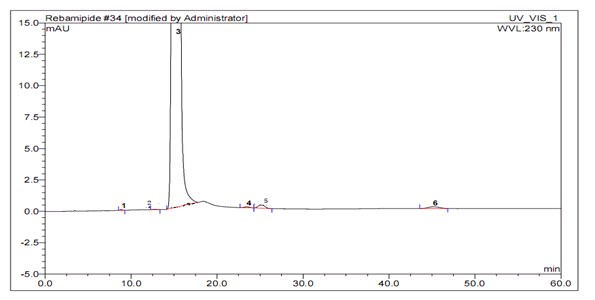

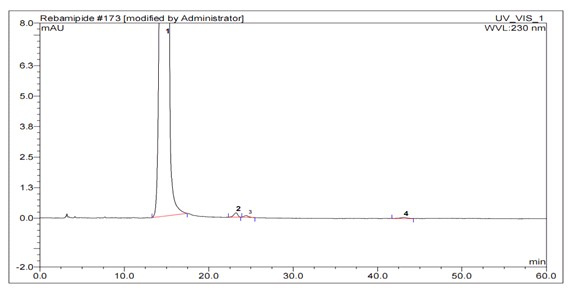

Refining method of rebamipide

The invention discloses a refining method of rebamipide, comprising the following steps of: firstly, reacting a rebamipide crude product with alkali to obtain a rebamipide salt crude product, recrystallizing to obtain a refined rebamipide salt, and acidifying to obtain refined rebamipide. In each step of operation for refining the rebamipide, active carbon can be respectively added for decoloring. Rebamipide acquired by the refining method disclosed by the invention has esthetic color of the product, good quality and high purity; and determined by HPLC (High Performance Liquid Chromatography), the purity is 99.8% and the total content of impurities is less than 0.20%. The used solvent is simple, a high boiling solvent needs not to be used, and in addition, the refining method is simple tooperate, has simple flow and equipment and is easy to realize industrial production.

Owner:JIANGXI SYNERGY PHARMA

High-whiteness pure cotton fabric processing technology

ActiveCN105297392AContinuityRealize continuous productionBleaching apparatusTextile printerPulp and paper industry

The invention belongs to the technical field of textile printing and dyeing, and particularly relates to a high-whiteness pure cotton fabric processing technology which comprises a whitening process. The whitening process comprises the following steps: conducting padding on a pure cotton fabric by use of a whitening liquid, carrying out steaming in a steaming box fully filled with saturated steam, and then carrying out water washing, neutralization and drying, wherein the pH value of the dried pure cotton fabric is controlled to be 6-7.5. According to the processing technology, padding by the whitening liquid, steaming, water washing, drying are conducted on the pure cotton fabric which is subjected to singeing, desizing, scouring, oxygen bleaching and mercerization, and then tentering and pre-shrinking are carried out; in the oxygen bleaching process, H2O2 is utilized for bleaching, and meanwhile organic peracid is added; a brightening agent with a medium or relatively high affinity is selected as the whitening liquid; after the pure cotton fabric is subjected to padding by the whitening liquid, the pure cotton fabric subjected to padding enters the guide roller type steaming box fully filled with the saturated steam for steaming, and then water washing, neutralization and drying are carried out; after the pure cotton fabric is treated according to the processing technology, the whiteness of the pure cotton fabric is improved to 155 or above, and the whitened pure cotton fabric is bright in color and has the soaping fastness of four-level or above.

Owner:鲁丰织染有限公司

Method for producing fluffed meat product

InactiveCN1742629AImprove water holding capacityDeliciousFood preservationFood preparationAdditive ingredientSalt water

The production method of fluffy meat product includes the following steps: cutting fresh meat or frozen meat, injecting sterile salt water mixture with 2-4deg.C into meat, its injected quantity is 90-110% of meat weight, placing the injected meat into cold storage with 0-4deg.C, pickling for 12-16hr, then placing the pickled meat with 6-8deg.C into tenderizing device and vacuum rolling machine to make tenderization for 2-3hr., then cutting, curing and dewatering and drying so as to obtain the invented fluffy meat product.

Owner:成都孔师傅食品有限公司

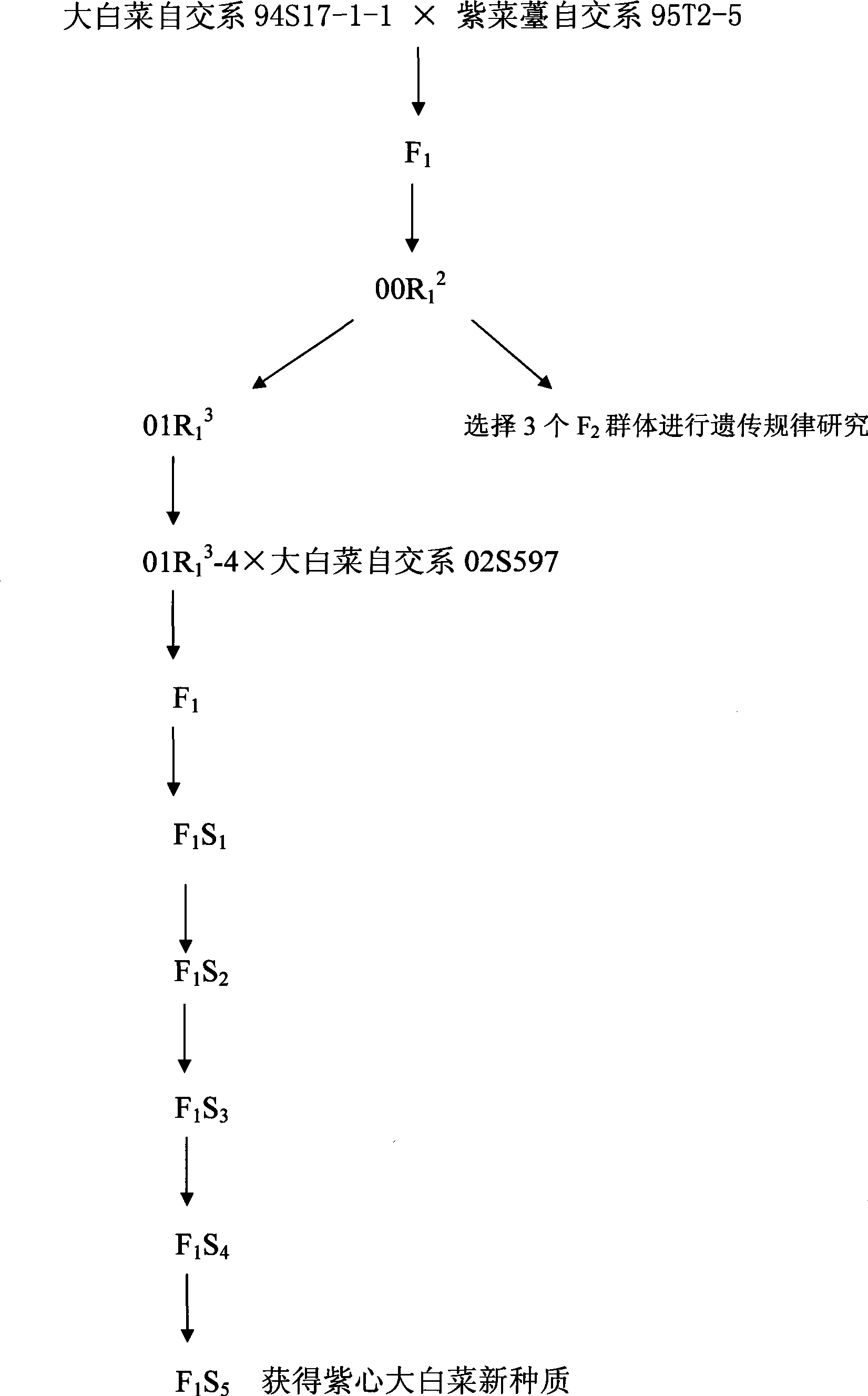

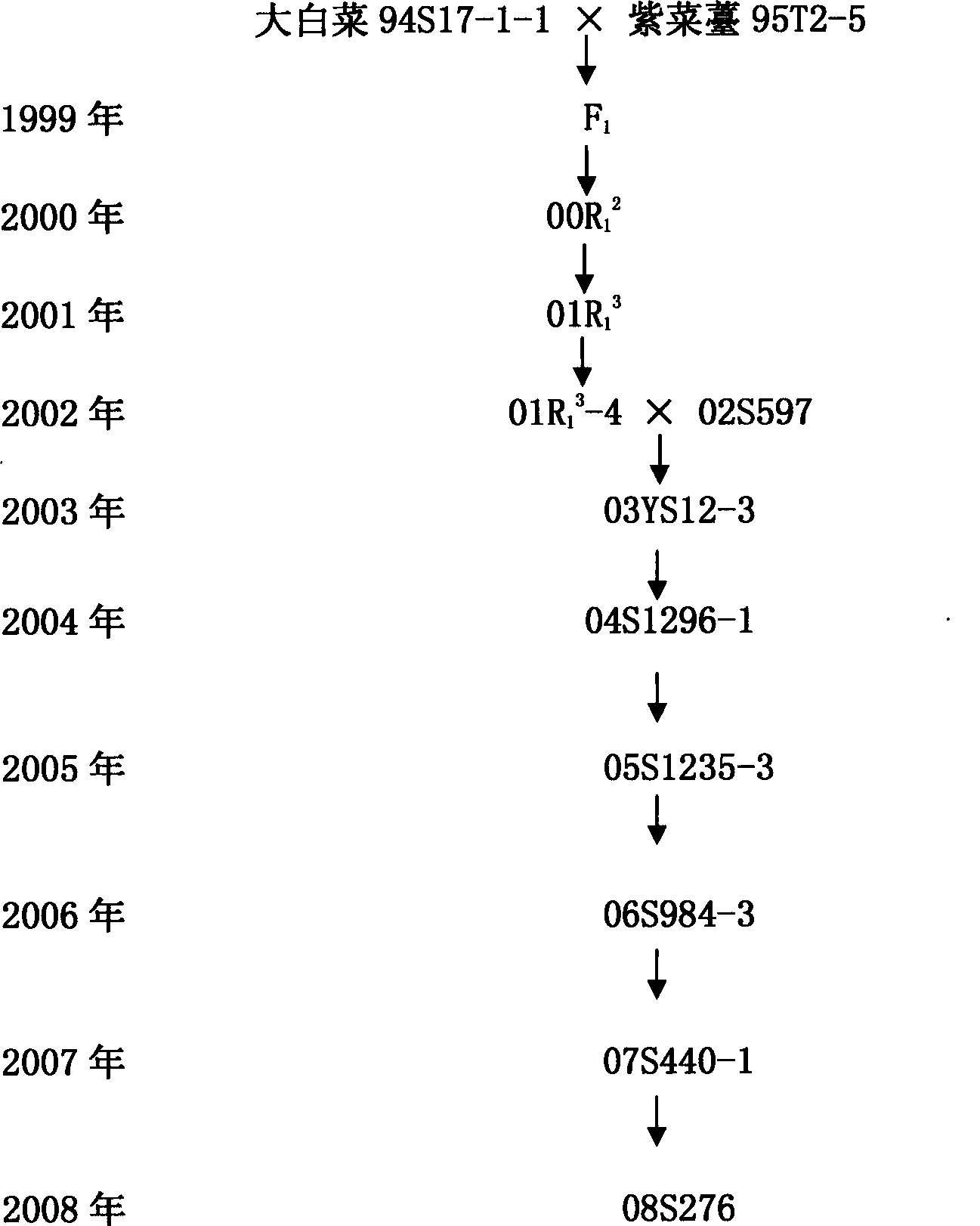

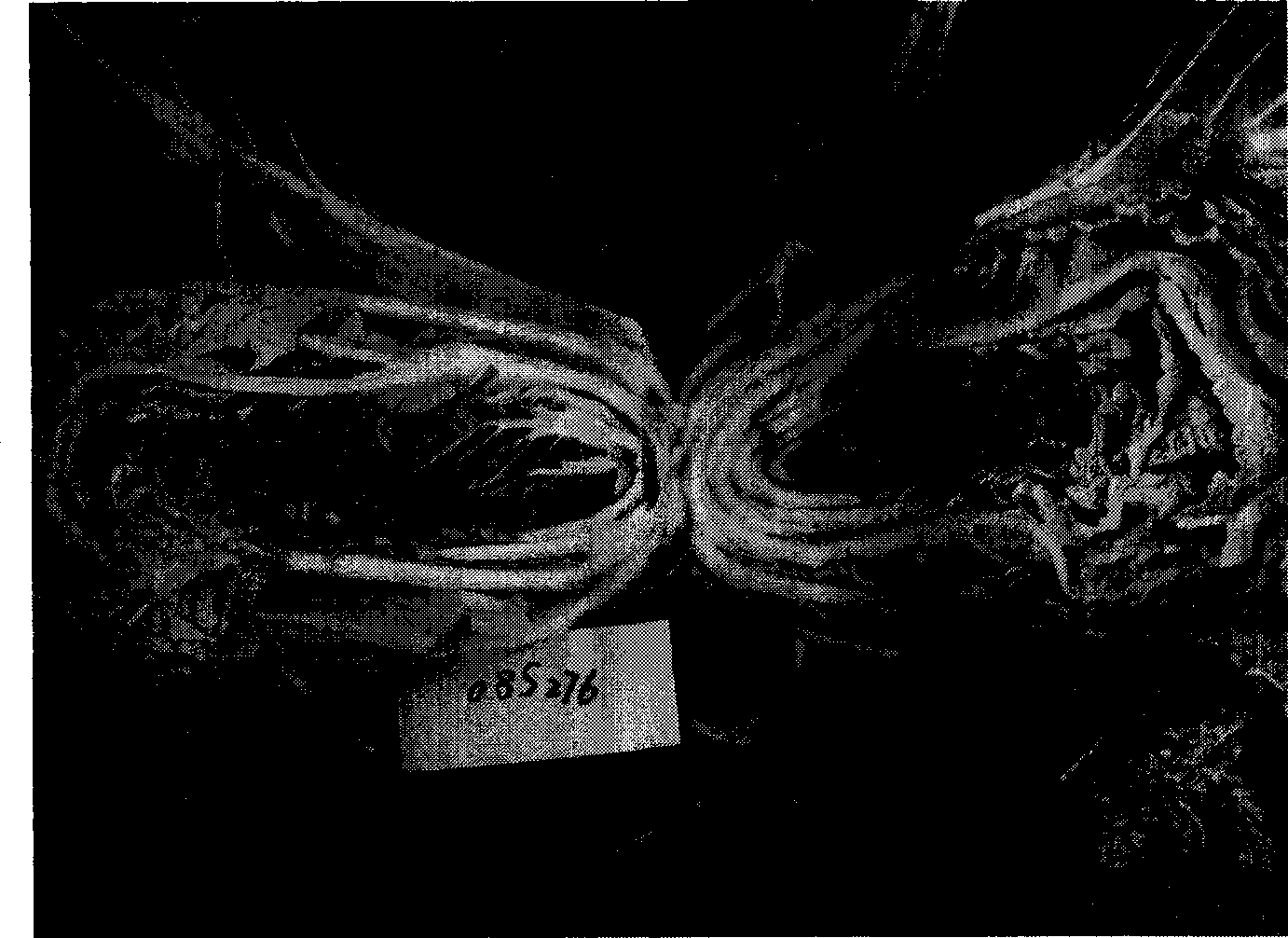

Method for breeding novel germplasm of Chinese cabbage with purple core

InactiveCN101480164ARich breeding materialBeautiful colorPlant genotype modificationAngiosperms/flowering plantsGermplasmSelfing

The invention discloses a method for breeding the new germplasm of purple Chinese cabbage. The method uses a white-core selfing line 95S17-1-1 of Chinese cabbage as a maternal plant and uses a selfing line 95T2-5 of laver stalks as a paternal plant for hybridization; after single plant selfing is continued for three generations, a selfing line 02S597 of orange-heading Chinese cabbage is used for testing hybridization; the single plant self breeding is continued for 5 generations, and the new germplasm of the purple Chinese cabbage with green external leaves and purple ball leaves is bred. The method not only enriches the breeding material of the Chinese cabbage, but also lays a good foundation for breeding the new germplasm of the purple Chinese cabbage, opens up a new path for the material creativity of the purple Chinese cabbage and solves the problem that only the ball leaves are purple in the material creativity of the purple Chinese cabbage.

Owner:NORTHWEST A & F UNIV

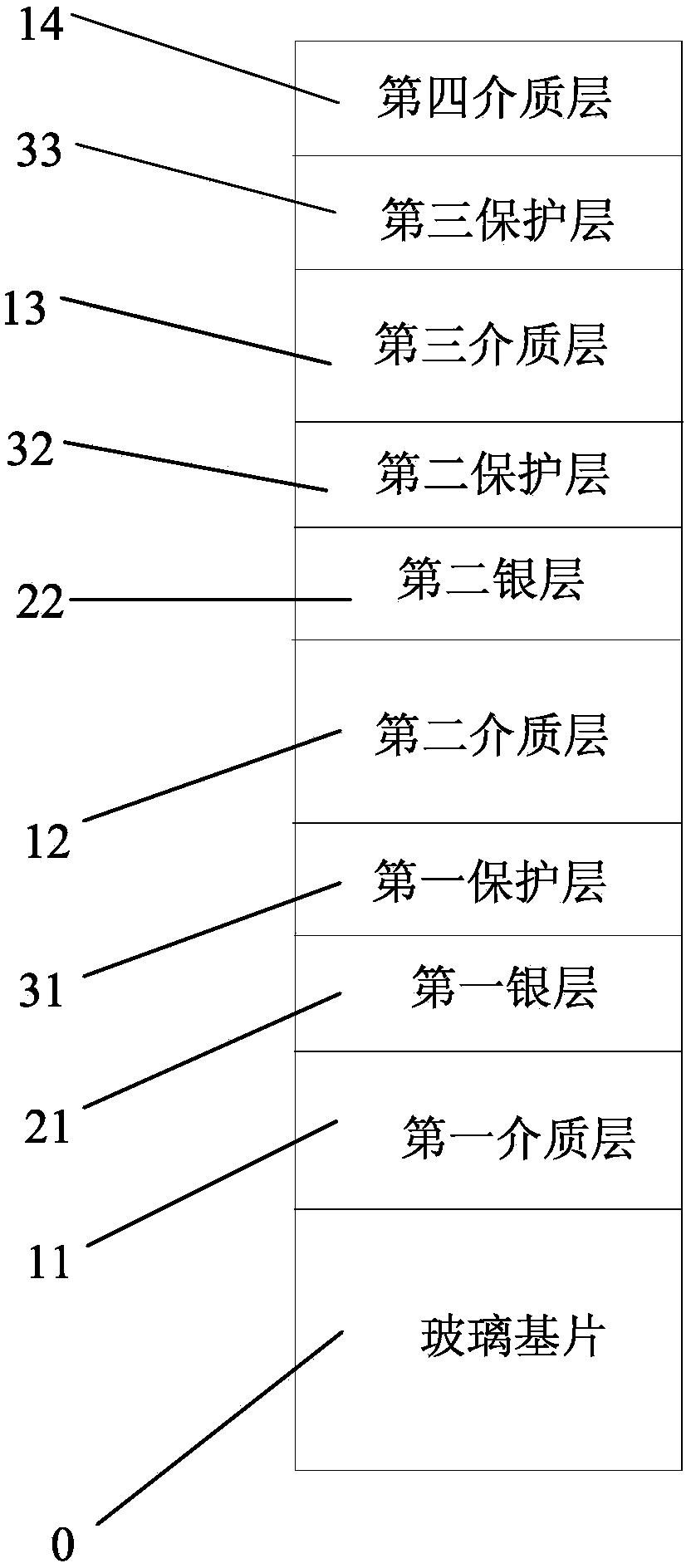

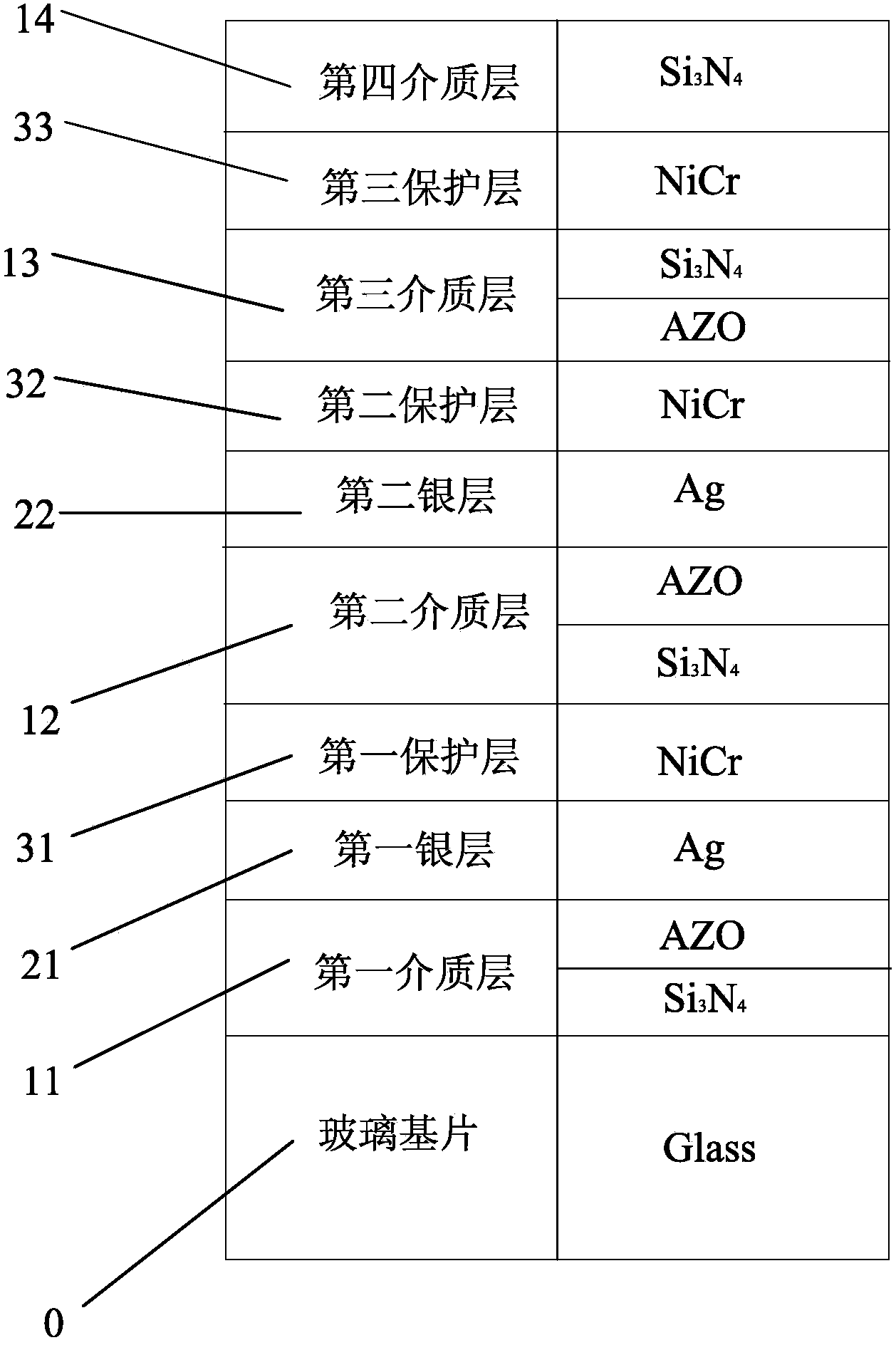

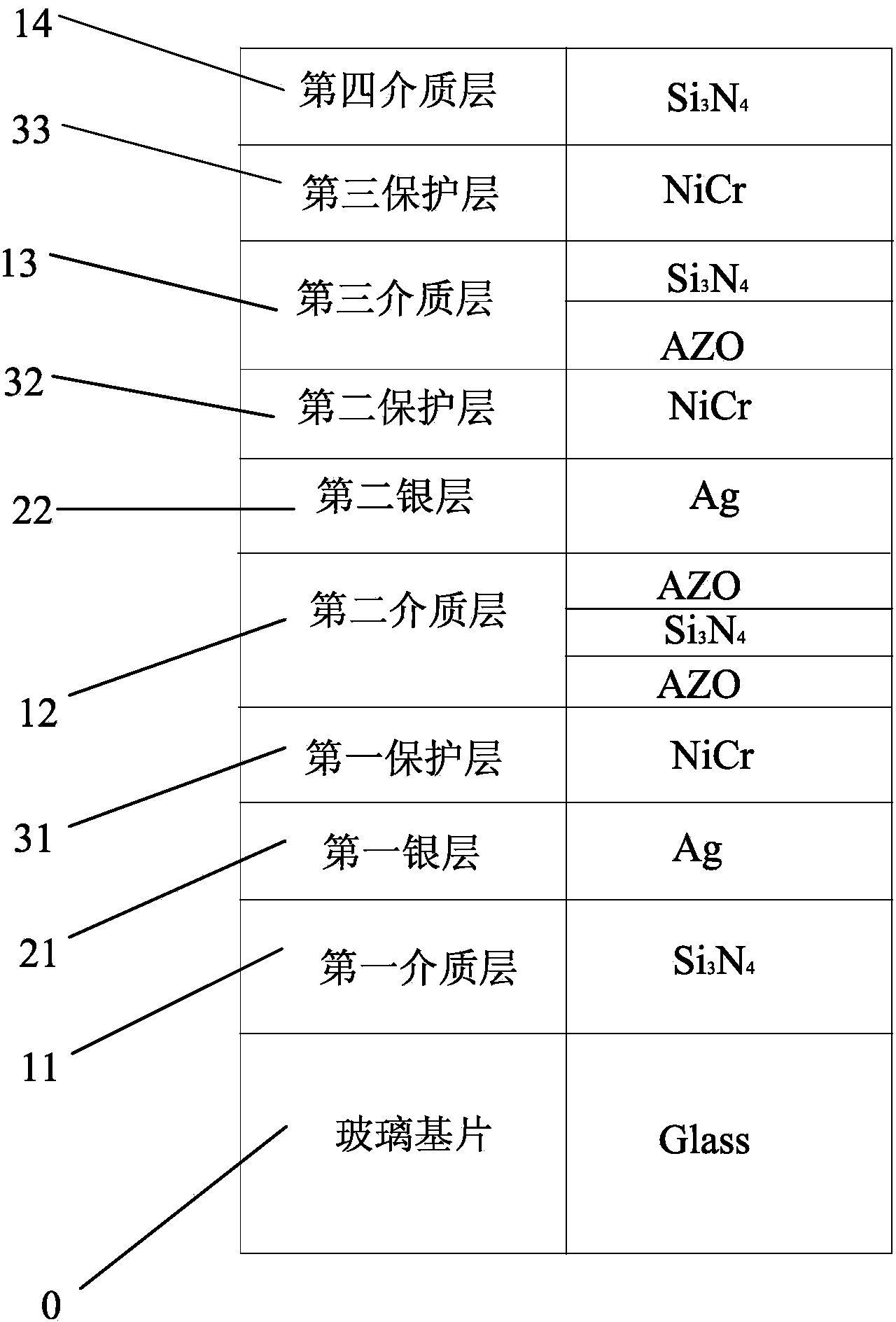

Double-silver low-emissivity coated glass and preparation method thereof

The invention relates to the technical field of coated glasses, in particular to a piece of double-silver low-emissivity coated glass and a preparation method thereof. The coated glass adopts magnetron sputtering coating and comprises a glass substrate, and a film layer coated on the surface of the glass substrate, wherein the film layer comprises a first dielectric layer, a first silver layer, a first protective layer, a second dielectric layer, a second silver layer, a second protective layer, a third dielectric layer, a third protective layer and a fourth dielectric layer from one side of the glass substrate outwards in sequence. Compared with the prior art, the third protective layer and the fourth dielectric layer are additionally arranged, and the problem that the side surface of the coated glass changes in color when being observed from small angle is solved. Moreover, the film surface color and the penetration color are neutral, the whole color is soft and beautiful, and as a result, a comfortable feeling is offered for people.

Owner:东莞南玻工程玻璃有限公司 +1

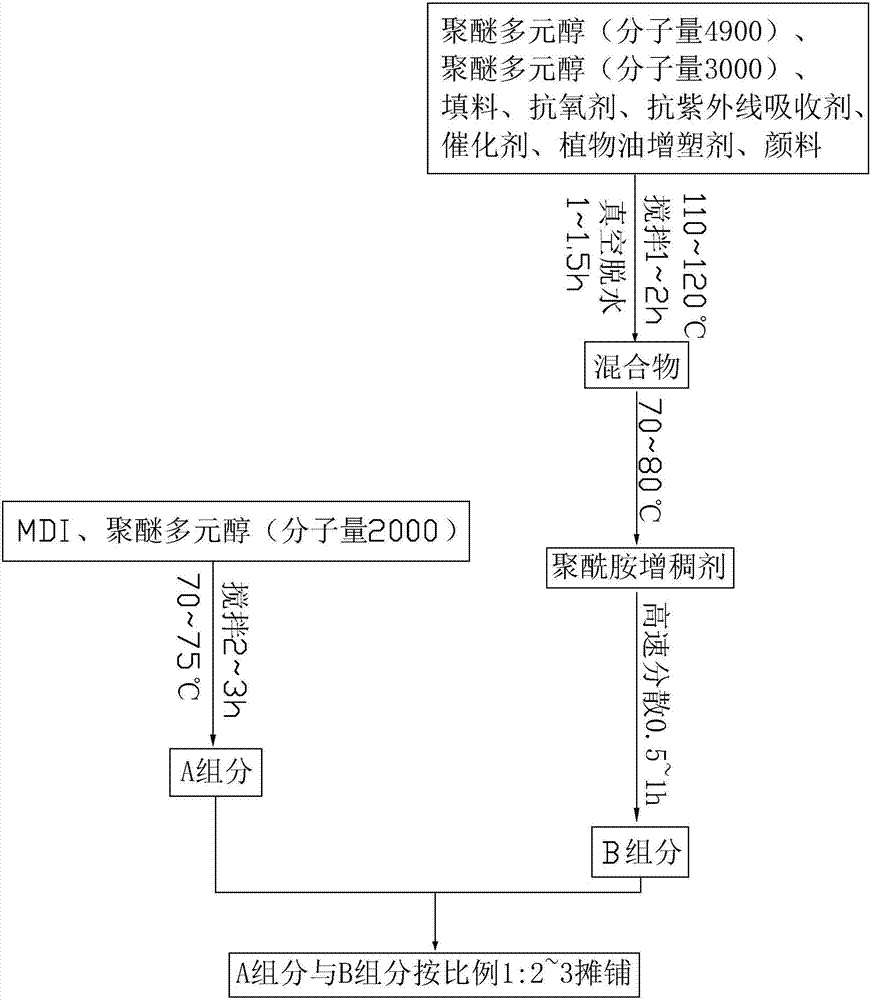

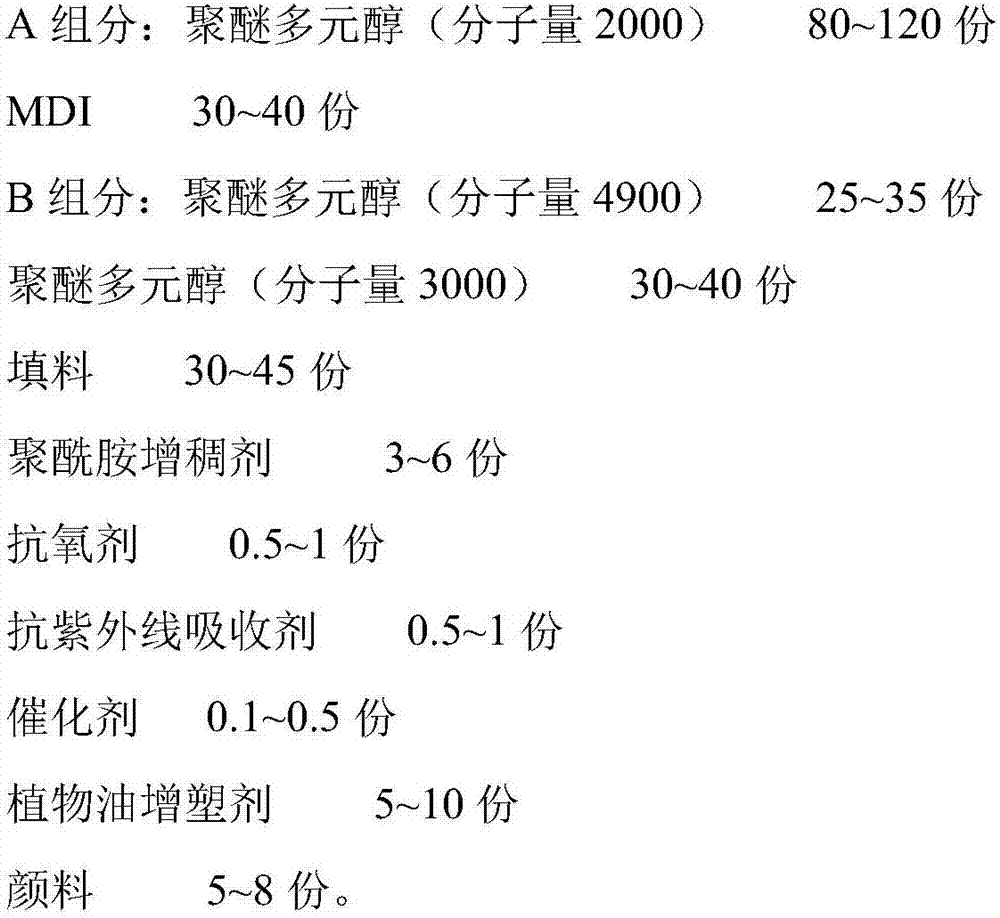

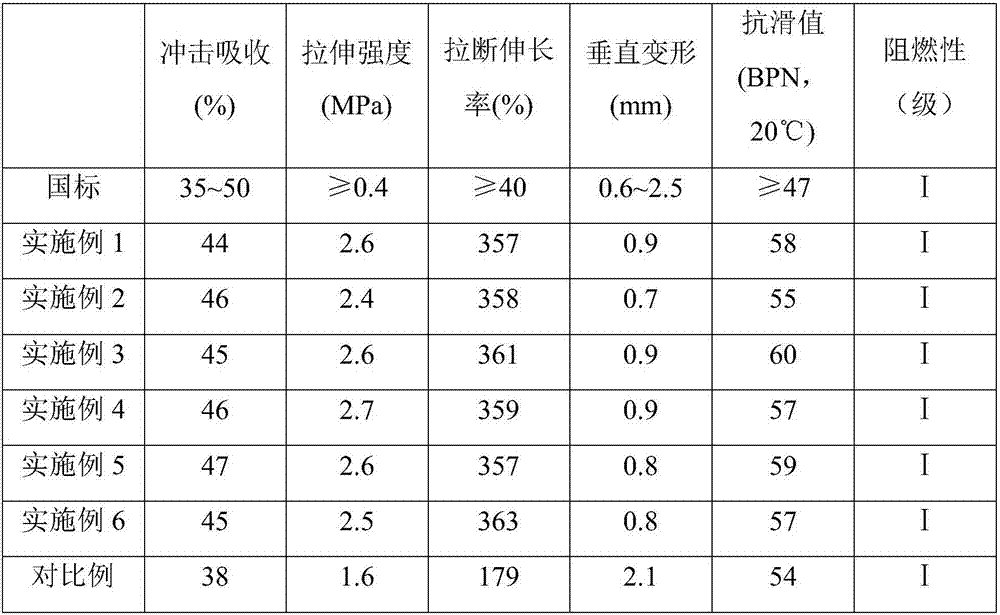

Non-solvent-type sports field skid-resistant layer texture self-formation material and preparation method thereof

InactiveCN106947241ANot easy to fall offNot easy to drop particlesGround pavingsVegetable oilAntioxidant

The invention discloses a non-solvent-type sports field skid-resistant layer texture self-formation material and relates to the field of plastic materials. The non-solvent-type sports field skid-resistant layer texture self-formation material comprises, by weight, a component A comprising 80 to 120 parts of polyether polyol (having molecular weight of 2000) and 30 to 40 parts of MDI (diphenylmethane diisocyanate), and a component B comprising 25 to 35 parts of polyether polyol (having molecular weight of 4900), 30 to 40 parts of polyether polyol (having molecular weight of 3000), 30 to 45 parts of a filler, 3 to 6 parts of a polyamide thickener, 0.5 to 1 part of an antioxidant, 0.5 to 1 part of an ultraviolet absorber, 0.1 to 0.5 parts of a catalyst, 10 to 15 portions of a vegetable oil plasticizer and 5 to 8 portions of a pigment. The non-solvent-type sports field skid-resistant layer texture self-formation material has the advantages that particles of the surface layer do not easily fall off, skid resistance, elasticity and shock absorption performances are good, comfort is improved, a fatigue degree is reduced, wear, oil and aging resistance is very strong, a service life is long, and the material is beautiful and environmentally friendly.

Owner:江苏耐斯坦建设有限公司

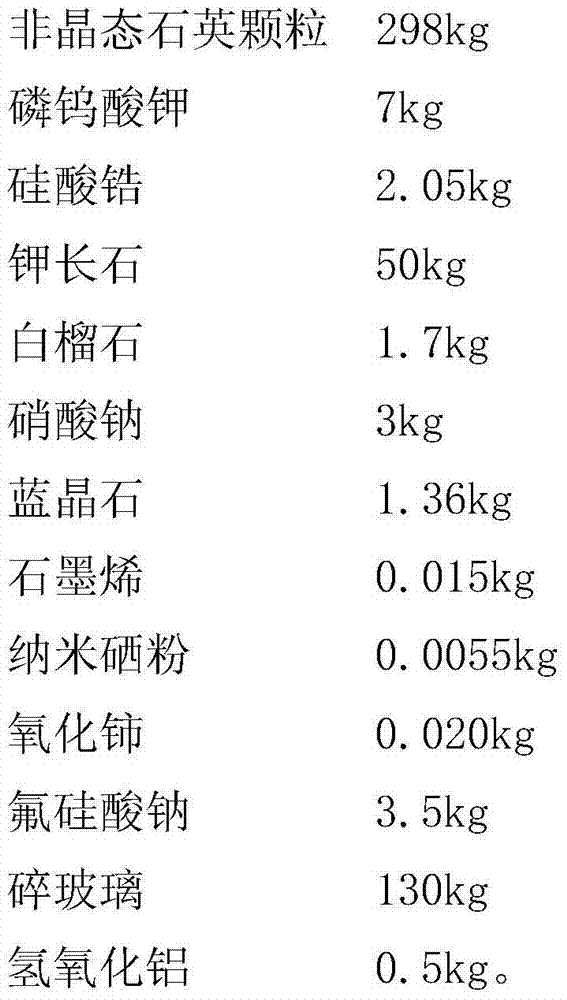

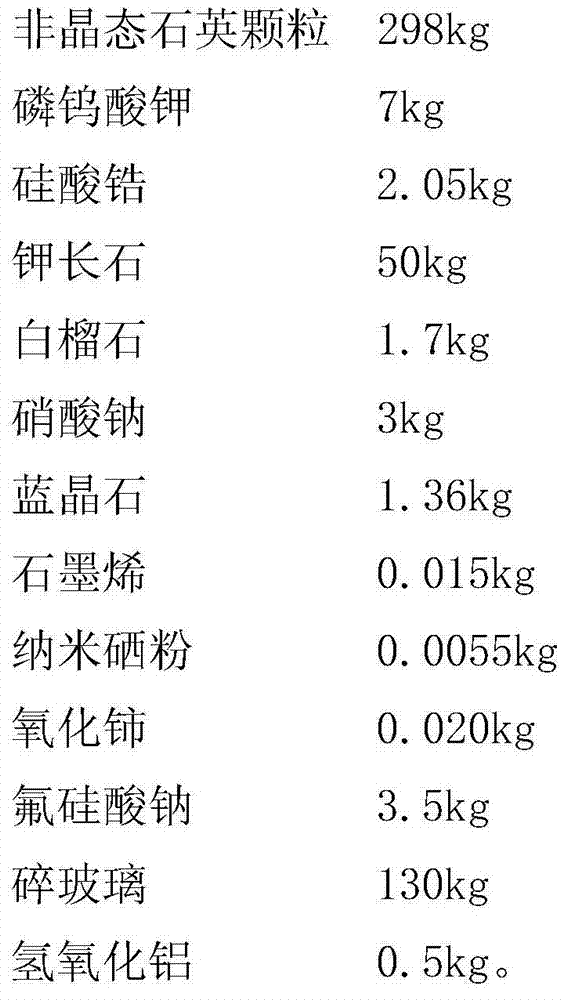

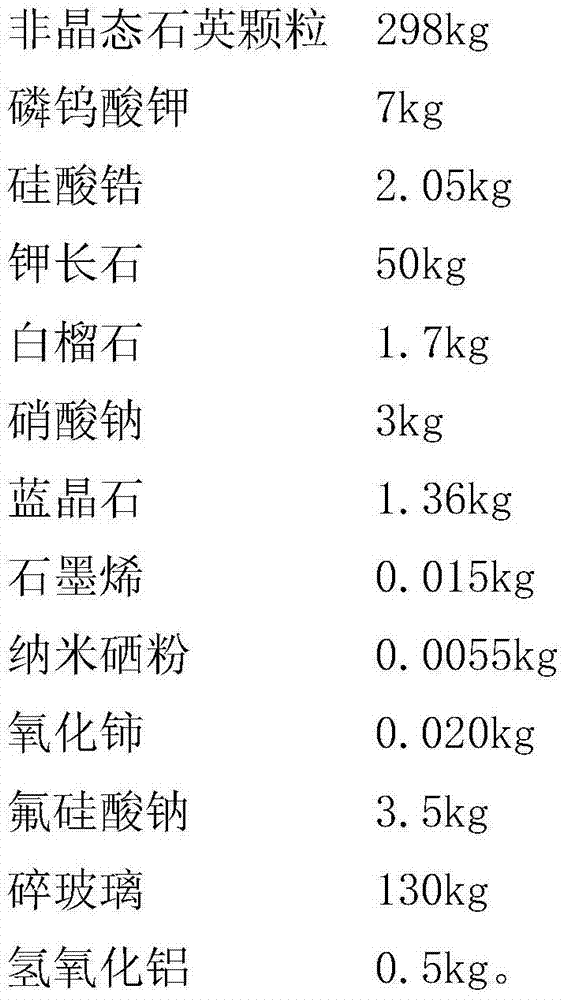

High-strength heatproof glassware

The invention relates to the technical field of glass and provides a high-strength heatproof glassware. The glassware comprises, by weight, 298 kg of an amorphous quartz granule, 7 kg of potassium phosphotungstate, 2.05 kg of zirconium silicate, 50 kg of potash feldspar, 1.7 kg of leucite, 3 kg of sodium nitrate, 1.36 kg of kyanite, 0.015 kg of graphene, 0.0055 kg of nanometer selenium powder, 0.020 kg of cerium oxide, 3.5 kg of sodium fluosilicate, 130 kg of cullet and 0.5 kg of aluminum hydroxide. According to the invention, since the amorphous quartz granule is used as a main material, a good molding effect and good glossiness are obtained; through addition of the component--graphene, electrochemical polarization among active substance particles is reduced, and the strength of the glassware is greatly improved due to structural strength and networking of graphene; a prepared glass is safe and reliable to use and has improved surface glossiness, an improved reflection effect and a beautiful color.

Owner:ANHUI FENGYANG HUAIHE GLASS

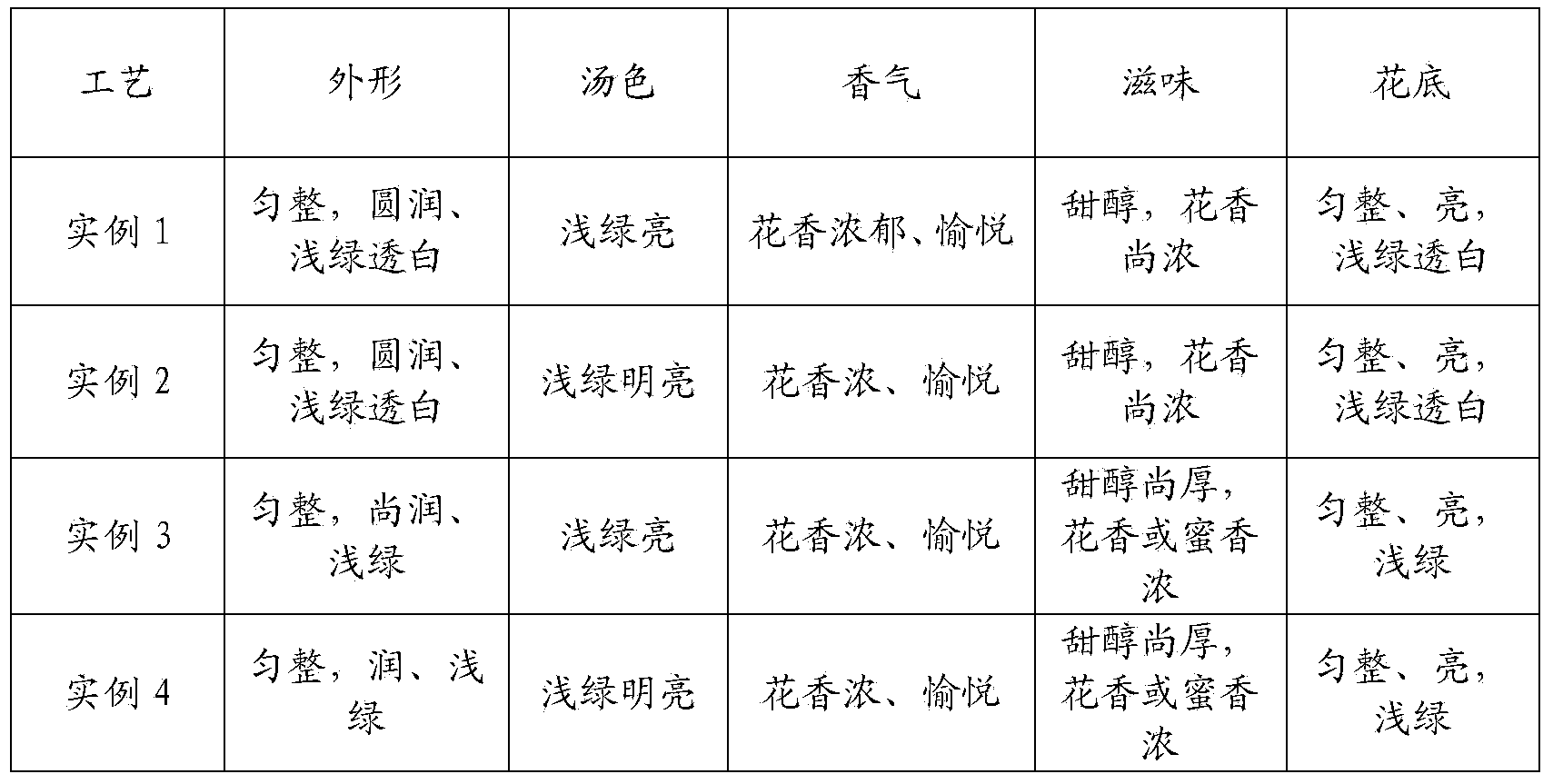

Processing method for tea flowers

The invention relates to a processing method for tea flowers. The processing method comprises the following steps: picking the tea flowers, withering, carrying out fixation, drying and packaging. According to the method, a microwave water removing machine is utilized for rapidly finish fixation in short time; meanwhile, in a fixation process, a lot of water molecules are escaped and evaporated from the tea flowers so as to realize the primary drying aim; the color, the flavor, the shape and the taste of the fresh tea flowers can keep unchanged to the greatest extent and effective substances are kept to the greatest extent; the high-aroma and the high-quality tea flowers are prepared.

Owner:GUANGXI GUILIN TEA RES INST

Anhydrous rapid preparation method of low-nitrite lactic acid-fermented vegetable

InactiveCN104738484AAvoid pollutionFast fermentationBacteriaMicroorganism based processesBiotechnologySalt content

The invention discloses an anhydrous rapid preparation method of a low-nitrite lactic acid-fermented vegetable. The method comprises the following steps: cleaning and draining off a to-be-fermented vegetable, and segmenting according to the requirements; and adding 1.5%-3.3% of salt and 0.05%-0.35% of functional bacteria powder according to the weight of the vegetable, mixing evenly, and fermenting at a room temperature for 1-4 days, so as to obtain the fermented vegetable product. The low-nitrite lactic acid-fermented vegetable is fast to ferment, low in nitrite and salt content, free of extra addition of water, and simple in production process.

Owner:GUIZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com