Method for preparing mineral organic fertilizer by using surplus sludge in municipal sewage plants

A technology for excess sludge and urban sewage, which is applied in the preparation of organic fertilizers, organic fertilizers, and bio-organic part treatment, etc., can solve the problems of increasing the cost of fertilizer production, the existence of toxic and harmful substances, and the long fermentation reaction time, so as to avoid stench. Problems, high added value, the effect of reducing the amount of flocculant added

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

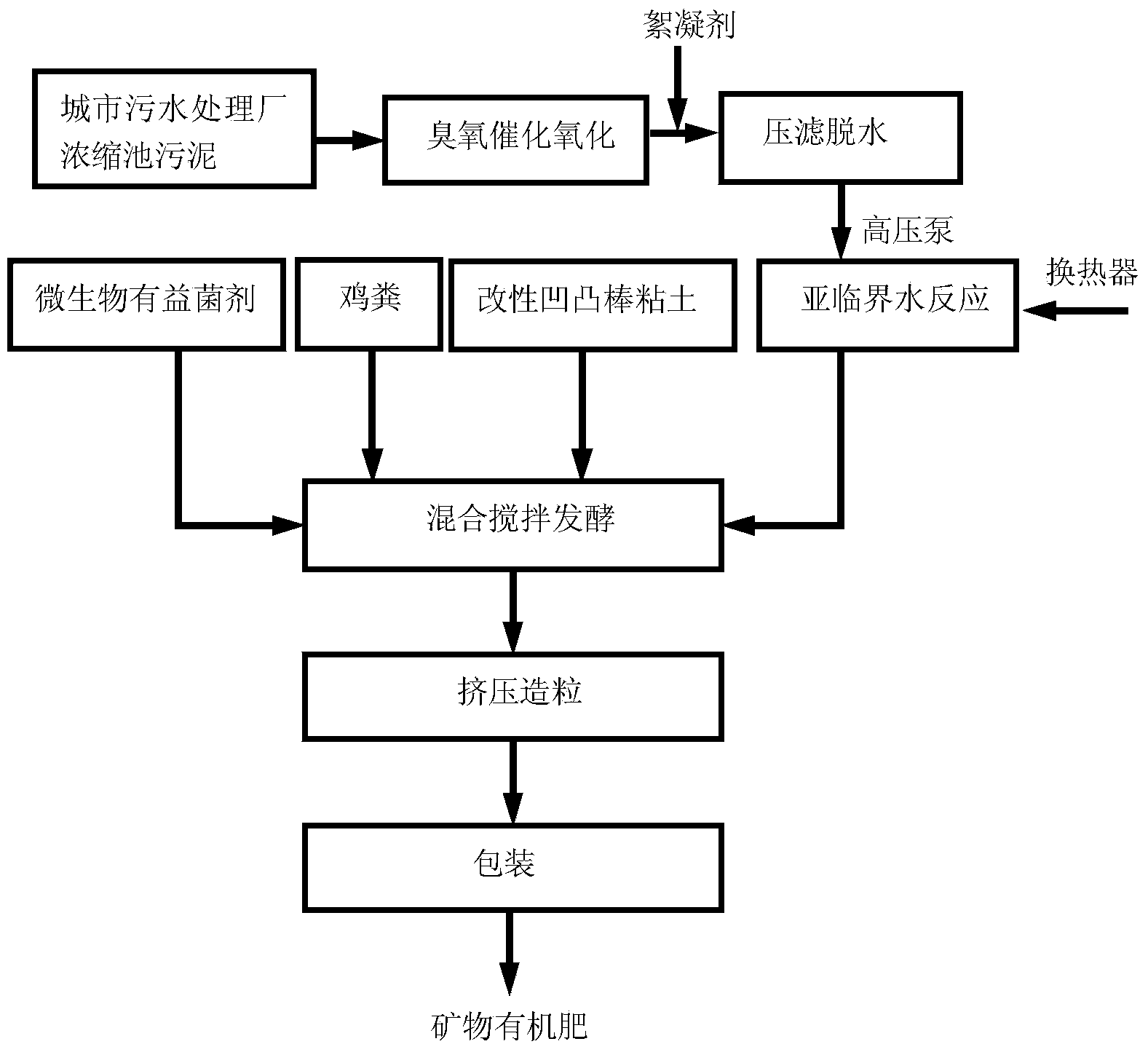

[0034] Such as figure 1 As shown, it is a process flow of the method for preparing mineral organic fertilizer by utilizing the surplus sludge of urban sewage plant, and the concrete steps are as follows:

[0035] (1) Place the ozone catalytic oxidation equipment outside the sludge concentration tank, and achieve sludge reduction through the sludge in and out of the equipment. The oxidation time is 120 minutes, so that the ozone dosage in the sludge reaches 0.07gO 3 / gSS, so as to achieve a 50% reduction in sludge and eliminate some heavy metals;

[0036] (2) Add flocculant polyacrylamide to the sludge obtained in step (1) for pressure filtration and dehydration, so that the moisture content of the sludge can reach 50%;

[0037] (3) The sludge obtained by pressure filtration and dehydration in step (2) is added to the subcritical water reaction kettle, and the subcritical water reaction step is carried out, and sodium hydroxide is added to the subcritical water reaction kettle...

Embodiment 2

[0041] A method for preparing mineral organic fertilizers by utilizing the surplus sludge of urban sewage plant, the specific steps are as follows: (1) the ozone catalytic oxidation equipment is placed outside the sludge thickening tank, the oxidation time is 100 minutes, and the ozone dosage in the sludge is 100 minutes. up to 0.05gO 3 / gSS, so as to realize the reduction of sludge and the elimination of some heavy metals;

[0042] (2) Add flocculant polyacrylamide to the sludge obtained in step (1) for pressure filtration and dehydration, so that the moisture content of the sludge can reach 60%;

[0043] (3) The sludge obtained by pressure filtration and dehydration in step (2) is added to the subcritical water reaction kettle, and the subcritical water reaction step is carried out, and sodium hydroxide is added to the subcritical water reaction kettle to adjust the sludge concentration. The pH is 8.5, and steam is introduced, the temperature is adjusted to 250°C, the press...

Embodiment 3

[0047] A kind of method that utilizes the surplus sludge of municipal sewage plant to prepare mineral organic fertilizer, concrete steps are as follows: (1) ozone catalytic oxidation equipment is placed on the outside of sludge thickening tank, oxidation time is 150 minutes, makes the amount of ozone in sludge up to 0.05gO 3 / gSS, so as to realize the reduction of sludge and the elimination of some heavy metals;

[0048] (2) Add flocculant polyacrylamide to the sludge obtained in step (1) for pressure filtration and dehydration, so that the moisture content of the sludge can reach 40%;

[0049] (3) The sludge obtained by pressure filtration and dehydration in step (2) is added to the subcritical water reaction kettle, and the subcritical water reaction step is carried out, and sodium hydroxide is added to the subcritical water reaction kettle to adjust the sludge concentration. The pH is 7.5, and steam is introduced, the temperature is adjusted to 100°C, the pressure is 4.0MP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com