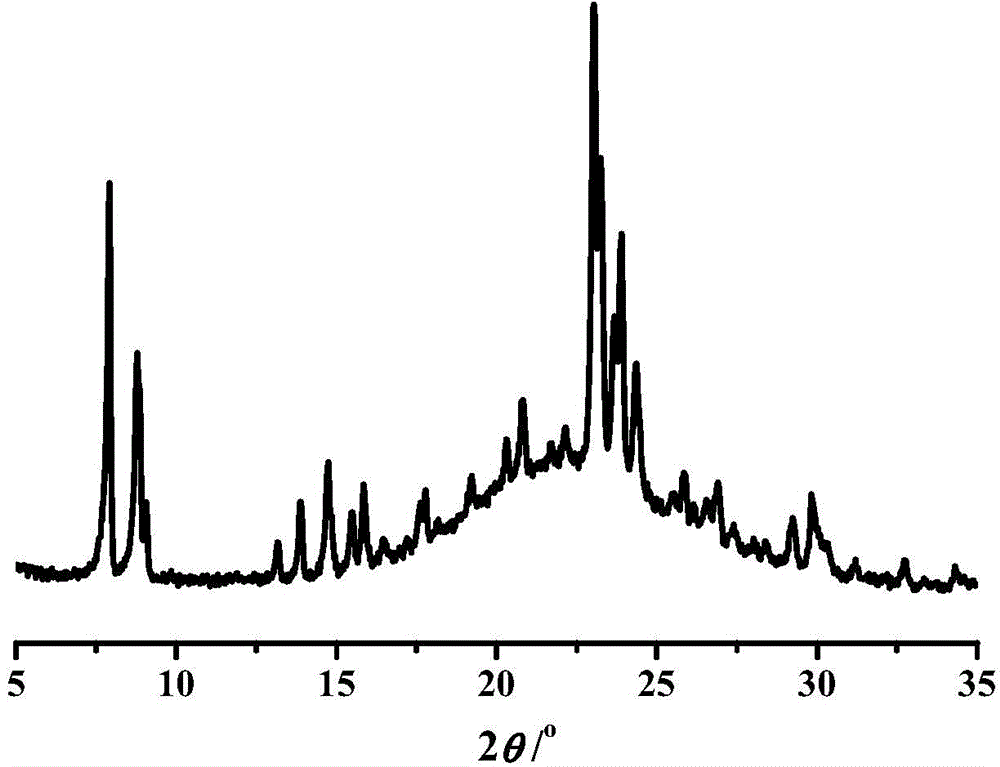

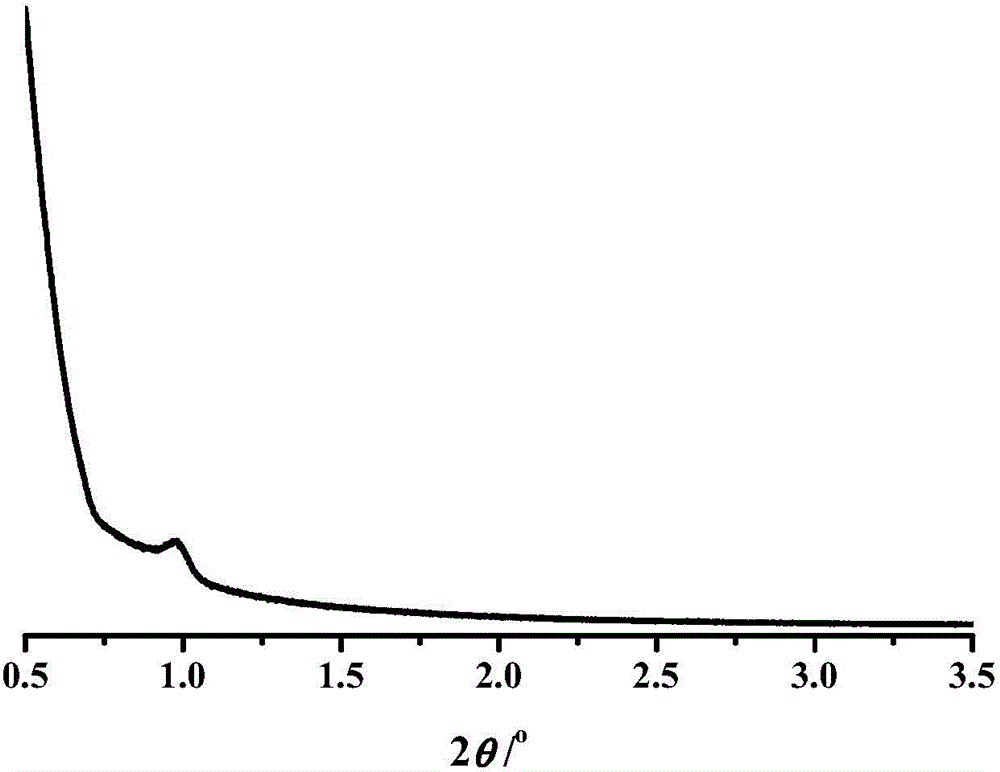

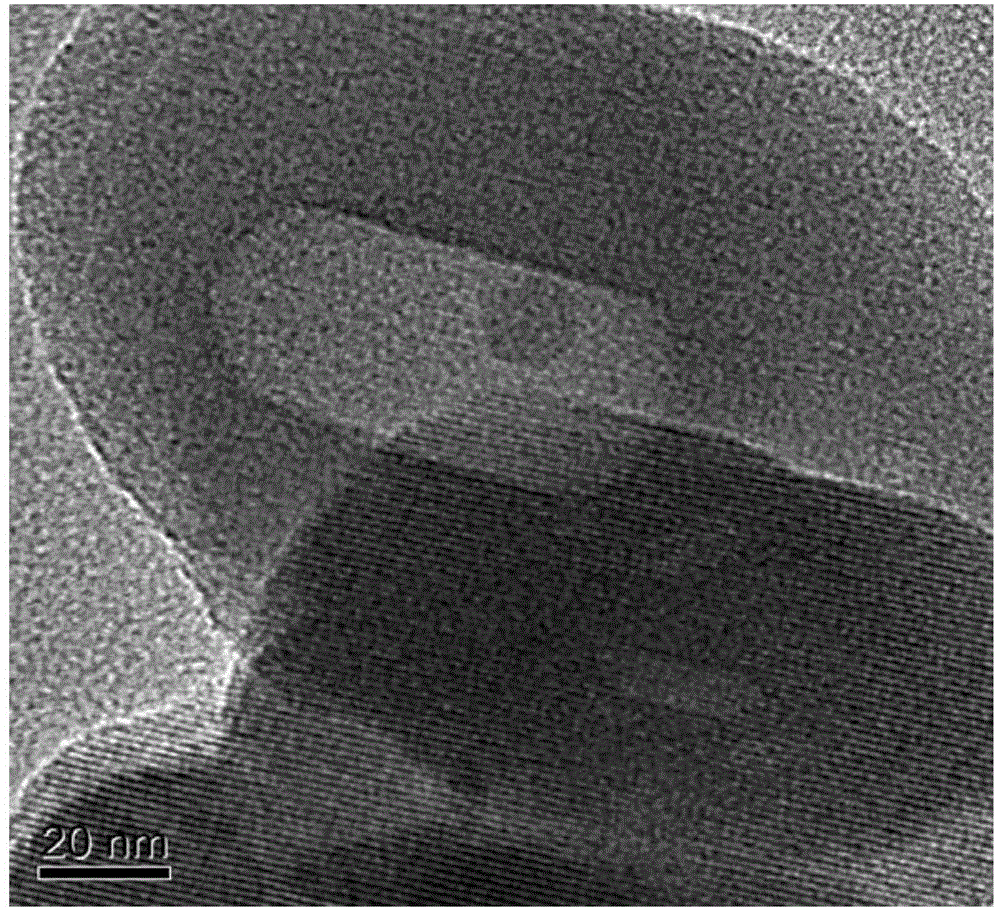

Method for synthesizing titanium-silicon micro-mesoporous composite material

A synthesis method and micro-mesoporous technology, applied in chemical instruments and methods, crystalline aluminosilicate zeolites, molecular sieves and alkali-exchange compounds, etc., can solve the problem of low activity of titanium-silicon molecular sieves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0039] The method for synthesizing titanium-silicon micro-mesoporous molecular sieve provided by the present invention, a preferred embodiment, comprises the following steps:

[0040] (1) Mix template agent, titanium source, organosilicon source, water, polyhydric alcohol and optional inorganic ammonium source, hydrolyze the alcohol, and then add peroxide; Stir the resulting mixture for at least 10 minutes at ~100° C., such as 50 to 95° C., wherein the stirring time for stirring is 10 minutes to 50 hours; wherein the inorganic ammonium source (in the form of NH 4 + Calculated): Titanium source (as TiO 2 The molar ratio of meter) is 0~5:1;

[0041] (2) Aging the product obtained in step (1), the aging is to leave the product obtained in step (1) at room temperature to 50°C for 1 to 60 hours, such as 2 to 50 hours or 3 to 30 hours, further such as 3 to 30 hours 15 hours;

[0042] (3) Mix the aging product obtained in step (2) with the solid silicon source according to a weig...

Embodiment 1

[0094] Mix 8.5g tetraethyl silicate, 0.44g glycerol with 2.66g tetrapropylammonium hydroxide aqueous solution (25.05% by weight), 1.12g hexadecyltrimethylammonium hydroxide, 0.24g ethylenediamine, add 24.35 g of deionized water were uniformly mixed; then hydrolyzed at 60° C. for 1.0 h to obtain a hydrolyzed solution of tetraethyl silicate. Then, under the action of vigorous stirring, a solution consisting of 0.41 g of tetrabutyl titanate and 5.0 g of isopropanol was slowly dropped into the above solution, and the mixture was stirred at 75° C. for 3 h to obtain a clear and transparent colloid. Add 0.39 g of 30% by weight hydrogen peroxide. Then move the colloid into a closed stainless steel reaction kettle, and crystallize at a constant temperature at 170° C. for 3 days to obtain TS-1 molecular sieve. Mix 6g of TS-1 sample with 25.05% by weight TPAOH aqueous solution uniformly, the weight ratio of TS-1 and TPAOH aqueous solution is 1:5, crystallize in a closed reaction kettle ...

Embodiment 2

[0100] (1) 15g concentration is the tetrapropyl ammonium hydroxide aqueous solution of 25.05% by weight, 2.04g tetrabutyl titanate, 5.49g hexadecyltrimethylammonium hydroxide (represented by MSDS), 8.5g tetrasilicate Ethyl ester, 4.87g glycerin, 2.38g triethylamine, 1.96g concentration are that the ammoniacal liquor of 20% by weight and 46.87g water are added in the beaker of 500ml successively, put into and mix evenly on the magnetic stirrer with heating and stirring function, and heated at 80° C. for 4 hours, replenishing the evaporated water at any time to obtain a colorless transparent hydrolyzate, then adding 1.18 g of hydrogen peroxide with a concentration of 30% by weight, and stirring evenly;

[0101] (2) aging the product obtained in step (1) at room temperature for 12 hours to obtain an aging product;

[0102] (3) Add 9.36g of white carbon black powder to the above aging product under stirring, and stir for 1 hour after adding to form a "viscous body". After 2 days,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com