Ethanol gas sensor based on In2O3 microflower/SnO2 nanoparticle composite material and preparation method of sensor

A gas sensor and nanoparticle technology, applied in the direction of material resistance, can solve the problems of national and personal life and property safety loss, ethanol evaporation or leakage, and decline in control ability, achieving rapid adsorption and desorption, increased sensitivity, and recovery speed up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

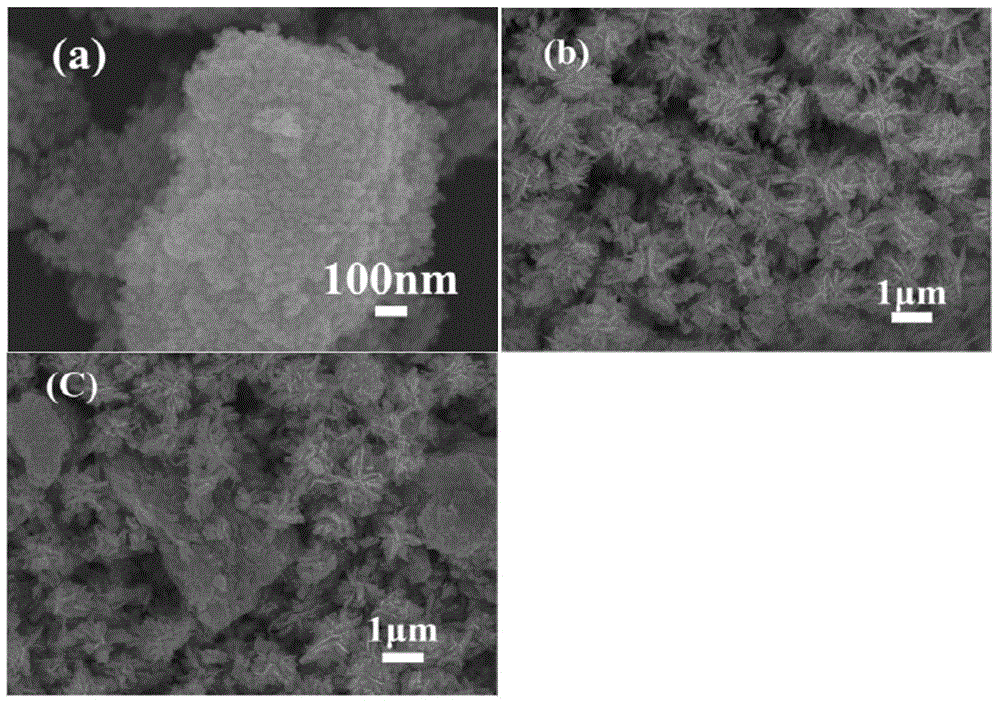

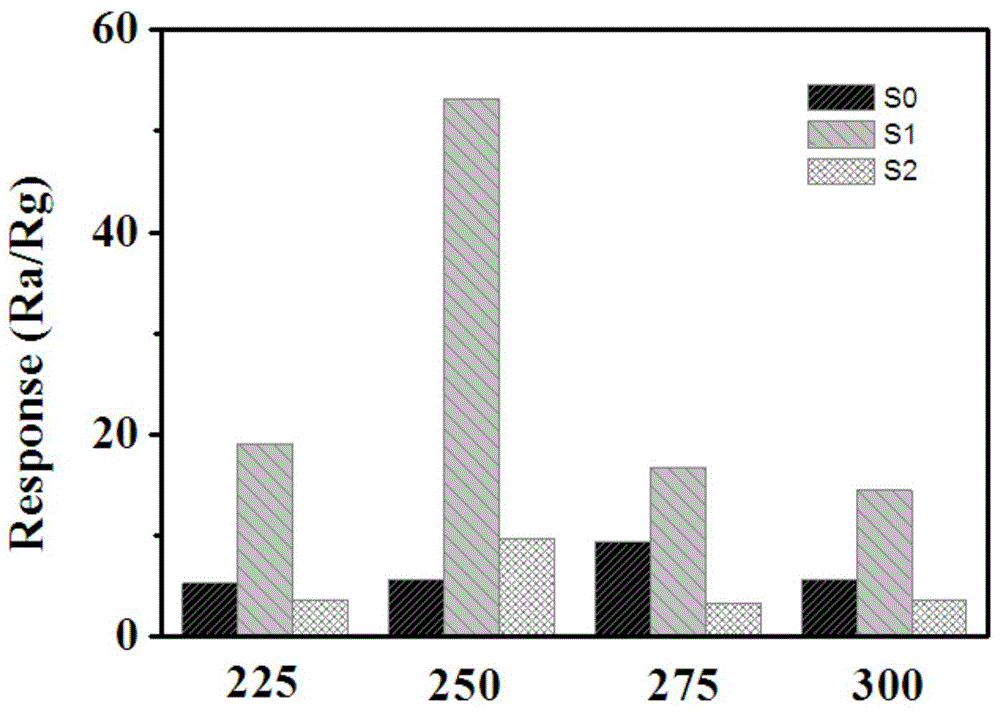

[0047] to In 2 o 3 Micron flowers and SnO 2 Nanoparticle mass ratio of 2:1 composite In 2 o 3 Micron flower / SnO 2 The nanoparticle composite material is used as a gas sensitive material to make the S1 type acetone sensor. The manufacturing process is as follows:

[0048] (1) Weigh 0.526g SnCl 4 ·5H 2 O, 0.6g CTAB (cetyltrimethylammonium bromide) and 0.2g HMT (hexamethylenetetramine), dissolved in 40mL solvent (deionized water and absolute ethanol each 20mL), stirred at room temperature Until it becomes clear, transfer the resulting solution into a hydrothermal kettle, react at 200°C for 4 hours, and take out the precipitate after cooling for a period of time to obtain SnO 2 Nanoparticle precursors.

[0049] (2) Weigh 0.381g In(NO 3 ) 3 4.5H 2 O, 0.15g urea, dissolved in 36mL deionized water, stirred at room temperature until clarified, moved the obtained solution into a hydrothermal kettle, reacted at 160°C for 4h, took out the precipitate after cooling for a period...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com