Montmorillonite composite material and application thereof in adsorbing heavy metals

The technology of composite material and montmorillonite is applied in the application field of montmorillonite composite material and its adsorption of heavy metals, which can solve the problems such as the adsorption efficiency of polluted heavy metals, and achieve the advantages of adsorption, low energy consumption, and orderly distribution of pore structures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

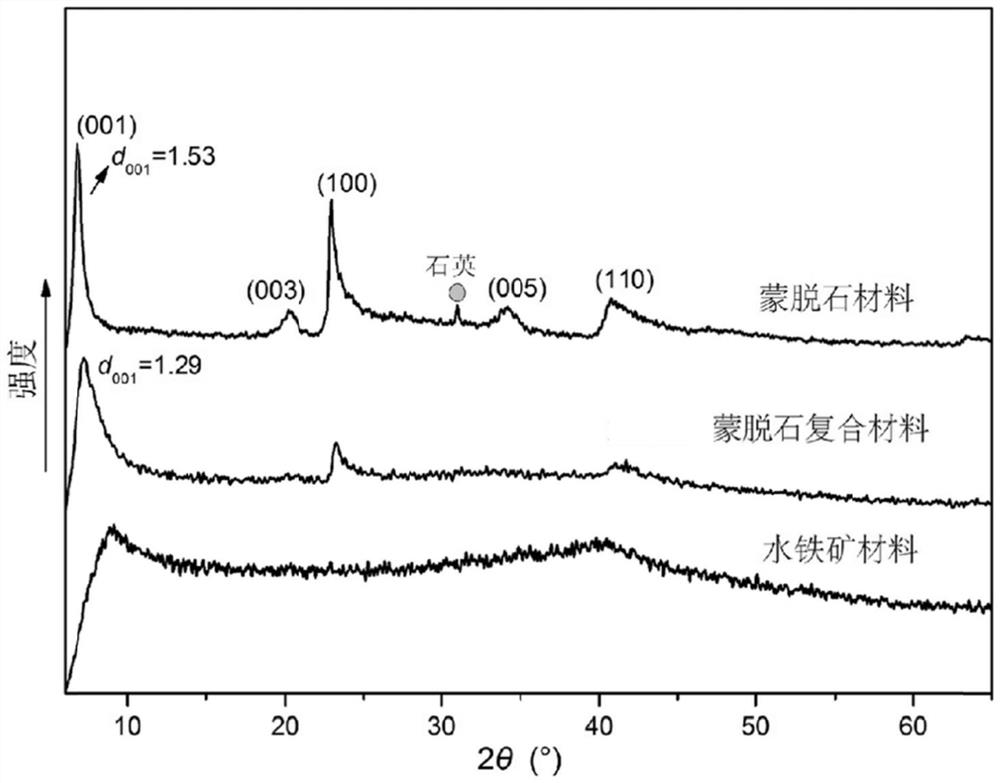

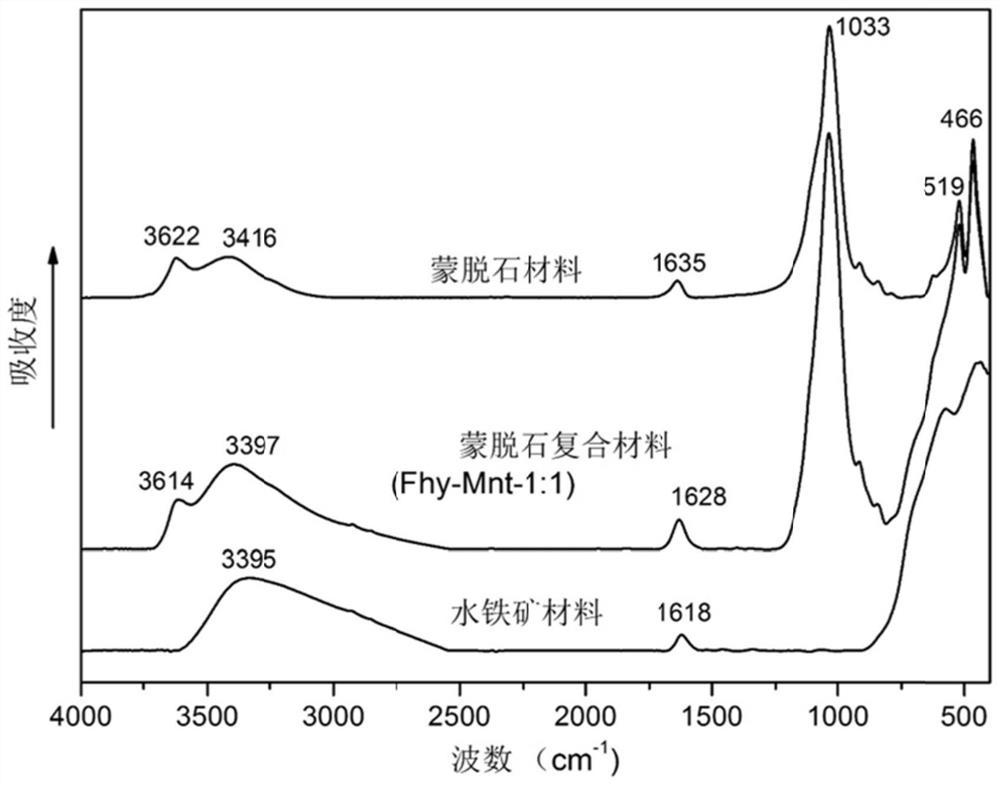

[0055] The method that present embodiment prepares montmorillonite composite material may further comprise the steps:

[0056] (1) Add 1.40g montmorillonite to 250mL FeCl with a concentration of 0.2mol / L 3 solution, fully stirred, the initial Fe / montmorillonite mass ratio of the resulting mixed solution is 1:0.5;

[0057] (2) Add 300 mL of NaOH solution with a concentration of 1 mol / L dropwise to the mixed solution obtained in step (1) at a rate of 0.5 mL / min, and continue stirring until pH=7.0 to obtain a precursor suspension of the composite material;

[0058] (3) aging the precursor suspension obtained in step (2) at room temperature for 4 hours, and re-adjusting the pH to 7.0 with the NaOH solution in step (2);

[0059] (4) The suspension in step (3) is centrifuged to obtain a montmorillonite composite material, which is freeze-dried and stored.

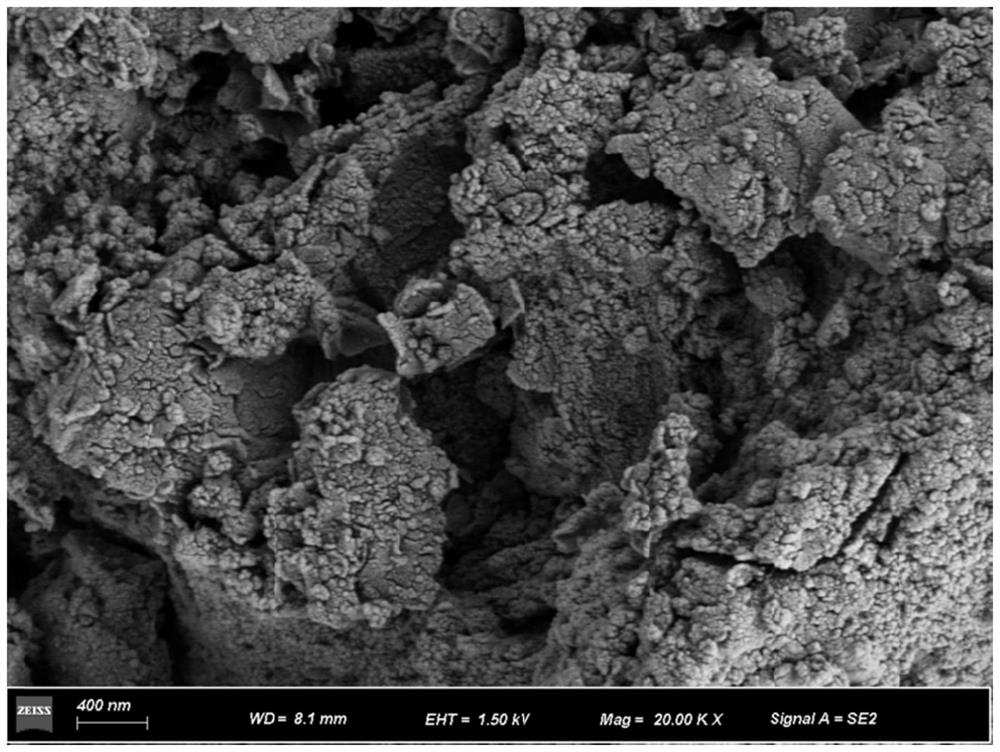

[0060] According to the Brunauer-Emmett-Teller (BET) method, the specific surface area of the montmorillonite composite mat...

Embodiment 2

[0063] The method that present embodiment prepares montmorillonite composite material may further comprise the steps:

[0064] (1) Add 1.87g montmorillonite to 250mL FeCl with a concentration of 0.2mol / L 3 solution, fully stirred, the initial Fe / montmorillonite mass ratio of the resulting mixed solution is 1.5:1;

[0065] (2) Add 300 mL of NaOH solution with a concentration of 1 mol / L dropwise to the mixed solution obtained in step (1) at a rate of 0.5 mL / min, and continue stirring until pH=7.0 to obtain a precursor suspension of the composite material;

[0066] (3) aging the precursor suspension obtained in step (2) at room temperature for 4 hours, and re-adjusting the pH to 7.0 with the NaOH solution in step (2);

[0067] (4) The suspension in step (3) is centrifuged to obtain a montmorillonite composite material, which is freeze-dried and stored.

[0068] According to the BET method, the specific surface area of the prepared montmorillonite composite material in the pre...

Embodiment 3

[0071] The method that present embodiment prepares montmorillonite composite material may further comprise the steps:

[0072] (1) Add 2.8g montmorillonite to 250mL FeCl with a concentration of 0.2mol / L 3 solution, fully stirred, the initial Fe / montmorillonite mass ratio of the resulting mixed solution is 1:1;

[0073] (2) Add 300 mL of NaOH solution with a concentration of 1 mol / L dropwise to the mixed solution obtained in step (1) at a rate of 0.5 mL / min, and continue stirring until pH=7.0 to obtain a precursor suspension of the composite material;

[0074] (3) aging the precursor suspension obtained in step (2) at room temperature for 4 hours, and re-adjusting the pH to 7.0 with the NaOH solution in step (2);

[0075] (4) The suspension in step (3) is centrifuged to obtain a montmorillonite composite material, which is freeze-dried and stored.

[0076] According to the BET method, the specific surface area of the prepared montmorillonite composite material in this embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com