Patents

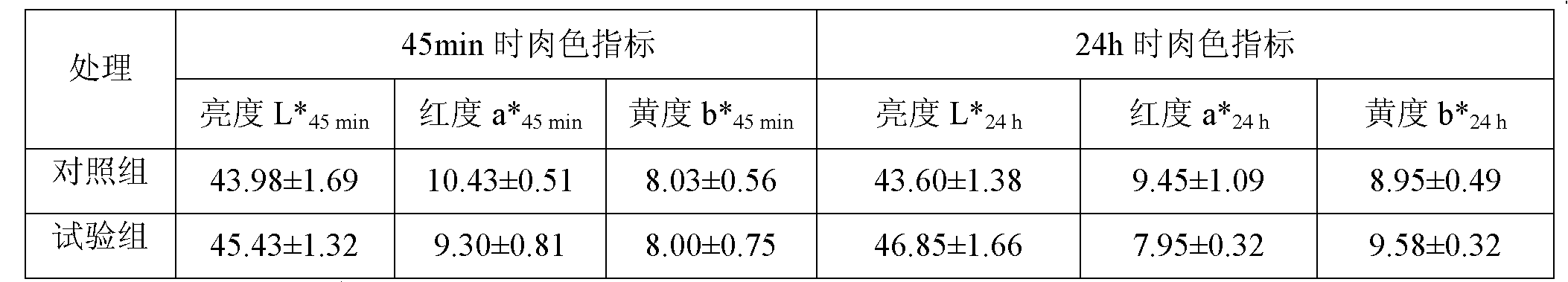

Literature

706 results about "Silicate minerals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicate minerals are rock-forming minerals made up of silicate groups. They are the largest and most important class of minerals and make up approximately 90 percent of the Earth's crust. In mineralogy, silica (silicon dioxide) SiO₂ is usually considered a silicate mineral. Silica is found in nature as the mineral quartz, and its polymorphs.

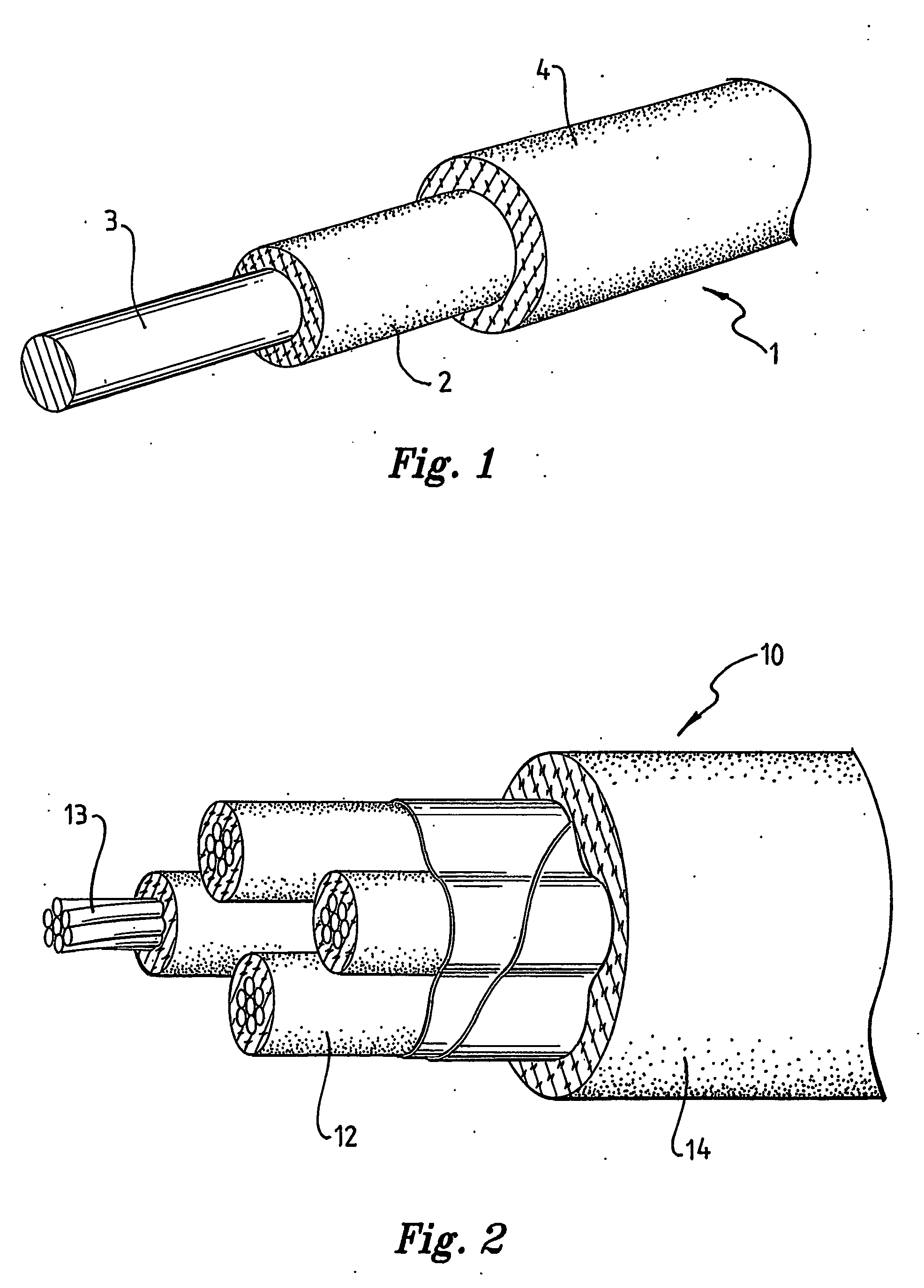

Ceramic bovine flame retardant polymer composite material and application thereof

InactiveCN104650441AImprove high temperature strengthImprove flame retardant performanceInsulatorsPolyolefinPlasticizer

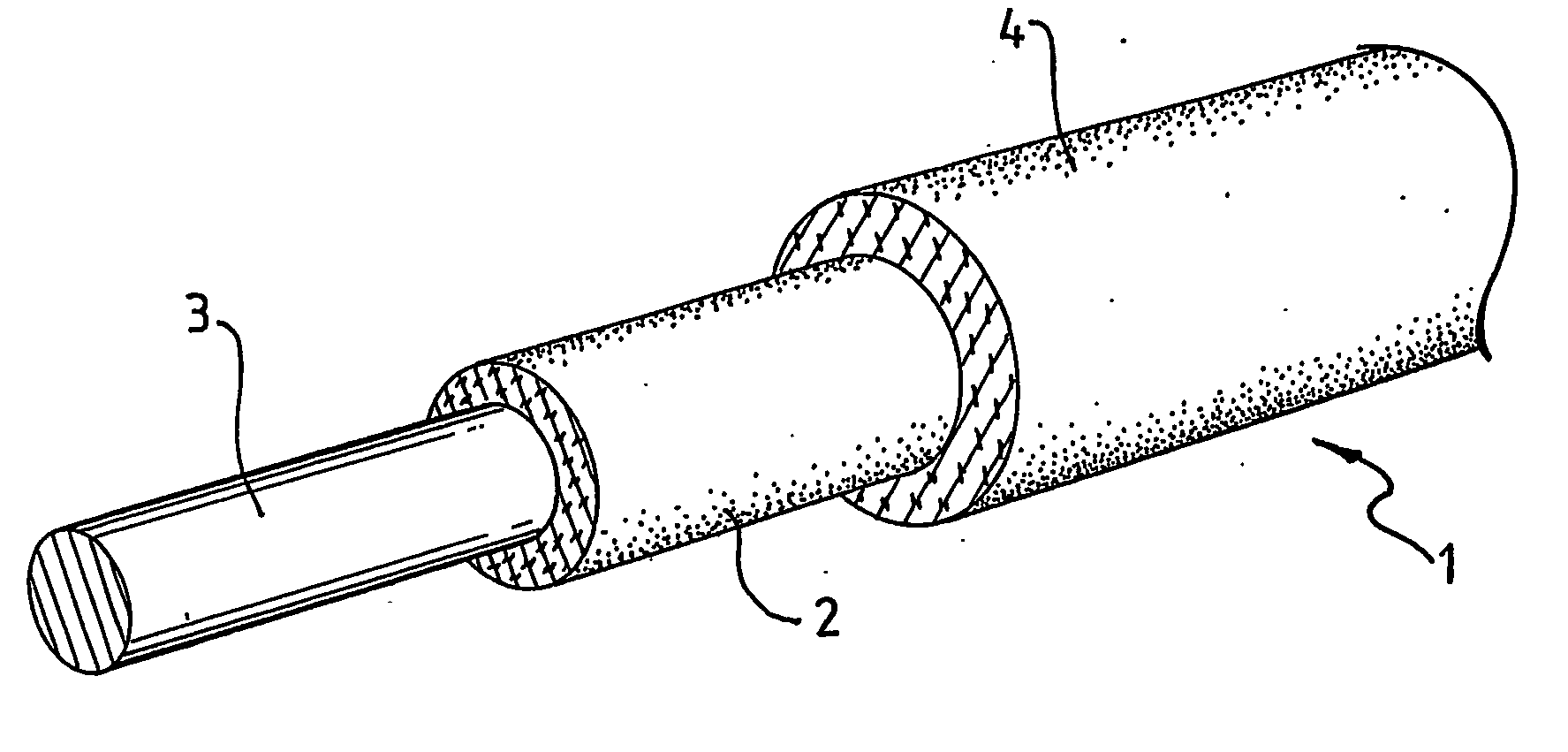

The invention provides a ceramic bovine flame retardant polymer composite material based on polyolefin or a thermoplastic polyurethane elastomer. The ceramic bovine flame retardant polymer composite material is prepared from the following components in parts by weight: 30-40 parts of polyolefin resin or the thermoplastic polyurethane elastomer, 25-45 parts of a ceramic forming filler, 20-30 parts of a halogen-free flame retardant, 1-5 parts of a flame-retardant synergist, 1-3 parts of a plasticizer, 0.5-2 parts of an antioxidant and 0.02-0.15 part of a crosslinking agent, wherein the ceramic forming filler is prepared from the following components including low softening point glass powder and a silicate mineral filler. The invention also provides application of the ceramic bovine flame retardant polymer composite material in the field of cables. According to the ceramic bovine flame retardant polymer composite material disclosed by the invention, a dense ceramic bovine product can be formed within a range from 600 DEG C to 1000 DEG C, and the formed ceramic bovine product is good in high-temperature strength and flame retardancy and is also good in mechanical properties under room temperature.

Owner:SICHUAN UNIV

Fire resistant polymeric compositions

InactiveUS20060068201A1Improve water resistanceLow thermal conductivityInsulated cablesCeramic layered productsPassive fire protectionSilicate minerals

Owner:OLEX AUSTRALIA

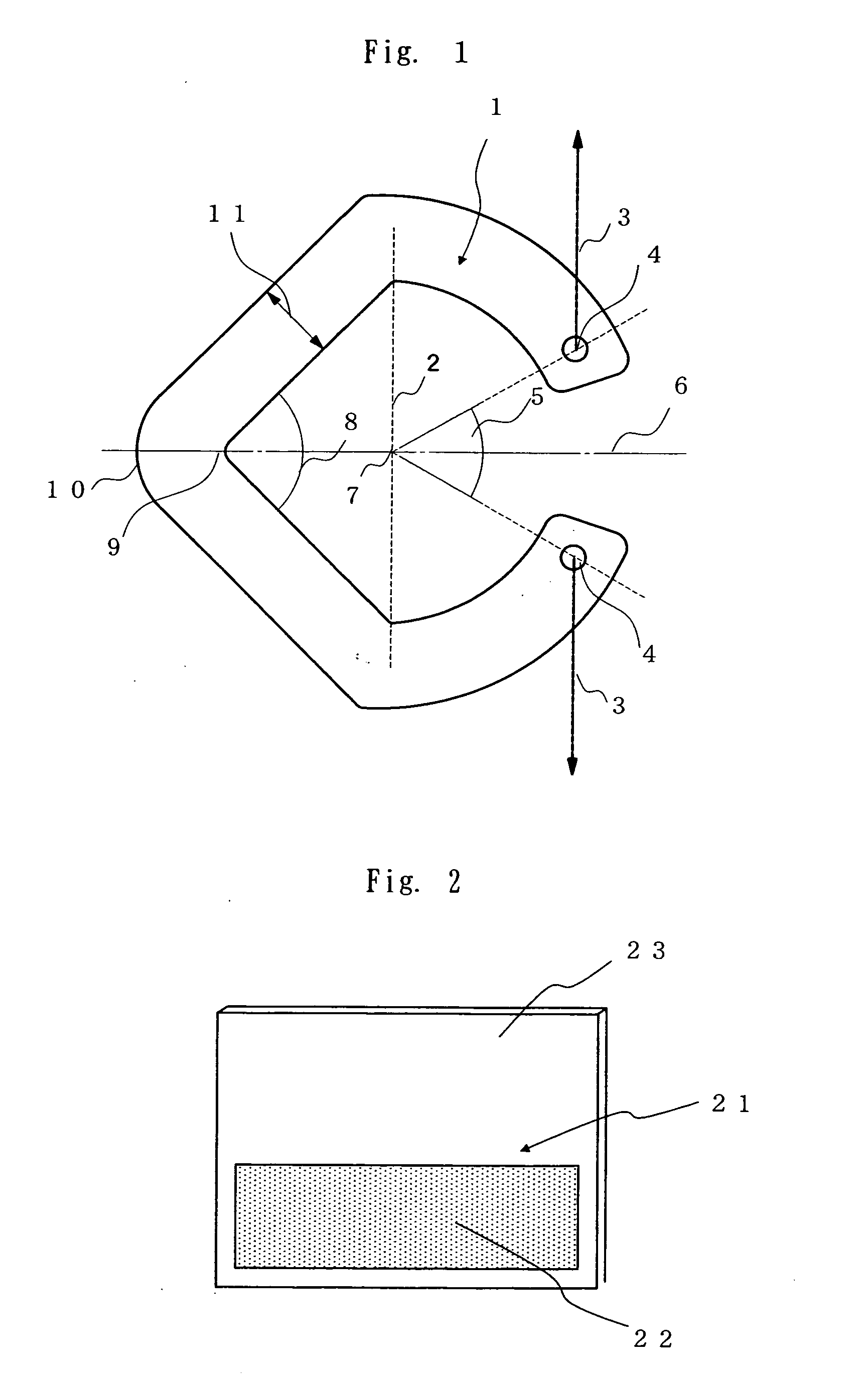

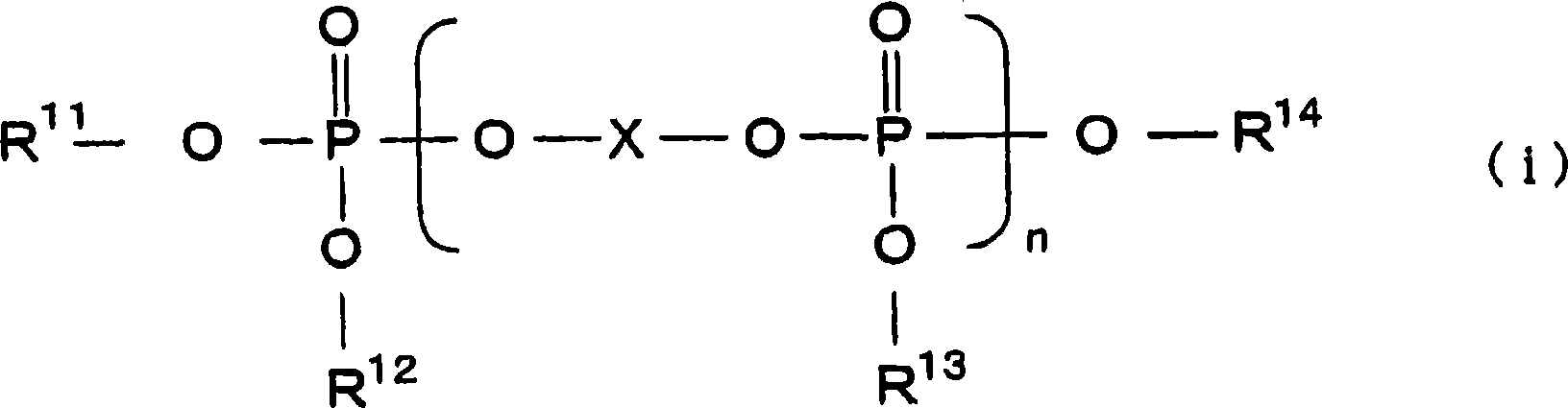

Aromatic Polycarbonate Resin Composition and Manufacturing Process Thereof

ActiveUS20070299169A1Improve flame retardant performanceHardly melt dripSemi-permeable membranesFibre treatmentFiberIon content

A resin composition comprising: (1) 100 parts by weight of an aromatic polycarbonate resin (component A); (2) 0.005 to 0.6 part by weight of a fluorine-containing organic metal salt having a fluoride ion content measured by ion chromatography of 0.2 to 20 ppm in terms of weight (component B); and (3) at least one component selected from the group consisting of a flame retardant (component C), a fatty acid ester (component D), an ultraviolet light absorber (component E), polytetrafluoroethylene having fibril formability (component F), a filler (component G), a silicate mineral (component H) and a titanium dioxide pigment (component I). A process of manufacturing the resin compositon and a method of preventing the melt dripping during combustion of the resin composition. The flame retardancy of the above aromatic polycarbonate resin composition comprising the fluorine-containing organic metal salt compound is improved.

Owner:TEIJIN KASEK KK

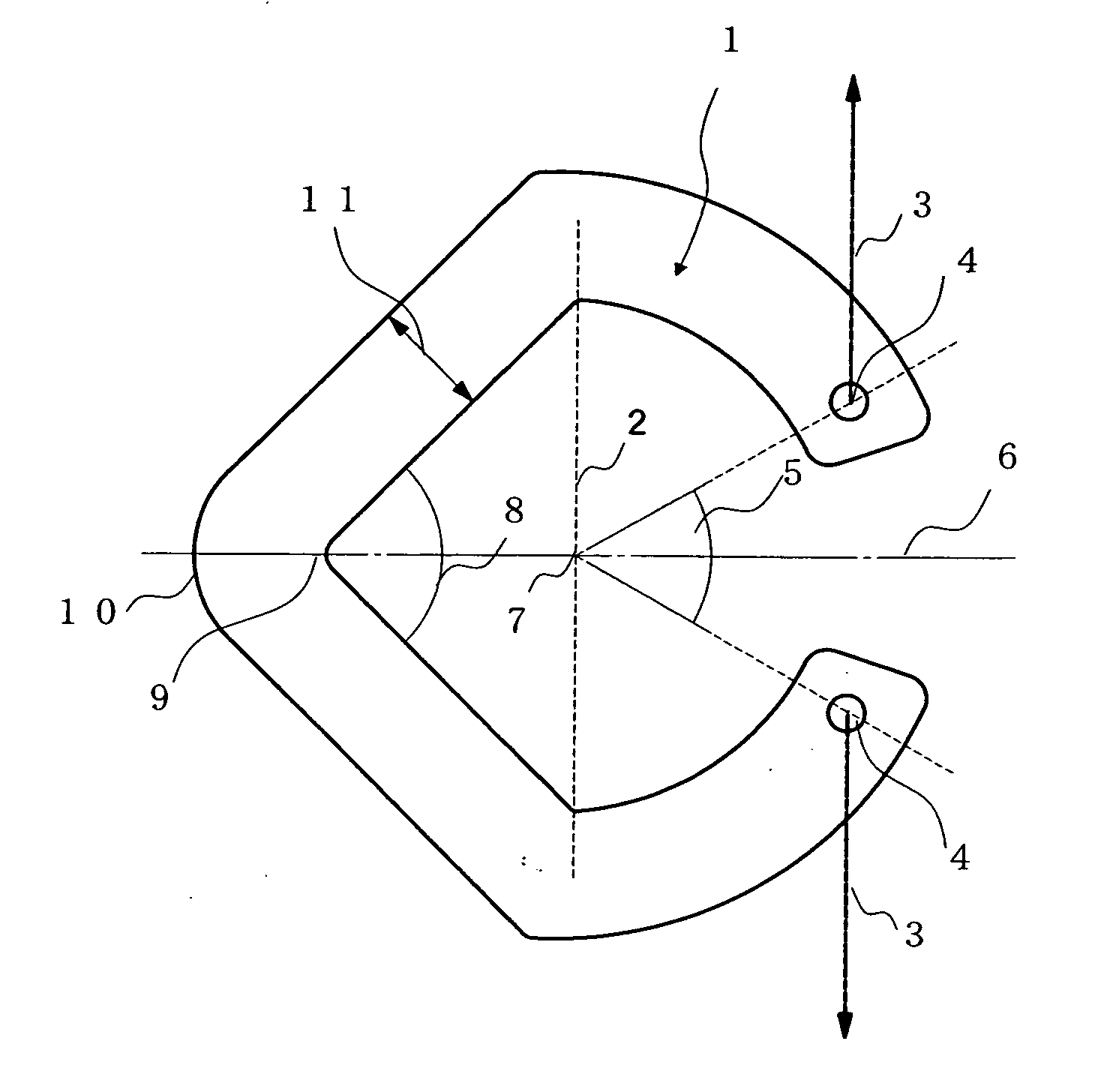

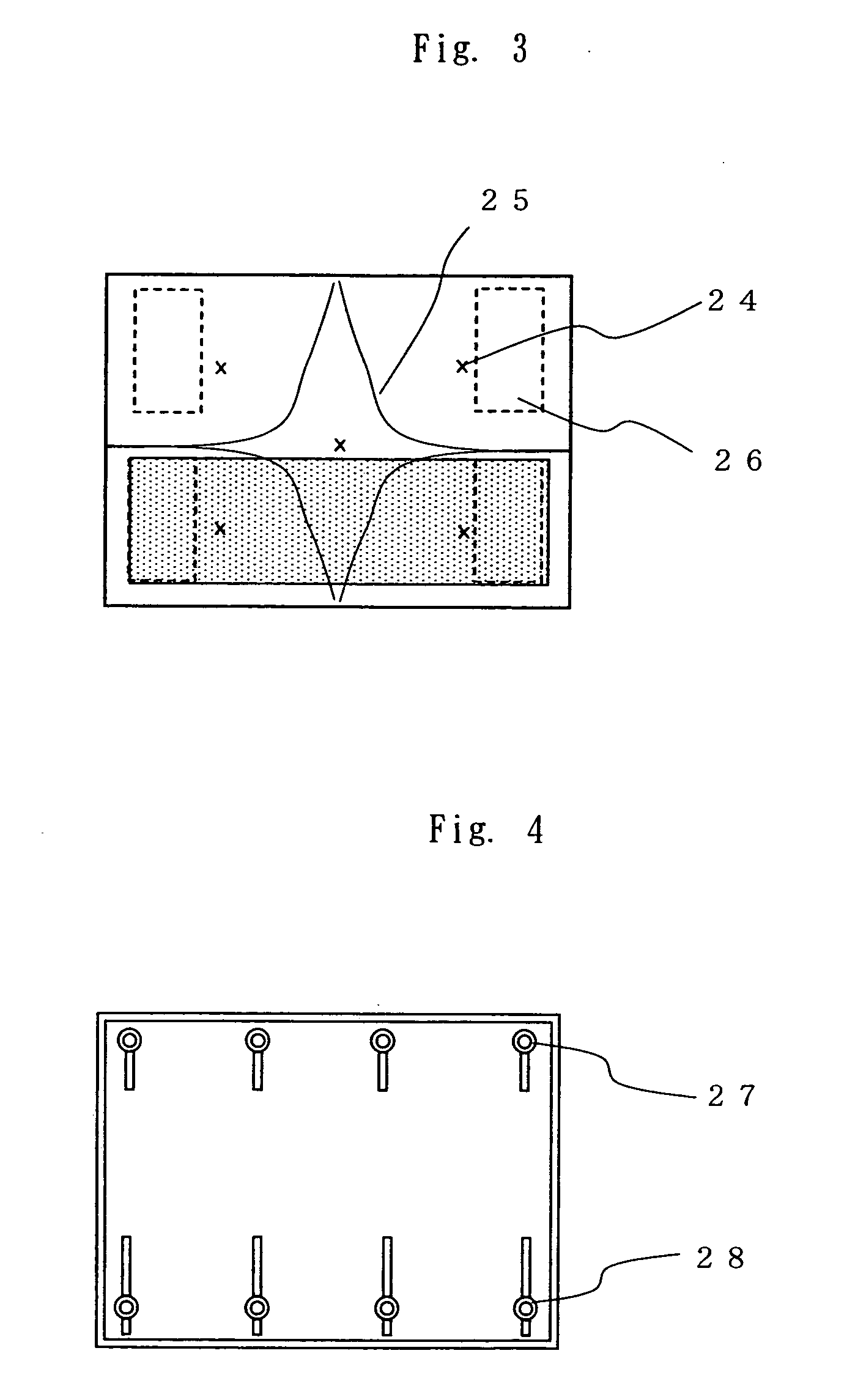

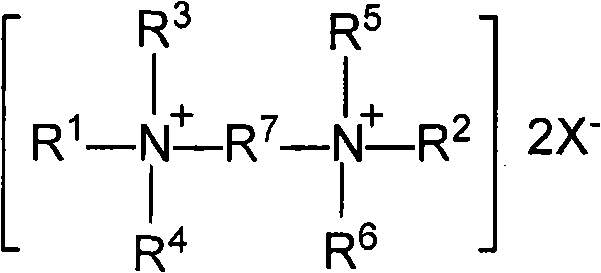

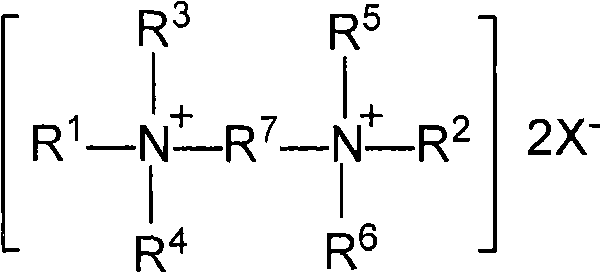

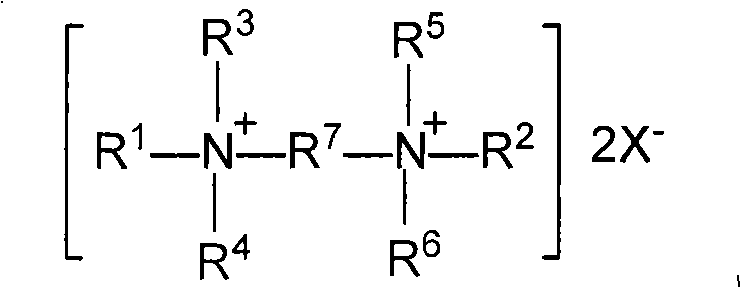

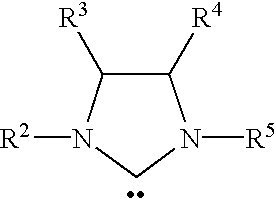

Use of quaternaries compound in floating silicate mineral

The invention relates to the field that biquaternary ammonium compounds are applied in silicate mineral flotation, and discloses a collector which applies the biquaternary ammonium compound with the constitutional formula shown as the formula I in bauxite or ironstone reverse flotation desiliconization. In the formula I, R<1> and R<2> are alkyls with 6-18 carbon atoms; R<3>, R<4>, R<5> and R<6> are respectively methyl, ethyl, -(CH2CH2O)nH, or -(CH(CH3)CH2O)nH, wherein, n is equal to 1-6; R<7> is alkylene with 2-6 carbon atoms; and X is Cl, Br or I. The collector of the invention has strong ability to collect quartz, kaolinite, illite and pyrophyllite, and is applicable to the silicate mineral separation from the bauxite or ironstone by reverse flotation, the suitable pH range of the flotation pulp is 5-13, and the dosage is equal to 50-500 g / t according to the content change of the silicate mineral in ores.

Owner:CENT SOUTH UNIV

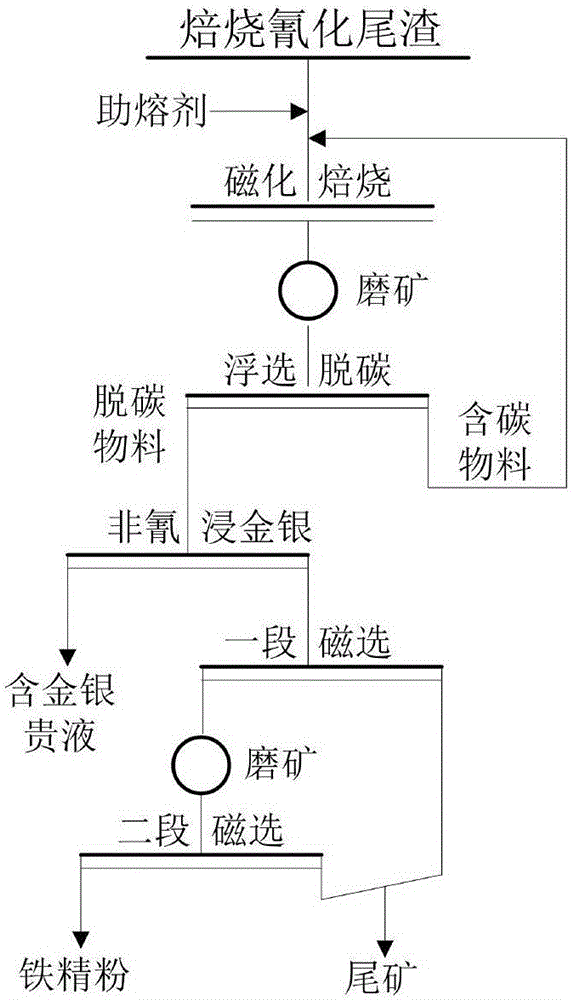

Method for recycling and synchronous harmless treatment of gold, silver and iron in roasting-cyanidation tailings

ActiveCN106498177ARealize harmless treatmentLow toxicityProcess efficiency improvementSilicate mineralsGold leaching

The invention provides a method for recycling and synchronous harmless treatment of gold, silver and iron in roasting-cyanidation tailings, and belongs to the technical field of metallurgical waste residue utilization. The method comprises the following steps: mixing dried roasting-cyanidation tailings with a fluxing agent and a reducing agent; carrying out roasting at 750 to 900 DEG C for 3 to 5 hours; conducting water quenching on hot roasted sand for cooling; carrying out ore grinding and flotation to remove residual carbon; leaching gold and silver with an environment-friendly gold leaching agent; and conducting magnetic separation on the leaching residue to obtain fine iron powder. Containing no highly toxic cyanide, the rejects belong to general industry solid waste. As the fluxing agent is added for magnetic roasting, not only can gold and silver coated with an iron mineral be exposed, but also the fluxing agent can perform a solid-phase reaction with a silicate mineral to generate a dissoluble silicate, and gold and silver coated with the dissoluble silicate can also be exposed after ore grinding. According to the method, gold, silver and iron in the roasting-cyanidation tailings are recycled, harmless treatment is realized synchronously, and the purpose of clean production is realized.

Owner:UNIV OF SCI & TECH BEIJING

Sustained-release organic fertilizer for fruits and vegetables and preparation method thereof

ActiveCN102659477AHigh yieldIncrease profitCalcareous fertilisersOrganic fertilisersNutrient deficiencySilicate minerals

The invention provides a sustained-release organic fertilizer for fruits and vegetables and a preparation method thereof. The sustained-release organic fertilizer for fruits and vegetables consists of lignin, kieselguhr, humic acid, calcium-based silicate minerals, a nitrogen fertilizer, a phosphatic fertilizer, a potassic fertilizer, trace elements, sesame-seed cake and water, wherein the trace elements comprise ferrous sulfate, boron sulphate, crystallized magnesium sulfate and molybdenum sulphate. According to the preparation method, the fertilizer is prepared by dissolving the components, stirring, mixing and granulating. The sustained-release organic fertilizer for the fruits and vegetables is reasonable in formula, the utilization rate of the organic fertilizer and the yield of the fruits and vegetables are improved greatly under the synergistic action of the components, the problems of eutrophy or nutrient deficiency symptoms of crops and water body pollution caused by fertilizer loss are solved effectively, resources are saved, and the cost is reduced; and the preparation method is simple, and is applicable for industrial production.

Owner:唐山欧润尼农业科技有限公司

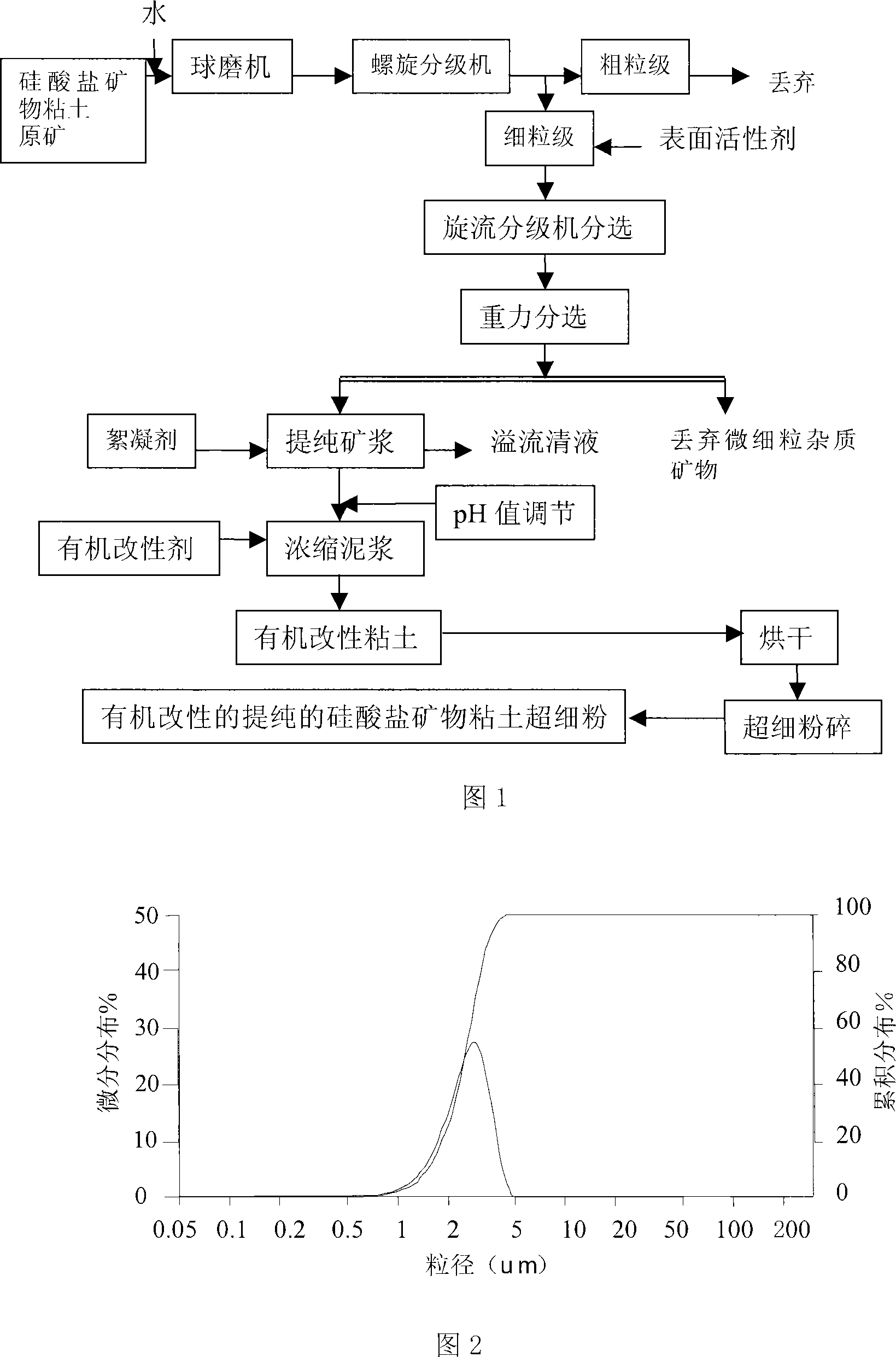

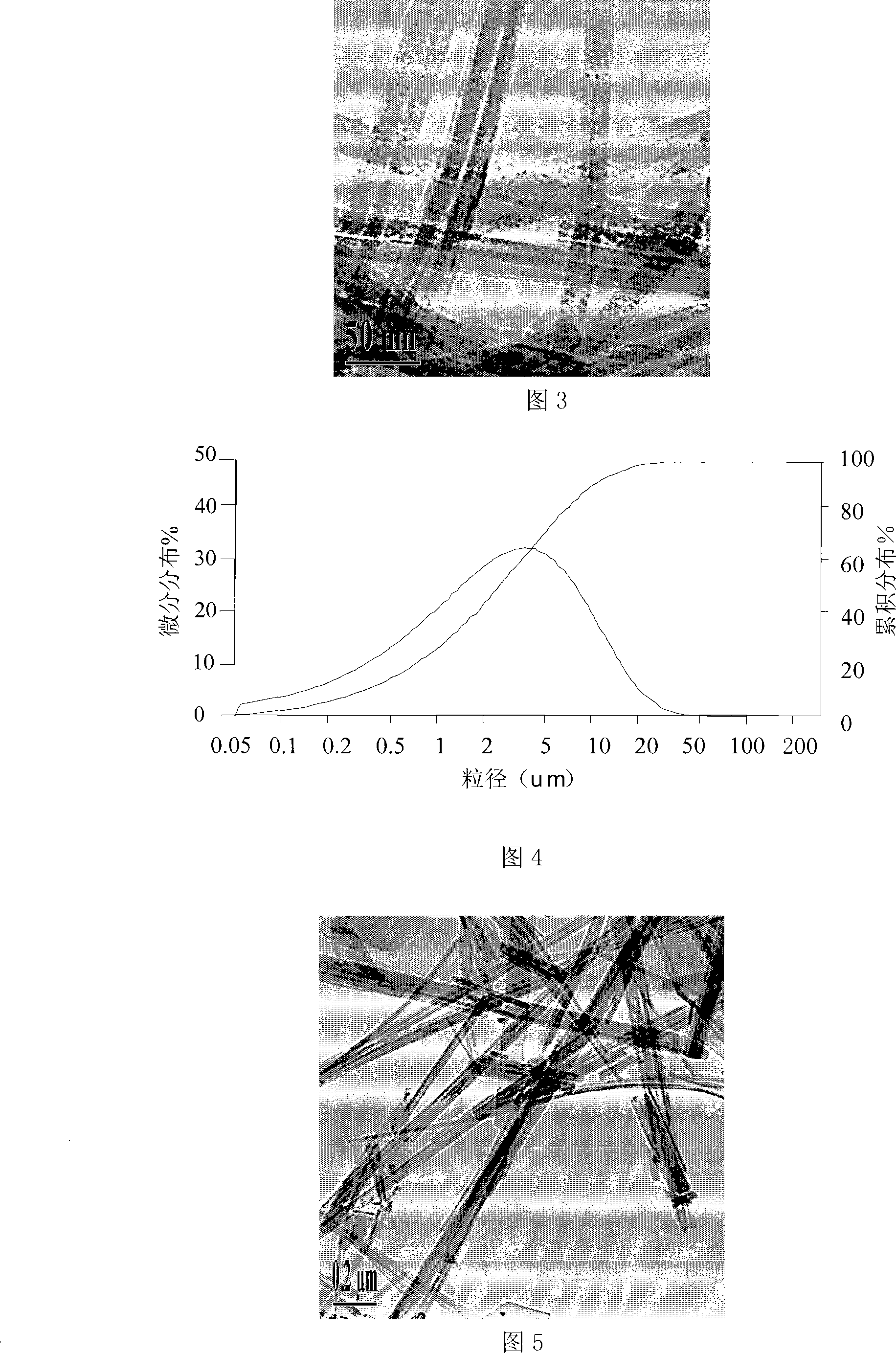

Method for preparing organic modified silicate mineral clay

InactiveCN101230210AQuality improvementRaise the gradeSilicon compoundsPigment treatment with non-polymer organic compoundsFlocculationSilicate minerals

The invention relates to a preparation method of organic modified silicate mineral clay, which belongs to the clay silicate technical field. The preparation method adopts the specific steps that a spiral classifier is utilized for primary purification, a cyclone separator is utilized for secondary purification, gravity sorting equipment is utilized for tertiary purification, flocculation and concentration, organic modification, drying and superfine grinding, and finally micropowder of organic modified silicate mineral clay with 2.5 to 6.0 average particle diameters is produced. The method realizes one step completion of the purification and modification technical processes of the silicate mineral clay, improves the quality of silicate mineral clay products, and has low requirements on the equipment; the process is simple, the condition is temperate, and the investment is low.

Owner:HEBEI UNIV OF TECH

Biodegradable polymer

A biodegradable polymer includes a) 20 to 60% of a mixture of starch and / or a modified starch, b) 8 to 22% of starch plasticisers and processing agents c) 30 to 70% of one or more biodegradable aliphatic polyesters d) 1 to 10% of a layered silicate clay mineral. The silicate mineral is an organoclay which has been formed by reacting clay with an intercalating chemical to compatibilise it with the polymers so that the clay is exfoliated and makes the blend amorphous. The polymers may also include the usual additives including e) from 0 to 20% by weight of a polyol plasticiser f) from 0.1 to 1.5% by weight of a C12–22 fatty acid or salt or a destructing agent preferably urea and / or urea derivatives, and g) from 0 to 12% by weight of added water. The polyester may be modified by reaction with maleic anhydride.

Owner:PLANTIC TECH

Biodegradable polymer

InactiveUS20040122135A1Significant comprehensive benefitsImproved melt processabilityFireproof paintsPigmenting treatmentUrea derivativesPolyester

A biodegradable polymer includes a) 20 to 60% of a mixture of starch and / or a modified starch, b) 8 to 22% of starch plasticisers and processing agents c) 30 to 70% of one or more biodegradable aliphatic polyesters d) 1 to 10% of a layered silicate clay mineral. The silicate mineral is an organoclay which has been formed by reacting clay with an intercalating chemical to compatibilise it with the polymers so that the clay is exfoliated and makes the blend amorphous. The polymers may also include the usual additives including e) from 0 to 20% by weight of a polyol plasticiser f) from 0.1 to 1.5% by weight of a C12-22 fatty acid or salt or a destructing agent preferably urea and / or urea derivatives, and g) from 0 to 12% by weight of added water. The polyester may be modified by reaction with maleic anhydride.

Owner:PLANTIC TECH

Metathesis-active adhesion agents and methods for enhancing polymer adhesion to surfaces

InactiveUS7339006B2Synthetic resin layered productsPaper/cardboard layered productsPolyolefinDouble bond

Owner:MATERIA

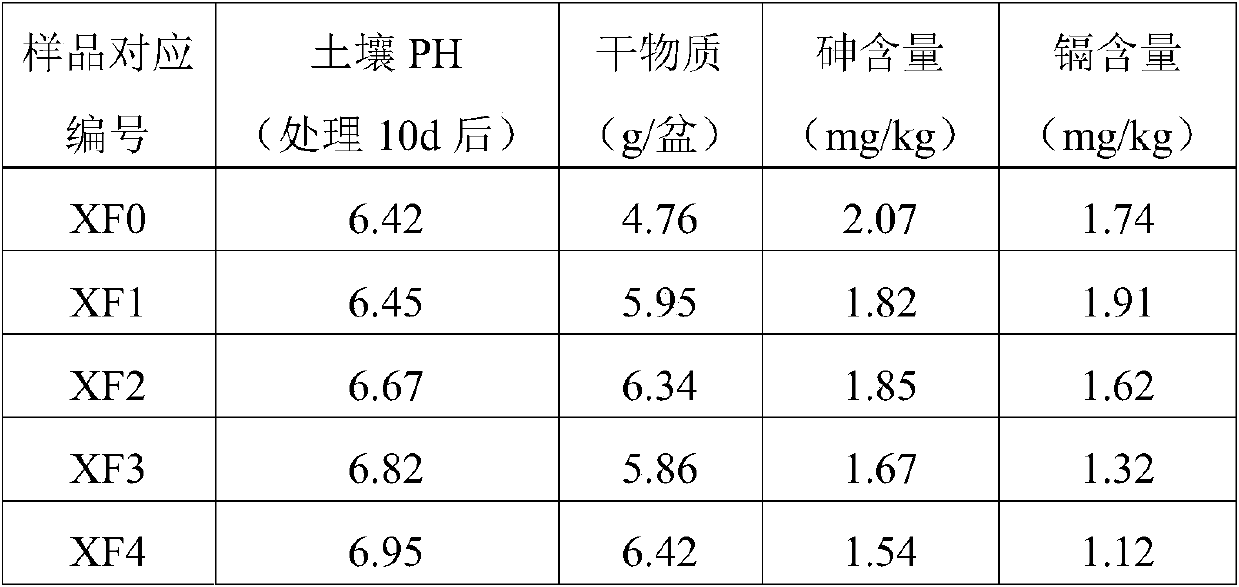

Mineral-based soil remediation agent, and preparation method thereof

ActiveCN107652976ARealize comprehensive utilizationRaise the pHAgriculture tools and machinesOther chemical processesSolubilitySoil remediation

The invention provides a mineral-based soil remediation agent, and a preparation method and application thereof. The mineral-based soil remediation agent is prepared by mixing calcium raw materials, sodium raw materials and silicate minerals, and then performing calcination and crushing; or further performing water immersion treatment on the mineral-based soil remediation agent, then performing solid-liquid separation, and then drying the obtained solid. The effective silicon content (solubility in citric acid) in terms of SiO2 is more than or equal to 20 wt%, and the effective calcium contentin terms of CaO is more than or equal to 40 wt%, and the content of harmful elements such as Hg, As, Cd, Pb and Cr is lower than 50 ppm.

Owner:HUNAN LONGE GALLOP TECH CO LTD

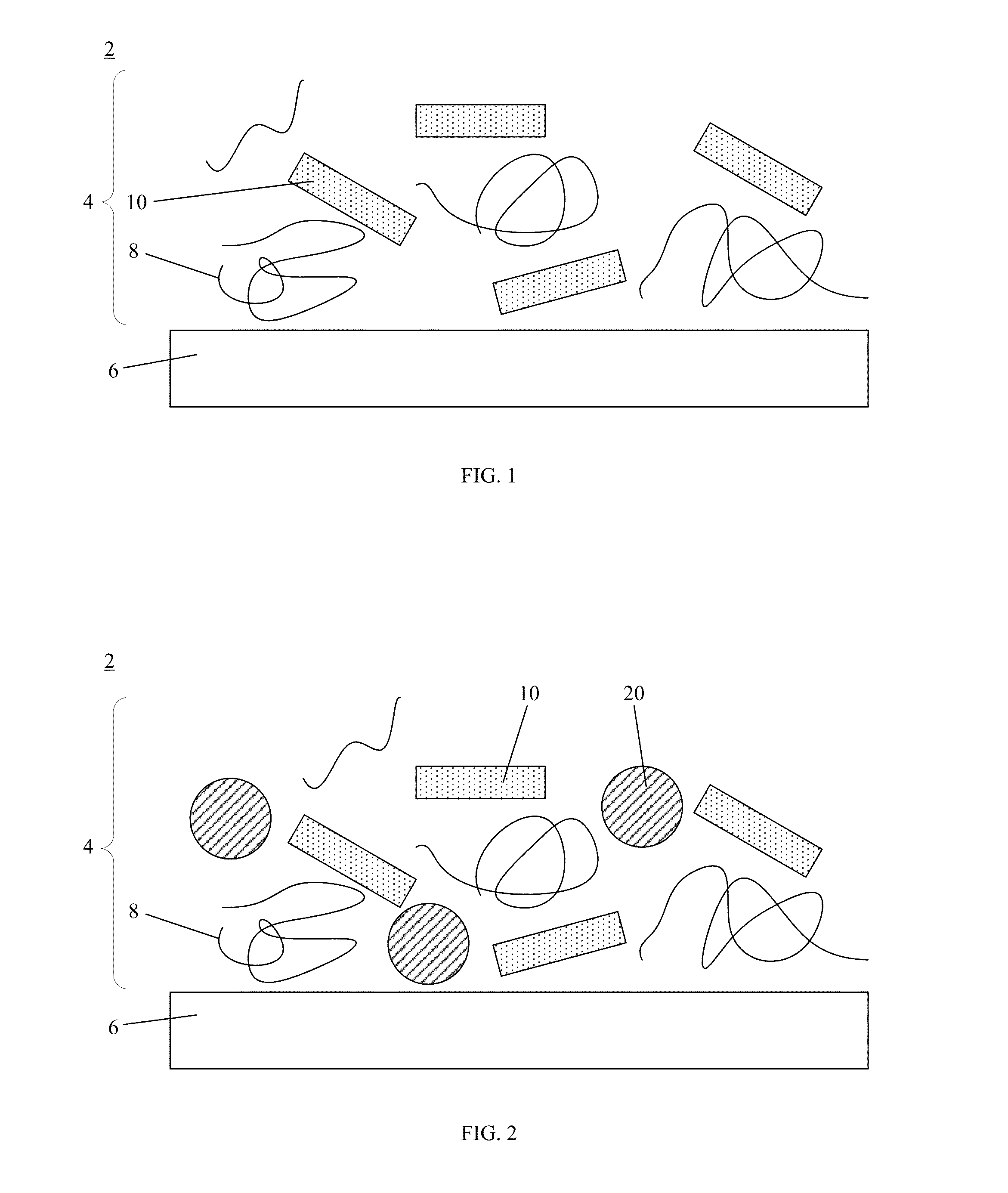

Article including intumescent coating, process for forming and use of same

InactiveUS20150017856A1Reduce flammabilityFire fastFireproof paintsSynthetic resin layered productsSolventSilicate minerals

An article includes a substrate and an intumescent coating to form an intumescent product in response to heating the article. The intumescent coating is disposed on the substrate and includes a primary intumescent precursor and a layered material that includes a silicate mineral, a layered double hydroxide, or a combination thereof. The primary intumescent precursor includes a carbohydrate polymer. A process for forming an article includes forming a liquid composition by disposing in a solvent a primary intumescent precursor and a layered material, contacting a substrate with the liquid composition, and forming an intumescent coating on the substrate to form the article.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE COMMERCE

Grain-saving growing and fattening pig feed and preparation method thereof

ActiveCN102524587ARelieve stressSave raw materialsAnimal feeding stuffAnimal scienceAdditive ingredient

The invention discloses a grain-saving growing and fattening pig feed and a preparation method of the grain-saving growing and fattening pig feed. The grain-saving growing and fattening pig feed comprises the following components by mass percentage: 0-35% of rice bran meal, 0-35% of wheat middling, 0-30% of bran, 0-8% of rice bran, 0-15% of corns, 0-25% of wheat, 3-18% of soybean meal, 0-3% of fermented soybean meal, 0-1% of fish meal, 0.5-2% of grease, 0-3% of silicate mineral feed, 0.3-1% of mountain flour, 0-0.8% of calcium hydrophosphate, 0.2-0.5% of salts, 0.5-1% of premix compound and 0.05-0.3% of compound additives. In the feed of the invention, a great amount of grain processing by-products are used to replace the corns and wheat, the nutrition ingredient proportioning is rational, a plurality of kinds of compound additives are used, and the processing technique improvement is combined to improve the feed utilization rate; and compared with the daily ration which takes the corns and the wheat as main energy feed, the grain-saving growing and fattening pig feed does not affect the growth property of pigs and the meat quality, and can reduce the formula cost and improve the comprehensive economic benefit.

Owner:哈尔滨众诚牧业有限公司

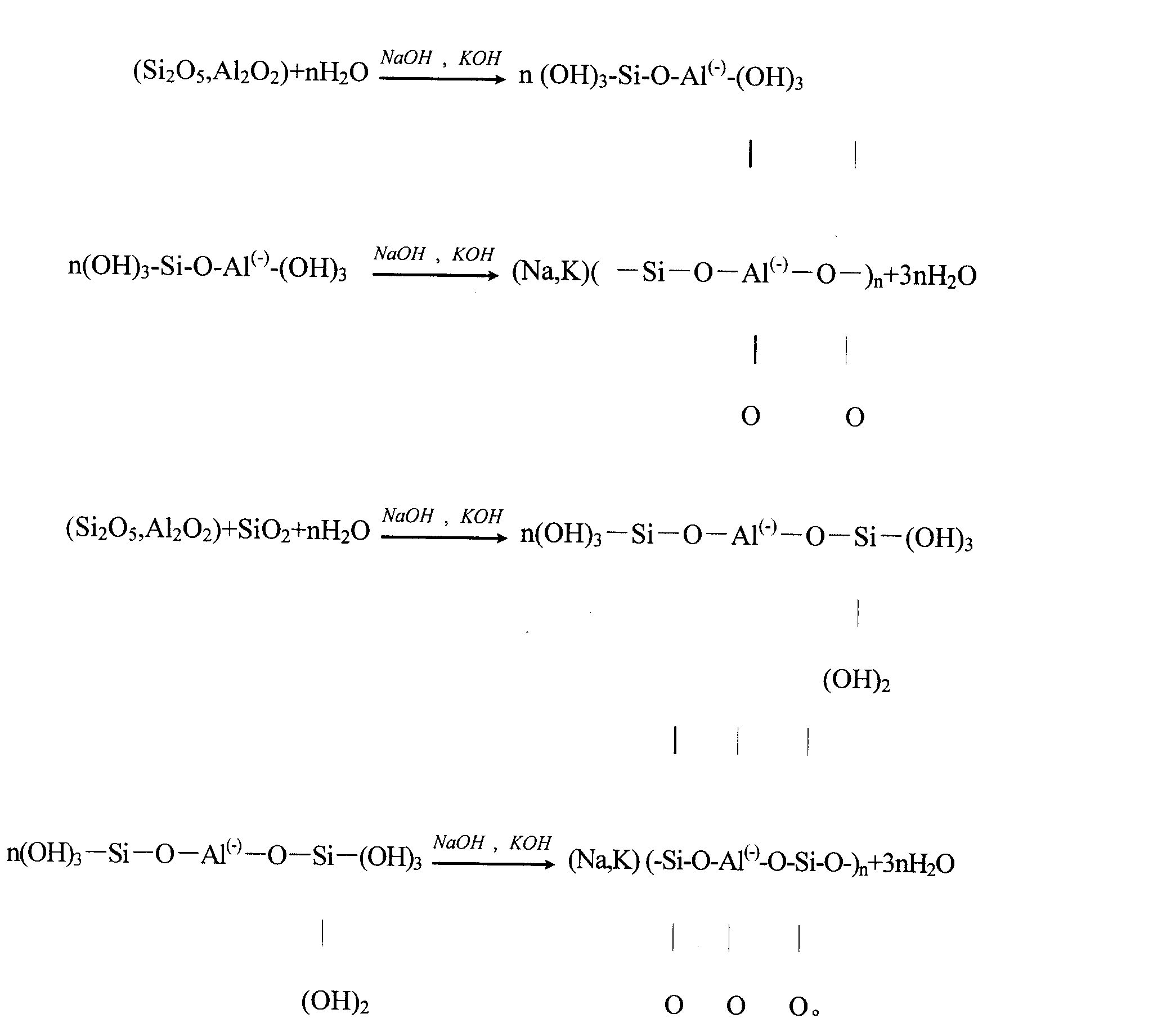

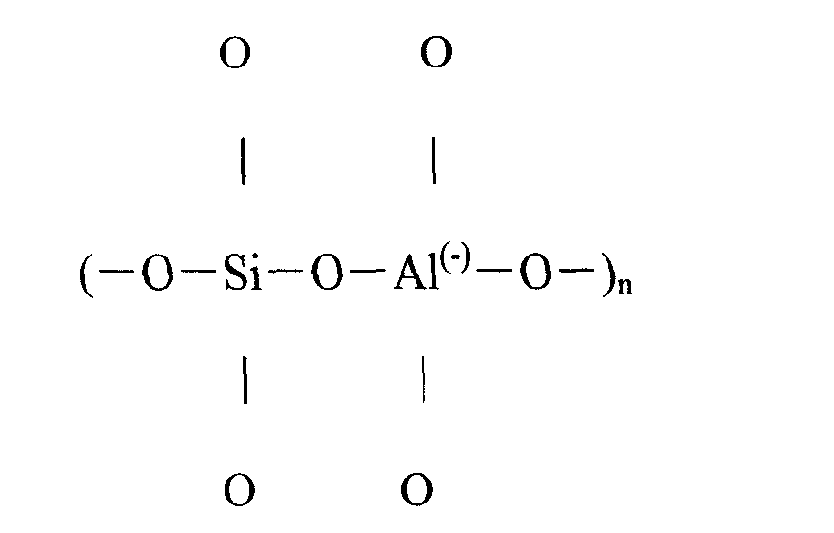

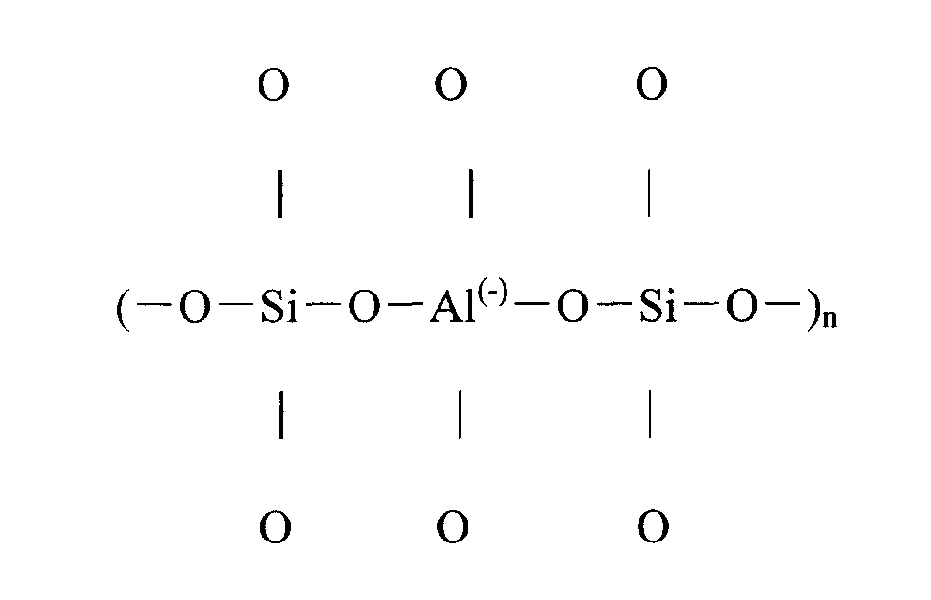

Polymeric aluminium-silica fireproof heat insulation material and preparation method thereof

The invention discloses an insulating refractory material of polymerized silicon and aluminum and the preparation method, applied in construction and industrial facilities, which is characterized in that: excitation, gas evolution and polymerization are carried out for industrial wastes abundant in aluminum oxide, silicon dioxide, and the complex of the silicon dioxide and aluminum oxide, so as to obtain a three-dimensional aluminum silicate minerals with an internal structure made of a plurality of phases from amorphous to semi-crystalline inside, and an internal form in silica tetrahedron and alumina tetrahedron; a plurality of molecules are linked mainly through ionic or covalent bonds, the mechanical properties of the inorganic concretion are externally presented. The raw materials are composed of silicon and aluminum materials as kaolin, fly ashes, coal gangue, cinder, and red mud; without adding any gelled materials, a high temperature and corrosion resistant porous long-chain structure is formed with an intensity over 0.8MPa and a thermal conductivity coefficient of 0.087 (kilocalorie / meter x hour x centigrade). The insulating refractory material is applied not only for the heat insulation wallboards in the building but also for the heat insulation and preservation of the industrial thermal pipelines and facilities.

Owner:中国安华(集团)总公司

Method for producing aluminium and aluminium alloy by low temperature electrolysis

InactiveCN1664170ALight in massNon-volatilePhotography auxillary processesProcess efficiency improvementMetallic materialsIonic liquid

The invention relates to a method of making aluminum and aluminum alloy through electrolyzing in low temperature, which belongs to the metal material field, characterized in that it uses the alumina or silicate mineral containing aluminum as raw materials, and gets anhydrous aluminum chloride after chloridization, then prepares AlCl3 ionic liquid with anhydrous aluminum chloride, and uses the AlCl3 ionic liquid as ionogen, the aluminum will be produced in the cathode while the chlorine will be discharged from the anode. When producing the aluminum alloy, preparing the alloy elements chloridate-AlCl3 ionic liquid through adding alloy elements chloridate MeCln to the AlCl3 ionic liquid, Using the direct current to electrolyzing, wherein the voltage is above the higher decomposition voltage of the aluminium chloride and chloridate and below the electrochemistry window of the ionic liquid, and the aluminum will be produced in the cathode while the chlorine will be discharged from the anode.

Owner:UNIV OF SCI & TECH BEIJING

Sintered strippable light-colored casting coating and preparation method thereof

ActiveCN103878299AExcellent sintering peelabilityLow anti-sand sticking performanceFoundry mouldsFoundry coresFoaming agentNonferrous metal

The invention discloses and provides a sintered strippable light-colored casting coating which is wide in application range, pollution-free, low in cost and good in sintering stripping performance and stability, and a preparation method thereof. The coating provided by the invention completely does not contain graphite powder; composite zirconium-containing silicate mineral powder is adopted as a main fireproof base material and a suspending agent, a bonding agent, a de-foaming agent and the like are added at the same time; the raw materials are low in price and sufficient in source; the coating is excellent in sintering stripping performance, sand bonding resistance and suspension stability, unlikely to generate deposits in long-term storage and transportation processes, low in production cost and free of environmental pollution, and can be used for producing various cast steel parts and various cast iron and non-ferrous cast parts; especially the sintering stripping performance of the coating is wide in adaptability and breaks through the limitation of narrow adaptation range of the sintering stripping performance ubiquitous in a conventional sintered strippable coating. The coating is applied in the technical field of casting coatings.

Owner:广东省铸力铸材科技有限公司 +1

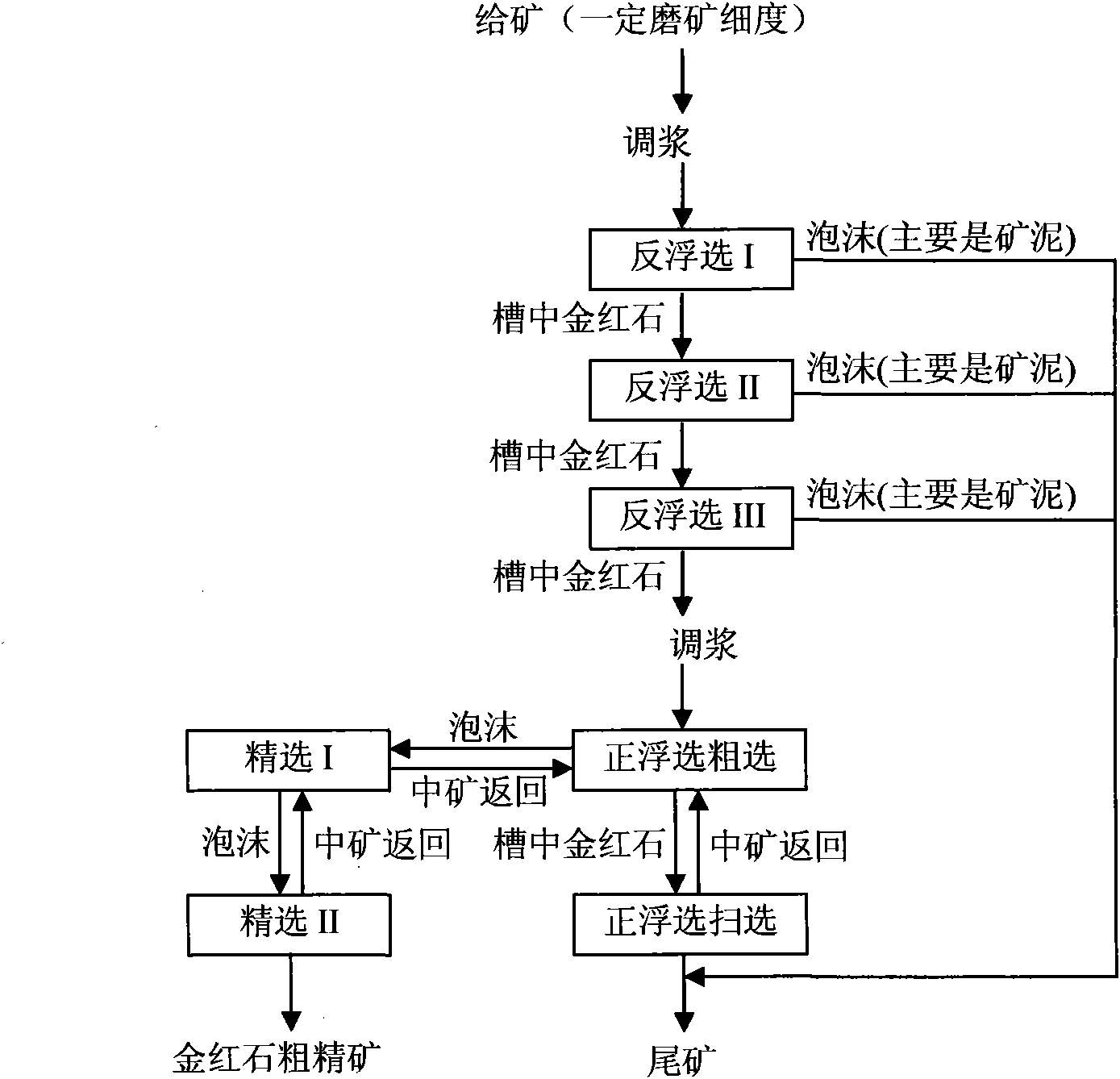

Method for roughing and tailings-discarding of fine rutile ore by multi-stage floatation

The invention provides a method for roughing and tailings-discarding of fine rutile ore by multi-stage floatation, relating to the technique for roughing and tailings-discarding of fine rutile ore by multi-stage floatation and belonging to the technical field of mineral processing engineering. The method of the invention comprises the following steps: firstly, conducting the reverse floatation of rutile by using sodium oleate as a collector according to the characteristics that aluminum sulfate can inhibit the rutile and activate silicate minerals in varying degrees, so as to effectively deslime in the process of reverse floatation; and then, conducting the forward floatation of rutile by using lead nitrate (or lead acetate) as an activator of rutile and using sodium alkyl hydroxamate and benzyl arsonic acid (or styryl phosphonic acid) as a combined collector according to the characteristic that gangue minerals can be inhibited on a combined basis under the synergistic action of sodium fluorosilicate, carboxymethylcellulose and the residual aluminum sulfate in the ore pulp, briefly, the method of the invention can realize the roughing and tailings-discarding of fine rutile by the multi-stage floatation comprising the following steps: firstly, conducting the reverse floatation by inhibiting the rutile; and then, conducting the forward floatation by activating the rutile. The method of the invention has the advantages that the enrichment ratio and recovery rate of rutile are high, the tailings of rutile ore can be discarded thoroughly and the mineral processing cost of rutile can be greatly reduced.

Owner:KUNMING UNIV OF SCI & TECH

Aromatic polycarbonate resin composition and process for producing the same

InactiveCN101023134AImprove flame retardant performancePrevent molten drippingIon contentIon chromatography

A process of manufacturing the resin compositon and a method of preventing the melt dripping during combustion of the resin composition. The flame retardancy of the above aromatic polycarbonate resin composition comprising the fluorine-containing organic metal salt compound is improved. An aromatic polycarbonate resin composition containing a fluorinated organometal salt compound. The resin composition has improved flame retardancy. The resin composition comprises (1) 100 parts by weight of an aromatic polycarbonate resin (ingredient (A)), (2) 0.005-0.6 parts by weight of a fluorinated organometal salt (ingredient (B)) having a fluoride ion content as measured by ion chromatography of 0.2-20 ppm by weight, and (3) at least one ingredient selected from the group consisting of a flame retardant (ingredient (C)), fatty acid ester (ingredient (D)), ultraviolet absorber (ingredient (E)), polytetrafluoroethylene having fibril-forming ability (ingredient (F)), filler (ingredient (G)), silicate mineral (ingredient (H)), and titanium dioxide pigment (ingredient (I)). Also provided is a method of preventing a resin composition from melting / dripping upon combustion.

Owner:TEIJIN LTD

Diatom ooze decorative wall material modified by silicate mineral powder

The invention discloses a diatom ooze decorative wall material modified by silicate mineral powder, and relates to the technical field of interior decoration materials. The diatom ooze decorative wall material is prepared from the following raw materials in percentage by weight: 30-35% of diatomite (325-800 meshes), 10-15% of clay sepiolite (200-300 meshes), 0.4-0.6% of sodium-based bentonite (200-400 meshes), 0.3-0.4% of fibrous sepiolite, 35-45% of sierozem (calcium content: 95%),10-20% of natural colored sand (5-10 meshes), 0.15-0.17% of high-strength adhesive, 0.01-0.05% of water-retention and thickening plasticizer, 0.01-0.1% of ecological pigments, 0.005-0.01% of wetting dispersant, and 0.03-0.04% of nano titanium dioxide diatomite composite photocatalytic material. The wall material disclosed by the invention has the advantages of simple production process, easily-purchased raw materials, low cost, simple construction, low cost, strong adsorption, easiness for maintenance, and capability of preventing dust retention and degrading formaldehyde, and the like.

Owner:湖南博通新型建材有限公司

Concrete material and preparation method thereof

The invention provides a concrete material, comprising the following components with corresponding proportions: cement, fine aggregate, coarse aggregate, fly ash, silica fume, carbon nanotube, nano silica, ceramsite, polyphenyl particles, steel fibers, nano kaolin particles, ultrafine natural zeolite powder, gypsum, polymer emulsion, a diol compound, modified lignosulfonate, a layered silicate mineral material, polysiloxane, oxalic acid, styrene acrylic emulsion, crystalline hydrated magnesium aluminum silicate minerals, water, a super plasticizer, a barium-containing naphthalene superplasticizer, an organic polymer plastic retaining agent, a composite retarder and an air entraining agent. The invention further relates to a preparation method of the concrete material. Compared with the existing concrete, various properties of the concrete material provided by the invention are greatly improved. The concrete material has a wide application range, a significant practical engineering value and remarkable technical and economic significance.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

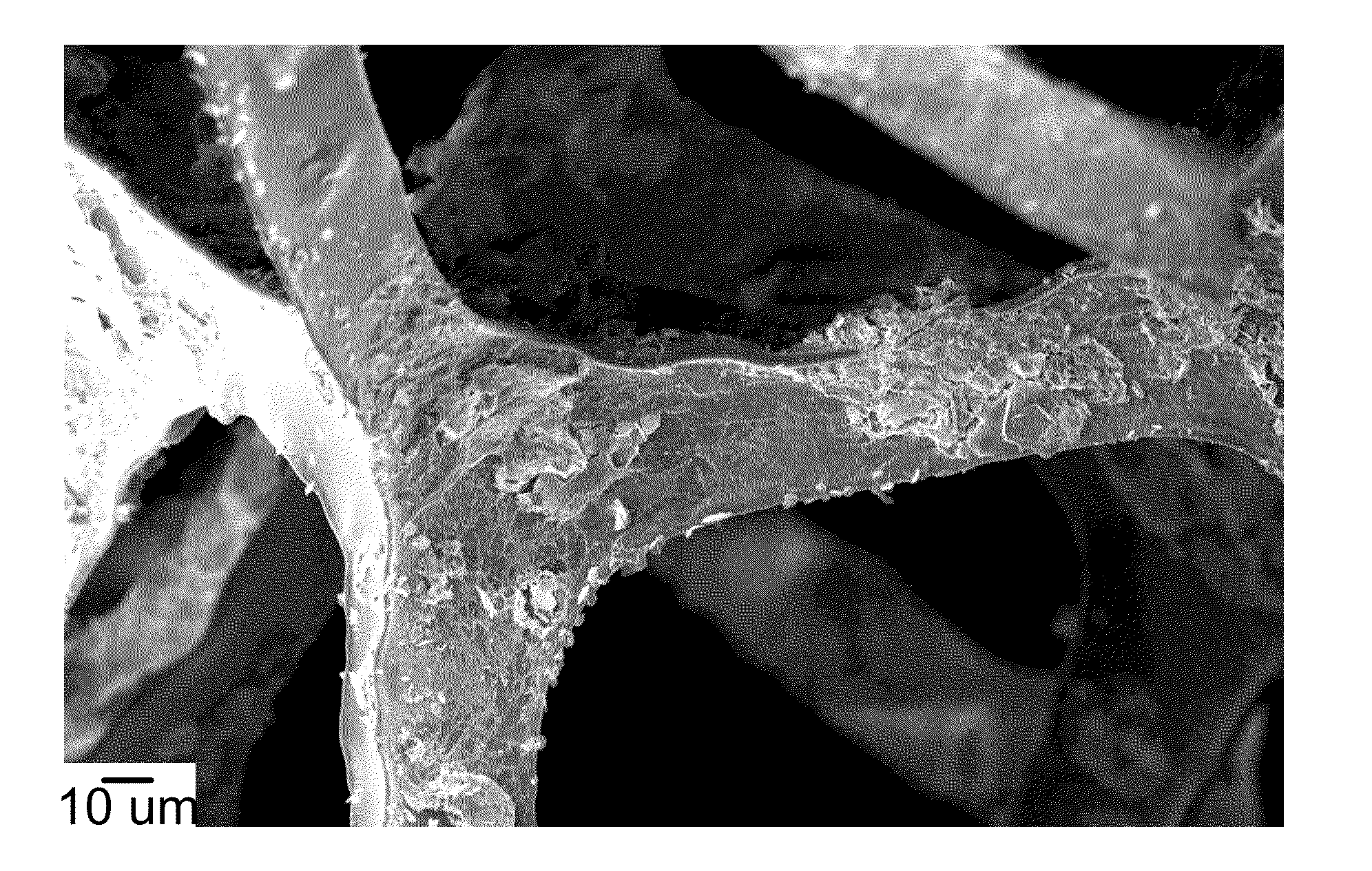

Wear repairing lubricating agent composition containing sheet silicate mineral substances and preparation method thereof

The invention relates to a wear repairing lubricating agent composition containing sheet silicate mineral substances and a preparation method thereof. The lubricating agent composition provided by the invention comprises the following components in percent by mass: 10-20 percent of sheet silicate mineral substances, 0.1-5 percent of surface modifying agent, 0.1-5 percent of metal catalytic object, 1-10 percent of performance regulating agent composition and 70-80 percent of base lubricating agent. The preparation method comprises the steps of: mixing and grinding the sheet silicate mineral substances according to the proportion, preferably, sheet silicate mineral substances with granularity D90 of not more than 3mu m; and then adding in a base lubricating agent prepared from a surfactant, the metal catalytic object and the performance regulating agent in different proportions, and grinding. The using method is as follows: 0.2-1 wt percent of the wear repairing lubricating agent composition is added in the traditional lubricating agent system of equipment. The lubricating agent composition provided by the invention has better self-repairing effect and remarkable energy-saving and consumption-reducing effect; and due to a repairing layer formed on the surface through friction, the hardness of a matrix is improved, and the roughness is lowered.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

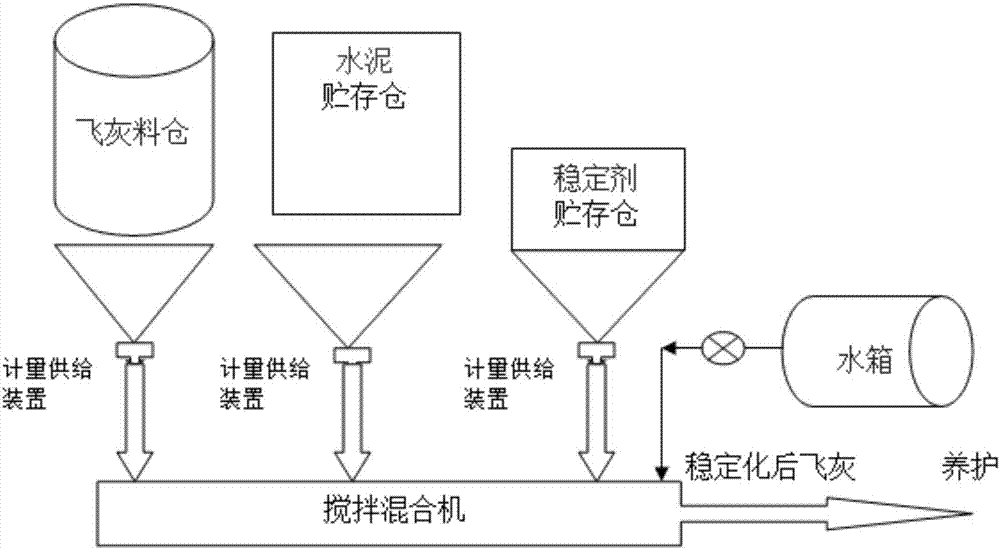

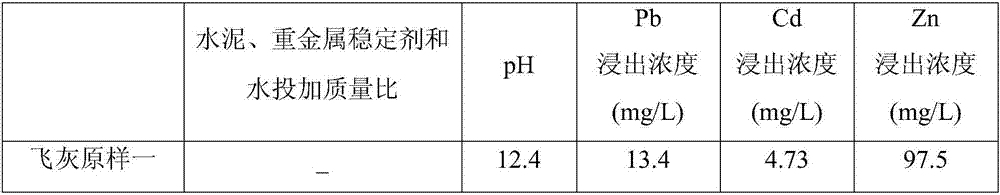

Heavy metal stabilizer for disposing waste incineration flying ash, and usage method thereof

InactiveCN107537129AReliable long-term stabilityNo secondary pollutionChemical protectionDiethyl dithiocarbamatePhosphate

The invention relates to a heavy metal stabilizer for treating waste incineration fly ash and a method for using the same. Composition of alkaline substances and silicate minerals and / or adsorbents. The use method includes: fully stirring and mixing phosphate, inorganic alkaline substances, silicate minerals and / or adsorbents in proportion, and then adding waste incineration fly ash for maintenance. The invention does not contain any organic chelating agent such as dithiocarbamate or sulfide, has no secondary pollution and pollution-free; the method of use is simple, the cost is low, and it meets the benefits of energy saving and carbon reduction, economic benefits, and has good application prospects.

Owner:李杰

Phyllosilicate mineral depressor for sulfide ore floatation and preparation method thereof

The invention provides a phyllosilicate mineral depressor for sulfide ore floatation and a preparation method thereof. The phyllosilicate mineral depressor for the sulfide ore floatation is prepared from the following components in part by weight: 0 to 20 parts of modified corn starch, 8 to 30 parts of sodium alginate, 1 to 35 parts of carboxymethyl cellulose or polyanionic cellulose or methylenenapadisilate dinaphthalene sulfonate, and 5 to 55 parts of sodium hexametaphosphate. The preparation method comprises the following steps of: selecting the reagents according to types of depressed minerals; adding the reagents in a high-speed mixing granulator in the set ratio for granulation; and drying the obtained grains to obtain the phyllosilicate mineral depressor for the sulfide ore floatation. The product has the characteristics of small dosage, good depression selectivity, low toxicity, and the like. The specific depressor is mainly applied to depressing phyllosilicate minerals such as talcs, serpentines, chlorites, kaolinites and the like during the sulfide ore floatation, thus the specific depressor is favorable for improving floatation concentrate grade and metal recovery rate, and is particularly suitable for floating talc-containing molybdenites and nickel sulfide ores.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

Retarding superplasticizer composition for roller compacted concrete

InactiveCN102659342AVC value loses quicklyVC value loss is smallRoller-compacted concreteSuperplasticizer

The invention relates to a retarding superplasticizer composition for roller compacted concrete, which is prepared from 40-80 percent of barium-containing naphthalene based superplasticizer, 10-30 percent of modified lignosulfonate, 3-7 percent of plastic retaining agent, 5-15 percent of composite retarder, 1-7 percent of layer silicate mineral material, 0.1-0.5 percent of polysiloxane and 0.1-0.2 percent of air entraining agent. The retarding superplasticizer composition does not contain alkali harmful to alkali-aggregate reaction, has a better inhibition effect to the alkali-aggregate reaction, and has the advantages of high water reducing rate, strong VC value retaining capacity, good water retaining property, small bleeding rate, remarkable retarding effect and the like, so that the prepared roller compacted concrete mixture has the characteristics of good workability, small VC value loss, small bleeding rate, long setting time, greatly reduced early hydration heat and delayed occurrence time of a hydration heat peak, so as to have better construction property, mechanical property and durability.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

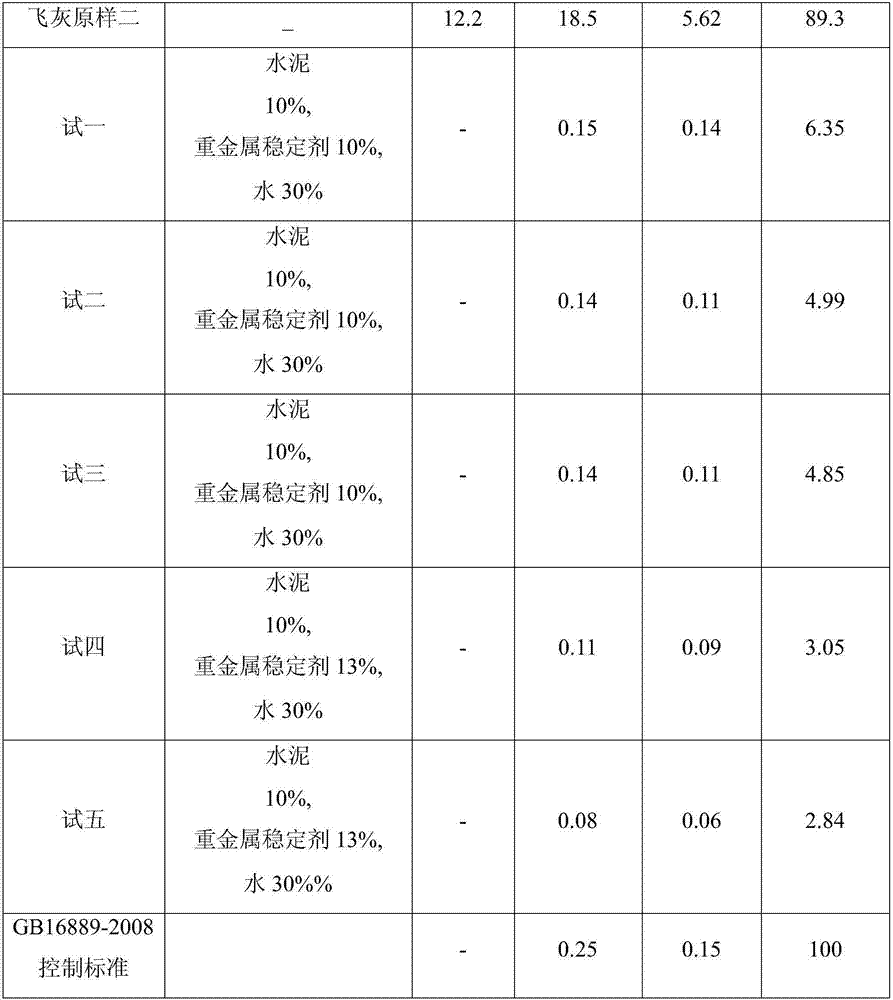

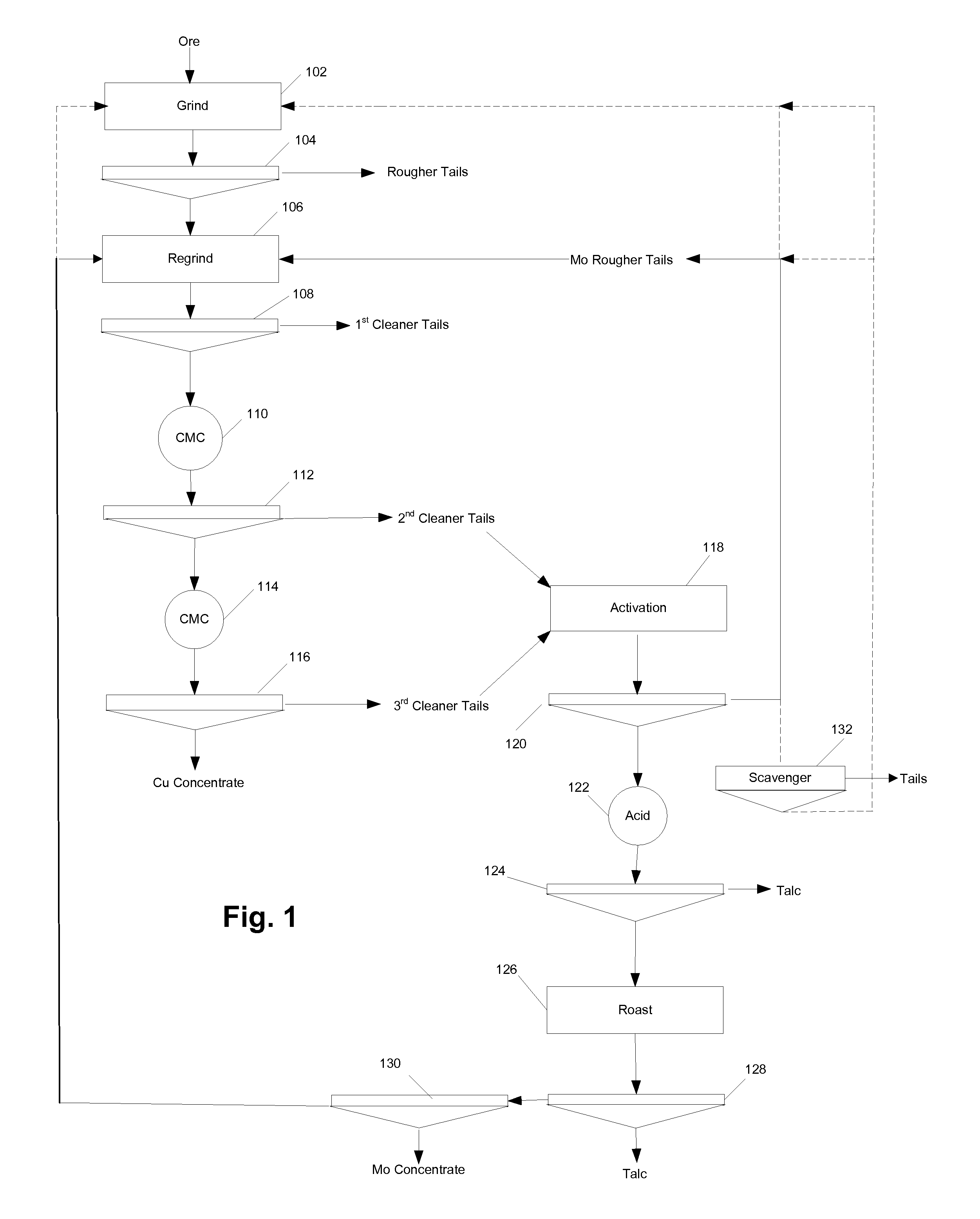

Methods for the recovery of molybdenum

A method for the recovery of molybdenum from an ore that includes a molybdenum-bearing mineral, such as molybdenite. The ore is treated to recover metal values from the ore, such as base metals, by utilizing a depressant to depress the flotation of the molybdenite. The tailings, which can include insoluble silicate minerals in addition to the molybdenite, are then activated to render the molybdenite floatable in one or more subsequent flotation steps, thereby producing a high-grade molybdenum concentrate.

Owner:KUHN MARTIN C

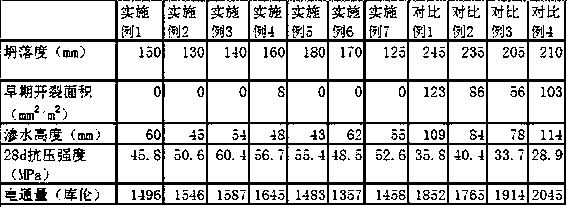

Anti-cracking high-performance concrete and preparation method thereof

The invention discloses anti-cracking high-performance concrete. The anti-cracking high-performance concrete includes, by weight, 70-120 parts of cement, 30-60 parts of layered silicate minerals, 0.5-1 part of an air-entraining agent, 3-10 parts of bentonite, 0.2-1.2 parts of a water reducing retarder, 20-60 parts of porous particle aggregate, 3-5 parts of alkali-resistant glass fiber, 0.2-0.5 part of polyoxyethylene, 10-20 parts of epoxy resin emulsion and 5-10 parts of a curing agent. The anti-cracking anti-seepage capabilities of the concrete are improved, and the mechanical properties of the concrete are improved. A preparation method of the anti-cracking high-performance concrete comprises the steps that the porous particle aggregate, the layered silicate minerals, the water reducing retarder and the bentonite are added into cement and are stirred, then the air-entraining agent is added to continue to perform stirring, and the obtained mixture is divided into a mixed material I and a mixed material II; the epoxy resin emulsion, the alkali-resistant glass fiber and the polyoxyethylene are added into the mixed material I and are stirred for 40 minutes; the curing agent is added into the mixed material II and is fully stirred for 30 minutes; the mixed material I and the mixed material II are mixed, are fully stirred for 30 minutes and then are put into a mold for forming.

Owner:BEIJING TONGYOU CONCRETE POURING TECH CO LTD

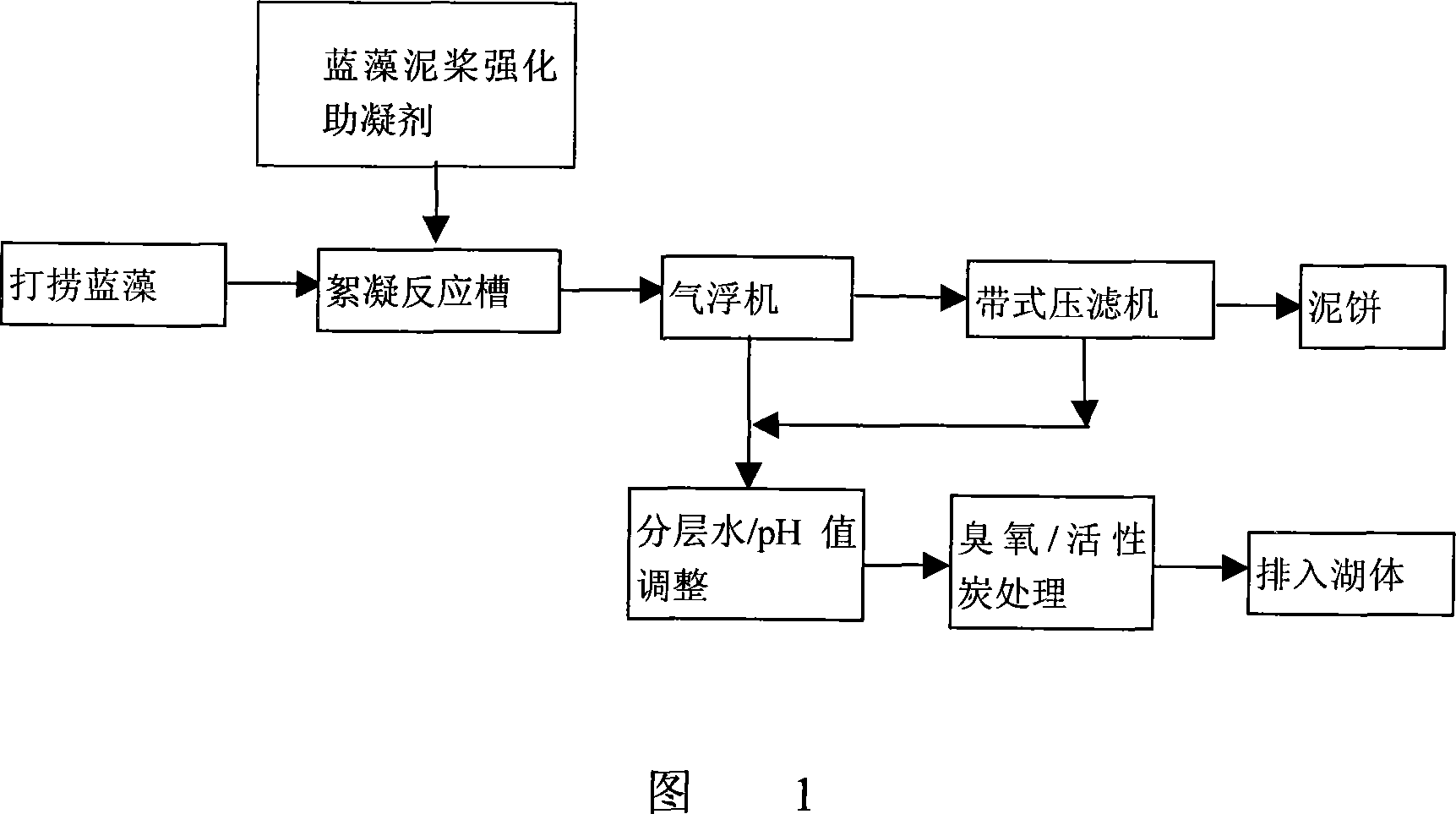

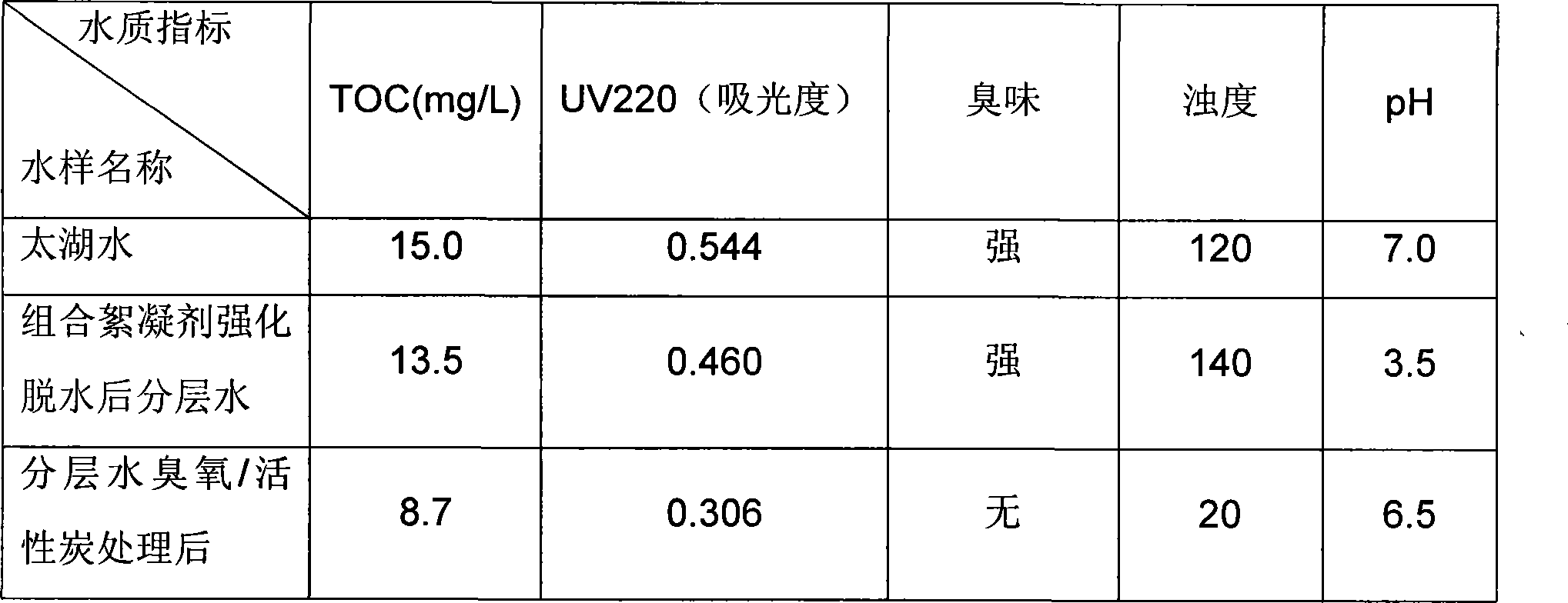

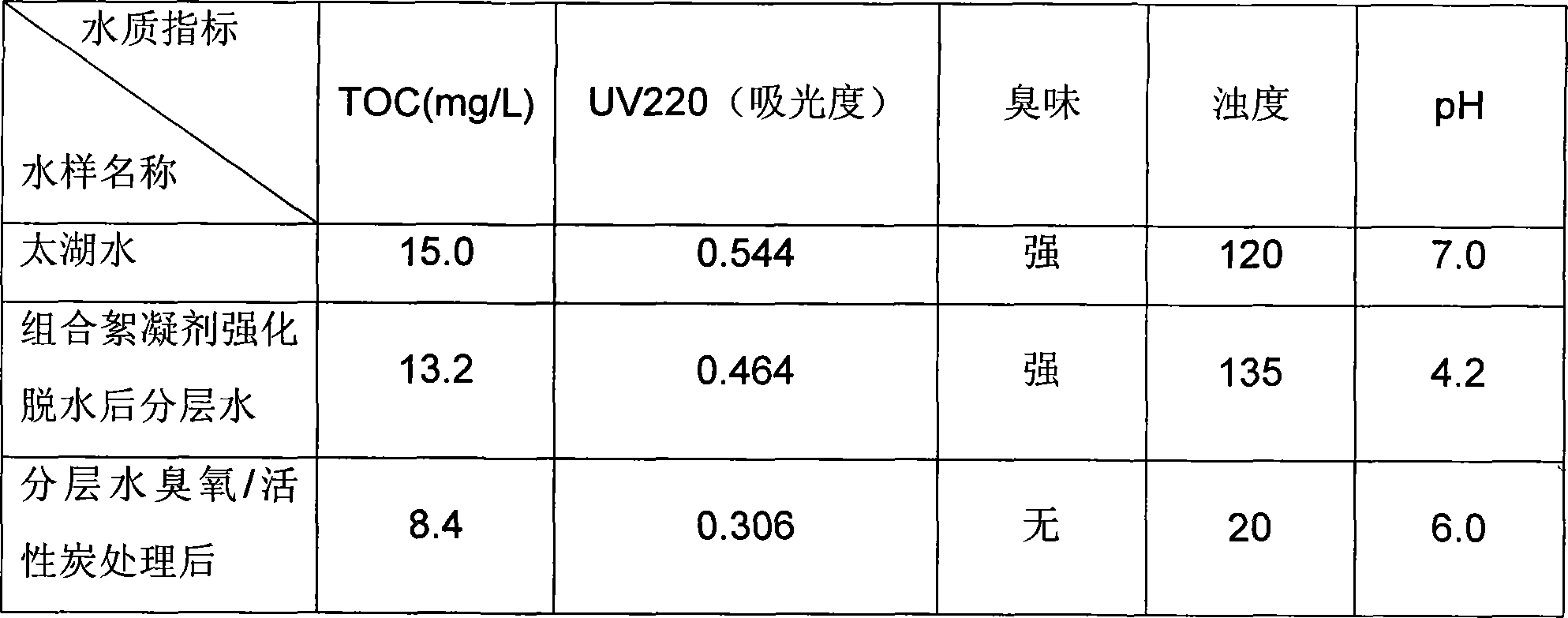

Blue algae mud reinforced coagulant aid and application thereof in blue algae mud treatment

InactiveCN101125701AImprove fishing efficiencySolve the problem of intensive dehydrationWater/sewage treatment by flocculation/precipitationPhylum CyanobacteriaSodium Bentonite

The invention discloses a cyanobacteria mud enhancing auxiliary agent and application in cyanobacteria mud processing thereof. The cyanobacteria mud enhancing auxiliary agent, which is measured by 100 weight portions, consists of the materials: aluminum iron line soluble salt: 10-50 portions; silicate mineral rock soil powder: 50-90 portions. The aluminum iron line soluble salt is mixture of aluminum chloride, aluminum sulfate, ferric sulfate, ferrous sulfate, polymeric aluminum chloride, polymeric ferric sulfate and polymeric aluminum ferric sulfate or mixture of any of aluminum chloride, aluminum sulfate, ferric sulfate, ferrous sulfate, polymeric aluminum chloride, polymeric ferric sulfate and polymeric aluminum ferric sulphate. The silicates mineral rock soil powder is the mixture of diatomite, fly ash, acid clay and bentonite or the mixture of any of diatomite, fly ash, acid clay and bentonite. Before the cyanobacteria mud enhancing auxiliary agent is used for the cyanobacteria mud processing, a reserved weight ratio of 10-30 percent of suspension liquid is prepared by the cyanobacteria mud enhancing auxiliary agent, then a weight ratio of 1-5 percent of the suspension liquid is added into the cyanobacteria mud. The invention has good dehydration effect, promptly control the serious threat caused by algae toxins and lays the solid foundation of the utilization of cyanophytes.

Owner:NANJING UNIV

Ceramic material, compositions and methods for manufacture thereof

InactiveUS20070149383A1Improve textureSurface highlightGlass/slag layered productsMetal layered productsSilicate mineralsSILICONE DIOXIDE

The present invention relates to a method of producing a ceramic material comprising the steps of: a) mixing a first clay composition comprising silica and a silicate mineral with a second clay composition; and b) firing the mixed clay composition from step a) to form a ceramic product. The present invention also relates to an engobe clay composition, sanitary ware and methods of productions thereof.

Owner:CAROMA IND LTD

Ceramic material, compositions and methods for manufacture thereof

InactiveUS20080300129A1Reduce cracking and chippingExcellent glaze appearanceClaywaresSilicate mineralsSilicon dioxide

The present invention relates to a method of producing a ceramic material comprising the steps of: a) mixing a first clay composition comprising silica and a silicate mineral with a second clay composition; and b) firing the mixed clay composition from step a) to form a ceramic product. The present invention also relates to an engobe clay composition, sanitary ware and methods of productions thereof.

Owner:CAROMA IND LTD

Method for simultaneous anti-flotation of carbonate and silicate in phosphorus ore

The invention relates to a method for simultaneous anti-flotation of carbonate and silicate in phosphorus ore. The method comprises the specific steps that phosphate ore is added into a mill to be ground; the ground phosphate ore pulp is subjected to desliming to remove fine fraction; rest coarse ore pulp enters a phosphorus inhibitor agitator, and a phosphorus inhibitor is added into the agitator for pulp mixing; after pulp mixing is conducted through the phosphorus inhibitor, the ore pulp enters a collecting agent agitator, and a collecting agent is added into the agitator for pulp mixing; and after pulp mixing is conducted through the collecting agent, the ore pulp enters a flotation machine for phosphorus ore anti-flotation, floating foam is carbonate minerals and silicate minerals, and underflow in a tank is phosphorus concentrate. By the adoption of the method, the carbonate and the silicate in the phosphorus ore can be floated out simultaneously, the flotation process and the flotation reagent system are simplified, and the reagent use amount and the cost of phosphorus ore anti-flotation are reduced.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com