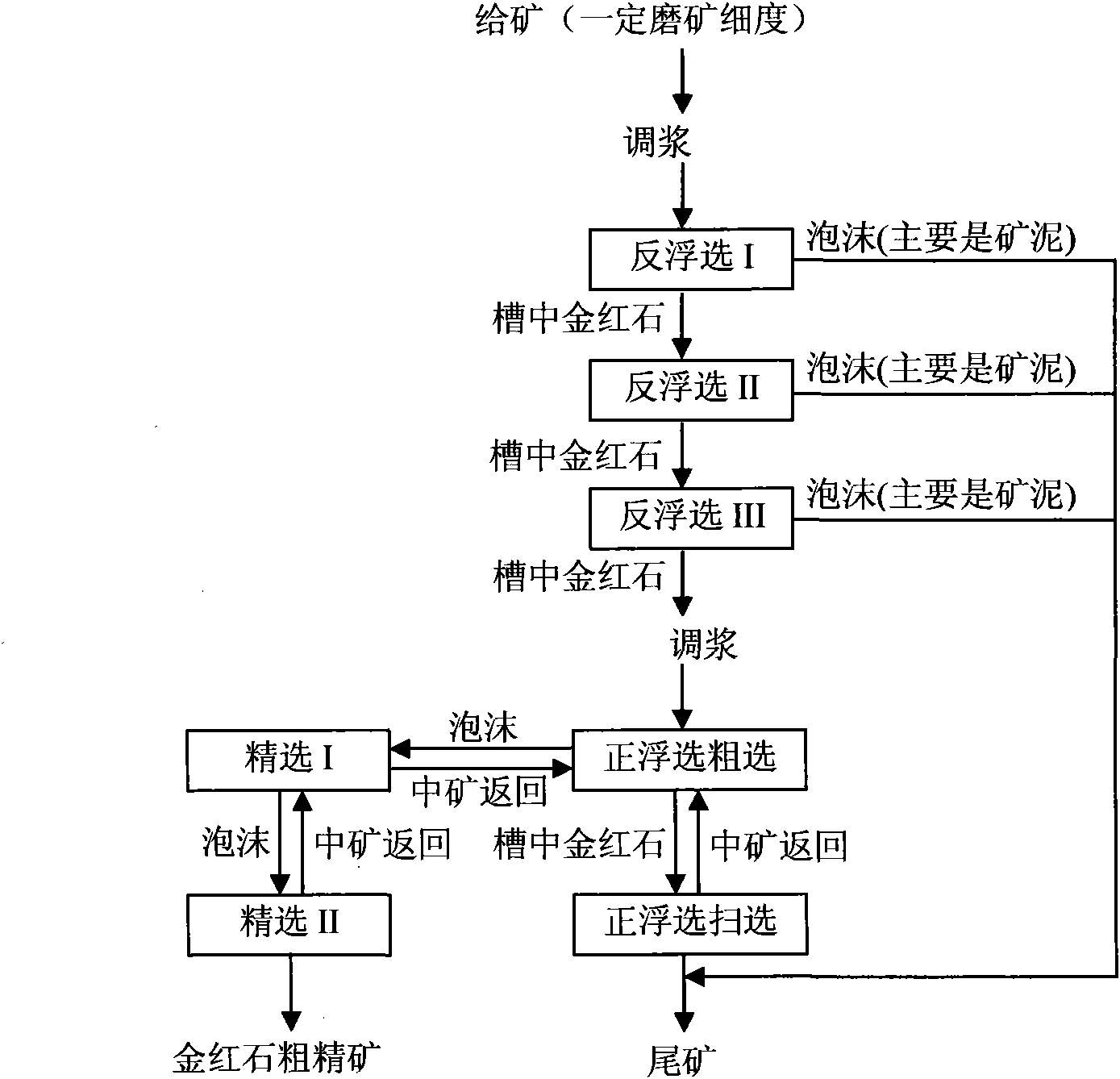

Method for roughing and tailings-discarding of fine rutile ore by multi-stage floatation

A rutile ore, step-by-step flotation technology, applied in flotation, solid separation and other directions, can solve the problems of complex gravity separation desliming process and large rutile loss, and achieve good desliming effect, small rutile loss, and chemical consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Rutile TiO in Shangnan Rutile Deposit, Shaanxi Province 2 1.96%, the gangue minerals are mainly vermiculite, hydromica, hornblende, etc., and also contain a small amount of iron-containing minerals magnetite, hematite and clay minerals. The particle size of rutile intercalation is fine, generally ranging from 0.01 to 0.1mm, which belongs to fine-grained and micro-fine particle uneven intercalation. Most rutile is arranged in intermittent stripes and streaks in the form of monomers and aggregates along the slab direction of the ore. Some are mixed with vermiculite and hydromica to form agglomerates, and some are wrapped by hornblende and biotite. Crushing, screening, grinding and grading the raw ore to achieve a suitable concentration of pulp with a fineness of 200 mesh accounting for 81.42%, adding sodium carbonate to adjust the pH value to 8, adding 800g / t of aluminum sulfate, adding 50g / t of sodium oleate, adding Pine oil 20g / t, carry out reverse flotation I; after r...

Embodiment 2

[0028] Ankang Rutile Mine in Shaanxi Province Contains Rutile TiO 2 4.71%, the gangue minerals are mainly chlorite, calcite, quartz, feldspar, and also contain a small amount of pyrite, pyrrhotite, limonite, etc. The particle size is about 0.0001-0.10mm, mostly 0.005-0.05mm, and the rutile is mainly embedded in chlorite and calcite in the form of inclusions, which is a refractory rutile ore. Crushing, screening, grinding and grading the raw ore to achieve a suitable concentration of ore pulp with a fineness of 200 meshes accounting for 98%, adding sodium carbonate to adjust the pH value to 8, adding 800g / t of aluminum sulfate, adding 50g / t of sodium oleate, adding Pine oil 20g / t, carry out reverse flotation I; after reverse flotation I, add sodium oleate 30g / t, add pine oil 10g / t, carry out reverse flotation II; after reverse flotation II, add pine oil 5g / t, carry out reverse flotation III, the foam yield of three reverse flotations is 34.21%, which contains 0.46% rutile, an...

Embodiment 3

[0030] Rutile TiO in Fangcheng Rutile Mine, Henan Province 2 2.09%, rutile intercalation particle size is fine, generally ranging from 0.01 to 0.2mm, which belongs to fine grain, micro-fine grain uneven intercalation, and is refractory rutile ore. Crushing, screening, grinding and grading the raw ore to achieve a suitable concentration of pulp with a fineness of 200 meshes accounting for 82.06%, adding sodium carbonate to adjust the pH value to 8, adding 800g / t of aluminum sulfate, adding 50g / t of sodium oleate, adding Pine oil 20g / t, carry out reverse flotation I; after reverse flotation I, add sodium oleate 30g / t, add pine oil 10g / t, carry out reverse flotation II; after reverse flotation II, add pine oil 5g / t, carry out reverse flotation III, the foam yield of three reverse flotations is 31.14%, which contains 0.39% rutile, and the removal rate of 10 μm in the ore reaches 76%. After reverse flotation III, add sodium carbonate to adjust the pH value to 8.5, add sodium fluo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com