Patents

Literature

36 results about "Hornblende" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hornblende is a complex inosilicate series of minerals (ferrohornblende – magnesiohornblende). It is not a recognized mineral in its own right, but the name is used as a general or field term, to refer to a dark amphibole.

Environment-friendly type ceramic-based friction material

InactiveCN104164211AImproved resistance to heat fadingImprove thermal conductivityOther chemical processesFriction liningBorideFiber

The invention discloses an environment-friendly type ceramic-based friction material, and is characterized in that the ceramic-based friction material includes the following materials in parts by weight: 16-31 parts of cashew nut shell oil modified phenolic resin, 3-18 parts of carbon fiber, 12-30 parts of organosilicon modified phenolic resin, 25-60 parts of graphite, 3-9 parts of molybdenum disulfide, 11-14 parts of a talc powder, 3-9 parts of mica, 5-18 parts of zircon, 35-60 parts of ceramic fiber, 20-60 parts of butadiene-acrylonitrile rubber, 10-20 parts of a scallop shell powder, 3.5-7 parts of a zeolite powder, 1.5-3.9 parts of zinc sulfide, 1-5 parts of hornblende, 5-11 parts of borax, 3-6 parts of titanium oxide, 0-2 parts of quartz sand, 4-8 parts of a boride, 6-18 parts of silicon nitride, and 1-5 parts of titanium carbide. The ceramic-based friction material has the beneficial effects that the ceramic-based friction material has excellent heat-conducting property, ensures the stability of the friction material, improves heat fading resistance of the friction material, provides good and stable braking force output, and has longer service life and comfort.

Owner:QINGDAO QIANXIANG ENVIRONMENTAL PROTECTION TECH

Ceramic pug and method for preparing ceramic product from same

InactiveCN106747308AFine granularityImprove plasticityCeramic materials productionClaywaresPorosityCrack resistance

The invention discloses a ceramic pug and a method for preparing a ceramic product from the same. The raw materials of the ceramic pug include kaolin, granite waste, argil, bluestone, montmorillonite, hornblende, potassium feldspar, quartz, nano silicon dioxide, aluminum oxide, mica powder, haycite powder, magnesium oxide, potassium oxide, magnesium oxide, calcium oxide, iron oxide, aluminum hydroxide, sodium metaaluminate, tetrahydroxy sodium aluminate and a polycarboxylate superplasticizer. The pug disclosed by the invention has fine particle size and good plasticity; the prepared purple product has the advantages of delicate touch, high porosity, good heat insulation effect, strong crack resistance and good water absorption rate; in a process of preparing a ceramic product from a body, the volume shrinkage of the body is minimum, the fired product does not deform easily, the firing shrinkage ratio is controlled to 14-15%, the product firing temperature range can be widened, and the yield of the product firing is higher; and moreover, the color of the ceramic product is relatively uniform, and the phenomenon of relatively obvious color contrast does not occur basically.

Owner:顾广才

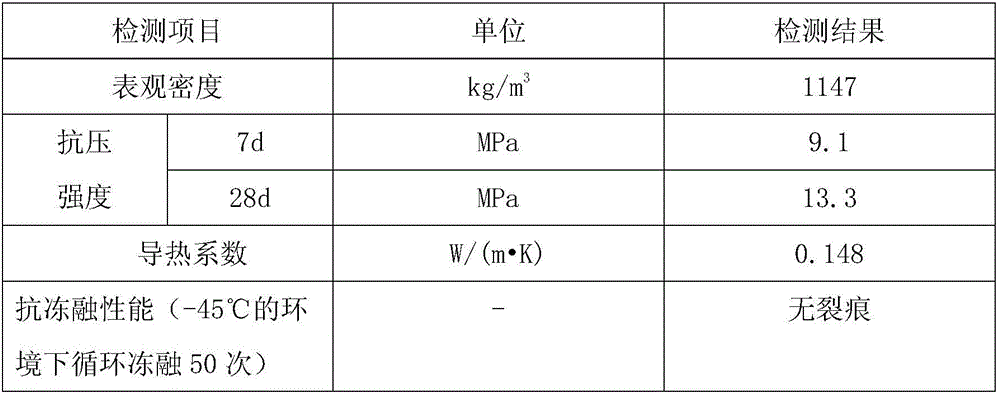

Freeze-thaw resistant cement hollow brick and preparation method thereof

InactiveCN105967585AImprove freeze-thaw resistanceHigh mechanical strengthSolid waste managementSodium acetateBrick

The invention discloses a freeze-thaw resistant cement hollow brick and a preparation method thereof. The brick of the invention is prepared from the following raw materials (by weight): 42-54 parts of ordinary Portland cement, 22-28 parts of construction waste residue, 16-22 parts of mountain sand, 8-14 parts of sulfur fixation ash, 5-10 parts of hornblende, 10-15 parts of silica powder, 3-6 parts of barium carbonate, 8-12 parts of halloysite slag, 4-8 parts of copper ore tailings, 7-11 parts of coal gangue, 9-14 parts of electrolytic manganese residue, 5-10 parts of boric sludge, 6-12 parts of loess, 2-4 parts of calcium nitrite, 3-5 parts of urea, 2-3 parts of sodium acetate, 1-2 parts of 1,3-propylene glycol, 4-8 parts of calcium hydrophosphate, 6-9 parts of hydroxypropyl methyl cellulose and a proper amount of water. By compounding of raw materials including calcium nitrite, urea, sodium acetate, 1,3-propylene glycol and the like, freeze-thaw resistance of the cement hollow brick is enhanced, and the brick will not crack after 50 times of frozen-thaw cycles in an environment of minus 45 DEG C.

Owner:ANHUI XINRUN NEW MATERIALS

Soldering flux for cast iron welding and use method of same

InactiveCN102962607AAvoid it happening againQuality improvementWelding/cutting media/materialsSoldering mediaFerrosiliconCalcite

The invention provides a soldering flux for cast iron welding and a use method of same. The soldering flux is prepared mainly by mixing powder and a liquid additive, wherein the powder is obtained mainly by mixing the following components with 100-200-mesh particle size: yttrocalcite powder, calcite powder, celestite powder, hornblende asbestos plaster, ferromolybdenum powder and ferrosilicon powder; the liquid additive is obtained by mixing an emulsifier and a wetting agent; and the mass percentages of all the components in the soldering flux are as follows: 25-30 percent of yttrocalcite powder, 20-30 percent of calcite powder, 10-12 percent of celestite powder, 10-20 percent of ferrosilicon powder, 3-5 percent of ferromolybdenum powder, 2-5 percent of ferrosilicon powder, 3-5 percent of emulsifier and 4-6 percent of wetting agent. The soldering flux and the use method thereof are simple, quick and convenient; heating is not needed before welding, and heat preservation is not needed after welding; the obtained weld metal has a beautiful appearance, and has no hot crack, cold crack, gas pores or fracture structures; and the welding technology is simple, the quality is stable and reliable, the cost is low, machining can be performed after welding, and pressure tests can achieve the index requirements.

Owner:杨文宝

Ceramic-based friction material with high heat-conducting property

InactiveCN104140784AImproved resistance to heat fadingImprove thermal conductivityOther chemical processesFriction liningTetramethylammonium hydroxideCarbon fibers

The invention discloses a ceramic-based friction material with a high heat-conducting property. The ceramic-based friction material with the high heat-conducting property is characterized by comprising, by weight part, 35-50 parts of cashew nut shell oil modified phenolic resin, 15-30 parts of kieselguhr, 1-8 parts of carbon fibers, 11-30 parts of boride, 1-5 parts of boride tetramethylammonium hydroxide, 0.5-5.5 parts of quartz sand, 15-20 parts of magnesium carbonate, 1-5 parts of barium carbonate, 3-11 parts of zirconium silicate, 6-18 parts of silicon nitride, 3-8 parts of diboron trioxide, 15-20 parts of talc, 10-31 parts of sorbitan monooleate, 0.5-3.2 parts of hydrophobic-modification nanoscale silicon oxide, 2-9 parts of hornblende, 1.8-13.5 parts of cadmium sulfate, 1.5-3.9 parts of zinc sulfate, 5-11 parts of borax, 3-6 parts of titanium oxide and 1-5 parts of titanium carbide. The ceramic-based friction material with the high heat-conducting property has the advantages of being excellent in heat-conducting property, guaranteeing stability of friction materials, improving heat fading resistance of the friction materials, providing good and stable brake force output, and being long in service life and comfortable.

Owner:QINGDAO XIANGHAI ELECTRONICS

Ceramic pug

InactiveCN104086157AAvoid deformationExtended temperature rangeClaywaresAluminium hydroxideExpanded clay aggregate

The invention discloses ceramic pug. The ceramic pug is prepared from the following raw material components in parts by weight: 30-40 parts of kaolinite powder, 1-2 parts of nanosilicon dioxide, 2-3 parts of aluminium oxide, 2-5 parts of montmorillonite powder, 10-20 parts of mica powder, 15-20 parts of vermiculite powder, 5-10 parts of ceramsite powder, 3-5 parts of turf, 5-10 parts of zeolite powder, 10-15 parts of pyroxene powder, 10-15 parts of hornblende powder, 2-5 parts of magnesium oxide, 2-3 parts of ferric oxide, 3-5 parts of aluminium hydroxide, 5-8 parts of limestone, 2-3 parts of sodium metaaluminate, 3-5 parts of Na[Al(OH)4] and 5-8 parts of polycarboxylate water reducing agent. The ceramic pug has the advantages that the defects of easy deformation and unstable shrinkage ratio in a firing process are overcome, the shrinkage ratio is controlled under the synergistic effect of all the components in a formula, so that a product has small possibility of deformation in the firing process; meanwhile, firing shrinkage ratio is controlled to be 14-15%, the range of firing temperature of the product can be expanded, so that yield of fired products is high, and the requirement of large-scale industrial production is met.

Owner:梁胜光

Ceramic product material composition

The invention discloses a ceramic product material composition. According to the raw material formula, the composition comprises 100-150 parts of kaolin, 30-50 parts of sepiolite powder, 30-50 parts of illite powder, 30-50 parts of pyrophylite powder, 30-50 parts of epidote powder, 30-50 parts of hornblende powder, 1-5 parts of nano-silica, 1-5 parts of nano-copper dioxide, 1-5 parts of nano-titanium dioxide, 1-5 parts of nano-zirconium dioxide, 1-5 parts of nano-manganese oxide and 1-5 parts of nano-stannic oxide. The ceramic product material composition has excellent physical and chemical properties of freezing resistance, a low water absorption rate, high hardness, corrosion resistance, excellent thermal change resistance, thermal shock resistance and the strength requirement for impact force resistance.

Owner:谢伟杰

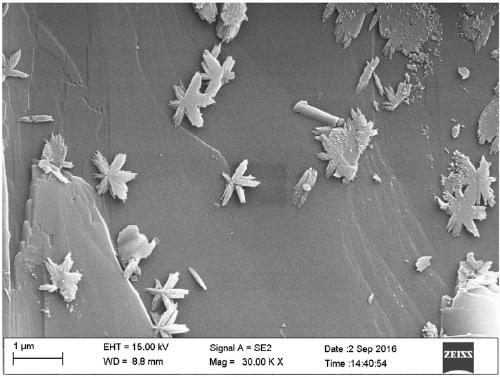

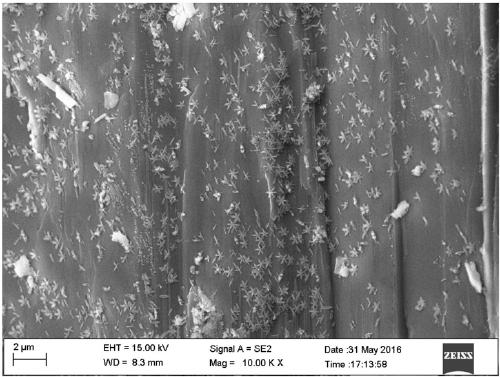

Nanometer negative ion function material for paint and preparing method thereof

InactiveCN106009874AImprove adsorption capacityFeatures ultra-thin, breathable performanceCoatingsPyrophylliteGraphene

The invention discloses a nano anion functional material for coatings and a preparation method thereof, which is made of the following raw materials in parts by weight: sepiolite 24-32, germanite 36-44, seabed placer 28-39, kaolin 19-44 27. Clastic rock 22‑30, pyrophyllite 15‑25, hornblende 10‑20, graphene 5‑10, silver-loaded zirconium phosphate 8‑16. The nano negative ion functional material prepared by the present invention not only has the functions of releasing negative ions such as germanium stone, seabed placer, silver-loaded zirconium phosphate, antibacterial and sterilization, but also has excellent adsorption performance of sepiolite, clastic rock, pyrophyllite, etc., and has graphite The ultra-thin and air-permeable properties of alkene, when added to coatings, integrate functions that are beneficial to human health such as air purification, odor removal, antibacterial, anti-mildew, radiation of far-infrared rays, and release of negative ions, which greatly improves the practical value of functional coatings.

Owner:沈平

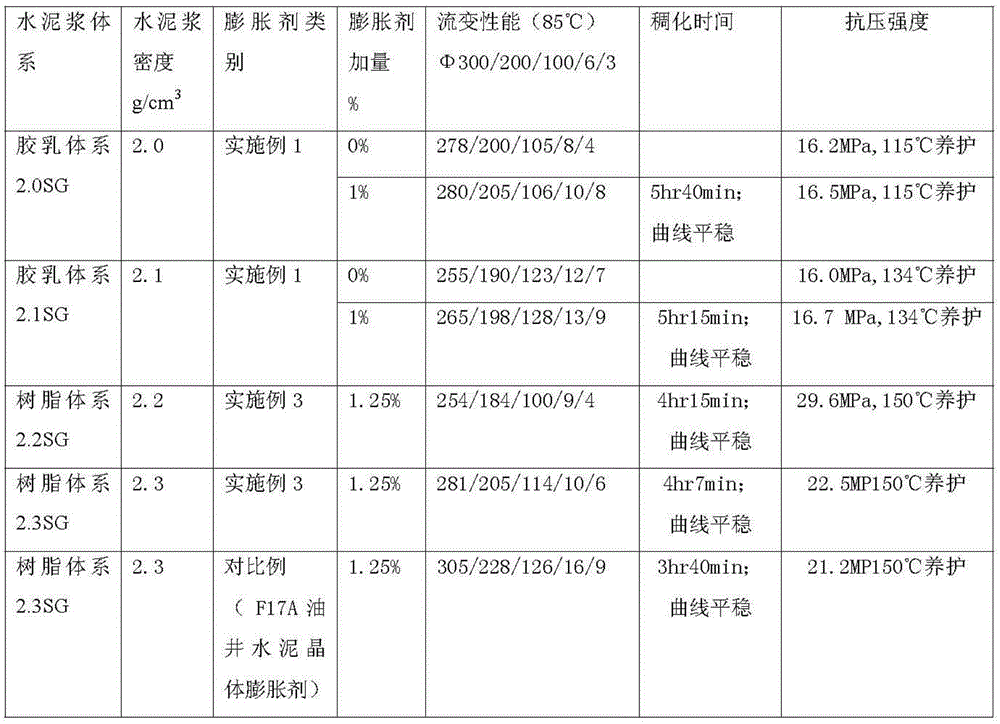

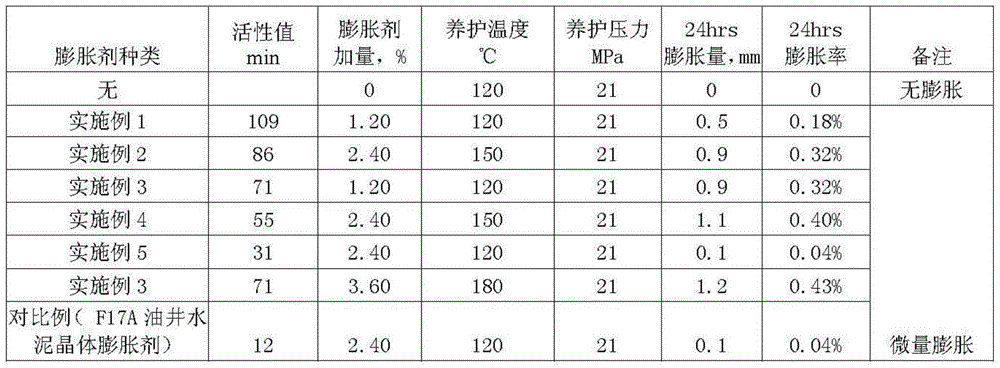

Cement expansion agent suitable for high temperature environment and preparation method thereof

InactiveCN105084800AModerate onset timeAppropriate hardening expansionCalcium in biologyFumed silica

The invention discloses a cement expansion agent suitable for a high temperature environment and a preparation method thereof. The cement expansion agent comprises the following components by mass percent: 85.0%-99.5% of a magnesium material, 0.5%-10.0% of a silicon material, 0-0.50% of an expansion inhibitor and 0-5.0% of a calcium material, wherein the magnesium material is prepared from any one or multiple combinations selected from magnesite, serpentine and hornblende through high-temperature calcination and sintering; the content of magnesium oxide in the magnesium material is greater than or equal to 85 wt%; the silicon material is one or multiple combinations selected from quartz sand and fumed silica; the content of silicon dioxide in the silicon material is greater than or equal to 92 wt%; the expansion inhibitor is one or multiple combinations selected from sodium citrate, tartaric acid and ethylenediamine tetraacetic acid disodium salt; the calcium material comprises calcium oxide and semi-hydrated gypsum; the content of calcium oxide is 0-45 wt%; the content of semi-hydrated gypsum is 55-100 wt%. When the cement expansion agent is used in a high-temperature oil well cement paste environment, the effect onset time of expansion of oil well cement is moderate, so that microgaps caused by shrinkage after cement paste solidification can be effectively filled up.

Owner:NANJING YUNYUE NEW MATERIAL TECH CO LTD

Hydroxyapatite whisker reinforced glass ceramic dish and preparation method thereof

The invention discloses a hydroxyapatite whisker reinforced glass ceramic dish and a preparation method thereof. The hydroxyapatite whisker reinforced glass ceramic dish is prepared from the following raw materials in parts by weight: 20-30 parts of broken glass, 5-10 parts of hydroxyapatite whisker, 12-18 parts of basalt, 10-15 parts of hornblende, 4-7 parts of violaceous halite, 2-4 parts of coal powder, 8-14 parts of analcite, 5-10 parts of goldstone, 10-15 parts of limestone, 2-3 parts of manganese sulfate, 4-6 parts of barium metaphosphate and 6-8 parts of auxiliary agent. In the invention, the hydroxyapatite whisker is composited with glass ceramic matrixes, so that a very good strength and toughness enhancing effect is achieved, and the mechanical property of the glass ceramic dish is greatly improved. The breaking strength of the prepared glass ceramic dish is greater than or equal to 400 MPa, and the fracture toughness is greater than or equal to 4.5 MPa.m1 / 2. Fracture during use of the glass ceramic dish is significantly reduced, and the service life of the glass ceramic dish is prolonged.

Owner:ANHUI YIMIN IND & TRADE GRP CO LTD

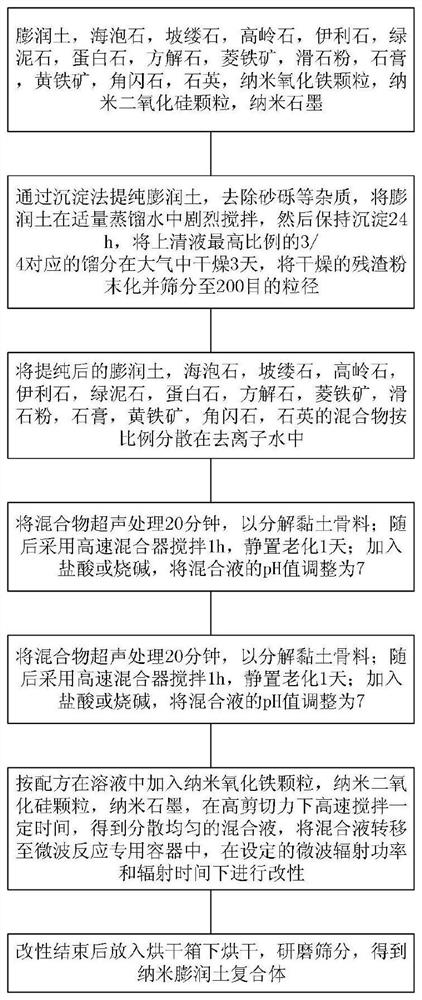

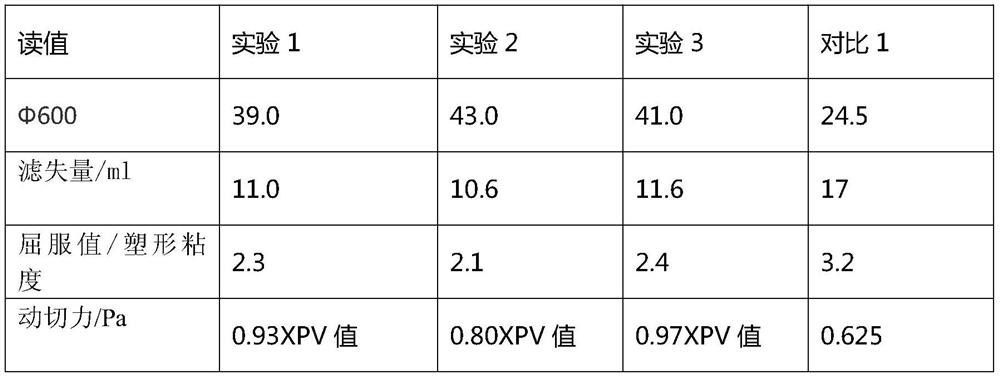

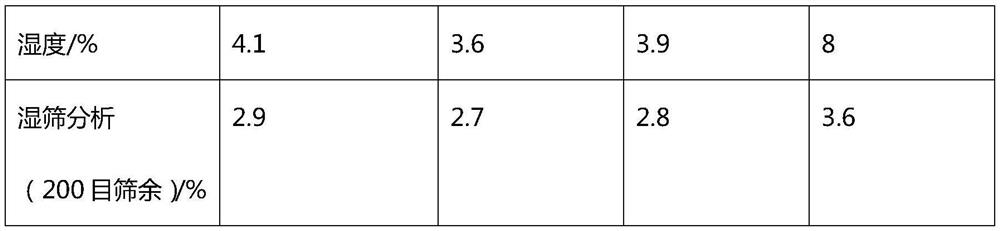

Modified bentonite for seawater drilling and preparation method thereof, and drilling fluid

PendingCN112011320AFast pulpingReduce sand contentDrilling compositionSilicon compoundsPalygorskiteSlurry

The invention provides modified bentonite for seawater drilling and a preparation method thereof, and a drilling fluid. The modified bentonite for seawater drilling comprises the following components:bentonite, sepiolite, palygorskite, kaolinite, illite, chlorite, opal, calcite, siderite, talcum powder, gypsum, pyrite, hornblende, quartz, nanometer iron oxide particles, nanometer silicon dioxideparticles and nanometer graphite. The bentonite prepared from the components is high in slurrying speed, low in sand content, good in slurry making rate, high in sand carrying capacity, low in filterloss and high in stability.

Owner:WUHU FEISHANG NONMETAL MATERIAL

Laterite porcelain bowl and preparation method thereof

InactiveCN104926277AHigh temperature resistantLow thermal conductivityPlatesClaywaresBrickHeat stability

The invention discloses a laterite porcelain bowl and a preparation method thereof. The laterite porcelain bowl is prepared from the following raw materials in parts by weight: 18-26 parts of zirconite, 20-30 parts of laterite, 14-22 parts of sea mud, 24-38 parts of illite, 15-25 parts of hornblende, 5-10 parts of egg shell, 8-14 parts of red brick powder, 4-6 parts of zinc molybdate, 5-10 parts of silicon whiskers, 8-14 parts of a tannin extract, 6-9 parts of propylene glycol alginate, 3-6 parts of calcium lignosulphonate, 2-4 parts of potassium pyrophosphate and 4-8 parts of antimicrobial powder. According to the laterite porcelain bowl and the preparation method thereof, laterite and sea mud are compounded to serve as a clayey raw material, so that the prepared porcelain bowl has the advantages of high temperature resistance, low heat conductivity coefficient and high mechanical strength and the like, the added firebrick powder can improve the heat stability and aging resistance of the porcelain bowl, the added crystalline silicon has a better reinforcing and toughening effect on the proclaim bowl, and not only can improve the strength and harness of the porcelain bowl, but also improve the chemical stability and wear resistance of the porcelain bowl.

Owner:安徽省含山瓷业股份有限公司

High-refractoriness and low-expansion molding sand for steel castings and preparation method of molding sand

InactiveCN105983645AHigh refractorinessQuality improvementFoundry mouldsFoundry coresThermal expansionPericlase

The invention discloses high-refractoriness and low-expansion molding sand for steel castings and a preparation method of the molding sand. The molding sand is prepared from raw materials in parts by weight as follows: 36-48 parts of kaolin, 17-33 parts of desulfurized petroleum coke waste, 14-26 parts of lithium chinastone, 10-20 parts of sericite, 12-24 parts of aluminum ash, 41-53 parts of carborundum, 9-18 parts of hornblende, 5-10 parts of volcanic, 4-7 parts of ultrafine cobalt powder, 3-6 parts of cerium oxide hollow nanospheres, 10-15 parts of periclase, 6-12 parts of sodium carboxymethyl inulin, 5-8 parts of sodium tungstate and 490-530 parts of a modifier. The added raw materials such as the desulfurized petroleum coke waste, the aluminum ash, the ultrafine cobalt powder, the cerium oxide hollow nanospheres, periclase, sodium tungstate and the like can significantly improve the refractoriness of the molding sand and reduce the thermal expansion coefficient of the molding sand, so that the molding sand is not expanded and broken easily at the high temperature, the quality of the castings is improved, and the rejection rate of the castings is reduced.

Owner:安徽创奇乐智能游乐设备有限公司

Low-gas-evolution-amount high-fire-resistance clay molding sand used for casting and preparation method thereof

InactiveCN105562581AImprove liquidityImprove breathabilityFoundry mouldsMould handling/dressing devicesPhosphoric acidHeat stability

The invention discloses low-gas-evolution-amount high-fire-resistance clay molding sand used for casting and a preparation method thereof. The low-gas-evolution-amount high-fire-resistance clay molding sand is made from, by weight, 26-38 parts of bauxite, 14-18 parts of hornblende, 10-15 parts of coal cinder, 10-15 parts of high-silicon iron tailings, 20-30 parts of fused magnesia, 15-20 parts of papermaking white clay, 18-24 parts of dickite, 12-16 parts of marlstone, 5-10 parts of chalk powder, 6-12 parts of condensed aluminum phosphate, 8-14 parts of light burning powder, 4-9 parts of sodium polystyrene sulfonate and 280-340 parts of improver. Compared with existing molding sand, the molding sand made from the bauxite, the fused magnesia, the papermaking white clay, the coal cinder, the marlstone and other raw materials has the advantages of being low in gas evolution amount, good in gas permeability and heat stability and the like, and the defects that a casting produces air holes, cold shut, and the like can be overcome, so that the quality of the casting is improved.

Owner:安徽创奇乐智能游乐设备有限公司

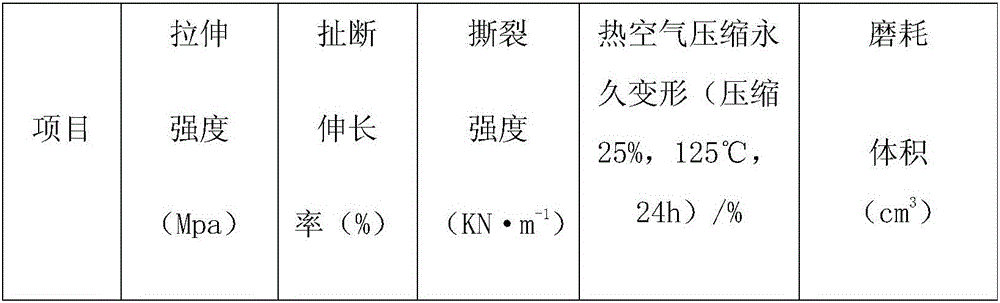

Calcium titanate fiber reinforced fluororubber sealing gasket and production method thereof

InactiveCN106084801AHigh mechanical strengthHigh strengthBuilding insulationsFiberTriethylenetetramine

The invention discloses a calcium titanate fiber reinforced fluororubber sealing gasket and a production method thereof. The sealing gasket is produced from, by weight, 44-66 parts of fluoro-phosphazene rubber, 26-42 parts of styrene butadiene rubber, 5-8 parts of magnesite, 7-13 parts of coal tar pitch, 3-4 parts of triethylenetetramine, 20-30 parts of hornblende powder, 3-5 parts of 2,2-di(tert-butylperoxy)butane, 10-15 parts of datolite powder, 2-4 parts of lead stearate, 8-14 parts of tall oil modified phenolic resin, 2-3 parts of N,N'-di-n-butylthiourea, 5-10 parts of octyl epoxystearate, 15-20 parts of calcium titanate fibers, 1-2 parts of ethoxyquinoline, 3-5 parts of 2,5-di-t-butylhydroquinone, 2-3 parts of nickel dibutyl dithiocarbamate and 13-15 parts of a modifier. The sealing gasket produced in the invention has the advantages of excellent comprehensive performances, long service life and wide application range.

Owner:HUAINAN CAOAN RUNLONG PLASTIC CO LTD

Environmentally-friendly landscape electric pole and preparation method thereof

The invention provides an environmentally-friendly landscape electric pole and a preparation method thereof. Per cubic meter of concrete comprises the following raw materials by weight: 700-800 kg ofmud, 200-300 kg of silica fume, 700-803 kg of coarse sand, 300-420 kg of medium sand, 150-230 kg of fine sand, 90-120 kg of gravel, 68-83 kg of steel fibers, 55-86 kg of basalt fibers, 60-80.5 kg of awater reducing agent, 100-320 kg of water, 30-68 kg of shell powder, 28-52 kg of hornblende, 33-50 kg of glass powder and 18-43 kg of ebony powder. The environmentally-friendly landscape electric pole provided by the invention has the advantages of strong pressure resistance and good durability, and achieves consistency and harmony in power supply, landscape and road travel safety, and the environmentally-friendly landscape electric pole can achieve environmental friendliness and landscape harmony on the premise that power supply is guaranteed, and is better applied to scenic area line design.

Owner:HAINAN POWER GRID CO LTD ELECTRIC POWER RES INST

Novel ceramic composite material

The invention discloses a novel ceramic composite material. The novel ceramic composite material comprises, by weight, 20 parts to 78 parts of sodium silicate binder, clam shell power, 20 parts to 56 parts of pyrophyllite, 3 parts to 25 parts of medical stone, 11 parts to 54 parts of carclazyte, 3 parts to 18 parts of perlite, 1 part to 12 parts of zinc sulfide, 3 parts to 4 parts of hornblende, 11 parts to 25 parts of montmorillonite, 3 parts to 8 parts of calcium sulfate, 21 parts to 42 parts of ferrovanadium powder, 10 parts to 24 parts of sodium citrate, 3.5 parts to 11 parts of titanium oxide, 10 parts to 36 parts of silochrom, and 25 parts to 70 parts of fused alumina zirconia ceramic balls. The novel ceramic composite material avoids the problem that single low alloy steel is incomplete in function; as for the same volume, the cost of the fused alumina zirconia ceramic balls is close to the cost of the low alloy steel, and thus the service life of the novel ceramic composite material can be substantially prolonged without increasing the product cost.

Owner:QINGDAO QIANXIANG ENVIRONMENTAL PROTECTION TECH

High-temperature environment-friendly colored glaze

The invention mainly relates to the technical field of ceramic glaze processing, and discloses a high-temperature environment-friendly colored glaze. The high-temperature environment-friendly colored glaze is prepared from the following raw materials: silicon dioxide, magnesium oxide, iron nitride, niobium pentoxide, vanadium boride, silicon nitride, aluminum nitride, zirconium oxide, cerium dioxide, hornblende, hard clay, table salt and pigments. A glaze surface becomes flat and smooth through short-time high-temperature burning and expansion coefficient matching, energy is saved, and no lead is dissolved out; the high-temperature environment-friendly colored glaze is safe, nontoxic and environment-friendly, and the production cost is lower by about 12.6 percent; the raw materials are mixed after being subjected to one-time ball milling, and are then subjected to repeated melting, quenching and ball milling, so that the colored glaze is fine and smooth in texture; the table salt is added after primary quenching, so that the high-temperature environment-friendly colored glaze is convenient to be added with water and mixed uniformly in use, and has the advantages of fineness, high fluidity, uniform glazing and smooth texture; the pigments are added after second melting, and high-temperature calcination is performed, so that the stability of the colored glaze and the pigments are enhanced, and the colored glaze is gorgeous, uniform in brightness and colorfast.

Owner:界首市伟盛古窑彩陶制作发展有限公司

High-temperature-resistant ceramic material for manufacturing pot body

The invention relates to a high-temperature-resistant ceramic material for manufacturing a pot body. A manufacturing method of the high-temperature-resistant ceramic material comprises the following steps: S1, weighing raw materials in parts by mass: 11-18 parts of purple clay, 5-9 parts of black soil, 15-17 parts of sericite, 4-7 parts of hornblendes, 3-9 parts of vermiculite, 2-4 parts of pyroxene, 8-11 parts of granite, 5-10 parts of calcined talcum and 4-7 parts of quartz, mixing the raw materials, introducing the raw materials to a ball mill for grinding, and sieving with a 250-mesh sieve for later use; S2, dehydrating products obtained in the step S1; S3, drying, preserving the heat for 30 minutes and calcining the products dehydrated in the step S2 at the sintering temperature of 1320-1380 DEG C, thereby obtaining the high-temperature-resistant ceramic material for manufacturing the pot body. A special raw material formula is adopted, so that the high-temperature-resistant ceramic material for manufacturing the pot body has the properties, such as high strength, wear resistance and high temperature resistance, and is suitable for manufacturing various pot bodies.

Owner:南通恒龙齿条有限公司

Glass microspheres for micro-prismatic reflective film, and preparation method thereof

The invention discloses glass microspheres for a micro-prismatic reflective film, and a preparation method thereof. The glass microspheres are prepared from the raw materials of, by weight, 32-46 parts of river sand, 23-37 parts of kaolin, 16-28 parts of wavellite, 30-40 parts of datolite, 15-25 parts of calcium hydroxide, 20-30 parts of silica, 10-15 parts of titania, 12-23 parts of hornblende, 4-6 parts of dodecyl dihydroxyethyl betaine, 5-8 parts of sodium tall oil pitch sulfonate, 3-5 parts of dodecyl dimethylbenzyl ammonium chloride, 4.5-6.5 parts of fatty alcohol polyether amide, and 5-10 parts of an additive. The glass microspheres provided by the invention have high brightness, good mechanical performances, excellent weatherability, excellent corrosion resistance, excellent heat resistance and excellent durability. The glass microspheres are durable, and can be widely applied in micro-prismatic reflective films. The glass microspheres have a good market prospect.

Owner:ANHUI TIANTANG WEIGAO PLASTIC TECH

PET reflective membrane glass bead and preparation method thereof

InactiveCN104965250AGood optical performanceImprove mechanical propertiesGlass shaping apparatusOptical elementsSlagCyclohexene oxide

The invention discloses a PET reflective membrane glass bead and a preparation method thereof. The glass bead is prepared by the following raw materials by weight: 56-72 of silicon powder, 38-56 of serpentine, 32-48 of hornblende, 16-28 of crystal broken stone, 27-41 of datolite, 42-64 of quartz sand, 15-25 of fluorine contained slag powder, 10-15 of diethylene glycol distearate, 8-14 of cyclohexene oxide, 5-7 of polypropylene glycol dipivalate, 4-6 of lauramidopropylamine oxide, and 12-16 of additives. Serpentine, hornblende, crystal broken stone, datolite, and fluorine contained slag powder are the main raw materials of the prepared glass bead, the effects of the raw materials are fully played, the performance of the produced glass bead is high, and the glass bead has excellent optical performance, mechanical properties, and heatproofing and aging properties, and is resistant to corrosion.

Owner:HEFEI DINGLIANG OPTICAL TECH

Formula of cast stone slab

The invention discloses a formula of a cast stone slab, and relates to the field of building materials. According to the formula of the cast stone slab, granite, calcite and gneiss are used as the main materials, sandstone, obsidian, hornblende, dolomite, lapis lazuli, iron gallbladder stone, chrismatite and chromite are used as matching raw materials, the strength of cast stone is sufficiently improved, the increase of the bearing capacity of the cast stone slab is ensured, and the service life of the cast stone slab is prolonged.

Owner:SHAANXI SCI TECH UNIV

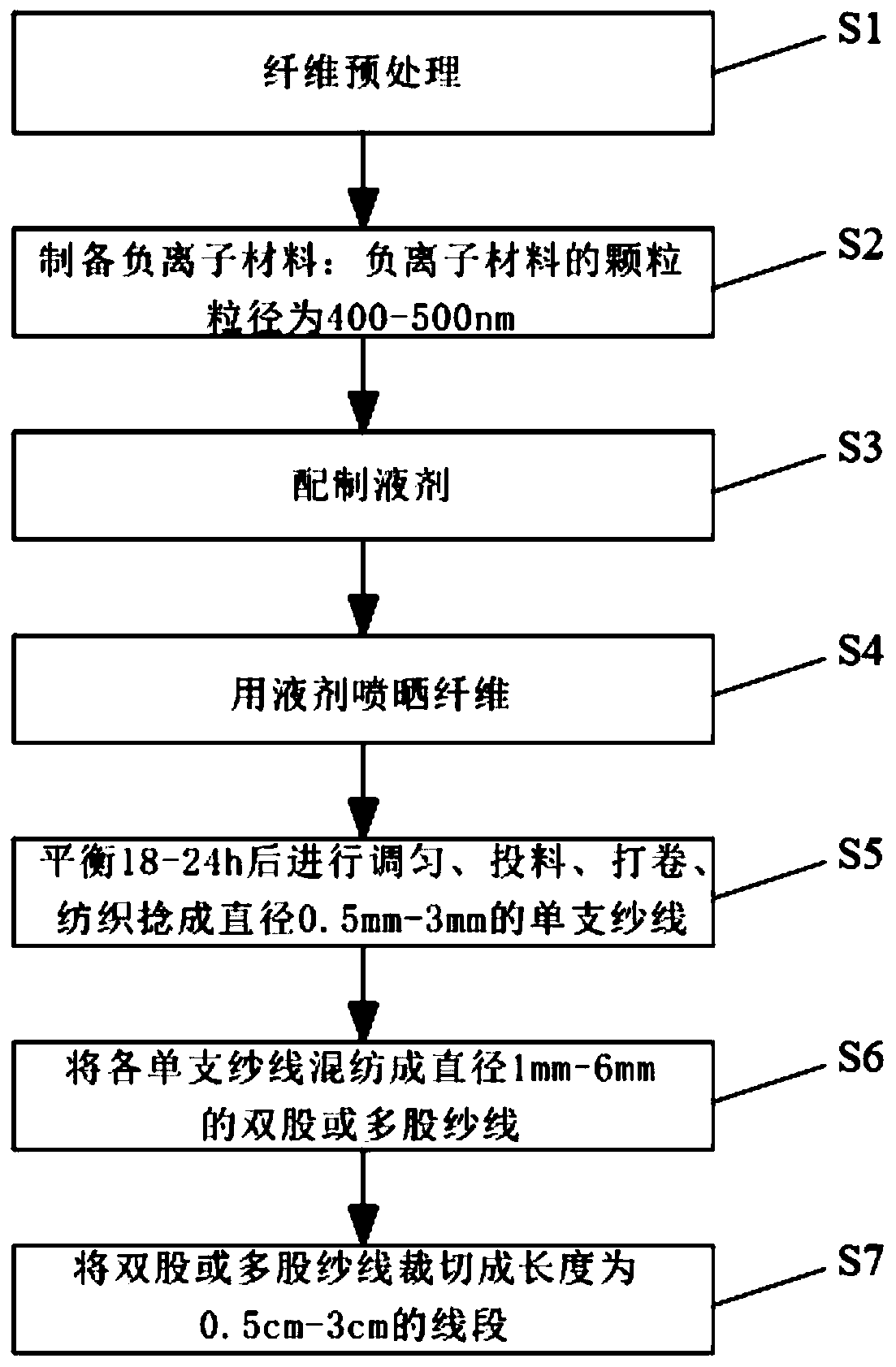

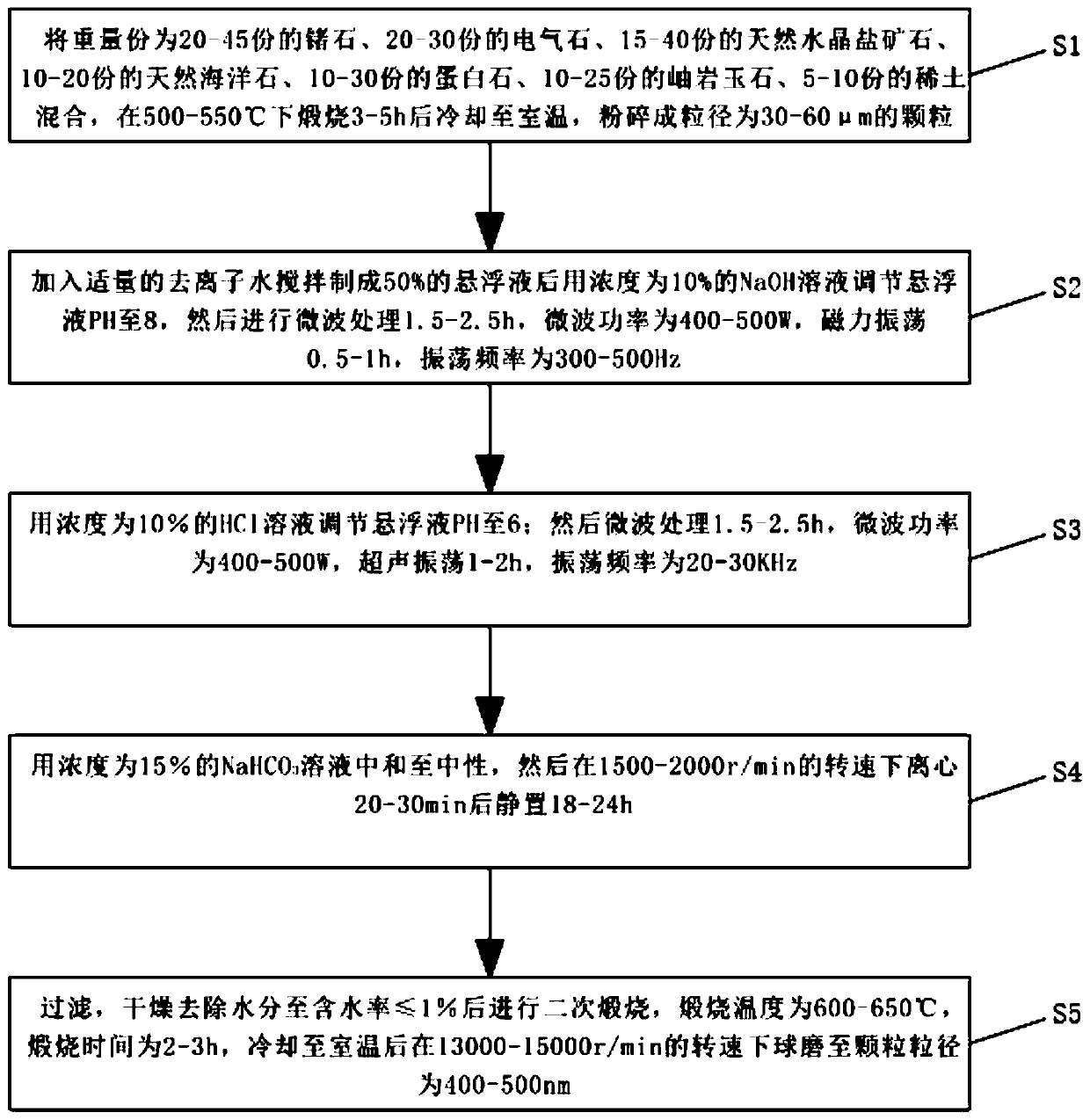

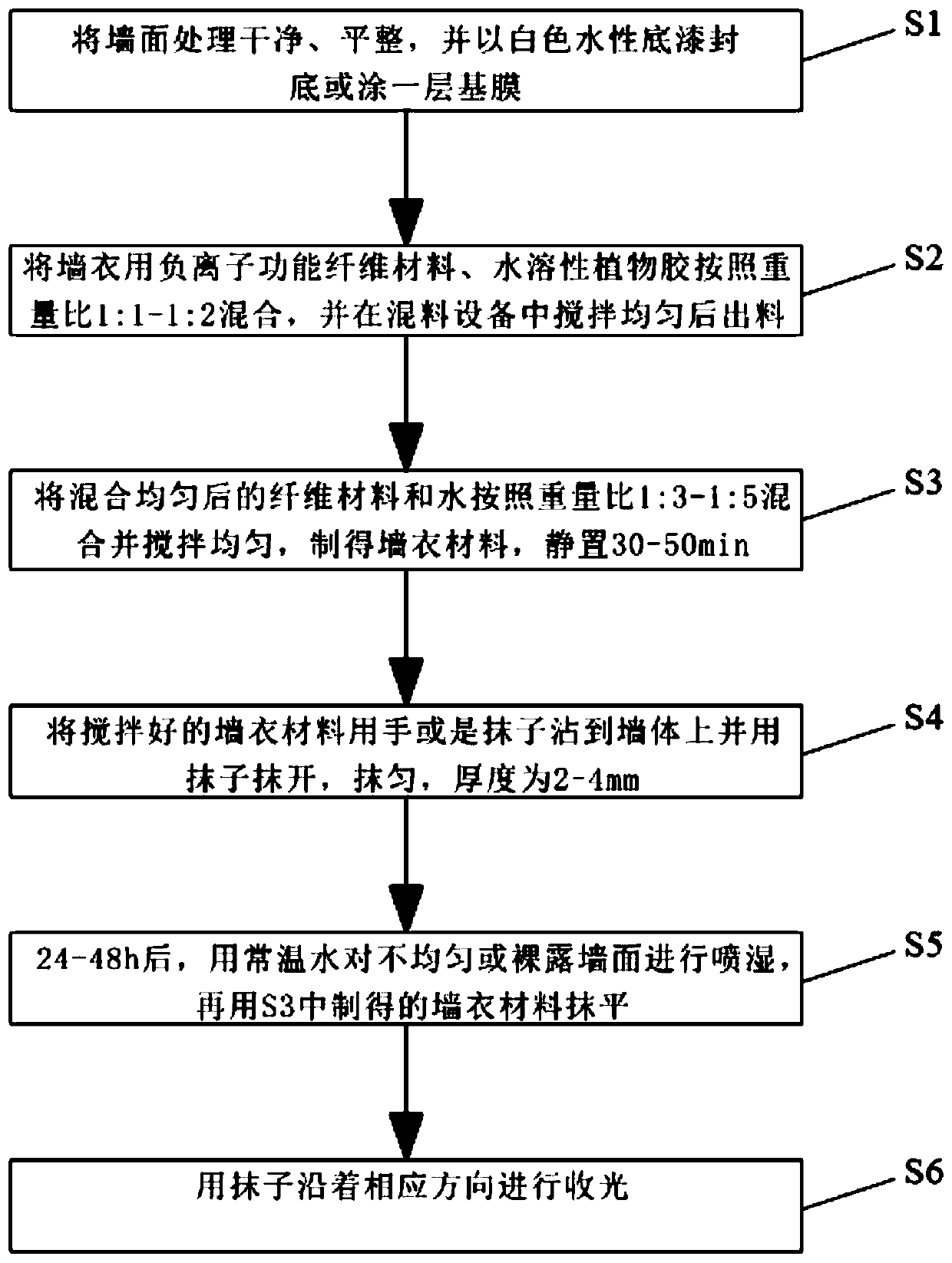

Liquid agent for spraying anion functional fiber material for wall coating and preparation method of liquid agent

The invention discloses a liquid agent for spraying an anion functional fiber material for a wall coat and a preparation method of the liquid agent. The liquid agent is used for spraying a base material before the base material is woven into a fiber material, wherein the base material is a fiber; and the liquid agent contains the following components in parts by weight: 200-300 parts of an anion material, 20-50 parts of a softener, 20-50 parts of a finishing agent, 5-10 parts of a mildew preventive and 590-755 parts of deionized water; and the anion material is prepared from the following components in parts by weight through mixing and processing: 20-45 parts of germanite, 20-30 parts of tourmaline, 15-40 parts of seabed placer deposits, 10-20 parts of hornblende, 10-30 parts of opal, 10-25 parts of pyrophyllite and 5-10 parts of rare earth. The liquid agent has the functions of releasing air anions and far infrared ray, is capable of eliminating toxic and harmful gas and dust suspending in air and inhibiting bacterial mold and purifying air and further has the anti-mold property of the mildew preventive, so that the practical value of the fiber material for the wall coat is greatly increased.

Owner:福建省绿城环保科技有限公司

Method for preparing saponite crystals under hydrothermal conditions

The invention belongs to the technical field of preparation of clay mineral crystals, and particularly relates to a method for preparing saponite crystals under hydrothermal conditions. The technicalscheme of the invention is as follows: a method for preparing saponite crystals under hydrothermal conditions comprises the following steps: (1) preparation of a solution; (2) pulverization and impurity removal for a raw material; (3) pretreatment; (4) constant-temperature nucleation; (5) cooling crystallization; and (6) washing and drying. The method for preparing saponite crystals under hydrothermal conditions has the beneficial effects that a large amount of pure nano-scale saponite crystals are obtained by using widely existing hornblende as the raw material, thereby reducing the production cost of saponite. Reduction in the use of chemical reagents in conventional soapstone preparation avoids the occurrence of a potential problem of environmental pollution. Unique excellent performance of crystal materials can broaden the resource utilization of saponite minerals.

Owner:NORTHEASTERN UNIV

Method for preparing mineral ore powder using vegetable organic matters and microorganisms

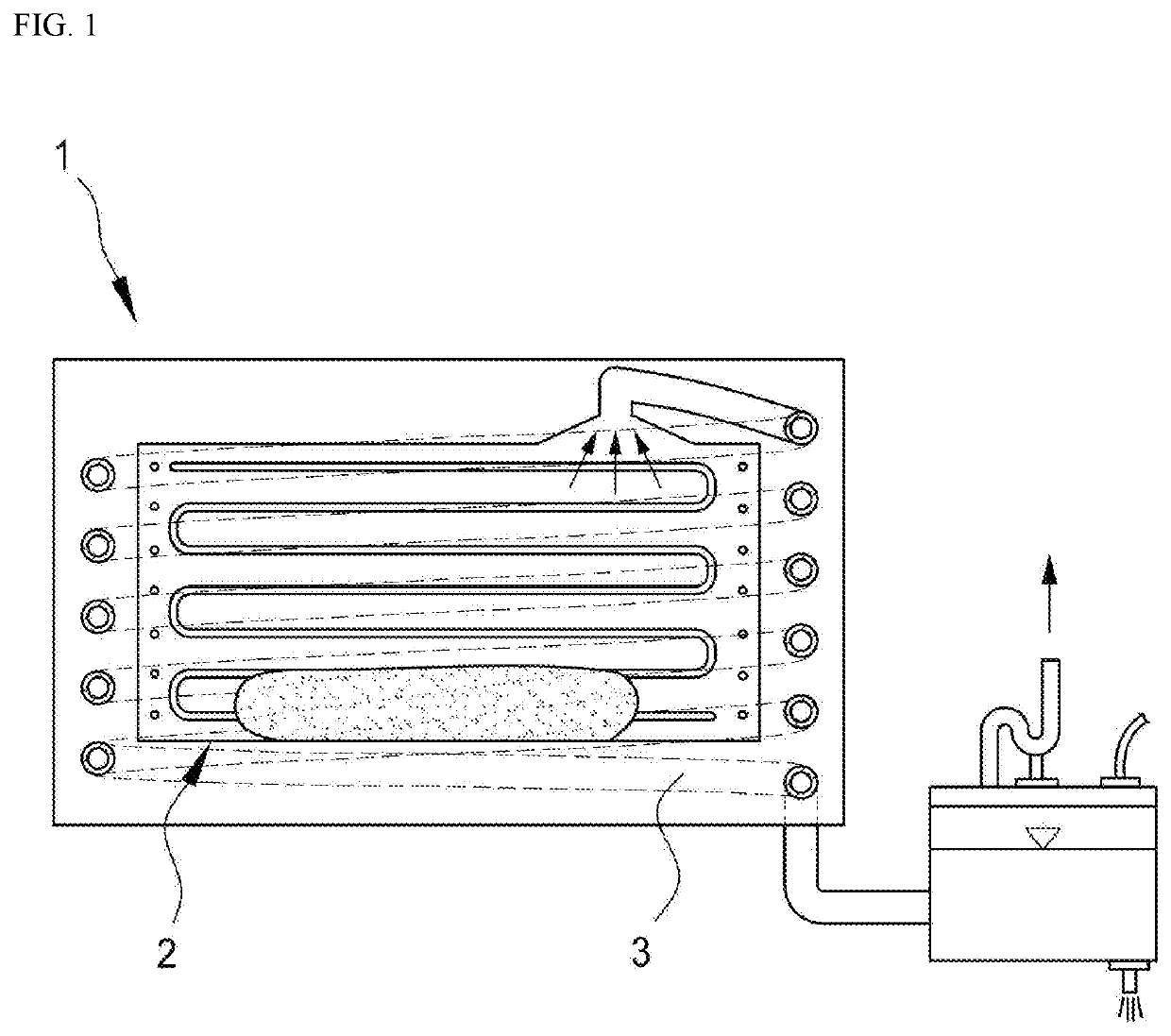

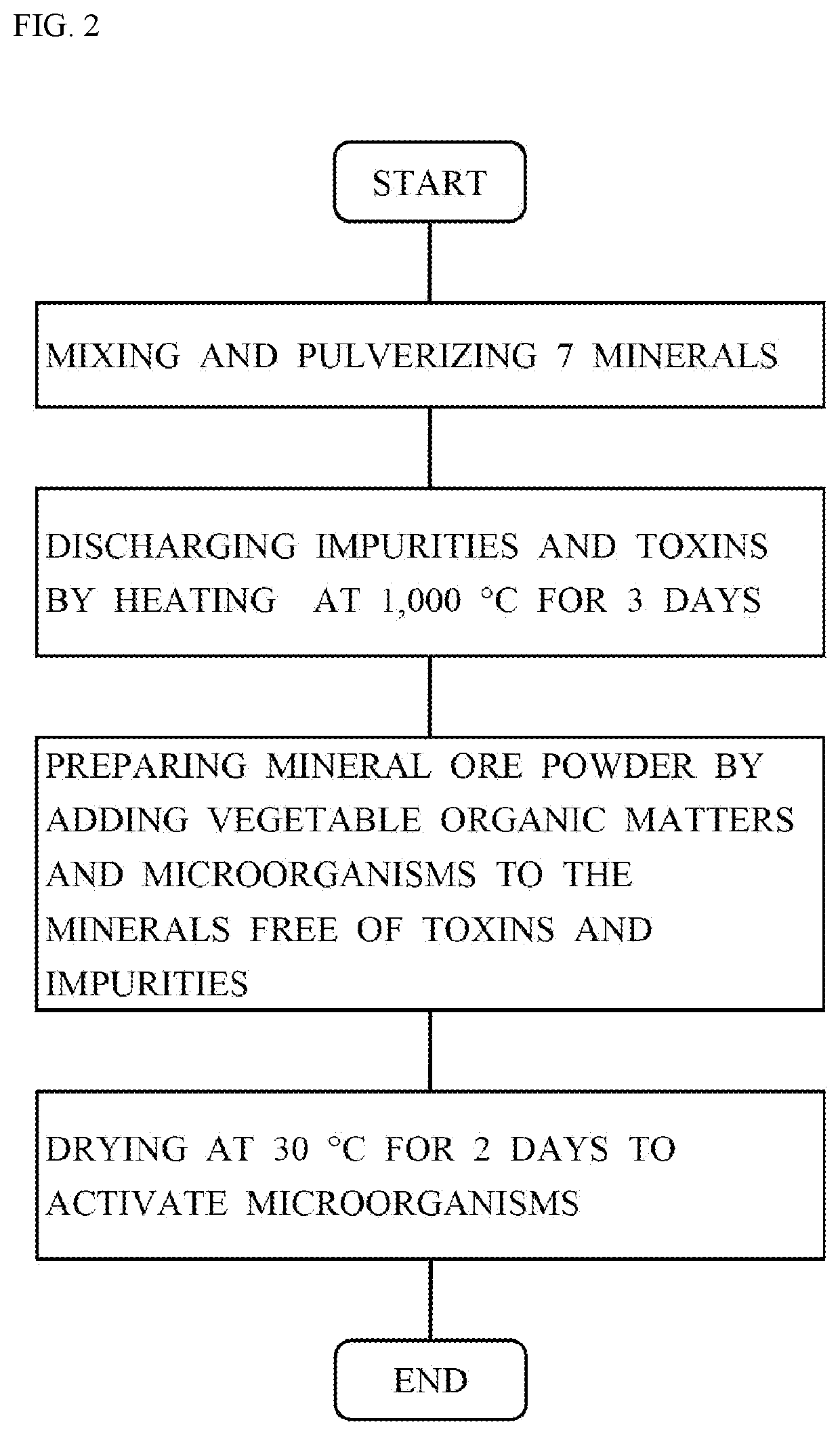

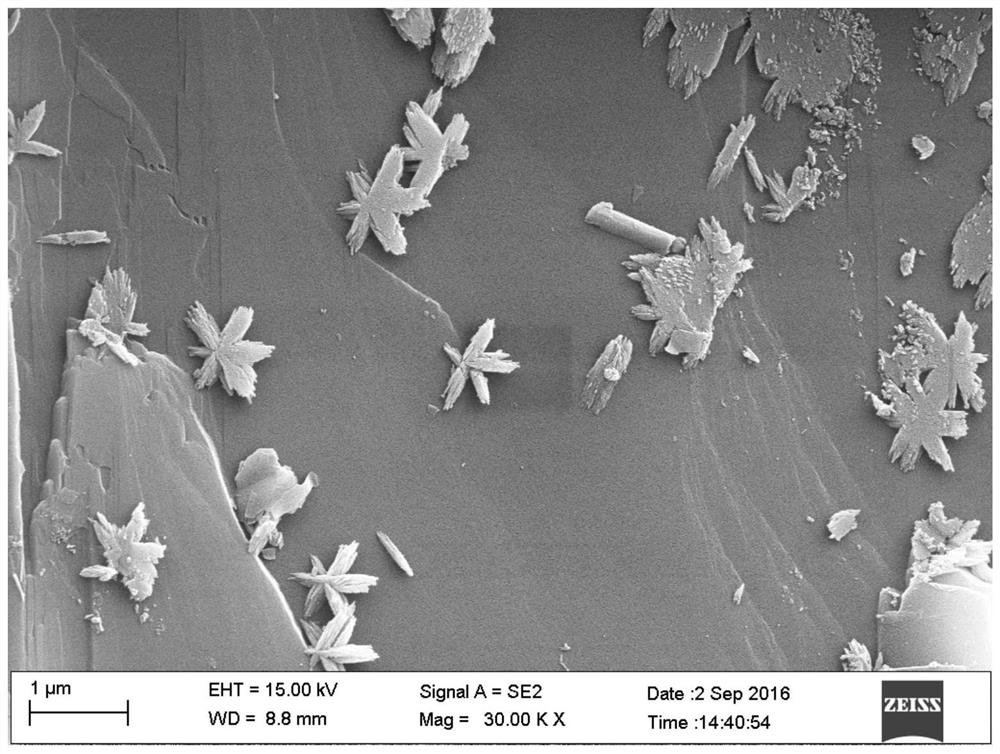

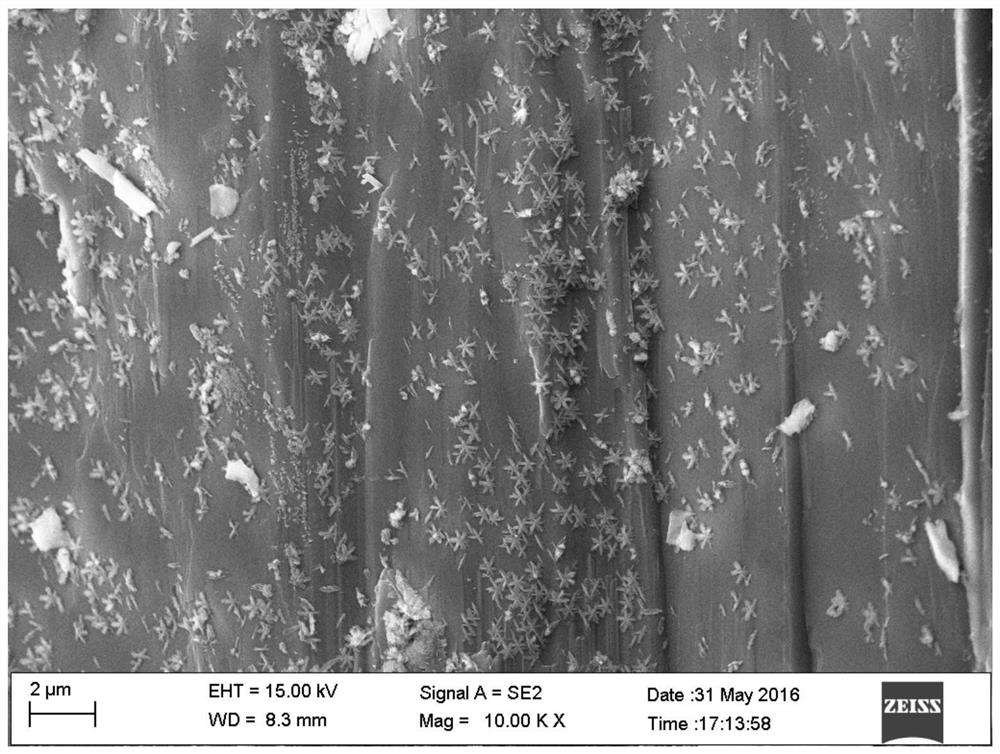

ActiveUS20200407614A1High strengthHigh activityInorganic active ingredientsHeat-exchange elementsMicroorganismToxic gas

The present invention relates to a method for preparing mineral ore powder using vegetable organic matters and microorganisms, particularly a method for preparing mineral ore powder by heating and pulverizing seven (7) minerals that are beneficial to the human body but contain toxins and impurities at high temperatures in a furnace, removing toxin gases and impurities through carbonization, and drying the minerals for two days with liquid or powdered vegetable organic matters and microorganisms at room temperature.The present invention provides a method for preparing mineral ore powder, the method comprising a step of pulverizing seven (7) minerals consisting of 20% of zeolite, 10% of hornblende, 10% of elvan, 10% of illite, 10% of biotite, 20% of tourmaline and 10% of white clay into 325 mesh; a step of discharging impurities by heating the pulverized mineral powder at a temperature of 1,100° C. for a few days; a step of preparing a mineral ore powder by adding microorganisms and liquid or pulverized vegetable organic matters consisting of 30% of mulberry bark, 25% of pine needles, 20% of cypress, 15% of ginger plant and 15% of bush clover; and a step of drying the mineral ore powder at a temperature of 30° C. for 2 days to activate the microorganisms.

Owner:KONG BYUNG SEOK

A method for preparing saponite crystals under hydrothermal conditions

Owner:NORTHEASTERN UNIV LIAONING

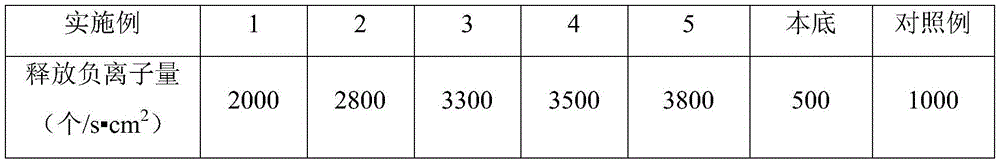

Negative ion composite powder suitable for building materials

PendingCN105621933ASimple preparation processSuitable for mass productionRare earthMaterials science

The invention discloses negative ion composite powder suitable for building materials. The negative ion composite powder is prepared from the following components in parts by mass: 30-80 parts of schorlite powder, 1-8 parts of sodium hexametaphosphate, 1-5 parts of cerium oxide, 0-30 parts of rare earth, 1-30 parts of iron trioxide powder, 1-5 parts of poly cellulose ether and 1-40 parts of titanium magnesium hornblende powder. According to the technical scheme, a preparation process is simple, raw materials are low in cost, a negative ion plate has durability, high efficiency and environment-friendliness, the prepared negative ion plate can efficiently and stably release 2000-3000 negative ions in per square centimeter per second, and can purify air and remove gas with peculiar smell and harm gas indoors, and the negative ion composite powder is an environment-friendly negative ion additive.

Owner:ZHUO DA NEW MATERIAL TECH GRP

Fluxes for Cast Iron Welding and How to Use Them

InactiveCN102962607BAvoid it happening againRecovery refinementWelding/cutting media/materialsSoldering mediaFerrosiliconCalcite

The invention provides a soldering flux for cast iron welding and a use method of same. The soldering flux is prepared mainly by mixing powder and a liquid additive, wherein the powder is obtained mainly by mixing the following components with 100-200-mesh particle size: yttrocalcite powder, calcite powder, celestite powder, hornblende asbestos plaster, ferromolybdenum powder and ferrosilicon powder; the liquid additive is obtained by mixing an emulsifier and a wetting agent; and the mass percentages of all the components in the soldering flux are as follows: 25-30 percent of yttrocalcite powder, 20-30 percent of calcite powder, 10-12 percent of celestite powder, 10-20 percent of ferrosilicon powder, 3-5 percent of ferromolybdenum powder, 2-5 percent of ferrosilicon powder, 3-5 percent of emulsifier and 4-6 percent of wetting agent. The soldering flux and the use method thereof are simple, quick and convenient; heating is not needed before welding, and heat preservation is not needed after welding; the obtained weld metal has a beautiful appearance, and has no hot crack, cold crack, gas pores or fracture structures; and the welding technology is simple, the quality is stable and reliable, the cost is low, machining can be performed after welding, and pressure tests can achieve the index requirements.

Owner:杨文宝

Novel microcrystalline material and application thereof

InactiveCN110342918AImprove thermal efficiencyBurn fullyUnderstructuresFuel supplyFuel tankMaterials science

The invention provides a novel microcrystalline material and application thereof. The novel microcrystalline material is prepared form the following components in parts by weight: 15-25 parts of medical stone, 15-25 parts of tourmaline, 10-20 parts of hexacyclic stone, 5-8 parts of hornblende, 10-15 parts of hexagonal-prism stone, 10-15 parts of far infrared stone, 5-8 parts of crystal stone, 7-15parts of magnesium stone, 3-5 parts of fluorite, 10-15 parts of quartz stone, 10-15 parts of hematite stone, 10-15 parts of mica, 7-15 parts of high-calcium stone, 5-8 parts of vermiculite, 10-15 parts of granite, 10-20 parts of marble, 10-20 parts of feldspar, 10-15 parts of high-aluminum stone, 3-5 parts of wollastonite, 3-5 parts of sillimanite, and 1-3 parts of coal gangue. The microcrystalline material is applied to an automobile fuel tank, the arrangement of fuel molecules is changed through quanta and negative ions, far-infrared light wave materials can be generated, matter capable ofreleasing a magnetic field can further be contained, the novel microcrystalline material has energy, the thermal efficiency of gasoline can further be improved, the gasoline burns more fully, automobile power is stronger, carbon deposition is effectively removed, exhaust emission is lowered, and fuel saving and emission reduction are achieved.

Owner:中德道合科技有限公司

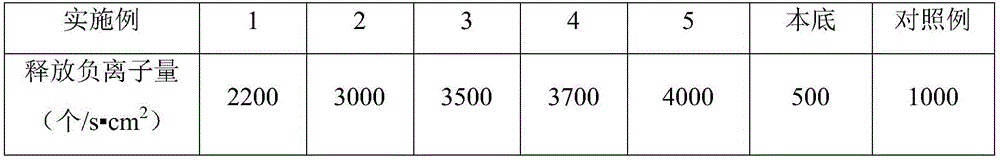

Negative ion composite powder suitable for building materials

The invention discloses negative ion composite powder suitable for building materials. The negative ion composite powder is prepared from, by mass, 30-80 parts of black tourmaline powder, 1-8 parts of calcium stearate, 1-5 parts of zinc oxide, 0-30 parts of rare earth, 1-30 parts of zeolite powder, 1-5 parts of cerium oxide, 1-8 parts of waterborne acrylic acid, 1-30 parts of anatase powder and 1-8 parts of titanium-megnesium hornblende powder. According to the technical scheme, the preparation process is simple, raw materials are low in price, a negative ion plate has durability, high efficiency and environment friendliness, the made negative ion plate can release 2200-4000 negative ions per second.cm<2> efficiently and stably, purify air and eliminate indoor peculiar smells and harmful gases, and the composite powder is an environment-friendly negative ion additive.

Owner:ZHUO DA NEW MATERIAL TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com