Patents

Literature

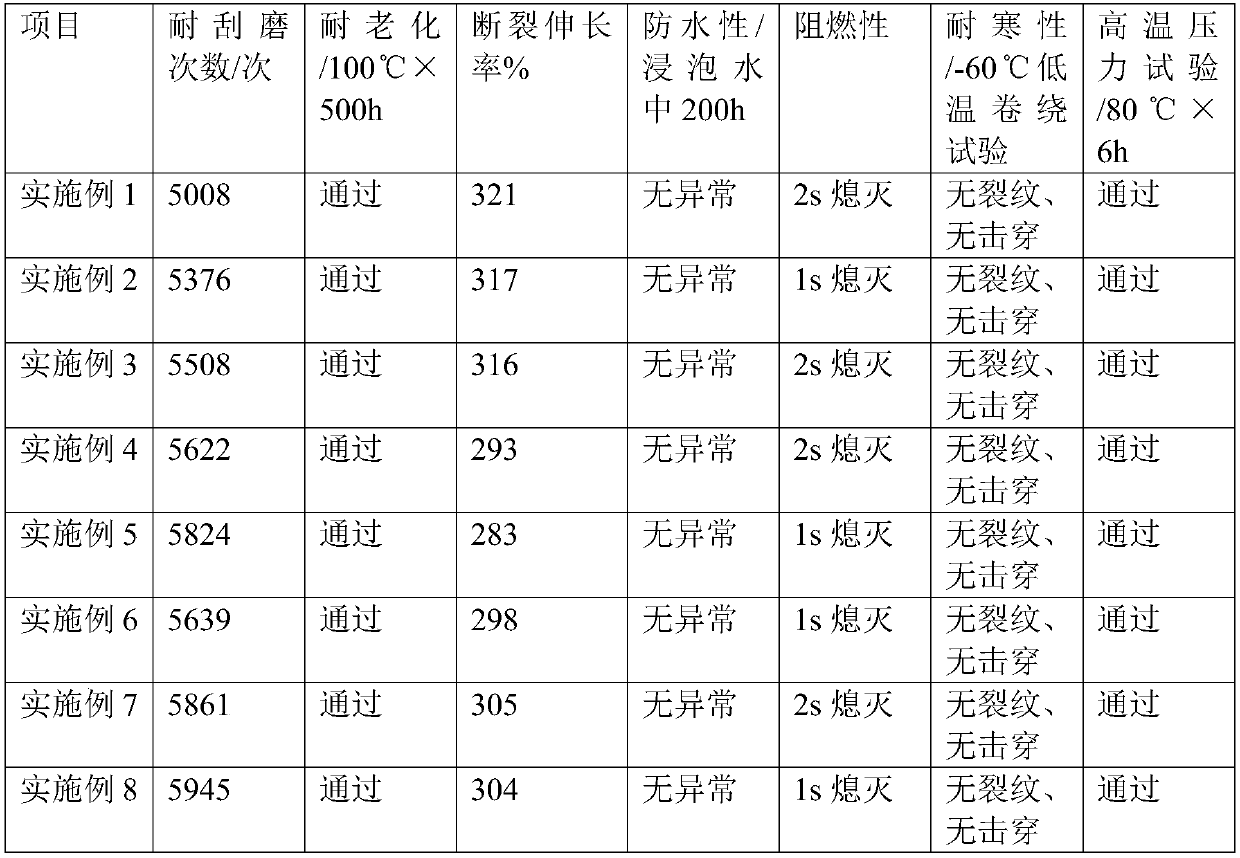

58results about How to "Frost resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

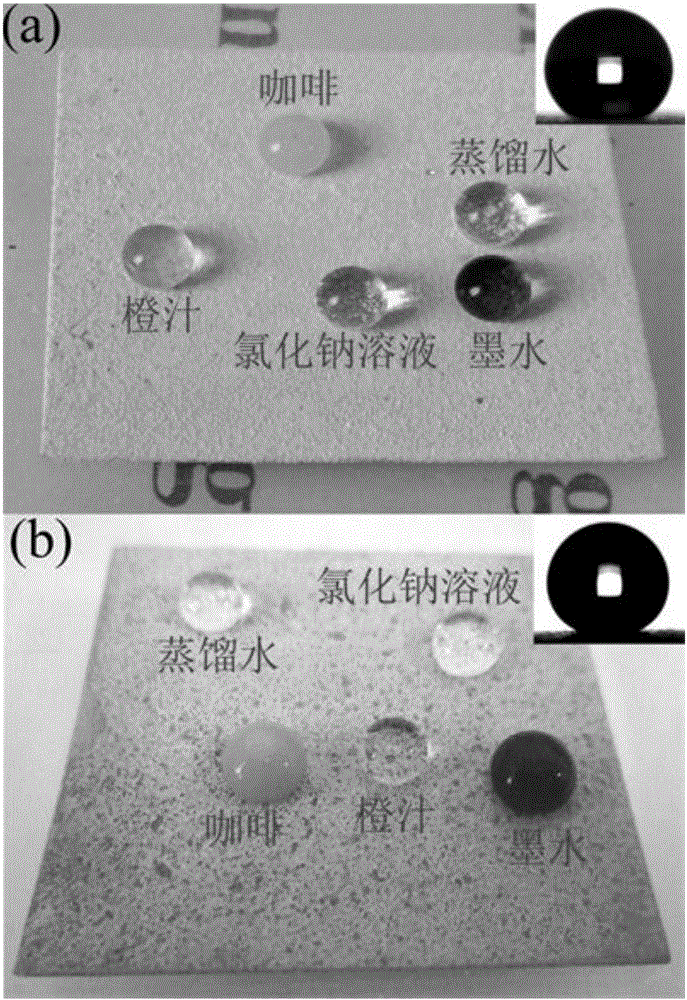

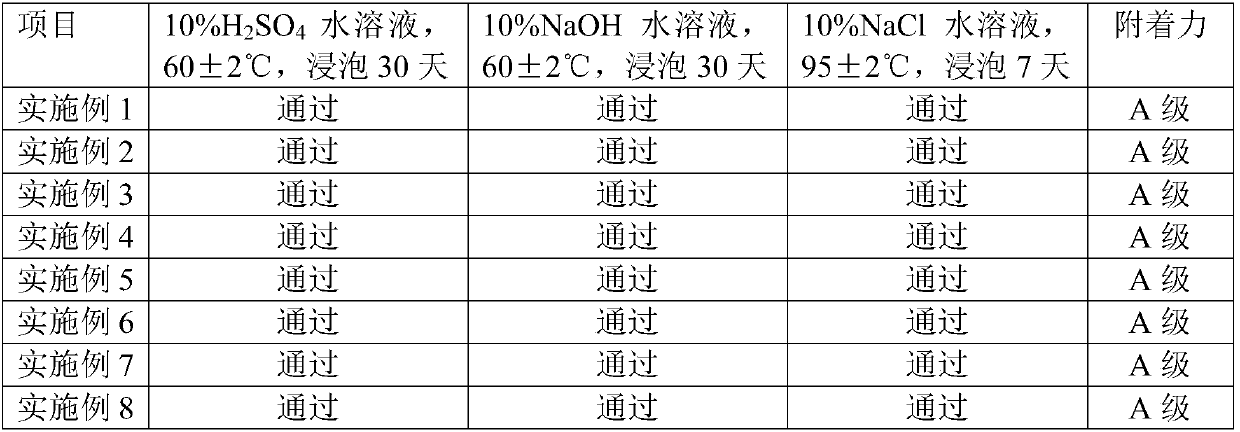

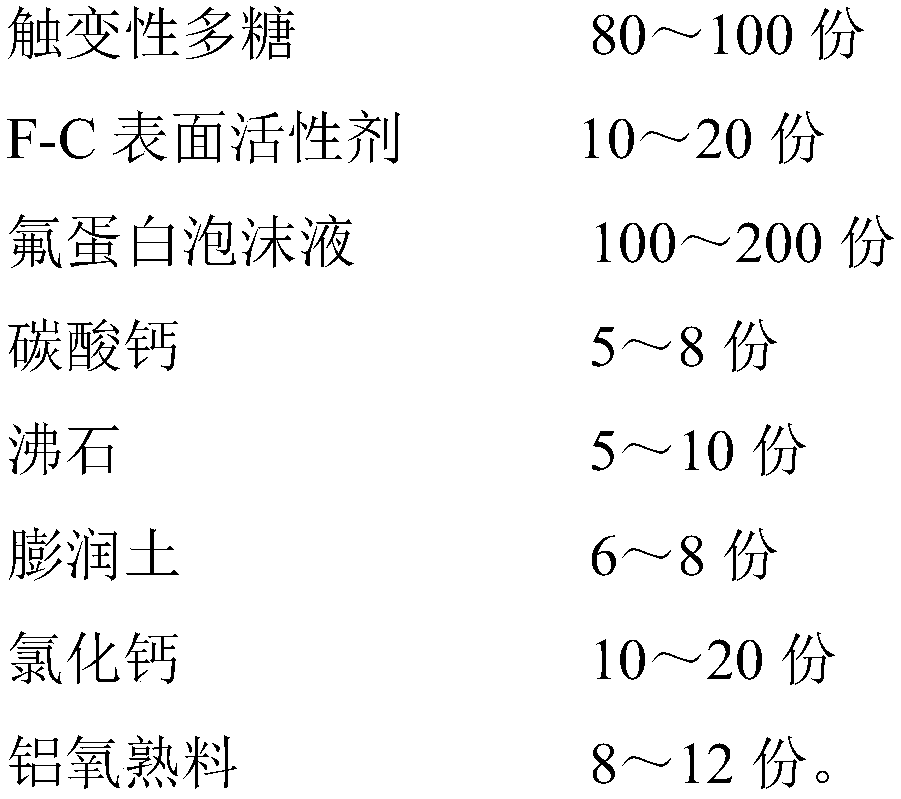

Preparation method of super-hydrophobic, super-oleophobic and high transparency triple-function coating film

InactiveCN103965673AExcellent superhydrophobic propertiesFrost resistantCoatingsCoated membraneSolar battery

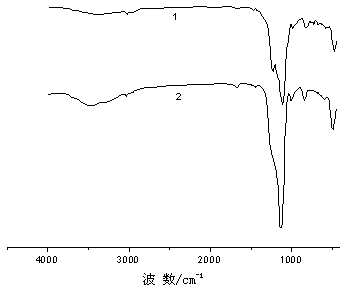

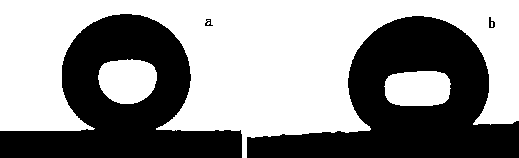

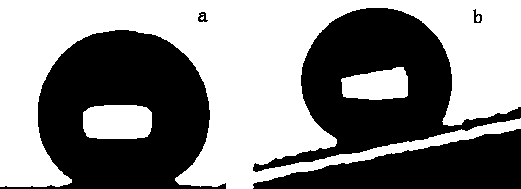

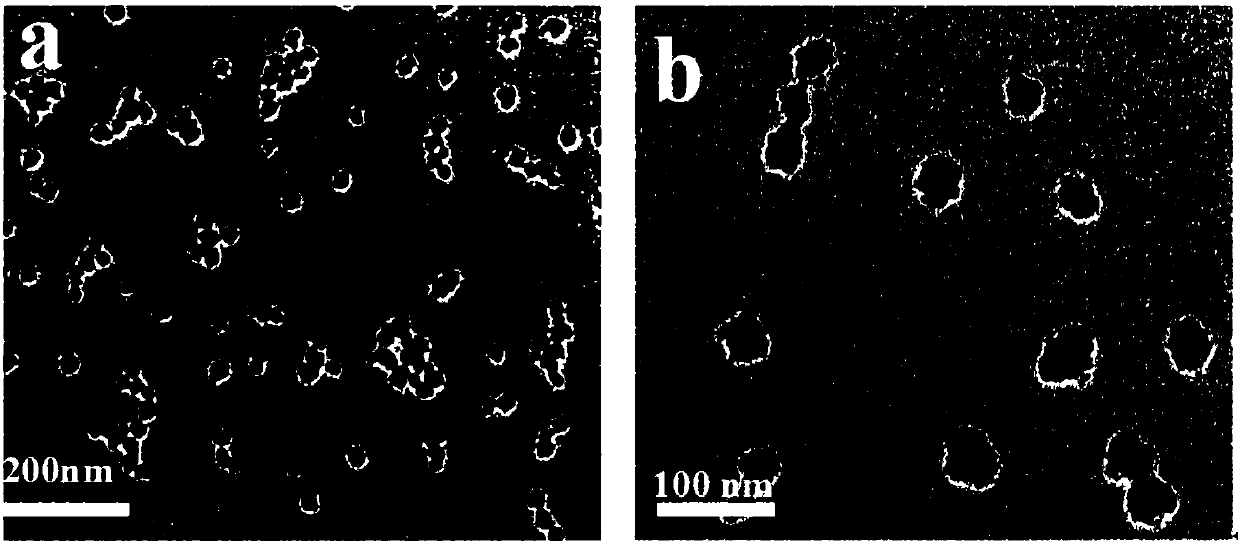

The invention discloses a preparation method of a super-hydrophobic, super-oleophobic and high transparency triple-function coating film, belongs to the field of novel materials, and particularly belongs to the field of self-cleaning optical materials. The method comprises the steps of firstly assembling large-grained SiO2 nano particles on a glass substrate, so as to form the lower layer of the fine structure of a functional coating layer, simultaneously adding pore-foaming agent, so as to adjust and control space filling factors, then assembling upper layer fluoride SiO2 nano fine particles, and constructing a two-stage uneven surface coating layer with a suspension structure and super-hydrophobic, super-oleophobic high and transparency functions. The functional film has frost prevention, fog prevention, pollution prevention, bacteriostasis and self-cleaning properties, also has excellent translucency, can effectively prevent properties of optical elements, photoelectron elements, solar batteries and laser systems from being influenced by environment in severe environment, greatly expands the application range of the equipment, guarantees the operational reliability, and prolongs the service life, thereby greatly improving the practical values of the equipment.

Owner:JIANGNAN UNIV +1

Heat pipe and heat-conducting medium thereof

InactiveCN102878838AImprove thermal efficiencyIncrease mobilityChemical industryIndirect heat exchangersZinc hydroxideHeat conducting

The invention relates to the technical field of heat-conducting components, in particular to a heat pipe with efficient heat-conducting effect and a heat-conducting medium thereof. The hot pipe comprises a metal pipe and the heat-conducting medium packaged in the metal pipe; and the heat-conducting medium is made from the following raw materials: 1,000g of deionized water, and 40-60g of potassium dichromate, 3-5g of boric acid, 8-12g of sodium perborate, 2-4g of sodium peroxide, 1-3g of calcium chloride, 6-10g of ethanol, 0.5-1g of manganese dioxide and 0.2-0.8g of zinc hydroxide, which are added into 1,000g of deionized water. By the technical scheme, a plurality of materials are cooperated with one another, and heat-conducting efficiency of a product is improved. By the heat pipe made from the heat-conducting medium, the heat-conducting efficiency is improved by 200-300% compared with that of the heat-conducting medium of an ordinary heat pipe, and the applicable temperature range of the heat pipe is wide.

Owner:东莞市焊宏爱法电子科技有限公司

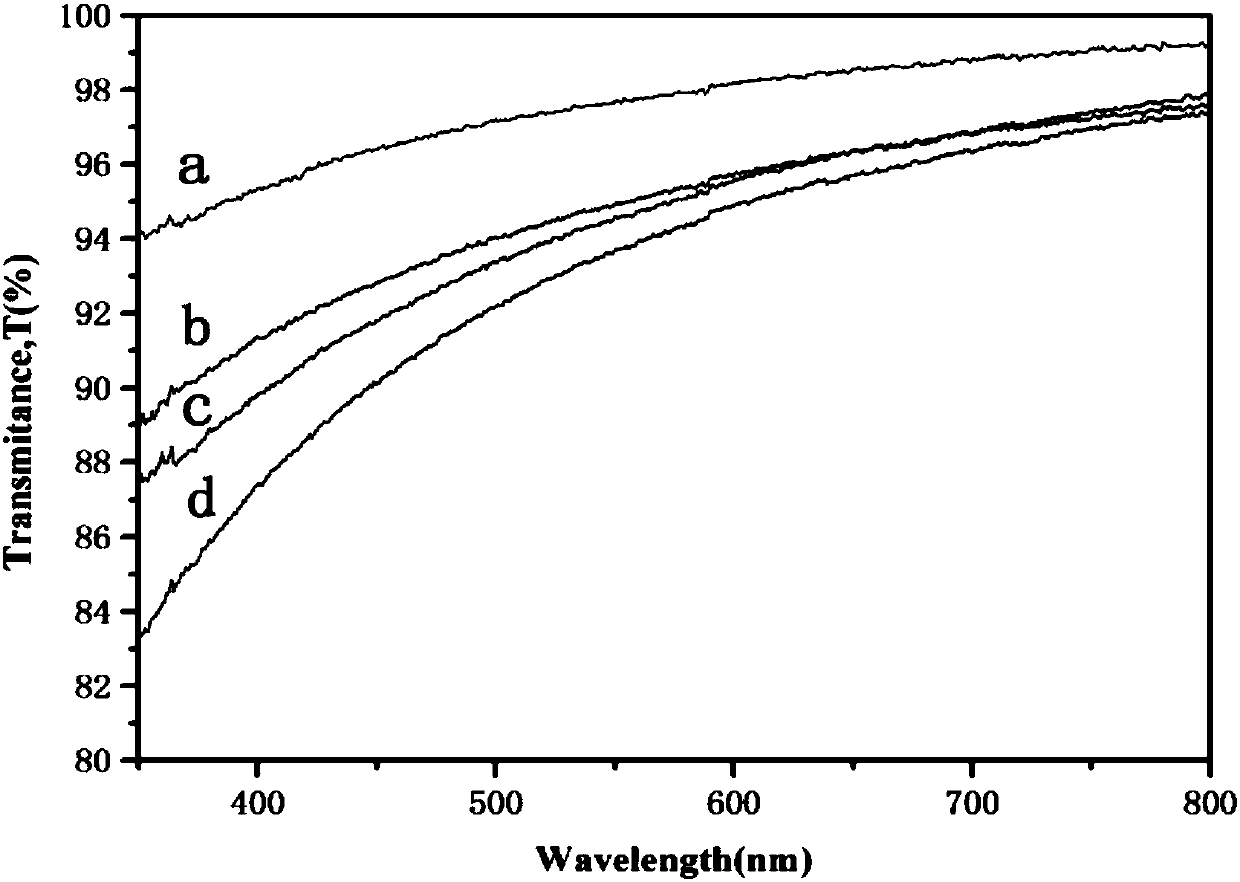

Superhydrophobic coating preparation method, coating prepared therethrough, and application of coating in production of highly-transparent superhydrophobic coating layer

The invention discloses a superhydrophobic coating preparation method, a coating prepared therethrough, and an application of the coating in the production of a highly-transparent superhydrophobic coating layer. The superhydrophobic coating preparation method comprises the following steps: adding a certain volume of a solvent, a cosolvent and a catalyst into a container one time, stirring the added substances at a certain rotating speed for a period of time, adding a certain volume of silicate ester and fluorine-containing siloxane, and continuously reacting all above substances at room temperature for a certain period of time to obtain the coating. The superhydrophobic coating prepared in the invention can be sprayed, dip-spread or dip-coated on glass, sheet paper, steel or other different substrates, and the transmittance of the produced coating layer in a visible light range reaches 92% or more. Compared with coating layers in the prior art, the produced coating layer has the advantages of simple production method, low cost, and facilitation of large-scale industrial production, has multiple uses in window glass, skyscraper light curtains, mobile phone screens and computer screens, and has great commercial values.

Owner:SOUTHEAST UNIV

Preparation method of cellulose ion conductive hydrogel and prepared hydrogel prepared

ActiveCN109503765AFrost resistantImprove ionic conductivityMeasurement devicesConductive materialCelluloseEvaporation

The invention discloses a preparation method of a cellulose ion conductive hydrogel and the prepared hydrogel. The preparation method comprises the following steps: S1, adding cellulose in a water solution of sodium hydroxide and urea, dissolving at the temperature of -5 DEG C to -20 DEG C, and stirring to obtain a transparent cellulose solution; S2, dropwise adding allyl glycidyl ether in the cellulose solution, reacting for 20-30 hours at the temperature of 25-35 DEG C and under the protection of an inert gas; S3, cleaning a product obtained in the step S2 with diethyl ether, performing rotary evaporation so as to remove the residual diethyl ether to obtain an allyl cellulose solution; and S4, adding ammonium persulfate in the allyl cellulose solution, stirring for 3-10 minutes, then centrifuging for defoaming, and reacting for 20-30 hours at the temperature of 25-35 hours so as to obtain the hydrogel. The cellulose ion conductive hydrogel provided by the invention has high stretchability, high compressibility, high freezing resistance and excellent ionic conductivity.

Owner:SOUTH CHINA UNIV OF TECH

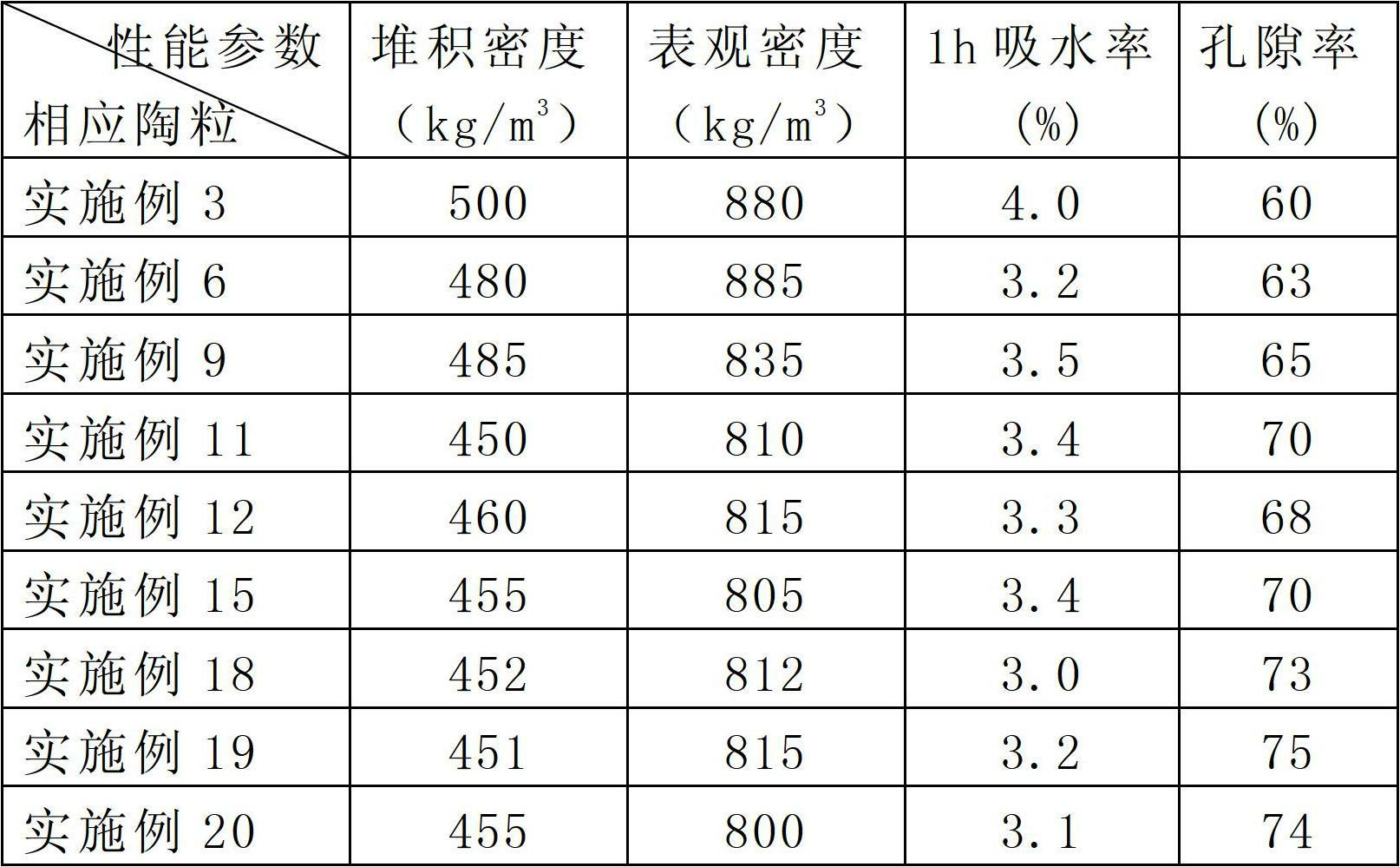

Efficient sound-absorbing ceramsite

InactiveCN102633491AImprove the sound absorption coefficientLightweight and high strengthCeramic materials productionCeramicwarePorositySludge

The invention relates to an efficient sound-absorbing ceramsite, belonging to the technical field of a building material. Aiming to solve the problems that city pollution can not be well solved, product properties are poor, the poor sound-absorbing effects are poor and the production cost is high in the prior art by mainly using the shale as ceramsite, can be solved, The invention provides the efficient sound-absorbing ceramsite, which is prepared from raw materials mainly consisting of raw materials of 60-80% of sludge, 5-20% of the shale, 5-20% of coal ash and 1.0-10% of additive. The efficient sound-absorbing ceramsite provided by the invention has the properties of wide sound-absorbing frequency band, fire resistance, good durability, freezing resistance, seismic resistance, high sound-absorbing coefficient, high porosity, light weight, high strength, heat resistance, anti-permeability and the like. The efficient sound-absorbing ceramsite further can be used for preparing a road barrier and a metro sound-absorbing material and has wide application prospect. Furthermore, the efficient sound-absorbing ceramsite provided by the invention mainly uses city sludge, so that not only can the problem of the city sludge be solved well, but also the overuse of a natural resource of the shale is reduced.

Owner:ZHEJIANG FANGYUAN BUILDING MATERIALS TECH

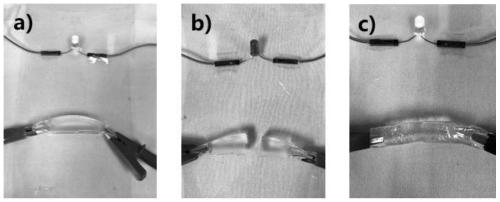

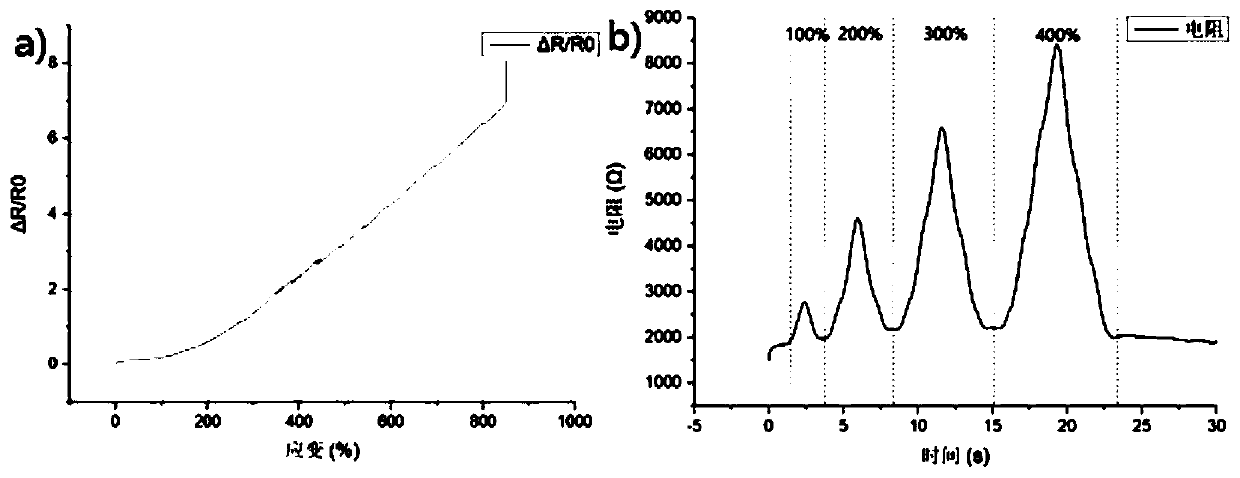

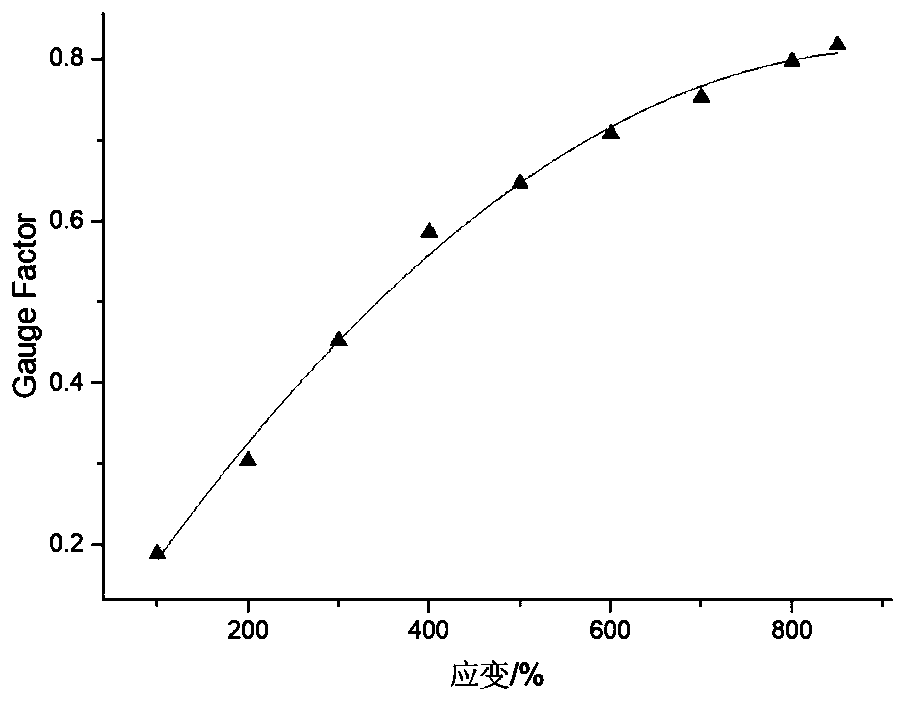

Hydrogel flexible strain sensor and preparation method thereof

PendingCN111234112AHeat repairableFrost resistantElectrical/magnetic solid deformation measurementCarrageenanEngineering

The invention provides a hydrogel flexible strain sensor and a preparation method thereof. The K-type carrageenan double-network hydrogel is prepared, and the flexible strain sensor with thermal repairability, freezing resistance and stretchability is obtained after ethylene glycol is modified. The sensor has the excellent performances of high sensitivity, wide detection range, high response speed, high dynamic durability and the like, the toughness and elasticity modulus of the sensor can be adjusted by adjusting the soaking time of hydrogel in ethylene glycol, so that the performance of thesensor is more excellent, and the sensor can be applied to the fields of wearable equipment, flexible robots, electronic skin, medical care and the like.

Owner:广州钰芯传感科技有限公司

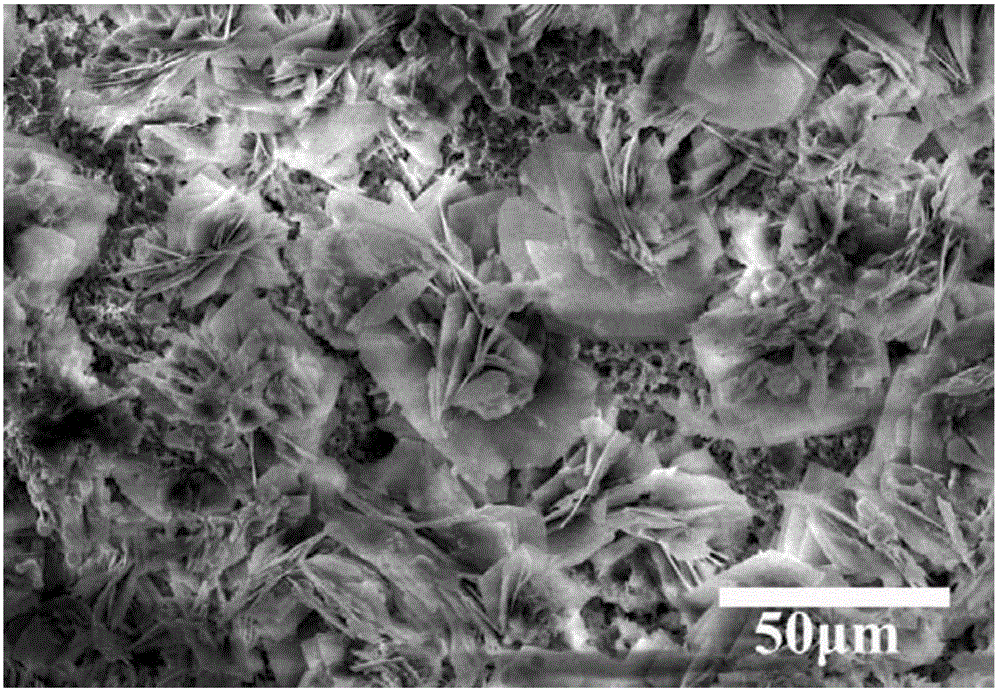

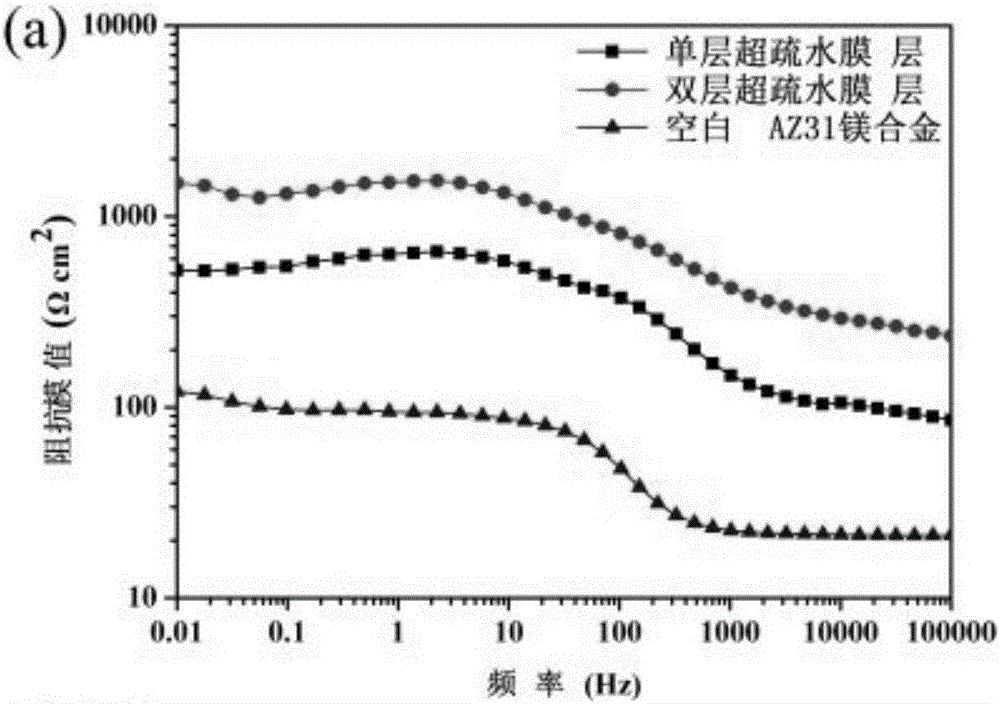

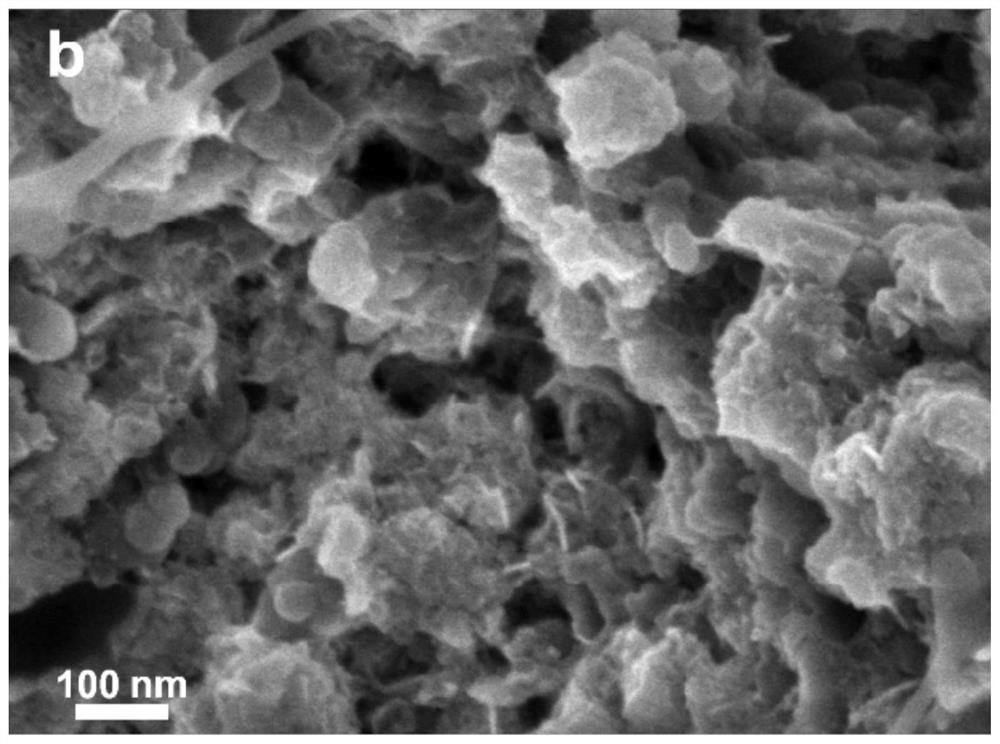

Double-layer super-hydrophobic material and preparation method thereof

ActiveCN106119842AIncrease roughnessCorrosion rate slows downMetallic material coating processesAlloy substrateCorrosion

The invention provides a double-layer super-hydrophobic material and a preparation method thereof. An alloy substrate material is ground through abrasive paper and ultrasonically cleaned by being soaked in absolute ethyl alcohol, so that oxide films and oil stains on the surface of the alloy substrate material are removed, and A is obtained; the A is soaked in a mixed solution, formed by equivalent-volume mixing of a 0.01 mol / L stearic acid ethanol solution and a 0.01 mol / L nickel sulfate aqueous solution, according to the proportion of 0.5-10 mL / cm<2>, and then heated for 7 h through water at the temperature of 140 DEG C; the A is cooled, taken out and dried to obtain B; the B is soaked in a mixed solution, formed by equivalent-volume mixing of a 0.01-0.2 mol / L stearic acid ethanol solution and a 0.01-0.2 mol / L cobalt sulfate aqueous solution, according to the proportion of 0.5-10 mL / cm<2>, and then heated for 5-8 h through water at the temperature of 90-130 DEG C; and the B is cooled, taken out and dried to obtain the double-layer super-hydrophobic material. According to the double-layer super-hydrophobic material and the preparation method thereof, the purpose that alloy is provided with super-hydrophobic films with the corrosion resistance and the antifouling property being stable for a long time can be achieved.

Owner:HARBIN ENG UNIV

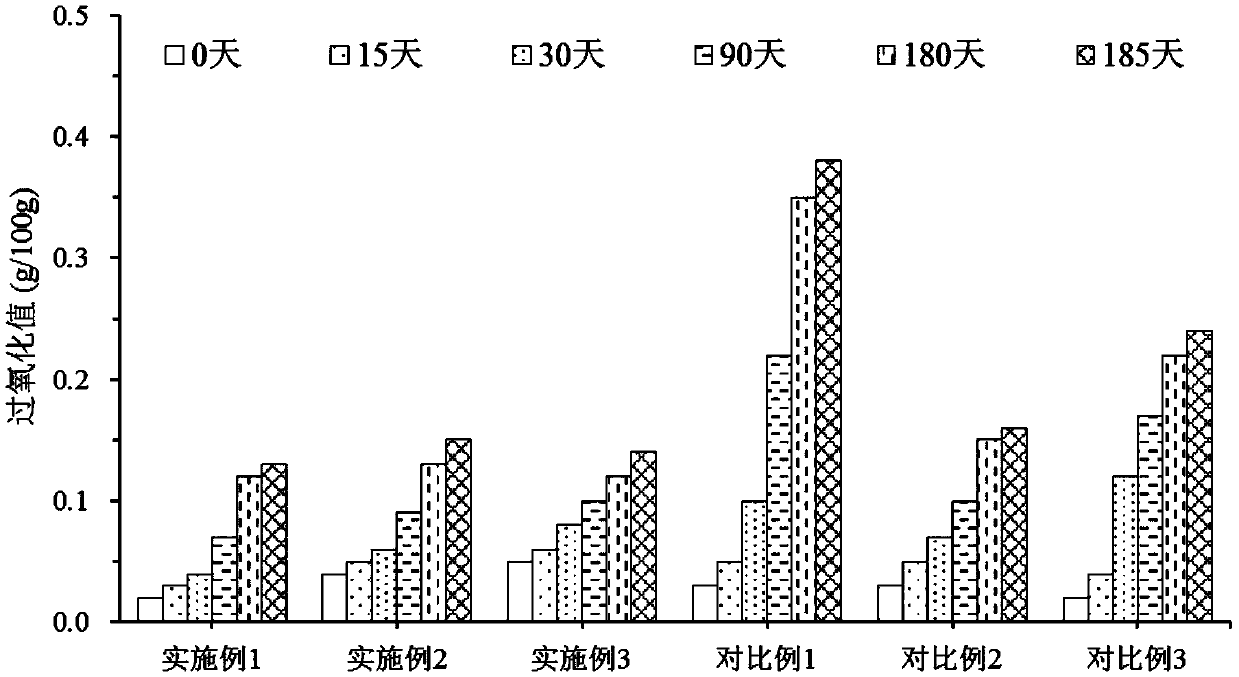

Bread jam and preparation method thereof

InactiveCN109549146AExtended shelf lifeGrowth inhibitionFood preservationFood ingredient as mouthfeel improving agentFruit juiceWater activity

The invention discloses a bread jam, wherein the bread jam comprises the following components: mixed dried fruits, a mixed juice, sweetening substances, edible colloid, an edible emulsifier, modifiedstarch, oil, wine, edible salt, spices and water. The bread jam is used in a Panettone bread processing technology and meets the market demand for product diversification. The Panettone bread jam hasfresh taste, rich fruit flavor, moderate sweet and sour taste and mellow aftertaste. The sugar degree is 55-60 degrees, the pH value is 3.2-3.8, and the water activity Aw is 0.86-0.89. No chemically synthetic preservatives are added.

Owner:GUANGZHOU HAODAO FOOD CO LTD

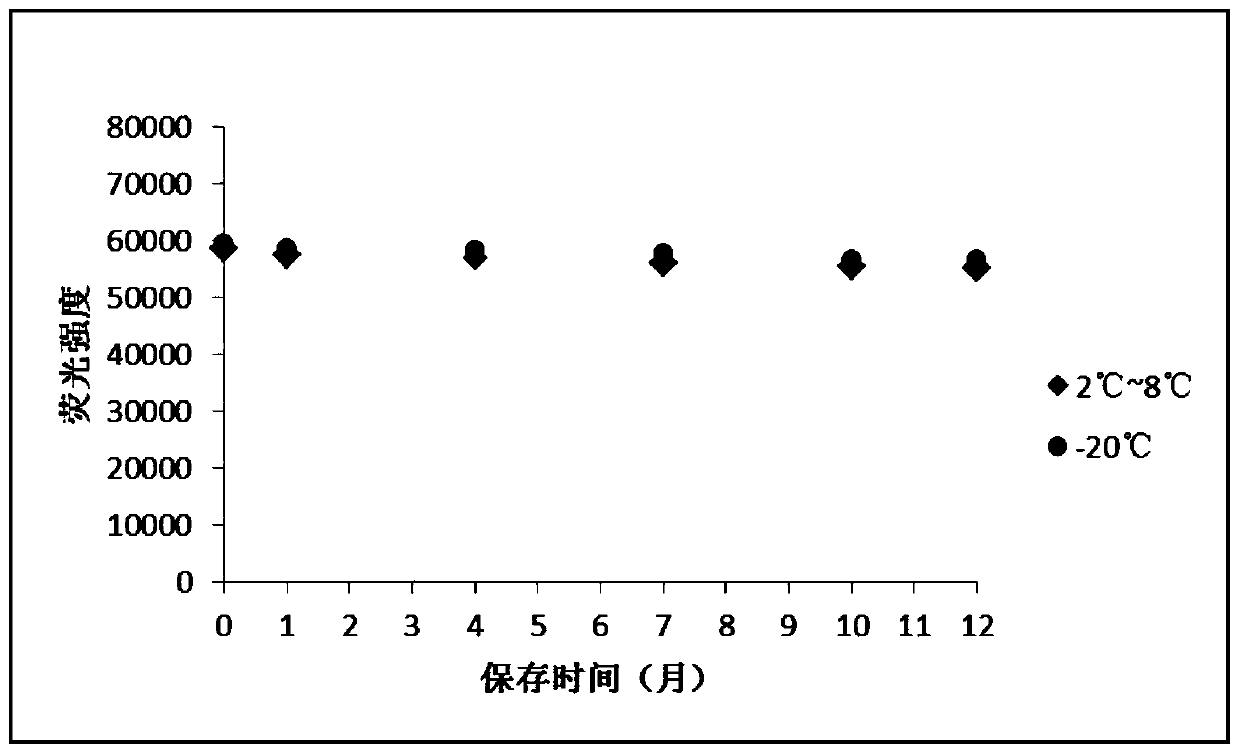

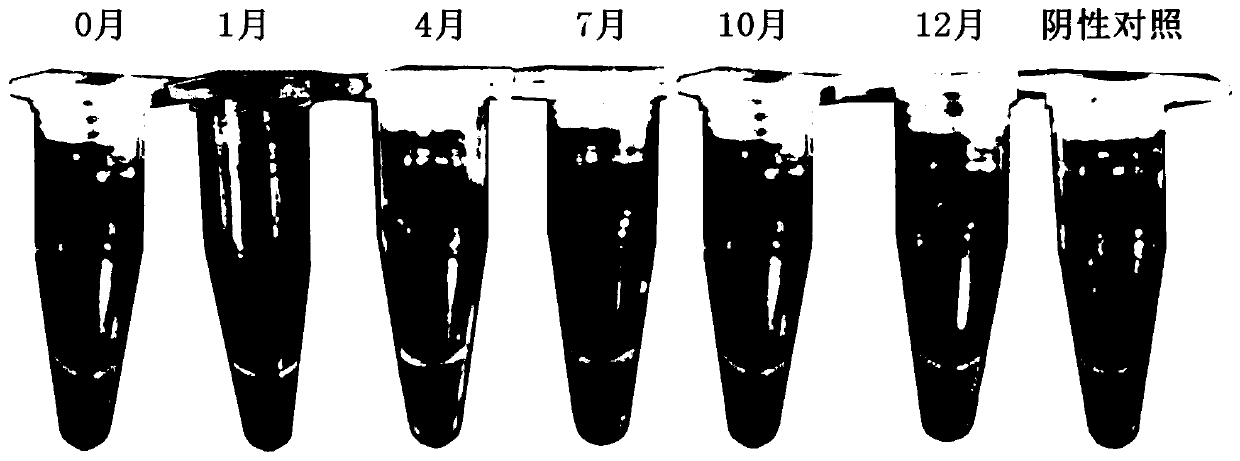

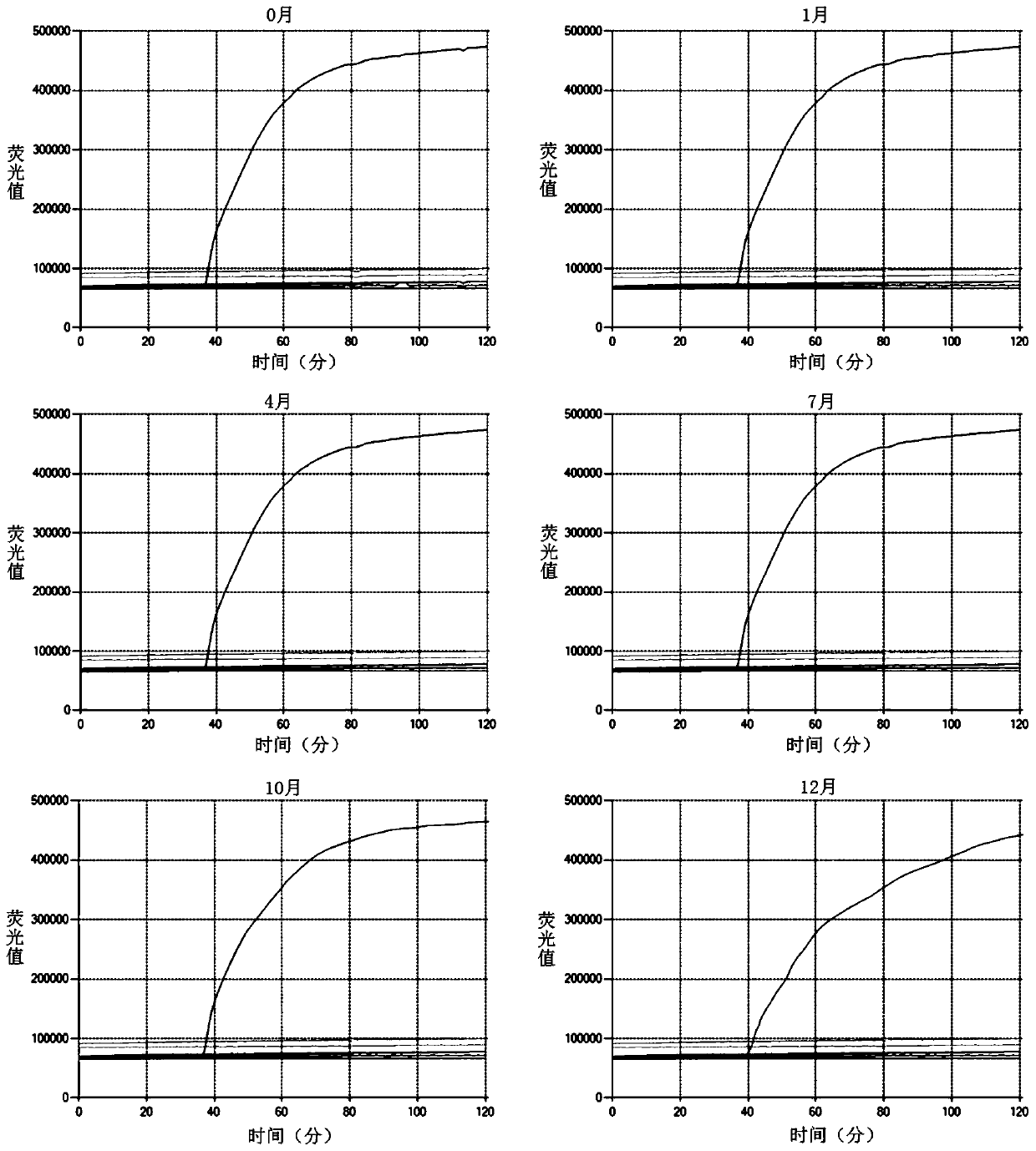

Exosome preserving fluid and exosome preserving method

The invention relates to an exosome preserving fluid and an exosome preserving method, which belong to the technical field of biology. The exosome preserving fluid comprises bovine serum albumin, trehalose, glycerol, dimethyl sulfoxide and a phosphate buffer solution. The invention also provides the exosome preserving method comprises the following steps: heating the preserving fluid at 85-95 DEGC for 10-30 minutes to form a colloidal solution, and preserving the exosome in a colloidal solution. The exosome preserving fluid provided by the invention can maintain the integrity, biological activity and inclusion stability of exosomes for a long time.

Owner:中国科学院大学深圳医院

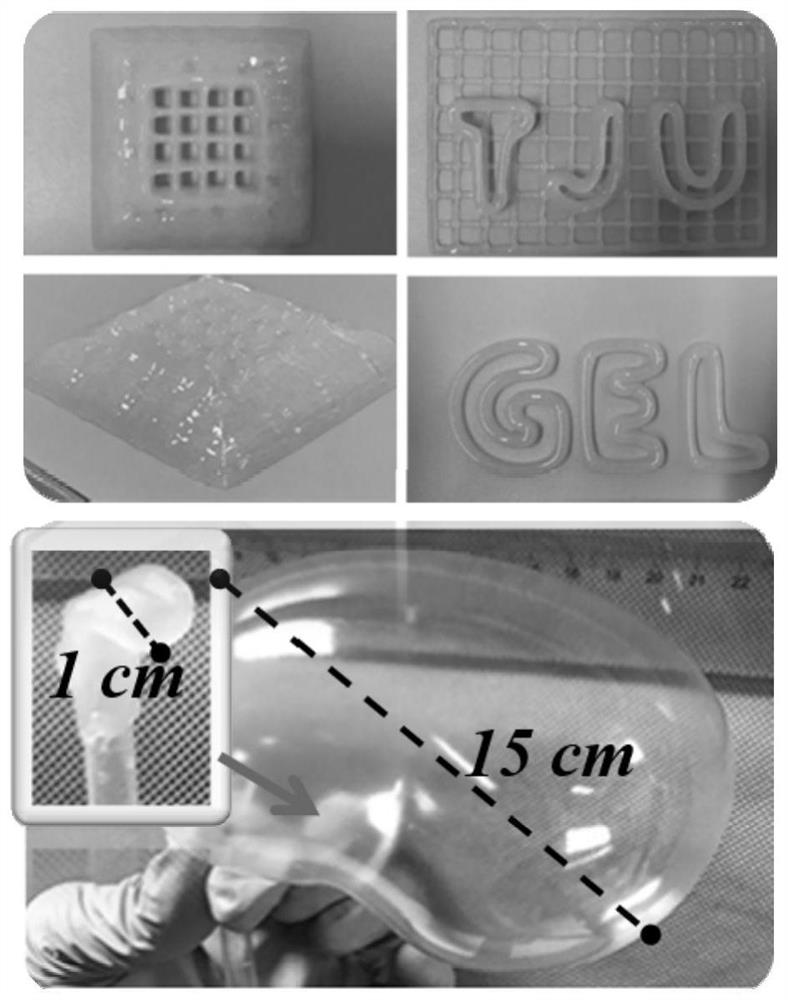

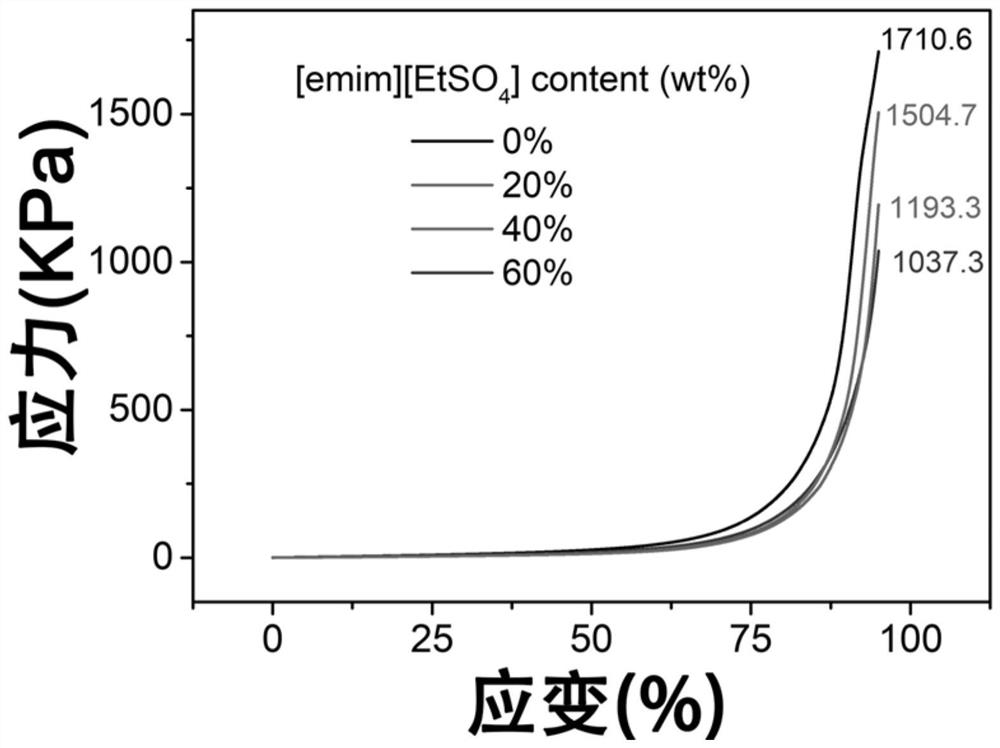

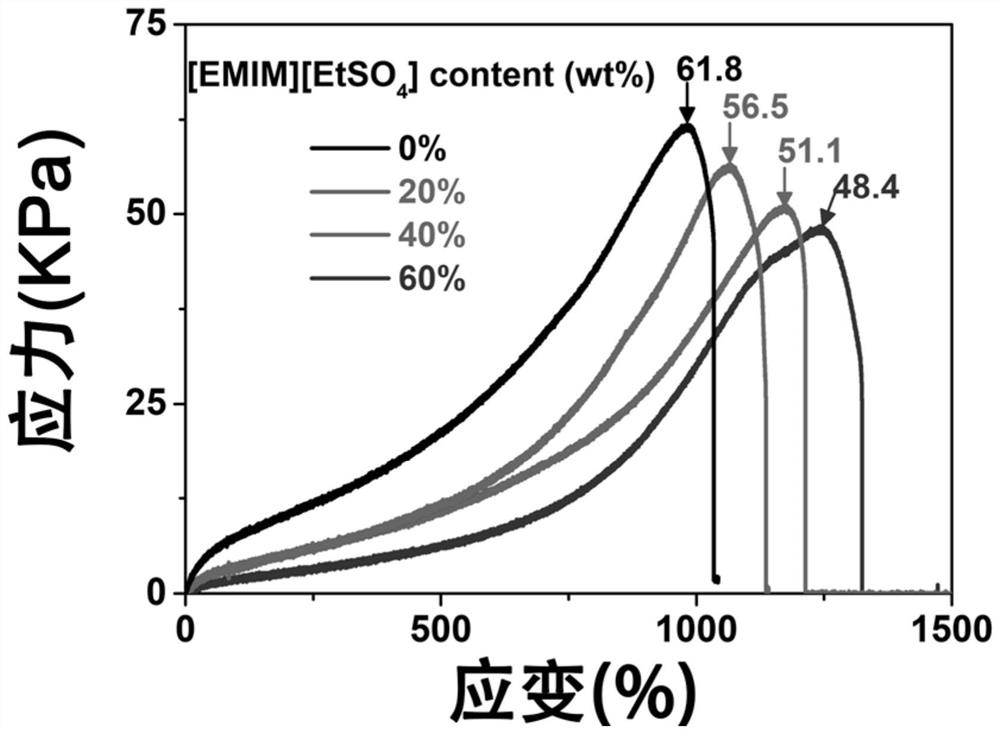

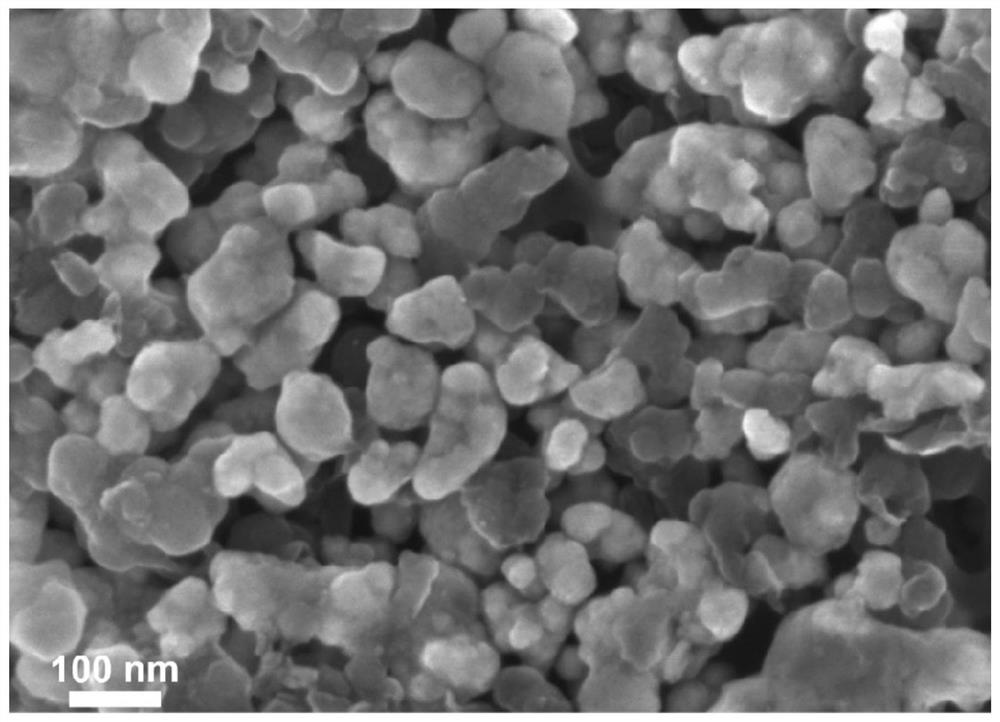

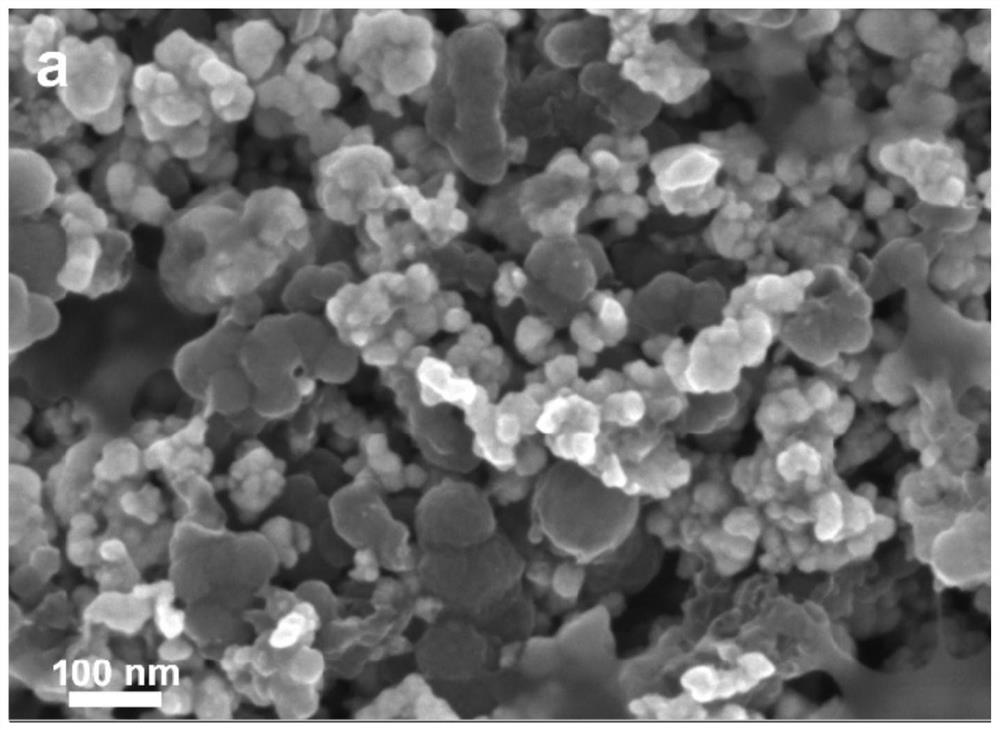

Hydrated ionic liquid gel and preparation method and application thereof

The invention relates to hydrated ionic liquid gel and a preparation method and application thereof. The hydrated ionic liquid gel is prepared through the following method that when gel is prepared through enzymatic gelling, hydrated ionic liquid serves as a solvent, contains organic substances of anions and cations and follows the Huffman ion effect, and the hydrated ionic liquid gel is preparedthrough a hydrothermal method. The hydrogel can be used as a protective agent to stabilize a hydration layer of an enzyme, and has good biocompatibility. Compared with the prior art, the preparation process is mild and efficient, materials are environmentally friendly, and the prepared bioelectronics platform has enzymatic electron transfer and ion transfer capacity and can be widely applied to bioelectronics devices such as glucose sensors, motion sensors and energy storage devices.

Owner:TONGJI UNIV

Road paving method

The invention discloses a road paving method, relating to the technical field of highway construction. The method adopts a cement concrete roadbed and comprises the following steps: (A) preparing a black pavement material by adopting the following raw materials in parts by weight: 30-45 parts of asphalt, 20-31 parts of deep-color silica powder, 13-25 parts of black iron powder, 10-18 parts of carbon powder, 25-35 parts of low-heat cement, 40-50 parts of stone sand, 36-45 parts of water and 12-25 parts of water reducing agent; and (B) paving the black pavement material on the cement concrete roadbed, and compacting by a rolling machine, wherein the paving thickness is 5-7 centimeters. The road paving method is used for changing a white pavement into a black pavement; and compared with the prior art, the road paving method has the advantages of solving the problems that the white pavement is poor in elasticity, poor in visual effect and easy to cause traffic accidents.

Owner:南丹县交通运输局

Soil improvement organic matter fertilizer capable of preventing, controlling and inhibiting soil plant diseases and insect pests

InactiveCN109305849AGood characterImprove fertilityPotassium fertilisersFertilizer mixturesSinomeniumInsect pest

The invention discloses soil improvement organic matter fertilizer capable of preventing, controlling and inhibiting soil plant diseases and insect pests. The soil improvement organic matter fertilizer is prepared from the following ingredients in parts by weight: 20-80 parts of soya-bean oil dreg, 20-80 parts of peanut oil dreg, 20-80 parts of tea oil dreg, 20-80 parts of rapeseed oil dreg, 20-70parts of cottonseed oil dreg, 30-60 parts of radix sophorae flavescentis, 20-60 parts of fructus toosendan, 10-40 parts of stems of sinomenium acutum, 20-50 parts of felon herb, 20-50 parts of herb of sweet wormwood, 20-60 parts of pepper, 5-30 parts of selenium soil, 5-30 parts of calcium soil, 10-50 parts of torpedo rattan and 10-40 parts of garlic. The soil improvement organic matter fertilizer capable of preventing, controlling and inhibiting soil plant diseases and insect pests does not use any chemical additive, and the soil improvement organic matter fertilizer has dual efficacies of fertilizer and the prevention and control of soil diseases and insect pests.

Owner:朱小飞

Really-through ceramic tile preparation method

The invention discloses a really-through ceramic tile preparation method. Really-through ceramic tiles are prepared from, by weight, 35-40% of clay, 25-30% of kaolin and 30-40% of gravel stone, and total aluminum content of raw materials is 14.5-18% while total iron content of the same is less than or equal to 1%. The method includes following steps: A, grinding the raw materials and water until granularity is 40-45um, spray-drying to form granules, and aging until water content is 6.5-7%; B, drying at temperature of 200-250 DEG C for forming, and controlling water content of tile blanks to 0.5-1%; C, spraying glaze water to the surfaces of the tile blanks, putting into a roller kiln, drying at a temperature interval of 200-400 DEG C, and feeding into a temperature interval of 1210-1220 DEG C for firing until water absorptivity is 1-3%. By the method, the problem that existing really-through ceramic tiles are poor in compression resistance and anti-freezing performance, high in water absorptivity, unitary in pattern color and poor in texture.

Owner:广西梧州市远方陶瓷有限公司

Production technique of simulated grey brick

InactiveCN103449774AEfficient use ofAvoid damageWater-setting substance layered productBrickWaste material

The invention discloses a production technique of a simulated grey brick. The simulated grey brick is composed of an upper layer and a lower layer, wherein the lower layer is prepared by mixing and pressing cement, sand, black powder and water; and the upper layer is prepared by mixing and pressing cement, sand, rock powder and water. The production technique comprises the following steps: filling a mixture of cement, sand, black powder and water into a mold, and forming the lower layer of the simulated grey brick in a layer-by-layer wet pressing mode in batches; filling a mixture of cement, sand, rock powder and water into the lower layer, and forming the upper layer of the simulated grey brick in a layer-by-layer wet pressing mode in batches; demolding, and curing in a steam drying chamber for 24 hours; and finally, naturally curing in a place. The technique uses local materials, and utilizes the rock powder instead of the black powder, thereby better utilizing the waste materials, lowering the production cost, reducing the damage to the environment, and enhancing the competitive power of the product.

Owner:ZHEJIANG HENGDIAN CONSTR ENG CO LTD

Alkaline secondary battery and preparation method thereof

ActiveCN113314770AImproved magnification performanceGood electrochemical reversibilityAlkaline accumulatorsAlkaline accumulator electrodesAlkaline waterElectrical battery

The invention discloses an alkaline secondary battery and a preparation method thereof, and belongs to the technical field of alkaline secondary batteries. The alkaline secondary battery comprises a diaphragm, an alkaline aqueous solution electrolyte, a positive electrode and a negative electrode, an active matter of the positive electrode is a Co-Ni-B compound, and an active matter of the negative electrode is a boride. The invention also comprises a preparation method of the alkaline secondary battery, which comprises the following steps: assembling the positive electrode, the diaphragm and the negative electrode in sequence, and adding the alkaline aqueous solution electrolyte to obtain the alkaline secondary battery, wherein the boride in the negative electrode is prepared by the following steps: dissolving hydroboron in an alkaline aqueous solution with the pH value of 10-14, and then dropwise adding the alkaline aqueous solution into a metal salt solution to obtain the boride. The alkaline secondary battery still has outstanding electrochemical performance at low temperature.

Owner:WUHAN UNIV OF TECH

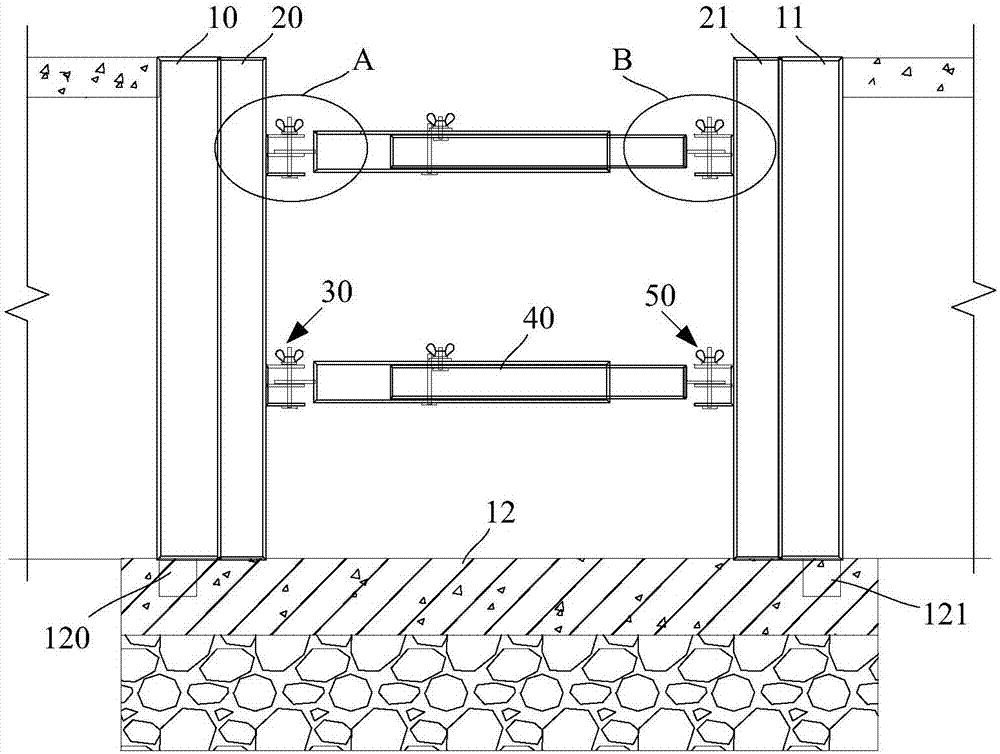

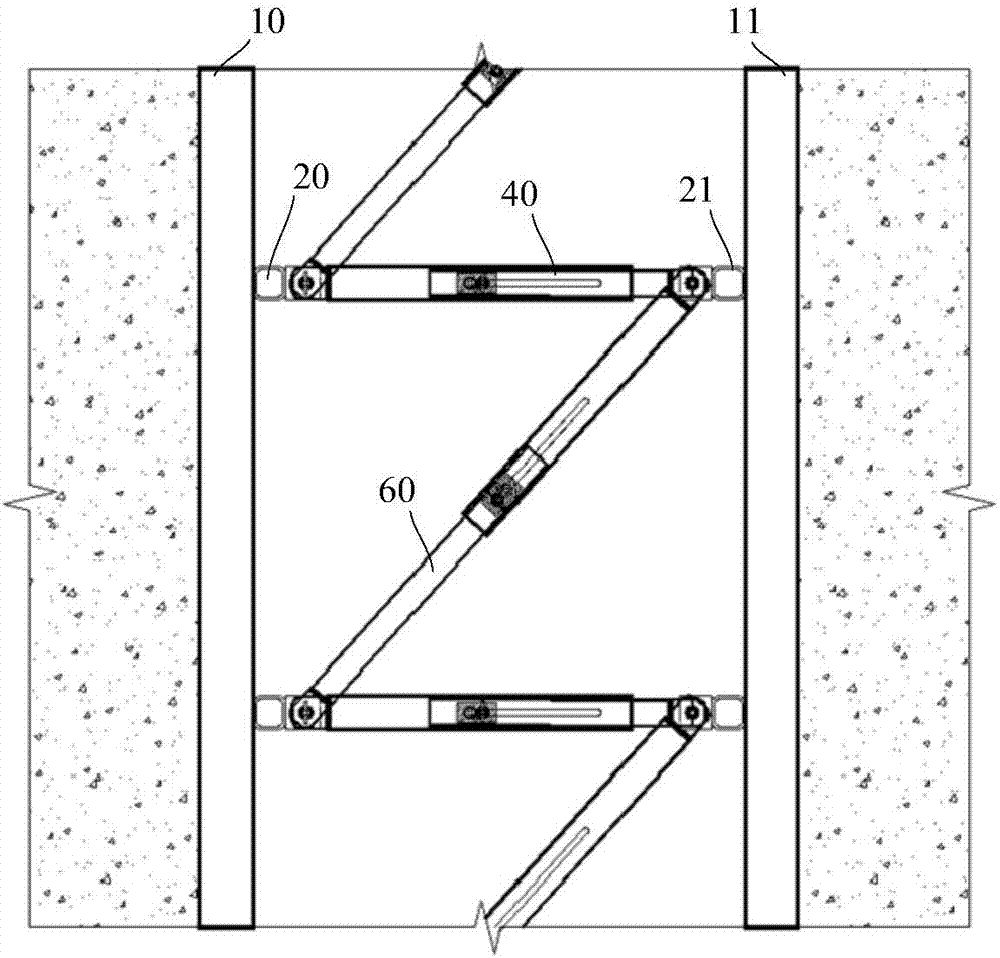

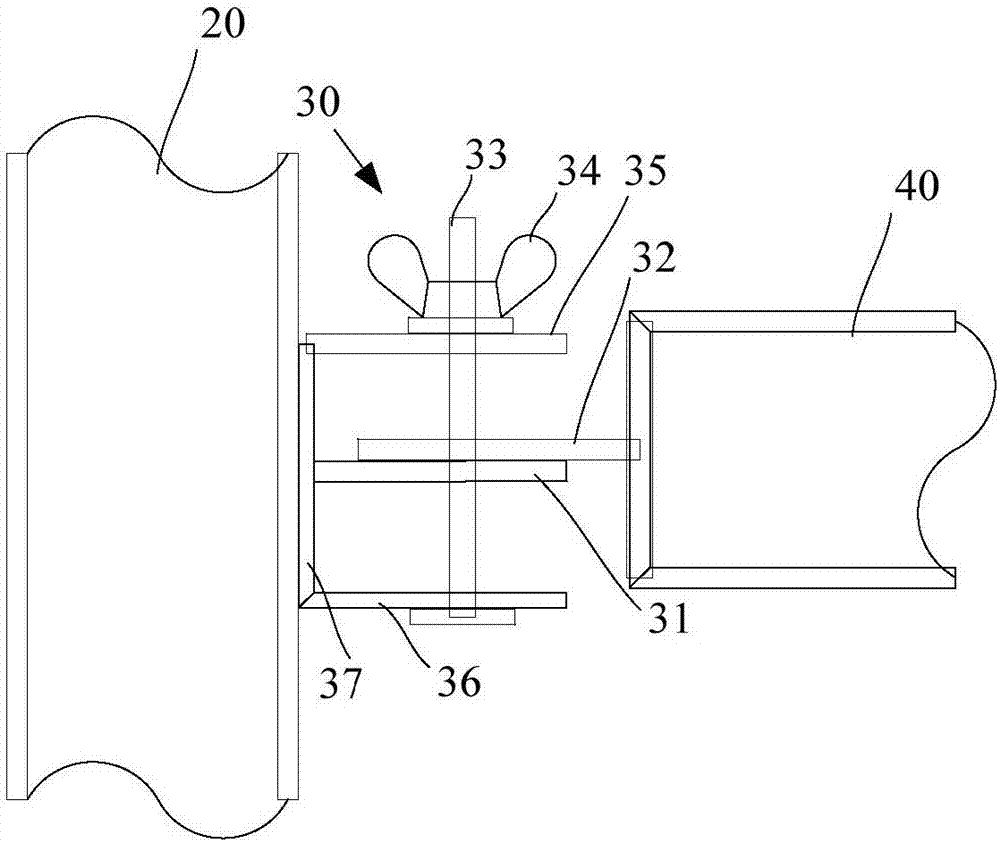

Inner support device of basement precast slab mold and construction method

ActiveCN107313451AGeometrically accurateStable structureArtificial islandsUnderwater structuresBasementCushion

The invention relates to an inner support device of a basement precast slab mold and a construction method. The device is used for supporting between a first precast slab and a second precast slab oppositely arranged; the first precast slab and the second precast slab are vertically arranged on the edge of a basement cushion layer; and the inner support device of the basement precast slab mold comprises at least one first stand column vertically arranged in a basement and bonded on the first precast slab, at least one second stand column vertically arranged in the basement and bonded on the second precast slab, at least one first hinge piece fixed on the first stand column, at least one second hinge piece arranged corresponding to the first hinge piece and fixed on the second stand column, and at least one support pipe capable of adjusting the length, connected between the first hinge piece and the second hinge piece and supported between the first stand column and the second stand column. The device is convenient in disassembly and capable of recycling.

Owner:CHINA CONSTR EIGHTH ENG DIV CORP LTD ZHEJIANG CONSTR CO LTD

Corrosion-resistant electric power steel pipe pole

InactiveCN107936734AImprove corrosion resistanceImprove wear resistanceFireproof paintsAntifouling/underwater paintsCyclodextrinHydroxyethyl cellulose

A corrosion-resistant electric power steel pipe pole belongs to the technical field of an electric power steel pipe pole. The electric power steel pipe pole includes a steel pipe pole body and a protective layer arranged at the external surface of a steel pipe pole wall. The protective layer comprises, by weight, 20-30 parts of a hydroxyethyl cellulose aqueous solution, 0.1-0.2 part of glycerin, 1-3 parts of propanediol, 3-5 parts of propylene glycol butyl ether, 60-70 parts of a pure silicone acrylic emulsion, 0.05-0.1 part of sodium trichlorophenolate, 0.1-0.2 part of magnesium hydroxide, 0.1-0.2 part of zinc dimethyldithiocarbamate, 0.1-0.2 part of castor bean carbonized powder, 0.3-0.5 part of hydroxypropyl starch ether, 0.2-0.4 part of ethylene bisstearamide, 0.05-0.1 part of aluminium-magnesium silicate, 0.05-0.1 part of corn pollen, and 0.05-0.1 part of cyclodextrin. The pH value is adjusted to 8-9. The electric power steel pipe pole is good in corrosion resistance and long in service life, and has advantages of permeability resistance, water resistance, small mass, good flexibility and high strength.

Owner:STATE GRID CORP OF CHINA +1

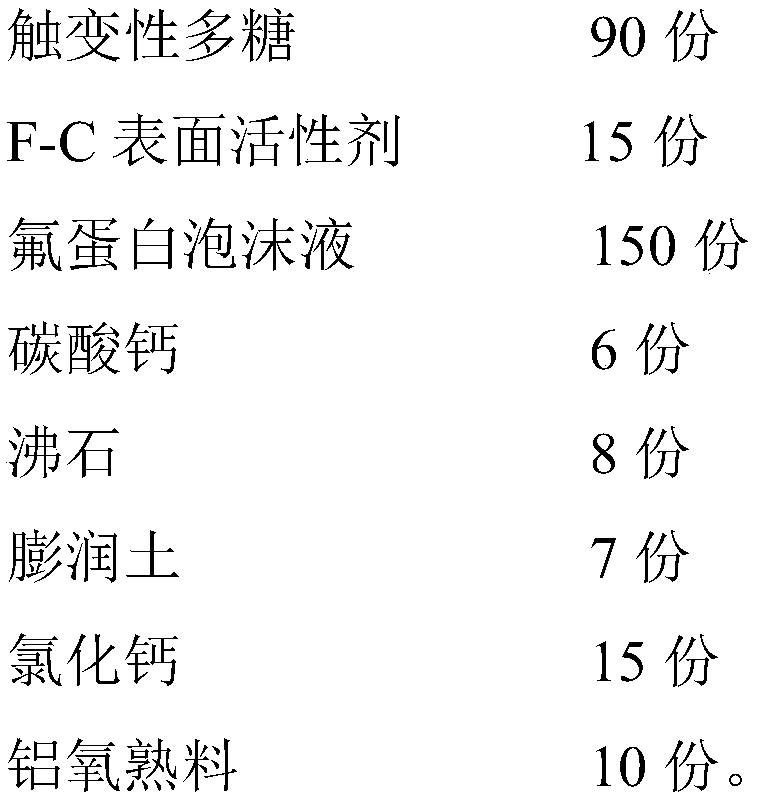

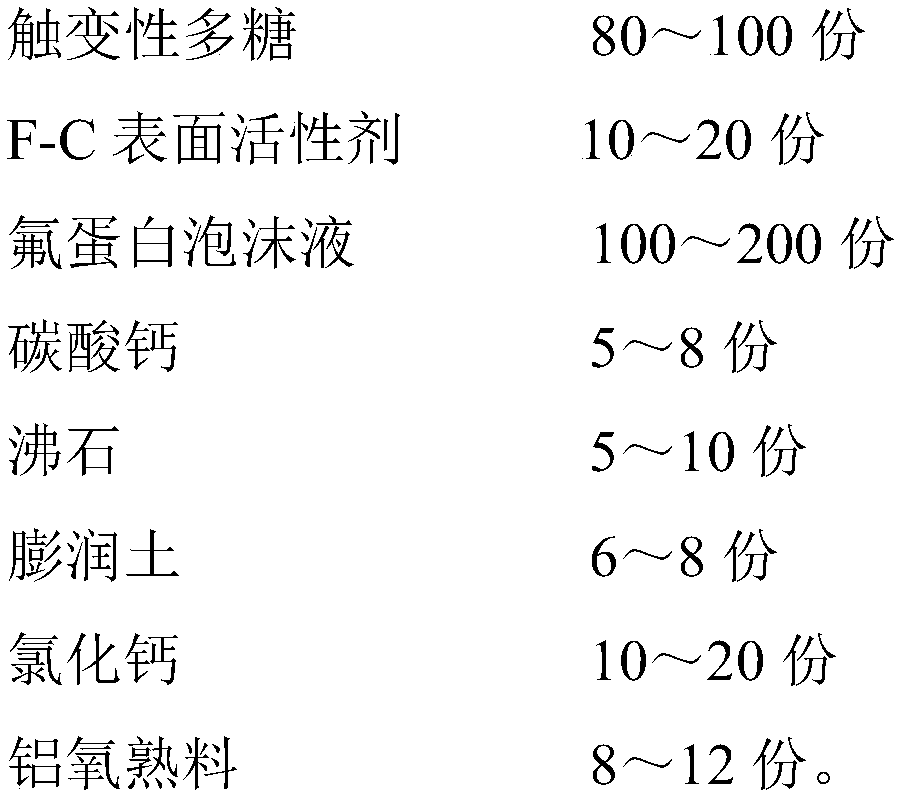

A kind of protein foam fire extinguishing agent and preparation method thereof

Owner:BENGBU LONGTAI FIRE PHARMACY CO LTD

Simulated grey brick

InactiveCN103448313AEfficient use ofAvoid damageWater-setting substance layered productBrickWaste material

The invention discloses a simulated grey brick which is composed of an upper layer and a lower layer, wherein the lower layer is prepared by mixing and pressing cement, sand, black powder and water; and the upper layer is prepared by mixing and pressing cement, sand, rock powder and water. The simulated grey brick uses local materials, and utilizes the rock powder instead of the black powder, thereby better utilizing the waste materials, lowering the production cost, reducing the damage to the environment, and enhancing the competitive power of the product.

Owner:ZHEJIANG HENGDIAN CONSTR ENG CO LTD

Lightweight heat-insulation antifreezing cement and preparation method thereof

The invention discloses lightweight heat-insulation antifreezing cement. The lightweight heat-insulation antifreezing cement comprises the following raw materials in parts by weight: 120-127 parts oflimestone, 8-15 parts of gypsum, 7-14 parts of magnesium carbonate, 0.5-4 parts of sodium sulfate, 0.5-4 parts of potassium nitrate, 0.5-3 parts of slag, 1-5 parts of kieselguhr, 0.5-1.5 parts of talcum powder, 0.5-1.5 parts of mica powder, 11-15 parts of glass fibers, 3-8 parts of silica sand, 6-15 parts of acetylene black, 1-8 parts of dolomite, 30-40 parts of propylene carbonate and 10-17 partsof glycol dimethyl ether. The invention further discloses a preparation method of the lightweight heat-insulation antifreezing cement. The lightweight heat-insulation antifreezing cement has the advantages of lightweight, heat insulation and antifreezing performance.

Owner:苏相伟

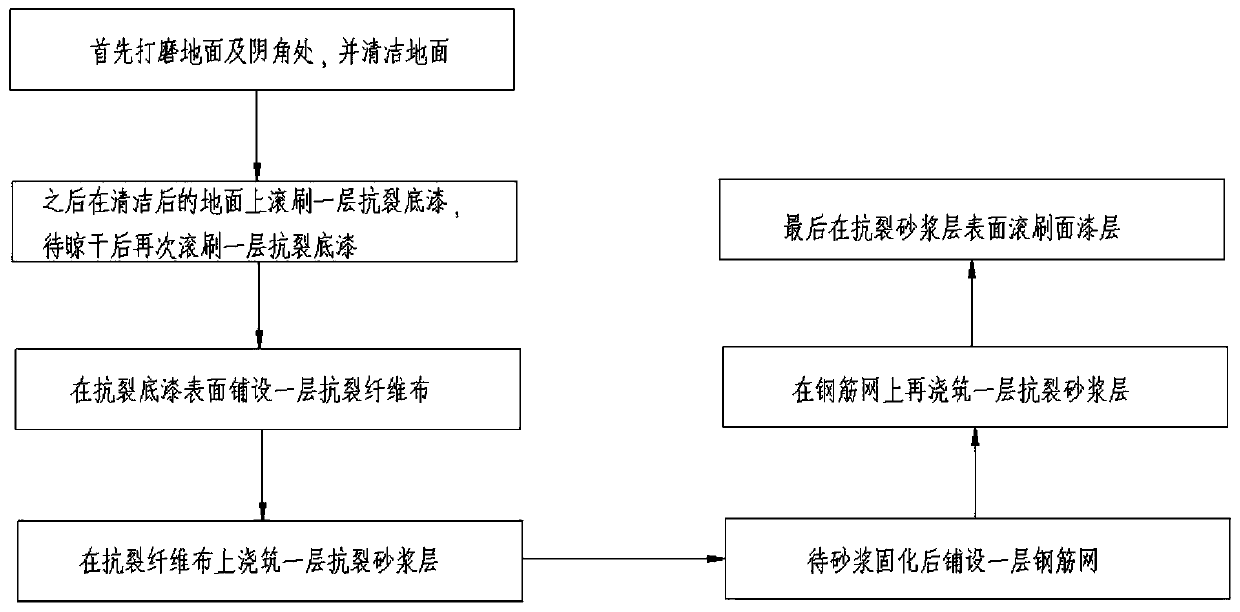

Building ground anti-crack construction process

InactiveCN111305510AImprove crack resistanceImprove impact resistanceEpoxy resin coatingsFlooringFiberScreed

The invention discloses a building ground anti-crack construction process. The building ground anti-crack construction process comprises the following steps of A, grinding the ground and internal corners, and cleaning the ground; B, brushing a layer of anti-crack primer on the cleaned ground, and brushing a layer of anti-crack primer again after the first layer of anti-crack primer is air-dried; C, laying a layer of anti-crack fiber cloth on the surface of the anti-crack primer; D, pouring a layer of anti-crack mortar on the anti-crack fiber cloth; E, laying a layer of reinforcement fabric after curing of the mortar; F, pouring a layer of anti-crack mortar on the reinforcement fabric again; and G, finally, brushing a layer of finish paint on the surface of the anti-crack mortar layer. Through the building ground anti-crack construction process provided by the invention, the properties of crack resistance, impact resistance, pressure resistance and deformation resistance of the ground can be improved, and the durability of the ground is ensured.

Owner:杭州麟奇金属材料有限公司

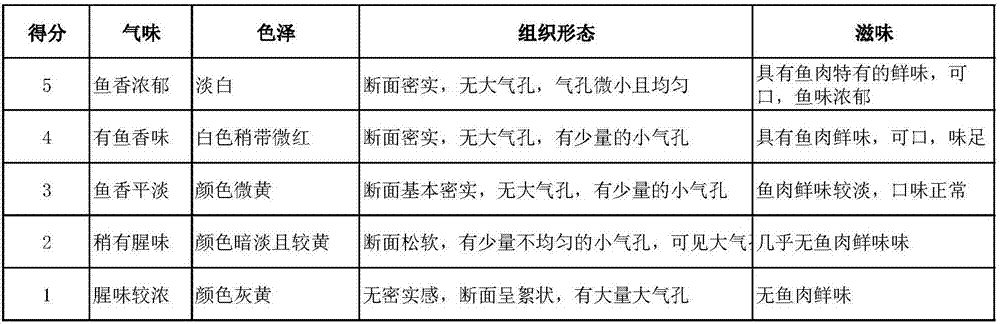

Spotted maigre meat ball and processing technology thereof

The invention discloses a Spotted maigre meat ball. The Spotted maigre meat ball is produced from, by mass, 0.1-0.3% of carnosol, 1-3% of sucrose ester, 0.1-0.3% of chitin, 3-5% of glucomannan, 0.5-1% of betaine, 3-5% of peach gum powder, 1-3% of rice embryo oil, 1.5-2% of edible salt, 0.5-1% of a ginger juice, 1-3% of cooking wine, 0.5-1% of white sugar, 1-2% of soy proteins, 3-5% of egg white, 0.2-0.5% of transglutaminase, 5-10% of potato starch, 20-25% of water, and the balance of Spotted maigre meat. The Spotted maigre meat ball has the characteristics of good frost resistance, good color, good sensory quality, good texture properties and good flavor. The invention also discloses a processing technology of the Spotted maigre meat ball. The technology has the advantages of simple steps, high operability, suitableness for industrialized production, provision of an effective way for the rich resource of Spotted maigre in China, and facilitation of the increase of the economic values of the Spotted maigre.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

Ceramic stone for building

InactiveCN104072101AMeet the strength requirements for impact resistanceFrost resistantClaywaresAluminium hydroxidePotassium dioxide

The invention discloses a ceramic stone for a building. The ceramic stone comprises the following components by weight parts: 50-80 parts of kaolin, 30-50 parts of coal gangue, 20-45 parts of aluminum hydroxide, 10-15 parts of titanium dioxide, 5-8 parts of calcium carbonate, 5-8 parts of ferrous oxide, 5-10 parts of nano iron dioxide, 5-10 parts of nano calcium dioxide, 5-10 parts of nano magnesium dioxide, 5-10 parts of nano sodium dioxide, 5-10 parts of nano potassium dioxide, 5-10 parts of nano zinc dioxide and 5-10 parts of nano aluminum dioxide. The ceramic stone subjected to high-temperature sintering has excellent physical and chemical properties, relatively meeting the building requirements, of freezing resistance, low water absorption rate, high hardness, corrosion resistance and the like of fine ceramics; glazes with various colors can be applied to the surface of the ceramic stone, so that the aesthetic limitations, subjecting to mineral products, of natural stones are greatly eliminated; the ceramic stone has a good self-cleaning function and can meet the impact-resistant strength requirements of the building.

Owner:陈新棠

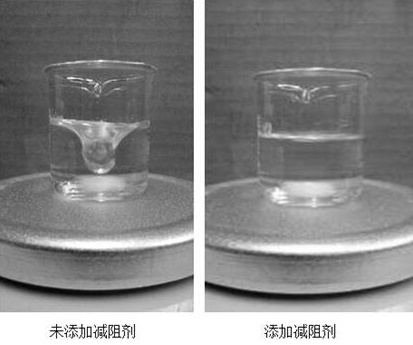

A water-based fire extinguishing agent

ActiveCN110465039BLow flow resistanceImprove cooling effectFire extinguisherProcess engineeringEnvironmental engineering

The invention discloses a water system fire extinguishing agent and belongs to the technical field of fire extinguishing agent preparation. It includes: drag reducer, coolant, antifreeze, anti-corrosion agent, and water-based medium, and the above-mentioned components are compounded according to a certain proportion to obtain a water-based fire extinguishing agent. When the water system fire extinguishing agent of the present invention flows in the pipeline, the flow resistance of the water system fire extinguishing agent can be reduced, and the fire can be released faster. When the water system fire extinguishing agent is used for fire extinguishing, the cooling effect of the water system fire extinguishing agent can be improved, the temperature of the fire site can be reduced, and the fire extinguishing efficiency of the fire extinguishing agent can be higher. The water-based fire extinguishing agent has a certain anti-corrosion performance, so as to reduce the corrosion effect of the water-based fire extinguishing agent on the water tank. It has certain antifreeze performance and is suitable for use in northern cold regions.

Owner:NANJING UNIV OF SCI & TECH

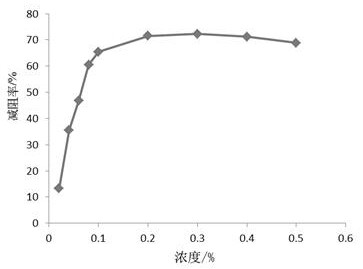

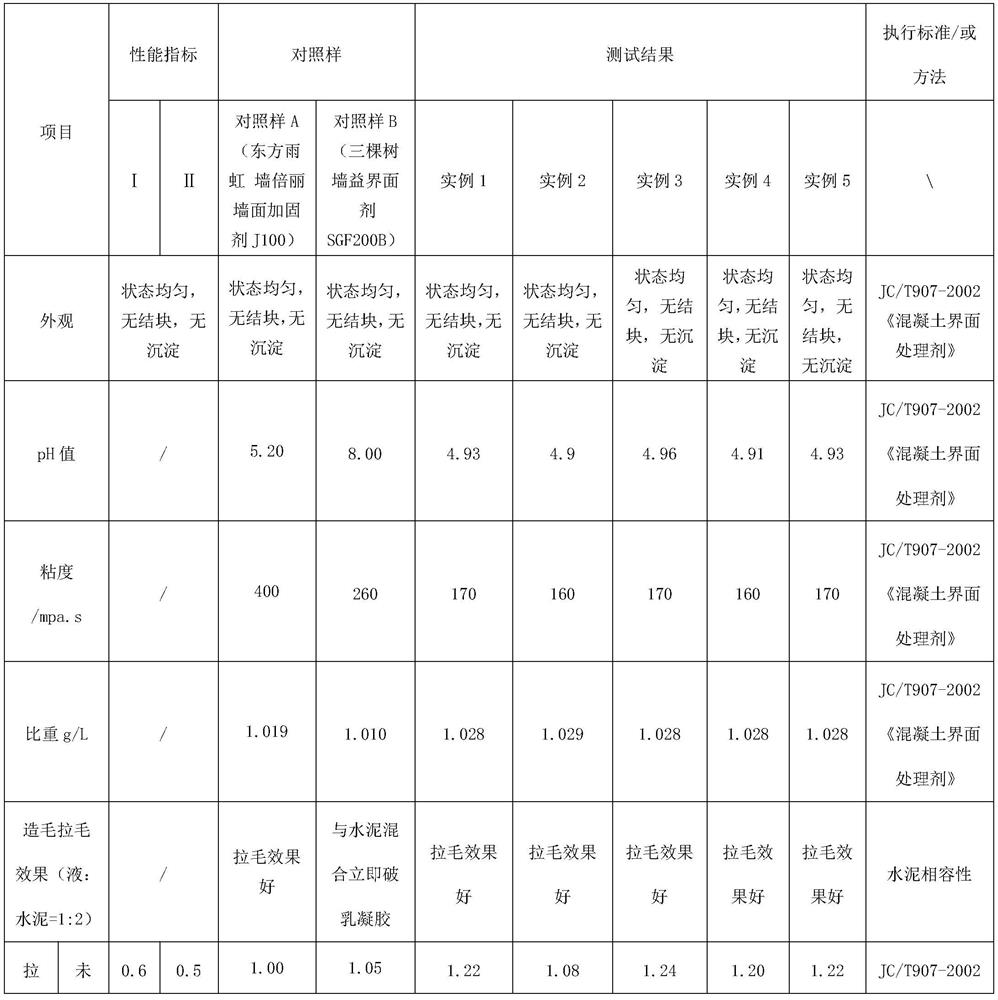

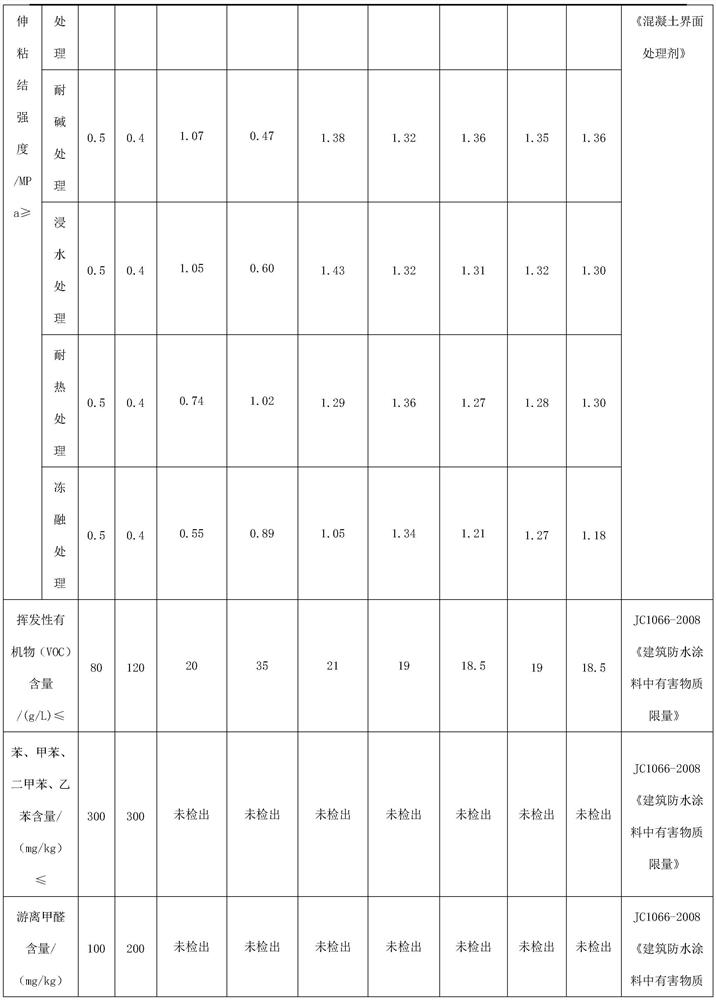

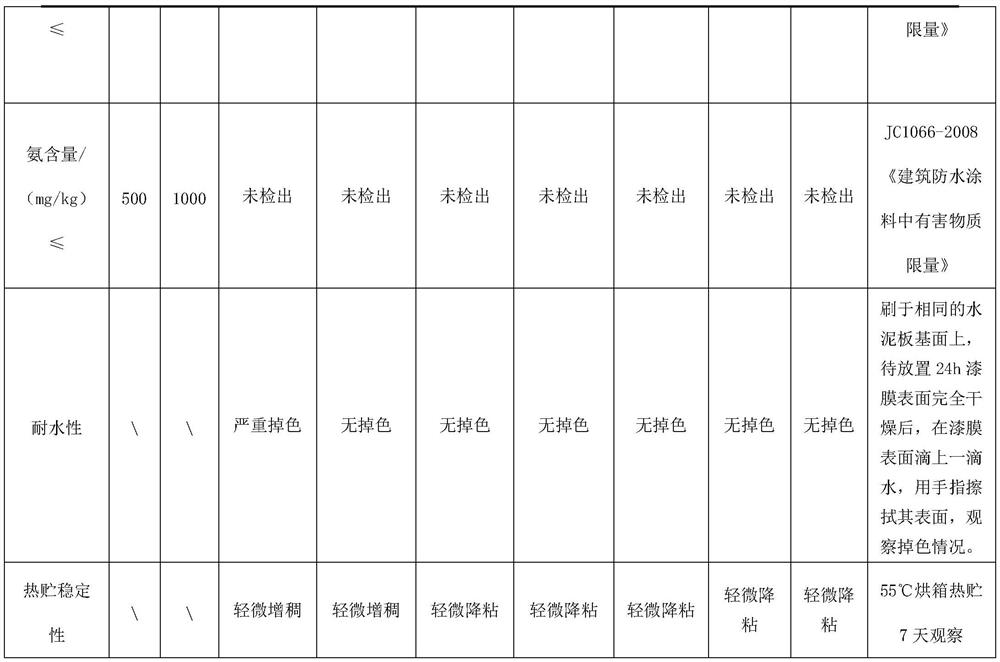

Universal vinyl acetate-vinyl versatate-acrylate copolymer emulsion interface agent and preparation method thereof

ActiveCN111848216ALow costGood heat storage stabilityAgainst vector-borne diseasesButyl acrylateVinyl acetate

The invention relates to a universal vinyl acetate-vinyl versatate-acrylate copolymer emulsion interface agent and a preparation method thereof. The universal vinyl acetate-vinyl versatate-acrylate copolymer emulsion interface agent is mainly prepared from the following components in parts by weight: 10-20 parts of polyvinyl alcohol with a mass percent concentration of 10-15%, 20-30 parts of a vinyl acetate-vinyl versatate-acrylate copolymer emulsion and 55 to 65 parts of water. According to the invention, the defects that a conventional polyvinyl acetate emulsion interface agent has insufficient permeability and poor capacity in infiltration into a base material surface of a wall and is poor in compatibility with cement and low in adhesive force to a wall surface and that the bonding strength of mortar or putty and the surface of a wall body is insufficient are overcome; vinyl versatate, butyl acrylate, hydroxypropyl acrylate and vinyl acetate are added and subjected to copolymerization so as to prepare the vinyl acetate-vinyl versatate-acrylate copolymer emulsion which is used for preparing the universal vinyl acetate-vinyl versatate-acrylate copolymer emulsion interface agent; and the universal vinyl acetate-vinyl versatate-acrylate copolymer emulsion interface agent has characteristics of excellent tensile bonding strength, excellent water resistance, excellent freezing resistance after construction, excellent thermal storage stability, excellent environmental protection property and the like.

Owner:SKSHU PAINT

Heat insulation and heat preservation exterior wall paint and preparing method

InactiveCN105255222AWaterproofScrub resistantAntifouling/underwater paintsPaints with biocidesThermal insulationRutile

The invention relates to heat insulation and heat preservation exterior wall paint and a preparing method. The heat insulation and heat preservation exterior wall paint is prepared from, by weight, 28 parts of water, 1.1 parts of dispersant, 0.51 part of humectant, 2.3 parts of ethylene glycol, 1.2 parts of coalescing agents, 1.4 parts of nanometer Al2O3, 19 parts of rutile titanium dioxide, 20.3 parts of talcum powder, 15 parts of modifier, 12.1 parts of light calcium carbonate, 0.6 part of defoamer and 3.8 parts of thickener. The heat insulation and heat preservation exterior wall paint can be used for painting exterior walls of buildings such as residences, hotels, schools, institutions, dormitories and apartments, has the advantages of being simple for construction, waterproof, free of pollution, toxins and smells, good in heat insulation effect and the like, and has the advantages of being high in adhesive force, good in heat preservation and heat insulation, high in stain resistance, resistant to scrubbing, waterproof, high in corrosion resistance and whether resistance, long in service life and the like.

Owner:景晓丽

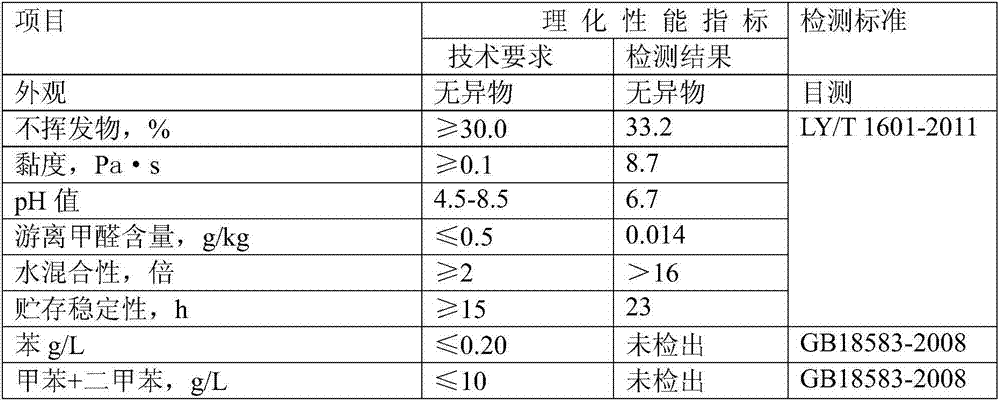

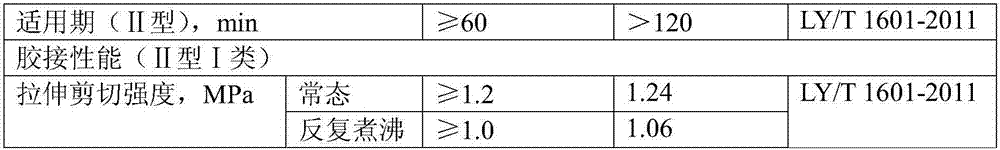

Silanol-based bicomponent waterborne polyurethane wood adhesive and preparation method thereof

ActiveCN107446538AHigh solid contentGood flexibilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesCross-linkVegetable oil

The invention discloses a silanol-based bicomponent waterborne polyurethane wood adhesive and a preparation method thereof. The adhesive mainly comprises a main agent and a cross-linking agent, wherein the main agent is mainly prepared from the following components in parts by weight: 9 to 15 parts of polyving akohol, 6 to 12 pars of pluronic polyols, 15 to 25 parts of silica sol, 0.2 to 0.4 part of propylene glycol, 0.03 to 0.06 part of polyacrylamide, 50 to 65 parts of water, 0.05 to 0.2 part of a surfactant, 0 to 0.15 part of a defoamer, 0 to 0.2 part of a preservative, and 8 to 15 parts of a filler; the pluronic polyol is formed by mixing soybean oil polyol, polyether polyol, and dibutyl phthalate or dioctyl phthalate according to the weight ratio of (6-15):(1-4):(30-60); the cross-linking agent is prepared from the following components in parts by weight: 5 to 8 parts of vegetable oil, 20 to 30 parts of polyol benzoate, and 65 to 75 parts of isocyanate. The isocyanate is high in adhesive strength, good in water weather resistance and weather resistance and environmentally friendly.

Owner:桂林新美环保科技有限公司

Mortar exterior wall coating and preparation method

InactiveCN105295604AAdhesiveFrost-resistantAntifouling/underwater paintsPaints with biocidesEnvironmental resistanceHydroxyethyl cellulose

The invention discloses a mortar exterior wall coating and a preparation method, wherein the mortar exterior wall coating comprises components with weight proportion: water 18 parts, hydroxyethyl cellulose 0.9 part, calcium carbonate 6 parts, acrylic polymer latex paints 39 parts, ethylene glycol 1.1 parts, defoamers 0.6 part, ammonia water 0.4 part, preservatives 0.07 part, dispersants 0.7 part, 80 meshes silica sands 88 parts, titanium dioxide 6 parts, talcum powder 8 parts and heavy calcium carbonate 11 parts. The mortar exterior wall coating and the preparation method can be used to press and wipe building exterior walls of stadiums, cultural palaces, residences, grogshops, schools and hospitals and the like, has the advantages of excellent environmental protective performance, simple construction, simple process, no pollution, no toxicity and no flavor and the like, and has the characteristics of strong adhesive force, frost resistance, strong corrosion resistance, gloss retention, color retention, strong weatherability, mold prevention and algae resistance and the like.

Owner:景晓丽

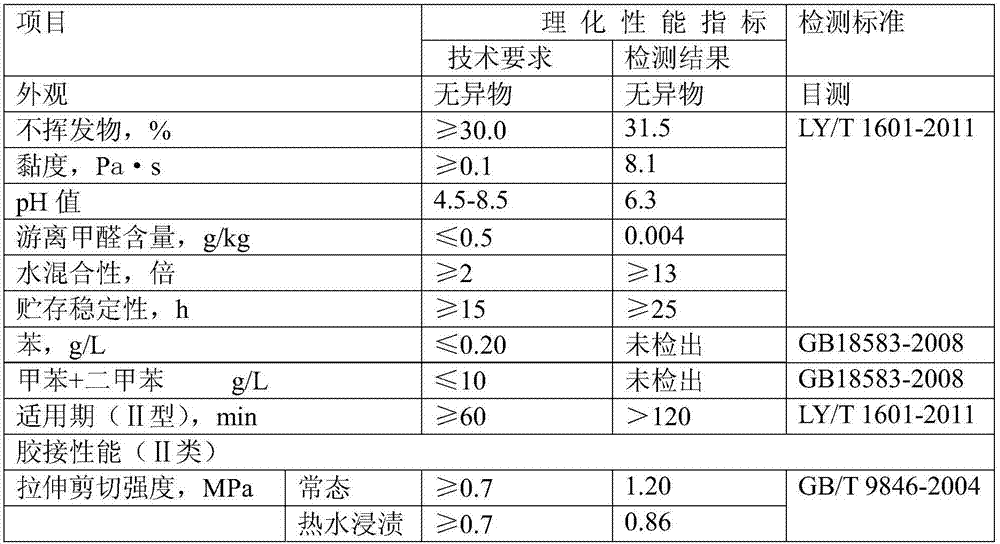

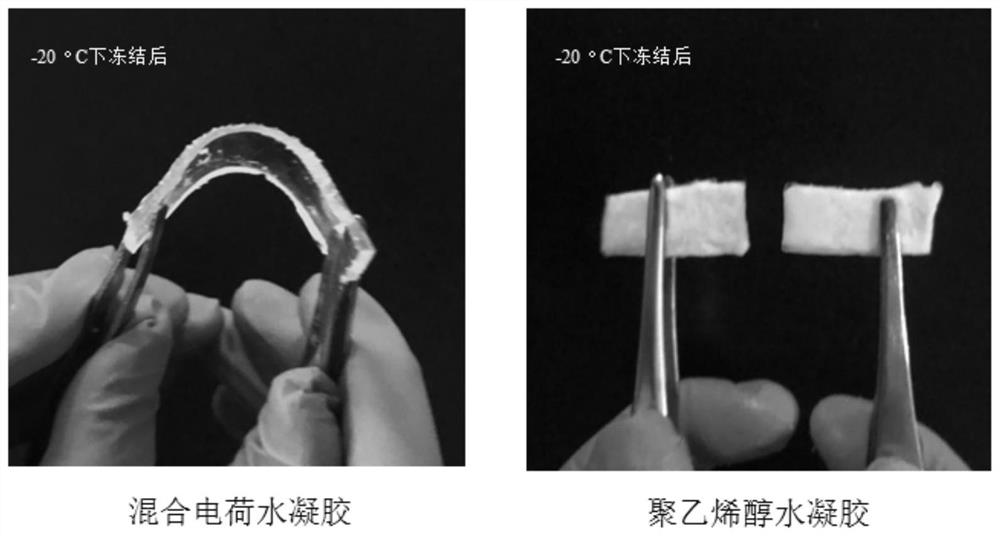

Mixed charge antifreeze hydrogel and preparation method thereof

The invention discloses a mixed charge antifreeze hydrogel and a preparation method thereof. The present invention uses chemical methods to modify the polymer network to reduce the freezing point of the hydrogel to prepare a freeze-resistant and stable hydrogel, and provides a method to make the polymer of the hydrogel have antifreeze performance without adding water to the gel. The innovative idea of adding additional antifreeze substances in the gel, the present invention introduces a variety of charged structures into the hydrogel polymer itself, so that by interfering with the water molecules to form a dense hydrogen bond structure, the formation of water contained in it is inhibited. ice process. The invention can solve the technical problem of how to make the polymer of the hydrogel have antifreeze performance without adding additional antifreeze substances into the hydrogel, so that the hydrogel has antifreeze performance.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Manufacturing method of glazed ceramic exterior wall tile

The invention discloses a manufacturing method of a glazed ceramic exterior wall tile, and relates to the technical field of building material production. The glazed ceramic exterior wall tile is prepared from the following raw materials by weight percent: 25-30% of clay, 25-35% of Tongfu soil, 20-22% of gravel stone and 20-25% of potassium sand; the total aluminum content of the glazed ceramic exterior wall tile is 14.5-18%, and the total iron content of the glazed ceramic exterior wall tile is less than or equal to 2%. The manufacturing method comprises the steps of adding water into the raw materials, wherein the amount of the water is 10% of the total amount of the raw materials, carrying out ball-milling, then deironing and sieving, carrying out spray drying to obtain granules, and staling for 48h or more; pressing a green body under the pressure of 180-230MPa, and drying to obtain a green tile with the water content of 0.5-1%; spraying glaze water onto the surface of the green tile, then putting the green tile into a roller kiln, drying at a temperature region of 200-400 DEG C, and then sending to a temperature region of 1210-1220 DEG C for sintering until the water absorption of a tile body is 1-3%, so as to obtain the glazed ceramic exterior wall tile. The manufacturing method provided by the invention solves the problems that a glazed ceramic exterior wall tile manufactured by the existing production technology is high in water absorption, and is not wear-resistant, pressure-resistant and cold-resistant.

Owner:广西梧州市远方陶瓷有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com