Hydrated ionic liquid gel and preparation method and application thereof

A technology of hydrated ions and lyogels, which is applied in the field of gel materials, can solve the problems of enzyme denaturation, poor gel storage stability, inability to achieve effective combination of ion conduction and enzymatic electron transfer, and achieve stable ion conduction performance and protection No denaturation, guaranteed activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

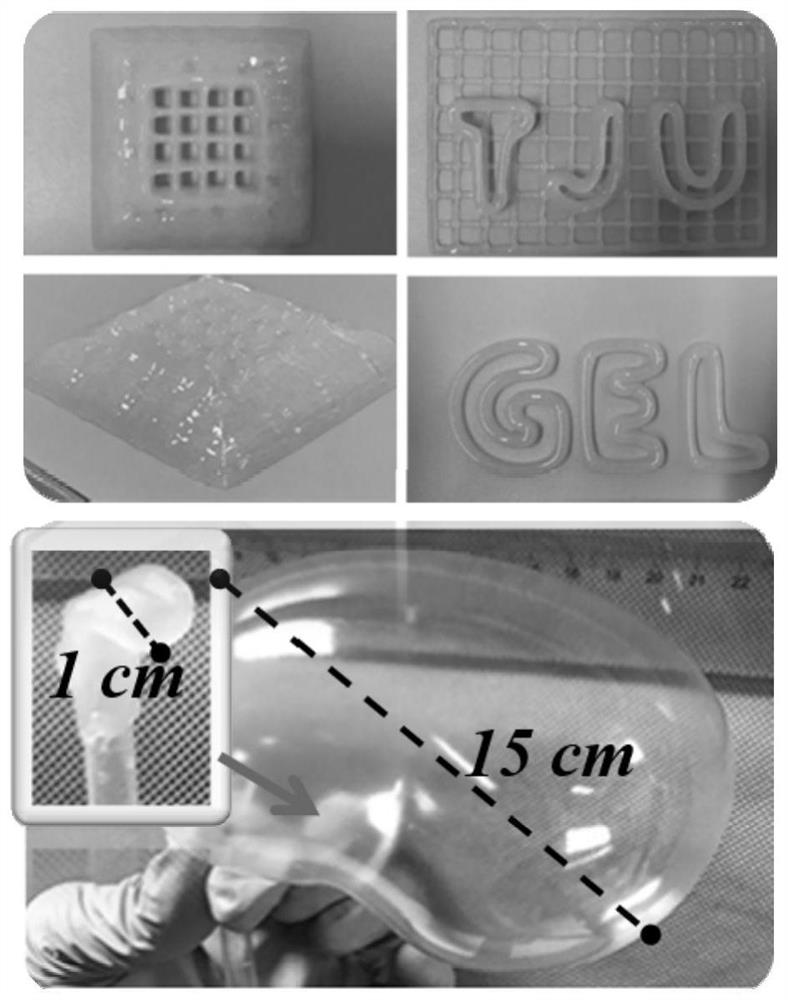

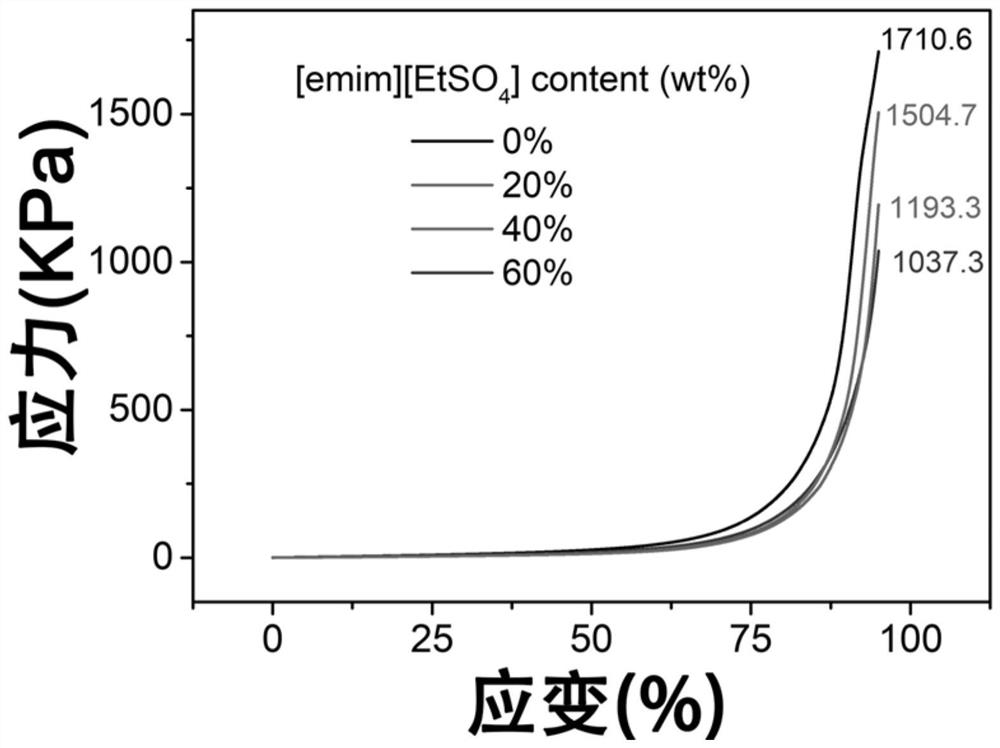

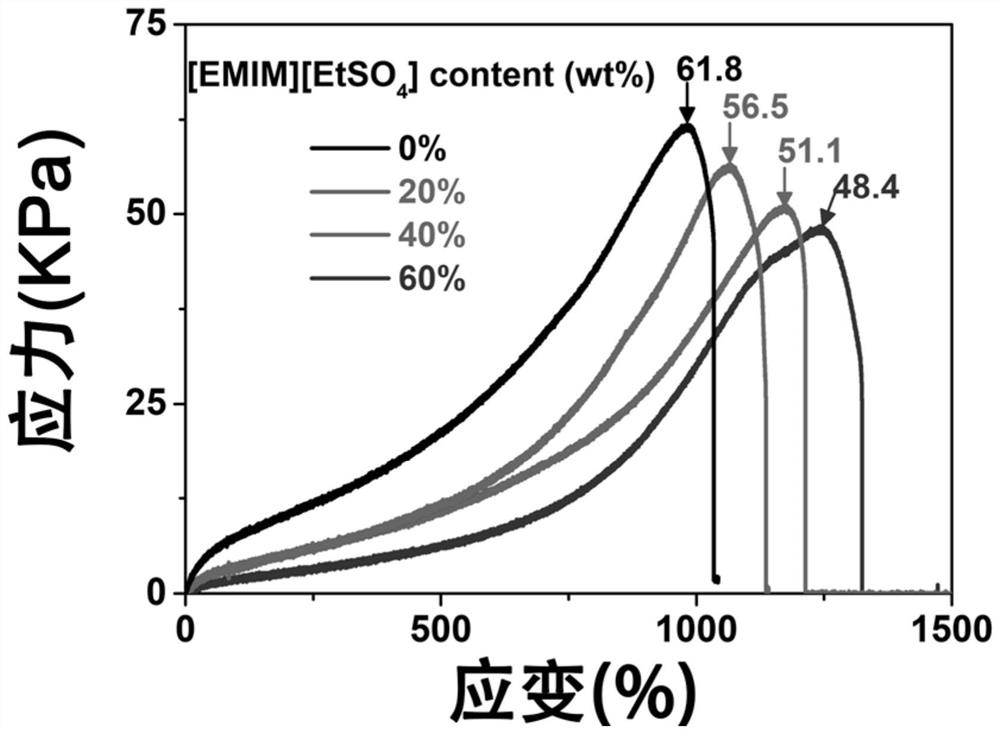

[0052] Add 200 μL acrylic acid (AA), 10 mg double bond chondroitin sulfate (CSMA), 10 mg N-hydroxysuccinimide (NHS), 50 μL glucose solution (40 mmol / L) into 500 μL hydrated ionic liquid (containing 1-ethyl -3-Methylimidazole ethyl sulfate salt 100 μL), stir evenly until the solution becomes homogeneous and transparent. Then, add dilute sodium hydroxide solution dropwise to adjust the pH value of the solution to 4-5, then add hydrated ionic liquid (containing 20% mass fraction of 1-ethyl-3-methylimidazole ethyl sulfate salt) to constant volume to 900 μL; finally, add 100 μL of glucose oxidase solution (10 mg / mL) to obtain a precursor solution. Put the precursor solution in a constant temperature water bath and incubate at 37°C for 60min. Finally, a hydrated ionic liquid gel bioelectronics platform is obtained. Its compressive strength is 1.5MPa, which can withstand 95% of its own deformation; its tensile strength is 56.5KPa, and its maximum tensile deformation is 1300%; its...

Embodiment 2

[0068] Add 200 μL acrylic acid (AA), 10 mg double bond chondroitin sulfate (CSMA), 10 mg N-hydroxysuccinimide (NHS), 50 μL glucose solution (40 mmol / L) into 500 μL hydrated ionic liquid (containing 1-ethyl -3-Methylimidazole ethyl sulfate salt 200 μL), stir evenly until the solution becomes homogeneous and transparent. Then, add dilute sodium hydroxide solution dropwise to adjust the pH value of the solution to 4-5, then add hydrated ionic liquid (containing 40% 1-ethyl-3-methylimidazole ethyl sulfate salt) to constant volume to 900 μL. Finally, add 100 μL of glucose oxidase solution (10 mg / mL) to obtain a precursor solution. Put the precursor solution in a constant temperature water bath and incubate at 37°C for 60min. Finally, a hydrated ionic liquid gel bioelectronics platform is obtained.

Embodiment 3

[0070] Add 200 μL acrylic acid (AA), 10 mg double bond chondroitin sulfate (CSMA), 10 mg N-hydroxysuccinimide (NHS), 50 μL glucose solution (40 mmol / L) into 500 μL hydrated ionic liquid (containing 1-ethyl -3-Methylimidazole ethyl sulfate salt 300 μL), stir evenly until the solution becomes uniform and transparent. Then, add dilute sodium hydroxide solution dropwise to adjust the pH value of the solution to 4-5, then add hydrated ionic liquid (containing 60% 1-ethyl-3-methylimidazole ethyl sulfate salt) to constant volume to 900 μL. Finally, add 100 μL of glucose oxidase solution (10 mg / mL) to obtain a precursor solution. Put the precursor solution in a constant temperature water bath and incubate at 37°C for 60min. Finally, a hydrated ionic liquid gel bioelectronics platform is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com