Preparation method of composite fiber of cellulose nanometer fibrils/alginate

A technology of nanofibrils and composite fibers, which is applied in the fields of cellulose/protein conjugated rayon, rayon manufacturing, and fiber chemical characteristics, and can solve the problems of composite fibers such as biosafety and in vivo degradability, and limited applications , to achieve the effect of high crystallinity, high modulus and high Young's modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

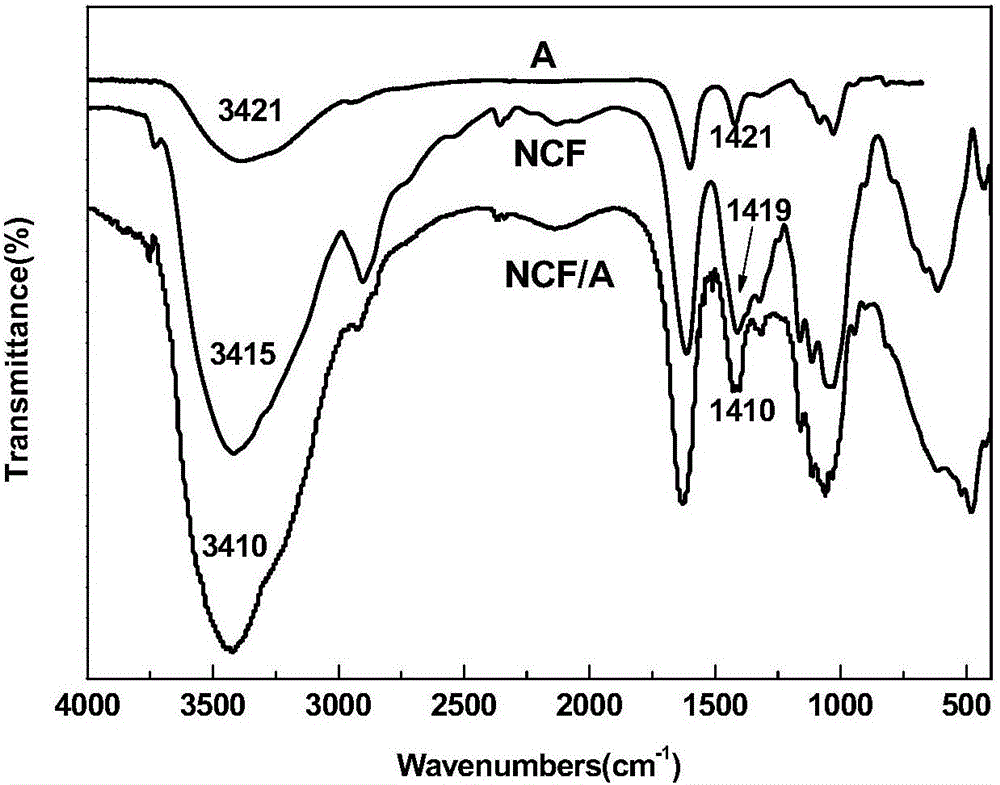

Image

Examples

Embodiment 1

[0053] Under the action of ultrasonic waves, cellulose nanofibrils with an aspect ratio greater than 50 are uniformly dispersed in deionized water, and prepared into a gel-like suspension with a concentration of 2 wt % for later use.

[0054] Weigh sodium alginate and dissolve it in deionized water, let it stand for 3 hours to fully swell the sodium alginate, then stir for 4 hours to prepare a 4% sodium alginate solution by mass, and filter for later use.

[0055] According to the mass ratio of 1:100, slowly add the above-mentioned gelatinous cellulose nanofibril suspension into the sodium alginate solution while stirring, and continue to carry out ultrasonic dispersion treatment for 20 minutes to prepare cellulose nanofibril / seaweed Sodium acid mixed solution; stand for 8 hours to form spinning stock solution after defoaming.

[0056] The spinning dope is extruded into a coagulation bath at 25° C. at a speed of 10 m / min through wet spinning equipment. The diameter of the spin...

Embodiment 2

[0062] Under the action of ultrasonic waves, cellulose nanofibrils with an aspect ratio greater than 50 are uniformly dispersed in deionized water, and prepared into a gel-like suspension with a concentration of 2 wt % for later use.

[0063] Weigh sodium alginate and dissolve it in deionized water, let it stand for 3 hours to fully swell the sodium alginate, then stir for 4 hours to prepare a 4% sodium alginate solution by mass, and filter for later use.

[0064] According to the ratio of mass ratio 3:100, slowly add the above-mentioned gelatinous cellulose nanofibril suspension into the sodium alginate solution while stirring, and continue to carry out ultrasonic dispersion treatment for 20 minutes to prepare cellulose nanofibril / seaweed Sodium acid mixed solution;

[0065] After standing still for 8 hours to defoam, the spinning stock solution is formed.

[0066] The spinning stock solution is extruded into a coagulation bath at 25° C. at a speed of 10 m / min through wet sp...

Embodiment 3

[0071] Under the action of ultrasonic waves, cellulose nanofibrils with an aspect ratio greater than 50 are uniformly dispersed in deionized water, and prepared into a gel-like suspension with a concentration of 2 wt % for later use.

[0072] Weigh sodium alginate and dissolve it in deionized water, let it stand for 3 hours to fully swell the sodium alginate, then stir for 4 hours to prepare a 4% sodium alginate solution by mass, and filter for later use.

[0073] According to the ratio of mass ratio 5:100, slowly add the above-mentioned gelatinous cellulose nanofibril suspension into the sodium alginate solution while stirring, and continue to carry out ultrasonic dispersion treatment for 60min to prepare cellulose nanofibril / seaweed Sodium acid mixed solution;

[0074] After standing still for 8 hours to defoam, the spinning stock solution is formed.

[0075] The spinning dope is extruded into a coagulation bath at 25°C at a speed of 10m / min through wet spinning equipment, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com