Patents

Literature

197results about How to "Low saturated vapor pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting high-quality soybean germ oil by using subcritical butane

ActiveCN102161932AAccelerate the speed of desolvationResidue reductionFatty-oils/fats productionEdible oils/fatsBiotechnologySoy germ

The invention relates to a method for extracting high-quality soybean germ oil by using subcritical butane and relates to the field of grain fine and deep processing. The method comprises: cutting purified soybean germs into slices which are 0.3 to 0.4 millimeters thick; placing the slices in an extraction kettle; performing 1 to 5 times of countercurrent leaching of the cut soybean germs by using liquefied butane as a solvent, wherein the extraction time is 10 to 120 minutes, the material to liquid ratio is 1:(1-6), the extraction temperature is 10 to 90 DEG C, and the extraction pressure is0.2 to 0.1MPa; delivering extracted mixed oil and wet dregs into an evaporation system and desolventizing under reduced pressure; and subjecting the obtained soybean germ crude oil to normal winterization, alkali refining and decolorization processes to obtain a soybean germ oil product with high beta-sitosterol content. In the invention, the soybean germ oil is extracted by using subcritical butane, the manufacturing cost of equipment is reduced considerably, the operation cost is low, the production period is shorter, the yield is high, and the method represents a low-consumption and environment-friendly practical technique for producing soybean germ oil.

Owner:江苏鸿祺生物科技有限公司

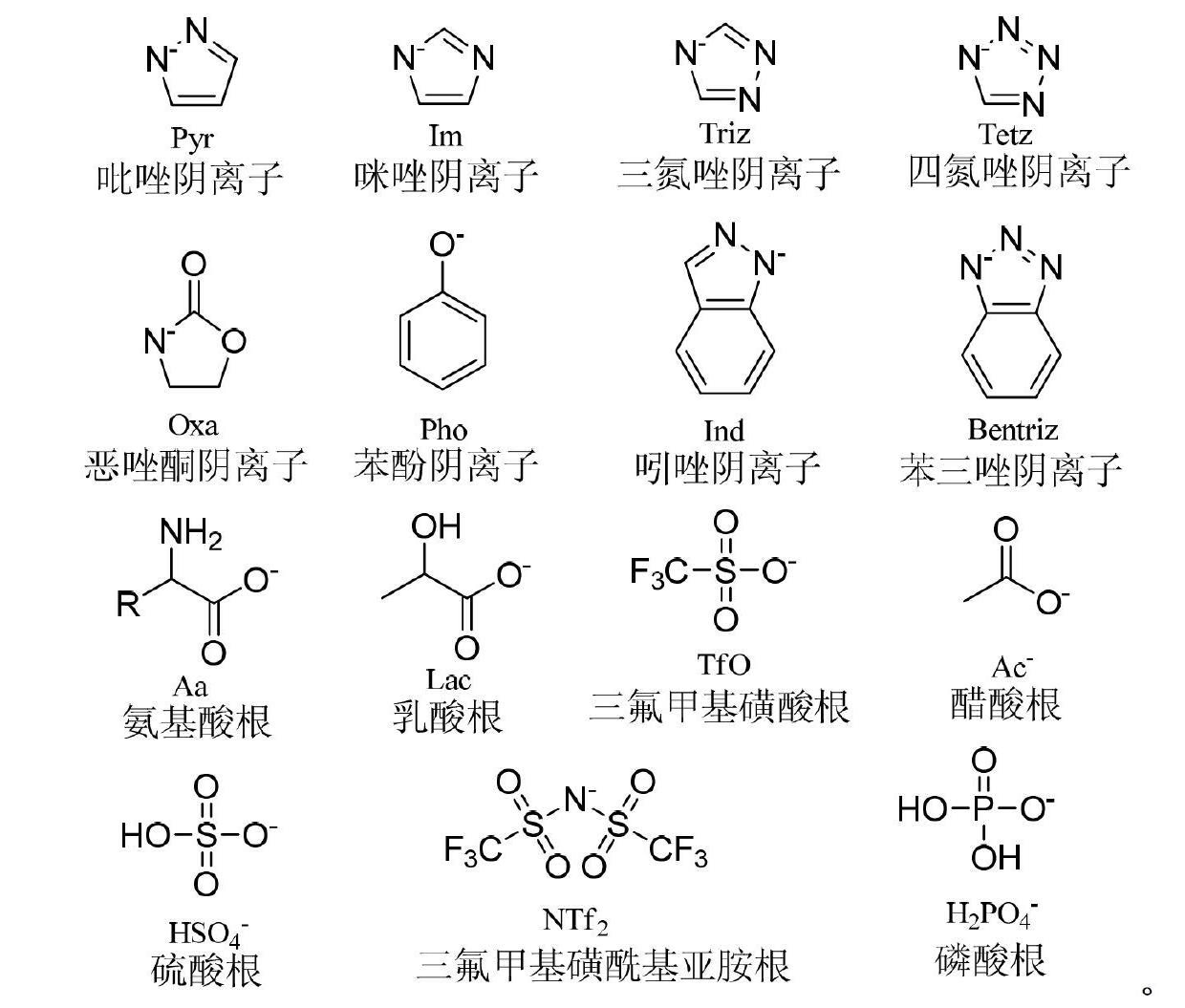

Working substance pair for absorptive thermal cycling system with heat source temperature ranging from 60 to 130 DEG C

ActiveCN102965082AImprove solubilityLow saturated vapor pressureHeat-exchange elementsAlkaneOrganic liquids

The invention provides a working substance pair for an absorptive thermal cycling system with heat source temperature ranging from 60 to 130 DEG C. The working substance pair comprises a working substance and an absorbing substance, wherein the working substance is one or the mixture of more than two substances selected from hydrofluoroalkane, fluoro olefin, fluoro-ether, non-substituted alkane or olefin; the absorbing substance is the mixed liquid consisting of 1 to 50% by mass of ionic liquid and 50 to 99% by mass of organic liquid; and the working substance and the absorbing substance are mixed at 20 to 80 DEG C. The working substance pair can overcome the shortcomings of the conventional working substance pair, and has the characteristics of nontoxicity, safety, and environment conservation.

Owner:WUHAN IND TECH RES INST OF GEO RESOURES ENVIRONMENT CO LTD

Light-color quenching oil complexing agent composition and preparation method thereof

ActiveCN101603118AImprove cooling effectExcellent high temperature cooling performanceQuenching agentsAntioxidantOxygen

The invention relates to a light-color quenching oil complexing agent composition and a preparation method thereof. The light-color quenching oil complexing agent composition comprises the following materials according to proportion by weight: 40 to 88 parts of refrigerant catalyst, 1 to 10 parts of brightener, 1 to 15 parts of antioxidant and 10 to 40 parts of anti-precipitation agent. The prepared composition product has high-temperature and low-temperature refrigeration catalysis functions and favorable brightness property and high-temperature and low-temperature anti-oxygen property and is suitable for preparing common and fast quenching oil with fast brightening.

Owner:锦州康泰润滑油添加剂有限公司

Lasting and effective antistatic polyolefin composite material and preparation method thereof

The invention discloses a lasting and effective antistatic polyolefin composite material. The lasting and effective antistatic polyolefin composite material comprises, by weight, 70-99 parts of polyolefin resin, 0-30 parts of packing, 0-6 parts of compatilizer, 0.5-5 parts of ionic liquid antistatic agent and 0.2-0.5 part of anti-oxygen. The invention further discloses a preparation method of the lasting and effective antistatic polyolefin composite material. The lasting and effective antistatic polyolefin composite material is low in additive amount of the antistatic agent, superior in antistatic performance, the surface resistance can reach 108-1,011 ohm, and the lasting and effective antistatic polyolefin composite material is little influenced by the temperature and humidity, is lasting in antistatic performance and is capable of being applied to various fields with antistatic and dust-free requirements.

Owner:ZHEJIANG JAVA SPECIALTY CHEM CO LTD

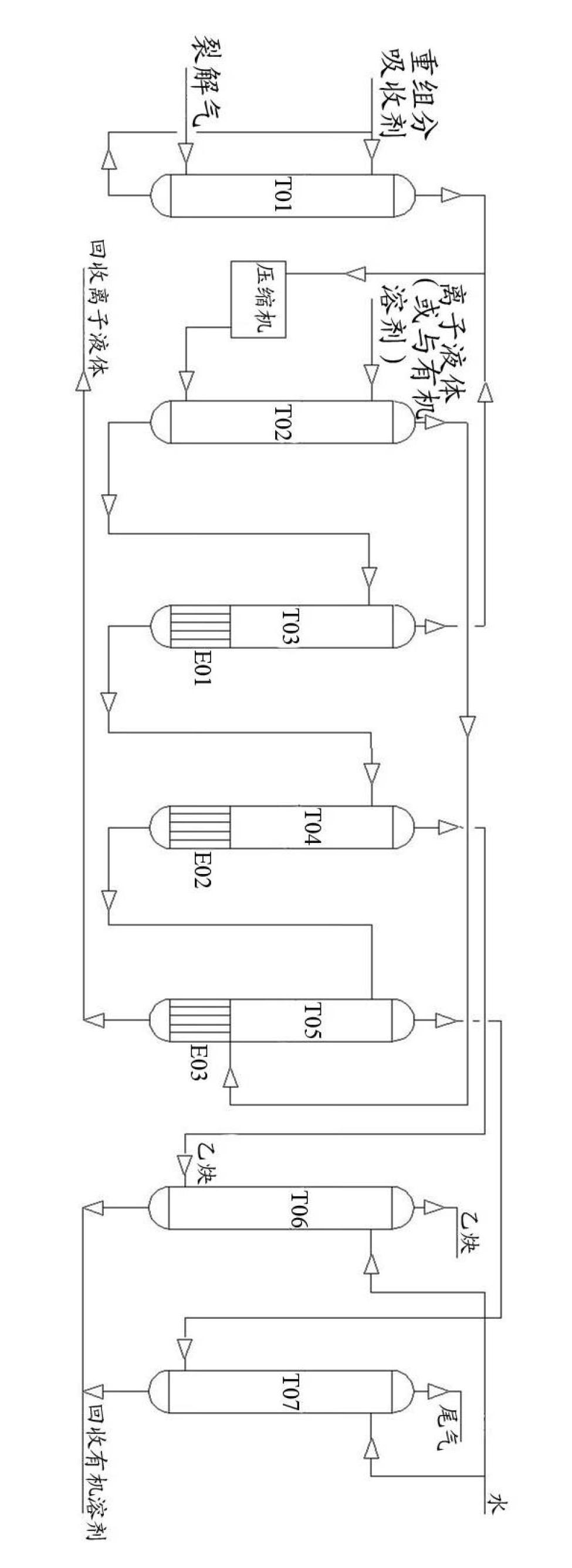

Method for absorbing and separating light hydrocarbons from dry gas or industrial tail gas by utilizing ionic liquid

ActiveCN104277880ARealize multiple recyclingNo pollutionDispersed particle separationLiquid hydrocarbon mixture recoveryAlkaneSolubility

The invention discloses a method for absorbing and separating light hydrocarbons from dry gas or industrial tail gas by utilizing an ionic liquid. The ionic liquid or a mixed solvent of the ionic liquid and a molecular solvent is taken as an absorbent to be in contact with the dry gas or the industrial tail gas, an absorption liquid containing the light hydrocarbons is obtained by absorption and the light hydrocarbons are further obtained by desorption and separation; and the light hydrocarbons are alkanes or olefins which mainly contain C2-C4. The invention provides the method for absorbing and separating the light hydrocarbons from the dry gas or the industrial tail gas by utilizing the ionic liquid. The ionic liquid or the mixed solvent of the ionic liquid and the molecular solvent is taken as the absorbent, an absorption-desorption method is adopted for recovery and separation of the light hydrocarbons, and the absorbent has very high solubility of the light hydrocarbons and separation selectivity, so that efficient separation and recovery of the light hydrocarbons can be realized and the highest comprehensive recovery rate can achieve 98.5%.

Owner:ZHEJIANG UNIV

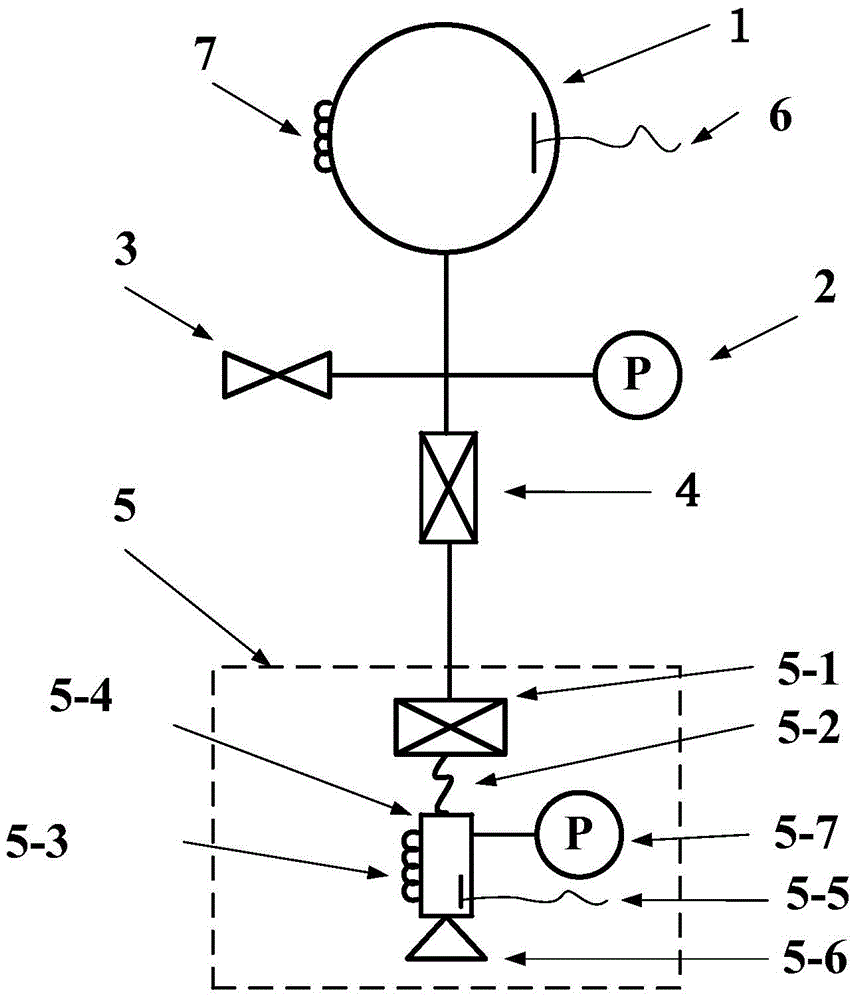

Low-pressure liquefied gas thrust generating method for spacecraft

ActiveCN104828262AReduce weightImprove storage densityCosmonautic propulsion system apparatusSpacecraft guiding apparatusAttitude controlSelf locking

The invention relates to a low-pressure liquefied gas thrust generating method for a spacecraft. According to the method, a specially-designed thrust generating module is adopted to generate thrust and torque for the spacecraft and comprises a storage tank, a first pressure sensor, a charging / discharging valve, a self-locking valve, a thruster, a first temperature sensor and a first heater; the thrust generating module adopts a liquid-storage gas-use working mode, so that pressurized gas is not required to be additionally added into the storage tank, and the supply of a propellant can be driven by only using saturated vapor pressure of liquefied gas; thus, the thrust generating module only needs a liquid charging / discharging valve, and an additional gas charging / discharging valve is not required to be arranged, so that the weight of a system is greatly lowered, and thrust and torque, which have enough accuracy, can be provided for a miniature spacecraft in a microgravity environment and are applied to the attitude control, orbit control or formation flying of the miniature spacecraft.

Owner:BEIJING INST OF CONTROL ENG

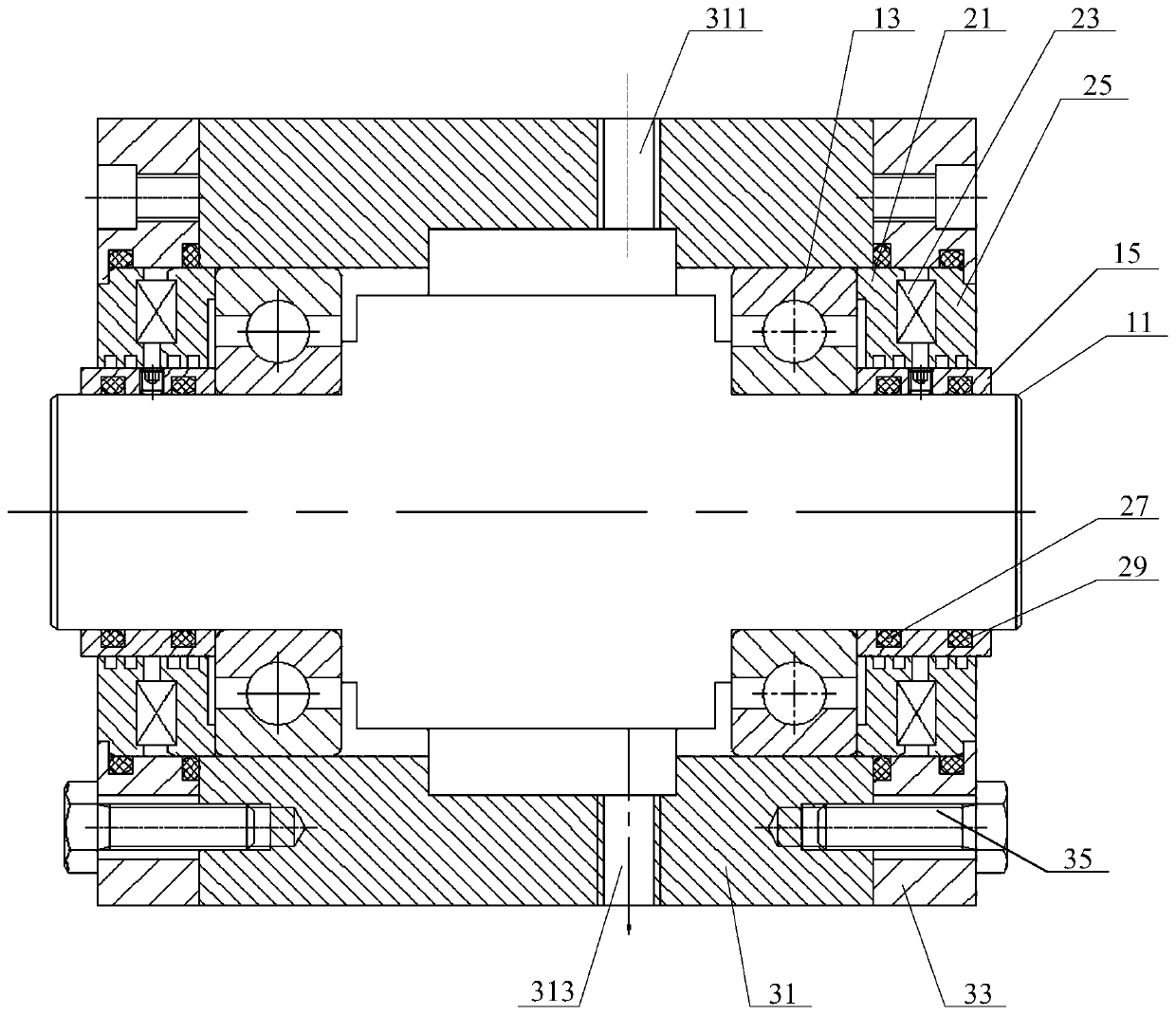

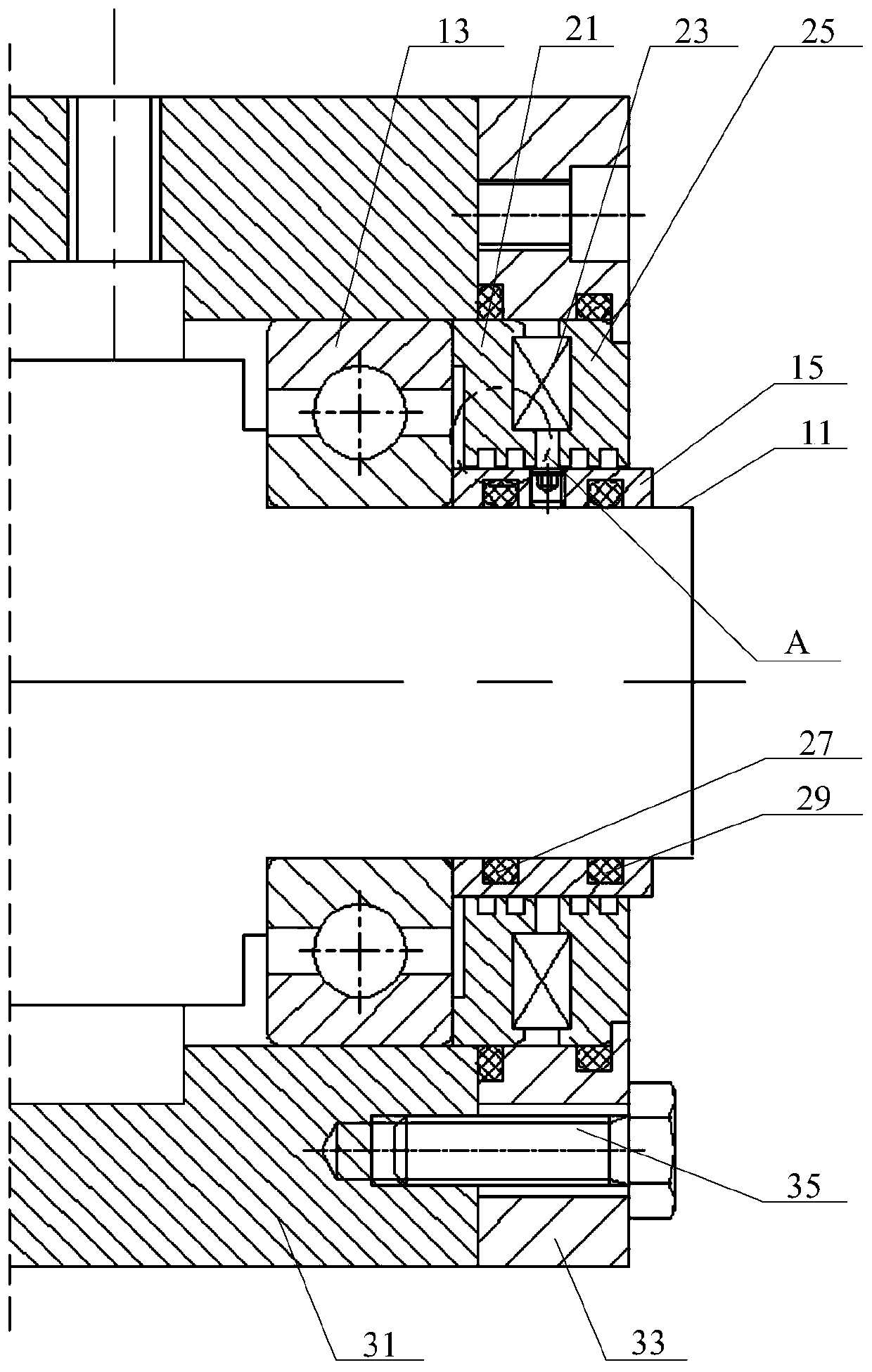

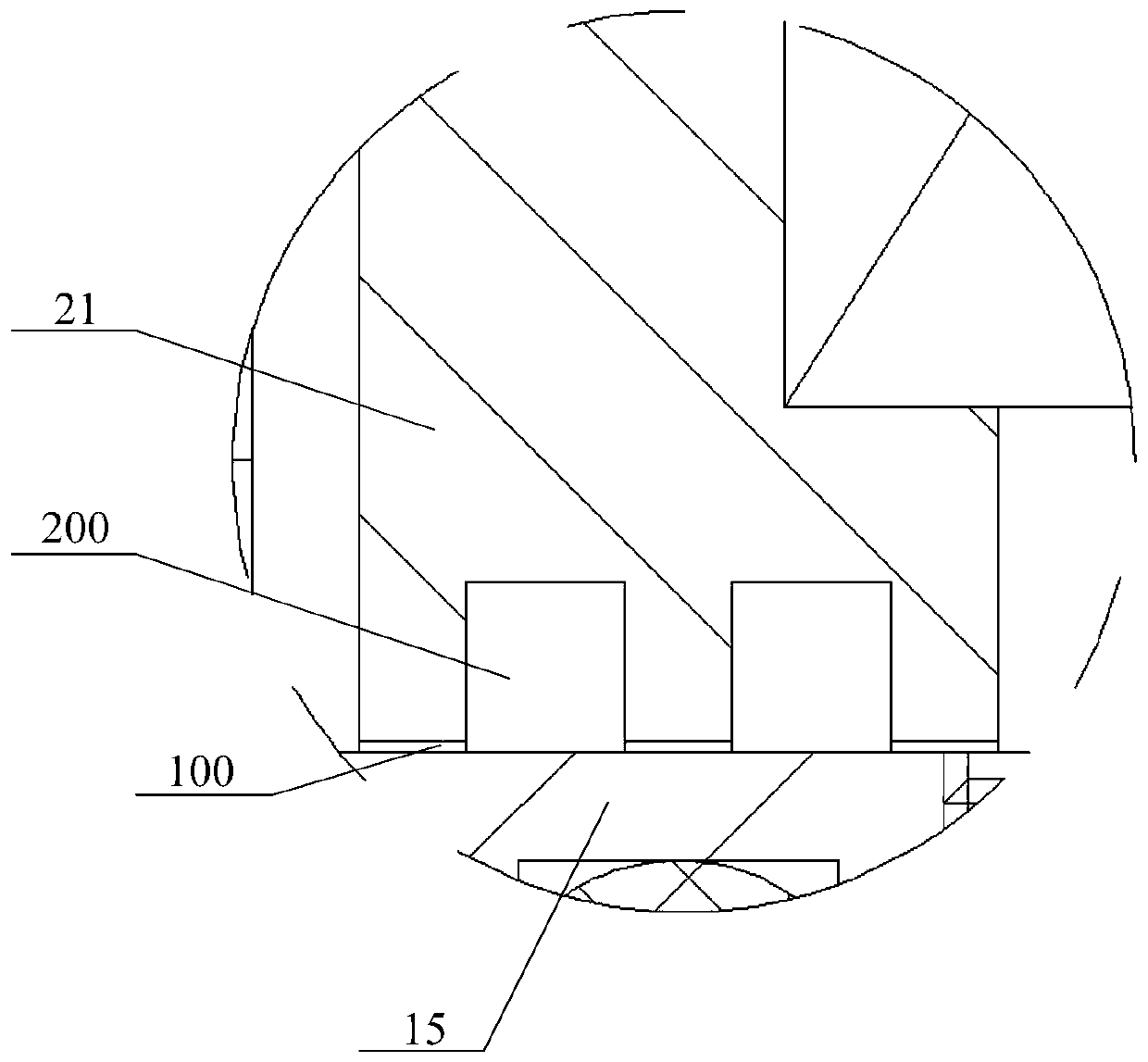

Sealing device and bearing box system

PendingCN110081177AImprove reliabilityGuaranteed service lifeEngine sealsBearing unit rigid supportHuman healthMagnetic line

The invention provides a sealing device and a bearing box system. The device is installed in a bearing cavity which is provided with a shaft, a bearing and a shaft sleeve, wherein the bearing and theshaft sleeve are arranged outside the shaft in a sleeving mode, the shaft sleeve abuts against the end surface of the bearing, and the shaft sleeve is made of a magnetic material; the sealing device comprises a first magnetic conductor, a permanent magnet and a second magnetic conductor; the first magnetic conductor, the permanent magnet and the second magnetic conductor are arranged outside the shaft sleeve in a sleeving mode, the first magnetic conductor abuts against the end surface, the permanent magnet is clamped between the first magnetic conductor and the second magnetic conductor, andthe permanent magnet, the first magnetic conductor, the shaft sleeve and the second magnetic conductor are matched to form a closed magnetic line; and gaps are formed between the outer wall of the shaft sleeve and the inner wall of the first magnetic conductor and between the outer wall of the shaft sleeve and the inner wall of the second magnetic conductor, and pole teeth are arranged on the inner wall of the first magnetic conductor and the inner wall of the second magnetic conductor, and the gaps and the pole teeth are all filled with magnetic fluid. The embodiment of the sealing device caneffectively ensure the sealing effect on the bearing cavity, thereby avoiding environmental pollution and harm to human health.

Owner:BEIJING UNIV OF CHEM TECH

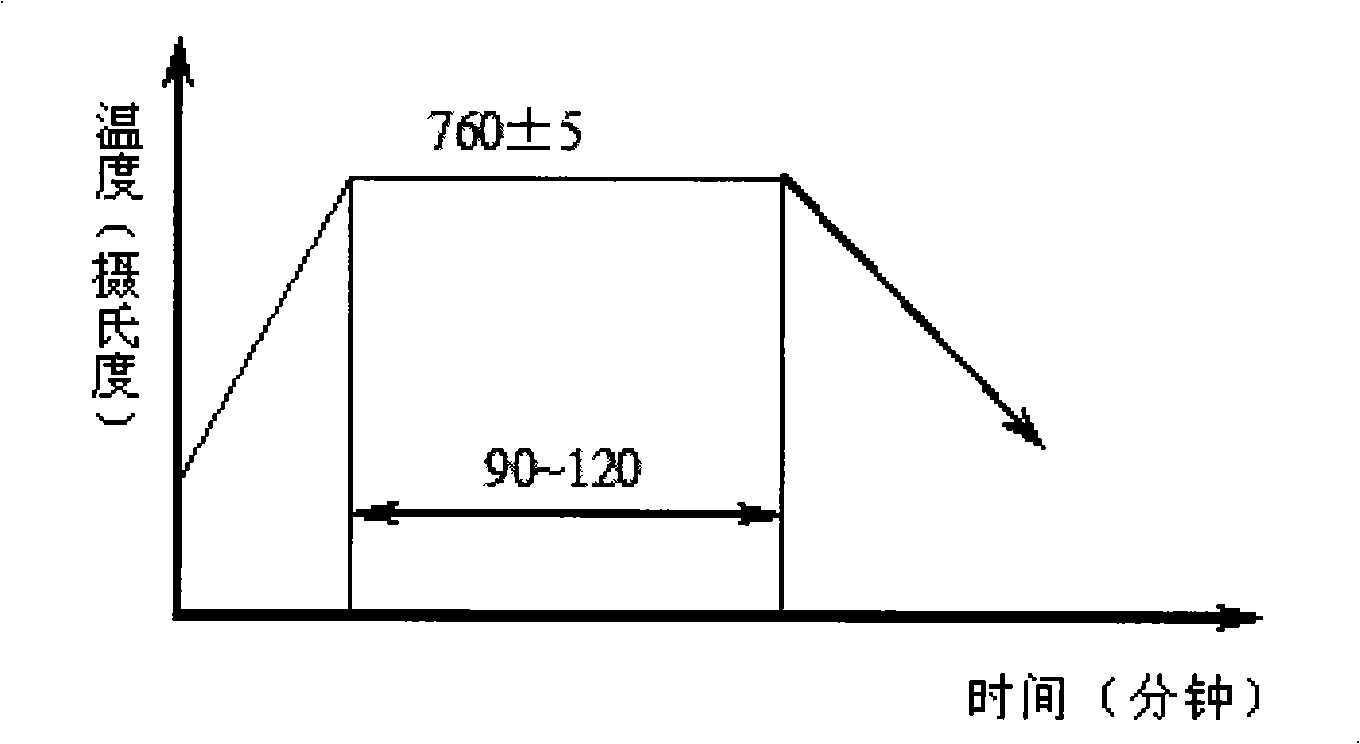

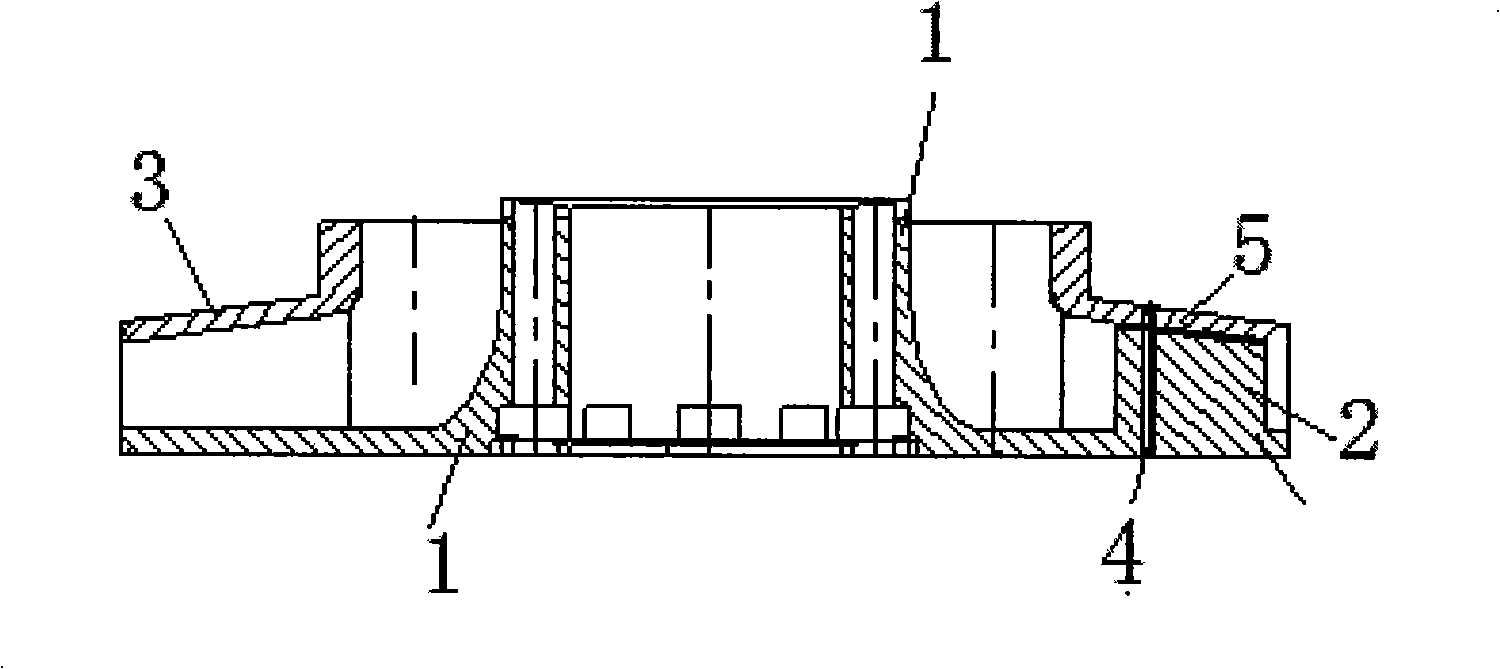

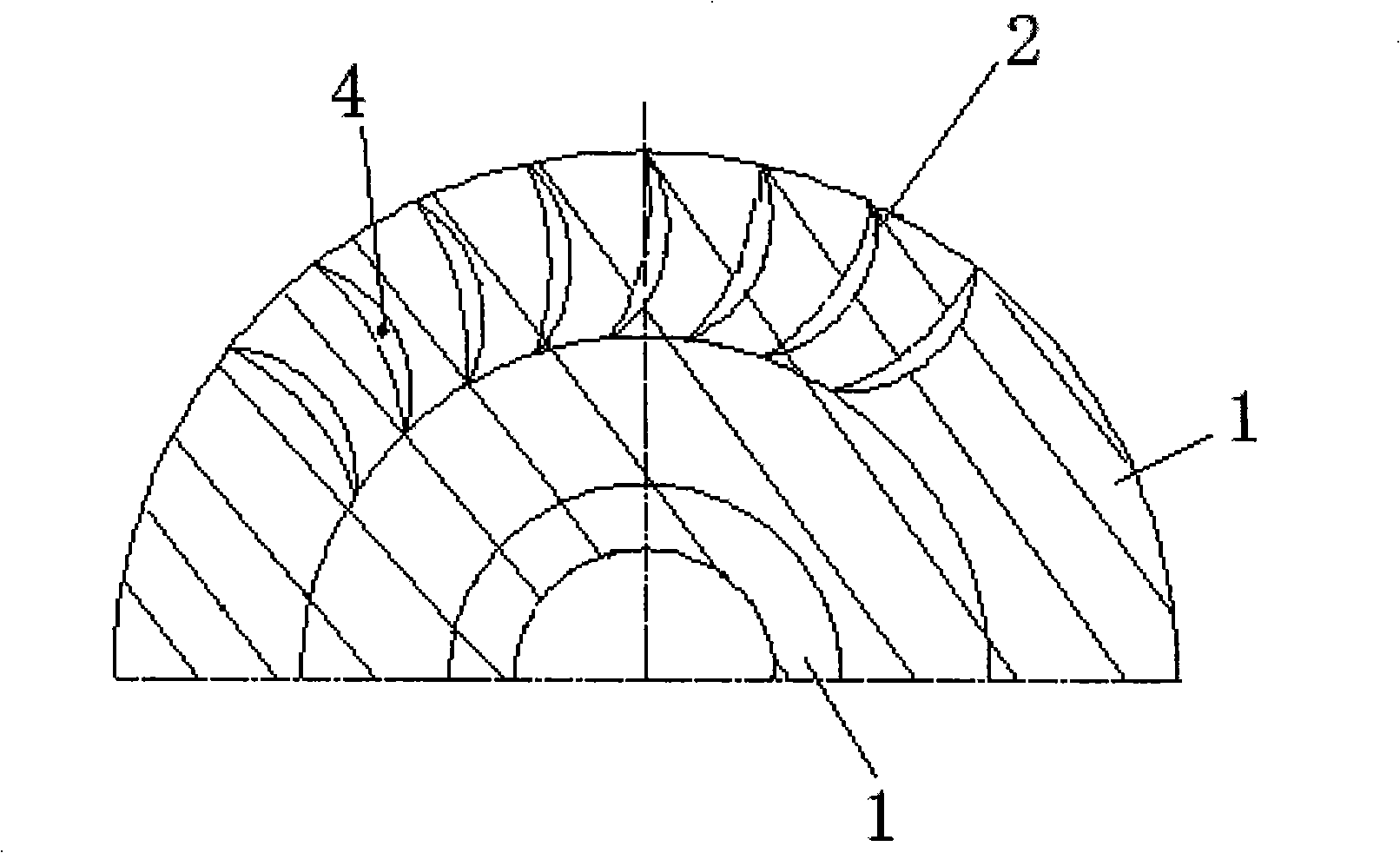

Vacuum brazing method for pump impeller

The invention relates to a vacuum brazing method for a pump impeller, which comprises the following steps: 1) cutting soldering terminals into shapes corresponding to those of the cross sections of blades on an impeller, and punching positioning holes on the 2 to 3 soldering terminals; 2) cleaning a pump impeller to be welded and the soldering terminals, and checking the smoothness of welding surfaces of the blades; 3) preheating the pump impeller to be welded; 4) coating the welding surfaces of the blades to be welded with welding flux, placing the soldering terminals on the welding surfaces of the blades, and then coating the welding flux on the upper surfaces of the soldering terminals; 5) using a pump cover to cover the upper surfaces of the soldering terminals, and using positioning pins to fix the pump cover on the soldering terminals; 6) assembling an upper pressed tyre and a lower pressed tyre together by the pump impeller to be welded; 7) sending an assembly into a heating chamber in a vacuum furnace for heating; and 8) taking out a workpiece after the temperature reduction. The pump impeller brazed by the method has uniform and full welding seams, apparent circular arcs at interfaces, compactly combined welding surfaces, no air holes, high welding strength, and longer service life.

Owner:CRRC BEIJING ERQI LOCOMOTIVE CO LTD

Preparation of magnetic fluid for ultra-high vacuum sealing device

ActiveCN101388270AHigh strengthImprove stabilityMagnetic liquidsIron compoundsWater bathsUltra-high vacuum

The invention relates to a method for preparing magnetic fluid for a ultrahigh vacuum sealing device, which uses the following steps: A) Fe2+ soluble salt and aqueous solution of Fe3+ soluble salt are mixed according to the molar ratio of Fe2+ and Fe3+, which is 1:2. B) obtained mixed solution is placed in 80 DEG C constant temperature water bath, excessive ammonia is added to generate Fe3O4 particles, oleic acid is added, thereby obtaining magnetic nano Fe3O4 particles which are coated with the oleic acid. C) the magnetic nano Fe3O4 particles which are coated with the oleic acid are dispersed in dioctyl sebacate and is placed in 100 DEG C constant temperature water bath, modified polyoxyethylene ether is added after being stirred for 30min, the temperature is increased to 150 DEG C, emulsification pretreatment is done for 60min, the temperature is reduced below 60 DEG C, thereby obtaining the magnetic fluid for the ultrahigh vacuum sealing device. The method for preparing the magnetic fluid for the ultrahigh vacuum sealing device has lower requirements for experiment instruments and operation conditions, the prepared magnetic fluid is very steady, the saturated vapor pressure is very low, and the startup torque is also low.

Owner:浙江微磁精密技术股份有限公司

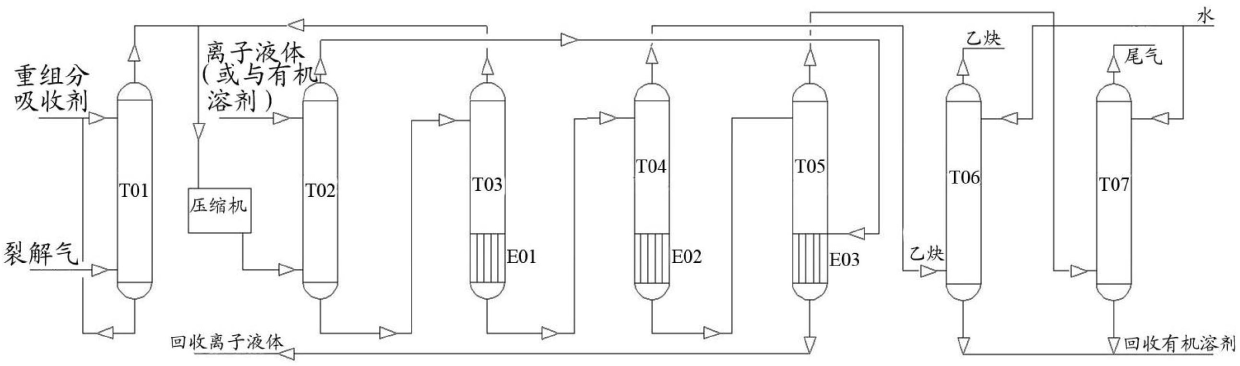

Separating preparation method of acetylene by absorbing pyrolysis gas with ionic liquid

ActiveCN102675028ARealize multiple recyclingImprove thermal stabilityAbsorption purification/separationBulk chemical productionEnvironmental resistanceDesorption

The invention discloses a separating preparation method of acetylene by absorbing pyrolysis gas with ionic liquid, which comprises the following steps of: absorbing heavy components in pyrolysis gas by heavy component absorbent, sequentially absorbing the pyrolysis gas under high pressure by taking the ionic liquid or the mixed solution consisting of the ionic liquid and organic solvent as absorbent and adopting an absorption-desorption method, and carrying out split reduction and warming desorption on the preheated absorption liquid, to desorb the light components, the acetylene and the high alkyne, so as to obtain the high-purity acetylene in a separation way. The method has the characteristics of being high in separation efficiency, less in solvent energy consumption, safe, environment-friendly, suitable for the industrial production, and the like.

Owner:XINJIANG YUEHETAI CHEM TECH CO LTD

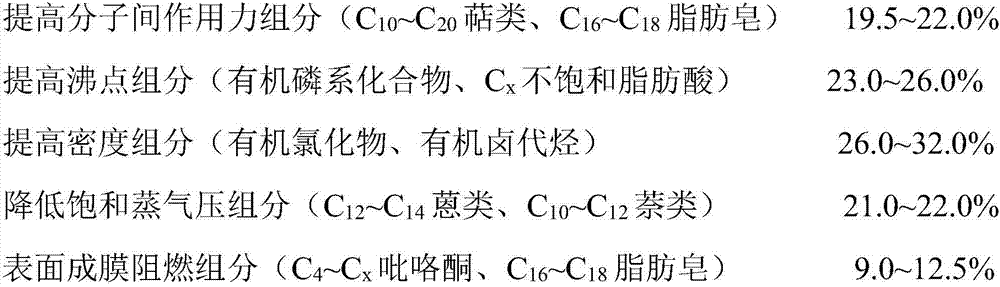

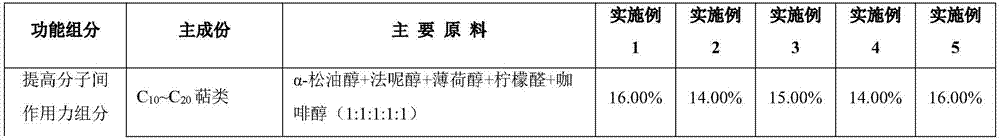

Biological alcohol-based light fuel flash point improver

ActiveCN106906014ATurn waste into treasureTurn waste into energyLiquid carbonaceous fuelsSpontaneous combustionAlcohol

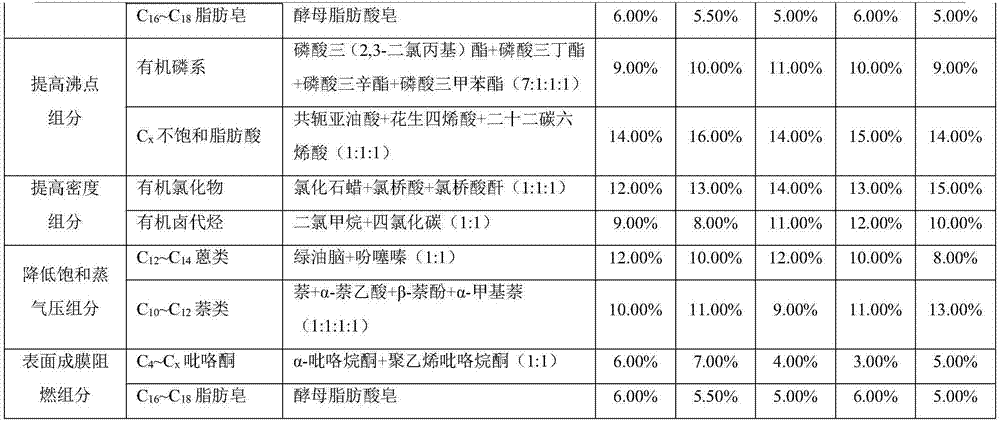

The invention discloses a biological alcohol-based light fuel flash point improver, which is composed of 19.5 to 22.0% of a component capable of increasing intermolecular force, 23.0 to 26.0% of a component capable of increasing the boiling point, 21.0 to 22.0% of a component capable of increasing density, 21.0 to 22.0% of a component capable of reducing saturated vapor pressure, and 9.0 to 12.5% of a component having surface with film forming and flame retardantion. The five functional components can be stirred evenly under normal temperature, and the biological alcohol-based light fuel flash point improver product can be obtained. The improver can increase the intermolecular force, and improves the boiling point of an oil-alcohol system, increases density of the oil-alcohol system, reduces saturated vapor pressure of the oil-alcohol system, forms a flame retardant film on the surface of oil-alcohol system, blocks the spontaneous combustion of methanol, improves the non corrosive performance of the flash point of the oil-alcohol system, has the characteristics of biodegradability, no harmful components and no secondary pollution to the environment, and effectively solves the technical problems of low flash point, large transportation and storage safety hazard of light fuel.

Owner:LANZHOU YINENG BIOTECHNOLOGY CO LTD

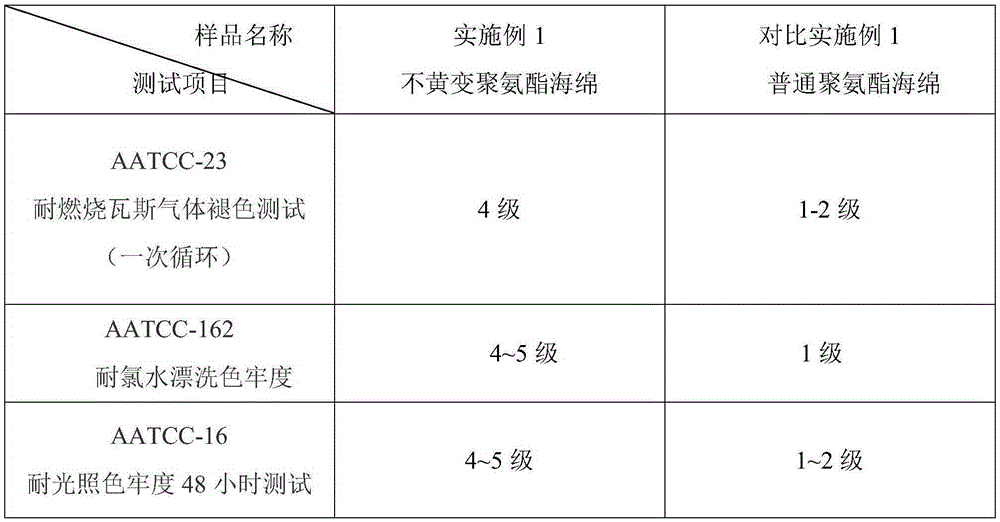

Method for preparing no-yellowing polyurethane sponge capable of being foamed at normal temperature

The invention discloses a method for preparing no-yellowing polyurethane sponge capable of being foamed at normal temperature. 4,4'-dicyclohexylmethane diisocyanate or a prepolymer thereof and polyether polyol serve as main raw materials; an environment-friendly catalyst and other auxiliary materials are added, the reaction and foaming are performed through a conventional polyurethane sponge production line at normal temperature, and the no-yellowing polyurethane sponge is obtained through a curing stage. The no-yellowing sponge can be obtained through the conventional polyurethane sponge production line at normal temperature, the raw materials do not need to be heated, existing equipment does not need to be modified, and the method has the advantages of small equipment investment and low energy consumption. In addition, since 4,4'-dicyclohexylmethane diisocyanate does not contain a benzene ring structure, obtained polyurethane sponge does not yellow, is excellent in aging resistance, oxidization resistance and illumination resistance and can be widely applied to the fields of shoe materials, furniture, electronics, printing supplies, aviation, automobiles, medical beauty, packaging, sports goods and articles for daily use.

Owner:CHANGZHOU SHUNXIANG NEW MATERIAL TECH CO LTD

Graphite powder purification method and high-purity graphite powder prepared by method thereof

The invention provides a graphite powder purification method. The method comprises the following steps: graphite powder to be purified is placed into a high-temperature sealed kiln and undergoes vacuum calcination in the atmosphere of protective gas; when the calcination temperature reaches 2,000-3,000 DEG C, multiple pneumatic control variation steps are carried out to control periodic pulsative oscillation change of air pressure in the high-temperature sealed kiln. Each pneumatic control variation step contains a gas withdrawal step and a gas injection step. For 1-3 h of each pneumatic control variation step, range of pressure change in the high-temperature sealed kiln is controlled to 1-10 kPa. According to the invention, the graphite powder with high carbon content can be obtained under the condition of low calcination temperature. The preparation process is simple, and the requirement on equipment is low.

Owner:陕西六元碳晶科技有限公司

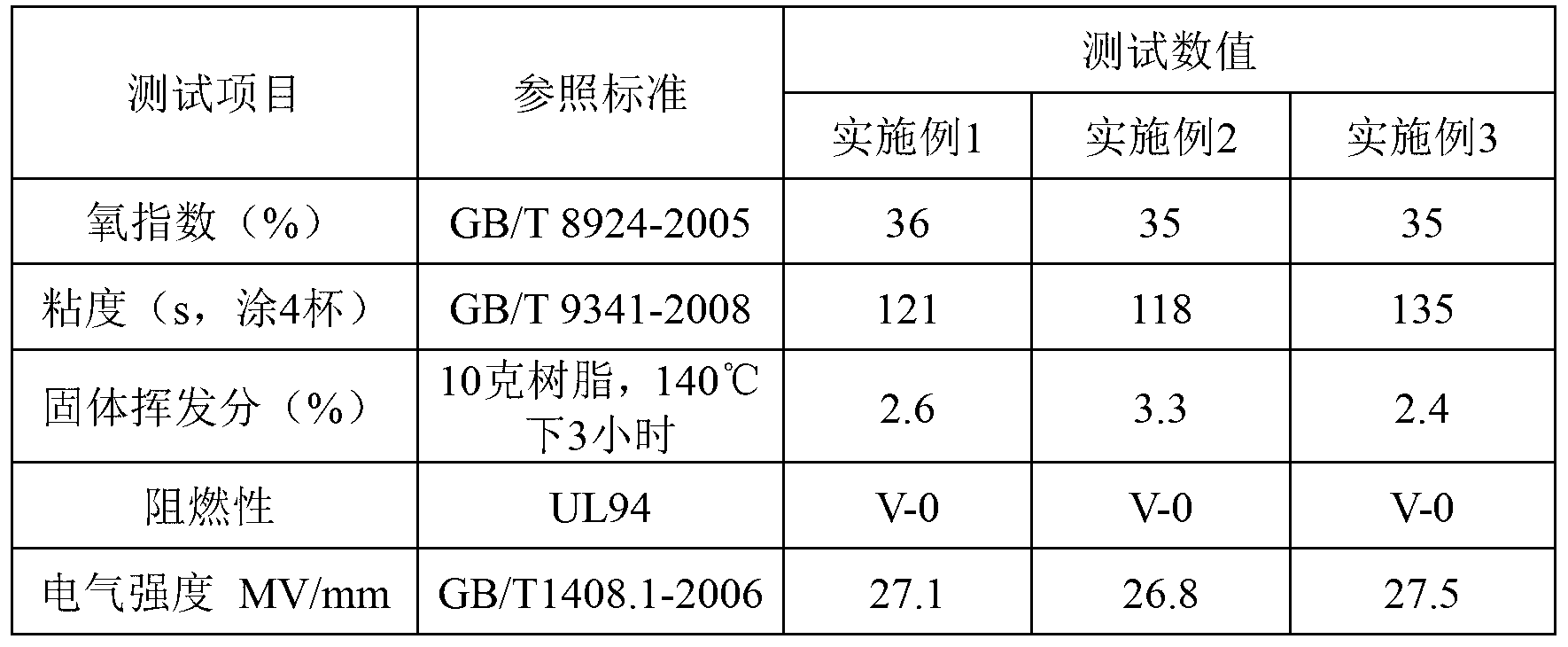

Polymerizable flame retardant resin

The invention discloses polymerizable flame retardant resin which is prepared by adding low molecular phosphate modified unsaturated polyester resin on the basis of a composition composed of a plurality kinds of epoxy resin. Under the action of such related reagents as a diluent, a curing agent, an initiator and an accessory ingredient, a blend of phosphorus-containing epoxy resin and nitrogen-containing epoxy resin can form an interpenetrating network polymer with crosslinked phosphorus-containing unsaturated polyester resin to improve the high voltage insulation performance, the non-air-gap VPI (Vacuum Pressure Impregnation) property and insulation fullness so as to be applied in the field of VPI insulation impregnation of OVDT (Open Ventilated Dry-Type) VPI dry type transformers.

Owner:ZHEJIANG RONGTAI TECH ENTERPRISE

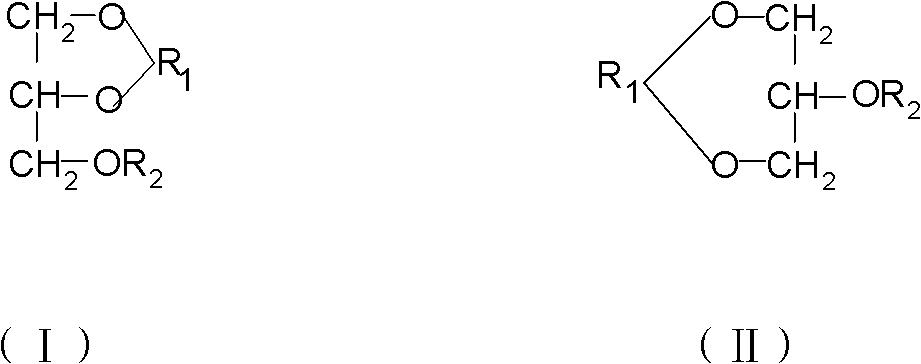

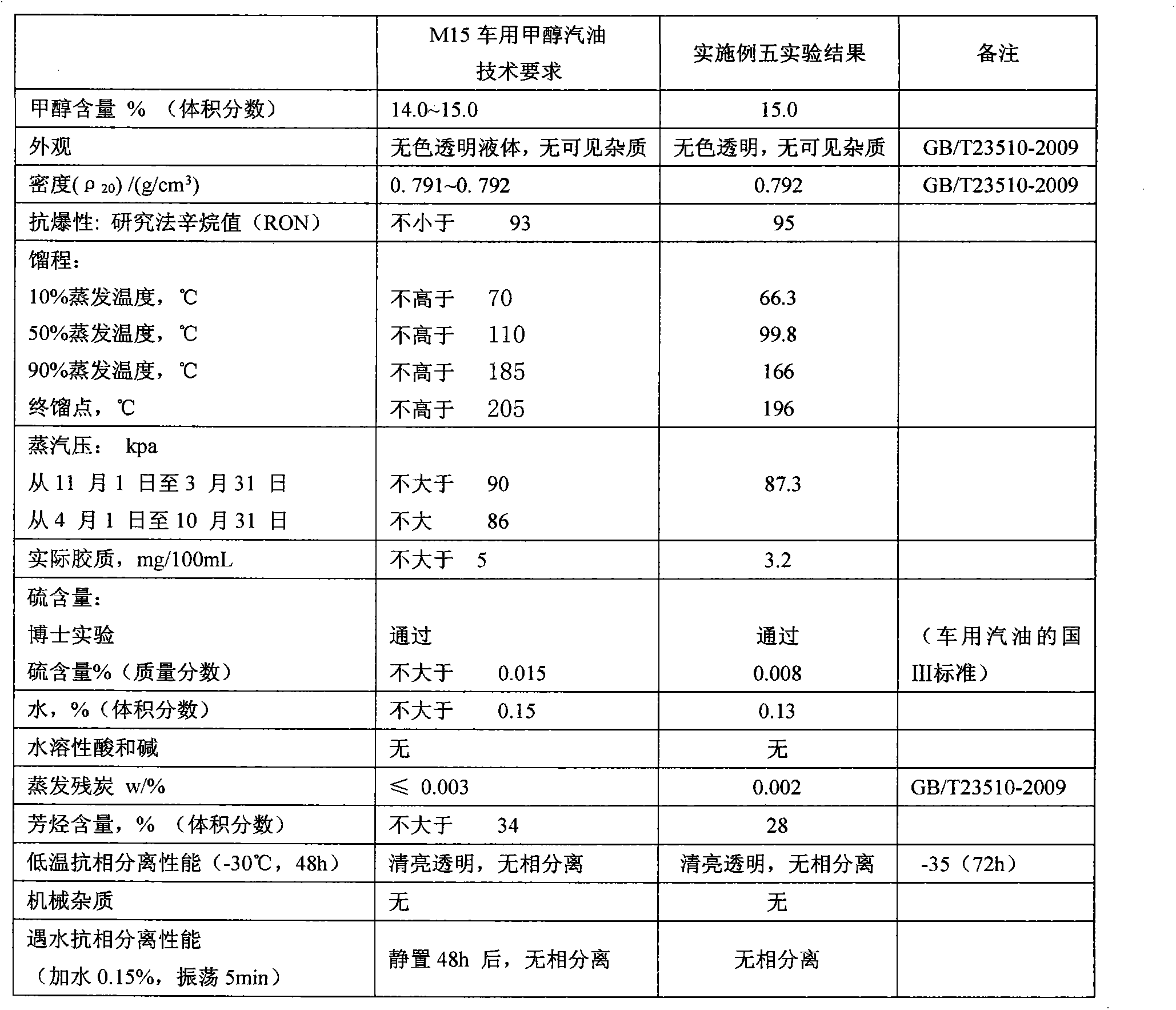

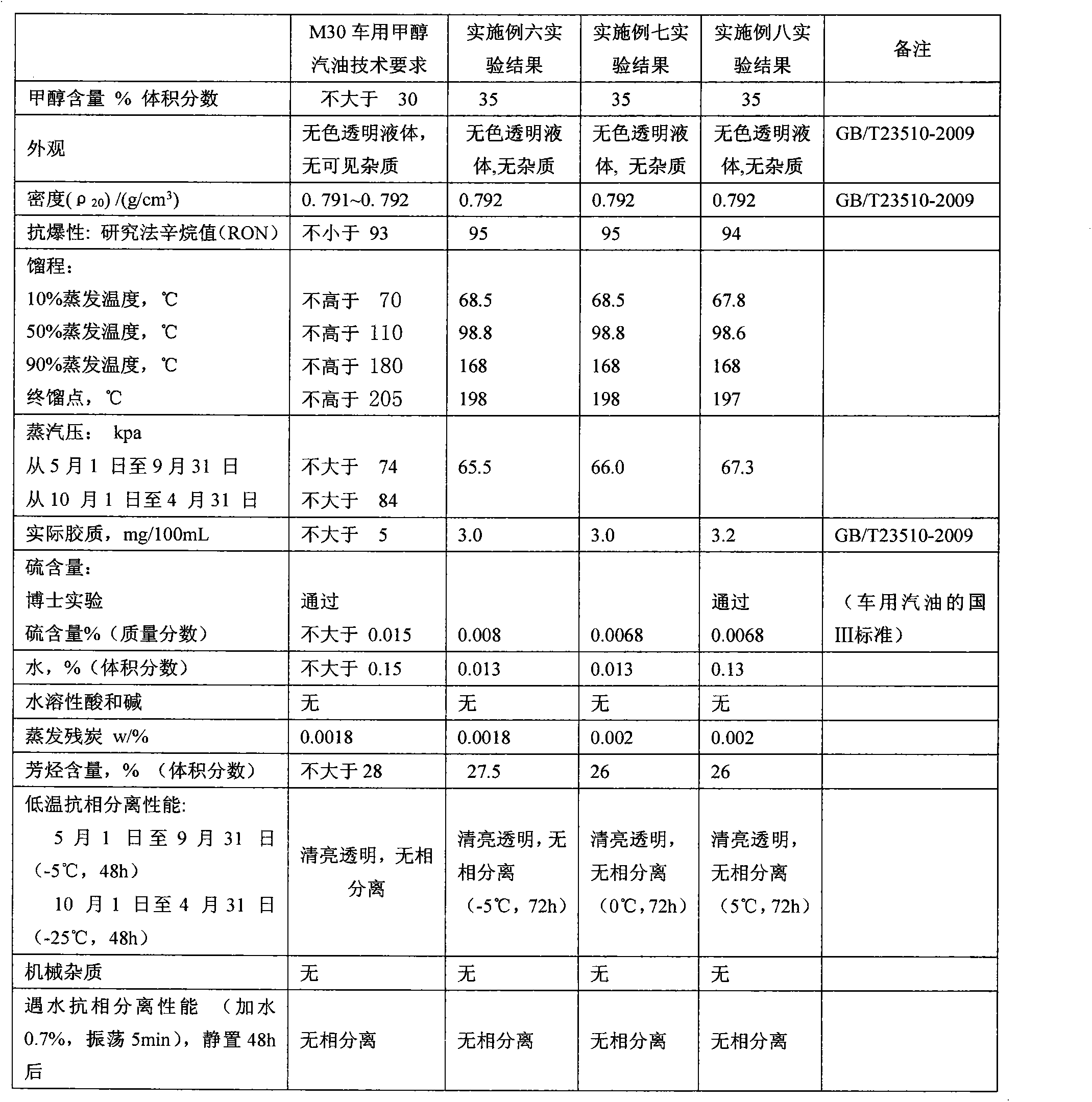

Methanol gasoline with low gas resistance

ActiveCN103695047ALow saturated vapor pressureGuaranteed uptimeLiquid carbonaceous fuelsNaphthaBase oil

The invention discloses methanol gasoline with low gas resistance. The methanol gasoline with low gas resistance is prepared by mixing and blending 60-80 wt% of base oil, 10-15 wt% of constituent oil and 10-30 wt% of denatured methanol, wherein the constituent oil is a mixture composed of 25-30 wt% of aromatic oil and 70-75 wt% of naphtha; the denatured methanol is formed by mixing methanol with a volume ratio of 95-98% and a depressurization additive with a volume ratio of 2-5%; the depressurization additive is prepared by blending the main materials of polymethoxy dimethyl ether with 3-6 polymerization degrees and dimethyl carbonate, and the auxiliary materials of ethanol, isopropanol, ethylene glycol monomethyl ether, methyl tertiary butyl ether, isoamylol and isooctanol. According to methanol gasoline with low gas resistance disclosed by the invention, the saturated vapour pressure of the low-proportion methanol gasoline is obviously decreased by changing the property of the base oil and adding the depressurization additive.

Owner:CRPC INNOVATION ENERGY

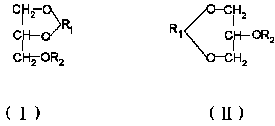

Carbinol gasoline additive and preparation method and application thereof

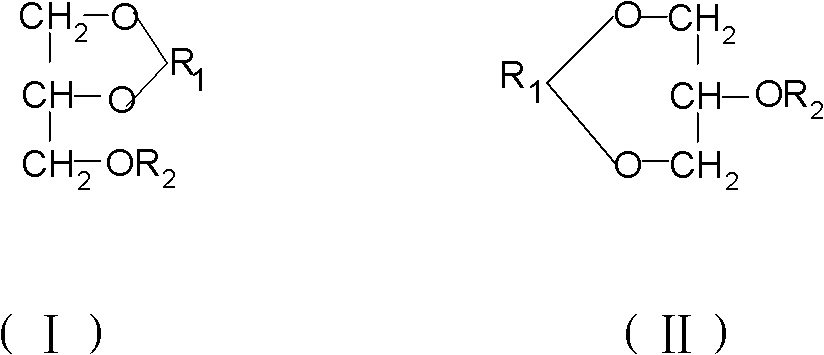

InactiveCN102031164ALow saturated vapor pressureSolve the problem of easy air resistanceOrganic chemistryLiquid carbonaceous fuelsGasolineEther

The invention relates to glycerin ring acetal (ketal) ether used as a carbinol gasoline additive, and also relates to a preparation method of the glycerin ring acetal (ketal) ether and carbinol gasoline added with the carbinol gasoline additive. The glycerin ring acetal (ketal) ether consists of glycerin ring acetal (ketal) ether shown in a formula (I) and / or glycerin ring acetal (ketal) ether shown in a formula (II), wherein R1 is CnH2n, and n=1or 2 or 3; and R2 is CmH2m, m is an integer from 1 to 10. The invention contains the carbinol gasoline for combining the glycerin ring acetal (ketal) ether, thus the performance of low temperature cold boot is excellent, and the problem that air resistance can be generated when an automobile engine is filled with the carbinol gasoline under a high temperature environment can be solved.

Owner:山东华阳油业有限公司 +1

Method for absorbing and separating ammonia gas from ammonia-containing exhaust gas

ActiveCN106474873AImprove solubilityHigh separation selectivityGas treatmentDispersed particle separationSolubilityDesorption

The invention discloses a method for absorbing and separating ammonia gas from ammonia-containing exhaust gas. The method comprises the following steps: adopting a hybrid eutectic solvent as an absorbent, the solvent contacting with ammonia-containing exhaust gas to obtain an ammonia-absorbing liquid, and then conducting the desorption of the ammonia-absorbing liquid to obtain ammonia gas. The hybrid eutectic solvent consists of three components, weak acid compounds, salt compounds and additives. The invention adopts the method of absorption and desorption by using the hybrid eutectic solvent as the absorbent to recover and separate ammonia gas. The absorbent has high ammonia solubility and separation selectivity, and can achieve the efficient separation and recovery of ammonia gas.

Owner:ZHEJIANG UNIV

Method for absorbing and separating light hydrocarbon from dry gas or industrial tail gas

ActiveCN106474869ALow saturated vapor pressureThe synthesis method is simpleDispersed particle separationSolubilityAlkane

The invention discloses a method for absorbing and separating light hydrocarbon from dry gas or industrial tail gas. The method comprises the following steps: allowing a deep eutectic solvent used as an absorbent to contact with the dry gas or the industrial tail gas, carrying out absorption so as to obtain an absorption solution containing the light hydrocarbon, and subjecting the absorption solution to desorption and separation so as to obtain the light hydrocarbon, wherein the light hydrocarbon mainly contains C2-C4 alkane or olefin. According to the invention, the deep eutectic solvent is used as the absorbent, and an absorption-desorption method is adopted to recycle and separate the light hydrocarbon, wherein the absorbent has significantly high light hydrocarbon solubility and separation selectivity, so highly-efficient separation and recycling of the light hydrocarbon can be realized.

Owner:ZHEJIANG UNIV

Methanol gasoline additive and methanol gasoline containing same

InactiveCN103710058AGood compatibilityLight colorOther chemical processesAluminium silicatesIsobutanolSolvent

The invention relates to a methanol gasoline additive and a methanol gasoline containing the same. The methanol gasoline additive comprises the following components in parts by mass: 4-32% of toluene, 4-42% of dimethylbenzene, 0.5-10% of C5H12 and C7H16, 3-43% of isobutanol, 4-33% of isopropanol, 0.8-15% of isoamyl alcohol, 1-8% of ethanol, 1-6% of antifreezing agent, 0.2-3% of antioxygen antigum inhibitor, 0.05-0.6% of metal passivator, 0.008-0.06% of detergent dispersant, 1-6% of preservative and 2-8% of emulsifier. The methanol gasoline is prepared by the following steps: uniformly mixing gasoline, naphtha, petroleum ether, 120# solvent oil, light hydrocarbon, methanol fuel and the methanol gasoline additive, and filtering through a modified attapulgite adsorption stabilizer. The methanol gasoline produced from the methanol gasoline additive is especially suitable for high altitude anoxia regions. The methanol gasoline has the advantages of quick cycling start, stable idle speed, low harmful substance emission during combustion, favorable dynamic performance in high altitude anoxia regions, high corrosion resistance, and no stratification at low temperature, and does not generate air resistance.

Owner:兰州市新城炼化厂

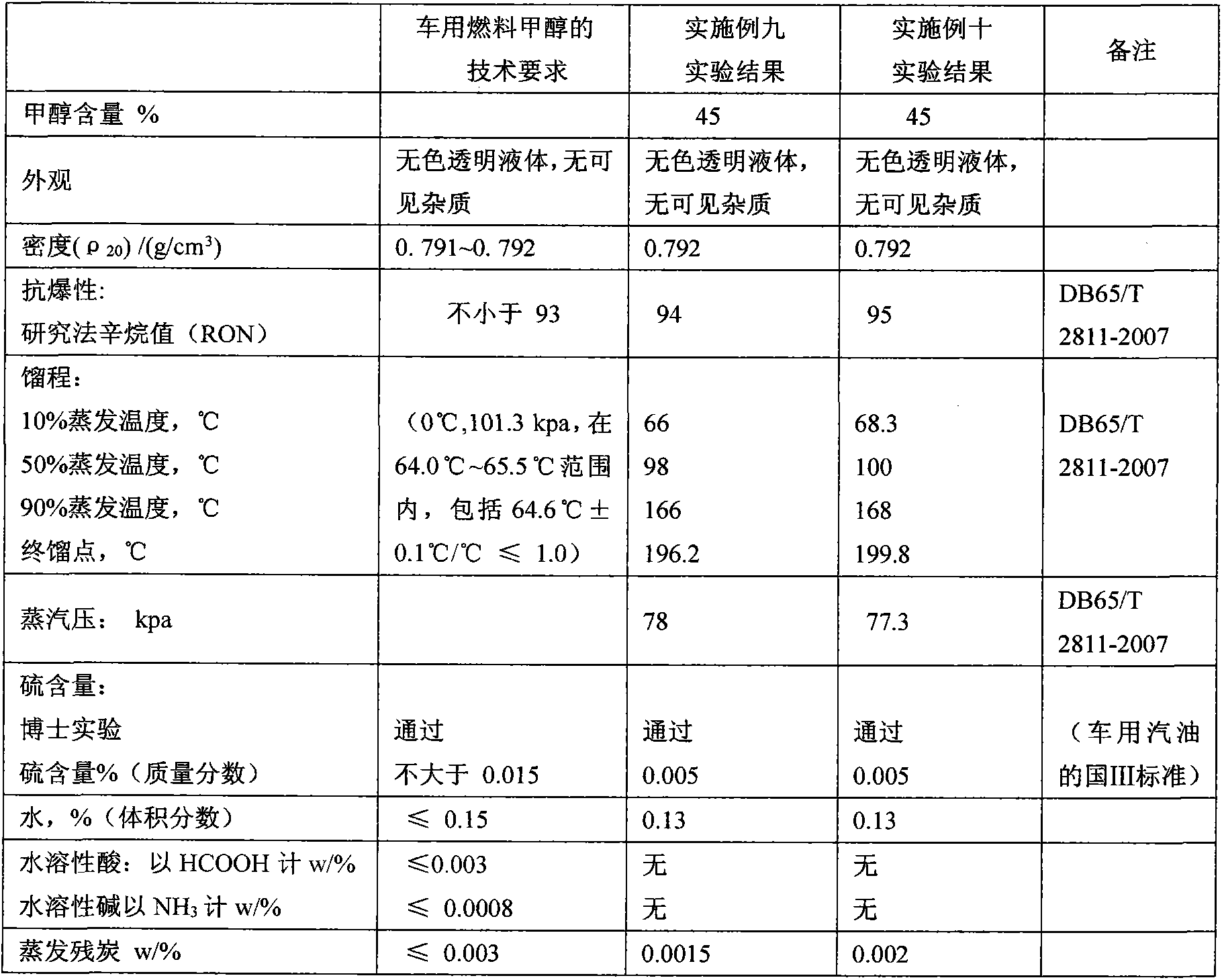

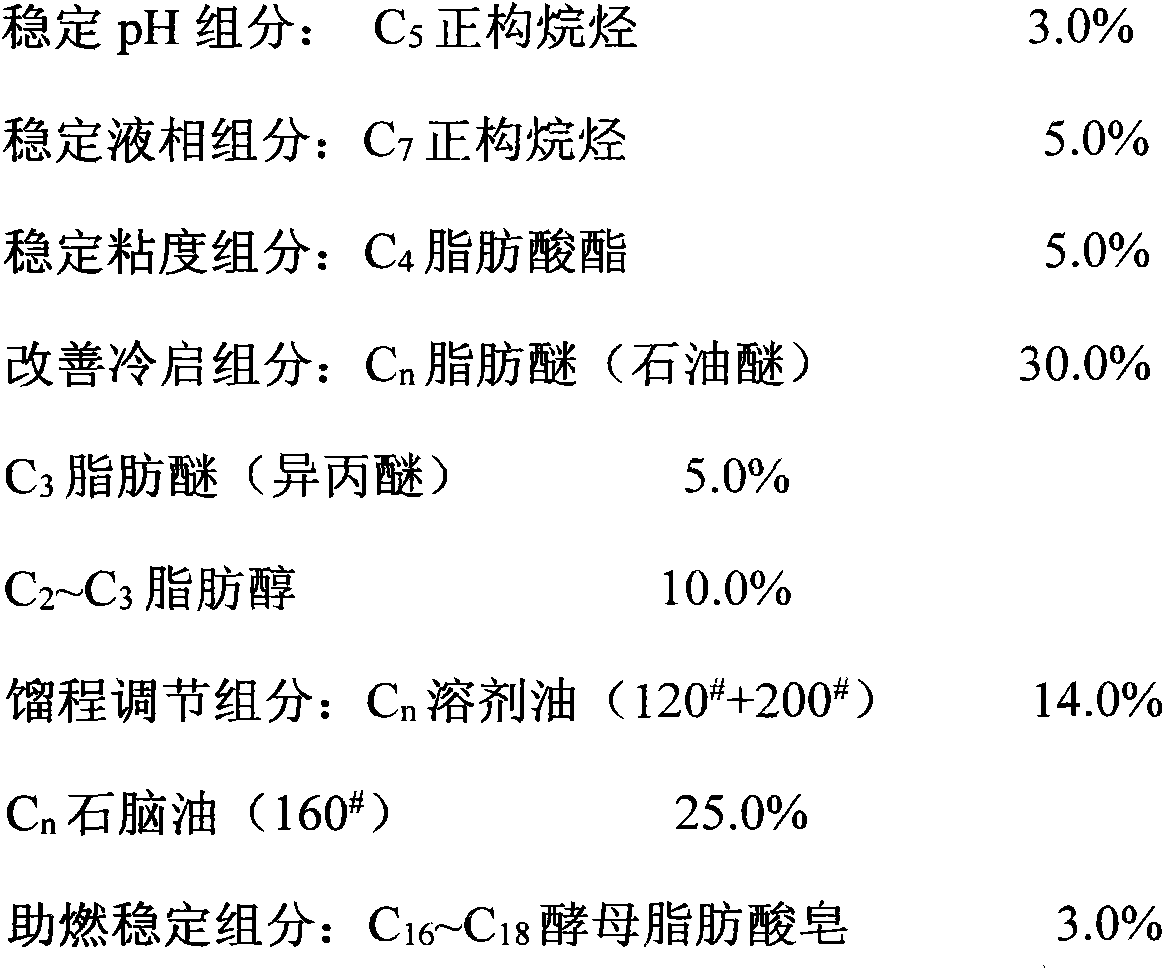

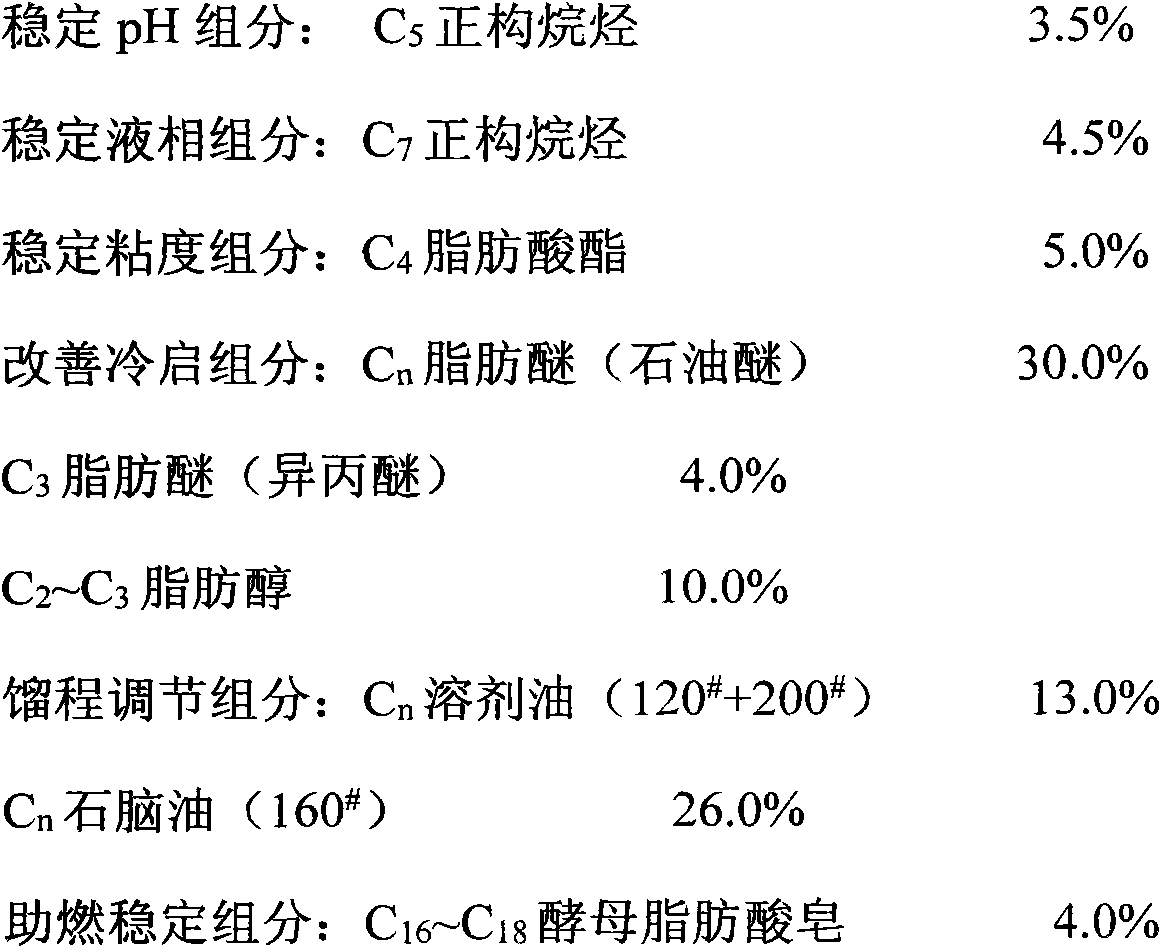

Bio-based methanol gasoline component oil and preparation method thereof

ActiveCN103396843ALow costNo pollution in the processLiquid carbonaceous fuelsCombustionDistillation

The invention discloses bio-based methanol gasoline component oil and a preparation method thereof. The bio-based methanol gasoline component oil consists of a sable pH component, a stable liquid-phase component, a stable viscosity component, a cold initialing improving component, a distillation range regulating component and a combustion-supporting stable component, wherein the six functional components are uniformly stirred under the normal temperature to obtain the bio-based methanol gasoline component finished product. The component oil which is prepared by the preparation method disclosed by the invention can be used for effectively regulating and improving saturated vapor pressure, distillation range temperature, acid alkali balance, dynamic viscosity and low-temperature cold initiating performance of the large-proportion methanol gasoline. Moreover, the bio-based methanol gasoline component oil is simple to prepare, convenient to use, and easily available in material, so that a novel way is developed for stably improving various indexes of the methanol gasoline, and therefore, the popularization and use value is broad.

Owner:NORTHWEST UNIVERSITY FOR NATIONALITIES

Component oil capable of reducing saturated vapor pressure of methanol gasoline

InactiveCN101760258ALow saturated vapor pressureCorrect positive deviationLiquid carbonaceous fuelsFuel additivesCatalytic reformingNaphtha

The invention discloses component oil capable of reducing saturated vapor pressure of methanol gasoline, which is prepared from 20 to 25 percent of No.120 solvent oil, 20 to 25 percent of No.200 solvent oil, 5 to 10 percent of methylbenzene, 3 to 5 percent of dimethylbenzene, 20 to 30 percent of heavy naphtha and 20 to 25 percent of catalytic reformed gasoline. The component oil is mainly used for blending with traditional national standard No.90 and No.93 gasoline to prepare low proportional methanol gasoline with the methanol content of 10 to 30 percent, so that the positive deviation of the saturated vapor pressure of the low proportional methanol gasoline is rectified, the saturated vapor pressure of the low proportional methanol gasoline is effectively reduced, the vapor pressure is ensured to be not high when the national standard No.90 and No.93 gasoline are doped with the low proportional methanol, a 'vapor lock' phenomenon cannot happen in high temperature weather, and an engine can normally work.

Owner:山西华顿实业有限公司

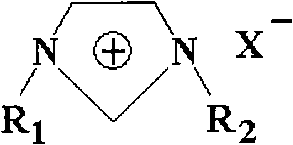

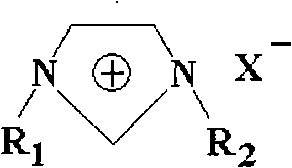

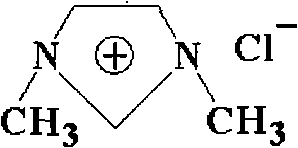

Preparation method of lithium bromide absorption cycle working fluid

InactiveCN102212343AImprove thermodynamic propertiesHigh cycle performance coefficientHeat-exchange elementsTetrafluoroborateWorking fluid

The invention relates to a preparation method of lithium bromide absorption cycle working fluid. A defined amount of imidazole type ionic liquid such as chlorinated 1,3-dimethylimidazole and 1,3-dimethylimidazolium tetrafluoroborate is added in lithium bromide aqueous solution working fluid, thus the refrigeration cycle performance coefficient can be increased and the problem that the lithium bromide aqueous solution working fluid is easy to crystallize and corrode can be relieved. The raw material cost and preparation cost of unit cycle working fluid can be reduced by 5-15%. In the method, the preferable ionic liquid [DMIm]Cl which is prepared by the gas / liquid phase synthesis method is added, organic solvent is not adopted, no byproduct is generated, the product is easy to separate and refine; and when the finished product is added in the lithium bromide aqueous solution working fluid, the lithium bromide absorption cycle performance can be obviously improved.

Owner:BEIJING UNIV OF CHEM TECH

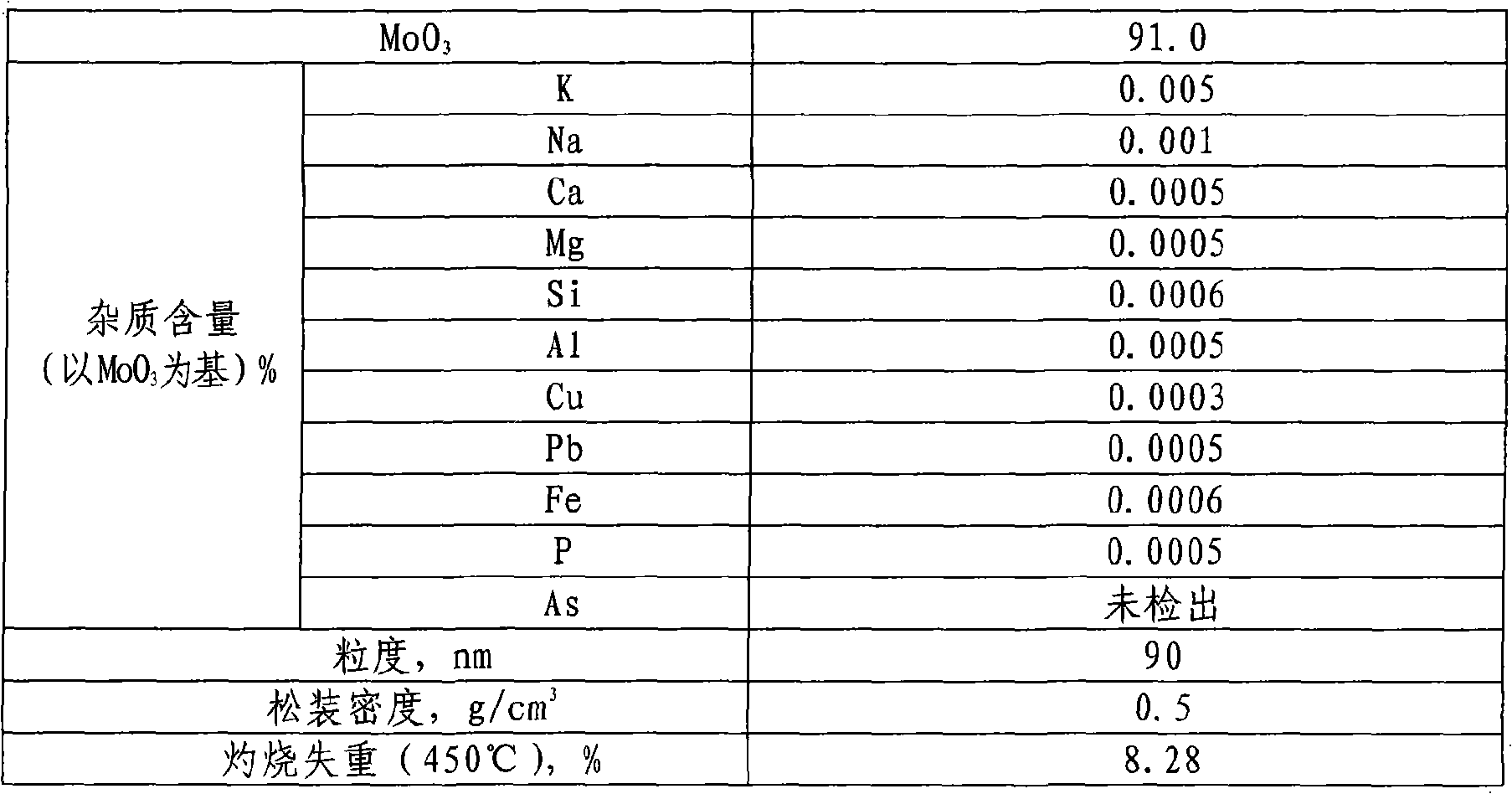

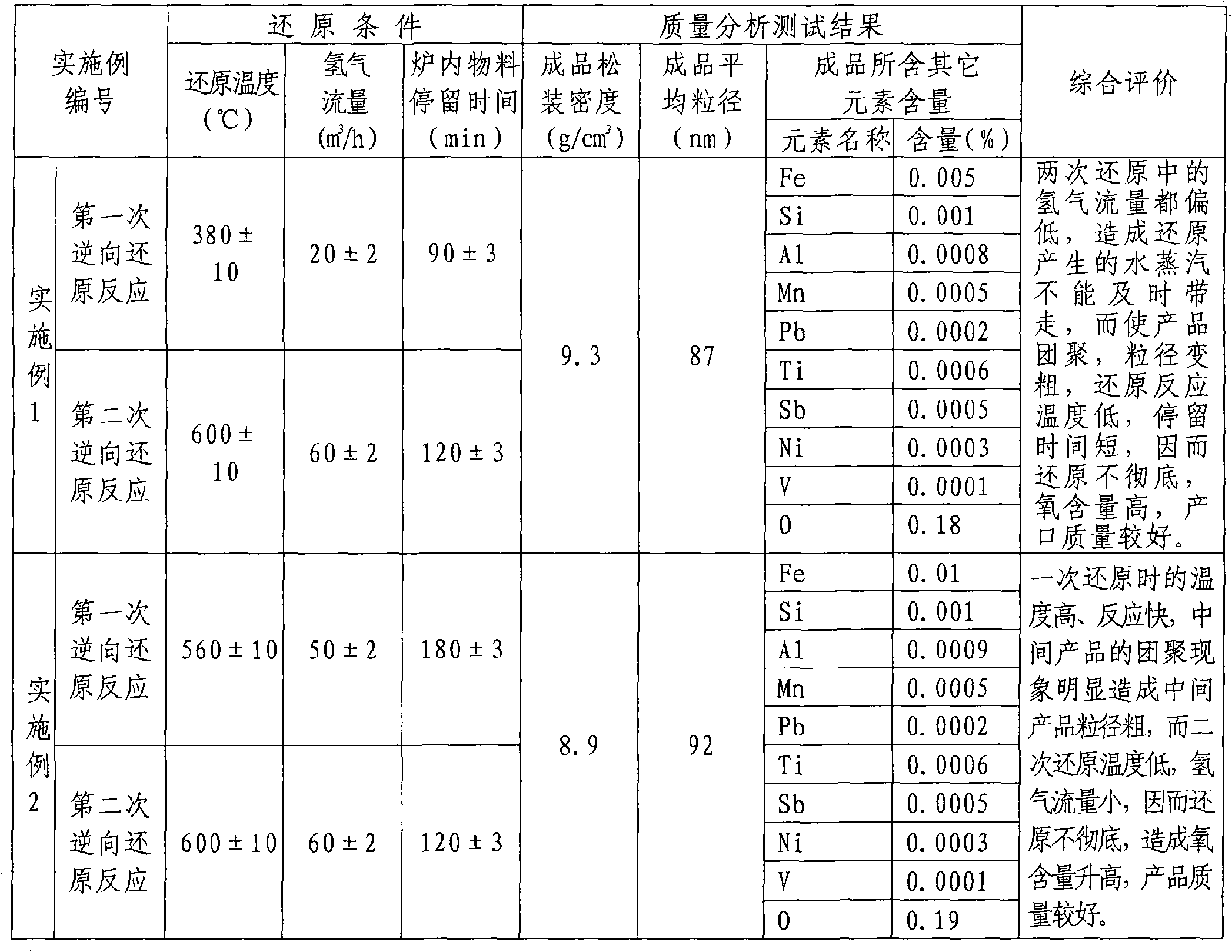

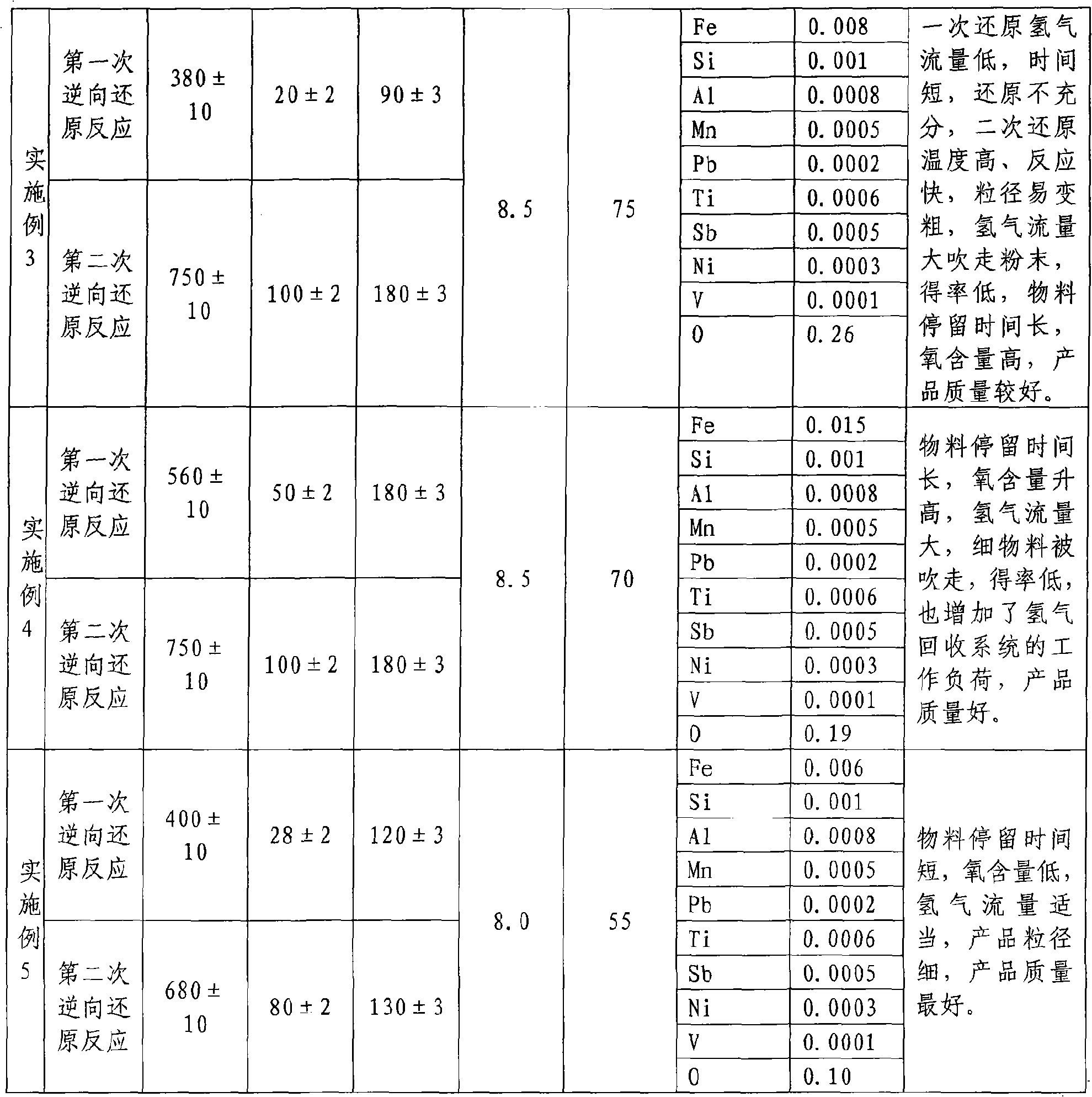

Method for preparing nano-scale molybdenum powder

The invention discloses a preparation method for nanometer molybdenum powder, and the method takes nanometer ammonium octamolybdate as raw material. In a closed environment, hydrogen backward reduction reaction is carried out twice, and the prepared nanometer molybdenum powder is purple and is of grain diameter of 55 to 92nm and the average purity of above 99.80 percent by controlling the furnace temperature and the hydrogen flow in the first reduction and the second reduction. In the invention, the hydrogen can be recycled, thus saving the production cost, and the method also has the advantages of short process flow, easy control of process conditions, no special requirement on production equipment and being suitable for industrial production.

Owner:JIANGSU GUANGMING NEW MATERIAL

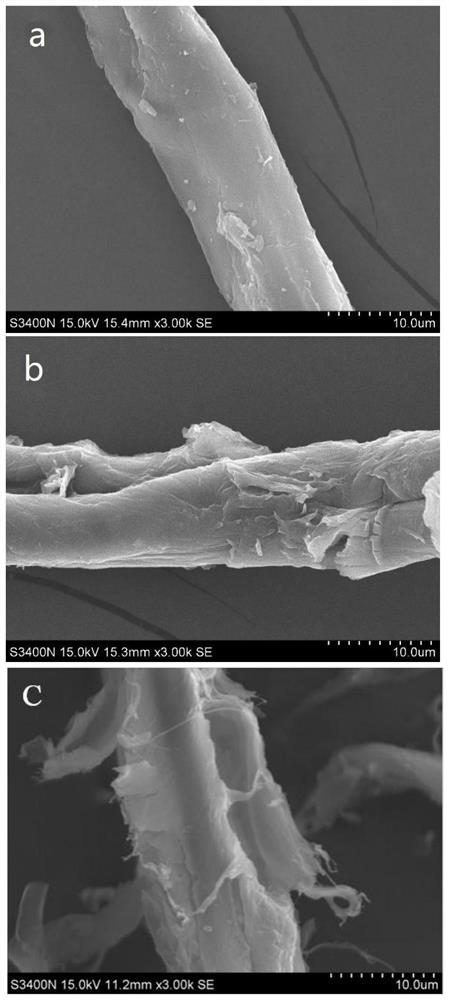

Fabric multifunctional durable after-treatment method based on deep-eutectic solvent

ActiveCN108797115AUV resistantConductiveBiochemical fibre treatmentLight resistant fibresAfter treatmentWastewater

The invention discloses a fabric multifunctional durable after-treatment method based on a deep-eutectic solvent. The fabric multifunctional durable after-treatment method comprises following steps: ahydrogen bond acceptor compound and a hydrogen bond donor compound capable of realizing light initiated polymerization are mixed to be uniform so as to prepare the deep-eutectic solvent, a metal oxide is added, and stirring dissolving is carried out so as to obtain a pre-finishing solution; before finishing, a photo-initiation polymerizer is added into the pre-finishing solution, and stirring dissolving is carried out so as to prepare a finishing solution; the finishing solution is adopted for finishing of fabric to be finished, the fabric treated through finishing is subjected to ultravioletirradiation, normal temperature water washing, and airing so as to obtain a durable multifunctional fabric. The durable multifunctional fabric is provided with corresponding functions, the fabric antibacterial performance, static resistance or electric conductivity, and crease resistance are achieved. The fabric multifunctional durable after-treatment method can be used for a plurality of kinds of fabric. The fabric multifunctional durable after-treatment method is green; no pollution is caused; less waste water is discharged; cost is low; operation is convenient; and the functional dyeing method is suitable for industrialized production.

Owner:DONGHUA UNIV

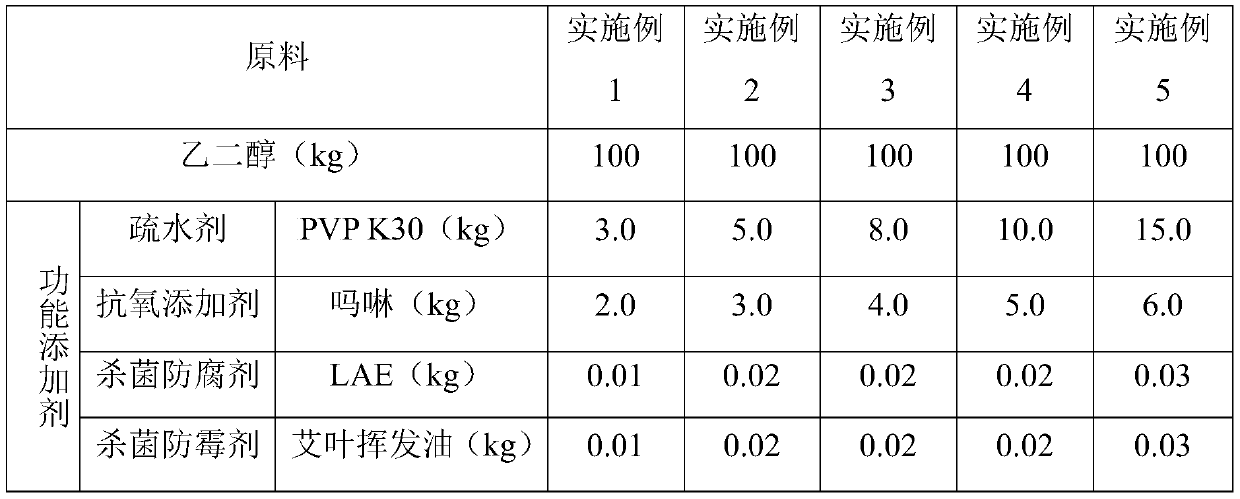

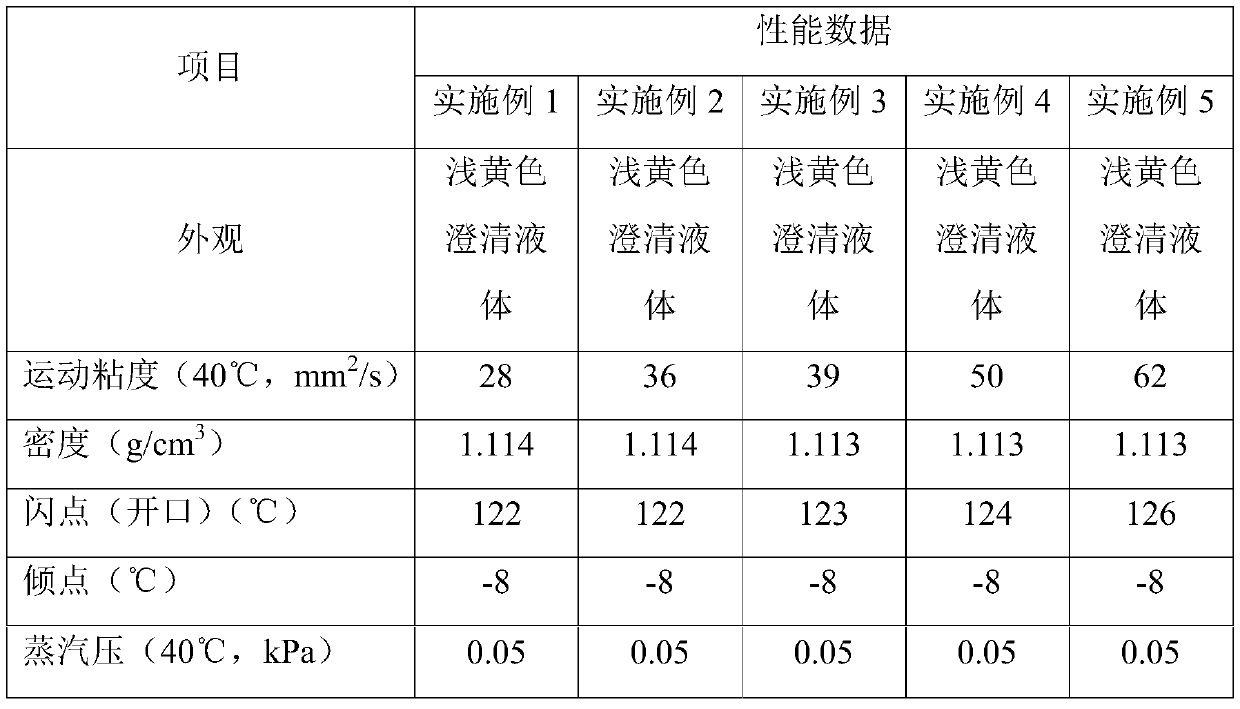

Industrial water-saving agent, preparation method and applications thereof

ActiveCN111018010AImprove Oxidation StabilityImprove thermal stabilitySpecific water treatment objectivesScale removal and water softeningWater savingPolyol

The invention discloses an industrial water-saving agent, which is prepared from the following raw material components in parts by mass: 100 parts of polyol, 3.0 to 15.0 parts of polyvinylpyrrolidone,2.0 to 6.0 parts of an antioxidant additive, 0.01 to 0.03 part of a bactericidal preservative and 0.01 to 0.03 part of a bactericidal mildew preventive. The preparation method comprises the followingsteps: adding polyol accounting for 20-40% of the total amount into a reaction container, and heating; adding the components of functional additive into the reaction container, and uniformly stirringand mixing; and finally adding the residual polyol into the reaction container, and uniformly stirring and mixing to obtain the industrial water-saving agent. The production process is simple, safe and environment-friendly; the industrial water-saving agent is simple and convenient to use, suitable for water saving of circulating flowing water, capable of remarkably reducing volatilization loss of industrial water, remarkable in water-saving effect, small in use amount and low in cost; and during the use, system equipment does not need to be added or replaced, and normal operation of originalequipment is not affected.

Owner:佛山市南海区里水镇经济促进局 +1

Preparation method of durable graphene finished fabric

InactiveCN108468207AUV resistantAntistaticBiochemical fibre treatmentLight resistant fibresWastewaterUltraviolet lights

The invention discloses a preparation method of a durable graphene finished fabric. The preparation method is characterized in that a deep eutectic solvent is prepared after a hydrogen bond acceptor compound and a photo-initiated polymerized hydrogen bond donor compound are uniformly mixed, then graphene is added and stirred for dissolution, and a graphene pre-finishing solution is prepared; a photo-initiated polymerizer is added to the pre-finishing solution and stirred for dissolution, and a graphene finishing solution is prepared; the fabric is coated with the graphene finishing solution, the coated fabric is irradiated with ultraviolet light, washed with water at normal temperature and dried in the air, and the durable graphene finished fabric is obtained. The green and environment-friendly deep eutectic solvent is adopted as a finished medium of graphene, the fabric is treated directly by existing fabric equipment, and graphene is applied onto the fabric by finishing. The preparation method can be applied to various fabrics. As a functional durable graphene finished fabric technology, the preparation method has the advantages of being green, pollution-free, low in wastewater discharge, low in price, convenient to operate, suitable for industrial production and the like.

Owner:DONGHUA UNIV

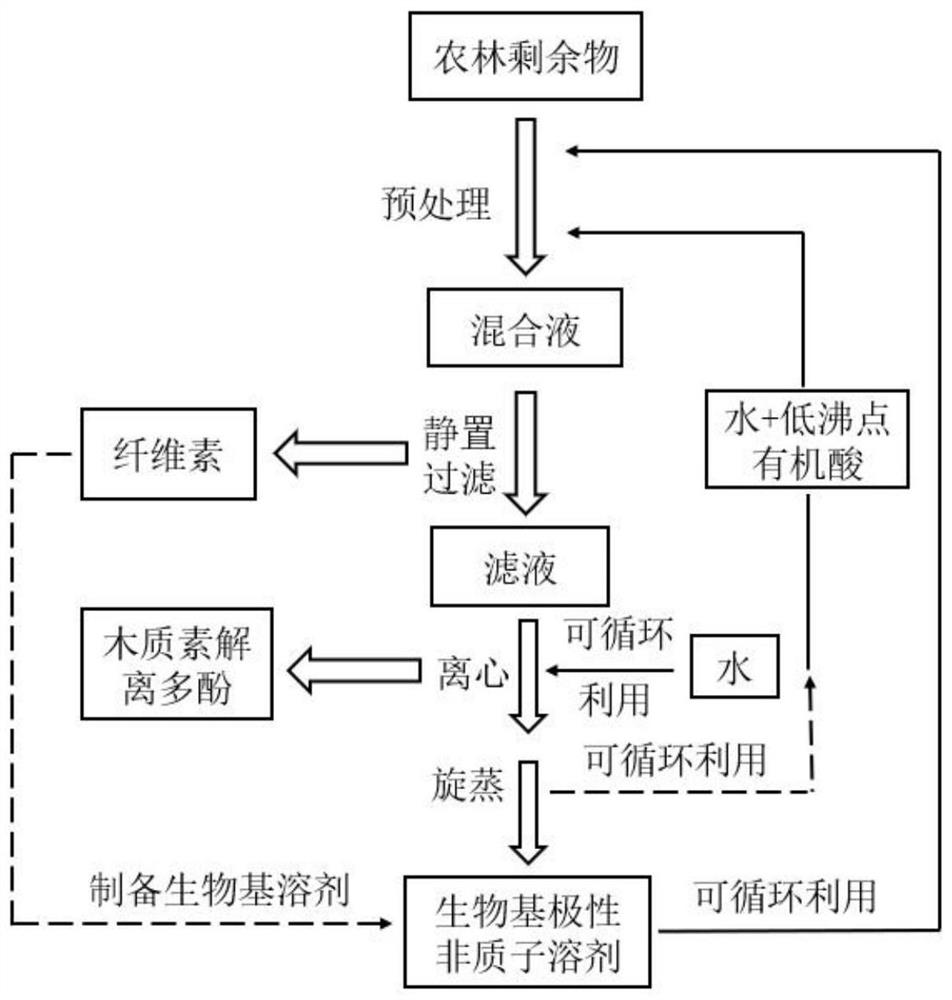

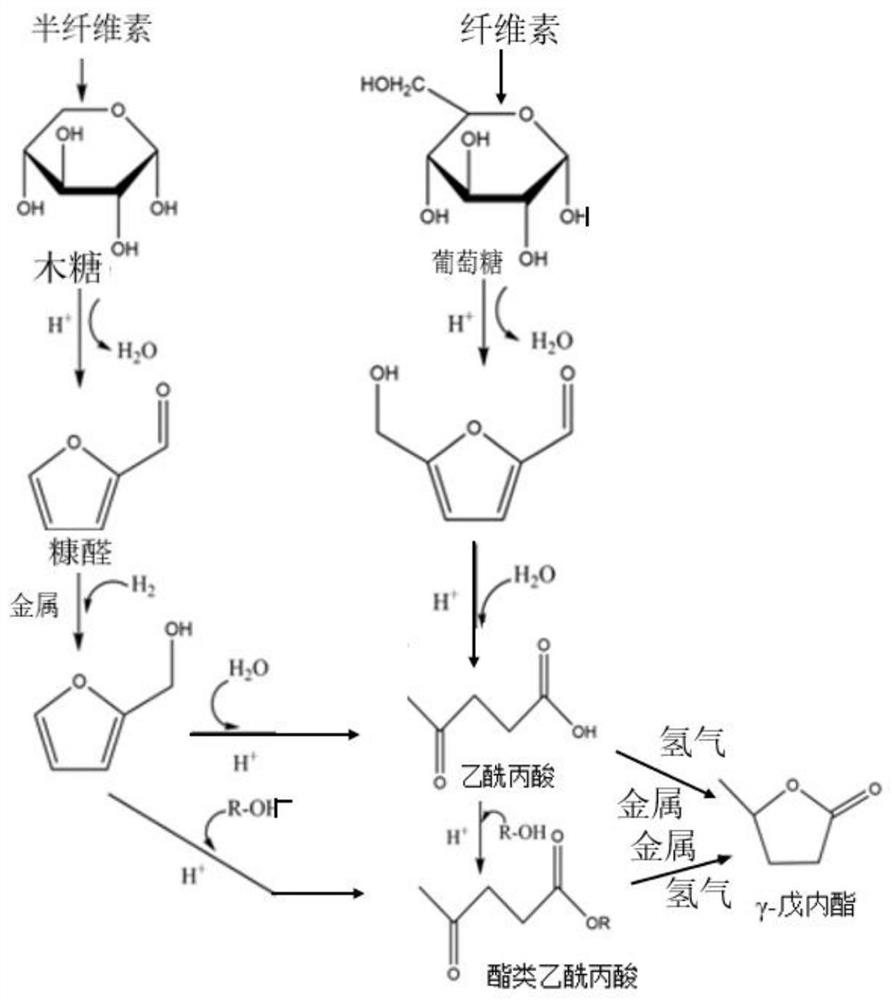

Method for pretreating wood fibers in bio-based polar aprotic solvent system

The invention provides a method for pretreating wood fibers in a bio-based polar aprotic solvent system, wherein the method comprises the steps: catalyzing and efficiently separating cellulose, hemicellulose and lignin in a bio-based polar aprotic solvent / water composite solvent by taking agricultural and forestry residues as raw materials; adding the agriculture and forestry residues, the bio-based polar aprotic solvent / water composite solvent and low-boiling-point organic acid into a pressurized reaction kettle, carrying out heating pretreatment, cooling to room temperature after pretreatment is finished, standing, filtering to obtain solid residues and filtrate, drying the solid residues, and weighing for preparing bio-based polar aprotic solvents such as gamma-valerolactone / dihydrolevoglucosenone and the like through hydrolysis and hydrogenation; and adding a certain amount of deionized water into the filtrate, filtering to obtain brown powdery lignin dissociation polyphenol, and performing reduced-pressure fractional distillation on the filtrate to recycle water, low-boiling-point organic acid and the bio-based polar aprotic solvent. The recycled water, the recycled low-boiling-point organic acid and the recycled bio-based polar aprotic solvent can be recycled.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

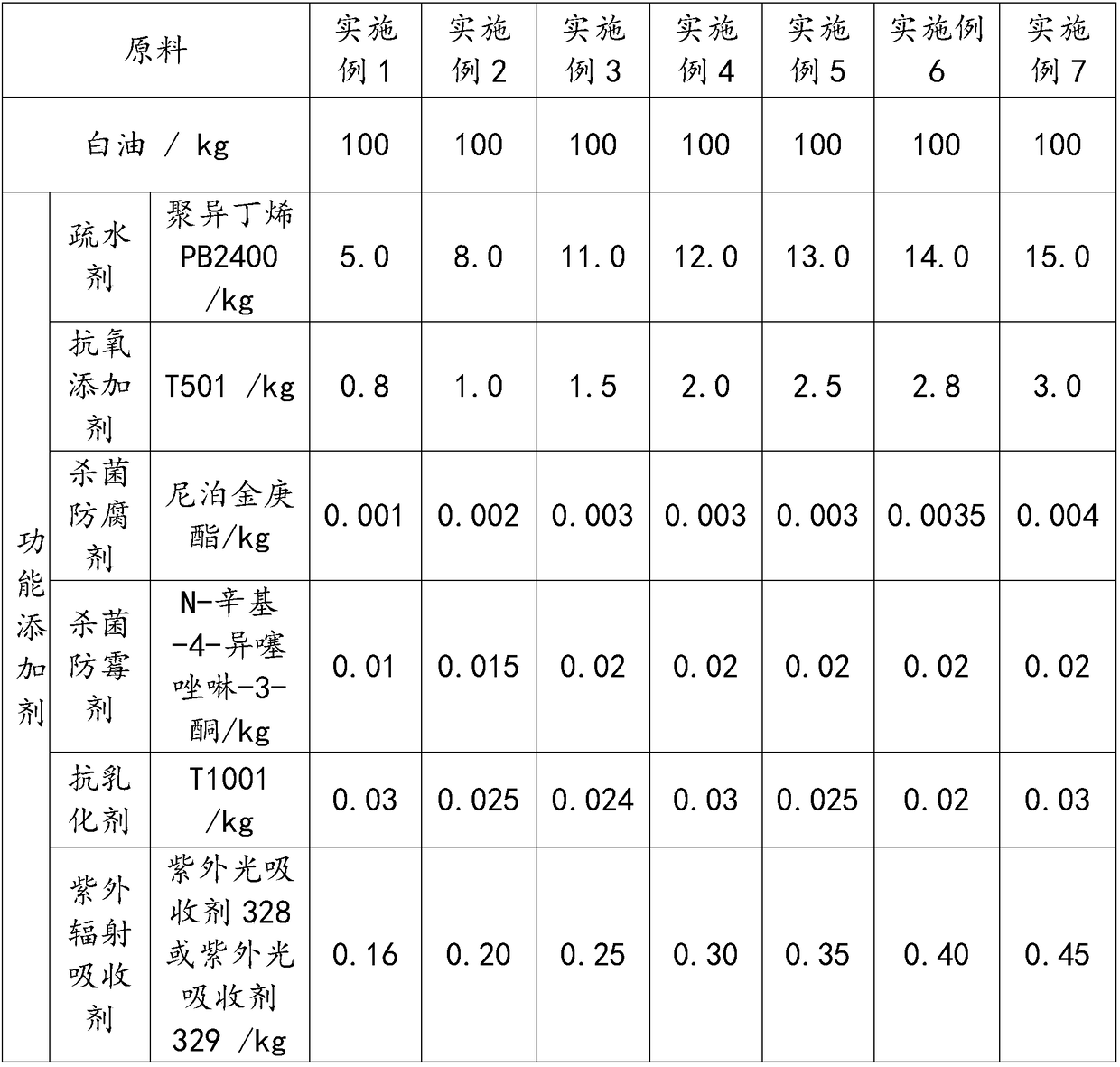

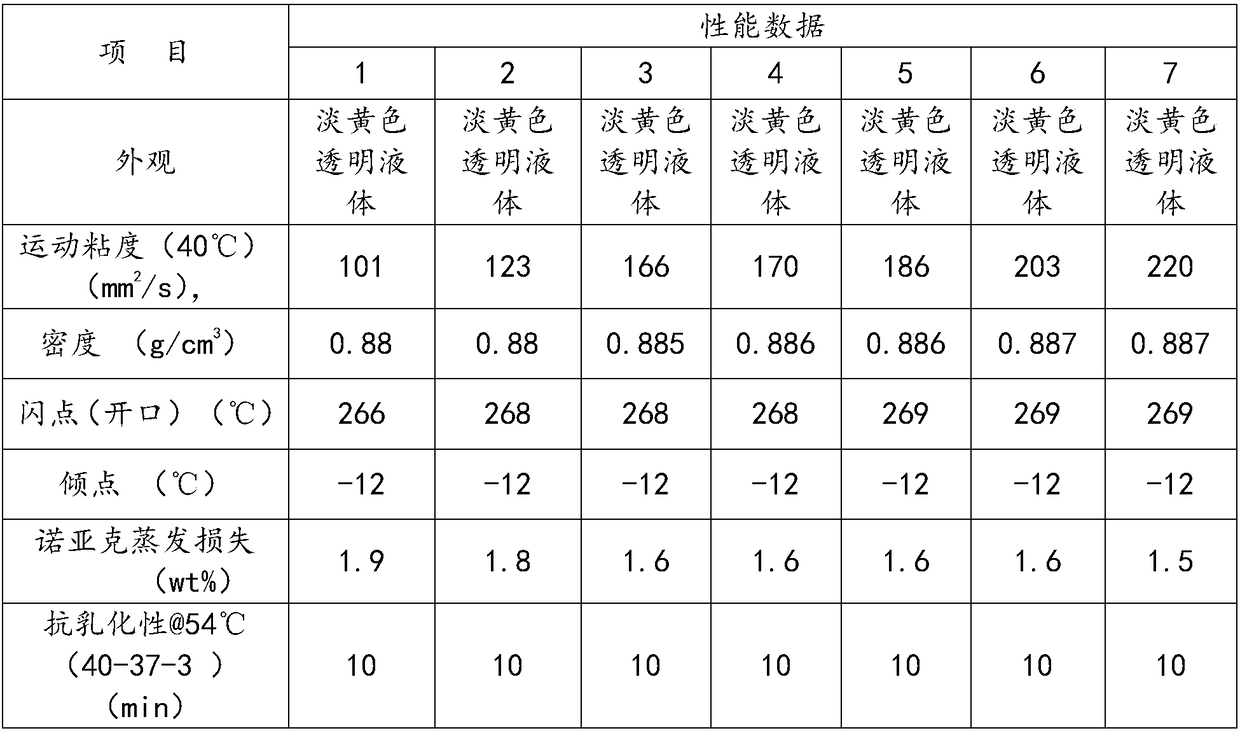

Industrial water saving agent and preparation method therefor

InactiveCN108996626ALight weightHigh flash pointWater/sewage treatment using germicide/oligodynamic-processTO-18Water saving

The invention discloses an industrial water saving agent and a preparation method therefor. The preparation method comprises the steps: (1) proportioning 100 parts (by weight) of white oil (total volume), and adding 60% to 90% of the total volume of the white oil into a product pot for preheating; (2) adding the white oil remaining in the step (1) into a mixing pot for heating, adding 6.0 to 18.6parts (by weight) of functional additives (additional, similarly hereinafter) into the mixing pot, and carrying out uniform mixing, so as to prepare a stock solution; and (3) adding the stock solutionin the mixing pot in the step (2) into the product pot in the step (1), and carrying out uniform stirring. The functional additives contain part or all of the following ingredients: a water repellent, an antioxidant, an ultraviolet radiation absorber, a sterilizing mildew preventive, an anti-emulsifier and a sterilizing preservative. The industrial water saving agent has a good barrier effect onwater vapor and is low in consumption and remarkable in water saving effect; in addition, the use is simple and convenient, and system facilities are not required to be increased and replaced.

Owner:SHANDONG KEYSTONE LUBRICANT TECH

High-efficiency pretreatment separation of hemicellulose from fiber-based biomass raw material and comprehensive utilization method

ActiveCN110272509ARealize comprehensive utilization of high quality and high valueEfficient separationLignin derivativesPulping with organic solventsFiberDistillation

The invention provides high-efficiency pretreatment separation of hemicellulose from a fiber-based biomass raw material and a comprehensive utilization method. The method comprises the following steps: the forest biomass resource fiber-based biomass raw material is used as a raw material, and the fiber-based biomass raw material is firstly subjected to slurry method pretreatment: the fiber-based biomass raw material is ground by a ball mill, sieving is performed to obtain fiber-based biomass raw material powder with a certain mesh, and the powder and water are mixed according to a ratio at a room temperature to obtain a fiber-based biomass raw material powder slurry premixed liquid; through regulation and control of the reaction temperature, time and water quantity, high-efficiency hydrothermal removal of the hemicellulose in the fiber-based biomass raw material powder in the slurry fiber-based biomass raw material powder premixed liquid system is realized; after the mixed liquid is filtered, the filtrate is subjected to gradient precipitation to separate low-dispersion hemicellulose, the precipitate is dried, and the dried material is stored; after the filter residues, a polar aprotic solvent and water are mixed, the mixture is heated and stirred in a pressurized reaction kettle for a certain period of time, filtering separation is performed to obtain high-purity cellulose, the high-purity cellulose is washed by using water, drying is performed, and the dried high-purity cellulose is stored; the filtrate and water are mixed, the mixture is allowed to stand, the precipitated powder is filtered, drying is performed, and the dried material is stored; and the filtrate is subjected to reduced-pressure distillation to recover water, the solvent and a small amount of small-molecular chemicals, and recycling is performed. The method provided by the invention adopts the fast-growing forest fiber-based biomass raw material unique in China as the raw material, and has a green and environmentally-friendly process and low costs, the hemicellulose has a low dispersion degree and a high yield, the solvent used in the method can be efficiently recycled, and the method is friendly to the environment, and suitable for industrial production.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Preparation method of polyolefin/montmorillonite nano-composite material

The present invention discloses a preparation method of polyolefine / montmorillonite nano composite material. Under the condition of having no need of any solvent said invention adopts the following steps: using imidazole salt or pyridine salt ionic liquid as organic modifying agent, grinding said organic modifying agent and montmorillonite at room temperature to implement organization of the montmorillonite and form nano organic montmorillonite particles with ionic liquid intercalation, then melting and mixing the polyolefine and organic montmorillonite so as to form the invented polyolefine / montmorillonite nano composite material.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com