Patents

Literature

177results about How to "Realize multiple recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anhydrous recycling dyeing method of activated dye

The invention relates to an anhydrous recycling dyeing method of an activated dye. The method comprises the following steps: adding the dye to a polar organic solvent; adding electrolyte and organic alkali, and dissolving, so as to obtain a dye bath, wherein the proportional relation of the dye to the polar organic solvent to the electrolyte to the organic alkali is (0.5-30g):1L:(0-10g):(0.1-30g); pre-swelling a pure cotton fabric in the polar organic solvent at 50-150 DEG C for 0.5-24 hours; then dyeing in the dye bath at 45-130 DEG C for 0.5-3 hours at the dyeing bath ratio of 1:10 to 1:50; and cleaning and drying, so as to obtain the dyed fabric. The residual dye liquid generated in the method disclosed by the invention does not contain a hydrolyzed dye, and can achieve recycling of dye liquor just by directly supplying the dye and assistants.

Owner:DONGHUA UNIV

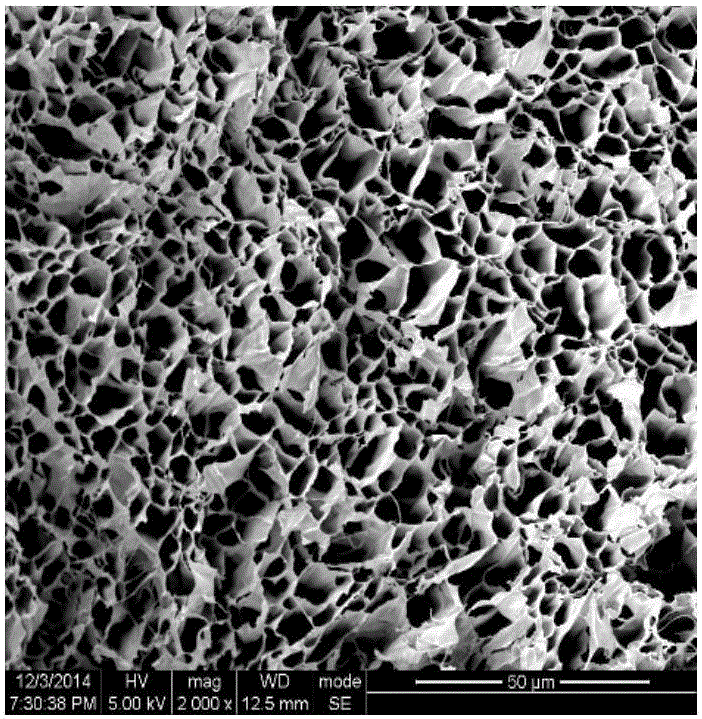

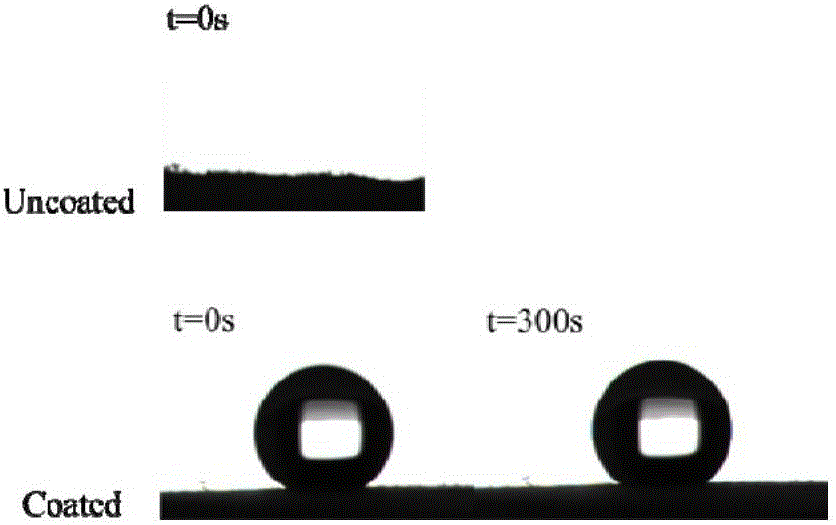

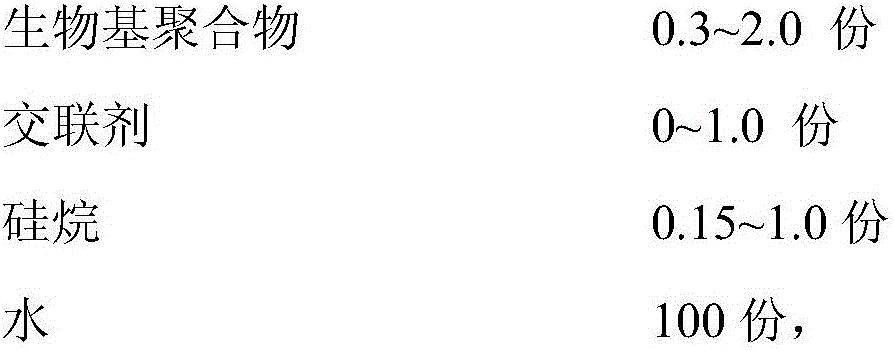

Biology base polymer aerogel oil absorption material and preparation method thereof

The invention discloses a biology base polymer aerogel oil absorption material. The oil absorption material is prepared by the following steps: at first, crosslinking biology base polymers by a crosslinking agent, to obtain a precursor liquid, then freeze-drying the precursor liquid to obtain aerogel, and finally grafting silane onto the aerogel surface to obtain the hydrophobic biology base polymer aerogel oil absorption material. The density of the oil absorption material is 3.8 to 23.1 kg / m3. The water contact angle is at least 117.8 degrees. The adsorption capacities on gasoline, paraffin oil, chloroform, and crude oil are 30.5-109.0 g / g, 33.2-131.2 g / g, 58.2-163.0 g / g, and 24.7-95.8 g / g. After 50 times of gasoline adsorption-extrusion circulation, the retention rate of adsorption capacity is 43 to 99%. The disclosed aerogel oil absorption material has the advantages of large oil absorption capacity and high oil absorption efficiency. Moreover, the oil absorption material can be repeatedly used by simply extruding the oil absorption material, while a high retention rate of adsorption capacity can be maintained. At the same time, the raw material sources are wide, the raw materials are cheap and easily available, the preparation is simple, the technology is matured, the method is environment-friendly, and the requirements of sustainable development can be met.

Owner:SICHUAN UNIV

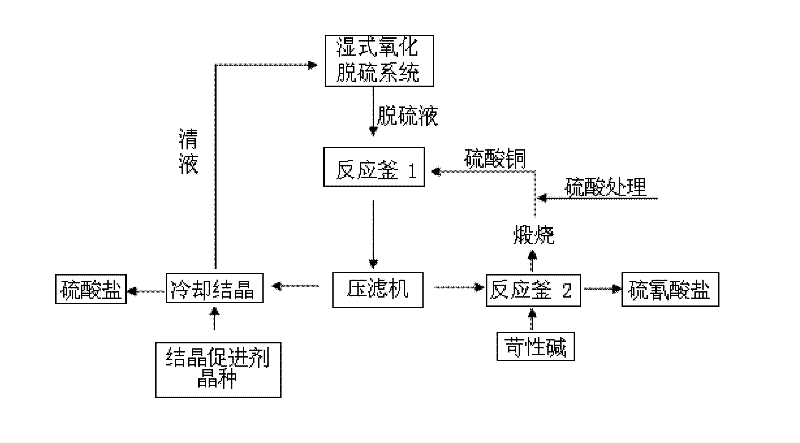

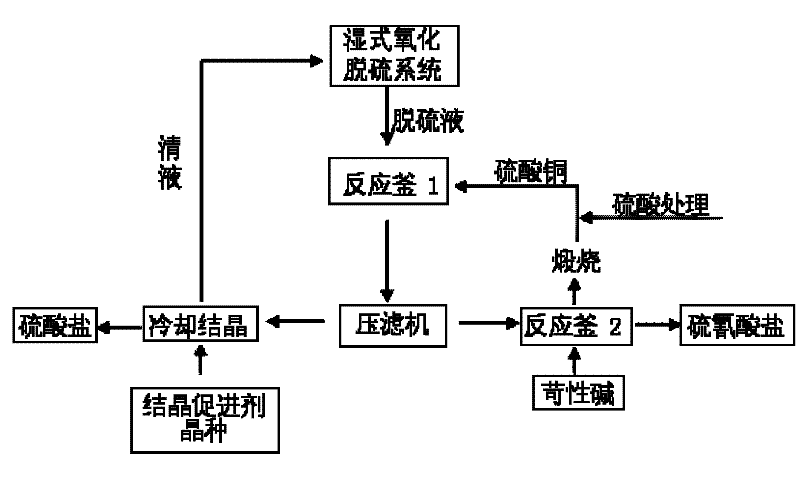

Method for recovering secondary salts from desulfurization liquid and recycling desulfurization liquid

ActiveCN102225816AAchieve recyclingHigh crystallinityThiocyanic acidMultistage water/sewage treatmentSulfatePollutant emissions

The present invention relates to a method for recovering secondary salts from a desulfurization liquid and recycling the desulfurization liquid, which comprises the following steps of: adding CuSO4 to the desulfurization liquid discharged from a wet oxidative desulfurization system for treatment, filtering to obtain CuSCN precipitates and a sulfate solution; adding the CuSCN precipitates to caustic alkali for treatment to recover thiocyanate; and cooling and crystallizing the sulfate solution to recover sulfates and returning the clear liquid to the desulfurization system. The method provided by the present invention simplifies the treatment process of desulfurization liquid wastewater, reduces pollutant emission, recovers the secondary salts from the desulfurization liquid and realizes the recycling of the desulfurization liquid, has a simple process, is environmentally-friendly, realizes the recycling of resources and has a good application prospect.

Owner:BEIJING BAIAONA HI TECH

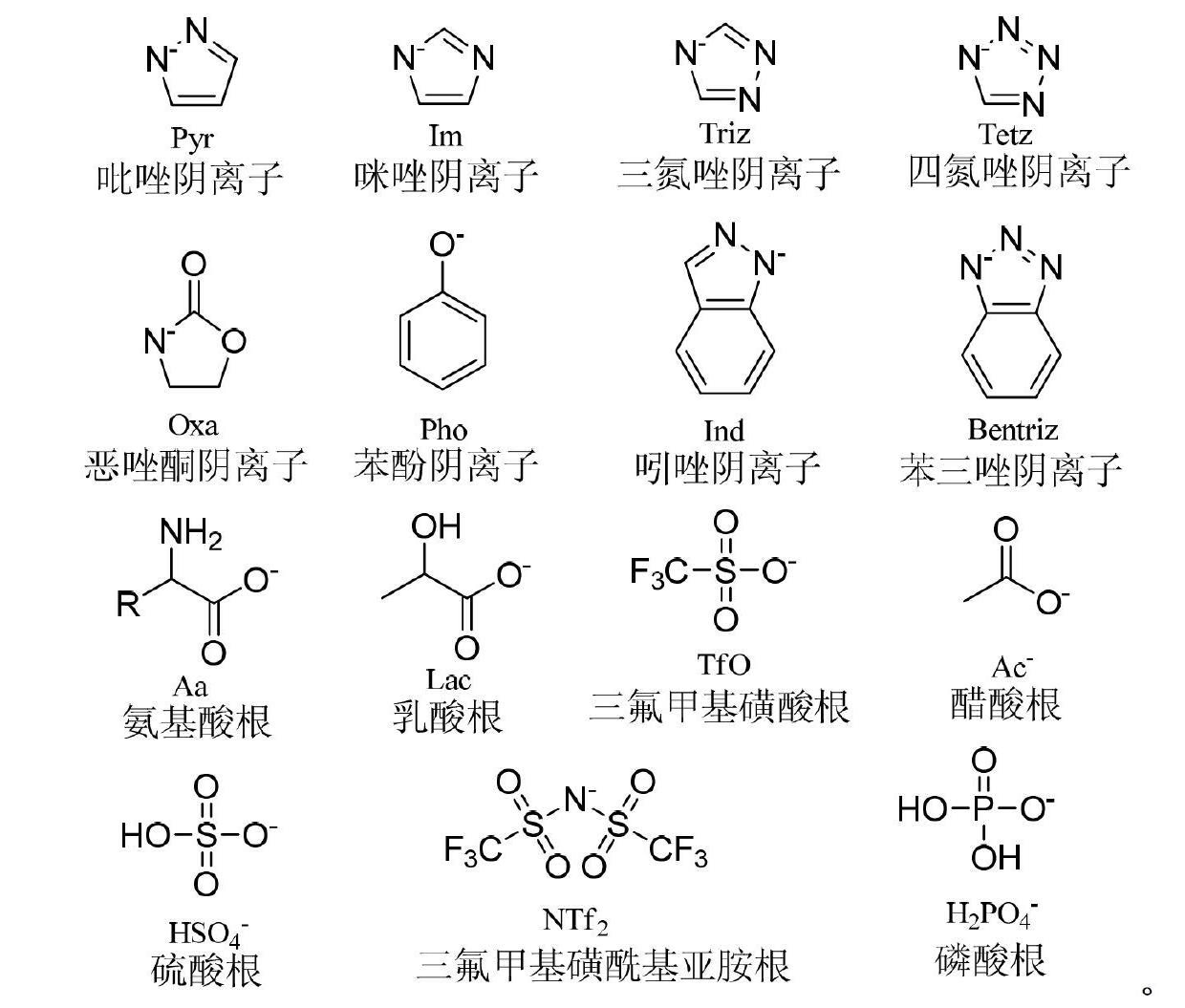

Method for absorbing and separating light hydrocarbons from dry gas or industrial tail gas by utilizing ionic liquid

ActiveCN104277880ARealize multiple recyclingNo pollutionDispersed particle separationLiquid hydrocarbon mixture recoveryAlkaneSolubility

The invention discloses a method for absorbing and separating light hydrocarbons from dry gas or industrial tail gas by utilizing an ionic liquid. The ionic liquid or a mixed solvent of the ionic liquid and a molecular solvent is taken as an absorbent to be in contact with the dry gas or the industrial tail gas, an absorption liquid containing the light hydrocarbons is obtained by absorption and the light hydrocarbons are further obtained by desorption and separation; and the light hydrocarbons are alkanes or olefins which mainly contain C2-C4. The invention provides the method for absorbing and separating the light hydrocarbons from the dry gas or the industrial tail gas by utilizing the ionic liquid. The ionic liquid or the mixed solvent of the ionic liquid and the molecular solvent is taken as the absorbent, an absorption-desorption method is adopted for recovery and separation of the light hydrocarbons, and the absorbent has very high solubility of the light hydrocarbons and separation selectivity, so that efficient separation and recovery of the light hydrocarbons can be realized and the highest comprehensive recovery rate can achieve 98.5%.

Owner:ZHEJIANG UNIV

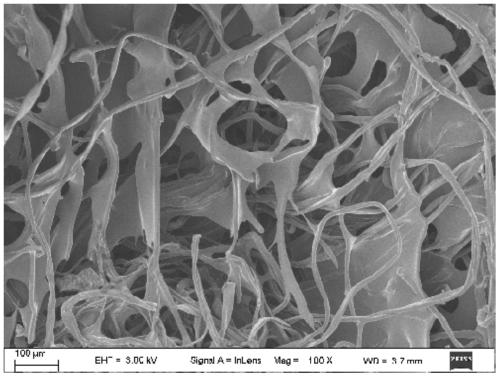

Three-dimensional fiber-based composite aerogel type adsorbent preparation method

InactiveCN110038529AImprove mechanical propertiesMaintain structureOther chemical processesWater contaminantsFreeze-dryingSorbent

The invention discloses a three-dimensional fiber-based composite aerogel type adsorbent preparation method. According to the method, cellulosic fiber, chitosan and sodium alginate which generally exist in natural world are utilized as raw materials. The method comprises the steps: firstly, utilizing periodate and metaphosphoric acid to sequentially chemically modify the cellulosic fiber; then crosslinking the modified cellulosic fiber with the chitosan; then compounding with the sodium alginate; freeze drying to obtain a three-dimensional fiber-based composite aerogel type adsorbent. The prepared adsorbent disclosed by the invention has high safe stability, has a good adsorption effect on negative ion pollutants and positive ion pollutants and can be applied to purifying heavy metal ion wastewater and dyestuff wastewater; in addition, the cellulosic fiber added into the adsorbent disclosed by the invention not only can serve as a framework and a reinforcing material, but also can be crosslinked with the chitosan to improve compression strength, morphology and structural stability of the whole aerogel adsorbent; thus, the adsorbent can be repeatedly used for many times, and the characteristics of rice inner holes and large specific surface area of the aerogel are fully played.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Method for planting forage grass using day-light greenhouse

InactiveCN101069469AContinuous harvestProvide continuouslyAgriculture gas emission reductionGreenhouse cultivationGreenhouseDaylight

The present invention relates to a method for planting forage grass by utilizing heliogreenhouse. It is characterized by that said method includes the following steps: close-planting and cultivating the germinated seeds in seedling room, controlling CO2 concentration and making it be 800-1200 ppm / cu.m, making cultivation at 10-40deg.C to obtain forage grass seedlings; transplanting the forage grass seedlings into a heliogreenhouse for promoting growth of forage grass, controlling CO2 concentration and making it be 800-1200 ppm / cu.m, after the forage grass seedlings are grown for 70-160 days at 10-40deg.C, harvesting forage grass. Several heliogreenhouses for promoting growth of forage grass can be combined together so as to form a forage grass production system.

Owner:苏亚杰

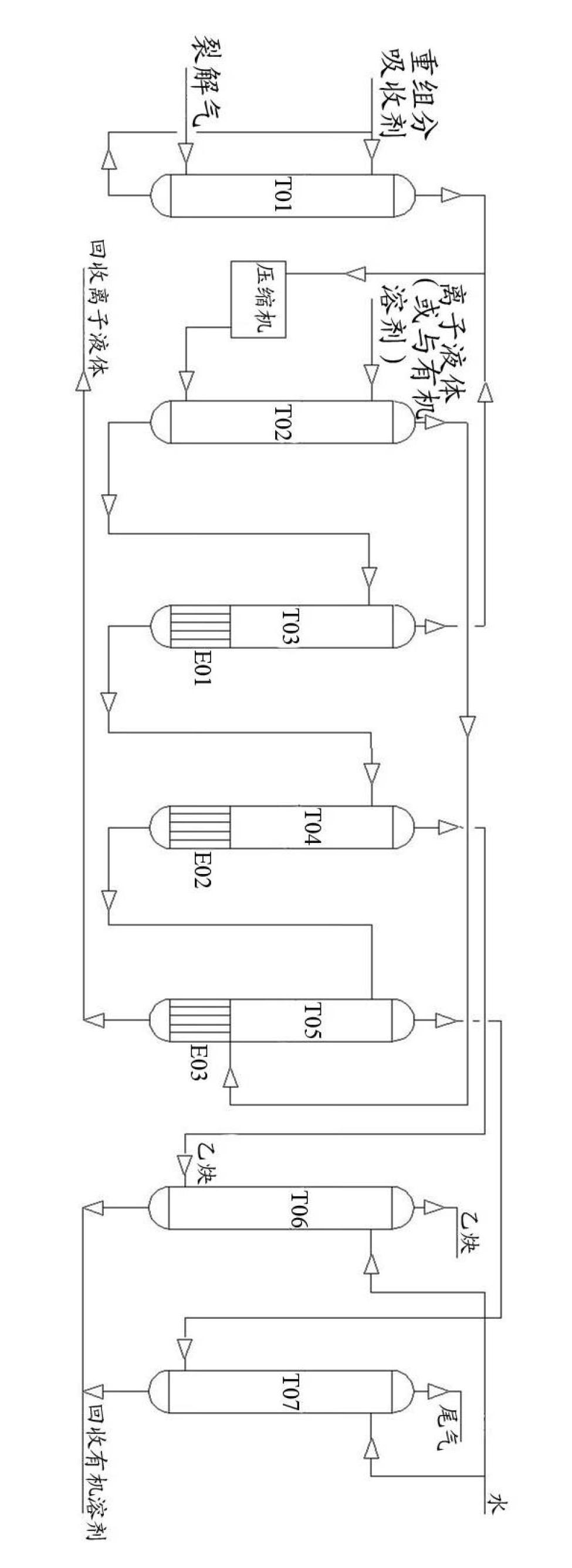

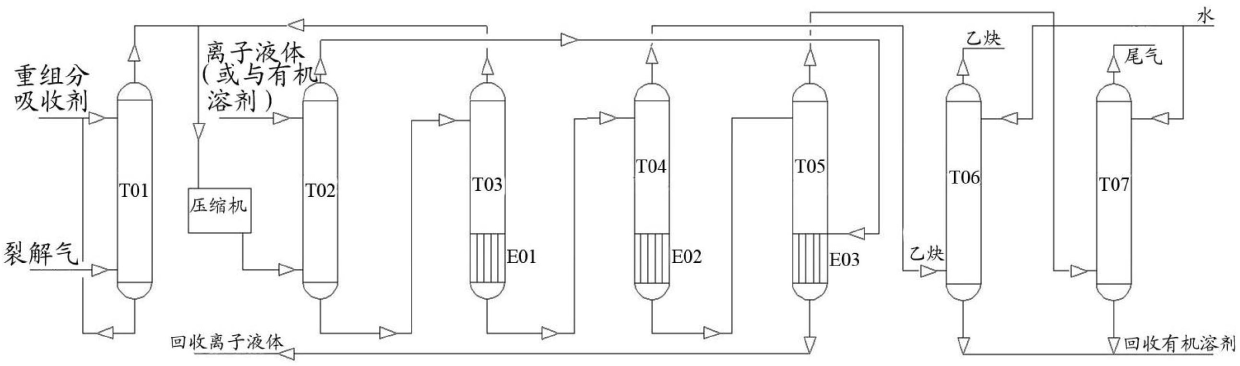

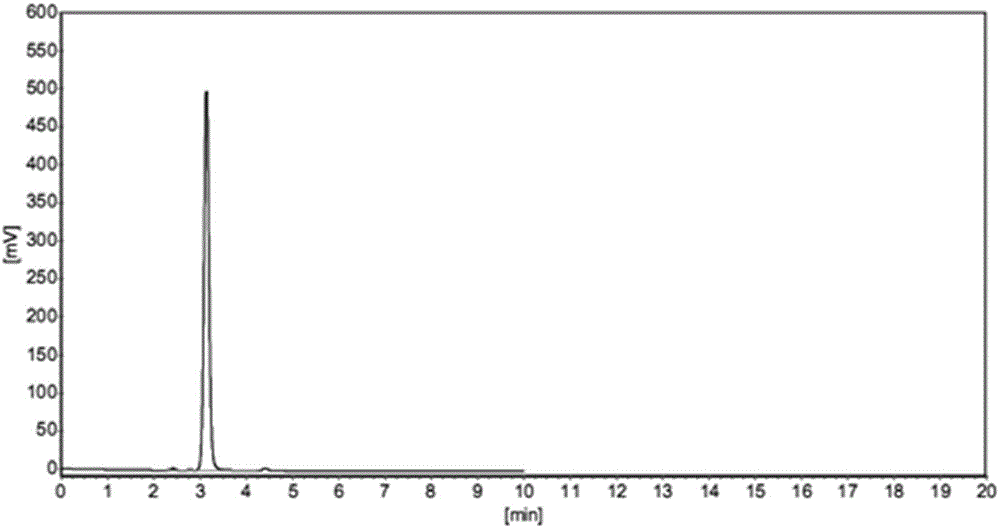

Separating preparation method of acetylene by absorbing pyrolysis gas with ionic liquid

ActiveCN102675028ARealize multiple recyclingImprove thermal stabilityAbsorption purification/separationBulk chemical productionEnvironmental resistanceDesorption

The invention discloses a separating preparation method of acetylene by absorbing pyrolysis gas with ionic liquid, which comprises the following steps of: absorbing heavy components in pyrolysis gas by heavy component absorbent, sequentially absorbing the pyrolysis gas under high pressure by taking the ionic liquid or the mixed solution consisting of the ionic liquid and organic solvent as absorbent and adopting an absorption-desorption method, and carrying out split reduction and warming desorption on the preheated absorption liquid, to desorb the light components, the acetylene and the high alkyne, so as to obtain the high-purity acetylene in a separation way. The method has the characteristics of being high in separation efficiency, less in solvent energy consumption, safe, environment-friendly, suitable for the industrial production, and the like.

Owner:XINJIANG YUEHETAI CHEM TECH CO LTD

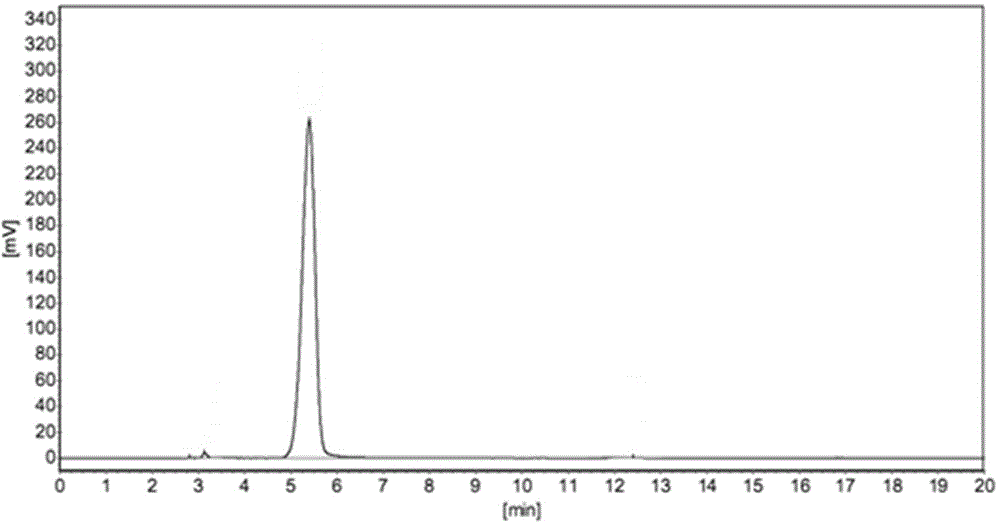

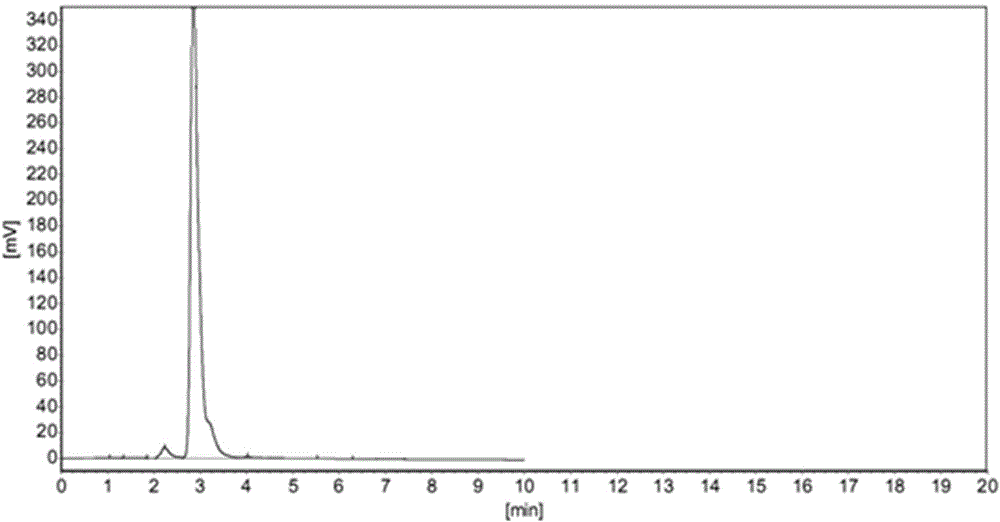

Method for separating alpha-ketoglutaric acid from conversion solution

ActiveCN104529755ARealize multiple recyclingAchieve recyclingOrganic compound preparationChemical industryUltrafiltrationSulfate

The invention discloses a method for separating alpha-ketoglutaric acid from a conversion solution, which comprises the following steps: sequentially carrying out ceramic filtration, ultrafiltration and reverse osmosis on the conversion solution to obtain an alpha-ketoglutaric acid concentrated solution; reacting the obtained concentrated solution with calcium superchloride, and filtering to obtain alpha-ketoglutarate; adding the alpha-ketoglutarate and ethanol into a reaction kettle, slowly and dropwisely adding sulfuric acid, stopping adding the acid when the pH value of the ethanol solution is 1.3-1.5, stirring to react to generate a calcium sulfate precipitate, filtering, and collecting the filtrate which is a ketoglutaric acid ethanol solution; eluting the residual alpha-ketoglutaric acid from the calcium sulfate with ethanol, and collecting the eluting solution; and mixing the filtrate and eluting solution, and heating and concentrating under reduced pressure to precipitate the alpha-ketoglutaric acid crystal. The membrane filtration technique is adopted to avoid abundant water evaporation; and thus, the method has the advantages of energy saving, high production yield, favorable crystal form, light color of the crystal grain, and stable product quality, and can easily implement industrialized large-scale production.

Owner:JING JING PHARMA

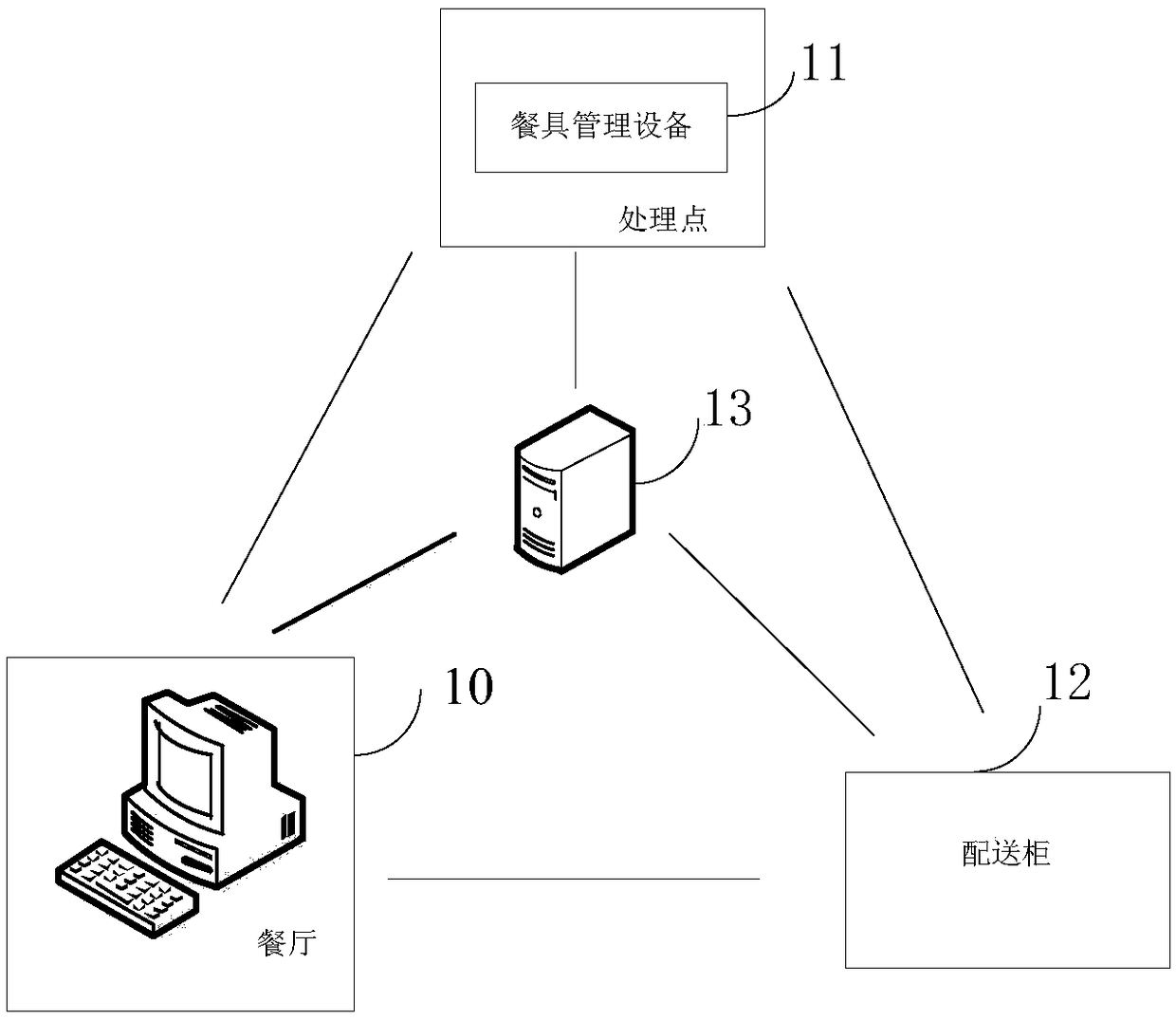

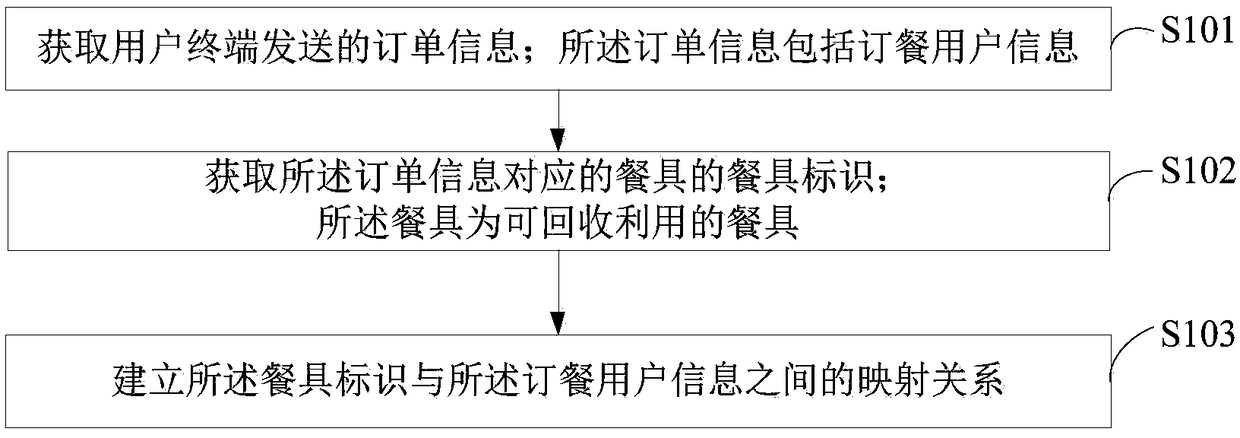

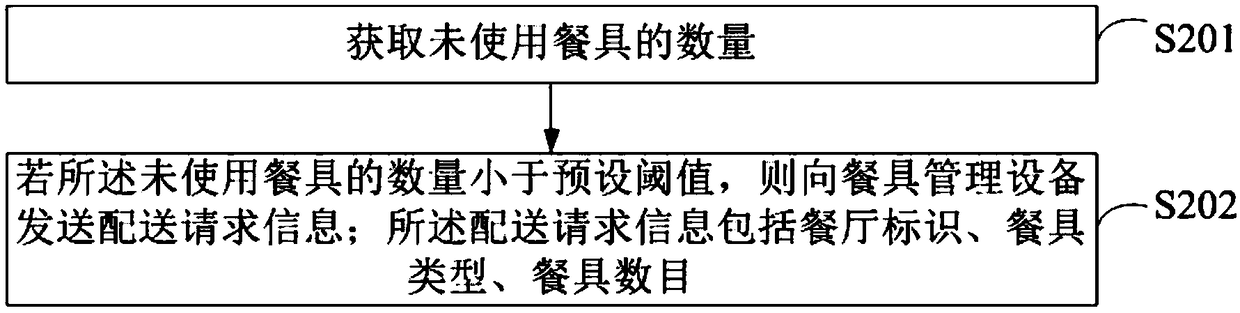

Tableware information processing method and device, equipment and readable storage medium

InactiveCN108876660AGuaranteed reliabilityImprove reliabilityData processing applicationsInformation processingComputer terminal

The invention provides a tableware information processing method and device, equipment and a readable storage medium. The method comprises the following steps: acquiring order information sent by a user terminal, wherein the order information includes order user information; acquiring tableware identification of tableware corresponding to the order information, wherein the tableware is recyclabletableware; and establishing a mapping relationship between the tableware identification and the order user information. The tableware in the method can be recycled, so that the tableware with the tableware identification can be used by different ordering users; repeated recycling of the tableware is realized; environmental pollution is lowered; and the tableware is safe and environmentally friendly to use and has high reliability.

Owner:唐红波

Method for cleaning filter element of polyester prepolymer filter

InactiveCN104474793ARealize multiple recyclingExtended service lifeFilter regenerationPolyesterMegasonic cleaning

The invention relates to the field of the cleaning method of polyester prepolymer filters, and particularly relates to a method for cleaning a filter element of a polyester prepolymer filter. The method comprises the steps of firstly, carrying out hydrolysis treatment; secondly, washing by using a high-pressure water gun; thirdly, soaking in an alkaline tank; fourthly, washing and soaking in a washing tank; fifthly, washing by using the high-pressure water gun again; sixthly, carrying out secondary hydrolysis; seventhly, repeating the steps three, four and five sequentially; eighthly, carrying out ultrasonic cleaning; ninthly, repeating the steps three, four and five sequentially; tenthly, carrying out ultrasonic cleaning again; and eleventhly, carrying out bubble detecting. According to the method for cleaning the filter element of the polyester prepolymer filter, residual polymers in the filter element are degraded by hydrolysis at high-temperature and alkaline conditions, and residues are removed by cleaning via high-temperature water, washing by using the high-pressure water gun and cleaning by using ultrasonic waves, so that multiple times of recycling of the filter element are realized. Residual polymers in the filter element are degraded by adopting a hydrolysis technology for the process, and pollution and obvious peculiar smell do not exist on the site in operation.

Owner:TONGKUN GRP

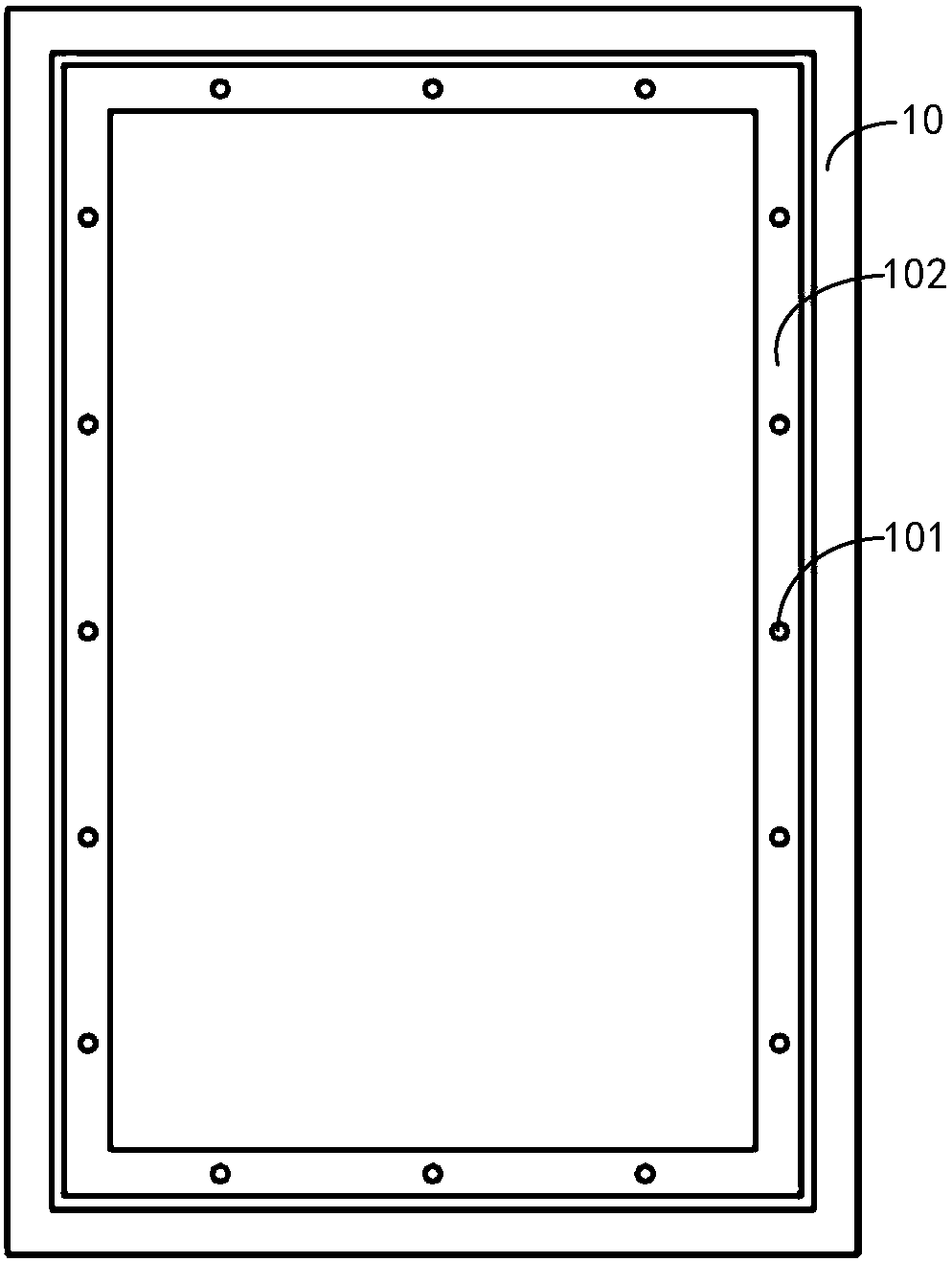

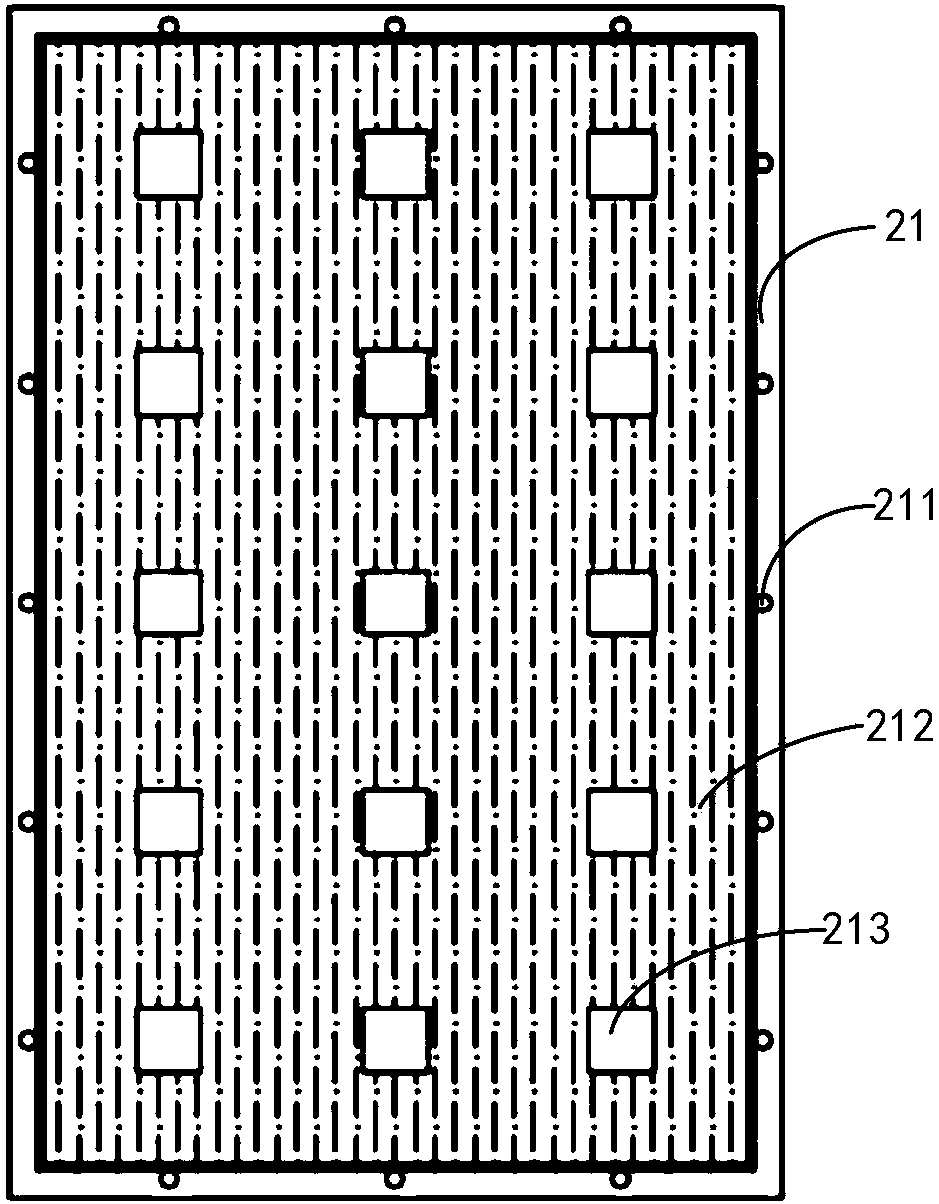

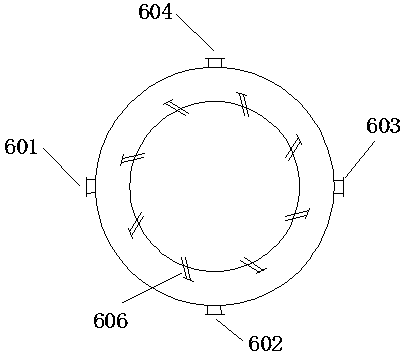

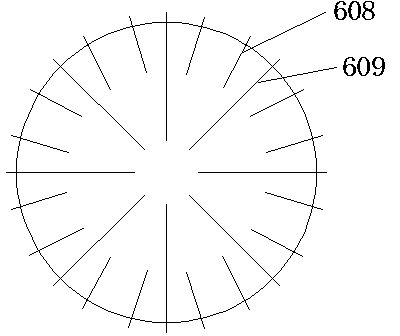

Mask assembly, mask frame and mask supporting frame

ActiveCN108034923ARealize multiple recyclingReduce replacement rateVacuum evaporation coatingSputtering coatingComputer science

The invention discloses a mask assembly, a mask frame and a mask supporting frame. The mask assembly comprises the mask frame and the mask supporting frame; the mask frame comprises at least one firstconnecting part; the mask supporting frame comprises at least one second connecting part; and the mask frame is detachably connected with the mask supporting frame through the at least one first connecting part and the at least one second connecting part. The mask assembly comprises the mask frame and the mask supporting frame which are detachably connected, when the mask assembly is replaced, the size of the mask frame is not changed, so that the mask frame can be directly recycled simply by replacing the mask supporting frame. Repeated recycling of the mask frame can be realized, the replacement rate of the mask frame is lowered and the production cost is lowered.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

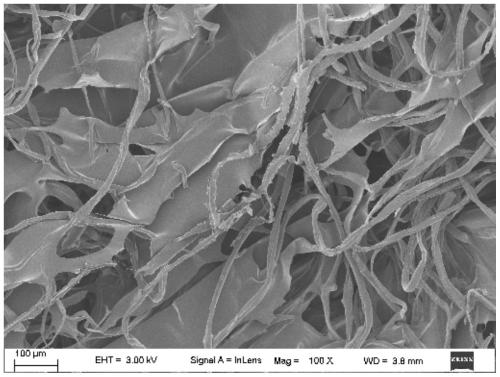

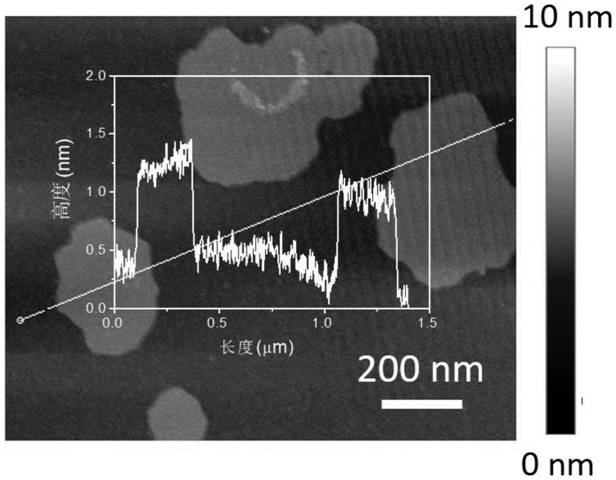

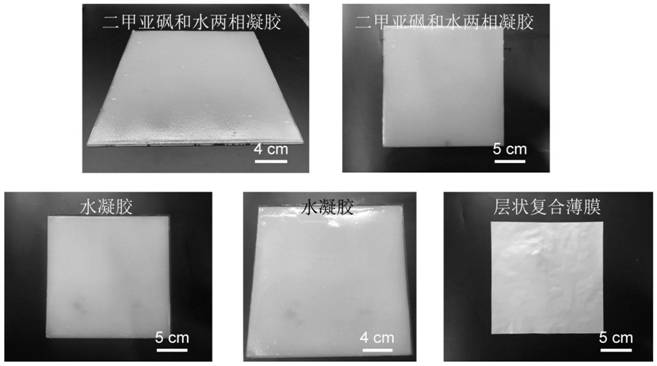

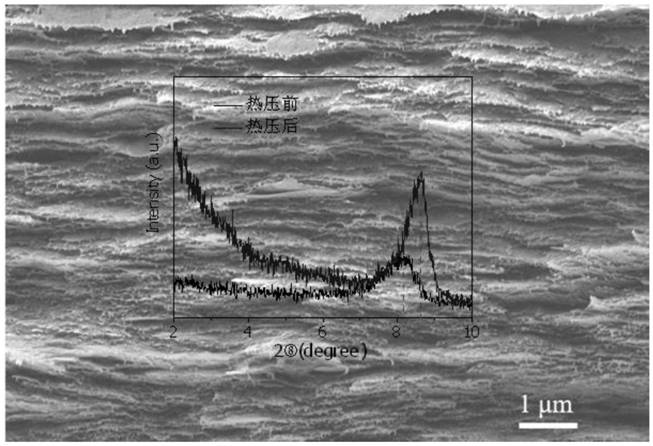

Aramid nanofiber-based layered composite film and preparation method and cyclic utilization method thereof

ActiveCN111732746AUniform thicknessExcellent overall performanceSynthetic resin layered productsLayered structureFiber matrix

The invention provides an aramid nanofiber-based composite film. The composite film is of a layered structure. The composite film is formed by stacking a plurality of single-layer aramid nanofiber-based films. The aramid nanofiber-based film comprises an aramid nanofiber matrix and an assembly element; the assembly element includes one or more of an inorganic sheet material, an inorganic line material and a polymer. The aramid nanofiber-based composite film provided by the invention has a compact layered structure, the thickness of a single-layer film is uniform, and the nano-scale uniform interlayer spacing is extremely small, so that the composite film has excellent comprehensive performance. The invention further provides a simple and efficient large-scale preparation method and a cyclic utilization method. The prepared aramid nano-fiber-based layered composite film material can be made into aramid nano-fiber-based composite slurry again, and then the aramid nano-fiber-based composite slurry is made into the layered composite film material again by virtue of a spraying and hot pressing combined method, so that repeated cyclic utilization of the layered composite film material isrealized.

Owner:UNIV OF SCI & TECH OF CHINA

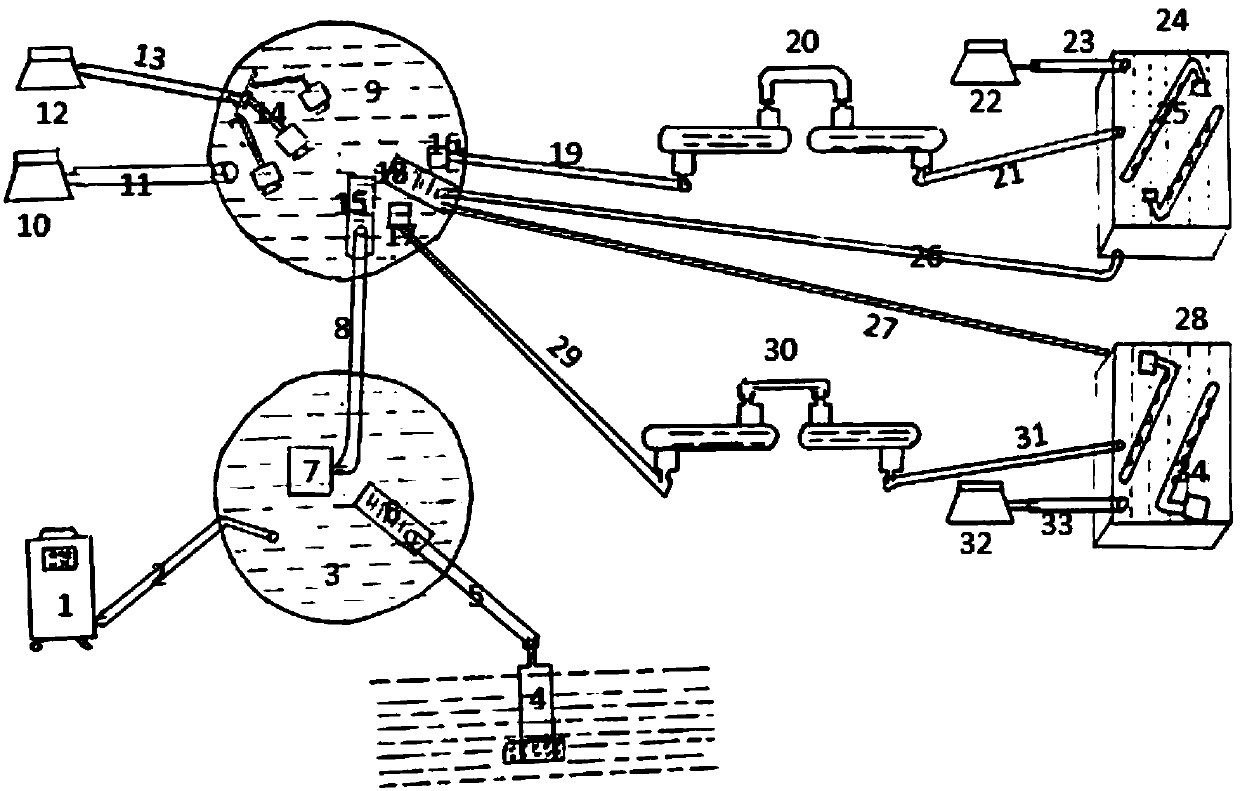

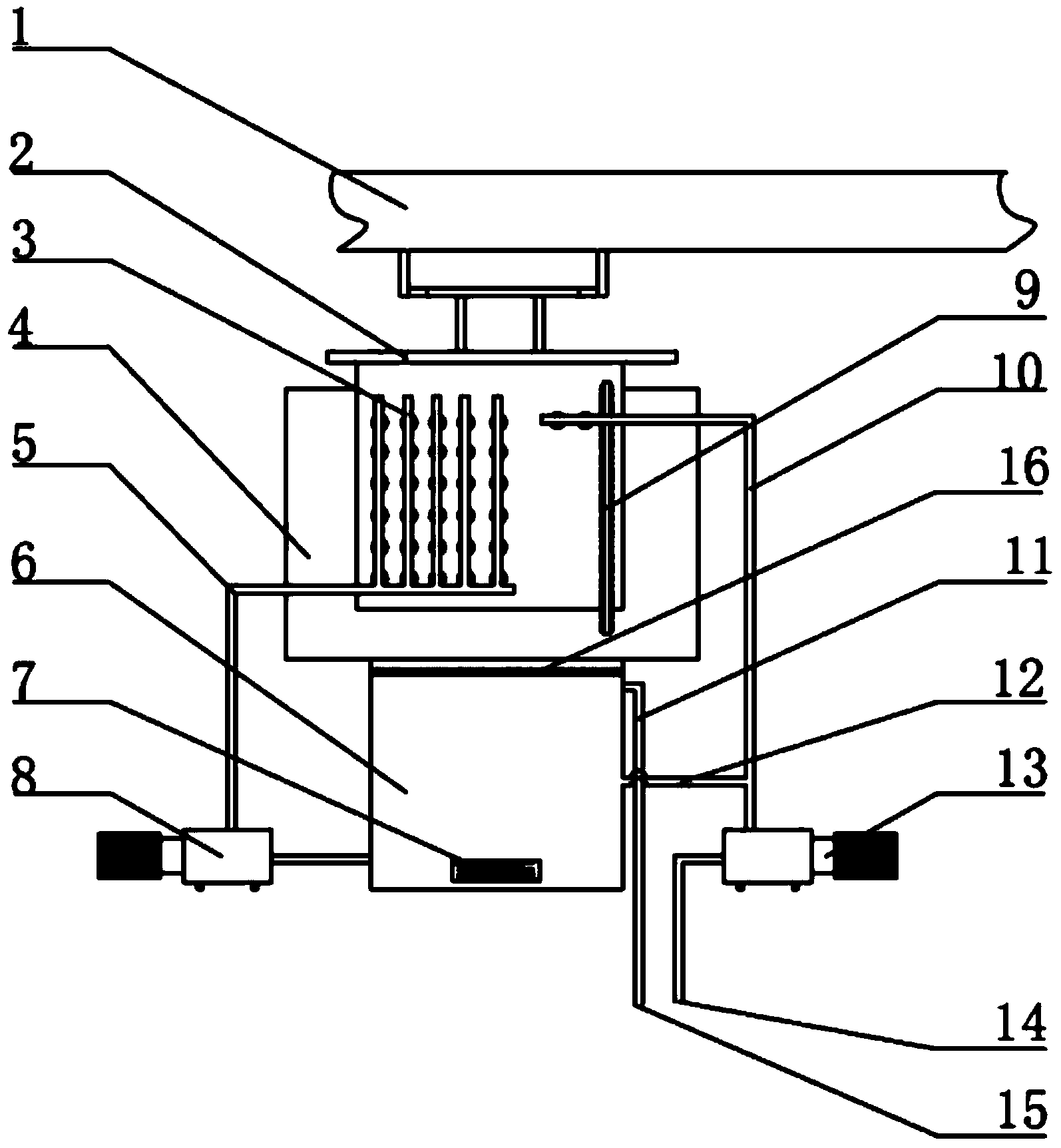

Simple circulating water culture method and device of coreius guichenoti fries

InactiveCN108040955ARealize multiple recyclingNormal growthClimate change adaptationPisciculture and aquariaDiseaseChlorine dioxide

The invention discloses a simple circulating water culture method and device of coreius guichenoti fries. The method comprises the following steps: A, constructing culture supporting facilities of coreius guichenoti fries, wherein the culture supporting facilities include an exogenous water treatment facility, culture equipment and a circulating water treatment system; B, adjusting and controllingthe water quality of water in a culture pool to obtain soft water of which the pH value is weakly alkaline; C, putting the coreius guichenoti fries into the pool, and then, feeding palatable bait according to different ages of the moon and mouth sizes of fishes; and D, preventing and treating fish diseases in a high-density culture process of the coreius guichenoti fries, namely spraying sea saltfor aquatic products, povidone-iodine, an enrofloxacin injection or hanging bag type chlorine dioxide effervescent tablets and isatis root powder in the whole pool so as to perform medication. The device is composed of an ozone generator, a pond, a culture pool, a water pump, an aerator, an ultraviolet sterilizer and a water pipe device. The method is easy to realize and simple and convenient tooperate, realizes intensive and efficient culture, fully utilizes limited purified water, and realizes a higher culture survival rate.

Owner:WATER ENG ECOLOGICAL INST CHINESE ACAD OF SCI

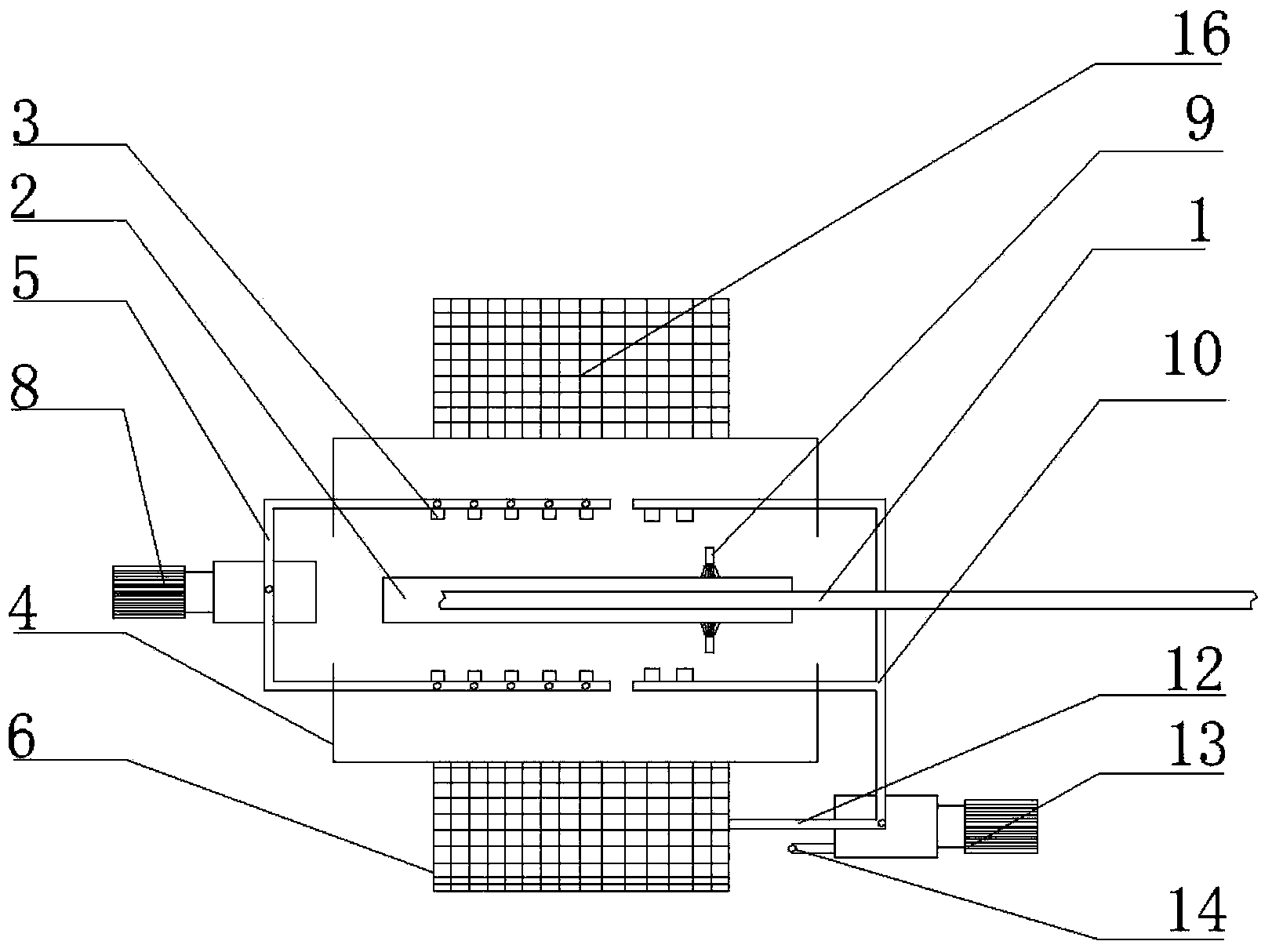

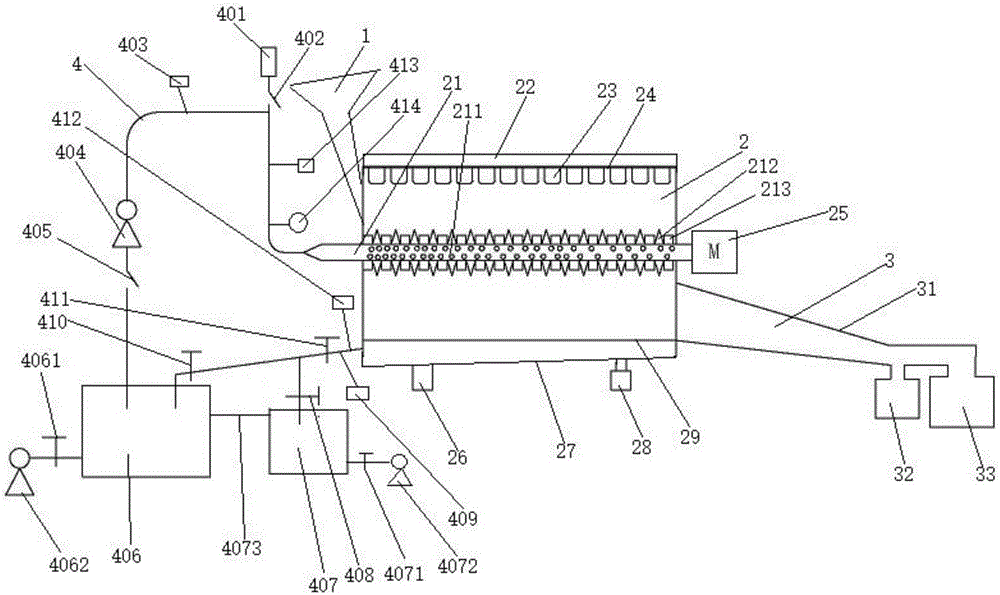

Negative polar plate needle-spraying counter-flow cleaning device in subsequent electrolysis working section of electrolytic zinc

ActiveCN103774186ARealize multiple recyclingRealize cleaning automationPhotography auxillary processesElectrolysis componentsHigh concentrationElectrolysis

The invention relates to a negative polar plate needle-spraying counter-flow washing device in a subsequent electrolysis working section of electrolytic zinc. The device comprises a conveying chain, a polar plate, a circulating washing assembly, a clean water washing assembly and a row brush, wherein the polar plate is connected with the conveying chain; the circulating washing assembly is connected with the clean water washing assembly; the row brush is mounted on the circulating washing assembly. According to the negative polar plate needle-spraying counter-flow washing device disclosed by the invention, the use period of plate washing wastewater in an electrolytic zinc workshop can be obviously prolonged, so that the generation amount of heavy metal wastewater is greatly reduced, the clean water consumption is reduced, and the potential safety hazard caused by the conventional large-tonnage plate immersion working procedure and high-concentration heavy metal wastewater is avoided; due to water balance, recycling of the heavy metal wastewater is realized.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

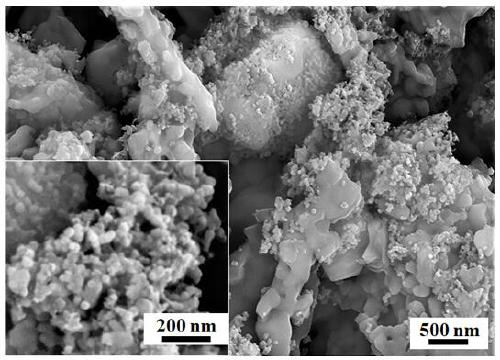

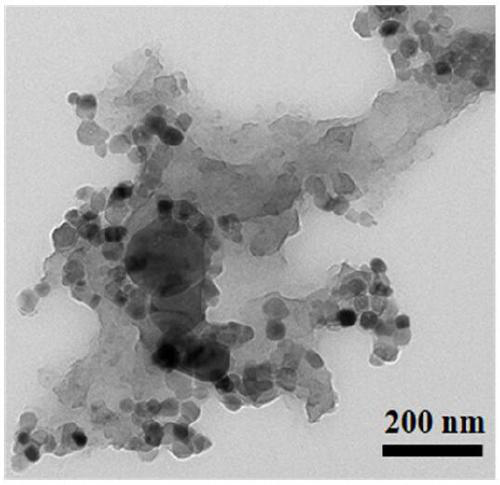

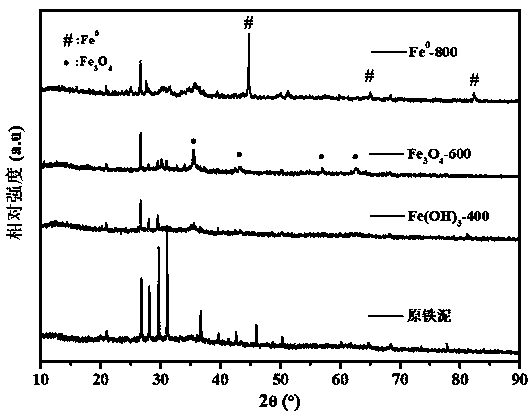

Method for preparing nano zero-valent iron from water purification plant iron-containing sludge and application

The invention provides a method for preparing nano zero-valent iron from water purification plant iron-containing sludge. After the sludge taken from a water purification plant settling pond is subjected to filter-press dewatering, air-drying and smashing, the sludge is subjected to high-temperature drying pretreatment, dry iron sludge particles are obtained, the dry iron sludge particles are ground and screened, and an iron sludge sample is obtained; and under inert gas shielding, high-temperature calcination and pyrolysis are carried out, and the magnetic nano zero-valent iron material is obtained. The invention relates to application of the nano zero-valent iron catalyst prepared with the method in activating persulfate to oxidatively degrade organic pollutants in water. The method is based on resource recovery of the sludge produced through a water purification plant, the prepared catalyst has an efficient catalytic degradation effect, the catalyst is easily separated, recovered and reused from a water phase under an external magnetic field, the raw materials are environmentally friendly and easy to obtain, the preparation method is simple and economical, waste is turned into wealth, the effect of treating waste water with waste is achieved, and broad practical application prospects are achieved.

Owner:HARBIN INST OF TECH

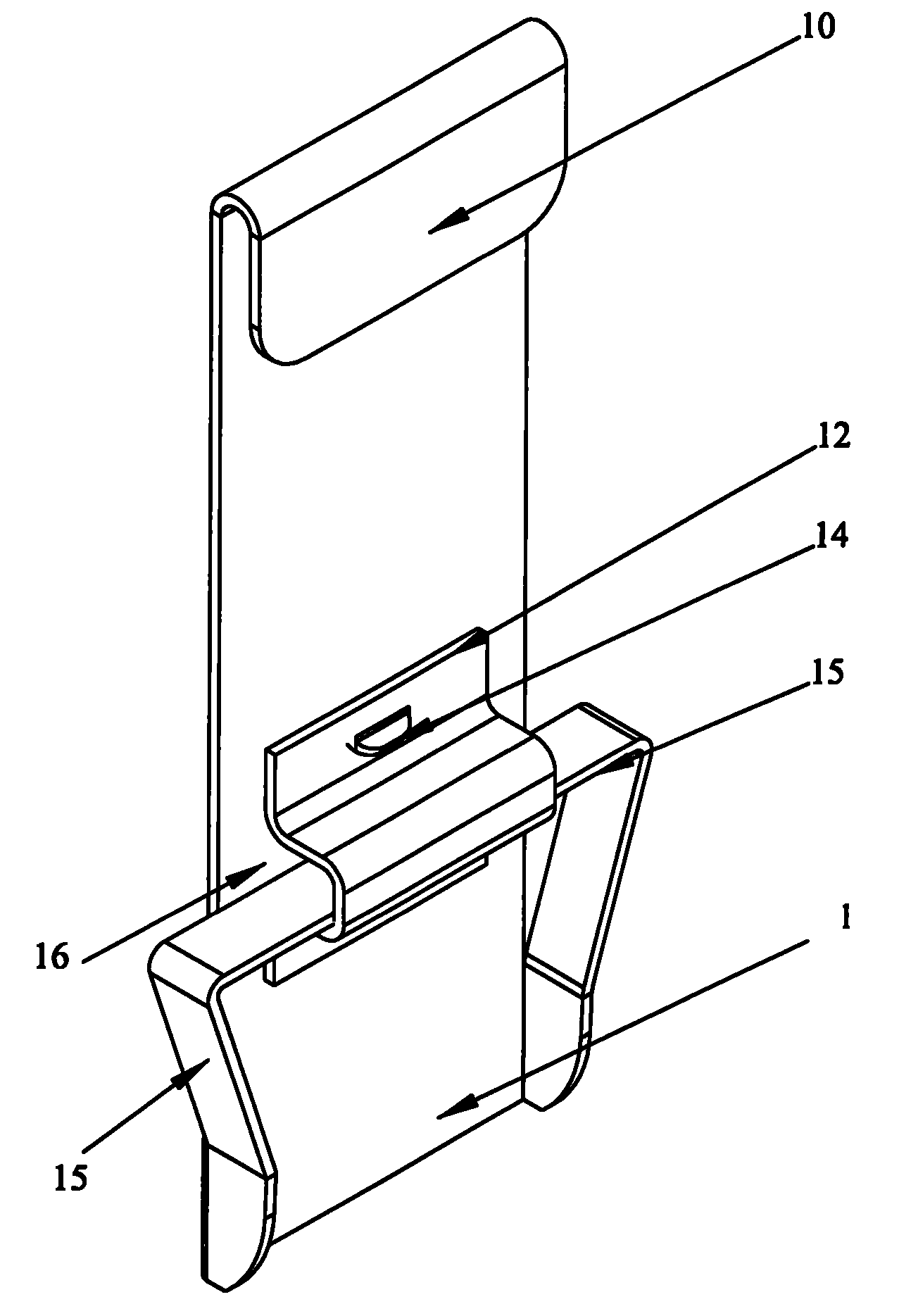

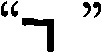

Connecting buckle element between box plates of circulating package box

The invention discloses a connecting buckle element between box plates of a circulating package box, which comprises a spring insertion sheet and a connecting insertion buckle, wherein the spring insertion sheet and the connecting insertion buckle can mutually buckled and dismounted, the upper part of the spring insertion sheet is a bending end capable of being inserted into a groove of a steel strip arranged at the outer edge of the box plates of the package box, the middle part is provided with an independent omega-shaped sheet metal component, a middle perforated hole groove is formed between the omega-shaped sheet metal component and a body of the spring insertion sheet, the lower part of the spring insertion sheets form two leaf springs in a bending mode, both ends of the leaf springs are embedded into the hole groove of the omega-shaped sheet metal component, a convex platform is formed in the middle part of the connecting insertion buckle, square holes are respectively punched in the middle parts of both ends connected with the convex platform, and press teeth capable of being fixedly connected with the box plates of the package box are formed at both sides of the square holes.

Owner:无锡市前程包装工程有限公司

Soil heavy metal chromium pollution repairing material and making method and application of soil heavy metal chromium pollution repairing material

InactiveCN107722991AImprove adsorption capacityAchieve separationContaminated soil reclamationOrganic fertilisersAdhesiveRepair material

The invention discloses a soil heavy metal chromium pollution repairing material. The soil heavy metal chromium pollution repairing material comprises the following materials by weight percent: 10%-30% of stabilizing and solidifying adhesive, 30%-50% of a composite adsorbent, and the balance of water. The invention also discloses a preparation method of the repairing material. The repairing material adsorbs the Cr material in the soil, is favorable for recycling of the material, realizes the efficient repairing, can be recycled for multiple times, and reduces the repairing cost.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

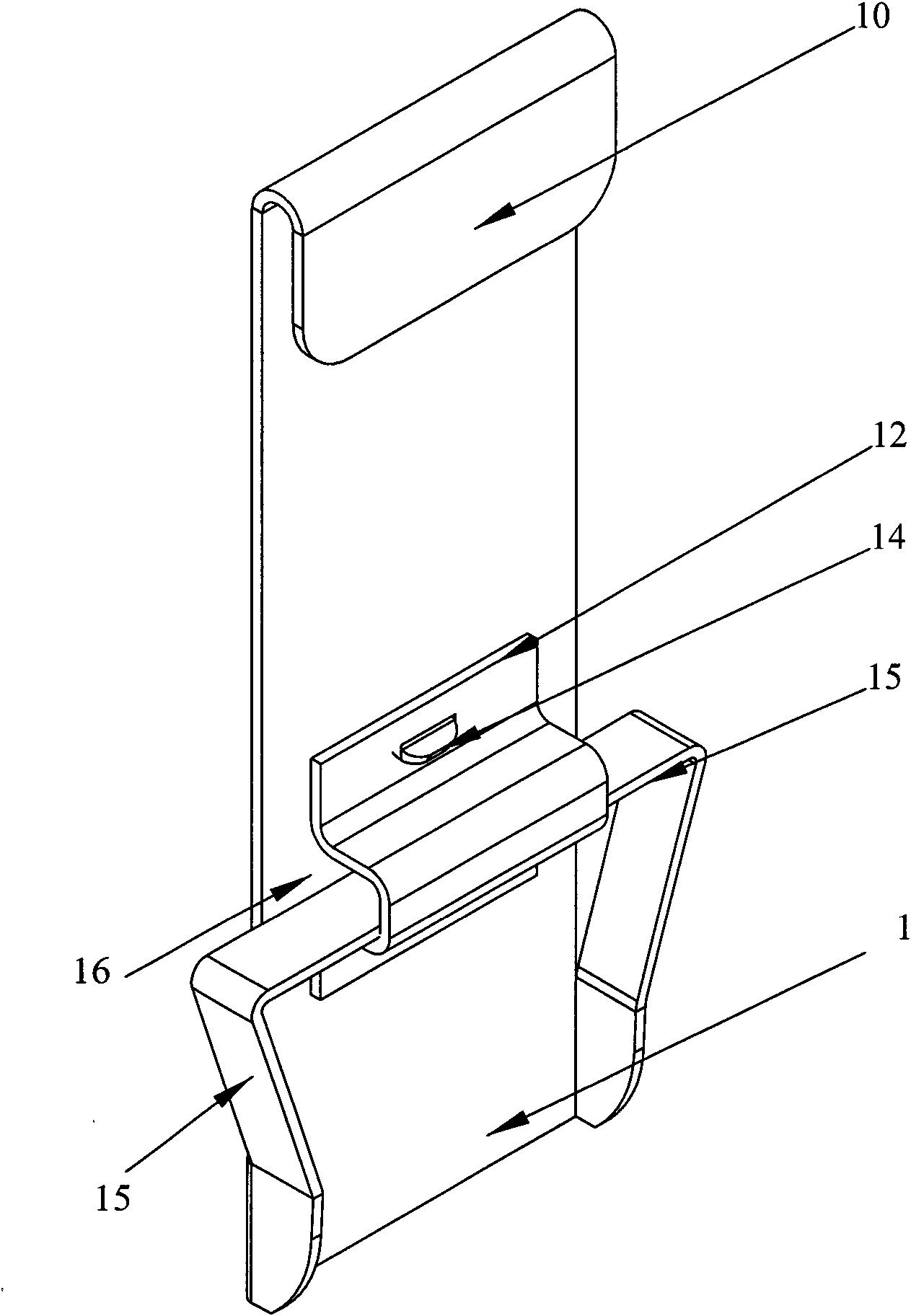

Clean coal gas production method

ActiveCN103725325AEasy to recycleSatisfy the production requirements of the follow-up processGas dust removalGranular/pulverulent flues gasificationProduct gasWater cooling

The invention discloses a clean coal gas production method. The clean coal gas production method is characterized in that the production method comprises the procedures of powdered coal gasification, dedusting in high-temperature segment and indirect cooling. The clean gas production method is composed of high-efficiency coal gas generation, heat recovery, high-temperature dedusting, and ash-free water cooling, therefore, the product gas can meet the requirement of the clean coal gas.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

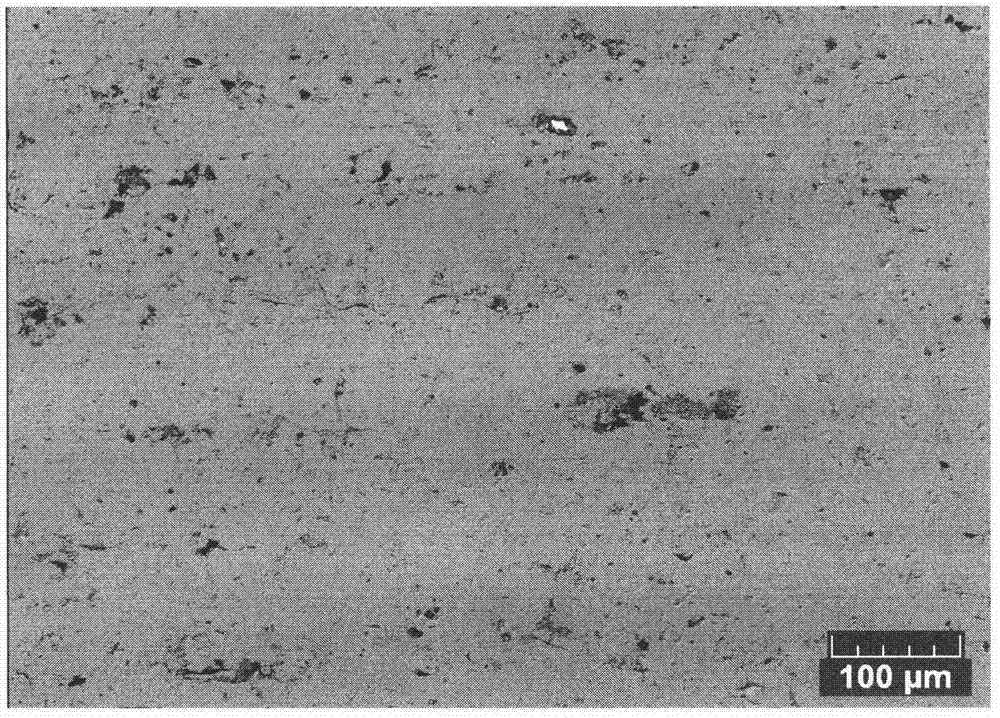

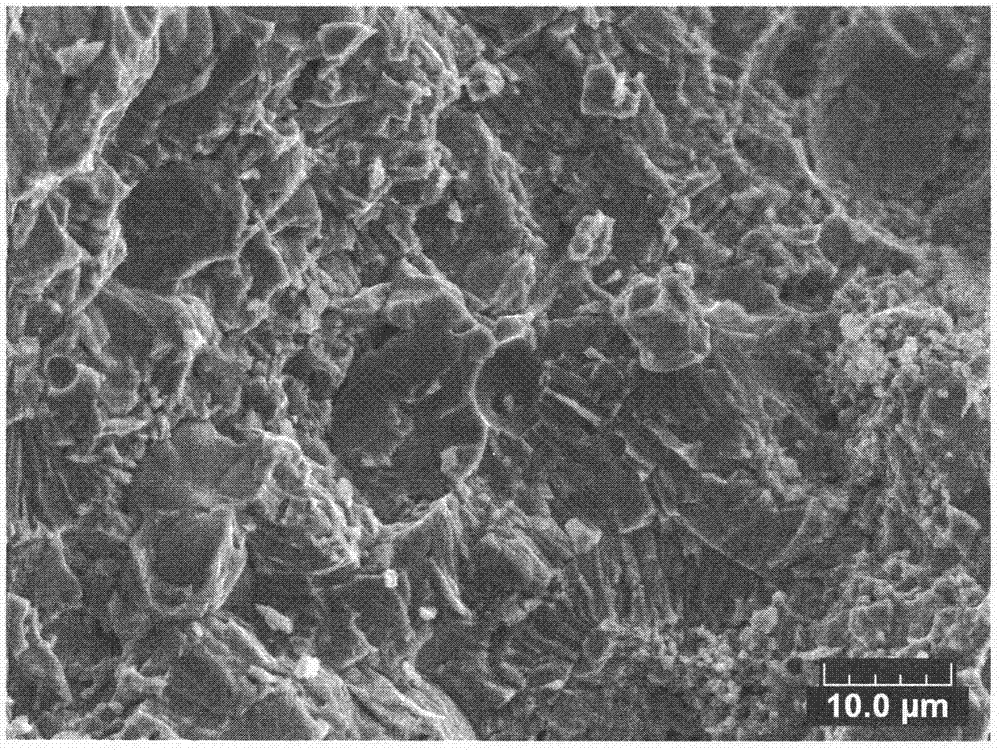

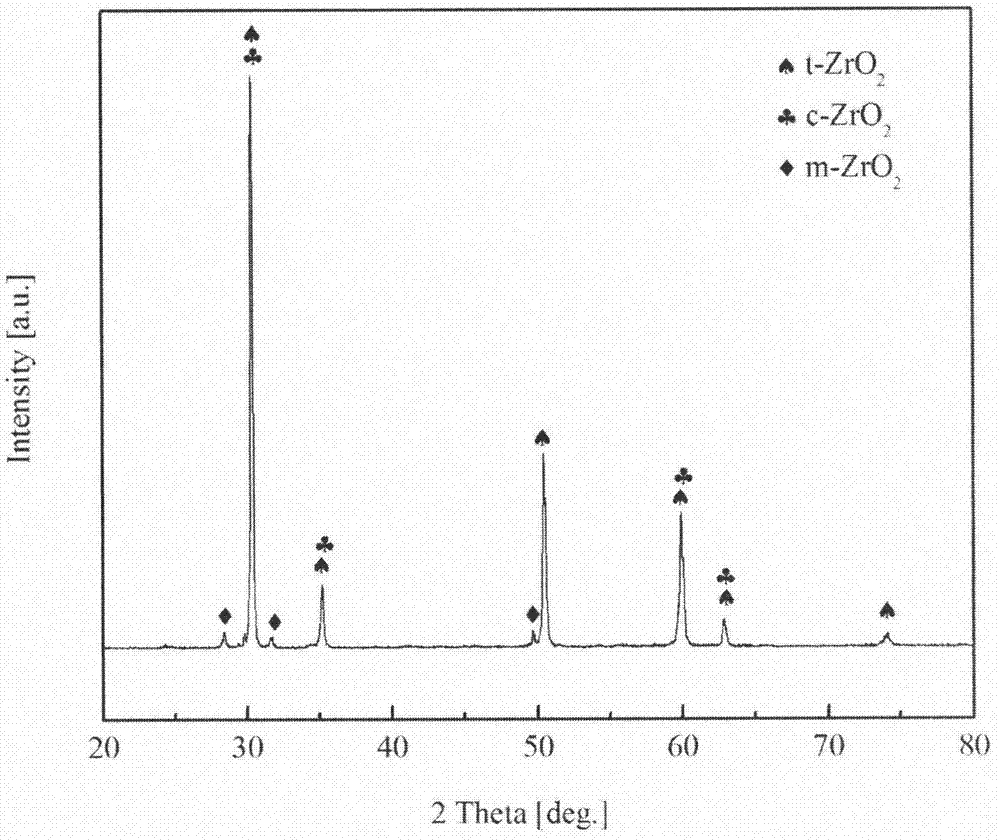

Preparation method of plasma-sprayed ceramic coating for strengthening surface of water pump impeller

InactiveCN107299310AExtend the life cycleHigh temperature resistantMolten spray coatingThermal sprayingChemical plating

The invention relates to a preparation method of a plasma-sprayed ceramic coating for strengthening surface of a water pump impeller. The preparation method comprises the following steps: ultrasonically washing the surface of the water pump impeller with acetone, and drying; processing the surface of the water pump impeller through sand-blasting roughening by brown aluminum oxide; preheating the surface of a base body; and spraying ceramic powder onto the surface of the base body of the water pump impeller to obtain a durable and corrosion-resistant ceramic coating, wherein the ceramic coating on the surface of the impeller is obtained by being spraying for a plurality of times. The preparation method overcomes shortages of laser surface modification, thermal spraying, chemical plating and electroplating. The preparation method has the advantages that the use cycle of a water pump is obviously prolonged; requirements of the water pump impeller surface on corrosion resistance and cavitation resistance are met; workpieces are recycled repeatedly; processes are simple and feasible; the production efficiency is high; the automation degree is high; the sustainable development strategy is met; and the method has market economic benefits.

Owner:YANGZHOU UNIV

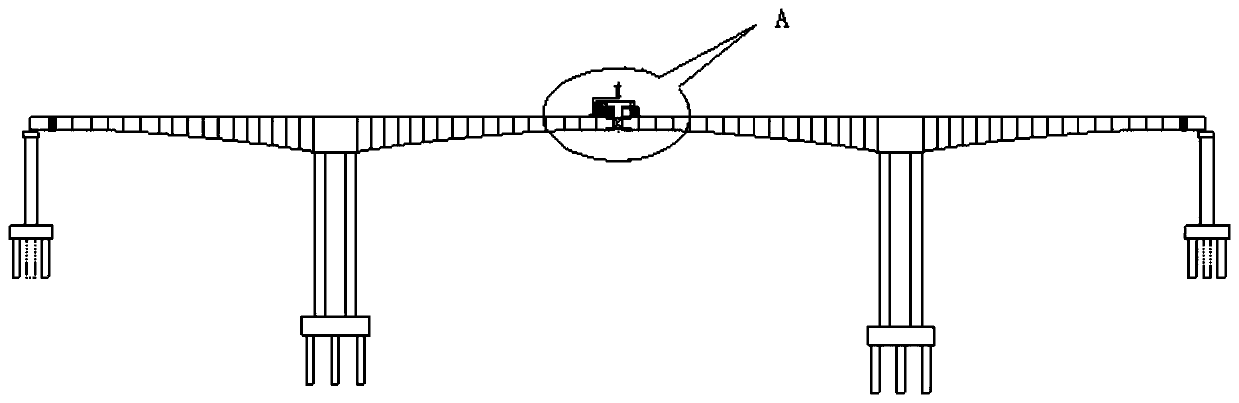

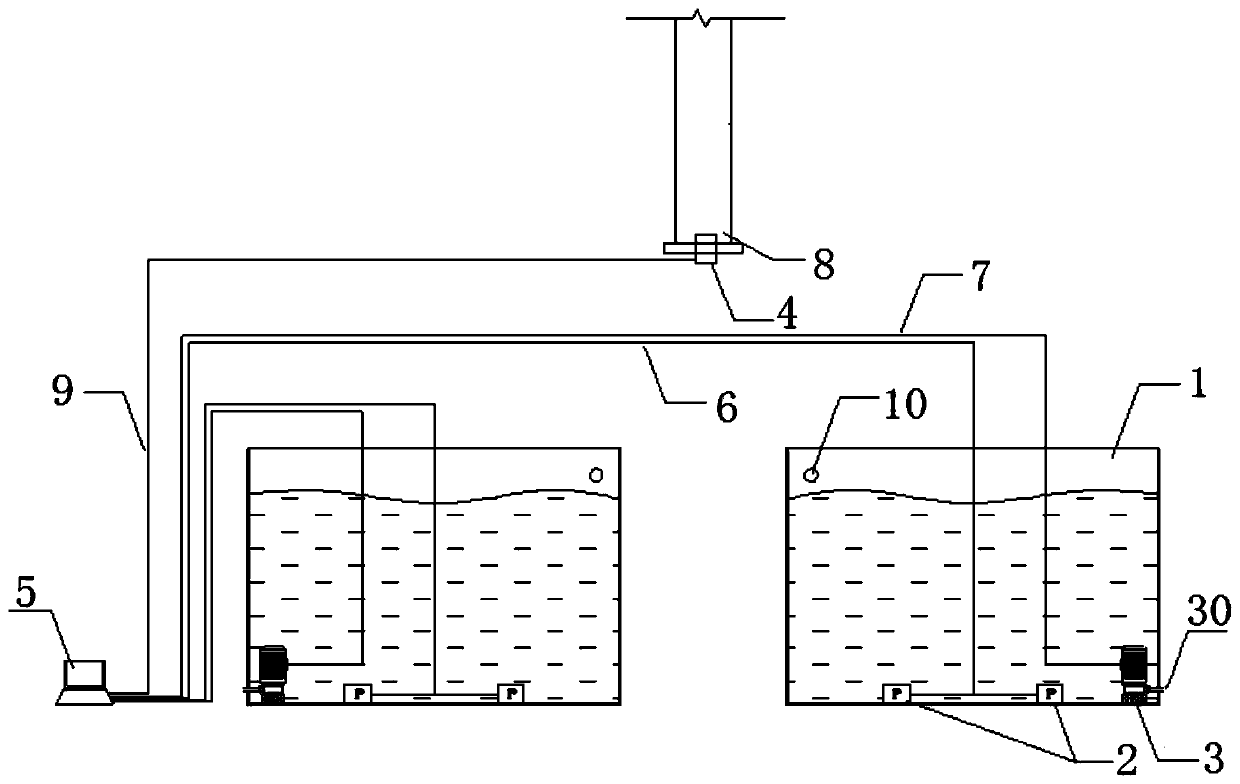

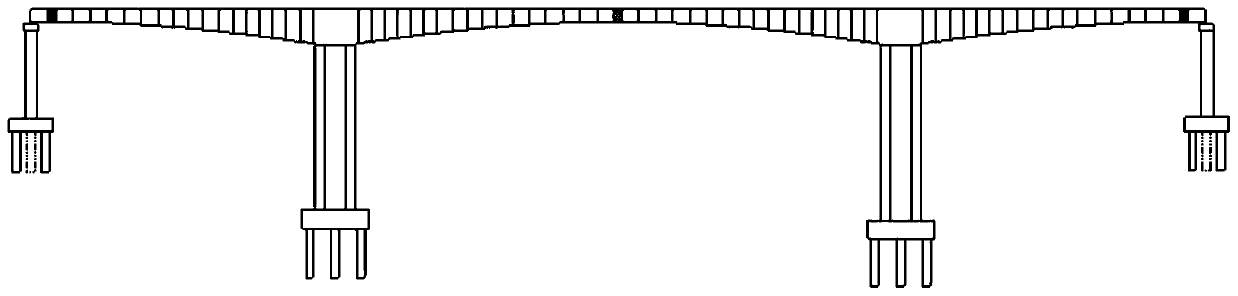

Counterweighting and unloading automatic adjusting system for closure section construction and construction adjusting method thereof

InactiveCN110644378ASolve the problem of unbalanced counterweight unloading speedEnsure safetyBridge erection/assemblyStructural engineeringMechanical engineering

The invention relates to a counterweighting and unloading automatic adjusting system for closure section construction. The automatic adjusting system comprises a plurality of counterweighting water tanks, a plurality of pressure sensors, two water pumps, a flow velocity measuring and calculating instrument, and a control device, wherein the plurality of counterweighting water tanks are symmetrically arranged on the two sides of a closure section, the total weight of the single-side counterweighting water tanks is equal to half of the total mass of a pouring concrete of the closure section whenthe single-side counterweighting water tanks are counterweighted, and water outlet pipeline holes are formed in the counterweighting water tanks; the plurality of pressure sensors are uniformly distributed at the bottoms of the counterweighting water tanks; each of the two water pumps is arranged at the bottom of one counterweight water tank on the each of two sides of the closure section, the water pumps are connected with water outlet pipes, and the water outlet pipes penetrate through the water outlet pipeline holes and extend out of the counterweight water tanks; the flow velocity measuring and calculating instrument is arranged at a pipe opening of a concrete pump; and the control device is electrically connected with the plurality of pressure sensors, the two water pumps and the flow velocity measuring and calculating instrument. The invention further discloses a construction adjusting method which applies to the above automatic adjusting system for counterweighting and unloading on the two sides of the closure section. The automatic adjusting system ensures that the concrete pouring weight and the counterweighting and unloading weight are kept accurate and synchronous, andsolves the problem that the counterweighting and unloading speed are unbalanced due to the fact that drainage valves are arranged at the bottoms of water tanks in the traditional process.

Owner:CHINA FIRST METALLURGICAL GROUP

Potato cleaning device

InactiveCN106418599ARealize multiple recyclingReduce breakage rateClimate change adaptationFood treatmentWater resourcesCleaning teeth

A potato cleaning device comprises a feeding device, a water supply device, a cleaning device body and a distribution device. The feeding device, the cleaning device body and the distribution device are sequentially communicated. The water supply device comprises a compound function pipeline system. The compound function pipeline system comprises a water inlet pipe and a drainage pipe, a water pump and a flow meter are arranged on the water inlet pipe, a flow meter is arranged on the drainage pipe, the water supply device is communicated with the cleaning device body through the water inlet pipe and the drainage pipe, and the water supply device and the cleaning device body form water supply device and cleaning device body internal circulation by means of backflow water from the cleaning device body to the water supply device. Soft cleaning teeth and cleaning cotton are distributed at intervals, so cleaning efficiency can be improved, and silt gathered in cleaning pits can be effectively cleaned away; a return water treatment device is added, so water resources are recycled many times; a guiding and classifying device is added, so potatoes are classified.

Owner:INNER MONGOLIA UNIV OF TECH

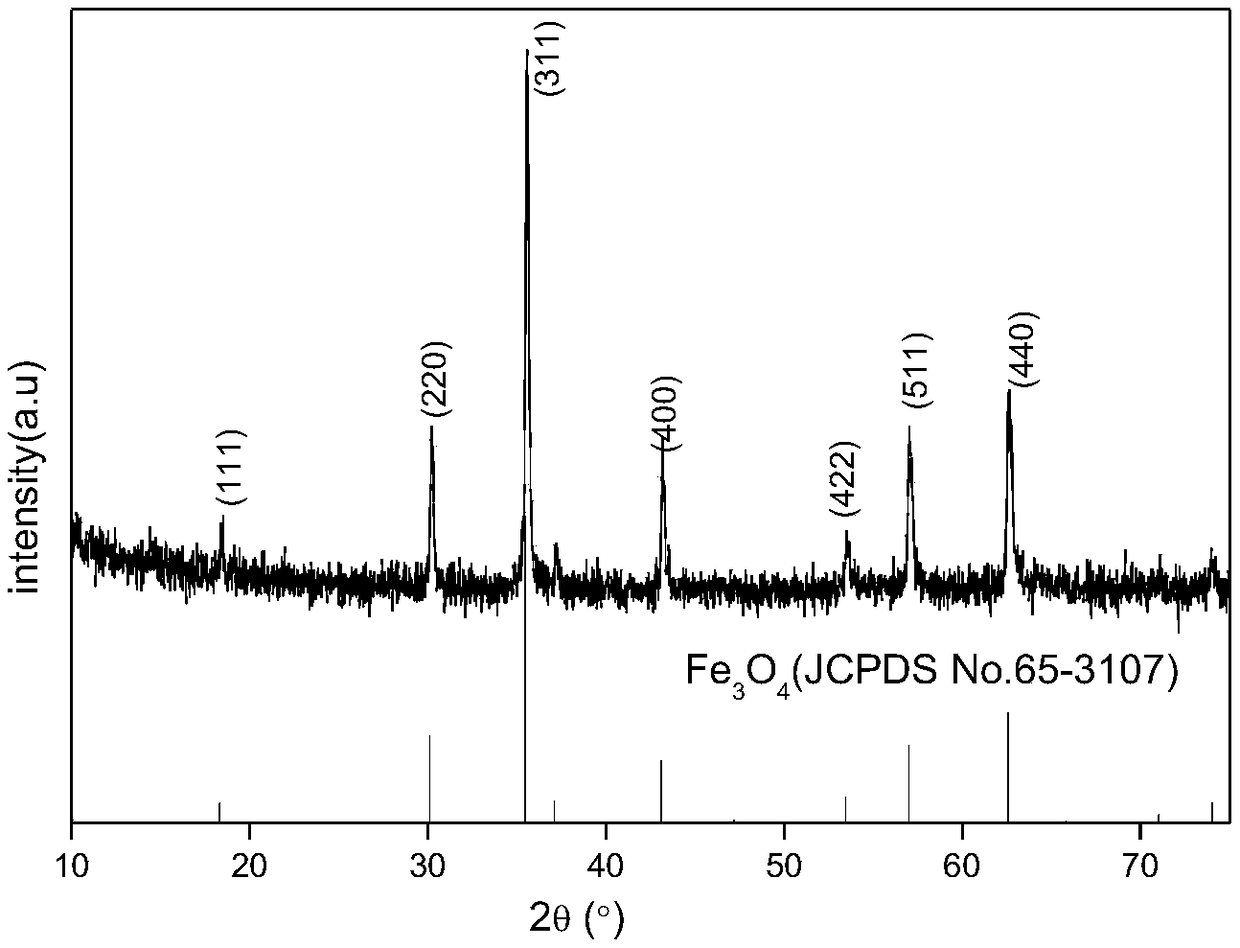

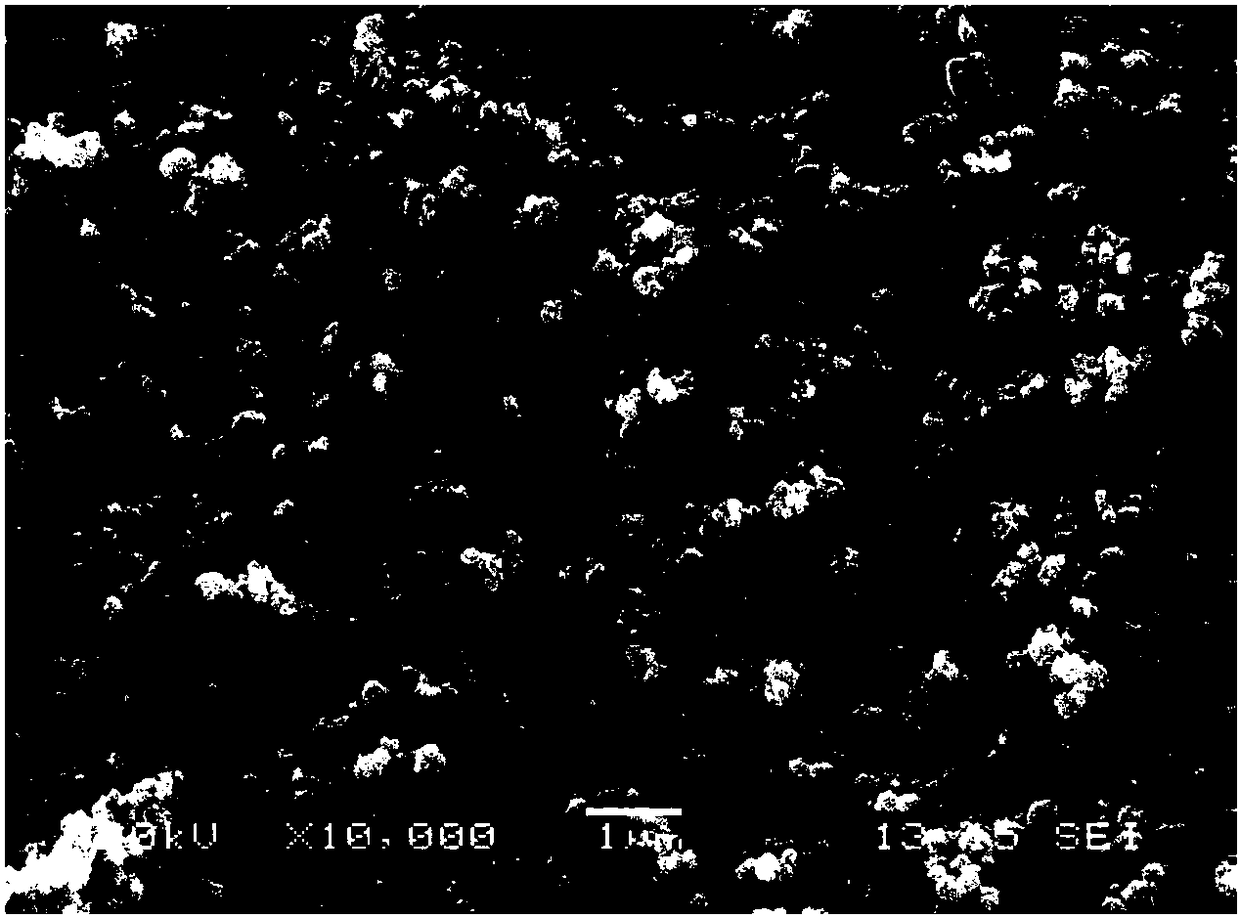

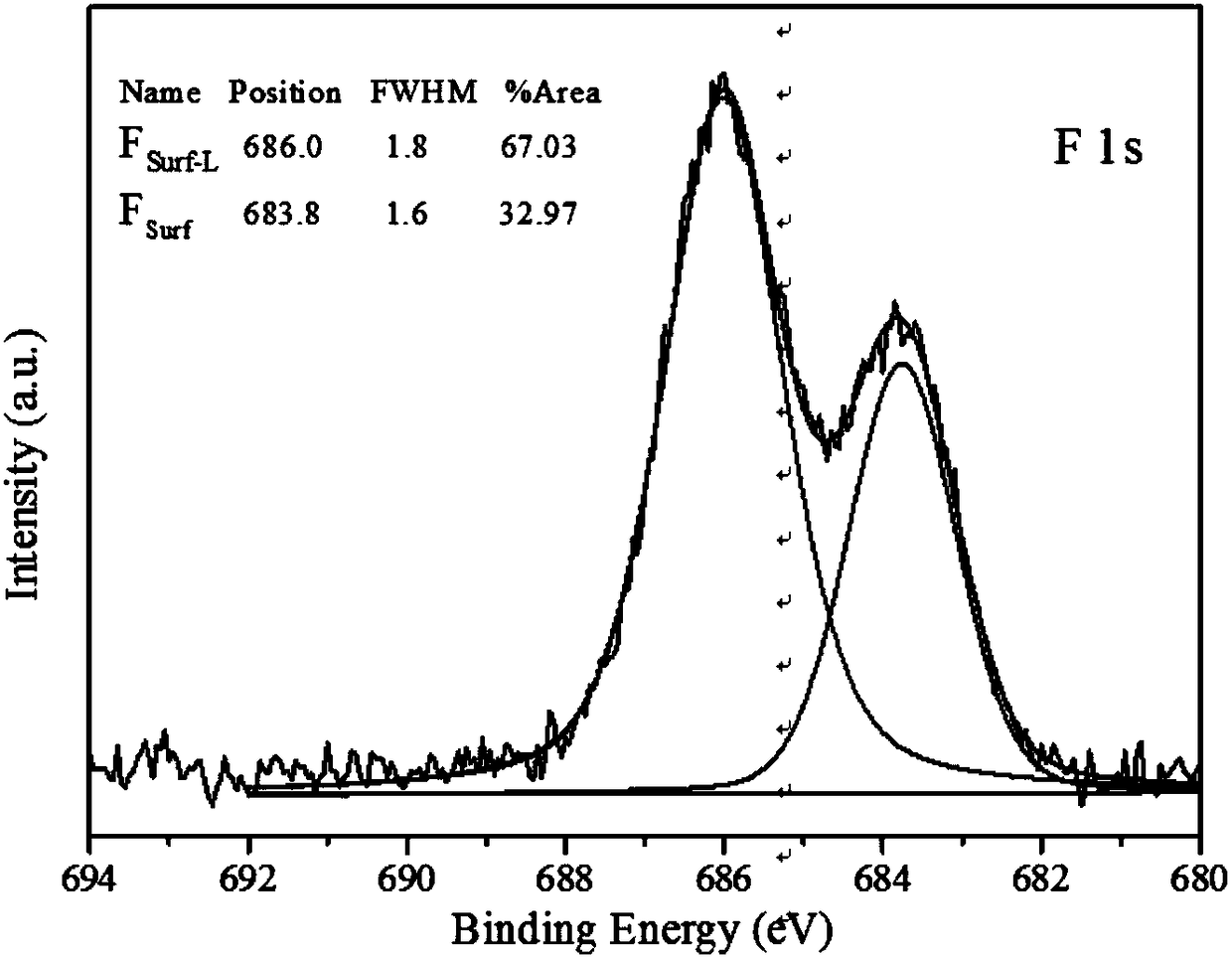

Fluorine modified Fe3O4 magnetic nano material and preparation method and applications thereof

ActiveCN108404942AImprove adsorption capacityPromote degradationPhysical/chemical process catalystsWater contaminantsSolventDyeing wastewater

The invention discloses a fluorine modified Fe3O4 magnetic nano material and a preparation method and applications thereof, and belongs to the fields of magnetic functional materials and water treatment research. For the first time, an Fe3O4 magnetic nano material is doped and modified by negative fluorine ions; a solvothermal method is adopted to in-situ synthesize the fluorine modified Fe3O4 magnetic nano material, which has an excellent degrading performance on orange G dye wastewater, can be easily and magnetically separated and recovered, and can be used in cycle; furthermore, the raw materials are cheap and easily available, the operation is simple and convenient, and the nano material has a potential application prospect.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

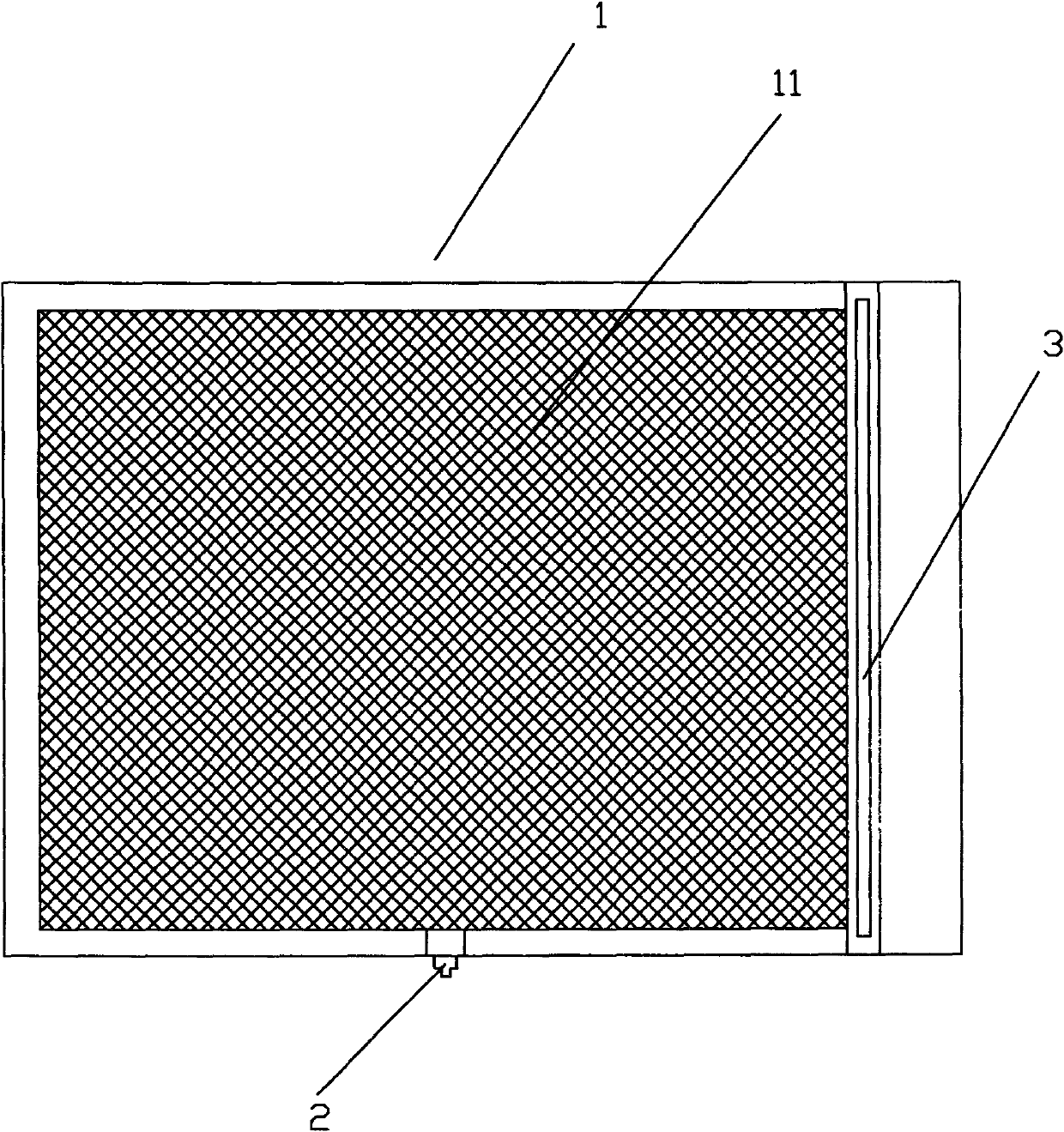

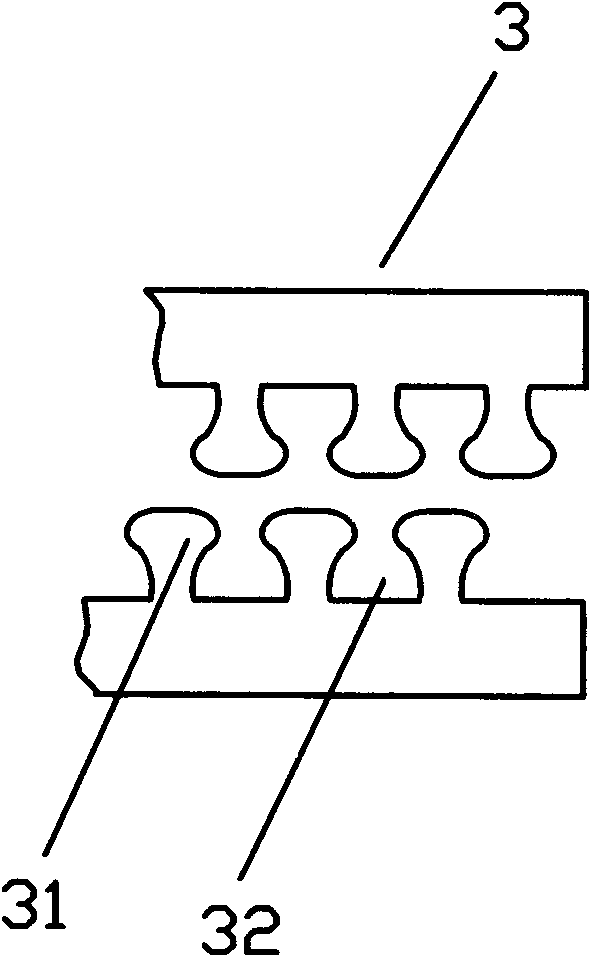

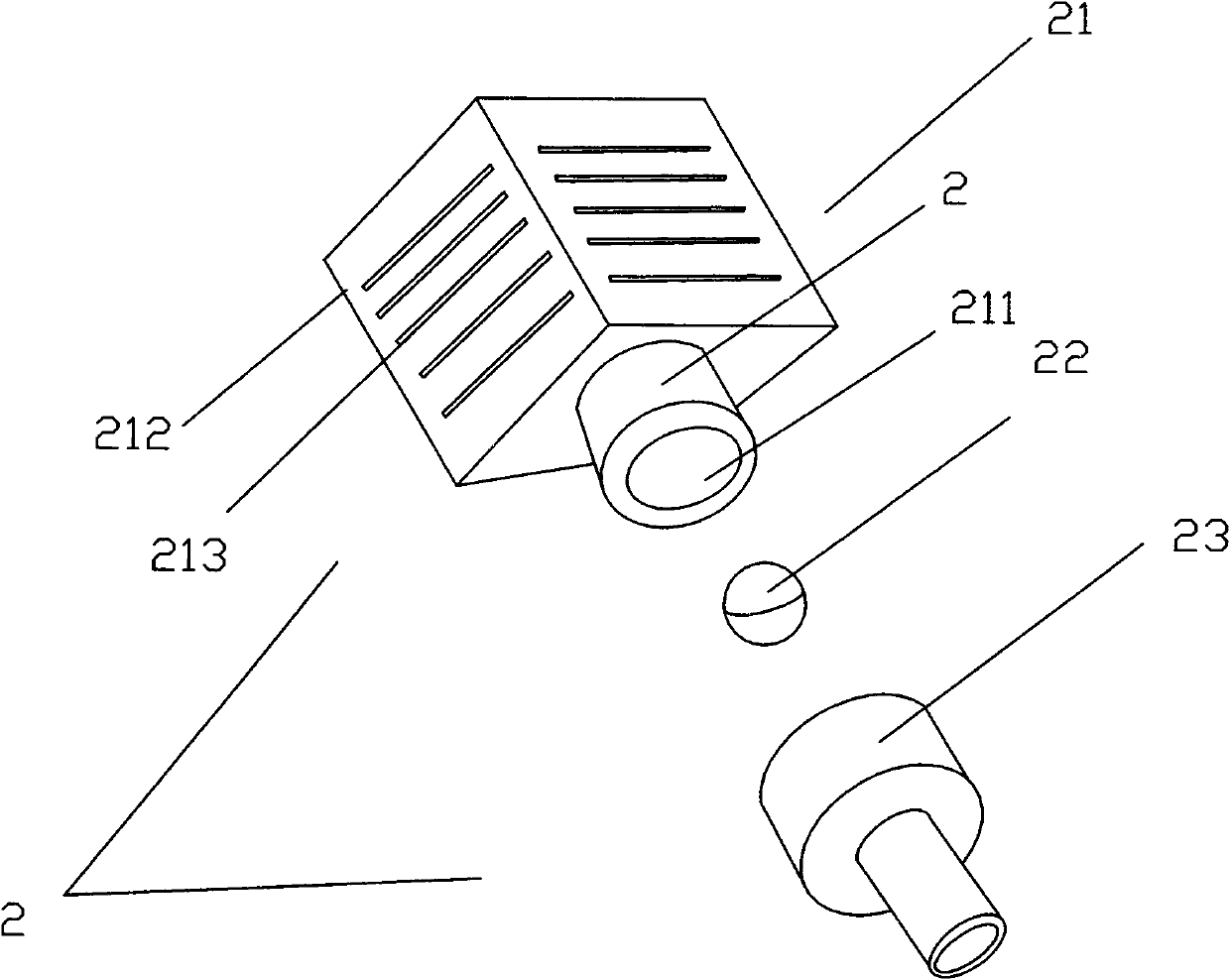

Vacuum bag convenient for exhausting and manufacturing process

The invention relates to a vacuum bag and a manufacturing process. The vacuum bag comprises a bag body, an air valve and a placing seal, wherein the air valve is sealed on the side part of the bag body, the inner side of the bag body is provided with an air guide groove, and the air guide groove is provided with pressing die groove grains of the bag body. The pressing die groove grains are netlike, and the pressing die groove grains are at least distributed on one bag surface of the vacuum bag. The air valve comprises an air valve seat, a sealing ball and an exhaust nozzle; a cylindrical hole is formed in the air valve seat, the diameter of an inner end hole is smaller than that of an outer hole, and the outer end of the air valve seat is provided with an exhaust nozzle mounting seat; the exhaust nozzle is sleeved on the air valve seat; and the sealing ball is placed in an air valve cavity formed by the cylindrical hole and the exhaust nozzle. The vacuum bag is made of 25 percent of polyamide (PA) material and 75 percent of polyethylene (PE) material. The production process comprises the following steps of: mixing PA and PE to manufacture a bag body film; and manufacturing the bag body, and pressing the air valve and the bag body. The air in the bag body is easily exhausted out of the bag body through the air guide groove on the inner side of the bag body so as to greatly improve the vacuum degree in the bag body.

Owner:DONGGUAN HAIYI INDAL

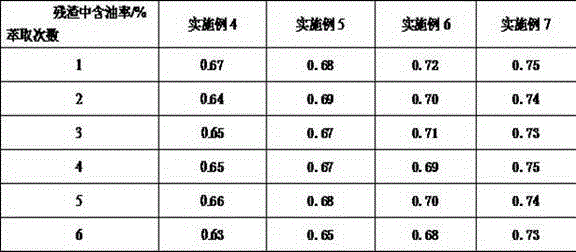

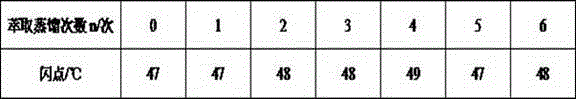

Extracting solvent for treating oil-based drillings and preparation method thereof

ActiveCN106010623AImprove securityGood compatibilityLiquid hydrocarbon mixture productionHydrocarbon oils treatmentSolventCost (economic)

The invention belongs to the technical field of oil-based drilling treatment, and particularly relates to an extracting solvent for treating oil-based drillings and a preparation method thereof. The extracting solvent is prepared from alkyl chloride, magnesium powder and vinyl chloride in a solvent. The preparation method comprises the following steps: adding the solvent in a reaction vessel, pumping nitrogen for protection, and then sequentially adding the solvent, the alkyl chloride and the magnesium powder for reaction; then adding a catalyst and the vinyl chloride in the reaction vessel for reaction, and heating, distilling and filtering after the reaction is completed, thus obtaining the extracting solvent. According to the extracting solvent disclosed by the invention, the problems of lower circulation utilization rate, higher economic cost, serious environment pollution and serious potential safety hazard caused by volatility and low flash point of an existing conventional solvent are solved, and the extracting solvent has the advantages of high flash point, high security, good extracting effect, high recovery rate, small emission pollution, simple process technology, easiness in implementation and the like.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

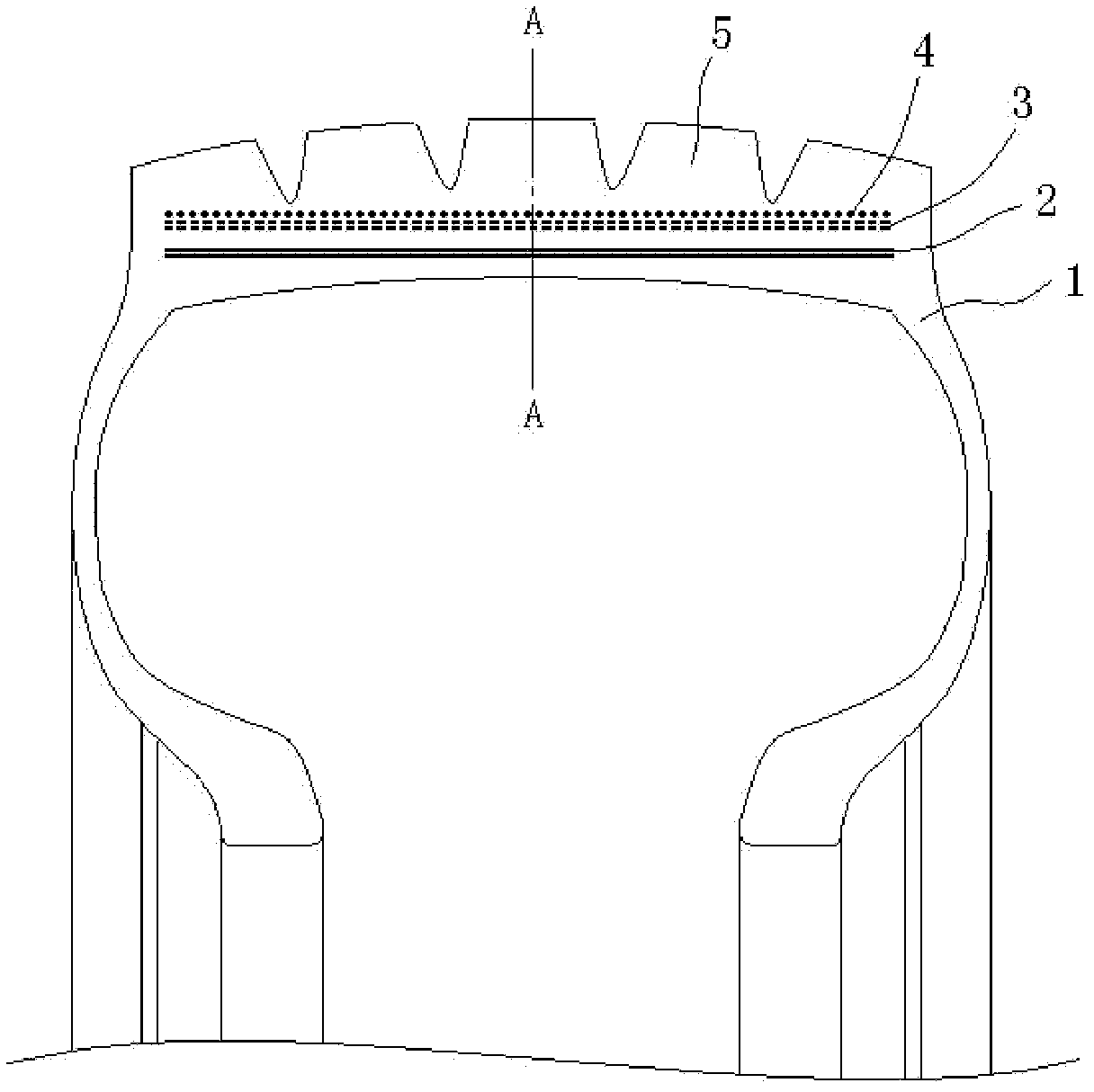

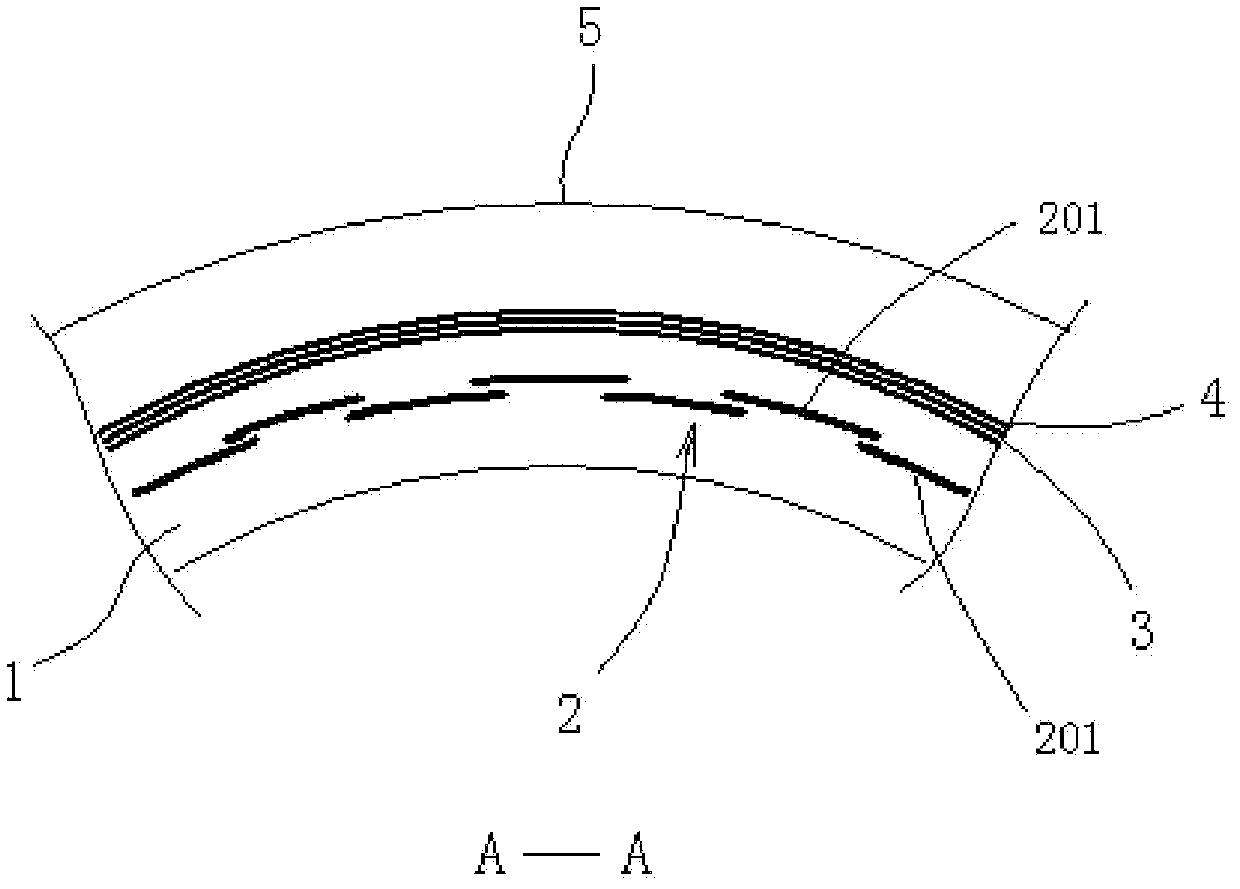

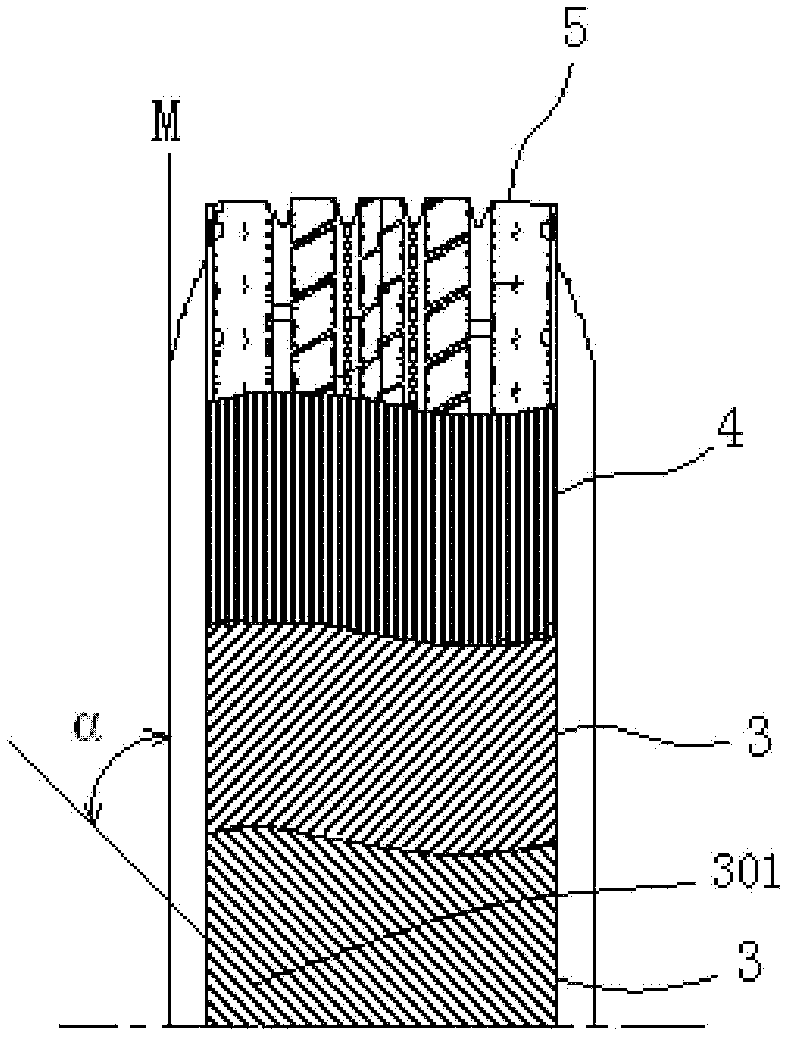

Anti-pricking tire

ActiveCN102602248AStrong carrying capacityTread balancePneumatic tyre reinforcementsAutomotive engineeringTire rotation

The invention discloses an anti-pricking tire, comprising a tire body, a tire tread integrally vulcanized with the tire body, or a tire tread matched with teeth and grooves on the tire body, wherein belted layers are arranged in the tire tread; and at least one of the belted layers is a spiral belted layer wound by steel wires along the rotary direction of the tire. According to the anti-pricking tire disclosed by the invention, the anti-pricking performance can be improved, and the service life can be prolonged.

Owner:罗茂湘

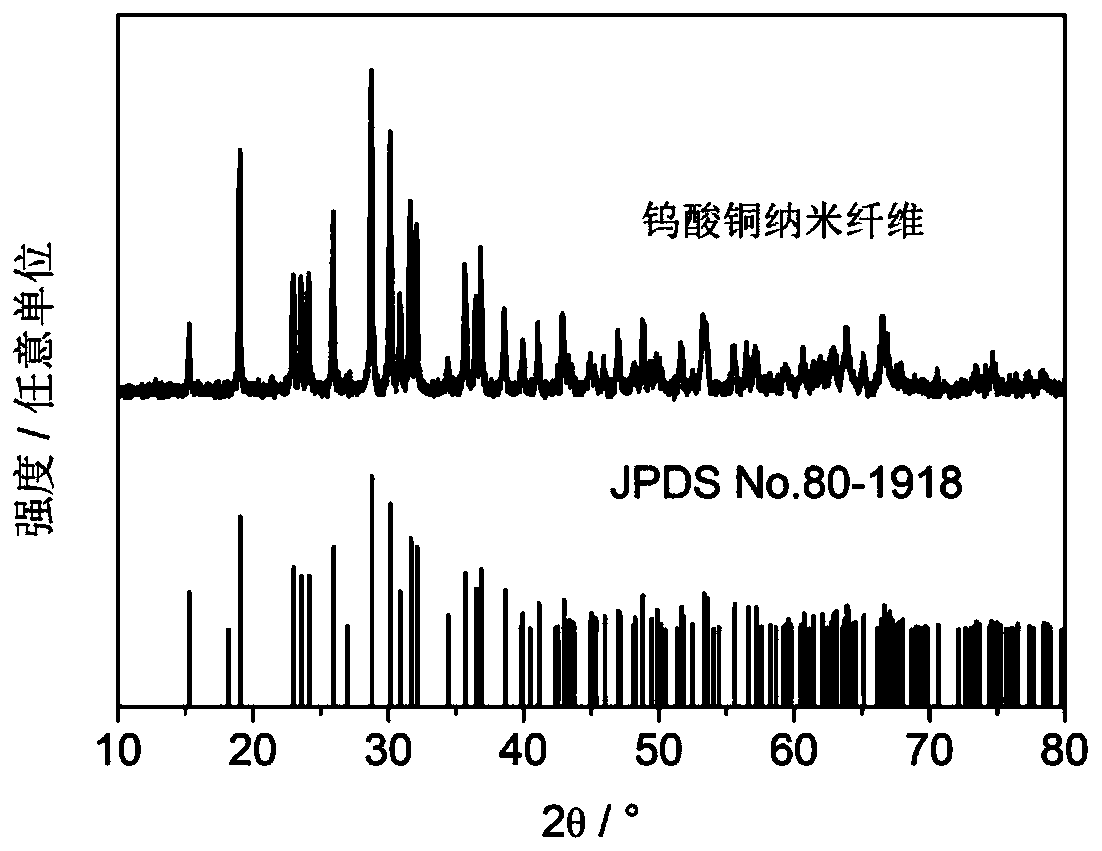

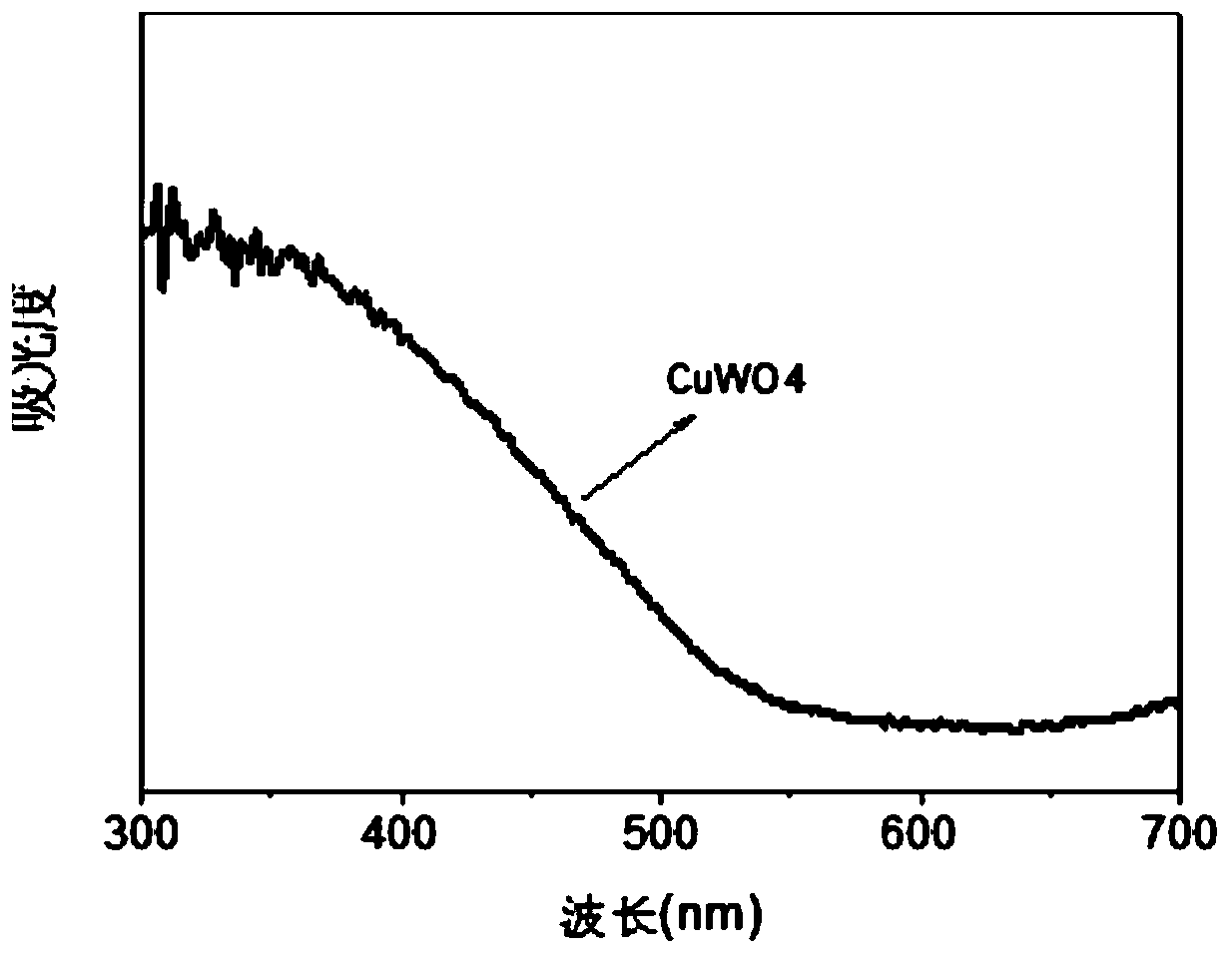

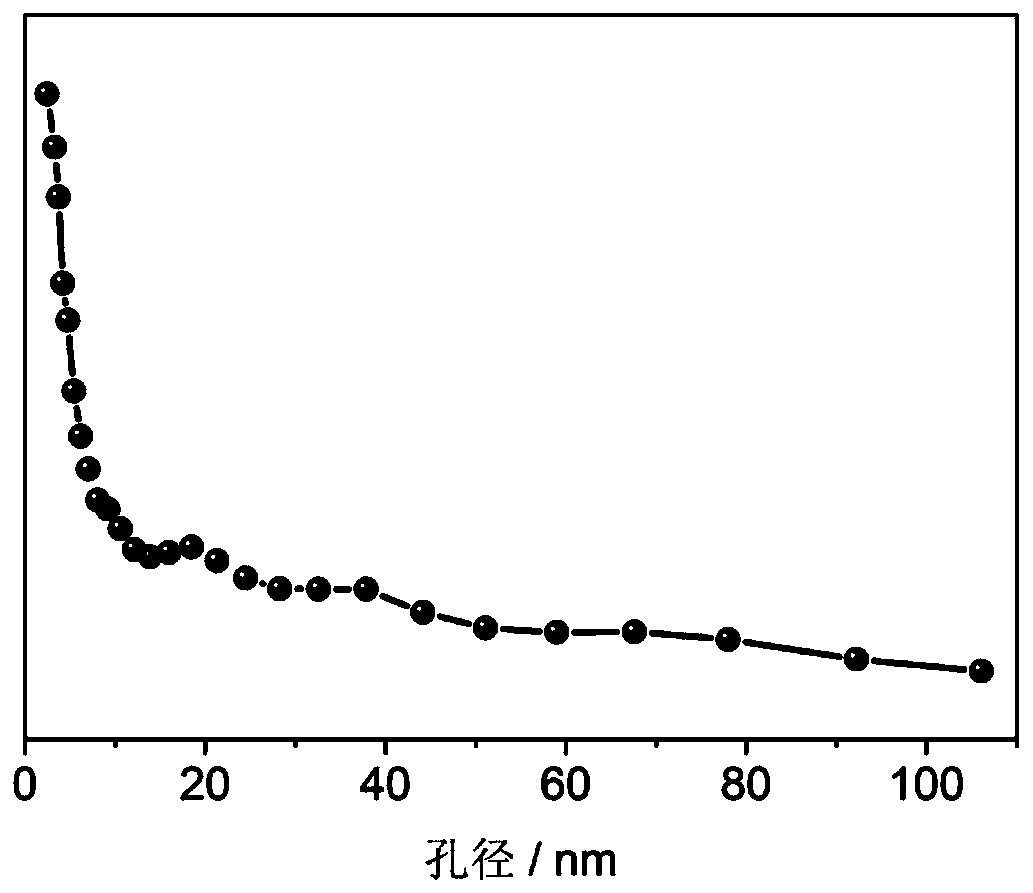

Preparation method of copper tungstate nanometer fiber photocatalyst

ActiveCN109926063AEasy to operateLow costWater/sewage treatment by irradiationWater contaminantsElectrospinningPhotocatalysis

The invention relates to a preparation method of a copper tungstate nanometer fiber photocatalyst, and belongs to the technical field of photocatalysis. According to the preparation method, adopted one-dimensional copper tungstate nanometer fiber is prepared through static spinning technology, is uniform in diameter, large in specific surface area, and short in photon-generated carrier transmission distance, and is capable of increasing visible light organic matter degradation catalytic activity effectively. The preparation method mainly comprises following steps: an inorganic tungsten salt and an inorganic copper salt are dissolved in ethanol of DMF solution, PAN or PVP is added so as to obtain a spinning solution, a static spinning device is adopted to obtain composite fiber, and high temperature sintering is carried out so as to obtain the porous copper tungstate nanometer fiber. The preparation method is simple in operation; cost is low; it is promising to realize large scale preparation of copper tungstate nanometer fiber; and the application prospect in the field of environment and energy is promising.

Owner:TAIZHOU UNIV

Application of waste tremella stick in cultivation of black fungus and cultivation method

InactiveCN108513859AReduce wasteRealize multiple recyclingCultivating equipmentsMushroom cultivationAgaricTremella

The invention provides an application of a waste tremella stick in cultivation of black fungus and a cultivation method. According to the method, the waste waste tremella stick is crushed and used asraw material of substitute agarics for cultivation. The method is characterized in that, firstly, the waste is changed into valuables, and multiple cyclic utilization is realized; secondly, the wasteof resources is reduced, and a contribution is made to the construction of the green hills and clear waters; thirdly, the production cost is reduced, and the pace of industrial development is accelerated.

Owner:巴中市通江银耳科学技术研究所

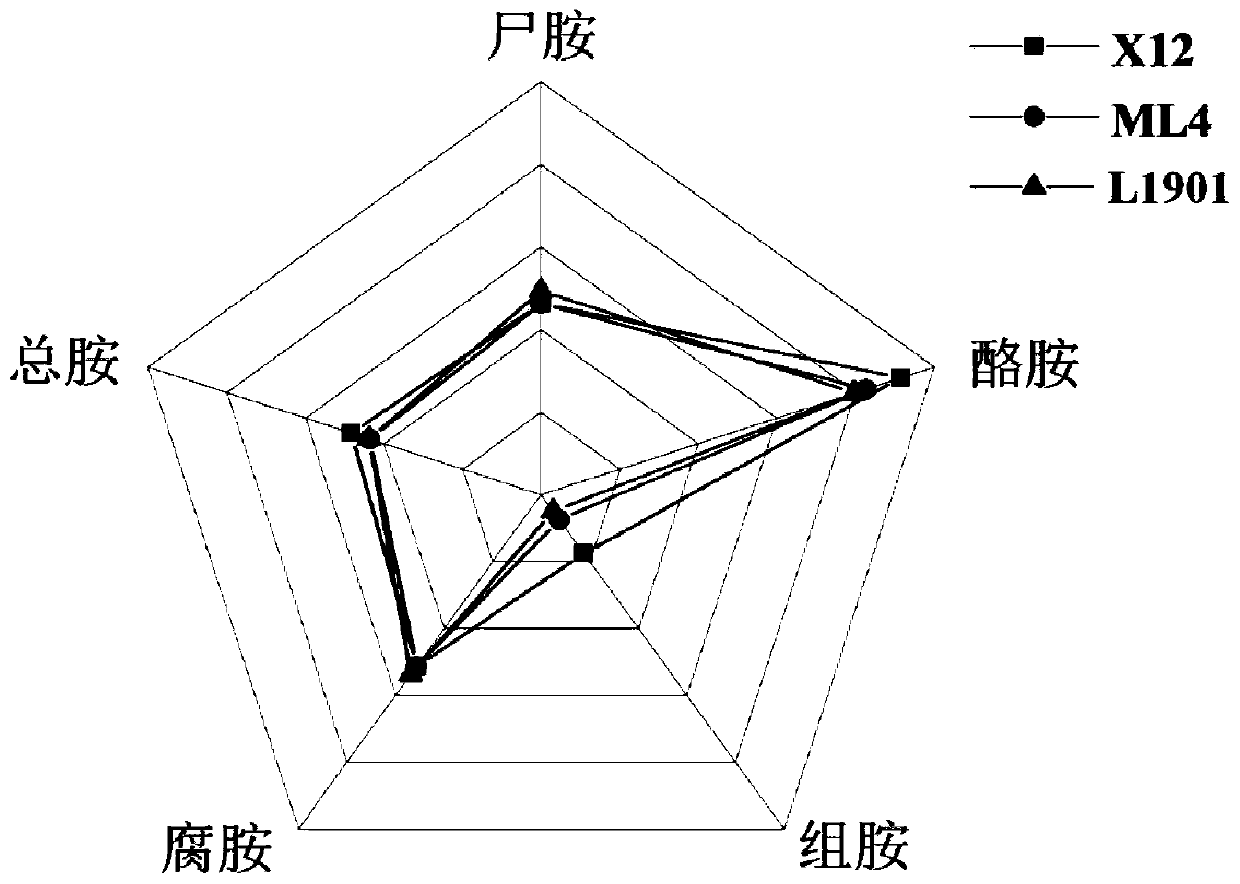

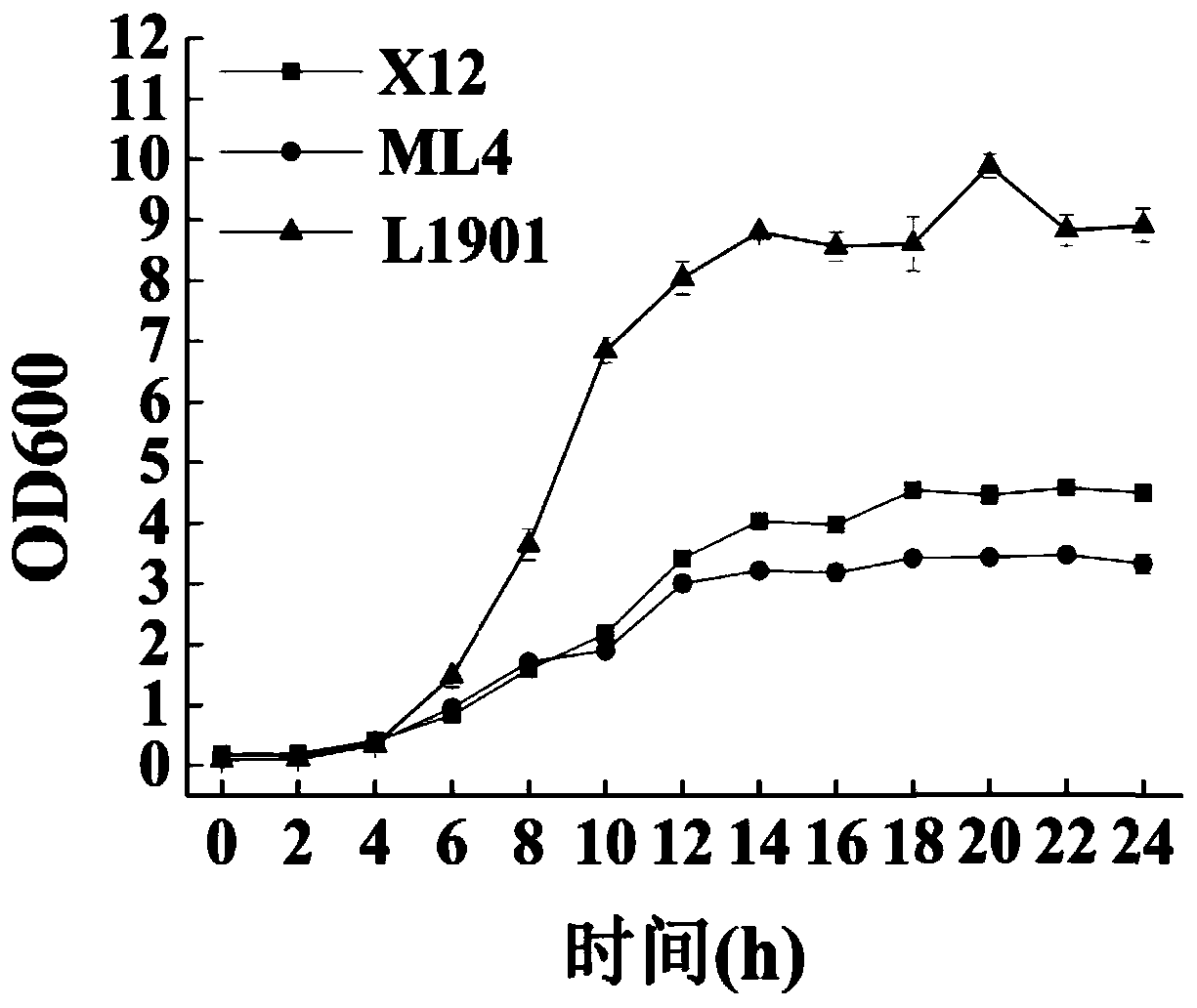

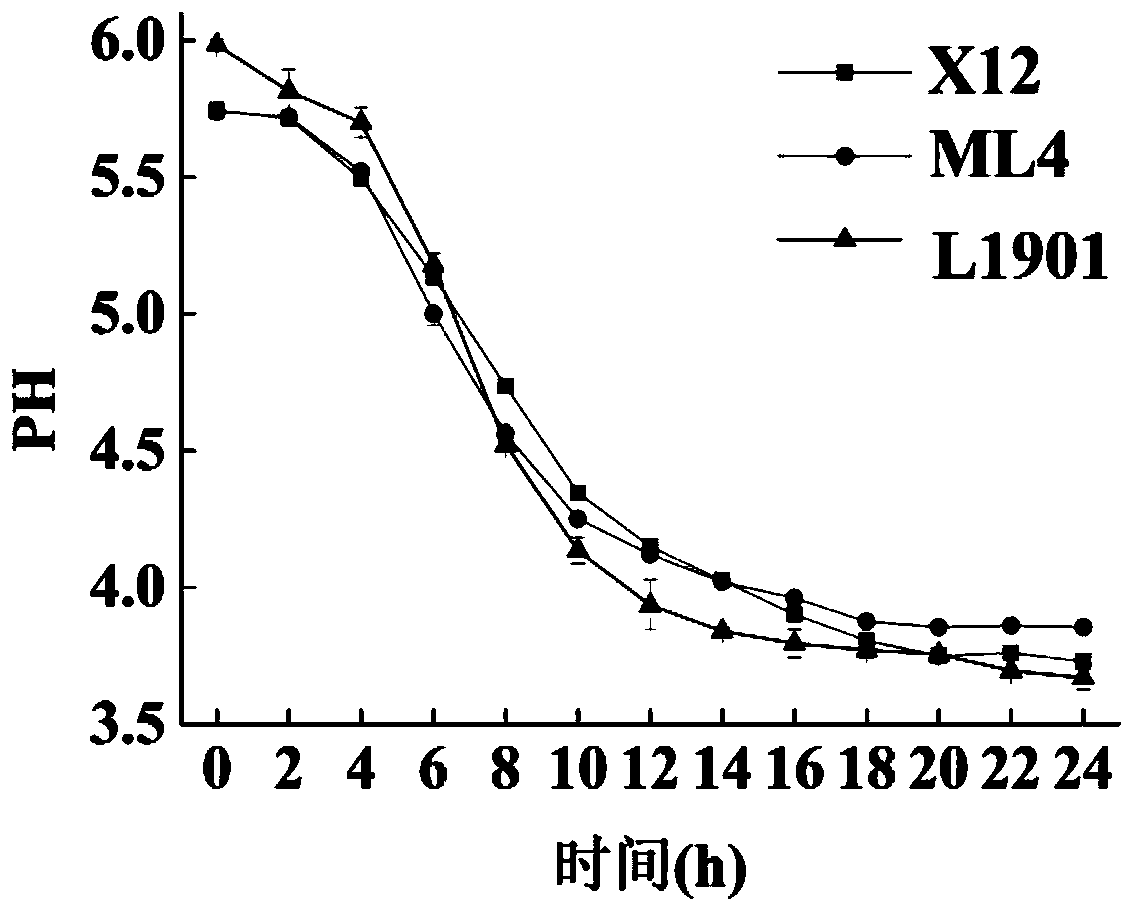

Method for reducing biogenic amine through cyclic rice soaking by inoculating lactobacillus plantarum not generating biogenic amine

ActiveCN110747143AIncrease the rate of acid productionShorten the soaking timeBacteriaAlcoholic beverage preparationBiotechnologyMicrobiology

The invention discloses a method for reducing biogenic amine through cyclic rice soaking by inoculating lactobacillus plantarum not generating the biogenic amine, and belongs to the technical field offood processing and manufacturing. The lactobacillus plantarum is inoculated in the rice soaking process of a grain product; the result shows that by inoculating the lactobacillus plantarum, the content of the biogenic amine in rice soaking water can be effectively reduced, so that the rice soaking water is clear; and conditions are created for the cyclic utilization of rice milk water.

Owner:JIANGNAN UNIV +2

Washing liquid for treating light oil product polluted mud and sand and recovering oil, and use method thereof

ActiveCN111218288AEasy to desorbHigh oil removal rateContaminated soil reclamationLiquid carbonaceous fuelsInorganic saltsFluid phase

The invention provides a washing liquid for treating light oil product polluted mud and sand and recovering oil, and a use method thereof, wherein the washing liquid comprises 68-92 parts by weight oftap water, 1-10 parts by weight of a water-soluble inorganic salt, 1-7 parts by weight of a gemini surfactant, 5-10 parts by weight of a cosurfactant and 1-5 parts by weight of hydrocarbons or lightoil. According to the invention, the washing liquid can be used at normal temperature; oil can be removed through simple mixing or stirring and mixing, and after cleaning is completed, the separated liquid phase is subjected to standing or centrifugation so as to be divided into an oil layer and a mixture layer containing effective components of the washing liquid, so that the oil is recycled while efficient oil removal is achieved, repeated cyclic utilization of the washing liquid can be achieved, the cost is low, and good economic value and application prospects are achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com