Patents

Literature

115results about How to "Low work efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

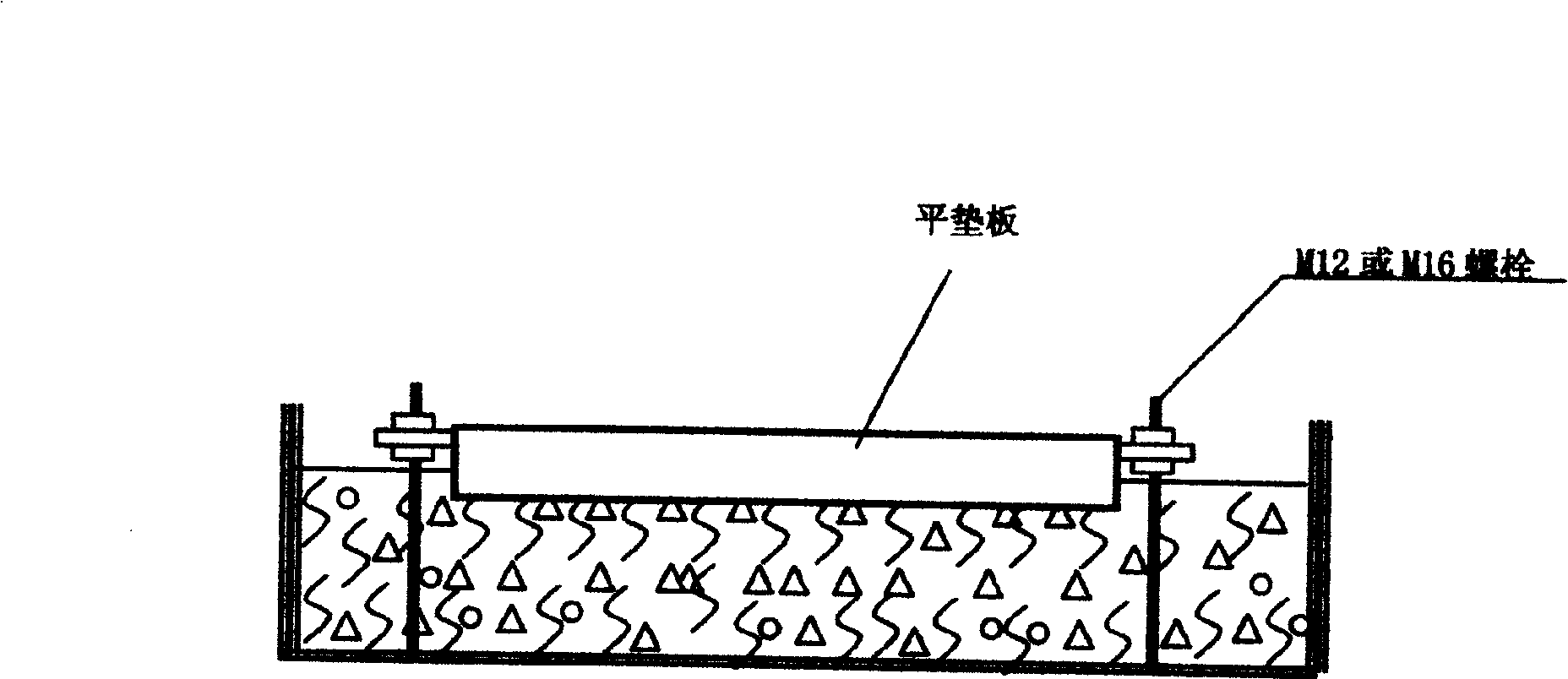

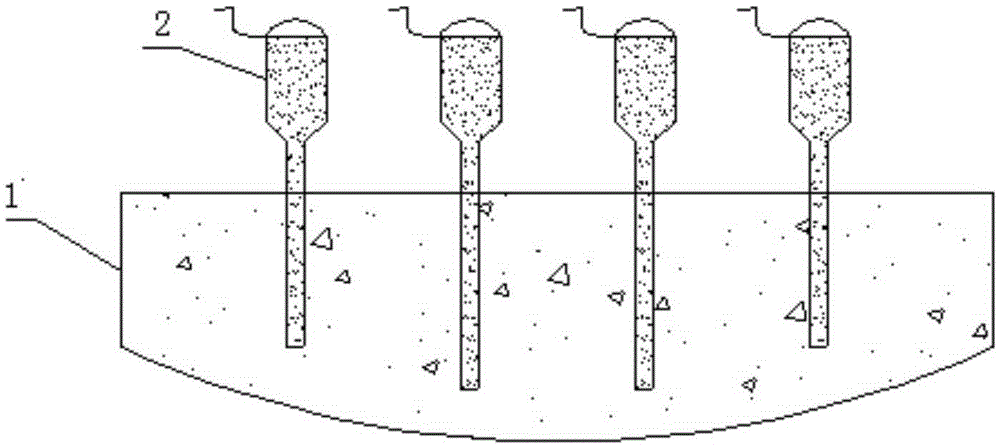

Grouting connection construction method

ActiveCN104314314AFast constructionImprove efficiencyBuilding reinforcementsBuilding material handlingRebarPrecast concrete

The invention discloses a grouting connection construction method which is used for connecting vertical reinforcements of an assembled concrete structure. The grouting connection construction method includes the steps: firstly, embedding a plurality of grouting connection devices at one end of a precast concrete unit to be connected in advance; secondly, lifting the precast concrete unit and then manufacturing a grouting box dam; thirdly, grouting horizontal gaps and then grouting the grouting connection devices. The grouting connection devices are connected with connection reinforcements extending out of a lower unit. Plugging grouting of the horizontal gaps and grouting of the grouting connection devices can be performed within the same day, so that the mounting efficiency of the precast concrete unit is greatly improved, the grouting connection construction method can be implemented in a subzero temperature environment even in winter, construction difficulty is reduced, and working efficiency is improved.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

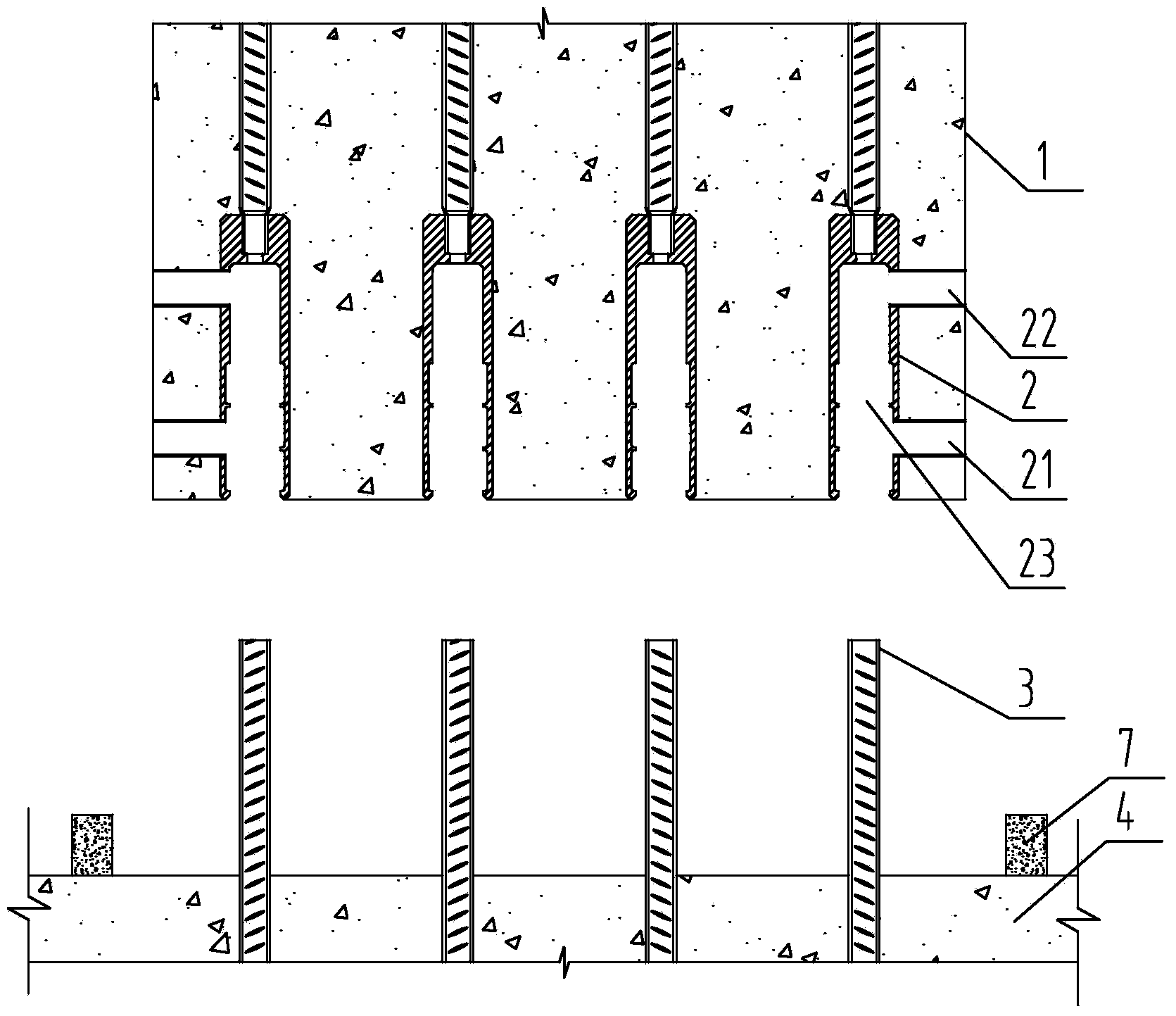

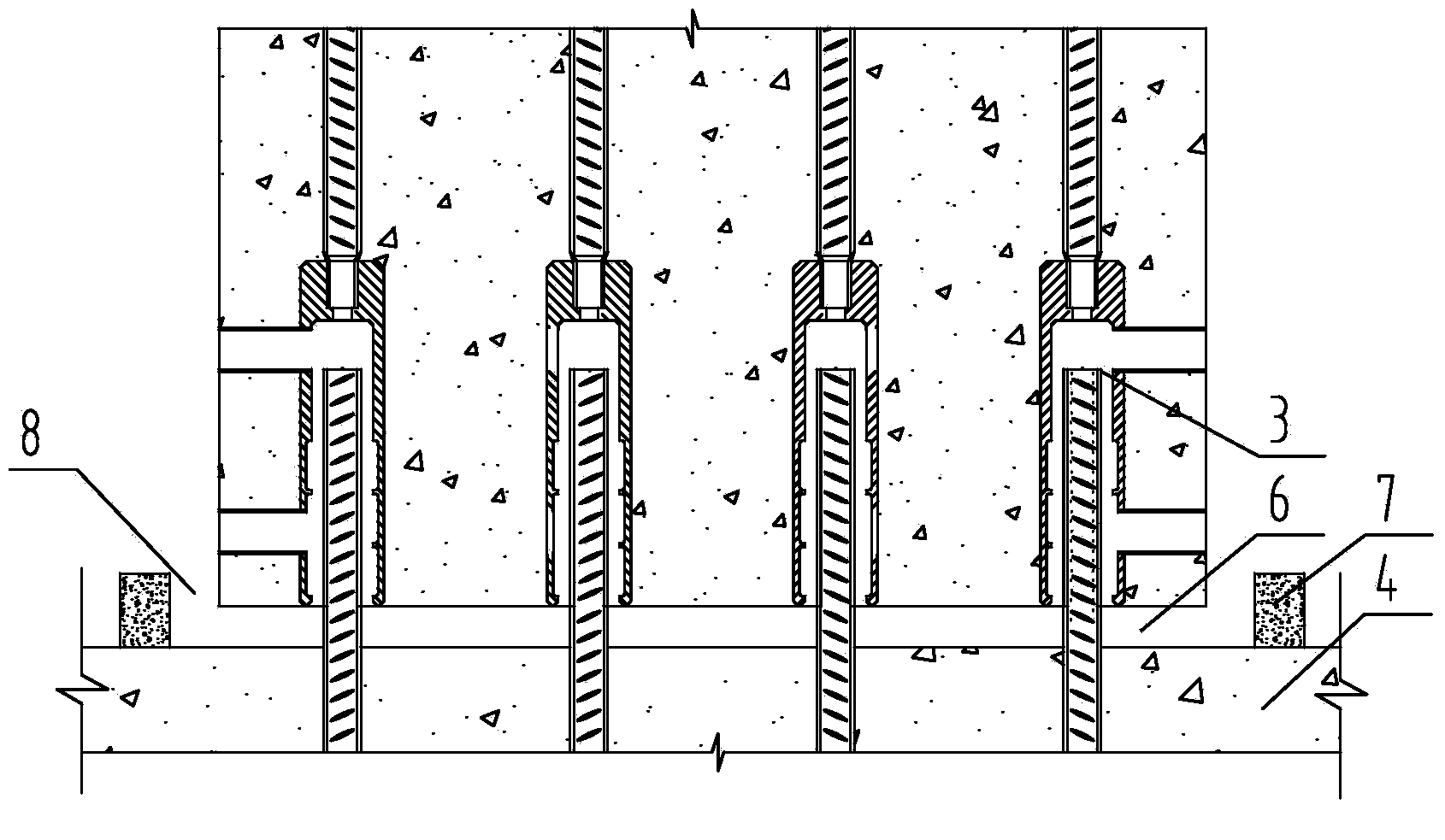

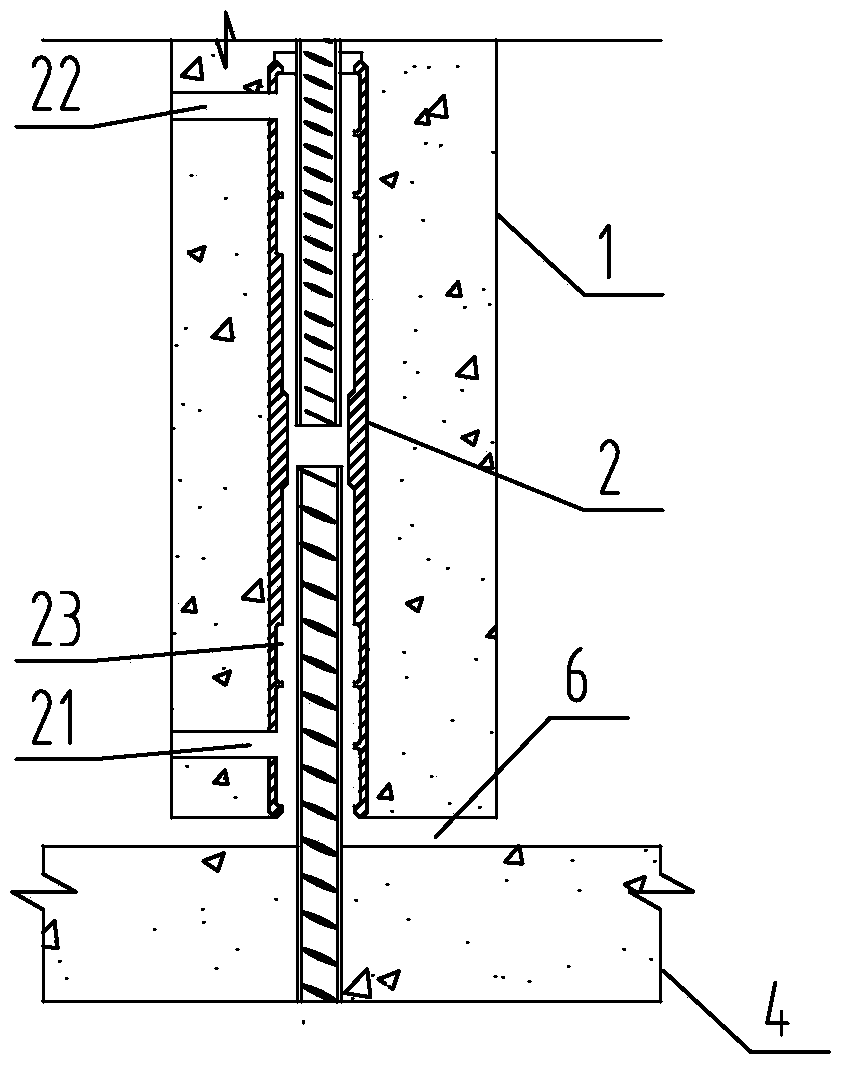

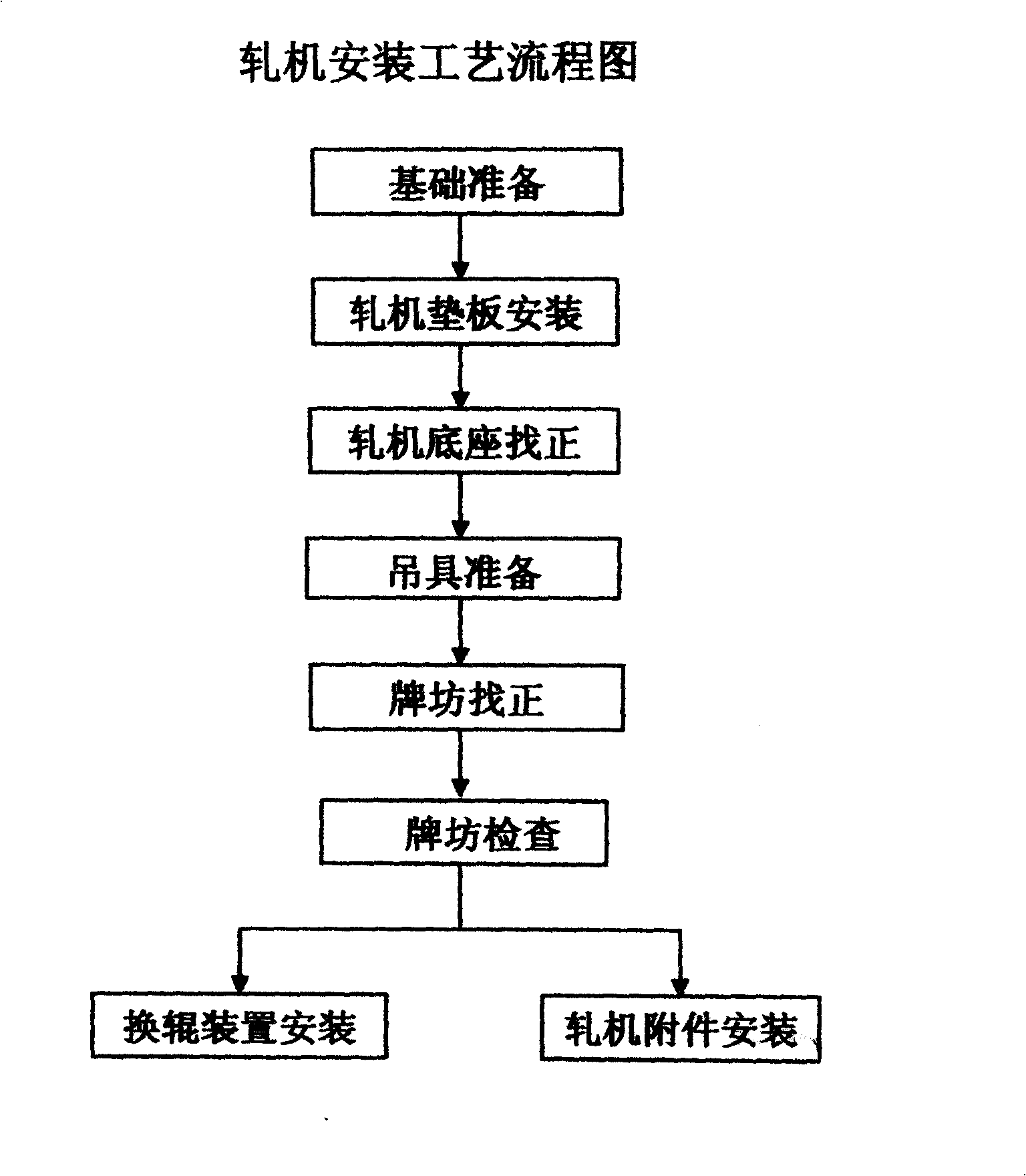

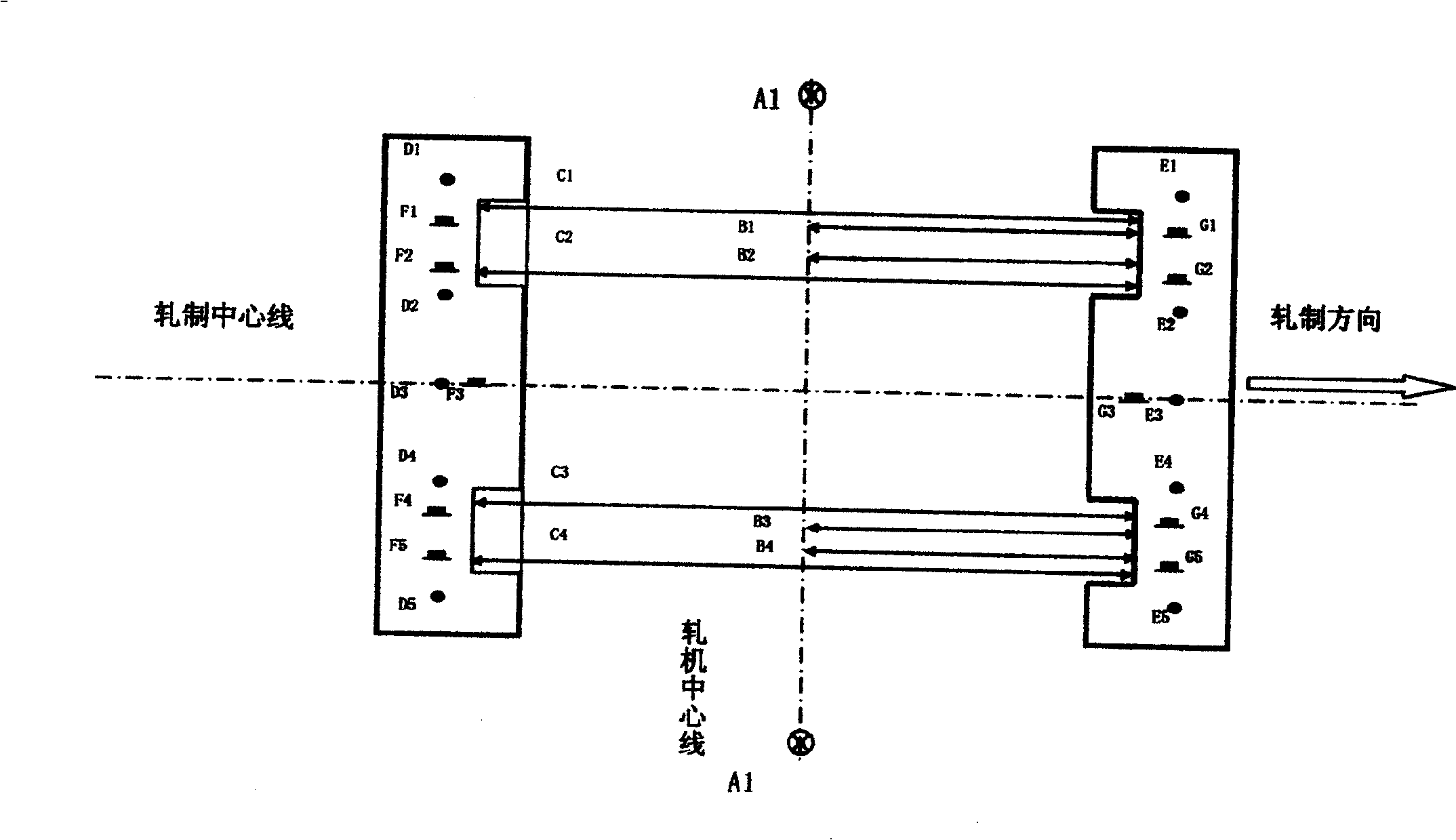

Method for mounting large-sized rolling mills

InactiveCN101275400AReduce loosenessAvoid damageFoundation engineeringBuilding material handlingStrip millMechanical equipment

The invention relates to an installation of metallurgy industry rolling mills, pinch pass mill, burnishing machines and the like large-scale mechanical equipment, especially to an installation method of a large-scale rolling mill, which is characterized in that the installation of a large-scale rolling mill is realized by the process steps of base preparation, rolling mills bearing plate installation, rolling mills motherboard transverse alignment, sling preparation, memorial archway transverse alignment, memorial archway check-up, roll-changer installation and rolling mill accessory installation. The invention satisfies all requirement of different construction sites, effectively resolves hanging difficult problem, saves work efficiency about 6-7 times, ensures installation quality, uses hydraulic bolt stretchers to avoid bolt up force moment from macrolesion bolt, and adopts small fastening force moment to allow rolling mills subbase to become flexible. Work difference bands are used to control the roll changing transmission device central line and the rolling mill central line to ensure installation quality. According to combination of calculation and on-site practicality, the invention not only can be used for rolling mills installation, but also can spread in mechanical equipment installation with common advising signification.

Owner:ANGANG CONSTR CONSORTIUM

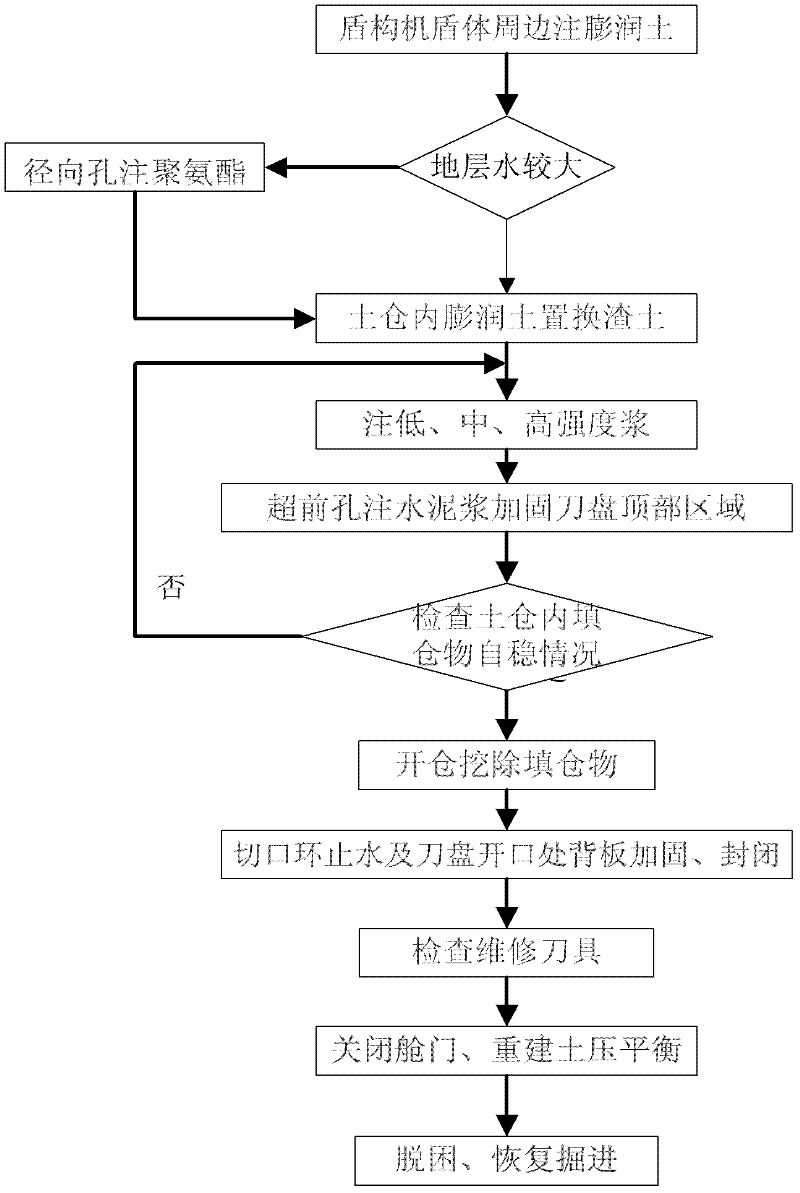

Construction method of earth cabin back filling and cabin entering operation during earth pressure shielding

ActiveCN102536253AIncrease the permeability coefficientDoes not have air pressure operating conditionsUnderground chambersTunnel liningHigh intensityOperability

The invention discloses a construction method of earth cabin back filling and cabin entering operation during earth pressure shielding. The construction method comprises the following steps: (1) injecting bentonite slurry outside the casing of a shield machine; (2) injecting polyurethane outside the body of a shield to form a seal ring; (3) injecting two-liquid slurry outside a tube piece to form a seal ring; (4) replacing muck in an earth cabin with bentonite, and carrying out muck replacement through the cooperation of the a bentonite injection system and a spiral conveyer; (5) carrying out pressure injecting on low, middle and high-strength cement bentonite mortar slurry, and allowing the bentonite slurry in the earth cabin to form cumulates with certain strength; (6) injecting slurry to a cutting ring of the shield machine and the top of a cutter head; (7) carrying out cabin entering operation by constructors; and (8) closing an earth cabin door after cutter replacement is completed, injecting and back-filling bentonite to the earth cabin to establish an earth pressure balanced mode to restore tunneling. The construction method disclosed the invention breaks through the difficulty of cabin entering operation below a special unstable formation and the difficulty of cabin entering operation under a building during shielding, and has the characteristics of high efficiency, strong operability and the like.

Owner:GUANGZHOU RAIL TRANSIT CONSTR SUPERVISION CO LTD

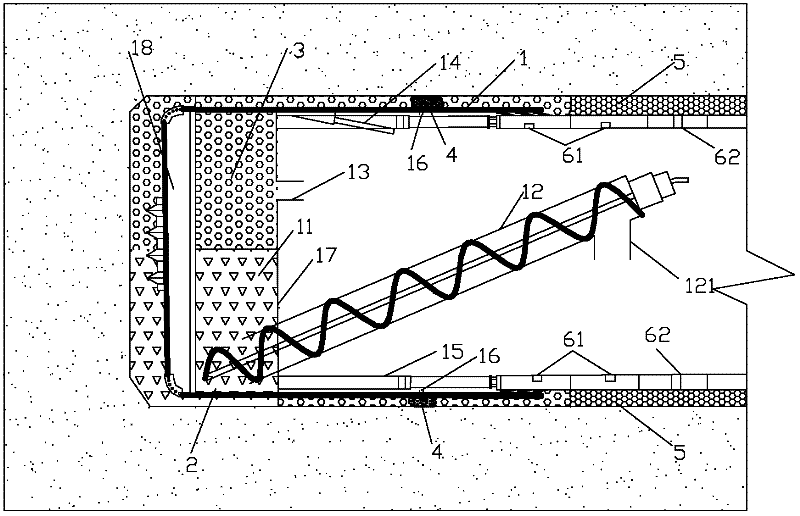

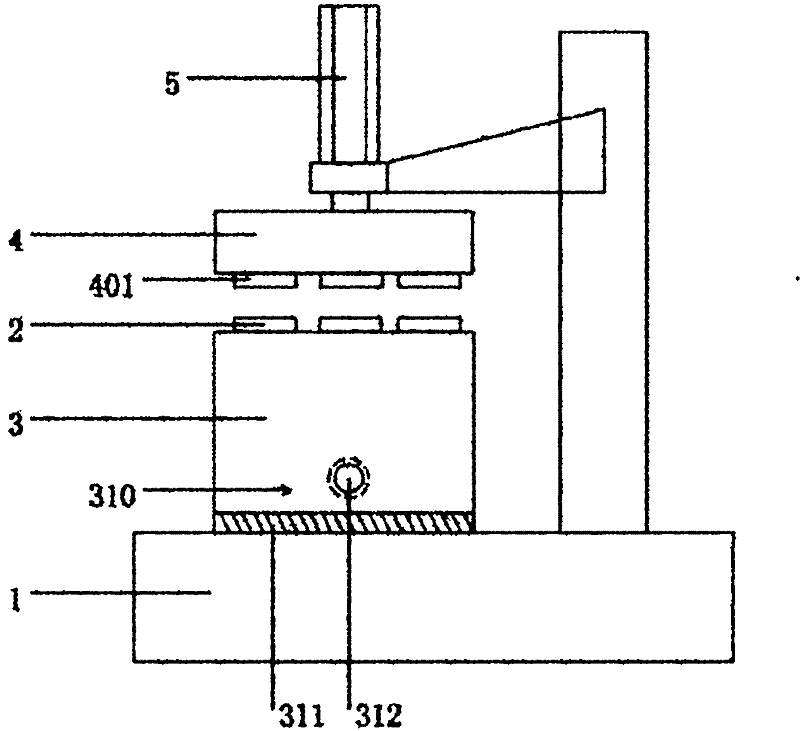

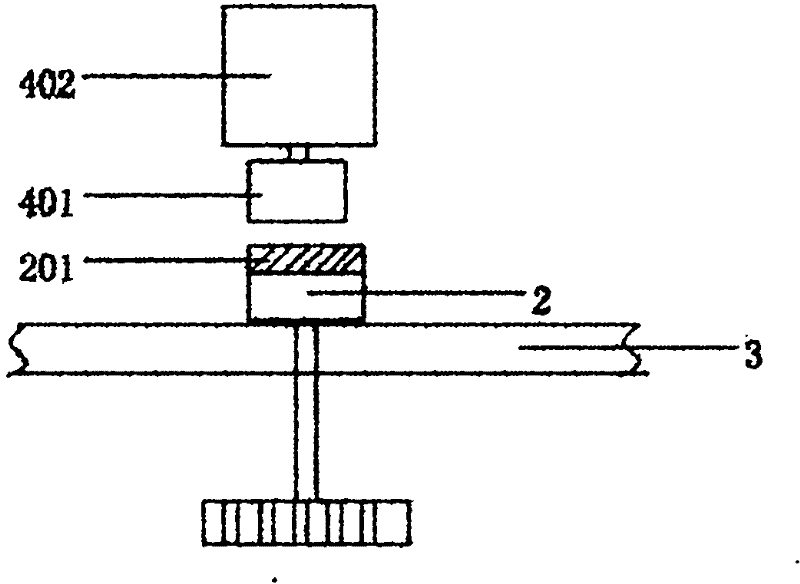

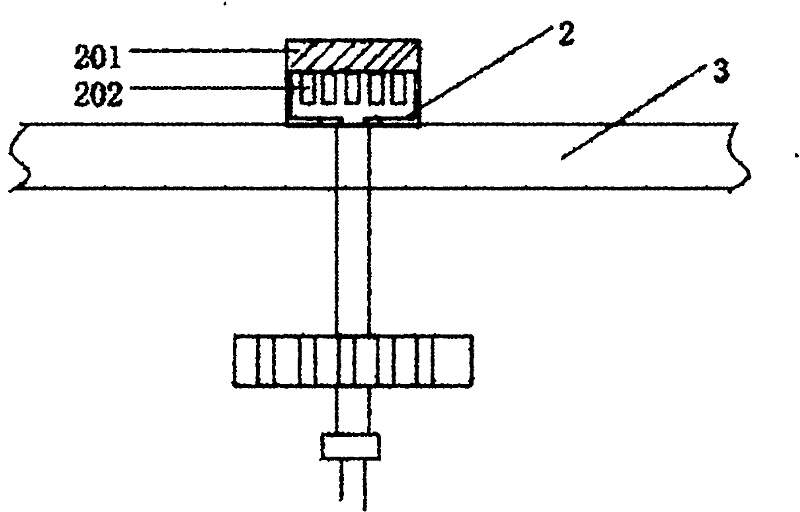

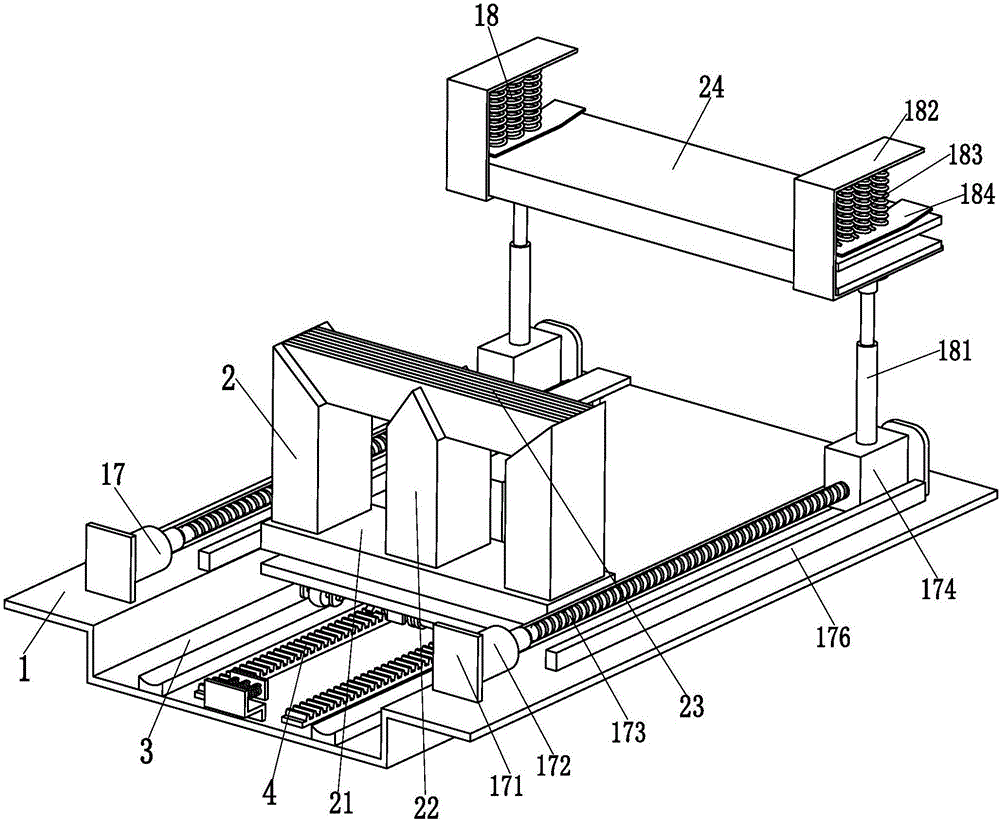

Wafer grinding device

ActiveCN102161179ALow work efficiencyElimination of edge collapseLapping machinesDrive motorSapphire substrate

The invention relates to a wafer grinding device for sapphire lining wafers. The invention provides a wafer grinding device which has high efficiency and avoids wafer edge collapse. The wafer grinding device comprises a base, a wafer carrier, a workbench, a grinding mechanism and a pressing mechanism, wherein the base is used for supporting components of the grinding device; the wafer carrier is used for fixing and holding the wafer; the workbench is used for supporting the wafer carrier and is installed on the base and comprises a first drive mechanism and a second drive mechanism, the first drive mechanism drives the workbench to do traverse and vertical reciprocation motion, and the second drive mechanism drives the wafer carrier to spin; the grinding mechanism is positioned above the workbench for grinding wafers and comprises a grinding head, a drive motor and a connection part, the drive motor drives the grinding mechanism to spin, and the connection part is used for fixing the grinding head; and the pressing mechanism is positioned above the grinding mechanism for applying a press onto the grinding head. The wafer grinding device basically eliminates the phenomenon of product edge collapse, and uses a single grinding head to grind a single wafer instead of multiple wafers adhered to the wafer carrier, so grinding efficiency is greatly improved.

Owner:青岛华芯晶电科技有限公司

Intermediate-frequency induction and directional solidification ingot casting process and equipment utilizing same

The invention discloses an intermediate-frequency induction and directional solidification ingot casting process and equipment utilizing the same, which are used for producing extra-thick plates capable of guaranteeing internal quality of ingots and meeting requirements of the compression ratio. The intermediate-frequency induction and directional solidification ingot casting process includes that after being subjected to external refining, molten steel is delivered to an ingot casting platform by the aid of steel ladles and then used for casting, is poured into tundish through a long nozzle,and then is poured into a water-cooled crystallizer in a protected manner after flowing through a slide nozzle and an embedded nozzle; a vibration device of the crystallizer vibrates to start intermediate-frequency coils arranged outside the water-cooled crystallizer, heating of induction current and electromagnetic stirring effect are realized to control stop time, power and frequency of the induction coils at different positions of steel ingots so as to control internal quality of the steel ingots; a drawing device of a water-cooled underpan is started to draw the steel ingots from the water-cooled crystallizer, and finally the steel ingots are sent to be rolled. According to the distribution characters of an induced magnetic field in an intermediate-frequency electric induction furnace, inverted-V type segregation of the steel ingot is avoided. Gas impurity can be removed according to the electromagnetic stirring principle. Excellent feeding capacity of steel ingots is guaranteed, and the steel ingots casted by the process have compact insides and are free of segregation and low in impurity by the aid of an upper heat center utilizing induction heating. Due to better head feeding, the yield and production efficiency of steel ingots are improved.

Owner:UNIV OF SCI & TECH LIAONING

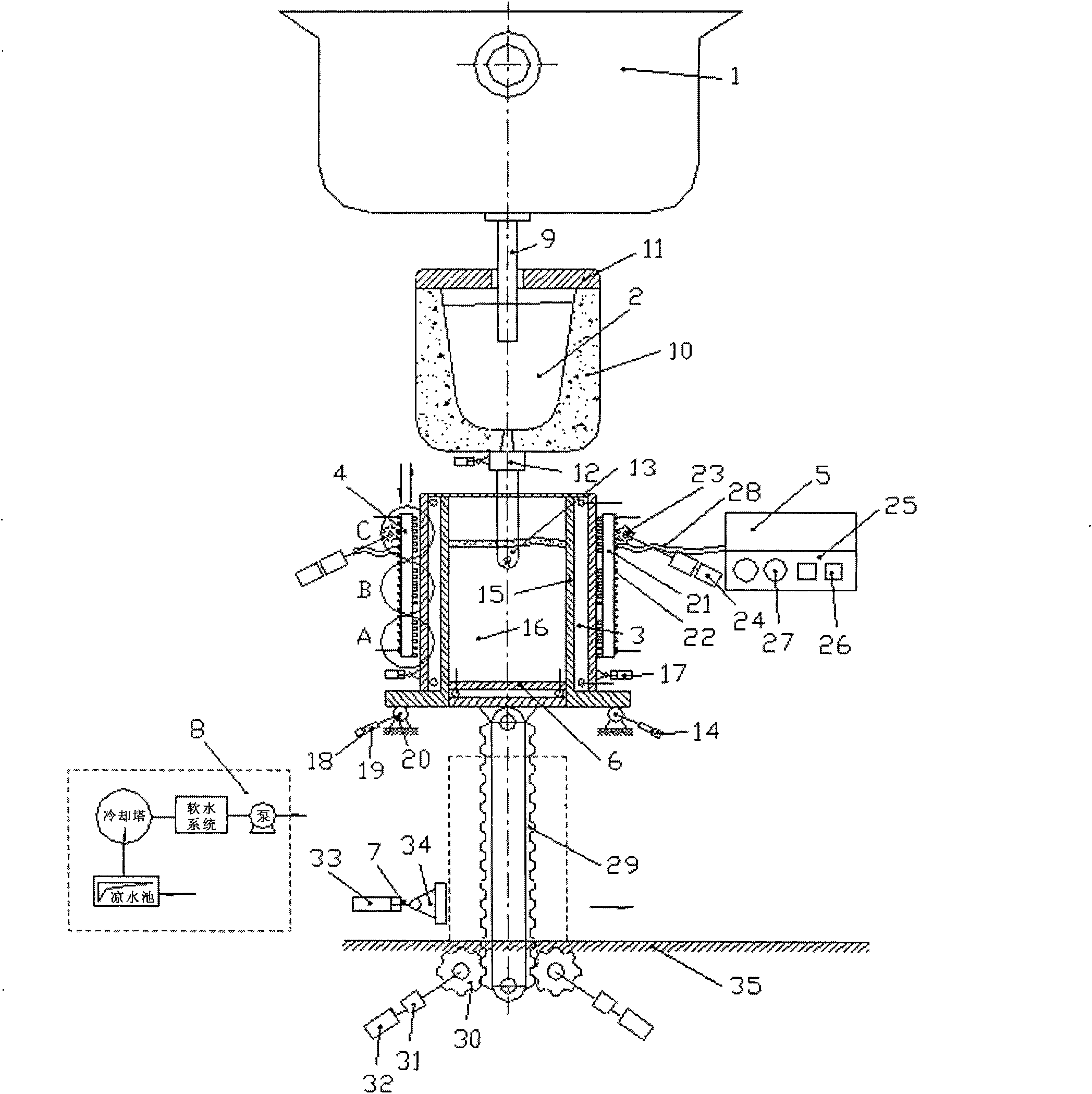

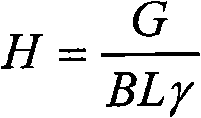

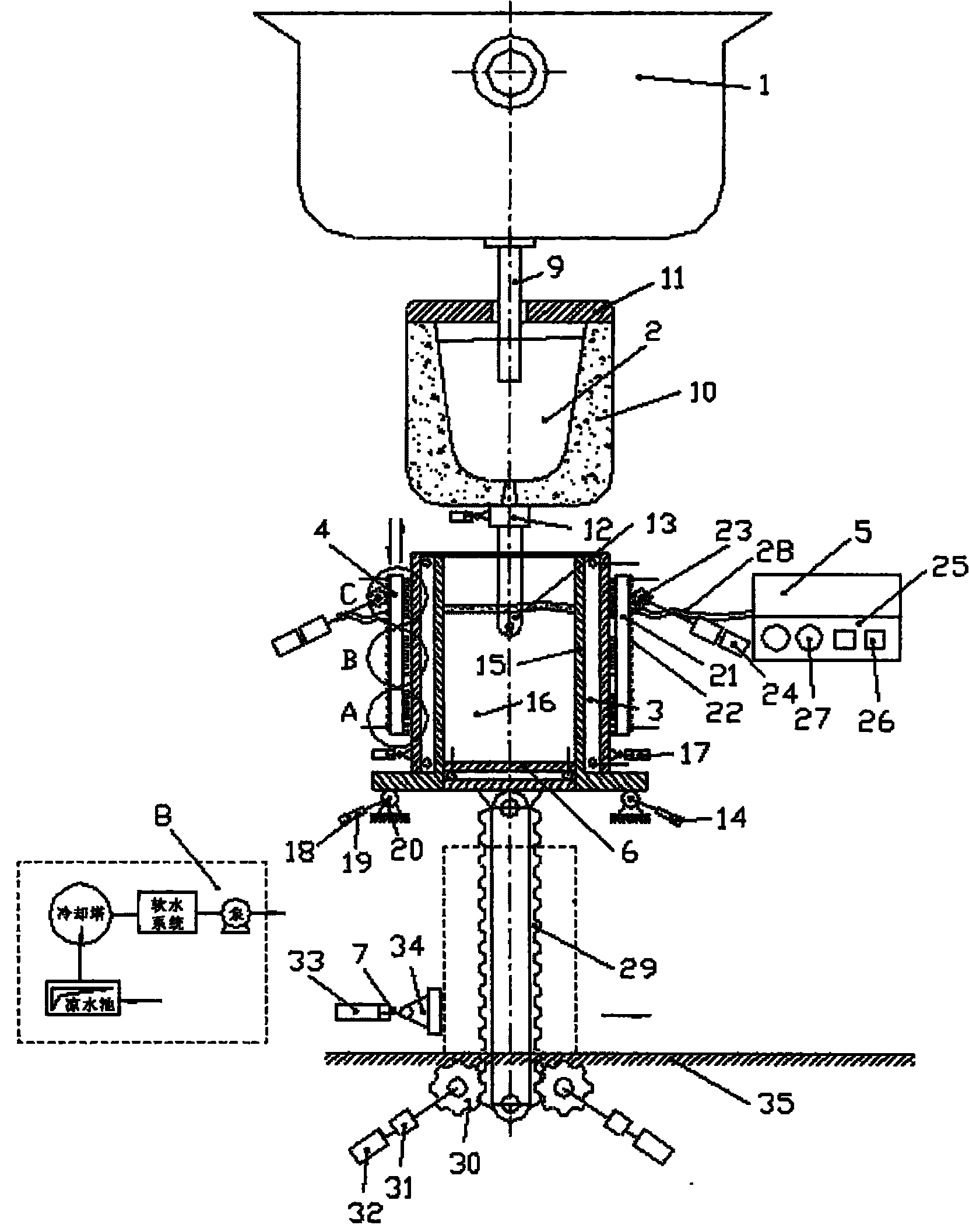

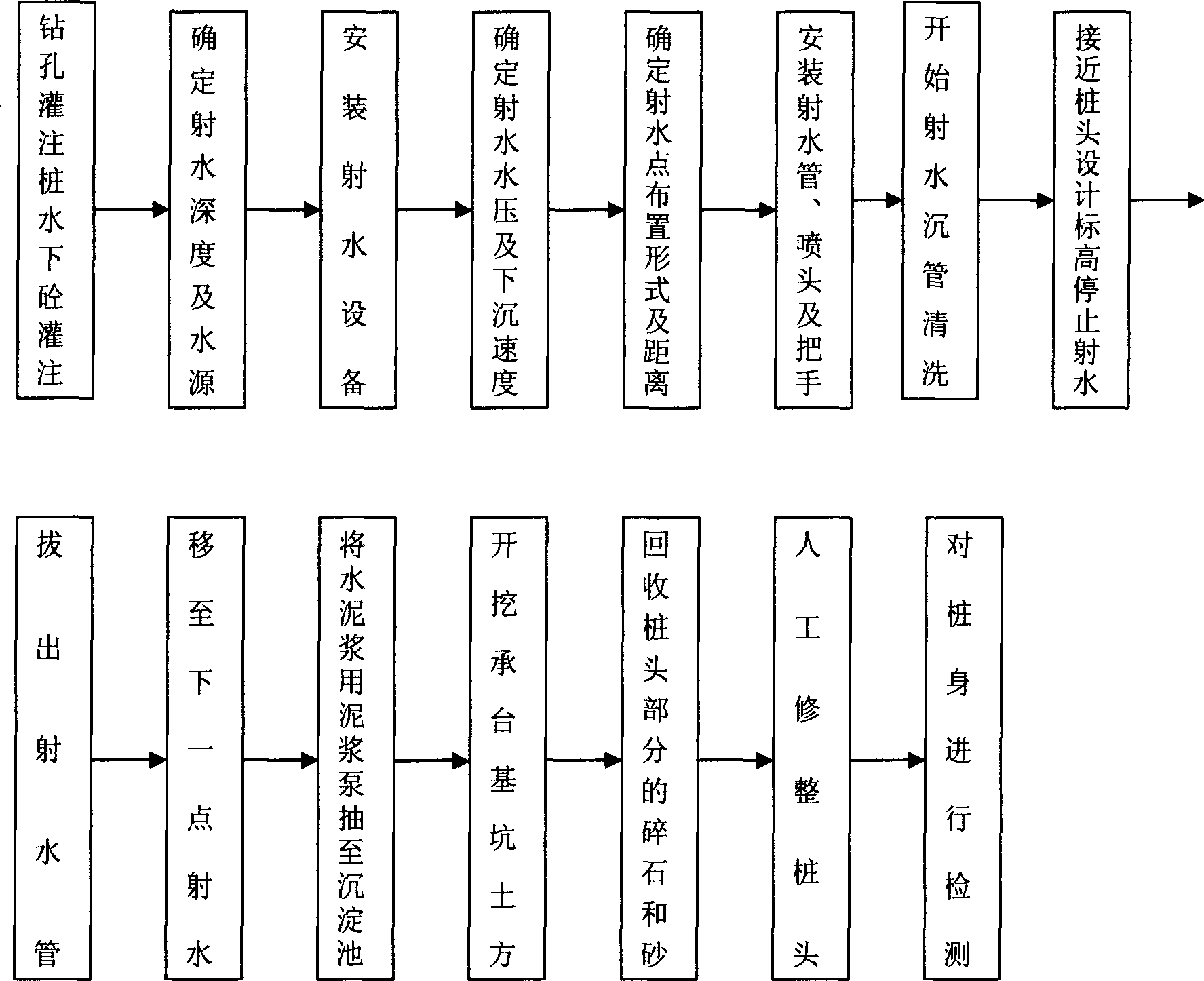

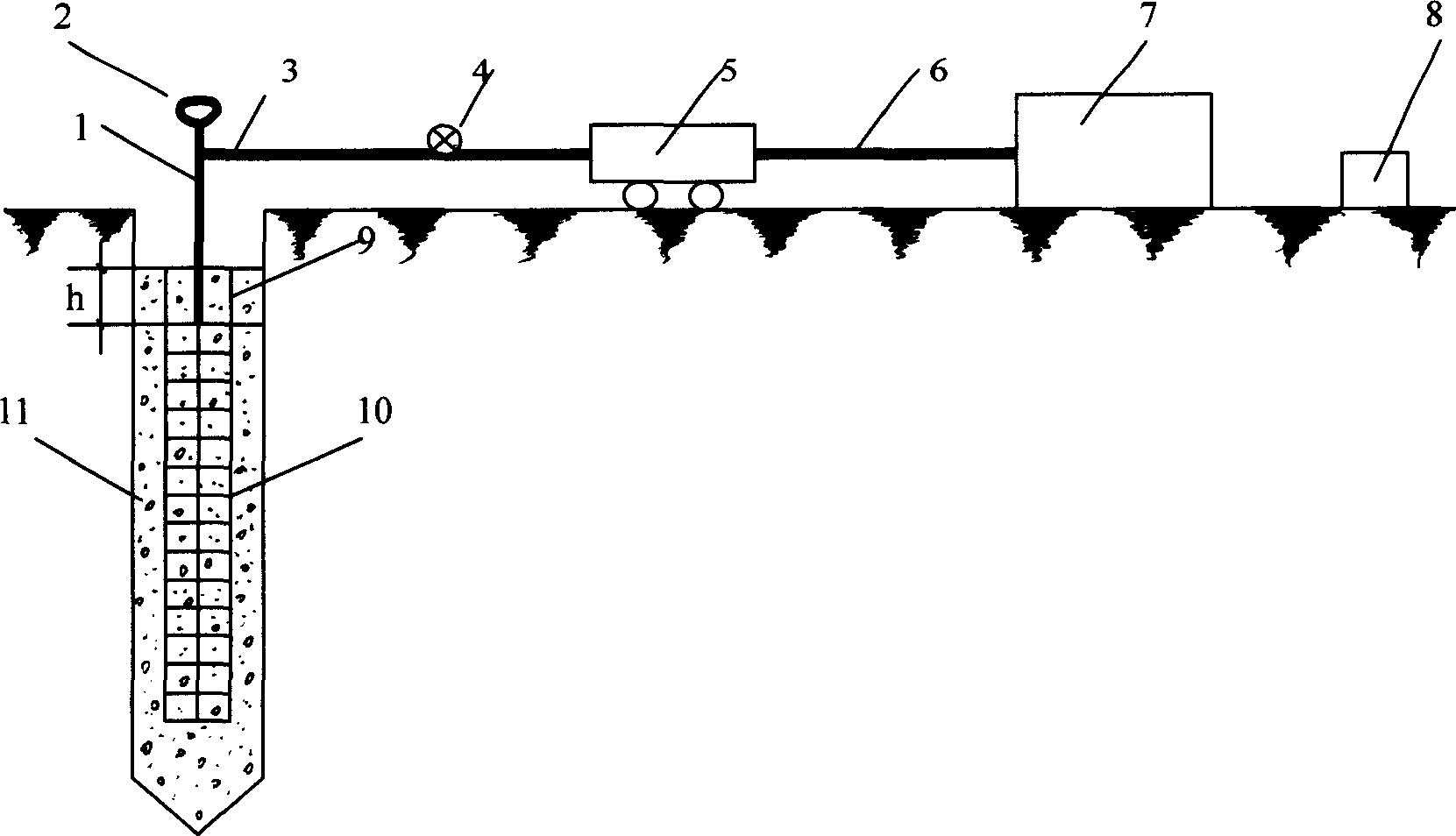

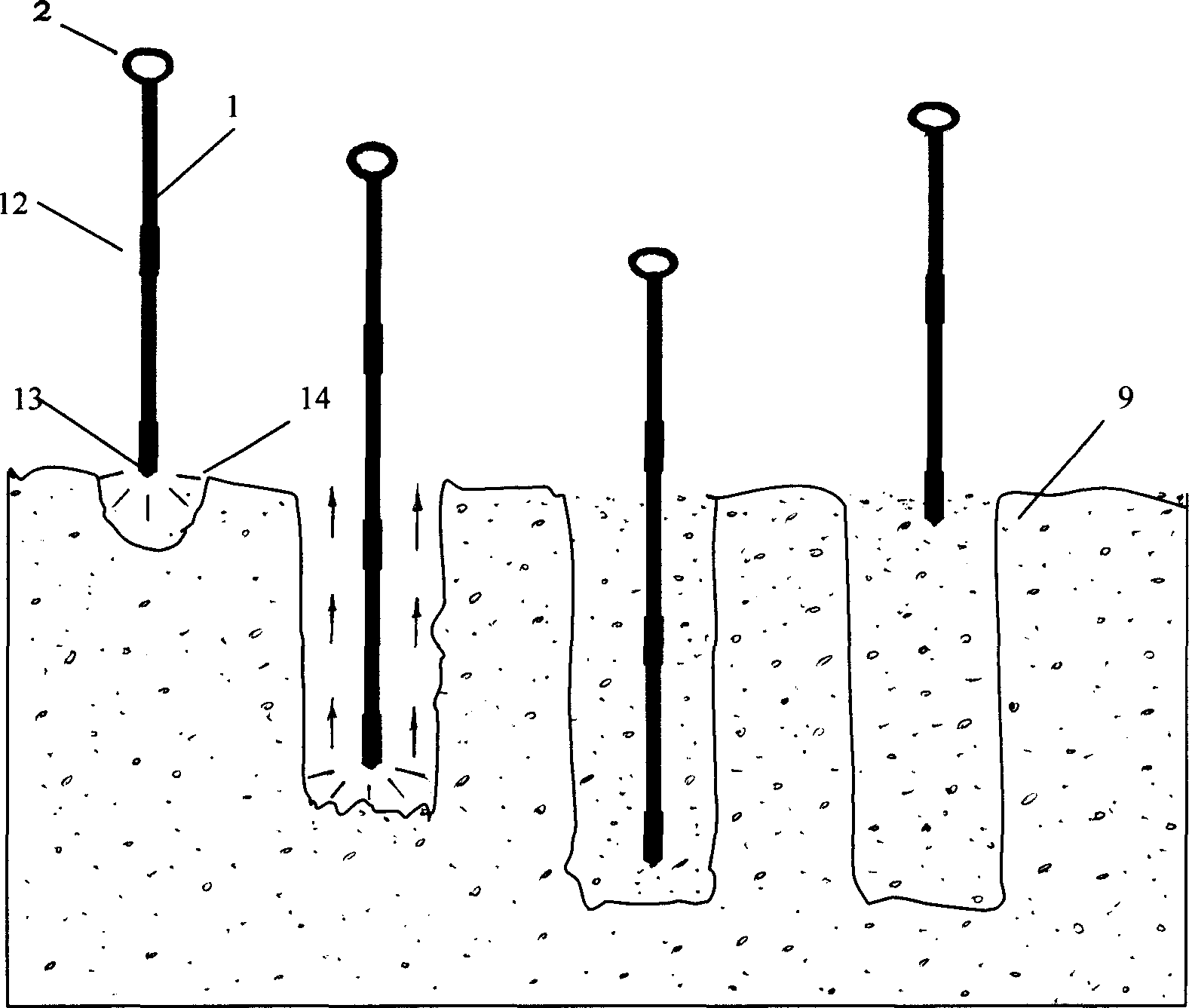

File head broken by water injection

A water jet method for breaking pile head includes such steps as drilling, pouring concrete pile underwater, sinking the water-jetting pipe in the concrete in fluid state, flushing the concrete above the designed height by high-pressure water for removing the cement from the concrete, and pumping the cement sludge in the tank or deposition pool by sludge pump.

Owner:刘思谋

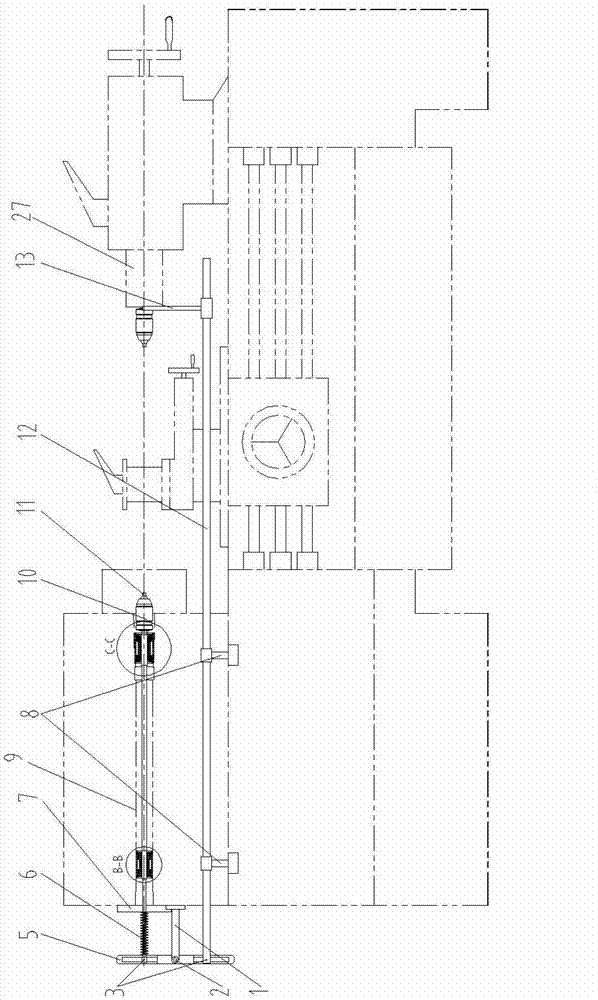

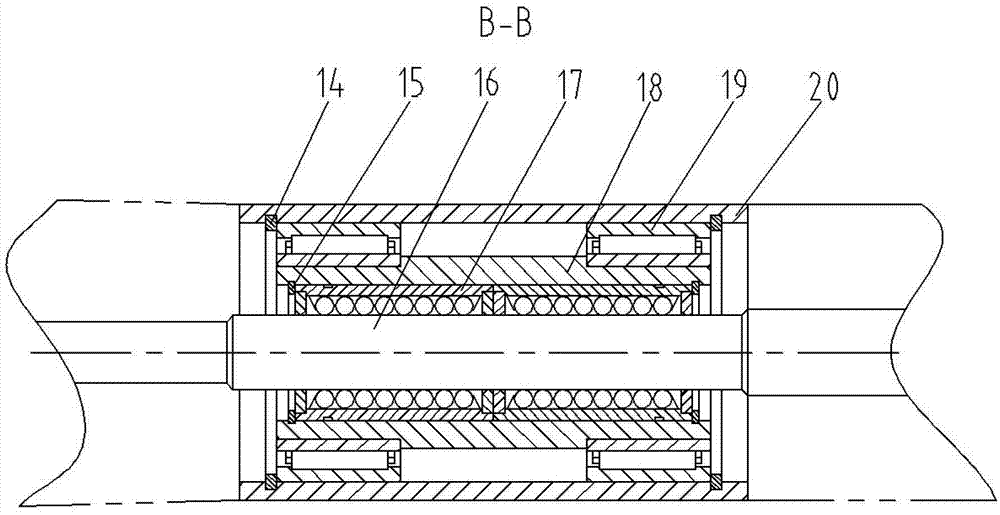

Processing device for double-center hole punching of common lathe

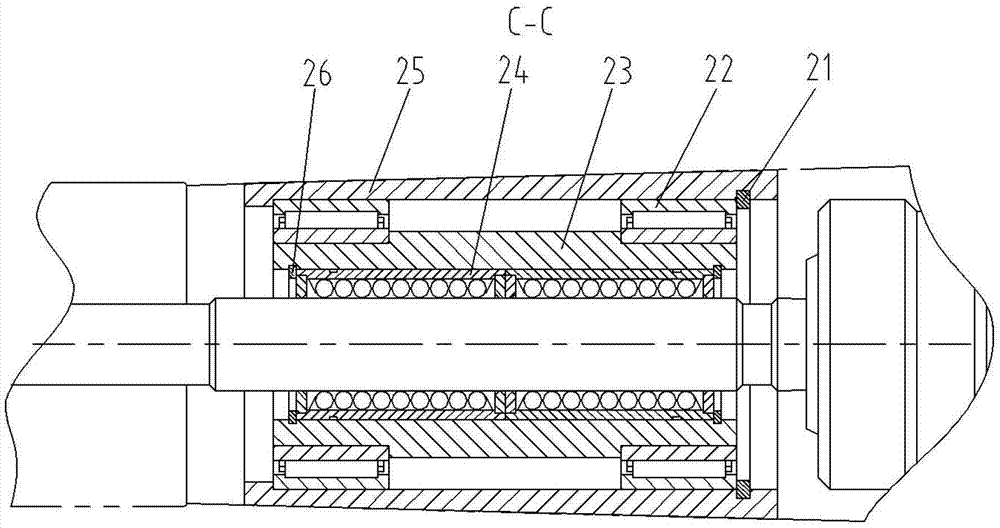

InactiveCN102784946APerformance is not affectedDoes not interfere with normal operationAttachable boring/drilling devicesNeedle roller bearingBall bearing

The invention discloses a processing device for double-centre hole punching of a common lathe. The processing device comprises a proportional reversing feeding device, two groups of shaft hole feeding devices arranged in main shaft holes, a drill chuck connecting rod, a drill chuck and a central drill, wherein the central drill is arranged at a front end of the drill chuck connecting rod through the drill chuck; two groups of shaft hole feeding devices are respectively arranged at front and back parts of the drill chuck connecting rod; each group of the shaft hole feeding devices structurally comprises a liner sleeve, needle rolling bearings, an shaft sleeve and a linear ball bearing which are arranged in the main shaft holes, wherein the linear ball bearing is tightly sleeved on the drill chuck connecting rod; the shaft sleeve is tightly sleeved on the linear ball bearing; the needle rolling bearings are respectively arranged at two ends of the shaft sleeve; and the liner sleeve tightly arranged in the main shaft hole is sleeved on the needle rolling bearing; and one end of the proportional reversing feeding device is connected with a rear end of the drill chuck connecting rod, and the other end of the proportional reversing feeding device is connected with a tail seat of a lathe main body for arranging the drill chuck. By adopting the processing device to punch centre holes at two ends of parts, such as shafts, clamping time can be reduced, efficiency can be improved, precision can be improved, the precision of coaxiality of processing workpieces can be ensured, and meanwhile, workpieces with central holes with different depth and different types at a left end and a right end can be processed through a left central drill and a right central drill with different-ratio feeding rate and feeding volume.

Owner:GUANGXI UNIV

Novel cotton cultivation method

InactiveCN102783345AImprove labor productivityReduce labor intensityHorticultureUltimate tensile strengthBiology

Seedling raising and transplanting in protected areas can prolong growth period by 30-40 days and promote increase of cotton yield. Traditional seedling raising and transplanting use soil nutrition pots. Manufacturing and transplanting of the soil nutrition pots are labor-consuming, high in labor intensity and low in efficiency. Paper-tube combined filled lightweight substrate and industrially made nutrition pots are used, mechanical seeding and mechanical transplanting are carried out and are development trends of cotton industry in China.

Owner:操宇琳

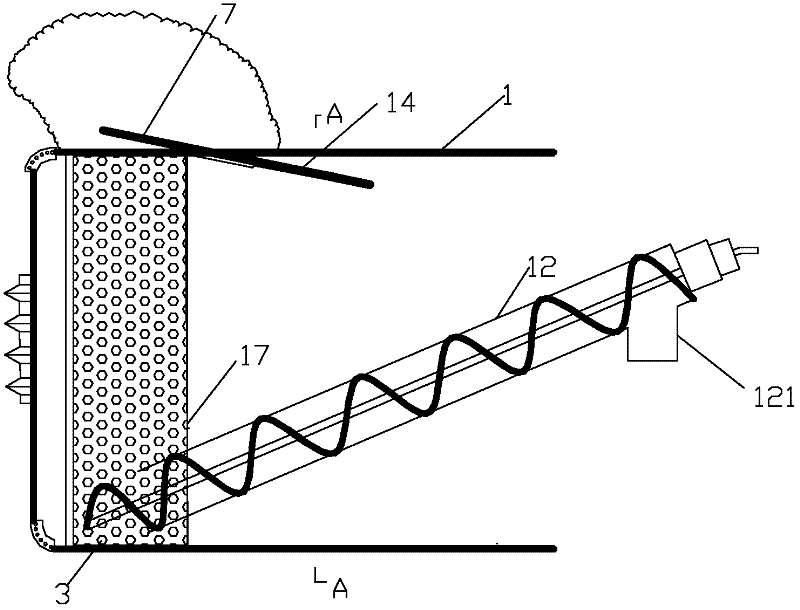

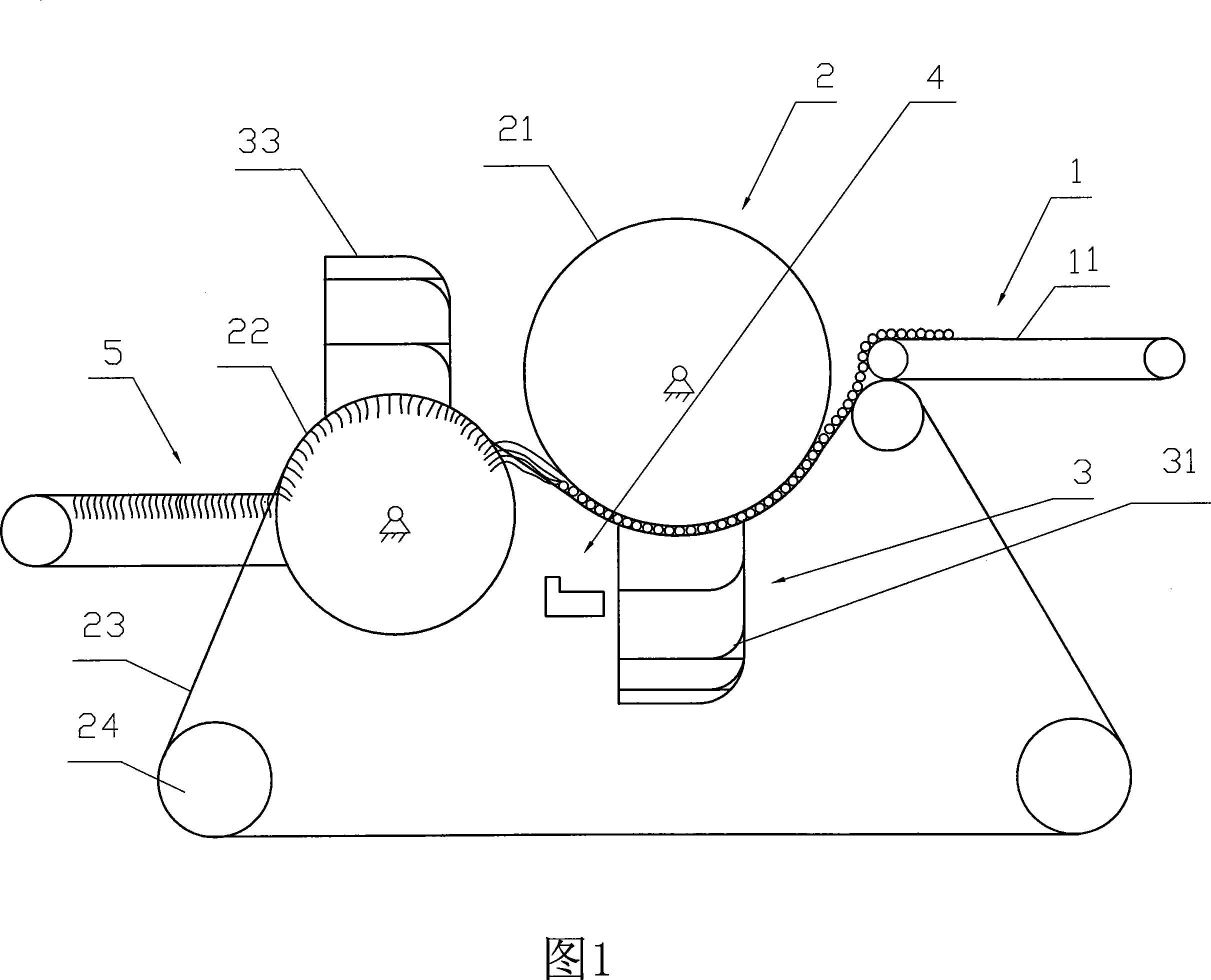

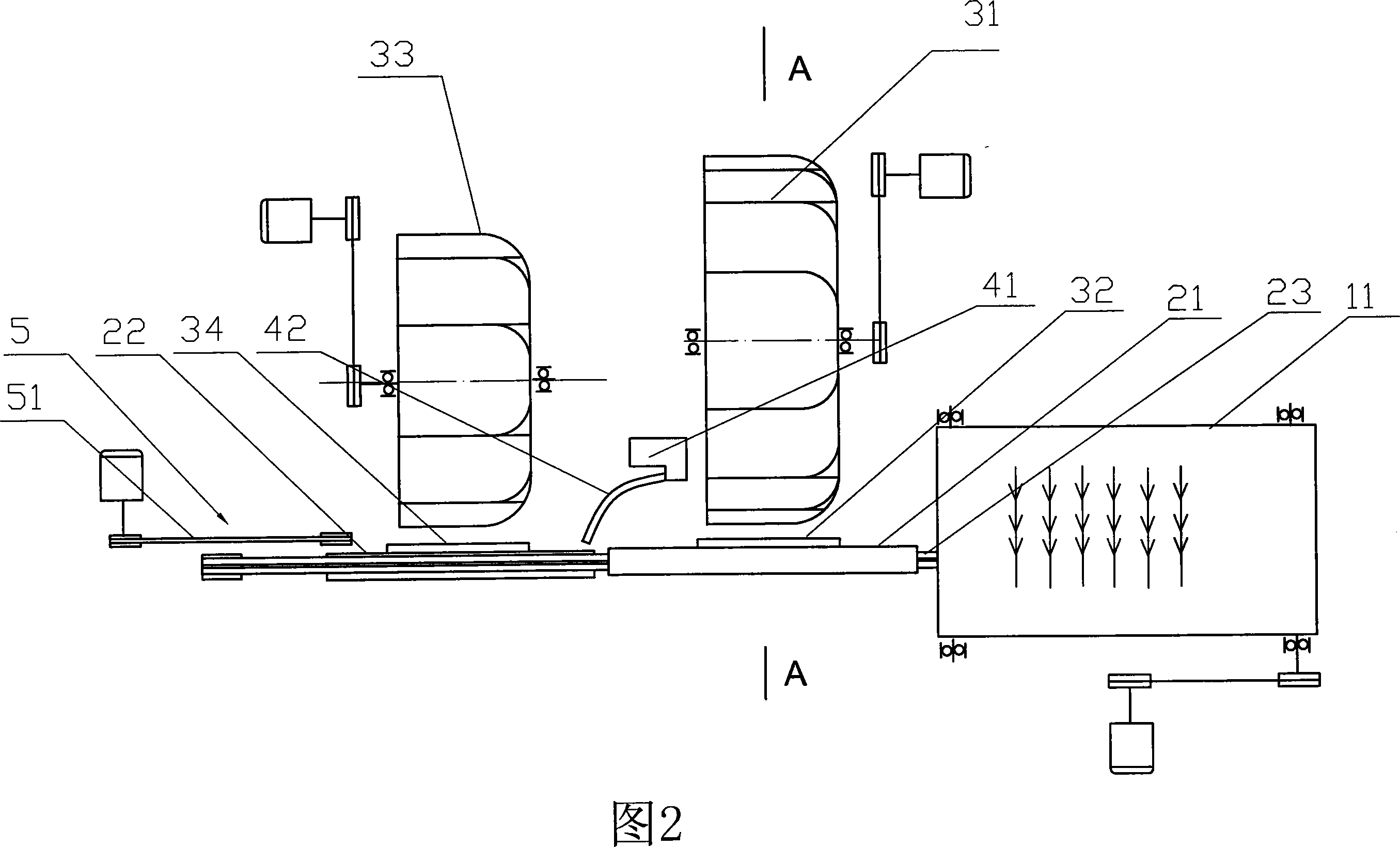

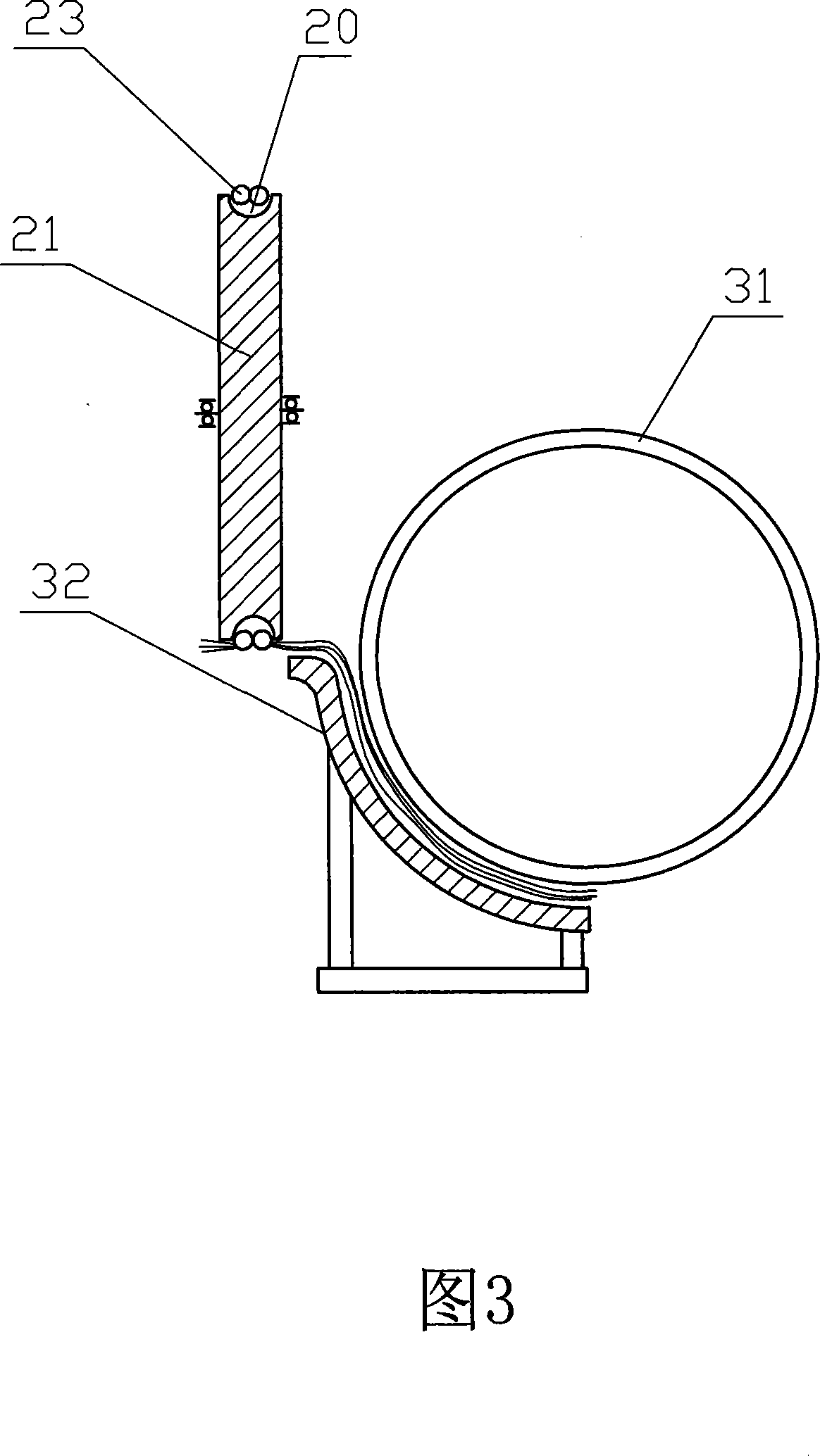

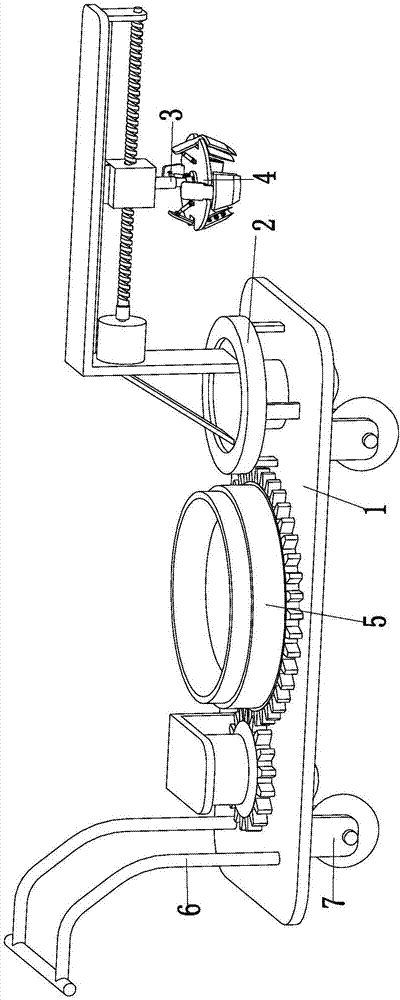

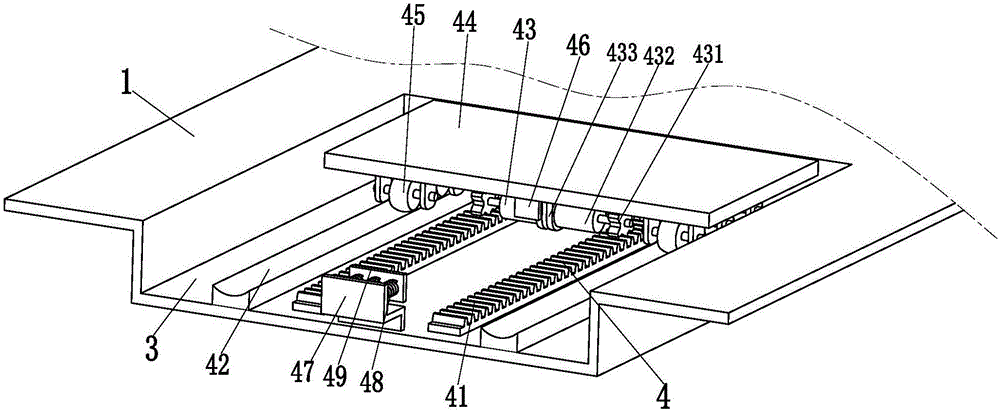

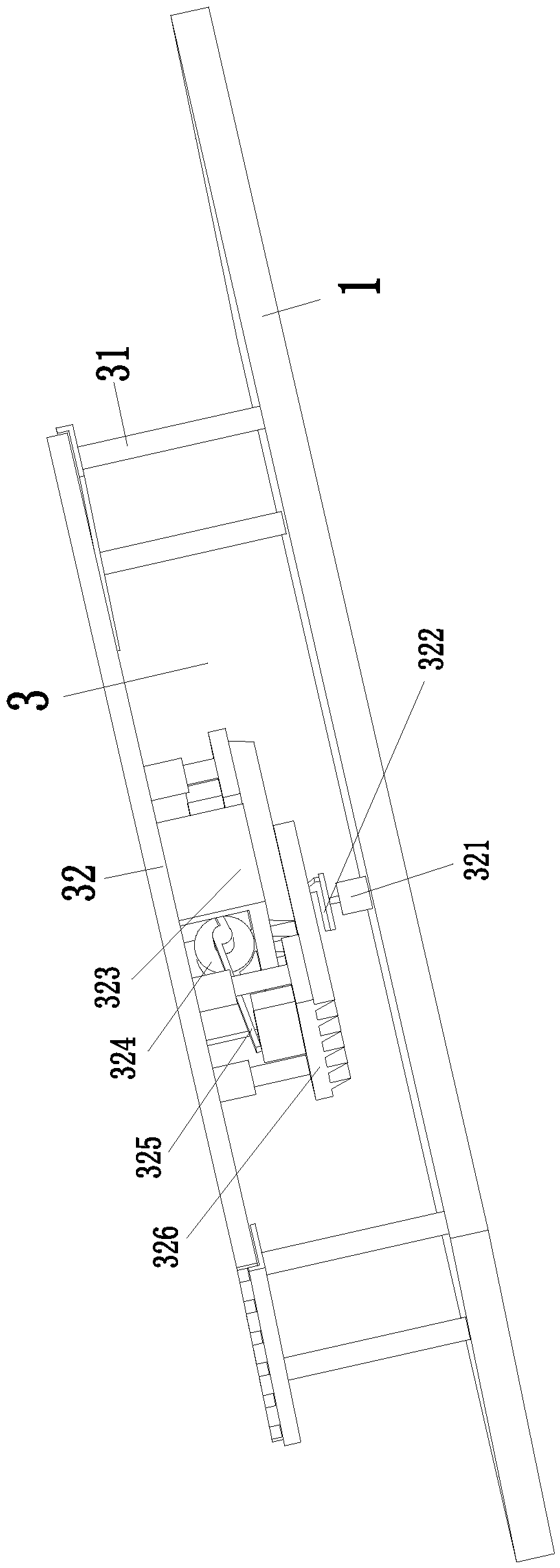

Ramie fibre decorticating method and transverse feeding type ramie raspador thereof

ActiveCN101168853ALow work efficiencyRealize automatic feedingMechanical fibre separationDecortication procedureEngineering

The invention discloses a ramie fiber stripping method and a transverse feeding type ramie stripping machine. The method is as follows: the ramie stems are stripped by transverse feeding, and the ramie stems are stripped in two stages. Make a section near the tip, and then peel off a section near the base. The ramie stripping machine includes a horizontal hemp feeding mechanism, a hemp clamping mechanism, a hemp scraping mechanism, a guiding mechanism, and a hemp receiving mechanism; wherein the horizontal hemp feeding mechanism is mainly composed of a conveyor belt; the hemp clamping mechanism is mainly composed of a primary hemp clamping wheel, a secondary Clamping wheel and clamping hemp rope are composed, and clamping hemp rope forms an S shape between the two clamping hemp wheels and bypasses the two clamping hemp wheels; The secondary hemp stripping hob and its matching concave plate are composed of the primary hemp clamping wheel corresponding to the position of the primary hemp stripping hob, and the secondary hemp clamping wheel is corresponding to the position of the secondary hemp stripping hob; the guide mechanism is mainly composed of The slightly end of the hemp stripped by the hob is blown to the blower on the secondary hemp wheel and the corresponding hemp guide plate; the hemp receiving mechanism is mainly composed of a conveyor belt. The invention can automatically feed and strip, thereby greatly reducing the labor intensity and improving the work efficiency of stripping hemp.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

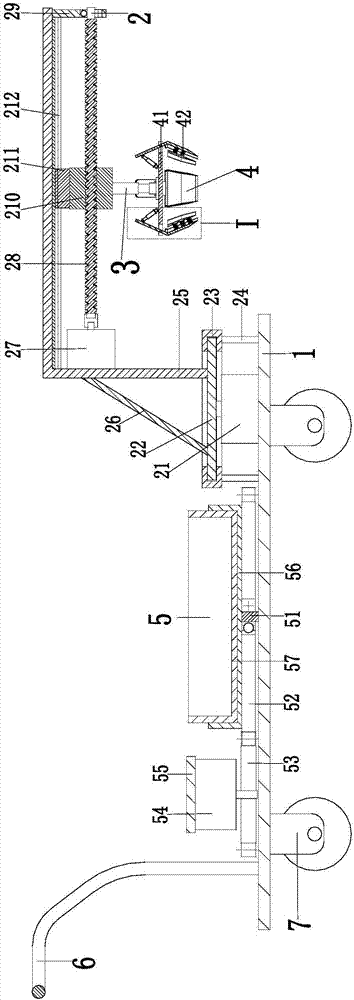

Efficient automatic fruit sorting robot

ActiveCN106976102AGrasp firmlyReduce labor intensityGripping headsConveyor partsHydraulic cylinderEngineering

The invention relates to an efficient automatic fruit sorting robot comprising a base plate. An adjusting mechanism is mounted at the front end of the base plate. A lifting hydraulic cylinder is mounted at the lower end of the adjusting mechanism. The bottom end of the lifting hydraulic cylinder is mounted on a hard-shell fruit grabbing mechanism through a flange. A collecting mechanism is mounted in the middle of the base plate, and a pushing handle is mounted at the rear end of the base plate. Four universal wheels are mounted symmetrically at the lower end of the base plate. The adjusting mechanism can drive the hard-shell fruit grabbing mechanism to conduct position adjusting. The adjusting mechanism, the hard-shell fruit grabbing mechanism and the collecting mechanism are mutually matched to complete the process of fruit sorting. The problems that in the existing fruit sorting process, soft-shell fruit and hard-shell fruit need to be carried through labor, the surface of the soft-shell fruit is prone to damaging, fruit selling is affected, and carrying of the hard-shell fruit through the labor is large in labor intensity and low in working efficiency can be solved, and the function of efficient fruit sorting can be achieved.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

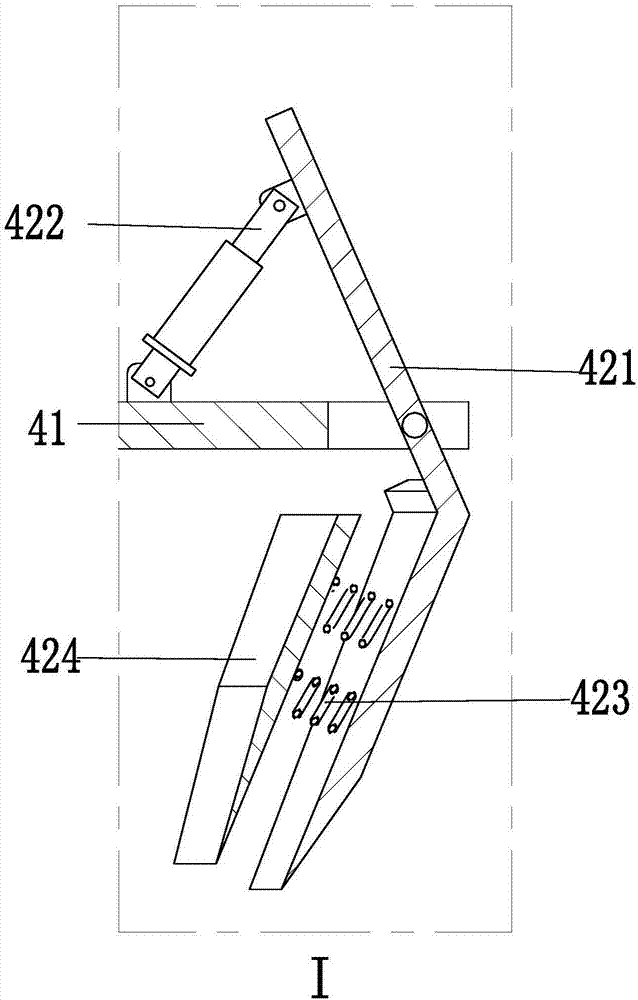

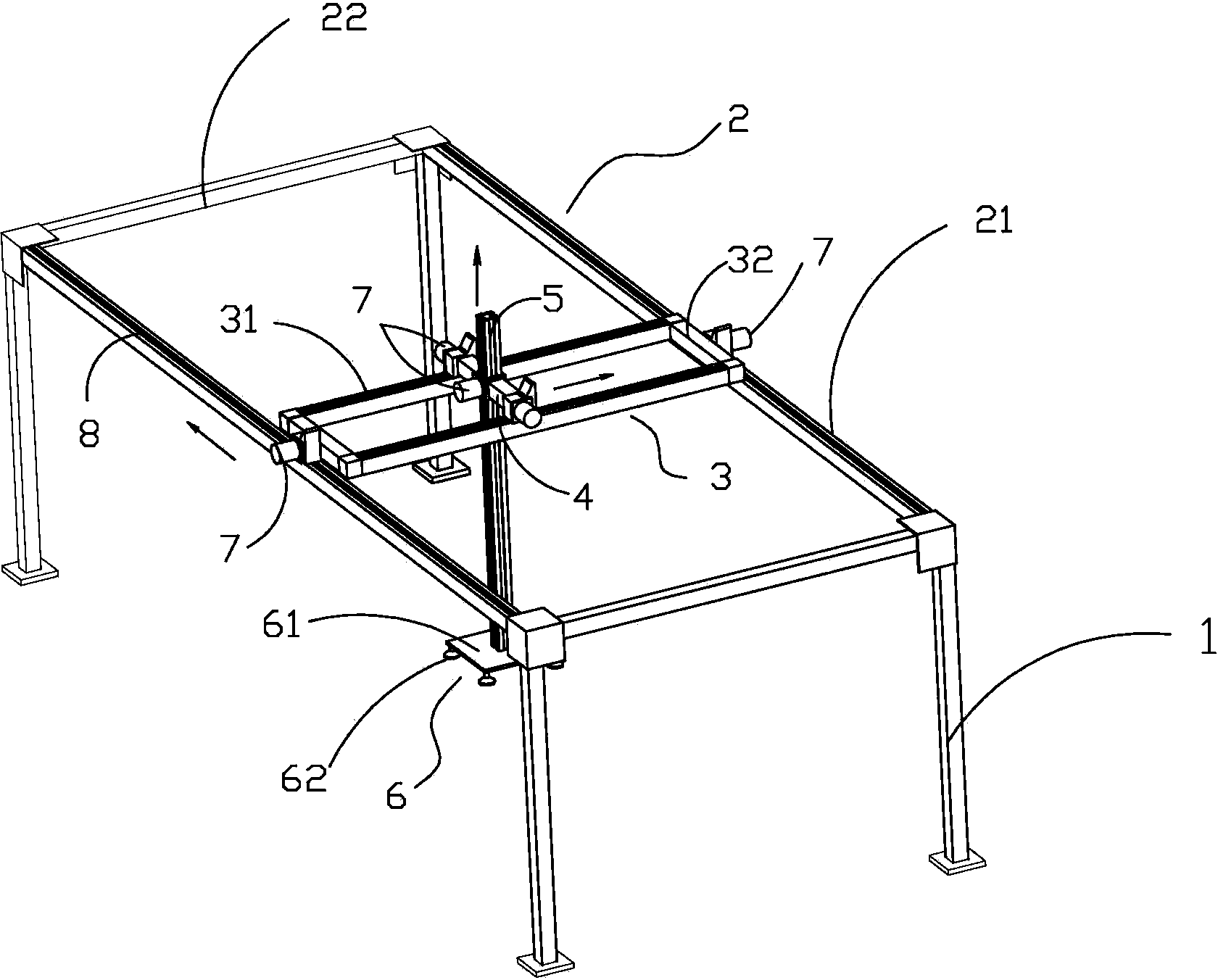

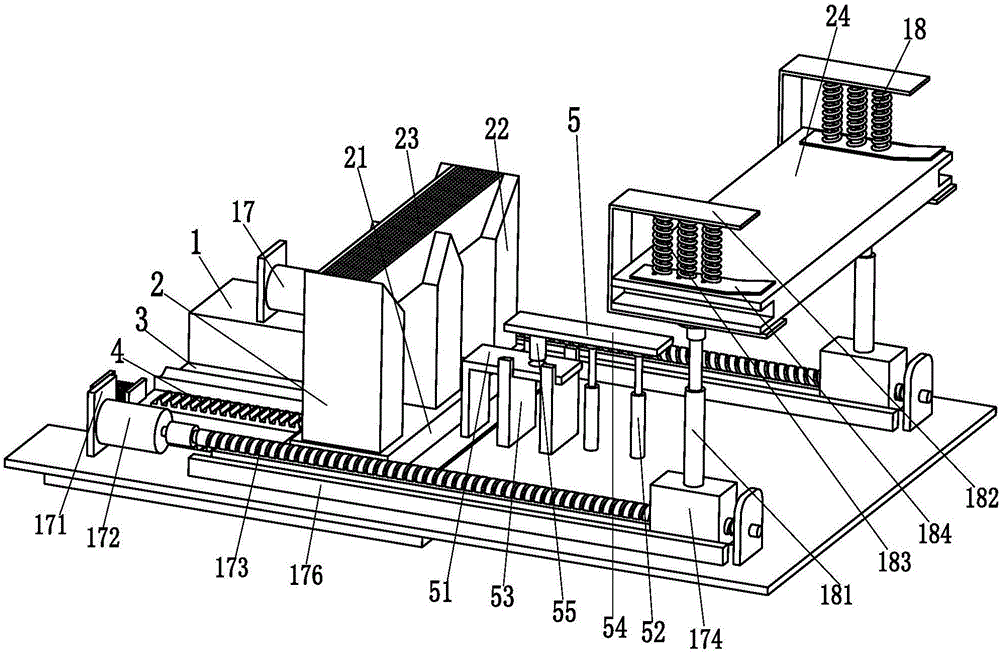

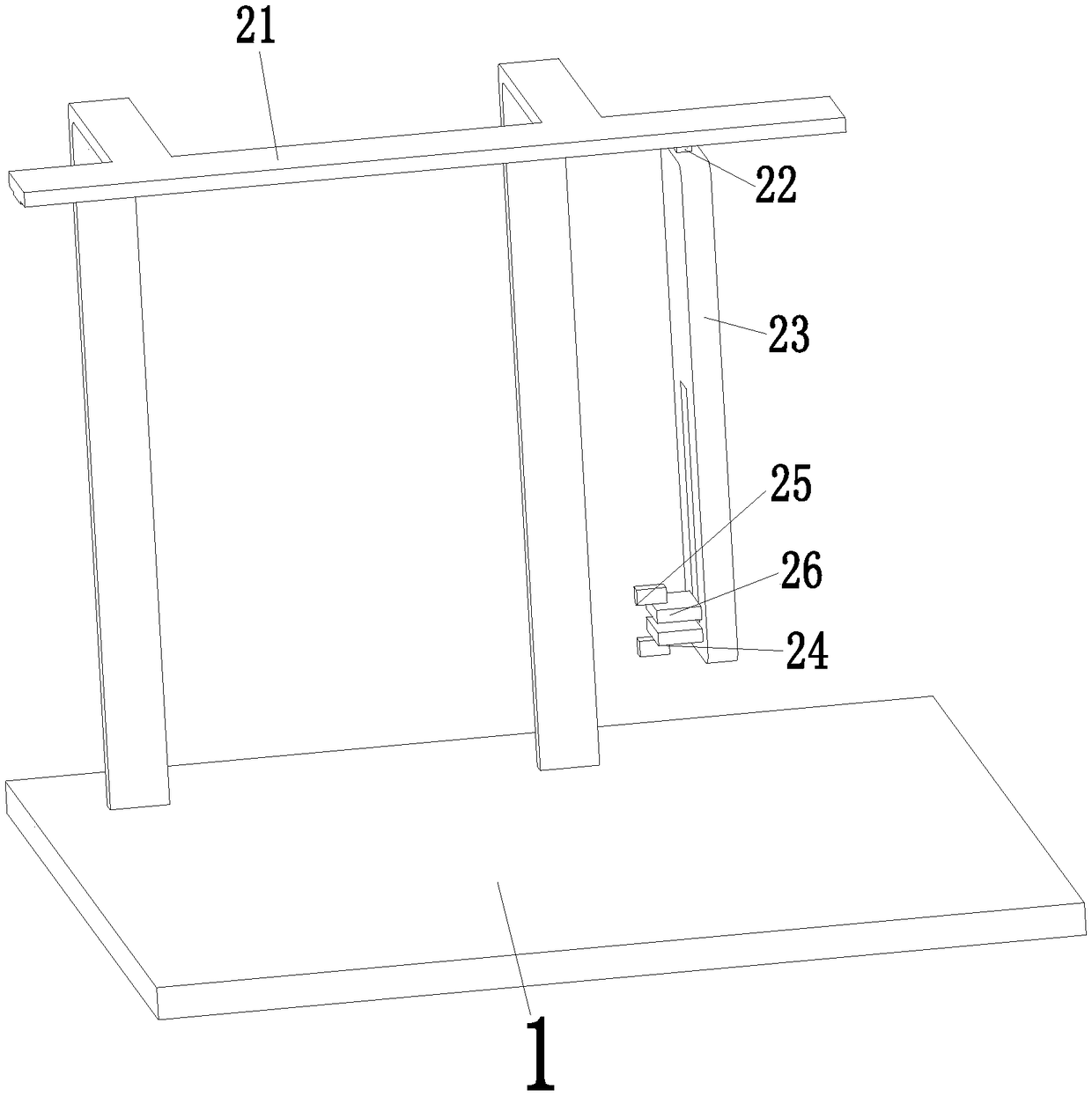

Automatic feeding machine structure

InactiveCN103407807ASimple structureEasy to operateArticle feedersArticle deliveryStructural engineeringControl engineering

The invention discloses an automatic feeding machine. The automatic feeding machine comprises a machine frame, wherein the machine frame comprises stand columns, balancing transverse beams arranged on the stand columns, moving racks, moving devices of the moving racks, a lifting beam, a lifting device of the lifting beam and an absorption device, the moving devices are fixed on the moving racks and enable the moving racks to move relative to the transverse beams, the lifting device is fixed onto the moving racks and enables the lifting rack to move vertically relative to the moving racks, and the absorption device is fixed below the lifting beam. The automatic feeding machine is simple and reasonable in structure, convenient to operate and use, safe in operation and usage, good in processing quality and high in work efficiency; meanwhile, saves manpower, reduces labor intensity of operators and is safe and reliable in operation.

Owner:钱旭荣

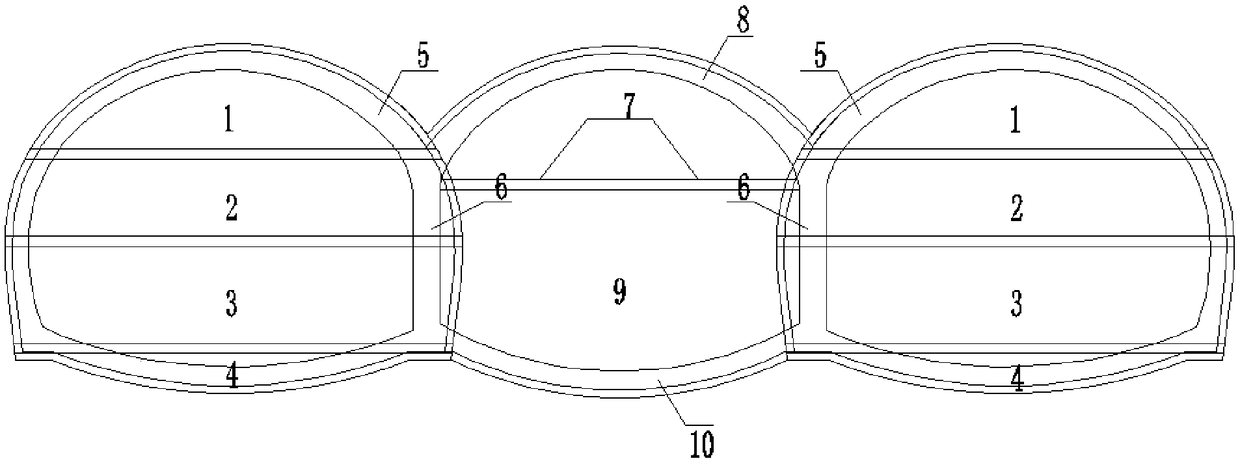

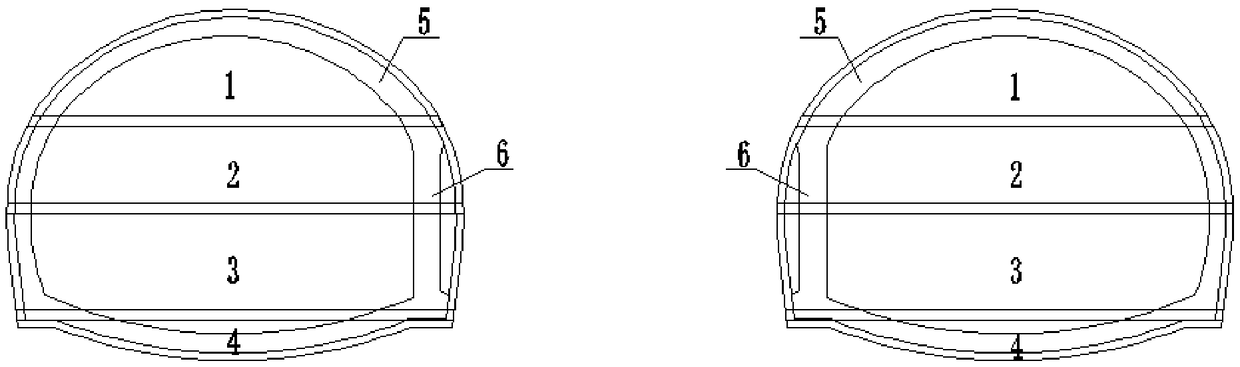

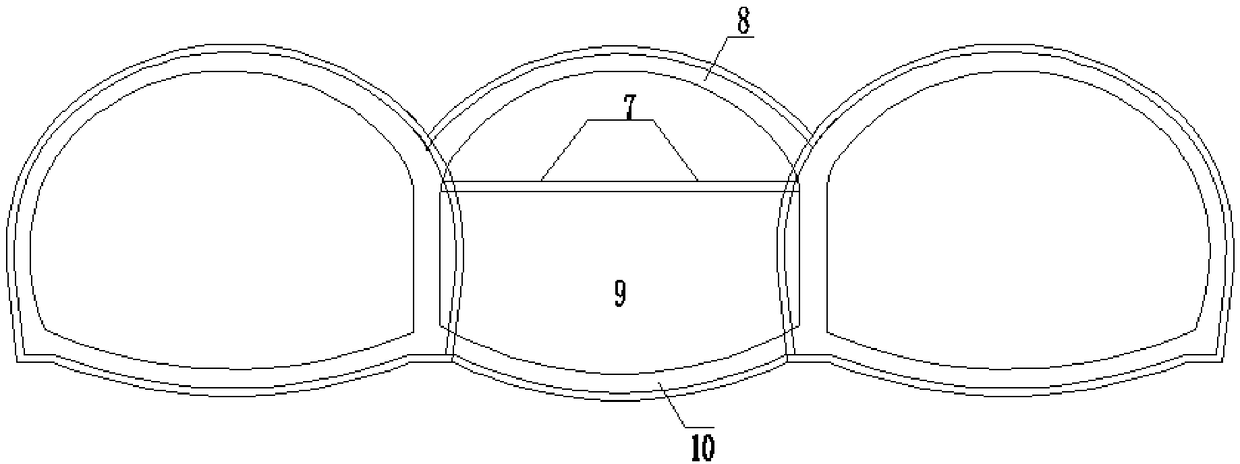

Three-arched tunnel construction method

InactiveCN109488311ALarge construction spaceImprove ergonomicsUnderground chambersTunnel liningTunnel constructionBuilding construction

The invention relates to a three-arched tunnel construction method. The three-arched tunnel construction method comprises the following steps that a left opening is first excavated, the complete crosssection of the left opening is preliminarily supported and close to form a ring, then a right opening is excavated, and the staggering distance of excavation of the left opening and the right openingis greater 15 meters; after secondary lining and a middle partition wall of the left opening and the right opening are completed, a middle opening is excavated; when the middle opening is excavated,an upper half cross section is firstly excavated, then arch lining is executed, the lower portion is excavated after the arch lining is completed, and finally an inverted arch of the middle opening isconstructed. The three-arched tunnel construction method has the advantages of few working processes, few surrounding rock disturbance times, good safety, high working efficiency, high construction progress and the like.

Owner:THE 4TH ENG OF CHINA RAILWAY 5TH ENG GROUP +1

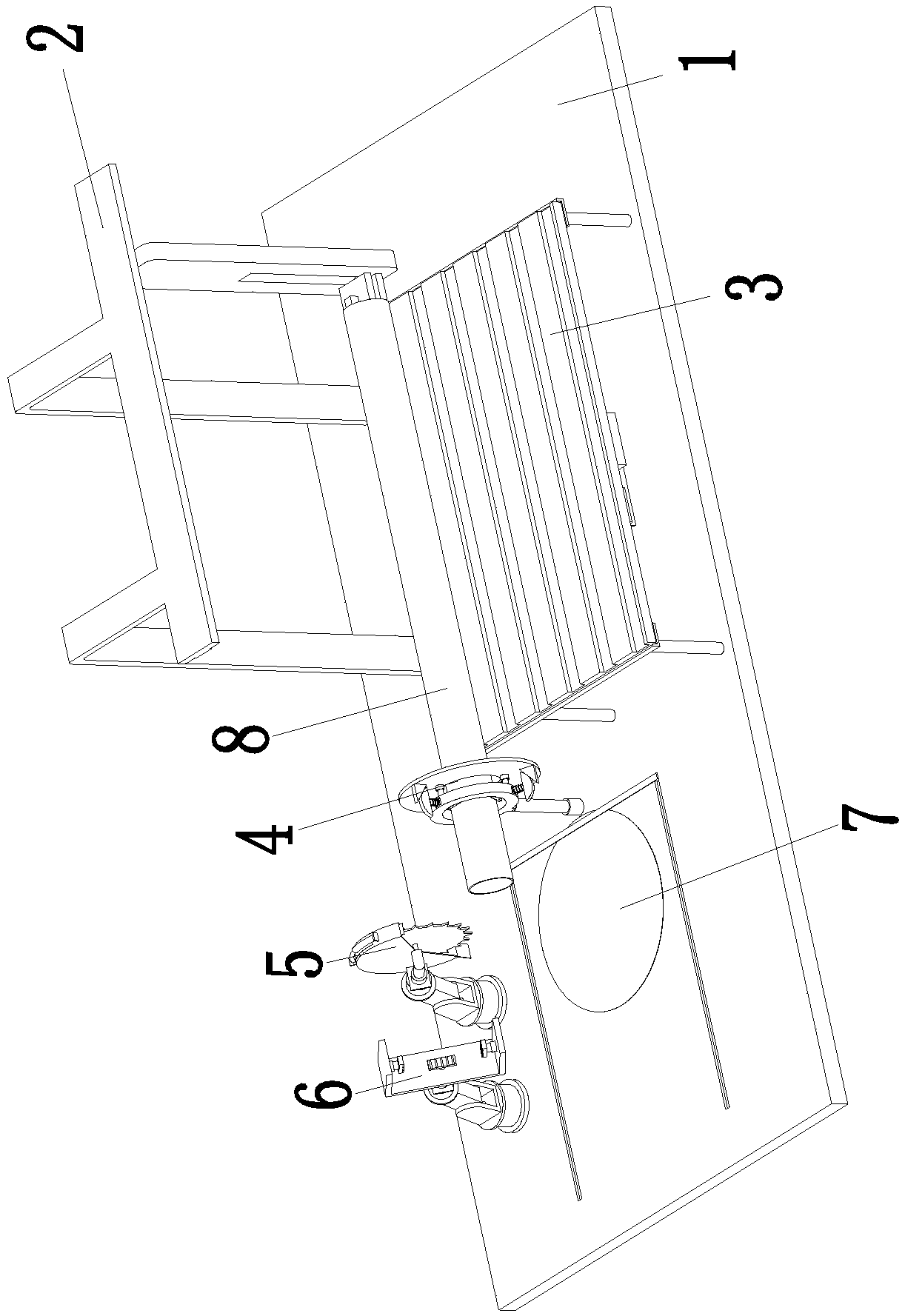

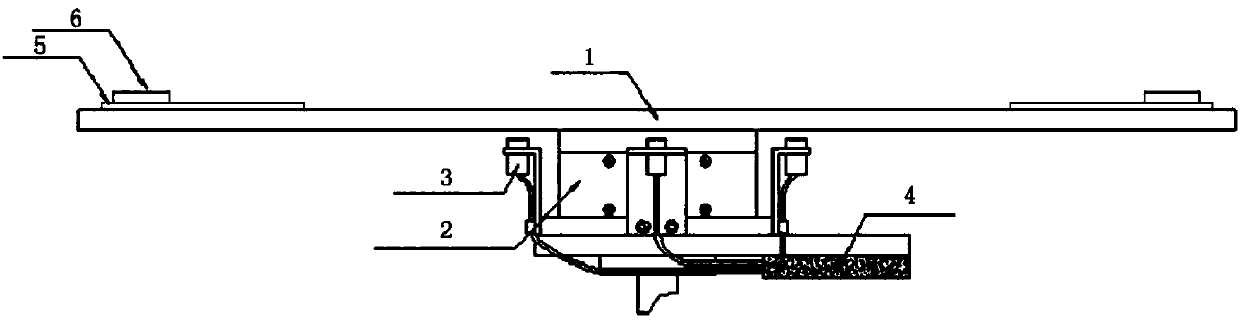

Upper clamp assembly and disassembly device with automatic carrying function for dry-type transformer

ActiveCN106548862ASmooth transmissionGood transmission effectInductances/transformers/magnets manufactureConveyor partsTransformerEngineering

The invention relates to an upper clamp assembly and disassembly device with an automatic carrying function for a dry-type transformer. The upper clamp assembly and disassembly device comprises a bottom plate and an iron core, wherein a concave installation groove is arranged in the front side of the upper end surface of the bottom plate; a sliding carrying mechanism is arranged on the upper end surface of the installation groove; the iron core is put on the upper end of the sliding carrying mechanism and a limiting mechanism is arranged in the middle of the bottom plate; after the sliding carrying mechanism automatically carries the iron core to a specified position, the iron core is locked through the limiting mechanism, so that the iron core does not move when the transformer is manufactured, and the condition that the iron core moves to affect the manufacturing efficiency of the transformer is avoided; two power mechanisms are symmetrically arranged at the left side and the right side of the upper end surface of the bottom plate; each power mechanism is provided with a clamping branch chain for clamping an upper clamp; and the two clamping branch chains are driven to move back and forth through the two power mechanisms. According to the upper clamp assembly and disassembly device, automatic carrying of the iron core of the transformer and the automatic assembly and disassembly function on the upper clamp can be achieved and manual operation is not needed.

Owner:HENGSHUI POWER SUPPLY BRANCH OF STATE GRID HEBEI ELECTRIC POWER

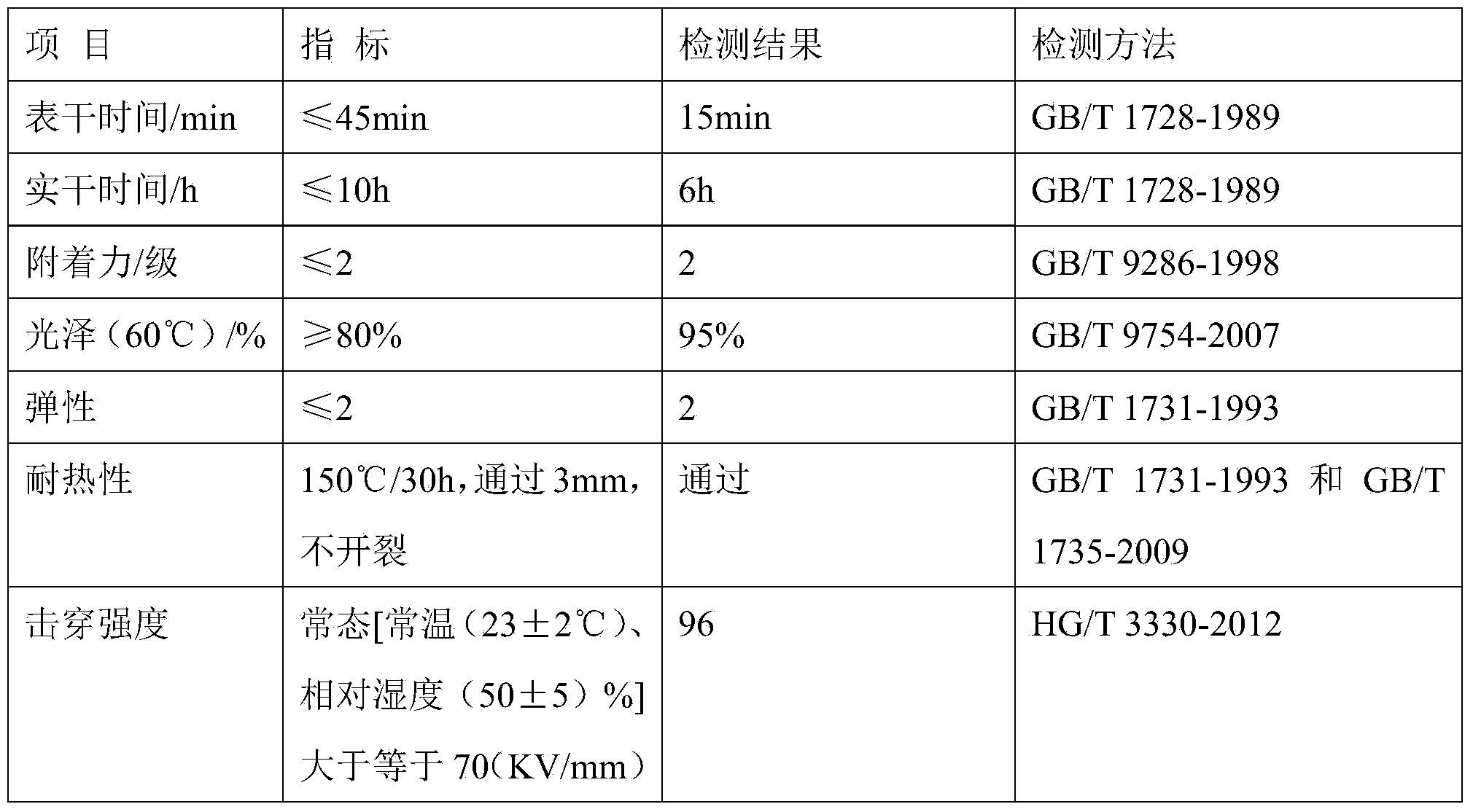

Styrene modified alkyd resin, preparation method thereof and alkyd resin paint

The invention discloses styrene modified alkyd resin which comprises the following raw materials in percentage by weight: 12-30% of styrene, 8-16% of xylene, 24-35% of trimethylbenzene, 14-19% of soybean oil, 1.5-1.8% of a toughening agent, 1-5% of tung oil, 7-9% of phthalic anhydride, 1-4% of pentaerythritol, 1-3% of epoxy resin, 1-3% of benzoic acid, 1-5% of maleic anhydride, 1.5-2% of grease leftovers, 0.01-0.03% of a catalyst, and 1-3% of an initiator. The invention further discloses alkyd resin paint containing the styrene modified alkyd resin. The alkyd resin paint comprises the following components in percentage by weight: 70-99% of the styrene modified alkyd resin disclosed by the invention, 0-30% of pigment and 0.2-1.5% of an additive. The styrene modified alkyd resin disclosed by the invention is simple in preparation method, due to copolymerization reaction of styrene, unsaturated fatty acid and maleic anhydride, the modified alkyd resin has the characteristics of high hardness and rapid dryness, when the modified alkyd resin is used in alkyd resin paint, the defects that the conventional alkyd resin paint is long in construction period, low in working efficiency and poor in water resistance are overcome.

Owner:广东鲸鲨化工有限公司

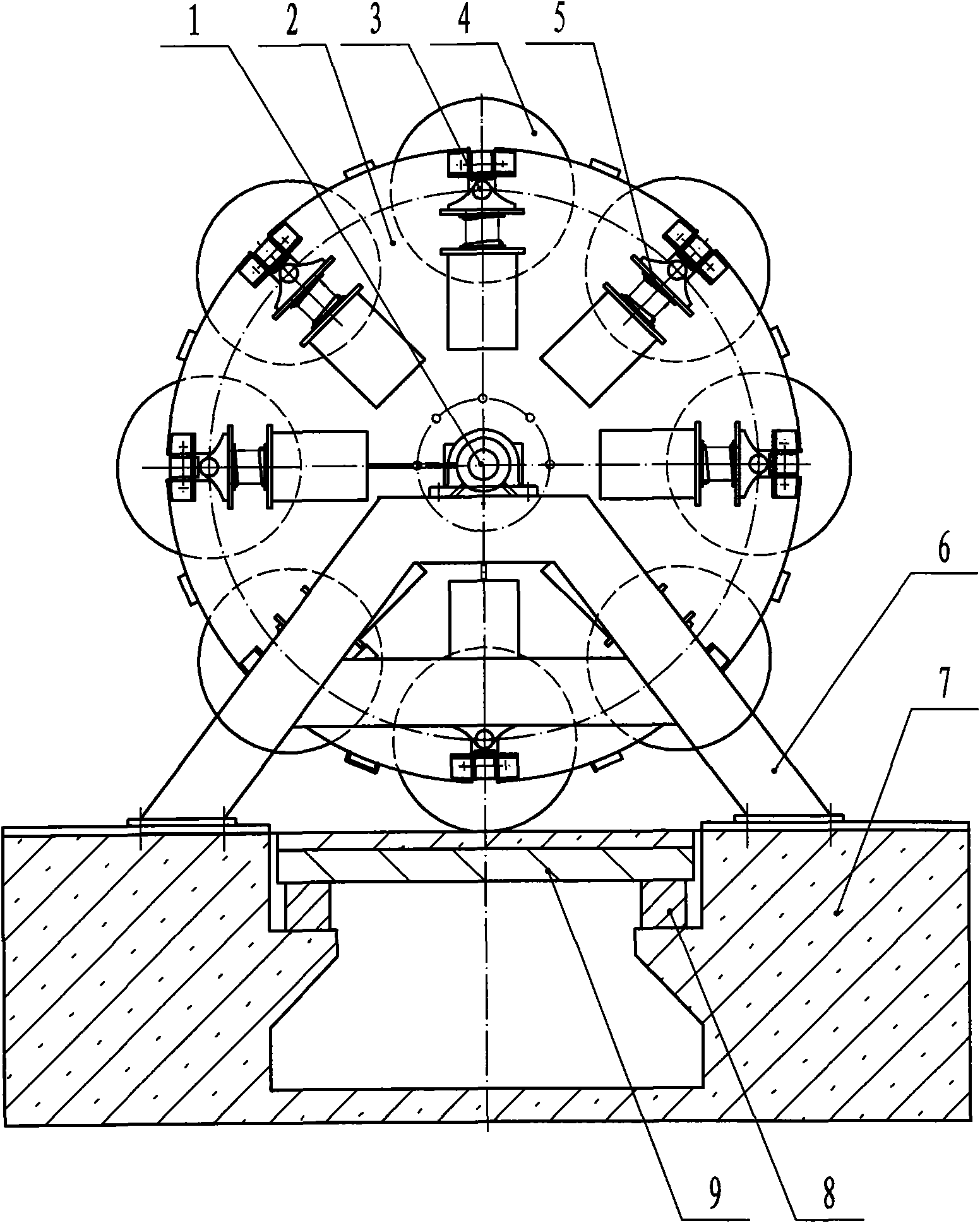

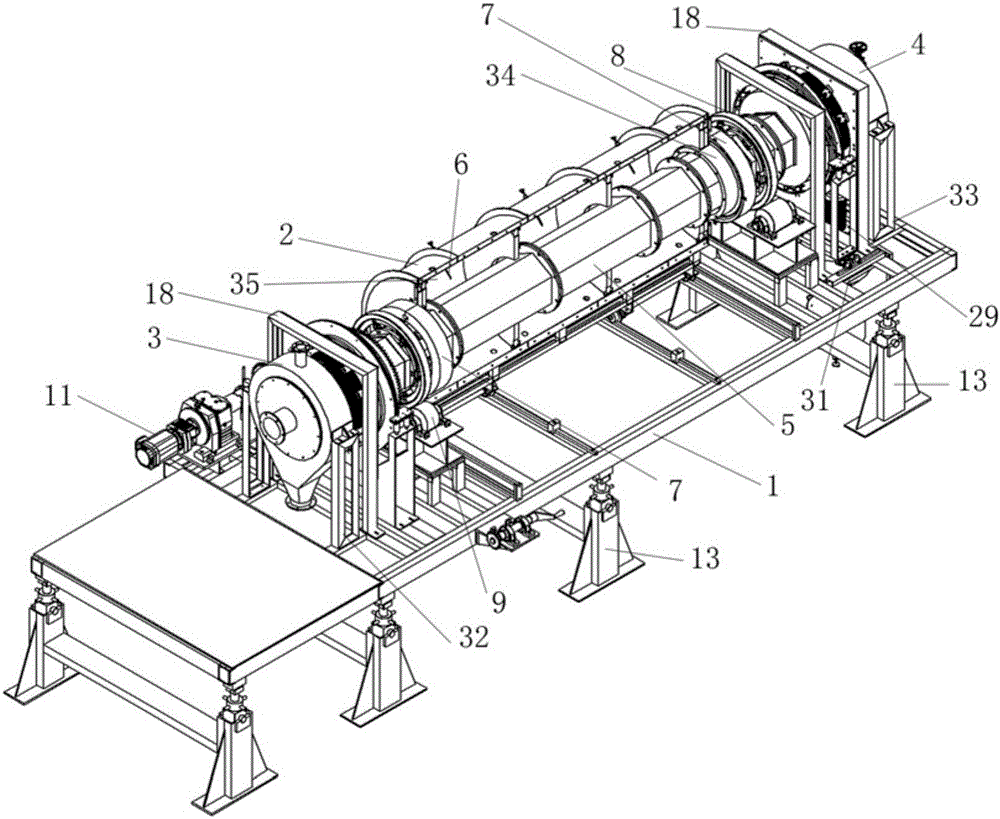

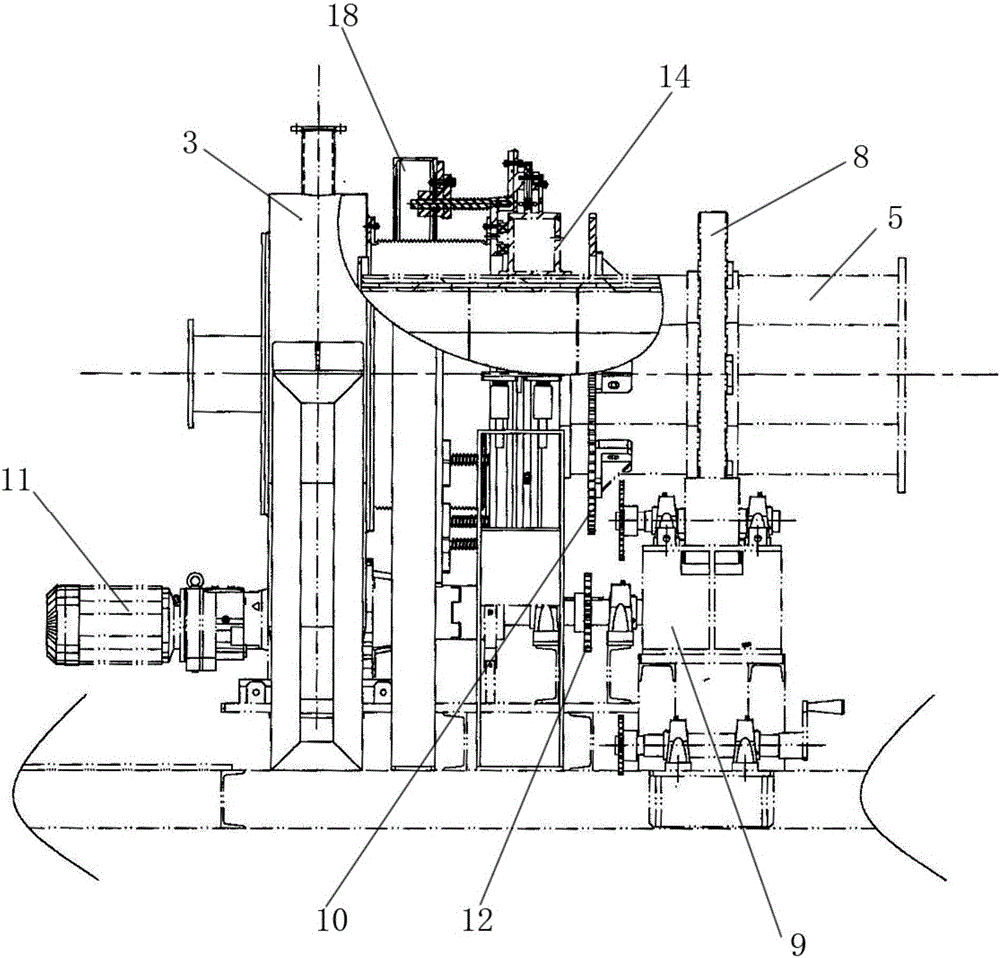

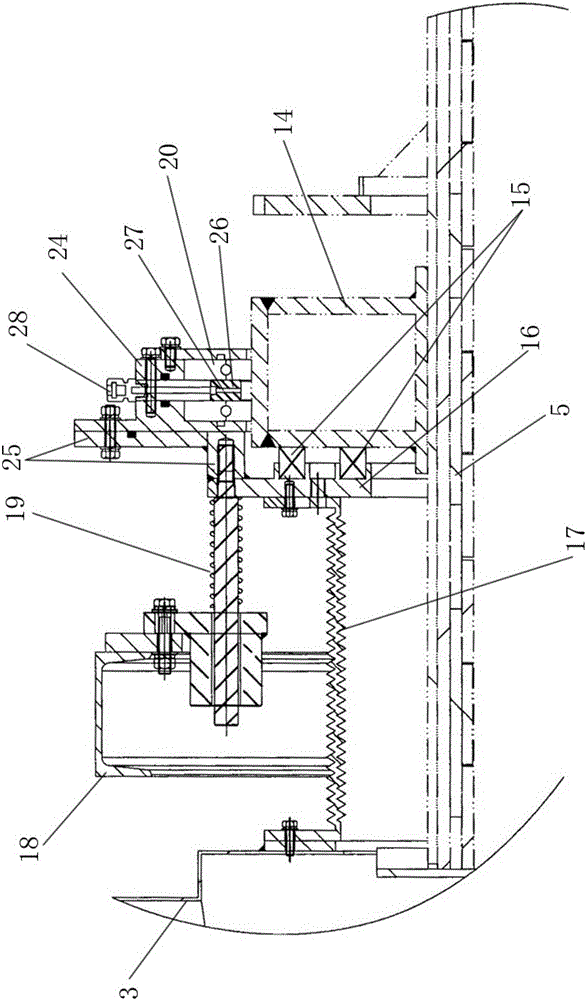

Fatigue tester for paving rotary wheel type bridge

InactiveCN101576457AShorten test timeTest time shortenedMaterial strength using tensile/compressive forcesDrive shaftReduction drive

The invention provides a fatigue tester for paving a rotary wheel type bridge. A concrete base is provided with a motor, a reducer, a driving shaft support, and a height adjustable test piece support, wherein the test piece support is provided with a test piece; the upper end of the driving shaft support is provided with a bearing support; the motor is connected with a driving shaft arranged on the bearing support through the reducer; and the driving shaft is provided with a rotary wheel which is at least provided with an axle along the circumferential direction of the same radial direction, and each axle is provided with one or two automobile wheels rolling on the test piece, and a loading mechanism connected with the rotary wheel. The tester really simulates the loading condition of an automobile on the road surface, overcomes the defects of untrue test data, long testing time and low work efficiency existing in the prior tester, and can greatly shorten the testing time and improve the work efficiency. The tester has the advantages of reasonable design, simple structure, short testing time, low testing expense and the like, and can simulate the actions of automobiles with different loads on the road surface at different temperatures.

Owner:张志宏

Method for large-scale breeding non-toxic myzus persicae

ActiveCN103004705AReduce the risk of primary infestationAvoid carryingPlant genotype modificationAnimal husbandryNicotiana tabacumTobacco mosaic virus

The invention discloses a method large-scale breeding non-toxic myzus persicae. A tobacco material resistant to TMV (Tobacco Mosaic Virus) and PVY (Potato Virus Y) is used as a breeding host of aphids. After seedling growing or potting or transplanting, the aphids are artificially bred in a net house or a greenhouse, and a double-resistant strain with a high aphid breeding efficiency is selected to be used for breeding non-toxic aphids. The method adopts the tobacco material resistant to the TMV and the PVY to breed the aphids and can effectively reduce the potential risk of the aphids carrying virus diseases under the condition that the current aphid parasitoid breeding process and the cost are not increased. The method has the characteristics of simplicity, convenience and easiness in operation, economy, reliability and the like and can promote popularization and application of aphid parasitoid control crop aphids.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

Plastic, film semic-enclosing package method for steel roll

The plastic film semi-enclosed packing method used in the steel coil belongs to the steel material packing, especially relates to the steel coil anti water and rust packing product. The method includes the below processes: the steel coil is transformed on the platform laid with the anti-rust paper, the under is hollow; the steel coil is packed with the anti-rust paper; the steel coil is set with the plastic film which through the steel coil eye and pull the plastic film which the two ends are rolled on the out surface of the steel coil; the two ends of the plastic film are plastered on the anti-rust paper by the adhesive tape; the semi-enclosed steel coil is transformed to the packing board. The advance of it is: it has new idea and meets for the packing quality; the process is simple and cost little time, decrease the energy cost and improve the work efficiency; the plastic film is covered at the steel coil end and the length is shortened, the dosage is decreased; also it has safe operation when working beside the platform.

Owner:安徽马钢和菱实业有限公司

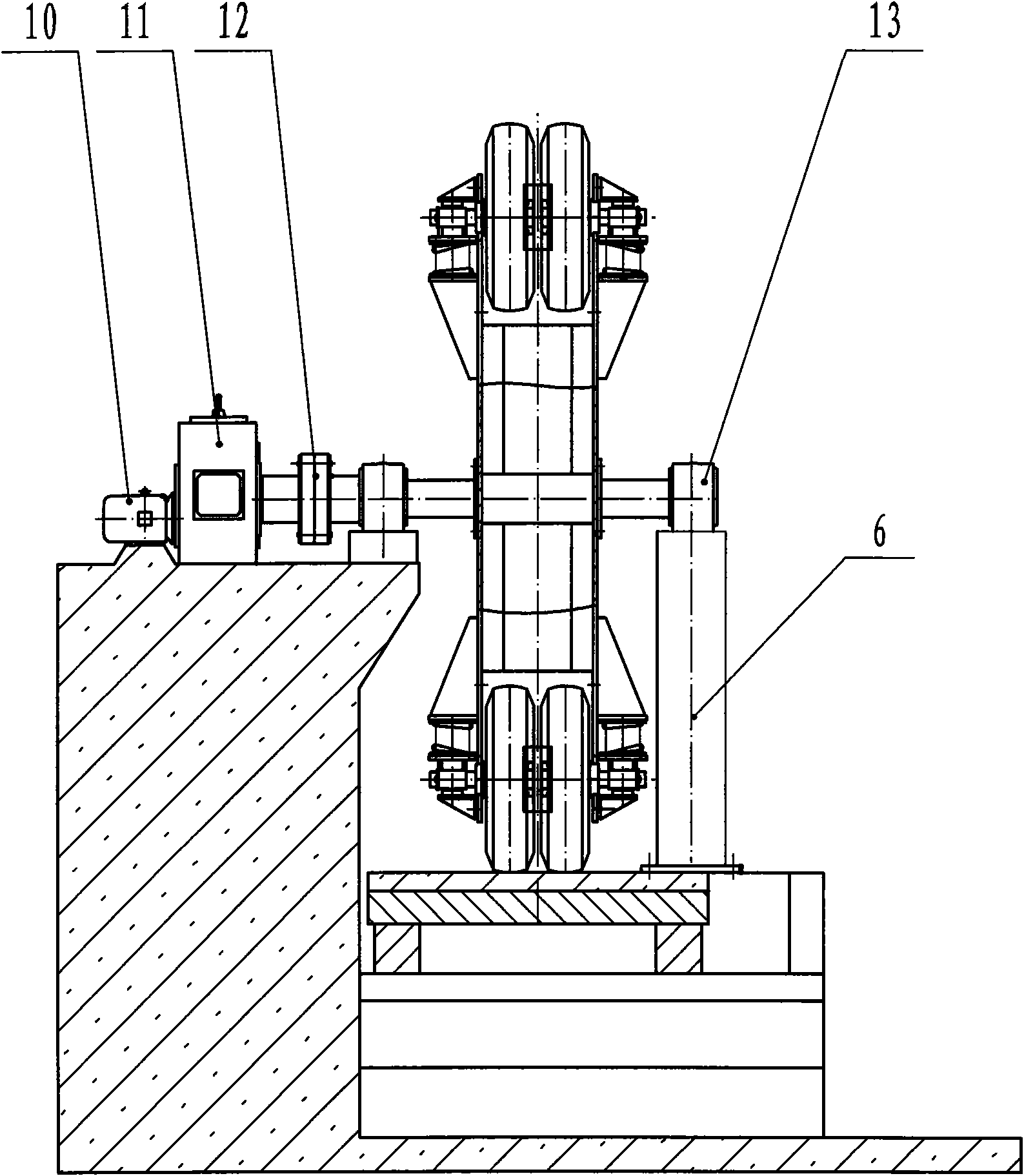

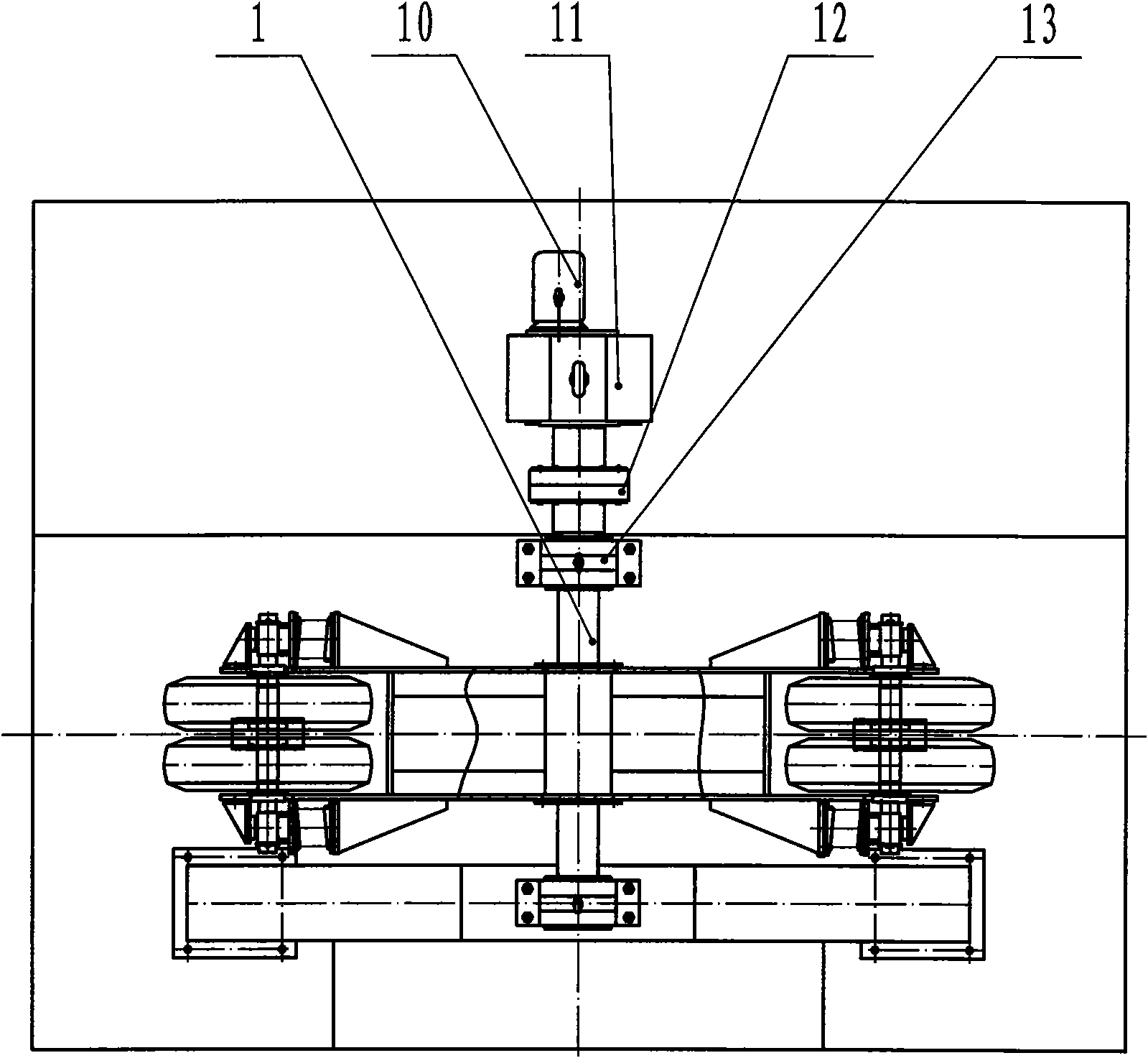

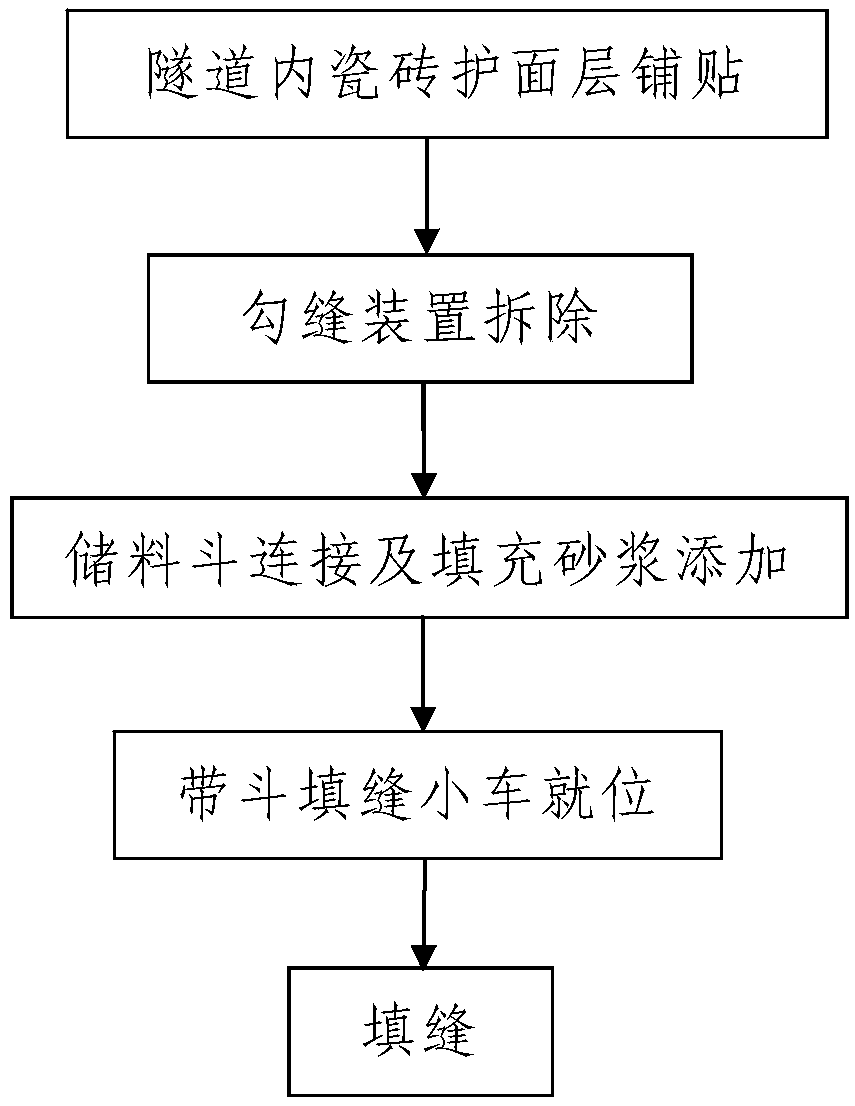

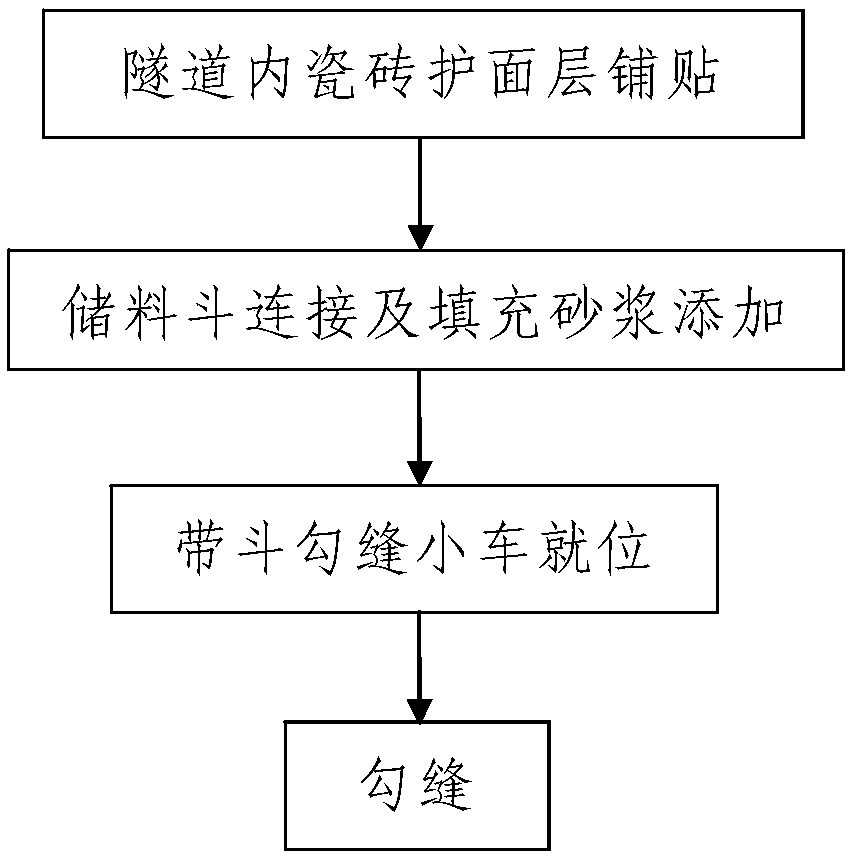

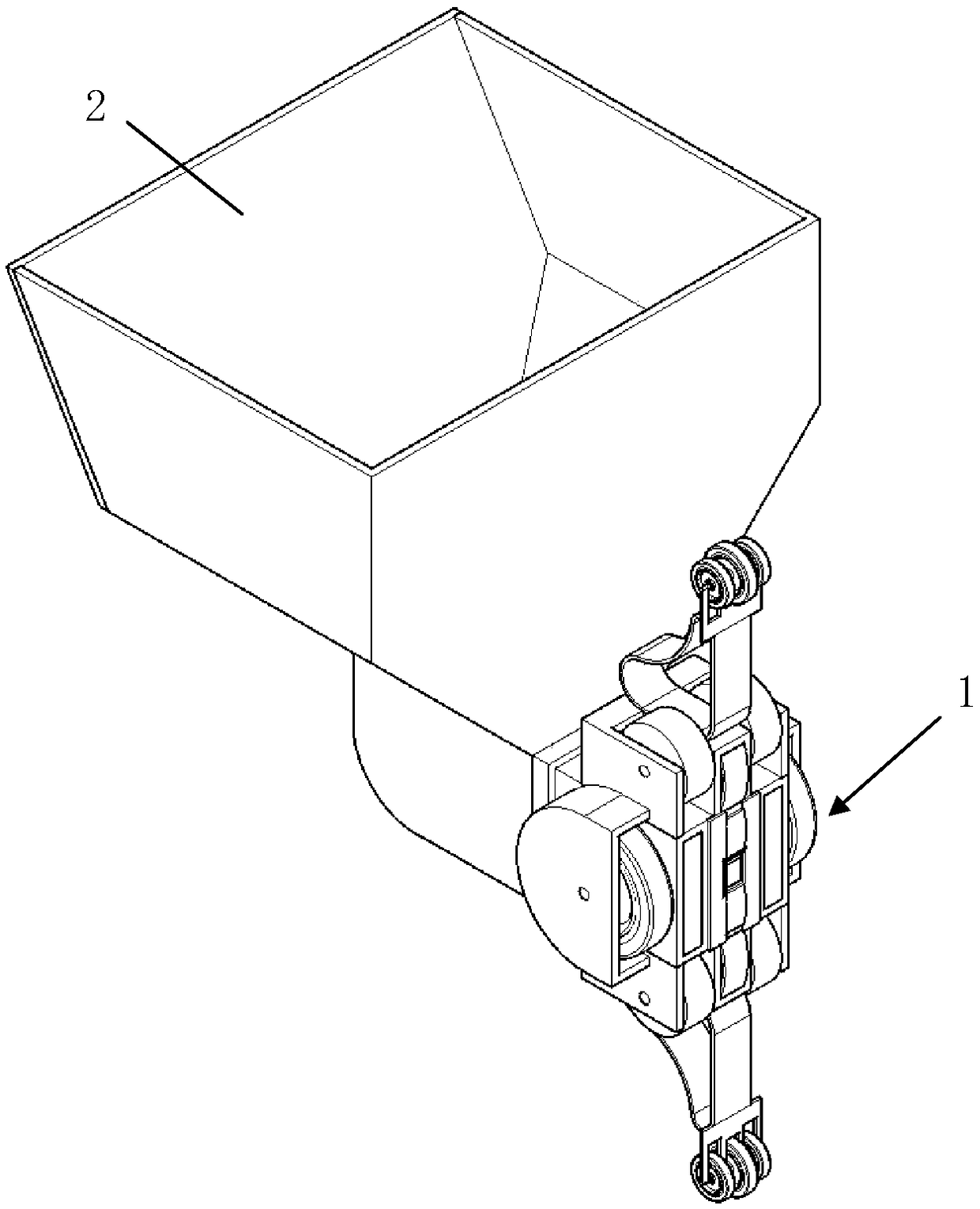

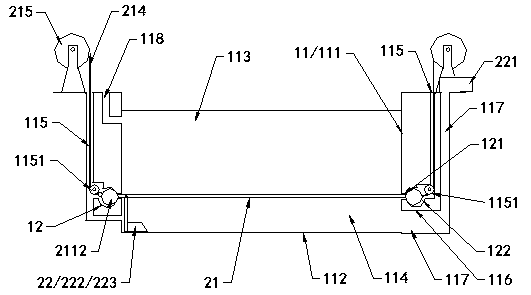

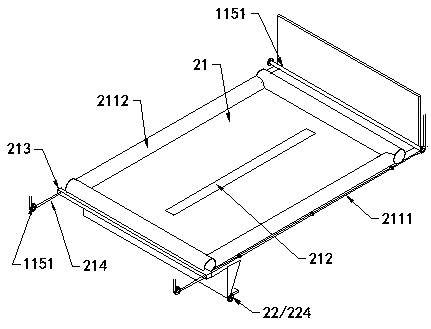

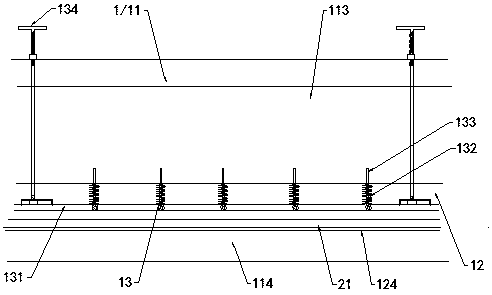

Caulking and jointing construction method for brick joints of tiles in tunnel

ActiveCN109296184AThe method steps are simpleReasonable designBuilding constructionsBrickMechanical engineering

The invention discloses a caulking and jointing construction method for brick joints of tiles in a tunnel. The caulking and jointing construction method is characterized in that a brick joint caulkingand jointing device is adopted to caulk or joint the brick joints of the tiles in the tunnel; the brick joint caulking and jointing device includes a caulking and jointing trolley capable of moving back and forth on the surface of a masonry structure and a storage hopper for storing filling mortar which is used for filling the brick joints; when caulking is actually performed, the steps of jointing device removal, storage hopper connection, filling mortar adding, being-in-place of a caulking trolley with a hopper and caulking are included; and when jointing is actually performed, the steps ofstorage hopper connection, filling mortar adding, being-in-place of a jointing trolley with a hopper and jointing are included. The caulking and jointing construction method has reasonable design, simple and convenient construction, high construction efficiency and good use effect, the movable brick joint caulking and jointing device is used for caulking or jointing the brick joints, the fillingmortar can be automatically fed into the treated brick joints, compaction and groove pressing forming can be performed on the filling mortar fed into the brick joints, and the quality of caulking andjointing can be ensured.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

Sedimentation tank desilting device

ActiveCN109045781AGuaranteed not to be cloudyNo change in water pressureSettling tanks feed/dischargeEngineeringSediment

The invention discloses a sedimentation tank desilting device. Annular groove passageways are formed in the lower section of a sedimentation tank; an isolating cloth membrane moves along the groove passageways in the two sides of a tank body after being drawn and can cover a silting layer at the bottom of the tank or wind one end of the tank body; clamping pieces on the periphery of the isolatingcloth membrane are clamped and sealed with the groove passageways in the corresponding positions; a desilting piece is arranged on the silting layer at the bottom of the tank. The sedimentation tank desilting device is different from a conventional desilting mode; the isolating cloth membrane can be drawn and can cover at the upper end of the silting layer in the state that stagnant water and sediment silt in the tank coexist; the periphery of the isolating cloth membrane and the groove passageways in the tank body are sealed and clamped to separate clean water from the silt in the tank body;flow state silt is scraped away or pumped away by a pump after the desilting piece stirs or flushes in the silting layer; when desilting is performed, the stagnant water and the silt are prevented from being mixed; water pressure does not change; work efficiency is reduced; the investment is low; a new desilting way is created.

Owner:崔璨

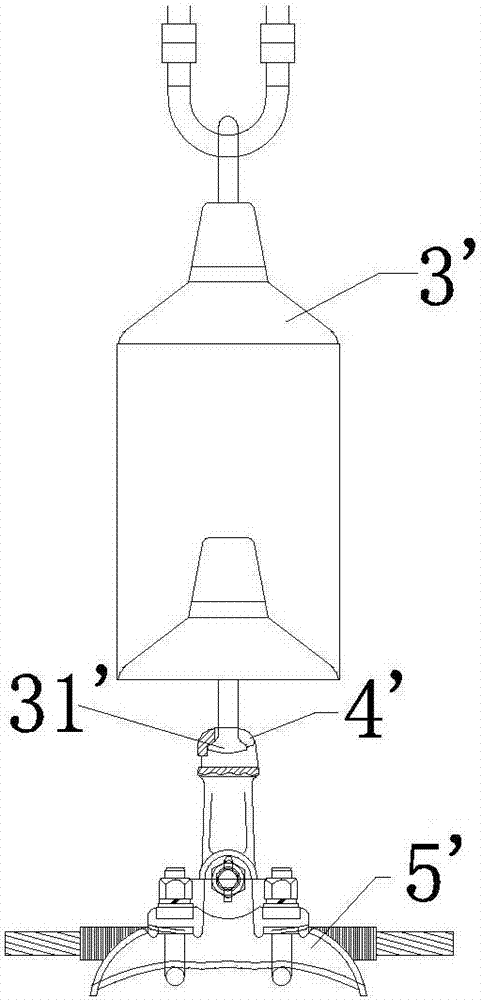

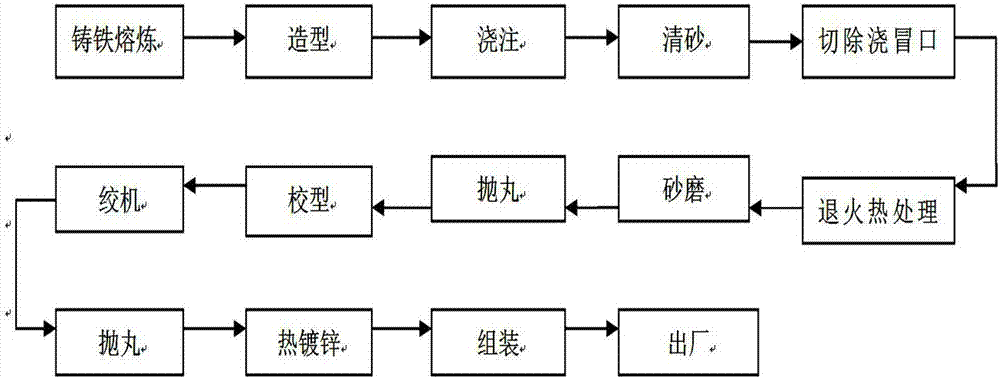

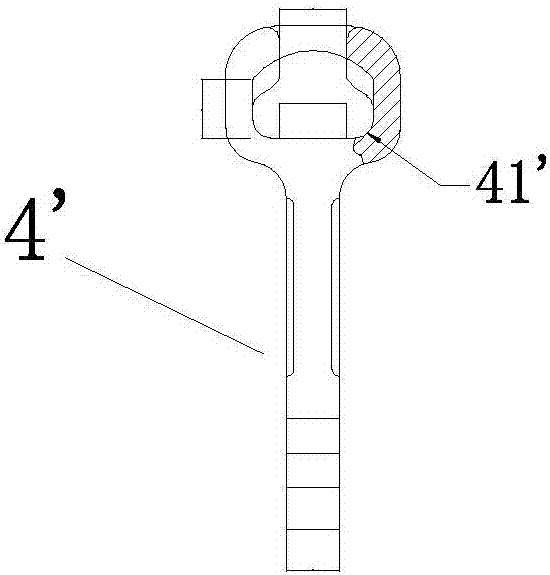

Processing method for forged socket clevis

ActiveCN107234198ASimple structural designSolve the mechanical strengthMetal-working apparatusPunchingUltimate tensile strength

The invention provides a processing method for a forged socket clevis. The processing method is characterized by comprising the following processes of: A, feeding; B, upsetting to prepare blank; C, integrally forging a product outline; D, cutting raw edges; E, punching socket holes, wherein a dually-linked socket punching mould of the forged socket clevis is adopted; F, grinding burrs; and G, performing hot galvanizing. Carbon structural steel with a trade mark of Q235A is selected during feeding. In order to overcome the defects in the prior art of the socket clevis, materials are reasonably selected, the product structural design is improved, and casting is changed into an integral forging production process; and the mould is selected to solve the problem that product mechanical strength is affected by casting internal defects and the problems that a production process is high in energy consumption, has pollution on environment, and is low in working efficiency.

Owner:SICHUAN PROVINCE FUXING ELECTRIC MFG CO LTD

Intelligent processing robot of stainless steel tube

ActiveCN109128364AEnsure safetyRealize automatic cutting productionMetal sawing devicesMetal sawing accessoriesAgricultural engineeringSteel tube

The invention relates to an intelligent processing robot of a stainless steel tube. The intelligent processing robot comprises a bottom plate, a conveying device, a cutting and feeding device, a sleeve type fixing device, a cutting device, a clamping device, an adsorption and cleaning device and a stainless steel hollow tube body, wherein the conveying device, the cutting and feeding device, the sleeve type fixing device, the cutting device and the clamping device are installed on the bottom plate in sequence from left to right, and the adsorption and cleaning device is installed on the bottomplate. According to the intelligent processing robot, the problems that a multi-caliber stainless steel hollow tube cannot be preferably clamped and fixed when the stainless steel hollow tube is cutin the prior art, sweeps which are generated when the stainless steel hollow tube is cut cannot be preferably prevented from splashing and hurting people, people need to wear protective equipment forprotection, the sweeps which are generated in a cutting process need to be manually cleaned and collected so as to be recycled and the people are easy to hurt by the sweeps which are generated when the stainless steel hollow tube is manually cut can be solved.

Owner:泰州市银杏舞台机械工程有限公司

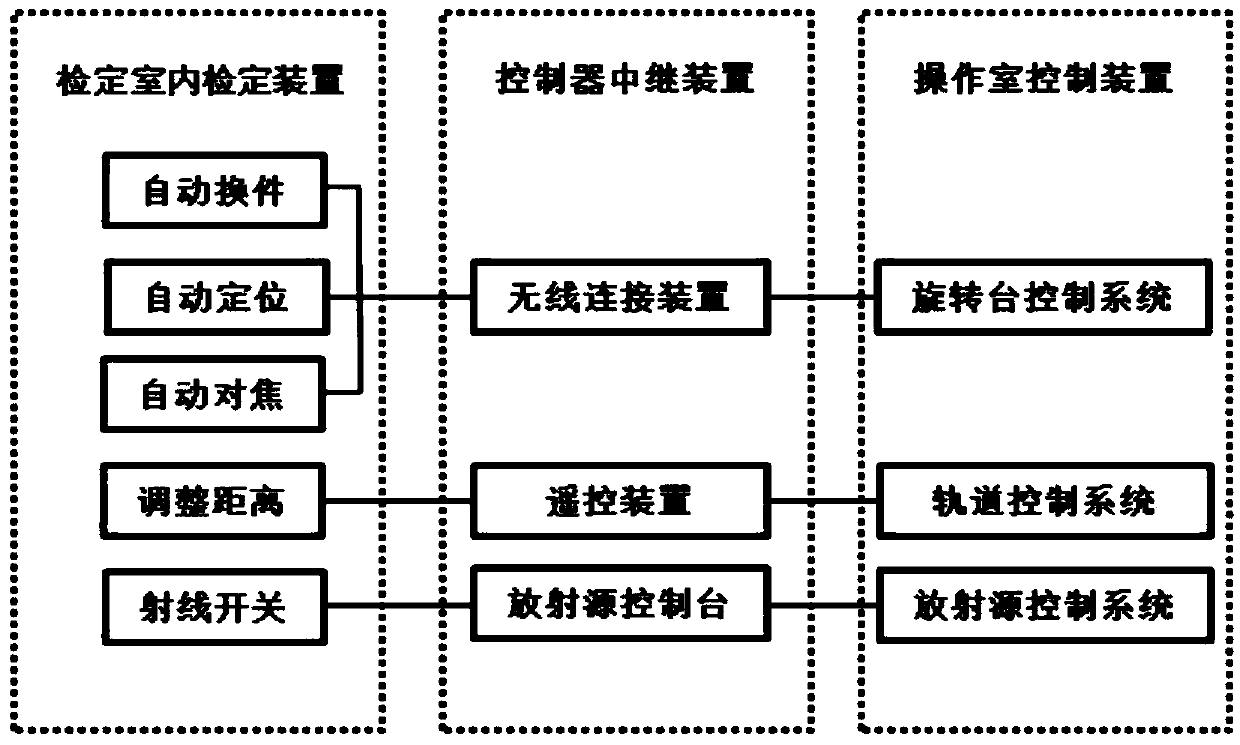

Ionization radiation protection instrument verification bench automatic control system

PendingCN107703536AImprove efficiencyImproving the Efficiency of Metrological Verification WorkRadiation measurementAutomatic controlIonization

The invention relates to an ionization radiation protection instrument verification bench automatic control system. The system includes a rotatable horizontal table, a drive motor, a positioning frameequipped with tested instruments, and a fast binding device. The rotatable horizontal table is engraved with coordinates and a scale. The rotatable horizontal table can rotate each tested instrumentto a verification point to make the tested instrument aligned with a radiation source through automatic control or manual control. The verification point on the rotatable horizontal table is monitoredthrough a camera. A rotary table capable of being controlled by a program and controlled remotely is adopted. Multiple instruments needing verification are firmly placed in corresponding positions ofthe rotary table in advance. The tested instruments are automatically replaced and positioned in turn through program control by the staff. The measurement and operation in the whole process is completed through remote control. The staff does not need to go into and out of a verification room repeatedly. The work efficiency and the accuracy of measurement are greatly improved.

Owner:JIANGSU INST OF METROLOGY

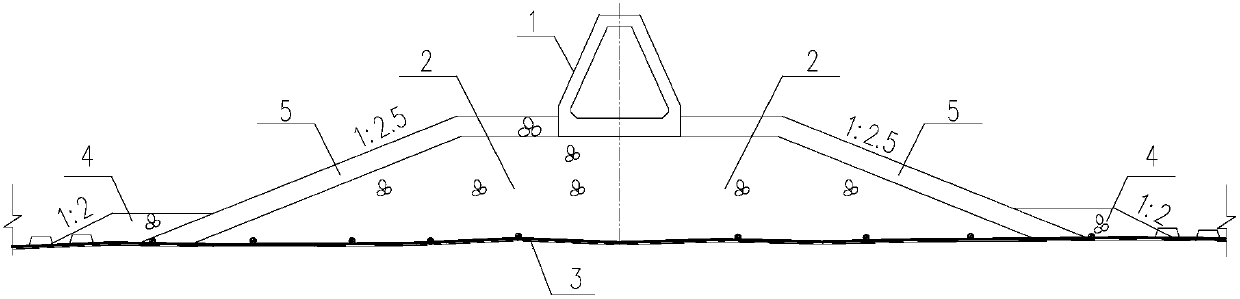

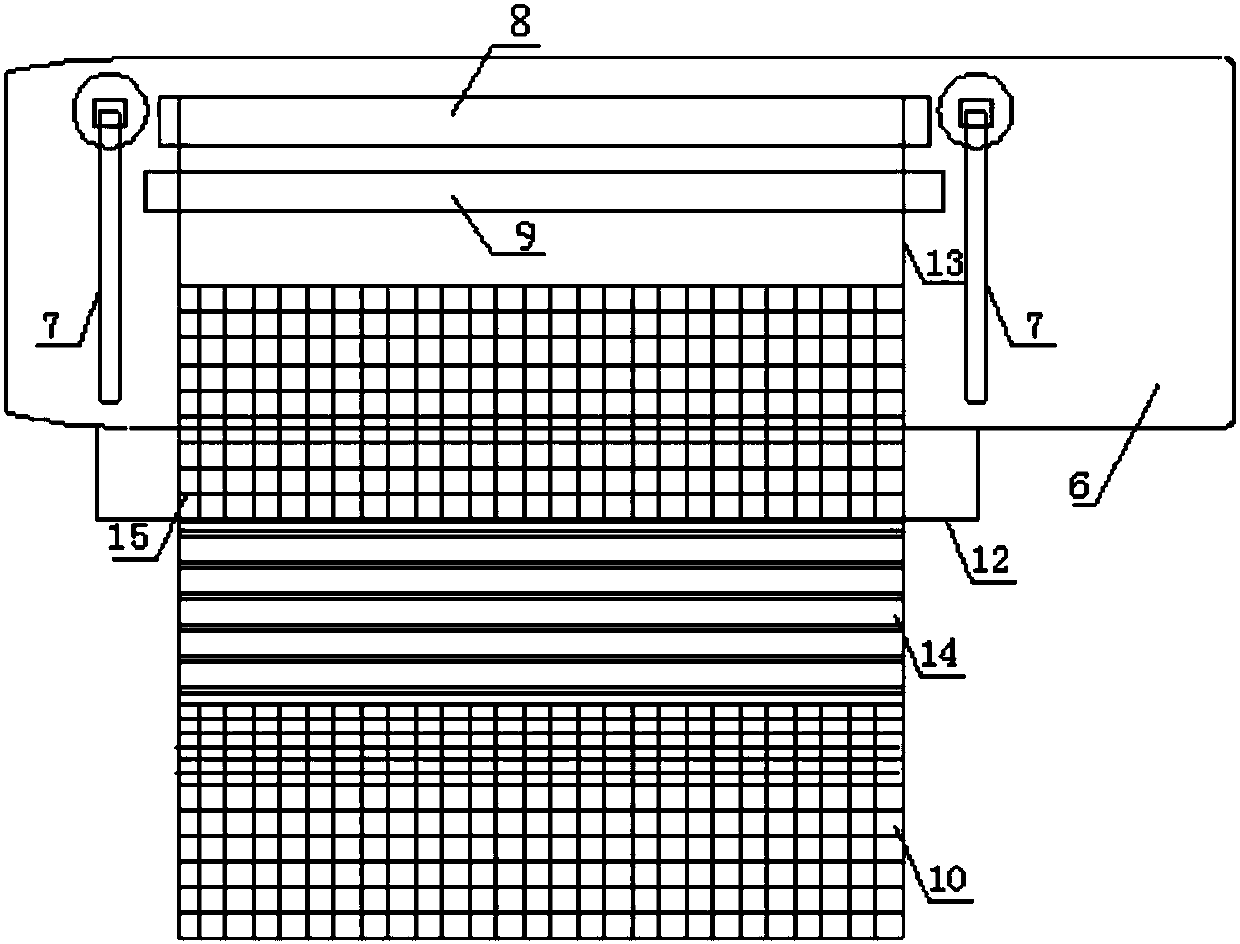

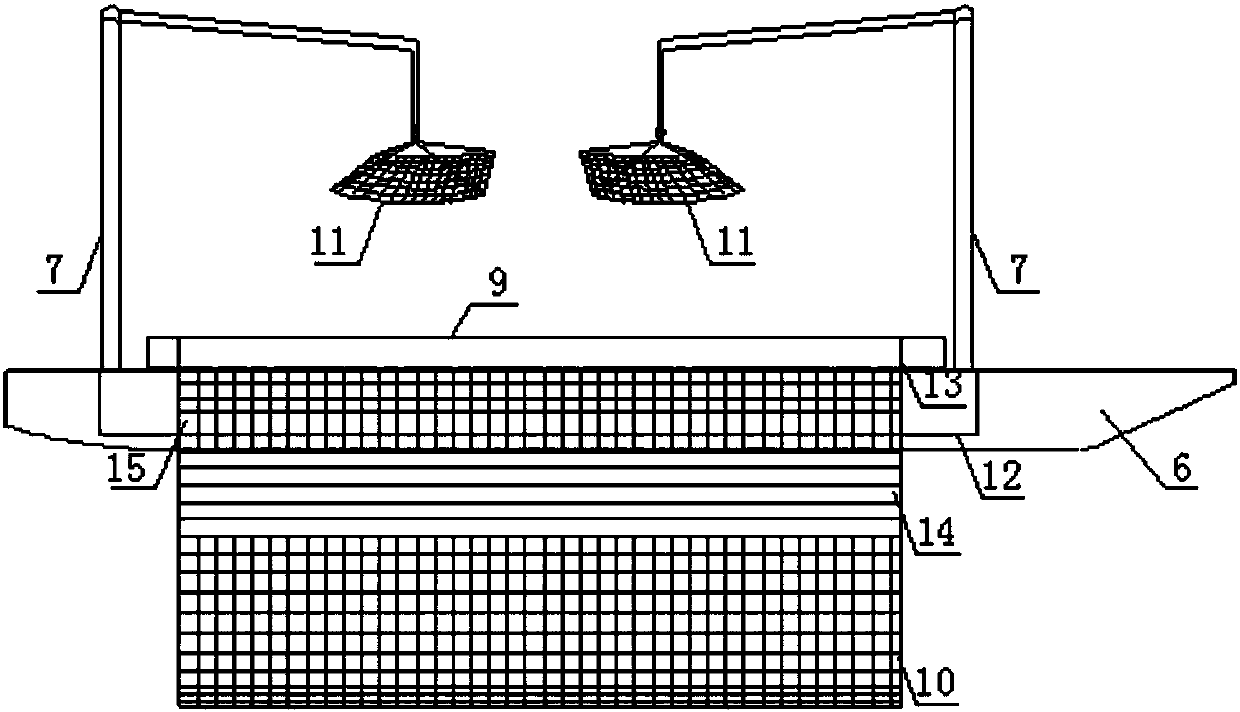

Construction method of deep water mixed embankment

ActiveCN107938594ALow work efficiencyGuaranteed accuracyDamsBreakwatersSoftwareBuilding construction

The invention discloses a construction method of a deep water mixed embankment. The mixed embankment includes a trapezoidal hollow component, a rock rip-rap foundation bed, a sand rib and concrete interlock block mixed software platoon, spats stones, and shoulder stones. The construction method includes the following steps of one, layout of the sand rib and concrete interlock block mixed softwareplatoon; two, rock rip-rap on water; three, foundation bed leveling; four, trapezoidal hollow component arranging; and five, rip-rap and filling of the spats stones and the shoulder stones. The construction method of the deep water mixed embankment solves the problems that precision is low and loss amount is high in deep water foundation bed rock rip-rap; efficiency of leveling and component prefabricating is low; accuracy of component arranging is low; the overall mechanization degree is low; and an overall construction process is not cohesive.

Owner:CCCC SECOND HARBOR ENG

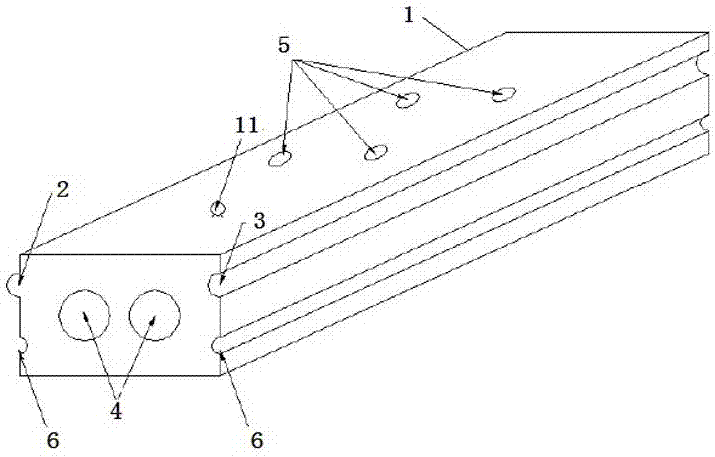

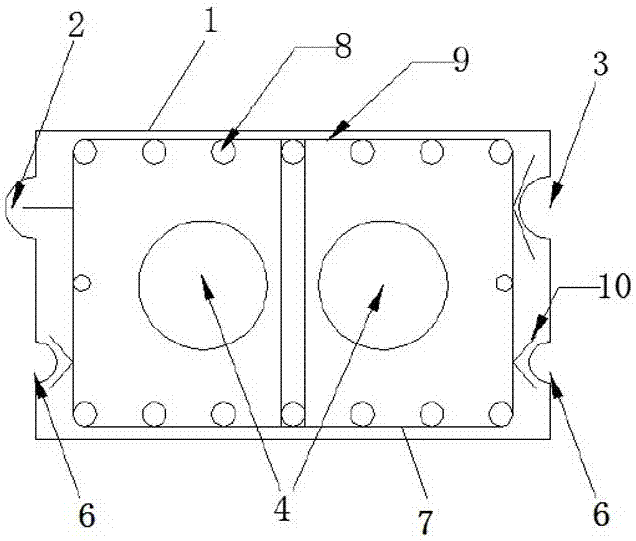

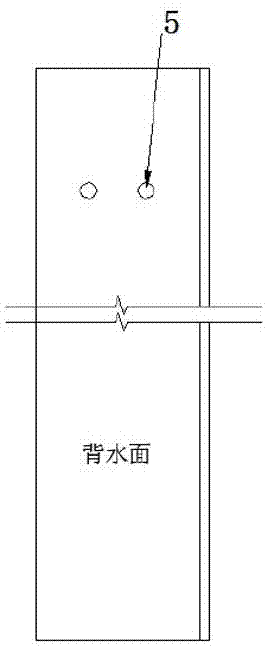

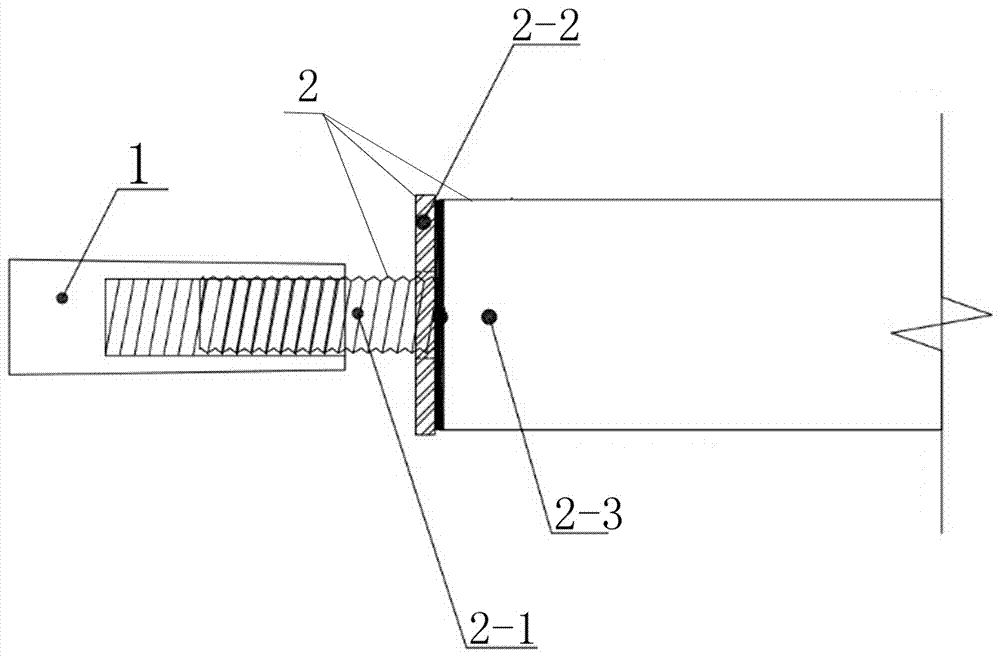

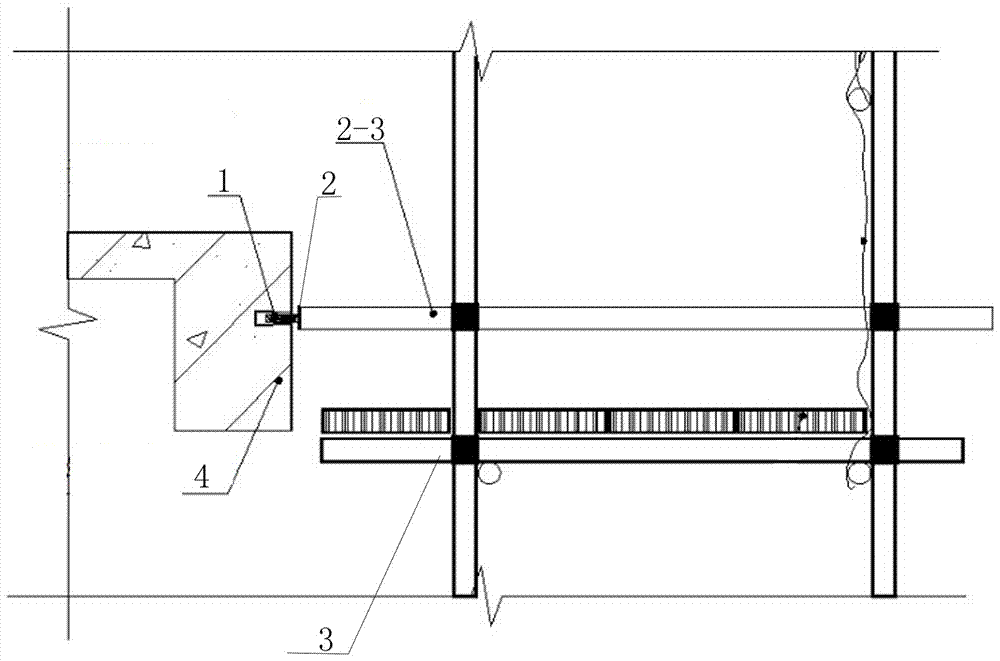

Pre-tensioning prestressed concrete porous hollow ecological pile and construction method thereof

PendingCN107059856ALow costHigh implementabilityCoastlines protectionBulkheads/pilesEcological environmentPre stress

The invention relates to a pre-tensioning prestressed concrete porous hollow ecological pile and a construction method thereof. The pre-tensioning prestressed concrete porous hollow ecological pile is characterized by comprising a pile body with a rectangular section as well as a tenon and a mortise trough which are connected and are correspondingly arranged at the sides of two short sides of the pile body; at least one hollow hole is longitudinally formed in the pile body; and an ecological through hole communicating with the hollow hole is formed in the side of the long side of the pile body. The pre-tensioning prestressed concrete porous hollow ecological pile has the advantages that the favorable bending resistance required in the supporting engineering is realized by a section way and a stress way; and due to the adoption of a grouting groove, the on-site construction is high in operability, the assembly degrees of members and the operation efficiency are high, the structural integrality and the construction quality can be guaranteed, the construction cost can be reduced, the construction effect of the engineering is good, the soil retaining and water stopping functions are achieved, and the existing defence pile wall structure can be replaced. In addition, the water power relationship between a water body and a soil body at the bank side is guaranteed, the flowability of nutrients and energy is favorably realized, and a bank protection member plays roles in retaining a slope and keeping the balance of an ecological environment.

Owner:福建省闽工科技发展有限公司

Conical nut wall-linking element of outer wall scaffold

The invention discloses a conical nut wall-linking element of an outer wall scaffold. The conical nut wall-linking element comprises a conical nut body and a wall-linking rod piece which are buried in the side face of a concrete structural beam / slab / column. The wall-linking rod piece is composed of a steel pipe, a steel plate and a threaded rod welded to the center of the steel plate. The threaded rod is matched with the conical nut body in specification, and the steel pipe is welded to the steel plate. In the using process, the threaded rod of the wall-linking rod piece and the conical nut body are screwed and fixed, the wall-linking rod piece is fixed to and buckled with an upright tube of the scaffold through a fastener, and thus, the conical nut wall-linking element is connected with the scaffold. The wall-linking element is simple in structure, convenient to operate, high in anti-uplift strength and good in safety property, the cost is reduced, the overall stability of the scaffold can be guaranteed, the working efficiency is improved, and the construction period is shortened.

Owner:桂林建安建设集团有限公司

High-temperature atmosphere rotary kiln with lining pipe of hexagonal structure

The invention provides a high-temperature atmosphere rotary furnace with a hexagonal inner lining tube. Due to the rotation of the furnace tube and the hexagonal inner lining tube of the furnace tube, it can ensure that the material in the furnace tube is heated evenly, so that the entire material The work efficiency of heating and conveying is low and high, which improves the production efficiency of the production line. It includes a bottom plate, a heating shell is arranged on the bottom plate, and the two ends of the heating shell are respectively provided with a hopper and a hopper. The inside of the heating shell is provided with a furnace tube. There are multiple sets of thermocouples. The cross-section of the lining tube of the furnace tube is a hexagonal structure. The inlet and outlet ends of the furnace tube are respectively exposed at the two ends of the heating shell. The two ends of the casing are respectively provided with circular rings at the connection positions, and the circular rings are covered with a rotating bearing structure, and the entrance and exit ends of the furnace tube exposed to the heating shell are respectively fastened with rolling ring structures.

Owner:SUZHOU HUIKE EQUIP CO LTD

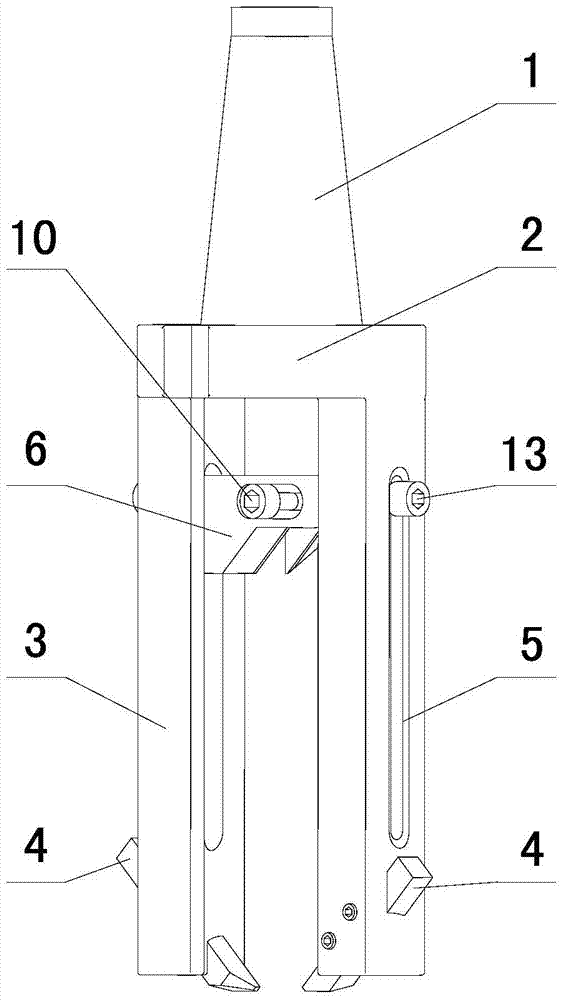

Cylindrical rapid-shaping combined cutter

InactiveCN103692216ASolve many processesLow work efficiencyOther manufacturing equipments/toolsTool bitStructural engineering

The invention discloses a cylindrical rapid-shaping combined cutter. The cylindrical rapid-shaping combined cutter comprises a cutter handle which is arranged on the rotating centerline of the cutter, wherein a cutter frame disc is arranged at one end of the cutter handle, a plurality of tool racks which are used for fixedly arranging machining tools are axially arranged at the outer edge of the cutter frame disc, each tool rack comprises a pair of cutting frames which are arranged at the two sides of the rotating centerline of the cutter, excircle cutting knives, of which knife heads are pointed to the direction of the rotating centerline of the cutter, are arranged at one ends, far away from the cutter frame disc, of the cutting frames, fixing grooves are axially formed in the cutting frames between the cutter frame disc and the excircle cutting knives, and chamfer cutters are arranged between the fixing grooves of the cutting frames at two sides. According to the cylindrical rapid-shaping combined cutter, the problems in the prior art that when an excircle surface of an irregular workpiece is machined, the working procedures are many, the work efficiency is low, the production cost is high and the product quality is difficult to guarantee are effectively solved, and the substantial effects of simple process, high work efficiency, low production cost and good product quality are achieved when the excircle surface of the irregular workpiece is machined by adopting the cylindrical rapid-shaping combined cutter.

Owner:ZHEJIANG GEELY POWERTRAIN CO LTD +3

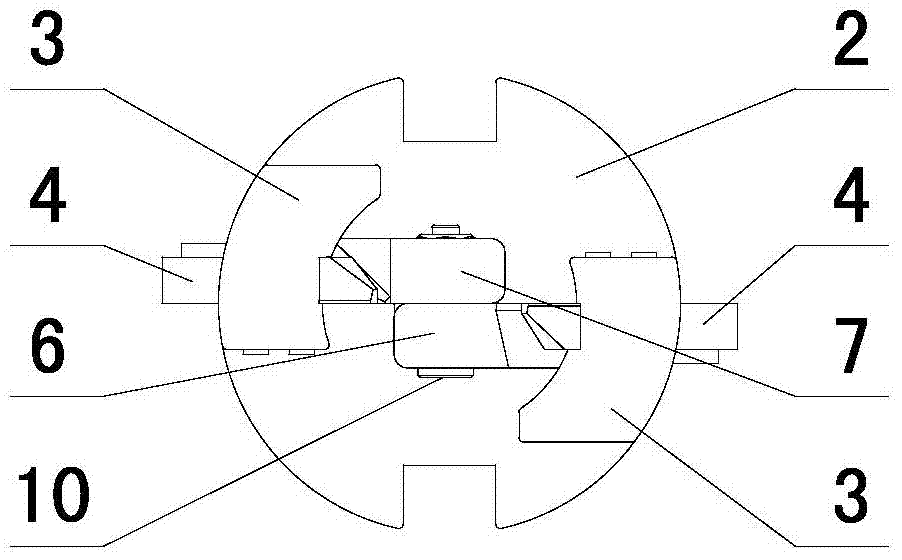

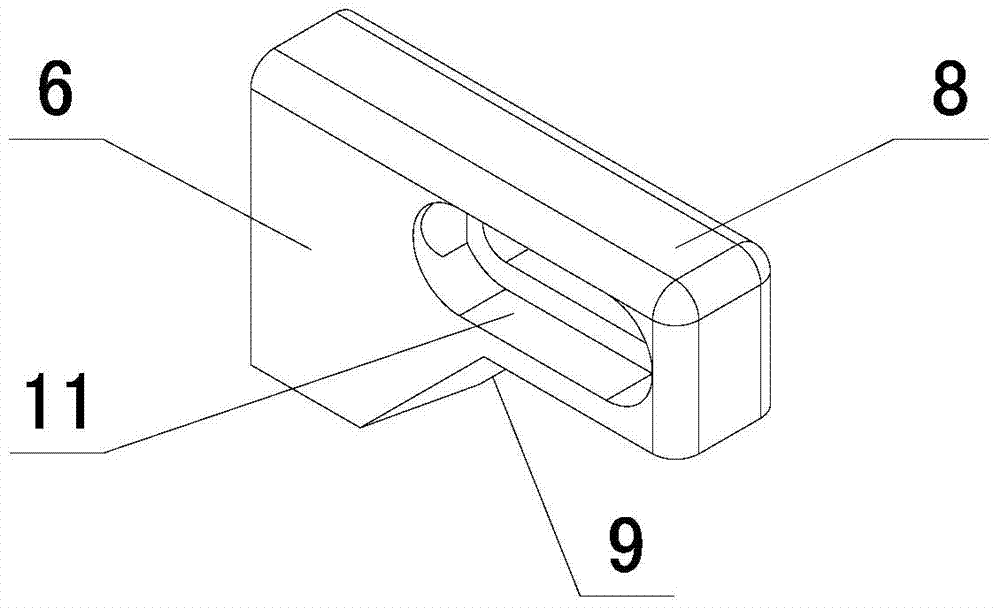

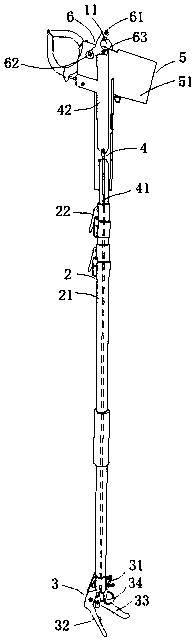

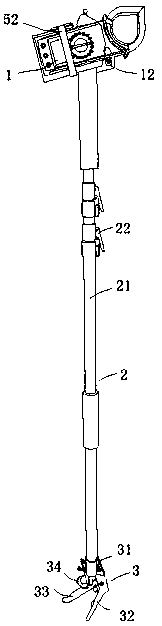

Current measurement device added with lengthened operating handle

PendingCN108508254AImprove work efficiencySafe and fast operationCurrent measurements onlyVoltage/current isolationCurrent meterMeasurement device

The invention relates to the technical field of current measurement instruments, in particular to a current measurement device added with a lengthened operating handle. The current measurement devicecomprises a plier-type current meter and the telescopic operating handle, wherein the plier-type current meter is provided with a jaw button for opening a jaw of the plier-type current meter and a reading button for opening a reading locking key of the plier-type current meter. The plier-type current meter is connected to the top of the operating handle, and a movable handle is connected to the bottom of the operating handle. A transmission mechanism arranged in the operating handle is connected to a movable handle, the movable handle can downward pull the transmission mechanism to extrude thejaw button so as to open the jaw button or upward push the transmission mechanism to extrude the reading locking key so as to lock a reading of the plier-type current meter. When the current measurement device is used, an operator can achieve jaw button or reading button pressing by tightening or loosening the movable handle on the ground and does not need climbing rods for climbing a tower to approach wires and measure current, the current measurement device is safe and quick to operate and high in working efficiency, saves time and labor and can avoid electric shock and falling risk.

Owner:GUANGDONG POWER GRID CO LTD SHANTOU POWER SUPPLY BUREAU

Low-noise lubricating grease and preparation method and application thereof

ActiveCN104087395AReasonable formulaImprove work efficiencyLubricant compositionLow noiseLithium hydroxide

The invention discloses a low-noise lubricating grease and a preparation method and application thereof. According to the technical scheme, the low-noise lubricating grease is characterized by being prepared from the following raw materials in parts by weight: 65-85 parts of base oil, 10-15 parts of C12-C22 hydroxy fatty acid, 3-9 parts of lithium hydroxide, 2-7 parts of boric acid and 4-8 parts of multi-effect additives. The invention also discloses the preparation method of the low-noise lubricating grease and an application of the low-noise lubricating grease in a high-accuracy micro mechanical bearing. The low-noise lubricating grease disclosed by the invention is reasonable in formula and high in production efficiency. According to the low-noise lubricating grease and the application thereof disclosed by the invention, the low-noise lubricating grease is ground by using a patent product grinding machine (a patent number: ZL201220281084.7) of the company, the particle diameters of mechanical impurities contained in the lubricating grease are controlled to be smaller than that of the prior art, the vibration decibel value of the micro mechanical bearing is less than that of the lubricating grease in the prior art, the operation accuracy of the micro mechanical bearing is ensured, the vibration and the abrasion are reduced, the vibration decibel value of the micro mechanical bearing is less than 40, and the mechanical impurities contained in the lubricating grease are smaller than 2 micrometers.

Owner:XINXIANG HENGXING TECH CO LTD

Cutting, splitting and breaking transformation construction method for existing overall ballast bed of subway

InactiveCN105350408AReduce construction costsEasy to operateRailway track constructionRebarDrill hole

The invention discloses a cutting, splitting and breaking transformation construction method for an existing overall ballast bed of a subway. The method includes the steps that the ballast bed is perpendicularly cut on a concrete ballast bed plate in the longitudinal direction of a line within the distance of not larger than 3.6 cm through a wall saw, and cutting is conducted to the depth that the part between a concrete face to steel bars is cut off but a pipe piece is not damaged; then, a coring drilling machine is used for drilling along a cutting line, the number of drill holes is 2-6, the diameter of the drill holes is determined according to requirements, the depth of the holes is determined according to the requirement of a splitting bar, the hydraulic splitting bar is inserted into the drill holes to adjust the splitting direction, and pressurizing expanding is conducted until the plate disengages from a pipe wall; and finally, a cantilever crane in a subway tunnel is used for craning the existing broken plate and conducting construction to newly lay a floating plate, and accordingly the transformation of the existing ballast bed is completed. The method is low in construction cost, easy to operate, high in construction speed and low in noise, construction is not stopped on an operation line, safety and reliability are achieved, and the requirements for urban civilized construction, operation line transportation, operation line safety and construction efficiency are met. The popularization prospects are wide.

Owner:CHINA TIESIJU CIVIL ENG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com