Caulking and jointing construction method for brick joints of tiles in tunnel

A construction method and technology in tunnels, which are applied in the direction of construction and building construction, can solve the problem that manual filling and pointing cannot meet the needs of large-area filling and pointing construction, the compactness and depth quality of filling and pointing Problems such as unevenness, façade and wall mortar flow, slide and fall, etc., achieve the effect of simple equipment processing and installation, reducing construction labor input, and reducing waste of power resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

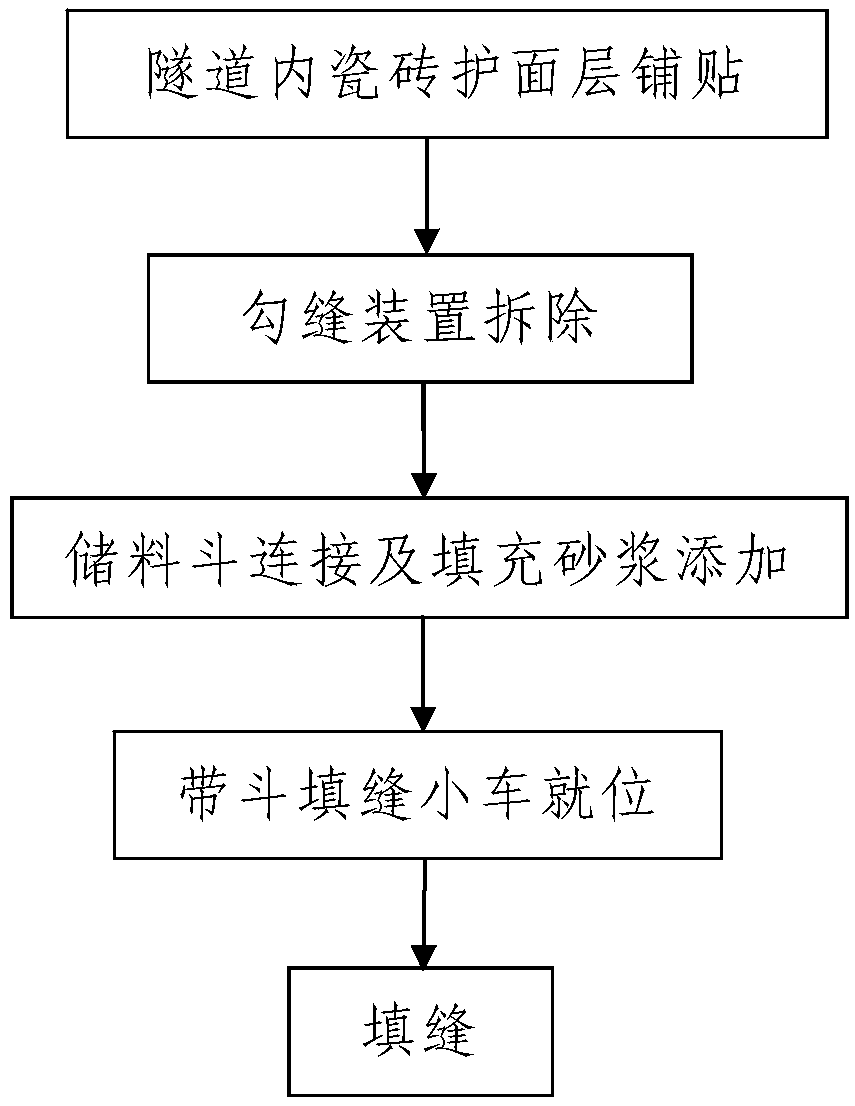

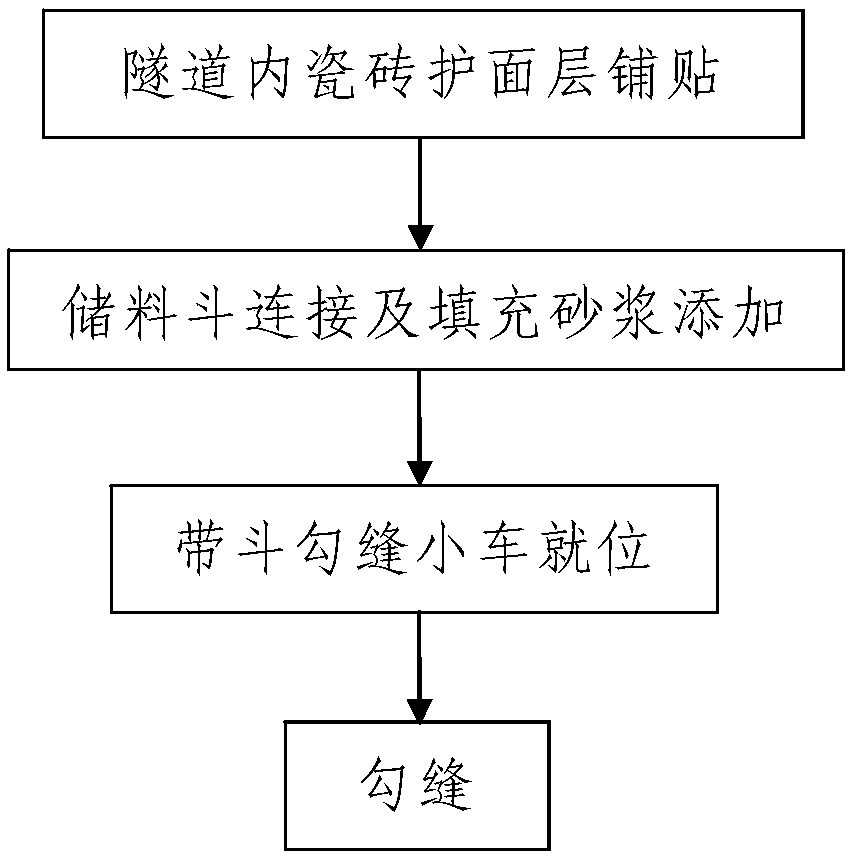

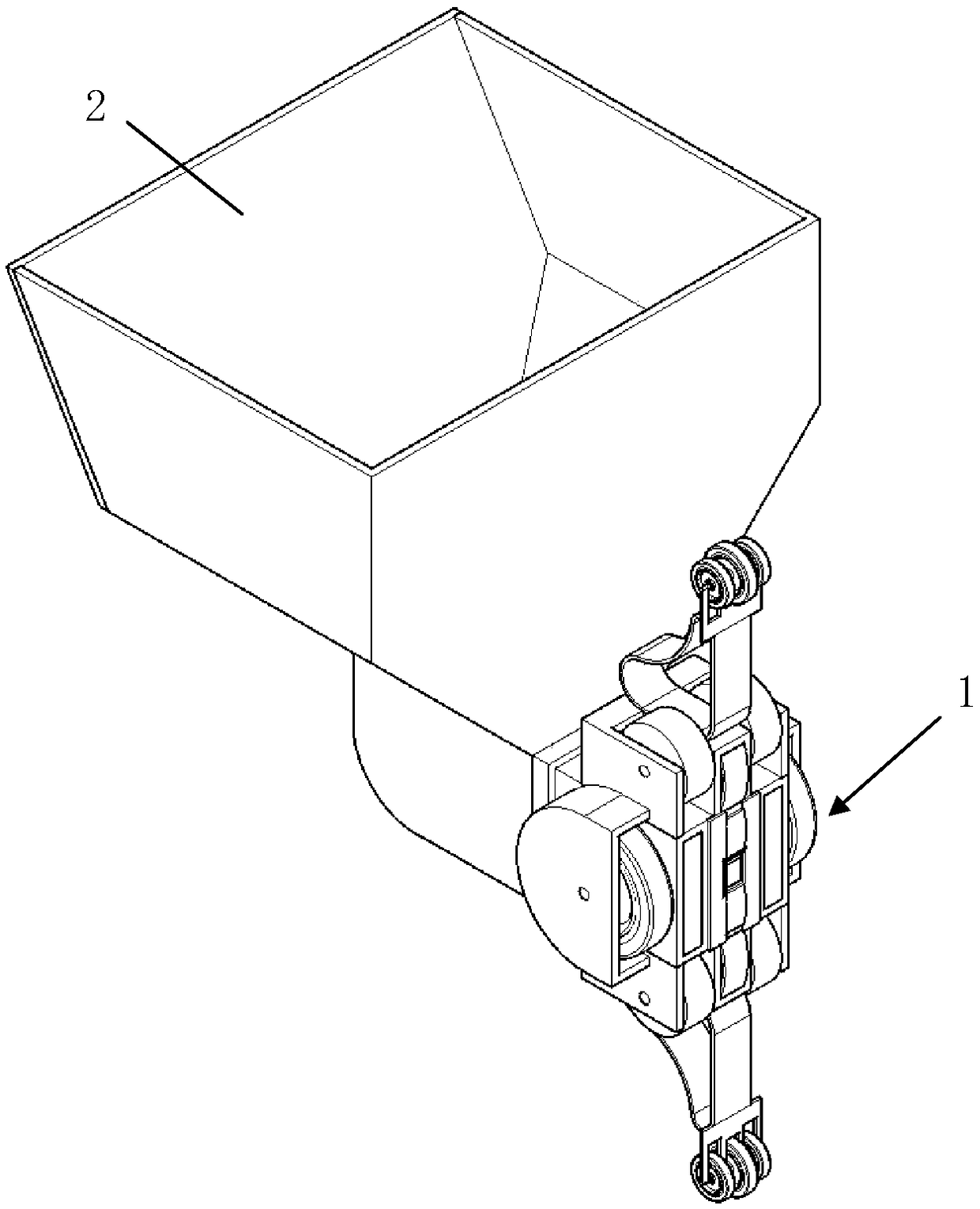

[0081] Such as figure 1 , figure 2 As shown, a kind of construction method for filling and pointing joints of tiles in a tunnel according to the present invention uses a brick joints filling and pointing device to fill or point the joints of tiles in a tunnel, and the brick joints are filled The structure of seam and pointing device is detailed in image 3 and Figure 4 The tile joints in the tunnel are the tile joints in the tile paving layer in the tunnel, and the tile paving layer is formed by laying multiple tiles, and the multiple tiles are arranged in multiple rows and columns; The tile joints are the horizontal joints between the upper and lower adjacent rows of tiles in the tile laying layer or the vertical joints between the left and right adjacent rows of the tiles;

[0082] Such as image 3 , Figure 4 As shown, the brick joint filling and jointing device includes a joint filling and jointing trolley 1 capable of moving back and forth on the surface of the mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com