Patents

Literature

813 results about "Rock tunnel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

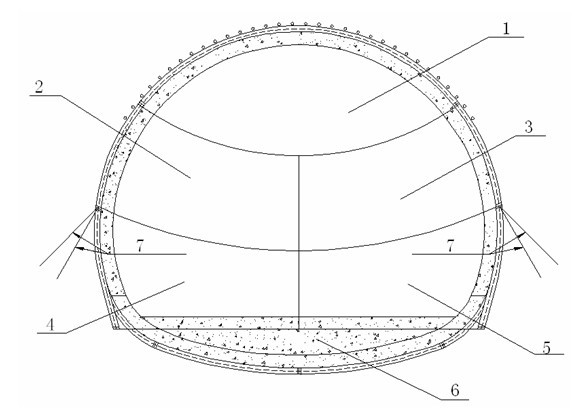

Construction method of V-level surrounding rock tunnel

InactiveCN101614125AAvoid defects such as cavity collapseRealize safe constructionUnderground chambersTunnel liningRock tunnelTunnel wall

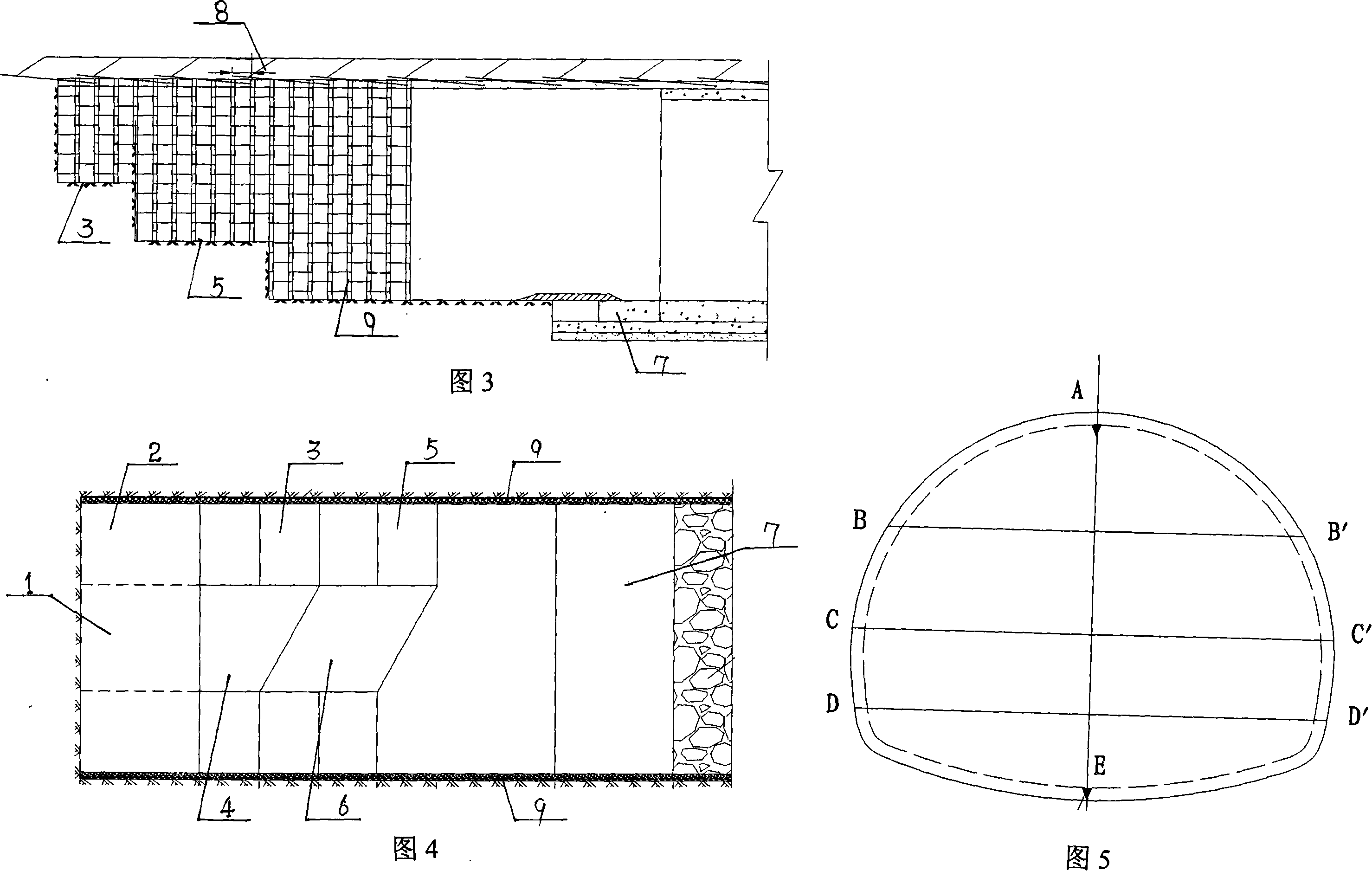

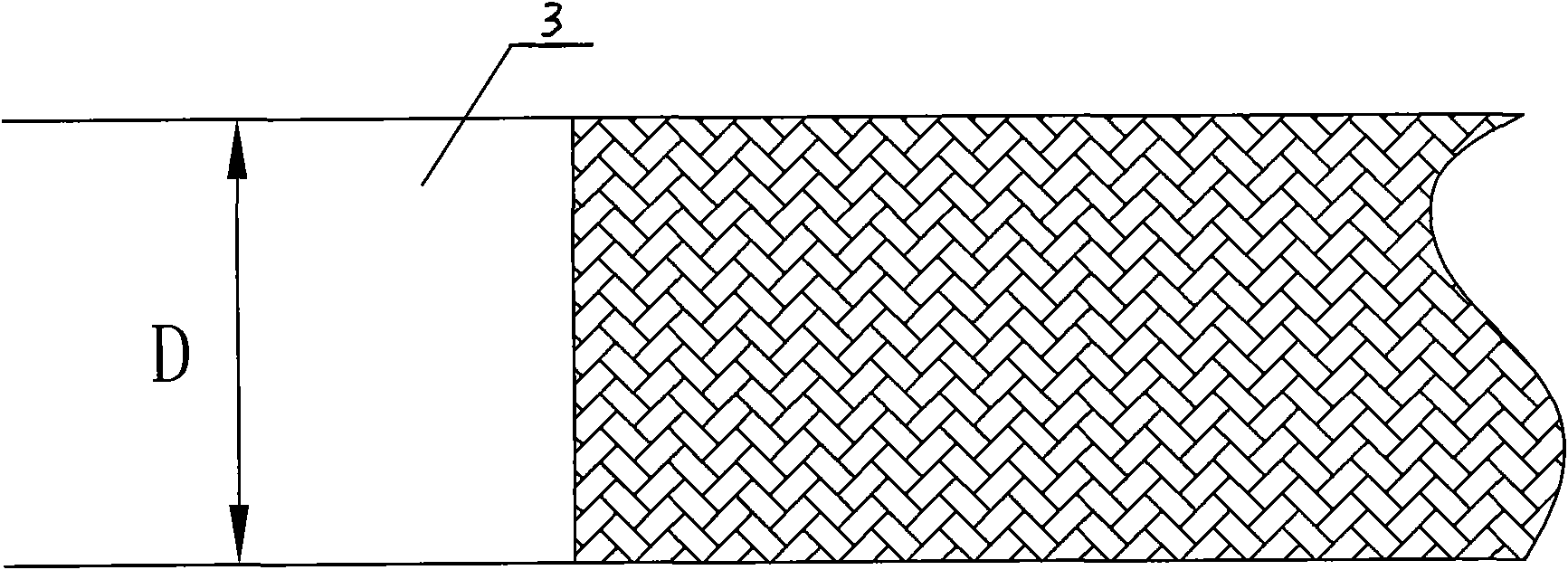

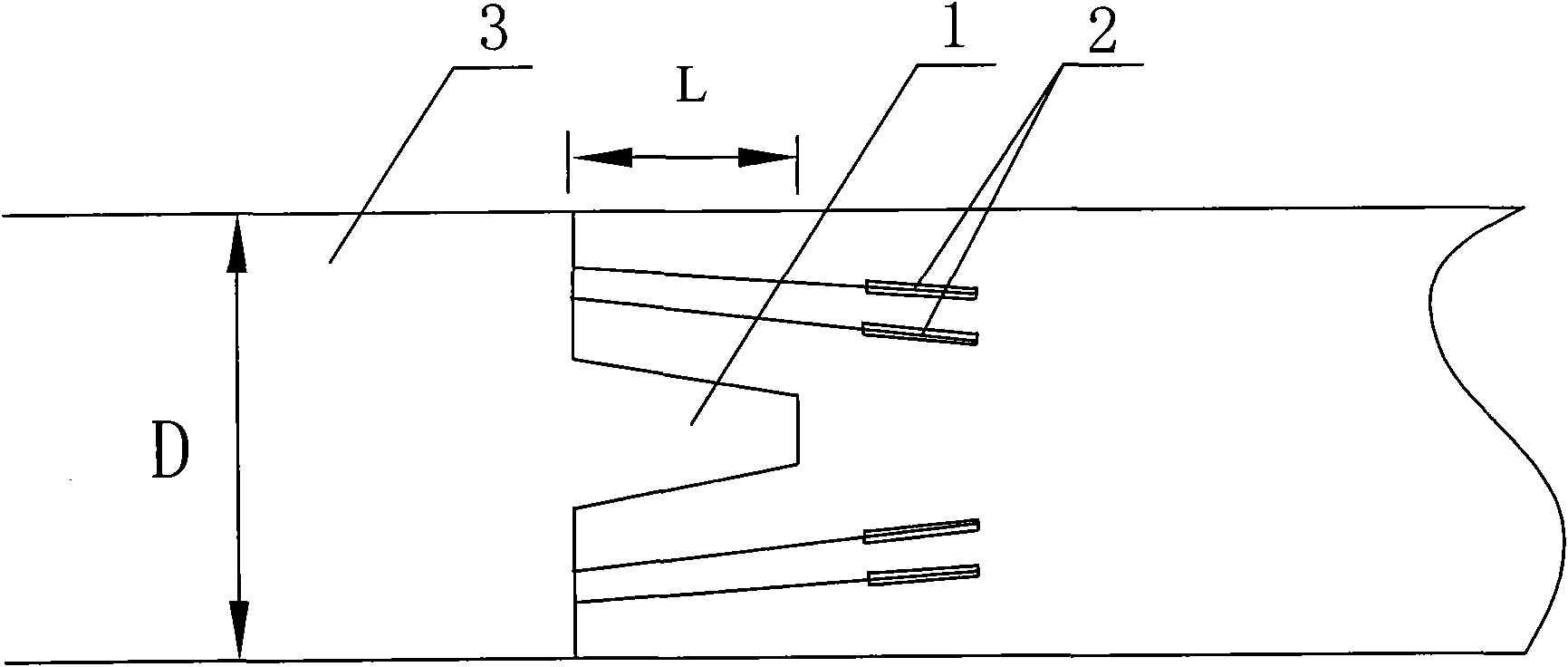

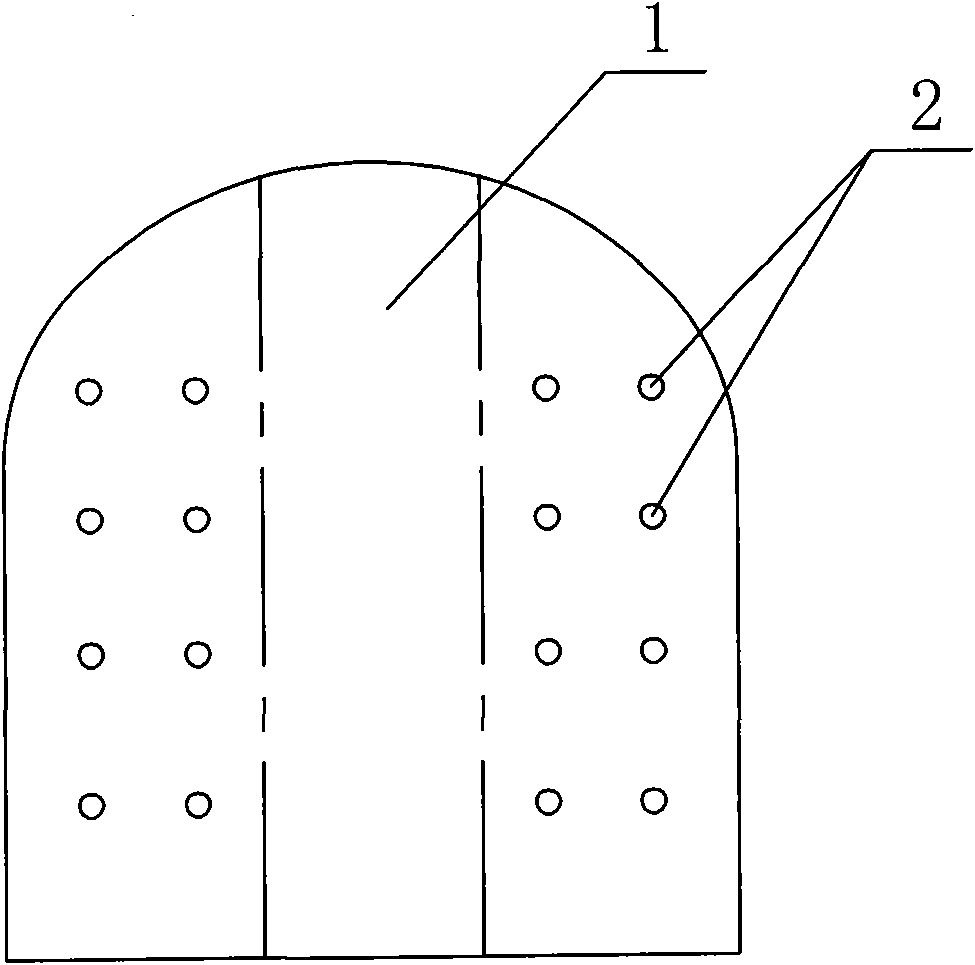

The invention relates to a construction method of a V-level surrounding rock tunnel, comprising the following steps: (1) making a drill guiding I-beam steel lagging jack, i.e. mounting an I-beam steel lagging jack, a groove steel trimming beam, a lock pin anchor rod, a guiding steel pipe, a longitudinal connection steel rib and face injecting concrete in sequence; and (2) construction and support in the tunnel, i.e. drilling pipe shelter steel pipe holes, mounting pipe shelter steel pipes, filling slurry inwards. The earthwork construction of a pilot tunnel comprises earthwork construction, primary support, injecting concrete on a pilot tunnel wall, suspending steel bar nets, casting concrete basis, mounting I-beam steel lagging jack, groove steel trimming beam, steel pads, I-shaped steel inclined strut and lock pin anchor rods, welding longitudinal connection steel bar, injecting concrete on the face and removing core soils; mounting a first-level step temporary inverted arch comprises: constructing lower-level earthwork, performing primary support in the pivot tunnel, mounting the second-level step temporary inverted arch, constructing the following level of earthwork, performing primary support, casting and filling inverted arch, and casting lining concrete at a time inside the pivot tunnel. The invention has the advantage of rapid penetration speed and safe construction.

Owner:CHINA RAILWAY NO 9 GRP

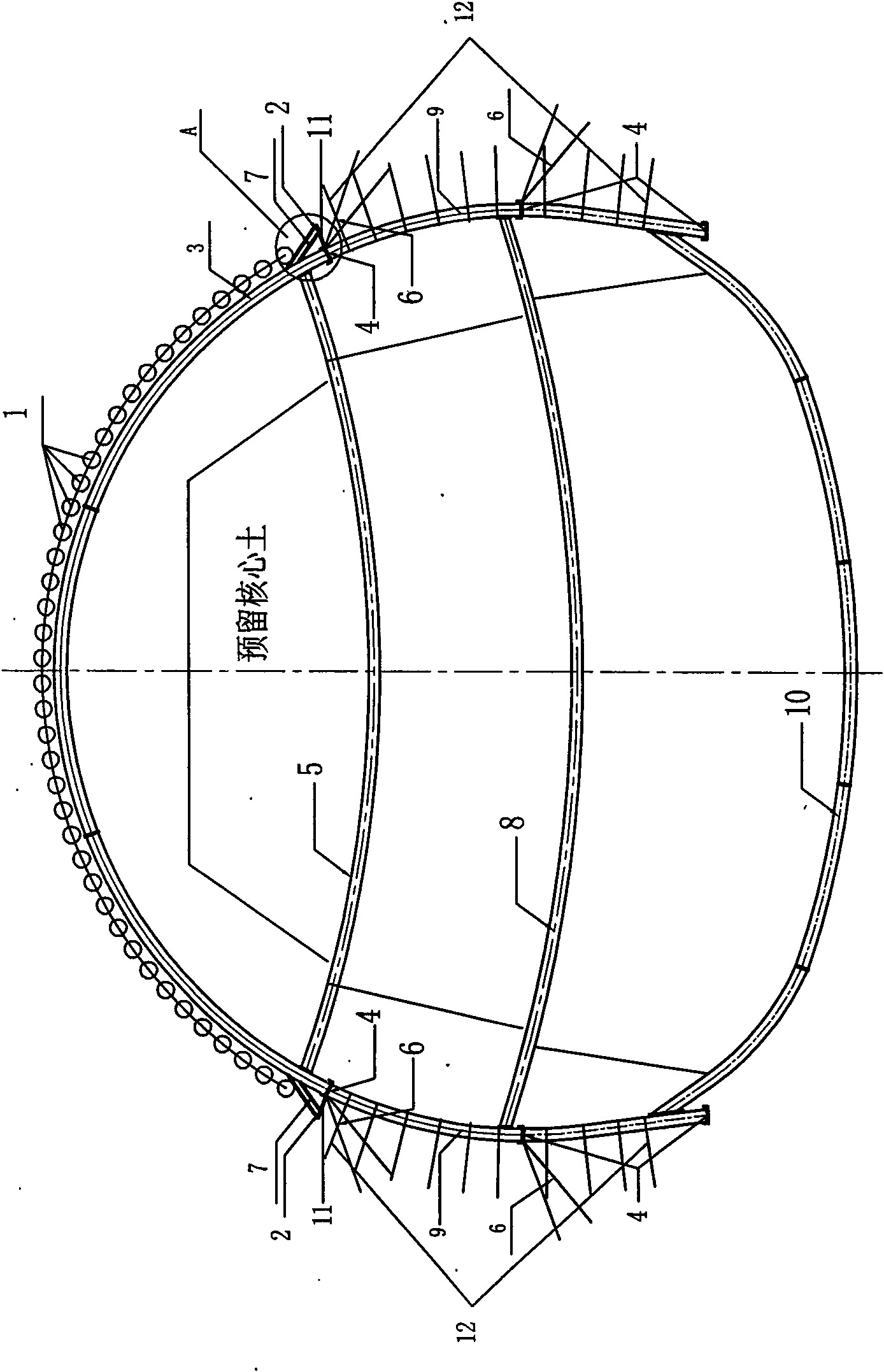

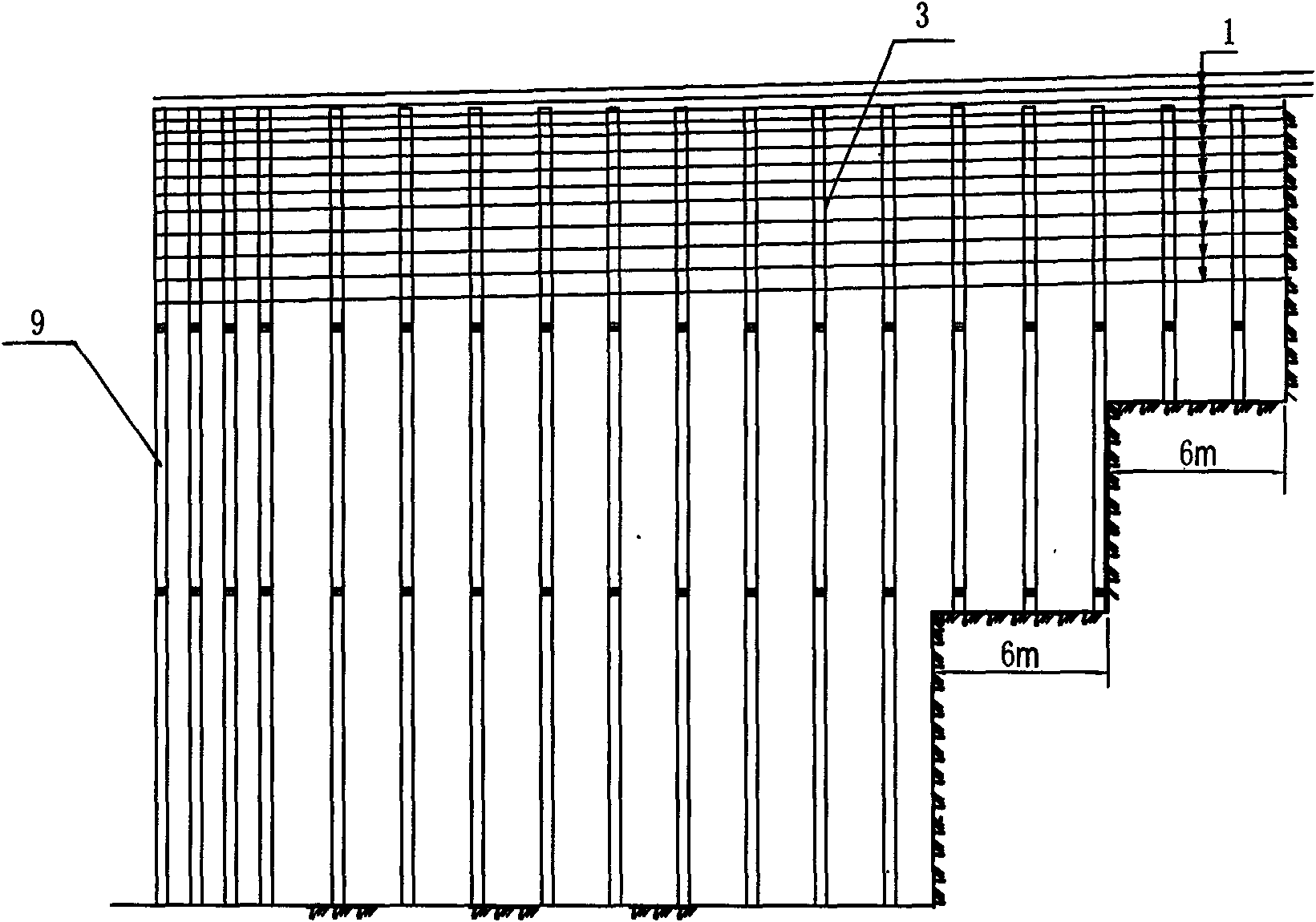

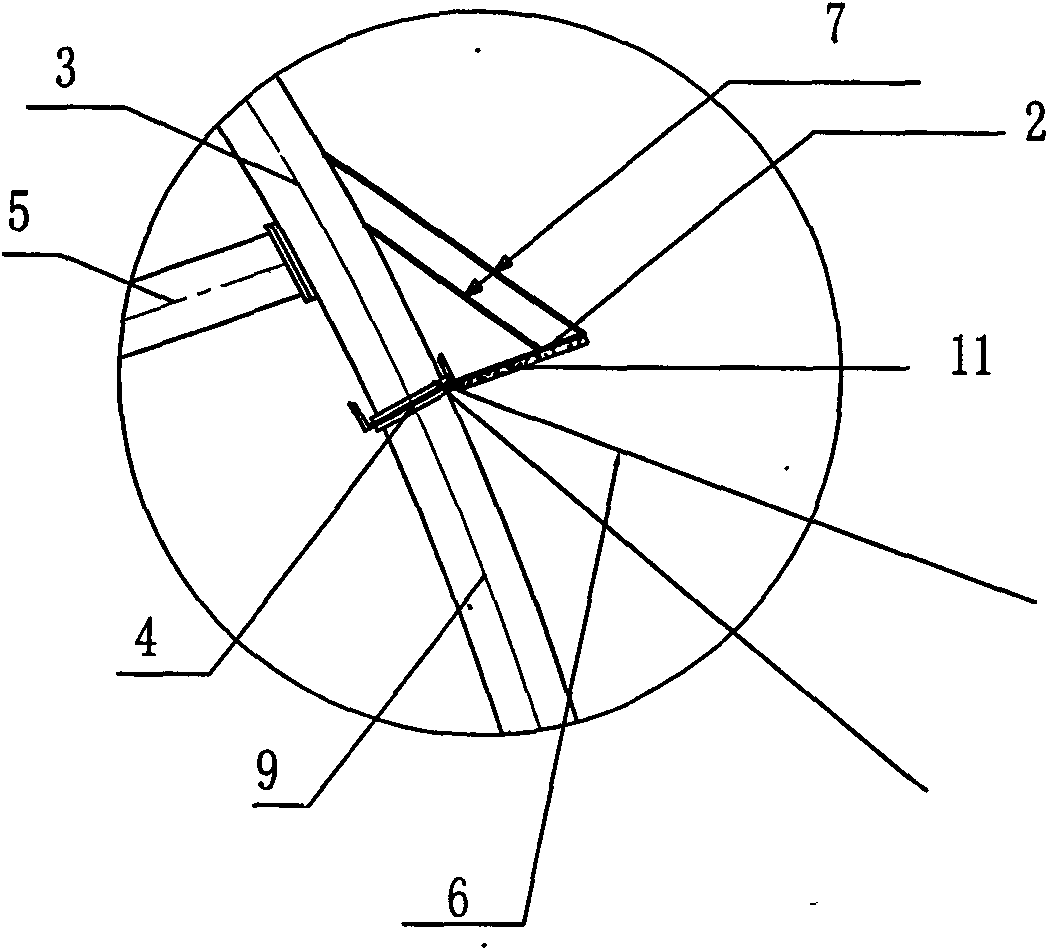

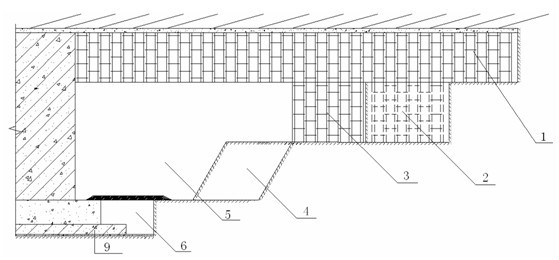

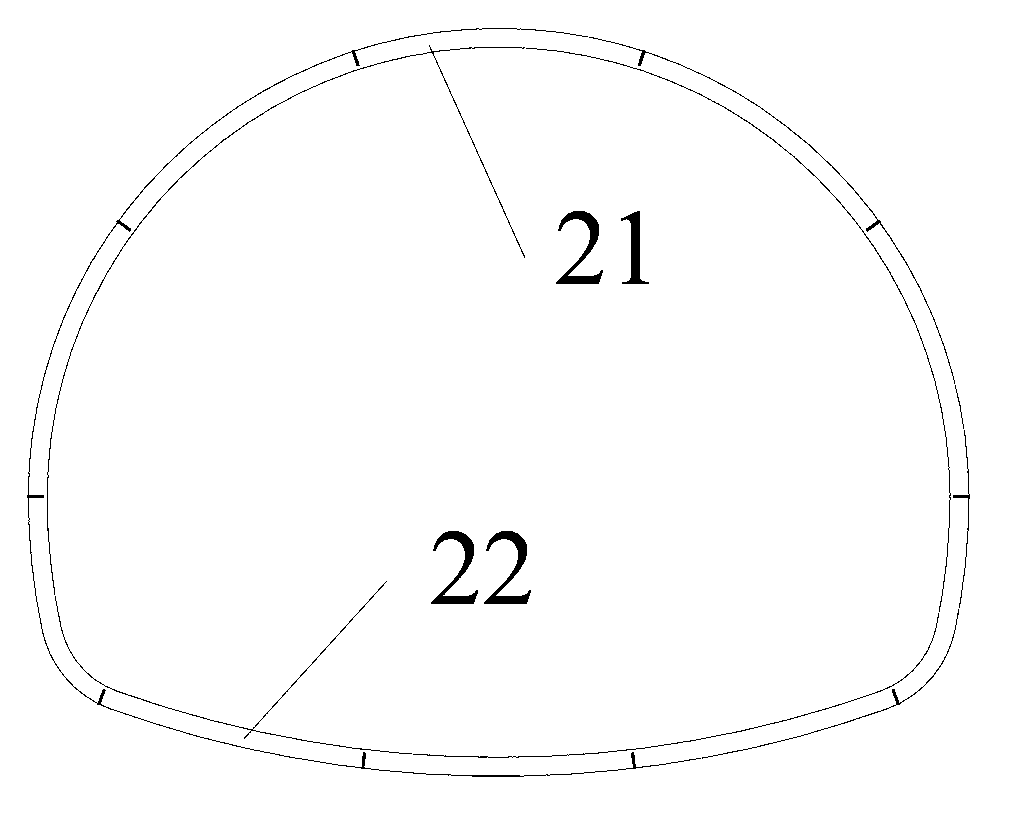

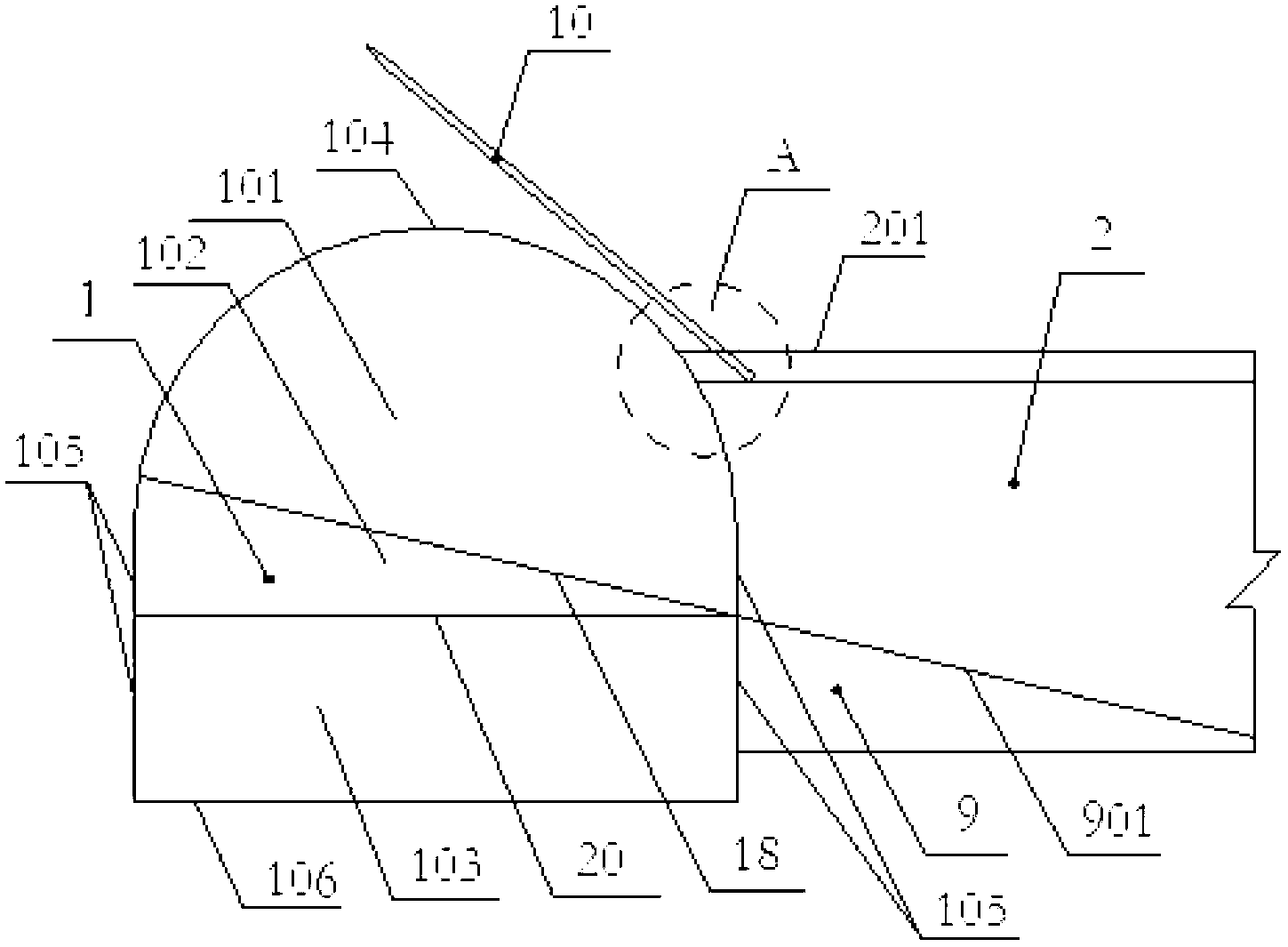

Tunnel dredging method suitable for railway large section IV, V class rock tunnel

ActiveCN101105131ASimple and fast operationLarge construction spaceUnderground chambersTunnel liningRailway tunnelRock tunnel

The invention relates to the technical field of railway tunnel construction, specifically a digging method of IV and V-class surrounding rock railway tunnel with large cross section, aiming to solve the problems of the existing railway tunnel digging method including narrow operation space, low work efficiency, inflexible construction method, instable construction progress, high deformation potential of surrounding rock, and inconvenient operation. The method comprises performing leading support, digging arc-shaped pilot tunnel and preserving core soil; staggeredly digging left / right side walls of middle sidestep and preserving core soil; staggeredly digging left / right side walls of lower sidestep and preserving core soil; sequentially digging upper, middle and lower sidesteps and preserving core soil; and digging inverted arch and carrying out preliminary support. The invention has large construction space and high work efficiency, and can perform multi-job parallel operation. When the geologic conditions are changed, the invention can be flexibly and timely converted to other construction method. Preservation of core soil and left / right staggeredly digging are helpful to the stability of the digging working face. When the surrounding rock has large deformation, the invention can adjust closure time as soon as possible under the prerequisite of assuring safety and meeting requirements of clearance cross section.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

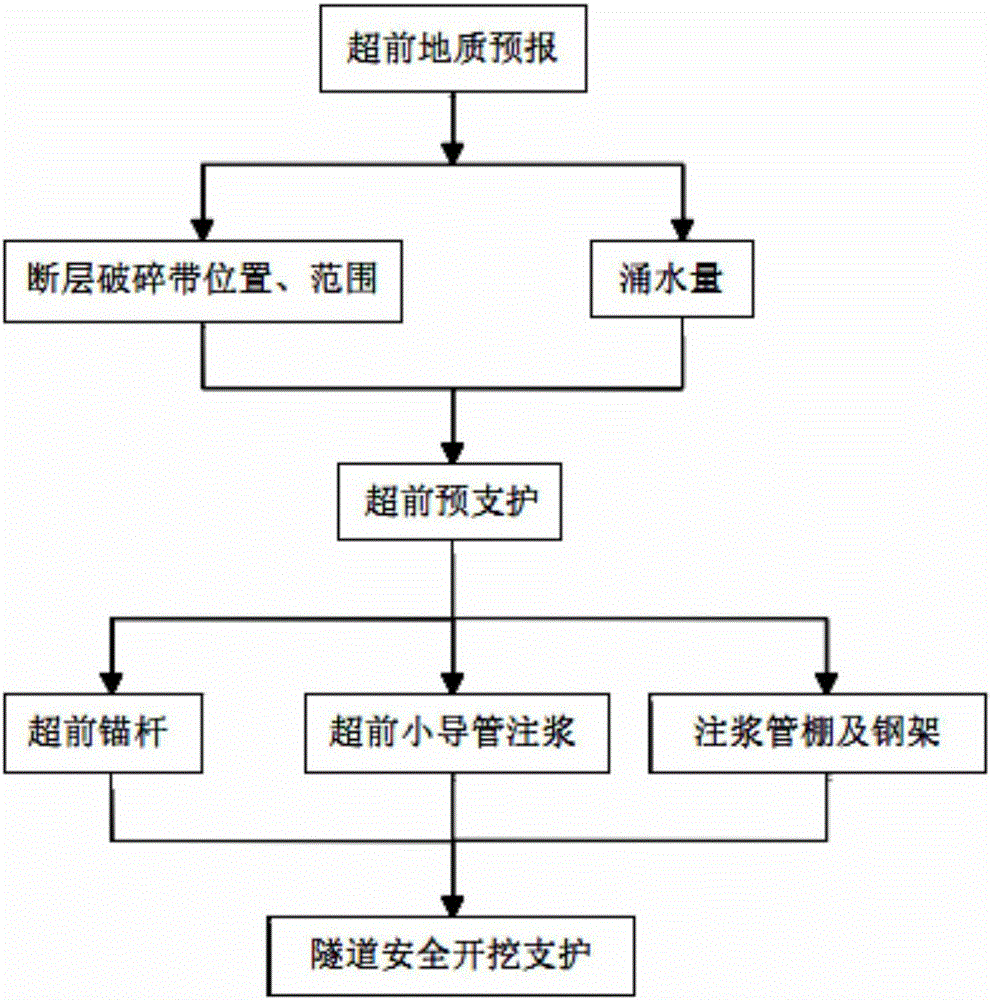

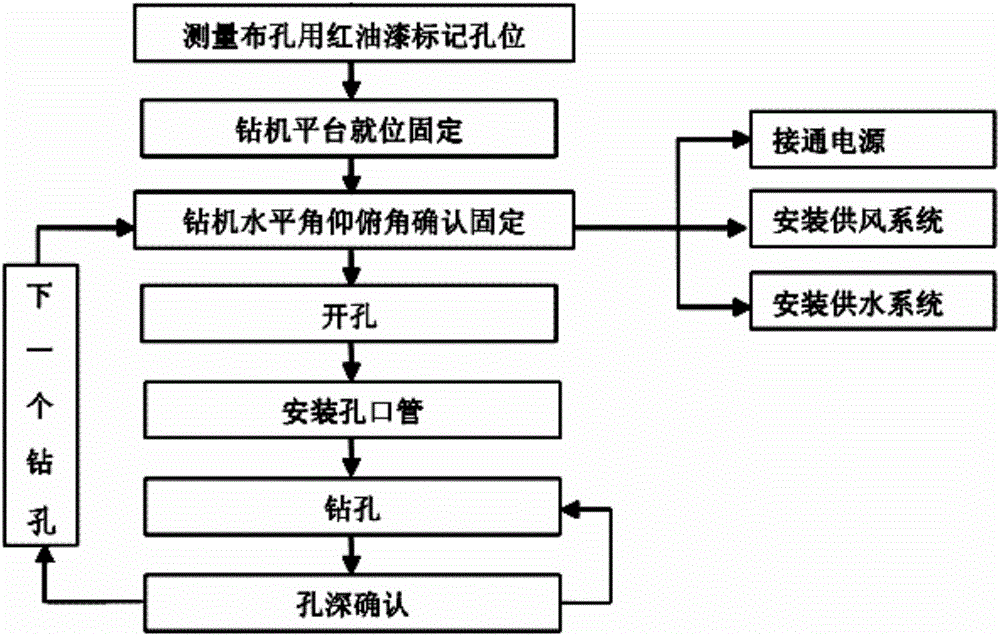

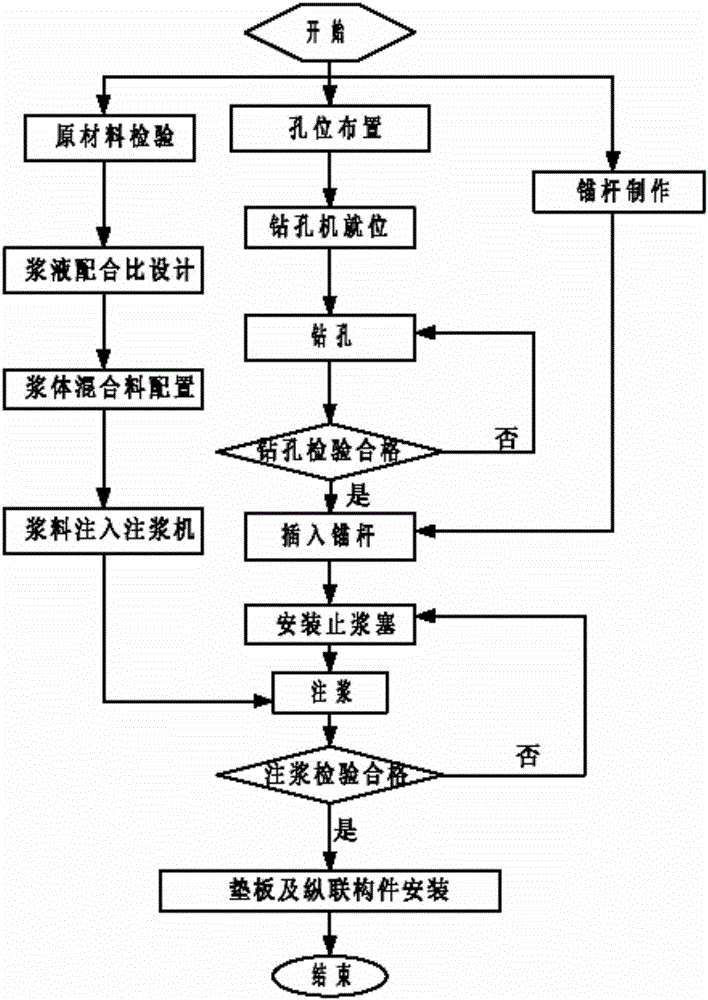

Construction method for fault fracture zone surrounding rock tunnel

InactiveCN106837352AEnsure safetyImprove applicabilityUnderground chambersTunnel liningGeomorphologyShortest distance

The invention discloses a tunnel construction method in a fault fracture zone, which comprises the following steps: a. adopting the method of combining geophysical prospecting and drilling and combining long-distance and short-distance to ascertain the geological situation in front, and carry out advanced geological prediction; b. adopting advanced Anchor construction, pre-grouting construction of the surrounding walls of small conduits in advance, and advance support construction of grouting pipe shed and steel frame, and advance pre-support; c. Tunnel excavation and support. It provides a theoretical basis for detecting the specific location, range and water inflow of the fault fracture zone; ensures the safety of tunnel construction; on the basis of analyzing the specific location and scope of the fault fracture zone and adopting a reasonable advanced pre-support method, comprehensive and specific According to the geological conditions, choose a reasonable tunnel excavation method. It has strong applicability for the construction of expressway tunnels crossing fault fracture zones; at the same time, it has reference and reference significance for the construction of railway, municipal and water conservancy tunnels (holes) with similar geological conditions.

Owner:CENT SOUTH UNIV +2

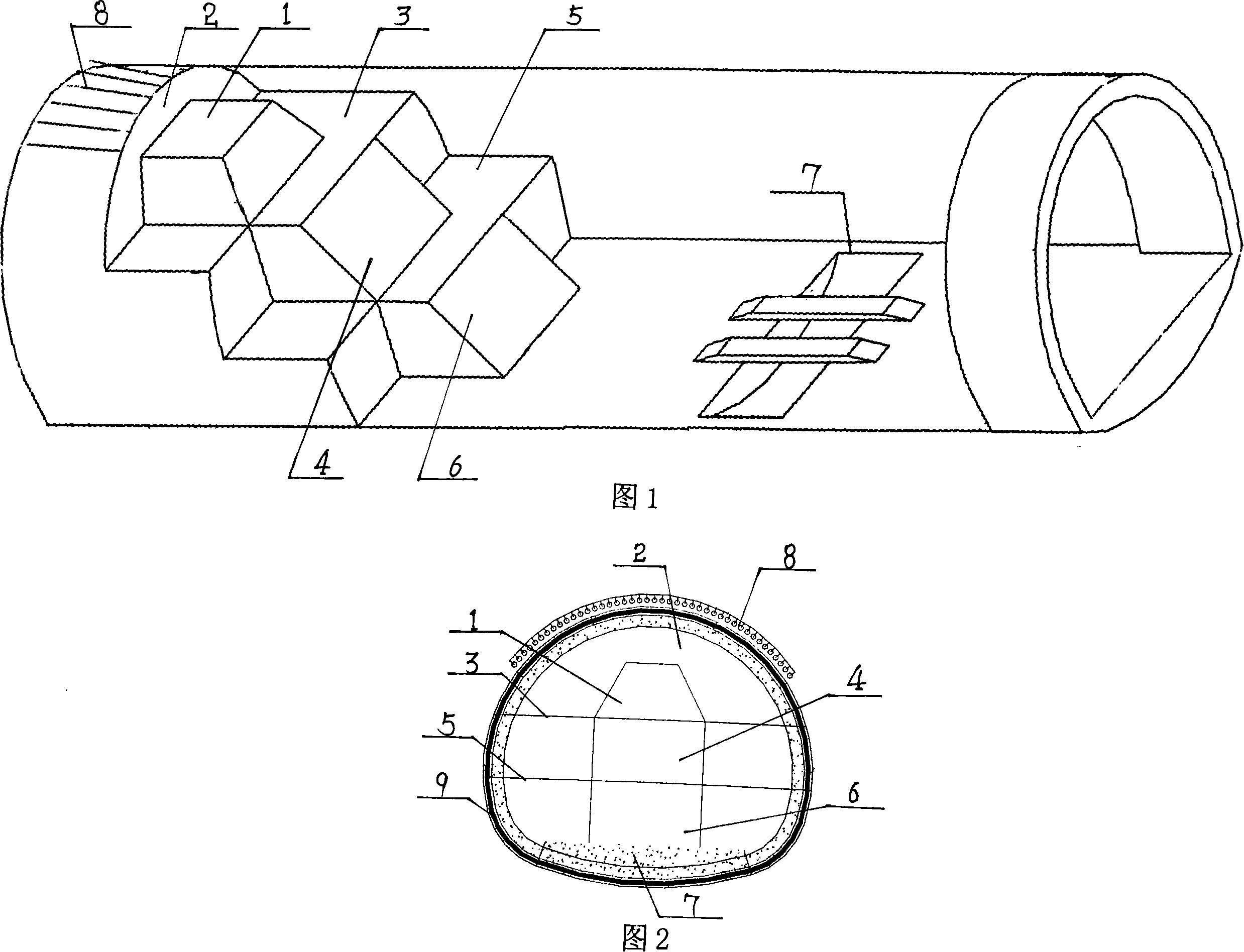

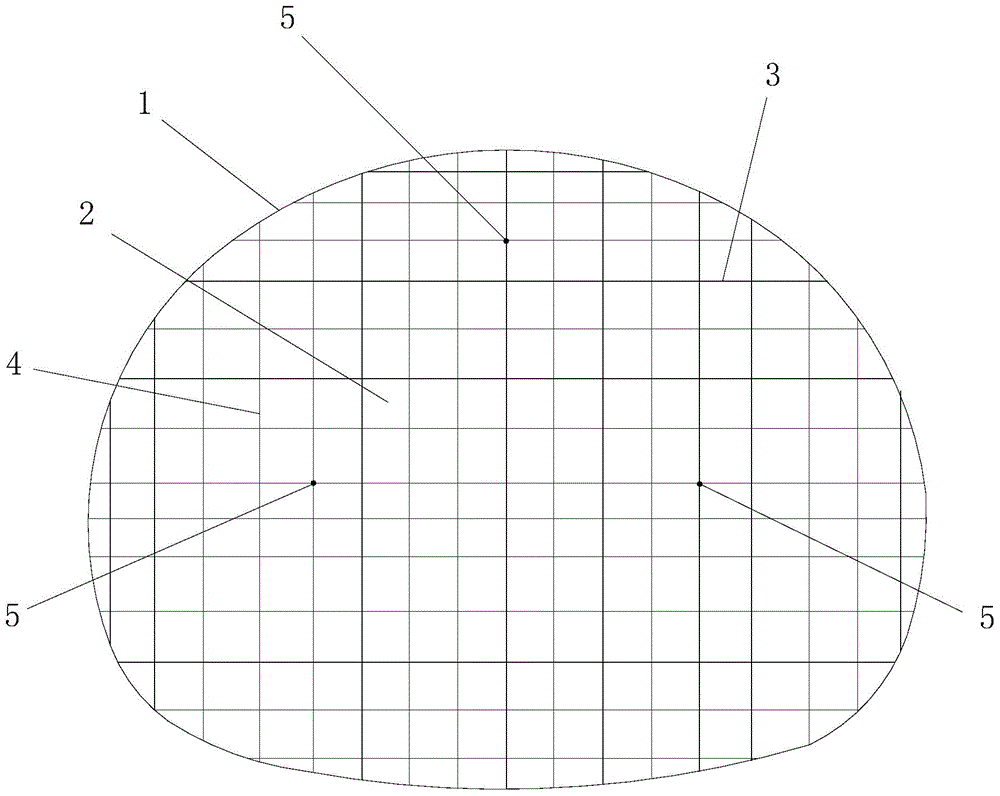

Hard rock tunnel non-blasting digging blocking method and construction method

The invention relates to a hard rock tunnel non-blasting digging blocking method and a construction method. According to the method, a hole drilling core taking technology is utilized, mutually engaged cutting peripheral holes are formed along a tunnel digging contour line, so that a hole wall-shaped digging free face is formed on the periphery of a tunnel face; a hydraulic splitting machine splitting technology is used, in addition, the characteristic that the tensile intensity and the shearing-resistant intensity of rock are much smaller than the pressure-resistant intensity is utilized, the tunnel face digging blocking is firstly carried out, in each digging block, the synchronous splitting digging splitting surfaces do not exceed two, in addition, the two splitting surfaces are in large-angle obtuse angle intersection, in addition, at least one digging free face vertical to the tunnel face is included, then, the digging construction sequence from the lower side to the upper side and from the periphery to the middle is adopted, and the smaller splitting force is used for carrying out rock pulling cracking and shearing cutting splitting digging on the tunnel face along the splitting surface. The hard rock tunnel non-blasting digging blocking method has the advantages that the adverse influence of vibration, noise and dust in the hard rock digging construction can be eliminated, and the utilization rate of tunnel hole slag as building stone materials can be improved.

Owner:FUZHOU PLANNING DESIGN & RES INST

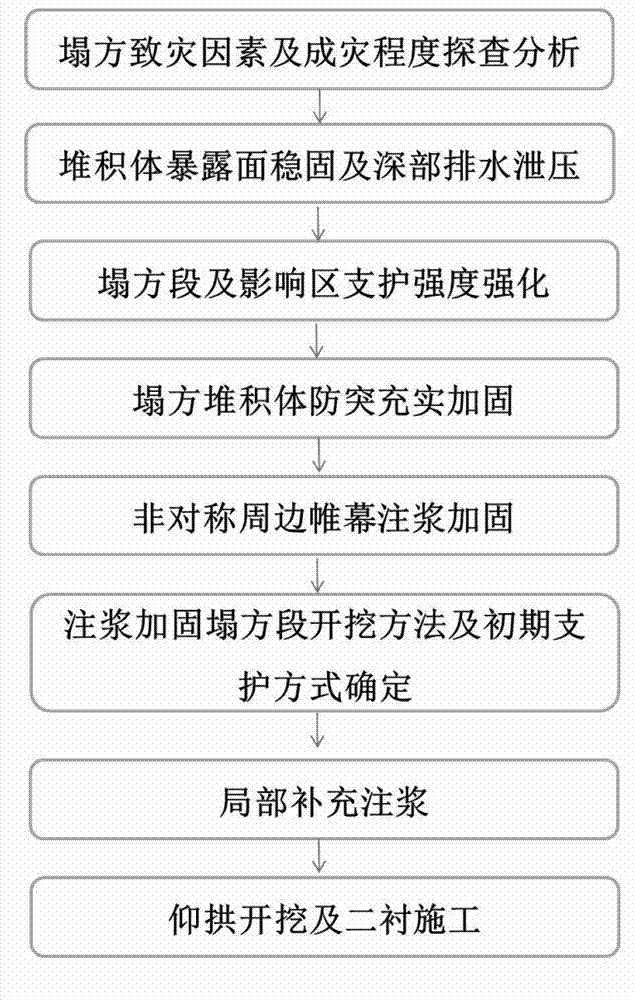

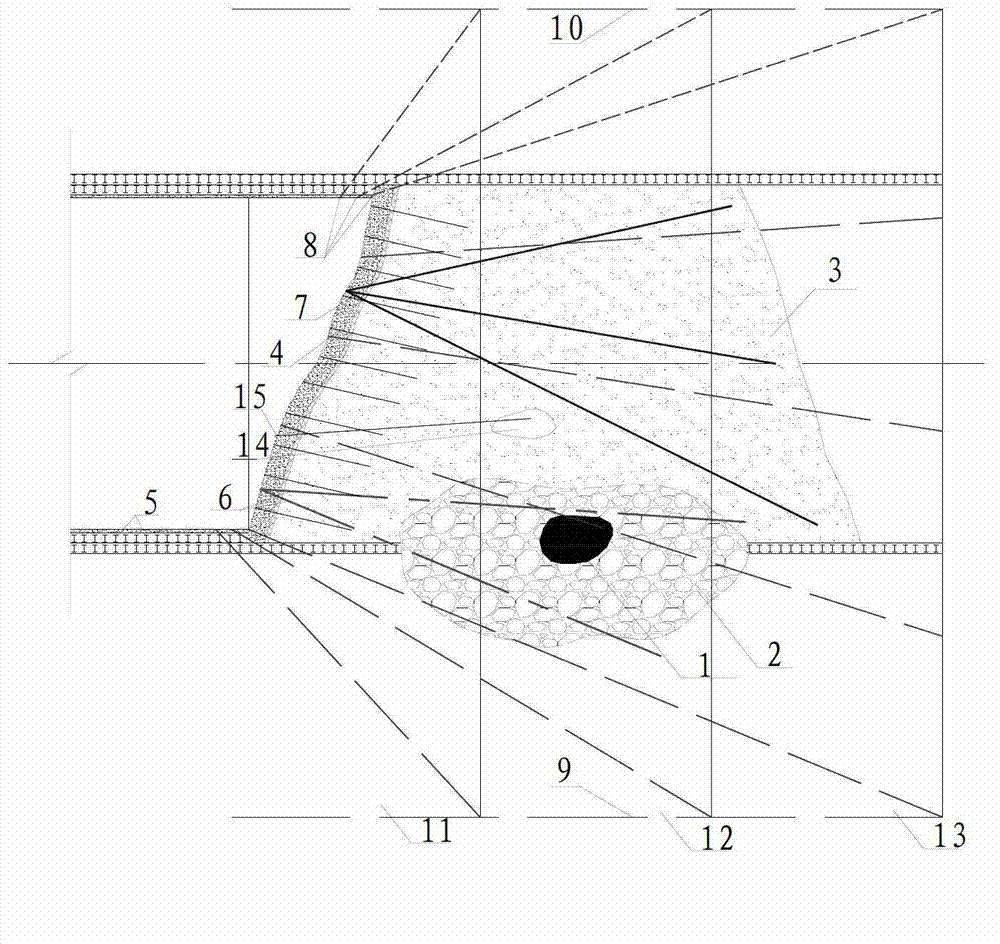

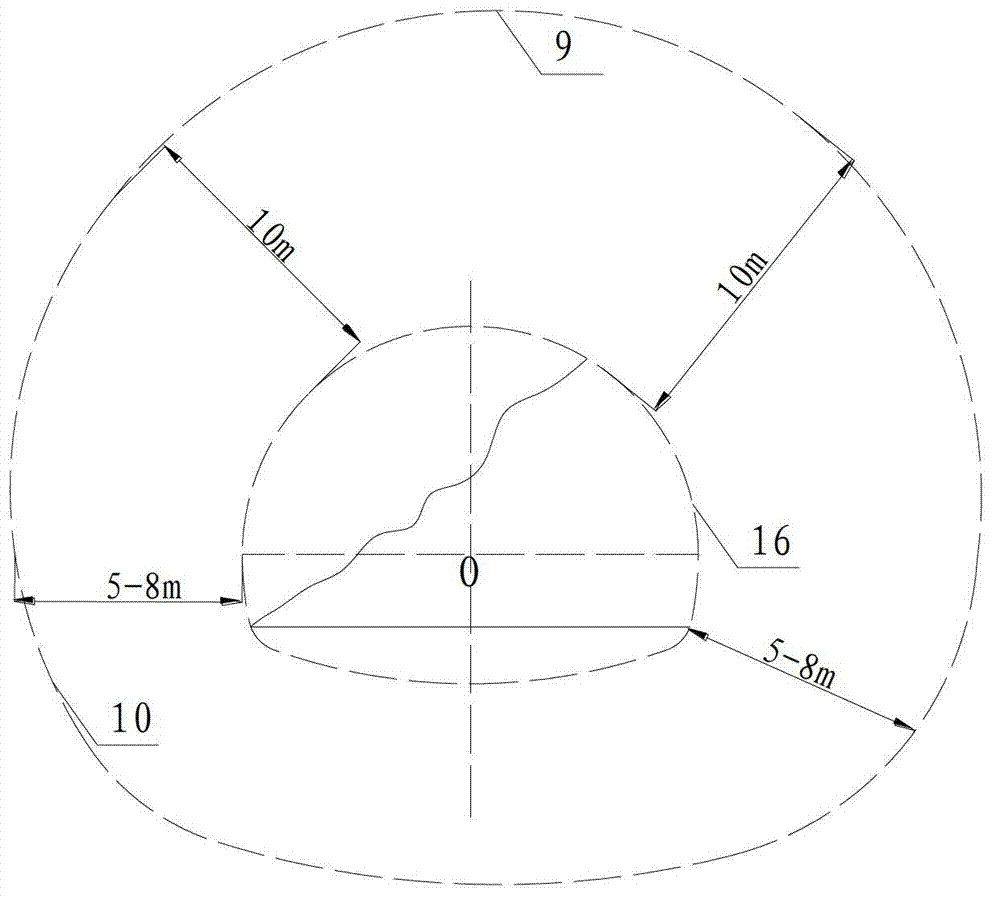

Control method of surrounding rocks in water-rich very-broken surrounding rock tunnel collapse sections

ActiveCN103089275AImprove stabilityEnsure stabilityUnderground chambersDrainageSocial benefitsRock tunnel

The invention relates to the field of tunnel engineering construction, in particular to a control method of surrounding rocks in water-rich very-broken surrounding rock tunnel collapse sections. According to the control method, problems in the existing methods that managing circle is long, reinforcing range and effect are bad, secondary geological disasters are triggered easily because of deformation and cracking of exceeding clearance limit of preliminary bracing and the like are solved. The method includes the following steps: searching and analyzing factors leading to collapse and disaster degree, stabilizing exposed face of an accumulation body and dewatering and decompressing deep parts, strengthening supporting intensity in the collapse sections and influencing areas, outburst prevention filling and strengthening the collapse accumulation body, grouting reinforcing asymmetrical peripheral curtains, confirming an excavating method in grouting reinforcing collapse sections and primary supporting patterns, replenishing grouting in parts, excavating inverted arches, and constructing second liners. The control method of surrounding rocks in water-rich very-broken surrounding rock tunnel collapse sections has the advantages that collapse disposing construction period of water-rich very-broken surrounding rock tunnels is shortened, reinforcing range and intensity of the surrounding rocks are guaranteed, grouting reinforcement is fully conducted on the surrounding rocks in direct collapse areas, deformation in the preliminary bracing is relieved, occurrence of the exceeding clearance limit and the secondary geological disasters is avoided, disposing quality of collapse accidents is improved effectively, and good social benefit and economical benefit are created.

Owner:SHANDONG UNIV

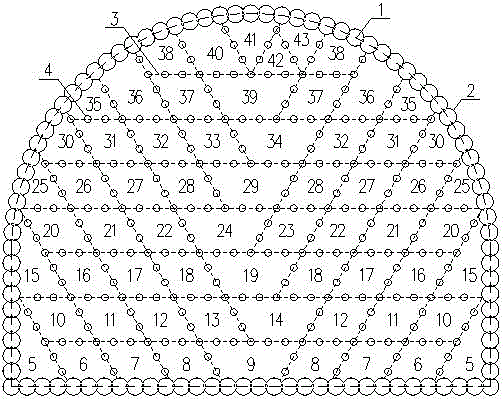

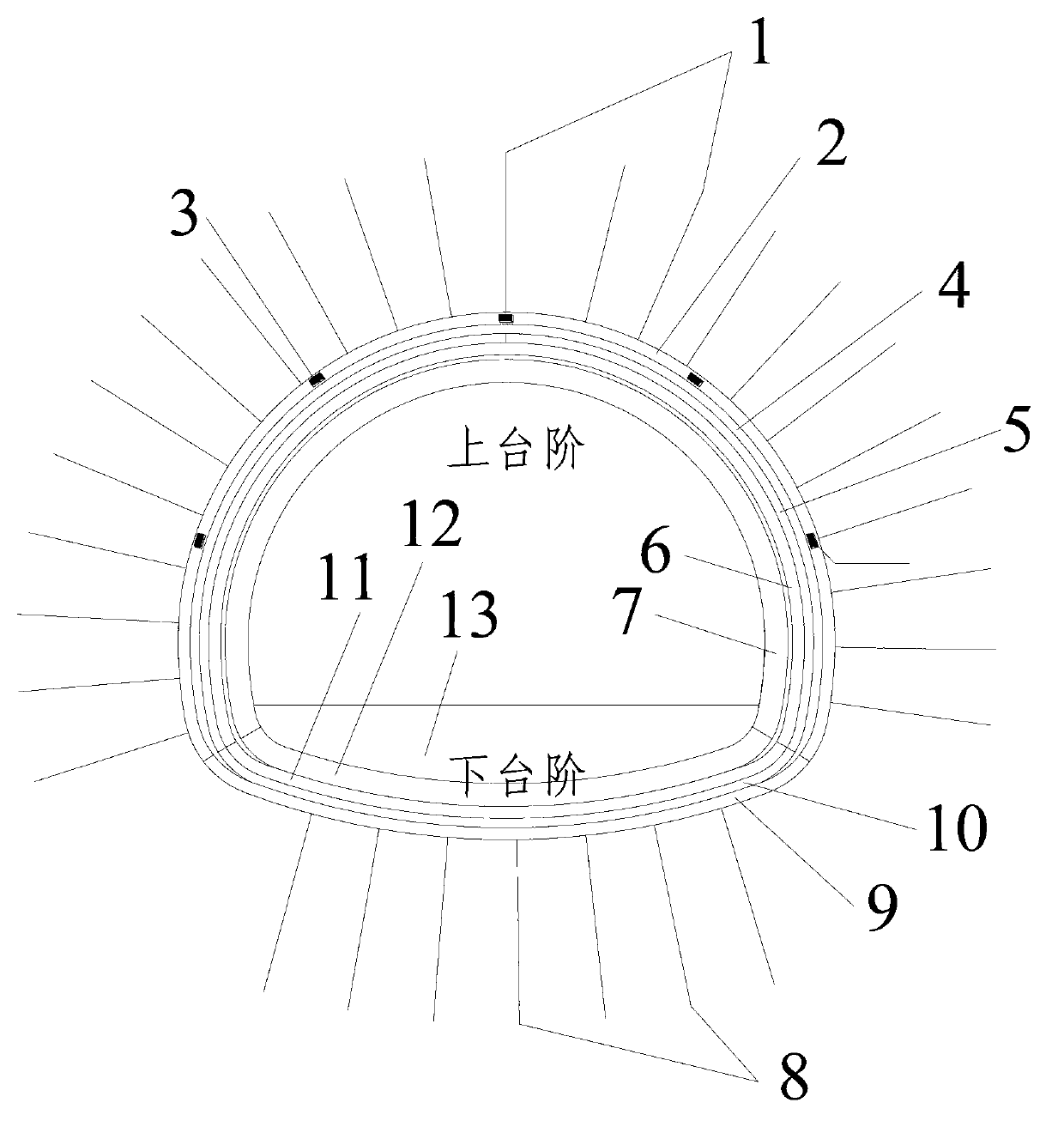

Large cross-section weak surrounding rock tunnel three-step and six-part short-distance construction method

ActiveCN102562075AMeet the requirements for enhanced controlsSpeed up early closure timesUnderground chambersTunnel liningShortest distanceRock tunnel

The invention discloses a large cross-section weak surrounding rock tunnel three-step and six-part short-distance construction method, which comprises the steps as follows: (1) annularly excavating an upper step of an upper part arc pilot tunnel, transferring excavated earthwork of the upper step to a lower step; (2) excavating a left part of a middle step about 4.5-5 meters behind the upper step, and transferring excavated earthwork to the lower step; (3) excavating a right part of the middle step about 3-4 meters behind the left part of the middle step, and transferring excavated earthwork to the lower step;(4) excavating a left part of the lower step about 6-8 meters behind the left part of the middle step or about 3-4 meters behind the right part of the middle step, and conveying excavated earthwork of the left part of the lower step out of the tunnel; (5) excavating a right part of the lower step about 3-4 meters behind the left part of the lower step, and conveying excavated earthwork of the lower step out of the tunnel; and (6) excavating the rest part of the tunnel bottom about 20-25 meters behind the right part of the lower step, excavating continuously according to the steps in a circulating and interlacing manner, and finally realizing tunnel excavating construction. The method can be used for building a large cross-section tunnel in a safe, rapid and economic manner.

Owner:CCCC SECOND HIGHWAY ENG CO LTD +1

High-ground stress soft rock highway tunnel supporting method

ActiveCN102996148AEnsure safetyEnsure stabilityUnderground chambersTunnel liningRock tunnelPlastic property

The invention discloses a high-ground stress soft rock highway tunnel supporting method. The high-ground stress soft rock highway tunnel supporting method comprises the steps of: A. excavating upper steps, and carrying out anchor-plate retaining construction; B. erecting second I-shaped steel supports for the upper steps after ending anchor-plate retaining; C. building foamed concrete buffer layers for the upper steps; D. carrying out secondary injection concrete construction on the upper steps; E. excavating lower steps and erecting first I-shaped steel supports for the lower steps, and spraying concrete; F. pouring plastic concrete into the lower steps; G. erecting second I-shaped steel supports for the lower steps, and spraying the concrete; H. carrying out secondary lining construction on the lower steps; J. backfilling inverted arches; and K. carrying out secondary lining construction on the upper steps, that is, determining the erection position of a formwork by measurement lofting, carrying out arch crown backfill grouting by the concrete having the same grade with a tunnel lining, and dismantling a plug mold after the strength of the arch crown concrete is satisfied. The high-ground stress soft rock highway tunnel supporting method has an obvious effect on control on large deformation of a soft rock tunnel under a high-ground stress, is simple, convenient and easy and is simple in operation and low in cost.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

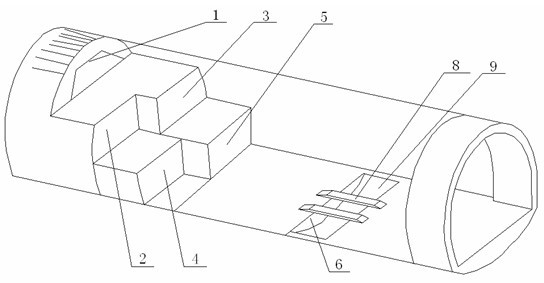

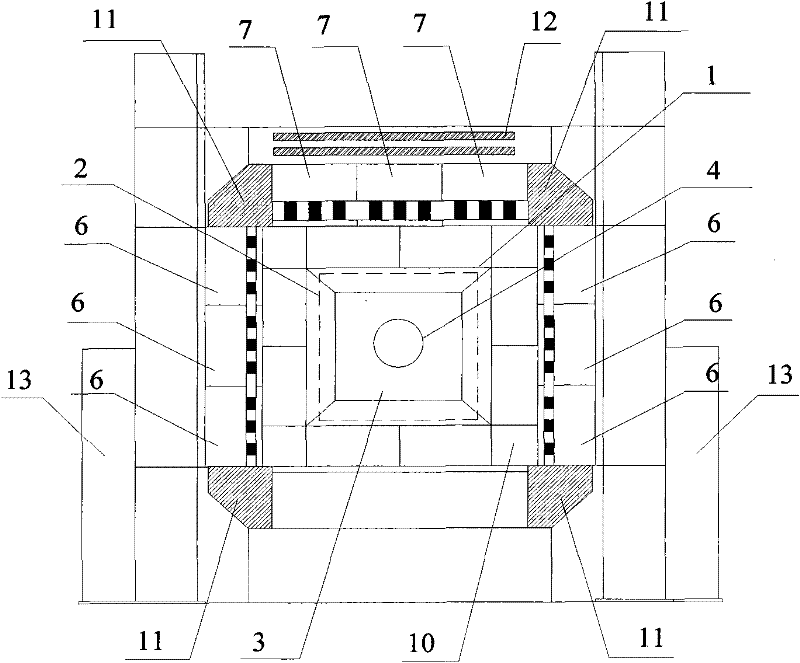

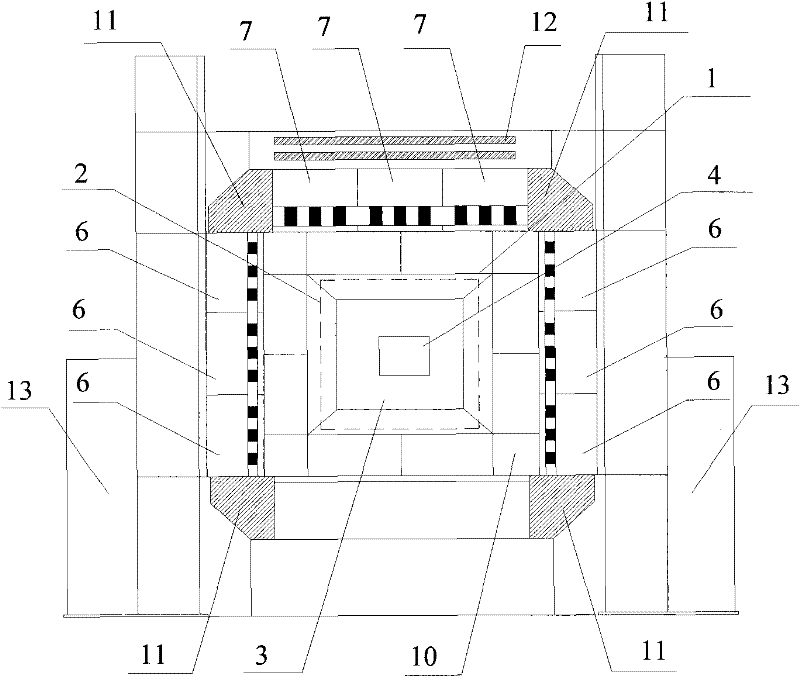

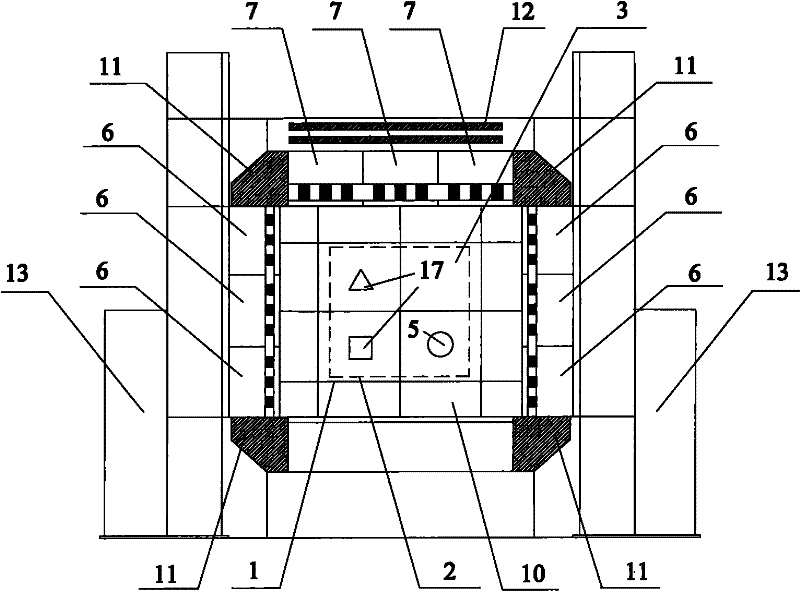

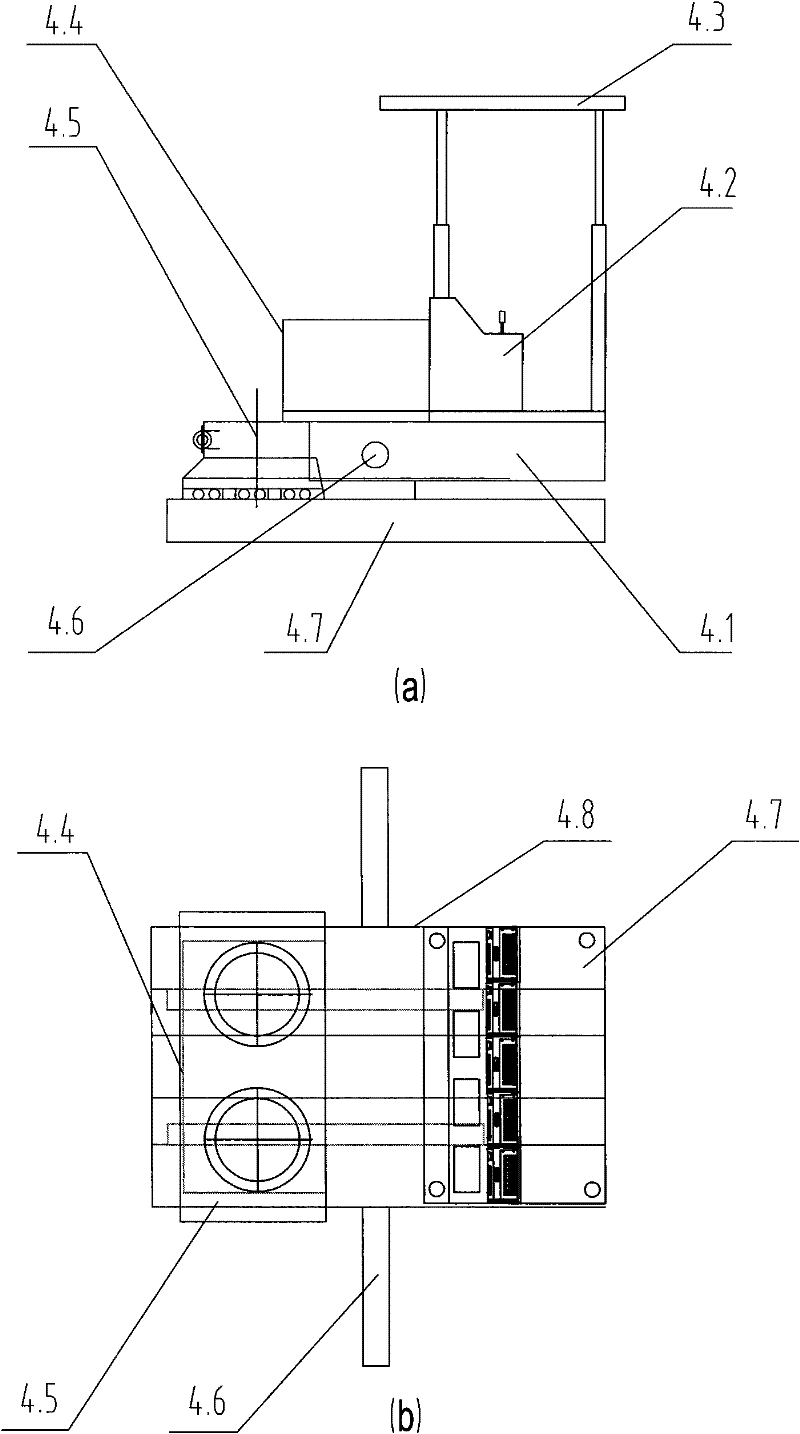

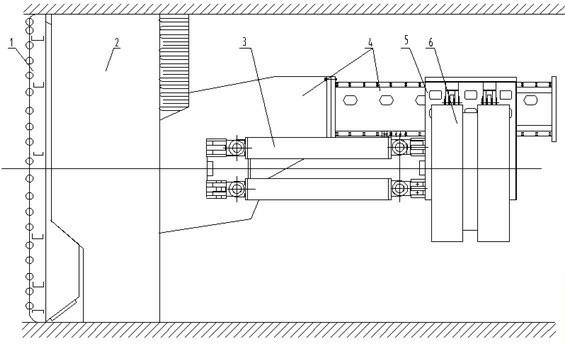

Multifunctional model test system for tunnel and underground engineering

InactiveCN102235942AWith a multi-purpose functionRealize simulationStructural/machines measurementPilot systemRock tunnel

The invention relates to a multifunctional model test system for tunnel and underground engineering. The test system comprises a rail, a model box, a servo-controlled test loading device, a rotating seat, rotating shafts and a bracket, wherein the rail is arranged on the upper part of the test system; the model box is arranged on the middle part of the test system and comprises an outer frame, an inner frame and an organic glass plate; the servo-controlled test loading device comprises a horizontal loading jack and a vertical loading jack; the rotating shafts are arranged on the two sides of the middle part of the test system; and the rotating seat is arranged on the back surface of the upper part of the test system and is connected with the bracket through a rotating loading cylinder. The system can perform a model test on a block system, rock tunnel excavation, a tunnel chamber, a tunnel group, a side slope, shield excavation and building traversing, has a facade rotating loading function, effectively solves the technical problem that a strain field is required to have a wide uniformity range and a high uniformity degree in the model test, and can well simulate the stress environment of tunnels existing in a rock-soil body.

Owner:TONGJI UNIV

Construction method applicable to intersection between inclined shaft and slant hole of weak surrounding rock tunnel

The invention discloses a construction method applicable to an intersection between an inclined shaft and a slant hole of a weak surrounding rock tunnel, and the method comprises the following steps that (1) the inclined shaft is dug; (2) the arch part of an inclined shaft section is supported; (3) the vertical central line of a face at the intersection between the inclined shaft and the slant hole serves as a boundary, first a slant hole section on one side of the boundary is dug, and sectional digging is adopted on every side; an area which is enclosed by the arch top of the slant hole, the side walls of the slant hole on both sides and the extended surface of the ramp slope surface of the inclined shaft is a I part; an area which is enclosed by the plane of the intersection line of the ramp slope surface on an inclined shaft digging surface, the side walls of the slant hole on both sides and the extended surface of the ramp slope surface of the inclined shaft is a II part; and an area which is enclosed by the plane of the intersection line of the ramp slope surface on the inclined shaft digging surface, the side walls of the slant hole on both sides and the bottom of the slant hole is a III part; the slant hole section on the other side is dug in a sectional way; (4) supporting and reinforcement are carried out; and (5) inverted arch and lining construction are carried out. According to the method, the deformation of surrounding rock is reduced, some temporary supporting steps are saved on the premise of good safety, so that the procedures are simple, the construction cost is reduced, and the construction progress is improved.

Owner:中铁二十三局集团第四工程有限公司 +1

Digging method for preventing strong or strong rock burst on active face

ActiveCN101560882AImprove rockburst impact resistanceEnsure personal safetyBlastingTunnelsSlagRock tunnel

The invention relates to a digging method for preventing a strong or strong rock burst on an active face. The technical problem to be solved is to provide an active face strong or strong rock burst prevention digging method capable of effectively reducing the rock burst frequency on the active face and reducing the destructiveness of the rock burst. The method comprises the following specific steps: a, carrying out the shothole arrangement and charging design according to a conventional slotting proposal; b, drilling tunneling shotholes and stress-relief shotholes on the slotted active face; c, charging the tunneling shotholes in a convention mode, and charging the stress-relief shotholes in the 32 mm hole bottom within a deep buried range from 2 to 3m; d, detonating the stress-relief shotholes and the tunneling shotholes in turn; and e, tapping slag, and repeating the steps till the digging is completed. The method is mainly applied to deep buried hard rock tunnel projects for traffic, mining, water conservancy and hydraulic power, and the like.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

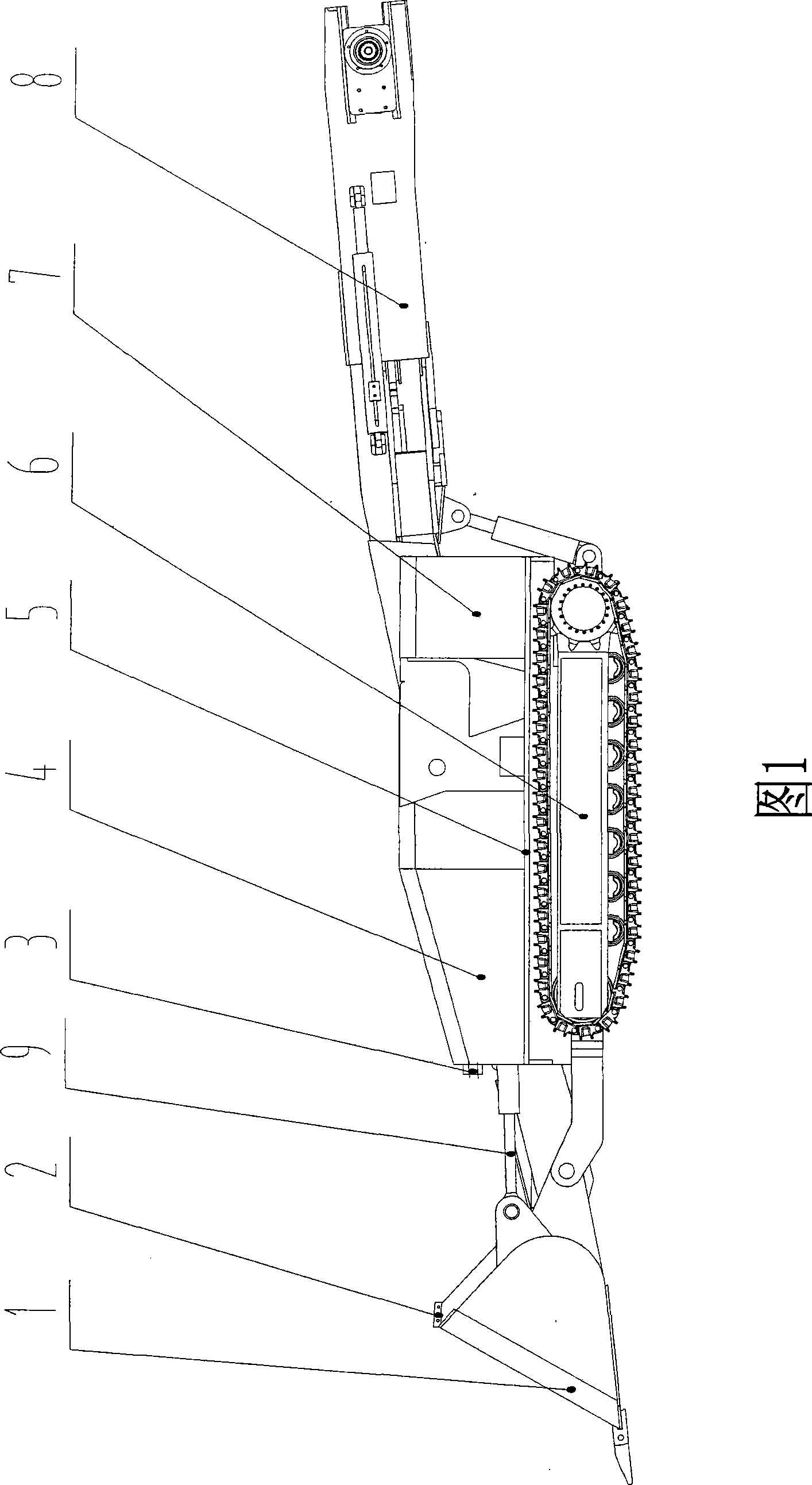

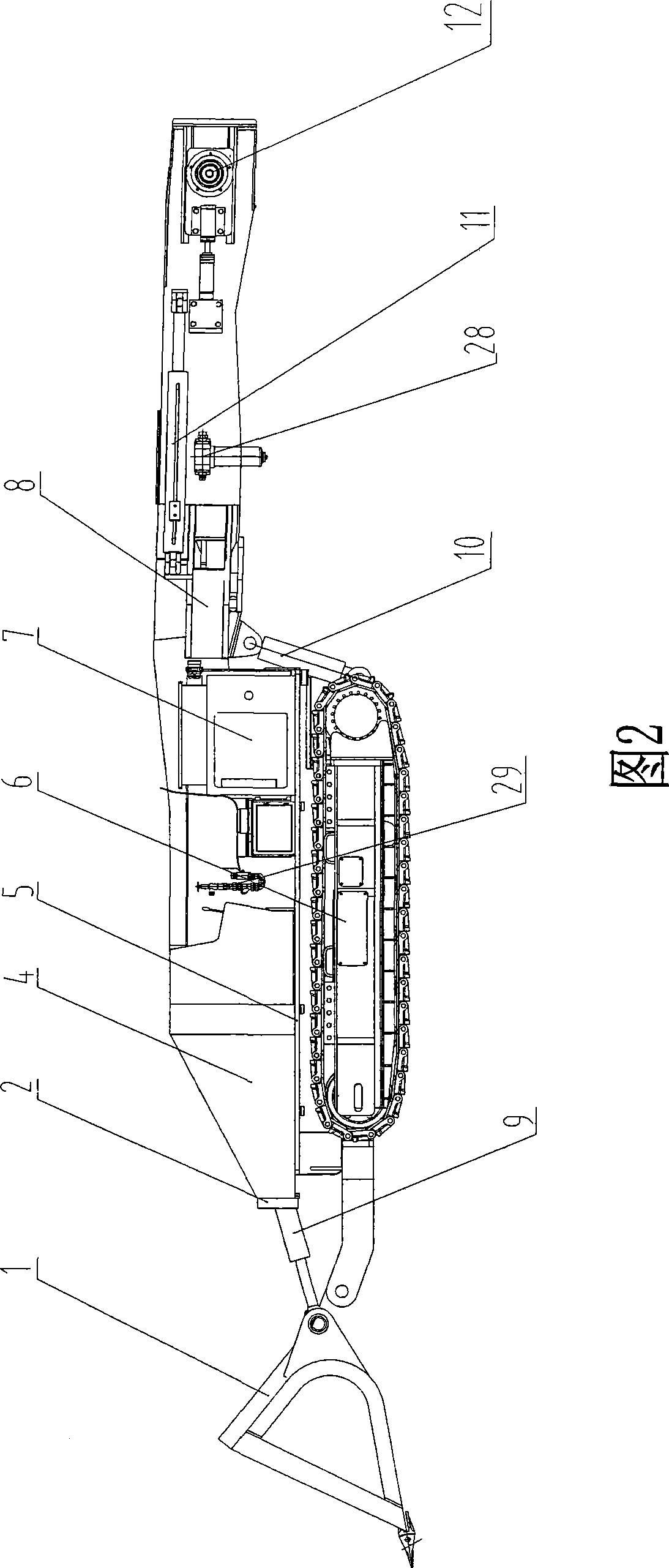

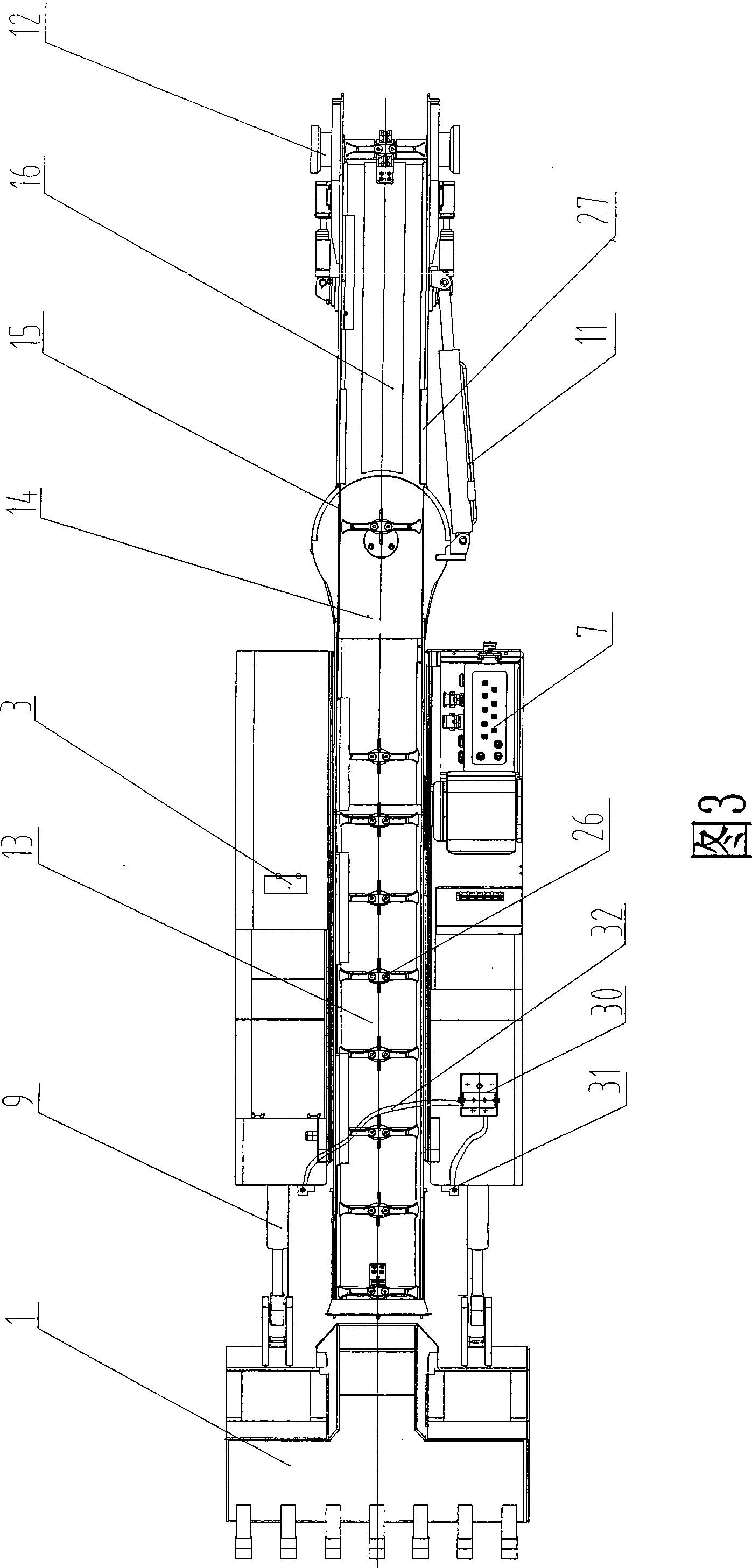

A hard rock hydraulic crushing roadheader

The invention relates to hard rock excavation equipment, in particular to a hard rock hydraulic crushing type excavation machine. It integrates the functions of drilling, rock breaking, material collection, transportation, walking and dust removal, and can realize fast and efficient excavation of all-rock roadways above f10 and above. The roadheader includes a running part, a rear support part, a transport part, a main body part, a rock drilling part, a rock breaking part and a shoveling part. Part, the rear part of the body part is provided with a rear support part and a transport part. The invention can solve the problems of low operation efficiency, harsh working environment and the like existing in the prior art. The whole equipment can realize the efficient, safe and high-quality rapid excavation of the whole hard rock roadway, replacing the more dangerous drilling and blasting method commonly used in hard rock excavation and the comprehensive excavation method with low efficiency in hard rock excavation.

Owner:SANY HEAVY EQUIP

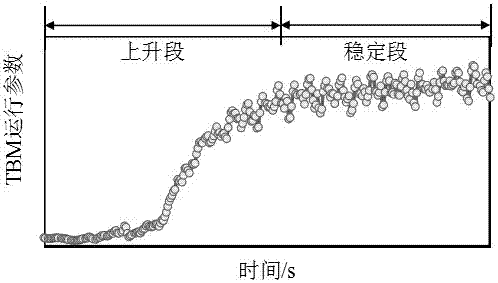

Real-time sensing system and method of tunneling rack mass state of TBM

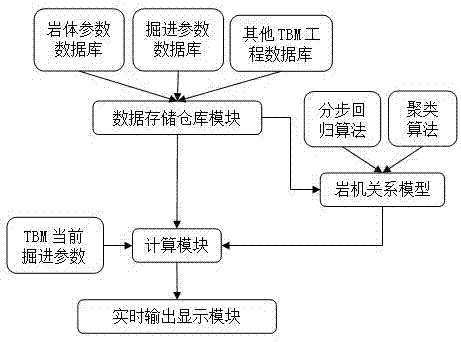

ActiveCN107577862ASolve the problem of real-time quantitative perception of statusSolving the challenge of real-time quantitative sensingGeometric CADDesign optimisation/simulationState parameterComputer module

The invention provides a real-time sensing system and method of the tunneling rack mass state of a TBM. The method and system is used for solving the problem that an adaptive tunneling scheme cannot be selected due to the fact that the tunneling tunnel rack mass state of the TBM cannot be effectively reflected in real time through existing means. By collecting hard-rock tunnel TBM tunneling parameters and corresponding rock mass state parameter data, a data storehouse module is built; step-by-step regression is adopted, a rock-machine relationship sensing model is built, and a clustering algorithm is adopted to achieve rock mass quality grading and form a calculation module kernel; in a model calculation module, by reading current tunneling parameters of the TBM in a tunneling project, back calculation is conducted to obtain rock mass state information, and the rock mass state information is displayed on a TBM upper computer visible interface in a real-time output and display module inreal time. By means of the system and method, the deficiencies of difficult obtaining of traditional rock mass condition parameters, backward means and unknown rock mass state in front of the tunnelface are made up for; energy consumption of the TBM is reduced, the equipment and personnel safety is guaranteed, the tunneling efficiency of the TBM is improved, and the safe efficient tunneling capability of the TBM is greatly improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD +1

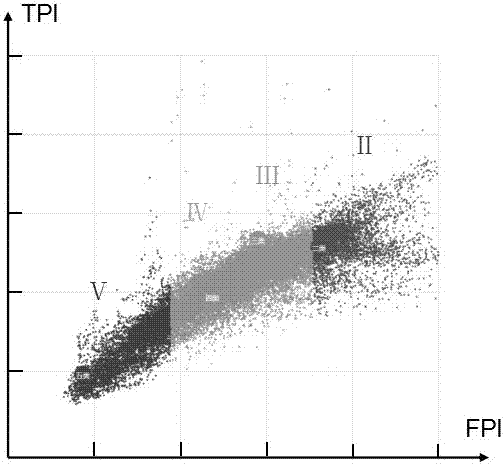

Hard rock tunnel boring machine (TBM) boring control parameter intelligent decision method and system

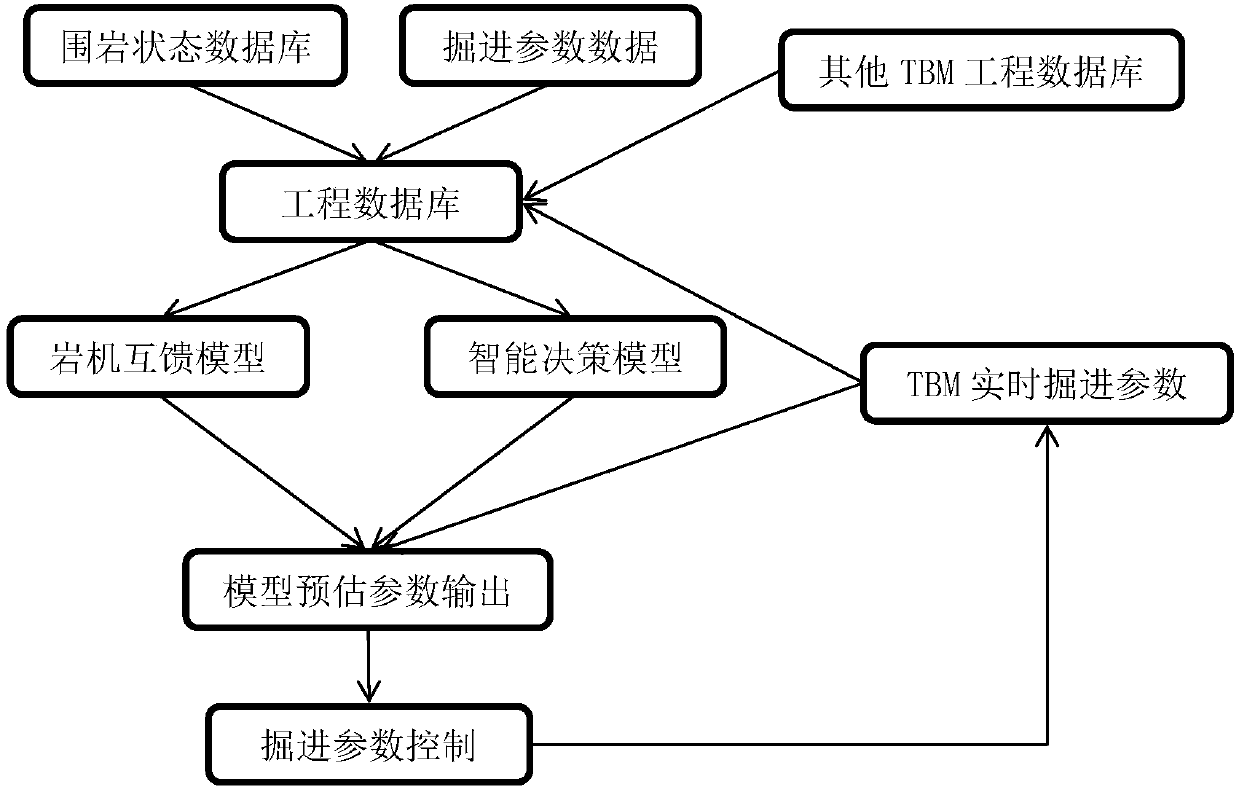

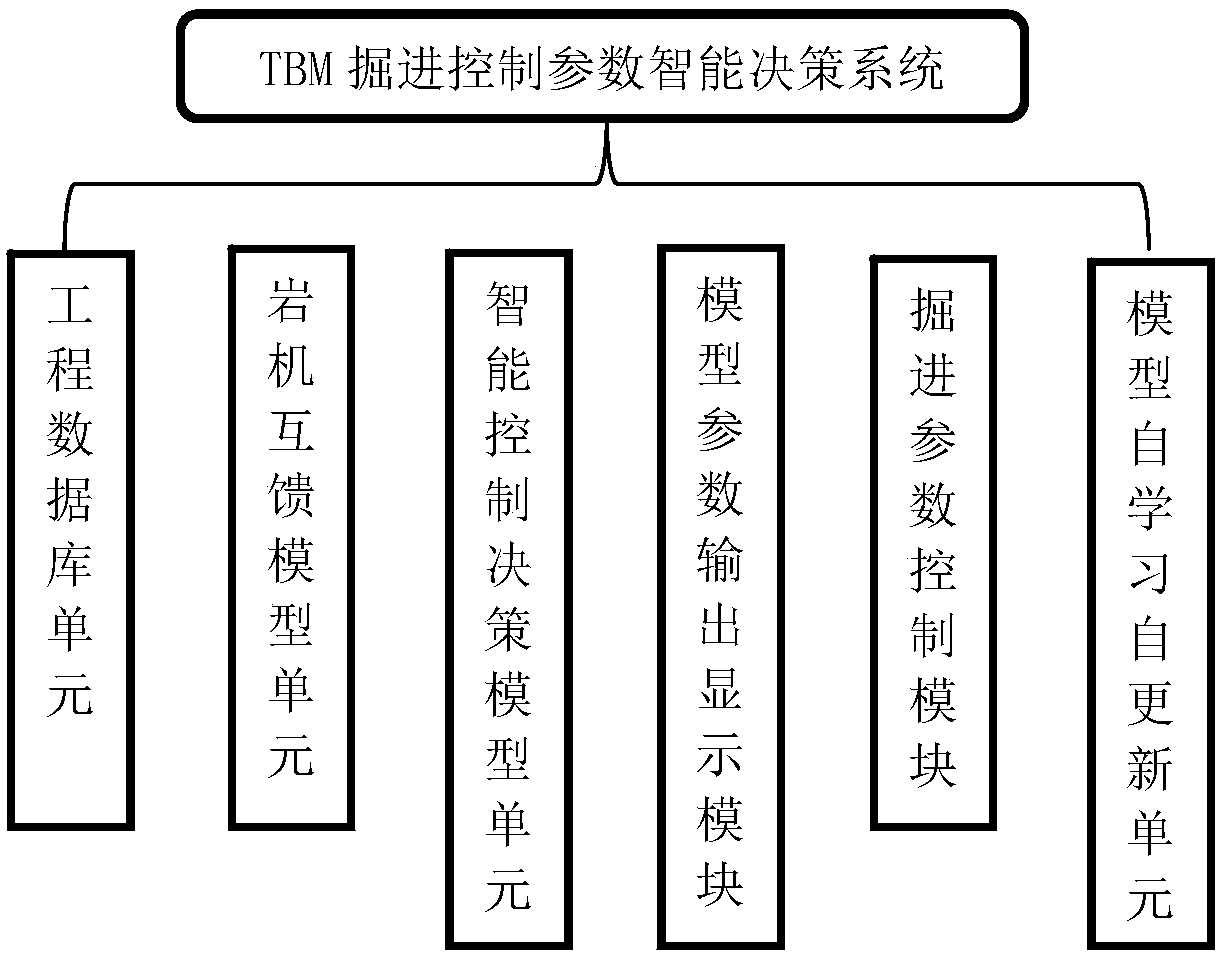

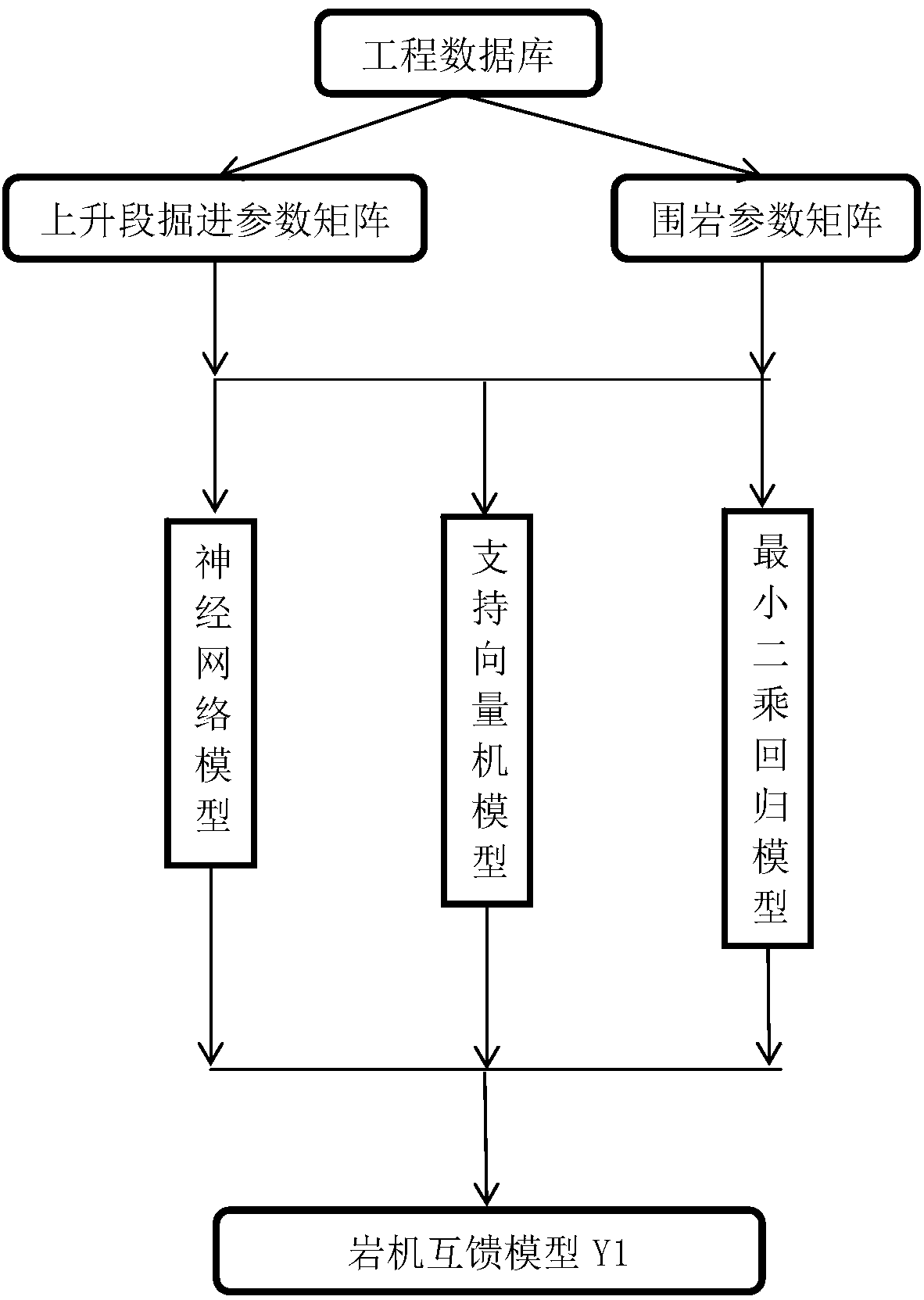

ActiveCN107632523ASafe, efficient and stable excavationTunnelsAdaptive controlDecision modelState parameter

The present invention provides a hard rock TBM boring control parameter intelligent decision method and system. The method comprises the establishment of an engineering database, the establishment ofa rock-machine mutual feedback model and an intelligent control decision model based on the engineering database, the model parameter output, display and updating, an automatic / manual boring parametercontrol method and a model self-learning and self-updating algorithm, and the system comprises an engineering database unit, a rock-machine mutual feedback model unit, an intelligent control decisionmodel unit, a model parameter output real-time display module, an automatic / manual boring parameter control module, and a model self-learning and self-updating unit. According to the present invention, the rock-machine mutual feedback model predicts the state parameter of a current surrounding rock and senses the boring environment of a TBM real-timely according to the operation parameters of theequipment, the intelligent control decision model predicts an optimal control boring parameter according to the current boring environment, and adjusts the current boring parameter timely according to the control boring parameter to adapt to the current boring environment, thereby keeping the safe, efficient and stable boring.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Construction method for deformation control via horizontal whirling jet grouting of long cantilever in soft-rock tunnel

InactiveCN103306687AImprove stabilityControl deformationUnderground chambersTunnel liningGlass fiberEngineering

The invention discloses a construction method for deformation control via the horizontal whirling jet grouting of a long cantilever in a soft-rock tunnel. The method comprises the following steps of: (1) drilling on the periphery of a dug outline, carrying out the whirling jet grouting while retreating a drill stem, and lowering a first profile component after the whirling jet grouting to form a first profile pile body; (2) repeating the step (1) to construct a first curtain system; (3) drilling on a tunnel face designed in a tunnel, carrying out the whirling jet grouting while retreating the drill stem, lowering a second profile component after the whirling jet grouting to form a second profile pile body; (4) repeating the step (3) to construct a second core earth reinforcing system; (5) carrying out the mechanical digging and initial supporting on a large section; (6) drilling in the arch springing position of middle and lower steps obliquely towards the lower direction of the tunnel at 30-45 degrees, lowering a third profile component to form a third profile pile body; and (7) repeating the step (6) to construct a locking whirling jet grouting pile stabilization system. According to the construction method, the advanced reinforcement of a horizontal whirling jet grouting pile with a highly strong tunnel outline, the binding and deforming effect of a tunnel face glass fiber anchor stem, and the anchoring of the locking whirling jet grouting pile are utilized, and the deformation of rock-soil is effectively controlled.

Owner:北京中铁瑞威基础工程有限公司

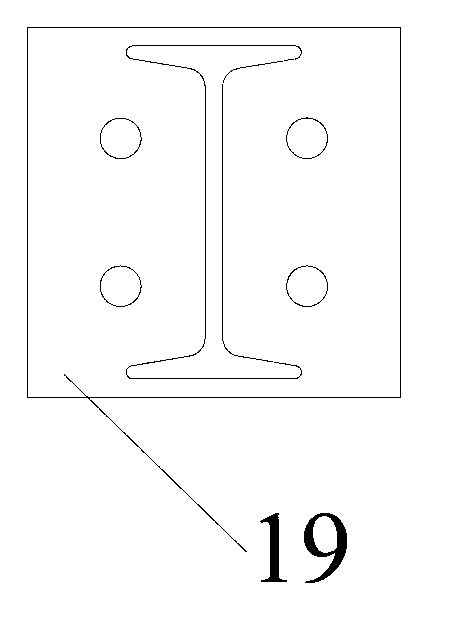

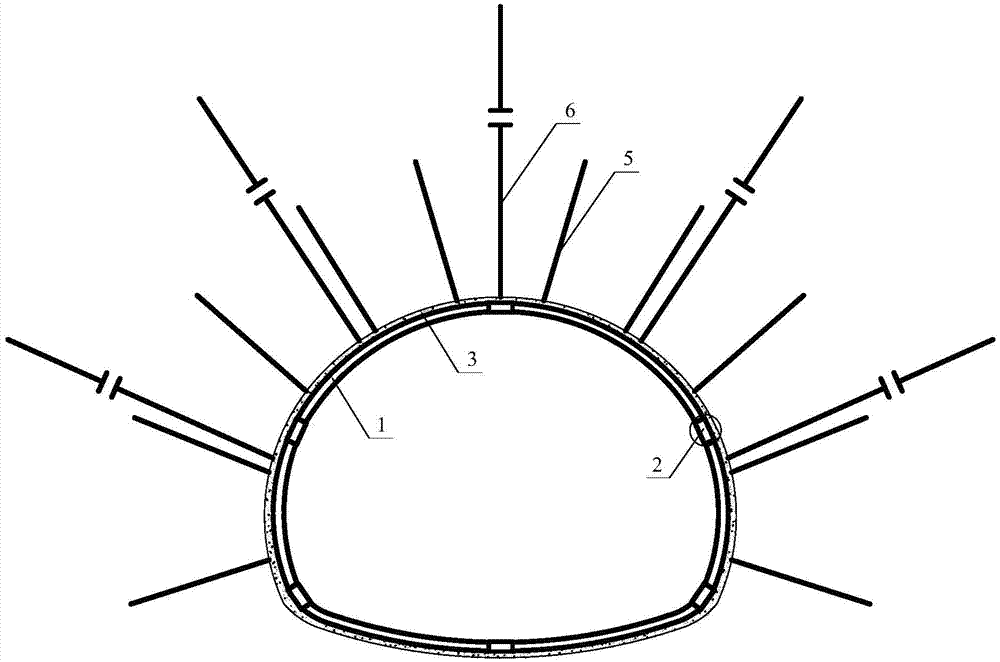

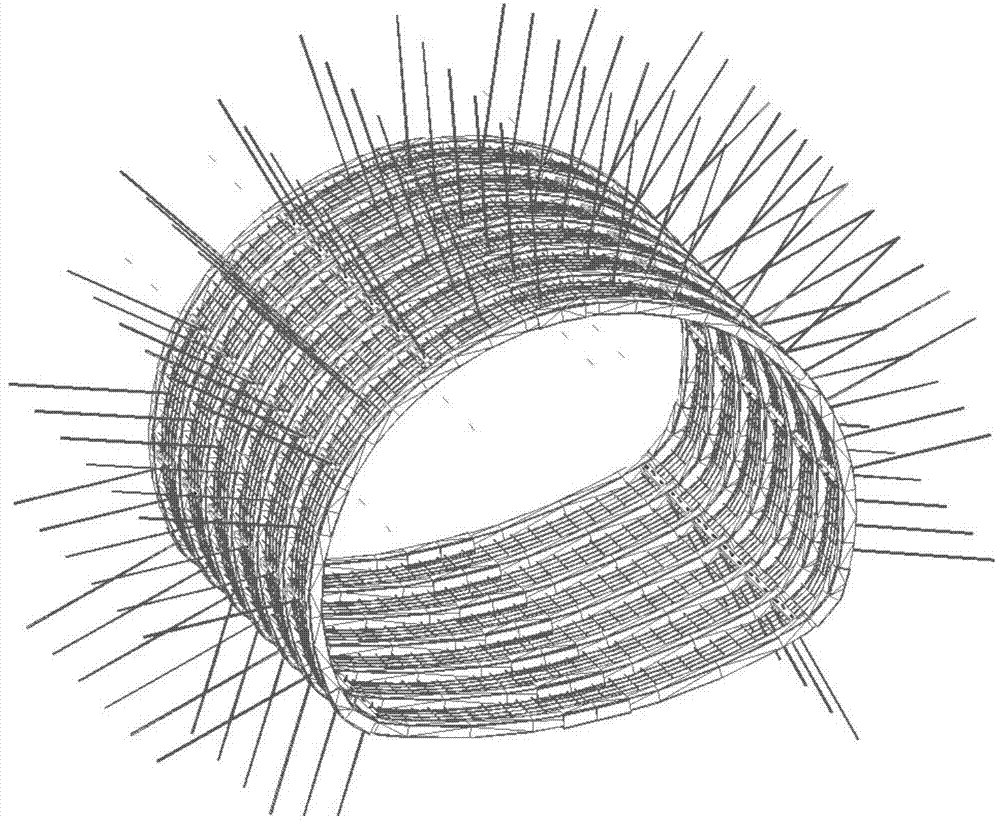

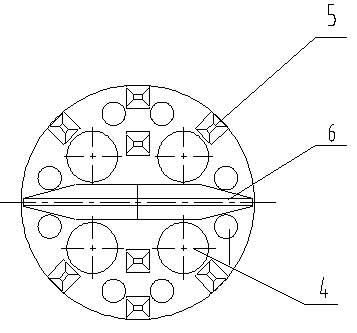

Square steel confined concrete arch center wall back filling bolting-grouting support system and construction method

InactiveCN103615273AImprove self-supporting capacityFill in timeAnchoring boltsSupporting systemRock tunnel

The invention discloses a square steel confined concrete arch center wall back filling bolting-grouting support system and a construction method. The square steel confined concrete arch center wall back filling bolting-grouting support system comprises high-strength anchor rods, grouting anchor rods, grouting anchor cables and multiple square steel confined concrete arch centers, wherein adjacent square steel confined concrete arch centers are connected through longitudinal beams, anchor rod holes are formed in the longitudinal beams, longitudinal beam anchor rods penetrate the longitudinal beams through the anchor rod holes to be anchored into a surrounding rock, a wall back filling layer is arranged between the square steel confined concrete arch centers and the surrounding rock, and the square steel confined concrete arch centers, the wall back filling layer and the tunnel surrounding rock are connected through the longitudinal beam anchor rods. The high-strength anchor rods, the grouting anchor rods and the grouting anchor cables are constructed before the square steel confined concrete arch centers are erected. The square steel confined concrete arch center wall back filling bolting-grouting support system and the construction method are applicable to supporting of underground projects including weak broken surrounding rock tunnels and the like, the square steel confined concrete arch center wall back filling bolting-grouting support system has the advantages of being high in strength, good in stability, reasonable in stress and the like, and the square steel confined concrete arch center wall back filling bolting-grouting support system and the construction method can effectively improve the primary supporting strength after tunnel excavation and ensure the stability of the tunnel surrounding rock.

Owner:SHANDONG UNIV

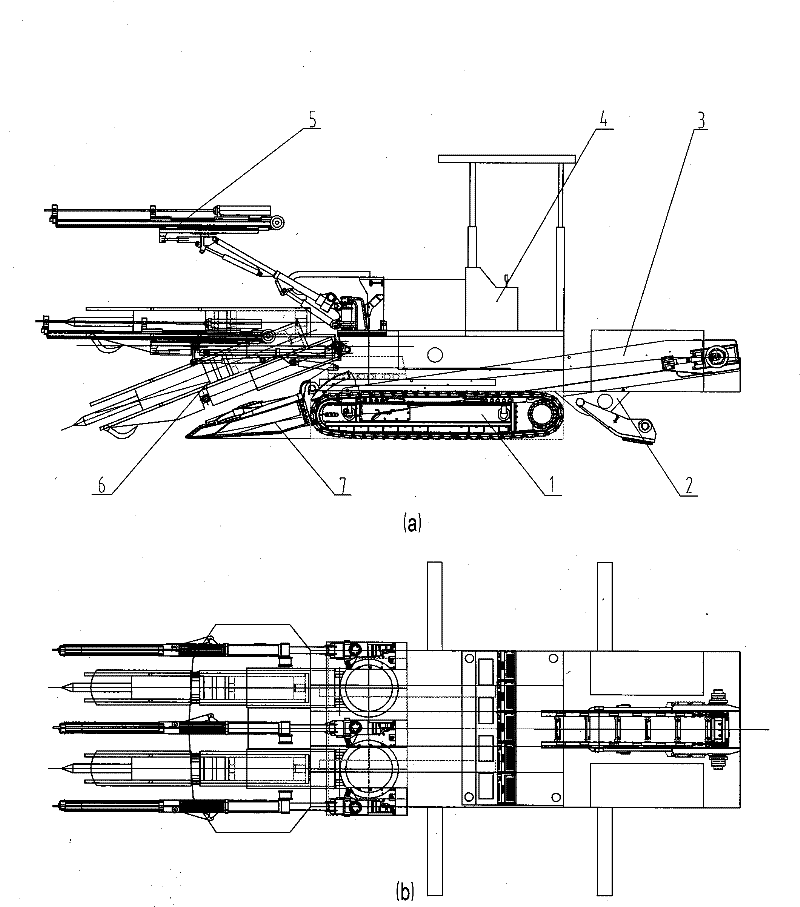

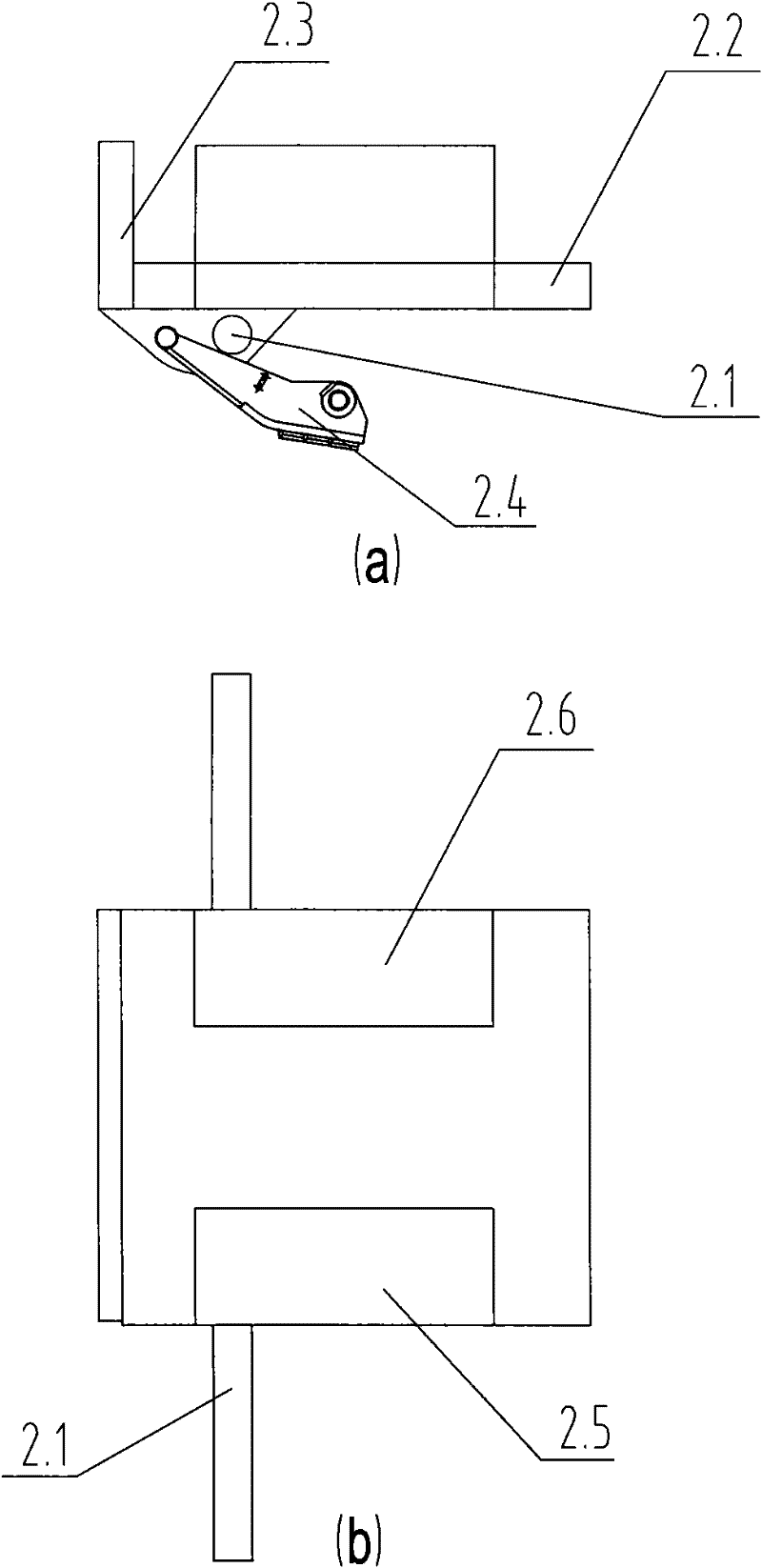

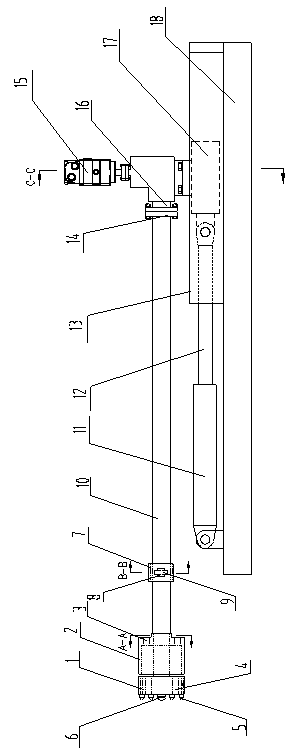

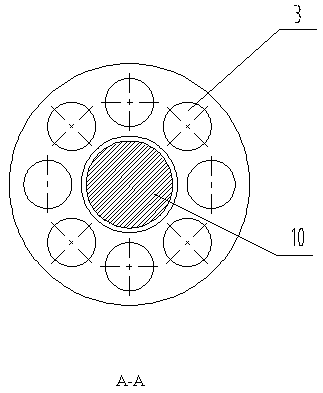

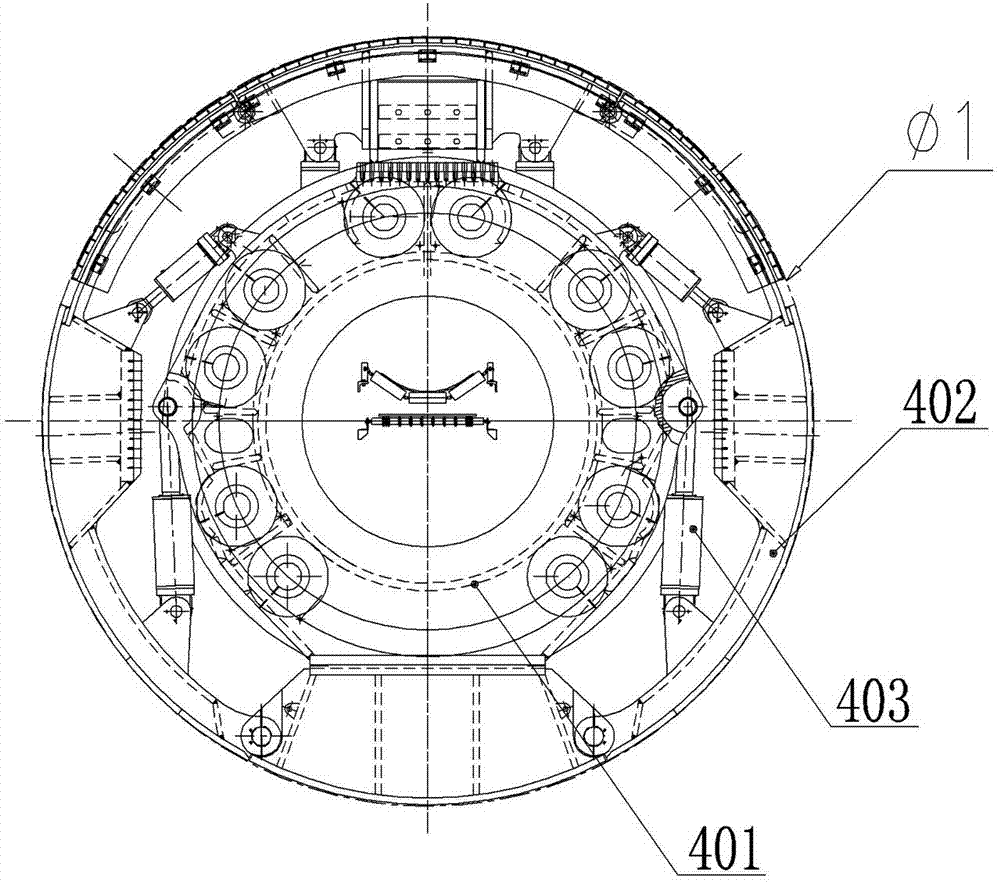

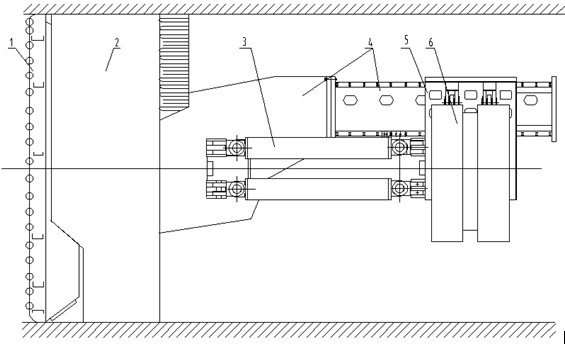

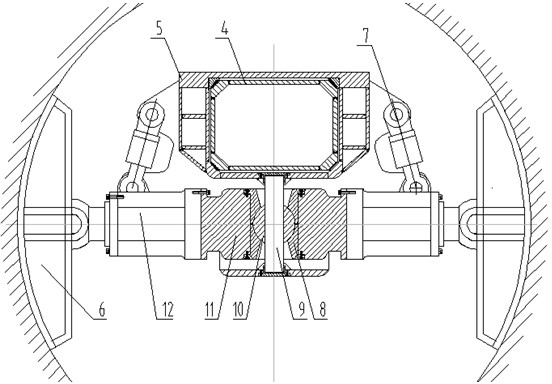

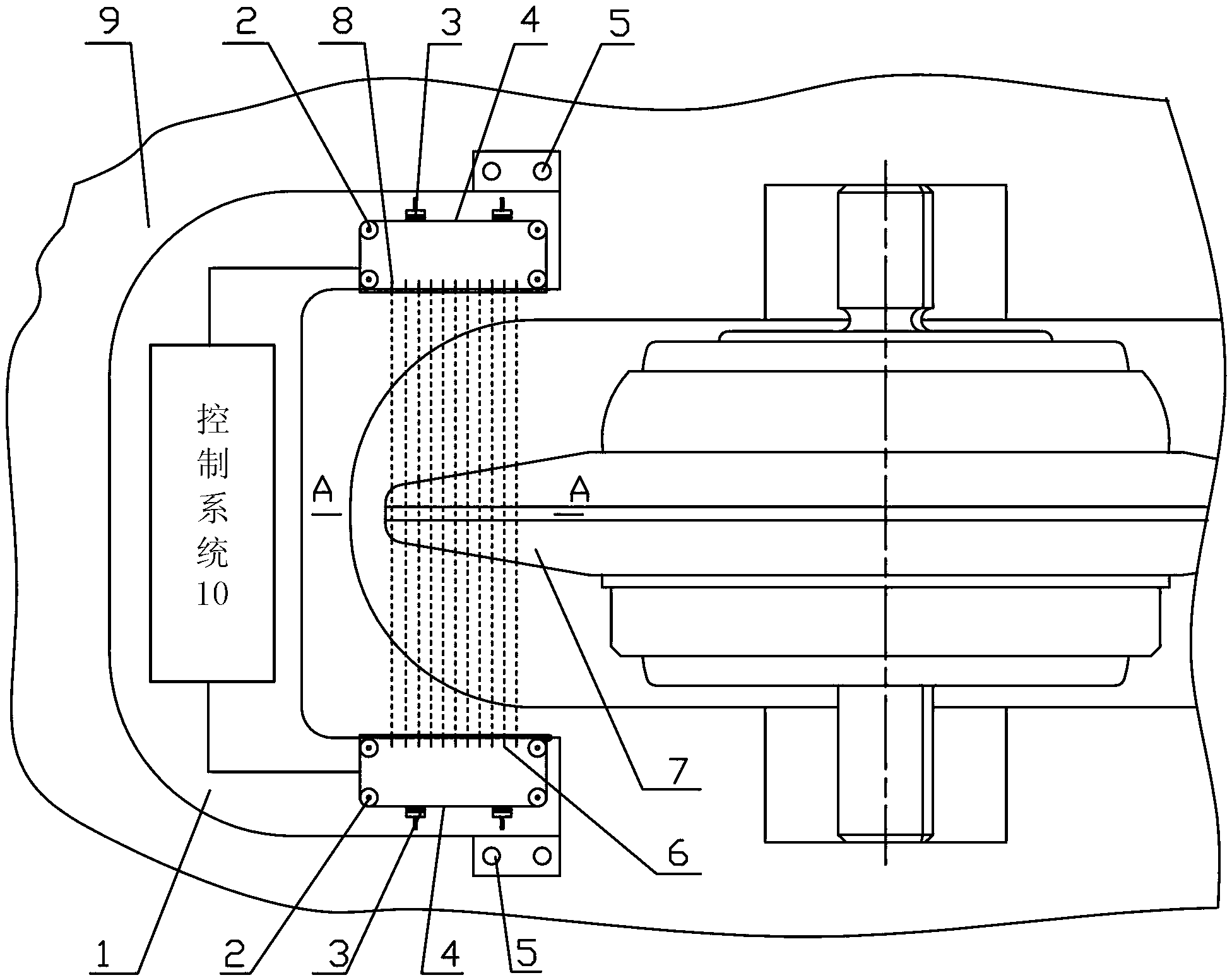

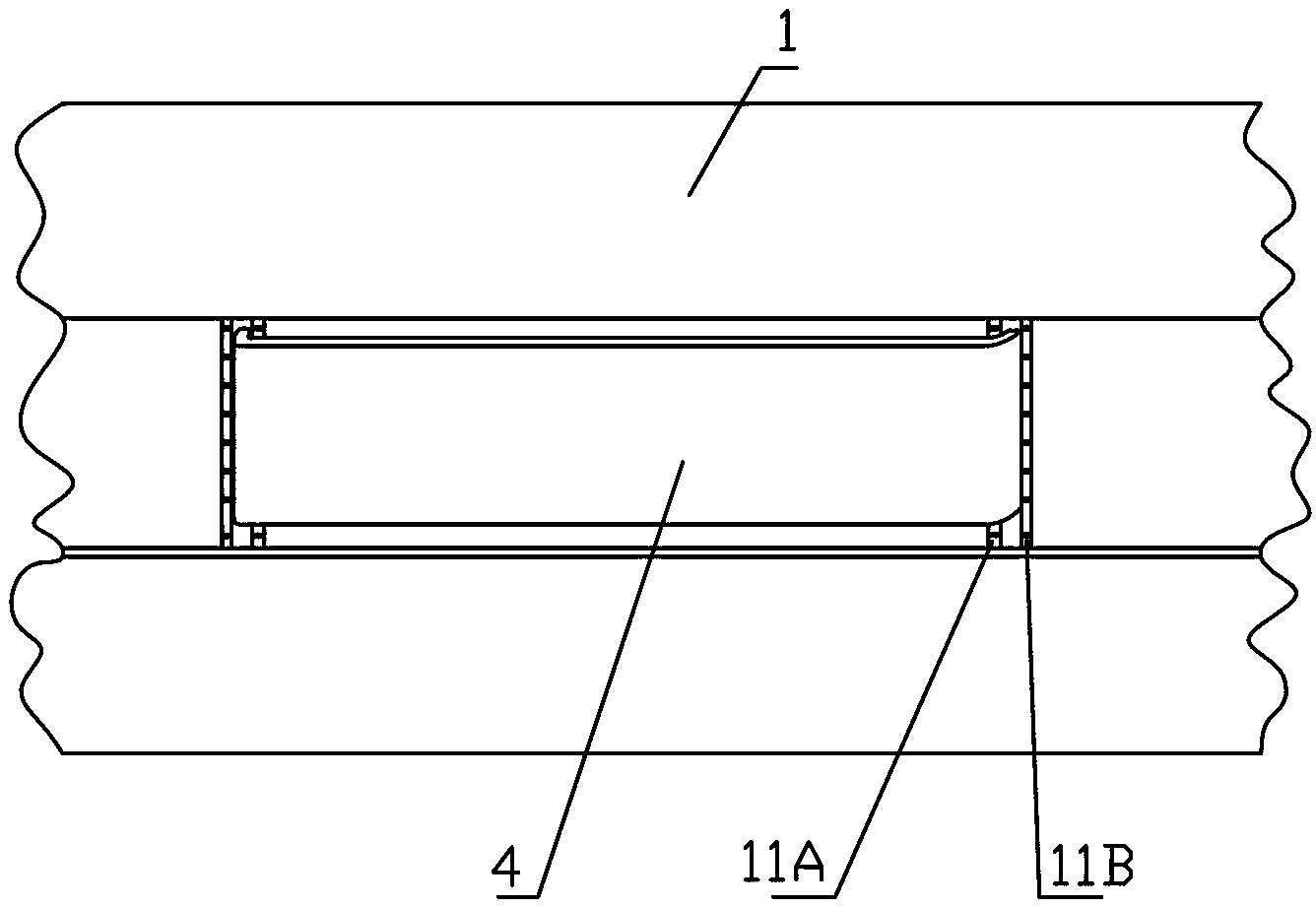

Miniature TBM (Tunnel Boring Machine) excavation system for tunnel excavation in physical simulation test

InactiveCN103364218AImprove excavation efficiencyImprove accuracyStructural/machines measurementTunnelsEngineeringRock tunnel

The invention relates to a miniature TBM (Tunnel Boring Machine) excavation system for tunnel excavation in a physical simulation test and belongs to the technical field of geotechnical engineering. The system comprises a cutter head, a protective shield, a gripper, a transmission shaft, a pulling jack, a guide rail, a motor, a base and the like; one end of the pulling jack is fixed to a support rack; a piston at the other end of the pulling jack is used for pulling the base and the motor to move forwards or backwards together; the motor is used for driving the transmission shaft to rotate to push the cutter head to move forwards to cut tunnel face rock mass; jacks on two sides of the gripper can push gripper arms to exert specified pressure to wall rock. The system can accurately simulate the rock breaking process of the cutter head, takes the interaction between the wall rock and the gripper, the interaction between the tunnel face and cutter head and the interaction between the wall rock and the protective shield into consideration, can be applied for simulating a shield TBM to excavate a soft rock tunnel, a subway or the like in a common geomechnical model test and can also be applied for simulating excavation of a TBM for a deep-lying hard rock tunnel to study the relationship between rock-machine interaction and rock burst.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

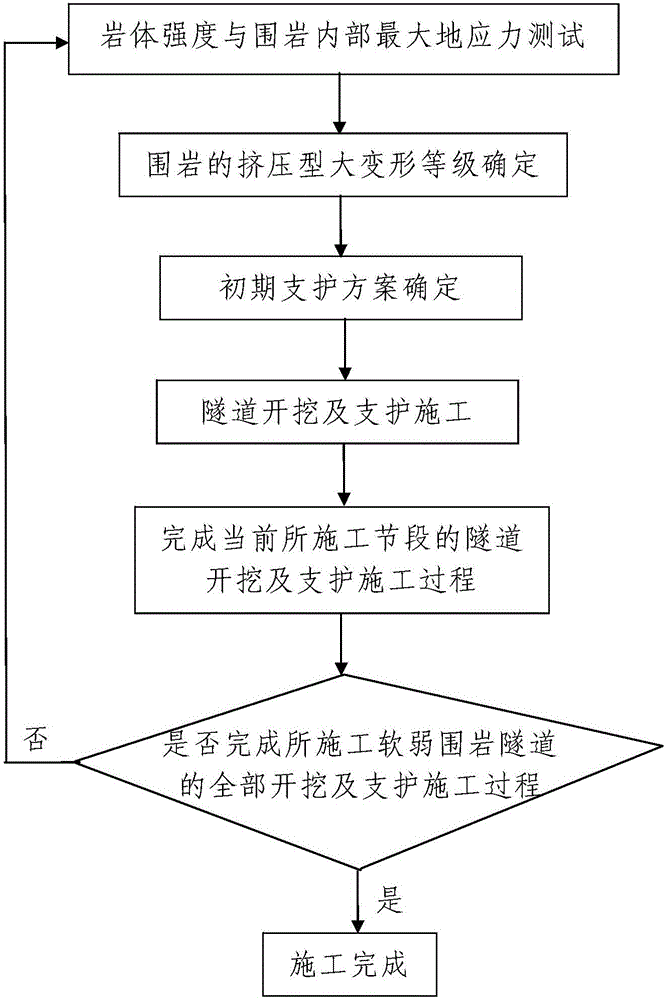

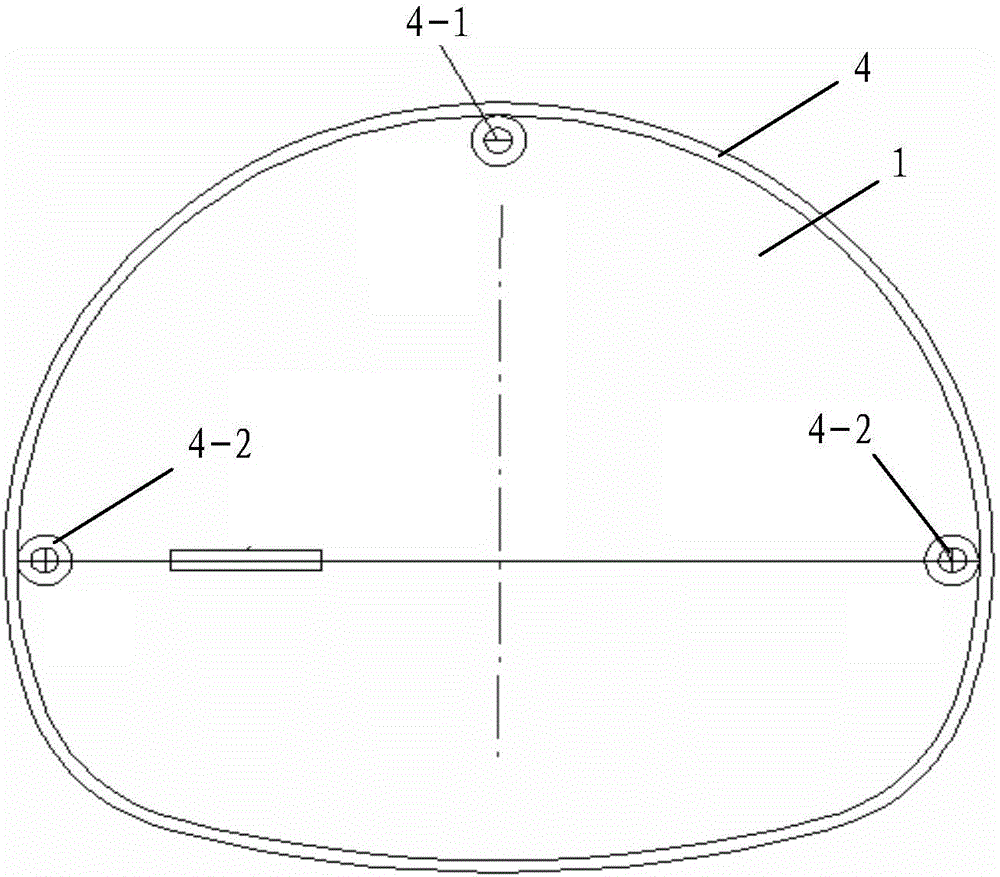

High ground stress weak surrounding rock tunnel excavation and support construction method

ActiveCN105156118AThe method steps are simpleReasonable designUnderground chambersTunnel liningSteel frameRock tunnel

The invention discloses a high ground stress weak surrounding rock tunnel excavation and support construction method. Excavation and support construction are conducted on a weak surrounding rock tunnel to be constructed in multiple sections from rear to front in the longitudinal extension direction of the tunnel. The method comprises the steps that 1, rock body strength and the maximum ground stress inside surrounding rock are tested; 2, the extrusion-type large-deformation level of the surrounding rock is determined; 3, a primary support scheme is determined, wherein the primary support scheme is determined according to the determined extrusion-type large-deformation level, and the primary support scheme is a profile steel frame support scheme or a grid steel frame and cover arch combined support scheme; 4, tunnel excavation and support construction are conducted; 5, excavation and support construction of the next section are conducted; 6, the fifth step is repeated for many times till the whole excavation and support construction process of the weak surrounding rock tunnel to be constructed is completed. According to the high ground stress weak surrounding rock tunnel excavation and support construction method, the steps are simple, the design is reasonable, construction is convenient, the use effect is good, the tunnel excavation and support construction process of the high ground stress weak rock tunnel can be completed easily, conveniently and rapidly, and the construction process is safe and reliable.

Owner:CHINA RAILWAY 20 BUREAU GRP

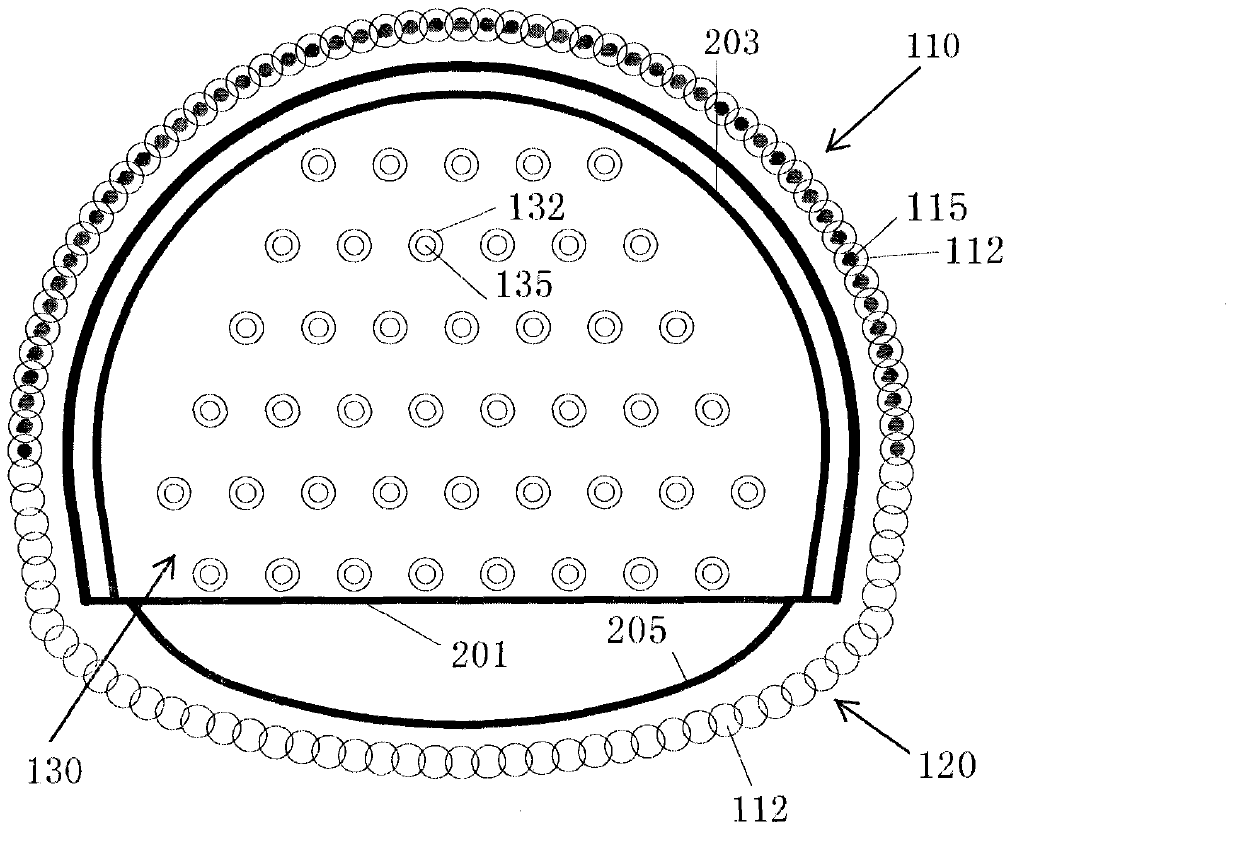

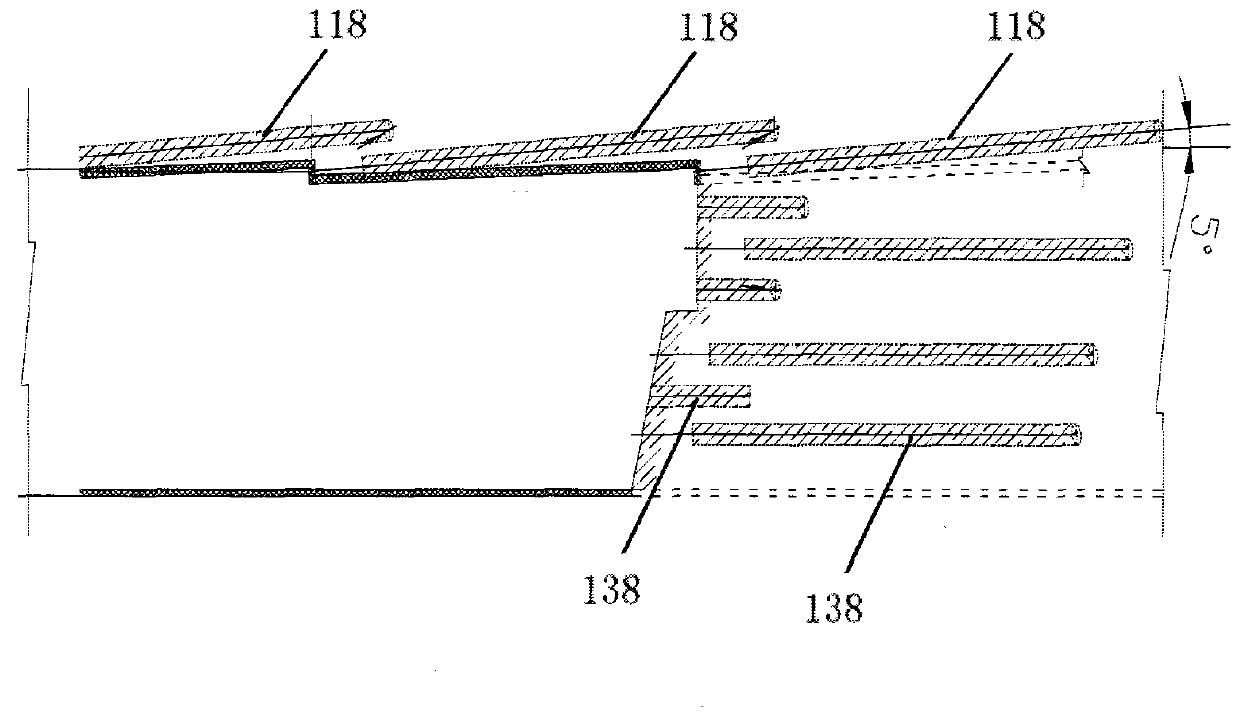

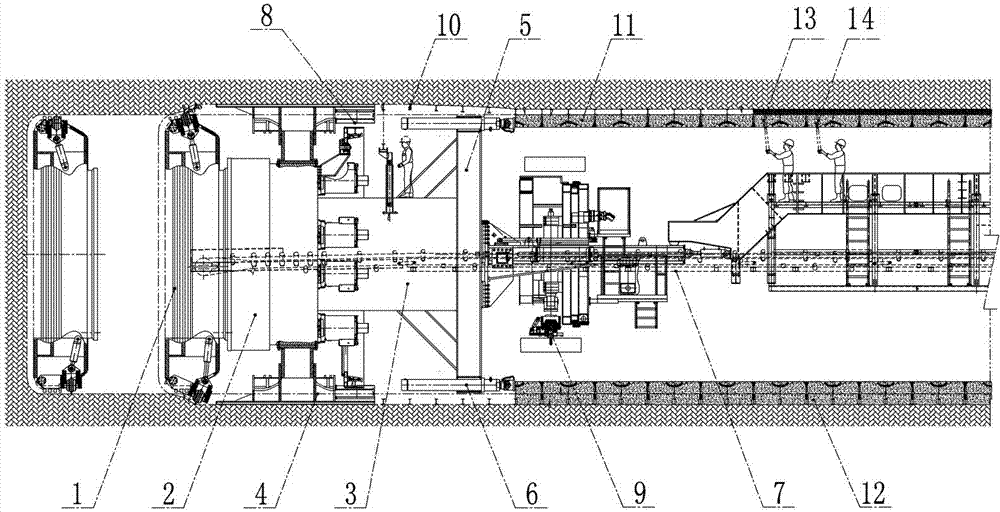

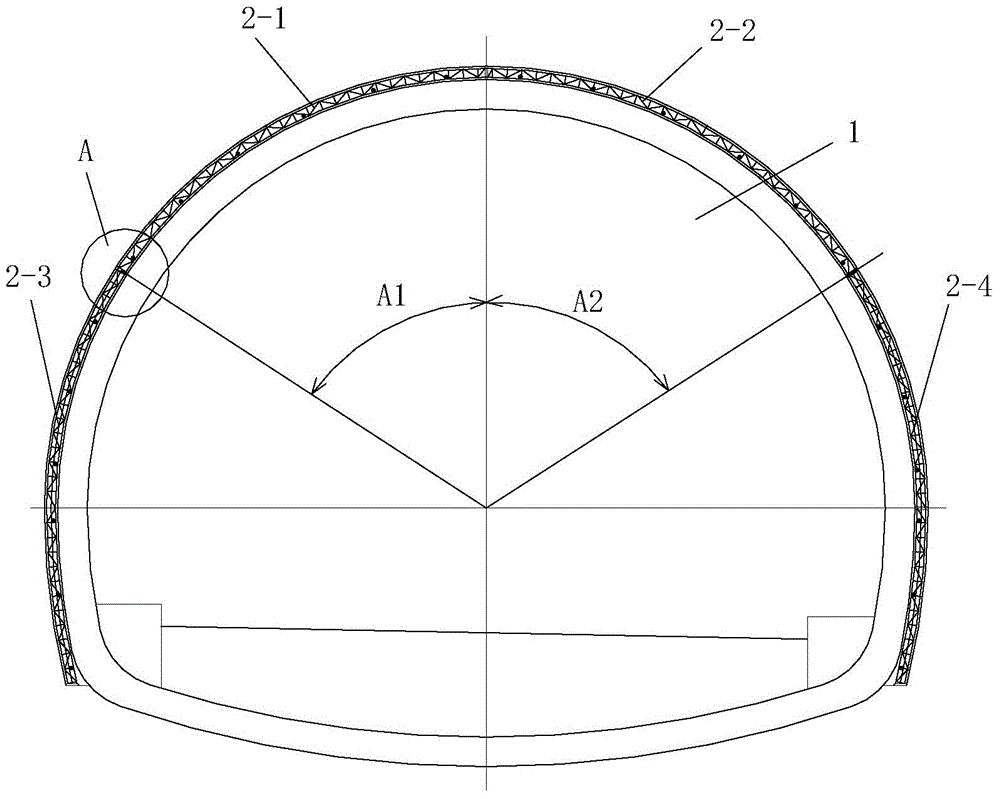

Pipe segment diameter adjustable hard rock tunneling machine adopting double-layer supporting mode and construction method thereof

ActiveCN104747200AEasy to assembleImprove stabilityUnderground chambersTunnel liningRock tunnelStructural engineering

The invention discloses a pipe segment diameter adjustable hard rock tunneling machine adopting a double-layer supporting mode and a construction method thereof. The pipe segment diameter adjustable hard rock tunneling machine comprises a cutter disc capable of performing expanded excavation, a round shield capable of extending radially, a flexible steel arch frame splicing machine, a pipe segment splicing machine and the like. The hard rock tunneling machine creatively enables shield clamping to be nipped in the bud through coordinative operation of expanded excavation, flexible supporting, pipe segment supporting, pea gravel filling, grouting and other processes in the high-stress formation tunneling process, and meanwhile lining operation of a hard rock tunnel can be completed from beginning to end without stopping in a mechanical mode. Therefore, the shield clamping problem of the hard rock tunneling machine can be avoided, further the tunneling efficiency is improved, and the lining time and the amount of used labor of the hard rock tunnel can be also decreased.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

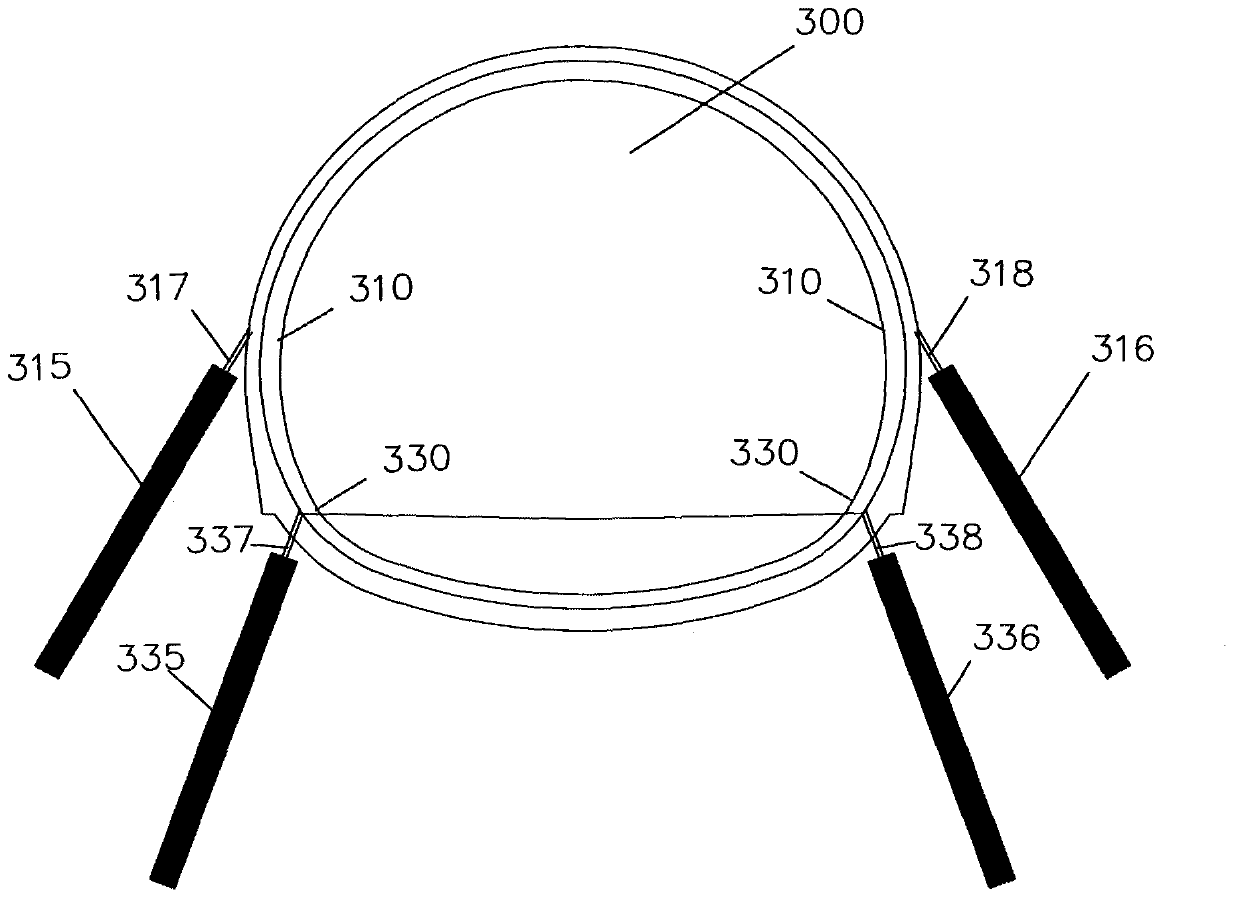

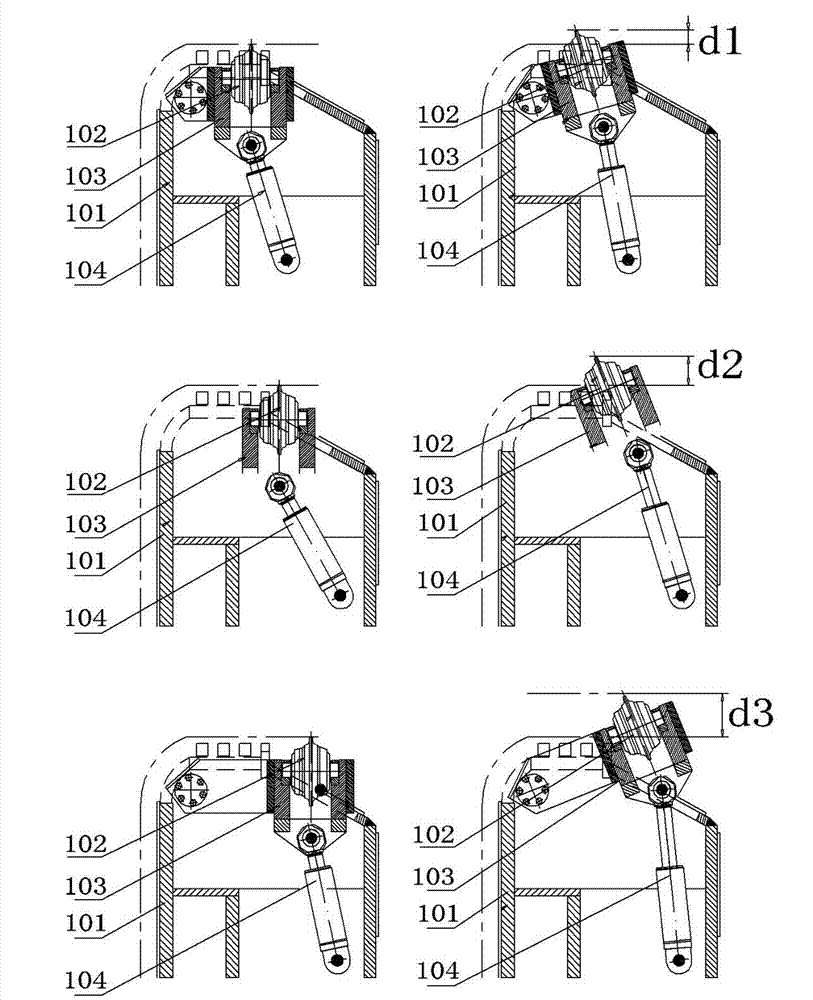

Spherical support girder turning mechanism for open-type hard-rock boring machines

InactiveCN102691506AEasy to operateExcellent anti-vibration performanceTunnelsEngineeringRock tunnel

The invention discloses a spherical support girder turning mechanism for open-type hard-rock boring machines, which is applied to the field of full-face hard-rock tunnel boring machines. The spherical support girder turning mechanism comprises a cutterhead, a shield, a thrust cylinder, a girder, torque cylinders, an articulated ball gland and horizontal support cylinders and the like, wherein the cutterhead, the shield and the girder of the full-face hard-rock tunnel boring machine are connected into a whole through bolts, the girder and a saddle are assembled together through a box structure with a guide slideway, the two ends of the thrust cylinder are respectively articulated on the girder and a bracing shoe, the four corners of the girder and the saddle are respectively provided with a guide slideway, the saddle is connected with the horizontal support cylinders through the torque cylinders on both sides of the saddle, a central pin shaft is arranged in an articulated ball, the two ends of the central pin shaft are fixed on upper and lower plates of the saddle, and a central block is fastened with the two horizontal support cylinders through a bolt. The most striking design characteristic of the invention focuses on the central pin shaft and the articulated ball; and the spherical support girder turning mechanism disclosed by the invention is easy to operate, safe and reliable, good in vibration-resistant effect and uneasy to damage.

Owner:NORTHERN HEAVY IND GRP CO LTD

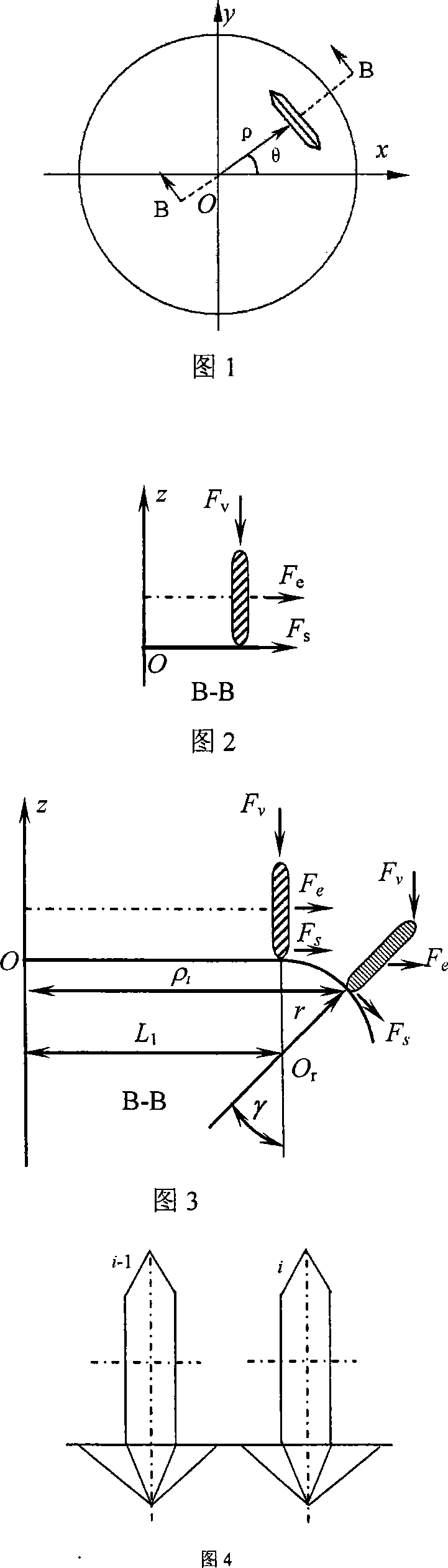

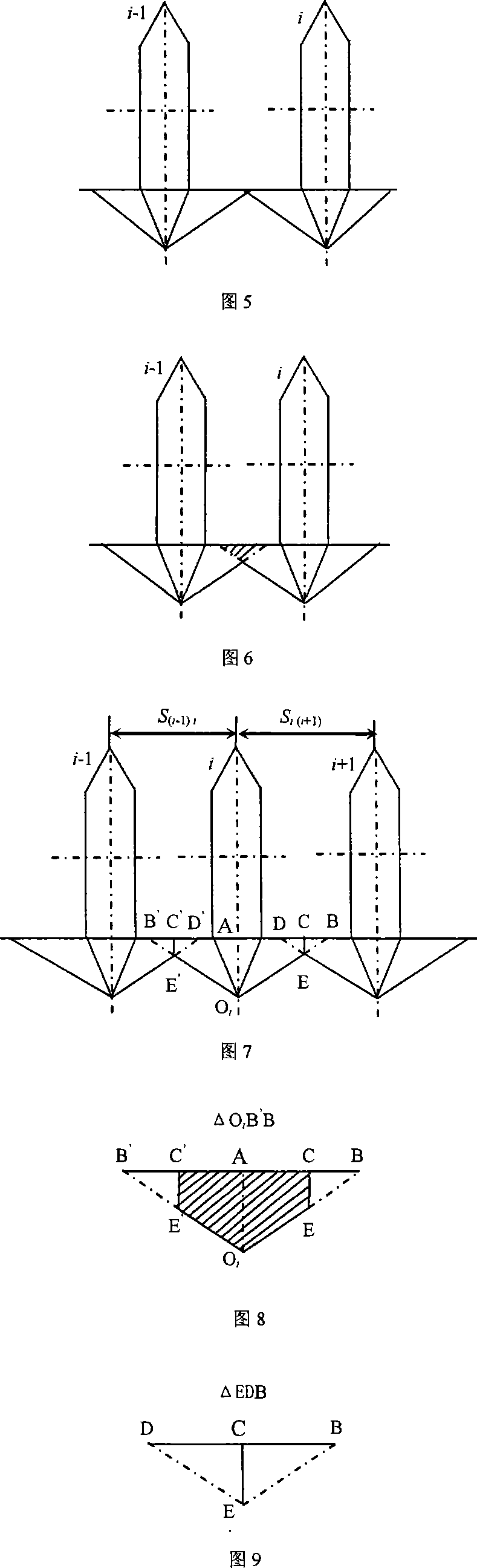

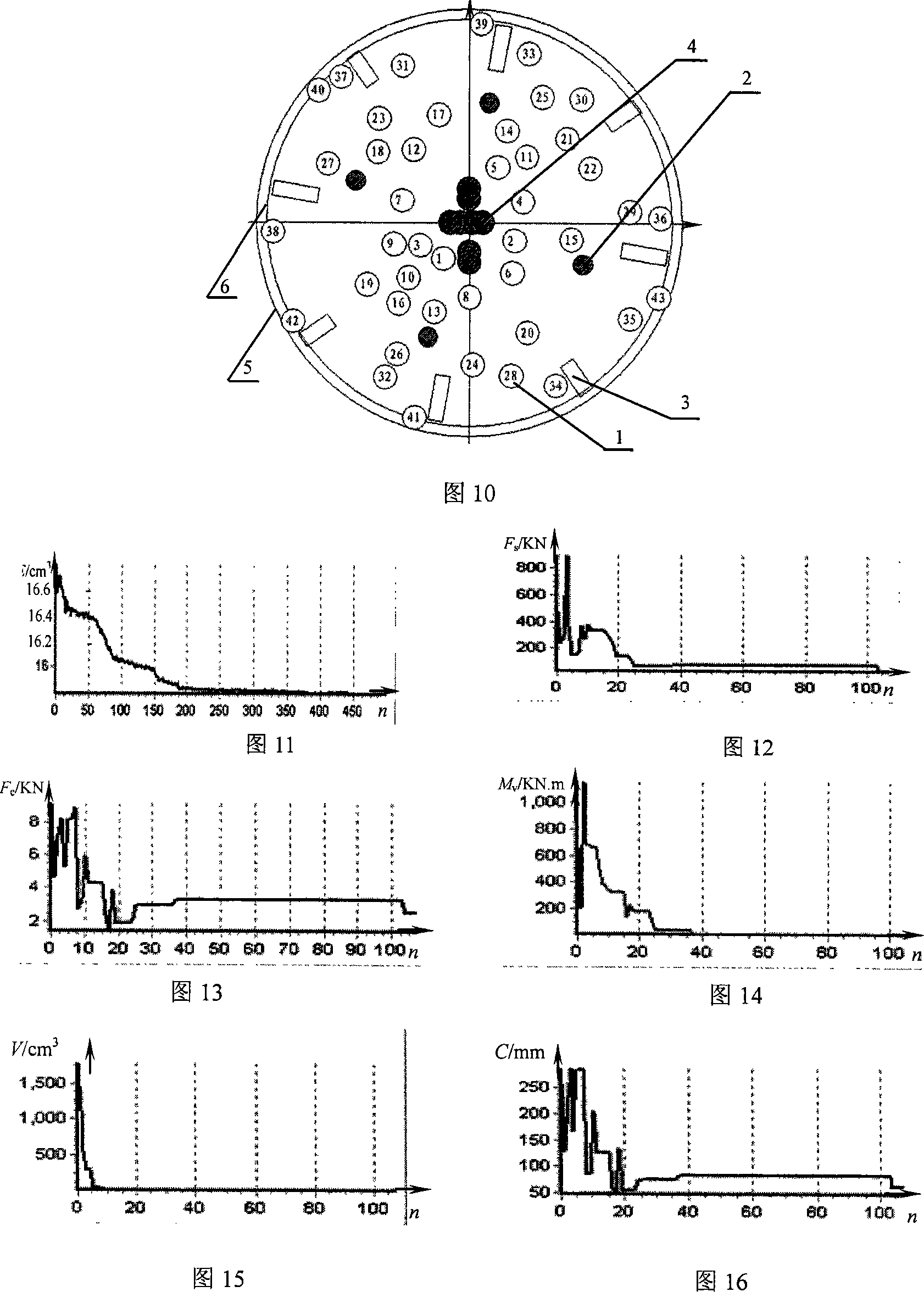

All-section rock tunneling machine cutter layout design optimization method

InactiveCN101086208AShorten the development cycleReduce vibrationTunnelsDesign cycleGenetic algorithm

The invention relates to a disk cutter layout design optimization method of development machine, concerning not micro and multi-modal disk cutter layout design optimization problems, especially applicable to full-face rock tunnel boring machine tool optimized layout design. A full-face rock tunnel boring machine knife tool layout design method, first determine disc hob position on the knife set and knife set overall technical performance parameters, in accordance with the actual knife tool layout technical requirements of the full-face rock tunnel boring machine, establishment of the binding properties of complex nonlinear multi-objective optimization model for knife tool layout; layout tool to establish grading optimization design model of knife tool layout polar pathway and angle calculation; putting the knife tool polar pathway and disc cutter knife polar angle as a design variable, adoption the genetic algorithm. The invention fast and effective in the determination of the knife tool optimized layout on the knife disc, made the knife disc having a small outside force and outside torque, thereby prolonging knife disc, knife tool and knife disc axletree life of the development machine, shorten the design cycle and improve design efficiency .

Owner:XCMG KAIGONG HEAVY IND NANJING

TBM hob abrasion detection device

InactiveCN103234903ACompact structureEasy to assembleMaterial analysis by optical meansUsing optical meansControl systemEngineering

The invention discloses a TBM (tunnel boring machine) hob abrasion detection device comprising a concave shaped shell, the inward concave side wall of which is made of a transparent material. Two ends of the concave shaped shell inward concave side wall are an optical signal emission end and a receiving end respectively. The optical signal emission end can emit a set of parallel laser beams, and the optical signal receiving end is a set of photosensitive sensors, so that a plurality of parallel optical paths can be formed, and the on-off state of the optical paths can be determined by the abrasion degree of a hob ring. The device is also provided with a cleaning structure, a power supply and a control system. The control system receives data coming from the photosensitive sensors, and transmits the data to a TBM operation room host machine. With the advantages of simple structure, convenient installation, high efficiency and reliable work, strong practicality, cheapness, portability, easy control and the like, the TBM hob abrasion detection device provided in the invention also can eliminate the optical path breakover problem probably caused by rock powder during use, and is especially suitable for hard rock tunneling TBM hobs, thus making real time dynamic abrasion detection on the hob installed on a cutterhead become possible.

Owner:TIANJIN UNIV

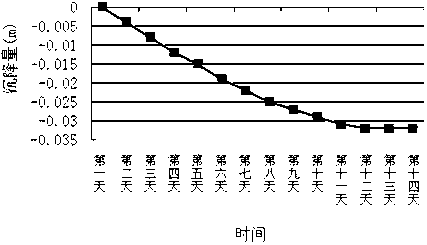

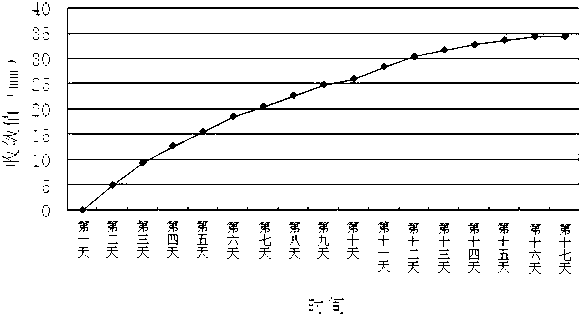

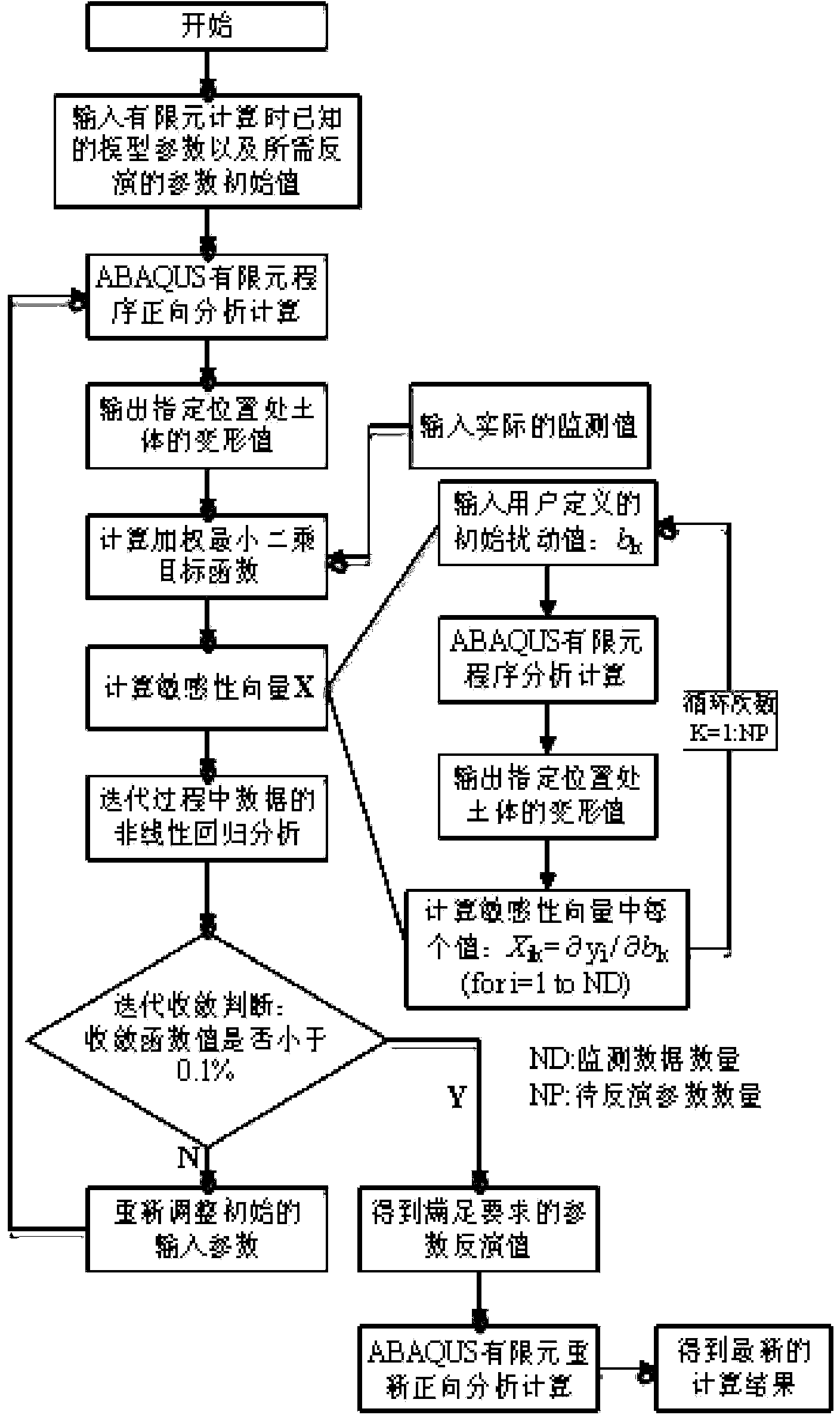

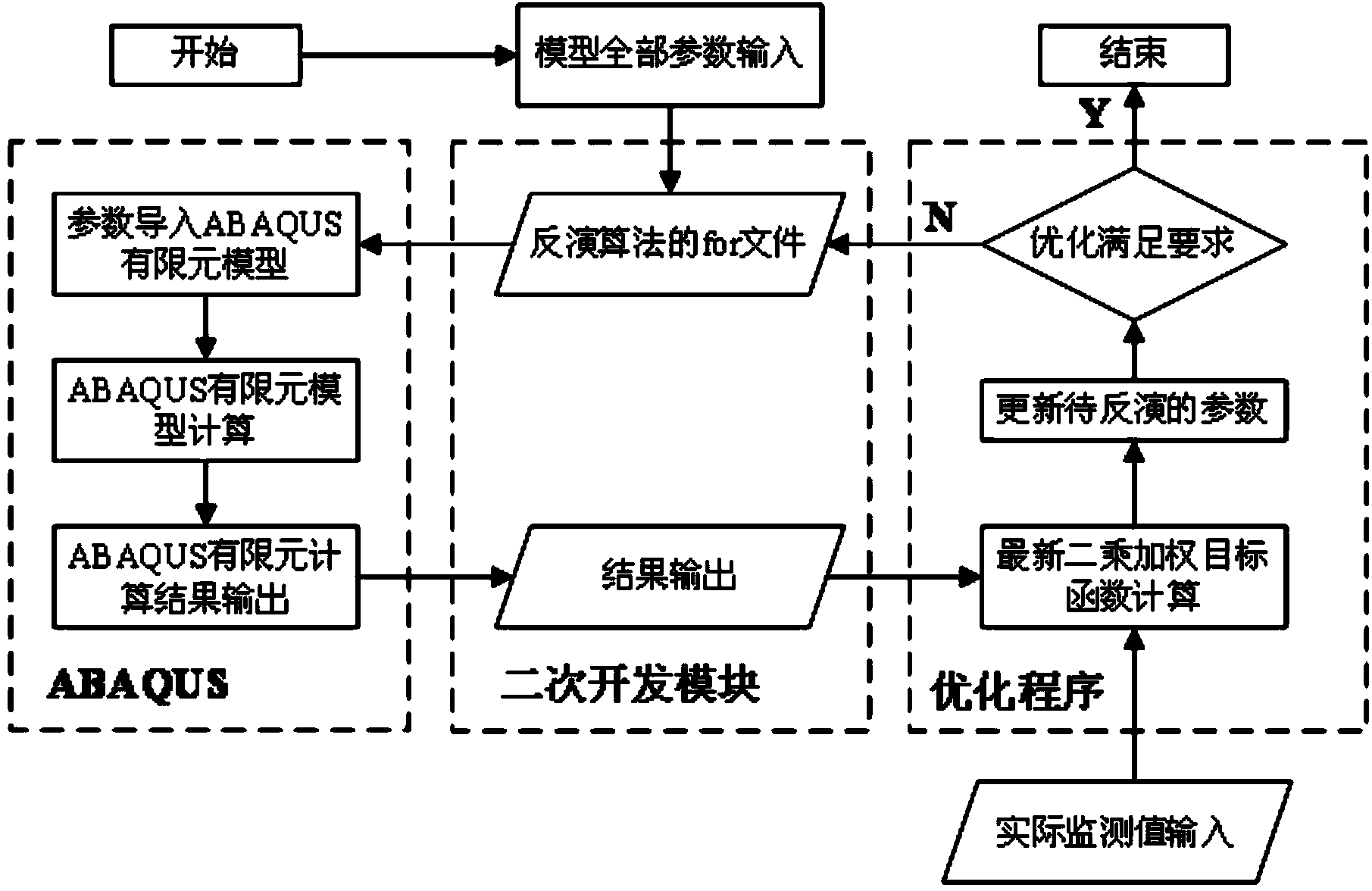

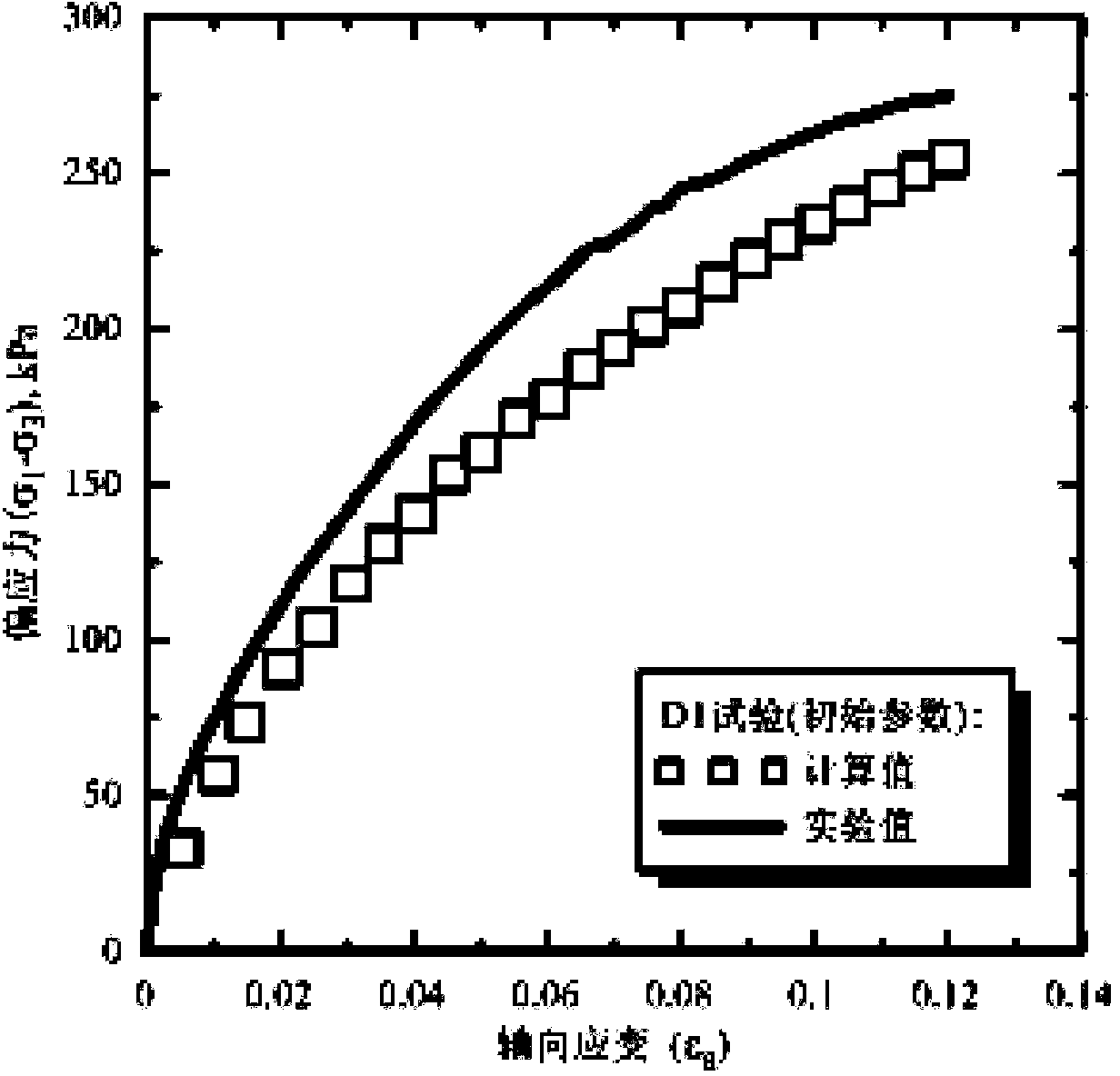

Deep soft soil metro foundation pit soil body parameter inversion analyzing method

InactiveCN104077451AAdd sensitivity settingsEasy to monitorSpecial data processing applicationsSoil scienceRock tunnel

The invention relates to the technical field of rock tunnel construction and earthwork parameter calculation, in particular to a deep soft soil metro foundation pit soil body parameter inversion analyzing method. The method includes multiplying a least square function of a difference value between a finite element numerical calculation result and an actually monitored value by a specific weighting coefficient to obtain the function which serves as a target function, utilizing an improved Gaussian-Newton method to conduct optimal solution on the target function, and conducting repeated iterative computation to enable the finite element numerical calculation result to gradually approach the actually monitored value to determine an optimal solution of a parameter to be confirmed and build the relation between the monitored value and the foundation pit soil body parameter basic characteristic value. By means of the method, the actual observation value is combined to conduct constant soil body parameter inversion and correction to further predict the soil body deformation of the next stage, a prediction result is more and more accurate with the number increase of the monitored value, a very good monitoring and early warning method is provided for deep soft soil metro foundation pit project construction, and the method has high application value in the soil body parameter determination process.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

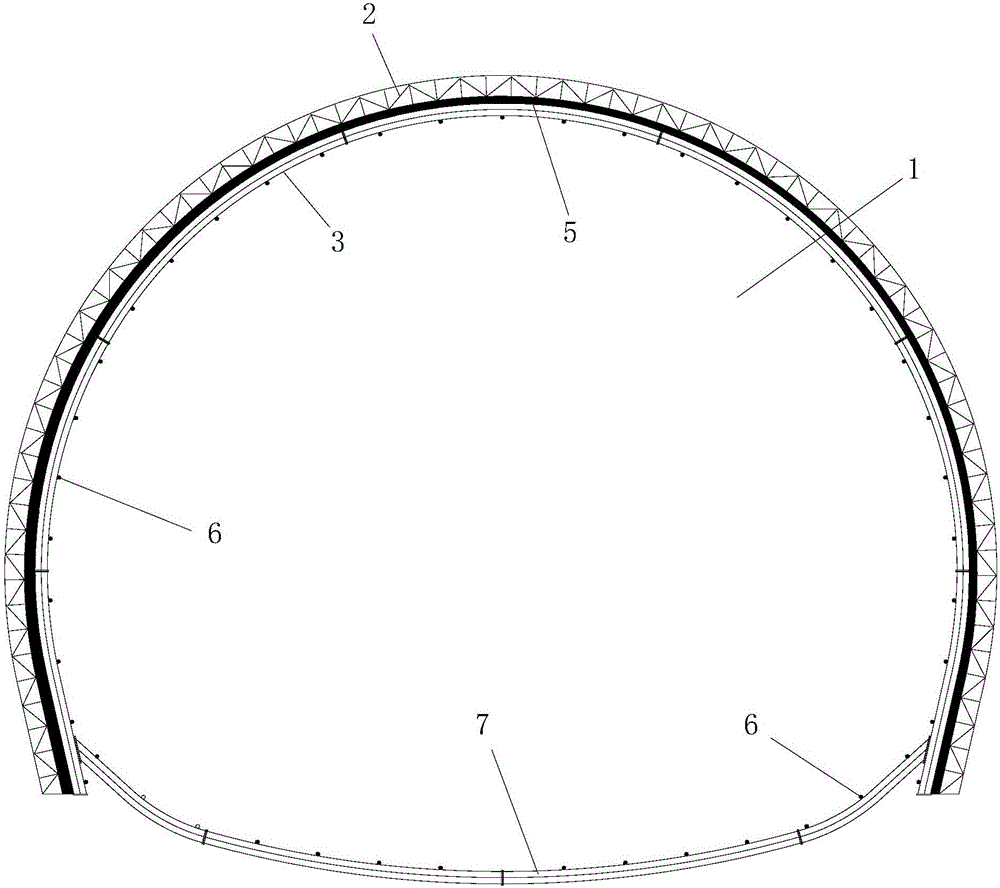

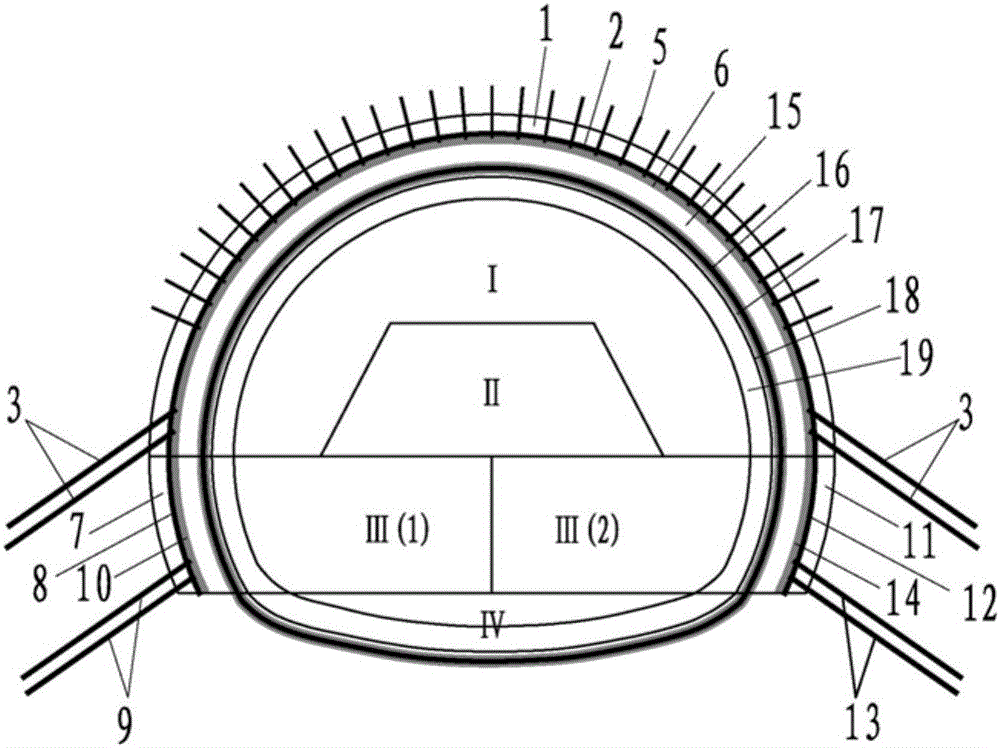

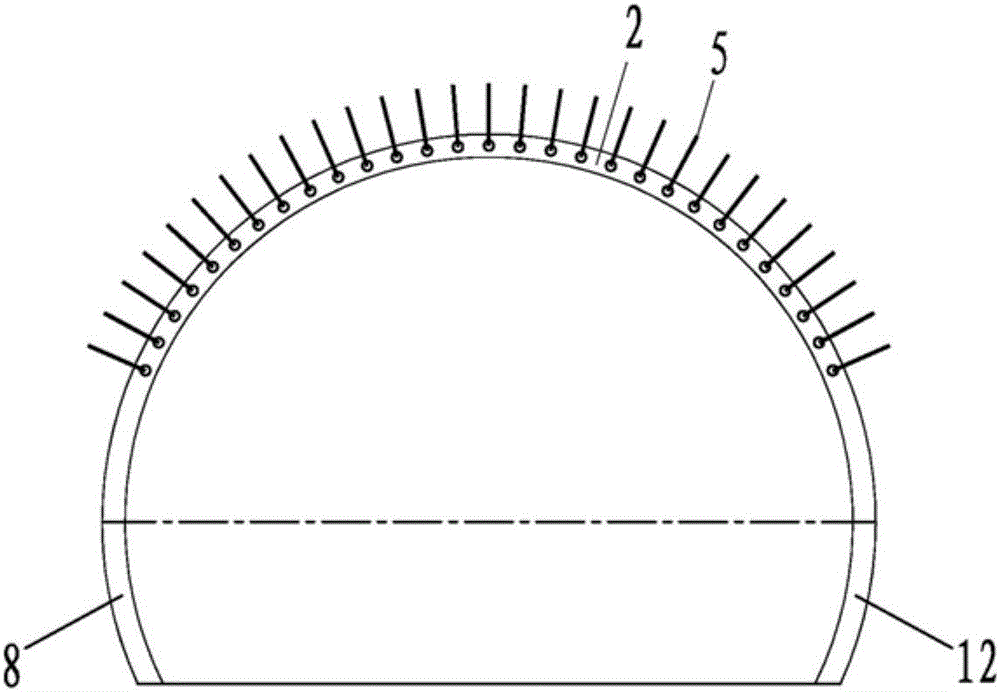

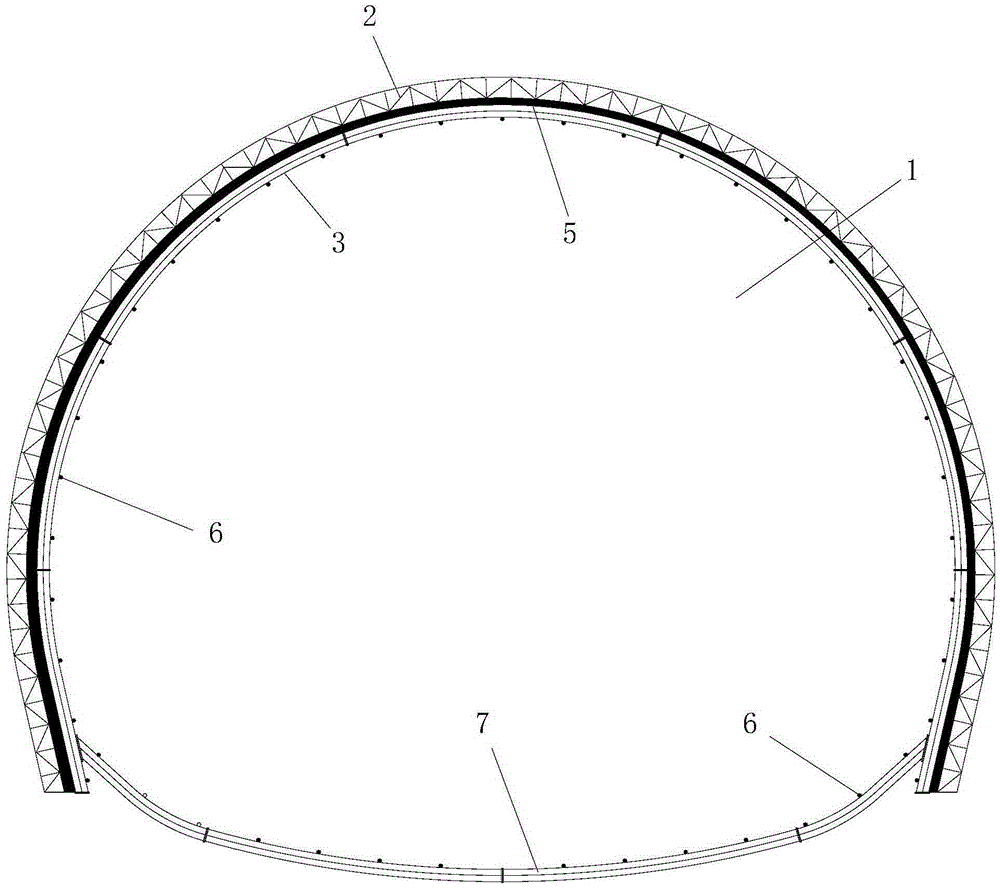

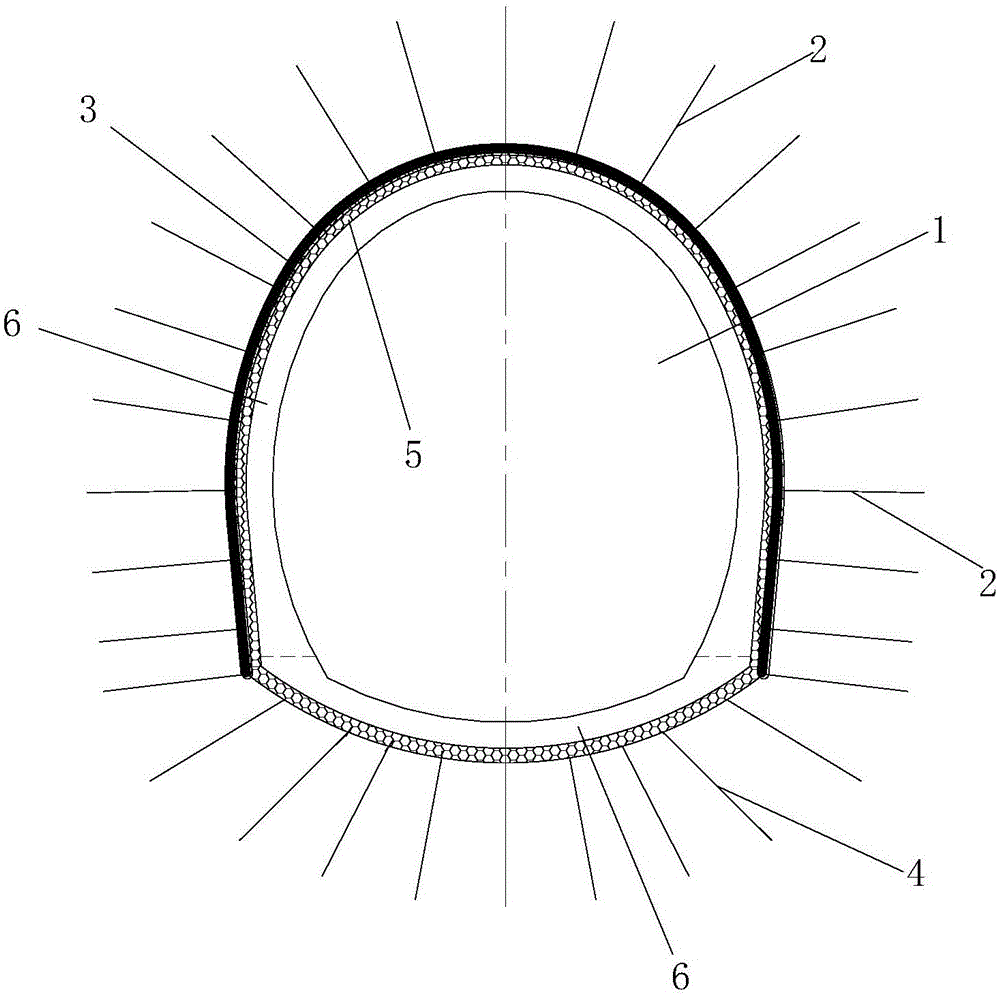

Soft rock large-deformation tunnel support structure system and construction method thereof

ActiveCN106761810APrevent intrusionReduce surrounding rock pressureUnderground chambersTunnel liningShotcreteStructure of the Earth

The invention relates to the field of tunnel engineering, in particular to a soft rock large-deformation tunnel support structure system and a construction method thereof. According to the soft rock large-deformation tunnel support structure system and the construction method thereof, double layers of elastic foam boards are arranged between surrounding rock and primary supports, thus enough surrounding rock deformation space is reserved so as to adapt to the requirement of soft rock tunnel large deformation, the problem of limit intrusion caused by too large surrounding rock deformation can be avoided, and surrounding rock pressure acting on a support structure can also be reduced effectively. The primary supports are reinforced, sprayed concrete spalling chipping, steel frame warp dislocation breakage, secondary lining cracking and other phenomena caused by too large stress on the support structure can be avoided by adopting the double-layer primary supports, and finally safety and reliability of the soft rock large-deformation tunnel support structure are ensured. Aiming at the characteristics that a soft rock large-deformation tunnel system is not obvious in anchor rod effect and waste time and labor, application of a system anchor rod in a soft rock large-deformation tunnel is canceled, the measures of reinforcement of a locking anchor pipe and steel frame longitudinal connection are provided, corresponding reasonable support parameters are given, and thus tunnel subsidence can be controlled better.

Owner:CHANGAN UNIV

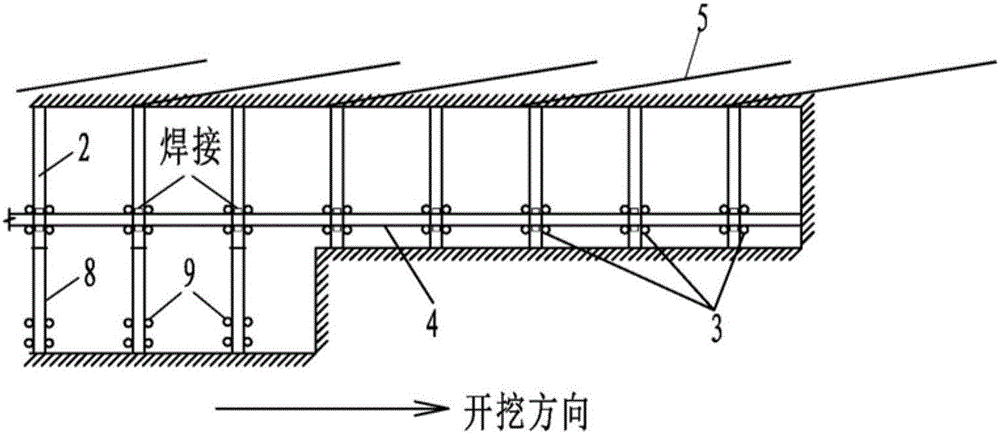

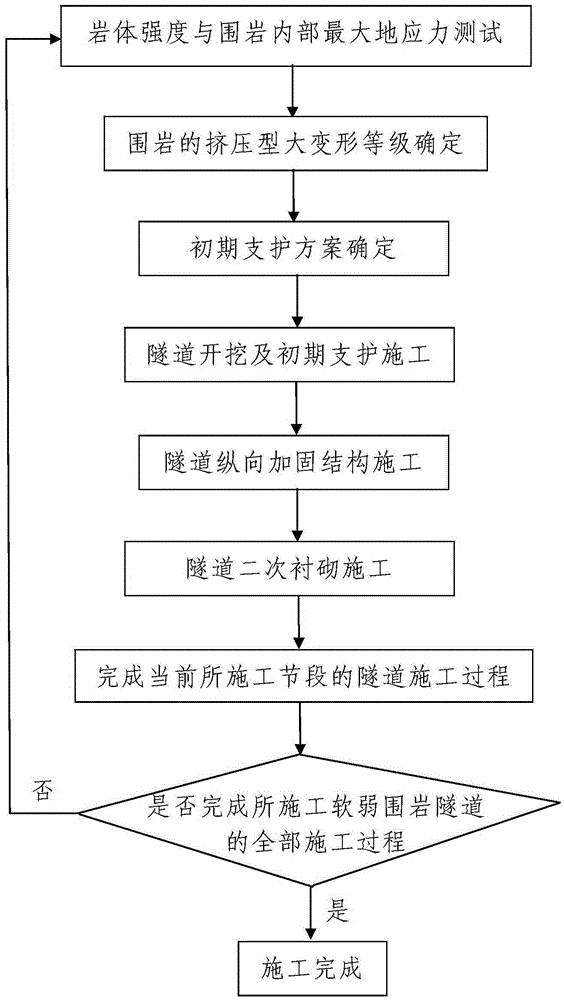

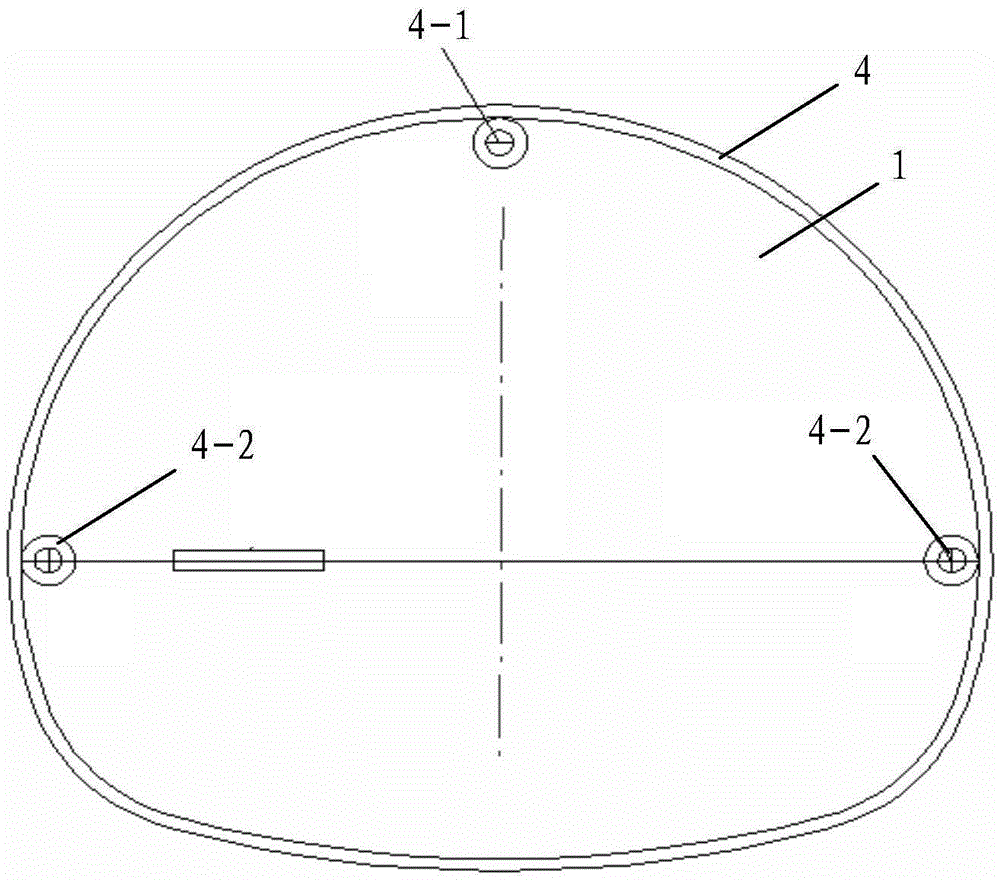

Large-deformation control construction method for high ground stress weak surrounding rock tunnel

ActiveCN105401947AThe method steps are simpleReasonable designUnderground chambersTunnel liningStructure of the EarthRock tunnel

The invention discloses a large-deformation control construction method for a high ground stress weak surrounding rock tunnel. A plurality of segments are arranged in the longitudinal extending direction of the tunnel from back to front to construct the constructed weak surrounding rock tunnel. The method comprises the steps that firstly, the rock strength and surrounding rock interior maximum ground stress test is carried out; secondly, the large extrusion deformation grade of the surrounding rock is determined; thirdly, a primary support scheme is determined; fourthly, tunnel excavation and primary support construction are carried out; fifthly, longitudinal tunnel strengthening structure construction is carried out; sixthly, tunnel secondary lining construction is carried out; seventhly, construction of the next segment is carried out according to the first step to the sixth step; and eighthly, the seventh step is repeated many times till the whole construction process of the constructed weak surrounding rock tunnel is finished. According to the method, the steps are simple, the design is reasonable, construction is convenient, and the using effect is good. The tunnel construction process of the high ground stress weak surrounding rock tunnel can be easily, conveniently and rapidly finished, the construction process is safe and reliable, and the large deformation of the weak rock can be effectively controlled.

Owner:CHINA RAILWAY 20 BUREAU GRP

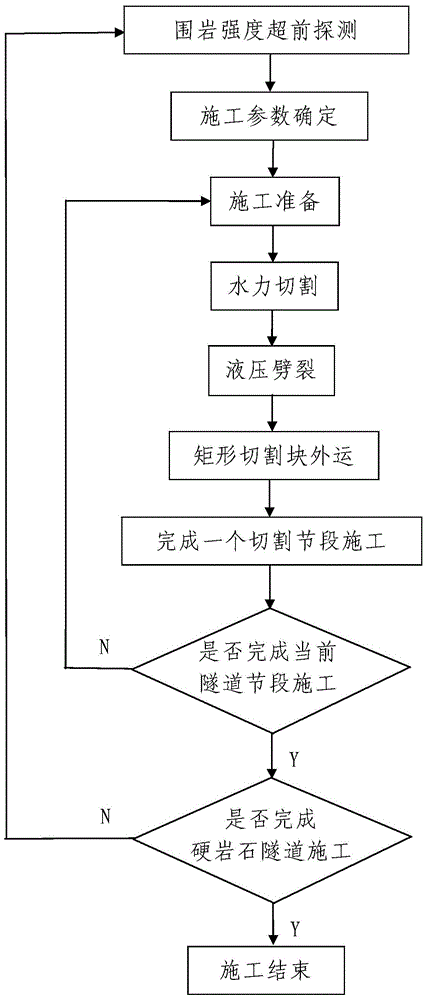

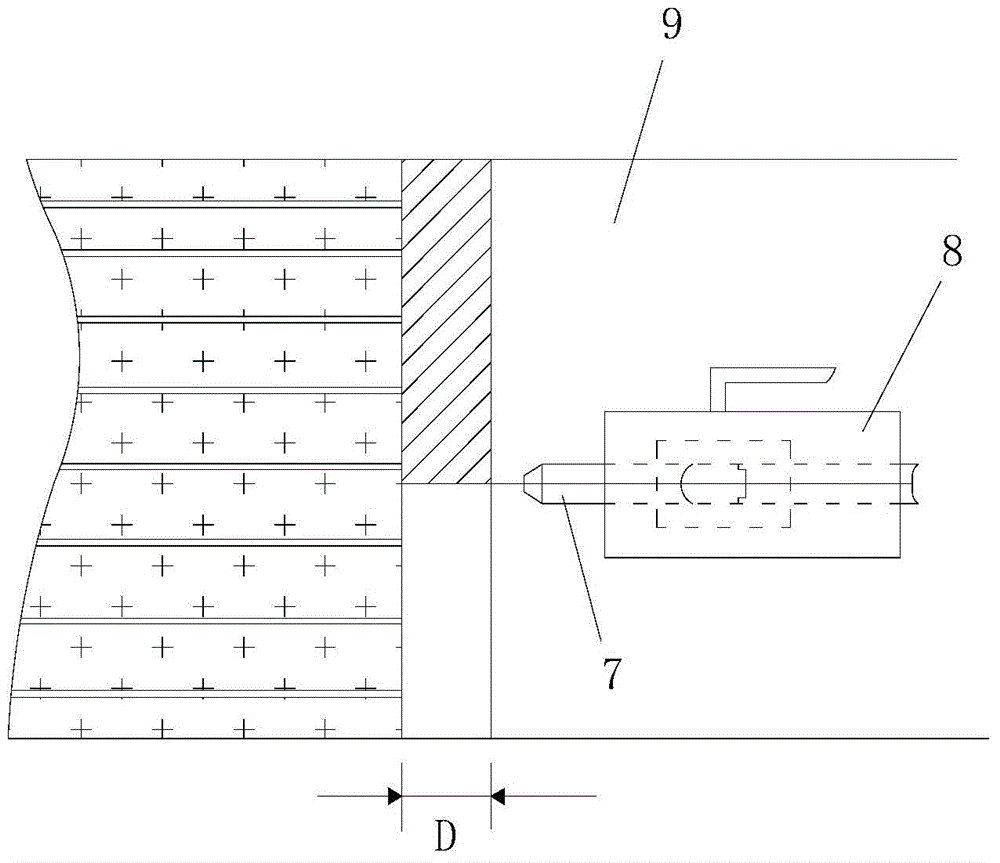

Hard rock tunnel construction method based on water power cutting

The invention discloses a hard rock tunnel construction method based on water power cutting. The hard rock tunnel construction method based on the water power cutting is characterized by constructing multiple tunnel sections from back to front along the longitudinal extending direction of a tunnel. When any one tunnel section is constructed, the process is as follows: 1, surrounding rock classification advanced detection; 2, construction parameter confirmation, wherein the confirmed construction parameters comprise cutting parameters of a water power cutting machine and split force of a hydraulic splitter; 3, current constructed tunnel section construction: constructing multiple cutting sections of the current constructed tunnel sections from back to front along the longitudinal extending direction of the tunnel, wherein when any one cutting section is constructed, the process is as follows: construction preparation, water power cutting, hydraulic splitting and rectangular cutting block outward transporting; 4, repeating steps one, two and three for many times until the construction process of the constructed hard rock tunnel is finished. The method provided by the invention is simple in steps, convenient to implement, lower in input cost, high in construction efficiency, good in construction effect, and can simply, conveniently and quickly finish the construction process of the hard rock tunnel.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

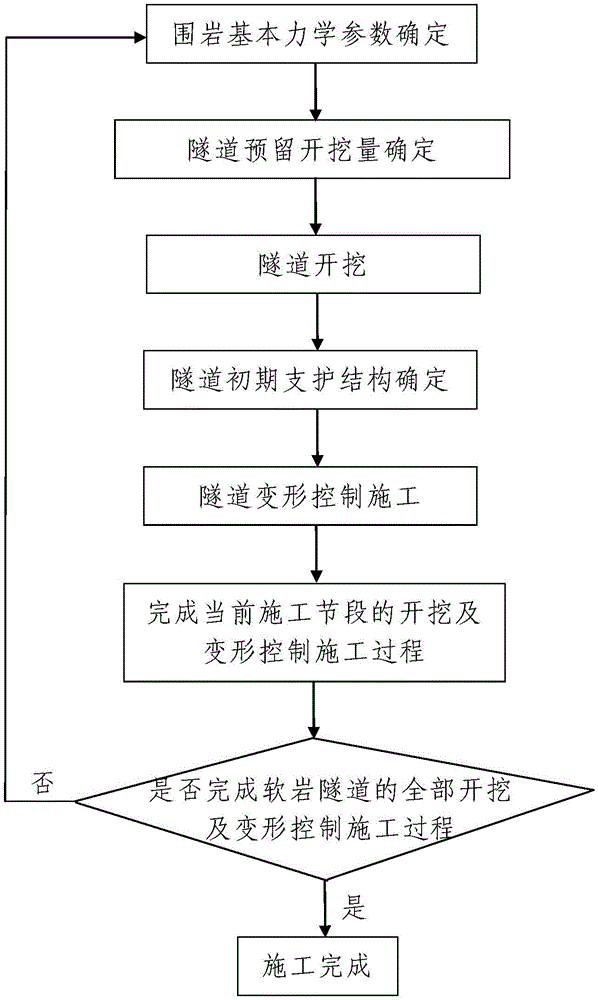

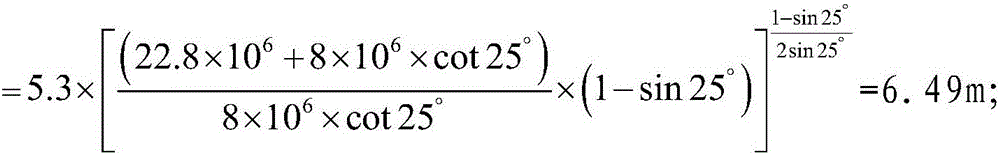

Soft rock tunnel deformation control method based on anchor rod force analysis

InactiveCN106499397AThe method steps are simpleEasy to implementUnderground chambersTunnel liningStructure of the EarthForce analysis

The invention discloses a soft rock tunnel deformation control method based on anchor rod force analysis. A soft rock tunnel is excavated and subjected to deformation control construction from back to front according to multiple segments, and when any segment is excavated and subjected to deformation control construction, the method includes the steps that 1, surrounding rock basic mechanical parameters are determined; 2, the tunnel reserved excavated volume is determined; 3, the tunnel is excavated; 4, a tunnel preliminary bracing structure is determined; 5, tunnel deformation control construction is carried out, wherein in the tunnel preliminary bracing construction process, a flexible mold bracing structure is constructed from back to front; 6, a next segment is excavated and subjected to deformation control construction; 7, the step 6 is repeated multiple times till the full excavation and deformation control construction process of the soft rock tunnel is completed. The soft rock tunnel deformation control method is reasonable in design, convenient to achieve and good in use effect, the reserved excavated volume is determined according to the surrounding rock deformation condition of the soft rock tunnel, the flexible mold bracing structure is adopted for carrying out full-section bracing on the tunnel, the flexible mold bracing structure and the tunnel preliminary bracing structure are in coordination deformation, and deformation of the soft rock tunnel can be effectively controlled.

Owner:XIAN UNIV OF SCI & TECH

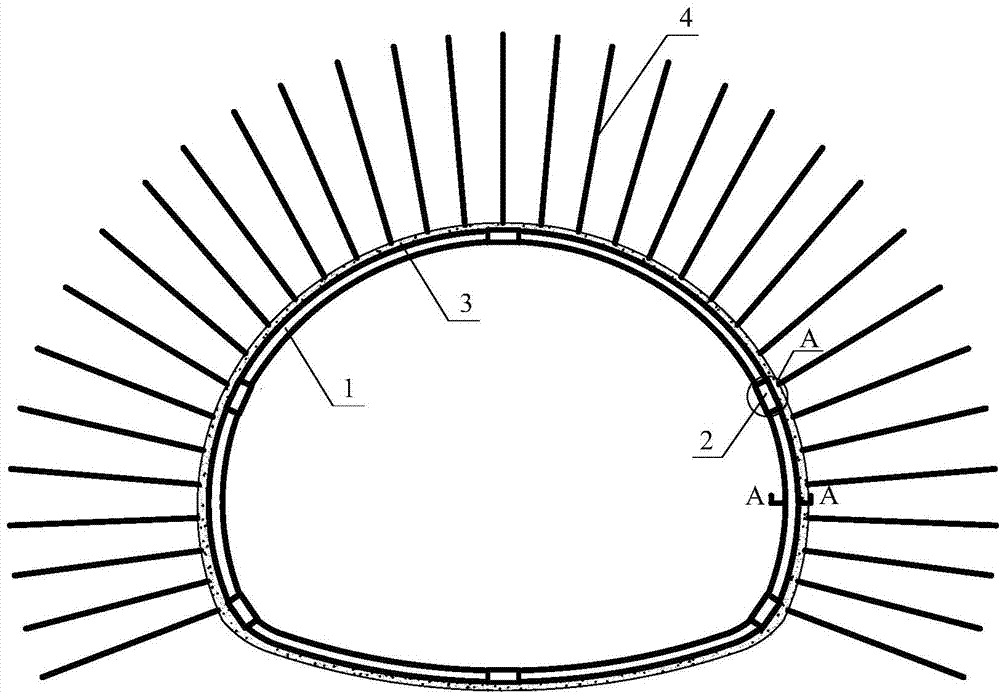

Method for synchronic construction of tunnelling of open-type hard rock tunnel boring machine and secondary lining

ActiveCN101614124ARelieve schedule pressureSecondary lining construction went smoothlyUnderground chambersTunnel liningCompletion timeRock tunnel

The invention provides a method for synchronic construction of the tunnelling of an open-type hard rock tunnel boring machine TBM and a secondary lining and relates a construction method for collaborative following up and joint of the construction tunnelling of the open-type hard rock tunnel boring machine TBM and the secondary lining working procedure at the same time. The tunnel second lining is synchronically carried out when the TBM tunnels. The implementing method comprises following steps that: when the TBM tunnels by about 1,000 m, the second lining construction is started; the second lining is provided with a respective waterproof plate laying bench and a mending frame; secondary lining concrete is poured into a marshalling cart ready for supplying mixed clay. The method mainly solves the problems of mutual interference and influence the tunneling construction of the TBM and the secondary lining construction which are carried out at the same time, and particularly the mutual interference and influence of transportation and construction organization. The method ensures smooth, quick and synchronic secondary lining construction which is synchronically carrying out when the TBM tunnels, relieves the pressure of the project construction period, and obviously advances the completion time.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

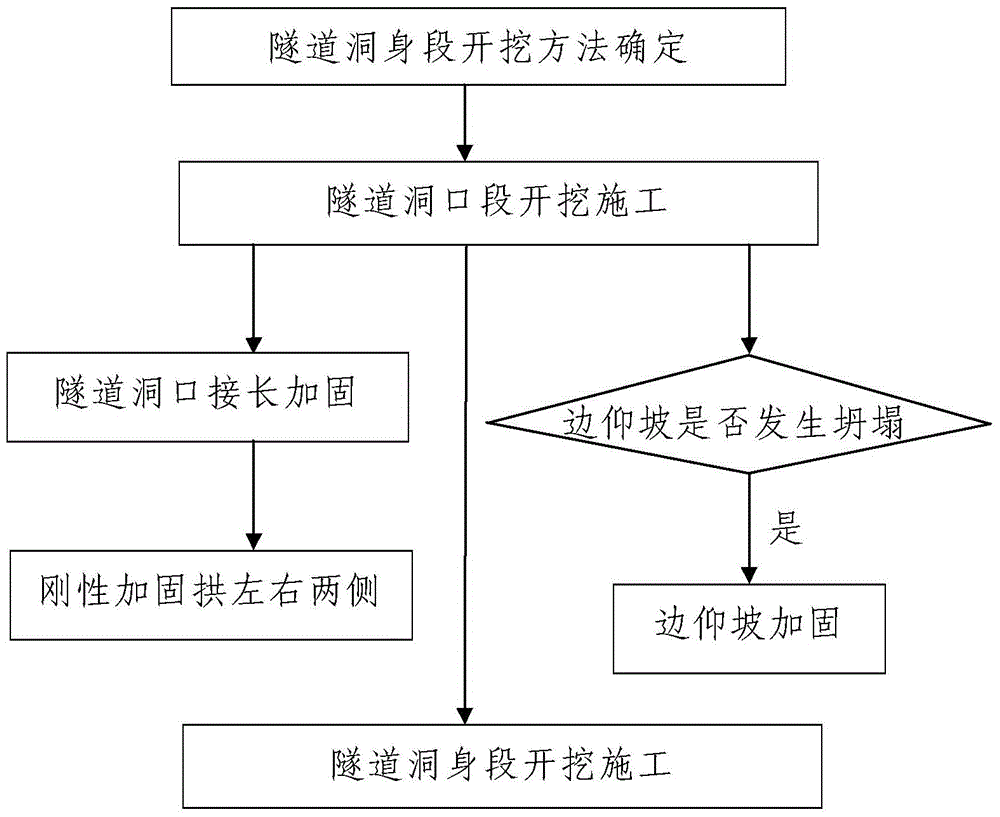

Process for excavating and constructing soft rock tunnels

ActiveCN104453921AThe process steps are simpleReasonable designTunnel liningStructural engineeringRock tunnel

The invention discloses a process for excavating and constructing soft rock tunnels. Each constructed soft rock tunnel comprises two tunnel portal sections and a tunnel trunk section. Each tunnel trunk section is arranged between the two corresponding tunnel portal sections in a connected manner, surrounding rock level of two tunnel portals of each constructed soft rock tunnel is V level, surrounding rock level of each tunnel trunk section is IV level, and entrances and exits of the constructed soft rock tunnels simultaneously start to be constructed and are constructed in opposite directions. The process includes constructing procedures of firstly, determining methods for excavating the tunnel trunk sections, to be more specific, simulating excavating and constructing procedures by the aid of tunnel excavating and constructing simulation software, and determining the methods for excavating and constructing the tunnel trunk sections according to simulation results; secondly, excavating and constructing the tunnels, to be more specific, dividing each soft rock tunnel to be constructed into a plurality of sections from the rear of the corresponding tunnel portal to the front and starting to excavate and construct the multiple sections. The tunnel trunk sections are excavated in the excavating and constructing procedures by the aid of full-section techniques. The process has the advantages of simple steps, reasonable design, convenience in construction, good service effects, safe constructing procedures and capabilities of easily and conveniently completing the soft rock tunnel excavating and constructing procedures and guaranteeing the construction periods.

Owner:CHINA RAILWAY 20 BUREAU GRP

Scraper bucket type transloader

The invention relates to a bucket-type transloader, which belongs to the fields of tunnel mining and transportation machinery and solves the problems of slow coal transportation speed and the like in the drivage of the coal rock tunnels. A crawler attachment of the transloader is installed at two sides of a frame, a transporter is installed in the middle of the frame, a hydraulic system is installed on the frame, an anchor rod power supply is installed at the side surface of the frame, and a bucket part is articulated on the frame. The transloader adopts full-hydraulic drive, has the characteristics of compact structure, safe and reliable operation, flexible transfer, convenient operation and maintenance, strong adaptability to complicated geological conditions, and the like. The transloader is applicable to blasting work face of coal mine and can also be used for the loading of the ground coal yard, as well as can be used in tunnels of railways, highways, water conservancy projects and the like. The conveyer selects types according to different loading equipment, and can be matched with such equipment as a jumbolter, a drill carriage, a scraper conveyor, a belt conveyor, a shuttle car, a mine car and the like. Both a loading part and an unloading part are equipped with atomizing devices, thus being capable of effectively reducing dust.

Owner:SANY HEAVY EQUIP

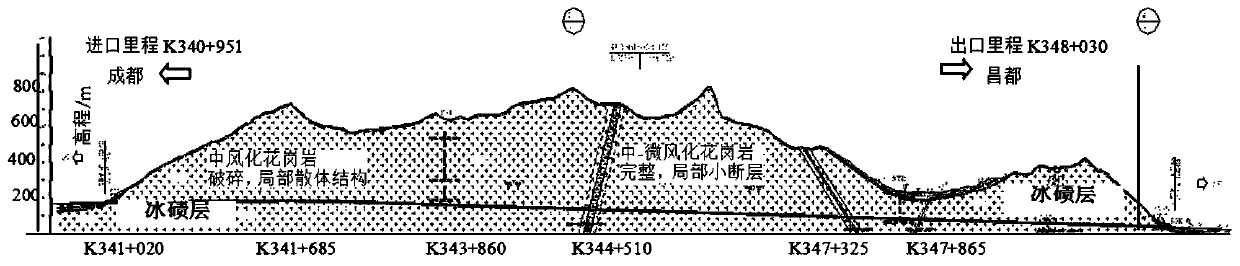

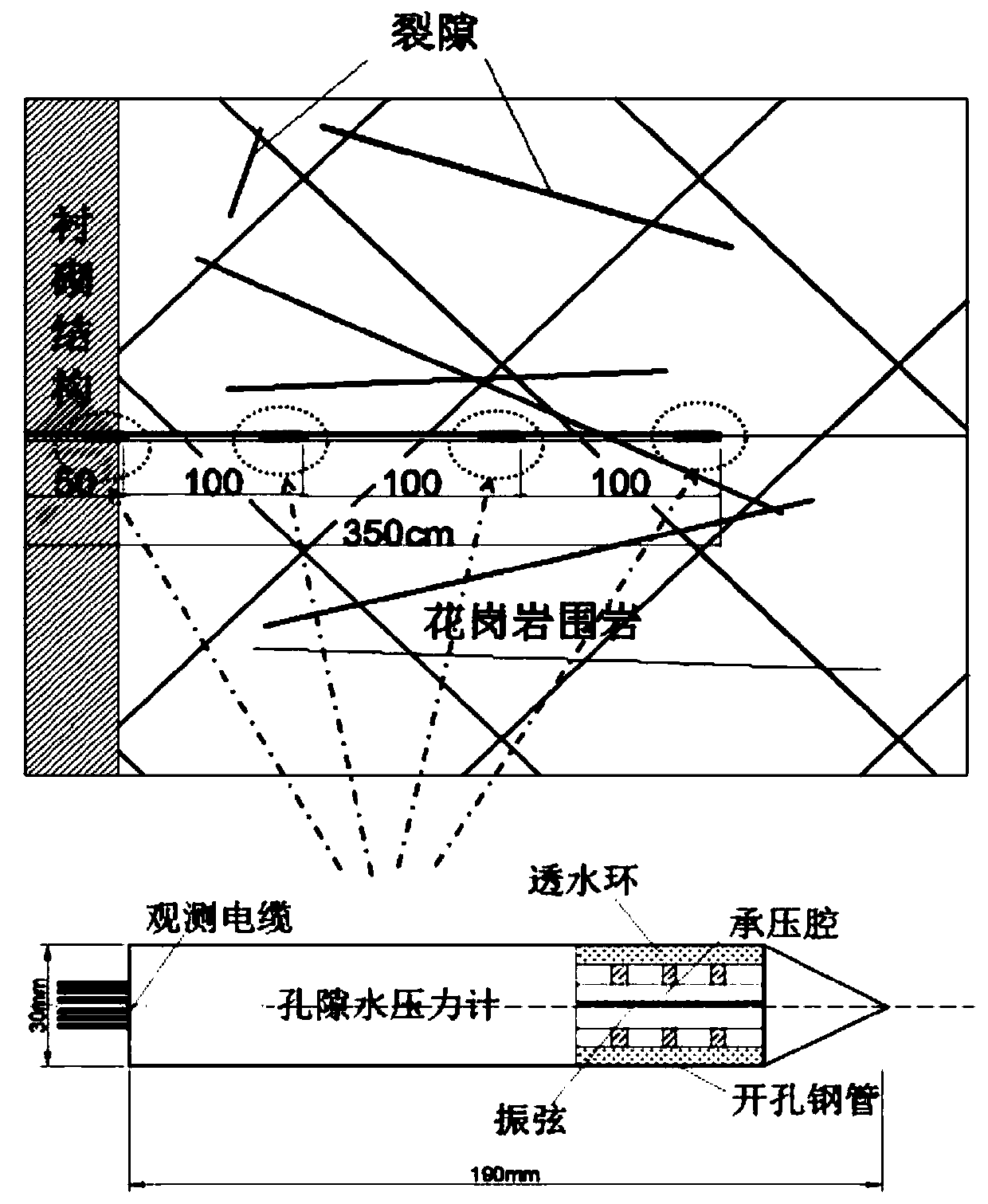

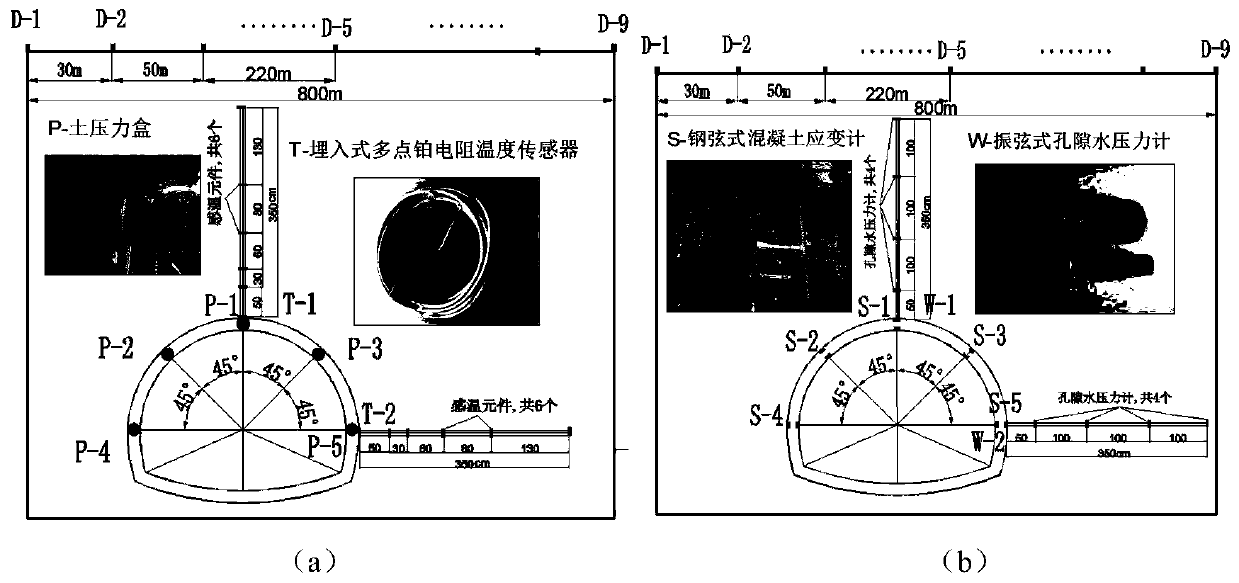

Frost heave force model of rock tunnel based on rock-water-ice force in-situ test

InactiveCN110596177AAvoid structureAvoid discussionEarth material testingMaterial thermal analysisFreeze thawingPore water pressure

The present invention discloses a frost heave force model of a rock tunnel based on a rock-water-ice force in-situ test. A pore water pressure gauge, an earth pressure box, and a multi-point platinumresistance temperature sensor are used in a combination manner to perform a frost heave force in-situ test on fractured rocks, the temporal and spatial evolution laws of the fissure water pressure, the ice pressure, and the surrounding rock pressure before and after freezing of the fractured rocks are obtained, and theoretical model calculation results, in-situ test results, and existing researchresults are compared and analyzed. According to the frost heave force model of the rock tunnel based on the rock-water-ice force in-situ test provided by the present invention, in-situ testing on siteis used, the test method is innovated outside the previous test system mainly containing the freeze-thaw cycle mechanics test of fractured rock masses, the lack of measurement methods is compensated,the frost heave force in natural water-containing cracks is obtained, and starting from macro and engineering applications, the discussion of the meso-structure and fracture geometry of fractured rocks is avoided; the general area of low-temperature water-ice phase transition and the direction of water migration are considered; and the frost heave force model of the rock tunnel based on the rock-water-ice force in-situ test provided by the present invention will provide a reference for similar projects of the currently developed Sichuan-Tibet Highway.

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com