Process for excavating and constructing soft rock tunnels

A technology for tunnel excavation and construction technology, applied in tunnels, tunnel linings, mining equipment, etc., can solve problems such as the decline of support quality, hidden dangers, and hidden safety hazards, and achieve the effects of simple process steps, good use effects, and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

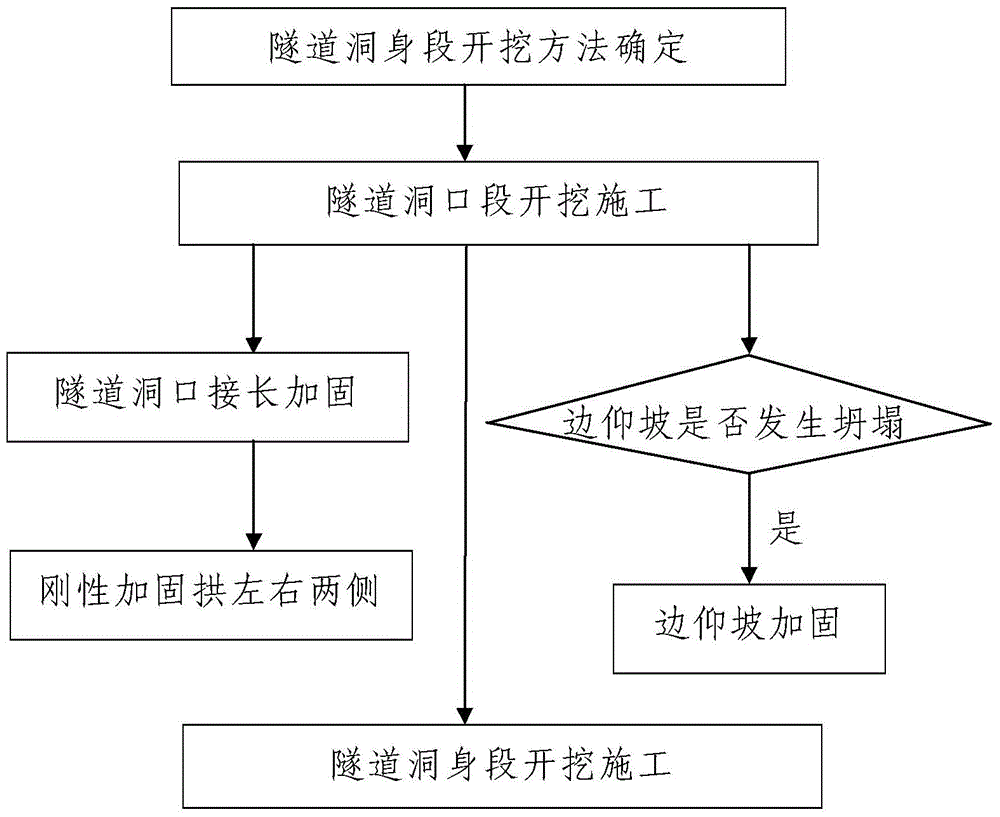

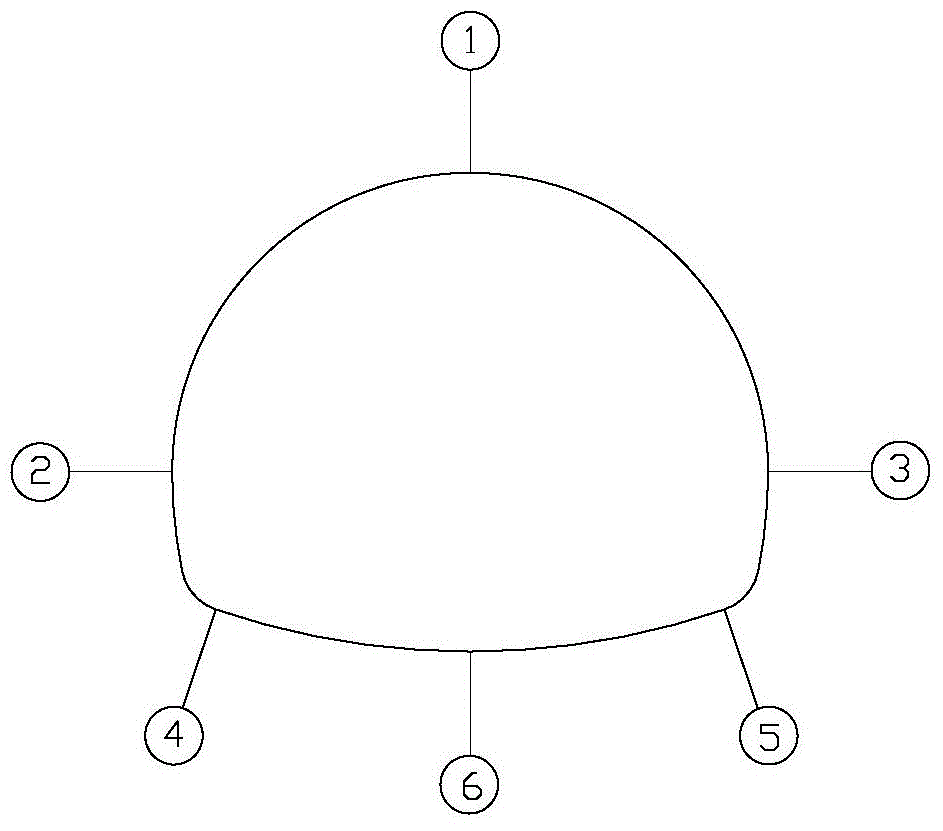

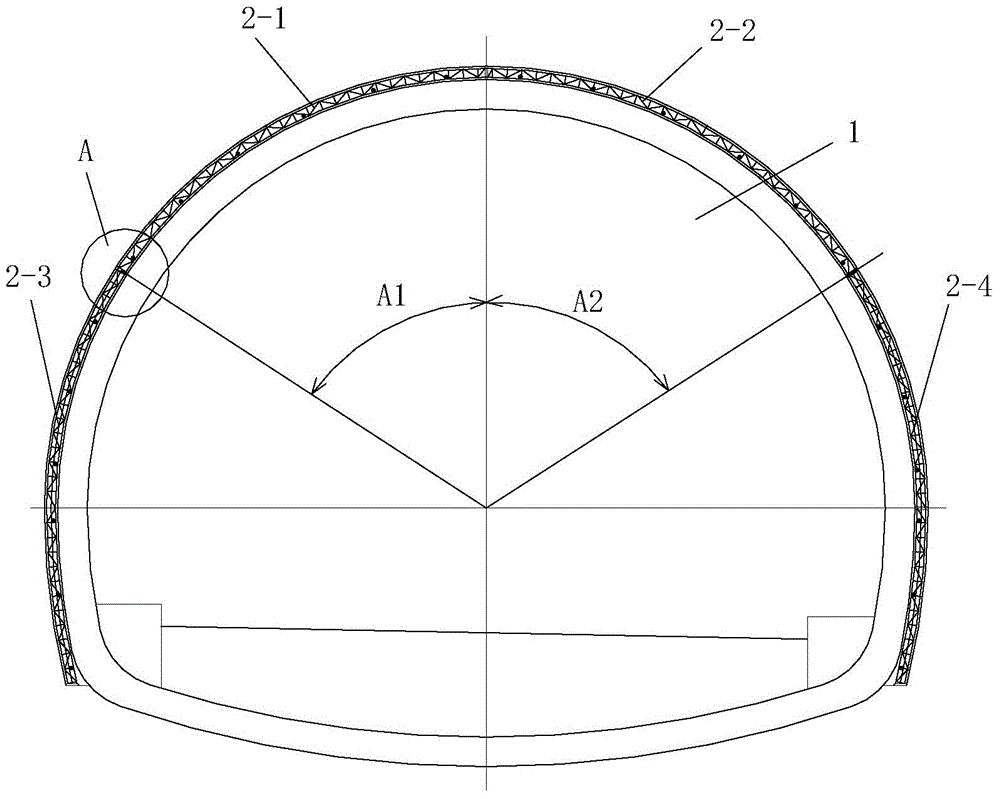

[0065] like figure 1 A soft rock tunnel excavation construction process is shown. The constructed soft rock tunnel includes two tunnel entrance sections and a tunnel body section connected between the two tunnel entrance sections. The two tunnel entrance sections are respectively The tunnel excavation section located at the two tunnel entrances 1 of the constructed soft rock tunnel, the two described tunnel entrances 1 are respectively the entrance and exit of the constructed soft rock tunnel; the surrounding rock level of the two described tunnel entrance sections is V The surrounding rock grade of the tunnel body is grade IV; during the actual excavation construction, the entrance and exit of the soft rock tunnel under construction are started at the same time, and the opposite construction is carried out from the entrance and the exit respectively, and the tunnel construction method from the entrance to the exit direction is the same as The tunnel construction method from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com