Method for preparing calcium sulfate dihydrate crystal whisker from phosphorus gypsum

A technology of calcium sulfate dihydrate and phosphogypsum, which is applied in the direction of chemical instruments and methods, single crystal growth, crystal growth, etc., can solve the problem of low yield of impurity-removing products by sulfuric acid leaching, difficulty in industrialized production, and calcium sulfate whisker damage. It is easy to put into industrial production, with good quality and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

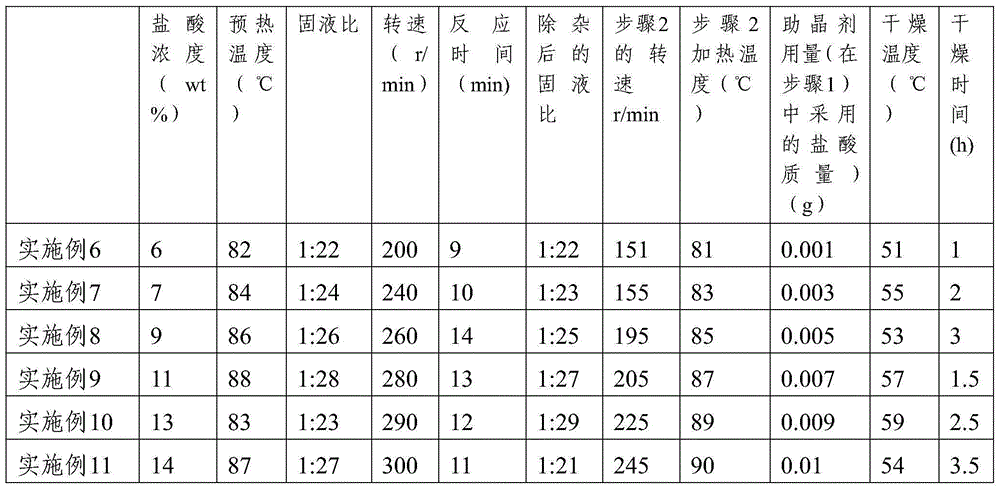

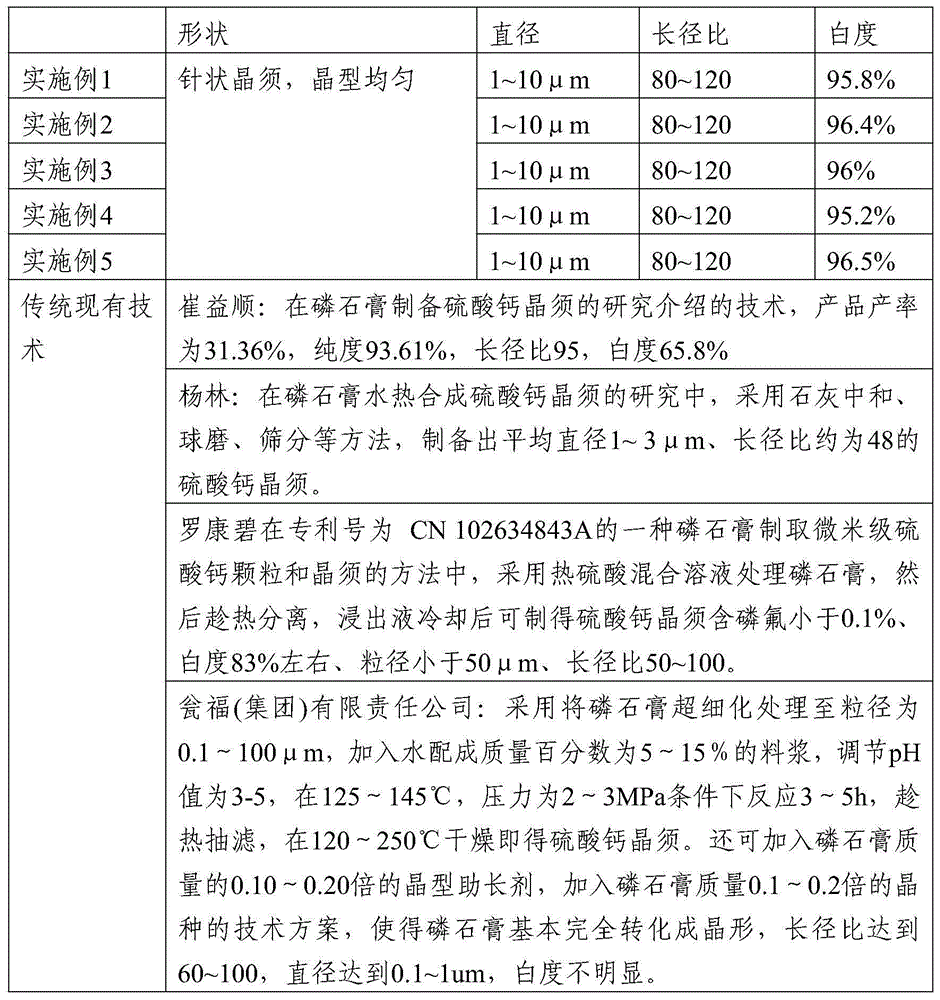

Examples

Embodiment 1

[0037] A method for preparing calcium sulfate dihydrate whiskers from phosphogypsum, comprising the following steps:

[0038] (1) Preparation of impurity-removing calcium sulfate dihydrate: preheat 500g of 5wt% hydrochloric acid solution to 90°C, add phosphogypsum at a solid-to-liquid ratio of 1:30, stir and react for 15min at a speed of 200r / min, and heat Once filtered, the filter cake is reused. The filtrate is cooled and crystallized at room temperature. After the crystallization is completed, it is filtered twice. The filter cake is calcium sulfate dihydrate after removal of impurities, and the filtrate is reused to dissolve phosphogypsum.

[0039] (2) Whisker preparation: Take 50g of calcium sulfate dihydrate after removing impurities, add 5wt% dilute hydrochloric acid at a solid-to-liquid ratio of 1:30, stir at a speed of 150r / min, and heat it in a water bath to 90°C to dissolve it completely , add 0.025g sodium lauryl sulfate, continue to stir until dissolved, place in ...

Embodiment 2

[0044] A method for preparing calcium sulfate dihydrate whiskers from phosphogypsum, comprising the following steps:

[0045] (1) Preparation of calcium sulfate dihydrate for impurity removal: Preheat 1000g of 8wt% hydrochloric acid solution to 85°C, add phosphogypsum at a solid-to-liquid ratio of 1:25, stir and react for 10min at a speed of 250r / min, and heat Once filtered, the filter cake is reused. The filtrate is cooled and crystallized at room temperature. After the crystallization is completed, it is filtered twice. The filter cake is calcium sulfate dihydrate after removal of impurities, and the filtrate is reused to dissolve phosphogypsum.

[0046] (2) Whisker preparation: Take 100g of calcium sulfate dihydrate after removing impurities, add 8wt% dilute hydrochloric acid at a solid-to-liquid ratio of 1:25, stir at a speed of 200r / min, and heat it in a water bath to 85°C to dissolve it completely , add 0.05g sodium lauryl sulfate, continue to stir until dissolved, place...

Embodiment 3

[0051] A method for preparing calcium sulfate dihydrate whiskers from phosphogypsum, comprising the following steps:

[0052] (1) Preparation of impurity-removing calcium sulfate dihydrate: Preheat 1000g of 10wt% hydrochloric acid solution to 80°C, add phosphogypsum at a solid-to-liquid ratio of 1:20, stir and react for 8 minutes at a speed of 300r / min, and Filtrate once, and reuse the filter cake. The filtrate is cooled and crystallized at room temperature. After the crystallization is completed, filter twice. The filter cake is calcium sulfate dihydrate after impurity removal.

[0053] (2) Whisker preparation: Take 100g of calcium sulfate dihydrate after removing impurities, add 10wt% dilute hydrochloric acid at a solid-to-liquid ratio of 1:20, stir at a speed of 250r / min, and heat it in a water bath to 80°C to dissolve it completely , add 0.05g sodium lauryl sulfate, continue to stir until dissolved, place at room temperature to cool and crystallize, filter three times, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com