A metal spherical powder impurity removal device and impurity removal method

A spherical powder and metal powder technology, applied in the field of high-performance powder metallurgy near-net-shape manufacturing, can solve the problems of no-size, large-size non-metallic inclusions, inability to remove foreign metal inclusions, etc. Excellent hybrid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

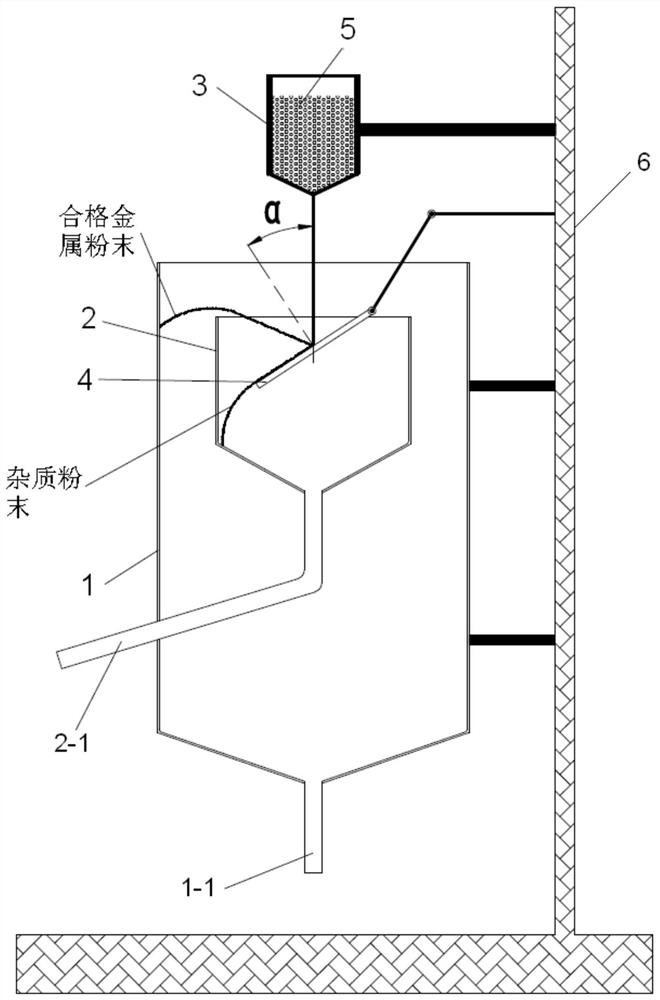

[0065] According to attached figure 1 The schematic diagram of the preferred powder particle device shown, taking the TA2 titanium powder prepared by the plasma rotating electrode process as an example, illustrates the implementation of a technical method for the optimization and impurity removal of a titanium and titanium alloy spherical powder, wherein the particle size distribution of the TA2 spherical powder is: 58% of 180μm-250μm powder, 16% of 150μm-180μm powder, 22% of 45μm-150μm powder, 4% of <45μm powder, and no powder larger than 250μm is allowed.

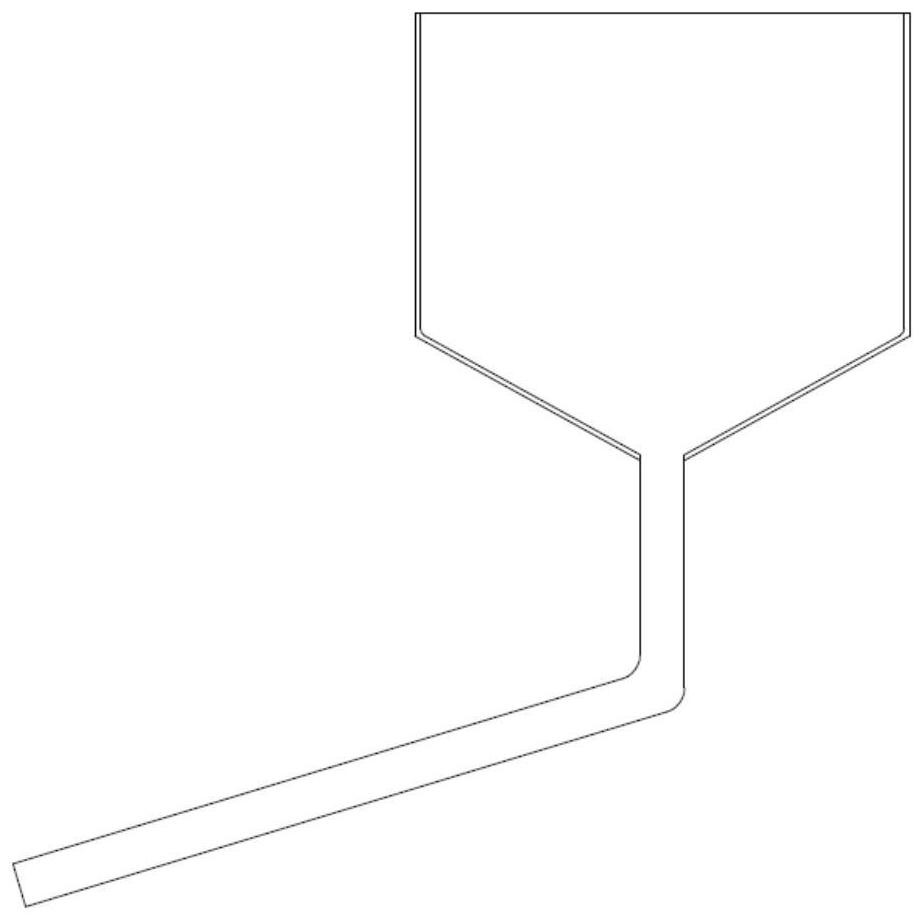

[0066] (1) First make an L-shaped bracket, use a stainless steel rod of Φ30×1000mm, and weld it vertically to a stainless steel plate with a size of 30×260×380mm.

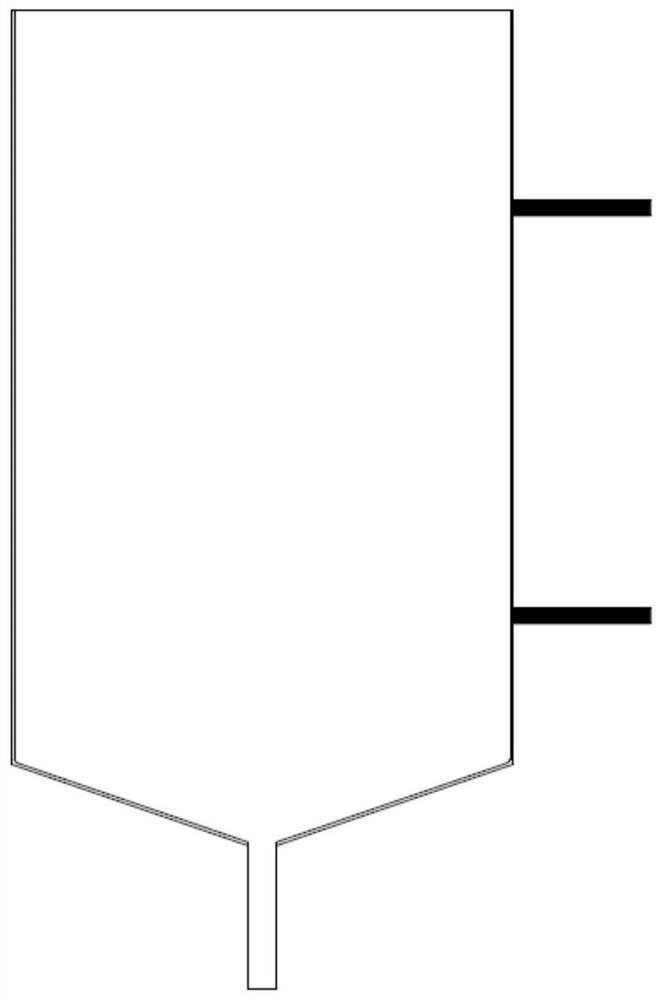

[0067] (2) Two large and small thin-walled steel cylinders are processed with stainless steel with a wall thickness of 2mm. The diameter of the large steel cylinder is Φ330mm, and the diameter of the small steel cylinder is Φ160mm. Steel pipes with a diameter ...

Embodiment 2

[0076] According to attached figure 1 The schematic diagram of the preferred powder particle device is shown, taking the TC4 titanium alloy powder prepared by the plasma rotating electrode process as an example to illustrate the implementation of a technical method for optimizing and removing impurities from titanium and titanium alloy spherical powder, wherein the TC4 titanium alloy spherical powder The particle size distribution is 2% of 180μm-250μm powder, 6% of 150μm-180μm powder, 85% of 45μm-150μm powder, 7% of <45μm powder, and no powder larger than 250μm is allowed.

[0077] (1) First make an L-shaped bracket, use a stainless steel rod of Φ30×1000mm, and weld it vertically to a stainless steel plate with a size of 30×260×380mm.

[0078] (2) Two large and small thin-walled steel cylinders are processed with stainless steel with a wall thickness of 2mm. The diameter of the large steel cylinder is Φ290mm, and the diameter of the small steel cylinder is Φ130mm. Steel pipes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com