A kind of spinning system and using method thereof

A hemp fiber and frame technology, applied in the field of spinning systems, can solve the problems of difficult mixing and adhesion, fiber crushing damage, poor quality, etc., and achieve the effect of increasing the adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

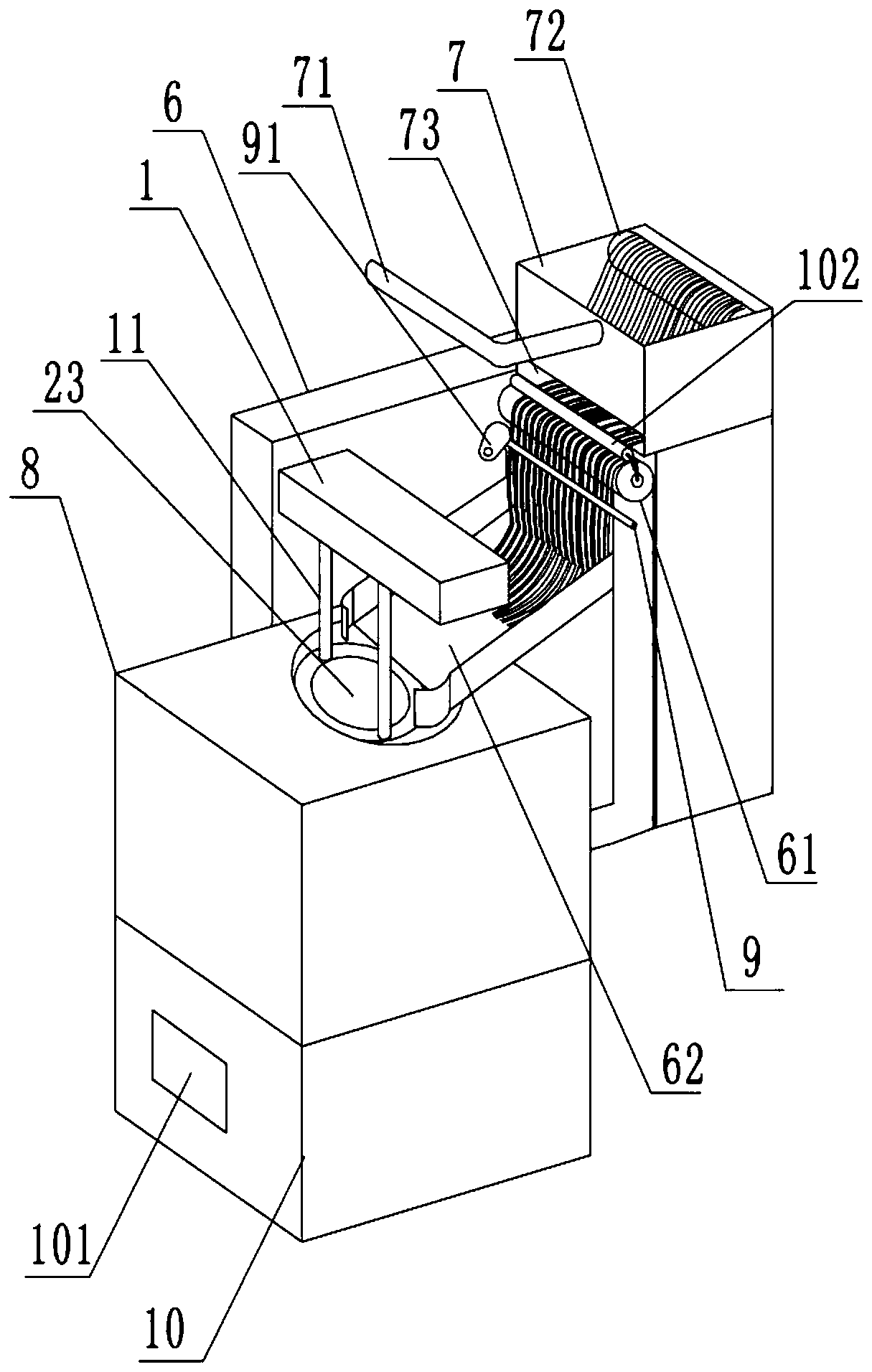

[0038] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, in order to achieve the above objective, the basic scheme of the present invention is as follows:

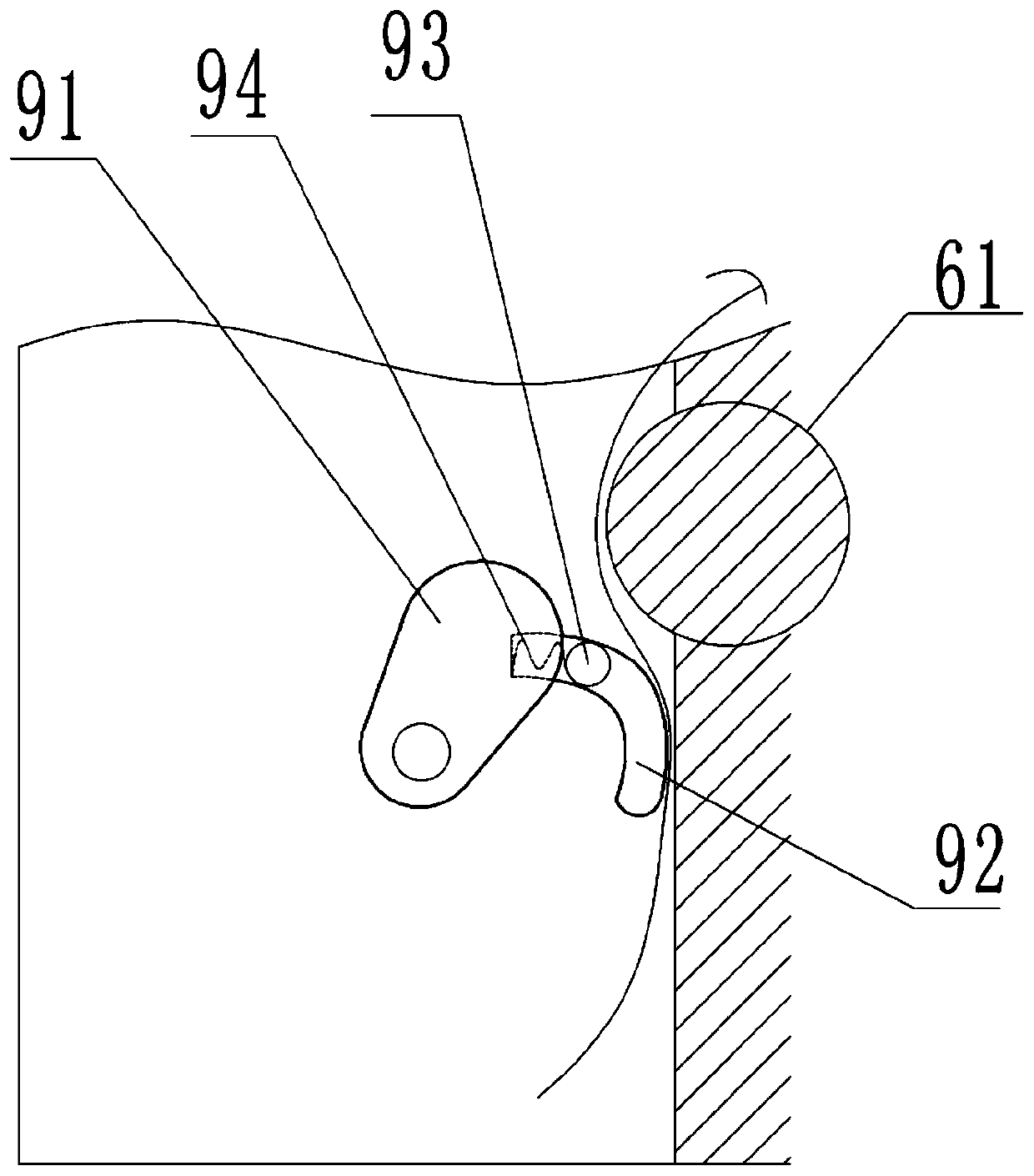

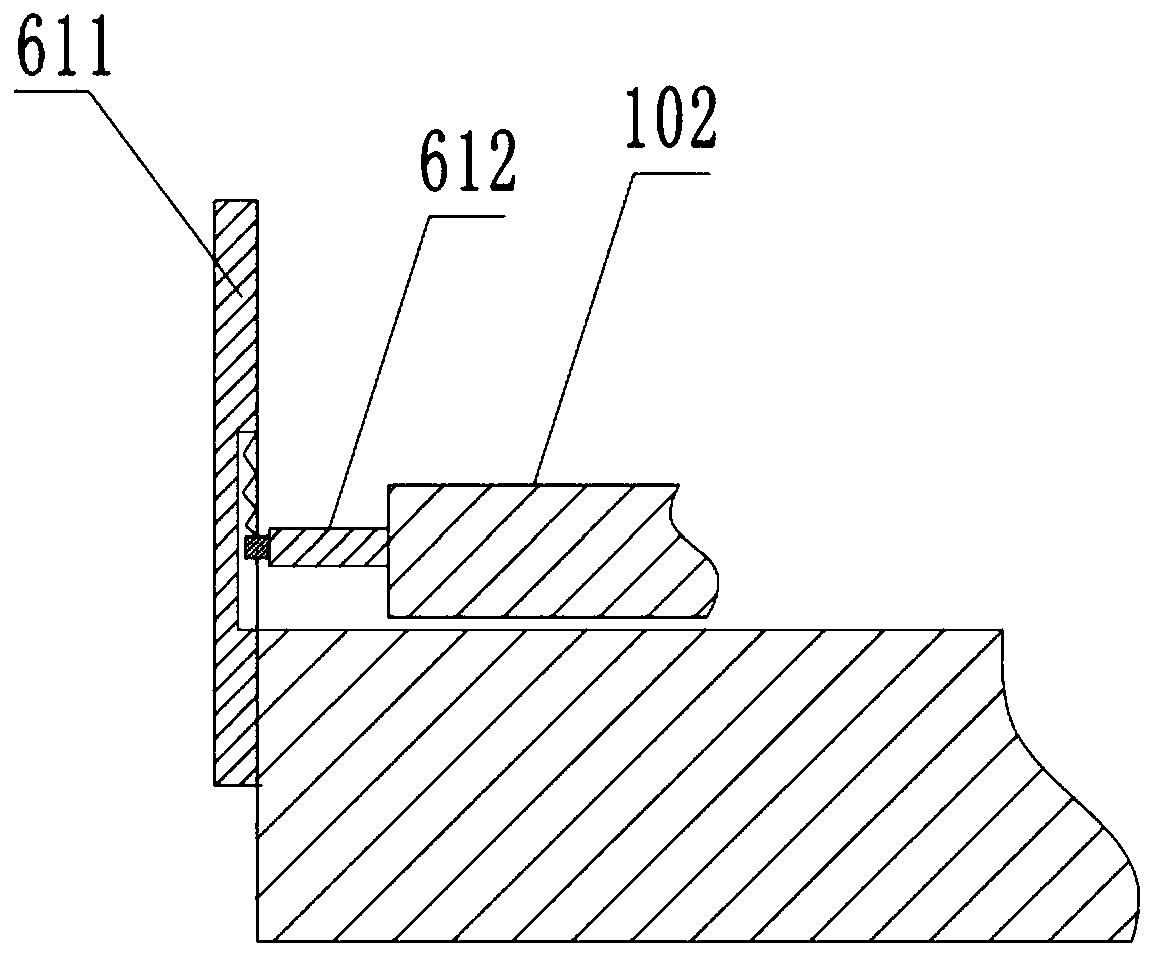

[0039] A spinning system includes a frame 6, a cleaning part, a conveying part and a cutting part 8. The cleaning part, the conveying part and the cutting part 8 are all connected to the frame 6; the frame 6 is figure 1 L shape shown. The cleaning part includes a cleaning box 7, a blowing pipe 71, and a fiber roller 72 wrapped with hemp fibers. The cleaning box 7 is fixed on the top of the frame 6; the fiber roller 72 is rotatably connected to the cavity wall of the cleaning box 7; the cleaning box 7 is far away from the fibers. One side of the roller 72 is provided with an opening 73 for the hemp fiber to pass through, and the blowing pipe 71 is located above the opening 73; the frame 6 is also provided with a transition roller 61 for the hemp fiber to pass through, and a conveying channel 62 is pr...

Embodiment 2

[0049] A method for using a spinning system is characterized in that it comprises the following steps:

[0050] Step 1. Unwinding: Wrap the hemp fiber on the fiber roller 72, draw the hemp fiber between the transition roller 61 and the squeeze roller 102, and then pass through the conveying rod 9;

[0051] Step two, removing impurities: start the blowing pipe 71, the blowing pipe 71 blows and cleans the hemp fiber in the cleaning box 7, so that the impurities are blown out from the gap of the hemp fiber;

[0052] Step 3. Transmission: start the power device, the power device drives the cam 91 to rotate, the cam 91 presses the transmission rod 9 during the rotation, and the transmission rod 9 moves along the arc slide 92 toward the direction of the hemp fiber and moves the hemp fiber When pressed onto the frame 6, the cam 91 continues to press the conveying rod 9, and the conveying rod 9 moves down along the arc-shaped slide 92 to realize the downward conveying of the hemp fiber; in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com