Patents

Literature

247results about How to "Reduce iron content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

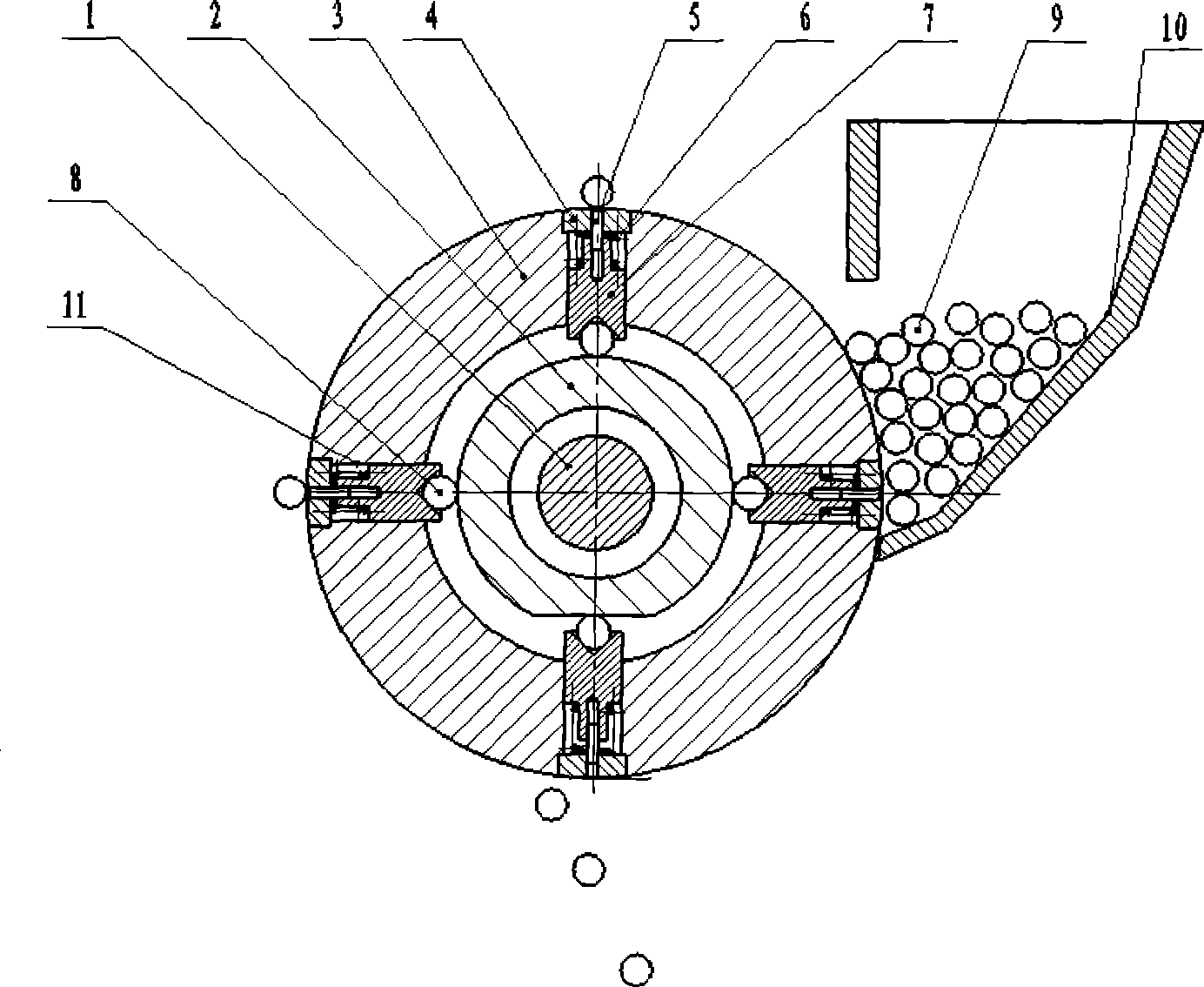

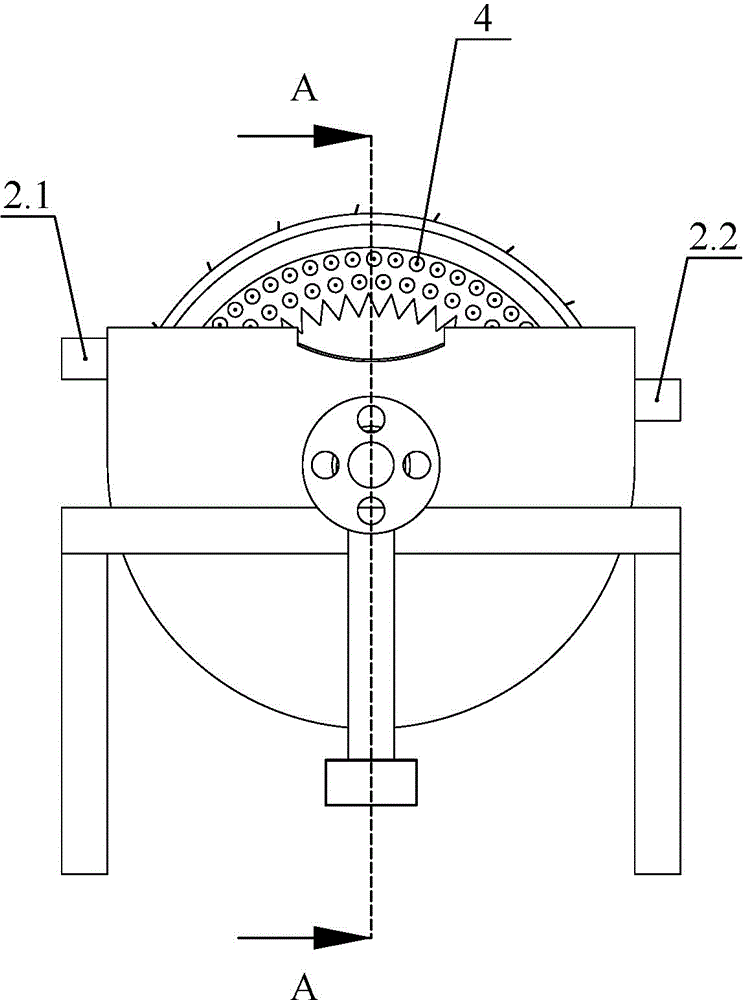

Permanent-magnet magnetic-attraction precision seeding device

InactiveCN101530030ASolve fever problemSmall structure sizeSeed depositing seeder partsSingle grain seedersIron powderSemi open

The invention belongs to agricultural seeding machinery, and in particular relates to a permanent-magnet magnetic-attraction precision seeding device. A semi-open type seed box is arranged on the side of a roller; the roller is fixedly connected with a transmission shaft and follows the transmission shaft to rotate in the single direction; the upper edge of the wall of the roller is uniformly provided with a plurality of through holes in the circumferential direction; a permanent-magnet magnetic attraction head, a magnetic-attraction-head jacket, a magnetic-attraction-head cover plate and a pressure spring are arranged in each through hole; one end of the permanent-magnet magnetic attraction head is arranged in the magnetic-attraction-head jacket, and the other end of the permanent-magnet magnetic attraction head passes through a center hole of the magnetic-attraction-head cover plate but does not exceed the upper surface of the magnetic-attraction-head cover plate; the pressure spring is positioned between the magnetic-attraction-head jacket and the cover plate; a cylindrical cam is hollowly sleeved on the transmission shaft and is fixed; the outline of the cylindrical cam consists of a circular arc surface and a platform surface; and the platform surface is partially arranged on the lower part of the cam. The seeding device has the advantages of improving the magnetic attractive force of the magnetic attraction head, reducing the content of iron powder needed by magnetic-powder coatings of seeds, reducing the structure size of seeding elements and conveniently realizing the automatic seed-taking function and automatic seeding function of the magnetic attraction head.

Owner:JIANGSU UNIV

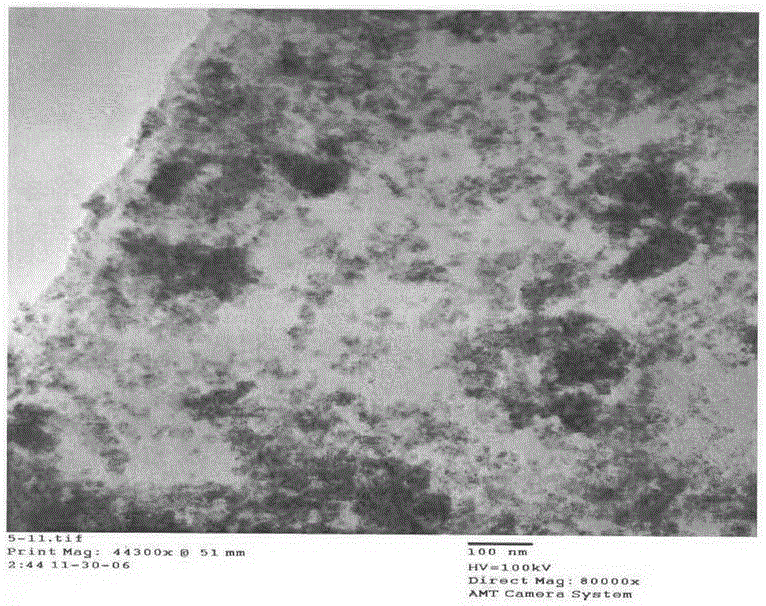

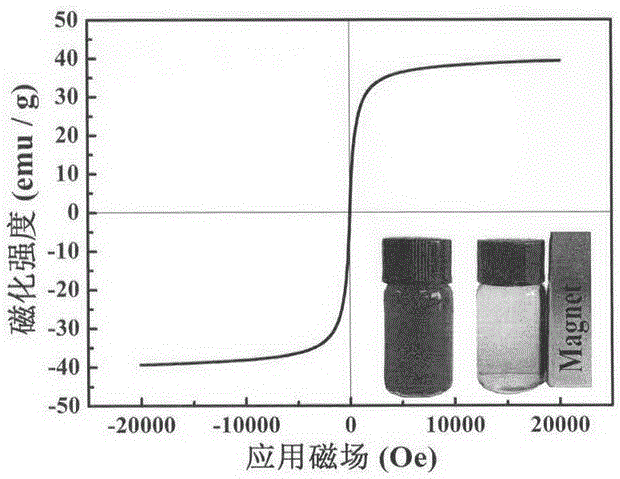

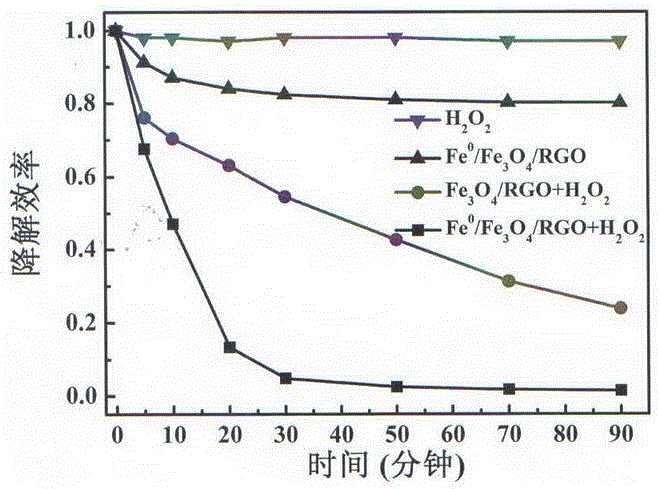

Preparation method of magnetic iron-based heterogeneous Fenton catalyst taking graphene as carrier and application

InactiveCN106669677APromote decompositionGood removal effectWater treatment compoundsWater contaminantsPtru catalystGraphene

The invention relates to a preparation method of a magnetic iron-based heterogeneous Fenton catalyst taking graphene as a carrier and an application. According to the method, the graphene serves as the carrier, magnetic nano-scale ferroferric oxide and nano-scale zero-valent iron (Fe0) are compounded to the surface of the graphene to serve as the heterogeneous Fenton catalyst in an in-situ growth mode, aggregation of catalytic active nano-particles can be effectively prevented by the graphene serving as the carrier, and more active sites are exposed. Besides, the graphene has high electron transfer capability, Fe0 easily transfers electrons to Fe3+ by taking the graphene as the carrier, Fe3+ is promoted to be transformed into Fe2+, so that catalytic activity of the catalyst is improved, the catalyst is easily recovered and reusable, pollutant removal efficiency is improved, phenol removal efficiency reaches 99% or more, and the used catalyst is recovered by an external magnetic field. The preparation method solves the problems that traditional Fenton catalysts are difficultly recycled and generate a lot of chemical sludge, and the preparation method has a certain economic value and practical value.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Silica heat-proof firebrick

ActiveCN101139210AExcellent physical and chemical indicatorsHigh temperature resistantSlurryRaw material

The present invention relates to the fireproof material technology field, in particular to a silicon heat insulation fireproof brick adaptable to be used in coke oven and carbon stove. The present invention can solve the shortcomings in the prior clay heat-insulation and fireproof brick that load distortion temperature is low; the material is easy to be shrunk in the high temperature; the heat conductivity ratio is much larger and the heat preservation effect is much worse and so on. The components and the relative weight ratio in the present invention are that: 81-85 percent of silica powder, 15-19 percent of perlite, and the following assistant materials, whose weight ratio occupied in the main raw materials is as follow: 045-0.55 percent of iron scale powder, 0.9-1.1 percent of cement, 6.5-7.5 percent of lime milk, 1.95-2.2 percent of paper slurry. The silica powder and the perlite with the stated matched ratio are added into a humid grinder and then the iron scale powder and the cement are added into to be grinded for 1-2 minutes; and then the water with the weight ratio occupied in the main raw material 1.8-2.2 percent is added, and then the lime milk is also added to be grinded and pressed for 10-15 minutes. Finally, the paper slurry is added to be grinded and pressed for 10-15 minutes. The mixture is taken out from the grinder to be molded. Each physical and chemical index of the silicon heat insulation fireproof brick in the present invention is better than the national standard; the present invention has the advantages of heat-resisting, low heat conductivity, low iron content, large compression strength and much better heat stability and so on. The present invention can be directly used as the inner bushing for the industrial stove.

Owner:山西盂县西小坪耐火材料有限公司

Deironing method for vanadium-bearing stone coal lixivium

ActiveCN105695738AReduce loss rateReduce the impact of vanadium enrichmentOrganic compound preparationCarboxylic acid salt preparationPregnant leach solutionIron powder

The invention relates to a deironing method for vanadium-bearing stone coal lixivium. According to the technical scheme, the deironing method comprises the steps that vanadium-bearing stone coal is firstly subjected to crushing, roasting and ore grinding to obtain vanadium-bearing stone coal roasted ore, the vanadium-bearing stone coal roasted ore and water are stirred to obtain vanadium-bearing stone coal ore pulp, then a leaching agent is added, heating and stirring are carried out, and solid-liquid separation is carried out to obtain the vanadium-bearing stone coal lixivium and leaching residues; reduced iron powder is added into the vanadium-bearing stone coal lixivium, and the adding amount of the reduced iron power is 2-4 times the stoichiometric number of the chemical reaction for reducing Fe3+ in the vanadium-bearing stone coal lixivium into Fe2+; heating and stirring are carried out, the pH value is adjusted to range from 1.5 to 5, heating and stirring are carried out, solid-liquid separation is carried out, and deironed lixivium and a filter cake are obtained; and the deironed lixivium is used for the vanadium enrichment technology, and a ferrous oxalate dehydrate byproduct is obtained after the filter cake is dried. Vanadium and iron in the vanadium-bearing stone coal lixivium can be effectively separated, the iron in the vanadium-bearing stone coal lixivium can be recycled, the vanadium loss rate in the deironing process is low, the iron content of the deironed lixivium is low, and the influence of the iron on the subsequent vanadium enrichment technology is reduced.

Owner:WUHAN UNIV OF SCI & TECH

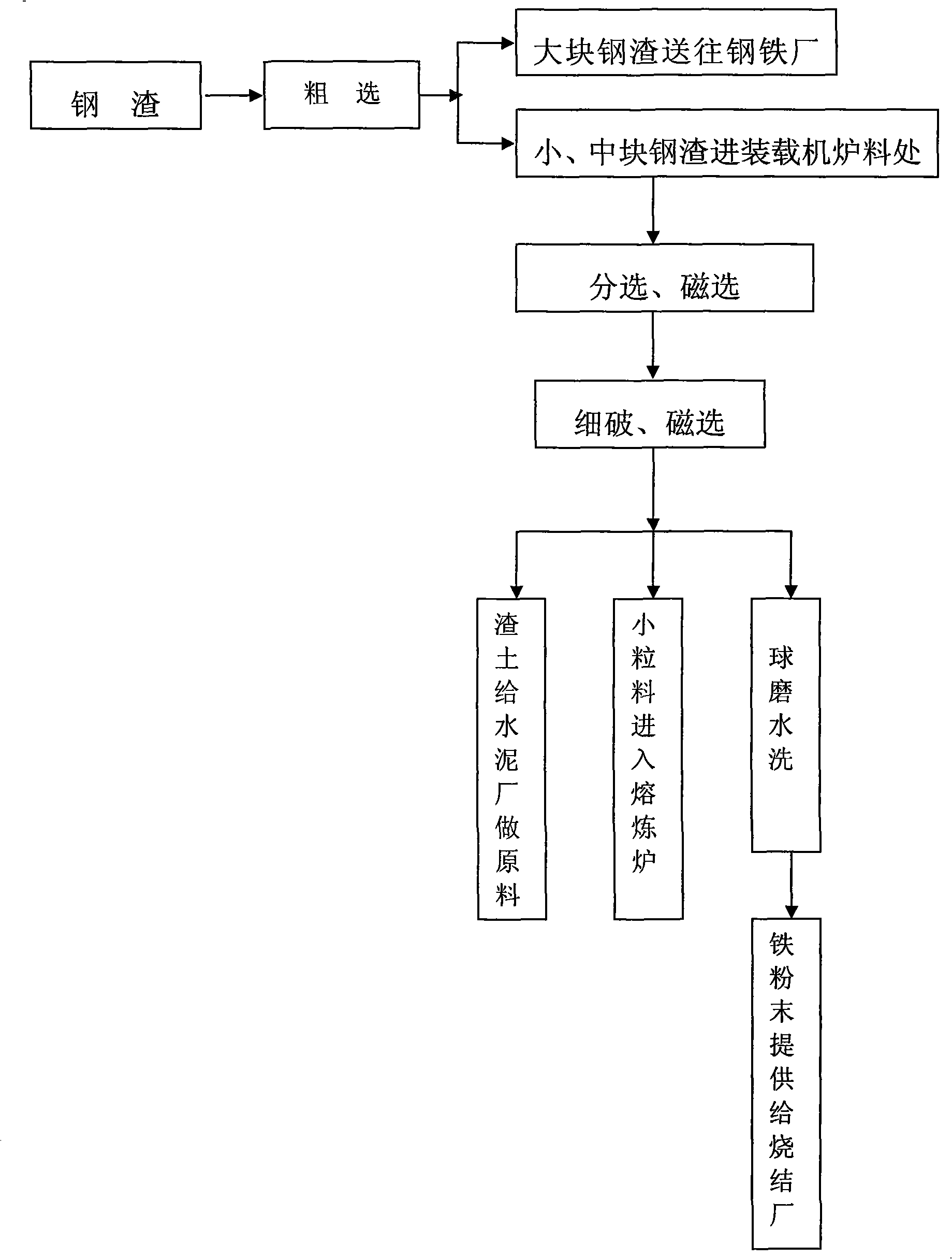

Steel scoria processing method

The invention relates to a steel-slag processing method, including the procedures of separation, magnetic separation, fine crushing, magnetic separation, ball-mill washing, etc. The slag and steel are separated by fine processing of waste steel slag, the iron content in the waste slag is lowered, the waste steel is smelted again and recovered for use. The invention can ensure high yield and high economic benefit; and is capable to remove pollution and achieve a benign cycle.

Owner:NANJING BANQIAO SLAG

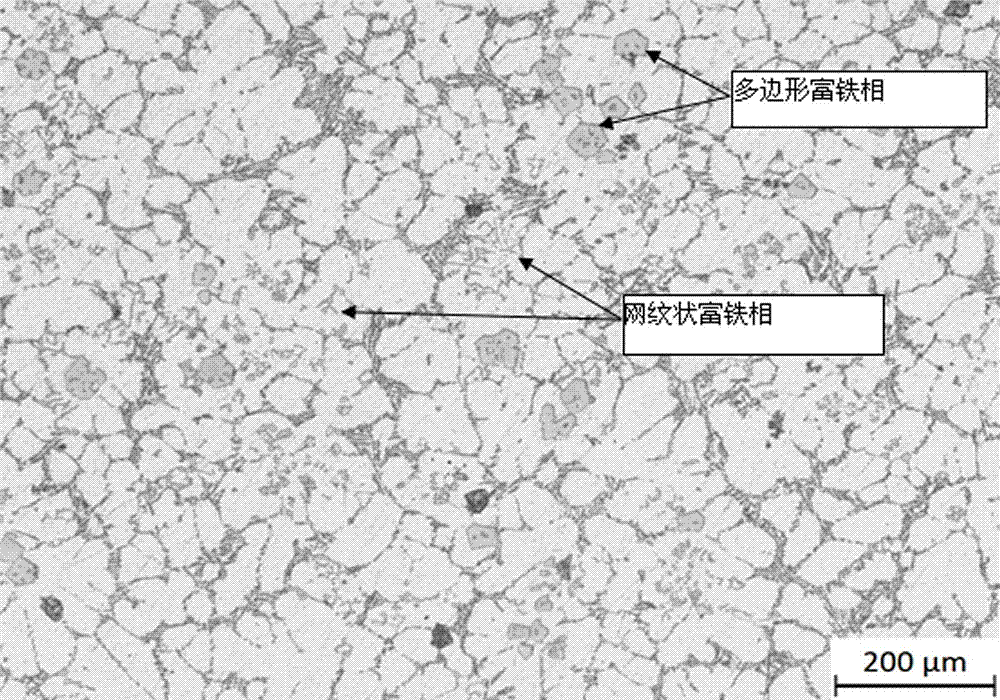

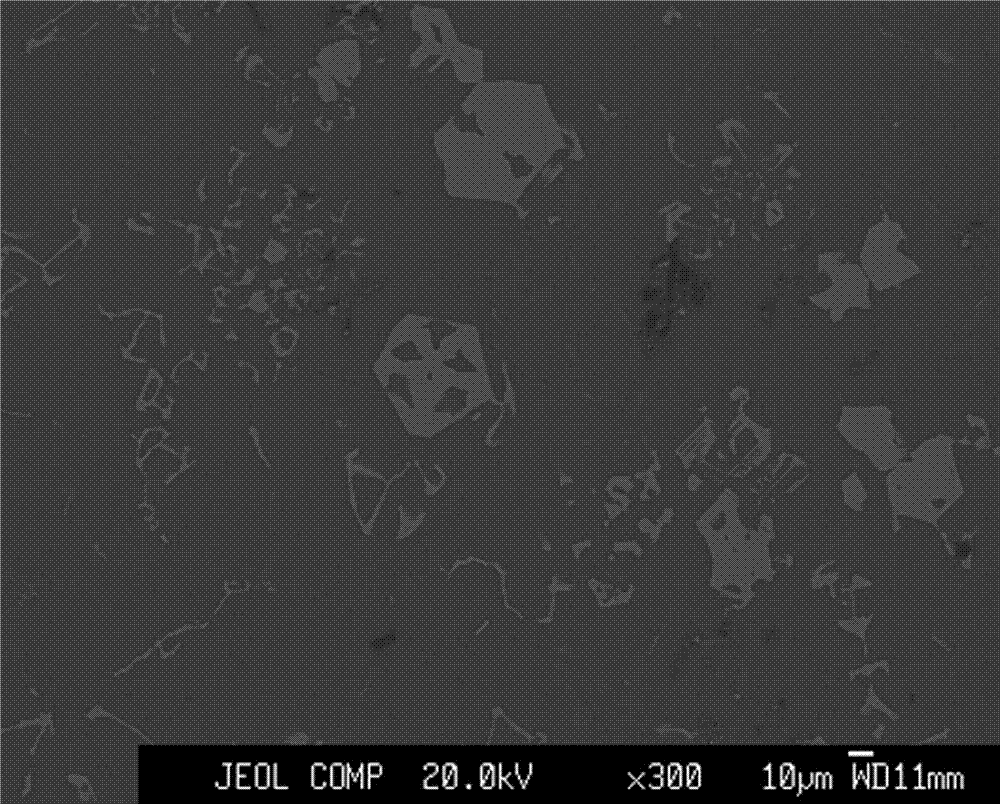

Deironing method for secondary aluminum

The invention relates to a deironing method for secondary aluminum. The deironing method is characterized by comprising the following steps of (1) preheating 50-70% Al-B intermediate alloy and 30-50% Al-Mn intermediate alloy for 30-60 minutes at 150-250 DEG C, wherein the intermediate alloys account for 0.5-2% of mass of aluminum-silicon secondary aluminum; (2) maintaining the temperature for 10-30 minutes after heating the aluminum-silicon secondary aluminum to 400 DEG C; and raising the temperature to 700 DEG C; (3) after the aluminum-silicon secondary aluminum is melted, adding the intermediate alloys, slowly stirring, and standing for 0.5-4 hours after the intermediate alloys are melted; (4) dusting casting, fixing a mold on a vibration platform, and casting and cooling under the condition of mechanical vibration, wherein the frequency of the vibration platform is 10-40 Hz and the amplitude of the vibration platform is 5-10 cm. The deironing method is used for removing iron, refining grains and improving the shape of an iron-rich phase, can reduce the iron content of the secondary aluminum and improve the extension strength and rate of the secondary aluminum and is suitable for the aluminum-silicon secondary aluminum.

Owner:GUANGDONG INST OF NEW MATERIALS

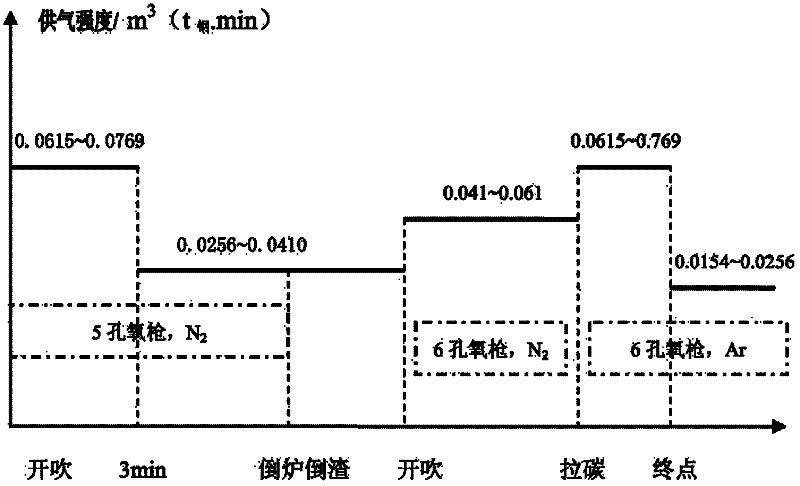

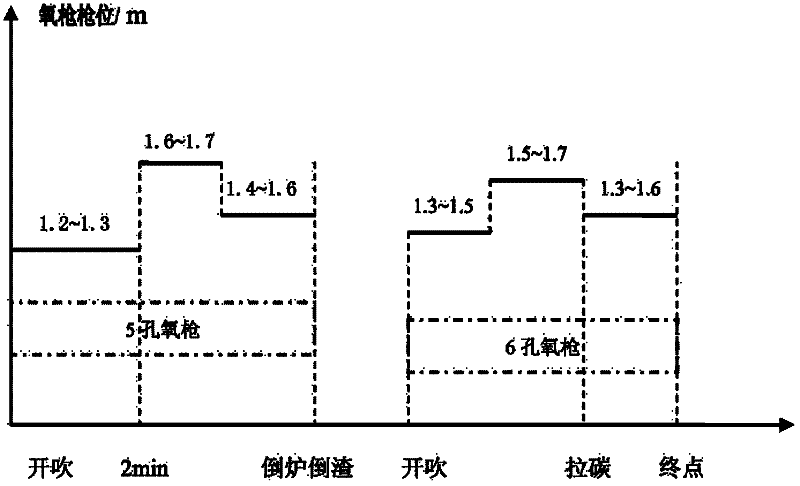

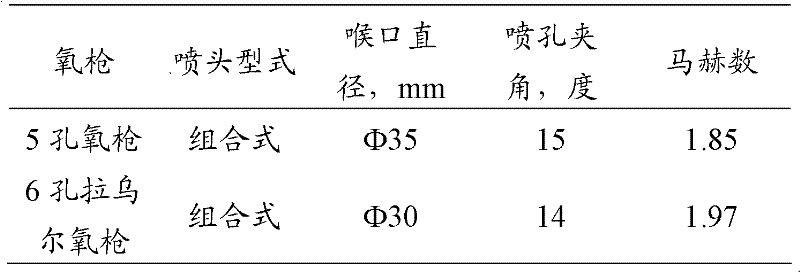

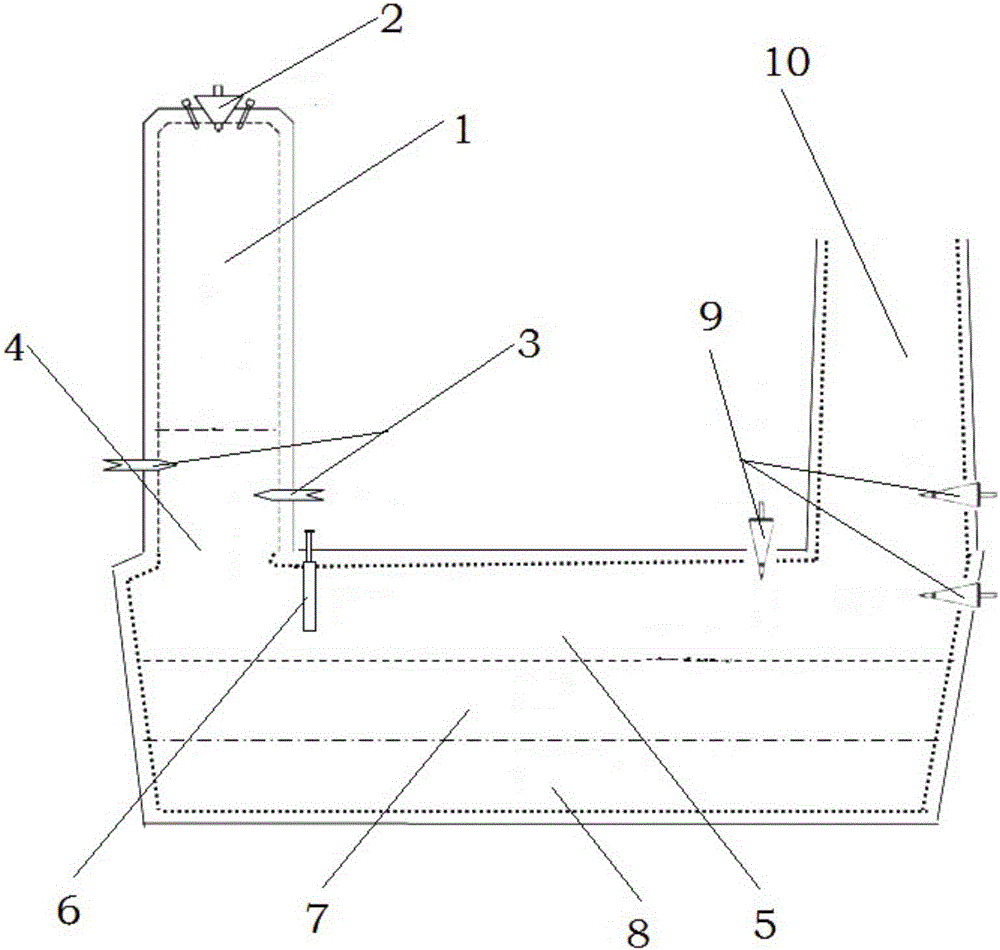

Semi-steel making method

The invention provides a semi-steel making method. The method comprises the following steps of: a, adding a slag forming material into a molten pool of a converter, performing blowing slag formation by a 5-hole oxygen lance oxygen-blowing process at the top of the converter and an inert gas bottom blowing process at the bottom of the converter to remove phosphorus in the molten steel, and discharging slag when the molten pool temperature in the converter is 1,410 to 1,460 DEG C, the alkalinity of the slag is 2.0 to 2.5 and the full iron content of the slag is 10 to 15 weight percent; and b, adding the slag forming material into the molten pool of the converter again, performing blowing slag formation again by a 6-hole Raoult oxygen lance oxygen-blowing process at the top of the converter and the inert gas bottom blowing process at the bottom of the converter to further remove the phosphorus in the molten steel, blocking slag and discharging steel when the molten pool temperature in the converter is 1,670 to 1,700 DEG C, the alkalinity of the slag is 3 to 4.5 and the full iron content of the slag is 17 to 20 weight percent, and thus obtaining molten steel, the phosphorus element content of which is not more than 0.006 weight percent. The method has the advantages of good slag formation effect, short slag formation time, high phosphorus removal efficiency and capabilities of remarkably reducing the full iron content of the final point slag and keeping the phosphorus content of the steel less than 0.006 percent.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

A kind of high lithium heat-resistant ceramic material

The invention belongs to the field of ceramic materials and relates to a high-lithium heat-resisting ceramic material. The high-lithium heat-resisting ceramic material is formed by combining and sintering petalite, Waring soil, kaolin and waste ceramic powder which are mainly used as raw materials. The high-lithium heat-resisting ceramic material is characterized by comprising the following raw materials in parts by weight: 40-55 parts of petalite, 12-20 parts of Guizhou kaolin, 20-30 parts of Waring soil, 5-10 parts of waste ceramic powder, 6-8 parts of Yichun kaolin, 6-8 parts of Zhongxia soil, 2-4 parts of Zhangzhou black soil, 2-4 parts of talcum powder, 2-4 parts of alumina and 3-6 parts of quartz powder. According to the invention, the produced heat-resisting ceramic pot has good thermal stability, i.e., the produced heat-resisting ceramic pot dose not break under the quenching condition at the temperature of 520 DEG C-20 DEG C; a quality index exceeds a standard requirement of GB / T258-2002; and the thermal stability is better, thus the prepared heat-resisting ceramic pot is longer in service life, is good in cooking effect, is clean and is easy to wash.

Owner:江西欣天利陶瓷有限公司

Glass refining agent, production method and application

ActiveCN102659311AQuality improvementReduce iron contentGlass furnace apparatusSpray GranulationAlkaline earth metal

The invention discloses a glass refining agent for forming an echelon refining effect in glass melt so as to eliminate bubbles in melted glass liquid, a production method of the glass refining agent and application of the glass refining agent to glass production. The glass refining agent comprises one or a combination of an oxide refining agent, an alkaline-earth metal salt refining agent and a halide refining agent, and is characterized in that the glass refining agent is prepared by raw material via procedures of distribution, ball milling, sieving, spray granulation and mixing, and comprises three particle groups with different specific surface areas, the first particle group accounts for 20%-30% by weight, the grain size of the first particle group is larger than 1.5mm and smaller than or equal to 2.0mm, the second particle group accounts for 40%-50% by weight, the grain size of the second particle group is larger than 0.5mm and smaller than or equal to 1.5mm, the third particle group accounts for 25%-35%, the grain size of the third particle group is larger than or equal to 0.5mm, and the sum of the three particle groups is 100%. The glass refining agent is not made of arsenic trioxide, is non-toxic, is safe in use and favorable for environmental protection and human health, plays an active role in developing green glass products, and can be applied to production of ultra-white glass as the iron content of the refining agent is low.

Owner:YIYANG SHENGLI CHEM IND

Process for producing steel slag iron fine powder

The process of producing fine iron powder with steel slag includes the following steps: stoving steel slag in a drum type drier to water content less than 1.5%, pre-magnetizing steel slag in an electromagnetic pre-magnetizing device, pre-homogenizing, dry pulverizing, separating steel slag powder of 3 mm below size, wind separating steel slag powder of 3 mm below size into two parts including steel slag powder of 180 mesh over size and steel slag powder of 180 mesh below size, magnetically separating the steel slag powder of 180 mesh over size in a permanent magnetic separator, demagnetizing the separated steel slag powder, grinding the demagnetized steel slag powder to 180 mesh below size, and separating steel slag fine iron powder from superfine steel slag powder. The present invention has low production cost and no environmental pollution.

Owner:济南鲁新新型建材股份有限公司

High-calcium pre-molten slag modification aluminium slag ball and preparation method thereof

The invention relates to a high-calcium pre-molten slag modification aluminium slag ball and a preparation method thereof, wherein the high-calcium pre-molten slag modification alumina slag ball is used for covering the surface of molten steel for heat preservation and improving the properties of steel slag in refining treatment for smelting clean steel. The high-calcium pre-molten slag modification alumina slag ball contains metallic aluminium, calcium oxide, aluminium sesquioxide, silicon dioxide, magnesium oxide, a little water and other inevitable impurities, and is adapted to smelt the clean steel. During refining, such high-calcium pre-molten slag modification alumina slag balls are added and spread on the surface of the molten steel to achieve a good thermal insulation effect, and the uniformity and the fluidity of molten slag are improved through pre-melting treatment; the metallic aluminium not only can reduce the total iron content in the slag, but also can reduce the content of finished calcium oxide with a high oxygen content in the molten steel, so as to reduce the ratio of aluminium to calcium, and improve the capability of the molten slag in adsorbing the oxide inclusion (Al2O3) in the molten steel to purify the molten steel; and meanwhile, the high-calcium pre-molten slag modification alumina slag ball doesn't contain F<->, thereby being favorable for environmental protection and a furnace lining. Compared with the prior art, the invention has the advantage that the high-calcium pre-molten slag modification alumina slag ball is more favorable for adsorbing and removing the inclusion, reduces the oxygen content in the finished product, ensures an extremely low content of harmful impurities, is environment-friendly and cannot corrode the furnace lining.

Owner:西峡县恒基冶材有限公司

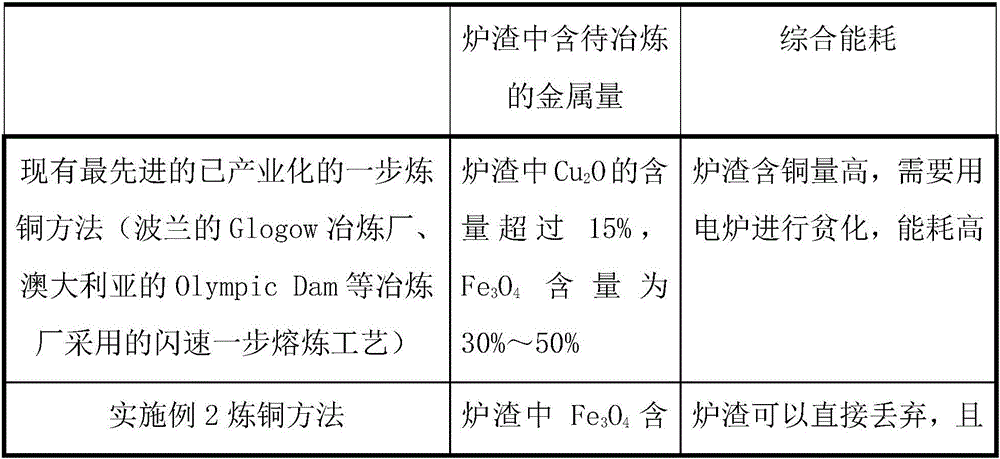

Single-step metallurgical flash furnace and metallurgical method

ActiveCN105803201AGuaranteed RecoveryReduce iron contentRotary drum furnacesCrucible furnacesMelting tankSlag

The invention provides a single-step metallurgical flash furnace. The single-step metallurgical flash furnace comprises a reaction tower, and a spraying nozzle is arranged at the top of the reaction tower; the lower portion of the reaction tower is connected with one end of a molten pool, and a rising flue is arranged above the other end of the molten pool; and a gas guide-in device is arranged at the lower half portion of the reaction tower and used for guiding in reducing gas, and a reducing gas cushion layer is formed in space at the lower portion of the reaction tower. By means of the single-step metallurgical flash furnace, to-be-smelted metallic oxide and Fe3O4 in mineral are almost reduced into metal and FeO completely through the arrangement of the reducing gas cushion layer, the amount of to-be-smelted metal in slag is extremely low, the character of the furnace slag is improved, the viscidity of the furnace slag is reduced, and discharging is facilitated.

Owner:TIANJIN FLASH IRONMAKING TECH CO LTD

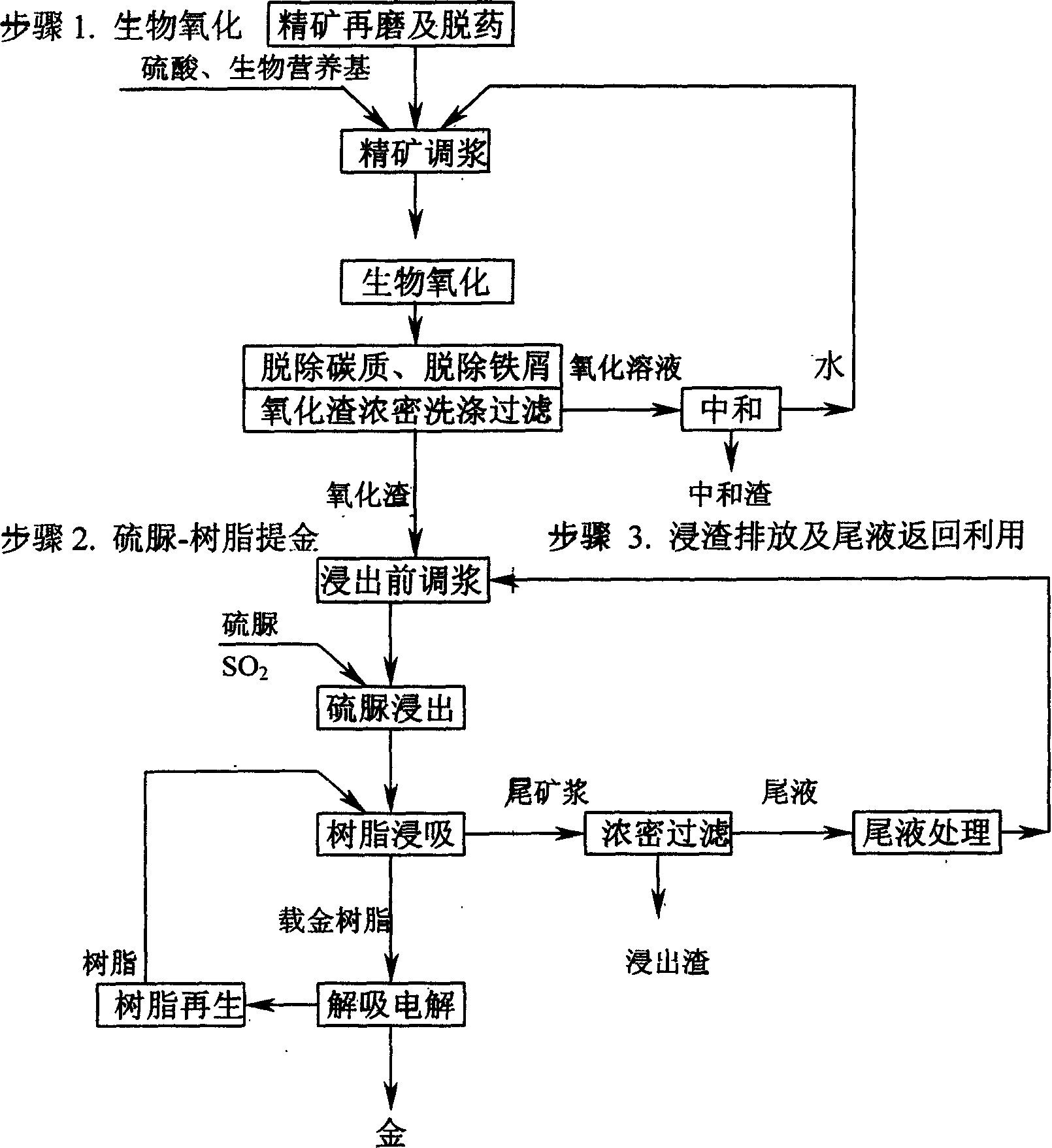

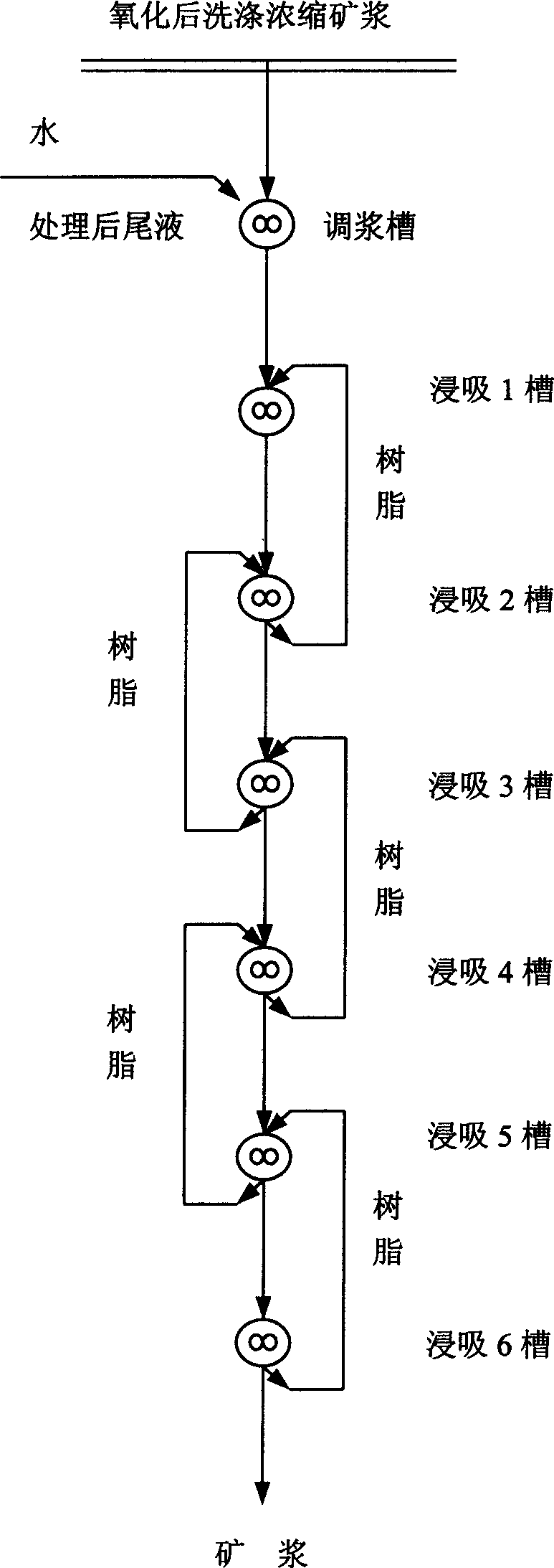

Biological oxidation and thiourea resin slurry method gold extraction technology for difficultly leachable gold concentrate

The invention disclose a refractory gold concentrate's biological oxidation---an gold extracting technique by thionura-resin ore pulp method, including the following steps: making biological oxidation of gold concentrate, using thionura to extract gold and using resin to absorb the gold, processing the tail solution and then returning it to the mixing pulp work before extraction for circular use; the gold extraction can reach above 90%, the tail solution is circularly used so as to be able to reduce consumption of thionura, sulphuric acid and water, thus reducing production cost and beneficial to environmental protection.

Owner:CHANGCHUN GOLD RES INST

Method for preparing ceramic tiles from calcium silicate slag

InactiveCN103641446ARealize mass utilizationReduce consumptionCeramic materials productionClaywaresCalcium silicatePyrophyllite

The invention relates to a method for preparing ceramic tiles from calcium silicate slag, belonging to the field of comprehensive utilization of resources and novel technologies for ceramic preparation. The ceramic tiles contain the following raw materials in percentage by weight: 30-60% of calcium silicate slag, 10-30% of clay, 2-25% of quartz, 0-20% of feldspar, 0-10% of pyrophyllite, 0-10% of green coke and 0-10% of talc. According to the method, ceramics are produced from calcium silicate slag, so that the stacked discharge of calcium silicate slag is reduced, the aim of resource recycling is achieved, and a new way for the high-added-value utilization of calcium silicate slag is added; the utilization ratio of calcium silicate slag in calcium silicate slag ceramics can reach 60%; by using the characteristic that a great deal of alkali metal ions are contained, a feldspar raw material can be replaced partially or totally, and the ceramic tiles are produced under the low-temperature condition of 1,130-1,180 DEG C; all properties of the ceramic tiles prepared by the method disclosed by the invention are better than the national ceramic standards.

Owner:UNIV OF SCI & TECH BEIJING

On-batch steel hot galvanizing environment-friendly type multi-effect galvanization helping liquid and use method thereof

The invention discloses an on-batch steel hot-galvanizing environment-friendly type multi-effect galvanization helping liquid and a use method thereof. Each liter of the on-batch steel hot galvanizing environment-friendly type multi-effect galvanization helping liquid comprises the following substances: a filming agent, an accelerant, a complexing agent, an anti-explosion zinc agent and water. The invention further provides the use method of the on-batch steel hot galvanizing environment-friendly type multi-effect galvanization helping liquid. The use method requires that the working temperature is 50-60 DEG C, the pH value is 3.5-5, and the galvanization time is 3-6 minutes, and a workpiece can be directly fed to a next zinc immersion procedure after galvanization helping without being dried, so that the time is saved, and the efficiency is improved. In addition to the capability of meeting the common requirements of an on-batch steel hot-galvanizing process, the on-batch steel hot-galvanizing environment-friendly type multi-effect galvanization helping liquid further has the characteristics that the energy consumption for heating the galvanization helping liquid is reduced due to adoption of intermediate temperature galvanization helping, the investment is reduced as no drying is needed after galvanization helping, and the energy consumption for drying is reduced; the increase of Fe<2+> in the galvanization helping liquid is effectively controlled, zinc ash and zinc slag are reduced in zinc immersion, no dust is generated, explosion is effectively avoided, and multiple effects that a galvanization helped film layer is uniform and free of galvanization omission, a zinc layer is bright, and the like, are achieved.

Owner:钱宏彬

Converter final-slag modifier and use thereof

The invention relates to a converter final-slag modifier and a use thereof, and belongs to the technical field of metallurgy. The invention provides the converter final-slag modifier and the use thereof. Active components of the converter final-slag modifier comprise, by weight, 13.5-37.5 parts of CaO, 2.4-7.5 parts of SiO2, 15-35 parts of MgO and 4-14 parts of C. The converter final-slag modifier can effectively reduce total iron content of furnace slag produced by semi-steel converter melting. The furnace slag modified by the converter final-slag modifier has total iron content reduced to 16%. Fly ash, steelmaking mud, waste magnesia brick, anthraciferous coal and a binder are mixed according to a certain ratio and are subjected to pressing ball to form balls of the converter final-slag modifier can be prepared so that secondary resource comprehensive utilization is realized. The converter final-slag modifier has a low cost and good modification effects and can effectively reduce iron loss.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

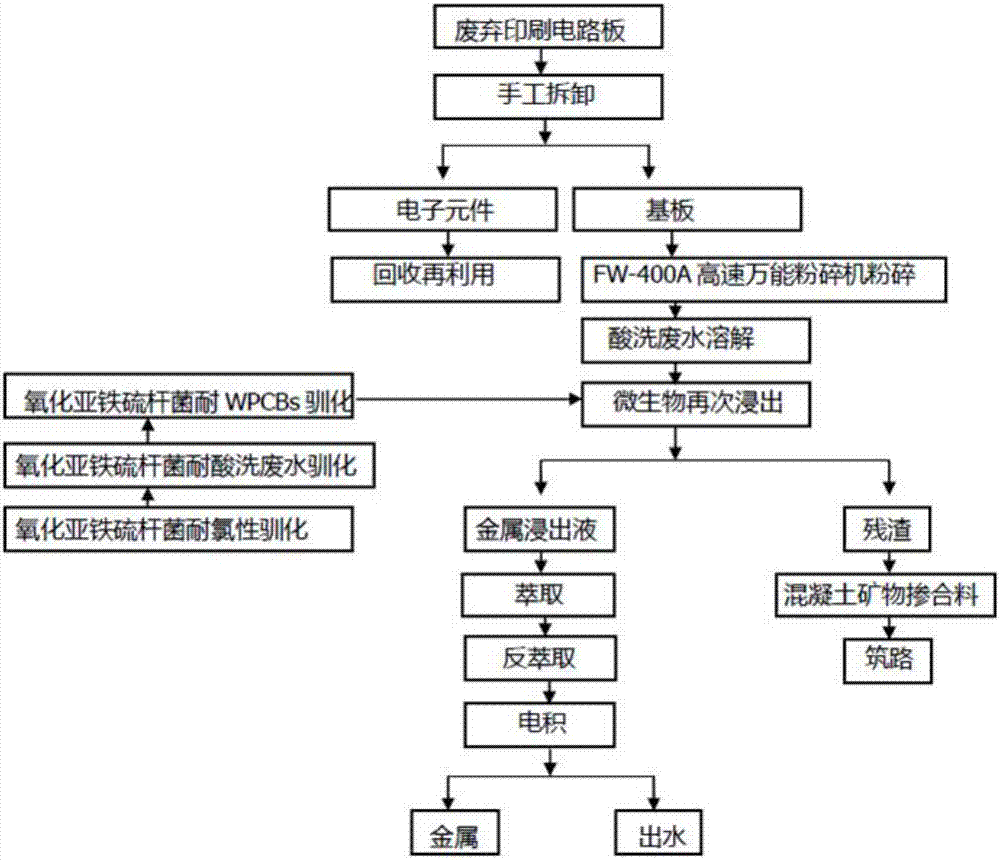

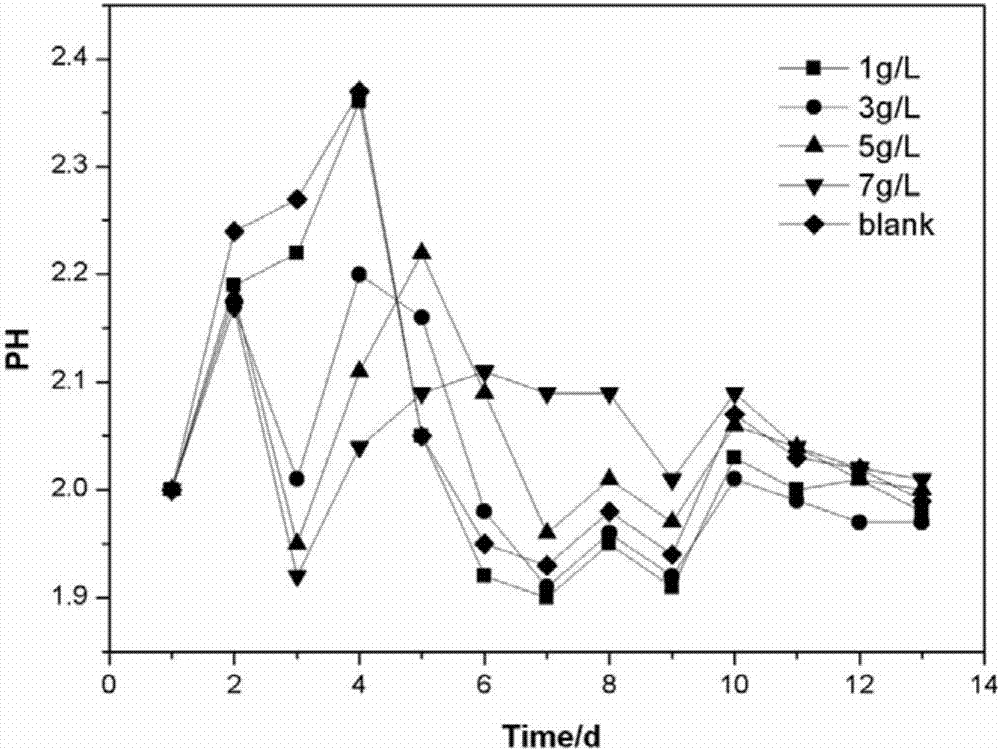

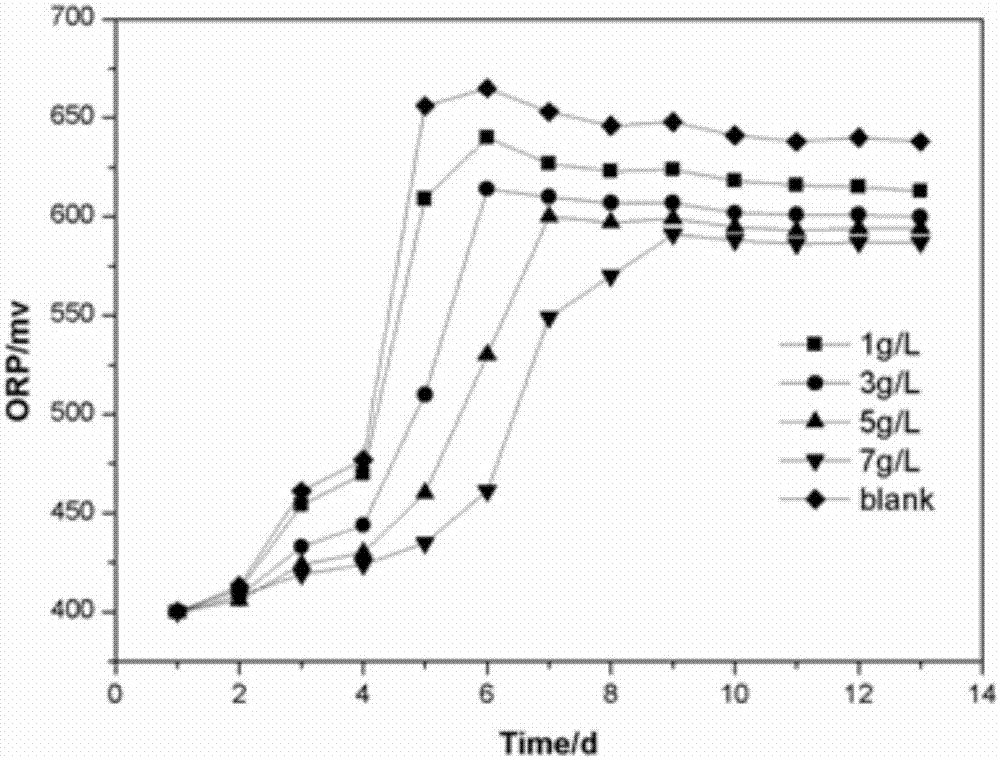

Recycling method of waste printed circuit board

InactiveCN106947866AAvoid recontaminationSolve the problem of high iron content that is difficult to removePhotography auxillary processesProcess efficiency improvementWastewaterCopper

The invention discloses a recycling method of a waste printed circuit board. Chemical-biological joint leaching is used for lixiviating metal in the waste printed circuit board by using strong acidity and high ferroic of pickling waste water. The recycling method includes the steps of conducting chemical leaching by using the pickling waste water to lixiviate Pb, Zn, Al, Fe, Sn and the like metal completely till the leaching rate of Cu reaches to 30% and over, and adding domesticated acidithiobacillus ferrooxidans to conduct microbial leaching till the leaching rate of Cu reaches to 90% and over. By adoption of the recycling method, the waste printed circuit board and the pickling waste water can be utilized comprehensively, the principle of using waste to eliminate waste is fully carried out, maximal resource recycling and treatment of the two wastes are achieved, not only the heavy metal in the waste printed circuit board is leached completely, but also the effective treatment of the pickling waste water is achieved.

Owner:NANJING UNIV OF SCI & TECH

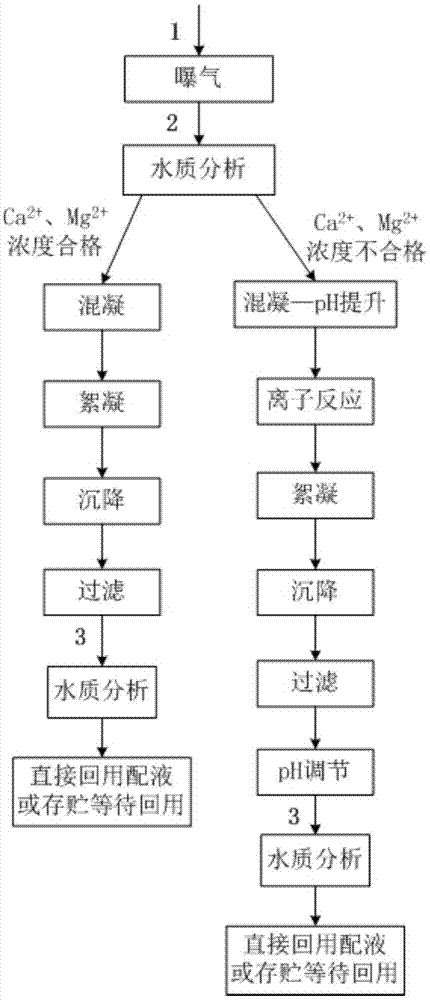

Method for treating and reusing fracturing backflow fluid of shale gas

ActiveCN106892513AImprove adaptabilityReduce equipment investment costsWaste water treatment from quariesMultistage water/sewage treatmentShale gasWater quality

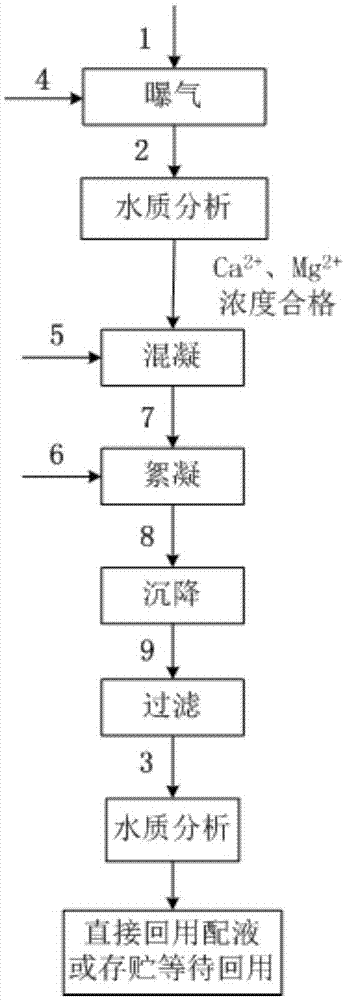

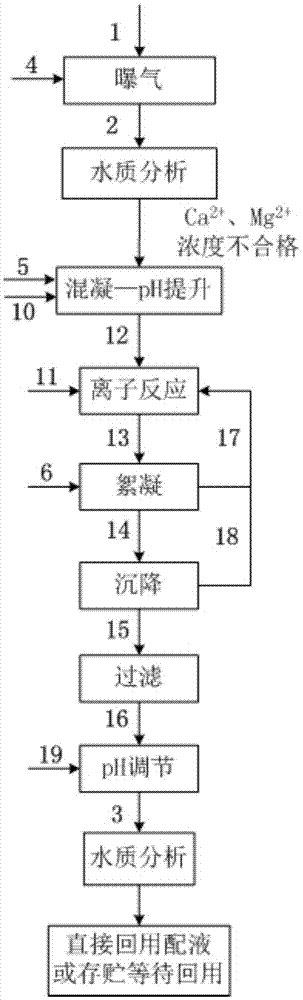

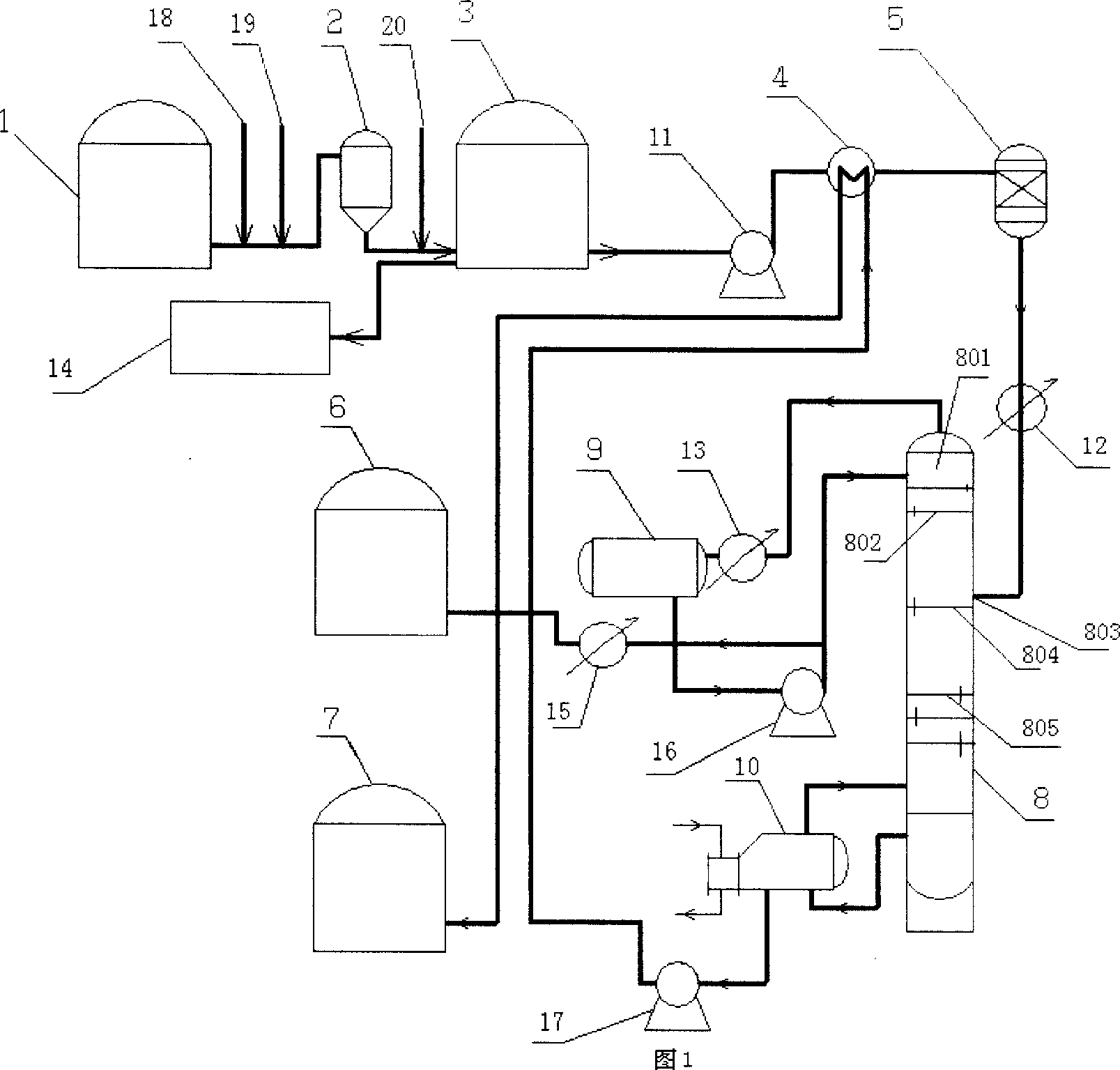

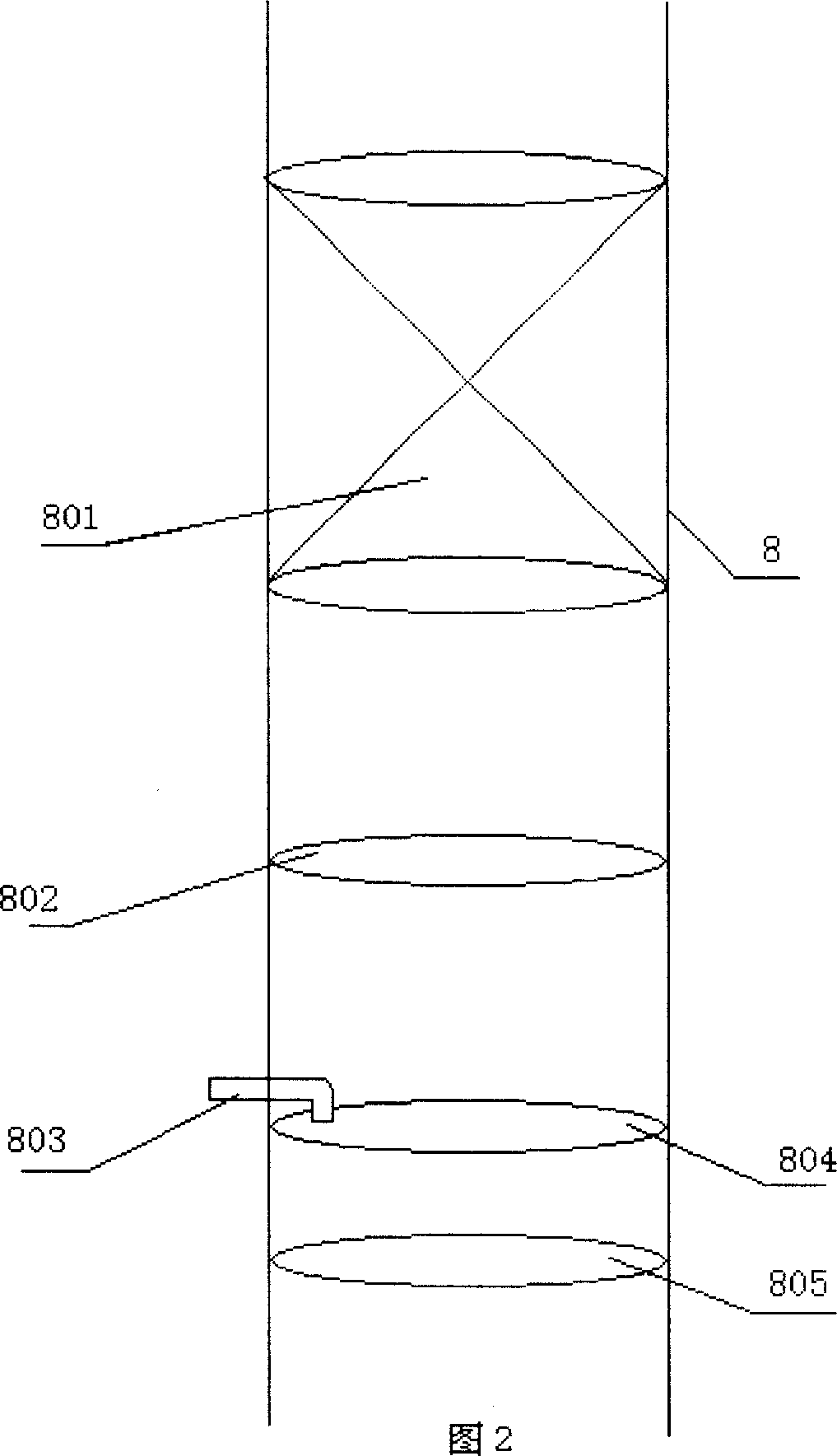

The invention discloses a method for treating and reusing fracturing backflow fluid of shale gas. The method comprises the following steps: (a) oxidizing Fe<2+> in original fracturing backflow fluid into Fe(OH)3, so as to obtain oxidized fracturing backflow fluid; (b) carrying out water quality analysis on the oxidized fracturing backflow fluid; (c) making comparison on the water quality of the oxidized fracturing backflow fluid and a reuse liquid preparation water quality requirement, and judging whether the concentrations of Ca<2+> and Mg<2+> in the oxidized fracturing backflow fluid of the shale gas are qualified; (d) if yes, sequentially carrying out coagulation, flocculation, sedimentation and filtration on the oxidized fracturing backflow fluid, and if no, sequentially carrying out coagulation-pH increase, ionic reaction, flocculation, sedimentation, filtration and pH value adjustment on the oxidized fracturing backflow fluid, so as to obtain treated fracturing backflow fluid; and (e) directly reusing the treated fracturing backflow fluid for liquid preparation or directly storing the treated fracturing backflow fluid. The method can adapt to the characteristics that the change of the water quality of the fracturing backflow fluid of the shale gas is large and reuse fracturing construction liquid preparation standards are different, and the instant continuous treatment can be realized.

Owner:PETROCHINA CO LTD

Converter less-slag smelting method

ActiveCN112646944ALow oxygenCutting costsManufacturing convertersProcess efficiency improvementSmelting processHeat balance

The invention relates to a converter less-slag smelting method. The converter less-slag smelting method uniformly adopts a less-slag single-slag mode under the conditions of high iron consumption or low iron consumption and complex molten iron silicon change. The converter less-slag smelting method comprises the following process flows of: finishing tapping, remaining slags, adjusting the slags, splashing the slags, adding scrap steel, mixing molten iron, conducting calculation, conducting blowing, controlling an end point and tapping. In the smelting process, the lance position and the oxygen supply intensity are controlled by referring to the CO value; the end oxidizability is effectively controlled through heat balance accurate calculation; the molten steel oxidizability is reduced through process low lance position control; the alloying cost is effectively reduced; and meanwhile, the final slag oxidizability is reduced; the slag splashing furnace protection effect is promoted; and the furnace condition maintenance cost is effectively reduced.

Owner:扬州圣莱特冶金科技有限公司

Gas field methanol sewage disposal process

InactiveCN1966428AIncrease turbidityHigh salinityOrganic chemistryMultistage water/sewage treatmentSewageTower

The invention relates to the water treatment technology, especially a gas field methanol sewage treatment technology which at least includes pretreating technology, methanol reclaiming technology and sewage back-flowing technology. The characteristic of the invention: after removing oil, adjusting Ph value, oxidizing to remove iron and flocculating / precipitating, separate the methanol from the sewage in the methanol-reclaiming device the core of which is dephlegmation tower, the treated water goes back to stratum. The invention finally managed to reclaim the methanol with zero release of waste liquids. The methanol-reclaiming dephlegmation tower adopts ''filling material + sieve pore (or oblique aperture)'' and ''floating valve + sieve pore (or oblique aperture)'' complex tower model to solve many problems such as obstructing and the adaptability of the dephlegmation tower to the large change of methanol content in different sewages.

Owner:XIAN CHANGQING TECH ENG

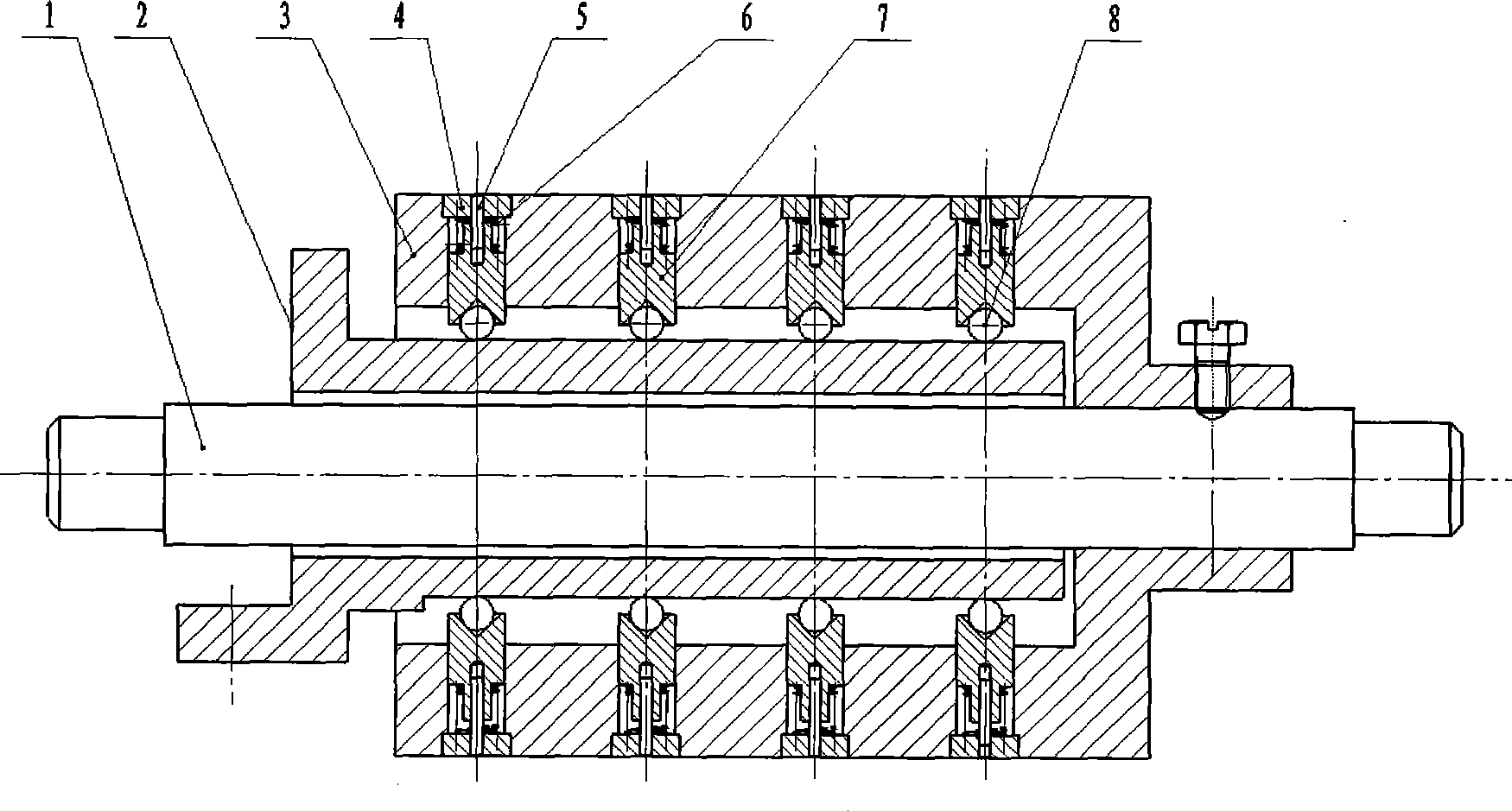

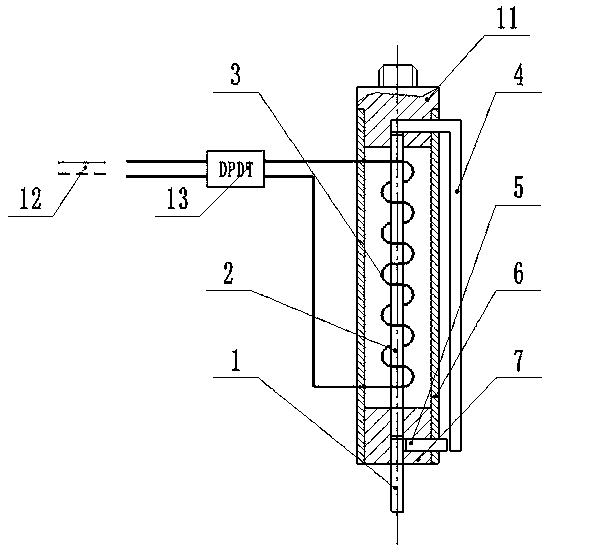

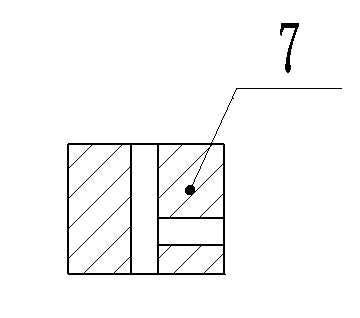

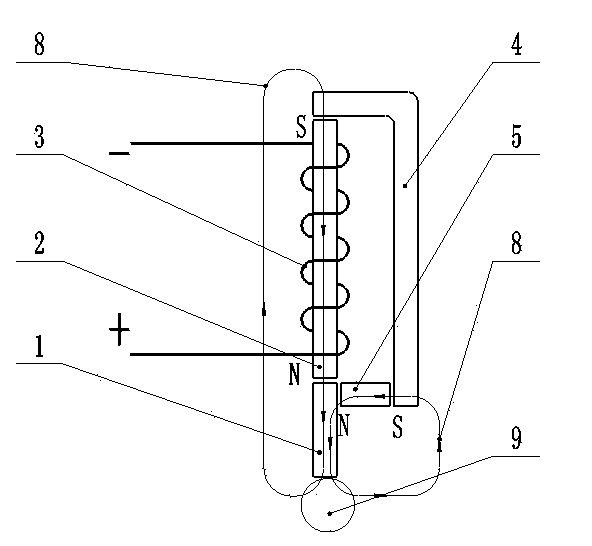

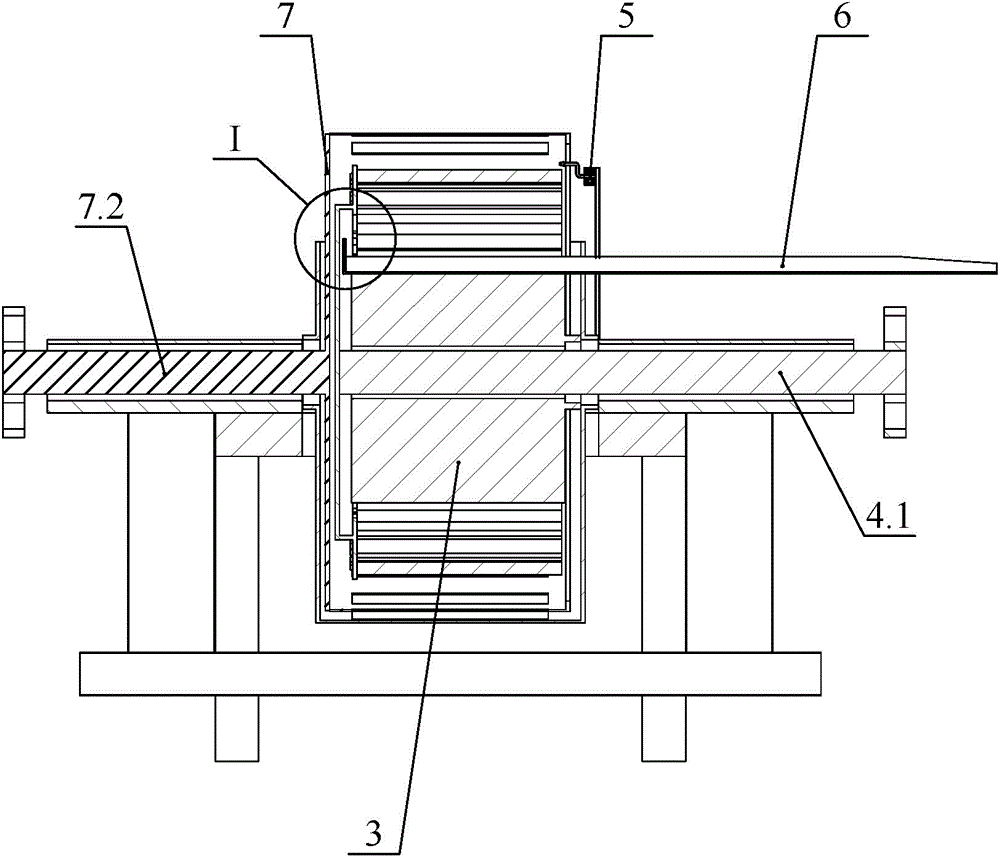

Magnetic-type precise seed-metering device

InactiveCN102918965AIncrease magnetic attractionAdjustable magnetic forceSeed depositing seeder partsPower flowMagnetic poles

The invention discloses a magnetic-type precise seed-metering device, and relates to the field of agricultural sowing machinery. The precise seed-metering device comprises a seed-metering element, a seed-metering element sleeve pipe, a mounting bracket, an adjustable DC stabilized power supply, and a power supply polarity switch. Output current of the DC stabilized power supply is adjusted, and current direction of a solenoid coil is changed. Magnetic induction intensity of a seed-suction end face of a magnetic head is changed, and polar N, S pole directions of an electromagnet magnetic pole end are changed. With the changes of the magnetic induction intensity of the seed-suction end face of the magnetic head, seed metering requirements of seeds of different specifications can be satisfied. With the changes of the polar N, S pole directions of the electromagnet magnetic pole end, seed-metering device seed suction and seed discharging actions can be achieved. Compared with a permanent magnet seed-metering element, with the device provided by the invention, a special forced seed discharging mechanism is not needed, such that seed damage caused by mechanical seed discharging is avoided; the magnetic head suction power is adjustable, such that sowing requirements of coated seeds with different specifications can be satisfied by a seed-metering element with a single specification.

Owner:JIANGSU UNIV

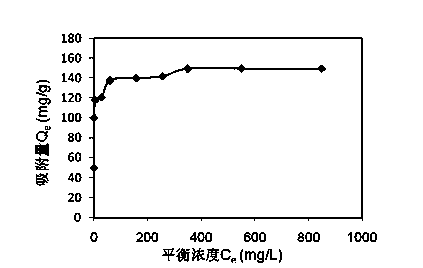

Method for removing metal ions in water by utilizing magnetically-separated steel slag tailings

The invention discloses a method for removing metal ions in water by utilizing magnetically-separated steel slag tailings. The method for removing heavy metal ions from waste water by utilizing magnetically-separated steel slag tailings containing less iron content comprises the steps of grinding, drying and screening the magnetically-separated steel slag tailings, and then placing into a reactor; adding waste water (containing heavy metal ions) into the reactor, and fully mixing; and separating solid from liquid to obtain tailings, and treating to discharge water. According to the method, as a material for water treatment, the magnetically-separated steel slag tailings is low in cost, wide in sources and large in specific weight, thus being convenient to recycle, and having less possibility of causing secondary pollution. In addition, the steel slag tailings belong to solid waste, thus achieving the purpose of treating wastes with wastes after being applied into waste water treatment, and having excellent economic and environment-friendly benefits.

Owner:NANJING UNIV OF SCI & TECH

Method for lowering contents of oxygen and nitrogen in molten steel at smelting end in semisteel smelting converter

InactiveCN103173586ASolve the problem of high oxidationReduce oxygen contentManufacturing convertersSmelting processNitrogen

The invention provides a method for lowering the contents of oxygen and nitrogen in molten steel at the smelting end in a semisteel smelting converter. The method comprises the following steps: before the blowing and smelting process, adding waste steel into semisteel in the converter, thereby controlling the content of carbon in the molten steel to be between 3.0% and 3.5% by weight and the temperature to be between 1250 DEG C and 1274 DEG C; and adopting different bottom-blowing modes during the oxygen top-blowing process in the converter, wherein carrying out the bottom-blowing on carbon dioxide before the oxygen blowing quantity during the semisteel smelting reaches 75% of the total oxygen blowing quantity during the whole semisteel smelting process; carrying out the bottom-blowing on argon before the oxygen blowing quantity during the semisteel smelting reaches 75% to 90% of the total oxygen blowing quantity during the whole semisteel smelting process; stopping the oxygen top-blowing when the oxygen blowing quantity during the semisteel smelting reaches 90% of the total oxygen blowing quantity during the whole semisteel smelting process; and carrying out the bottom-blowing on the carbon dioxide until the steel tapping. When the method provided by the invention is used for smelting the semisteel, the problem that molten steel and steel slags at the smelting end are high in oxidability due to the semisteel steel-smelting reblowing is solved. In addition, the oxygen content and the nitrogen content in the molten steel at the smelting end in the converter are lowered; and the total iron content in converter slags at the end is low.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Potassium silicate binder

InactiveCN105440957AReduce iron contentHigh bonding strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesPotassium silicateChloride

The invention provides a potassium silicate binder. The potassium silicate binder is characterized by comprising raw materials in parts by mass as follows: 30-50 parts of potassium silicate, 8-14 parts of white carbon black, 14-28 parts of magnesium oxide, 5-10 parts of magnesium chloride, 5-10 parts of magnesium sulfate, 5-10 parts of condensed aluminum phosphate, 2-8 parts of peregal O and 6-12 parts of water. The potassium silicate binder has the advantages as follows: the price is low, the application range is wide, normal-temperature curing is realized, water resistance is good, high temperature resistance is realized, flame retardancy is good, binding strength is high, the raw materials are foamed, the dosage is saved, the cost is reduced and the like.

Owner:LUOYANG LVREN ENVIRONMENTAL EQUIP

Mineral processing technology of potash feldspar

InactiveCN109046752ASolve the problem of high iron contentProtect resourcesWet separationMineral processingMaterials science

The invention provides a mineral processing technology of potash feldspar, and relates to the technical field of the mineral processing technology. The mineral processing technology of the potash feldspar comprises the following steps of (1) crushing, (2) ore grinding, (3) desliming, (4) magnetic separation, (5) flotation, (6) acid pickling of potash feldspar fine powder, (7) flushing washing of the potash feldspar and (8) drying. According to the mineral processing technology of the potash feldspar, the final fine powder is obtained from raw ores, the recovery rate reaches more than 90%, thetechnology procedure is simple, the operation is convenient, production water generated in the technology is recycled, the water consumption is saved, and environmental resources are protected.

Owner:贺州市骏鑫矿产品有限责任公司

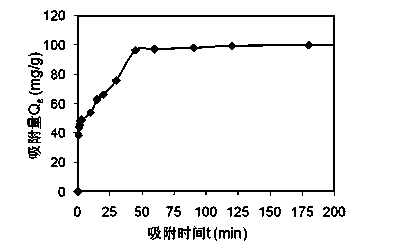

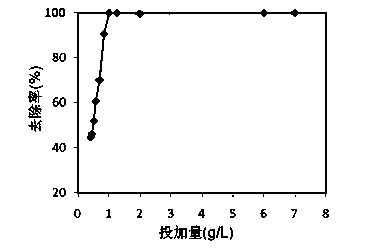

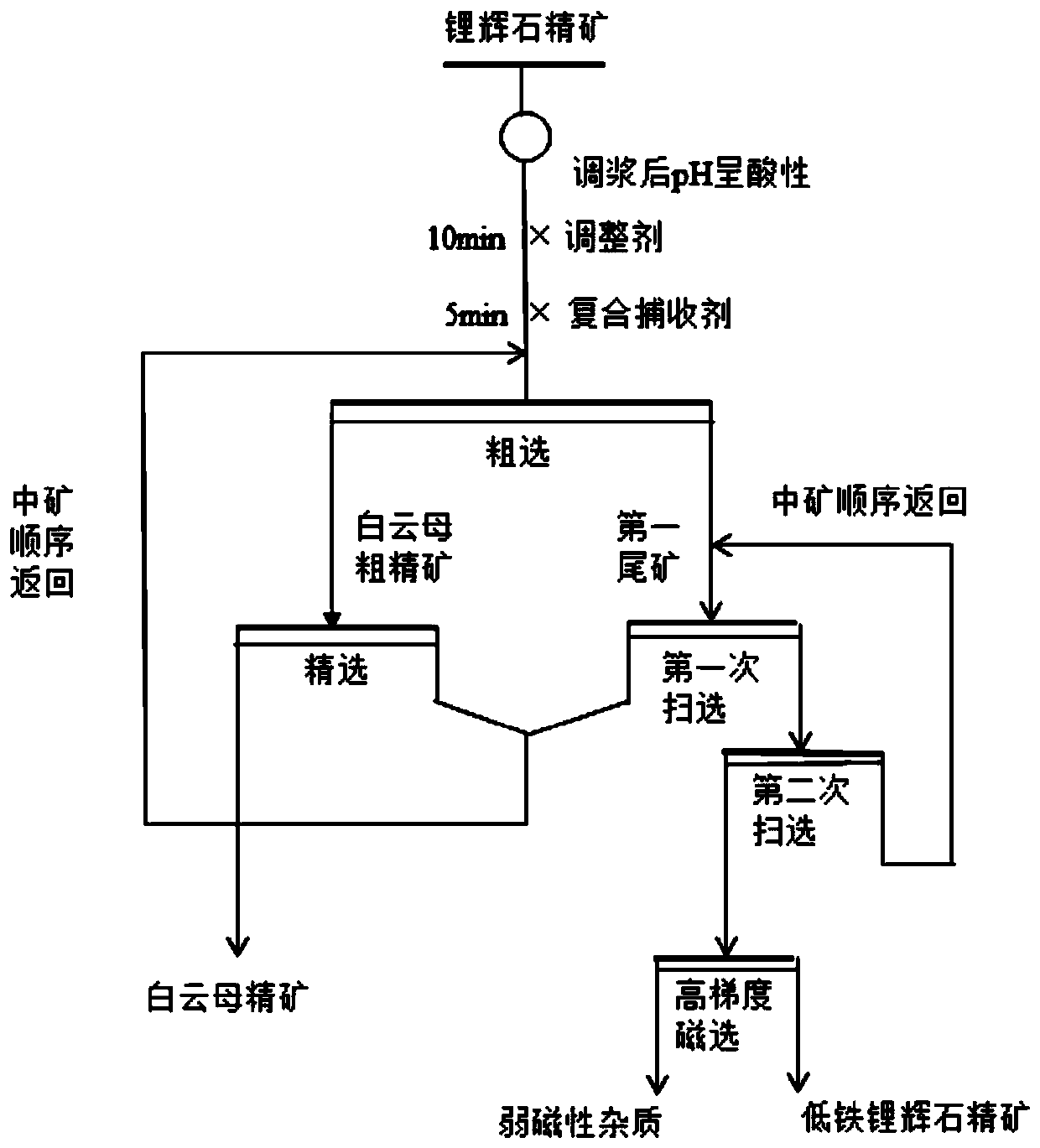

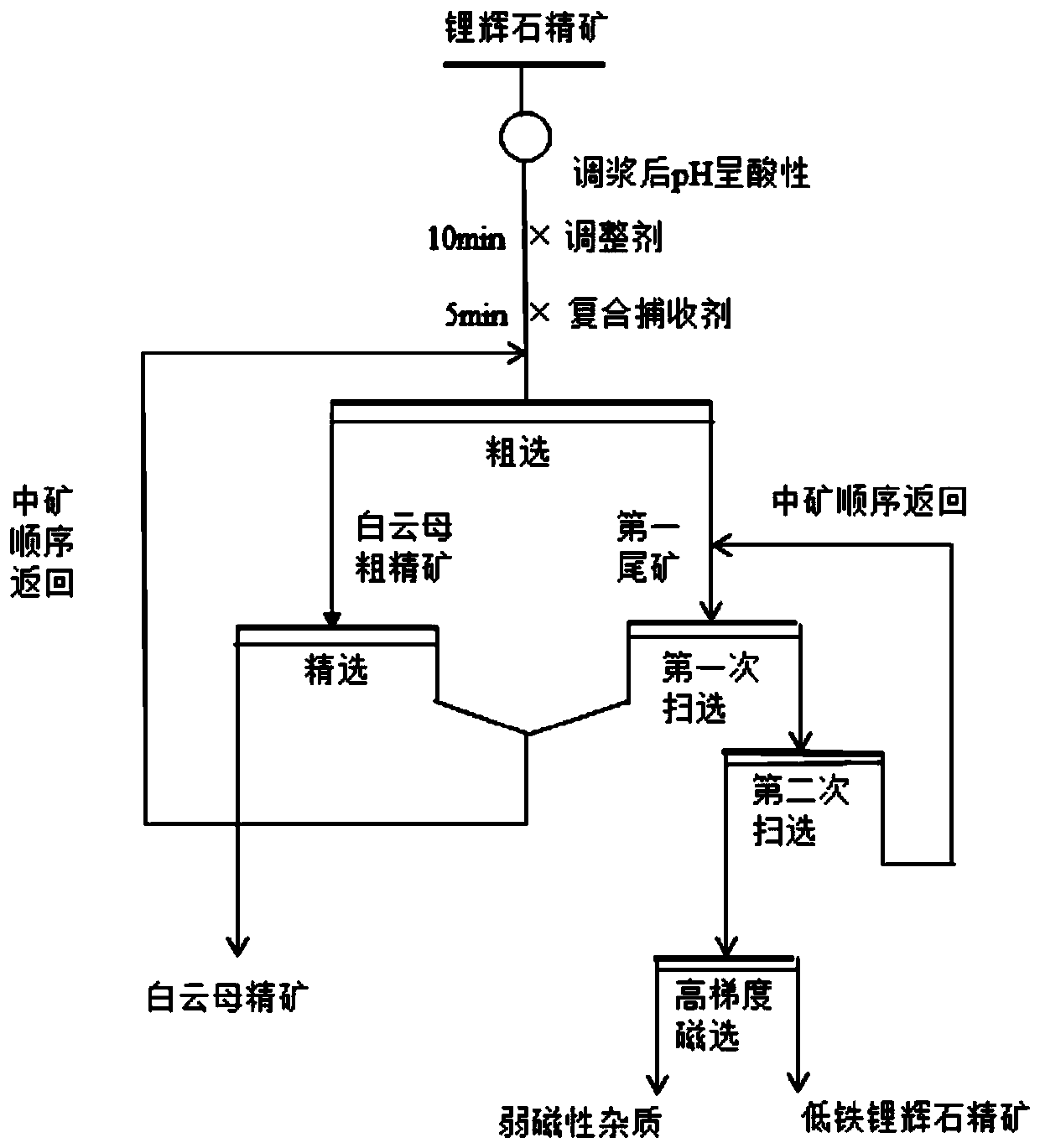

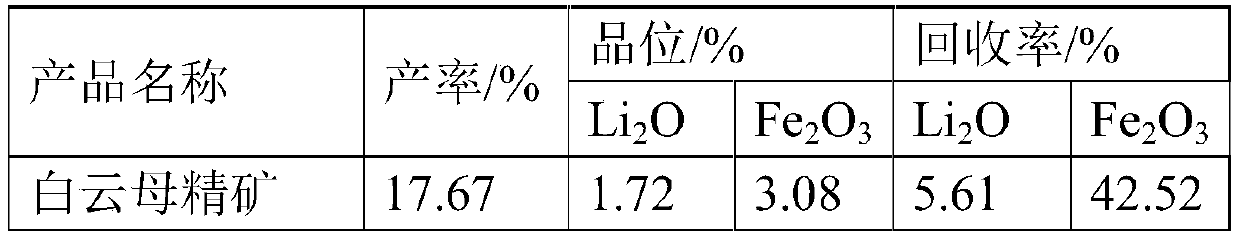

Composite collector, low-iron spodumene concentrate and preparation method for low-iron spodumene concentrate

The invention relates to a composite collector, low-iron spodumene concentrate and a preparation method for low-iron spodumene concentrate. The composite collector comprises amino acid, fatty acid anddiesel oil, wherein the weight ratio of the amino acid to the fatty acid to the diesel oil is (80 to 90): (5 to 10): (5 to 10). The composite collector is capable of increasing the grade of lithium in the spodumene concentrate, free from causing the waste of lithium resources, and capable of lowering the content of iron impurity.

Owner:GUANGDONG GUANGHUA SCI TECH

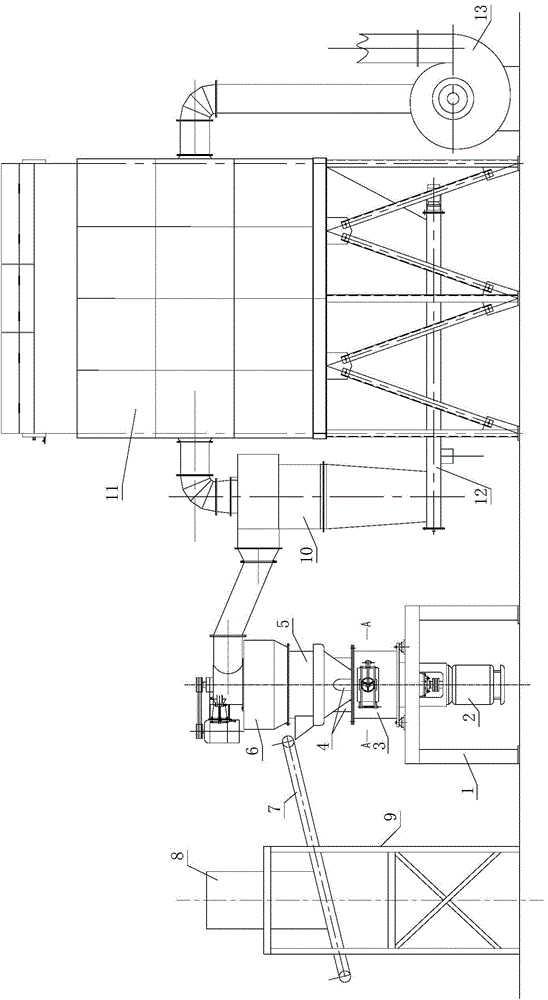

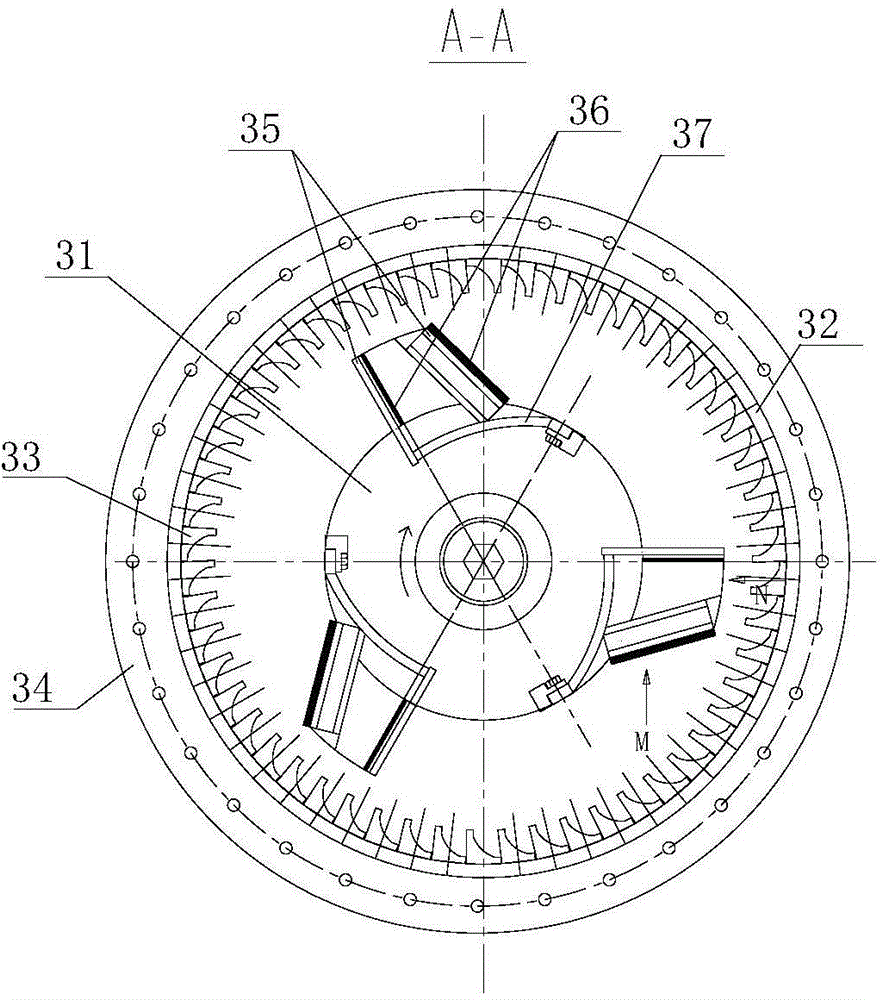

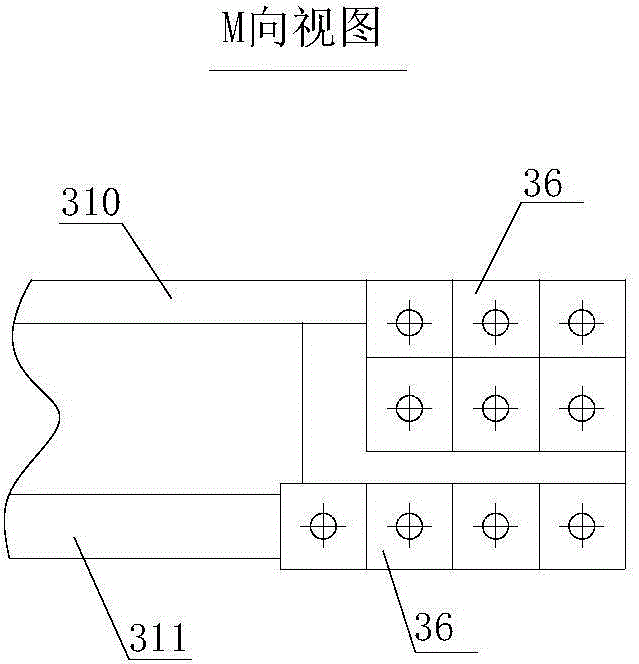

Solid material grinding method and solid material grinding machine

The invention relates to a solid material grinding method and a grinding machine. Solid materials enter a grinding body of a grinding room after being subjected to primary air classification, and are thrown onto a lining plate along the radial direction to be broken due to collision under the centrifugal effect of the grinding body in high-speed rotation; after rebounding from the lining plate, the broken materials oppositely collide newly-added materials to be broken; large-particle materials drop under the gravity effect and upwards enter a working cabin through a guide pipe after being subjected to high-speed hammering; the working bin has the functions of feeding and wind mixing elutriation; the materials subjected to wind mixing elutriation enter a classifier to be classified; finished material products achieving the granularity requirements are collected by a spiral collector and a bag-type dust remover and then are discharged from a finished product discharging device; and materials not achieving the granularity requirements are returned to the grinding room to be reground. The grinding machine has the beneficial effects that the grinding granularity is small, the grinding efficiency is high, the fine powder collecting effect is good, the equipment is compact in structure, the maintenance cost is low, powder bodies with the granularity in a range of 80-1,500 meshes can be produced, and the grinding machine has the advantages of high yield ad stable quality particularly when producing ultrafine powder with the granularity being greater than 800 meshes and materials with higher rigidity.

Owner:蔡昌荣

Moderate-strength electric porcelain product and manufacturing method thereof

The invention provides a moderate-strength electric porcelain product and a manufacturing method of the moderate-strength electric porcelain product, wherein the moderate-strength electric porcelain product is produced by taking 35-40 parts of kaolin, 5-10 parts of Al2O3 powder, 25-30 parts of quartz sand, 10-15 parts of bauxite, 5-10 parts of hydromica, 5-10 parts of potassium-soda feldspar and the like in parts by weight as raw materials according to an ordinary processing technique of the electric porcelain product, wherein the kaolin, the quartz sand, the Al2O3 powder and the bauxite are framework materials of the product, and the hydromica and the potassium-soda feldspar are fluxing materials of the product. The moderate-strength electric porcelain product and the manufacturing method of the moderate-strength electric porcelain product provided by the invention have the beneficial effects that the method can be widely applied to the production of electric porcelain suspension insulator products with different strength grades such as 70kN, 80kN, 100kN and 120kN; the iron content of the products is decreased and the quality of the products is improved; the molding process of the preparation method is excellent, product defects are few, the qualification rate of semi-finished products is more than 97%, and the qualification rate of firing is more than 95%.

Owner:萍乡百斯特电瓷有限公司

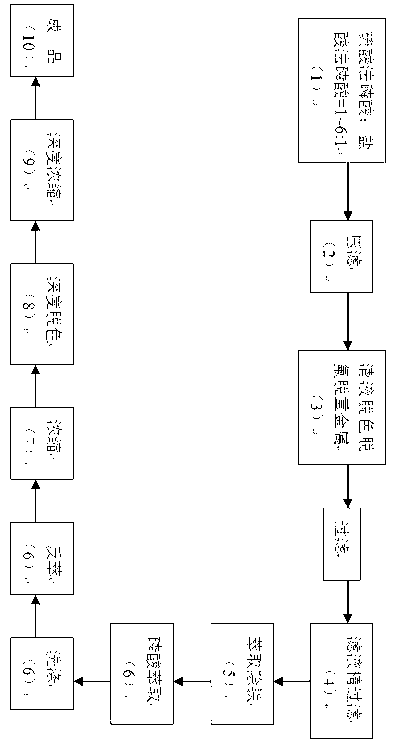

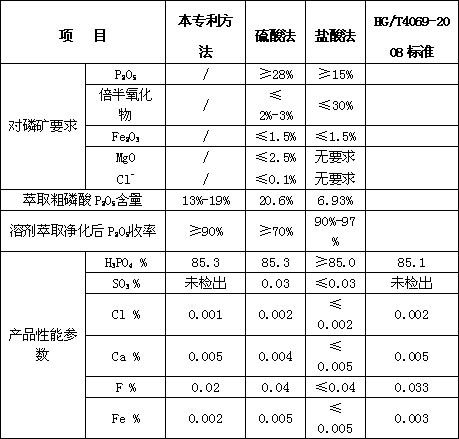

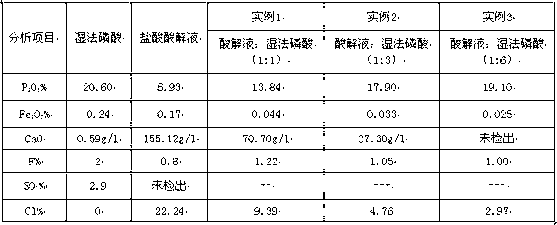

Novel method for producing industrial phosphoric acid by purification with wet process phosphoric acid

ActiveCN103303886ALight colorReduce iron contentPhosphorus compoundsO-Phosphoric AcidSulfate radicals

The invention relates to a novel method for producing industrial phosphoric acid by purification with a wet process phosphoric acid and belongs to the fields of a refining technology of wet process phosphoric acid and processing of industrial phosphoric acid. The core of the method provided by the invention is as follows: the content of P2O5 of wet process phosphoric acid produced by a sulfuric acid method is higher, and a lot of SO4<2-> ions are comprised in the phosphoric acid. The content of P2O5 of an acidolysis liquid produced by decomposing phosphate ore by hydrochloric acid is lower, and calcium ions in high content are comprised. The wet process phosphoric acid and the acidolysis liquid are mixed, so that the content of P2O5 in the mixed liquid is improved, and the contents of calcium ions and sulfate radicals in the mixed liquid are reduced. The novel method has a certain promoting effect on separation out of other impurities. According to the novel method, mixed desulfuration is used to replace conventional desulfurization technology by phosphoric ore pulp and barium carbonate, so that the desulfurization rate in one step can reach over 99%. Two different phosphoric acids are mixed, so that SO4<2-> and Ca<2+> generate CaSO4 precipitates to remove SO4<2->. The optimal decontamination index w of the mixed acidic liquid obtained is w(H3PO4)=(10-25)%, while w (SO4<2->) is not monitored. The main component of the filter residue is CaSO4, and the purity is high and reaches 99%.

Owner:SHANDONG LUBEI ENTERPRISE GROUP

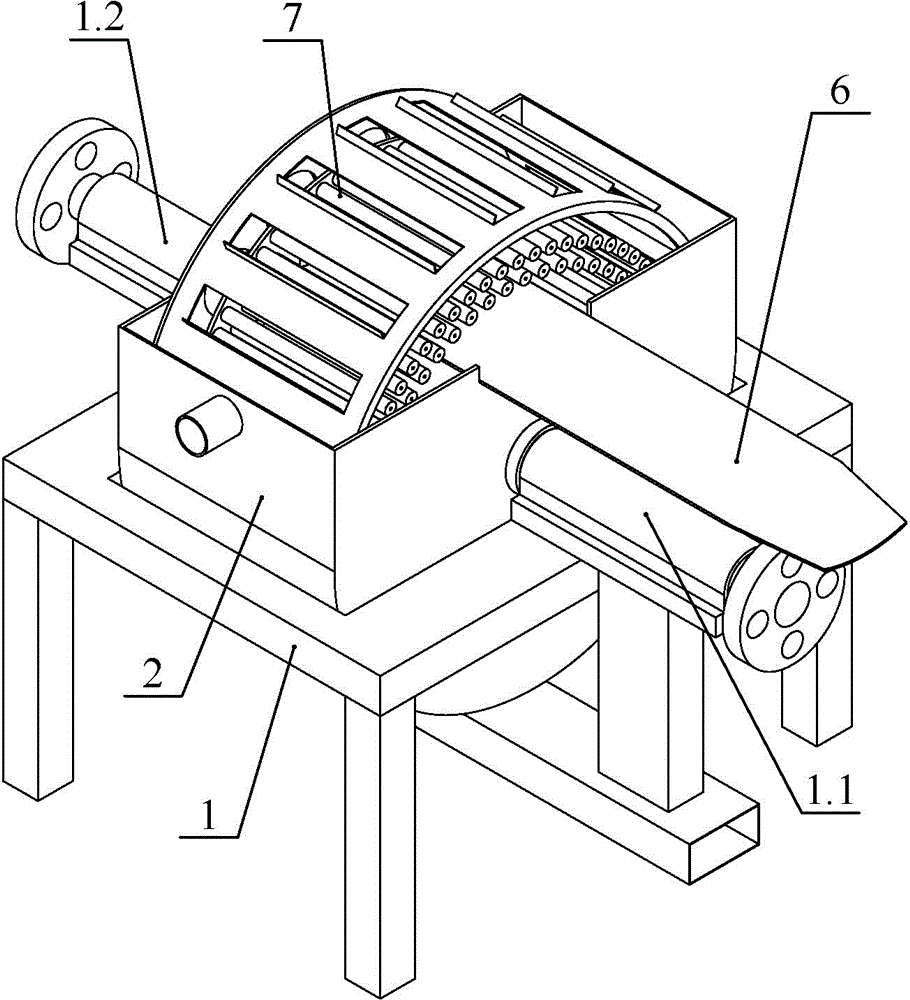

Method and device for deironing continuously in slurry in bi-twisting mode

InactiveCN103977888AGood iron absorption effectImprove slurry qualityMagnetic separationScrapEngineering

The invention discloses a method and device for deironing continuously in slurry in a bi-twisting mode, and belongs to the field of magnetically separating solids in slurry. Magnetic bars in magnetic bar groups are placed in a slurry barrel for adsorbing scrap iron in slurry, and then the scrap iron adsorbed on the magnetic bars is removed. The method and device for deironing continuously in slurry in a bi-twisting mode are characterized in that the magnetic bars in the magnetic bar groups are arranged horizontally; one part of the magnetic bars in the magnetic bar groups are positioned in the slurry, and the other part of the magnetic bars are all exposed out of the liquid level of the slurry; the magnetic bar groups rotate, so that the scrap iron adsorbed on the part of magnetic bars exposed out of the liquid level of the slurry is removed. The method and device for deironing continuously in slurry in a bi-twisting mode, which are provided by the invention, have the beneficial effects that the skillful design of a sandwiched wall cavity enables the slurry in the cavity to be in contact with the magnetic parts maximally, and the magnetic force is applied to the slurry uniformly, and a preferable deironing effect is obtained; the magnetic parts rotate continuously so that deironing is carried out uninterruptedly, and the deironing efficiency is improved greatly; the stability is extremely high, and the maintenance cost is extremely low.

Owner:钟娟英

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com