Patents

Literature

596 results about "Semi-steel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semi-steel casting is a lower cost method to produce a casting that is not quite as strong as a steel casting but less expensive to manufacture. It was used more commonly as a marketing term. The carbon and silicon percentages are reduced to the amount approximately consistent with those in steel. This is done using pig iron or gray iron casting scrap and reducing the amount of carbon through the addition of relatively pure steel or wrought iron scrap in a well heated cupola furnace. The percentage of carbon is typically between foundry cast iron and wrought iron.

Method of producing titanium enriched material using titanium mineral

InactiveCN1429919AEfficient recyclingImprove resource utilization efficiencyMagnetic separationAdhesiveMagnetite

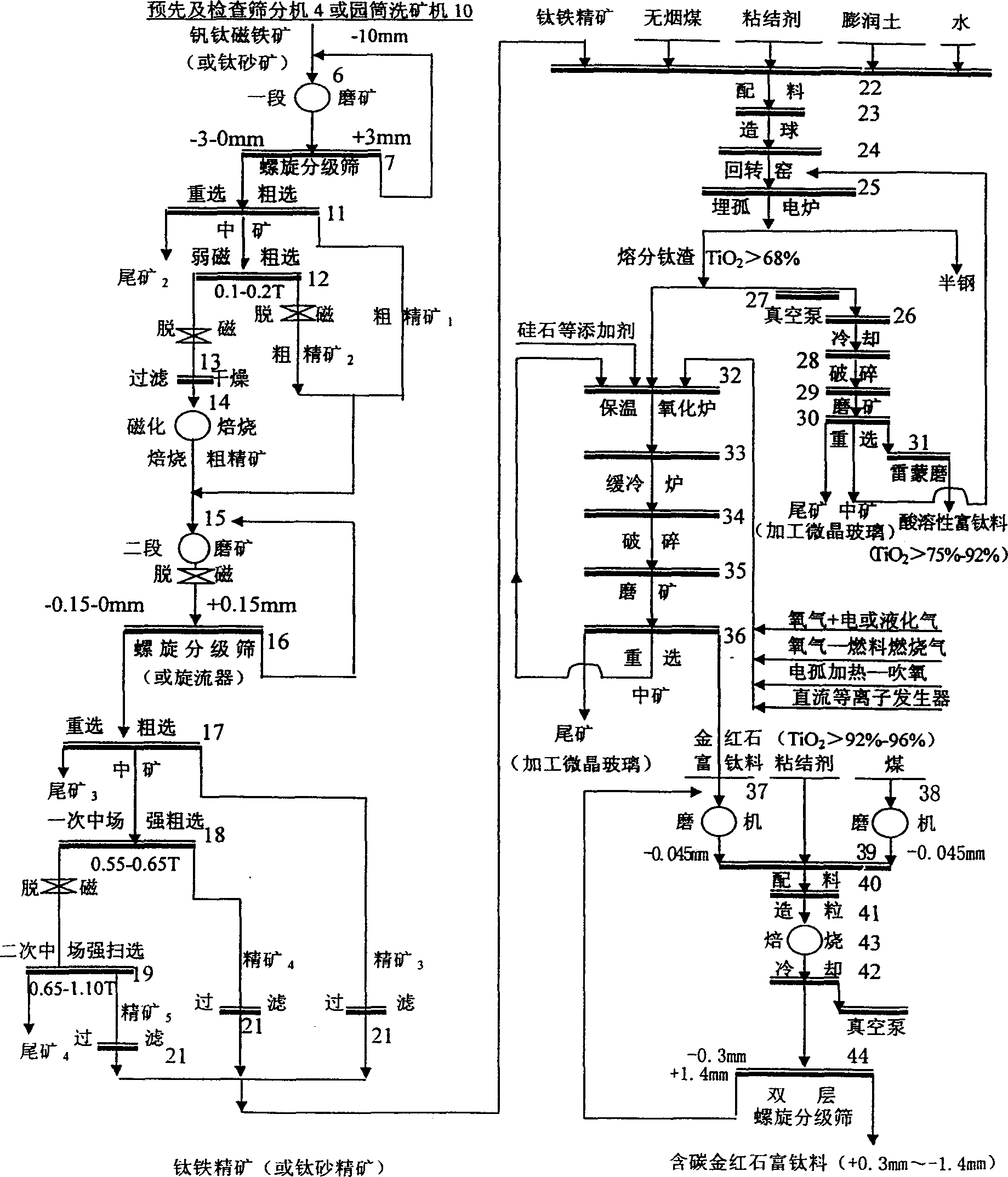

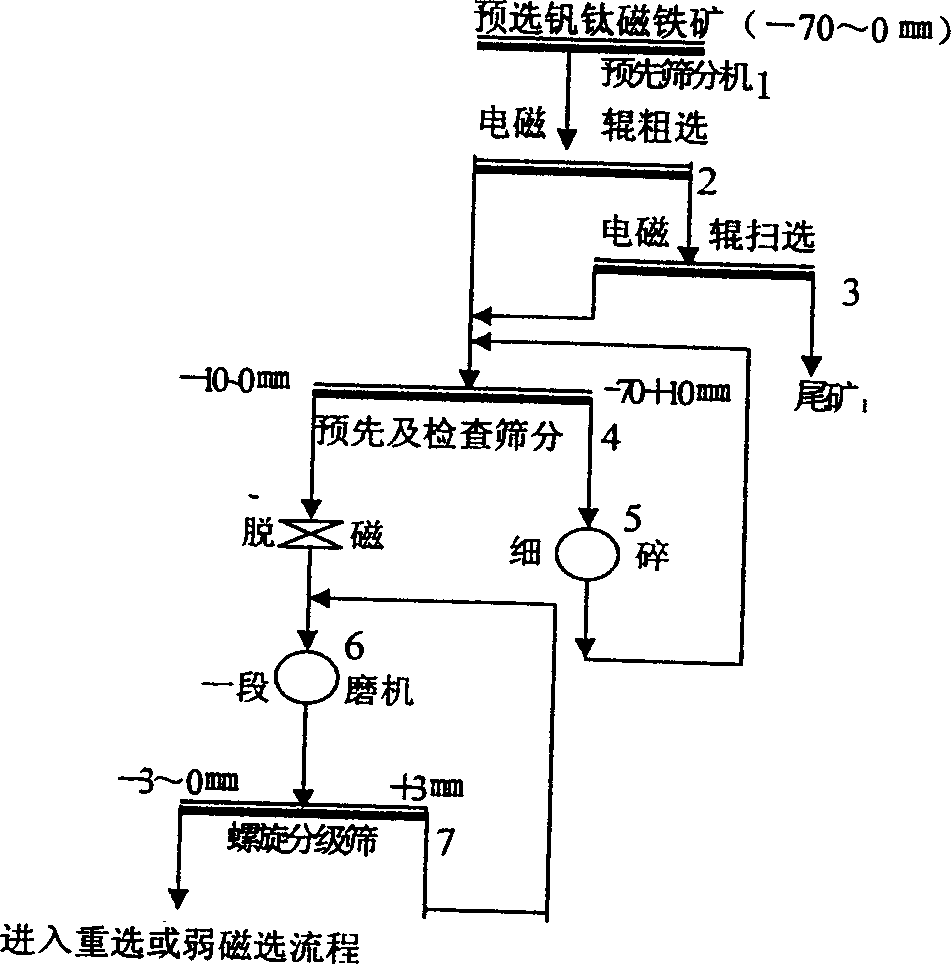

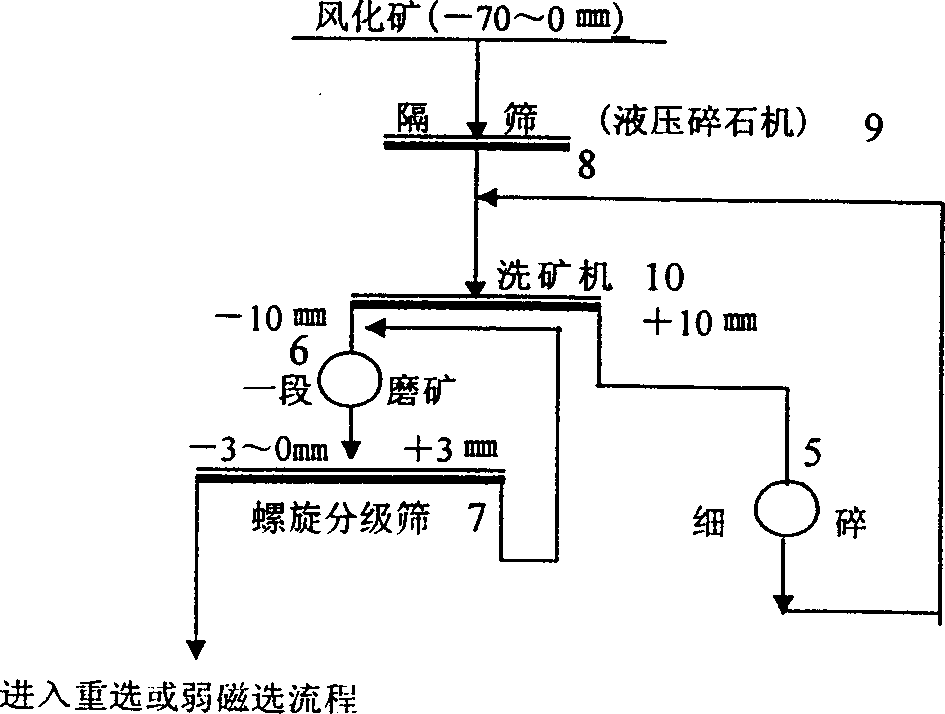

A process for preparing Ti-enriched material from V-Ti magnetite through preseparating to obtain Ti-Fe ore concentrate, proportionally mixing it with V-Ti-Fe core concentrate, adhesive and carbon reducer, smelting to obtain high-Ti slag and semi-steel, blowing V-Cr to melten alloy iron to obtain V-Cr contained steel slag, separating V and Cr, fire metallurge of high-Ti slag to obtain artificial rutile and microcrystal glass, ball grinding of artificial rutile and coal while adding adhesive to obtain C-contained Ti particles, calcining, cooling and classifying.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

Method for separating vanadium-titanium magnetite to extract iron, vanadium and titanium

InactiveCN102179292AHigh technical difficultyIncrease processing costWet separationSmelting processMagnetite

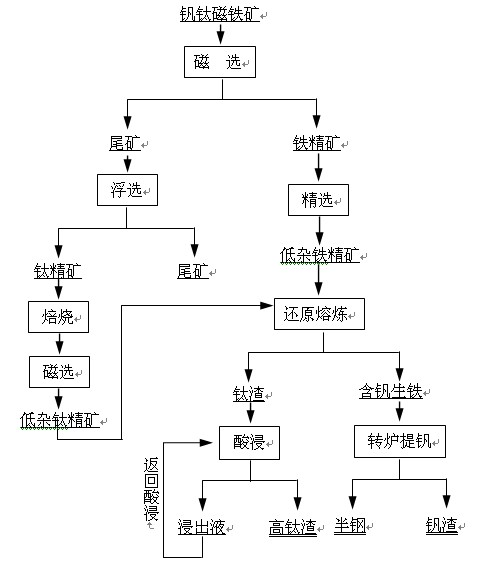

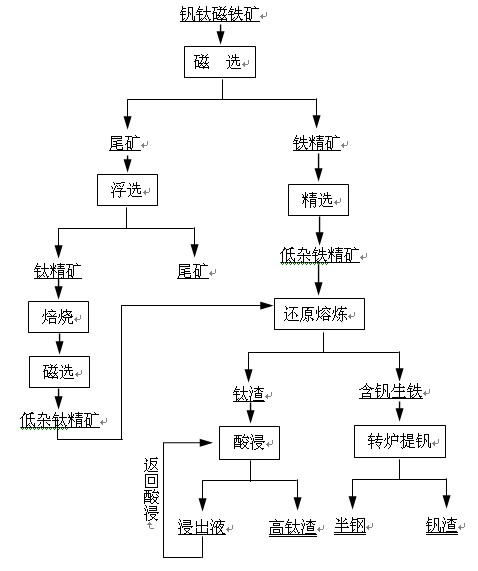

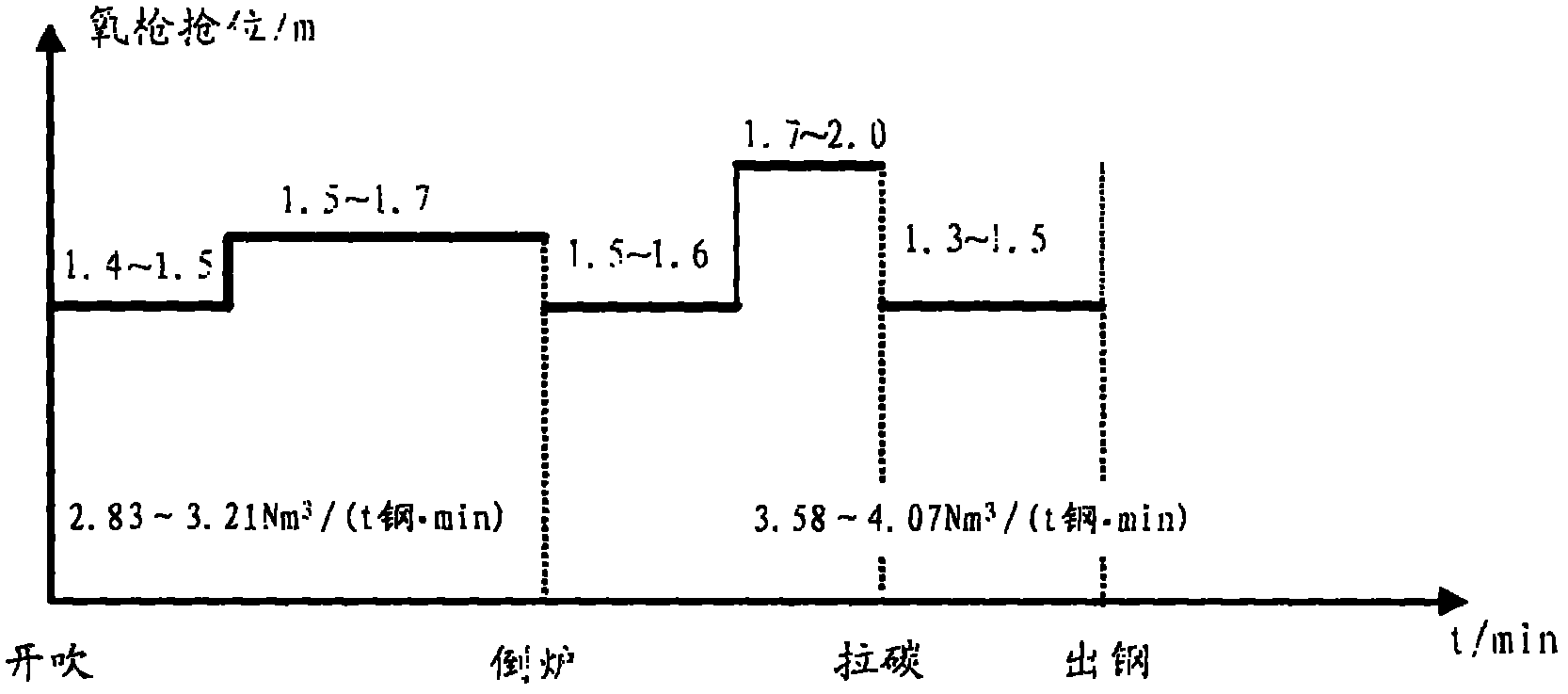

The invention discloses a method for separating vanadium-titanium magnetite to extract iron, vanadium and titanium, comprising the following steps of: magnetically selecting raw magnetite, that is, acquiring iron-vanadium concentrate and tail magnetite after performing magnetic selection on the vanadium-titanium magnetite; sorting titanium concentrate from the tail magnetite, that is, acquiring the titanium concentrate after performing floating selection on the obtained tail magnetite; roasting and magnetically selecting the titanium concentrate, that is, performing enriched-titanium impurity-removing magnetic selection after roasting the titanium concentrate; finely selecting the iron-vanadium concentrate, that is, performing the magnetic selection and fine section again on the iron-vanadium concentrate obtained from magnetic selection; reducing and smelting, that is, mixing the titanium concentrate obtained from the impurity-removing process with the iron concentrate according to the beneficiation yield, adding in a reducer and soda ash to perform reduced iron and vanadium smelting process; purifying vanadium slag, that is, removing the impurity of the vanadium slag obtained by reducing and smelting by using the acidic dipping to obtain the high-quality titanium slag product with the content of TiO2 larger than 92%; and extracting vanadium from pig iron, that is, performing vanadium extraction by converter blowing on the vanadium-containing pig iron obtained by reducing and smelting to obtain the semi-steel and vanadium slag. The method not only improves the utilization ratio of titanium, iron and vanadium but also obtains the high-titanium slag product with the content of TiO2 larger than 92% so as to widen the application field of titanium.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Titanium slag smelting method

The invention provides a titanium slag smelting method which comprises the following steps: preparing a mixture of titanium concentrates, a bonding agent and a carbonaceous reducing agent into pellets or briquettes; drying the pellets or briquettes; prereducing the pellets or briquettes by utilizing an annular furnace or a rotary hearth furnace, thereby preparing metallized pellets or metallized briquettes; and loading the metallized pellets or metallized briquettes into an electric furnace so as to melt and separate the metallized pellets or metallized briquettes, thus obtaining semisteel and titanium slag, wherein the smoke generated by prereducing the pellets or briquettes is used for providing heat for drying the pellets or briquettes, and the smoke generated in the melting and separating process is used for providing heat for prereducing the pellets or briquettes.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +1

Dephosphorization method of semi-steel

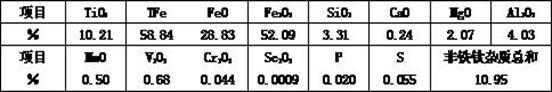

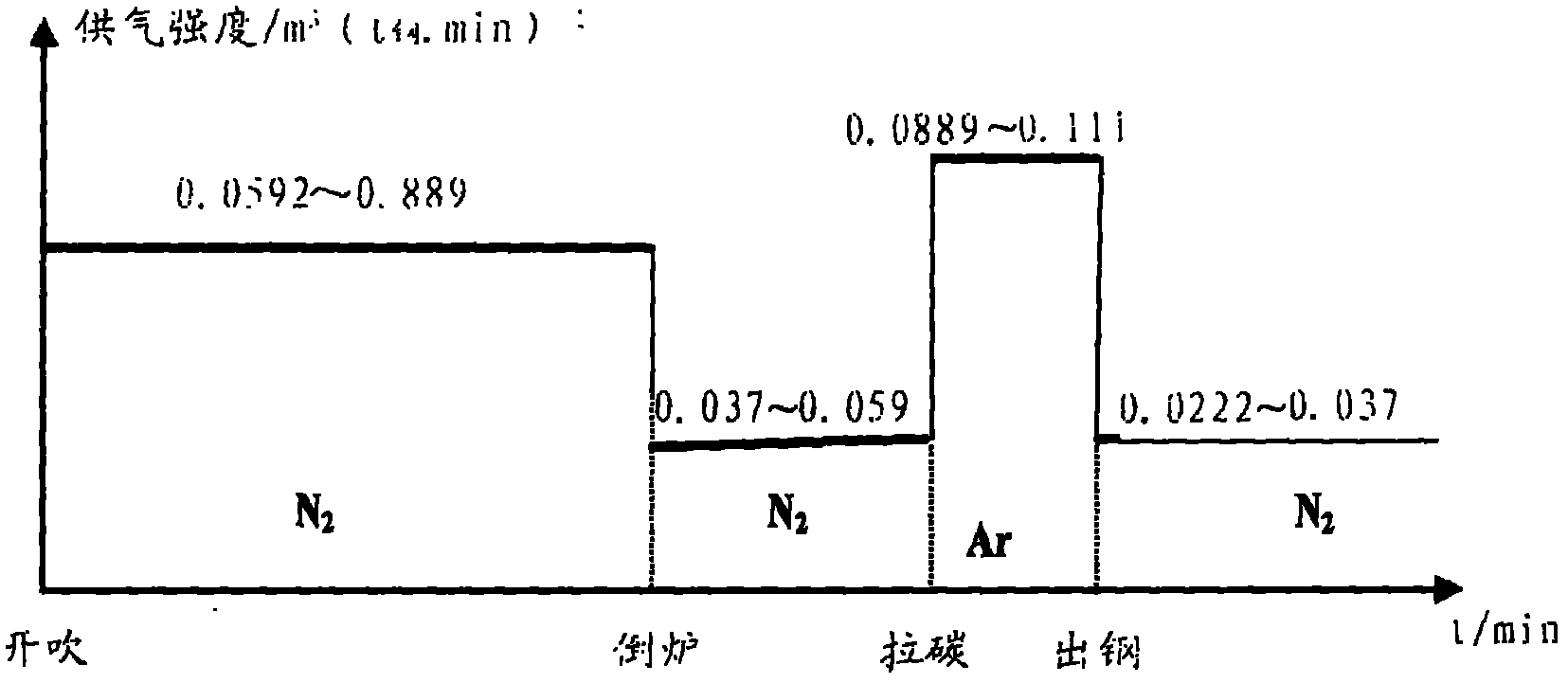

The invention provides a dephosphorization method of semi-steel. The method comprises the following steps: adopting a six-hole oxygen gun to perform sectional smelting through a way of adjusting the oxygen supply strength of the oxygen gun, namely first dephosphorization smelting, adding a first batch of slag-making materials, controlling the oxygen supply strength of a top-blowing oxygen gun at 2.83-3.21Nm3 / (t steel. min), simultaneously bottom-blowing nitrogen, smelting and deslagging; performing second dephosphorization smelting, adding a second batch of the slag-making materials, controlling the oxygen supply strength of the top-blowing oxygen gun at 3.58-4.07Nm3 / (t steel. min), bottom-blowing the nitrogen during the time period from the beginning of the second dephosphorization smelting to carbon catching, bottom-blowing argon during the time period from the carbon catching to the terminal point of converting, smelting, stopping slag, tapping for getting molten steel with the content of a phosphorus element, which is not more than 0.008% by weight percentage, and performing the operation of remaining the slag after the tapping. By adopting the method, the dephosphorization effect is good, the dephosphorization efficiency is high, the smooth operation of the smelting process of a converter can be ensured, the steel-making production cost can be reduced and the semi-steel can be adopted for producing low-phosphorus steel with high grade and high added value.

Owner:PANZHIHUA IRON AND STEEL +2

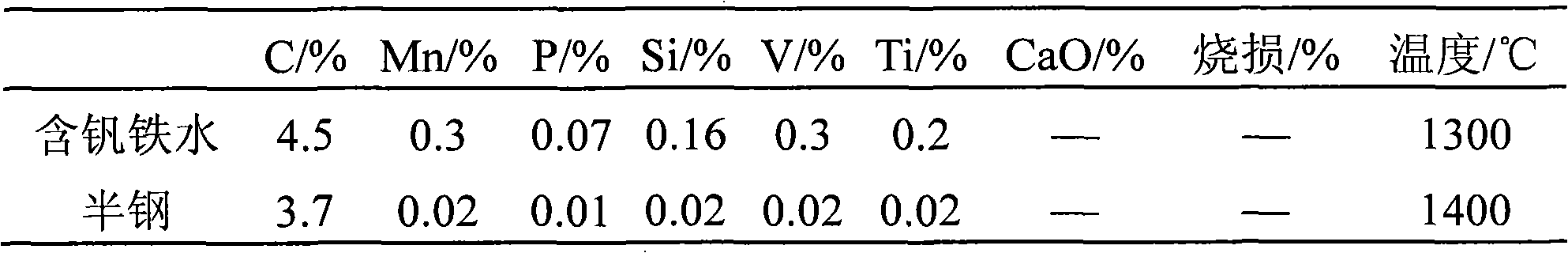

Method for smelting high-carbon steel from semi-steel

InactiveCN102766722ARealize the purpose of simultaneous dephosphorization and carbon conservationShorten the formation timeManufacturing convertersMelting tankSilicon alloy

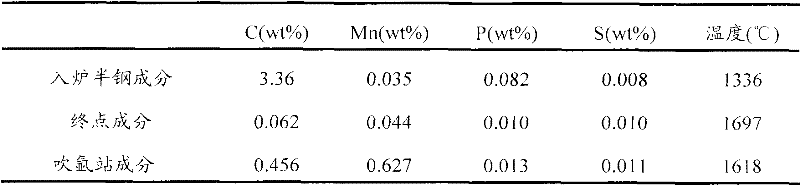

The invention provides a method for smelting high-carbon steel from semi-steel. The method adopts the semi-steel after extraction of vanadium as a raw material, and comprises the following steps of: adopting a low vanadium extraction process during smelting of a vanadium extraction converter to ensure that the carbon content of the semi-steel after the extraction of vanadium is not smaller than 3.70 weight percent, and the temperature of the semi-steel is not lower than 1,290 DEG C; adding active lime into the converter according to a standard of 10 to 15 kg in a ton of steel, adding high-magnesium lime into the converter according to a standard of 7 to 10 kg in a ton of steel, shaking the converter back and forth to ensure that the active lime and the high-magnesium lime are uniformly mixed with steel slag in the converter, then adding the semi-steel into the converter, and adding a ferro-silicon alloy into the converter, wherein the added amount of the ferro-silicon alloy can ensure that the initial alkalinity of furnace slag is 2 to 3; performing converting, and pouring out the furnace slag when the temperature of a molten pool is raised to be 1,400 to 1,500 DEG C; adding active lime into the converter according to a standard of 12 to 18 kg in a ton of steel and adding high-magnesium lime into the converter according to a standard of 9 to 12 kg in a ton of steel to perform secondary slagging; performing converting, and adding manganiferous iron ore into the converter to ensure that the alkalinity of the furnace slag is 4 to 5 and a CaO-SiO2-FeO-MnO low-melting-point slag system is formed; adding a cooling agent into the converter after converting for 3 to 5 minutes, and continuously converting until target molten steel and terminal furnace slag are obtained; and tapping. According to the method, dephophorization and carbon maintenance can be realized at the same time.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

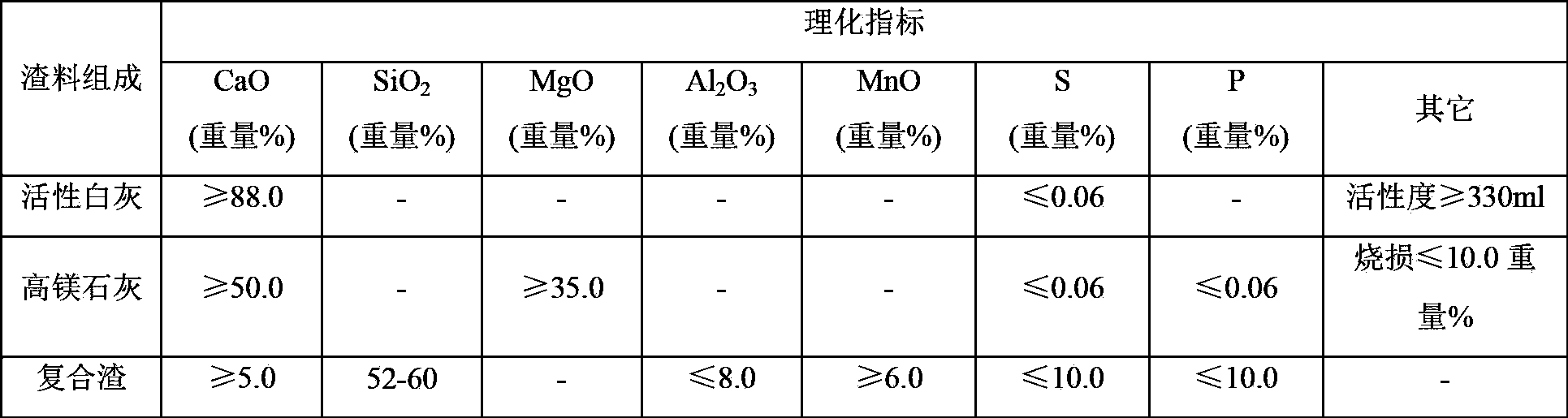

Steelmaking and slagging method

The invention provides a steelmaking and slagging method. The method comprises the following steps of: adding semisteel from which vanadium is extracted into a steel refining furnace; blowing oxygen into the steel refining furnace and blowing; in two minutes after the blowing is started, adding 9 to 11kg of lime, 9 to 11kg of high-magnesium lime, 3 to 8kg of fluxing agent, and 11 to 14kg of acid composite slag into the steel refining furnace based on one ton of semisteel from which vanadium is extracted; and in 9 minutes after the first slag is formed and blowing is started, adding 9 to 11kg of lime and 9 to 11kg of high-magnesium lime into the steel refining furnace based on one ton of semisteel from which vanadium is extracted, and continuously blowing to obtain molten steel and final slag. The fluxing agent is refined steel slag. Slagging is performed by the method, the slag can be formed quickly, the consumption of an iron and steel material is reduced, smelting time is shortened and steelmaking cost is saved.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

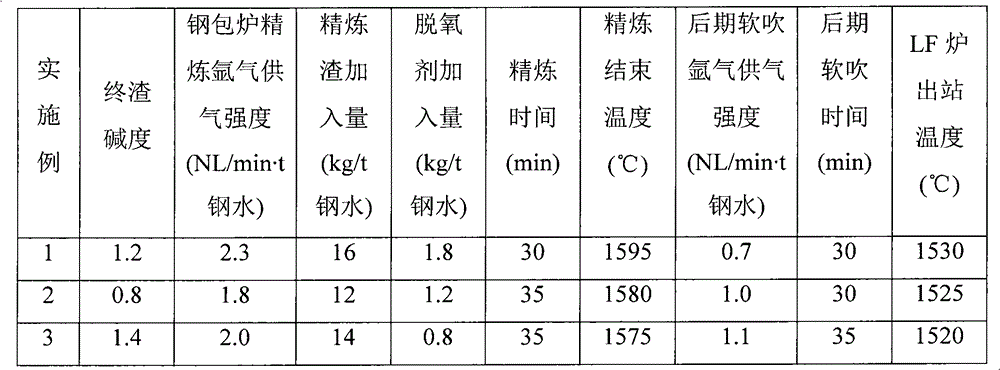

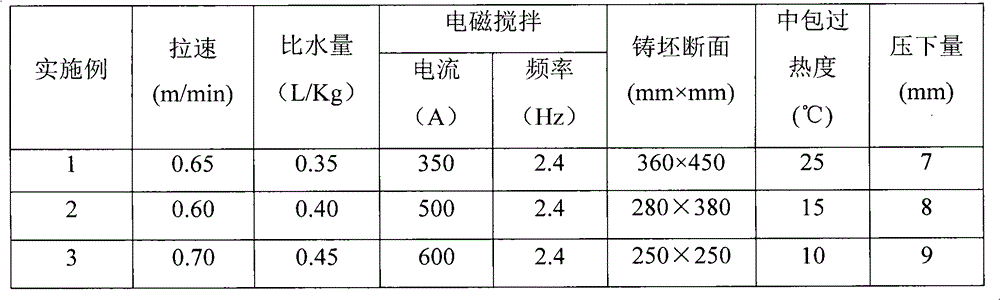

Method for smelting tire cord steel and method for continuously casting tire cord steel

ActiveCN103060513ARealize clean productionInclusion deformable strongManufacturing convertersIngotOxygen content

The invention discloses a method for smelting tire cord steel and a method for continuously casting tire cord steel; the methods comprise the following steps of: (1), carrying out primary smelting on molten iron or semi-steel by converter top-bottom blowing, and tapping into a steel ladle without deoxidization; (2), carrying out recarburization and pre-alloying on the molten steel in the tapping process, so on the basis of the total weight of the molten steel, the activity oxygen content in the molten steel is 0.004-0.008wt%, the C content is 0.64-0.68wt% and the Al content is less than 0.4wt%; (3), blowing argon to the molten steel in the steel ladle after tapping, and carrying out vacuum refining and alloy fine adjustment; and (4), carrying out ladle furnace refining on the molten steel which is subjected to the vacuum refining by using the manner of bottom blowing argon, adding refining slags batch by batch and adding deoxidizing agents batch by batch, so the total content of FeO and MnO in the steel ladle top slag is less than or equal to 10wt%. In the methods, the tire cord steel is produced by using the technological process consisting of converter primary smelting, vacuum refining and steel ladle furnace refining and cogged ingot continuous casting pouring, and thus the clean production of tire cord steels is achieved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

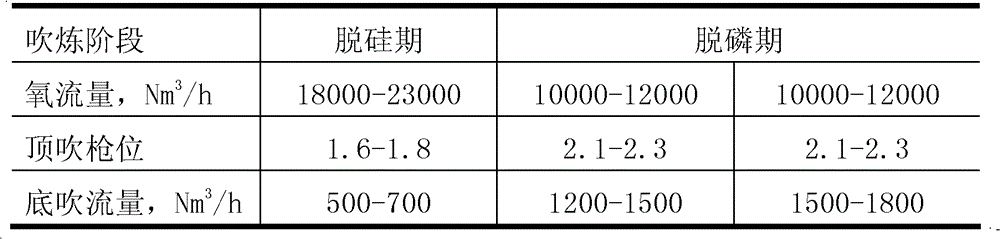

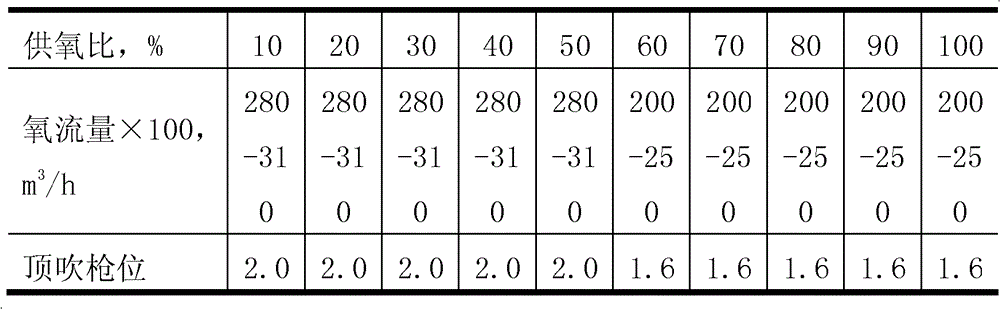

Method for synchronously dephosphorization and vanadium extraction of vanadium-containing molten iron

The invention discloses a method for synchronously dephosphorization and vanadium extraction of vanadium-containing molten iron. The method comprises the following steps of: controlling temperature of vanadium-containing molten iron at 1230-1250 DEG C; carrying out oxygen-injection blowing, wherein oxygen flow is constantly controlled at 17000-25000Nm<3> / h, and the blowing process sequentially comprises three stages; the first stage starts from blowing to 1-2min of blowing, gun position is 1.6-1.8m, and lime for controlling alkalinity of slag to be 2-4 lime and 15-20kg / tFe of iron scale are added simultaneously; the second stage starts after 1-2min of blowing, gun position is 1.8-2.1m, and 5-18kg / tFe of iron scale is added in the process that oxygen-injection time is not greater than 3min; and the third stage starts from blowing to 2min of the end, 0.5-2kg / tFe of high-magnesium lime is added, and gun position is reduced to 1.6-1.8m; and blowing to end, and discharging semi-steel and vanadium slag. The method disclosed by the invention has the advantages that corrosion to lining of a vanadium extraction converter is effectively avoided, and dephosphorization and vanadium extraction are synchronously implemented; and TFe content in the vanadium slag is reduced.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Two-step stainless steel smelting method

ActiveCN101457272AHigh recovery rateReduce consumptionProcess efficiency improvementElectric furnacePresent methodChromium nickel

The invention relates to a stainless steel smelting method by a two-step process. The method comprises the following steps: (1) smelting dephosphorized molten iron; (2) smelting semisteel; (3) lifting the semisteel to a deslagging station for deslagging treatment; (4) adding the semisteel to a GOR refining furnace for air refining; (5) refining; (6) continuous casting and (7) finishing, thinning and then rolling. Compared with the present method for producing the stainless steel by smelting, the method has the advantages of wide application scope of raw materials, low energy and resource consumption, strong variety development capacity, high recovery rate of chromium-nickel metal, high production efficiency and the like. Sulfide, oxide, silicate and punctiform non-metallic inclusion in the steel have low grade, the dephosphorized molten iron is provided by a top-bottom combined blowing converter and smelting is performed by the two-step process in an EAF+GOR refining furnace, thus the method has relatively low production cost and relatively large cost advantage, and the performance of a rolled finished product is consistent with a user quality standard.

Owner:SHANDONG TAISHAN STEEL GROUP

Smelting method of 9Ni steel

ActiveCN102747181AMeet the requirements of continuous castingReduce lossesManufacturing convertersCritical control pointSmelting process

A smelting method of 9Ni steel. The method has the following characteristics: 1.a smelting process comprises steps of pretreatment on molten iron (desulfuration), converter (double dephosphorization, melting nickel plate), LF furnace (desulfuration) and RH (degassing); 2. dephosphorization is conducted in the converter and comprises two steps: step one: blending molten iron desulphurized by KR and steel scrap into a dephosphorization converter for primary smelting, using ''dephosphorization converter smelting critical control point'' to desulphurize the molten iron to a phosphorus content below 0.020%, and carrying out semi-steel tapping; and step two: blending the molten semi-steel and nickel plate into a decarburization converter for converting, desulphurizing the molten steel after converting to a phosphorus content below 0.003%, and carrying out tapping; and 3. the nickel plate is melted in the decarburization furnace. According to the present invention, the two-step dephosphorization is carried out in the converter that molten steel after converting has low phosphorus content and is stably controlled, so as to benefit improvement on the yield of 9Ni steel. Decarburization converter slag has low phosphorus content, and ladle molten steel has a low rephosphorization amount, so as to clear out molten steel in the decarburization furnace and reduce molten steel loss in a steel leaving operation.

Owner:BAOSHAN IRON & STEEL CO LTD

Semi-steel wire radial tire undertread calendering sizing compound

The invention relates to calendering belt compound in a semi-steel wire radial tyre. The main points are as follows: the belt glue stuff is prepared from various materials which comprise natural rubber (code: SMR20), carbon black N326, carbon black N660, white carbon black, a silane coupling agent, zinc oxide, an antioxidant 4020, an antioxidant RD, resorcinol-80, a binding agent RA-65, an accelerator DZ, insoluble sulfur IS-7020 and a scorch retarder CTP.

Owner:SICHUAN TYRE & RUBBER CO LTD

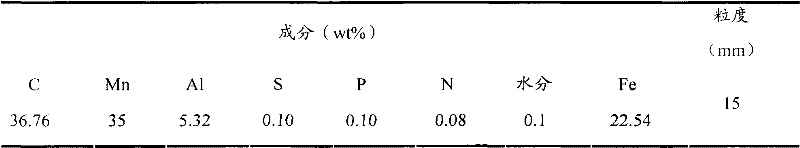

Coolant for dephosphorizing and extracting vanadium of converter, production method thereof, and method for dephosphorizing and extracting vanadium of converter

The invention discloses a coolant for dephosphorizing and extracting vanadium of a converter, a production method of the coolant, a method for dephosphorizing and extracting vanadium of the converter by using the coolant. The production method of the coolant for dephosphorizing and extracting vanadium of the converter comprises the following steps of: mixing sodium salt particles, oxidized iron sheet particles, bauxite fine powder and water, so that mixture can be formed; pressing the mixture into small balls by a ball press; and baking the small balls to remove moisture, so that a cold solid pellet final product can be obtained. The coolant, the production method of the coolant, and the method for dephosphorizing and extracting vanadium of the converter have the advantages that the dephosphorization and the vanadium extraction can be simultaneously realized when the vanadium is extracted in the converter; the operation is simple; the influences on the existing vanadium extracting technology and the quality of semisteel are small; the dephosphorizing efficiency is high, and the production efficiency of the vanadium extracting converter can be guaranteed. Furthermore, according to the invention, part of the dephosphorizing task of the steel converter can be forwarded to the vanadium extracting converter, so that the semisteel low-cost converter steelmaking can be realized, and the molten steel with eligible ingredients and temperature can be conveniently obtained.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

Method for smelting low-phosphorous molten steel by utilizing semisteel

InactiveCN101962700AReduce phosphorus contentEasy to controlManufacturing convertersProcess efficiency improvementSteelmakingMolten steel

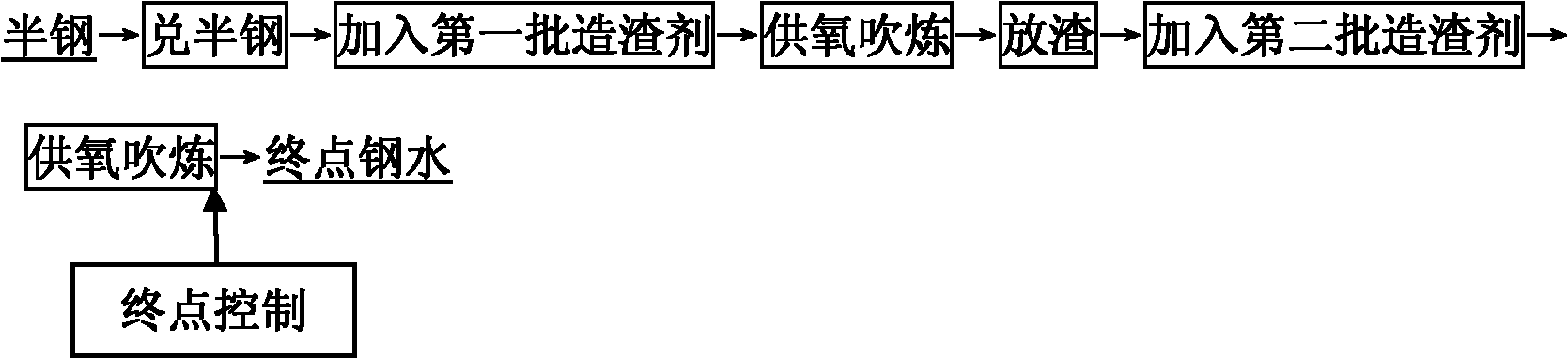

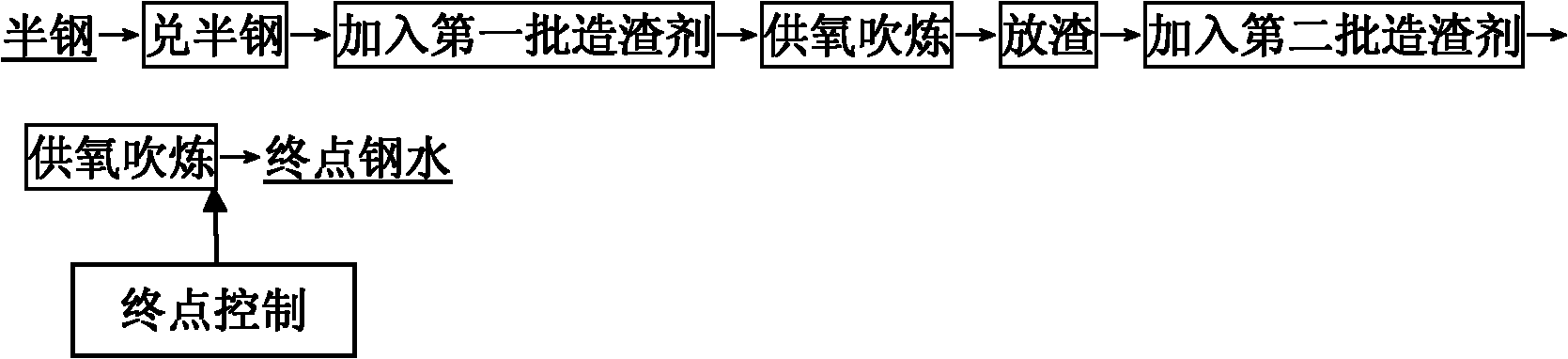

The invention belongs to the metallurgical field, particularly relating to a method for smelting low-phosphorous molten steel by utilizing semisteel. The technical problem solved by the invention is to lower the phosphorus content of the final molten steel so as to be beneficial for producing the low phosphorus steel on the premise of ensuring converter decarburization effect. The technical scheme for solving the technical problem in the invention is to provide the method for smelting the low-phosphorous molten steel by utilizing the semisteel. The method comprises the following steps: mixing the semisteel subjected to desulfuration and vanadium extraction into a converter; adding the first batch of steelmaking slagging agent; converting for 4-6 minutes in the converter; slagging; and adding the second batch of slagging agent for converting. By adopting the method of the invention, the final molten steel can be obtained, wherein, the phosphorus content is less than or equal to 0.006%; and the dephosphorization rate of the converter achieves over 92.5%. On the premise of not influencing steelmaking dephosphorization and decarburization tasks, the method of the invention lowers the phosphorus content of the final molten steel, and provides important technical support for producing the low phosphorus steel.

Owner:PANZHIHUA IRON AND STEEL +3

Semi-steel steelmaking method

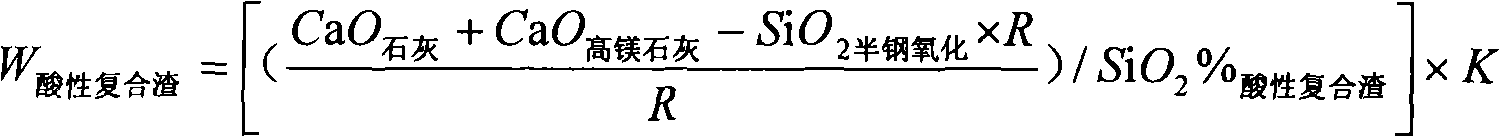

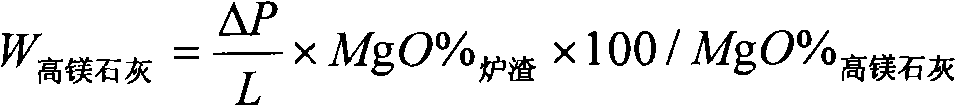

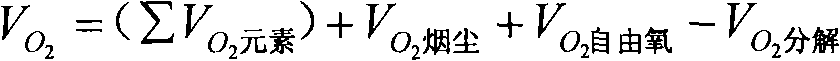

The invention discloses a semi-steel steelmaking method, wherein the method comprises the steps of: adding raw materials into a steel making furnace, blowing oxygen into the furnace to obtain molten steel and slag; the raw materials comprises raw steel, lime, high-magnesium lime and acid composite slag; the raw steel contains semi-steel after vanadium extraction; the addition of the acid composite slag meets the following formula: W (acid composite slag) is equal to (( (CaO (lime) plus CaO (high-magnesium lime) minus SiO2 (oxidized semi-steel) multiplied by R) divided by R ) divided by SiO2% (acid composite slag) ) multiplied by K, wherein W acid composite slag refers to the addition of the acid composite slag, CaO lime refers to the quantity of CaO brought in by the lime, CaO high-magnesium lime refers to quantity of CaO brought in by the high-magnesium lime, SiO2 oxidized semi-steel refers to the quantity of SiO2 converted from the quantity of Si element in the semi-steel, R refers to the alkalinity of slag, and ranges from 3 to 5, SiO2% acid composite slag refers to the weight percentage of SiO2 in the acid composite slag, and K refers to a fluctuation coefficient with a value ranging from 0.98 to 1.02. The semi-steel steelmaking method can achieve good dephophorization and desulfurization and is applicable to the automation production.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +2

Method for controlling nitrogen content in steel by semi-steel smelting

InactiveCN102230051AReduce the amount of nitrogenReduce nitrogen contentManufacturing convertersFoaming agentLow nitrogen

The invention discloses a method for controlling nitrogen content in steel by semi-steel smelting. According to the invention, the method for controlling nitrogen content in steel by semi-steel smelting comprises the following steps of: performing oxygen top blowing by using a converter, performing slag-modifying treatment before tapping, and blocking the slag and tapping. In addition, according to the requirements steel on nitrogen content, different bottom-blowing modes are adopted in the oxygen top blowing process by converter, a foaming agent is added at the last stage of blowing, argon gas is blown to ladles 1 to 3 minutes before tapping, and the soft argon blowing operation is performed on ladles during the tapping step. By adoption of the method provided by the invention, the nitrogen content in steel at the converter end-point can be controlled to be within 11 ppm and the nitrogen increase can be controlled to be between 1ppm to 3 ppm during the tapping step. The method provided by the invention can effectively reduce the nitrogen content at the converter end-point and the nitrogen increase in the tapping step, thereby providing a technical support for the production of low-nitrogen steel and ultra-low nitrogen steel.

Owner:PANZHIHUA IRON AND STEEL +2

Method for simultaneously removing sulfur and phosphorus from semi-steel

The invention provides a method for simultaneously removing sulfur and phosphorus from semi-steel. The method comprises the following steps sequentially carried out on a semi-steel sulfur removal station: carrying out first-stage injection on the semi-steel by using a sulfur removal oxygen lance, wherein an injection material is injection-assisted powder taking an inert gas as a carrier; carrying out second-stage injection on the semi-steel by using the sulfur removal oxygen lance, wherein an injection material is a mixture of the injection-assisted powder taking the inert gas as the carrier and passivating magnesium powder; carrying out third-stage injection on the semi-steel by using the sulfur removal oxygen lance, wherein the injection material is the injection-assisted powder taking the inert gas as the carrier, the semi-steel is molten iron obtained after vanadium is extracted from vanadium-containing molten iron by using a converter, and the injection-assisted powder is prepared from 55-80 parts by weight of passivating lime, 5-15 parts by weight of ferric oxide and 20-30 parts by weight of sodium oxide. The method has the advantages that the semi-steel without the vanadium can be simultaneously subjected to pretreating sulfur and phosphorus removal; the corrosion on a lining of a vanadium extracting converter can be avoided, and meanwhile, the content of sodium in vanadium residues can be reduced.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for smelting of ultra-low carbon steel and continuous casting method for ultra-low carbon steel

InactiveCN103911487AMeet the requirements of C contentImprove cleanlinessProcess efficiency improvementAlkalinityOxygen

The invention provides a method for smelting of ultra-low carbon steel and a continuous casting method for ultra-low carbon steel. The method comprises: (1) employing a converter to perform primary smelting on molten iron or semisteel with a sulfur content of less than 0.015wt%, and then subjecting the molten steel obtained by primary smelting to tapping into ladle; adding a slag material with alkalinity of 4-5 and an SiO2 content of less than or equal to 20wt% during tapping; making the total content of FeO and MnO% in the ladle slag less than or equal to 15wt%; controlling the tapping temperature of the converter at 1600-1700DEG C, the carbon content at a blowing end point at 0.04-0.06wt%, and the oxygen activity at 0.03-0.07wt%; and (2) carrying out decarbonization and deoxidation alloying on the molten steel obtained in step (1) in an RH vacuum device under vacuum conditions in order recurrently, with the carbon content of the molten steel being less than 30ppm under the decarbonization conditions. The method provided by the invention can improve the molten steel quality of ultra-low carbon steel, ensures stable and batch production of IF (interstitial free) steel with a C content of less than 30ppm and deepest decarbonization of less than 6ppm.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Semisteel steelmaking method

The invention provides a semisteel steelmaking method, which comprises: blowing semisteel in a converter; adding a slag former; controlling the terminal of converter blowing; tapping; and stirring molten stirring at an argon flushing station. In the control of the terminal of converter blowing, the carbon content in the molten steel is kept between 0.04 and 0.10 weight percent; and carbon is added into a ladle in a tapping process. When the semisteel steelmaking method provided by the invention is used, the problem that the terminal carbon content in molten steel is high while the tapping temperature is low during semisteel smelting, and the problem that the terminal carbon content in molten steel is low while the carburant yield in the tapping process is low and / or instable are solved.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Method for preventing electric precipitation explosion venting during blowing igniting of semi-steel steelmaking

ActiveCN103555880AAvoid explosive limitReduce missed gun accidentsManufacturing convertersSteelmakingEvaporative cooler

The invention provides a method for preventing electric precipitation explosion venting during blowing igniting of semi-steel steelmaking, and belongs to the technical field of converter steelmaking methods. According to the technical scheme, the mixed gas of oxygen and nitrogen is used for igniting and blowing in the blowing stage, instead of single oxygen; the total amount of the mixed gas is the amount of the oxygen supplied for normal blowing, wherein the flow rate of oxygen is 50 to 60% of the amount of oxygen supplied for normal blowing; the gas supply pressure required by normal blowing is provided to a smelting pool; the jet impact area and penetration depth are improved; the igniting time is reduced; if the raise of the temperature of an inlet of an evaporative cooler is beyond 4 DEG C, the flow rate of oxygen can be gradually raised, and simultaneously the flow rate of nitrogen can be reduced; the nitrogen is stopped after the flow rate of oxygen is raised to reach the normal oxygen supply; and the contents of CO and O2 in smoke are controlled to be beyond the explosion venting range. According to the method, the problem which enables the enterprise to be bothered for a long time that electric precipitation explosion venting occurs during blowing igniting of converter semi-steel steelmaking can be solved in a simple way; the potential risk is removed; the production can be carried out smoothly; a great contribution is brought for the safe and efficient production of semi-steel steelmaking.

Owner:HEBEI IRON AND STEEL

Slag former and slagging method for semisteel steelmaking

InactiveCN102304606AShorten the formation timeImprove dephosphorization rateManufacturing convertersProcess efficiency improvementHigh magnesiumSteelmaking

The invention provides a slag former and a slagging method for semisteel steelmaking. The slag former comprises 60 to 75 percent of SiO2, 10 to 15 percent of CaO, 1 to 3 percent of MgO, 7 to 15 percent of FeO, 1 to 3 percent of Fe2O3 and a small quantity of inevitable impurities. The slagging method comprises the following steps of: slagging by using the slag former for the semisteel steelmaking,active lime and high-magnesium lime, and controlling the addition opportunity and addition quantity of slagging materials appropriately. By the slag former and the slagging method for the semisteel steelmaking, the problems of low slagging speed and dephosphorization rate during semisteel smelting can be solved, initial slag formation time and pure oxygen blast time can be shortened effectively, and the molten steel dephosphorization rate of a finishing point of a converter can be improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Half steel roller submerged arc building-up flux-cored wire

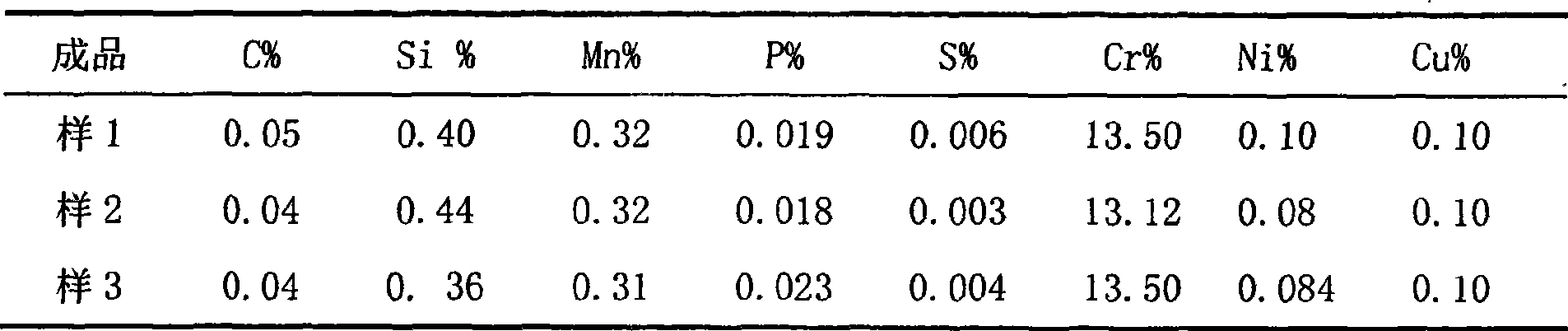

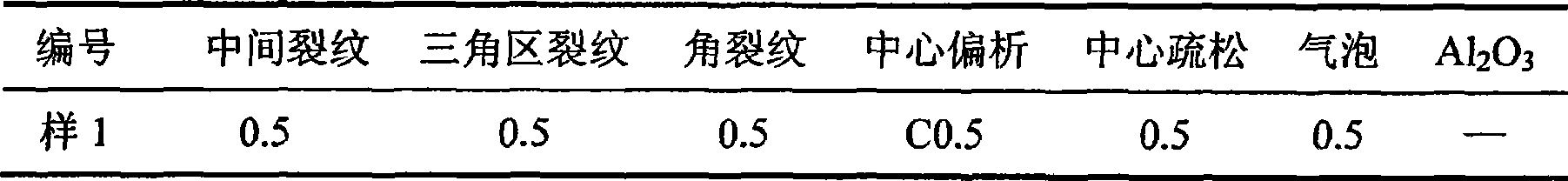

ActiveCN101077554AHigh carbon contentExtend your lifeWelding/cutting media/materialsSoldering mediaChemical compositionWeld seam

The present invention relates to one kind of flux-core wire for submerged arc build-up welding of semisteel roller, and the flux-core wire may be applied widely in the build-up welding repair of semisteel plate, roller, etc. The flux-core wire has the chemical components comprising C 1.0-2.5 wt%, Mn 1.0-2.5 wt%, Si 0.2-1.5 wt%, Cr 12-22 wt%, Ni 0.5-2.5 wt%, Mo 0-1.5 wt%, V 0-0.5 wt%, P less than or equal to 0.030 wt%, S less than or equal to 0.030 wt%, and Fe for the rest. When the flux-core wire is used in build-up welding under SJ107 flux protection, the weld seam metal has hardness of HRC35-45 and may reach hardness of HRC45-55 after heat treatment at 600 deg.c. The deposited metal has high toughness, excellent high temperature wear resistance and excellent heat fatigue resistance.

Owner:SHOUGANG CORPORATION

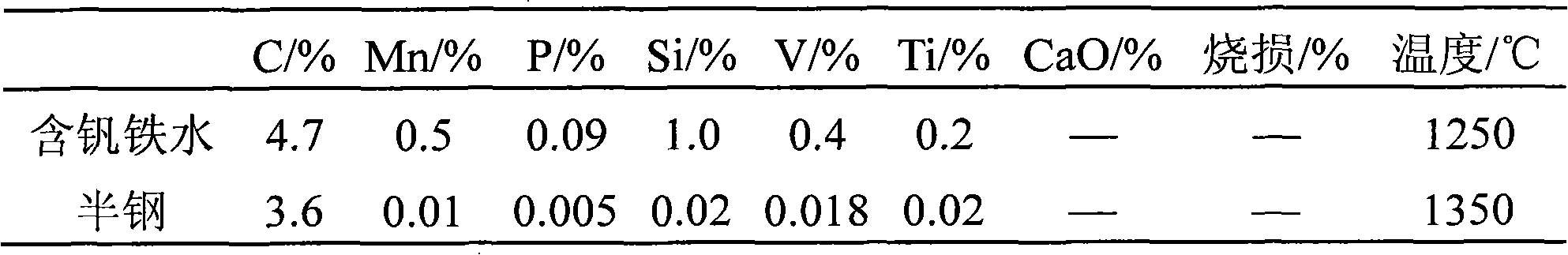

Dephosphorization process for high phosphorous molten iron

InactiveCN102776311AHigh carbonIncrease temperatureManufacturing convertersProcess efficiency improvementSteelmakingEconomic benefits

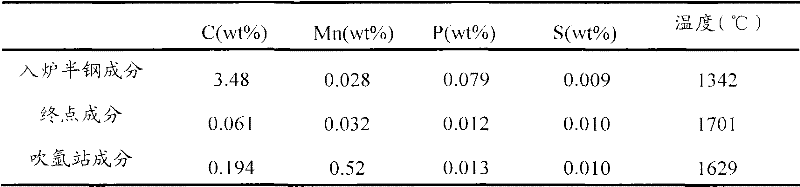

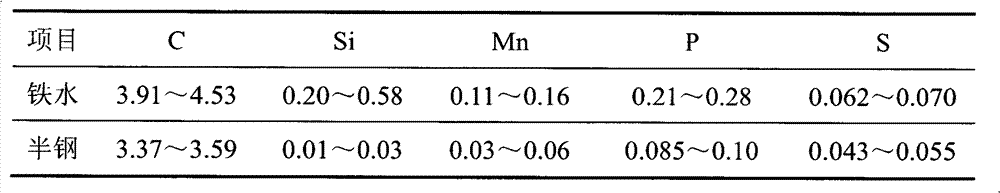

The invention belongs to the technical field of molten iron preprocessing and relates to a dephosphorization process for high phosphorous molten iron. The dephosphorization process is performed in a converter container, the molten iron phosphorous achieves 0.20% to 0.30%, the use amount of dephosphorizing agents achieves 20kg / t to 25kg / t, the end slag basicity after dephosphorization is no less than 2.5, semi-steel [P] can be stably controlled between 0.08% to 0.10%, and semi-steel [C] is controlled in a range of 3.3% to 3.6%. The dephosphorization process has the advantages of being stable in process, low in semi-steel phosphorous, high in carbon and temperature, large in processing capability and the like, solves the problem of steelmaking by using the high phosphorous molten iron thoroughly, and improves economic benefits of iron and steel enterprises greatly.

Owner:LIAONING TIANHE TECH

Method for comprehensively utilizing vanadium titano-magnetite by melting and separating through reduction-fuel smelting furnace of rotary hearth furnace

ActiveCN102690921AImprove purityReduce carbon contentRotary drum furnacesManufacturing convertersMagnetiteLiquid iron

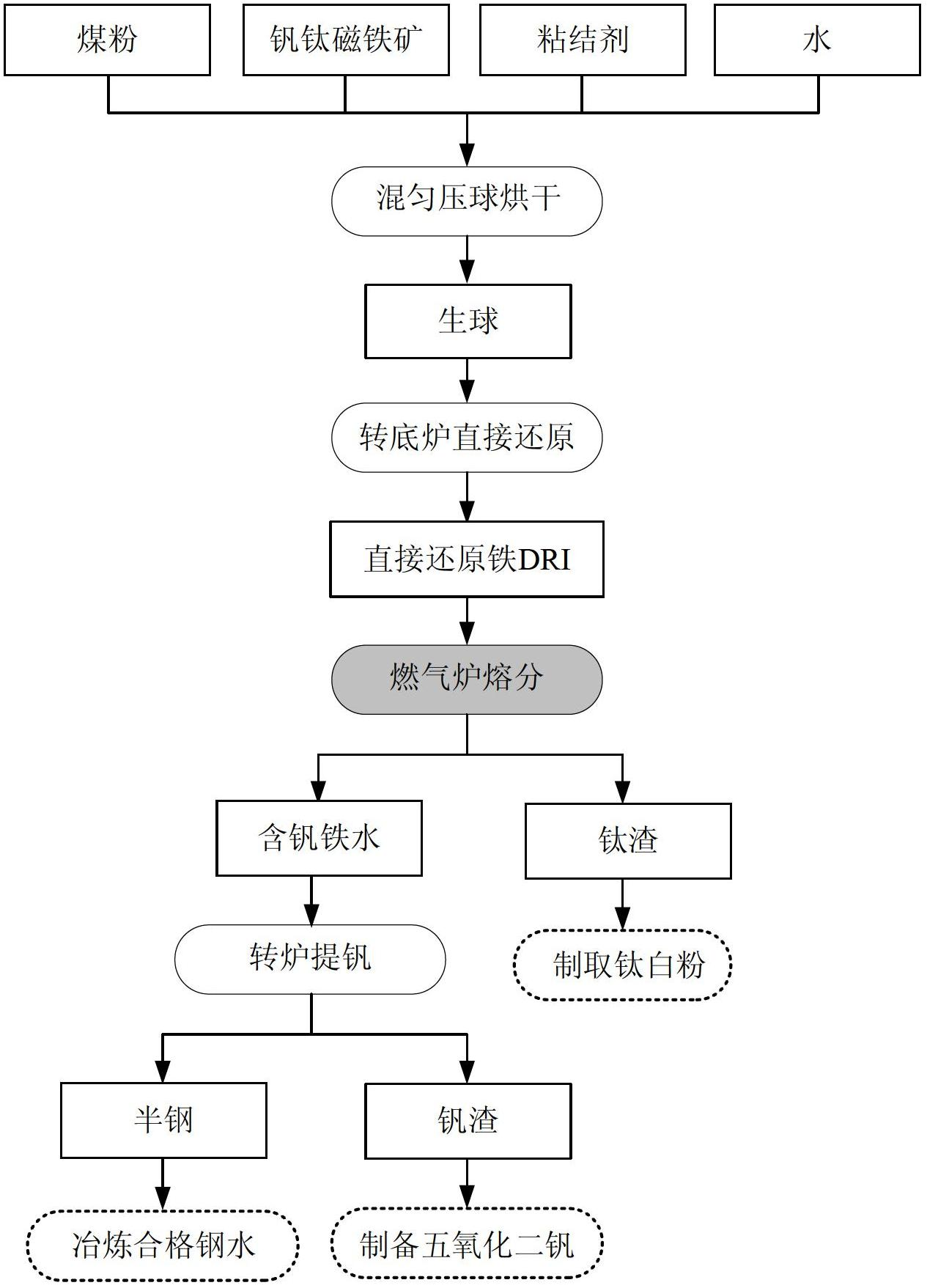

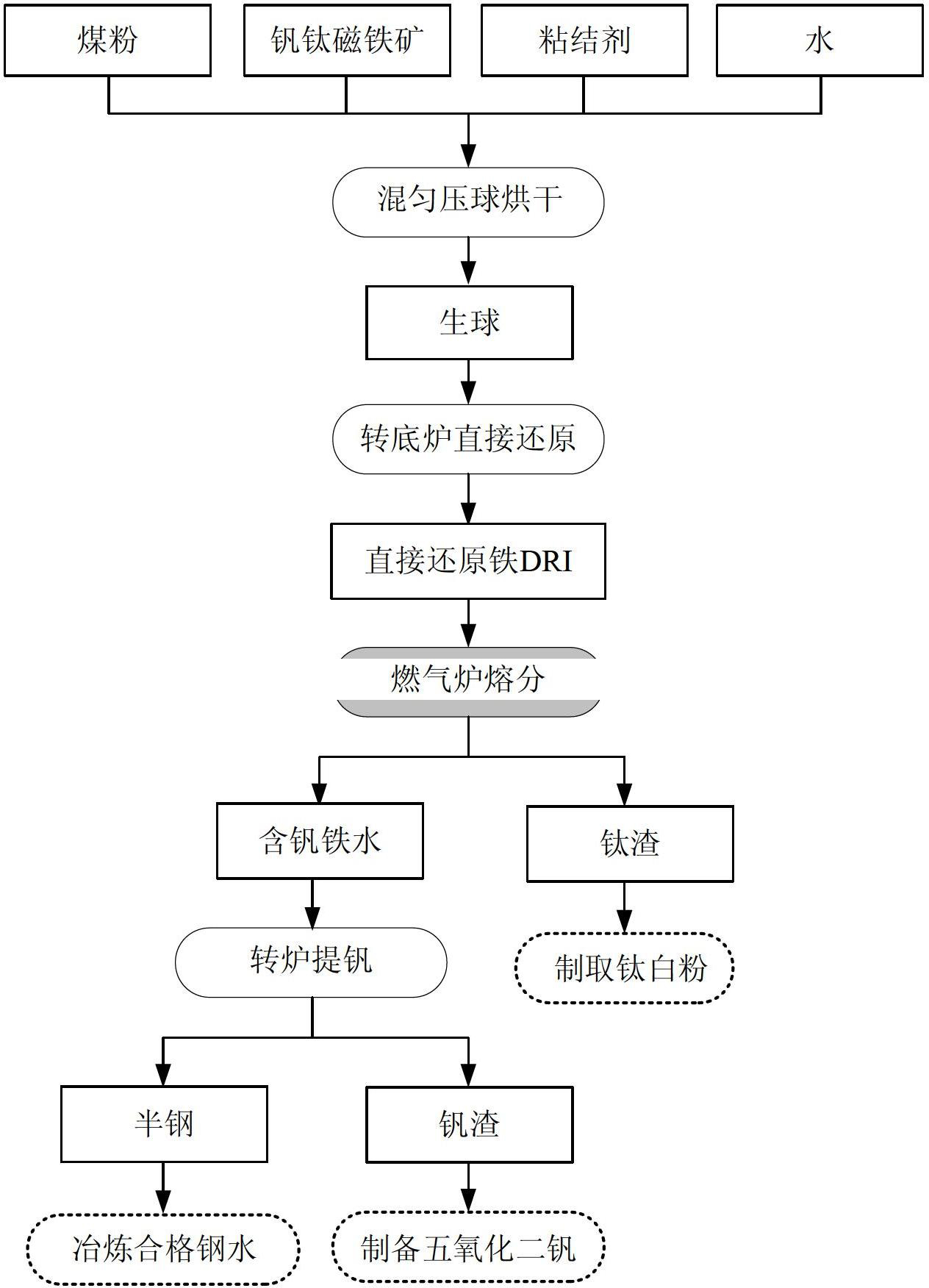

The invention discloses a method for comprehensively utilizing vanadium titano-magnetite by melting and separating through a reduction-fuel smelting furnace of a rotary hearth furnace, comprising the following steps of: firstly, uniformly mixing the vanadium titano-magnetite, reduced coal and a bonding agent and pressing into a pellet; drying the pellet and filling into the rotary hearth furnace to be heated to be at 1150-1350 DEG C, and reducing for 30-40 minutes; directly conveying an obtained high-temperature metallized pellet into a heat accumulating type fuel melting furnace in which coal-derived gas is taken as fuel for melting and separating; controlling the temperature of the fuel melting furnace to be at 1500-1620 DEG C to obtain liquid iron containing vanadium and titanium slag; producing titanium dioxide powder by taking the titanium slag as a raw material or producing a titanium-enriched material through using a flotation process; conveying the liquid iron containing the vanadium into a converter to blow oxygen to obtain vanadium slag and semi-steel; and removing the vanadium slag and continually smelting the semi-steel into steel liquid. The method takes the coal-derived gas with a low calorific value as motive power for the melting and the separating of the heat accumulating type fuel melting furnace so as to combine a coal-derived gas procedure and a melting and separating procedure; blast furnace gas and coal-derived natural gas which have the low calorific value can be used; and the carbon content of the liquid iron containing the vanadium obtained by the melting and the separation of the fuel furnace is very low and the purity is very high.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Method for enhancing end point carbon content in smelting medium-carbon steel from semisteel and semisteel steelmaking method

ActiveCN103627842AShorten the formation timeIncrease the speed of slaggingManufacturing convertersSteelmakingMaterial consumption

The invention provides a method for enhancing end point carbon content in smelting medium-carbon steel from semisteel and a semisteel steelmaking method. The method comprises the following steps: in the process of discharging semisteel into a ladle, adding 3-8kg / (t semisteel) silicon iron into the ladle; adding semisteel into the steelmaking furnace, and lowering an oxygen lance to perform oxygen blowing smelting while adding related slagging materials and alloys according to the blowing smelting requirements; and after catching carbon, supplementing oxygen blowing according to the carbon content to control the end point carbon content of the molten steel at 0.20-0.30%, and lifting the oxygen lance to stop blowing smelting, wherein the semisteel is molten steel prepared by carrying out vanadium extraction converter or dephosphorization converter blowing on vanadium-containing molten iron, and contains 3.20-3.80 wt% of C and 0.001-0.05 wt% of Si, and the temperature of the semisteel is 1320-1390 DEG C. The method can shorten the early slag formation time, enhance the steelmaking slagging speed, enhance the molten steel temperature, effectively control the steel material consumption in the steelmaking process, and avoid the problem of low utilization ratio of carbon carburizing materials.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

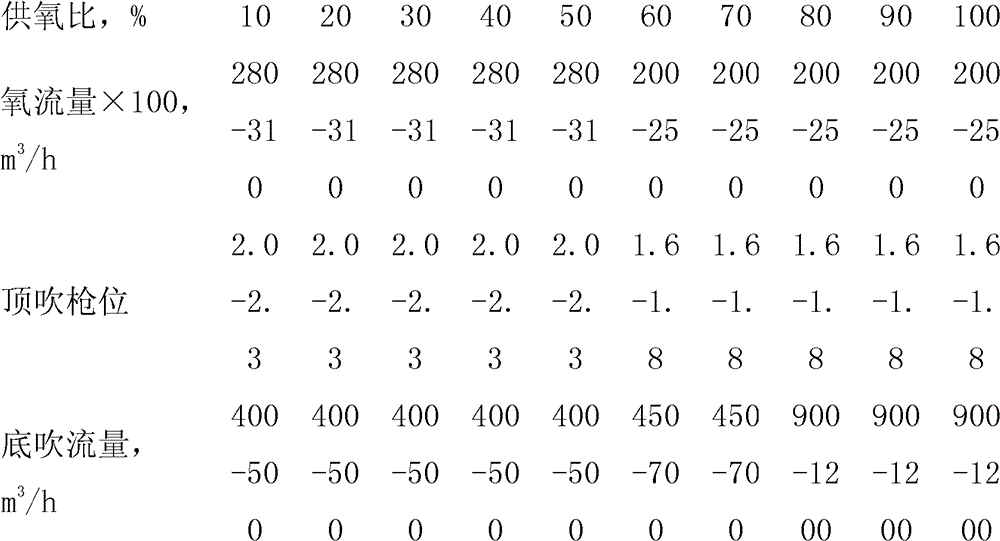

Method for preventing blowing explosion venting of dry dust-removing system of semi-steel steelmaking converter

ActiveCN104313235AReduce the number of explosion ventsReduce non-productive work timeManufacturing convertersSteelmakingCombustion

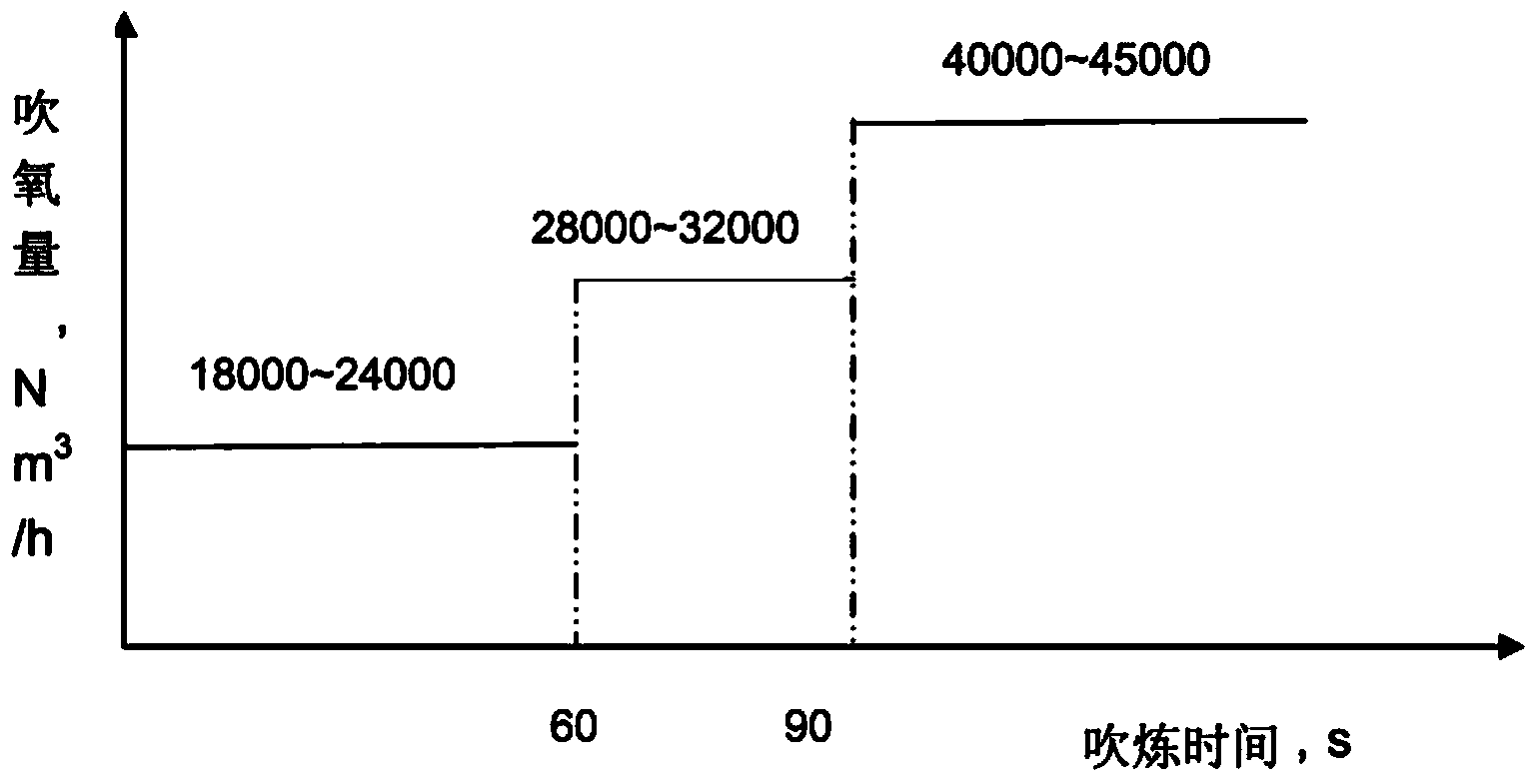

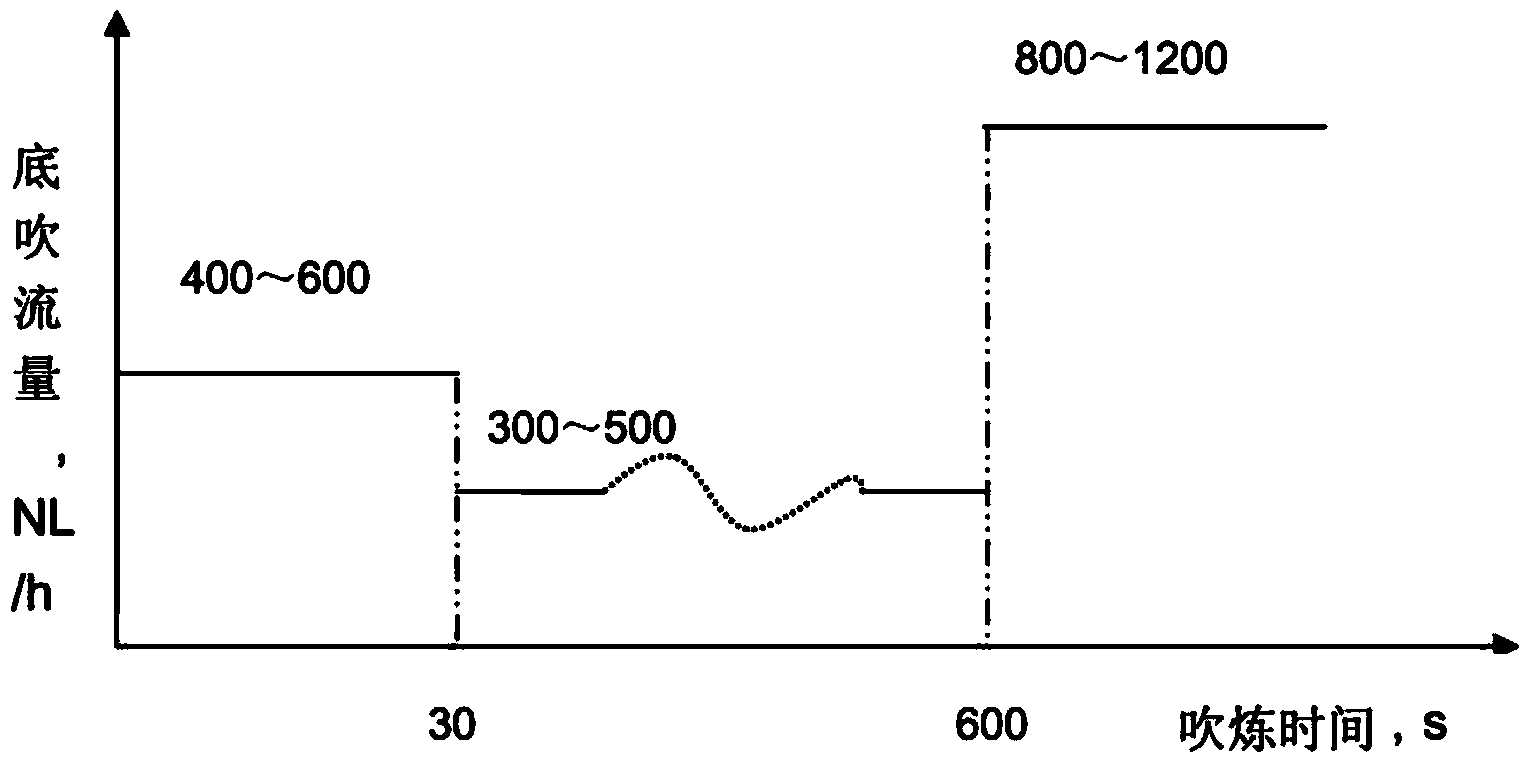

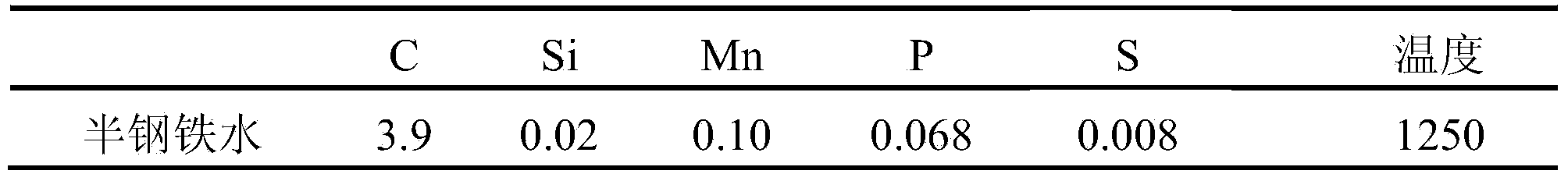

The invention provides a method for preventing blowing explosion venting of a dry dust-removing system of a semi-steel steelmaking converter. The method comprises the following steps: adding semi-steel into a 180-260T steelmaking converter; after the beginning of blowing, within 60s, controlling the oxygen blowing amount to be 18000-24000Nm<3> / h and controlling the position of an oxygen lance at 2-2.4m; after blowing for 60-90s, controlling the oxygen blowing amount to be 28000-32000Nm<3> / h; after blowing for 90s, controlling the oxygen blowing amount to be 40000-45000Nm<3> / h; after the beginning of blowing, within 30s, adding a combustion accelerator into the converter and controlling the bottom blowing gas supplying amount to be 400-600NL / h; within 30-600s of blowing, reducing the bottom blowing gas supplying amount and controlling the bottom blowing gas supplying amount to be 300-500NL / h; after blowing for 600s, controlling the bottom blowing gas supplying amount to be 800-1200NL / h. By the method, in the smelting process of the converter, the dry dust-removing system can be protected from explosion venting.

Owner:攀钢集团西昌钢钒有限公司

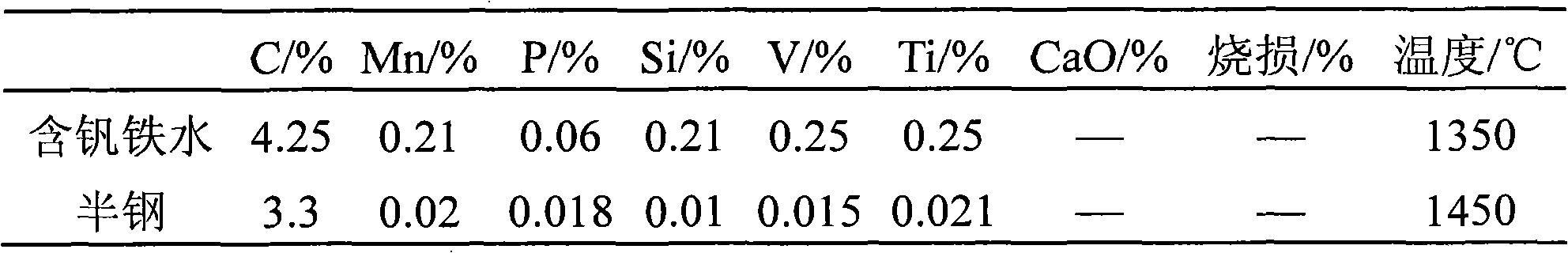

Double-slag and full-slag-remaining semi-steel steelmaking method

InactiveCN107151723ARapid dephosphorizationGood for dephosphorizationManufacturing convertersProcess efficiency improvementHigh magnesiumSteelmaking

The invention belongs to the technical field of metallurgy, particularly relates to a double-slag and full-slag-remaining semi-steel steelmaking method and provides the double-slag and full-slag-remaining semi-steel steelmaking method so as to solve the problems of late initial smelting slag forming time, poor dephosphorization effect, high auxiliary material consumption and the like for existing semi-steel steelmaking. The method comprises the steps as follows: a, the first furnace: after semi-steel is mixed, active lime, high-magnesium lime and an acidic compound slag former are added to the furnace while top blowing of oxygen is performed, then silicon iron is added, the oxygen is blown continuously, and molten steel and slag are obtained; b, the second furnace: the slag obtained in the previous furnace is completely left in the furnace, and the acidic compound slag former is added; the oxygen is blown continuously after the semi-steel is mixed, and when the temperature of the semi-steel ranges from 1,350 DEG C to 1,400 DEG C, part of the slag is discarded; and then secondary slag forming is performed, and molten steel and slag are obtained. According to the method, 4-5 furnaces form a cycle, the auxiliary material consumption is low, early-stage dephosphorization is fast, and the dephosphorization effect is good. The method is simple to operate, low in production cost and suitable for popularization and use.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for compositely centrifugal pouring high chromium centrifugal composite cast iron roll with alloy semisteel intermediate layer

The invention relates to a composite cast iron roll technology field, in particular to a method for using alloy semi-steel middle transition layer composite centrifugation to cast high chromium double composite cast iron roll, which includes the following process steps: respectively melting the steel water in the transition layer of the alloy semi-steel, external high chromium casting iron melting and core ball graphite casting iron melting; conducting modification treatment to the steel water in the transition layer in the middle of the alloy semi-steel and the steel water of the external high chromium casting iron and conducting spheroidization and inoculation treatment to the core ball graphite casting iron steel water, and adopting the centrifugation casting method to cast high chromium casting steel and the steel water in the transition layer of the alloy semi-steel; preparing fixture and mould closing; casting core ball graphite casting steel water with static casting method; cooling and opening box, conducting heat treatment and processing inspection. The component weight percentage of the steel water in the middle transition layer of the alloy semi-steel is: C 1.4 to 2.6, Si 1.0 to 2.0, Mn 0.5 to 1.5, P being less than 1.0, S being less than 0.03, Cr 3 to 8, Ni 0.5 to 1.5 and Mo 0.5 to 1.5. The structure layer and the core strength of the roll are respectively over 320MPa and 400MPa, thus the performance being very safe and reliable.

Owner:ANSTEEL HEAVY MACHINERY CO LTD

Method for reducing and smelting titania slag by utilizing vanadium-titanium-iron ore concentrates in molten state

The invention provides a method for reducing and smelting titania slag by utilizing vanadium-titanium-iron ore concentrates in a molten state. The method comprises the following steps: mixing the vanadium-titanium-iron ore concentrates with titanium ore concentrates and adding a carbonaceous reducing agent and a binder, thus forming a mixture; reducing the mixture and then performing slag-iron separation treatment, thus obtaining semisteel and titanium slag; and spraying water to the surface of the titanium slag obtained through slag-iron separation treatment so as to rapidly cool the titanium slag to 600-850 DEG C in a cooling process, thus forming the acidsoluble titania slag. The method provided by the invention can be used for efficiently utilizing the Fe and TiO2 in the vanadium-titanium-iron ore concentrates and has the advantages of stable molten-state reduction process, good effect in smelting and separating process, stable furnace condition, short smelting period, low power consumption level, low production cost and the like.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Tread rubber composition of all-steel truck snow tire

ActiveCN105037824AImprove driving performanceImprove driving safetySpecial tyresPolymer scienceMicrocrystalline wax

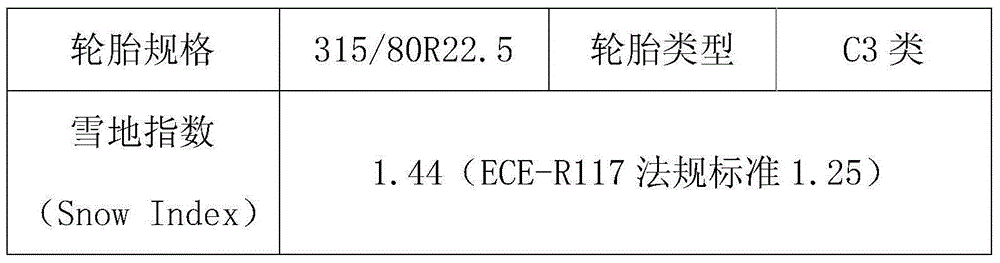

The invention discloses a tread rubber composition of an all-steel truck snow tire. The tread rubber composition is characterized by being composed of, by weight, 42-62 parts of natural rubber, 15-35 parts of oil-extended neodymium-based butadiene rubber, 25-34 parts of solution-polymerized styrene-butadiene rubber, 23-38 parts of high-dispersion white carbon black, 30-55 parts of carbon black N220, 2-4 parts of coupling agent liquid Si69, 1-10 parts of aromatic oil, 2-8 parts of zinc oxide, 0.5-3 parts of stearic acid, 2-4 parts of antiager 6PPD, 1.5-3 parts of antiager RD, 2-5 parts of microcrystalline wax, 1-3.5 parts of oil-extended sulfur, 1-2.5 parts of accelerator NS, 0.1-1 part of accelerator DPG and 0.1-0.5 part of scorch retarder CTP. By the adoption of the solution-polymerized styrene-butadiene rubber with the Tg appropriate to that of natural rubber, the neodymium-based rare-earth butadiene rubber with the lower Tg and white carbon black commonly used for semi-steel snow tires, at a specific proportion, the tire is moderate in tread hardness and good in elasticity, and has the advantages of excellent snow slip resistance, good snowfield road holding, high snowfield indexes and the like in a freezing snowfield.

Owner:HANGZHOU CHAOYANG RUBBER

Multistage combined pretreatment method for vanadium-bearing molten iron

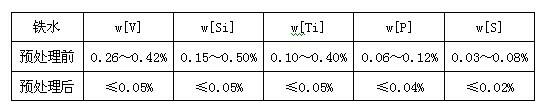

The invention relates to a multistage combined pretreatment method for vanadium-bearing molten iron, in particular to a molten iron pretreatment process for realizing desulfurization, dephosphorization and vanadium extraction on the vanadium-bearing molten iron, belonging to the technical field of refinement of pig iron. According to the technical scheme, converter vanadium extraction is performed on the vanadium-bearing molten iron to obtain semisteel, and then converter steelmaking is performed on the semisteel. The technical scheme is characterized in that vanadium-bearing molten iron obtained by iron tapping of more than one blast furnace is collected, and the molten iron is pretreated in a three-stage combined mode, wherein at the first stage, granulated magnesium is singly blown in a ladle for desulfurization; at the second stage, vanadium extraction, desilicification and titanium removal are performed by a converter; and at the third stage, dephosphorization is performed in the semisteel tapping process of the vanadium extraction converter. The multistage combined pretreatment method for vanadium-bearing molten iron combines a common molten iron pretreatment process with a special converter vanadium extraction process, thus effectively reducing the costly desulfurization burden of a blast furnace, realizing low coke-ratio operation, and further improving and optimizing the furnace charge structure; and in addition, the multistage combined pretreatment method is favorable for high-speed converting of a steelmaking furnace, and also can provide favorable conditions for intelligent control of the steelmaking furnace by a computer.

Owner:HEBEI IRON AND STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com