Patents

Literature

119results about How to "Improve dephosphorization rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

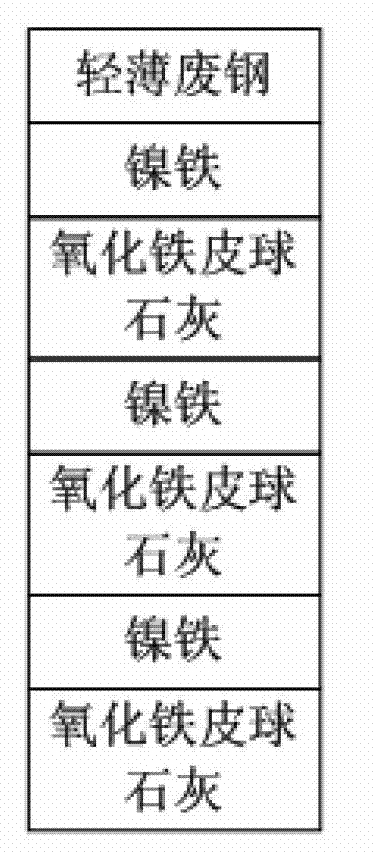

Two-step stainless steel smelting method

ActiveCN101457272AHigh recovery rateReduce consumptionProcess efficiency improvementElectric furnacePresent methodChromium nickel

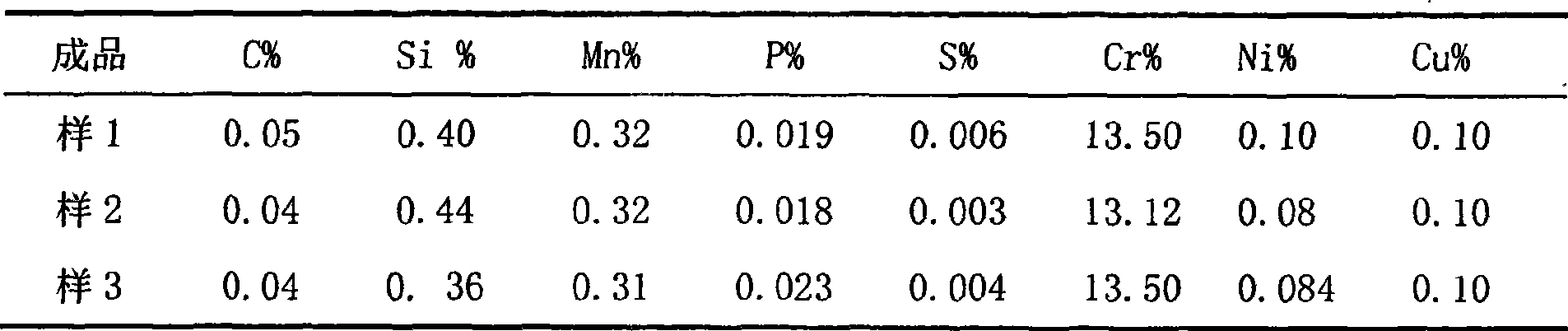

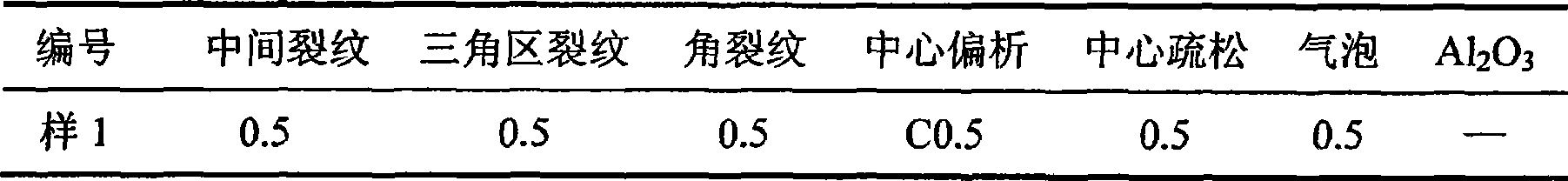

The invention relates to a stainless steel smelting method by a two-step process. The method comprises the following steps: (1) smelting dephosphorized molten iron; (2) smelting semisteel; (3) lifting the semisteel to a deslagging station for deslagging treatment; (4) adding the semisteel to a GOR refining furnace for air refining; (5) refining; (6) continuous casting and (7) finishing, thinning and then rolling. Compared with the present method for producing the stainless steel by smelting, the method has the advantages of wide application scope of raw materials, low energy and resource consumption, strong variety development capacity, high recovery rate of chromium-nickel metal, high production efficiency and the like. Sulfide, oxide, silicate and punctiform non-metallic inclusion in the steel have low grade, the dephosphorized molten iron is provided by a top-bottom combined blowing converter and smelting is performed by the two-step process in an EAF+GOR refining furnace, thus the method has relatively low production cost and relatively large cost advantage, and the performance of a rolled finished product is consistent with a user quality standard.

Owner:SHANDONG TAISHAN STEEL GROUP

Refined rice suitable for patients suffering from kidney disease and processing method thereof

ActiveCN103564306AHigh deproteinization rate and dephosphorization rateImprove quality and tasteFood ingredient functionsFood preparationNephropathyChemistry

The invention provides a processing method of refined rice suitable for patients suffering from kidney disease. The processing method comprises the following steps: (I) carrying out pretreatment, specifically, soaking the cereal raw material, separating out soaking liquid, crushing and levigating until the particle size is 10-100 meshes; (II) carrying out protease hydrolysis deproteinization; and (III) carrying out dephosphorization: dephosphorizing the cereal raw material subjected to deproteinization in the step (II) by phytase hydrolysis, or addition of yeast for fermentation, or a composite mode of phytase hydrolysis and yeast fermentation, or a composite mode of yeast and lactic acid bacteria microbial fermentation or phytase hydrolysis, yeast and lactic acid bacteria microbial fermentation; separating, cleaning, separating again, drying and crushing; and (IV) performing sieving, mixing, hardening and tempering, preheating, gelatinization, extrusion forming and drying processing on the cereal raw material processed by the step (III) to obtain the refined rice. According to the method provided by the invention, the processes of deproteinization and dephosphorization of the cereal raw material can be finished at a time, the deproteinization rate and the dephosphorization rate are high, and food raw material and products are provided for the patients suffering from kidney disease and other diseases.

Owner:成都东洋百信制药有限公司

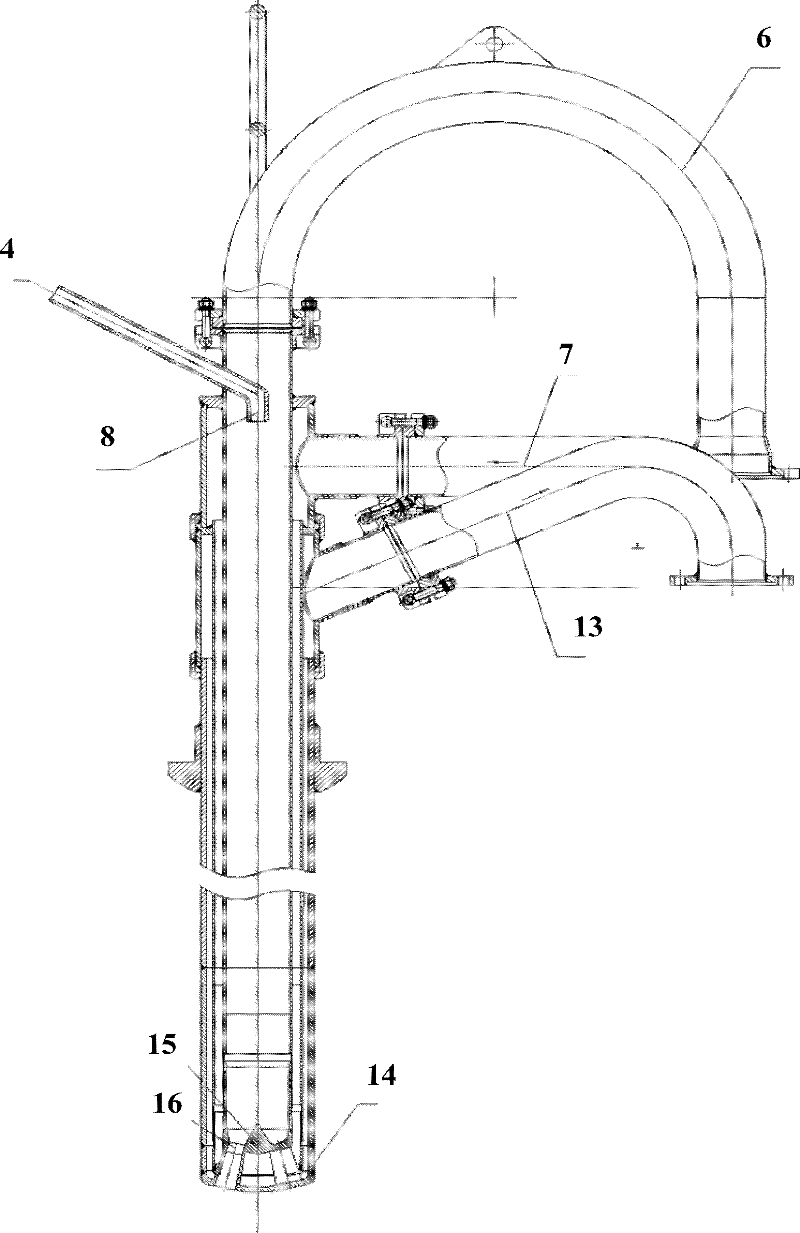

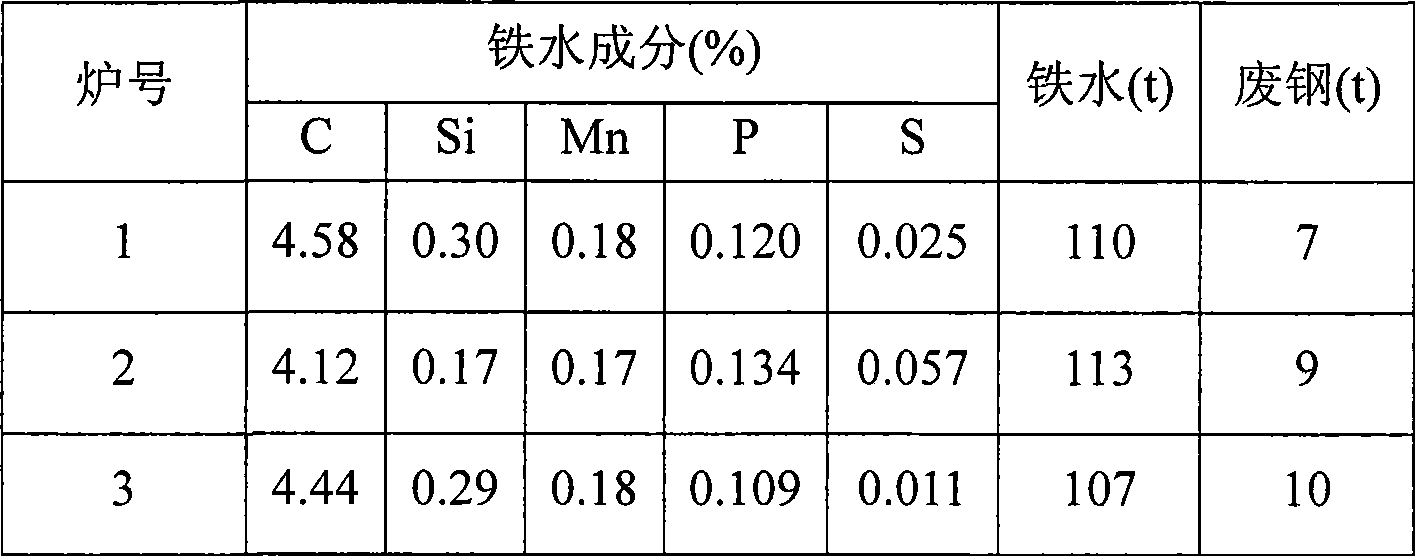

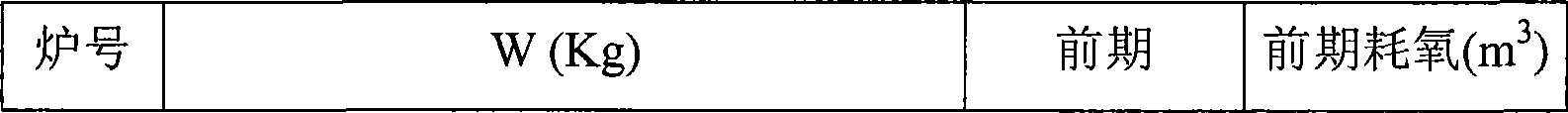

Converter steelmaking method through power injection dephosphorization by adopting supersonic speed oxygen lance and supersonic speed oxygen lance

The invention relates to a converter steelmaking method through power injection dephosphorization by adopting a supersonic speed oxygen lance and a supersonic speed oxygen lance, which can be used for solving the problems that slagging is slow in the steelmaking process and the dephosphorization rate is low caused by low stirring intensity in a dephosphorization period. A slagging material used for dephosphorization is transmitted through a supersonic speed oxygen lance and is sprayed into a molten pool in a supersonic speed power gas jet flow state and is fully contacted, so that rapid slagging is realized in the steelmaking process; thermodynamic and dynamic conditions of dephosphorization reaction are improved; and the steelmaking dephosphorization rate is improved; a power feeding pipe of the supersonic speed oxygen lance is connected with a oxygen blowing central pipe; the outlet of a power supply pipe is positioned between the upper part of the oxygen lance and the outlet of a sprayer; the inner diameter is 10-150mm; the power injection flow is 30-500kg / min; the carrier gas flow is 50-3000Nm3 / h and the pressure is 0.4-1.4MPa; a wear-resistant material is adopted at the damage part of a lance sprayer; and the mach number is 1.5-2.1. The converter steelmaking method is suitable for30-350 tons of a converter steelmaking dephosphorization process; compared with the traditional steelmaking process, the dephosphorization rate using the method can be improved by over 5%; the consumption amount of the slagging material is lowered by over 10%; and the metal yield is improved by over 0.5%.

Owner:UNIV OF SCI & TECH BEIJING

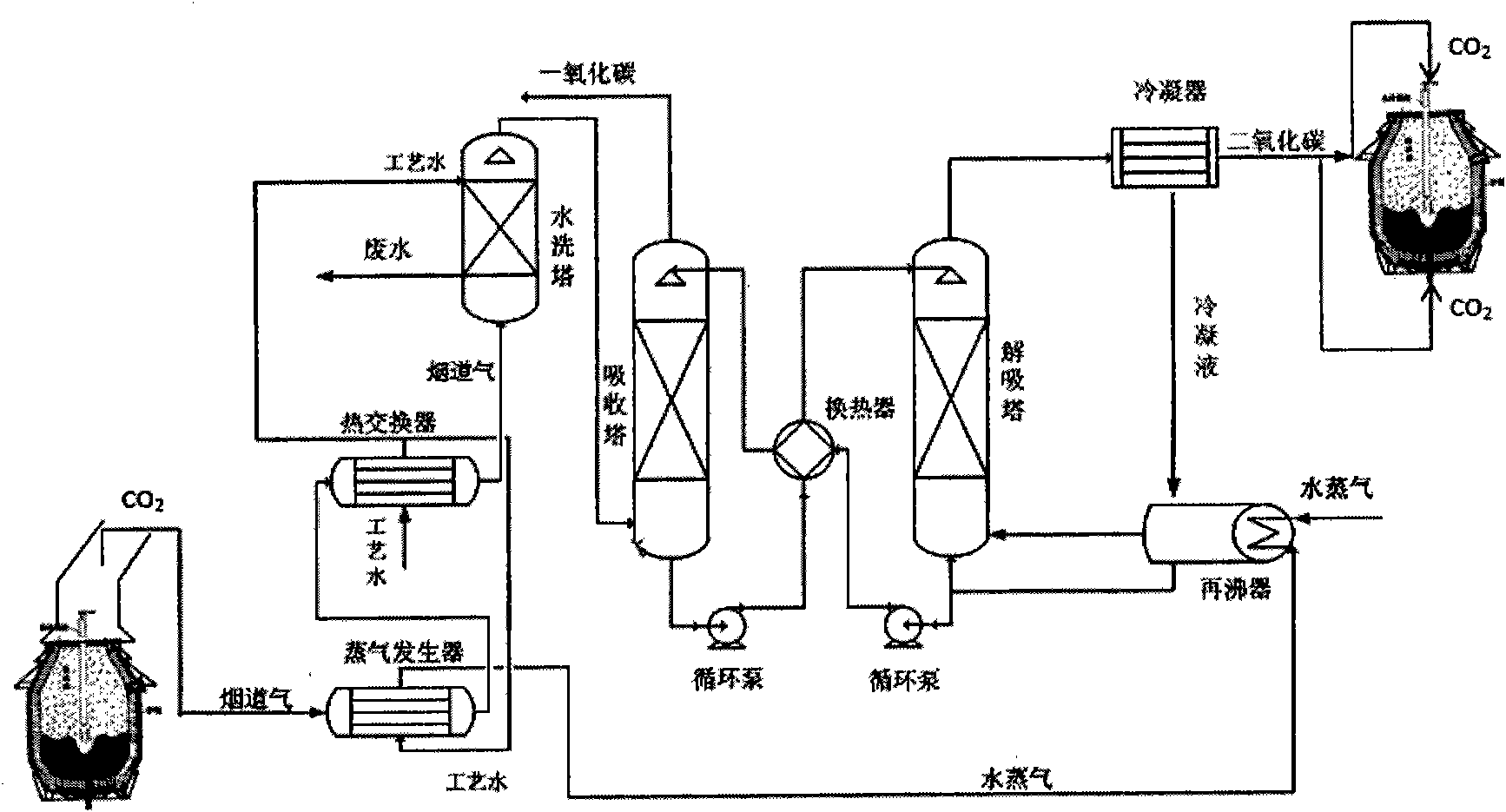

Method for recycling CO2 separated from converter steel-making gas for top blowing and bottom blowing

InactiveCN101818227AHigh carbon contentControl heating rateManufacturing convertersGas emission reductionProduct gasProcess engineering

The invention discloses a method for recycling CO2 separated from converter steel-making gas for top blowing and bottom blowing and belongs to the fields of ferrous metallurgy, energy conservation and environment protection. In the invention, the CO2 in the converter steel-making gas is separated and recycled after being cooled and dedusted; the recovery is 100 to 15,000Nm<3> / h; and the concentration of CO in the converter gas is improved by 5 to 20 percent at the same time. The CO2 serves as a gas source for the top blowing and the bottom blowing of a top and bottom combined blown converter. A chemical absorption separation method is adopted to separate the CO2; steam added with rich liquid is generated by using the residual heat of the converter gas; and almost no additional energy is consumed in the process for separating the carbon dioxide. 1 to 30 percent of the CO2 and 99 to 70 percent of O2 are blown from the top part; pure CO2 or a mixture of the CO2 and N2 or Ar or O2 or gas and the like is adopted in the whole process of the bottom blowing; and the amount of the CO2 is 100 to 3,000Nm<3> / h. The method is applicable to a steel-making process for a 30 to 350 ton converter. By adopting the method, for each ton of steel, 1 to 20 m3 of CO2 emission is reduced synthetically; the soot amount is reduced by 1 to 30 percent; and the content of the CO in the gas is improved to more than 2 to 15 percent.

Owner:UNIV OF SCI & TECH BEIJING

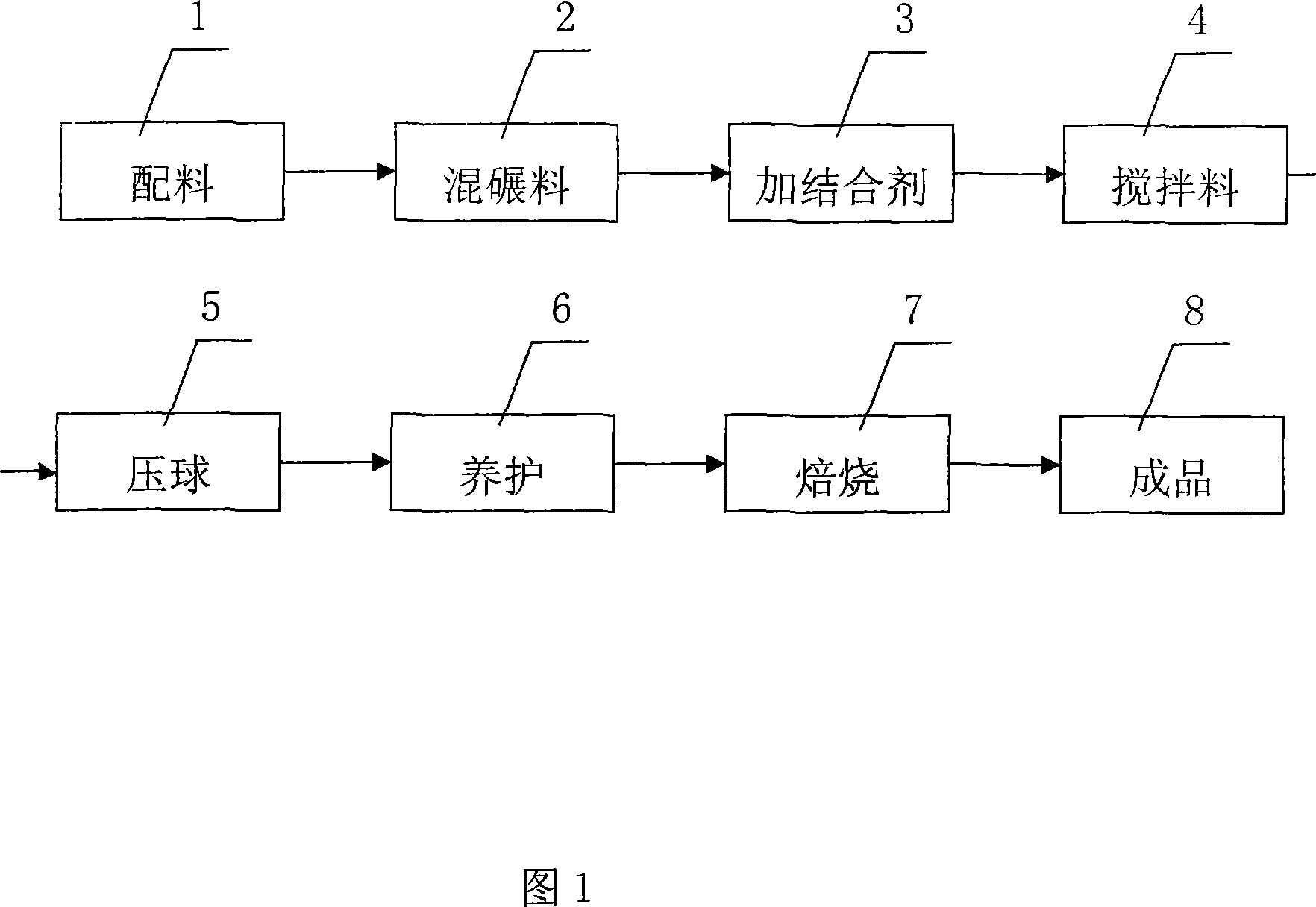

No-fluorine composite slag melting agent for converter steelmaking and its production process

The present invention is one kind of no-fluorine composite slag melting agent for converter steelmaking and its production process. The no-fluorine composite slag melting agent as one kind of steelmaking supplementary material consists of FeO 40-50 wt%, CaO 10-20 wt%, MnO 12-45 wt%, H2O 0.5-1 wt%, MgO 1-8 wt%, Al2O3 and SiO2 1-10 wt%, and impurity for the rest. Its production process includes the steps of compounding, grinding, adding adhesive, stirring, pelletizing, curing and roasting. It is used in no-fluorine steelmaking with less invasion to converter lining, long converter service life, less environmental pollution, low production cost and other advantages.

Owner:郎雪 +1

Converter steelmaking process

InactiveCN1470653AImprove efficiencySave operating timeManufacturing convertersSteelmakingLate stage

The convertor steel-smelting method adopts the top and bottom combined converting process, uses molten iron and solid iron material as raw material, their weight percentage are, molten iron 85%-95% and solid iron material 5-15%. The pretreatment of desilication, dephosphorization and decarbonization of molten iron and decarbonizing refining process are implemented in same convertor, i.e. front stage is pretreatment of molten iron, and late stage is decarbonizing refining stage, in the pretreatment stage the dephosphorization agent can be added, the top-bottom combined converting process can be adopted, top converting adopts flow rate changed oxygen supply, and its medium and late stage adopts weak oxygen supply, and the decarbonizing refining stage adds lime, makes secondary slag formation and adopts large quantity of oxygen to make top and bottom combined converting process.

Owner:CENT IRON & STEEL RES INST

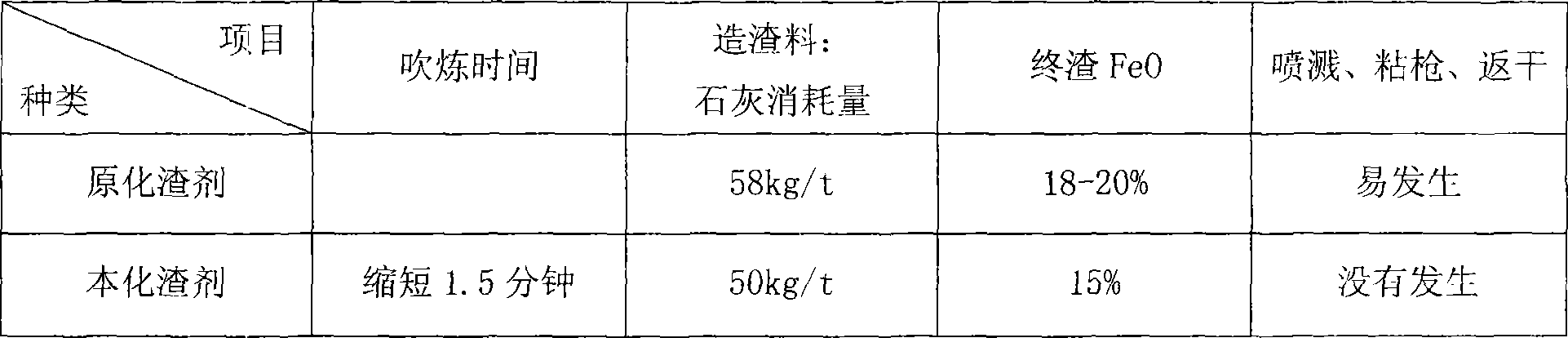

Slag former and slagging method for semisteel steelmaking

InactiveCN102304606AShorten the formation timeImprove dephosphorization rateManufacturing convertersProcess efficiency improvementHigh magnesiumSteelmaking

The invention provides a slag former and a slagging method for semisteel steelmaking. The slag former comprises 60 to 75 percent of SiO2, 10 to 15 percent of CaO, 1 to 3 percent of MgO, 7 to 15 percent of FeO, 1 to 3 percent of Fe2O3 and a small quantity of inevitable impurities. The slagging method comprises the following steps of: slagging by using the slag former for the semisteel steelmaking,active lime and high-magnesium lime, and controlling the addition opportunity and addition quantity of slagging materials appropriately. By the slag former and the slagging method for the semisteel steelmaking, the problems of low slagging speed and dephosphorization rate during semisteel smelting can be solved, initial slag formation time and pure oxygen blast time can be shortened effectively, and the molten steel dephosphorization rate of a finishing point of a converter can be improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Dephosphorization and iron-increasing method of high phosphorus hematite by direct reduction

InactiveCN101984079ATo achieve the purpose of dephosphorization and ironSimple processProcess efficiency improvementIron increasedPotassium carbonate

The invention particularly relates to a dephosphorization and iron-increasing method of high phosphorus hematite by direct reduction, and the technical scheme comprises the following steps: mixing 60-83wt% of high phosphorus hematite powder, 10-15wt% of carbonaceous reducing agent, 6-15wt% of quicklime and 1-10wt% of additive uniformly, pressing the mixture into blocks, drying, reducing in a high temperature furnace under 1250-1350 DEG C, and keeping the temperature for 15-30 minutes; carrying out furnace cooling until the temperature is 600-800 DEG C, taking the reduction product out, naturally cooling, grinding and performing the magnetic separation to obtain pig iron particles. The additive is sodium carbonate, or potassium carbonate, or the mixture of the sodium carbonate and the potassium carbonate; drying is carried out under the condition of 110-120 DEG C until the weight of the mixture of raw materials is constant; and the high temperature furnace is a resistance furnace, or a rotary kiln, or a rotary hearth furnace, and the atmosphere in the high temperature furnace is neutral or weak-reductive. The invention has the advantages of short reduction time, simple process, high dephosphorization rate, high iron yield, less environmental pollution, recyclable residue and the like.

Owner:WUHAN UNIV OF SCI & TECH

Converter smelting process using dephosphorization agent

InactiveCN101476013ALow investment costShorten the smelting cycleManufacturing convertersSteelmakingSmelting process

The invention pertaining to the field of convertor steelmaking technology provides a technique of converter smelting by using a dephosphorization agent. In a same convertor, dephosphorization is performed by using a CaO-base ephosphorization agent containing a few CaCl2 under favorable thermodynamics and combined-blowing dynamics conditions such as low temperature at the prior period, high content of iron oxide and the like, the prior period, desilication and dephosphorization slags of 50-70% are poured away in the molten iron preprocessing process, in the later period, decarburization process is performed and decarburization slag is formed and is then utilized as dephosphorization slag of the lower converter. According to the smelting technology, CaCl2 is added to the CaO-base ephosphorization agent to accelerate the burn-off rate of CaO by using the eutectic point character of CaCl2 and CaO binary system, the utilization ratio of lime is also improved, the utilizing of decarburization slag not only fully utilizes the physics heat brought by the decarburization slag, but also provides high content iron oxide for the dephosphorization of the prior period and accelerates the dephosphorization reaction.The invention has advantages of low cost of investment, shortened smelting period, carbon content of 0.4% at the end point of smelting, phosphorus content capable of being reduced to 0.006% and dephosphorization ratio up to 95.5%.

Owner:CHINA IRON & STEEL RES INST GRP +1

Method for producing high carbon steel through double-slag high drawing carbon tapping

ActiveCN102559984AGood dephosphorization effectLess slagManufacturing convertersSteelmakingHigh carbon

A method for producing high carbon steel through double-slag high drawing carbon tapping belongs to the technical field of smelting high carbon steel through a converter. The method comprises processing steps as follows: molten iron and steel scraps are loaded in the converter according to a certain molten iron ratio; in a first stage of converter steelmaking, the converting is performed at the oxygen supplying intensity of 2.8 Nm<3> / min / t, active lime and ore fluxing mediums are added in the converter, and a larger bottom blown flow rate is adopted to stir; the converting is performed at a standard lance height in the prior period for the converting of the converter, and then the lance height rises gradually; part of furnace slag is dumped through a rocking furnace; in the second stage for the converting of the converter, the converting is performed at the oxygen supplying intensity of 3.3 Nm<3> / min / t, and active lime and the ore fluxing mediums are added in the converter; the lance height rule that the converting is performed at a higher lance height in the later period and the lance height descends stage by stage is adopted; a small quantity of ores and fluorites are added frequently within 80 to 90 percent of total converting oxygen consumption; after the converting of the converter is finished, deslagging is performed through the rocking furnace of the converter, and temperature measurement and sampling are carried out; and converter tapping is carried out. The method has the advantage of overcoming the shortages of serious rephosphoration caused during the tapping process, low production efficiency, and so on.

Owner:SHOUGANG CORPORATION

Method for slagging steelmaking by side blowing of powder particle limestone in top-bottom combined blown converter

InactiveCN102796841ATake away decreaseIncrease profitManufacturing convertersSteelmakingMelting tank

The invention belongs to the technical field of metallurgy, and particularly relates to a method for slagging steelmaking by side blowing of powder particle limestone in a top-bottom combined blown converter. The method of the invention comprises the following steps: arranging at least one side blowing spray gun at one side of a converter trunnion center line, wherein the installation site of the side blowing spray gun is located between a molten pool liquid level and a level 500 mm below the liquid level, an angle between the installation range of the side blowing spray gun and the installation site tangent plane is 10 degrees-75 degrees, the side blowing direction of the spray gun is that the included angle between the side blowing spray gun center line and a horizontal line is 10 degrees-60 degrees, the spray gun faces the bottom of the molten pool, the insertion depth of the side blowing spray gun is 0.1-0.6 times larger than the radius of the molten pool; blowing powder particle limestone with carrier gas through a center pipe of the spray gun by using the side blowing spray gun, blowing protective gas around the circular seam. The method of the invention directly sprays powder particle limestone into the molten pool through the side blowing spray gun; the limestone rapidly decomposes and rapidly participates in slagging reactions; limestone taken away by converter furnace gas is reduced; dust is minimized; and the utilization rate of limestone is improved.

Owner:NORTHEASTERN UNIV

Dephosphorization agent prepared by taking slag of decarbonization furnace as raw material and molten iron dephosphorization method

The invention discloses a dephosphorization agent prepared by taking slag of a decarbonization furnace as a raw material and a molten iron dephosphorization method, and belongs to the technical field of molten iron desulphurization. The dephosphorization agent is composed of, by weight, 40-60% of the slag of the decarbonization furnace, 10-30% of fly ash, 10-30% of lime powder and 5-10% of a slagging agent; after being processed by a slag processing method, the slag of the decarbonization furnace is taken as a standby material of the dephosphorization agent after magnetic separation, smashing and levigating, and a prepared material is pressed to be the dephosphorization agent by a high-pressure ball press after uniform mixing. After a converter starts blowing, the dephosphorization agent is added in 10-20kg / t of steel, 10-20kg / t of lime and 10-20kg / t of magnesium balls or light-burned dolomite to form pre-slag of molten iron desulphurization at the early stage of the converter, and more than 60% of molten iron desulphurization rate at the early stage of the converter can be obtained. A condition is created for realizing a converter clean steal smelting platform.

Owner:CENT IRON & STEEL RES INST

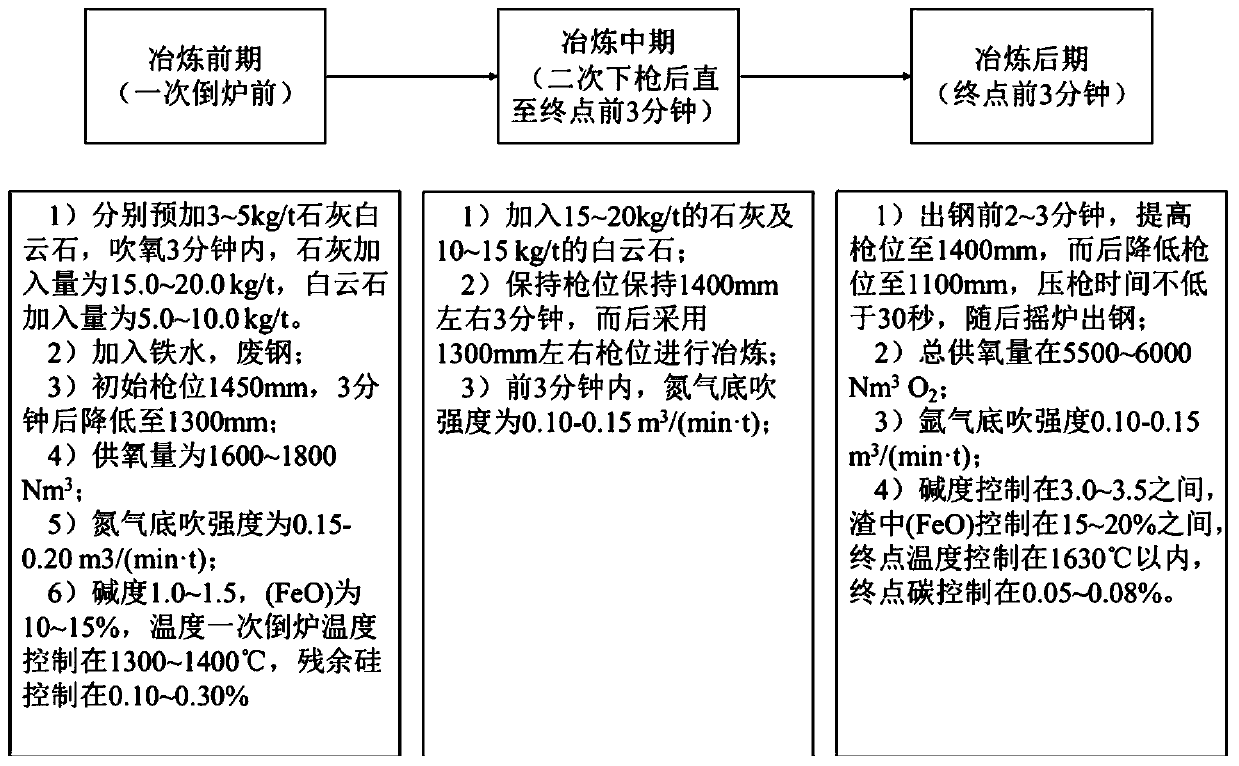

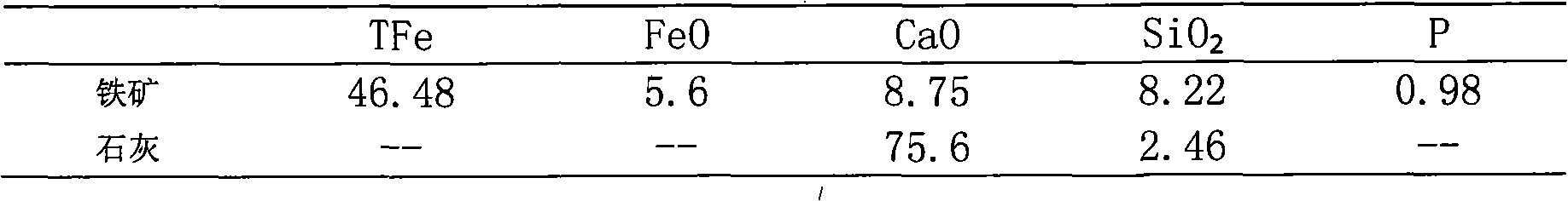

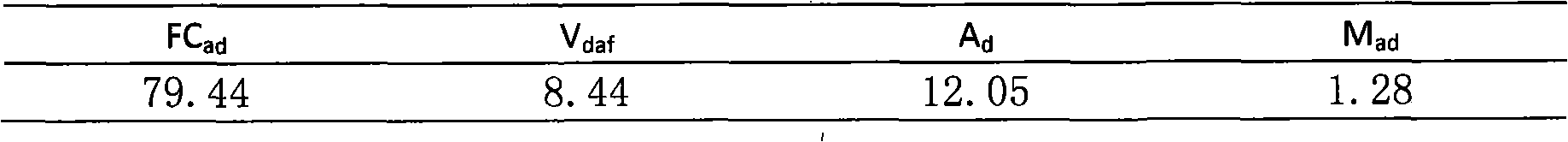

Converter high-carbon low-phosphorous end-point control metallurgy method under condition of phosphorous molten iron in blast furnace

ActiveCN106048129AStable temperature controlCarbon Stabilization ControlManufacturing convertersProcess efficiency improvementPhosphorous acidHigh carbon

Disclosed is a converter high-carbon low-phosphorous end-point control metallurgy method under the condition of phosphorous molten iron in a blast furnace. The method comprises the steps that the residual slag generated after slag splashing is reserved, molten iron and scrap steel are fed into a converter, an oxygen lance is controlled in the distance of 1.3m after ignition is finished, top oxygen blowing operation is conducted, and bottom argon blowing operation is conducted in the whole process; iron ore and lime are added to the converter, the turning-down temperature in the early period ranges from 1350DEG C to 1400DEG C, and the slag basicity in the early period ranges from 1.6 to 2.0; when the oxygen blowing quantity is 10%-15% of the total oxygen quantity, the oxygen lance is located in the distance of 1.5m-1.8m; when the oxygen blowing quantity is 30%-50% of the total oxygen quantity, slag generated in the early period is poured, the oxygen lance is located in the distance of 1.5m-2.3m, top oxygen blowing operation is conducted, bottom argon blowing operation is conducted in the whole process, lime is added to the converter to enable the final slag basicity to range from 3.2 to 3.4, and addition of the iron ore and the lime is accomplished before the oxygen blowing quantity is 75% of the total oxygen quantity; and when the oxygen blowing quantity is 85%-90% of the total oxygen quantity, the oxygen lance is located in the distance of being larger than or equal to 1.5m, and turning-down operation is conducted, when the content of carbon in molten steel is larger than 0.50% and the temperature is larger than or equal to 1580DEG C, oxygen blowing operation continues, and oxygen is blown to the molten steel, when [C] is larger than or equal to 0.30%, [P] is smaller than or equal to 0.013% and the temperature ranges from 1580DEG C to 1600DEG C, hot ladle tapping is conducted, and when tapping is conducted, aluminum iron alloy is added to a ladle to conduct deoxidization. The quality of the molten steel for hot rolled plates is ensured.

Owner:湖南华菱涟源钢铁有限公司

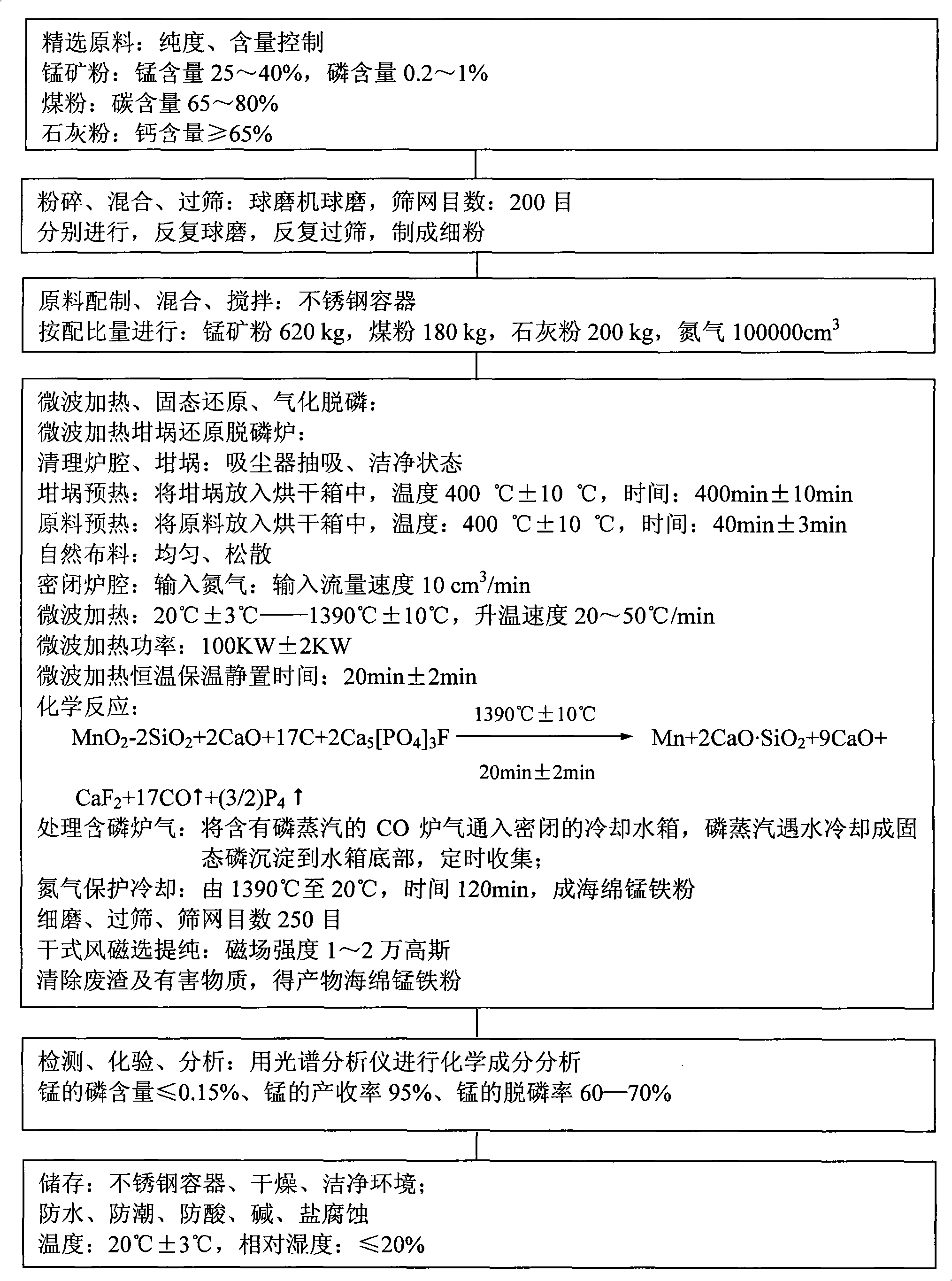

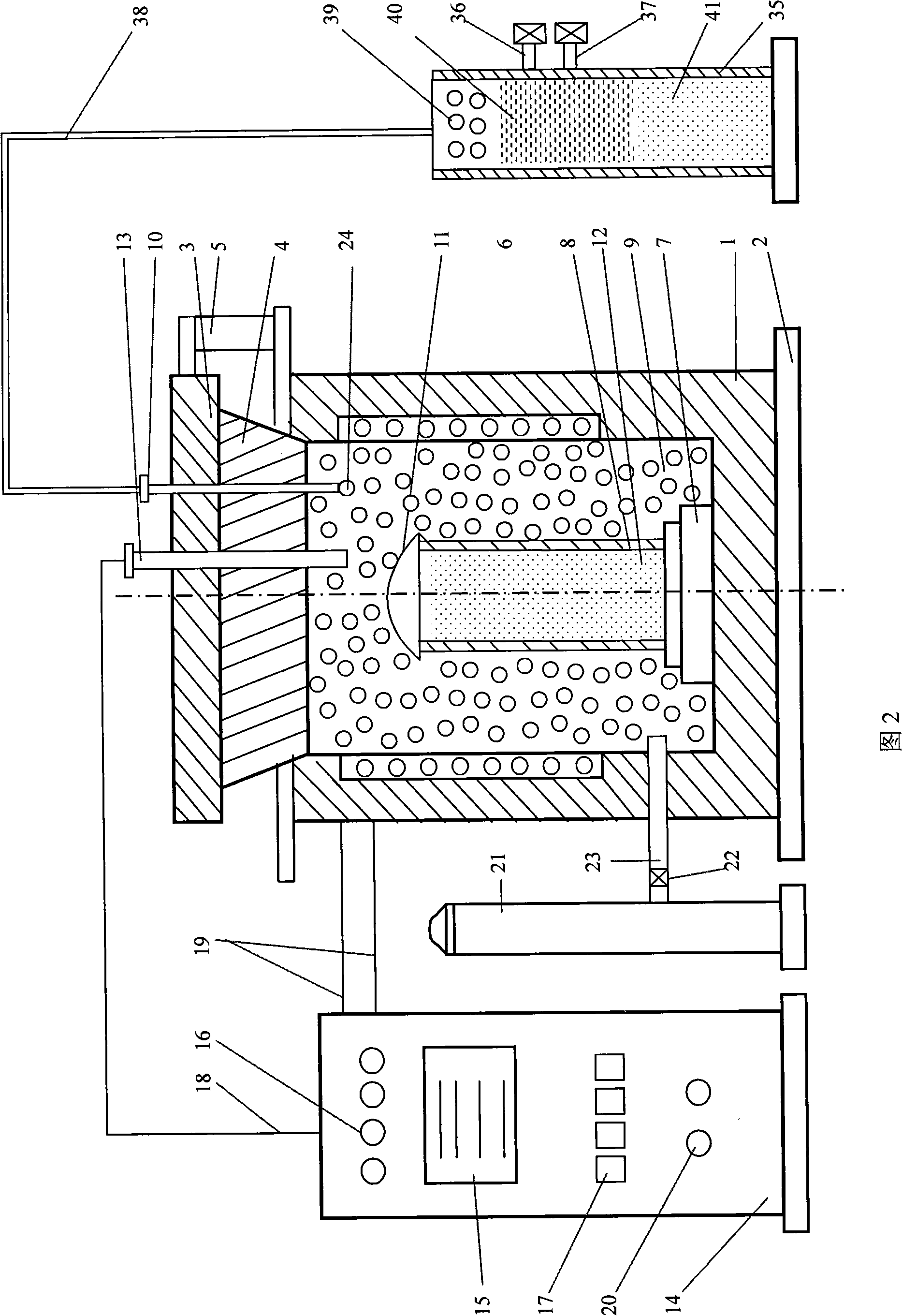

Microwave heating, solid state reduction and gaseous dephosphorization method for manganese ore powder

InactiveCN101302586AImprove dephosphorization rateNo pollutionProcess efficiency improvementChemical reactionHazardous substance

The invention provides a method of microwave heating, solid-state reduction and gasification dephosphorization for manganese ore powder. The invention adopts a novel method of microwave heating, solid-state reduction and gasification dephosphorization against the characteristic of the manganese ore powder with high content of phosphorus. The method uses the manganese ore powder as a raw material, coal powder as reducing agent, and nitrogen as reduction and dephosphorization protecting gas to perform solid reduction and gasification dephosphorization in a reduction dephosphorization crucible, through raw material selecting, thinning, mixing, stirring and distributing, in an airtight microwave reduction dephosphorization furnace, in the nitrogen atmosphere, at a high temperature of 1390 DEG C, for 20 minutes to preserve heat and keep stand at constant temperature, so that the manganese ore powder can react with the coal powder and lime powder to prepare sponge ferromanganese powder; and manganese powder can be separated from phosphorus and hazardous substances via cooling, fine grinding and dry magnetic separation purifying. The yield of the sponge ferromanganese can reach 95 percent, the dephosphorization rate can reach 60 to 70 percent, and the phosphorus-containing rate is less than or equal to 0.15 percent. The manganese ore powder has the advantages of good reduction effect, high dephosphorization rate, short process flow and no environmental protection, and can be reused after phosphorus is collected.

Owner:TAIYUAN UNIV OF TECH

Molten iron dephosphorizing agent and application method thereof

The invention discloses a molten iron dephosphorizing agent and an application method thereof. The dephosphorizing agent comprises the following components in percentage by weight: 75 to 85 percent of calcium oxide, 10 to 21 percent of iron oxide and 4 to 5 percent of calcium fluoride. The application method of the molten iron dephosphorizing agent sequentially comprises the following steps of: 1) weighing prepared pig iron, adding into an induction furnace, and starting to heat and melt the pig iron; 2) measuring the temperature and sampling after the pig iron is melted down, blowing oxygen in a molten pool from an oxygen pipe on the top of the furnace when the temperature is raised to 1,350+ / -10 DEG C, and adding the premixed dephosphorizing agent in batches simultaneously, wherein 60 to 80 percent of dephosphorizing agent is added first, and the residual dephosphorizing agent is added after 3 to 5 minutes; and 3) continuously heating for 12 to 18 minutes, and finishing dephosphorization. By adjusting a ratio of the dephosphorizing agent to the oxygen, alkalinity and an adding mode, the consumption of the solid dephosphorizing agent is effectively reduced while high dephosphorizing rate is achieved, so that advantages are provided for the pretreatment of high-phosphorus molten iron in a converter.

Owner:武钢集团有限公司

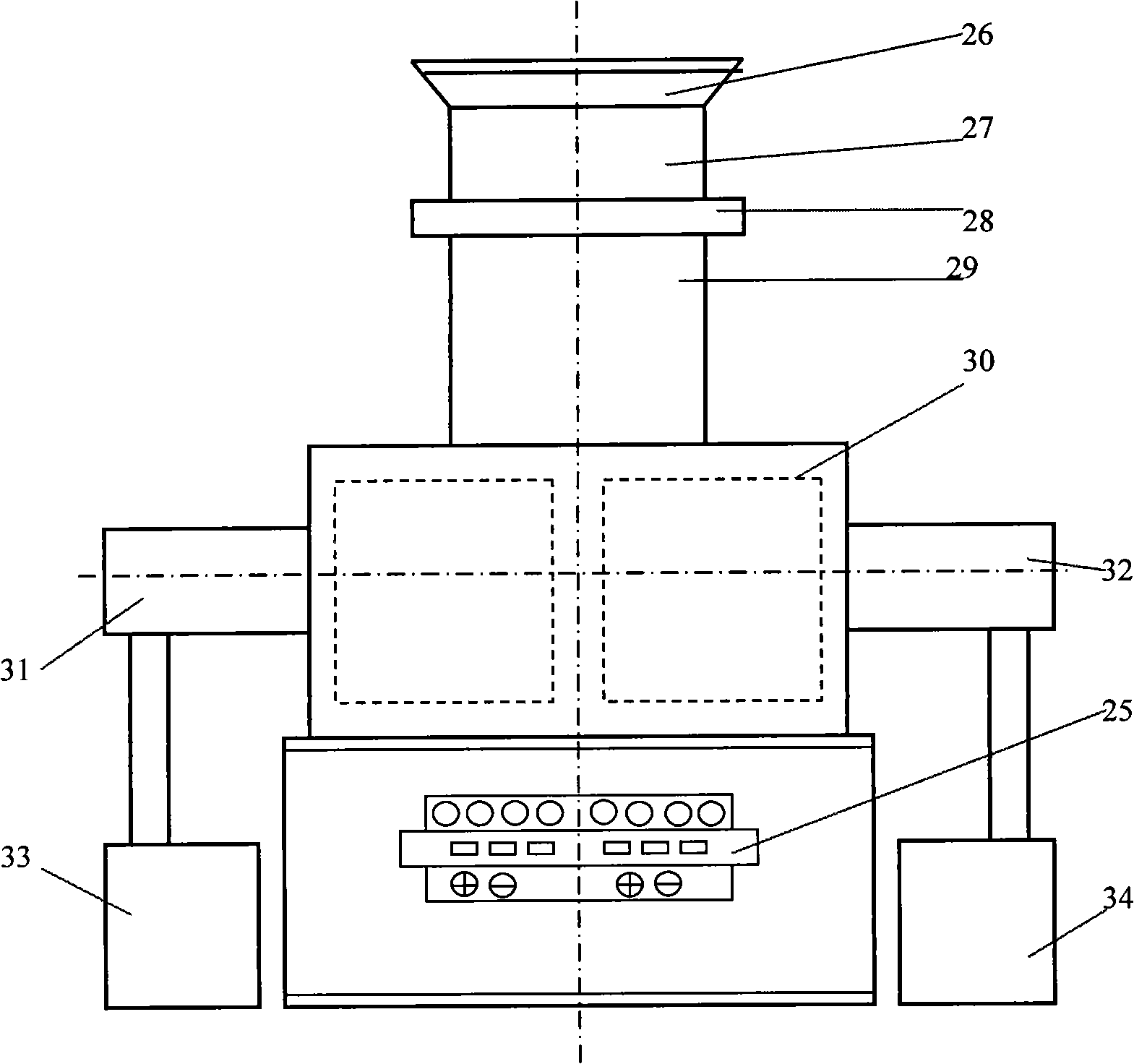

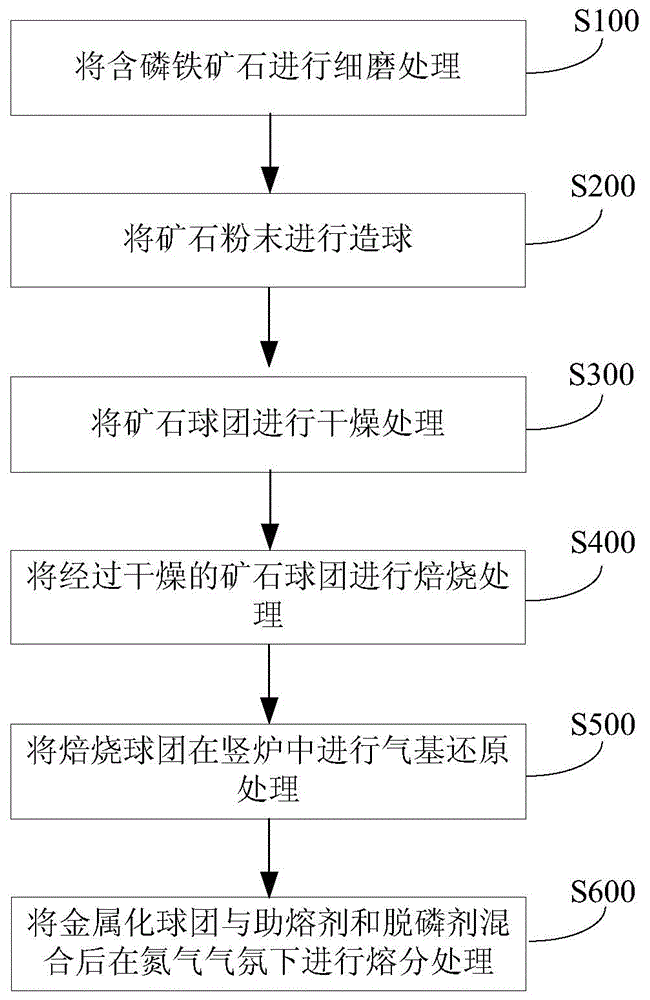

Method for separating metal iron from phosphorus containing iron ore

ActiveCN104451016AEfficient removalReduce phosphorus contentShaft furnaceIronstoneNitrogen atmosphere

The invention discloses a method for separating metal iron from phosphorus containing iron ore. The method includes the following steps: (1) fine grinding the phosphorus containing iron ore to obtain iron ore powder; (2) pelletizing the iron ore powder to obtain iron ore pellets; (3) drying the iron ore pellets to obtain dried iron ore pellets; (4) roasting the dried iron ore pellets to obtain roasted iron ore pellets; (5) performing gas-based reduction on the roasted iron ore pellets in a shaft furnace at the temperature of 800-900 DEG C to obtain metallized pallets; (6) performing melt separation under the nitrogen atmosphere after the metallized pallets are mixed with a fluxing agent and a dephosphorization agent to obtain metal iron and phosphorus containing tailings. The method can be used for effectively separating phosphorus in phosphorus containing iron ore, so as to obtain the metal iron with the phosphorus content lower than 0.2 wt% after separation.

Owner:SHENWU TECH GRP CO LTD

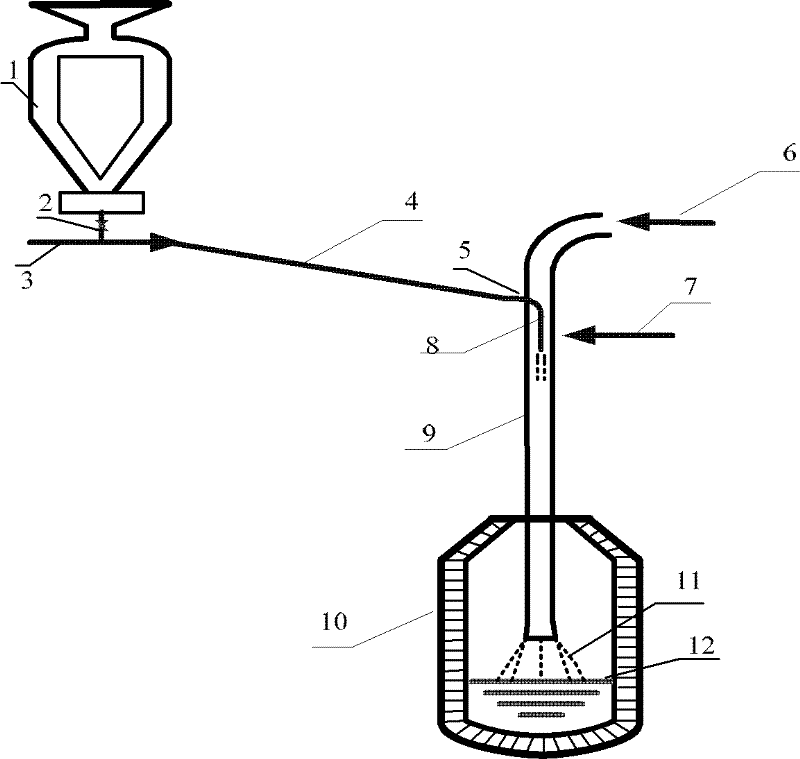

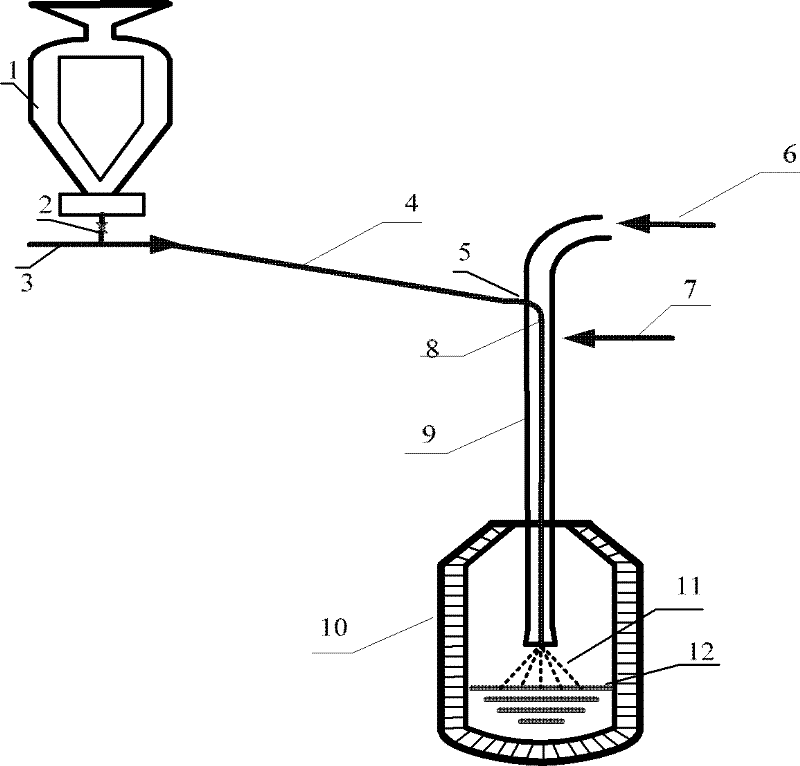

Dephosphorization method for molten iron in converter by blowing dust removal ash

The invention relates to a dephosphorization method for molten iron in a converter by blowing dust removal ash and belongs to the technical field of steelmaking. According to the dephosphorization process for dephosphorizing molten iron in the converter by blowing lime powder and dust removal ash through a dephosphorization oxygen lance, the device used in the dephosphorization process comprises an oxygen supply system and a powder blowing system; during the method, the oxygen supply system and the powder blowing system are adopted, the lime powder and dust removal ash are blown into a molten tank through the top-blowing dephosphorization oxygen lance, since the dust removal ash contains relatively high content of iron oxides, the content of ferric oxide in slag can be rapidly increased so as to promote the dissolution of lime and rapidly form slag having relatively high dephosphorization capability, the dephosphorization reaction is accelerated and meanwhile, the efficient utilization of the dust removal ash is achieved, the environmental secondary pollution due to the wastes is avoided and the dephosphorization method has relatively high economic and social benefits.

Owner:BEIJING SHOUGANG INT ENG TECH

Method for smelting low-phosphor steel based on high-silicon molten iron converter double-slag process

ActiveCN110117689AImprove stabilityImprove dephosphorization rateManufacturing convertersProcess efficiency improvementSmelting processPhosphor

The invention provides a method for smelting low-phosphor steel based on a high-silicon molten iron converter double-slag process, and relates to the technical field of steel smelting. The method caneffectively improve sable performance of smelting of the high-silicon molten iron converter double-slag process, reduces occurrence of a splashing phenomenon, increases a phosphor removal rate of a desilicication furnace, reduces slag consumption and reduces the production cost. A slag-retaining double-slag process is adopted; a steel scrap ratio and auxiliary material adding are reasonably controlled at the early stage of smelting, and the temperature in the furnace stably increases by utilizing heat released by oxidizing reaction of silicon, so that splashing is reduced; once furnace pouringopportunity is controlled by oxygen blowing amount; and after dropping to a gun position for a second time, the final point components and the temperature are controlled by controlling an oxygen gunand auxiliary material adding, so that the requirements on phosphor content of low-phosphor steel are achieved. The technical scheme provided by the invention is suitable for a low-phosphor steel smelting process.

Owner:UNIV OF SCI & TECH BEIJING

Method for separating rare-earth element and fluorapatite, calcium chloraphosphate and calcium phosphate

InactiveCN1928131AImprove dephosphorization rateEasy dischargeProcess efficiency improvementCalcium phosphate productCalcium biphosphate

The process of separating RE elements from calcium fluorophosphate, calcium chlorophosphate and calcium phosphate is to wash mineral with the mixed solution of hydrochloric acid and citric acid to leach out calcium fluorophosphate, calcium chlorophosphate and calcium phosphate while limiting the leaching of RE elements and other matters. The solution containing calcium fluorophosphate, calcium chlorophosphate and calcium phosphate is alkalized to produce precipitate and recover calcium fluorophosphate, calcium chlorophosphate and calcium phosphate product; and the small amount of RE elements are recovered with P204 or P507 extractant. The said process has calcium fluorophosphate, calcium chlorophosphate and calcium phosphate leaching rate not lower than 95 wt%, RE element leaching rate not higher than 10 wt% and total RE element yield not lower than 97 wt%.

Owner:NORTHEASTERN UNIV

Method for decreasing phosphorus of high-phosphorus iron ore by adopting microwave reduction-magnetic separation

InactiveCN102382920AImprove dephosphorization rateIncrease iron yieldProcess efficiency improvementMicrowaveIron powder

The invention discloses a method for decreasing phosphorus of high-phosphorus iron ore by adopting microwave reduction-magnetic separation, solving the problems that the dephosphorizing speed of the high-phosphorus iron ore is low, and the iron recovery rate and the dephosphorizing rate are low. The method is characterized by comprising the following steps: material smashing, blending, microwave reduction, sponge iron smashing, magnetic separation and post-treatment. Compared with the existing dephosphorizing method for the high-phosphorus iron ore, the method in the invention has the following benefits: high-phosphorus iron ore carbon heat reduction reaction is conducted faster and more thoroughly, the embedded structure of apatite is damaged, and the dephosphorizing rate and the iron recovery rate are improved by magnetic separation. By magnetic separation, low-phosphorus iron powder containing 0.2-0.3 percent of phosphorus can be obtained, and the dephosphorizing rate and the iron recovery rate can be more than 85 percent; and the carbon heat reduction time is short, the reduction temperature is lower than that in normal heating, the energy is saved, and the pollution is less.

Owner:UNIV OF SCI & TECH LIAONING

Foamed dephosphorization pellet and preparation method thereof

InactiveCN101818229ALess slagSolve the problem of moisture brought into molten steelProcess efficiency improvementElectric furnaceAdhesiveSulfur

The invention provides a foamed dephosphorization pellet and a preparation method thereof. The pellet consists of the following components: 15 to 40 percent of calcium oxide (CaO), 15 to 40 percent of carbon (C), 20 to 30 percent of ferric oxide (Fe2O3), 1 to 3 percent of sodium oxide (Na2O) and 20 to 40 percent of caustic soda. The preparation method for the pellet comprises the following steps of: preparing limestone, low-sulfur coal powder, iron oxide red and soda ash according to the component content of the foamed dephosphorization pellet, mixing the materials uniformly by using a mixer, then adding a little amount of adhesive into the mixture, and pelleting the mixture by using a disc pelleting machine. The dephosphorization pellet of the invention does not produce pollution to the environment, so the pellet is favorable for environmental protection; the pellet has good dephosphorization effect and is favorable for improving the quality of the steel; and the pellet has little corrosion to a furnace lining, can reduce the using amount of lime fed into the furnace so as to simplify the operation in front of the furnace, and has obvious comprehensive economic benefit.

Owner:ANGANG STEEL CO LTD

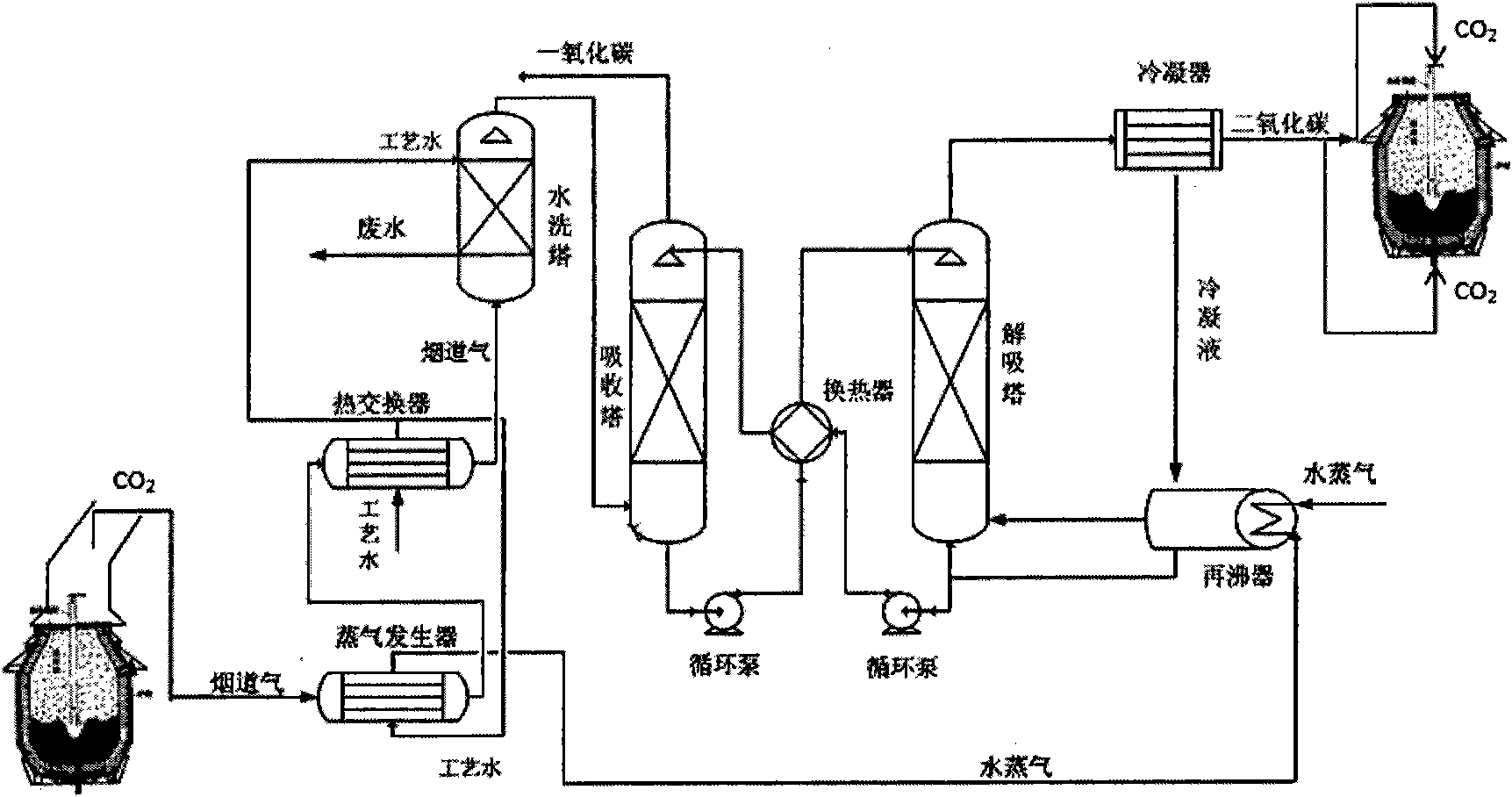

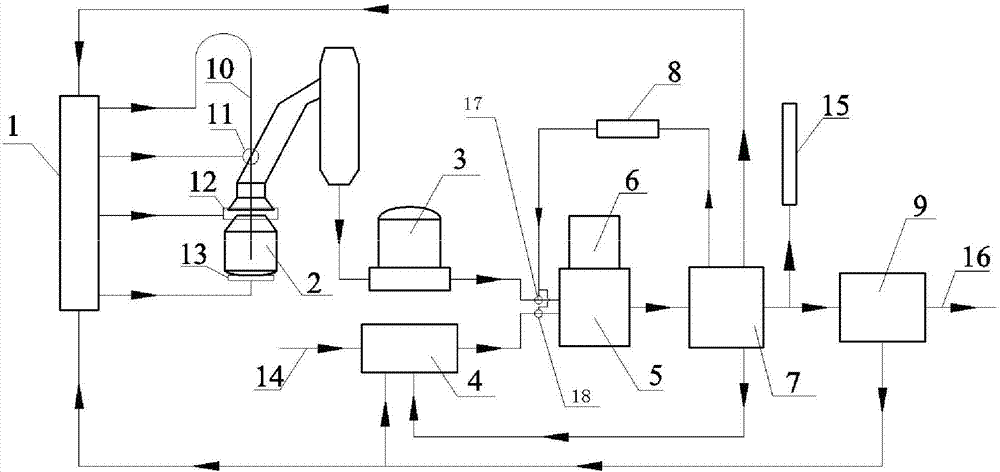

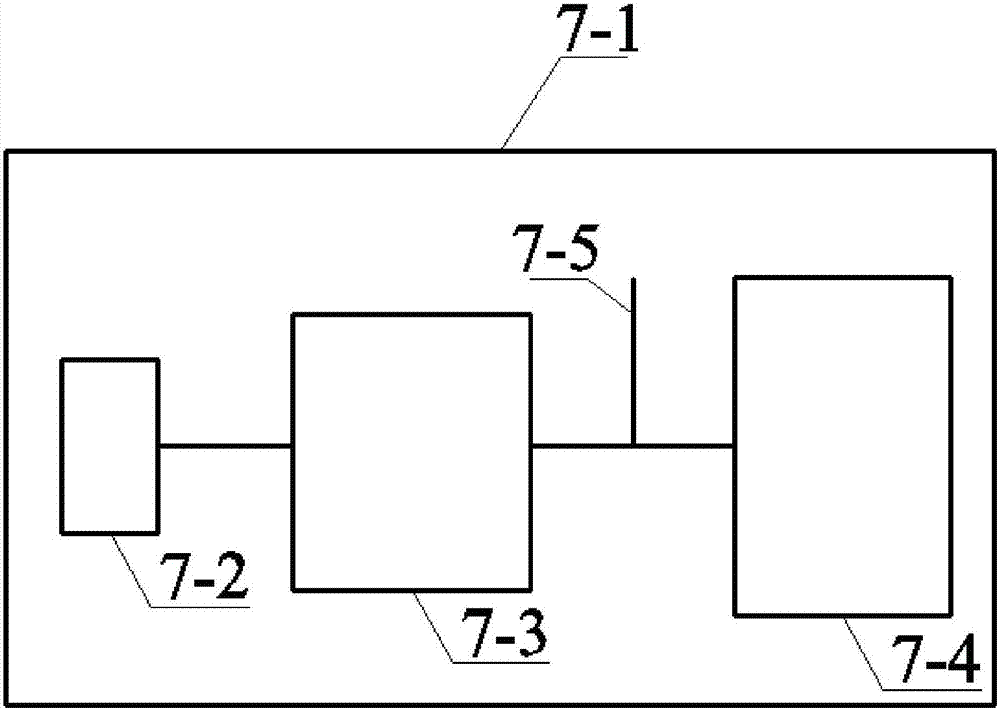

Circulation injection method and system for preparing CO2 through converter gas

ActiveCN107130079AStir wellReduce productionOxide/hydroxide preparationManufacturing convertersResource utilizationNitrogen oxide

The invention discloses a circulation injection method and system for preparing CO2 through converter gas and belongs to the technical field of converter gas resource utilization and CO2 purification preparation. The converter gas with the low N2 content and an oxidizing agent with the main components being O2 and CO2 are burnt in a closed burning device, burning heat is utilized through a heat exchange device, CO2-rich pure gas is obtained through purification treatment of the burning gas, can be used for purification and preparation of high-purity CO2 and can also be directly used as low-purity CO2, and the low-purity CO2 and the high-purity CO2 are circularly used for converter injection, converter sealing and preparation of oxidizing agents needed by gas burning. The method and system have the advantages that the converter gas with the low N2 content can be obtained, the gas produced through converter gas burning is circularly used, production and emission of nitric oxides are reduced, the low-purity CO2 is efficiently obtained and the high-purity CO2 is efficiently prepared with low cost.

Owner:UNIV OF SCI & TECH BEIJING

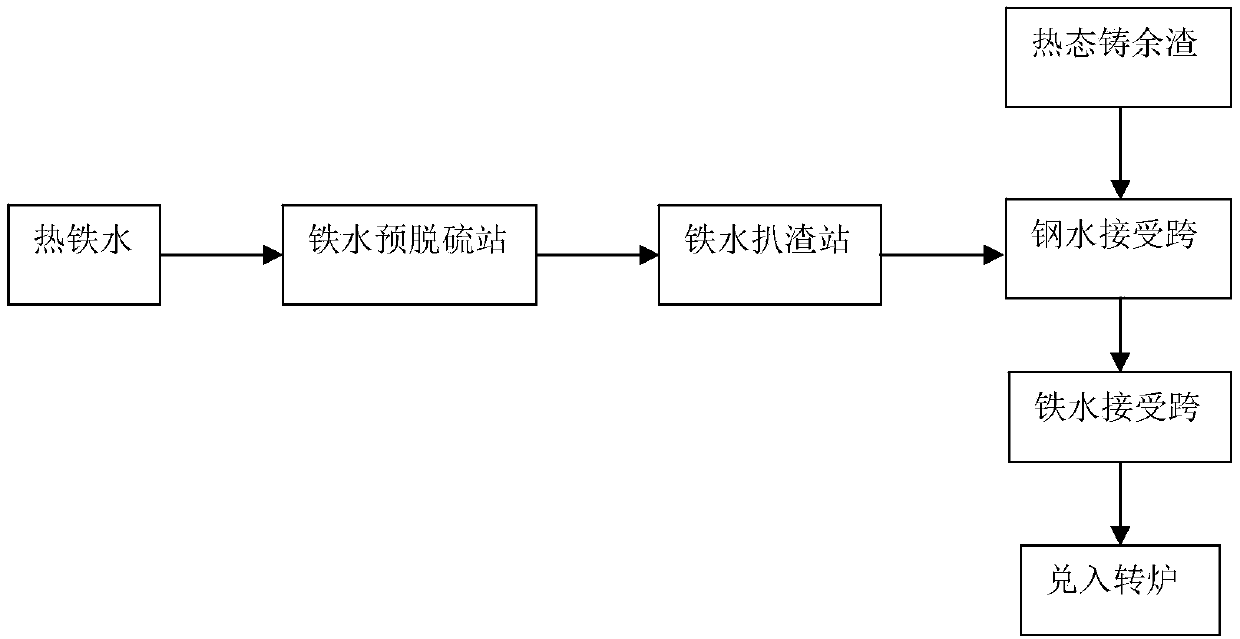

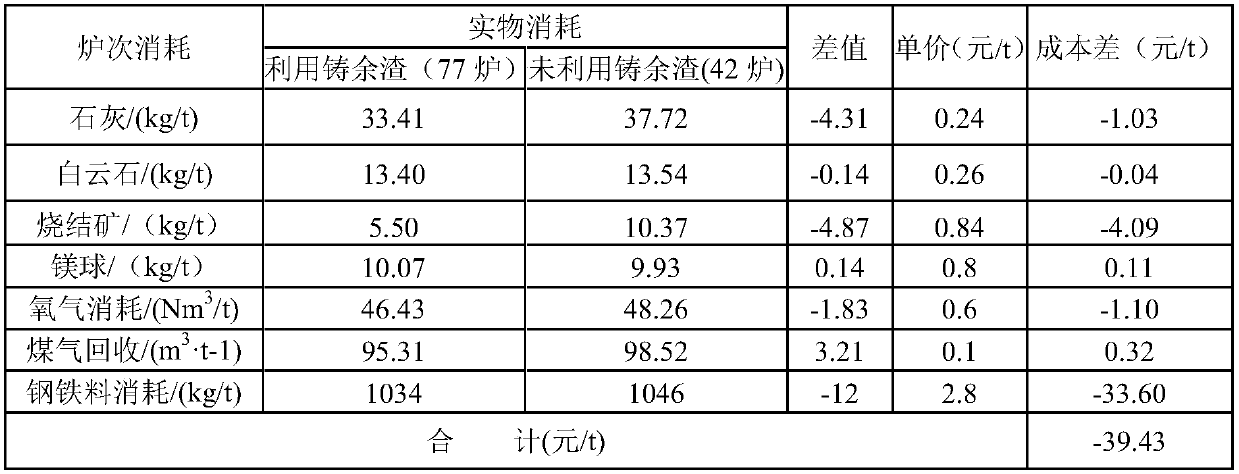

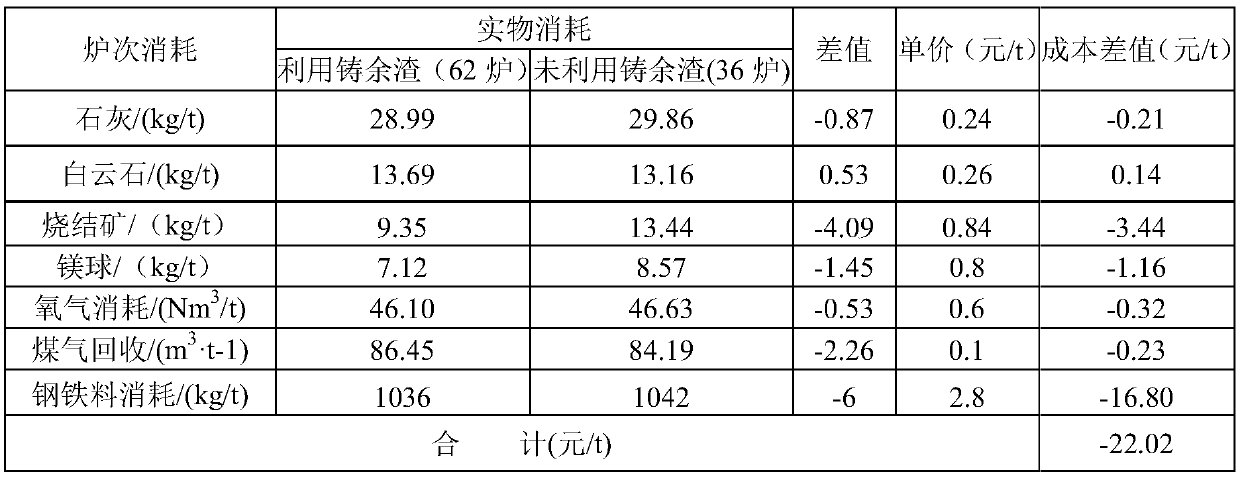

Method for recycling steel-ladle hot-state casting residues by means of converter

ActiveCN109609721AReduce steel consumptionUse efficientlyManufacturing convertersFerrous metallurgySmelting

The invention discloses a method for recycling steel-ladle hot-state casting residues by means of a converter, and belongs to the technical field of ferrous metallurgy. The problem that the casting residues and self waste heat of the casting residues cannot be effectively utilized in the prior art is solved. The method comprises the following steps that the hot-state casting residues remaining inthe steel ladle after molten steel pouring are returned to the converter steelmaking process for recycling and utilization, and the alkalinity of the hot-state casting residues ranges from 6 to 8. According to the method, the liquid-state continuous casting residues are used in an energy-saving, environment-friendly, effective and stable manner for realizing the heat-state recycling of the castingresidues; and the consumption of steel materials can be reduced, the sensible heat of furnace slag can be effectively utilized, the smelting efficiency can be improved, the steelmaking production cost is reduced, the quality of molten steel is improved, and the environment-friendly benefit is obvious.

Owner:CENT IRON & STEEL RES INST

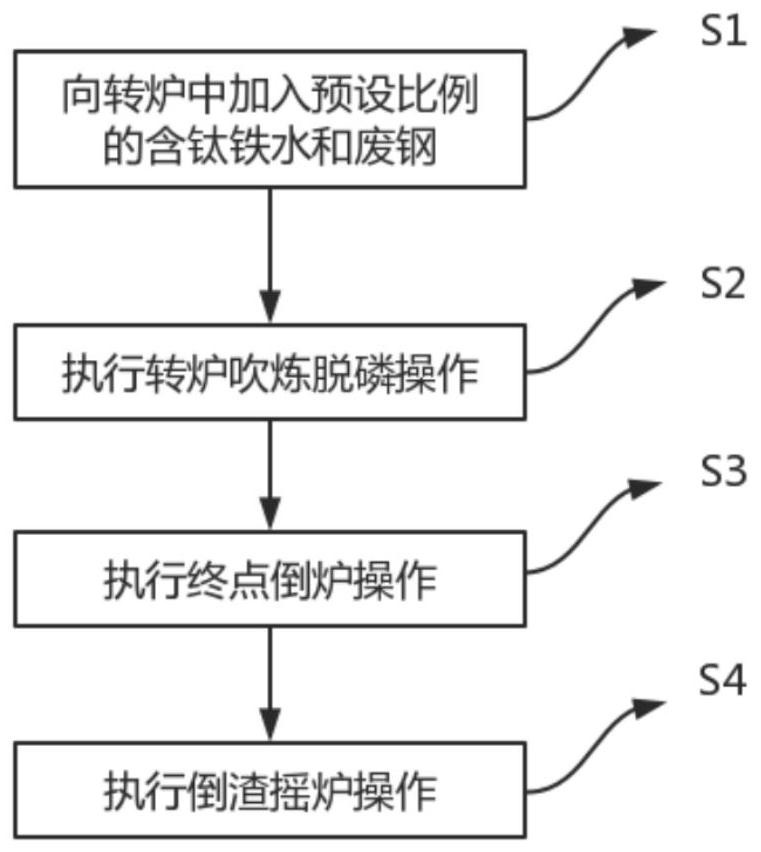

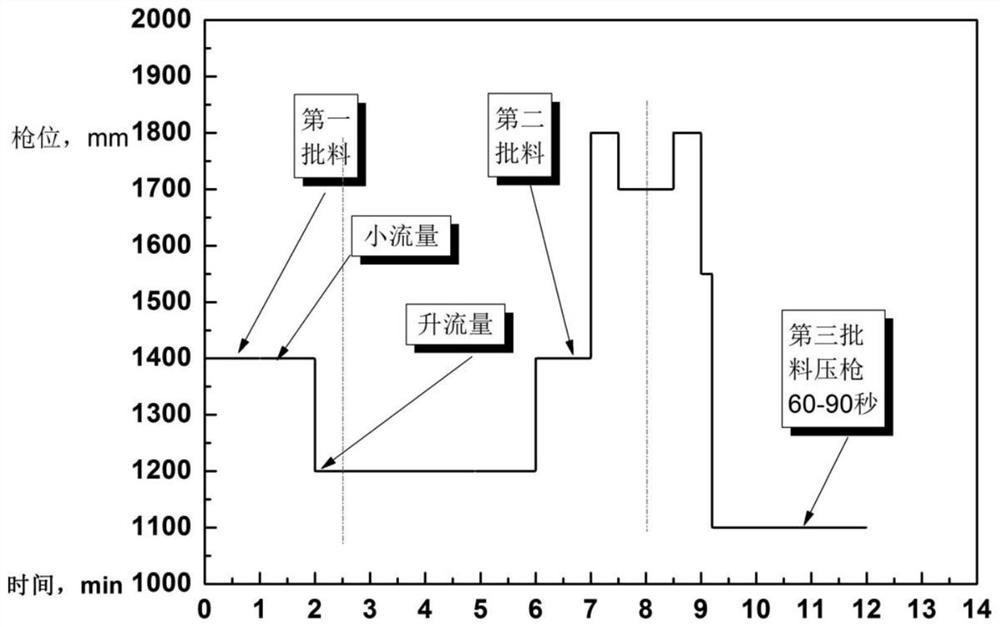

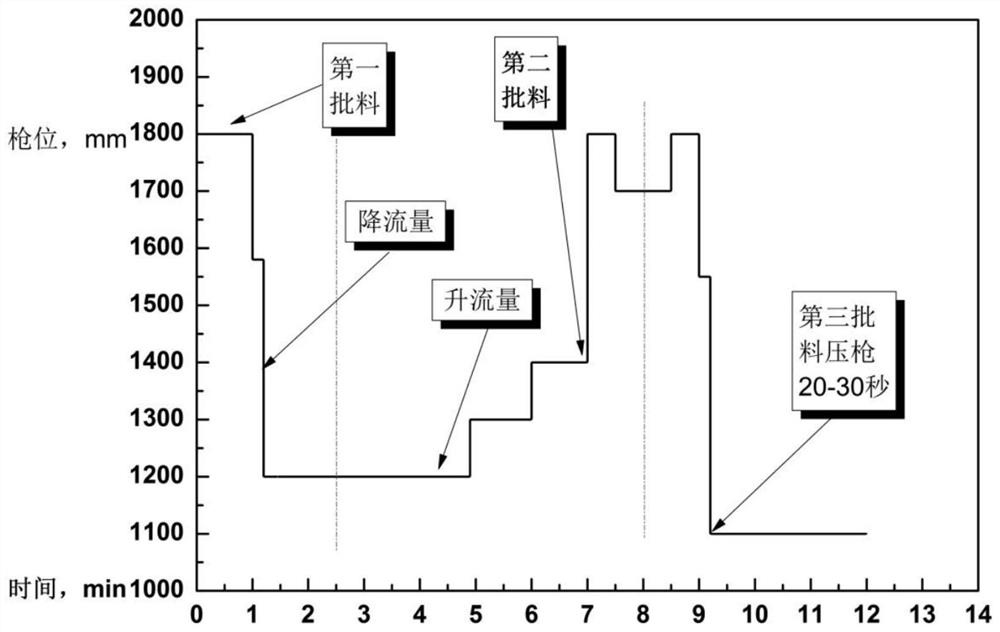

Titanium-containing molten iron converter high-scrap-ratio rapid heating production method

ActiveCN112708716AEfficient dephosphorizationMeet Phosphorus and Temperature RequirementsManufacturing convertersProcess efficiency improvementSlagTitanium

The invention discloses a titanium-containing molten iron converter high-scrap-ratio rapid heating production method. The method comprises the following steps that titanium-containing molten iron and scrap steel in a preset proportion are added into a converter; converter blowing dephosphorization operation is executed; an end-point furnace turning-down operation is executed; and slag pouring and furnace shaking operation is executed. According to the titanium-containing molten iron converter high-scrap-ratio rapid heating production method, efficient dephosphorization of the converter under the same molten iron condition at the scrap steel ratio of 20% or above is achieved, the one-time converter turning-down temperature of the converter is increased by 30-50 DEG C compared with conventional smelting operation, the requirements of the steel grade end point for phosphorus and temperature are met, and the smelting period is shortened by 1-2 minutes.

Owner:SHOUGANG CORPORATION

Production method for extremely-low-phosphorous steel

InactiveCN107557534AReduce phosphorus contentGood dephosphorization effectManufacturing convertersProcess efficiency improvementSteelmakingMolten steel

The invention belongs to the field of steel smelting and particularly relates to a production method for extremely-low-phosphorous steel. The production method for the extremely-low-phosphorous steelis used for solving the problem that when an existing method is used for producing low-phosphorous steel, it is difficult to reduce the phosphorous content to 0.002% or below, and consequently it is difficult to produce the extremely-low-phosphorous steel. The production method for the extremely-low-phosphorous steel comprises the steps of vanadium recovering converter dephosphorization, desulfuration, steelmaking converter dephosphorization and decarburization, LF finery deep dephosphorization, desulphurization station dephosphorization slagging off, LF refining and the like. By means of a step-by-step dephosphorization manner, the dephosphorization effect is improved, the dephosphorization rate is increased, the phosphorous content in molten steel can be reduced to 5*10<-6> or below. Compared with the low-phosphorous produced in the prior art, the phosphorous content in the low-phosphorous steel produced through the production method is reduced 10 times or above. The production method is simple, the equipment requirement is not high, and the production method is worthy of popularization and use.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

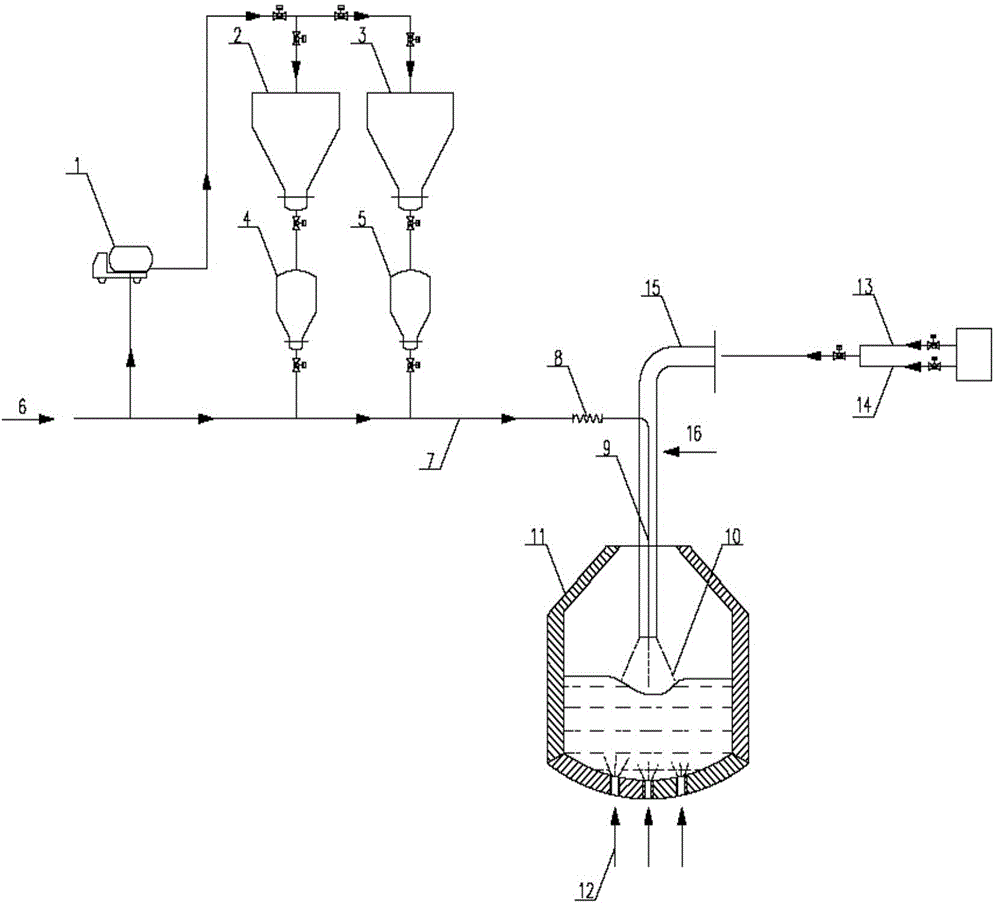

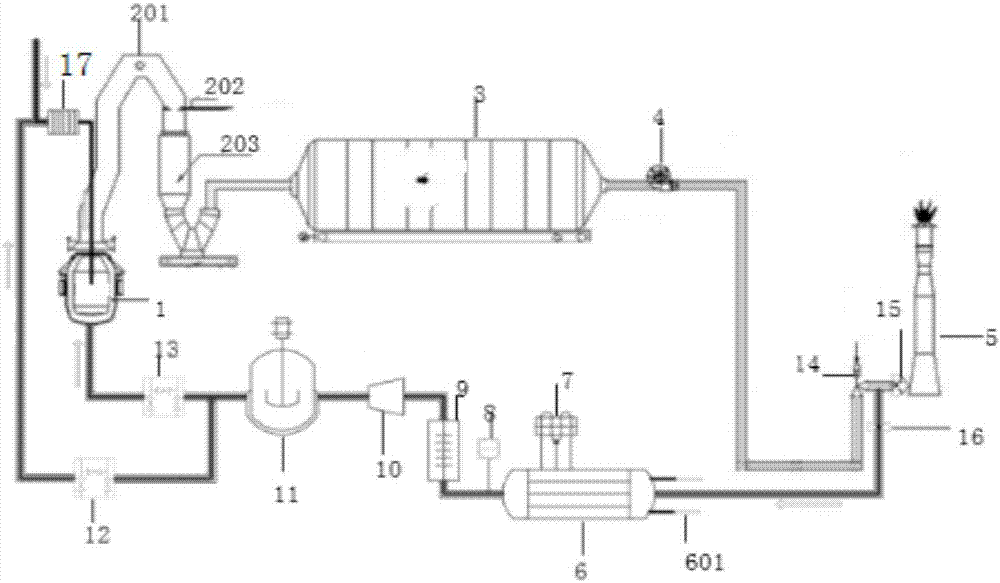

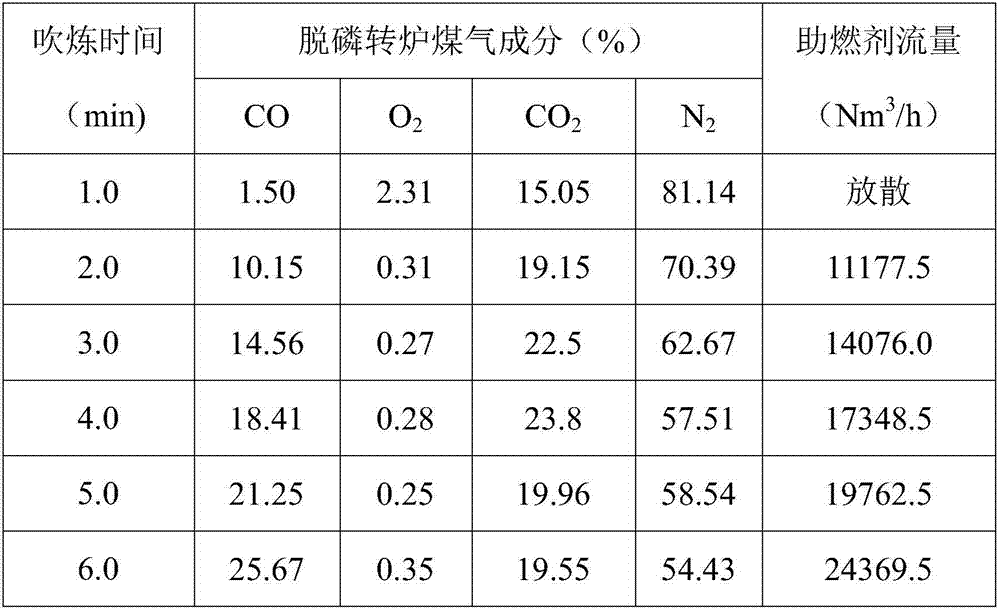

Multi-element-injection efficient dephosphorization method and device for dephosphorization converter gas mass energy conversion cycle

ActiveCN107151724AImprove mechanical propertiesImprove dynamic conditionsManufacturing convertersExhaust gas handlingSteelmakingTemperature control

The invention belongs to the technical field of ferrous metallurgy and relates to a multi-element-injection efficient dephosphorization method and device for the conversion cycle of dephosphorization converter gas mass energy of duplex steelmaking. According to the multi-element-injection efficient dephosphorization method and device, dephosphorization converter gas enters a combustion chamber after being subjected to cooling and dedusting, the gas CO component is converted into CO2 in the combustion chamber, meanwhile heat generated during combustion is recycled, dephosphorization converter gas mass energy conversion is achieved, the injection and dephosphorization of multiple gas elements of O2, N2 and CO2 of the converted gas are achieved through a dephosphorization converter top-blowing system, bottom blowing stir of the mass energy conversion gas is achieved through a bottom blowing system, and the multi-element-injection process is controlled in a sectioned manner. The method and device are suitable for 30-350-ton dephosphorization converter, the strong stir and temperature control functions of N2 and CO2 in the mass energy conversion gas are used, the good thermodynamics and kinetics conditions are provided for dephosphorization, the dephosphorization rate is increased over 5%, the resource utilization of steel with dephosphorization gas of 10-50 Nm<3> / t is achieved, and steel with the quantity of steam of 5-20 kg / t of is recovered.

Owner:UNIV OF SCI & TECH BEIJING +1

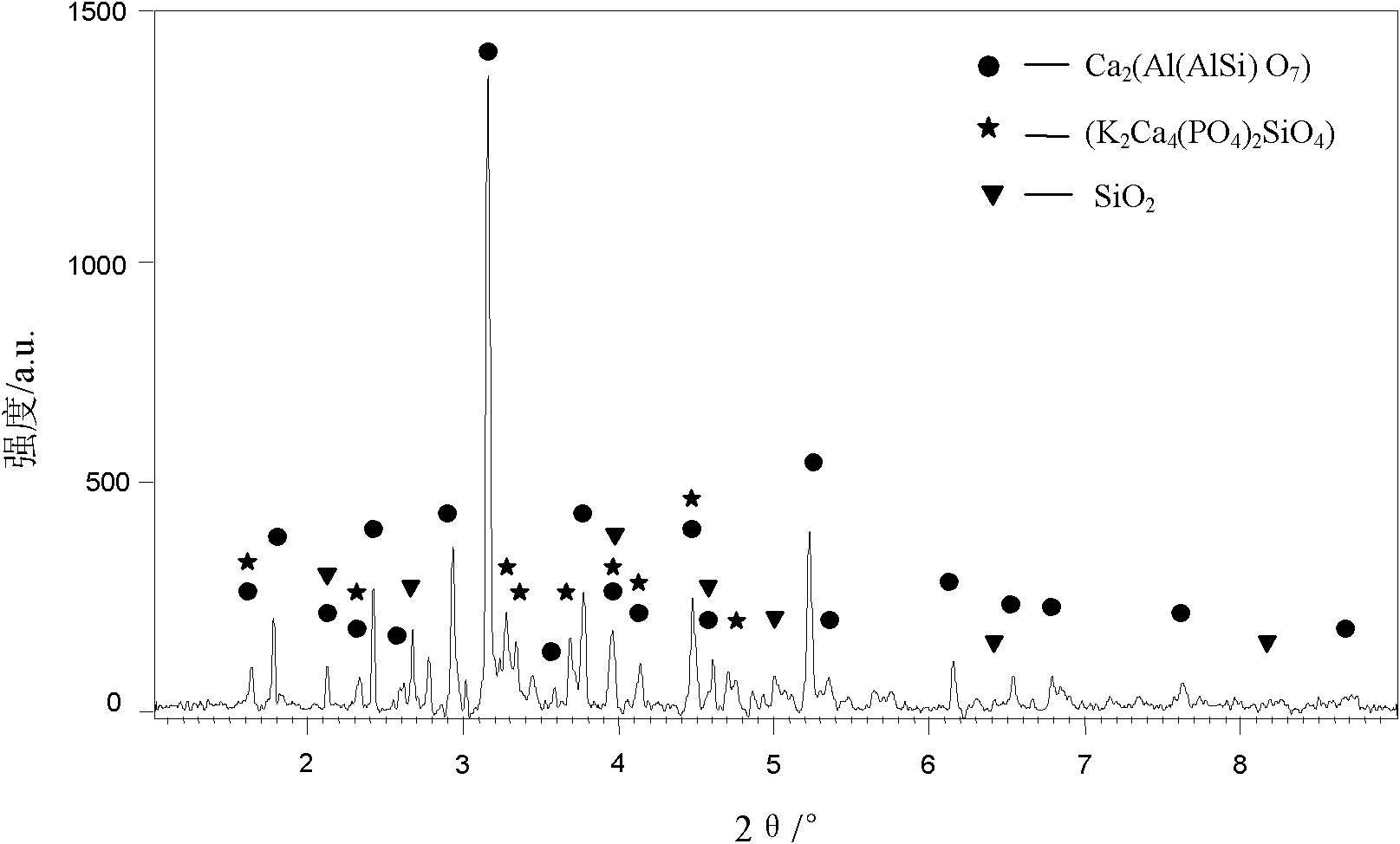

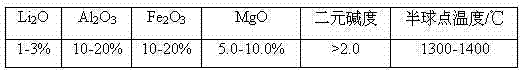

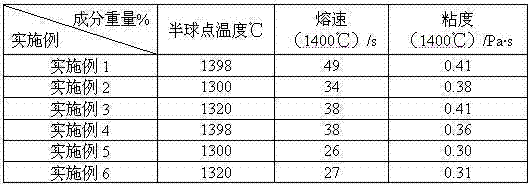

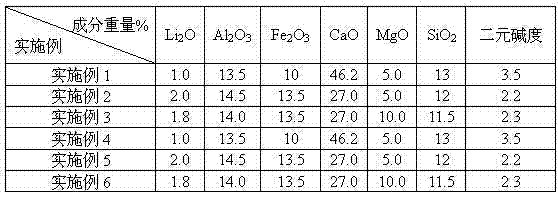

Fluoride-free slagging flux for electric-arc furnace steelmaking

The invention belongs to the technical field of iron and steel smelting and particularly relates to a fluoride-free slagging flux for the electric-arc furnace steelmaking and a preparation method thereof. The invention aims to provide the fluoride-free slagging flux for the electric-arc furnace steelmaking and the preparation method thereof and solve various problems of low slagging speed, poor slag melting effect, fluorine pollution, high cost, serious corrosion of a furnace lining, large dust capacity and the like which are generated due to the case that currently, lime, fluorite, calcium aluminate and iron oxide are used as slags. The fluoride-free slagging flux is characterized by being prepared from the following raw materials in percentage by weight: 20 to 40 percent of spodumene, 15 to 20 percent of red bauxite, 30 to 50 percent of active lime, 5 to 10 percent of iron oxide and 5 to 10 percent of magnesia.

Owner:JIANGSU UNIV

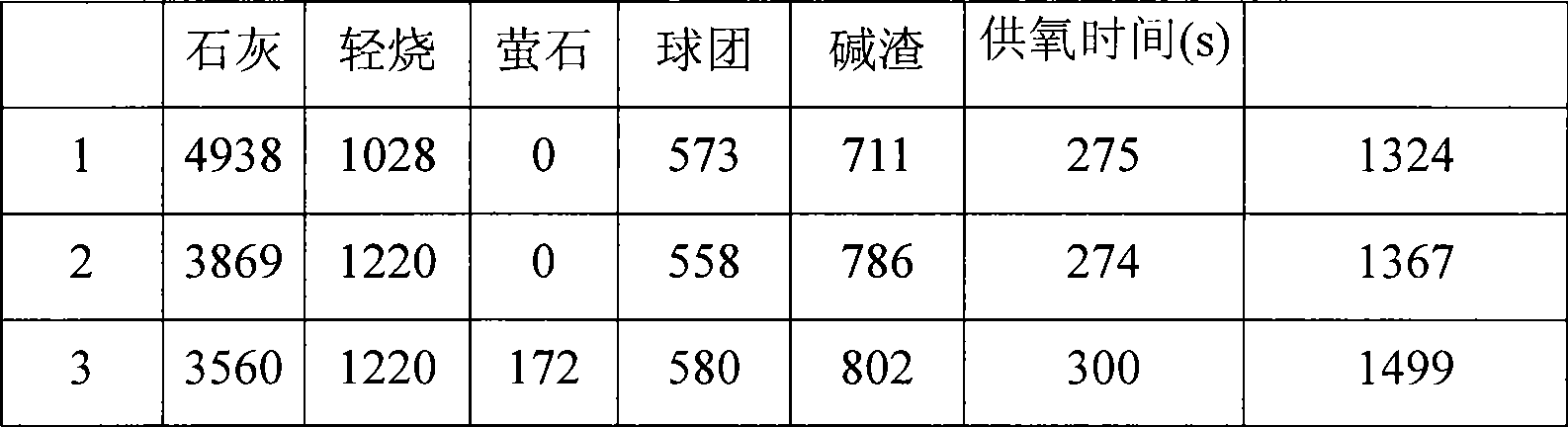

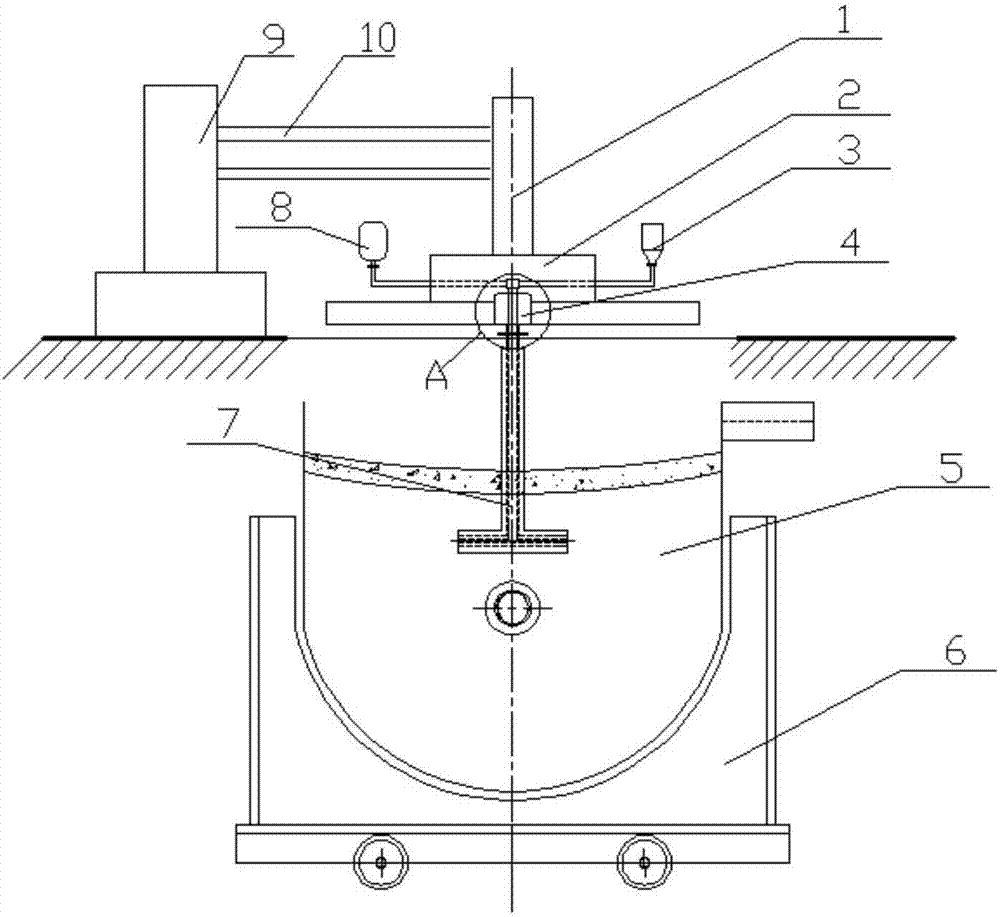

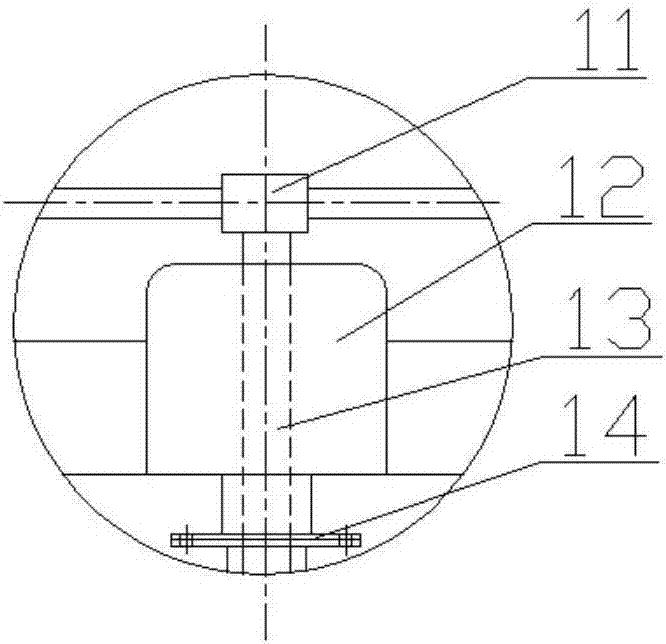

Molten iron dephosphorizing device adopting rotary injection of powder, and dephosphorizing method

The invention discloses a molten iron dephosphorizing device adopting rotary injection of powder, and a dephosphorizing method. Through the molten iron dephosphorizing device adopting rotary injection of powder, a multipoint simultaneous dephosphorizing process can be achieved by using an inverted T-shaped powder gun, and the dynamic conditions of dephosphorization reaction are improved; the dephosphorization rate is improved effectively, and the dephosphorization reaction speed increases; the dephosphorization processing time is shortened, and the investment is low; a feeding system and an injection system can be controlled automatically and adjusted on line; and the powder gun is prevented from being blocked effectively, and automatic deslagging of the powder gun can be achieved.

Owner:ANGANG STEEL CO LTD

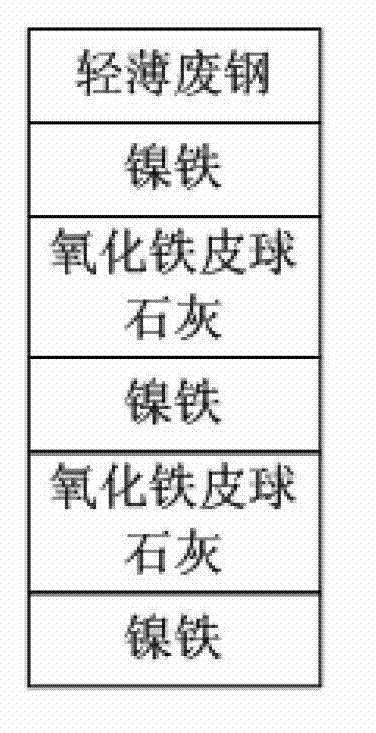

Low-cost efficient dephosphorization smelting process for electric arc furnace

InactiveCN102965467AOvercoming the problem of low dephosphorization efficiencyFlexible structureProcess efficiency improvementElectric furnacePhosphorus lowAlkalinity

A low-cost efficient dephosphorization smelting process for electric arc furnace belongs to the field of electric arc furnace smelting. According to the invention, reasonable blending process is carried out in a charging stage of the electric arc furnace; accessories in a traditional electric arc furnace smelting process is moved to a charging stage; through reasonable distribution of the cold raw materials and accessories in the electric arc furnace, problems of contradiction of theoretical demands of the dephosphorization oxygen potential, alkalinity and temperature during melting process of the cold raw materials and accessories is solved; and smelting dephosphorization process of the electric arc furnace runs through the whole process from starting to the end of the melting, so as to achieve the goal of efficient dephosphorization. The invention has the following advantages: the difficulty in dephosphorization of electric arc furnace traditional smelting process is solved; dephosphorization is basically realized when the melting down of the cold materials; and the process realizes dephosphorization rate of 75%-90%, rephosphorization rate after deslagging less than 5%, and end point phosphorus lower than 0.01%.

Owner:德龙钢铁有限公司

Double-slag process for smelting ultralow-phosphorus and low-carbon steel in combined-blown converter

The invention relates to a double-slag process for smelting ultralow-phosphorus and low-carbon steel in a combined-blown converter. The double-slag process comprises the following steps: (1) molten iron and waste steel are put into the converter according to the molten iron ratio of 85% to 90%; (2) bottom blowing gas adopts nitrogen and argon in a switched manner, the nitrogen is adopted before the supply of 80% of oxygen, and the argon is automatically switched after the supply of 80%t of oxygen; (3) at the first stage of blowing, the flow rate of the oxygen adopts 20000-21000 Nm<3> / h within the first minute, and a normalized slag lance position of 1800-2000 mm is adopted; after the start of blowing for one minute, the flow rate of the oxygen is adjusted to be 13000 Nm<3> / h; (4) a de-slagging moment is set as 8-10 minutes after the start of blowing; (5) at the second stage of blowing, blowing is started when the high lance position is 1700-1800 mm, the flow rate of the oxygen is adjusted to be 18000 Nm<3> / h, and the converter end point control target is that carbon is less than 0.05%, and phosphorus is less than 0.004%. According to the double-slag process provided by the invention, the converter end point phosphorus can be stably controlled to be less than or equal to 0.004 percent, so that the target of smelting the ultralow-phosphorus and low-carbon steel by a single converter is stably realized.

Owner:NANJING IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com