Microwave heating, solid state reduction and gaseous dephosphorization method for manganese ore powder

A technology of microwave heating and manganese ore powder is applied in the direction of improving process efficiency, which can solve the problems of polluting the environment, not being suitable for large-scale production, and long dephosphorization time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] The present invention will be further described below in conjunction with accompanying drawing:

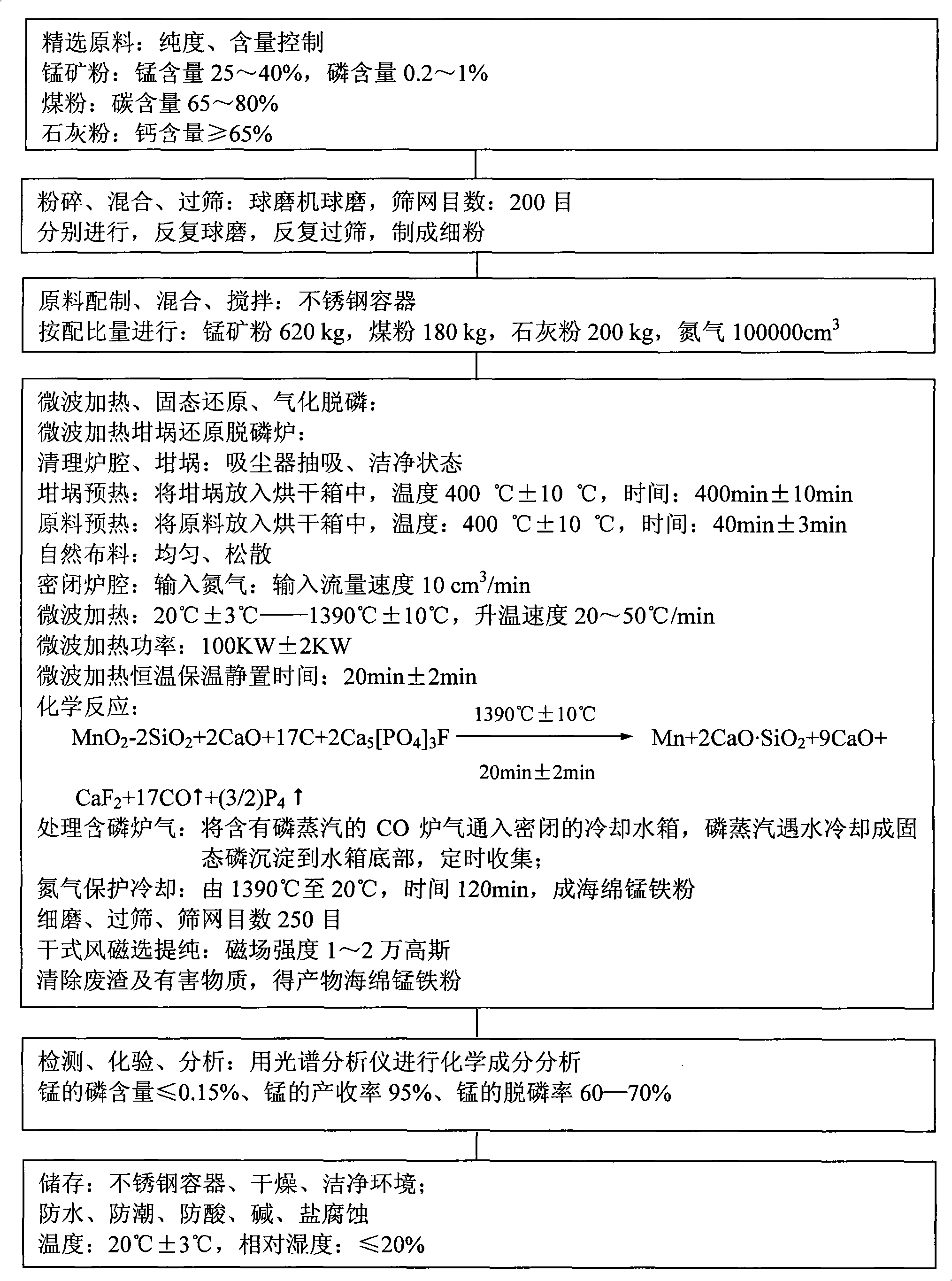

[0094] figure 1 Shown is the process flow chart of microwave heating, solid state reduction, and gasification dephosphorization of manganese ore powder, which must be carried out in strict accordance with the process flow and operated in sequence.

[0095] The chemical raw materials used must be strictly selected, finely ground, sieved, and repeatedly cycled, and the particle size of the fine powder must be strictly controlled, because the carbon monoxide reduction and gasification dephosphorization of manganese ore powder are carried out simultaneously during the preparation process , so the raw material powder must be refined, and the mesh size of the screen should be 200-250 mesh, which is conducive to the solid-state reduction of manganese and gasification dephosphorization treatment.

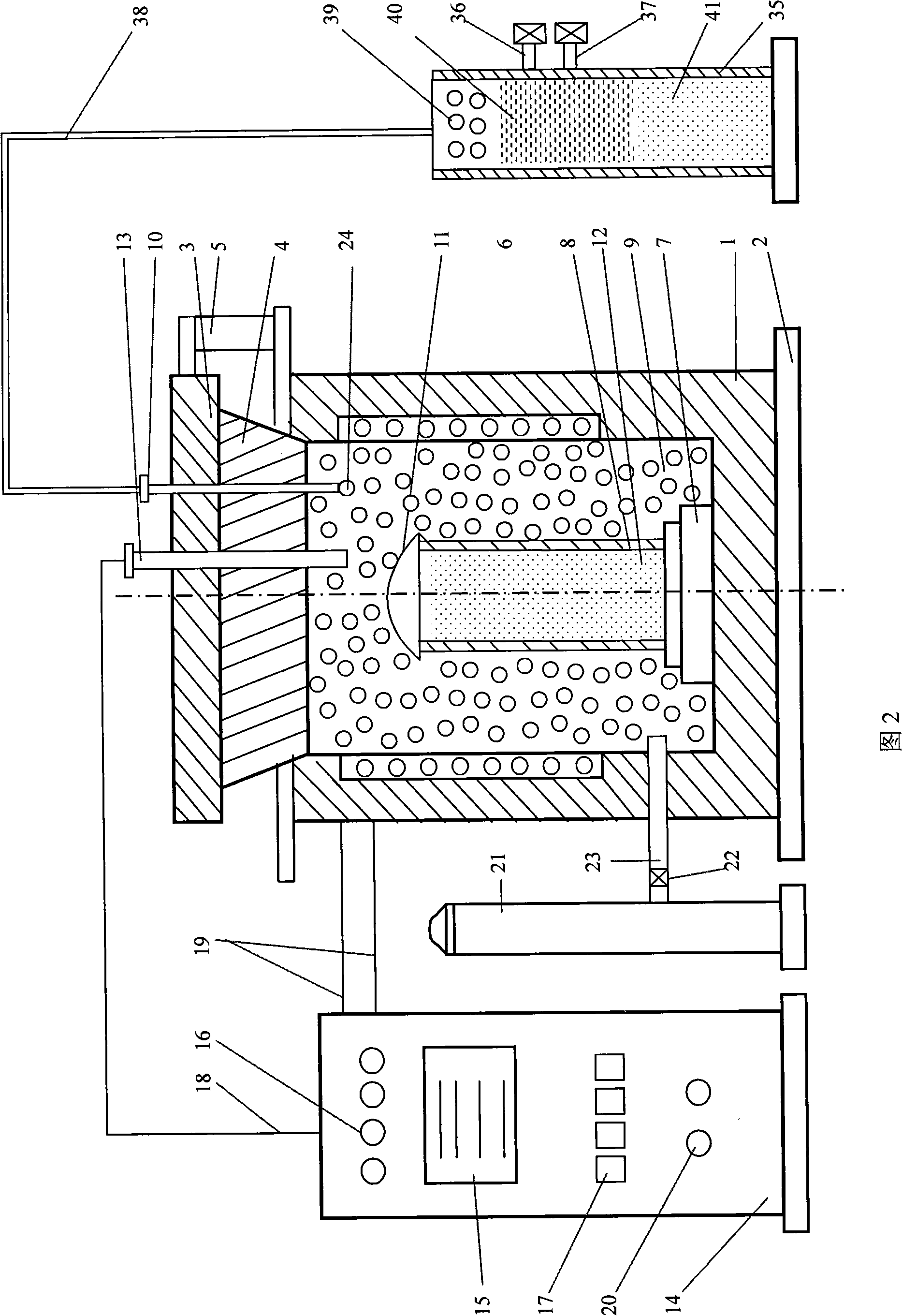

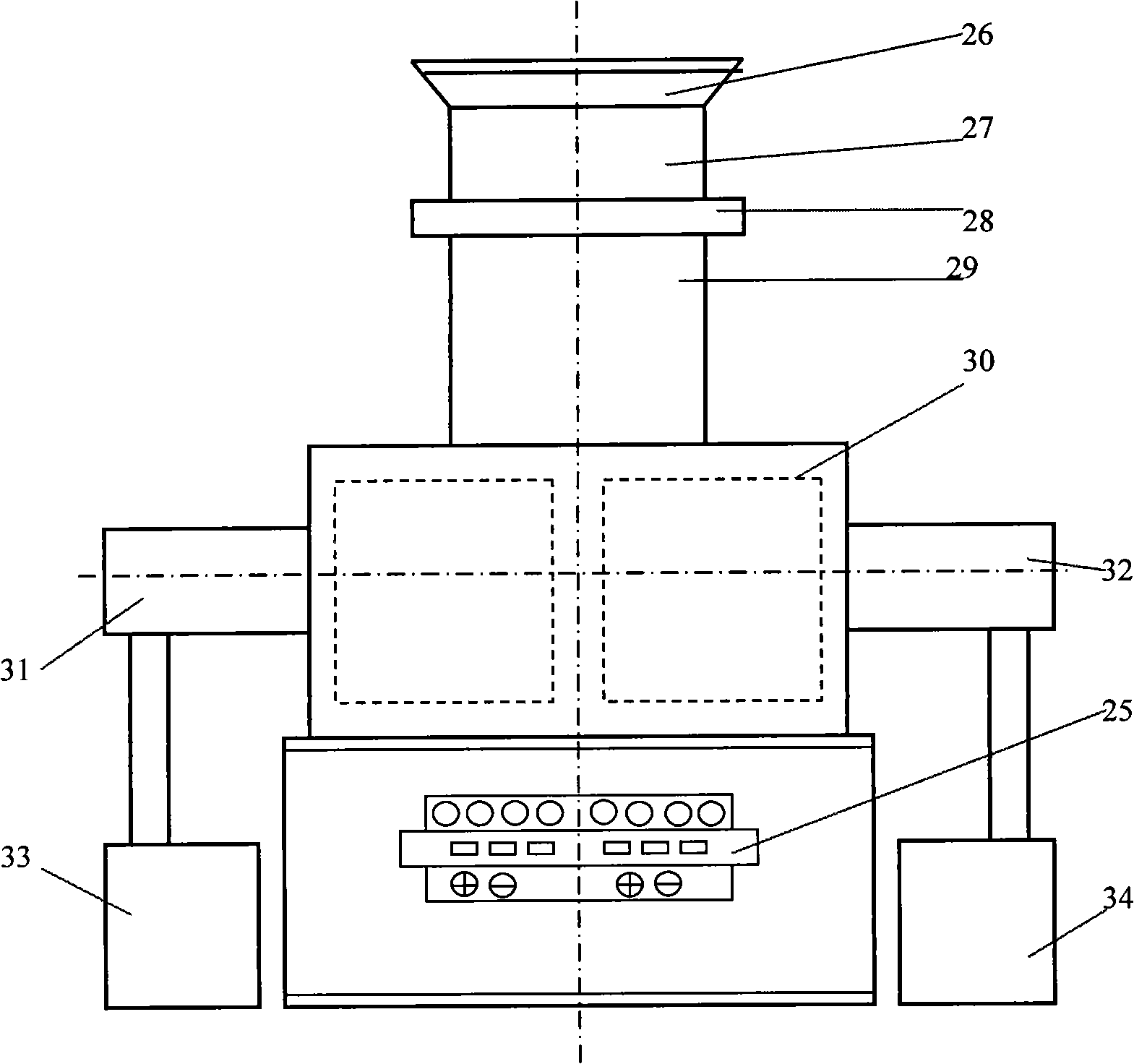

[0096] The microwave heating reduction dephosphorization furnace must be strictly s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com