Multi-element-injection efficient dephosphorization method and device for dephosphorization converter gas mass energy conversion cycle

A dephosphorization converter and mass-energy conversion technology, which is applied in the manufacture of converters, energy efficiency improvement, waste gas treatment, etc., can solve the problems of low calorific value of gas, no economic value of recycling, pollution of the environment, etc., and achieve improved dephosphorization Effect of rate, favorable thermodynamic and kinetic conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

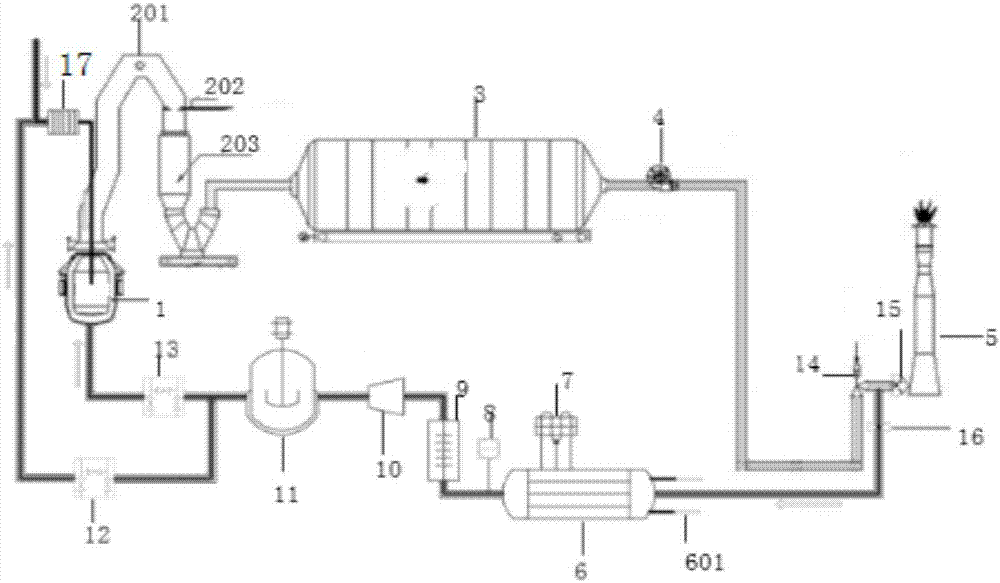

[0034] A method for efficient dephosphorization of dephosphorized converter gas gas-energy conversion cycle multiple injection, said method is:

[0035] In the double steelmaking dephosphorization converter, the gas released from the dephosphorization converter is cooled and dedusted, and then burned in the combustion chamber with a combustion accelerant to convert the CO component in the released gas into CO 2 , the combustion chamber includes a combustion aid nozzle and an ignition device. The lining of the combustion chamber is made of refractory materials, and the shell is made of vaporization cooling pipes. Can convert gas;

[0036] After the mass-energy conversion gas is cooled and pressurized, part of it enters the dephosphorization converter bottom blowing system as the bottom blowing gas to realize the mass-energy conversion gas and bottom blowing stirring, and the other part mixes with oxygen and enters the dephosphorization converter top blowing system as the top bl...

Embodiment 2

[0062] This embodiment adopts the method and device in embodiment 1, and the specific conditions are:

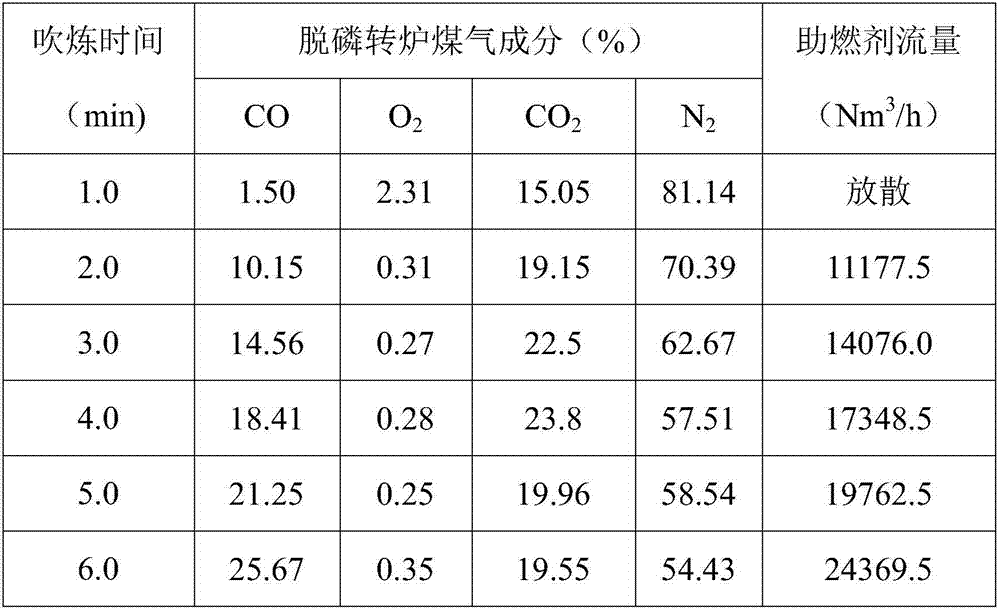

[0063] For the 300t dephosphorization converter, the change of gas content in the blowing process is shown in Table 1. Gas instantaneous flow rate is 160000-190000Nm 3 / h, the gas passes through the vaporization cooling flue and the dry dust removal system to cool down and remove dust, then enters the combustion chamber through the release pipe, and uses 8 combustion nozzles to spray the combustion aid. Show.

[0064] Table 1 Dephosphorization converter gas and combustion aid flow rate

[0065]

[0066] Use the compressor to pressurize the mass-energy conversion gas to above 2.2MPa and store it in the buffer device, the average composition is CO 2 : 39%, N 2 : 59.25%, the rest is a small amount of residual gas. The mass-energy conversion gas is blown into the multi-component gas main pipe by jetting, and passes through the gas mixing device with oxygen, and the mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com