Patents

Literature

3138 results about "Gas mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modular pressure swing adsorption with energy recovery

InactiveUS6051050AHigh-frequency operationCompact equipmentIsotope separationRefluxProcess engineering

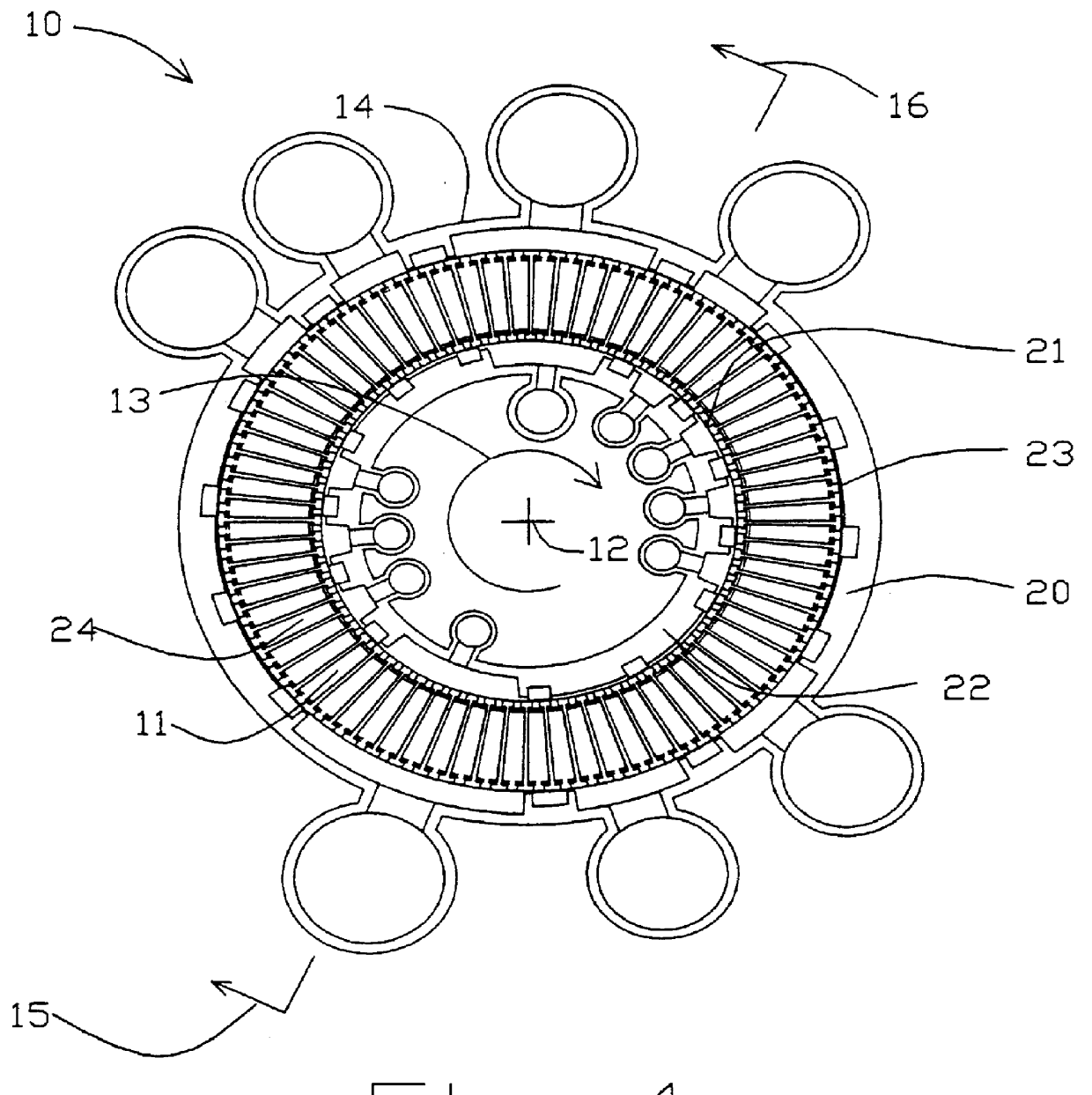

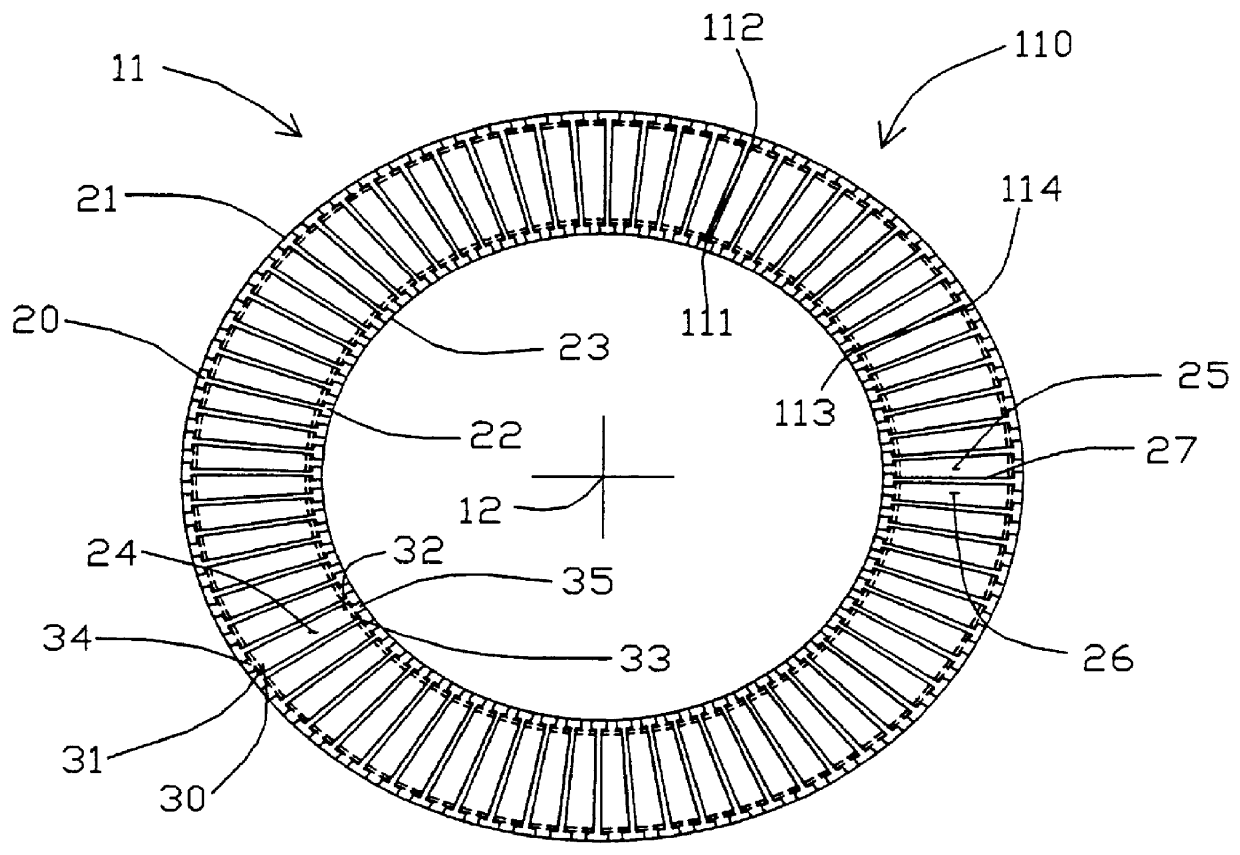

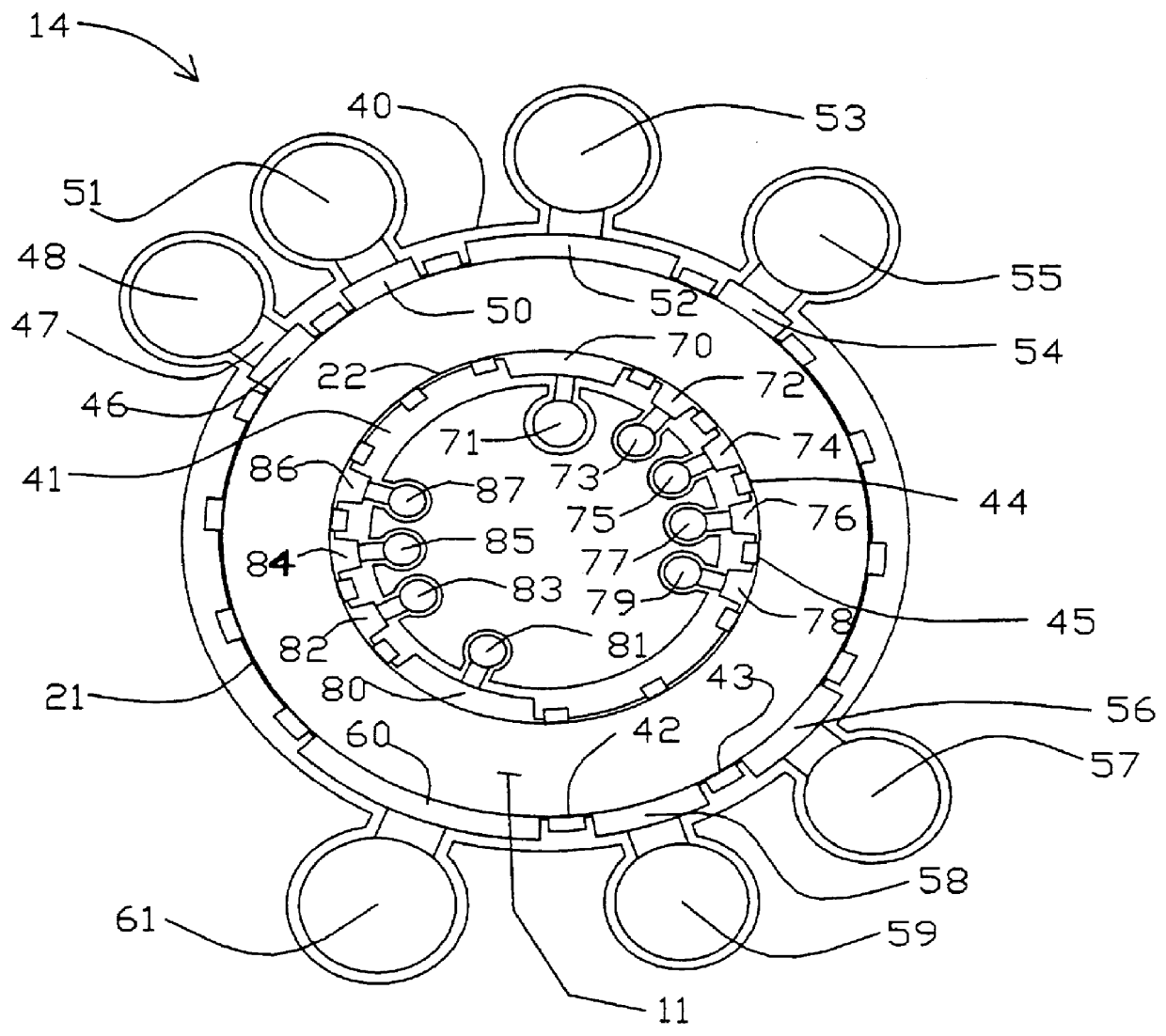

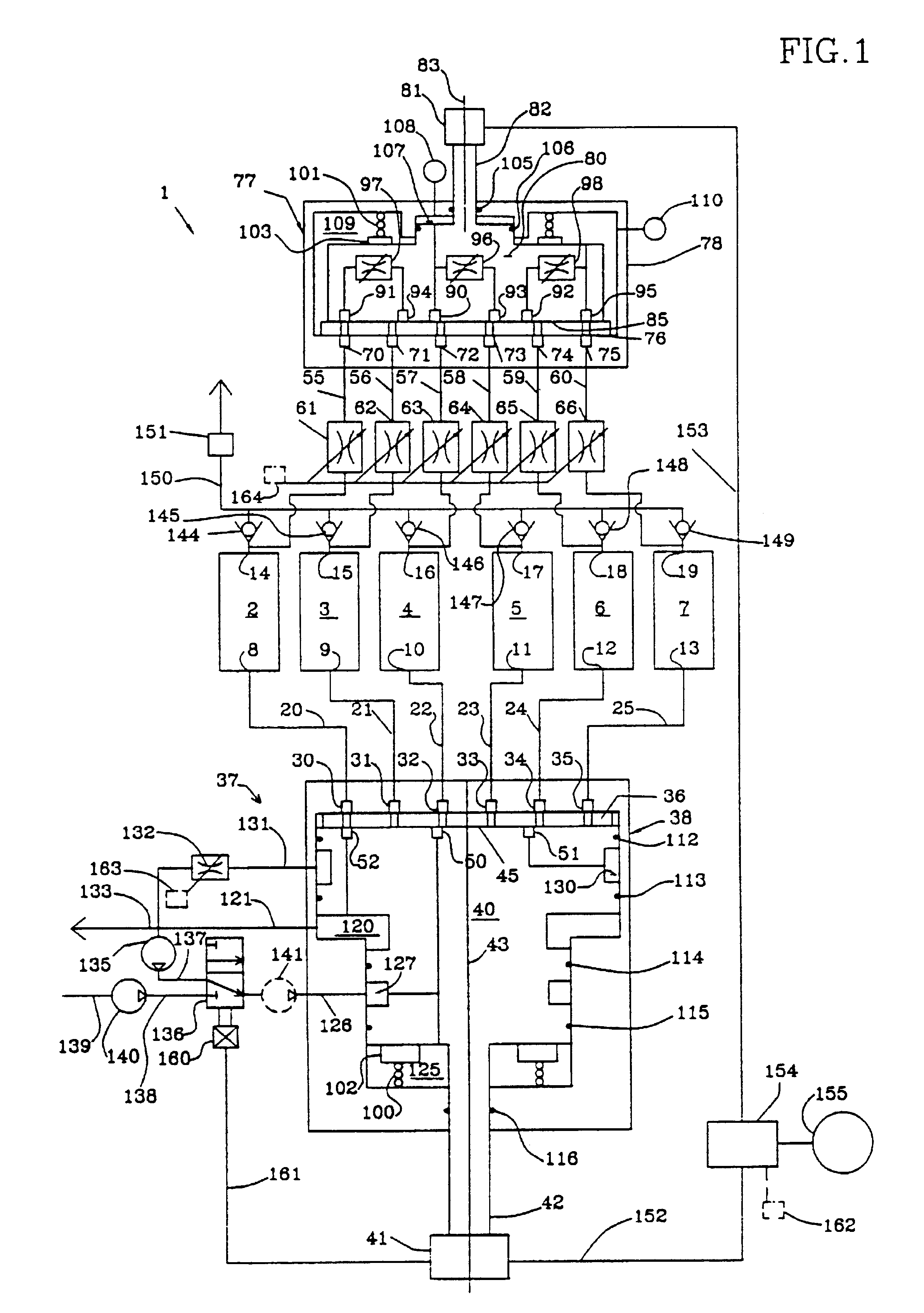

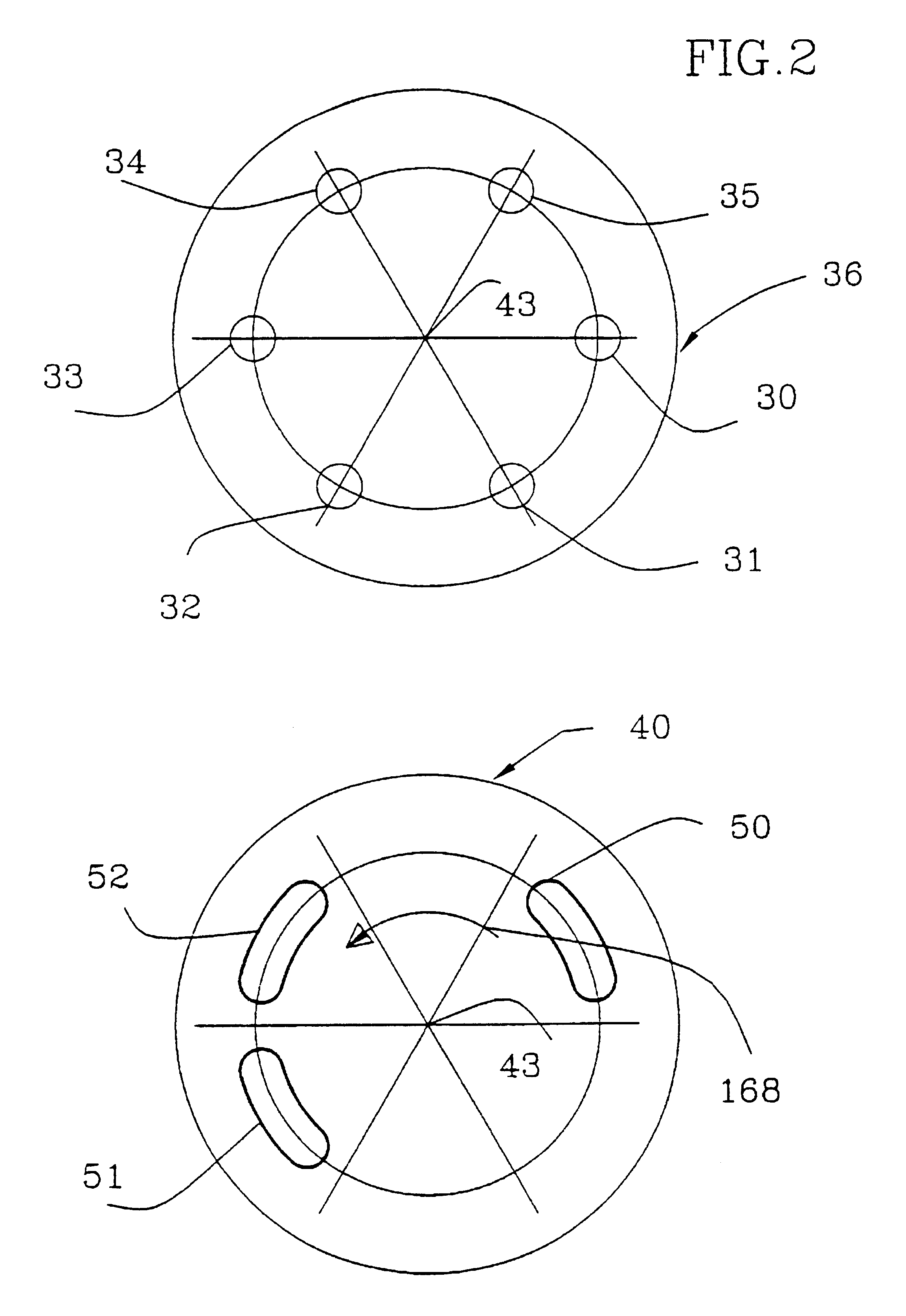

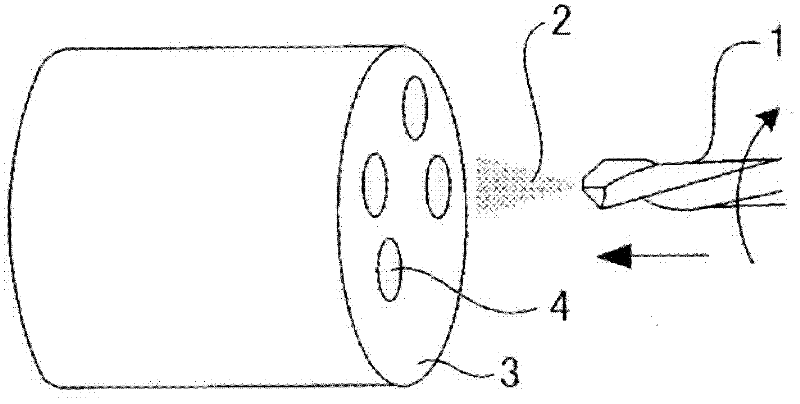

Pressure swing adsorption (PSA) separation of a feed gas mixture is performed within an apparatus having typically a single prime mover powering a feed compressor for one or multiple rotary PSA modules in parallel, each module including a rotor with a large number of angularly spaced adsorber elements, with valve surfaces between the rotor and a stator so that individual adsorber elements are opened to compartments for staged pressurization and blowdown, with thermally boosted energy recovery from staged expansion of countercurrent blowdown and light reflux gases, and a plurality of adsorber elements opened at any instant to each compartment so that each compressor and expander stage operates under substantially steady conditions of flow and pressure.

Owner:AIR PROD & CHEM INC

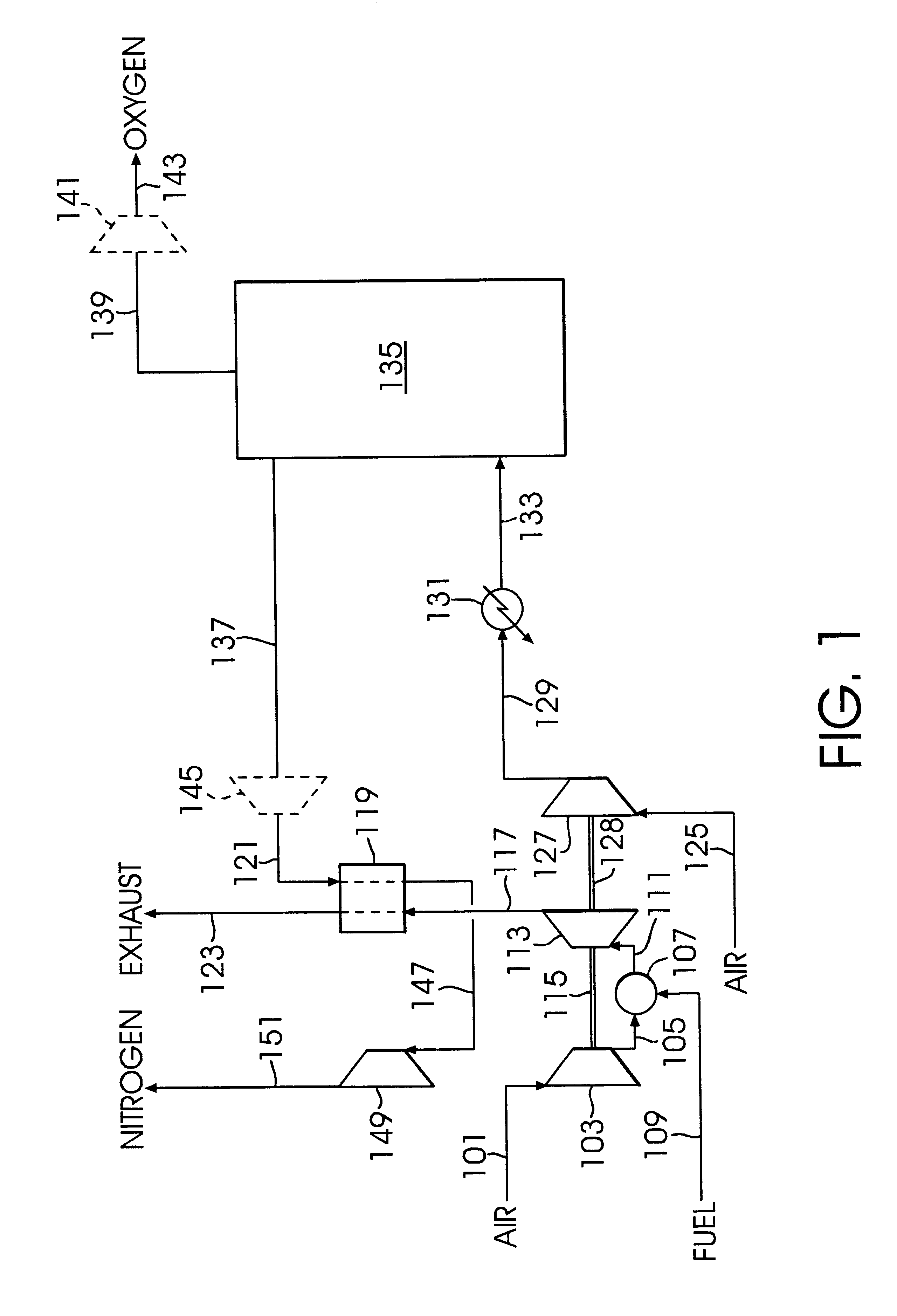

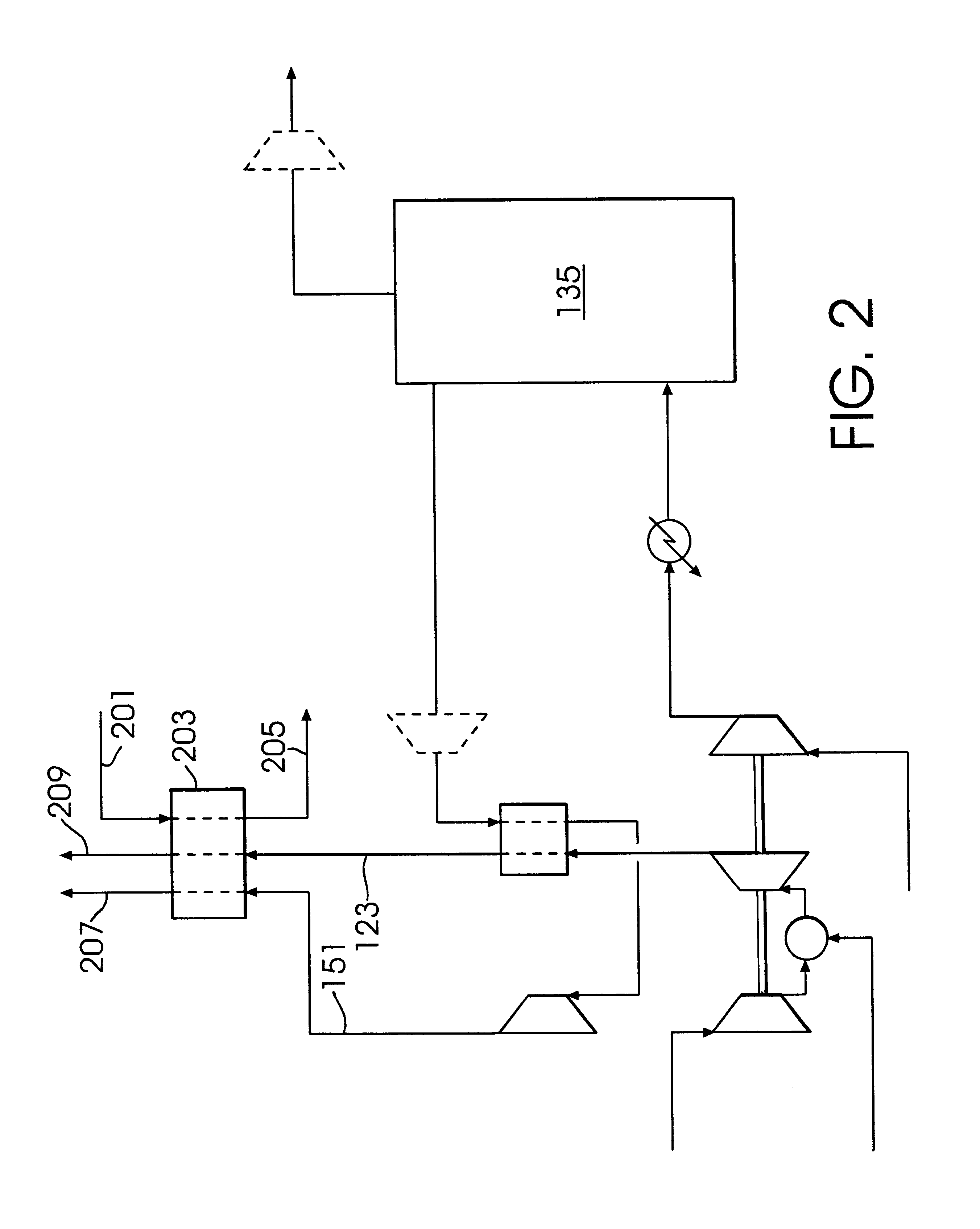

Air separation process integrated with gas turbine combustion engine driver

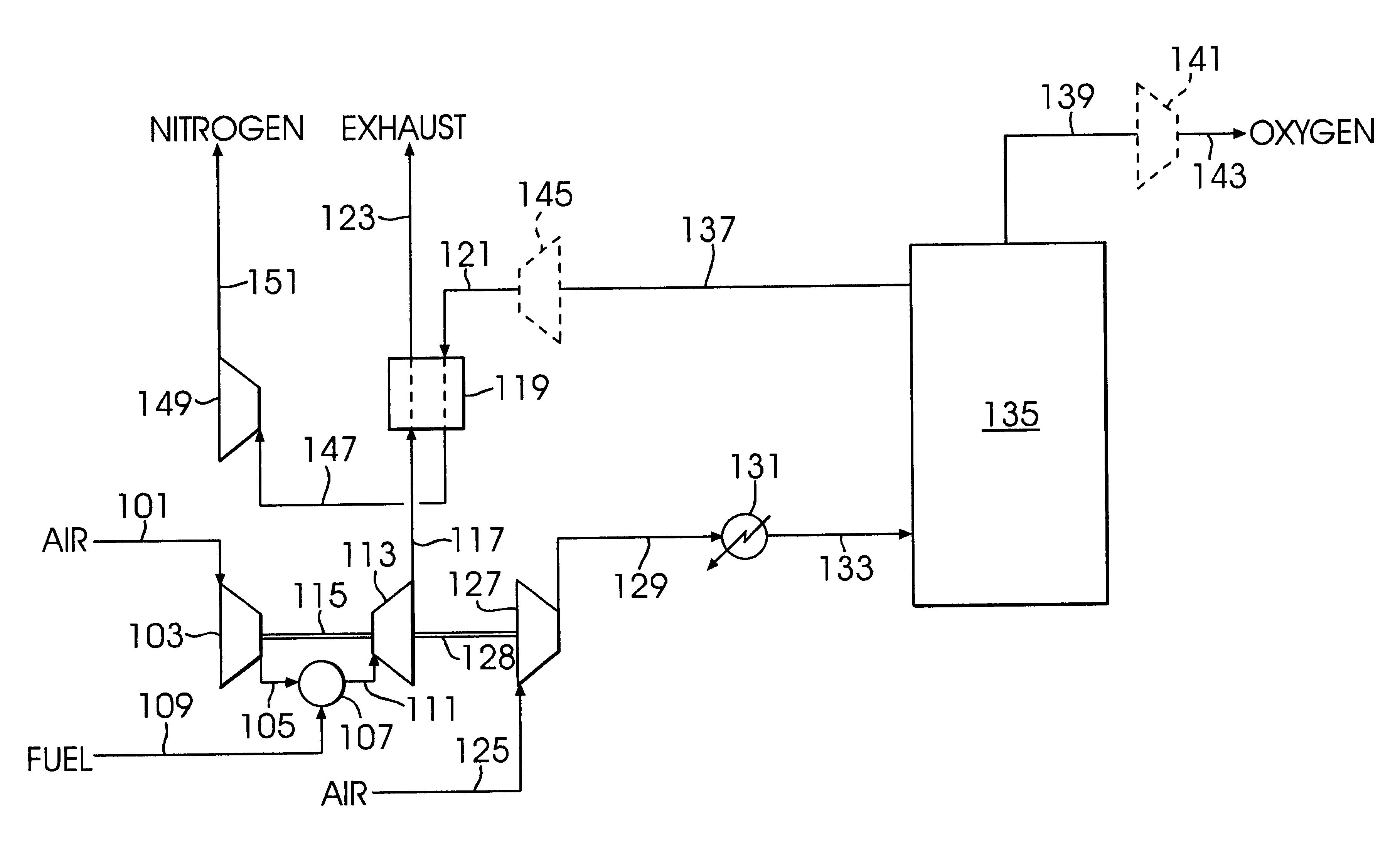

A method for the separation of a feed gas mixture comprising oxygen and nitrogen in which an oxidant gas and fuel are combusted in a combustion engine to generate shaft work and a hot exhaust gas, the feed gas mixture comprising oxygen and nitrogen is compressed, and the resulting compressed feed gas mixture is separated into two or more product gas streams with differing compositions. The shaft work of the combustion engine is utilized to provide at least a portion of the work required for compressing the feed gas mixture, one of the product gas streams by is heated by indirect heat exchange with the hot exhaust gas from the combustion engine, and the resulting heated product gas is work expanded to generate shaft work and yield an expanded product gas stream. The combustion engine may be a gas turbine combustion engine.

Owner:AIR PROD & CHEM INC

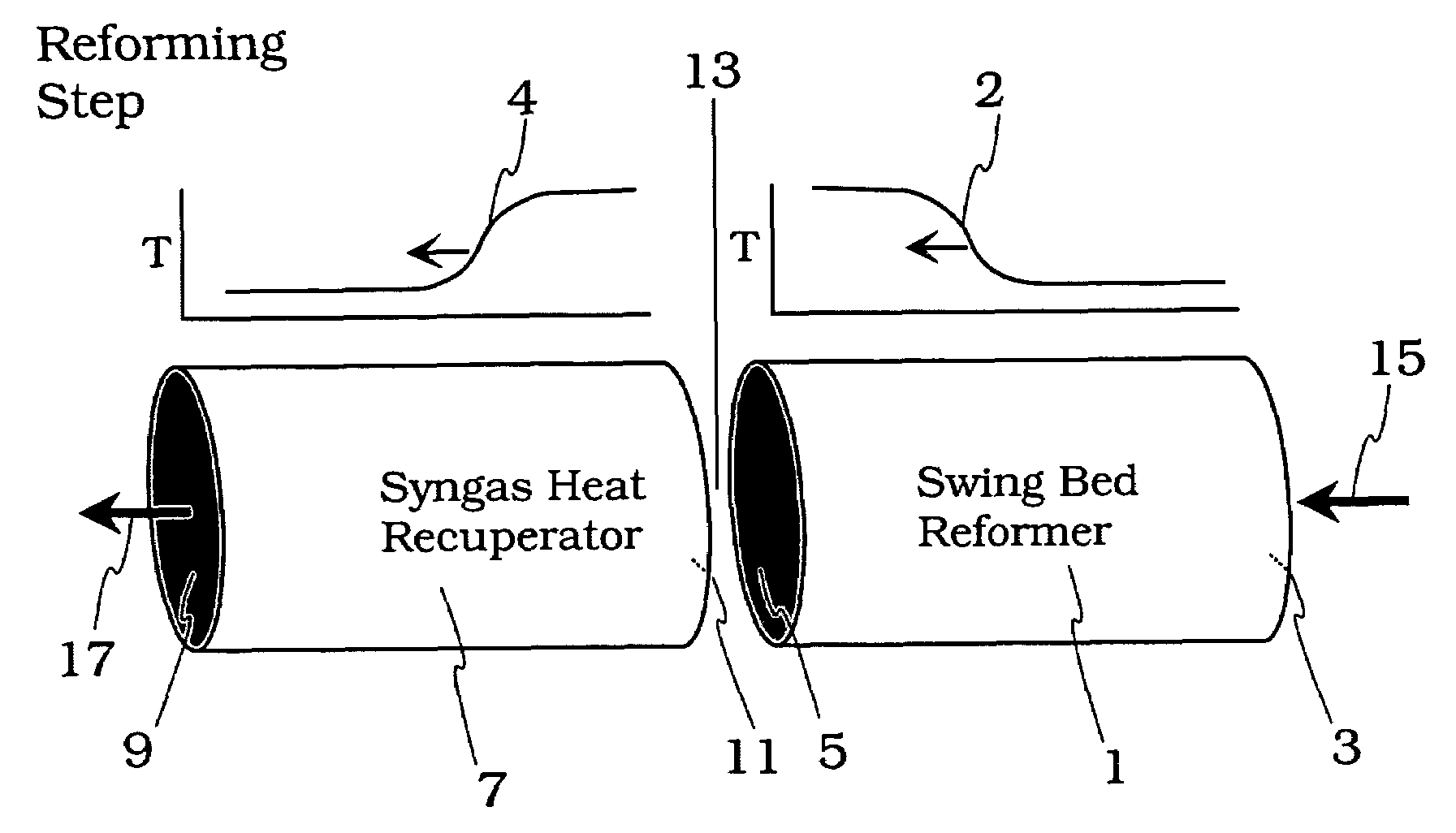

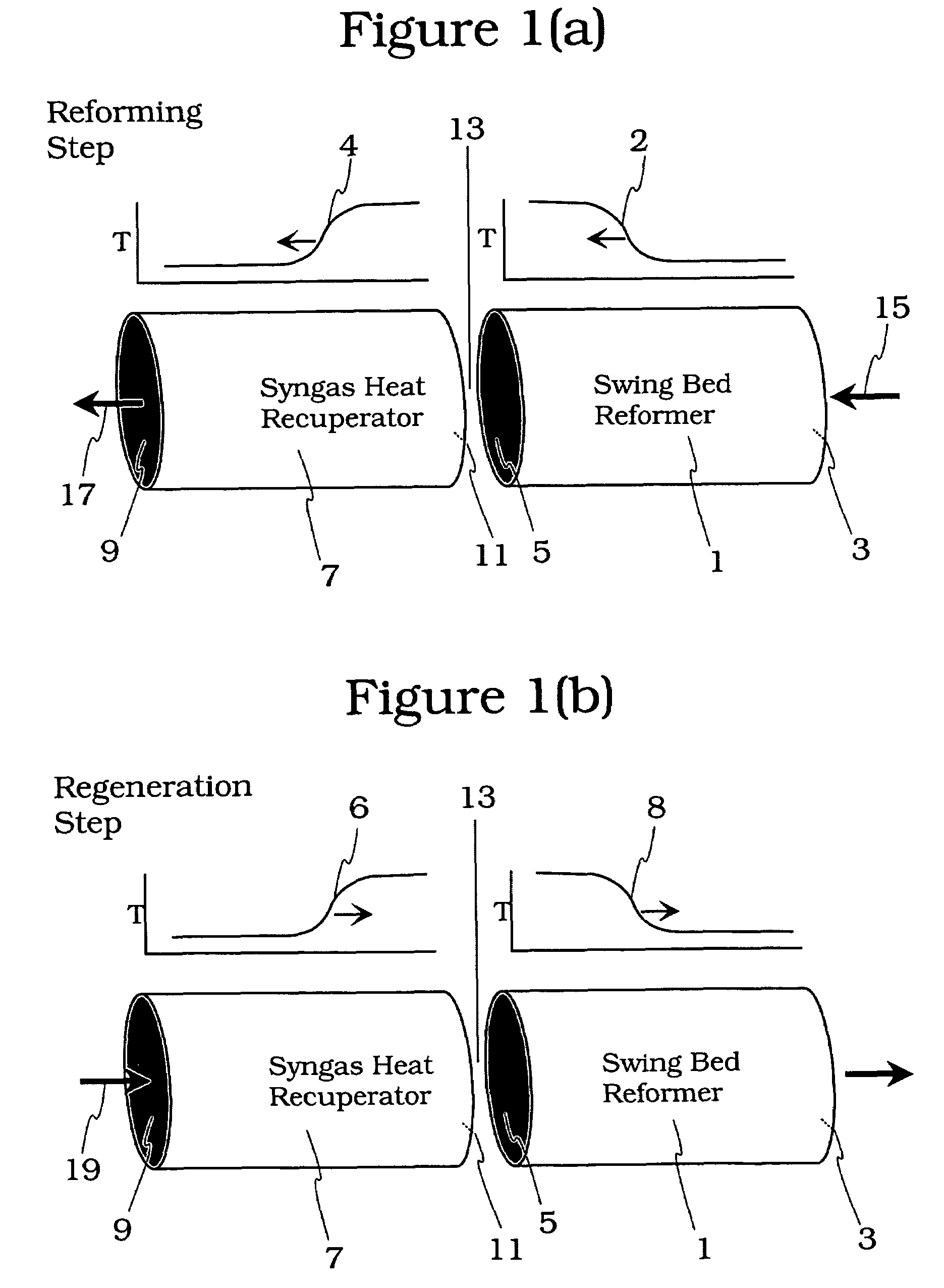

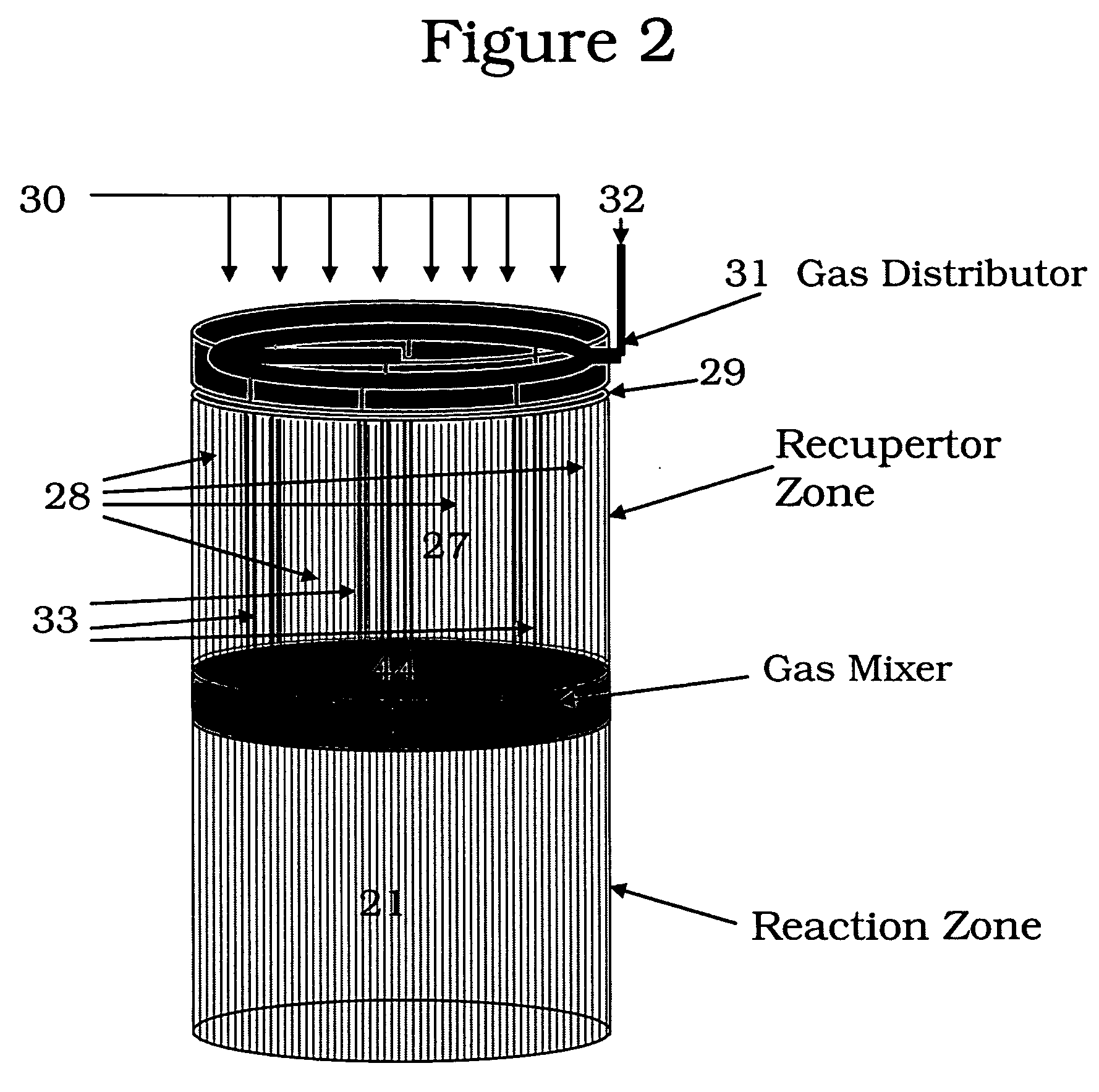

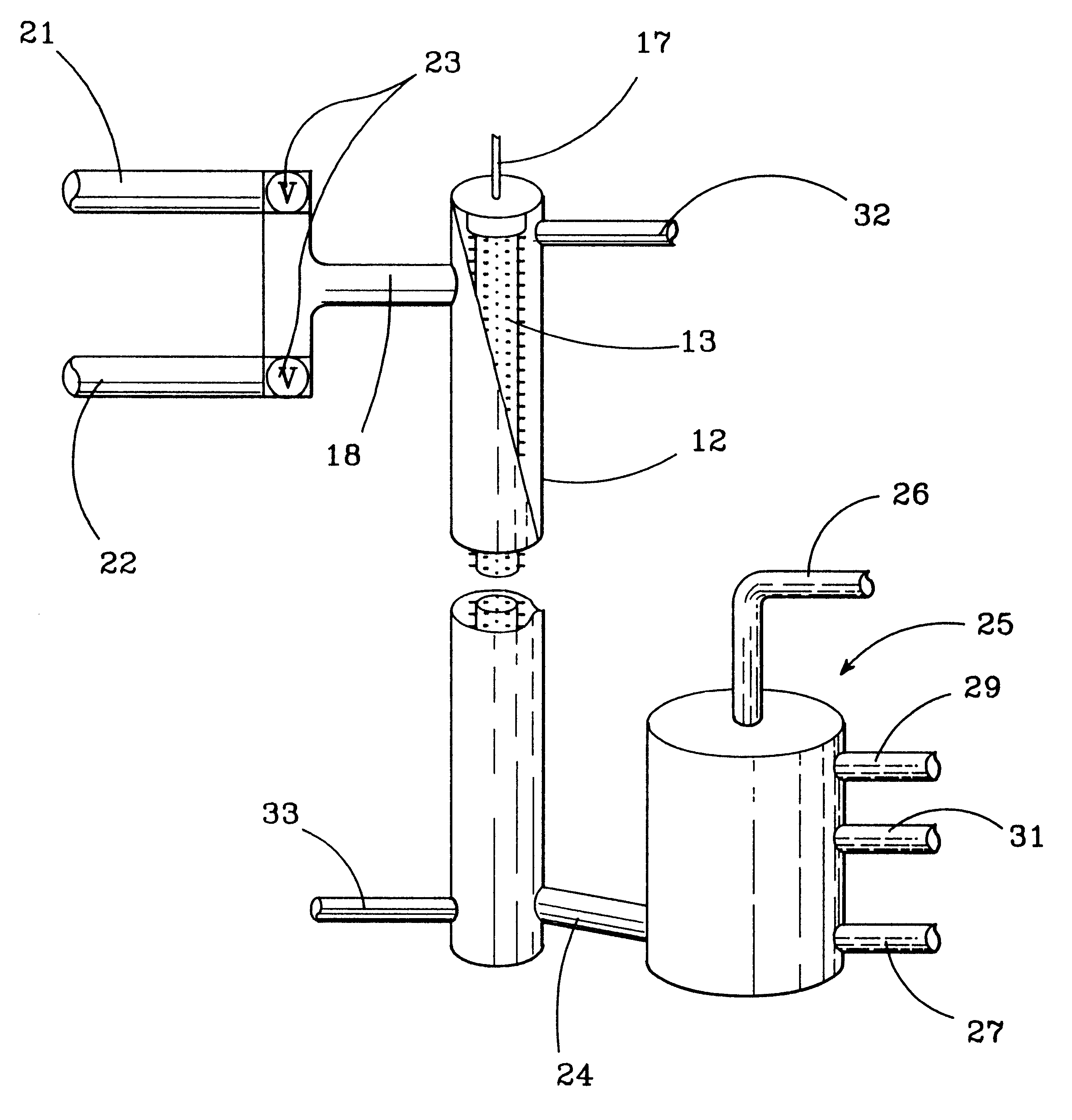

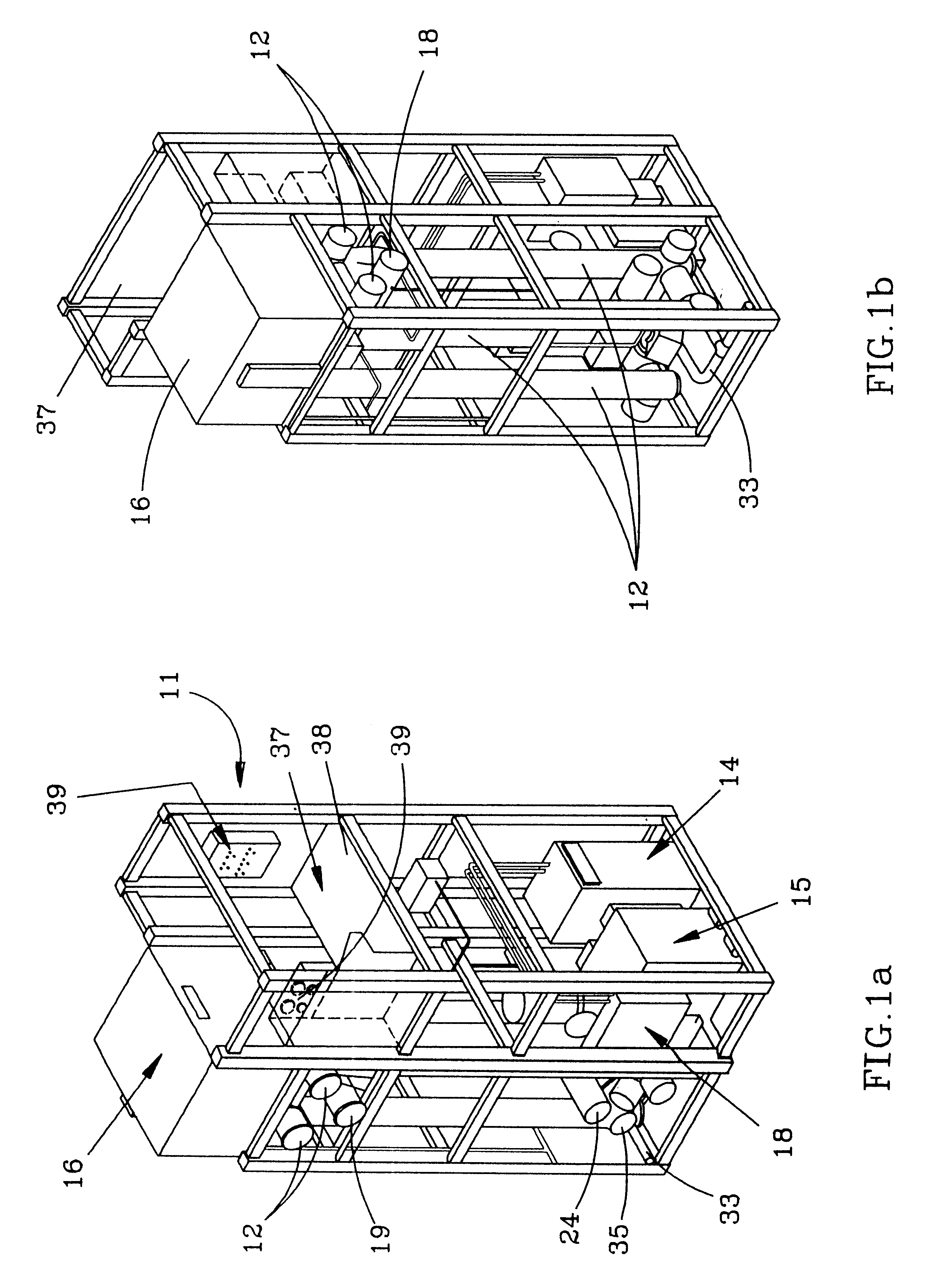

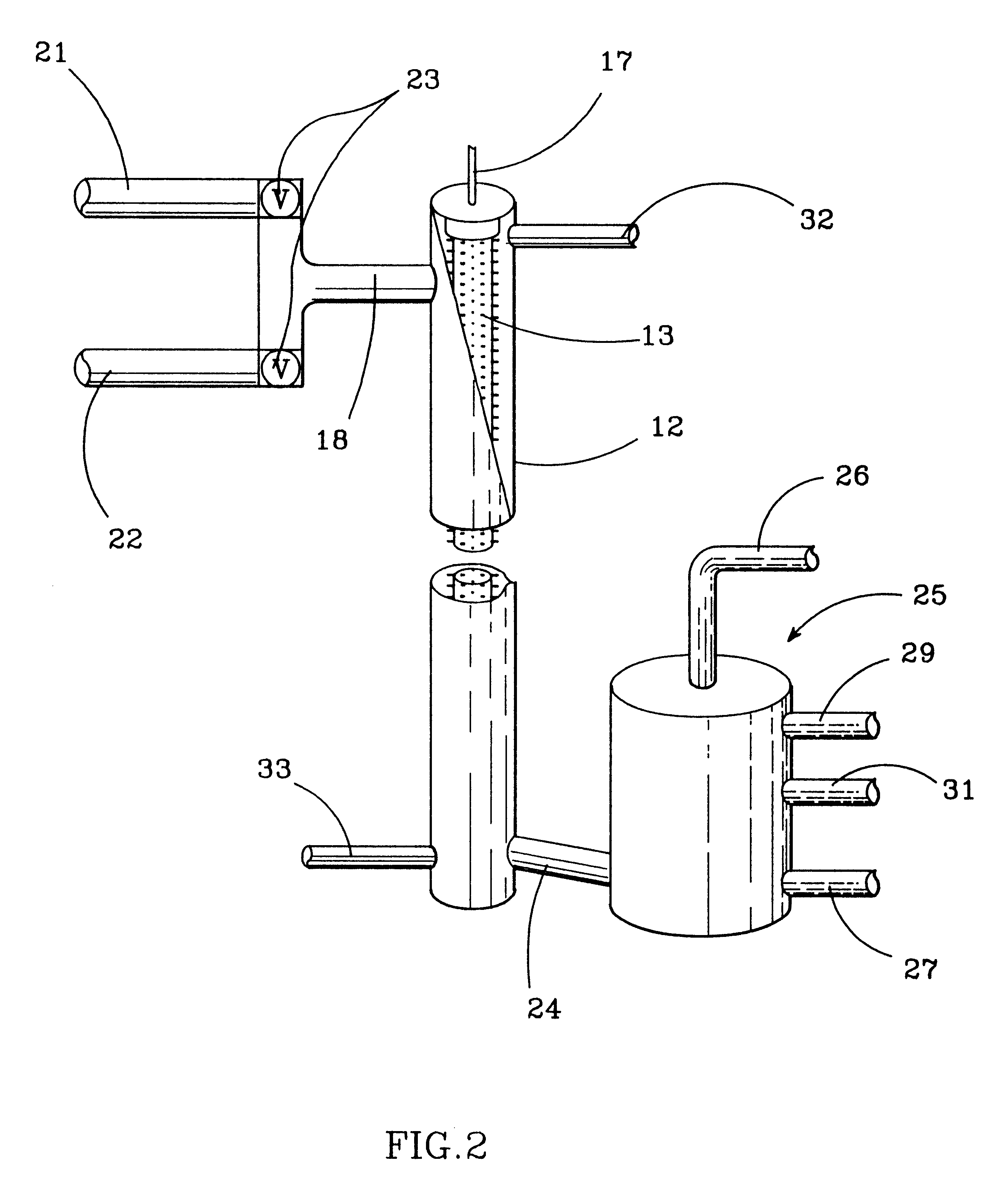

Controlled combustion for regenerative reactors

The overall efficiency of a regenerative bed reverse flow reactor system is increased where the location of the exothermic reaction used for regeneration is suitably controlled. The present invention provides a method and apparatus for controlling the combustion to improve the thermal efficiency of bed regeneration in a cyclic reaction / regeneration processes. The process for thermal regeneration of a regenerative reactor bed entails(a) supplying the first reactant through a first channel means in a first regenerative bed and supplying at least a second reactant through a second channel means in the first regenerative bed,(b) combining said first and second reactants by a gas mixing means situated at an exit of the first regenerative bed and reacting the combined gas to produce a heated reaction product,(c) passing the heated reaction product through a second regenerative bed thereby transferring heat from the reaction product to the second regenerative bed.

Owner:EXXON RES & ENG CO

Electrostatic method and means for removing contaminants from gases

InactiveUS6224653B1Easy to operateHigh voltageGas treatmentDispersed particle separationHigh concentrationCorona discharge

An electrical apparatus includes a reaction chamber. A stream of contaminated gasses flows through the chamber. An elongated coronating electrode is positioned in the reaction chamber for producing a corona discharge within the chamber. A multi-stage Fitch generator connected to the electrode produces a high level, rapidly pulsating voltage in the electrode. Controlled amounts of an inert gas or inert gas-air mixture are combined with the contaminated gases to provide a high concentration of inert gas in the reaction chamber. In the inert gas-enriched atmosphere, the pulsating corona discharge produces a high concentration of metastable intermediates that greatly increase the rate of chemical conversion of the contaminants. Switching circuitry allows the pulsating voltage output of the Fitch generator to be superimposed on a constant direct current voltage in the electrode, setting up an electrostatic field in the reaction chamber for removing conversion byproducts from the gas stream.

Owner:PULSATRON TECH CORP

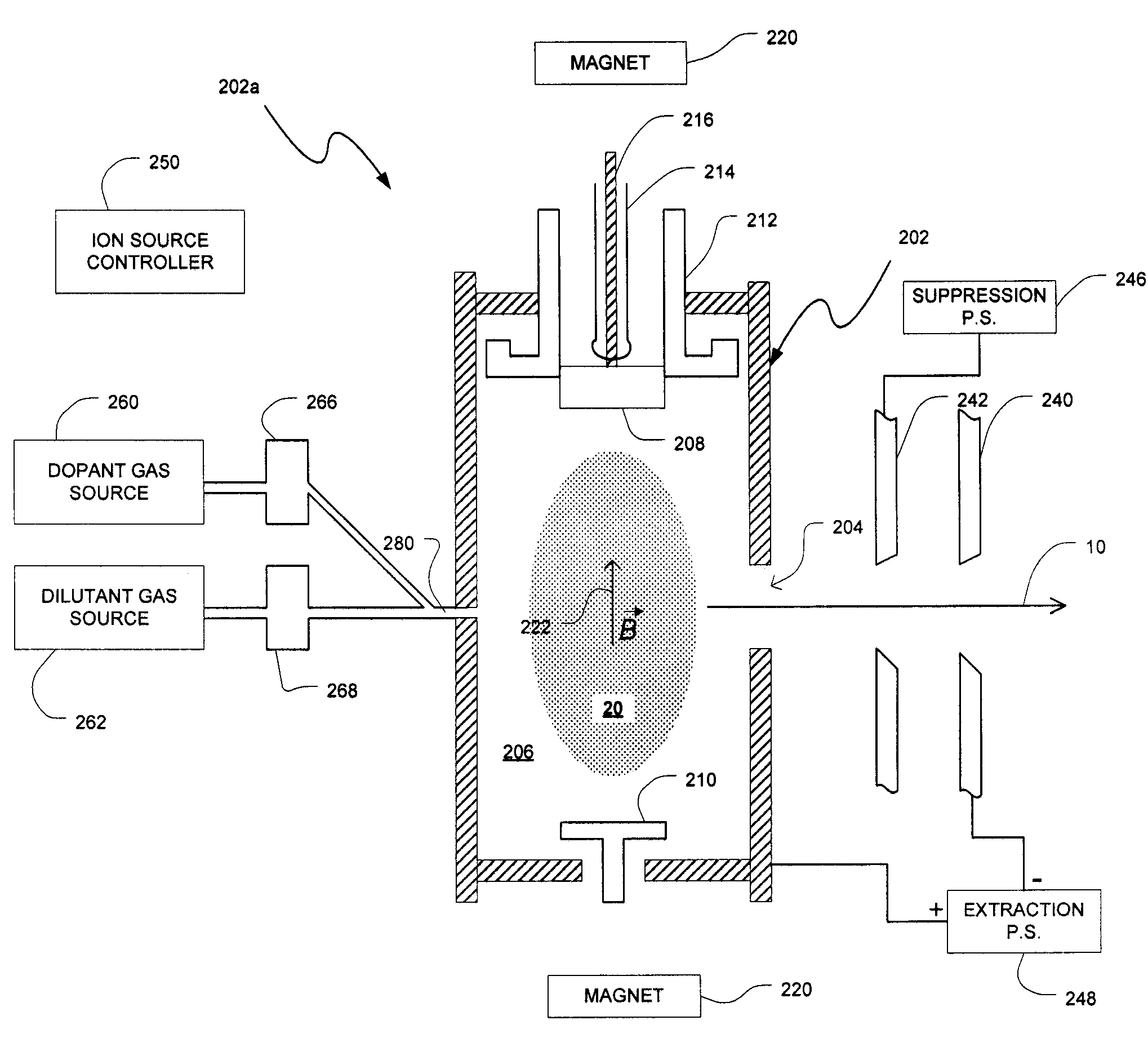

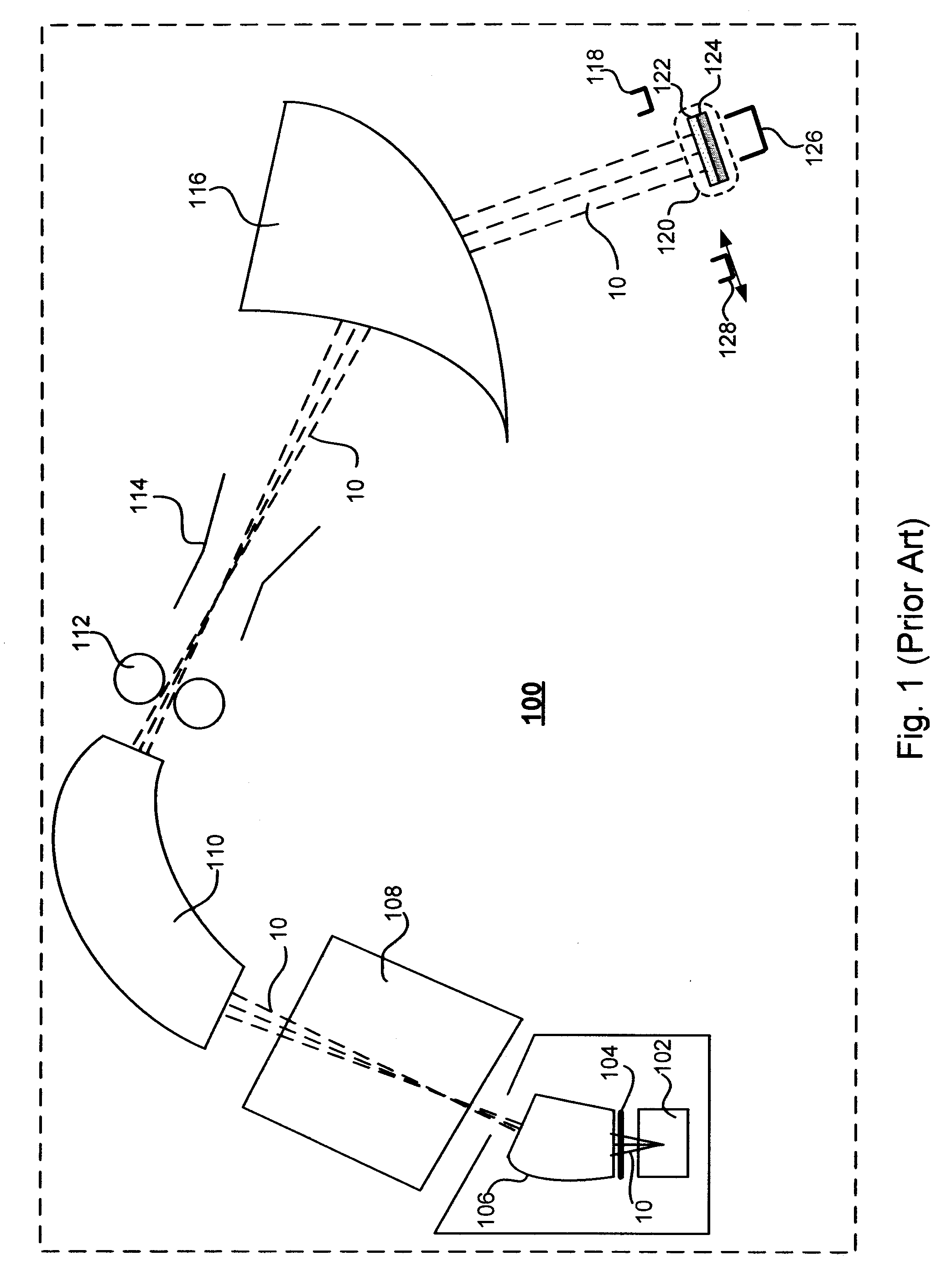

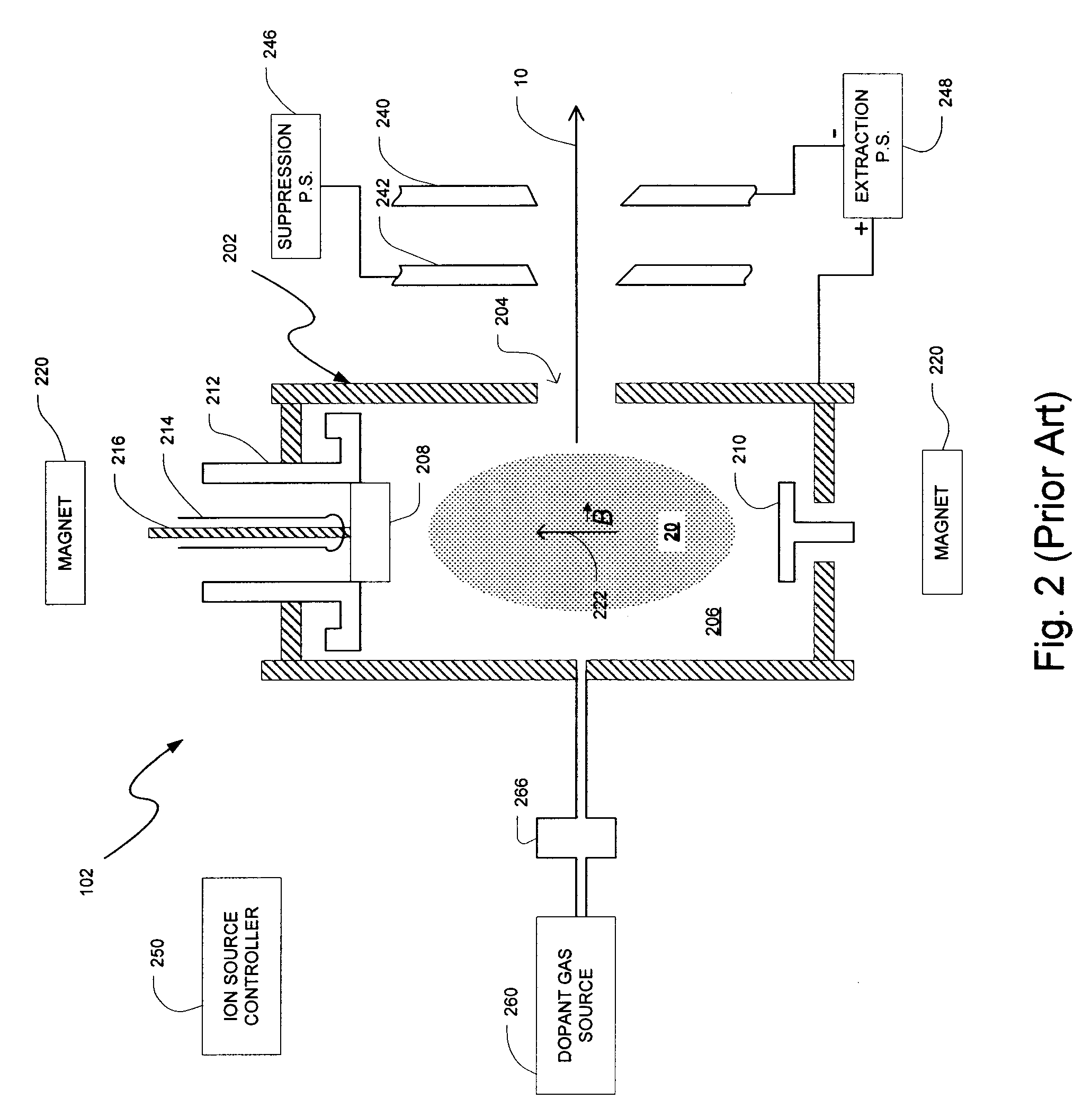

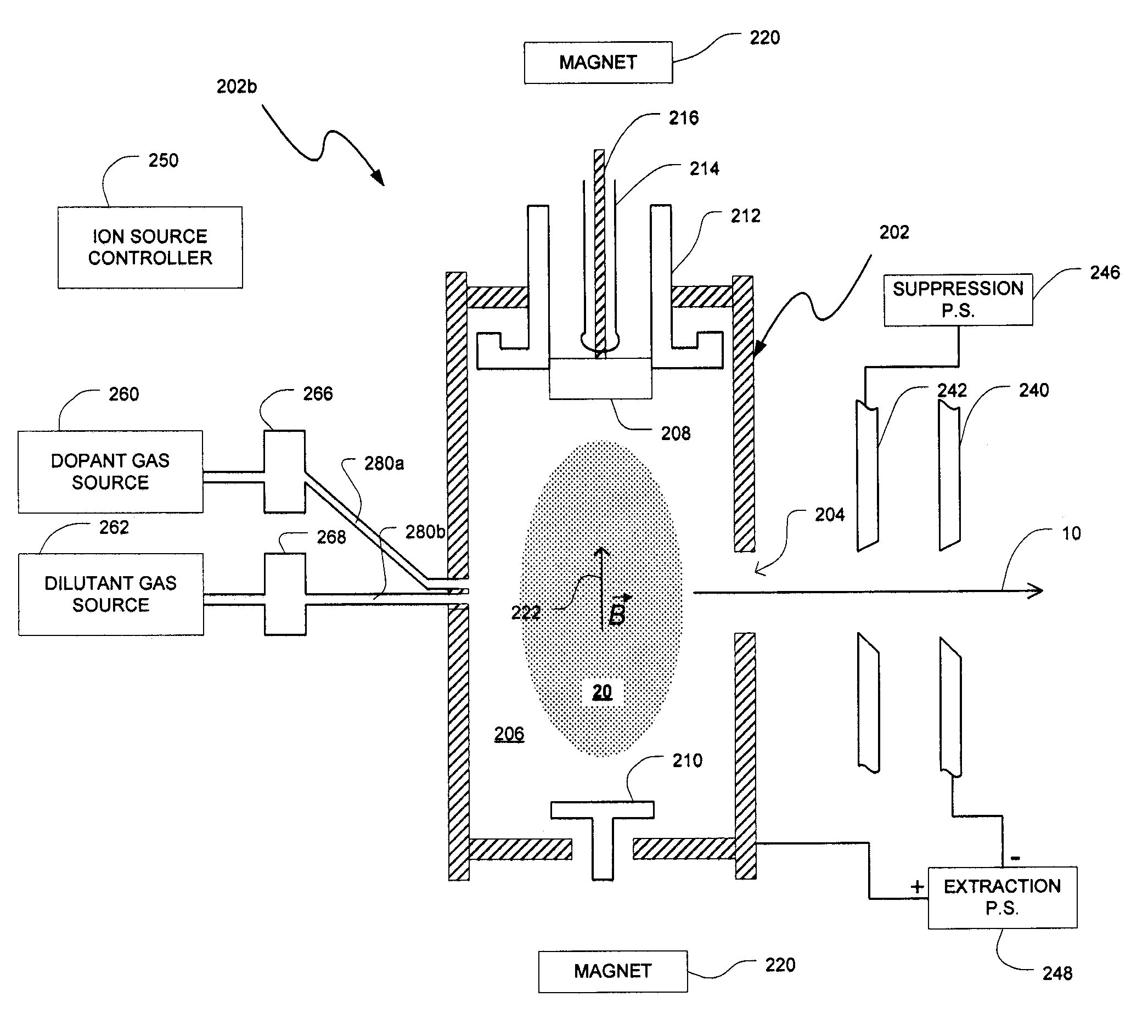

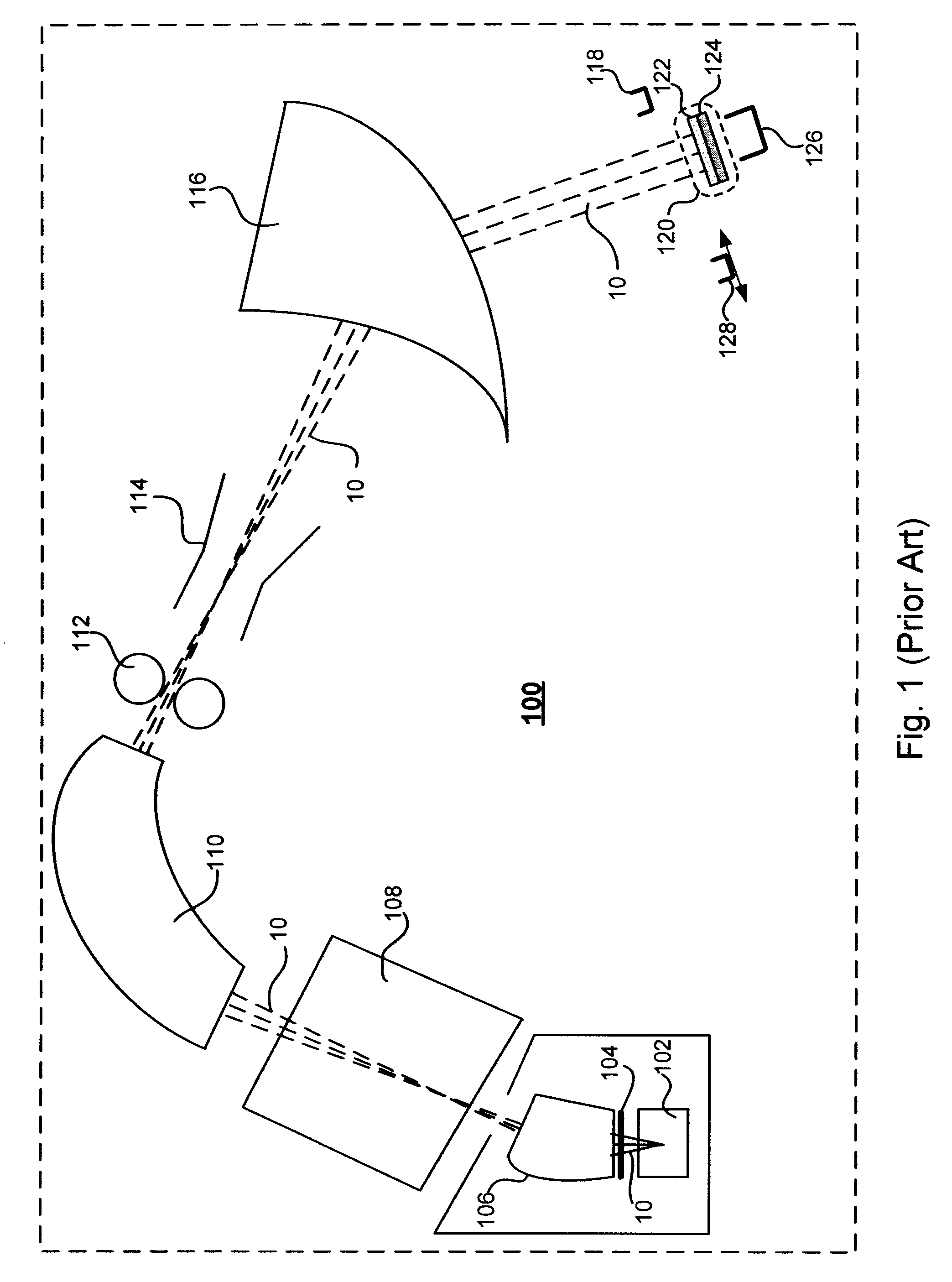

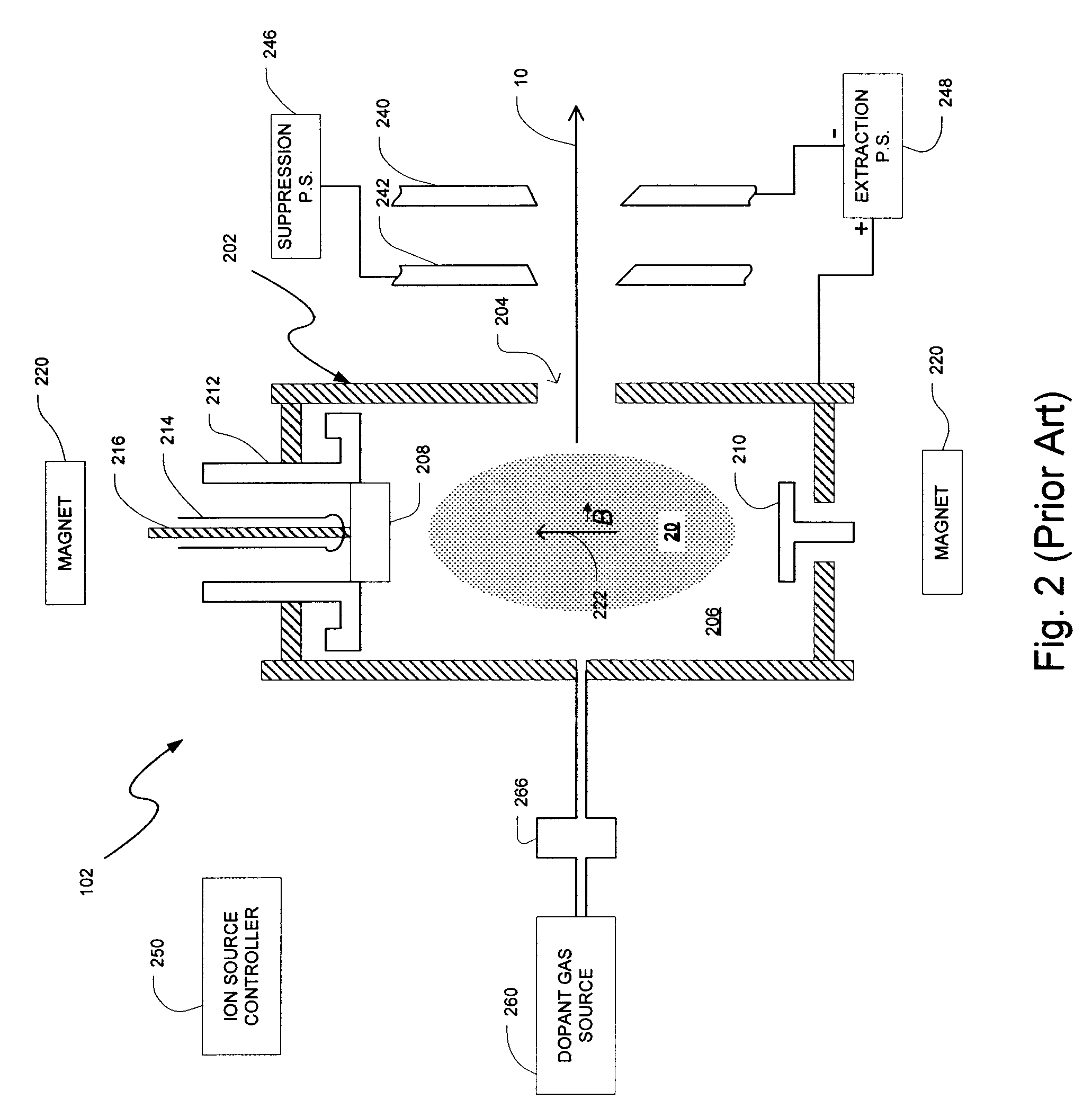

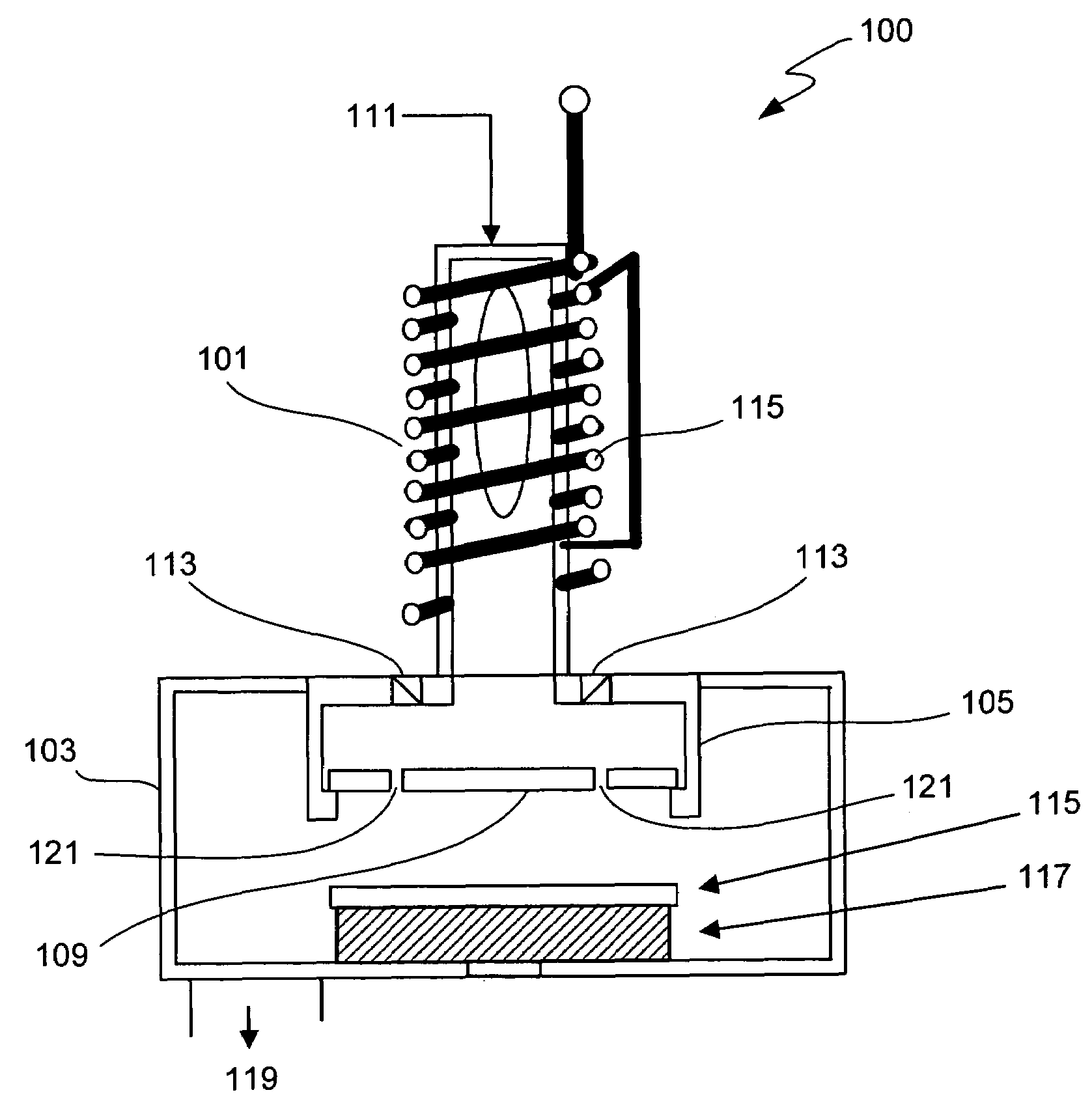

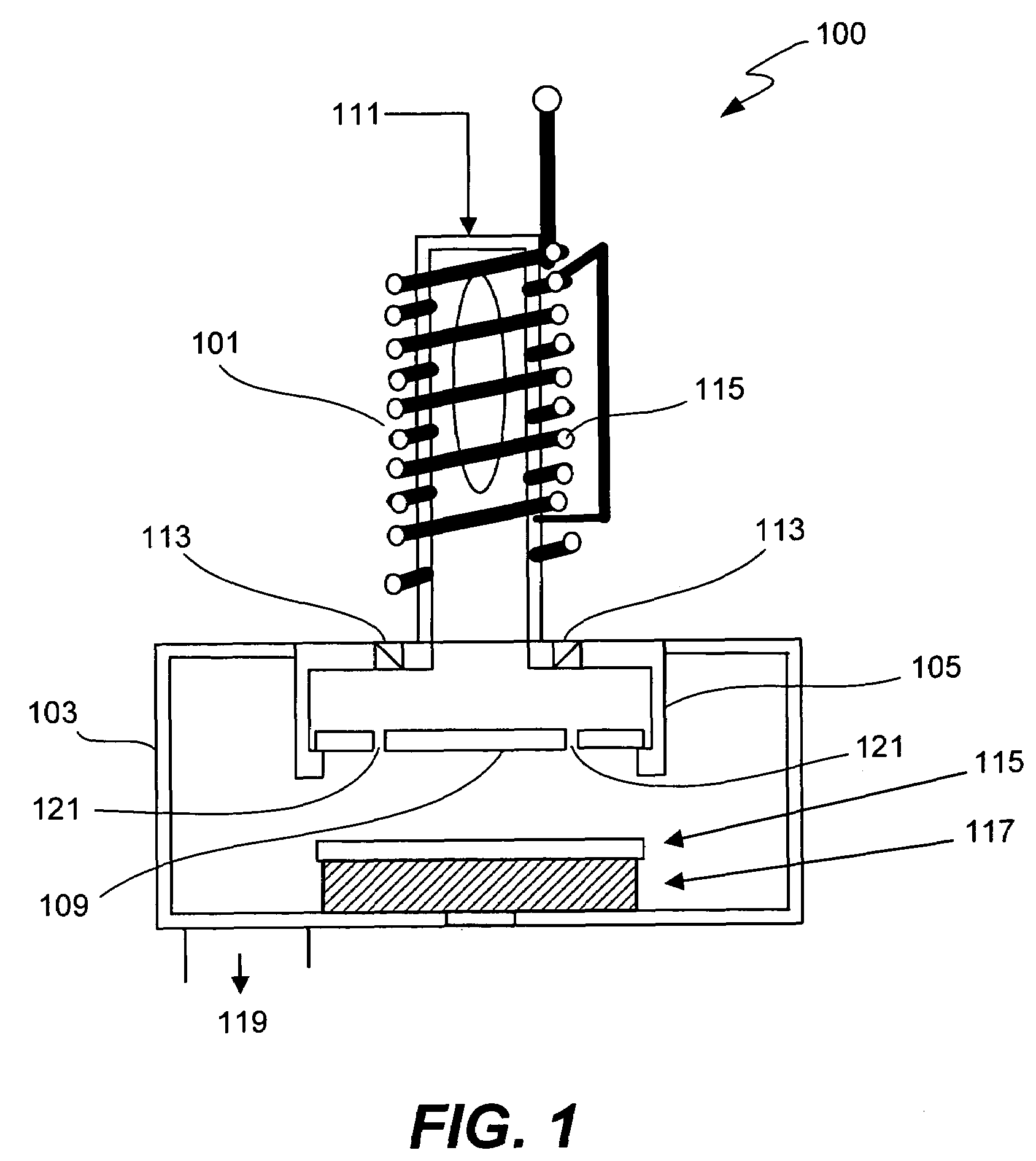

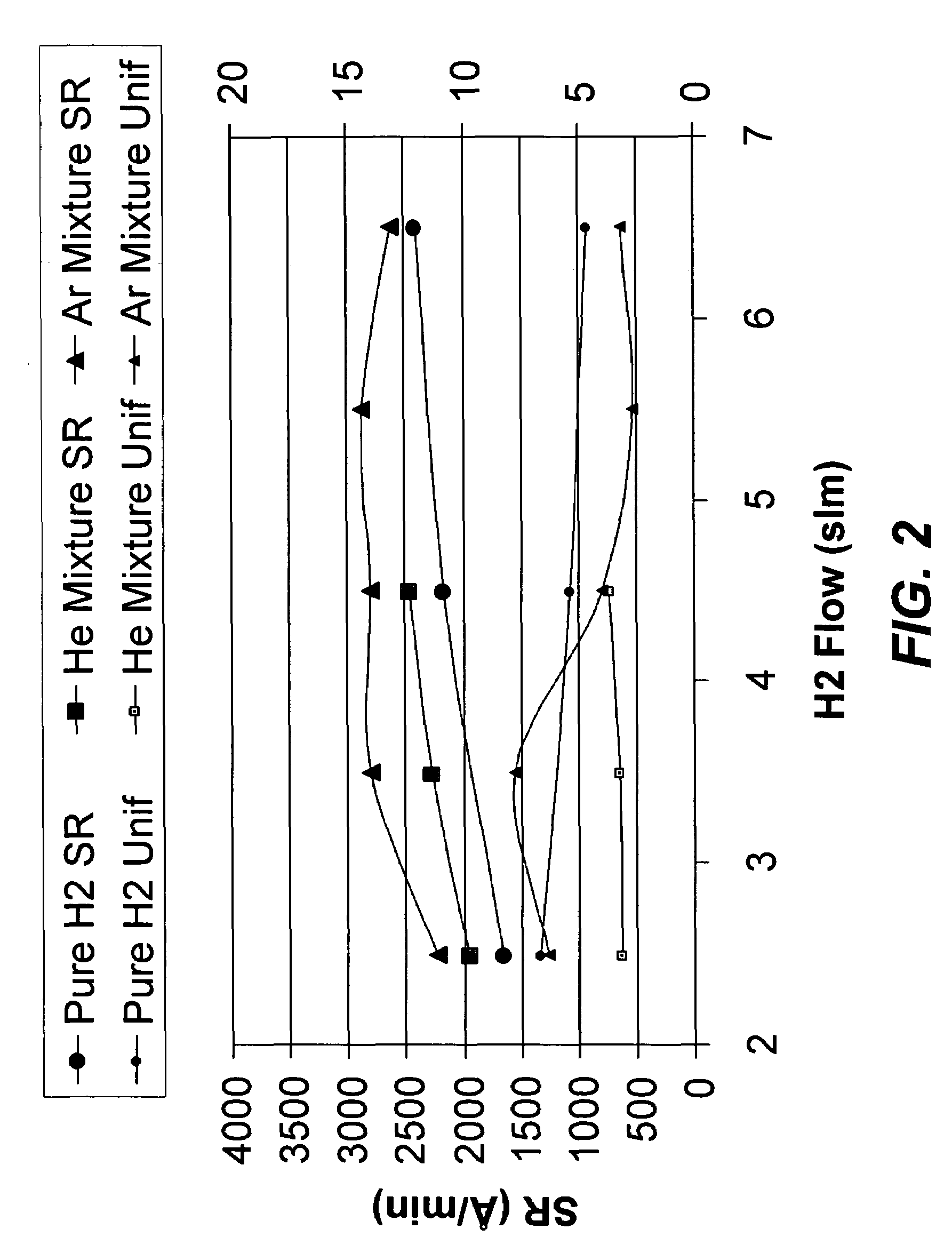

Techniques for Improving the Performance and Extending the Lifetime of an Ion Source with Gas Mixing

ActiveUS20080237496A1Improve performanceExtended service lifeElectric arc lampsSemiconductor/solid-state device manufacturingDopantProduct gas

Techniques improving the performance and extending the lifetime of an ion source with gas mixing are disclosed. In one particular exemplary embodiment, the techniques may be realized as a method for improving performance and extending lifetime of an ion source in an ion implanter. The method may comprise introducing a predetermined amount of dopant gas into an ion source chamber. The dopant gas may comprise a dopant species. The method may also comprise introducing a predetermined amount of diluent gas into the ion source chamber. The diluent gas may dilute the dopant gas to improve the performance and extend the lifetime of the ion source. The diluent gas may further comprise a co-species that is the same as the dopant species.

Owner:VARIAN SEMICON EQUIP ASSOC INC

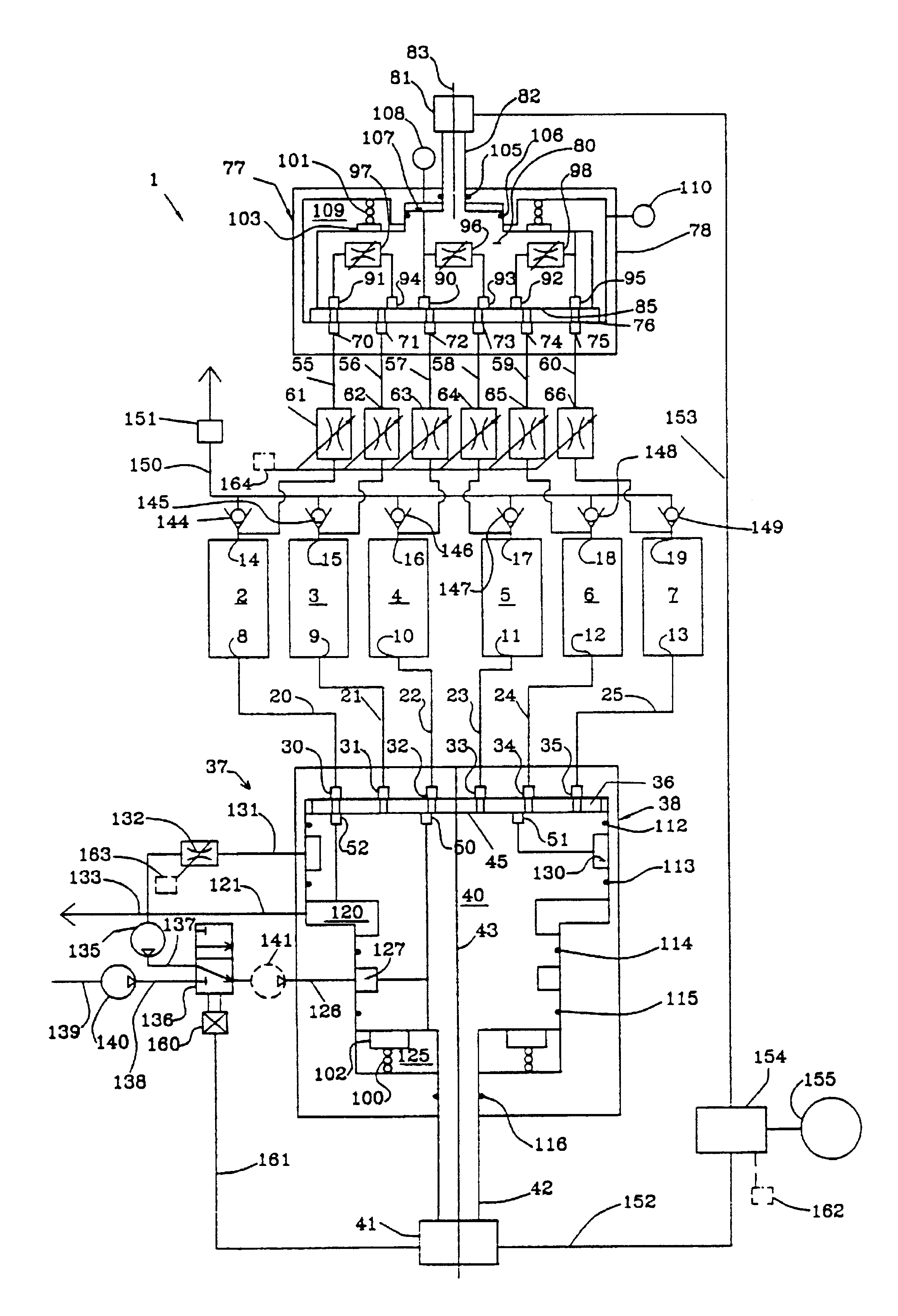

Flow regulated pressure swing adsorption system

InactiveUSRE38493E1Satisfactory operationGas treatmentIsotope separationSystem pressureProcess engineering

Pressure swing adsorption (PSA) separation of a gas mixture is performed in an apparatus with a plurality of adsorbent beds. The invention provides rotary multiport distributor valves to control the timing sequence of the PSA cycle steps between the beds, with flow controls cooperating with the rotary distributor valves to control the volume rates of gas flows to and from the adsorbent beds in blowdown, purge, equalization and repressurization steps.

Owner:AIR PROD & CHEM INC

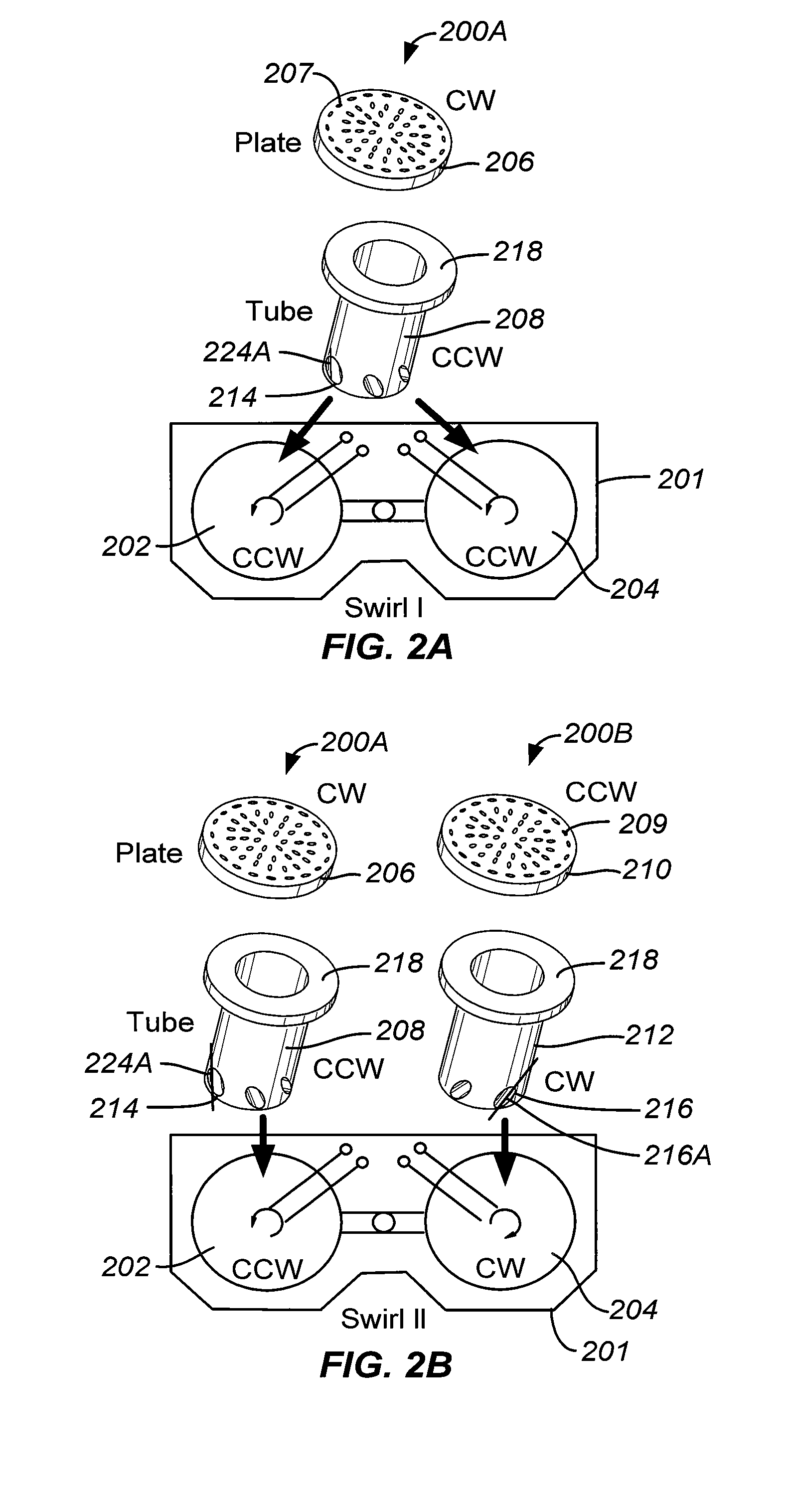

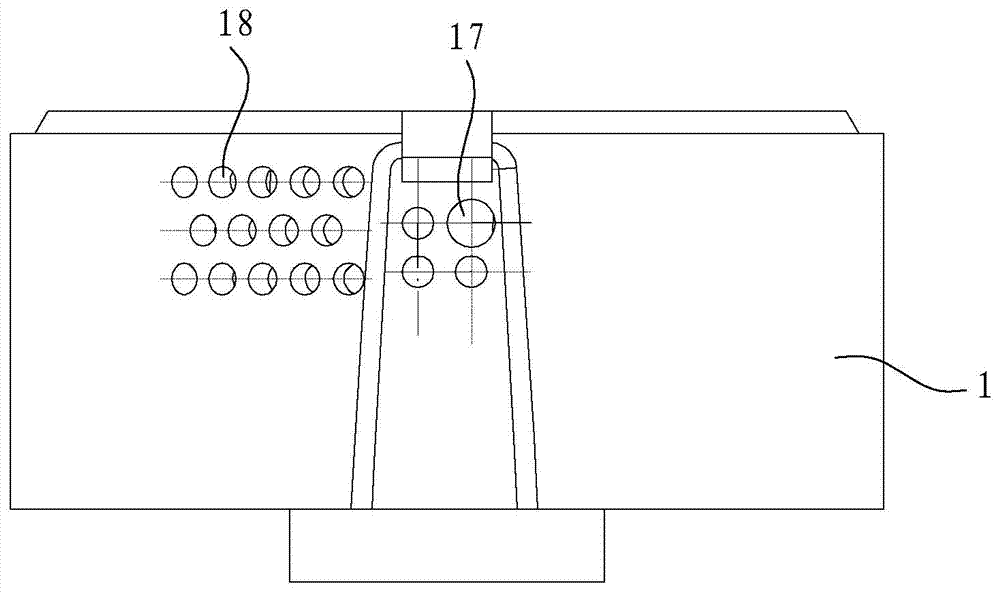

Gas mixing swirl insert assembly

InactiveUS20090120364A1Improve completenessFlow mixersSpray nozzlesMechanical engineeringMixed systems

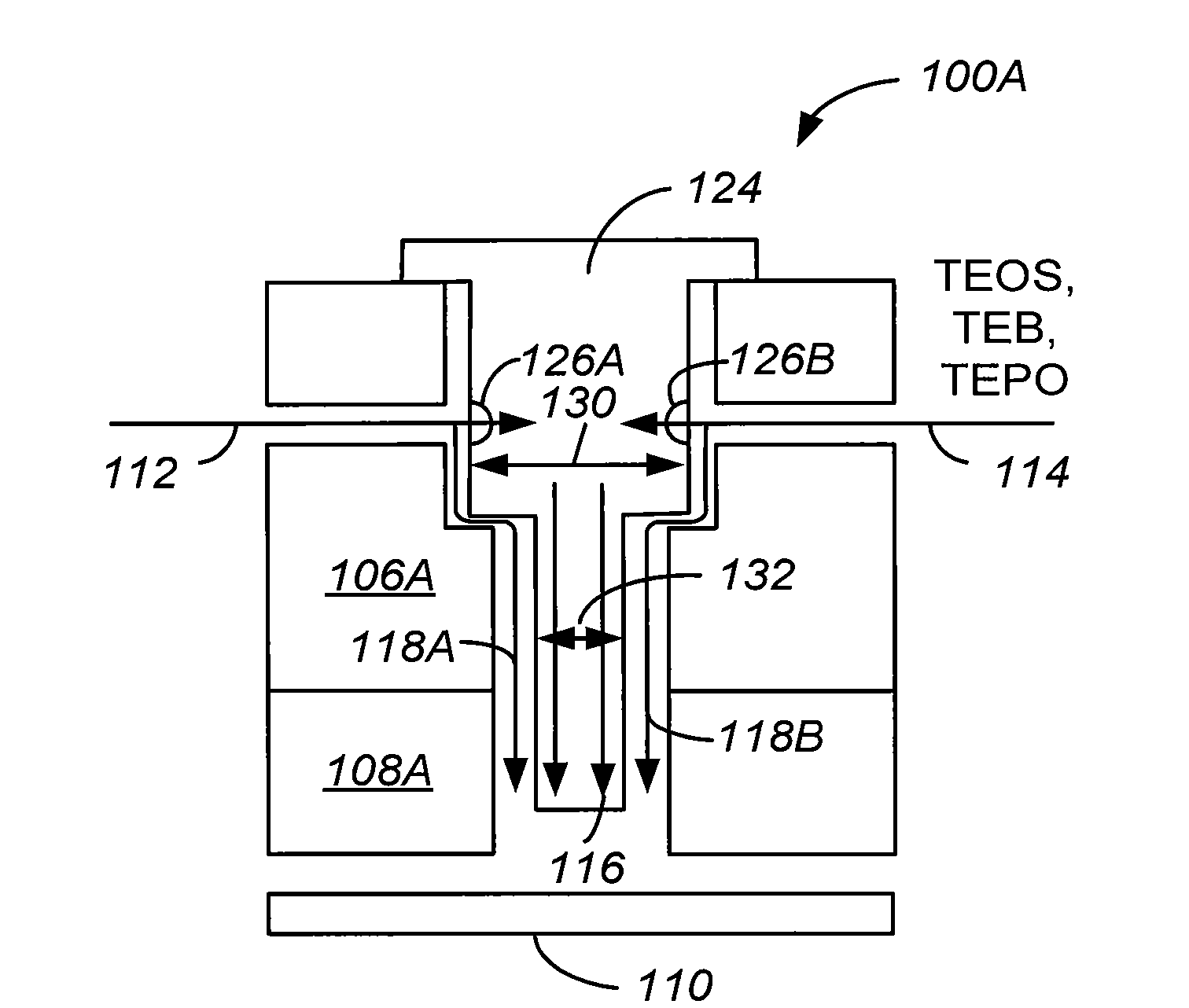

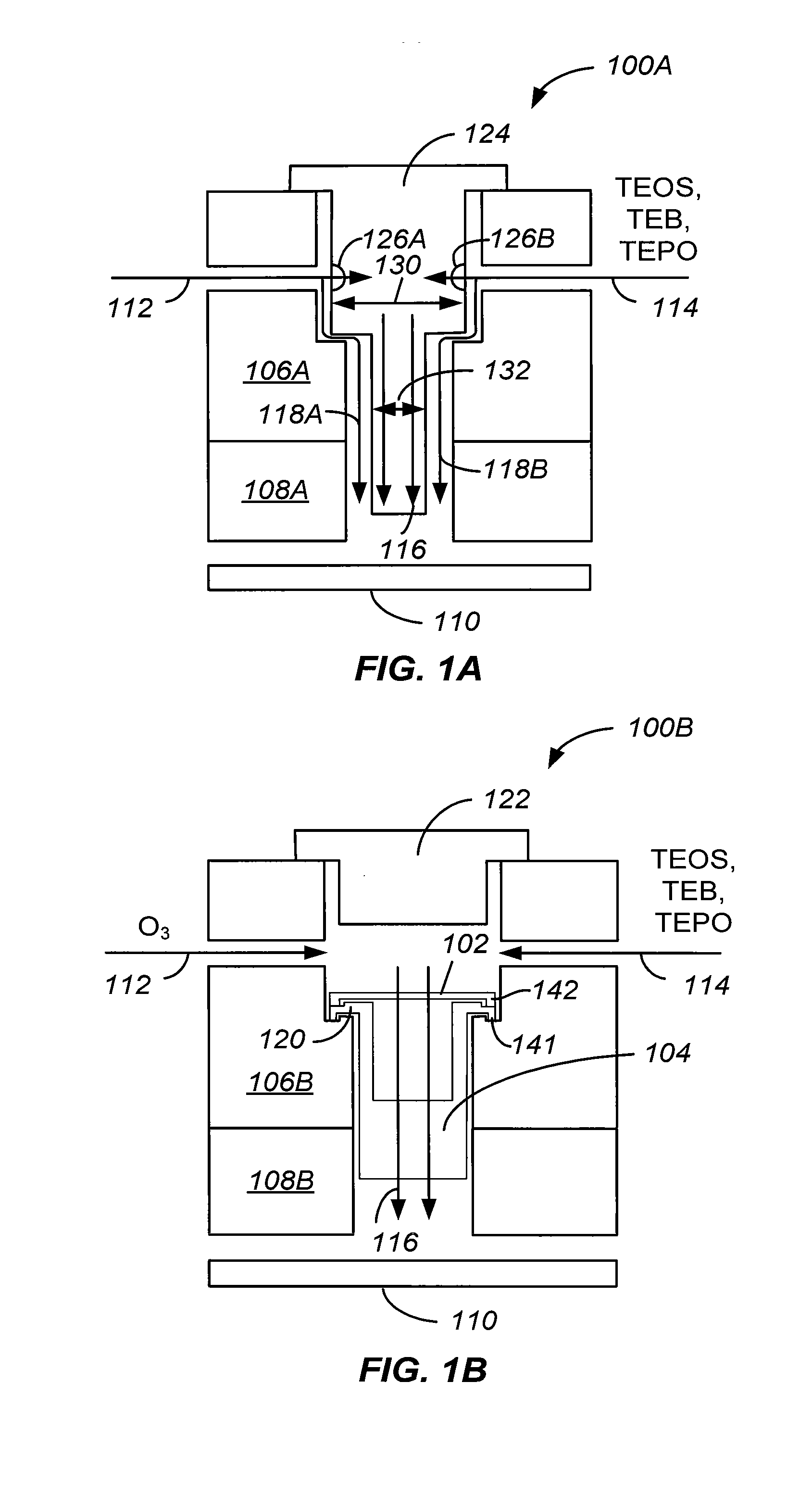

A gas mixing system for a semiconductor wafer processing chamber is described. The mixing system may include a gas mixing chamber concentrically aligned with a gas transport tube that extends to a blocker plate. The gas mixing chamber and the transport tube are separated by a porous barrier that increases a duration of gas mixing in the gas mixing chamber before processes gases migrate into the transport tube. The system may also include a gas mixing insert having a top section with a first diameter and a second section with a second diameter smaller than the first diameter and concentrically aligned with the top section. The processes gases enter the top section of the insert and follow channels through the second section that cause the gases to mix and swirl in the gas mixing chamber. The second section extends into the gas mixing chamber while still leaving space for the mixing and swirling around the sidewalls and bottom of the mixing chamber.

Owner:APPLIED MATERIALS INC

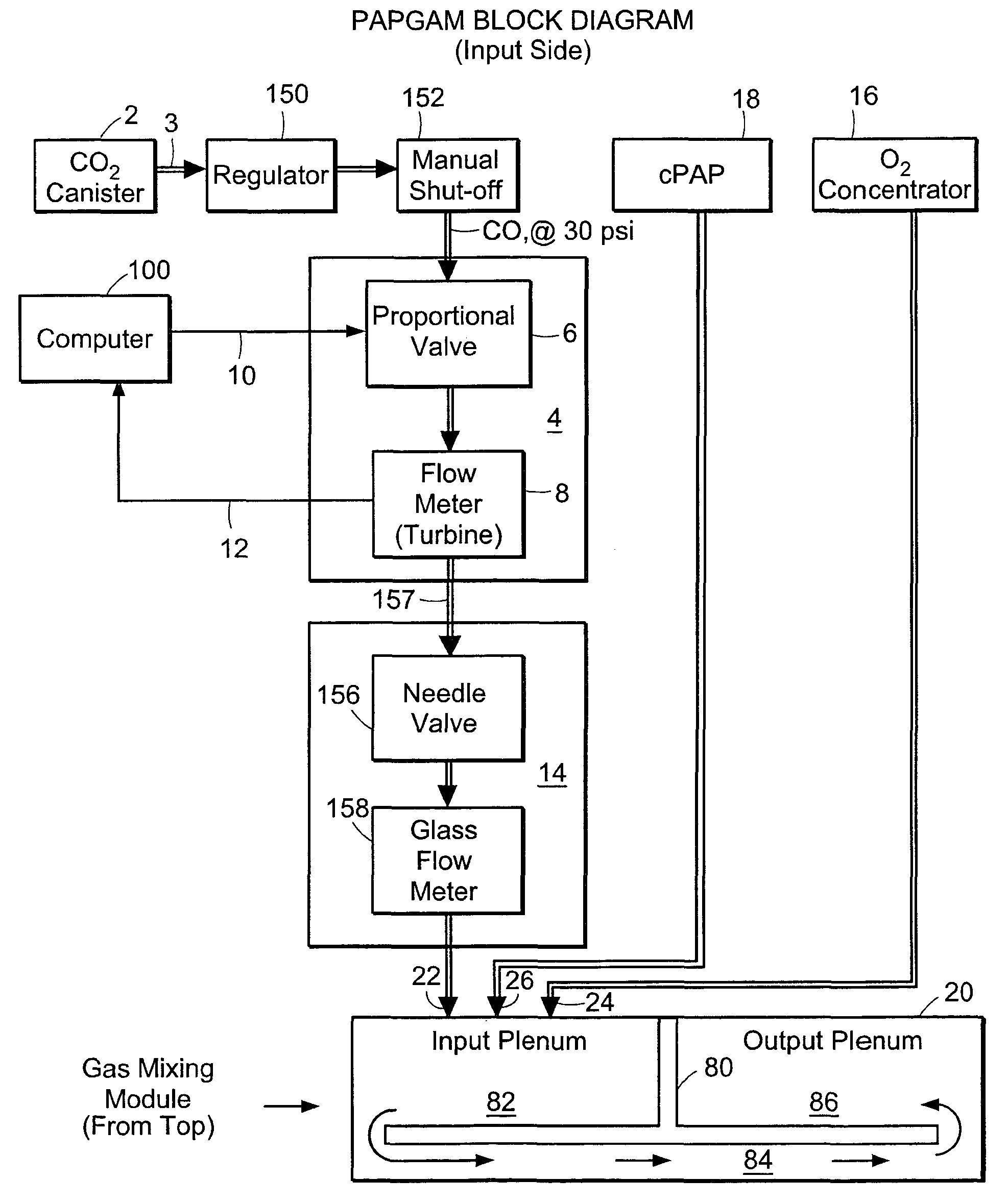

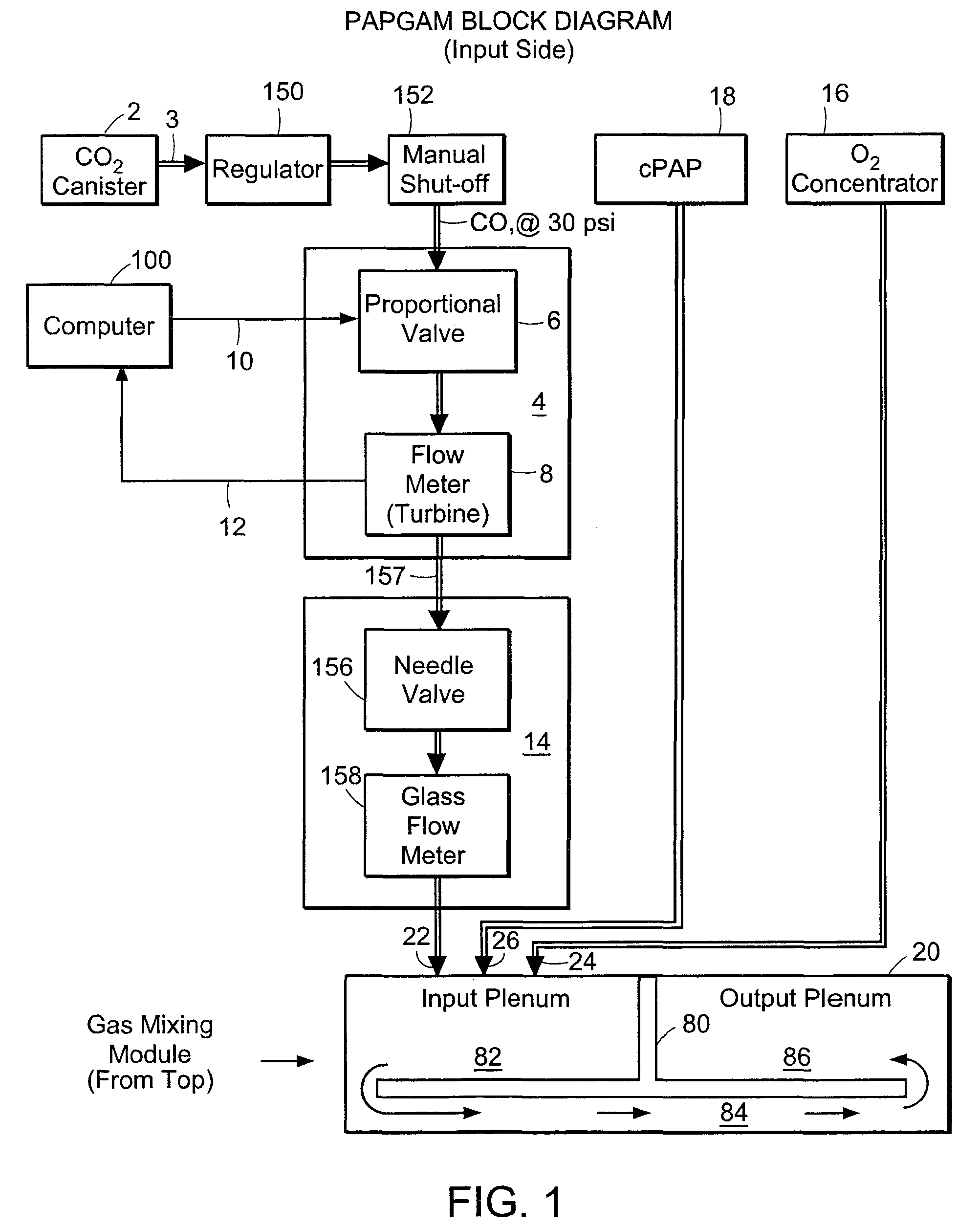

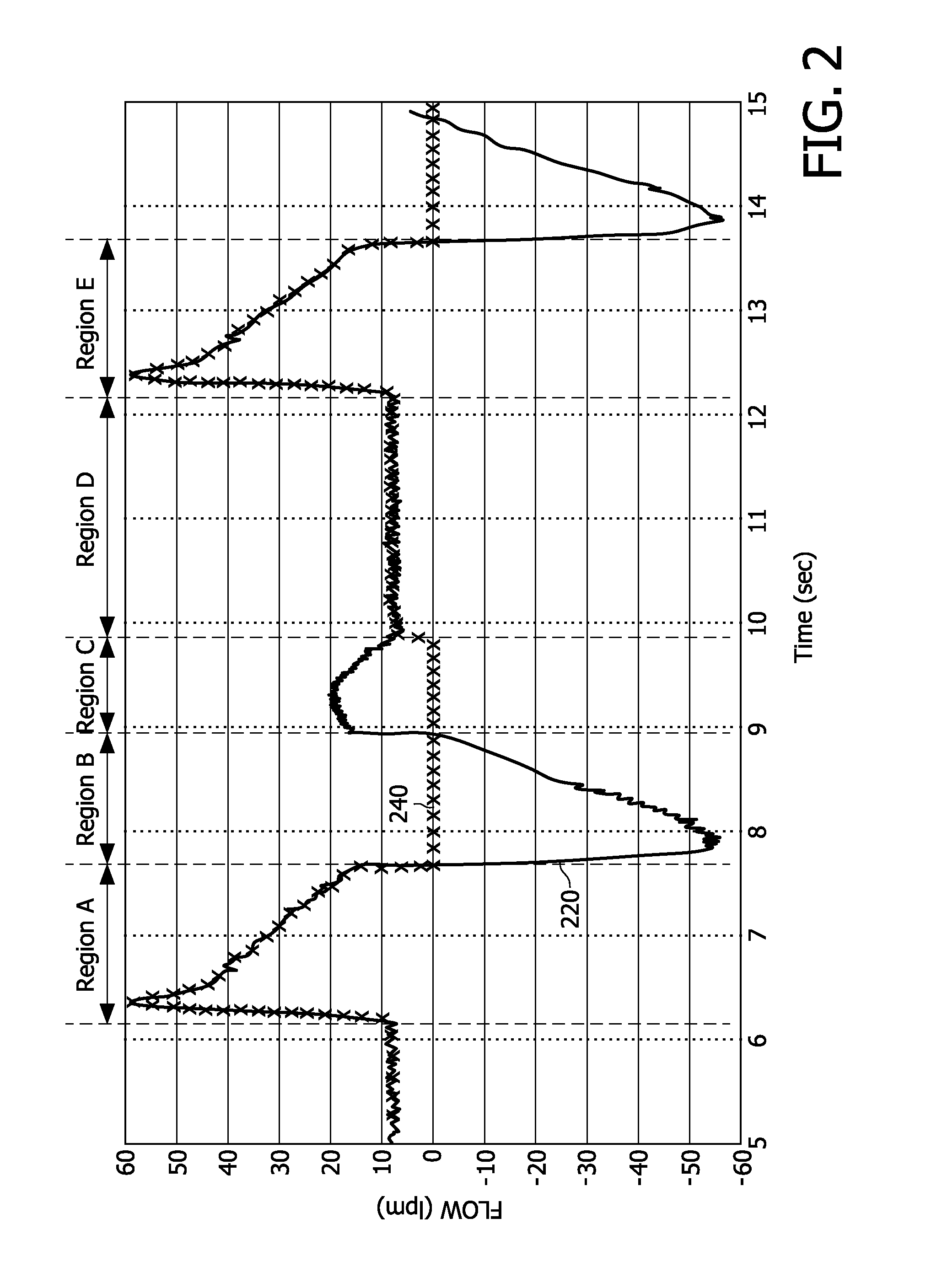

Gas systems and methods for enabling respiratory stability

ActiveUS7886740B2Improve respiratory stabilityFunction increaseRespiratorsOperating means/releasing devices for valvesEngineeringProduct gas

Minimal concentrations of CO2 are mixed with pressurized air to provide a gas mix effective for stabilizing breathing of target patients or users. CO2 concentrations below about 2% and preferably between about 0.5% and 1.25% are employed. A gas modulator includes a gas mixing module, a sensor and a control processor. The gas mixing module mixes plural gases, including CO2, into a gas mix, for delivery to a substantially leak-proof patient face mask. The sensor, located substantially at the face mask, measures CO2 concentration in the face mask. The control processor, based on a signal from the sensor, controls the CO2 concentration in the gas mix.

Owner:BETH ISRAEL DEACONESS MEDICAL CENT INC

Hydrogen transport membranes

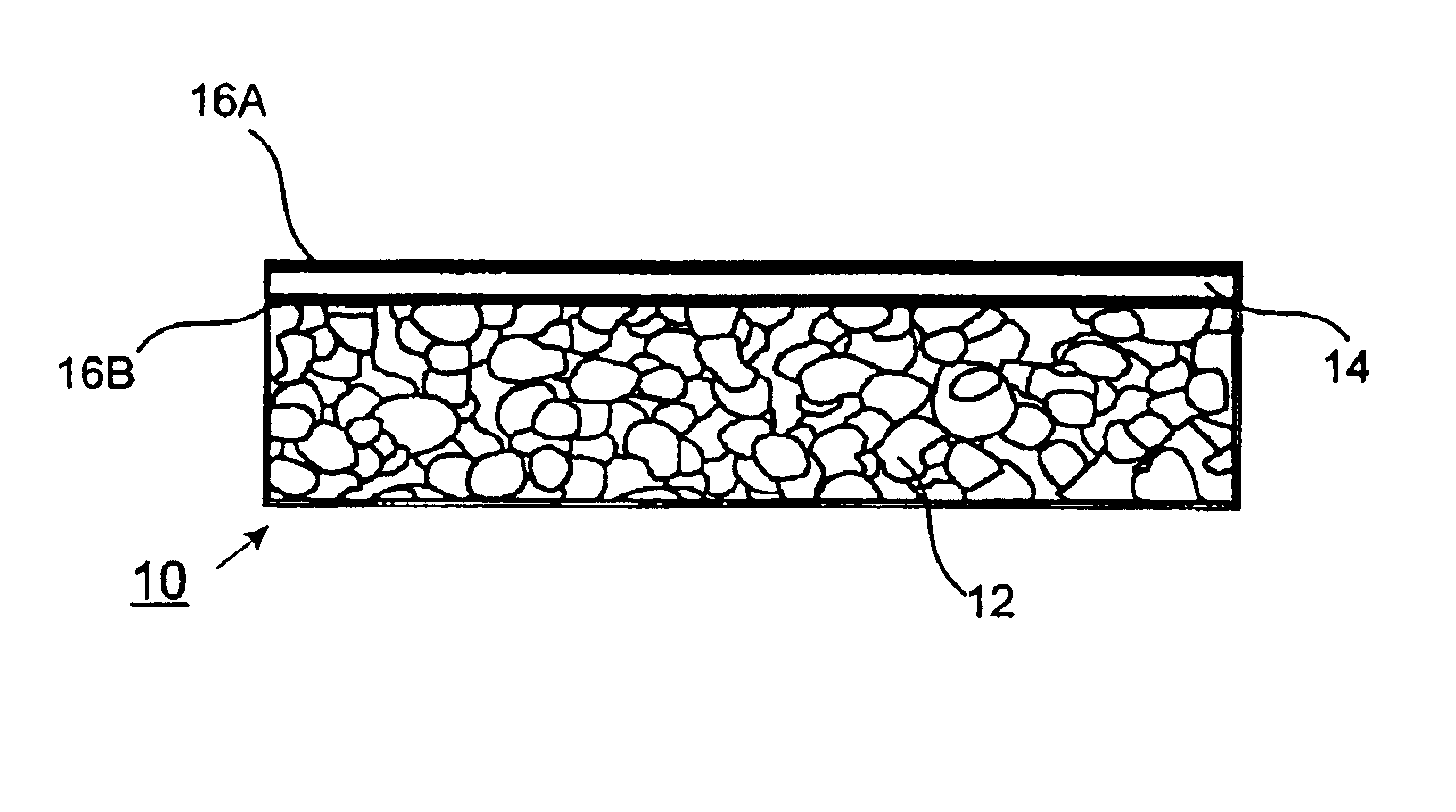

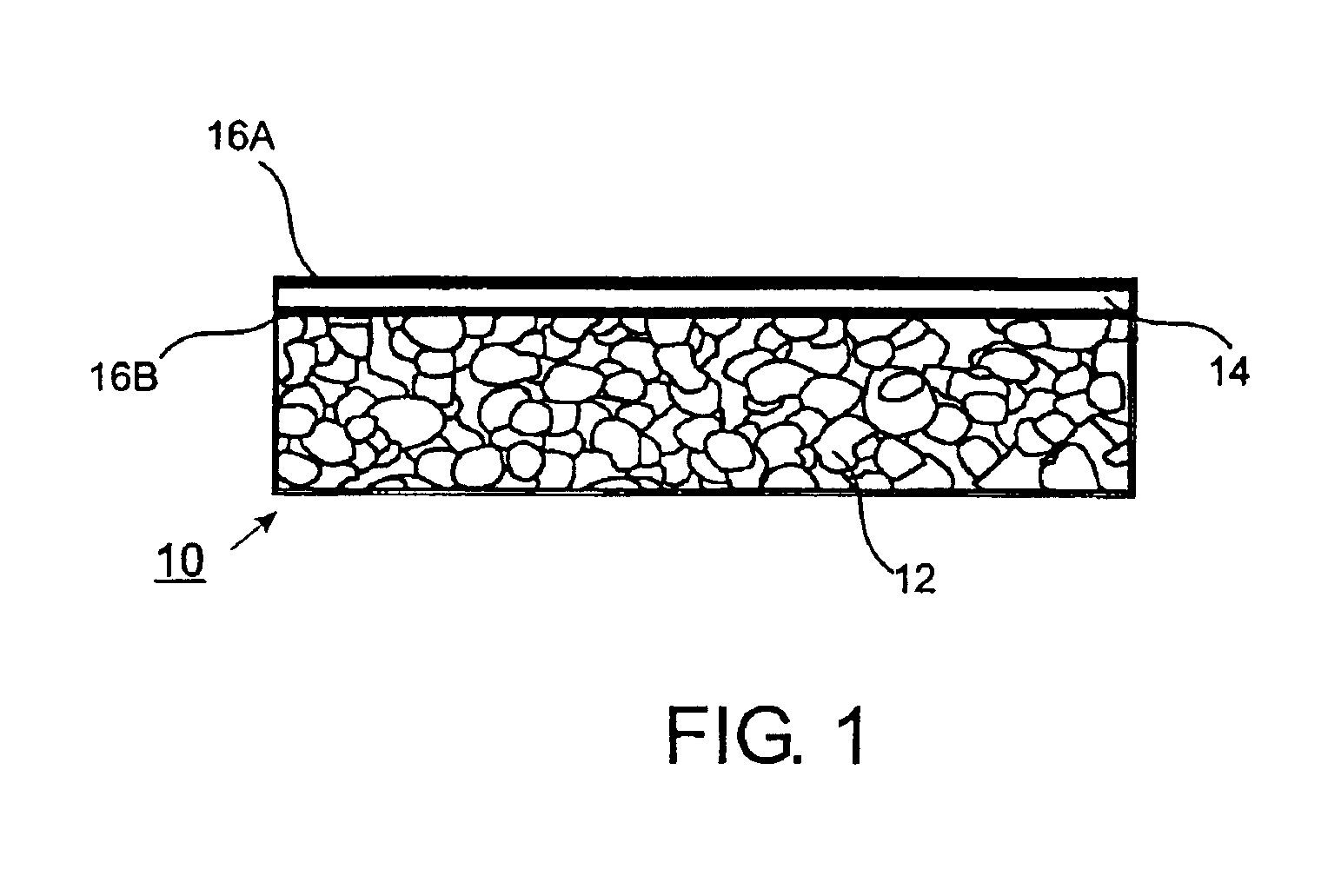

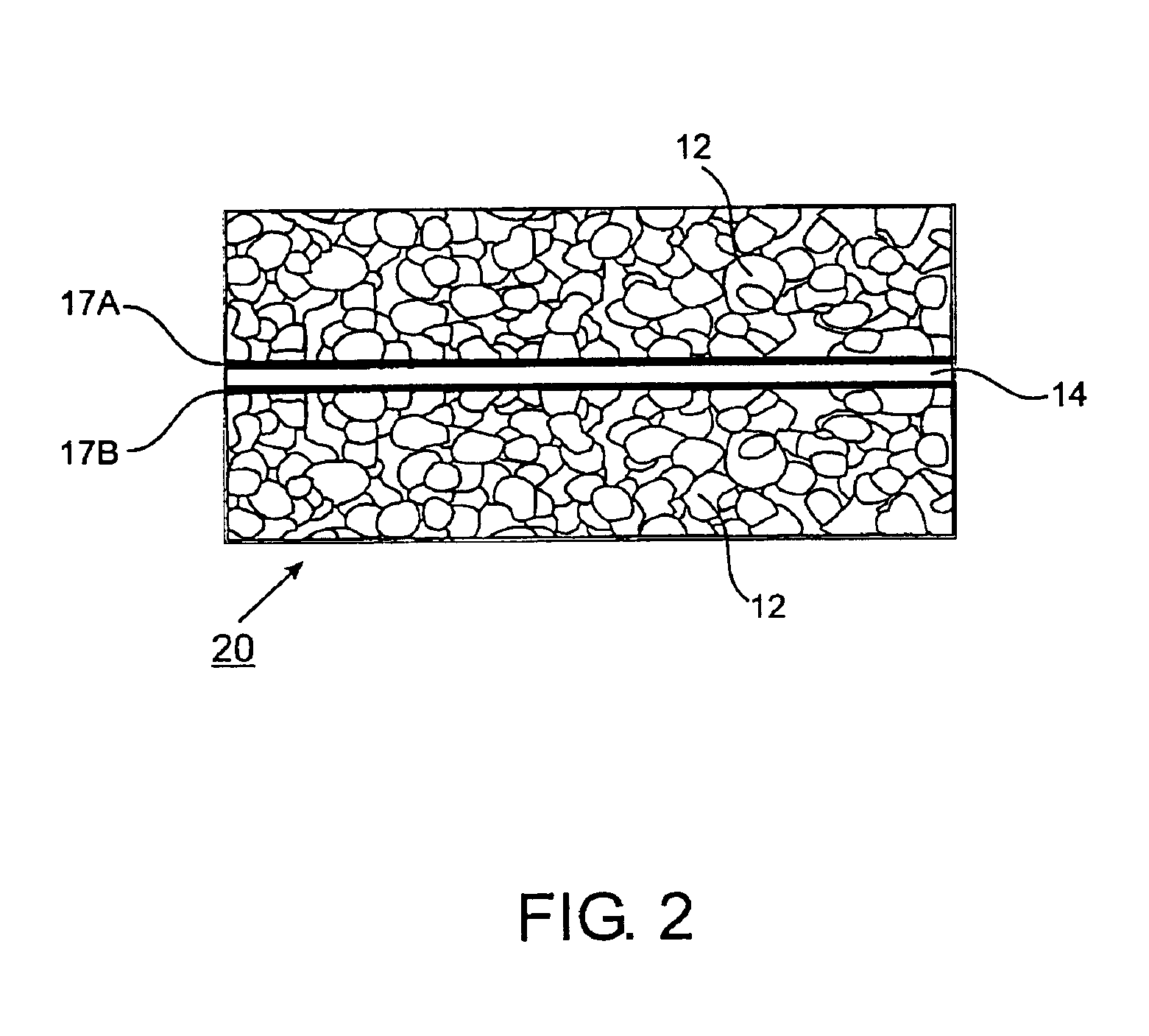

InactiveUS6899744B2Increase ratingsThickness minimizationSemi-permeable membranesMembranesSupport matrixNiobium

Composite hydrogen transport membranes, which are used for extraction of hydrogen from gas mixtures are provided. Methods are described for supporting metals and metal alloys which have high hydrogen permeability, but which are either too thin to be self supporting, too weak to resist differential pressures across the membrane, or which become embrittled by hydrogen. Support materials are chosen to be lattice matched to the metals and metal alloys. Preferred metals with high permeability for hydrogen include vanadium, niobium, tantalum, zirconium, palladium, and alloys thereof. Hydrogen-permeable membranes include those in which the pores of a porous support matrix are blocked by hydrogen-permeable metals and metal alloys, those in which the pores of a porous metal matrix are blocked with materials which make the membrane impervious to gases other than hydrogen, and cermets fabricated by sintering powders of metals with powders of lattice-matched ceramic.

Owner:ELTRON RES

Techniques for improving the performance and extending the lifetime of an ion source with gas mixing

ActiveUS7655931B2Improve performanceExtended service lifeElectric arc lampsMaterial analysis by optical meansDopantIon implantation

Techniques improving the performance and extending the lifetime of an ion source with gas mixing are disclosed. In one particular exemplary embodiment, the techniques may be realized as a method for improving performance and extending lifetime of an ion source in an ion implanter. The method may comprise introducing a predetermined amount of dopant gas into an ion source chamber. The dopant gas may comprise a dopant species. The method may also comprise introducing a predetermined amount of diluent gas into the ion source chamber. The diluent gas may dilute the dopant gas to improve the performance and extend the lifetime of the ion source. The diluent gas may further comprise a co-species that is the same as the dopant species.

Owner:VARIAN SEMICON EQUIP ASSOC INC

Enhanced stripping of low-k films using downstream gas mixing

ActiveUS7202176B1Reducing required hydrogen flow rateImprove stripping rateHydrogenElectric discharge tubesResistHydrogen

The present invention pertains to methods for removing unwanted material from a work piece. More specifically, the invention pertains to stripping photo-resist material and removing etch-related residues from a semiconductor wafer during semiconductor manufacturing. Methods involve implementing a hydrogen plasma operation with downstream mixing with an inert gas. The invention is effective at stripping photo-resist and removing residues from low-k dielectric material used in Damascene devices.

Owner:NOVELLUS SYSTEMS

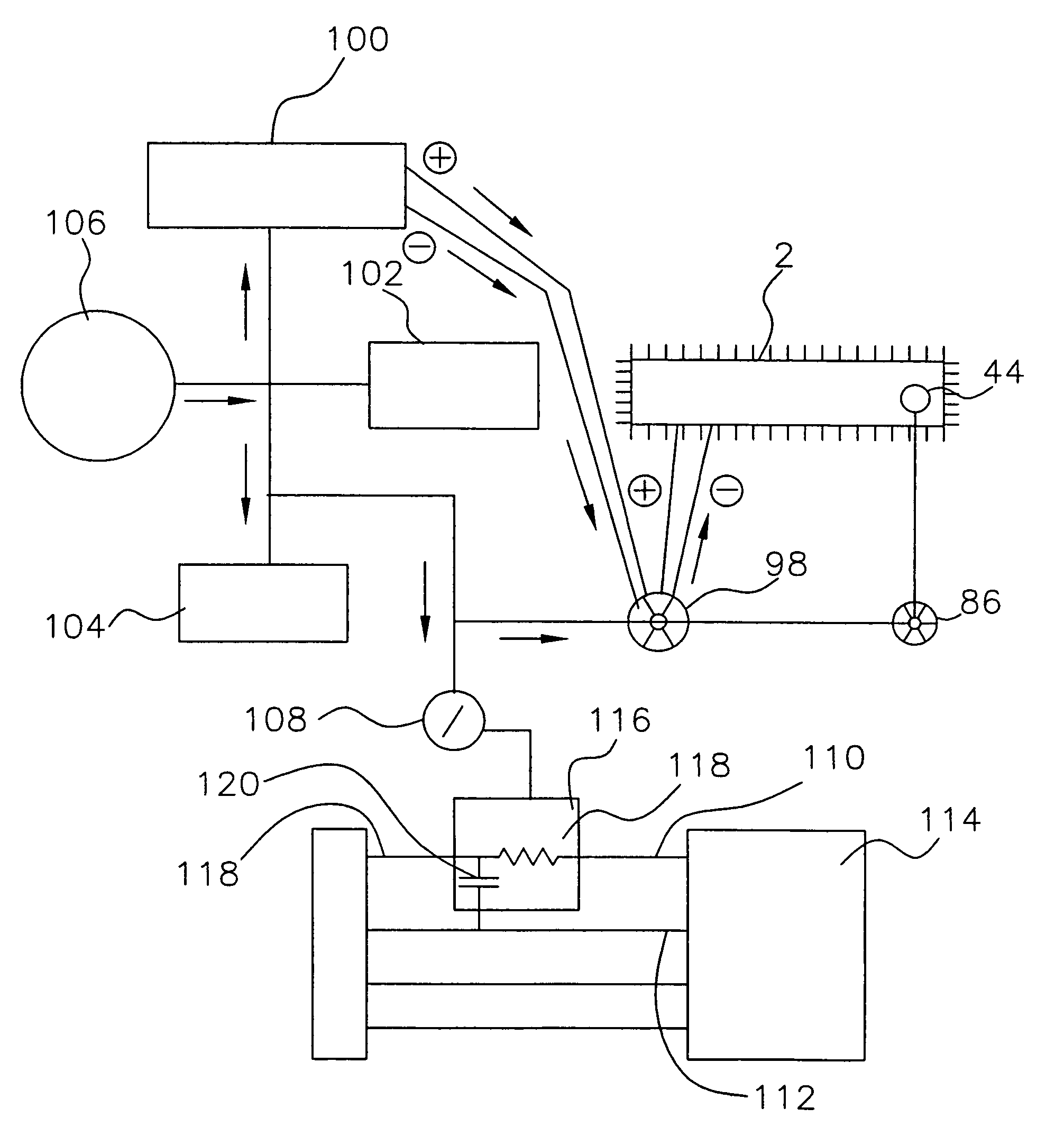

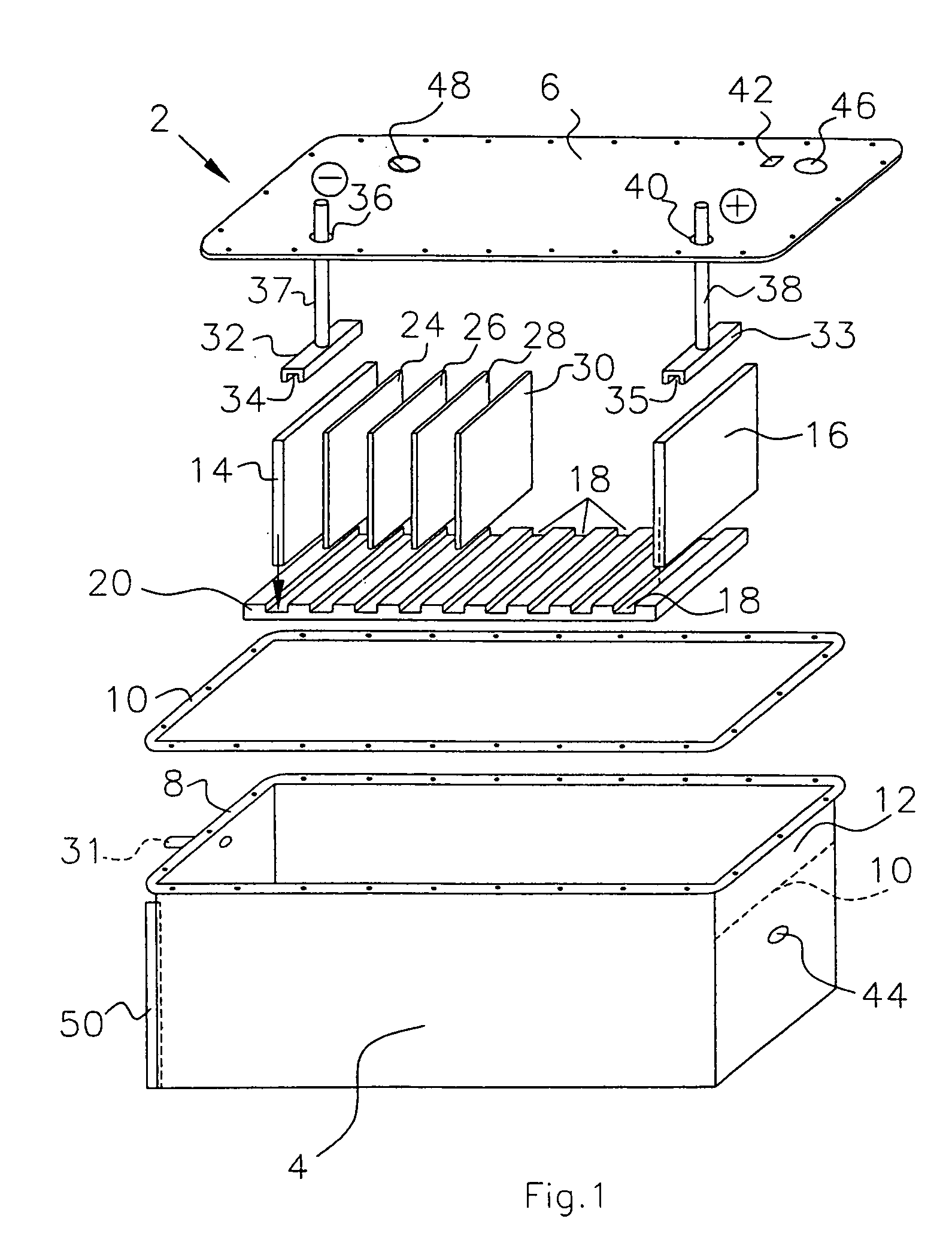

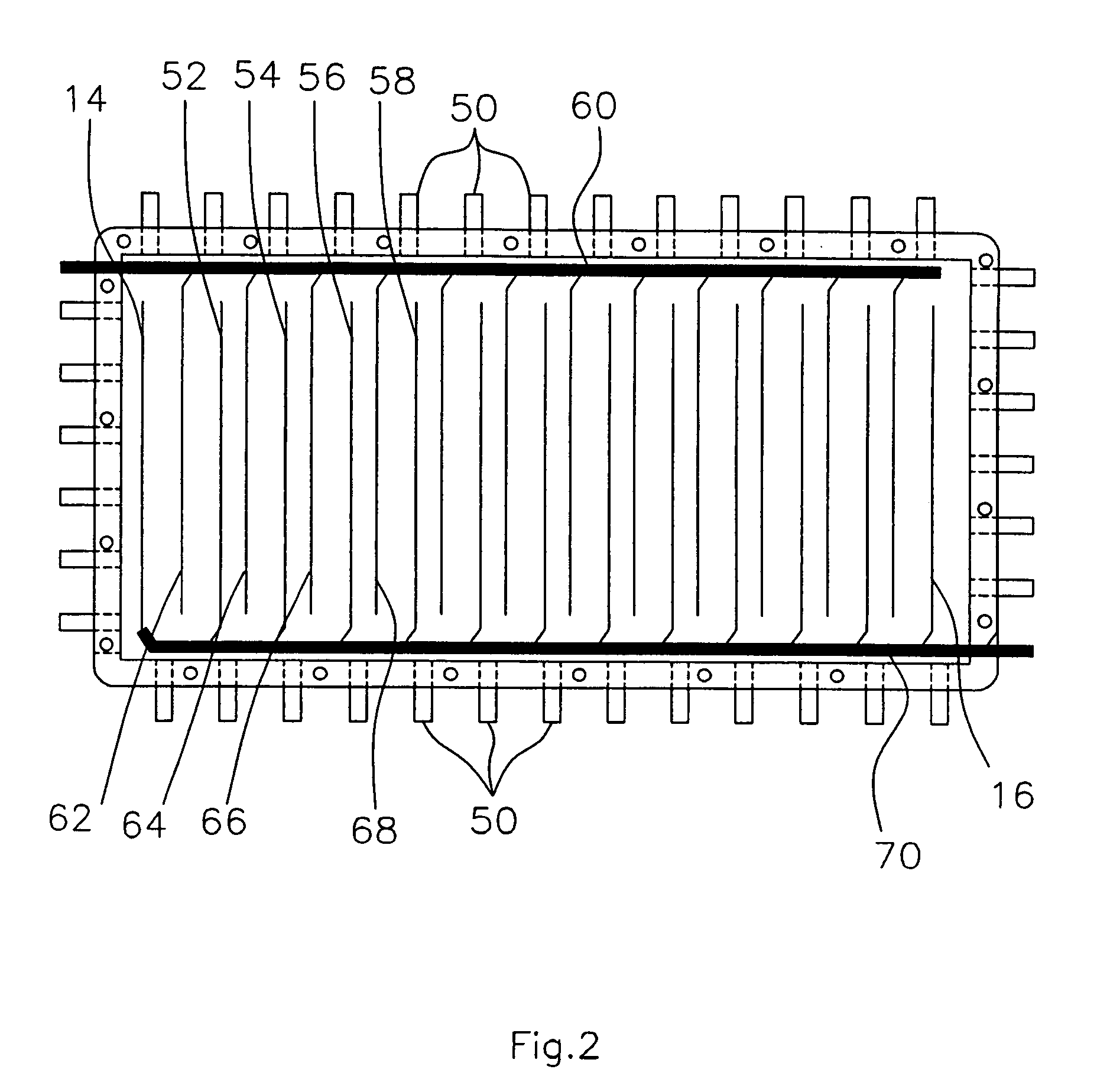

Hydrogen generator for uses in a vehicle fuel system

InactiveUS7191737B2Improve efficiencySimple designCellsPhotography auxillary processesElectrolysisProcess engineering

The present invention discloses an electrolyzer for electrolyzing water into a gaseous mixture comprising hydrogen gas and oxygen gas. The electrolyzer is adapted to deliver this gaseous mixture to the fuel system of an internal combustion engine. The electrolyzer of the present invention comprises one or more supplemental electrode at least partially immersed in an aqueous electrolyte solution interposed between two principle electrodes. The gaseous mixture is generated by applying an electrical potential between the two principal electrodes. The electrolyzer further includes a gas reservoir region for collecting the generated gaseous mixture. The present invention further discloses a method of utilizing the electrolyzer in conjunction with the fuel system of an internal combustion engine to improve the efficiency of said internal combustion engine.

Owner:HYDROGEN TECH APPL

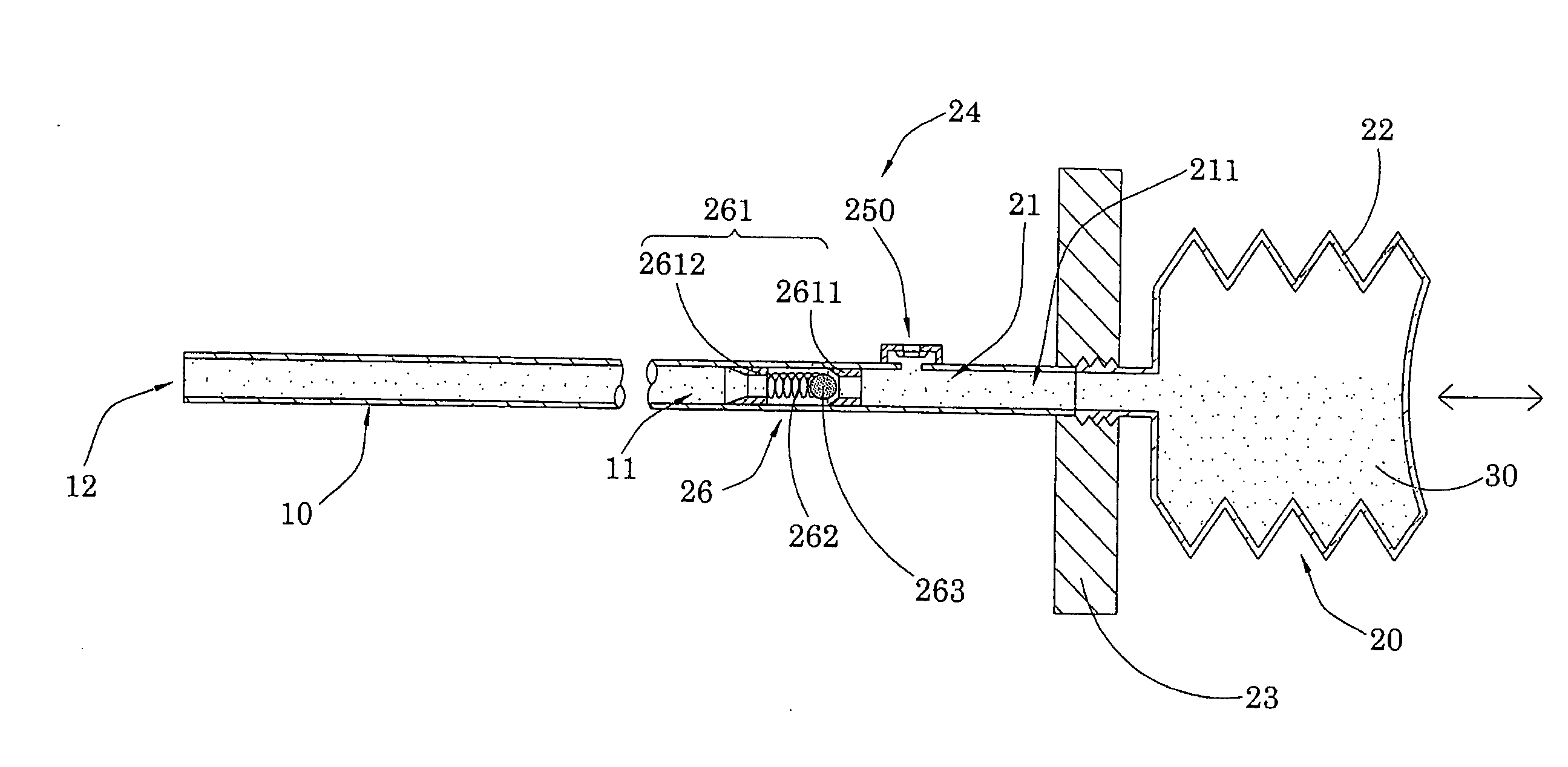

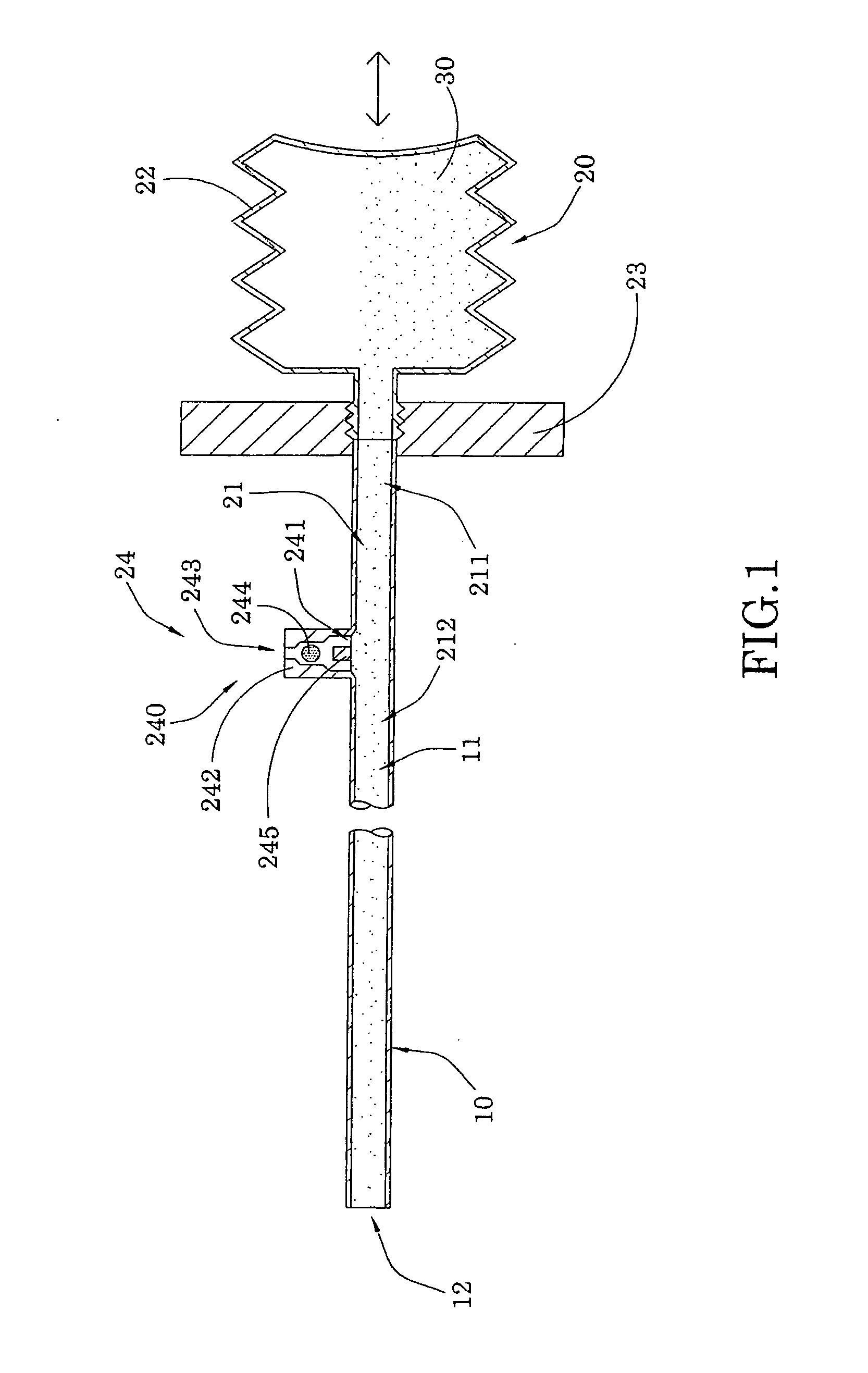

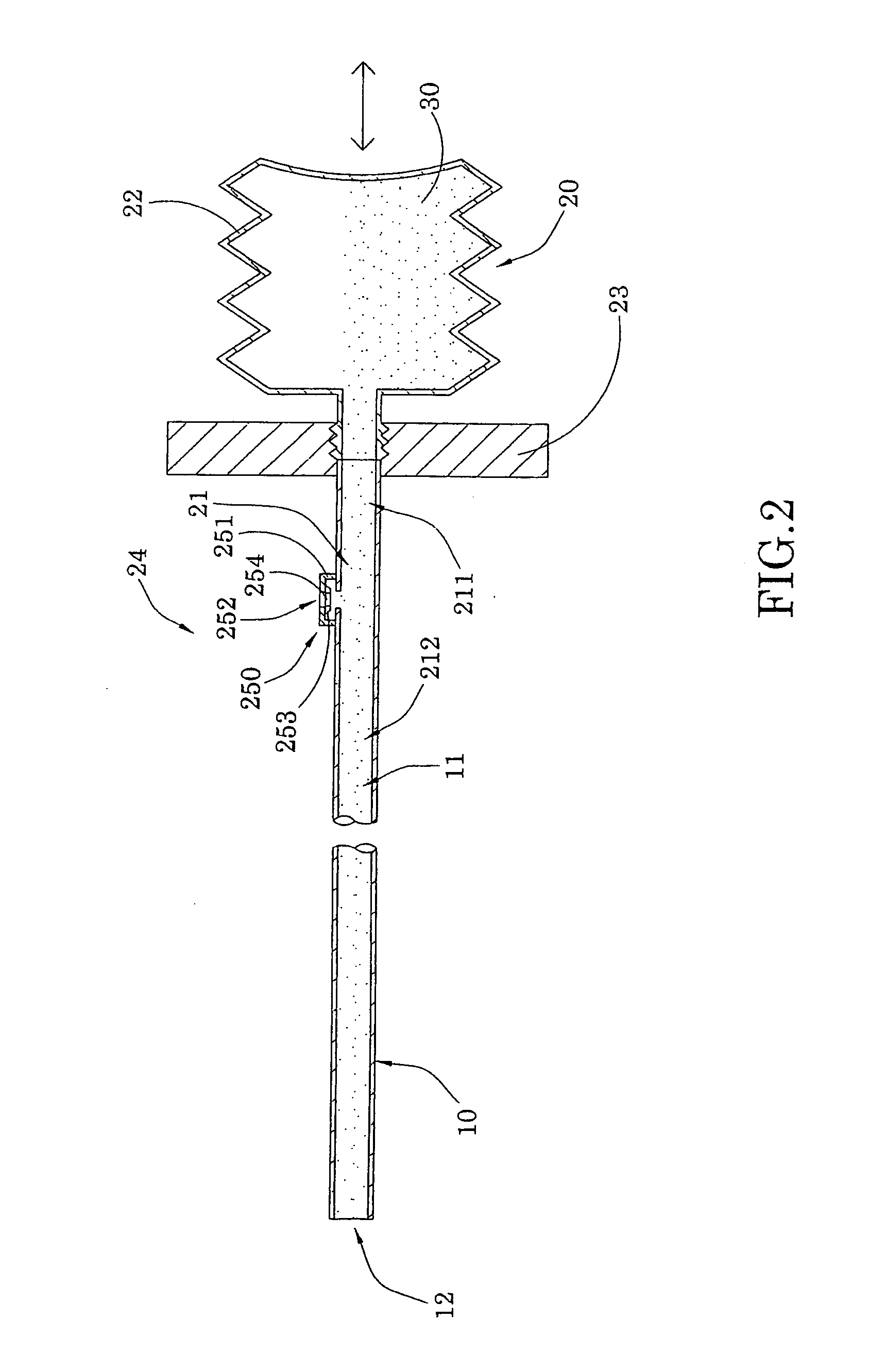

Internal dry powder delivery system and method thereof

ActiveUS20110178495A1Overcome difficultiesCommon problemMedical devicesSingle-unit apparatusProduct gasEndoscope

An internal dry powder delivery system through a working channel of an endoscopic cannula for directly applying the powder form medication to an internal tissue / organ site, includes an elongated tubular delivery channel and a powder supply device for producing pressurized gas mixing with the dry powder for feeding to form a mixture of dry powder and pressurized gas delivering to an internal tissue / organ site through the delivery channel via endoscopic cannula. It ensures a smooth powder release by preventing liquid from accumulation at the tip of the delivery channel and offers physicians a new powder form drug delivery method via endoscope. Also, it offers new minimal invasive application by directly and precisely applying the powder format drug to the internal sites of human gastrointestinal organ via endoscope to achieve hemostasis, anti-inflammation, anti-ulcer and anti-tumor treatment, etc.

Owner:ENDOCLOT PLUS INC

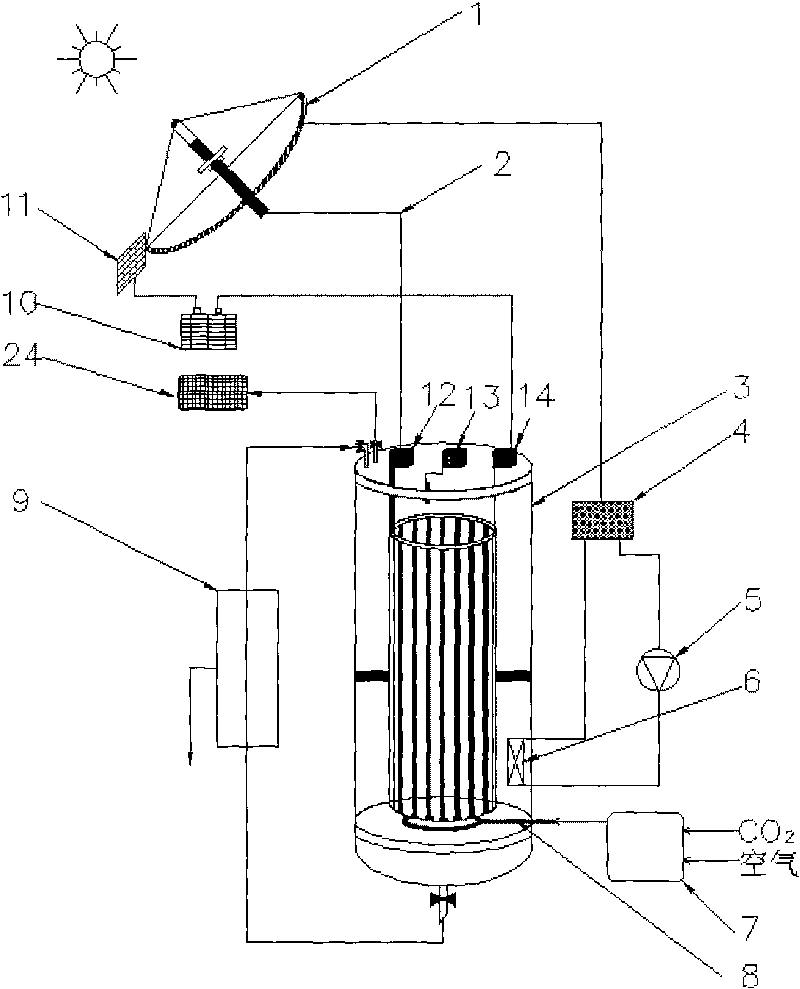

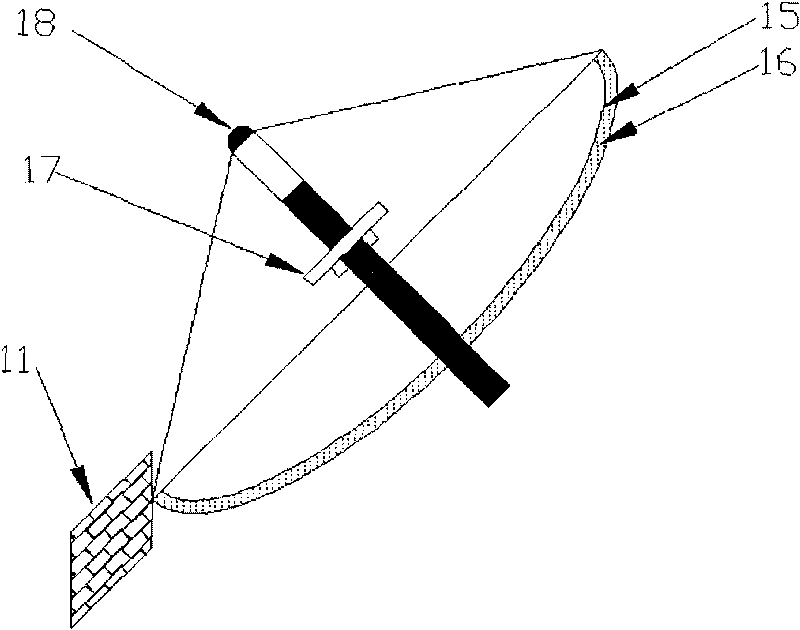

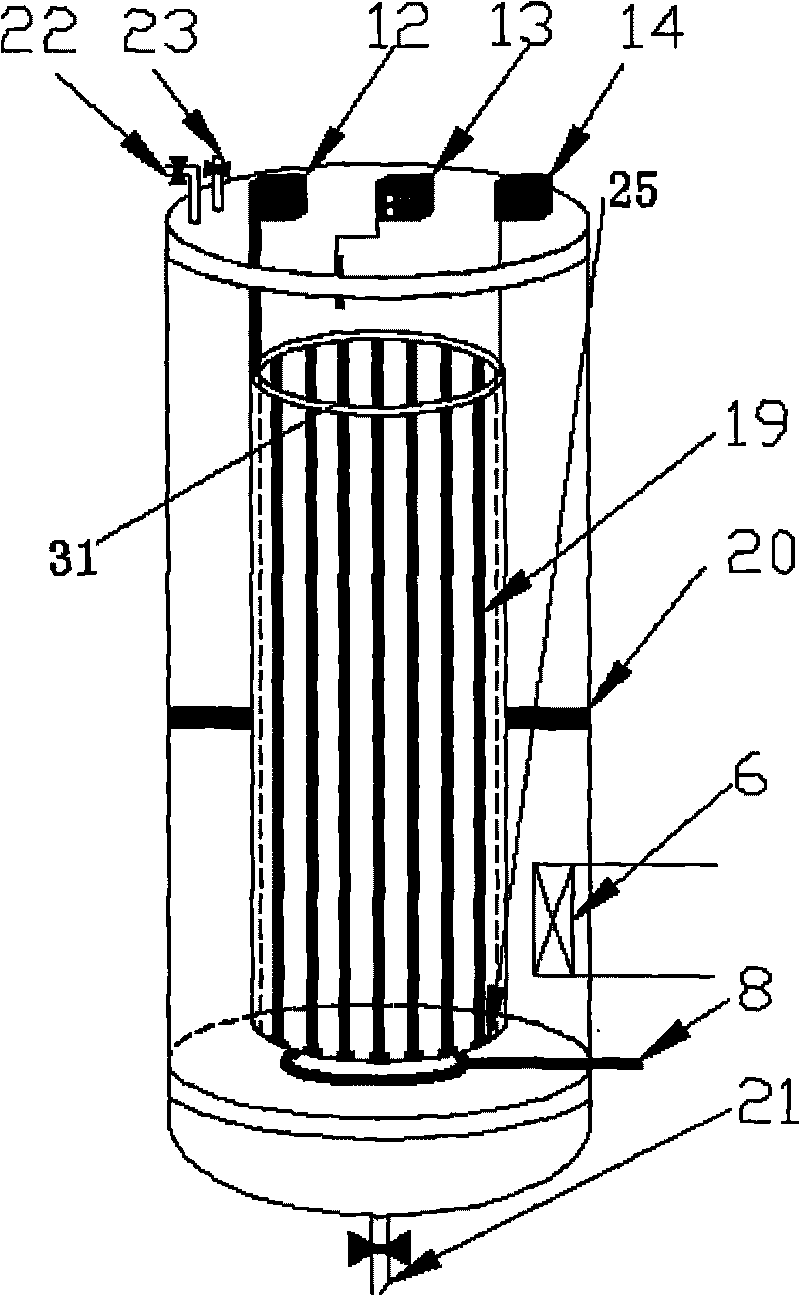

Solar spectral photosynthetic bioreactor system for culturing microalgae in high density

InactiveCN101709262AIncrease profitGuaranteed normal cultureBioreactor/fermenter combinationsBiological substance pretreatmentsFiberInstability

The invention discloses a solar spectral photosynthetic bioreactor system for culturing microalgae in high density, which comprises a photosynthetic bioreactor, a solar energy collector, light-guide fibers, a light distribution device arranged in the photosynthetic bioreactor, a residual gas absorption device and a culture solution separation recovery device, wherein the residual gas absorption device and the culture solution separation recovery device are respectively connected with the photosynthetic bioreactor. One end of the light distribution device is connected with a spectral light-intensity adjustment device arranged on the photosynthetic bioreactor; the spectral light-intensity adjustment device is connected to the solar energy collector through the light-guide fibers; and a gas distribution device is arranged between the position below the light distribution device and the bottom of the photosynthetic bioreactor and is connected with the output end of a gas mixing device. The system can effectively improve the utilization ratio of solar energy, reduce the consumption of external electrical energy, solve the problems of solar energy utilization, such as intermittence, instability difficult collection, and ensure the continuous and stable culture of microalgae.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

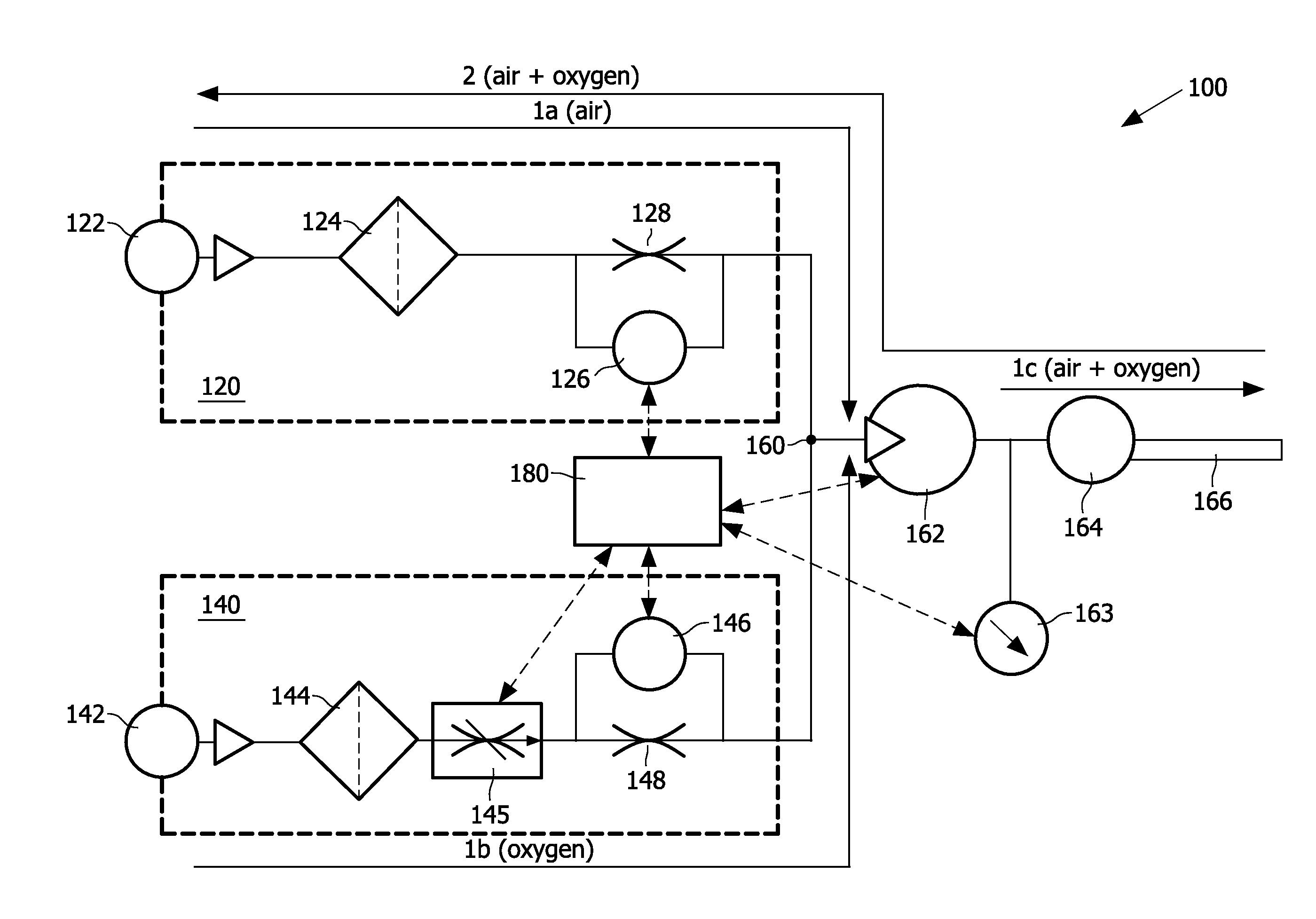

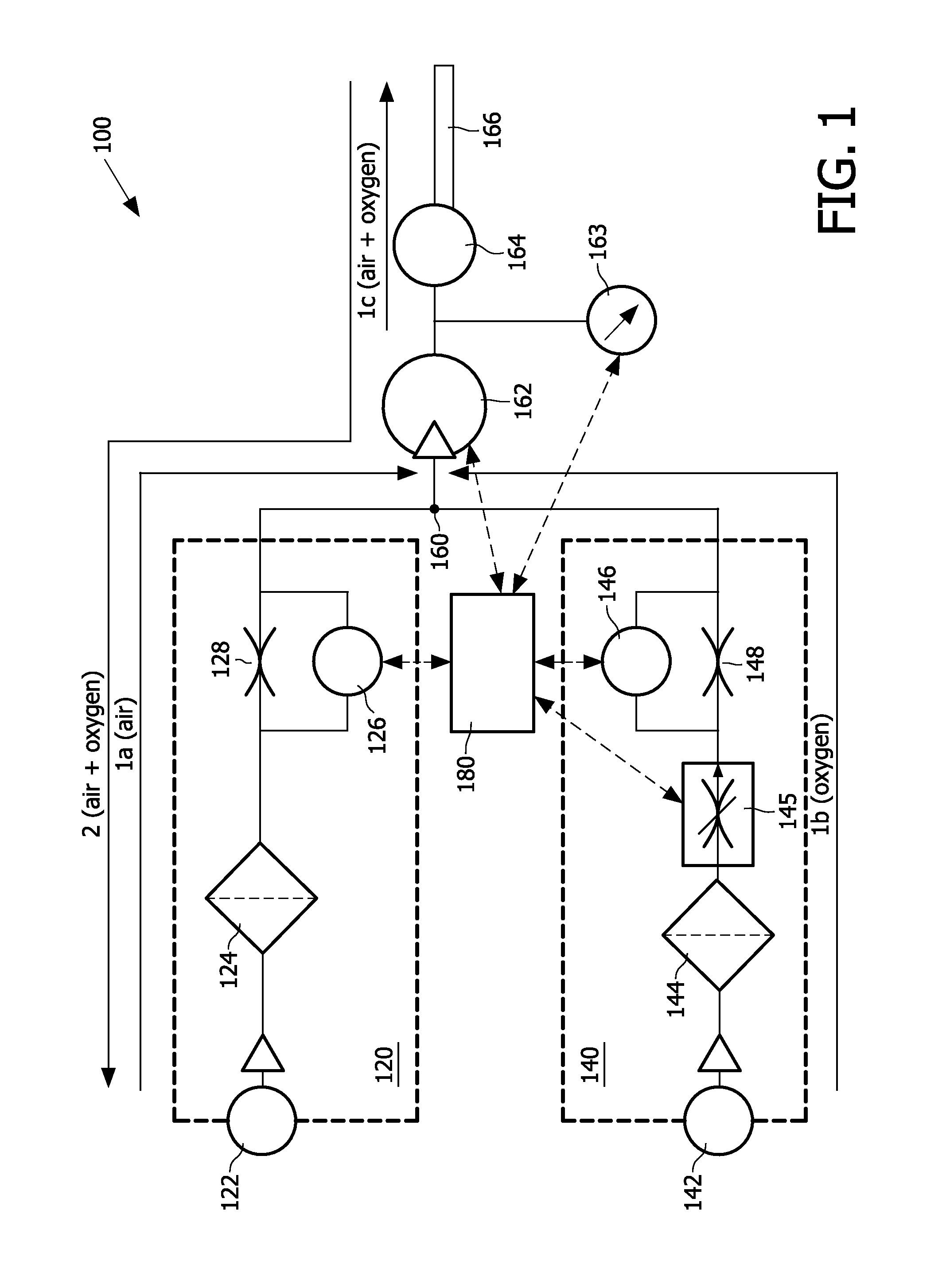

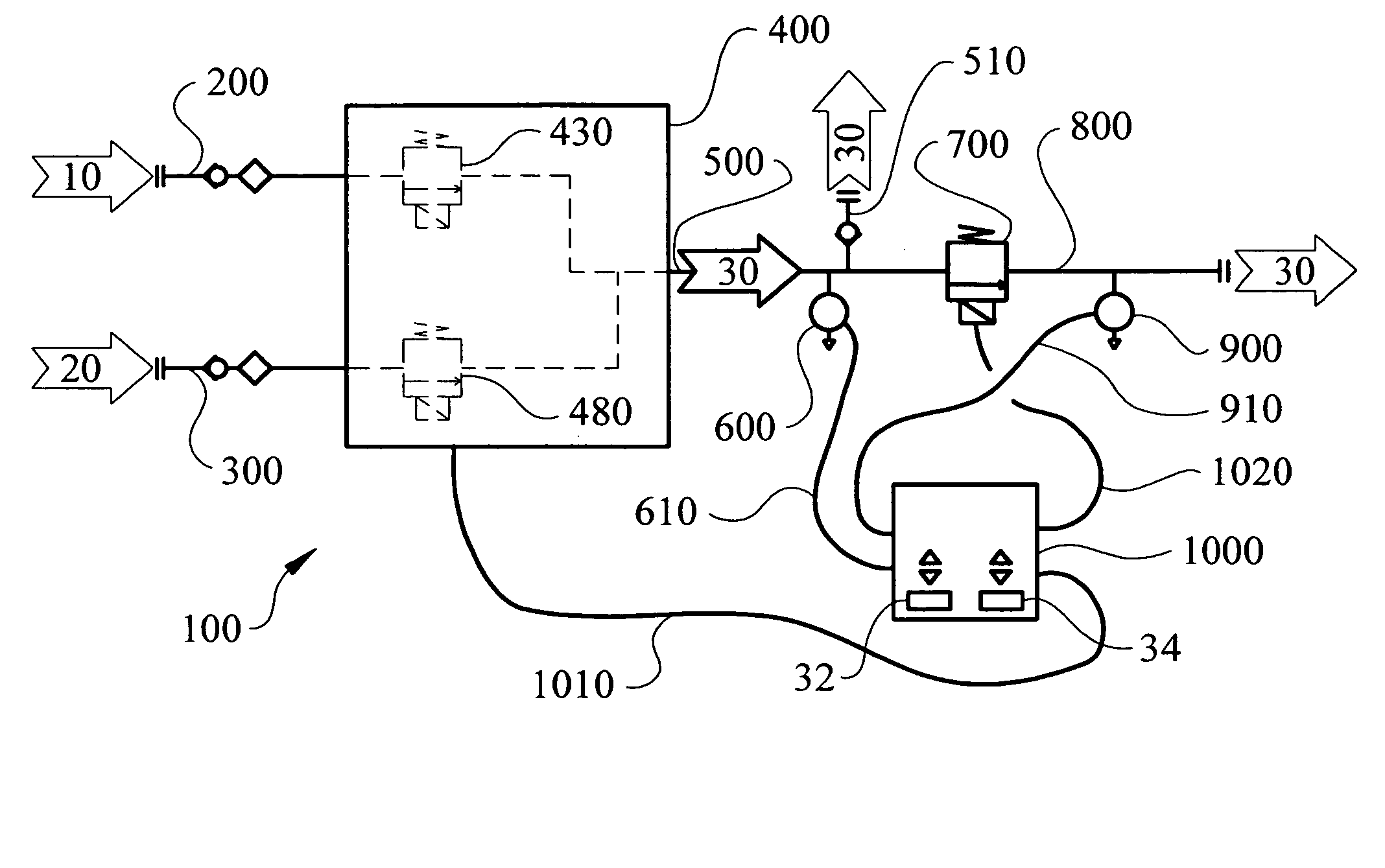

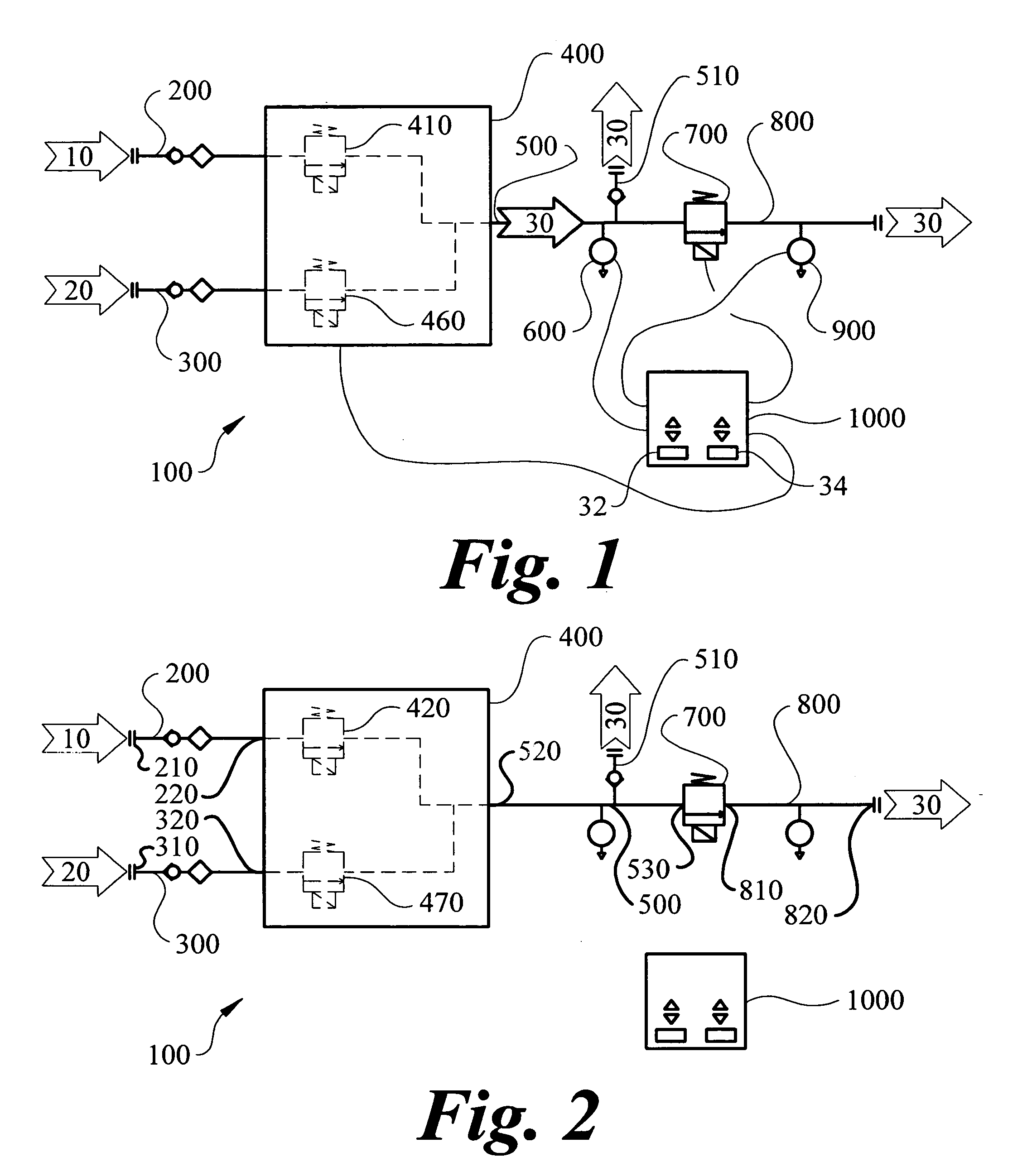

Gas mixing control apparatus and method

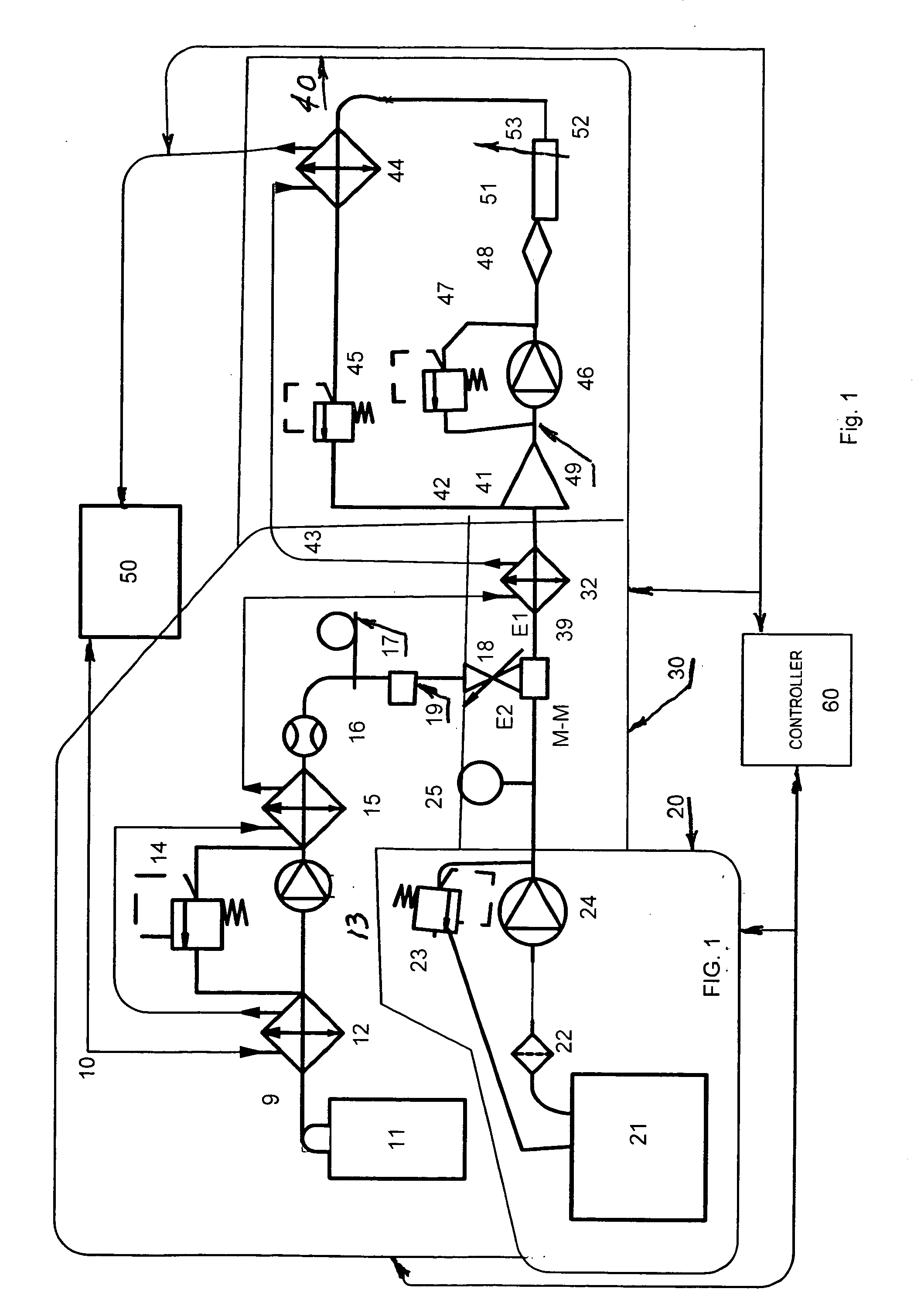

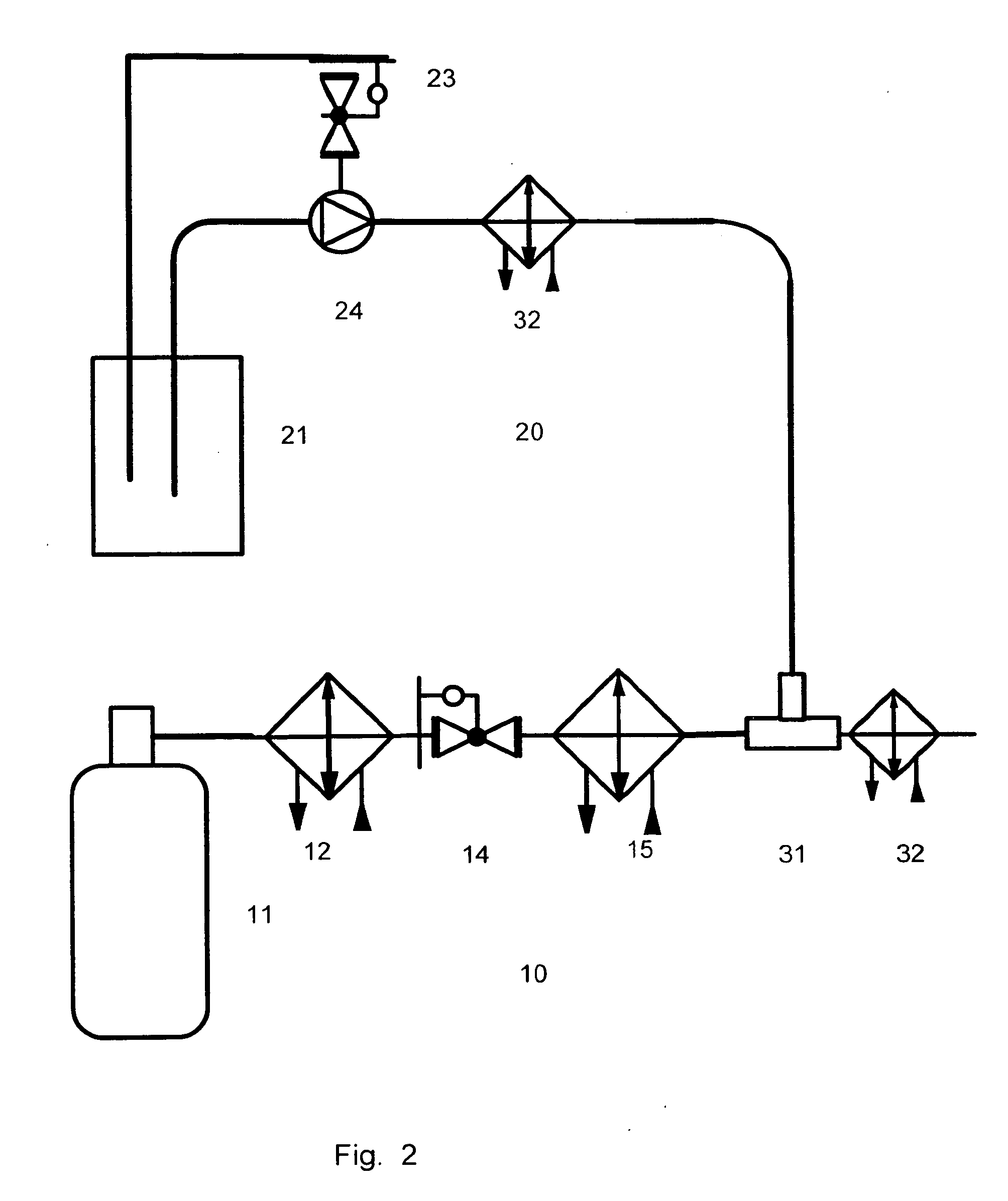

ActiveUS20120006326A1Avoids oxygen contaminationIncreased complexityRespiratorsOperating means/releasing devices for valvesFirst pathwayProcess engineering

A ventilator includes first and second pathways, a conduit and a controller. The first pathway (120) is configured to supply a first gas and the second pathway (140) is configured to supply a second gas, where the second gas is mixed with the first gas to produce mixed gas having a predetermined percentage of the second gas. The conduit (166) is configured to provide the mixed gas from the first and second pathways to an access port during an inspiratory phase, and to provide discharged gas from the access port to the first pathway during an expiratory phase. The controller (180) is configured to delay supply of the second gas from the second pathway for a delay time in order to maintain the predetermined percentage of the second gas in the mixed gas provided to the access port during a subsequent inspiratory phase.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

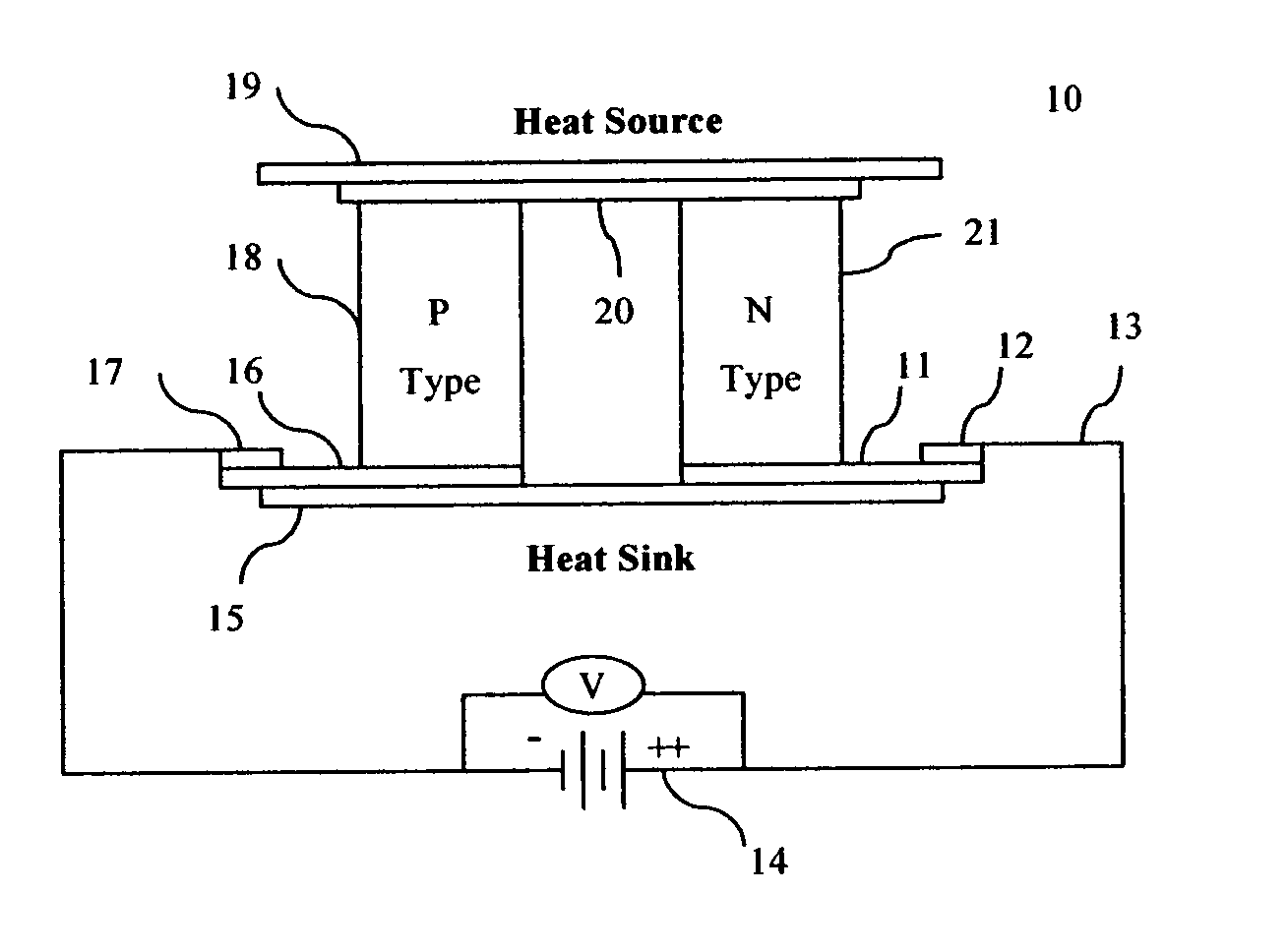

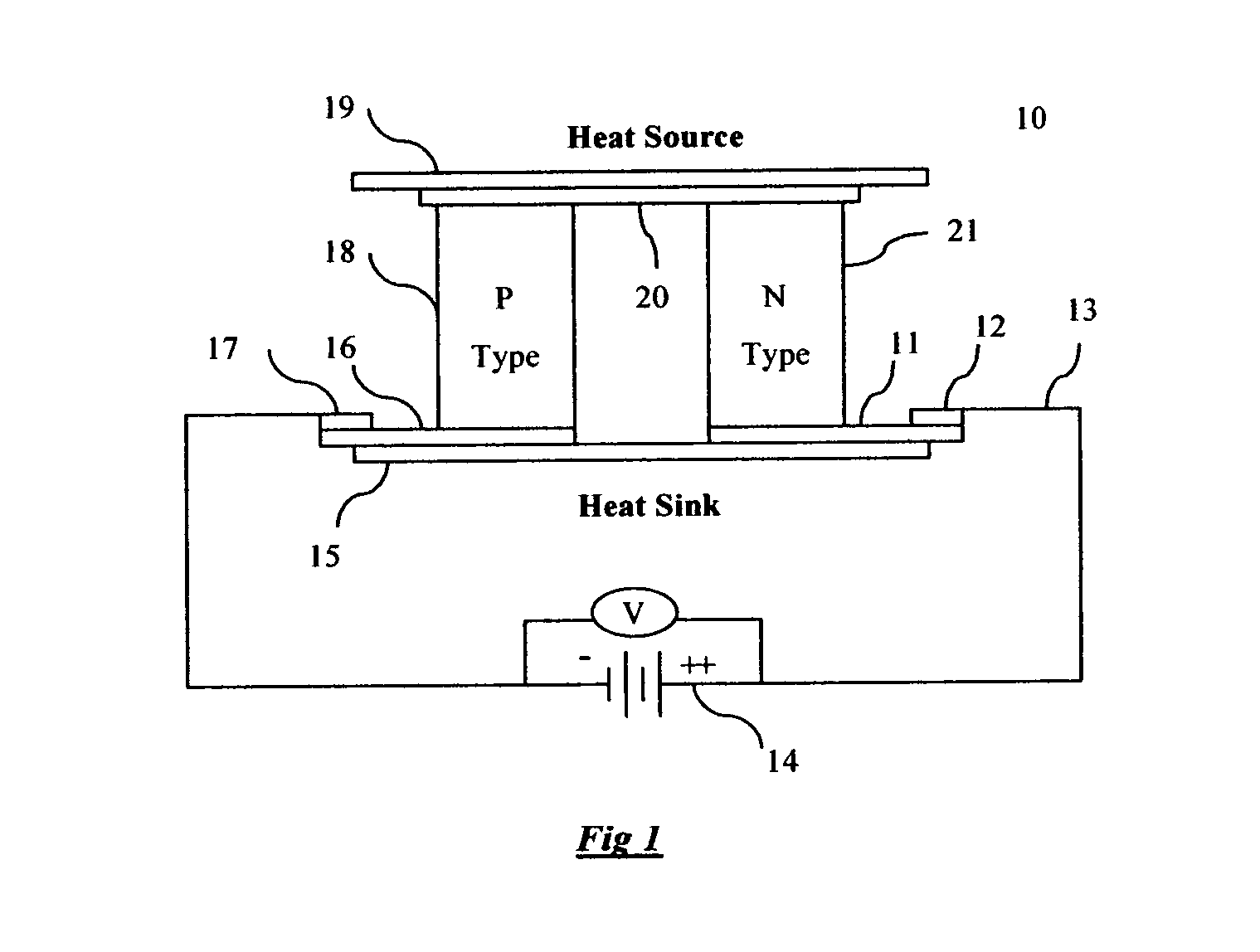

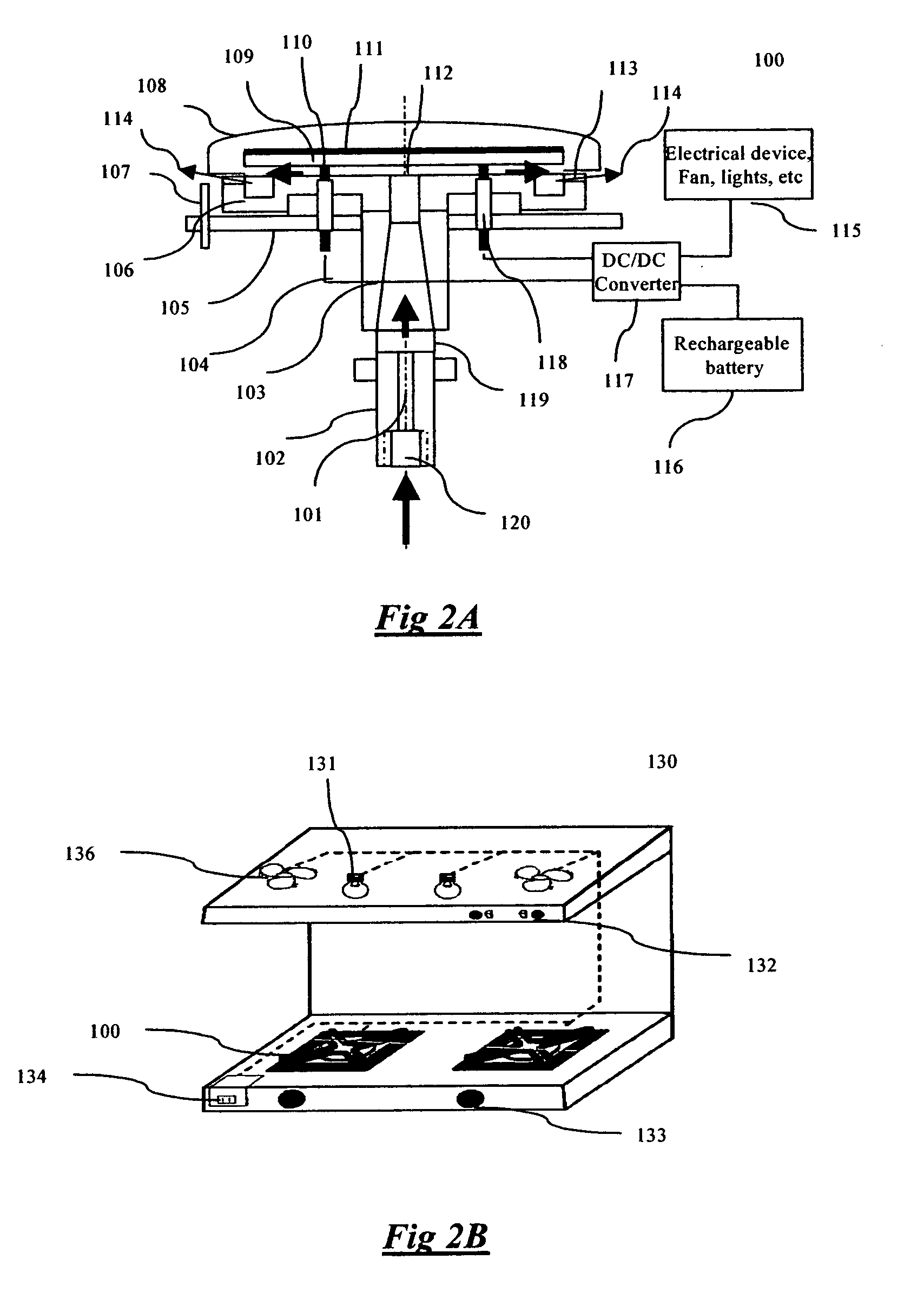

Gas stove with thermoelectric generator

InactiveUS20060016446A1Wasted thermal energyDomestic stoves or rangesGaseous heating fuelElectrical batteryEngineering

A gas burner generates electricity with waste heat energy. At least one thermoelectric unit is installed underneath the burner cap of the gas burner. Gas flame at the edge of the burner cap creates heat sources (hot side) for the thermoelectric unit. A gas-mixing chamber underneath the thermoelectric unit functions as heat sinks (cold side) for the thermoelectric unit. An insulation plate is inserted in between the thermoelectric unit and the burner cap to control the hot side temperature. The thermoelectric unit generates electricity while the gas burner is in use and the flame heats up the burner cap. The thermoelectric unit connects to an electric circuit and provides electricity to power devices such as electric fans, lights, TVs, battery chargers etc.

Owner:HU CAROLINE K +1

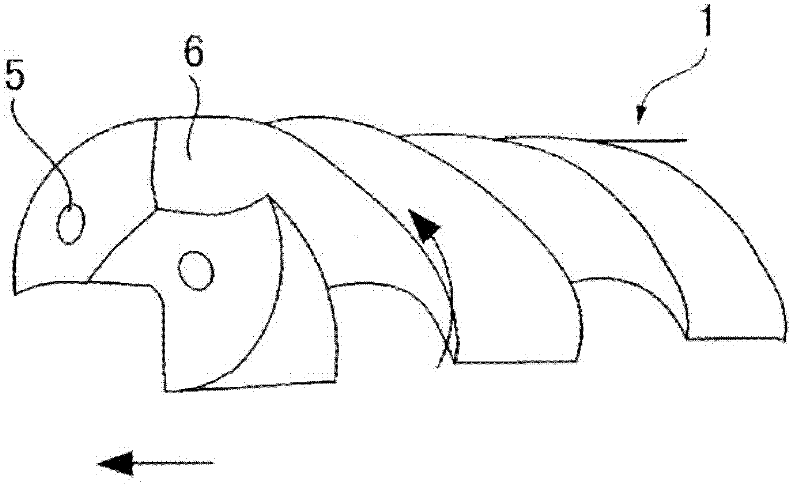

Cutting method for steel for use in machine structure

InactiveCN102470502AImprove overall lifespanMilling cuttersWorkpiecesMechanical engineeringGas mixing

Owner:NIPPON STEEL CORP

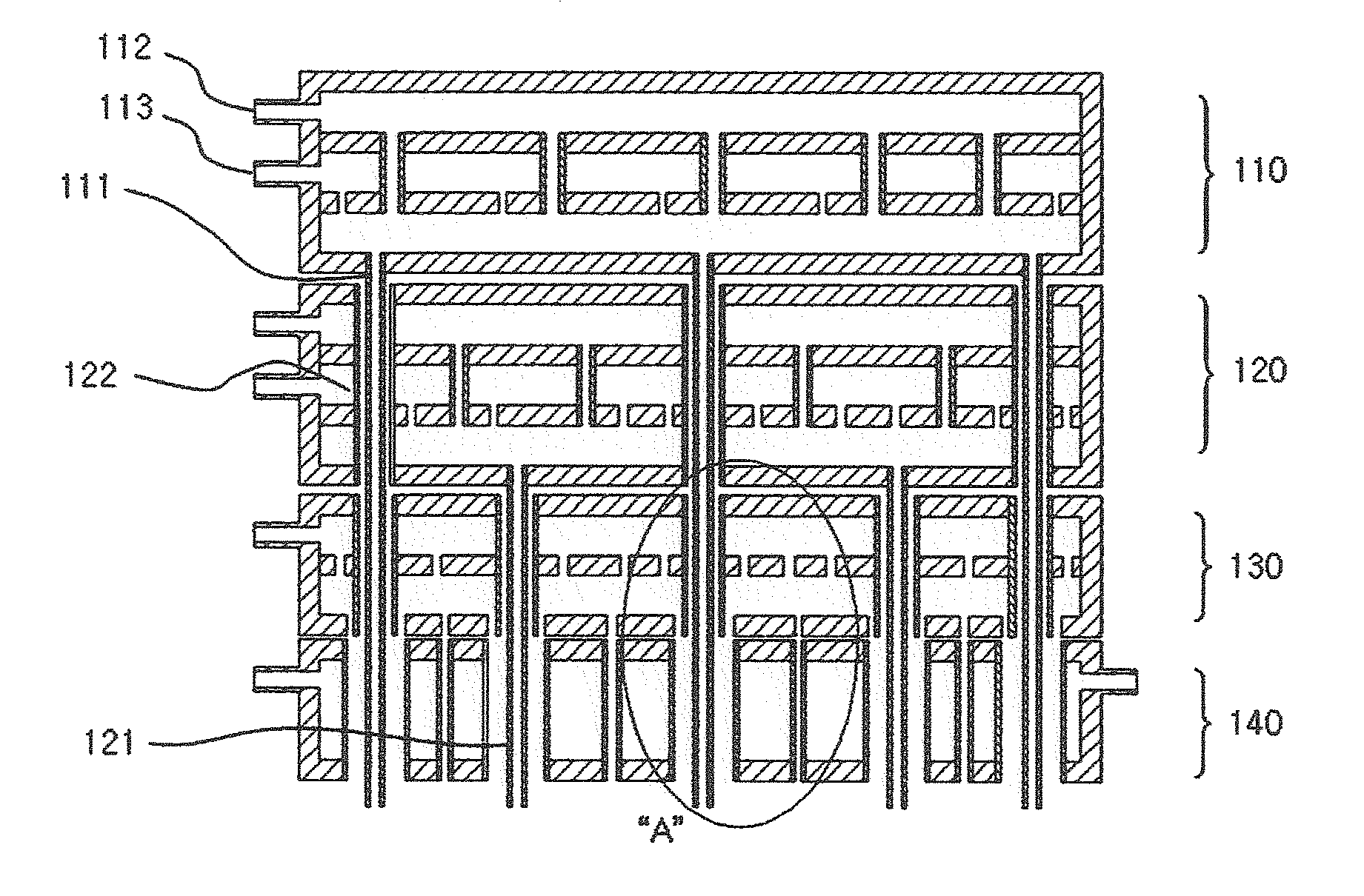

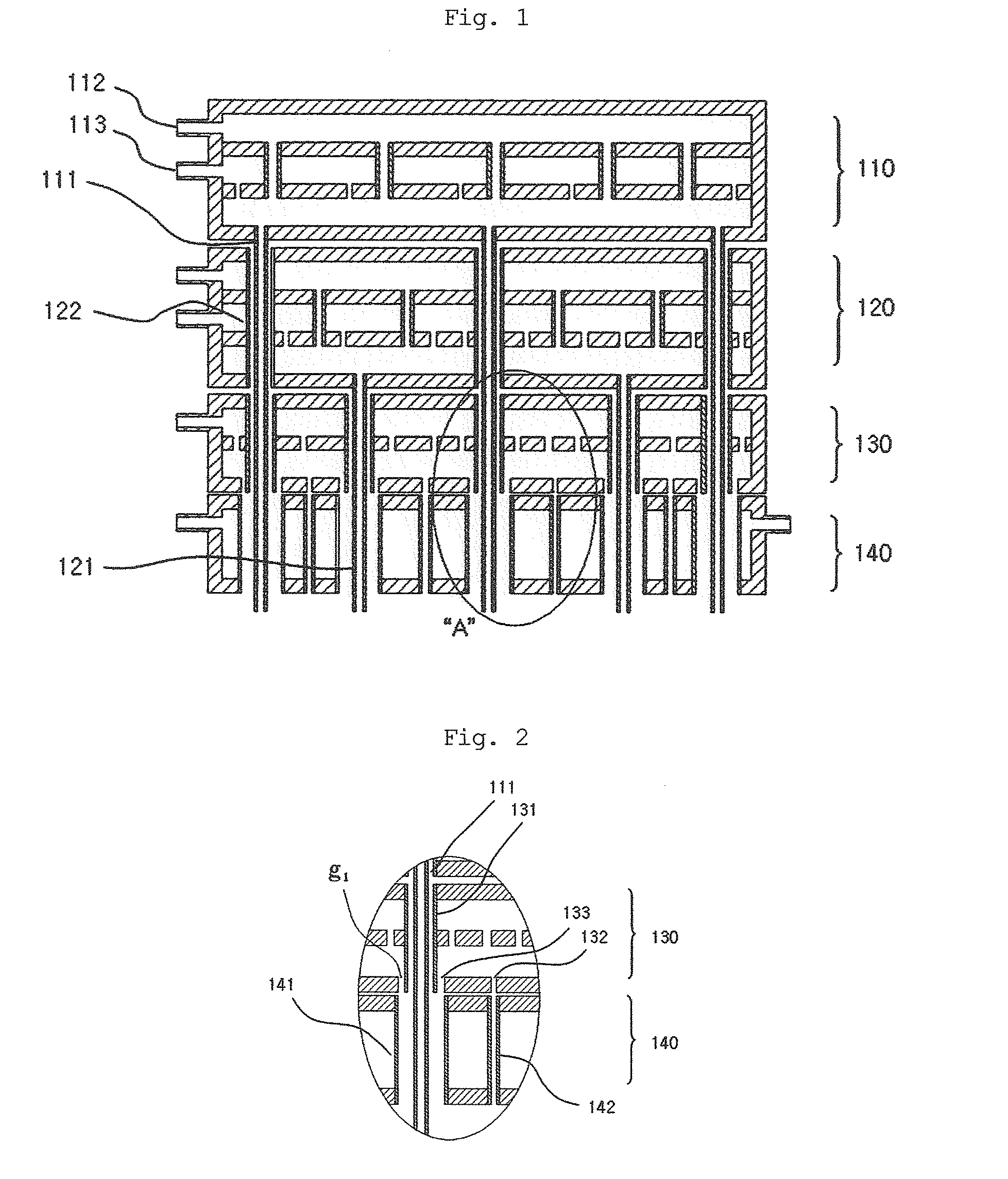

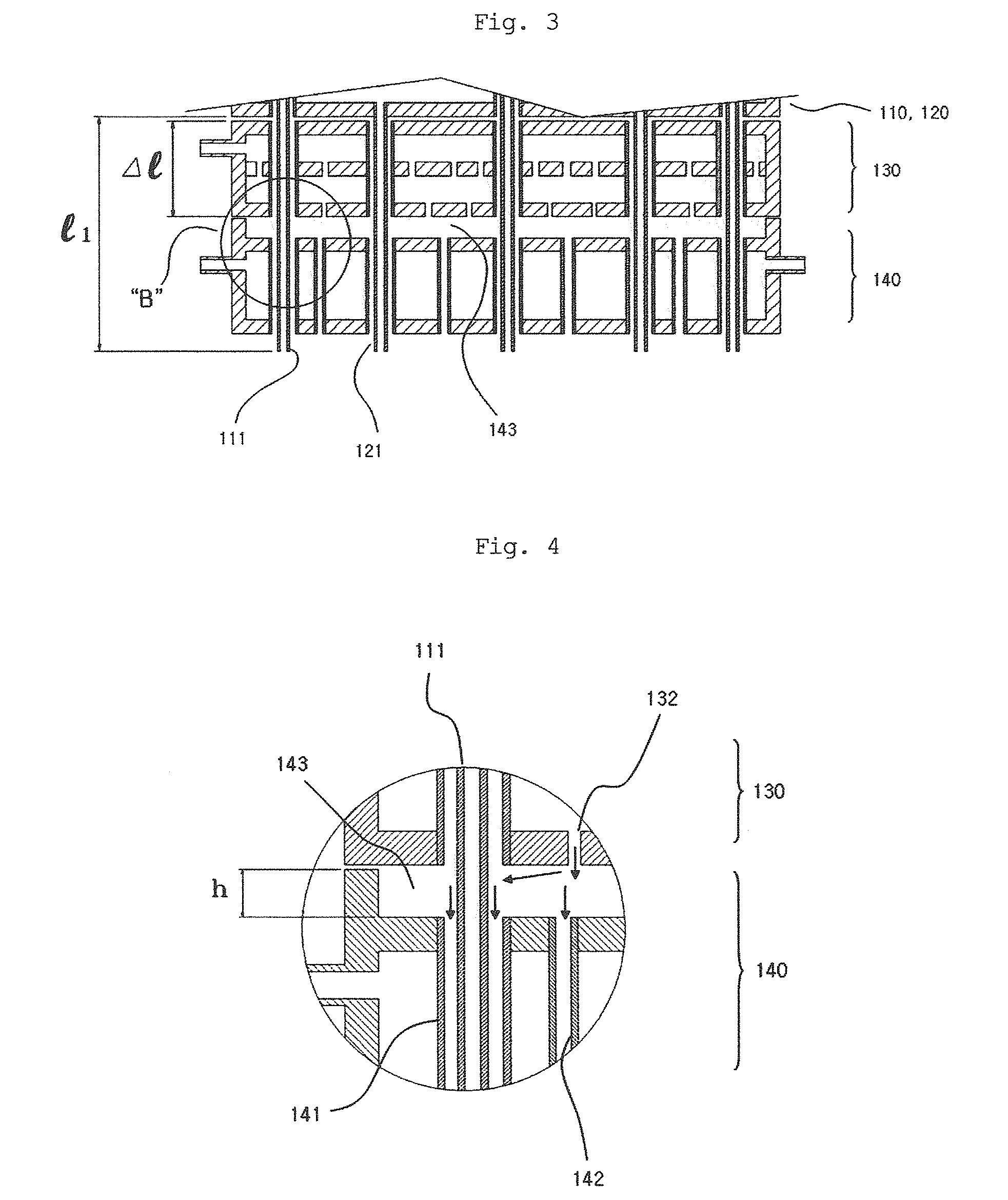

Showerhead for film depositing vacuum equipment

ActiveUS20120067971A1Shorten the lengthAccurate supplySpraying apparatusSemiconductor/solid-state device manufacturingReactive gasProduct gas

A showerhead for film-depositing vacuum equipment having an effect shortening the length of injection tubes for a reactive gas is presented. The injection tubes extend from the bottom of a reactive gas showerhead module, and two different kinds of reactive gases are mixed with an injection support gas within a reactive showerhead module so as to inject the mixed gas. The showerhead for film-depositing vacuum equipment includes the reactive gas showerhead module above a cooling jacket and a purge gas showerhead module above the reactive gas showerhead module. The injection tubes of the reactive gas showerhead module pass through the cooling jacket disposed below the reactive gas showerhead module, and the injection tubes of the purge gas showerhead module pass through the reactive gas showerhead module disposed below the purge gas showerhead module, thereby enabling the purge gas to flow into a purge gas redistribution space defined above the cooling jacket.

Owner:KOREA INST OF IND TECH

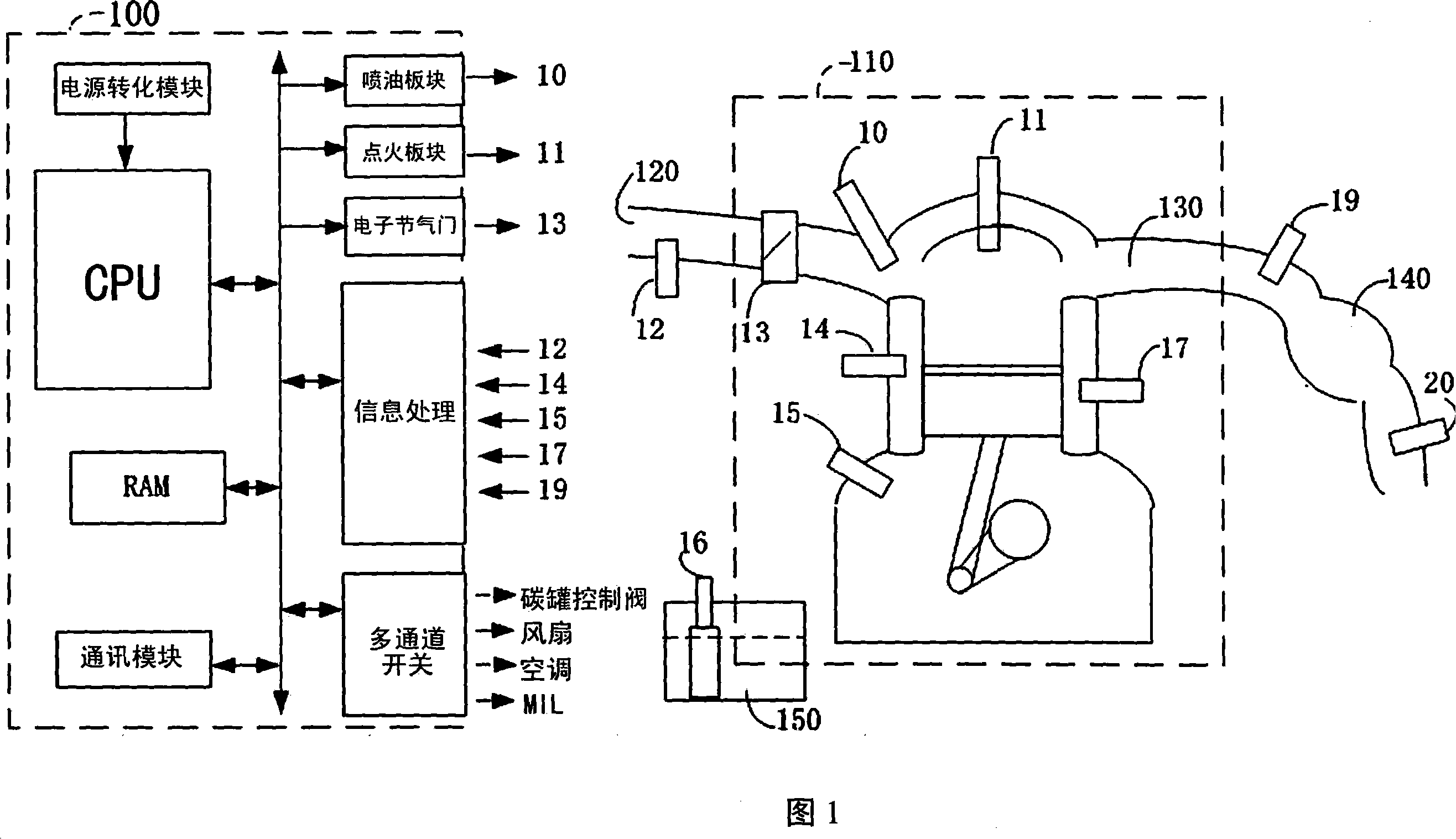

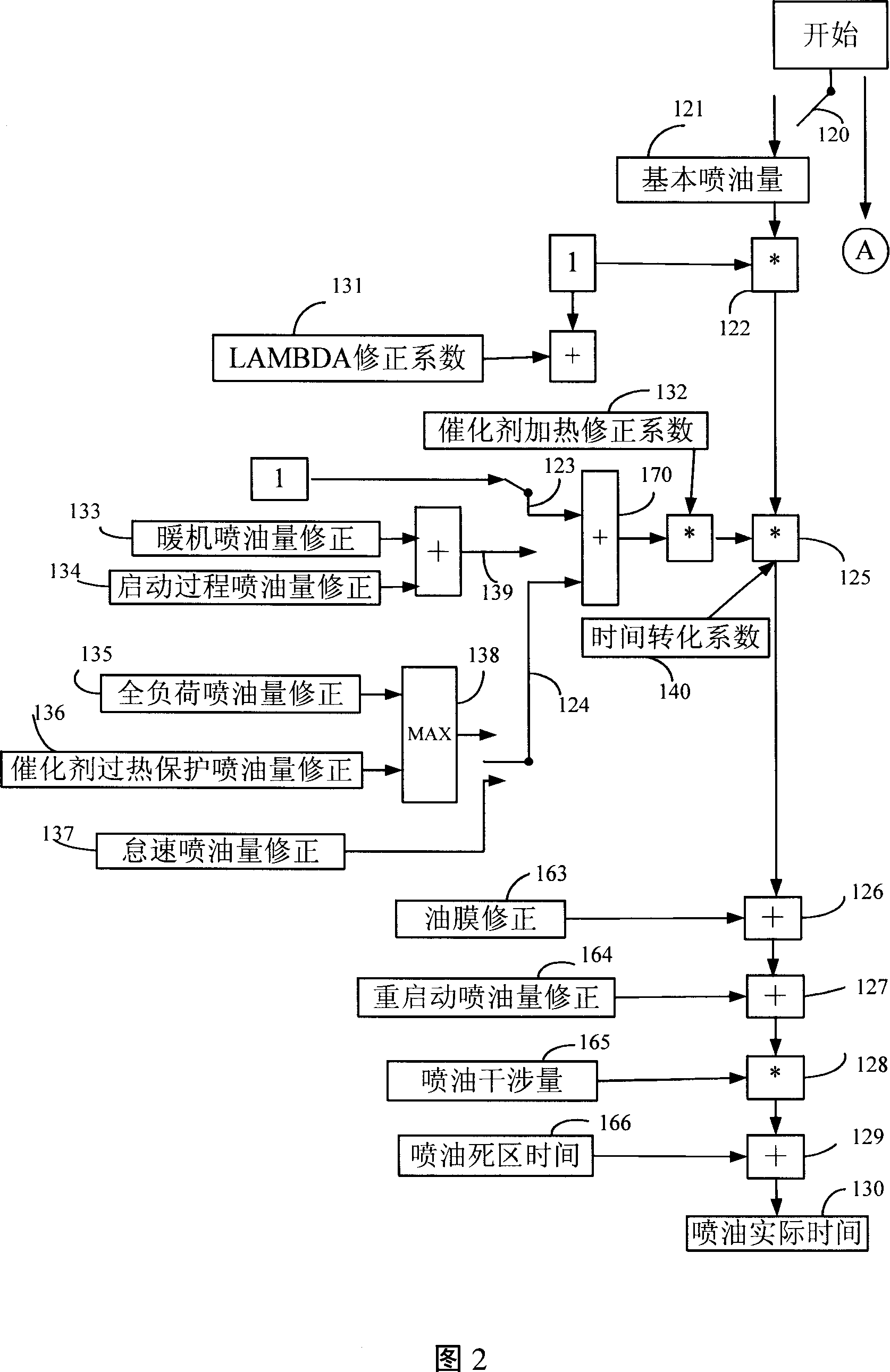

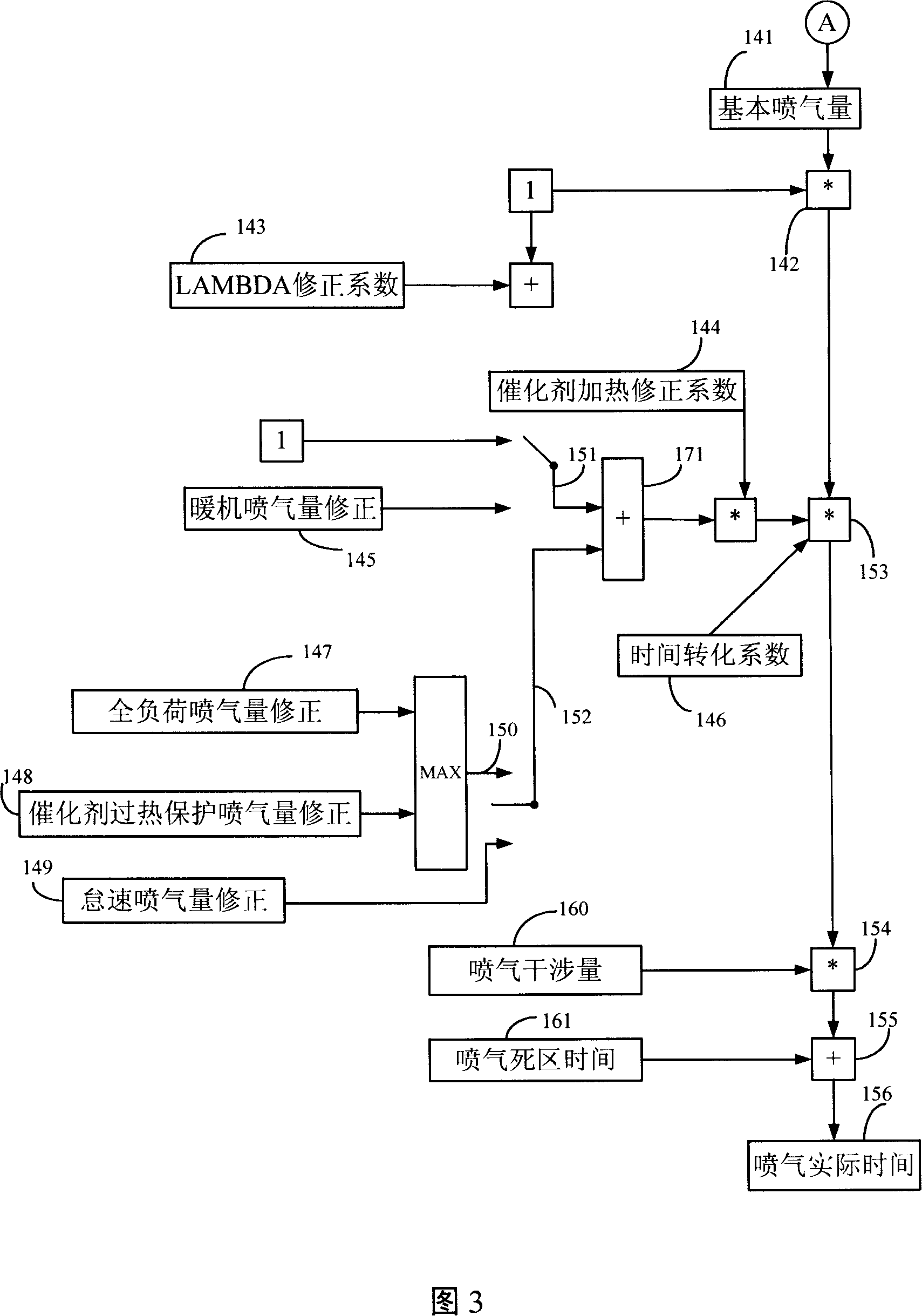

Engine oil gas mixing ECU control method

InactiveCN101105155AImprove performanceImprove powerElectrical controlMachines/enginesOxygen sensorClosed loop

The invention relates to a controlling method of fuel-air mixture electronic control unit (ECU) of engine. In the controlling method, through acquisition of air inlet temperature and pressure, water temperature, engine rotational speed, throttle position and oxygen sensor signal, the ECU accurately controls the oil (gas) spraying quantity and ignition angle; the oil (gas) spraying adopts multipoint grouping or multipoint sequential technique, and the ECU calculates the actual oil (gas) spraying quantity and actual oil (gas) spraying time with one same algorithm and two sets of rating data in the same hardware platform; the ECU performs closed-loop control to air fuel ratio; the oil (gas) spraying is controlled based on the torque of an electronic air throttle, and ECU acquires the air throttle pedal position signal and calculates the maximal torque at that time to control the opening extent of the air throttle. The controlling method can remarkably improve the performance of engine, obtain the optimal air fuel ratio under various operating conditions, and make the automobile to achieve the optimal dynamic force.

Owner:CHINA VAGON AUTOMOTIVES HLDG CO LTD

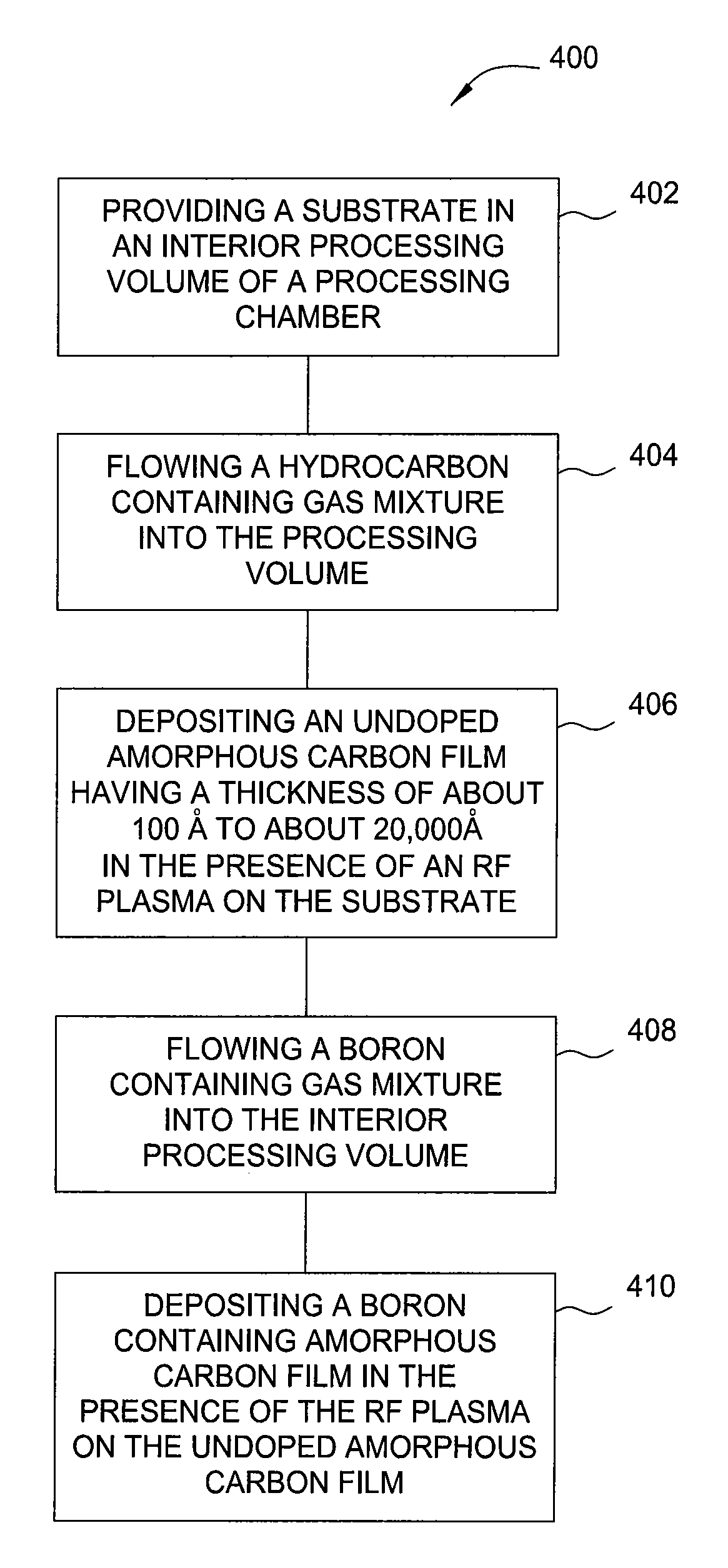

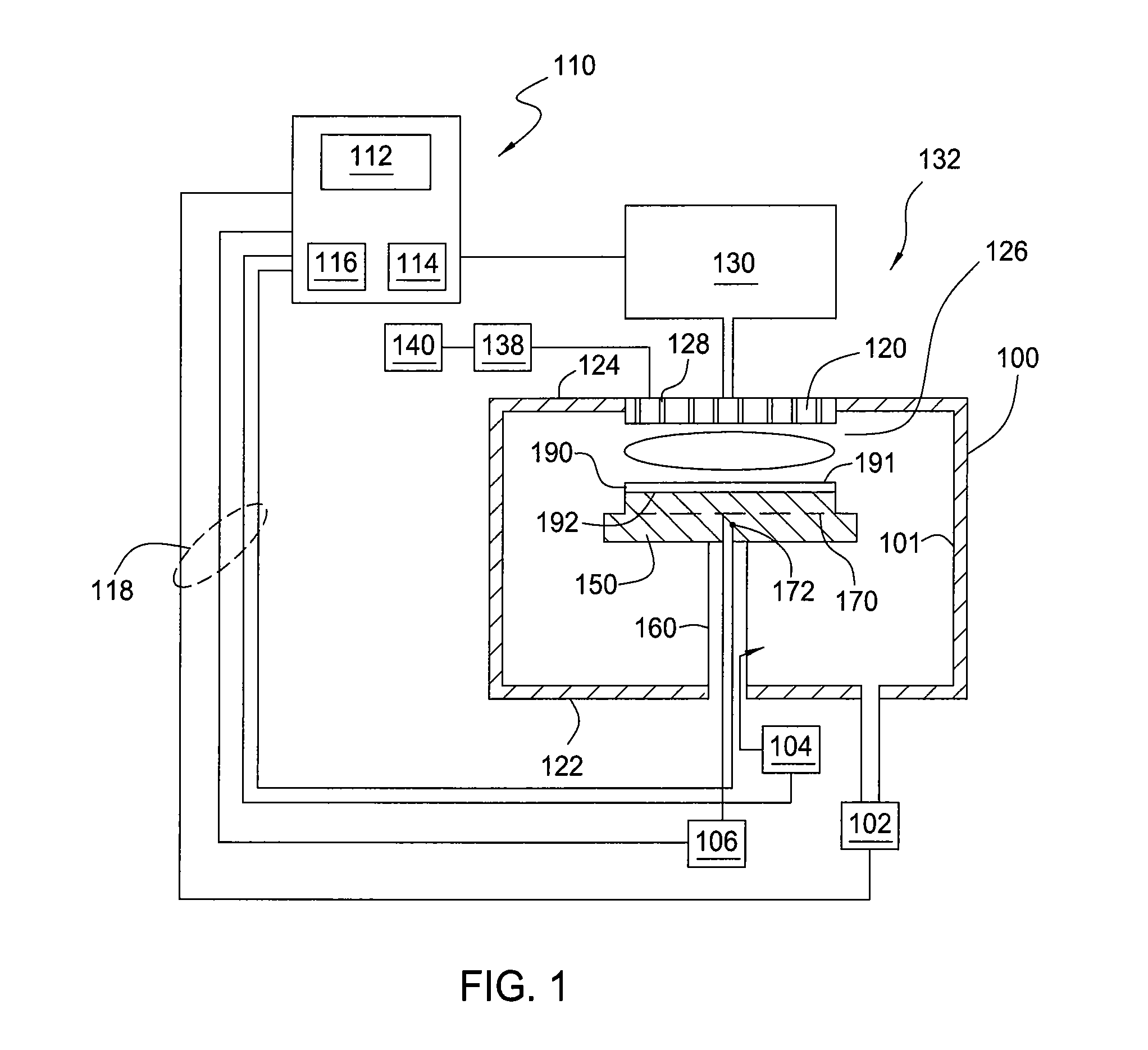

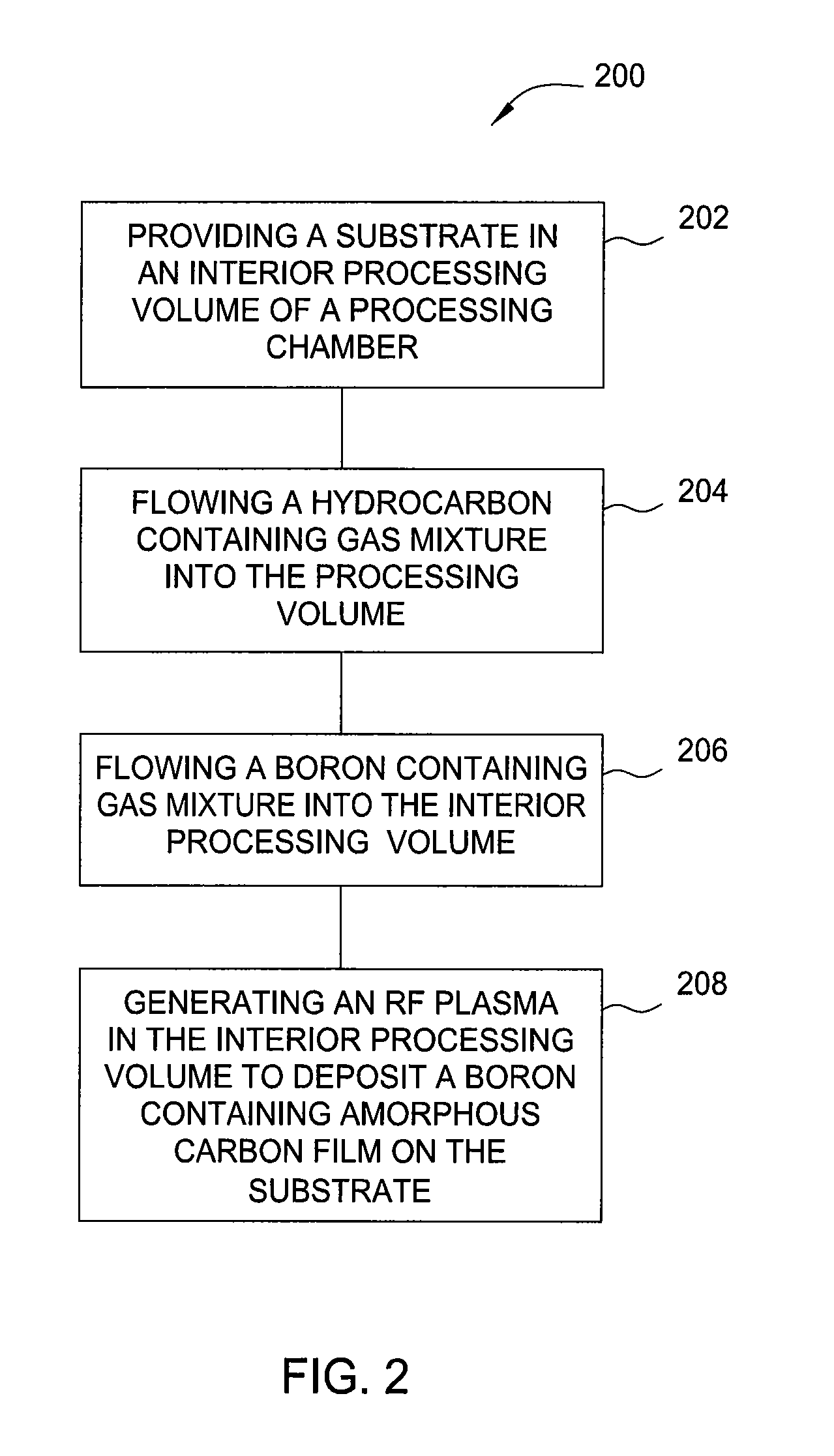

Ultra high selectivity doped amorphous carbon strippable hardmask development and integration

ActiveUS20120080779A1Electric discharge tubesSemiconductor/solid-state device detailsCarbon filmCarbon layer

Embodiments of the present invention generally relate to the fabrication of integrated circuits and particularly to the deposition of a boron containing amorphous carbon layer on a semiconductor substrate. In one embodiment, a method of processing a substrate in a processing chamber is provided. The method comprises providing a substrate in a processing volume, flowing a hydrocarbon containing gas mixture into the processing volume, generating a plasma of the hydrocarbon containing gas mixture by applying power from an RF source, flowing a boron containing gas mixture into the processing volume, and depositing a boron containing amorphous carbon film on the substrate in the presence of the plasma, wherein the boron containing amorphous carbon film contains from about 30 to about 60 atomic percentage of boron.

Owner:APPLIED MATERIALS INC

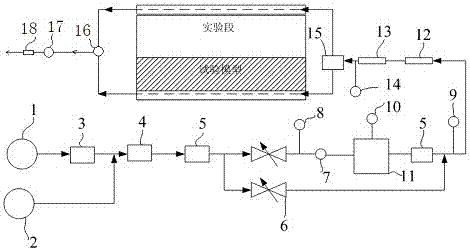

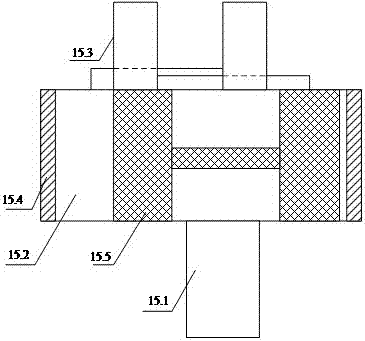

Icing wind tunnel hot gas anti-icing test high-precision simulation method and device

ActiveCN107271134AAvoid low temperature freezing and other problemsReduce high pressure heatAerodynamic testingWind energy generationThermodynamicsTemperature conditioning

The present invention discloses an icing wind tunnel hot gas anti-icing test high-precision simulation method and device. The device comprises a gas source, a pressure reduction device, a filter, an air heater, a multistage electric heating device and a test section in order from a gas input direction to a gas output direction. The gas path behind the pressure reduction device is divided into two paths, one path is heated and then is subjected to flow mixing with the other unheated path, a pneumatic switching valve in an icing wind tunnel plenum chamber is configured to divide the gas path into two paths, gas of one path enters a test section and flows out after passing through a test model to perform flow measurement, gas of the other path is flown through from the external portion of the test section and performs flow measurement, and gas of a model main path and gas of a simulation bypass path are combined into one path after passing through the wind tunnel test section and are exhausted through a flowmeter and a silencer; a cold and hot gas mixing mode is employed to rapidly reduce the high-pressure hot gas behind the air heater so as to reach the effect of rapid temperature adjustment; and the multistage electric heating device is employed to perform high-precision temperature regulation and control so as to perform high-precision temperature adjustment of high-pressure hot gas prior to the high-pressure hot gas entering a test model step by step.

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

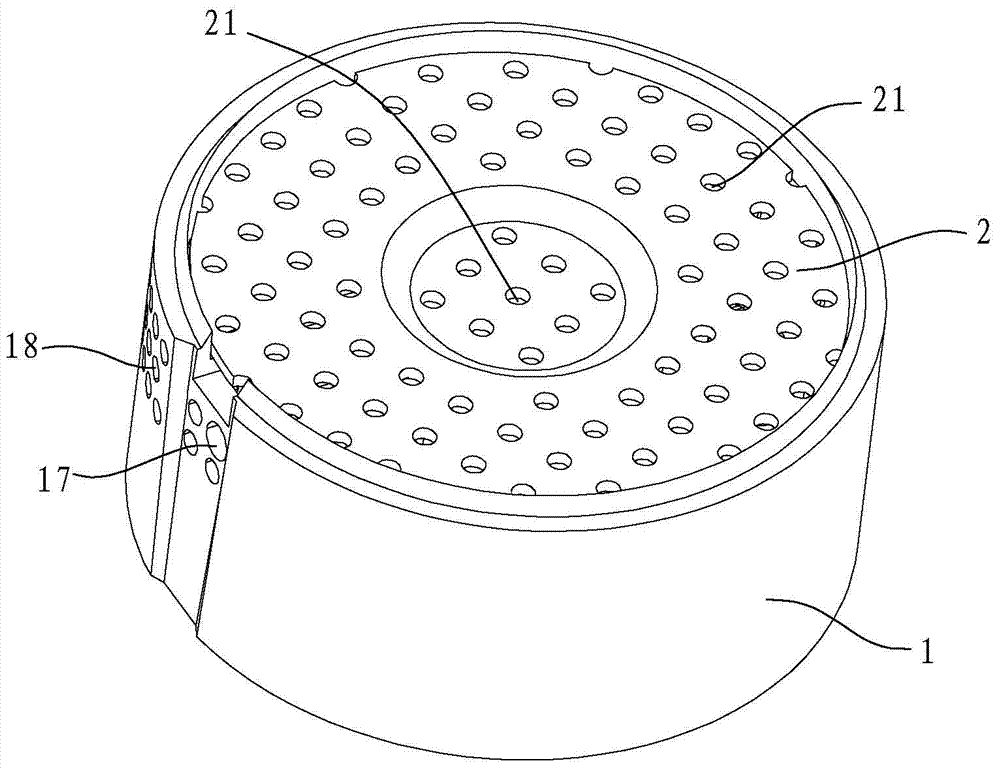

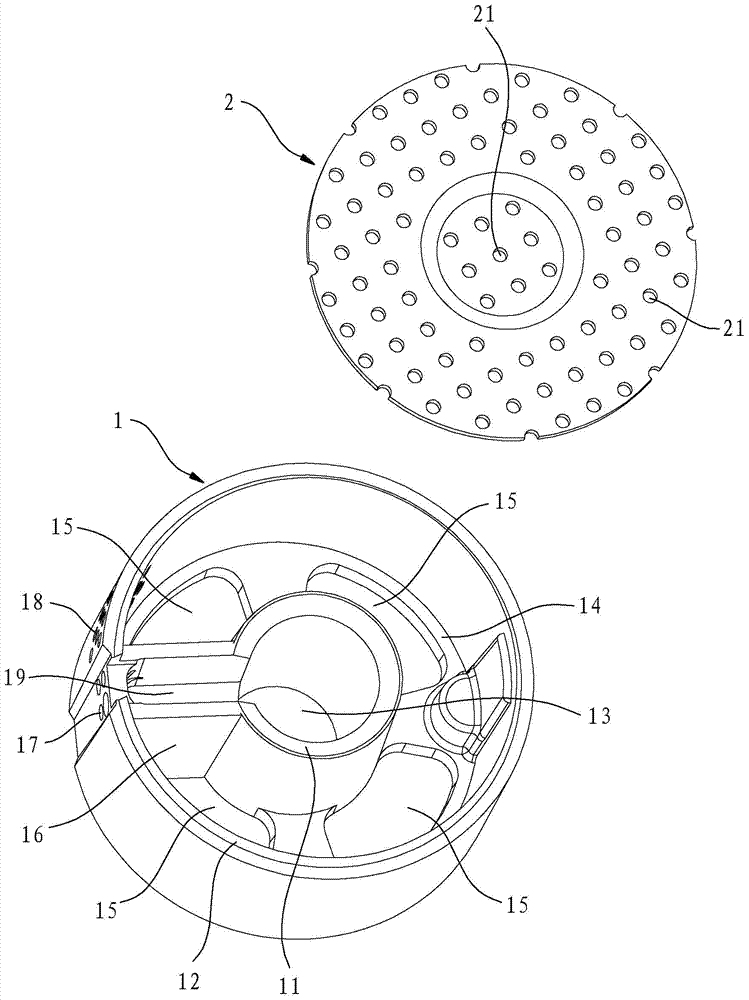

Burner cap of household gas stove and combustor provided with same

The invention discloses a burner cap of a household gas stove. The burner cap of the household gas stove comprises a burner cap body and an upper cover arranged at the top of the burner cap body. The burner cap is characterized in that the burner cap body is provided with an inner ring wall and an outer ring wall, a center through hole is formed in the center of the inner ring wall, an annular channel is formed between the inner ring wall and the outer ring wall, a through hole is formed in the bottom of the annular channel, and the upper cover is of a sheet structure densely provided with meshes. The invention further discloses a combustor provided with the burner cap of the household gas stove, the burner cap is arranged on a gas mixing chamber, the center through hole is communicated with an inner ring gas mixing cavity, and the through hole in the bottom of the annular channel is communicated with a middle ring gas mixing cavity. The burner cap of the household gas stove has the advantages that by the adoption of the burner cap, a middle ring needs little secondary air, an inner ring achieves fully premixed atmospheric combustion, the temperature of burning flame reaches about 1000 DEG C, the flame is directly injected, combustion is centralized, the secondary air takes little heat away, and therefore the heat efficiency is good; on the premise of ensuring the heat efficiency, little secondary air is needed, and the diameter of the combustor can be small relatively.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

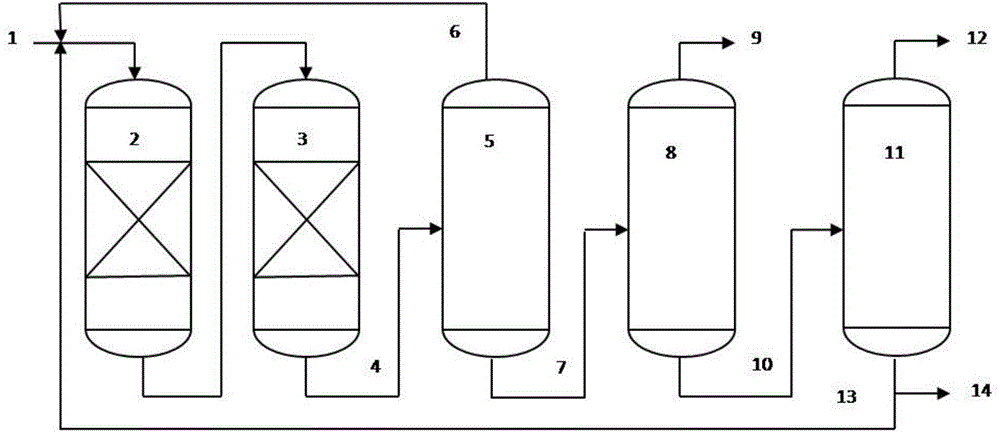

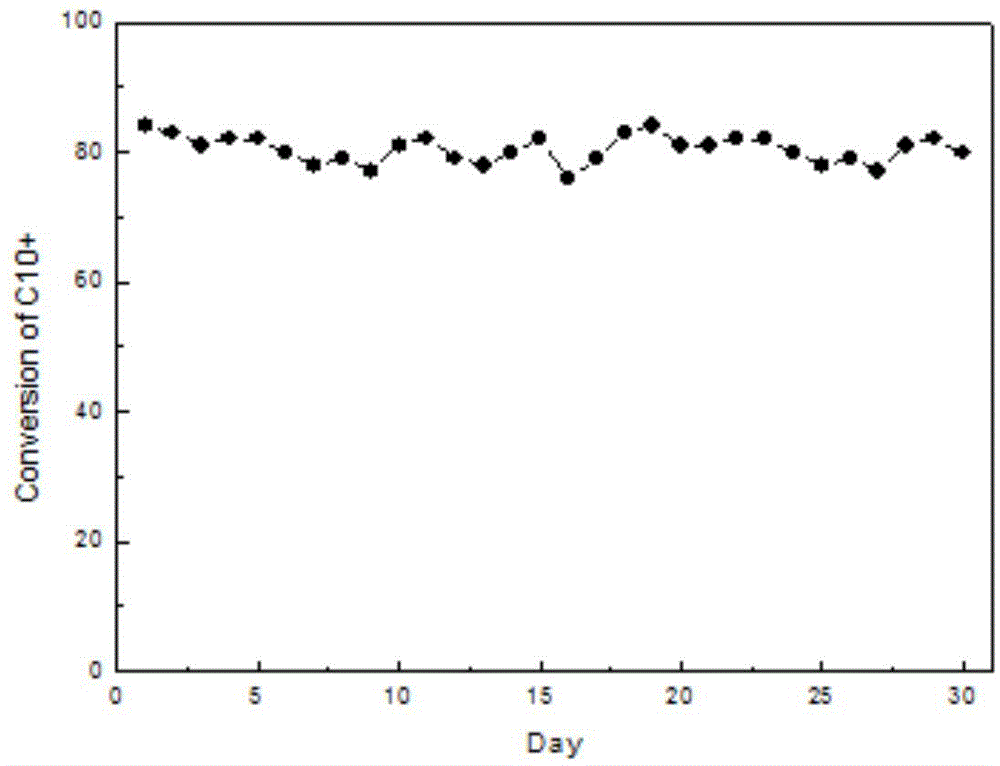

Method for conversion of C10+ heavy aromatics into light aromatics by virtue of hydrogenation

ActiveCN104357083AHigh quality feedHigh activityTreatment with hydrotreatment processesBenzeneHydrogen

The invention relates to a method for conversion of C10+ heavy aromatics into light aromatics by virtue of hydrogenation. The method is characterized by comprising the following steps: preheating heavy aromatics raw material through a heating furnace, performing oil-gas mixing on the preheated heavy aromatics raw material and hydrogen, respectively performing pre-hydrogenation saturation and hydrocracking reaction through two reactors in series connection in order; isolating benzene, toluene and light alkane mixture from reaction product through one-step rectification, isolating C8-C9 aromatics crude product or light fraction before 205 DEG.C for high-octane petrol blending component from tower bottom material through rectification, and circularly reacting tower bottom heavy fraction. The method can be used for processing byproduct C10+ heavy aromatics of a reformer or a steam cracking device in a refinery plant, and increasing the production of light aromatics or high-octane petrol blending component. The method provided by the method has the features of high heavy aromatics conversion activity, good catalyst stability and flexible product on the process.

Owner:CHINA NAT OFFSHORE OIL CORP +2

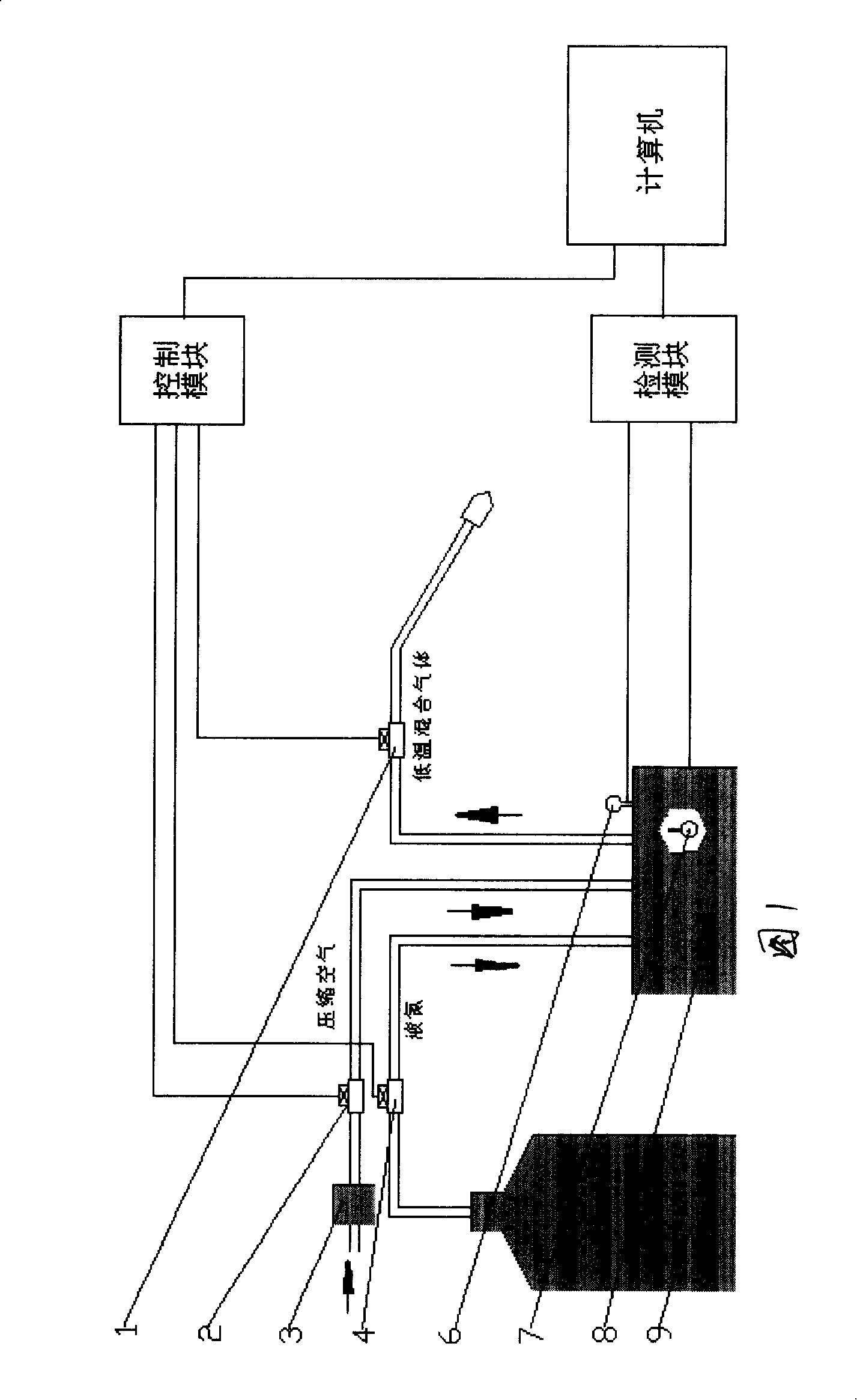

Cooling device for cutting process

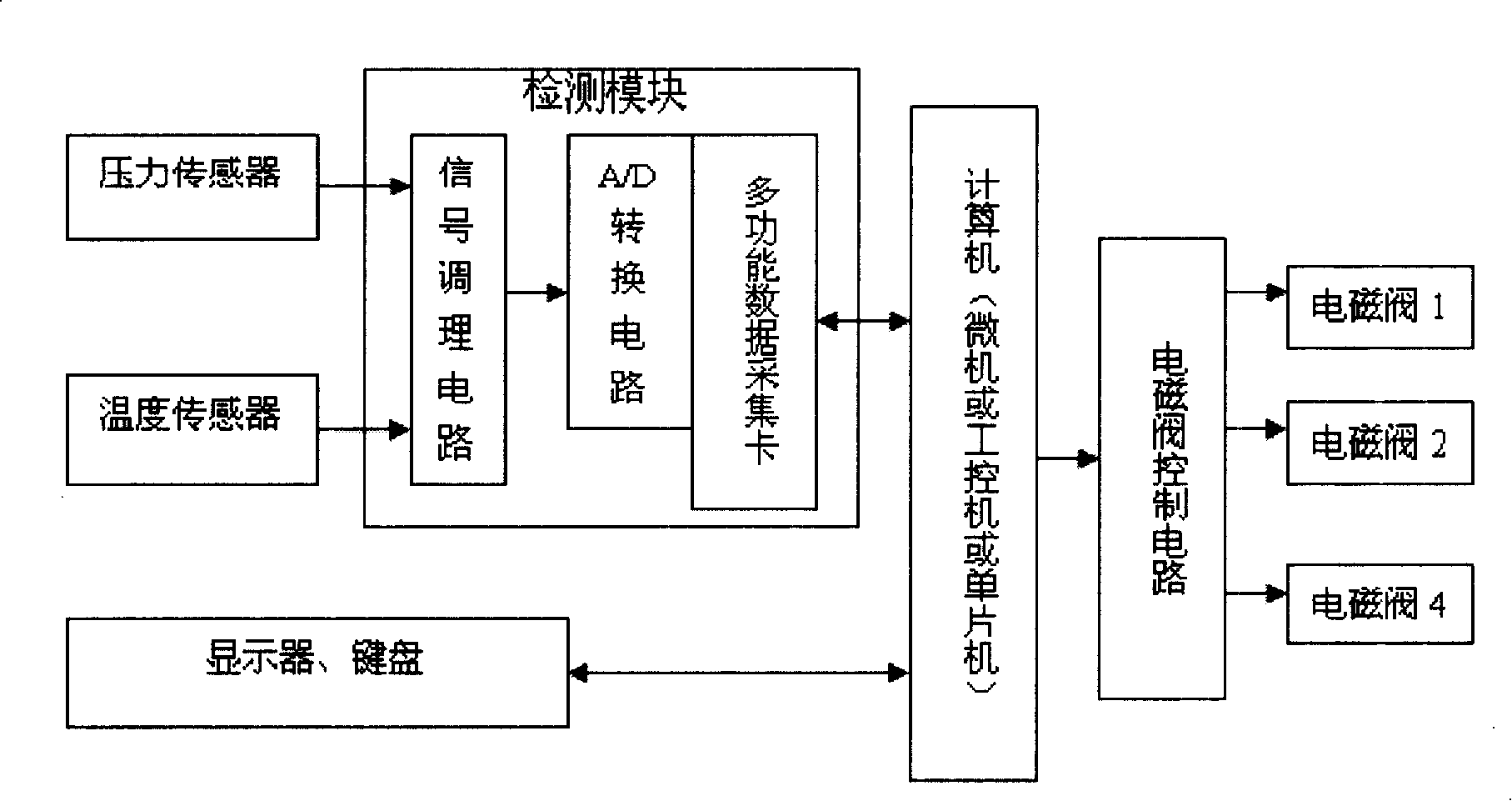

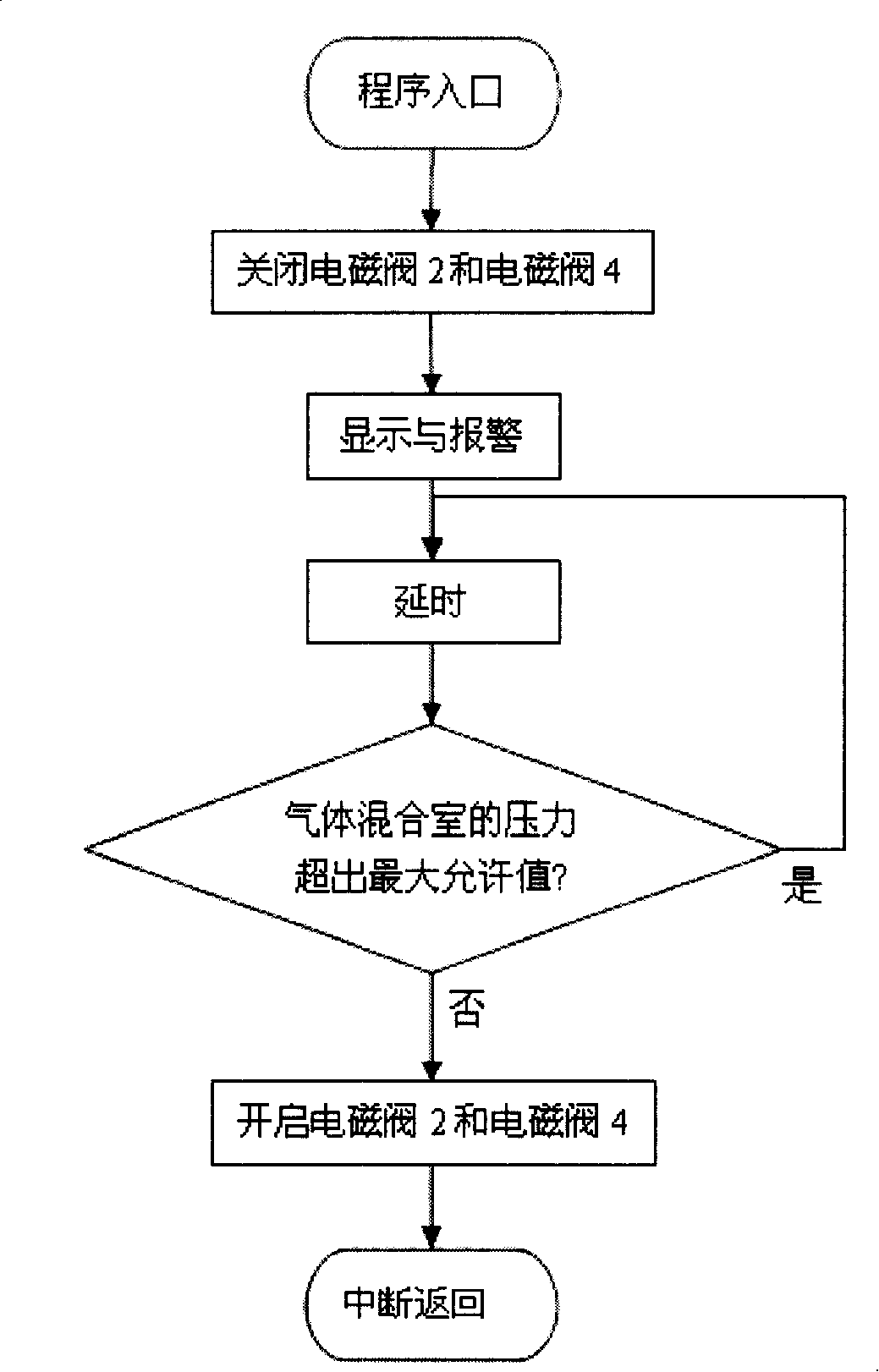

InactiveCN101209528AReduce the temperatureSimple and fast operationPipeline systemsPressure vesselsMicrocontrollerControl signal

The invention provides a cutting processing cooling device, comprising a low-temperature liquid storage tank 9, a gas mixing room 8, a compressed air filter 3, a pipe joint, a liquid nitrogen conveying pipe, electromagnetic valves 1, 2, 4, a pressure sensor 6, a temperature sensor 7, a control module, a detection module, a computer (industrial computer, micro-computer or singlechip), a display, a keyboard, and a signal line. The low-temperature liquid storage tank 9 is connected with the gas mixing room 8 through a gas conveying pipe and the electromagnetic valve 4; the compressed air is connected with the gas mixing room 8 through the gas conveying pipe, the filter 3 and the electromagnetic valve 2; the low-temperature gas and the normal-temperature gas are mixed in the mixing room; the output of the gas mixing room 8 passes through the gas conveying pipe and the electromagnetic valve 1; the temperature sensor 7 and the pressure sensor 6 in the gas mixing room 8 are connected with the detection module through the signal line; the electromagnetic valve 1, the electromagnetic valve 2 and the electromagnetic valve 4 are connected with the control module through the control signal line; the control module and the detection module are connected with the computer through communication lines.

Owner:ZHEJIANG UNIV OF TECH

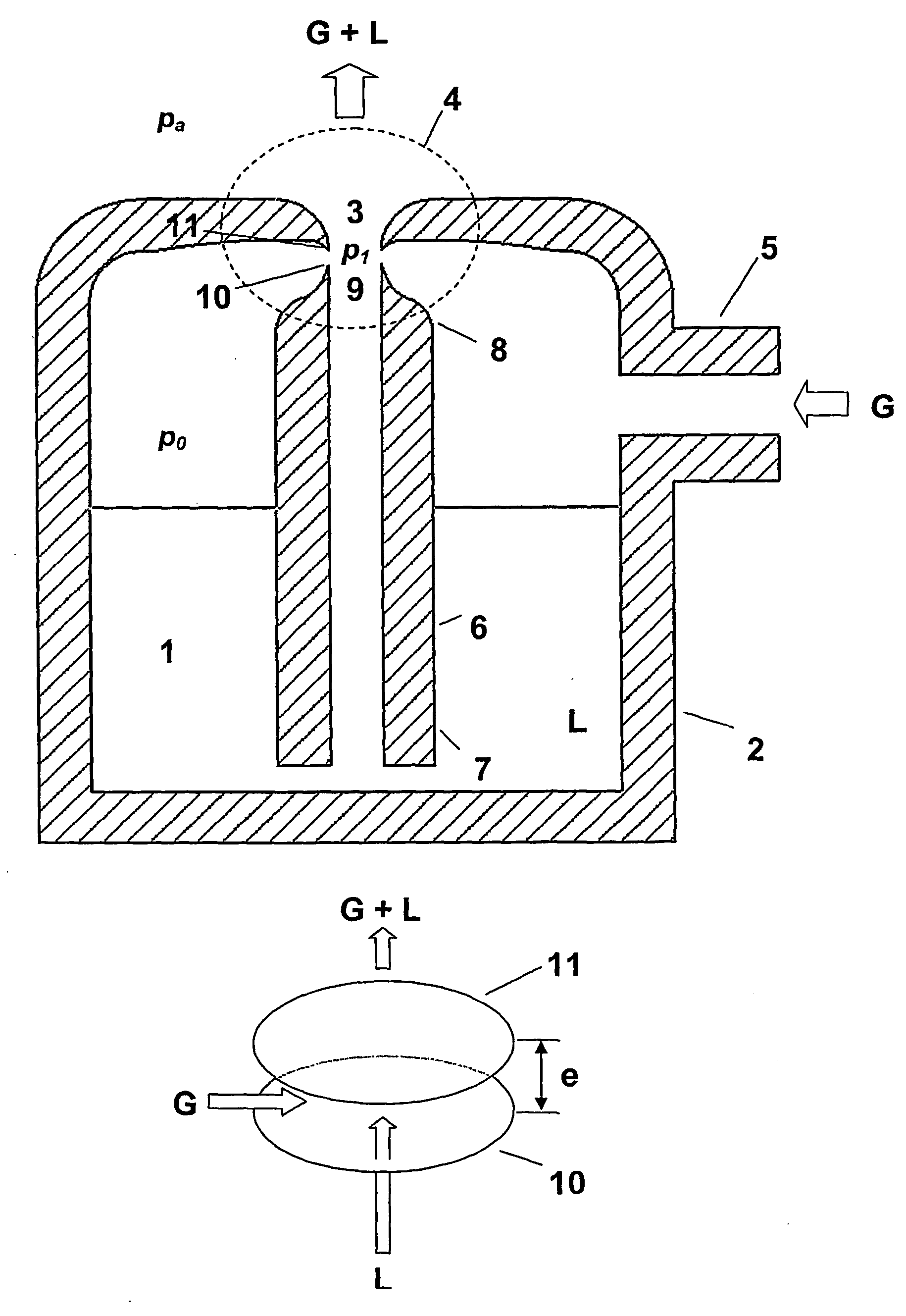

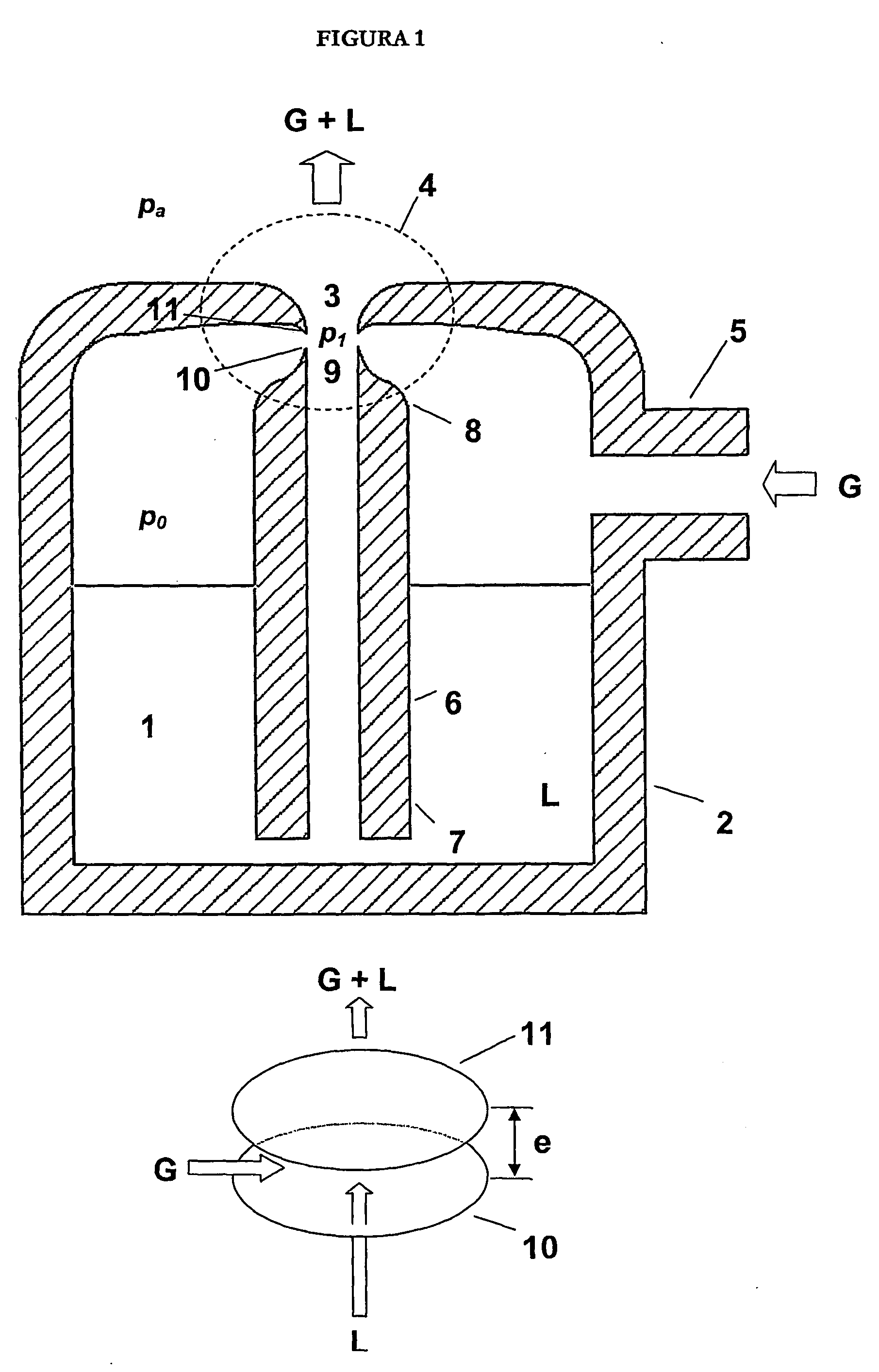

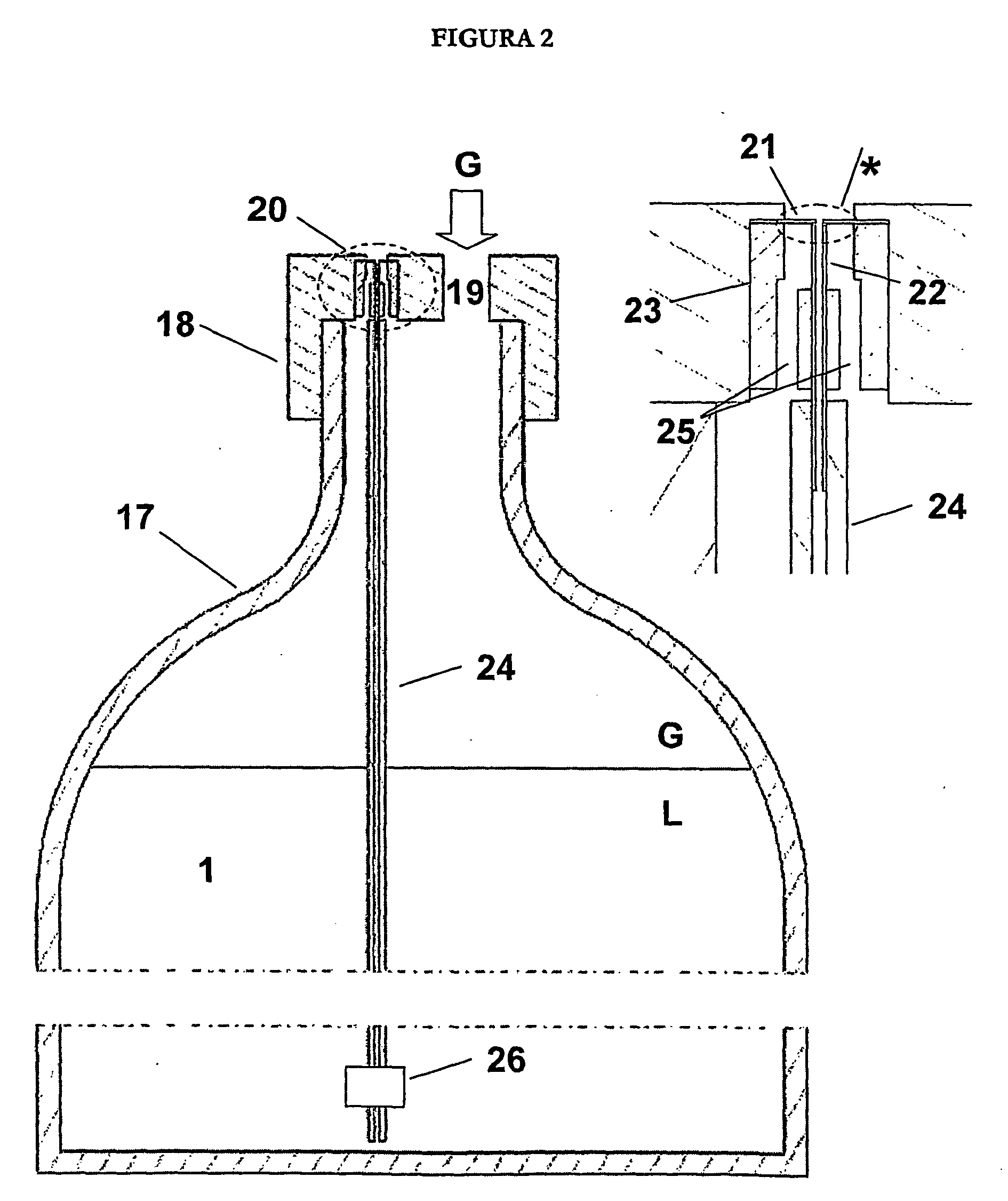

Device and procedure for the pneumatic atomization of liquids through an implosive gas flow

The invention relates to a device and method for the atomisation or nebulisation of a liquid using a propellant vapour or gas (referred to hereafter as gas) which is introduced into the device under pressure. According to the invention, the two fluids are mixed together and subsequently released to the exterior, such that the liquid is released in the form of an aerosol or a suspension of drops that is conveyed by the gas stream. The inventive device comprises a liquid storage chamber which is housed in a pressurised cylinder or container and a liquid / gas mixing area whereat the aforementioned two phases are combined and released to the exterior.

Owner:UNIV DE SEVILLA OTRI - UNIV DE SEVILLA

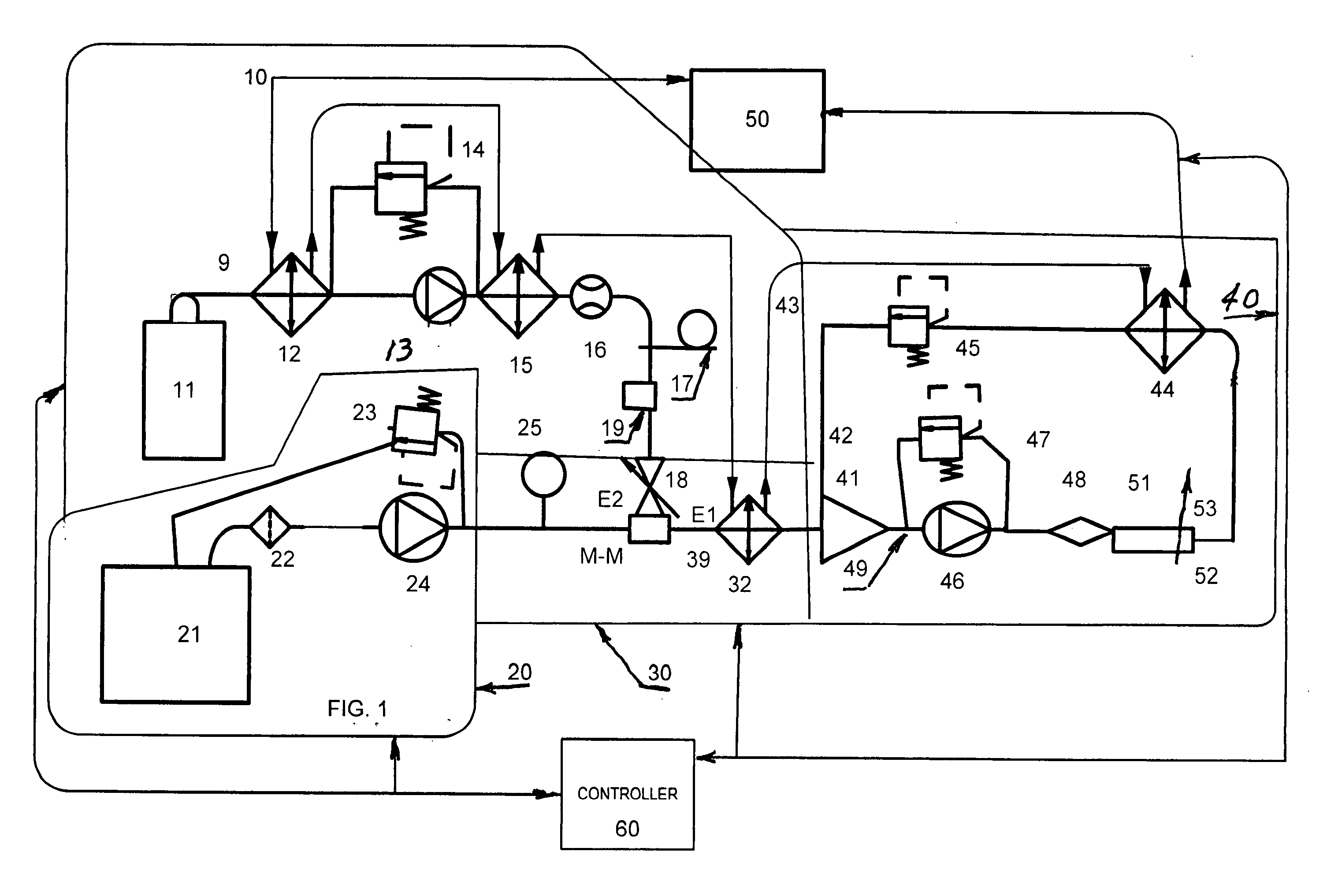

Gas blender with auxiliary mixed gas outlet

ActiveUS20070125374A1RespiratorsControlling ratio of multiple fluid flowsPositive airway pressureNebulizer

A gas blender with auxiliary mixed gas outlet for mixing a primary gas, generally air, and a secondary gas, generally oxygen, to obtain a mixed gas having several controlled characteristics. The gas blender may be incorporated into a Continuous Positive Airway Pressure (CPAP) device. The gas blender controls the mixing to produce the mixed gas having a predetermined mixture setpoint, generally an oxygen percentage, and a predetermined control setpoint, generally a pressure setpoint or flow rate setpoint. The gas blender provides an auxiliary mixed gas source for use by an auxiliary piece of equipment such as a nebulizer or resuscitation bag. The gas blender includes a primary gas inlet passageway, a secondary gas inlet passageway, a gas mixing apparatus, a mixed gas distribution passageway with an auxiliary mixed gas outlet, a gas sensor, a delivery sensor, a mixed gas delivery control valve, a mixed gas controlled passageway, and a controller.

Owner:VYAIRE MEDICAL CONSUMABLES LLC

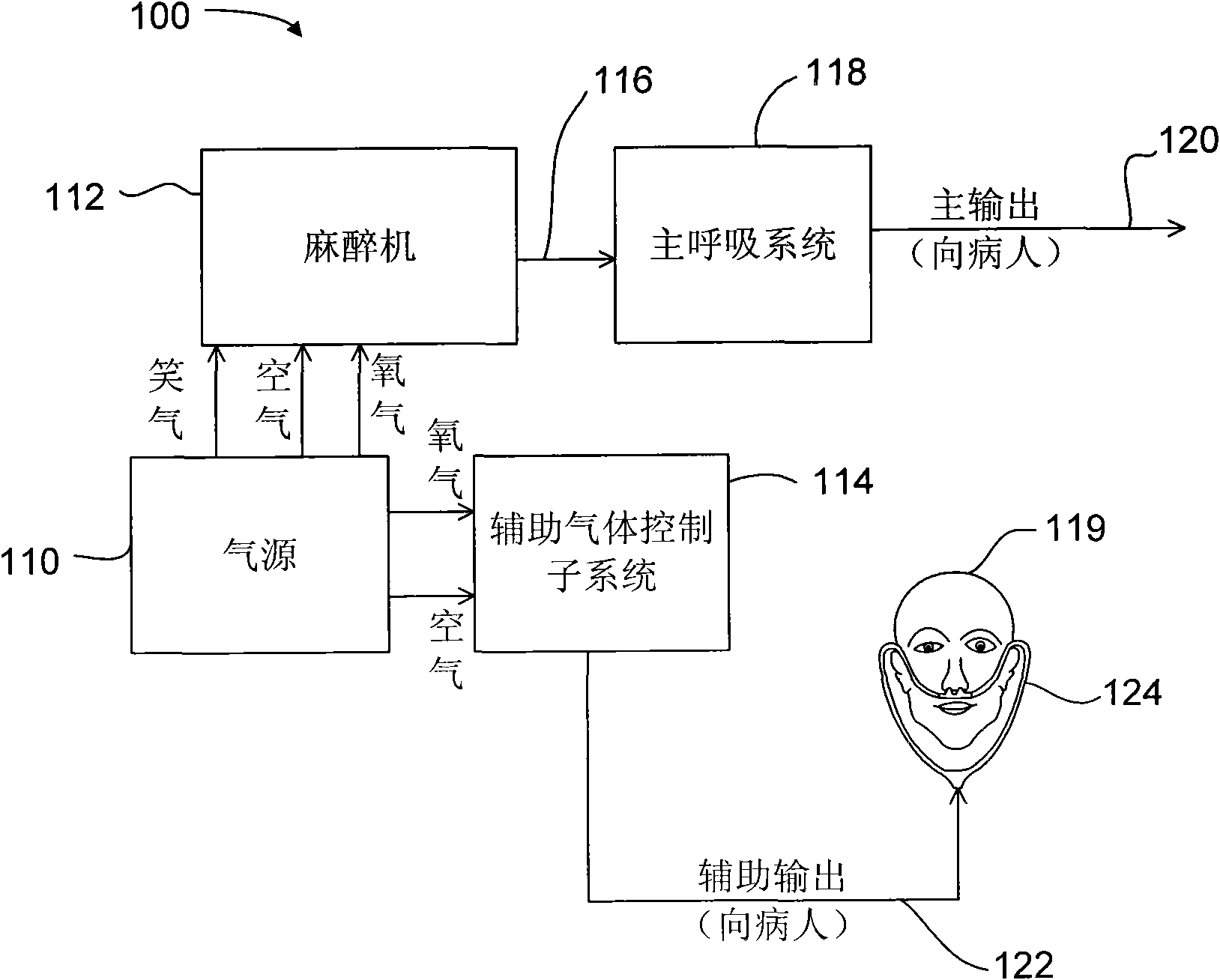

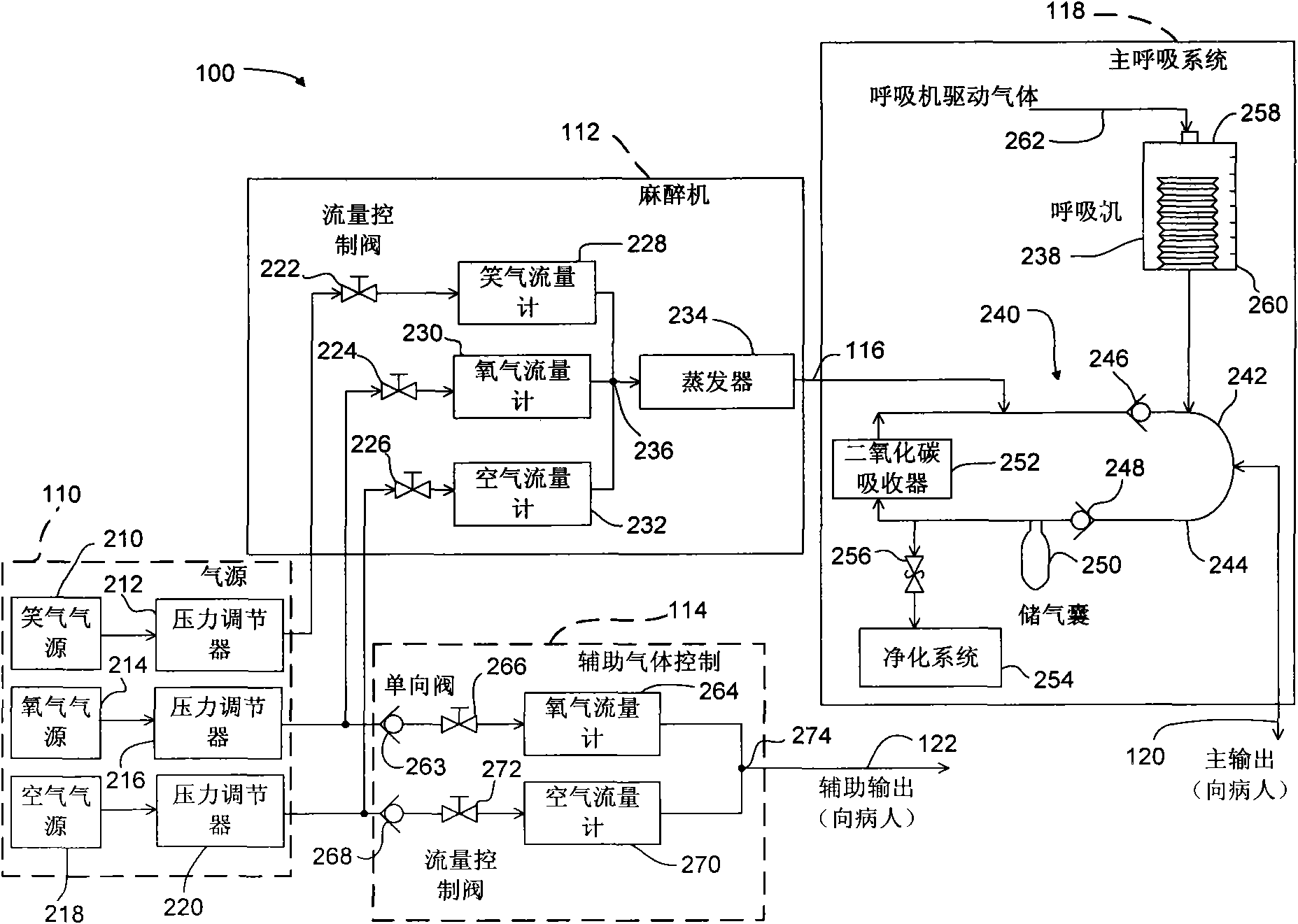

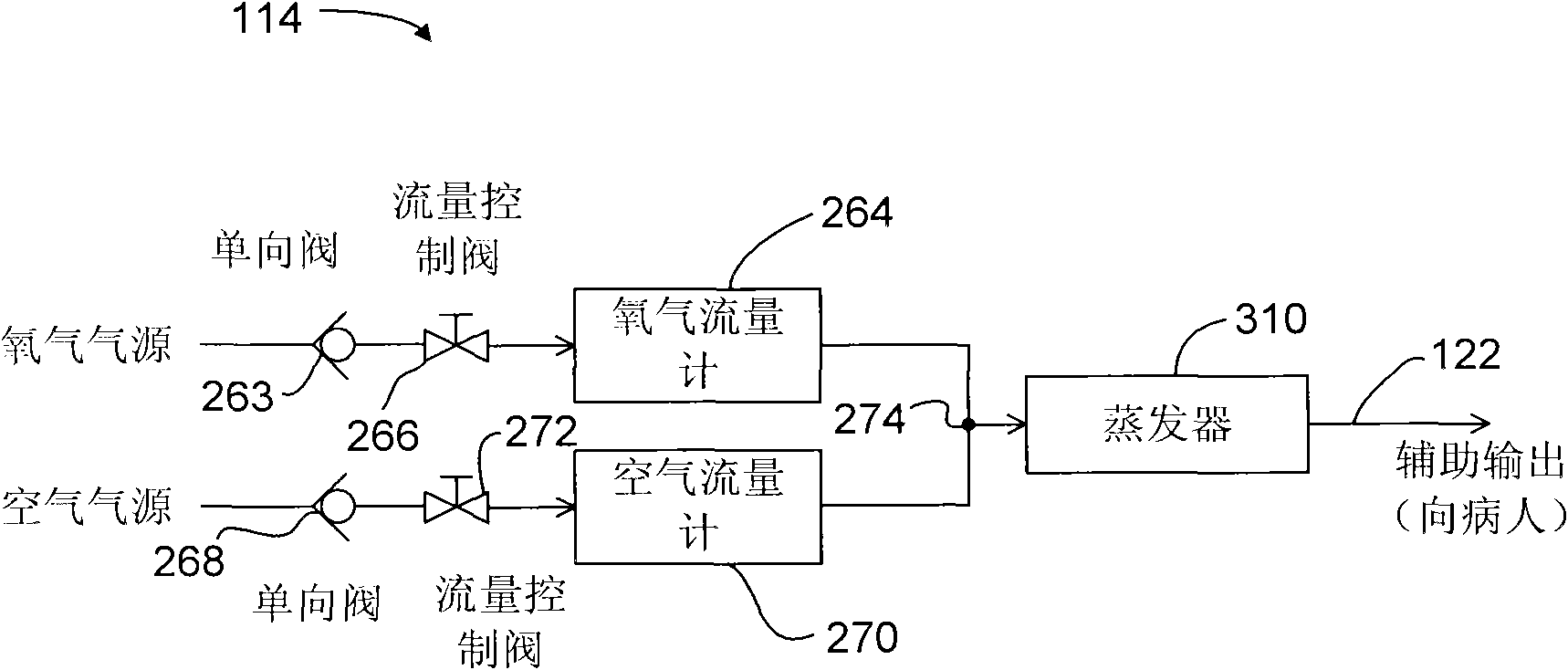

Anaesthetizing system and gas mixing method in anaesthetizing system

ActiveCN102139133AReduce ignitionReduce or prevent mutual contaminationRespiratorsEngineeringProduct gas

The invention provides an anaesthetizing system and a gas mixing method in the anaesthetizing system. The anaesthetizing system comprises a primary outlet and a secondary output, wherein the primary output and the secondary output work independent from each other; the primary output can be used for outputting first mixed gases and an anesthesia medium to a patient; and the secondary output can be used for outputting second mixed gases to the patient. A user can selectively mix oxygen and at least one other gas; thus, the second mixed gases provided to the secondary output have a desired flow rate and desired oxygen ratio. The second mixed gases passing through the secondary output are prevented from flowing into the anaesthetizing system again; thus, the possibility of polluting gases of the primary output can be reduced or eliminated.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

Fuel system and method for burning liquid ammonia in engines and boilers

ActiveUS20100288211A1Easy to igniteImprove combustion characteristicsElectrical controlControlling ratio of multiple fluid flowsCombustion chamberEngineering

A process and apparatus is provided for burning liquid ammonia in an energy device such as a diesel engine, boiler or gas turbine. In particular, the process and apparatus include mixing a renewable fuel with a low flame speed and high ignition temperature, e.g., ammonia, with a combustible liquid fossil or bio-fuel and supplying the mixture into a closed fuel loop where part is efficiently burned in an engine combustion chamber, and part is used to cool the engine and returned by the loop for mixture with fresh incoming fuel mixture. The invention provides for the mixing and emulsifying in such a way that vapour lock is avoided. In the loop, the mixture is emulsified into a disperse distribution of fuel droplets such that upon injection of a portion into the combustion chamber, the renewable fuel in an emulsified droplet evaporates, mixes with the air and forms a small combustion cell surrounding the liquid fuel droplet. The fuel droplet burns and then serves as an ignition kernel for the gas mixture in the small combustion cell producing efficient and rapid combustion of the renewable fuel. The fuel loop allows the fuel system to automatically scale for engines varying in power output from 1 to 35,000 horsepower.

Owner:CAHN RICHARD C +1

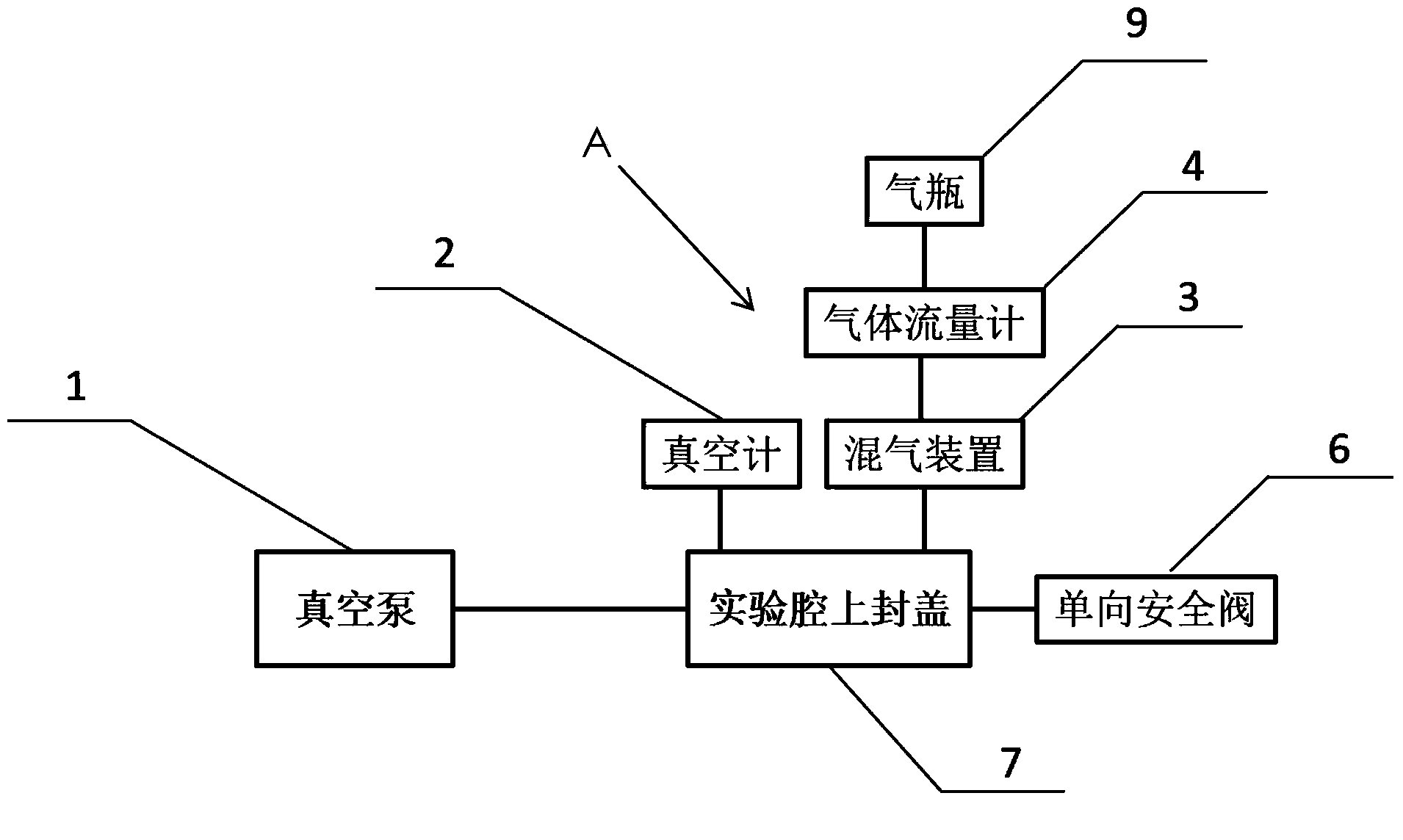

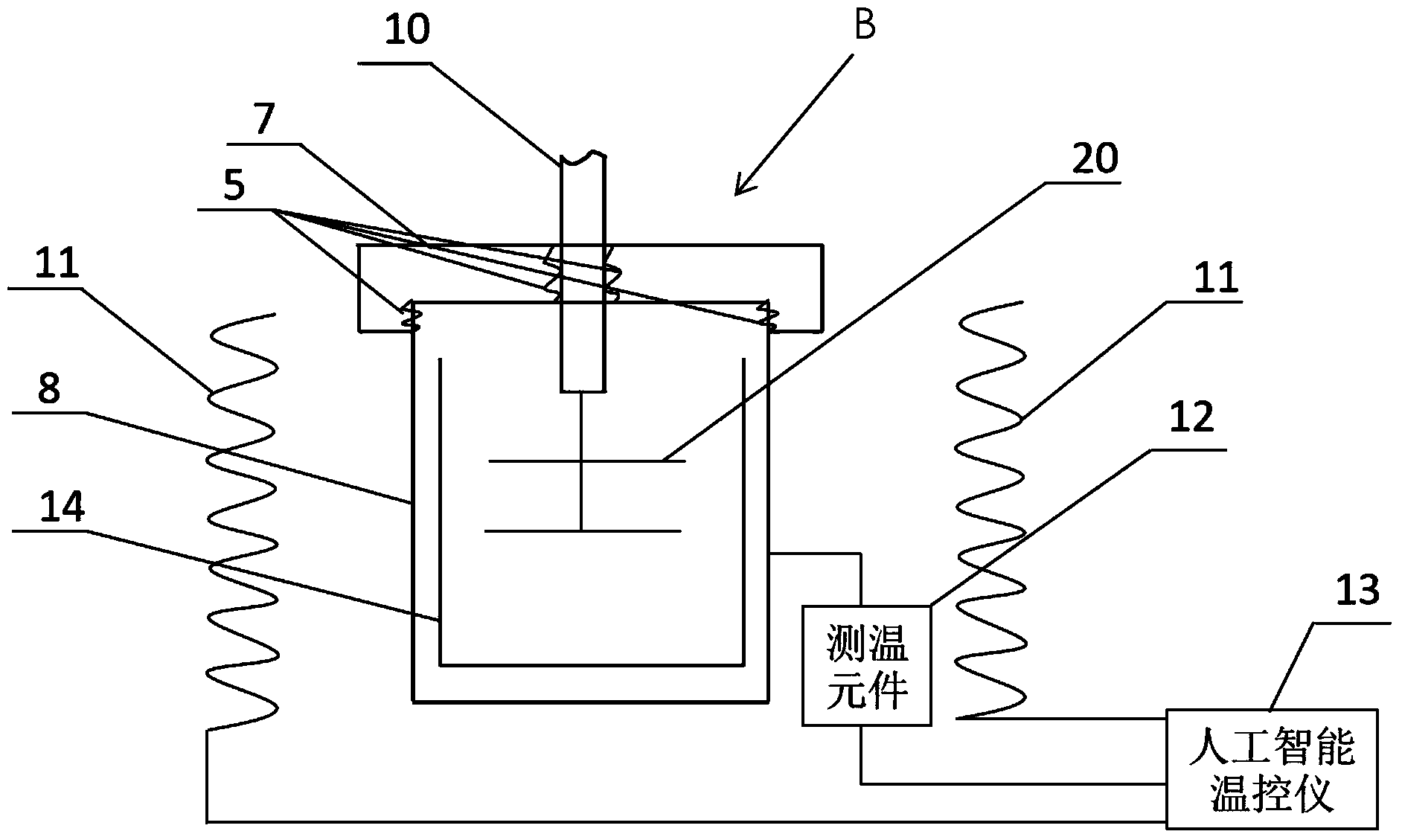

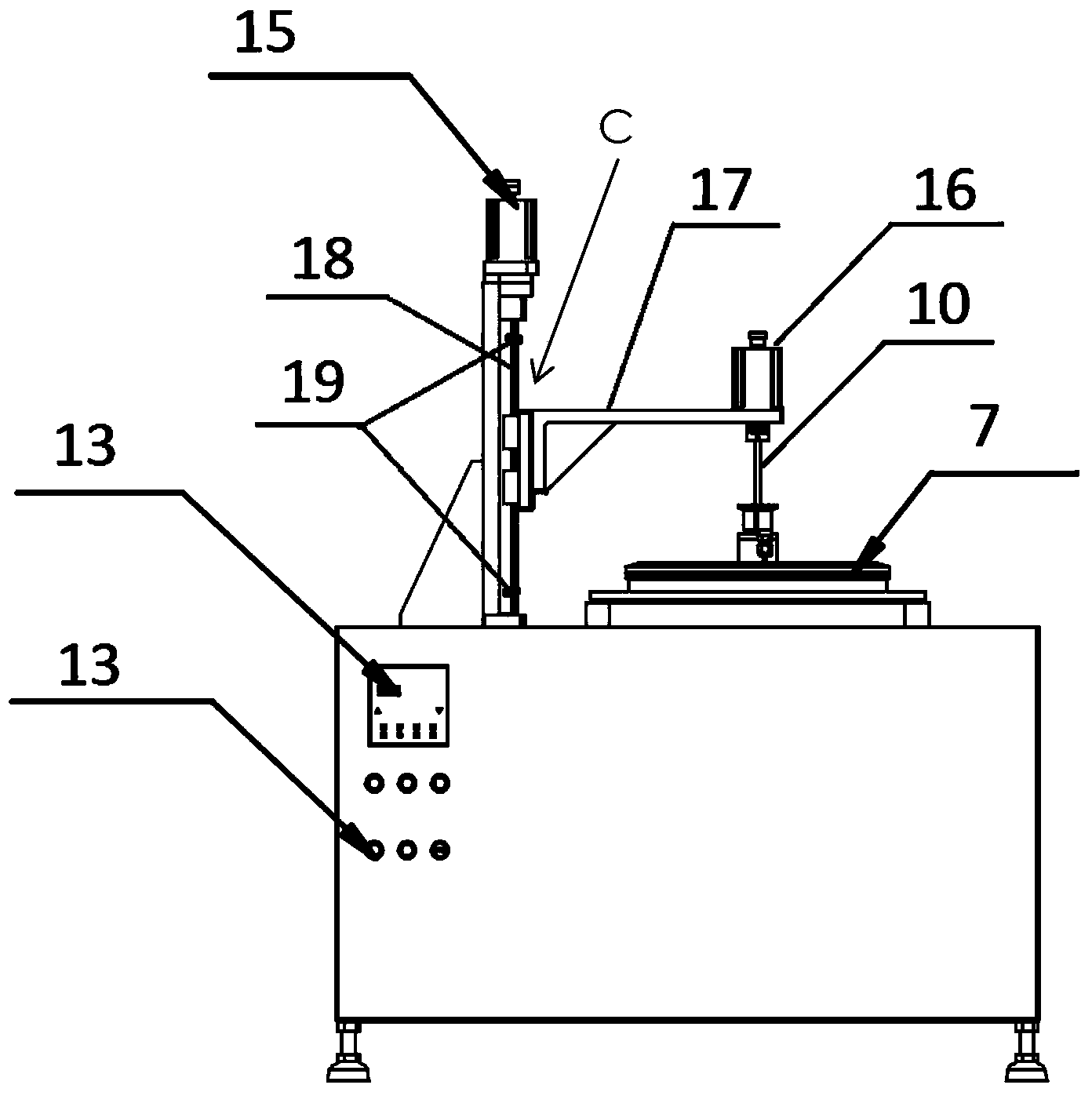

Rotary dynamic metal corrosion testing device and using method thereof

ActiveCN103454210AGuaranteed tightnessAchieving Relative Motion Rate ChangesWeather/light/corrosion resistanceEngineeringLiquid metal

The invention relates to the field of high-temperature corrosion of liquid metal and particularly relates to a rotary dynamic metal corrosion testing device and a using method thereof. The device is provided with a gas path and sealing system, a temperature control and reactor system and a lifting and rotating system, wherein the gas path and sealing system mainly comprises a vacuum pump, a resistance type vacuum gauge, a gas mixing device and a gas flow controller; the temperature control and reactor system mainly comprises heating elements, a temperature measuring element, an artificial intelligent temperature controller, a heat resistant steel experiment cavity, an experiment cavity upper sealing cover and glass lining; the lifting and rotating system mainly comprises a stepping motor, a sliding slipway, a ball screw, limiting stoppers, a rotary rod and a sample holder. According to the device, the experiment environment atmosphere is controllable through the extrusion sealing mode of metal and a high-temperature rubber ring, the experiment temperature is accurate and controllable through intelligent temperature control, the relative movement of a sample and a corrosive medium (liquid metal) is realized through the mode that rotary motor drives an agitator arm to rotate, and high-temperature dynamic corrosion experiment is realized under the simple dynamic equipment composing condition.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

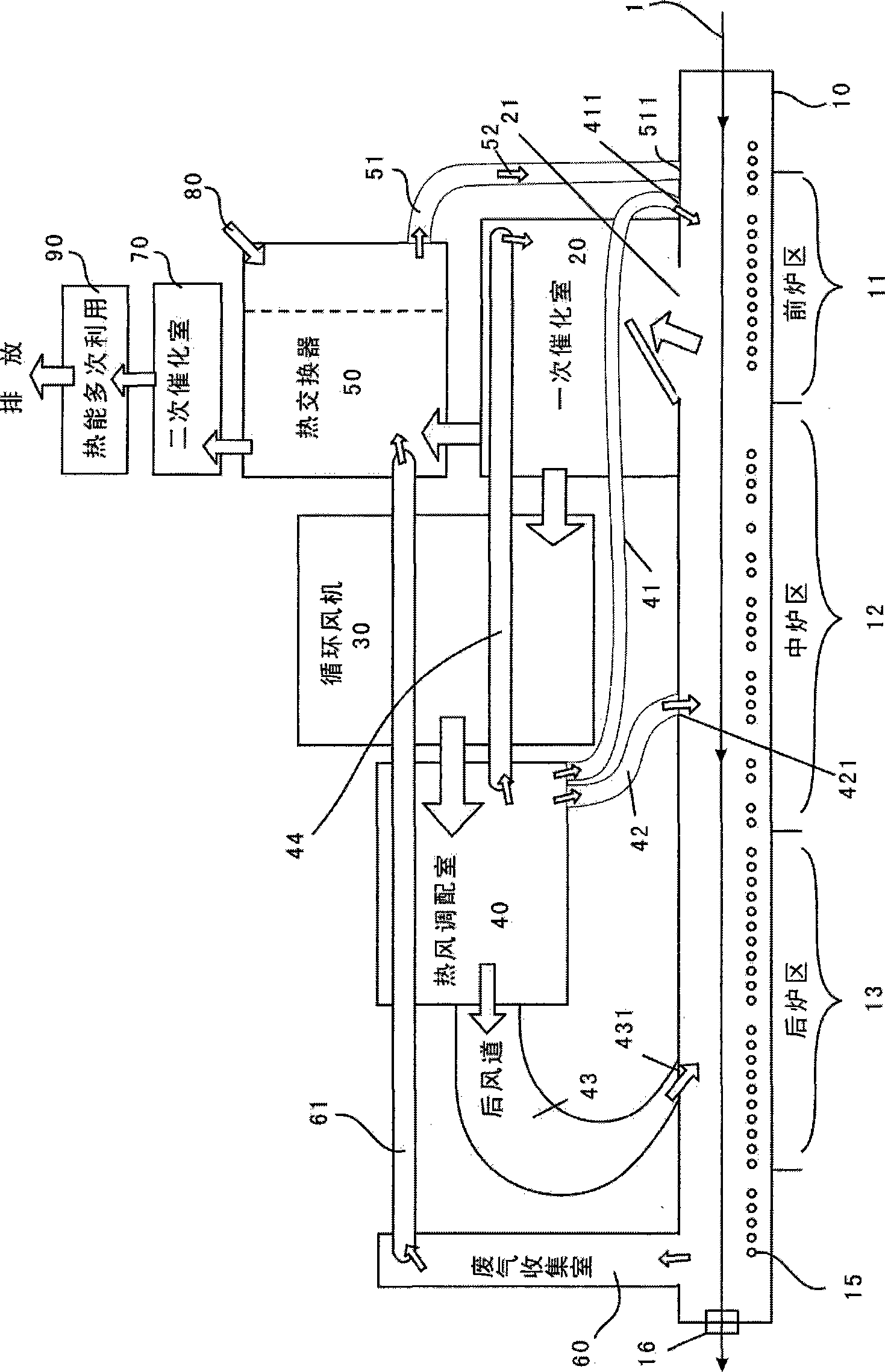

Reasonable catalytic combustion thermal energy distribution method and equipment of enameling machine

InactiveCN101482364ASave space on siteSimple installation and debuggingDrying solid materials with heatDrying gas arrangementsThermal energyDistribution method

The present invention provides a method for reasonably distributing catalytic combustion heat by an enamelling machine and a device thereof. A circulating fan is installed on a position which is at the upper part of main furnace body and is next to the middle part. An exhaust organic gas inlet is installed above a front furnace area. A primary catalyzing chamber is provided above the organic gas inlet. A hot air mixing chamber is positioned at the side surface of the primary catalyzing chamber. The circulating fan is communicated with the primary catalyzing chamber and the hot air mixing chamber, and drives the circulating hot air after catalytic combustion into the hot air mixing chamber. The hot gas mixing chamber is communicated with a front furnace area, a middle furnace area and a back furnace area of main furnace body through a front gas passage, a middle gas passage and a back gas passage. The invention quickens the baking process and increases the production efficiency by 20% due to the reasonable distribution of heat. As the exhaust gas is effectively collected and executed with the secondary catalytic combustion, and the circulating hot air is repeatedly executed with the primary catalytic combustion, the discharge standard is reduced to 500mg / m. The invention can save electrical energy by 50% as the catalytic combustion heat is used for baking.

Owner:DONGGUAN ZELONG WIRE & CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com