Patents

Literature

31results about How to "High quality feed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

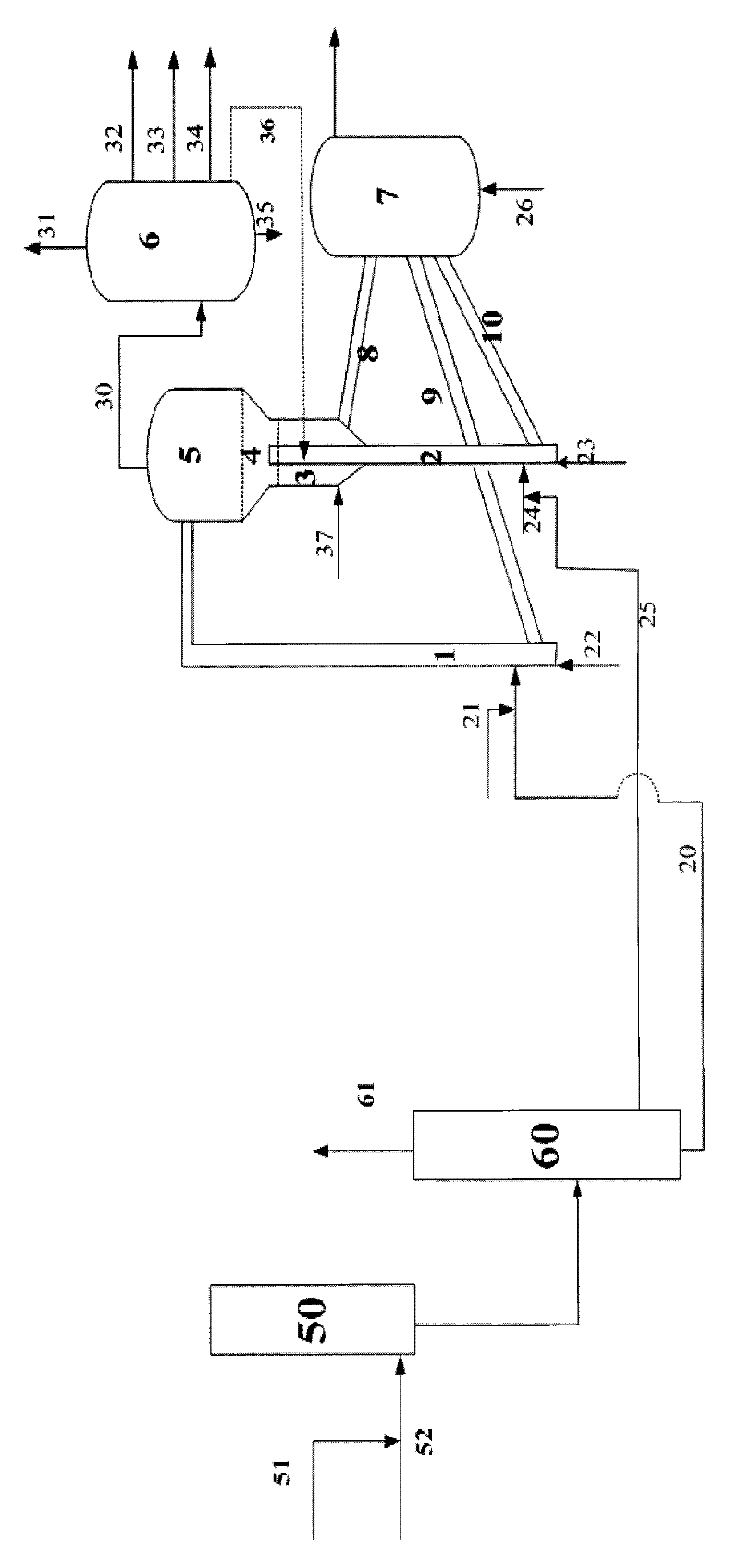

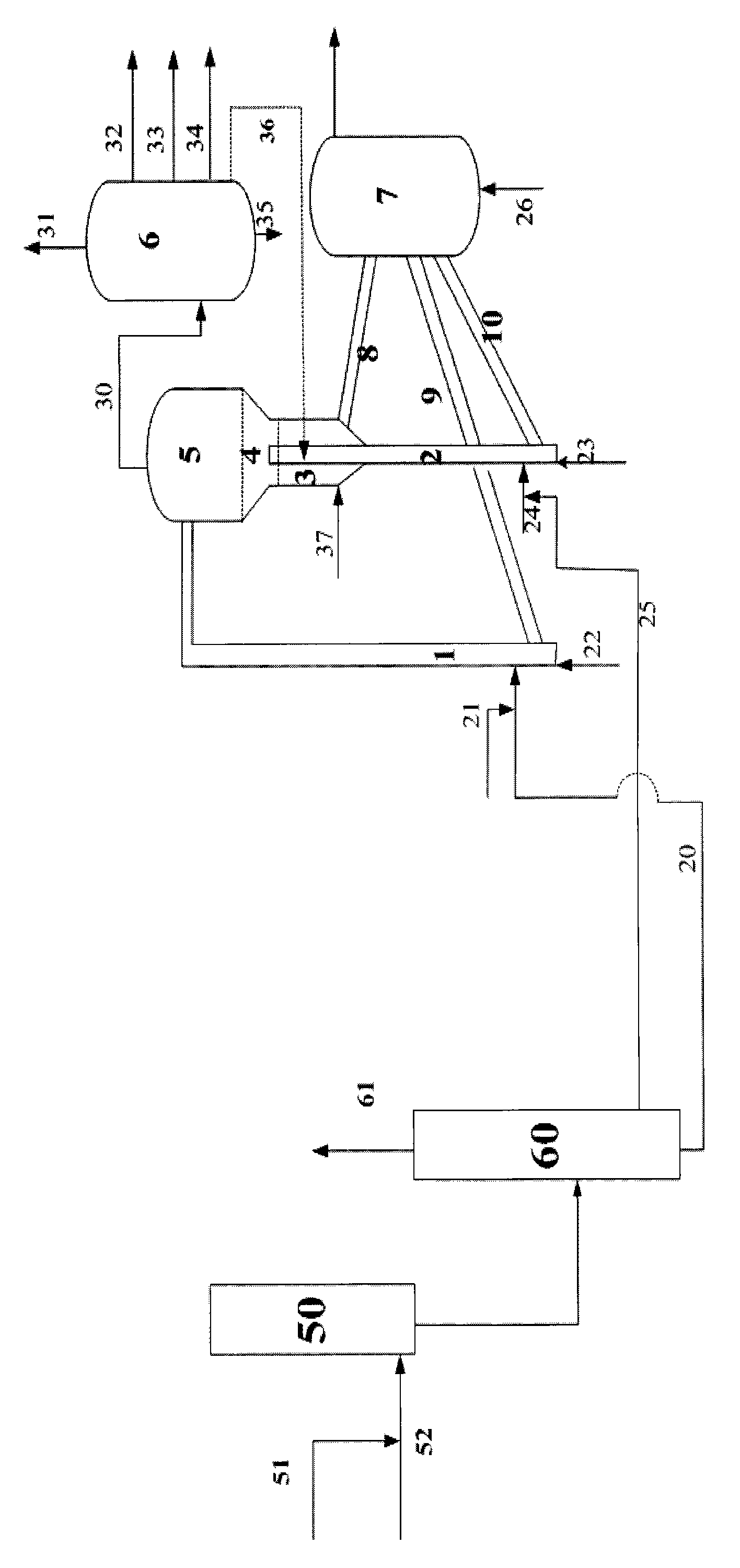

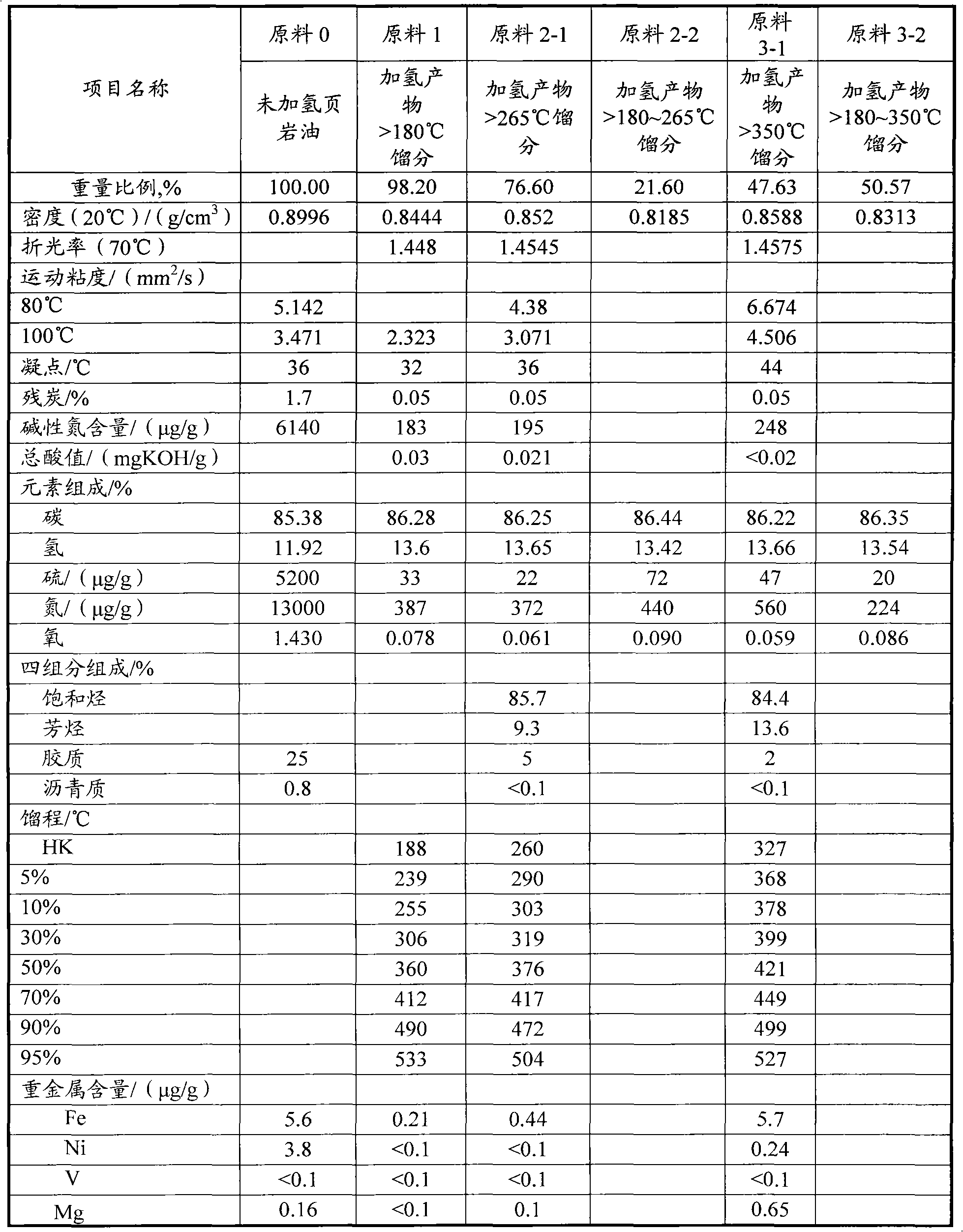

Shale oil processing method for producing propylene

ActiveCN102465036AReduce the number of extracted streamsReduce operating consumptionTreatment with hydrotreatment processesBulk chemical productionChemistryFuel oil

Owner:CHINA PETROLEUM & CHEM CORP

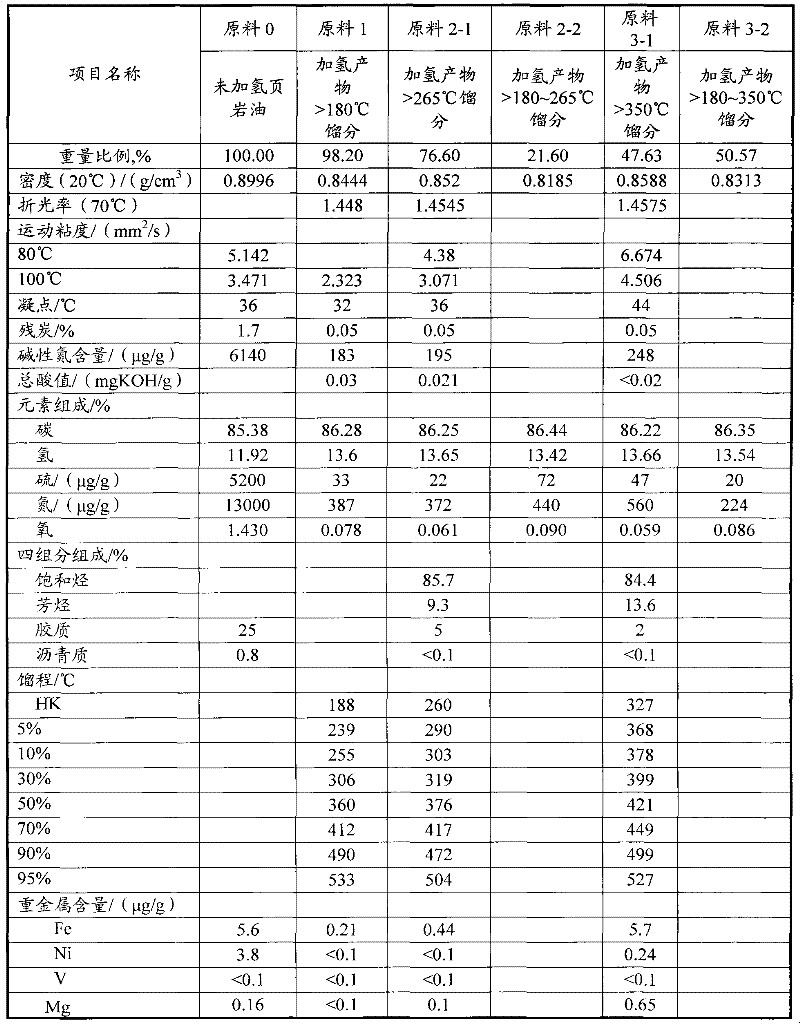

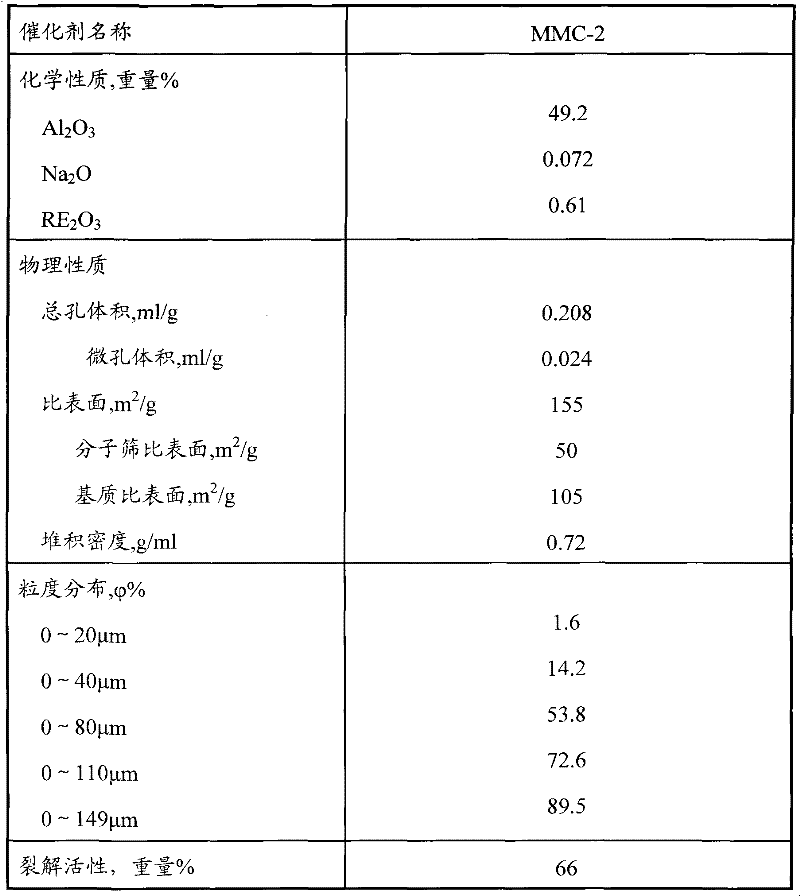

Hydrotreatment-catalytic cracking combination process method

ActiveCN103773495AReduce SOx contentImprove quality and yieldTreatment with hydrotreatment processesCycle oilChemistry

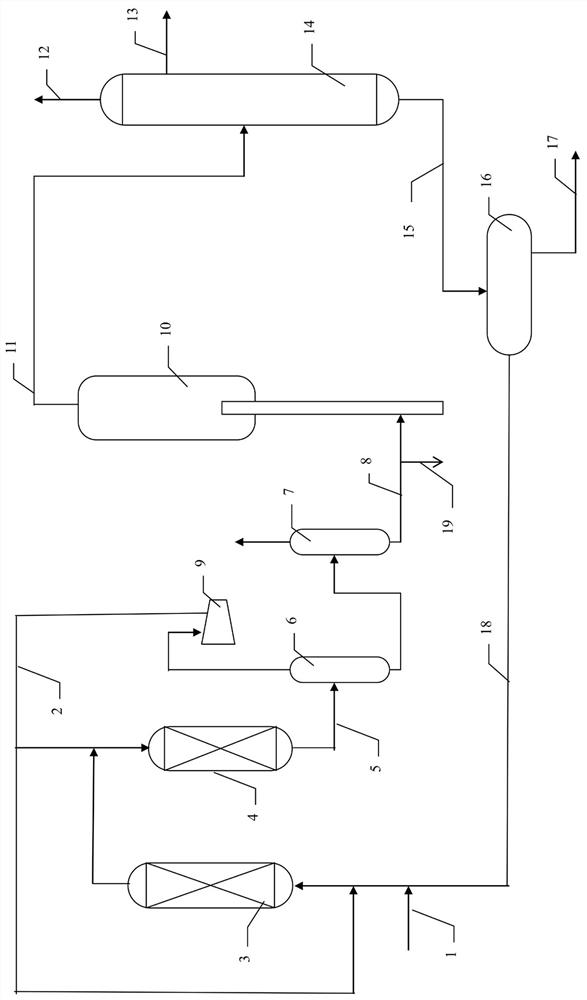

Provided is a hydrotreatment-catalytic cracking combination process method. Wax oil and catalytic cracking circulation oil go to a hydrotreatment reaction zone together, and are subjected to reactions of hydrodemetallization, hydrodesulfurization, hydrodenitrification, aromatic hydrogenation saturation and the like in the presence of hydrogen and hydrogenation catalysts. The obtained hydrogenated tail oil goes to a catalytic cracking device, a cracking reaction is carried out in the presence of catalytic cracking catalysts. Dry gases, liquefied gases, catalytic cracking gasoline, catalytic cracking light diesel oil, catalytic cracking circulation oil and slurry oil are obtained after separation, the catalytic cracking light diesel oil is subjected to self-circulation in the catalytic cracking device and the catalytic cracking circulation oil is circulated to the hydrotreatment reaction zone. The method can raise yield and quality of gasoline products greatly.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oil-water separation system and separation method

ActiveCN109652117AReduce cloggingPrevent adhesionFatty/oily/floating substances removal devicesDewatering/demulsification with mechanical meansFiltrationDistributor

The invention discloses an oil-water separation system and a separation method. The oil-water separation system comprises a membrane filtration / demulsification system, a pre-separation system, a lightphase separation system and a heavy phase separation system; the membrane filtration / demulsification system comprises a membrane module and a circulating pump, and the pre-separation system comprisesa feeding tube, a hollow filter element and a steady flow zone; the light phase separation system sequentially comprises a material uniform distributor I, an upper coalescence separation zone and a light phase discharge port from bottom to top; and the heavy phase separation system sequentially comprises a material uniform distributor II, a lower coalescence separation zone, a light phase and heavy phase separation zone and a heavy phase discharge port from top to bottom. The separation system can be used to achieve continuous removal and preliminary of granular suspended matters in a material to be separated, rapid removal of free water drops or oil drops and demulsification and coalescence of a small amount of a heavy phase entrained in a light phase and a small amount of the light phase entrained in the heavy phase, has the advantages of short material residence time, high dewatering / deoiling efficiency and small device size, can realize deep removal of water, especially emulsifiedwater, in an oil product and deep removal of emulsified oil drops in sewage, has obvious advantages in oil-water separation of complex-composition and high-viscosity particle-containing severely emulsified oil products, and enables the moisture or oil removal rate to reach 99% or above.

Owner:CHINA PETROLEUM & CHEM CORP +1

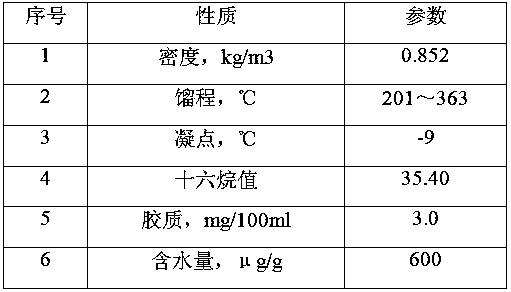

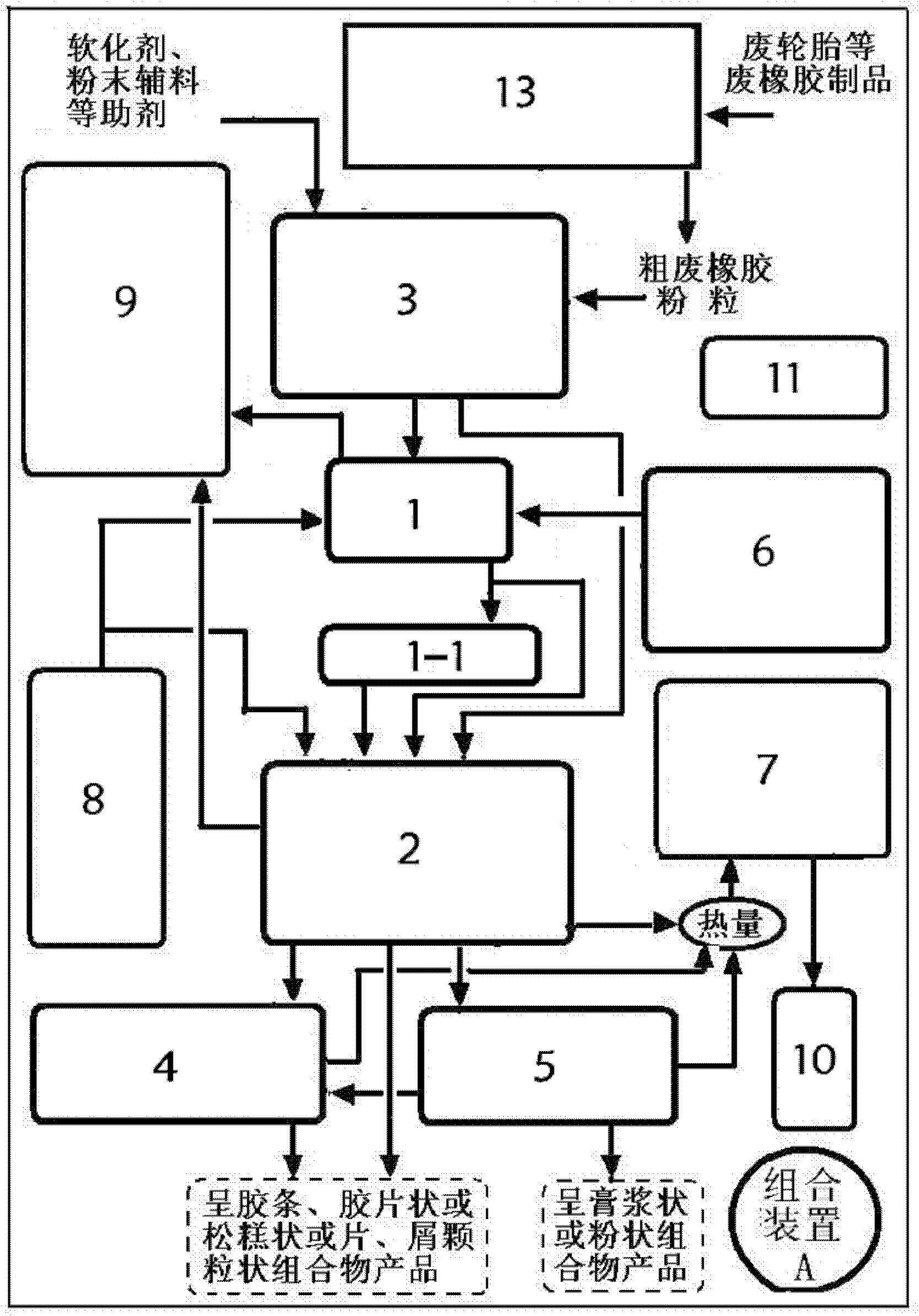

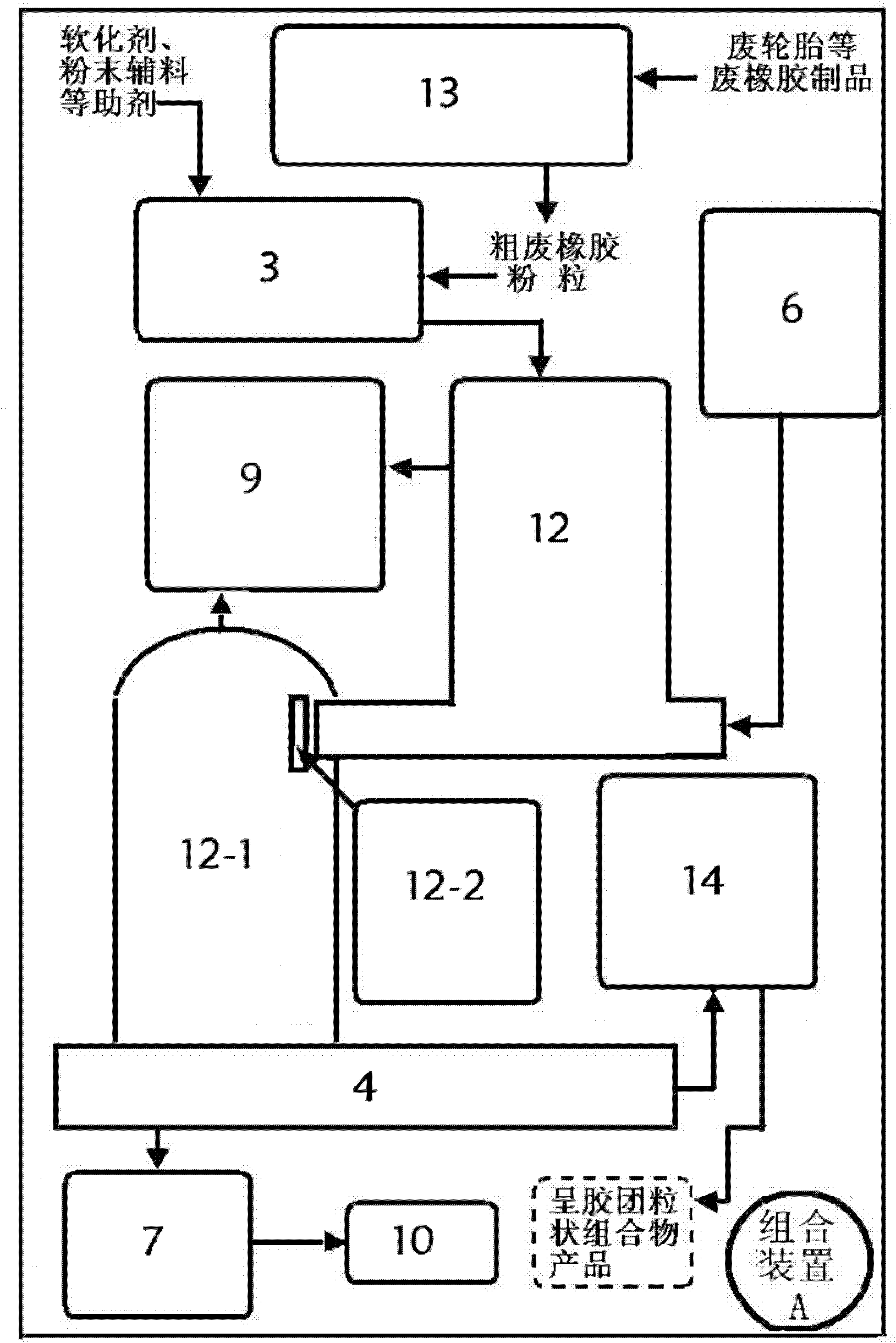

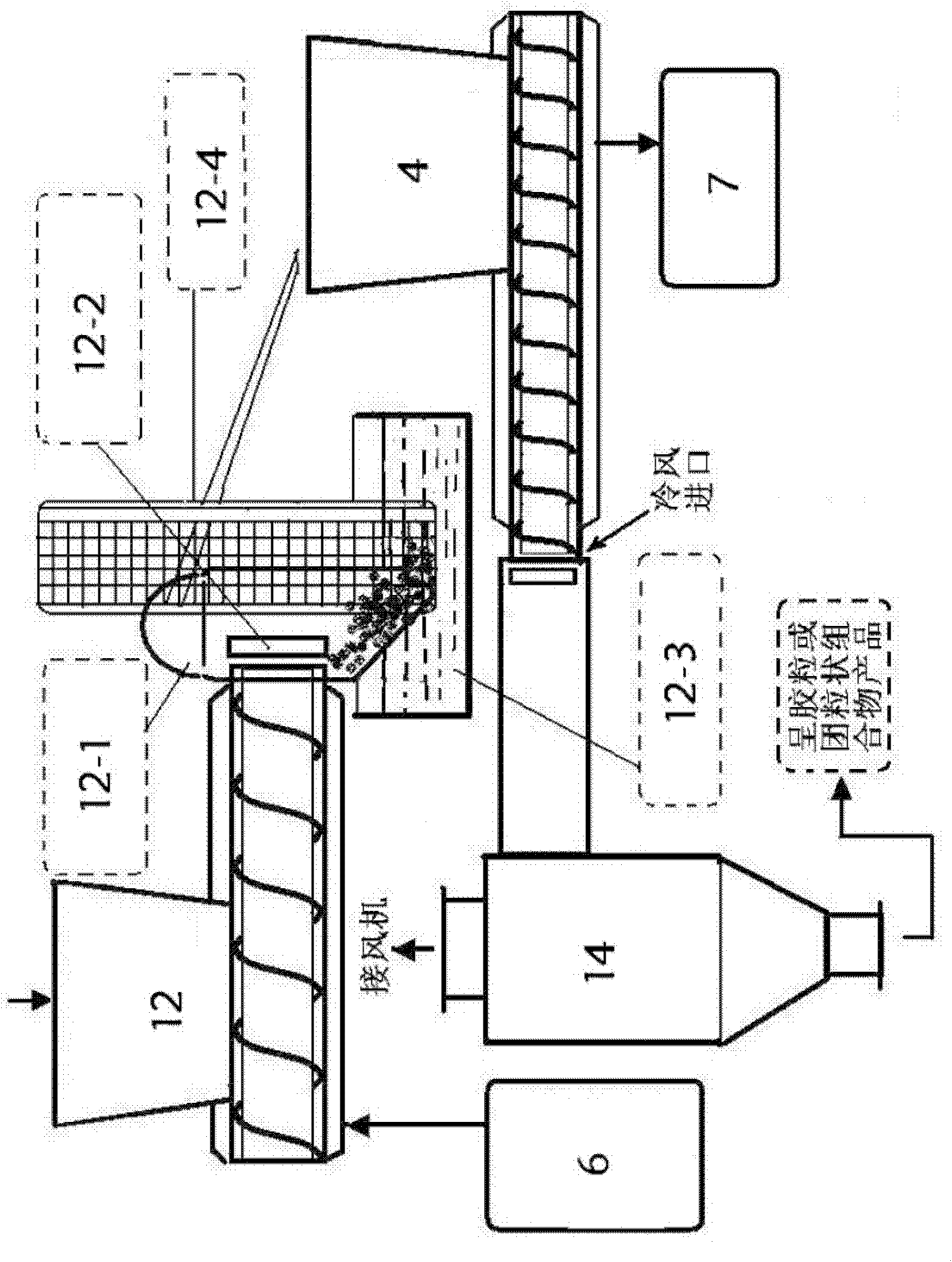

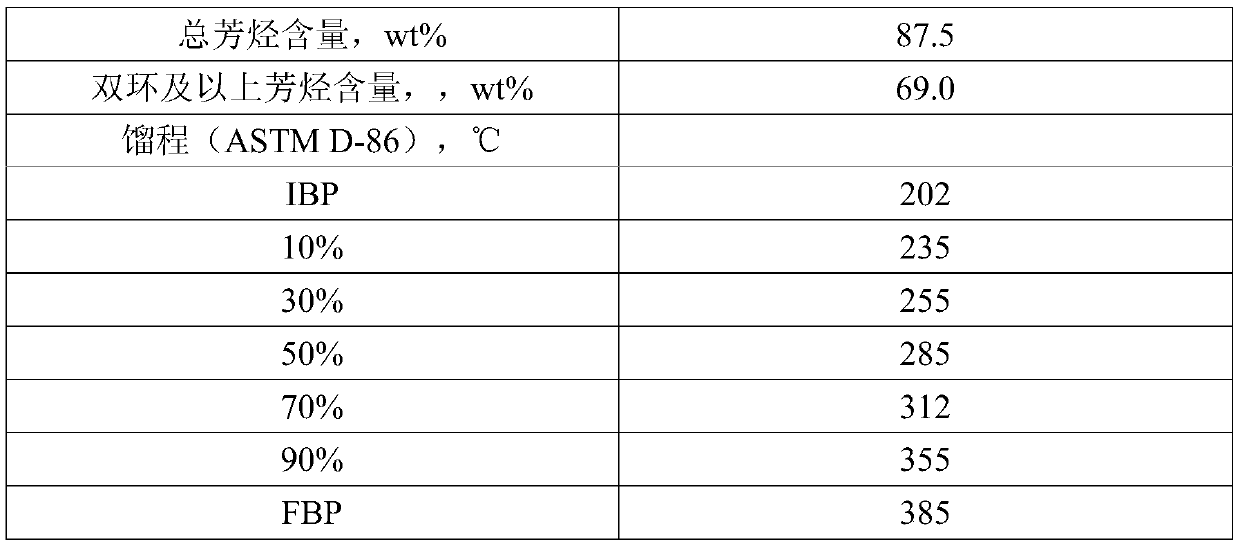

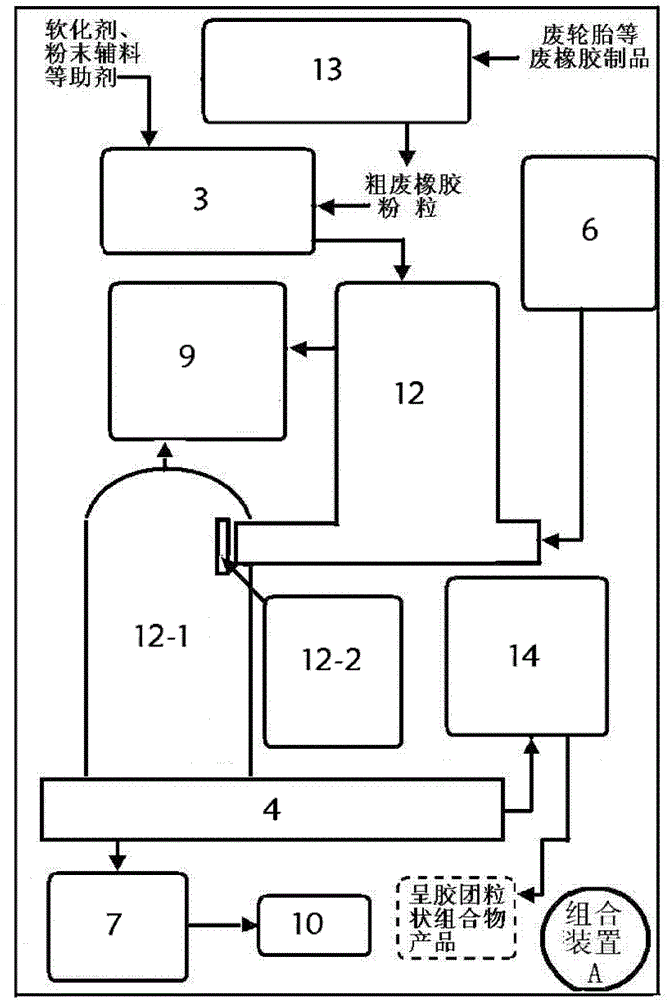

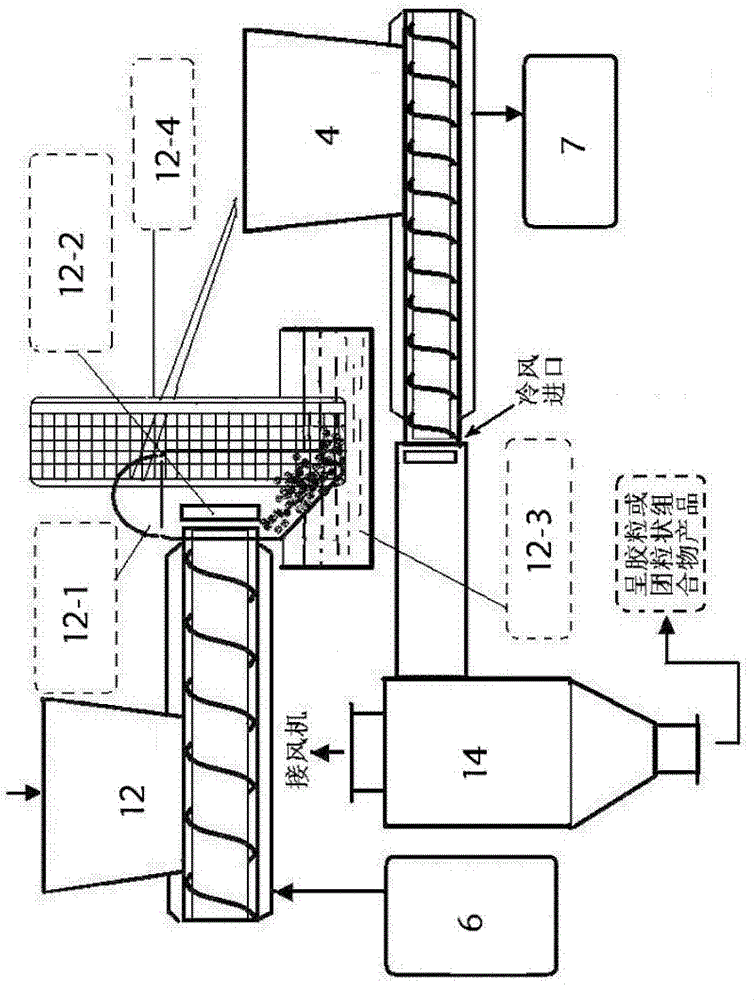

Heat regeneration method for waste rubber

InactiveCN102030934AMeet the environmental protection requirements of cleaner productionMeet environmental protection requirementsPlastic recyclingLiquid hydrocarbon mixture productionPolymer scienceWaste rubber

The invention provides a heat regeneration method for waste rubber. The method comprises the following steps of: feeding a waste rubber crude powder material / environmentally-friendly softening agent / powder auxiliary material in the weight ratio of 100 / 8-150 / 20-1,500 into a stirring heater, performing anoxybiotic heating, introducing into a stirring cooler and cooling to the temperature of less than 100 DEG C so as to obtain a product; or partially or completely extracting the powder auxiliary material in the fed materials for slow feeding, adding the extracted powder auxiliary material into the stirring heater before the materials which are put into the stirring heater at an early stage are discharged, or / and adding the extracted powder auxiliary material when a hot material is introduced into the stirring cooler, cooling the mixture to the temperature of less than 100 DEG C and discharging; or initially mixing the materials in a formula, guiding the mixture into a screw extruder, allowing the mixture to pass through a heating section and a mixing section, cooling the material to the temperature of less than 100 DEG C and discharging a product; or performing thermal cracking on all-known waste rubber through heat regeneration or establishing a multi-direction migration relation for a material or / and energy in the process of preparing carbon black from fuel oil and fuel gas.

Owner:陈汇宏 +1

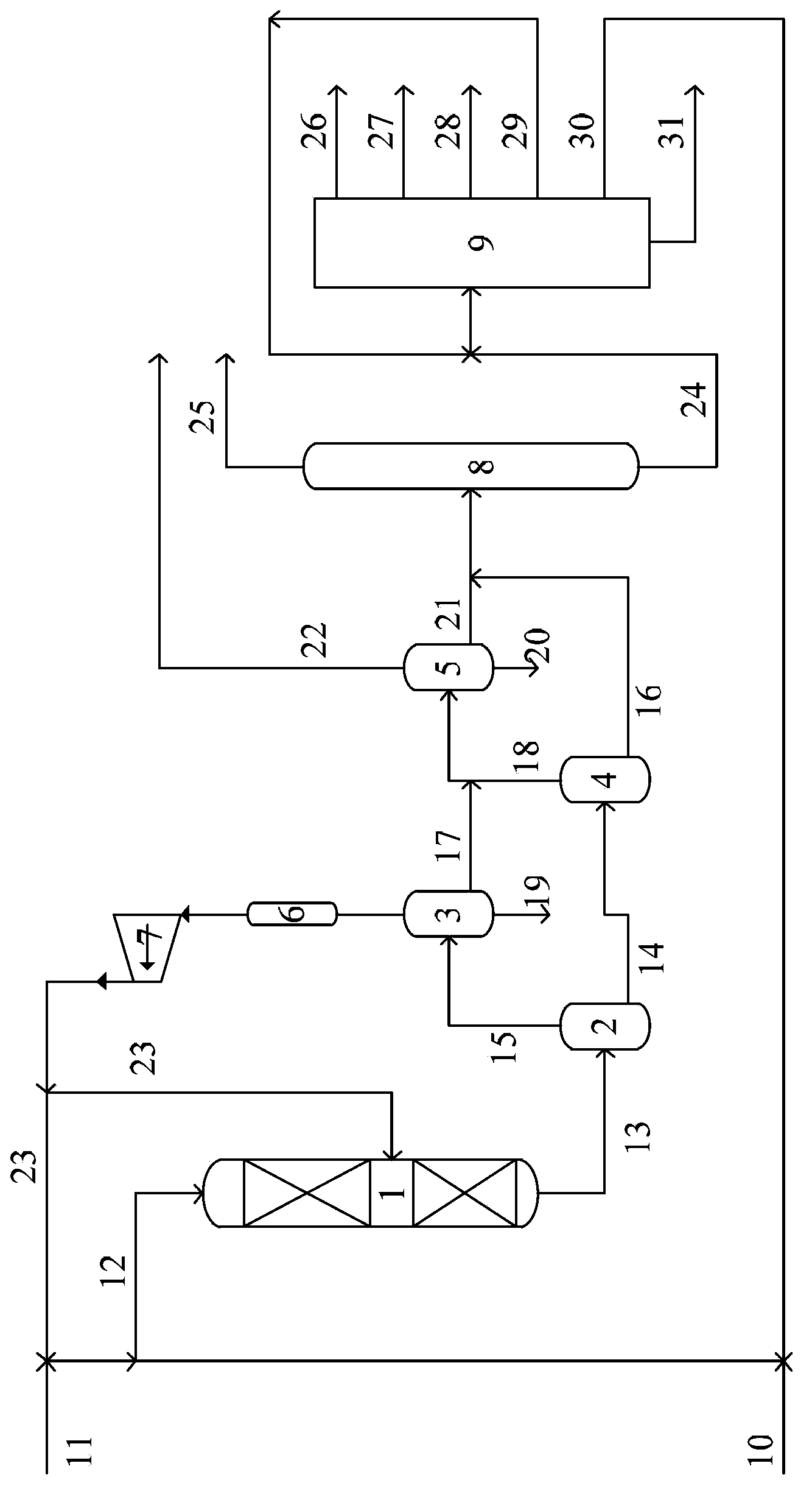

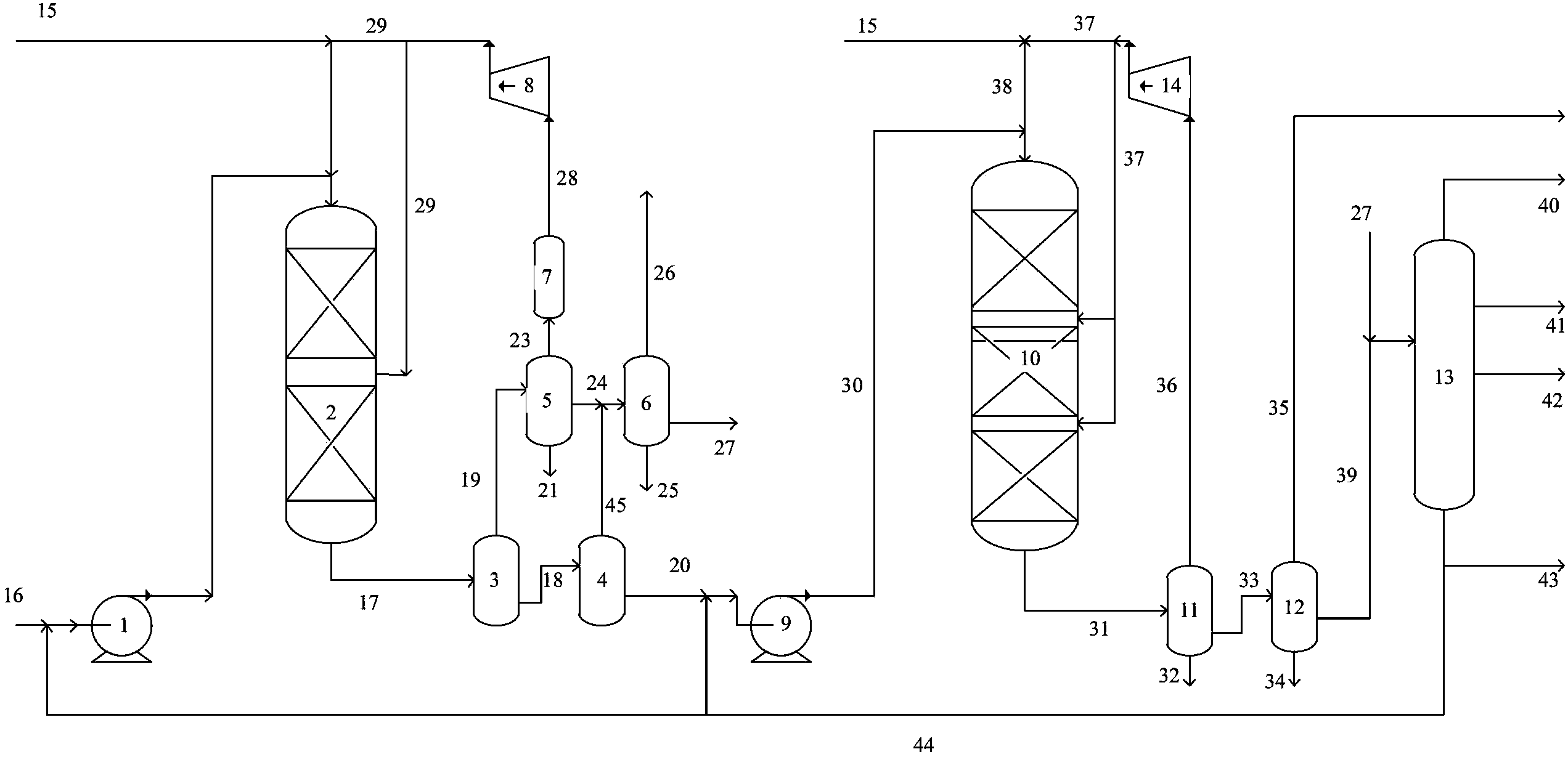

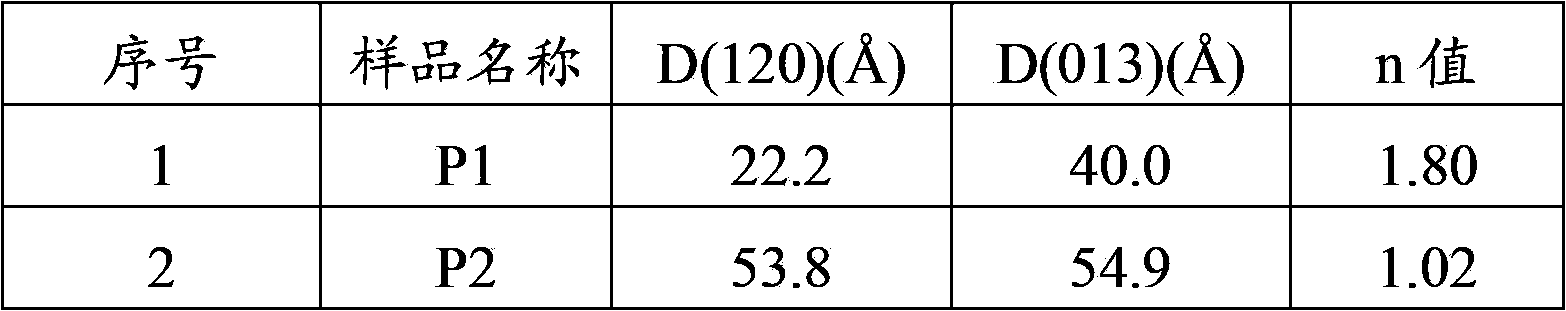

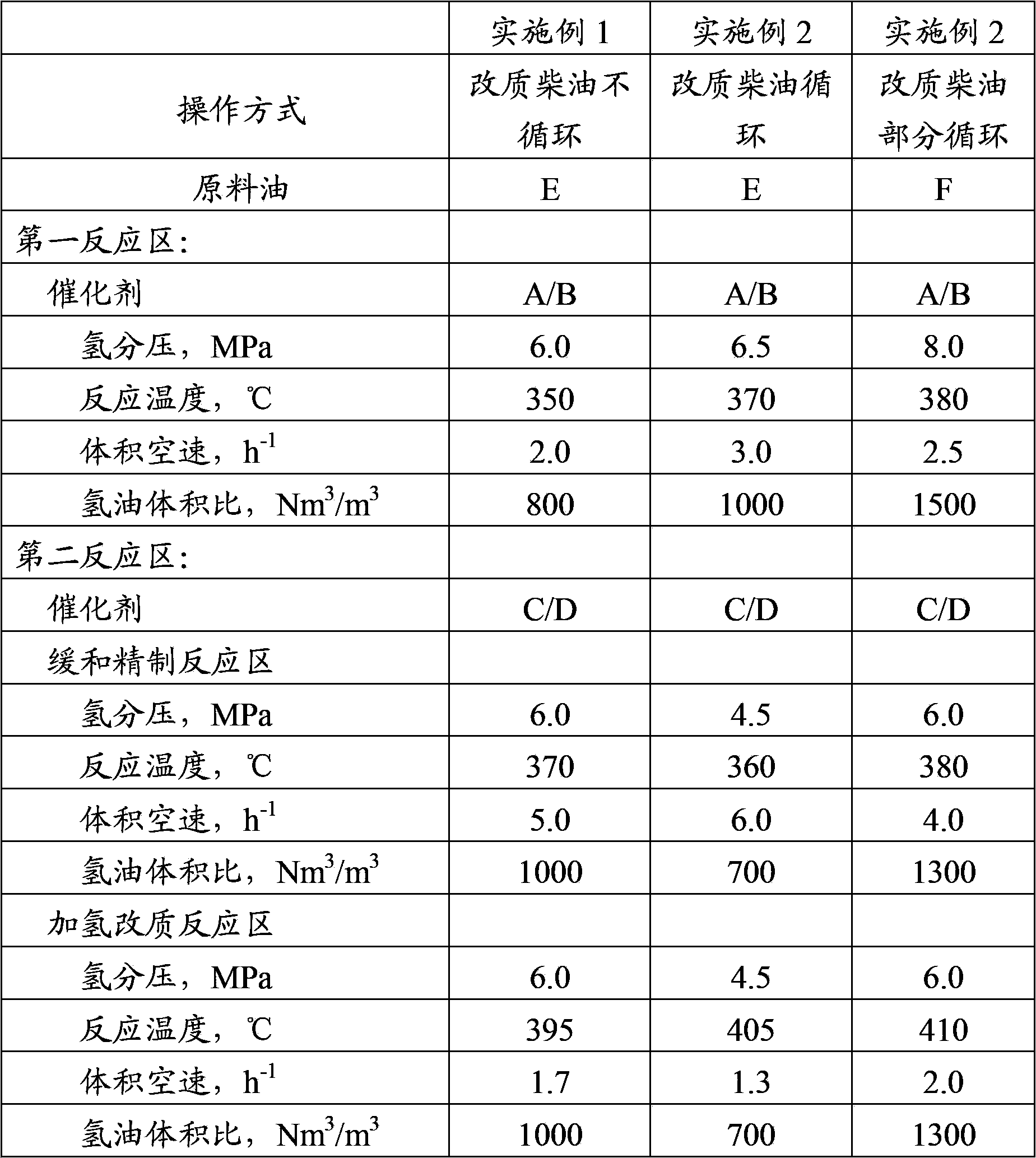

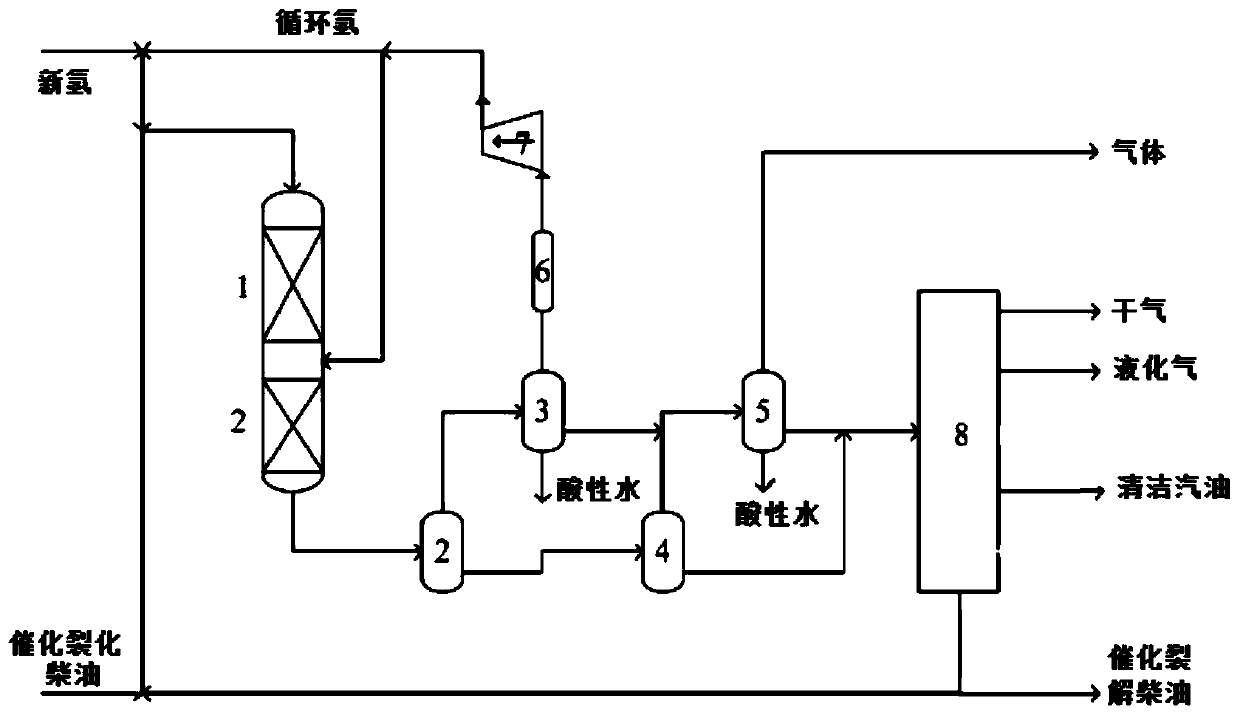

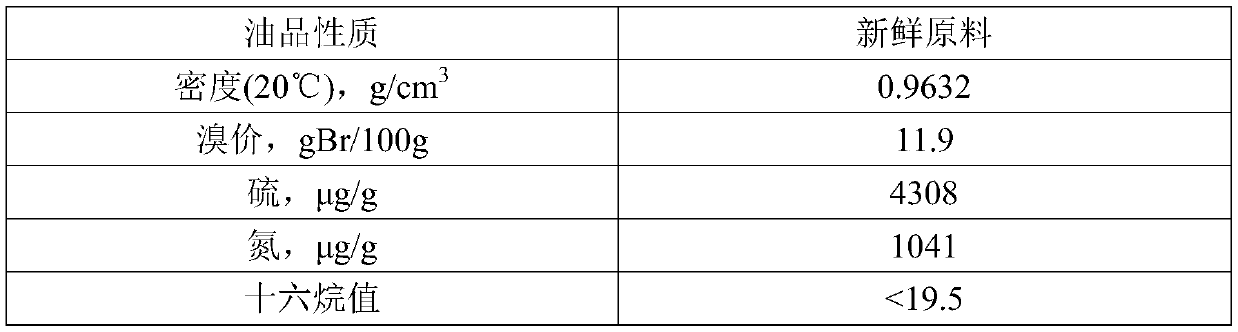

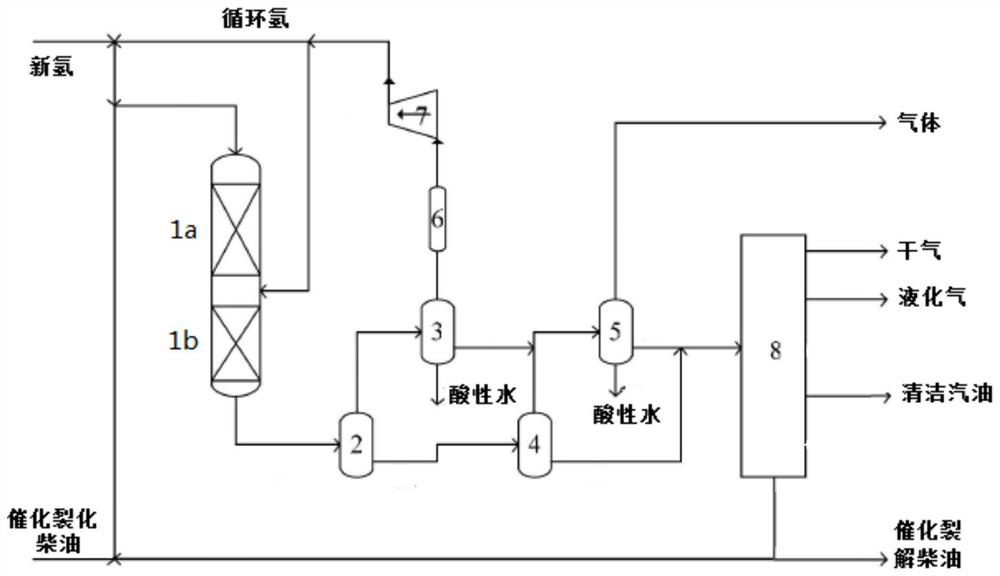

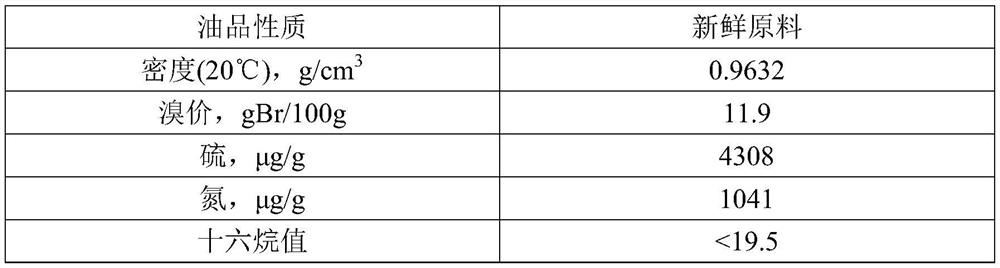

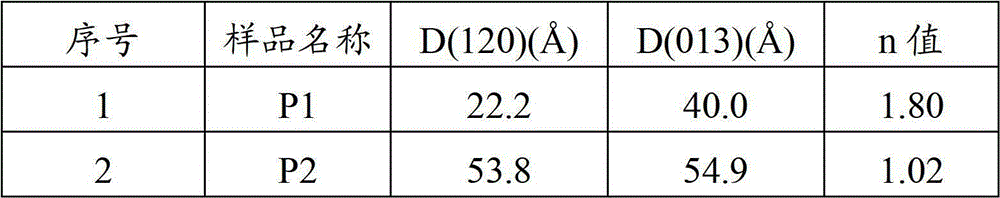

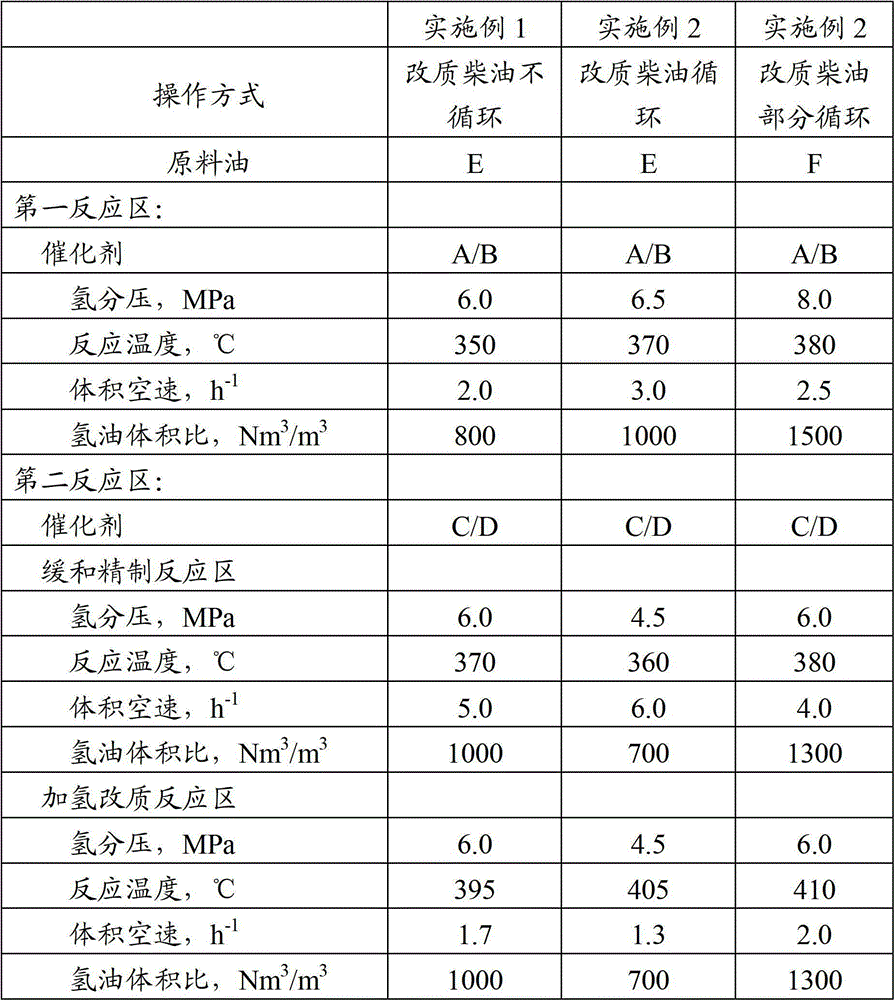

Hydrogenation method for treating high-nitrogen high-aromatic hydrocarbon inferior diesel oil raw materials

ActiveCN103773489AGood choiceImprove conversion rateTreatment with hydrotreatment processesFractionationGasoline

The invention discloses a hydrogenation method for treating high-nitrogen high-aromatic hydrocarbon inferior diesel oil raw materials. An integrated two-section process flow of a first reaction area, intermediate separation and a second reaction area is adopted. The method comprises the following steps: performing hydrodenitrogeneration and bicyclo- or multi-cyclo aromatic hydrocarbon hydrogenation saturation reactions on inferior diesel oil with high nitrogen and aromatic hydrocarbon content in the first reaction area, performing intermediate separation, obtaining a hydrogenated material flow in which the organic nitrogen content is less than 200 ug / g and the total aromatic hydrocarbon content is more than 60 weight percent, and providing the raw materials for the second reaction area; performing moderate refining and hydro-upgrading in the second reaction area, and performing fractionation to obtain gasoline components with high octane value. By adoption of the method provided in the invention, the inferior diesel oil fraction with high nitrogen and aromatic hydrocarbon content can be treated, and the gasoline components with high octane value and low sulfur content are obtained at high yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

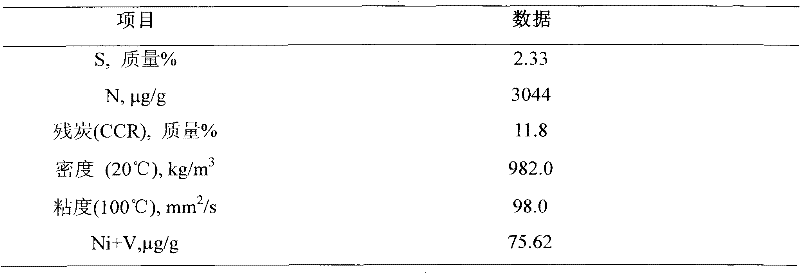

Combined process for pretreating and catalytically cracking hydrocarbon oil

InactiveCN102443438ALow desulfurization rateEasy to operateTreatment with hydrotreatment processesSlurrySolvent

The invention discloses a combined process for pretreating and catalytically cracking hydrocarbon oil. The process comprises the following steps of: feeding a residual oil raw material and catalytic cracking slurry oil into a solvent de-asphalting device for performing de-asphalting treatment; mixing de-asphalted oil with deep drawing VGO (Vacuum Gas Oil), feeding into a hydrogenation demetalization reaction area, and undergoing a reaction under the actions of hydrogen and a demetalization catalyst; mixing one or two of obtained hydrogenation demetalization effluent, light wax oil and coking gas oil, feeding into a hydrotreatment reaction area, and undergoing a reaction in the presence of hydrogen and a hydrotreatment catalyst, wherein a liquid phase separated from hydrotreatment reactor effluent is taken as a catalytic cracking raw material; and feeding the catalytic cracking raw material into a catalytic cracking device for reacting, and circularly returning the catalytic cracking slurry oil to the solvent de-asphalting device for performing circular processing. Due to the adoption of a method disclosed by the invention, different catalytic cracking raw materials can be treated segmentally, the operating flexibility and desulfuration efficiency of a device are increased, and the cost is lowered.

Owner:CHINA PETROLEUM & CHEM CORP +1

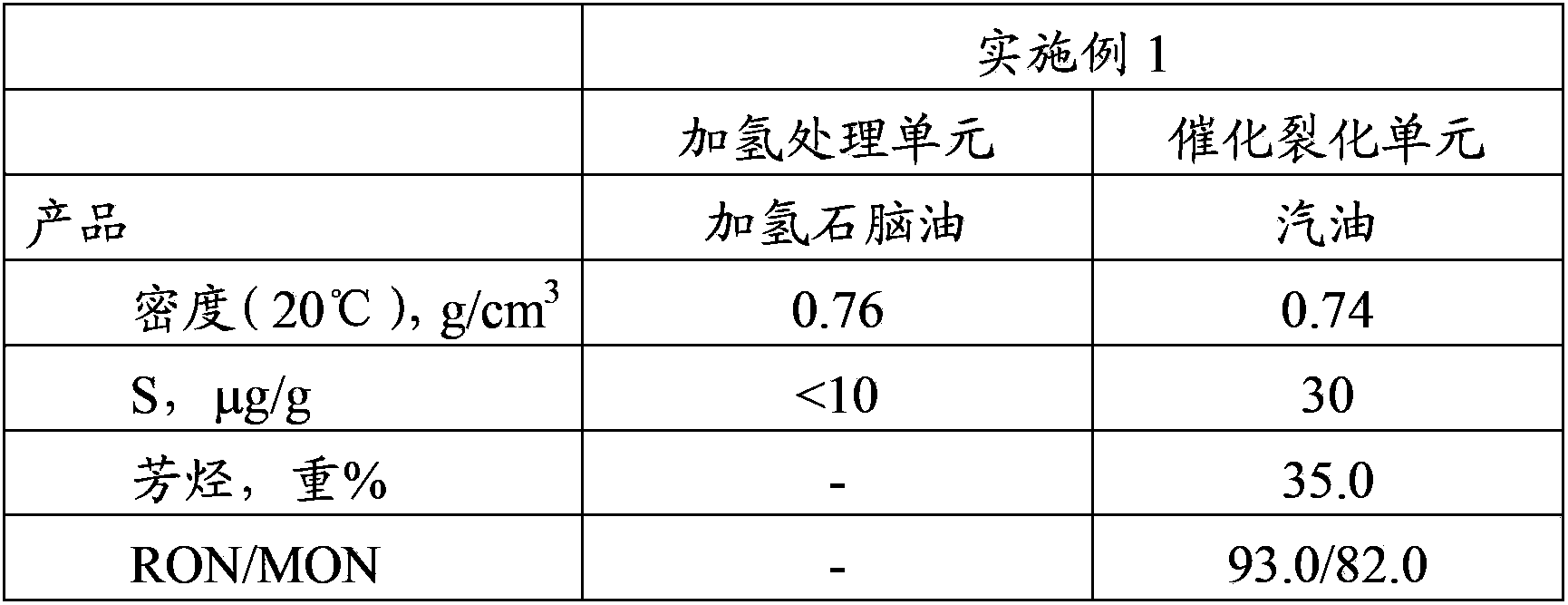

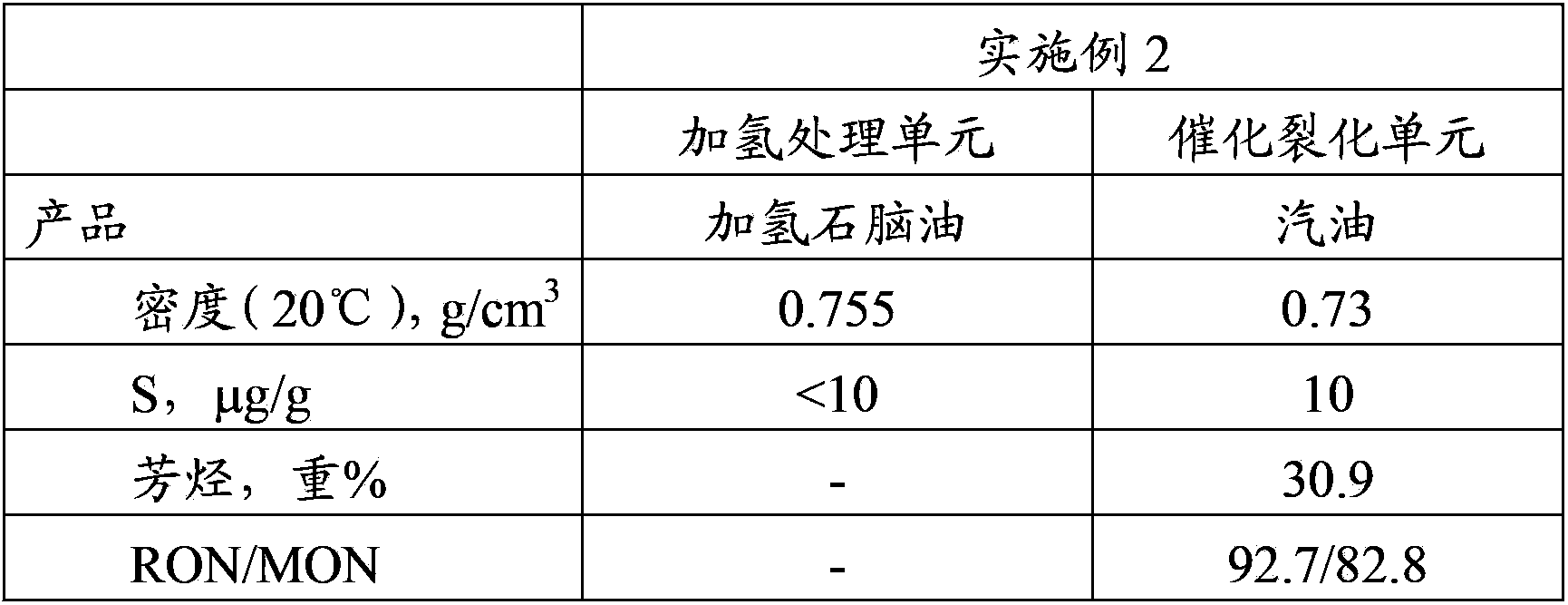

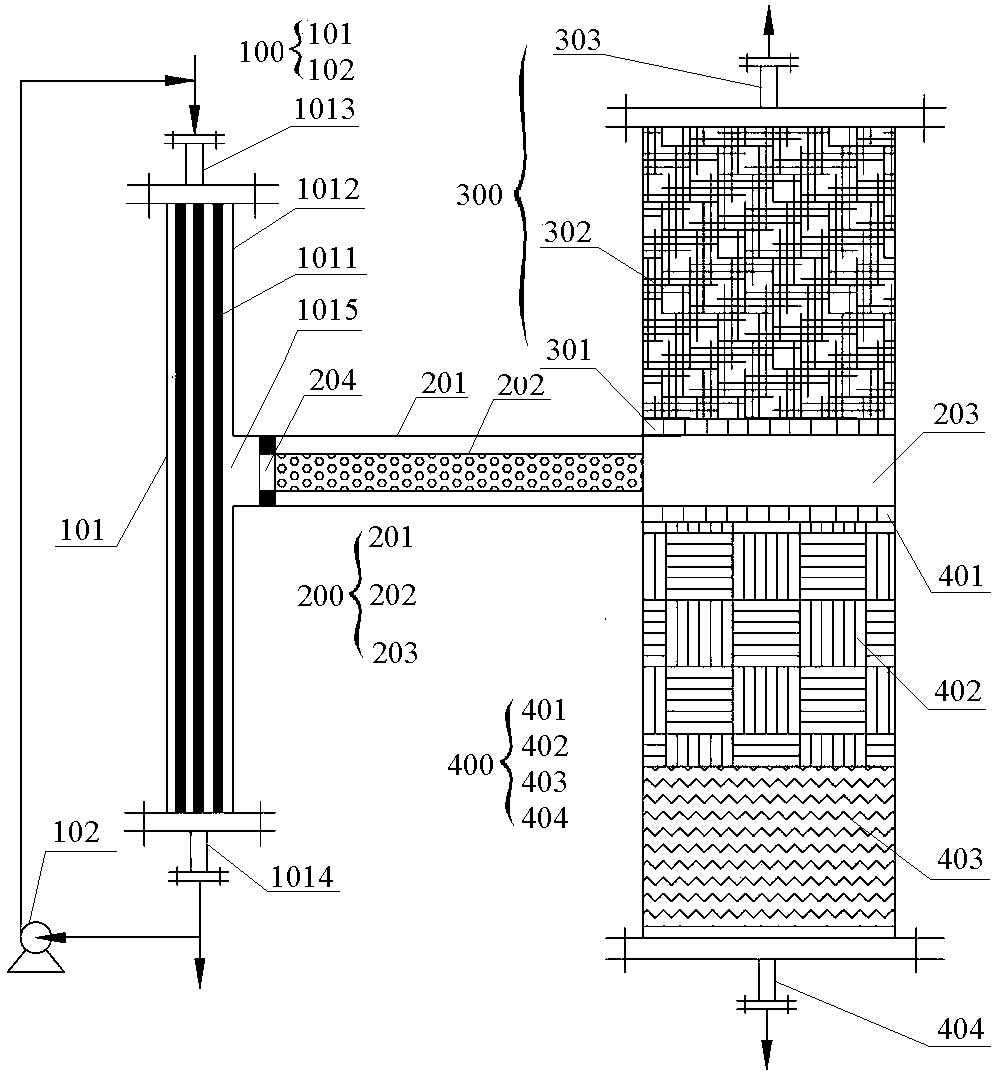

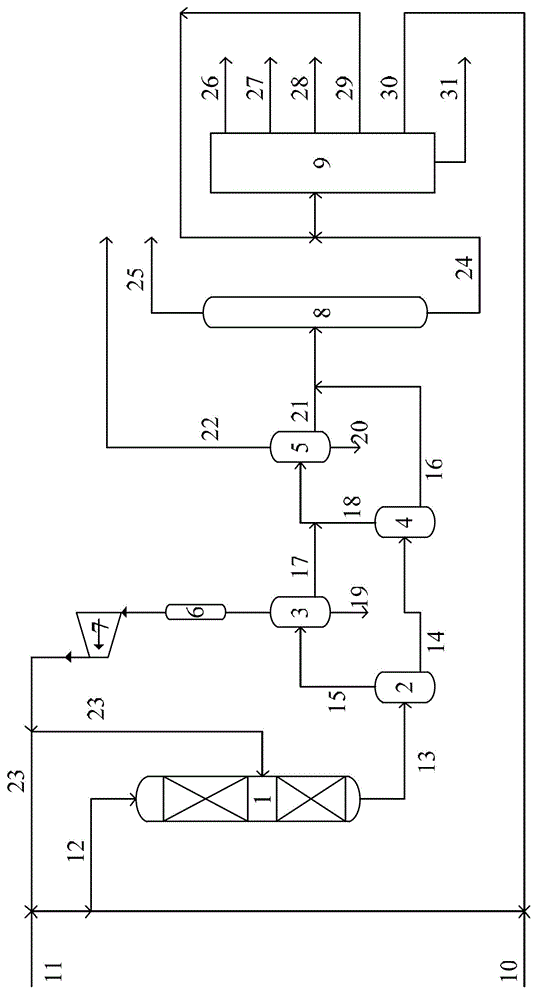

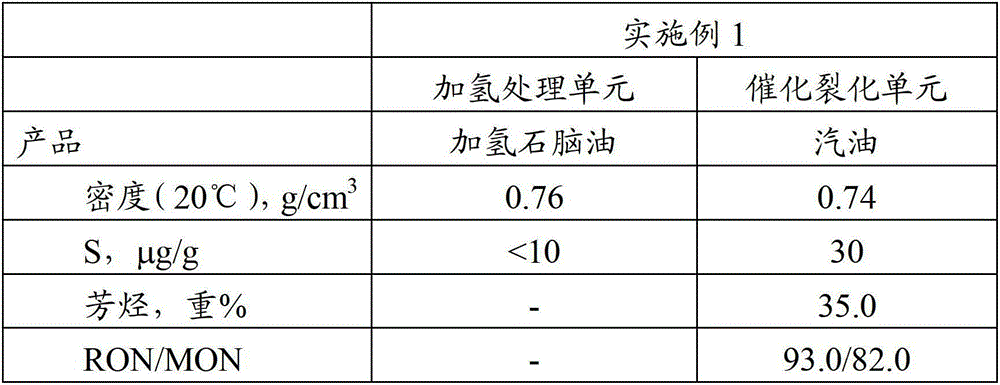

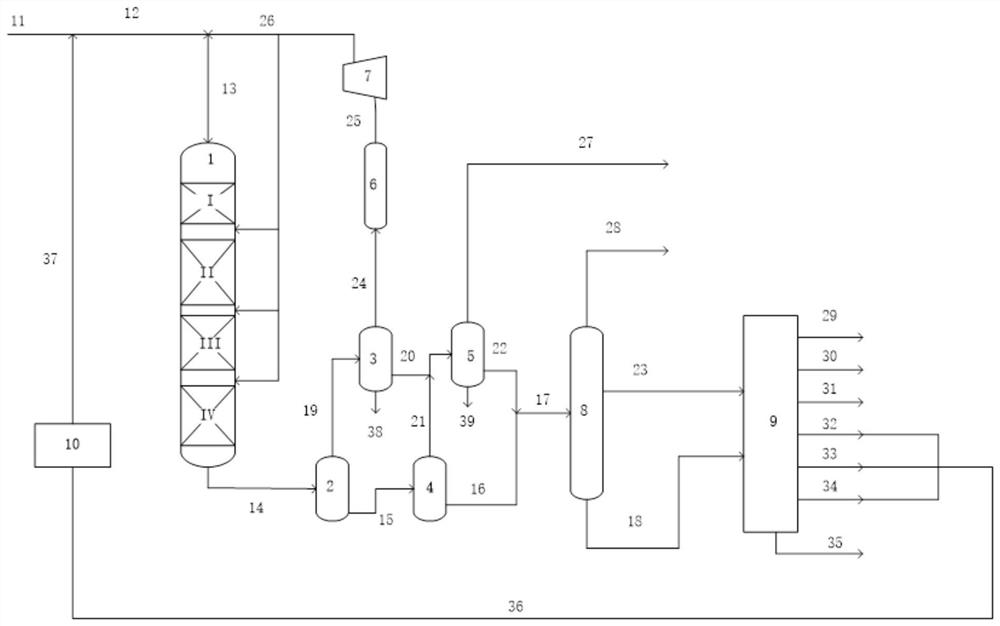

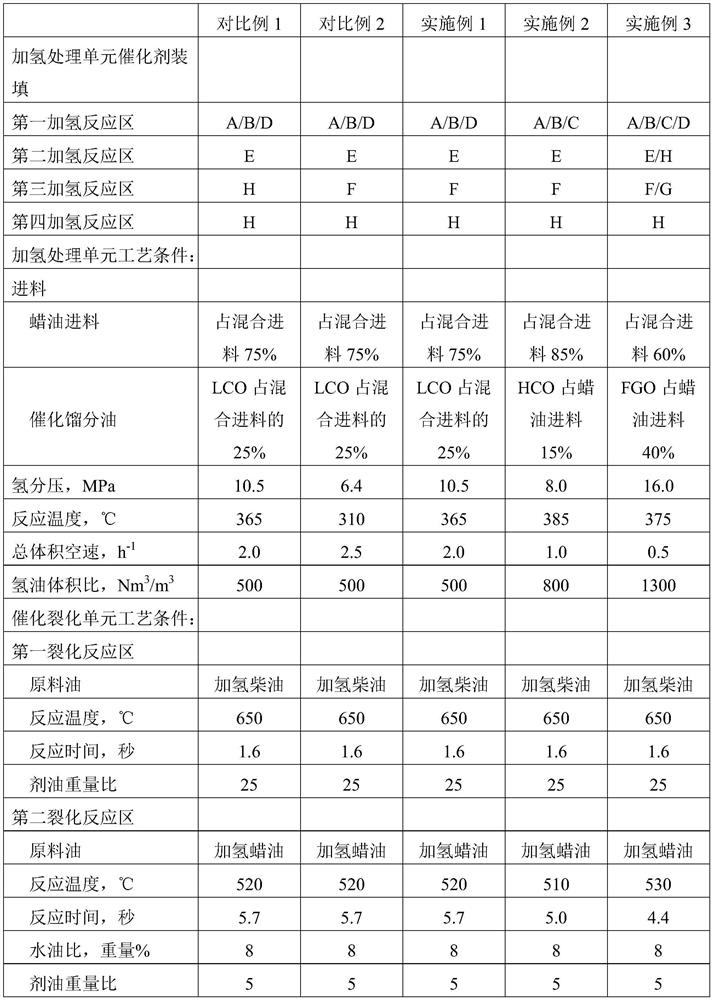

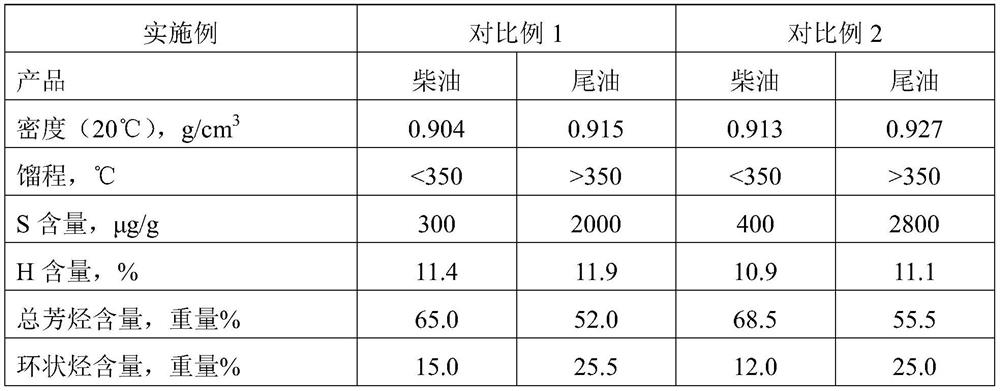

A combined hydroprocessing-catalytic cracking process

ActiveCN103773495BHigh yieldControl sulfur contentTreatment with hydrotreatment processesWaxHydrogen

Provided is a hydrotreatment-catalytic cracking combination process method. Wax oil and catalytic cracking circulation oil go to a hydrotreatment reaction zone together, and are subjected to reactions of hydrodemetallization, hydrodesulfurization, hydrodenitrification, aromatic hydrogenation saturation and the like in the presence of hydrogen and hydrogenation catalysts. The obtained hydrogenated tail oil goes to a catalytic cracking device, a cracking reaction is carried out in the presence of catalytic cracking catalysts. Dry gases, liquefied gases, catalytic cracking gasoline, catalytic cracking light diesel oil, catalytic cracking circulation oil and slurry oil are obtained after separation, the catalytic cracking light diesel oil is subjected to self-circulation in the catalytic cracking device and the catalytic cracking circulation oil is circulated to the hydrotreatment reaction zone. The method can raise yield and quality of gasoline products greatly.

Owner:CHINA PETROLEUM & CHEM CORP +1

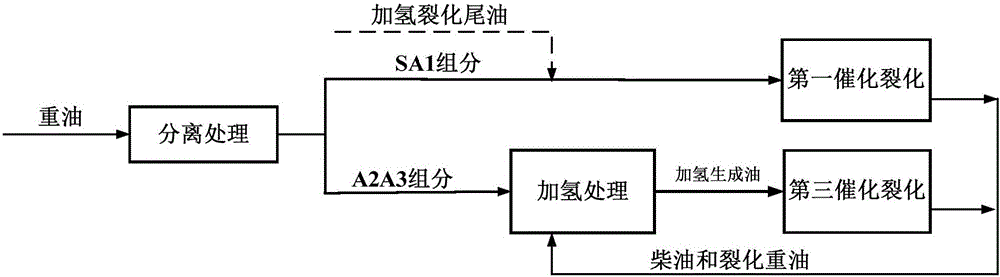

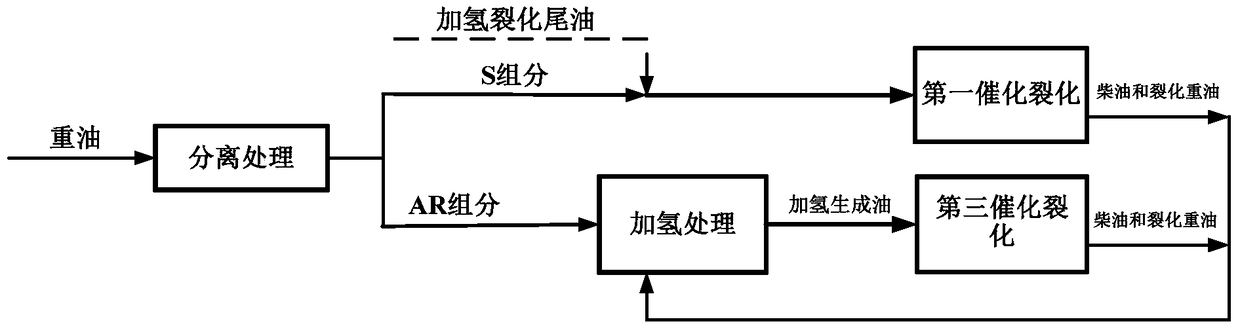

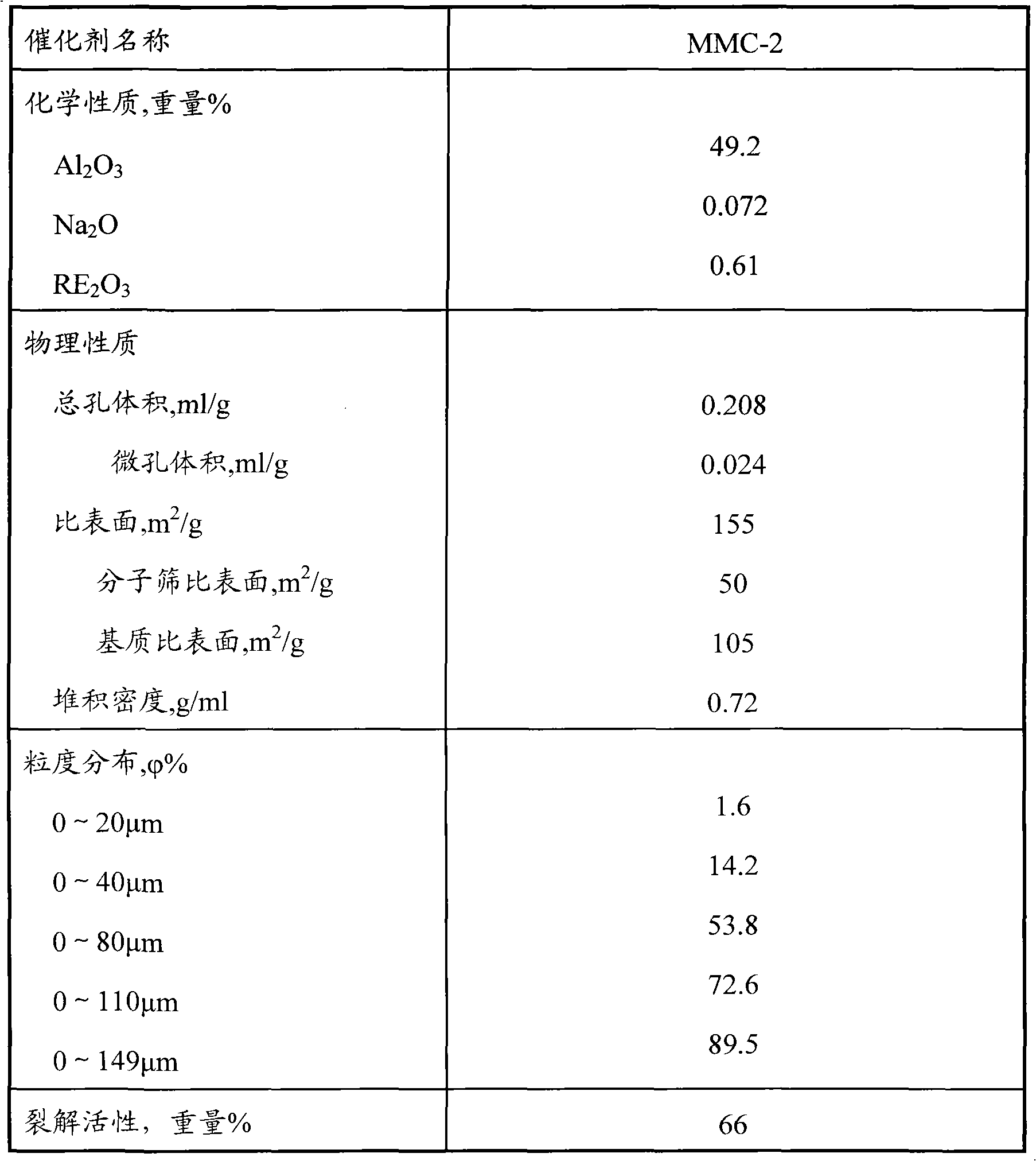

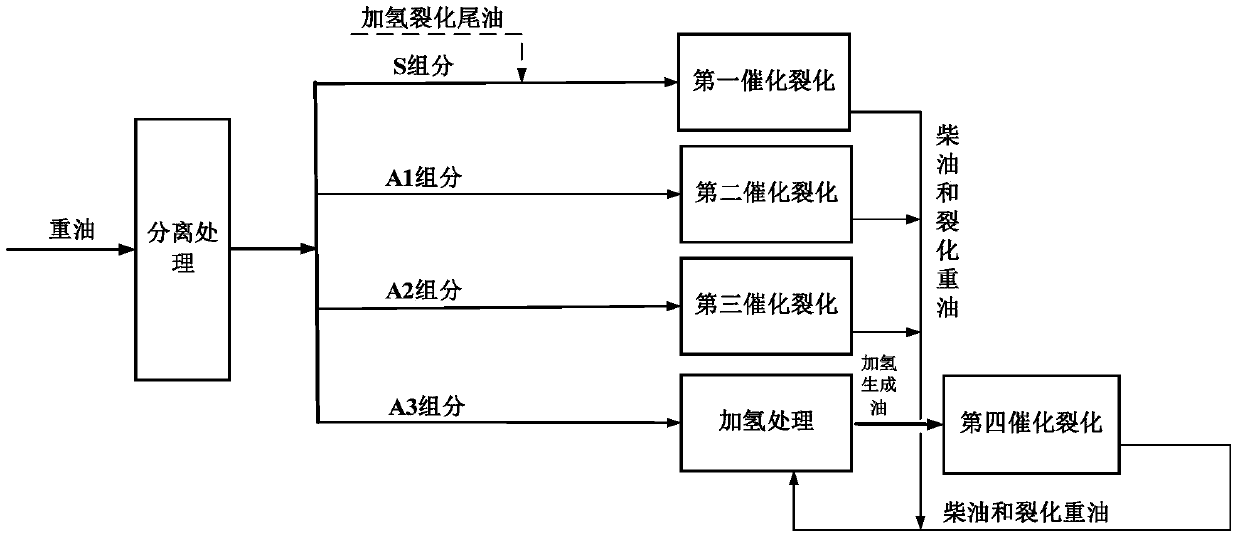

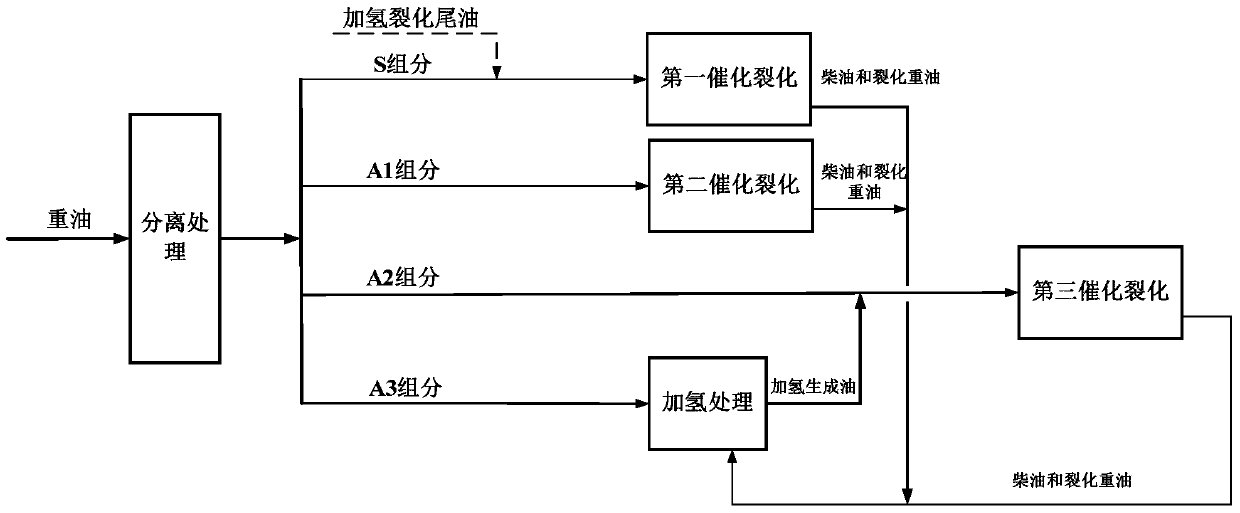

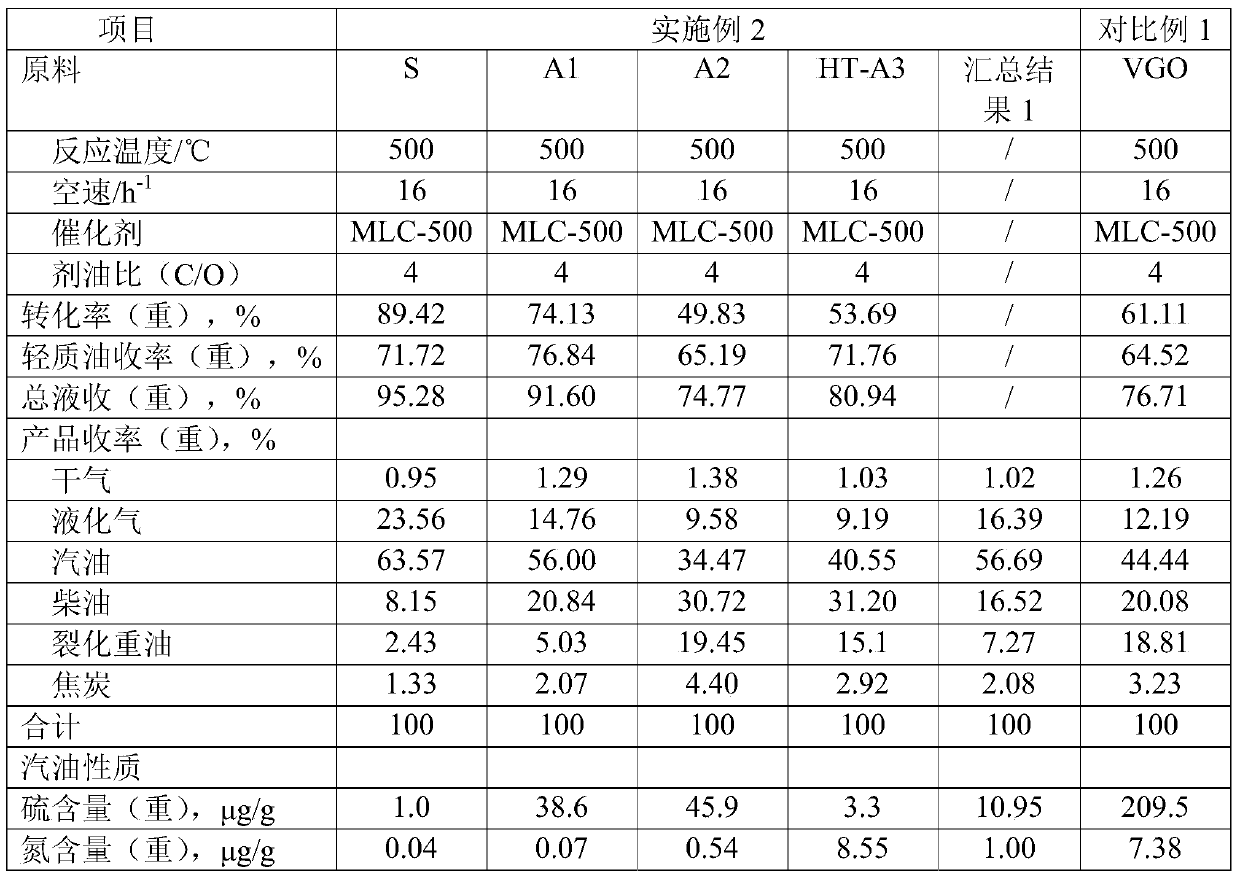

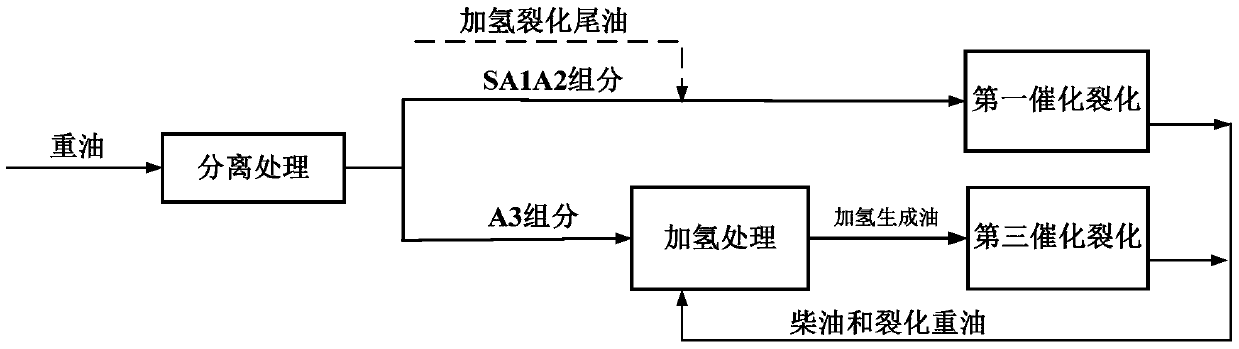

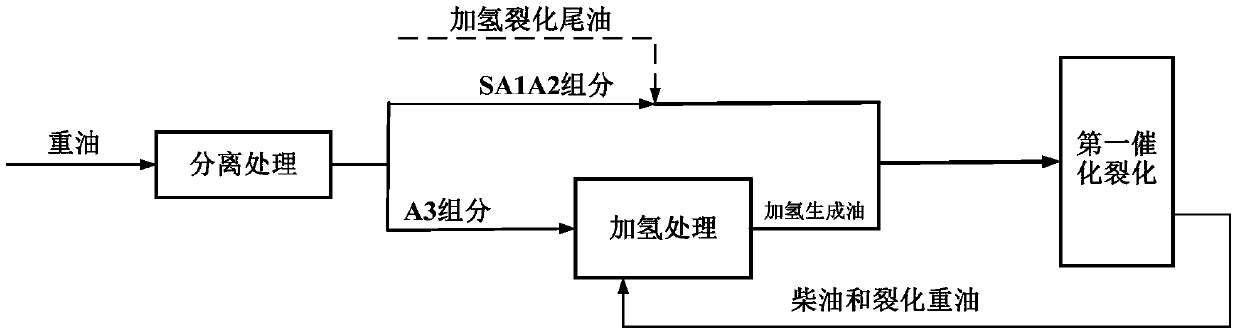

Heavy oil separation-hydrotreatment-catalytic cracking combined method

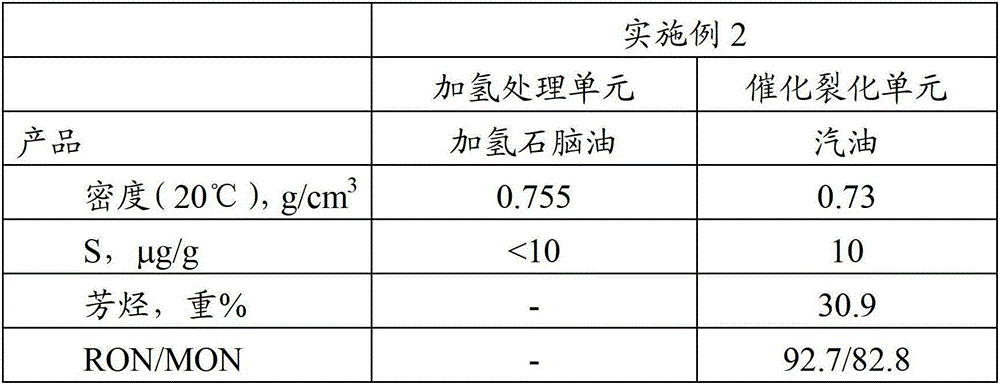

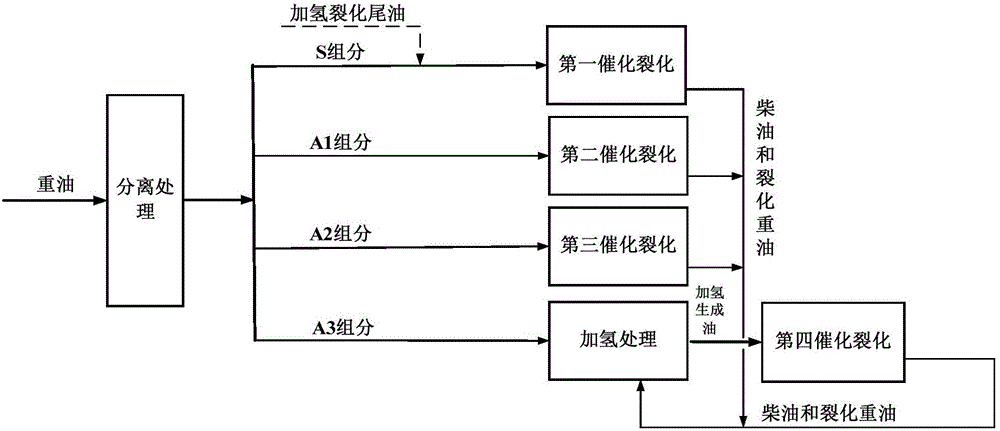

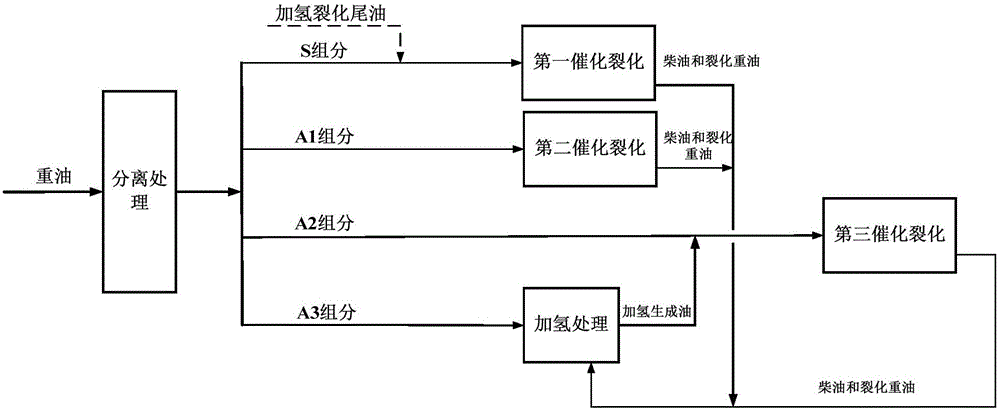

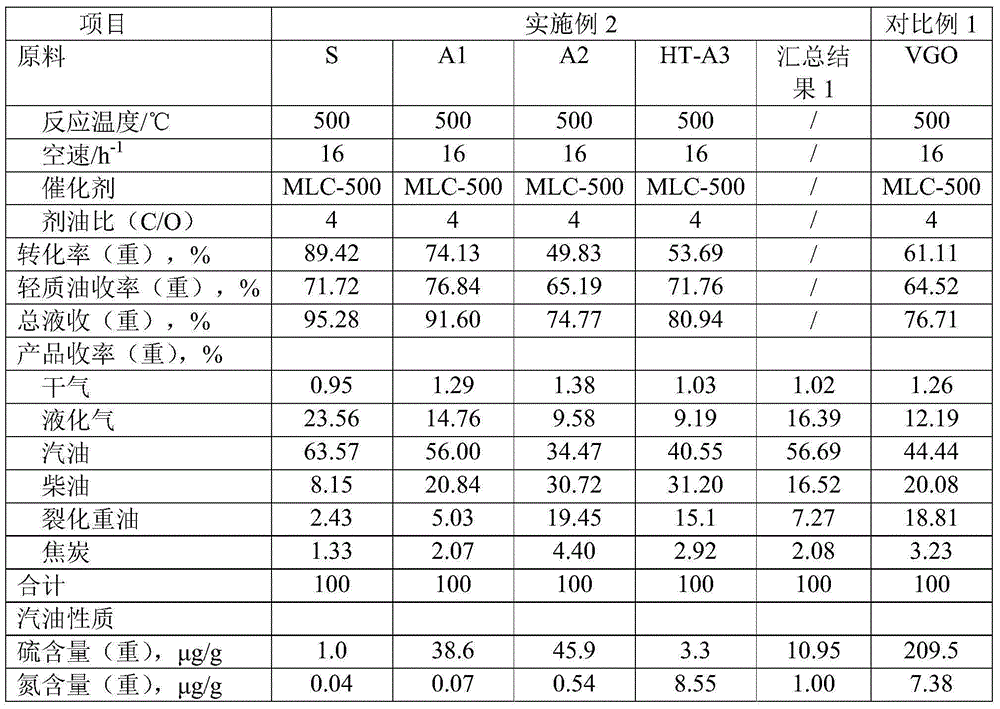

ActiveCN106467757AEliminate interactionIncrease profitTreatment with hydrotreatment processesSulfurNitrogen

The invention discloses a heavy oil separation-hydrotreatment-catalytic cracking combined method. the method comprises the following steps: a, separating heavy oil to obtain a component S, a component A1, a component A2 and a component A3; and b, carrying out a first catalytic cracking reaction on the component S obtained in the step a, so as to obtain dry gas, liquefied gas, gasoline, diesel oil, coke and cracked heavy oil; carrying out a second catalytic cracking reaction on the component A1 obtained in the step a, so as to obtain dry gas, liquefied gas, gasoline, diesel oil, coke and cracked heavy oil; carrying out a third catalytic cracking reaction on the component A2 obtained in the step a, so as to obtain dry gas, liquefied gas, gasoline, diesel oil, coke and cracked heavy oil; and carrying out a hydrotreatment reaction on the component A3 obtained in the step a under the action of a hydrotreating catalyst, so as to obtain hydrogenated oil. In comparison with the prior art, the method for heavy oil treatment and the subsequent catalytic cracking reactions has advantages of higher yield of gasoline and liquefied gas and lower sulfur / nitrogen content of gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

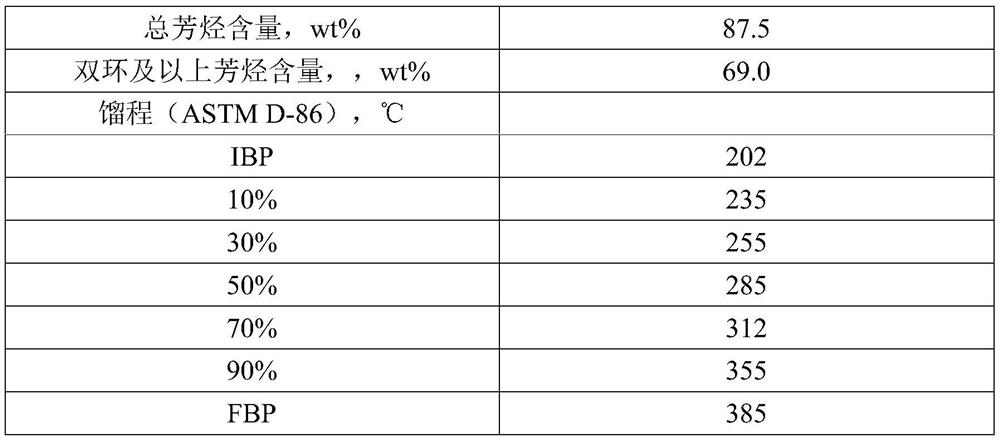

Hydroisomerization-catalytic cracking technology of catalytic cracking diesel oil

ActiveCN110437875AGood product qualityHigh product yieldTreatment with hydrotreatment processesChemistryFuel oil

The invention discloses a catalytic cracking diesel oil hydroisomerization-fluid catalytic cracking method, which comprises: 1) mixing catalytic cracking diesel oil and hydrogen, making the obtained mixture enters a section of hydrogenation reaction devices connected in series, and carrying out a hydrorefining-hydroisomerization reaction, wherein the hydrogenation reaction devices are sequentiallyfilled with a hydrogenation protecting agent, a hydrorefining catalyst and a hydroisomerization catalyst; and 2) making the hydroisomerized diesel oil enter a fluidized bed catalytic cracking device,and carrying out a catalytic cracking reaction. According to the present invention, with the method, low-carbon olefins and clean fuel oil are produced by using catalytic cracking diesel oil, and under the complete conversion of catalytic cracking diesel oil, the low-carbon olefin content in the product is more than 35 wt%, and the aromatic hydrocarbon content in the gasoline distillate is more than 50 wt%, such that the value of catalytic cracking diesel oil can be significantly increased.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +2

A method for thermal regeneration of waste rubber

InactiveCN102030934BAvoid the disadvantages of smelly hot steamRubber hydrocarbon content decreasedPlastic recyclingLiquid hydrocarbon mixture productionPolymer scienceWaste rubber

The present invention proposes a method for thermal regeneration of waste rubber, which is to feed materials with a weight ratio of "waste rubber coarse powder / environmentally friendly softener / powder auxiliary material" in the range of 100 / 8-150 / 20-1500, stir and heat In the container, it is first heated by anaerobic, and then introduced into the stirring cooler, cooled to below 100 ℃, and the product is obtained; or part or all of the powder auxiliary materials in the feeding are deducted and slowly thrown, and the materials that are fed into the stirring heater in the early stage Before the material is to be discharged, add the powder auxiliary material deducted first to the stirring heater, or / and add it when the hot material is introduced into the stirring cooler, and discharge the material after the mixture is cooled to below 100°C; or the formula After initial mixing, the material is introduced into the screw extruder, and after heating and mixing, the material is cooled to 100°C to obtain the product; Or in addition, between the process of preparing carbon black from combustible fuel and combustible gas, a multi-directional migration relationship of materials or / and energy is established.

Owner:陈汇宏 +1

Fresh corn dairy product and production method thereof

InactiveCN105231241AHas a clear fragranceHigh quality feedFood preservationFood ingredient as taste affecting agentSlagBran

The invention discloses a fresh corn dairy product and a production method thereof and relates to the field of dairy products and corn foods. The production method solves the problem that the existing dairy product has a peculiar smell such as a mutton or fishy smell and the existing corn food has a poor taste and is difficult to be digested. Through fresh and tender corn bran, impurity and worm-damaged part removal, cleaning, fragmentation, squeezing, filtering slag removal (wherein for preventing deterioration in long-term storage, the corn with slag is subjected to seal storage under high pressure and then is filtered to remove slag in selling or is subjected to refrigeration storage at a low temperature), loading, sterilization and drying, natural corn milk without a peculiar smell and a series of products of the natural corn milk are obtained and have a good dairy product taste. The production method can be widely used in regions where green corn is planted.

Owner:张思祥

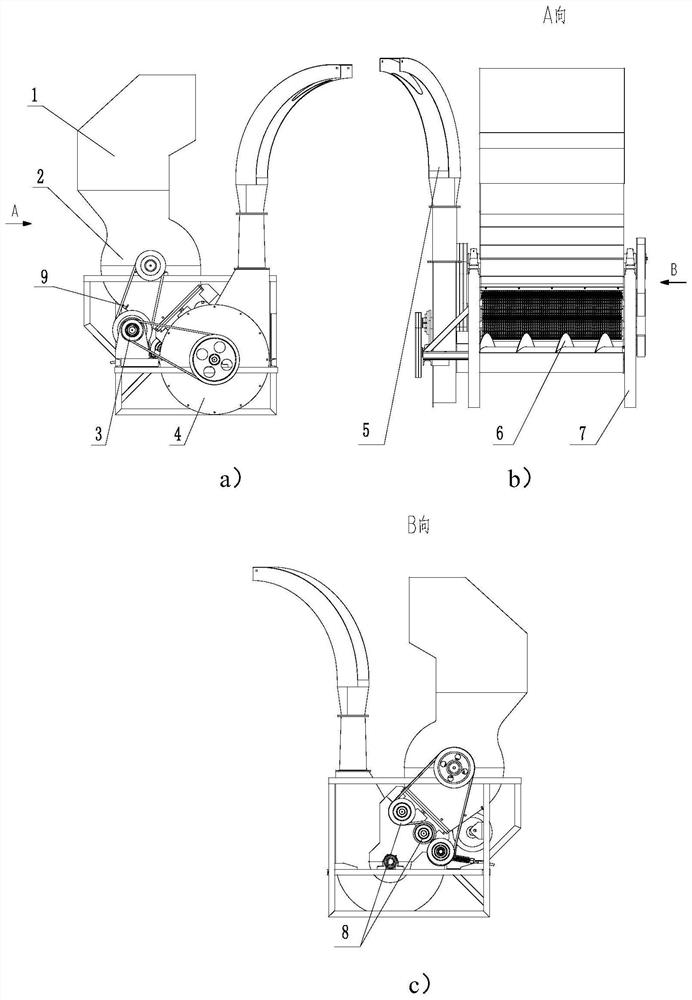

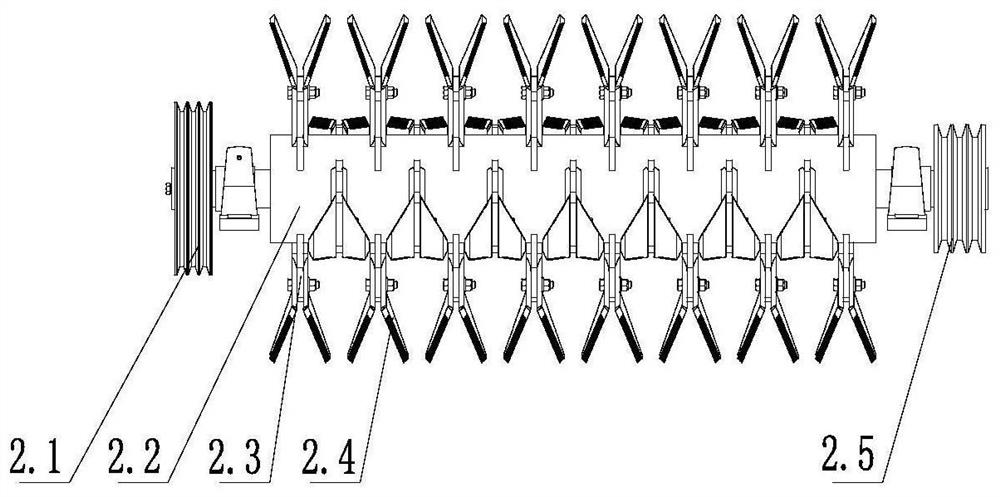

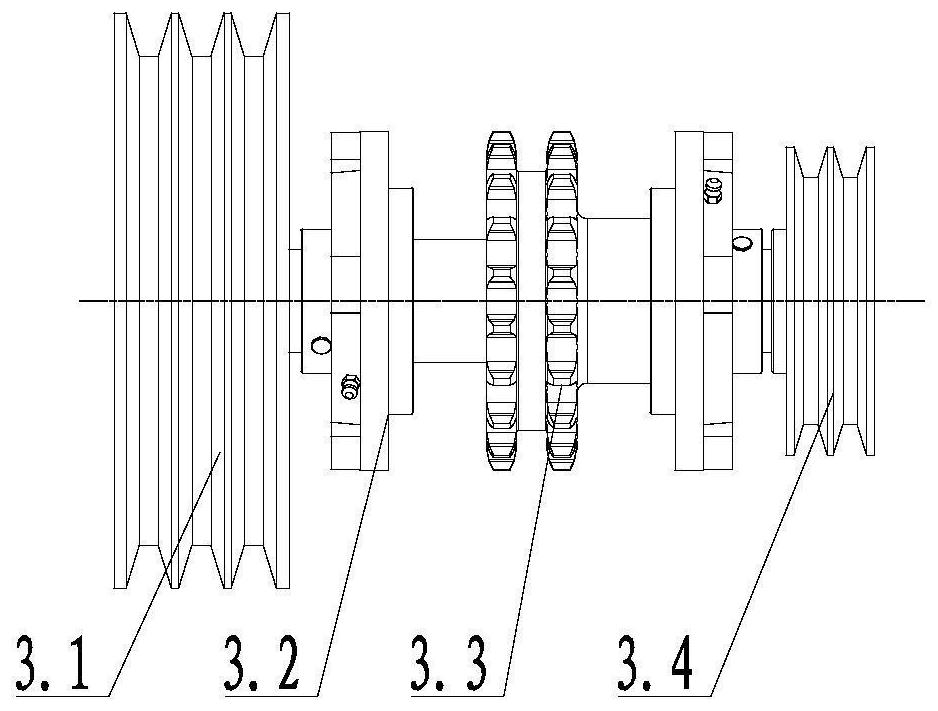

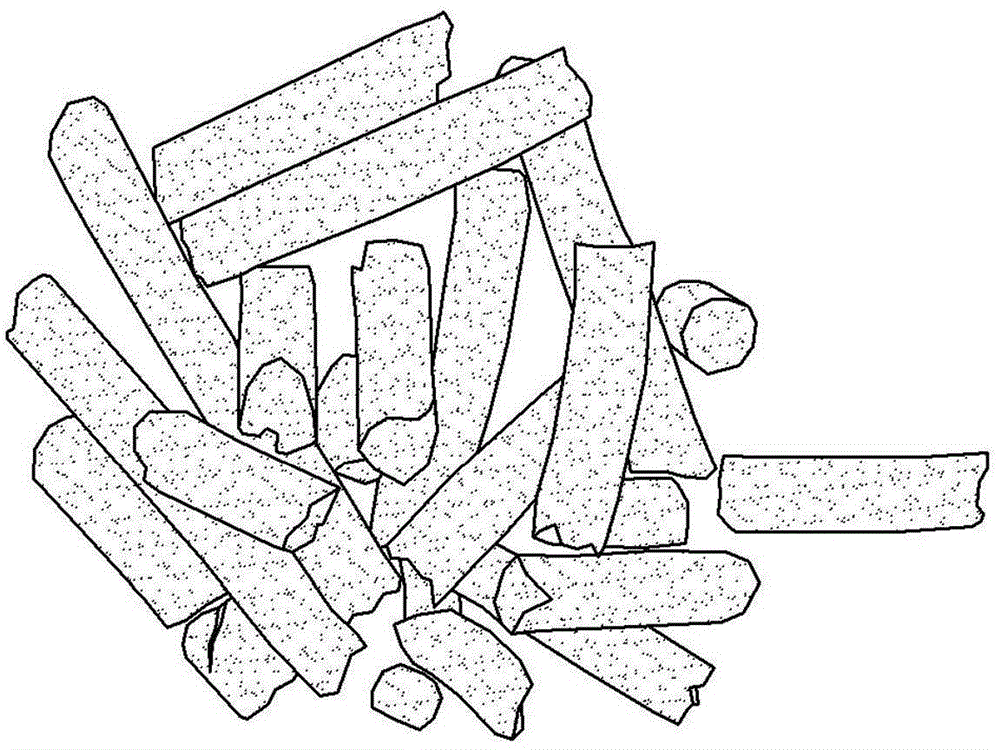

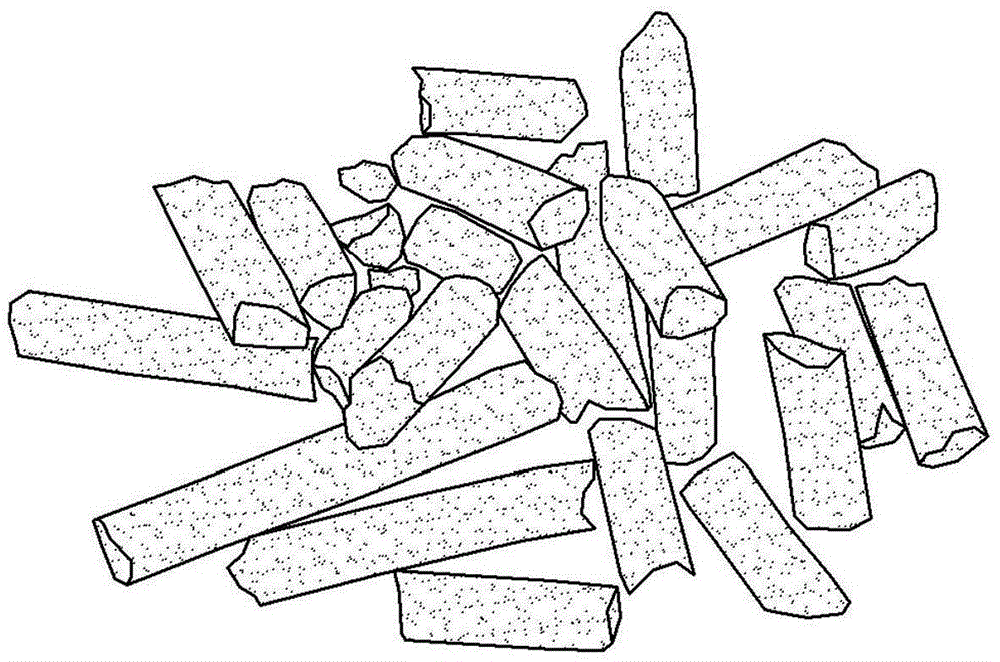

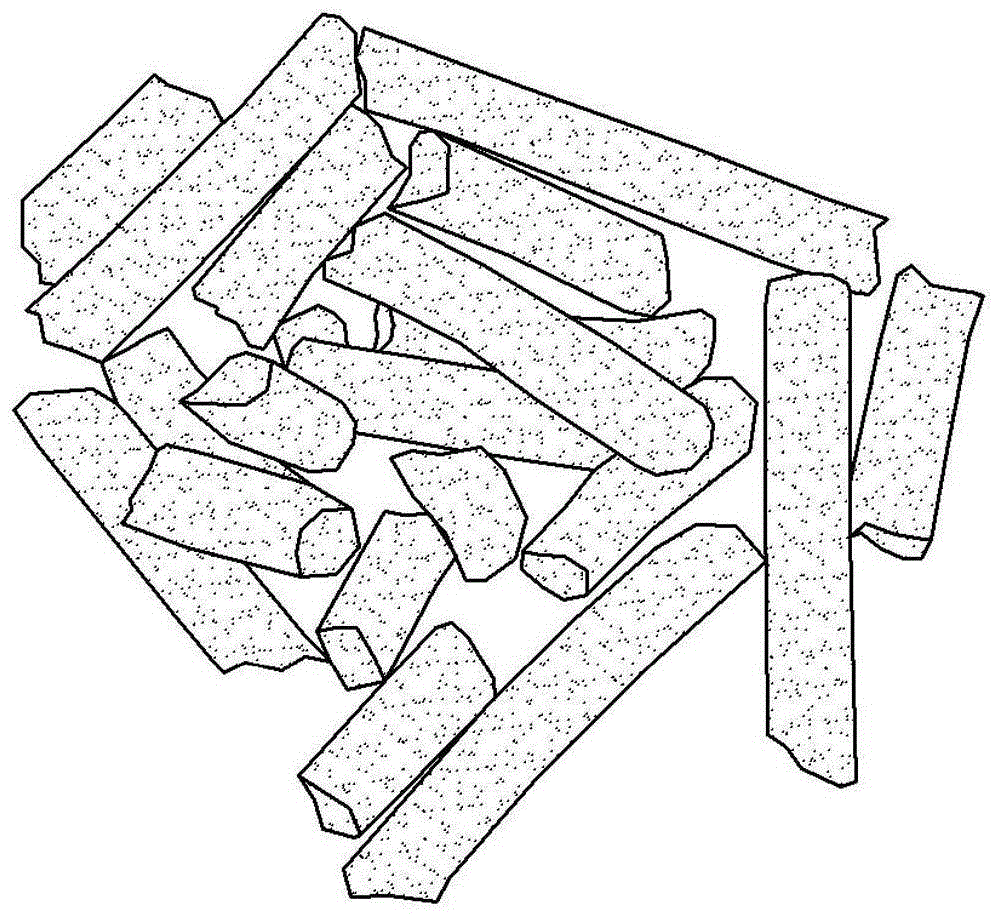

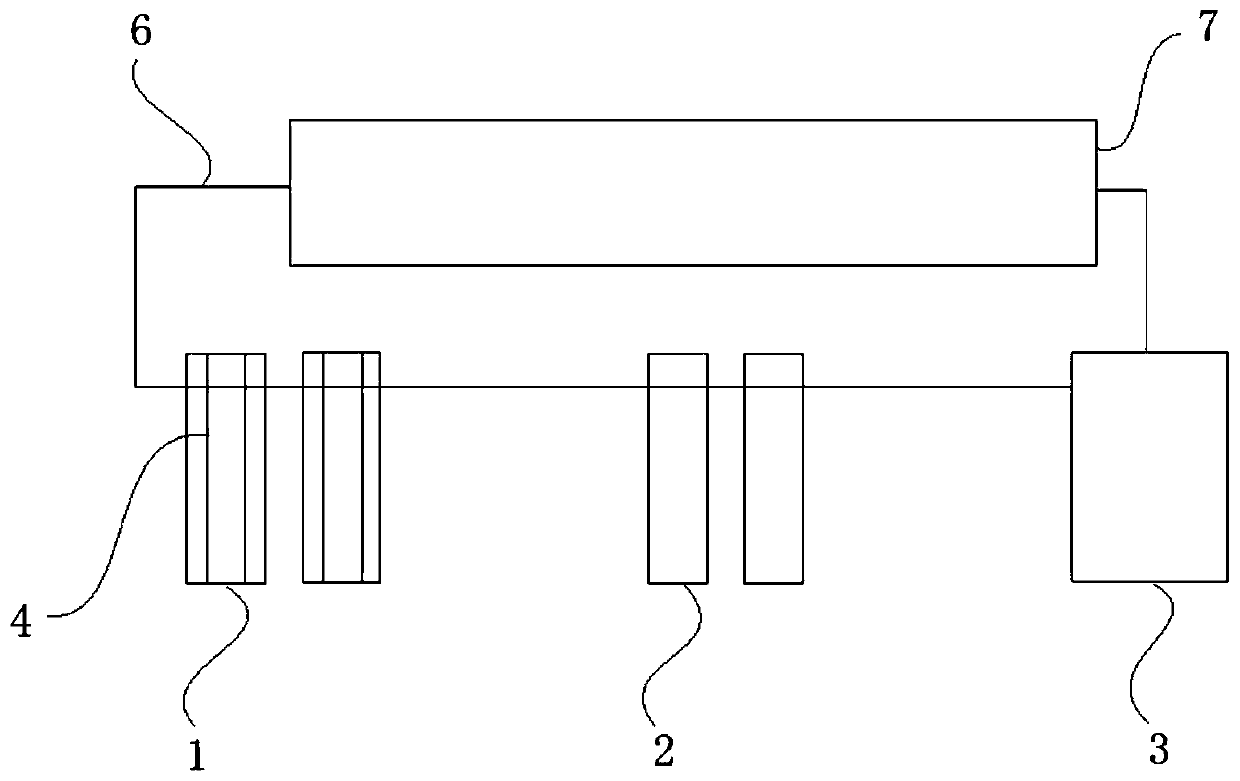

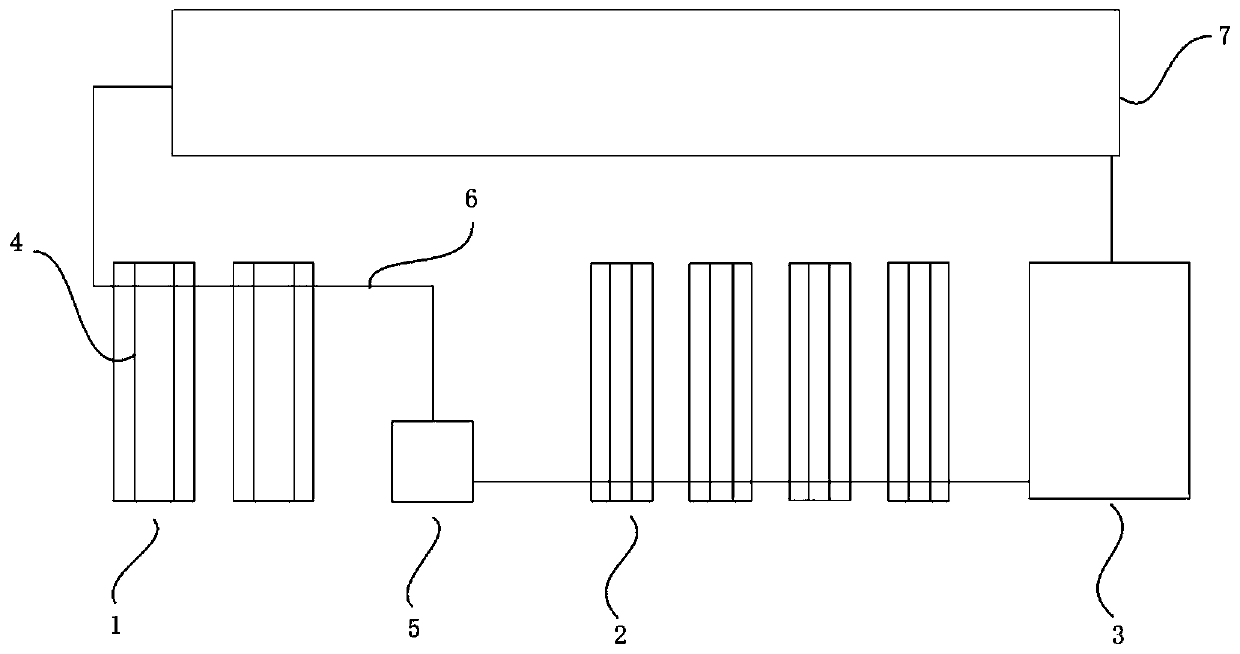

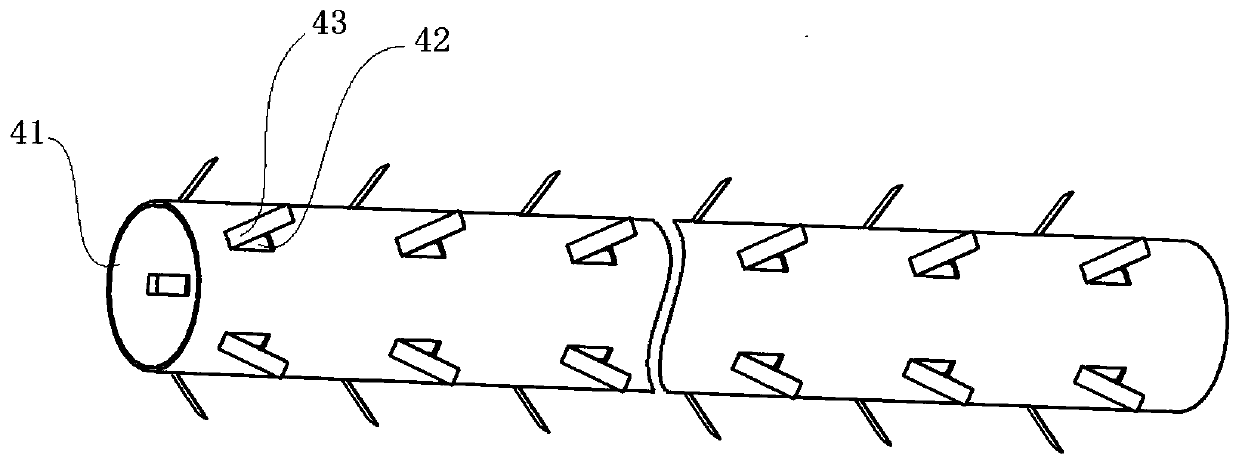

Corn ear chopping and kernel crushing device as well as working method and application thereof

InactiveCN112206891AAchieve shreddingAchieve brokenGrain treatmentsAgricultural scienceAgricultural engineering

The invention belongs to the technical field of agricultural machinery, particularly relates to a corn ear chopping and kernel crushing device as well as a working method and an application thereof, and discloses a corn ear smashing device capable of completing corn ear feeding, corn ear chopping, kernel crushing and material throwing. After corn ears are fed into the smashing device, the ears arechopped through the interaction of a movable cutter and a fixed cutter of a chopping device, chopped ear materials pass through kernel crushing rollers rotating oppositely, corn kernels are smashed into 1 / 3-grain to 1 / 4-grain, then the materials are conveyed to one side under the action of a conveying auger and thrown out through a throwing device and a throwing barrel, the ear smashing quality can be effectively improved, and high-quality feed is provided for the animal husbandry.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

Method for extracting tea saponin by utilizing microbes

InactiveCN101880307BPromote dissolutionIncrease contentSugar derivativesBiofuelsCamellia oleiferaDissolution

The invention relates to a method for extracting tea saponin by utilizing microbes. The method comprises the steps of firstly using an added exogenous high starch substance, mixing with complex enzyme and alcohol yeast for fermentation, leading starch in the exogenous high starch substance to be fully utilized by the alcohol yeast to produce alcohol, forming mash, then soaking a certain amount ofwell smashed oil tea cake powder in the well fermented mash, uniformly mixing, culturing for a plurality of days, carrying out solid-liquid separation, further carrying out concentration and drying on supernatant fluid of liquid obtained after separation and finally obtaining a final product of the tea saponin. The method can fully utilize original polysaccharides in the oil tea cake, use the alcohol yeast for fermentation, produce a certain alcohol degree, effectively promote the dissolution of the tea saponin, lead the extraction rate of the tea saponin to be above 80%, further consume a large amount of soluble sugar, lead the content of the tea saponin in a crude extract to be as high as above 60%, and lead the safety of the extracted tea saponin to be high; and the separated cake after extracting the tea saponin is a high-quality feed, thereby improving the economic value and the economic benefits of the cake and having simple process and low extraction cost.

Owner:TEA RES INST ANHUI ACAD OF AGRI SCI

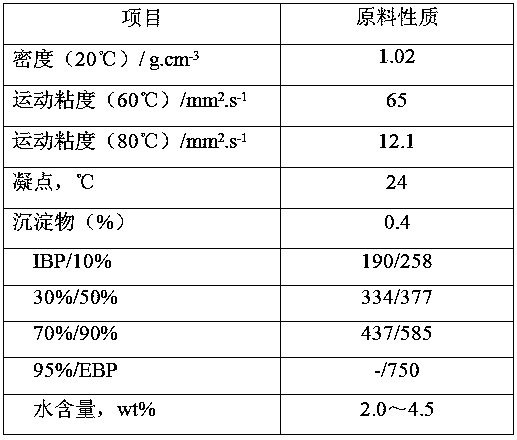

Method for producing gasoline and low-sulfur ship fuel

ActiveCN113046125AMaximize productionReduce investmentTreatment with hydrotreatment processesBio-feedstockHydrogenation reactionFluidized bed

The invention discloses a method for producing gasoline and low-sulfur ship fuel. The method comprises the following steps: hydrotreating a residual oil raw material through a fluidized bed hydrotreating reaction device and a fixed bed hydrotreating reaction device in sequence to obtain a hydrogenation reaction effluent; carrying out gas-liquid separation on the hydrogenation reaction effluent, not fractionating the obtained liquid phase, taking one part as low-sulfur ship combustion, and carrying out catalytic cracking on the remaining part; and returning a catalytic cracking heavy fraction in the effluent of the catalytic cracking reaction to be mixed with the residual oil raw material for hydrotreating. According to the combined process, high-octane catalytic cracking gasoline and low-sulfur ship fuel products can be produced to the maximum extent. Meanwhile, hydrogenation load is reduced, a catalytic cracking fractionation system is simplified, and equipment investment and operation energy consumption are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Introducing soybean total DNA to improve nutrient quality of barley grain

InactiveCN1548538AImprove nutritional qualityGenetic stabilityMicroinjection basedAnimal feeding stuffBiotechnologyNutrition

The method of producing barley seed with raised protein content includes the following steps: providing soybean total DNA and barley seed; introducing soybean total DNA with gene gun into barley seed; growing barley with the seed obtained in the last step and gathering the next generation seed; and identifying the next generation seed with raised protein content. The present invention also provides feed containing the barley seed. The first generation seed thus obtained has greatly raised protein content and unchanged other characteristics.

Owner:SHANGHAI NORMAL UNIVERSITY

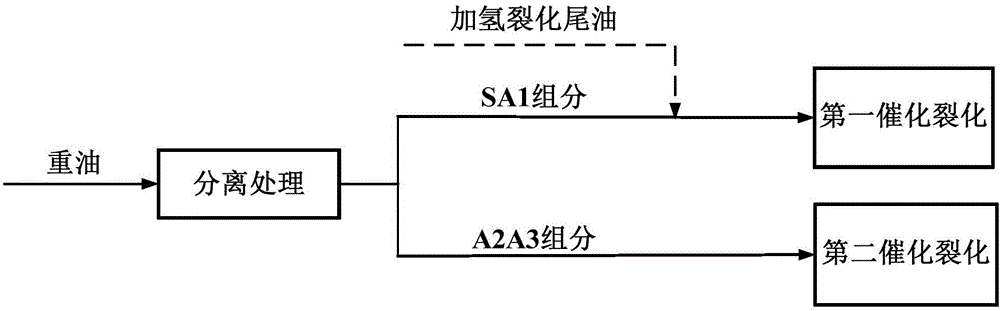

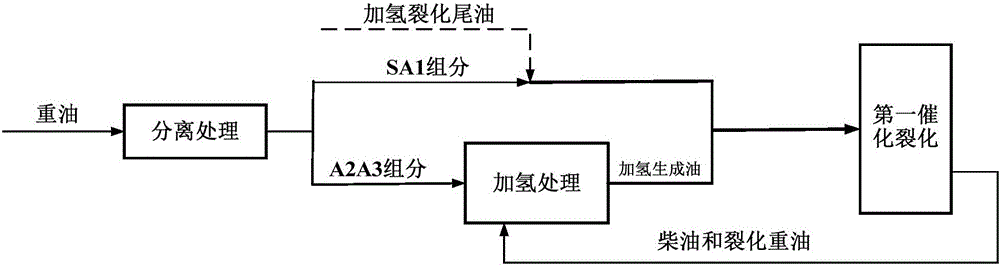

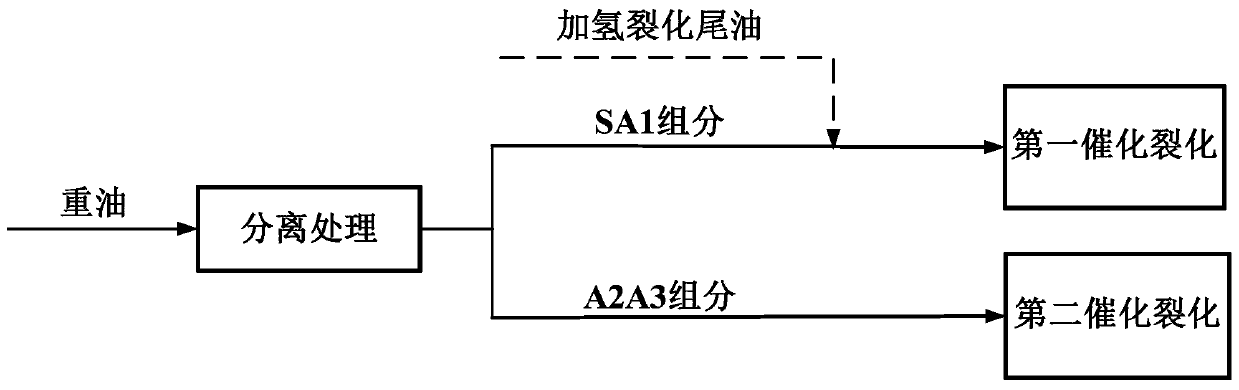

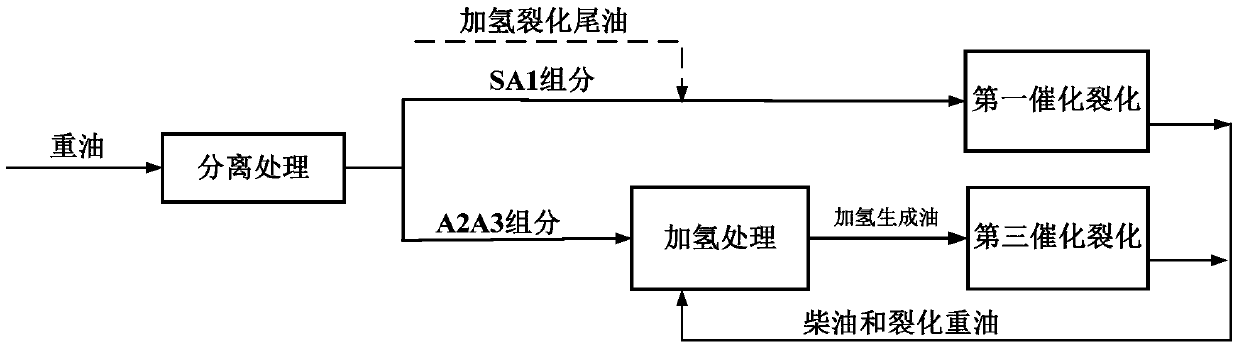

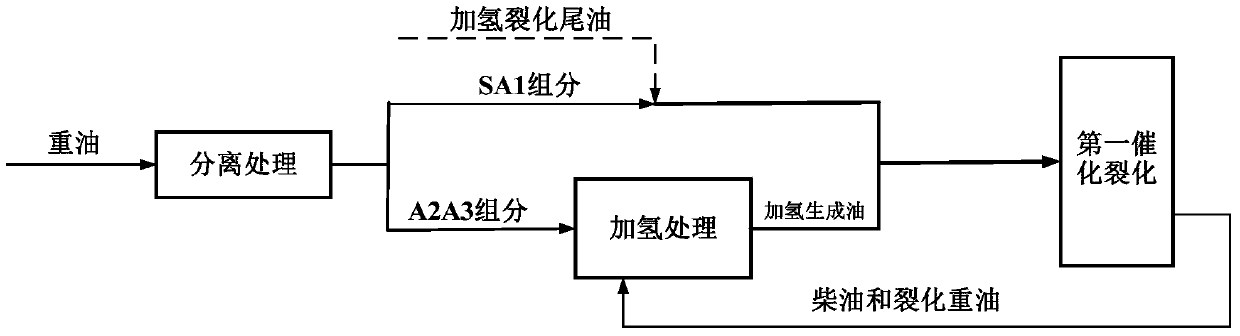

Method for processing heavy oil by combined process

ActiveCN106467758AEliminate interactionIncrease profitTreatment with plural serial stages onlySulfurNitrogen

The invention discloses a method for processing heavy oil by combined process. the method comprises the following steps: a, carrying out separation treatment on heavy oil to obtain a SA1 component and a A2A3 component, wherein with total mass of the SA1 component as the reference, total mass fraction of saturated hydrocarbon and monocyclic aromatics in the SA1 component is greater than 80 wt%; and with total mass of the A2A3 component as the reference, total mass fraction of aromatics with more than one ring and colloid is greater than 75 wt%, and mass fraction of aromatics with more than one ring is greater than 35 wt%; and b, carrying out first catalytic cracking reaction on a SA1 component obtained in the step a, so as to obtain dry gas, liquefied gas, gasoline, diesel oil, coke and cracked heavy oil. According to the method, the SA1 component and the A2A3 components obtained after the separation treatment of heavy oil are respectively subjected to the catalytic cracking reaction. By the method, yield of gasoline and liquefied gas is higher, and sulfur and nitrogen content of gasoline is lower.

Owner:CHINA PETROLEUM & CHEM CORP +1

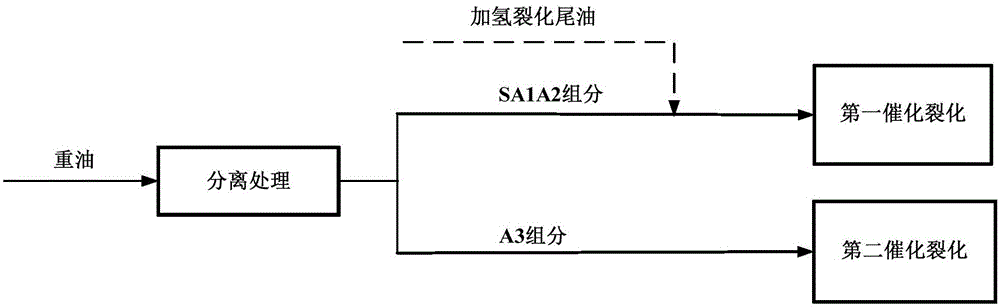

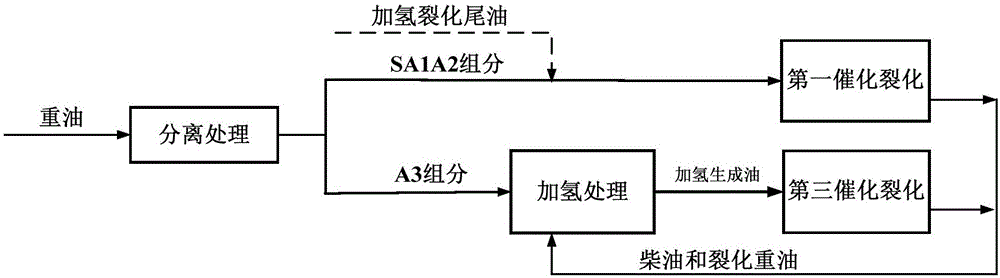

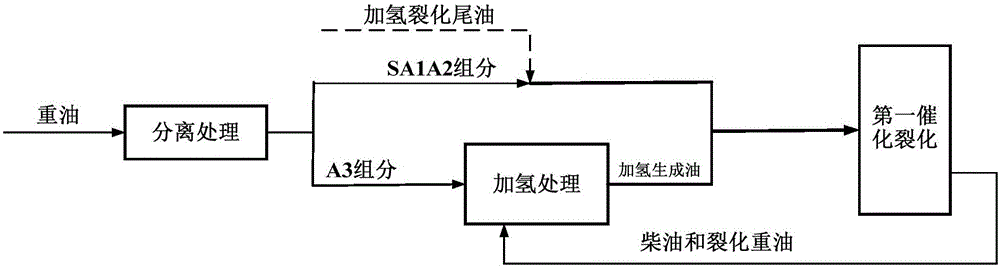

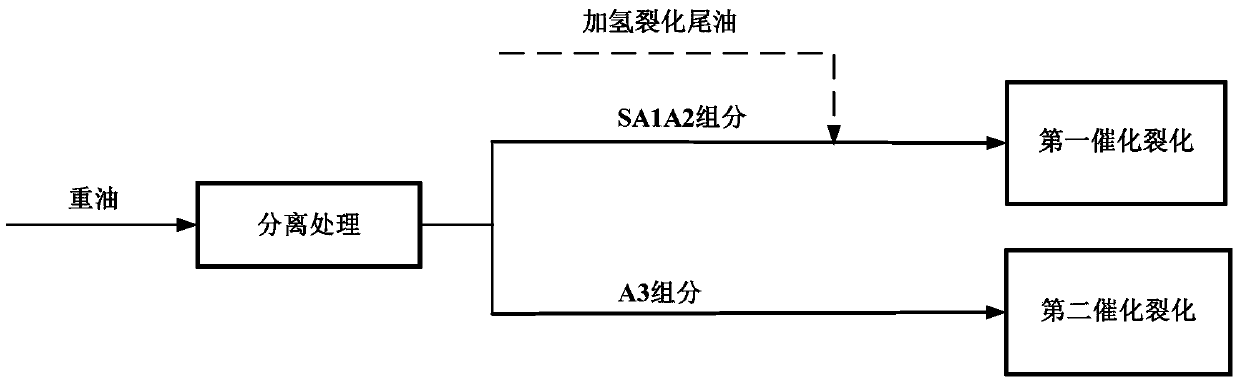

Heavy oil processing combined method

ActiveCN106467756ASave resourcesEliminate interactionTreatment with hydrotreatment processesOil processingSulfur

The invention discloses a heavy oil processing combined method. The method comprises a. separating heavy oil to obtain components SA1A2 and A3, wherein the component SA1A2 comprises greater than 80% by mass of a saturated hydrocarbon, a mono-aromatic hydrocarbon and a diaromatic hydrocarbon and the component A3 comprises greater than 50% by mass of colloid and aromatic hydrocarbons with two or more aromatic rings, and b, carrying out a first catalytic cracking reaction process on the component SA1A2 to obtain dry gas, liquefied gas, gasoline, diesel oil, coke and cracked heavy oil. Through catalytic cracking of the components SA1A2 and A3 obtained by separating the heavy oil, high gasoline and liquefied gas yields and low gasoline sulfur and nitrogen content are obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for treating green plum fruit wine vinasse residues and liquor

InactiveCN105558262AEmission reductionEliminate or effectively control pollutionAnimal feeding stuffFruit wineAluminium chlorohydrate

The invention relates to a method for treating green plum fruit wine vinasse residues and liquor. The method comprises the following steps that firstly, the green plum fruit wine vinasse residues and liquor are recycled in a settling basin, and the pH value of the green plum fruit wine vinasse residues and liquor is measured; secondly, alkali or alkaline matter is added in the settling basin in the first step to regulate the pH value of the green plum fruit wine vinasse residues and liquor to be 6-9; thirdly, destabilizing and settling accelerating agents polyaluminum chloride or / and polyferric sulfate are added with the adding quantity of the desertion stabilizing and settling accelerating agents accounts for 0.0015-0.003% of the plum fruit wine vinasse residues and liquor, and the mixture is evenly stirred and then subjected to standing; fourthly, water liquid on the middle and upper layers is drained; fifthly, bottom layer sediment obtained in the third step is dehydrated; sixthly, the dehydrated sediment is dried and ground, and an end vinasse powder product is obtained.

Owner:NANJING LOLIJIA AGRI DEV LTD

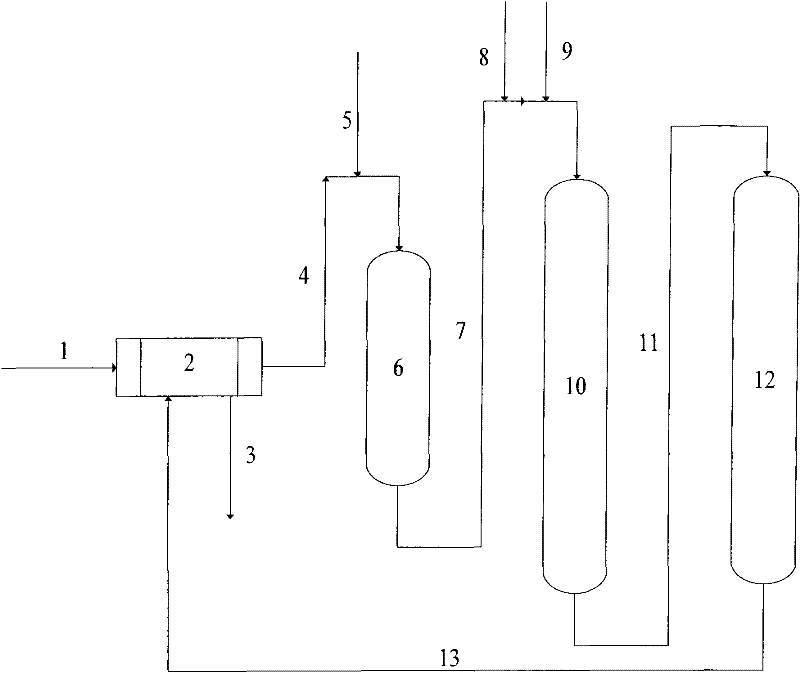

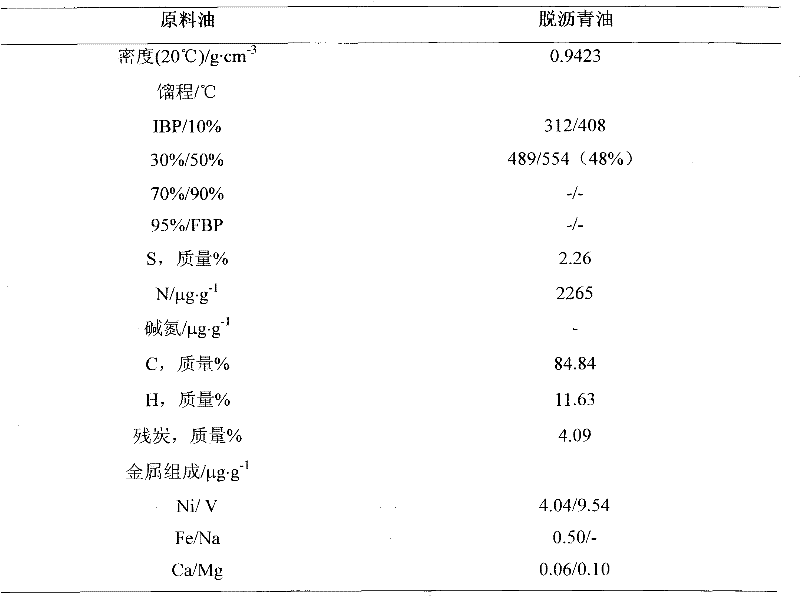

A combined hydrotreating-catalytic cracking process that produces more isobutane and light aromatics

ActiveCN112538384BHigh Aromatic Content of BTXHigh quality feedTreatment with hydrotreatment processesHydrocarbon oils treatment productsPtru catalystNaphtha

Owner:CHINA PETROLEUM & CHEM CORP +1

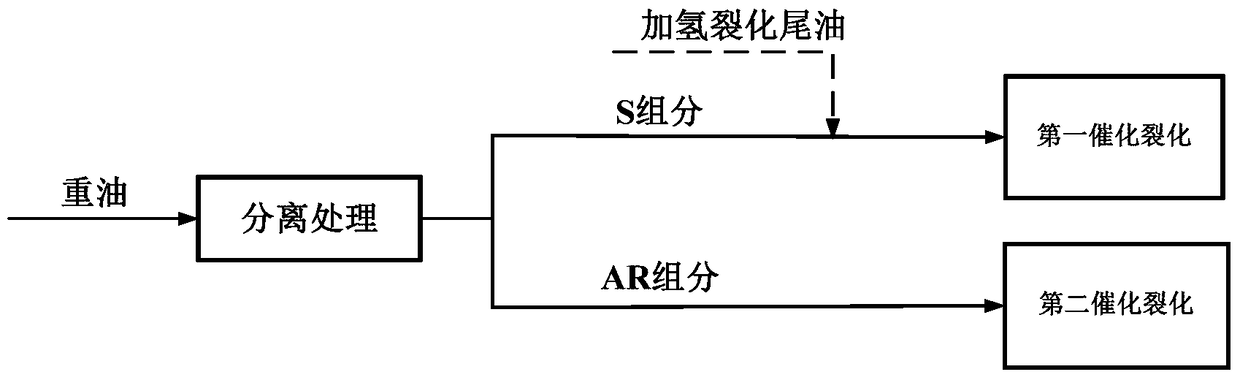

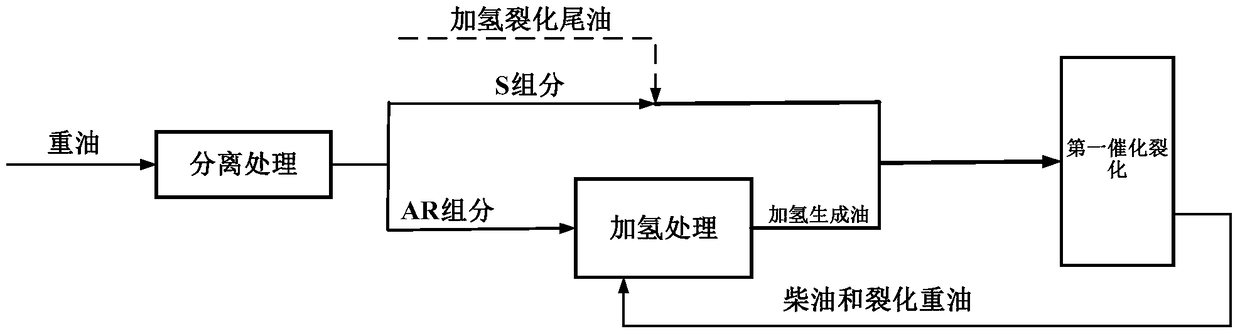

A combined method of heavy oil pretreatment and catalytic cracking

ActiveCN106467759BEliminate interactionIncrease profitTreatment with plural serial stages onlyTreatment with hydrotreatment processesOil processingPretreatment method

The invention discloses a heavy oil pretreatment and catalytic cracking combination method. The method comprises the following steps: a) separating the heavy oil to obtain a component S and a component AR; wherein, by taking total mass of the component S as a reference, the mass fraction of saturated hydrocarbon in the component S is greater than 90 mass%; by taking the total mass of the component AR as the reference, the sum of the mass fraction of the aromatic hydrocarbons and the mass fraction of the colloid in the component AR is greater than 90 mass%, the mass fraction of the aromatic hydrocarbon is greater than 50 mass%; and b) performing a first catalytic cracking reaction on the component S in the step a) to obtain dry gas, liquefied gas, gasoline, diesel oil, coke and cracking heavy oil. Compared with the prior art, after the method used for heavy oil processing and then the catalytic cracking reaction, gasoline and liquefied gas yield is higher, and the gasoline sulfur nitrogen content is lower.

Owner:CHINA PETROLEUM & CHEM CORP +1

Shale oil processing method for producing propylene

ActiveCN102465036BHigh yieldSuppress generationTreatment with hydrotreatment processesBulk chemical productionCatalytic pyrolysisFuel oil

The invention discloses a shale oil processing method for producing propylene. The method comprises the following steps of: hydrogenating shale oil, separating shale oil hydrogenation products to obtain gas and liquid reaction oils, and separating the liquid reaction oil into a shale oil hydrogenation light oil and a shale oil hydrogenation heavy oil; introducing the shale oil hydrogenation heavy oil into a first riser reactor for undergoing a catalytic pyrolysis reaction; and introducing a part of or all of the shale oil hydrogenation light oil into a second riser reactor for undergoing a catalytic pyrolysis reaction. The shale oil processing method provided by the invention has high propylene yield.

Owner:CHINA PETROLEUM & CHEM CORP

A method for processing heavy oil with combined process

ActiveCN106467758BEliminate interactionIncrease profitTreatment with plural serial stages onlyOil processingSulfur

The invention discloses a method for processing heavy oil by combined process. the method comprises the following steps: a, carrying out separation treatment on heavy oil to obtain a SA1 component and a A2A3 component, wherein with total mass of the SA1 component as the reference, total mass fraction of saturated hydrocarbon and monocyclic aromatics in the SA1 component is greater than 80 wt%; and with total mass of the A2A3 component as the reference, total mass fraction of aromatics with more than one ring and colloid is greater than 75 wt%, and mass fraction of aromatics with more than one ring is greater than 35 wt%; and b, carrying out first catalytic cracking reaction on a SA1 component obtained in the step a, so as to obtain dry gas, liquefied gas, gasoline, diesel oil, coke and cracked heavy oil. According to the method, the SA1 component and the A2A3 components obtained after the separation treatment of heavy oil are respectively subjected to the catalytic cracking reaction. By the method, yield of gasoline and liquefied gas is higher, and sulfur and nitrogen content of gasoline is lower.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for catalytic cracking diesel hydroisomerization-catalytic cracking

ActiveCN110437875BHigh aromatic contentAromatics content controlTreatment with hydrotreatment processesPtru catalystHydrogenation reaction

The invention discloses a method for catalytic cracking diesel hydroisomerization-fluid catalytic cracking, comprising the following steps: 1) mixing catalytic cracking diesel oil with hydrogen, and entering a series of hydrogenation reaction devices, wherein the hydrogenation reaction The device is sequentially filled with hydrogenation protection agent, hydrofinishing catalyst, and hydroisomerization catalyst for hydrofinishing-hydroisomerization reaction; 2) hydroisomerized diesel oil enters a fluidized bed catalytic cracking unit for catalytic cracking reaction. The method of the present invention utilizes catalytic cracking diesel oil to produce low-carbon olefins and clean fuel oil products. The method can produce low-carbon olefins content>35wt% in the product and aromatics content>50wt% in the gasoline fraction under the condition of full conversion of catalytic cracking diesel oil, which can be significantly improved. Increase the value of FCC diesel.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +2

A hydrogenation method for treating high-nitrogen and high-aromatic low-quality diesel feedstock

ActiveCN103773489BGood choiceImprove conversion rateTreatment with hydrotreatment processesGasolineProcess engineering

The invention discloses a hydrogenation method for treating high-nitrogen high-aromatic hydrocarbon inferior diesel oil raw materials. An integrated two-section process flow of a first reaction area, intermediate separation and a second reaction area is adopted. The method comprises the following steps: performing hydrodenitrogeneration and bicyclo- or multi-cyclo aromatic hydrocarbon hydrogenation saturation reactions on inferior diesel oil with high nitrogen and aromatic hydrocarbon content in the first reaction area, performing intermediate separation, obtaining a hydrogenated material flow in which the organic nitrogen content is less than 200 ug / g and the total aromatic hydrocarbon content is more than 60 weight percent, and providing the raw materials for the second reaction area; performing moderate refining and hydro-upgrading in the second reaction area, and performing fractionation to obtain gasoline components with high octane value. By adoption of the method provided in the invention, the inferior diesel oil fraction with high nitrogen and aromatic hydrocarbon content can be treated, and the gasoline components with high octane value and low sulfur content are obtained at high yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

A combined method of heavy oil separation-hydrotreating-catalytic cracking

ActiveCN106467757BEliminate interactionIncrease profitTreatment with hydrotreatment processesSulfurOil separation

The invention discloses a heavy oil separation-hydrotreatment-catalytic cracking combined method. the method comprises the following steps: a, separating heavy oil to obtain a component S, a component A1, a component A2 and a component A3; and b, carrying out a first catalytic cracking reaction on the component S obtained in the step a, so as to obtain dry gas, liquefied gas, gasoline, diesel oil, coke and cracked heavy oil; carrying out a second catalytic cracking reaction on the component A1 obtained in the step a, so as to obtain dry gas, liquefied gas, gasoline, diesel oil, coke and cracked heavy oil; carrying out a third catalytic cracking reaction on the component A2 obtained in the step a, so as to obtain dry gas, liquefied gas, gasoline, diesel oil, coke and cracked heavy oil; and carrying out a hydrotreatment reaction on the component A3 obtained in the step a under the action of a hydrotreating catalyst, so as to obtain hydrogenated oil. In comparison with the prior art, the method for heavy oil treatment and the subsequent catalytic cracking reactions has advantages of higher yield of gasoline and liquefied gas and lower sulfur / nitrogen content of gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fresh sorghum milk product and production method thereof

InactiveCN105661206APollution controlAchieve a double harvest a yearFood scienceAnimal scienceSorghum

The invention discloses a fresh sorghum dairy product and a production method thereof, which relates to the field of dairy products and sorghum food, and solves the problem of bad smells such as mutton or fishy smell in dairy products. Remove impurities and moth-eaten parts from the fresh and tender sorghum crop fruits on the day of harvest, clean them, crush, squeeze, and filter to remove slag (for long-term storage, they can be stored with slag under heavy pressure and sealed, and then filtered to remove slag while selling , can also be filtered and stored in low-temperature refrigeration, and can also be sealed after adding active lactic acid bacteria), filling, sterilization, drying and other processing processes to produce natural malt milk and its series of products without peculiar smell, making dairy products taste better it is good. The present invention can be widely used in all areas where sorghum crops can be grown.

Owner:张思祥

A kind of heavy oil processing combined method

ActiveCN106467756BSave resourcesEliminate interactionTreatment with hydrotreatment processesOil processingSulfur

The invention discloses a heavy oil processing combined method. The method comprises a. separating heavy oil to obtain components SA1A2 and A3, wherein the component SA1A2 comprises greater than 80% by mass of a saturated hydrocarbon, a mono-aromatic hydrocarbon and a diaromatic hydrocarbon and the component A3 comprises greater than 50% by mass of colloid and aromatic hydrocarbons with two or more aromatic rings, and b, carrying out a first catalytic cracking reaction process on the component SA1A2 to obtain dry gas, liquefied gas, gasoline, diesel oil, coke and cracked heavy oil. Through catalytic cracking of the components SA1A2 and A3 obtained by separating the heavy oil, high gasoline and liquefied gas yields and low gasoline sulfur and nitrogen content are obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

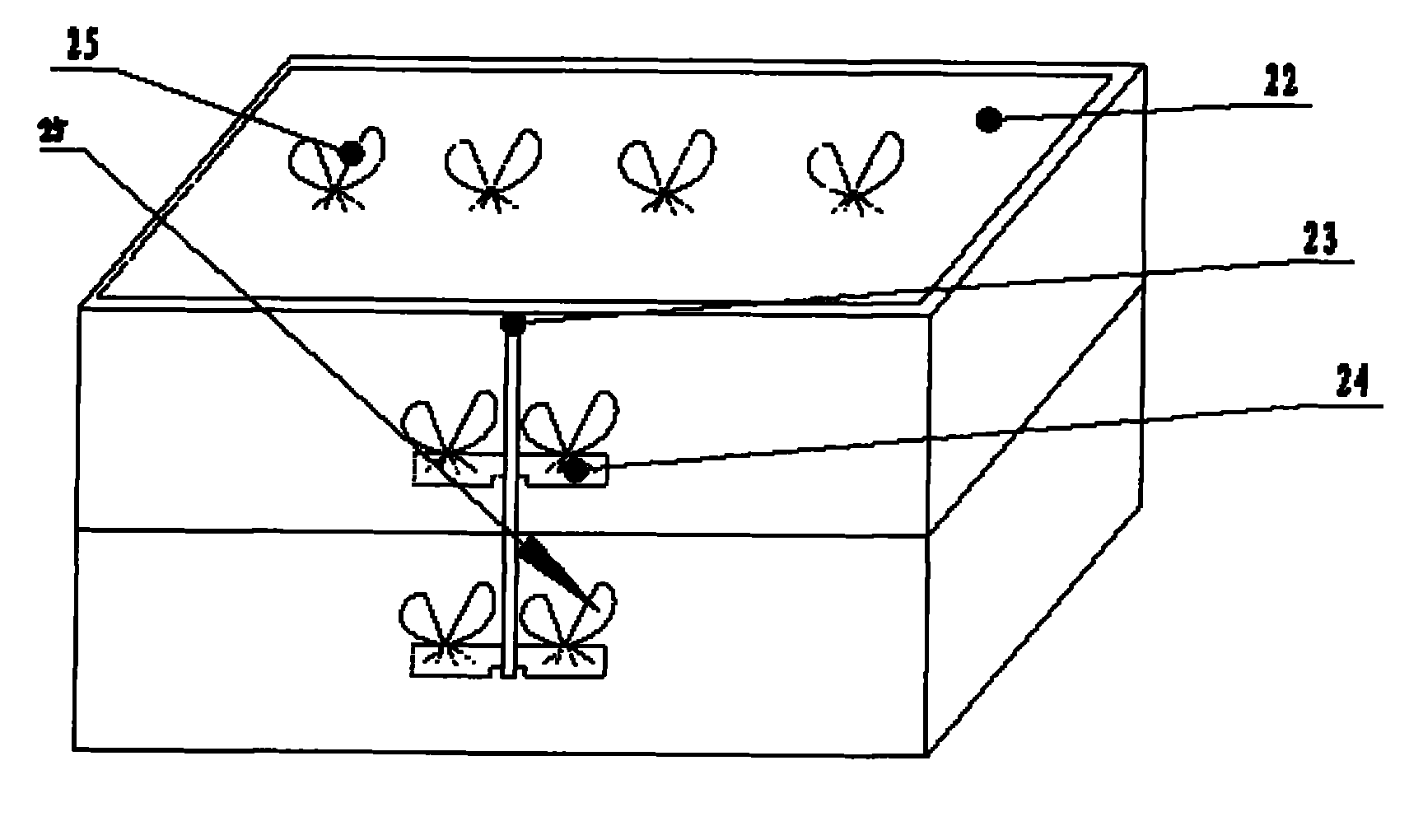

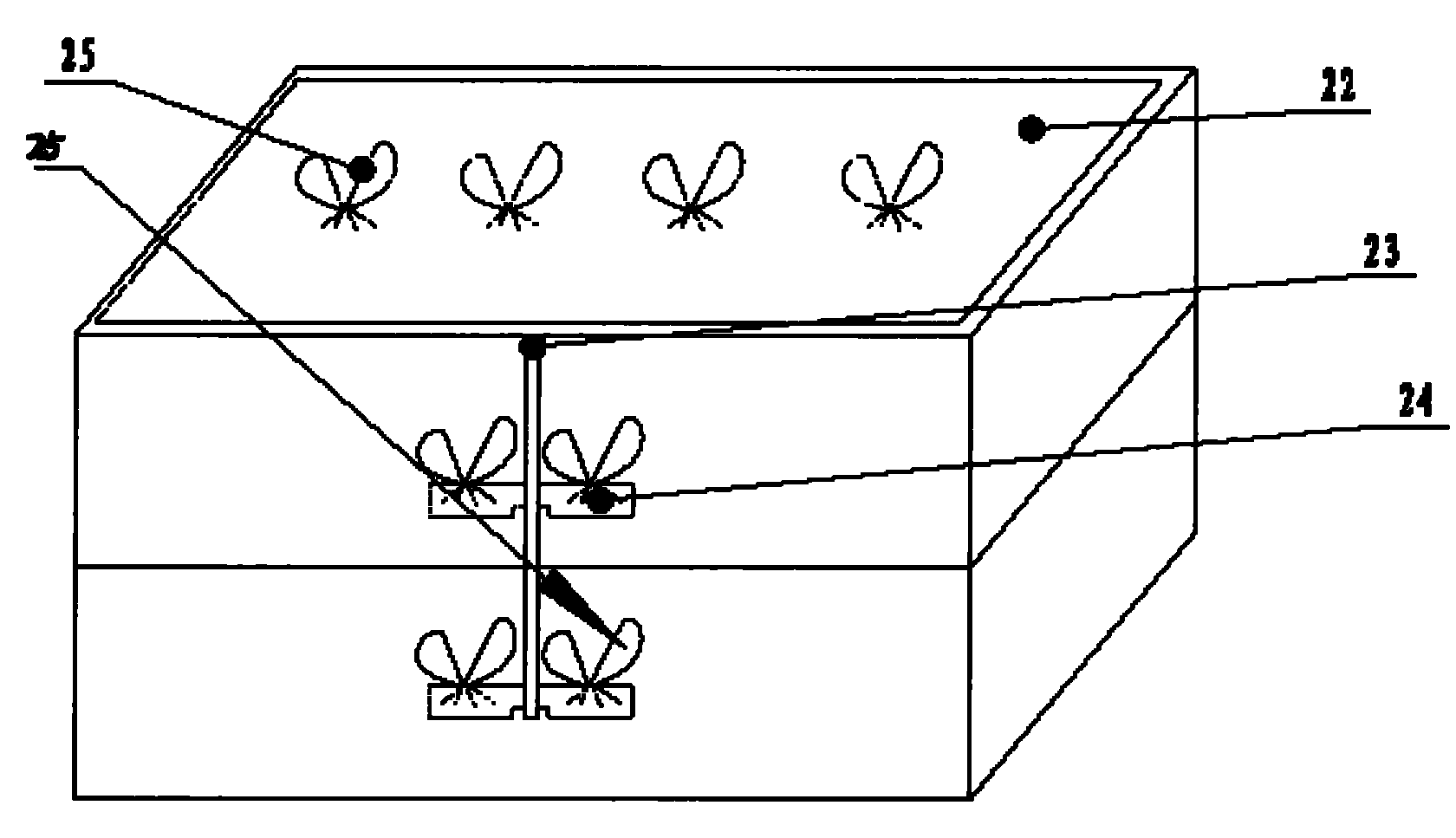

Garbage decomposition liquid ecological utilization system

InactiveCN102101121ASave land and mineral chemical fertilizersReduce indoor temperatureSolid waste disposalClimate change adaptationFertilizerRooming-in

The invention discloses a garbage decomposition liquid ecological utilization system. The garbage decomposition liquid ecological utilization system comprises a water pump, a decomposition liquid conveying pipe, a roof reservoir 22, a balcony liquid-conveying pipe 23 and flowerpots 24, wherein the decomposition liquid conveying pipe is communicated with the roof reservoir 22; the conveying pipe conveys the decomposition liquid into the roof reservoir under the action of the water pump; the roof reservoir 22 is connected with the flowerpots through the balcony liquid-conveying pipe 23; the decomposition liquid is conveyed into the flowerpots 24; and the flowerpots 24 are positioned in rooms in buildings. In the garbage decomposition liquid ecological utilization system, the garbage decomposition liquid is used for performing soilless culture, so that the growth of aquatic plants is contributed, optical radiation is absorbed, indoor temperature is reduced, water quality is purified, and high-quality feeds are provided to culture plants; and the garbage decomposition liquid serves as nutrient solution for soilless vegetable culture, so that high-quality green vegetables are produced locally, water quality is purified, and soil and mineral chemical fertilizers are saved.

Owner:周万松

Feed pellet using tapioca residual and production method thereof

InactiveCN106173192AImprove palatabilityKeep shapeFood processingAnimal feeding stuffWater contentTapioca starch

The present invention relates to a feed pellet using tapioca residue and a production method thereof, and wherein the feed pellet comprises 85 to 97% by weight of tapioca residue and 3 to 15% by weight of blackstrap molasses, wherein the tapioca residue has below 20% by weight of moisture content. Above described method for manufacturing the feed pellet using tapioca residue according to the present invention has an effect on manufacturing high quality feedstuffs, i.e. a high maintenance of shape, excellent palatability and low flying dust, by mixing tapioca residue with blackstrap molasses.

Owner:南文植 +1

An ecological cycle treatment method for livestock farm wastewater

InactiveCN110790449AHigh quality feedImprove water holding capacityWater contaminantsWaste water treatment from animal husbandryEnvironmental resource managementWater resources

An ecological cycle treatment method for livestock farm wastewater is disclosed. The method comprises anaerobic treatment and three-stage biological purification. Wastewater subjected to anaerobic treatment is then subjected to three-stage biological purification, and the three-stage biological purification comprises the steps of first-stage purification, second-stage purification and third-stagepurification. Pollutants in breeding wastewater are gradually absorbed and purified through multi-stage ecological treatment, the comprehensive utilization rate of breeding waste is increased, the cost is low, water resources are saved, grass is planted for breeding livestock, the economic utilization rate of land is increased, the industrial chain is prolonged, meanwhile, the daily ration structure of livestock and poultry can be improved, feed is saved, and the ecological benefit is good.

Owner:GUIZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com