Combined process for pretreating and catalytically cracking hydrocarbon oil

A catalytic cracking and combined process technology, applied in hydroprocessing process, petroleum industry, hydrocarbon oil treatment, etc., can solve problems such as operational flexibility limitations, achieve the effects of reducing costs, improving desulfurization efficiency, and improving flexible operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

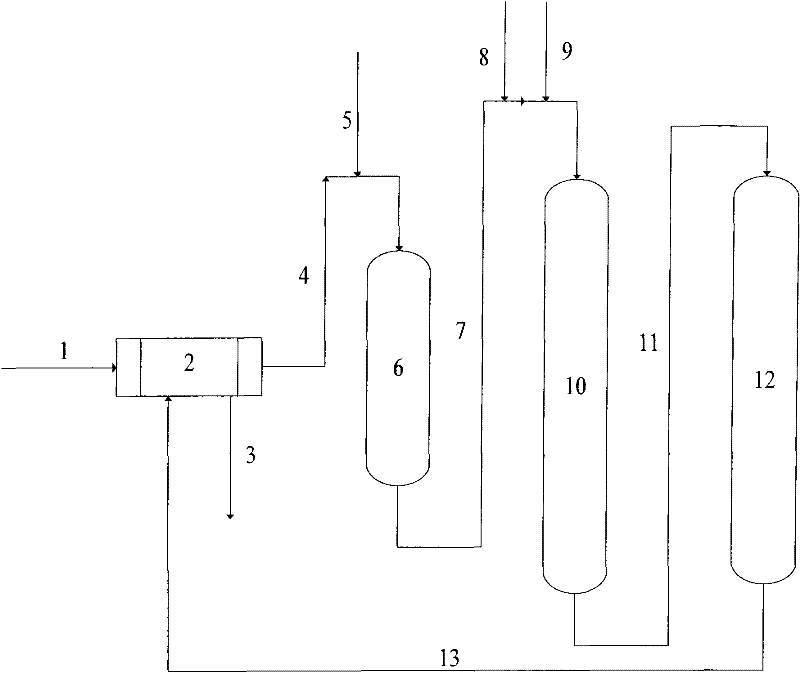

Method used

Image

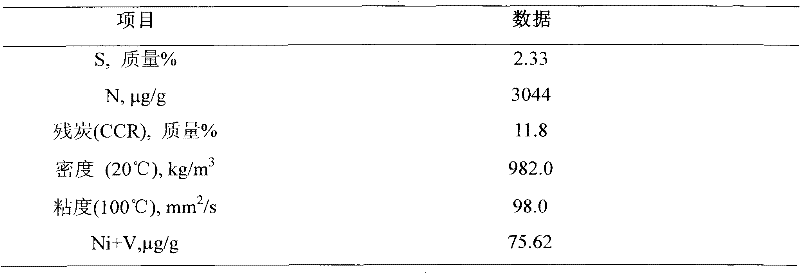

Examples

Embodiment 7

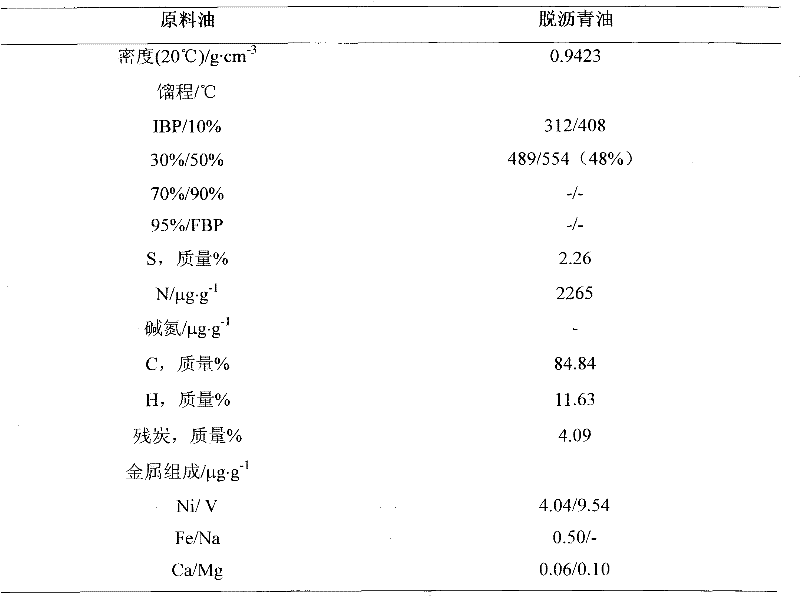

[0046] Example 7 is directly hydrogenated without demetallization, and Example 8 is hydrogenated after demetallization. The rest of the reaction conditions are the same, and the hydrogenation oil after 3000 hours of operation of the device has the properties of oil.

[0047] Table 10 FCC process conditions and main product properties

[0048]

[0049] As can be seen from the above examples, the inventive method has produced high-quality catalytic cracking raw materials through a simple process and mild process operating conditions, and the inventive method can effectively process residues including , catalytic cracking tail oil, low-quality wax oil, light wax oil and coker wax oil and other raw materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com